Patents

Literature

50results about How to "Improve organizational efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

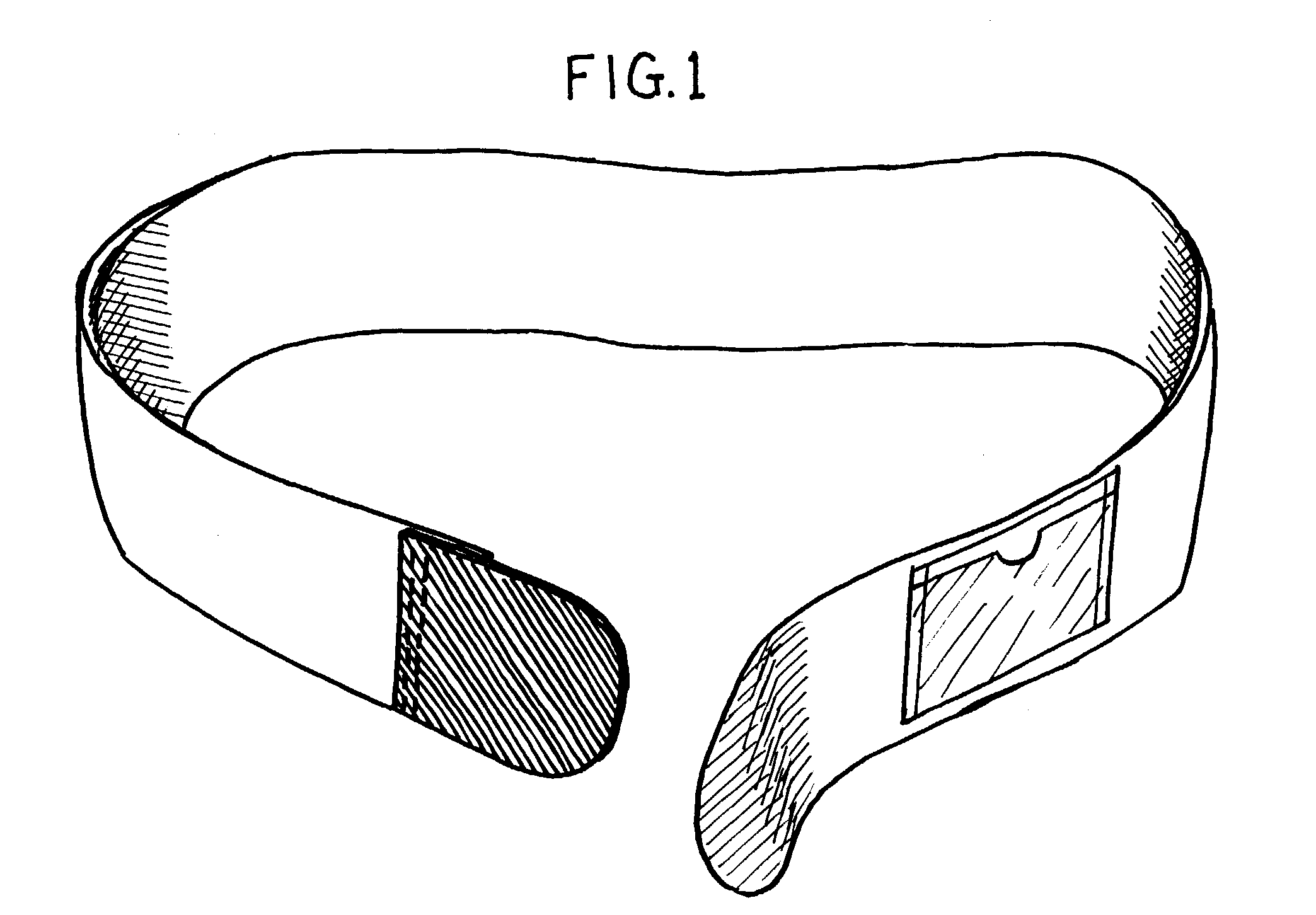

Wrap-it

InactiveUS7096544B2Improve organizational efficiencyEasy to addSnap fastenersTravelling carriersEngineeringFastener

An organizational device devised for the wrapping of articles. The device includes an elongate continuous elastic loop fabric strap. A hook fastener is imported at one end of the strap. The hook fastener is attachable to the strap at any location therealong. Once attached the strap forms a wrap about the articles. The strap may also include useful information, logos and the like thereon.

Owner:LUSARDI KEVIN TIMOTHY

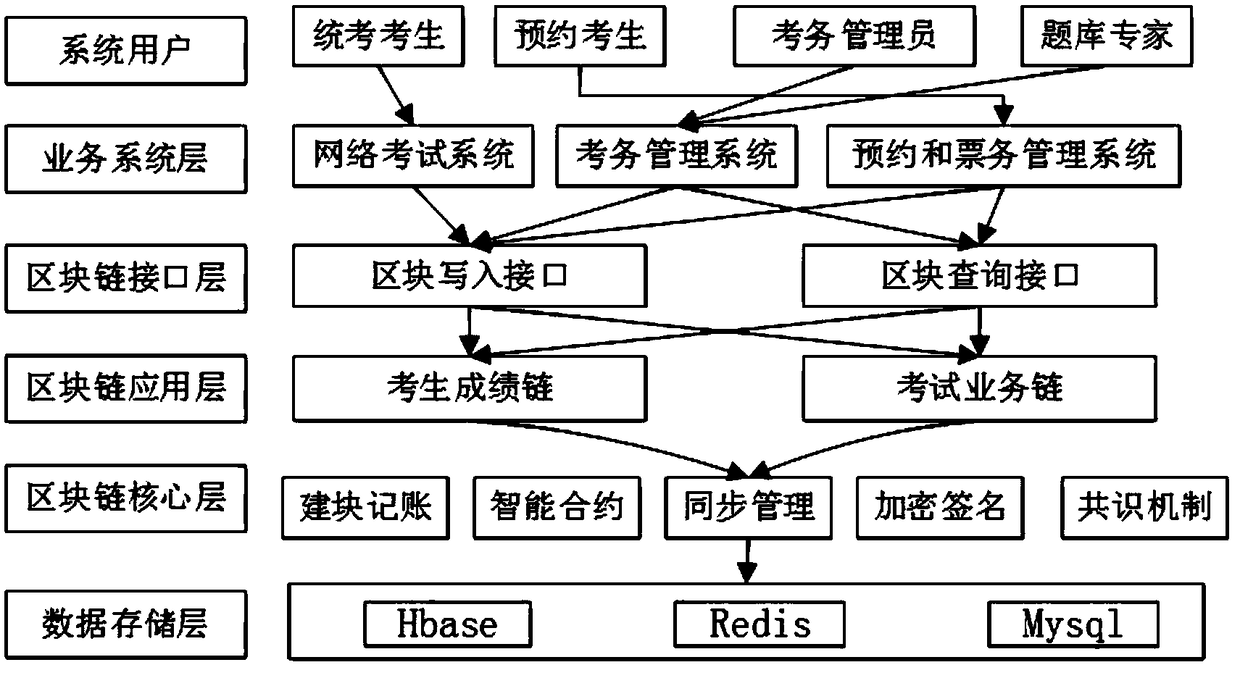

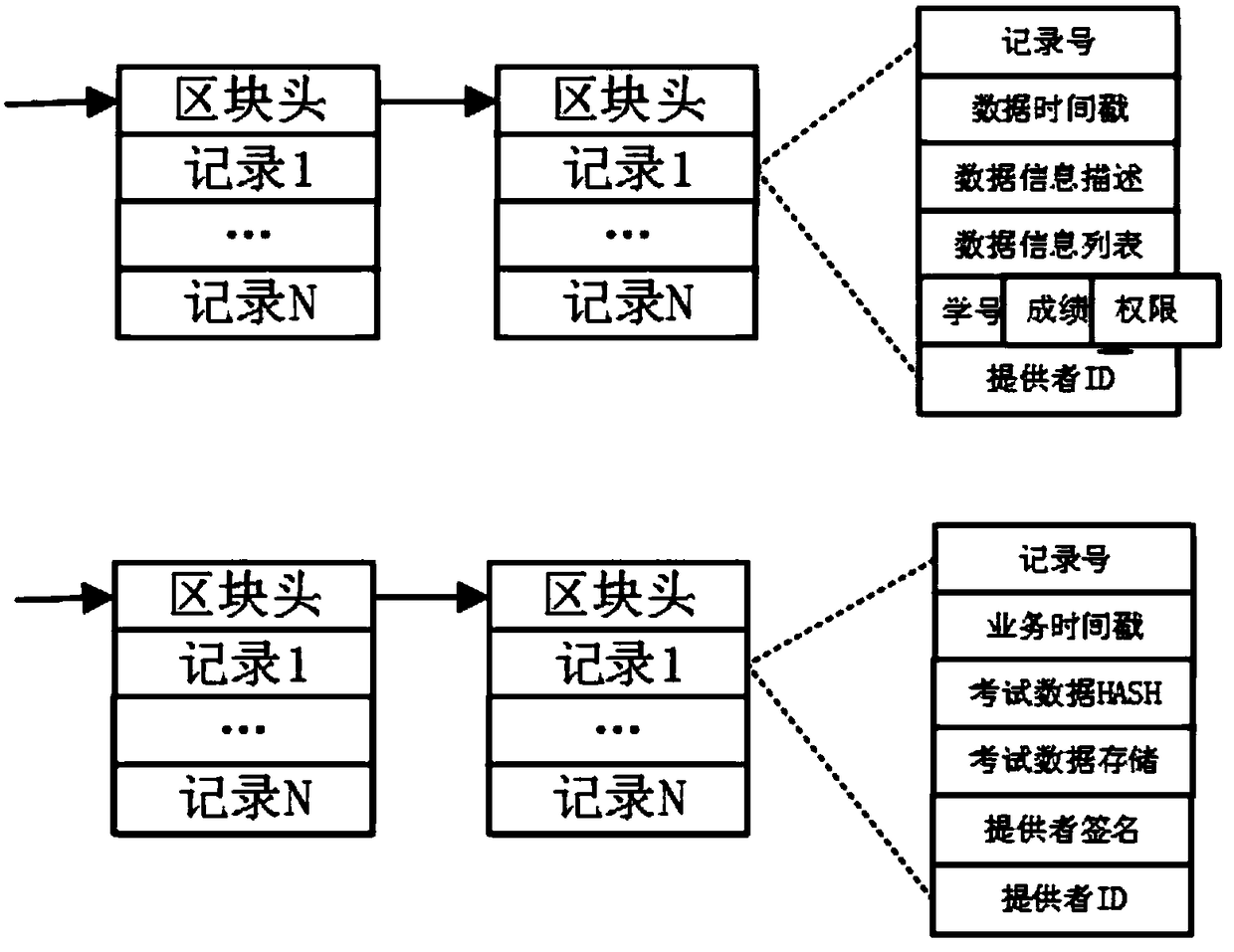

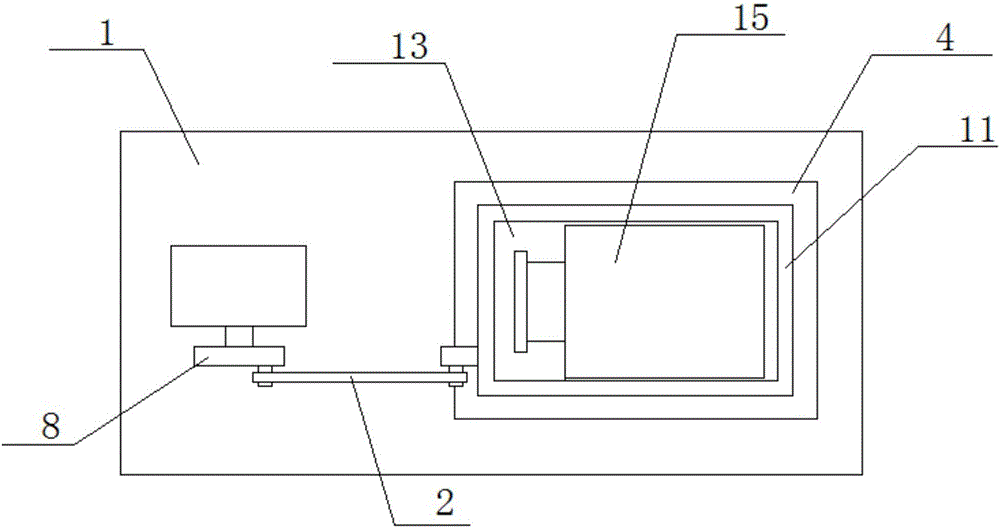

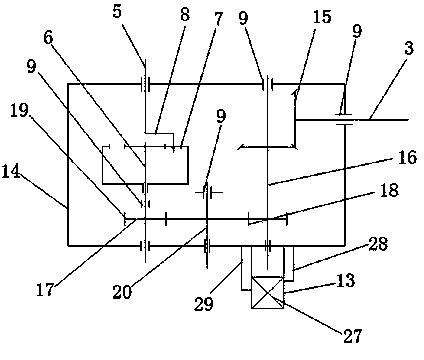

A network examination system based on a block chain and a method for managing the network examination by using the network examination system

ActiveCN109002527AAvoid lossPrevent malicious tamperingData processing applicationsSpecial data processing applicationsCredit systemManagement process

The invention relates to a network examination system based on a block chain and a method for managing the network examination by using the network examination system, belonging to the technical fieldof teaching management equipment. The system adopts double-block chain design, including a data storage layer, a block chain core layer, a block chain application layer, a block link interface layer,a business system layer and a system user layer. The API interface of the data storage layer is connected with the API interface of the core layer of the block chain, the core layer of the block chain is connected with the application layer of the block chain, and the application layer of the block chain is connected with the interface layer of the block link through the API interface. The blocklink interface layer is connected with the service system layer to realize the inquiry and writing of the block chain service. The business system layer is connected with the system user layer, whichprovides the interface between the user and the network examination service. The invention can prevent information from being lost or tampered with maliciously, construct a safe, reliable and non-tamper examination credit system, simplify the network examination management process, improve the network examination organization efficiency, and provide high-efficiency, convenient and humanized examination service for examinees.

Owner:JIANGSU OPEN UNIV

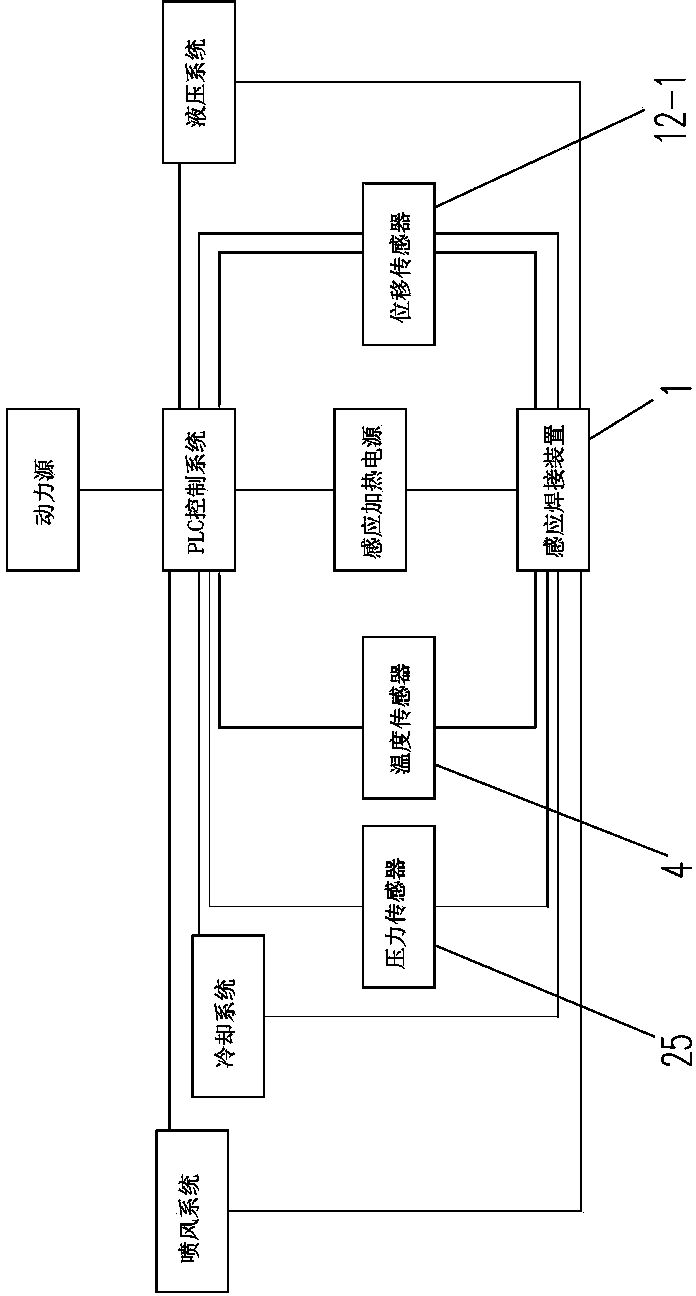

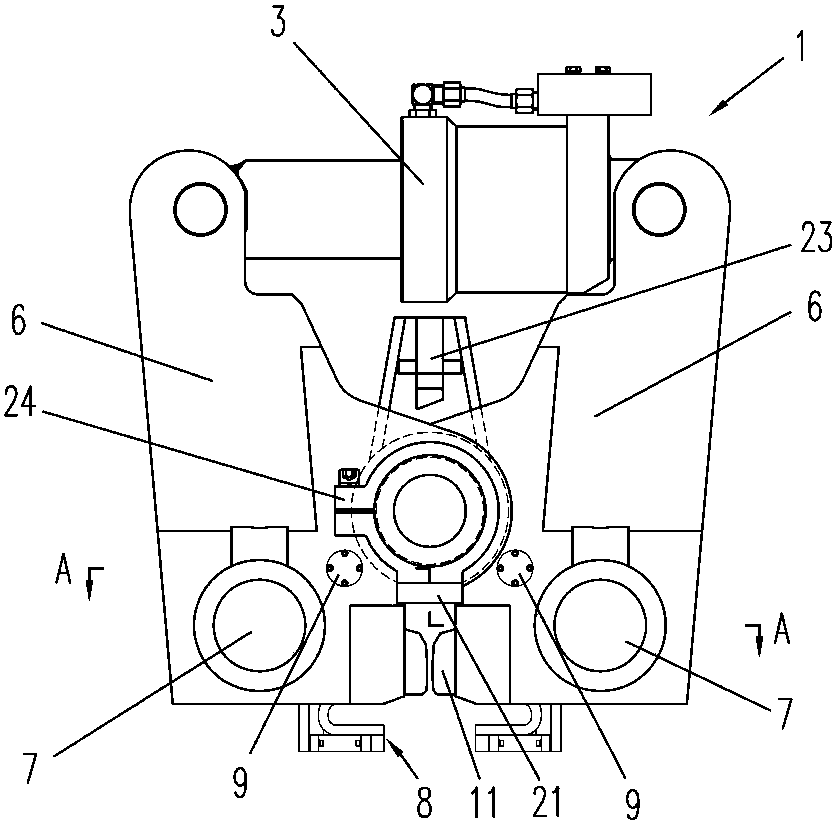

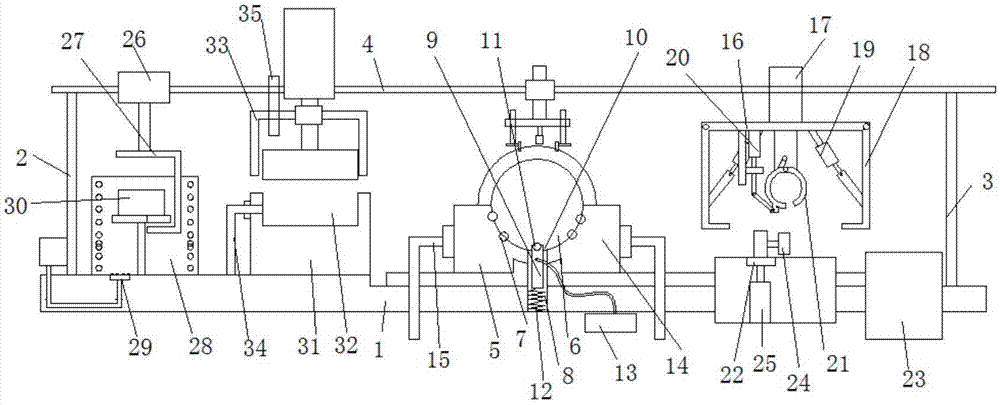

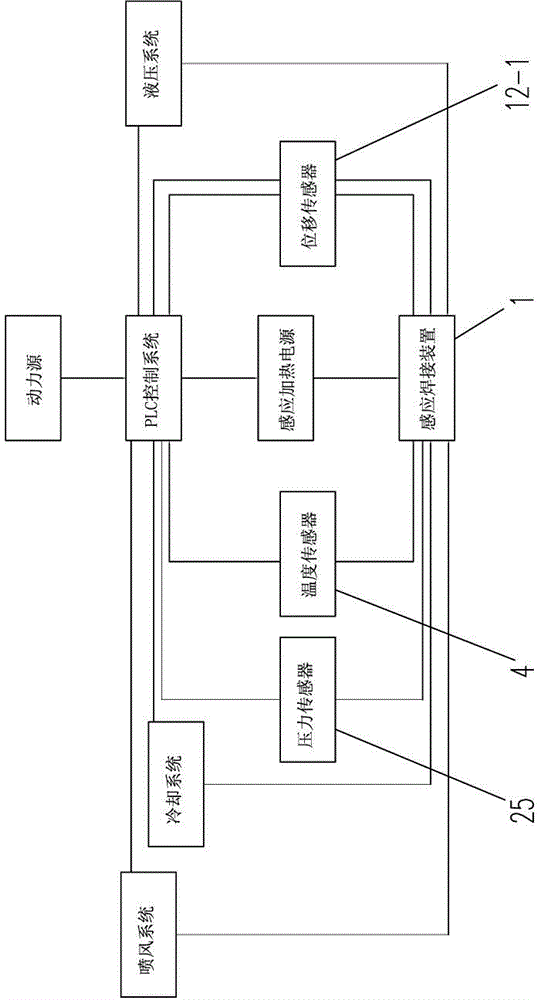

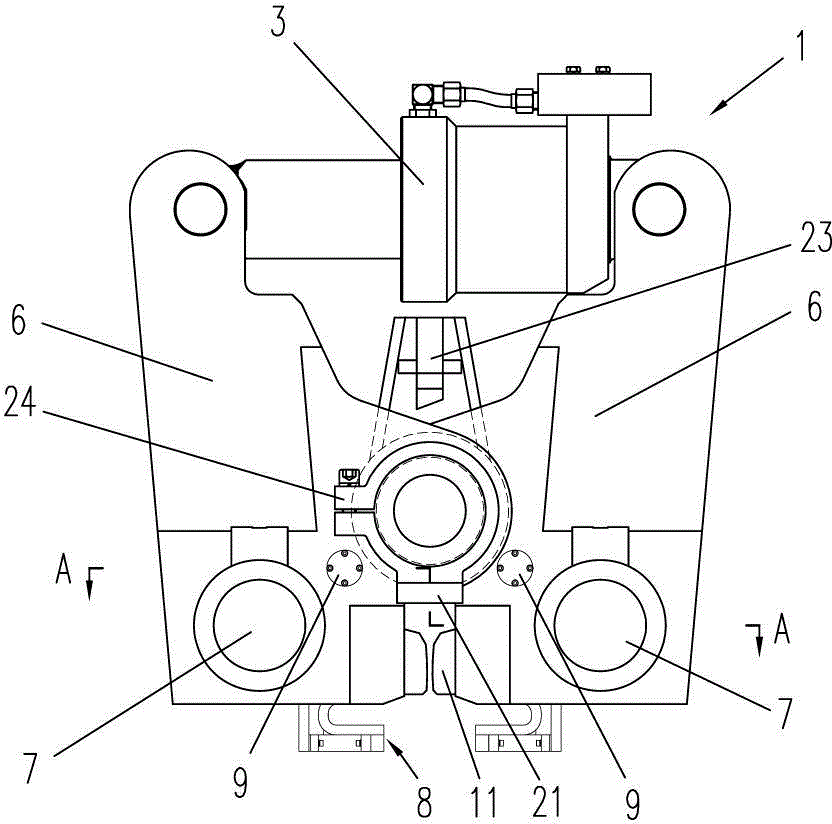

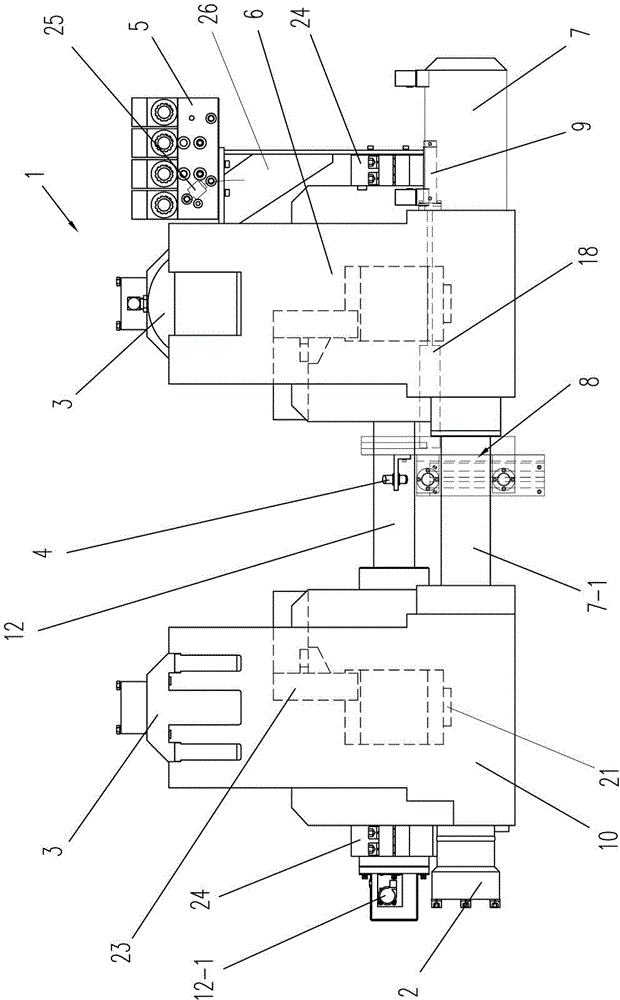

Steel rail induction butt welding and heat treatment method

ActiveCN103521935AImprove organizational efficiencyHigh degree of automationRailsWelding/cutting auxillary devicesButt weldingForceps

The invention discloses a steel rail induction butt welding and heat treatment method which includes the following steps: locating two steel rails through locating pieces which are installed on the lower portions of center shafts of an induction welding device in a connected mode, enabling jaws of two sets of clamp forceps to clamp the two steel rails respectively and carry out centring, enabling an opening-closing type induction heating coil to be moved to the joint of the two steel rails with the help of auxiliary oil cylinders and wrap the steel rails, enabling two sub-coils to be in contact with electrode structures, enabling a PLC to control the induction heating coil to heat the joint of the steel rails, when the temperature reaches the preset welding temperature of 1200 DEG C to 1430 DEG C, enabling upsetting oil cylinders to exert preset upsetting force to enable the end faces of the two steel rails to be tightly welded together, enabling a protrusion eliminating device to cut welding beading at the joint of the steel rails, enabling the induction heating coil to heat the weld joint of the steel rails again, after the temperature reaches the preset normalizing temperature of 830 DEG C to 950 DEG C, starting an air blasting system to cool the weld joint of the steel rails, and enabling the two sub-coils to be separated through the locating oil cylinders to enable the jaws of the two sets of clamp forceps to be opened to loosen the steel rails. The steel rail induction butt welding and heat treatment method is automatic in operation and high in efficiency.

Owner:CHANGZHOU RUITAI ENG MASCH CO LTD +1

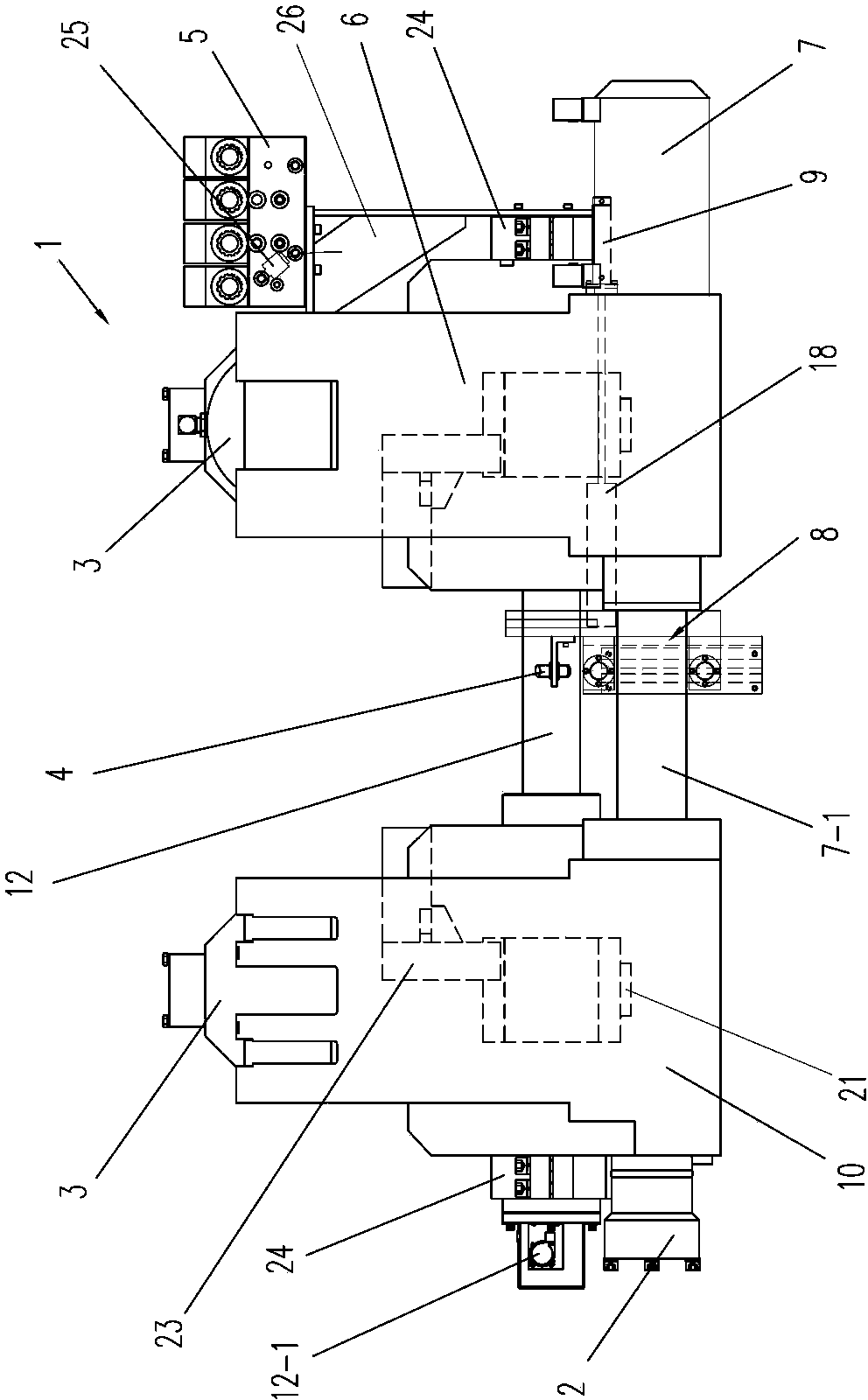

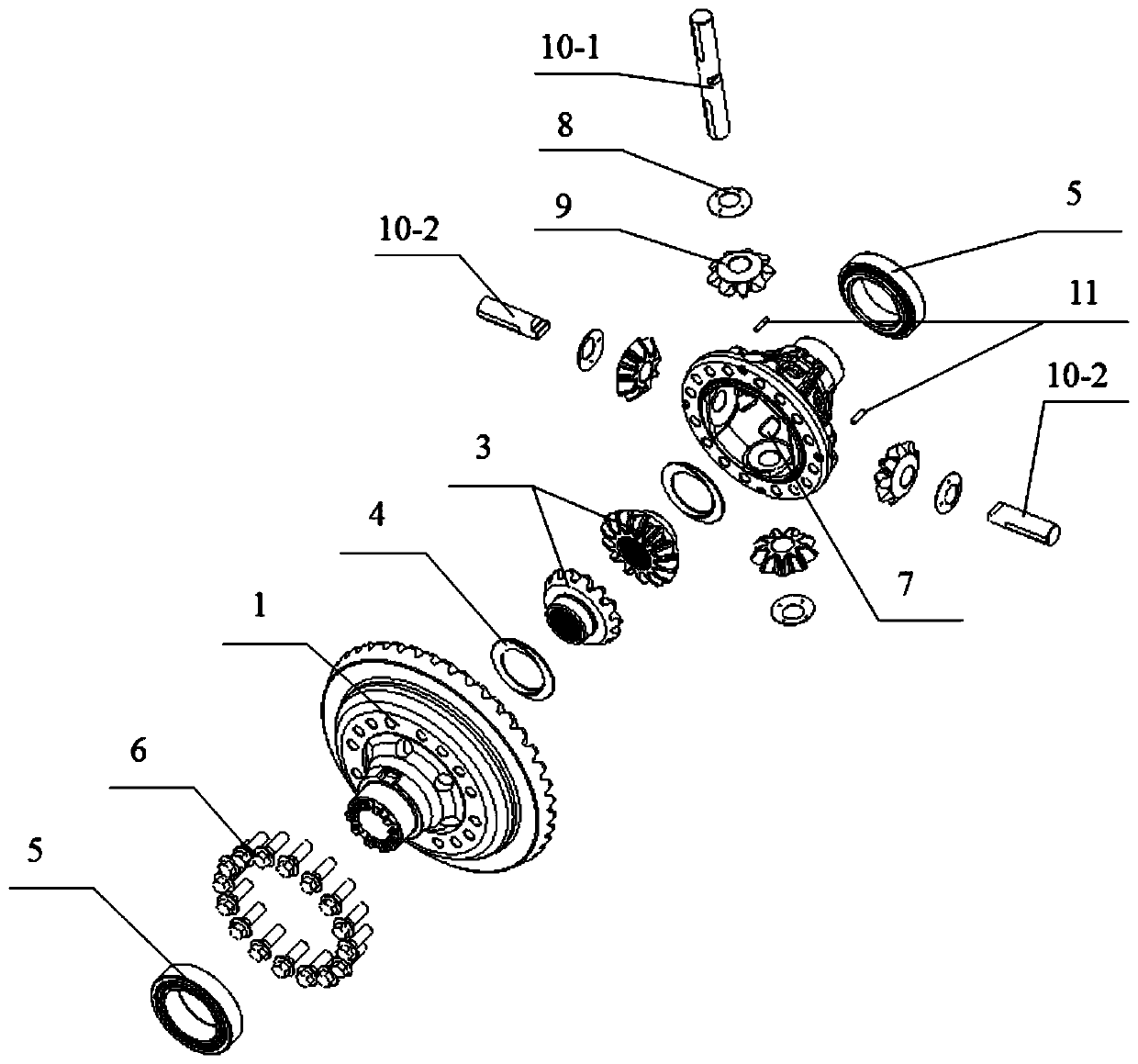

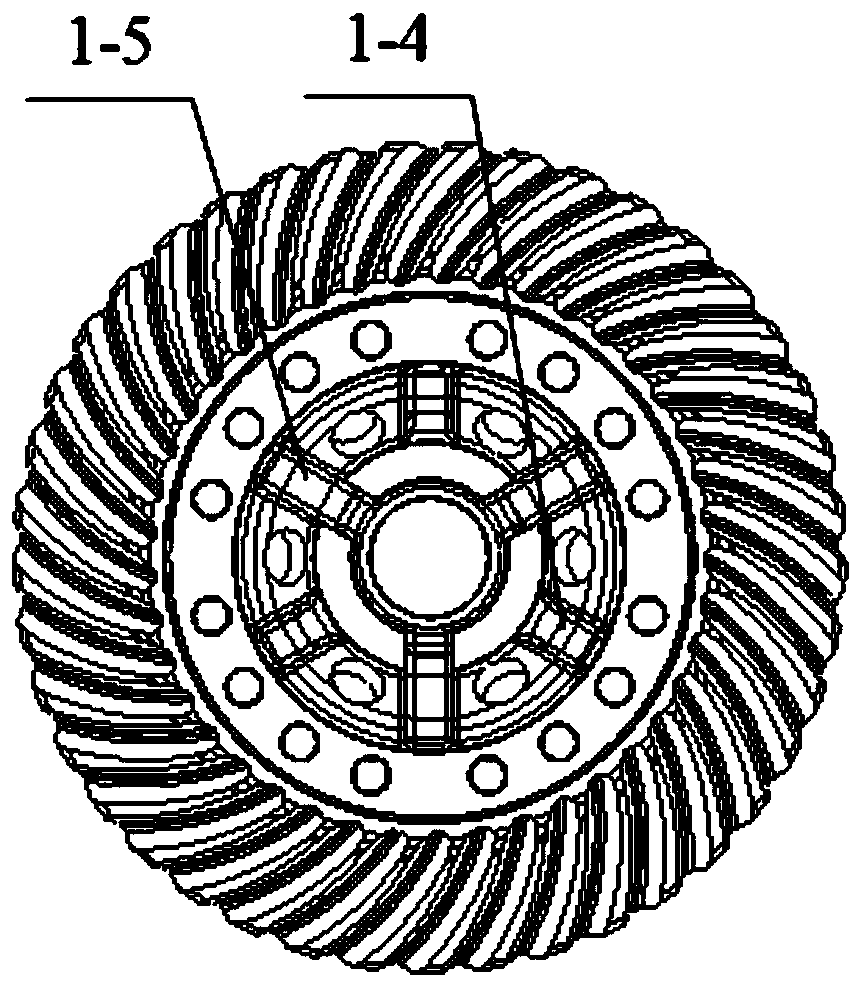

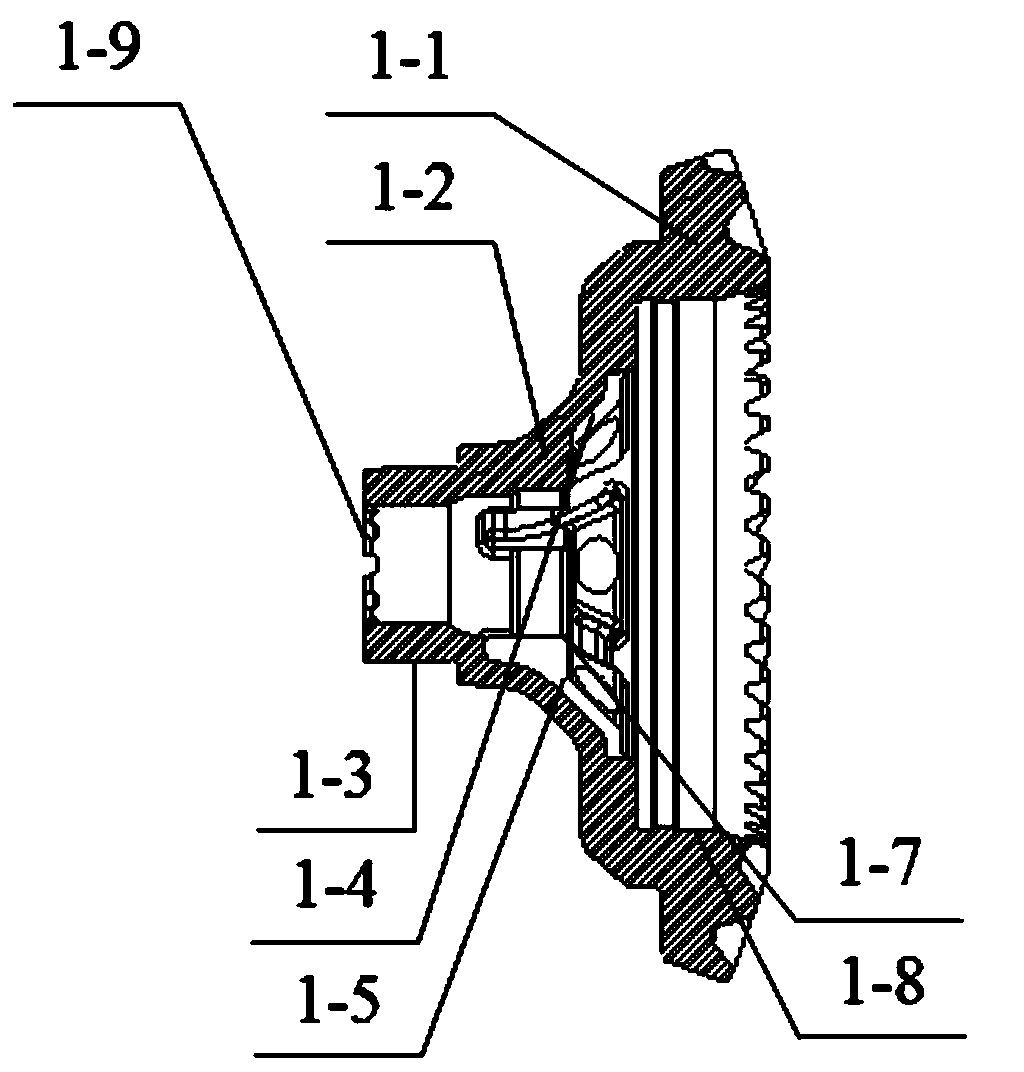

Novel commercial automobile wheel differential mechanism assembly and assembling method

PendingCN109973611AGuaranteed to workImprove organizational efficiencyDifferential gearingsCar manufacturingEngineering

The invention discloses a novel commercial automobile wheel differential mechanism assembly and an assembling method, and belongs to the technical field of automobile manufacturing. According to the wheel differential mechanism assembly and the assembling method, an integrated structure of a driven bevel gear and a left shell of the differential mechanism is adopted, an anti-rotation cross shaft assembly is integrated on a right shell of the differential mechanism, and a good lubricating system is arranged, so that the phenomena that the driven bevel gear is broken during connecting bolts, a driving bevel gear and the driven bevel gear are in collision with each other, and a spherical surface of a planetary gear of the differential mechanism is seriously worn can be eliminated; connectingparts are also reduced, processing and assembly processes are convenient, the production takt is improved, and the transmission efficiency and the reliability of the product are improved; compared with an original structure, the weight is reduced by 7.9%, and the cost is reduced by about 6%; and compared with an wheel differential mechanism assembly with different speed ratios, the right shell ofthe differential mechanism can be commonly used and interchanged, so that the organization production is facilitated, the interchangeability of the product and the organization efficiency of spare parts are also improved, and therefore the purposes of light weight, economy and refined production are achieved.

Owner:FAW JIEFANG AUTOMOTIVE CO

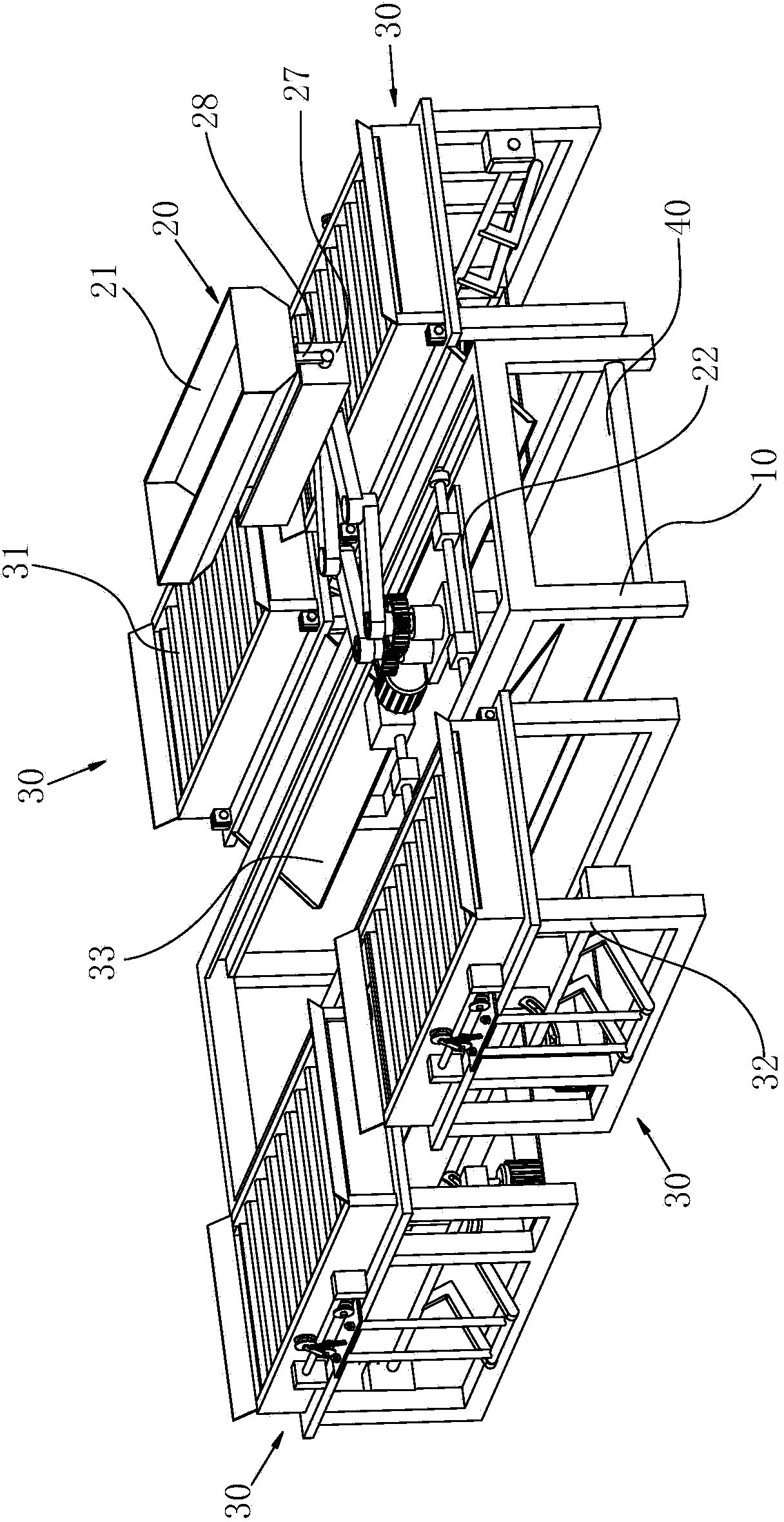

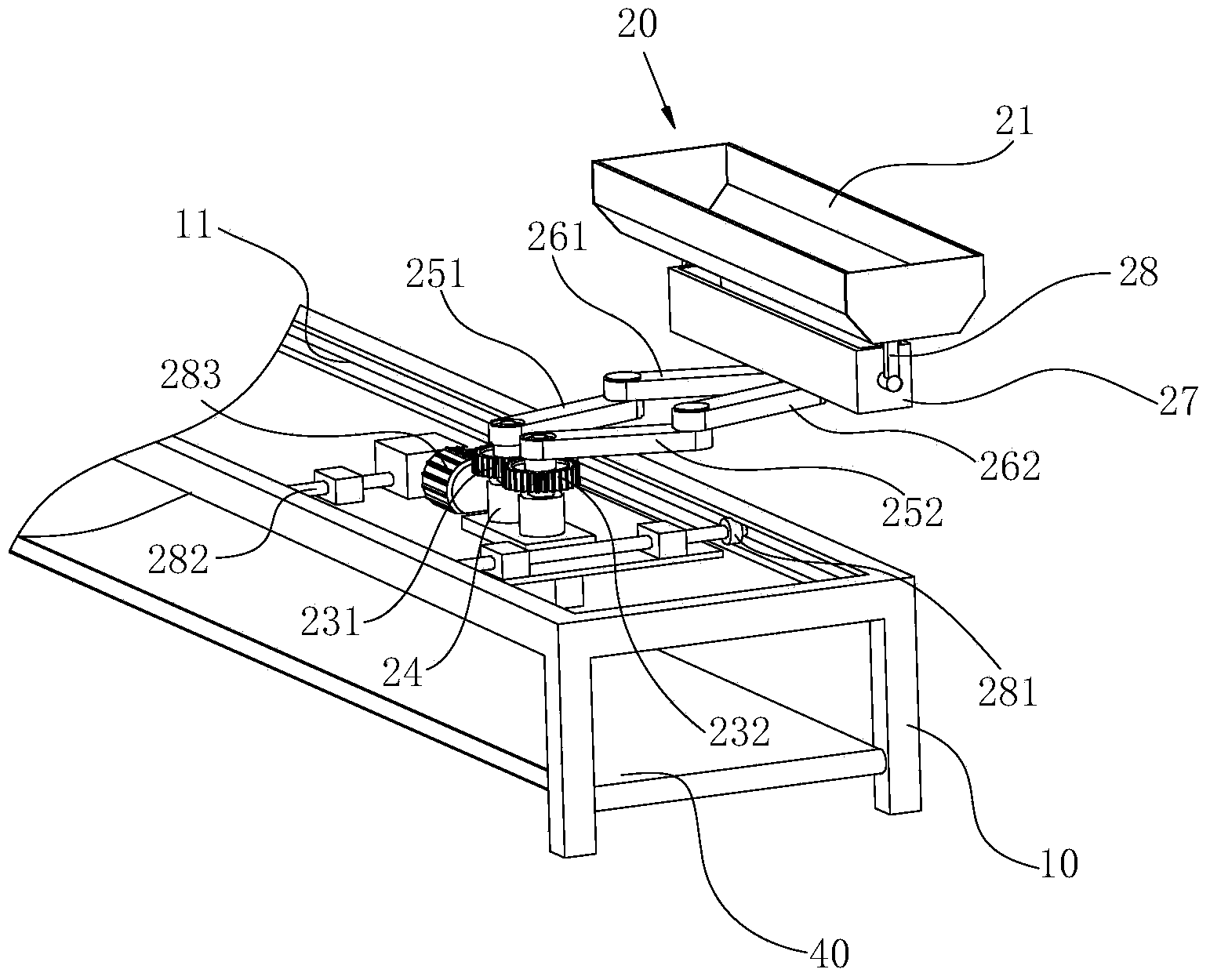

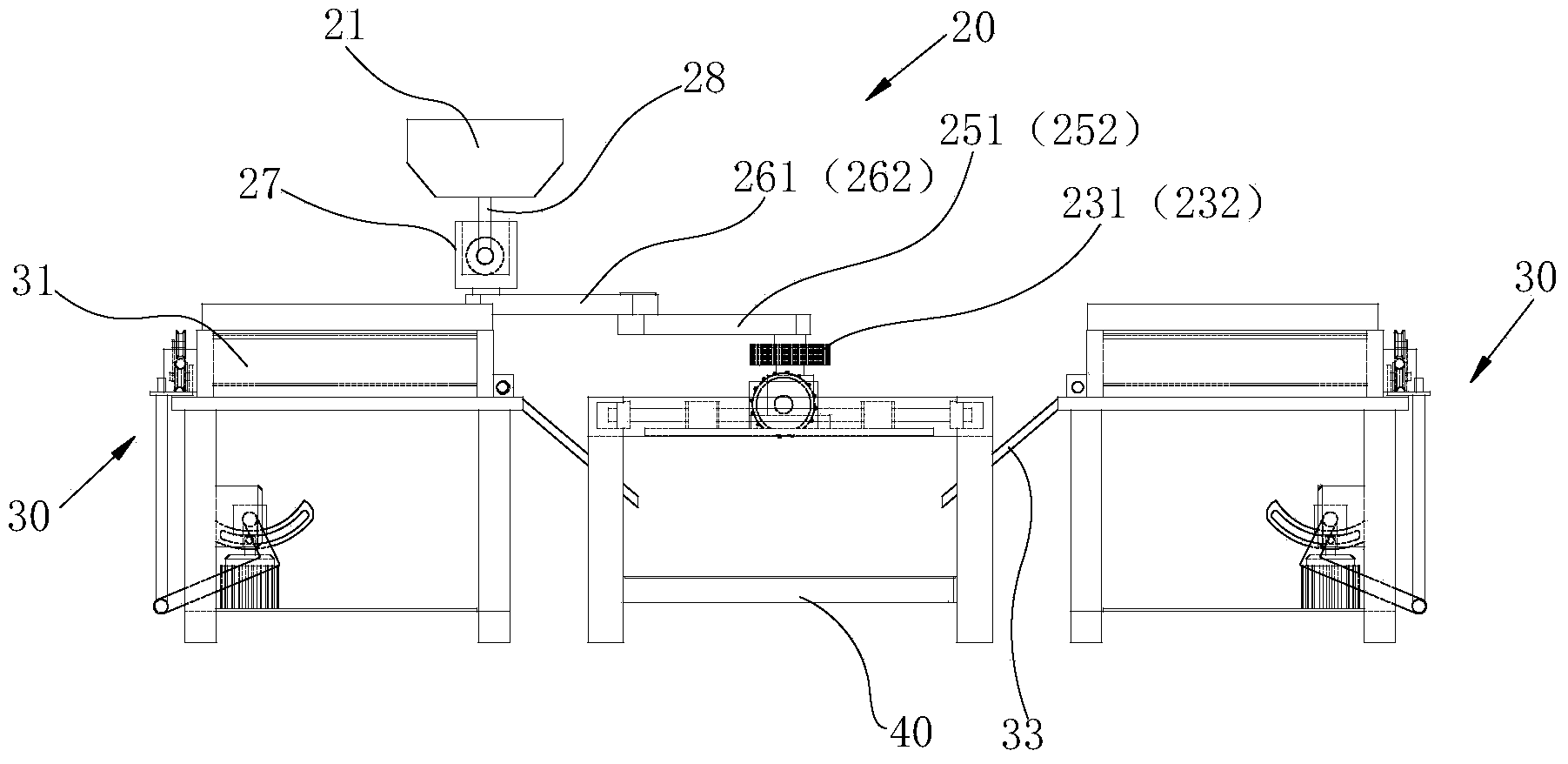

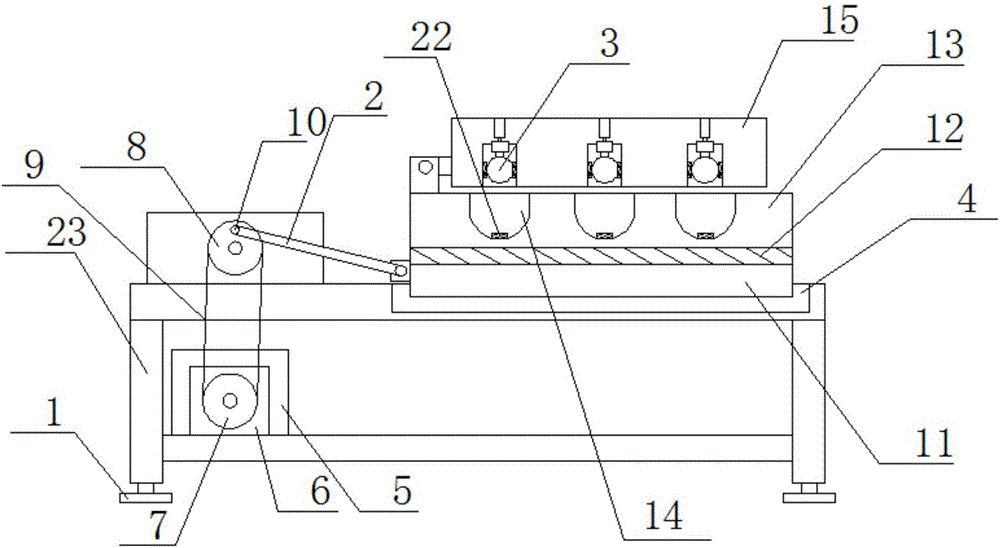

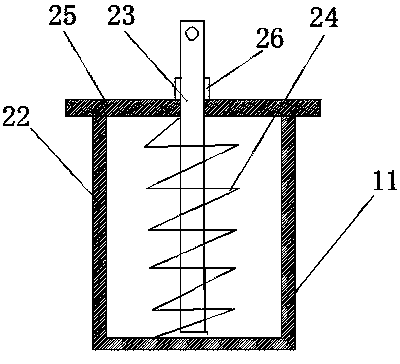

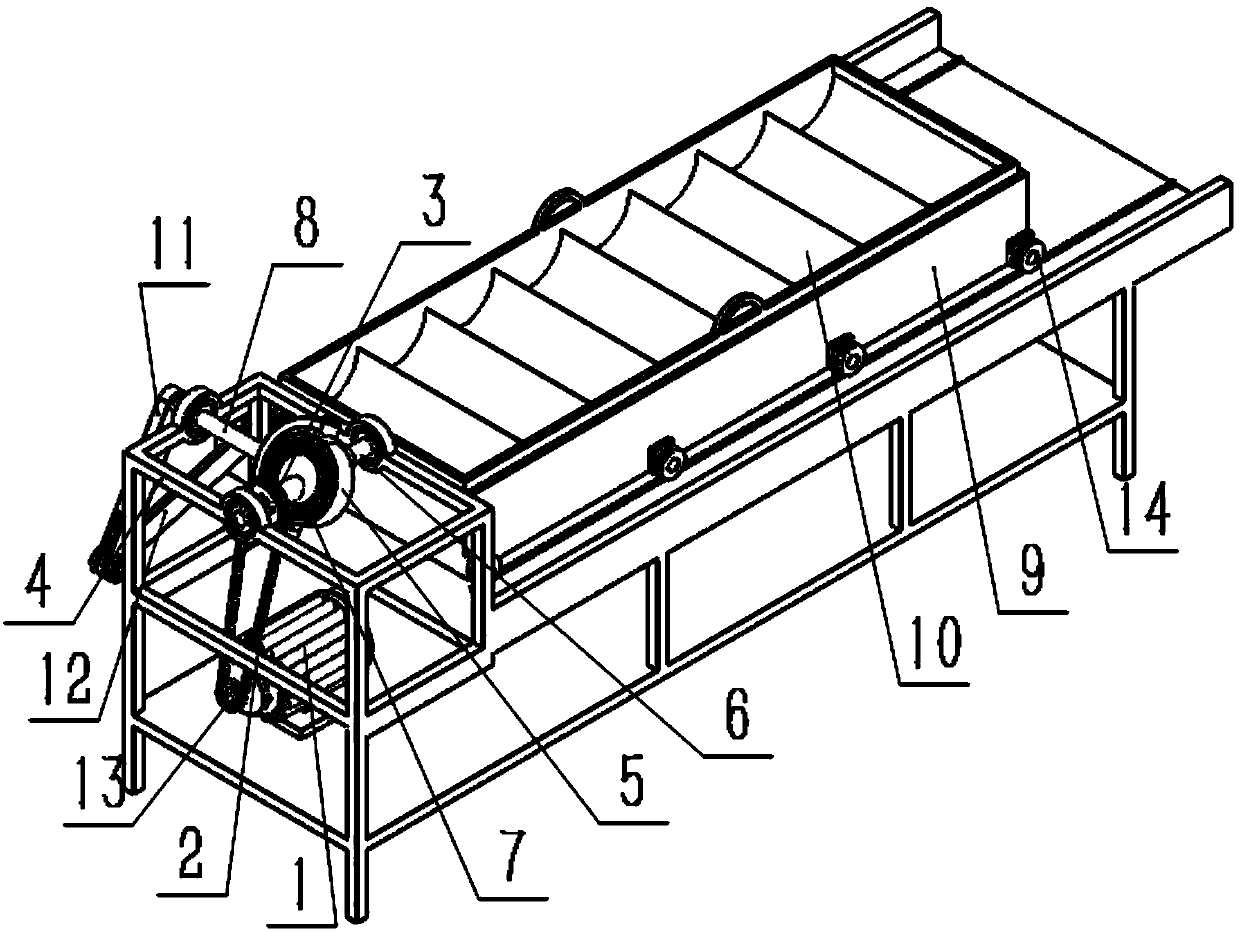

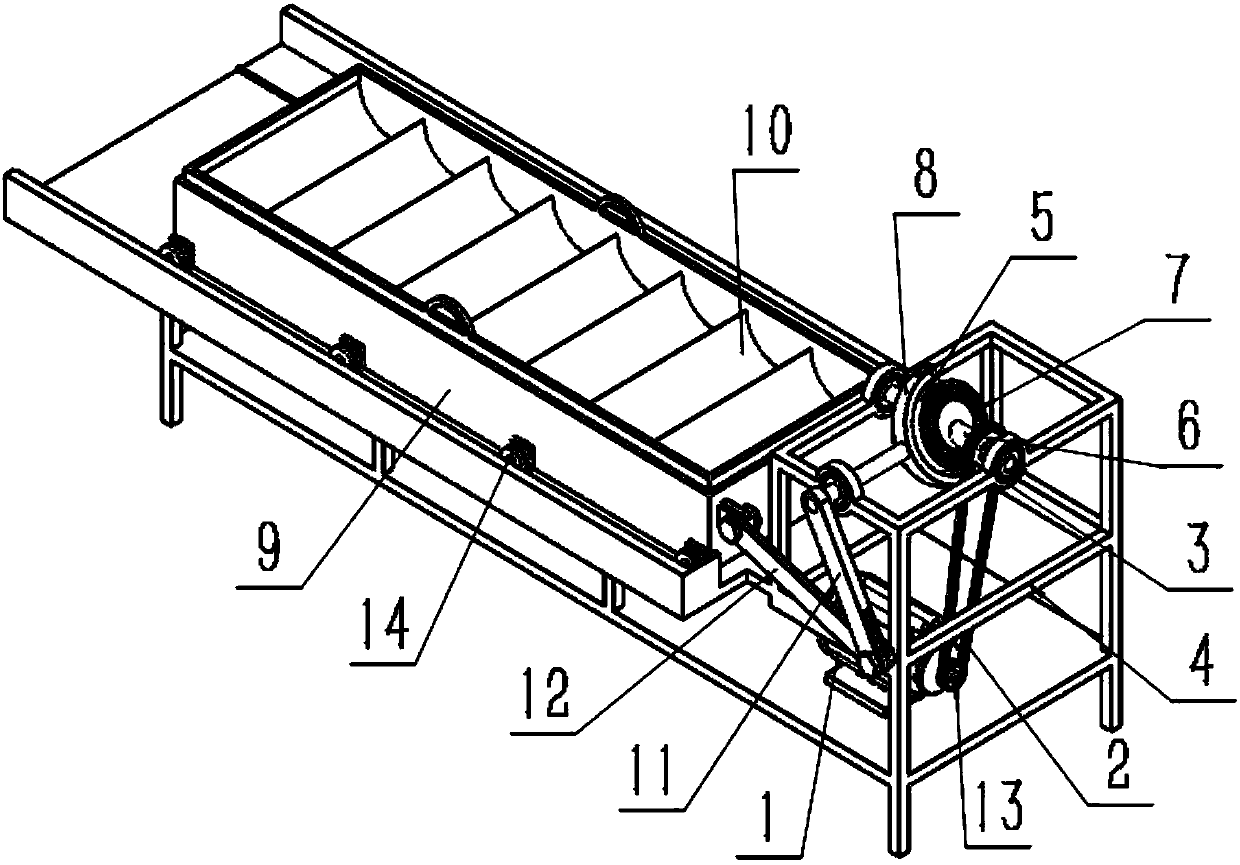

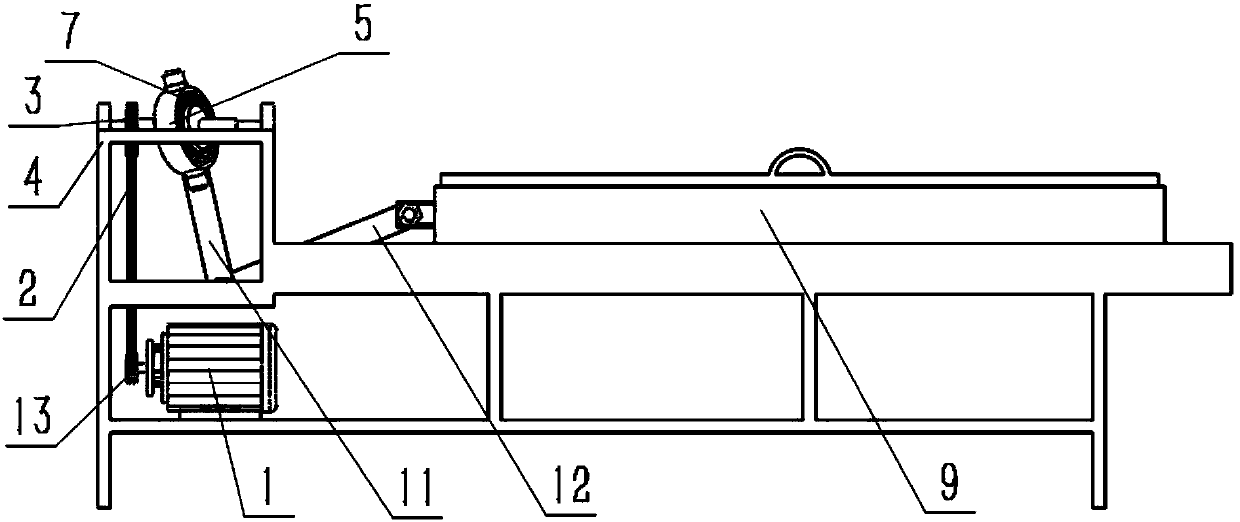

Automatic feeding device

ActiveCN104229398AContinuous strip operationImprove organizational efficiencyConveyorsConveyor partsCardingEngineering

The invention relates to the field of tea processing, in particular to an automatic feeding device. The automatic feeding device comprises a feeding mechanism arranged on a guide rail, wherein a carding machine is arranged at the side of the guide rail, the feeding device reciprocates along a limited direction of the guide rail, the feeding mechanism comprises a hopper used for containing tea leaves to be carded, the hopper presents an open action on the carding machine and is capable of dumping the tea leaves to be carded in the carding machine, the tea leaves to be carded are put into the hopper of the feeding mechanism, the feeding mechanism reciprocates on the frame, the tea leaves to be carded are transferred above the carding machine, the hopper takes a turning action, so that the tea leaves are dumped on the carding machine and carding operation is carried out, a plurality of carding machines can be arranged at the side of the track at intervals, through making the feeding device feed on the frame reciprocally, the continuous carding operation of the carding machines can be implemented, and the carding efficiency of the tea leaves is remarkably improved.

Owner:安徽三九农业装备科技股份有限公司

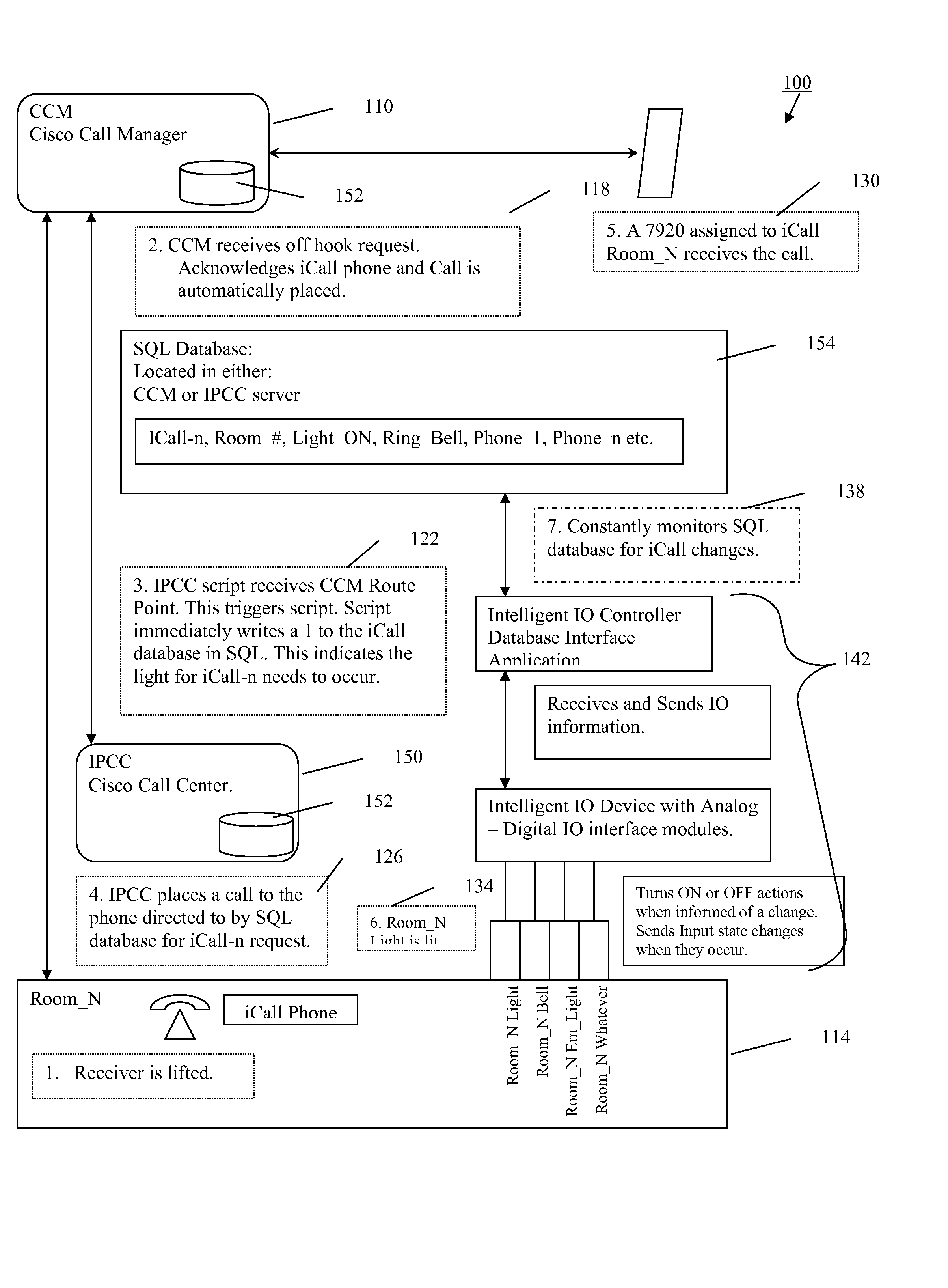

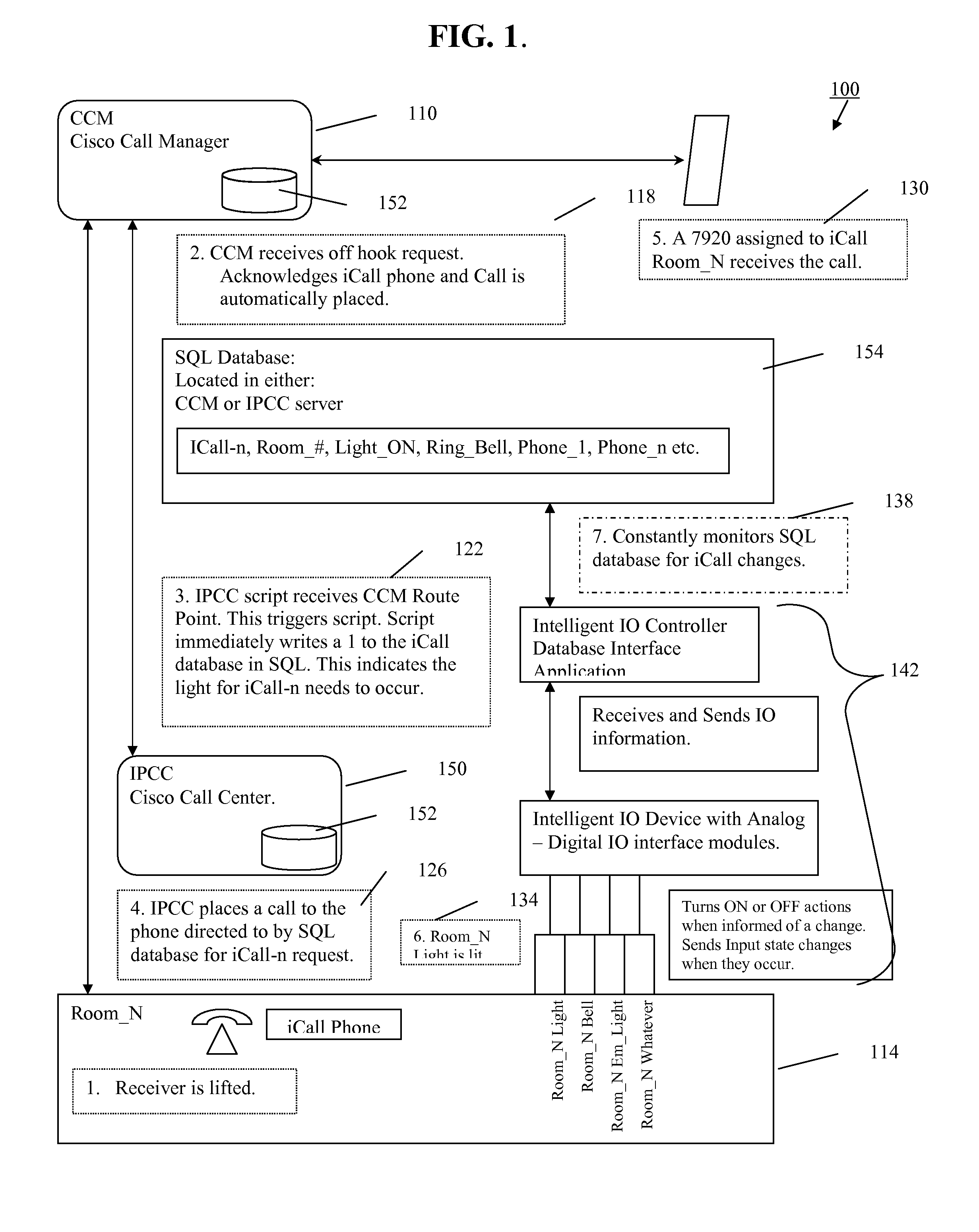

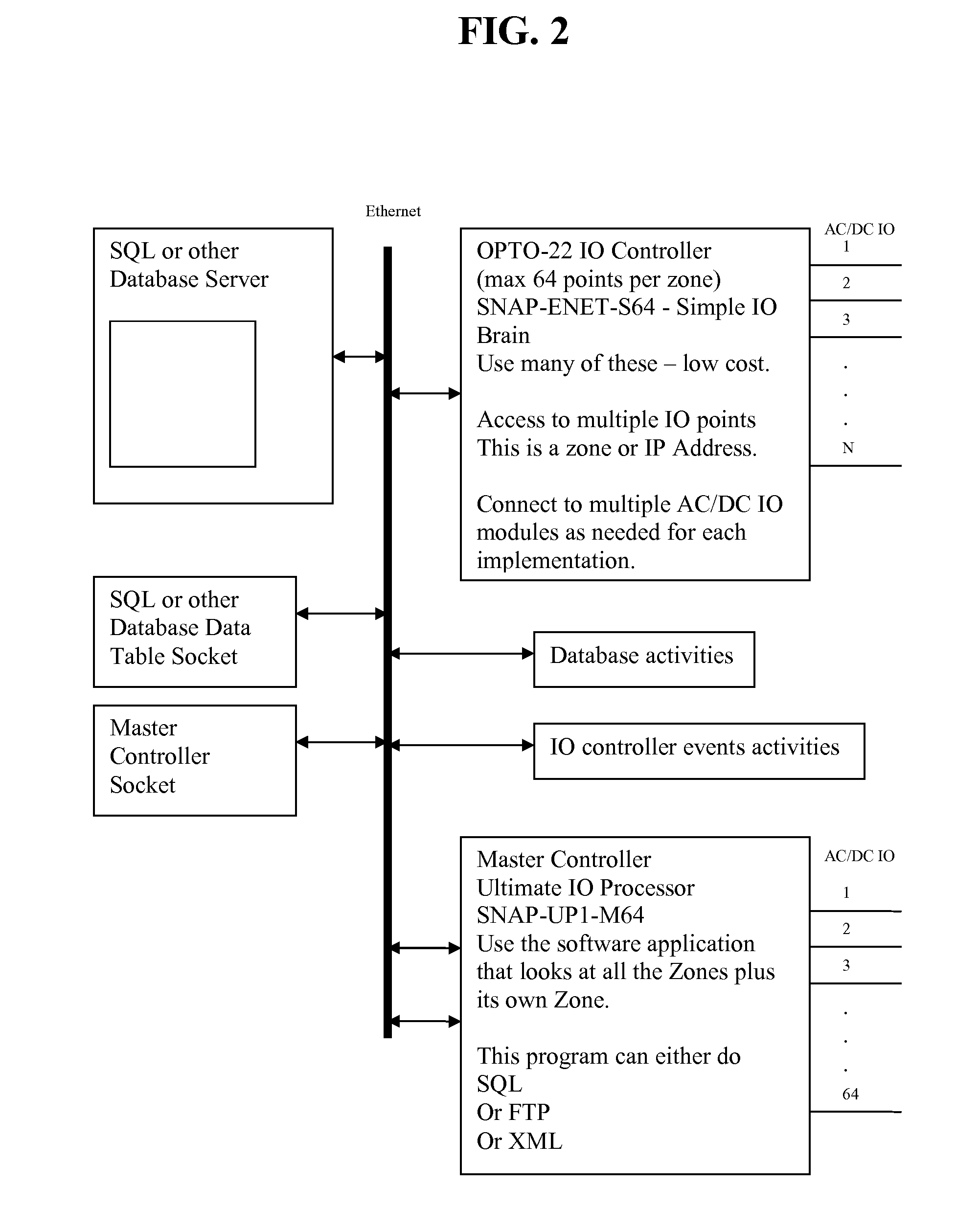

Input/output end point control for integrated telecommunications- network systems (VOIP)

InactiveUS20080107258A1Low costIncrease flexibilitySubstation equipmentWireless commuication servicesTelecommunications networkMonitoring and control

Disclosed are systems and methods that enable expanded functionality for call control monitoring and control of external electrical / electromechanical devices using a telecommunication system.

Owner:FITZSIMMONS CARL

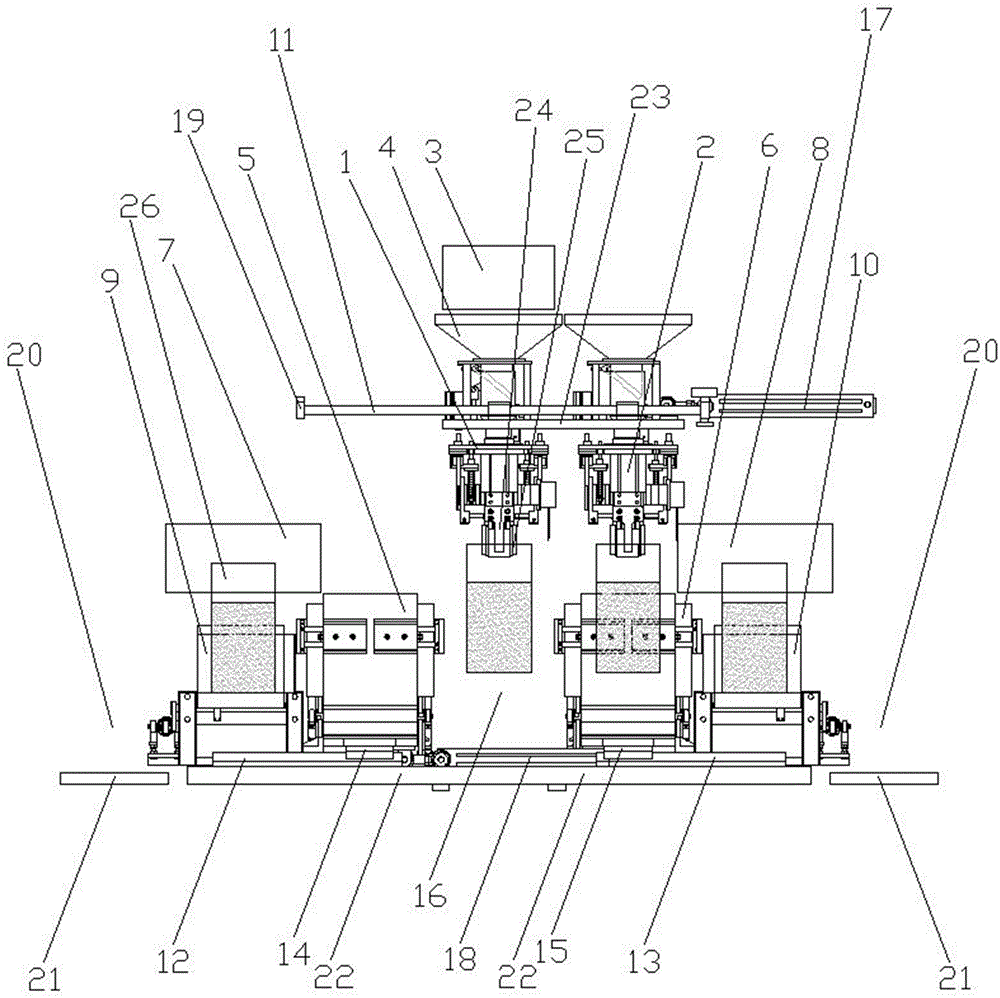

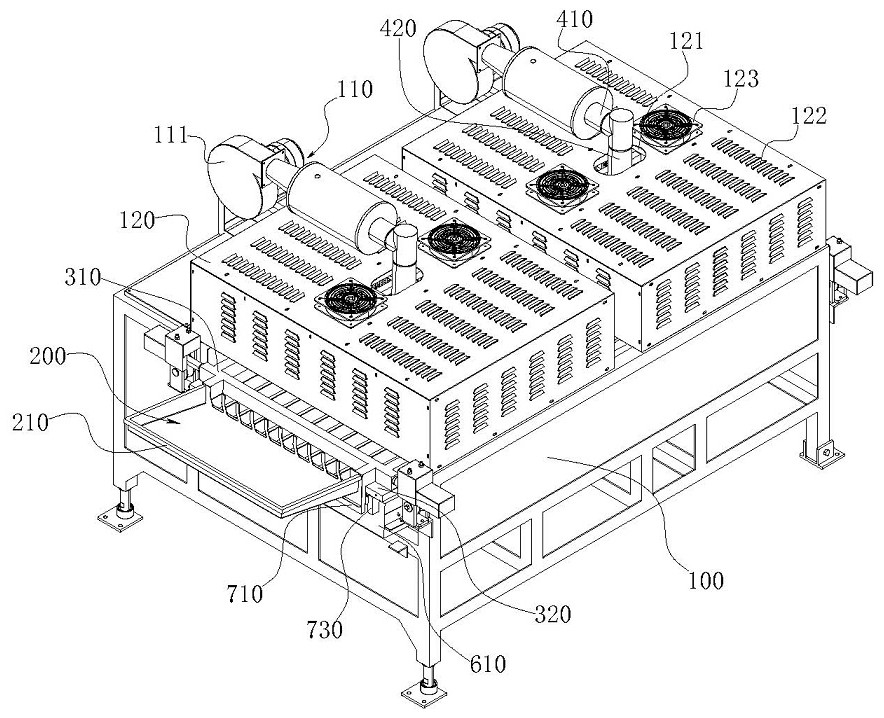

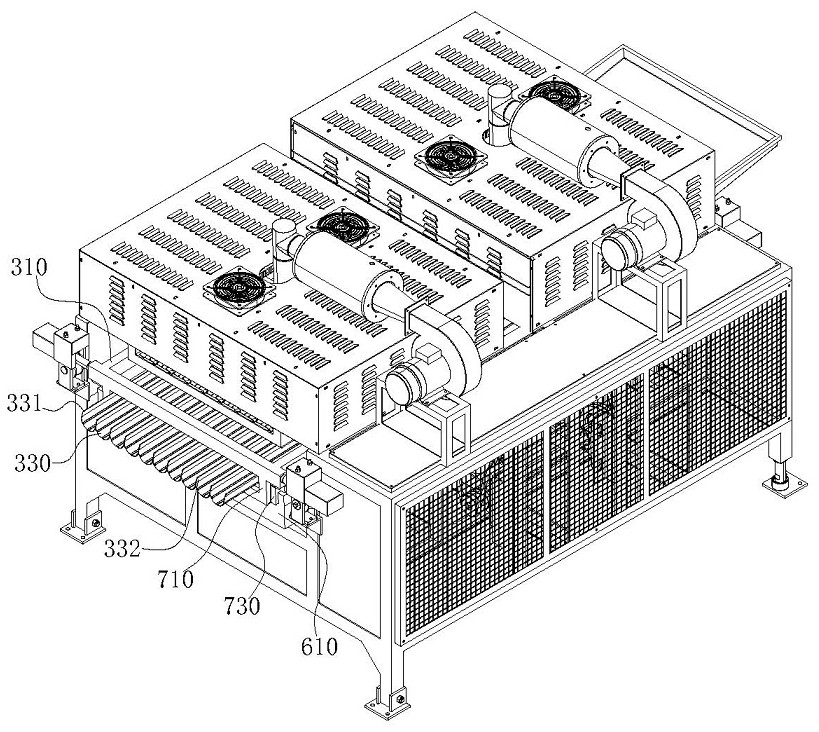

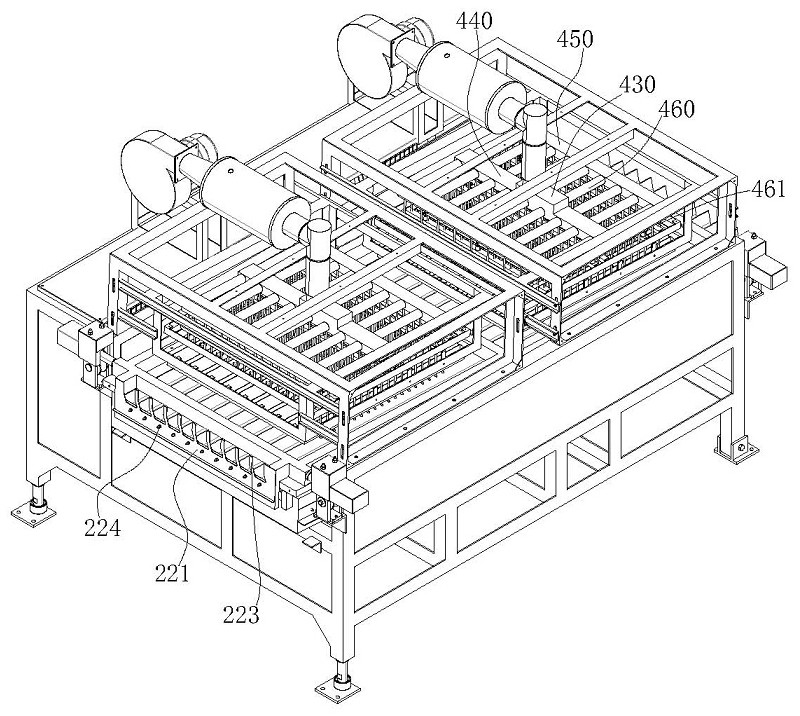

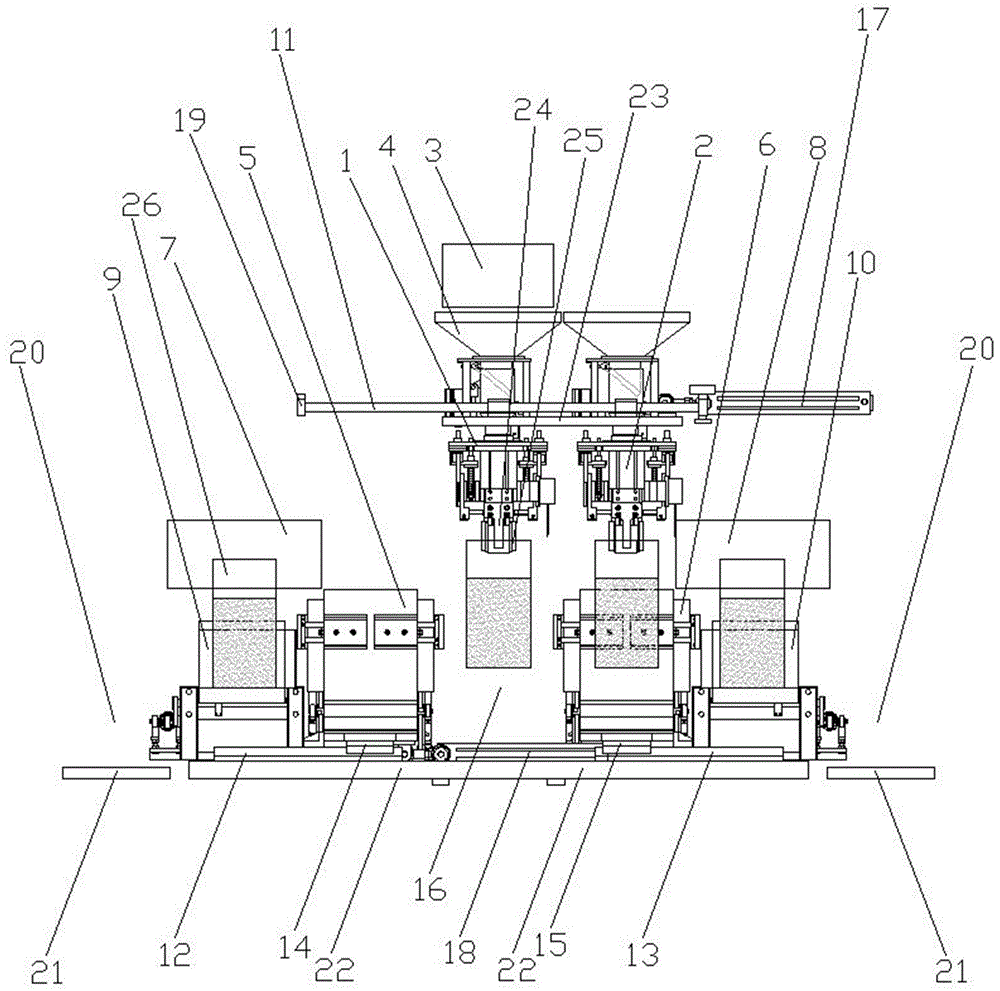

Double-station vacuum packaging mechanism capable of achieving continuous operation

ActiveCN104859871AImprove conversion efficiencyImprove organizational efficiencySolid materialEngineeringContinuous operation

The invention discloses a double-station vacuum packaging mechanism capable of achieving continuous operation. The double-station vacuum packaging mechanism is used for mass vacuum packaging of materials, and comprises a rack, a filling assembly, a quantitative scale, a first shaping part, a second shaping part, a first sealing assembly, a second sealing assembly, a first discharging device, a second discharging device, a guiding shaft, guiding rails and a PLC industrial control part. A packaging driving part is arranged on the lower portion of the rack, discharging stations are arranged on the two sides of the rack, a filling driving part and the horizontal guiding shaft are arranged on the upper portion of the rack, the quantitative scale is arranged above the middle of the guiding shaft, and the filling assembly is located at the guiding shaft and comprises a first filling part, a second filling part and a filling platform. Packaging bags are filled while the filling platform slides on the guiding shaft, the first shaping part, the second shaping part, the first discharging device and the second discharging device are fixed to guiding rail sliding blocks in a grouped mode, and the distance between the shaping part and the discharging device in any group is matched with the horizontal moving distance of the filling and discharging mechanisms. According to the double-station vacuum packaging mechanism, double-station design is achieved on the filling assembly, the filling, shaping, sealing and discharging actions of the double-station vacuum packaging mechanism are continuously carried out through structure matching, and thus efficiency is improved.

Owner:ZHANGZHOU JIALONG TECH INC

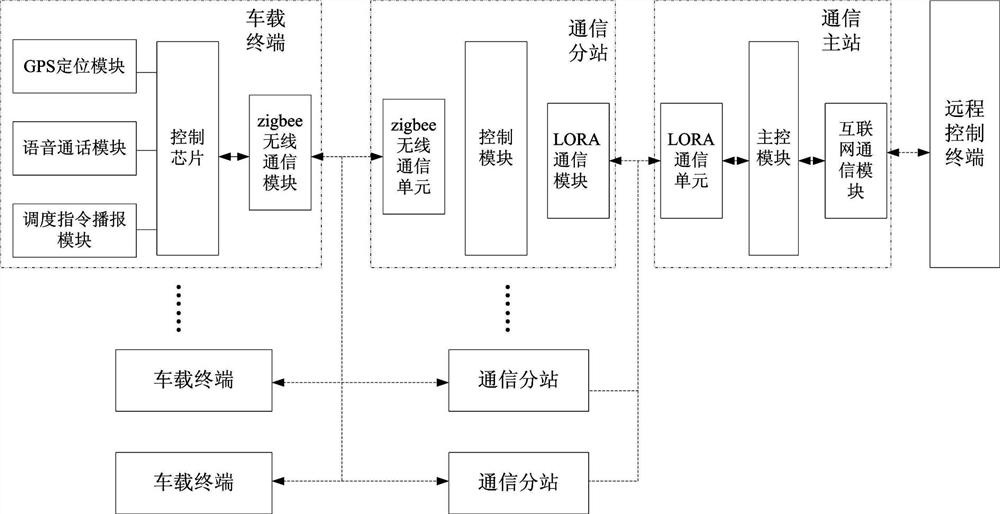

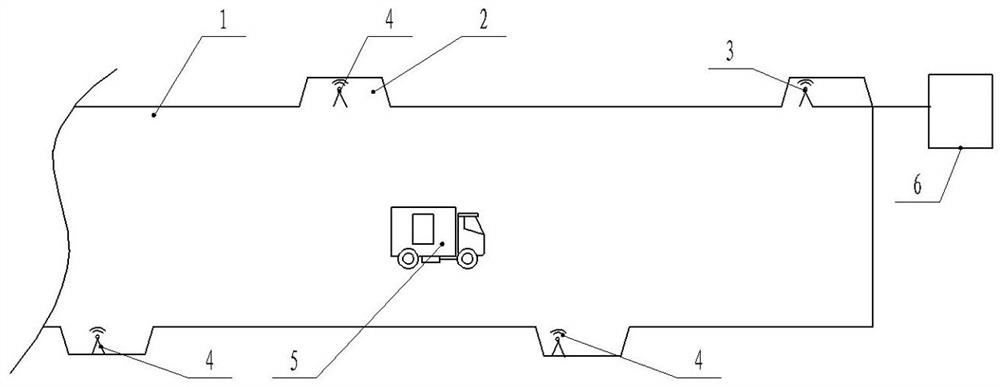

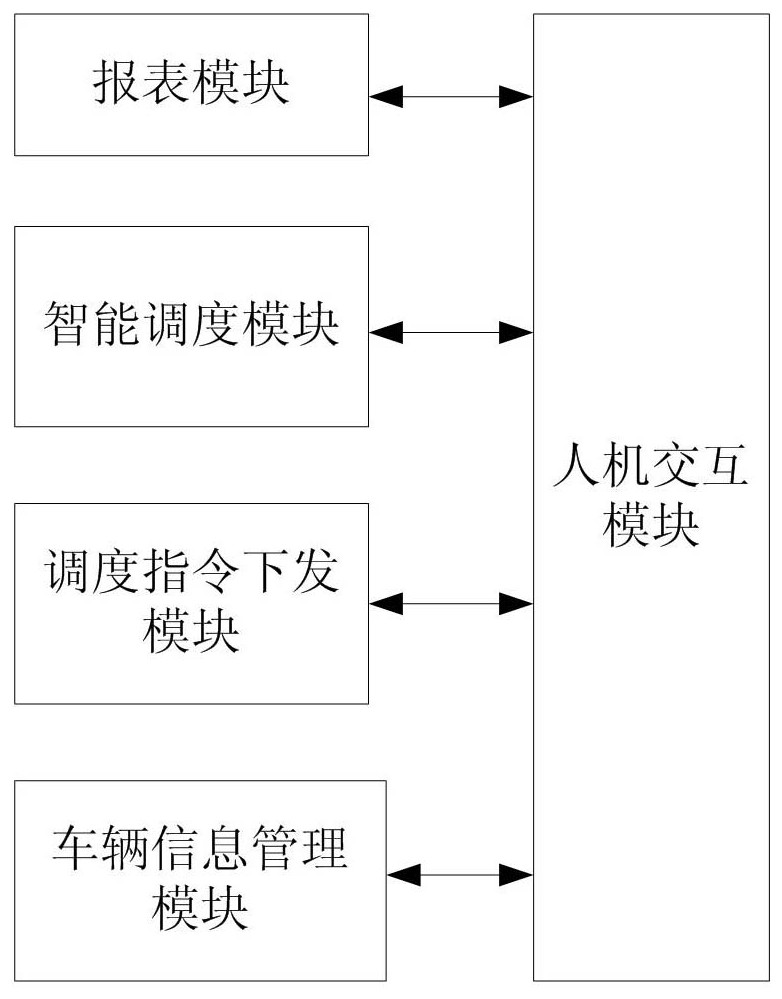

Tunnel vehicle intelligent scheduling command system

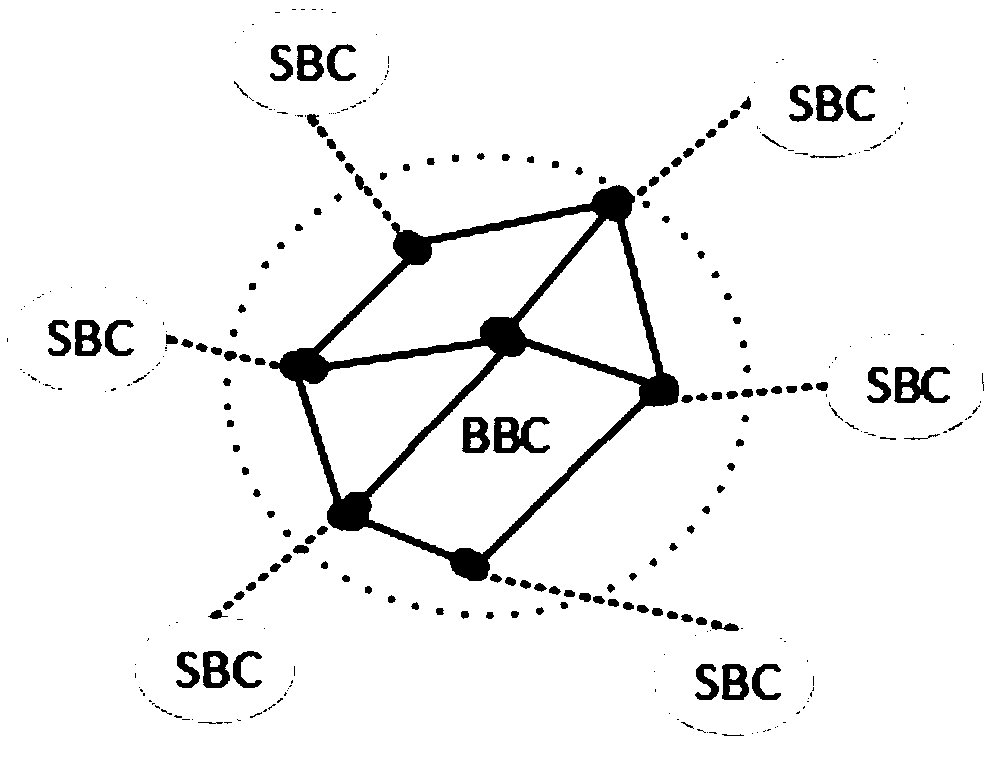

PendingCN112927549ARealize the purpose of dispatching and commandingRealize the effect of intelligent wrong carRoad vehicles traffic controlParticular environment based servicesInternet communicationIn vehicle

The invention belongs to the technical field of intelligent traffic guidance, and discloses a tunnel vehicle intelligent scheduling command system which comprises a vehicle-mounted terminal, a remote control terminal, a communication master station and a plurality of communication substations. The vehicle-mounted terminal is connected with the communication substation through ZIGBEE wireless communication, the communication substation is connected with the communication master station through wireless communication, and the communication master station is connected with the far-end control terminal through Internet communication; the communication substations are used for receiving signals sent by the vehicle-mounted terminals, calculating distance data of the vehicle-mounted terminals and sending the distance data to the communication master station, and the communication master station is used for determining position data of the vehicle-mounted terminals according to the distance data sent by the communication substations and sending the position data to the remote control terminal; and the remote control terminal calculates and processes the position data of all the vehicle-mounted terminals by using an intelligent scheduling instruction algorithm to obtain a vehicle staggering scheme, generates a scheduling instruction and issues the scheduling instruction to a corresponding vehicle in the tunnel. The system is reasonable in structure and convenient to deploy, and intelligent scheduling and manual scheduling of tunnel vehicles can be realized.

Owner:BRIDGE & TUNNEL ENG CO OF THE THIRD ENG GRP CO LTD OF CHINA RALLWAY +1

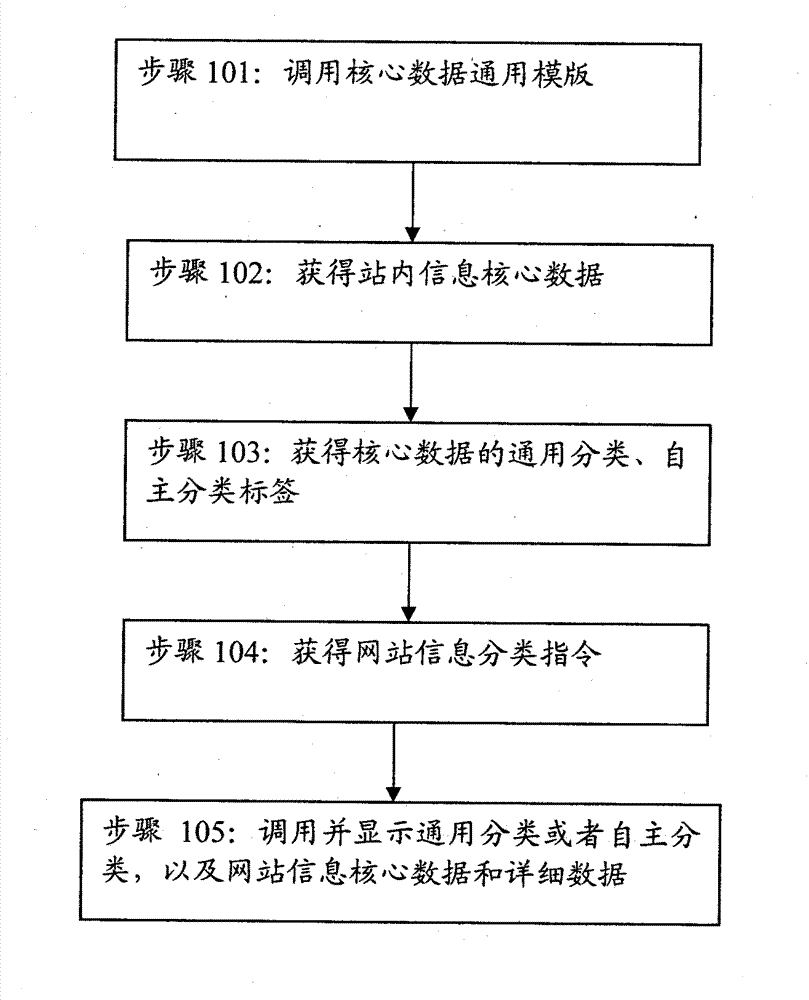

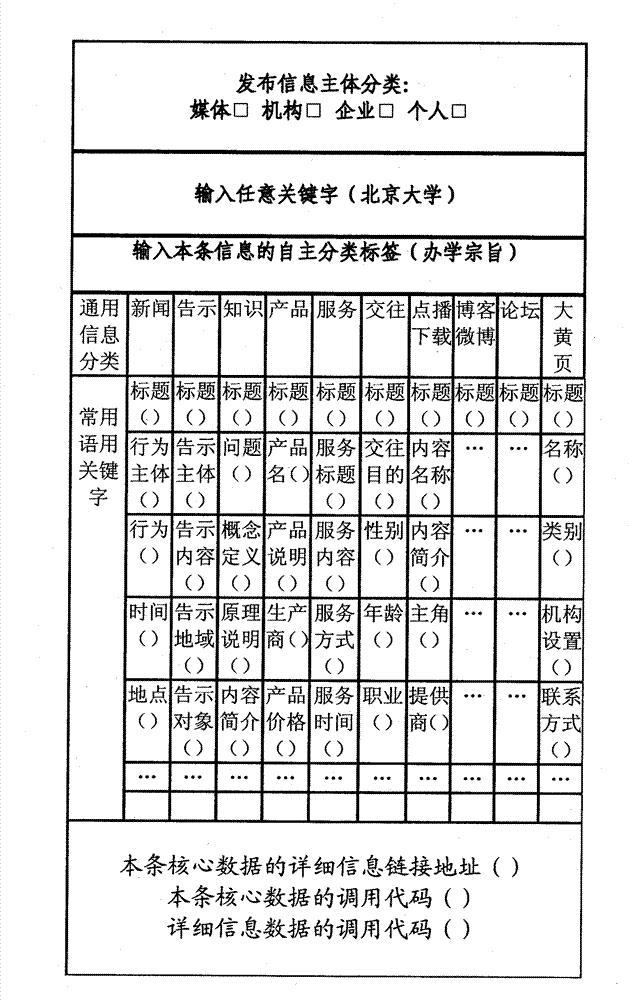

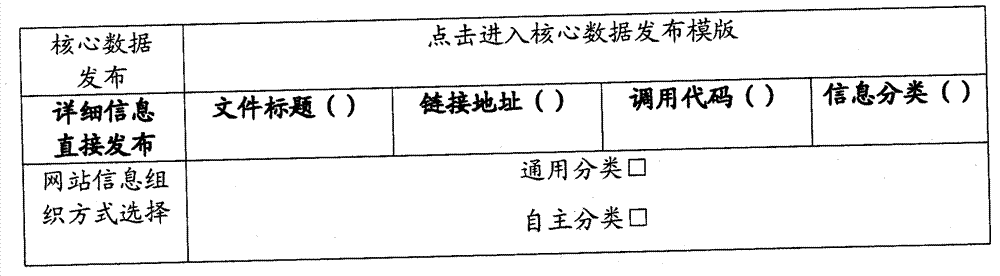

Method and device for organizing website information

ActiveCN102819594AImprove organizational efficiencyImprove comprehensive search efficiencySpecial data processing applicationsCommon methodThe Internet

The invention provides a method and a device for organizing website information. The method and the device are characterized in that classification, release and retrieval of general core data are used as basic organization modes of the website information, so that the organization efficiency of the website information is fundamentally improved and the comprehensive searching efficiency of internet information is fundamentally improved.

Owner:CHONGQING SIZAI INFORMATION TECH CO LTD

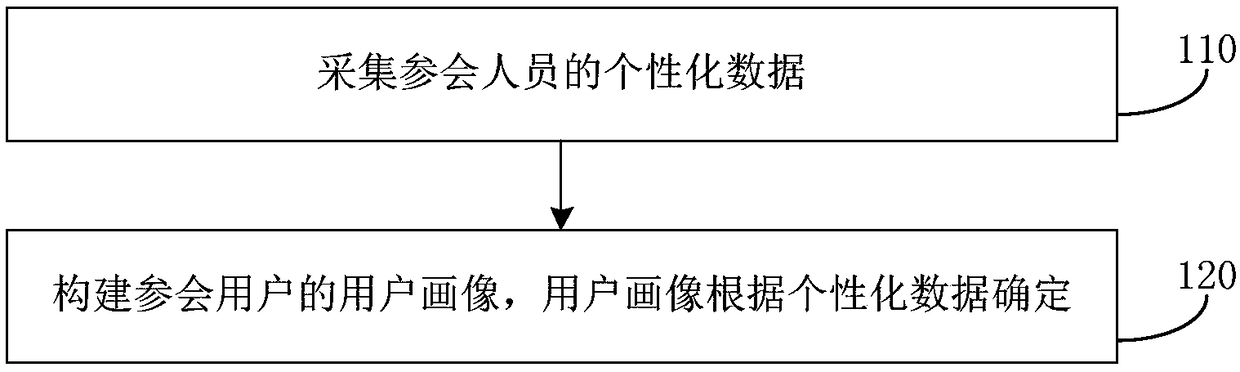

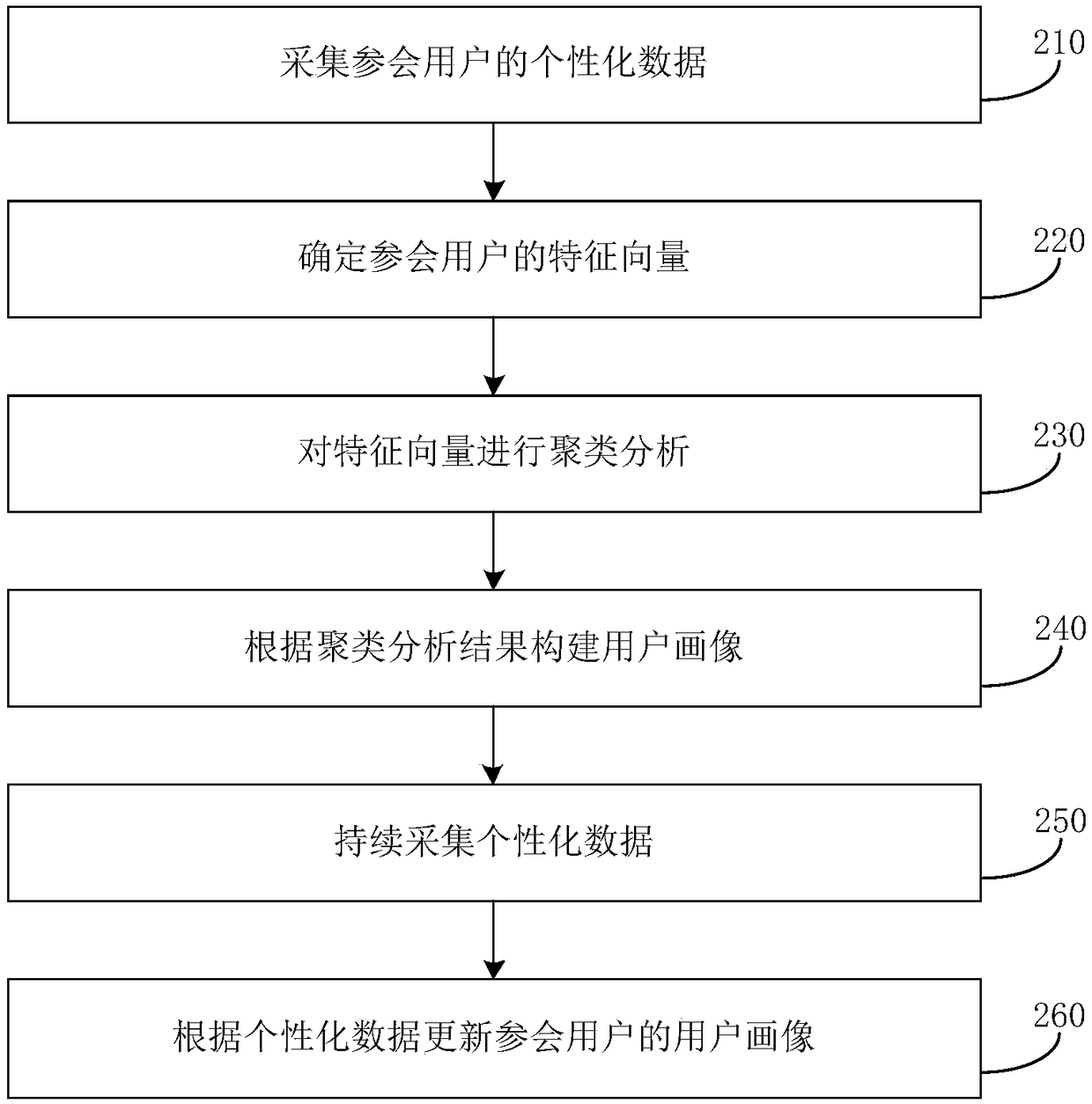

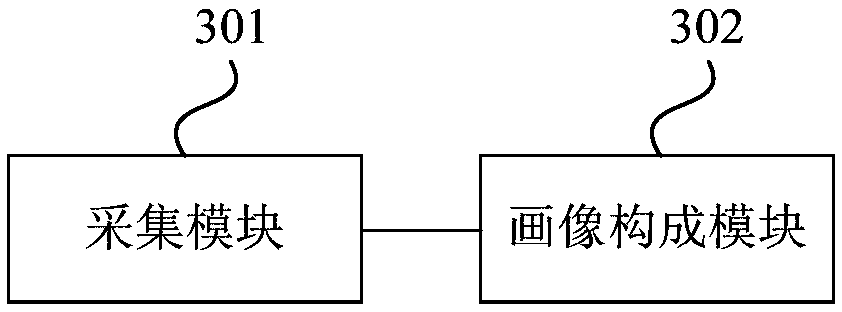

Participating user portrait generation method, device, intelligent conference device and storage medium

InactiveCN109242309AGuaranteed accuracyImprove organizational efficiencyInput/output for user-computer interactionResourcesPersonalizationHuman–computer interaction

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

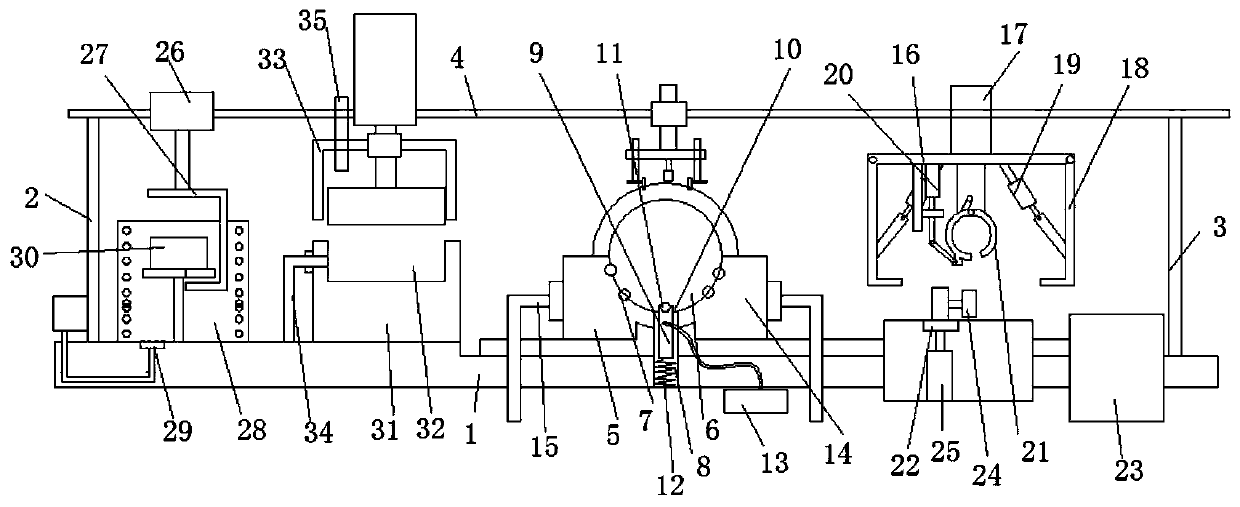

Automobile brake air inlet pipe heating forging detection device

ActiveCN107300506ATimely detection of stress resistanceAchieve liftingRevolution surface grinding machinesMaterial strength using tensile/compressive forcesEngineeringAtmospheric pressure

The invention discloses an automobile brake air inlet pipe heating forging detection device, which comprises a base and is characterized in that a left support post and a right support post are arranged on the base; a cross beam plate is fixedly arranged on the tops of the left and right support posts; a slide block is arranged on the cross beam plate; an air cylinder is arranged on the slide block; the lower end of the air cylinder is connected with a carrying frame; a heating tube is arranged under the carrying frame; a heating wire is arranged on the side wall of the heating tube; a protection air spraying nozzle is arranged at the bottom of the heating tube; a workpiece support frame is arranged in the heating tube; an air pressure detection table is arranged at one side of the heating tube; a convex cavity is formed in the center of the air pressure detection table; a sealing cover is arranged above the convex cavity; a cooling air spray pipe is connected onto the sealing cover; an air inlet pipe is arranged at the side wall of the detection table. The automobile brake air inlet pipe heating forging detection device has the advantages that the structure is simple; the automobile pipeline shaft roundness detection is accurate; the timely grinding regulation is convenient; the use is firm and stable; the position limiting effect is good.

Owner:ANHUI YUEZHONG AUTO BODY EQUIP

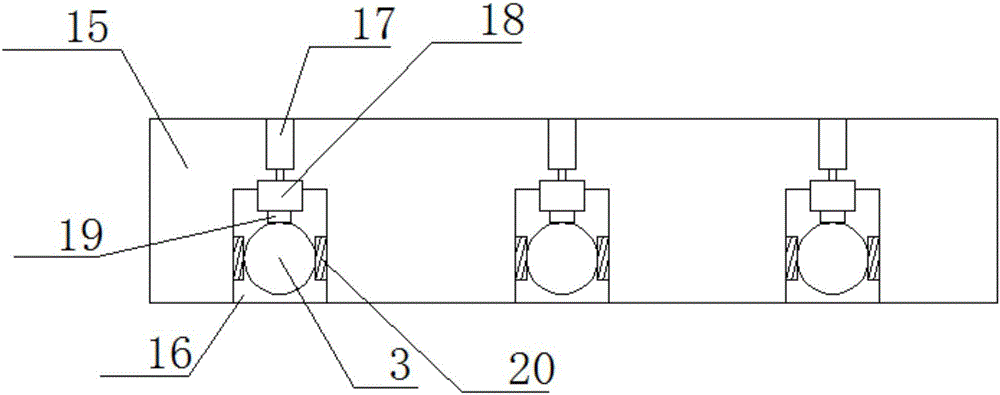

Far infrared hot air compounding and carding equipment

PendingCN111838345AHeating evenlyImprove drying effectPre-extraction tea treatmentDrying solid materials with heatCardingStraight tube

The invention relates to far infrared hot air compounding and carding equipment. The equipment comprises a machine frame, a strip tidying mechanism for carding tea leaves is arranged on the rack, a feeding mechanism for conveying tea leaves into the strip tidying mechanism is arranged at the feeding end of the strip tidying mechanism, the strip tidying mechanism comprises strip tidying grooves which are arranged in an arrayed manner, an air distribution mechanism for blowing hot air to the tea leaves in the carding process and a far infrared heating mechanism for heating the tea leaves are arranged on the upper side of the carding groove, the air distribution mechanism comprises a pipe body A, a straight pipe section is arranged on the upper side of the pipe body A, an inclined pipe section is arranged at the lower end of the straight pipe section, the air outflow direction of the inclined pipe section is consistent with the opening direction of the carding groove, and an electric heating mechanism is arranged on the lower side of the carding groove. The equipment is good in heating effect, low in heat loss rate, high in carding efficiency and high in automation degree.

Owner:YUEXI COUNTY GREAT WALL MACHINERY

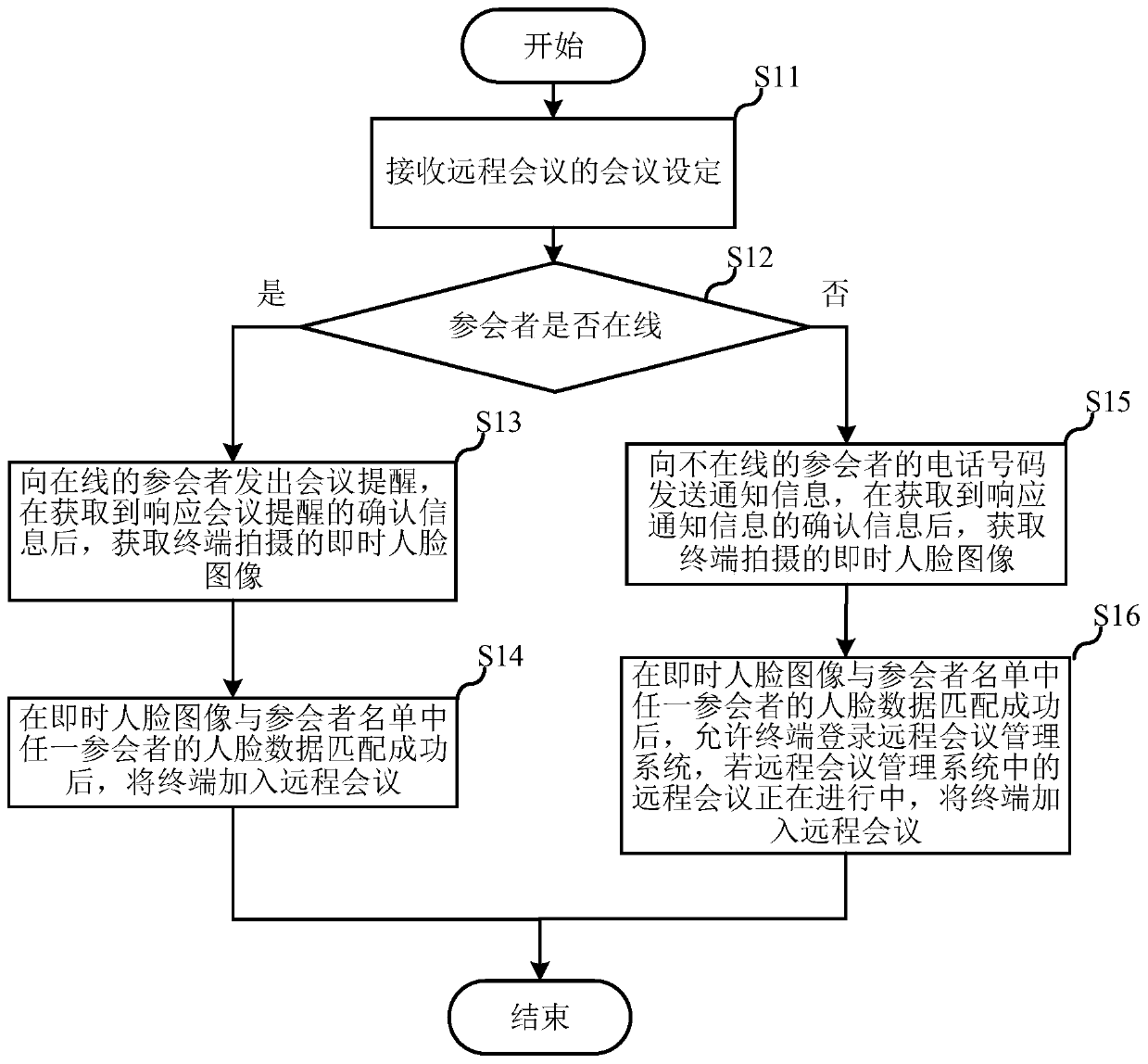

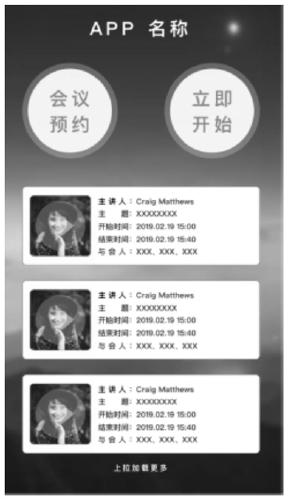

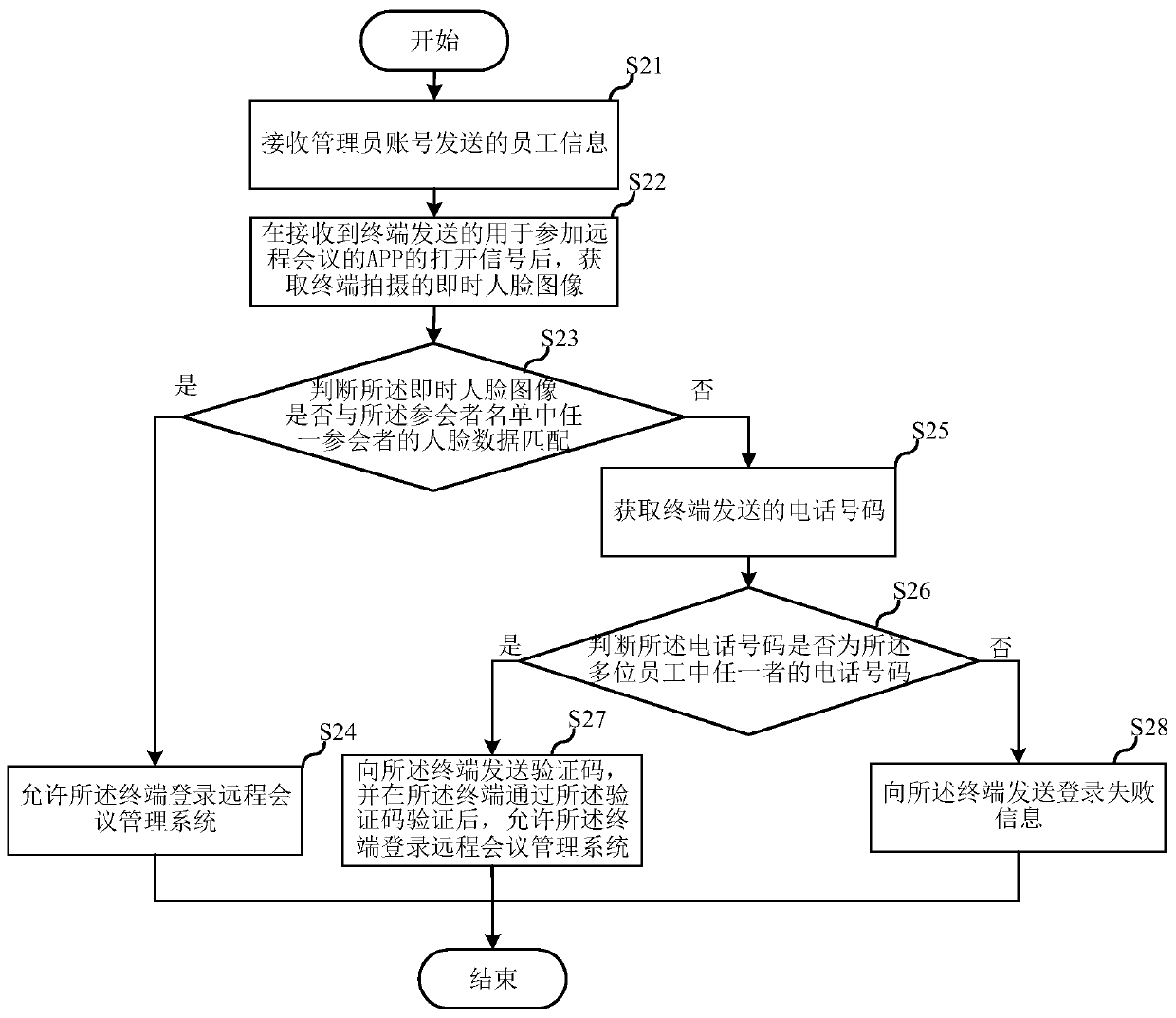

Teleconference management method, server and computer readable storage medium

ActiveCN111191205AImprove organizational efficiencyAvoid timeDigital data authenticationData matchingEngineering

The embodiment of the invention relates to the technical field of communication, and discloses a teleconference management method, a server and a computer readable storage medium. According to the invention, the teleconference management method comprises the following steps: receiving conference settings of a teleconference, the conference settings comprising a participant list; acquiring an instant face image shot by a terminal, and judging whether the instant face image is matched with the face data of each participant in the participant list or not; and after the instant face image is successfully matched with the face data of any participant in the participant list, adding the terminal into the teleconference. The invention further provides a server and a computer readable storage medium. According to the teleconference management method, the server and the computer readable storage medium provided by the invention, the security of the teleconference can be improved.

Owner:CHINA MOBILEHANGZHOUINFORMATION TECH CO LTD +1

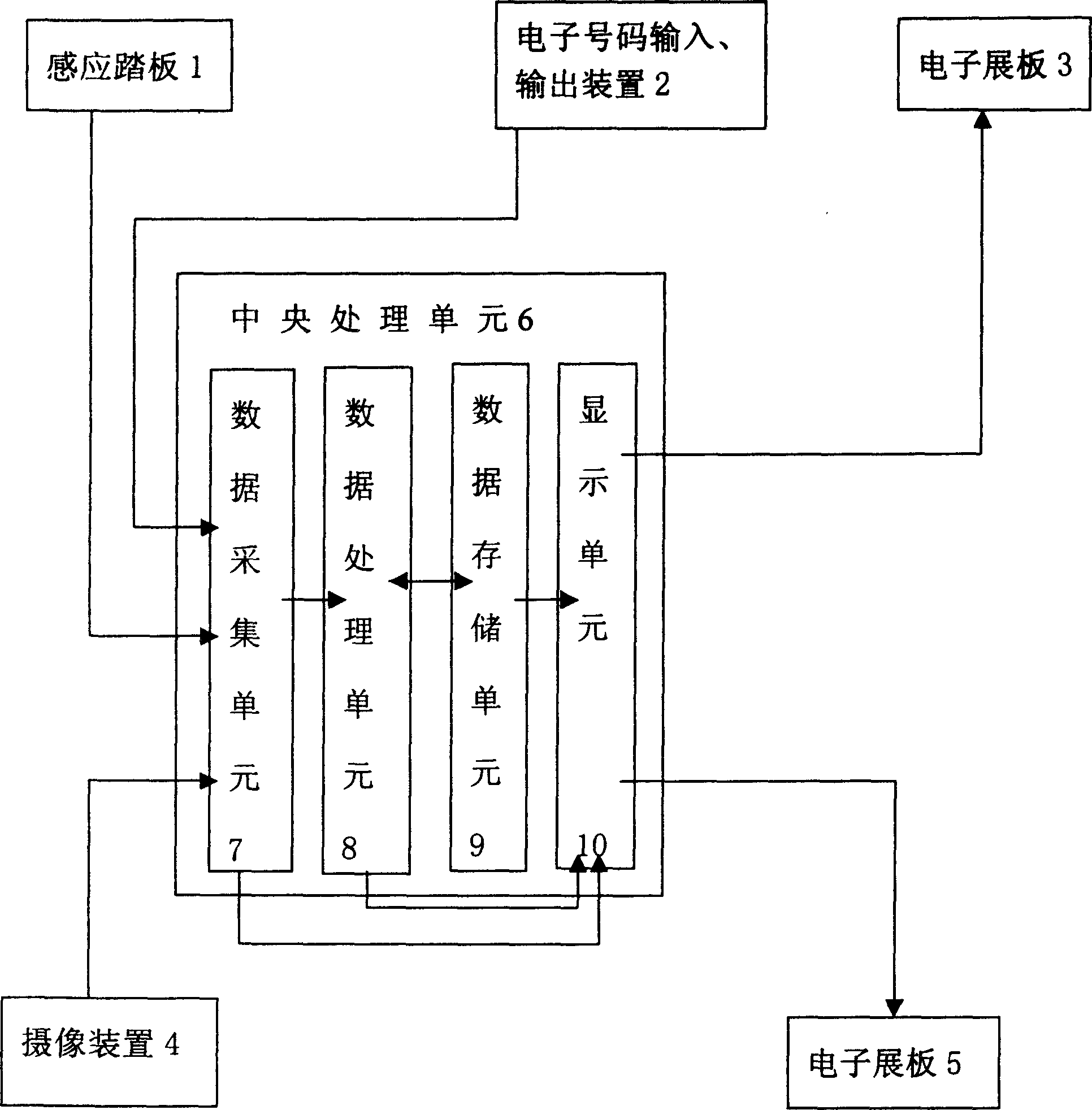

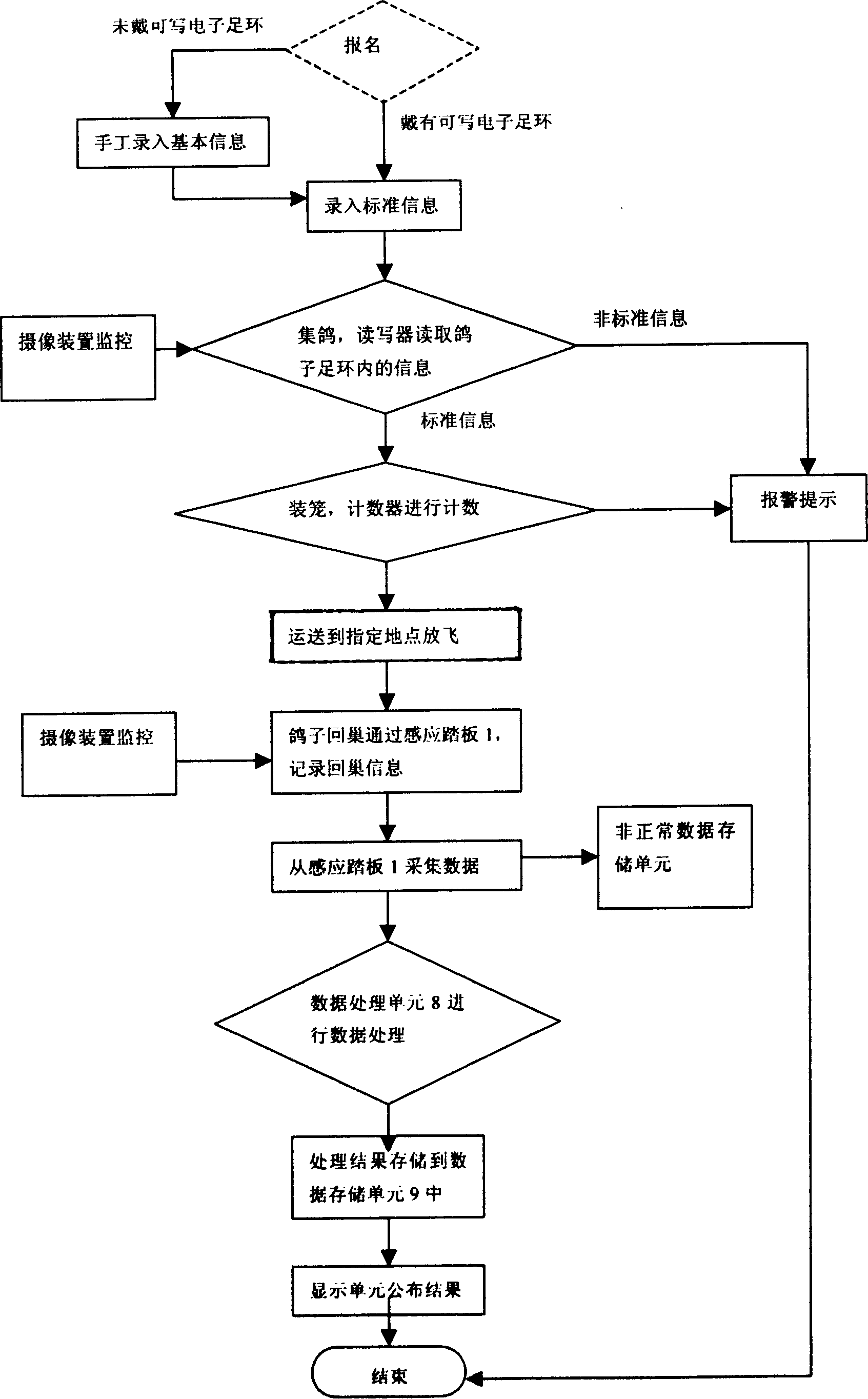

Homing pigeon public shed system and managing method thereof

The invention relates to a homing pigeon public shed system and managing method, wherein the booth management system comprises an electronic foot ring, a pigeonloft with induction pedal 1 and a connected central processing element which comprises a data acquisition unit, a data processing unit, a data memory unit and a display unit, the induction pedal is connected with the data acquisition unit, the data acquisition unit is connected with the data process unit and the data memory unit.

Owner:西安科汇科技发展有限公司

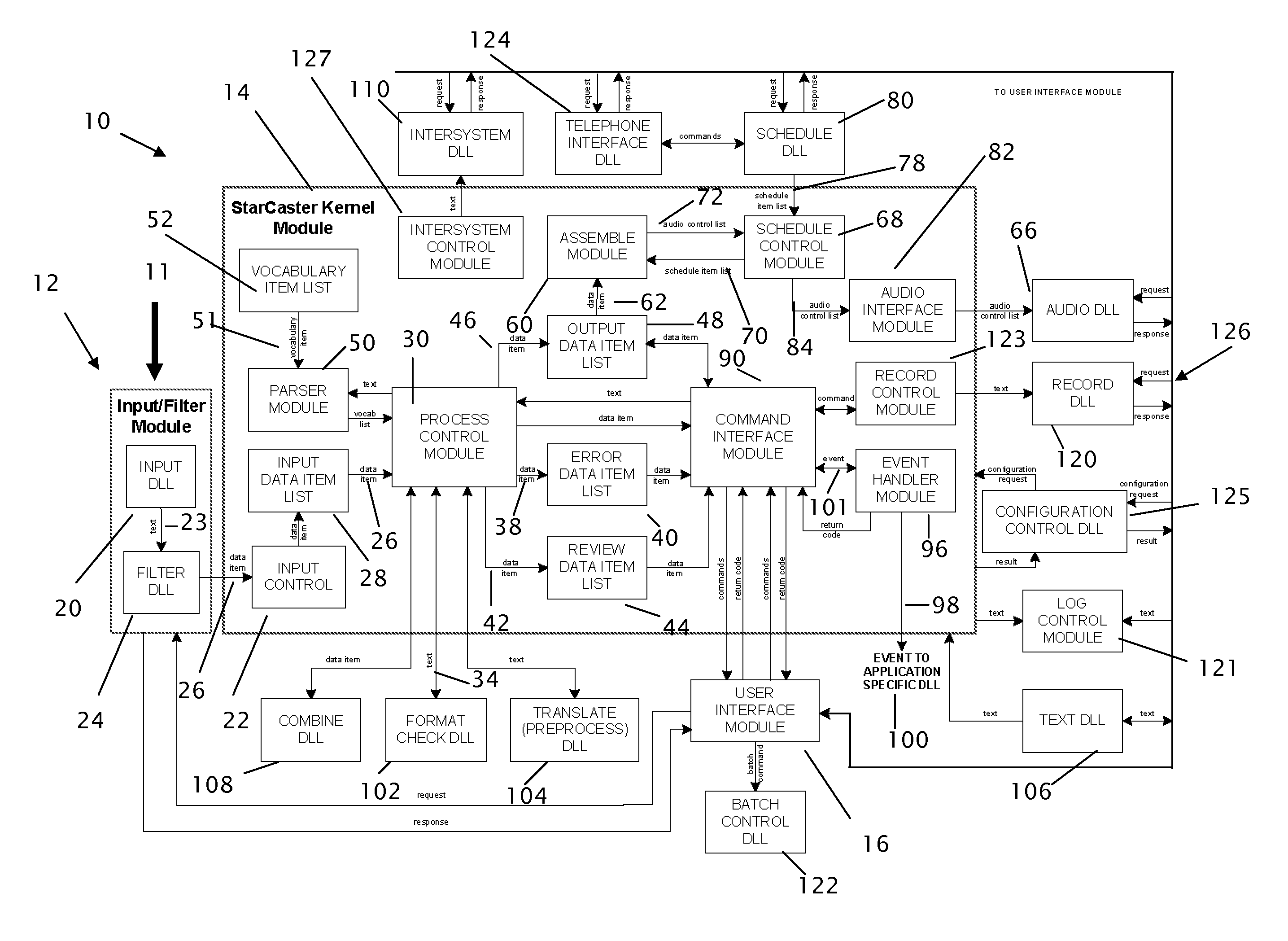

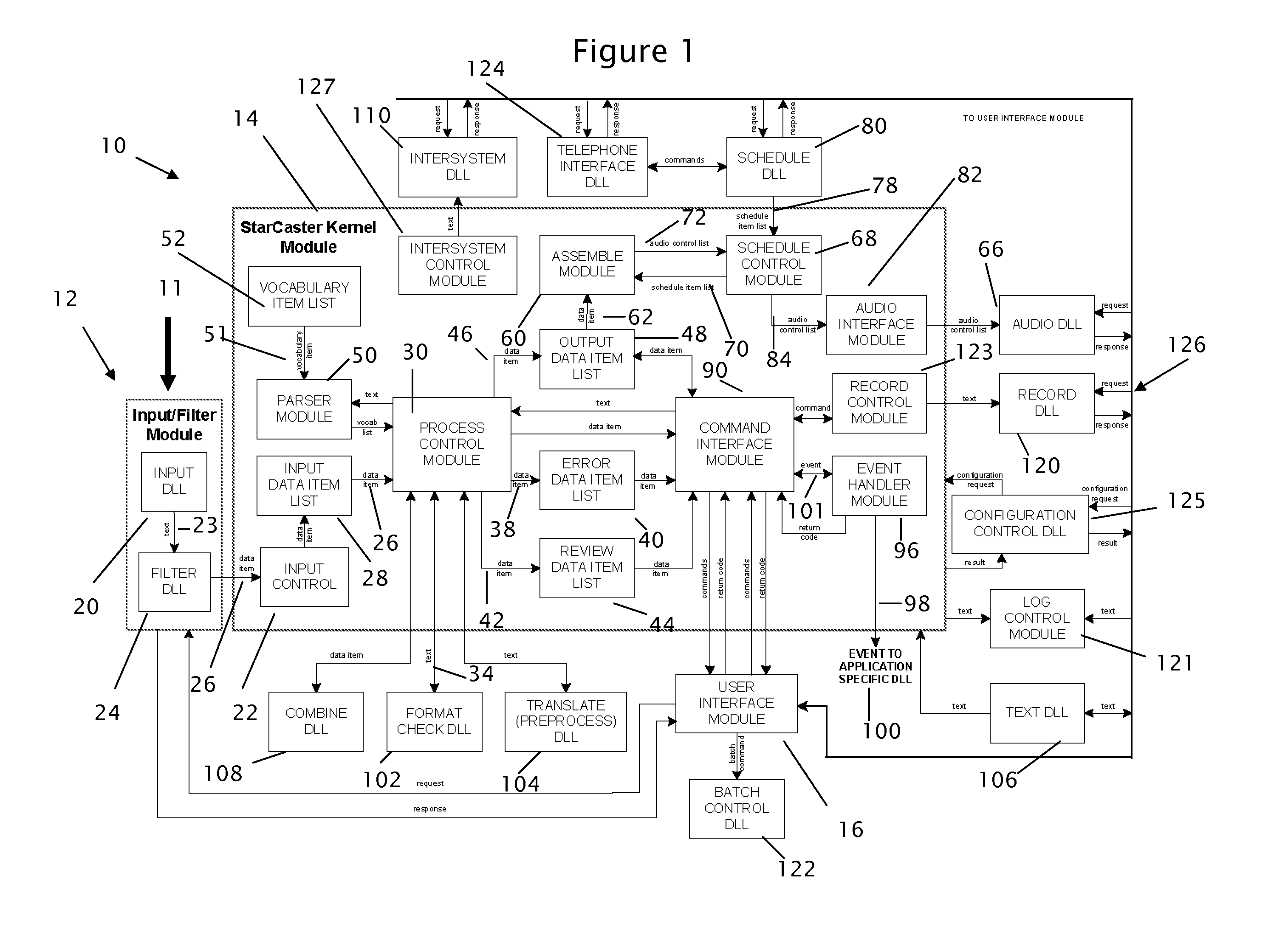

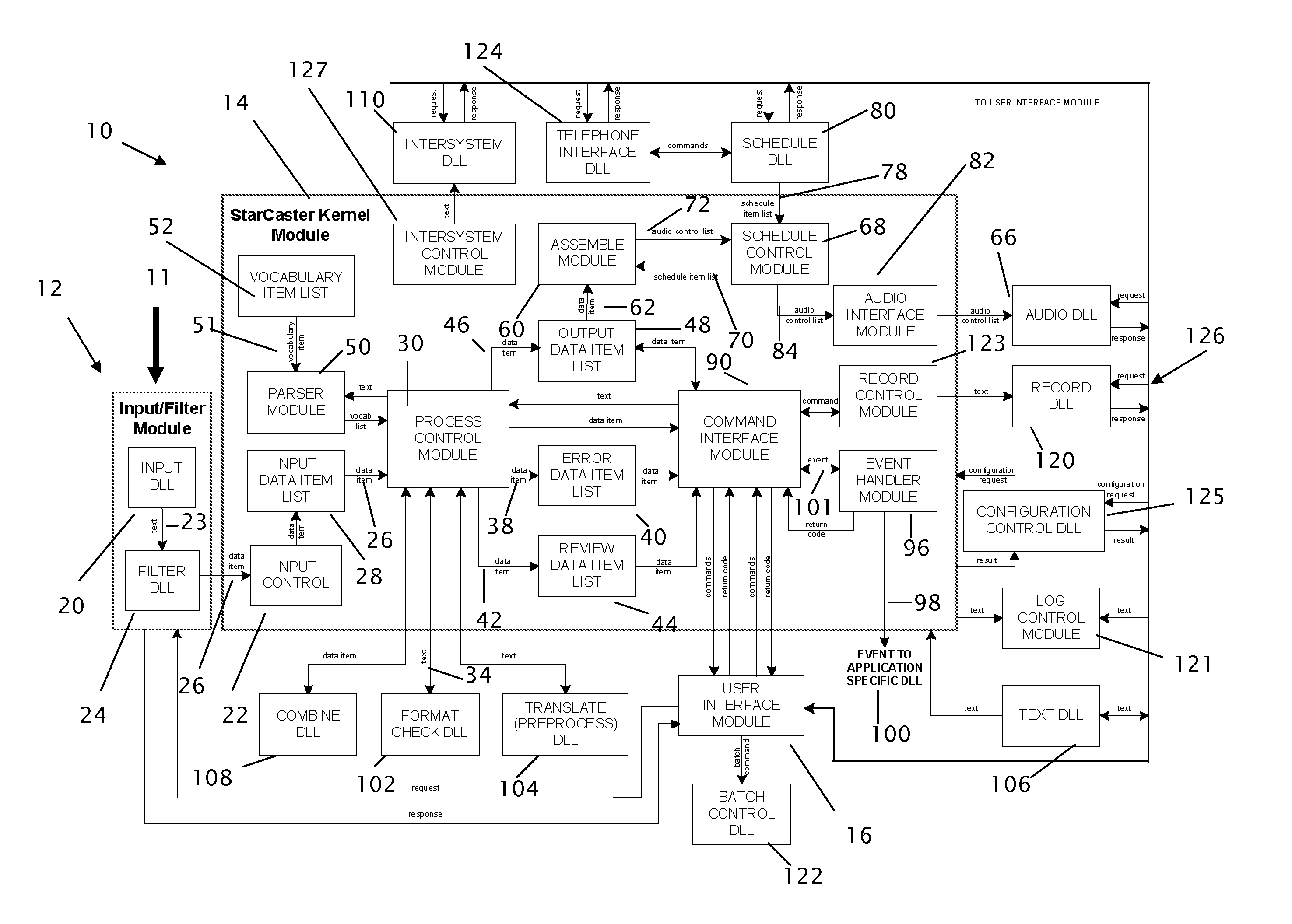

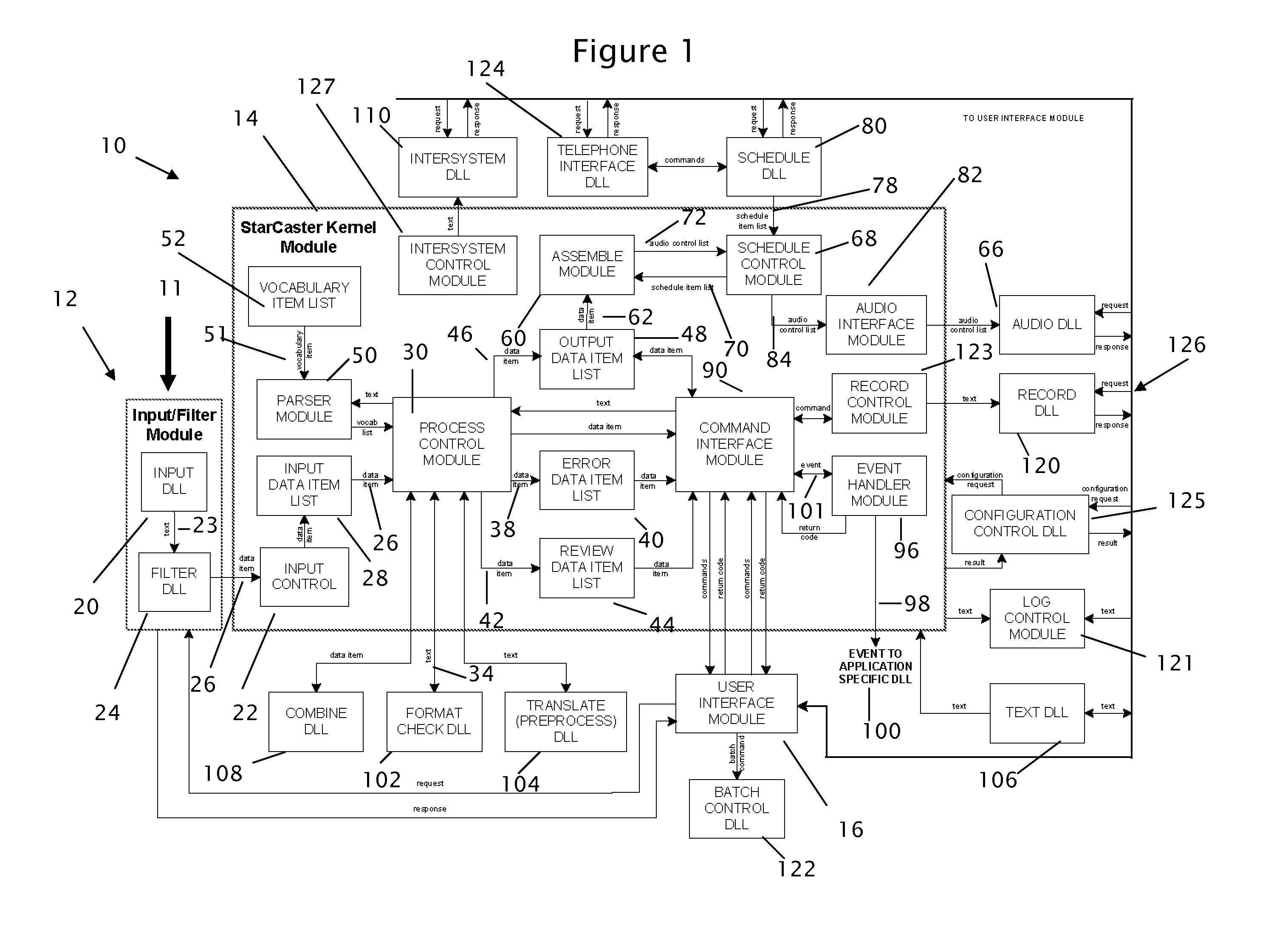

Text to speech interactive voice response system

InactiveUS7895041B2Quality improvementCost-effectiveSpeech recognitionSpeech synthesisData streamSystems management

A text to speech interactive voice response system is operable within a personal computer having a processor, data storage means and an operating system. The system comprises an input subsystem for receiving a text data stream from a source device in a predetermined format; a process control subsystem for converting the text data stream into corresponding output data items; an audio record subsystem for recording audio data to be associated with each output data item; and, a broadcast control subsystem for generating an audio broadcast based on the output data items. There is also disclosed a system management and control subsystem for user interface with the system.

Owner:DICKSON CRAIG B +2

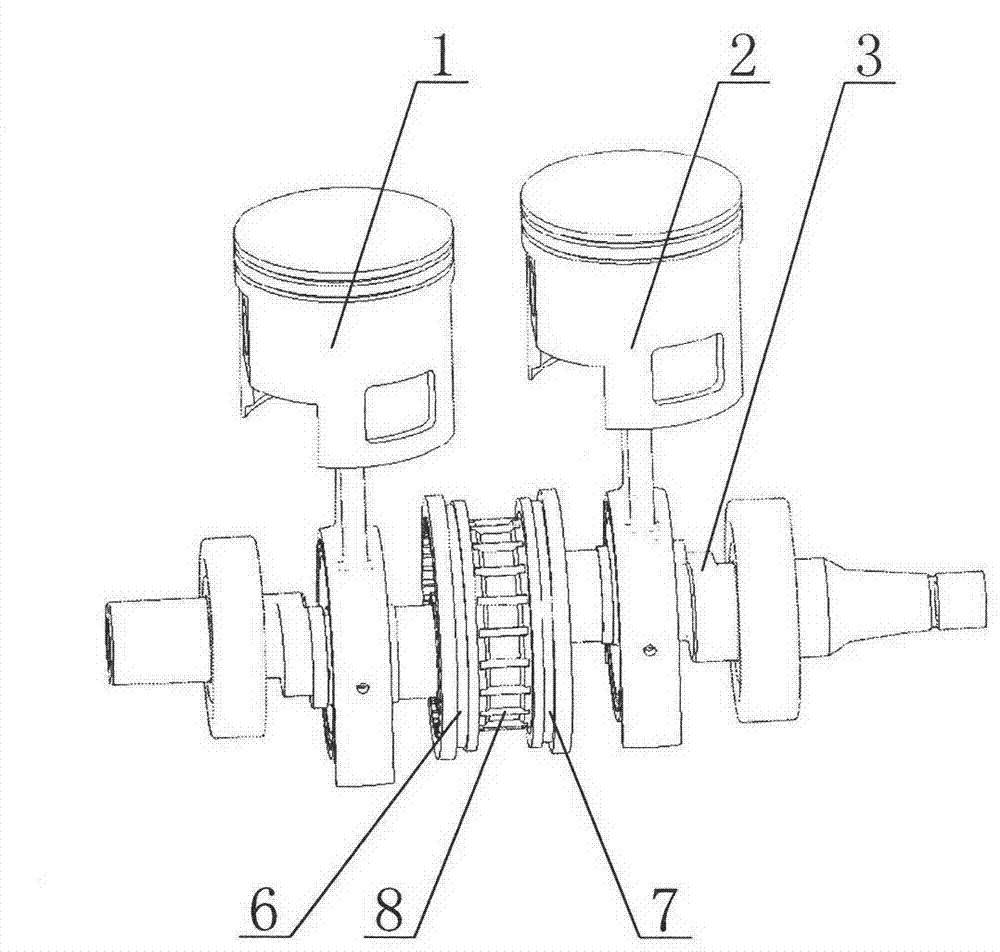

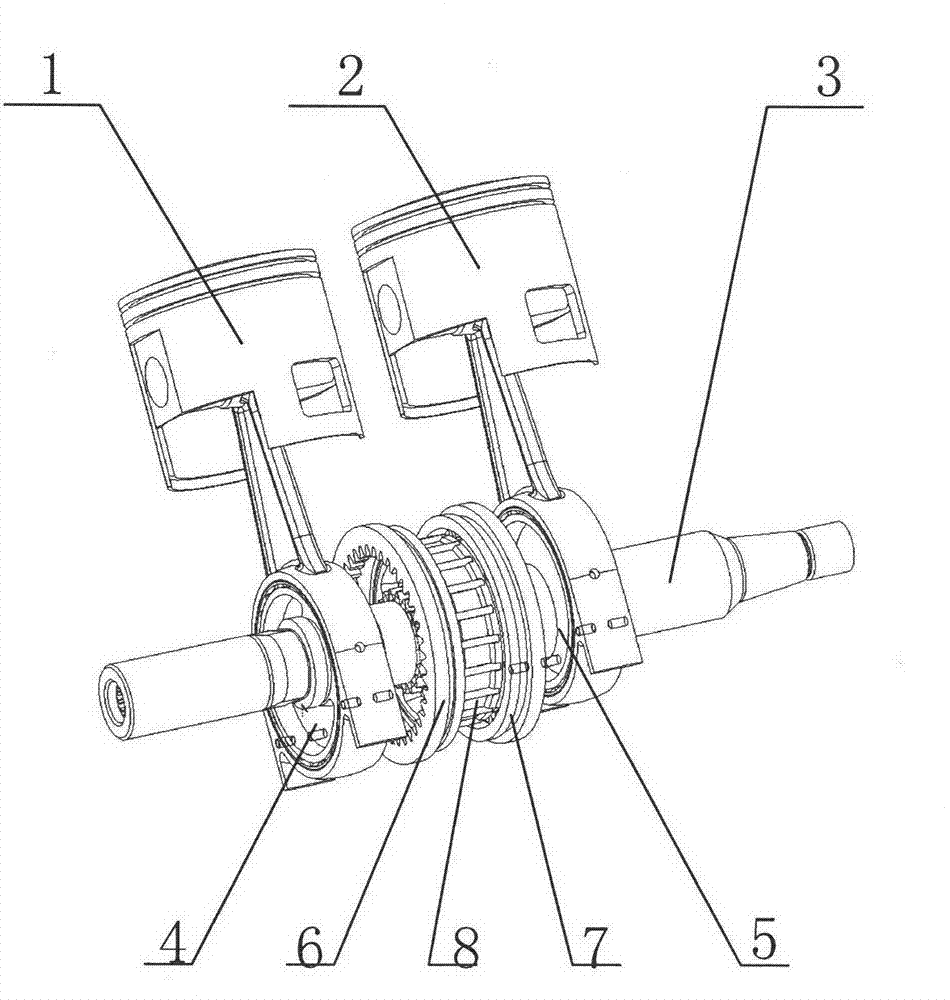

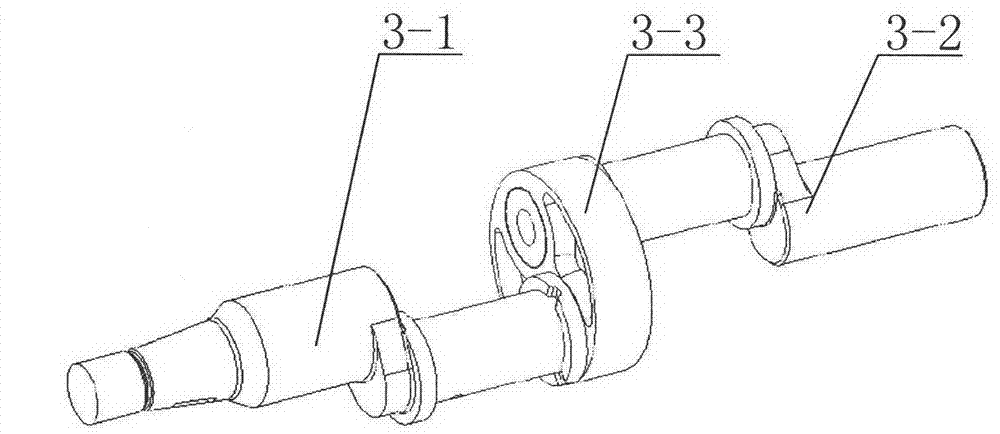

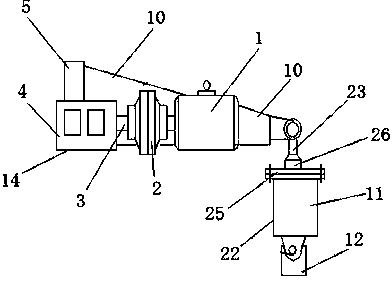

Double-cylinder crank round slide mechanism and combustion engine and compressor thereof

InactiveCN102817712AImprove organizational efficiencySmooth transitionPositive displacement pump componentsPositive-displacement liquid enginesCombustorReciprocating motion

The invention provides a double-cylinder crank round slide mechanism which adopts a separating type crank, wherein a crank pin of a first crank section is matched with a first round slide eccentric hole through a bearing, a first round slide is installed in a round slide containing hole of a first piston, and the first piston is installed in a first reciprocating motion track of the mechanism body; a crank pin of a second crank section is matched with a second round slide eccentric hole through a bearing, a second round slide is installed in a round slide containing hole of a second piston, and the second piston is installed in a second reciprocating motion track of the mechanism; and the first round slide and the second round slide are both arranged in outer gears coaxial with respective eccentric holes, a first inner gear ring and a second inner gear ring are arranged on the mechanism body and respectively meshed with the outer gears of the first round slide and the second round slide. The invention further provides an inner combustor and a compressor using the double-cylinder crank round slide mechanism. The double-cylinder crank round slide mechanism is particularly suitable for reforming the existing two-cylinder crank connection rod mechanism into a crank round slide mechanism and effectively reduces the cost in technological progress.

Owner:BEIJING SINOCEP ENGINE TECH

Text to speech interactive voice response system

InactiveUS20080270137A1Quality improvementCost-effectiveSpeech synthesisData streamOperational system

A text to speech interactive voice response system is operable within a personal computer having a processor, data storage means and an operating system. The system comprises an input subsystem for receiving a text data stream from a source device in a predetermined format; a process control subsystem for converting the text data stream into corresponding output data items; an audio record subsystem for recording audio data to be associated with each output data item; and, a broadcast control subsystem for generating an audio broadcast based on the output data items. There is also disclosed a system management and control subsystem for user interface with the system.

Owner:DICKSON CRAIG B +2

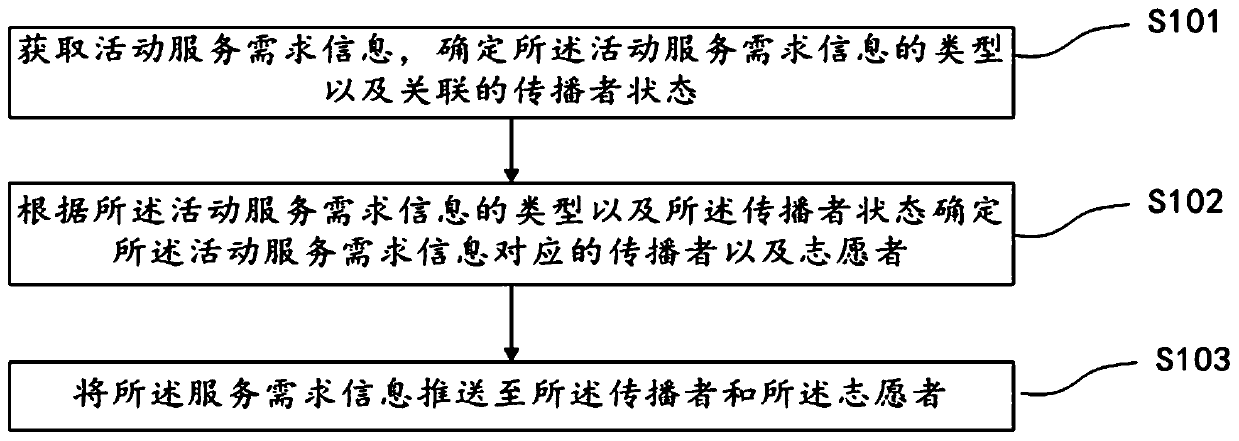

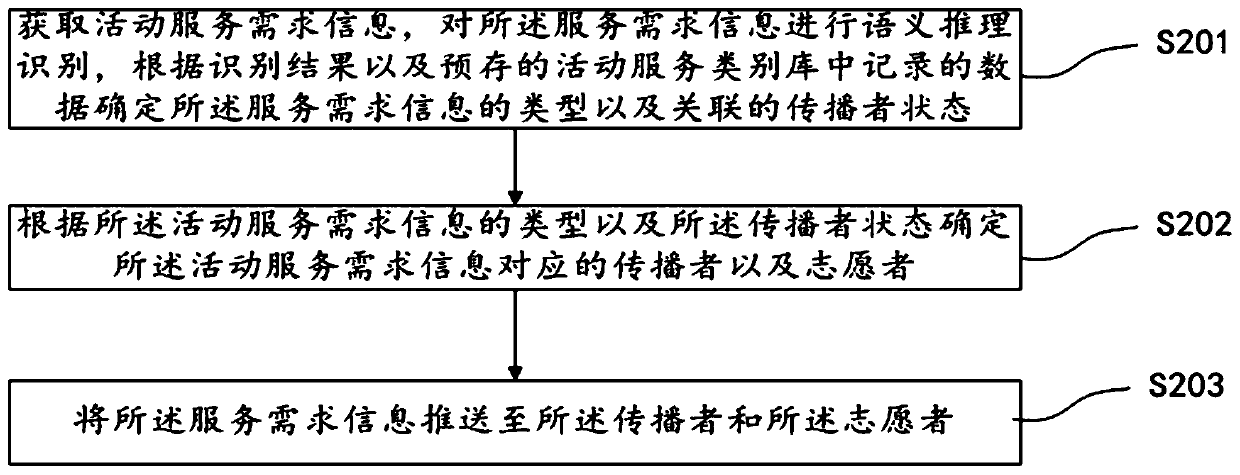

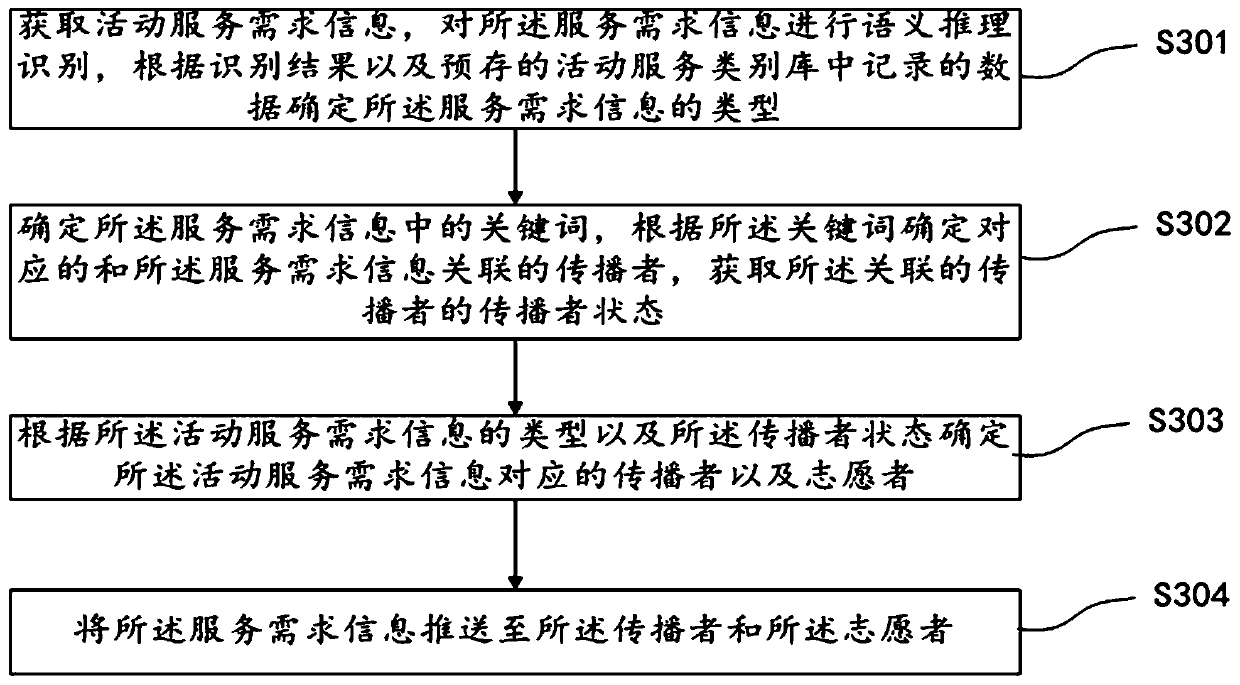

Activity service platform implementation method, device and equipment and storage medium

InactiveCN110177138AImprove organizational efficiencyReduce organizational costsData processing applicationsTransmissionComputer scienceService demand

The embodiment of the invention discloses an activity service platform implementation method and device, equipment and a storage medium. The method comprises the steps that activity service demand information is acquired, and the type of the activity service demand information and the associated propagator state are determined; a propagator and a volunteer corresponding to the activity service demand information are determined according to the type of the activity service demand information and the state of the propagator; and the service demand information is pushed to the propagator and thevolunteer. According to the scheme, the organization efficiency of the activity service is improved, and the organization cost is reduced.

Owner:古疁(上海)文化传媒有限公司

A double-station vacuum packaging mechanism for continuous operation

ActiveCN104859871BImprove conversion efficiencyImprove organizational efficiencySolid materialEngineeringContinuous operation

The invention discloses a double-station vacuum packaging mechanism capable of achieving continuous operation. The double-station vacuum packaging mechanism is used for mass vacuum packaging of materials, and comprises a rack, a filling assembly, a quantitative scale, a first shaping part, a second shaping part, a first sealing assembly, a second sealing assembly, a first discharging device, a second discharging device, a guiding shaft, guiding rails and a PLC industrial control part. A packaging driving part is arranged on the lower portion of the rack, discharging stations are arranged on the two sides of the rack, a filling driving part and the horizontal guiding shaft are arranged on the upper portion of the rack, the quantitative scale is arranged above the middle of the guiding shaft, and the filling assembly is located at the guiding shaft and comprises a first filling part, a second filling part and a filling platform. Packaging bags are filled while the filling platform slides on the guiding shaft, the first shaping part, the second shaping part, the first discharging device and the second discharging device are fixed to guiding rail sliding blocks in a grouped mode, and the distance between the shaping part and the discharging device in any group is matched with the horizontal moving distance of the filling and discharging mechanisms. According to the double-station vacuum packaging mechanism, double-station design is achieved on the filling assembly, the filling, shaping, sealing and discharging actions of the double-station vacuum packaging mechanism are continuously carried out through structure matching, and thus efficiency is improved.

Owner:ZHANGZHOU JIALONG TECH INC

A kind of rail induction butt welding and heat treatment method

ActiveCN103521935BImprove organizational efficiencyHigh degree of automationRailsWelding/cutting auxillary devicesButt weldingEngineering

Owner:CHANGZHOU RUITAI ENG MASCH CO LTD +1

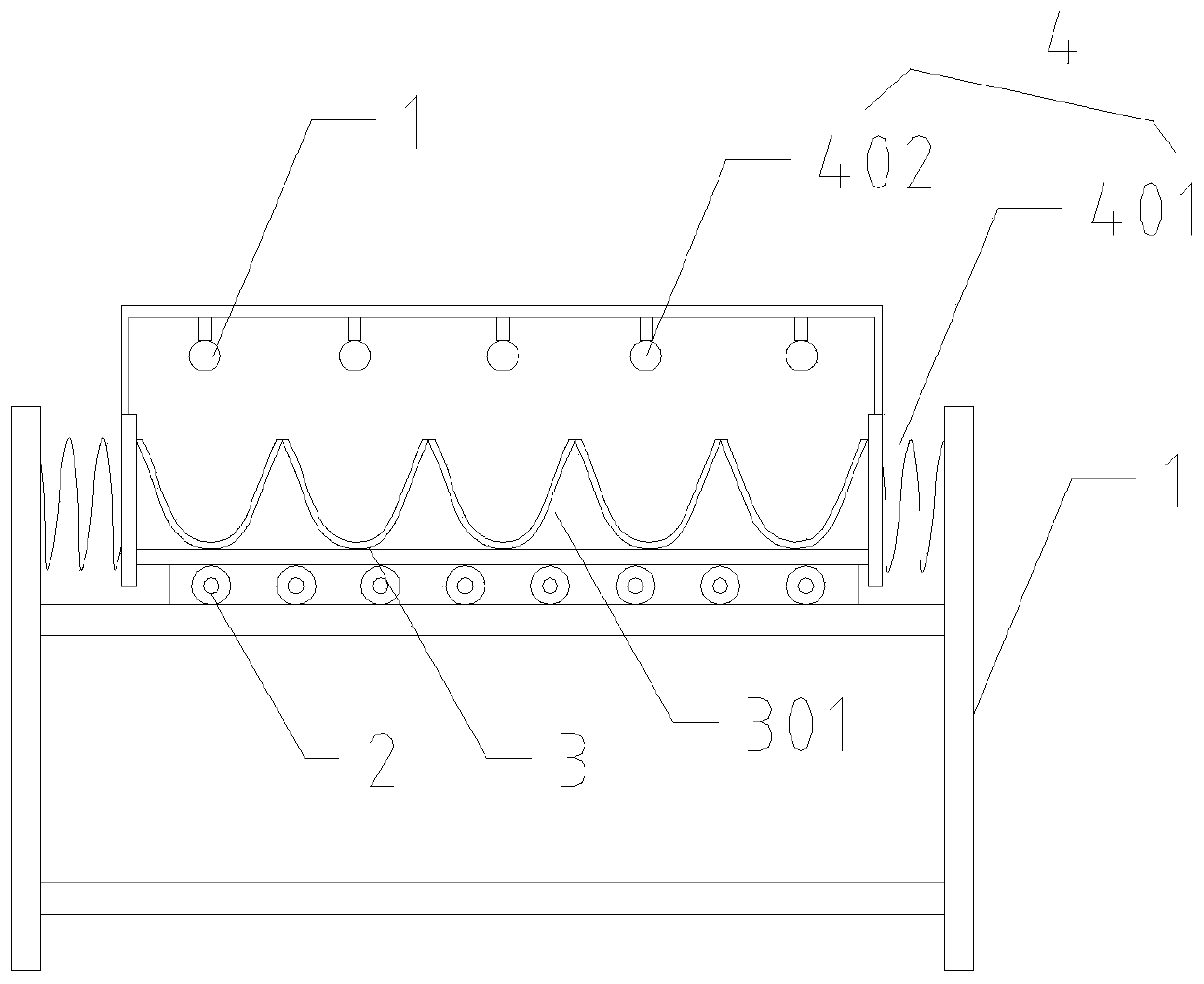

Tea carding machine capable of improving carding quality

InactiveCN106509184AHigh feasibilityPrevent leakagePre-extraction tea treatmentCardingElectric machinery

The invention relates to a tea carding machine capable of improving carding quality. The tea carding machine comprises a rack, a connecting rod, compressing rollers, a driving mechanism, a carding mechanism and an auxiliary mechanism. The driving mechanism comprises a motor, a reducer, a first belt pulley, a second belt pulley and a driving belt. The carding mechanism comprises a base and a carding pot. The auxiliary mechanism comprises a main body and auxiliary units installed on the main body, and each auxiliary unit comprises an air cylinder, a supporting rod, electromagnets and heating strips. According to the tea carding machine capable of improving the carding quality, an auxiliary carding method of compressing roller rolling is added on the basis of a vibration carding method, the compressing rollers are absorbed through the electromagnets and then stored in the auxiliary mechanism, and the compressing rollers can be ejected and taken in as required; the auxiliary mechanism can heat the compressing rollers, so that carding efficiency is further improved; and in addition, the situation that tea in vibration leaks out from a groove opening of a carding groove is avoided through the auxiliary mechanism.

Owner:安溪县海宏生物科技有限公司

Tea strip tidying machine

InactiveCN110463790ASpeed up the fallExtend exercise timePre-extraction tea treatmentElectrical and Electronics engineering

The invention provides a tea strip tidying machine comprising a frame, a heating mechanism, a strip tidying mechanism, a pressurization mechanism and a driving mechanism; the strip tidying mechanism is slidably arranged on the frame, and comprises at least two strip tidying grooves arranged side by side; the heating mechanism is used for providing heat for the strip tidying grooves; the driving device is used for driving the strip tidying mechanism to reciprocatingly slide on the frame; the pressurization mechanism comprises air blowing units and an air supply unit, the air blowing units are respectively arranged on both sides of the strip tidying mechanism in the sliding direction, and the strip tidying mechanism reciprocatingly slides to blow air to the air blowing units; the air supplyunit is connected with the air blowing units, and is arranged above the strip tidying grooves. The tea strip tidying machine can improve the strip tidying efficiency of the strip tidying machine.

Owner:安徽太湖画里天华实业有限公司

Bucket-wheel speed reducer having buffering function

InactiveCN104047999AReduce the number of seriesImprove organizational efficiencyToothed gearingsGear lubrication/coolingDrive shaftEngineering

The invention provides a bucket-wheel speed reducer having the buffering function. The bucket-wheel speed reducer having the buffering function comprises a motor, a coupler, a first transmission shaft, a gear reducer connected with the first transmission shaft, an output shaft, a first planet transmission shaft, a planet gear, a second planet transmission shaft and a transmission bearing pedestal. One end of a buffering plate is connected to the gear reducer. The other end of the buffering plate is connected with a buffer device through a hinge pin. The lower end of the buffer device is connected with a base through a hinge pin. The outer portion of the gear reducer is connected with an oil feeder. The base is connected with a field. The bucket-wheel speed reducer having the buffering function is compact in structure, stable in operation, high in transmission efficiency and high in lubrication performance, the gear damage degree and the bearing damage degree are remarkably reduced, and the service life of a unit can be prolonged.

Owner:武汉钢铁有限公司

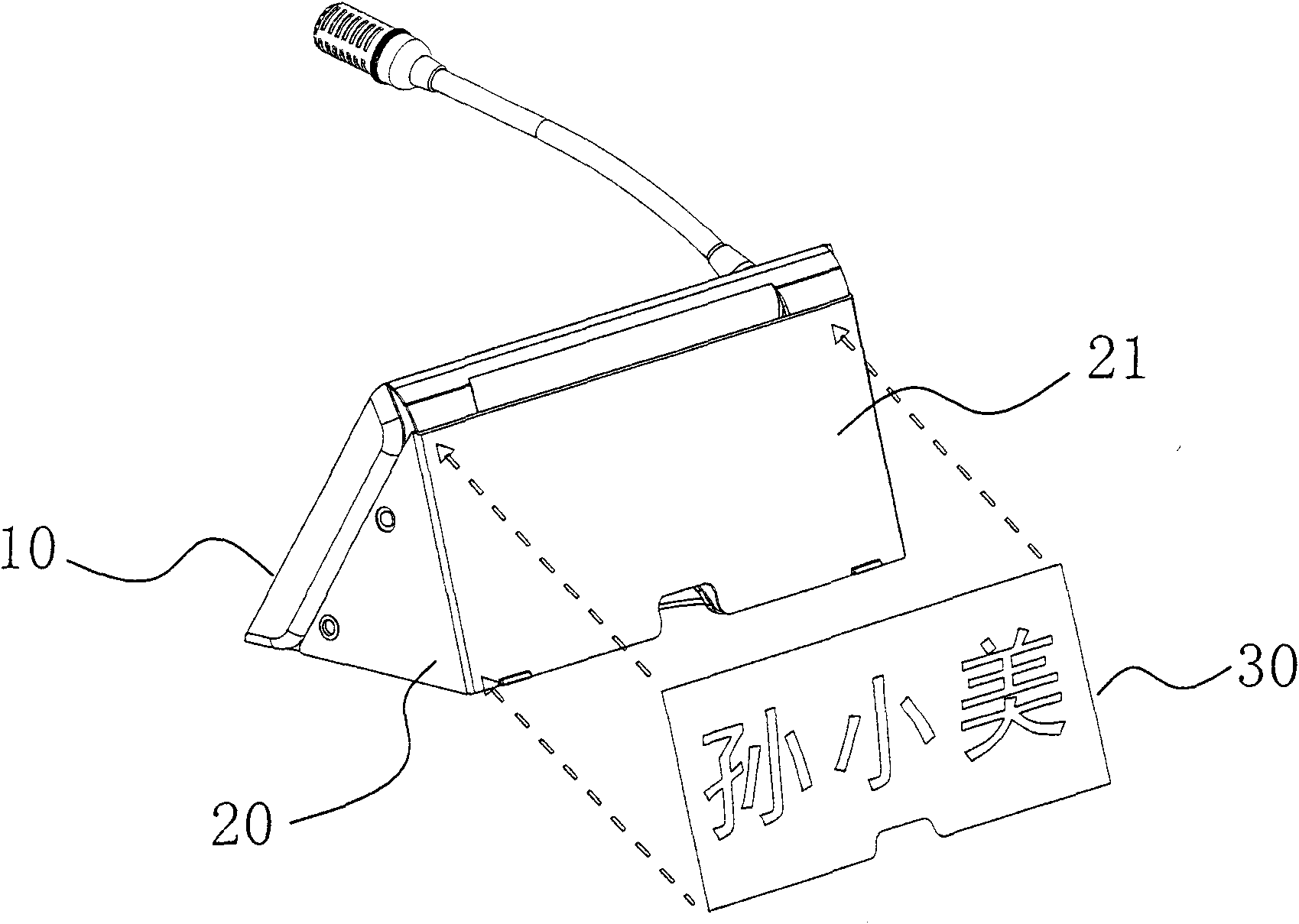

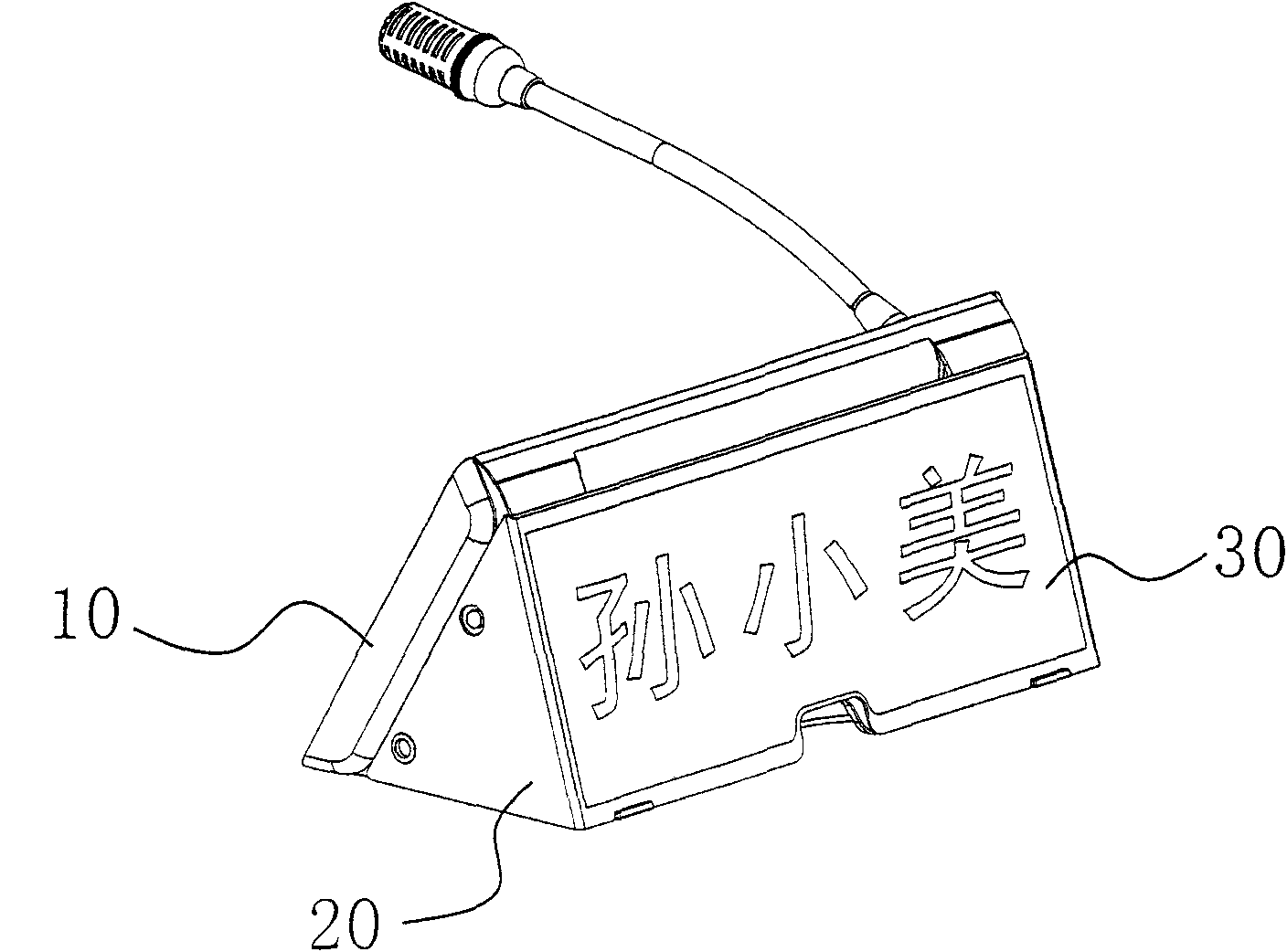

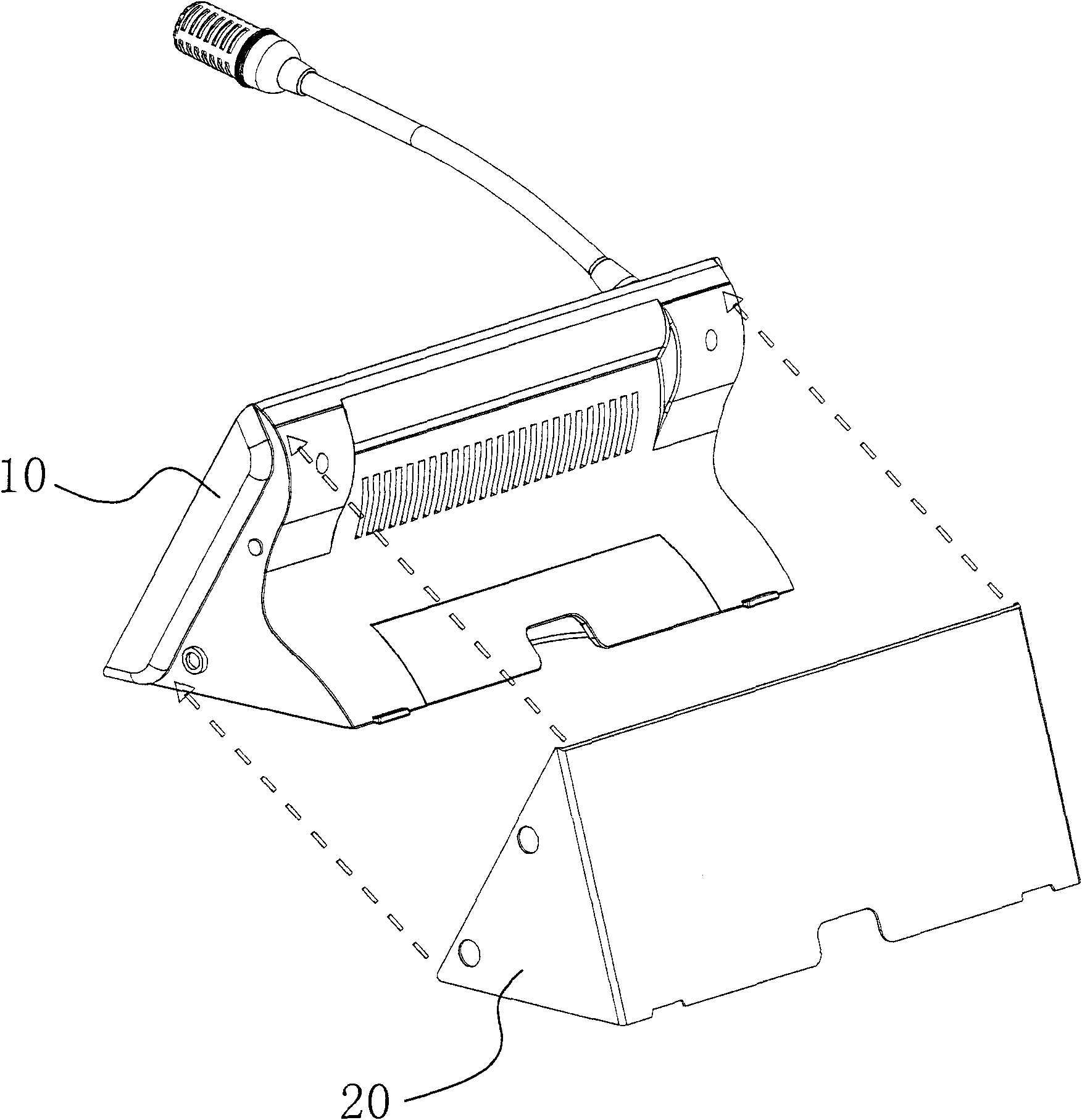

Terminal equipment of conference discussion system with function of conference table signing

InactiveCN101789203AImprove organizational efficiencySimplify the venue environmentSignsOrganizational efficiencyMicrophone

The invention relates to the field of a conference discussion system, in particular to terminal equipment of a conference discussion system with the function of conference table signing. The terminal equipment of the conference discussion system comprises terminal equipment for conventioneers and chairman to control microphones by means of dispersion or concentration to speak and discuss, wherein the terminal equipment back on to spokesman is connected with a non-electronic nameplate, and the non-electronic nameplate is provided with a carrier for displaying conference information. When in use, the terminal equipment can be used for the conventioneers and the chairman to control the microphones by means of dispersion or concentration to speak and discuss, and the non-electronic nameplate with the function of conference table signing, the carrier for displaying the conference information, and the terminal equipment are integrated into a whole, the terminal equipment simplifies the environment of the conference place, improves the organizational efficiency of the conference, is economic and practical due to the simple non-electronic nameplate, and overcomes the disadvantages of spotlighting caused by electronic conference table signing when photographing, high cost, no energy saving and no environment protection, etc.

Owner:SHENZHEN TAIDEN INDAL

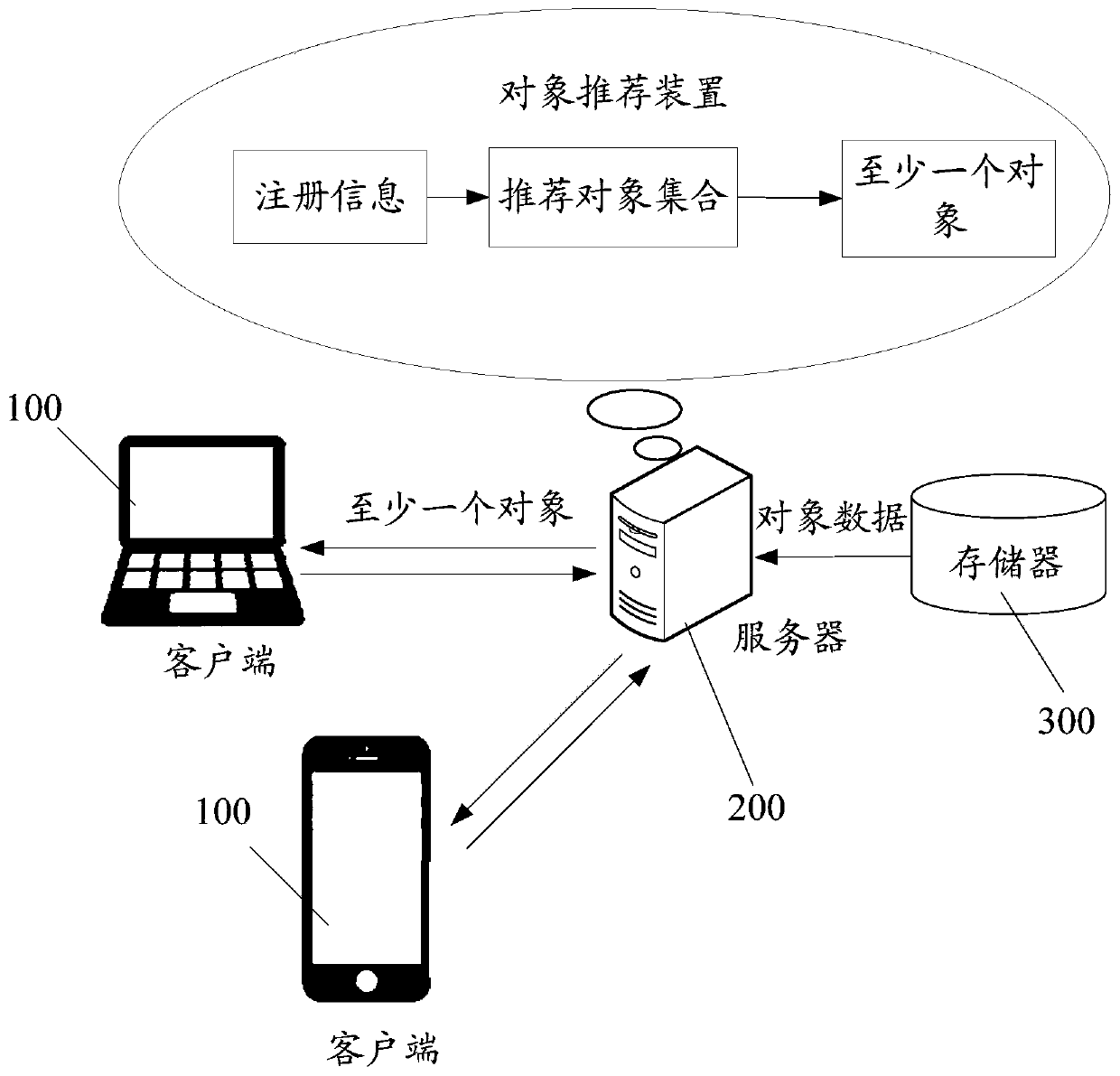

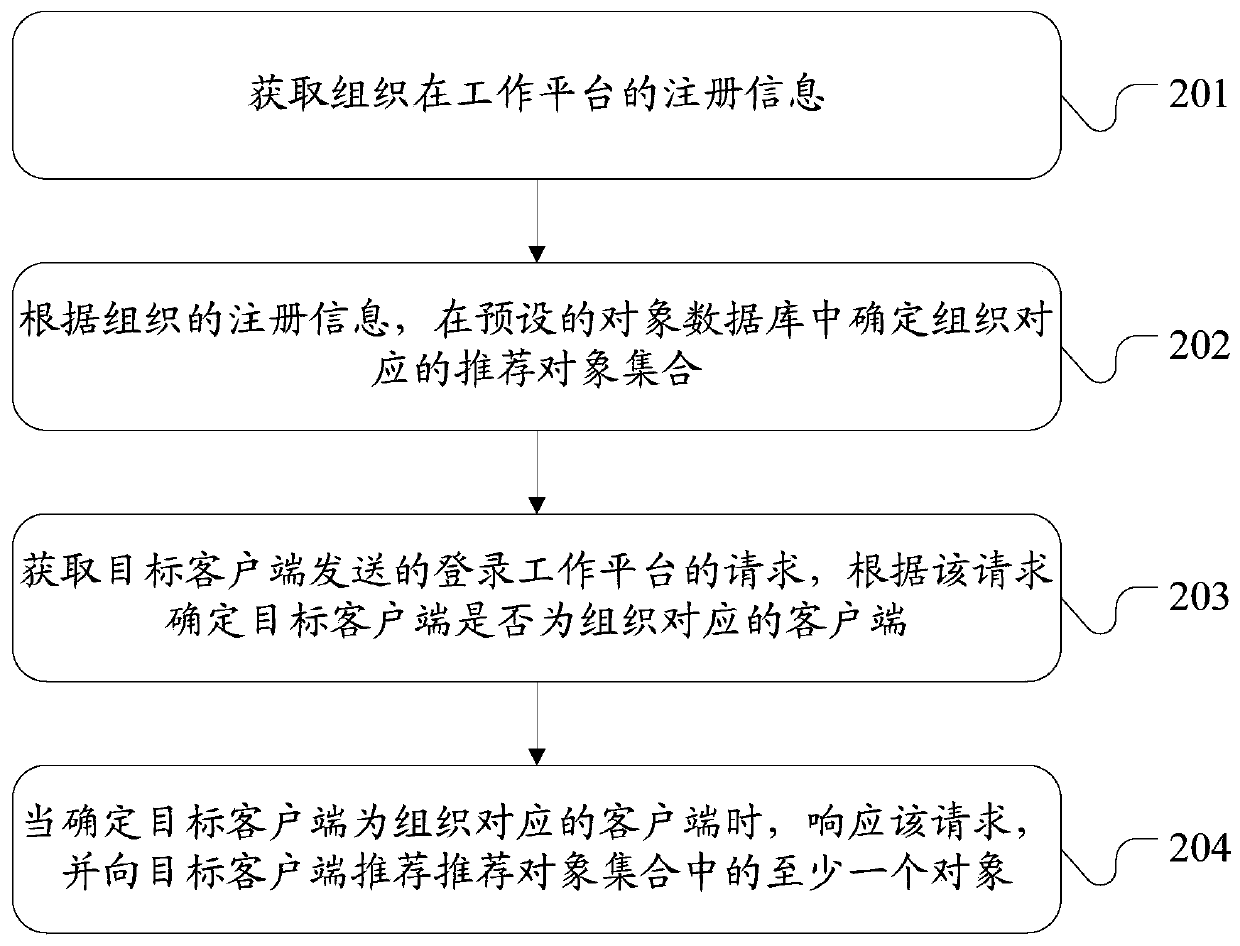

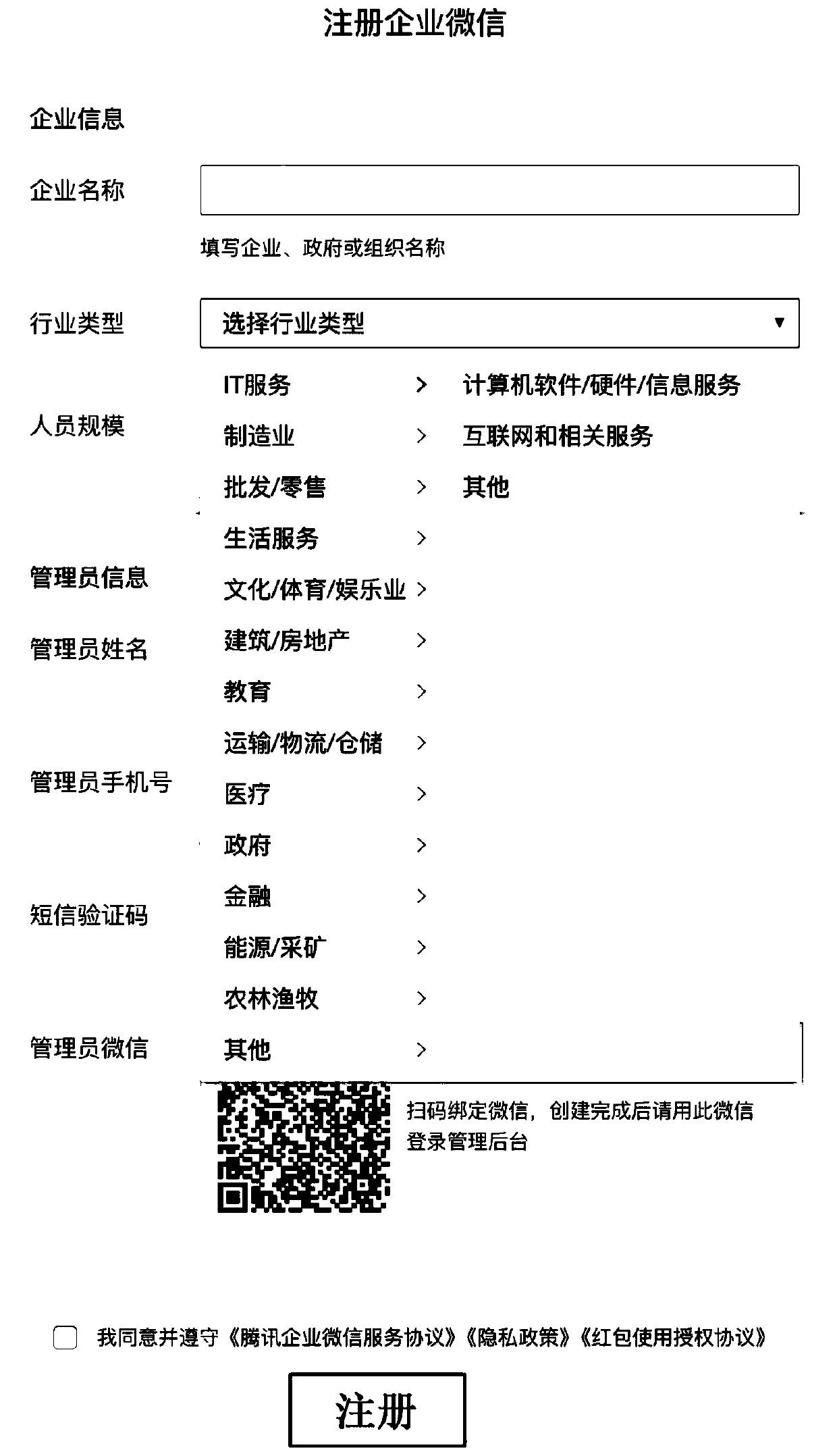

Object recommendation method and device, server and storage medium

PendingCN110276593AConvenient organization and office abilityImprove organizational efficiencyDigital data information retrievalOffice automationIdentifying goalsDatabase

Owner:TENCENT TECH (SHENZHEN) CO LTD

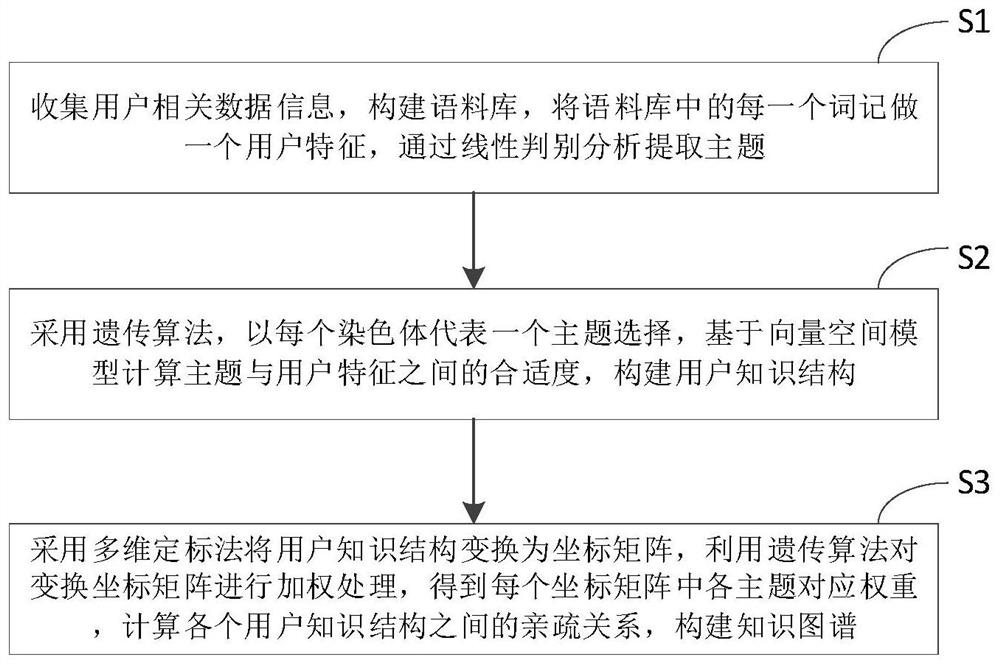

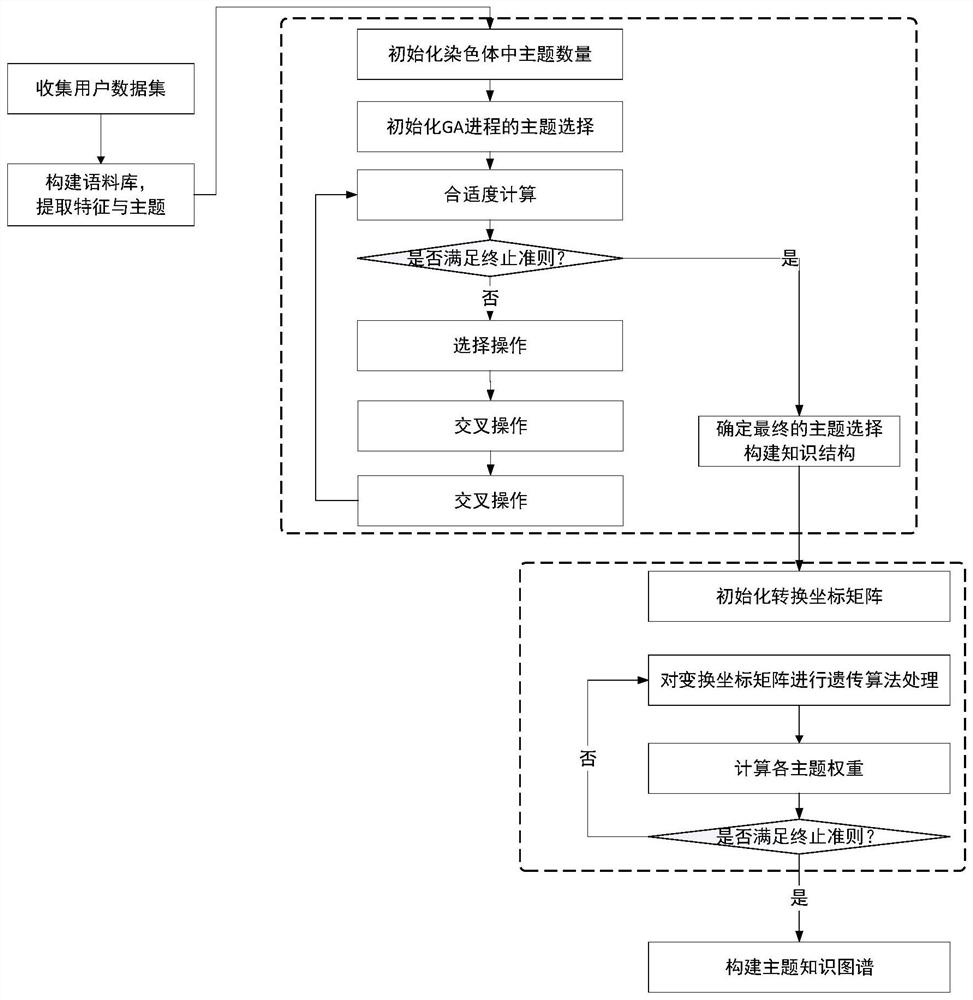

Topic knowledge graph construction method and device

ActiveCN112765367AAchieve integrationUnderstand complex relationshipsNatural language data processingEnergy efficient computingEngineeringVector space model

The invention discloses a topic knowledge graph construction method and device. The method comprises the following steps: collecting user related data information, constructing a corpus, recording each word in the corpus as a user feature, and extracting a topic through linear discriminant analysis; adopting a genetic algorithm, employing each chromosome for representing one topic selection, calculating the suitability between the topic and the user features based on a vector space model, and constructing a user knowledge structure; and finally, transforming the user knowledge structures into coordinate matrixes by adopting a multi-dimensional calibration method, performing weighting processing on the transformed coordinate matrixes by utilizing a genetic algorithm to obtain weights corresponding to themes in each coordinate matrix, calculating a hydrophilic-hydrophobic relationship among the user knowledge structures, and constructing a knowledge graph. The method effectively helps to understand the complex relationship between the user objects in the space, realizes related integration of massive information of the user, is high in visualization degree and good in interpretability, and can help enterprises in related fields to enhance communication and share public practice and improve organization efficiency.

Owner:浙江富润数链科技有限公司 +1

Automobile brake intake pipe heating forging detection device

ActiveCN107300506BTimely detection of stress resistanceAchieve liftingRevolution surface grinding machinesMaterial strength using tensile/compressive forcesSpray nozzleEngineering

The invention discloses an automobile brake air inlet pipe heating forging detection device, which comprises a base and is characterized in that a left support post and a right support post are arranged on the base; a cross beam plate is fixedly arranged on the tops of the left and right support posts; a slide block is arranged on the cross beam plate; an air cylinder is arranged on the slide block; the lower end of the air cylinder is connected with a carrying frame; a heating tube is arranged under the carrying frame; a heating wire is arranged on the side wall of the heating tube; a protection air spraying nozzle is arranged at the bottom of the heating tube; a workpiece support frame is arranged in the heating tube; an air pressure detection table is arranged at one side of the heating tube; a convex cavity is formed in the center of the air pressure detection table; a sealing cover is arranged above the convex cavity; a cooling air spray pipe is connected onto the sealing cover; an air inlet pipe is arranged at the side wall of the detection table. The automobile brake air inlet pipe heating forging detection device has the advantages that the structure is simple; the automobile pipeline shaft roundness detection is accurate; the timely grinding regulation is convenient; the use is firm and stable; the position limiting effect is good.

Owner:ANHUI YUEZHONG AUTO BODY EQUIP

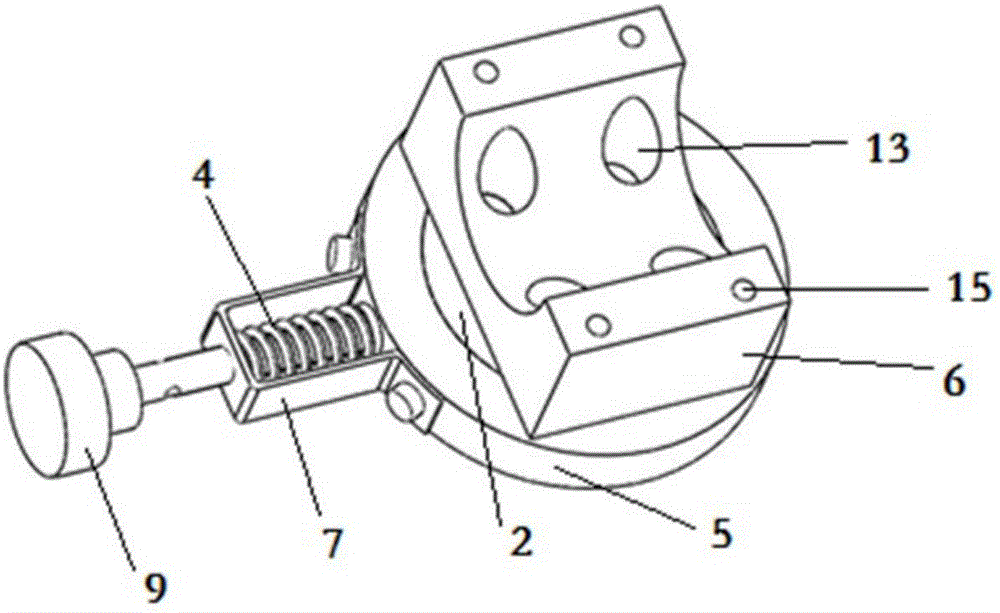

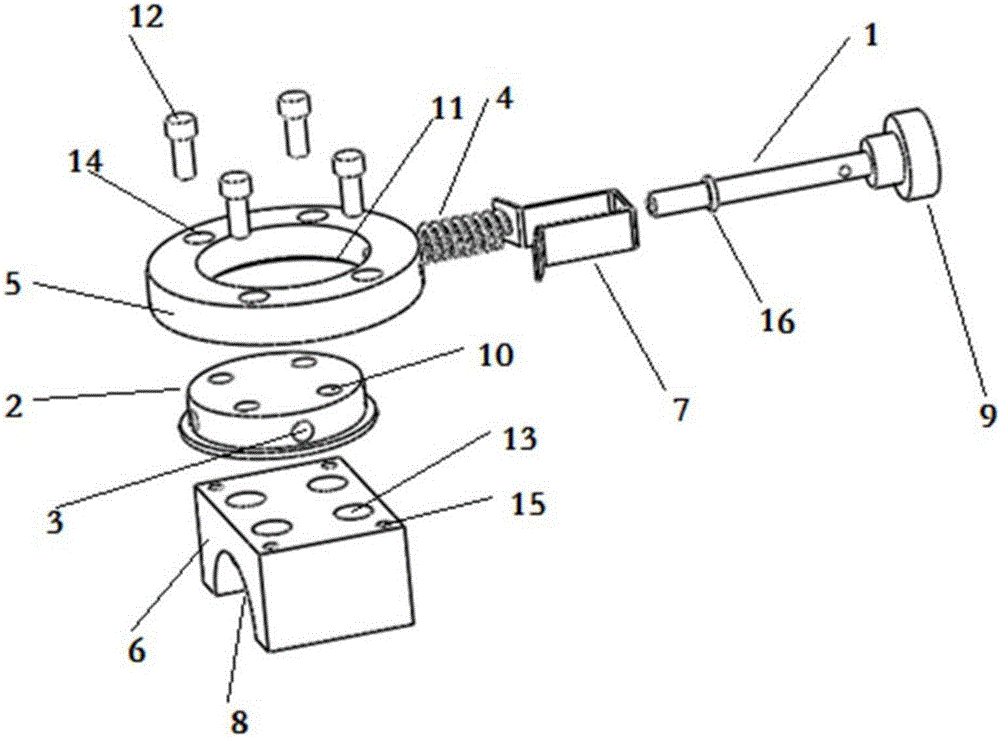

Cutting head reversing device for manual welding gun tip dresser

InactiveCN106736231AEasy to replaceReduce changeover timeResistance electrode holdersEngineeringWelding

The invention provides a cutting head reversing device for a manual welding gun tip dresser. The cutting head reversing device comprises a positioning device, a rotating module and a positioning pull rod, wherein the positioning device is used for being fixedly connected with the manual welding gun tip dresser, the rotating module is arranged in the positioning device and used for mounting a cutting head, and one end of the positioning pull rod passes through the positioning device to be positioned in the rotating module, so that the rotating module is positioned in the positioning device. When the positioning pull rod is separated from the rotating module, the rotating module is capable of rotating freely relative to the positioning device. The cutting head reversing device has the advantages that the cutting head for the tip dresser can be reversed in direction quickly and conveniently, welding guns at different dressing orientations can be dressed by the same tip dresser, cutting head replacement time is shortened, practical production efficiency is improved, and convenience in operation, safety and reliability are guaranteed.

Owner:SHANGHAI FAITH CO LTD

Tea leaf tidying machine based on spatial swaying mechanism

PendingCN108041199ACompact structureSmall footprintPre-extraction tea treatmentDrive shaftReciprocating motion

The invention relates to a tea leaf tidying machine based on a spatial swaying mechanism. The tea leaf tidying machine comprises a base frame, the spatial swaying mechanism, a tidying assembly, and adriving mechanism; the spatial swaying mechanism comprises a driving shaft and a bush ring, a bush ring journal is arranged on the driving shaft, the axis of the driving shaft and the axis of the bushring journal intersect with each other and make an angle, the bush ring is mounted on the bush ring journal through a bearing, the bush ring is connected to a driven rod, the axes of the driven rod and the driving shaft perpendicularly intersect with each other, and the driving shaft can drive the driven rod to rotate back and forth by means of the bush ring; the tidying assembly comprises a trough base, a plurality of troughs which are arranged side by side are mounted in the trough base, the driven rod can drive the trough base to linearly move back and forth along the track direction of the trough base, and the length direction of the troughs is perpendicular to the moving direction of the trough base. The structure of the spatial swaying mechanism of the tea leaf tidying machine is compact, so the occupied space is small; the troughs can stably and uniformly carry out tidying, noise produced in the tidying process is low, abrasion is little, and the service life of the equipment is long.

Owner:ANHUI AGRICULTURAL UNIVERSITY

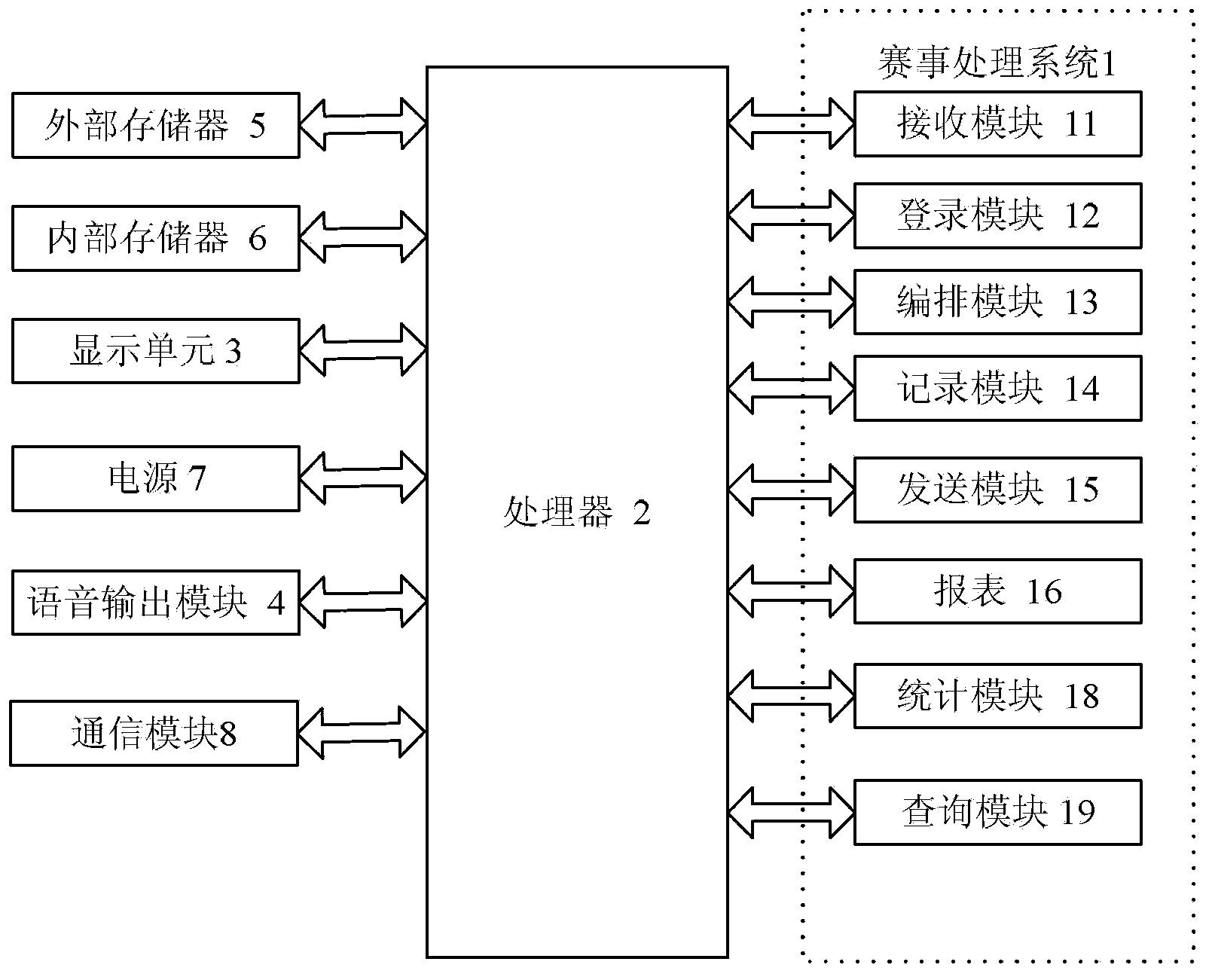

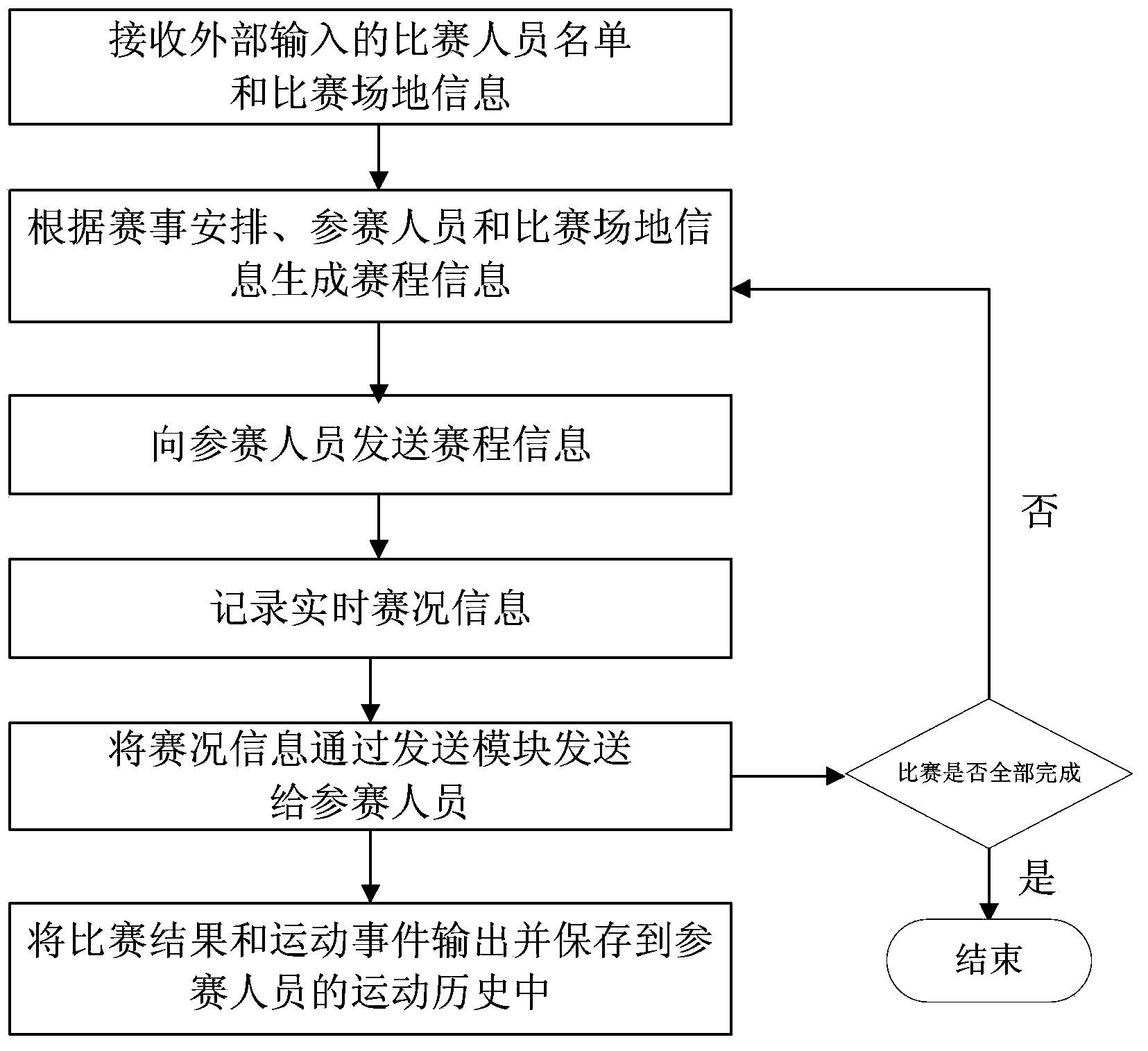

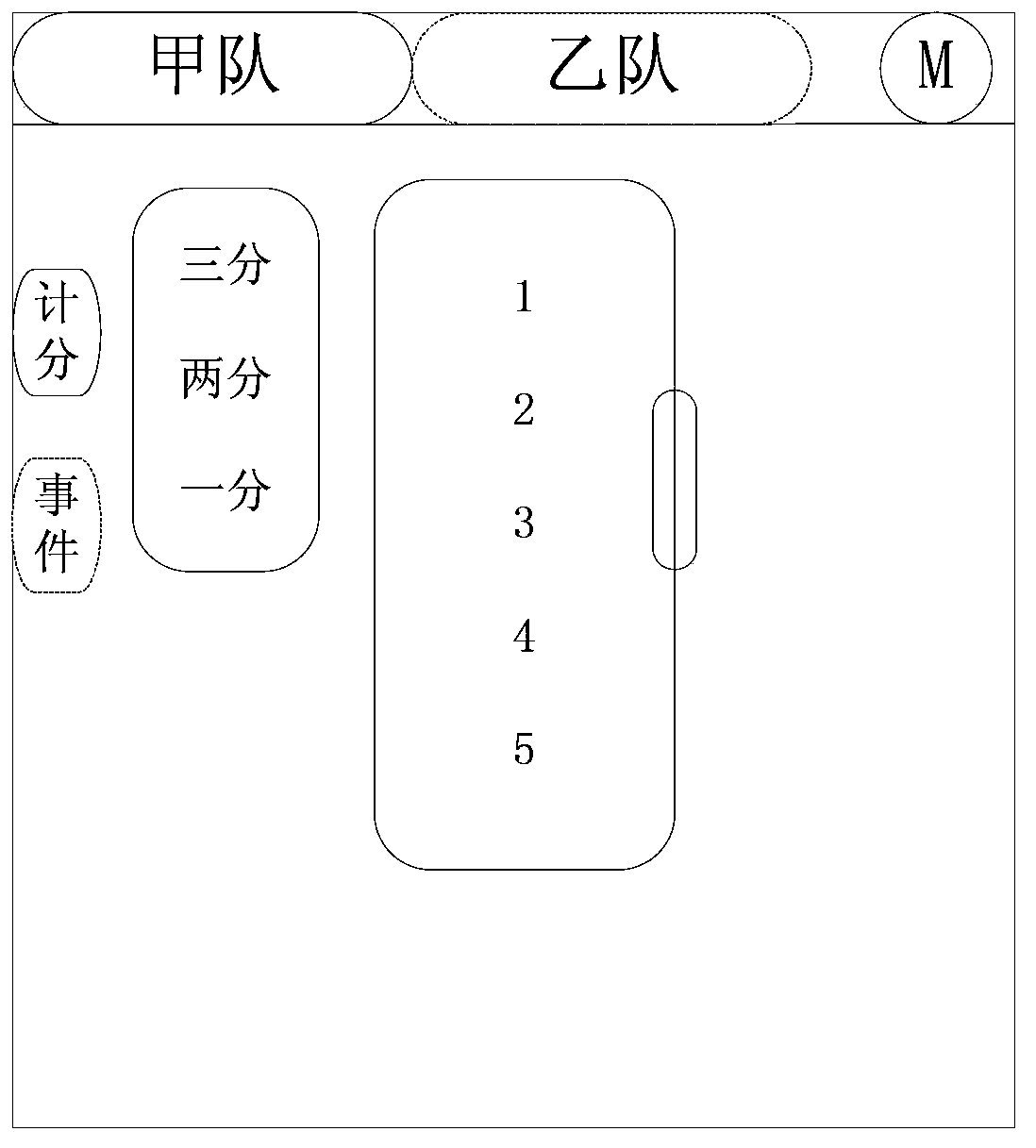

Mobile electronic device with scoring function

InactiveCN102772887BImprove organizational efficiencyRaise enthusiasm for participationSport apparatusExternal storageHandling system

The invention discloses a mobile electronic device with a scoring function. The mobile electronic device comprises a processor (2), an external storage (5), an internal storage (6), a display unit (3), a power supply (7), a communication module (8), a voice output module (4) and a competition processing system (1), wherein the external storage (5) is connected with the processor (2); the competition processing system (1) comprises a recording module (14); and the recording module comprises a competition selecting unit (141), a clock unit (142), a competition event recording unit (143) and a score recording unit (144). The mobile electronic device with the scoring function has the advantages of adapting to various sports competitions, recording an entire competition event, prompting relevant personnel of competition progresses, intelligently generating professional competition schedules, reducing labor organization cost, increasing the competition organization efficiency, recording the competition history information of players, and contributing to increasing the competition participation and competition enthusiasm of players.

Owner:SHENZHEN FANGGUO NETWORK TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com