Automatic feeding device

A feeding device and automatic technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problem of inaccurate control of weight and time, limited space for tea slitting machines, and restrictions on the development of tea processing enterprises, etc. problem, to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

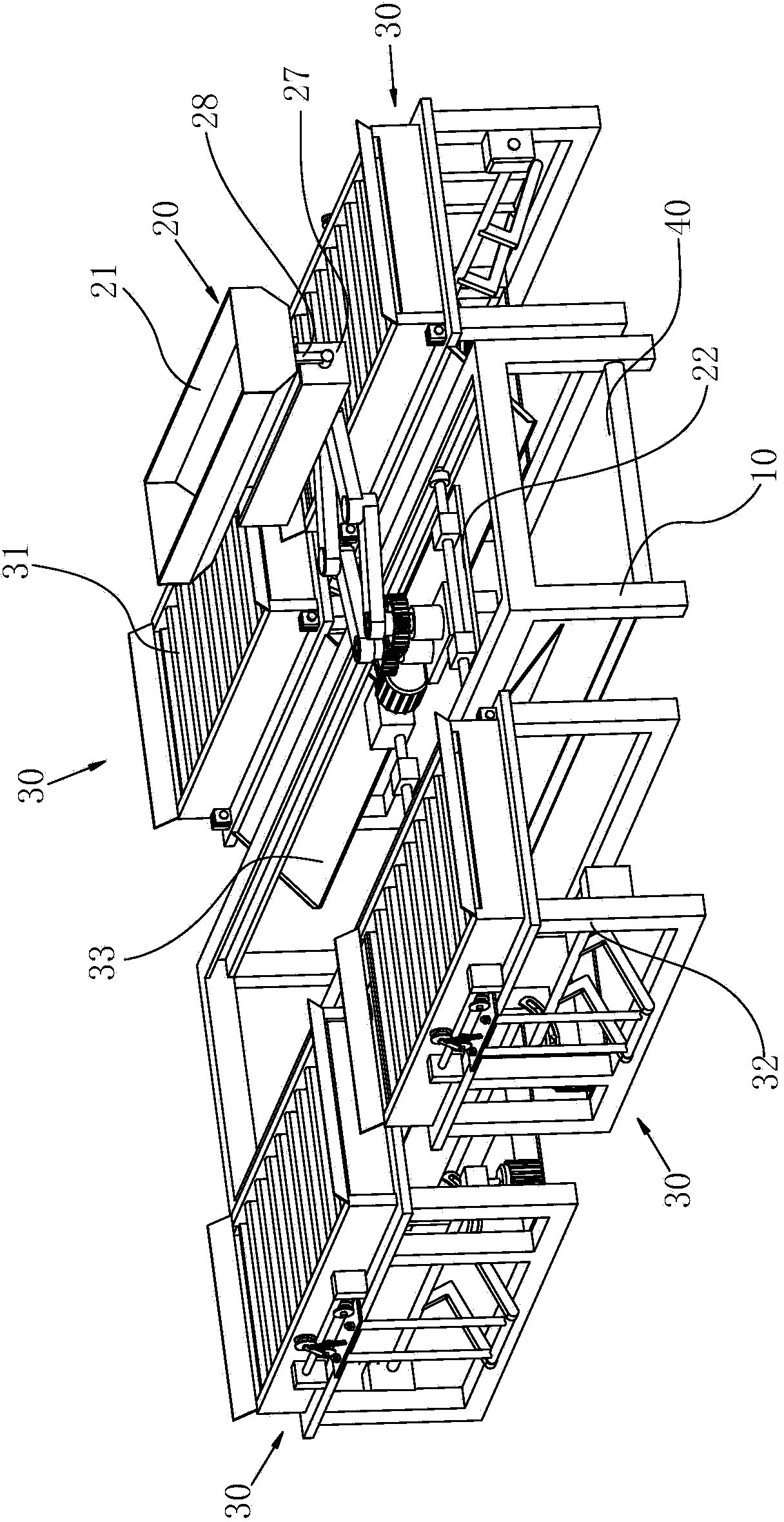

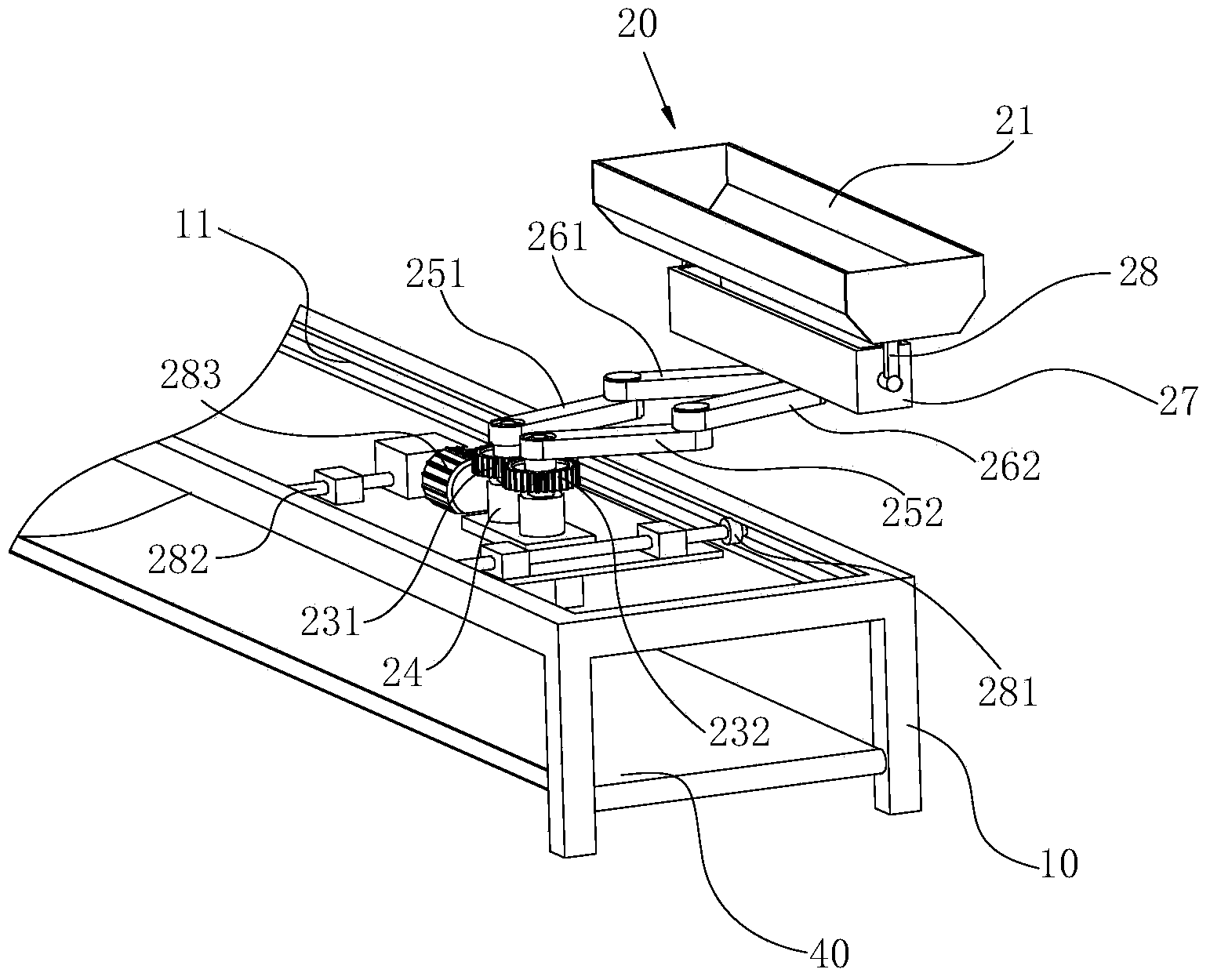

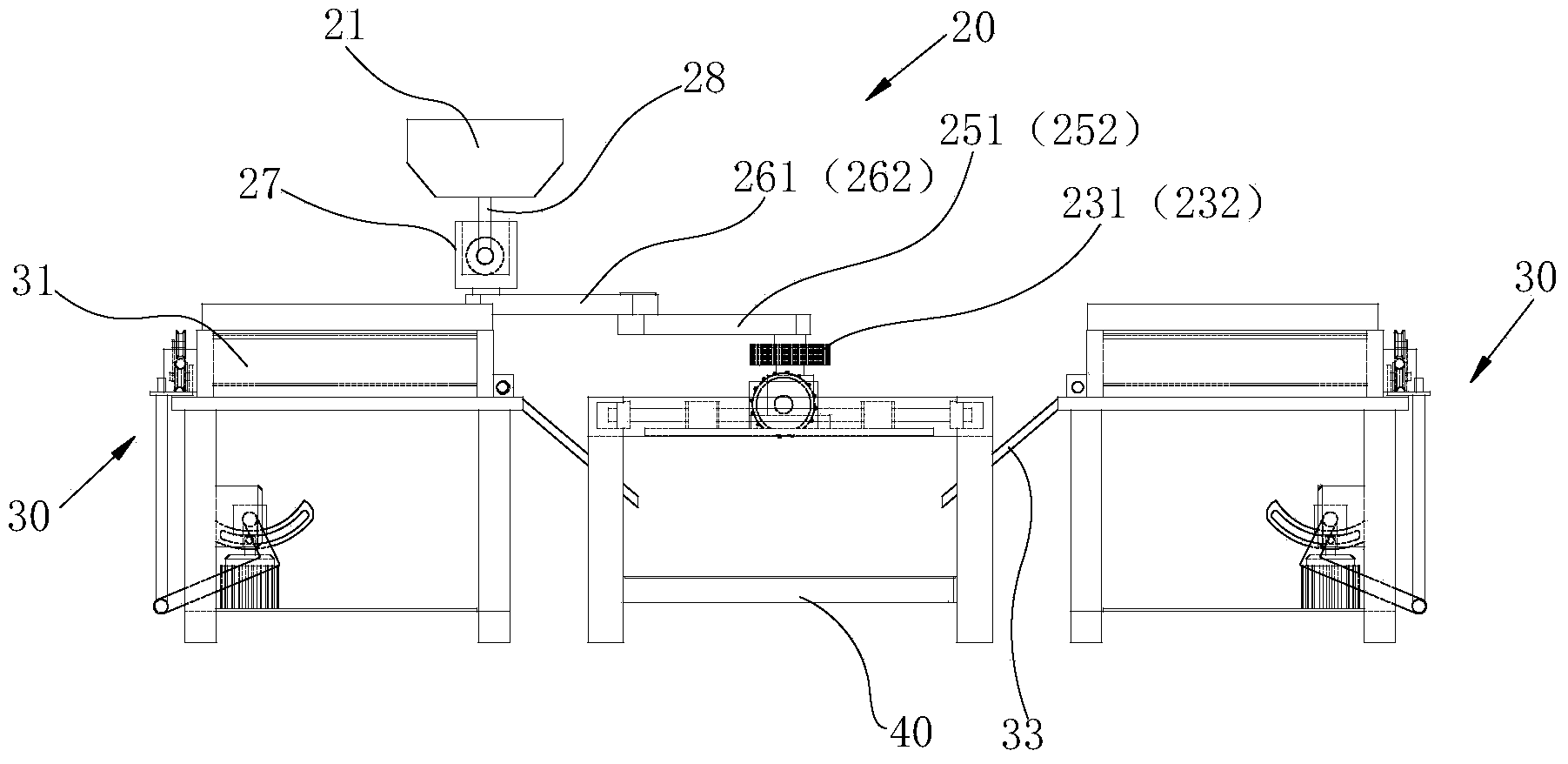

[0011] In conjunction with accompanying drawing, the present invention will be further described:

[0012] A kind of automatic feeding device, comprises the feeding mechanism 20 that is arranged on the guide rail 11; In the hopper 21 containing the tea leaves to be straightened, the hopper 21 presents an opening action on the top of the straightening machine 30 and pours the tea leaves to be straightened into the straightening machine 30 .

[0013] combined with figure 1 , the tea leaves to be sorted are transported to the electronic weighing hopper through the PLC automatic conveyor belt, the electronic weighing bucket is automatically turned over into the hopper, the feeding mechanism 20 reciprocates on the frame 10, and the tea leaves to be sorted are transferred to the strip sorting machine 30 Above, the hopper 21 makes a turning action, so that the tea leaves are dumped on the strip machine 30 and the strip operation is performed. The strip machine 30 can be arranged at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com