Patents

Literature

176results about How to "Reduce changeover time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

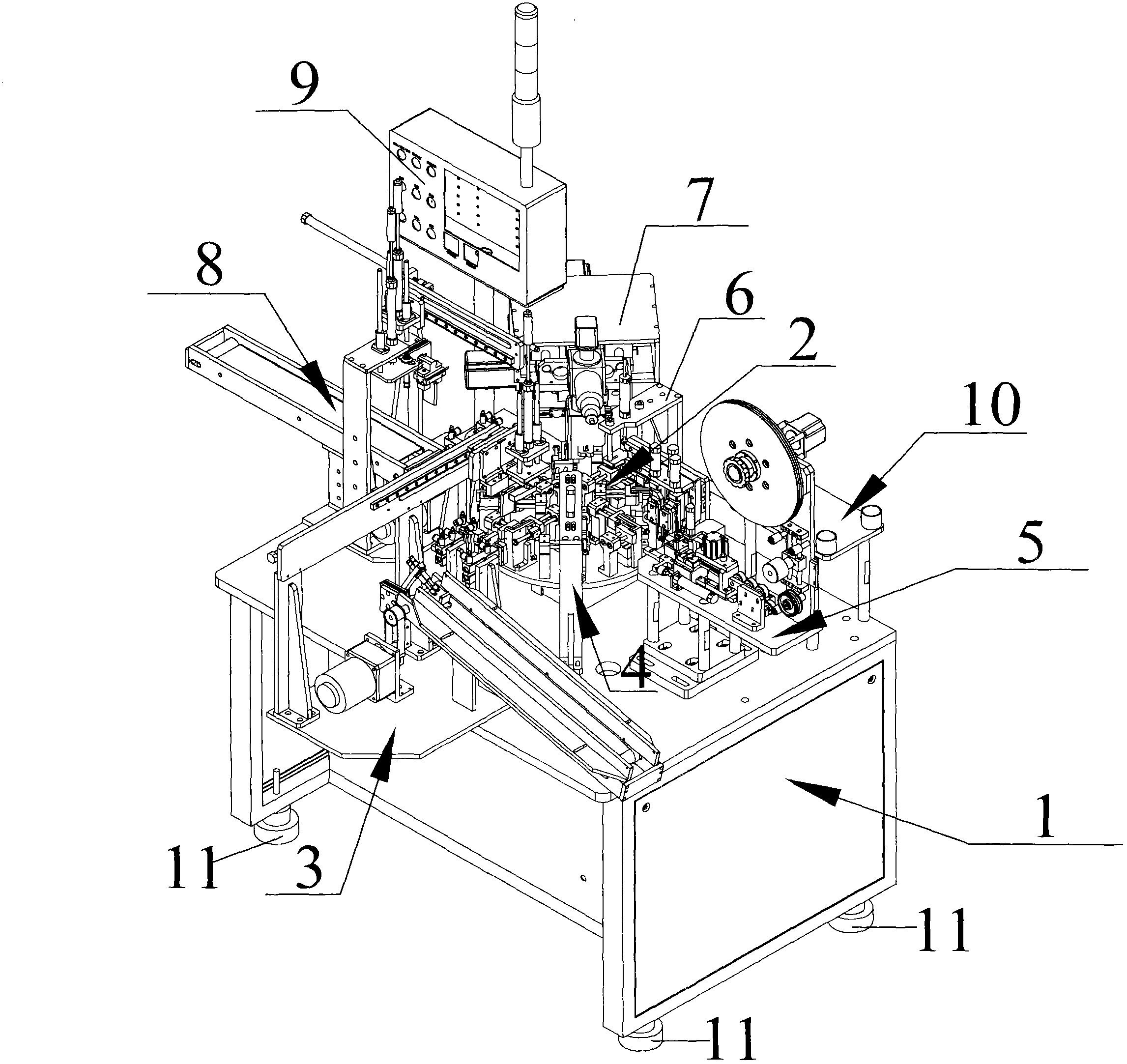

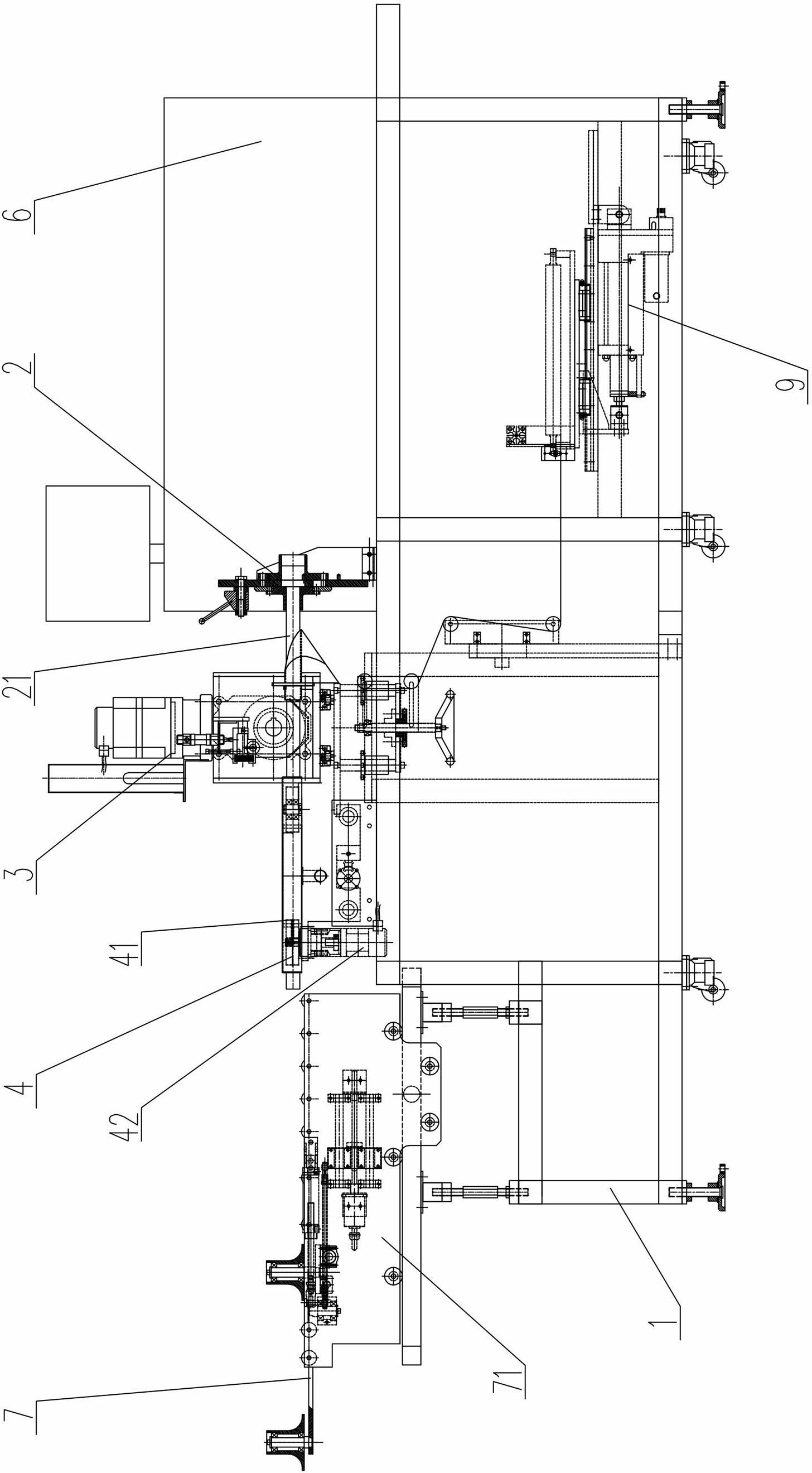

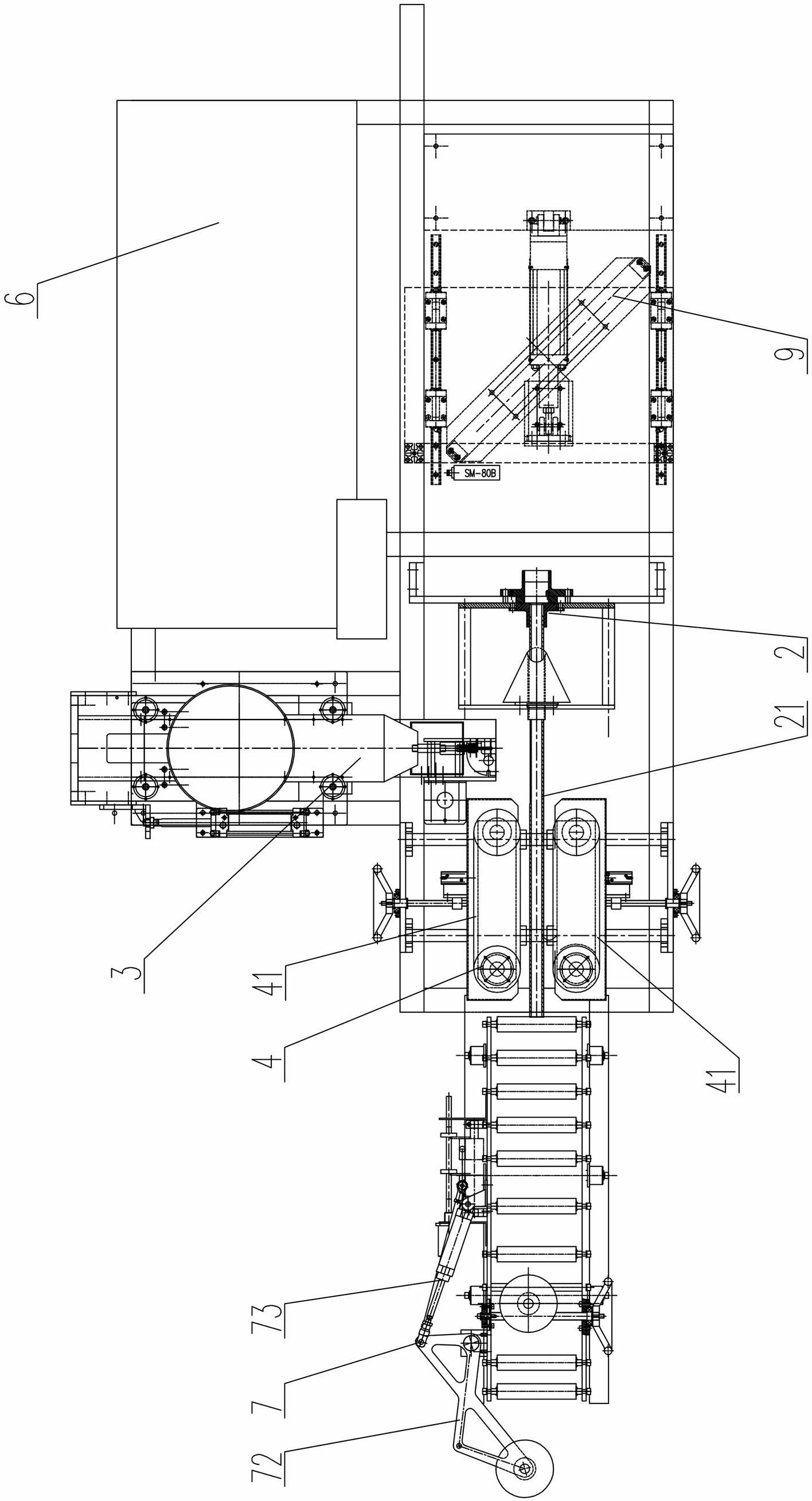

Lamination machine

InactiveCN102544435ASo as not to damageShorten the timeElectrode manufacturing processesFinal product manufactureEngineeringMechanical engineering

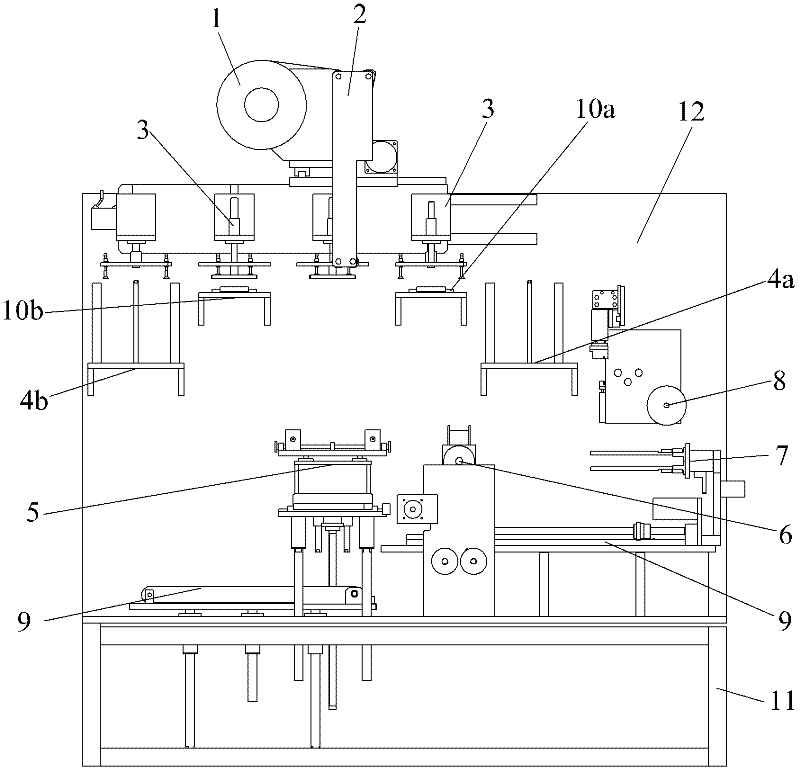

The invention discloses a lamination machine, which comprises a frame, a base board, a membrane releasing mechanism, a membrane tension edge correction mechanism, a lamination mechanism, a winding mechanism, a material moving mechanism, a discharging drawing string, a rubberizing mechanism, two feeding mechanisms, two location mechanisms and two material boxes. The base board is perpendicularly installed on the frame, the membrane releasing mechanism, the membrane tension edge correction mechanism, the two feeding mechanisms, the two location mechanisms, the two material boxes and the rubberizing mechanism are all installed on the base board, the lamination mechanism, the winding mechanism and the material moving mechanism are all installed on the frame, and the discharging drawing string passes through the material moving mechanism, the winding mechanism and the lamination mechanism to penetrate through the frame. A horizontal layout of each production mechanism is changed to be a vertical board layout, gaps between all mechanisms are enlarged, and the lamination machine is convenient to debug during product installation and replacement, shortens line changing time, saves labor and cost, and improves production efficiency.

Owner:SHANDONG ZOUPING HENGXING GRP

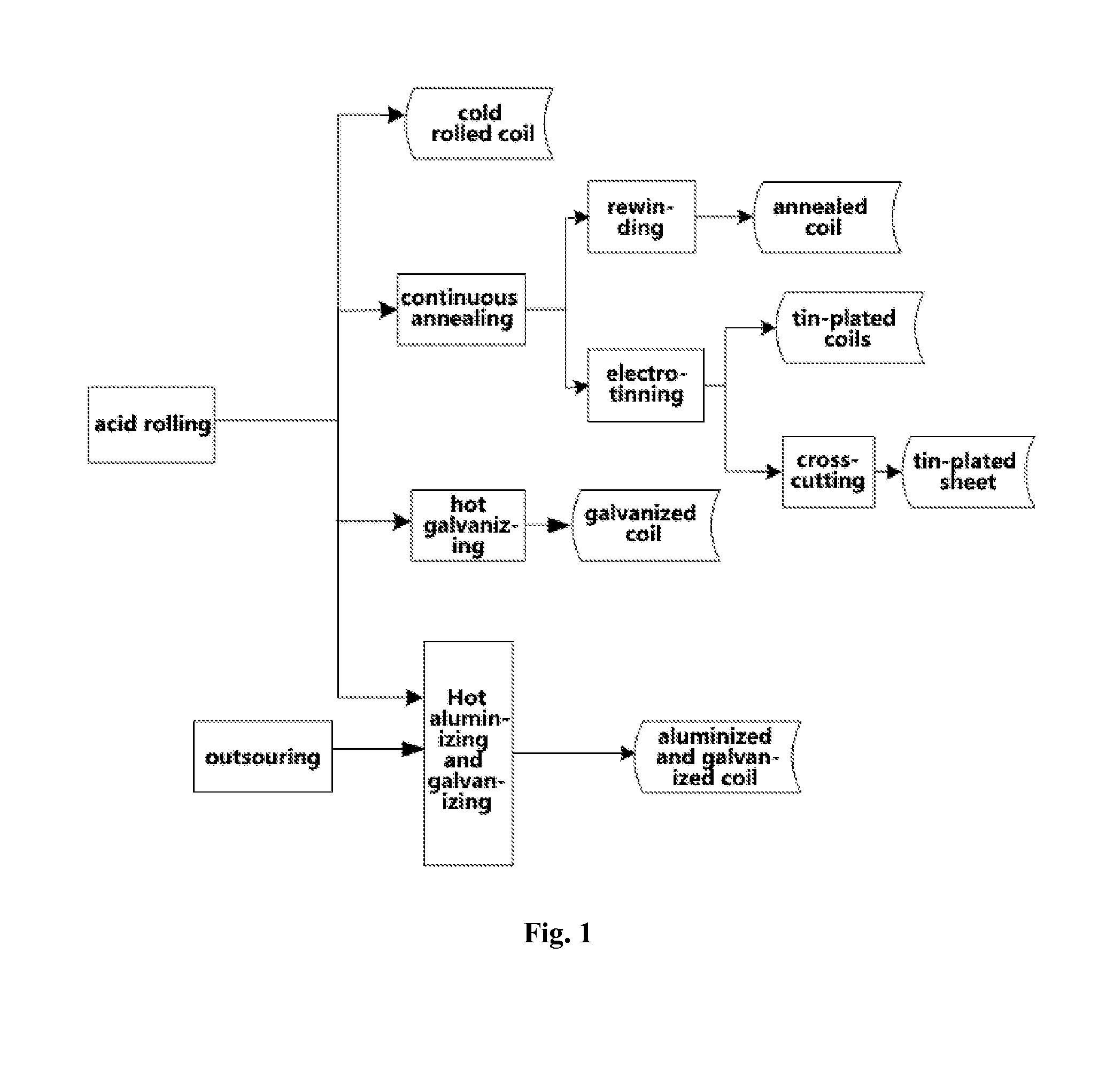

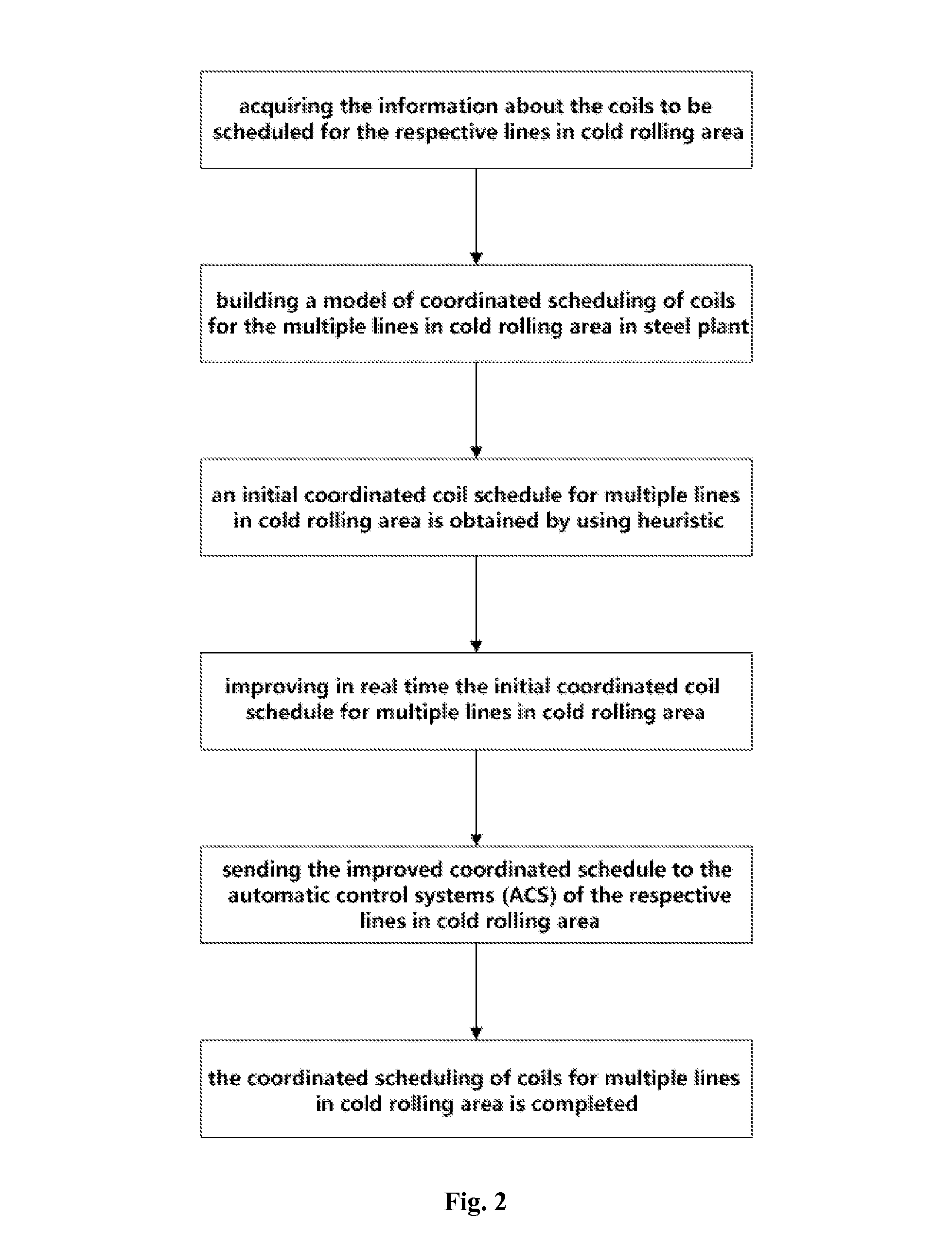

Coordinated coil scheduling method of multiple production lines for cold rolling area in steel plant

ActiveUS20160155204A1Steady and smoothly productionIncrease productivityResourcesManufacturing computing systemsProcess engineeringMaterial supply

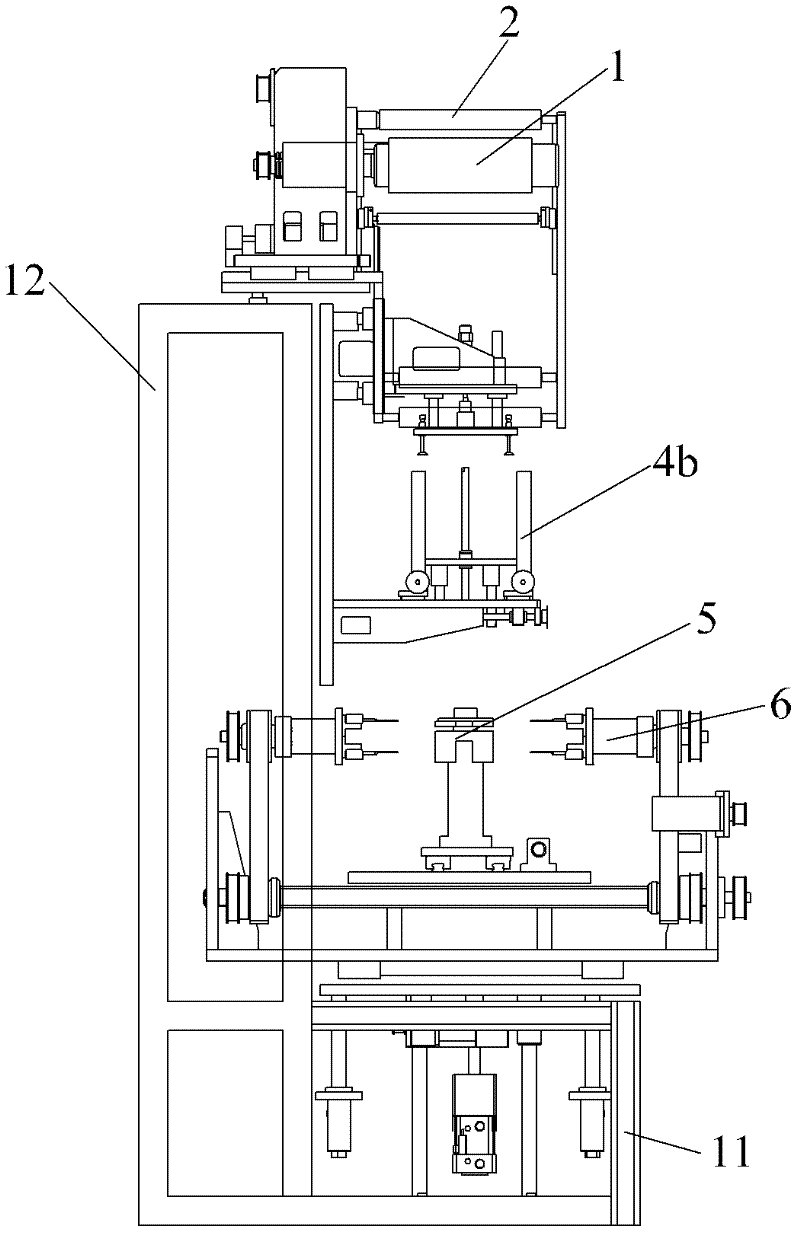

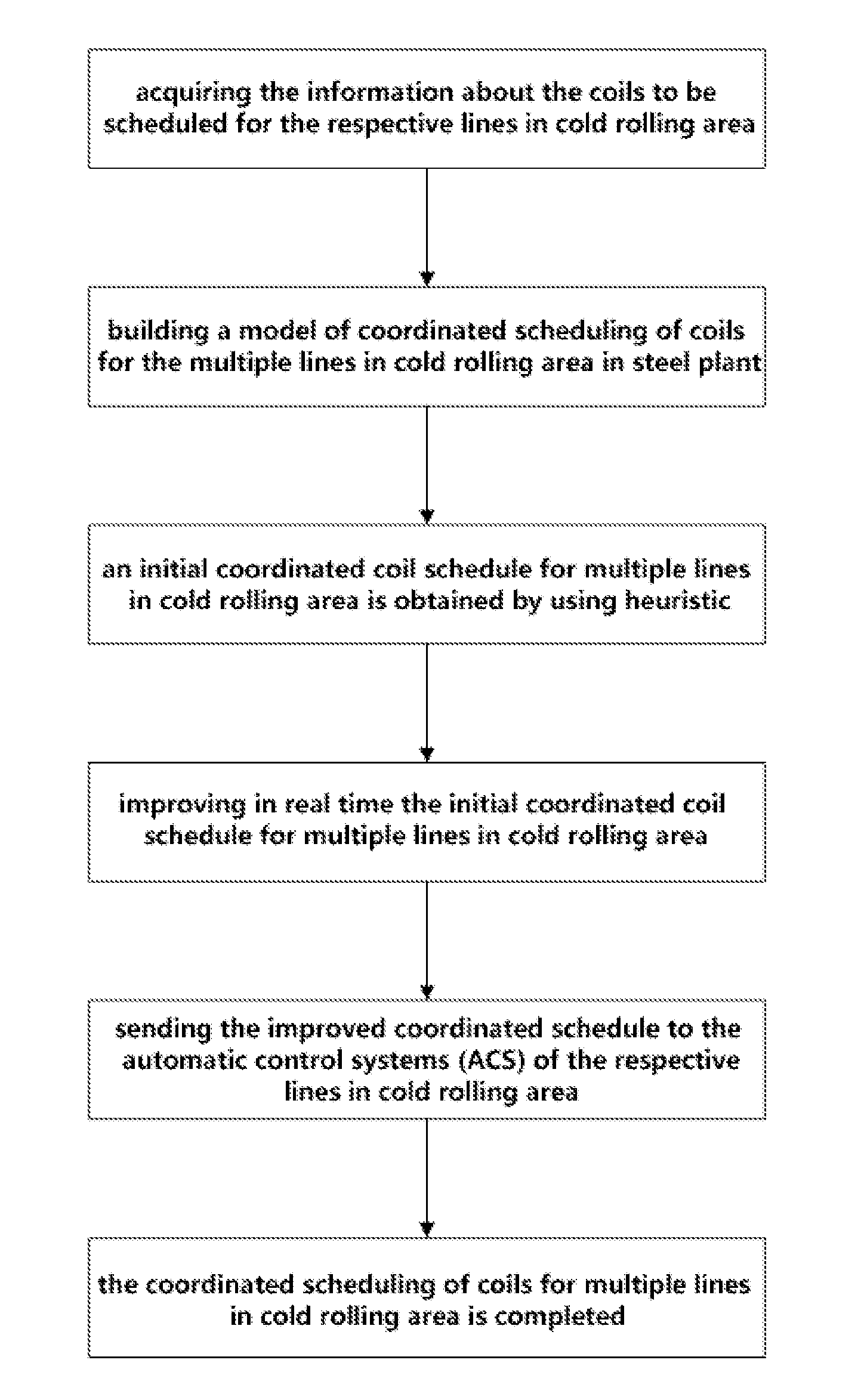

The present invention provides a coordinated coil scheduling method of multiple production lines in cold rolling area in steel plant, comprising: acquiring the information about the candidate coils to be scheduled in each of the multiple production lines in cold rolling area; building a coordinated coil scheduling model of multiple lines; obtaining the initial coordinated coil schedule of multiple lines by using a heuristic algorithm; improving the initial coordinated coil schedule in real time; and sending the improved coordinated coil schedule to the ACS of each production line. In this method, besides different production technological requirements of each coil, the cohesion relationship of different production lines are taken into account to make material supply to each equipment reasonable, and the smooth production process of coils in each of the lines is guaranteed with the changeover minimized, such that the whole efficiency of the manufacturing process is improved.

Owner:NORTHEASTERN UNIV

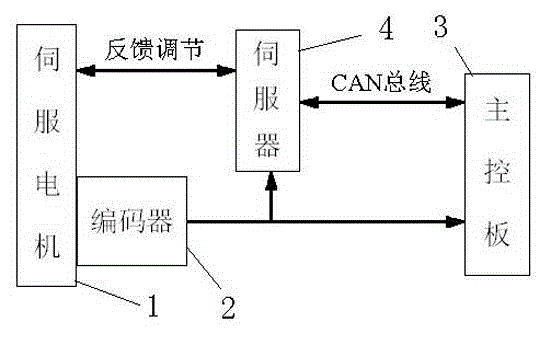

Safety control method for fast revolution of flat machine

ActiveCN103336484ASpeed Distortion ReductionReduce changeover timeProgramme controlComputer controlElectric machineSafety control

The invention discloses a safety control method for fast revolution of a flat machine, which comprises the following steps: firstly, a coder of a servo motor of the machine head of the flat machine is simultaneously connected with a main control panel and a server, the servo motor is in control connection with the server, and the main control panel is in communication connection with the server; then, the main control panel obtains both the operation start point and the operation end point of each line before operation, and the maximum coder value which the operation of each line reaches through reading and analyzing design information of a product, then the main control panel is combined with the acceleration and deceleration performance control parameter to calculate the coder values corresponding to each deceleration position point and each acceleration position point; the main control panel sends the positions of each deceleration position point and each acceleration position point, the corresponding coder values and target speed to the server; finally, in the process of operation of each line, the server directly monitors the output value of the coder to enable the servo motor to operate at each deceleration position point and each acceleration position point according to destined coder values, so that optimal revolution control is realized.

Owner:ZHEJIANG HENGQIANG TECH

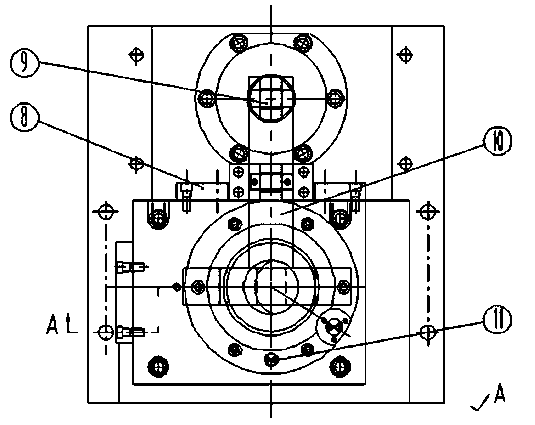

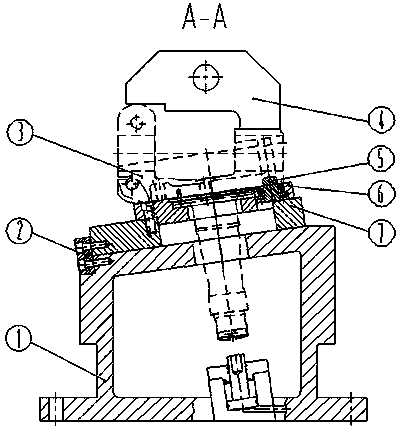

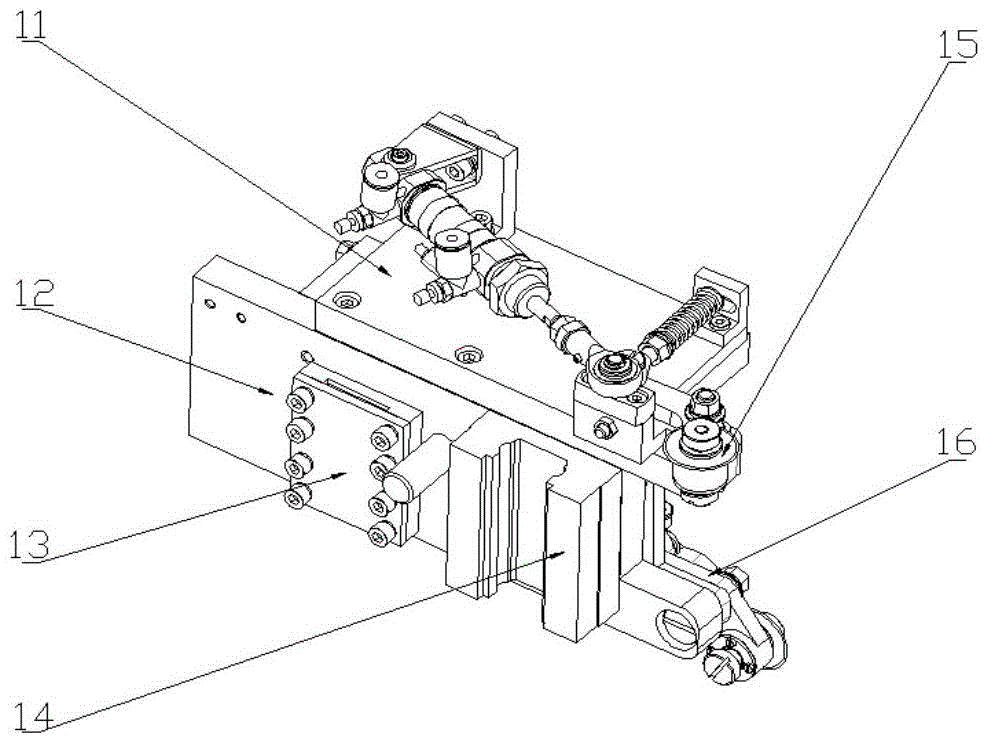

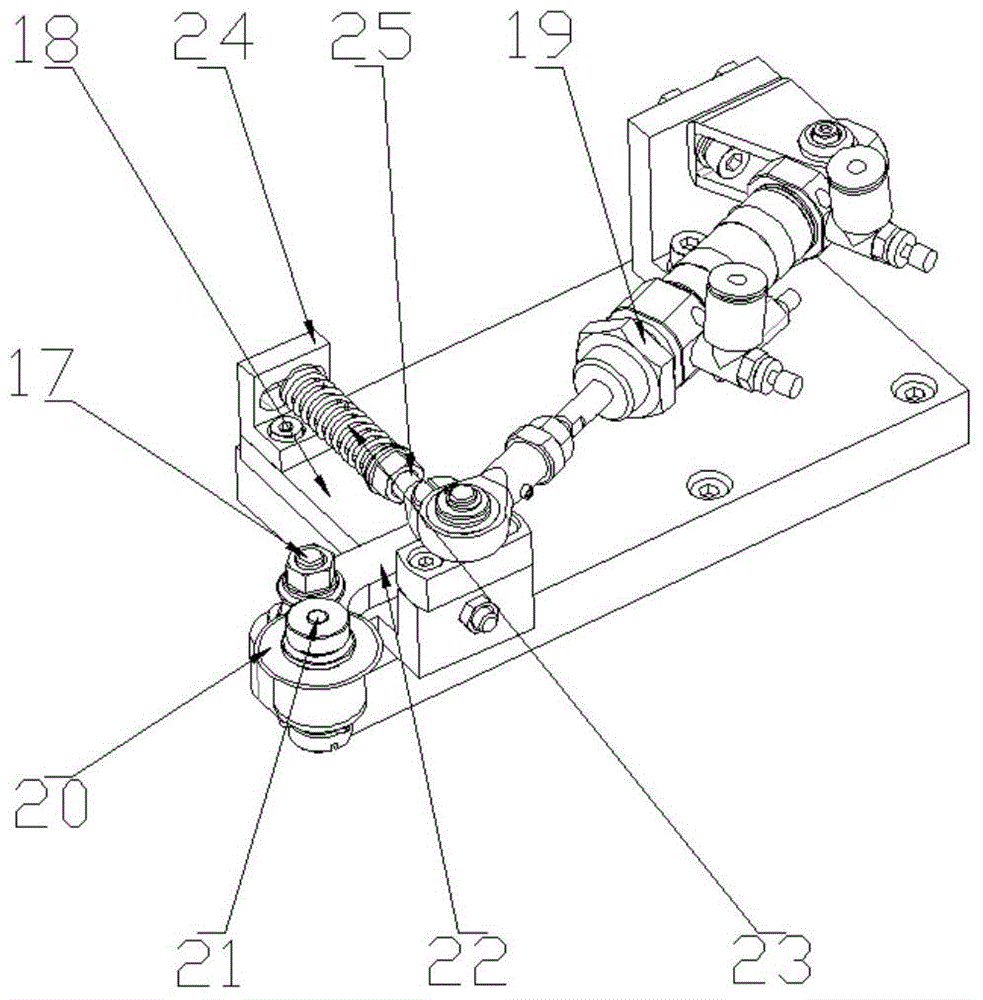

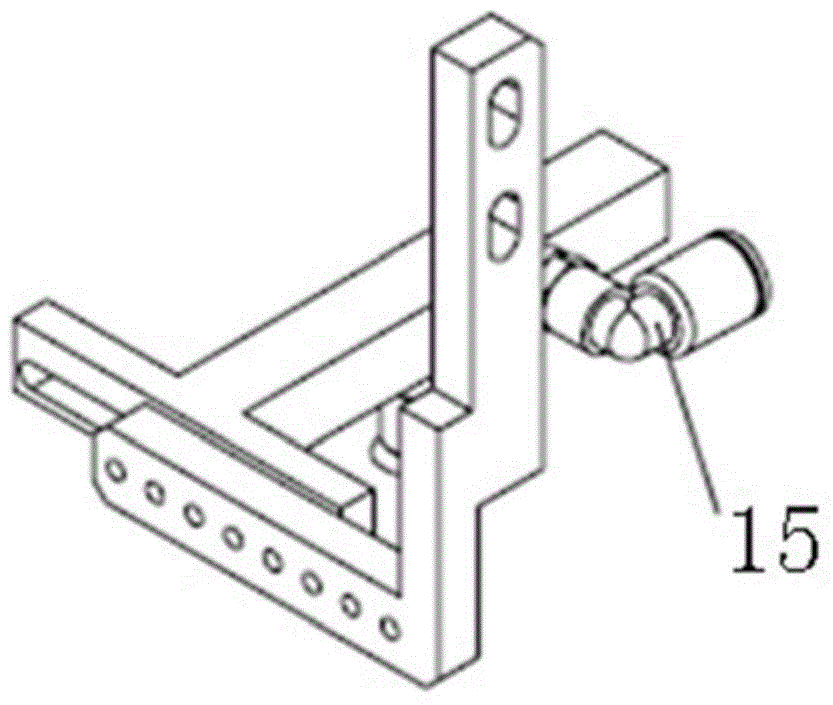

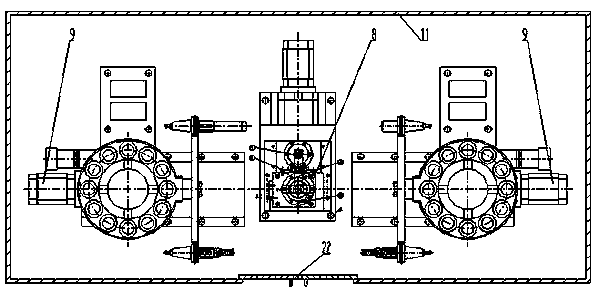

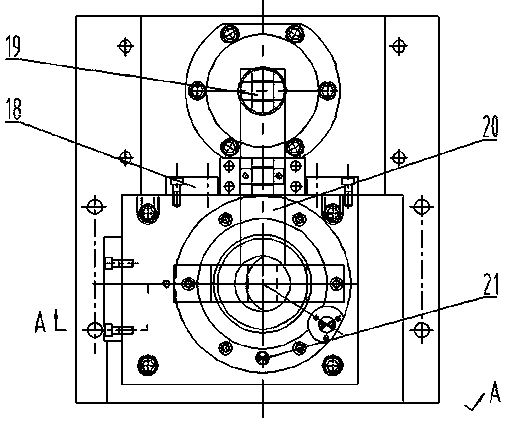

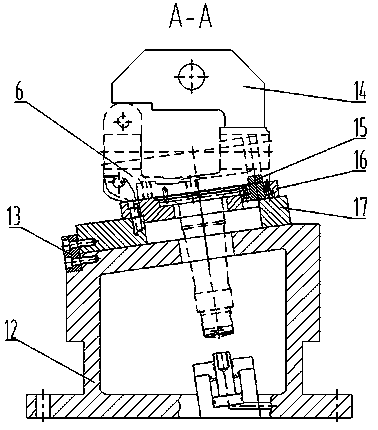

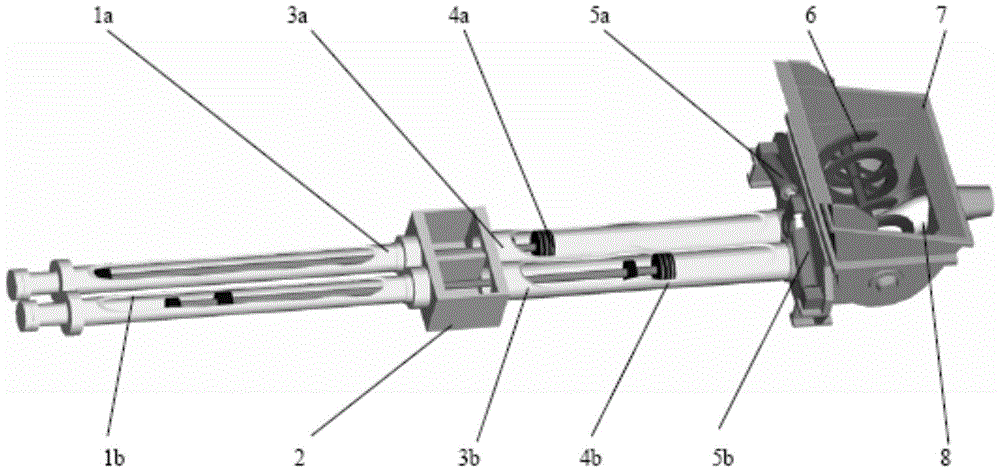

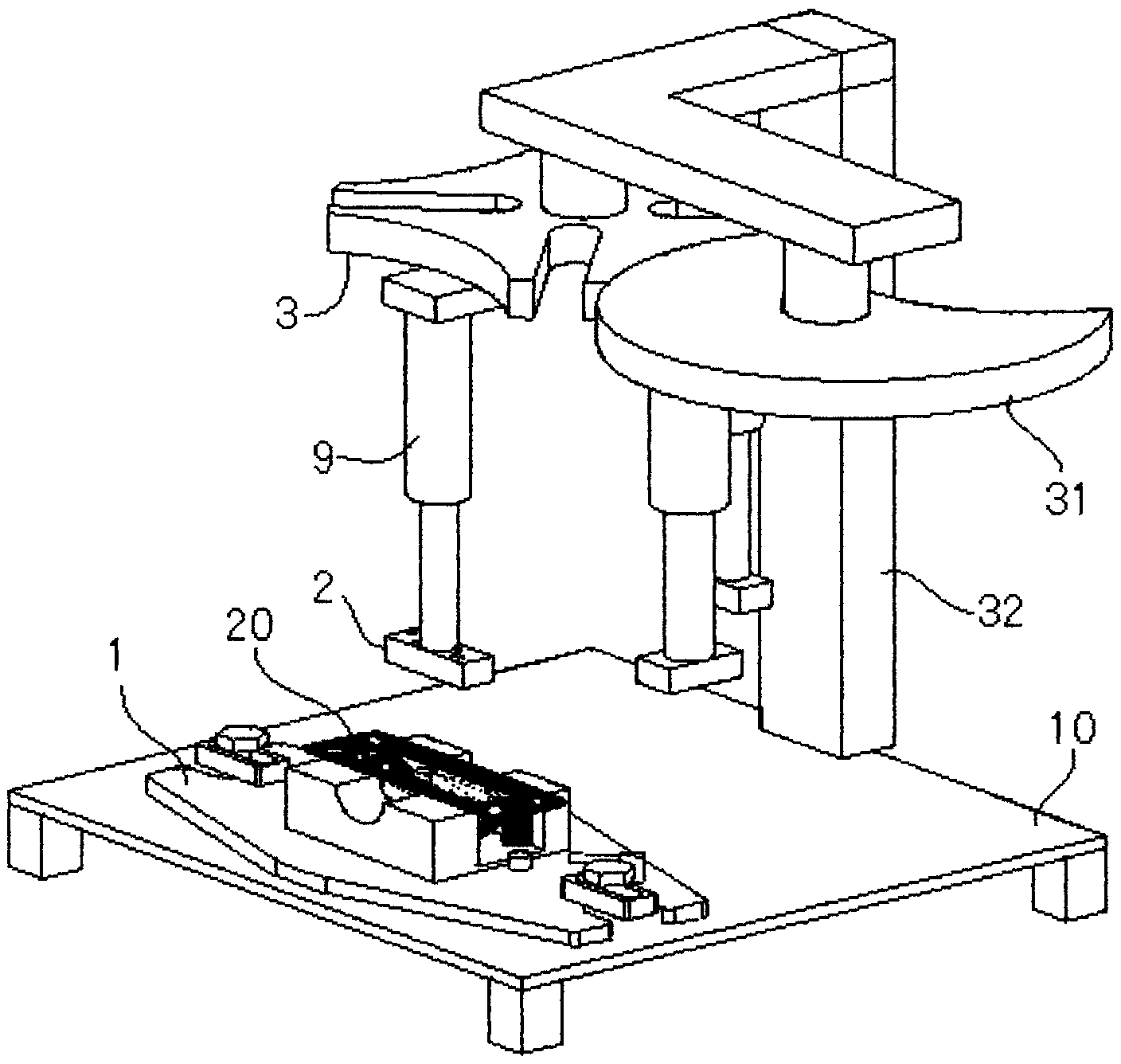

Flexible quick-changing locating device

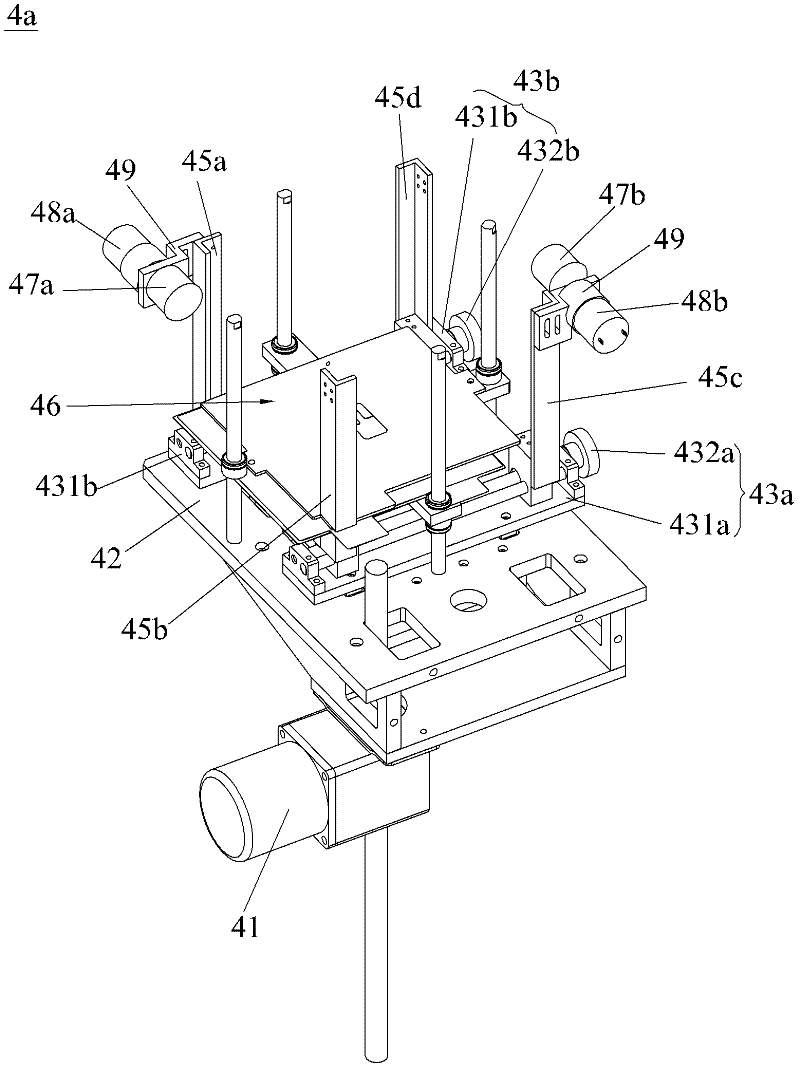

InactiveCN104339202ASave storage spaceEasy to managePositioning apparatusMetal-working holdersEngineeringUltimate tensile strength

The invention discloses a flexible quick-changing locating device. The flexible quick-changing locating device is suitable for flexibly producing different kinds of steering knuckles. A fixture body is fixed with a machine tool workbench through keys and bolts, the fixture body is provided with lateral and front locating plates, the lateral and front locating plates are respectively connected with the fixture body and an angle plate through bolts, the angle plate is connected with the fixture body through bolts, a locating plate is located through locating pins and angle plate bayonets and fixed on the angle plate through bolts, a workpiece is located on the locating plate through the locating pins and bayonets of the locating plate and compressed through a press block, the press block is fixed on a connecting bar through bolts, the connecting bar is connected with an oil cylinder push rod through bolts, and the oil cylinder push rod controls the compressing and loosening of the press block through the hydraulic system under program control. According to the flexible quick-changing locating device, the user only needs to change the locating element when changing varieties, the tool storage space can be reduced, the tool management is facilitated, the locating mode is practical, the locating precision is high, the labor intensity of the operator for changing the fixture is greatly alleviated, the operation is facilitated, the change time is short, and the production efficiency is effectively improved.

Owner:DONGFENG DANA AXLE

Multifunctional paper diaper robot box filling machine

The invention discloses a multifunctional paper diaper robot box filling machine. The robot box filling machine comprises a suction type box filling part and a clamping type box filling part, whereinthe suction type box filling part comprises a four-section feeding part, a six-axis box filling robot, a side pushing mechanism, a box opening mechanism, a sucker gripper, a suction platform and a roller conveying line; the clamping type box filling part comprises a four-section feeding part, a six-axis box filling robot, an arrangement mechanism, a clamping platform, a side pushing mechanism, a box opening mechanism, a clamping gripper and a roller conveying line. The multifunctional paper diaper robot box filling machine has the advantages as follows: the multifunctional paper diaper robot box filling machine has double functions, the suction type box filling form and the clamping type box filling form are combined, the application range of the box filling machine is greatly enlarged, and the production cost is reduced.

Owner:NANTONG UNIVERSAL MACHINERY

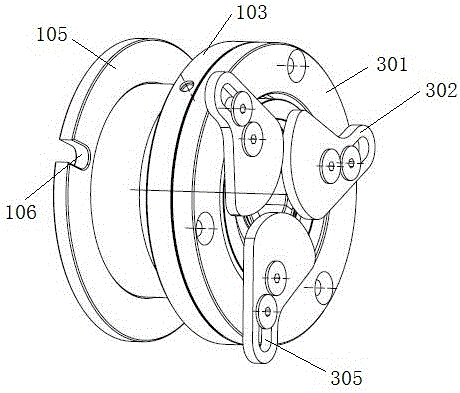

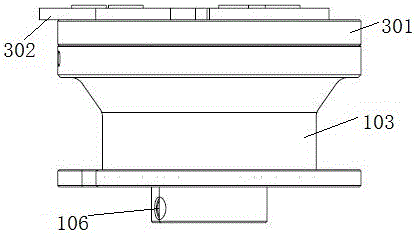

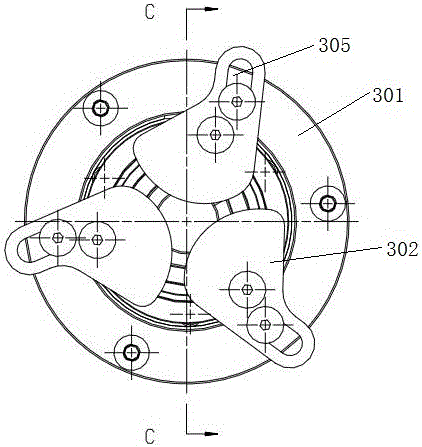

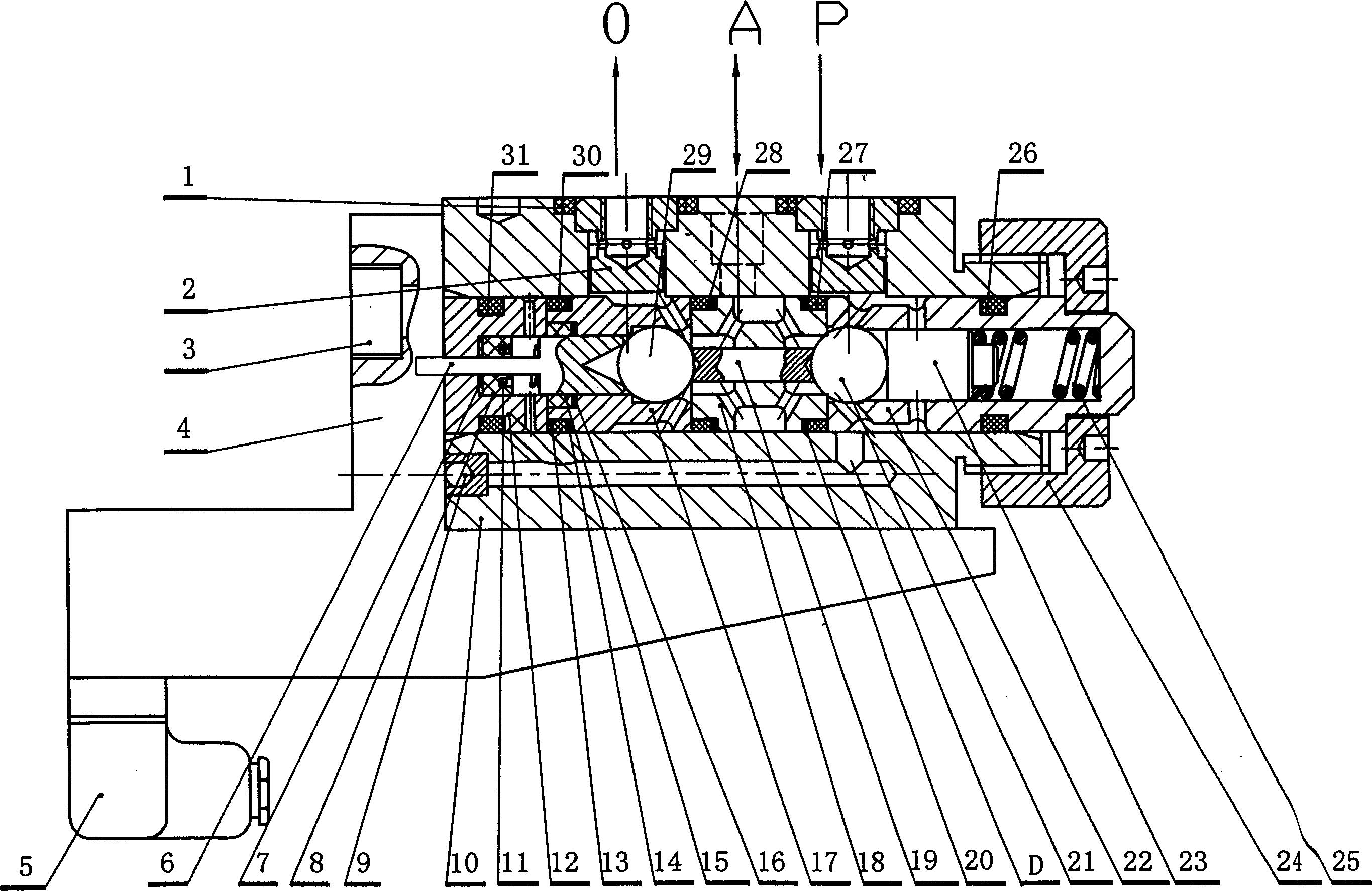

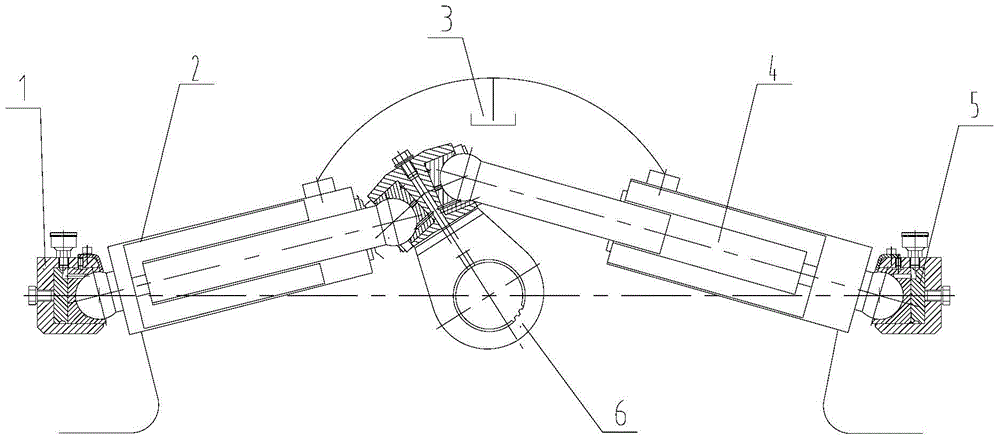

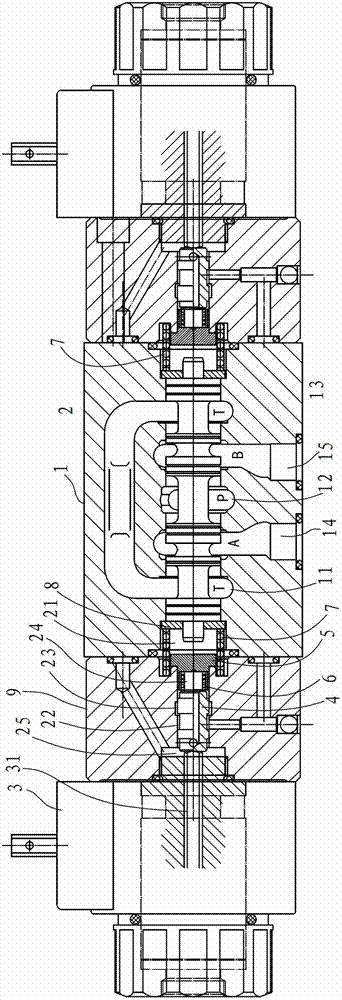

Swing mechanism and concrete pumping device

ActiveCN103470555AFast changeover timeReduce changeover timeServomotorsPumpsReverse timeMechanical engineering

The invention discloses a swing mechanism. The swing mechanism is used for driving a distributing valve of a concrete pumping device to swing and comprises a swing arm for driving the distributing valve and two hydraulic oil cylinders for driving the swing arm to swing from side to side. Ends of the two hydraulic oil cylinders are respectively connected with the left side and the right side of the swing arm, and the hydraulic oil cylinders are two-stage hydraulic oil cylinders. The invention further discloses the concrete pumping device comprising the swing mechanism. According to the swing mechanism and the concrete pumping device with the swing mechanism, the reversing speed is quick, impact is small, reversing time of the swing mechanism is close to reversing time of a main oil cylinder of the concrete pumping device, and pumping continuity is greatly improved.

Owner:SANY AUTOMOBILE MFG CO LTD

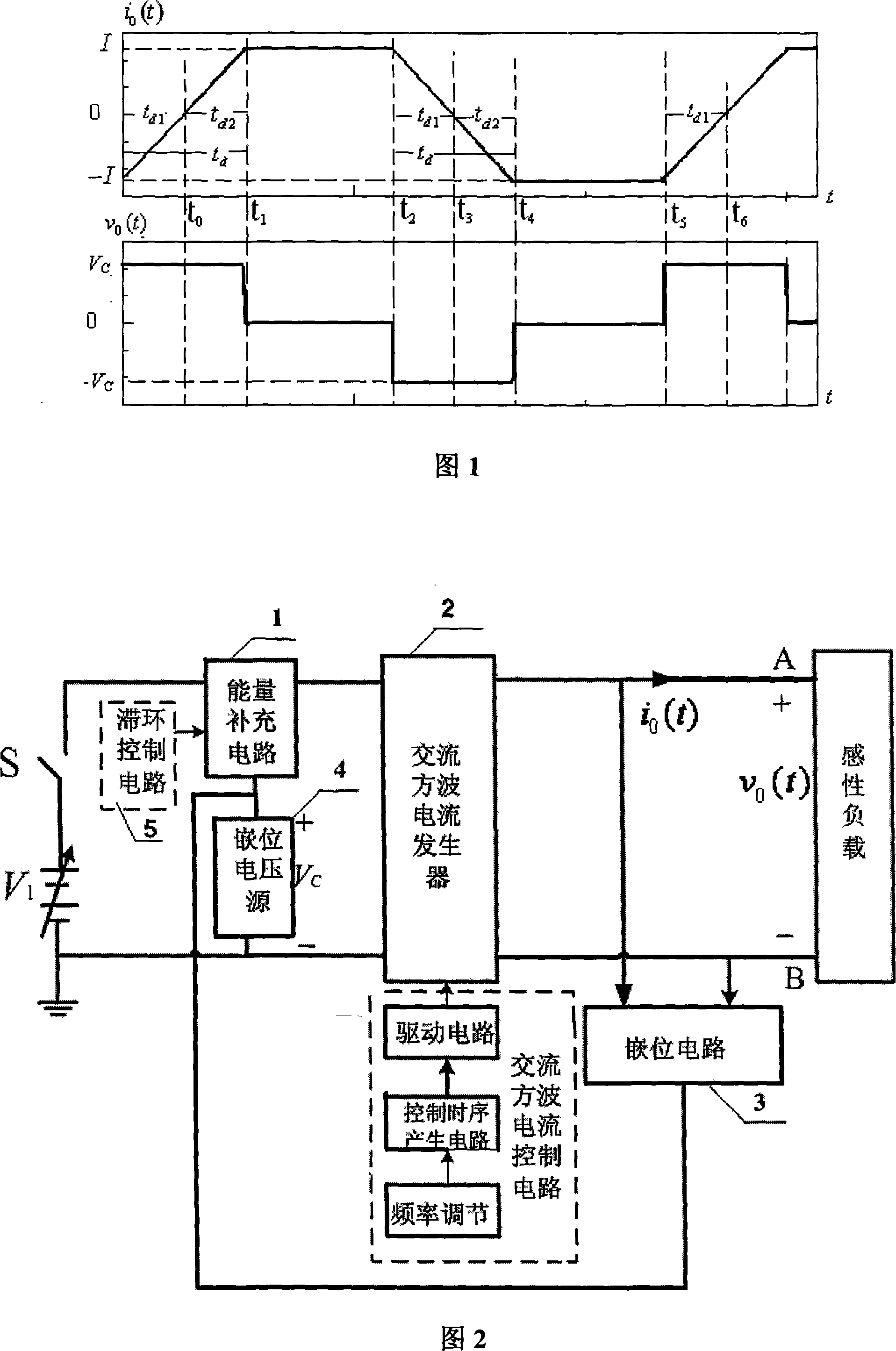

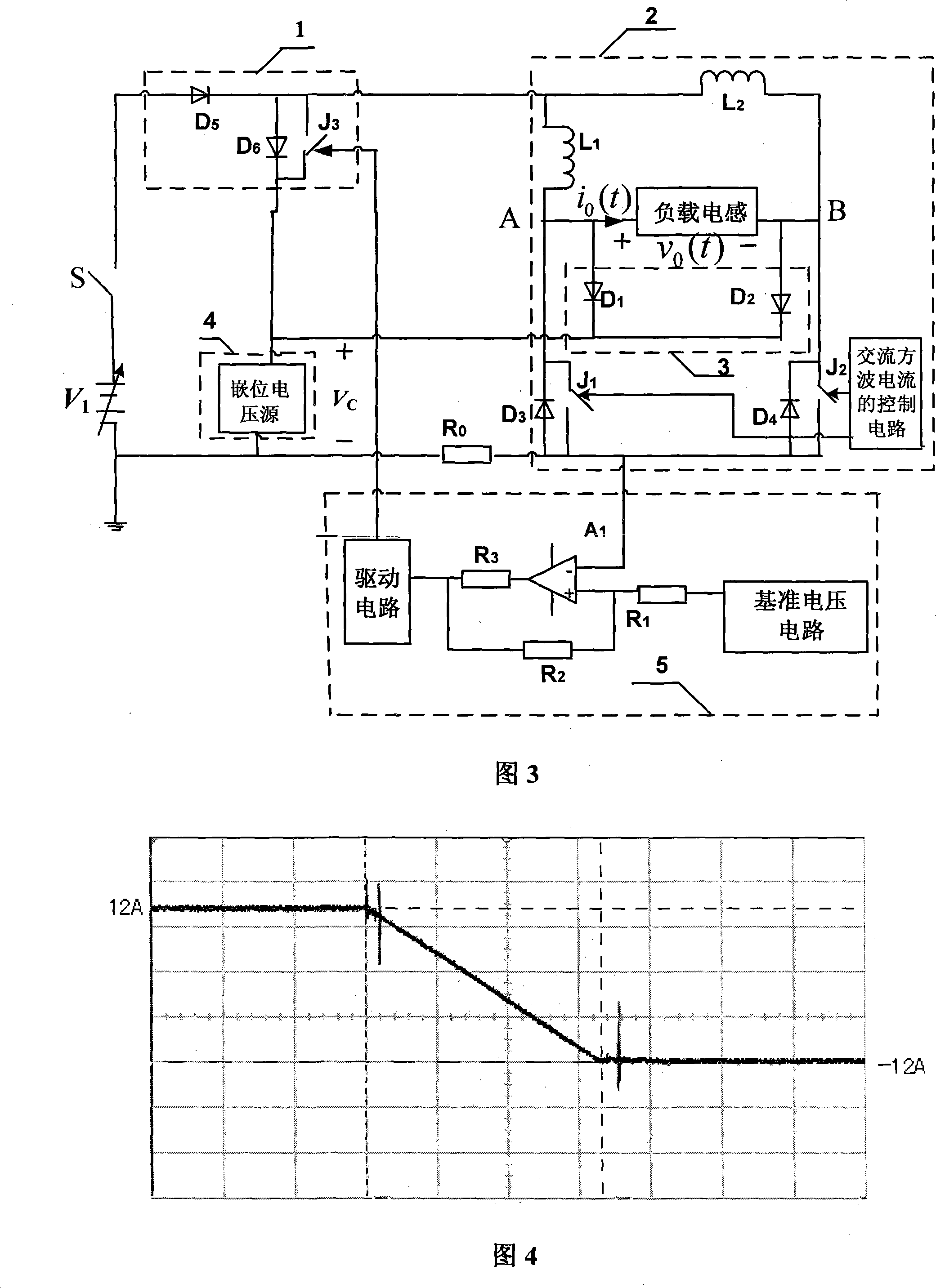

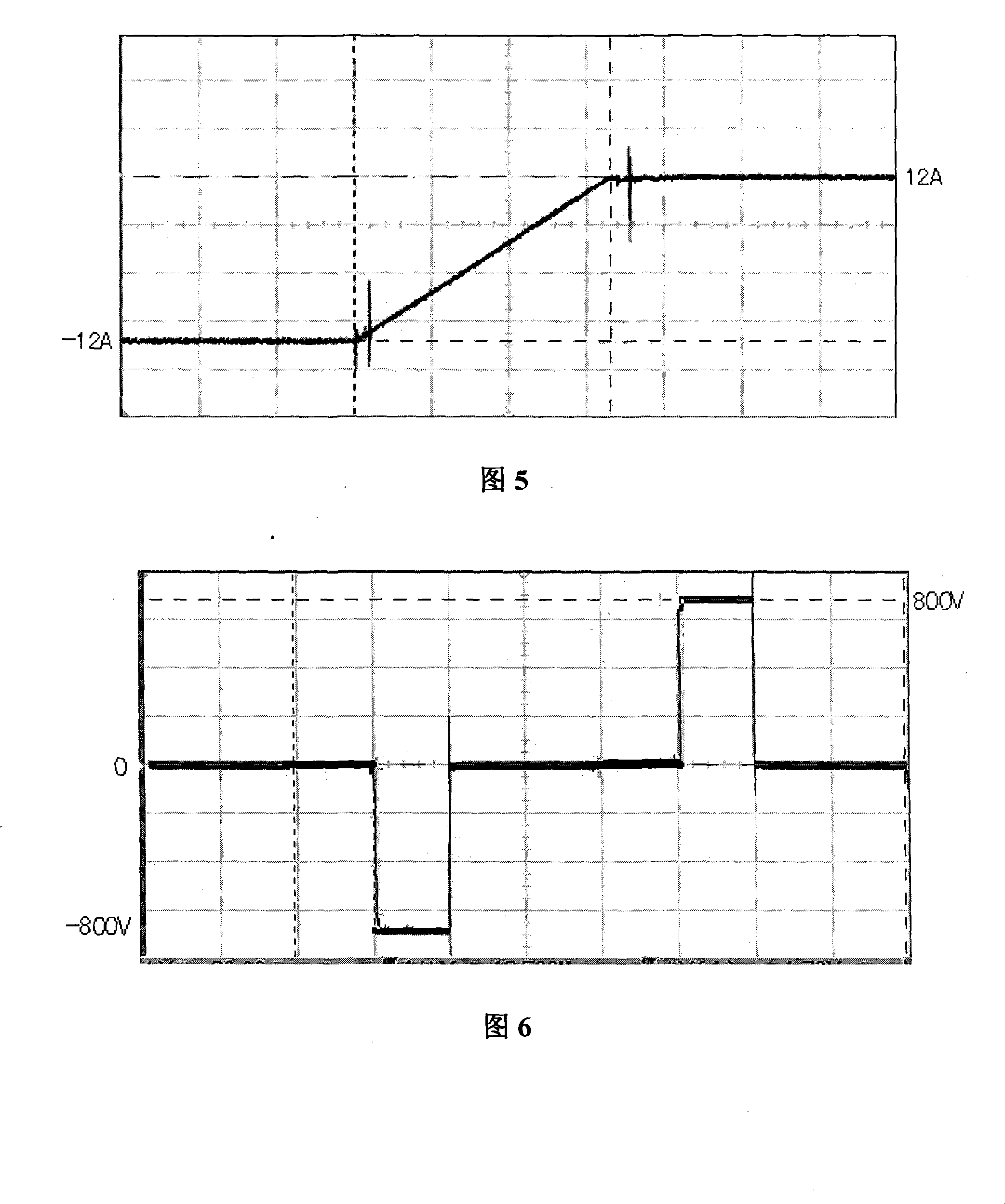

Control method and device for inductive load wide-frequency amplitude-constant AC square wave current

ActiveCN101242149AAchieve commutation along the linearShort commutation timeMaterial analysis by electric/magnetic meansElectric/magnetic detectionReverse timeHysteresis

A control method for sensitive load broadband constant amplitude alternating rectangular wave current is especially for alternating rectangular wave current generated by electromagnetic transmitting loop in frequency domain electromagnetic method which is applied to the geophysical prospecting and the nondestructive examination field. The method of the invention, comprising: regulating the voltage of an output current frequency, a voltage reference and an embedding voltage source to generate cyclic load current waveform with same shape and constant amplitude value, to calculate a reversing slope of the rectangular wave current, reversing time and amplitude value of the current. The device of the invention comprises a DC power supply, an alternating current rectangular wave current generator, an alternating current rectangular wave current control circuit, a sensitive load, an energy supplementing circuit, a hysteresis loop control circuit, an embedding circuit and an embedding voltage source. The invention improves gradient of reversing side of the alternating rectangular wave current, accomplishes reversing side linearity, and solves problems of improvement and invariableness of current amplitude value and expansion of frequency range and so on.

Owner:CHONGQING CUILU DETECTION TECH CO LTD

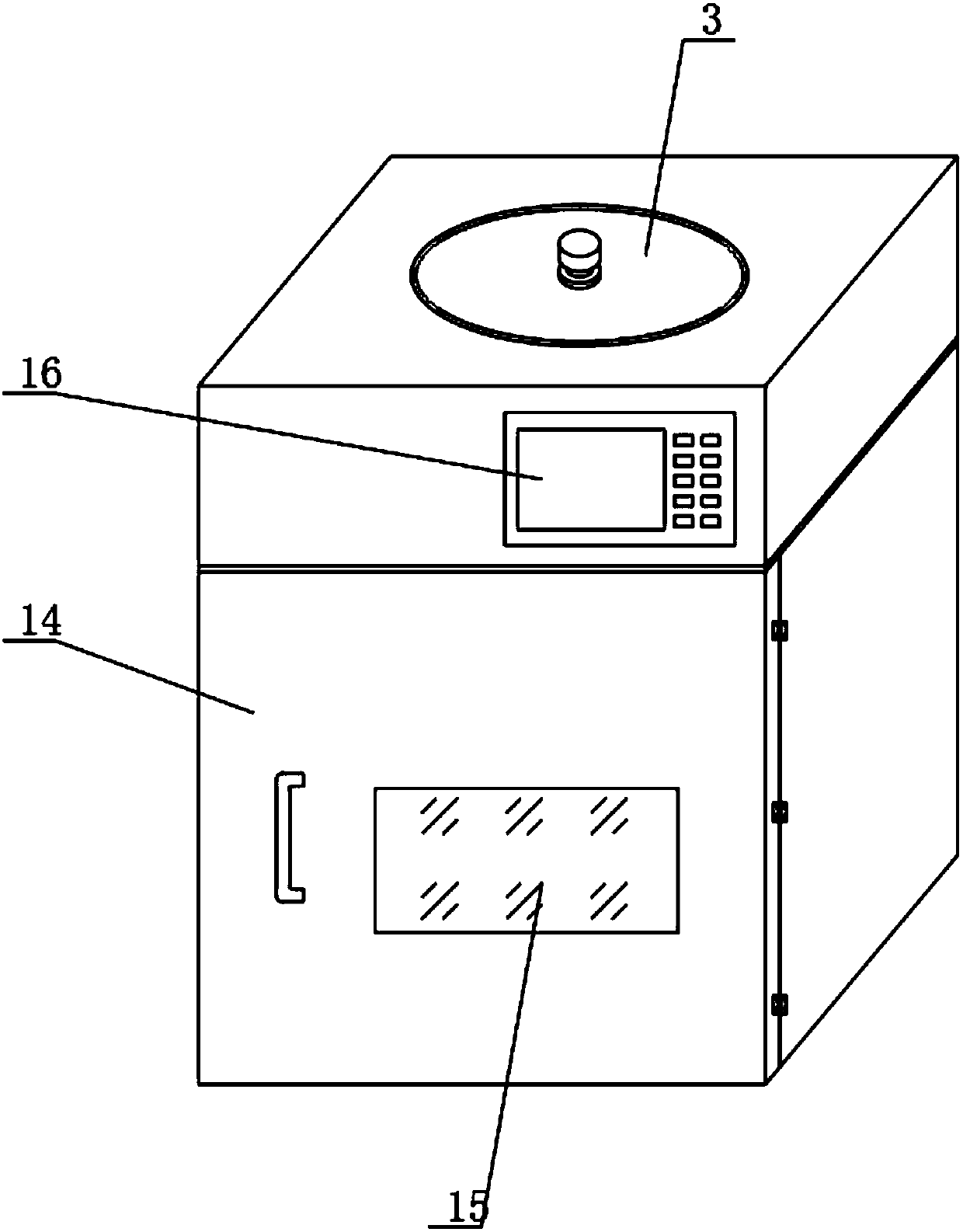

Full-automatic laser welder device and operation method

ActiveCN102689095AImprove compatibilityReduce the difficulty of debuggingLaser beam welding apparatusMechanical engineeringLaser

The invention belongs to the technical field of welding machines, and particularly relates to a full-automatic welder device and an operation method. The device comprises a cabinet, a turntable fixture, a feeding mechanism, a prepressing mechanism, a loading mechanism, a leveling mechanism, a welding mechanism, a discharging mechanism, a spot welder and a controller, wherein the turntable fixture is arranged on the cabinet, a workpiece is transferred onto the turntable fixture by the feeding mechanism, the prepressing mechanism is arranged on the cabinet, the loading mechanism is positioned on one side of the turntable fixture, the leveling mechanism is placed above the turntable fixture, the welding mechanism is arranged above the turntable fixture, the discharging mechanism is arranged on one side of the turntable fixture, the spot welder is disposed on one side of the loading mechanism, and the controller is arranged above the welding mechanism. The full-automatic welder device has the advantages that the device is high in compatibility, and is applicable to various types of products only by means of increasing or reducing assorted cushion blocks with proper heights, accordingly, fine adjustment is omitted, debugging difficulty is reduced, and type changing time is saved; and labor is saved, one person can operate multiple machines, and the quality of products, the qualified rate of the products, the consistency of the products and work efficiency are improved.

Owner:WUHAN YIFI LASER EQUIP CO LTD

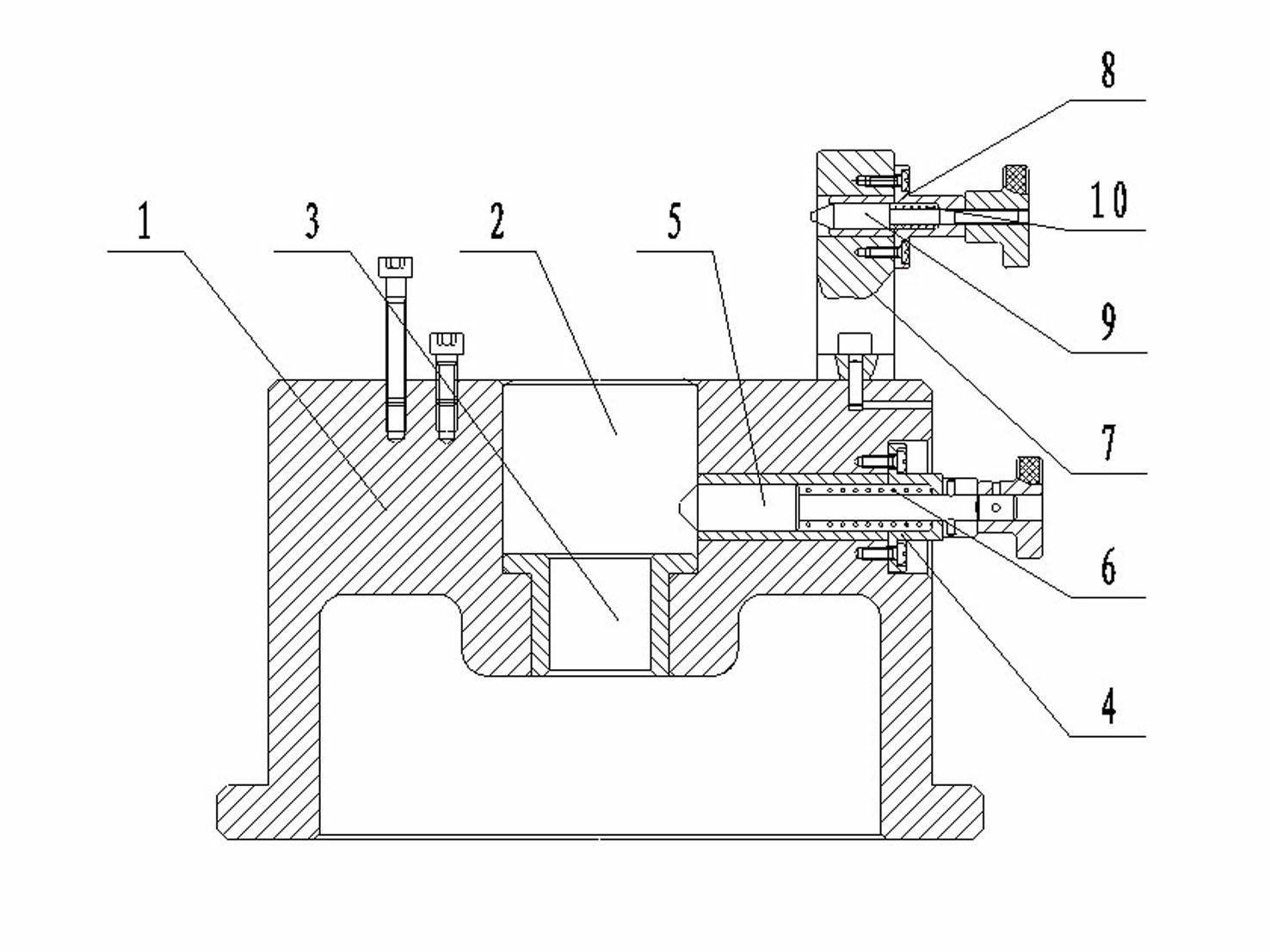

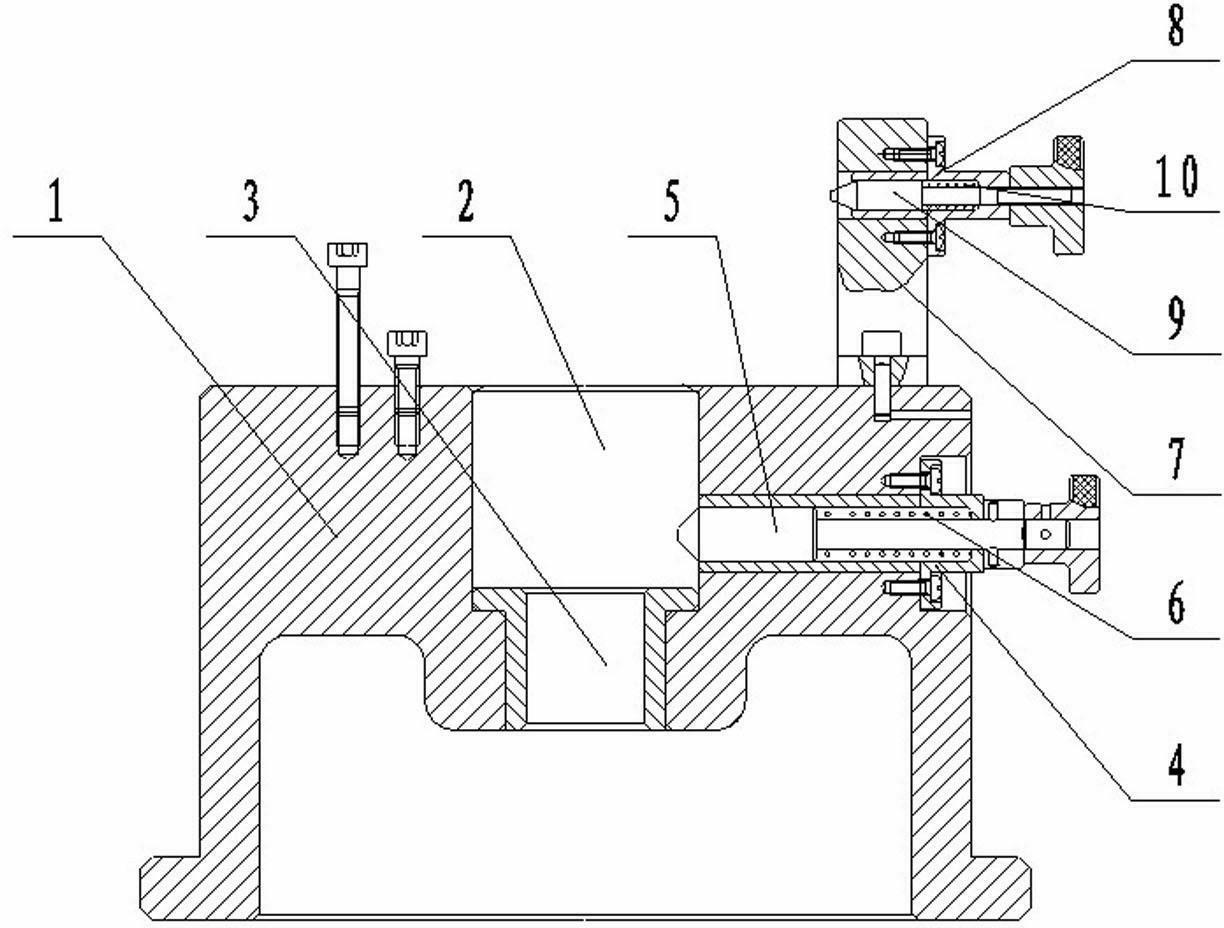

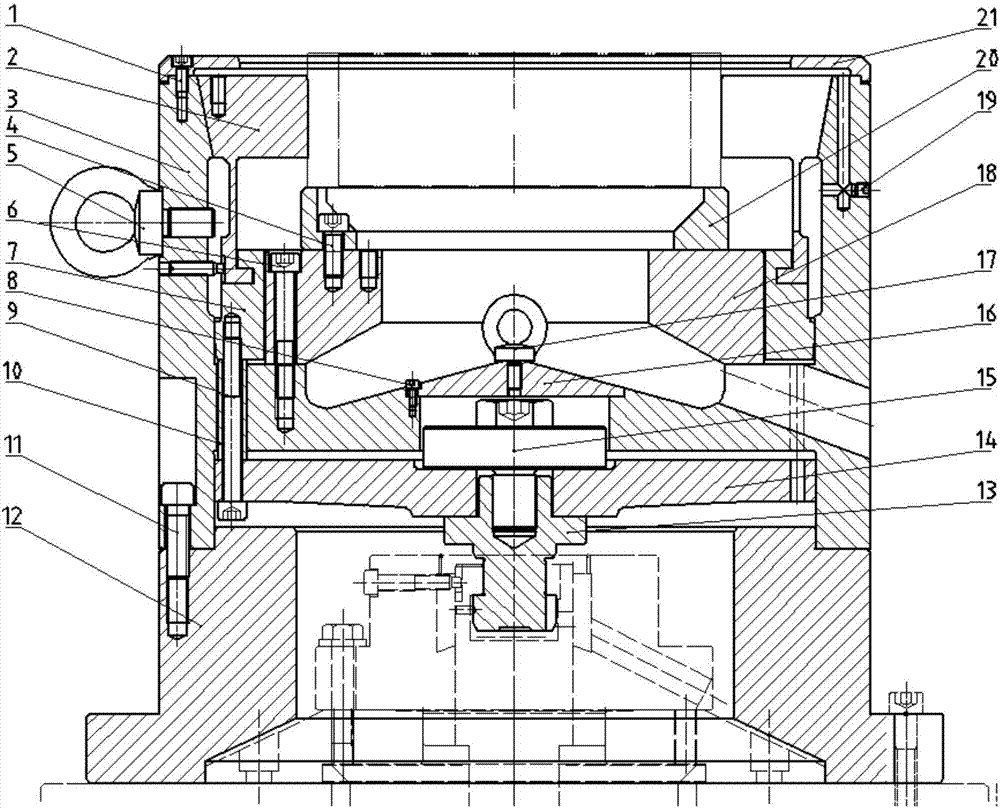

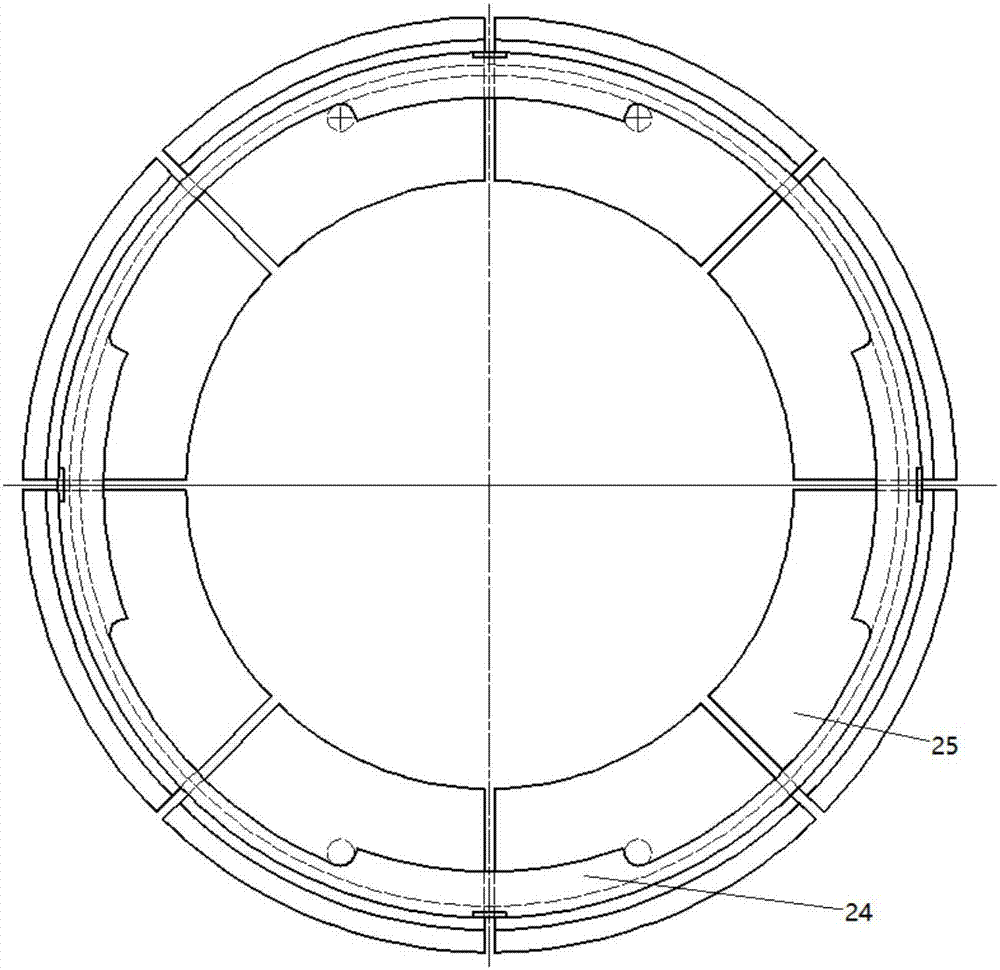

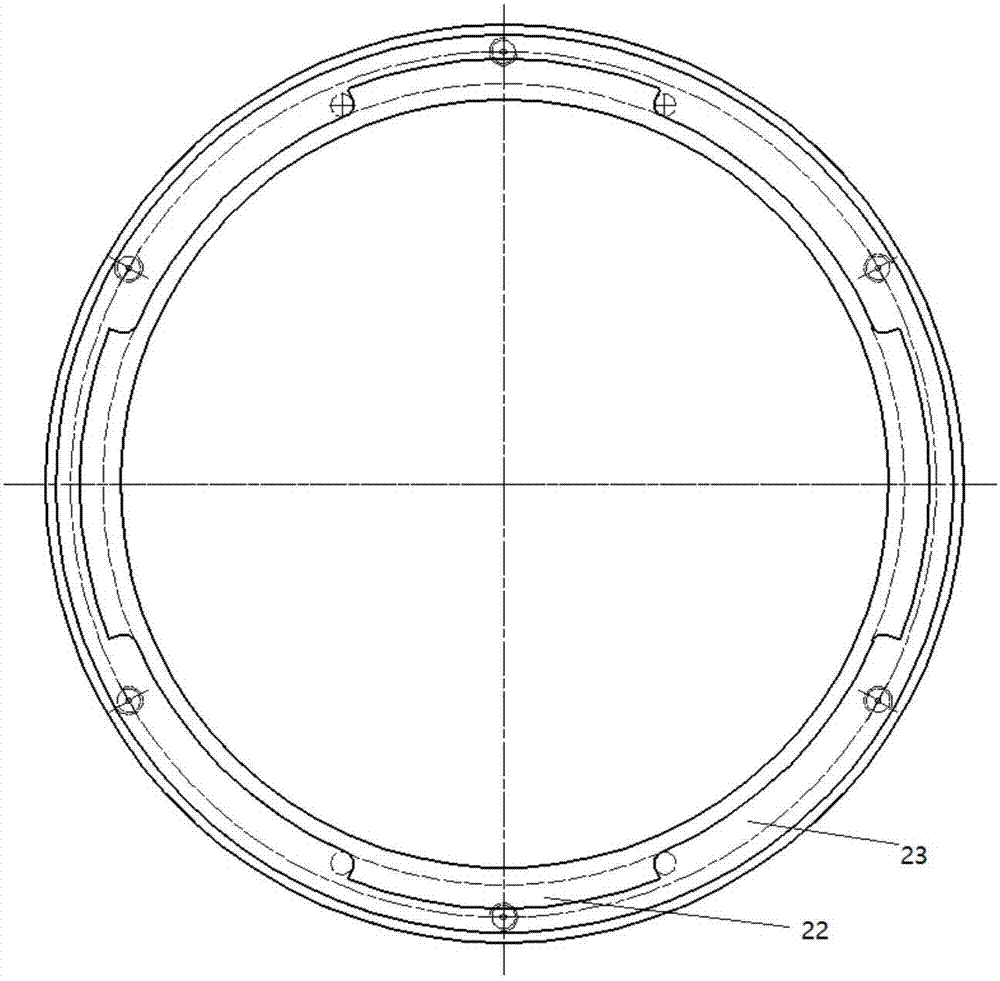

Self-compensation type floating three-jaw power chuck for cylindrical grinding machine

InactiveCN105881205AEasy to change production and adjustReduce changeover timeRevolution surface grinding machinesGrinding work supportsCylindrical grindingEngineering

The invention discloses a self-compensation type floating three-jaw power chuck for a cylindrical grinding machine. The self-compensation type floating three-jaw power chuck comprises a shell, a bearing connecting unit and a floating clamping unit. The shell comprises a center sleeve axially provided with a center through hole and an outer shell arranged outside the center sleeve in a sleeving manner. A containing cavity is formed between the center sleeve and the outer shell. The bearing connecting unit is arranged in the containing cavity and comprises a roller pin one-way bearing, a middle bearing sleeve and a rolling bearing. The roller pin one-way bearing is arranged on the outer circle of the center sleeve in a sleeving manner, the middle bearing sleeve is fixed to the outer circle of the roller pin one-way bearing, and the rolling bearing is arranged on the outer circle of the middling bearing sleeve in a sleeving manner and connected with the inner circle of the outer shell. The floating clamping unit comprises a floating disc and clamping jaws arranged on the outer end face of the floating disc and used for clamping a workpiece. The floating disc is arranged on the end face of the outer shell through a gland in a floating manner. The design of sealing structures is achieved on the front portion and the rear portion of the containing cavity, and accordingly cutting fluid and other pollutants are prevented from entering the containing cavity during using. According to the self-compensation type floating three-jaw power chuck, a machine tool and robot automatic feeding and discharging system can conveniently conduct production exchange adjustment, the production exchange time is saved, and production exchange errors are avoided.

Owner:合肥华兴机器人有限公司

Pure water electromagnetic ball valve

InactiveCN1587721AReduce changeover timeReduce reset timeServomotor componentsSpring forceStatic performance

The invention discloses a kind of pure water electromagnetic ball valve. It includes electromagnet, mechanism of force amplification, ball valve core in the hole of valve body, rest spring, valve cap and push bar. On the upper of valve body there is water inlet, water outlet and back water gap connected by channel; through leaving and covering of ceramic ball and valve seat, forming open and closed circuit to change the direction of fluid flow. The ceramic ball is generated by driving force of the dry-type DC electromagnet and spring force of the reset spring, and transmitted by the push bar. The proper layout of flow channel balance hydraulic pressure of the push bar and the ceramic ball. The invention achieves zero leakage by sealing directly valve plug and valve cover, valve cover and valve body, the core of ceramic ball and valve seat; improves static performance of the electromagnetic ball valve by add valve port dampers; switch fast by electromagnets with larger thrust and mechanism of force amplification. This valve is versatile and fit to work under conditions of middle and high pressure water medium.

Owner:ZHEJIANG UNIV

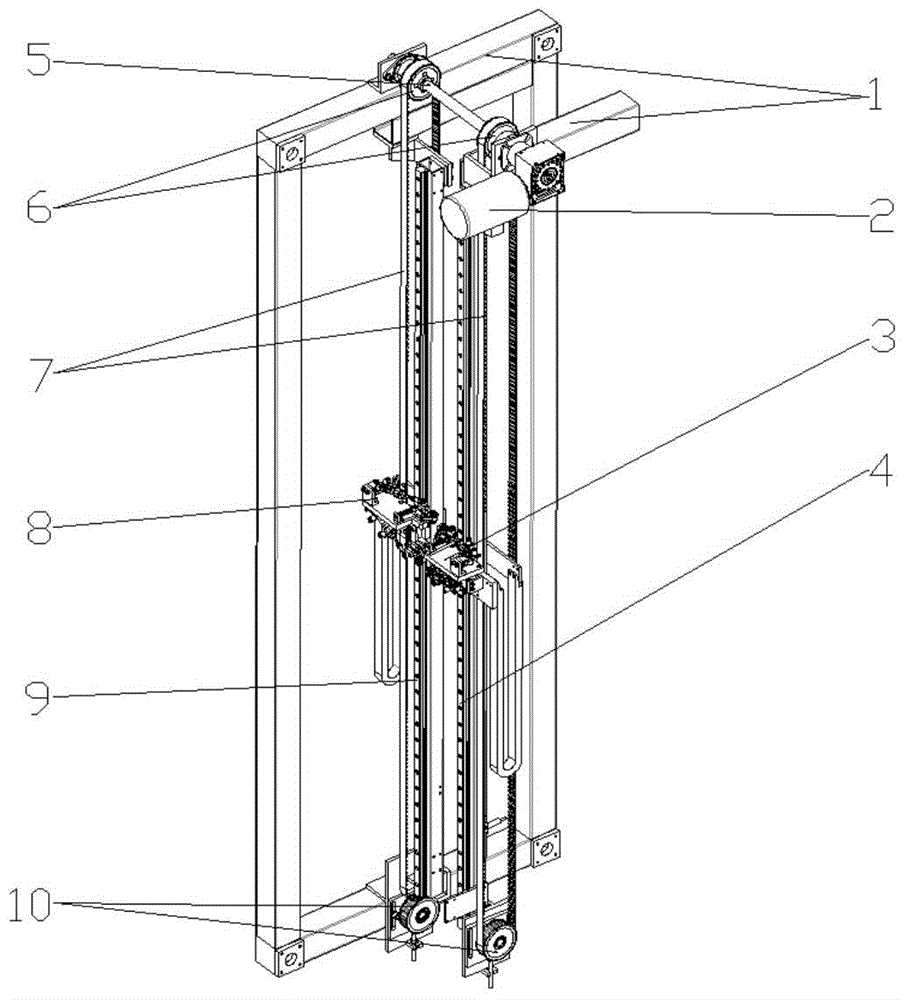

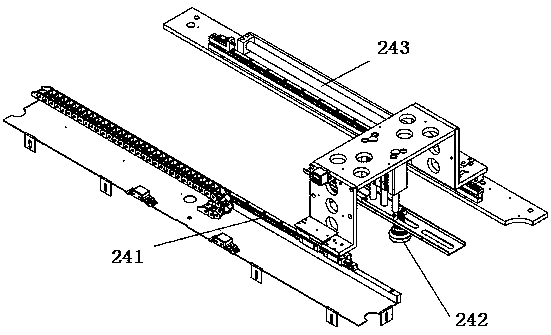

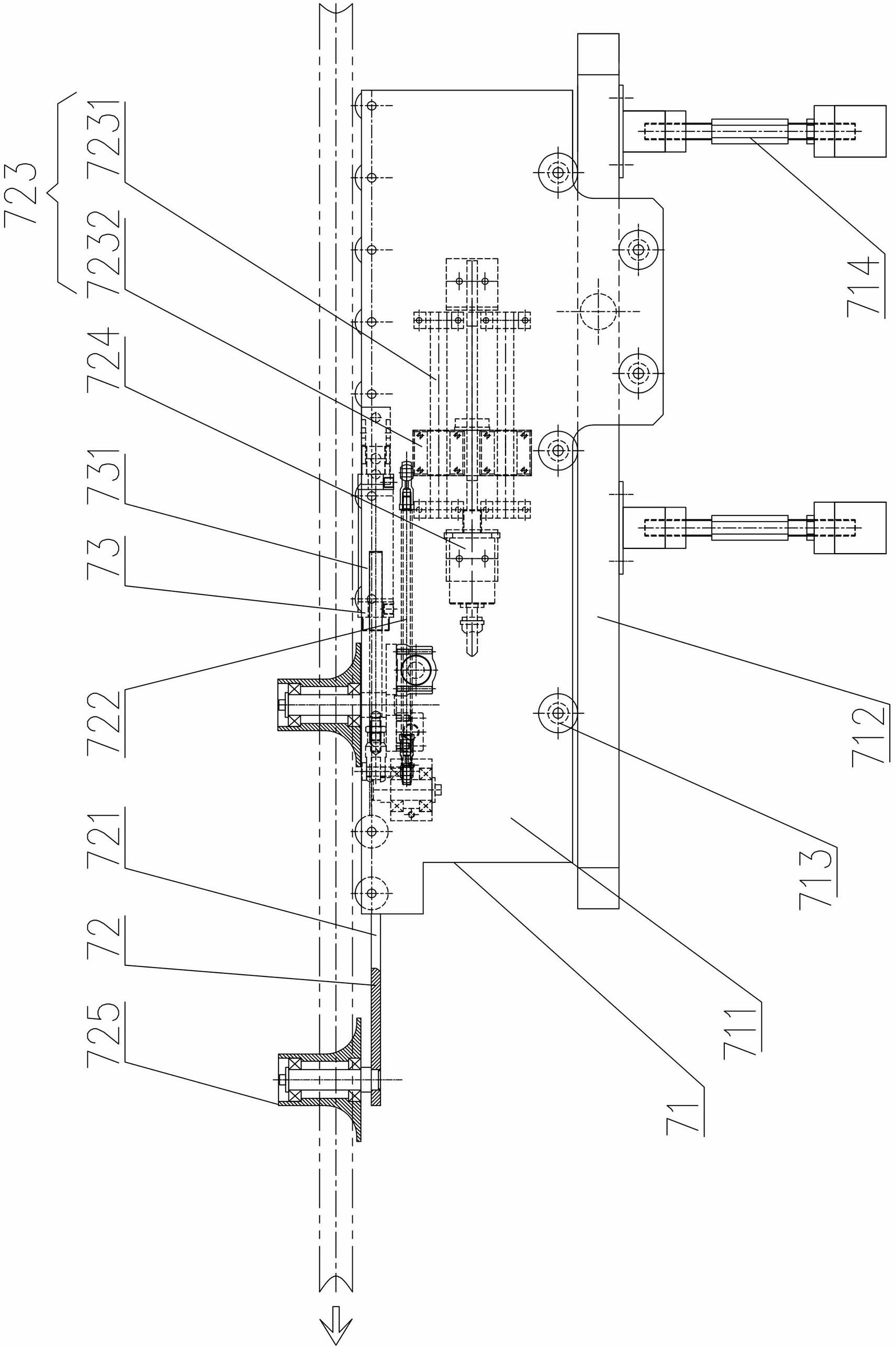

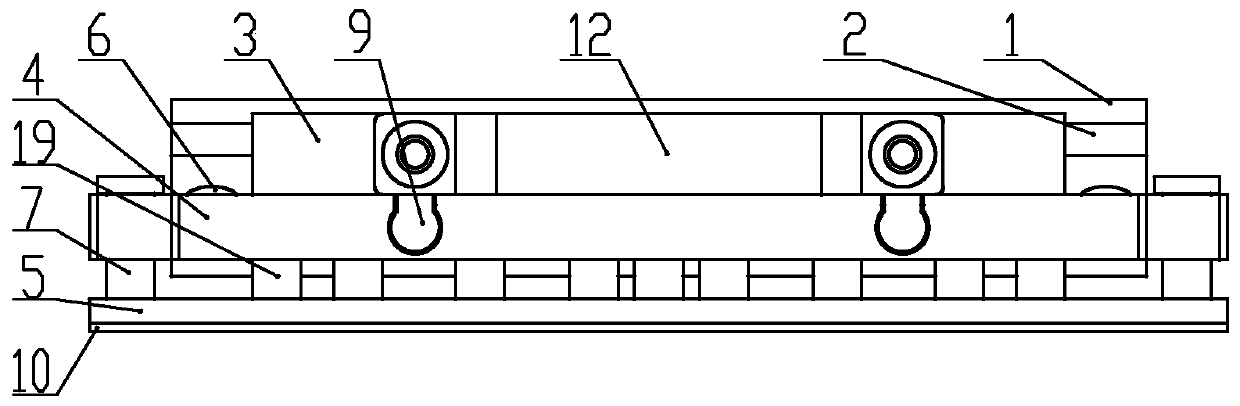

Thin film cutting mechanism of vertical type glass film laminating machine

ActiveCN104526736APrecise cut sizeReduce changeover timeMetal working apparatusEngineeringMechanical engineering

The invention provides a thin film cutting mechanism of a vertical type glass film laminating machine. The thin film cutting mechanism comprises a vertical type machine frame, a synchronous belt transmission mechanism, a thin film cutting knife wheel set and a knife wheel movement guide rail mechanism, wherein the synchronous belt transmission mechanism and the knife wheel movement guide rail mechanism are installed on the vertical type machine frame; the synchronous belt transmission mechanism is used for moving the knife wheel set and comprises a servo motor, a driving synchronous pulley, a driven synchronous pulley, synchronous belts and a synchronous belt driving shaft; the thin film cutting knife wheel set comprises a front face cutting knife wheel set body and a back face cutting knife wheel set body which are fixed to the two synchronous belts respectively; knife wheel movement guide rails are used for movement supporting and guiding of the knife wheel set and comprise the front face cutting knife wheel movement guide rail and back face cutting knife wheel movement guide rail. By means of the thin film cutting mechanism, the thin film cutting knife wheel set is controlled through servo control, the cutting size is accurate, manual operation of an operator is not needed, the remodeling time is saved, and the working efficiency is greatly improved.

Owner:江西仁义新能源有限公司

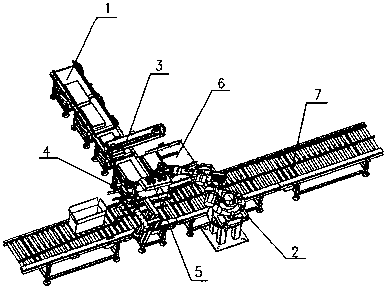

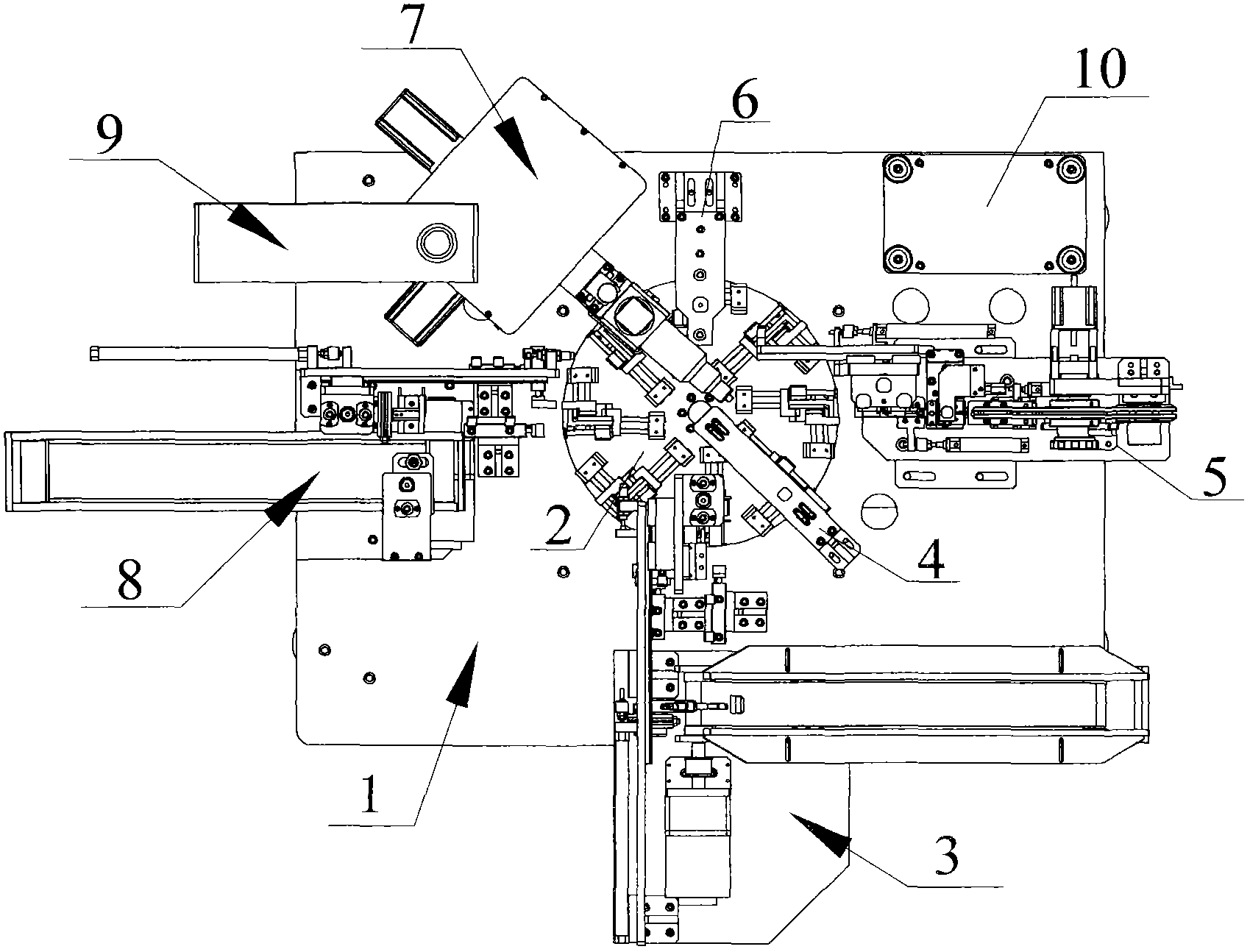

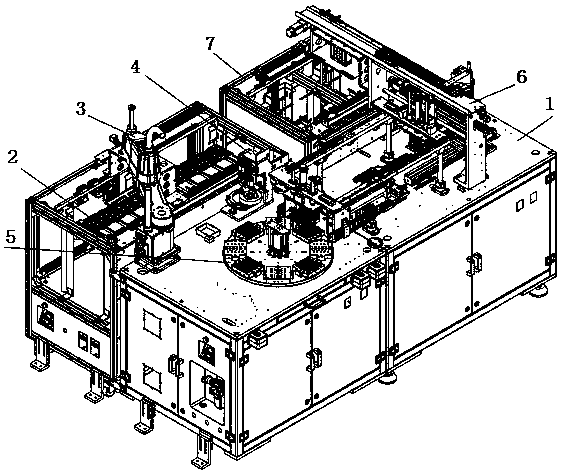

Automatic space key assembling system

ActiveCN108942137AReduce changeover timeReduce mistakesAssembly machinesMetal working apparatusManipulatorMultiple Models

The invention discloses an automatic space key assembling system. The automatic space key assembling system comprises a rack, and further comprises a space key lining feeding device, a four-axis mechanical arm, a CCD detecting device, a station rotating platform device, a roller press discharging device, a receiving device and a PLC which are arranged on the rack. By means of the above manner, theautomatic space key assembling system is characterized in that a tray feeding manner is adopted for automatic feeding, the mechanical arm is used for taking a material, CCD automatic detection is carried out, qualified space key linings are placed into key caps on positioning jigs, the linings and the key caps enter a roller press station to be subject to roller press after move loading and overturning, and pressed space keys are placed into the receiving device through the discharging device; in addition, the positioning jigs in multiple models are arranged in equipment, the procedure is orderly switched when model changing is needed without replacement of the jigs, and the model changing time is shortened; and meanwhile, errors generated by manual participation are reduced, the production efficiency is improved, and the advantages of being high in reliability, accurate in positioning, compact in structure, high in transposition speed, small in noise and the like are achieved.

Owner:苏州德机自动化科技有限公司

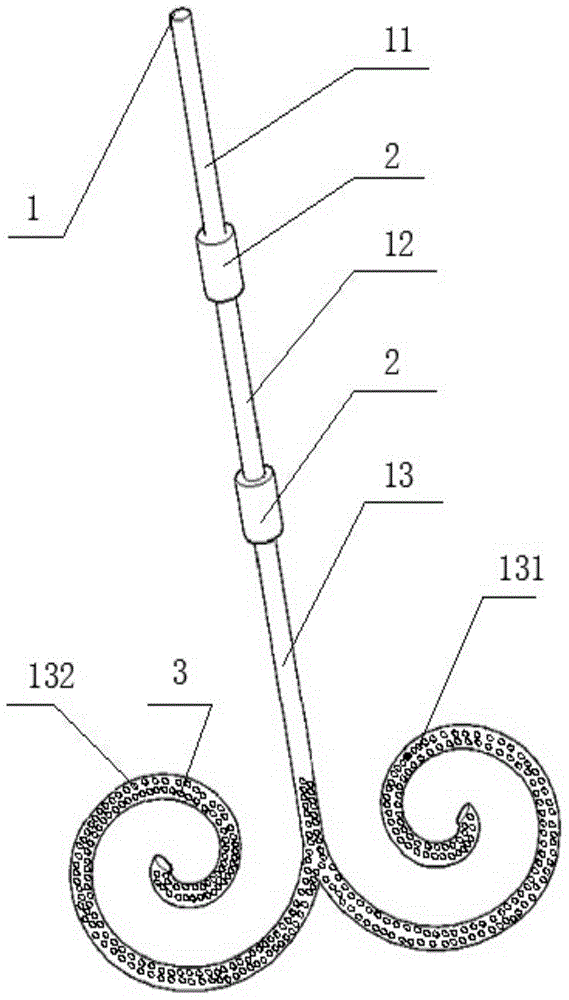

Novel dual-channel peritoneal dialysis catheter suitable for operation under endoscope

InactiveCN104383620AGood market benefitNot easy to driftCatheterPeritoneal dialysisUrologyPeritoneal dialysis catheter

The invention relates to a novel dual-channel peritoneal dialysis catheter suitable for operation under an endoscope. The peritoneal dialysis catheter comprises a peritoneal dialysis catheter body, the peritoneal dialysis catheter body comprises an external abdominal section, a gooseneck section and an abdominal cavity section, dacron buckles are disposed at two ends of the gooseneck section respectively, the abdominal cavity section comprises a first channel pipe and a second channel pipe, the first channel pipe and the second channel pipe are communicated with the peritoneal dialysis catheter body, drainage holes are formed in the first channel pipe and the second channel pipe, and the drainage holes are uniformly distributed. The novel dual-channel peritoneal dialysis catheter suitable for operation under the endoscope has the advantages that the dual-channel structural design is applied, catheter floating and blocking is not prone to occur, and the service life is long; more drainage holes are formed in the peritoneal dialysis catheter than those of single channel, the abdominal permeability is good, liquid replacing time is reduced, removing capacity of metabolic waste is increased, the efficiency is high, the peritoneal dialysis catheter is put under the endoscope, the positioning is accurate, operations are safe, reliable and low in price, and the cut part is small.

Owner:XIN HUA HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

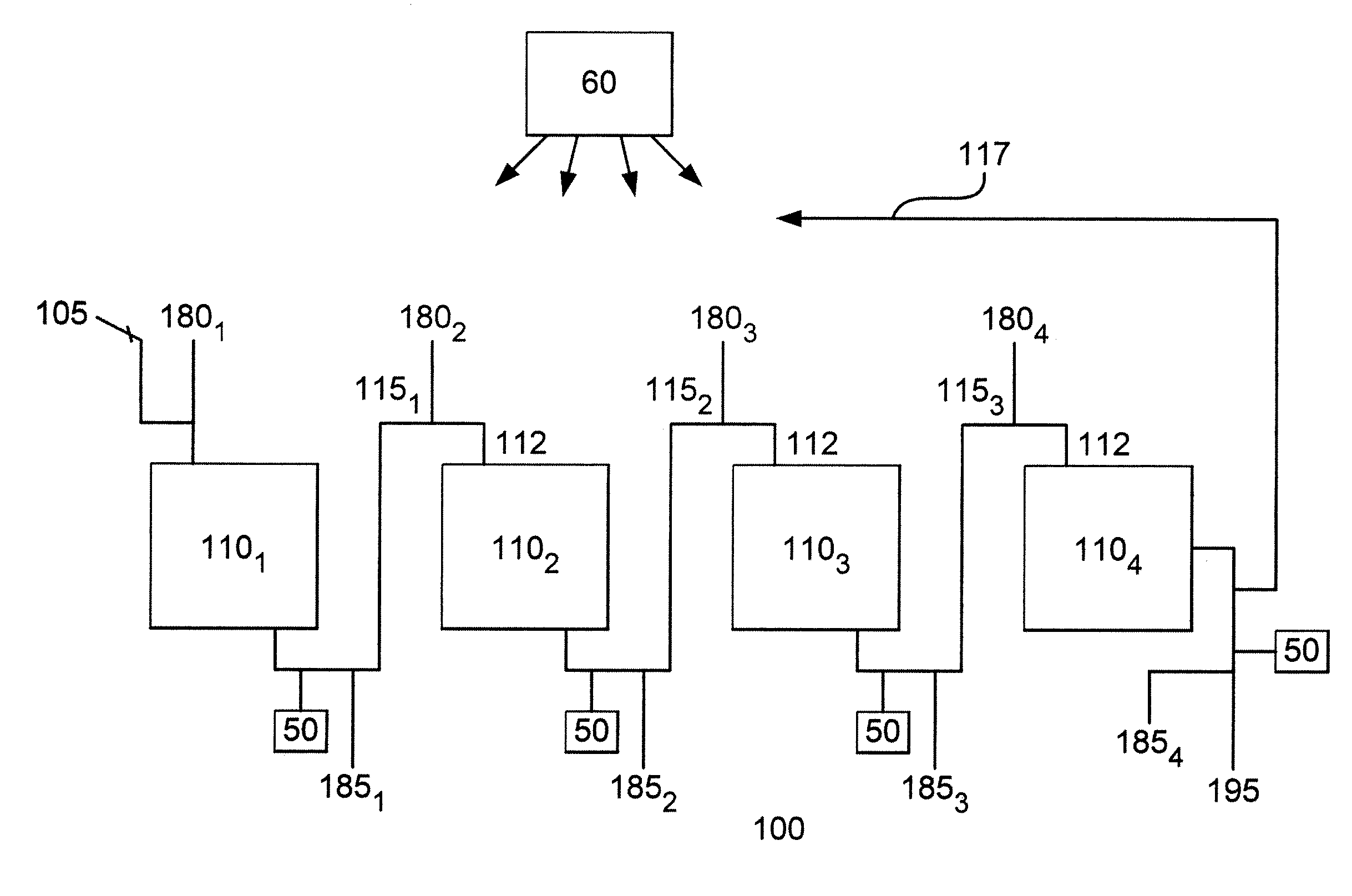

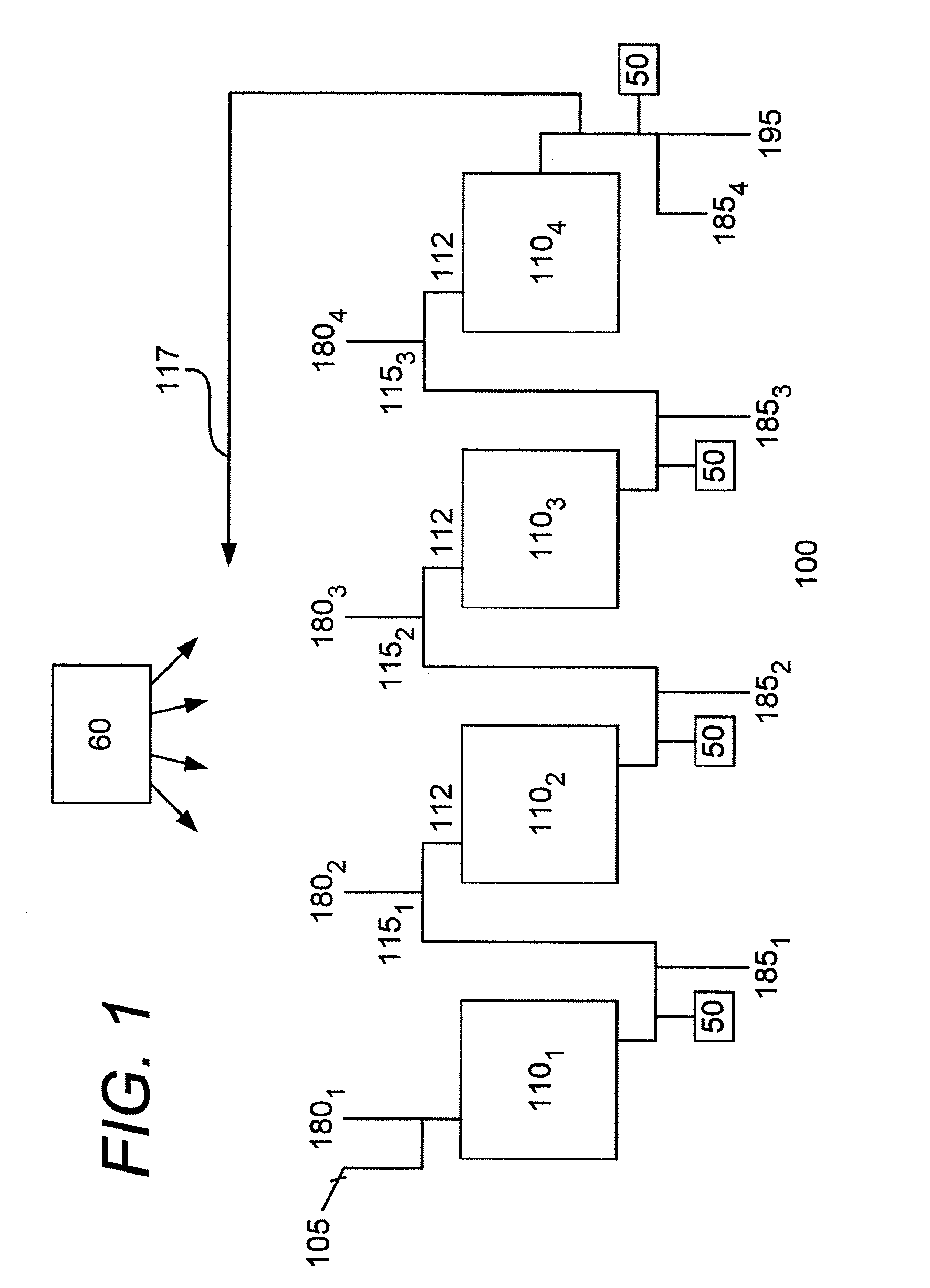

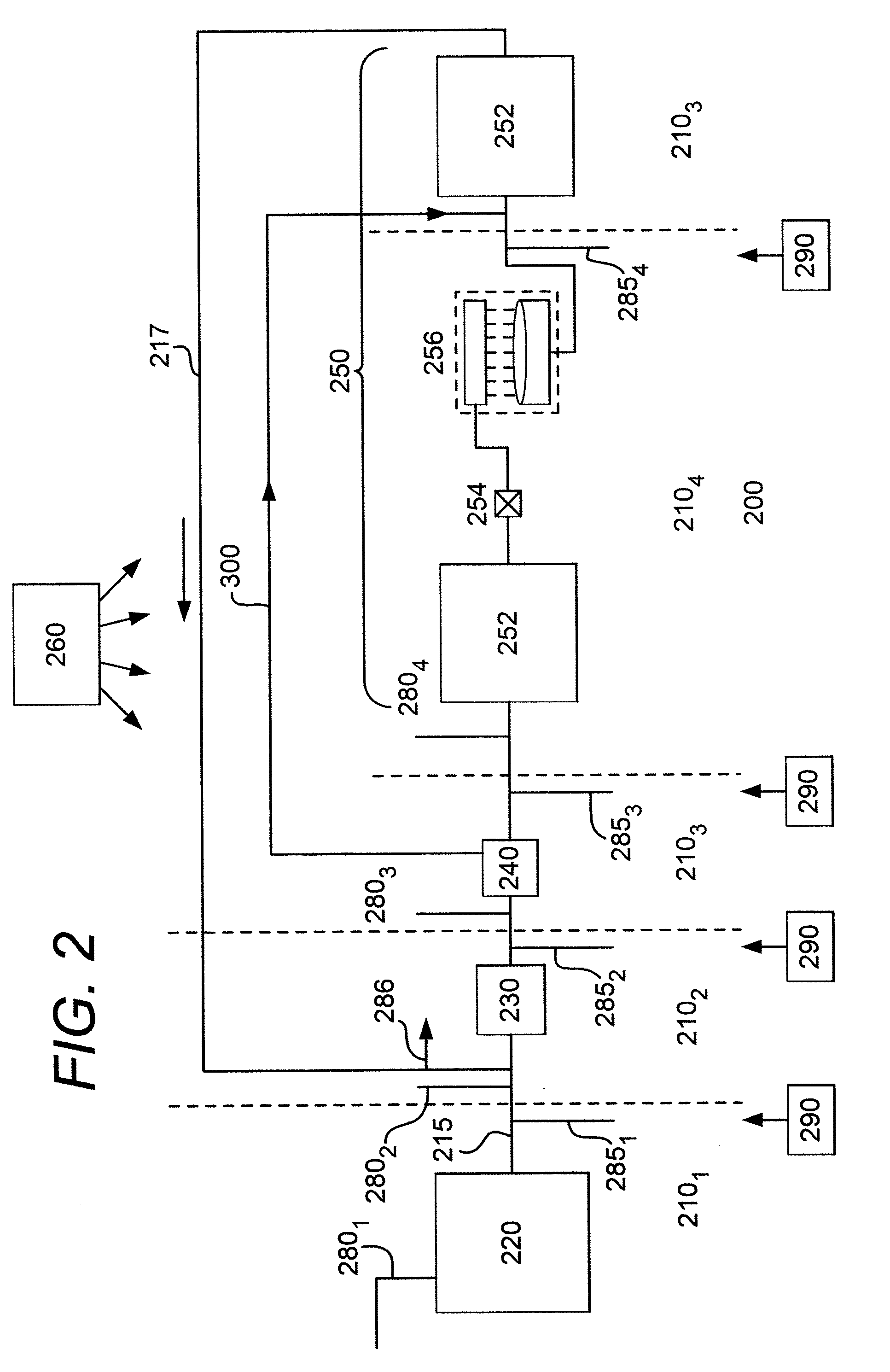

Efficient Liquid Processing System

InactiveUS20080066803A1Reduce changeover timeServomotor componentsMachines/enginesEngineeringHandling system

A fluid processing system has a plurality of segments configured to receive flow of a fluid product. Each of the plurality of segments has a line input, a line output, a cleaning input valve, and a cleaning discharge valve. The cleaning input valve connects to the line input and the cleaning discharge valve connects to the line output. A cleaning medium is provided wherein the cleaning medium is injected into a respective cleaning input valve and drained through a respective cleaning discharge valve, such that each segment can be cleaned independently of each other.

Owner:STOKLEY VAN CAMP INC

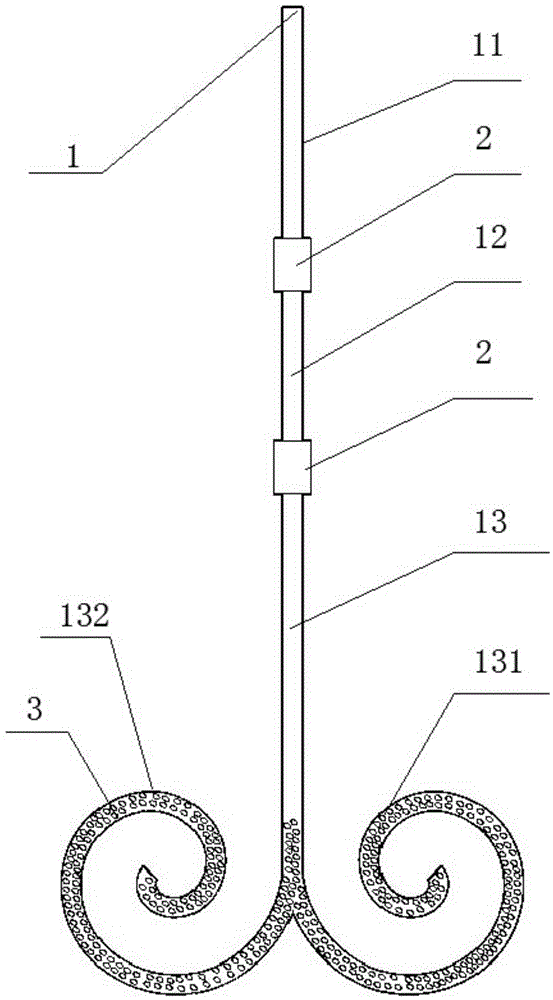

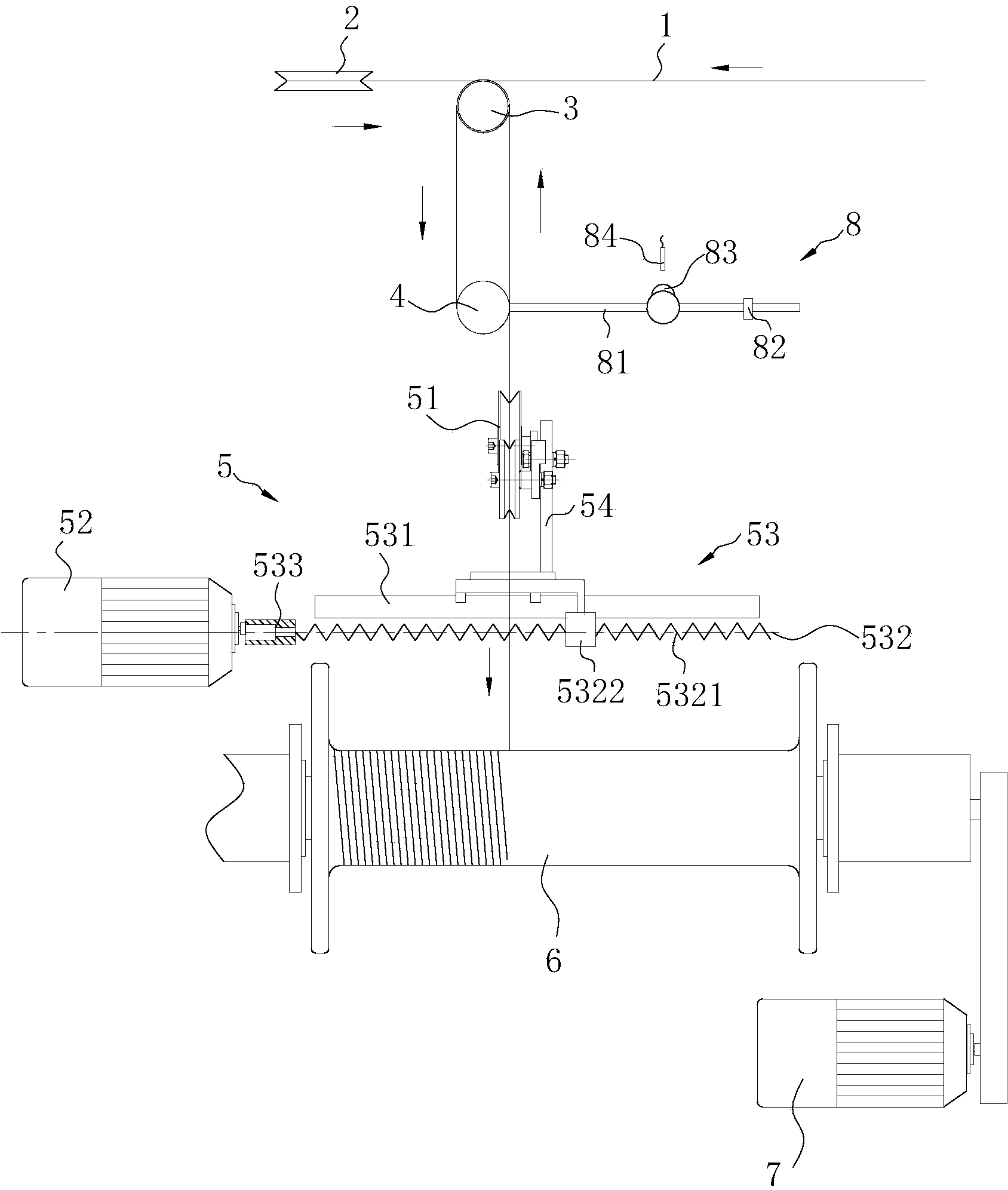

Wire arranging compensation device and wire arranging compensation method of wire cutting all-powerful winding machine

ActiveCN103588025AReduce changeover timeCommutation neatlyFilament handlingWinding machineWire cutting

The invention discloses a wire arranging compensation device of a wire cutting all-powerful winding machine. The wire arranging compensation device comprises steel wires, a first guide wheel, a second guide wheel, a third guide wheel, a wire arranging device and a winding wheel. The steel wires are sent in the main machine direction, sequentially pass through the guide wheels and the wire arranging device and are wound around the winding wheel. One end of the winding wheel is provided with a winding motor. The wire arranging device comprises a wire arranging guide wheel and a wire arranging motor. The output shaft end of the wire arranging motor is connected with the wire arranging guide wheel through a horizontal moving assembly so that the wire arranging motor can push the wire arranging guide wheel to move in the horizontal direction in a reciprocating mode. One side of the third guide wheel is provided with a tension oscillating bar device used for detecting tension variation of the steel wires, and the tension oscillating bar device is connected with a PLC. The output end of the PLC is connected with the wire arranging motor and the winding motor, and the wire arranging motor is a servo motor. The wire arranging compensation device of the wire cutting all-powerful winding machine is simple in structure, convenient to operate, capable of reducing reversing time of the wire arranging guide wheel, free of slip frequency, and capable of ensuring neatness of the wires arranged on the winding wheel.

Owner:WUXI SUNLIT SCI & TECH

Hot-press tooth-aligning clamp for toothed shaft part and gear

InactiveCN102672642AEliminate inaccuraciesGuaranteed accuracyWork holdersMetal working apparatusPosition toleranceBiomedical engineering

The invention particularly relates to a hot-press tooth-aligning clamp for a toothed shaft part and a gear, in order to solve the problems that the positioning is not accurate enough, the clamping force is insufficient and the operation is troublesome during installation of the existing hot-press tooth-aligning clamp for the toothed shaft part and the gear. The hot-press tooth-aligning clamp comprises a base, wherein the base is provided with a counter bore; a positioning sleeve is sleeved at the bottom of the counter bore; a guide shaft I penetrates through the side wall of the base; a step-shaped positioning pin I penetrates through the guide sleeve I; the large-diameter side of the positioning pin I is matched with the inner wall of the guide sleeve I; a spring I is sleeved at the small-diameter side of the positioning pin I; a support plate is fixed at the upper end of the base; a guide sleeve II penetrates through the side wall of the support plate; the position tolerance in the up-down direction of the center lines of the guide sleeve II and the guide sleeve I is smaller than or equal to 0.02mm; a step-shaped positioning pin II penetrates through the guide sleeve II; the large-diameter side of the positioning pin II is matched with the inner wall of the guide sleeve II; and a spring II is sleeved at the small-diameter side of the positioning pin II. The universality is improved, the accuracy and the stability of tooth alignment are ensured, and the hot-press tooth-aligning clamp has the advantages of simple structure and convenience in processing when the operation troublesome extent is reduced.

Owner:CHINA NAT HEAVY DUTY TRUCK GROUP DATONG GEARCO

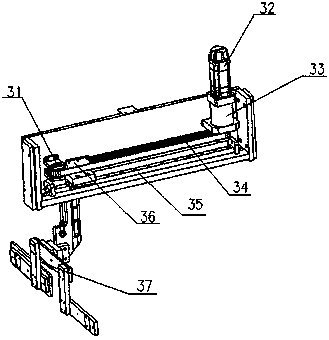

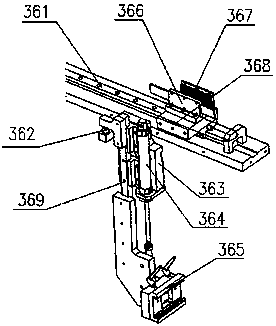

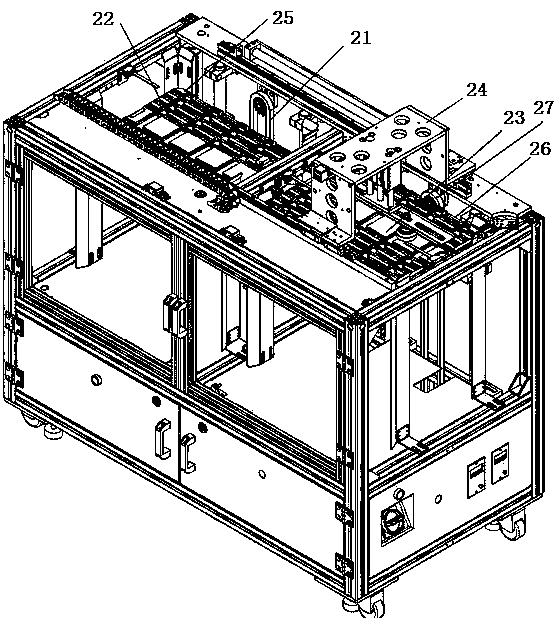

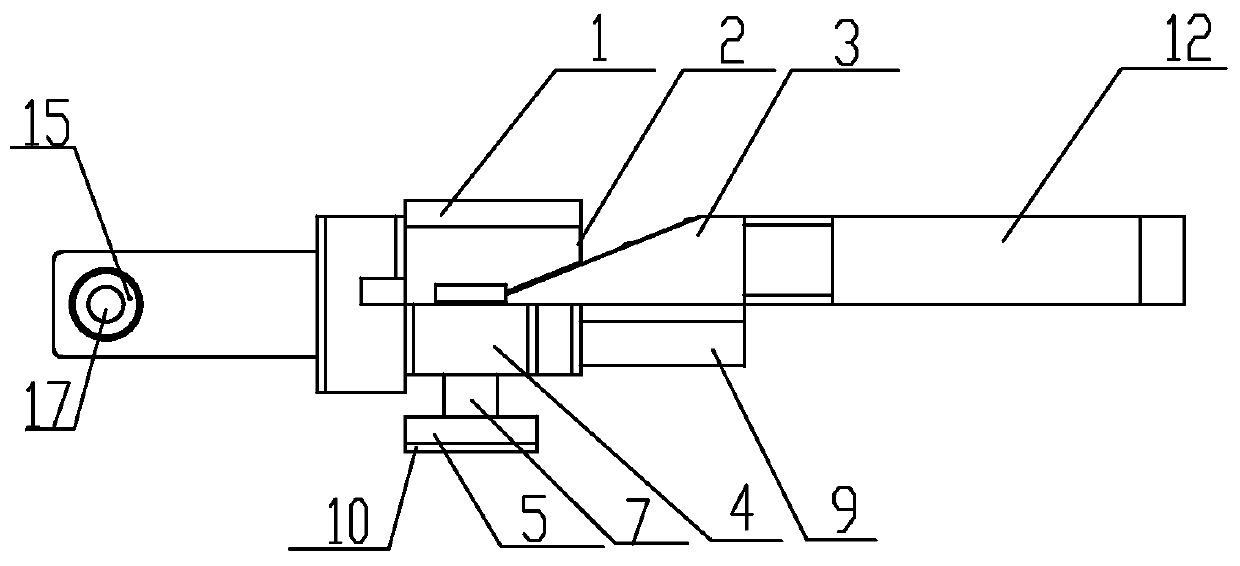

Flexible printed circuit (FPC) feeding mechanism and prepressing addition suction nozzle

The invention provides a flexible printed circuit (FPC) feeding mechanism and a prepressing addition suction nozzle. The feeding mechanism comprises a prepressing head, the prepressing addition suction nozzle, a conveying plate, a motor, a quartz strip and sliding rails, wherein the prepressing addition suction nozzle is fixed on the prepressing head, and the prepressing addition suction nozzle and the prepressing head share the same vacuum and act together to be used for adsorbing an FPC; the motor provides power for the mechanism. The prepressing addition suction nozzle is provided with joints capable of rotating flexibly, the positions of vacuum suction nozzle bodies can be adjusted at will, and FPCs of different lengths can be adsorbed conveniently. A flexible rotating mechanism is adopted for the FPC feeding mechanism, replacement can be achieved rapidly during product replacement, line change time is shortened, stability of all components is improved, and production efficiency is further improved.

Owner:SHENZHEN XINSANLI AUTOMATION EQUIP

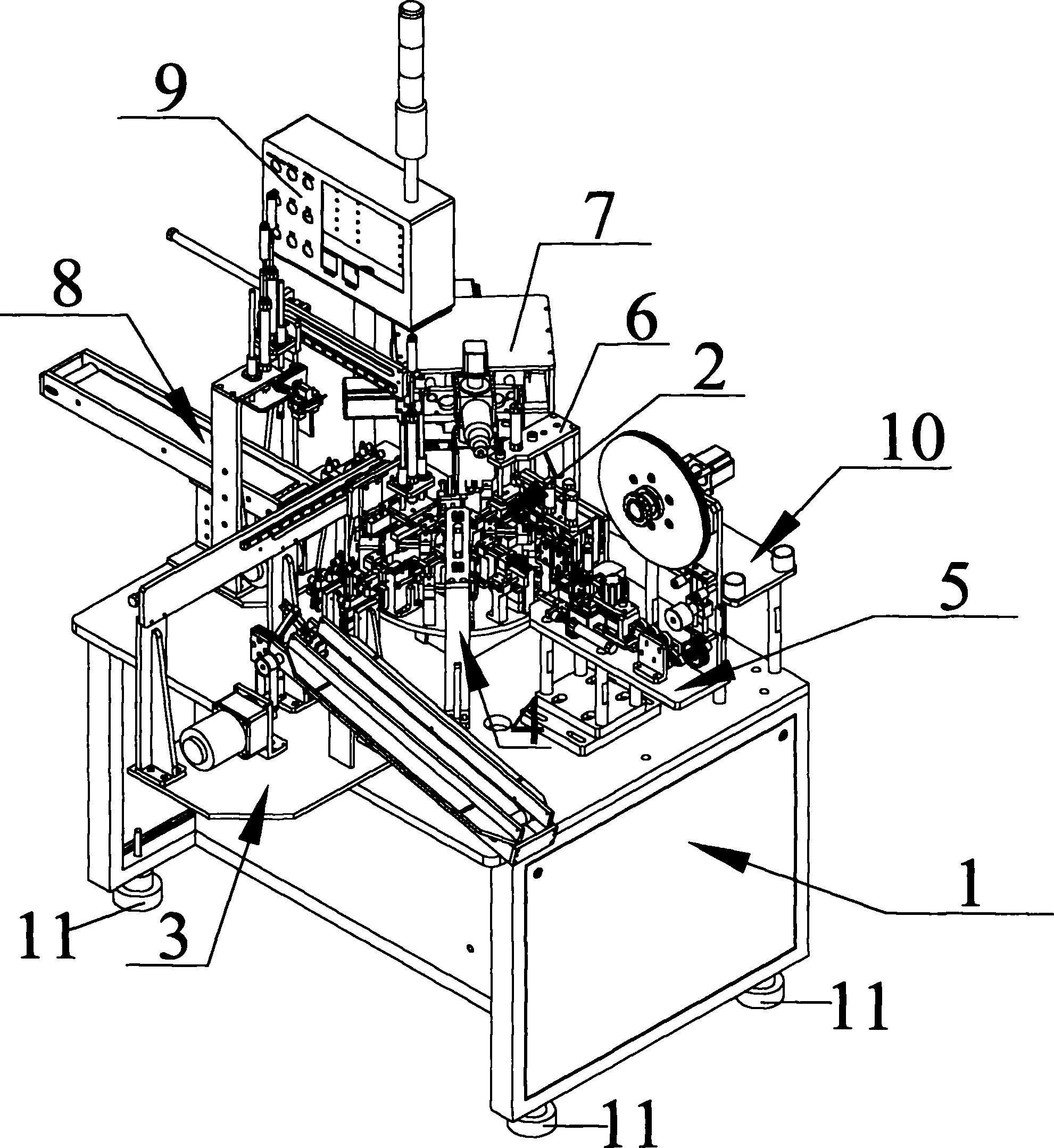

Film combining machine

ActiveCN102424153ASimple structureSimple actionWrapping material feeding apparatusWrapper twisting/gatheringEngineeringElectric control

The invention discloses a film combining machine, which comprises a forming device, a glue coating device, a material driving device, an electric control device and a speed synchronization device, wherein the forming device, the glue coating device, the material driving device, the electric control device and the speed synchronization device are arranged on a machine frame, the glue coating device comprises a glue outlet mechanism and a glue extruding mechanism for supplying glue to the glue outlet mechanism, the glue outlet mechanism is directly connected with a glue outlet of the glue extruding mechanism, and the glue extruding mechanism is arranged on a horizontal driving mechanism so that the glue outlet mechanism only moves in the horizontal direction for coating the glue. The film combining machine has the advantages that the structure is simple, the cost is low, the reliability and the harmony are high, the installation and the debugging are convenient, the production capacity and the production efficiency are greatly improved, and the like.

Owner:HUNAN KENON AUTOMATIC EQUIP

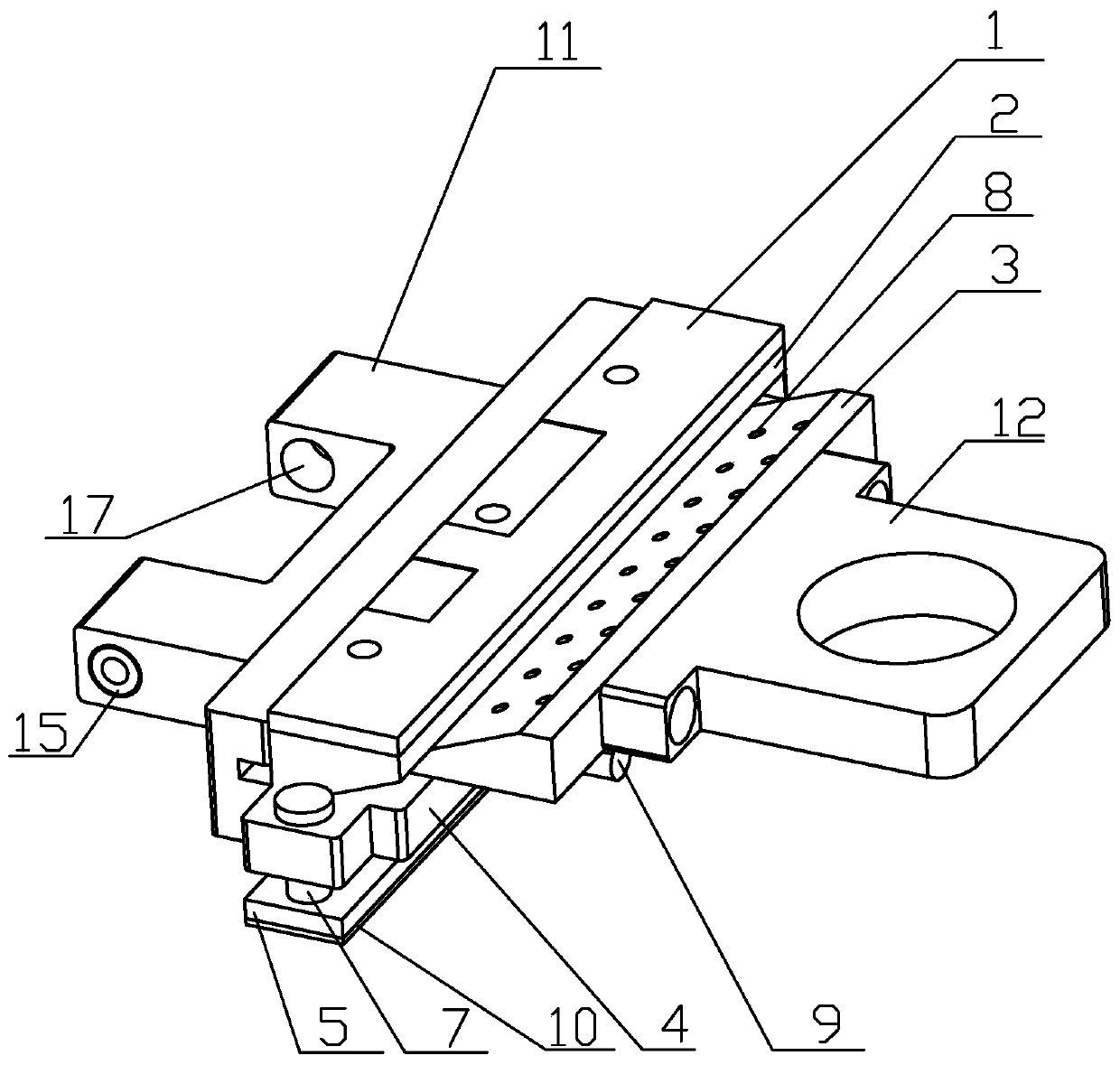

Expanding sleeve quick-change type general internal tooth inserting fixture

InactiveCN106903377AEliminate the disadvantages of not being universalReduce in quantityGear-cutting machinesGear teethEngineeringChange Type

The invention discloses an expansion sleeve quick-change universal inserting tooth clamp, which comprises an expansion sleeve, a clamp body, a stretch sleeve and an adapter plate; the adapter plate is supported and fixed on the work table; the lower end of the clamp body and the adapter plate Cooperate; there is a pull plate in the inner cavity of the lower end of the fixture body, a guide sleeve passes through the inner hole on the outer edge of the pull plate, the upper end of the guide sleeve passes through the fixture body and contacts the stretch sleeve, and a tension pulley is set in the center hole of the fixture body above the pull plate. Bolt, the tension bolt is provided with a stopper; the inner cavity of the upper end of the fixture body is provided with a support pad, and the upper end surface of the support pad is supported by a quick-change flat pad; Cooperate with the inner tapered surface of the upper end of the fixture body; the lower end of the expansion sleeve is inserted and connected with the tension sleeve; the tension sleeve is connected with the pull plate through the guide sleeve, and the lower end of the tension bolt on the pull plate passes through the center hole of the pull plate and the inside of the work table The cylinder assembly connection. The present invention does not need to re-align the fixture when changing production, which saves a lot of time for changing production.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

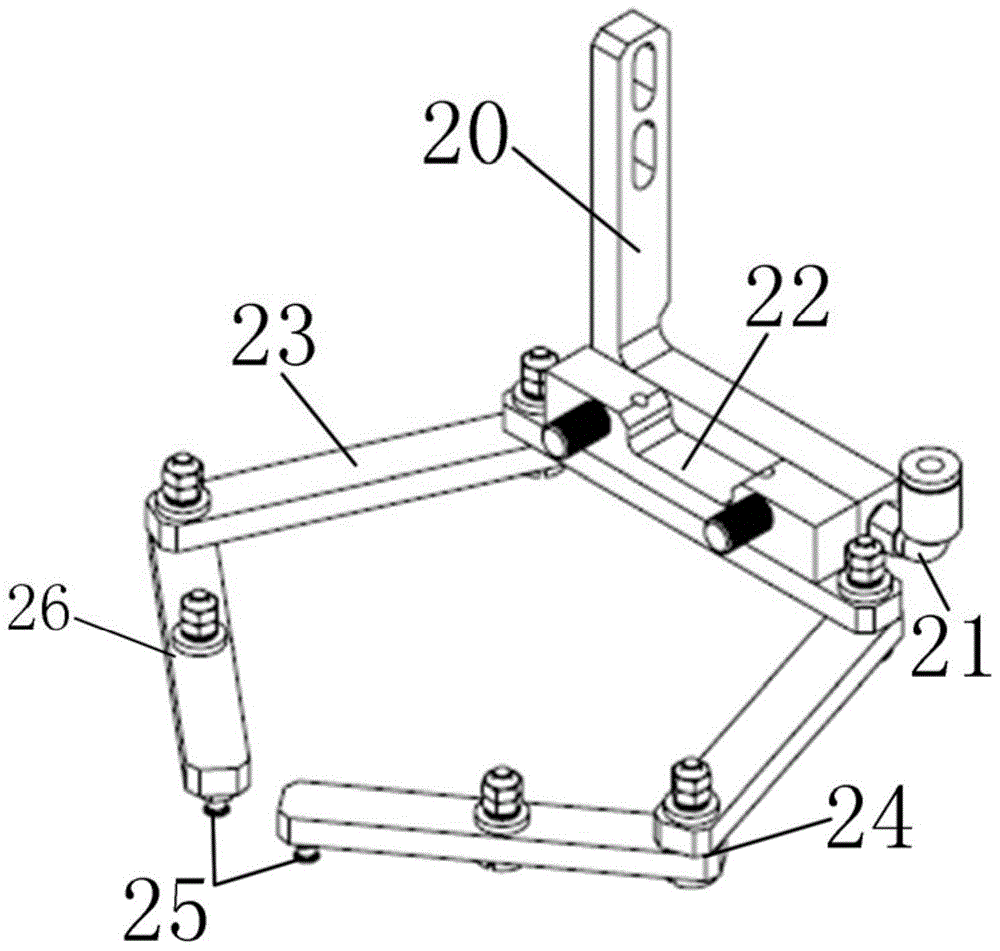

Steering knuckle master pin hole flexible positioning machining system.

InactiveCN104338958AHigh degree of flexibilityLess investmentPositioning apparatusMaintainance and safety accessoriesProduction lineNumerical control

The invention discloses a steering knuckle master pin hole flexible positioning machining system and relates to the technical field of automobile manufacturing. A worktable is provided with a quick-changing clamping fixture with a bottom surface provided with a key groove, and the quick-changing clamping fixture is fixed onto the worktable of a boring machine through keys and bolts; a workpiece is clamped on the quick-changing clamping fixture; a tool is connected with a boring machine spindle through a taper shank, the boring machine spindle drives the tool to rotate under the control of the numerical control procedure of a spindle motor, and a feed motor drives the tool to move transversely under the control of the numerical control procedure; the boring machine is provided with a boring head tool changer controlled by a tool-changing system; a cooling system is arranged inside the boring machine spindle; the spindle motor, the boring head tool changer, the tool-changing system, boring machine spindle, the boring tool, the workpiece, the worktable, the quick-changing clamping fixture and the feed motor are arranged inside a protective device in a closed mode. According to the steering knuckle master pin hole flexible positioning machining system, numerical control tool changing technology and quick-changing positioning technology are applied to simultaneous machining of different sizes and shapes of master pin holes or stepped master pin holes of steering knuckles of different varieties, working procedure flexibility and production efficiency of a production line are effectively improved and production line investment is reduced.

Owner:DONGFENG DANA AXLE

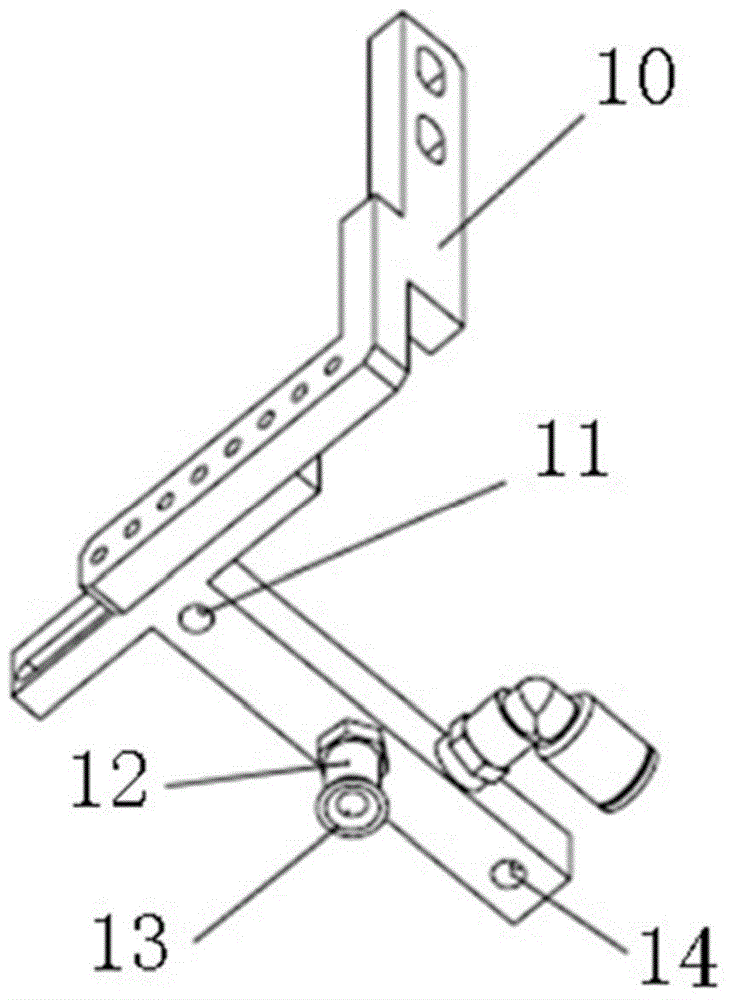

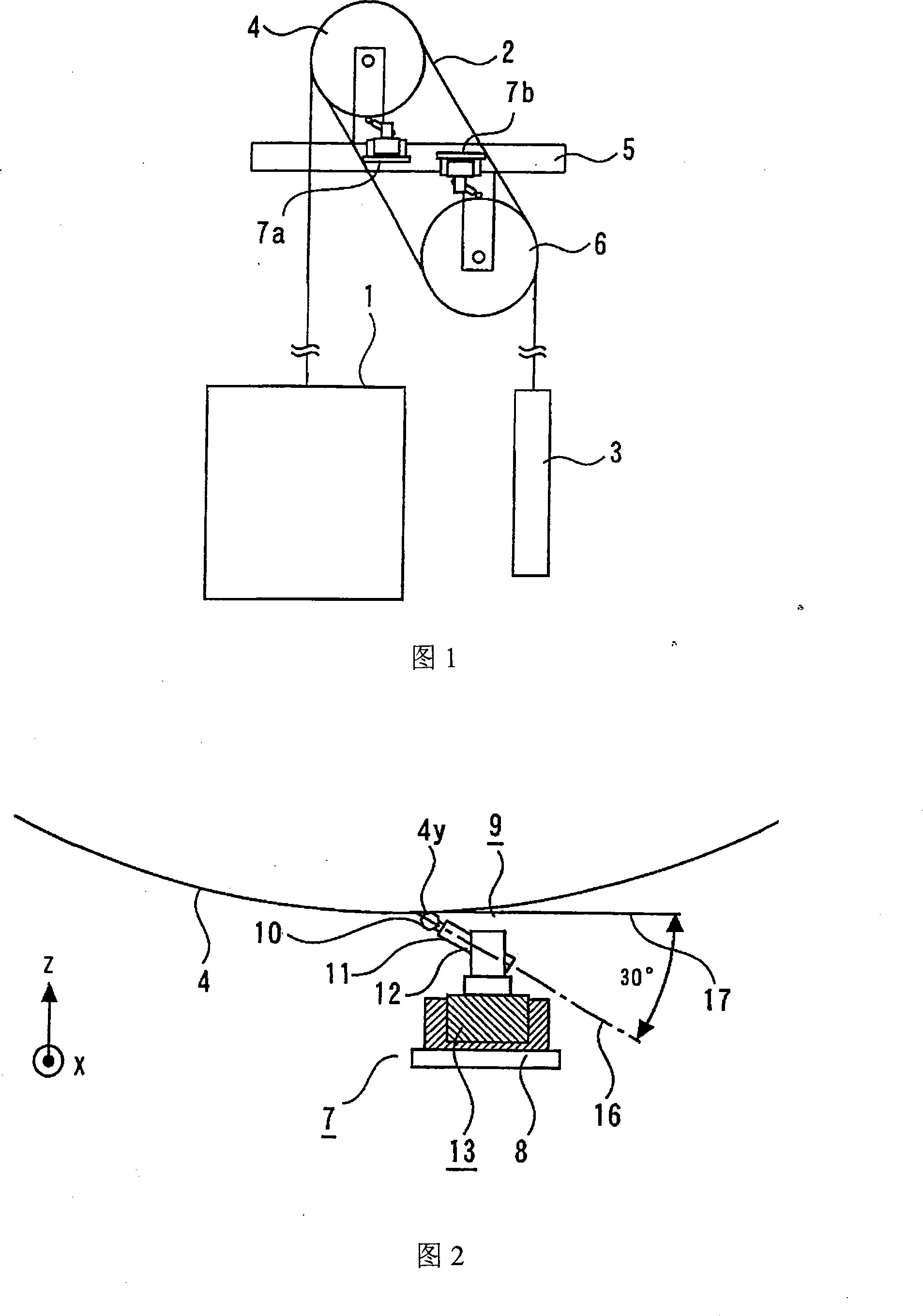

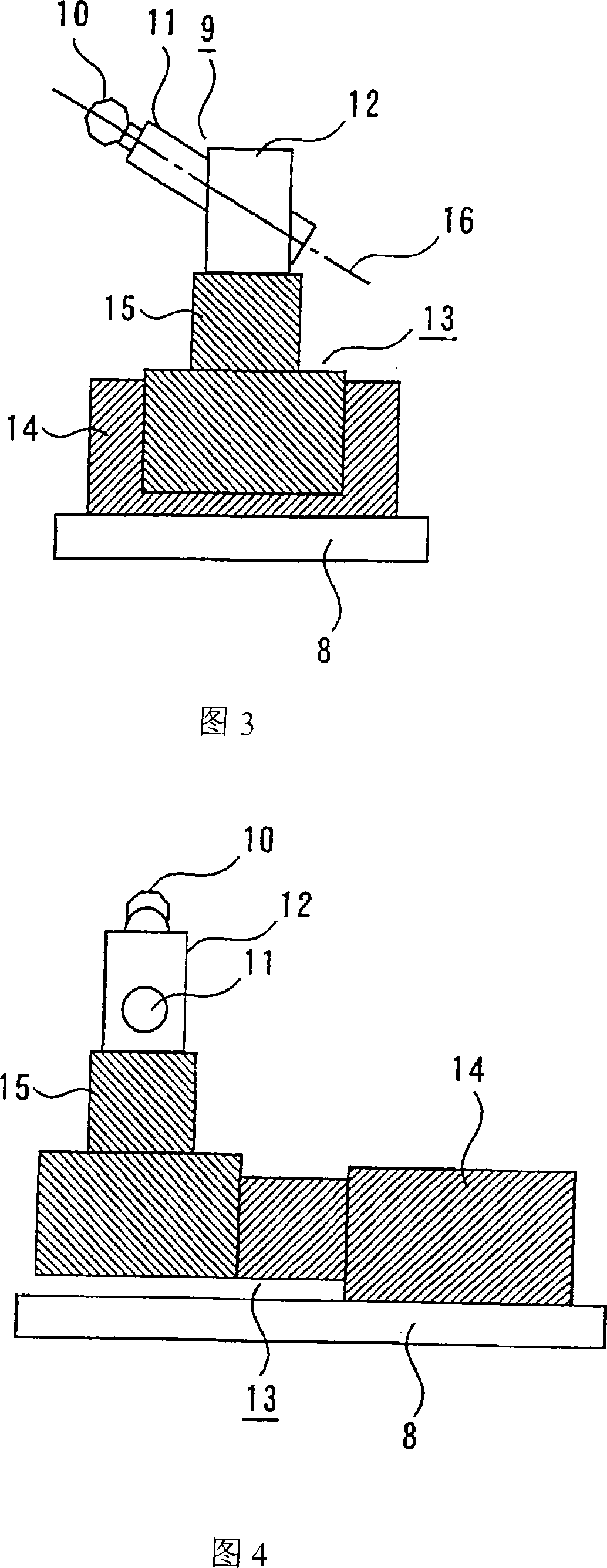

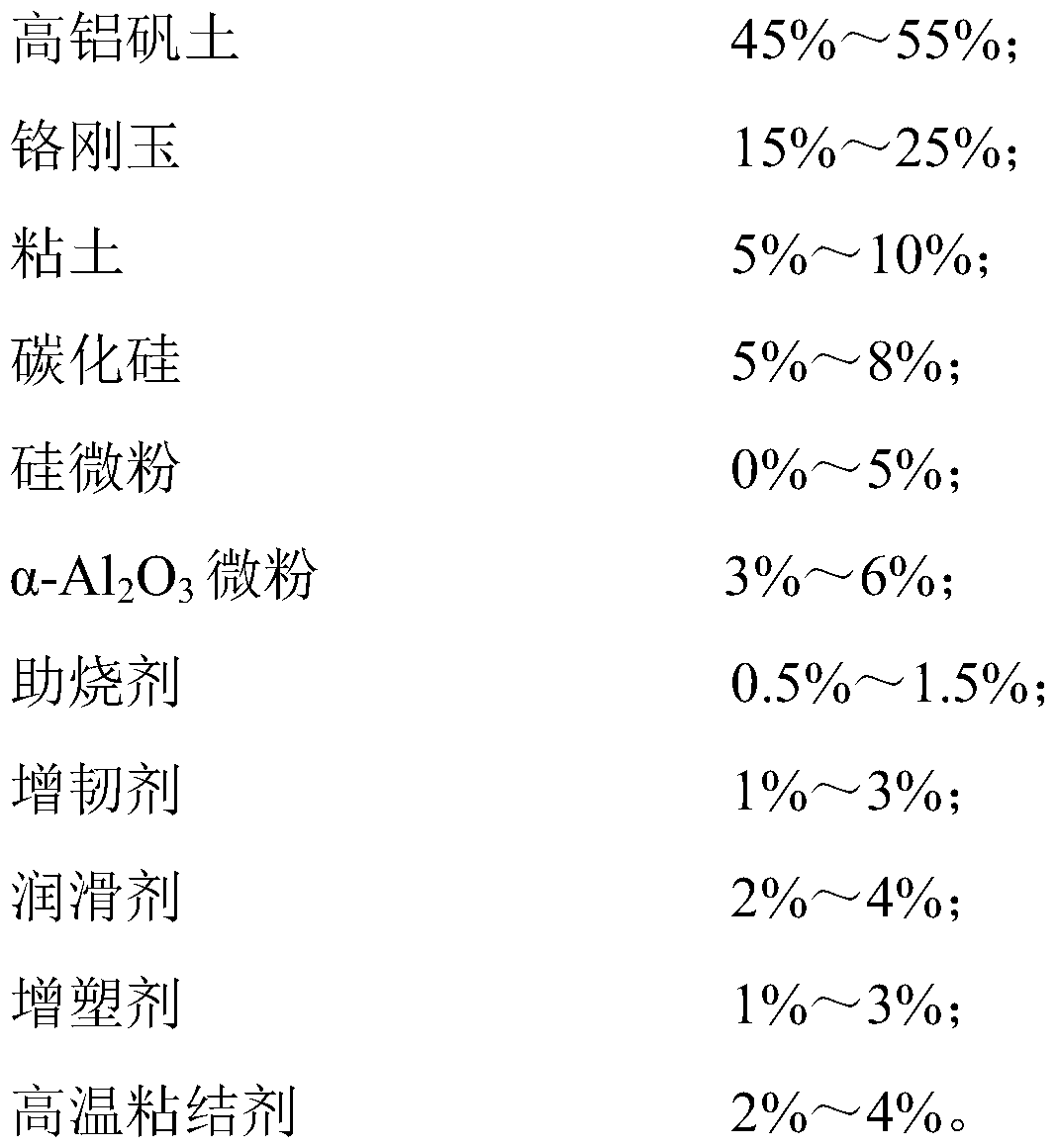

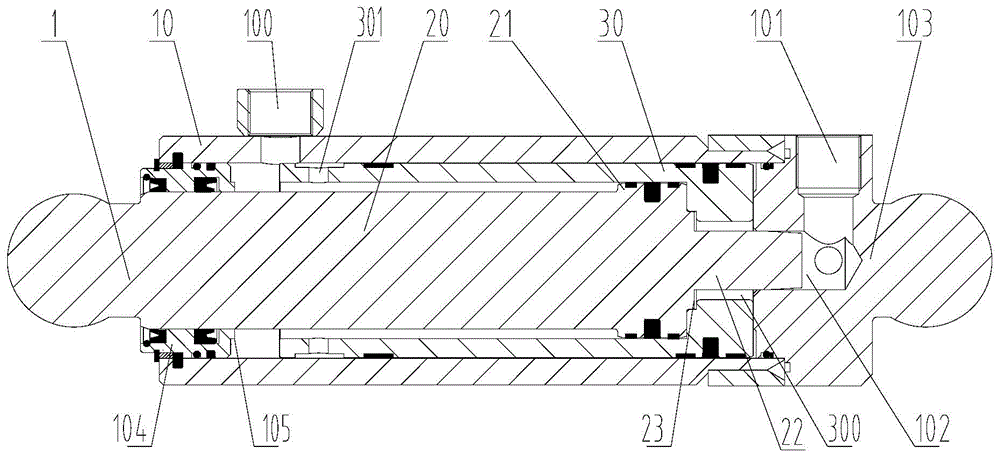

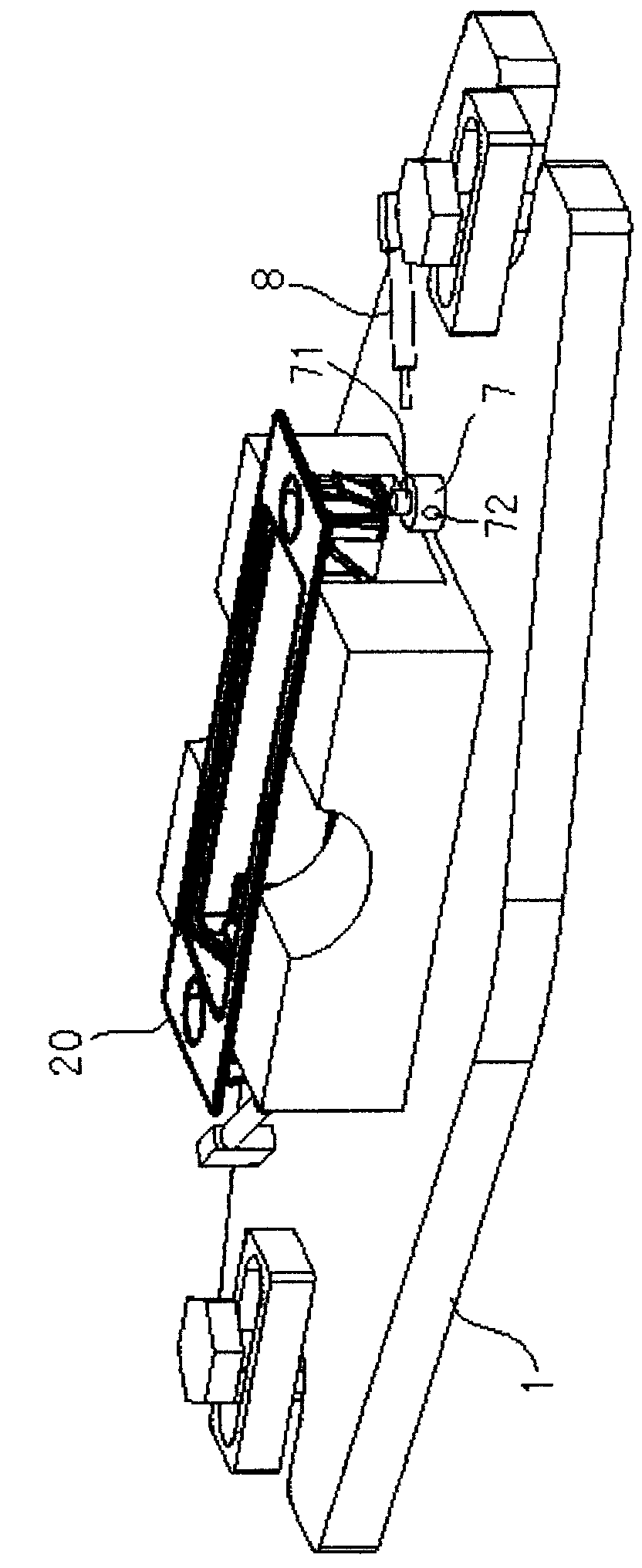

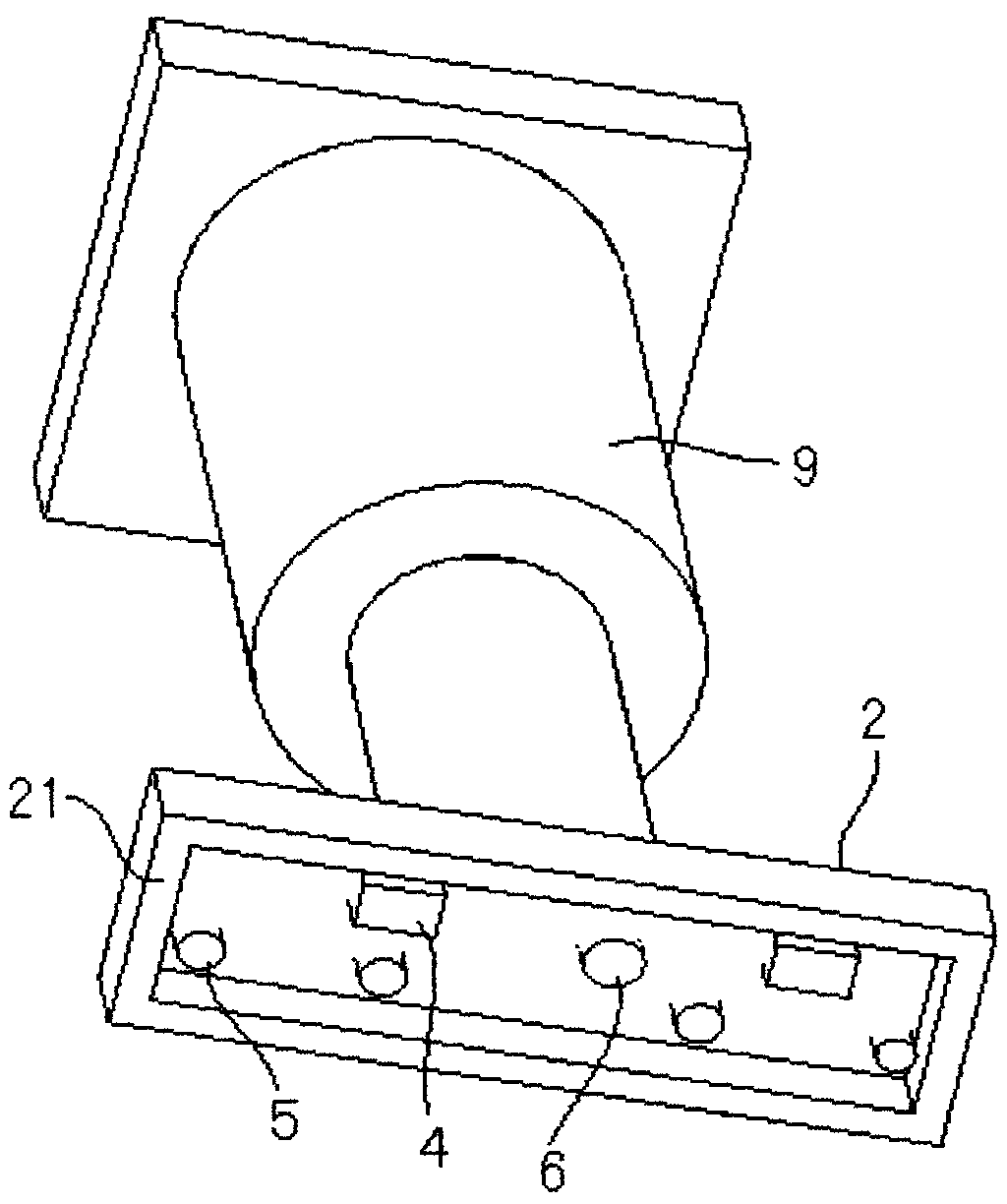

Apparatus and method for processing elevator wire rope groove

ActiveCN101157193ATo prevent degradation of service qualityPrevent deterioration of machining accuracyGrinding feed controlBuilding liftsService qualityWire rope

The invention provides a processing device for an elevator steel cable groove which can renovate and process the steel cable groove used for driving a steel cable wheel in a short time, and can prevent the service quality of the elevator from decreasing. The invention is provided with a mounting part (8) which is demountably arranged on a fixing rack (5) of the elevator, a processing part (9) which is arranged at the opposite position of the steel cable groove part of a main steel cable (2) being used for suspension hanging the case of the elevator and being positioned inside the steel cable groove (4a) of a driving steel cable wheel (4), and a movable bearing part (13) which is arranged on the mounting part and used for bearing the processing part and which can move along the rotating axle direction and the radius direction of the driving steel cable wheel. The processing part is provided with a rotary grinding wheel (10) which is used for grinding and processing the steel cable groove. The rotary axle (16) of grinding wheel forms an angle of about 30 degrees with a tangent (17) starting from the processing point of the driving steel cable wheel.

Owner:MITSUBISHI ELECTRIC BUILDING SOLUTIONS CORP

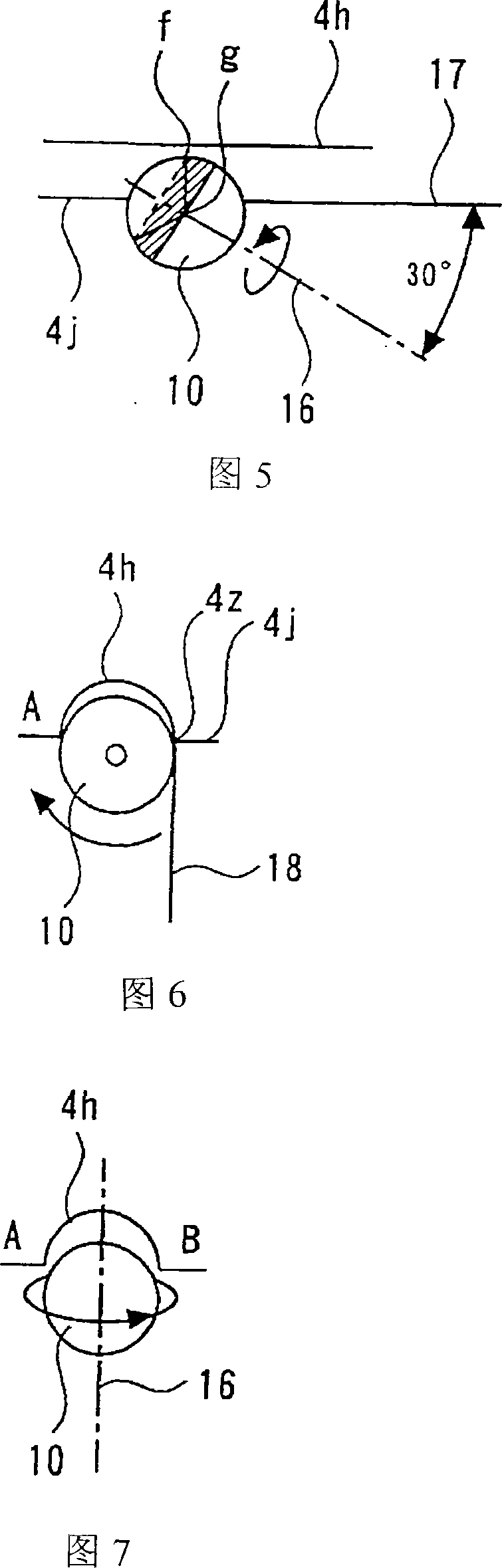

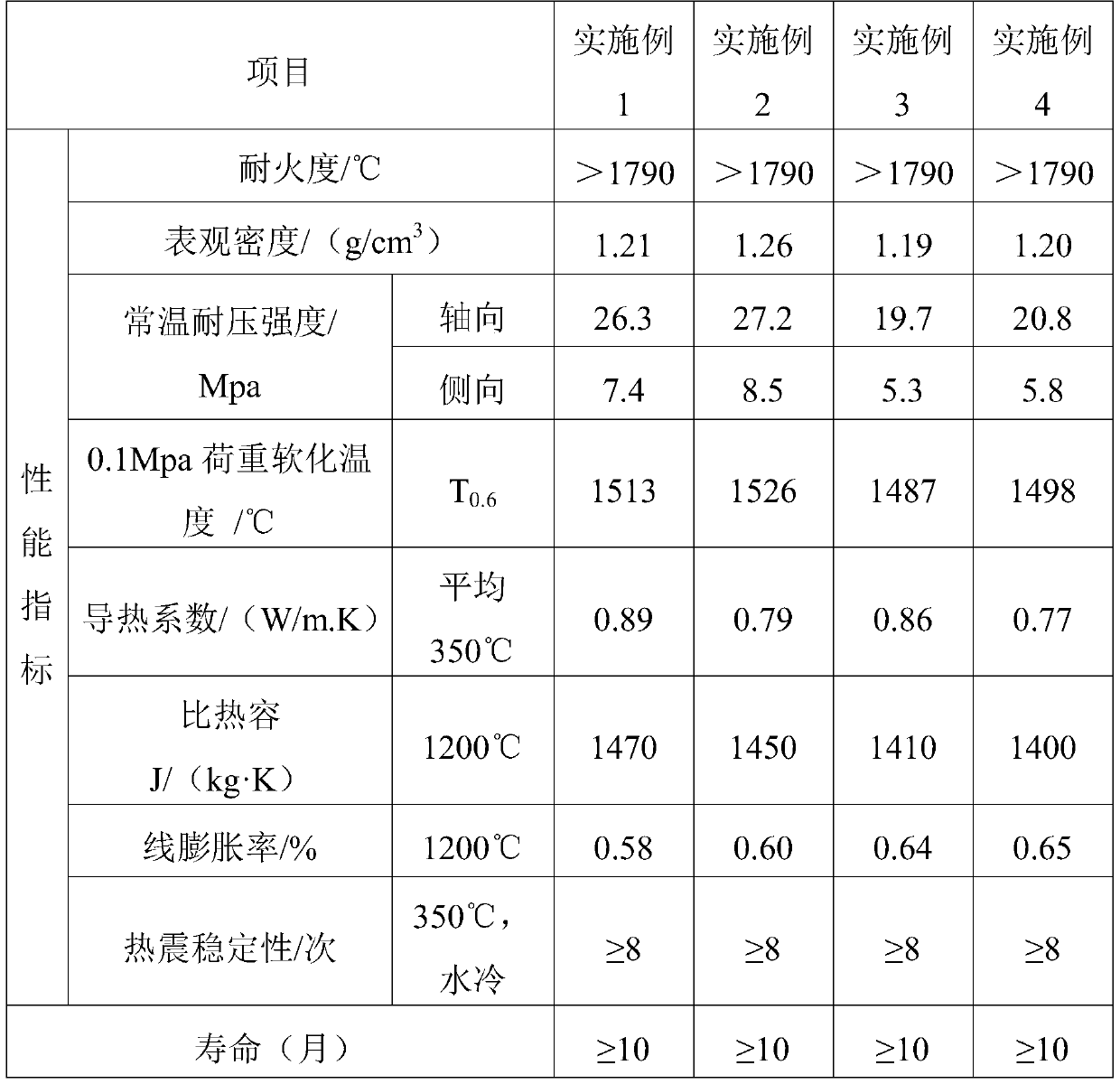

Honeycomb body used for regenerative heating furnace and production method of honeycomb body used for regenerative heating furnace

InactiveCN110372343AMeet the temperature requirementsHigh refractorinessCeramicwareCombustionPlasticizer

The invention discloses a honeycomb body used for a regenerative heating furnace and a production method of the honeycomb body used for the regenerative heating furnace. According to the honeycomb body, high bauxite and pink funsed alumina are adopted as main components, clay is adopted as a binder, silicon carbide, silica powder and alpha-Al2O3 powder are added, a sintering aid, a toughener, a lubricant, a plasticizer and a high-temperature binder are added at the same time, and through technology steps of mixing, vacuum pugging, extrusion, forming drying, firing and the like, the honeycomb body used for the regenerative heating furnace is produced. The honeycomb body meets the technology requirements of a regenerative combustion technology, has performance of large heat storage capacity,stable high-temperature performance, high heat exchange efficiency and a long service life, the number of times of blowing out due to replacement of honeycomb bodies of a steel plant can be decreased, the production operation rate of the heating furnace is improved, the equipment maintenance cost is reduced, and effects of increasing production and practising economy are truly achieved, so that the honeycomb body used for the regenerative heating furnace has obvious economic benefits and very wide use prospects.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

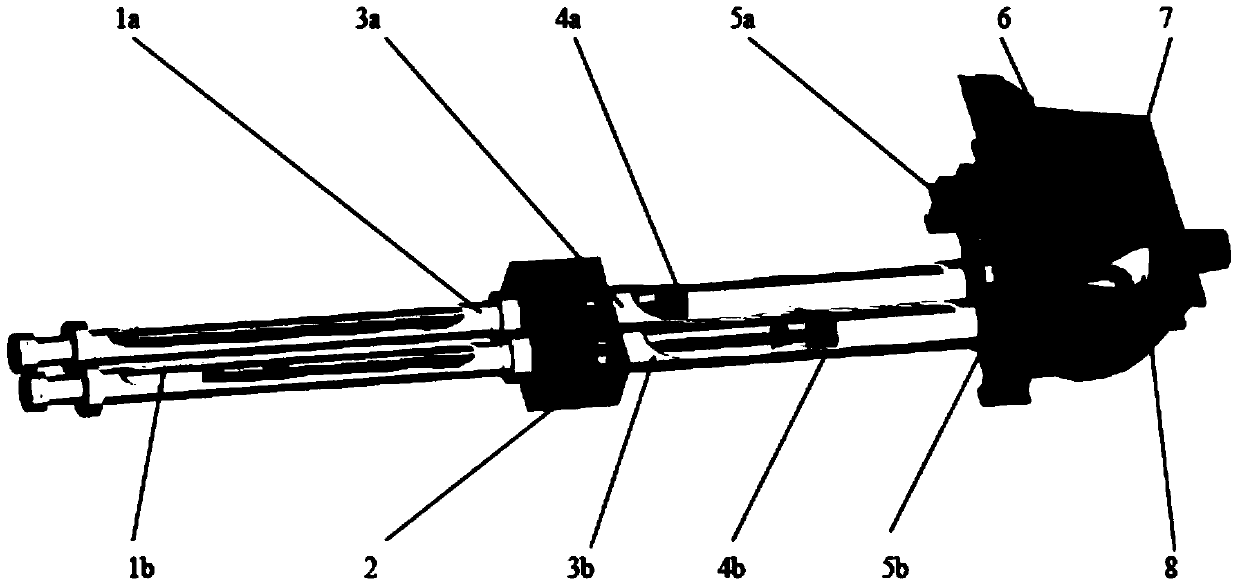

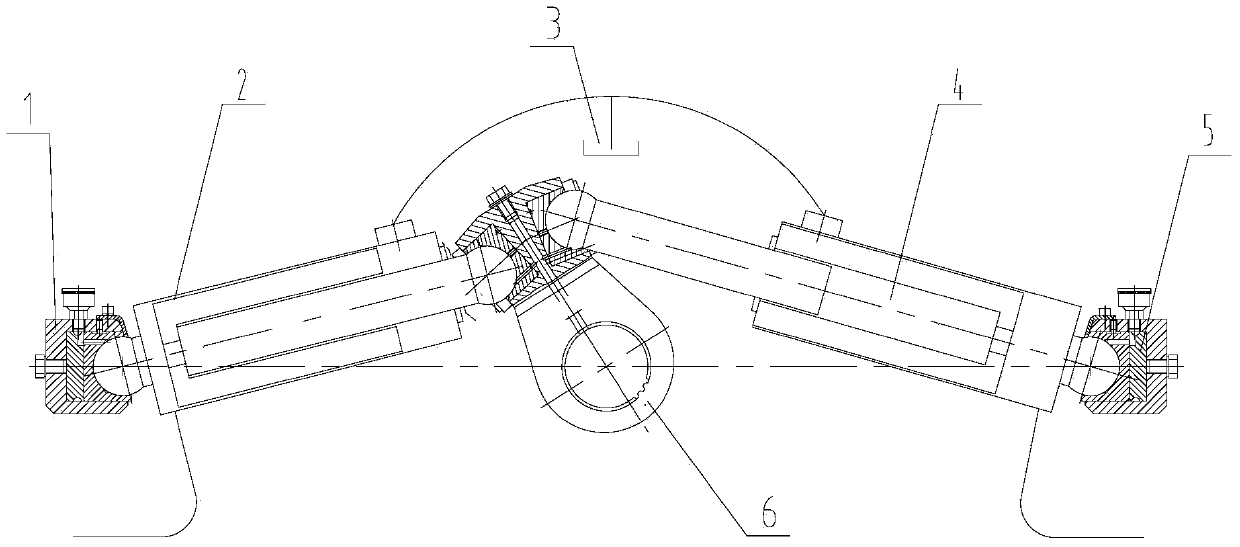

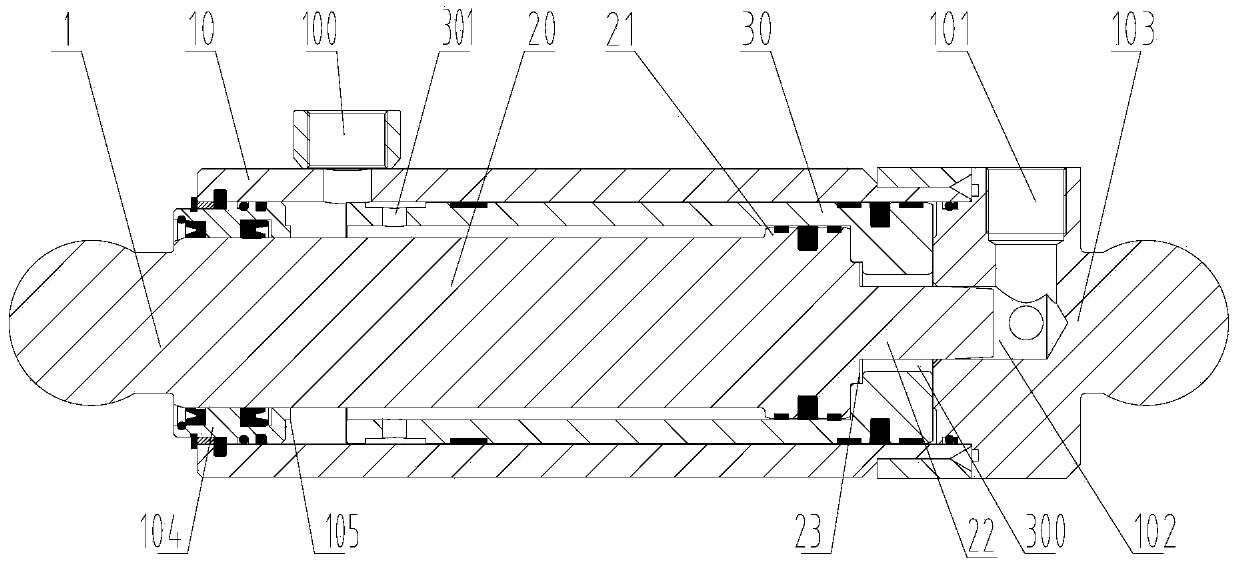

A swing mechanism and concrete pumping equipment

ActiveCN103470555BFast changeover timeReduce changeover timeServomotorsPumpsMaster cylinderEngineering

A wobbler mechanism is used for driving a distributing valve of a concrete pumping device to wobble, and comprises a wobbling arm (6) for driving the distributing valve, and two hydraulic oil cylinders (2, 4) for driving the wobbling arm (6) to wobble from side to side. One end of each of the two hydraulic oil cylinders (2, 4) is connected to left and right sides of the wobbling arm (6), and the hydraulic oil cylinders (2, 4) are two-stage hydraulic oil cylinders (2, 4). Also disclosed is a concrete pumping device having the wobbling mechanism. The wobbling mechanism and the concrete pumping device having the wobbling mechanism is fast in direction change and has a low impact, so that the direction change time of the wobbling mechanism is close to that of a master cylinder of the concrete pumping device, thereby greatly improving pumping continuity.

Owner:SANY AUTOMOBILE MFG CO LTD

Lithium ion battery lead anti-bending adjustment assembly and fixture

PendingCN110336084AImprove the yield of sortingRealize one-key adjustmentFinal product manufactureCell component detailsEngineeringLithium-ion battery

The invention discloses a lithium ion battery lead anti-bending adjustment assembly and a fixture, which belong to the technical field of lithium ion battery devices. In the specific scheme, the lithium ion battery lead anti-bending adjustment assembly comprises a PCB, a PCB mounting board, a wedge block, a main board and a pressing block, wherein the PCB is fixedly mounted on the upper surface ofthe PCB mounting board; the upper surface of the wedge block is in sliding connection with the lower surface of the PCB mounting board; the lower surface of the wedge block is in sliding connection with the upper surface of the main board; the pressing block is mounted on the lower surface of the main board; and the wedge block moves left and right to push the PCB mounting board and the main board to move to opposite directions. The PCB vertical direction and the battery thickness direction can be adjusted, the lead of the battery during formation and capacity grading processes is ensured notto be bent, the problems of battery short circuit, poor battery voltage, poor capacity and the like caused by bending of the lead are improved, and the lithium ion battery formation and sorting yieldis improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

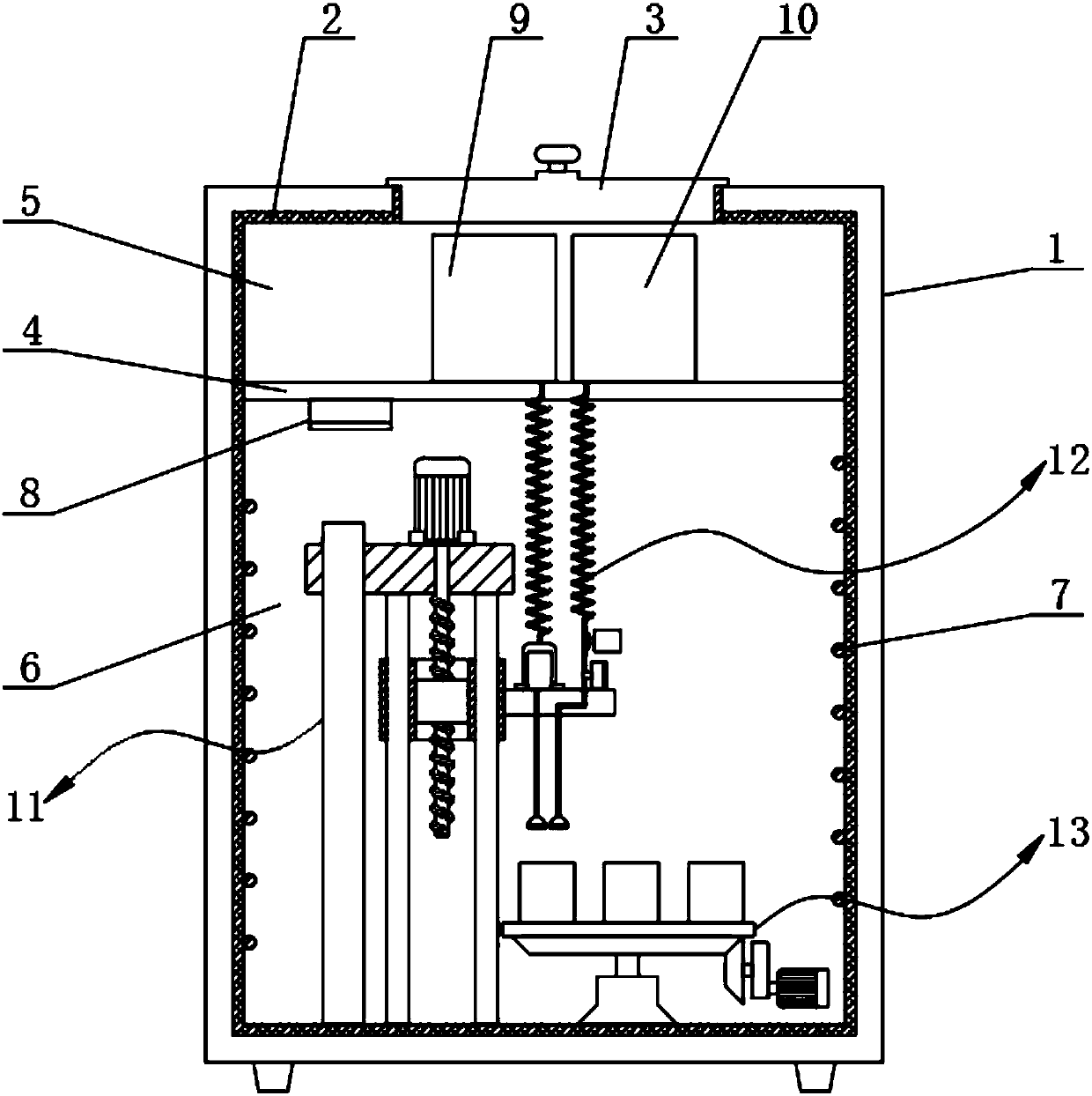

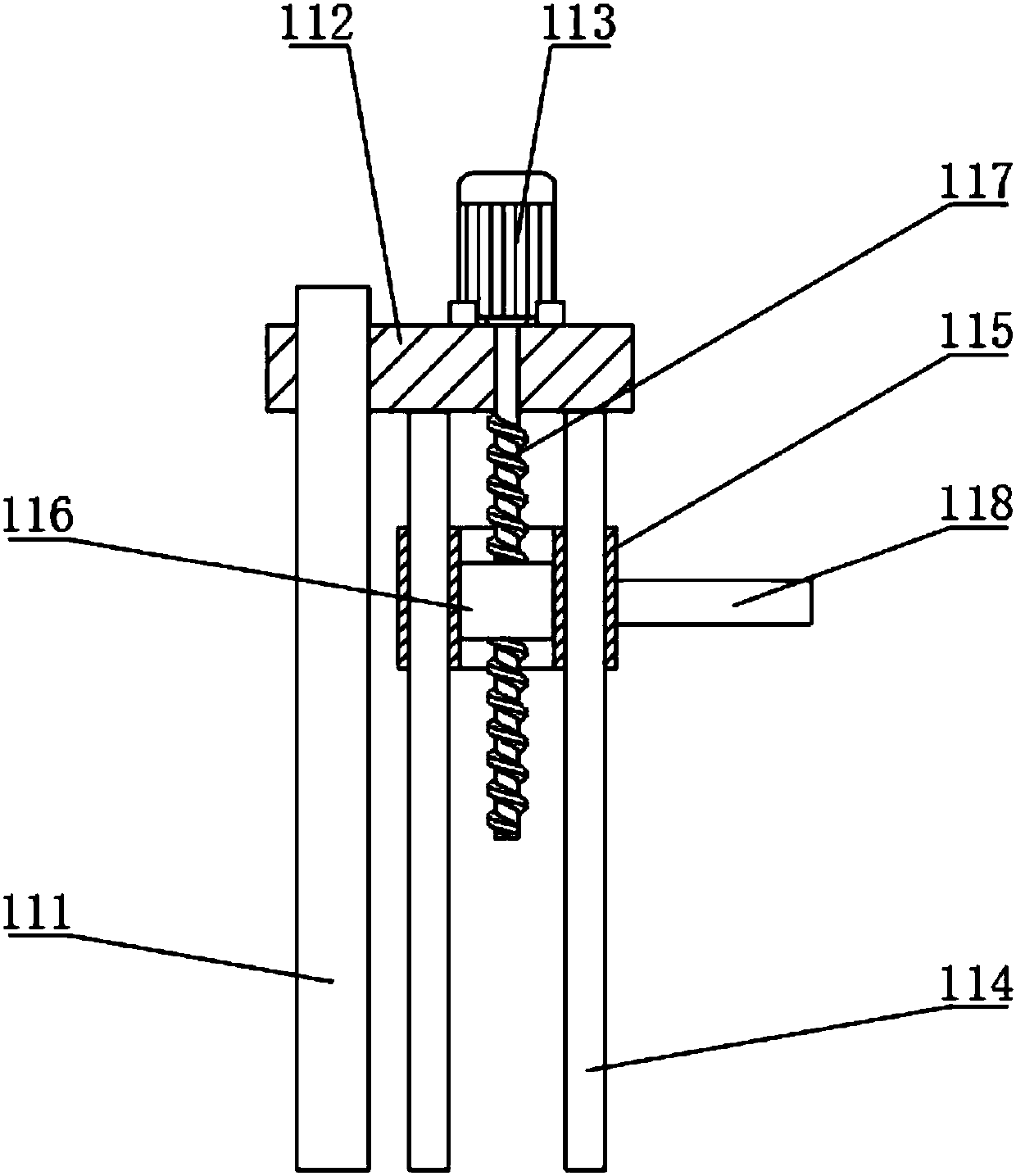

Culture tank with function of automatically changing culture solution for medical experiments

InactiveCN107686812ARealize automatic replacementAvoid timeBioreactor/fermenter combinationsBiological substance pretreatmentsDraining tubeCulture fluid

The invention provides an incubator for medical experiments that can automatically replace the culture solution, comprising a liquid storage room, a culture room, a lifting device, a liquid changing device, a carrying device, and a PLC controller; the lifting device includes a column, a fixed plate, Lifting motor, guide column, sliding seat, screw joint block, screw rod and support; the liquid changing device includes a liquid discharge pipe, a liquid discharge head, a liquid discharge pump, a liquid filling pipe, a liquid filling head, a liquid filling valve, an electronic flow meter and drip plate; the carrying device is located at the bottom of the liquid changing device; the carrying device includes a drive motor, a reduction gear set, a bevel gear set, a base, a bearing, a carrier plate, a petri dish, a positioning block and a positioning groove; The present invention realizes the automatic replacement of the culture solution in the cell culture process through the setting of the lifting device, the liquid changing device and the carrying device, avoids the problems of inaccurate timing of the manual replacement of the culture liquid and the problems that are easy to cause errors in the liquid changing, and significantly reduces the The liquid exchange time reduces the difficulty of liquid exchange.

Owner:竺灵云

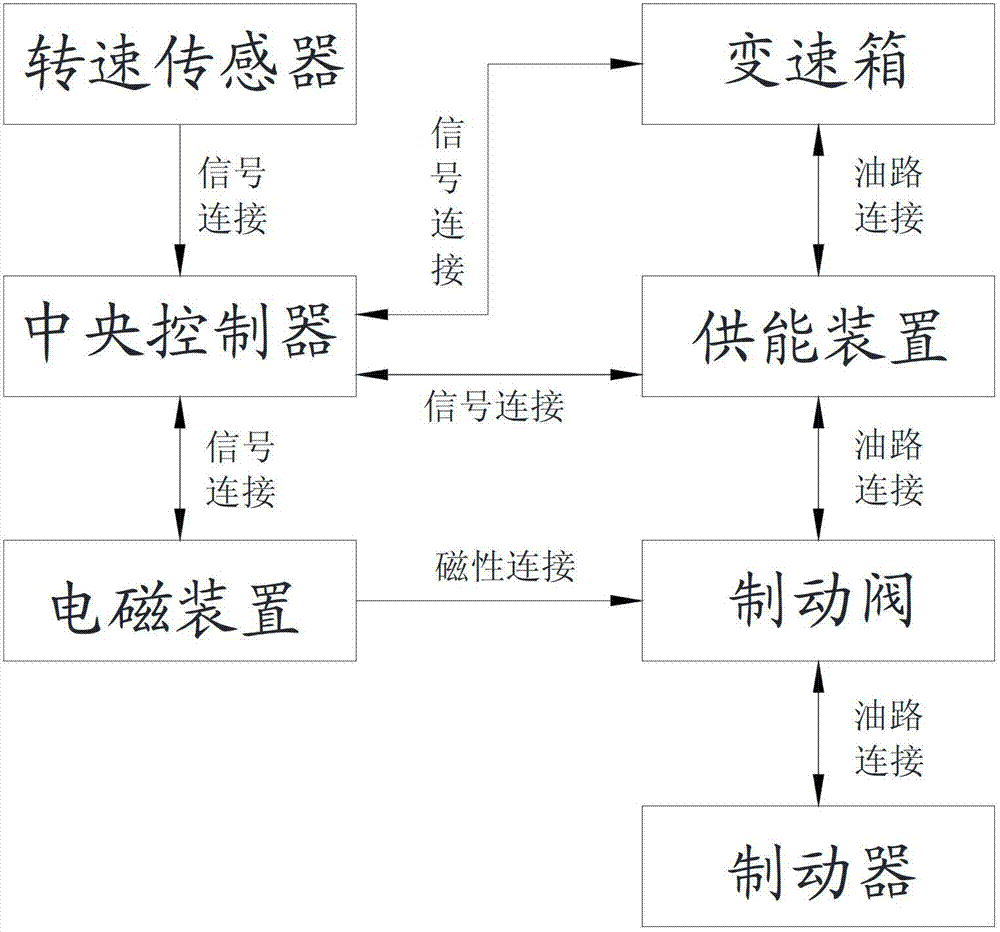

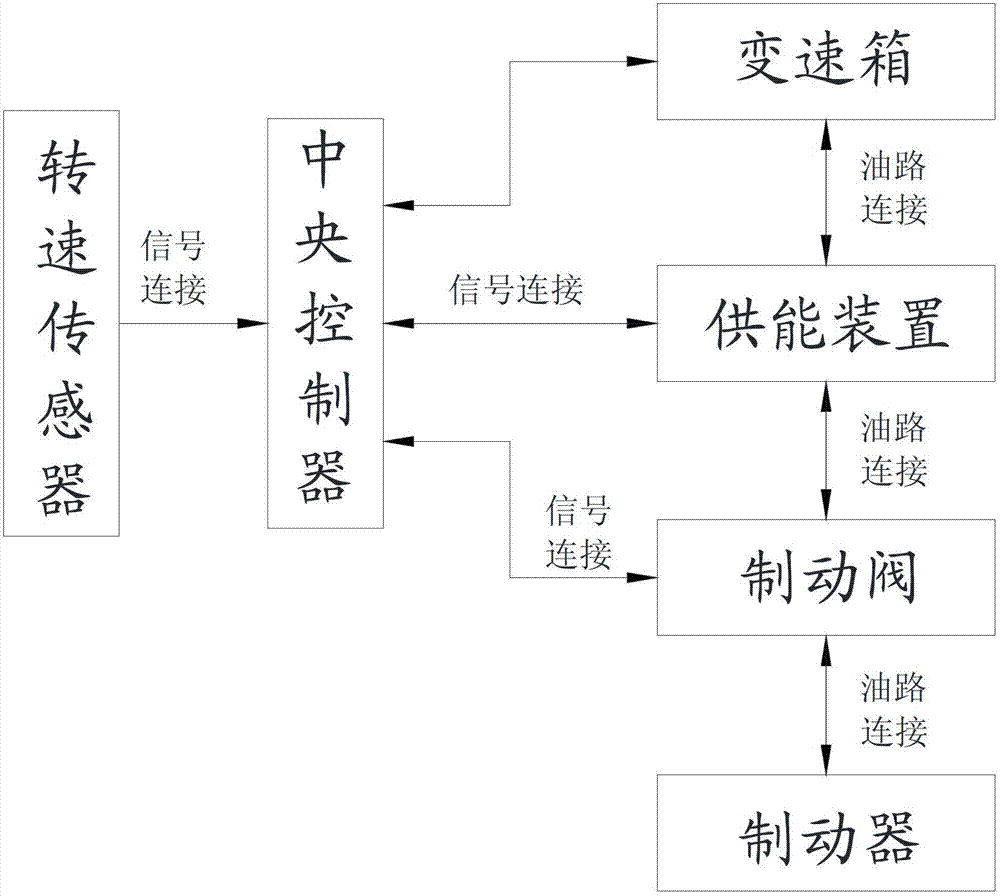

Electric control hydraulic reversing method, electric control hydraulic reversing system and engineering machinery

The invention provides an electric control hydraulic reversing method, an electric control hydraulic reversing system and engineering machinery. The electric control hydraulic reversing method comprises the following steps: a reversing command is received by a central controller; a gearbox is controlled to execute a neutral gear action; a brake valve is controlled to cause a brake to execute a brake action; a car speed is monitored in a real-time manner through a sensor; when the car speed is reduced to a shift condition, the brake valve is controlled to release the brake; and the gearbox is controlled to execute a reversing geared action. According to the electric control hydraulic reversing method and the electric control hydraulic reversing system provided by the invention, the brake valve and the gearbox are controlled by the central controller, so that a brake speed reduction action, a neutral position action and a shift reversing action after speed reduction, which are operated by an experienced worker, can be automatically completed, the reversing time and travel can be greatly reduced, and meanwhile, and a combination miss of firstly stepping on a brake pedal to reduce the speed and applying the reversing process can be avoided.

Owner:SANY HEAVY IND CO LTD (CN)

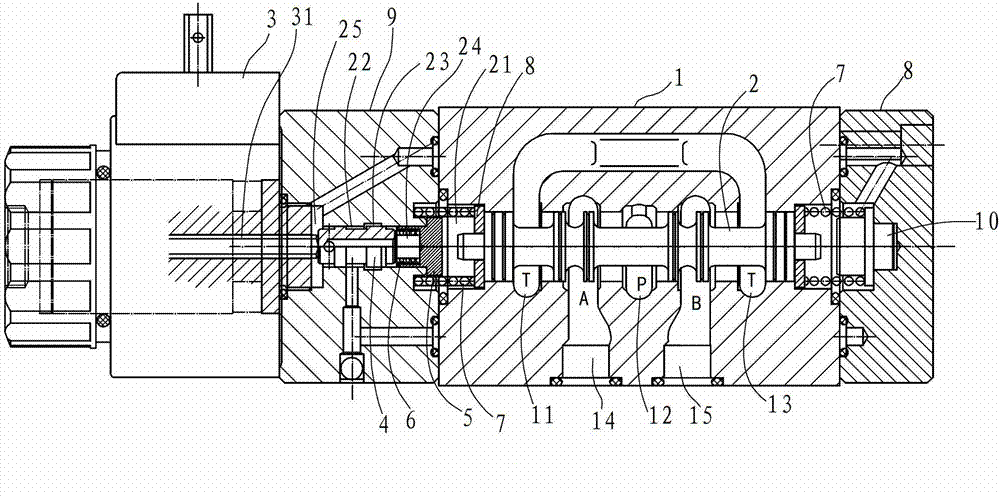

Electromagnetic directional valve

InactiveCN102829013ASmall reaction forcePower reduction requiredServomotor componentsMiniaturizationEngineering

The invention discloses an electromagnetic directional valve which comprises a valve body, a main valve core, an electromagnet and a main restoring spring, wherein the main valve core is positioned in the valve body and can move back and force along an axial channel of the valve body. The electromagnetic directional valve is characterized by also comprising a side cover, a pilot valve core and a pilot restoring spring, wherein the side cover is arranged on one side of the valve body; the pilot valve core can move back and force in an axial duct; the electromagnet is arranged on the other side of the side cover; and a push rod of the electromagnet pushes against the pilot valve core. Compared with the prior art, the electromagnetic directional valve provided by the invention has the advantages that with adoption of a hydraulic amplification principle and combination of a pilot control structure, an original working stroke is greatly shortened, and thus the miniaturization design on the electromagnetic directional valve is favorable; and meanwhile, the working stroke is shortened, and thus power can be greatly reduced.

Owner:NINGBO ZHENHAI HUALI HYDRAULIC ELECTROMECHANICAL CO LTD

Soft touch switch press fitting device

ActiveCN103273304AQuick changeReduce changeover timeMetal working apparatusPrinted circuit boardTouch switch

The invention discloses a soft touch switch press fitting device which comprises a working table board. A replaceable jig is connected on the working table board and used for fixing a soft touch switch casing, screw limit devices are arranged on two sides of the soft touch switch casing, and a replaceable pressing plate is arranged above the soft touch switch casing. The pressing plate is a box body with the bottom free of covers, pressing strips for press fitting a printed circuit board (PCB) are formed at the edges of the bottom of the pressing plate, an approaching switch, a detecting probe and a photoelectric sensor are arranged in the pressing plate, and the pressing plate is connected with a pressing cylinder. A detecting device of screws and a detecting device in the pressing plate achieve product installing and detecting through one-step clamping, time is saved, and labor intensity of working staff is reduced.

Owner:SUZHOU INST OF INDAL TECH

Automatic pneumatic saw web replacing device

ActiveCN105269074ACompact and reasonable structureShorten the changeover timeMetal sawing tool makingFault rate

The invention provides an automatic pneumatic saw web replacing device which comprises a rack. The rack is provided with a saw web base pushing mechanism, a saw web rotating mechanism and a finished product hanging rod and further provided with a swing arm mechanism. The swing arm mechanism comprises a swing arm, one end of the swing arm is connected with the rack through a rotary shaft, and the other end of the swing arm is provided with a first suction cup and a second suction cup. When the swing arm mechanism swings to one side, the first suction cup corresponds to the saw web base pushing mechanism in position, and the second suction cup corresponds to the saw web rotating mechanism in position; and when the swing arm mechanism swings to the other side, the first suction cup corresponds to the saw web rotating mechanism in position, and the second suction cup corresponds to the finished product hanging rod in position. The automatic pneumatic saw web replacing device is low in fault rate, small in occupied space, high in execution efficiency and good in machining accuracy.

Owner:潞太(浙江)智能设备有限公司

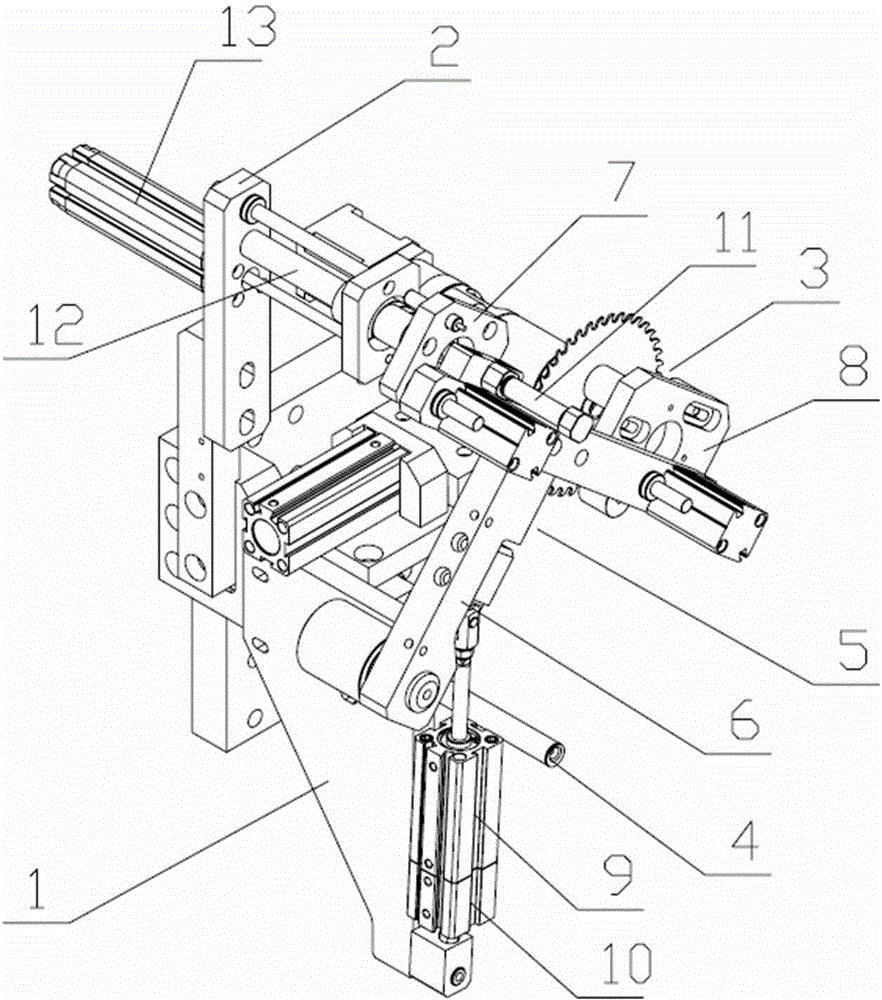

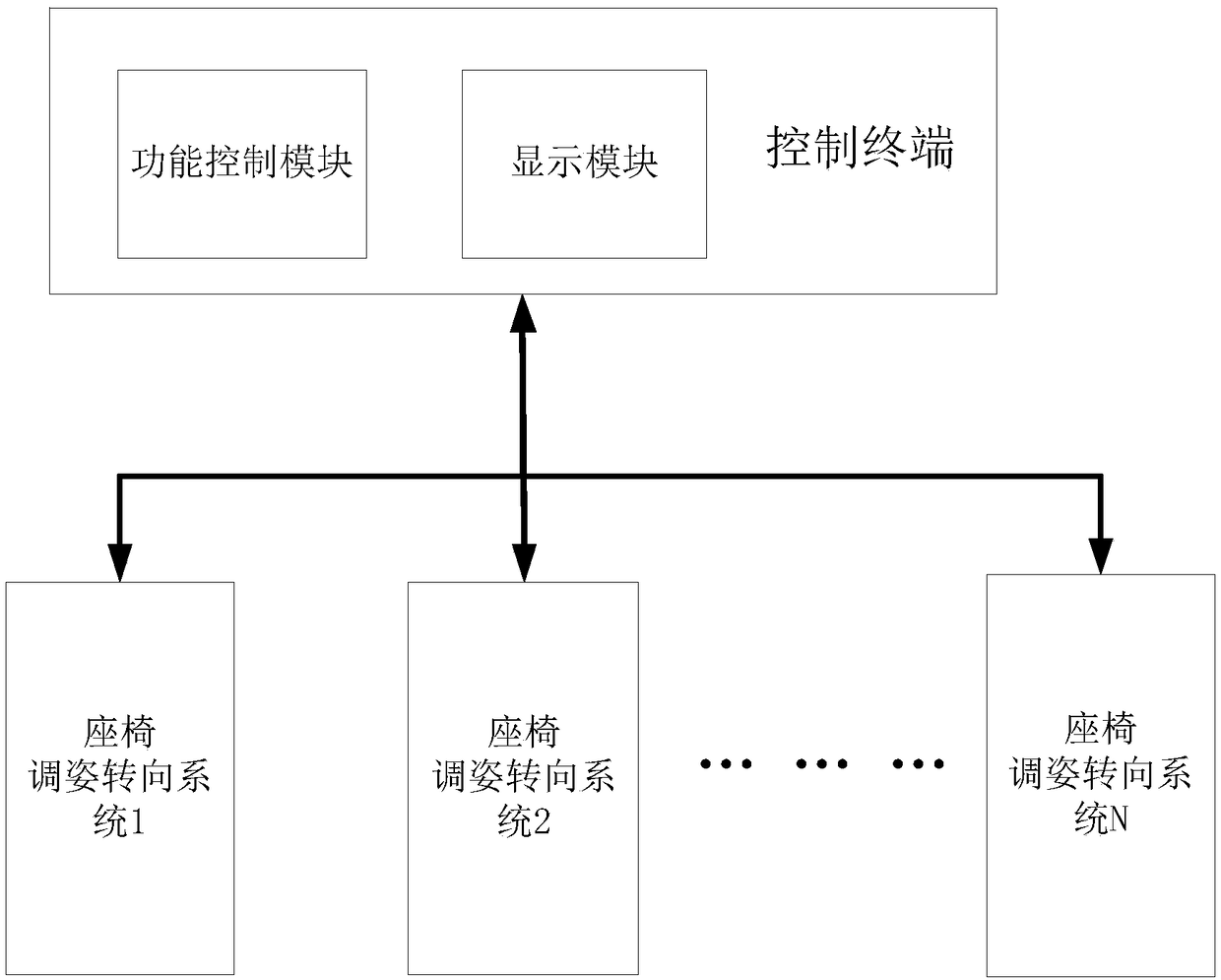

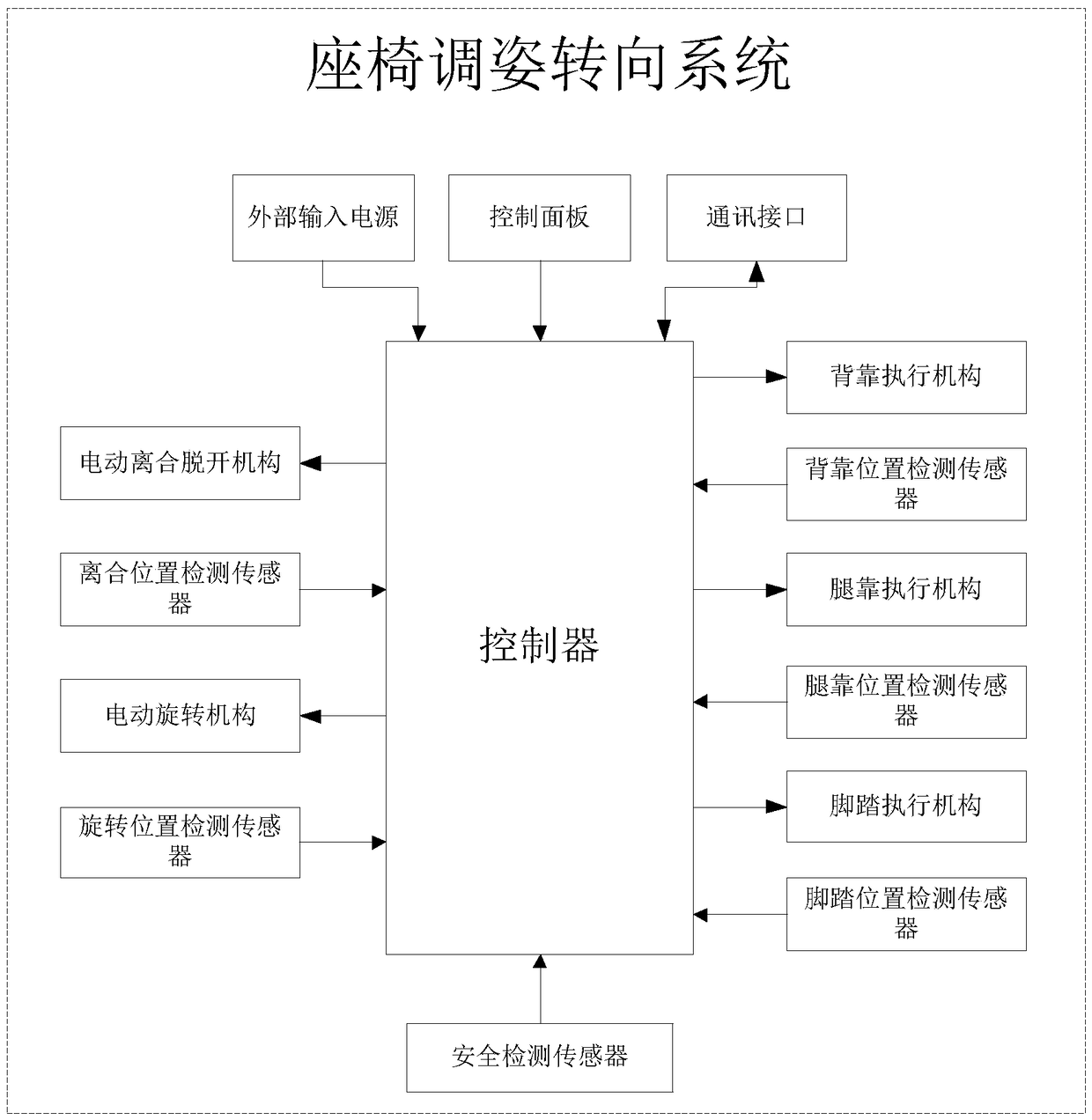

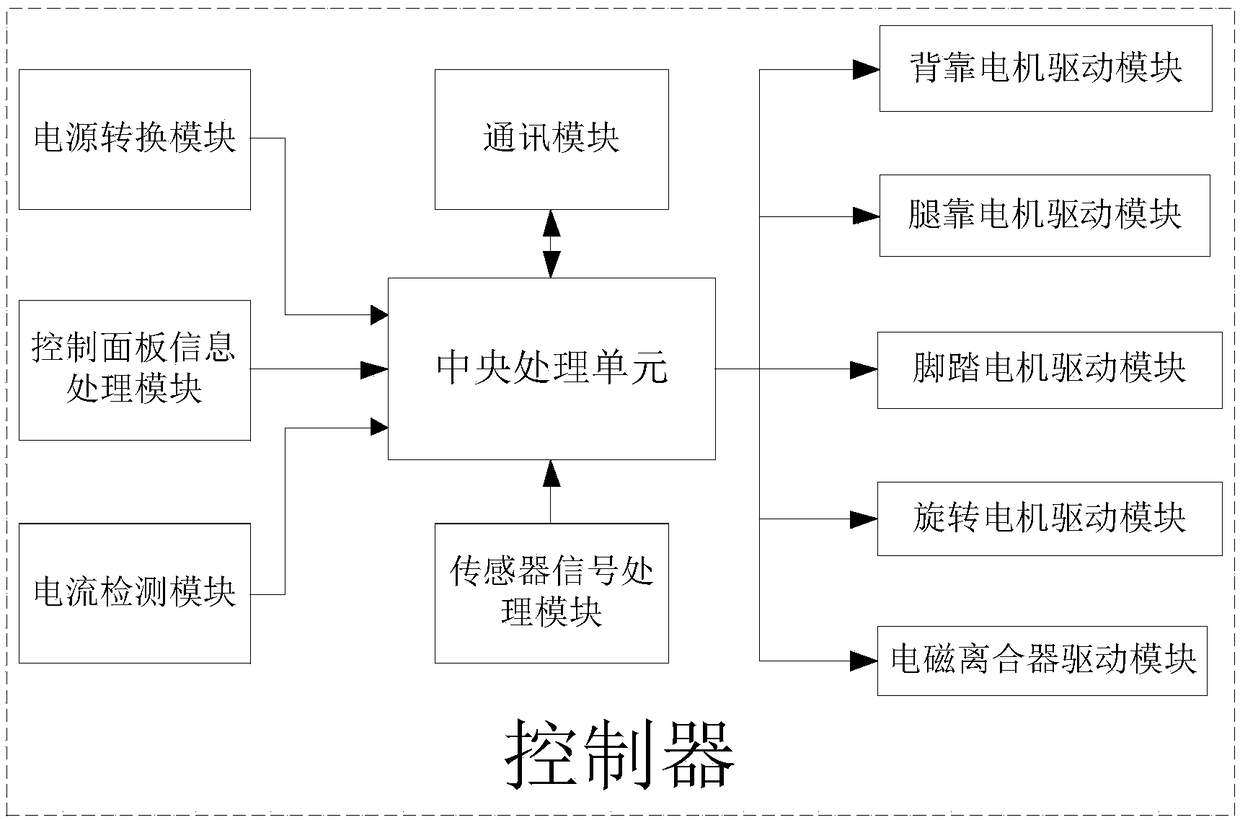

Attitude adjusting and steering system for business seats of rail transit

InactiveCN108725485AReduce changeover timeRealize energy saving and consumption reductionSeatsEngineeringActuator

The invention relates to an attitude adjusting and steering system for business seats of rail transit. The attitude adjusting and steering system for the business seats of the rail transit comprises the business seats, wherein each of the business seats mainly comprises a seat swivel, a seat base, a seat cushion, a backrest, leg rests, a pedal, control panels, a backrest actuator, a leg rest actuator, and a pedal actuator; a seat attitude adjusting and steering system is further arranged on each business seat, and comprises a controller, a control panel, an electric rotating mechanism and an electric clutch disengagement mechanism; the system further comprises control terminals connected with the seat attitude adjusting and steering systems on all the business seats in a same area; the control terminals comprise function control modules and display modules. The system can adjust seat attitudes through the control panels mounted on the seats, and the control panels can control the single seat to eclectically rotate at any angles to improve the ride experience, furthermore, the control terminals can control a single section of compartment seats to achieve automatic rotation completely.

Owner:湖北韵生航天科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com