Lithium ion battery lead anti-bending adjustment assembly and fixture

A technology for lithium-ion batteries and adjusting components, which is applied to battery pack components, electrical components, non-aqueous electrolyte batteries, etc., can solve problems such as the inability to adjust the position of the PCB board to adapt to batteries with different thicknesses, and the bending of lithium-ion battery tabs. , to achieve the effect of reducing changeover time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

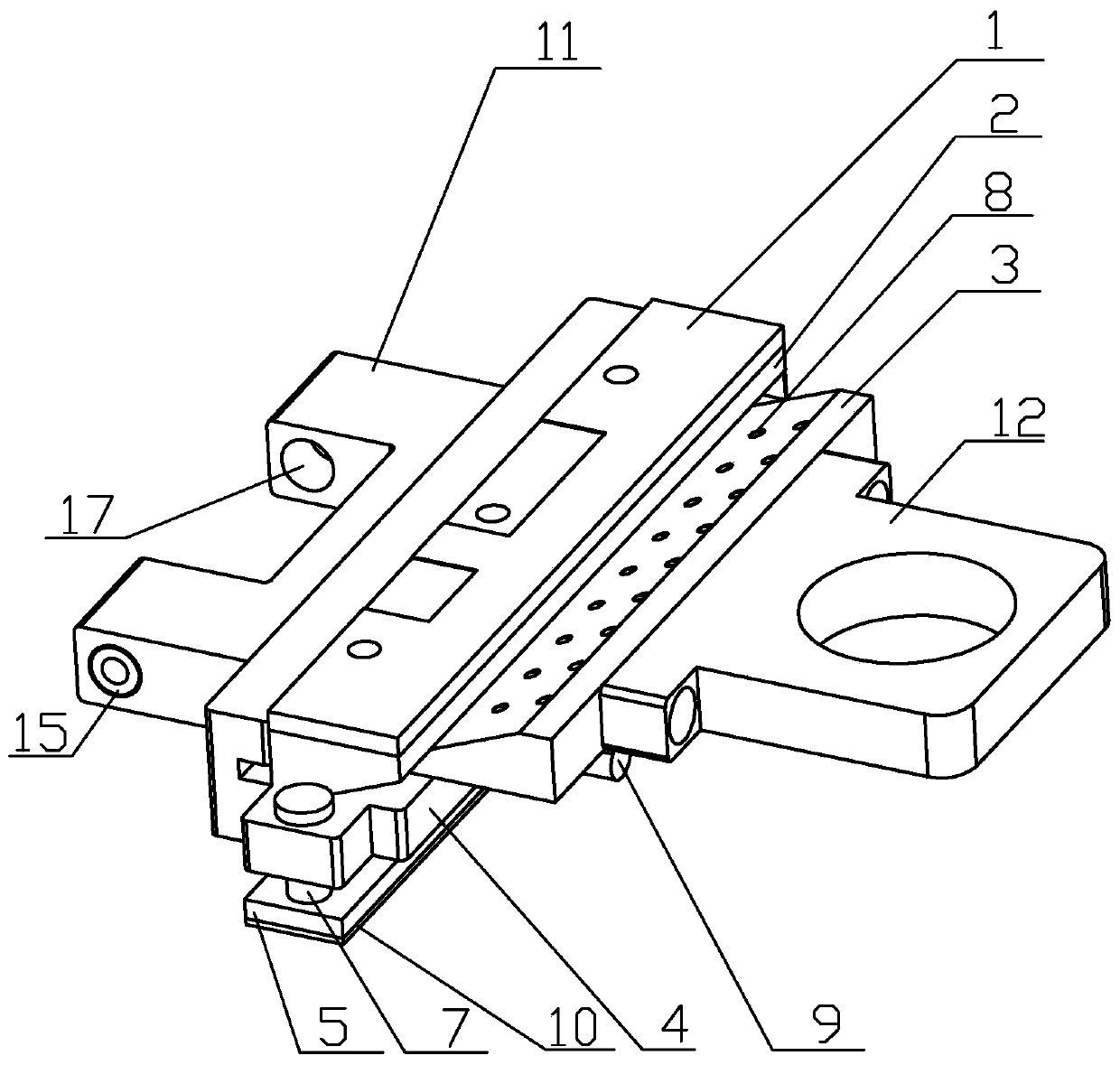

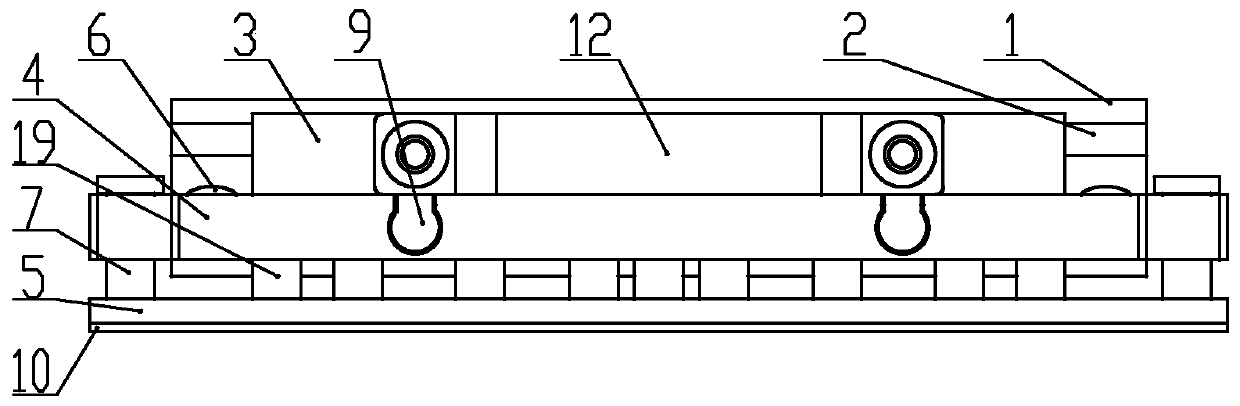

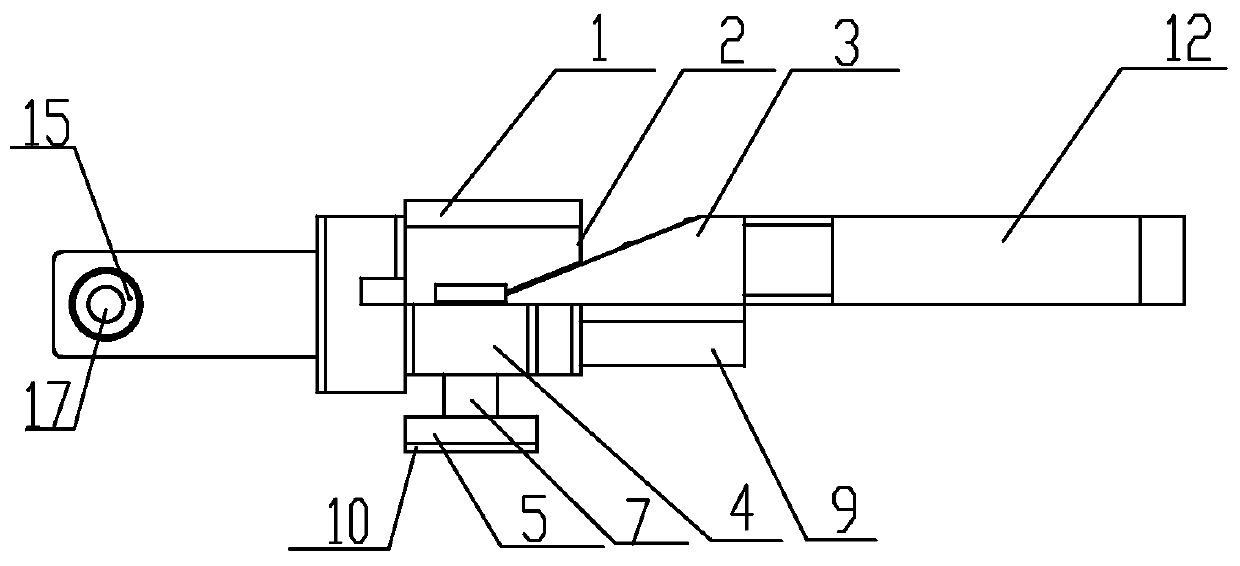

[0030] A lithium-ion battery lug anti-bending adjustment assembly, including a PCB board 1, a PCB mounting board 2, a wedge block 3, a main board 4 and a pressing block 5, the PCB board 1 is fixedly installed on the upper surface of the PCB mounting board 2, The upper surface of the wedge block 3 is slidingly connected to the lower surface of the PCB mounting board 2, the lower surface of the wedge block 3 is slidingly connected to the upper surface of the main board 4, and the pressing block 5 is installed on the main board 4, the left and right movement of the wedge block 3 pushes the PCB mounting board 2 and the main board 4 to move in opposite directions.

[0031] Further, the upper surface of the main board 4 is connected to the lower surface of the PCB mounting board 2 through at least one vertically arranged spring I, the upper surface of the main board 4 is vertically provided with at least one guide column I6, and the PCB The mounting plate 2 is provided with at least...

specific Embodiment approach 2

[0041] A clamp for applying the adjustment assembly described in Embodiment 1, comprising several adjustment assemblies, several clamp laminates 13 arranged vertically and parallel to each other, each of the two ends of the clamp laminate 13 is installed with a Adjustment components set vertically.

[0042] Further, the main board 4 of the adjustment assembly is vertically installed on the fixture layer 13 .

[0043] Further, the clamp also includes a guide post III14, which is fixed on the clamp laminate 13 along the width direction of the clamp laminate 13, and the connecting piece 11 integrally connected with the main board 4 in the adjustment assembly is passed through a linear bearing 15 is slidably connected to the guide post III 14, the installation direction of the adjustment components at the same end of two adjacent clamp laminates 13 is the same, and the installation direction of the adjustment components at both ends of each clamp laminate 13 is opposite.

[0044]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com