Patents

Literature

41results about How to "Small commutation impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

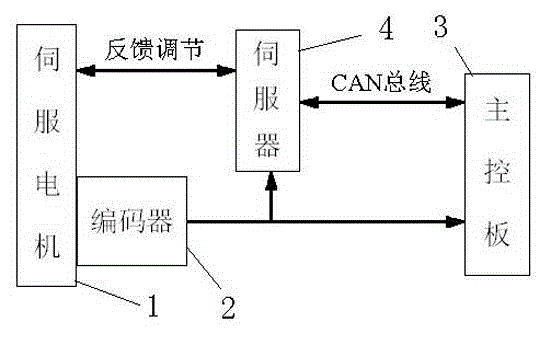

Safety control method for fast revolution of flat machine

ActiveCN103336484ASpeed Distortion ReductionReduce changeover timeProgramme controlComputer controlElectric machineSafety control

The invention discloses a safety control method for fast revolution of a flat machine, which comprises the following steps: firstly, a coder of a servo motor of the machine head of the flat machine is simultaneously connected with a main control panel and a server, the servo motor is in control connection with the server, and the main control panel is in communication connection with the server; then, the main control panel obtains both the operation start point and the operation end point of each line before operation, and the maximum coder value which the operation of each line reaches through reading and analyzing design information of a product, then the main control panel is combined with the acceleration and deceleration performance control parameter to calculate the coder values corresponding to each deceleration position point and each acceleration position point; the main control panel sends the positions of each deceleration position point and each acceleration position point, the corresponding coder values and target speed to the server; finally, in the process of operation of each line, the server directly monitors the output value of the coder to enable the servo motor to operate at each deceleration position point and each acceleration position point according to destined coder values, so that optimal revolution control is realized.

Owner:ZHEJIANG HENGQIANG TECH

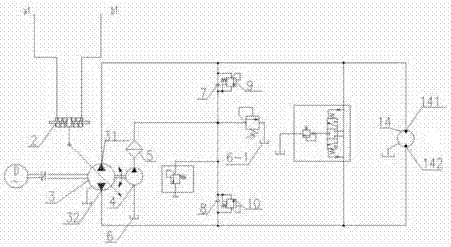

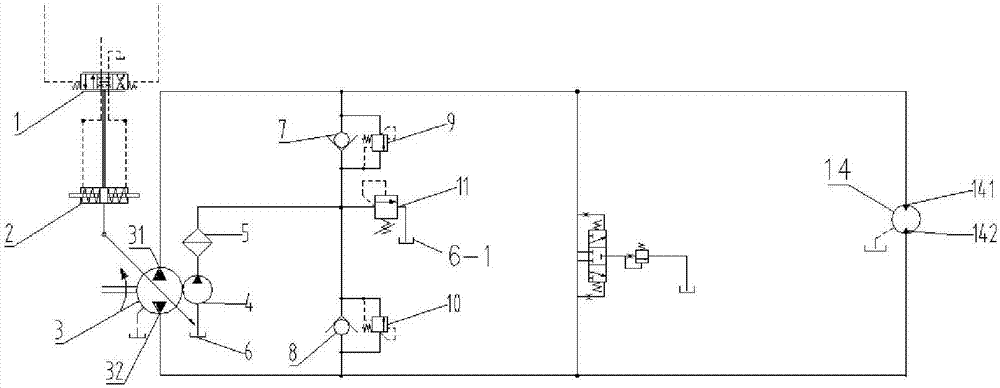

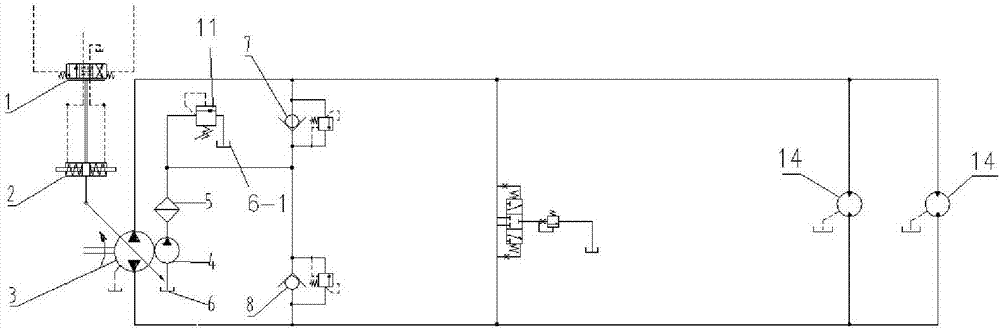

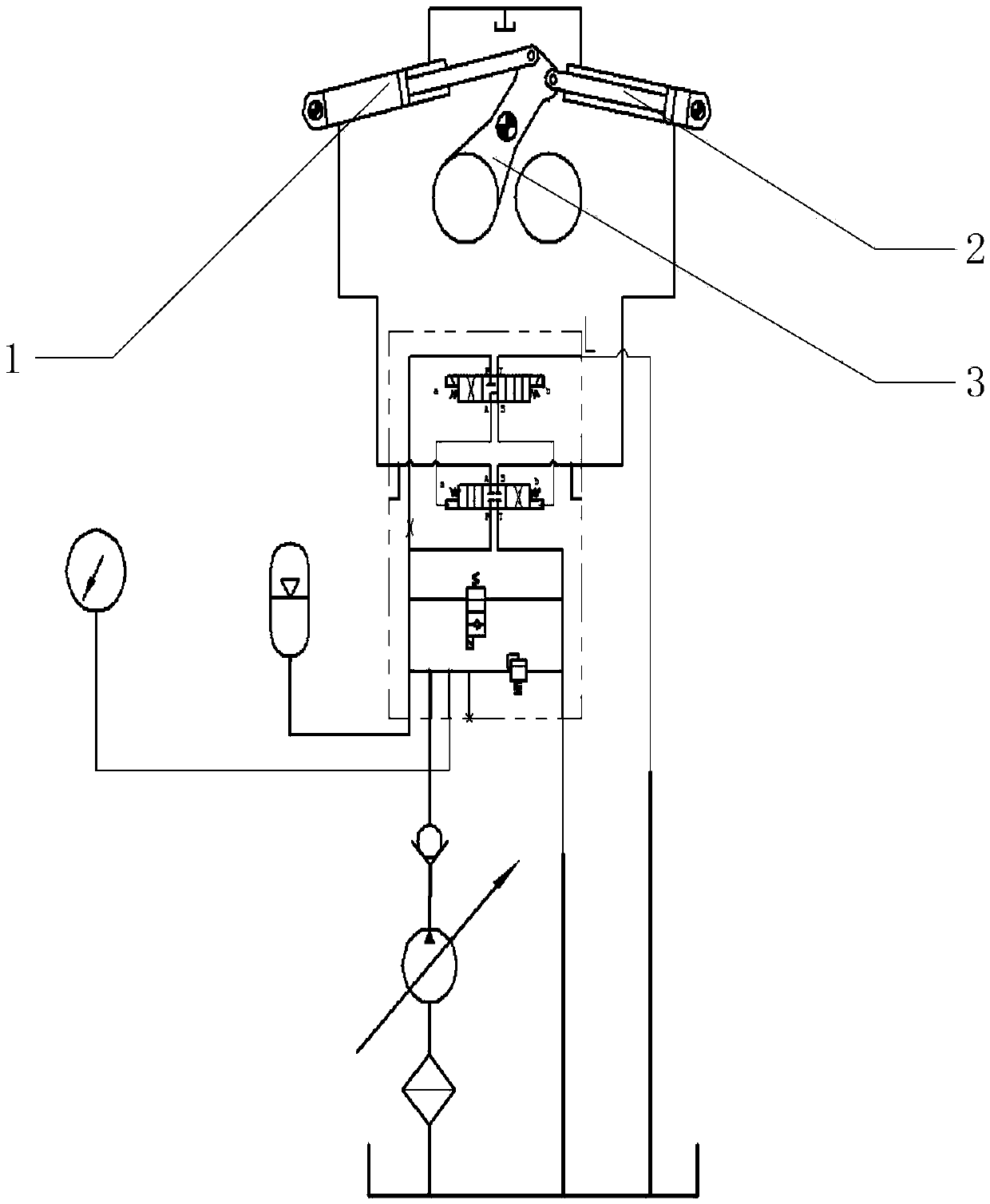

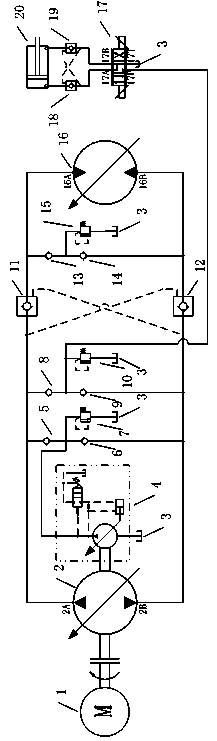

Closed hydraulic system for heading machine

PendingCN106907364AAvoid throttling lossesReasonable and novel structure designServomotor componentsServomotorsMechanical equipmentCoal

The invention discloses a closed hydraulic system for a heading machine and a heading machine using the system and relates the technical field of coal mine mechanical equipment. A main oil pump is a bidirectional variable pump. A first oil opening in the main oil pump communicates with a first end opening of a motor. A second oil opening in the main oil pump communicates with a second end opening of the motor. A pilot control device directly communicates with a main oil pump variable mechanism, and an inlet of a first high-pressure overflow valve and an inlet of a second high-pressure overflow valve are connected with the first oil opening of the main oil pump and the second oil opening of the main oil pump correspondingly. An outlet of the first high-pressure overflow valve and an outlet of the second high-pressure overflow valve are connected with an oil supplementing overflow valve which is connected with a second oil tank. A pilot control element is directly connected with the main oil pump variable mechanism to control the displacement of the main oil pump. The main oil pump is connected with the motor through a pipeline, and a valve throttle is arranged in the middle. Throttling losses of an opening system are avoided, energy consumption is reduced, and reversing impacts are reduced; and power losses of the device are low, the temperature rise of hydraulic oil is low, large-volume oil tank heat dissipation is not needed, only the requirement for oil supplementing needs to be met through to the oil tank volume, and equipment space and weight are saved.

Owner:无锡华瀚能源装备科技有限公司

Engineering machine and distribution system thereof

ActiveCN105370644AIncrease return oil back pressurePlay the role of deceleration brakeServomotor componentsServomotorsDistribution systemHigh velocity

The invention discloses a distribution system of an engineering machine. The distribution system of the engineering machine comprises a first swinging valve oil cylinder and a second swinging valve oil cylinder which are reverse in telescopic state and are opposite to each other, wherein a piston rod extending end of the first swinging valve oil cylinder and a piston rod extending end of the second swinging valve oil cylinder are hinged to the same end of a swinging and reversing mechanism; a rodless cavity of the first swinging valve oil cylinder and a rodless cavity of the second swinging valve oil cylinder are respectively communicated with two working oil openings of a reversing valve; a rod cavity of the first swinging valve oil cylinder is connected with an oil tank through a first throttling damper; a rod cavity of the second swinging valve oil cylinder is connected with the oil tank through a second throttling damper. Through the simple structure, the vibration and shock of the distribution system in the high-speed reversing process can be effectively solved; the stability and the reliability of the system are improved; the service life is prolonged; the development and production costs are reduced. The invention also discloses an engineering machine comprising the following distribution system.

Owner:河北雷萨重型工程机械有限责任公司

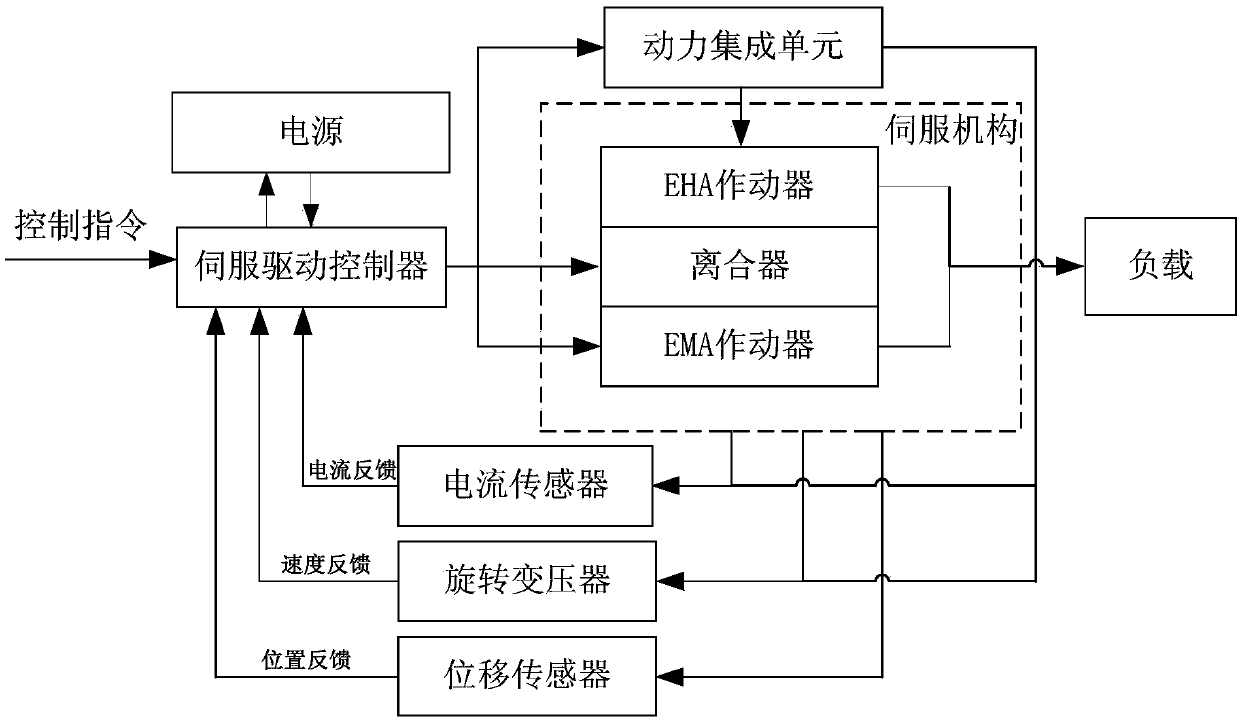

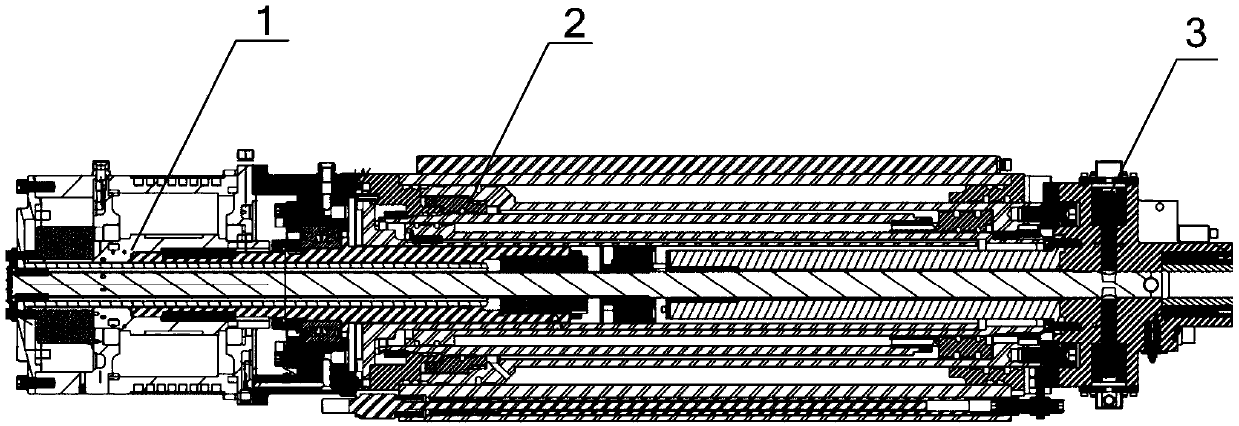

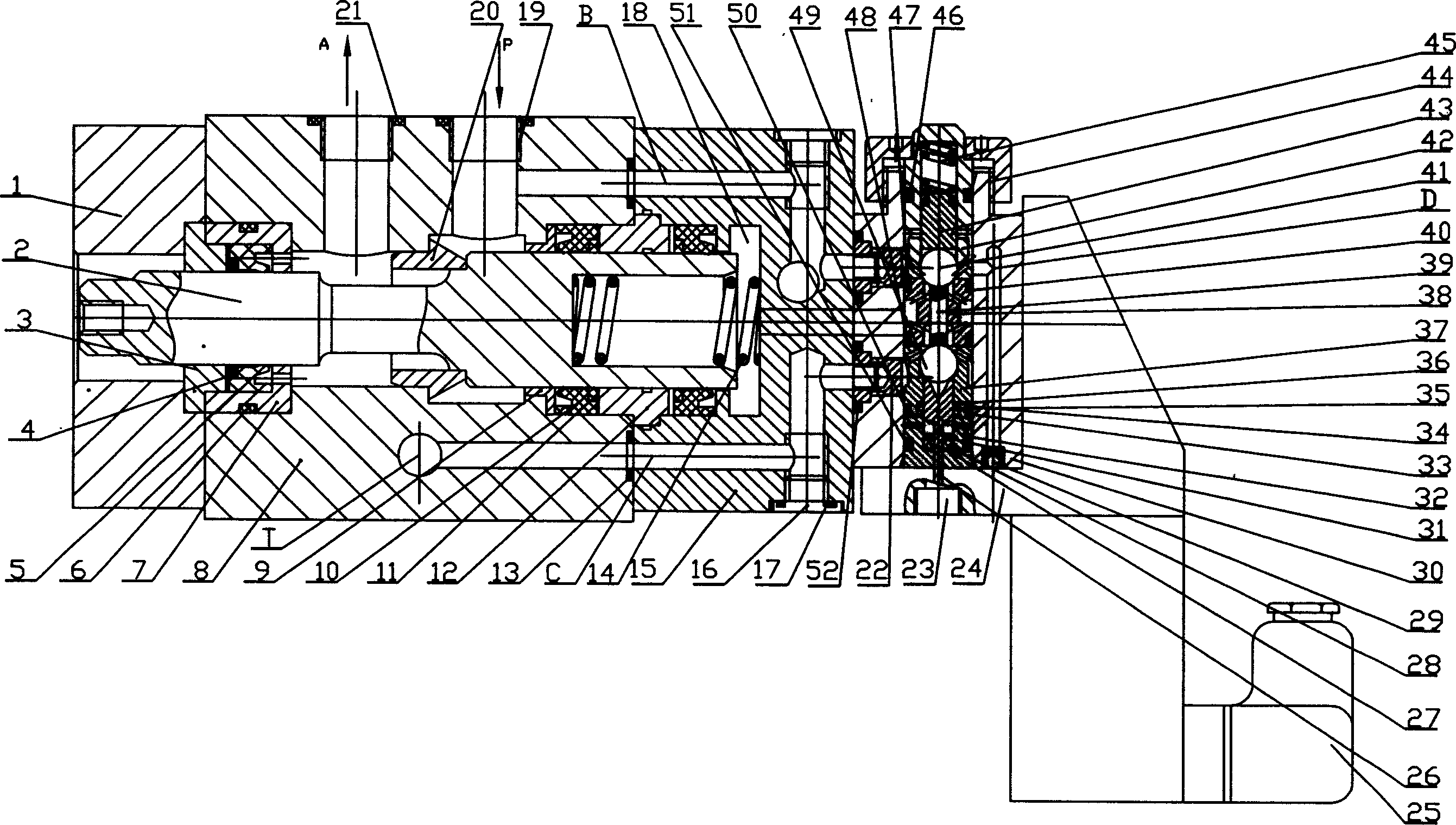

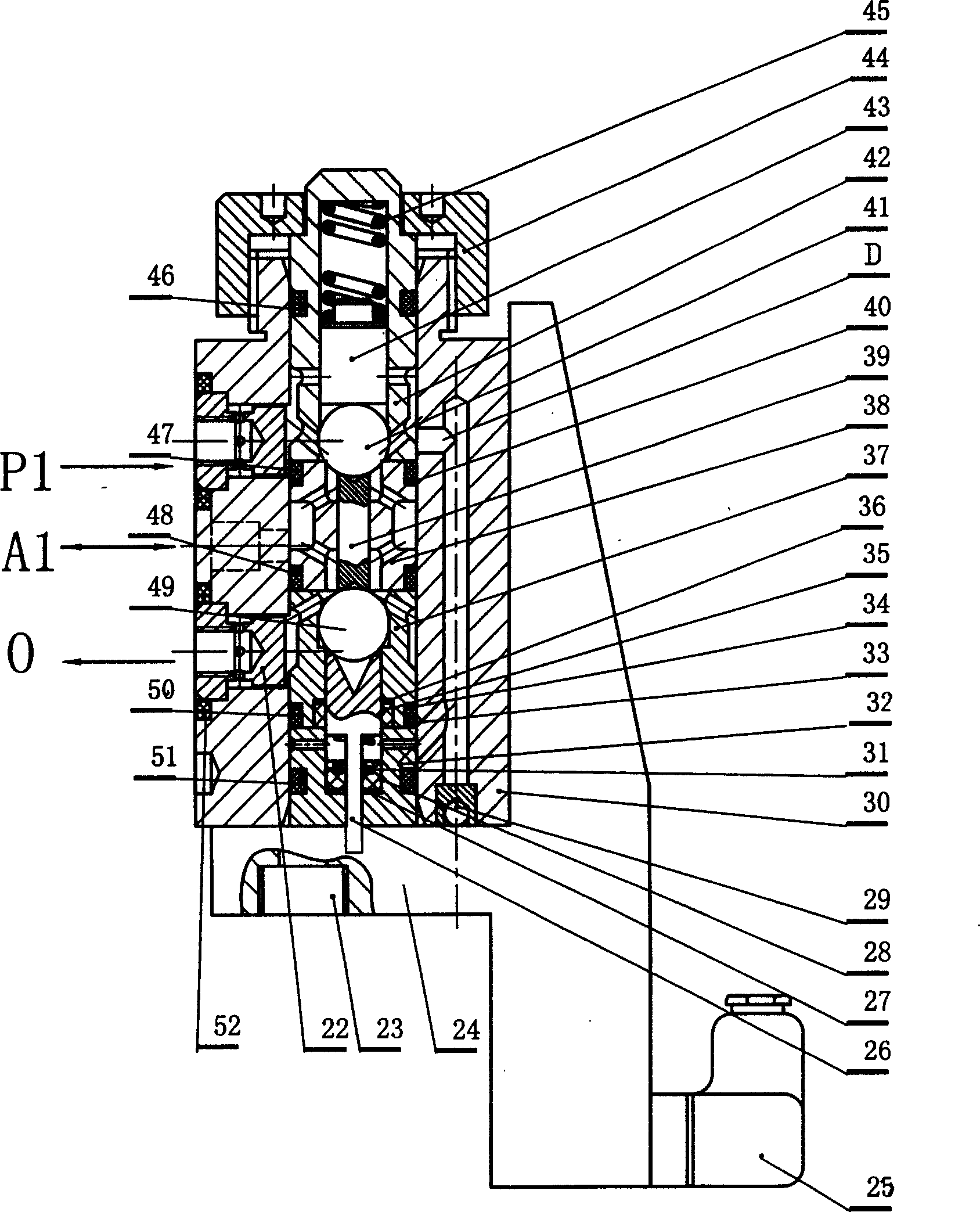

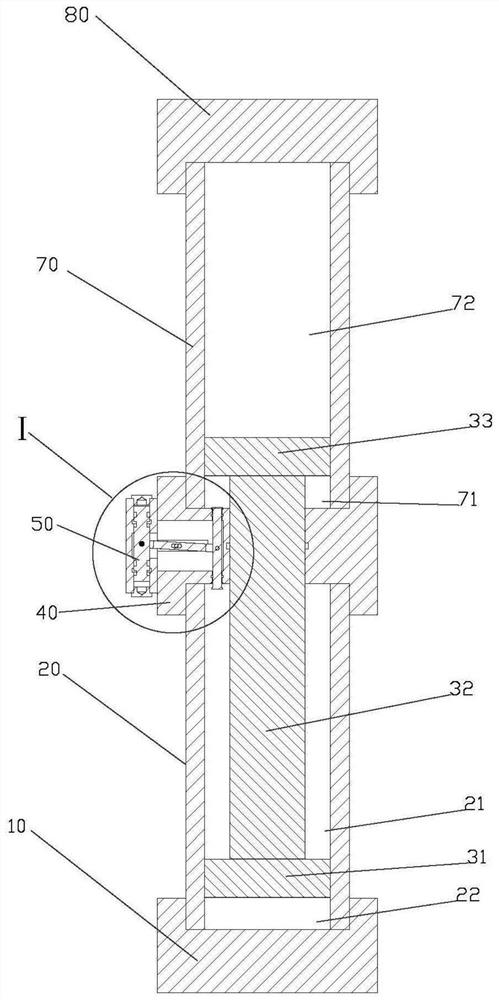

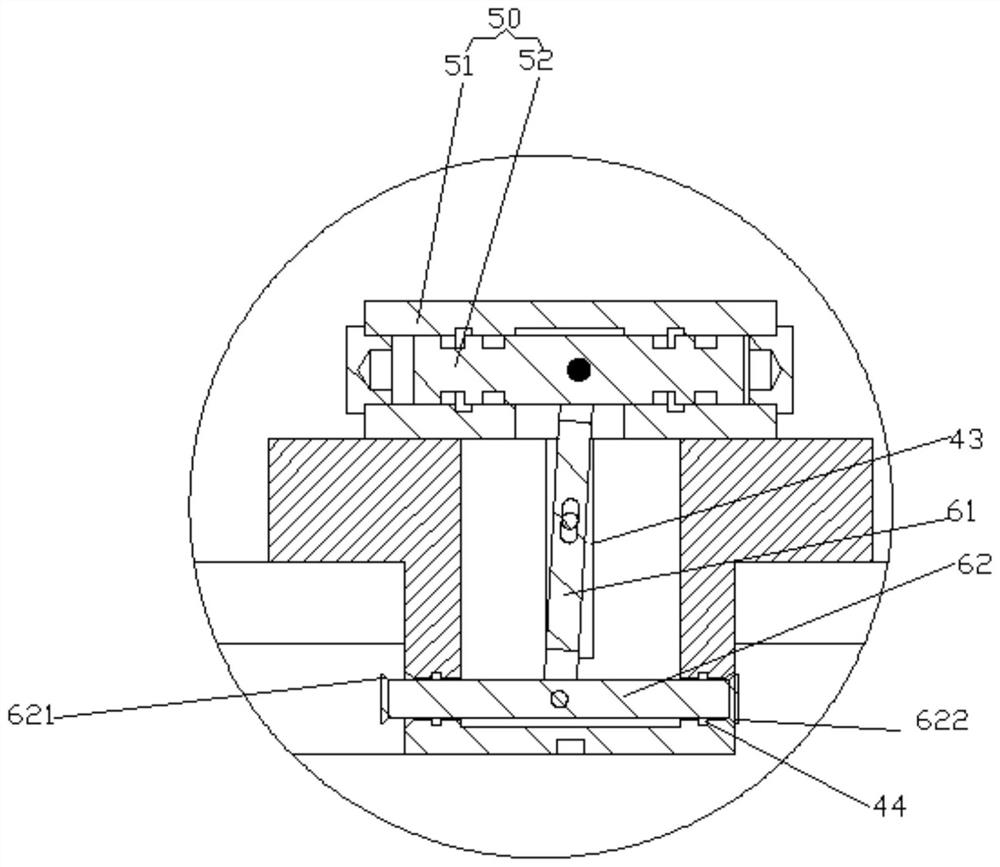

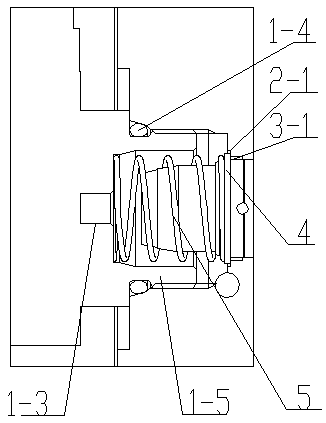

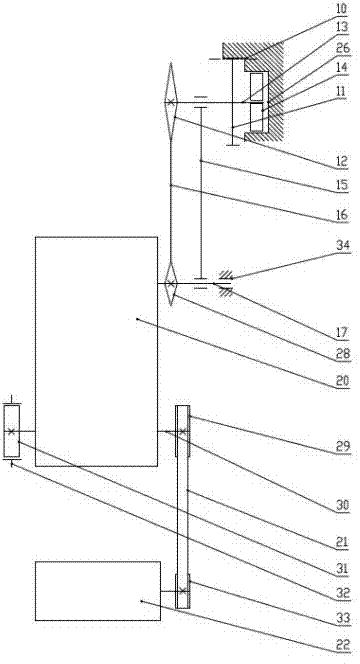

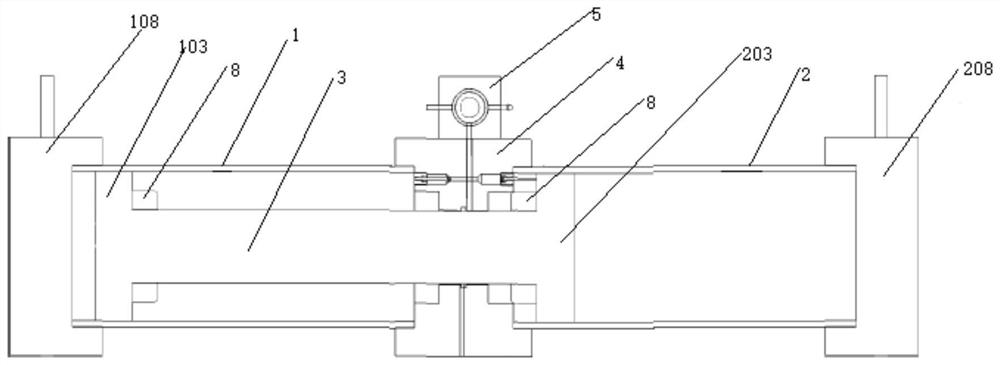

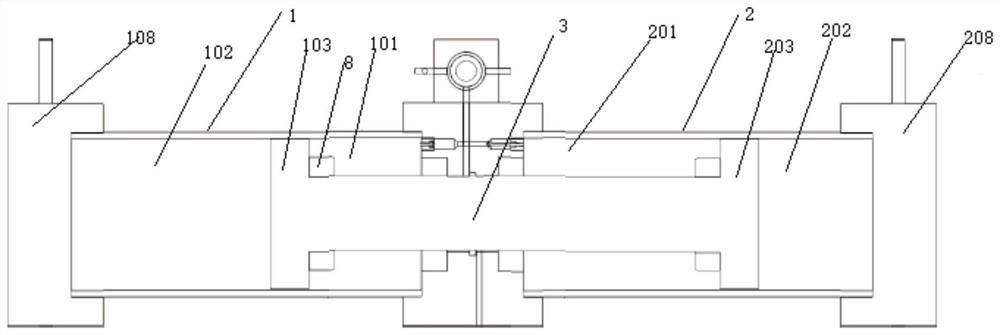

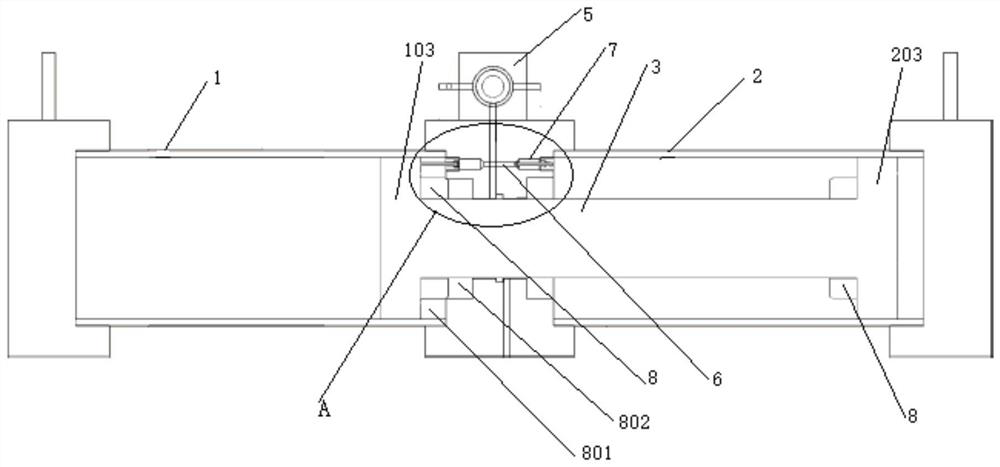

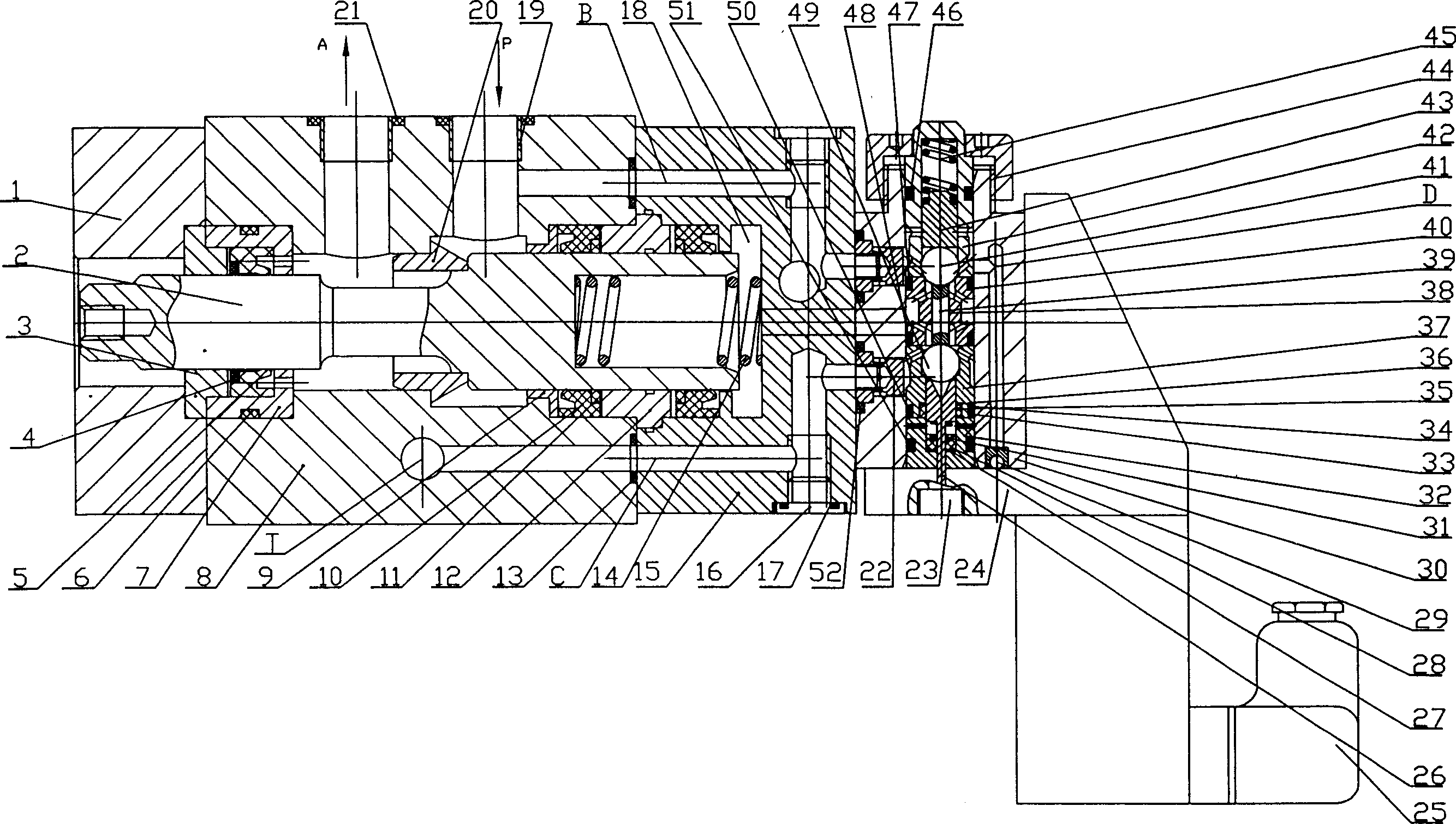

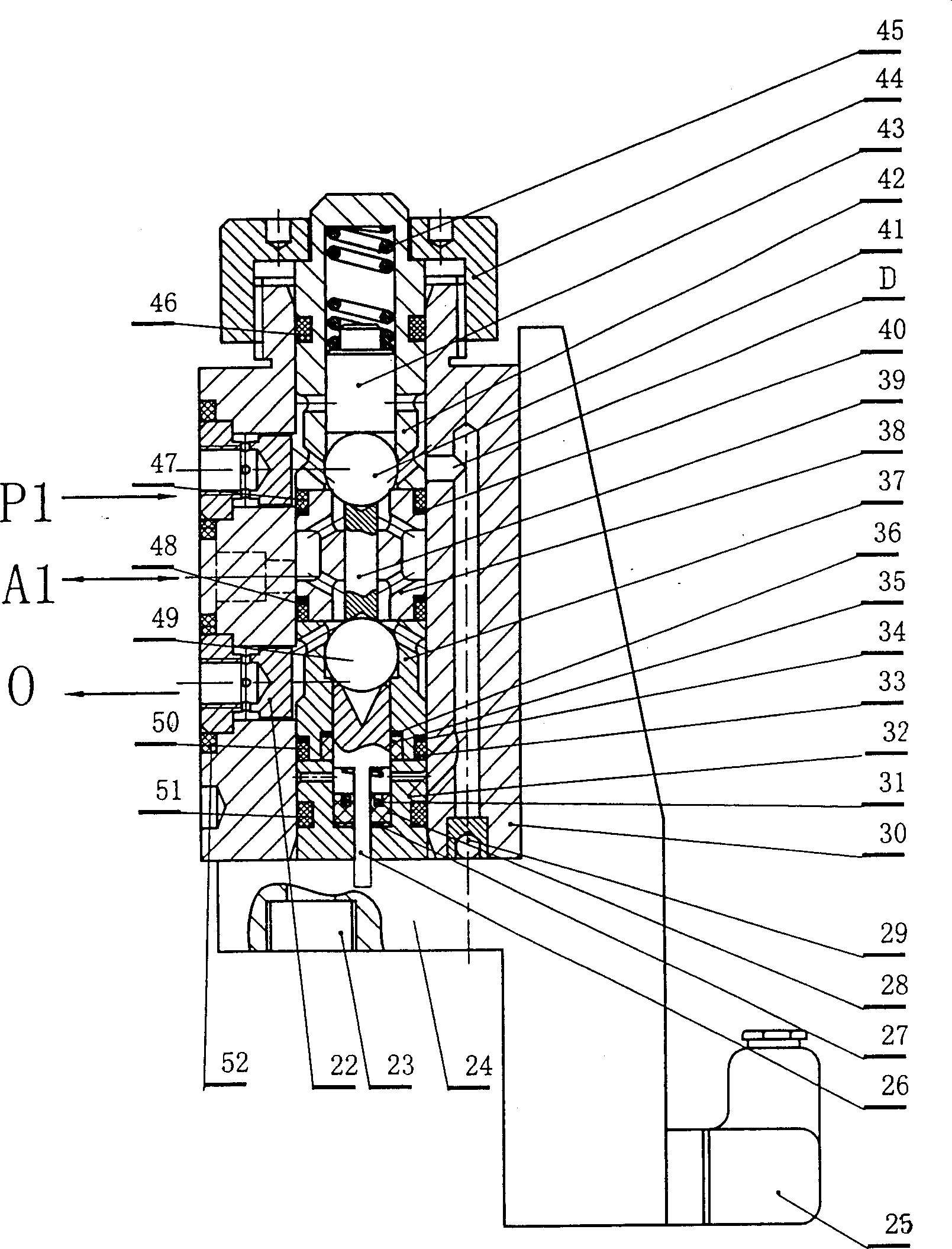

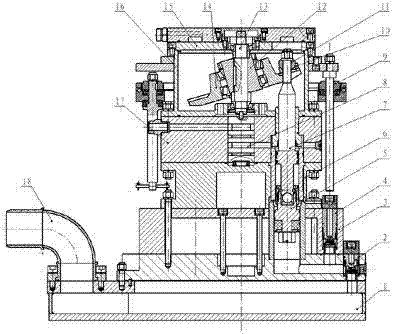

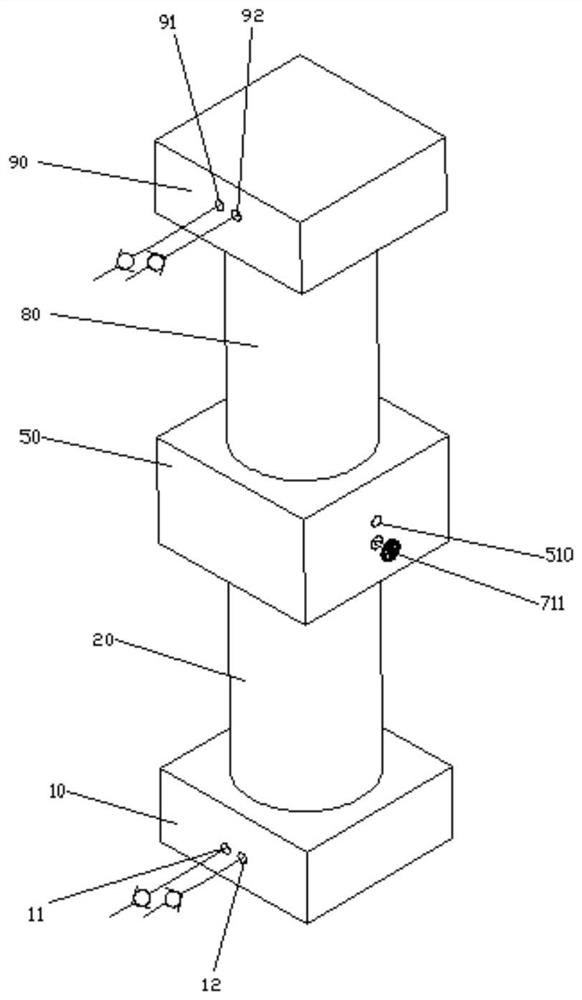

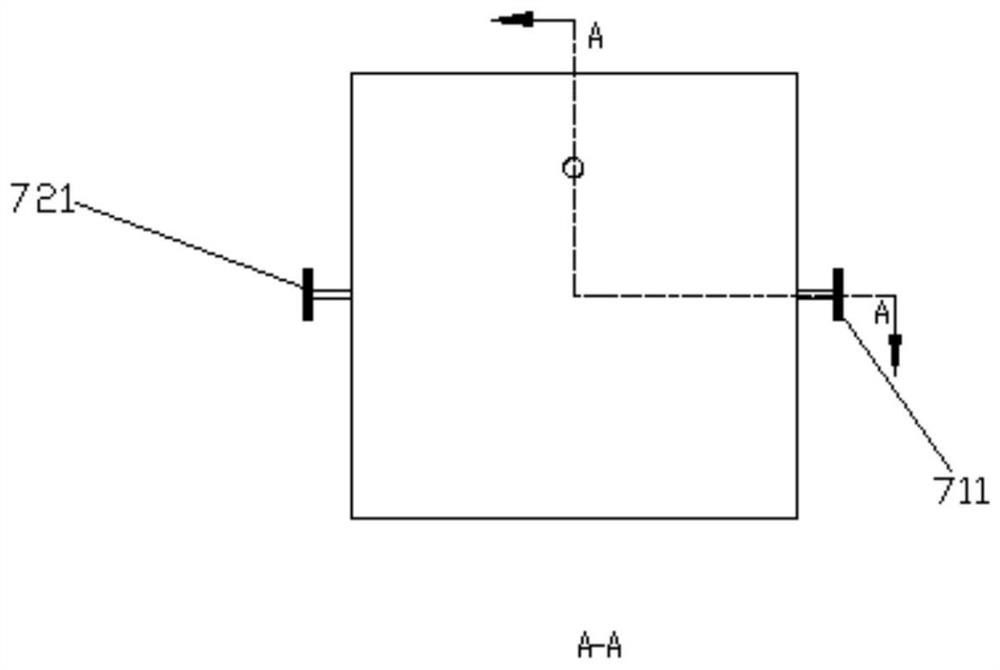

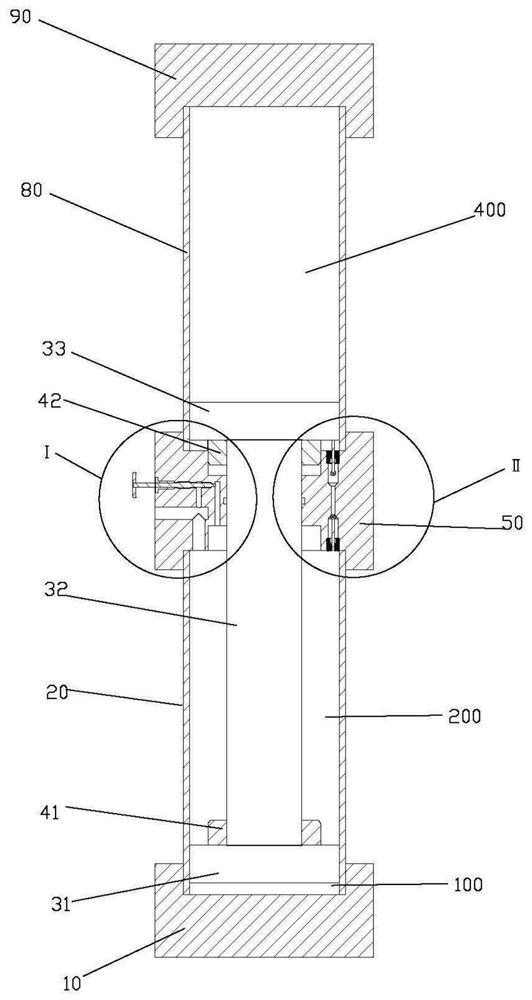

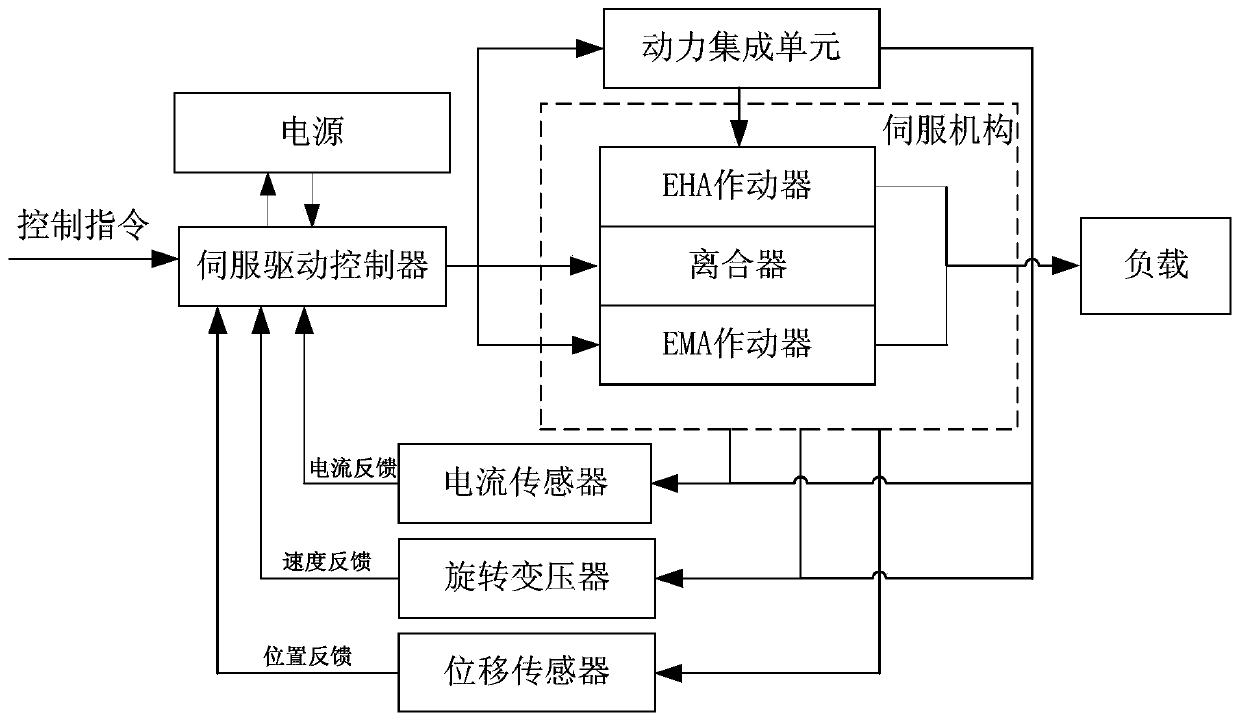

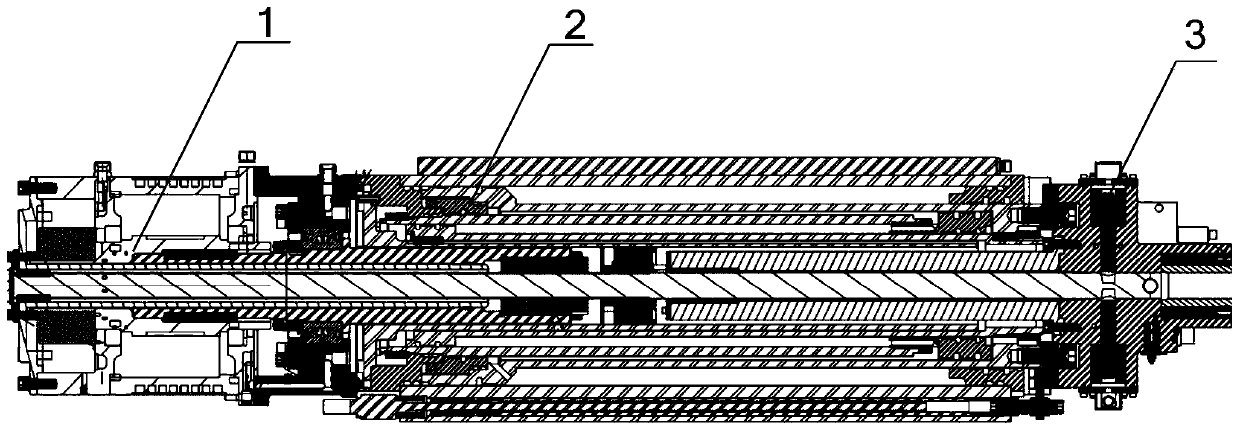

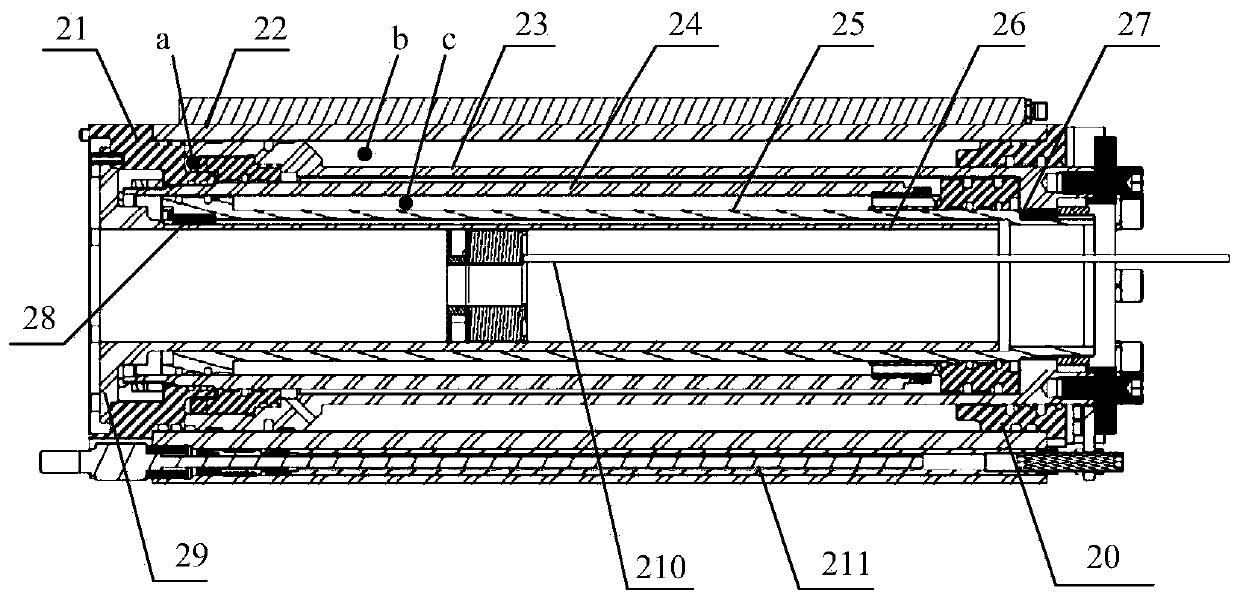

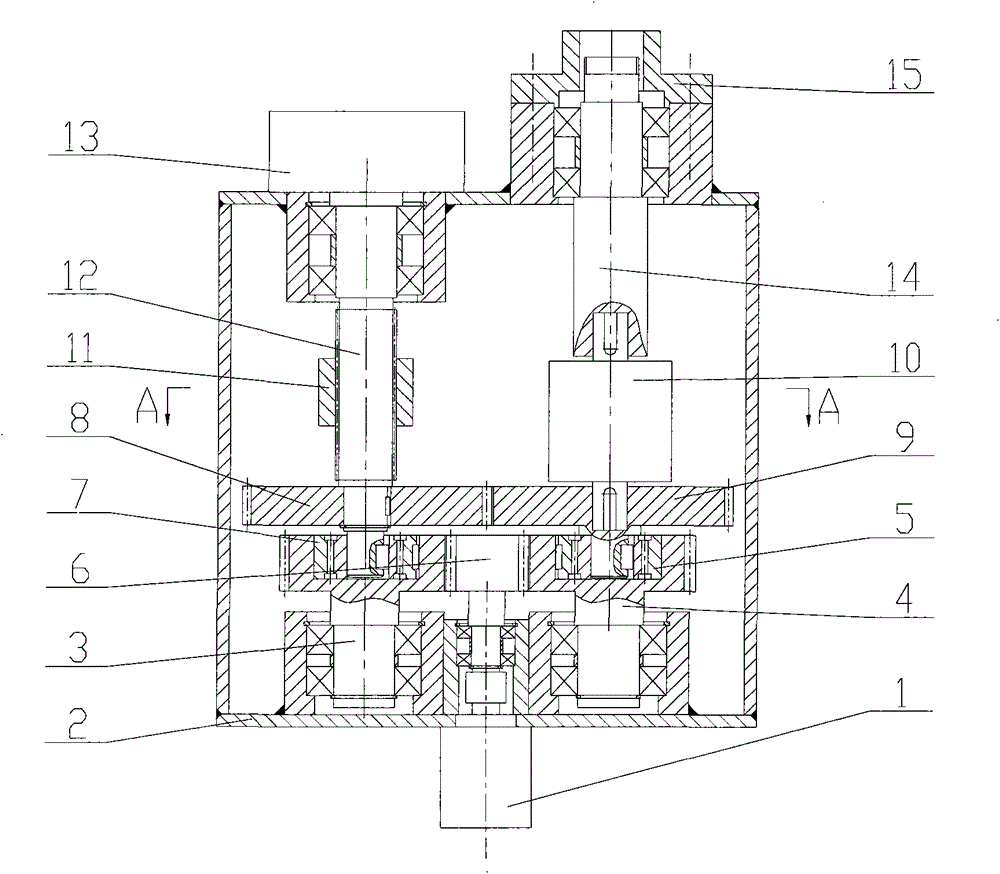

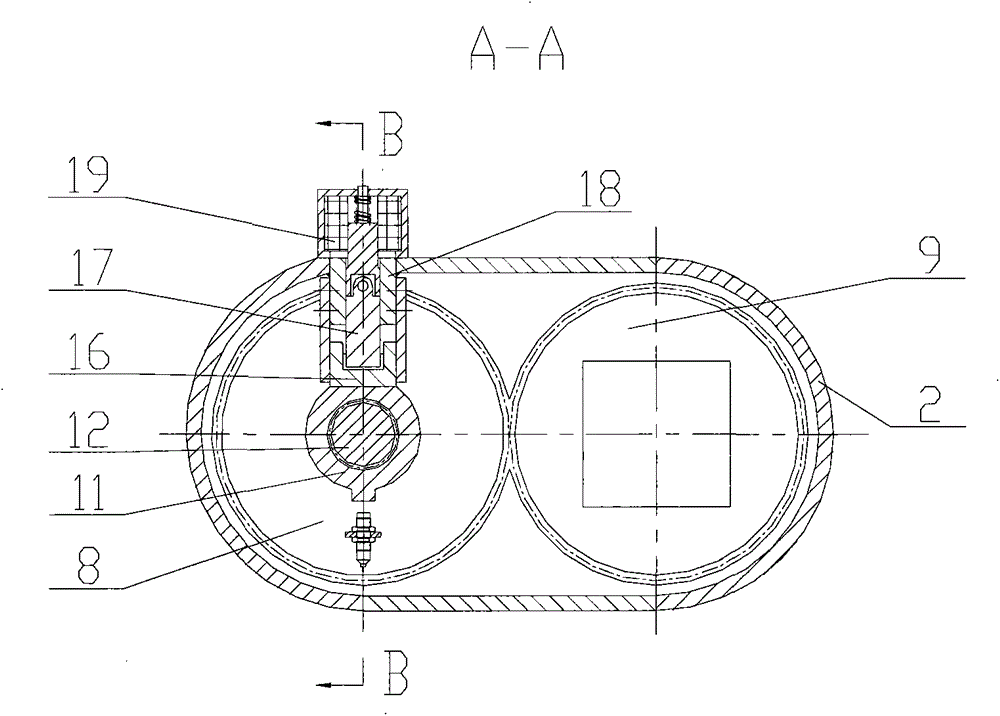

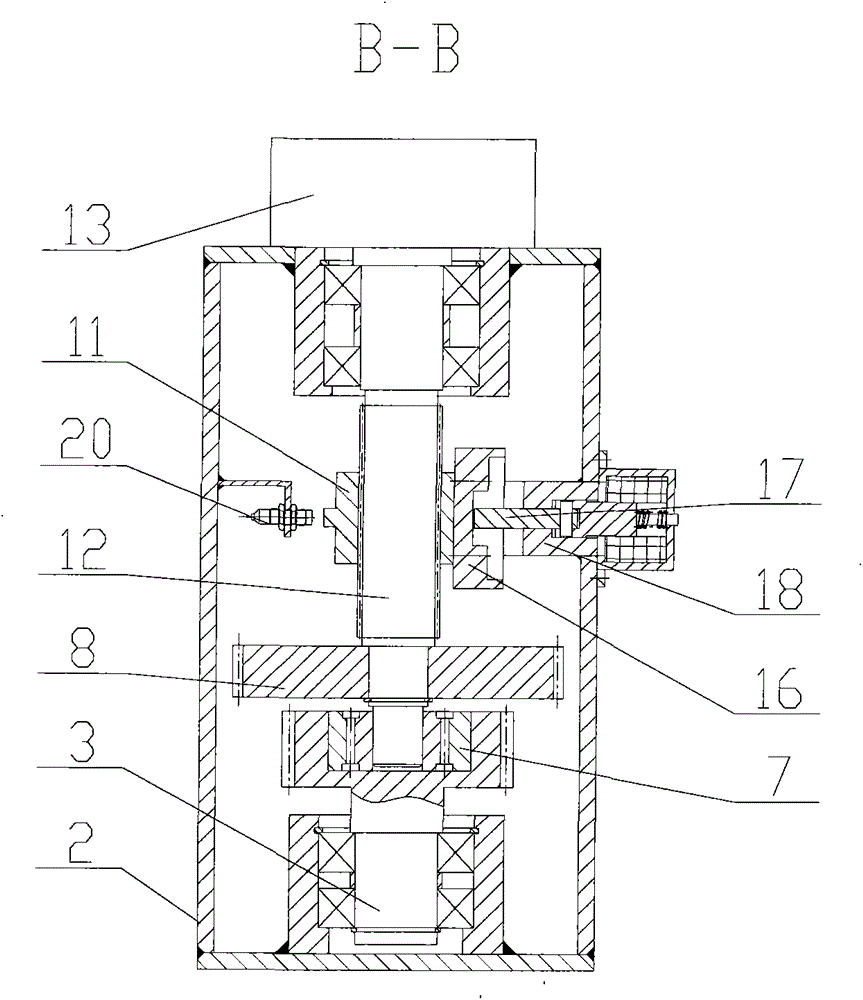

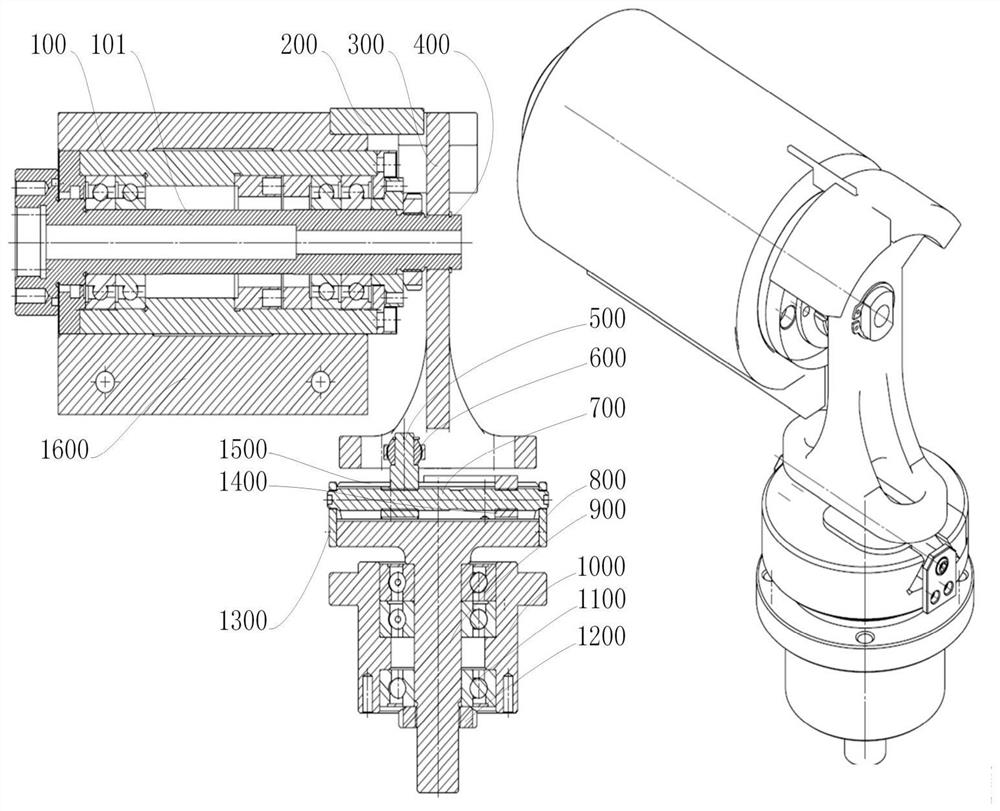

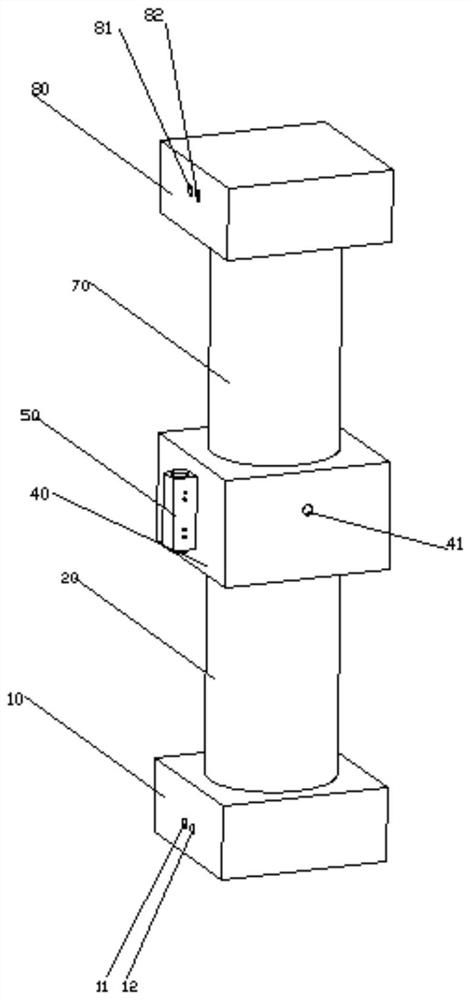

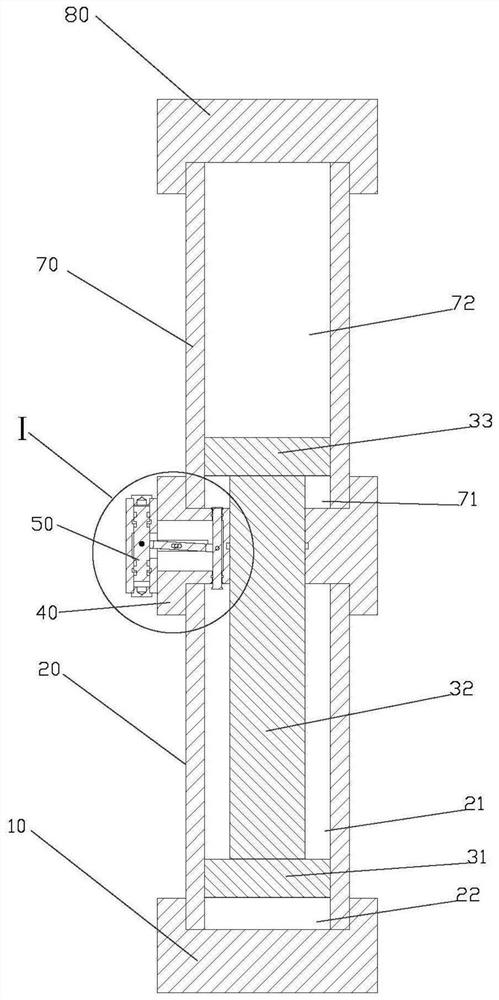

Integrated electromechanical servo mechanism

ActiveCN109519449ALess cross-linking linksEasy maintenanceServomotor componentsFluid-pressure actuator componentsModular designServomechanism

The invention relates to an integrated electromechanical servo mechanism. A redundant system is jointly composed of an EHA, an EMA and a clutch, wherein the EHA and the EMA are two electromechanical servo mechanisms different in principle. The clutch is used for achieving repeated switchover between the two servo mechanisms. Modular design is adopted in the EHA, the EMA and the clutch, and the respective functions of the EHA, the EMA and the clutch are independent. The EHA is of a symmetric cylinder structure, and a core part is hollow. The EMA is embedded in the EHA, and system paralleling ofthe two servo mechanisms is achieved. The integral self-lubricating and self-cleaning structure design is adopted in the EMA, lubricating and cleaning of an EMA lead screw, a bearing and other important components are achieved through a closed type hydraulic circulation system, and long-time work reliability of the servo mechanisms is guaranteed.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

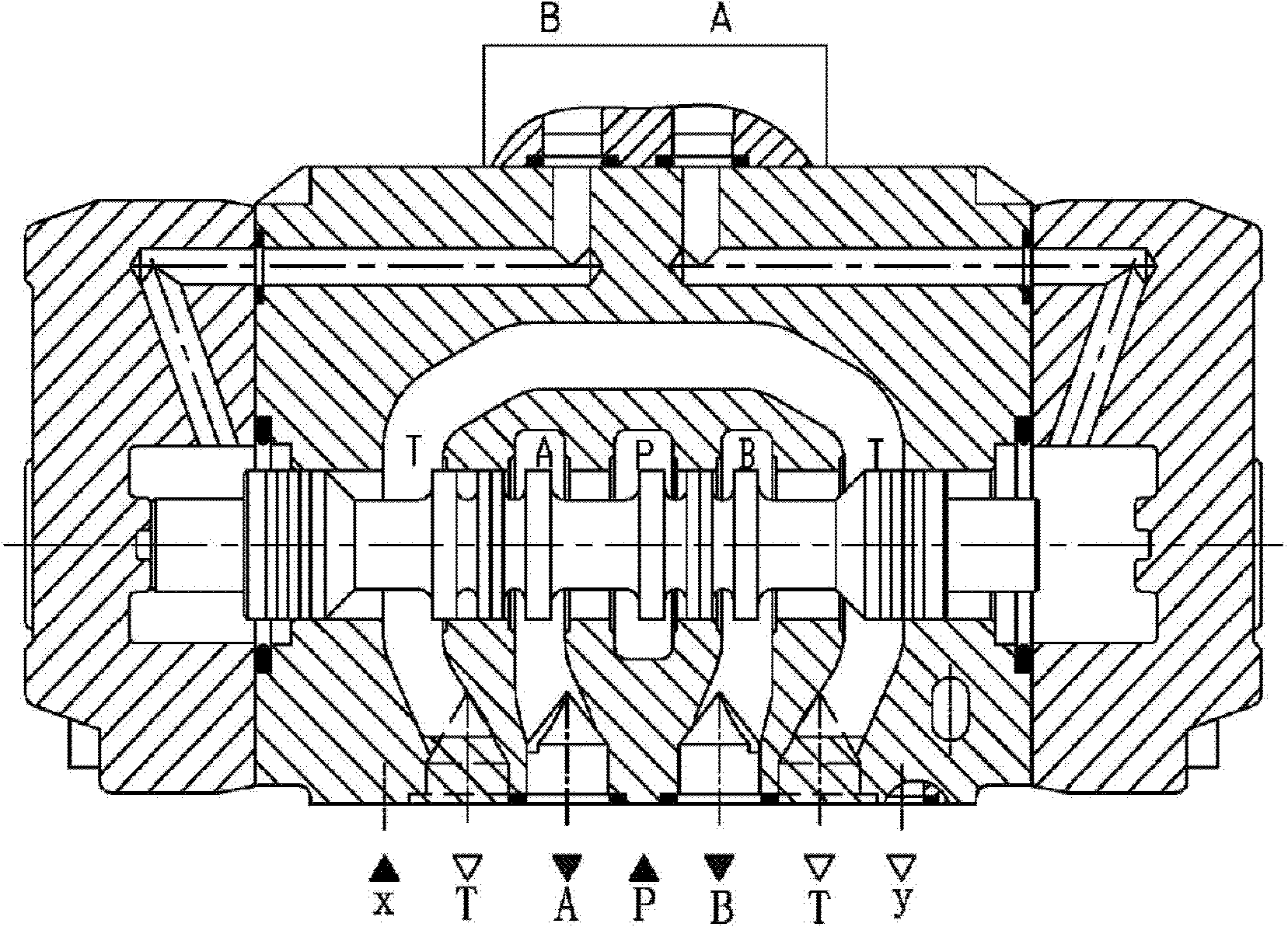

Leakless plane type pure water electrohydraulic change valve

InactiveCN1587720ASmall control forceCommutation is reliableOperating means/releasing devices for valvesServomotor componentsElectro hydraulicEngineering

The invention discloses a kind of no leakage and pure water flat electro-hydraulic directional control valve. A king valve cover is in the heart of the king valve and flat king valve core compacted by a spring lies in the cavity of axial of the king valve body; on the upper of king valve body there is a water inlet and a water outlet connected by the king valve's channel; in the king valve there is a sensitive cavity connected with electromagnetic ball valve by tunnels; a valve port damper installed at the valve entrance of electromagnetic ball valve matches with the sensitive cavity of king valve in order to control the flow velocity of fluid and reduce directional strike at the same time diverting fast. The invention adopt flat king valve core set on the packing force of the king valve cover and increase dramatically valve covers, adopt direct seal to realize zero leakage; divert fast and steadily through matching the sensitive cavity of king valve with the damper at the entrance of the electromagnetic ball valve; not change the structure of the king valve and only change structural form of electromagnetic ball valve in order to have different functions and fit to work under conditions of middle and high pressure water medium.

Owner:ZHEJIANG UNIV

Mechanical feedback type speed-adjustable self-reversing gas pressurization cylinder

ActiveCN111946588ARealize automatic reversingReduce vibrationPositive displacement pump componentsServomotorsCombustible gasEngineering

The invention discloses a mechanical feedback type speed-adjustable self-reversing gas pressurization cylinder comprising a hydraulic reversing valve and a tail end displacement feedback mechanism. Atthe tail end of the pressurization stroke, a piston of the pressurization cylinder pushes a feedback rod in a connecting body to move, and movement of the feedback rod is transmitted to a valve element of the hydraulic reversing valve through a feedback connecting rod, so that the valve element correspondingly moves; an internal flow channel is switched, and self-reversing of the gas pressurization cylinder is achieved; and the maximum displacement and the movement speed of the valve element of the reversing valve are changed by adjusting the position of the installation fulcrum of the feedback connecting rod and changing the feedback coefficient, and therefore the reversing speed of the pressurization cylinder is adjusted. According to the mechanical feedback type speed-adjustable self-reversing gas pressurization cylinder, compared with an electric control reversing pressurization cylinder, an electromagnetic reversing valve does not need to be adopted, the risk that electric sparksignite working gas is eradicated, the mechanical feedback type speed-adjustable self-reversing gas pressurization cylinder is particularly suitable for pressurizing conveying of flammable and combustible gas such as natural gas, and safety of the gas pressurization cylinder can be remarkably improved, reversing impact of the gas pressurization cylinder is reduced, and therefore vibration and noise of the gas pressurization cylinder are weakened.

Owner:CHINA PETROCHEMICAL CORP +1

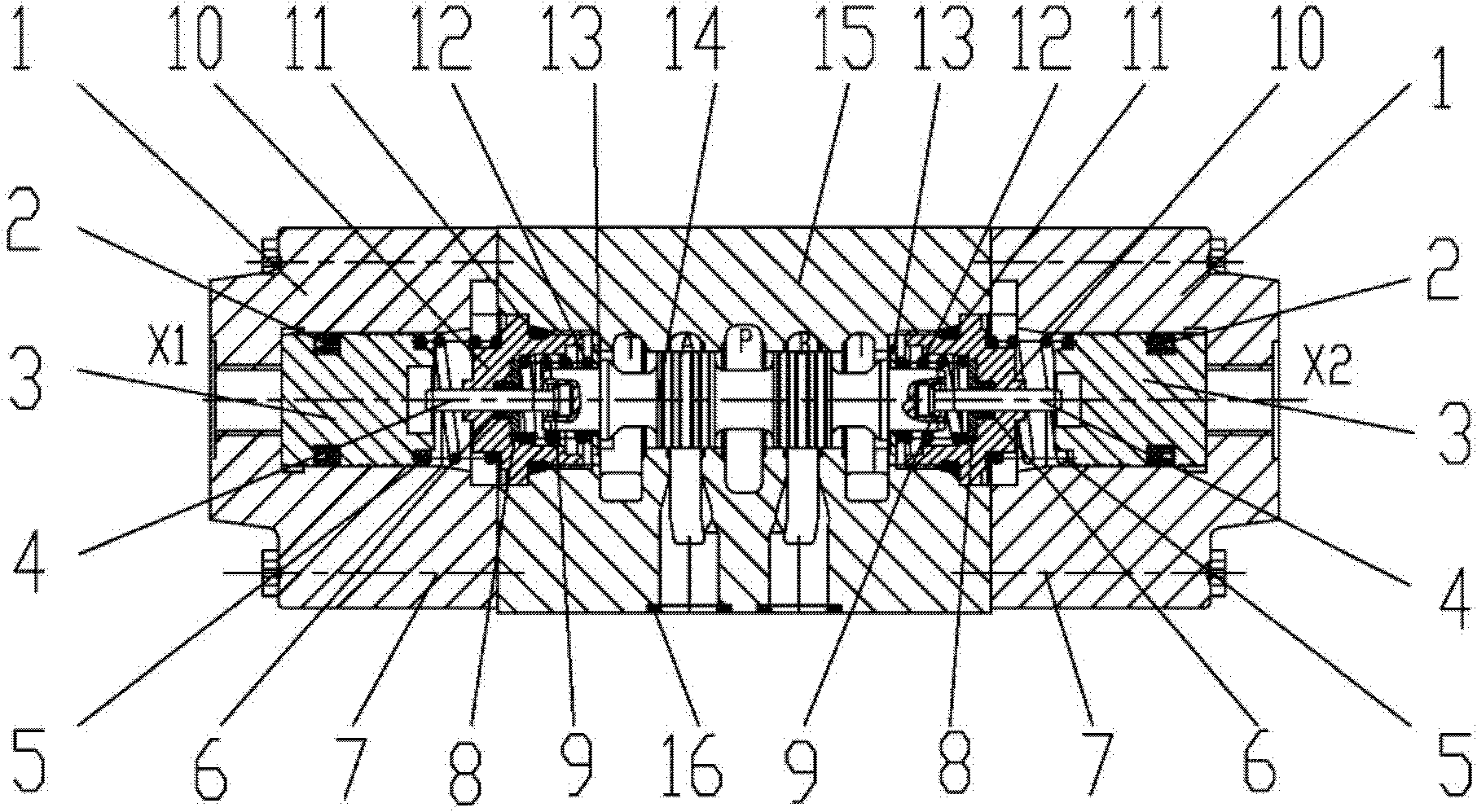

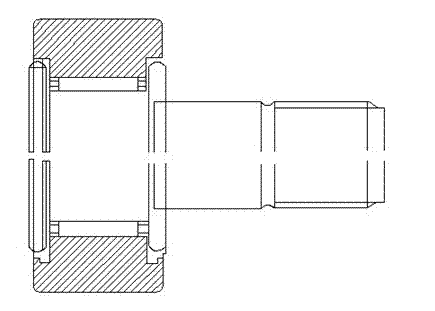

Piston-controlled reversing valve

InactiveCN102878131AWide versatilitySimple structureServomotor componentsEngineeringMechanical engineering

A piston-controlled reversing valve comprises a valve body; a valve core is arranged in the valve body, and is arranged in a main hole in the valve body; both ends of the valve core are provided with two pin shafts which are in contact with the end face of the valve core; both ends of the valve core are provided with restoring springs; both ends of the valve body are provided with end face screw-caps; the pin shafts run through the end face screw-caps; both ends of the valve body are connected with front caps; a piston is arranged in each front cap; the pin shafts contacts the pistons; and control oil ports are arranged on the outer side of the front caps. The control oil ports of the piston-controlled reversing valve are directly arranged on the two end caps; the pistons are driven by liquid or gas so as to drive the valve core to reverse. Due to the directly operated structure, the piston-controlled reversing valve is easy to machine and convenient to repair and disassemble.

Owner:SHANGHAI LIXIN HYDRAULIC

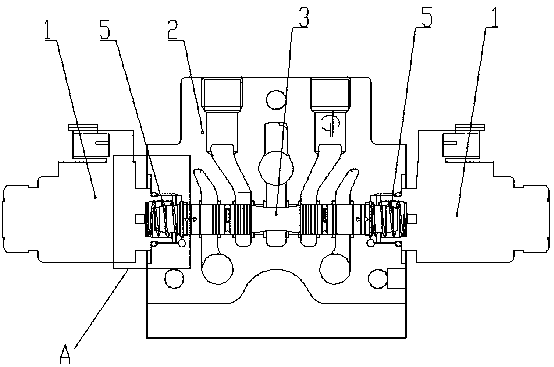

Electromagnetic direct-drive reversing multi-way valve

InactiveCN110939755AReduce weightSimple structural partsOperating means/releasing devices for valvesMultiple way valvesEngineeringMechanical engineering

The invention discloses an electromagnetic direct-drive reversing multi-way valve, and belongs to the technical field of multi-way valves. A reversing valve core is slidably mounted in the valve coremounting hole in a valve body, an electromagnetic driving device is fixedly connected with each of the two ends of the valve core mounting hole in the valve body, an inner spigot is formed in each ofthe two ends of the valve core mounting hole in the valve body, an outer blocking platform is arranged at the end of the reversing valve core, a pressing ring is mounted at the end of the reversing valve core in a sleeving mode, the inner ring of the pressing ring is pressed on the outer side of the outer blocking platform, the outer ring of the pressing ring is located in the inner spigot in theend of the valve core mounting hole in the valve body, and a resetting spring is connected with the outer side of the pressing ring. According to the electromagnetic direct-drive reversing multi-way valve, the electromagnetic driving device is connected with each of the two ends of the valve core mounting hole, driven connection with the reversing valve core through the pressing ring and the resetting spring is achieved, the structural part is simplified, and the valve body can be more compact and light in weight; and the valve core is flexible and fast in reversing action and high in controllability, the reversing impact is small, and the reversing response speed of the multi-way valve can be increased by more than 100 milliseconds.

Owner:徐州阿马凯液压技术有限公司

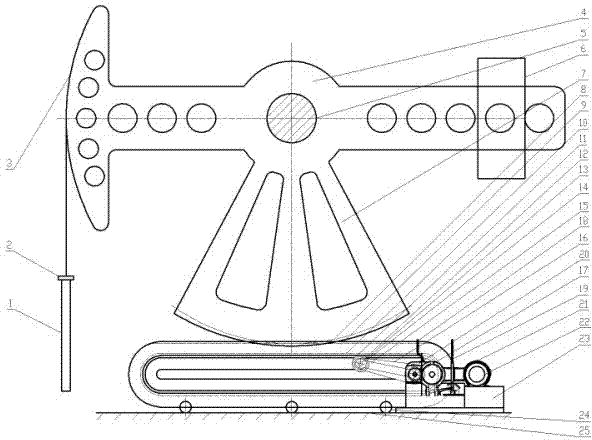

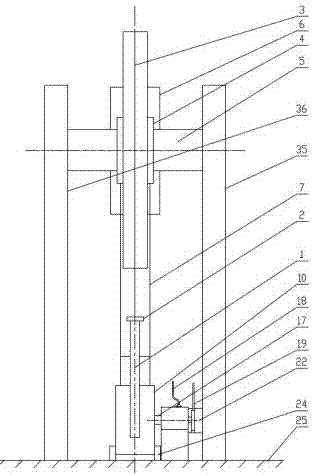

Horizontal planet gear ring walking beam pumping unit

InactiveCN104747134AGuaranteed correctnessGuaranteed reliabilityFluid removalRisk strokeBraking system

The invention discloses a horizontal planet gear ring walking beam pumping unit. The horizontal planet gear ring walking beam pumping unit is composed of an oil pumping system, a walking beam system, a balancing system, a machine frame system, an inner gear ring reversing system, a motor, a transmission system, a braking system and the like. The motor transfers movement and power to the inner gear ring reversing system through the transmission system. One-way rotational movement is converted into reciprocating rectilinear movement. A rack on the inner gear ring reversing system drives a big gear ring of a walking beam to do reciprocating rotation along a mandrel of the walking beam. A horse head of the walking beam and a steel rope are used for driving the oil pumping system to move, and then oil pumping is achieved in an oil field. The horizontal planet gear ring beam-pumping unit has the advantages that the reliability of the walking beam pumping unit is high, and the steel rope is not prone to damage and also has the advantages of a walking-beam-free oil pumping unit which is efficient, capable of saving energy, long in stroke, large in displacement, high in load, stable and reliable in reversing and the like, thereby being applicable to conventional well oil pumping, deep well oil pumping, extradeep well oil pumping, marine oil pumping and the like.

Owner:成都久井抽前瞻科技有限公司

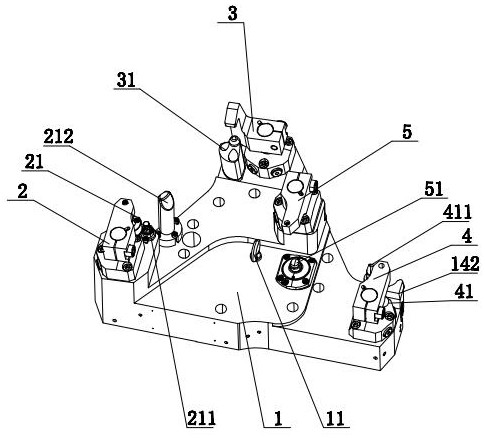

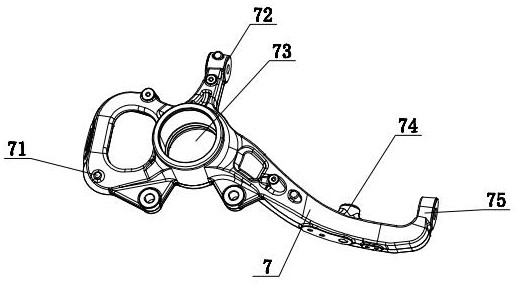

Special clamp for five-axis machining center of automobile steering knuckle structural part

PendingCN112692599AImprove machining accuracyImprove consistencyWork clamping meansPositioning apparatusStructural engineeringMachining process

The invention discloses a special clamp for a five-axis machining center of an automobile steering knuckle structural part, and relates to the technical field of tool clamps. A clamp body is of a triangular structure, a first telescopic fixing block is fixed to the first corner of the clamp body through a fastening screw, a second telescopic fixing block is fixed to the second corner of the clamp body through a fastening screw, and a third telescopic fixing block is fixed to the third corner of the clamp body through a fastening screw. A fourth telescopic fixing block is arranged between the second telescopic fixing block and the third telescopic fixing block and fixedly connected with the clamp body through a fastening screw. The four telescopic fixing blocks on the clamp are uniformly controlled by a hydraulic oil way system, a steering knuckle is placed at the corresponding positioning position, clamping and fixing actions can be completed at a time through the hydraulic oil way system, shaking cannot be generated in the machining process, movement is uniform and stable, reversing impact is small, the machining operation precision of workpieces is high, consistency is well, and the clamp has larger market popularization value.

Owner:丰飞

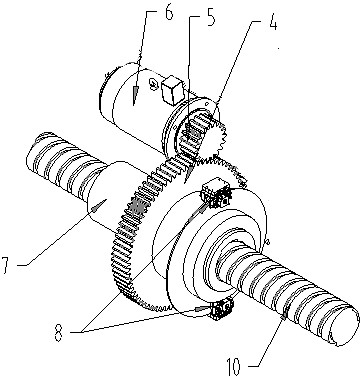

Device and method for achieving reciprocating motion of fracturing pump through rotation of lead screw nut

PendingCN112503153ASmall moment of inertiaSmall commutation impactPositive displacement pump componentsGearingReciprocating motionGear wheel

The invention discloses a device and method for achieving reciprocating motion of a fracturing pump through rotation of a lead screw nut. The device for achieving reciprocating motion of the fracturing pump through rotation of the lead screw nut comprises a brake B, a gear B, a gear C, the lead screw nut B, a motor and a lead screw B, wherein the gear C is connected with the power output end of the motor, the gear C meshes with the gear B, the lead screw nut B sleeves the lead screw B, the gear B sleeves the lead screw nut B, and the brake B is matched with the lead screw nut B. The device achieves reciprocating motion of the fracturing pump through the method for achieving reciprocating motion of the fracturing pump through rotation of the lead screw nut, and the device has the beneficialeffect that the reversing impact is small under the condition of driving constant rotating speed by reducing the rotational inertia in reversing.

Owner:SICHUAN HONGHUA ELECTRIC

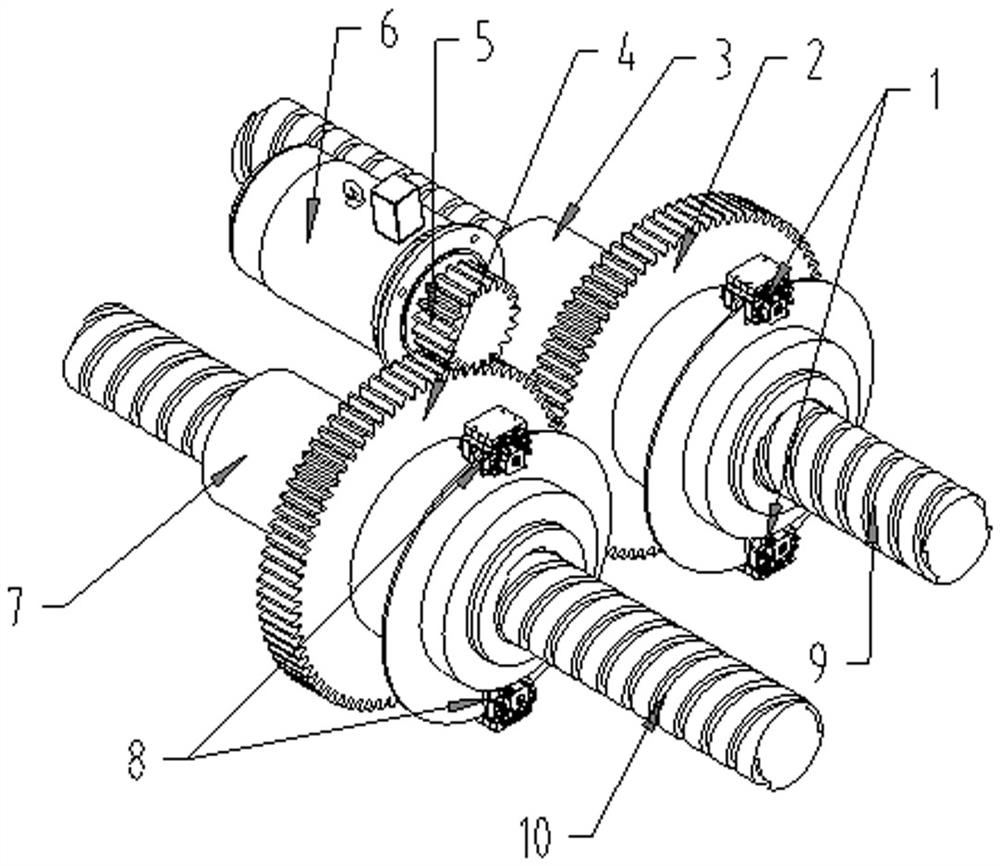

Incomplete gearbox cutting reversing device

ActiveCN102943847BReduce input speedSmall commutation impactGear lubrication/coolingToothed gearingsGear wheelEngineering

The invention belongs to the technical field of tooth pick testing devices, and in particular relates to an incomplete gearbox cutting and reversing device, which solves the problem that existing conventional transmission devices cannot meet the requirements of tooth picking testing. Including the input shaft and the box body, the box body is divided into a deceleration chamber and a reversing chamber, the No. 1 gear is installed on the input shaft, the No. 1 and No. 2 gears mesh, the No. 2 and No. No. 4 and No. 4 gears are meshed, No. 4 and No. 5 gears are installed on No. 2 shaft, No. 5 and No. 6 gears are meshed, No. 6, No. 7 gears and No. No. 8 gear meshes, No. 8 and No. 9 gears are installed on No. 4 shaft; No. 9 and No. 10 gears mesh, No. 10 and No. 11 gears are installed on No. 2 output shaft, and No. Fully toothed. The invention has beneficial effects: it can realize a stable transmission relationship, provide two kinds of stable output rotational speeds, and provide a reliable mechanical realization device for studying the cutting process of picks under laboratory conditions.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Hydraulically-controlled self-reversing gas pressurizing cylinder

ActiveCN112177990AImprove securityRealize automatic reversing functionServomotor componentsFluid-pressure convertersGas compressorEngineering

The invention discloses a hydraulically-controlled self-reversing gas pressurizing cylinder. The hydraulically-controlled self-reversing gas pressurizing cylinder is used in a gas compressor, a low-pressure hydraulic cavity is divided into two parts by buffering sleeves at the tail end of the stroke, one part discharges oil outwards through a throttling opening of an adjustable needle valve, hydraulic oil is provided for a control valve cavity of a hydraulically-controlled reversing valve through an internal flow channel, the automatic reversing action of the gas pressurizing cylinder is completed, the size of the throttling opening of the needle valve is adjusted, and the buffer effect of the inertia load of the pressurizing cylinder can be adjusted; and the other part is used for communicating a high-pressure hydraulic cavity and the low-pressure hydraulic cavity of the pressurizing cylinder at the tail end of the pressurizing stroke so as to realize self-pressure relief of a hydraulic system at the tail end of the stroke of the pressurizing cylinder. According to the hydraulically-controlled self-reversing gas pressurizing cylinder, self-reversing at the tail end of the stroke of the pressurizing cylinder and effective buffering of the inertia load of the pressurizing cylinder can be achieved at the same time, the gas pressurizing cylinder has the obvious effects of reducinghydraulic reversing impact and reducing inertia load impact, the service life of the gas pressurizing cylinder can be effectively prolonged, overall operation vibration and noises of the hydraulic compressor are reduced, and the gas pressurizing cylinder has the relatively-high engineering practical application value.

Owner:CHINA PETROCHEMICAL CORP +1

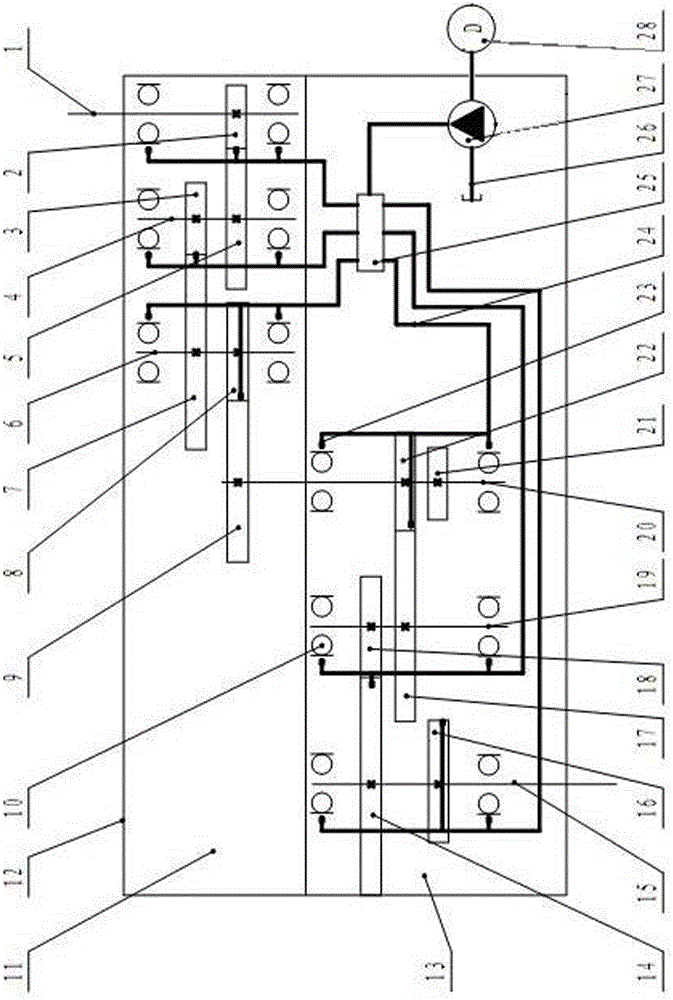

Closed energy-saving shield screw conveyor hydraulic system

InactiveCN103016018BAvoid valve lossImprove energy efficiencyServomotorsTunnelsHigh energyClosed loop

The invention discloses a closed energy-saving shield screw conveyor hydraulic system, which comprises a motor, a variable displacement pump, an oil tank, an oil replenishing constant pressure pump, two oil replenishing one-way valves, an oil replenishing safety valve, two system one-way valves, a system one-way valve, two hydraulic control one-way valves, two execution one-way valves, an execution safety valve, a conveyor variable displacement motor, a proportional reversing valve, a rodless chamber side hydraulic control one-way valve, a rod chamber side hydraulic side hydraulic control one-way valve and a dumping port hydraulic cylinder. In the shield thrust process, the rotating speed and the torque of a screw conveyor are adjusted by adjusting the displacement of the variable displacement pump and the variable displacement motor, so that the valve control loss of the proportional reversing valve is avoided, and the high energy efficiency is realized; the system adopts a closed loop, and has the advantages of simple pipeline, small installation space and small reversing shock; and the oil replenishing pump adopts a constant pressure pump, so that the energy utilization rate is further improved.

Owner:ZHEJIANG UNIV

Leakless plane type pure water electrohydraulic change valve

InactiveCN1271339CSmall control forceCommutation is reliableOperating means/releasing devices for valvesServomotor componentsElectro hydraulicEngineering

Owner:ZHEJIANG UNIV

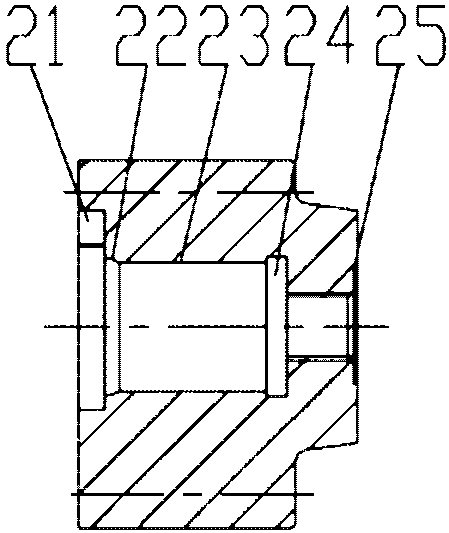

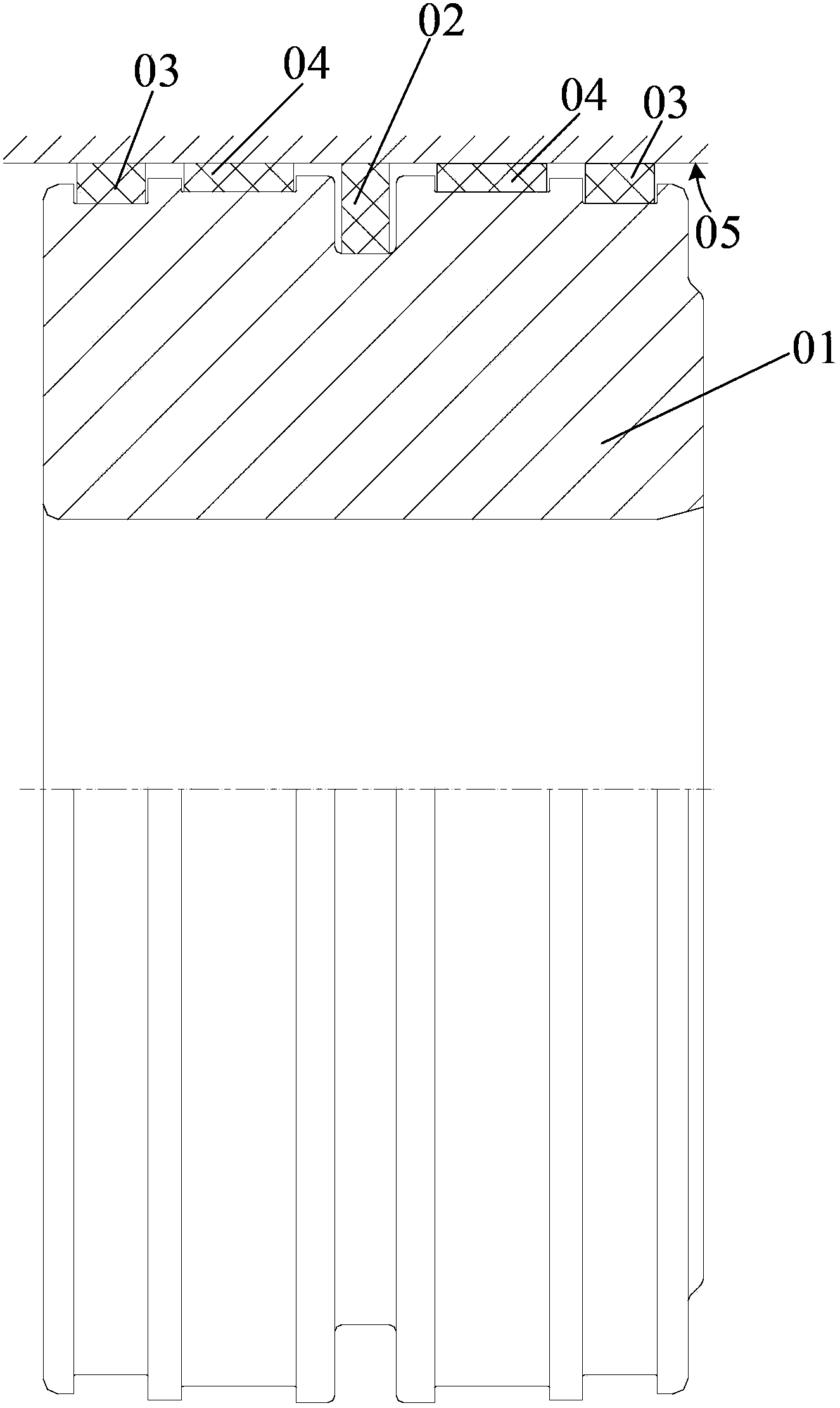

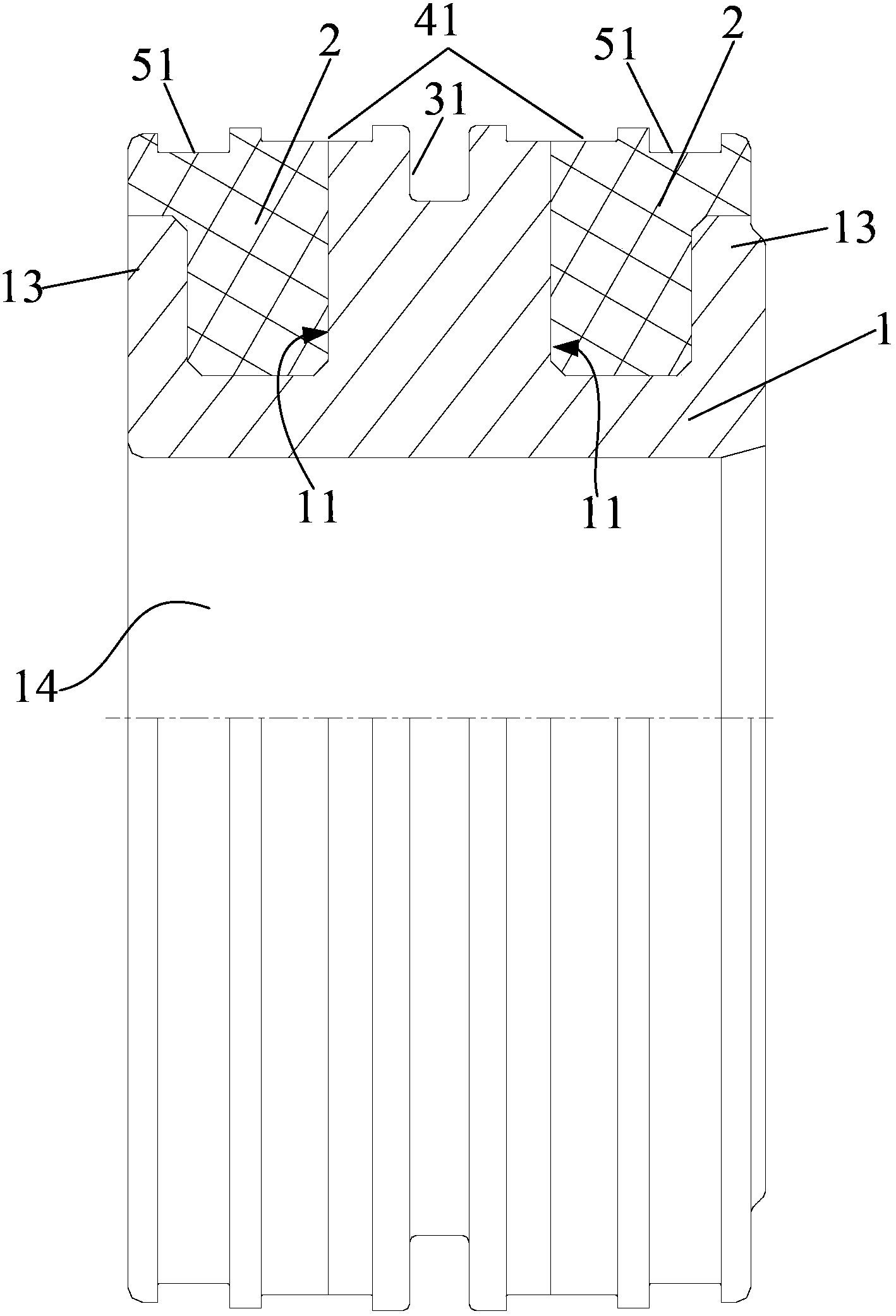

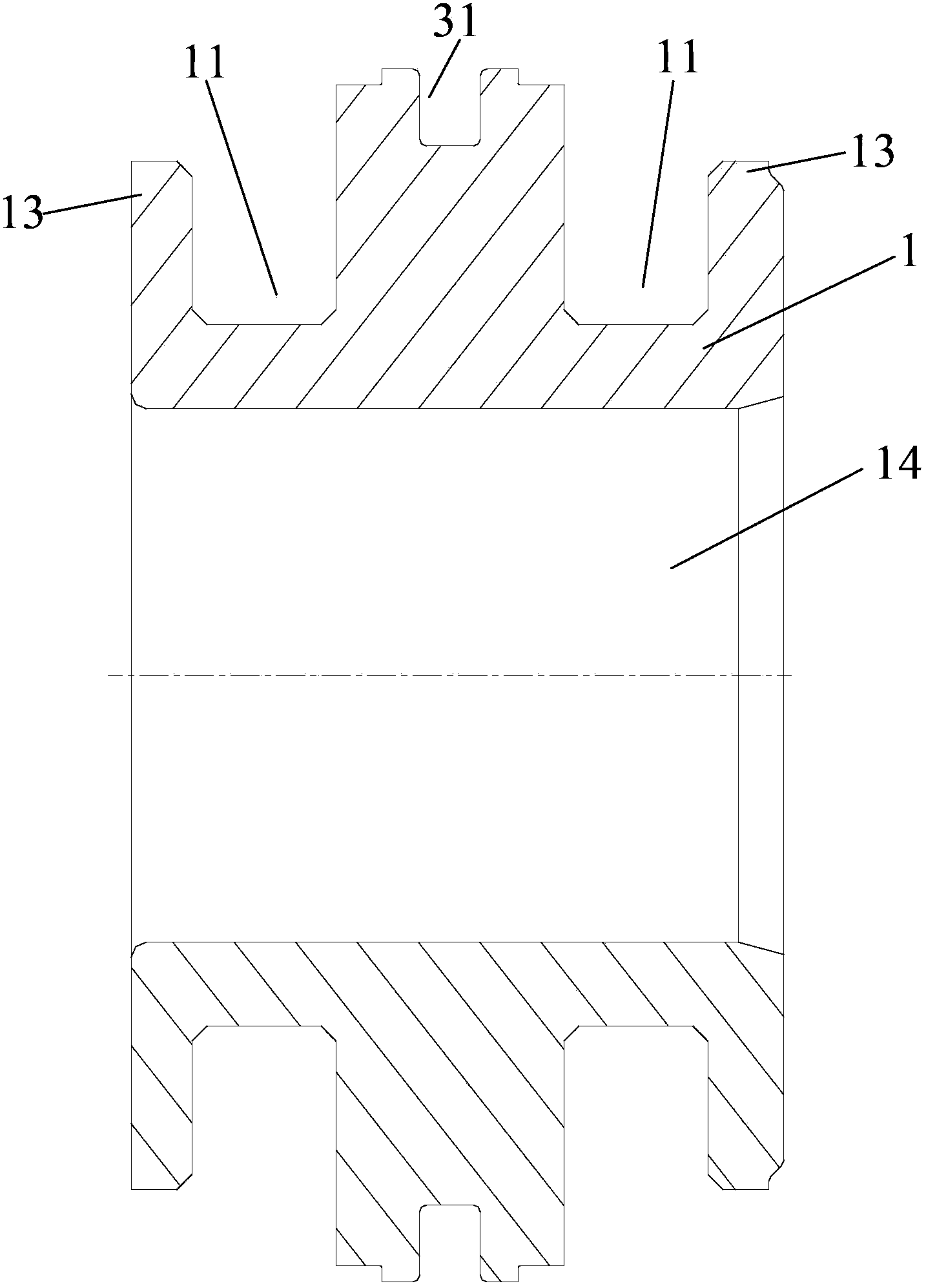

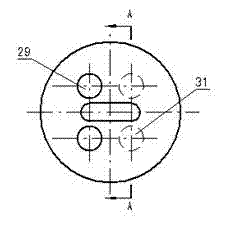

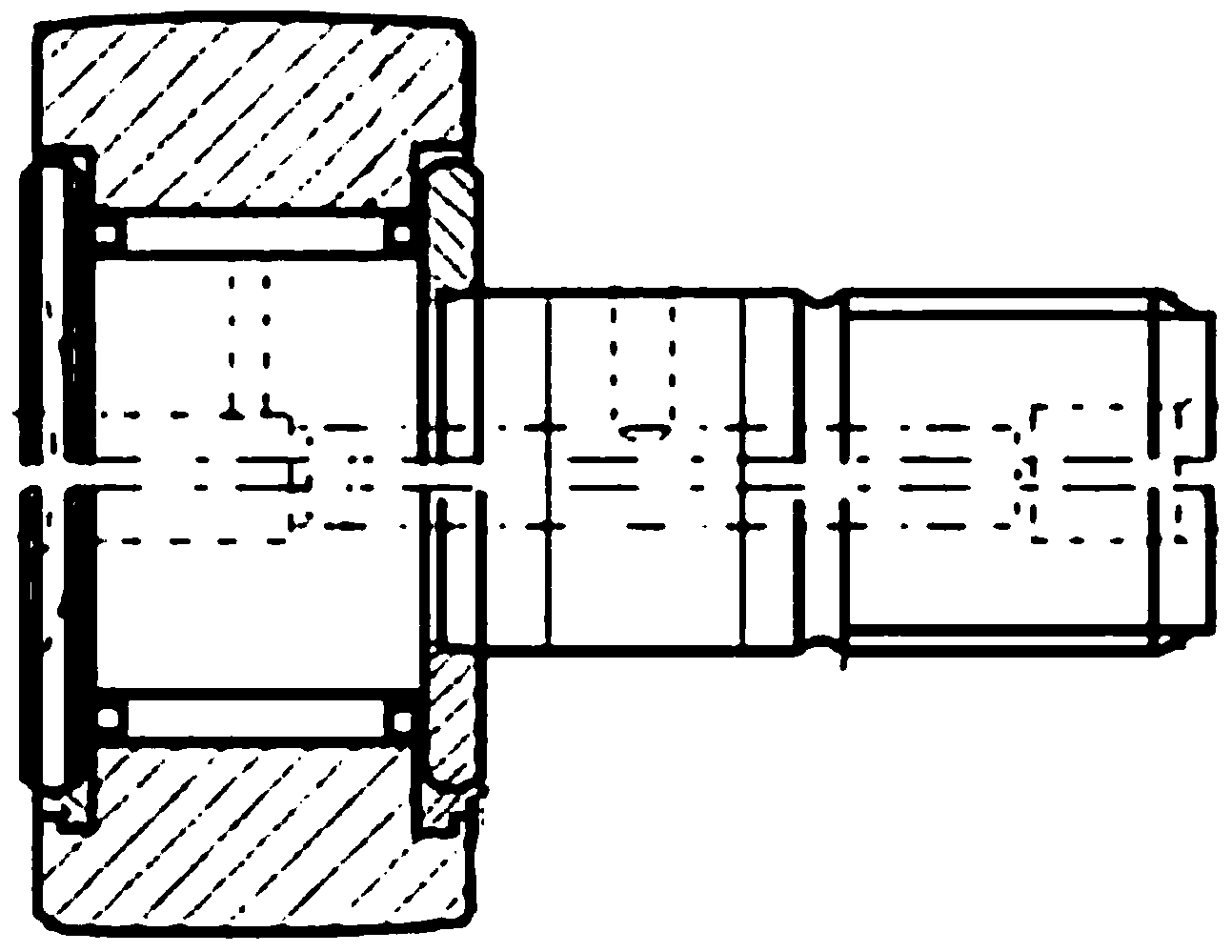

Piston body and hydraulic cylinder

InactiveCN102705297BReduce weightSmall commutation impactFluid-pressure actuatorsHydraulic cylinderUltimate tensile strength

The invention provides a piston body. The piston body is cylindrical, a sealing body mounting groove is formed on the outer peripheral surface of the piston body along the circumferential direction, guide ring mounting grooves are respectively formed on two sides of the sealing body mounting groove along the circumferential direction, the piston body comprises a rigid framework and an elastic filling material, wherein the elastic filling material is arranged on the rigid framework, and the outer peripheral surface of the piston body which is arranged between the end surfaces of the piston body and the groove edges of the guide ring mounting groove is formed by the elastic filling material. The invention further provides a hydraulic cylinder.. According to the technical scheme disclosed by the invention, the elastic filling material is filled in the piston body, so that the weight of the piston body can be effectively reduced, using occasions of the hydraulic cylinder are optimized and the application limitations of the hydraulic cylinder are reduced; a framework part of the piston body is still of a rigid structure and forms a support for a sealing body part, so that the piston body can effectively ensure that the strength can meet the requirements; in addition, when a fault or unbalanced loading occurs in guide of the piston body, damages on a cylinder barrel can be effectively reduced; and furthermore, the impact can also be reduced during the commutation of the piston body.

Owner:SANY HEAVY IND CO LTD (CN)

Hydraulic direct-drive vertical multi-cylinder mud pump

ActiveCN102168662BReduce lossesImprove utilization efficiencyPiston pumpsPositive-displacement liquid enginesInlet valveCam

The invention relates to a hydraulic direct-drive vertical multi-cylinder mud pump. At present, most of domestic and foreign mud pumps adopt a mechanical driving manner, such as a crank connecting rod, a cam, a swash plate and the like to convert the rotational movement of a motor into the reciprocating linear movement of a piston so as to finish the inflow and drainage processes of the mud pumps; and some hydraulic drive reciprocating mud pumps mostly take a hydraulic motor as a rotary input, and the driving manner is similar to that of the mechanical pump. The hydraulic direct-drive vertical multi-cylinder mud pump comprises a suction box body, a drainage box body, an oil inlet valve body, a hydraulic cylinder box body and a lifting device; and the oil inlet valve body, the hydraulic cylinder box body, and the drainage box body are arranged on the upper part of the suction box body in sequence in a laminated structure, and any two of the oil inlet valve body, the hydraulic cylinder box body, and the drainage box body are connected via a bolt and a double-end stud arranged in a circumferential direction. The invention adopts the structure of driving an oil pressure cylinder piston and a water pressure cylinder piston directly by hydraulic pressure, so the hydraulic energy is converted into water energy directly, the energy loss is reduced, and the utilization efficiency is improved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

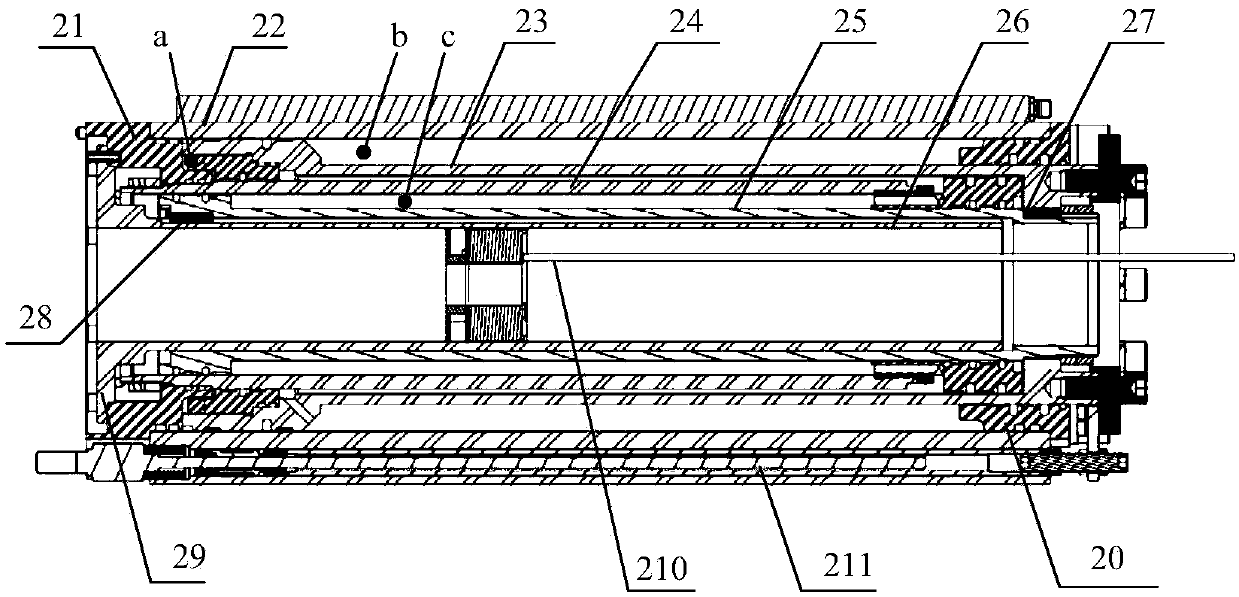

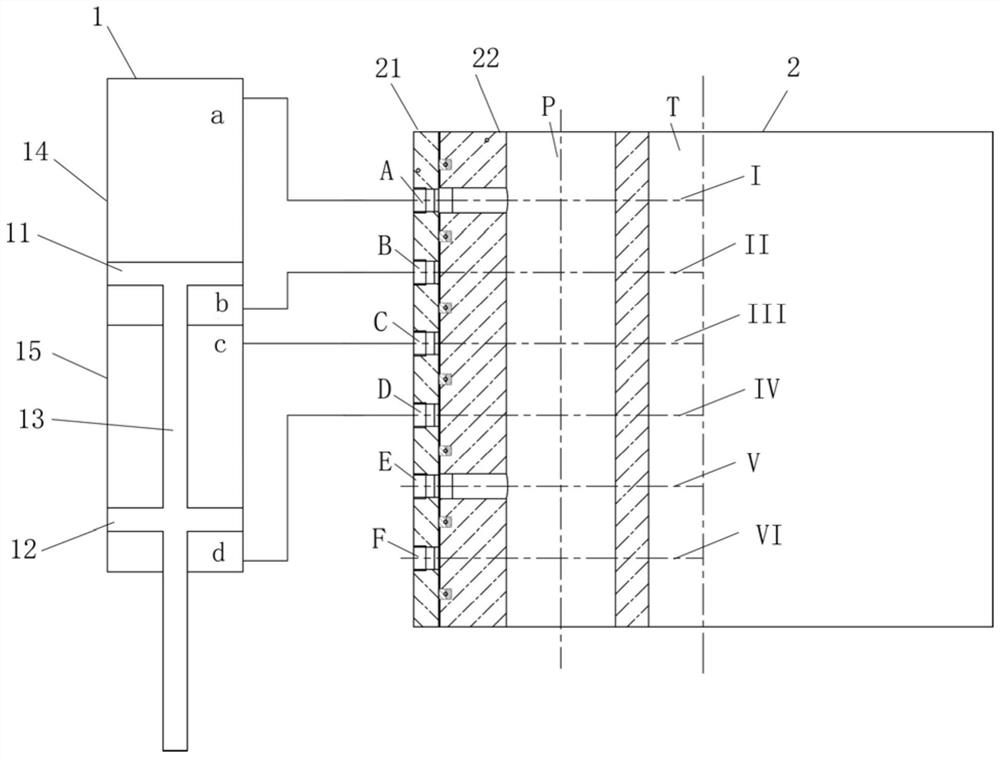

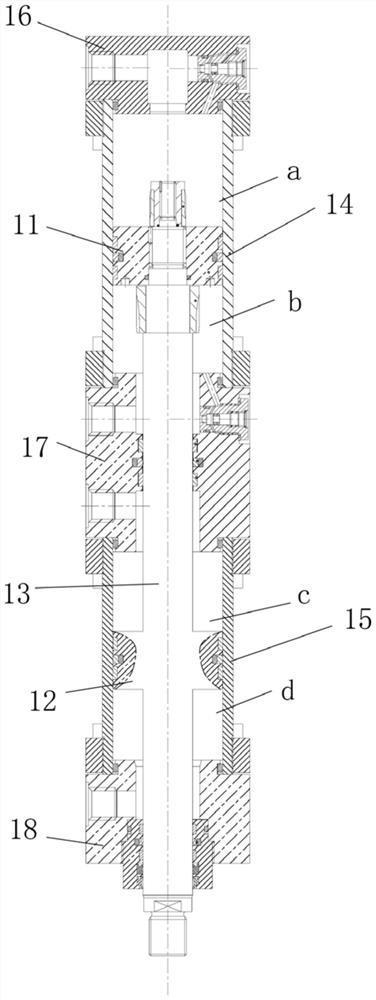

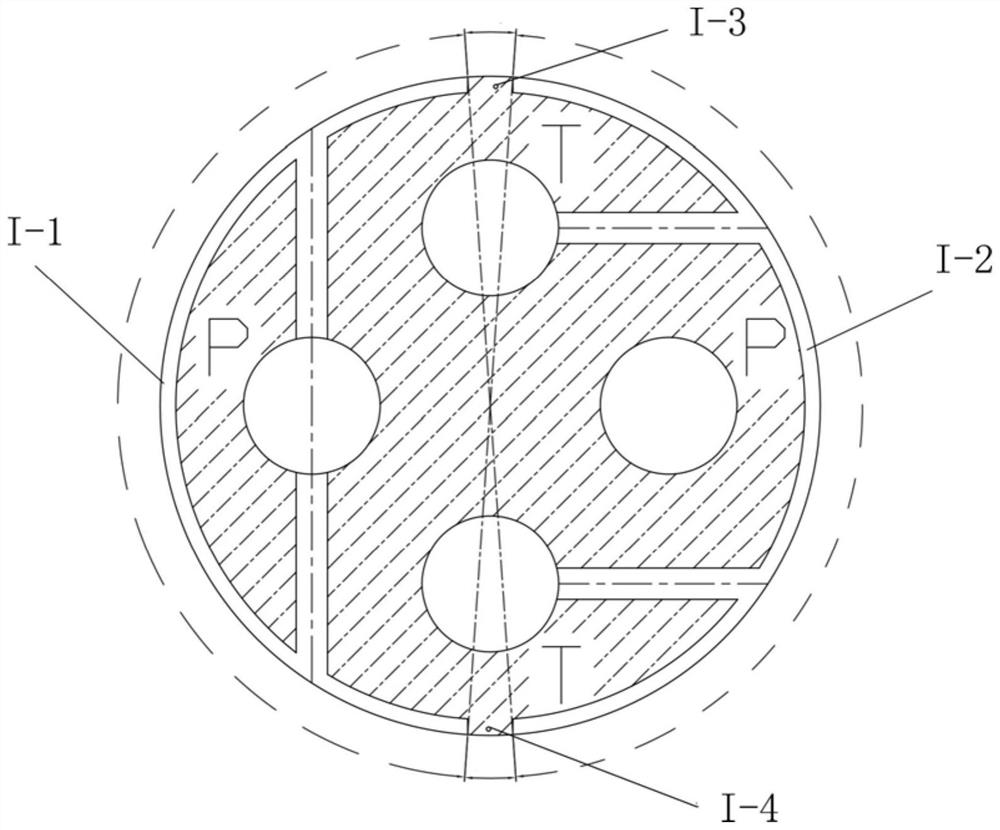

A Two-way Quick Action Large Flow Hydraulic Power Mechanism

ActiveCN112983918BSimplify hydraulic control logicSimple structureServomotor componentsMultiple way valvesHydraulic cylinderReciprocating motion

The invention relates to a two-way quick-acting large-flow hydraulic power mechanism, which comprises an interconnected hydraulic actuator and a shaft distribution valve; the hydraulic actuator is a hydraulic cylinder with a double-piston structure, including a cylinder block, a front piston and a rear piston , the front piston and the rear piston are arranged on a piston rod, the cylinder body includes a front cylinder tube and a rear cylinder tube, the front piston is located in the front cylinder tube, and the front cylinder tube is divided into a first working chamber and a second working chamber, and the rear piston Located in the rear cylinder, the rear cylinder is divided into the third working chamber and the fourth working chamber; the shaft distribution valve includes the shaft distribution valve body stator and the shaft distribution valve core rotor, and the shaft distribution valve core rotor is provided with an oil supply channel and a return valve. The oil channel, the oil supply channel and the oil return channel are connected to the external pipeline, and the stator of the shaft distribution valve body and the rotor of the shaft distribution valve core are separated into four sealing areas by the sealing ring from top to bottom. Compared with the prior art, the present invention has the advantages of simplified hydraulic control logic, simple structure, convenient adjustment, convenient rapid reciprocating motion of the piston, and the like.

Owner:TONGJI UNIV

Self-relieving adjustable buffer gas booster cylinder

ActiveCN111946587BExtended service lifeReduce performancePositive displacement pump componentsFluid-pressure actuatorsGas compressorCylinder (engine)

The invention discloses a self-unloading adjustable buffer gas booster cylinder, which is used in a gas compressor. The buffer sleeve at the end of the stroke divides the low-pressure hydraulic chamber of the booster cylinder into two parts: one part can only be passed through an adjustable needle The orifice of the needle valve discharges oil outwards. By adjusting the size of the orifice of the needle valve, the cushioning effect of the inertial load of the booster cylinder can be adjusted; the other part is used to connect the high-pressure hydraulic chamber and the low-pressure hydraulic chamber at the end of the booster stroke. , in order to realize the self-relieving pressure of the hydraulic system at the end of the stroke of the booster cylinder and reduce the shock of hydraulic reversing. Compared with the gas booster cylinder of the existing hydraulic compressor, the present invention can realize the self-relieving pressure of the hydraulic system at the stroke end of the booster cylinder and the effective buffering of the inertial load of the booster cylinder at the same time, and can significantly reduce the hydraulic reversing impact and reduce the inertia The effect of load impact can effectively increase the service life of the gas booster cylinder and reduce the overall operating vibration and noise of the hydraulic compressor, which has high engineering practical application value.

Owner:CHINA PETROCHEMICAL CORP +1

An integrated electromechanical servo mechanism

ActiveCN109519449BLess cross-linking linksEasy maintenanceServomotor componentsFluid-pressure actuator componentsServomechanismServo

The invention relates to an integrated electromechanical servo mechanism. A redundant system is jointly composed of an EHA, an EMA and a clutch, wherein the EHA and the EMA are two electromechanical servo mechanisms different in principle. The clutch is used for achieving repeated switchover between the two servo mechanisms. Modular design is adopted in the EHA, the EMA and the clutch, and the respective functions of the EHA, the EMA and the clutch are independent. The EHA is of a symmetric cylinder structure, and a core part is hollow. The EMA is embedded in the EHA, and system paralleling ofthe two servo mechanisms is achieved. The integral self-lubricating and self-cleaning structure design is adopted in the EMA, lubricating and cleaning of an EMA lead screw, a bearing and other important components are achieved through a closed type hydraulic circulation system, and long-time work reliability of the servo mechanisms is guaranteed.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

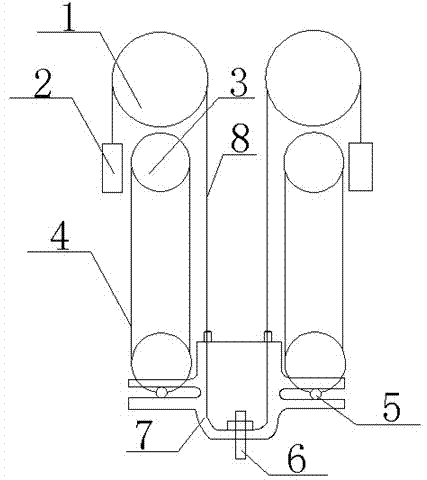

Dual-chain drive pumping unit

InactiveCN103615220ASolution to short lifeSmall commutation impactFluid removalNeedle roller bearingMechanical engineering

The invention relates to a pumping unit, in particular to a dual-chain drive pumping unit. The pumping unit comprises reverse wheels, balancing weights, chain wheels, chains, bolt cam follower needle roller bearings, a pumping rod, a reverse frame and steel wire ropes. The steel wire ropes are laid on the reverse wheels, one end of each steel wire rope is connected with the reverse frame, and the other end of each steel wire rope is connected with the balancing weight. The lower surface of the reverse frame is connected with the pumping rod. Bearing parts of the bolt cam follower needle roller bearings make contact with the reverse frame, and bolts of the bolt cam follower needle roller bearing are fixedly connected to hinge pins of the chains. The chains cover the two upper chain wheels and the two lower chain wheels, a U-shaped groove is formed in the reverse frame, a guide rail is arranged in the groove, the bolt cam follower needle roller bearings can roll on the guide rail, the two lower chain wheels are connected with an electromotor through a chain transmission device. The dual-chain drive pumping unit is large in stroke and load, high in pumping efficiency, small in reverse impact, and high in adaptability, and the reverse frame is long in service life.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

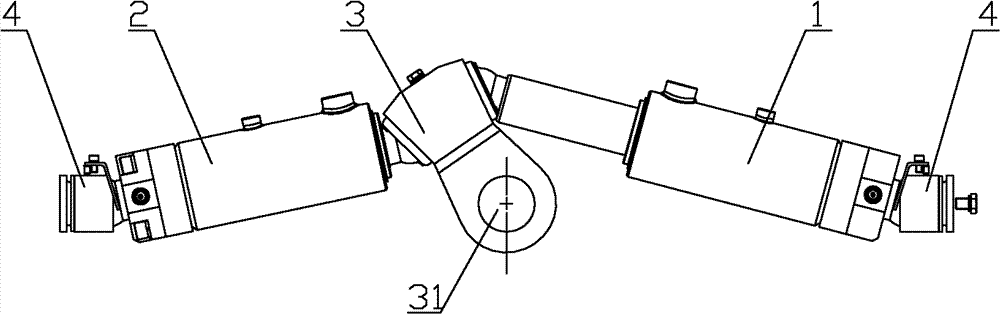

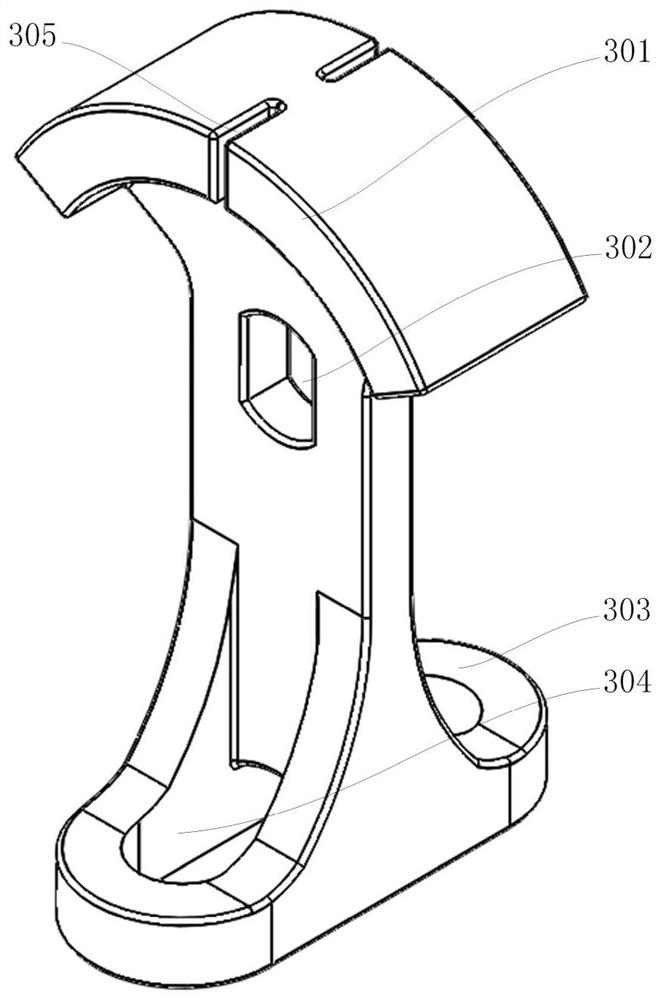

Rocker structure, bobbing mechanism, pumping system and engineering machine

ActiveCN102518304BOvercome the phenomenon of "can't move"Flexible layoutPiston pumpsBuilding material handlingVertical planeEngineering

Owner:SANY AUTOMOBILE MFG CO LTD

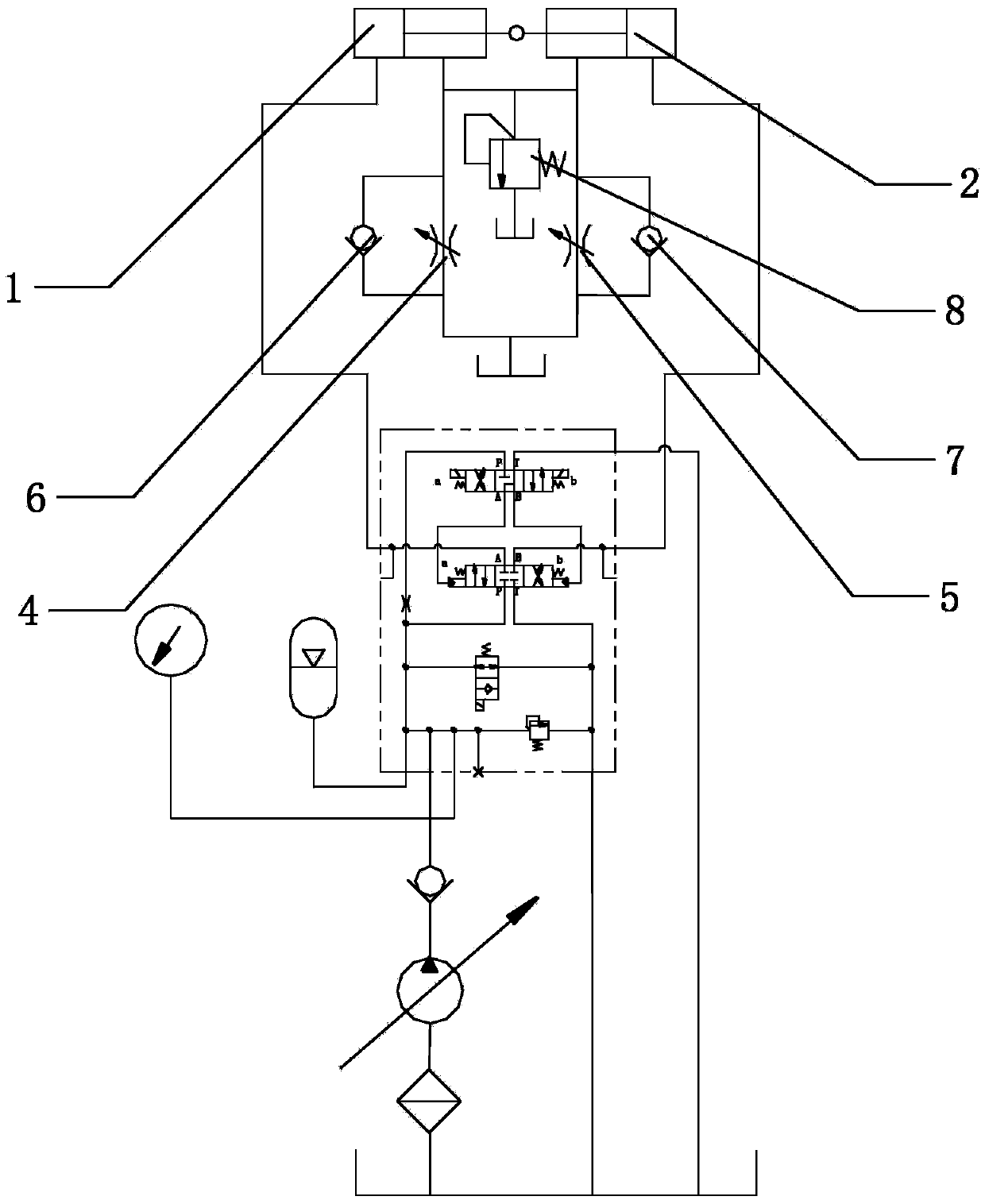

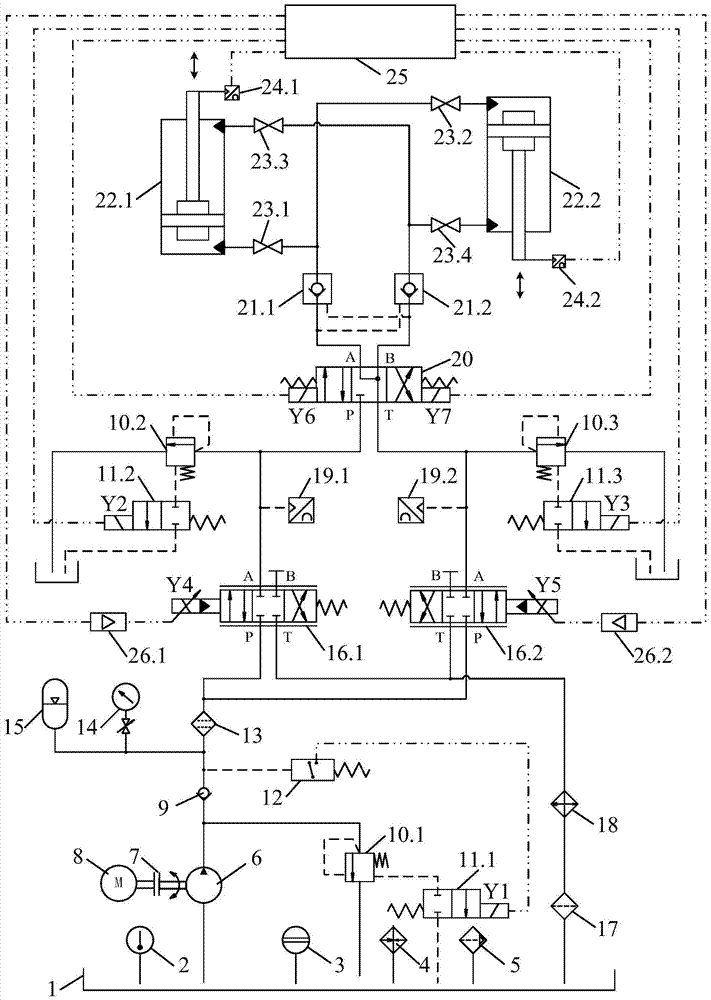

A hydraulic control system for opening and closing the cabin door of an underwater vehicle

ActiveCN105604991BQuick responseAutomate operationServomotor componentsAccumulator installationsNon symmetricAir filter

A cabin door opening and closing hydraulic control system of an underwater vehicle mainly comprises an oil tank, a thermometer, a liquid level meter, a heater, an air filter, a hydraulic pump, a coupler, a motor, a one-way valve, overflow valves, two-position and two-way electromagnetic reversing valves, a pressure relay, a fine filter, a pressure gauge, an energy accumulator, servo valves, a return oil filter, a cooler, pressure sensors, a three-position and four-way electromagnetic reversing valve, hydraulic one-way valves, non-symmetric hydraulic cylinders, check valves, displacement sensors, a controller, servo amplifiers and the like. The cabin door opening and closing hydraulic control system is high in responding speed, and can achieve automatic operation of opening and closing a cabin door of the underwater vehicle. Reversing impact can be lowered, and system stability is improved. Displacement of piston rods of the hydraulic cylinders can be precisely controlled, and the precision of the system is improved. The demand for positioning and locking in the opening and closing process of the cabin door is met, and the safety of the system is improved.

Owner:YANSHAN UNIV

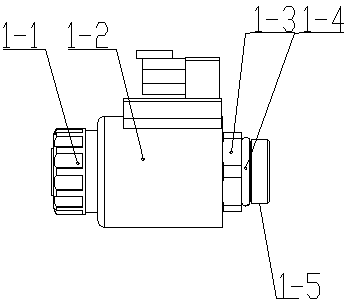

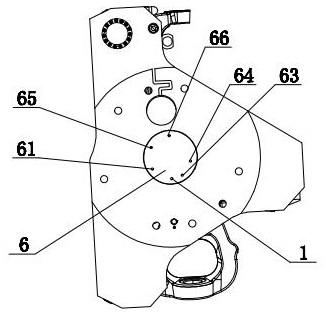

Vehicle steer-by-wire steering wheel device

InactiveCN103359161BSmall commutation impactExtend your lifeMechanical steering gearsElectrical steeringSteering wheelCoupling

The invention discloses a vehicle steer-by-wire steering wheel device, aiming at accurately detecting the rotating angle of a steering wheel, and providing adjustable and proper road feel and rotating number of turns which can change the working mode under different working conditions and adjusts the steering wheel to complete all wheel steering for a driver. A motor is fixedly connected with a box; the output shaft of the motor is fixedly connected with the lower end of a third gear shaft through a coupler; gears of the third gear shaft are in mesh transmission and matched mounting with gears of a second gear shaft; gears of the third gear shaft are in mesh transmission and matched connection with gears of a first gear shaft; gears are in mesh transmission and matched mounting with gears of a fourth gear shaft; an angle displacement sensor is fixedly connected with the upper end of a first transmission shaft; a transmission nut is in transmission and matched mounting with the thread part of the first transmission shaft; the shell of an electromagnet is fixedly connected with the box; and protecting plates at the two sides of a check block supporting seat are in movable fit and mounting with the two outer side walls of a travel check baffle. The vehicle steer-by-wire steering wheel device is suitable for being used as a steer-by-wire steering wheel of a vehicle.

Owner:QINGDAO UNIV OF SCI & TECH

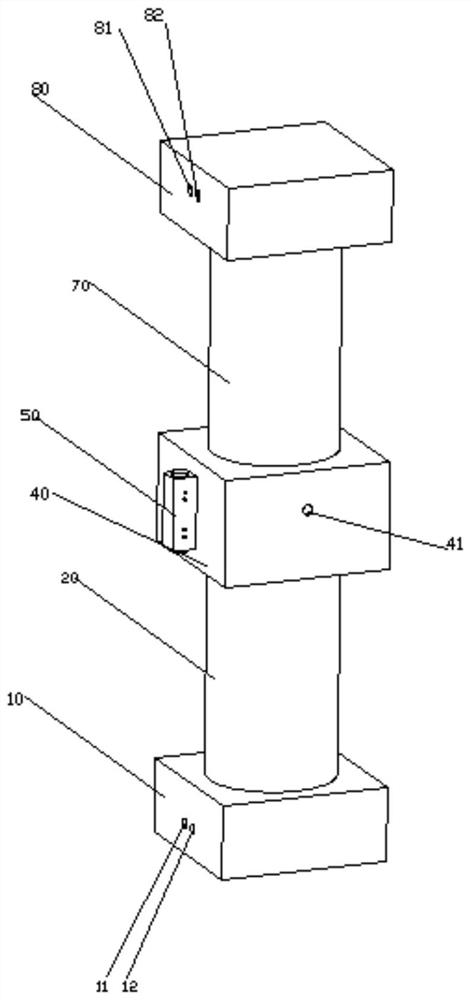

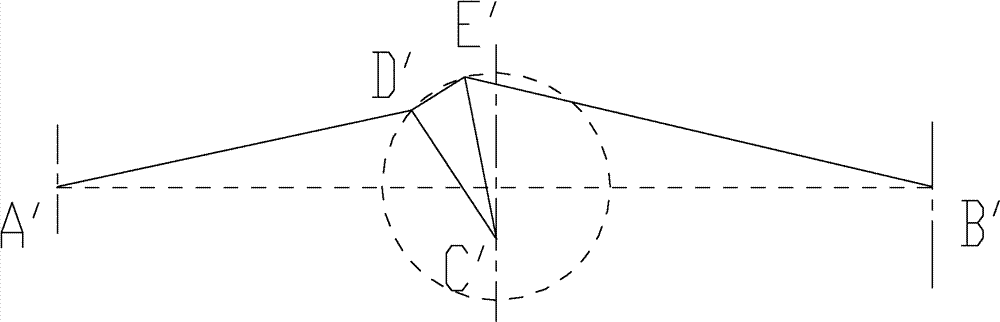

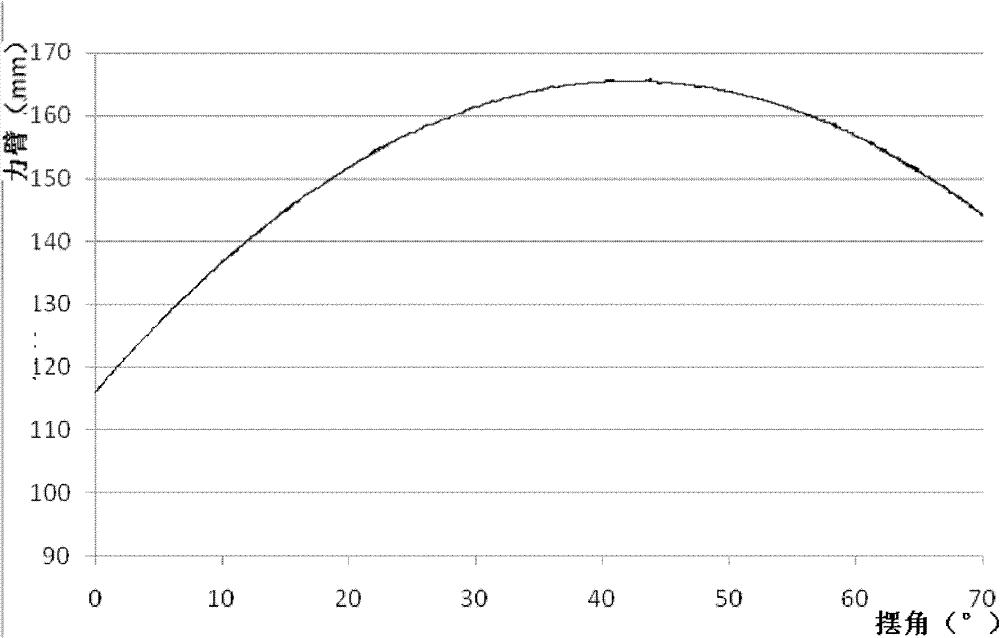

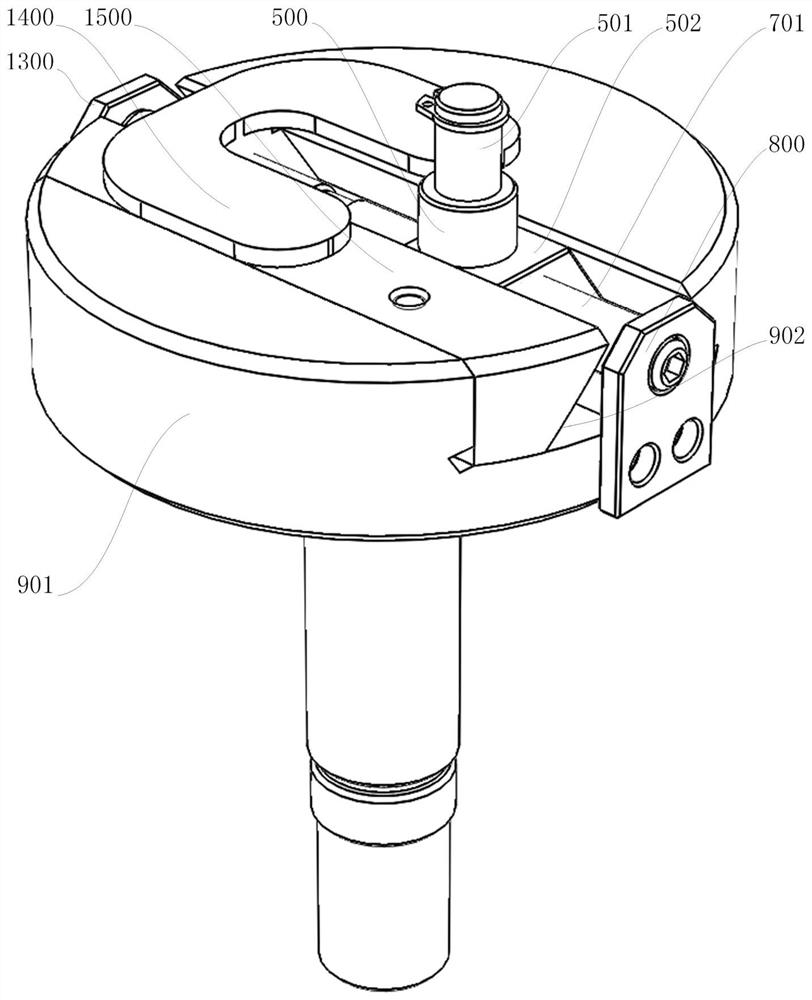

Self-balancing rotation and swing mechanism for bearing channel superfinishing

PendingCN113770909AHigh precisionImprove wavinessSuperfinishing machinesGrinding/polishing safety devicesRotational axisBalancing machine

The invention provides a self-balancing rotation and swing mechanism for bearing channel superfinishing. The mechanism comprises a rocker arm, a swing generation amplitude adjusting mechanism, a swing self-balancing mechanism and a reset clearance elimination mechanism, a swing shaft is sleeved with the rocker arm, the rocker arm swings around the swing shaft, a balance structure is arranged at the upper end of the rocker arm, and the lower end of the rocker arm slides with the swing generation amplitude adjusting mechanism in a matched mode. The swing generation amplitude adjusting mechanism and the swing self-balancing mechanism are arranged in a dovetail groove of a circular seat disc at the upper end of the rotating shaft, the swing self-balancing mechanism comprises an adjusting body, an adjusting screw rod, a balancing body and the like, a pressing block is used for pressing, and the adjusting screw rod is twisted to adjust the mutual position relation between the adjusting body and the balancing body. An elastic body is arranged between a pendulum shaft seat and the rocker arm. Through the rocker arm symmetry balance structure and the swing self-balancing mechanism, the force transmission process is stable and reliable, and the problem of superfinishing adaptability of different types of bearing channels is solved through the swing generation amplitude adjusting mechanism. The reset clearance elimination mechanism ensures that the swing generation amplitude adjusting mechanism timely resets to eliminate the clearance. The rotating shaft and the circular seat disc are designed into a whole, transmission links are reduced, and occupied space is small.

Owner:安阳市质量技术监督检验测试中心

A mechanical feedback adjustable speed self-reversing gas pressurized cylinder

ActiveCN111946588BRealize automatic reversingReduce vibrationPositive displacement pump componentsServomotorsEngineeringMechanical engineering

The invention discloses a mechanical feedback type adjustable speed self-reversing gas booster cylinder, which includes a hydraulic reversing valve and a terminal displacement feedback mechanism. The movement of the rod is transmitted to the spool of the hydraulic reversing valve through the feedback connecting rod, so that the spool moves correspondingly, switches the internal flow path, and realizes the self-reversing of the gas booster cylinder; by adjusting the position of the fulcrum of the feedback connecting rod, the feedback coefficient is changed To change the maximum displacement and movement speed of the reversing valve spool, thereby adjusting the reversing speed of the booster cylinder. The mechanical feedback type adjustable speed self-reversing gas booster cylinder provided by the present invention, compared with the electronically controlled reversing booster cylinder, does not need to use an electromagnetic reversing valve, which eliminates the risk of electric sparks igniting the working gas, and is especially suitable for For the pressurized delivery of flammable and explosive gases such as natural gas, it can significantly improve the safety of the gas booster cylinder, reduce the reversing impact of the gas booster cylinder, thereby weakening the vibration and noise of the gas booster cylinder.

Owner:CHINA PETROCHEMICAL CORP +1

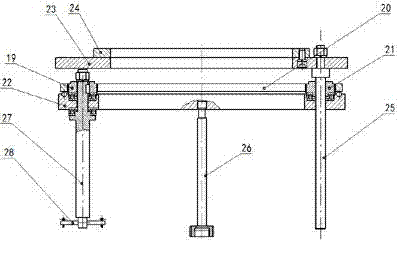

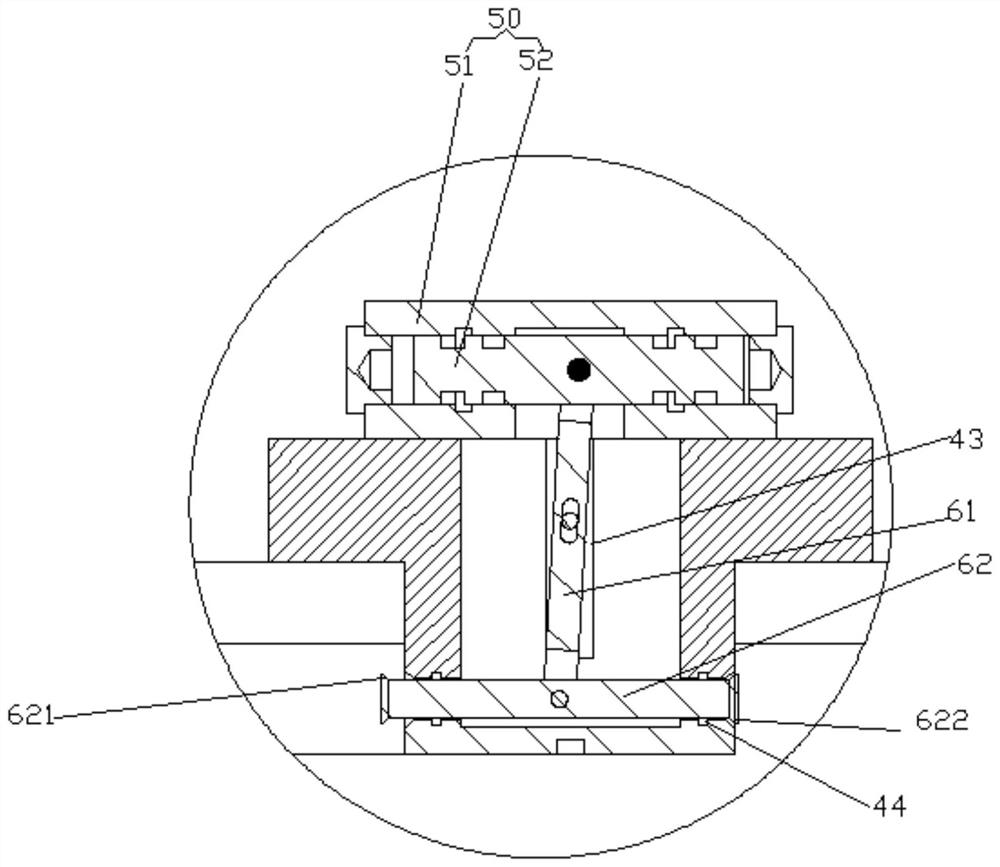

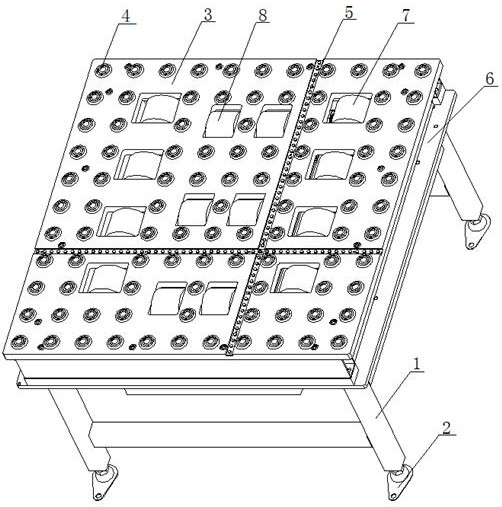

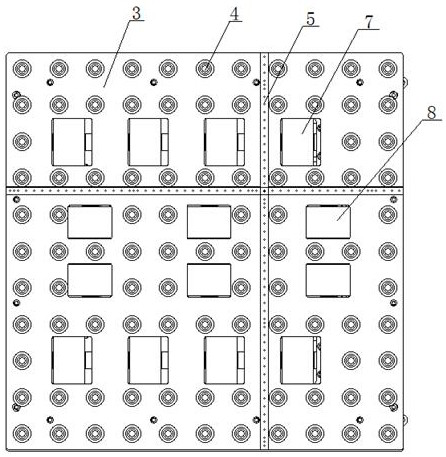

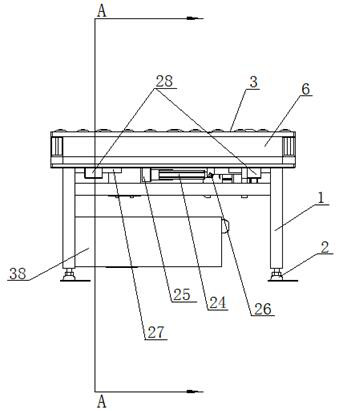

Mold conveying platform

PendingCN113602732ASmall commutation impactSimple structureConveyorsControl devices for conveyorsDrive wheelEngineering

Owner:武汉商贸职业学院

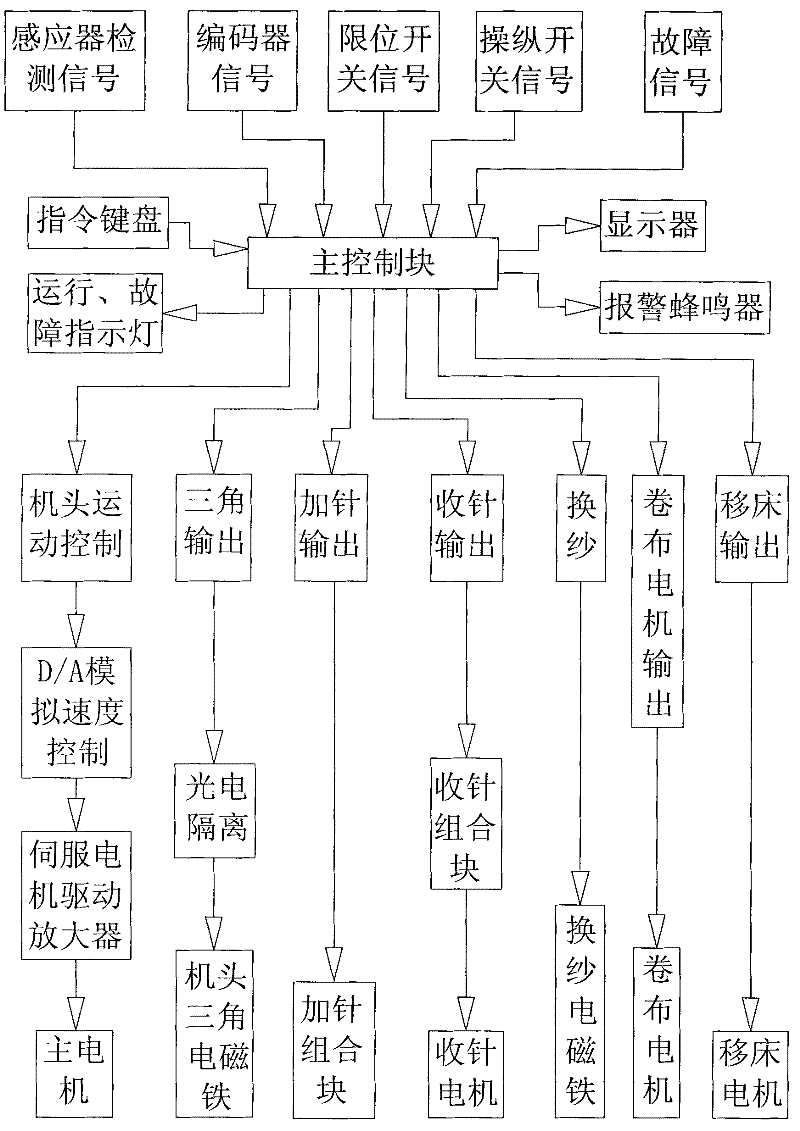

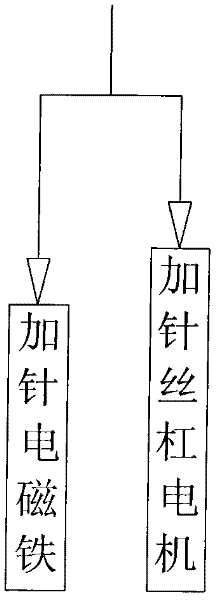

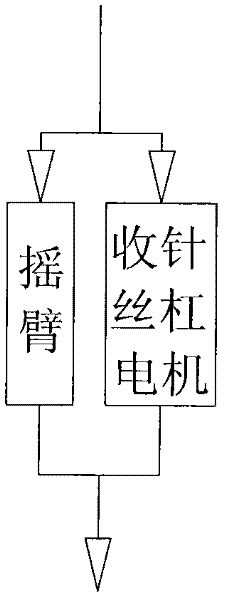

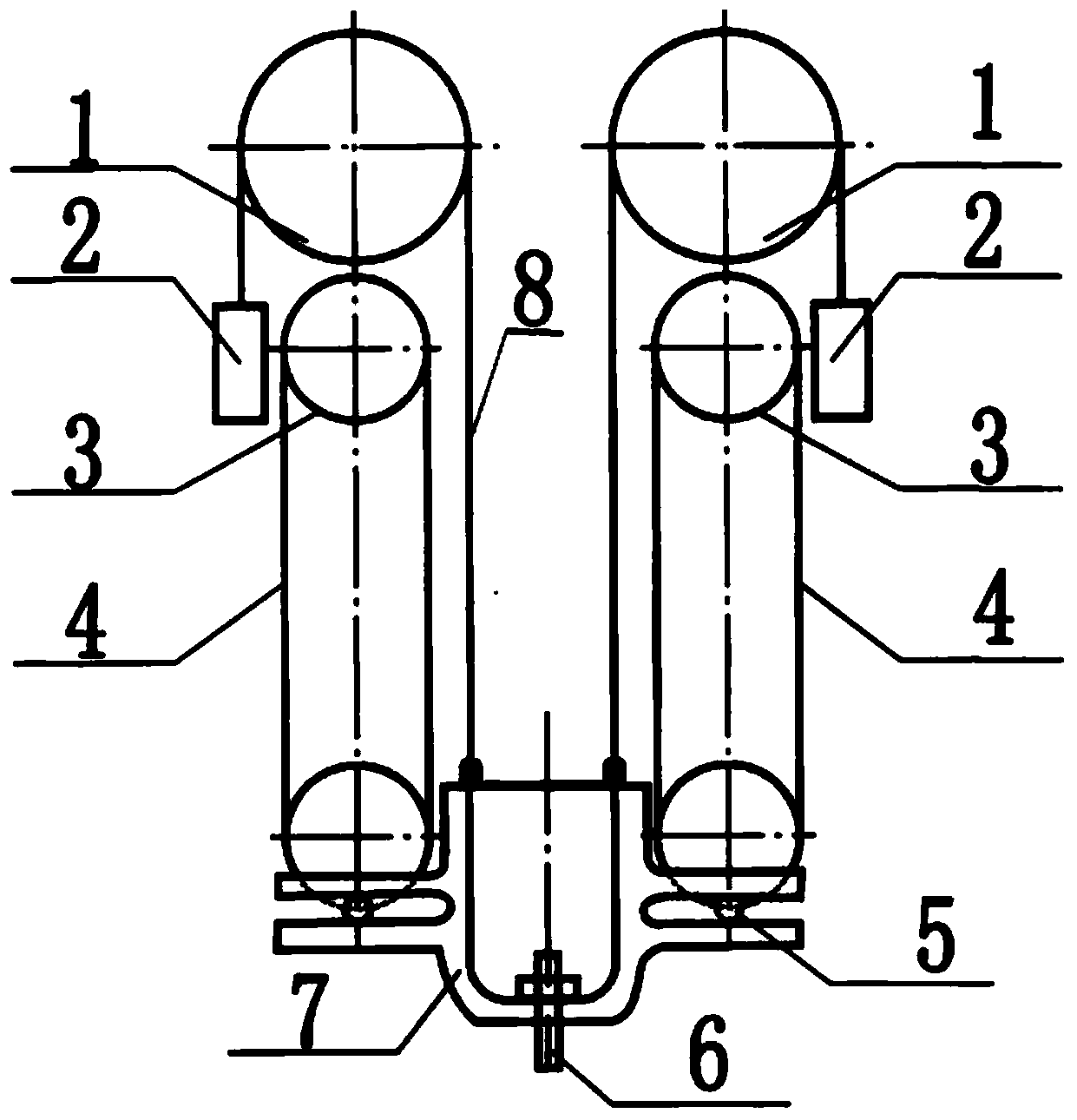

Full-automatic knitting machine

InactiveCN102041619BGuaranteed uptimeSmall commutation impactWeft knittingKey pressingFrequency changer

The invention discloses a full-automatic knitting machine. The machine comprises a machine head, a main control processor and a man-machine interface part which are matched with one another, wherein an output part and an input part are connected outside the main control processor; driving software is embedded into the main control processor and drives the output part, the input part and the man-machine interface part to run respectively; and the man-machine interface part comprises a display and keys. Due to the design of a unique frequency converter, the machine runs stably and reliably; speed sensor-free vector technology is adopted, so that high control accuracy is achieved; six weaving speeds can be selected according to different raw materials and different weaving widths and the machine can decelerate and reverse automatically when the machine head returns, so that the machine has the characteristic of small reversing impact and runs more stably and reliably; totally-loop-lockedmachine head position control is realized by a photoelectric encoder; and an automatic narrowing system which can narrow apparently and secretly consists of machinery, a matched motor, a control circuit and software.

Owner:朱红旗

Novel double-chain oil sucking machine

The invention relates to an oil sucking machine, in particular to a novel double-chain oil sucking machine. The novel double-chain oil sucking machine comprises reversing wheels, balancing weights, chain wheels, chains, screw bolt rolling wheel and rolling needle bearings, an oil sucking rod, a reversing frame and steel wire ropes, wherein each steel wire rope is paved on the corresponding reversing wheel; one end of each steel wire rope is connected with the reversing frame, and the other end of each steel wire rope is connected with the corresponding balancing weight; the lower surface of the reversing frame is connected with the oil sucking rod; a bearing part of each screw bolt rolling wheel and rolling needle bearing is in contact with the reversing frame; a screw bolt of each screw bolt rolling wheel and rolling needle bearing is fixedly connected onto a pin shaft of the corresponding chain; the chains cover the upper chain wheel and the lower chain wheel; the reversing frame is provided with a U-shaped groove; a guide rail is arranged in the groove; each screw bolt rolling wheel and rolling needle bearing can roll on the guide rail; and the two lower chain wheels are connected with an electric motor through a chain transmission device. The novel double-chain oil sucking machine has the advantages that the stroke is long; the load is great; the oil sucking efficiency is high; the reversing impact of the oil sucking machine is small; the service life of the reversing frame is long; and the adaptability is high.

Owner:QINGDAO KANGHEWEIYE COMML

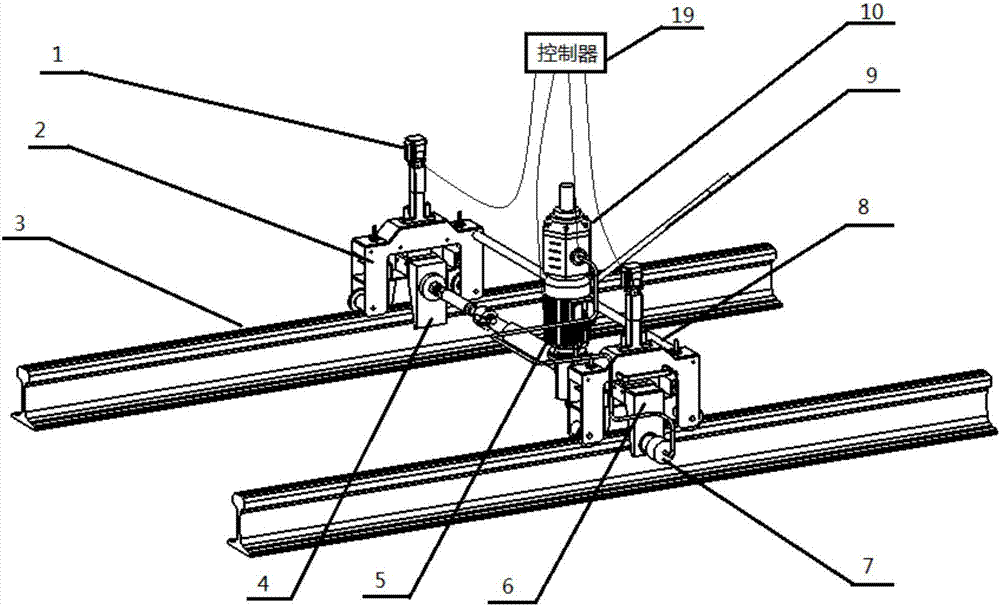

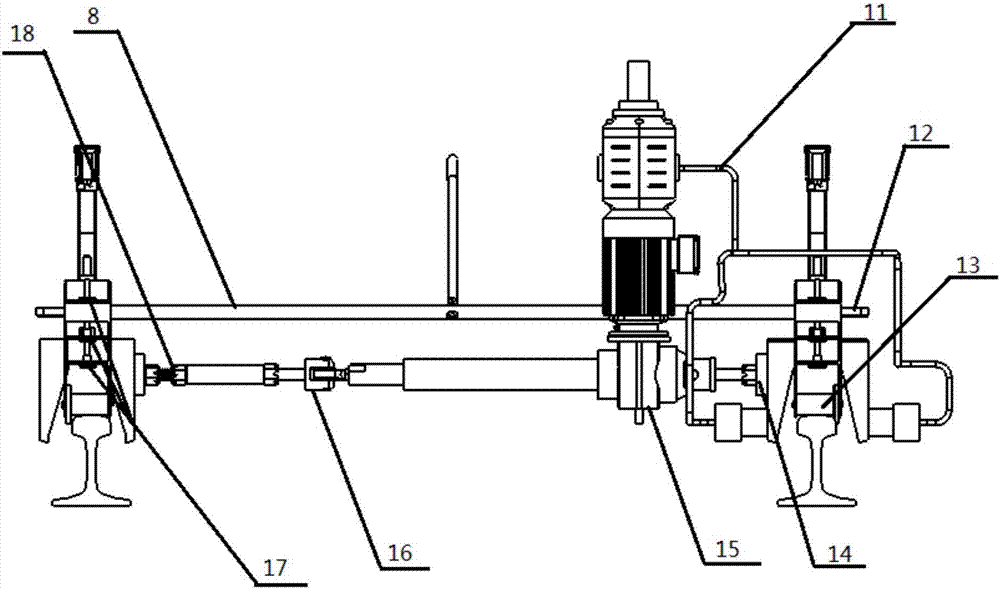

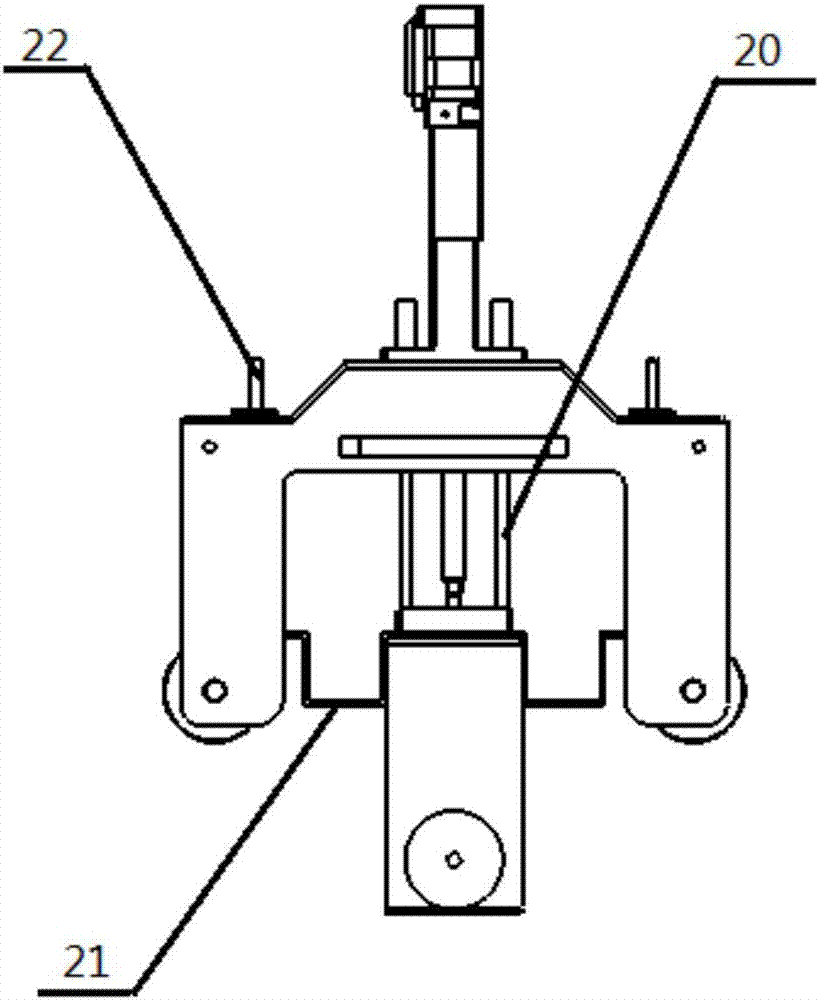

Gauge regulator for ballastless tracks

The invention relates to a gauge regulator for ballastless tracks comprising a controller, electromagnets for regulating lifting and lowering positions, guide piston rods for restricting a moving direction, a reference track clamping-track instrument and a movable track clamping-track instrument for fixing tracks, a hydraulic system for controlling the automatic clamping and unclamping of the reference track clamping-track instrument and the movable track clamping-track instrument and a gauge regulating mechanism connected between the reference track clamping-track instrument and the movable track clamping-track instrument. Compared with the prior art, the gauge regulator for the ballastless tracks can automatically regulate the gauge and can freely walk on the ballastless tracks; and the gauge regulator for the ballastless tracks has the advantages of high precision of the gauge regulating, high efficiency and convenient movement.

Owner:SHANGHAI UNIV OF ENG SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com