Piston-controlled reversing valve

A reversing valve and piston technology, which is applied in the field of hydraulic reversing valves, can solve the problems of high processing requirements, large pressure loss, energy waste, etc., and achieve the effects of wide versatility of parts, small hydraulic control force, and wide application occasions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

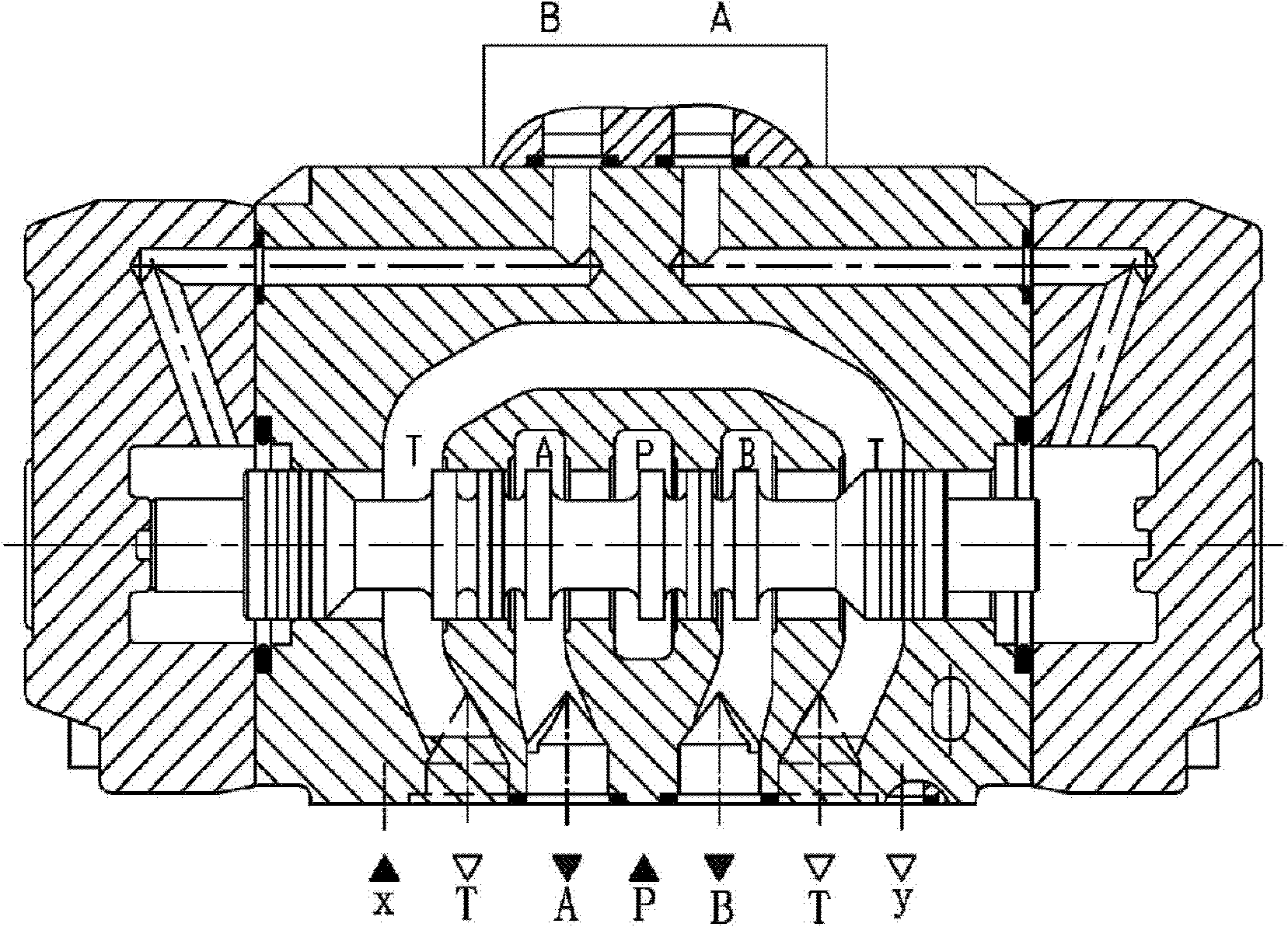

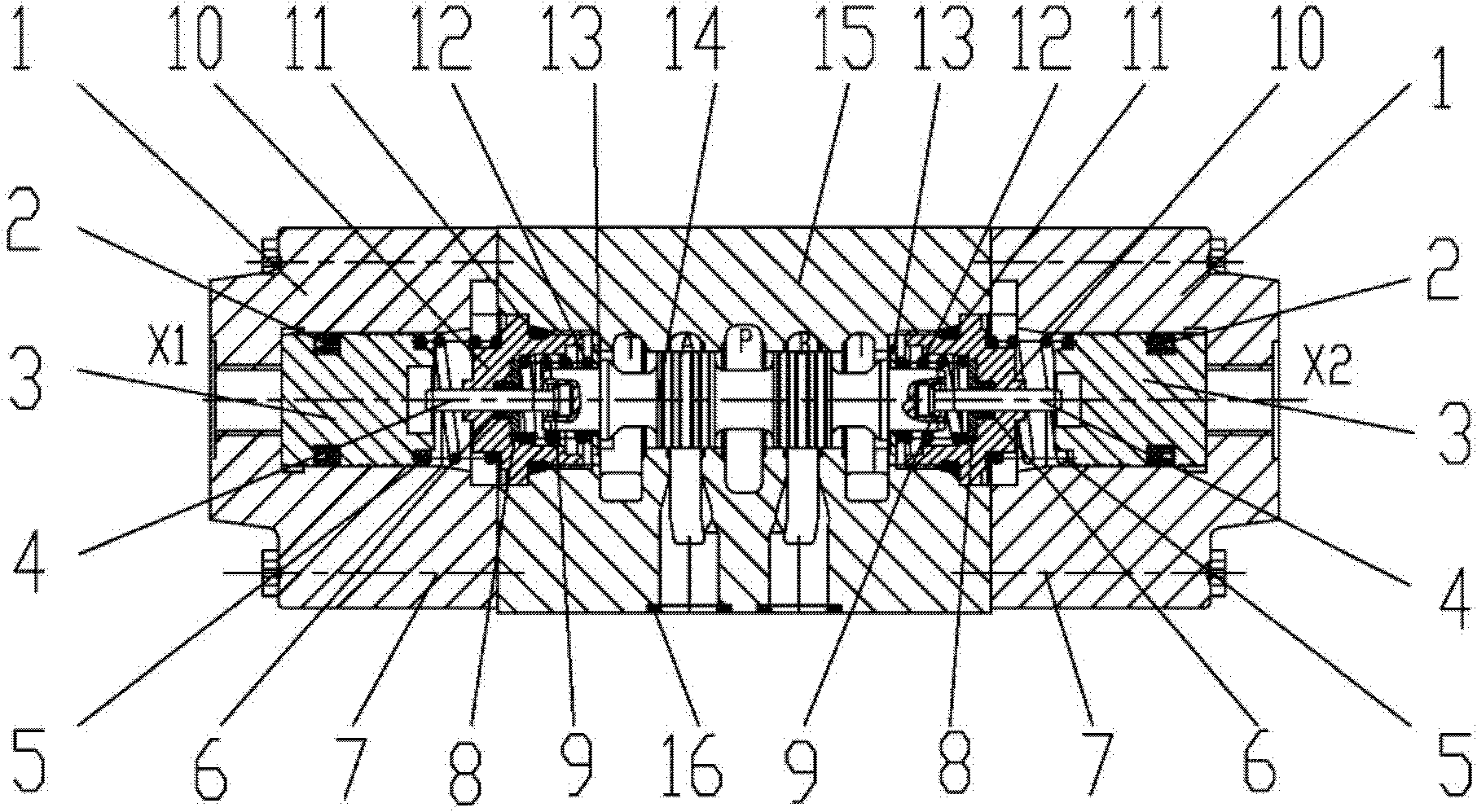

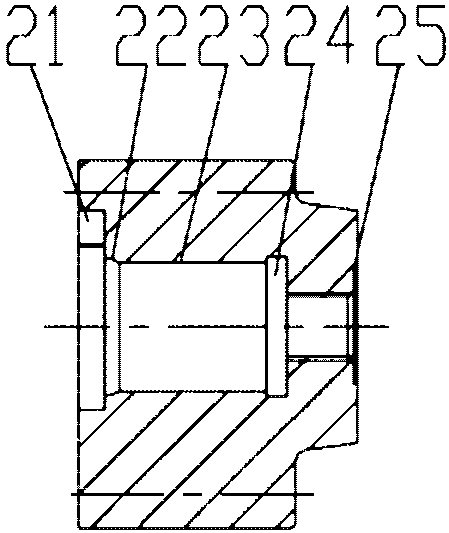

[0016] see figure 2 and image 3 , a piston-controlled reversing valve, mainly through the oil (air) pressure of the external control port X1 or X2 to push the valve core to move, so as to obtain the on-off of each oil (air) circuit, so as to realize the required function. The effective gap between the valve body 15 and the spool 14 ensures the reliability of the movement of the spool 14 . Back-up rings 13 and springs 12 are respectively arranged at both ends of the valve core 14, and the end face screw cap 10 is threadedly connected with the valve body 15, and a washer is set beside the multi-stage sealing ring 6 to seal the position, and the pin shaft passes through the passage of the end face screw plug 10. The holes correspond to the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com