Patents

Literature

166results about How to "Easy to batch process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intergrated photonic crystal structure and method of producing same

InactiveUS20040264903A1Simplifies fabricationNeed of be complexNanoopticsCoupling light guidesRadiation lossElectromagnetic radiation

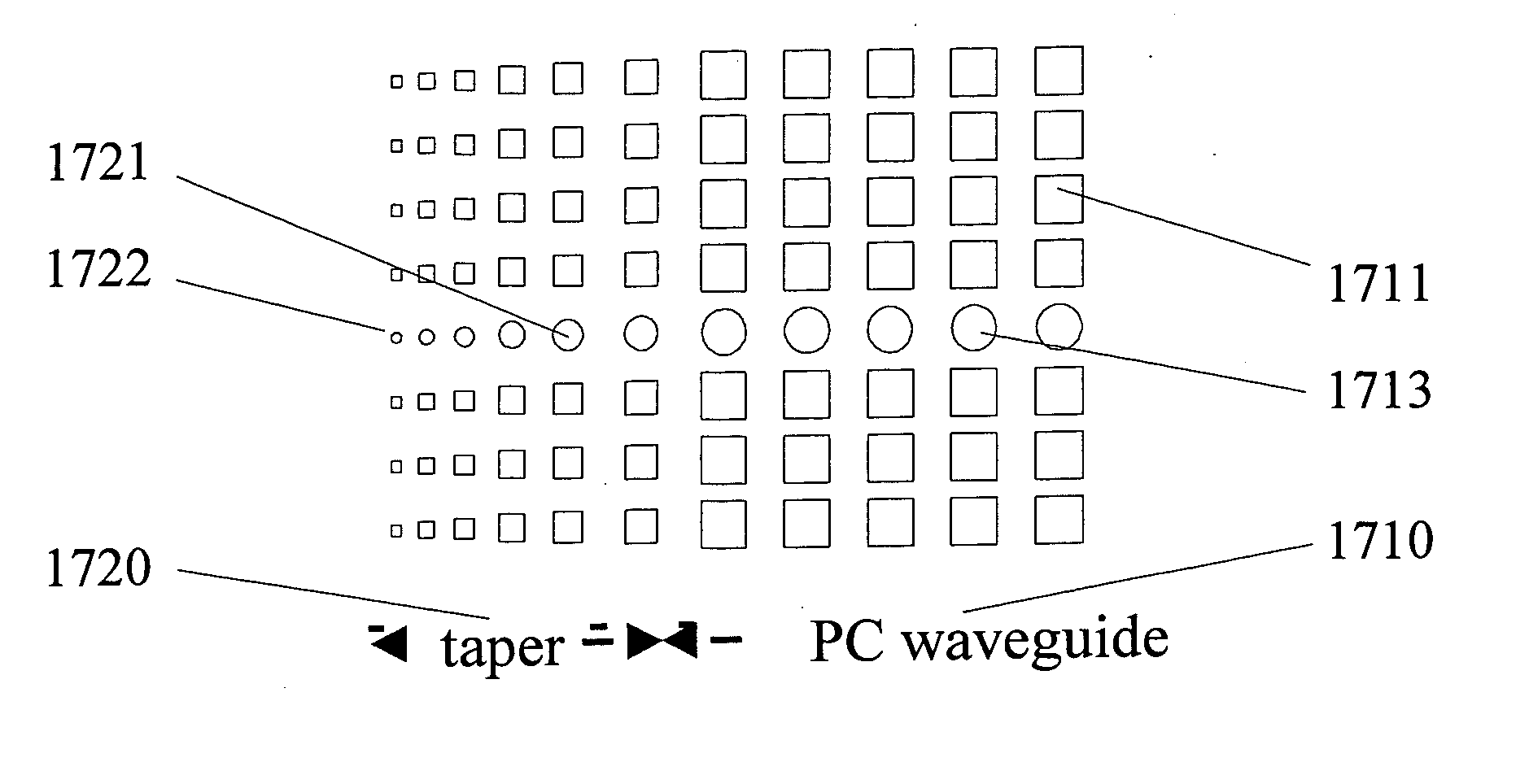

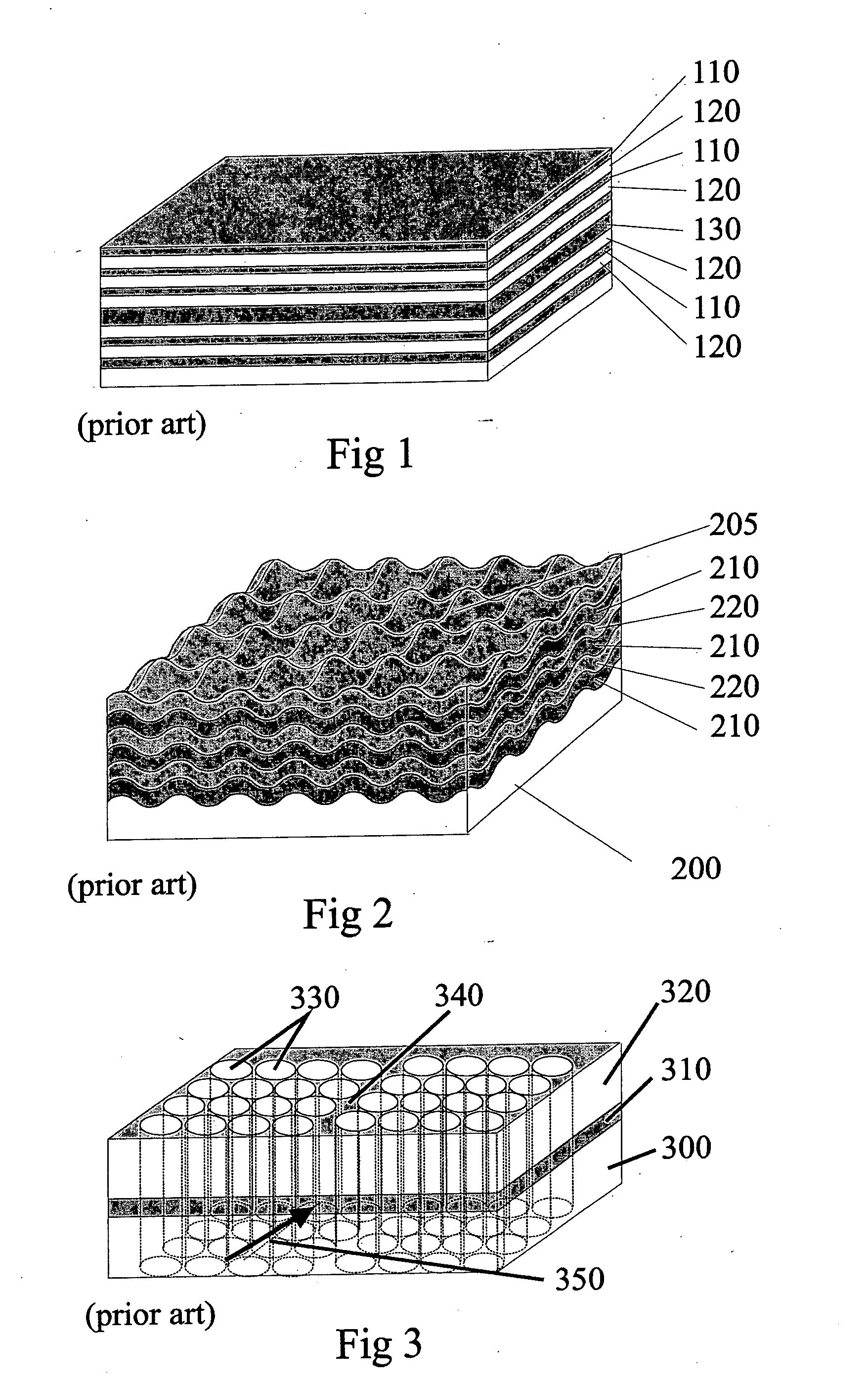

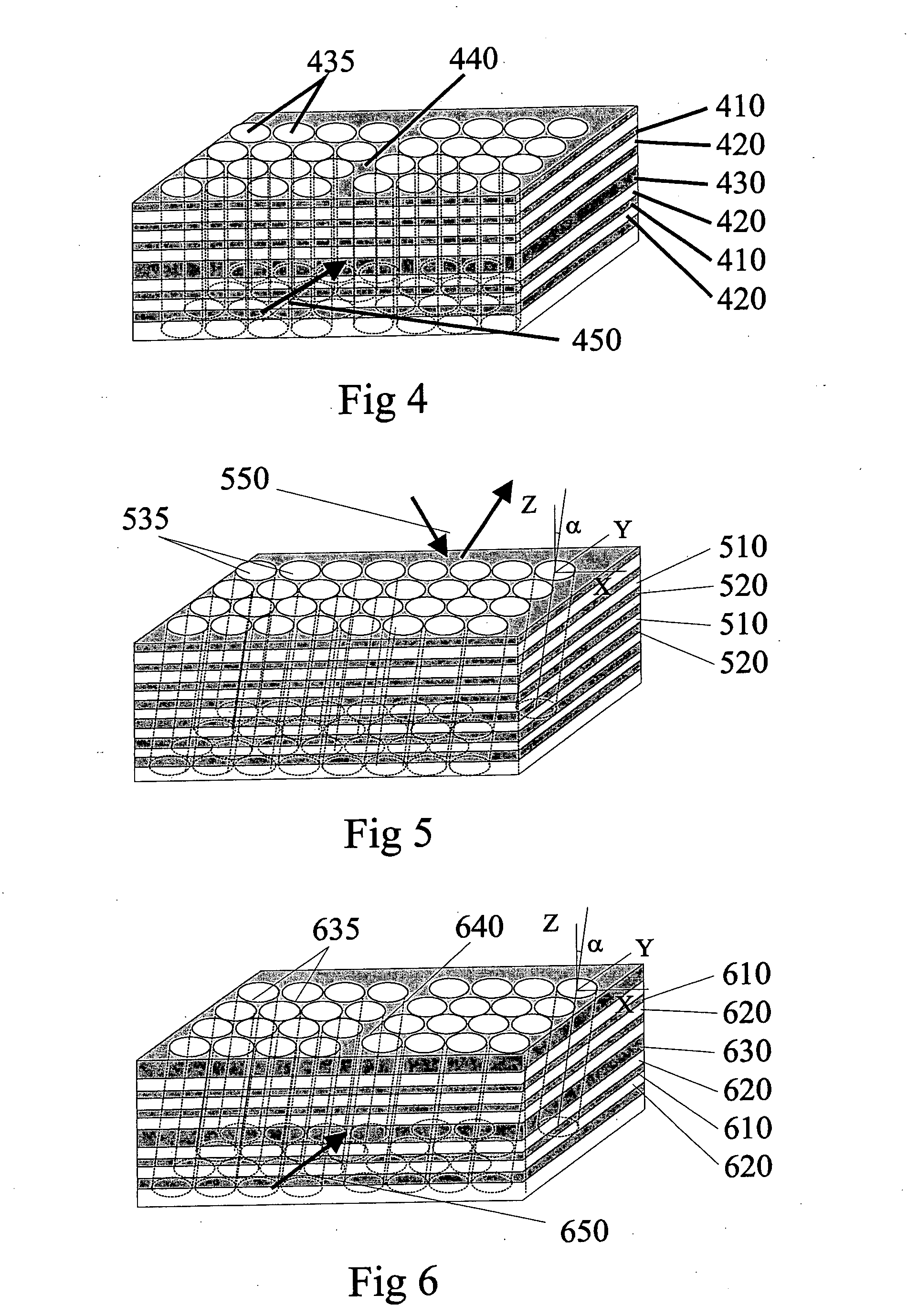

An integrated photonic crystal (IPC) structure and method of producing same is disclosed. The (IPC) structure includes a first layered sub-structure (610, 620) with a surface and a one-dimensional periodic refractive index variation along the direction perpendicular to the surface. This first layered sub-structure enables a photonic band gap or high omnidirectional reflectivity for propagation of radiation having a spectrum of electromagnetic modes incident from a direction perpendicular to the plane of the surface. The PC-structure further includes a first defect (630) in the first layered sub-structure that enables an electromagnetic mode to be localised in the vicinity of the first defect. The electromagnetic radiation is hereby vertically confined. Furthermore, the IPC-structure consists of a second sub-structure with a plurality of essentially straight identical passages (635) arranged in a two-dimensional periodic pattern cutting through the layered structure at an angle alpha. This second sub-structure enables a two-dimensional photonic band gap for propagation of radiation having a spectrum of electromagnetic modes incident from any direction in the plane of the surface. A second defect (640) in the second sub-structure enables an electromagnetic mode to be localised in the vicinity of the second defect. By means of the first and second defects in the first layered and second sub-structures a photonic crystal waveguide may e.g. be constructed (650). This photonic crystal waveguide can control and filter light very efficiently and radiation losses can be minimised significantly. The method is particularly well-suited for providing layered structures in which the layers are non-mono-crystalline. The method is based on standard processing steps and tools from the semiconductor and integrated optics industry such as vapour deposition or sputtering, (photo)lithography and etching. With the invention a basic building block for a high-density integrated optics platform for telecommunications and advanced optical signal processing in general is disclosed.

Owner:IGNIS PHOTONYX

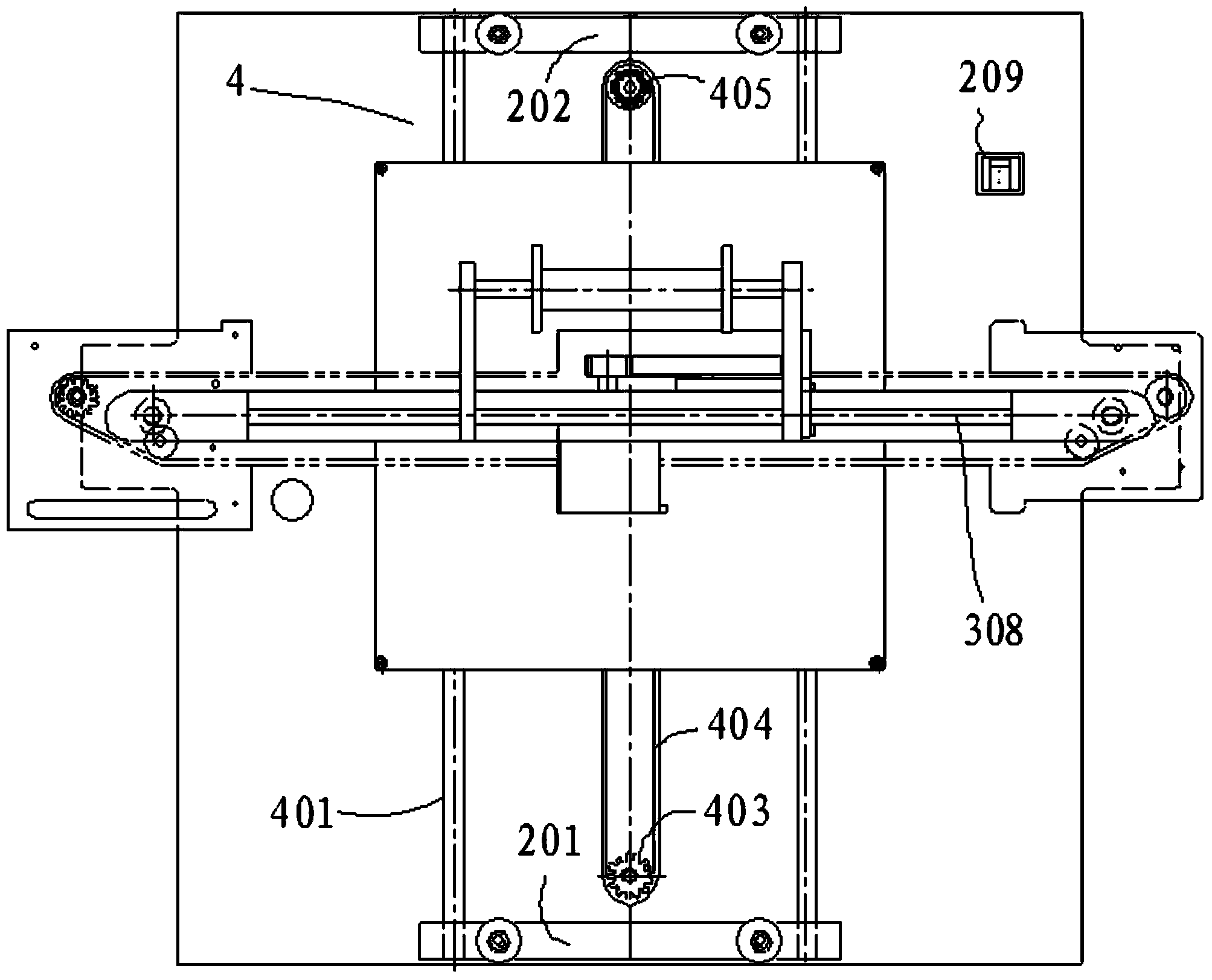

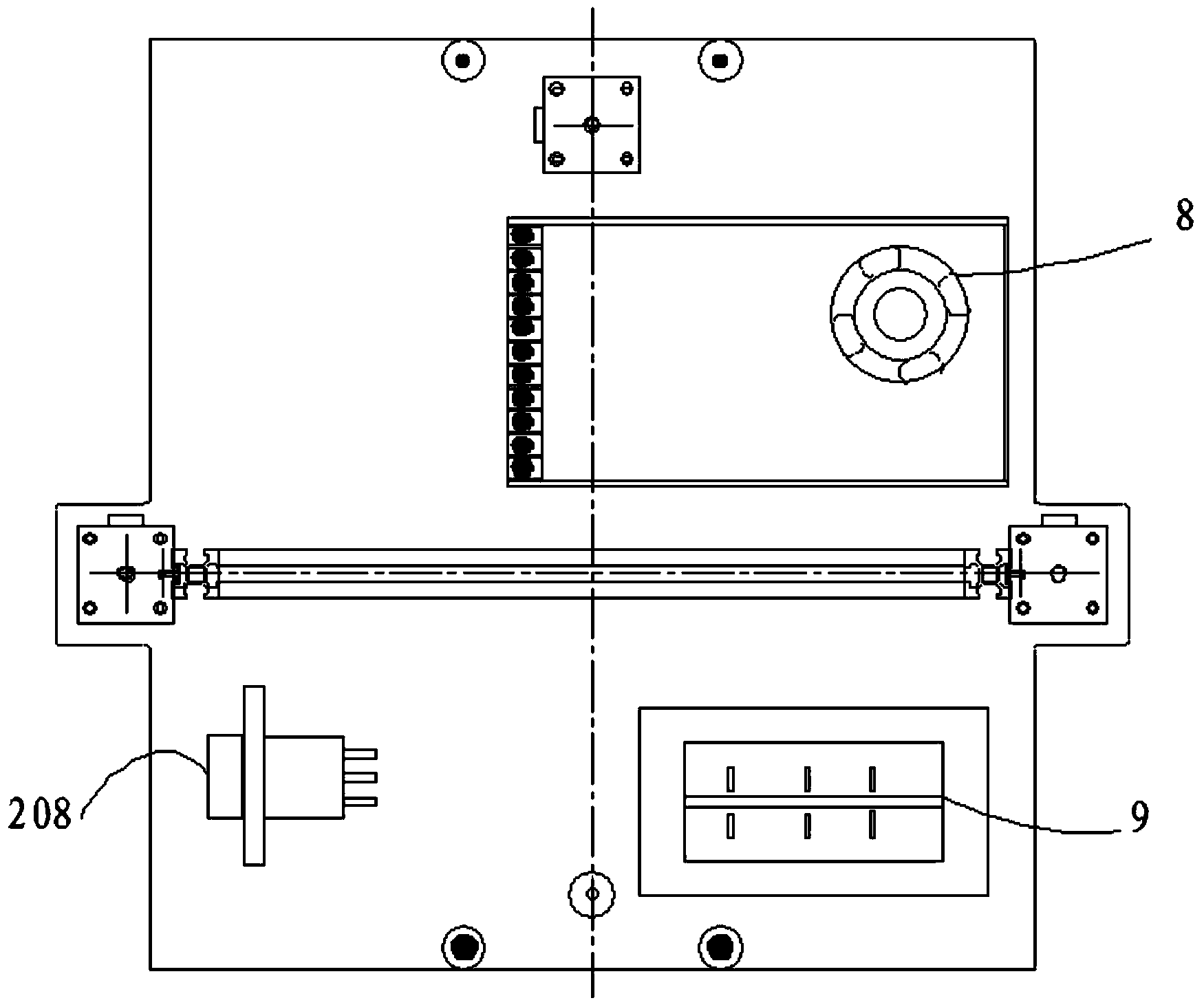

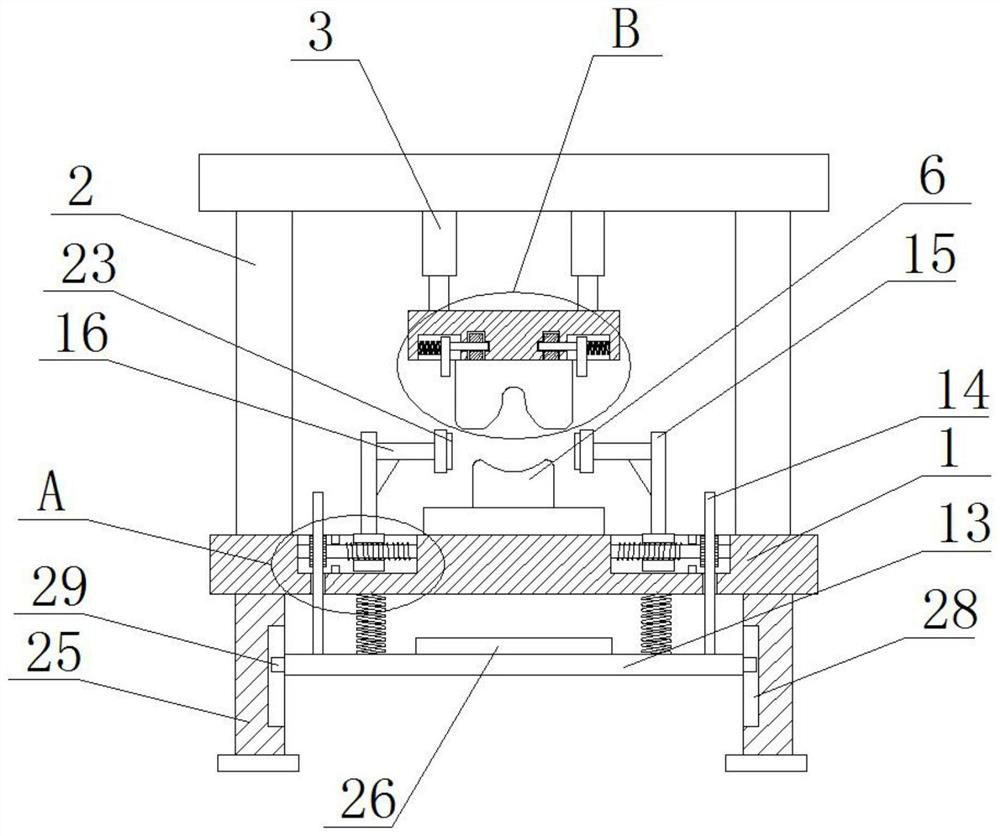

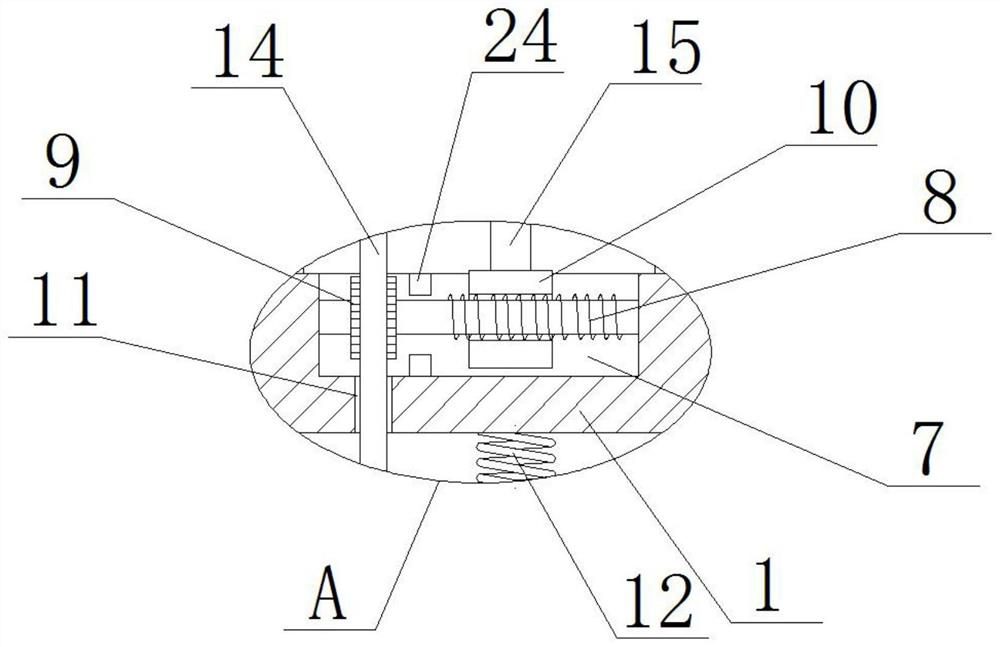

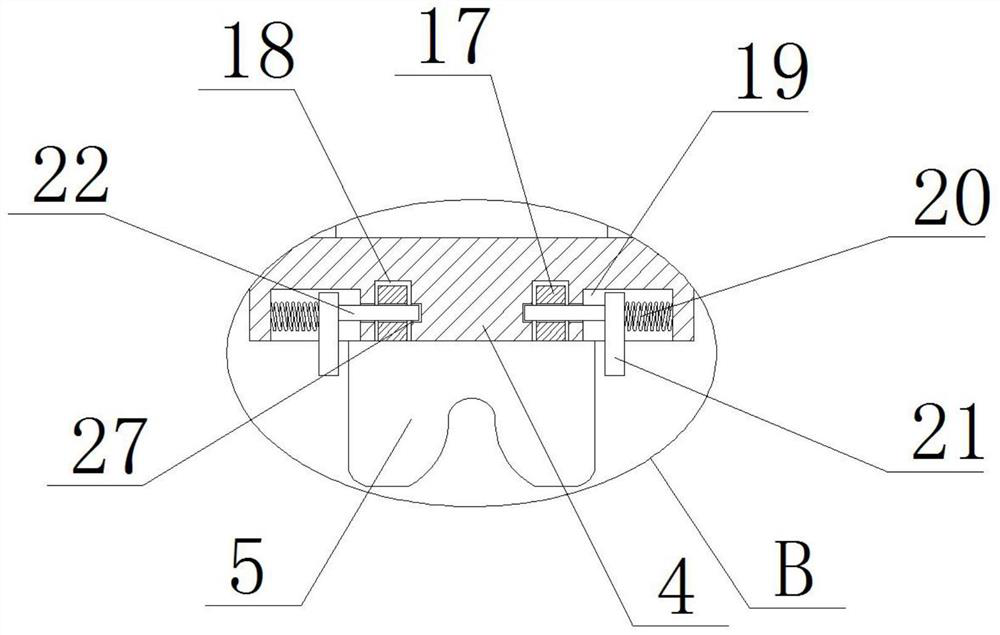

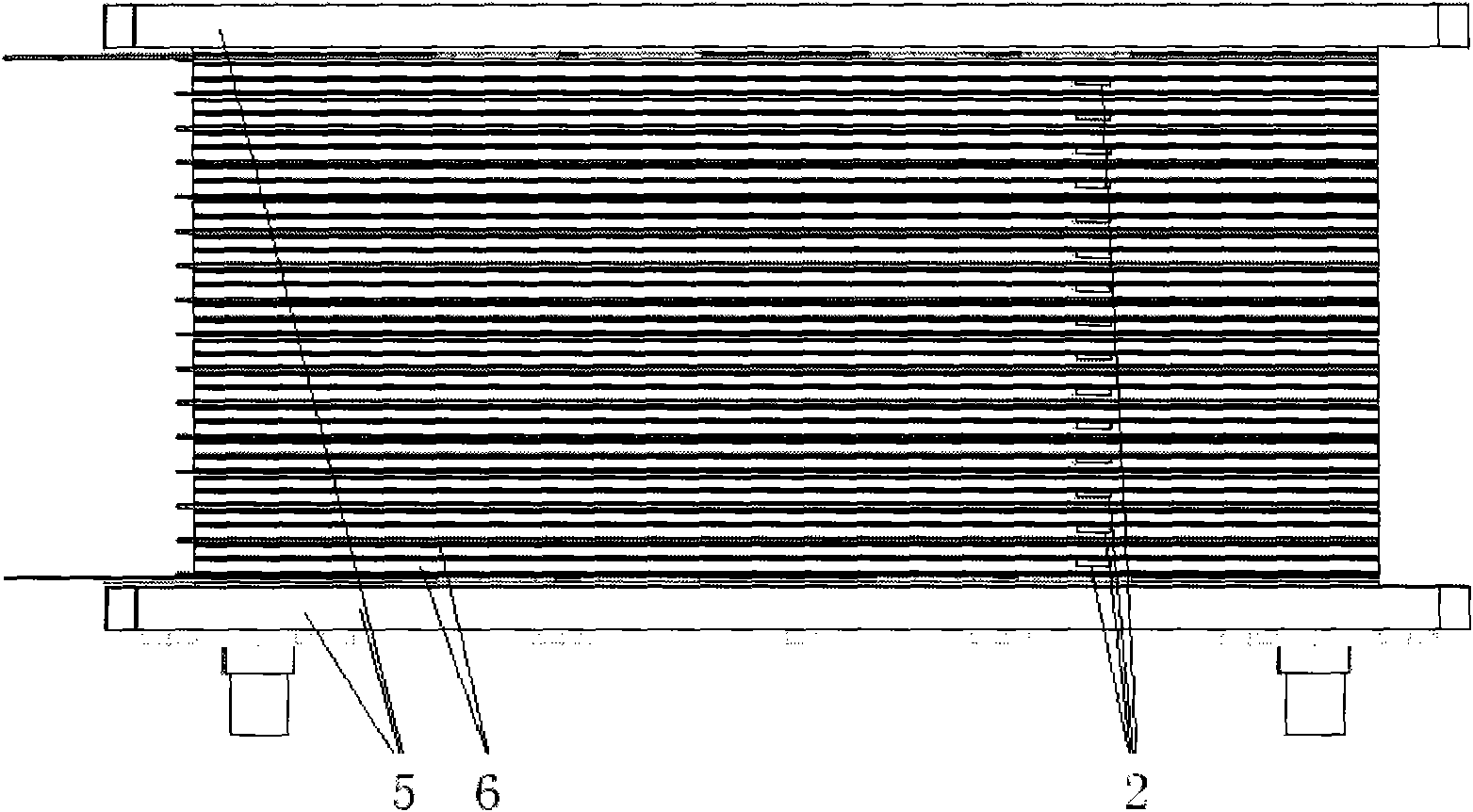

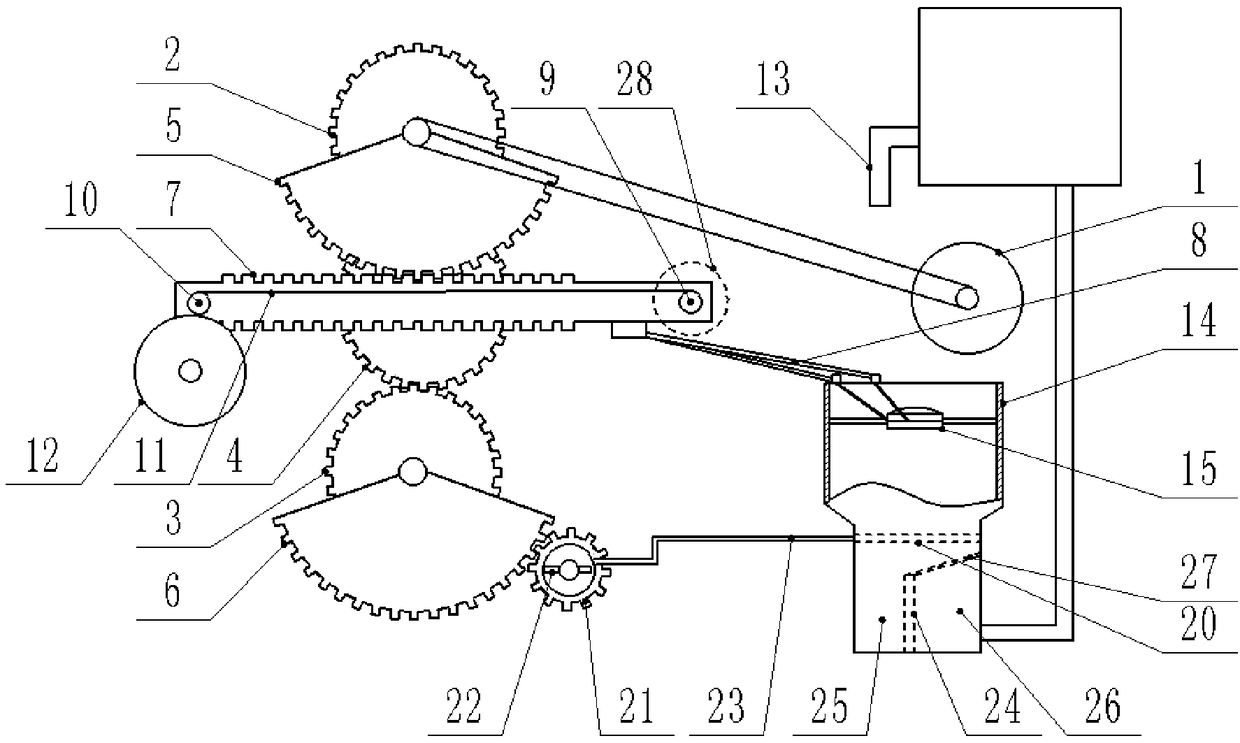

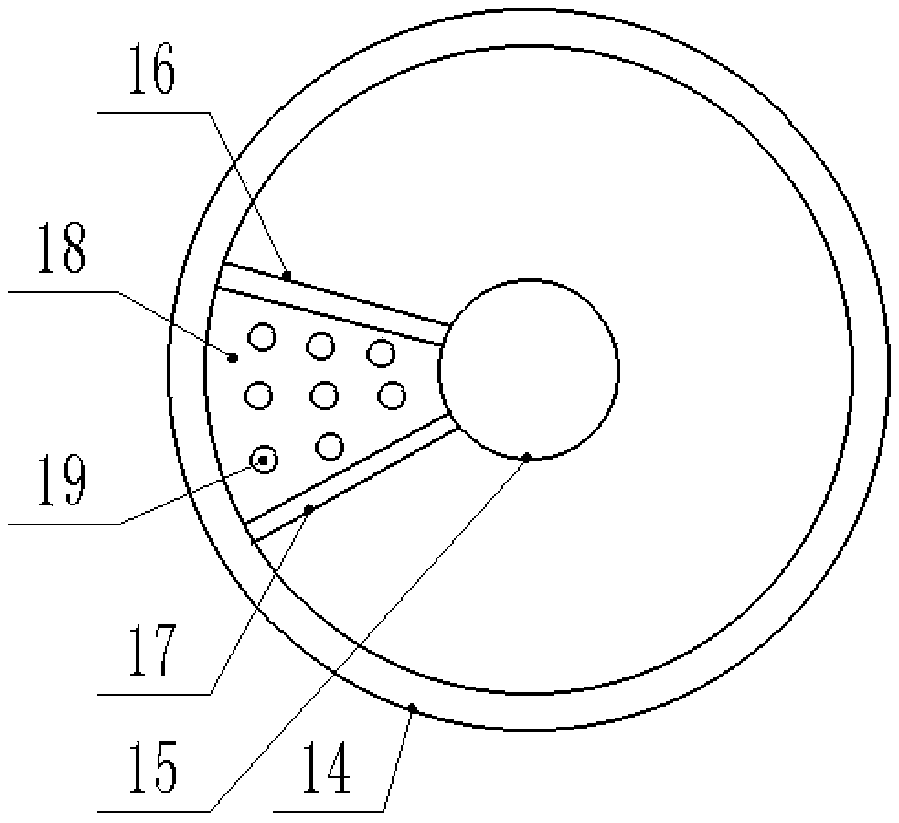

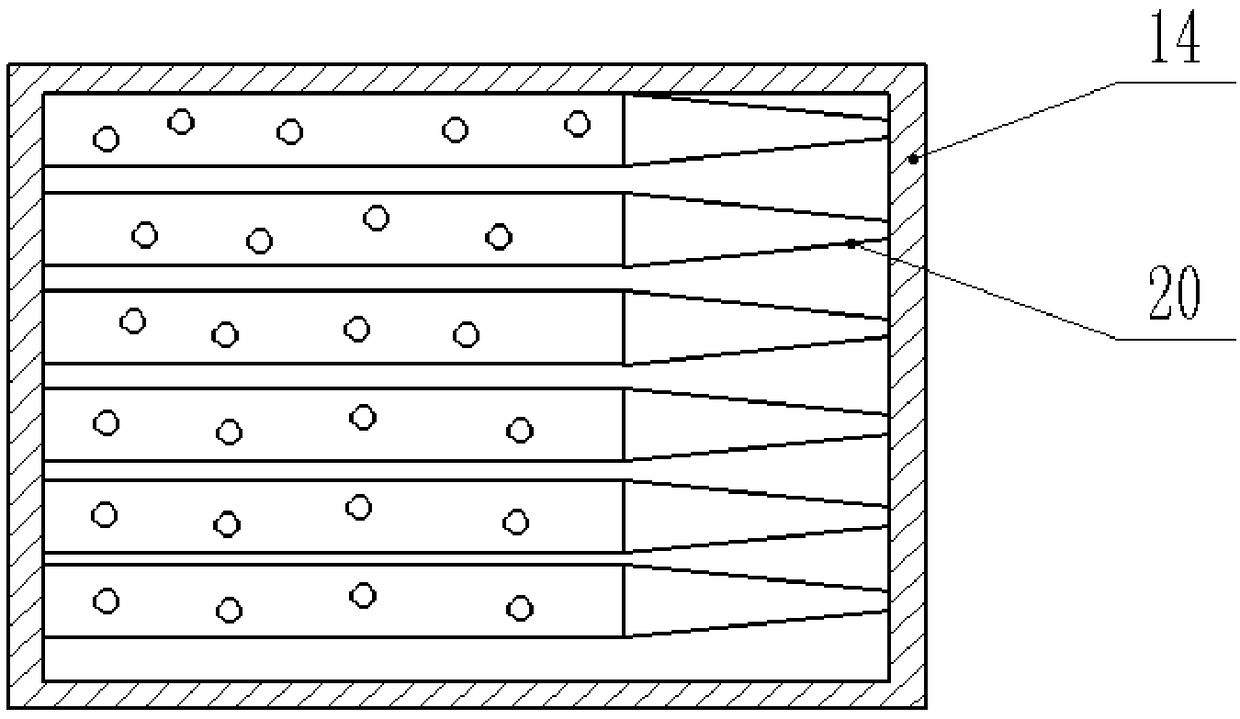

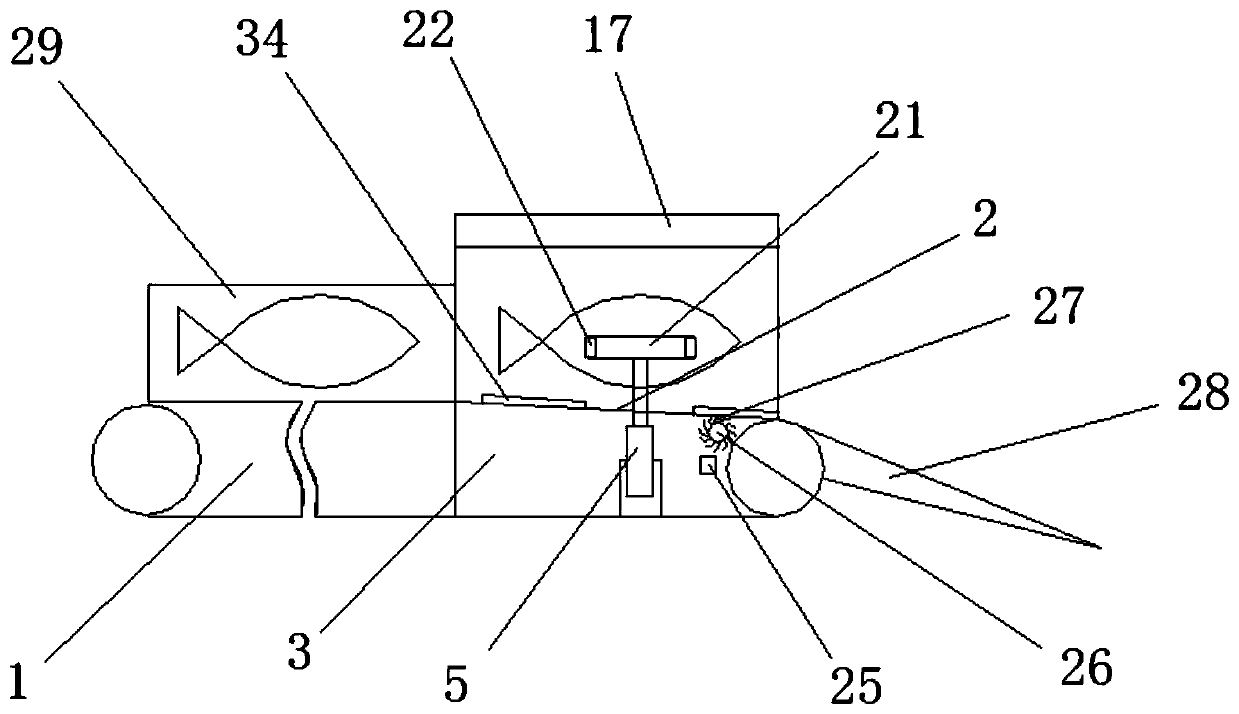

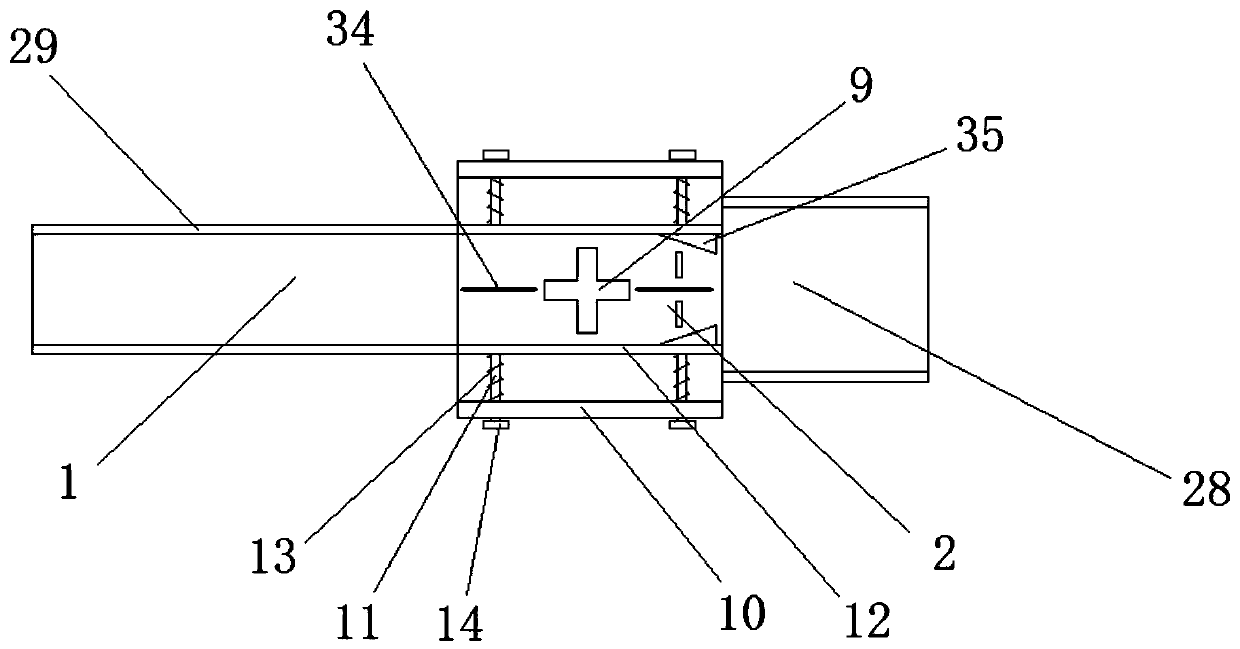

Three-dimensional (3D) printer

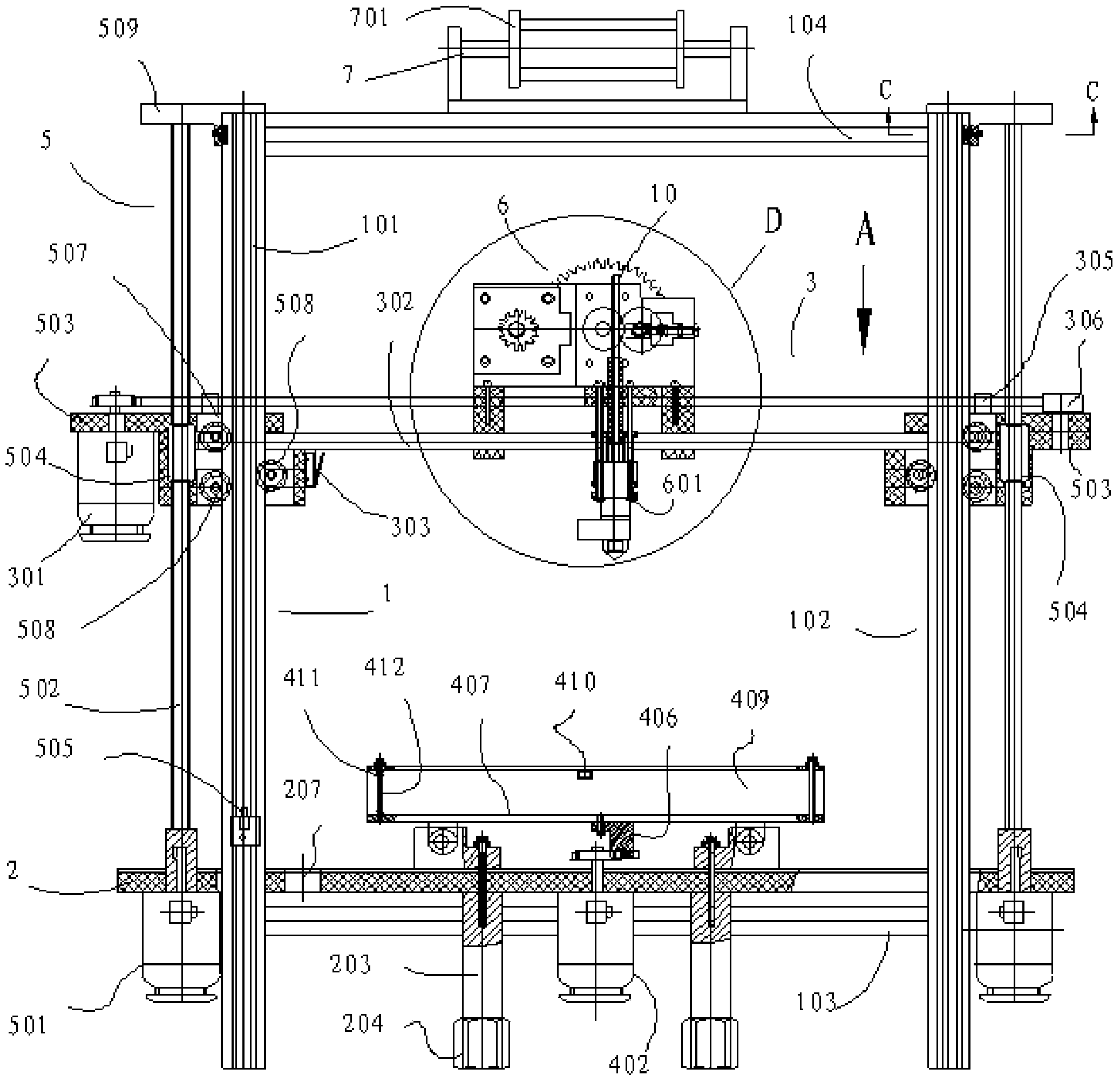

The invention discloses a three-dimensional (3D) printer which comprises a rack, a base, an X-axis movement system, a Y-axis movement system, a Z-axis movement system and a printing device, wherein the rack comprises a left upright post, a right upright post, an upper connecting plate and a lower connecting plate; the upper connecting plate and the lower connecting plate are connected with the left upright post and the right upright post, respectively; the base is connected with the lower connecting plate; the upper connecting plate is connected with a printing supplies connecting rack; the printing supplies connecting rack is connected with a printing supplies fixing disc; the printing device is connected with the X-axis movement system; the X-axis movement system is connected with the Z-axis movement system; the Z-axis movement system is connected with a guide rail of the left upright post and the right upright post; the Y-axis movement system is connected with the base; the X-axis movement system is provided with an X-axis movement guide rail through which the printing device moves; a power supply and a controller which are connected with each other are arranged at the bottom of the base; the controller is connected with the X-axis movement system, the Y-axis movement system, the Z-axis movement system and the printing device. The 3D printer is simple and compact in structure, small in size and low in manufacturing cost.

Owner:UNIV OF JINAN

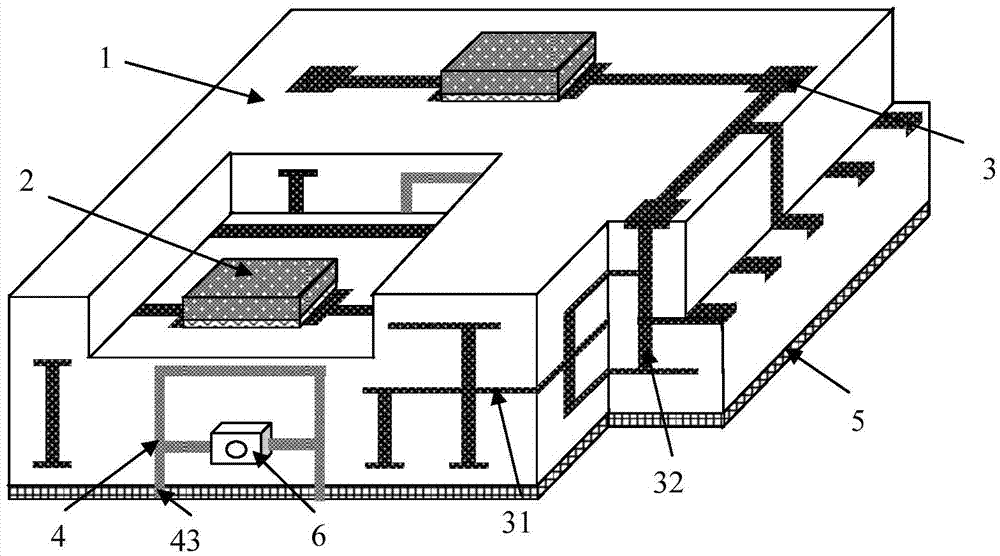

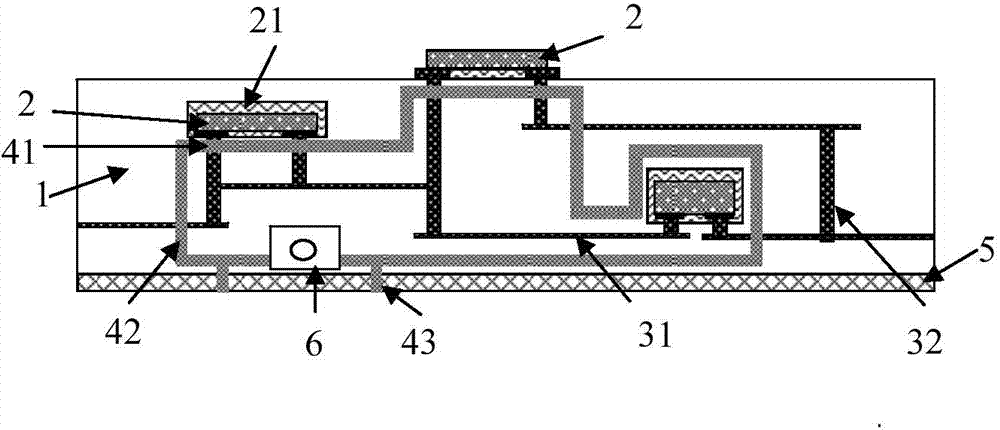

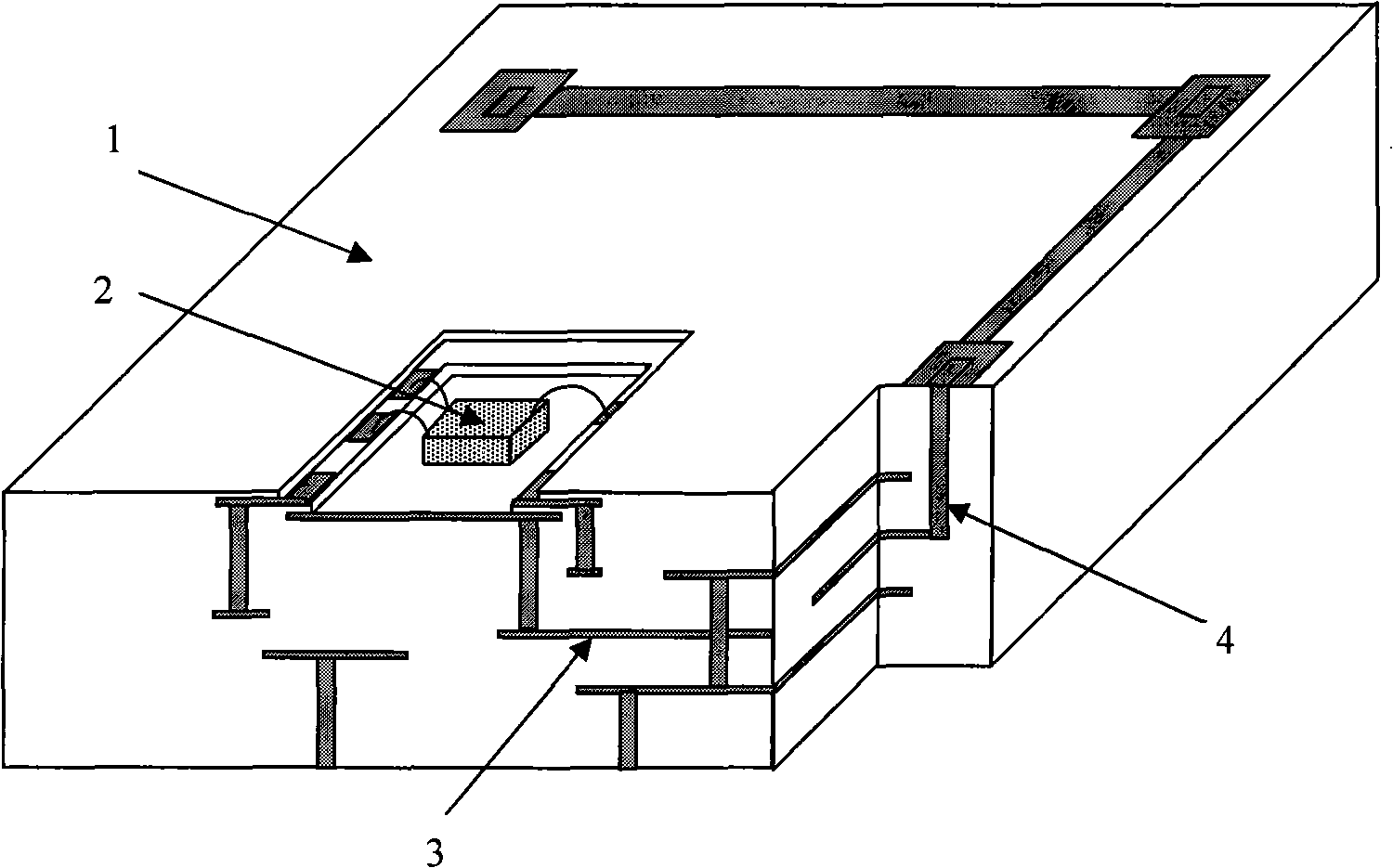

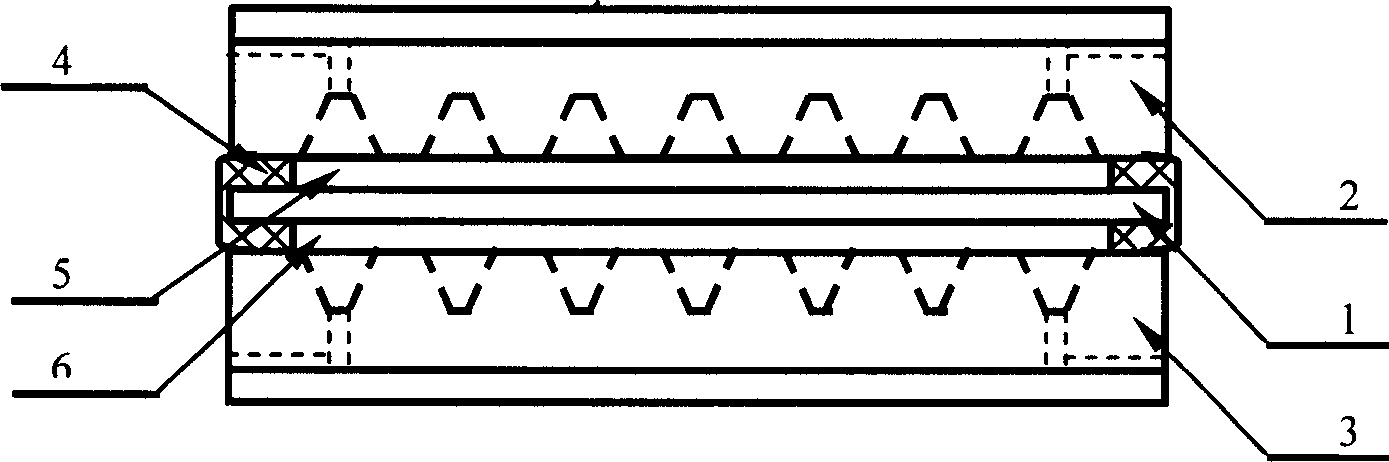

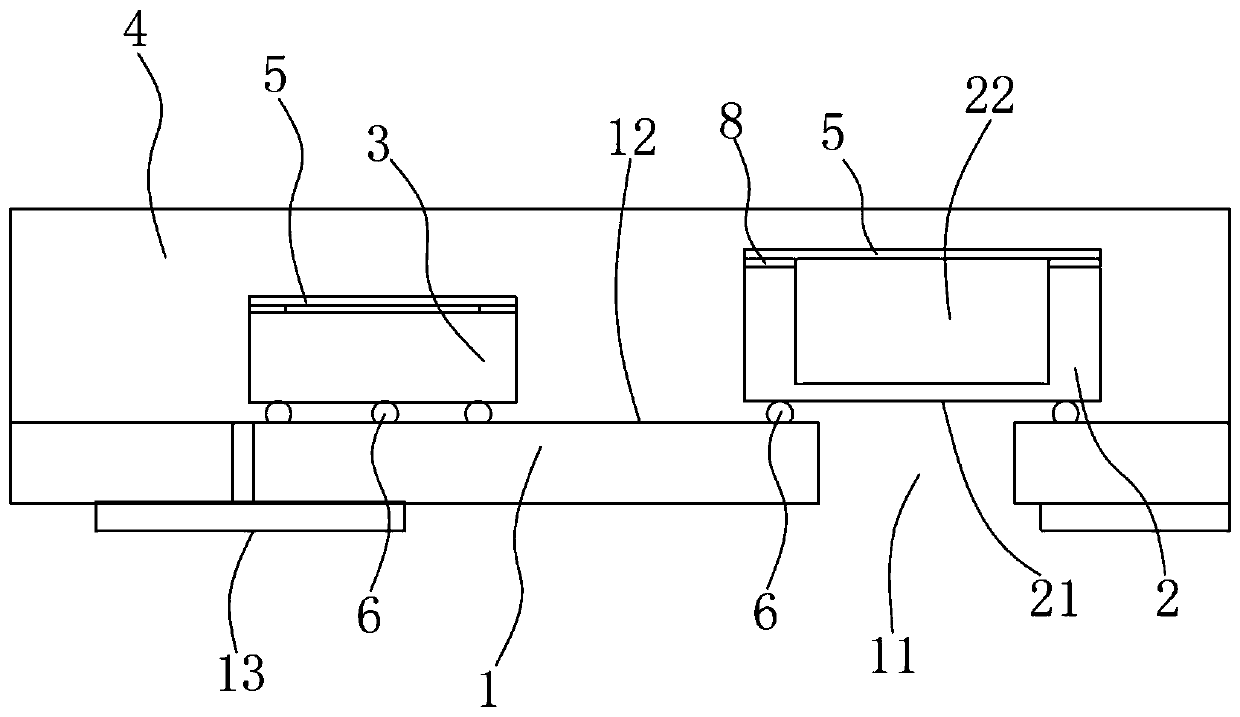

Enhanced radiation three-dimensional packaging structure and packaging method for same

InactiveCN103489838AHigh quality factorRealize integrated designSemiconductor/solid-state device detailsSolid-state devicesAutomatic controlOptoelectronics

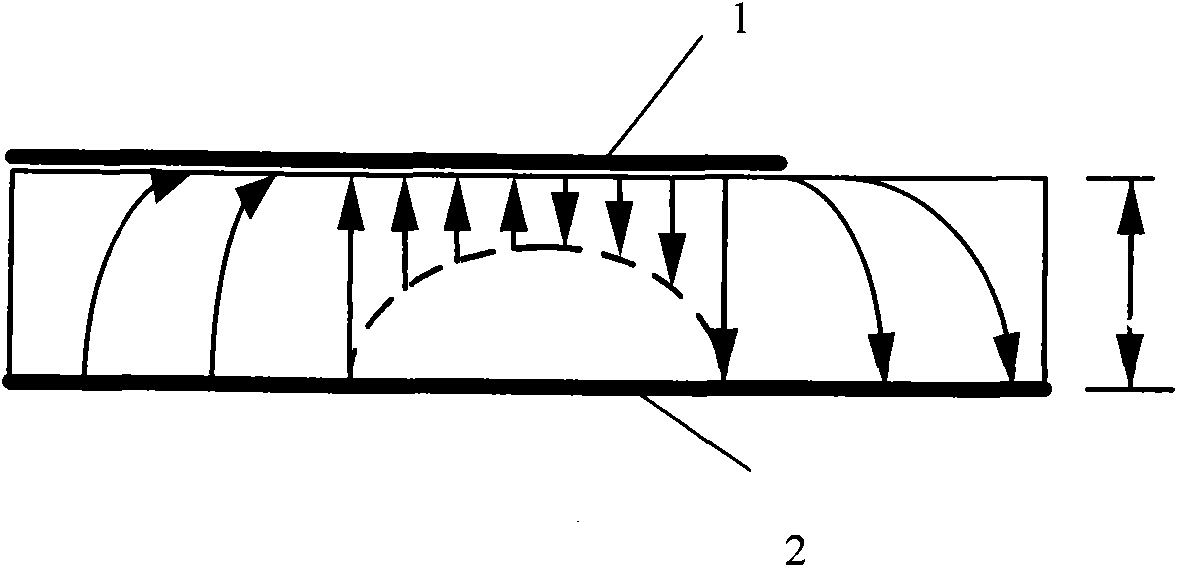

The invention discloses an enhanced radiation three-dimensional packaging structure and a packaging method for the same. The enhanced radiation three-dimensional packaging structure comprises a multilayer substrate, devices and an interconnection circuit for connecting the devices on the substrate, a micro-channel, a radiation plate, an external radiation device and a water pump. According to the enhanced radiation three-dimensional packaging structure and the packaging method for the same, a micro-fluid convection heat transfer mode is used for quickly conducting away the vast majority of heat produced by heating devices, and the three-dimensional interconnection circuit consisting of good metal conductors connected with the heating devices in the substrate is used for assisting the conduction of the heat into and out of the substrate in a metal heat conduction way; the radiation plate at the bottom of the substrate can be connected with various types of external radiation devices, so that the problem of thermally-induced failures of a multi-chip electronic product is effectively solved; process conditions are easy to implement, and the enhanced radiation three-dimensional packaging structure and the packaging method for the same are low in cost and convenient to machine in batches, and can be widely applied to a plurality of fields of aerospace, information communication, biochemistry, medicines, automatic control, consumer electronics and the like related to national electronic development and national security.

Owner:PEKING UNIV

MEMS device vacuum encapsulation method

InactiveCN101301993APlan Size and Cost SavingsDiverse microstructurePrecision positioning equipmentSoldering apparatusRadio frequencyCo-fired ceramic

The invention provides a method for vacuum packaging MEMS device by using low temperature co-fired ceramic substrate, comprising the following steps: first using the low temperature co-fired ceramic multilayer circuit structure and three-dimensional wiring to fully embed each passive component and transmission line etc. into the substrate dielectric; then bonding or welding the MEMS device onto the substrate and finishing the electrical connection; finally gaining the vacuum packaging for MEMS device by directly taking the integration of low temperature co-fired ceramic substrate with MEMS device as the base of the package, the metal package for traditional hybrid integrated circuit as the cap, and combining with traditional sealing methods, such as laser seal, land seal and metal tube seal. The technology conditions of the method has advantages of simple to realize, low in cost and easy to batch processes, and realizes vacuum seal for leads, greatly reduces leak bias rate, increases vacuum lifetime performance, particularly applicable to vacuum packaging for application of radio frequency / microwave and inert etc. oriented MEMS devices.

Owner:PEKING UNIV

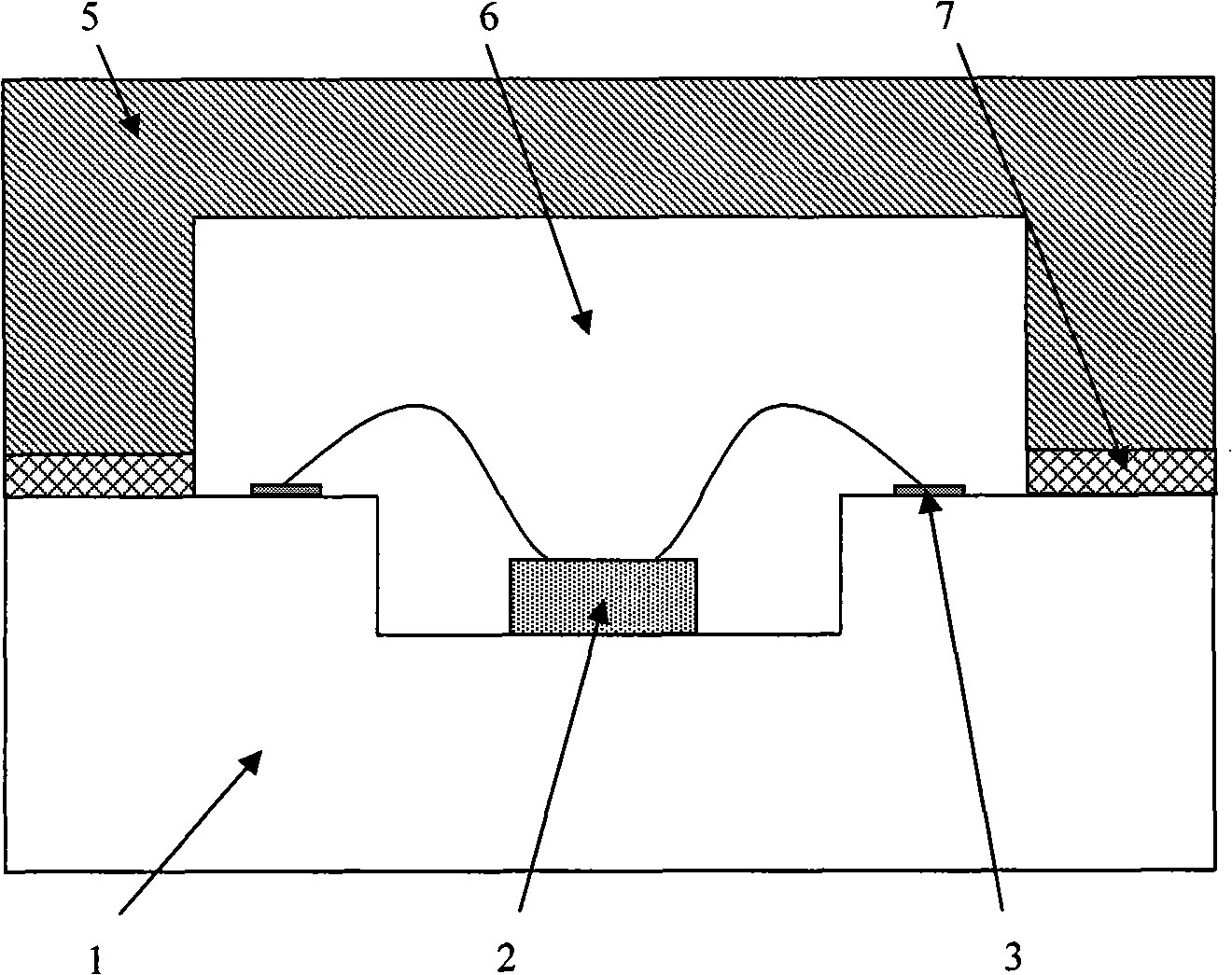

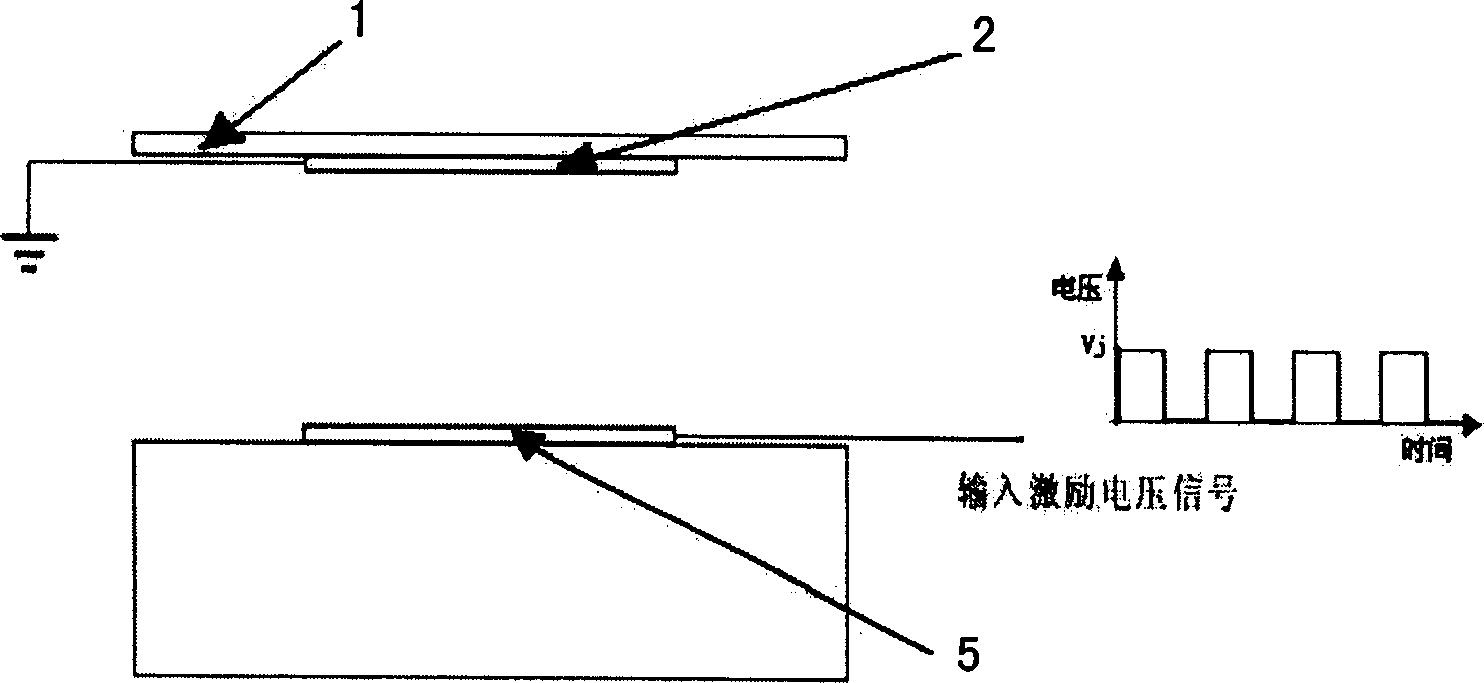

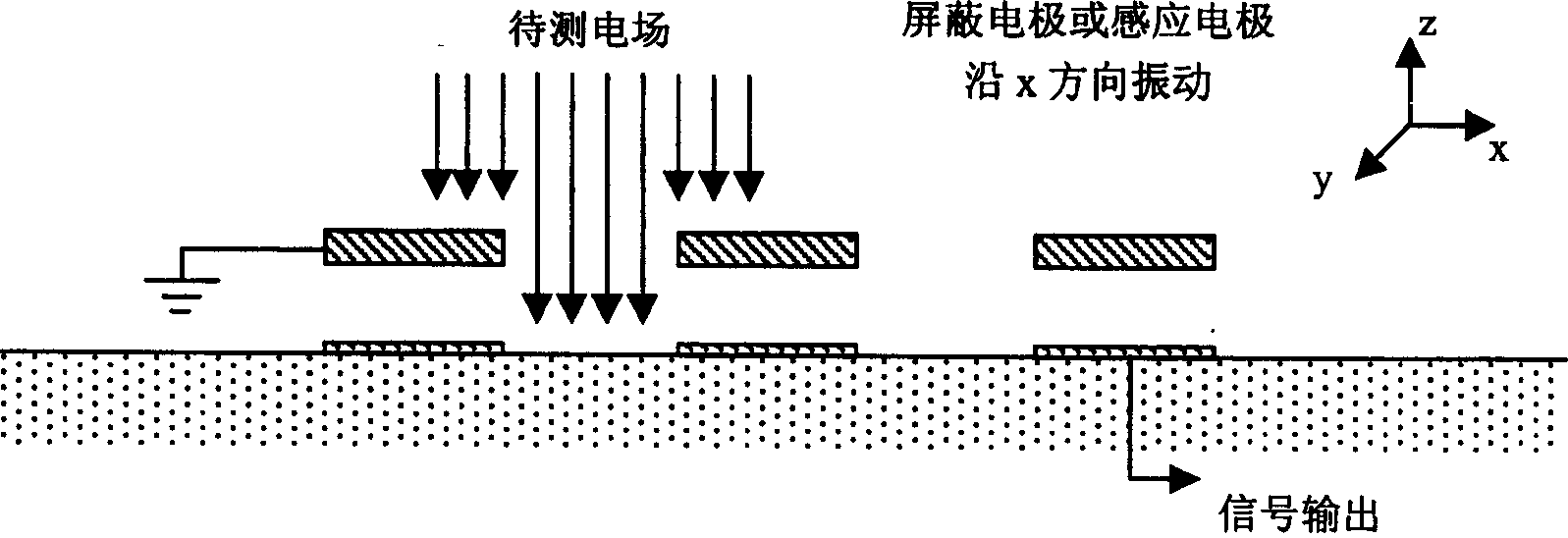

Vibrative micro electric field sensor

InactiveCN1492235AReduce volumeEasy to batch processElectrical measurementsElectric field sensorAcoustics

The vibration type micro electric field sensor includes vibration part and induction part, the vibration part is vibration film, the first excitation electrode and shielding electrode on the vibration film, and the induction part has the second excitation electrode and inducing electrode. The micro electric field sensor prepared based on the micro machining technology has small volume and low cost and is easy to mass produce.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

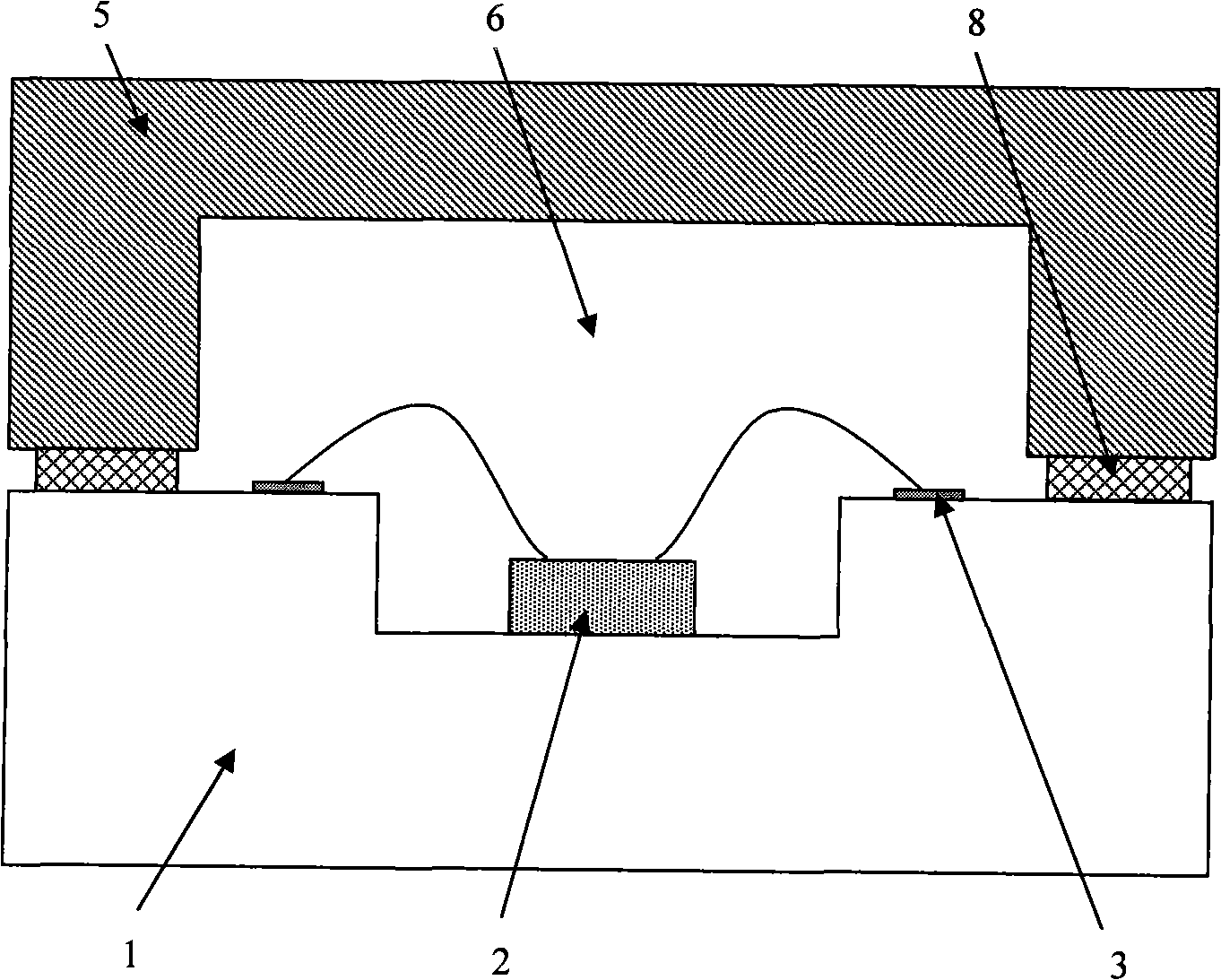

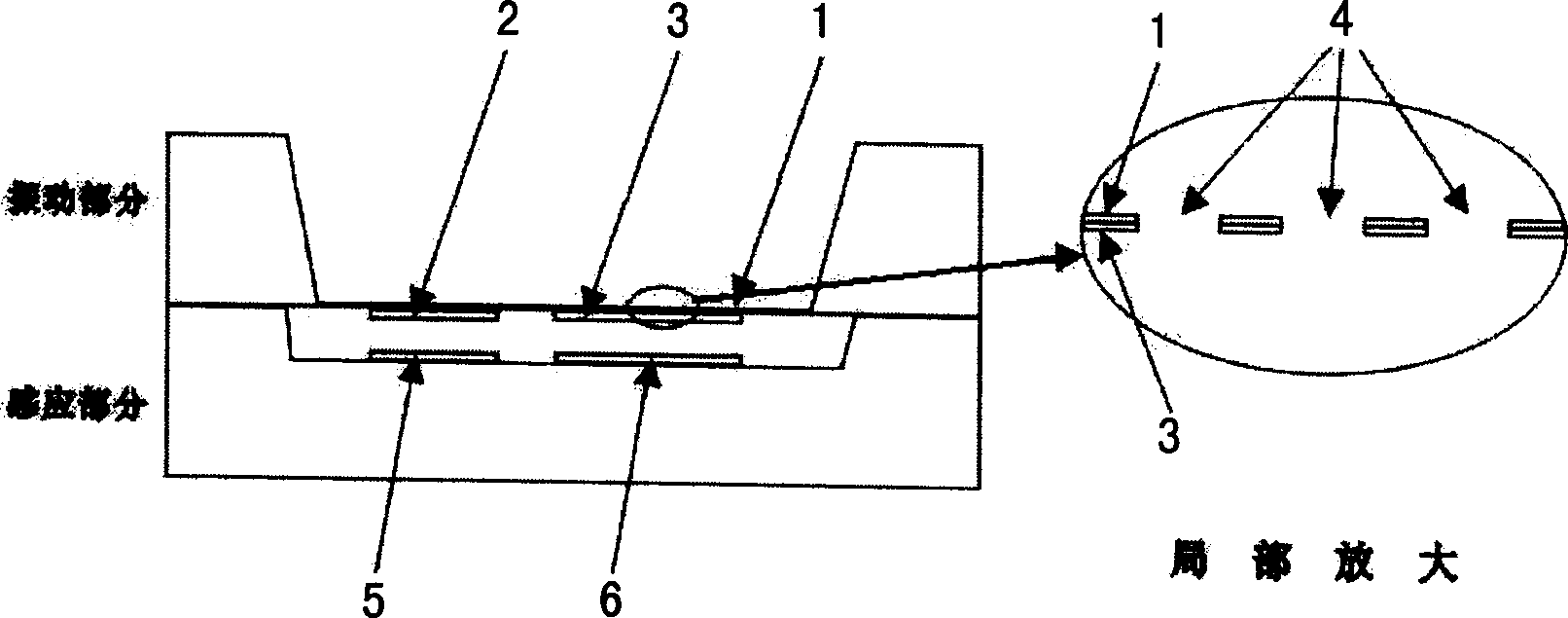

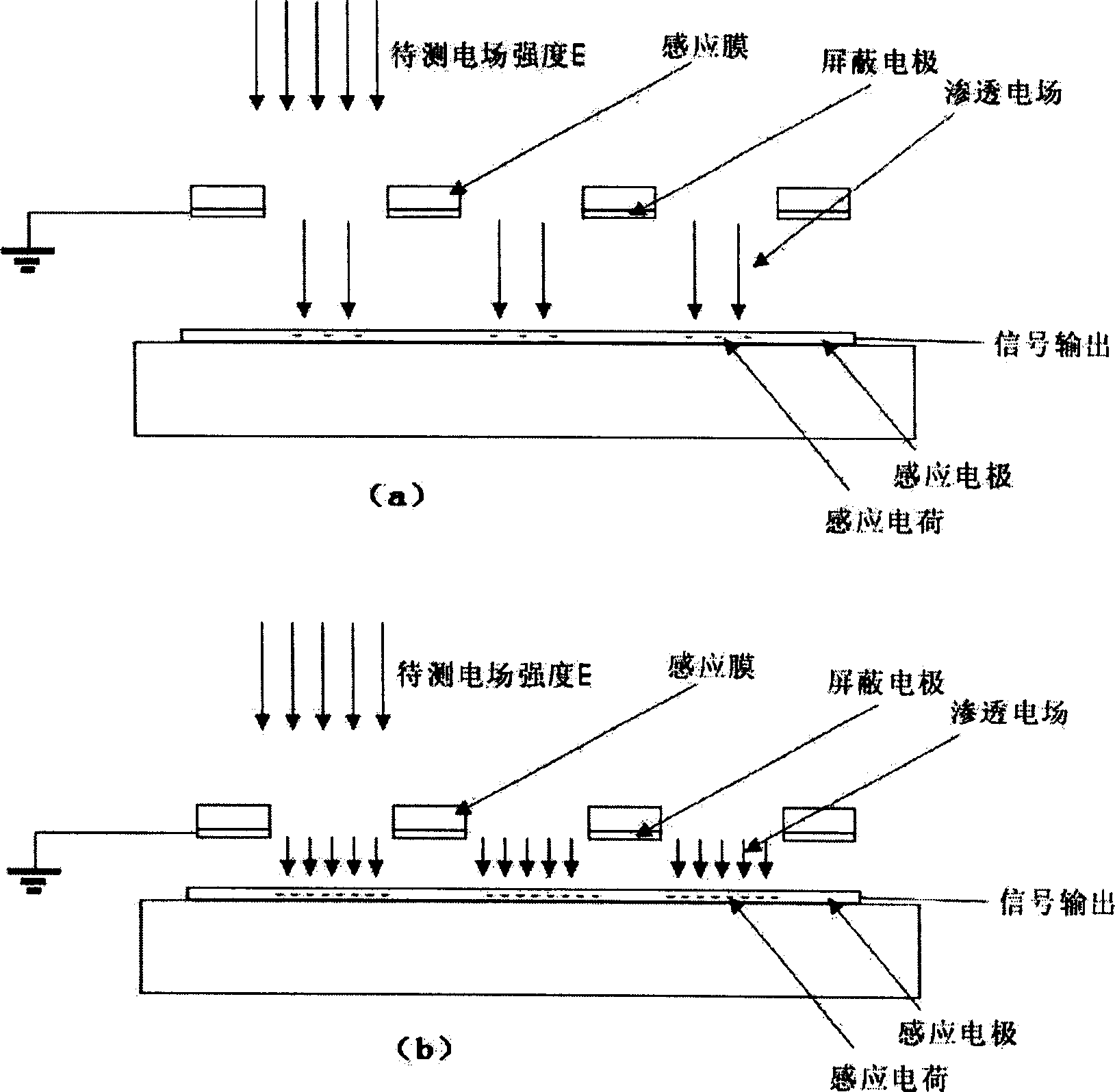

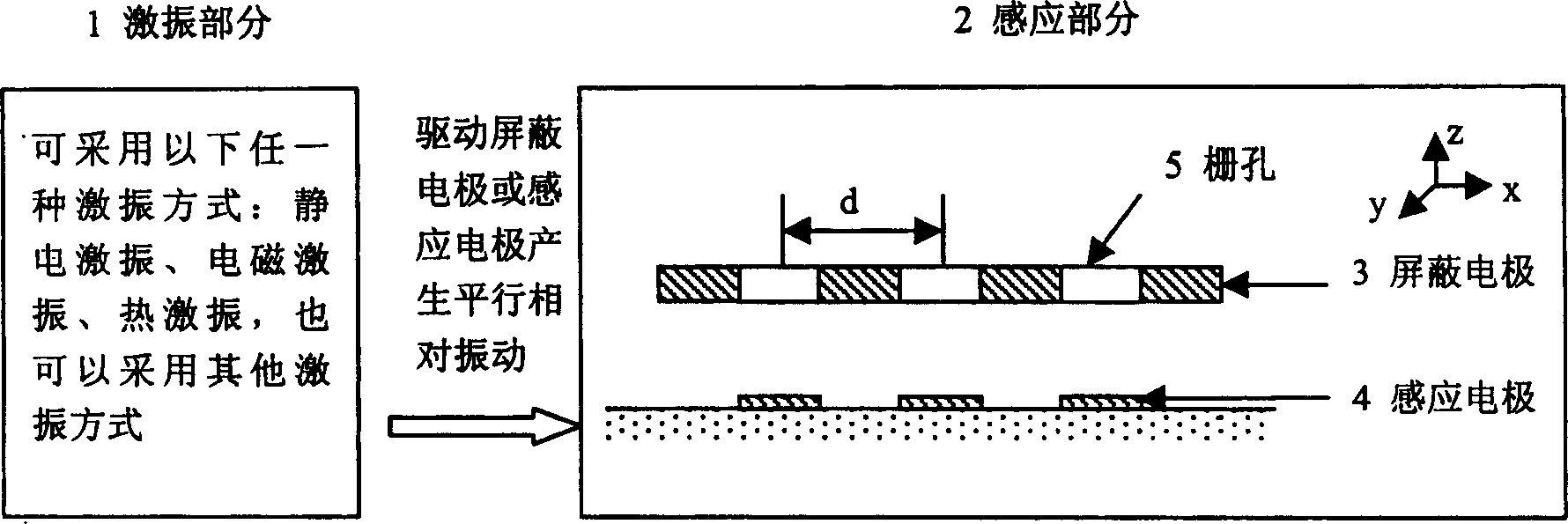

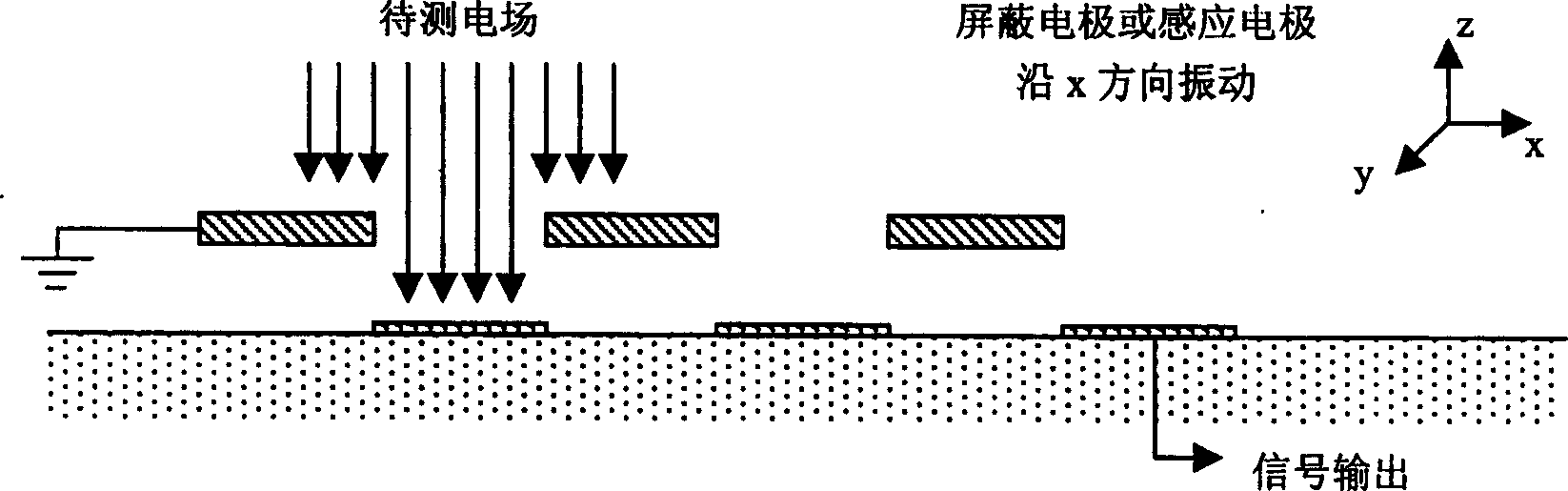

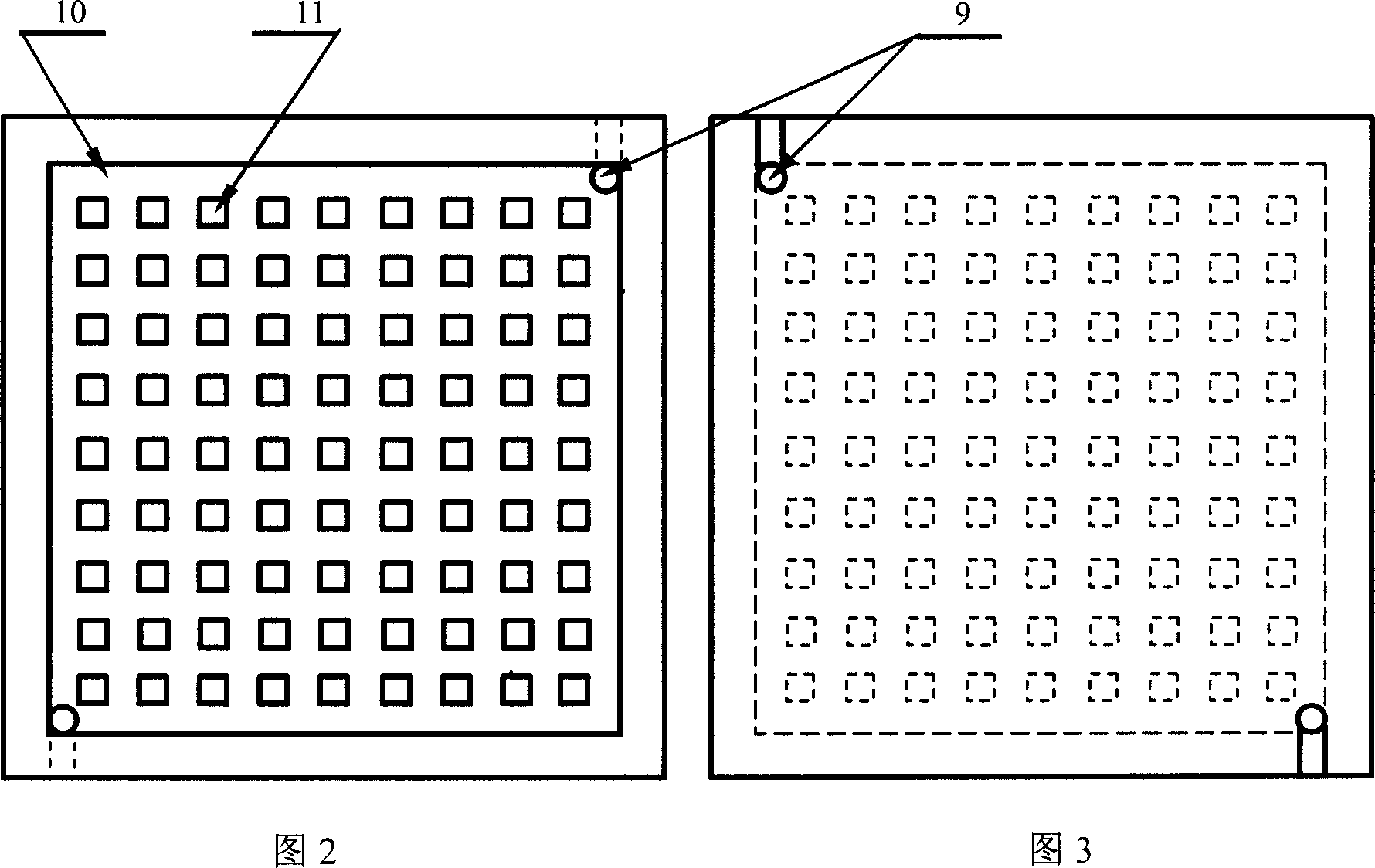

Parallel vibration pattern minitype electric field sensor

InactiveCN1525181AReduce volumeLow costConverting sensor output electrically/magneticallyElectrostatic field measurementsElectric field sensorRelative motion

The invention is a parallel vibrating micro electric field sensor, including: a vibration exciting part and a sensing part; the sensing part is composed of a screened electrode and a sensing electrode; there is a grating hole on the screened electrode. Under the action of vibration exciting driving force, the two electrodes move, relatively, horizontally and periodically. Compare with erect vibrating electric field, it has small air damping when vibrating and flexible vibration exciting driving mode, beneficial to reducing the electric interference between the vibration exciting signal and sensing signal.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

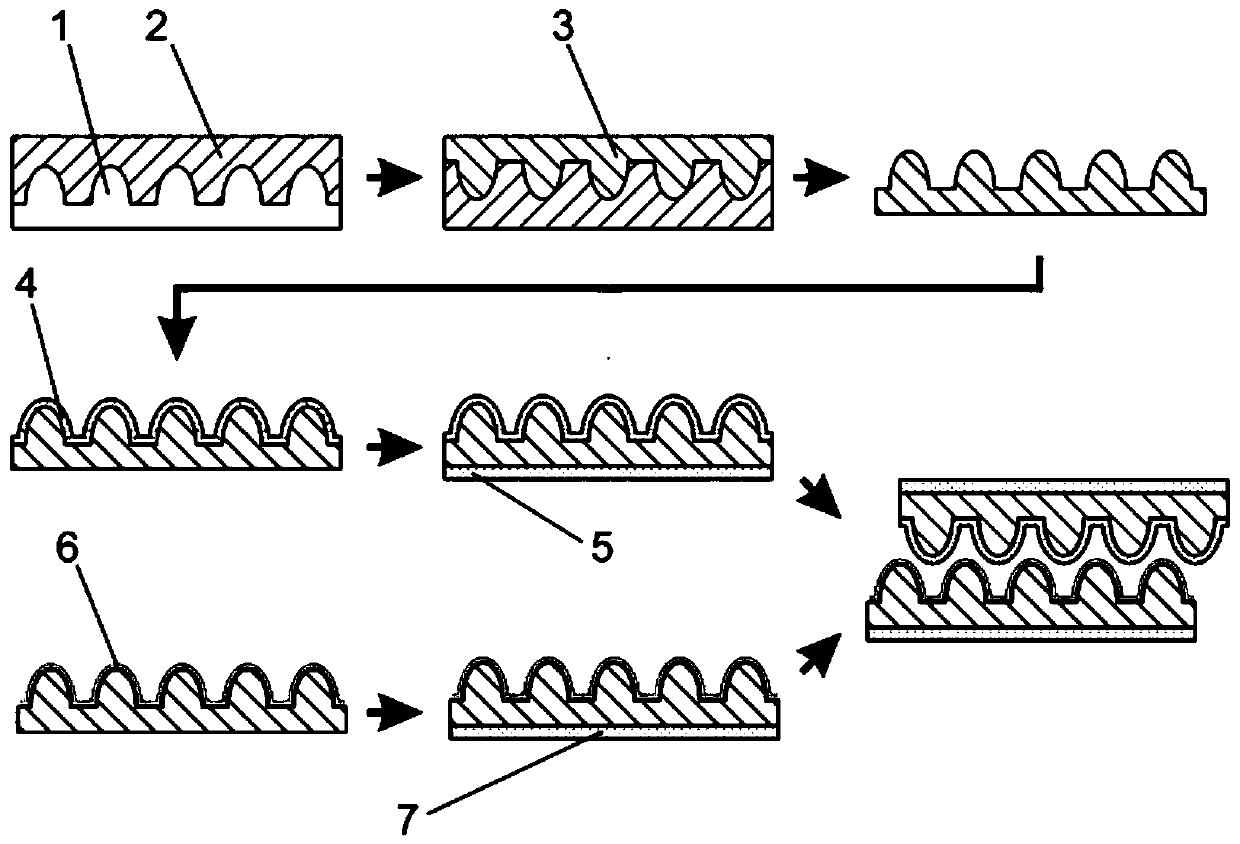

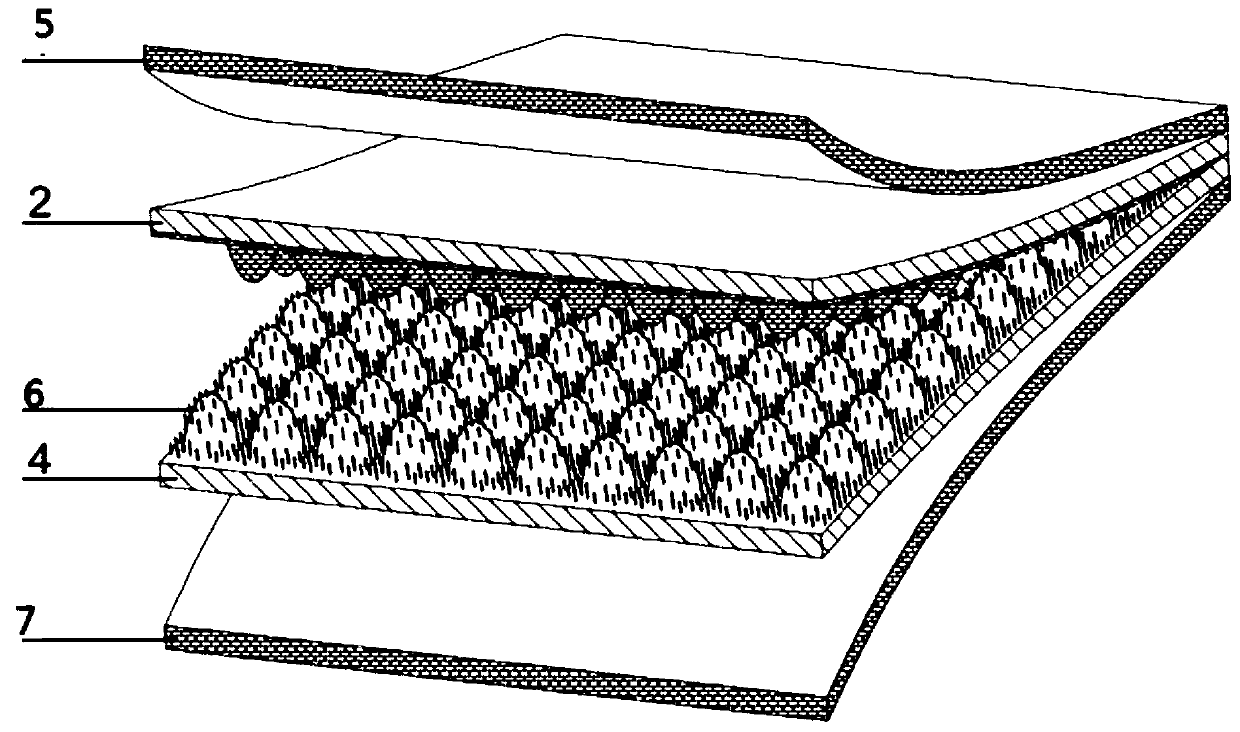

Bionic flexible force sensor and preparation method thereof

ActiveCN110329986ASimple processAvoid micro-nano fabrication processPiezoelectric/electrostriction/magnetostriction machinesDecorative surface effectsMicro nanoFlexible electronics

The invention belongs to the related technical field of flexible electronics, and discloses a bionic flexible force sensor and a preparation method thereof, the method comprises the following steps: (1) preparing a flexible substrate through a reverse mold technology, and forming a bionic microstructure on the surface of the flexible substrate; (2) preparing a layer of silver nanowire and a layerof micro hair on the bionic microstructures of the two flexible substrates respectively, and preparing a shielding layer and a negative friction layer back electrode on the surfaces, opposite to the surface where the bionic microjunctions are located, of the two corresponding flexible substrates respectively, so as to obtain a positive friction layer and a negative friction layer; and (3) packaging the positive friction layer and the negative friction layer to form a flexible force sensor, wherein the bionic microstructure of the positive friction layer and the bionic microstructure of the negative friction layer are interlocked to form interlocking. According to the invention, a complex micro-nano manufacturing process is avoided, the flow is simplified, the process is simple, and the implementation is easy.

Owner:HUAZHONG UNIV OF SCI & TECH

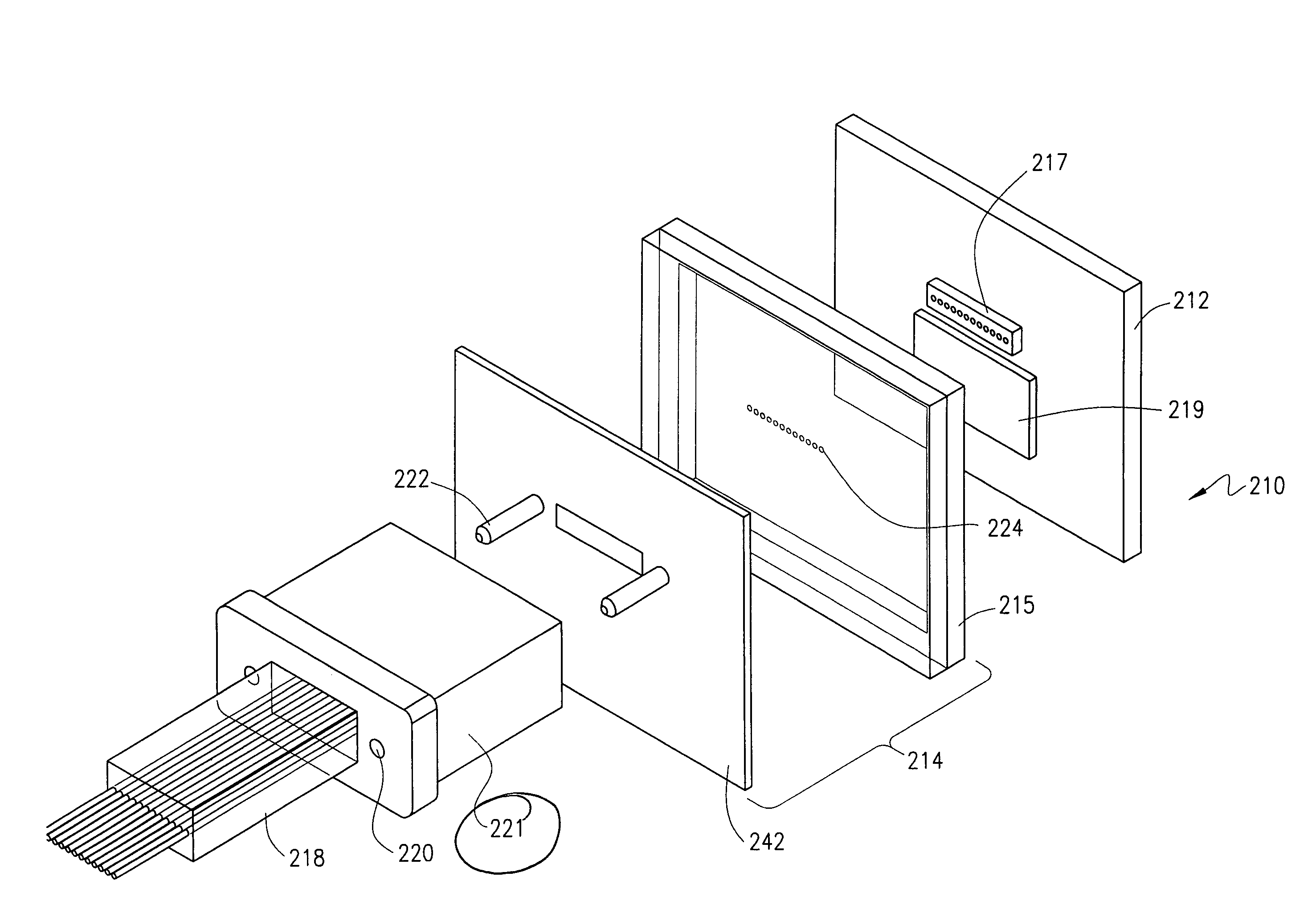

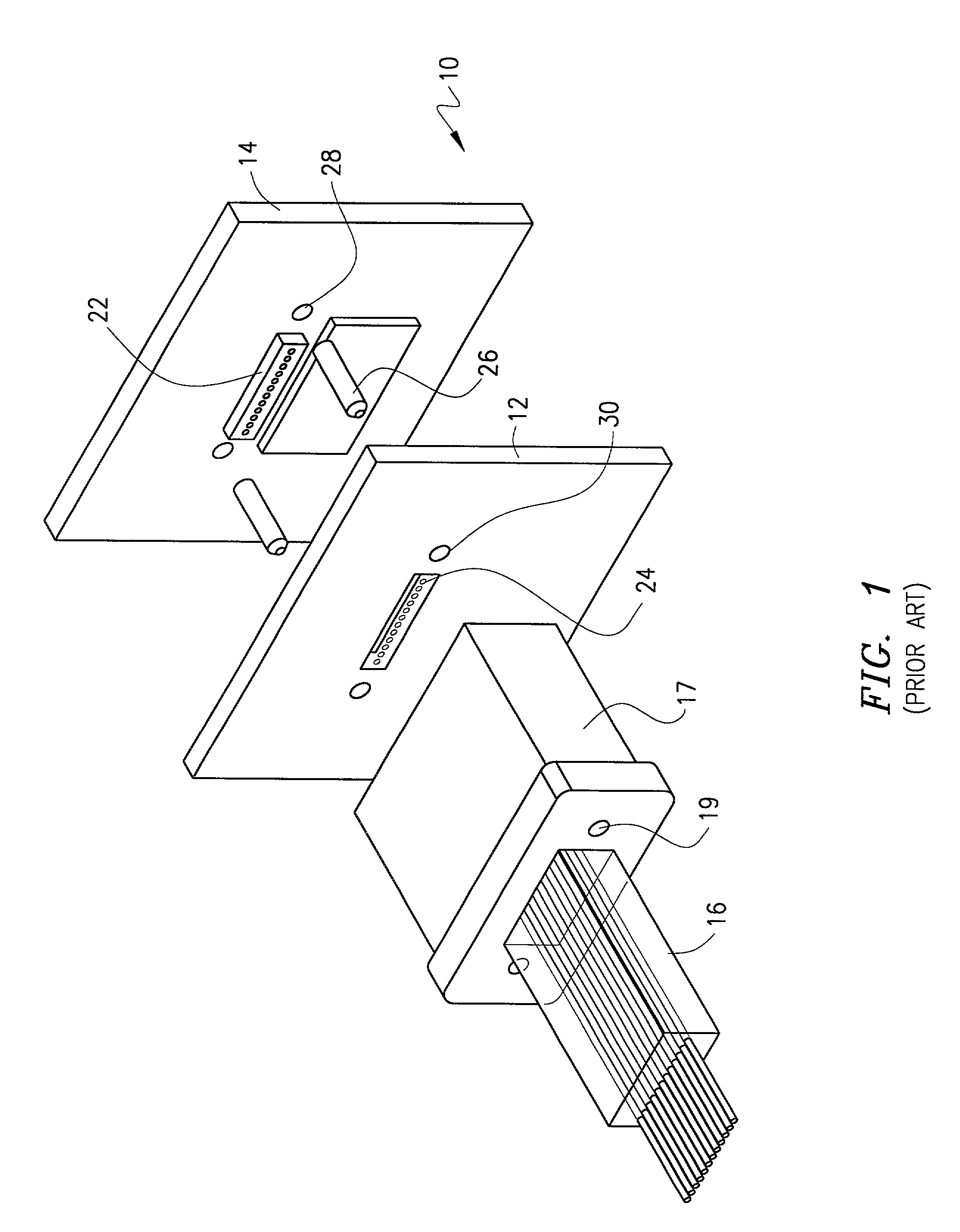

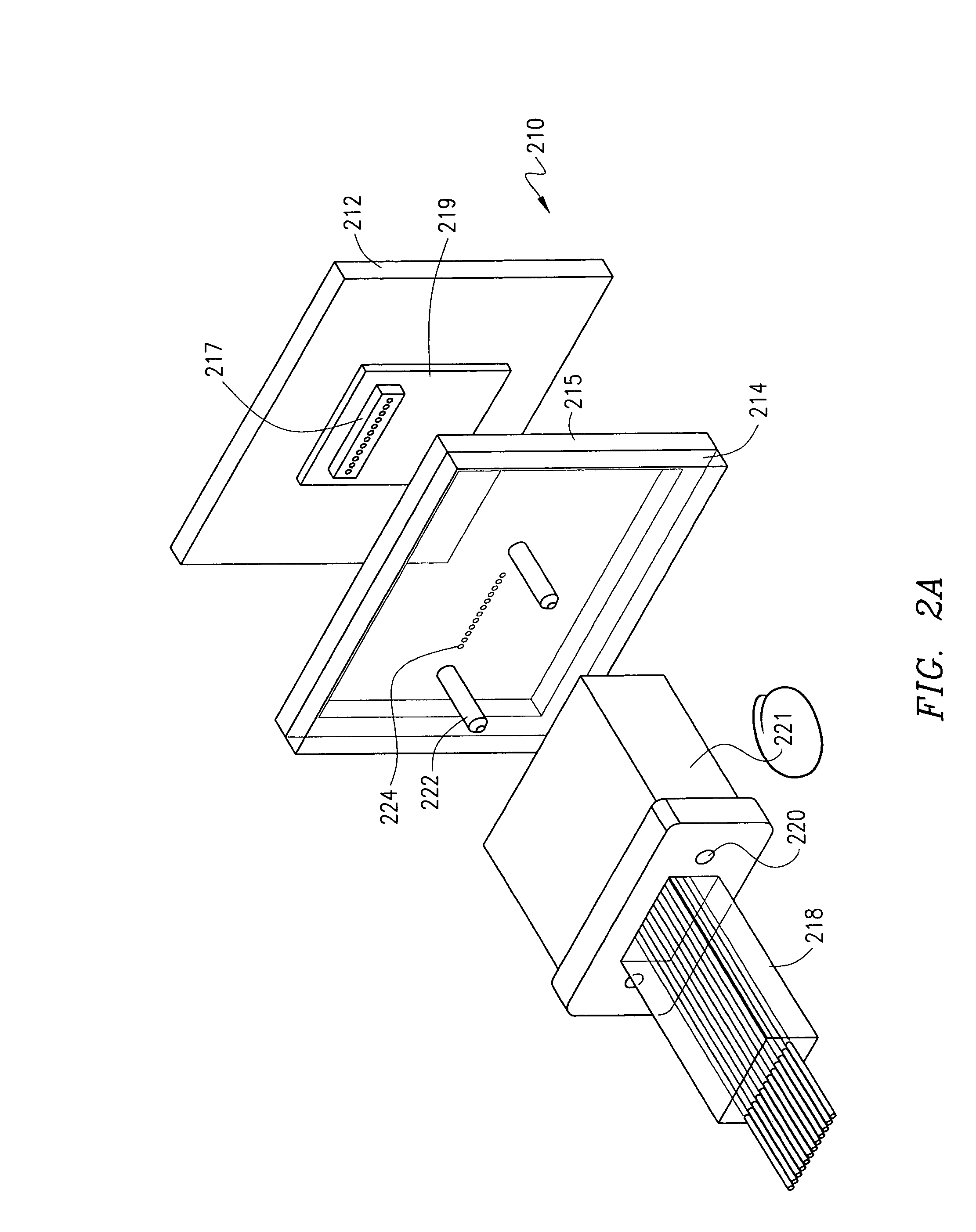

Optical device, enclosure and method of fabricating

InactiveUS7128474B2Easy to batch processMinimize the numberCoupling light guidesEngineeringOptical communication

An enclosure for an optical communications device having a lid portion and a base portion. Alignment members adapted to interface with an optical connector are formed on the lid portion. The lid portion is affixed to the base portion with a portion of the communications components therebetween. Multiple base portions formed in a unitary piece of material and multiple lid portions formed in another unitary piece of material can be affixed to one another, and then separated into individual devices to minimize time spent aligning each base and lid portion.

Owner:BROADCOM INT PTE LTD

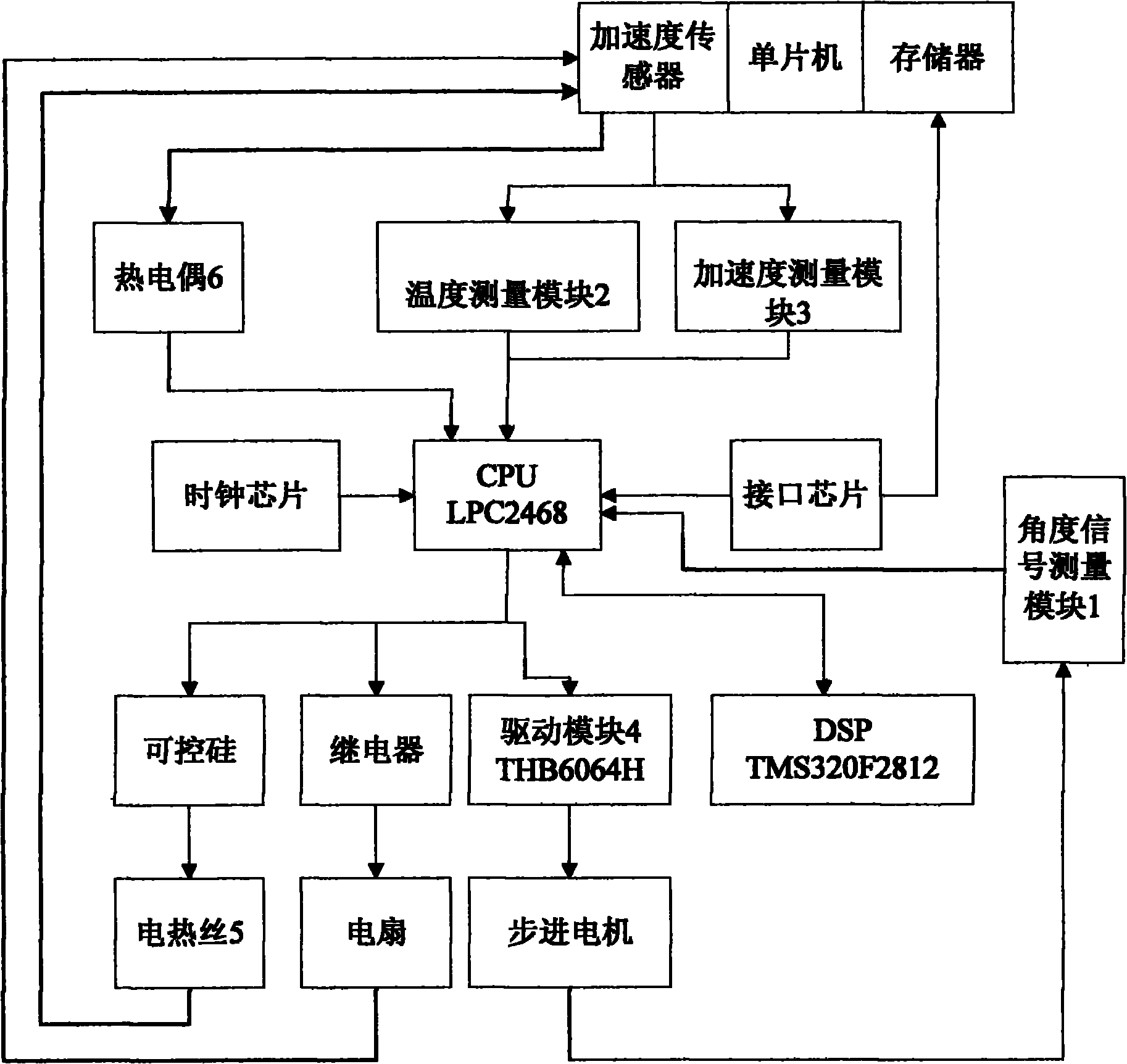

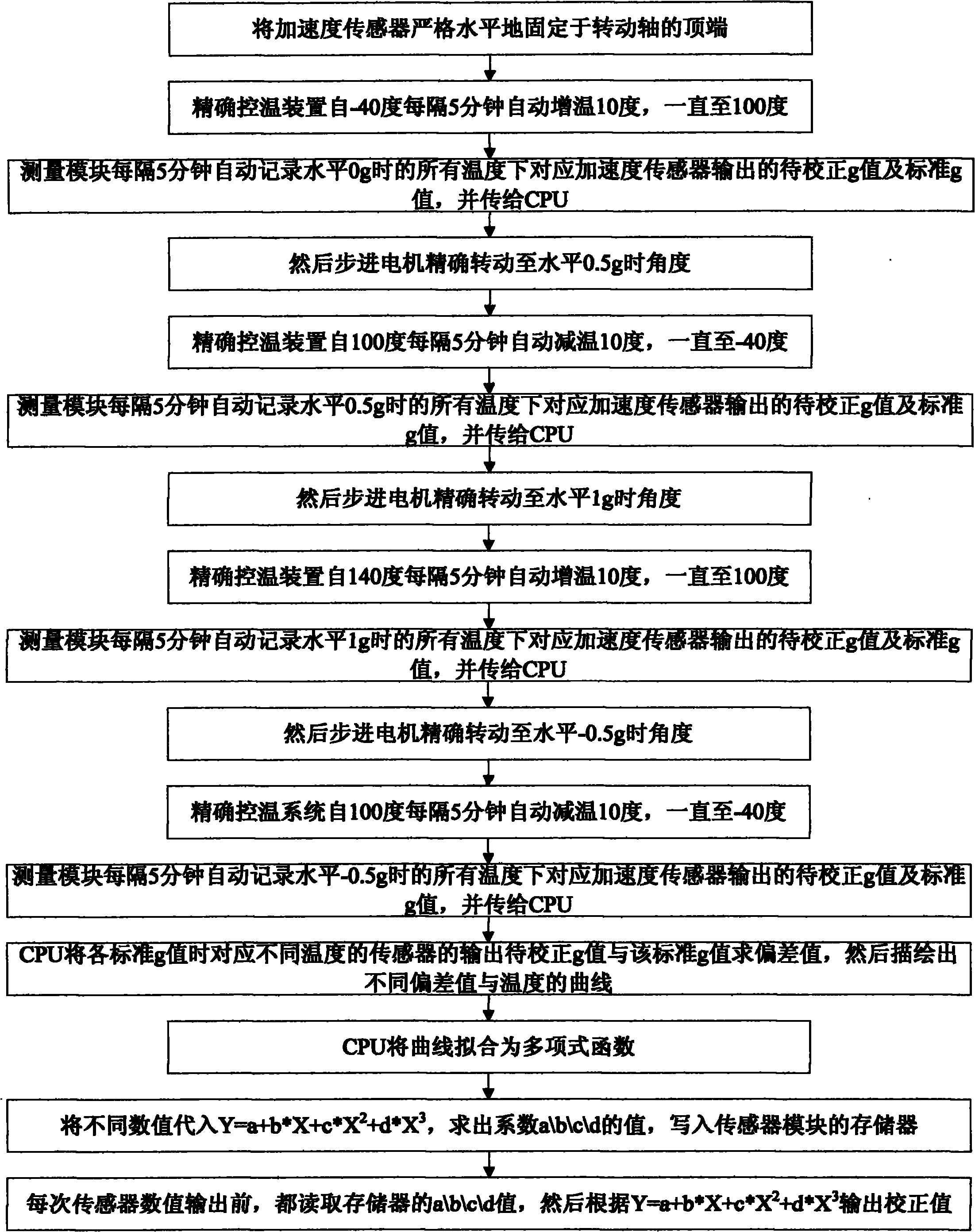

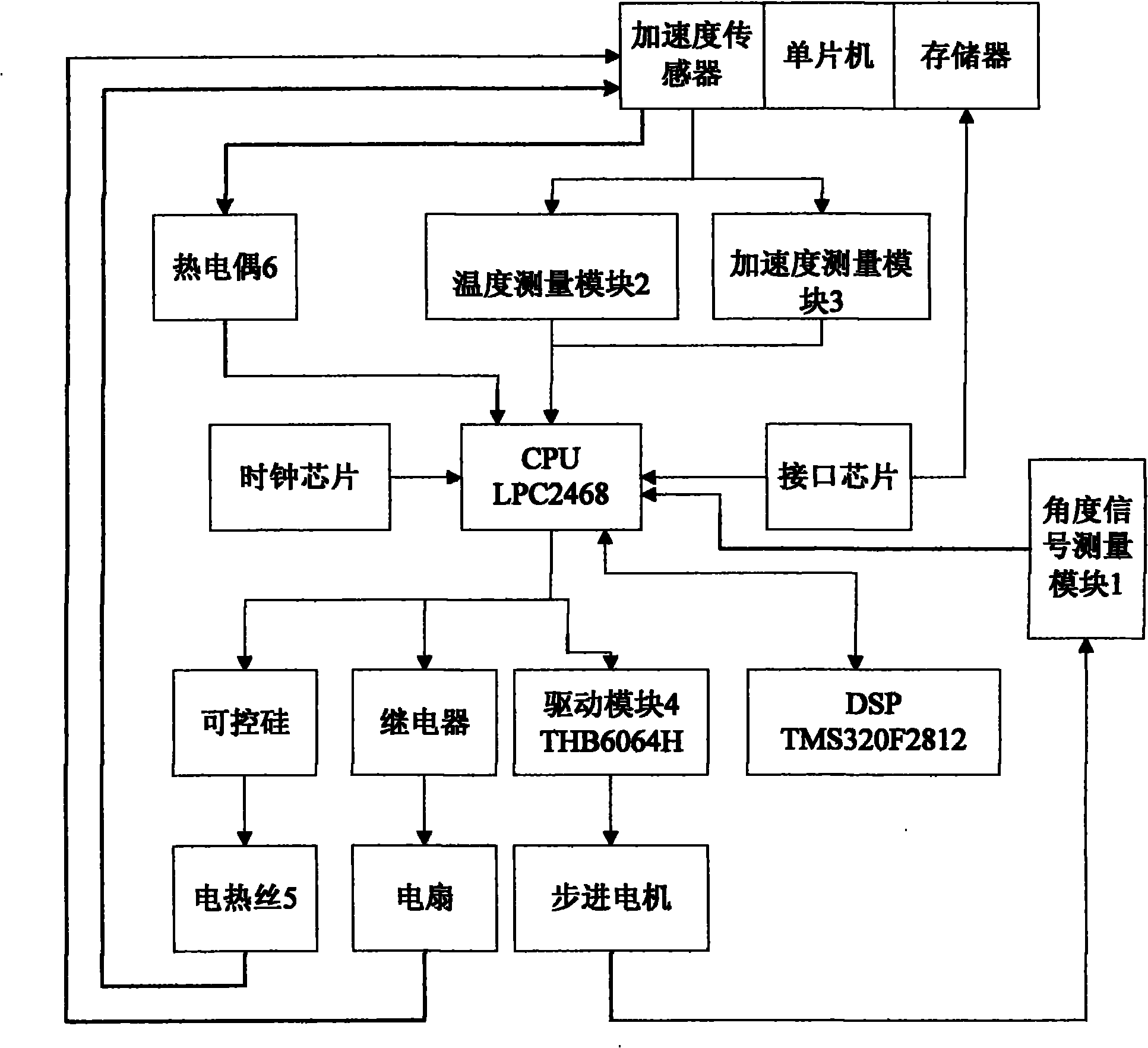

Full-automatic correction system for acceleration sensor

InactiveCN101968496AHigh measurement accuracyGet fastTesting/calibration of speed/acceleration/shock measurement devicesTemperature controlQuaternion

The invention discloses a full-automatic correction system for an acceleration sensor. The system comprises an accurate temperature-control device, an angle signal measurement module, a temperature measurement module, an acceleration measurement module, a drive module and a central processing unit (CPU), wherein the CPU is connected with the accurate temperature-control device, the angle signal measurement module, the temperature measurement module, the acceleration measurement module and the drive module; and the CPU calculates the offset value of a g value to be corrected corresponding to the acceleration sensor and the standard g value under each standard g value at different temperatures, and calculates a corresponding curve of the offset value and temperature, performs polynomial fitting on the curve, resolves the coefficients of quaternion linear equation, and writes the coefficient values into the memory of the acceleration sensor for correction. The system can automatically correct the acceleration sensor, removes the problems of null drift and temperature drift, and improves the measurement accuracy of the acceleration sensor.

Owner:中山市嘉科电子有限公司

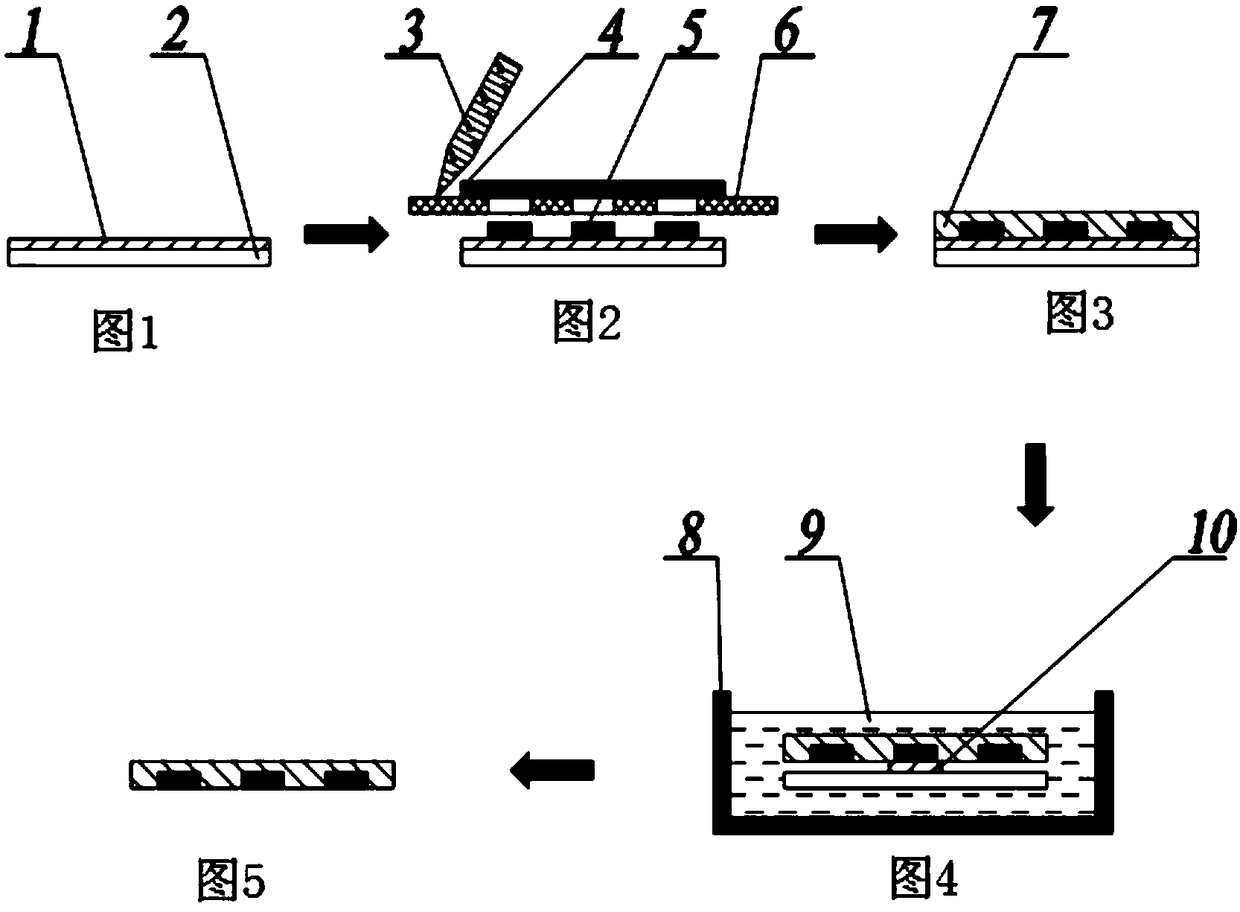

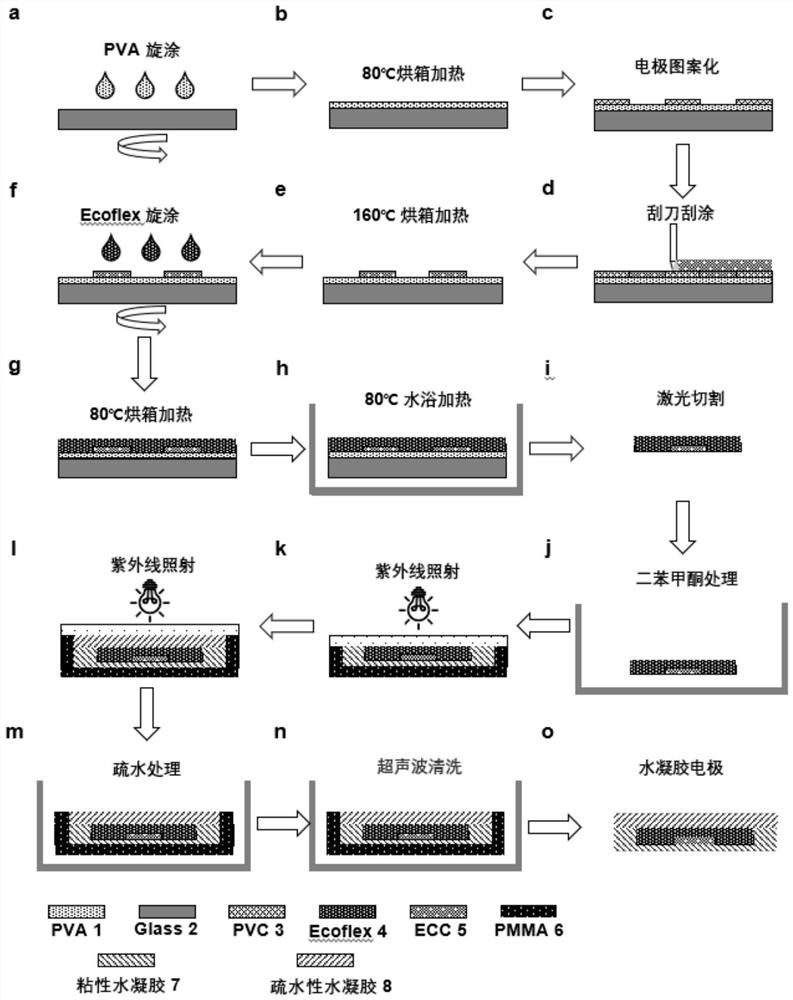

Preparing method of human body epidermis physiology electrode sensor

ActiveCN109077713AReduce contact resistanceIncrease contact areaDiagnostic recording/measuringSensorsPolyvinyl alcoholDynamic monitoring

The invention belongs to the field of flexible electronics, and discloses a preparing method of a human body epidermis physiology electrode sensor. The method comprises the following steps of 1, cleaning and blow-drying a hard substrate; 2, spin-coating the hard substrate with a polyvinyl alcohol solution, and heating and curing for film formation to form a sacrificial layer; 3, installing a screen printing plate and the hard substrate on a screen printing machine; 4, coating the screen printing plate with a conductive material, and utilizing a scraper for blade coating on the surface of the screen printing plate to form a function layer of the sensor; 5, spin-coating the sacrificial layer with a flexible high polymer, and heating to cure the flexible high polymer; 6, utilizing deionized water for heating to completely dissolve the sacrificial layer, so that the human body epidermis physiology electrode sensor is stripped from the hard substrate. The sensor prepared by means of the method has good wearability, and can move along with the human body without relative displacement; on one hand, the interference of movement with signals is reduced, and dynamic monitoring can be achieved; on the other hand, the sensor is comfortable, can be worn for a long term, and can collect richer physiology signals.

Owner:HUAZHONG UNIV OF SCI & TECH

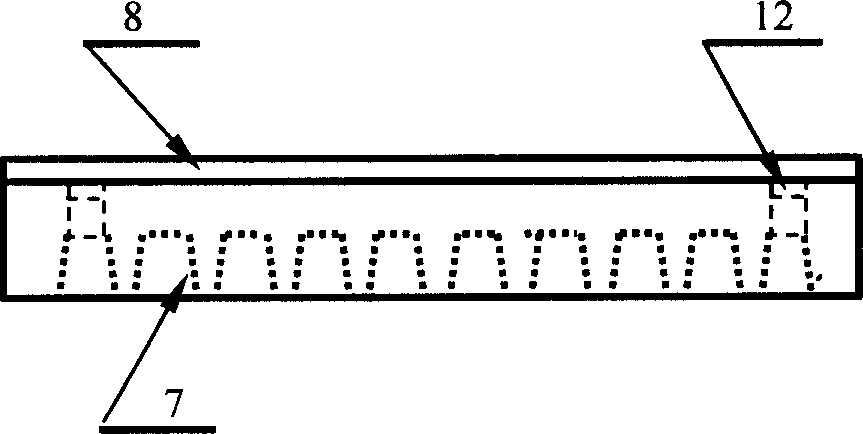

Method for manufacturing minitype liquid methanol fuel cell

InactiveCN1595703ASimple designImprove structural strengthPiezoelectric/electrostriction/magnetostriction machinesFinal product manufactureFuel cellsMethanol fuel

The invention is a manufacturing method for a micro liquid methanol fuel cell, using MEMS technique for processing bipolar plate which is pressed air tightly on membrane electrode and surrounding of fuel cell is sealed by resin glue. Use techniques of oxidation, lithographic process and silicon corrosion to manufacture bipolar plate, and its flow field and liquid inlet and outlet channel is plane arrangement, finally make glass and bipolar plate have bonding and manufacture sediment of vacuum metal layer. The invention can effectively finish the structure of flow field and electric current collection, reduce volume of fuel cell and is suitable for batch production.

Owner:HARBIN INST OF TECH

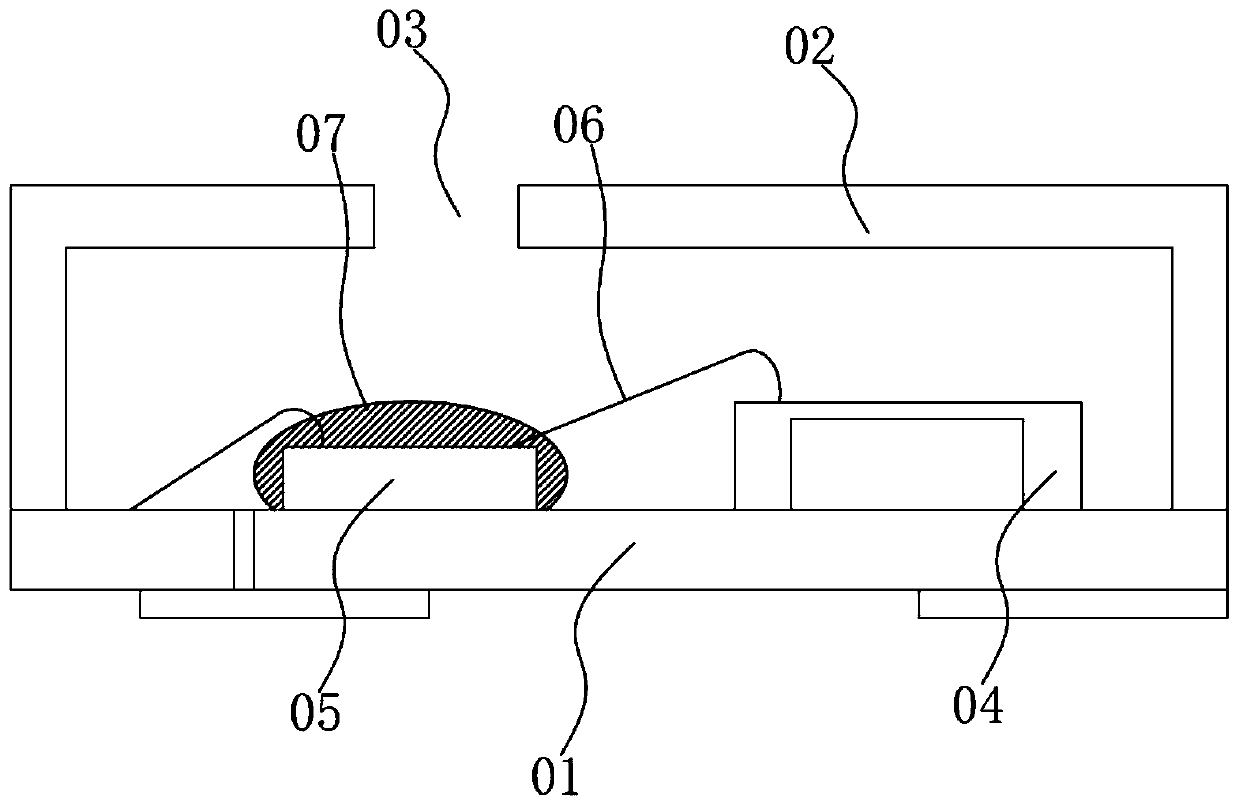

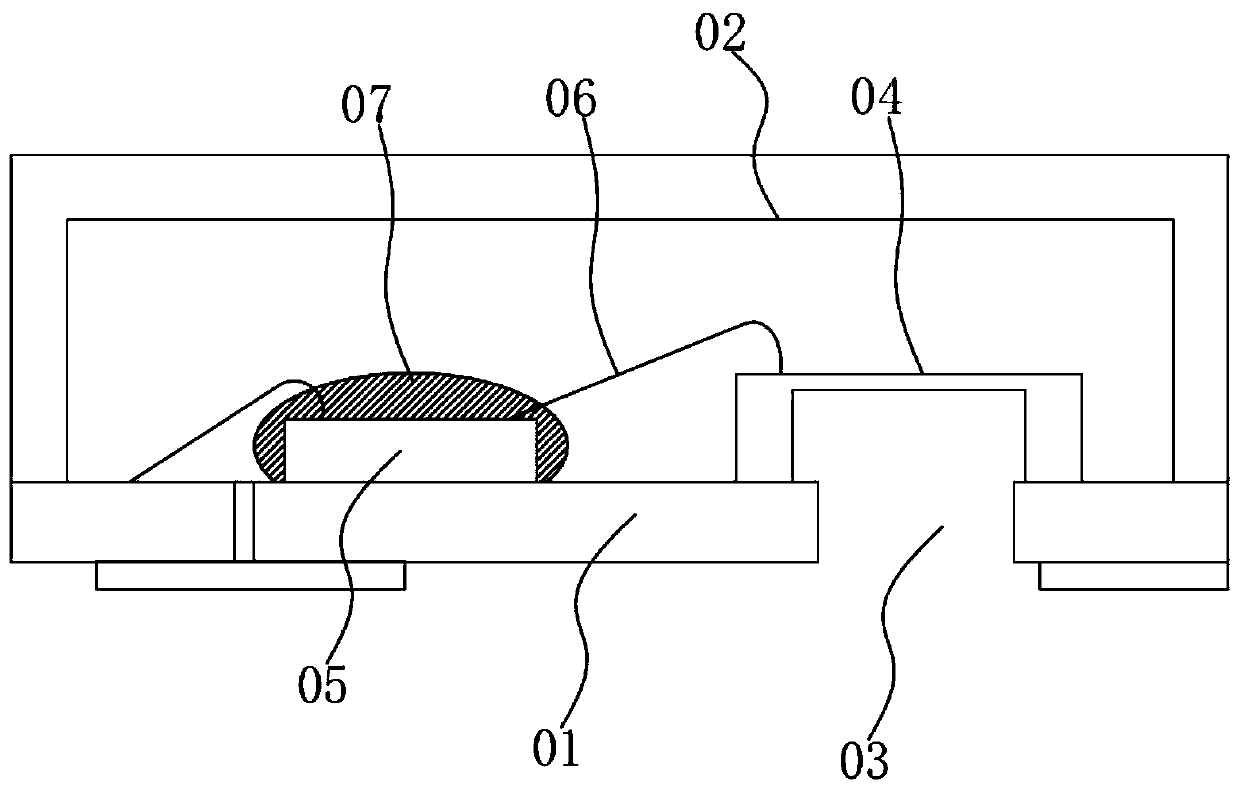

Silicon microphone and processing method thereof

The invention discloses a silicon microphone and a processing method thereof. The silicon microphone comprises a circuit board substrate, an MEMS sound pressure sensing chip and an ASIC chip. The circuit board substrate is provided with a sound inlet hole which is right opposite to an induction area of the MEMS sound pressure sensor chip, wherein the MEMS sound pressure sensing chip and the ASIC chip are in inverted interconnection with the circuit board substrate and are wrapped in the thermosetting plastic film layer, and the thermosetting plastic film layer is fixedly connected with the circuit board substrate and covers the chip mounting surface of the circuit board substrate. According to the scheme, the conventional thinking mode that the silicon microphone is packaged by the metal shell is changed; the MEMS sound pressure sensing chip and the ASIC chip are wrapped by a thermosetting plastic film. Compared with the prior art, the structure of a metal shell is omitted, the size of a device is greatly reduced, meanwhile, the connection stability of the thermosetting plastic film layer and the circuit board substrate is higher than that of a conventional conductive adhesive, welding operation is not needed, the problem of chip pollution possibly generated in the welding process is avoided, and the combination of the structural stability of a product and the improvement of the yield is effectively achieved.

Owner:SUZHOU JIEYANXIN NANO TECH CO LTD

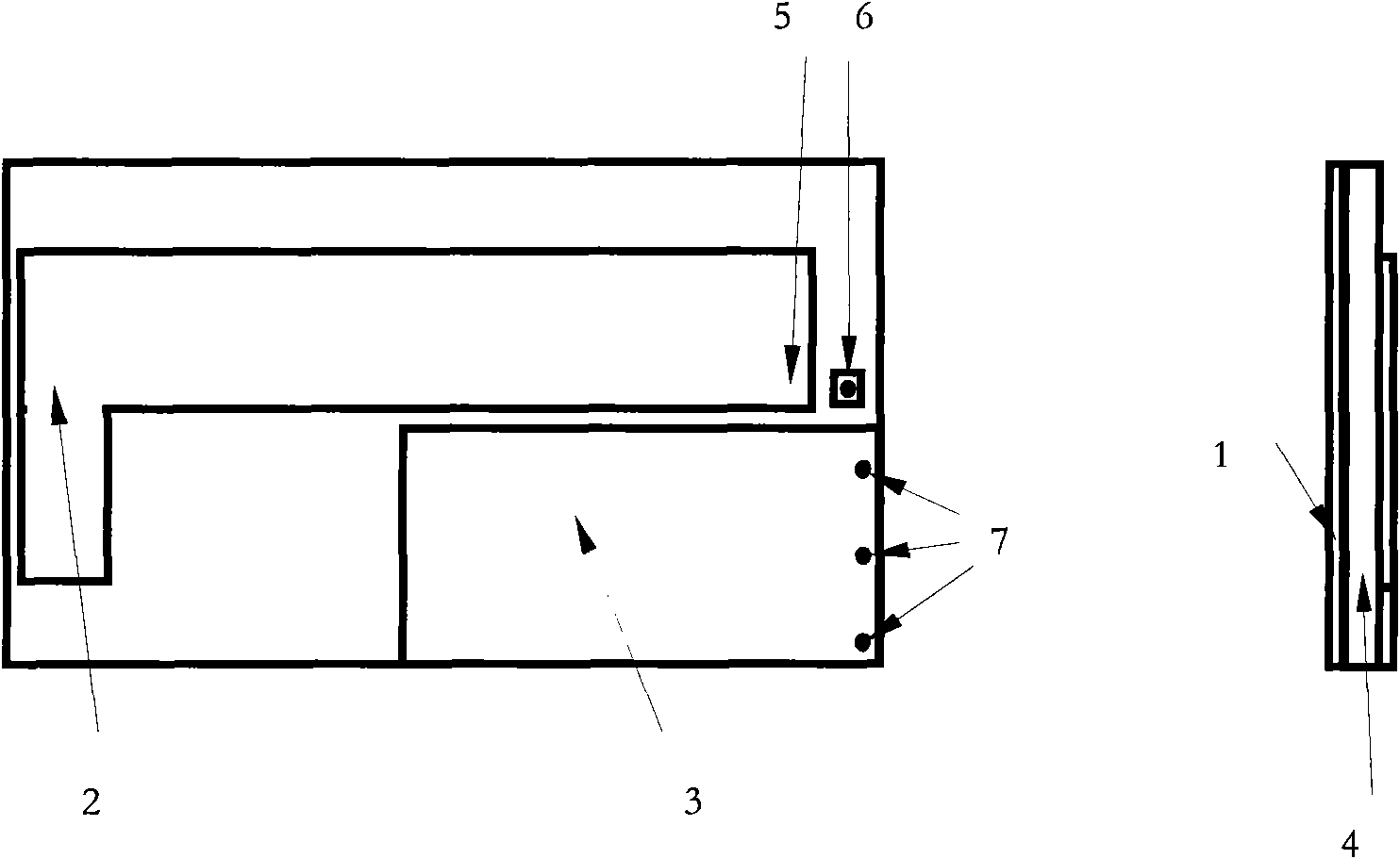

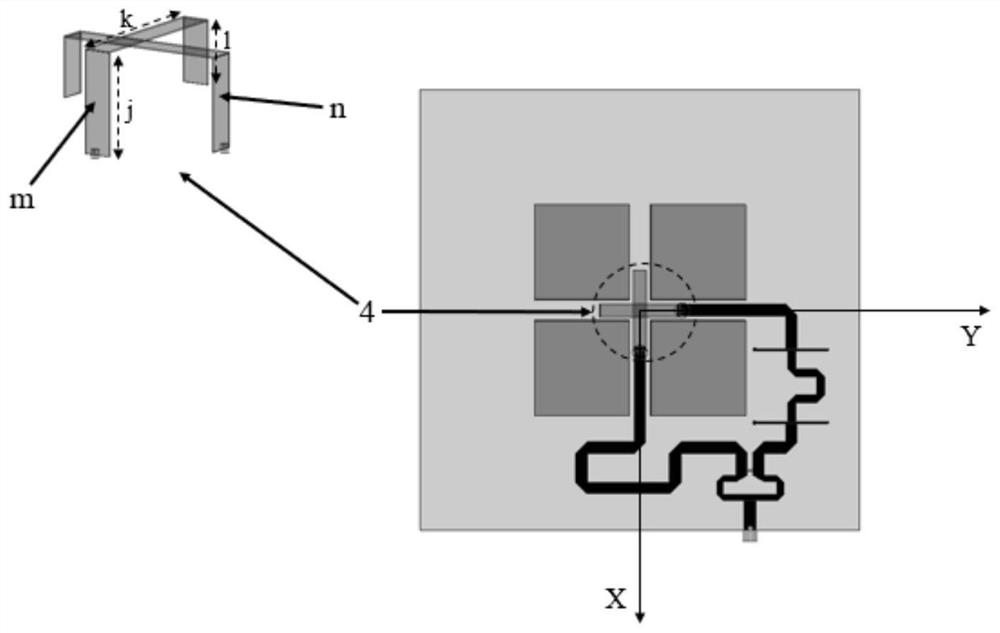

Metal electronic tag antenna

ActiveCN101527390ARadiation area is largeGood directionRadiating elements structural formsAntenna feed intermediatesElectrical conductorTag antenna

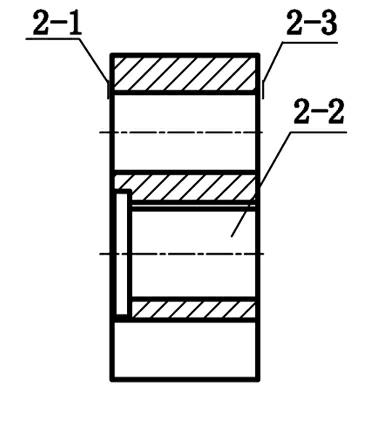

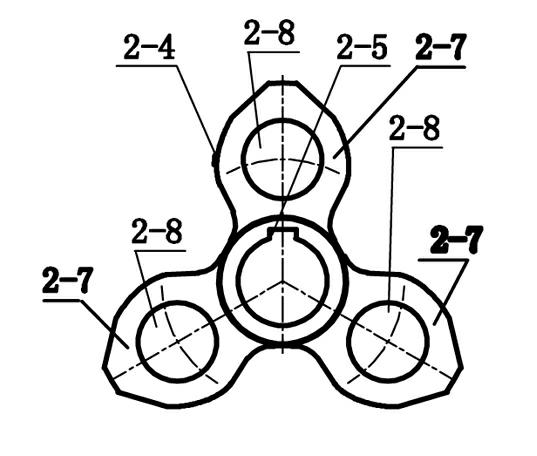

The invention discloses a high-gain and small-sized metal electronic tag antenna, which is formed by combining a microstripe antenna and a dipole antenna, wherein the microstripe antenna consists of a ground plate (1) and a main radiator (2), and the dipole antenna consists of a first arm (2) and a second arm (3); the main radiator (2) of the microstripe antenna and the first arm (2) of the dipole antenna share the same conductor; and a direct current short circuit is formed between the ground plate (1) of the microstripe antenna and the second arm (3) of the dipole antenna. The structure of the antenna comprises a bottom layer, a middle layer and a top layer, wherein the bottom layer is the ground plate (1), the top layer comprises the two arms of the dipole antenna, the middle layer comprises an FR4 substrate material (4) and a through hole (7), the substrate material (4) is used for filling a gap between the bottom layer and the top layer, and the through hole is used for the electric connection of two solid bodies on two sides of the substrate material (4). The antenna intelligently combines the microstripe antenna and the microstripe antenna and realizes the direct attachmentof the electronic tag on a metal surface.

Owner:ZTE INTELLIGENT IOT TECH

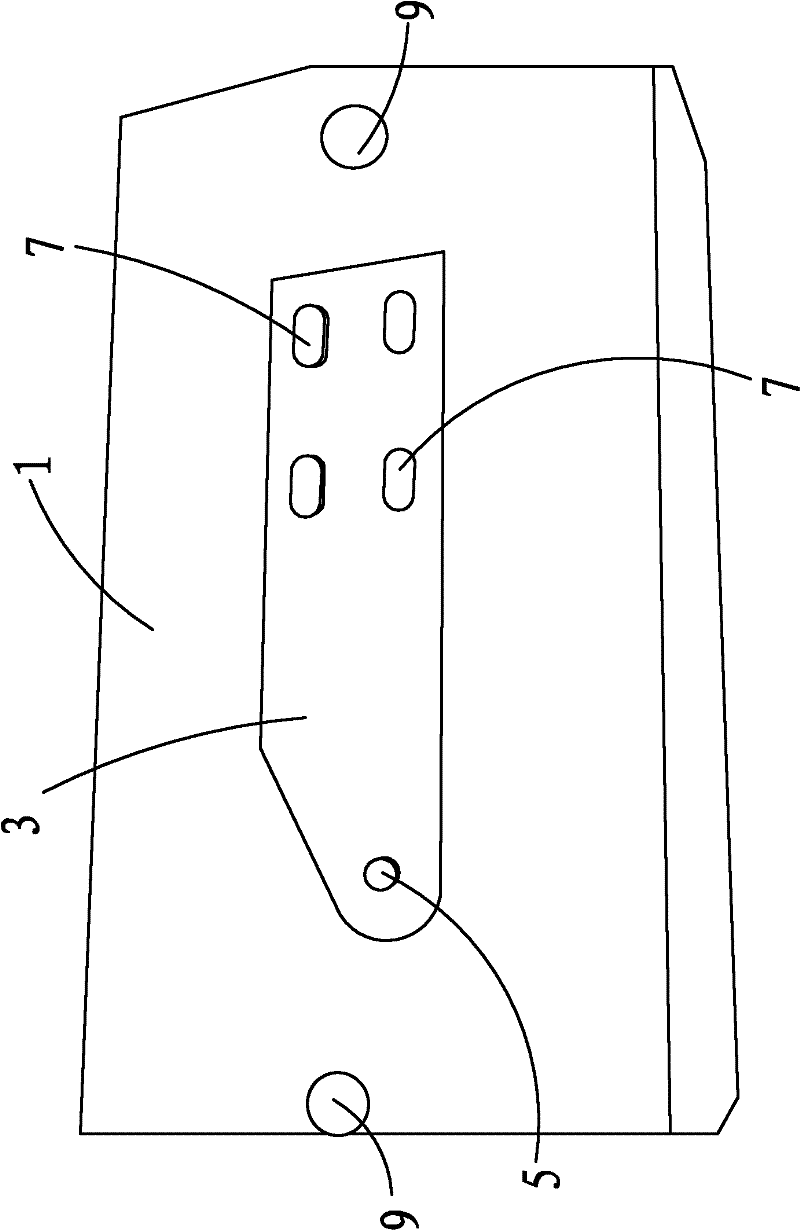

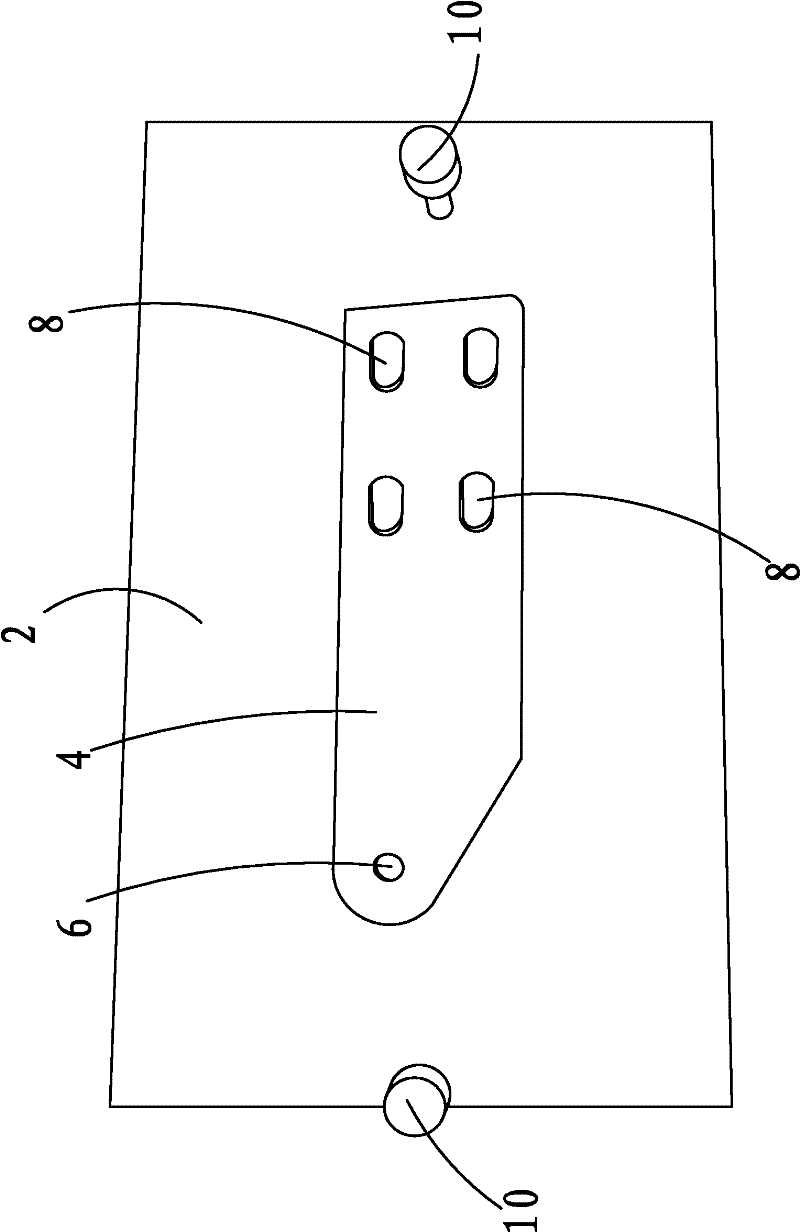

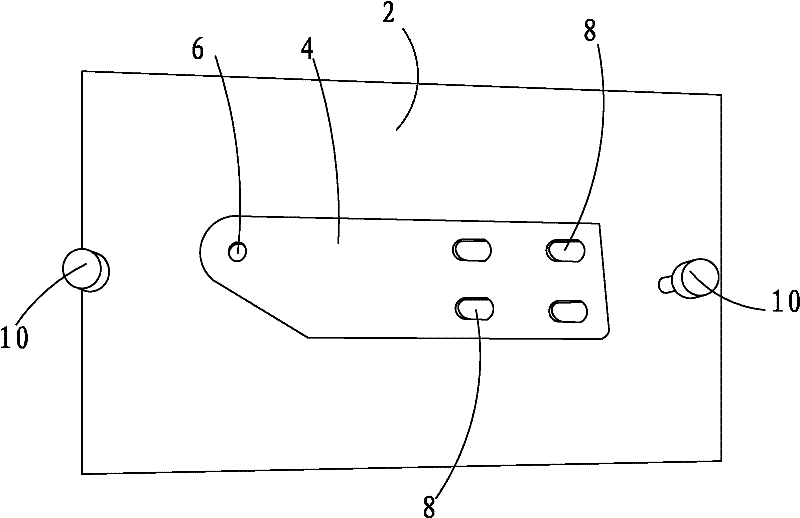

Stamping punching die

InactiveCN102294709AEasy to batch processPerforating toolsMetal working apparatusStructural engineeringManufacturing engineering

A stamping and punching die, comprising an upper die seat and a lower die seat matched with the upper die seat, the upper die seat is provided with an upper model hole, and the lower die seat is provided with a lower die seat Holes, the upper mold hole and the lower mold hole form a storage cavity for receiving processed workpieces, one of the upper mold hole and the lower mold hole is provided with a machining hole, and The other has processing protrusions, and the processing holes correspond to the processing protrusions one by one. Through the cooperation of the processing protrusion and the processing hole, holes can be drilled at the corresponding parts of the processing workpiece, and batch processing is more convenient.

Owner:WUJIANG WUGANG PUNCHING MACHINERY

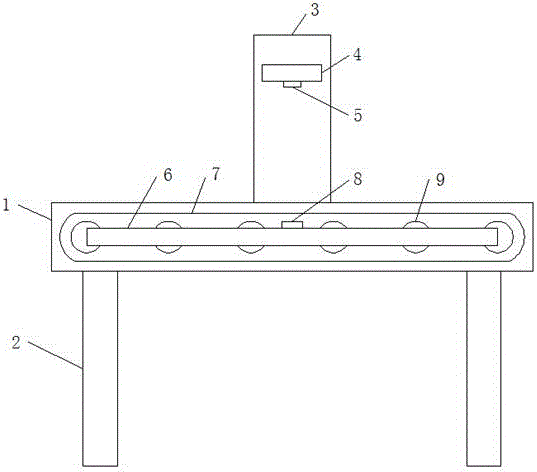

Processing fixture for elastic buckle

InactiveCN106541346ARealize intelligent transmissionAchieve positioningNon-electrical signal transmission systemsWork holdersEngineeringTransmitter

The invention discloses a processing fixture for an elastic buckle. The processing fixture comprises a worktable; the top end of the worktable is provided with an opening and a vertically-arranged supporting plate; the supporting plate is positioned at one side of the opening; one side, close to the worktable, of the supporting plate is provided with a horizontally-arranged mounting plate; an infrared transmitter is embedded in the bottom end of the mounting plate; the worktable is also provided with a clamping slot; a rotary motor is arranged inside the clamping slot; connecting plates are fixedly installed on the inner wall of the clamping slot; connecting rods are connected between the connecting plates; an infrared receiver is embedded in the top ends of the connecting rods; each connecting rod is rotationally connected with a rotating shaft; a conveying belt is arranged on the rotating shafts in a sleeved mode; the conveying belt is composed of two parts; one positioning block is fixedly installed at the top end of each part of the conveying belt; the two sides of each positioning block and the sides, far away from each other, of the positioning blocks are each provided with a groove. The processing fixture disclosed by the invention is reasonable in overall arrangement and high in automation degree, and can lower the cost and effectively improve the work efficiency.

Owner:芜湖光荣网络科技有限公司

Printing device

The invention relates to the technical field of printing equipment and discloses a printing device. The printing device comprises a printing roller and a grooved wheel mechanism. The grooved wheel mechanism comprises a grooved wheel and a rotating wheel. The end face of the grooved wheel is connected with an ink guide roller, and the ink guide roller is fixed to the printing roller. The ink guideroller is provided with a plurality of ink guide grooves distributed uniformly, an ink cavity communicating with the ink guide grooves is formed in the printing roller, and the outer surface of the printing roller is provided with ink outlet holes communicating with the ink cavity. The grooved wheel is provided with a plurality of clamping grooves, the number of the clamping grooves is equal to the number of the ink guide grooves, an opening of the side portion of each clamping groove is in sliding connection with a sliding plate for sealing the opening, the sliding plates can slide in the radial direction of the grooved wheel, a cavity is formed between each sliding plate and the groove wall of the corresponding clamping groove in an enclosed mode, a piston is connected in each cavity ina sliding mode, a nozzle is connected to the end, close to the circle center of the grooved wheel, of each cavity, a pressure valve is arranged on each nozzle, and each nozzle faces the interior of the corresponding ink guide groove. The rotating wheel is provided with a clamping post. By means of the printing device, the problem that ink liquid in ink grooves is thrown out during ink feeding of existing printing rollers can be solved.

Owner:重庆博创知识产权运营有限公司

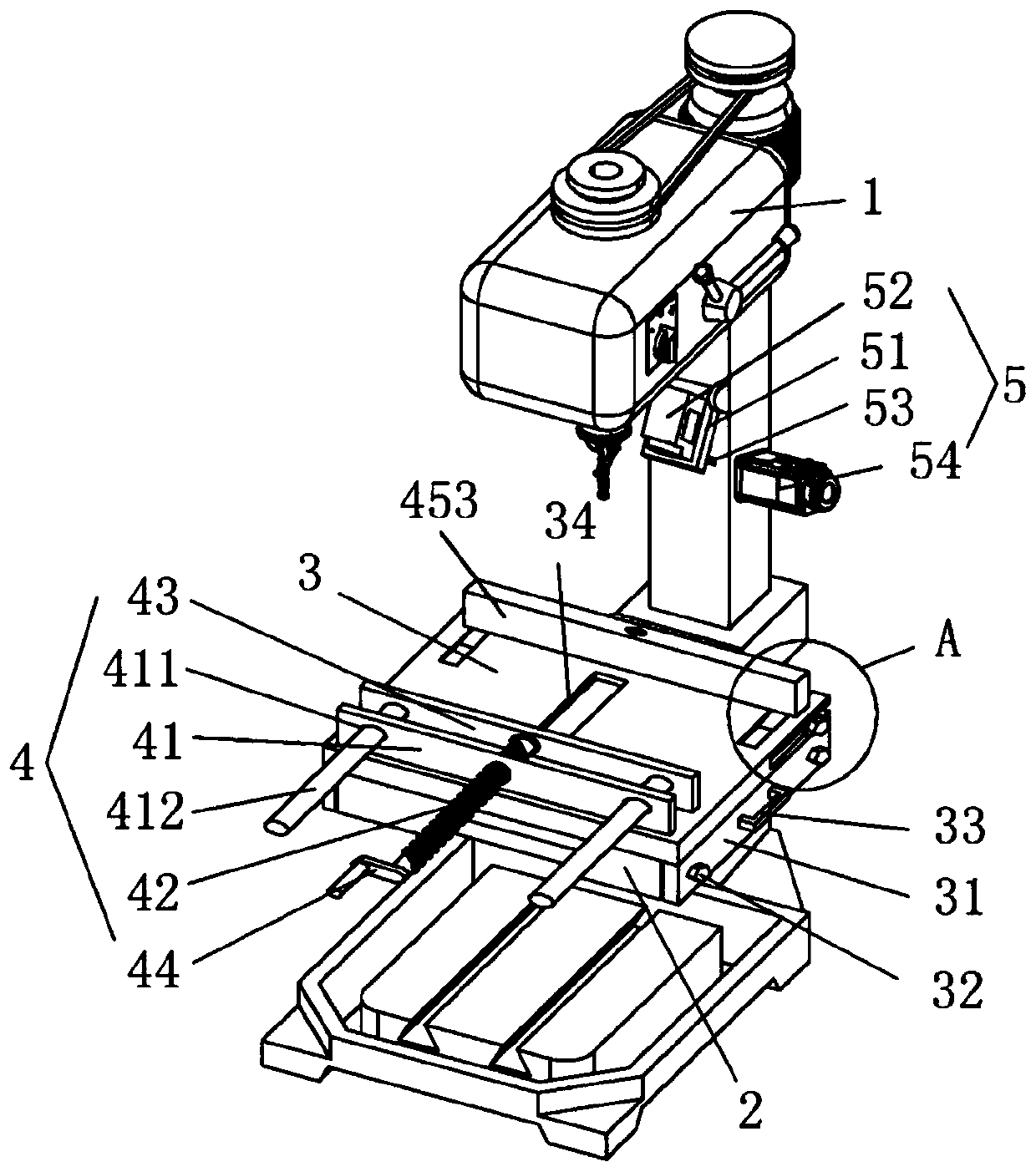

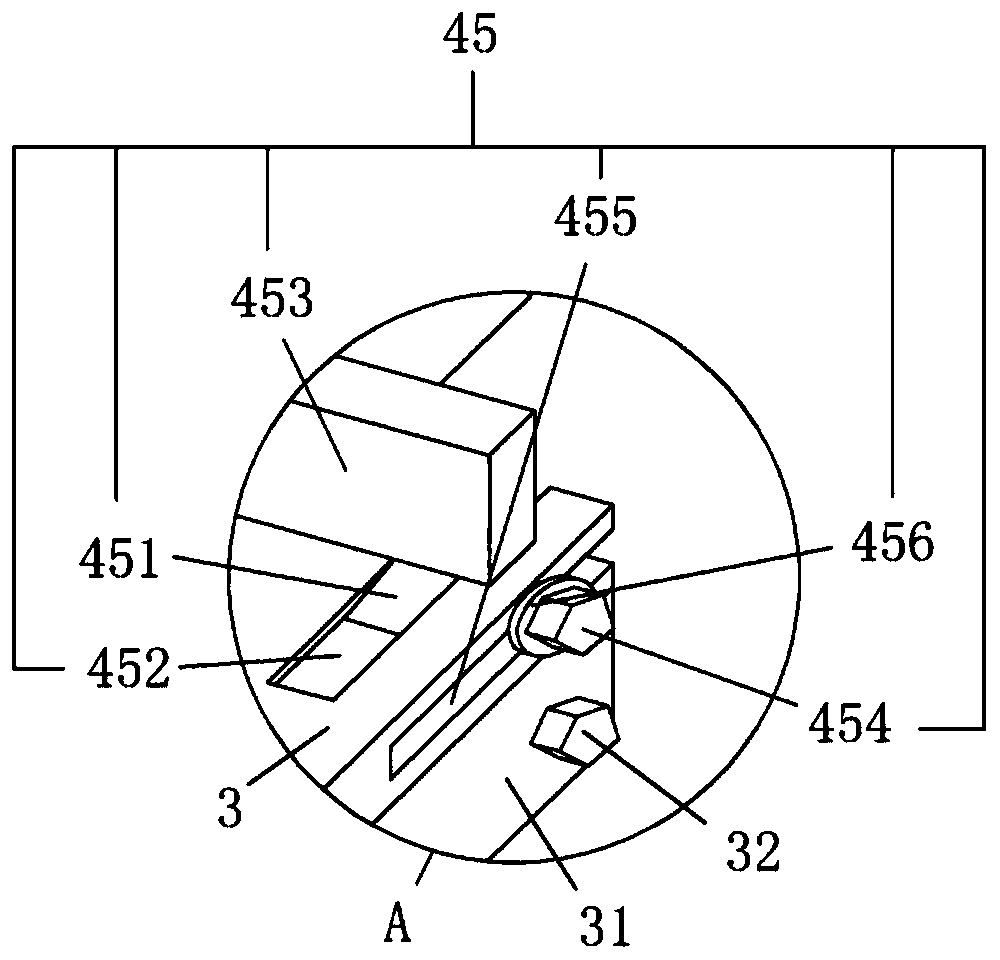

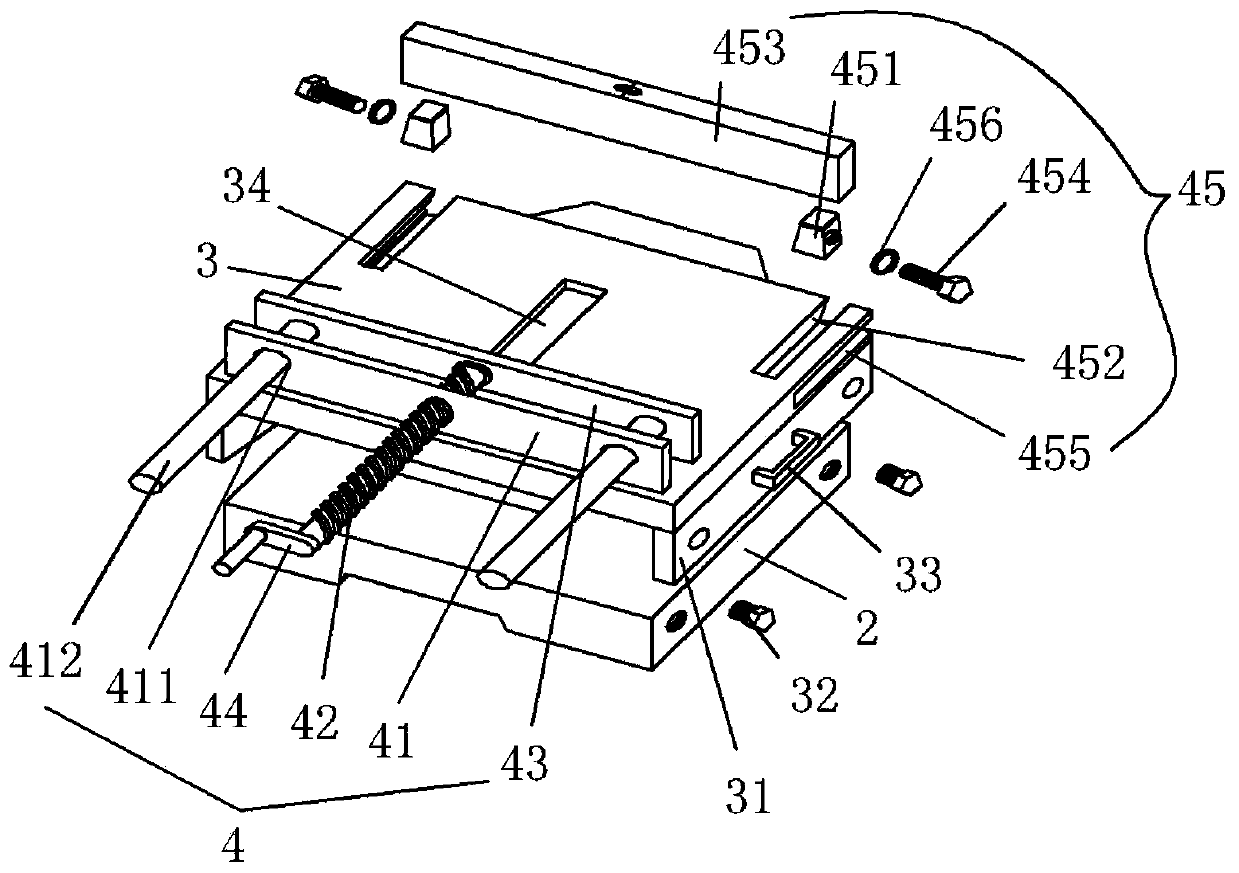

Bench drill for machining with accurate positioning

ActiveCN111283238AEasy to drill and locateThere will be no drilling deviationPositioning apparatusBoring/drilling componentsStructural engineeringMachining

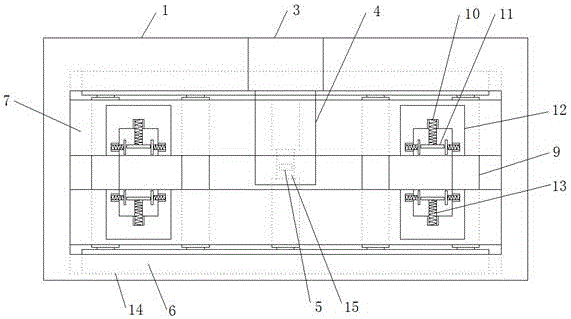

The invention provides a bench drill for machining with accurate positioning. The purpose is to solve the problem that the machining quality is affected due to the fact that the deviation of drillingis prone to occurring when a workpiece is drilled in the above background technology, and the drilling speed of the workpiece is reduced due to the poor applicability of existing bench drill fixtures.The bench drill includes a bench drill body, a lifting base, a fixed seat, a clamping mechanism and a positioning mechanism, wherein the lifting base is arranged at the bottom end of the front side of the bench drill body, the fixed seat is arranged at the top end of the lifting base, the clamping mechanism is arranged at the top end of the fixed seat, and the positioning mechanism is arranged atthe top end of the front side of the bench drill body. The bench drill for machining with accurate positioning can be convenient for drilling and positioning of subsequent workpieces, so that the deviation of the drilling is avoided, and the machining quality is improved. The bench drill for machining with accurate positioning can be used for fixing workpieces with different sizes, so that the workpieces are fixed and drilled quickly, the batch machining of the workpieces is facilitated, and the drilling speed is high.

Owner:HANGZHOU LIDAN MACHINERY

Anti-human body miniaturized electronic label and producing method thereof

InactiveCN101567482AHarm reductionTroubleshoot label performance issuesAntenna supports/mountingsRadiating elements structural formsHuman bodyElectronic tagging

The invention discloses an anti-human body miniaturized electronic label and a producing method thereof. The electronic label comprises a label antenna, an antenna base plate and a chip, wherein the label antenna is a mixed-type antenna formed by combining a microstrip and a doublet, and the radiating surface and the grounding surface of the label antenna are printed on the antenna base plate by metal wires to be used for receiving and sending the signal of the electronic label; and the chip and the label antenna printed on the antenna base plate are bound together by a via hole to be used for identifying the electronic label. The technical scheme of the invention is particularly designed for the human body, has anti-human body absorption and remote identification, and can reduce the harm for the human body by electromagnetic waves when the human body wears the electronic label.

Owner:ZTE CORP

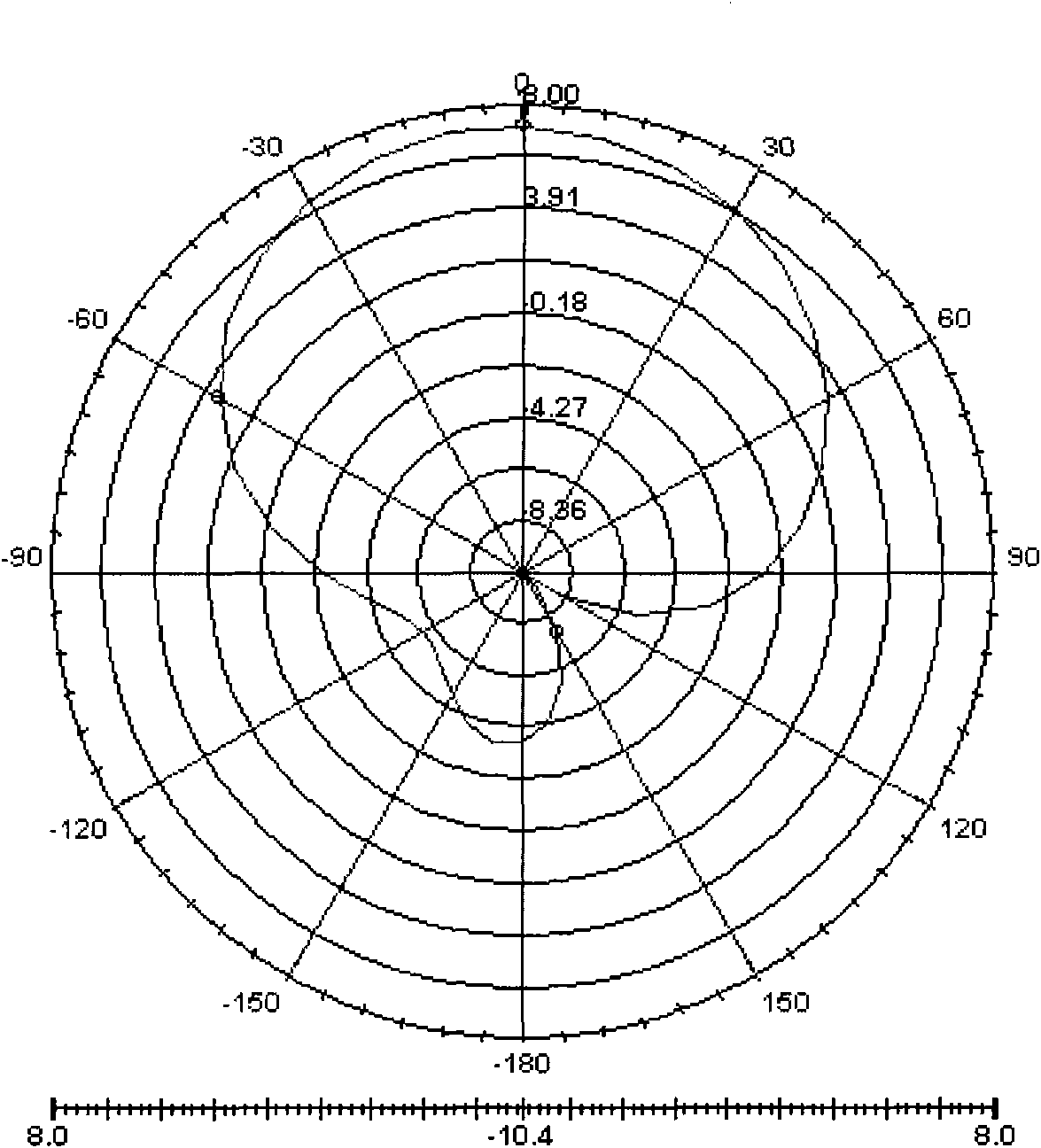

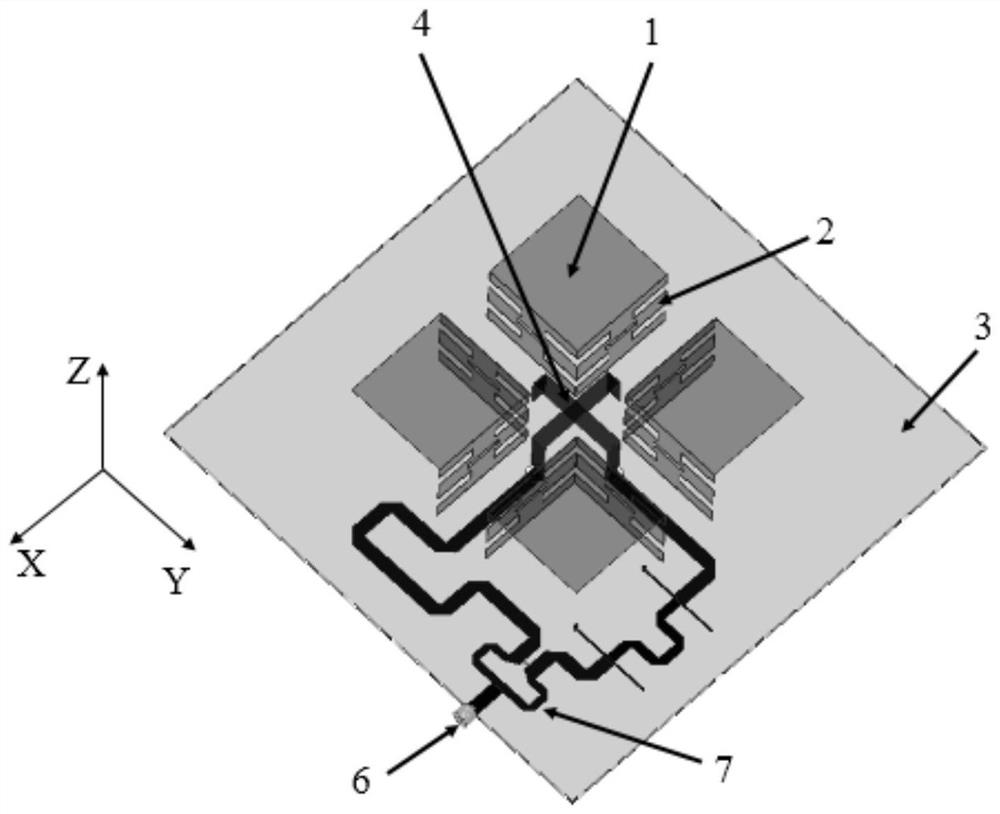

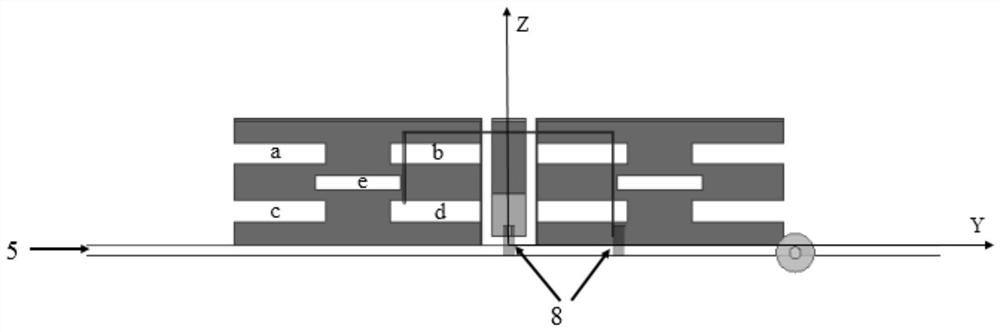

Low-profile broadband circularly polarized magnetoelectric dipole antenna

ActiveCN113078459ASimple structureEasy to batch processRadiating elements structural formsResonant antenna detailsBroadbandingMetal sheet

The invention provides a low-profile broadband circularly-polarized magnetoelectric dipole antenna, and belongs to the technical field of antennas. According to the antenna, the rectangular metal sheet of the magnetic dipole antenna is innovatively designed to be provided with the gap, so that the current path of the magnetic dipole antenna is prolonged, the profile height of the antenna is reduced from conventional 0.25[lambda] to 0.11[lambda] ([lambda] is the space wavelength at the center frequency), and the defect that the profile of the circularly polarized magnetoelectric dipole antenna is relatively high is effectively overcome; and the complexity of the three-dimensional structure is not increased while the height of the profile is reduced, so that the antenna also has the advantages of simple structure and easiness in batch processing, and in addition, the antenna still keeps the advantages of large bandwidth, high radiation gain, symmetric directional diagram, small back radiation and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Terminal crimping device for automobile wire harness

InactiveCN111900591AEasy to fix and removeReduced time spent on set-upLine/current collector detailsCable harnessHydraulic cylinder

The invention relates to the technical field of crimping devices. The invention further discloses a terminal crimping device for the automobile wire harness. The device comprises a machine base, and the upper end of the machine base is fixedly connected with a mounting frame. Hydraulic cylinders are symmetrically mounted on the inner side wall of the mounting frame; the output ends of the hydraulic cylinders are fixedly connected with a mounting base; an upper cutter is mounted at the bottom of the mounting base; a lower cutter is fixedly connected to the machine base under the upper cutter; movable grooves are formed in the positions, located at the four corners of the lower cutter, of the upper end of the machine base, threaded rods are rotatably connected to the opposite groove walls ofthe movable grooves through two bearings, gears are fixedly connected to the rod walls of the threaded rods in a sleeving mode, movable blocks are slidably connected into the movable grooves, and threaded holes are formed in the movable blocks. According to the terminal crimping device, the terminals are very convenient to fix and disassemble, the clamping time is shortened, the processing efficiency of the terminal crimping device is improved, and batch processing of the terminals is facilitated.

Owner:安徽佰尧电子科技有限公司

Thermal treating processing method of spring stop rings and special tempering tool of thermal treating processing method

InactiveCN109722521AResolve failureSolve the deformationFurnace typesHeat treatment furnacesRoom temperatureOil cooling

The invention relates to a thermal treating processing method of spring stop rings and a special tempering tool of the thermal treating processing method. The thermal treating processing method comprises the following steps of stringing the spring stop rings which are thoroughly cleaned into strings, loading the strings into a vacuum quenching material frame, transporting the vacuum quenching material frame into a vacuum quenching furnace for quenching, and before heating in the vacuum quenching furnace, performing vacuumizing; heating the equipment to 650-670 DEG C, performing insulating for20-30min, and performing heating to the quenching temperature of 860-870 DEG C for quenching; then transporting the spring stop rings into a cold chamber, performing quenching oil cooling, performingcooling in an oil groove until the temperature is 100 DEG C or below, performing discharging from the furnace, and performing air cooling to the room temperature; and then loading the spring stop rings to the tempering tool, performing shaping tempering, enabling the spring stop rings to be sleeved into a screw rod, performing thermal rectifying with a pressing plate through nuts, performing feeding in the furnace for tempering, and performing tempering and water-cooling to the room temperature. Through the adoption of the thermal treating processing method disclosed by the invention, the defect that after the spring stop ring is used after being quenched, brittleness breaking is generated is solved, the deformation of the spring stop rings is reduced, the planeness of the spring stop rings is improved, and in the subsequent assembling and using course, the spring stop rings are avoided from generating cracks.

Owner:HUBEI JIANGSHAN HEAVY IND

Electrode frame structure of redox flow battery

InactiveCN102148381ASimple structureEasy to identifyRegenerative fuel cellsCell component detailsElectrical batteryOxidation-Reduction Agent

The invention relates to a structure of an energy storage battery, in particular an electrode frame structure of a redox flow battery, a mark is made in a specific position of an electrode frame, and the position of an outlet / inlet of the electrode frame and the facing direction of a flow passage groove can be rapidly judged during the assembly process or after the assembly. Therefore, errors during the assembly process can be effectively corrected and the stacking efficiency can be improved. The electrode frame structure is particularly applicable to battery stack structures with the same structure for positive and negative electrode frames or the same shape and the different placement directions.

Owner:DALIAN RONGKE POWER

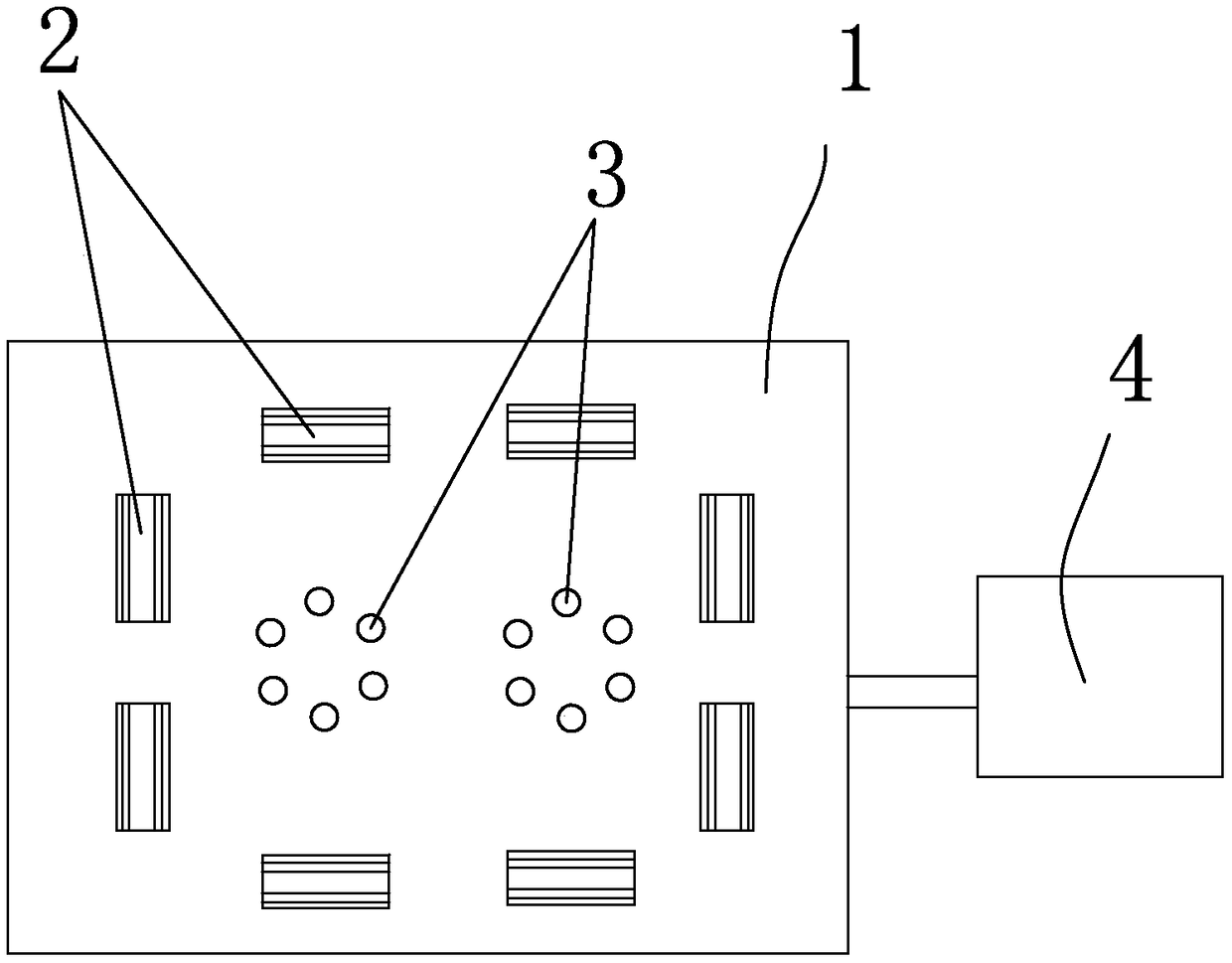

Casting machining device

ActiveCN108620977AReduce workloadEasy to batch processEdge grinding machinesGrinding carriagesEngineeringGrinding wheel

The invention relates to the field of casting machining and manufacturing and discloses a casting machining device. The casting machining device comprises a grinding wheel and a conveying mechanism; the conveying mechanism comprises a conveying gear and a convey-back gear which are both rotationally arranged, and a connection gear is arranged between the conveying gear and the convey-back gear; the connection gear is engaged with the conveying gear and the convey-back gear at the same time; the conveying gear is provided with a conveying fan gear, and the convey-back gear is provided with a convey-back fan gear; a rack is arranged between the convey-back fan gear and the conveying fan gear, and engaging between the rack and the conveying fan gear and engaging between the rack and the convey-back fan gear can be alternately performed; the end, close to the grinding wheel, of the rack is provided with a pay-off wheel, and the other end of the rack is provided with a wire winding wheel, and the pay-off wheel and the wire winding wheel are both rotationally connected to the rack through one-way bearings; the pay-off wheel and the wire winding wheel are the same in rotation direction; and a pulling rope is connected between the pay-off wheel and the wire winding wheel, and a friction wheel is arranged on the outer side of the rack. Due to the casting machining device, the casting machining portion can be automatically adjusted, and safety of the producing and machining activity is guaranteed.

Owner:YONGCHUAN DISTRICT CHONGQING HUAYI MACHINERY CASTING CO LTD

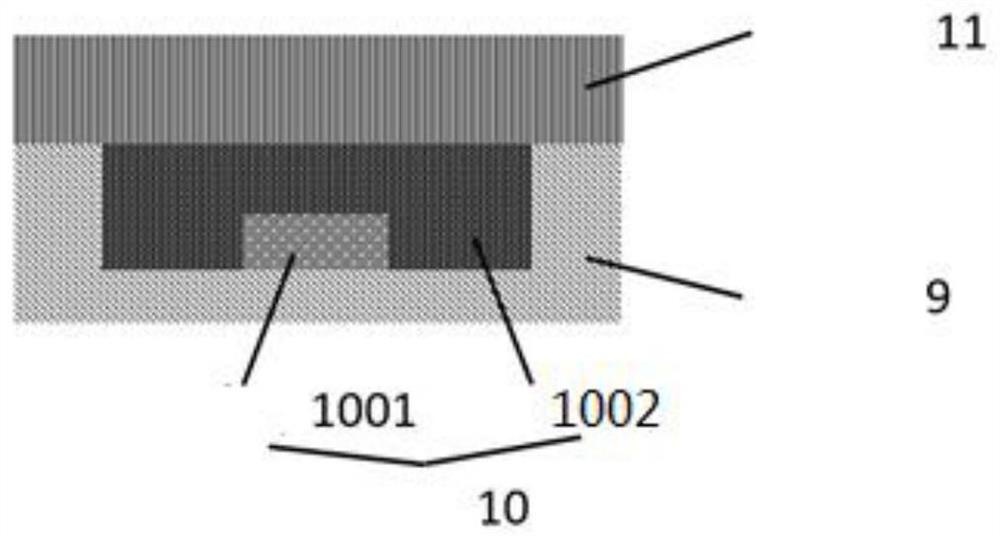

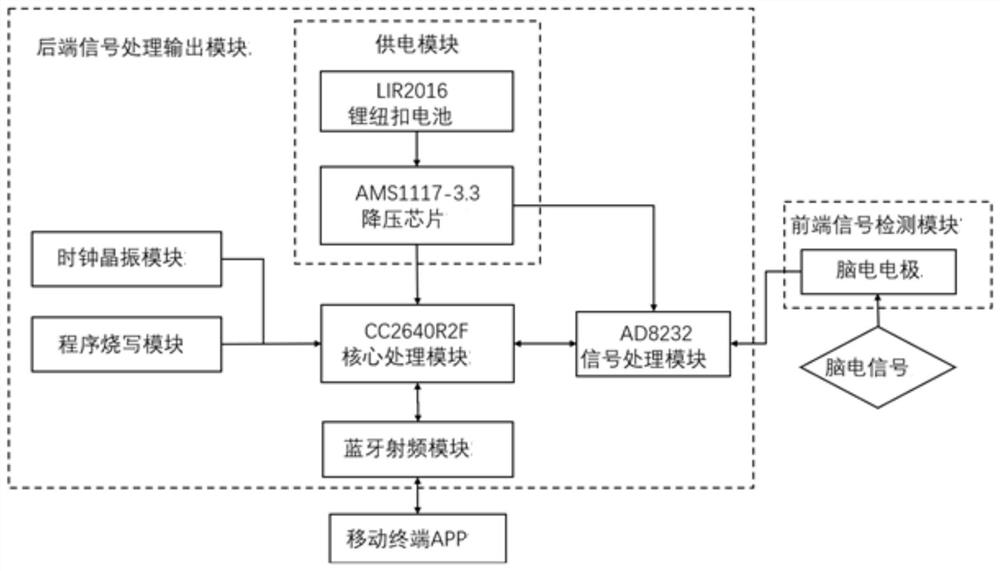

Electrode, signal detection system, hydrogel applied to electrode and preparation method thereof

ActiveCN113801265AImprove hydrophobicitySmall mechanical propertiesMaterial analysis by electric/magnetic meansDiagnostic recording/measuringMeth-Glycerol

The invention belongs to the technical field related to biomedical instruments, and discloses an electrode, a signal detection system, hydrogel applied to the electrode and a preparation method thereof, the hydrogel is hydrophobic hydrogel or viscous hydrogel, the hydrophobic hydrogel comprises an acrylamide monomer, a lauryl sodium sulfate monomer, Nacl, C18, a N, N'-methylene bisacrylamide monomer, clay and an initiator; and the viscous hydrogel comprises the following components: a zwitterionic monomer, an acrylamide monomer, clay, a viscous monomer, glycerol, an initiator and an N, N'-methylene bisacrylamide monomer. The hydrophobic hydrogel has good hydrophobicity, the mechanical performance and stretchability of the hydrogel are prevented from being reduced when the hydrogel encounters water, it is ensured that the hydrogel electrode stably works in a wet scene, the use scene of the hydrogel electrode is expanded, and therefore a detection system can conduct continuous detection while skin diseases are avoided.

Owner:HUAZHONG UNIV OF SCI & TECH

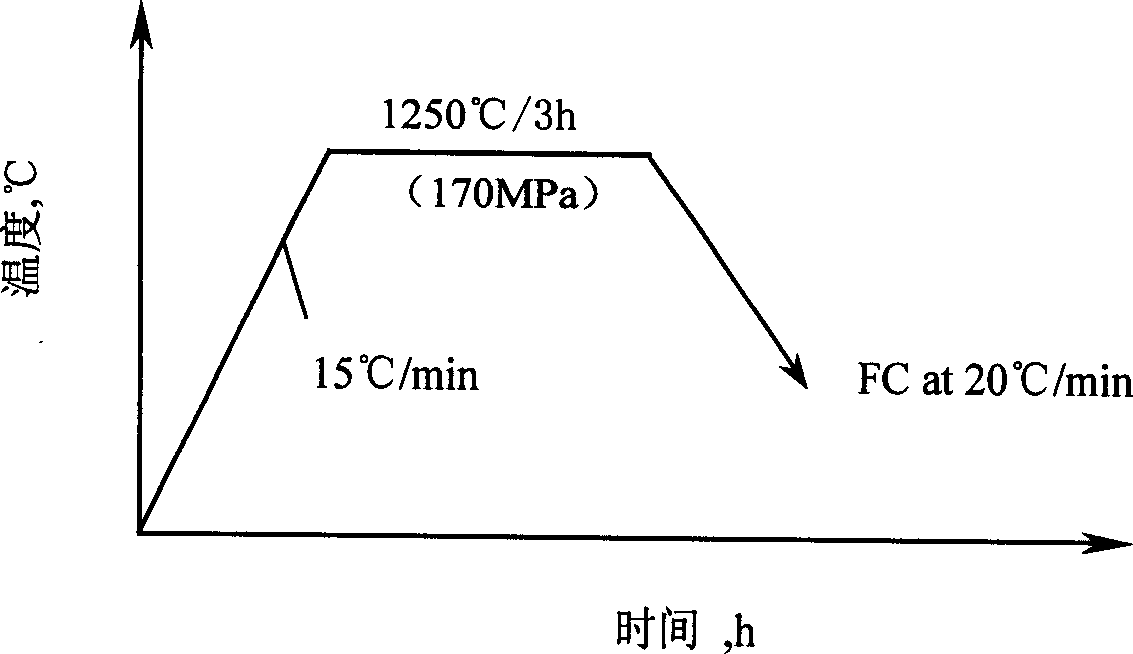

Surface treating method for improving TiAl base alloy surface property

InactiveCN1676658AImprove surface propertiesImprove high temperature oxidation resistanceSource materialBeta phase

This is a kind of surface handling method which can improve the surface performance of TiAl base alloy. It refers to a kind of method to treat the surface of TiAl base alloy containing large quantity of beta phase stable element. This invention puts this kind of alloy into the pot in which graphite or carbon included material is set as the heat-source material of hot isostatic apparatus, or it puts the alloy into the pot in which non-graphite or no-carbon included material is set as the heat-source material of hot isostatic apparatus. If the latter is chosen, 0.001-20000g graphite powder, carbon powder, carbon-included simple substance or compound should be put into it to make hot isostatic pressing surface treatment. The temperature during the treatment should be between 800-1500deg.C, while the pressure should be 1-300Mpa. It should take 1 minute-20 hours to keep warm during the hot isostatic pressing surface treatment. In a word, this invention uses the essential hot-working method to do the treatment, having the merits of little cost, easy realization and no need to increase additional device.

Owner:HARBIN INST OF TECH

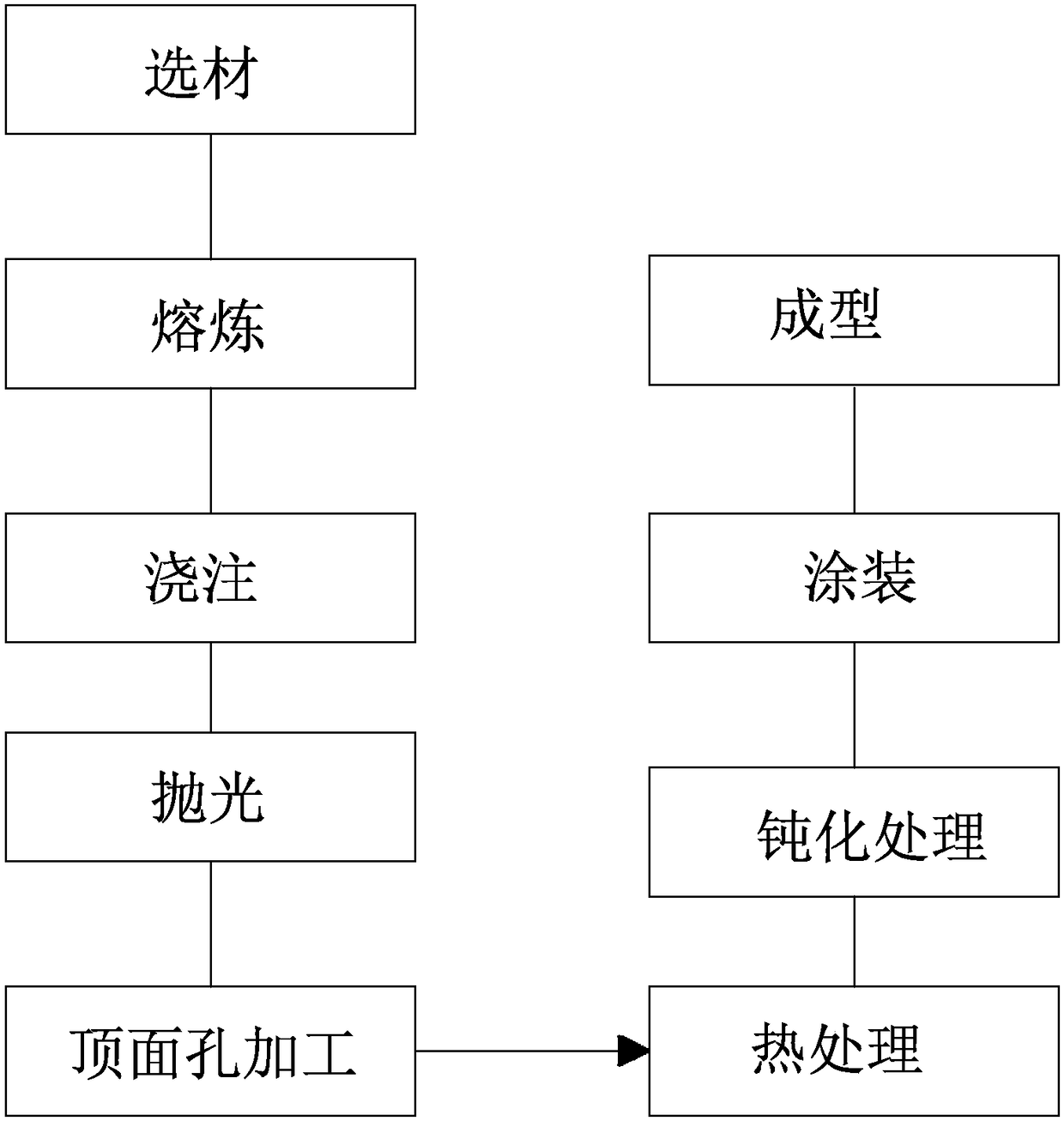

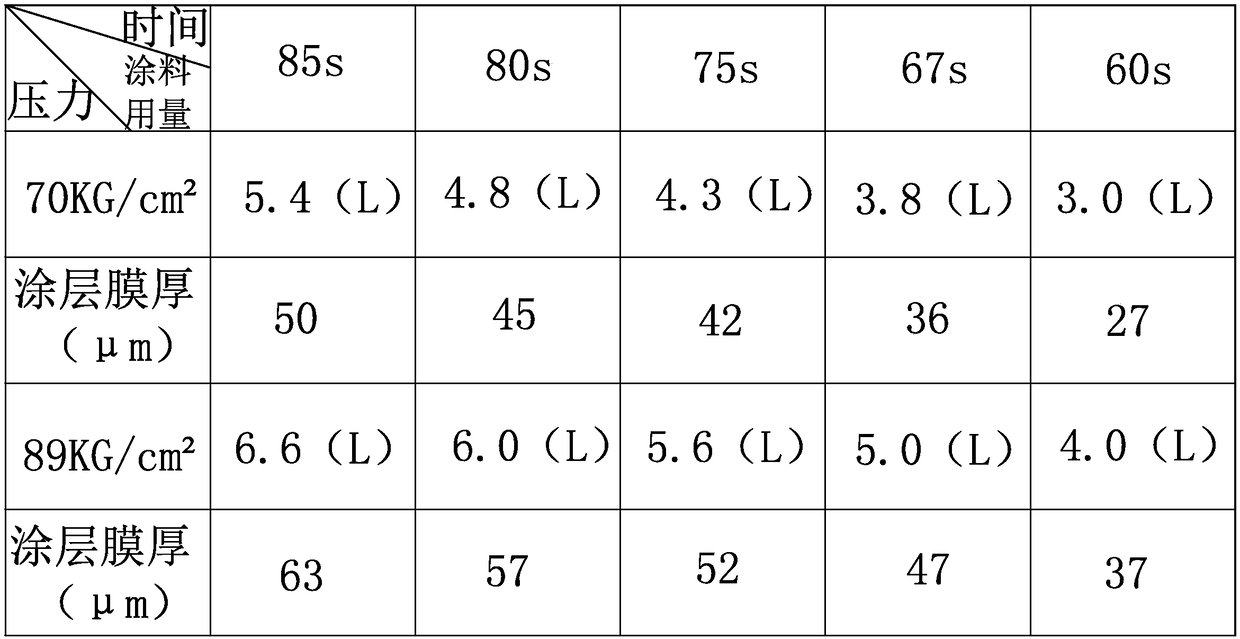

Production process of automobile air cylinder cover

InactiveCN108546851AImprove mechanical performanceHigh puritySolid state diffusion coatingSlagEngineering

The invention discloses a production process of an automobile air cylinder cover. The production process aims to achieve the effects that the inner stress of each part of areas of the air cylinder cover can be uniformly distributed, the uniformity degree of each part of components of the cylinder cover is ensured, and the stress capability of each part is improved. According to the technical scheme, the production process comprises the following steps that (1) a material is selected, wherein the raw material comprises the following chemical components (%) of less than or equal to 1.3 of Fe, 9.6-12 of Si, 1.5-3.5 of Cu, less than or equal to 0.5 of Mn, less than or equal to 0.3 of Mg, less than or equal to 0.5 of Ni, less than or equal to 3.0 of Zn, less than or equal to 0.2 of Pb, less than or equal to 0.2 of Sn and the balance Al; and (2) smelting is carried out, wherein the raw material in the step (1) is smelt to reach the temperature of around 800-850 DEG C, the raw material is subjected to refining, degassing and slag removal through GBF treatment, then molten aluminum subjected to refining and degassing is transferred into a protective furnace of a low-pressure casting machine after standing for 10 minutes, and the molten aluminum to be poured is controlled between 690 DEG C and 700 DEG C. The production process of the automobile air cylinder cover is applicable to the field of production processes of air cylinder covers.

Owner:ZHEJIANG HONG DING AUTO & MOTO PARTS

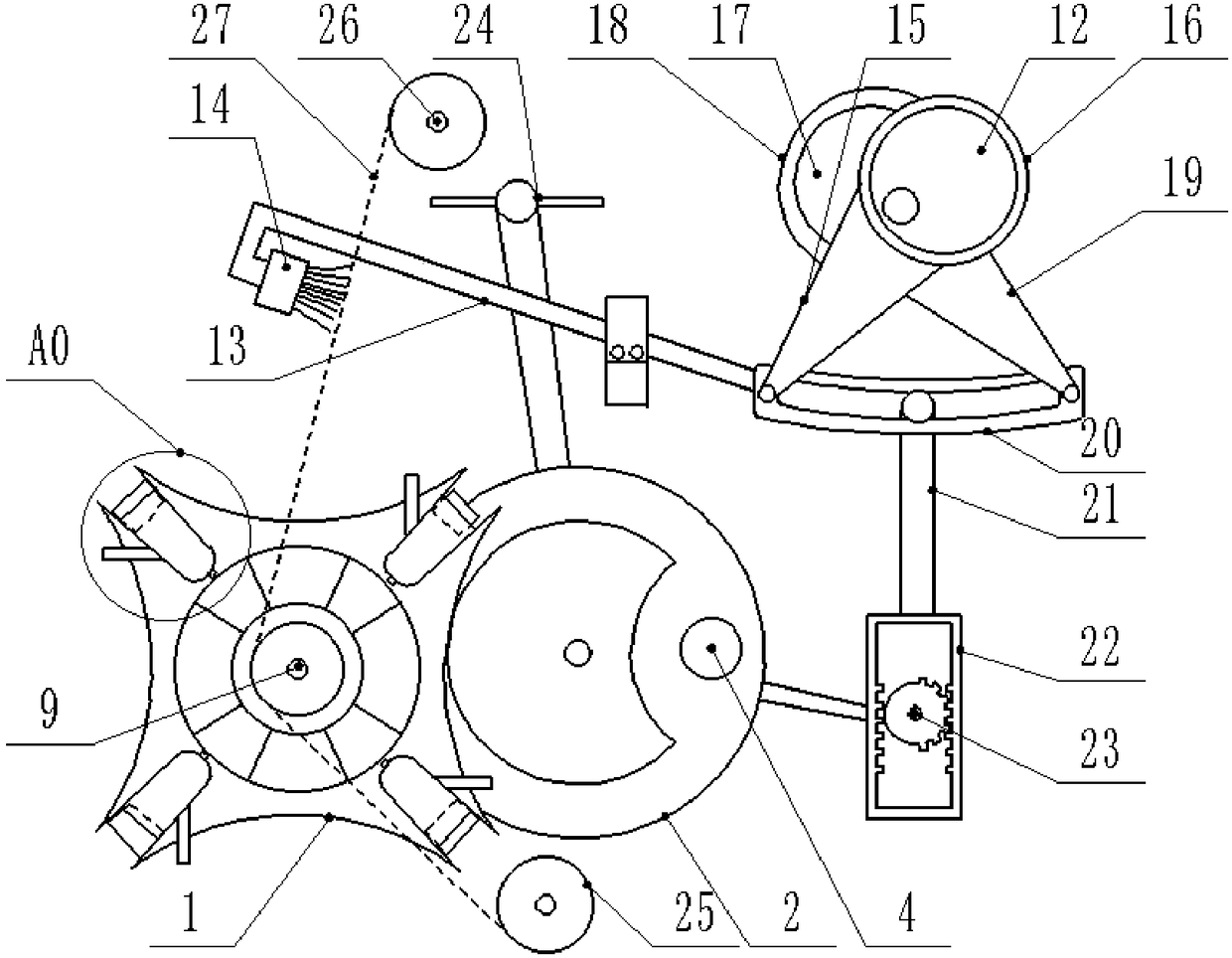

Root sectional type medicinal material slicing equipment for batch processing of rhizoma paridis

ActiveCN109079877AEasy to batch processAvoid stickinessMetal working apparatusMachining processEngineering

The invention provides root sectional type medicinal material slicing equipment for batch processing of rhizoma paridis, and relates to the field of Chinese medicinal materials. The root sectional type medicinal material slicing equipment comprises supporting legs, and the surfaces of the supporting legs are connected with a slicing supporting box body in a welded mode. The slicing supporting boxbody is internally provided with a segmented slicing collecting mechanism, and a straightening sorting feeding mechanism is arranged on the upper surface of the slicing supporting box body. Power support rods are welded on the lower surface of the slicing supporting box body, and a motor is welded on the surfaces of the power support rods. An output shaft of the motor is fixedly connected with a screening slicing rotating shaft through a coupling. According to the root sectional type medicinal material slicing equipment for batch processing of the rhizoma paridis, feeding, slicing and collecting are operated by a same drive device and carried out simultaneously, and the structures complement each other and do not interfere with each other, so that the rhizoma paridis slicing work can be carried out in a batch mode stably, the processing efficiency is improved, and the problems that general slicing equipment is not convenient to use in the rhizoma paridis processing process, and the rhizoma paridis slicing process is relatively time-consuming is effectively solved.

Owner:安徽徽草堂药业饮片股份有限公司

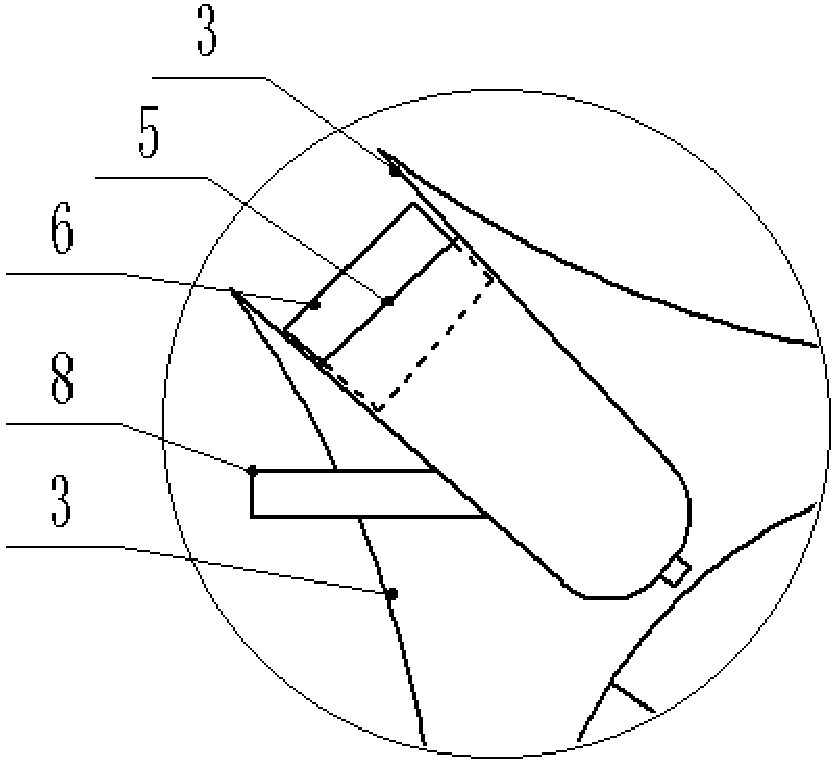

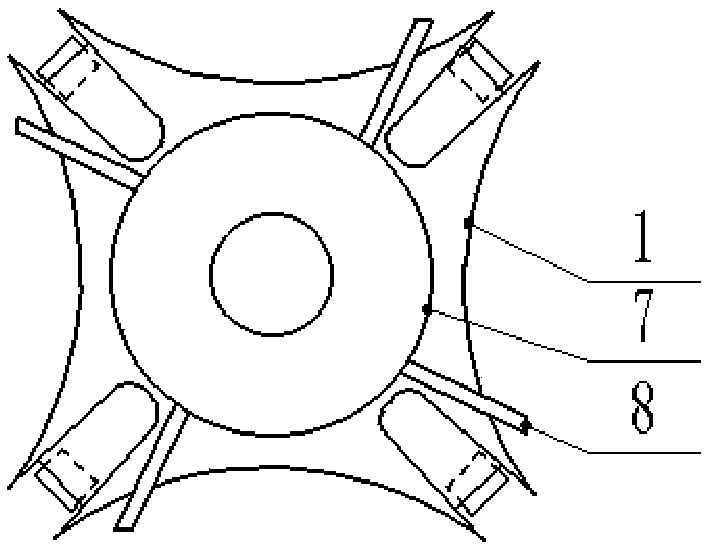

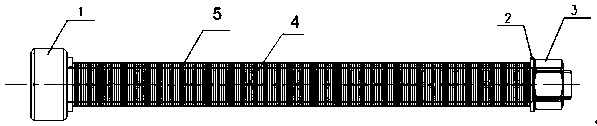

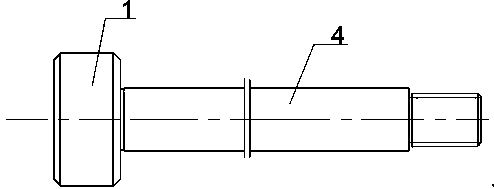

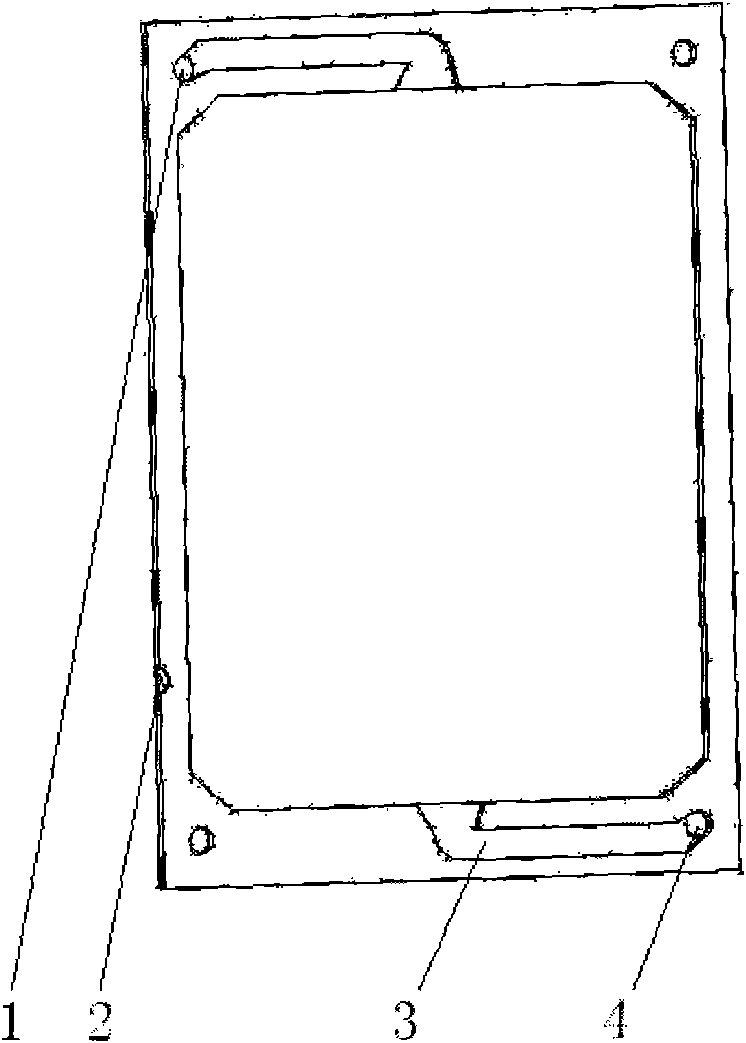

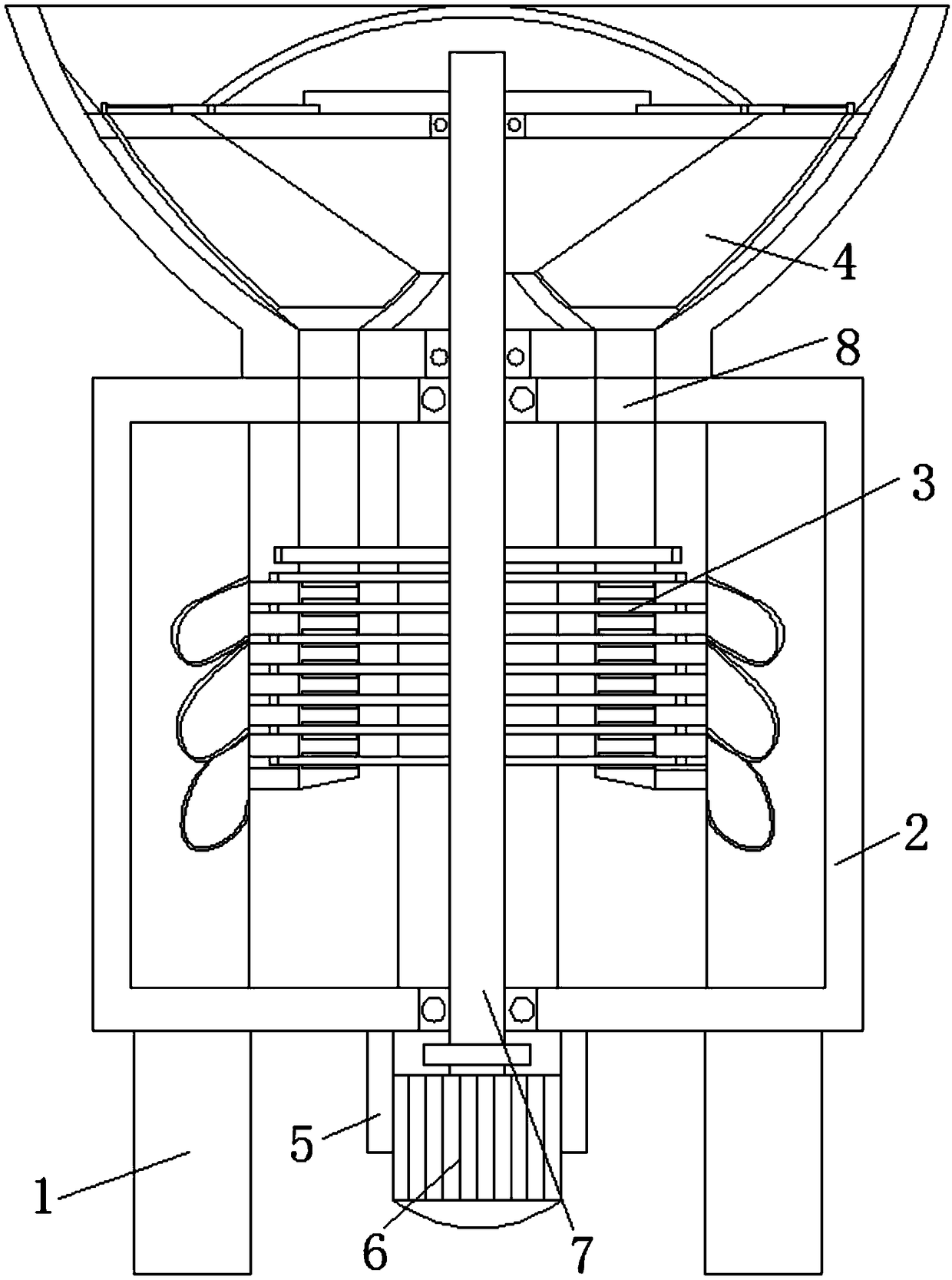

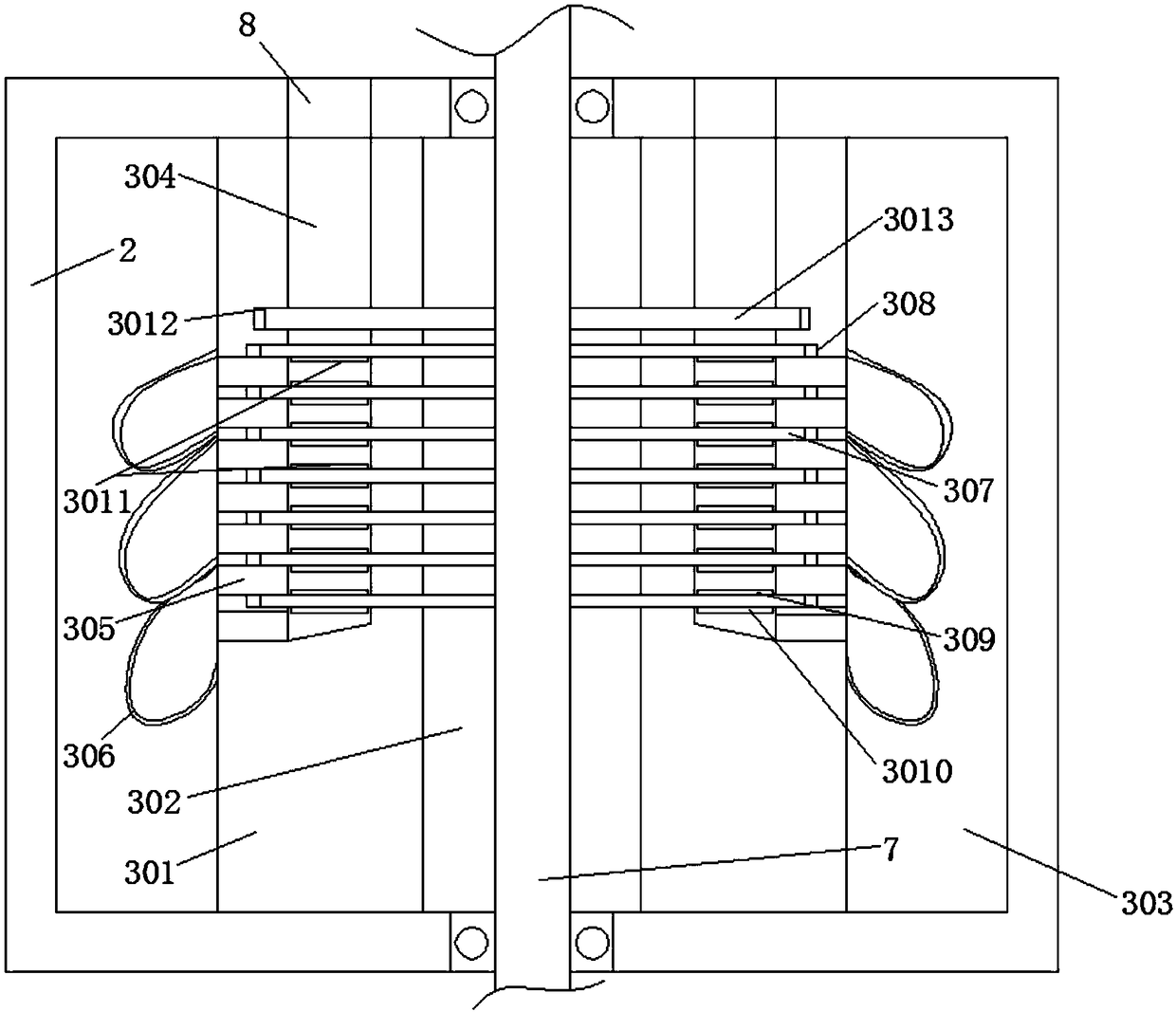

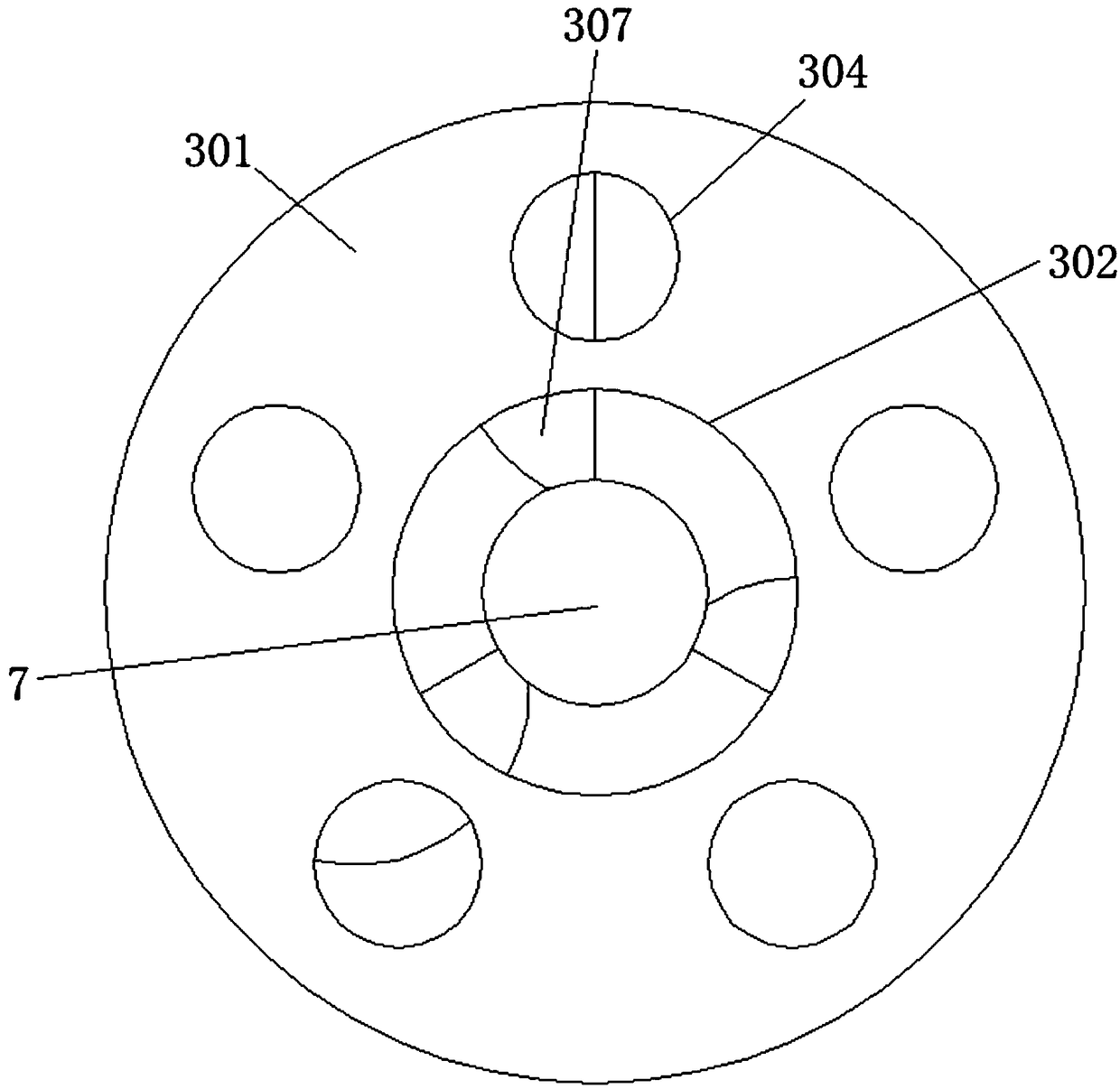

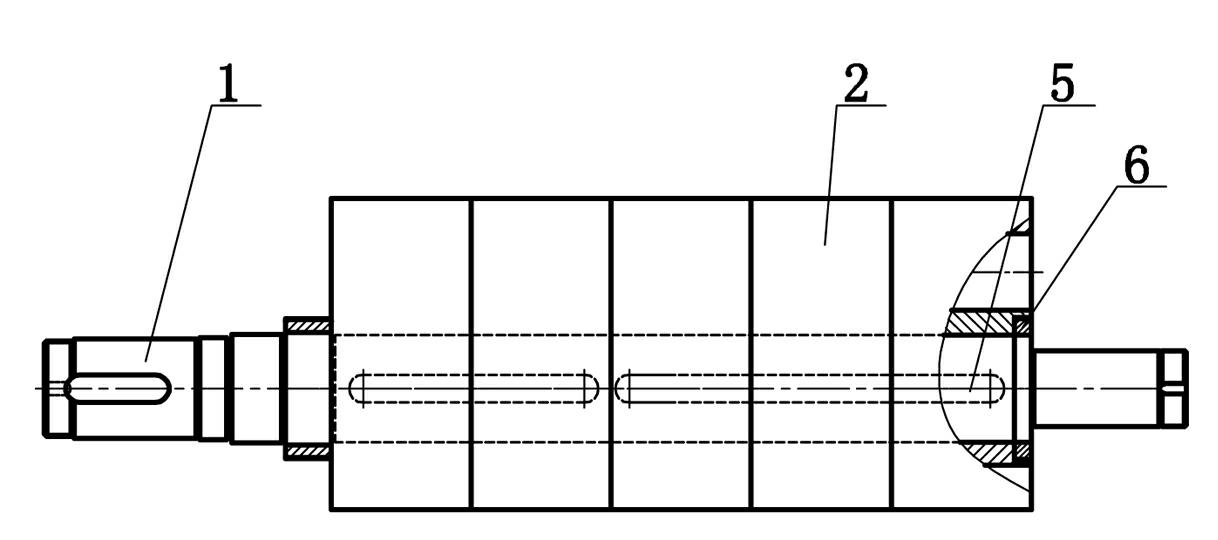

Processing technique of Roots blower impeller component

The invention provides a processing technique of a Roots blower impeller component. The impeller component is formed by positioning and pressing a plurality of impeller blades with positioning keys by a special pressing machine on an impeller shaft, stacking the impeller blades and then fixing and combining the impeller blades by locking nuts; each impeller blade is processed by processing steps of casting, annealing, turning, grinding, polishing, milling, linear cutting, boring and the like; the contour of each impeller blade is finished by the finish machining of a milling machine tooling on a numerical control milling machine; and a positioning key groove of each impeller blade is cut by a second tooling on an electric spark wire cutting machine, so that the axial hole positioning key grooves of all the impeller blades are accurate and consistent in position. Therefore, the finished impeller component processed by the processing technique disclosed by the invention has high accuracy, good surface quality and good interchangeability; after the impeller component is arranged in an inner cavity of the blower, all assembling gaps at different positions can be controlled in a smaller range, and the leakage rate is reduced, so that the temperature rise of gas at an outlet is lower, further the efficiency of a blower is improved and the energy is saved.

Owner:常州市风机制造有限公司

Pretreatment device for aquatic product before salting

InactiveCN111387261AEasy to marinateAvoid unfoldingFish work-tablesFish arrangingFisheryAquatic product

The invention discloses a pretreatment device for an aquatic product before salting. The pretreatment device comprises a conveyer belt and a processing table, wherein the processing table is located on the right side of the conveyer belt; a bottom bin is fixedly mounted at the bottom of the processing table, a bearing is fixedly installed at the bottom of an inner cavity of the bottom bin, the topof the bearing is rotationally connected with a telescopic rod, and a cross-shaped groove is formed in the processing table in a penetrating manner; positioning plates are fixedly connected to tops of two sides of the processing table, clamping plates are movably connected to the left part and the right part of the top side of the processing table, support frames are fixedly connected to tops ofthe two positioning plates, a top frame is fixedly connected between the tops of the support frames, an air cylinder is fixedly mounted at the bottom of the top frame, the bottom of the air cylinder is fixedly connected with a down press plate, and guide plates are fixedly connected to two sides of the down press plate. The pretreatment device is simple in structure, convenient and practical, andcan spread fish bodies after fish evisceration, increase the surface contact area between fish and a salting material and facilitate subsequent salting processing of the fish.

Owner:邵显伦

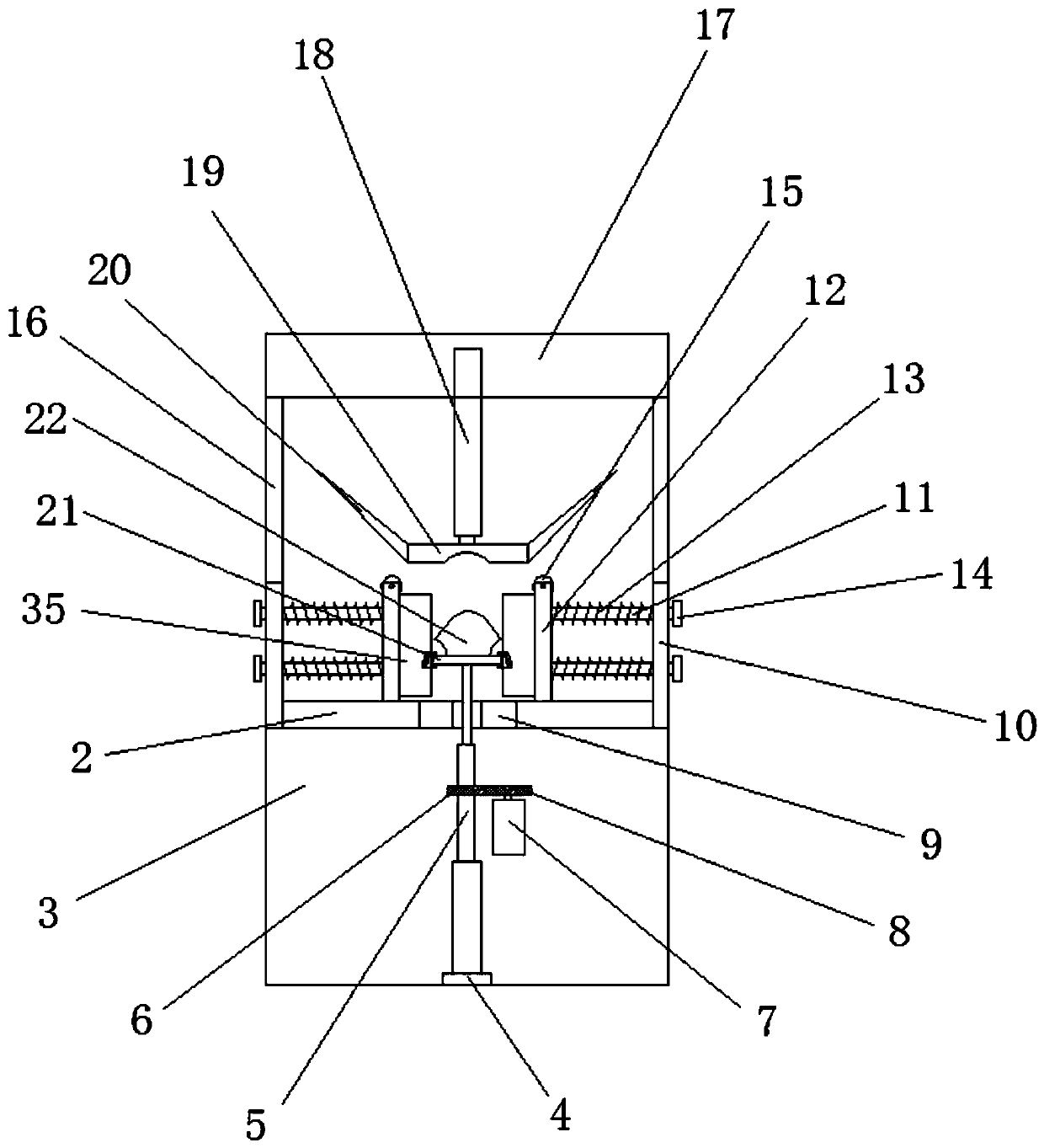

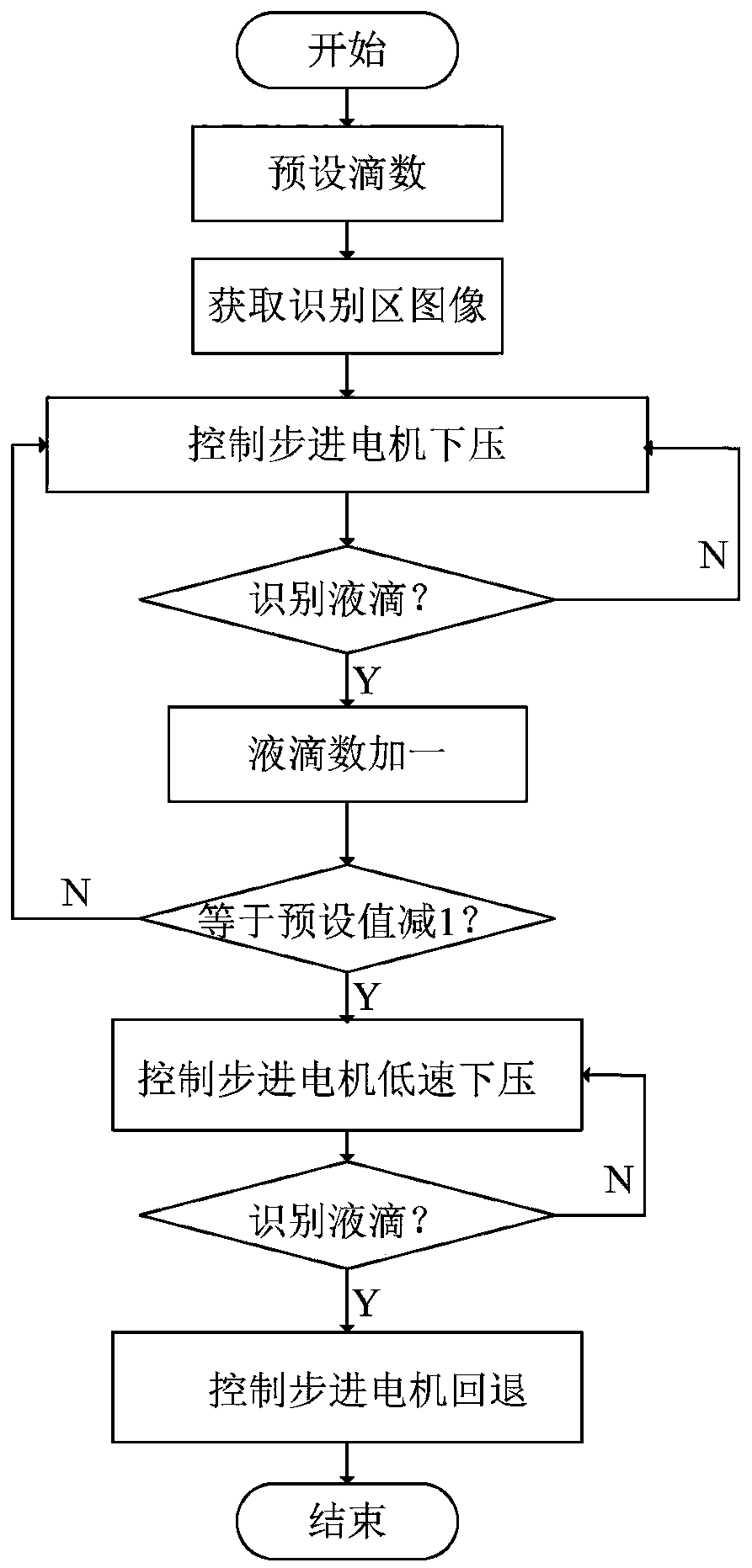

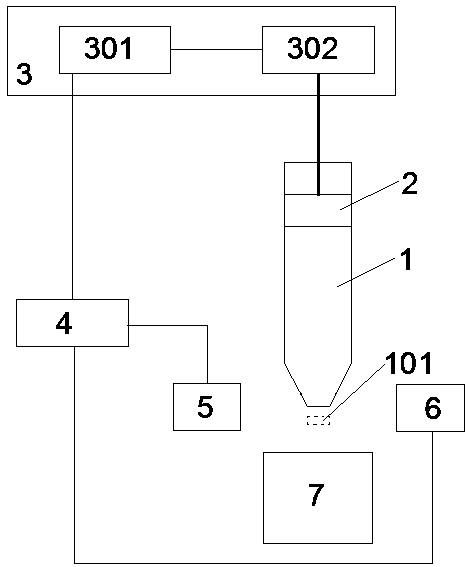

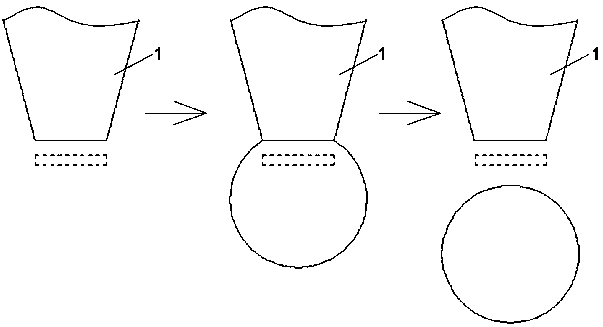

Quantitative reagent addition method and quantitative reagent addition system for biological chip

ActiveCN109759160AQuantitative addition with high precisionReduced precision requirementsBurettes/pipettesReagentPlunger

The invention discloses a quantitative reagent addition method and a quantitative reagent addition system for a biological chip. The quantitative reagent addition method comprises the steps of using adisplacement driving unit to drive a plunger in a biological chip reagent chamber to move downwards at a constant speed V1; when the plunger moves downwards at the constant speed, calculating the total amount of droplets dripping from a reagent chamber dripping port; when the total number of the droplets is equal to a preset value, enabling the displacement driving unit to stop driving the downward movement of the plunger; when the total number of the droplets is equal to a result of the preset value minus 1, using the displacement driving unit to drive the plunger to move downwards at a constant speed V2, wherein V2 is less than or equal to V1; before the plunger moves downwards at the constant speed, pre-calibrating an identification area under the reagent chamber dripping port; when the plunger moves downwards at the constant speed, acquiring the images of the identification area in real time, and determining whether the droplets drip or not according to the image recognition result of the identification area. The method and the system can accurately control the amount of reagents added into the reactor, and are high in precision of quantitative addition, low in requirements onthe overall biological chip, low in cost and is easy to implement.

Owner:HUNAN LEGEND AI CHIP BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com