Bionic flexible force sensor and preparation method thereof

A flexible force and sensor technology, applied in the direction of instruments, relays, measuring force, etc., can solve the problems of complex manufacturing and processing, and achieve the effect of increasing the contact area, improving sensitivity and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

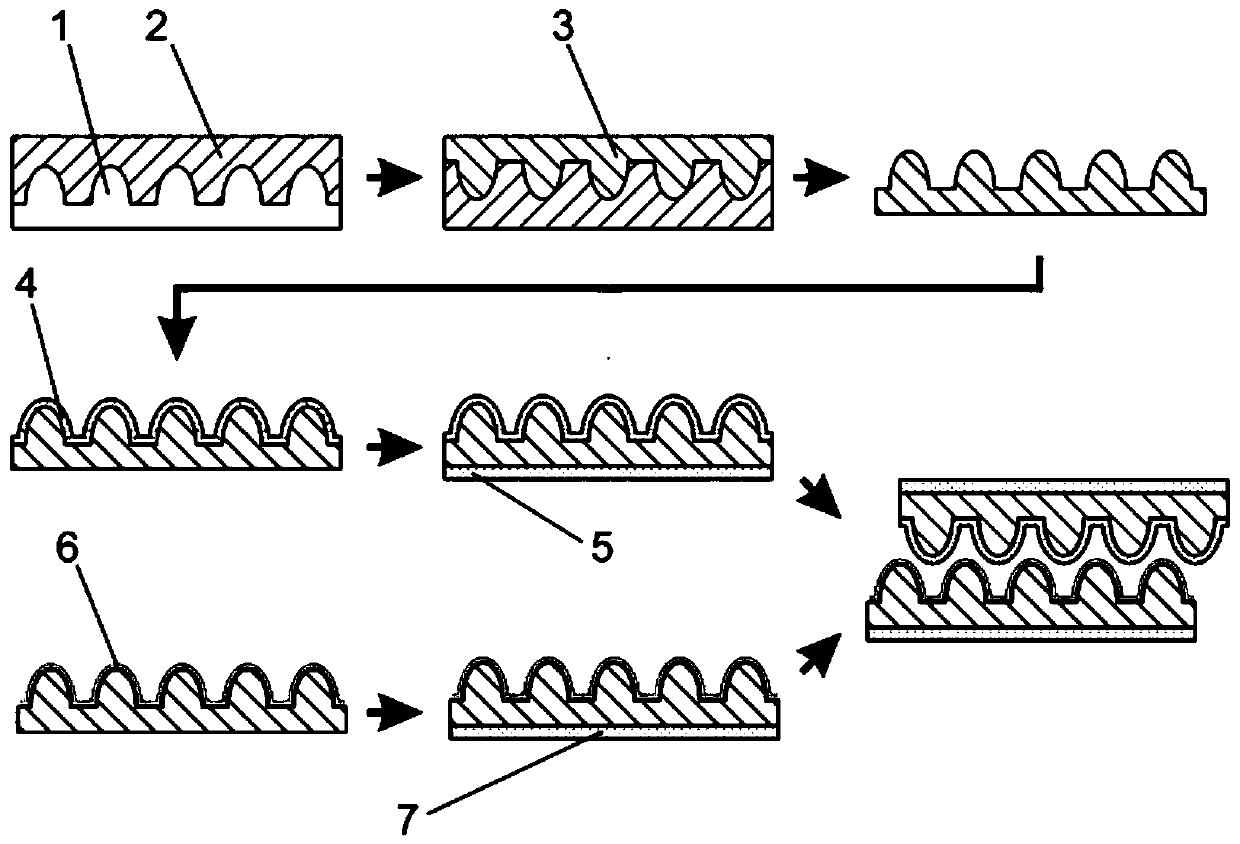

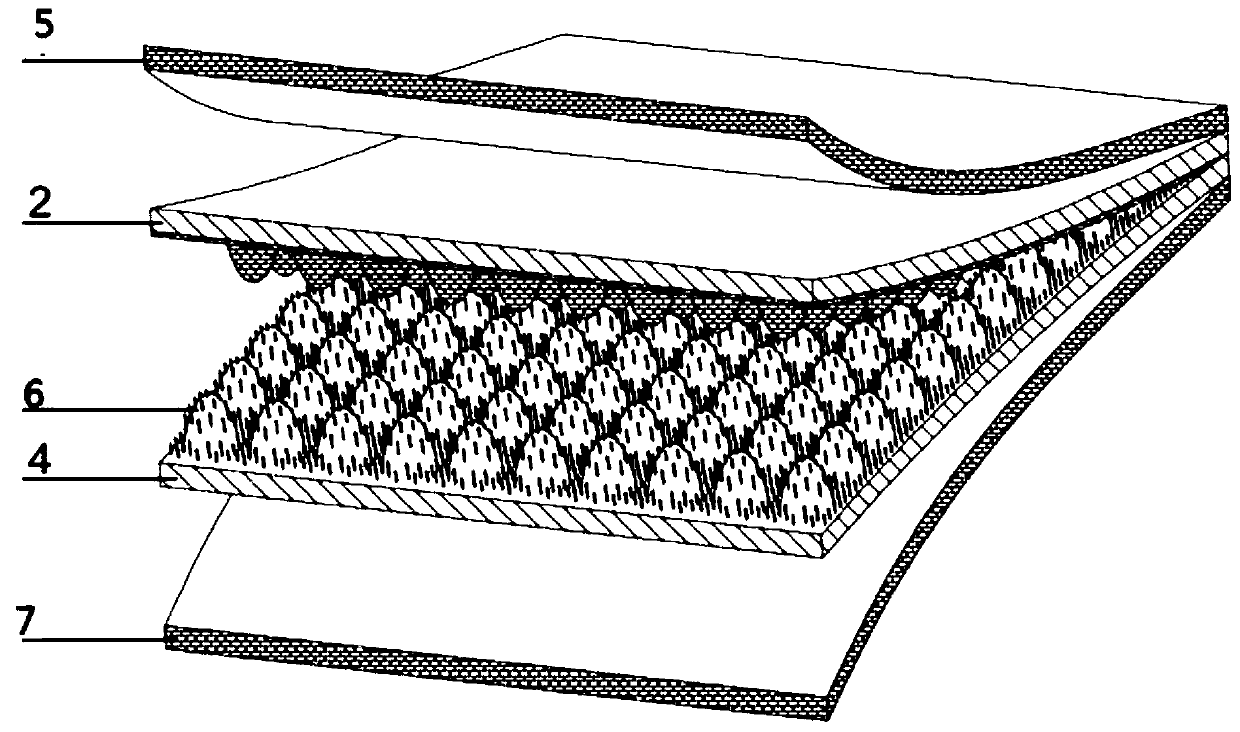

[0036] see figure 1 and figure 2 , The preparation method of the bionic flexible force sensor provided by the present invention, the preparation method mainly includes the bionic structure inversion process, silver nanowire spraying process, reactive ion etching process, device packaging process and so on. Among them, the bionic structure inversion process is used to replicate the microstructure of the leaf surface of Arrowroot velvet leaf. Through two inversions, the microstructure can be completely and effectively replicated; the silver nanowire spraying process is mainly used to prepare triboelectrodes, signal The back electrode and the shielding layer electrode are drawn out; the reactive ion etching process is mainly used to prepare a hydrophobic surface during the secondary inversion process of the leaf surface microstructure, which is convenient for the demoulding process after the inversion; the device packaging process is mainly used for the force sensor. assembly p...

Embodiment 1

[0061] The preparation method of the bionic flexible force sensor provided by Embodiment 1 of the present invention mainly includes the following steps:

[0062] (1) Rinse the velvet arrowroot leaves with deionized water for 2 minutes, and then blow dry the surface with nitrogen; then, blow the glass slides clean with nitrogen, and stick 3M double-sided adhesive on the glass slides, and cover the front of the leaves Apply face up to the slide, then cut off the excess, and blow the surface dust off again with nitrogen.

[0063] (2) Mix the polydimethylsiloxane prepolymer and the curing agent according to the mass ratio of 10:1, stir for 5 minutes, and then put the obtained mixture into a vacuum box with a vacuum degree of -0.1 MPa to evacuate 20 minutes to remove air bubbles from the mixture. Among them, polydimethylsiloxane adopts the Sylgard184 model of Dow Corning Company.

[0064] (3) Draw 9.4ml of polydimethylsiloxane with a syringe, inject the polydimethylsiloxane on th...

Embodiment 2

[0076] The preparation method of the bionic flexible force sensor provided by Embodiment 2 of the present invention mainly includes the following steps:

[0077] S1, rinse the velvet arrowroot leaves with deionized water for 2 minutes, and then blow dry the surface with nitrogen; then, blow the glass slides clean with nitrogen, and stick 3M double-sided adhesive on the glass slides, and put the leaves facing Stick it on the glass slide, then cut off the excess part, and blow off the dust on the surface again with nitrogen gas.

[0078] S2, stir the polydimethylsiloxane prepolymer and the curing agent according to the mass ratio of 10:1 for 5 minutes, and then put the obtained mixture into a vacuum box with a vacuum degree of -0.1 MPa for 20 minutes to remove air bubbles. Among them, polydimethylsiloxane adopts the Sylgard 184 model of Dow Corning Company.

[0079] S3, draw 9.4ml of polydimethylsiloxane with a syringe and inject it on the glass slide with velvet arrowroot lea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com