Patents

Literature

876results about How to "Improve high temperature oxidation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

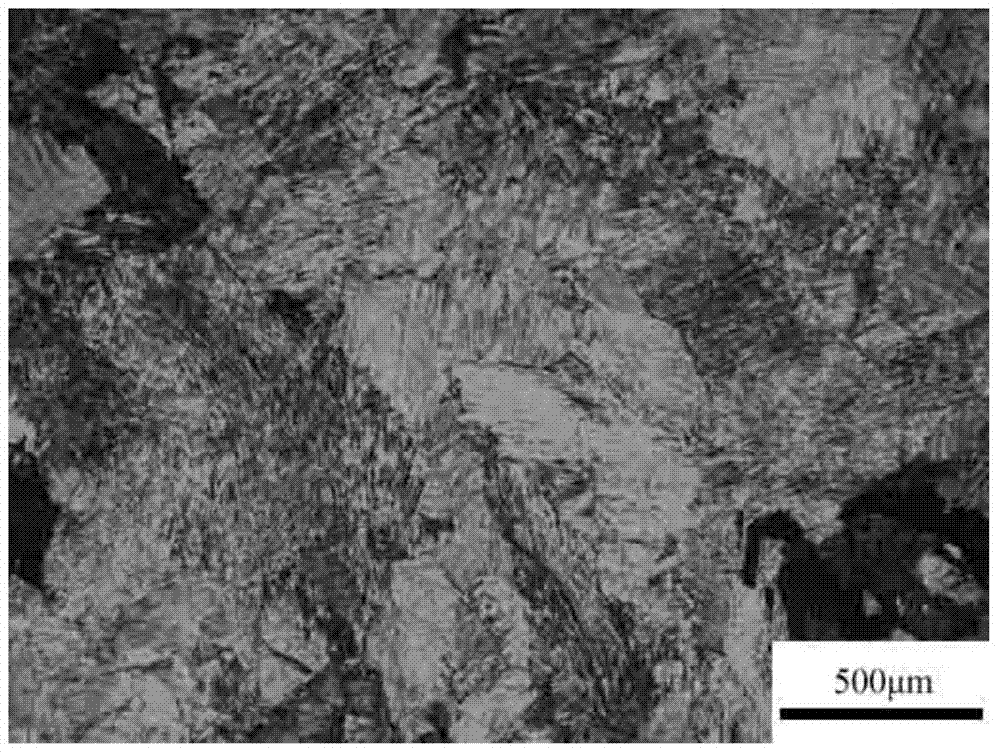

Multiphase high-entropy alloy and preparation method thereof

ActiveCN109252083AImprove bindingImprove high temperature oxidation resistanceHigh entropy alloysThermal treatment

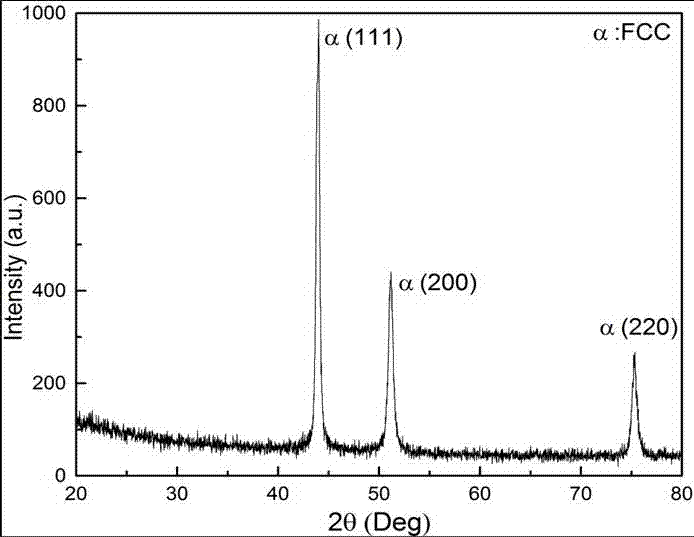

The invention belongs to the field of high-entropy alloy, and relates to multiphase high-entropy alloy with excellent high-temperature corrosion resistance and mechanical performance. The multiphase high-entropy alloy with the excellent high-temperature corrosion resistance and mechanical performance is prepared from the chemical components in percentage by mass(at.%): 5-40% of Fe, 2-30% of Cr, 15-45% of Ni, 3-25% of Al and 0.2-2.0% of Nb; meanwhile, one or more following element can be added: 0-0.5% of C, 0-4% of Mo, 0-35% of Mn, 0-35% of Cu, 0-35% of Co, 0-2.0% of Si, 0-1.0% of Ti, 0-1.0% ofV, 0-0.8% of W and 0-0.5% of Y; through treatment of the high-purity raw materials, blending, smelting in a vacuum induction furnace, moulding shaping and thermal treatment, the multiphase high-entropy alloy is obtained. By adjusting the element contents, a microstructure of FCC, a small amount of BCC and a second phase is achieved, and the comprehensive performance of the high-entropy alloy is obviously superior to the comprehensive performance of existing high-entropy alloy.

Owner:ANYANG INST OF TECH +1

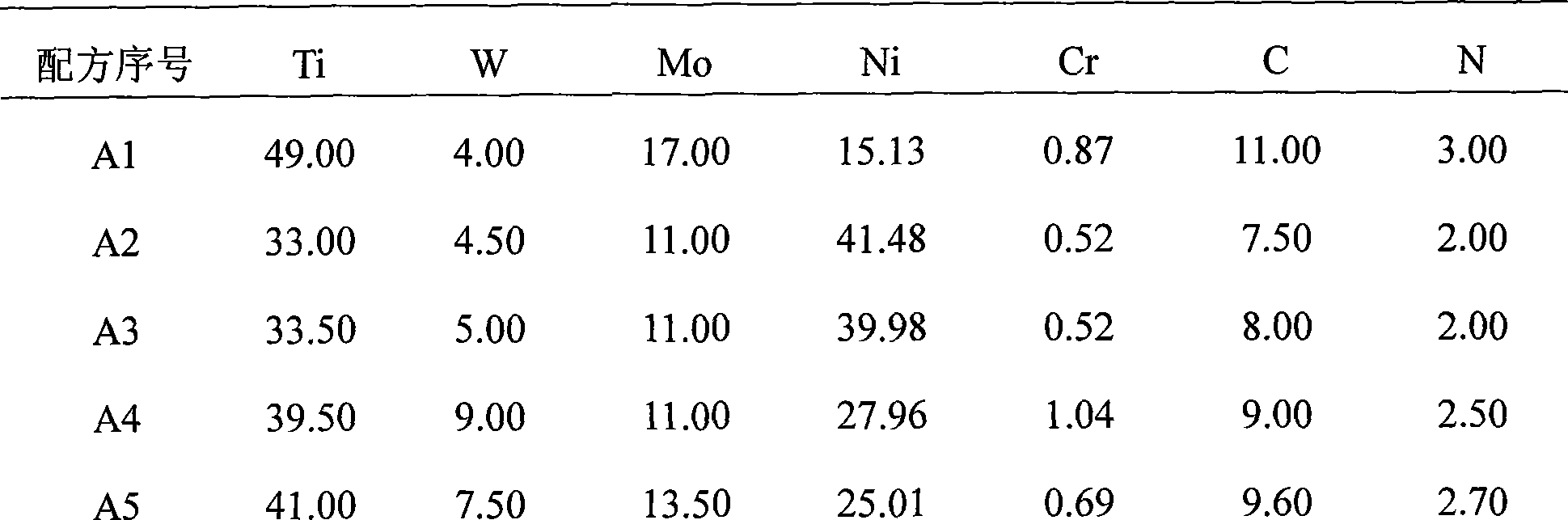

Metal ceramic cutter with gradient structure and preparation method thereof

The invention discloses a metal ceramic cutter with a gradient structure and a preparation method thereof, belongs to a metal ceramic material, and solves the problem that the conventional method for preparing the metal ceramic cutter has higher cost and lower comprehensive mechanical property. The metal ceramic cutter of the invention is characterized in that a hard phase in finally generated phases is (Ti, W, Mo, Ta, Nb) (C, N) and a bonding phase is Ni, wherein the hard phase and the bonding phase are in symmetrical gradient distribution from a surface layer to a middle layer. The method of the invention sequentially comprises the steps of raw material preparation and mixing, layer-by-layer paving and compression molding, degreasing and vacuum sintering. The method is simple and has low cost; the surface hardness of the manufactured metal ceramic cutter is 92.5 to 92.8HRA, the bending strength is more than or equal to 2,000MPa, and the fracture toughness KIC is more than or equal to 12.0MPa.m<1 / 2>; and the metal ceramic cutter has the advantages of good high-temperature red hardness, abrasion resistance, chemical stability and impact toughness resistance and strong high-temperature oxidation resistance, is suitable for high-speed efficient cutting and processing and dry cutting, and can reduce the using amount of cutting fluid or does not use cutting fluid.

Owner:HUAZHONG UNIV OF SCI & TECH

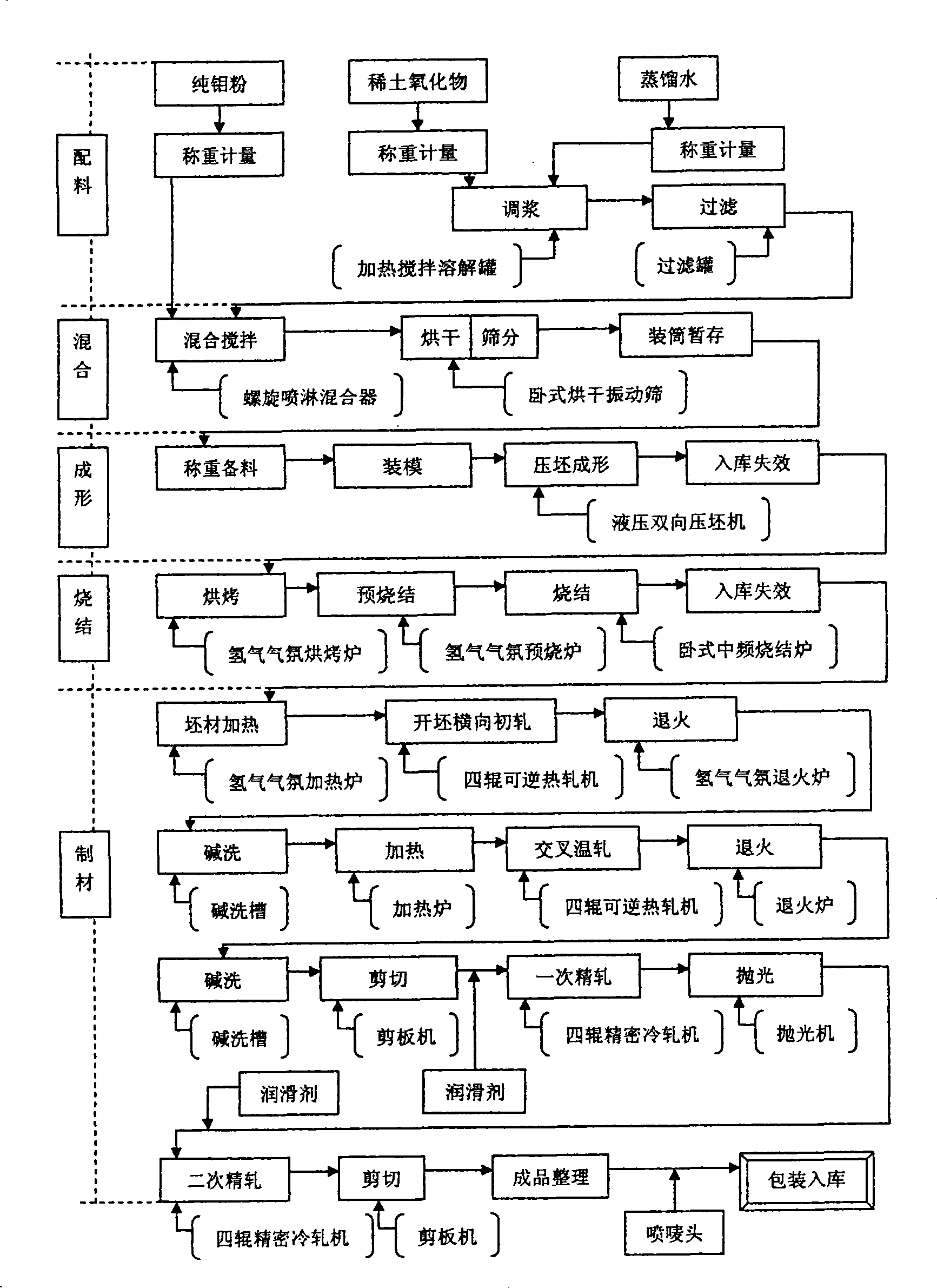

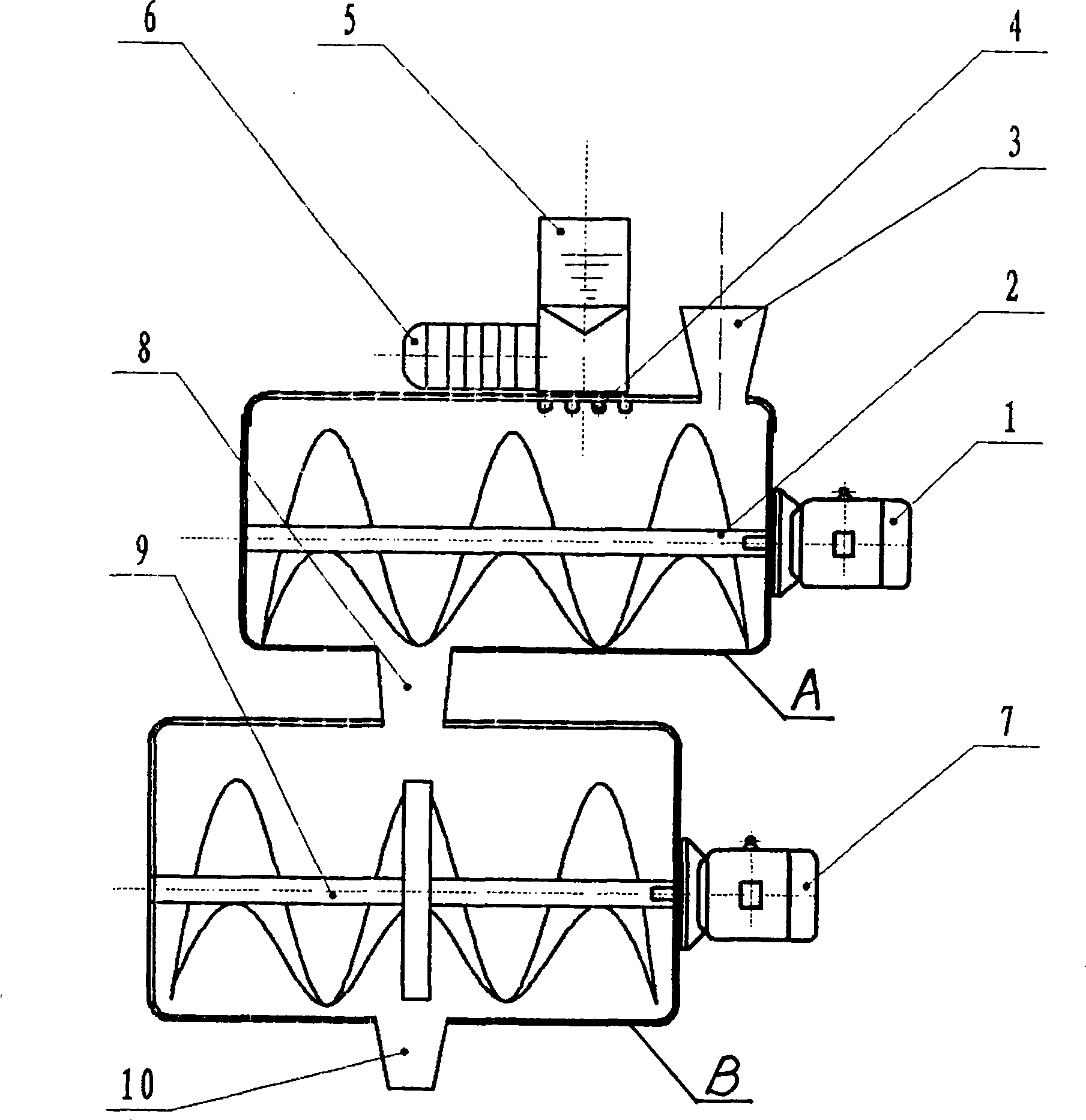

Manufacturing technology of molybdenum-based rare-earth alloy slab and equipment thereof

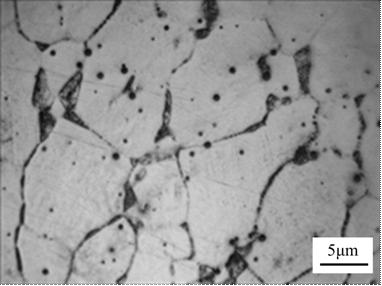

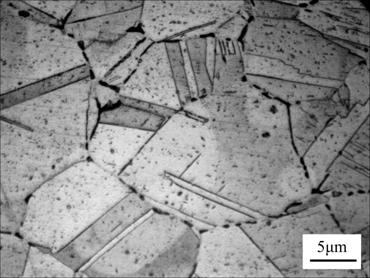

ActiveCN101423911AFull atomic diffusionFull liquidityRoll mill control devicesMetal rolling arrangementsExtensibilityManufacturing technology

The invention relates to a process for manufacturing the molybdenum based rare earth alloy plate and equipment for manufacturing the same, wherein pure molybdenum powder is simultaneously added with four rare earth oxides of ZrO2, Y2O3, La2O3 and Nd2O3 according to certain ratio, by utilizing the chrematistics of long and large crystal grain and strong sag resistance and anti-creep property of rare earth alloy elements and the dispersion strengthening function, the re-crystallization temperature of the metal molybdenum is increased, the mechanical performances of the molybdenum based material such as tensile property, yielding behavior and extensibility are improved, and the application range of the molybdenum based material is widened; and the manufacturing process comprises production procedures of material preparation treatment, mixing treatment, forming treatment, sintering treatment, material making treatment and the like and the setting of various technical parameters of special technical equipment and process. With the preparation process, the molybdenum based rare earth alloy plate which has the advantages of good electric conductivity and heat conductivity, excellent high-temperature resistance and corrosion resistance and better mechanical performances such as tensile property, yielding behavior and extensibility, and fills in domestic blank and can replace the imported material can be manufactured.

Owner:四平市北威钼业有限公司

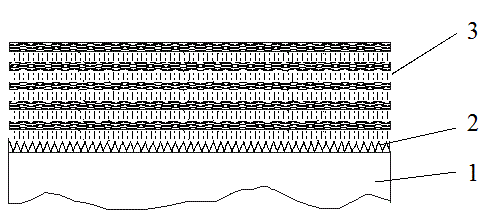

Lacunaris metal carrier and manufacturing method thereof

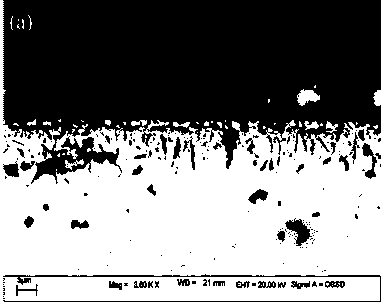

ActiveCN101229699AOvercome the defect of not resistance to oxidationImprove high temperature oxidation resistanceMolten spray coatingMetal layered productsPorous substrateRare-earth element

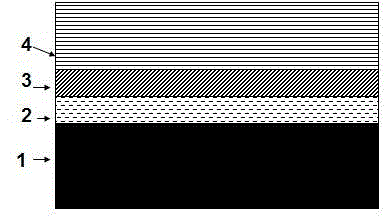

The invention discloses a porous metal carrier and a preparation method thereof. The porous metal carrier has a continuous micro-porous structure formed through mutual connection of polyhedron cabinets; a first layer is a substrate metal layer which comprises one or a plurality of the compositions: nickel, iron or copper; metal quantity of the substrate metal layer is more than or equal to 100g / m<2>; a function metal coating of MCrAl or MCrAlR is arranged on the substrate metal layer and M refers to Fe, Ni and Co or alloy of Fe, Ni and Co and R is rare earth element. The preparation method includes the following steps: first, metallization pretreatment is carried out for nonmetal porous substrate to form the substrate metal layer; second, the function metal layer with chromium and aluminum are sprayed on the substrate metal layer by adopting a thermal spraying process; at last, flame remelt and induction remelt are carried out for the function coating. The material provided by the invention has high porosity, large surface area, high strength, favorable flow disturbance, excellent high temperature and oxidization resistance, simple preparation method and process and low cost.

Owner:先进储能材料国家工程研究中心有限责任公司

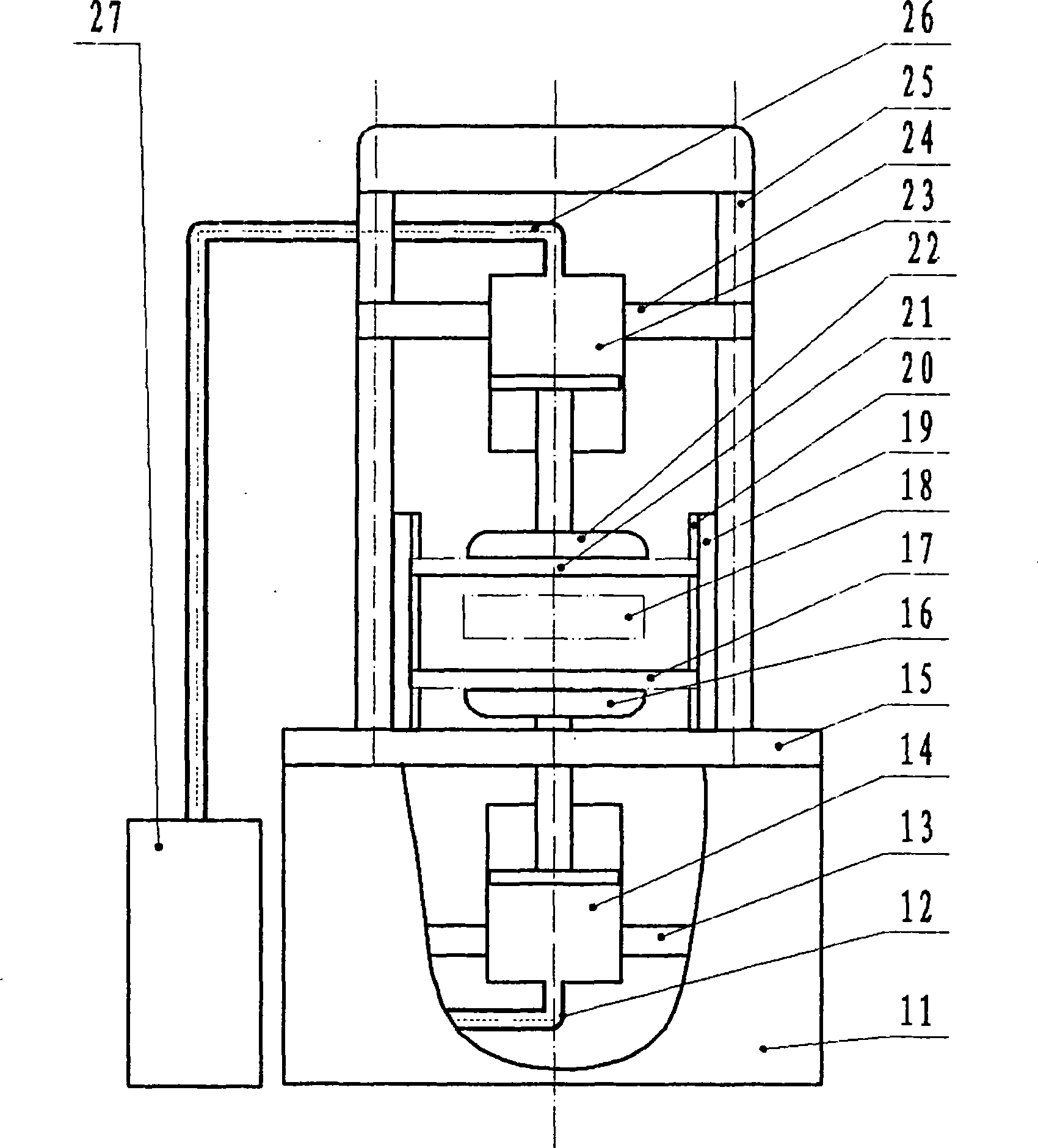

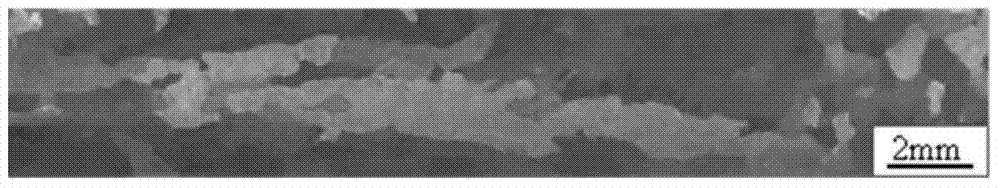

Directional TiAl-based alloy and preparation method thereof

ActiveCN103789598AImprove high temperature mechanical propertiesKeep low densityDirectional solidificationMaterials science

The invention discloses directional TiAl-based alloy and a preparation method thereof. According to the atomic percentage, TiAl alloy components are expressed as Ti-(40-50)Al-aNb-bCr-cMo-dV-eMn, wherein in the formula, a, b, c, d, e are atomic percentages, a+b+c+d+e is less than or equal to 10, and the balance is Ti. The method for preparing the columnar crystal TiAl-based alloy includes the following steps that mother alloy is smelted through vacuum induction suspension, and a mother alloy cast rod is prepared through vacuum suction casting; an optical floating zone crystal growth system is adopted, argon is used as protection gas, the flow speed is 3-3.6L / min, the width of a regional heating zone is 6-6.7mm, heat treatment is performed on the TiAl-based alloy cast rod, the heating temperature is controlled to be 1250-1350 DEG C, the drawing speed is in the range of 3-13 micrometers per second, and the columnar crystal TiAl-based alloy is prepared. Compared with a directional solidification technology, in the preparation method, peritectic reaction is omitted, and therefore peritectic segregation is avoided; the problem that refractory metal and alloy, such as tungsten and molybdenum, with direction tissue cannot be prepared through the direction solidification technology can also be solved.

Owner:NANJING UNIV OF SCI & TECH

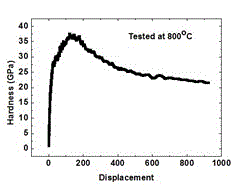

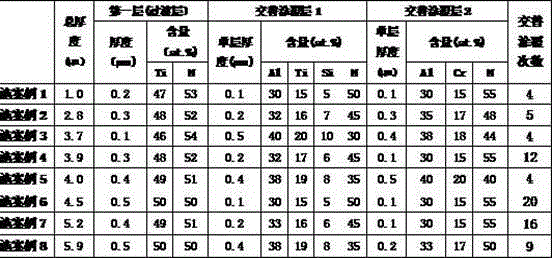

AlCrSiN-based multilayer nanometer composite cutter coating layer and preparation method thereof

InactiveCN104928638AExtend your lifeImprove mechanical propertiesVacuum evaporation coatingSputtering coatingWear resistantChromium

The invention relates to an AlCrSiN-based multilayer nanometer composite cutter coating layer and a preparation method thereof, and belongs to the technical field of preparation of cutter coating layers. A cutter basal body of the AlCrSiN-based multilayer nanometer composite cutter coating layer adopts a WC-Co hard allot or high-speed steel; the coating layer structure comprises a Ti metal bonding layer, an AlTiN transition layer and an AlCrSiN main wear resistant layer, wherein the AlTiN transition layer consists of 29-35 at.% of aluminum, 15-20 at.% of titanium, and 47-51 at.% of nitrogen; and the AlCrSiN main wear resistant layer consists of 25-30 at.% of aluminum, 20-25 at.% of chromium, 1-10 at.% of silicon, and 45-50 at.% of nitrogen. The transition layer AlTiN coating layer is prepared by a high-power pulse magnetron sputtering technology; and the AlCrSiN coating layer is prepared by an arc ion plating technology. The AlCrSiN-based multilayer nanometer composite cutter coating layer has the advantages of high hardness, low friction coefficient, low internal stress, high bonding strength and good high-temperature stability; a deposition coating cutter is suitable for cutting a high-hardness steel material under the condition of high speed; and the service life of the cutter can be largely prolonged.

Owner:GUANGDONG UNIV OF TECH

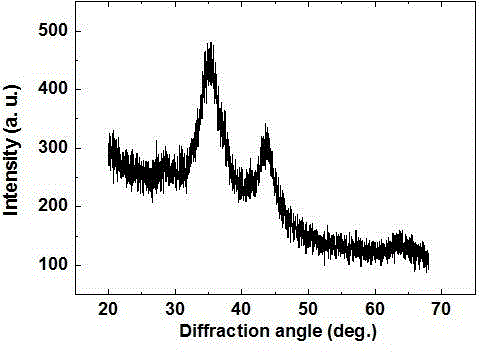

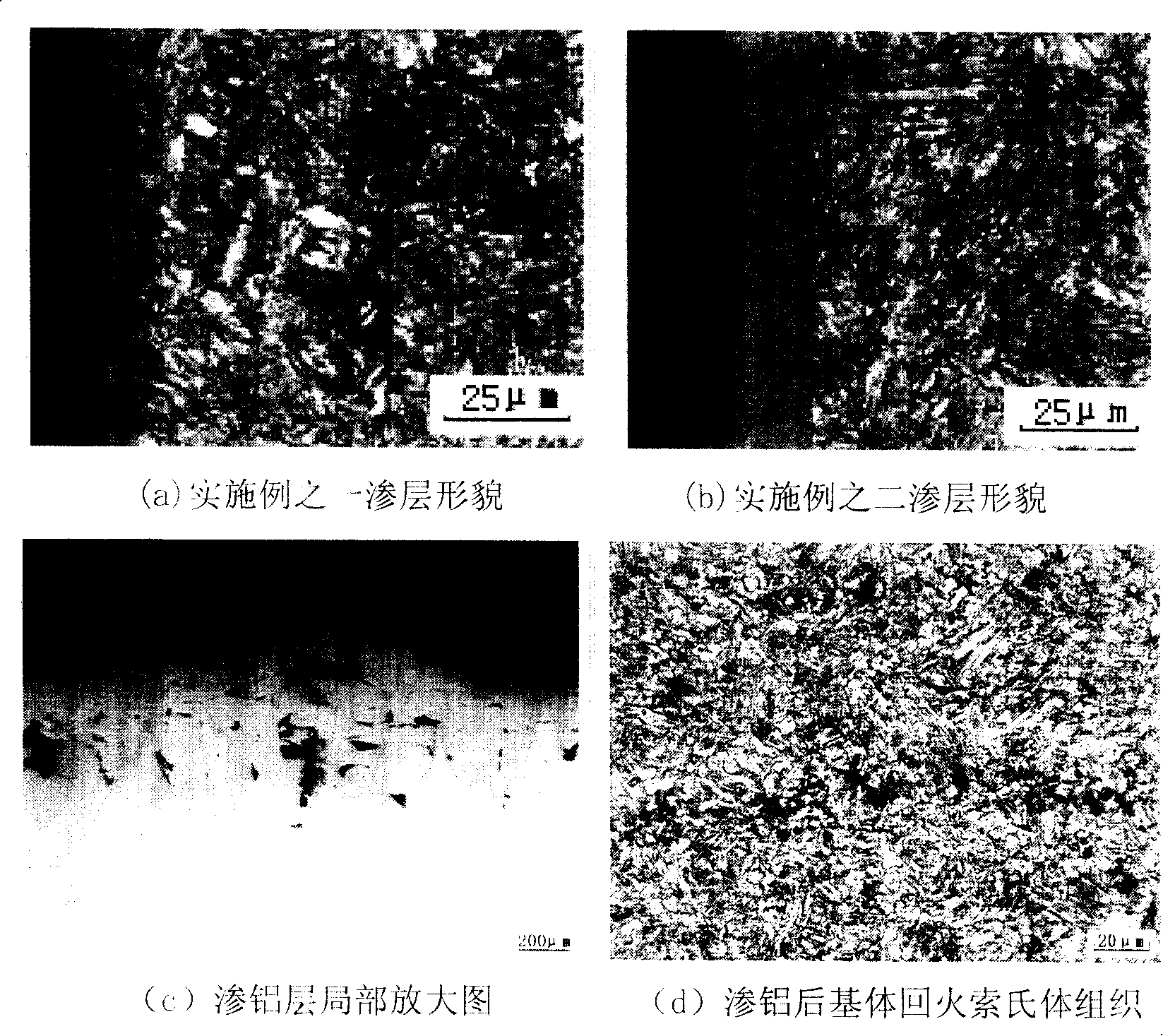

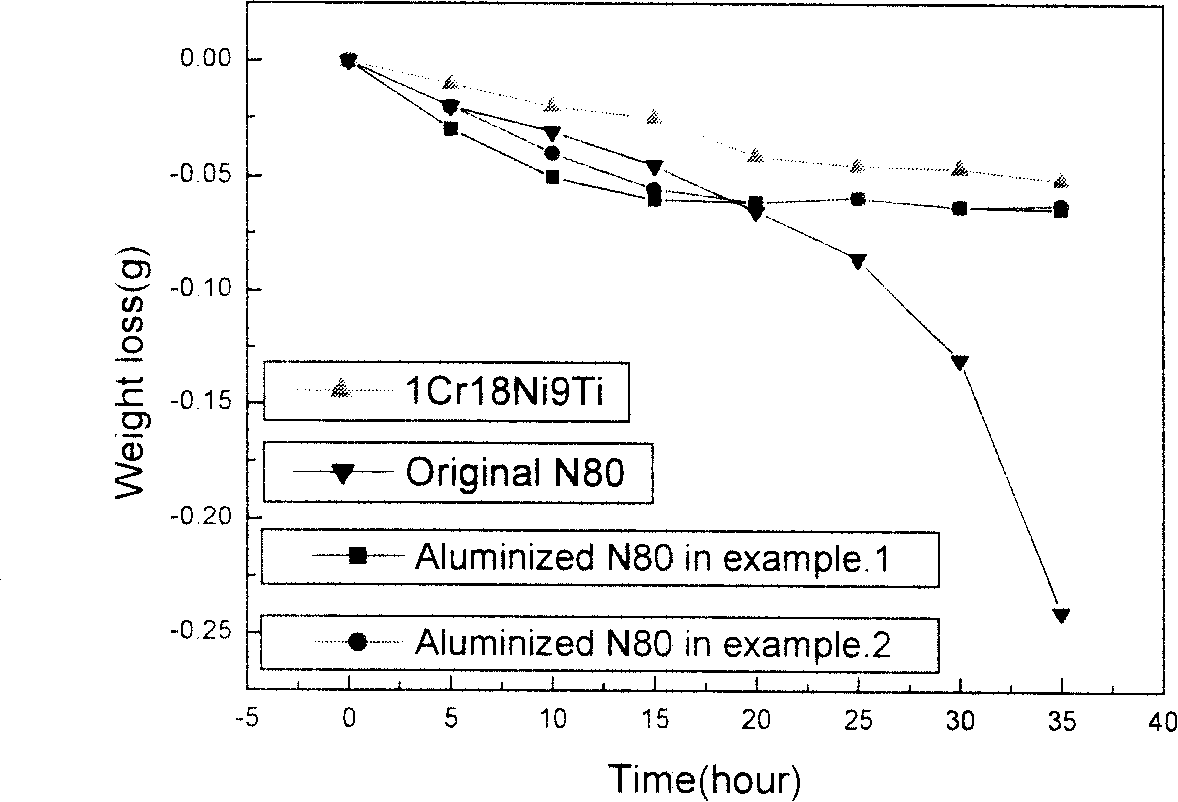

Oil and bushing low-temperature powder embedding aluminizing agent for petroleum

ActiveCN101165204AHigh bonding strengthDiffusion fastSolid state diffusion coatingAl powderSodium fluoride

The low temperature quick aluminizing agent specially for petroleum pipe and casing consists of metal source, activator, catalyst and stuffing. The metal source consists of 150-mesh Al powder in 10-20 wt% of the aluminizing agent, 120-mesh Zn powder in 10-25 wt%, 150-mesh Zn-Fe alloy powder in 10-20 wt% and / or 150-mesh Fe-Al alloy powder in 10-15 wt%. The activator consists of ammonium chloride, aluminum chloride, sodium fluoride and / or potassium bifluoride. The catalyst consists of 100-mesh Mo powder in 0-3 wt% and La and Os 0-3 wt%, with La and Os in the weight ratio of 1 to 1. The stuffing is 100-mesh alumina powder. The aluminizing agent is applied at 380-500 deg.c to obtain aluminized layer.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Preparation method of zirconium diboride and silicon carbide high-temperature antioxidant coating

ActiveCN103422046AImprove high temperature oxidation resistancePrevent oxidationMolten spray coatingCarbide siliconOxidation resistant

The invention relates to a preparation method of zirconium diboride and silicon carbide high-temperature antioxidant coating, belongs to the technical field of thermal spraying and particularly relates to a preparation method of material surface high-temperature antioxidant coating. ZrB2-SiC coated composite powder is prepared by spray-drying, so that volatilization of SiC during spraying is prevented; the SiC helps further improve high-temperature oxidization resistance of the coating. The ZrB2-SiC composite coating is prepared by means of ultralow-pressure plasma spraying, so that oxidization of the ZrB2-SiC composite powder during spraying is avoided effectively, porosity of the coating can be reduced and bonding strength of the coating can be improved. The prepared ZrB2-SiC composite powder is not larger than 45s / 50g in mobility and 2-3.0g / cm<3> in apparent density; the prepared coating is 7-10% in porosity and 20MPa in bonding strength.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Ceramet containing Ni-Cr binder and preparation thereof

Owner:HUAZHONG UNIV OF SCI & TECH

Nonuniform cemented carbide for hot extruding hot die and method for preparing same

The invention discloses a material for a hot heading die and a preparation process thereof. The compositions by weight percentage of the material are: 12 to 20 percent of cobalt, 3 to 10 percent of nickel, 50 to 70 percent of tungsten carbide with 20 to 25mu m, 10 to 30 percent of tungsten carbide with 1.0 to 1.5mu m. The preparation method for the material comprises the following steps: a step of mixing, during which the raw materials are taken in proportion and mixed evenly to obtain a mixture; a step of wet-grinding of the mixture, which is carried out inside a ball mill by using alcohol or acetone as the medium with a rotating speed of 36r / min and a grinding time of between 20 and 30 hours under the condition that the mixture is in accordance with the ratio of balls and the materials of 3-5 to 1, and the liquid-to-solid ratio of the mixture is 450-520ml / kg; a step of drying and press forming, and sintering in a vacuum furnace, thus the product is obtained. The invention uses the uneven structure theory of the hard alloy material, under the condition of certain content of cobalt in alloy, the fracture intensity and toughness of the alloy can be improved by reasonably collocating the proportion of coarse tungsten carbide powder and fine tungsten carbide powder, and inevitably the hardness and wear resistance can be improved thereafter. The different proportion between cobalt and nickel can obtain alloys with different impacting toughness and wear resistance. Furthermore, nickel powder is favorable to improve high-temperature oxidation resistance of the alloy.

Owner:ZHUZHOU JINGGONG CEMENTED CARBIDE

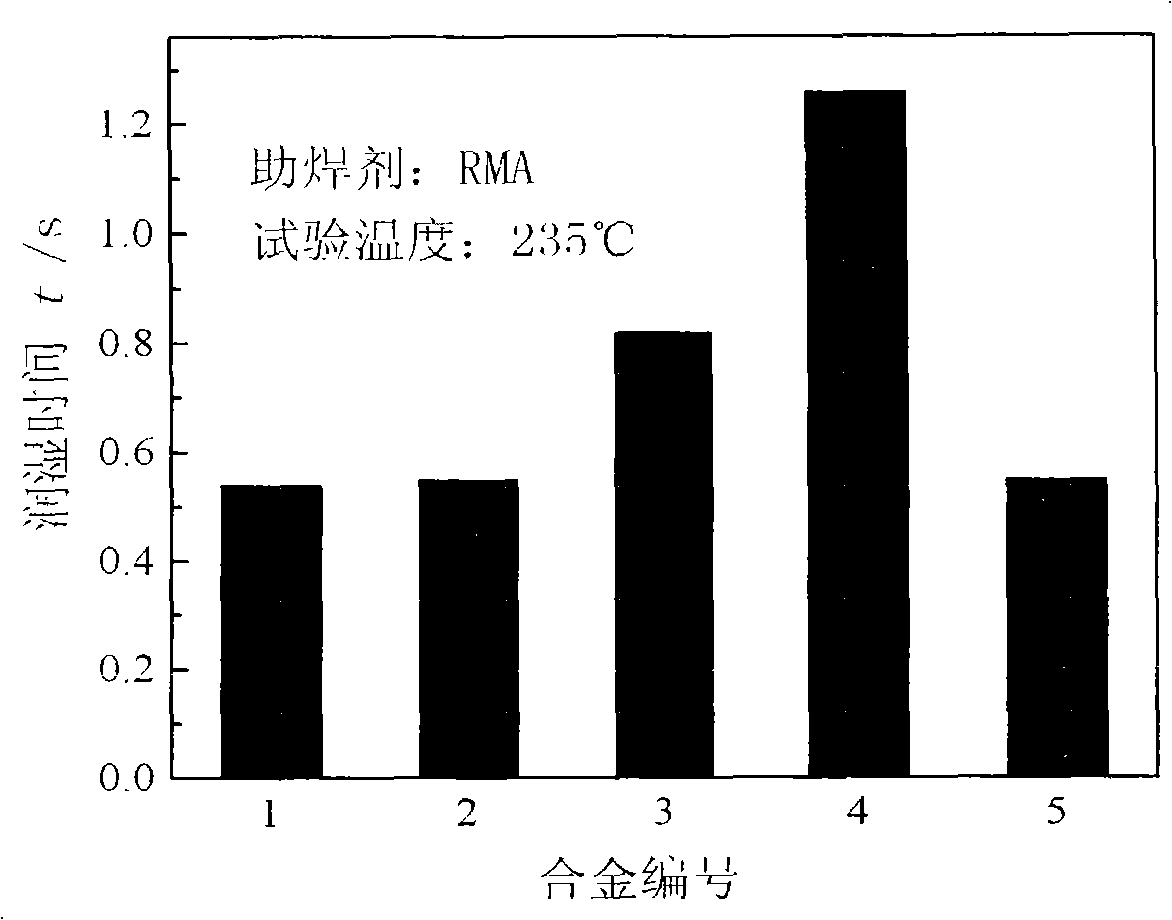

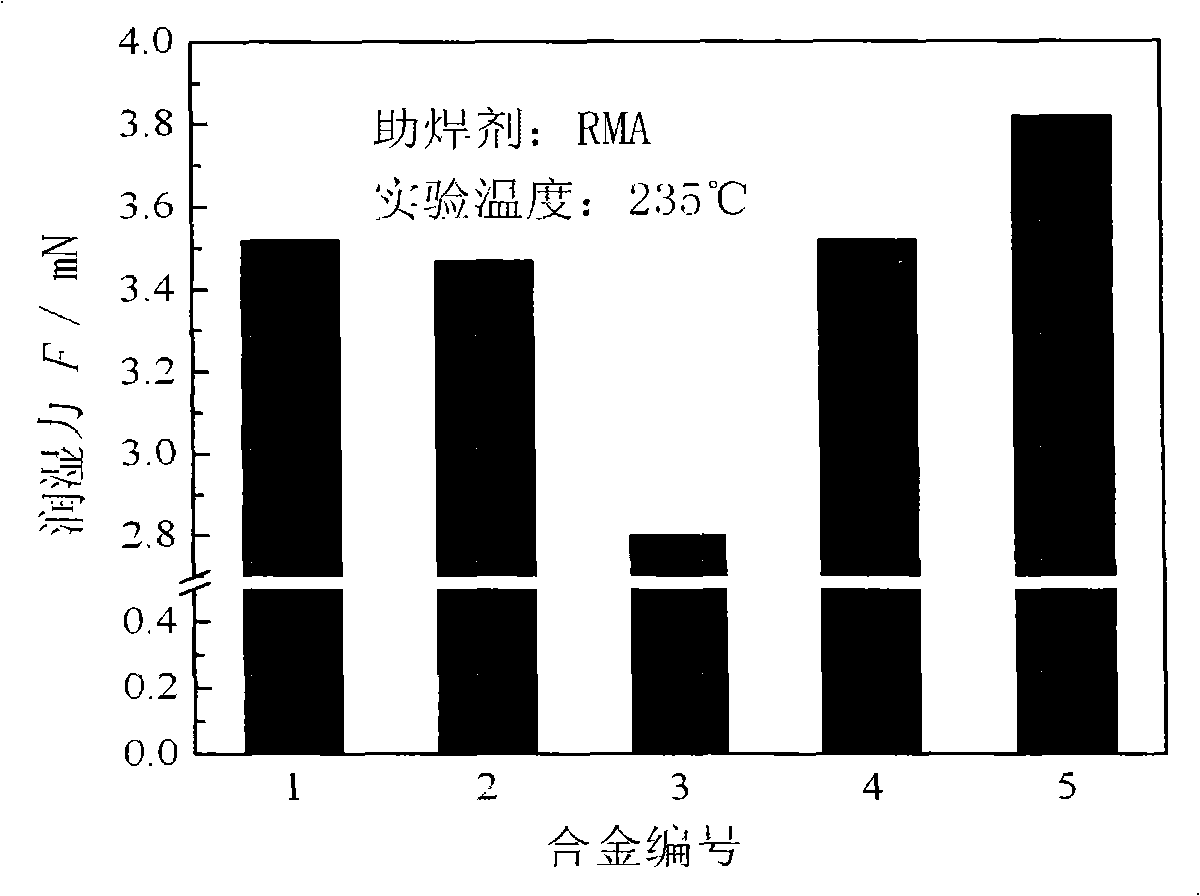

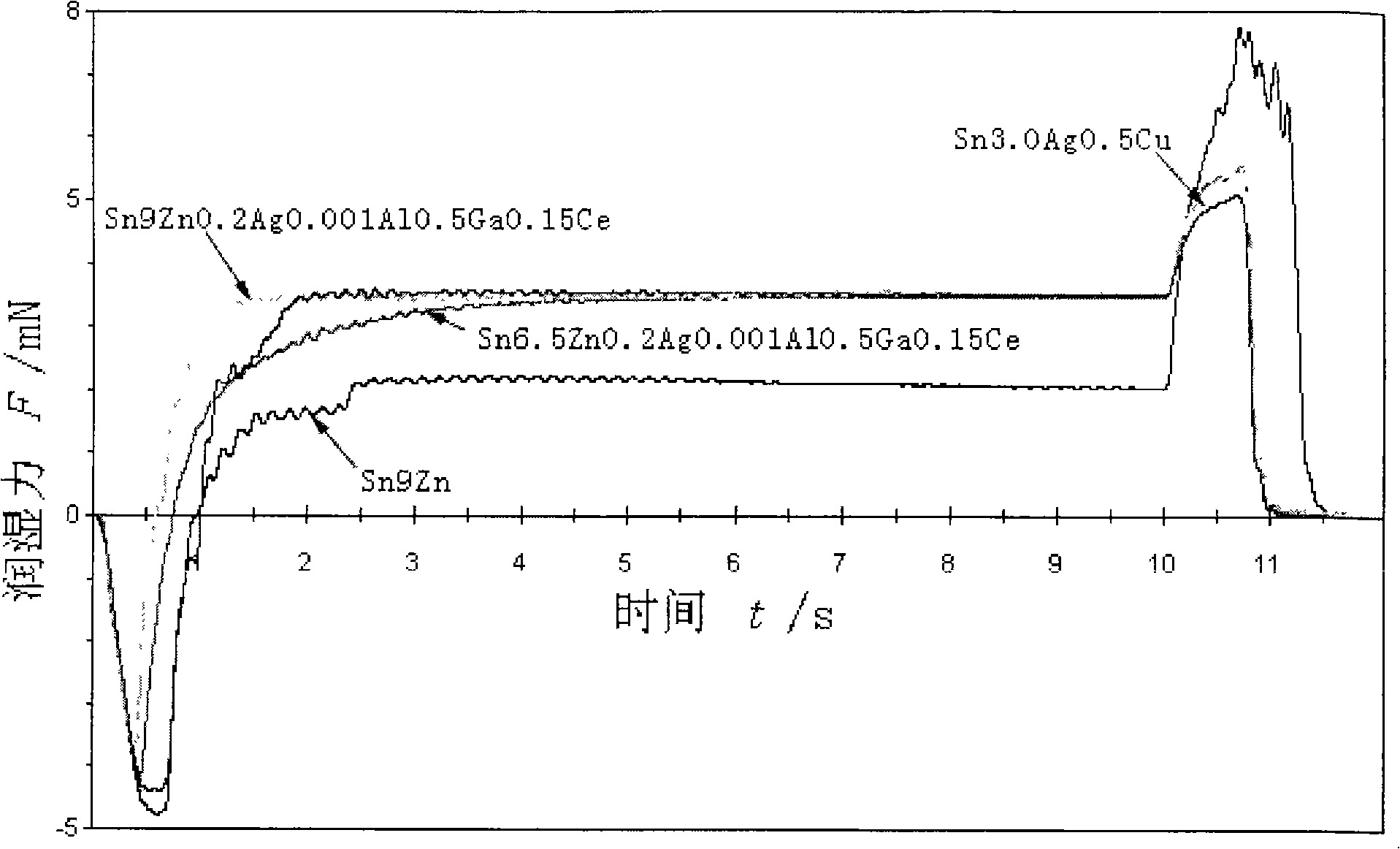

Sn-Zn-Ga-Ce leadless brazing filler metal

InactiveCN101269446AReduce oxidationImprove wettabilityWelding/cutting media/materialsSoldering mediaSilver plateCerium

The invention relates to Sn-Zn-Ga-Ce lead-free brazing filler metal, which belongs to a metal material and a braze welding material of the metallurgic field. The chemical constitution according to a mass percentage is as follows: 5 to 10 percent of zinc, 0.05 to 3 percent of gallium, 0.001 to 0.5 percent of cerium, 0.01 to 3 percent of silver, 0.001 to 0.5 percent of aluminum, and rest percent of tin. Market sold tin ingot, zinc ingot metal, gallium, silver ingot (or silver plate), aluminum ingot and metal cerium are in a mixture ratio according to requirements; when smelting, optimization screened and determined covering agentia is added or inactive gas protection is adopted for smelting and casting, so as to get a bar. Through extruding and drawing, the brazing filler metal silk material is gained (scaling powder can also be added so as to make flux-cored brace welding wire). With the adoption of a powder manufacturing apparatus, new brazing filler metal can be made to a graininess (the graininess size is between 0.106 mm (140 mu) to 0.0380 mm (400 mu)) so as to be used for BGA packaging or made to the soldering paste for use.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Boracic high-speed steel with good red hardness and preparation method thereof

The invention discloses boracic high-speed steel with good red hardness, and a preparation method of the boracic high-speed steel. The boracic high-speed steel comprises the following chemical components in percentage by weight: 0.30-0.5% of C, 3.8-5.5% of Cr, 0.9-3.5% of W, 0.9-2.1% of Mo, greater than or equal to 3.5% and less than or equal to 5.0% of (W+2Mo), 0.8-1.2% of Si, 0.3-1.5% of Mn, 3.0-3.5% of B, 0.8-2.6% of Cu, 2.8-3.6% of Al, 0.5-1.0% of V, 0.8-1.6% of Ti, 0.02-0.15% of Ca, 0.03-0.25% of Ce, 0.02-0.18% of N, 0.05-0.3% of Nb, 0.12-0.25% of Mg, 0.04-0.13% of K, 0.05-0.12% of Ca, 0.06-0.15% of Ba, less than or equal to 0.03% of S, less than or equal to 0.04% of P and the balance of Fe and inevitable impurity elements. The preparation method comprises the following steps: smelting waste steel and ferrochrome, subsequently adding copper plates, silicon iron and ferromanganese iron, adjusting the component at a stokehole, after being qualified, raising the temperature to be 1,560-1,620 DEG C, adding calcium-silicon and aluminum for deoxidation, adding ferrotitanium, ferro-boron and aluminum, smelting and discharging outside a furnace, adding a rare earth magnesium alloy and a composite inoculant consisting of metal cerium, Si3N4, VN (Vanadium Nitride), Nb and K, so as to perform inoculation treatment, wherein the molten steel casting temperature is 1,400-1,450 DEG C, keeping the temperature of a cast piece at 920-1,150 DEG C for 2-4 hours, and subsequently performing air cooling.

Owner:江苏盛伟模具材料有限公司

TiZrAlSiON nano composite superhard coating cutter and preparation method thereof

ActiveCN104060230AImprove high temperature oxidation resistanceReduce coefficient of frictionMaterial nanotechnologyVacuum evaporation coatingThin membraneCemented carbide

The invention relates to a TiZrAlSiON nano composite superhard coating cutter and a preparation method thereof, belonging to the technical field of thin-film materials. The coating cutter comprises a hard alloy cutter body, wherein a TiZrAlSiON nano composite coating is plated on the cutter body; the TiZrAlSiON coating comprises a 50-100nm-thick metal base layer-Zr metal layer, a 100-200nm-thick nitride transition layer ZrN and a 1000-4000nm-thick functional layer TiZrAlSiON; and the nano composite coating has a nano composite structure in which nanocrystal particles are embedded in the amorphous matrix, the nanoparticles comprise TiN and ZrN, and the amorphous matrix comprises Al2O3 and Si3N4. The preparation method comprises the following steps: carrying out glow cleaning on the hard alloy cutter, carrying out arc ion bombardment, and sequentially depositing the base metal layer, transition metal nitride layer and TiZrAlSiON coating. The TiZrAlSiON composite coating has the advantages of high hardness, low friction factor, high toughness, high binding force and excellent high-temperature oxidation resistance, has better comprehensive properties than the TiN, CrN and Ti-Al-N coatings which are industrially produced at present, and can effectively enhance the toughness and cutting characteristic of the cutting tool and prolong the service life of the hard alloy cutter body.

Owner:东莞市鑫硕机械科技有限公司

High-temperature oxidation resistant plating layer material and hot dipping method for hot stamping formed steel

ActiveCN104233149AImprove high temperature oxidation resistanceImprove corrosion resistanceHot-dipping/immersion processesHot stampingSheet steel

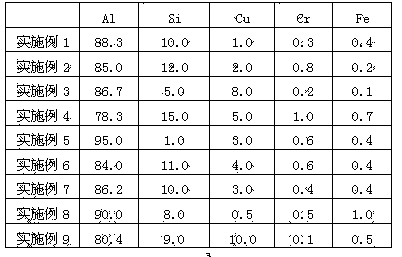

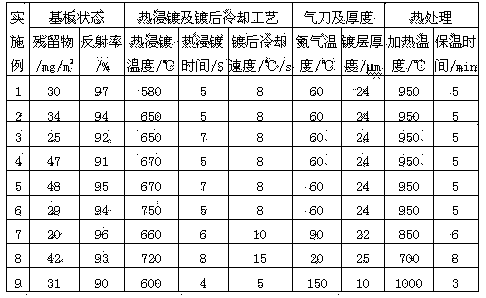

The invention discloses a high-temperature oxidation resistant plating layer material and a hot dipping method for hot stamping formed steel. A hot stamping formed steel plate enters a plating solution for hot dipping and then is subjected to cooling and heat treatment so that a hot dipping steel plate can be obtained, wherein the plating solution comprises the following components in percentage by mass: 1.0%-15.0% of Si, 0.5%-10.0% of Cu, 0.1%-1.0% of Cr, less than or equal to 1.0% of Fe and the balance of Al and inevitable impurities. According to the method, the Cu element and Al element which are contained in a plating layer form a high-melting point intermetallic compound in a cooling process after the hot dipping, and Cr is gathered on the surface of the plating layer to form a compact oxidation film, so that the high-temperature oxidation resistant property of the plating layer is greatly enhanced; the Cu element is enriched on the surface of the plating layer, so that the corrosion-resisting property of the plating layer is greatly enhanced. The high-temperature oxidation resistance and the high-temperature corrosion resistance of the plating layer are enhanced by utilizing the intermetallic compounds formed among Al, Si, Cr, Cu and Fe; and the obtained plating layer has the advantages of reasonability in structure, tight combination with a substrate and good high-temperature oxidation resistance and corrosion-resisting property.

Owner:HEBEI IRON AND STEEL

Method for preparing high-bonding strength catbon steel based Al2O3 ceramic coating with colloidal sol-gel rubber

InactiveCN101270476ASimple processGood compactnessLiquid/solution decomposition chemical coatingSuperimposed coating processIonSolvent

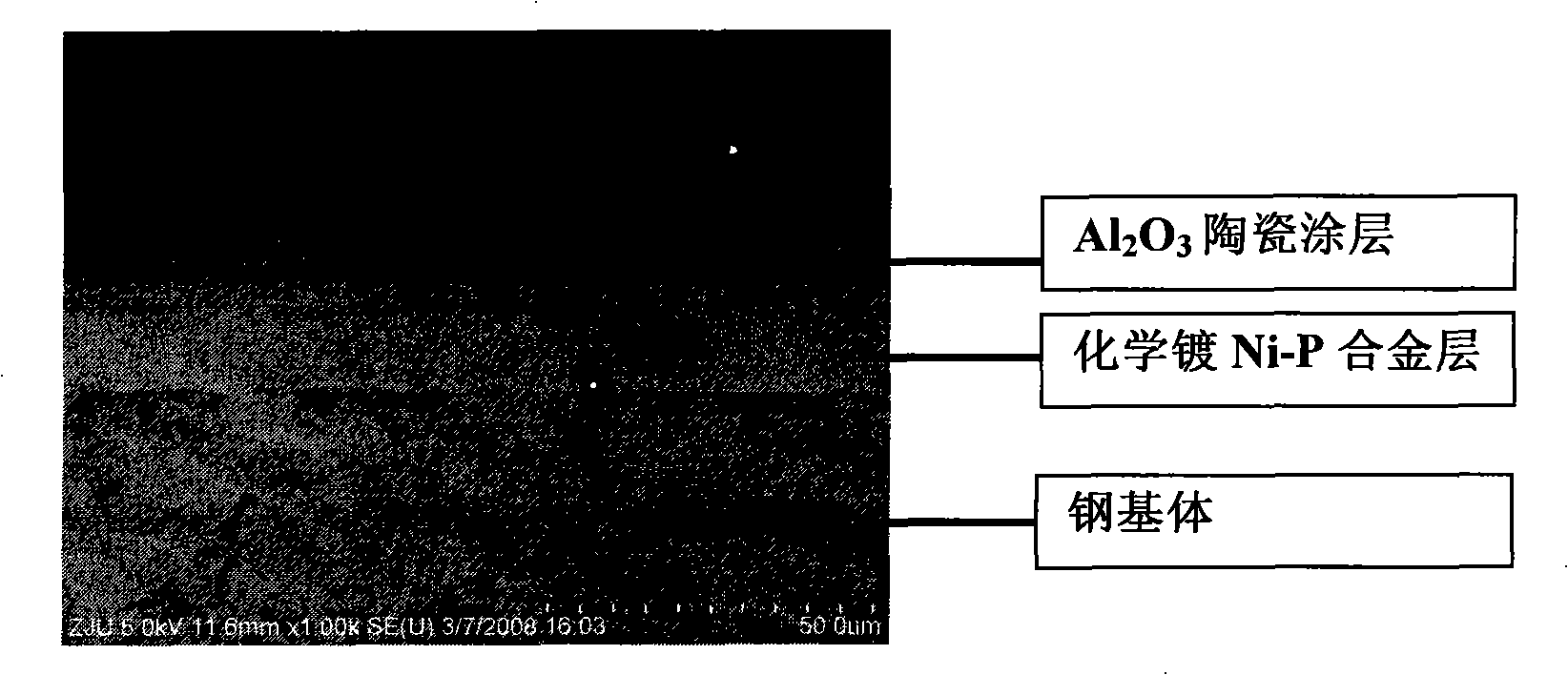

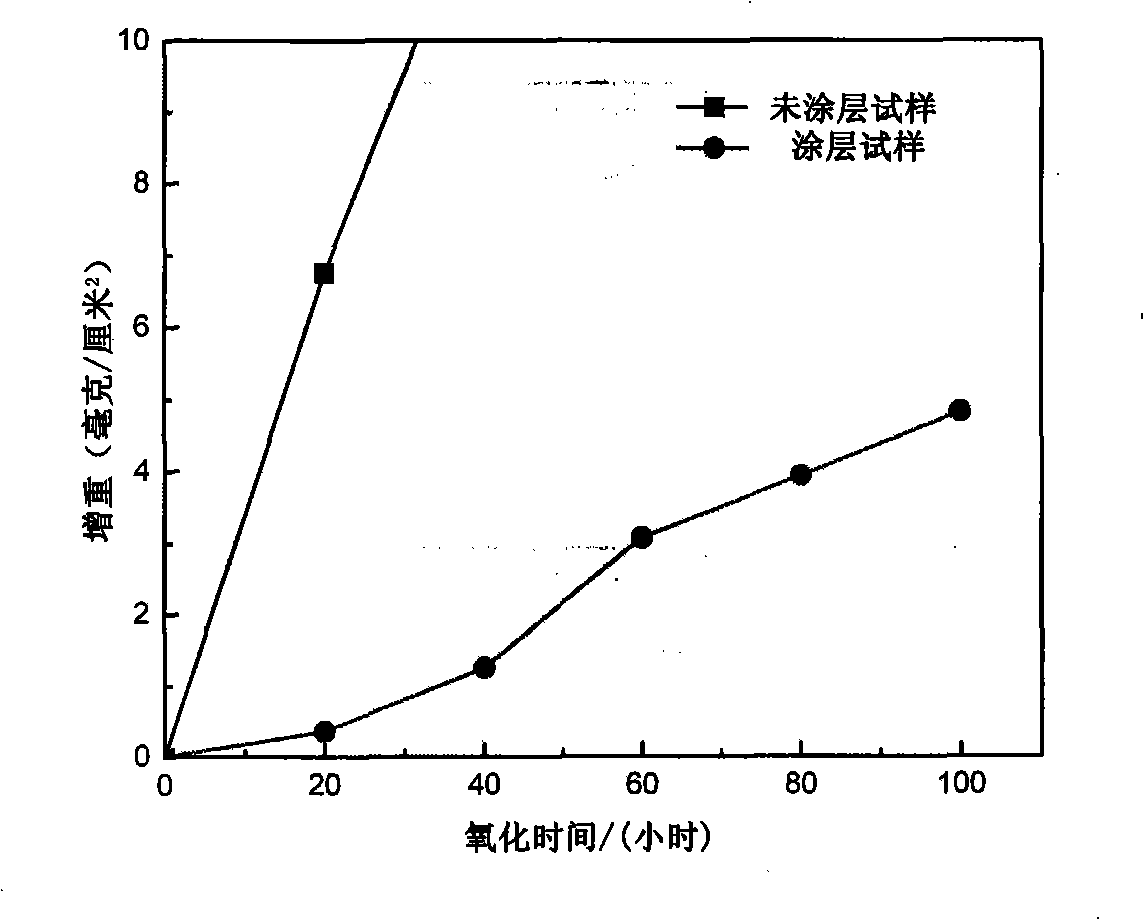

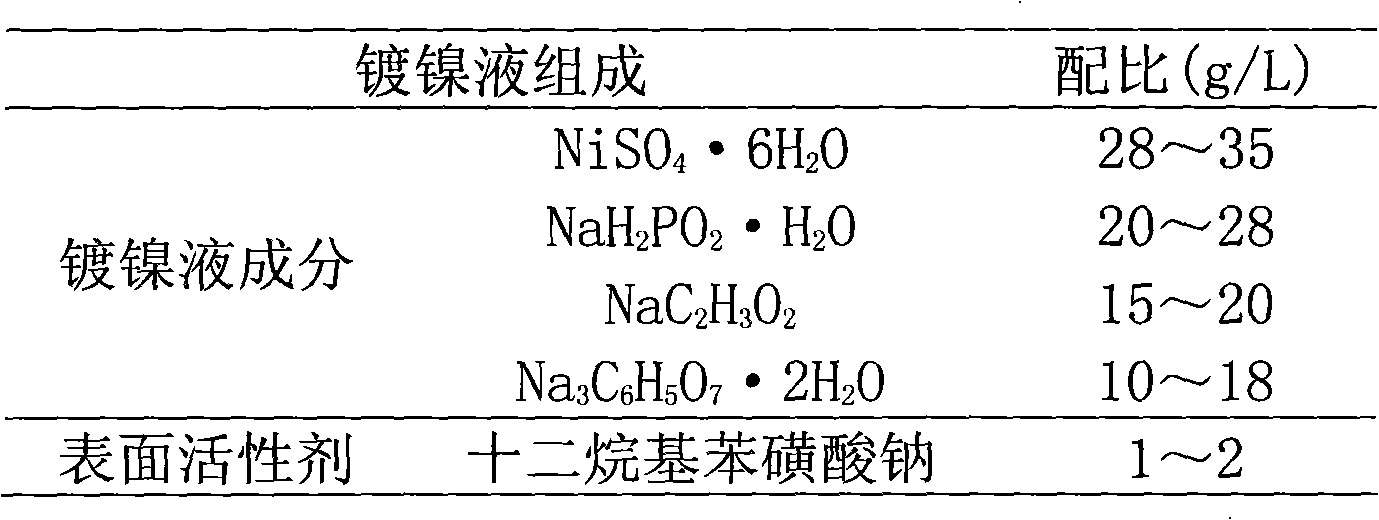

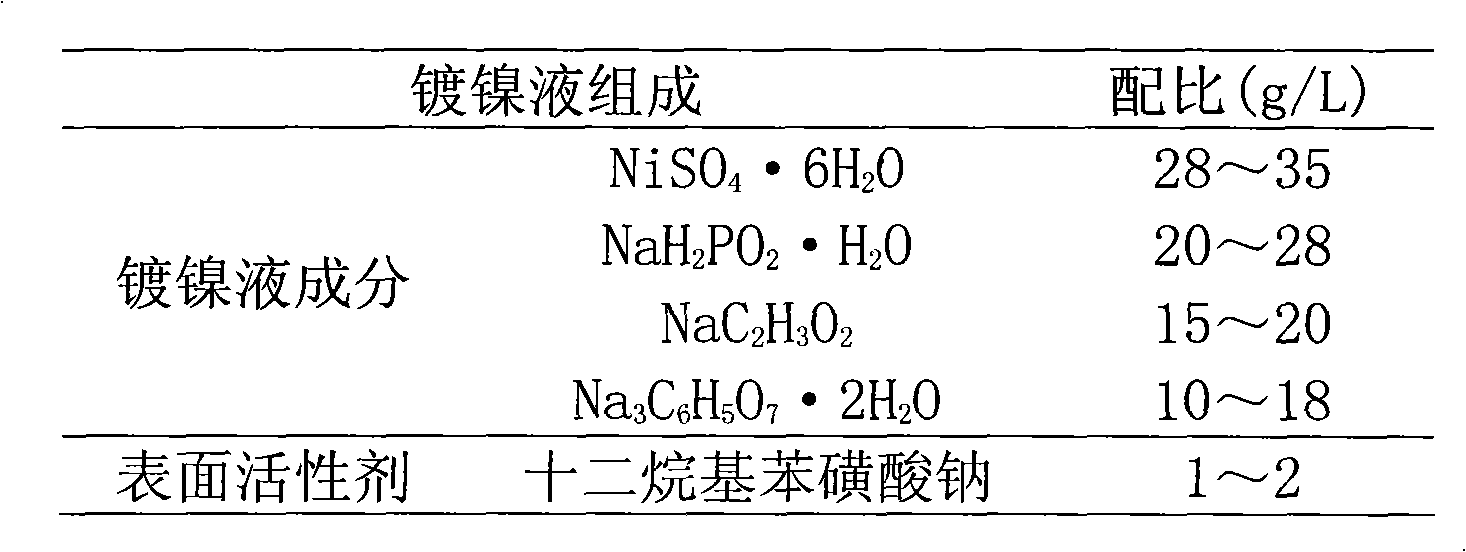

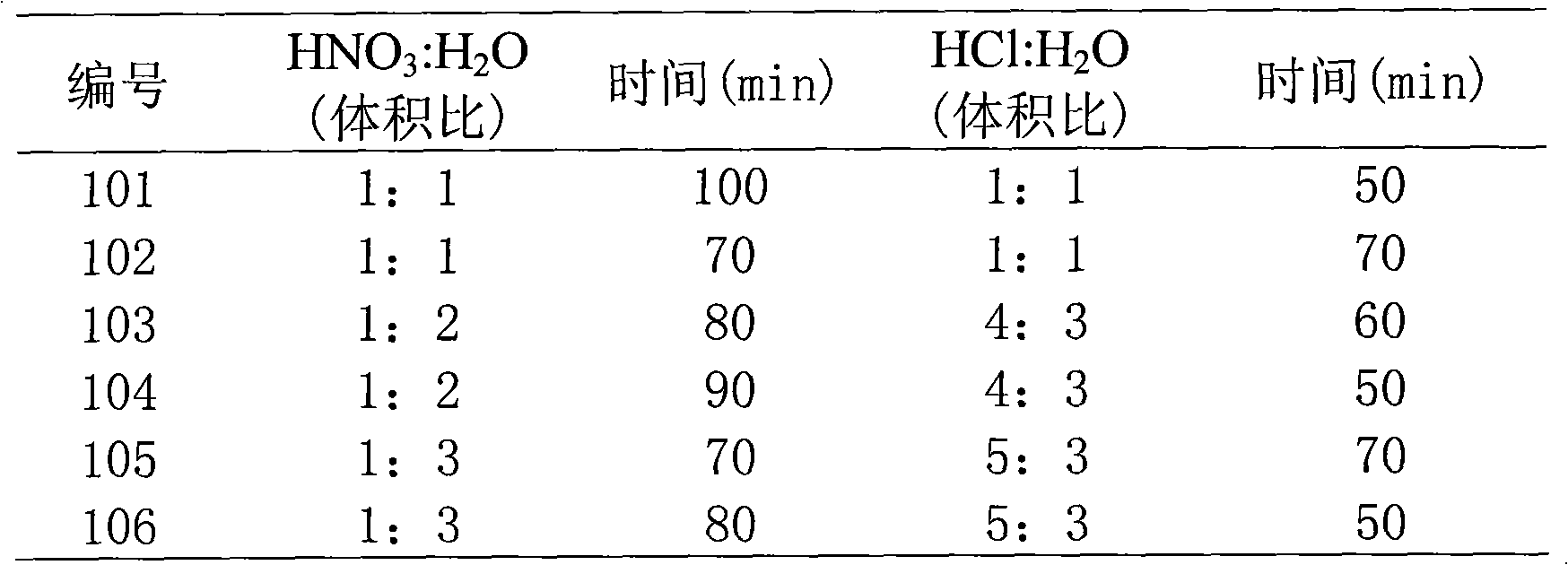

The invention discloses a method for preparing high bonding intensity carbon steel-based Al2O3 ceramic coat by sol-gel. The method adopts the carbon steel as a compound coating basic body, adopts nickel vitriol as main salt, adopts NaH2PO2 as a reducer to chemically plate a Ni-P alloy in an acid medium, takes aluminium isopropoxide as a precursor, takes secondary de-ionized water as a solvent and takes nitric acid as a glue solvent to prepare boehmite sol acordign to a mol ratio of 1:80 to 120: 0.1 to 03; adopts a dip-coating method to coat and then bake the gel. The invention takes a chemically plated Ni-P alloy as a middle transition layer and adopts the sol-gel method to prepare the Al2O3 ceramic coat on the surface of the carbon steel, thus solving the technical difficulty of the lower bonding force of the carbon steel-based ceramic coat. The compound processing method provided by the invention has a simple and convenient technique and needs no expensive and complex devices; besides, the prepared compound coat has excellent compactness and uniform components. The technique can be used for carbon steel anti-high temperature oxidation coat; the technique of the method is easy to realize industrialization and is not restrained by the shape of a workpiece.

Owner:ZHEJIANG UNIV

Whisker- toughened cermet cutting tool and method for preparing same

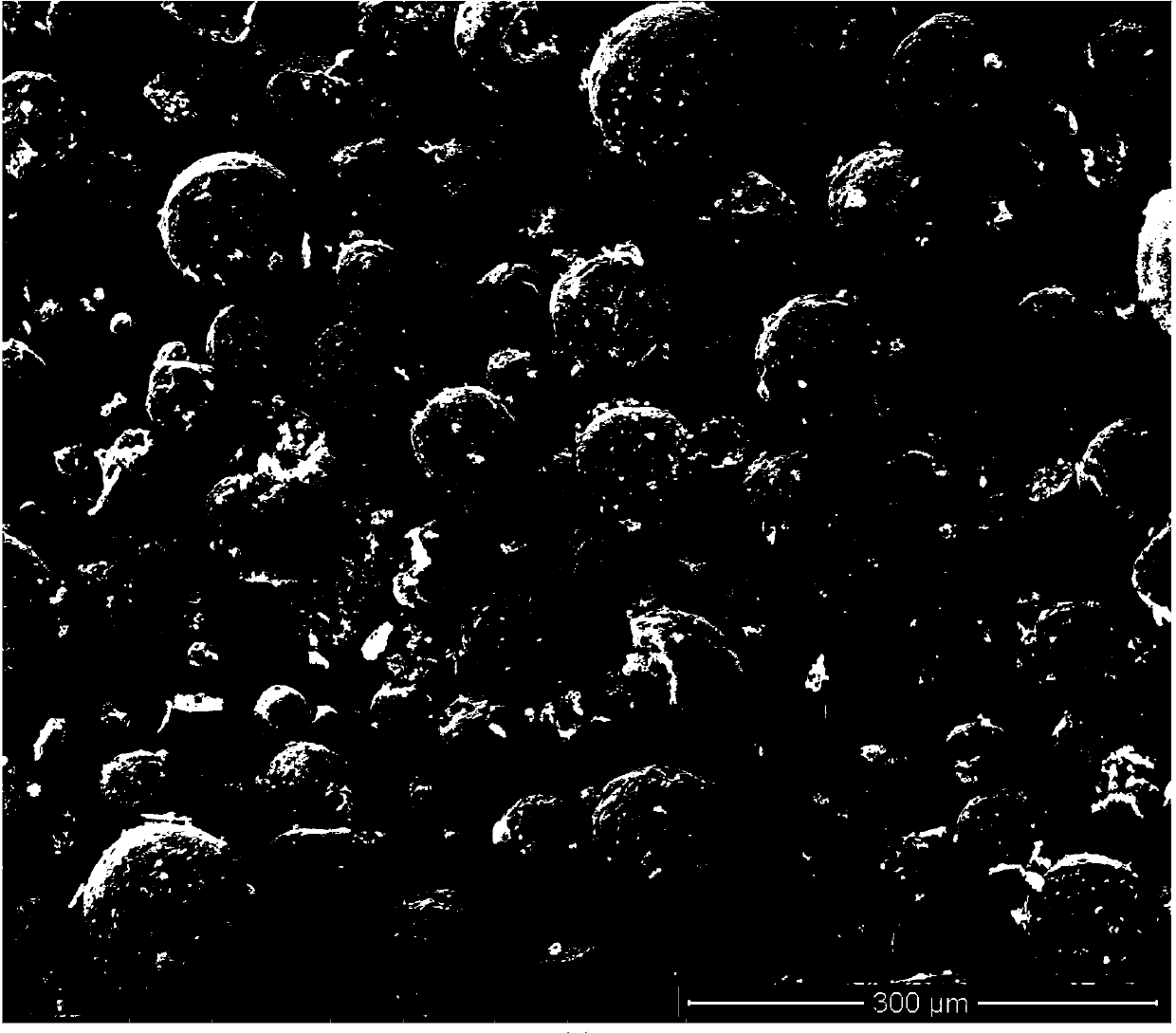

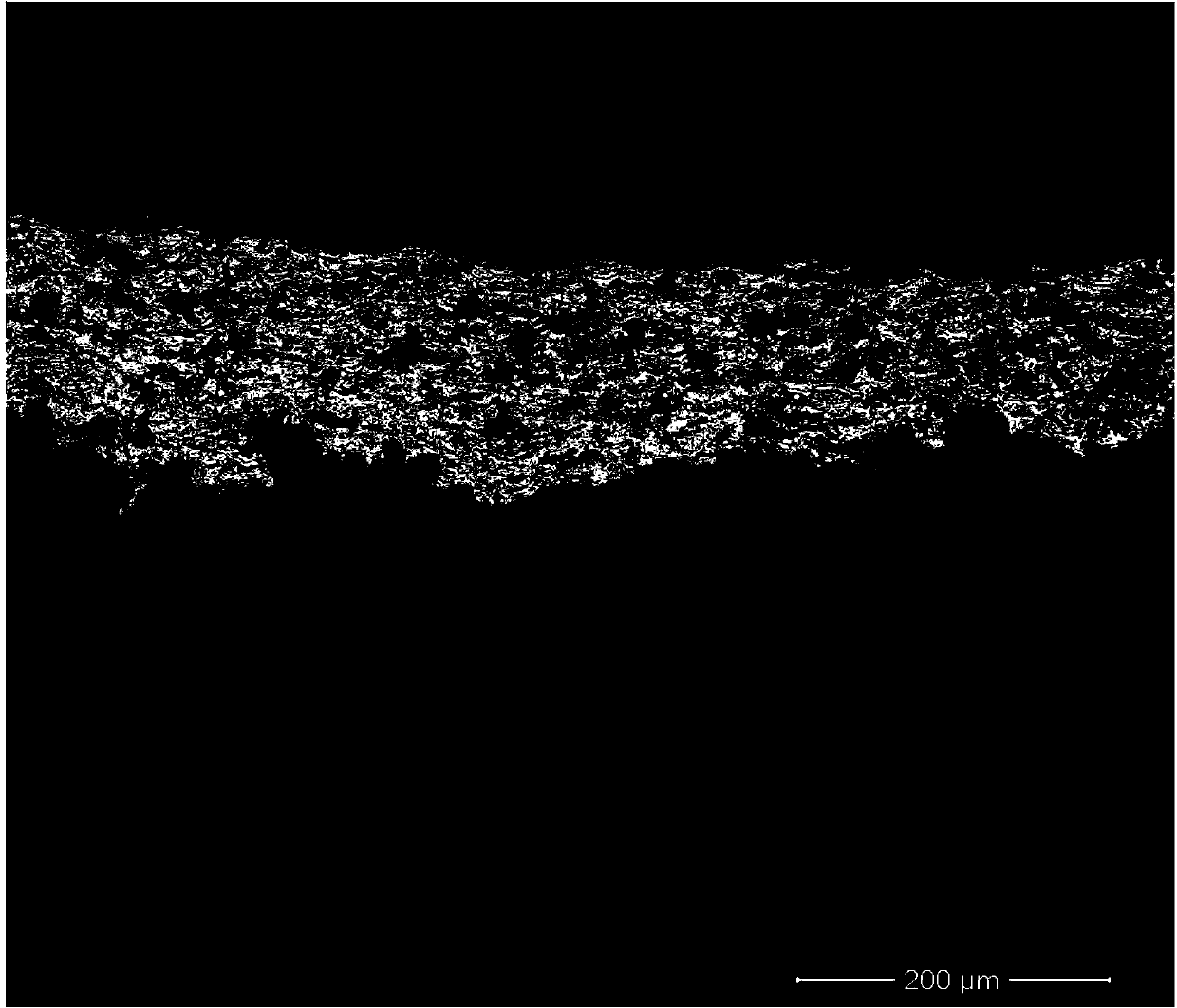

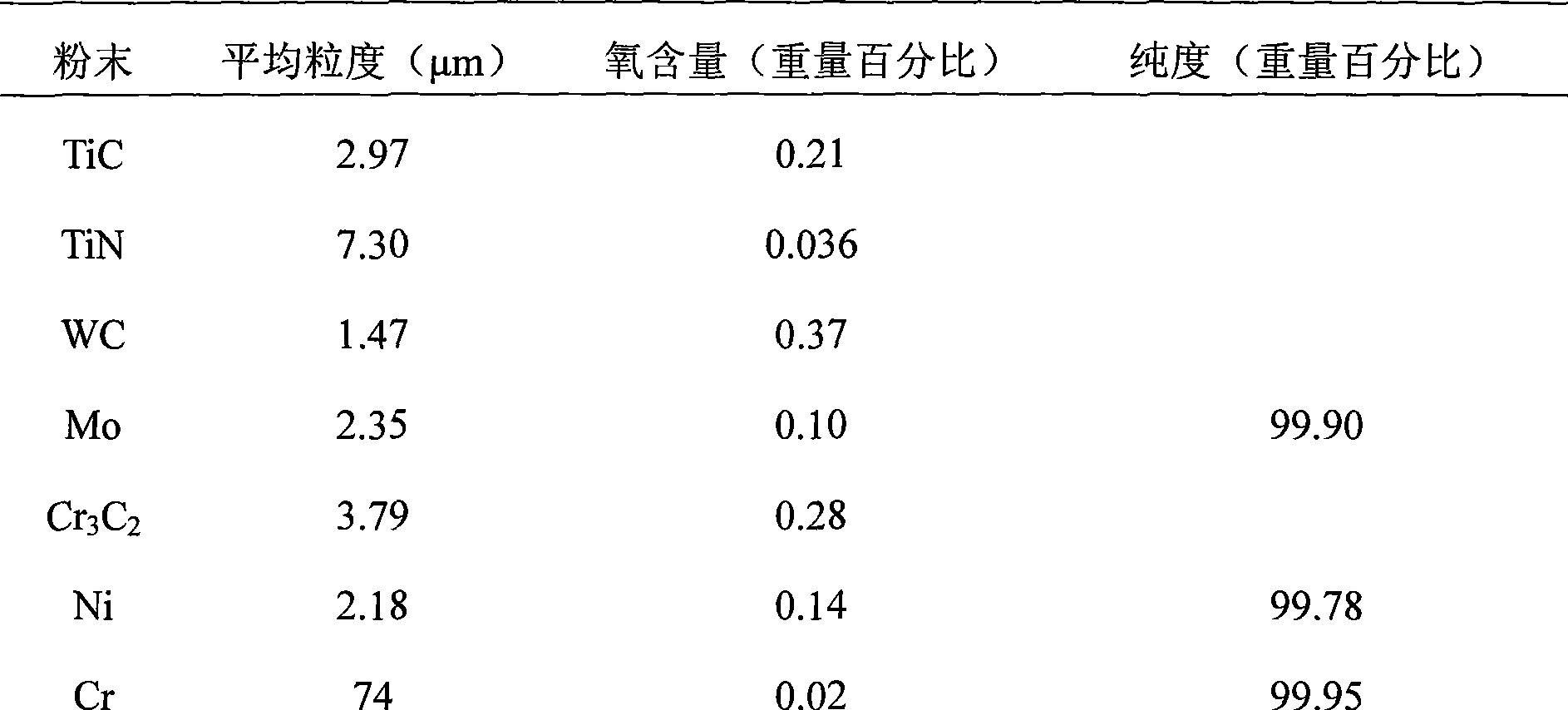

InactiveCN101333616AImprove wear resistanceGood chemical stabilityLiquid/solution decomposition chemical coatingHardnessGraphite

The invention relates to a crystal whisker toughening cermet cutter and a method for the production thereof, belonging to metal ceramic materials. The cutter is made by taking TiC, TiN, Ni, WC, Mo, Cr3C2 and graphite powder as matrix materials for mixing and ball milling and then adding nickel plating SiC crystal whiskers through ball milling and material mixing, compression molding, degreasing and sintering, finally the produced phases are: a medium hard phase of Ti(C, N), a binder phase of Ni and a toughening phase of SiC. The method for the production thereof comprises steps of: SiC crystal whisker surface nickel plating, material mixing, compression molding, degreasing and vacuum sintering. The cermet phases of the cutter have Ti(C, N), Ni and SiC. The hardness is 90.5 to 92.8HRA, the bending strength is equal to or higher than 1800MPa, and the fracture toughness KIC is equal to or higher than 10.0MPa.m<1 / 2>. The cutter and the method have advantages of good high temperature red hardness, wear resistance, chemical stability and impact toughness resistance, and high cutting temperature, and are suitable for high-speed and high-efficient cutting processing.

Owner:HUAZHONG UNIV OF SCI & TECH

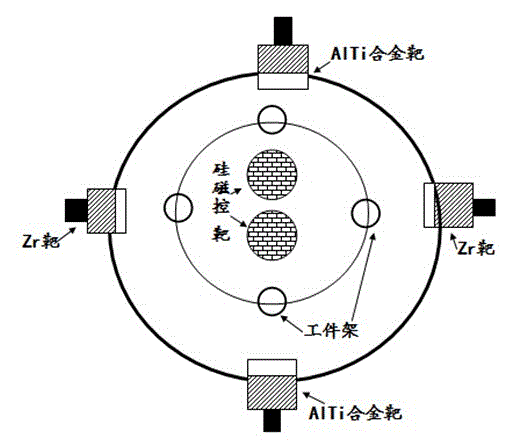

Zirconium cladding surface resistant to high temperature and oxidation ZrCrFe/AlCrFeTiZr composite gradient coating preparing technology

ActiveCN107513694AImprove the interface binding forceHigh strengthVacuum evaporation coatingSputtering coatingHigh entropy alloysAlloy coating

The invention discloses a zirconium cladding surface resistant to high temperature and oxidation ZrCrFe / AlCrFeTiZr composite gradient coating preparing technology. Ultrahigh vacuum multitarget co-sputtering technique is adopted, a ZrCrFe / AlCrFeTiZr composite gradient alloy resistant to high temperature and oxidation protecting coating is prepared on the surface of a zirconium alloy base body, and the zirconium cladding surface resistant to high temperature and oxidation ZrCrFe / AlCrFeTiZr composite gradient coating preparing technology comprises the steps of predepositional treatment, bias voltage anti-splash washing and ZrCrFe / AlCrFeTiZr composite gradient alloy coating deposition. The preparing process of the composite coating is divided into two steps, the first step is to prepare ZrCrFe gradient transition layer coating, in a deposited ZrCrFe transition layer, the atomic percentage content of Zr element is changed from the gradient of 100 at%-35 at% in the thickness direction, the atomic percentage content of Cr element is changed from the gradient of 0 at%-33 at% in the thickness direction, and the atomic percentage content of Fe element is changed from the gradient of 0 at%-33 at% in the thickness direction; the second step is to prepare a AlCrFeTiZr high-entropy alloy coating, in a deposited AlCrFeTiZr high-entropy alloy coating, the atomic percentage content of Al element is controlled in 0.5 at%-1.0at %, and the atomic percentage of other elements is between 10 at%-35 at%. Bonding force of the coating prepared by the technology is excellent, the surface is dense and uniform, and the coating has excellent performance such as high strength, resistance to high temperature and oxidation and irradiation resistance.

Owner:田雨

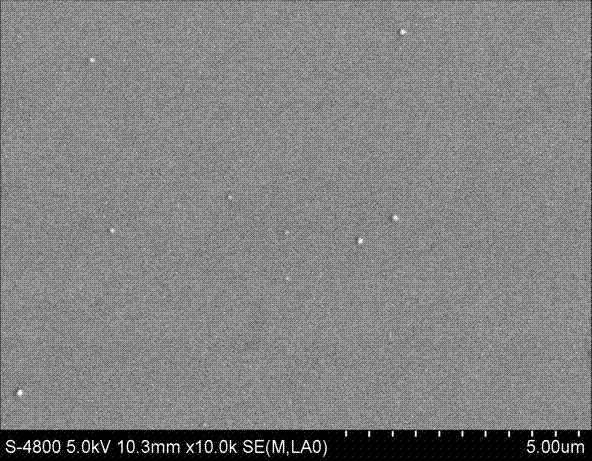

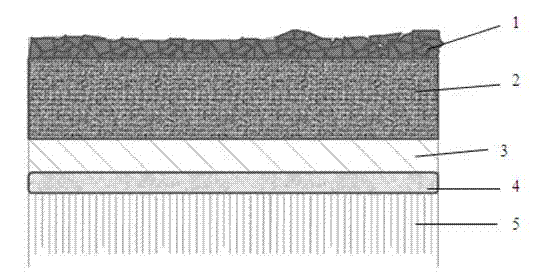

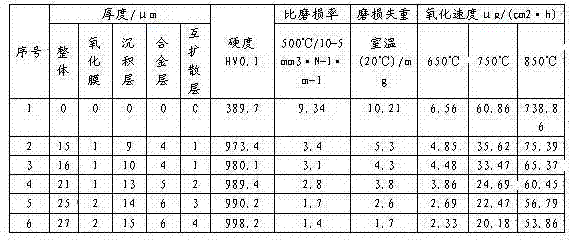

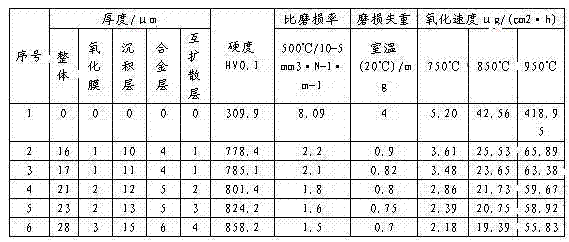

Composite coating with high-temperature oxidation resistance and abrasion resistance on surface of titanium alloy and preparation method of composite coating

ActiveCN103305844AImprove wear resistanceLimited thicknessSuperimposed coating processCoated surfaceSurface layer

The invention relates to a composite coating with high-temperature oxidation resistance and abrasion resistance prepared on the surface of a titanium alloy. The surface layer of the composite coating is a continuous compact Al2O3 oxidation film layer with the thickness of 1-3 microns; an Al settled layer with the thickness of 10-15 microns and a Ni-Co-Cr-Al-Y alloy layer with the thickness of 4-6 microns are arranged in the middle of the composite coating; the metallurgical bonding between the composite coating and a matrix is realized through a NiCoCrAlTi diffusion alloy layer; a uniform continuous compact Al2O3 oxidized film layer is arranged on the surface of the composite coating, and the surface of the composite coating does not have defects of holes, cracks and the like, so that the wear resistance and high-temperature oxidation resistance of the composite coating are greatly improved; the element Al is in graded distribution along the thickness direction in a NiCoCrAlY alloy layer and a NiCoCrAlY diffusion layer to facilitate the combination of coatings, and the storage content of Al phase is high, so that the high-temperature oxidation resistance of the composite coating can be further improved; the juncture part between the composite coating and the matrix is flat and straight and is provided with a bright white mutual diffusion layer which is in metallurgical bonding with the matrix with a firm bonding force. An alloy infiltrated layer is prepared from gamma'-Ni3Al which is a hard phase, is tiny and in dispersed distribution, and can strengthen the matrix and improve the hardness and wear resistance of the matrix.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

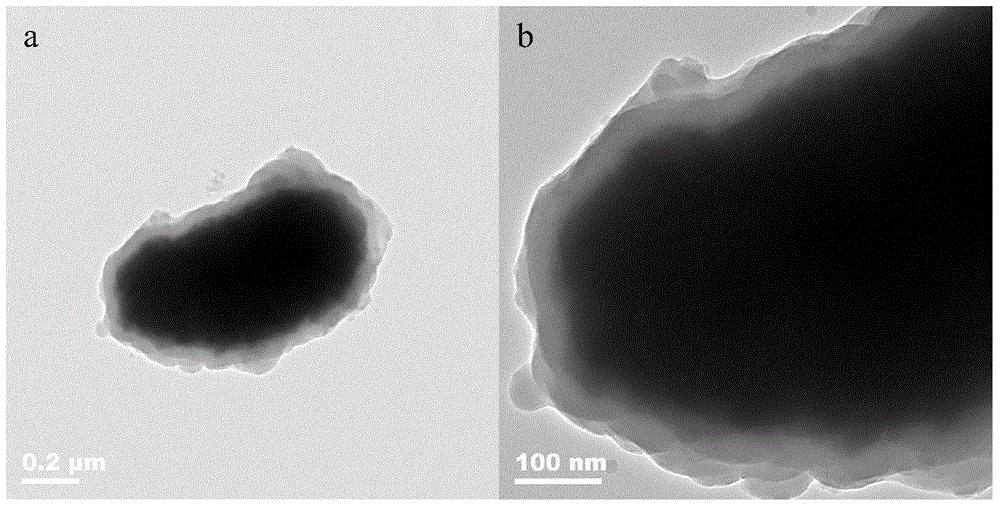

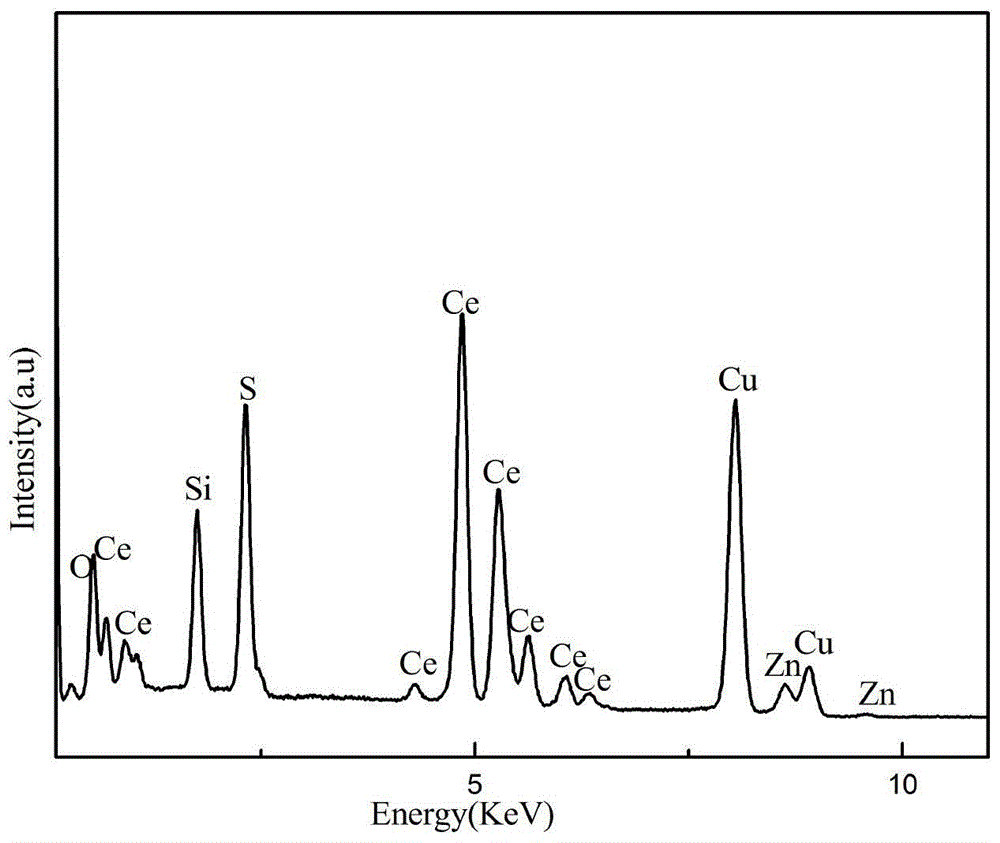

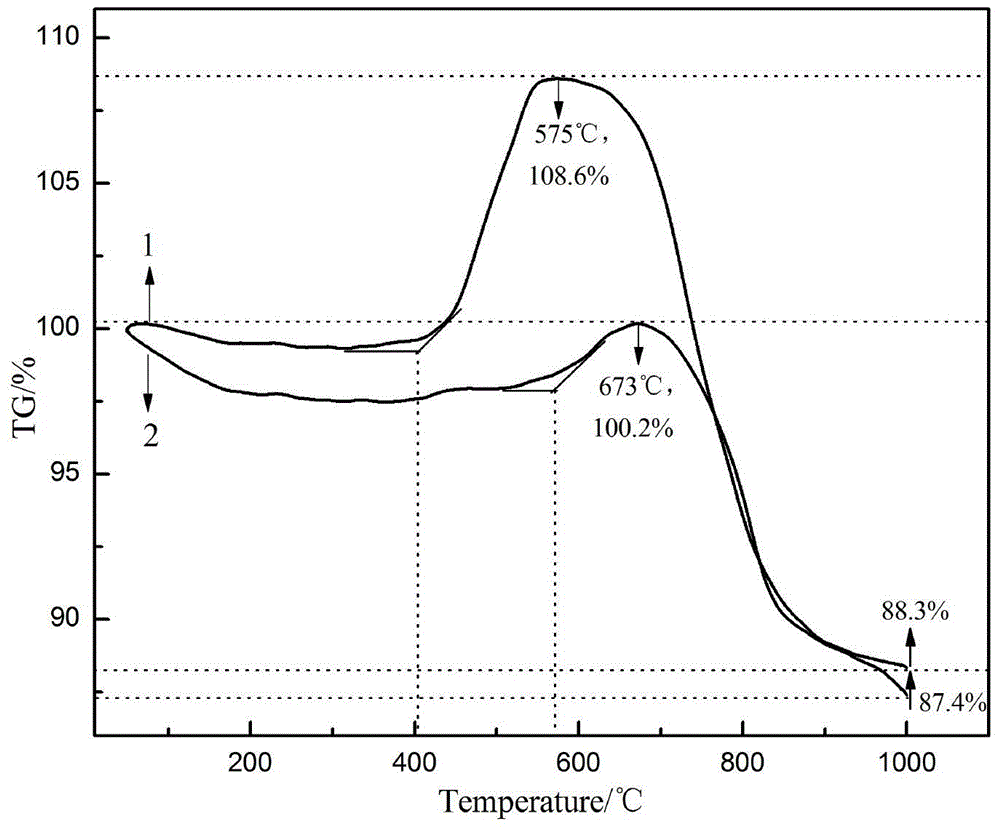

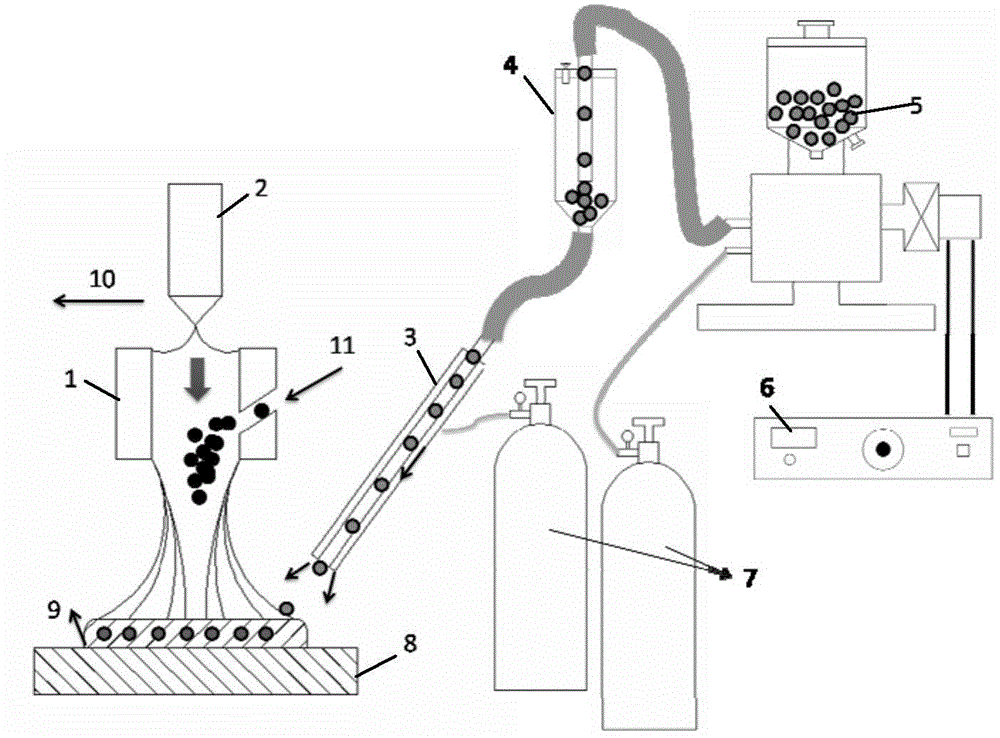

Preparation method of silica-coated cerium sulphide red pigment and prepared product thereof

ActiveCN104877392AHigh densityImprove high temperature oxidation resistancePigment treatment with non-polymer organic compoundsCeriumOxidation resistant

The invention discloses a preparation method of a silica-coated cerium sulphide red pigment. The preparation method comprises the following steps of firstly, preparing pigment suspension liquid and silicon source solution; secondly, adding the silicon source solution into the pigment suspension liquid at the speed of 0.02-0.15ml / min according to the mole ratio of Si4+:Ce2S3=1-3:1-2, stirring to react, and obtaining precursor powder after cleaning and drying a reaction product; thirdly, calcining the precursor powder under the non-oxidizing atmosphere, and obtaining the compact encapsulated silica-coated cerium sulphide red pigment. The invention also discloses a product prepared by the preparation method. The preparation method is high in encapsulating efficiency and complete in encapsulating, the obtained product is thick and compact in the encapsulated layer, the high-temperature oxidation resistance of the cerium sulphide pigment is greatly improved, the cerium sulphide pigment can be in red under the oxidizing atmosphere with the temperature above 450 DEG C, and the application field is greatly expanded; in addition, the preparation process is simple to operate and easy to popularize and use, and the product is wide in application range and beneficial to the development of high-temperature ceramic pigment technology and application.

Owner:JINGDEZHEN CERAMIC INSTITUTE

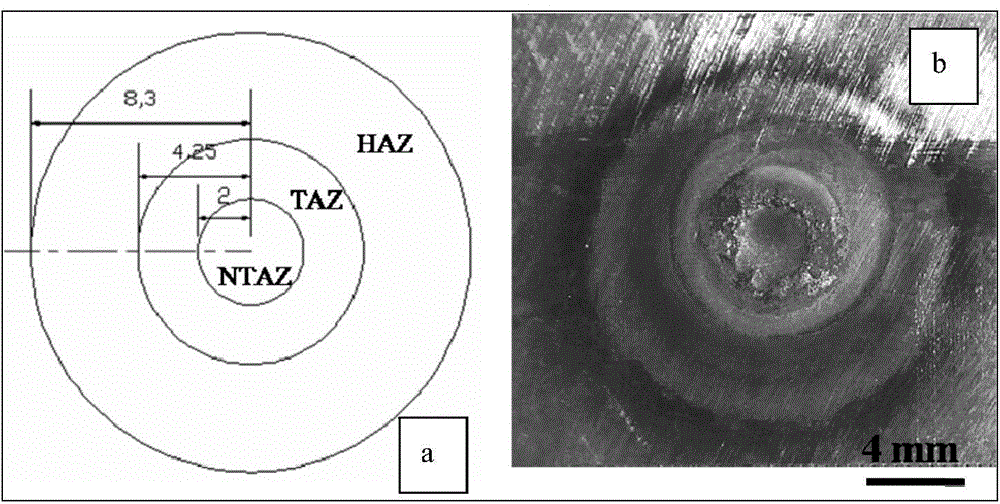

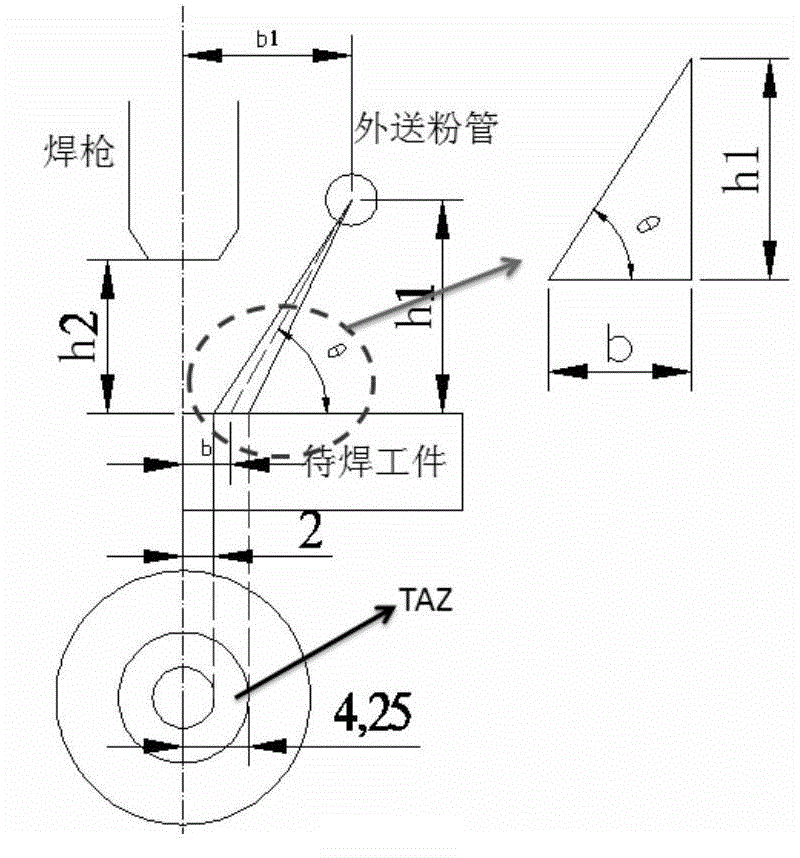

Ceramic reinforced metal matrix composite welding layer plasma overlaying preparation method

InactiveCN104096958AReduce direct burning lossIncrease profitPlasma welding apparatusMelting tankChemical reaction

The invention provides a ceramic reinforced metal matrix composite welding layer plasma overlaying preparation method, which comprises the following steps: 1) pretreatment before overlaying; 2) melting, injecting and feeding of powder outside a gun; 3) performing plasma overlaying to prepare a ceramic reinforced metal matrix composite welding layer. The ceramic reinforced metal matrix composite welding layer plasma overlaying preparation method has the beneficial effects that the utilization ratio of reinforced ceramic in the overlaying process is increased, the chemical reaction rate of the reinforced ceramic and metal molten is lowered due to chemical coating, the trend that the defect is generated in the composite welding layer due to the sharp reaction between the reinforced ceramic and the metal interface is reduced, meanwhile, the composite welding layer prepared by the method has a lot of in situ generated large granular carbides, and thus the mechanical properties (such as strength, hardness and wear resistance) and thermal physical properties (such as thermal expansion coefficient, high temperature oxidation resistance and thermal intensity) of the composite welding layer are significantly improved.

Owner:WUHAN UNIV OF TECH

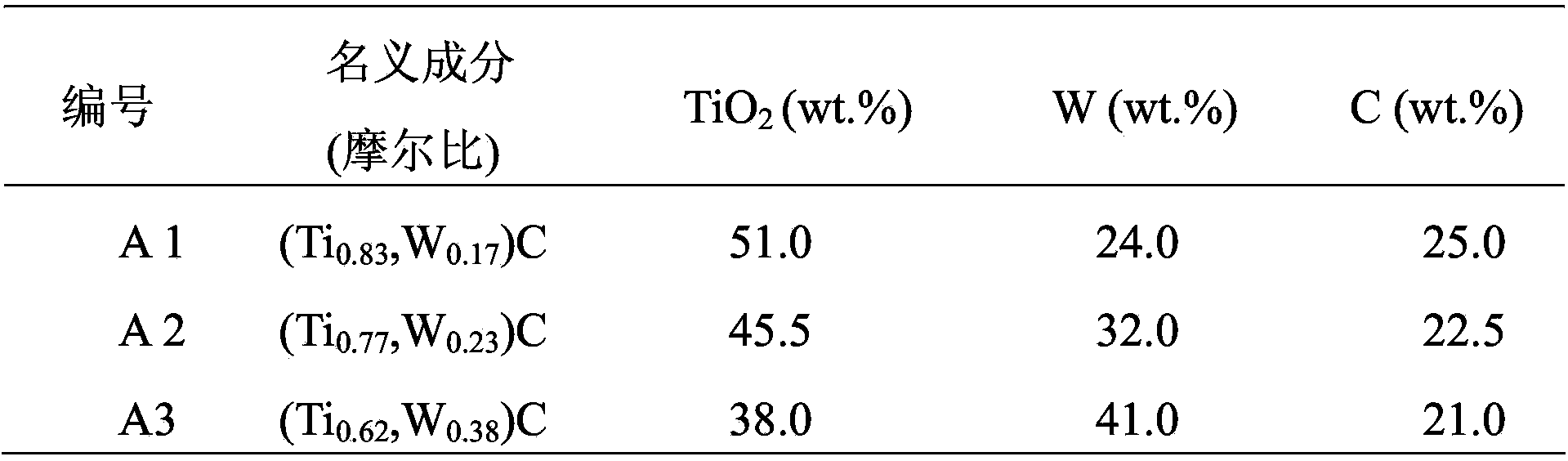

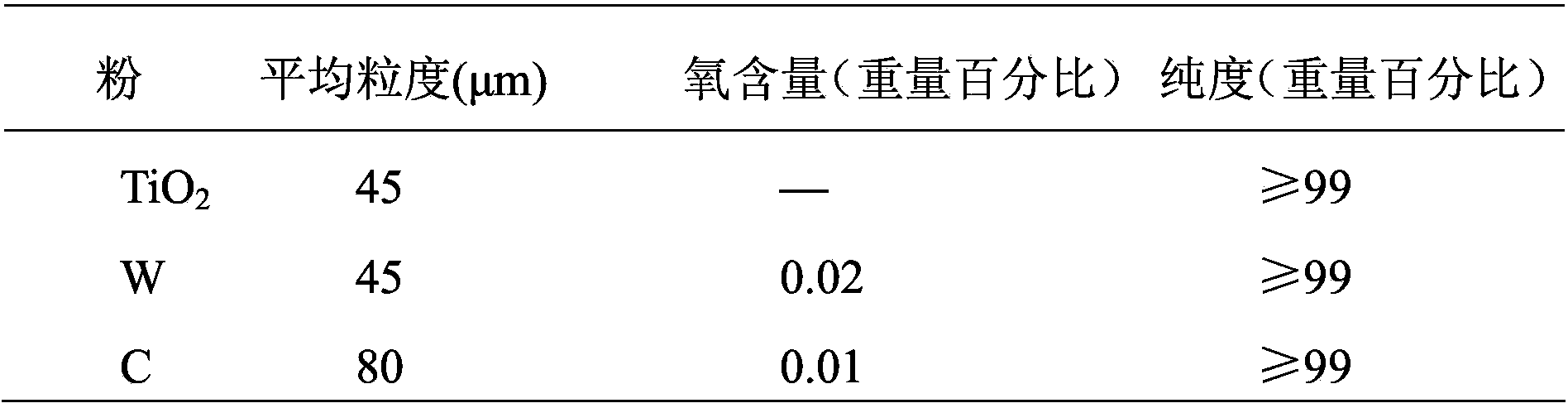

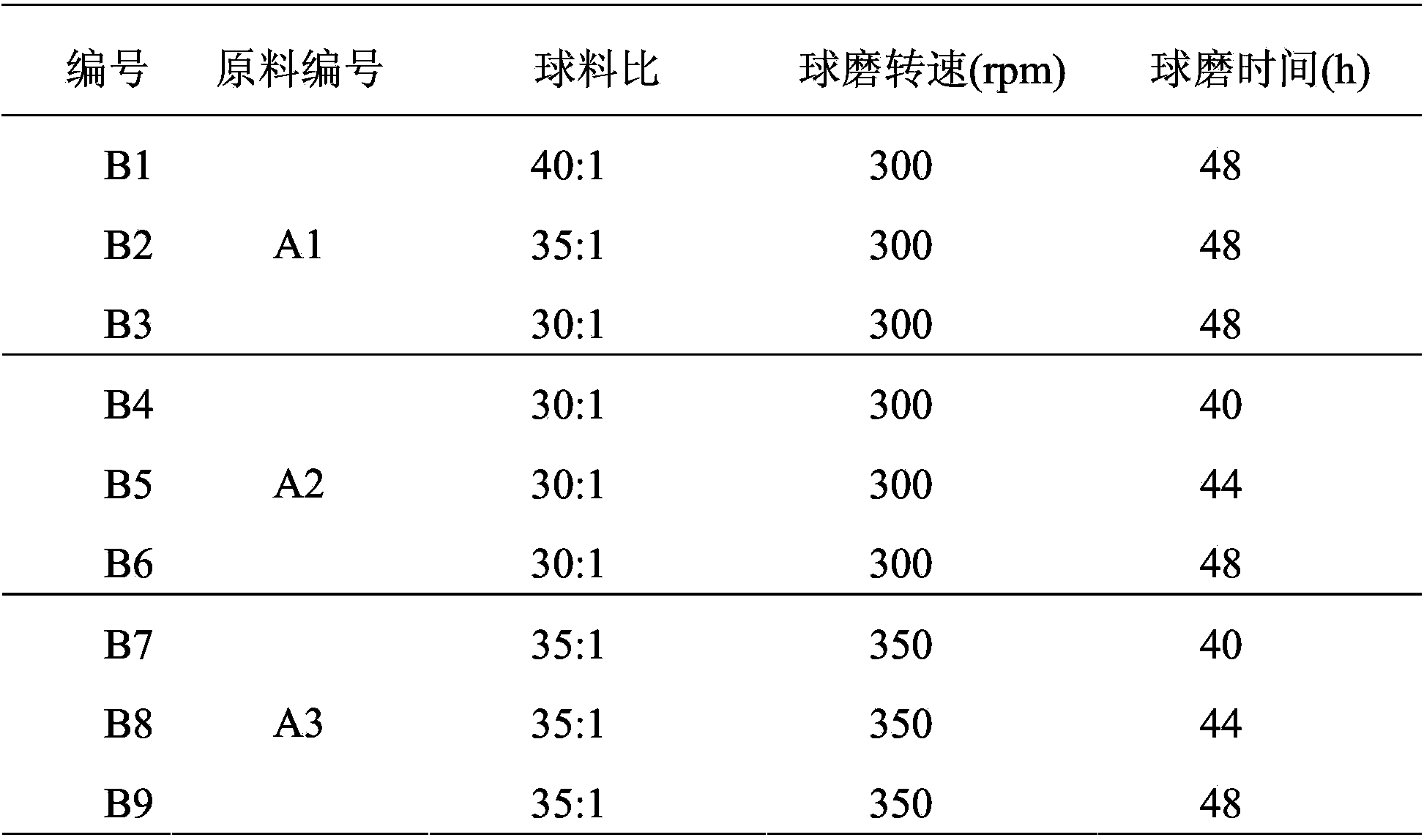

Sosoloid toughened metal ceramic and preparation method thereof

The invention discloses sosoloid toughened metal ceramic and a preparation method thereof. The sosoloid toughened metal ceramic is prepared from the materials through mechanical ball-milling, die forming and vacuum sintering. The sosoloid toughened metal ceramic comprises a hard phase and a bonding phase, wherein the hard phase comprises two ceramic phases; the bonding phase is Ni-Mo-W sosoloid with the following components in percentage by weight: not less than 8.8% and not more than 67.2% of (Ti(1-x), Wx) C, not less than 0% and not more than 58.4% of TiC, not less than 10% and not more than 15% of Mo, not less than 0.8% and not more than 1.2% of C, not less than 20% and not more than 32% of Ni, wherein x is not smaller than 0.17 and not bigger than 0.38. The preparation method of the sosoloid toughened metal ceramic is capable of synthesizing (Ti(1-x), Wx) C sosoloid by adopting mechanical ball-milling and low-temperature carbon heat reducing, short is time, small in energy consumption, capable of preparing the blank by adopting the existing powder metallurgy method, free of an improving device and an improving process, and simple and economical to implement. Moreover, the prepared sosoloid toughened metal ceramic has hardness of 89 HRA-92 HRA, bending strength not lower than 1850 MPa, breaking tenacity not lower than 13.4MPa.m1 / 2 and good application prospect in a dry type high-speed cutting tool and a heat working mould.

Owner:HUAZHONG UNIV OF SCI & TECH

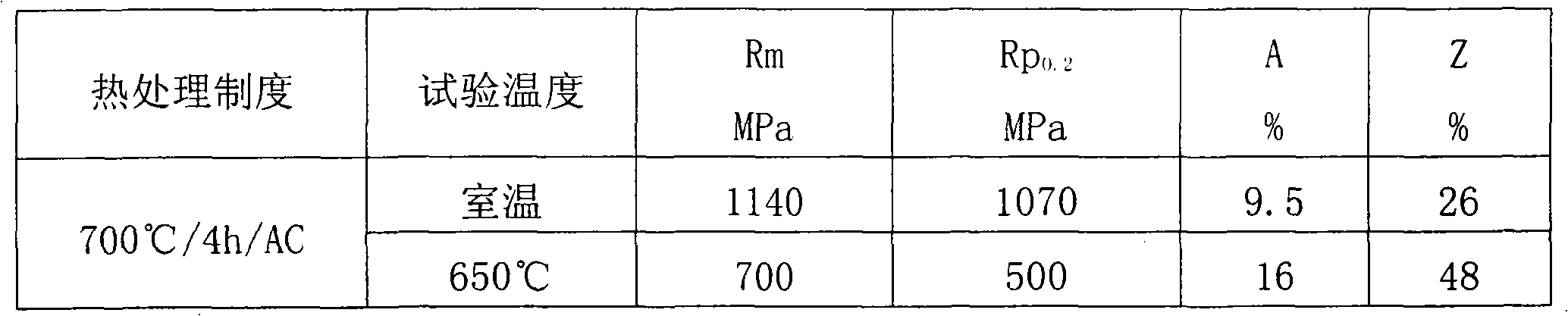

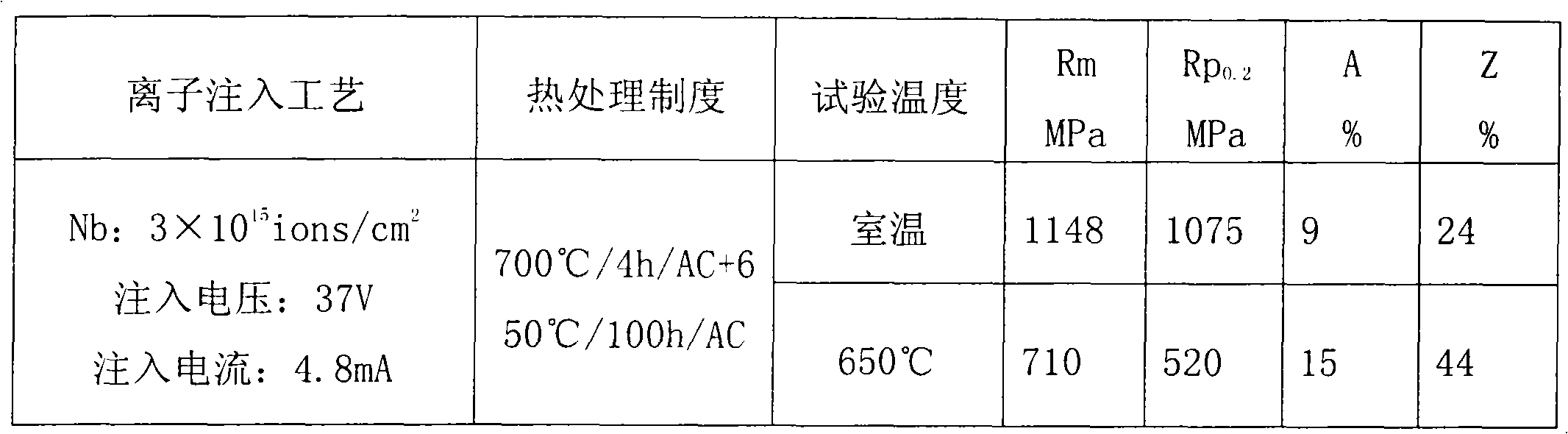

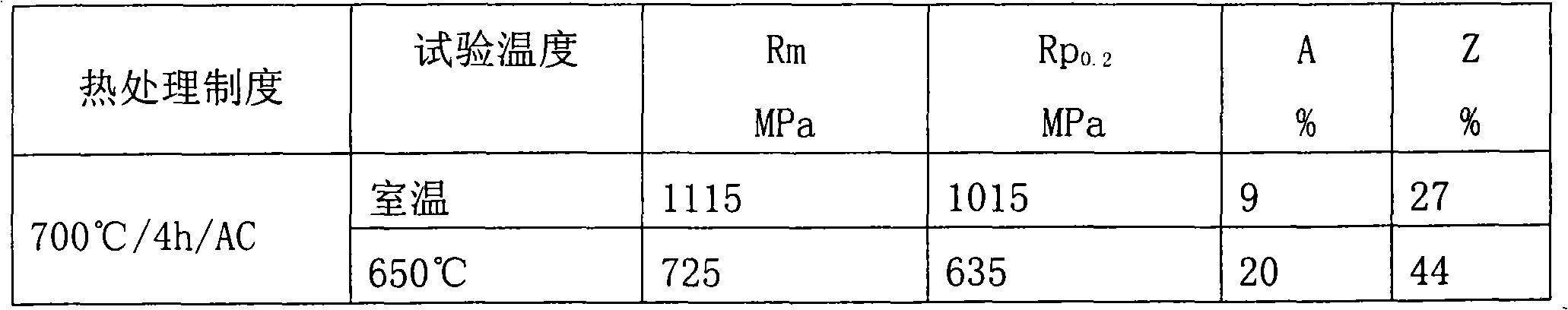

High temperature titanium alloy and surface modification method thereof

InactiveCN101768684ASolution to short lifeAdapt to useVacuum evaporation coatingSputtering coatingRare-earth elementRoom temperature

The invention relates to a high temperature titanium alloy and a surface modification method thereof, in particular relating to a high temperature titanium alloy containing rare earth elements and a surface modification method thereof. The alloy in the invention comprises the following raw materials: 5.5-7wt% of Al, 0.5-3wt% of Sn and / or Ga, 0.08-0.2wt% of O, 7.5-8.5 wt% of [Al], 0.45-0.55wt% of Si, 4-5.5wt% of Zr or Hf, 0.3-0.5wt% of Mo, 0.3-0.5wt% of Nb and / or Ta, 0.6-0.85wt% of rare earth elements Y, Nd or Er and the balance titanium. The tensile strength of the alloy in the invention at room temperature is not lower than 1100MPa, the tensile strength at the high temperature of 650 DEG C is not lower than 650MPa; and surface modification is carried out on the high temperature titanium alloy in the invention by adopting the method of ion implantation, and the high temperature property of the alloy can be greatly improved after surface modification.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Application of high-entropy alloy powder to laser cladding

InactiveCN105401042AImprove wettabilityHigh hardnessMetallic material coating processesHigh entropy alloysHardness

Owner:TIANJIN UNIV

Method for producing oxide ceramic shell capable of improving TiAl alloy casting surface performances

InactiveCN102873273AReduce oxidation behaviorImprove high temperature oxidation resistanceFoundry mouldsFoundry coresOxide ceramicSurface layer

A method for producing an oxide ceramic shell capable of improving TiAl alloy casting surface performances relates to a method for producing an oxide ceramic shell. The invention aims to solve the defect that a TiAl alloy casting surface does not have enough oxidation resistance, and provides the method for producing the oxide ceramic shell capable of improving the TiAl alloy casting surface performances. The method comprises: 1. surface layer coating production; 2. surface layer shell production; 3. adjacent surface layer shell production; 4. back layer shell production; and 5. shell dewaxing and calcinating, so that the production of the oxide ceramic shell capable of improving the TiAl alloy casting surface performances is completed. The method is applied to the field of producing the oxide ceramic shell capable of improving the TiAl alloy casting surface performances.

Owner:HARBIN INST OF TECH

Preparation method of laser cladding high-entropy alloy powder and cladding layer and application

InactiveCN104141084AImprove wettabilityHigh hardnessMetallic material coating processesHigh entropy alloysManganese

The invention discloses a preparation method of laser cladding high-entropy alloy powder and a cladding layer and application. The laser cladding high-entropy alloy powder is composed of iron, nickel, chromium, aluminum, silicon and manganese element powder, the Fe, Ni, Cr, Al and Si are in equal mole ratio, and the mole ratio x of Mn is 0-1. The preparation method includes: conducting proportion calculation according to the mole ratio of each element, accurately weighing the mass of each component, then mixing the components fully and evenly, mixing the components with ethanol, coating the surface of a matrix material with the mixture evenly, performing drying, and then carrying out laser cladding so as to obtain the cladding layer. Specifically, the matrix material is 42CrMo steel. According to the preparation method of the laser cladding high-entropy alloy powder and cladding layer provided by the invention, the good cladding layer can be formed, and the material hardness and wear resistance can be improved.

Owner:TIANJIN UNIV

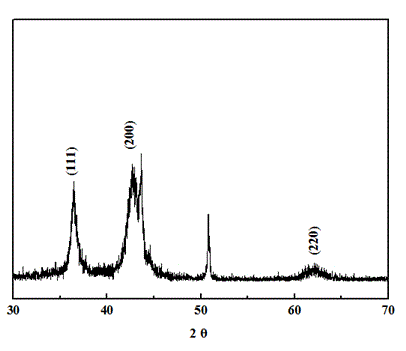

Multilayer nanometer composite cutting tool coating and preparation method thereof

ActiveCN104131256AAdjust the microstructureTuning Microhardness PropertiesLayered productsVacuum evaporation coatingTitanium nitrideTotal thickness

The invention discloses a multilayer nanometer composite cutting tool coating and a preparation method thereof. The surface of a cutting tool substrate is coated with a titanium nitride transition layer by using physical vapor deposition technology and is then alternately and periodically coated by multiple layers of an aluminum-titanium-silicon nitride coating and an aluminum-chromium-nitrogen coating, wherein the thickness of the titanium nitride transition layer is 0.1 to 0.5 mu m, the thickness of each layer of the aluminum-titanium-silicon nitride coating and the aluminum-chromium-nitrogen coating is 0.1 to 0.5 mu m, and the substrate is coated by 4 to 20 layers, thereby forming the AlTiSiN / AlCrN nanometer composite cutting tool coating with a multilayer structure. According to the invention, the crystal size of the coating is in a range of 5 to 15 nm, the total thickness of the coating is 1 to 6 mu m, the microscopic hardness of the coating is 25 to 40 GPa, and high temperature stability reaches more than 1050 DEG C. A cutting tool prepared by using the coating has greatly improved resistance to mechanical wear and high temperature oxidation resistance and can meet demands of high speed processing for better performance of a cutting tool material.

Owner:GUANGDONG UNIV OF TECH

SiC-BN-C composite material and preparation method thereof

InactiveCN101100389AImprove mechanical propertiesImprove high temperature oxidation resistanceGraphiteTemperature and pressure

A SiC-BN-C composite material and its production are disclosed. The materials contain Si3N4 6.4-63.8%, B4C 2.5-24.9% and C 11.9-91.1%. The process is carried out by taking various powders, ball grinding, wet mixing, drying, crushing, packing into graphite mould, pre-pressurizing, putting into hot-press furnace, hot pressing while sintering at 1700-2200 deg. C in vacuum or under protecting atmosphere, pressurizing at 15-30 MPa, keeping temperature and pressure for 30 min-2 hrs, or taking amorphous carbon containing volatile composition as carbon source, crushing for mixed dried materials, packing into steel mould, pressurizing at 50-300 MPa, keeping pressure for 10 min-2 hrs, putting into hot-press furnace or atmosphere sintering furnace, sintering in vacuum or under protecting atmosphere, raising temperature to 800-1400 deg. C and keeping temperature for 30 min-2 hrs. It's simple and costs low.

Owner:HARBIN INST OF TECH AT WEIHAI

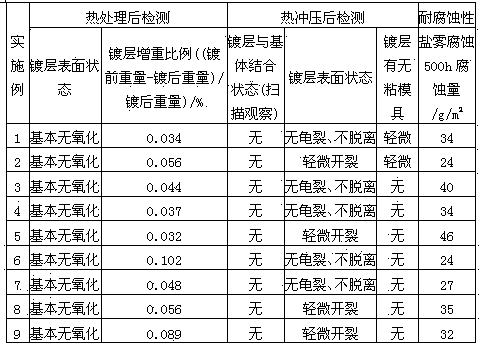

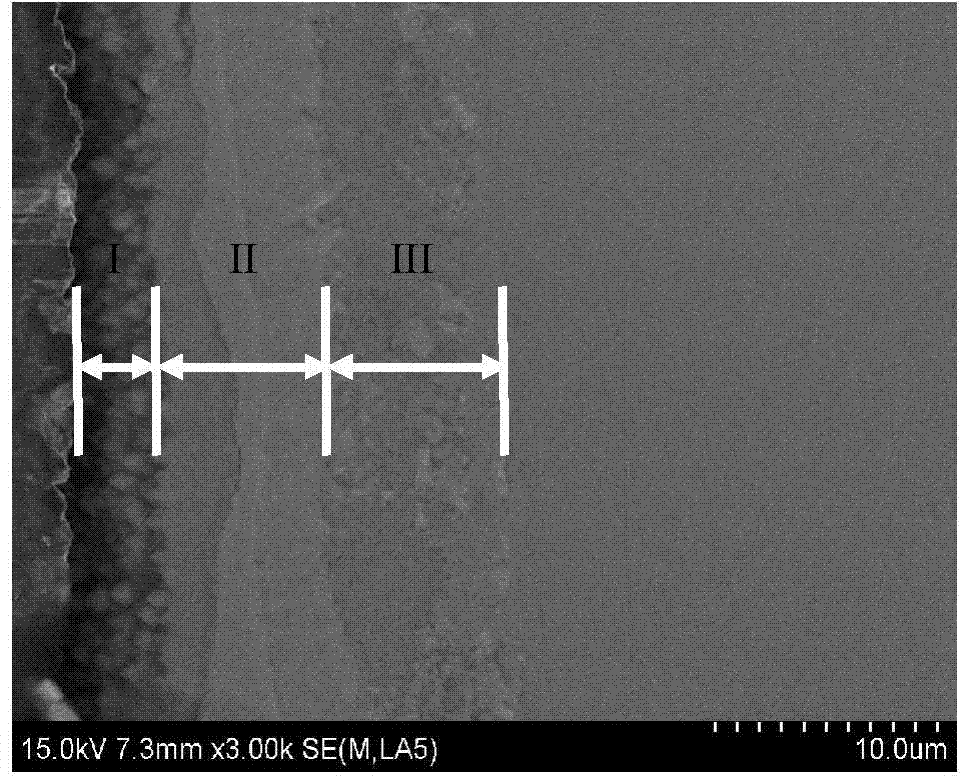

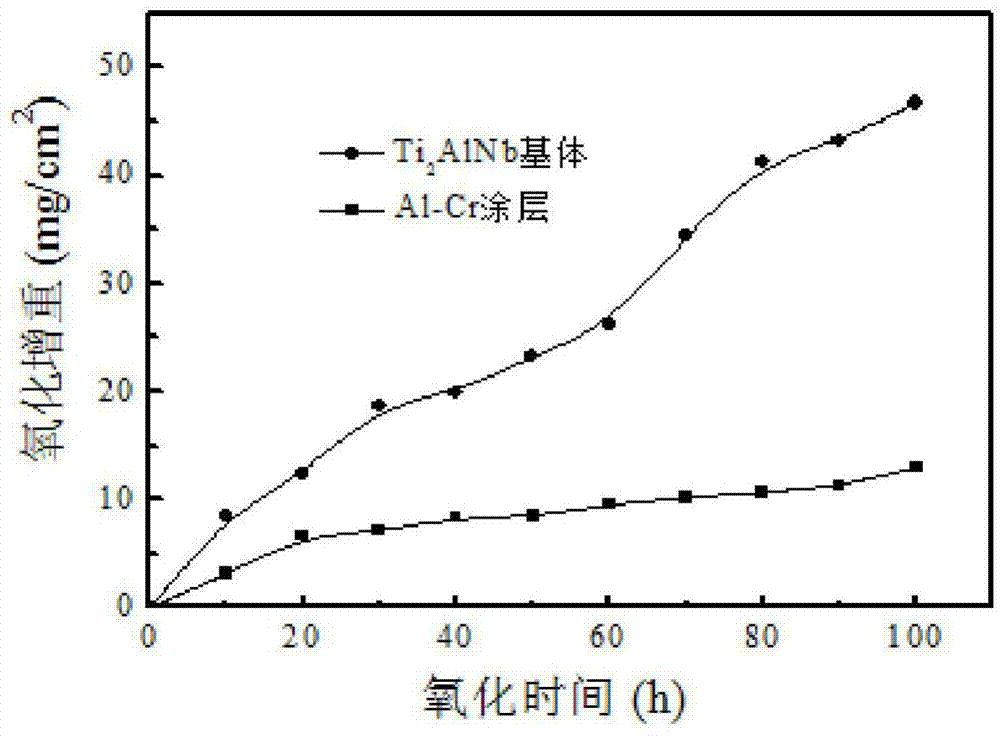

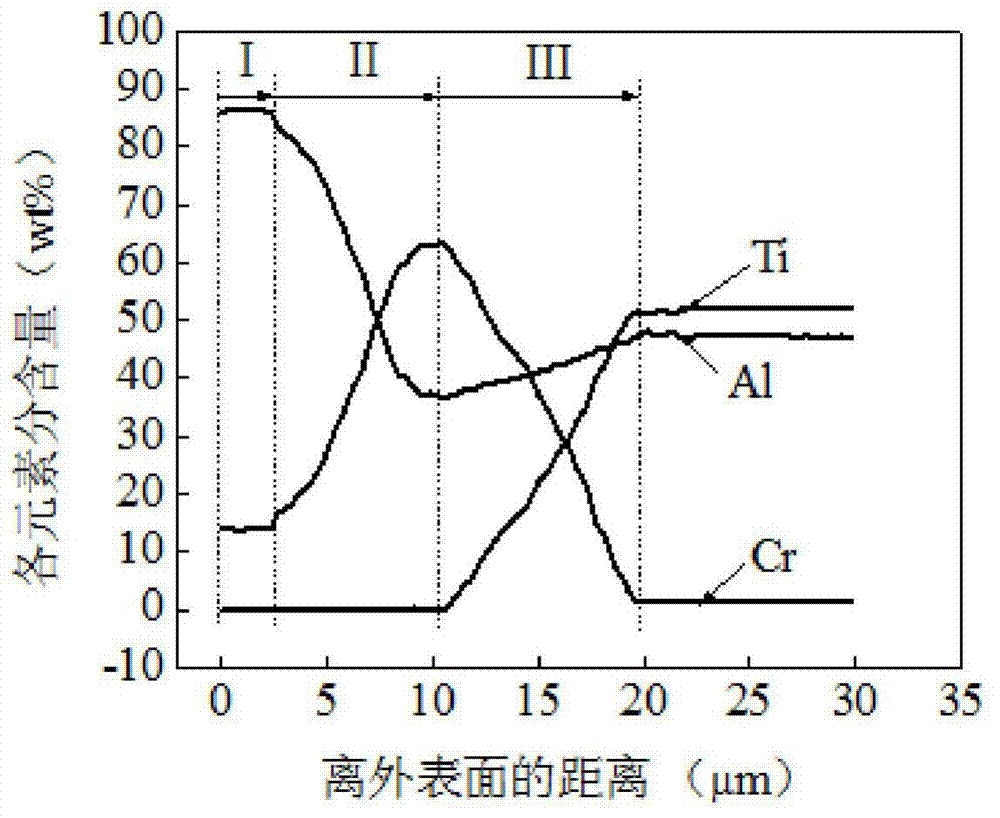

Titanium aluminum alloy surface high temperature oxidation and hot corrosion resistant Al-Cr coating and preparation method thereof

InactiveCN104760349AImprove high temperature oxidation resistanceAccelerated corrosionVacuum evaporation coatingSputtering coatingOxidation resistantThermal shock

The present invention discloses a titanium aluminum alloy surface high temperature oxidation and hot corrosion resistant Al-Cr coating; an Al-rich deposition layer, an Al-Cr alloy layer and a Cr diffusion layer are successively arranged from surface to a titanium aluminum alloy substrate. The content of Al in the Al-rich deposition layer remains the same. The content of Al in the Al-Cr alloy layer gradually reduces outside-to-inside to 70%-100% of the content of Al in the titanium aluminum alloy substrate, and the rest in the Al-Cr alloy layer is Cr. The contents of Cr and Al in the Cr diffusion layer respectively gradually reduces outside-to-inside to same as the contents of Cr and Al in the titanium aluminum alloy substrate, and the rest in the Cr diffusion layer is other elements in the titanium aluminum alloy substrate, and the contents of other elements in the Cr diffusion layer respectively gradually rise to same as the contents of the other elements in the titanium aluminum alloy substrate from zero. The invention also discloses a preparation method of the titanium aluminum alloy surface high temperature oxidation and hot corrosion resistant Al-Cr coating; the titanium aluminum alloy surface high temperature oxidation and hot corrosion resistant Al-Cr coating can give titanium aluminum alloy excellent oxidation resistance and heat resistance corrosion performance under high temperature and long term service conditions, and due to the presence of the diffusion layer of the gradient components, the reliable binding strength and excellent thermal shock resistance can be realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Copper strip preparation process for high-end frame material

Provided is a copper strip preparation process for a high-end frame material. According to the weight percentage of components in a smelting furnace, the total content of standard electrical cathode copper and Cu in all alloys is 96.5% or above, iron Fe accounts for 2.1-2.6%, phosphor P accounts for 0.015-0.15%, zinc Zn accounts for 0.05-0.20%, stannum Sn accounts for 0.005-0.050%, magnesium Mg accounts for 0.008-0.05%, the sum of impurities does not exceed 0.1%, the sum of alloy elements and impurities is 0.15% or below, and the weight sum of the above components is 100%; then, the followingsteps of smelting, casting, saw cutting, hot rolling, face milling, cold rolling, edge cutting, annealing, rolling of finished products, cleaning, shearing of finished products and package and warehousing are carried out. The problem of high temperature softening and other aspects of an original TFe2.5 and other frame material copper strips is solved, the high-end frame material has the obvious advantages of high strength, excellent electrical conductivity, good subsequent processing performance and the like compared with frame materials prepared by adopting an original process, the chemical composition of the material is stable, and the surface is clean, smooth and free of oxidation and discoloration.

Owner:中铝洛阳铜加工有限公司

High-temperature alloy, alloy hood manufactured from same and manufacturing technology of alloy hood

ActiveCN103173692AHigh hardnessImprove high temperature oxidation resistanceChemical/physical processesManufacturing technologyHardness

The invention provides a high-temperature alloy which comprises the components such as C, Cr, Ni, Mo, Mn, Si, Nb, RE, N, Ti, B, Zr and the like, wherein the optimal content of each component is selected after reasonable analysis and repeated tests so that the components of the alloy realize the best interaction effect; and the tests prove that the high-temperature alloy provided by the invention is obviously superior to 25-20 steel and 316 steel in terms of average hardness, high-temperature oxidation resistance, high-temperature corrosion resistance and high-temperature washout resistance, and has good high-temperature comprehensive performance.

Owner:浙江科得力新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com