Method for producing oxide ceramic shell capable of improving TiAl alloy casting surface performances

A technology of oxide ceramics and surface properties, which is applied in the direction of casting molding equipment, casting molds, casting mold components, etc., and can solve the problems of insufficient oxidation resistance of TiAl alloy high-temperature surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

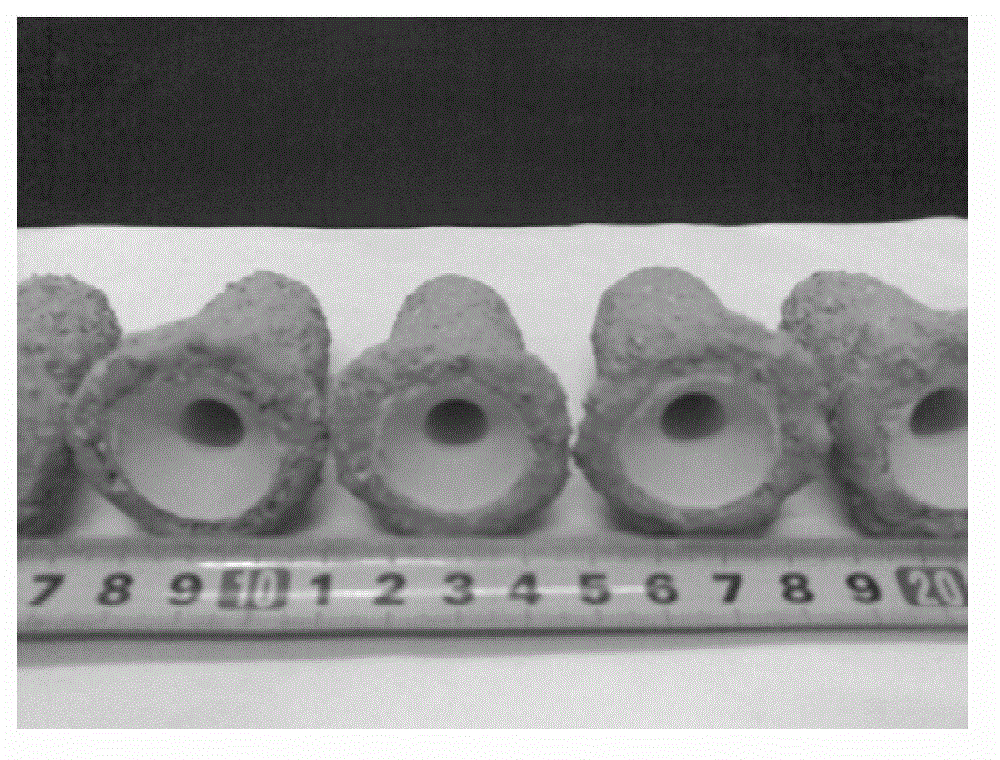

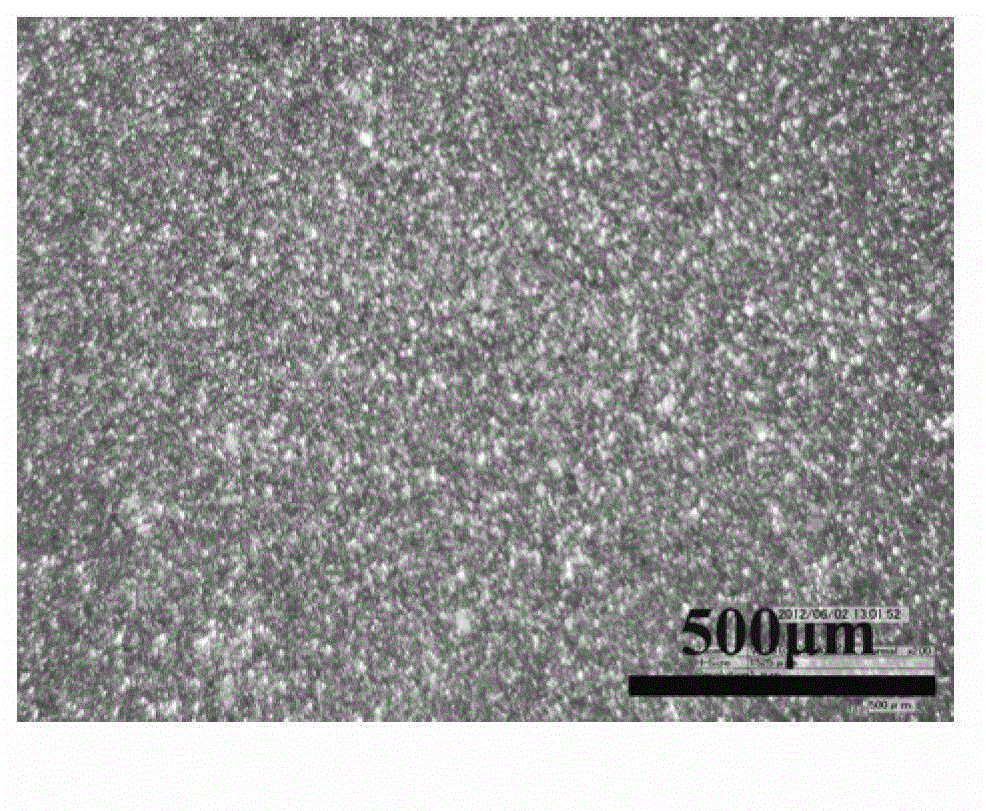

Image

Examples

specific Embodiment approach 1

[0015] One: Preparation of surface coating: Add defoamer and wetting agent to the binder at a stirring speed of 100-300r / min, and then according to the volume ratio of the oxide powder to the binder ( 2.0~3.8) g: 1mL Add oxide powder to the binder, stir while adding, and prepare a coating after mixing, and then at a stirring speed of 100~200r / min, according to the oxide powder in the coating and the addition The material mass ratio is (0.1~20): 100. Add additional materials to the paint, stir evenly and let stand to complete the preparation of the surface coating; wherein, the binder is zirconium sol, and the defoamer is positive Octanol, the wetting agent is fatty alcohol polyoxyethylene ether JFC, the mass ratio of the defoamer to the binding agent is (0.01~0.5): 100, the mass ratio of the wetting agent to the binding agent (0.01-0.5): 100, the oxide powder is zirconia or yttrium oxide, the particle size is 270-320 mesh, and the additive material is one or a combination of s...

specific Embodiment approach 2

[0023] Specific embodiment 2: The difference between this embodiment and the specific embodiment 1 is: in step 1, stir evenly and then let stand for 8-12 hours. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0024] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the viscosity of the surface coating in step 1 is 80-90s. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com