Preparation method of large-size corrosion-resistant Ti35 alloy forge piece

A large-size, forging technology, applied in the field of preparation of large-size corrosion-resistant Ti35 alloy forgings, can solve the problems of increased alloy heating times, high-temperature oxidation material loss, difficulty in ensuring sufficient deformation of the core of the forging, and long processing cycles, etc., to reduce heating and forging cost, reduce high temperature oxidation material loss, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

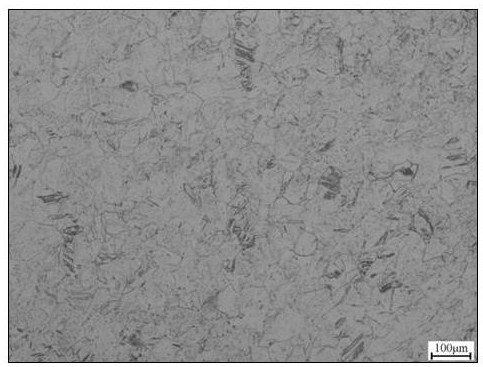

Embodiment 1

[0027] This embodiment includes the following steps:

[0028] Step 1. High-temperature billet forging: the Ti35 alloy ingot with a diameter of 720mm is subjected to billet forging at 1025°C with 1 upset and 2 draws to obtain the first forging; the heating coefficient used in the billet forging is 0.7, and the Ti35 The deformation of the alloy ingot in the three directions of 1 upsetting and 2 drawing is 35%, and the deformation speed is 10mm / s;

[0029] Step 2, one-time medium-temperature forging: the first forging obtained in step 1 is forged at 850°C with 1 upsetting and 2 drawing to obtain the second forging, and the hot material is returned to the furnace; the heating coefficient used in the forging is 0.7, and the first The deformation of the forging in the three directions of 1 upsetting and 2 drawing is 35%; the reheating coefficient used for the reheating of the hot material is 0.4;

[0030] Step 3. Low-temperature forging: Forging the second forging with the hot mate...

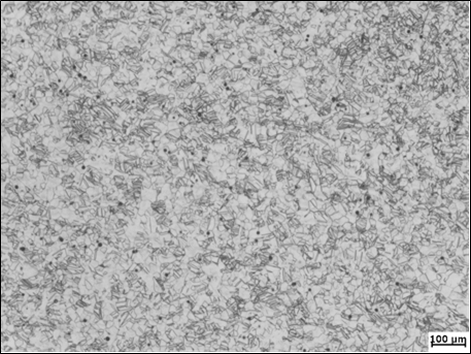

Embodiment 2

[0035] This embodiment includes the following steps:

[0036] Step 1. High-temperature billet forging: Carry out billet forging of Ti35 alloy ingot with a diameter of 650mm at 1000°C for 1 upset and 2 draws to obtain the first forging; the heating coefficient used in the billet forging is 0.6, Ti35 The deformation of the alloy ingot in the three directions of 1 upsetting and 2 drawing is 30%, and the deformation speed is 10mm / s;

[0037] Step 2, one-time medium-temperature forging: the first forging obtained in step 1 is forged at 800°C with 1 upsetting and 2 drawing, to obtain the second forging and to carry out hot material refurbishment; the heating coefficient used in the forging is 0.6, the first The deformation of the forging in the three directions of 1 upsetting and 2 drawing is all 30%; the reheating coefficient used for the reheating of the hot material is 0.3;

[0038] Step 3. Low-temperature forging: Forging the second forging with the hot material back to the fur...

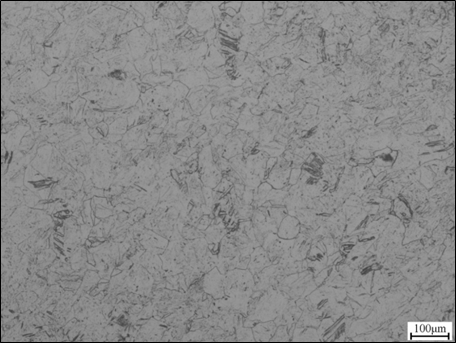

Embodiment 3

[0043] This embodiment includes the following steps:

[0044] Step 1. High-temperature billet forging: Carry out billet forging of Ti35 alloy ingot with diameter φ of 720mm at 1050°C with 1 upset and 2 draws to obtain the first forging; the heating coefficient used in the billet forging is 0.8, Ti35 The deformation of the alloy ingot in the three directions of 1 upsetting and 2 drawing is 40%, and the deformation speed is 10mm / s;

[0045] Step 2, one-time medium-temperature forging: the first forging obtained in step 1 is forged at 900°C with 1 upsetting and 2 drawing to obtain the second forging, and the hot material is returned to the furnace; the heating coefficient used in the forging is 0.8, and the first The deformation of the forging in the three directions of 1 upsetting and 2 drawing is 40%; the reheating coefficient used for the reheating of the hot material is 0.5;

[0046] Step 3. Low-temperature forging: Forging the second forging with the hot material back to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com