Patents

Literature

69results about How to "Reduce forging cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

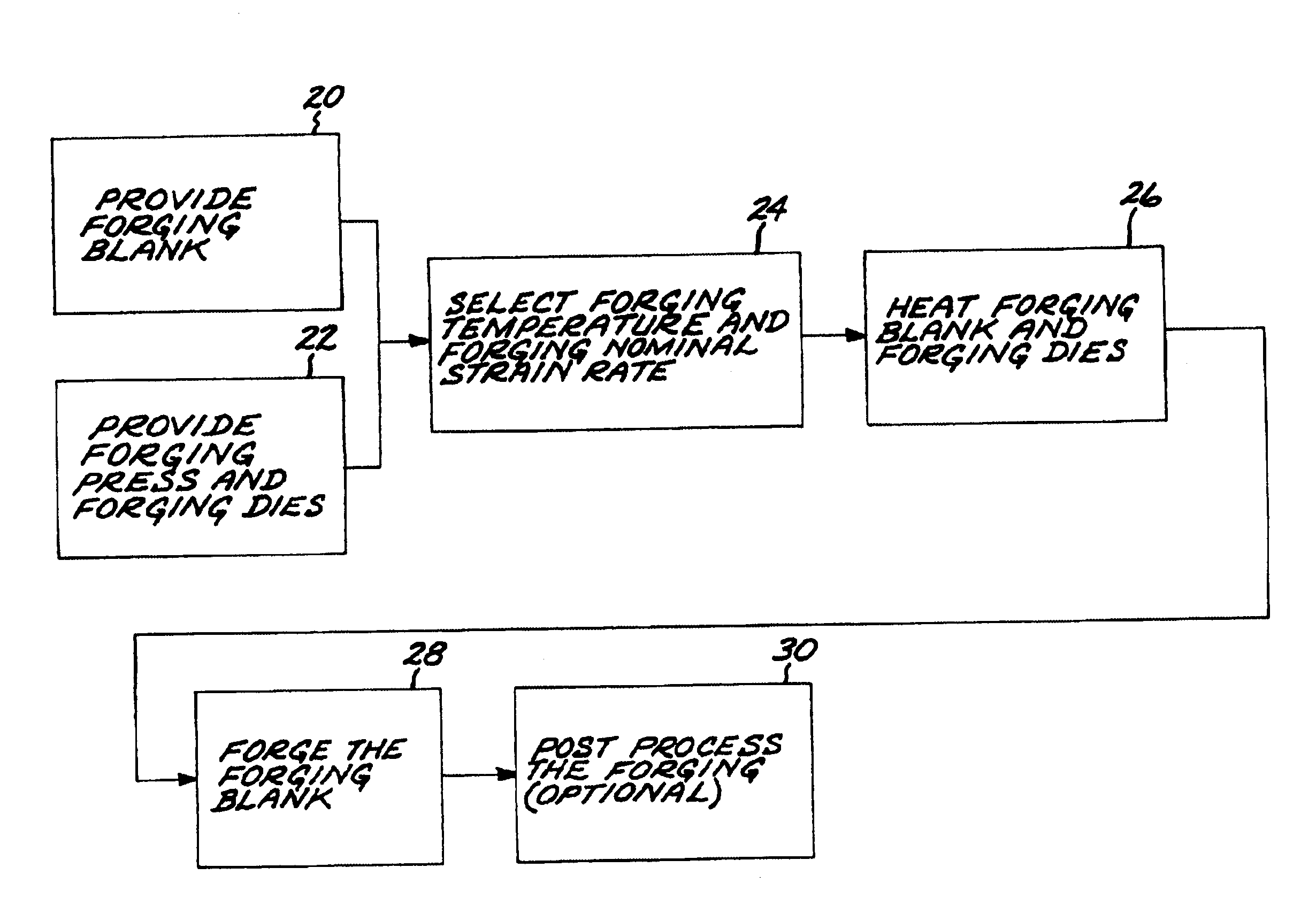

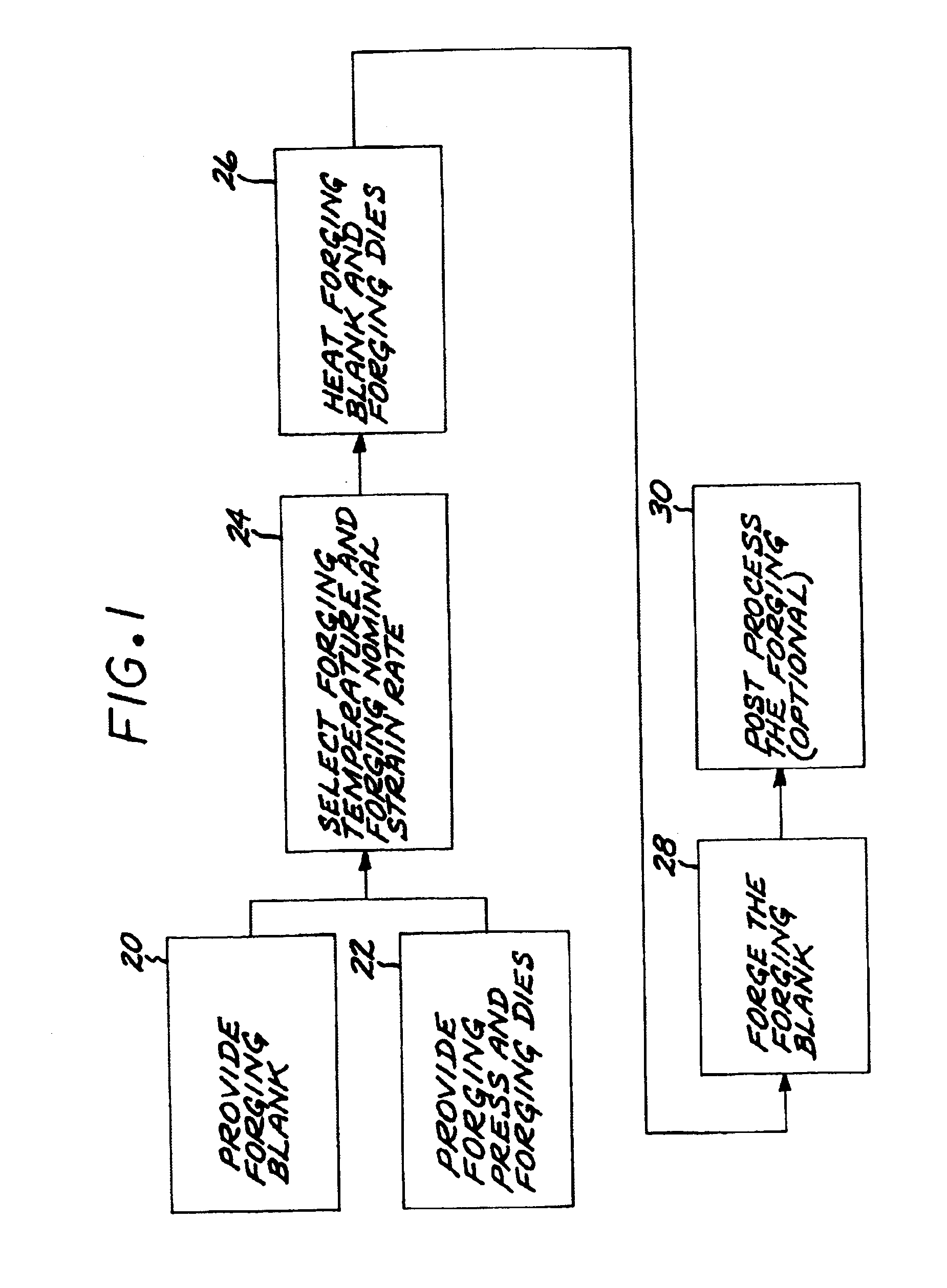

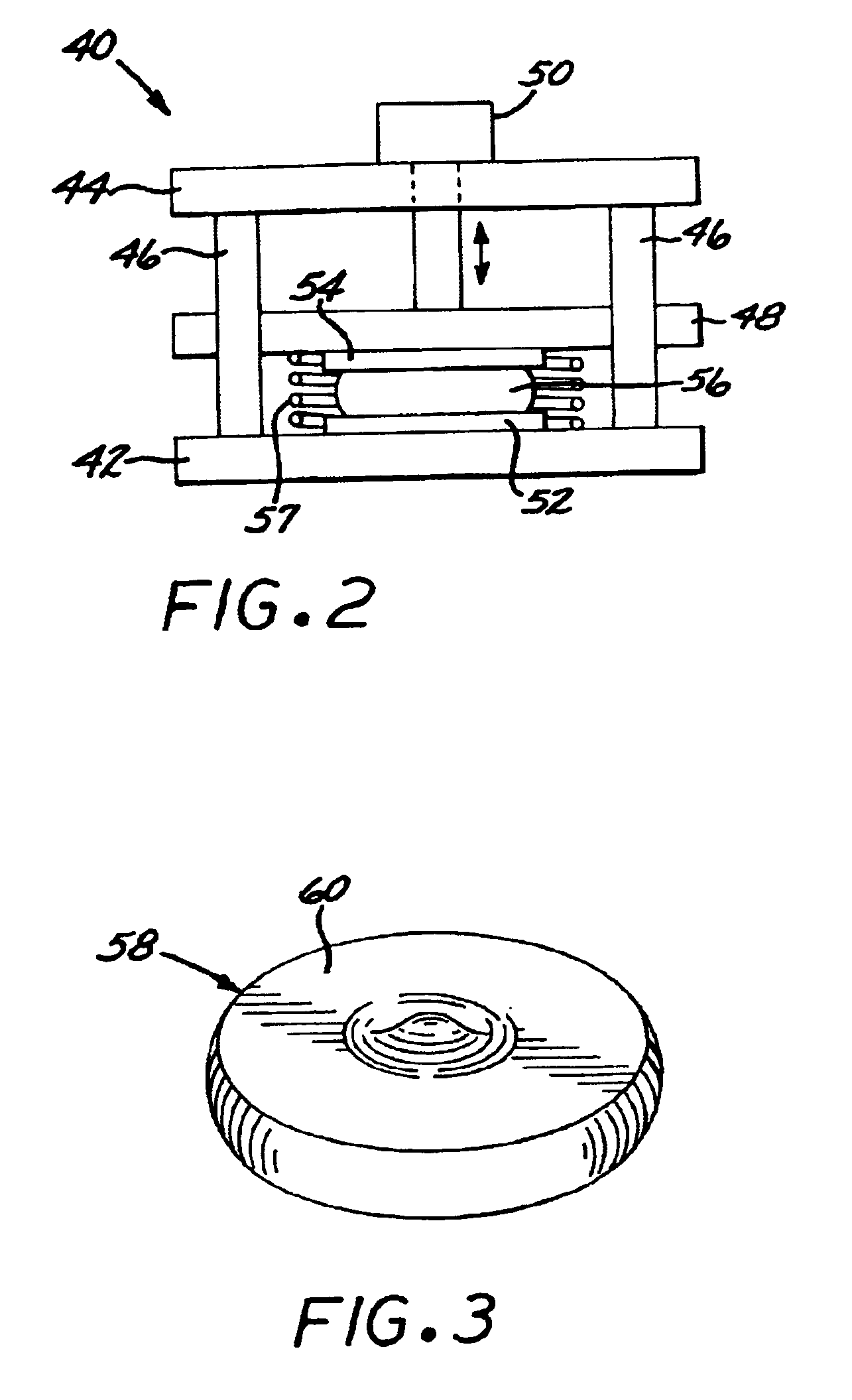

Isothermal forging of nickel-base superalloys in air

A superalloy made of a forging nickel-base superalloy such as Rene™ 88DT or ME3 is forged in a forging press having forging dies made of a die nickel-base superalloy. The forging is accomplished by heating to a forging temperature of from about 1700° F. to about 1850° F., and forging at that forging temperature and at a nominal strain rate. The die nickel-base superalloy is selected to have a creep strength of not less than a flow stress of the forging nickel-base superalloy at the forging temperature and strain rate.

Owner:GENERAL ELECTRIC CO

Cogging forging method

ActiveCN106975719AUniform hot forgingImprove plasticityMetal-working apparatusWheelsIngotHeat treated

The invention provides a cogging forging method. The cogging forging method includes the following steps of 1, forging heating, wherein a proper heating technology is formulated according to the heat conductivity of a material and changes of the specific heat capacity, and it is guaranteed that the center of a forging is completely forged so that the plasticity of the forging can be improved and the deformation resistance of the forging can be reduced; 2, blank cogging forging, wherein the upsetting process and the drawing-out process are specifically carried out so that the overall uniformity of the forging can be improved, and regions which are difficult to deform can be eliminated; 3, forging melting-down heating, wherein when the temperature of the forging is lower than 800 DEG C, forging is stopped, and the melting-down heating process is carried out; 4, molding, wherein a steel ingot is forged to be in a target forging shape; 5, post-forging heat treatment of the forging. According to the cogging forging method, the regions which are difficult to deform in the cogging process are eliminated, and the strain uniformity of the center of the forging is improved; due to a combined cogging tool, the upsetting process and the drawing-out process are rapidly switched, the heating number required during cogging forging is decreased, the forging cost is reduced, and the production efficiency is improved.

Owner:SOUTHEAST UNIV

Method for processing large combination type herringbone gear

ActiveCN101862945ASave materialShorten the timeTransportation and packagingTrepanning drillsGear grindingHobbing

The invention discloses a method for processing a large combination type herringbone gear, which comprises the following steps of: forging; carrying out rough processing of the end surface, an incircle and an excircle on a processed workpiece by utilizing a lathe; drilling a hoisting hole; carrying out rough gear hobbing on the workpiece by utilizing a gear hobbing machine; carrying out tempering processing on a gear; semifinishing an inner hole, the end surface and an addendum circle by utilizing the lathe; drawing any pair of end surface gear central lines based on the end surface of one side of a reference groove, making a reference groove mark on an addendum and drawing a position line of each hole; drawing and drilling each hole by using a drilling machine; finishing and lathing the inner hole and both end surfaces of the lathe to a preset size; positioning based on a reference surface, carrying out correcting gear grinding on the addendum circle ; chambering, drilling and articulating each hole on a gear ring; and screwing a bolt and hinging the bolt and combining two gears into a pair. The invention has the advantages of material saving, cost reduction and mechanical performance improvement of products.

Owner:SHANGHAI ZHENHUA HEAVY IND GRP NANTONG TRANSMISSION MACHINERY

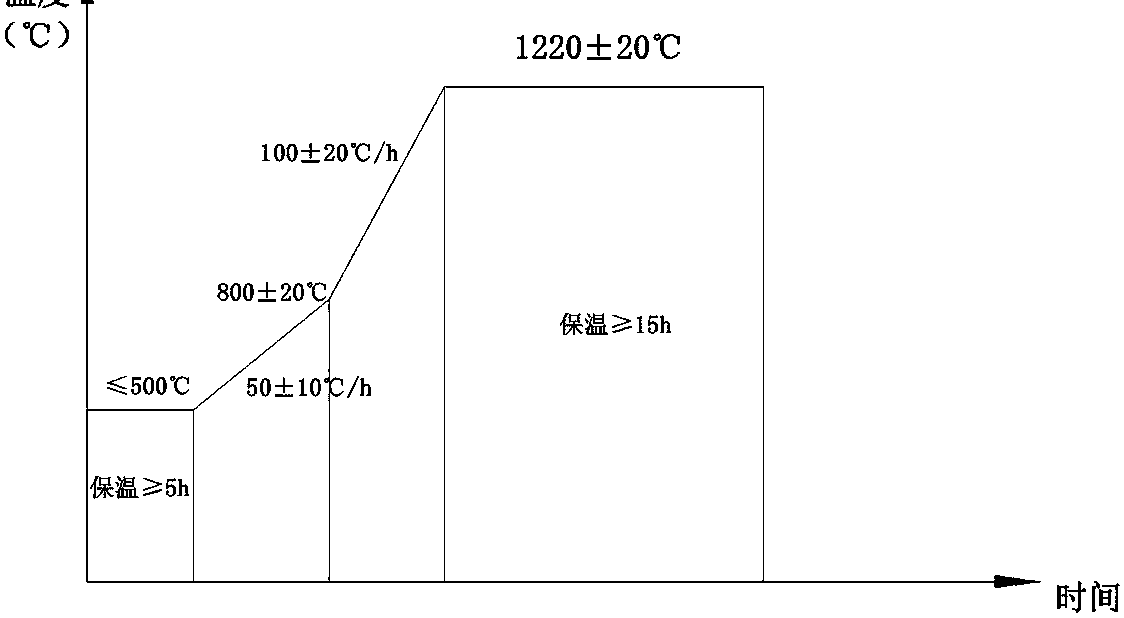

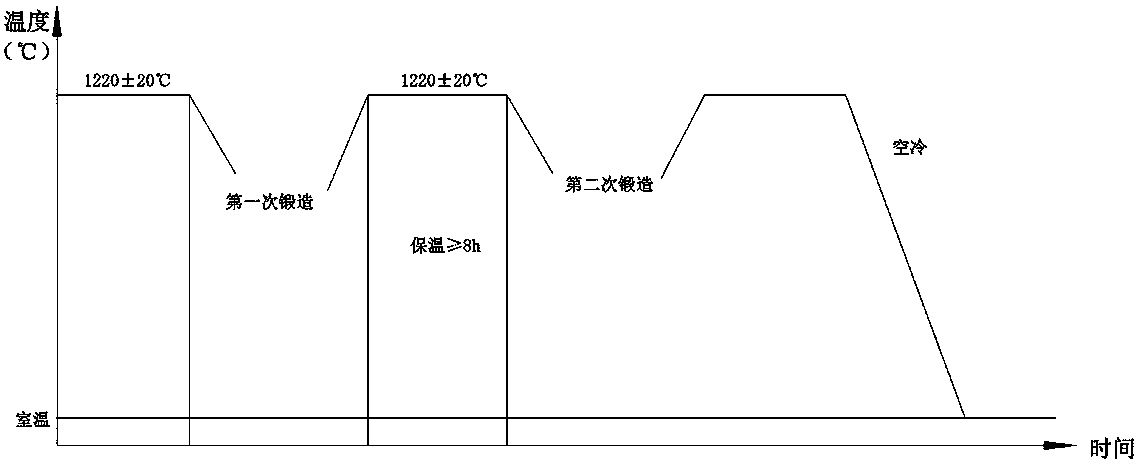

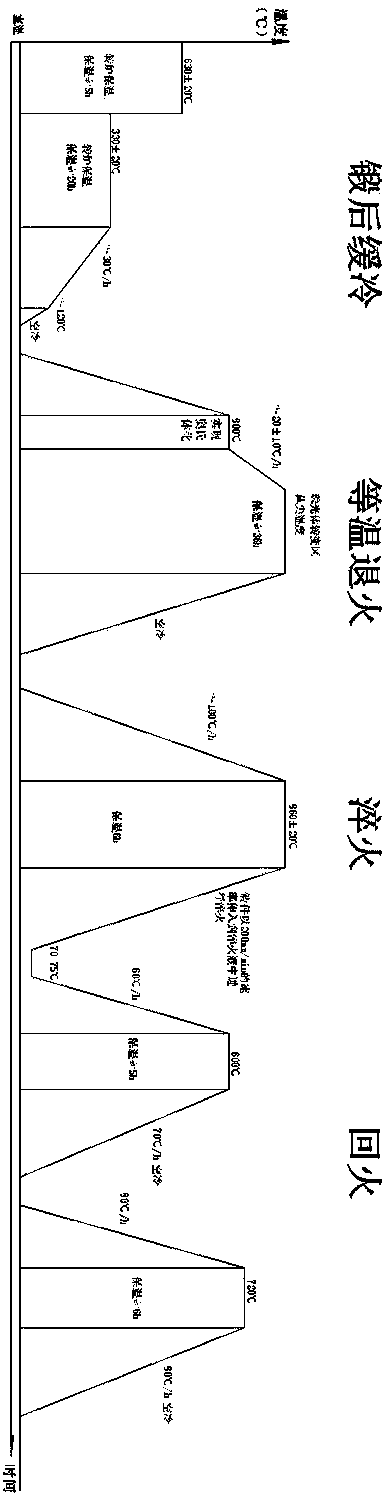

Manufacturing process for manufacturing large ship-used shafting forge pieces

InactiveCN108453202AEfficient crushingReasonable upsetting processMetal-working apparatusFurnace typesSolubilityHydrogen

The invention provides a manufacturing process for manufacturing large ship-used shafting forge pieces and belongs to the field of ship-used shafting forge pieces. The manufacturing process for manufacturing large ship-used shafting forge pieces specifically comprises the following steps: heat treatment before forging; two-time upsetting and stretching and forging (a WHF method); and thermal treatment on the forged shafting forge pieces. The two-time upsetting and stretching process is reasonable. Cast state tissues can be crushed effectively in first time stretching, and inner hole defects are forged; strip-type plastic inclusions of a core of a blank are fractured to smaller impurities in second time upsetting; the impurities are stretched to disperse impurity granules in the second stretching process, and the action of white points is eliminated effectively by the two-time upsetting process. As a result of temperature change condition in the two-time upsetting and stretching process, the solubility of hydrogen in the forge pieces changes continuously, and distribution and diffusion of hydrogen are facilitated well.

Owner:WUXI HONGDA HEAVY IND

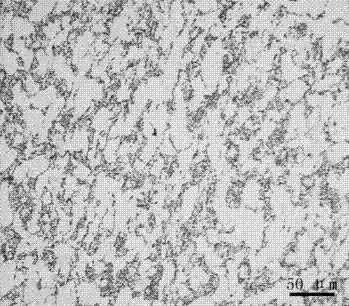

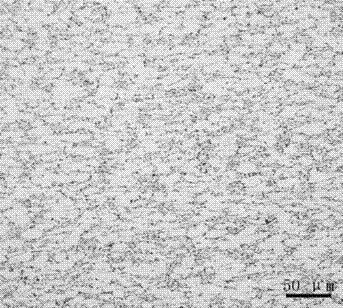

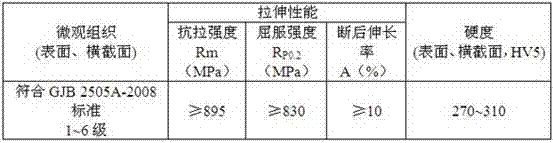

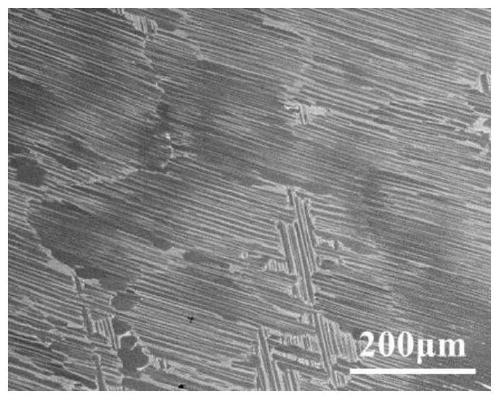

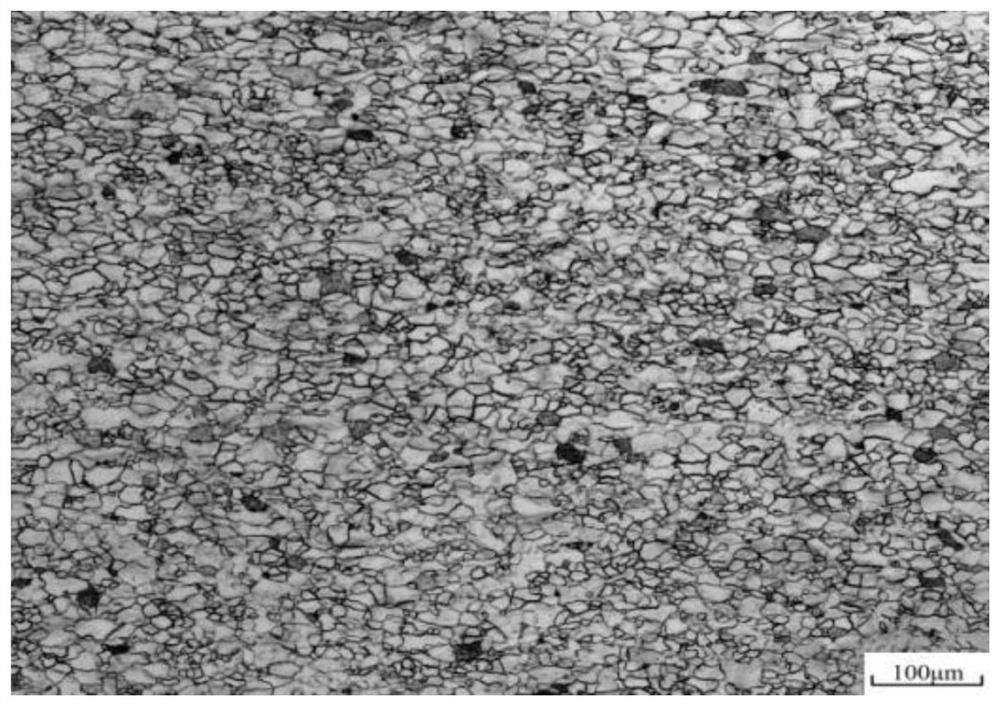

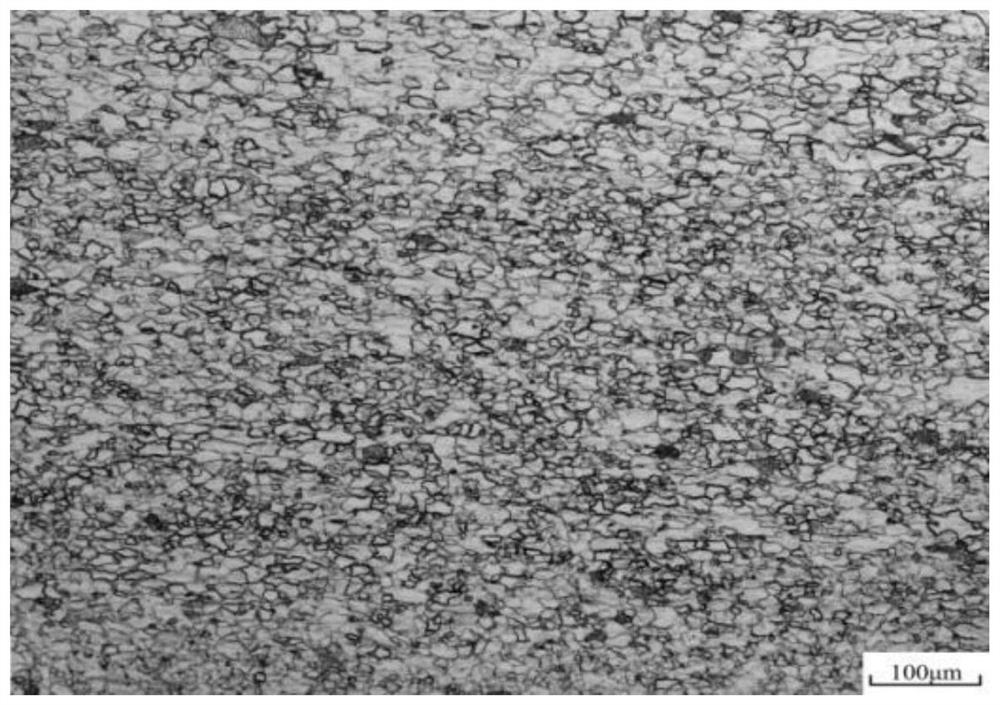

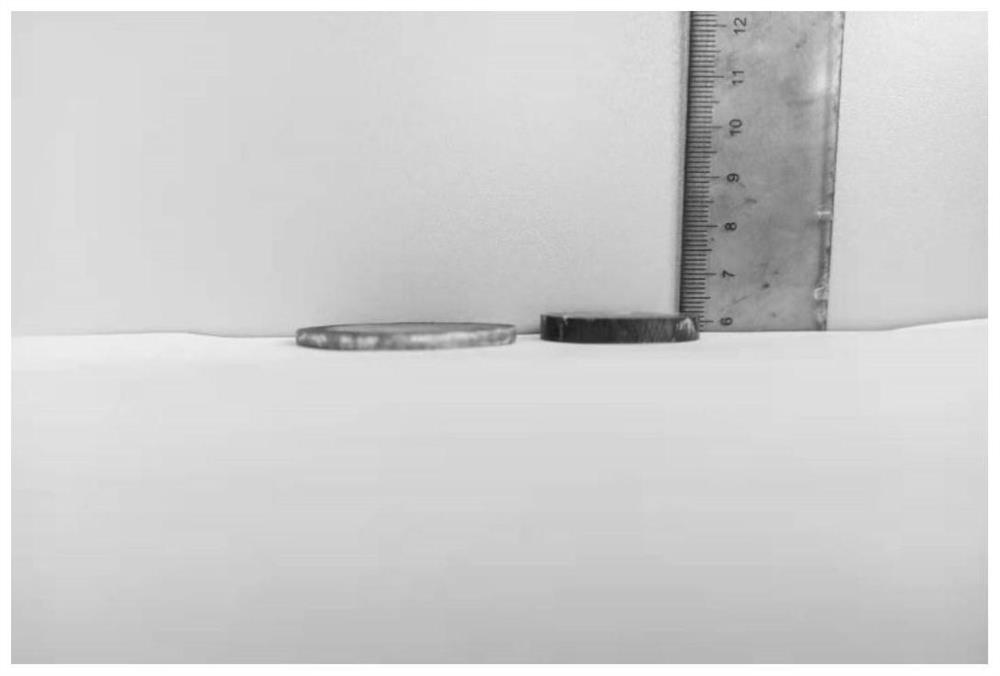

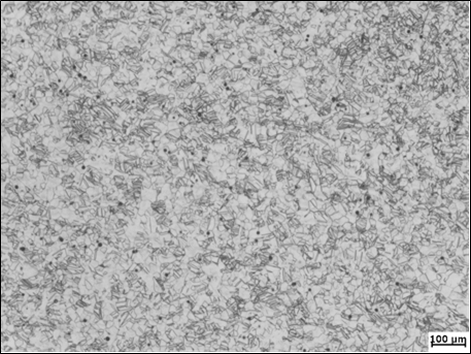

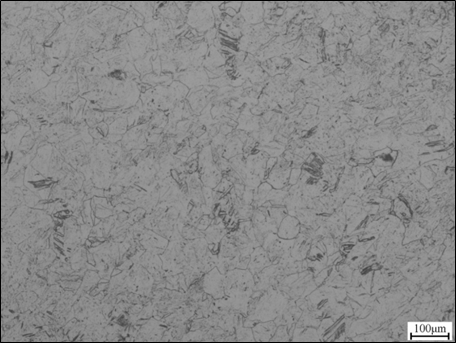

Preparation method of TC4 titanium alloy plate material for 3C products

The invention relates to a preparation method of a TC4 titanium alloy plate material for 3C products. The preparation method comprises the following steps: cast ingot smelting, plate blank preparation, plate rolling, heat treatment, plate shape correction, surface treatment, discharging and machining. According to the preparation method of the TC4 titanium alloy plate material for 3C products, through the control over the components and the processing technology, both the microstructure and the mechanical property of the plate material are optimized, a fine, uniform and microscopic equiaxed structure is obtained, an medium and low range microhardness characteristic is achieved, and follow-up surface treatment processing steps such as polishing are facilitated; besides, with the adoption of the TC4 titanium alloy plate material prepared by adopting the preparation method, the 3C products are more uniform and beautiful in color and luster due to surface treatment, the problems such as nonuniform color and spot defects caused by surface treatment are avoided, the requirements of the 3C products and related accessories on the manufacturing cost and quality of shells are met, both the equipment and process are simple, and the stable and large-scale production is realized.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

High strain rate forming of dispersion strengthened aluminum alloys

InactiveUS20100077825A1Reduce number of stepFinal property be increaseShaping toolsPump componentsAg elementAluminium alloy

Dispersion strengthened aluminum base alloys are shaped into metal parts by high strain rate forging compacts or extruded billets composed thereof. The number of process steps required to produce the forged part are decreased and strength and toughness of the parts are increased. The dispersion strengthened alloy may have the formula Albal,Fea,SibXc, wherein X is at least one element selected from Mn, V, Cr, Mo, W, Nb, and Ta, “a” ranges from 2.0 to 7.5 weight-%, “b” ranges from 0.5 to 3.0 weight-%, “c” ranges from 0.05 to 3.5 weight-%, and the balance is aluminum plus incidental impurities. Alternatively, the dispersion strengthened alloy may be described by the formula Albal,Fea,SibVdXc, wherein X is at least one element selected from Mn, Mo, W, Cr, Ta, Zr, Ce, Er, Sc, Nd, Yb, and Y, “a” ranges from 2.0 to 7.5 weight-%, “b” ranges from 0.5 to 3.0 weight-%, “d” ranges from 0.05 to 3.5 weight-%, “c” ranges from 0.02 to 1.50 weight-%, and the balance is aluminum plus incidental impurities. In both cases, the ratio [Fe+X]:Si in the dispersion strengthened alloys is within the range of from about 2:1 to about 5:1.

Owner:HONEYWELL INT INC

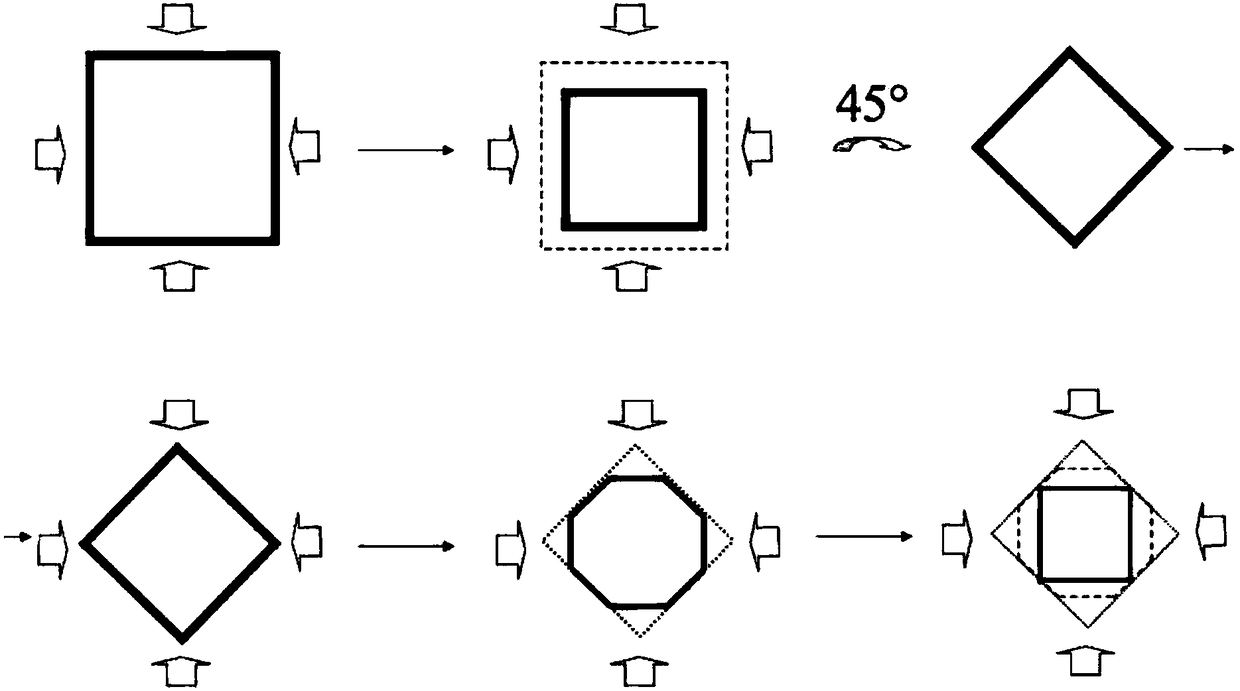

Forging method capable of improving structure uniformity of titanium alloy forging stock

ActiveCN108057829AClear grain boundariesGuarantee organizationMetal-working apparatusTitanium alloyTransition temperature

The invention discloses a forging method capable of improving structure uniformity of a titanium alloy forging stock. Differential thermal analyzing is used for measuring the phase transformation temperature beta t of a titanium alloy blank to be forged; under the temperature from (beta t+100) DEG C to (beta t+150) DEG C, heat preservation is carried out for 4 hours to 6 hours, and the blank to beforged is forged into a square blank; the obtained square blank is subject to heat preservation for 2 hours to 4 hours at the temperature from (beta t-20) DEG C to (beta t-10) DEG C, second-heating forging is carried out, the obtained square blank is subject to free drawing until the deformation amount reaches 50% to 60% of the total deformation amount, and the square blank obtained after free drawing is obtained; the obtained square blank obtained after free drawing rotates by 45 degrees around the center axis of the length direction of the square blank, pressing is carried out, and the final square blank is obtained; and the macrostructure of the cross section of the forge blank obtained after machining is uniform, the grain boundary is clear, no special-shaped piebald defects exist, the microstructure is uniform and consistent, the whole is of a net basket structure or equal-axis structure, and the edge and heart structures have no difference.

Owner:西安赛特思迈钛业有限公司

Hollow near-forming forging method of large MW wind power main shaft

InactiveCN109290503AAdd depthAvoid foldingMetal-working apparatusEngine componentsElectricityPunching

The invention discloses a hollow near-forming forging method of a large MW wind power main shaft. The method is characterized by comprising the following specific steps that 1, a steel ingot is heatedto 1200-1250 DEG C, heat preservation is carried out, then chamfering is carried out, water removing and upsetting are carried out, and blanking is carried out after the steel ingot is pulled out; 2,the steel ingot subjected to the first step is heated to 1200-1250 DEG C, heat preservation is carried out, then upsetting is carried out by adopting a special anti-extrusion leakage disc, then the hole is punched downwards to a certain height through a special punching core rod, and then the special punching core rod is used for drawing to a certain size; 3, the steel ingot subjected to the second step is heated to 1200-1250 DEG C, heat preservation is carried out, then upsetting is carried out by adopting a special anti-extrusion leakage disc, then the hole is punched downwards to a certainheight through a special punching core rod, and then a flange is printed out; and 4, the steel ingot subjected to the third step is heated to 1150-1250 DEG C, heat preservation is carried out, then locally upsetting the flange through the leakage disc, and finally the flange is formed and finished to obtain a finished product. According to the method, the problem that the small-head-end inner hole is very small in wind power main shaft production is solved, the waste of raw materials in the production process is greatly reduced, and the production cost is low.

Owner:SHANDONG LAIWU JINLEI WIND POWER TECH

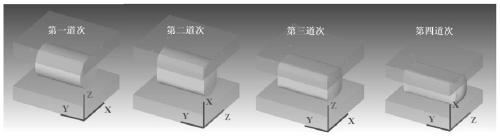

TiAl alloy near-isothermal forging method

The invention discloses a TiAl alloy near-isothermal forging method. The method comprises the following steps that a pretreated cast ingot is put into a sheath, and a sheath end cover and the sheath is sealed; the cast ingot loaded into the sheath is put into a heat treatment furnace, heating is conducted to 1270 DEG C-1320 DEG C, and heat preservation is conducted for 1-2h after the target temperature is reached; a press head of a hydraulic press is heated to 600 DEG C; at least four passes of forging and heat preservation are completed; and the cast ingot is rotated by 90 degrees in an axialdirection before each next pass of forging compression, furnace return heat preservation time after the first pass forging and the second pass forging is 1.5h, furnace return heat preservation time after the third pass forging and following pass forging is 1.5h-2.5h, after furnace return heat preservation of the last pass is finished, furnace cooling is conducted to 900 DEG C, and taking-out, cooling, and sheath removing are conducted to obtain a forged blank. According to the method, a forging process is in a near- isothermal environment, cracking tendency of the forging blank is reduced while operation can be carried out on a common forging machine, the forging cost is reduced, and the method can be better used for forging alpha solidification TiAl alloy.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

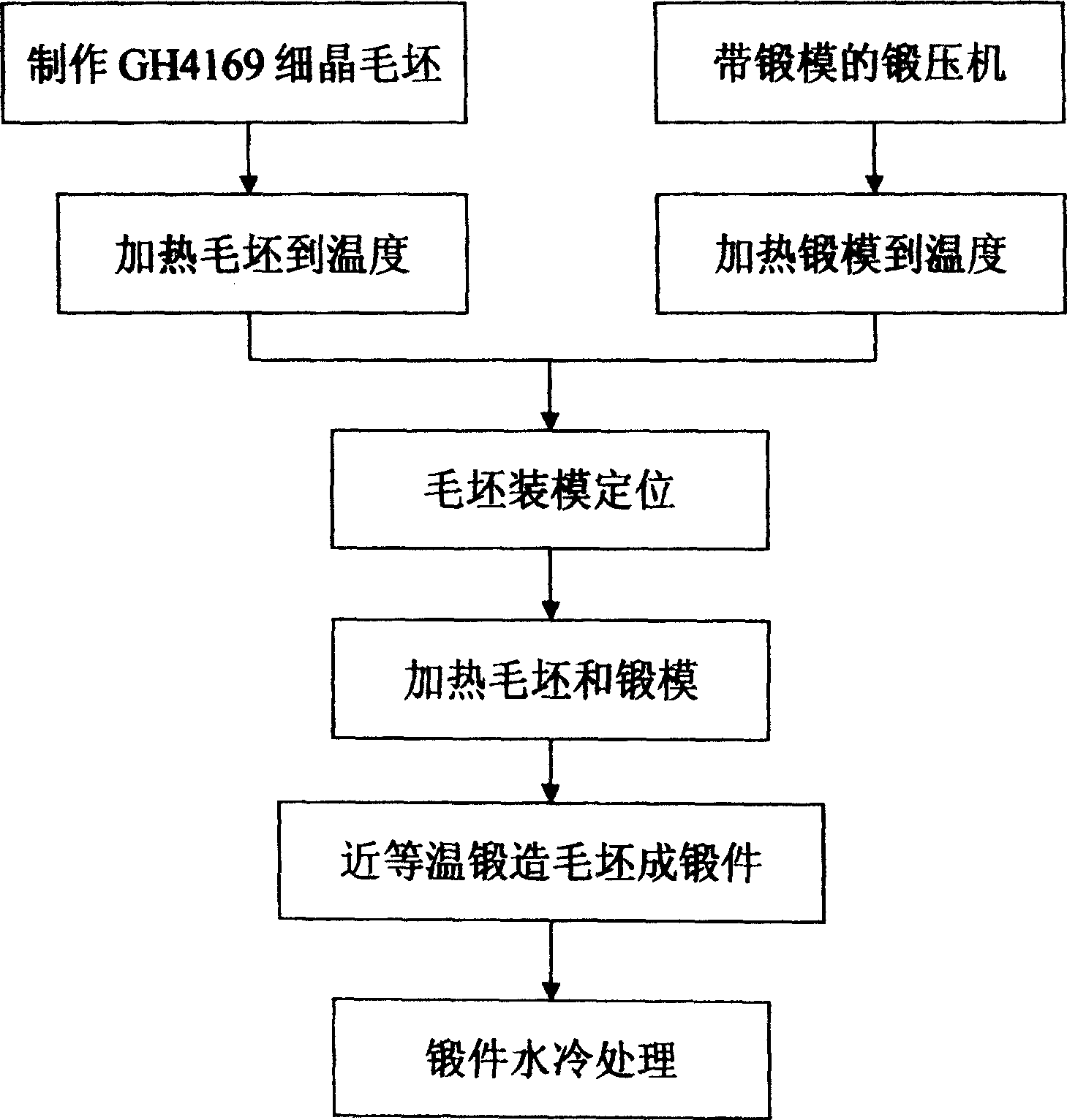

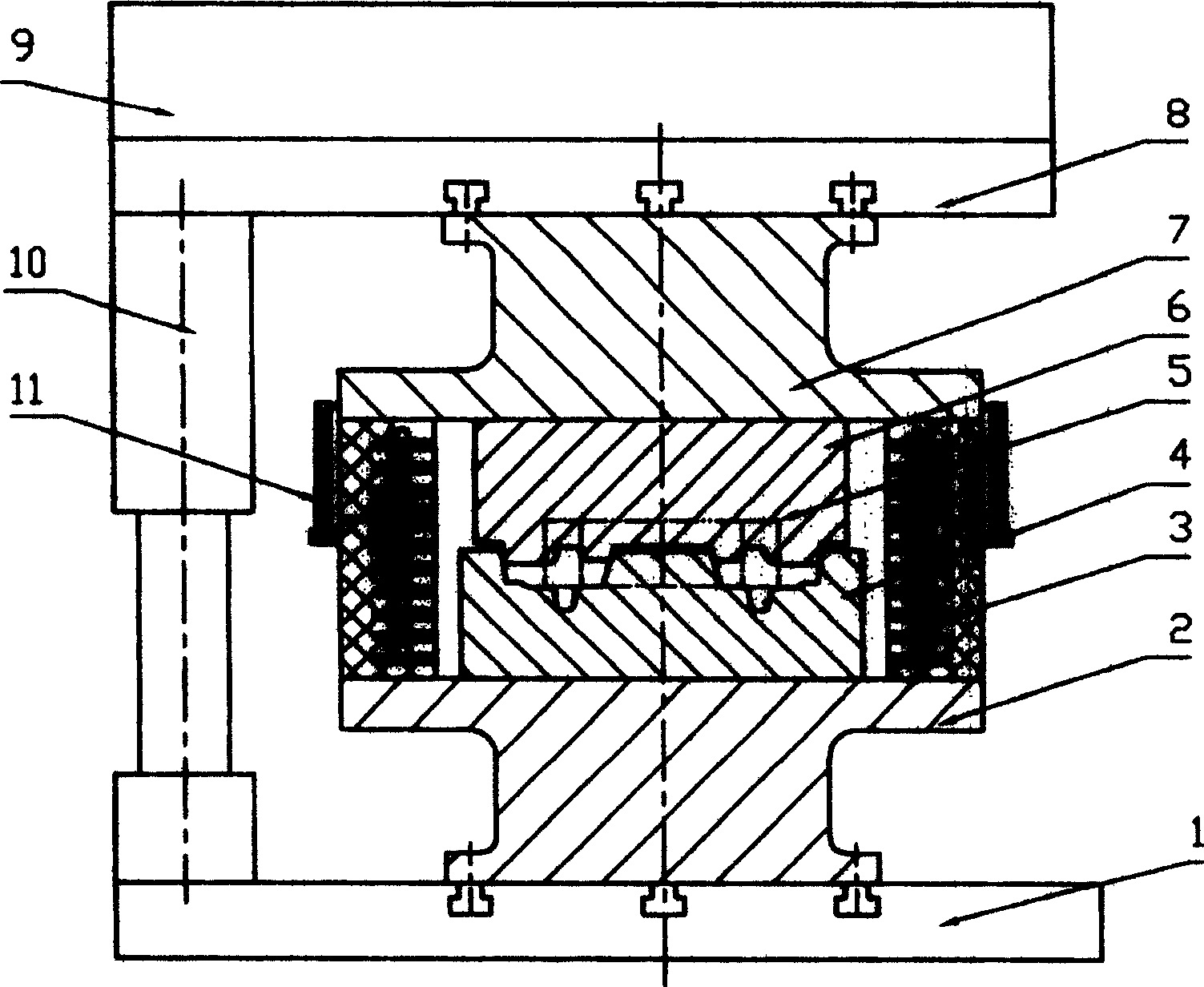

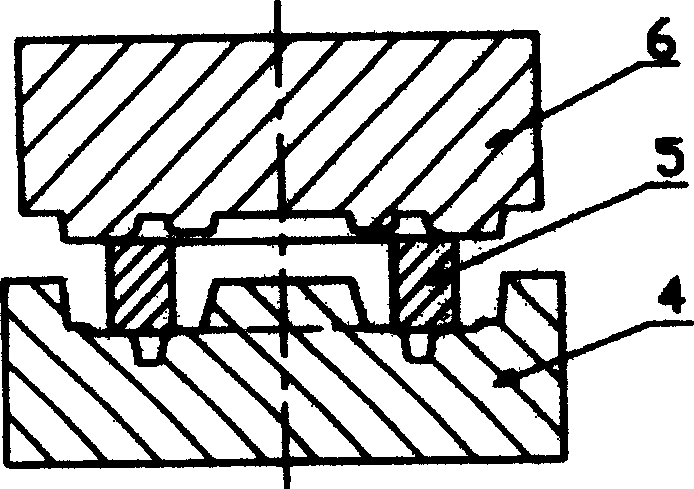

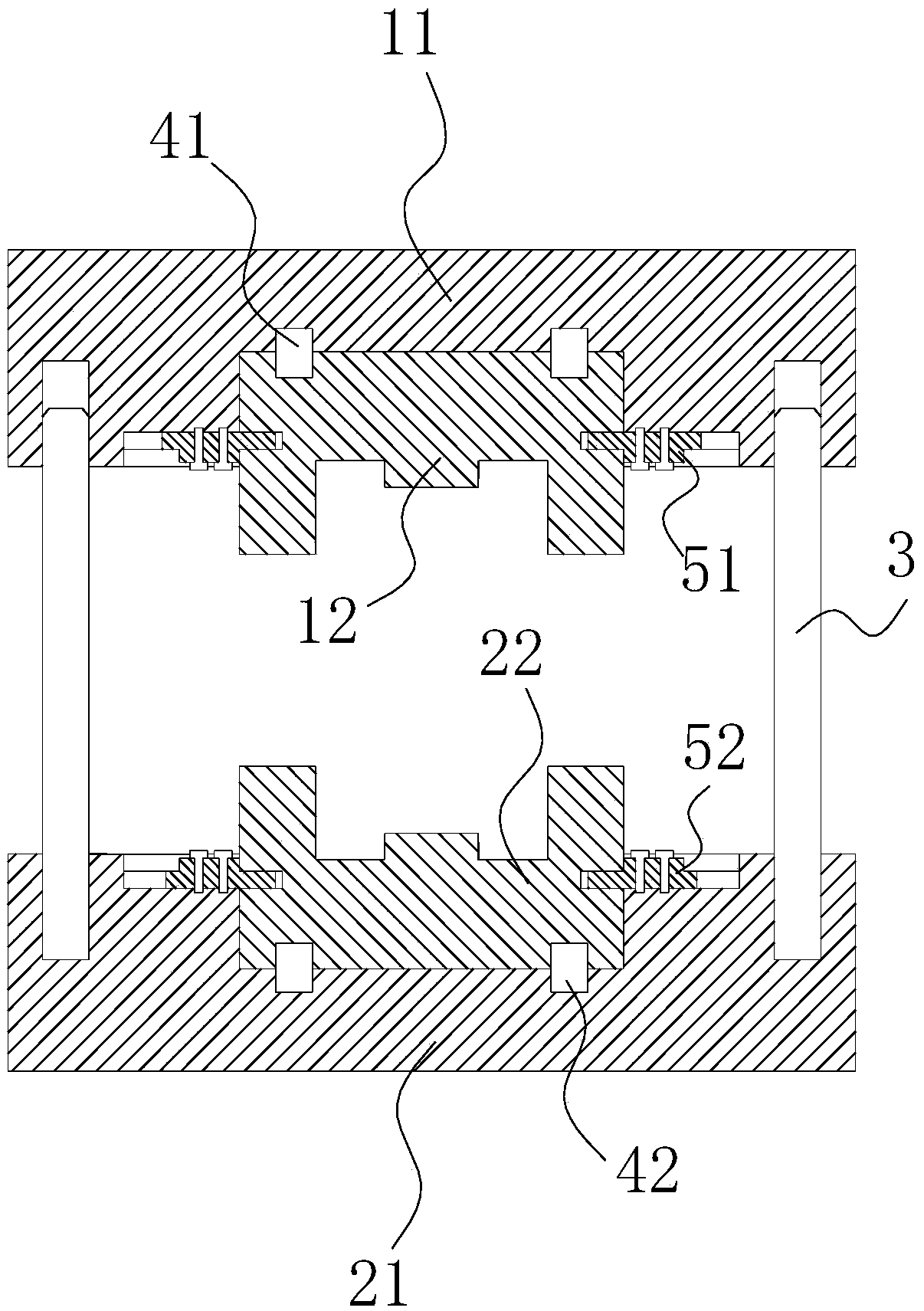

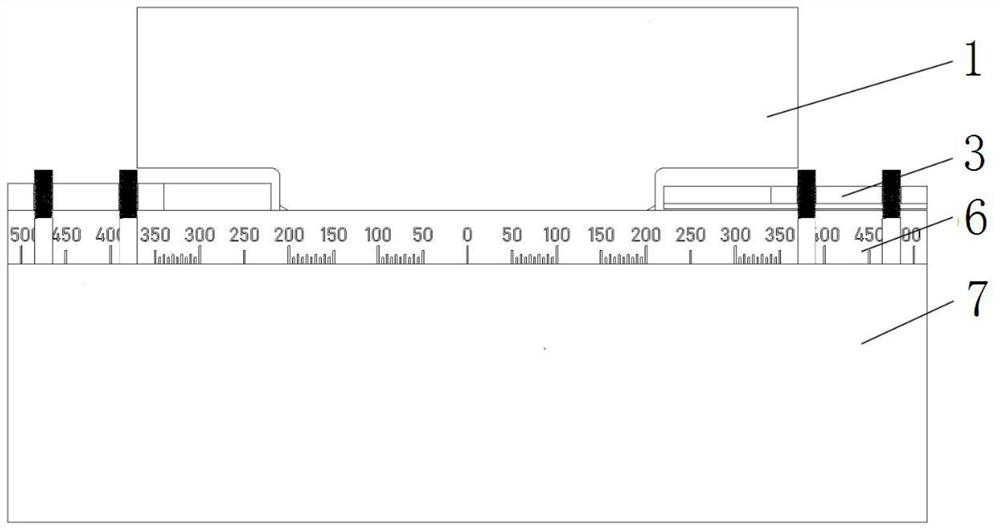

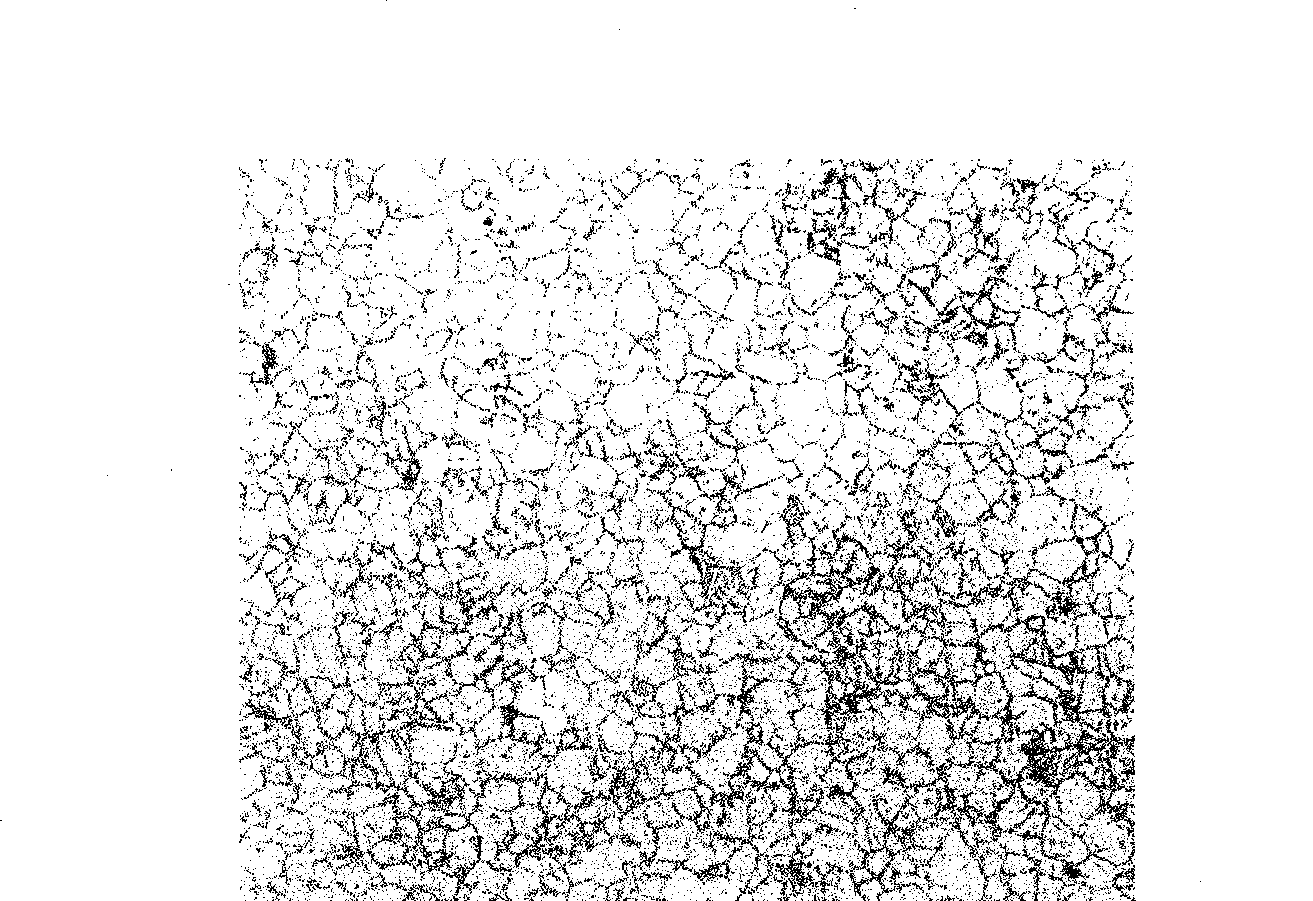

Method for smithing GH4169 alloy plate shaped forgeable piece in air at an approximately equal temperature

ActiveCN100467156CGrain refinementRefine grain sizeForging/hammering/pressing machinesWheelsPunchingHigh intensity

The invention discloses a close isothermal forging method of GH4169 alloy tray-shaped forging in the air, the technological process is that: making GH4169 finegrain roughcast adopting method of upsetting, punching and rolling after heating GH4169 alloy original rod material to 995-1005 DEG C; respectively heating the finegrain roughcast to 995-1005 DEG C and forging die to 950-965 DEG C; diefilling and positioning the finegrain roughcast; while heating finegrain roughcast and forging die to keep the heating warm humidity; forging die and forging press the finegrain roughcast forming under the 55MN to 65MN forging pressure and 0.01s-1 to 0.05s-1 strain rate; obtaining the tray-shaped forging; water-cool processing the tray-shaped forging. Adopting forging method of the invention can realize forming of the GH4169 alloy material tray-shaped forging difficult to deform and obtain the GH4169 alloy tray-shaped forging with weensy crystal grain, high intensity and complicated shape.

Owner:GUIZHOU ANDA AVIATION FORGING

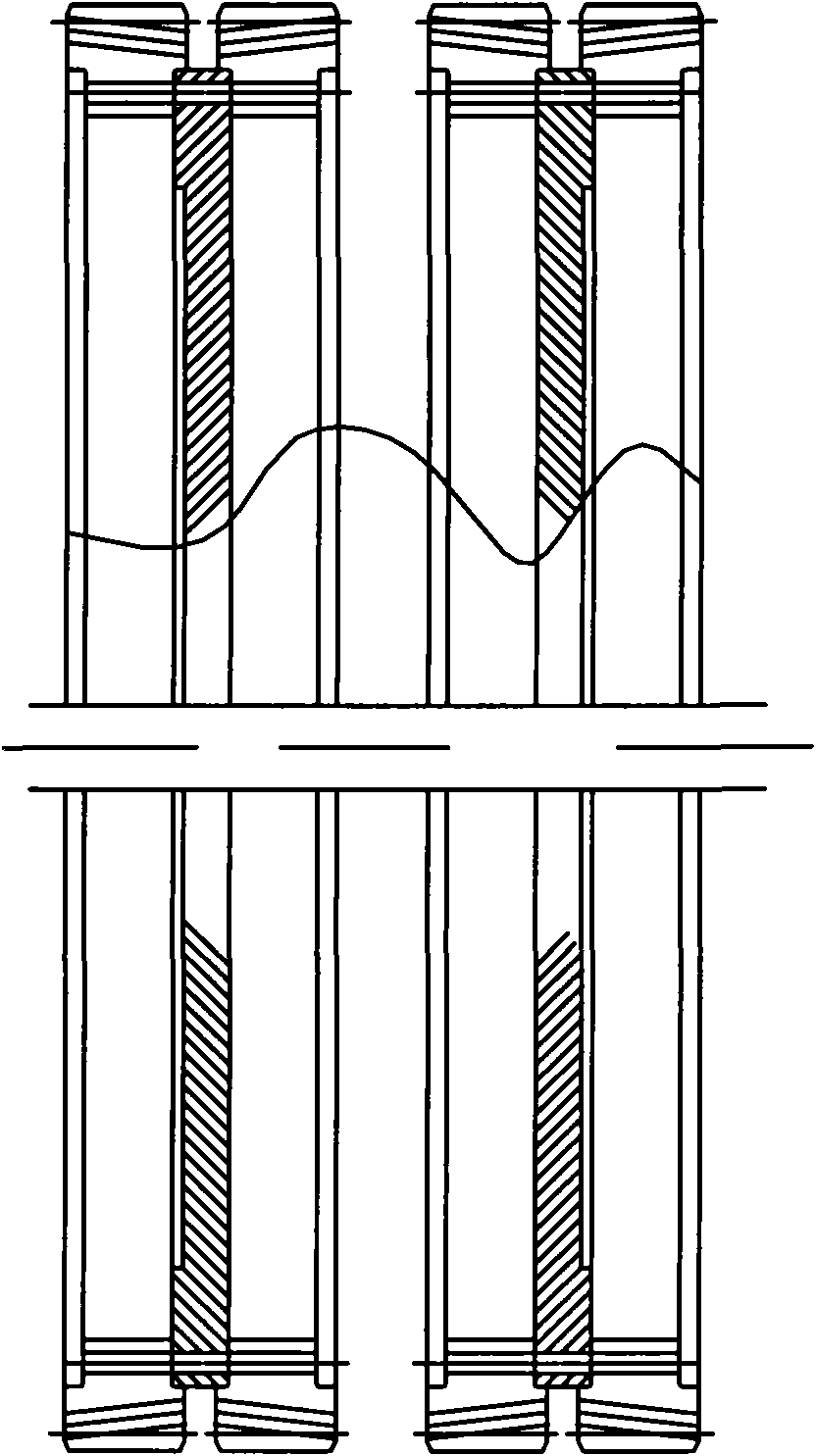

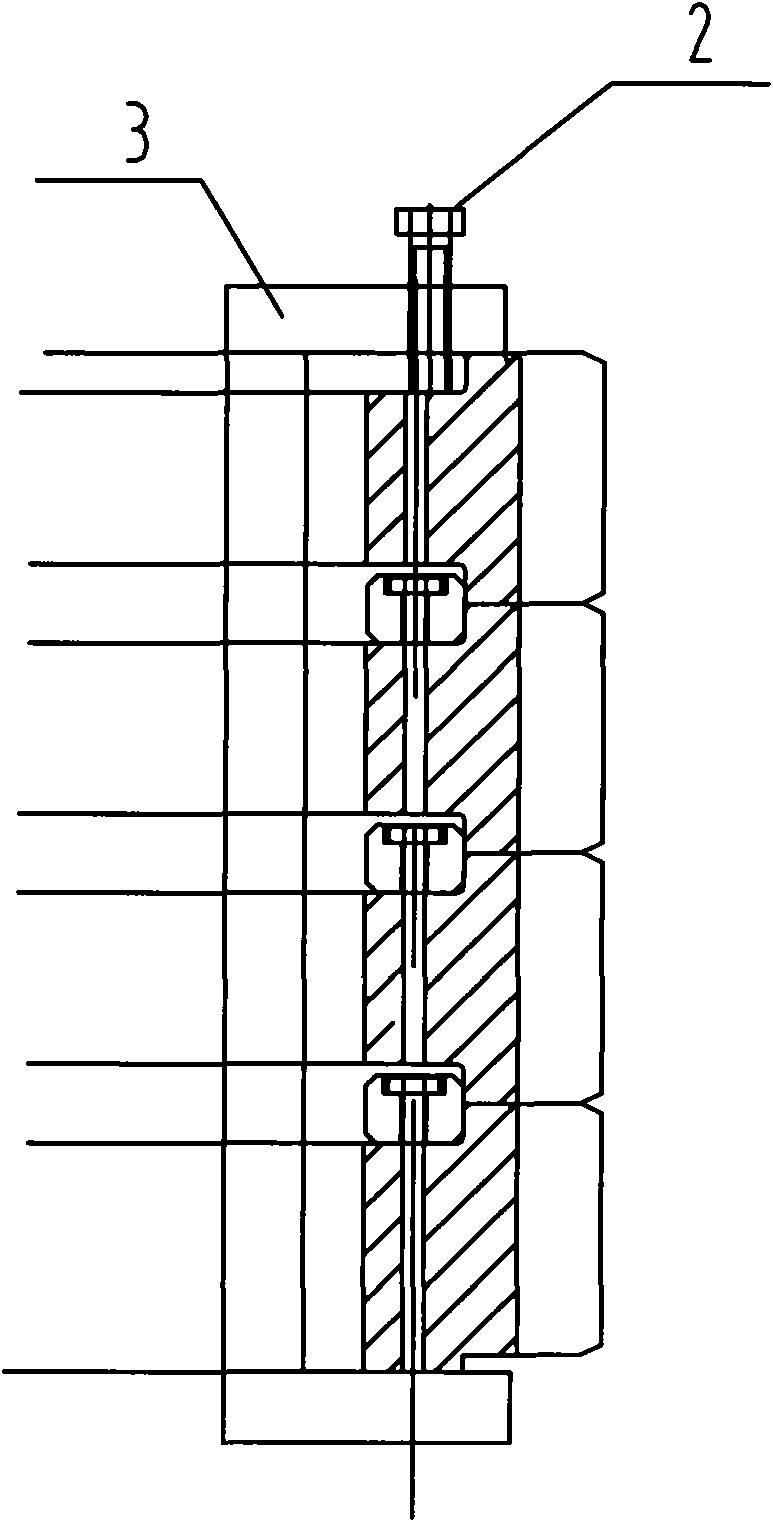

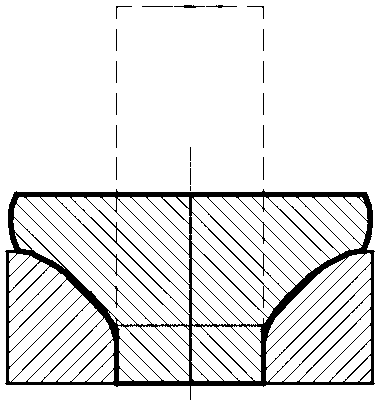

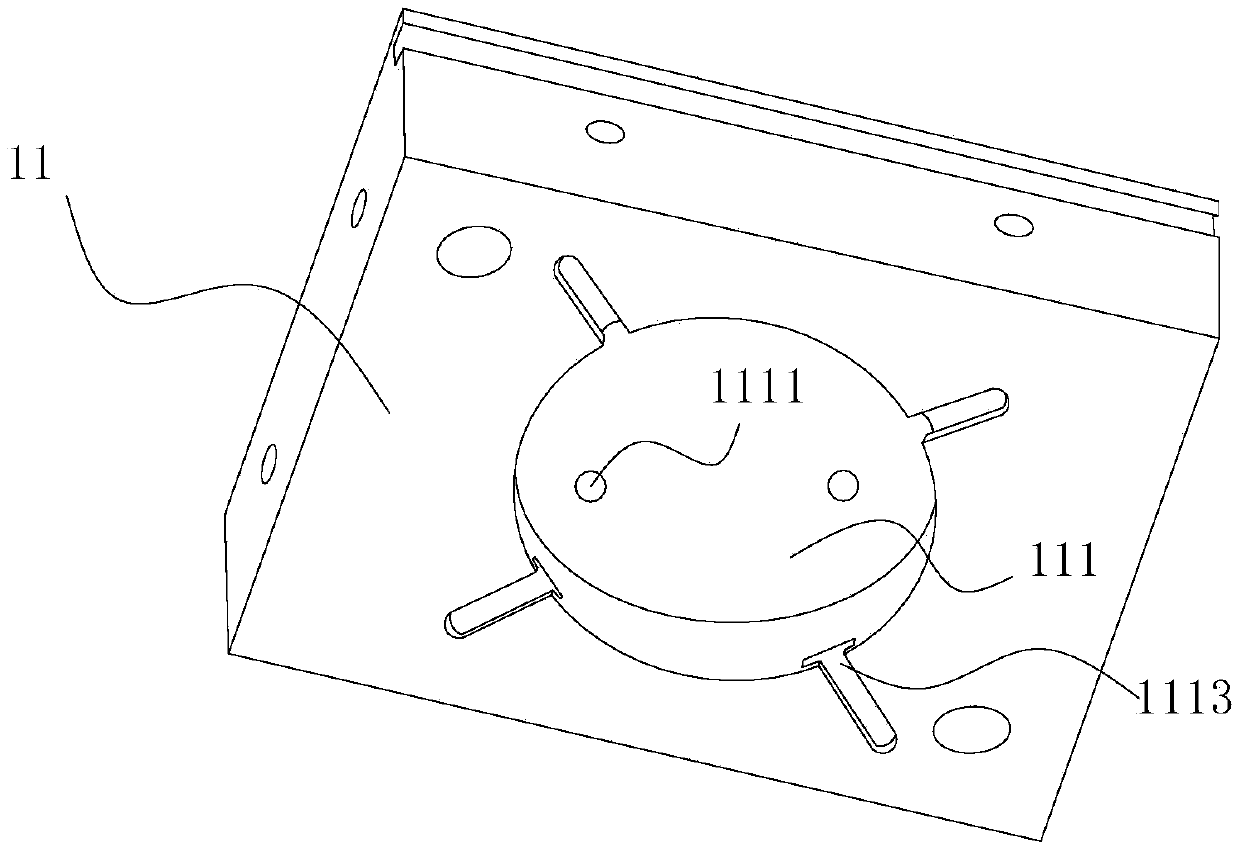

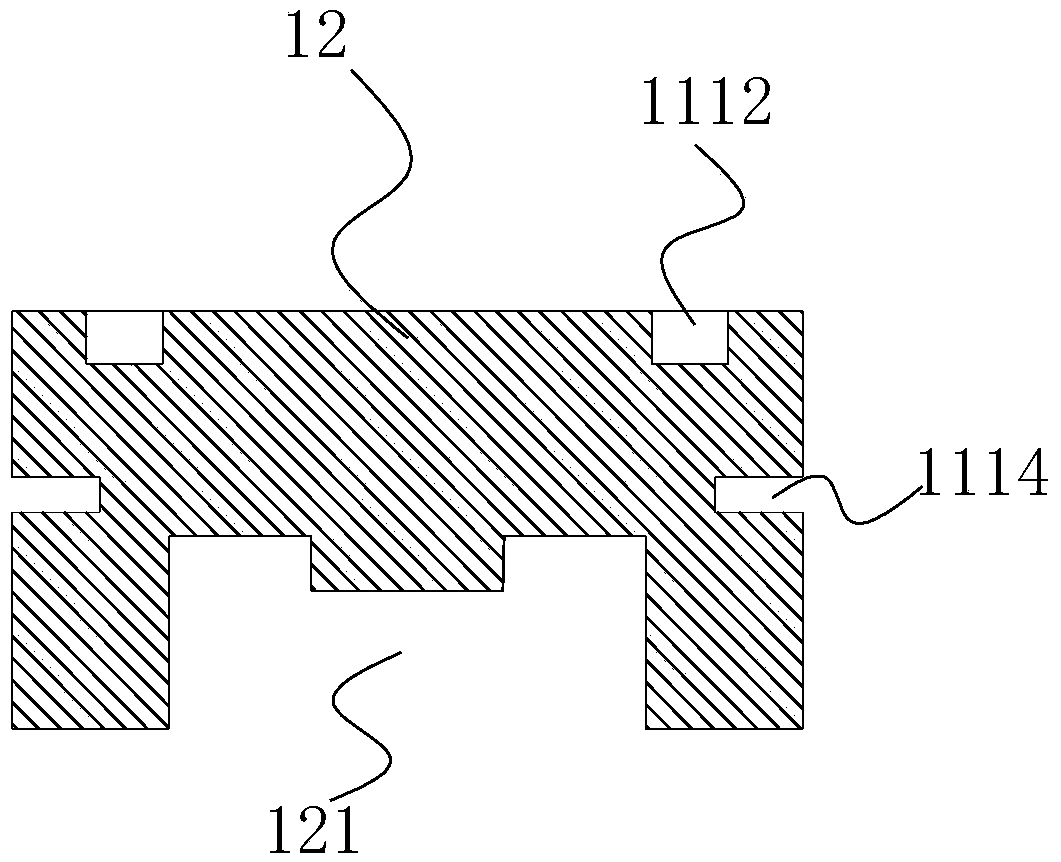

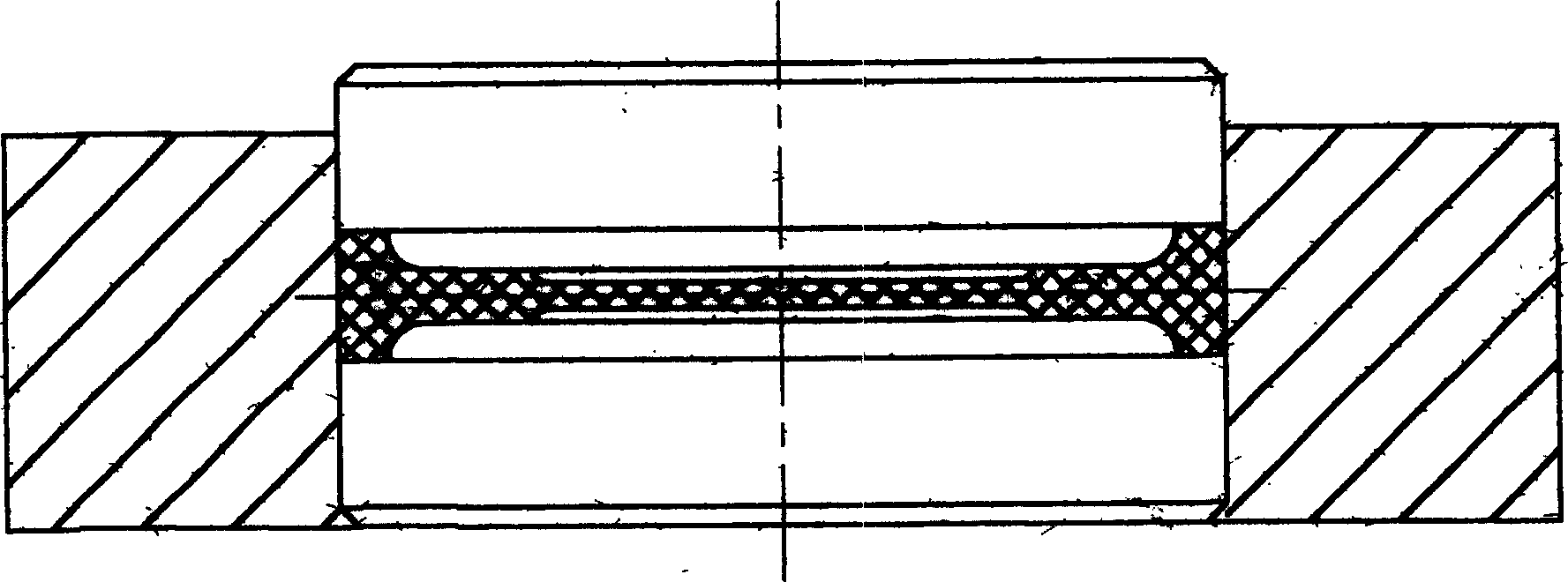

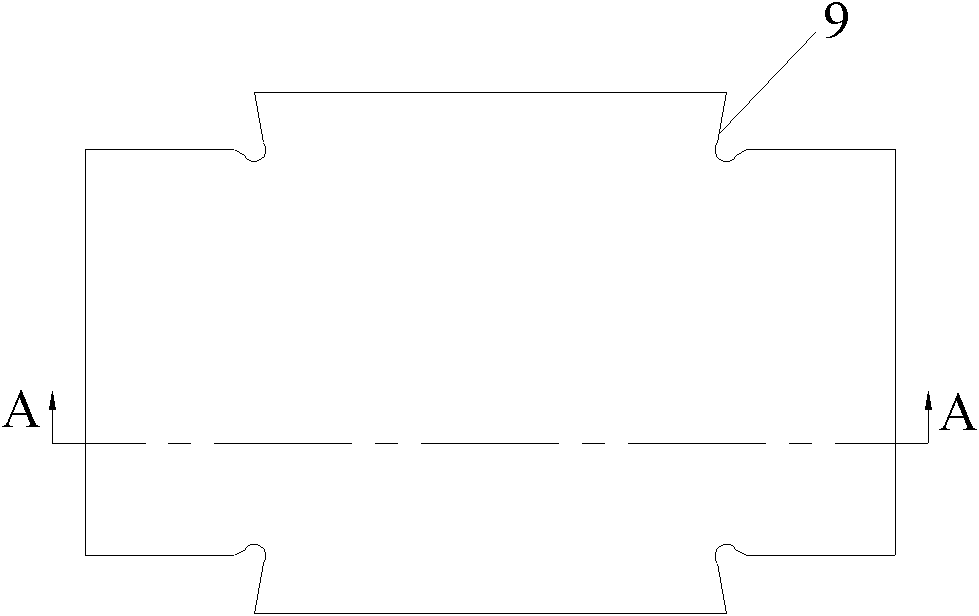

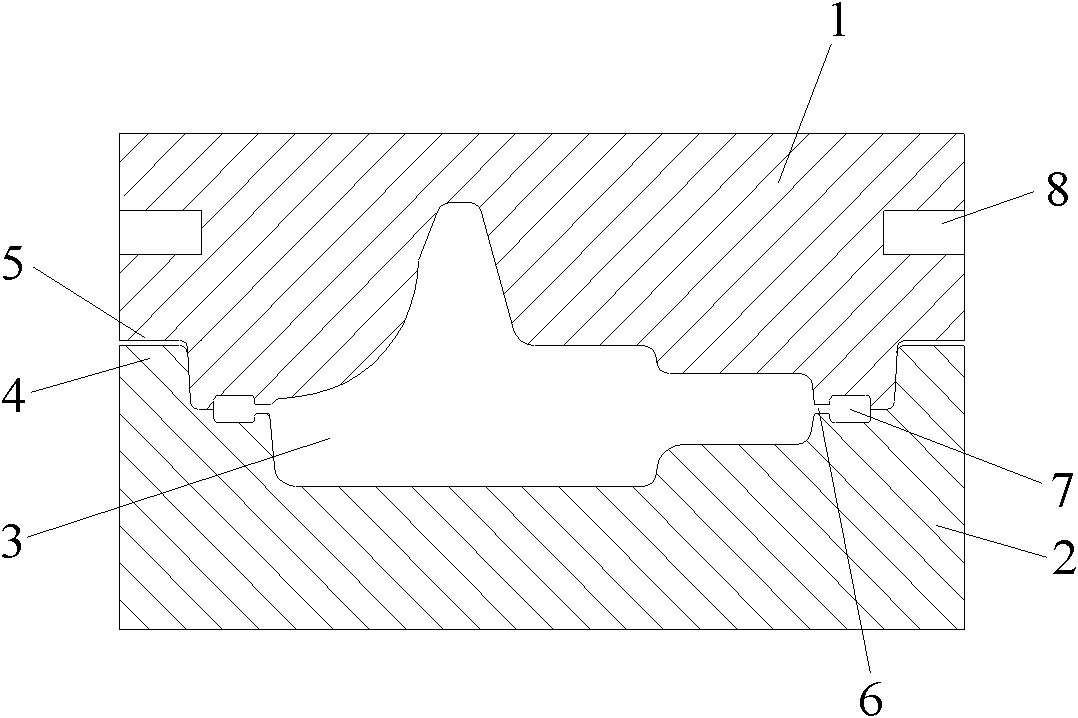

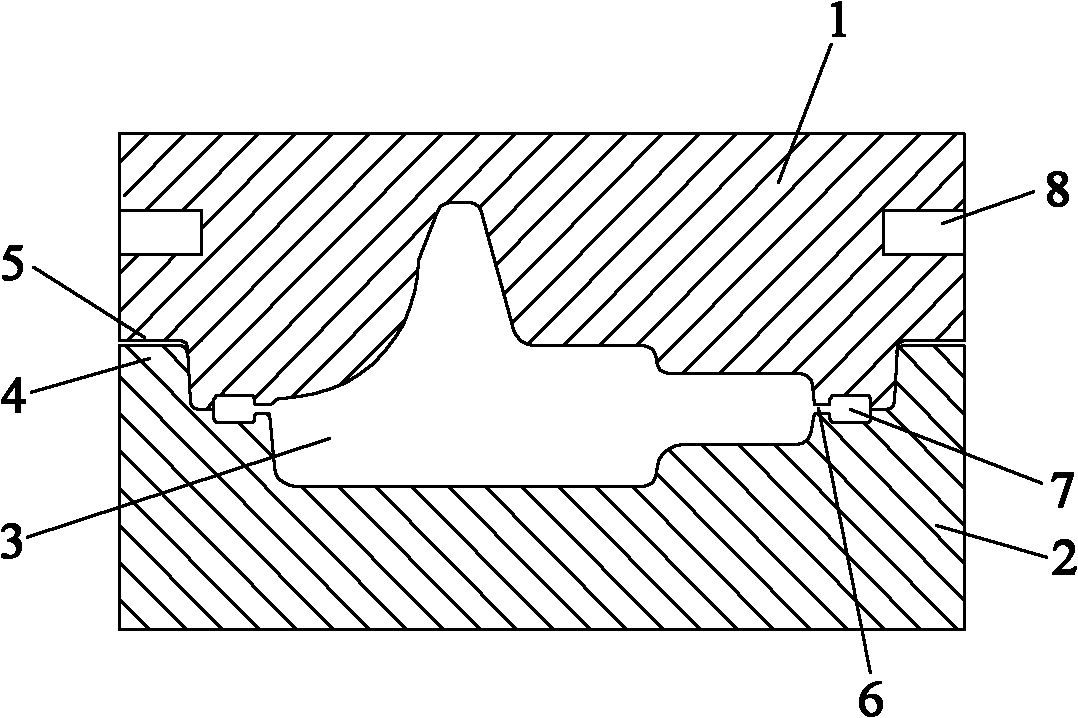

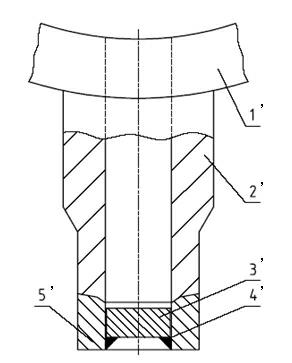

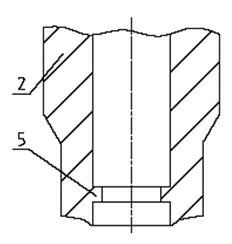

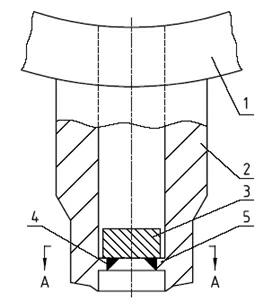

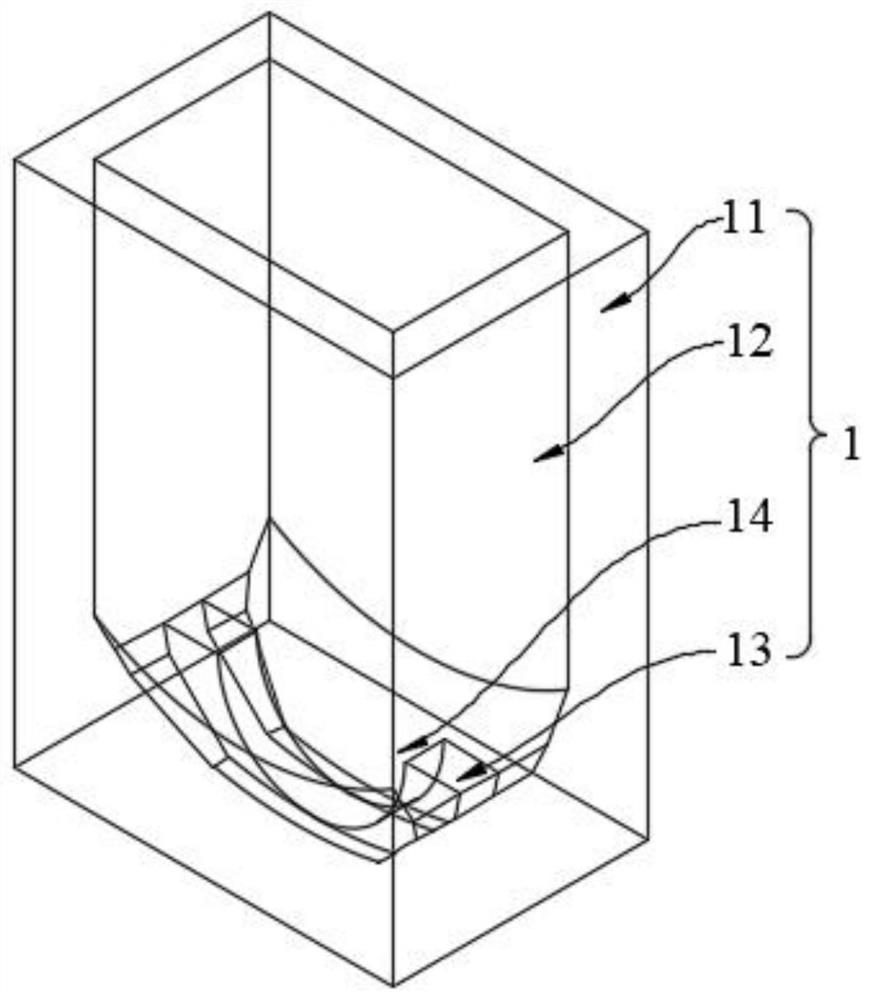

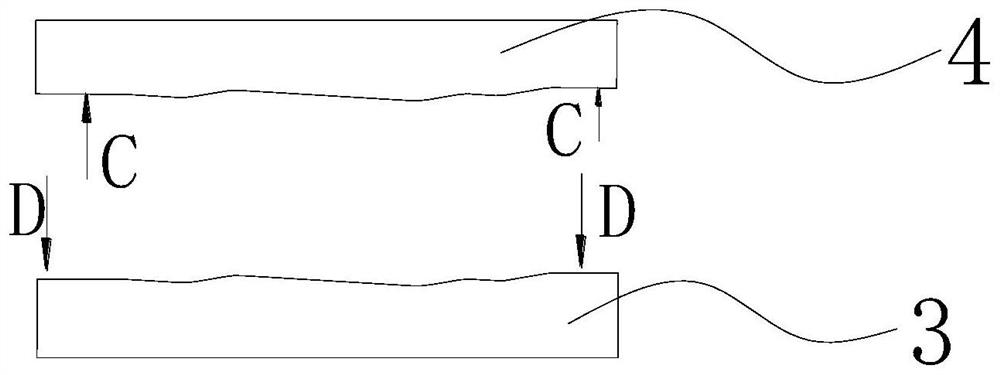

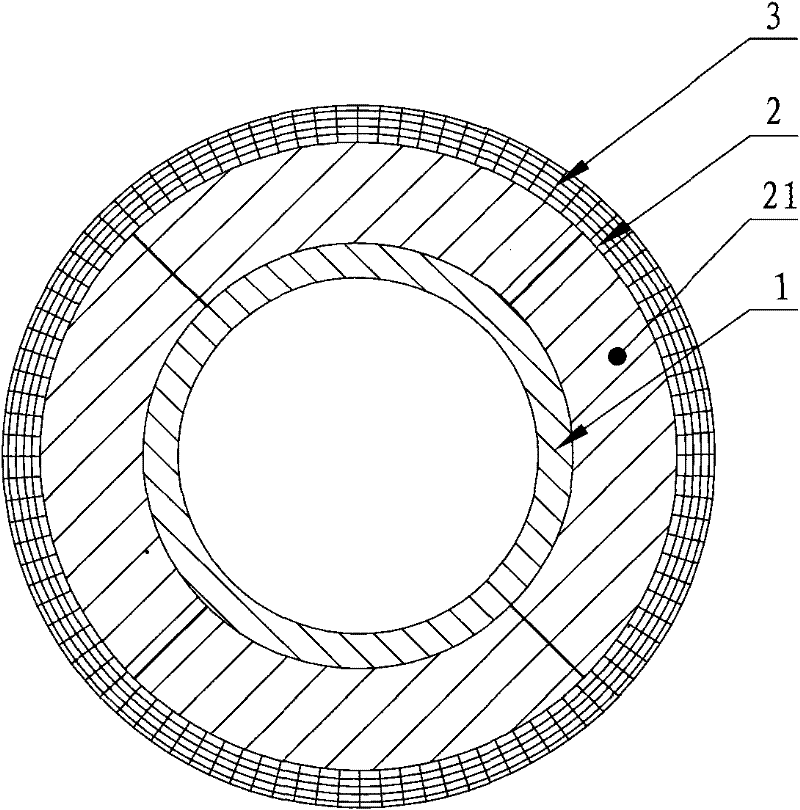

Combined core-inlaid die and application method thereof

InactiveCN105499462AReduce manufacturing difficultyLow costForging/hammering/pressing machinesEngineeringCavity size

The invention relates to the technical field of forging, in particular to a combined core-inlaid die. The combined core-inlaid die comprises a die sleeve and a die core. The die sleeve comprises an upper die sleeve body and a lower die sleeve body. The die core comprises an upper die core body and a lower die core body. An upper mounting groove is formed in the upper die sleeve body. The upper die core body is mounted in the upper mounting groove. A lower mounting groove is formed in the lower die sleeve body. The lower die core body is mounted in the lower mounting groove. An upper die cavity is formed in the upper die core body. A lower die cavity is formed in the lower die core body. A set of guide posts are arranged between the upper die sleeve body and the lower die sleeve body. According to the combined core-inlaid die, the material cost can be reduced, and the die manufacturing difficulty can be lowered; meanwhile, the strength of the die core can meet the forging requirements, and the quality of forged pieces is not affected. An application method of the combined core-inlaid die comprises the following steps: A, selecting the corresponding upper die core body and the corresponding lower die core body according to the size of a forged piece; B, mounting the upper die core body on the upper die sleeve body, and mounting the lower die core body on the lower die sleeve body; C, mounting the guide posts; and D, conducting forging. By means of the method, the same die sleeve is applicable to die cores of various different die cavity sizes, the manufacturing quantity of dies is reduced, and the forging cost is lowered.

Owner:中国第二重型机械集团德阳万航模锻有限责任公司

Non-trimming closed type tyre die forging technological method of middle part punched black skin kind forged piece

InactiveCN1597173AEasy to moveReduce the amount of processingMetal-working apparatusMechanical engineeringRaw material

Owner:YONGJI ELECTRIC FORGING & PRESSING

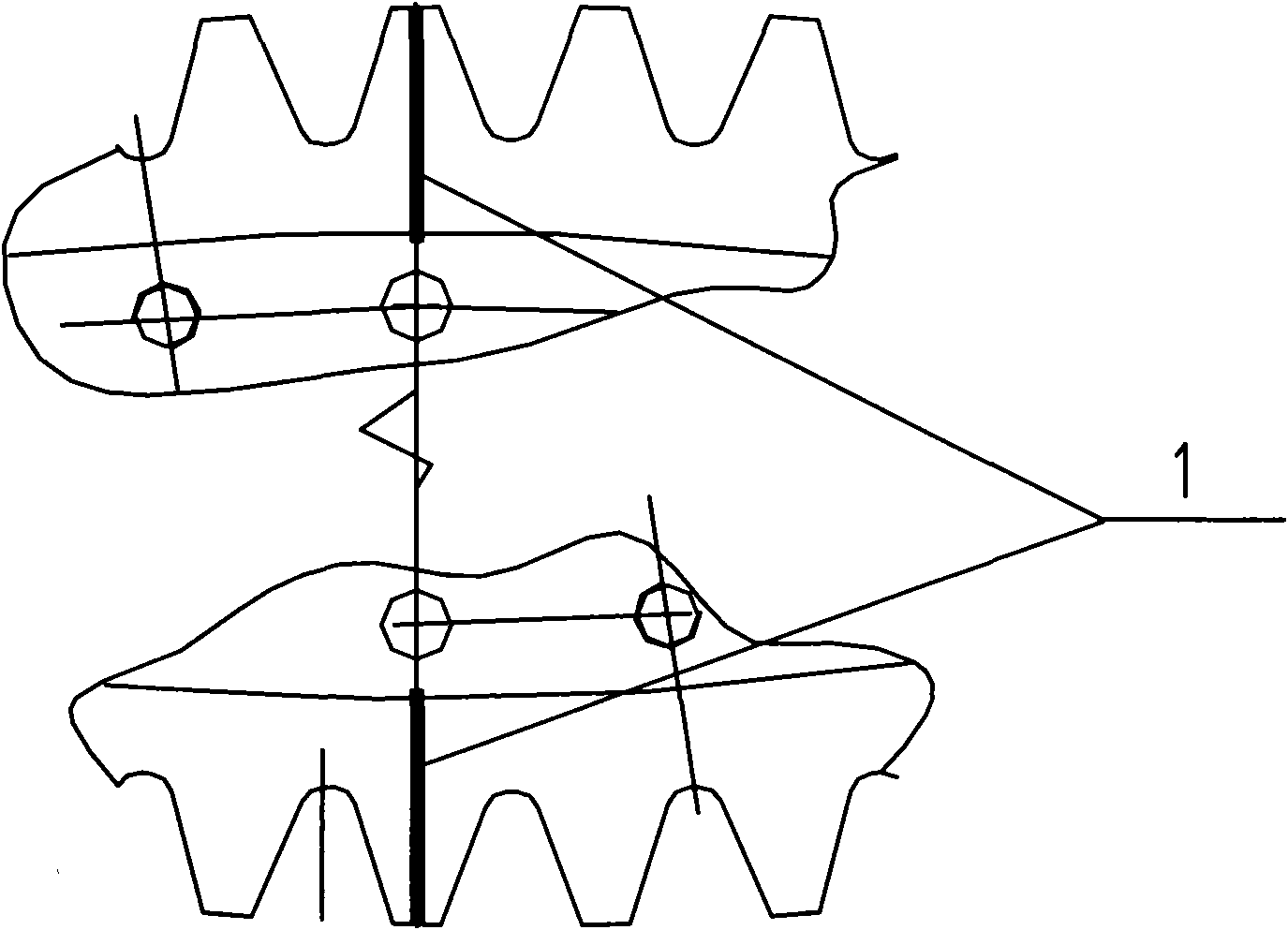

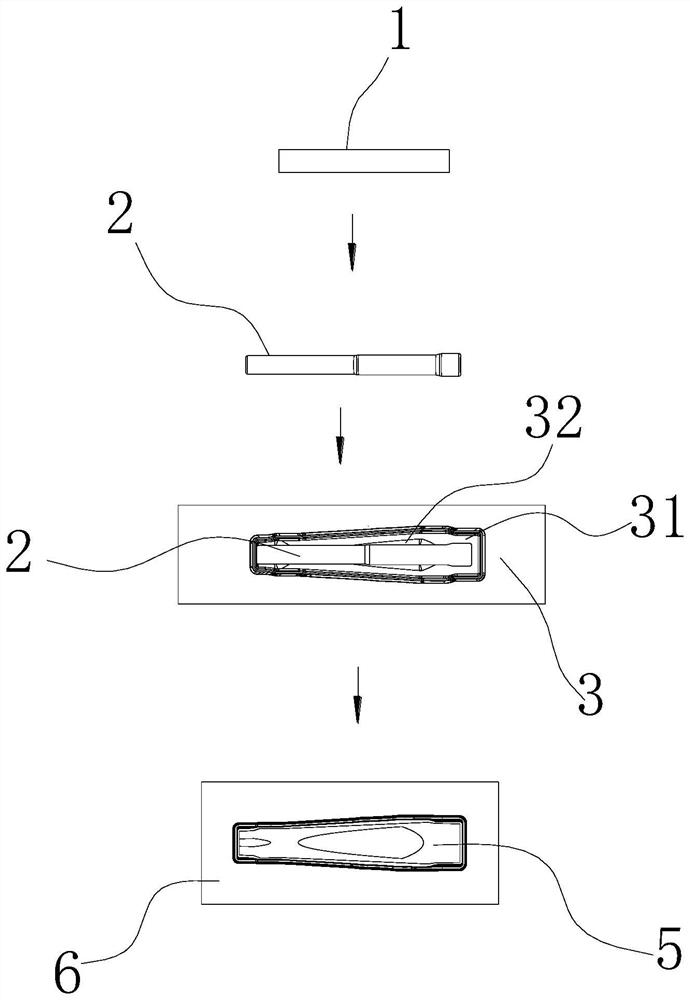

Blade forging preformed blank design method capable of accurately controlling material flow distribution

ActiveCN110941900AIncrease profitHigh control requirementsGeometric CADShaping toolsDeformation controlDesign methods

The invention discloses a blade forging preformed blank design method capable of accurately controlling material flow distribution. According to the technical scheme, the traditional design thought isbroken through; slicing type scanning analysis is carried out according to the designed forging structure; according to the novel design method, the prefabricated blank capable of achieving refined metal flow distribution is designed, then preparation of the prefabricated blank is achieved through a traditional blank manufacturing means, and the novel design method can effectively and greatly improve the material utilization rate, improve the deformation control requirement, reduce the equipment striking difficulty, prolong the service life of a die and reduce the forging cost.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Forging and stamping die of brake cylinder seat

InactiveCN102085558AExtended service lifeReduce forging costForging/hammering/pressing machinesEngineeringForging

The invention discloses a forging and stamping die of a brake cylinder seat, which comprises an upper die and a lower die, and a die cavity formed between the upper die and the lower die, wherein the upper die and the lower die are matched and positioned through a concave lock catch of the upper die and a convex lock catch of the lower die, a flash cavity is arranged on the edge of the die cavity between the upper die and the lower die, and a flash bridge part is arranged between the die cavity and the flash cavity. Furthermore, the distance from the upper die to the lower die at the flash bridge part is 1 / 3 of that from the upper die to the lower die at the flash cavity. During the forging, a metal blank is not easy to extrude out of the die cavity during the forging to ensure that the forged forging has stable quality; and the die has long service life and low forging cost.

Owner:WUHU XINDA FORGING

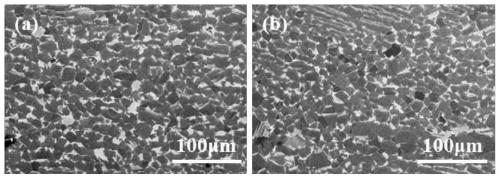

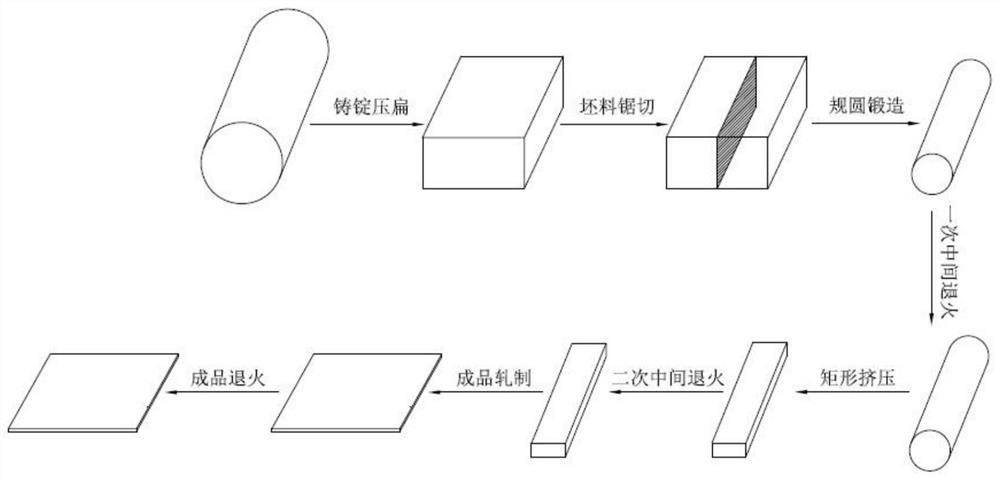

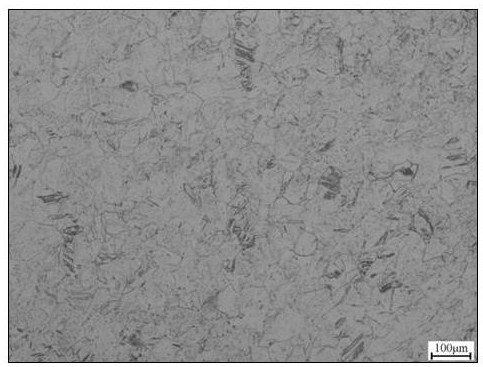

Method for optimizing grain size and uniformity of tantalum plate

ActiveCN112410699AUniform grain sizeIncreased degree of grain fragmentationCircular sectionSquare Shape

The invention discloses a method for optimizing grain size and uniformity of a tantalum plate. The method comprises the following steps: 1, a tantalum cast ingot with a circular section shape is flattened by using a rapid forging machine in a room-temperature environment to obtain a tantalum blank with a rectangular section shape; 2, saw cutting is conducted, and a tantalum blank with the square cross section is obtained; 3, forging and rounding are conducted after heat preservation, and a bar blank with a circular cross section is obtained; 4, primary annealing treatment is performed to obtain an annealed bar billet; 5, the bar billet is extruded after heat preservation to obtain a plate blank with a rectangular section; 6, secondary annealing treatment is conducted, and an annealed plateblank is obtained; 7, rolling is performed to obtain a plate; and 8, third-time annealing treatment is conducted, and a finished tantalum plate is obtained. By the method, preparation of the medium-thickness tantalum plate with the thickness ranging from 5 mm to 20 mm can be achieved, the grain size is superior to 6.5 levels, the maximum grain size is less than or equal to 38 [mu]m, the grain size of the plate in the thickness direction is uniform, and the grain size level difference between a surface layer and the core portion is within 0.5 level.

Owner:西安诺博尔稀贵金属材料股份有限公司

Flange shaft forging method

InactiveCN103192021AReduce weightExtended service lifeForging/hammering/pressing machinesEngine componentsEngineeringFlange

The invention discloses a flange shaft forging method. The flange shaft forging method includes steps of (1) manufacturing a special composite die composed of an outer die, an inner die, a press block and a drain plate; (2) placing the inner die into the outer die and pressing to form a complete die; (3) placing a heated blank into an inner die cavity; (4) placing the pressing block on the blank and in the die cavity; (5) forging and pressing the press block into the die cavity so as to allow the blank to deform and fill with the die cavity; and (6) lifting the integral die to place on the drain plate, stamping the press block to enable the press block and the inner die to separate from the outer die, separating the press block and the inner die, and taking out the forged blank. Compared the prior art, the flange shaft forging method is easier in demoulding, reverse rotation dies are omitted, demounting way is changed, time and labor are saved, and speed and efficiency are high. The inner die is light in weight and easy to carry and cool. Further, multiple inner dies can be used by turns, the service live of the die is prolonged, and forging cost is reduced. The flange shaft forging method is convenient to operate, low in consumption and applicable to forging and forming of circular and special-shaped flange shafts.

Owner:WUQIAO COUNTY HUAFENG HARDWARE & TOOL

Special machining method of large module gear of heavy anchor machine

The invention discloses a special machining method of a large module gear of a heavy anchor machine. The special machining method comprises the following steps that forging is conducted; rough machining of the end faces, the inner circle and the outer circle of a processed workpiece is conducted by using a lathe; a lifting hole is drilled; rough hobbing is conducted the workpiece by using a machining center; quenching and tempering is conducted on the gear; semi-finish machining of an inner hole, the end faces and crest circles is conducted by using the lathe; by making the end face of one side of a benchmark groove as a benchmark, the centerlines of any one pair of end face teeth are marked out, benchmark groove marks are made on crests, and the position line of each hole is marked out; each hole is drilled through a drilling machine; the inner hole and the two end faces are turned to preset sizes through the lathe in a finish machining mode; positioning is conducted according to a datum plane, and correction gear grinding is conducted on the crest circles; each hole in a gear ring is expanded, drilled and reamed. The special machining method has the advantages of saving materials, reducing cost and improving product mechanical properties.

Owner:SHANGHAI ZHENHUA HEAVY IND GRP NANTONG TRANSMISSION MACHINERY +1

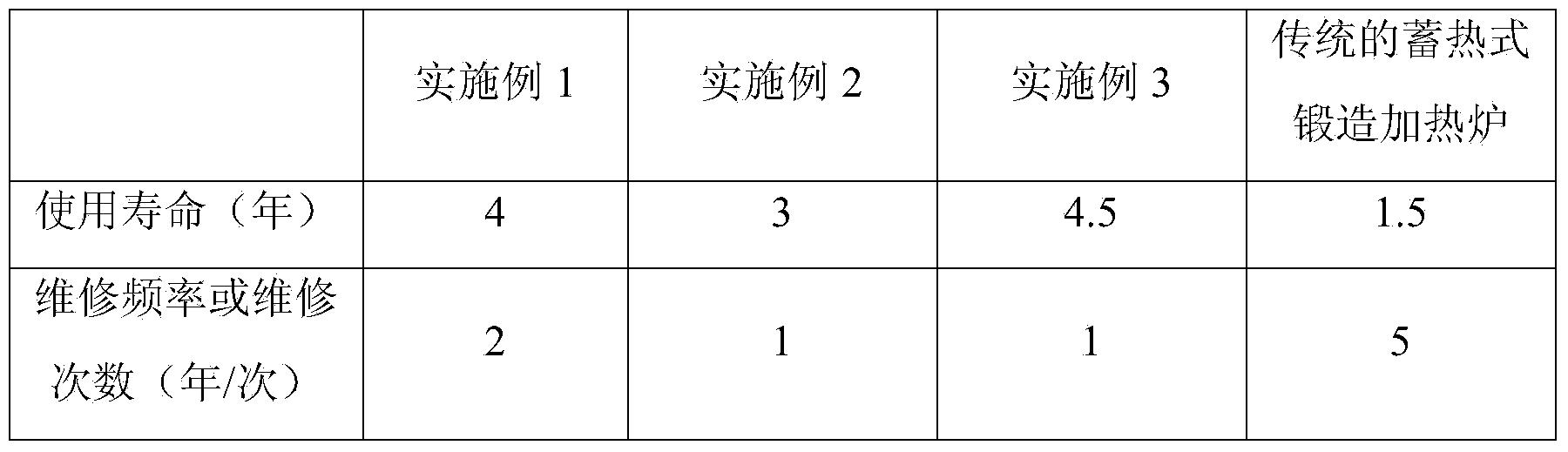

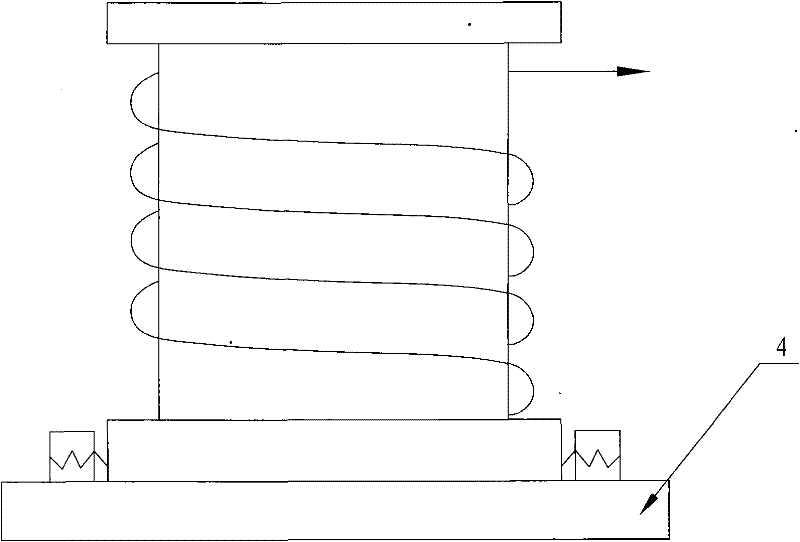

Method for manufacturing heat-storage forging heating furnace by utilizing quartzitic sandstone

ActiveCN103851916AExcellent physical and chemical propertiesHigh densityMonolithic liningsStructure chartRefractory

The invention belongs to the technical field of the production method of a heating furnace, and particularly relates to a method for manufacturing a heat-storage forging heating furnace by utilizing quartzitic sandstone, which aims at solving the technical problems of the existing refractory material heating furnace that the service life is short, the repairing frequency is high, the energy consumption is high, the cost is large, the high-temperature strength is low, the high-temperature anticorrosion capacity is poor, a furnace body is likely to fracture and even to explode and collapse, and the like. The invention provides the method for manufacturing the heat-storage forging heating furnace by utilizing the quartzitic sandstone. The method comprises the following steps of manufacturing a forging heating furnace by utilizing the quartzitic sandstone according to a furnace body structure chart, drying the furnace after the furnace is molded, wherein the heating speed for drying the furnace is 5 to 10 DEG C per hour, and the final drying temperature is 1100 to 1400 DEG C. The novel method is provided for manufacturing the heat-storage forging heating furnace.

Owner:CHENGDU SHUANGLIU HENGSHENG FORGING

Hydrostatic test device used for large-diameter thick-wall pipe joint and hydrostatic test method thereof

InactiveCN102384873ASave rough materialReduce forging costFlanged jointsMaterial strength using tensile/compressive forcesThick wallWeld line

The invention discloses a hydrostatic test device used for a large-diameter thick-wall pipe joint and a hydrostatic test method thereof. When the large-diameter thick-wall pipe joint is forged, a pipe joint bulge part is forged at the inner diameter of the pipe joint; a closing plate is welded on the bulge part; a gap between the bulge and the closing plate is subjected to seal welding; because the bulge and the pipe joint are integral, big action force can be borne so as to prevent the closing plate from flying out because of overlarge pressure; at the time, a welding line only play the effect of sealing, and welding height is far smaller than the welding height in the traditional hydrostatic test device, thereby greatly lowering welding cost; then, the hydrostatic test is carried out; after the hydrostatic test is finished, the bulge is cut off; and then, the inner wall of the pipe joint at the position where the bulge is arranged is machined to a designed size. Therefore, the hydrostatic test is safely finished, material is saved, the forging cost of the pipe joint is lowered, the welding cost of the closing plate is lowered, the preparation period of the hydrostatic test is shortened, and production cost is lowered.

Owner:SHANGHAI BOILER WORKS

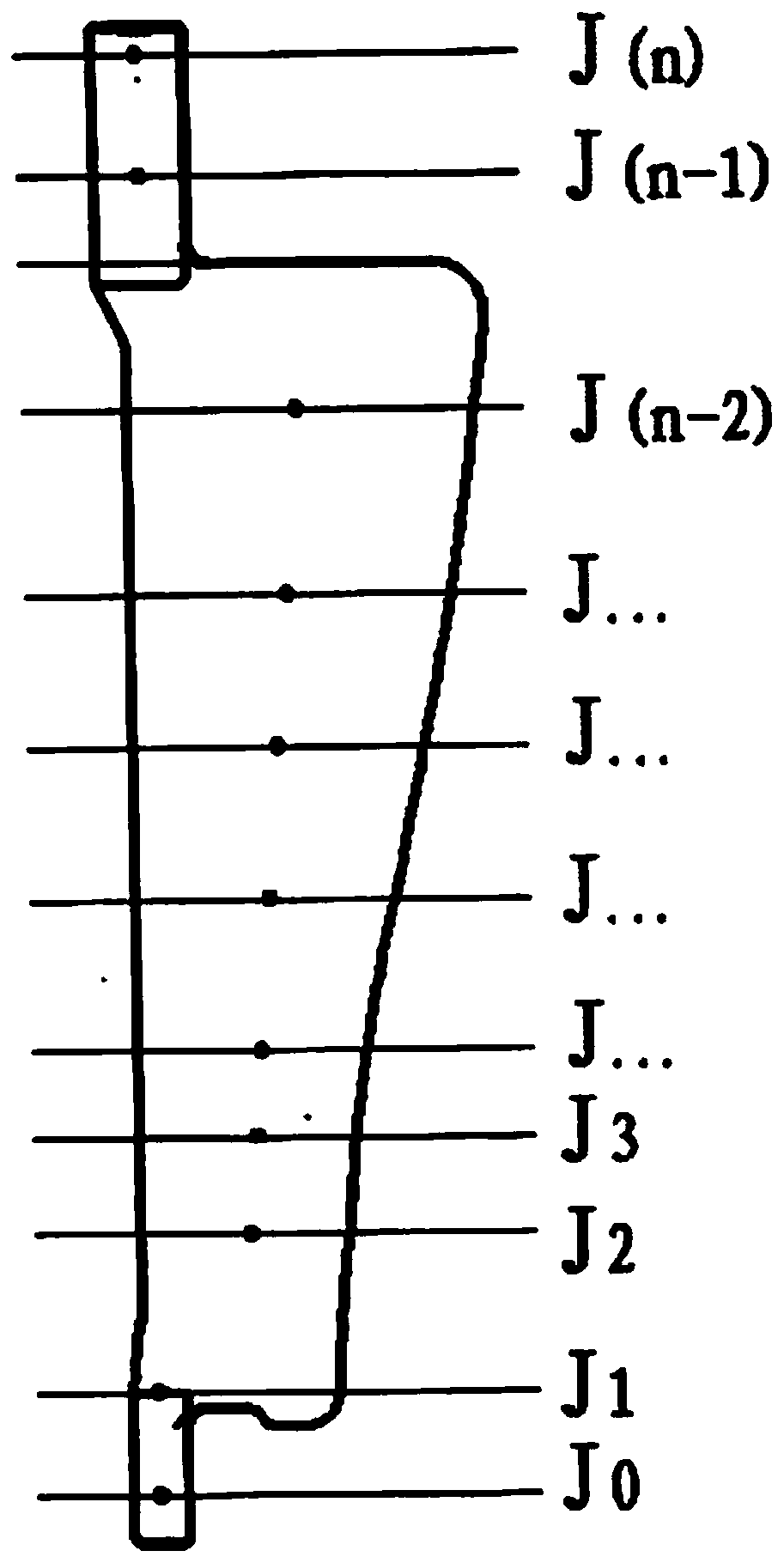

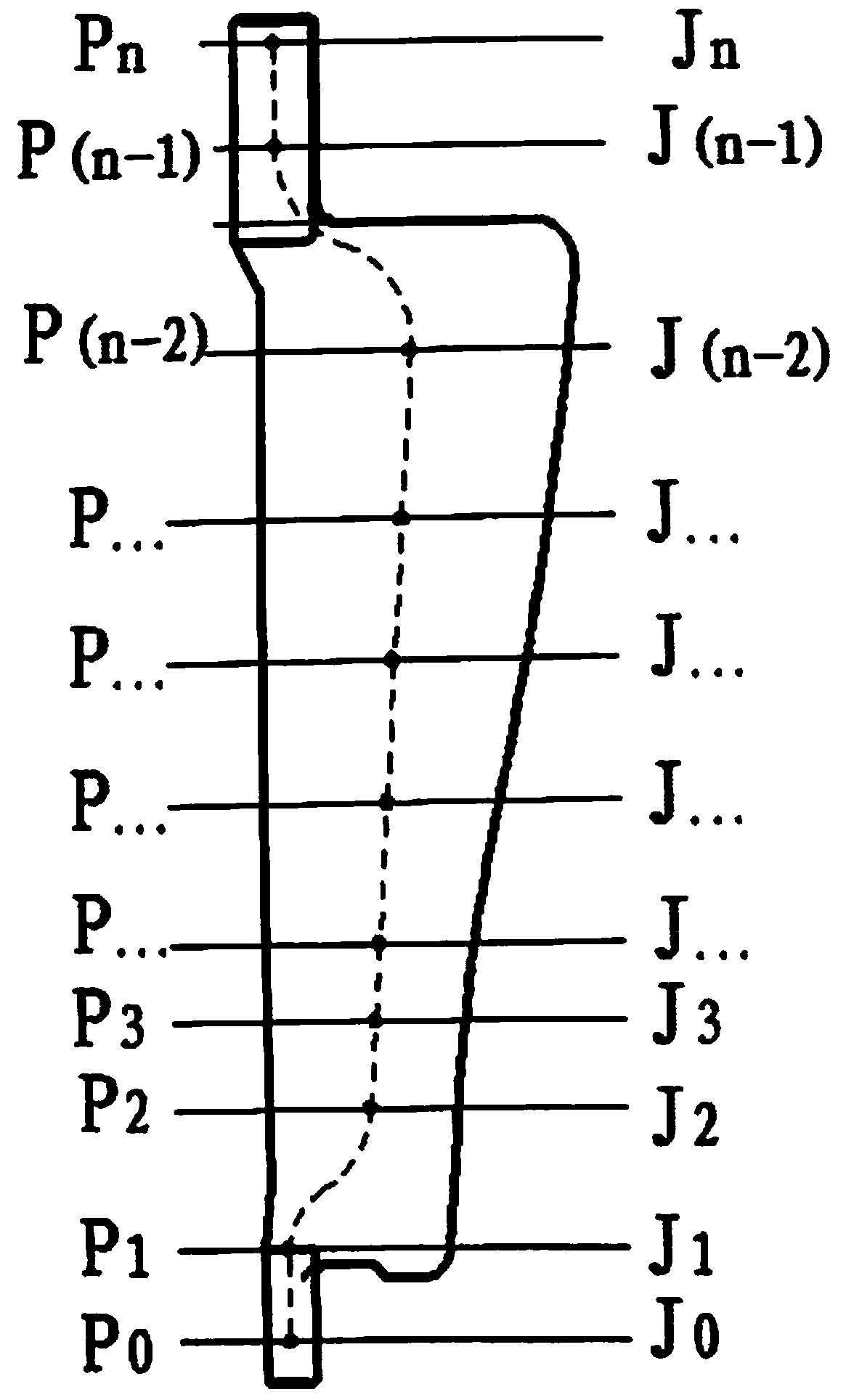

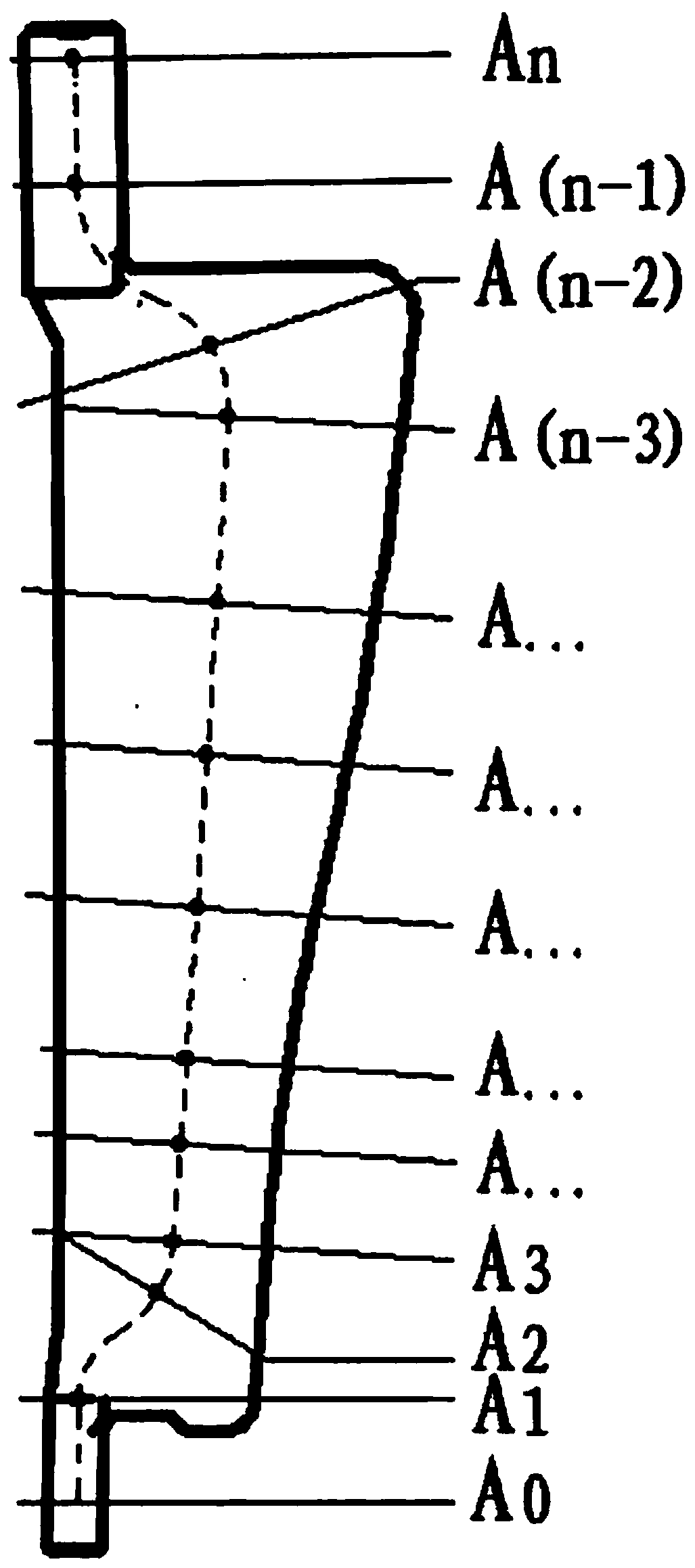

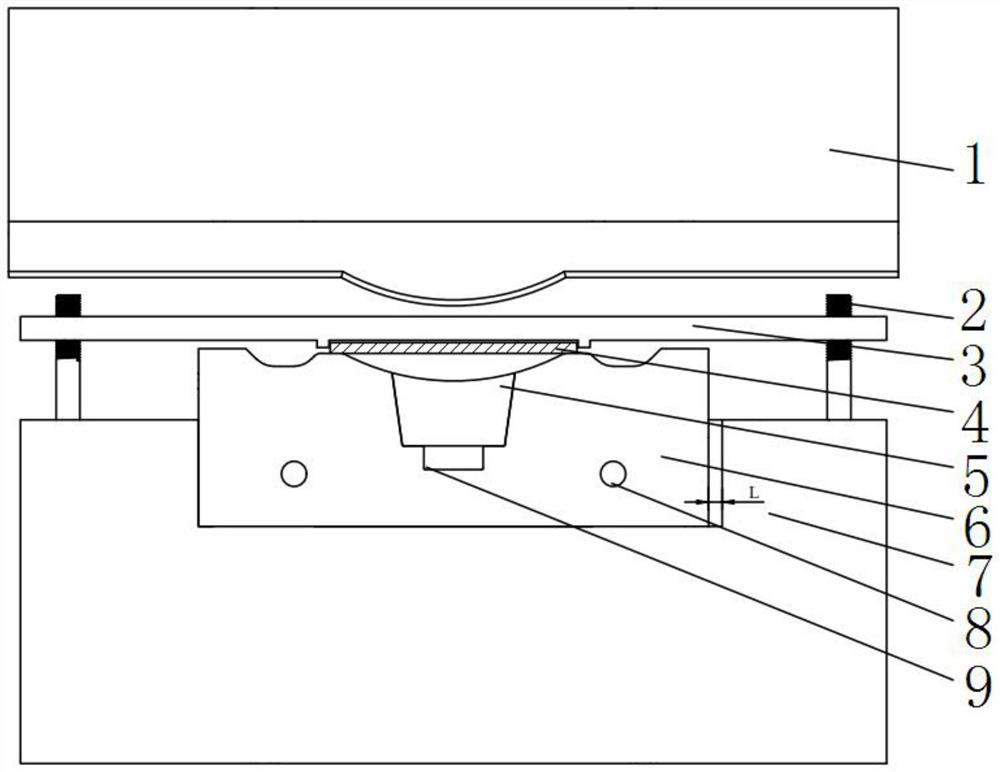

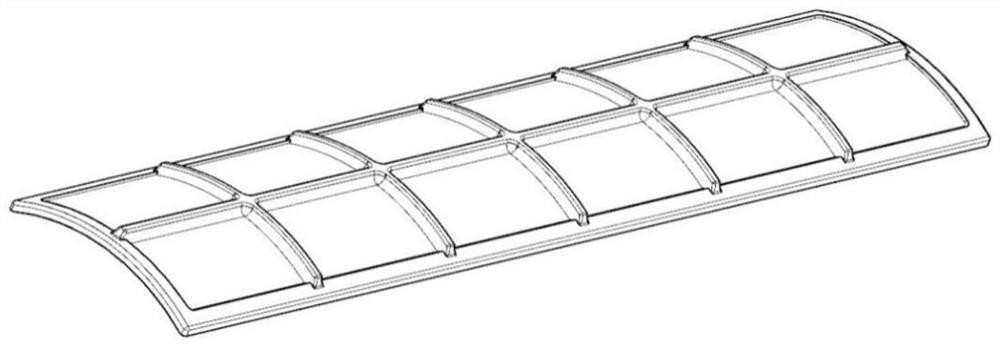

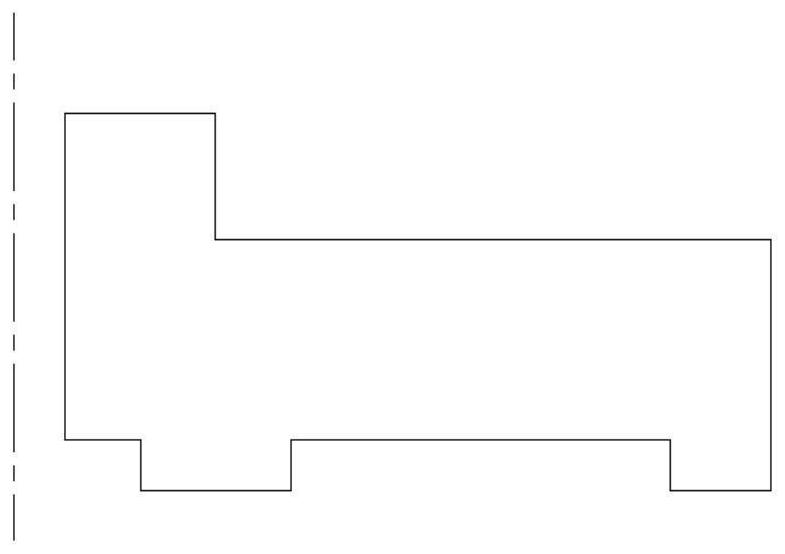

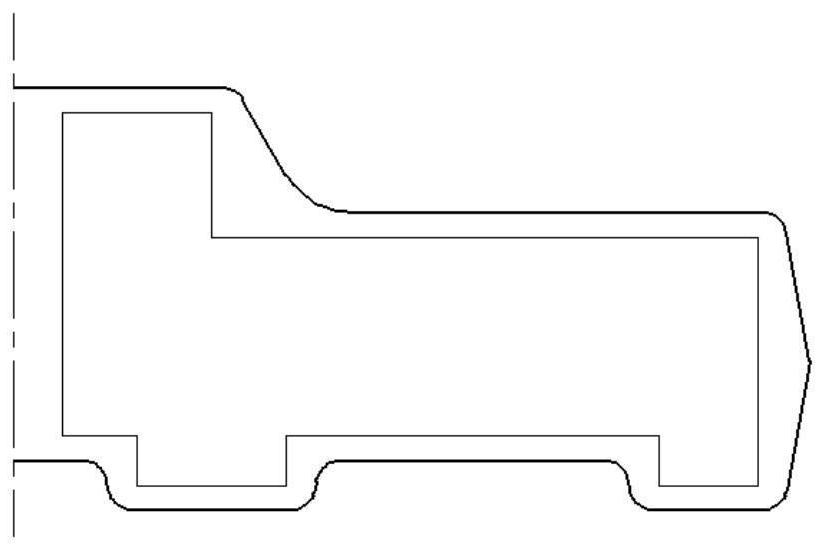

Progressive loading precision forming die device and process method for complex component of ultra-long grid high-rib wall plate

ActiveCN111872300ASave mold materialsReduce forging costForging/hammering/pressing machinesHeating/cooling devicesMachine pressMesh grid

The invention discloses a progressive loading precision forming die device and process method for a complex component of an ultra-long grid high-rib wallboard, and relates to the technical field of hot working. The progressive loading precision forming die device comprises an upper die and a lower die, and a punch is arranged on the upper die; and the lower die comprises an insert, a die core anda die holder, an installation groove is formed in the upper surface of the die holder, the die core is installed in the installation groove in a sliding mode, and the insert is installed on the uppersurface of the die core. According to the device and method, through horizontal sliding of the die core on the die holder, local progressive loading of a forging on a single-action press is realized,the die size is reduced, and the folding defect caused by overall loading is avoided.

Owner:HARBIN INST OF TECH +1

Ceramic forging method

PendingCN113650168AReduce forging costImprove deformation abilityCeramic shaping apparatusWorking accessoriesLarge deformationMaterial Deformation

The invention relates to a ceramic forging method, and belongs to the technical field of ceramic preparation. The ceramic forging method comprises the following step that oscillating pressure is applied on to-be-forged ceramic at the forging temperature for forging. According to the ceramic forging method, the deformation mechanism of a ceramic material at the high temperature is changed under the oscillating pressure, the deformation capacity and the deformation rate of the ceramic material are improved, generation of micro fatigue in the ceramic material and the material deformation process are greatly improved, then the ceramic material can reach the higher deformation rate and the larger deformation amount at the lower temperature and pressure, and therefore ceramic forging can be achieved, and the cost is greatly reduced. In addition, through the deformation process generated by oscillating pressure forging, improvement of the relative density and strengthening of the performance of the ceramic material can be achieved, and forging forming of ceramic components in certain shapes and sizes can be achieved.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Preparation method of large-size corrosion-resistant Ti35 alloy forge piece

ActiveCN112692204AImprove tissue uniformitySmall sizeMetal-working apparatusRecycling and recovery technologiesIngotTitanium alloy

The invention discloses a preparation method of a large-size corrosion-resistant Ti35 alloy forge piece. The method comprises the steps of 1, performing high-temperature blooming forging on a Ti35 alloy cast ingot to obtain a first forge piece; 2, performing primary medium-temperature forging on the first forge piece to obtain a second forge piece; 3, performing low-temperature forging on the second forge piece to obtain a third forge piece; 4, performing secondary medium-temperature forging on the third forge piece to obtain a fourth forge piece, and forming to obtain a formed forge piece; and 5, performing short-time annealing heat treatment on the formed forge piece, and obtaining the Ti35 alloy forge piece after air cooling. According to the method, a high-temperature forging process, a medium-temperature forging process, a low-temperature forging process and a medium-temperature forging process are sequentially adopted for the Ti35 alloy cast ingot, and medium-temperature annealing is combined, so that as-cast coarse grains are refined by improving the recrystallization degree of the forge piece, the structure uniformity of the Ti35 alloy forge piece is improved, then the size of the Ti35 alloy forge piece is increased, and the urgent requirements of the Ti35 titanium alloy large-size forge piece for components, structure uniformity and the flaw detection grade A requirement at present are met.

Owner:西安稀有金属材料研究院有限公司

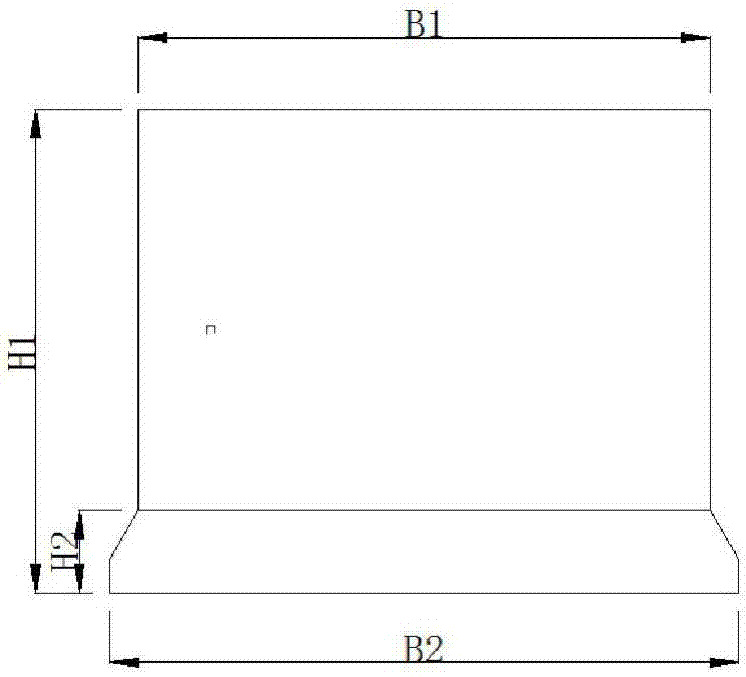

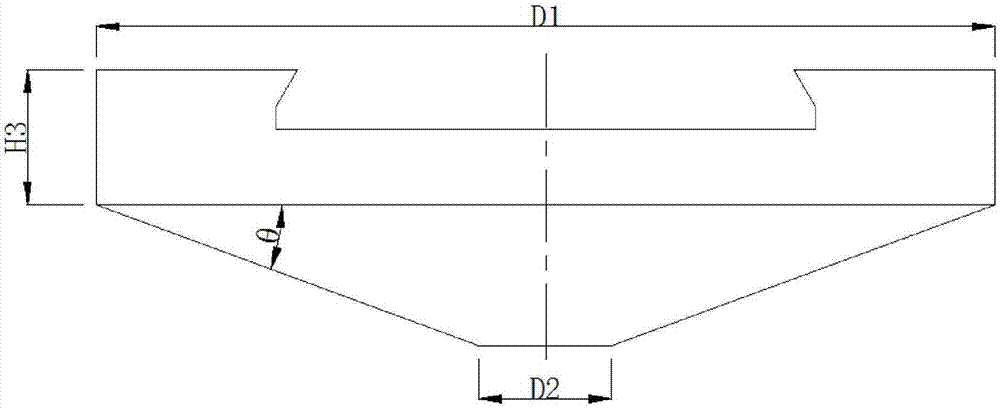

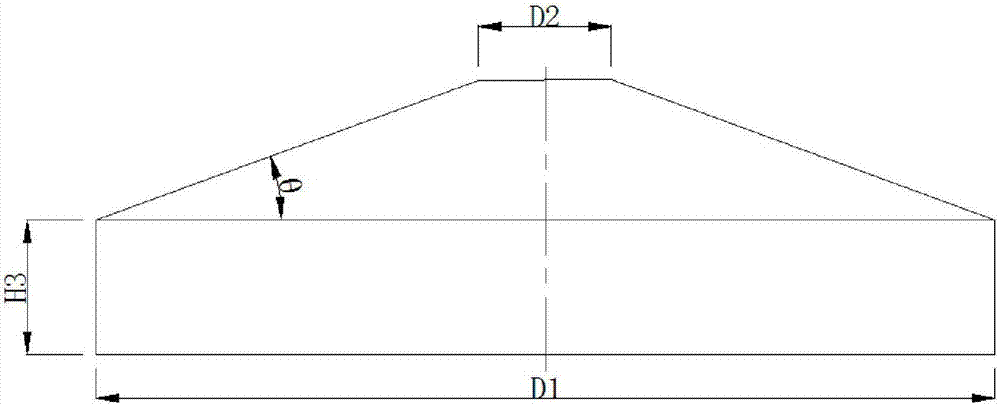

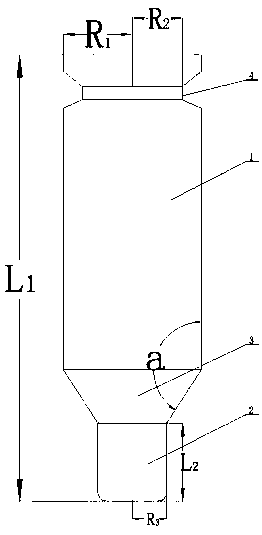

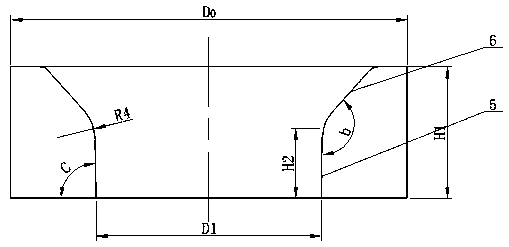

Free forging method for central hollow trapezoidal forged piece

ActiveCN105728616ASettlement feeGuaranteed Streamline RequirementsMetal-working apparatusMaterials scienceForging

The invention discloses a free forging method for a central hollow trapezoidal forged piece. The problem of the streamline and the problem of the high cost in the forging process of the central hollow trapezoidal forged piece are solved by means of an effective tool through the free forging method. In this way, the streamline requirement of the central hollow trapezoidal forged piece is met, and the forging cost of the central hollow trapezoidal forged piece is reduced.

Owner:SHAANXI HONGYUAN AVIATION FORGING

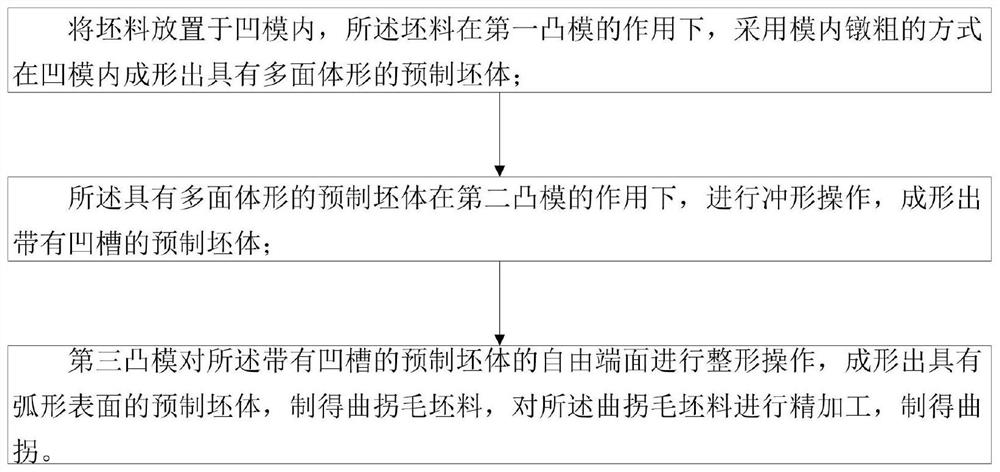

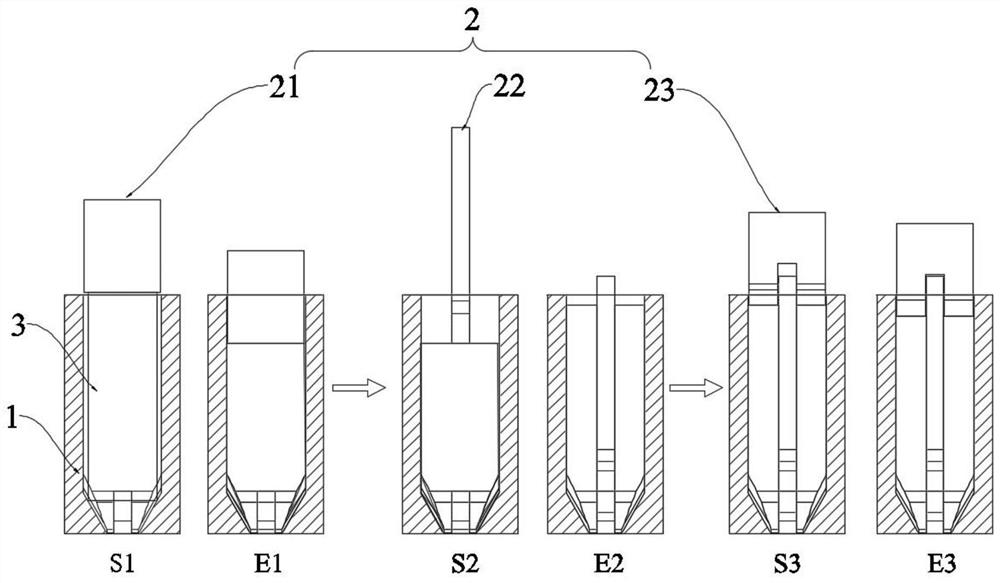

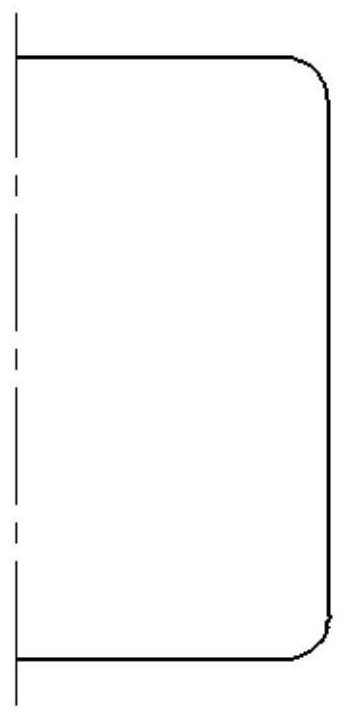

Marine crank throw die forging forming method and die

ActiveCN112676515ASmall forming forceEasy to shapeForging/hammering/pressing machinesEngine componentsPunchingForge

The invention provides a marine crank throw die forging forming method and die. The marine crank throw die forging forming die comprises a female die for die forging forming and a male die for in-die upsetting blank making, and a die cavity matched with a crank throw blank in contour shape is formed in the female die; and the male die comprises a first male die body, a second male die body and a third male die body, the first male die body is used for stretching into the die cavity to conduct in-die upsetting, the second male die body is used for stretching into the die cavity to conduct punching operation, and the third male die body is used for stretching into the die cavity to conduct shaping operation. According to the die, the male die bodies used in all stages are designed separately and used in a segmented mode, the crank throw die forging forming force can be obviously reduced, die forging forming of crank throw forge pieces can be completed through a ten-thousand-ton press, the crank throw die forging cost is reduced, the shapes of the formed crank throw forge pieces are more ideal, the machining allowance of die forging crank throws is reduced, and the manufacturing cost is further reduced.

Owner:CHINA FIRST HEAVY IND +1

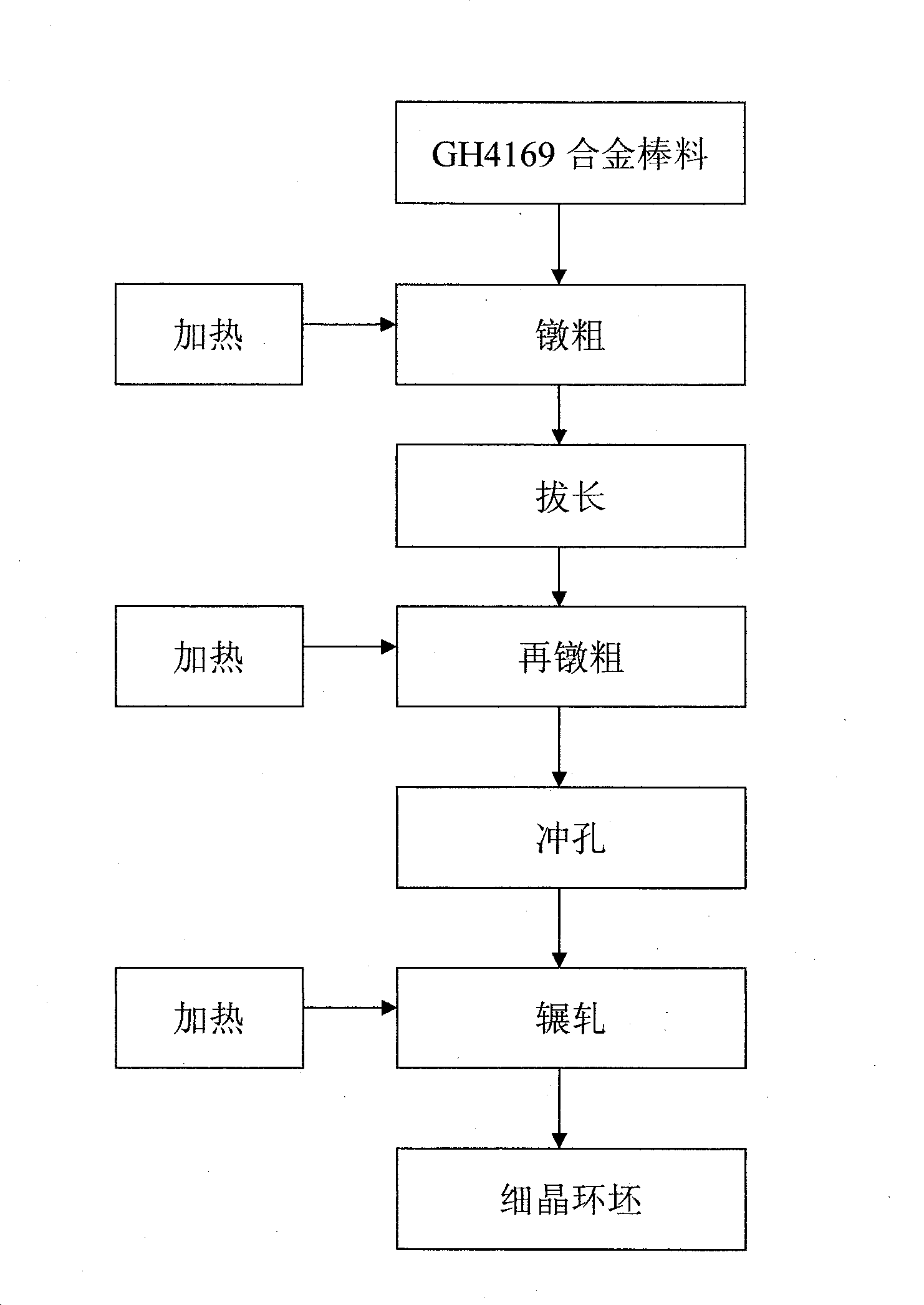

Process of making ring fine crystal blank of GH4169 alloy for near constant temperature forging

The technological process of making ring fine crystal blank of GH4169 alloy for near constant temperature forging includes the following steps: heating the GH4169 alloy rod to 980-1010 deg.c, upsetting into the first cake blank of thickness in 1 / 3-1 / 2 the rod height, drawing the cake blank to secondary rod of original height, heating the secondary rod to 980-1010 deg.c, upsetting into the secondary cake blank of thickness in 1 / 3-1 / 2 the rod height, punching hole in the secondary cake blank, heating the cake blank to 980-1010 deg.c, and rolling to obtain ring fine crystal blank of 35-45 % deformation. The ring fine crystal blank may be near constant temperature forged into forging with fine crystal grains.

Owner:GUIZHOU ANDA AVIATION FORGING

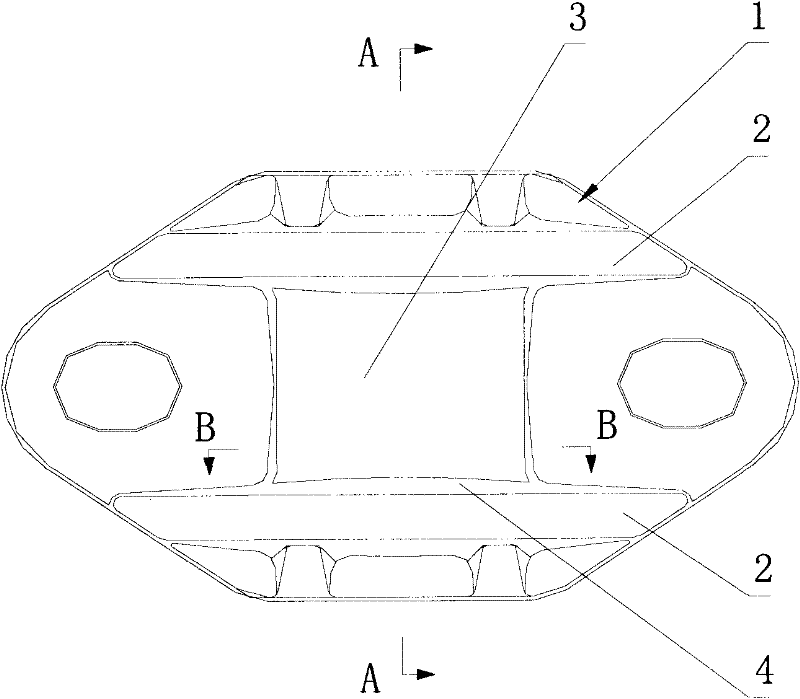

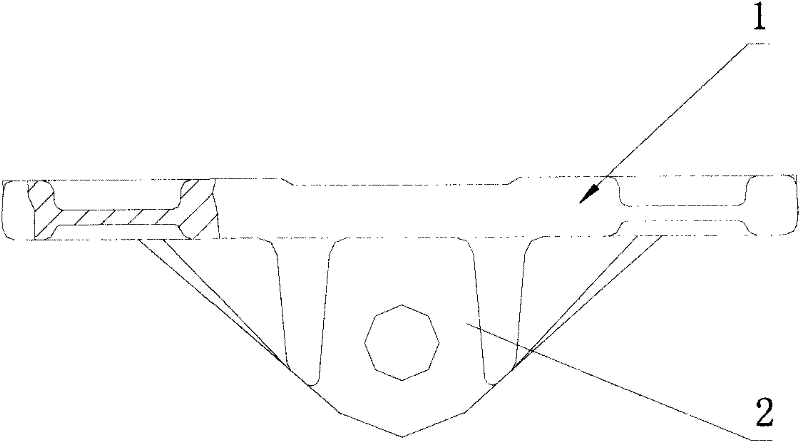

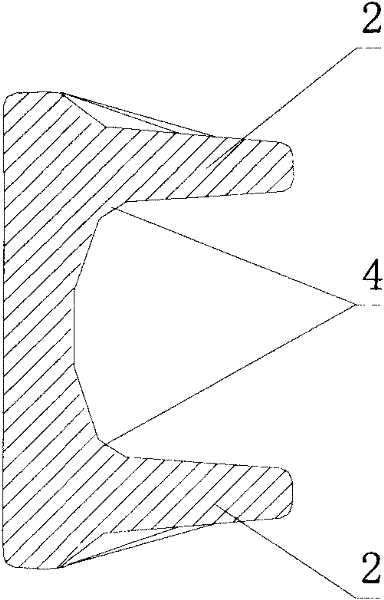

Lower cantilever base for support seat of railway line contact network

The invention discloses a lower cantilever base for a support seat of a railway line contact network. The whole lower cantilever base is an integrated die forging. On a base body, a boss is arranged between two installation plates; the surface of the boss is an indent and arc curved surface; the axis line of the indent and arc curved surface is parallel to the installation plates; and a circular arc transmission mode is adopted by the connection part of the boss and the installation plates. The lower cantilever base is manufactured in a die forging mode, so that the mechanical properties such as intensity, rigidity and the like of the lower cantilever base are greatly improved; when the curved surface with radian of R45 to 80 mm and the circular arc with radian of R5 to 15 mm are stressed, the force can be quickly transferred to the base body, the crack is prevented from generating on the curved surface under the condition that the shaking is enhanced, the service life of the lower cantilever base is prolonged and the replacement and maintenance cost is reduced; simultaneously, the implementation of the die forging mode is facilitated and the forging cost is reduced; and the lower cantilever base has a reasonable structure, and high intensity, and meets the requirements of the safety travelling of rapid trains which have a speed per hour of 250 to 350h / km or have a higher speed; and the travelling safety coefficient of the rapid trains is high.

Owner:CHONGQING ZHONGCHENG PRECISION DIE FORGING

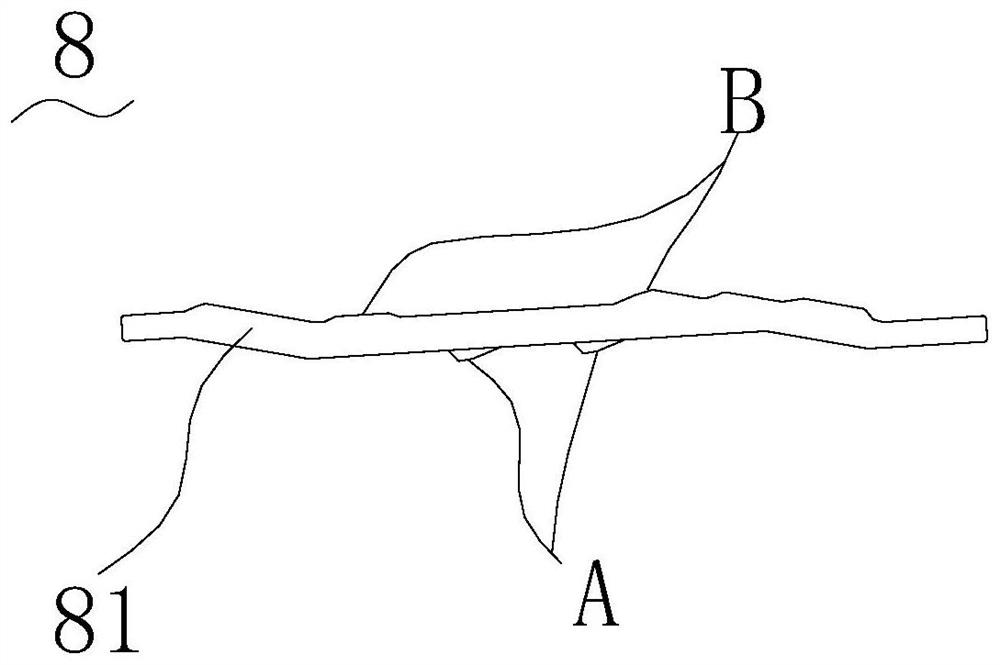

Forming method of thin web forge piece

PendingCN114799004AQuality improvementSimple methodMetal-working apparatusEngine componentsIndustrial engineeringManufacturing engineering

The forming method of the thin web type forge piece is simple, the production period can be shortened, the forging cost can be reduced, and the forge piece quality can be improved. The forming method of the thin web type forge piece comprises the steps that blank manufacturing is conducted, specifically, a bar is drawn out according to the length of the forge piece, and a cylindrical rough blank is manufactured; pre-forging is conducted, specifically, a rough blank is laid in a pre-forging lower cavity, the side face of the rough blank is made to be matched with a positioning groove, the position of the rough blank is determined, then a pre-forging die upper die moves downwards, the pre-forging lower cavity and a pre-forging upper cavity are made to be matched to flatten the rough blank till a pre-forging cavity is filled with materials, and a plate-shaped pre-forged piece with a rib structure A initial blank on one side is obtained; and finish forging is conducted, specifically, the pre-forged piece is placed in a finish forging lower cavity, the initial blank of the rib structure A of the pre-forged piece is made to be matched with the forming groove of the rib structure A, the pre-forged piece is positioned, an upper die of a finish forging die moves downwards, the finish forging lower cavity and a finish forging upper cavity are made to be matched to flatten the pre-forged piece till the finish forging cavity is filled with materials, and therefore the forged piece is obtained.

Owner:中国第二重型机械集团德阳万航模锻有限责任公司

High strain rate forming of dispersion strengthened aluminum alloys

InactiveUS8323428B2Increase speedReduce the number of stepsShaping toolsPump componentsToughnessImpurity

Dispersion strengthened aluminum base alloys are shaped into metal parts by high strain rate forging compacts or extruded billets composed thereof. The number of process steps required to produce the forged part are decreased and strength and toughness of the parts are increased. The dispersion strengthened alloy may have the formula Albal,Fea,SibXc, wherein X is at least one element selected from Mn, V, Cr, Mo, W, Nb, and Ta, “a” ranges from 2.0 to 7.5 weight-%, “b” ranges from 0.5 to 3.0 weight-%, “c” ranges from 0.05 to 3.5 weight-%, and the balance is aluminum plus incidental impurities. Alternatively, the dispersion strengthened alloy may be described by the formula Albal,Fea,SibVdXc, wherein X is at least one element selected from Mn, Mo, W, Cr, Ta, Zr, Ce, Er, Sc, Nd, Yb, and Y, “a” ranges from 2.0 to 7.5 weight-%, “b” ranges from 0.5 to 3.0 weight-%, “d” ranges from 0.05 to 3.5 weight-%, “c” ranges from 0.02 to 1.50 weight-%, and the balance is aluminum plus incidental impurities. In both cases, the ratio [Fe+X]:Si in the dispersion strengthened alloys is within the range of from about 2:1 to about 5:1.

Owner:HONEYWELL INT INC

Method for controlling forging deformation of complex plate-like die forging

ActiveCN111790862AReduce the amount of designLarge amount of deformationWheelsStructural engineeringIndustrial engineering

The invention discloses a method for controlling forging deformation of a complex plate-like die forging. By setting step structures on a preform model and a final forging model, when the forging is formed, about the step structure corresponding to a final forging forming die and the step structure provided on the preform model, two or more deformation fulcrums are formed between the final forgingforming die and the perform at the corresponding step structure position. By providing a plurality of deformation fulcrums on an insufficient deformation area, the deformation amount of the insufficient deformation area can be greatly increased when forming the perform, thereby greatly reducing the design amount of the forging remaining blocks, reducing the raw materials required for the forging,and reducing the forging cost while ensuring the deformation amount during the forming process of the forging.

Owner:SICHUAN ENG TECHN COLLEGE +1

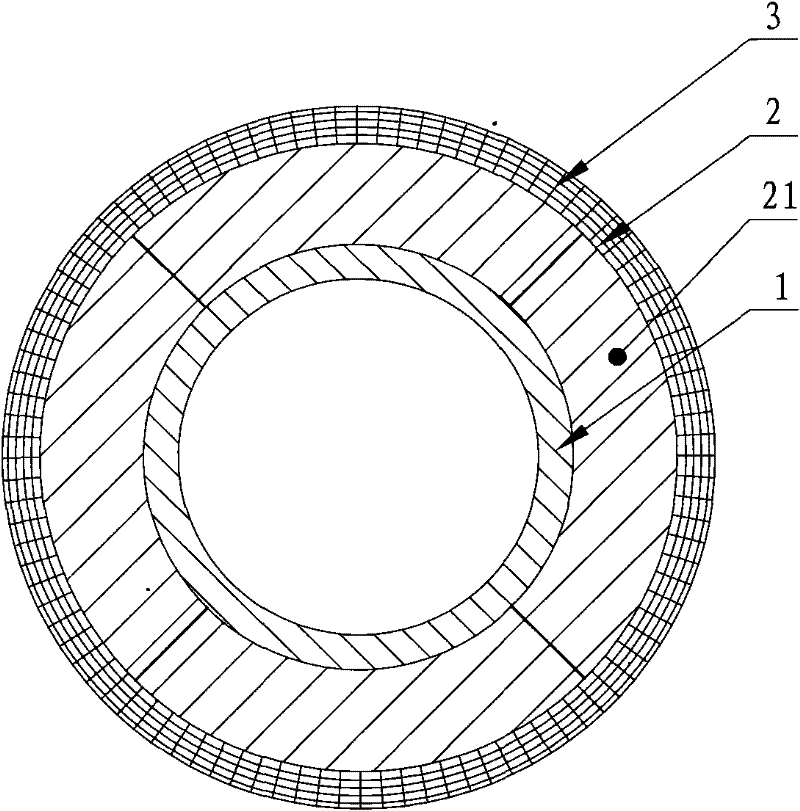

Combined heavy-duty prestressed oil cylinder split along the busbar and its manufacturing method

The invention discloses a manufacturing method of a combined heavy-duty prestressed oil cylinder split along a bus bar. A processing method of the oil cylinder comprises the following steps of: performing forging, rough processing and semi-finishing on a steel ingot to obtain an inner layer barrel which is consistent with a requirement; processing a middle layer component; detachably and fixedly connecting the inner layer barrel with the middle layer component; performing finish machining on the outer diameter of the inner layer according to the inner diameter of the middle layer; splicing the middle layer component on the outer side of the inner layer (outer cylindrical surface); and winding and fastening the outer side of the middle layer with a steel wire. By adopting the combined heavy-duty prestressed oil cylinder, the tangential prestressing force of the barrel is enhanced, the axial bending of the barrel is reduced, and the barrel is prevented from being damaged by excessive bending stress. The barrel produced with the manufacturing method has short manufacturing cost and period, is safe and reliable, has long service life, and can be manufactured in medium and small machinery factories.

Owner:KUNSHAN YONGNIAN ADVANCED MFG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com