Lower cantilever base for support seat of railway line contact network

A catenary and support seat technology, applied in overhead lines and other directions, can solve problems such as poor structure and strength, high replacement and maintenance costs, and affect the safety of trains, so as to achieve reasonable structure, reduce replacement and maintenance costs, and extend the effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

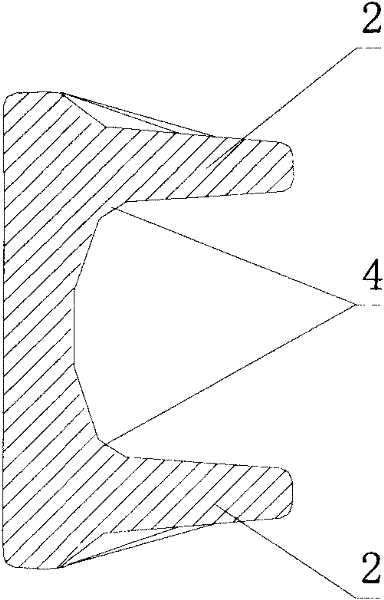

[0020] like Figure 5 As shown, a lower arm base of a route catenary support seat, the lower arm base is an integrated die forging as a whole. The die forging is obtained by deforming a blank using a die. During die forging, the pipe or bar is placed in the die forging cavity, and then radial pressure is continuously applied to achieve the deformation of the metal. The method of pressure die forging can be used, that is, the forging method of obtaining forgings by using dies to form blanks on die forging equipment (hammer die forging, crank press die forging, flat forging machine die forging or friction press die forging, etc.) , the integrated die forging can not only save metal and realize precision forging, but also requires equipment with simple structure, low cost and convenient maintenance.

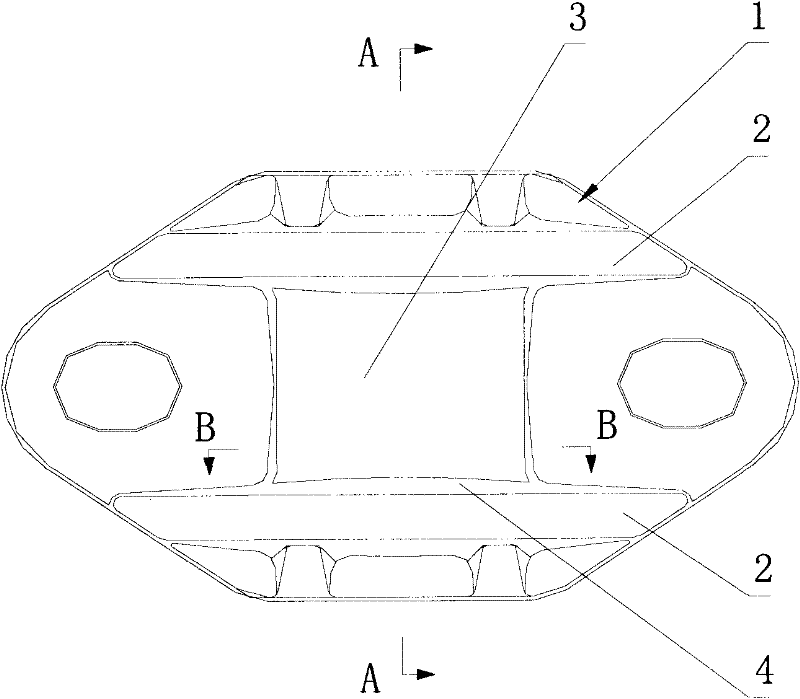

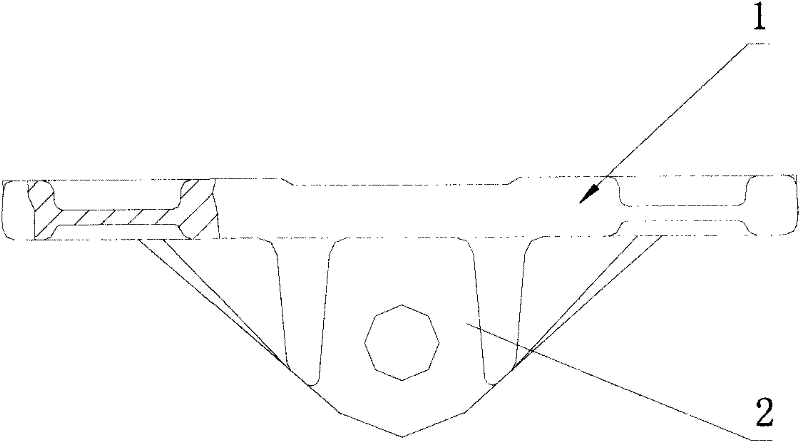

[0021] like Figure 1 to Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com