Blade forging preformed blank design method capable of accurately controlling material flow distribution

A material flow, precise control technology, applied in design optimization/simulation, manufacturing tools, metal processing equipment, etc., can solve the problems of increased material cost and forging cost, difficult to achieve, etc., to improve material utilization, reduce forging cost, The effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

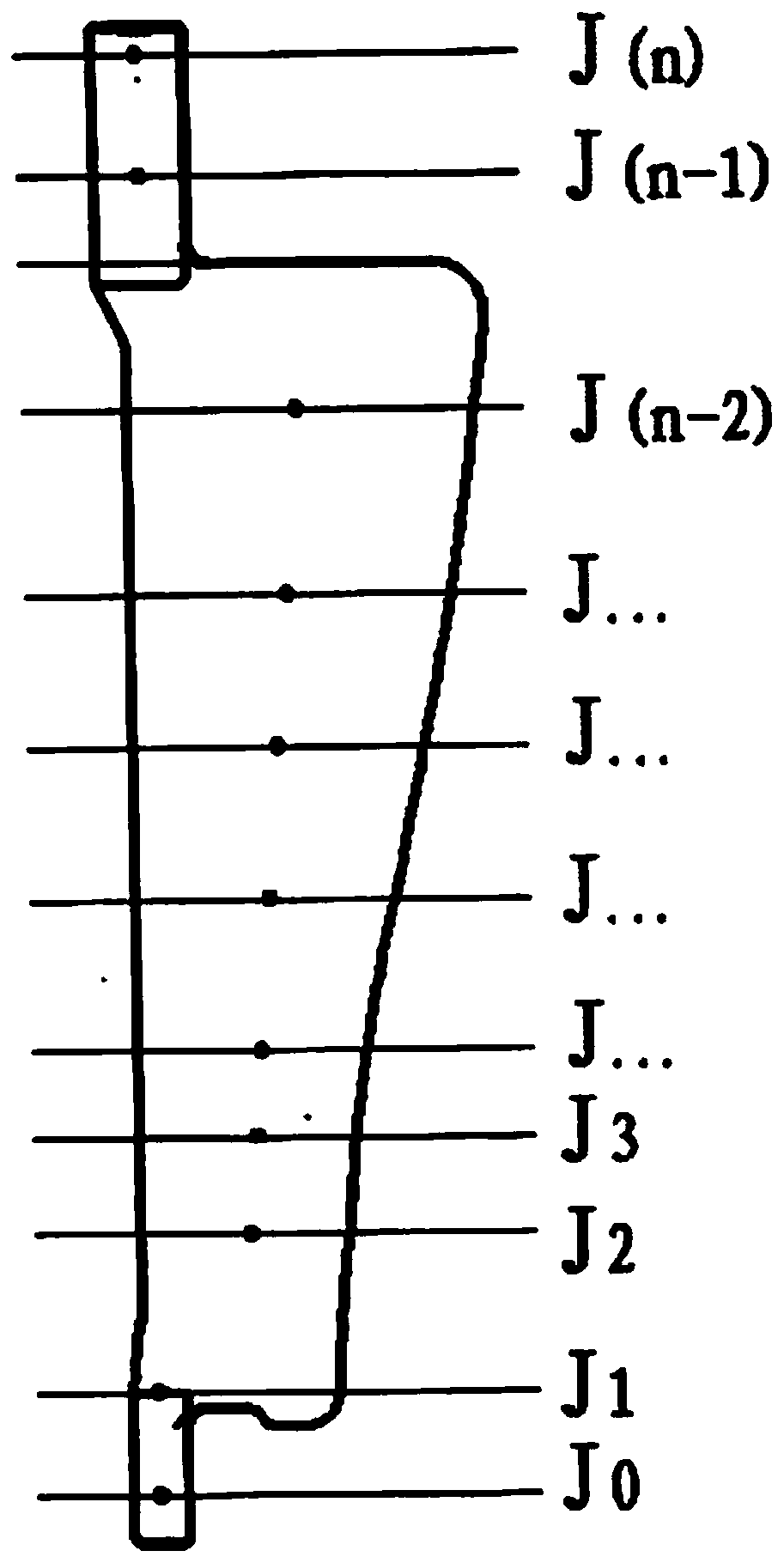

[0036] Step 1: Determine the forging direction of the forging, use 3D software, such as UG, to project the outline of the forging onto the 2D image on the forging surface, and perform horizontal segmentation in the 2D image. The number and position of the segmented segments depend on the structure and size of the forging. In principle, the divisions of the forgings with large changes are dense, and the more divisions, the more accurate the calculation results. After division, mark the midpoint of each division line, such as figure 1 As shown, from J 0 Split to J n , and point out the center point;

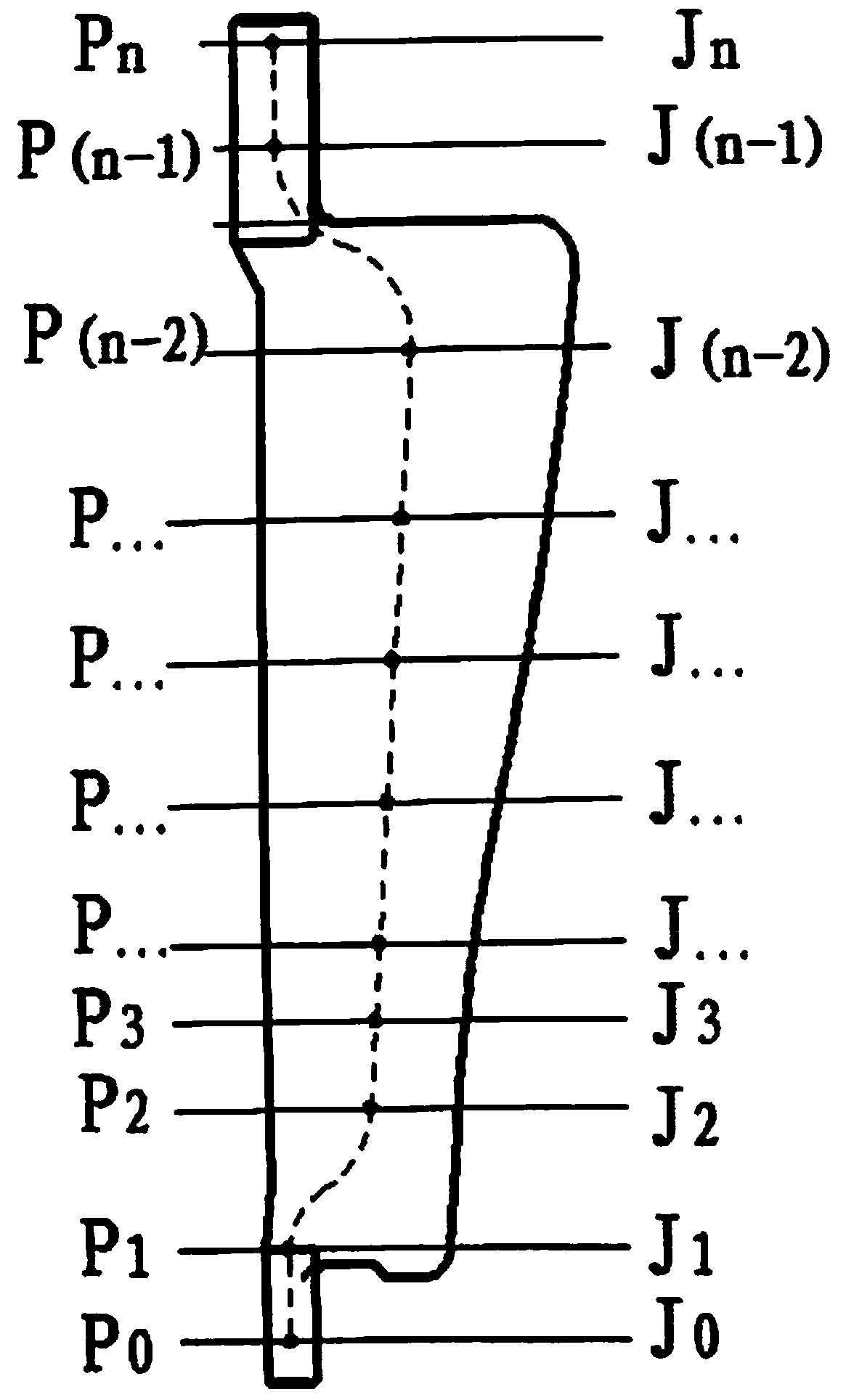

[0037] Step 2: Mark the center points obtained in Step 1 as P 0 -P n , make a spline through this set of center points, where P 2 -P (n-2) The curvature approximation of the spline line segment can simplify the line segment into a straight line for subsequent preform calculations, such as figure 2 shown;

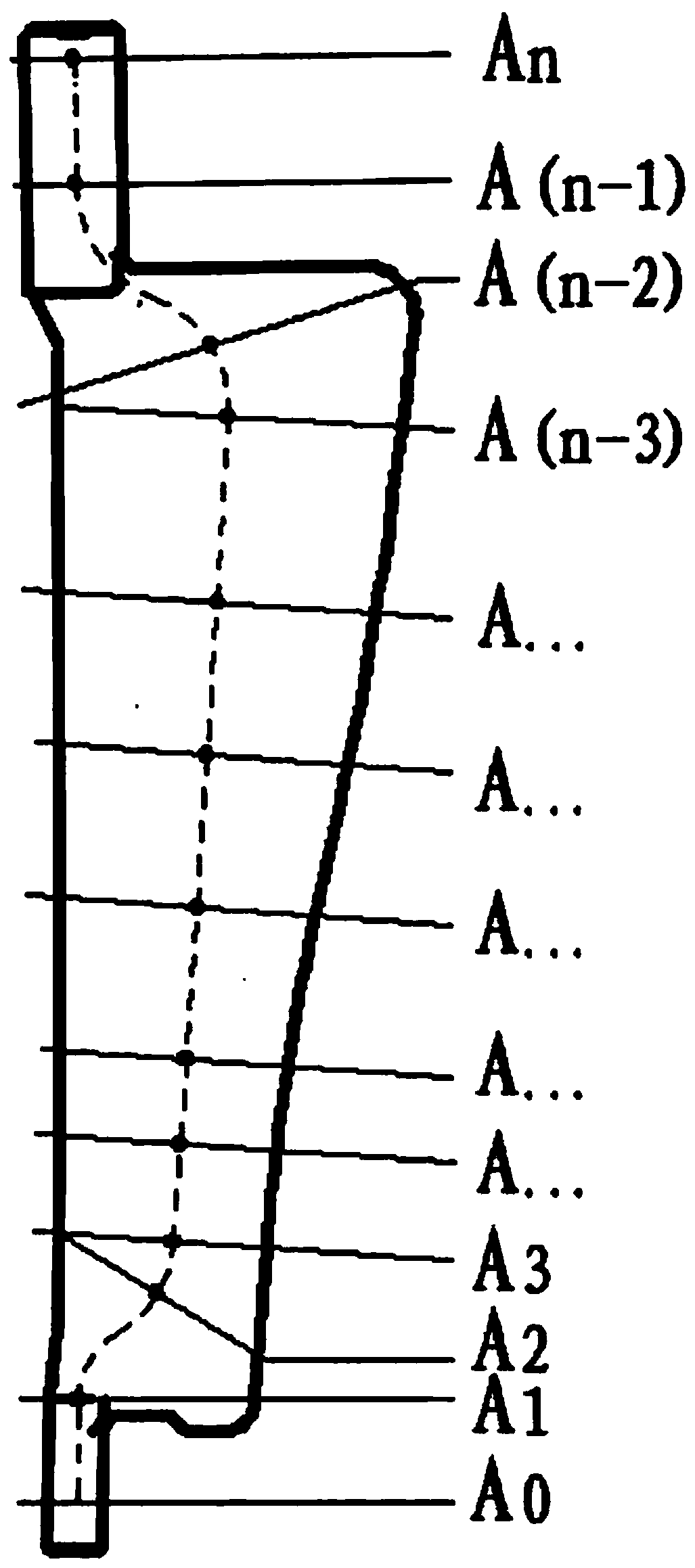

[0038] Step 3: Pass the center point in step 2 to make the normal ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com