Non-trimming closed type tyre die forging technological method of middle part punched black skin kind forged piece

A process method and a flash-free technology, applied in the field of forging technology, can solve the problems of increased raw material consumption, unsatisfactory filling, and increased cost of forgings, and achieve the effect of reducing the amount of machining, reducing the cost of forging, and saving the cost of raw materials and molds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] This specific embodiment takes forging an oil seal as an example. The oil seal is a black leather pie forging with a hole punched in the middle.

[0012] The non-flash closed tire die forging process method of the oil seal includes the preparation of the blank, putting the blank into the forging die for forging and pressing, first punching the surface of the blank, and then turning it over and putting it into the forging die for forging forming.

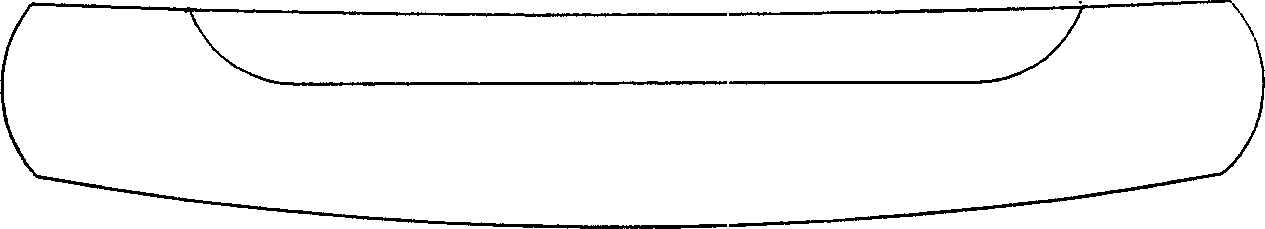

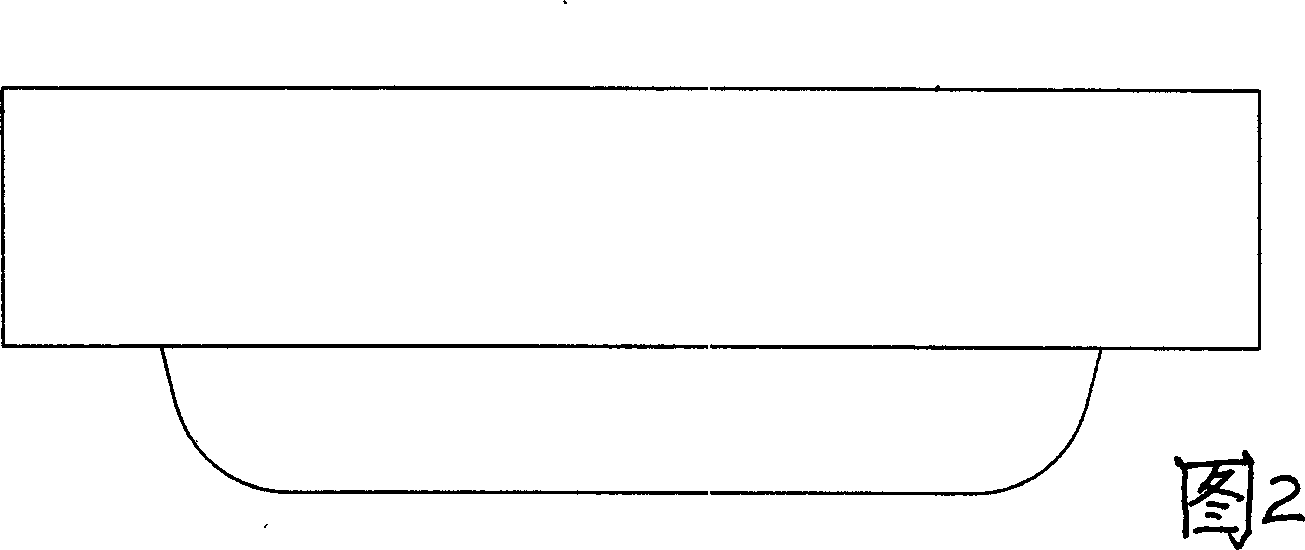

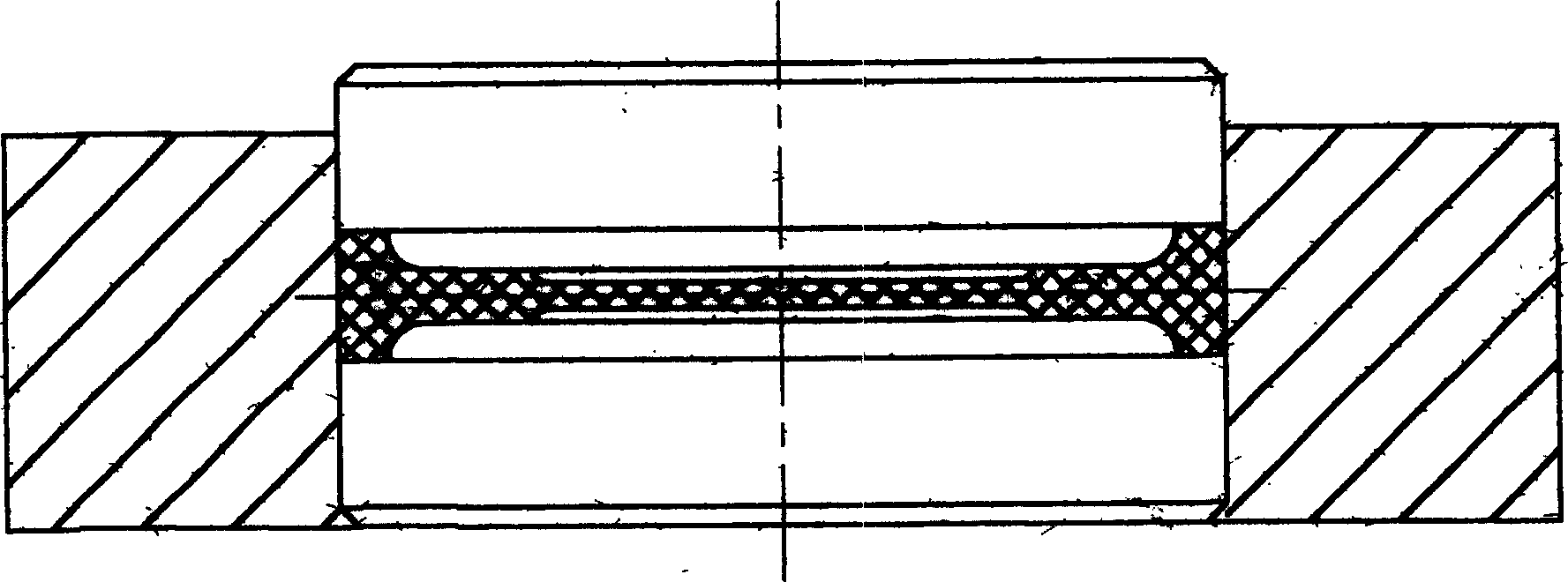

[0013] Using the billet mold shown in Figure 2 with known forging or stamping technology, the surface of the billet is punched and concaved to form figure 1 As shown in the punched blank, then turn the punched blank (that is, the punched downward) into the forging die for forging and forming (see attached image 3 ). Take out the formed forging, punch a hole in the middle part of the forging with known free forging equipment, and complete the final forming of the oil seal (see attached Figure 4 ).

[0014] The diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com