Patents

Literature

68results about How to "Reduced likelihood of cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly colorful tile joint mixture and preparation method thereof

ActiveCN103172330AReduce consumptionImprove early strengthSolid waste managementEmulsionShrinkage coefficient

The invention discloses an environment-friendly colorful tile joint mixture. The environment-friendly colorful tile joint mixture is characterized by comprising the following components in percentage by weight: 35%-40% of white cement, 40.73%-47.75% of waste porcelain powder, 0-15% of quartz powder, 0-10% of titanium dioxide, 1%-1.5% of re-dispersible emulsion powder, 0.1% of water repellent, 0.15% of water-retaining agent, 0.4% of lignin fiber, 0.1%-0.25% of water reducing agent and 0-2% of pigment. The invention further discloses a preparation method of the environment-friendly colorful tile joint mixture. The consumption of quartz sand and heavy calcium powder is reduced by using the waste porcelain powder as the joint mixture filler; the early strength of the joint mixture is improved by virtue of early strength function of the white cement, so that the construction process requirements are satisfied. The waste porcelain powder is sintered at a high temperature, so that the physical and chemical performances are stable, the volume is stable, and the expansion-shrinkage coefficient is close to that of the tile; the material with the same expansion-shrinkage coefficient is used as the filler, so that the possibility that the tile joint mixture generates cracks can be further reduced.

Owner:厦门路桥翔通股份有限公司

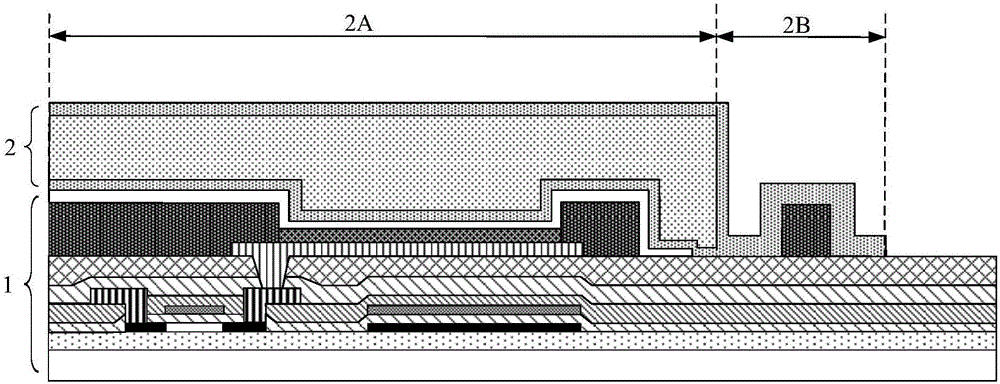

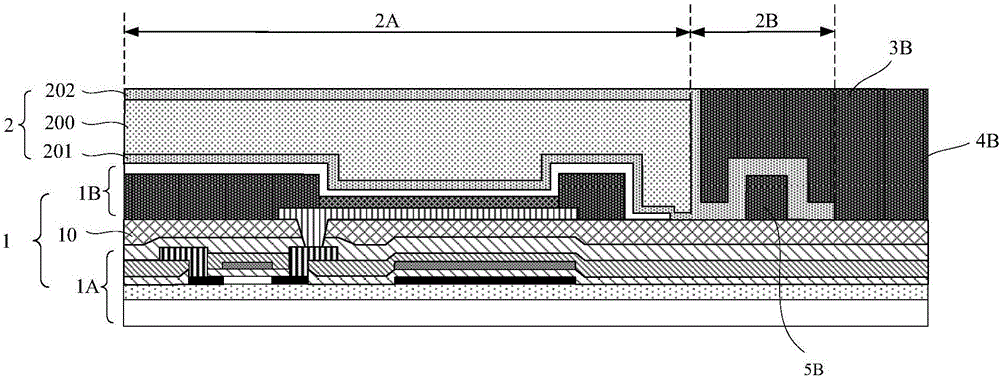

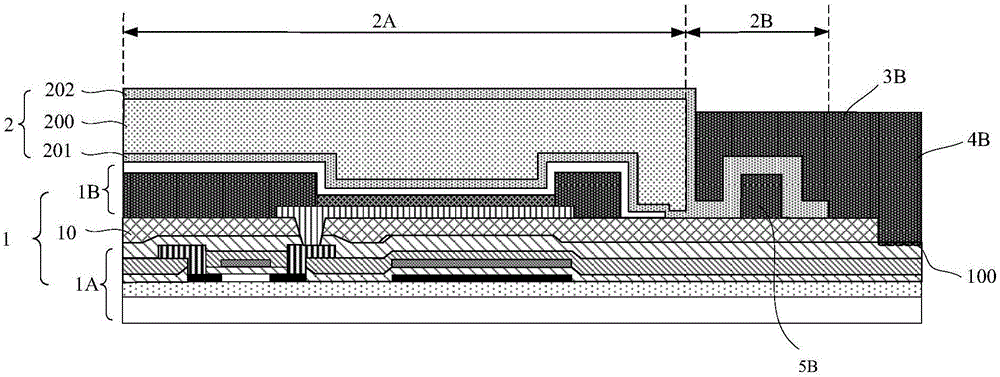

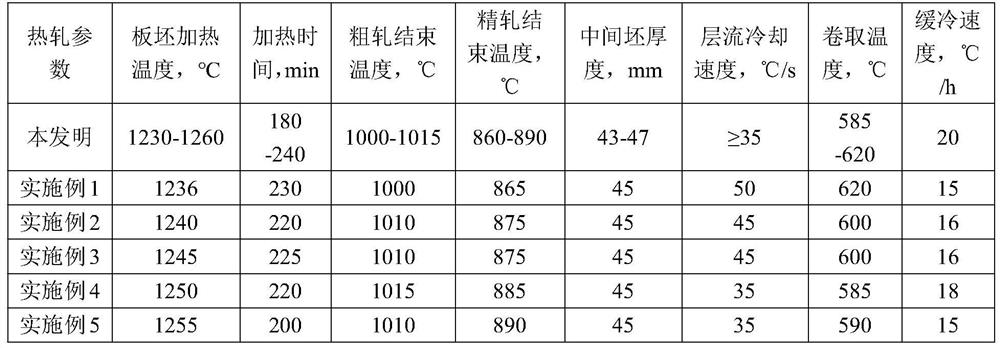

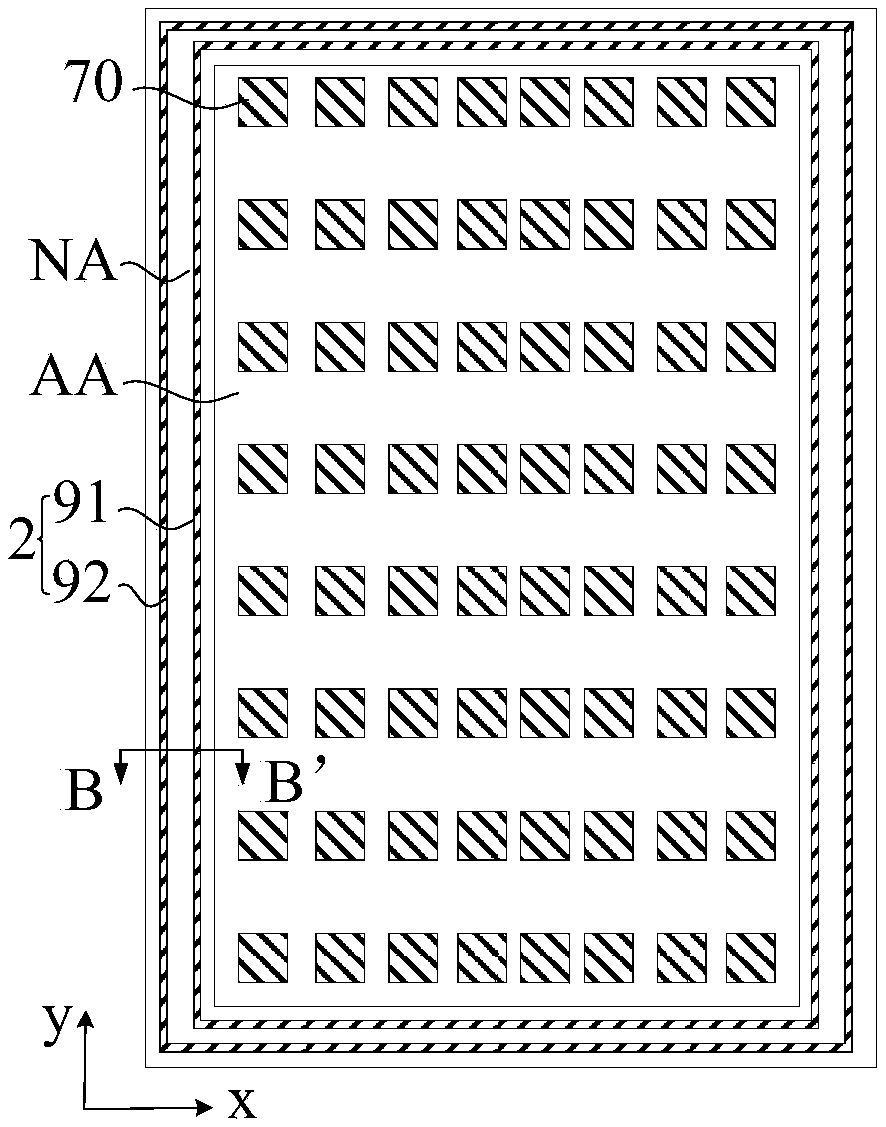

Flexible display panel, manufacturing method, flexible display device

ActiveCN106653820AReduced likelihood of cracksFinal product manufactureSolid-state devicesEngineeringFlexible display

The invention discloses a flexible display panel, a manufacturing method and a flexible display device, and relates to the technical field of flexible display. The possibility that cracks are generated on an inorganic packaging structure when the flexible display panel is bent is reduced, so that the service life of a luminescent device inside a flexible display substrate is prolonged. The flexible display panel comprises the flexible display substrate and a packaging structure arranged on the surface of the flexible display substrate, and the part, corresponding to a non-display area, of the packaging structure is the inorganic packaging structure; and the flexible display panel also comprises an organic packaging layer with which the inorganic packaging structure is covered. The manufacturing method of the flexible display panel comprises manufacturing the flexible display panel proposed in the technical scheme. The flexible display panel provided by the invention is used in the flexible display device.

Owner:BOE TECH GRP CO LTD

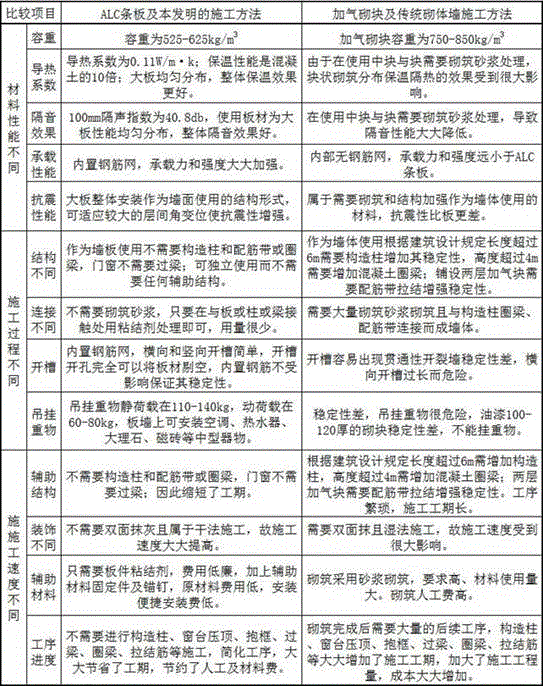

Construction method for fabricated type partition wall based on ALC board

The invention discloses a construction method for a fabricated type partition wall based on an ALC (Adaptive Logic Circuit) board, relating to the technical field of fabricated wall construction. According to the invention, the ALC board can be used in the frequently flooded or easily wetted places, such as a bathroom and a kitchen; in a construction process, no structural column or lintel is additionally arranged on the door and window parts; tools, materials and manpower are saved, so that the purposes of relieving labor intensity and shortening construction period can be achieved; the manual horizontal and longitudinal pressing manner is adopted for mounting battens, so that the combination between the binder and the panel as well as concrete surface is benefited, no higher stress exists on the wall and the joint after the binder is solidified and contracted and the possibility of generating cracks on the wall and the joint is greatly reduced; the anti-cracking treating step is performed at last and anti-cracking cloth is used for reinforcing the joint, so that the connecting effect of the joint is further guaranteed; the mounting for the ALC board is further adjusted and corrected in the construction process, so that the mounting precision of the wall is further guaranteed, the wall is prevented from cracking and the forming quality of the wall is promoted.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

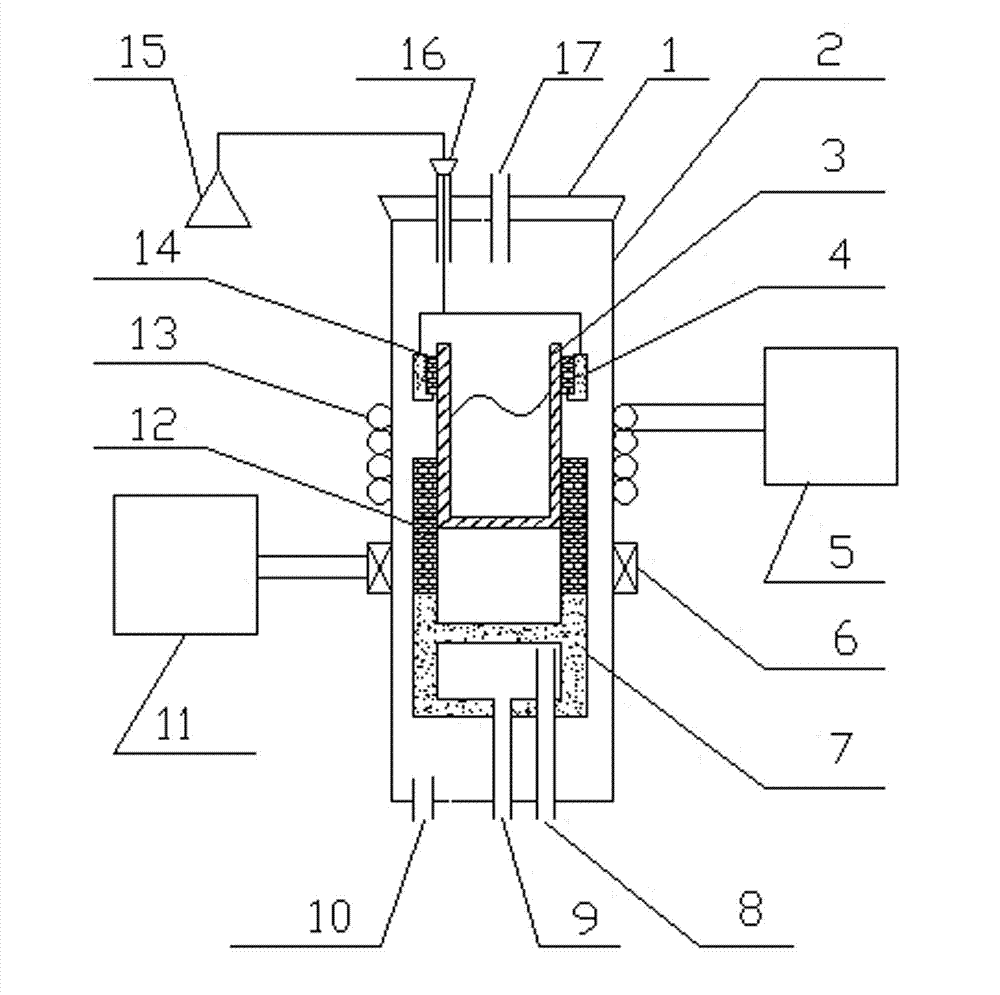

Gold base alloy casting blank melting and casting integrated device and utilization method thereof

ActiveCN103691912AReduce the number of oxide inclusionsEliminate severe oxidationIntegrated devicesCrucible

The invention discloses a gold base alloy casting blank melting and casting integrated device and a utilization method thereof. The gold base alloy casting blank melting and casting integrated device comprises a melting pot, a fireproof material cylinder, a cooling base, an outer cylinder, a heating induction coil and a magnetic stirring device. The utilization method of the gold base alloy casting blank melting and casting integrated device comprises putting gold into the melting pot and inserting the melting pot into the fireproof material cylinder; piping inert gas or reducing gas into the outer cylinder; heating the metal inside the melting pot to be melted through magnetic fields, adding other metal or alloy and performing alloying; enabling the melting pot with the fusant to descend to an annual boss of the cooling base and cooling the fusant to cast the fusant which is gradually solidified from bottom to upper during the cooling process. The gold base alloy casting blank melting and casting integrated device has the advantages of being simple in structure, convenient to operate and low in integral cost and enabling prepared gold base alloy to be uniform in ingredient and less in internal defect. The gold base alloy casting blank melting and casting integrated device and the utilization method thereof have good application prospects.

Owner:NORTHEASTERN UNIV

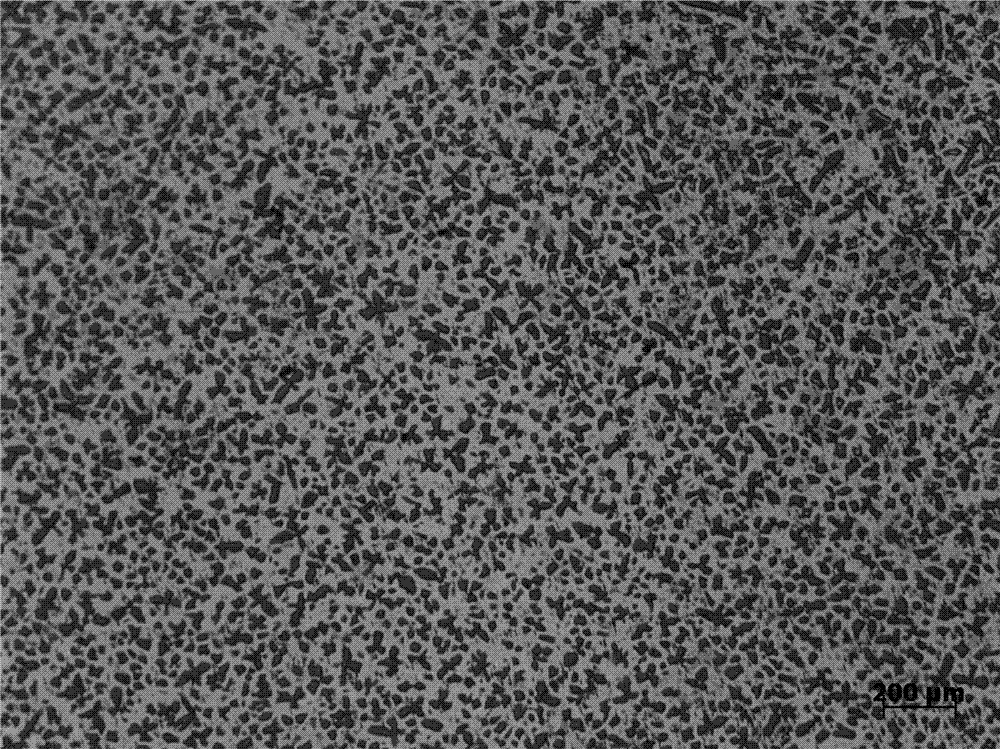

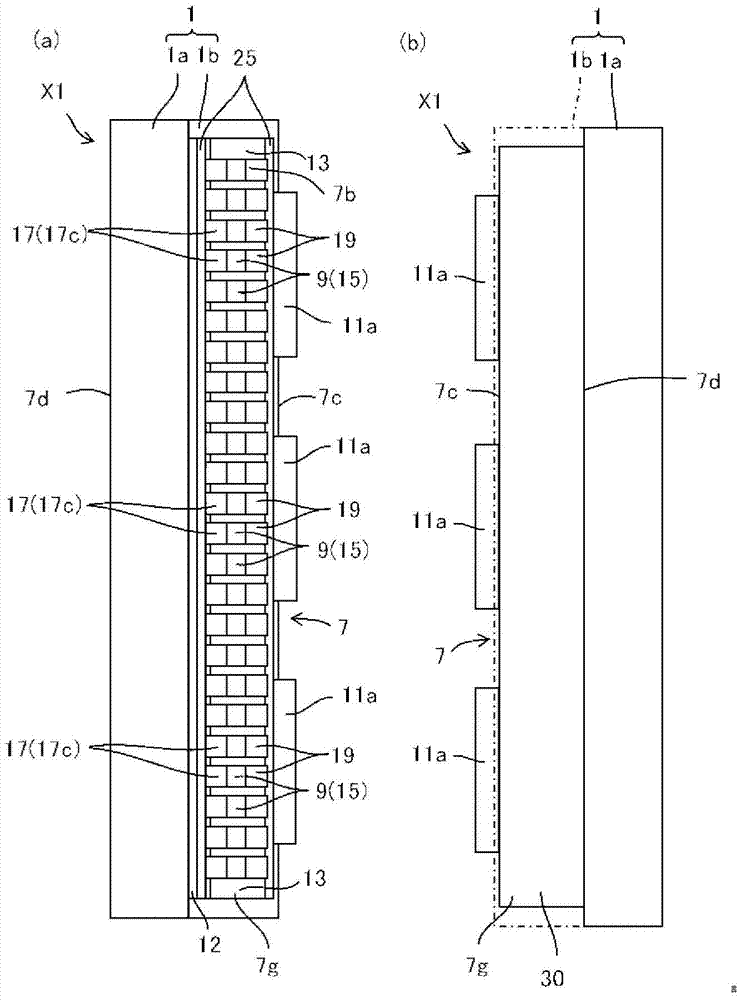

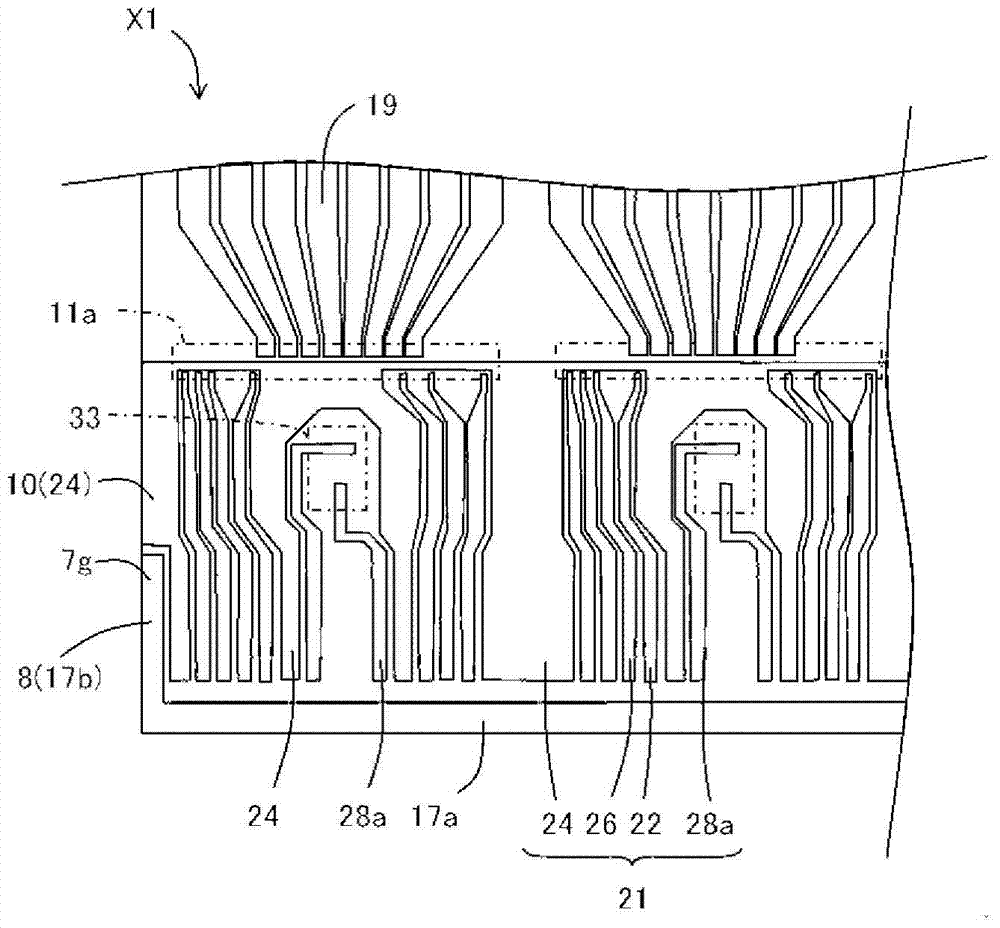

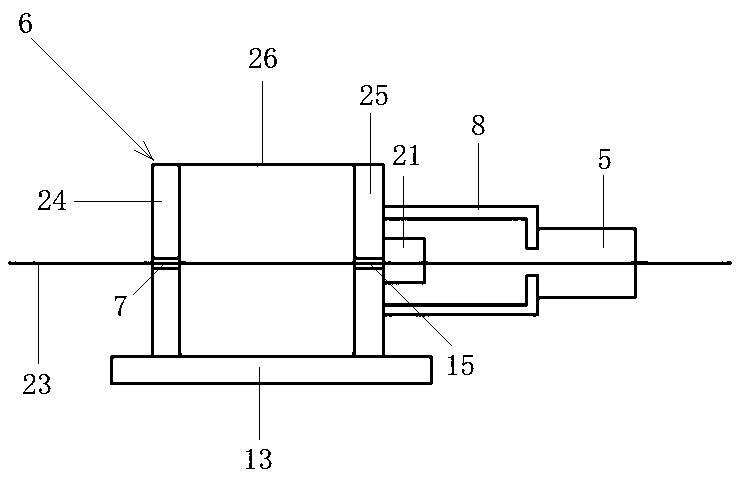

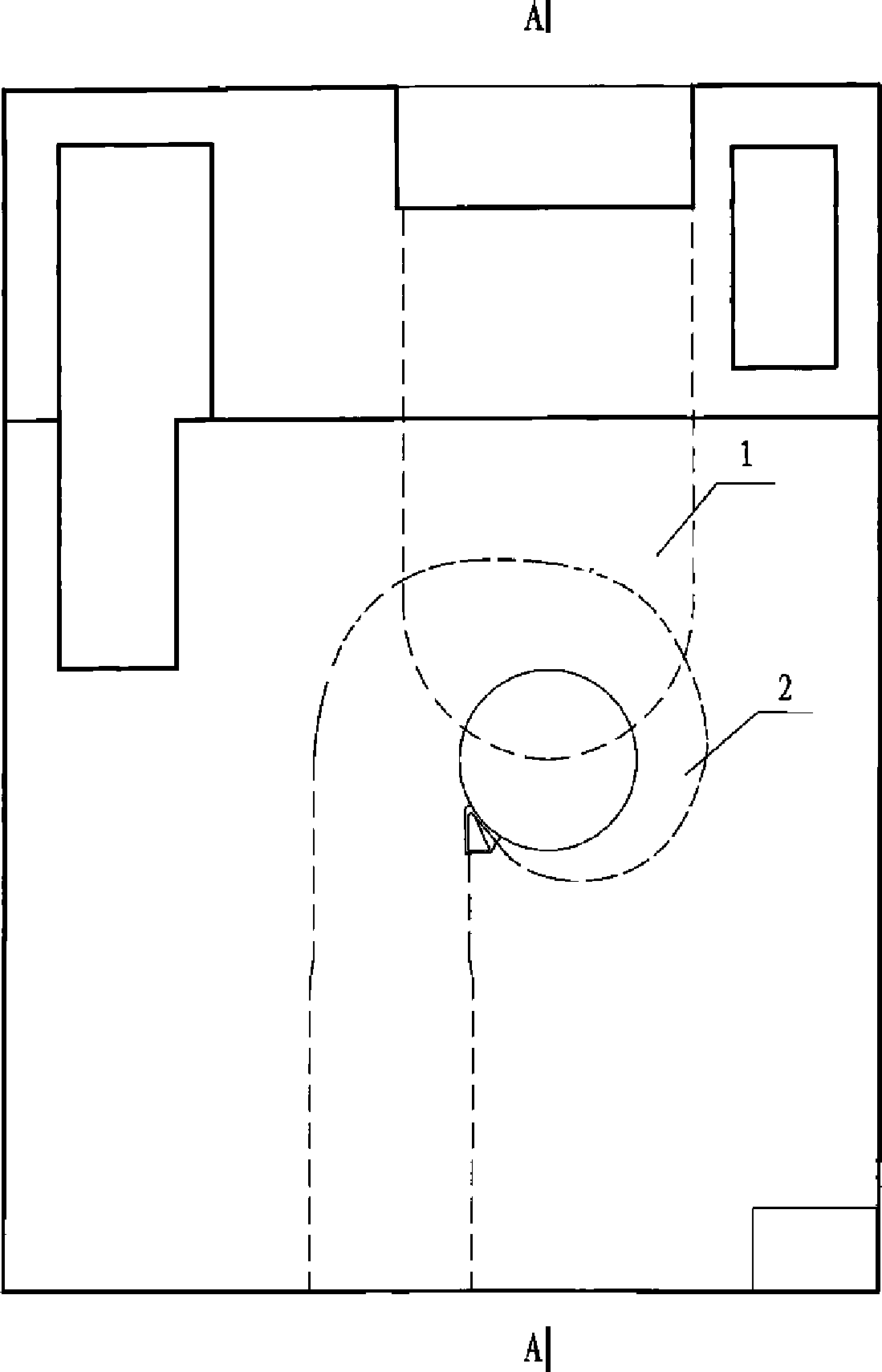

Thermal head and thermal printer provided with same

[Problem] To provide a thermal head that reduces the possibility of splintering or cracking at the edge of the substrate. [Solution] A thermal head (X1) has a substrate (7) and multiple heat-generating parts (9) provided on the substrate (7). The substrate (7) has a first main surface (7c), a second main surface (7d) positioned on the side opposite the first main surface (7c), and a first end face (7a) that is connected to the first main surface (7c) and the second main surface (7d) and follows the direction in which the multiple heat-generating parts (9) are arrayed. On each of the first main surface (7c), the first end face (7a) and the second main surface (7d) of the substrate (7), an edge (7g) is provided in directions that are orthogonal to the direction in which the multiple heat-generating parts (9) are arrayed. On the edge (7g) of the first main surface (7c) of the substrate, a first reinforcing member (8) and a second reinforcing member (10) that is separated from the first reinforcing member (8) are provided. The first reinforcing member (8) is provided from on the edge (7g) of the first main surface (7c) onto the edge (7g) of the first end face (7c) and onto the edge (7g) of the second main surface (7d).

Owner:KYOCERA CORP

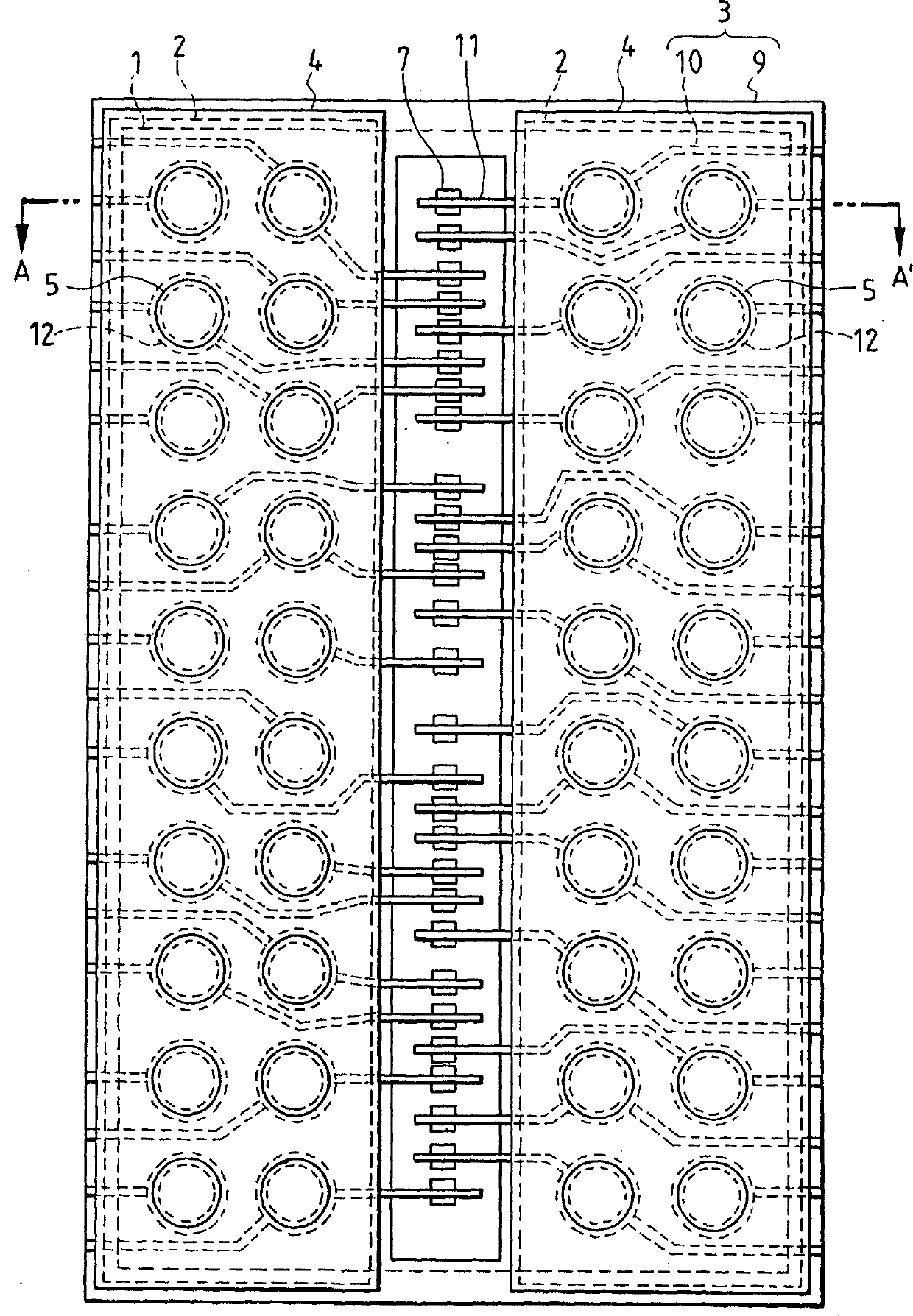

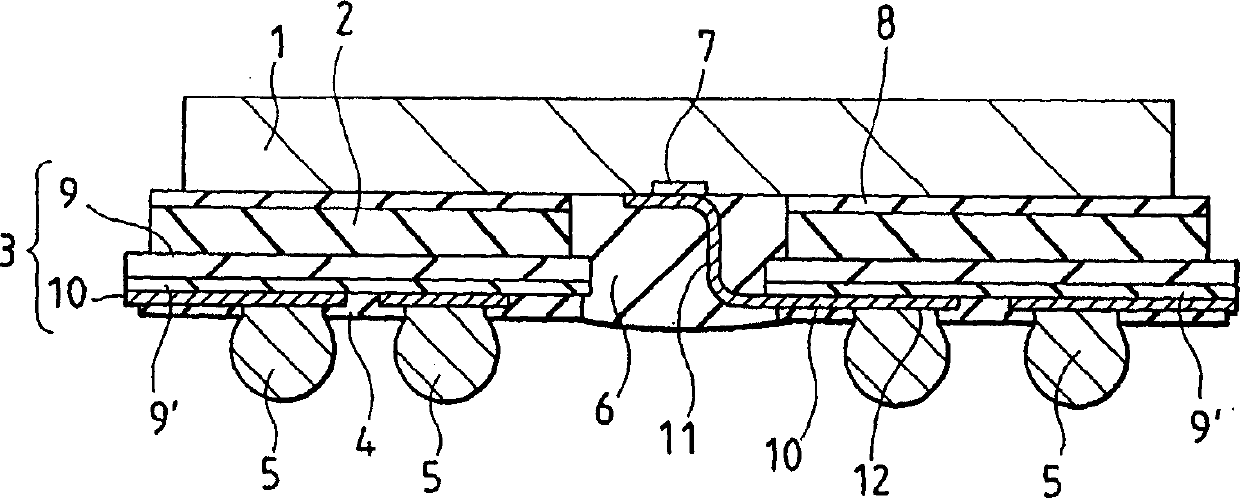

Semiconductor device

InactiveCN1728372AReduce flatnessReduce crackingSemiconductor/solid-state device detailsSolid-state devicesResistElastomer

A ball grid array type semiconductor package includes a semiconductor chip formed with bonding pads, an elastomer bonded to the semiconductor chip, a flexible wiring substrate bonded to the elastomer and formed with wirings connected at one end of the bonding pads of the semiconductor chip, a solder resist formed on the main surface of the flexible wiring substrate and solder bump electrodes connected to the other ends of the wirings. The elastomer is bonded to the flexible wiring substrate on the side of the tape, the solder resist is formed on the side of the wirings, and the solder bump electrodes are connected with the wirings by way of through holes formed in the solder resist.

Owner:HITACHI LTD +1

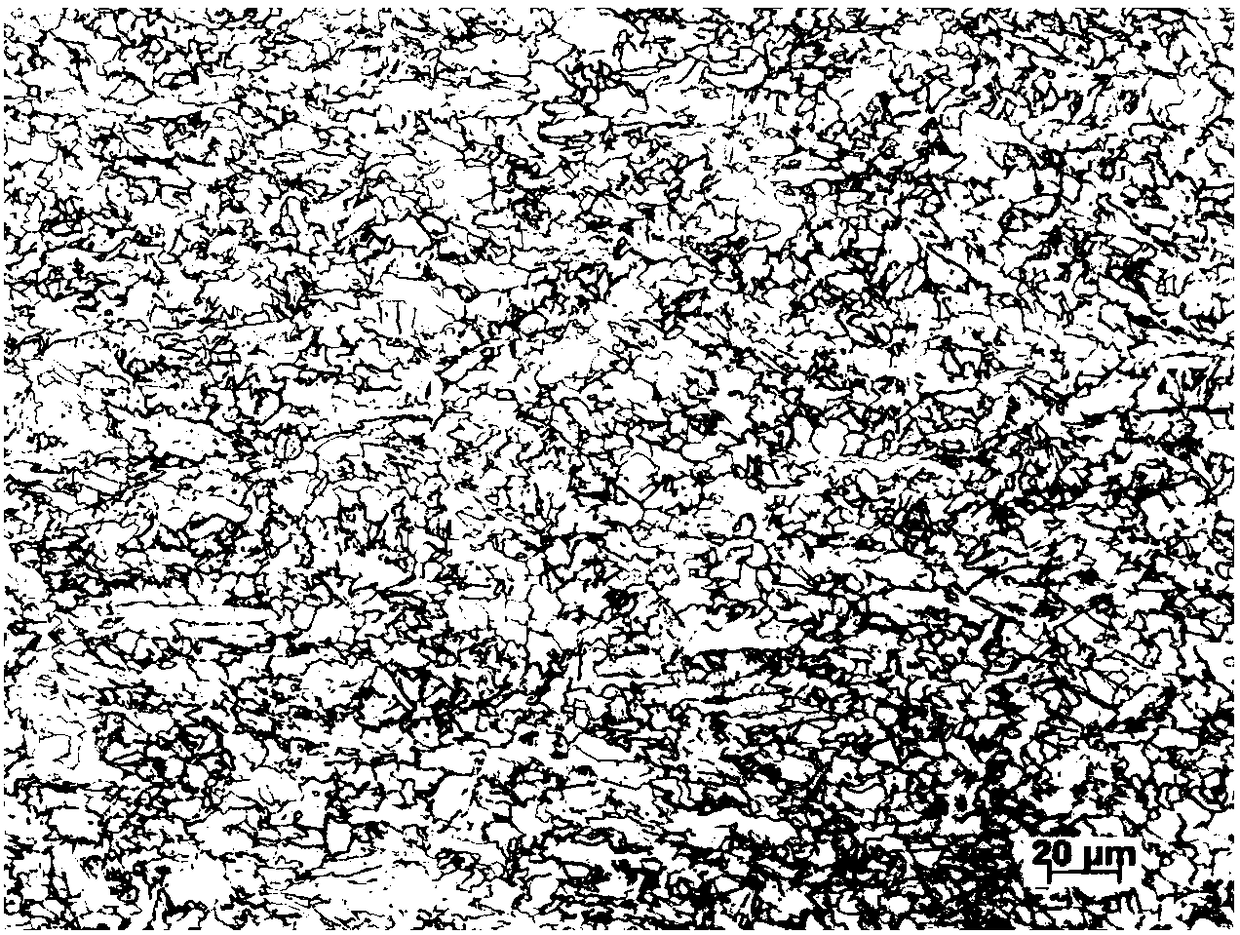

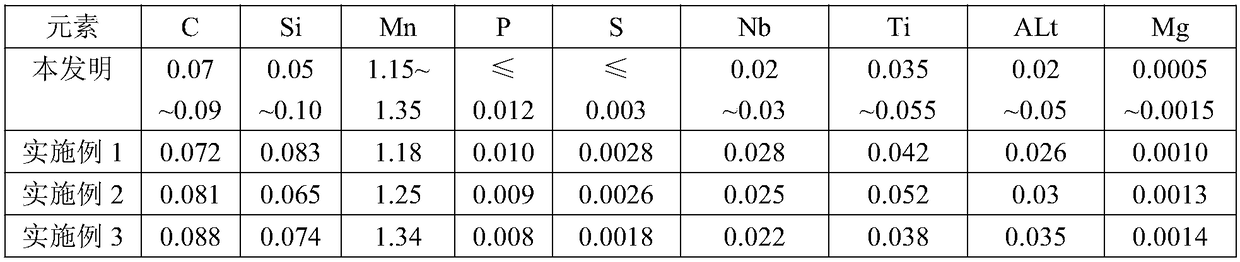

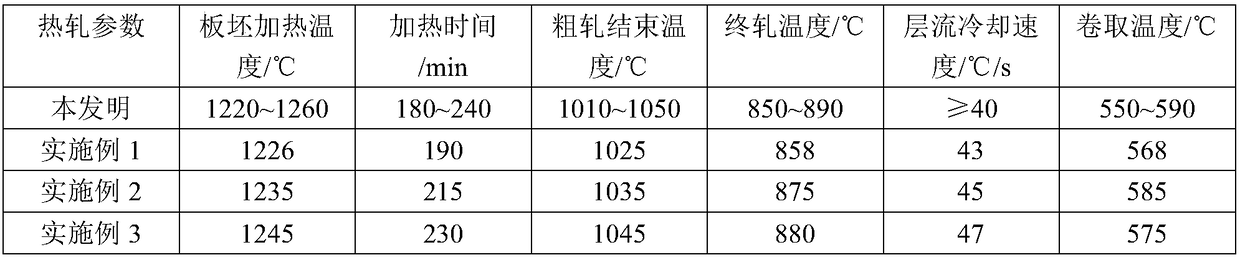

Hot-rolled steel sheet for automobile wheels with tensile strength of 590 MPa

The invention relates to a hot-rolled steel sheet for automobile wheels with tensile strength of 590MPa, which solves the technical problem that the existing hot-rolled steel sheet for automobile wheels has low tensile strength and insufficient fatigue performance of the wheel after the automobile wheel is produced by the existing steel sheet. The hot-rolled steel sheet for automobile wheels withtensile strength of 590 MPa provided by the invention has a chemical composition weight percentage: 0.07% to 0.09% of C, 0.05% to 0.10% of Si, 1.15% to 1.35% of Mn, less than or equal to 0.012% of P,less than or equal to 0.003% of S, 0.02% to 0.03% of Nb, 0.035% to 0.055% of Ti, 0.0005% to 0.0015% of Mg, 0.02% to 0.05% of Alt, less than or equal to 0.0040% of N, and the balance being Fe and unavoidable impurities. The hot-rolled steel sheet is mainly used for making automobile wheel rims and spokes.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Tile surface material composite plate and novel construction method thereof

ActiveCN104775589AReduce the stringent requirements of the technical level of the installationImprove performanceCovering/liningsBuilding material handlingComposite materialCeramic tiles

The invention relates to a tile surface material composite plate and a novel construction method thereof. The construction method comprises the following steps: (1) sticking the tile surface material on a base plate to form a tile surface material spliced plate; (2) cleaning the tile surface material spliced plate; (3) forming straight-line-shaped cutting grooves on connecting seams of the tile surface material spliced plate in batches; (4) filling the cutting grooves with a crack-sealer, then curing to obtain the tile surface material composite plate and finishing the construction. The cutting grooves are formed in the modularized tile surface material composite plate in the construction method; the construction efficiency of the tile surface material composite plate can be improved, the labor intensity of the construction staff is reduced, the technological dependence of the construction staff is reduced; in addition, the butt seam precision of the tile is greatly improved, and the attractive effect of the buildings appearance is improved.

Owner:GUANGZHOU HONLLEY COMPOSITE MATERIAL

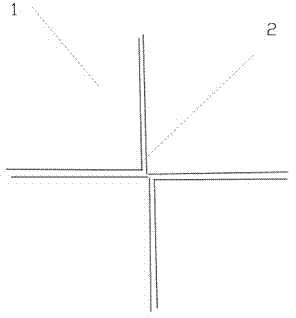

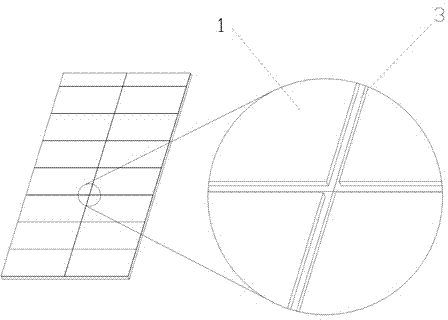

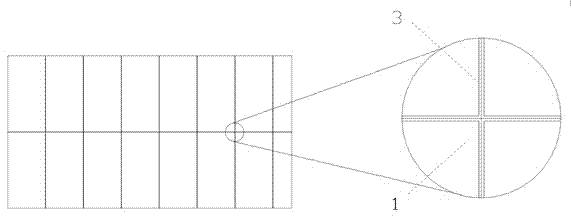

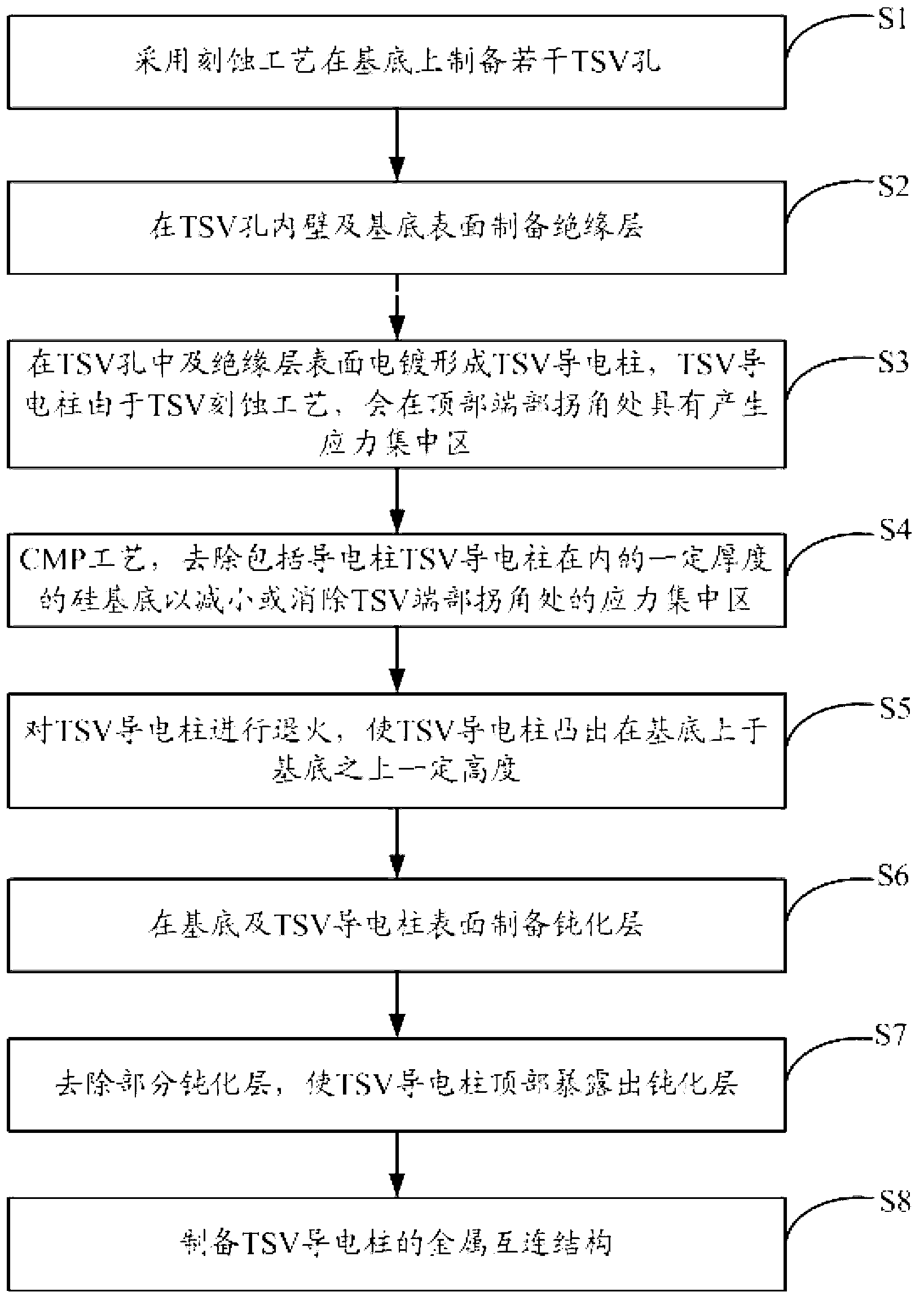

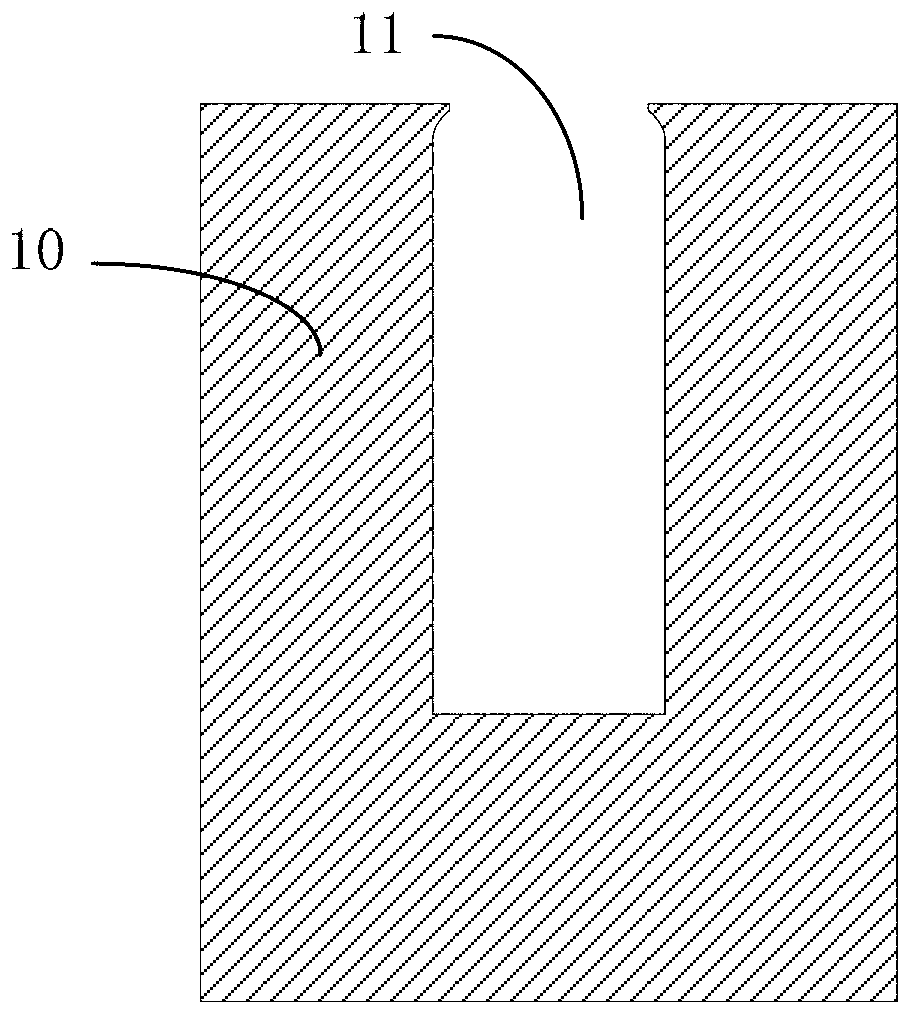

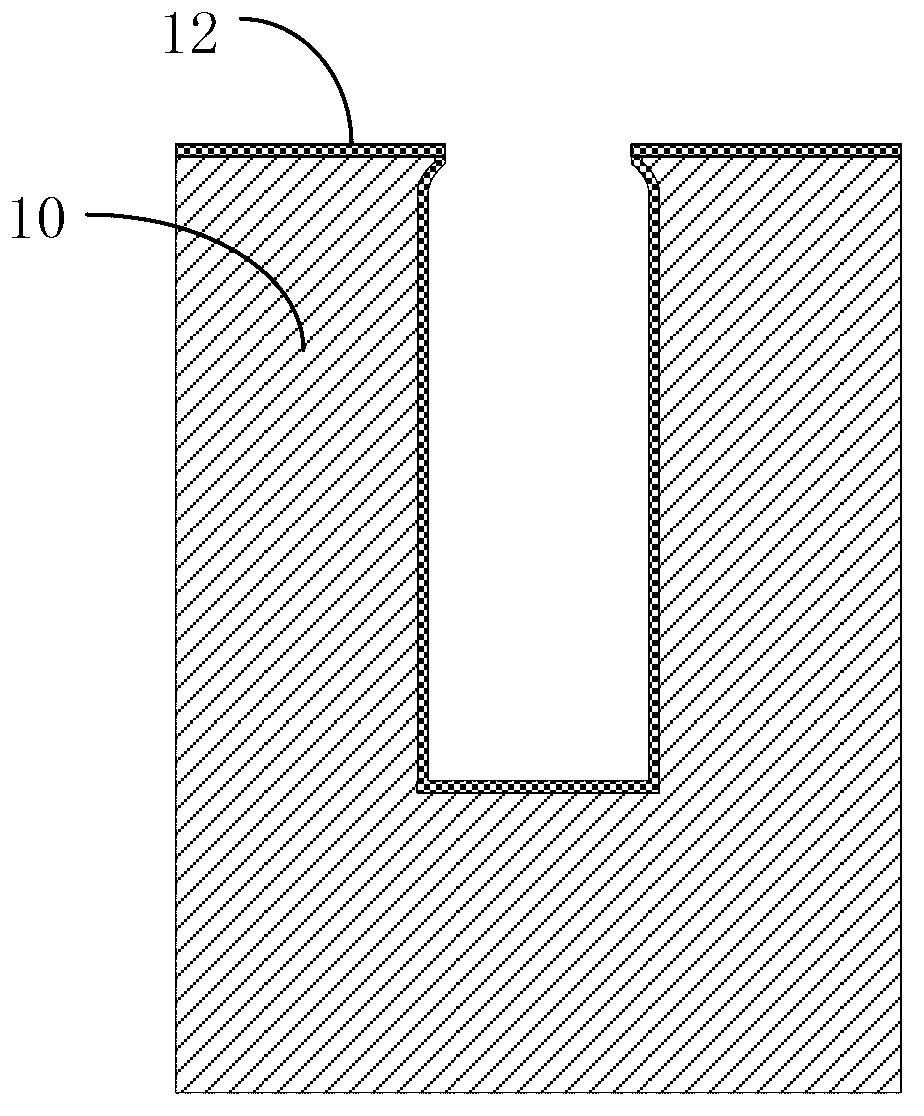

TSV front end portion interconnection process

ActiveCN103280427AReduce layeringReduced likelihood of cracksSemiconductor/solid-state device manufacturingStress concentrationRedistribution layer

The invention discloses a TSV front end portion interconnection process. The process includes preparing a plurality of TSV holes in a substrate by means of the etching technology; preparing insulating layers on the inner walls of the TSV holes and on the surface of the substrate; forming TSV conductive columns in the TSV holes and on the surfaces of the insulating layers through electroplating; eliminating a silicon substrate with a certain thickness including the TSV conductive columns through the CMP technology; carrying out annealing on the TSV conductive columns so that the TSV conductive columns can extrude out of the substrate at a certain height; preparing passivation layers on the substrate and the surfaces of the TSV conductive columns, and eliminating a part of the passivation layers so that the tops of the TSV conductive columns can be exposed out of the passivation layers; preparing a metal interconnection structure of the TSV conductive columns. The TSV front end portion interconnection process reduces or eliminates stress concentration areas at corners of the end portions of the TSV conductive columns, reduces probability that due to stress, delamination and cracks are formed between the insulating layers and the substrate, and meanwhile achieves interconnection of the TSV conductive columns and redistribution layer metal through use of the defect that after the TSV conductive columns are electroplated and processed through annealing, the TSV conductive columns will extrude.

Owner:NAT CENT FOR ADVANCED PACKAGING CO LTD

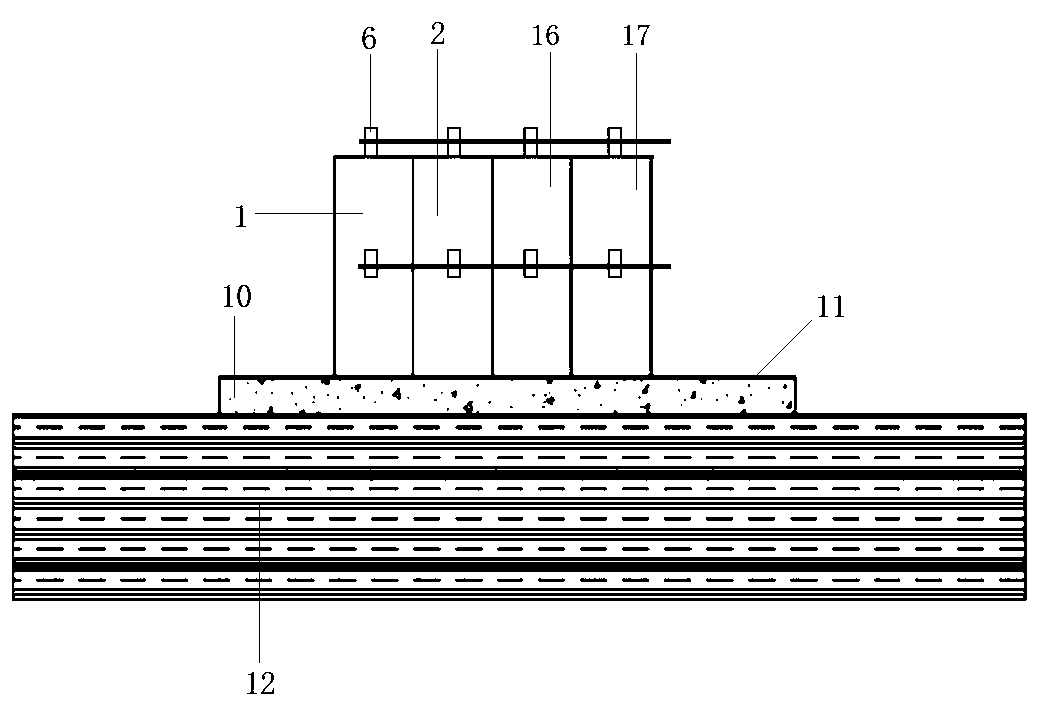

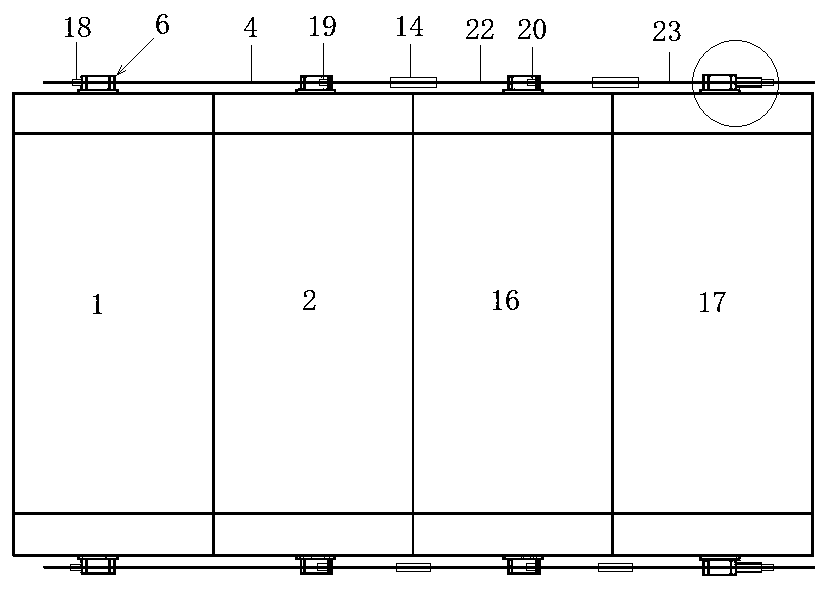

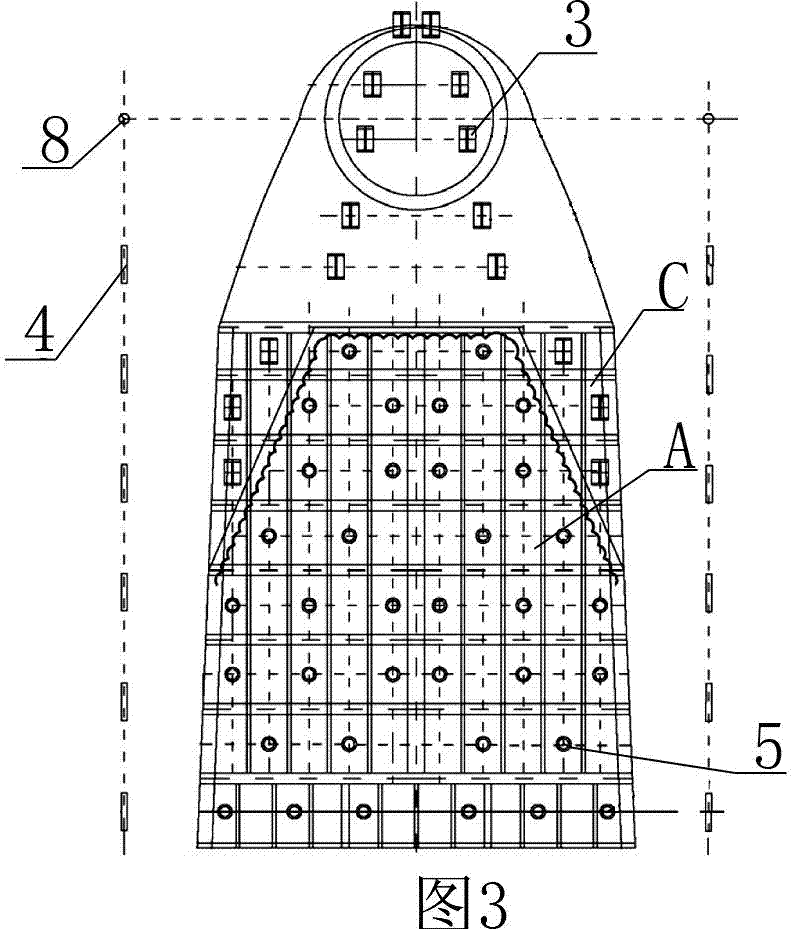

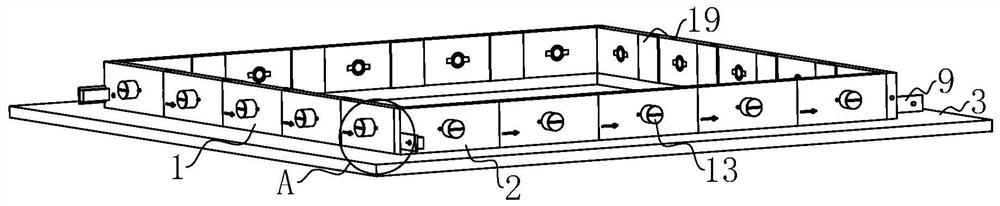

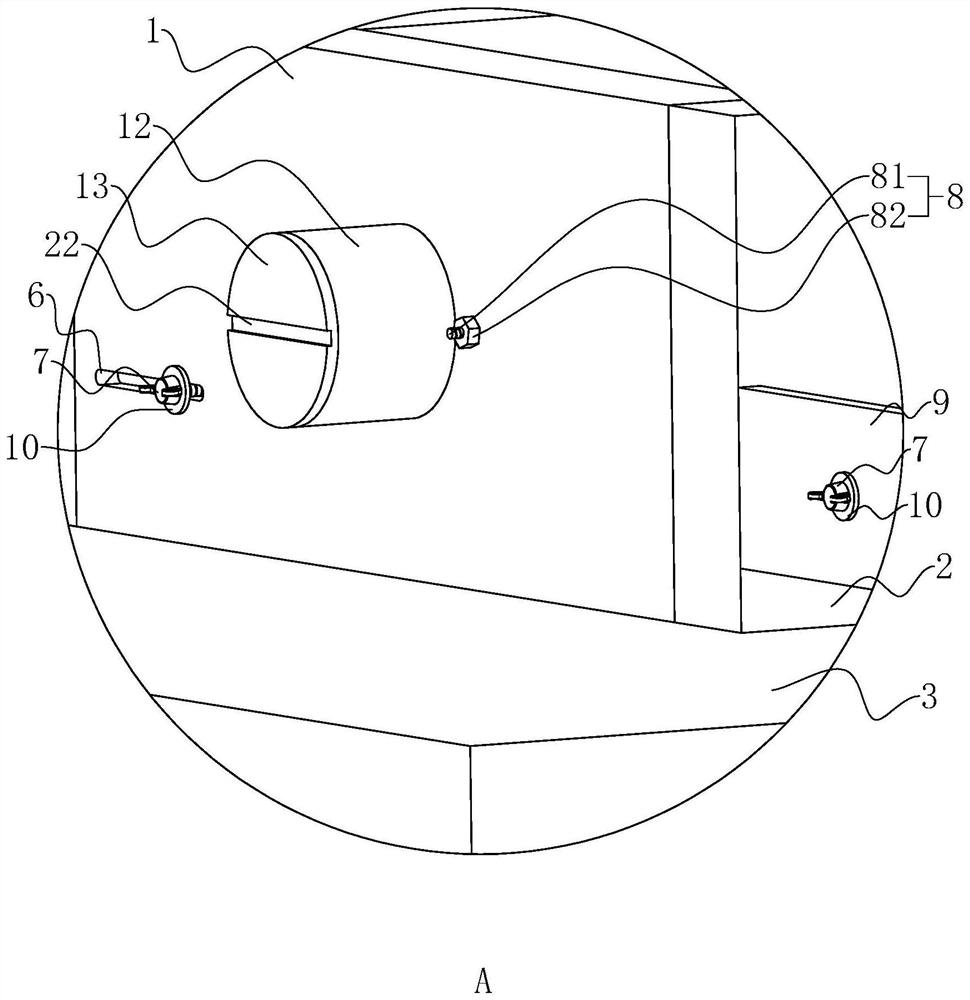

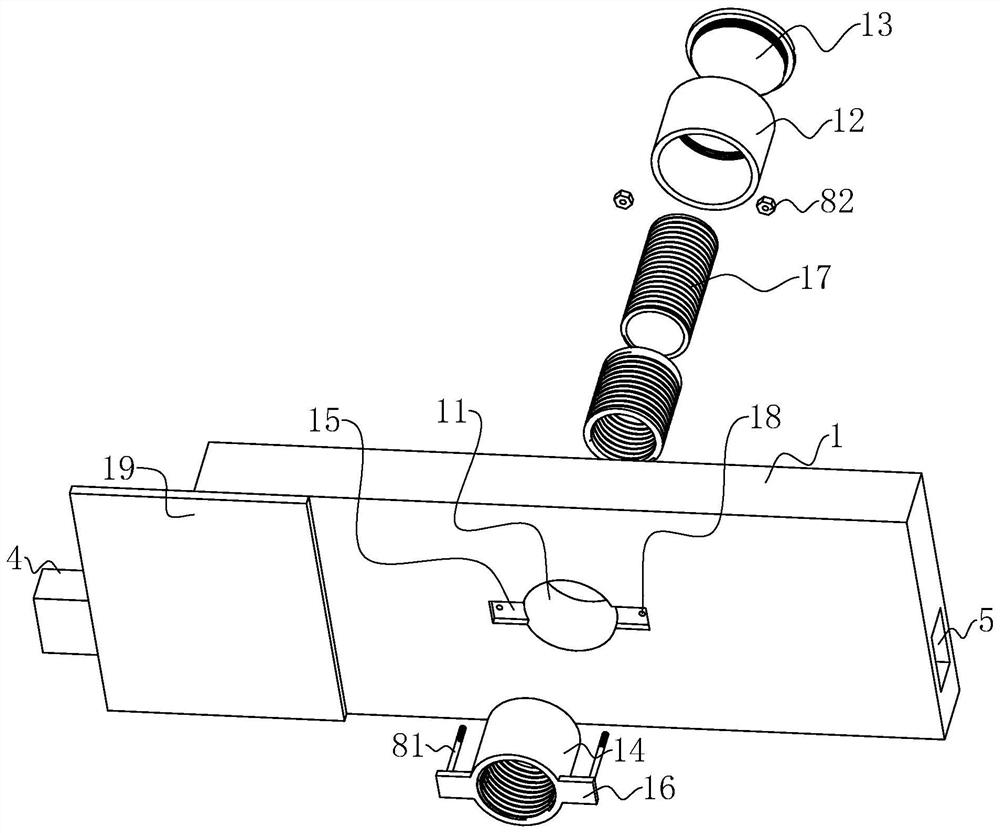

Prefabricated comprehensive pipe gallery tensioning method

PendingCN109555159AEnsure waterproof and airtight effectPrevent crushingArtificial islandsProtective foundationUtility tunnelRebar

The invention relates to the technical field of prefabricated structures, in particular to a prefabricated comprehensive pipe gallery tensioning method. The prefabricated comprehensive pipe gallery tensioning method is characterized by comprising the steps that a plurality of pipe gallery sections are connected and compressed through prestressed steel bars, a jack and a two-way bracket are used for conducting section-by-section preliminary prestress tensioning on the multiplepipe gallery sections until allpipe gallery sections are tensioned, and thus the multiple pipe gallery sections are mutually spliced and fixed and form a continuous pipe gallery; permanent prestressed tensioning is conducted after completion of preliminary prestressed tensioning, and initial prestressing force is unloaded after completion of the permanent prestressed tensioning. The prefabricated comprehensive pipe gallery tensioning method has the advantages that preliminary prestressed tensioning of the latter pipe gallery section cannot affect the already pipe gallery sections; waterproof components between the pipe gallery sections are always in a compressed state, and the pipe gallery sections are prevented from being crushed while the waterproof sealing effect of the pipe gallery is ensured; and the possibility of cracks in the assembly process of the pipe gallery sections is lowered.

Owner:上海城建预制构件有限公司

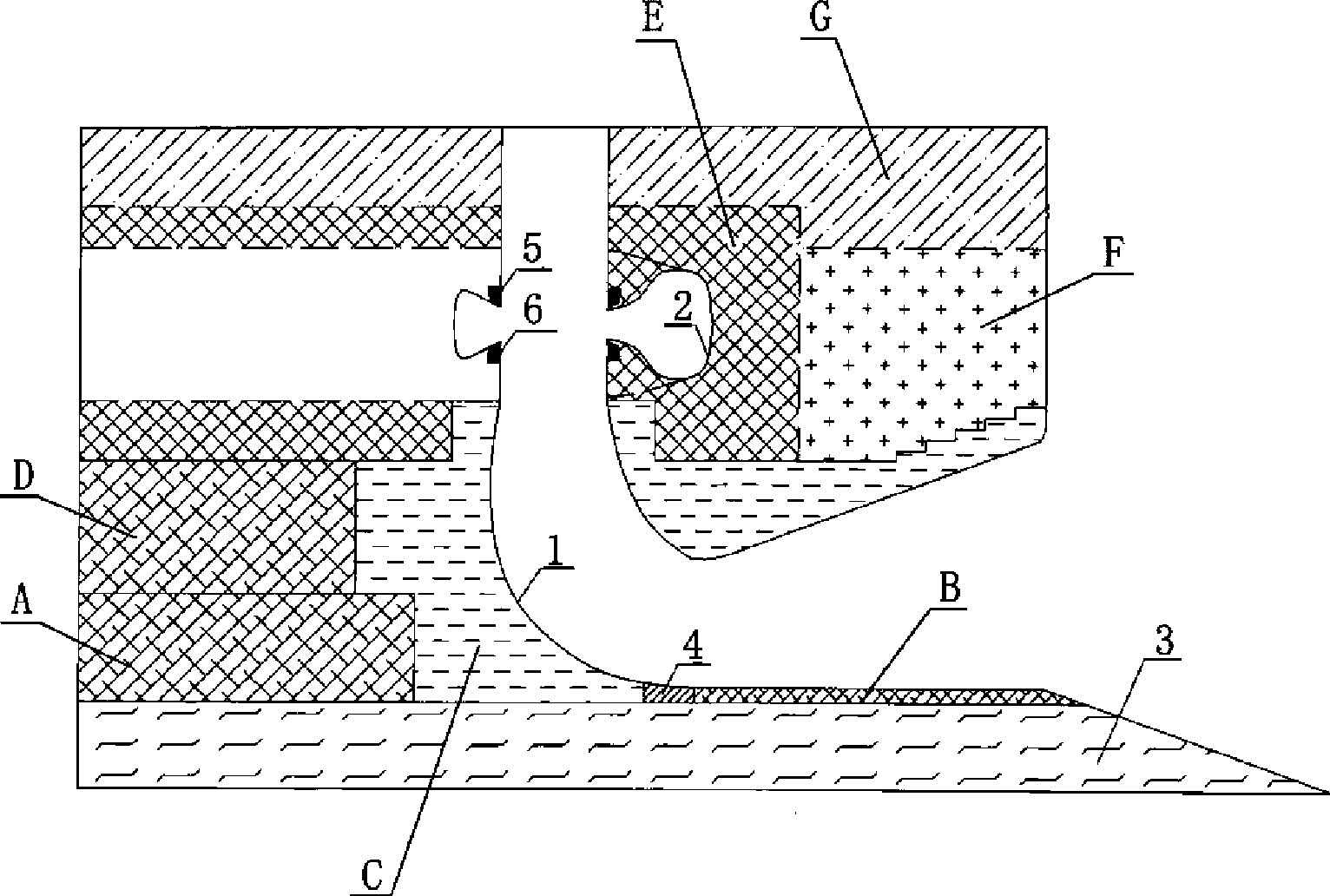

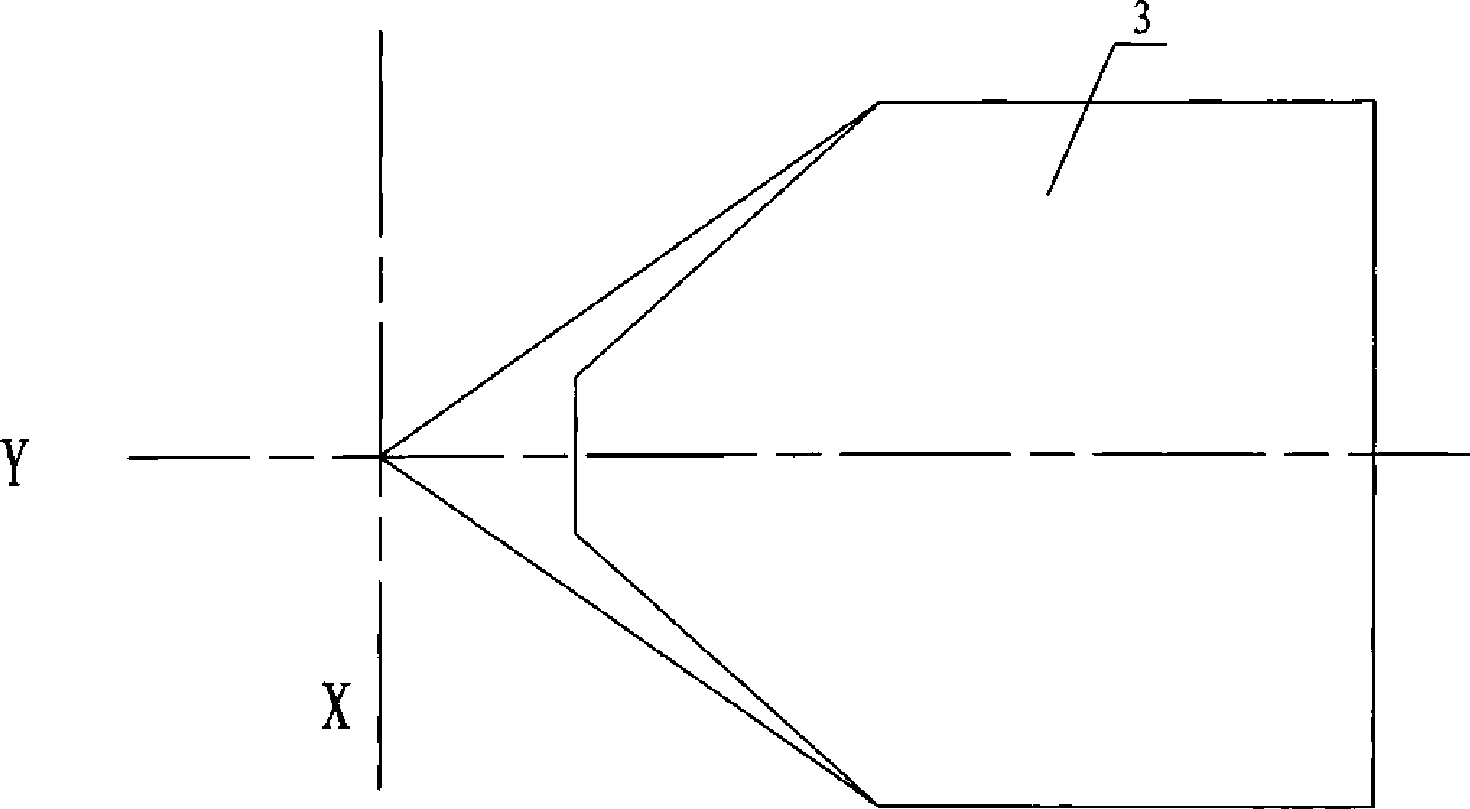

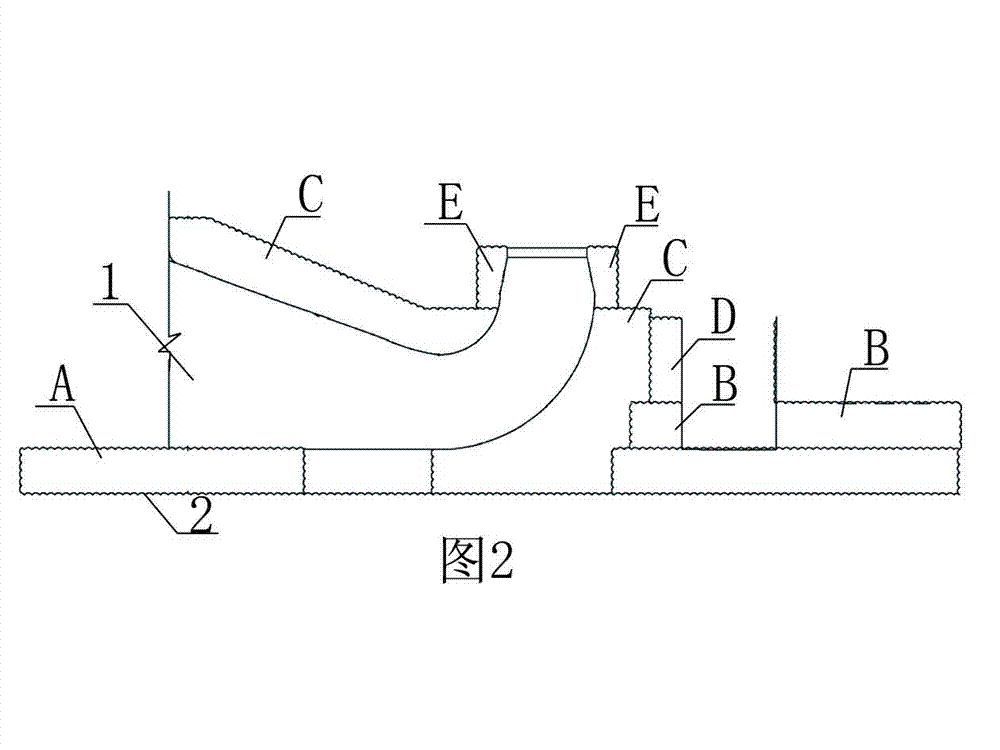

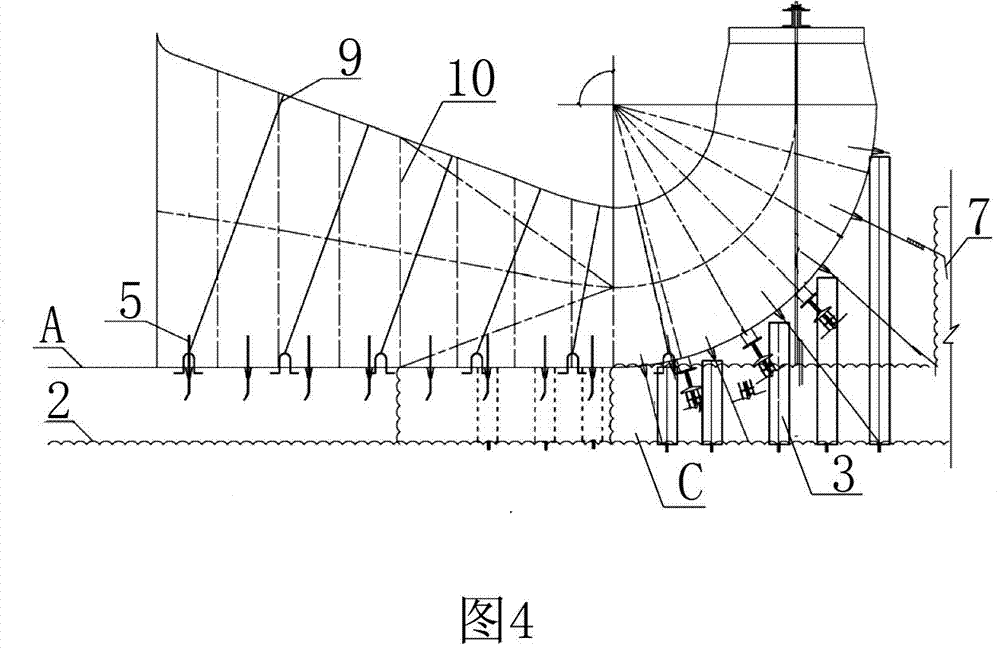

Construction method for large cast-in-situ steel reinforced concrete inlet channel and turbine housing

InactiveCN101476308AReduced likelihood of cracksConstruction quality is easy to guaranteeArtificial water canalsFoundation engineeringInlet channelReinforced concrete

The invention relates to a large-scale cast-in-situ reinforced concrete water inlet duct and scroll case construction method, the construction sequence is: bottom board of the water inlet duct, far end lower part outside the turning of the water inlet duct, far end upper part outside the turning of the water inlet duct, outer circumference of the turning of the water inlet duct, far end outside the scroll case, near end outside the scroll case, top outside the scroll case and the second pouring construction. The construction method has clear levels, reduces the concrete pouring amount at the key parts of the water inlet duct: the outer circumference of the turning of the water inlet duct and the near end outside the scroll case, by partitioning construction; ensures the concrete forming quality of the water inlet duct and the scroll case; and avoids large volume concrete cracks.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD +1

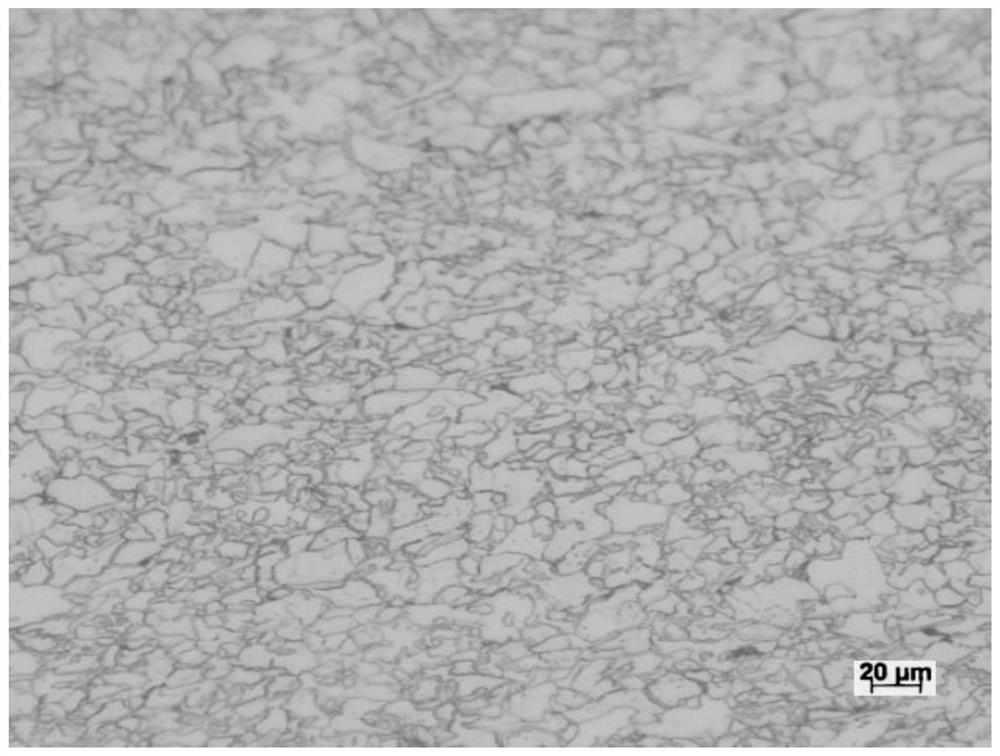

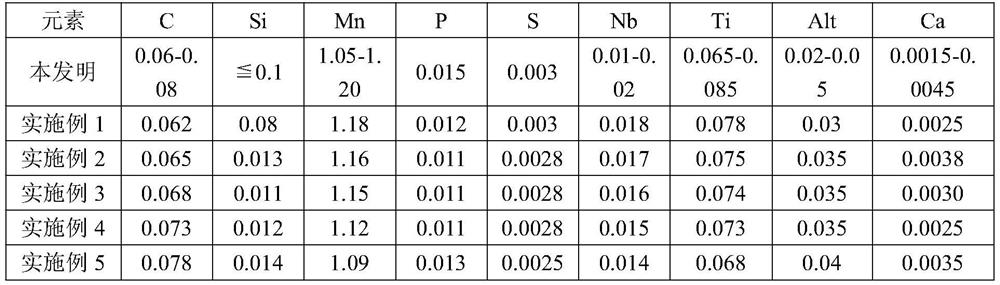

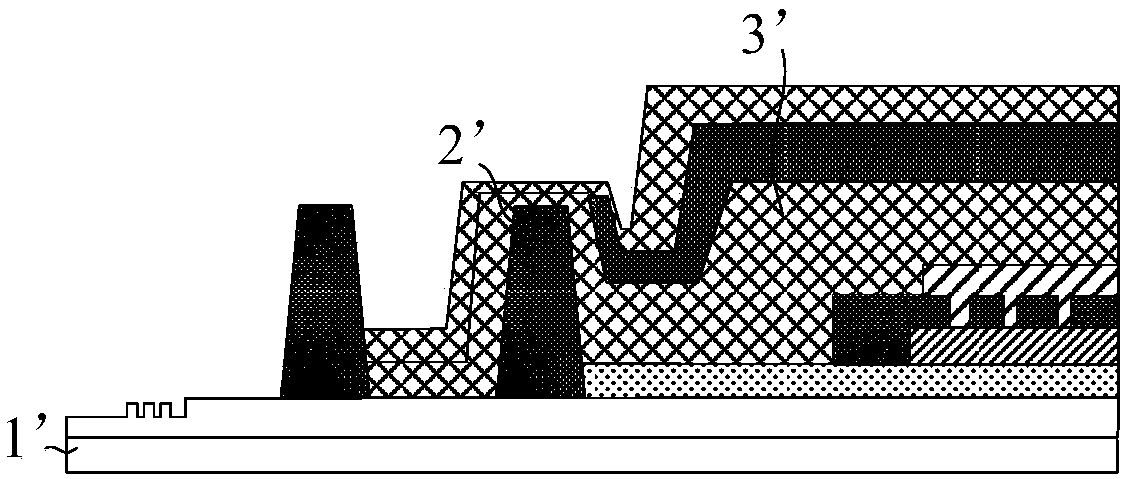

Hot-rolled steel plate with tensile strength of 650 MPa and manufacturing method thereof

The invention discloses a hot-rolled steel plate with tensile strength of 650 MPa and a manufacturing method thereof, and mainly solves the technical problems of high manufacturing cost, low strengthand low low-temperature impact performance of an existing hot-rolled steel plate for an automobile frame. The hot-rolled steel plate with tensile strength of 650 MPa comprises the following chemical components in percentage by weight: 0.06 to 0.08 percent of C, less than or equal to 0.1 percent of Si, 1.05 to 1.20 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.003percent of S, 0.01 to 0.02 percent of Nb, 0.065 to 0.085 percent of Ti, 0.0015 to 0.0045 percent of Ca, 0.02 to 0.05 percent of Alt, and the balance Fe and inevitable impurities, wherein the contentof the above elements meets the requirement that the carbon equivalent is less than or equal to 0.32. The percentage elongation A of the hot-rolled steel plate after fracture ranges from 18 to 24 percent. The hot-rolled steel plate provided by the invention is mainly used for manufacturing cross beams, longitudinal beams and other structural parts of trucks.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

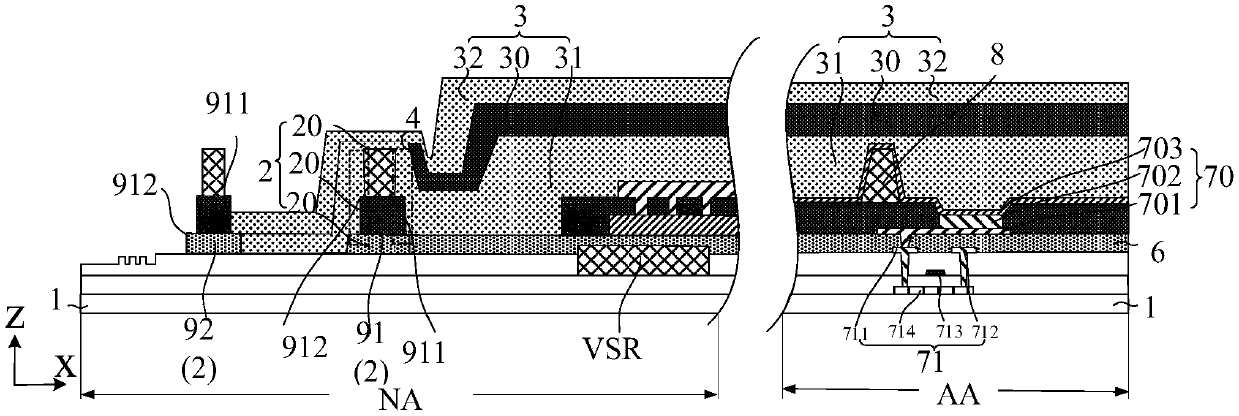

Display panel and display device

ActiveCN109585690AImprove bindingReduced likelihood of cracksSolid-state devicesSemiconductor/solid-state device manufacturingConvex structureSurface plate

The embodiment of the invention provides a display panel and a display device, and relates to the technical field of display for solving the problem that in the prior art, a packaging layer and a blocking part are easy to peel off. The display panel comprises a substrate, a blocking part and a packaging layer, wherein the blocking part surrounds a display area of the display panel; and the blocking part is located on one side of the substrate; and the packaging layer is located on one side, away from the substrate, of the blocking part, wherein the surface of the blocking part in contact withthe packaging layer comprises a concave-convex structure.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

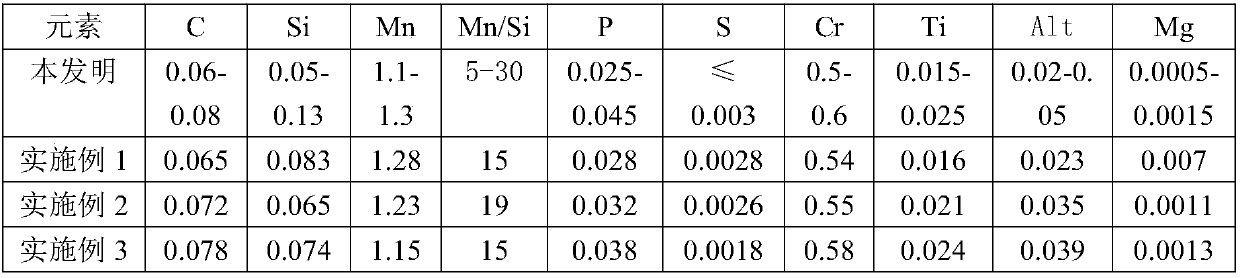

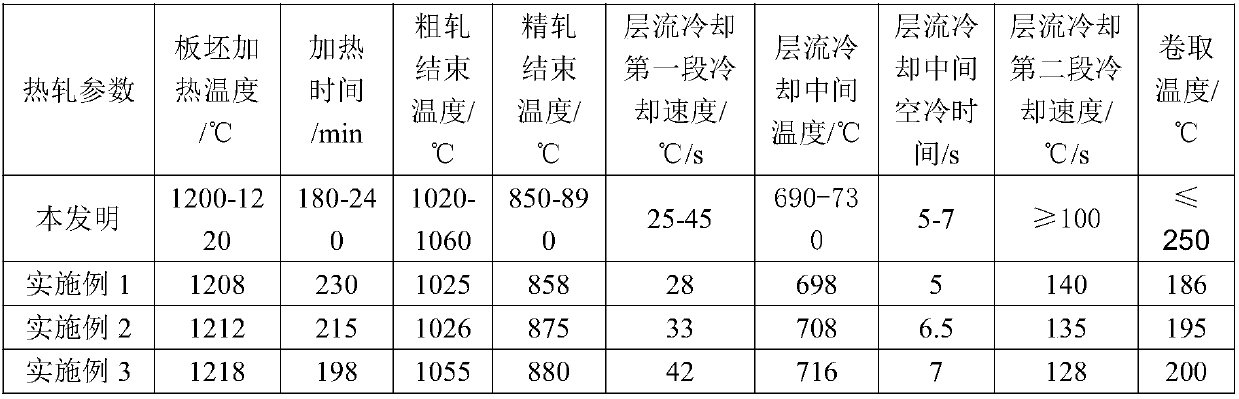

Hot-rolled biphase steel plate with tensile strength of 580 Mpa grade for automobile rims

The invention discloses a hot-rolled biphase steel plate with tensile strength of 580 Mpa grade for automobile rims. The technical problems of cracking and necking of an existing hot-rolled steel plate for automobile wheels after welding and poor fatigue performance of finished products are solved. The hot-rolled biphase steel plate with tensile strength of 580 Mpa grade for automobile rims is prepared from, by weight, 0.06%-0.08% of C, 0.05%-0.13% of Si, 1.1%-1.3% of Mn, greater than or equal to 0.035% but smaller than or equal to 0.045% of P, less than or equal to 0.003% of S, 0.5%-0.6% of Cr, 0.015%-0.025% of Ti, 0.0005%-0.00015% of Mg, 0.02%-0.05% of Alt, less than or equal to 0.0040% of N, and the balance Fe and inevitable impurities, specifically, Mn / Si is 5-30. The hot-rolled biphase steel plate is mainly applied to manufacturing car rims.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Checkered plate roller and using method thereof

InactiveCN104707886AOptimization parametersAdd depthRollsMetal rolling arrangementsEngineeringLens esculenta

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

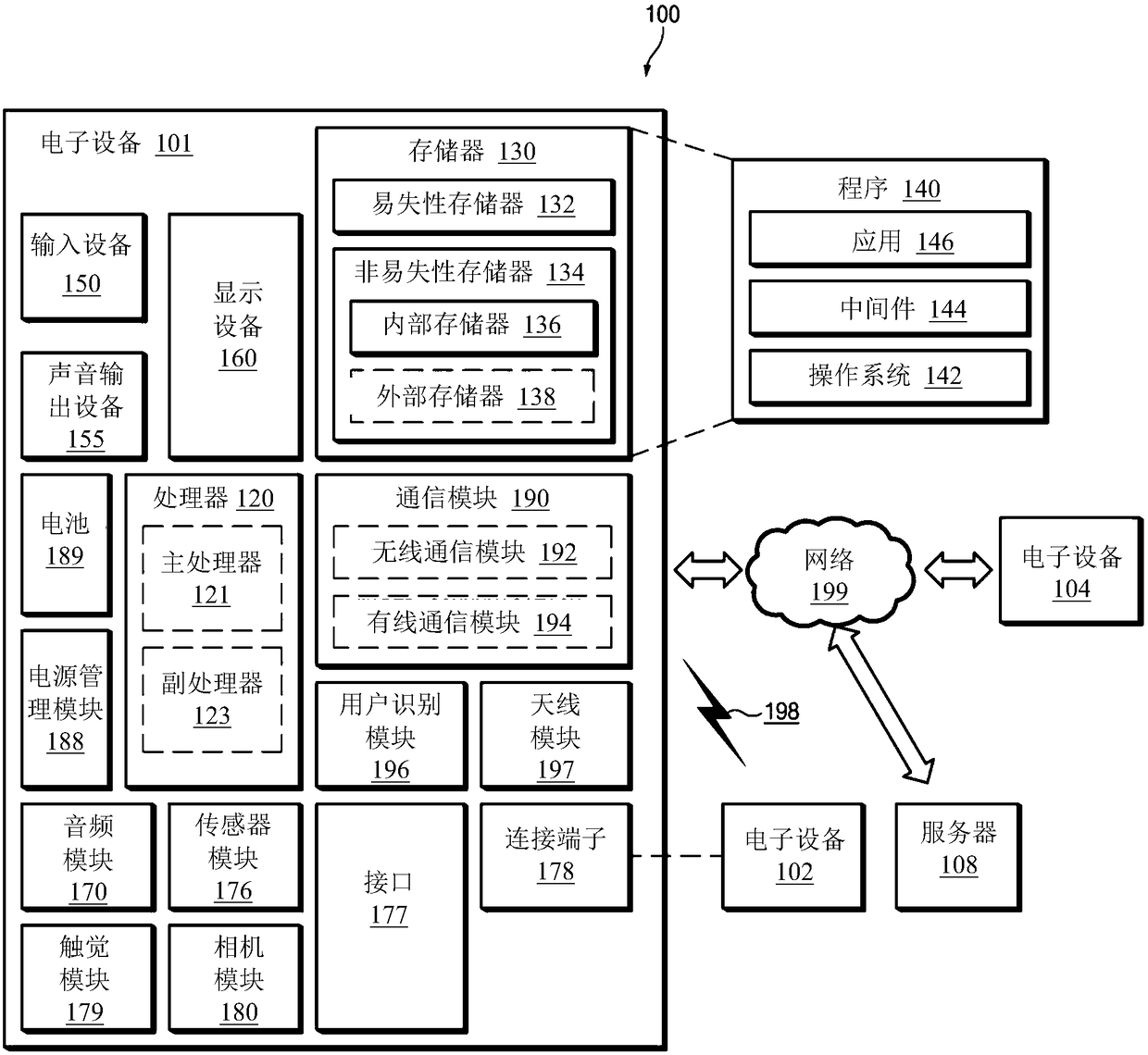

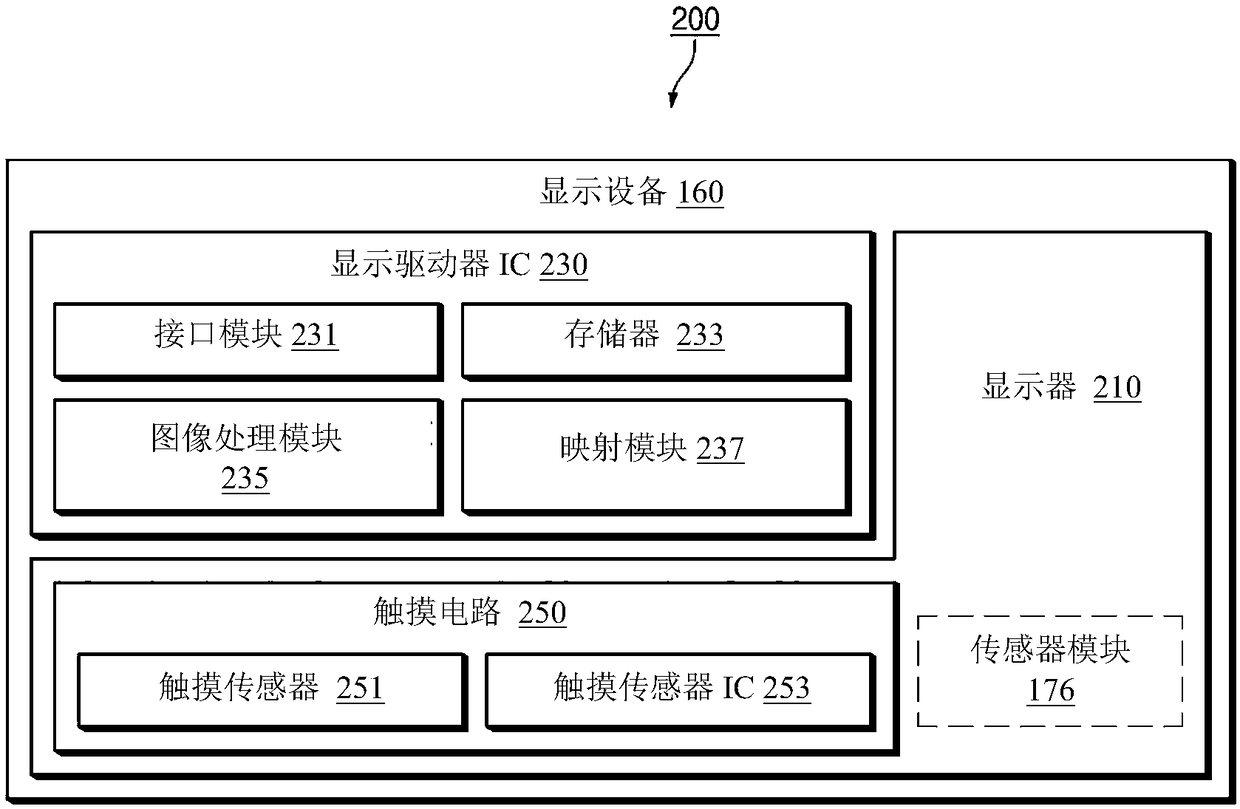

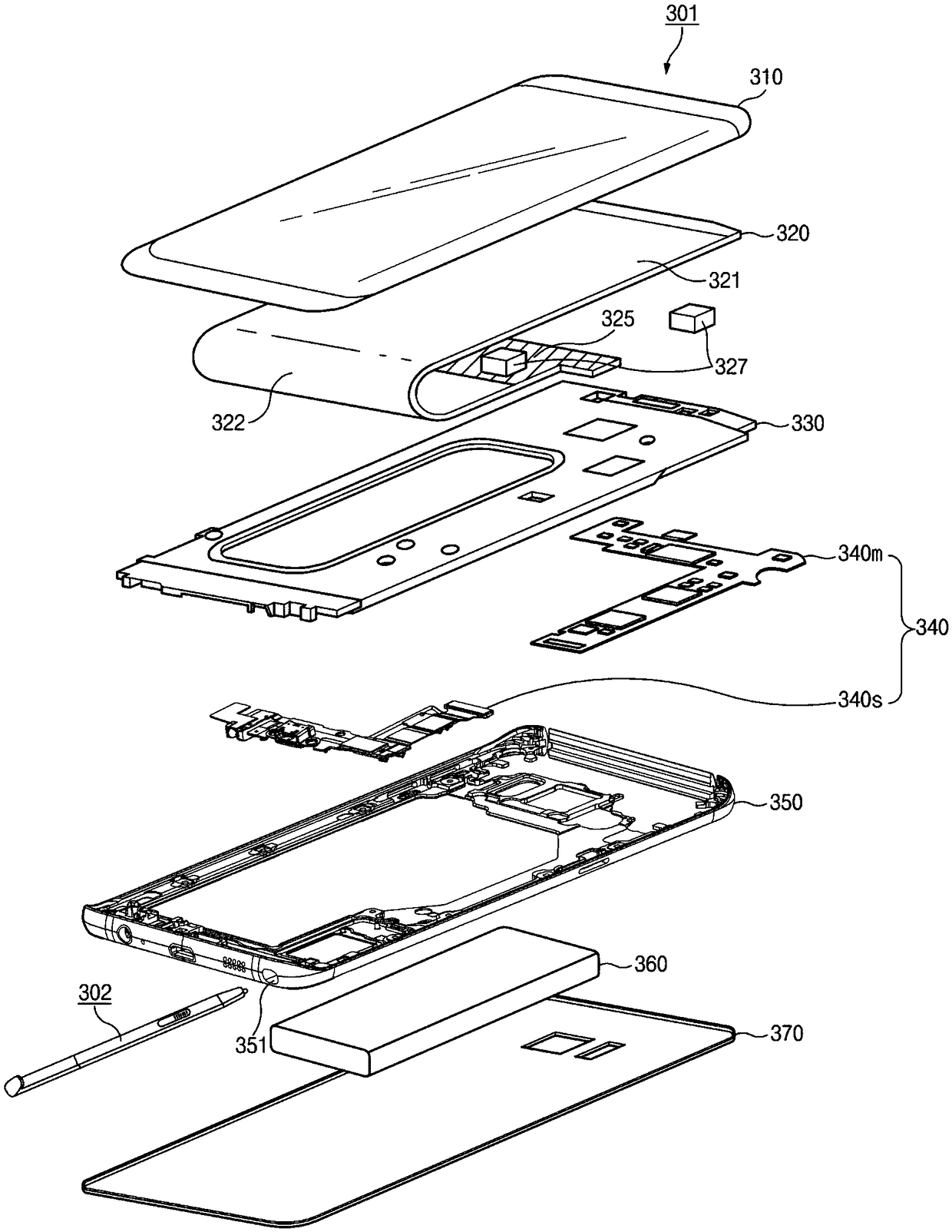

An electronic device

ActiveCN109388278AReduced likelihood of cracksDigital data processing detailsPhotovoltaic energy generationInsulation layerControl circuit

An electronic device includes a first lead, a second lead, a touch sensitive display panel including a screen area and an extended area that extends from the screen area, and a control circuit. The touch sensitive display panel includes a flexible substrate, a thin film transistor (TFT) layer including a plurality of light-emitting elements, an insulation layer in which a via-hole is formed, and atouch sensor. The first lead is formed on the TFT layer in the screen area and the extended area and connects the control circuit and the plurality of light-emitting elements. The second lead is formed on the insulation layer in the screen area and on the TFT layer in the extended area, and extends from the screen area to the extended area through the via-hole formed in the insulation layer and connects the control circuit and the touch sensor.

Owner:SAMSUNG ELECTRONICS CO LTD

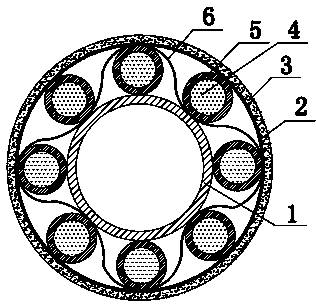

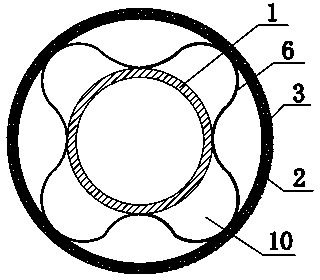

High-temperature concrete pumping pipeline cooling device and cooling method thereof

ActiveCN104179353AIncrease temperatureGuaranteed mold entry temperatureBuilding material handlingMetallurgyConcrete pump

The invention relates to a high-temperature concrete pumping pipeline cooling device and a cooling method thereof. The cooling device is characterized in that the cooling device comprises steel ice, a sleeve and a thermal insulating layer, the steel ice integrally comprises refrigerating fluid and a stainless steel shell, the refrigerating fluid comprises edible alcohol and purified water, the stainless steel shell is set into a ball or cylinder, a hollow structure is arranged inside the stainless steel shell and filled with the refrigerating fluid, the sleeve comprises an inner pipe, an outer pipe and an arc slab, the arc slab is welded between the inner pipe and the outer pipe to form spaced arc grooves for placing the steel ice, the steel ice is slidably arranged in the arc grooves, and the thermal insulating layer wraps the outside of the sleeve. The cooling device is connected with a pumping pipeline, heat generated by friction between concrete and the pipeline and heat generated by hydration of the concrete are evenly absorbed, and the temperature of the pumping pipeline and the temperature of the concrete are reduced by the aid of the steel ice, so that the temperature of casting concrete is kept within a specified range.

Owner:MINGYE CONSTR GRP

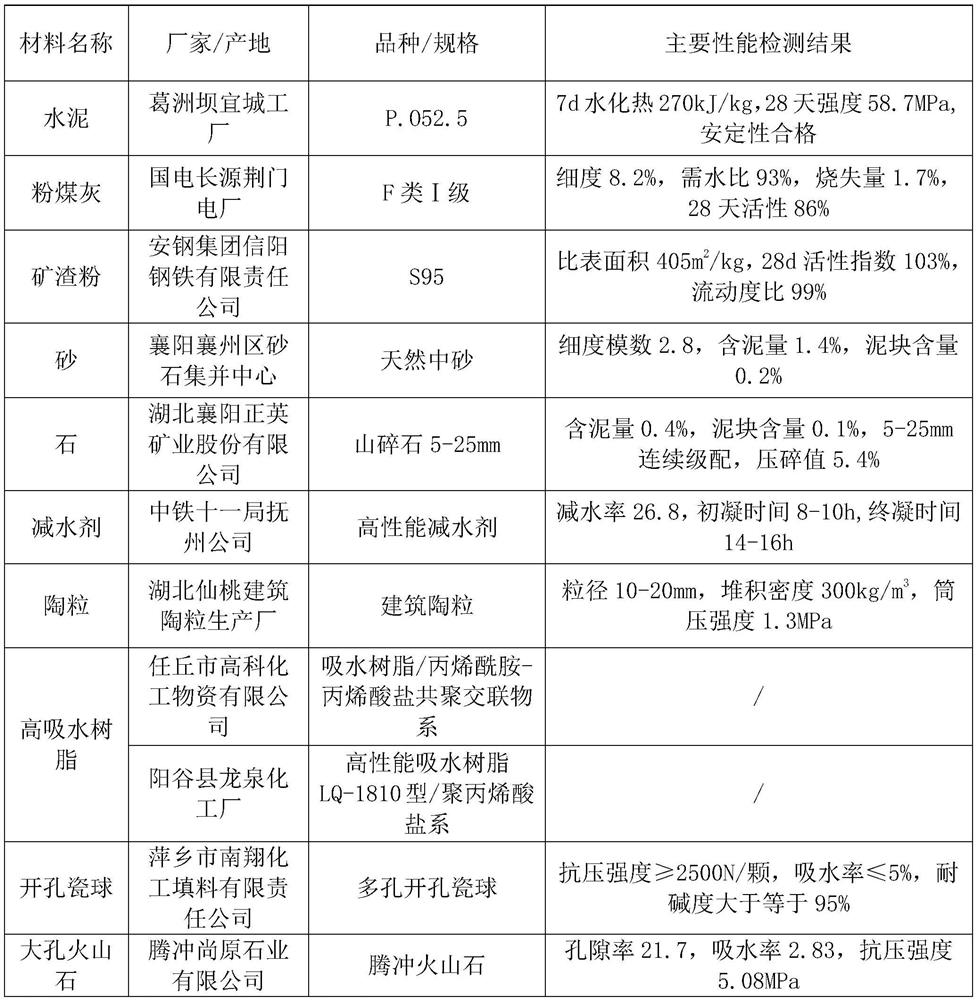

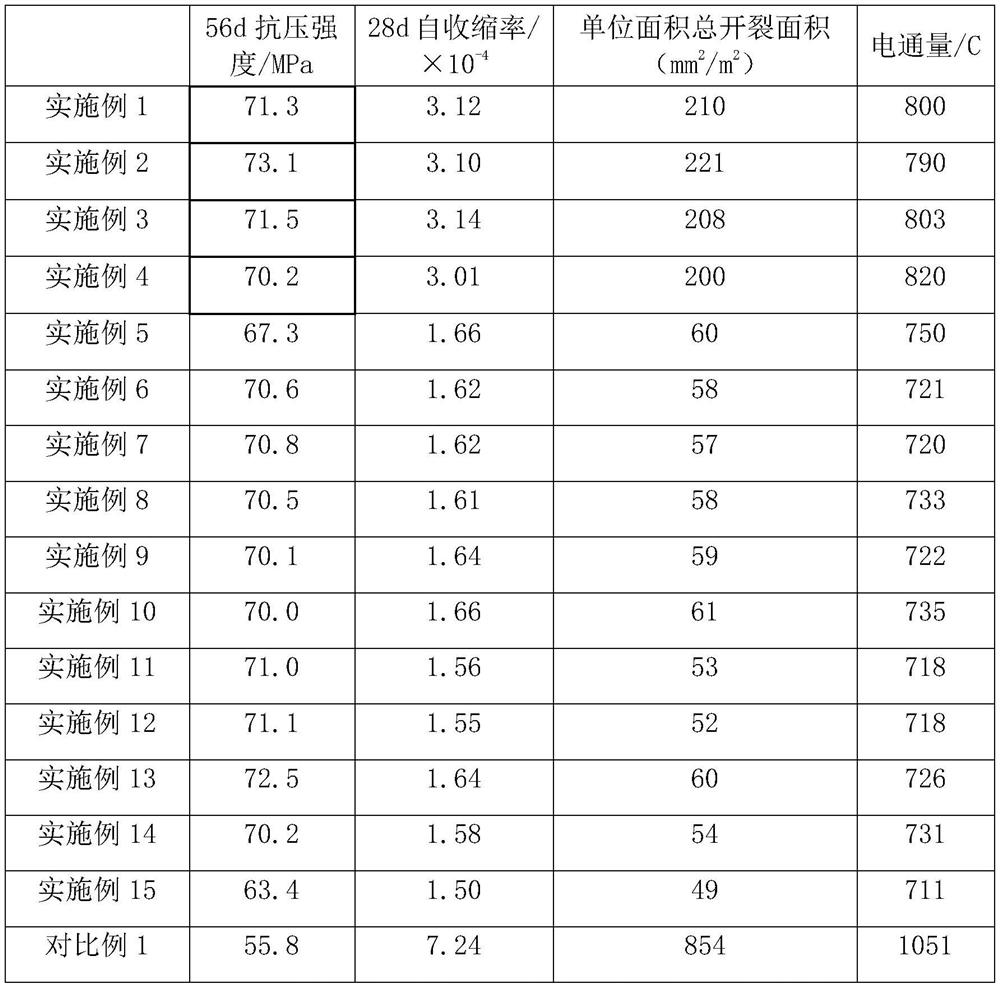

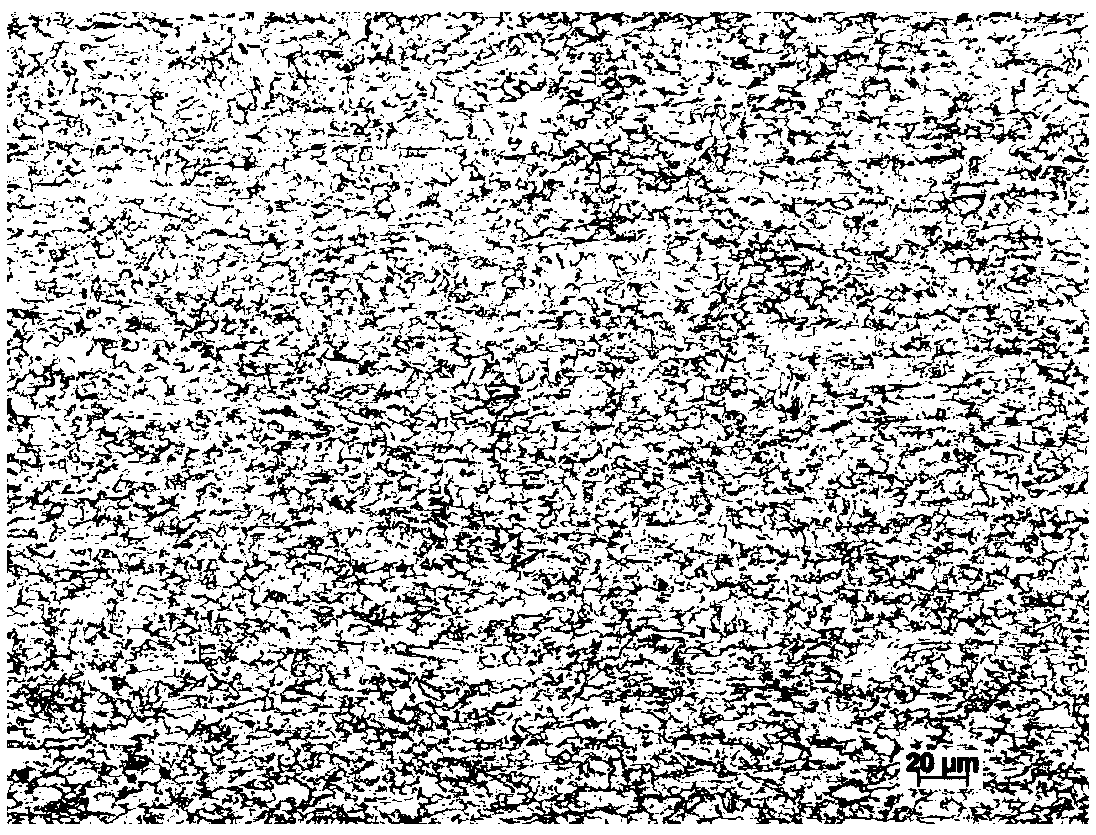

Mass concrete and preparation method thereof

The invention relates to the field of concrete, and particularly discloses mass concrete as well as a preparation method and application thereof. The mass concrete is prepared from the following raw materials in parts by weight: 340-355 parts of cement; 40 to 45 parts of fly ash; 100 to 110 parts of mineral powder; 680 to 720 parts of fine aggregate; 1080 to 1100 parts of coarse aggregate; 7-9 parts of a water reducing agent; and 135 to 145 parts of water. The preparation method comprises the following steps: weighing the cement, the fly ash, the mineral powder, the fine aggregate and the coarse aggregate in proportion, and uniformly mixing and stirring to obtain a first mixture; and weighing the water reducing agent and the water according to the proportion, adding the weighed water reducing agent into the water, uniformly mixing, adding the water doped with the water reducing agent into the first mixture, and uniformly stirring to obtain the mass concrete. The mass concrete has the advantages that the crack generation probability is reduced, and the crack generation amount is reduced.

Owner:襄阳嘉众和建材实业有限公司

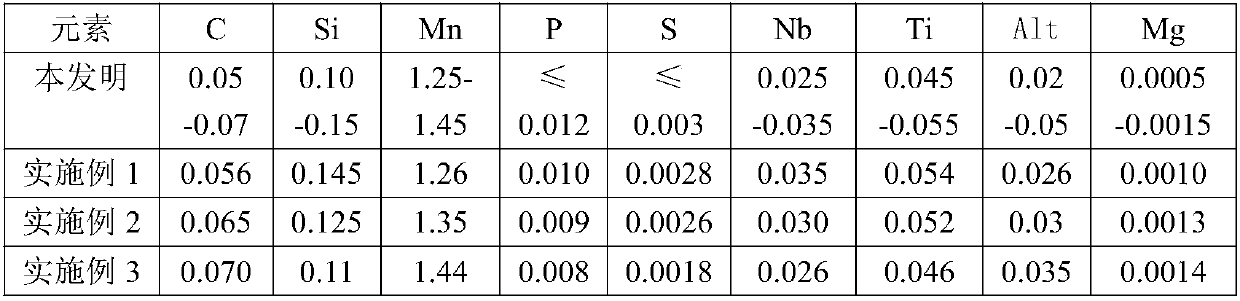

630 MPa-grade tensile strength hot-rolled steel plate for wheel and manufacturing method thereof

InactiveCN110938771AGood welding performanceGive full play to the controlled cooling process of hot rollingChemical compositionMetallurgy

The invention discloses a 630 MPa-grade tensile strength hot-rolled steel plate for a wheel and a manufacturing method thereof. The hot-rolled steel plate and the manufacturing method thereof mainly solve the technical problems that the tensile strength of an existing hot-rolled steel plate for the car wheel is low, the manufacturing cost is high, and the fatigue performance of the wheel is insufficient after the car wheel is manufactured by using the existing hot-rolled steel plate. The hot-rolled steel plate comprises the chemical components of, by weight, 0.05%-0.07% of C, 0.10%-0.15% of Si, 1.25%-1.45% of Mn, less than or equal to 0.012% of P, less than or equal to 0.003% of S, 0.025%-0.035% of Nb, 0.045%-0.055% of Ti, 0.0005%-0.0015% of Mg, 0.02%-0.05% of Alt, less than or equal to 0.0040% of N and the balance Fe and inevitable impurities, wherein the content of the elements needs to satisfy the requirement that the carbon equivalent is less than or equal to 0.35%. The hot-rolledsteel plate is mainly used for manufacturing a car spoke.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

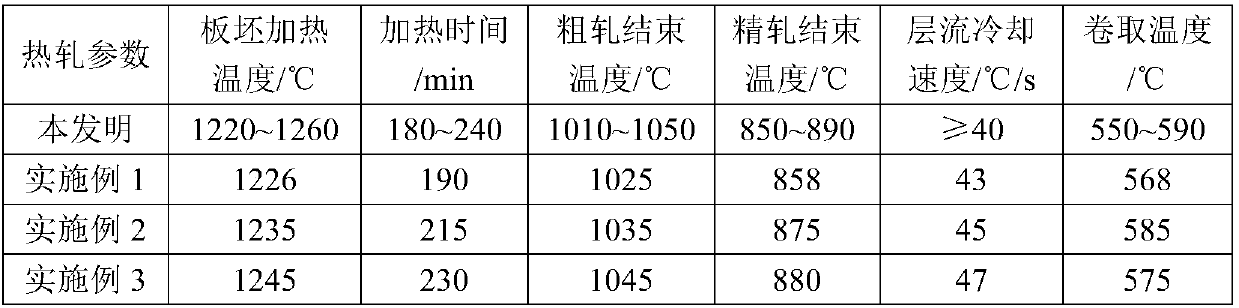

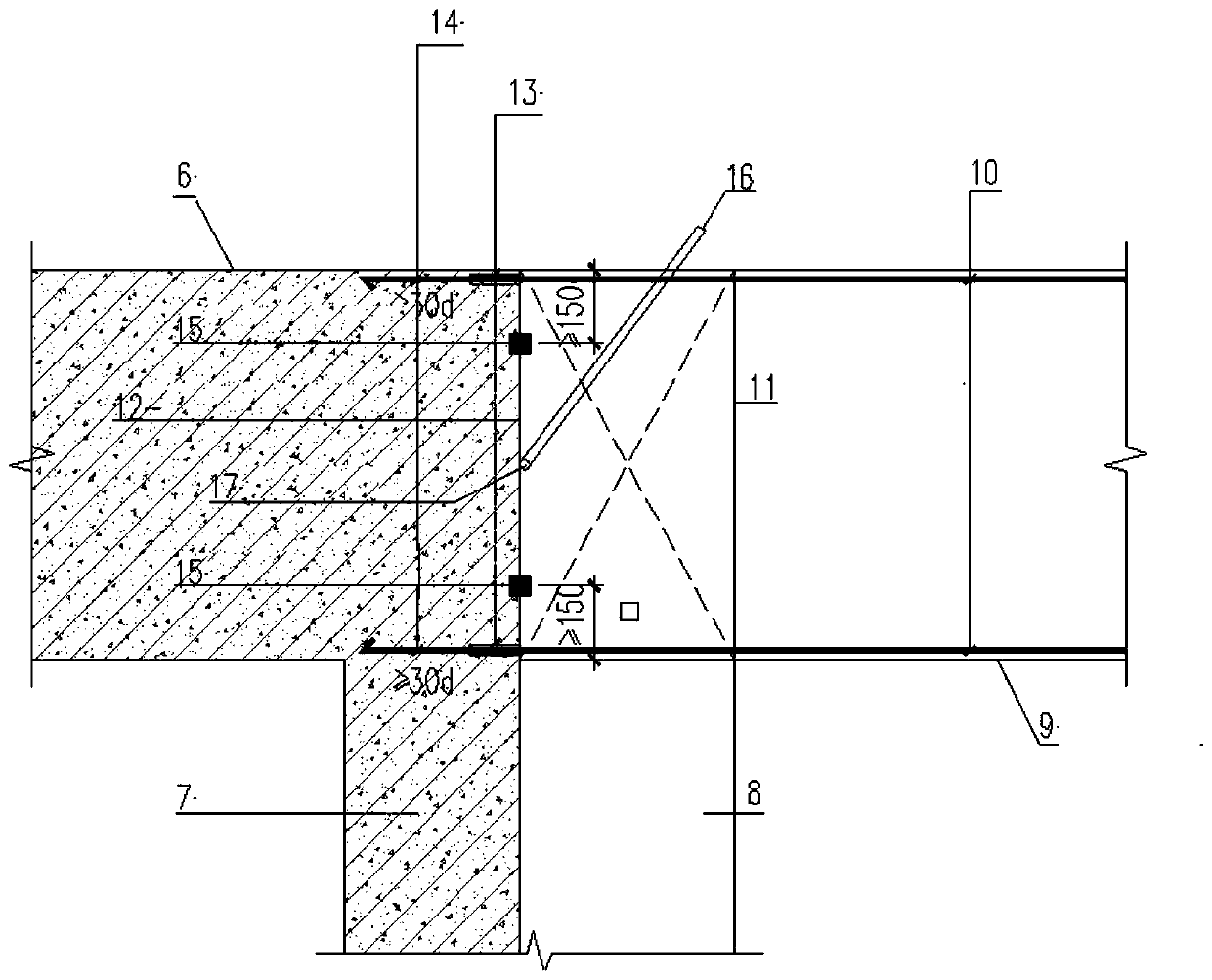

Connecting structure and method for joint of new and old concrete members

PendingCN110067311AImprove inspection pass rateSolve the problem of internal force transmissionBuilding material handlingBuilding insulationsSteel barGuide tube

The invention provides a connecting structure and method for the joint of new and old concrete members. The connecting structure for the joint of the new and old concrete members includes a new concrete member and an old concrete members which are oppositely arranged; a construction joint exists between the new concrete member and the old concrete member; first stressed steel bars are horizontallyembedded in the old concrete member, and second stressed steel bars are horizontally embedded in the new concrete member; the first stressed steel bars and the second steel bars are all used for supporting the new concrete member; the first stressed steel bars and the second stressed steel bars are coaxially connected through steel bar connectors, and the steel bar connectors are embedded in theold concrete member and the end parts of the steel bar connectors are exposed on the wall surface, opposite to the new concrete member, of the old concrete member; water expansion water stop strips are arranged on the wall surface, opposite to the new concrete member, of the old concrete member; and concrete is poured into the construction joint between the new concrete member and the old concretemember through a grouting duct and a grouting pipe. The connecting structure and method for the joint of the new and old concrete members is suitable for situations that the buried depth is large, the groundwater level is high, and the construction joints are influenced by the groundwater environment for a long time.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

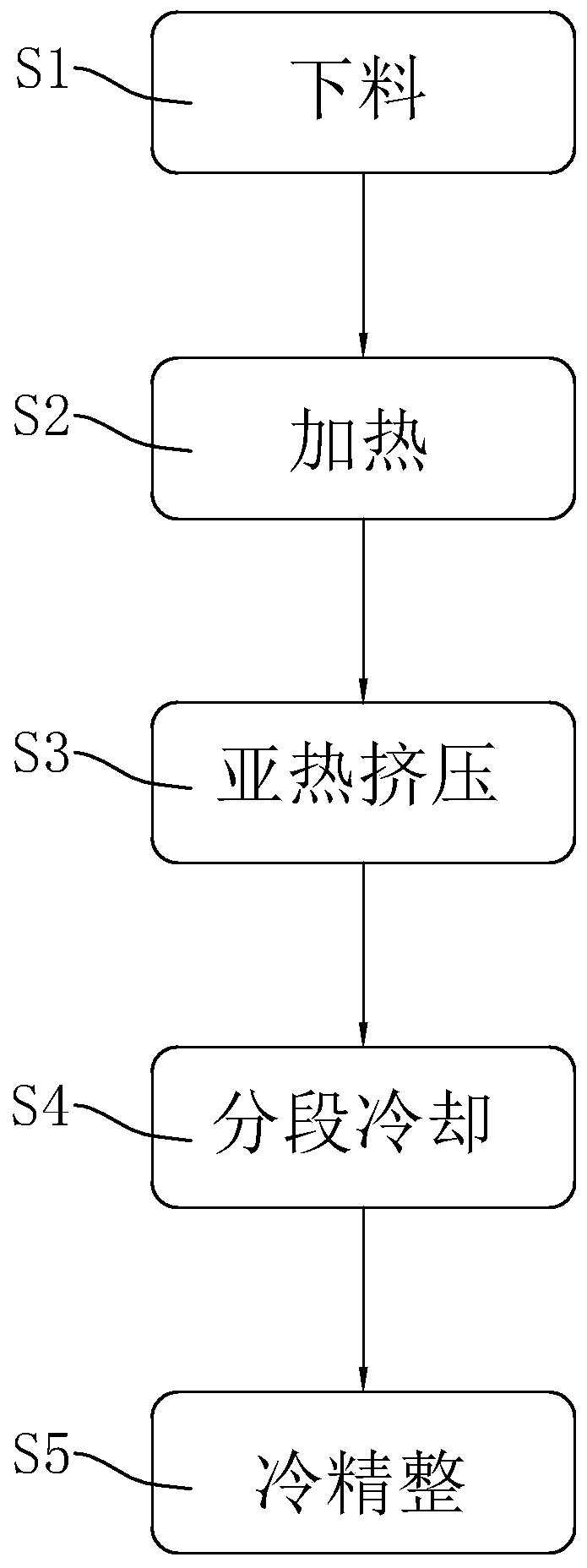

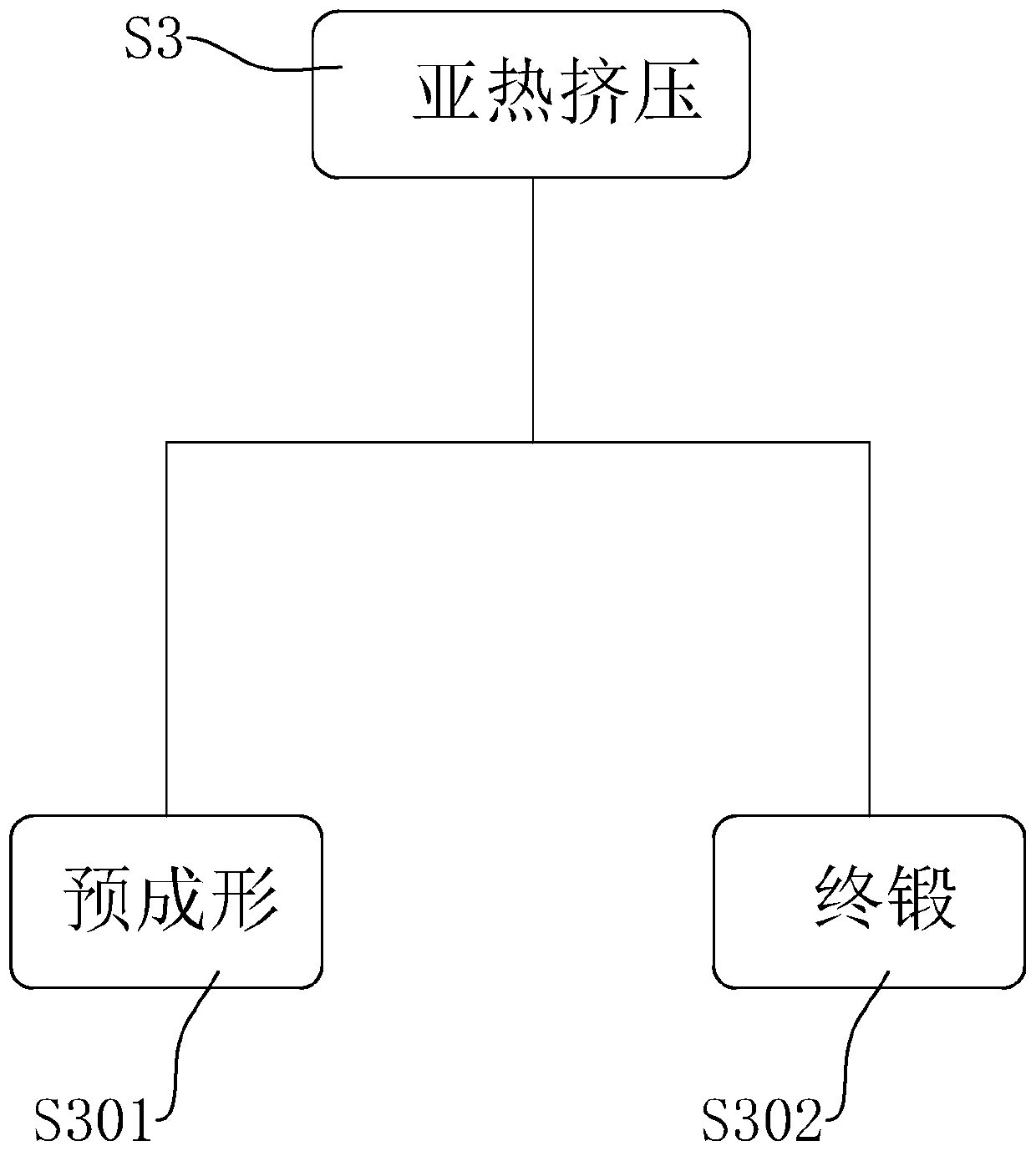

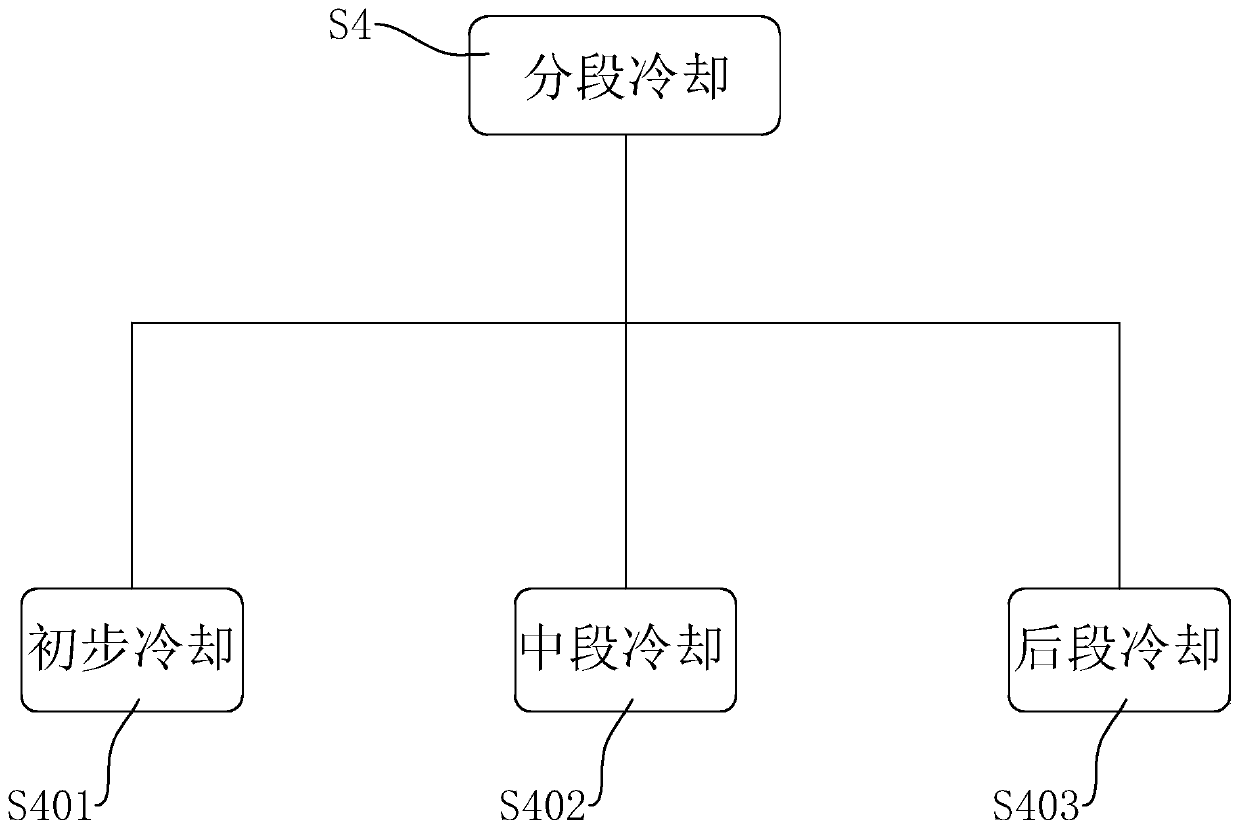

Forging process of external star wheel provided with handle

ActiveCN111375717AConsistent internal temperatureReduce crackingExtrusion diesForging/hammering/pressing machinesForgingMaterials science

Owner:上海长特锻造有限公司

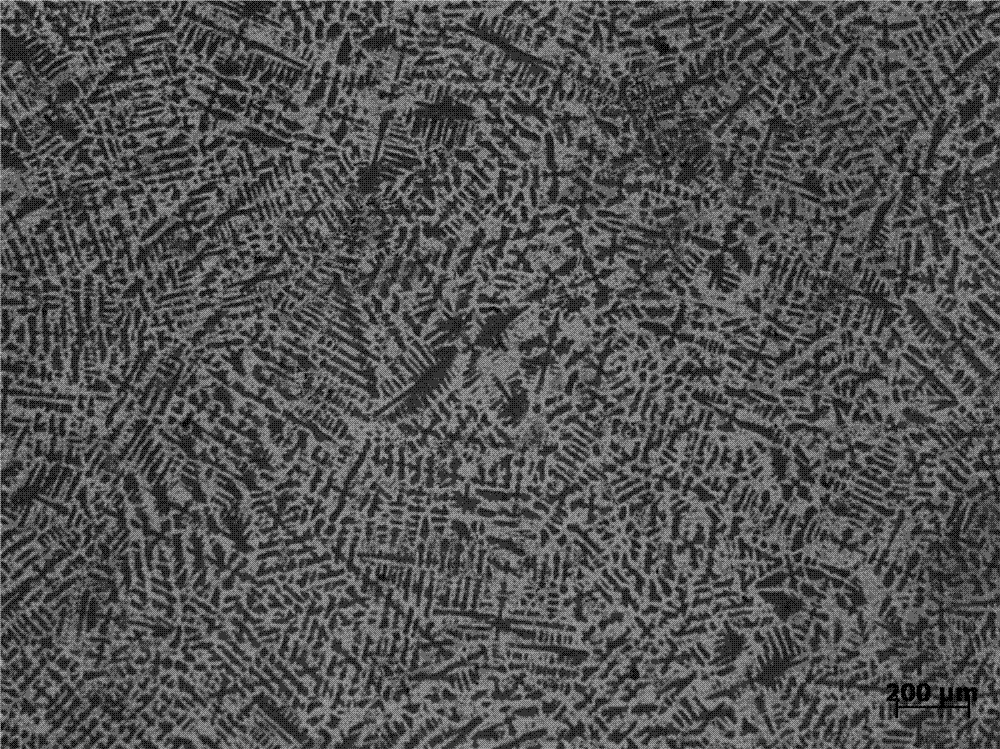

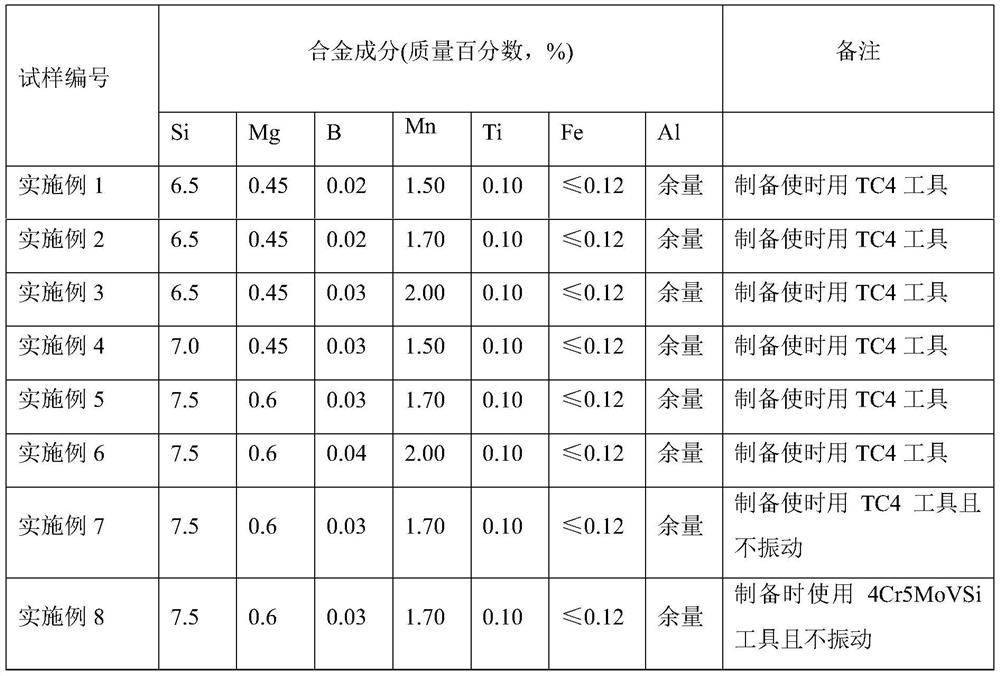

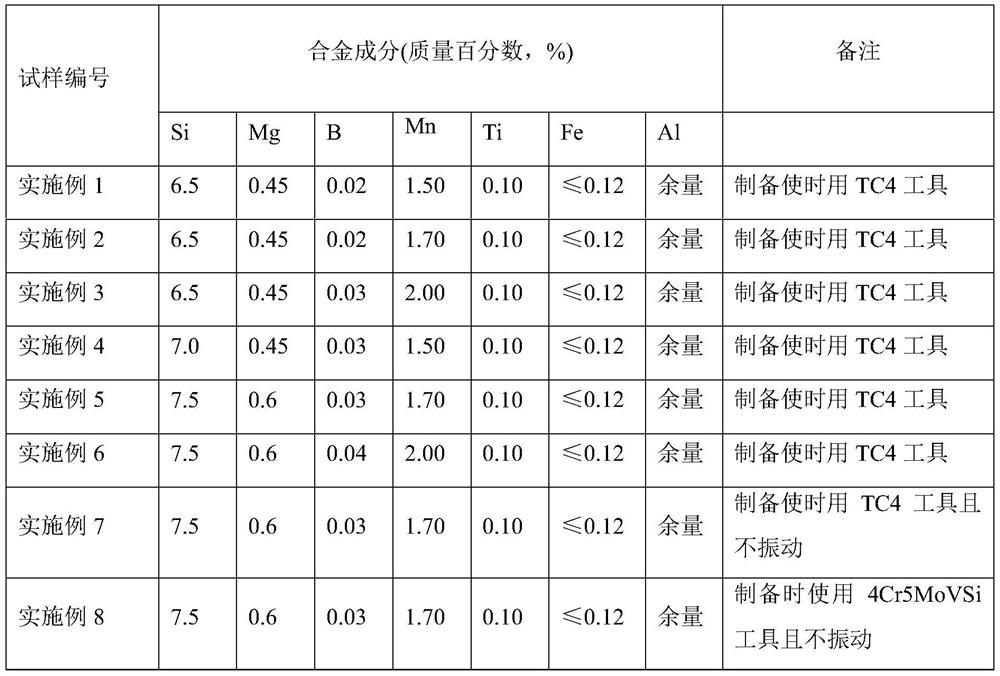

Preparation process of Al-Si-Mg-B-Mn casting alloy with excellent flowing property

The invention discloses a preparation process of an Al-Si-Mg-B-Mn casting alloy with an excellent flowing property, wherein the Al-Si-Mg-B-Mn casting alloy is prepared from the following components including, by mass, 6.50 to 7.50 percent of Si, 0.25 to 0.45 percent of Mg, 0.02 to 0.03 percent of B, 1.50 to 2.00 percent of Mn, less than or equal to 0.12 percent of Fe, 0.10 to 0.20 percent of Ti and the balance aluminum. According to the preparation process, the microstructure and performance of the Al-Si alloy are improved through the technological processes of burdening, smelting and casting, heat treatment and the like, the fluidity of the alloy is improved while higher strength and hardness can be ensured, the cost is reduced, and the Al-Si alloy can be widely applied to the manufacturing industry of automobile parts.

Owner:HEFEI UNIV OF TECH

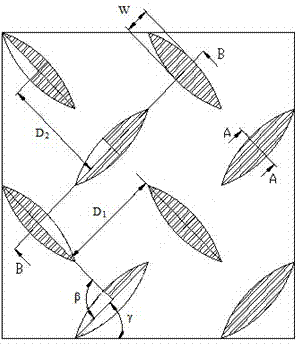

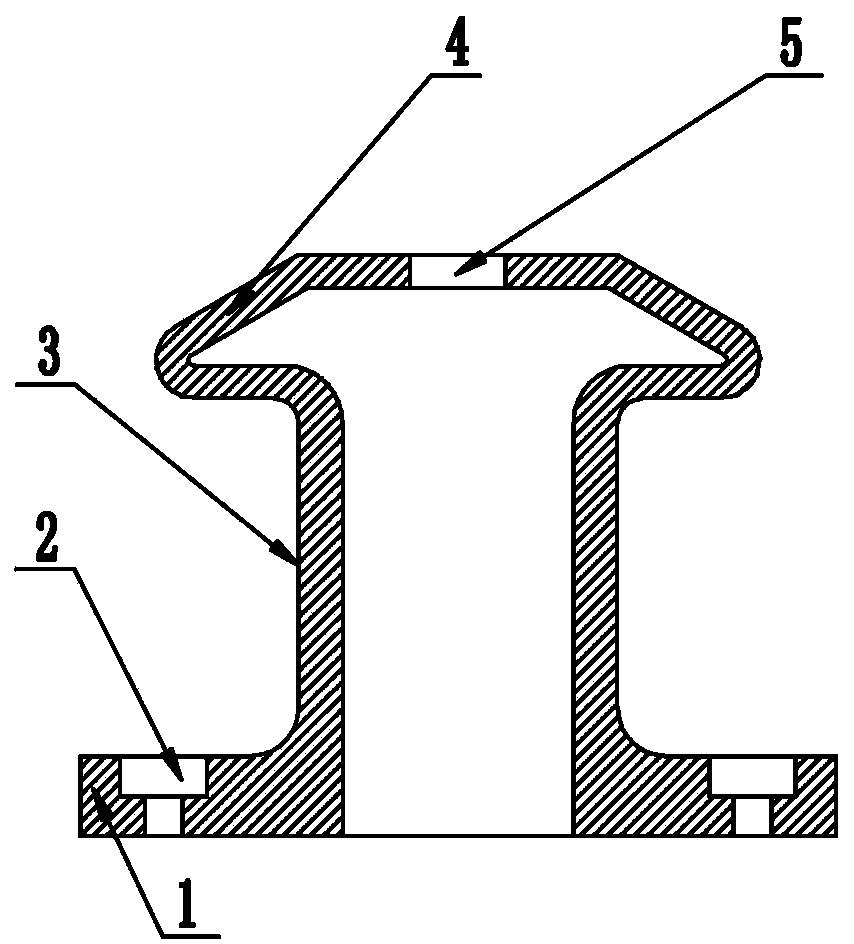

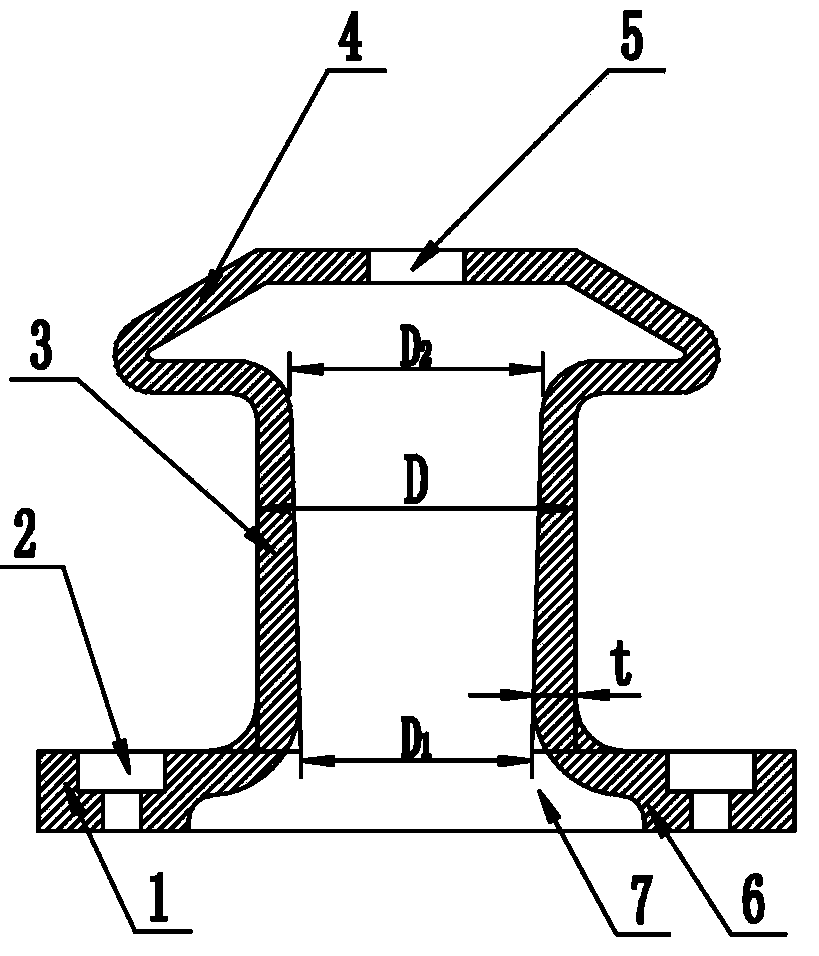

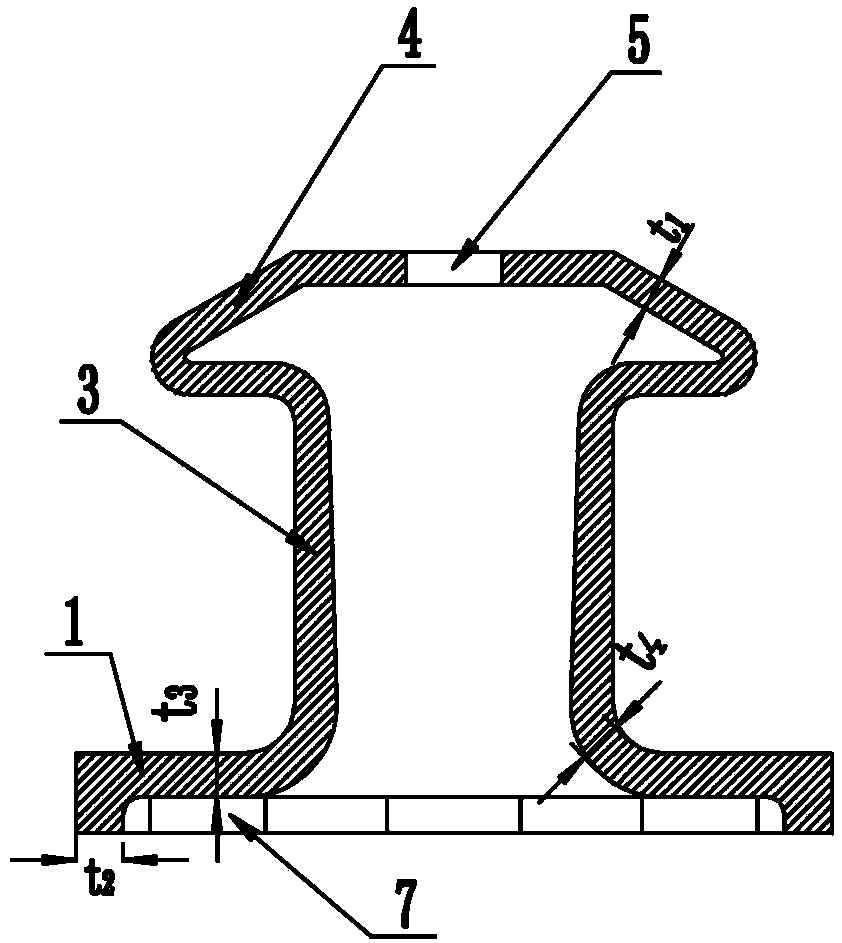

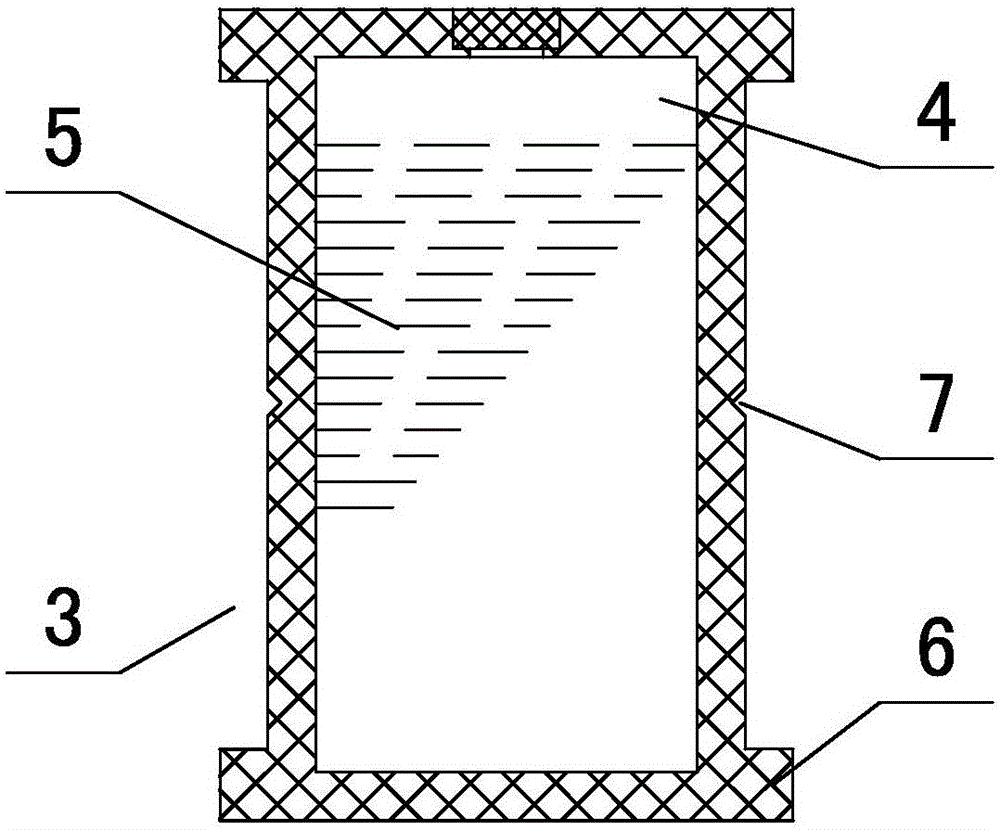

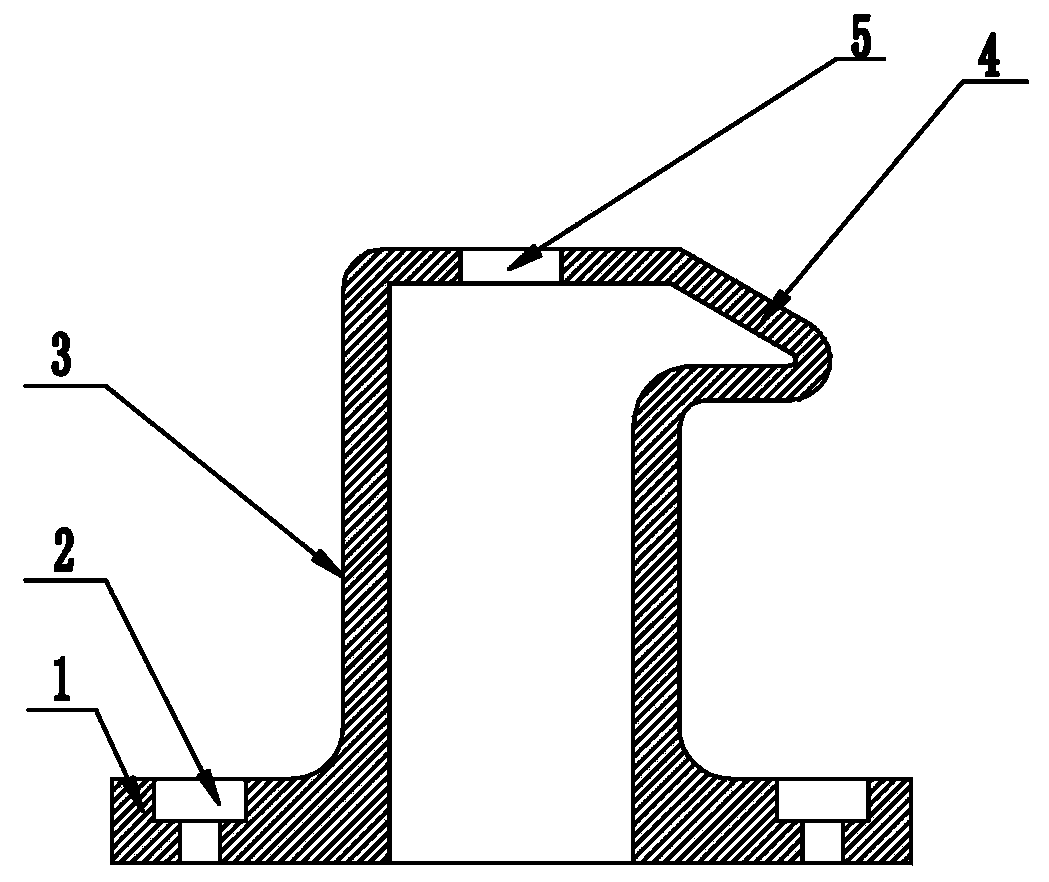

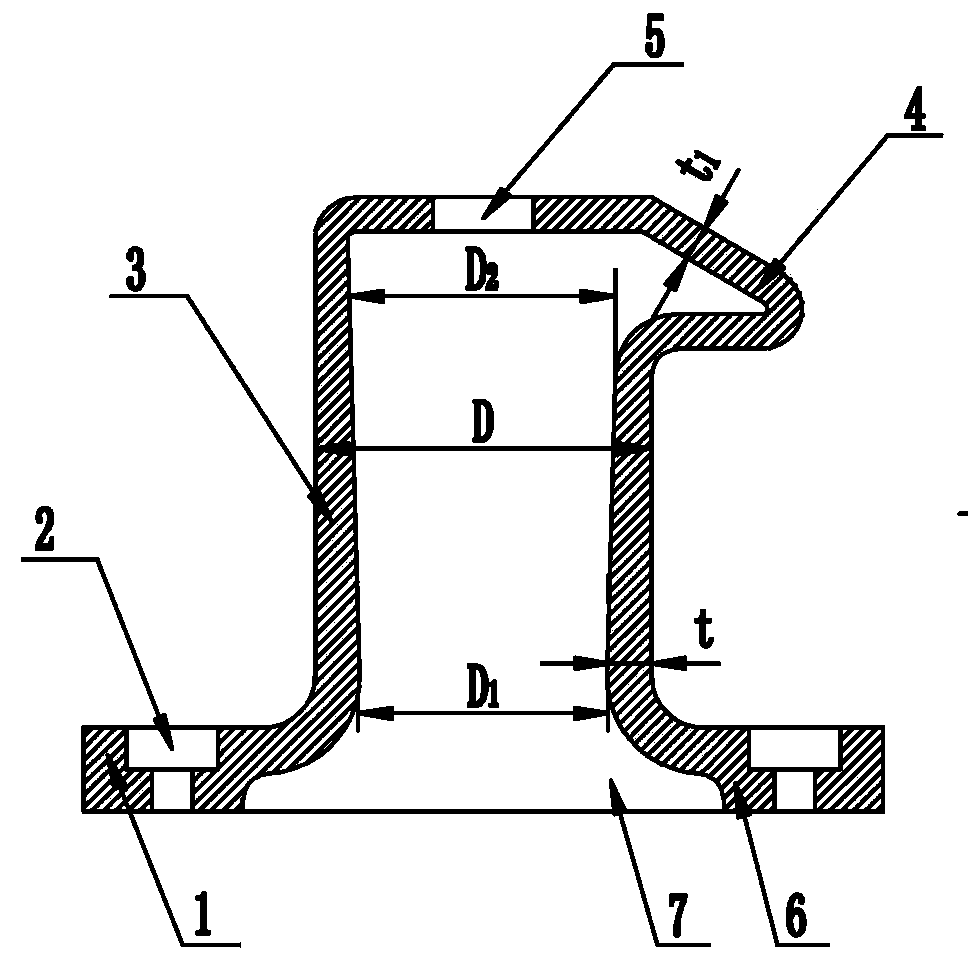

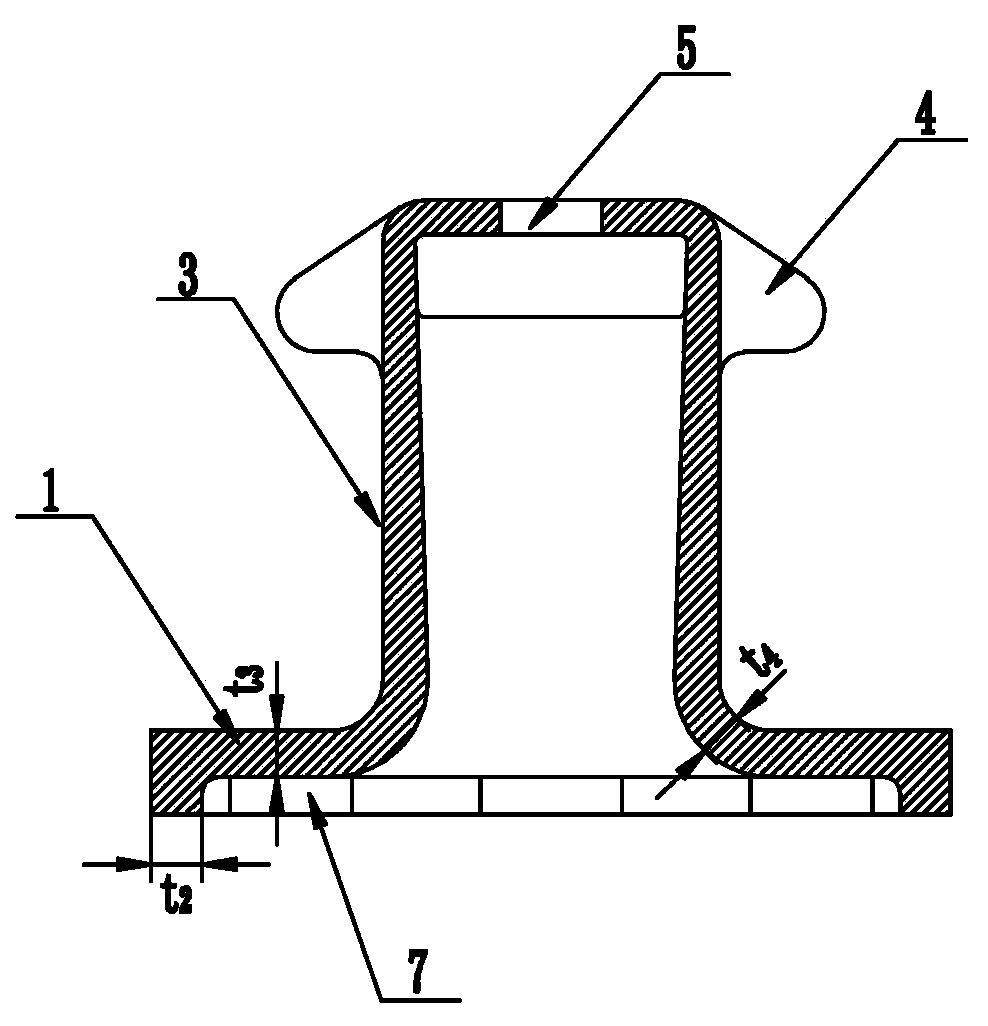

Reinforced full-blocking-eave bollard

InactiveCN104213542AImprove tethering forceReasonable geometryShipping equipmentDesign standardEaves

The invention relates to a reinforced full-blocking-eave bollard used for wharves and ship locks. The reinforced full-blocking-eave bollard is provided with a base plate, a bollard body and a full-blocking eave. A plurality of anchor bolt countersinks are formed in the base plate, a top hole is formed in the top of the full-blocking eave, the bollard and the full-blocking eave are respectively of a cavity structure, the standard wall thickness of the bollard body is designed to be t, and accordingly the wall thickness of the blocking eave is 0.75t. The reinforced full-blocking-eave bollard is characterized in that a cavity of the bollard body is a conical cavity, the inner diameter D1 of a lower end opening of the cavity of the bollard body is equal to the outer diameter D-2t of the bollard body, and the inner diameter D2 of an upper end opening of the cavity of the bollard body is equal to the outer diameter D-1.5t of the bollard body. A cavity is formed in the base plate, the wall thickness of the top face of the cavity of the base plate is kept to be t, and the lateral wall thickness is larger than or equal to t. A reinforcing table is arranged at the position, located in each anchor bolt countersink, of the cavity of the base plate. The reinforced full-blocking-eave bollard overcomes the casting defects that an existing full-blocking-eave bollard is unreasonable in structural design and shrinkage, contraction cavities, cracks and the like are prone to being generated, solves the problem that material waste is high, and is mainly used in the places such as the wharves and the ship locks for ship cable mooring.

Owner:HUANGSHI ONTIME ELECTROMECHANICAL

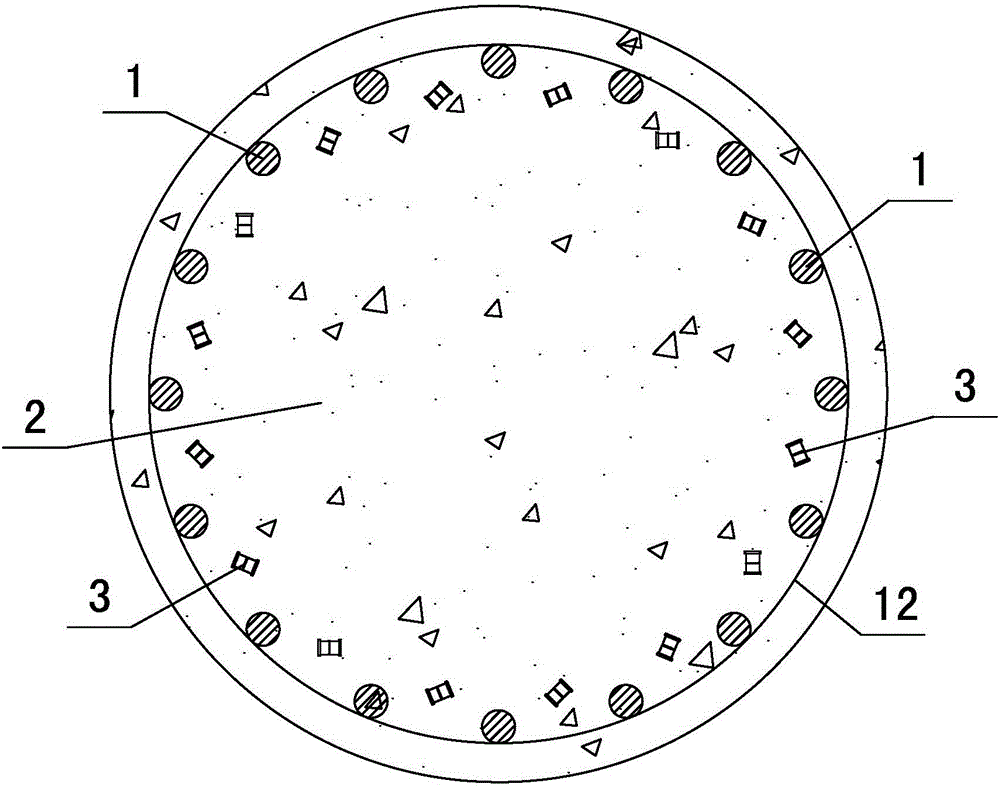

Anti-corrosion reinforcing structure for column

The invention discloses an anti-corrosion reinforcing structure for a column. The column comprises concrete and main steel bars arranged in the concrete. Joint mixture releasing blocks are arranged in the concrete of the column and internally provided with cavities, and joint mixtures are packaged in the cavities. When cracks appear in the column, the joint mixture releasing blocks crack, and the cracks are filled with the joint mixtures. By means of the anti-corrosion reinforcing structure, the problem that the service life of a column is shortened due to the fact that internal steel bars are corroded easily after cracks appear in the reinforced concrete column in the prior art is effectively solved; the anti-corrosion reinforcing structure has an automatic crack filling function after cracks appear in the column, meanwhile, the possibility of crack occurrence in the column is greatly lowered through the reinforcing structure, and therefore the service life of the column is greatly prolonged; and the anti-corrosion reinforcing structure has high practical value.

Owner:舟山市宏达交通工程有限责任公司

Decorative caulking agent and preparation method thereof

Relating to the technical field of caulking agents, the invention discloses a decorative caulking agent and a preparation method thereof. The decorative caulking agent comprises the following raw materials: 55-60 parts of water absorbent resin, 45-47 parts of modified vegetable oil, 38-39 parts of waste porcelain powder, 32-33 parts of redispersible latex powder, 28-29 parts of paraffin phase change microspheres, 21-23 parts of citric acid, 15-17 parts of plant dehydrated fiber filament, 12-14 parts of a colorant, 20-23 parts of assistants and 57-65 parts of water. The decorative caulking agent provided by the invention has decorative effect and certain aesthetics, and excellent crack resistance, overcomes the shortcomings of existing caulking agents, and prolongs the service life of itself and tiles.

Owner:合肥市一片叶装饰工程有限公司

Protecting welding process with mixed Ar plus CO2 gas

InactiveCN101020273ALow splash rateReduce lossesArc welding apparatusWelding/cutting media/materialsMaterial consumptionProduct gas

The protected welding process with mixed Ar plus CO2 gas includes the following steps: selecting arc voltage in 20-26 V; selecting welding current in 200-230 A; selecting gas flow rate in 15-20 l / min; connecting to power source in correct polarity; selecting wire feeding speed in 5.25 m / min; determining wire extending length of 15 mm; feeding wire in equal speed; and continuously welding. The present invention has the advantages of excellent welding performance, lowered welding material consumption, high welding quality, etc. and may be used in welding rotor rack, machine foundation, etc.

Owner:SICHUAN DONGFENG ELECTRIC MACHINARY WORKS CO LTD

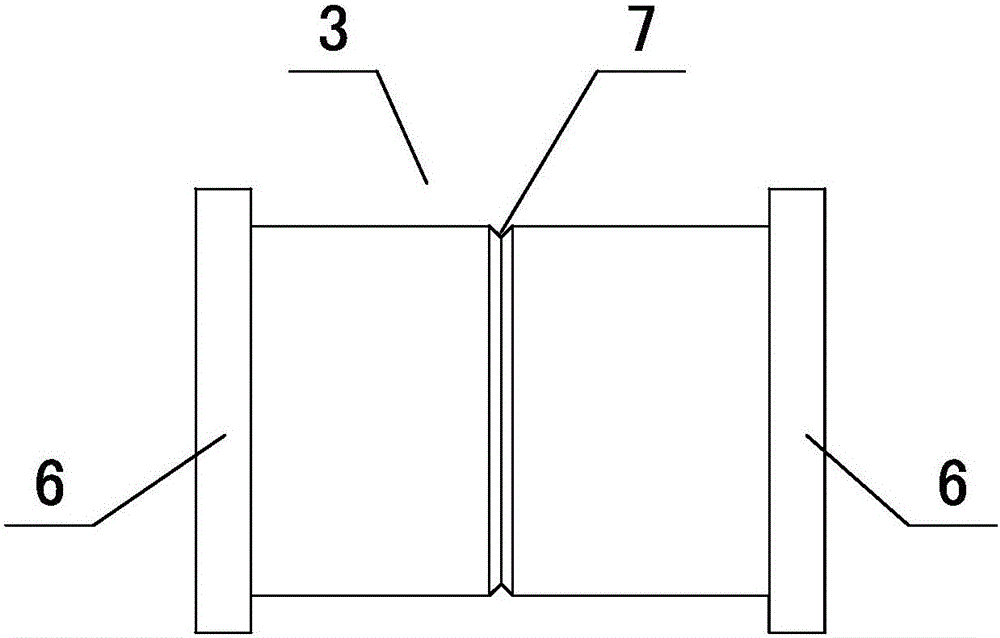

Reinforced unidirectional-blocking-eave bollard

The invention relates to a reinforced unidirectional-blocking-eave bollard used for wharves and ship locks. The reinforced unidirectional-blocking-eave bollard is provided with a base plate, a bollard body and a unidirectional-blocking eave. A plurality of anchor bolt countersinks are formed in the base plate, a top hole is formed in the top of the unidirectional-blocking eave, the bollard and the unidirectional-blocking eave are respectively of a cavity structure, the standard wall thickness of the bollard body is designed to be t, and accordingly the wall thickness of the blocking eave is 0.75t. The reinforced unidirectional-blocking-eave bollard is characterized in that a cavity of the bollard body is a conical cavity, the inner diameter D1 of a lower end opening of the cavity of the bollard body is equal to the outer diameter D-2t of the bollard body, and the inner diameter D2 of an upper end opening of the cavity of the bollard body is equal to the outer diameter D-1.5t of the bollard body. A cavity is formed in the base plate, the wall thickness of the top face of the cavity of the base plate is kept to be t, and the lateral wall thickness is larger than or equal to t. A reinforcing table is arranged at the position, located in each anchor bolt countersink, of the cavity of the base plate. The reinforced unidirectional-blocking-eave bollard overcomes the casting defects that an existing unidirectional-blocking-eave bollard is unreasonable in structural design and shrinkage, contraction cavities, cracks and the like are prone to being generated, solves the problem that material waste is high, and is mainly used in the places such as the wharves and the ship locks for ship cable mooring.

Owner:HUANGSHI ONTIME ELECTROMECHANICAL

Preparation process of an al-si-mg-b-mn casting alloy with excellent flow properties

Owner:HEFEI UNIV OF TECH

Construction method for large cast-in-situ reinforced concrete water inlet channel

InactiveCN102296570BWill not cause serious delays in the construction periodShorten the construction periodArtificial water canalsInlet channelReinforced concrete

The invention relates to a construction method for a large cast-in-situ reinforced concrete water inlet channel. The construction method comprises the following steps: the construction of concrete near the water inlet channel is divided into five main parts, wherein the construction of the concrete around the water inlet channel adopts integral layered casting, the secondary pouring in the traditional casting process is eliminated, and the integration of the concrete around the water inlet channel is ensured; for the parts at which the concrete at the bottom of the elbow of the water inlet channel is not easily vibrated, a vibration guiding device is bound in advance when the parts pass through the bound steel bars, so that the density of the compact at the bottom is realized, and simultaneously a method for combining supporting and pulling is adopted for reinforcing a water inlet channel template. According to the construction method, the condition that a plurality of more complex construction areas are not mutually influenced can be guaranteed, so that the construction period is shortened, the possibility of large-volume concrete cracks is reduced, and the construction accuracy of the whole water inlet channel, the floating deformation resistance of the template in the construction process and the quality of products are better guaranteed. The construction method can be widely applied in construction of the large cast-in-situ reinforced concrete water inlet channel.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

A kind of preparation technology of concrete prefabricated wallboard

ActiveCN111499302BAvoid crackingHigh compressive strengthConstruction materialWallsCompressive resistanceDioxyethylene Ether

The present invention relates to the technical field of wall panels, and discloses a preparation process for concrete prefabricated wall panels, including the following steps: S1: mold preparation; S2: installation of steel bars; installation of steel bars in the mold after S1 mold preparation; S3: pouring Concrete; pouring concrete towards the mold after S2 treatment; the raw materials of the concrete include by weight: 180-240 parts of cement, 550-630 parts of coarse aggregate, 100-150 parts of fine aggregate, 300 parts of fly ash ‑430 parts, 6‑15 parts of calcium lignosulfonate, 60‑80 parts of water, 20‑40 parts of fatty alcohol polyoxyethylene ether and 13‑37 parts of acrylamide grafted co-polymerized starch; S4: Vibration curing; S3 vibrating and curing the poured concrete; S5: dismantling the mold; S6: continuous curing; after the continuous curing in S6, the concrete prefabricated wall panel is obtained. The manufactured prefabricated wall panels can avoid cracks, thereby improving the compressive strength of the prefabricated wall panels.

Owner:浙江欣成建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com