Construction method for large cast-in-situ steel reinforced concrete inlet channel and turbine housing

A reinforced concrete and construction method technology, which is applied in water conservancy projects, artificial waterways, hydroelectric power generation, etc., can solve problems such as difficulty in guaranteeing molding quality, achieve clear construction levels, reduce the possibility of cracks, and facilitate construction organization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The steps of the construction method of the large-scale cast-in-situ reinforced concrete inlet and the scroll shell of the present invention are as follows:

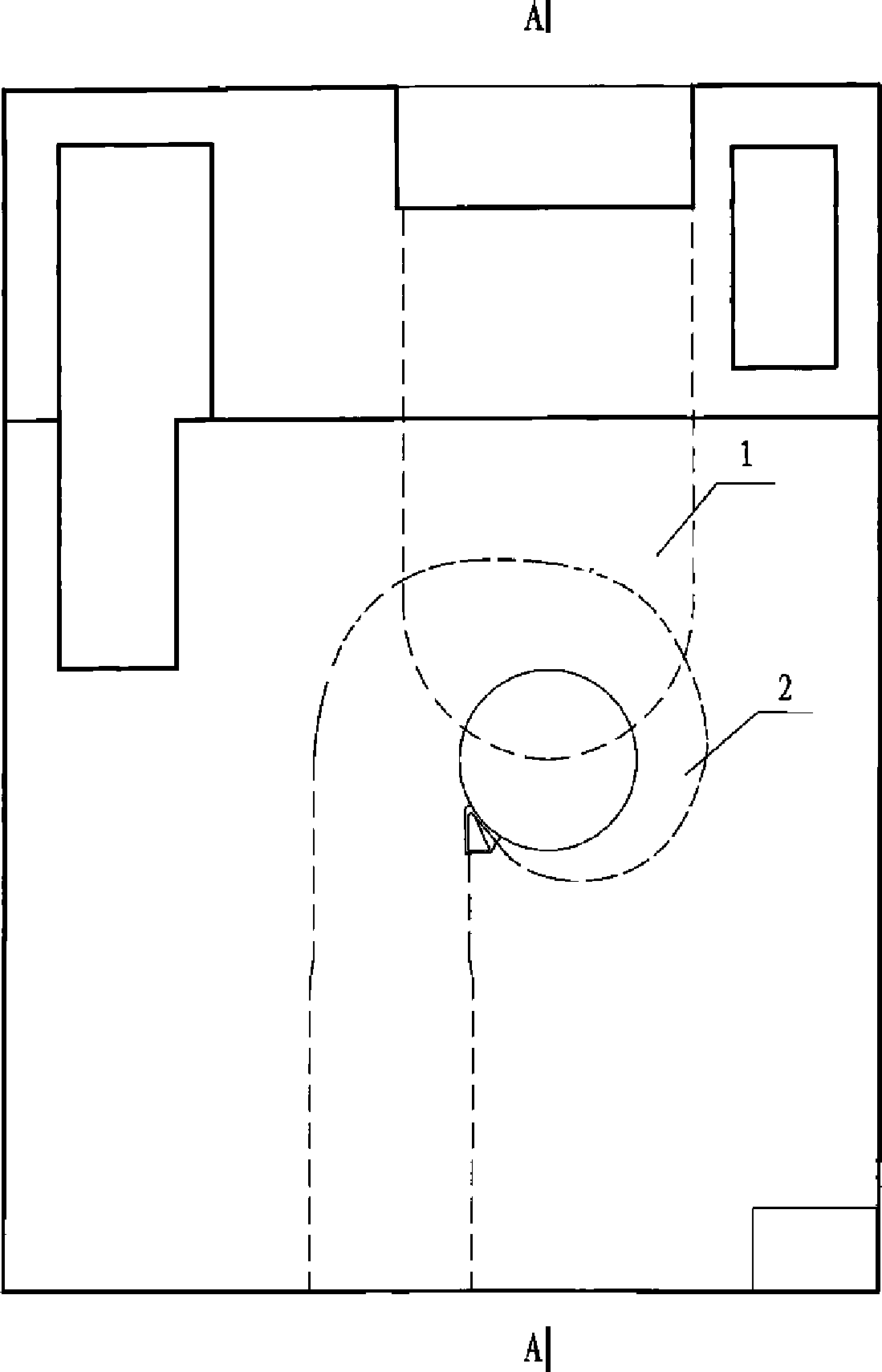

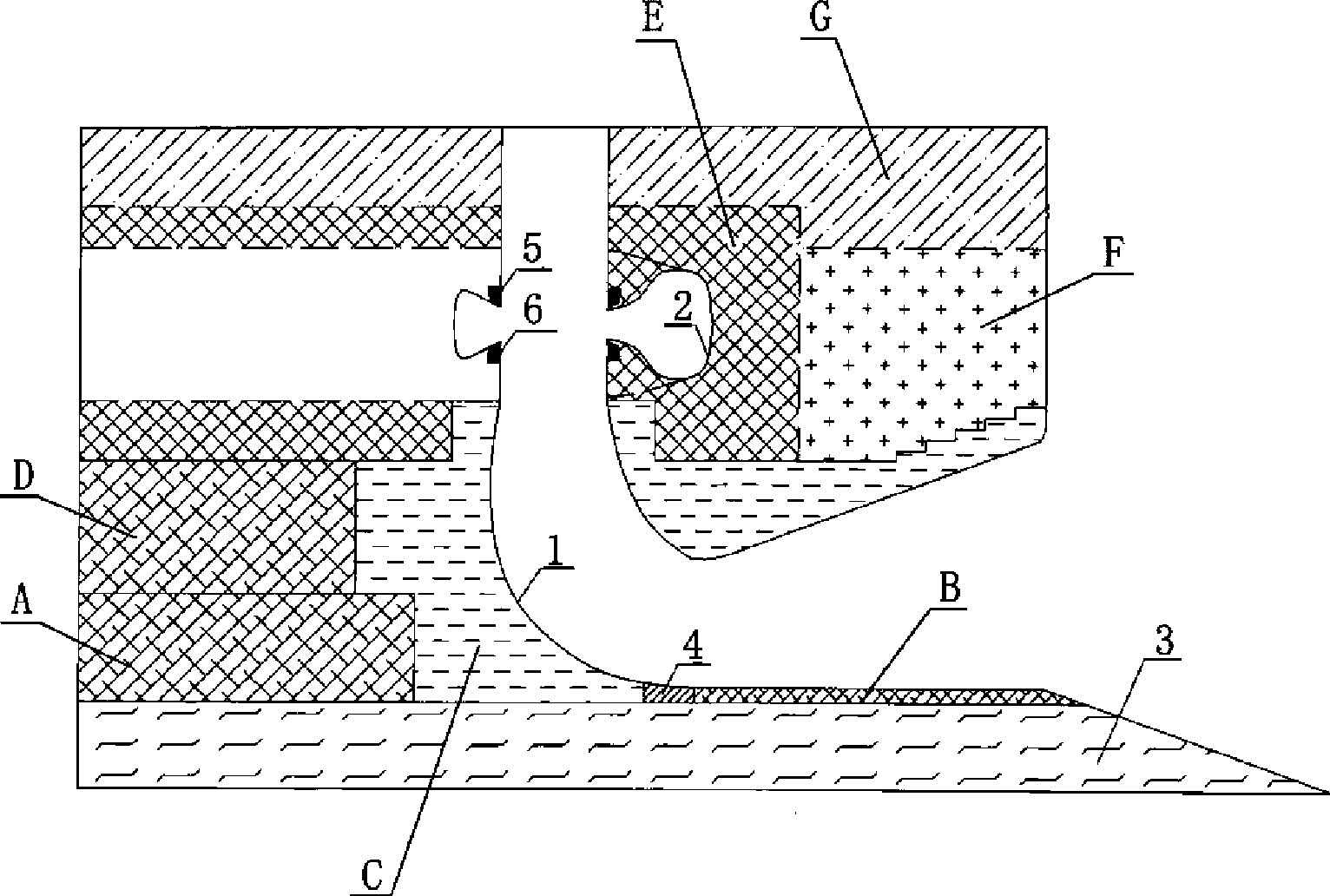

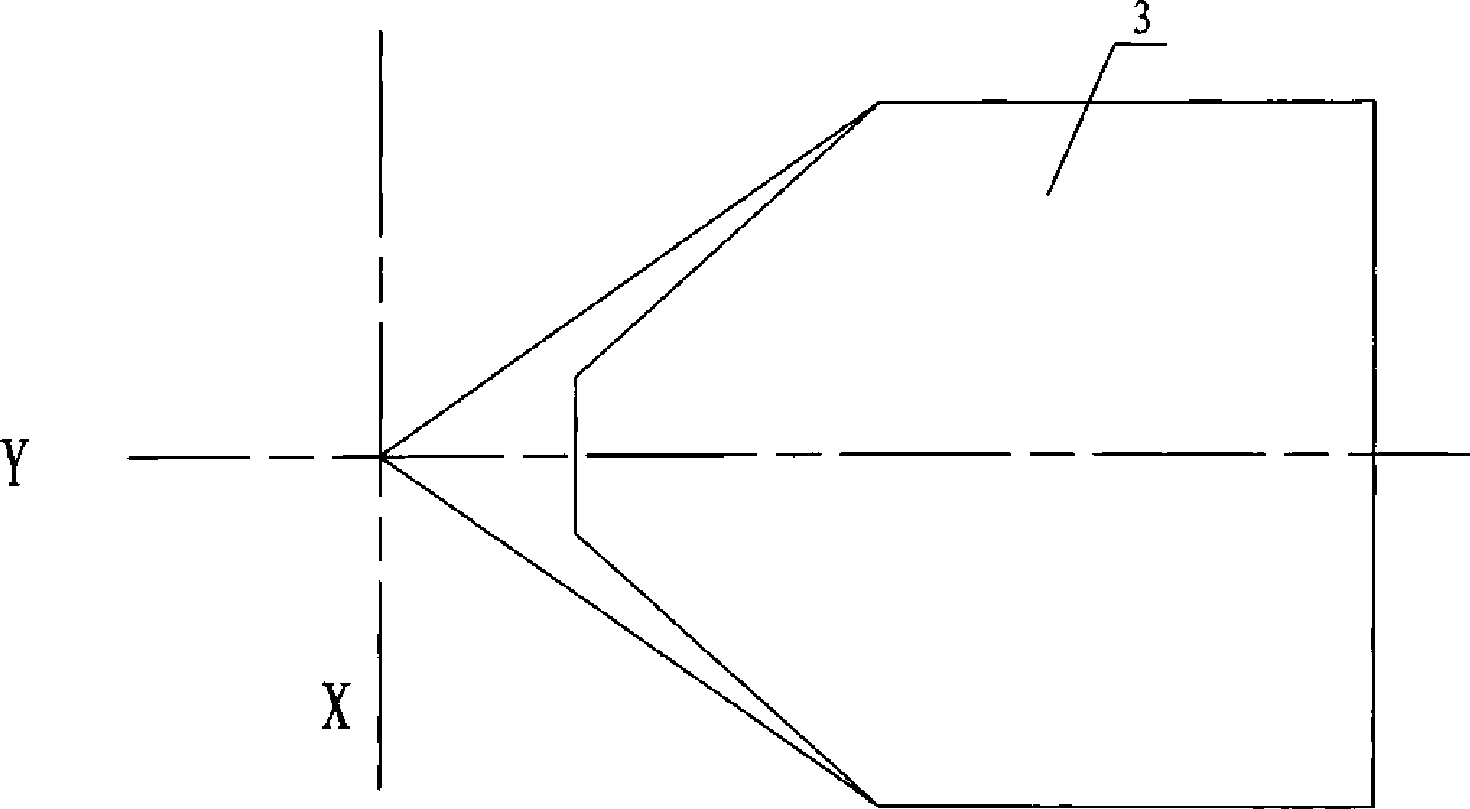

[0047] Step 1 see figure 1 , 2 7, 8, the intake channel and volute are located on the raft foundation of the water intake structure, the bottom raft 3 is constructed first, the ground anchor 10 is embedded in the bottom raft 3 of the intake channel and volute area, and the top surface of the raft foundation concrete is high-pressure Rinse with water to form a uniform and rough construction surface.

[0048] Step 2 see figure 1 , 2 According to the structural characteristics of the inlet and the volute, the inlet area 1 is divided into four parts: the lower part of the outer side of the inlet turn, A, the bottom plate of the inlet B, the outer circumference of the inlet C, and the upper part D of the outer distal end of the inlet. The secondary irrigation area 4 is constructed in blocks, and the volute area 2 is divi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com