Patents

Literature

112results about How to "Reduce the amount of pouring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quick construction method of embedded rail system

ActiveCN103362036ANovel construction methodReasonable construction methodRailway tracksHardnessPlastic film

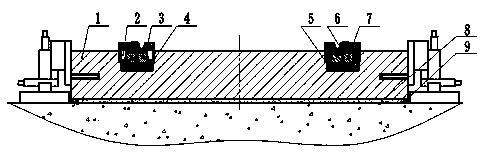

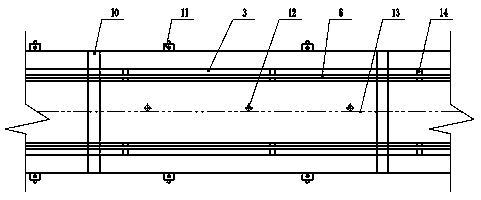

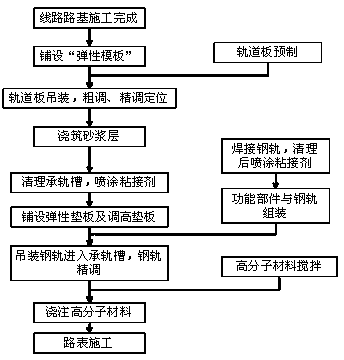

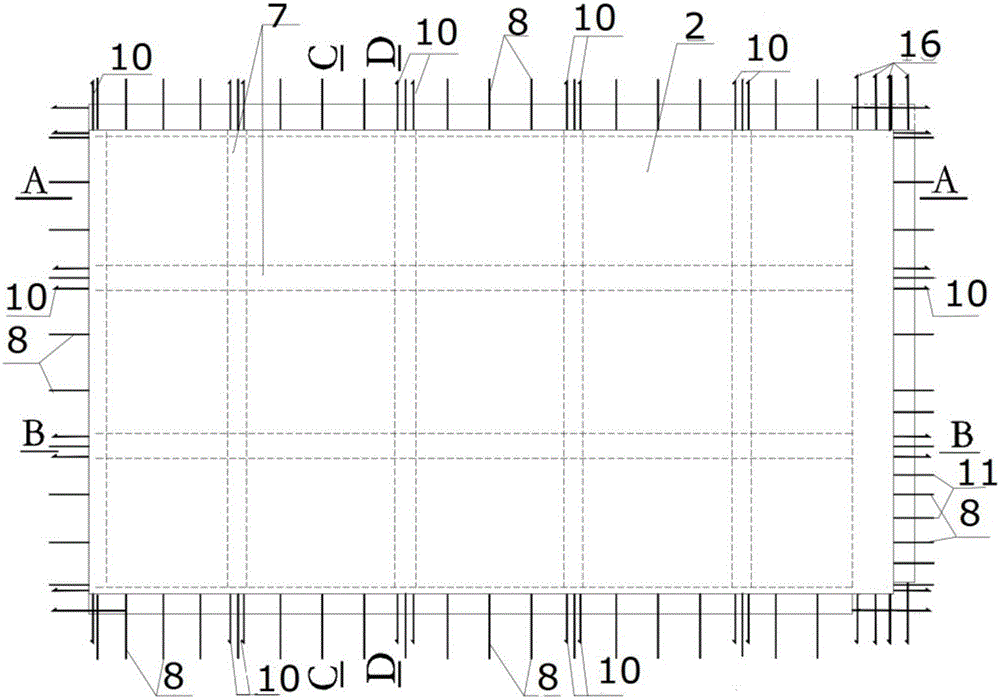

The invention discloses a quick construction method of an embedded rail system. The quick construction method comprises the following construction steps: performing construction preparation; paving a template; paving rail plates; casting a mortar layer; performing rail bearing groove pretreatment; welding a steel rail; adjusting the steel rail finely; performing antipollution protection and partitioning the rail bearing groove; casting the rail bearing groove; uniformly stirring high polymer material; casting material to the partitioned rail bearing groove with special equipment; clearing plastic films or adhesive tapes after the high polymer material achieves required hardness; and paving on the surfaces of the top surfaces of the rail plates according to construction requirements. Through being combined with prefabricated rail plates, the quick construction method has the characteristics of being quick in construction, high in efficiency and little in influence on surrounding environment, and is a green and environment-friendly construction method.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

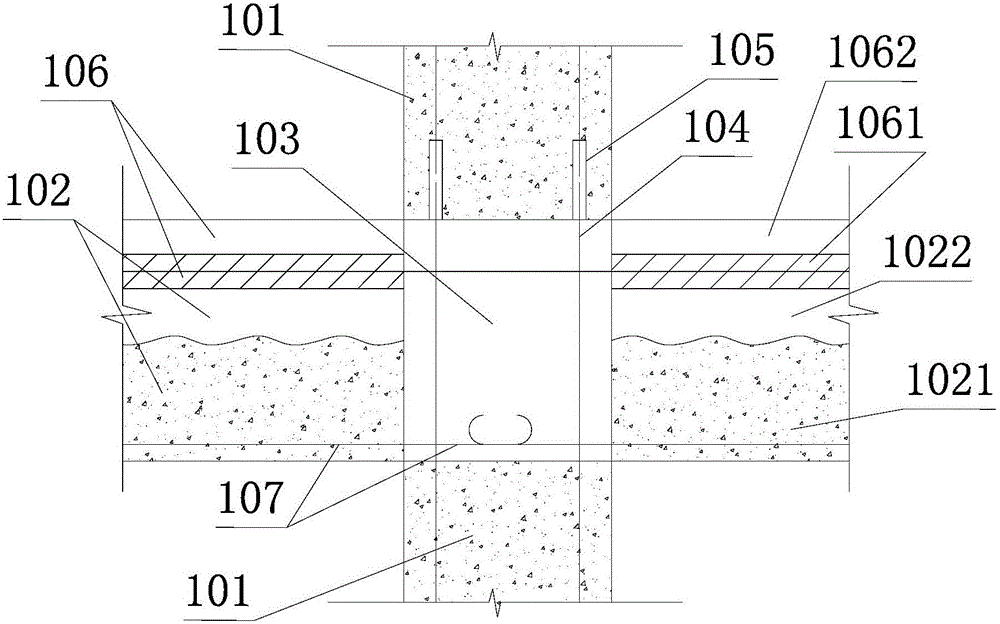

Connecting node of assembled whole thick prefabricated slab unit and slab unit thereof

The invention discloses a connecting node of an assembled whole thick prefabricated slab. Connecting steel bars are reserved on the connecting surface of a prefabricated slab unit in the mode, the exposed parts of the connecting steel bars are ' '-shaped, and the exposed parts and the connecting surface form a closed polygon. In the connecting mode for the prefabricated slab unit and a beam or a wall, the connecting steel bars of the prefabricated slab unit are inserted with steel bars configured for the beam or the wall together at the connecting positions in a penetrating mode. Viewing from the cross section of the whole connecting node, the connecting steel bars and the steel bars configured for the beam or the wall form a single closed stirrup or a composite stirrup, and longitudinal bolt steel bars penetrate into the inner corner position of the single closed stirrup or the composite stirrup. The connecting node of the whole thick prefabricated slab unit can achieve the equivalent performance as a prefabricated slab connecting nodes and a cast-in-place concrete structure while achieving higher prefabrication rate and assembly rate. The invention further provides the whole thick prefabricated slab unit for achieving the connecting mode.

Owner:刘祥锦

Profile steel-UHPC (ultra-high performance concrete) combined bridge deck structure suitable for cantilever state as well as construction method thereof

ActiveCN109610310ALight weightReduced risk of crackingClimate change adaptationBridge structural detailsPre stressBridge deck

The invention discloses a profile steel-UHPC (ultra-high performance concrete) combined bridge deck structure suitable for a cantilever state as well as a construction method thereof. A profile steel-UHPC lightweight combined bridge deck slab is mainly formed by combining profile steel, steel plate strips welded with short studs as well as an UHPC slab; the profile steel serving as a longitudinalrib is arranged in a transverse bridge direction at intervals; the steel plate strips are arranged on an upper flangeslab of the profile steel in the bridge direction at intervals; and longitudinal and transverse seam structures are T-shaped seams. Finished product profile steel is adopted, so that the manufacturing cost is low, the welding quantity is small and the risk of fatigue cracking is greatly reduced; meanwhile, higher bending-resistant inertia moment is achieved, the cracking risk of the bridge deck slab is reduced and the transverse tension resistance of the bottom surface of the bridge deck slab is enhanced; UHPC in the longitudinal seam position is converted from a pulled state to a pressed state, so that the fact that the operation stage is not cracked can be guaranteed without configuring a prestressing force when the bridge deck slab is under the transverse cantilever state; moreover, breakage in a high tensile stress area can be avoided, shrinkage crack can be avoided,the self weight of the bridge deck slab is reduced, and the method is simple to operate and easy to construct.

Owner:HUNAN UNIV

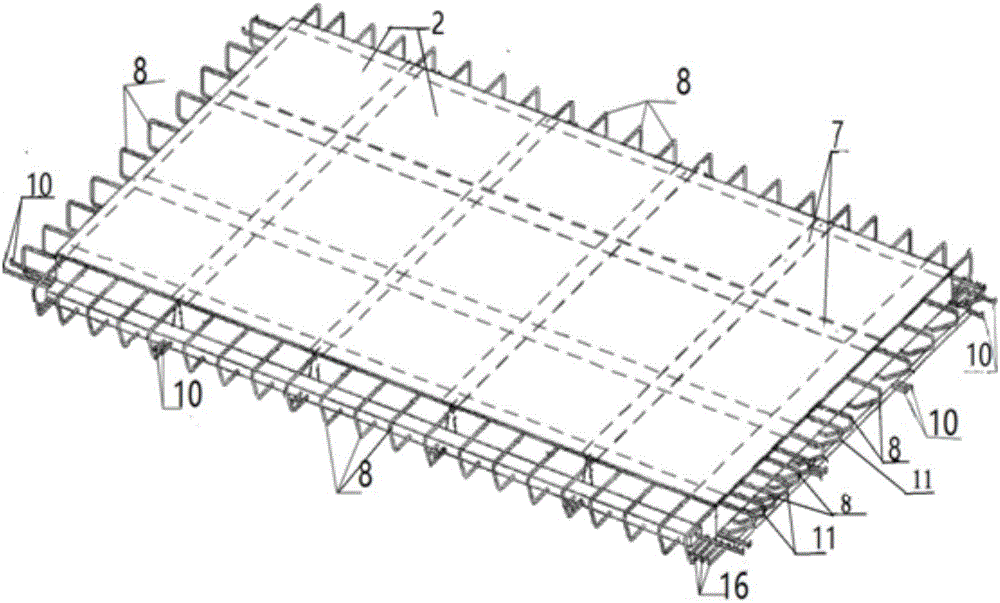

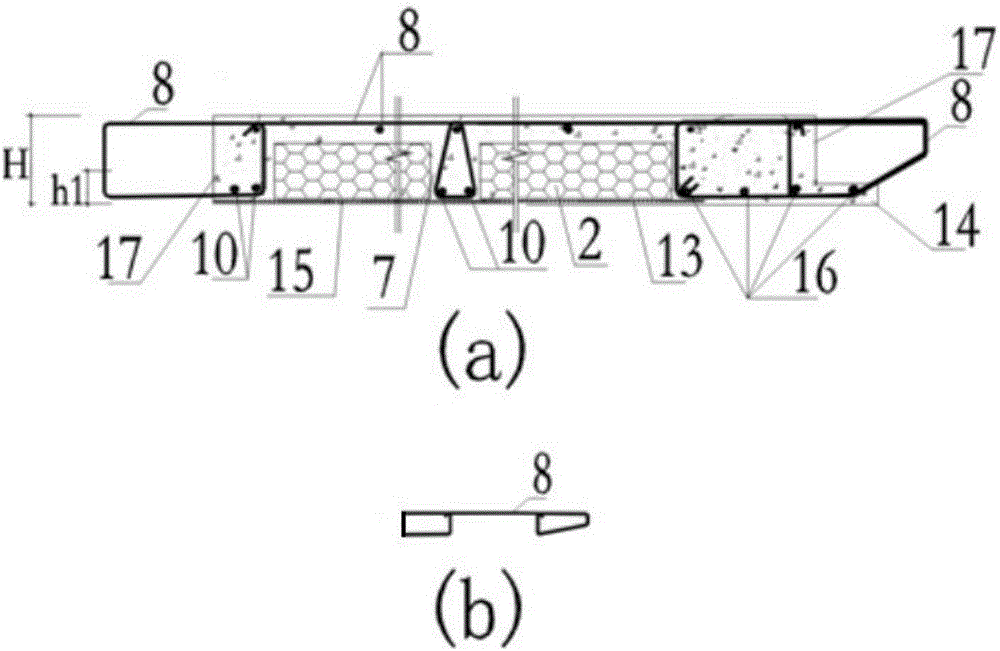

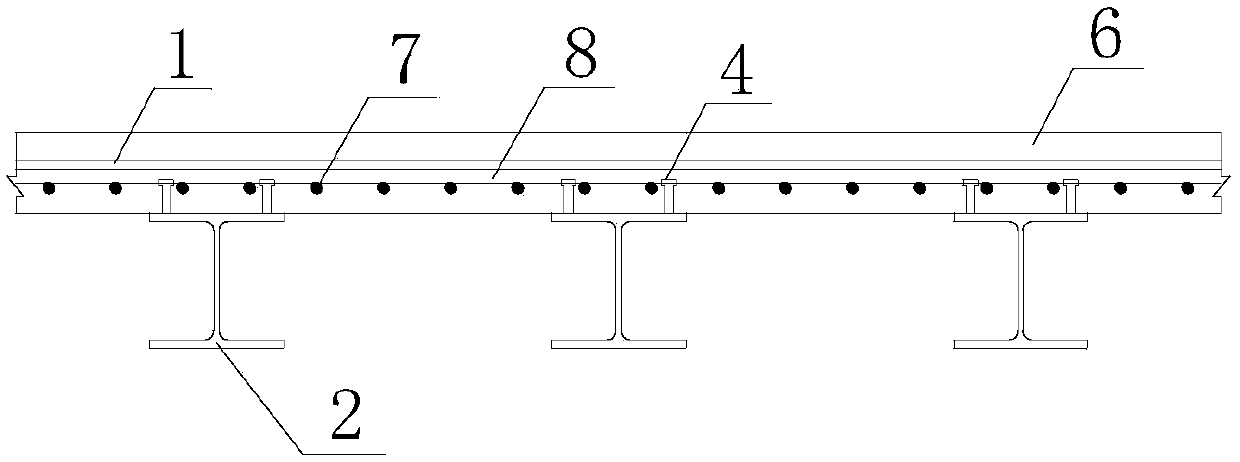

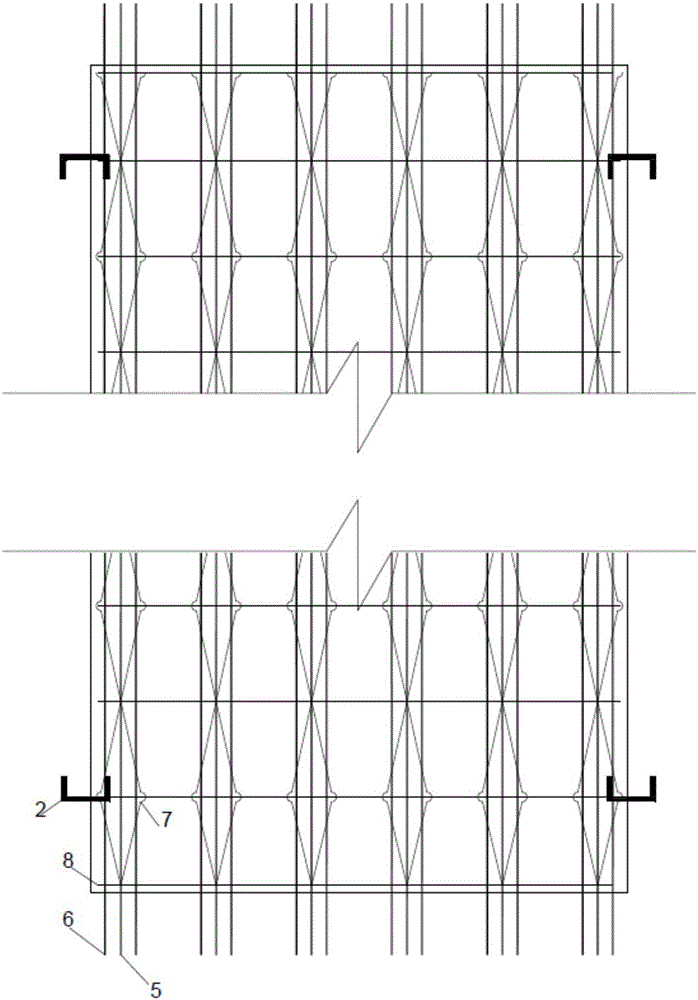

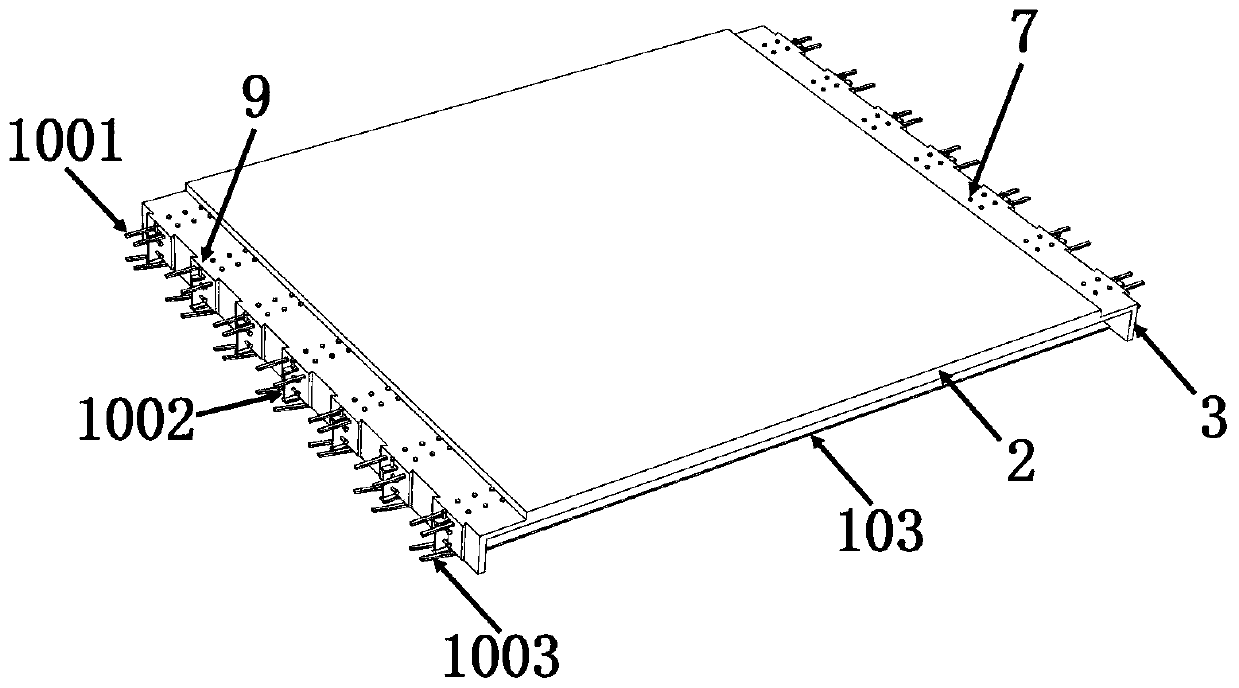

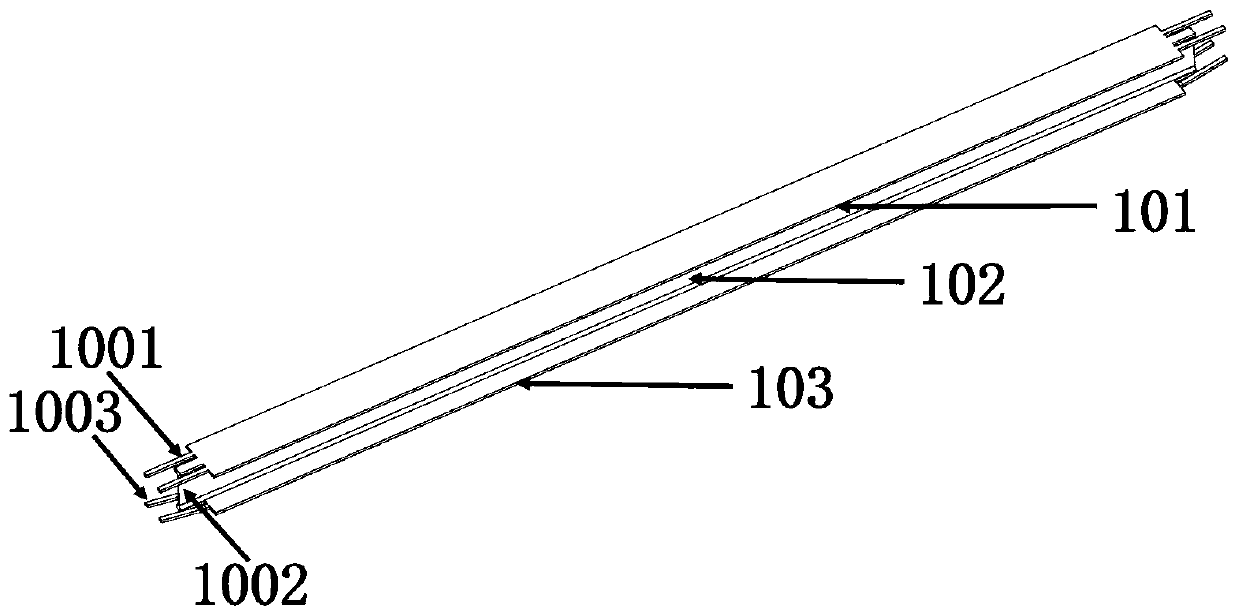

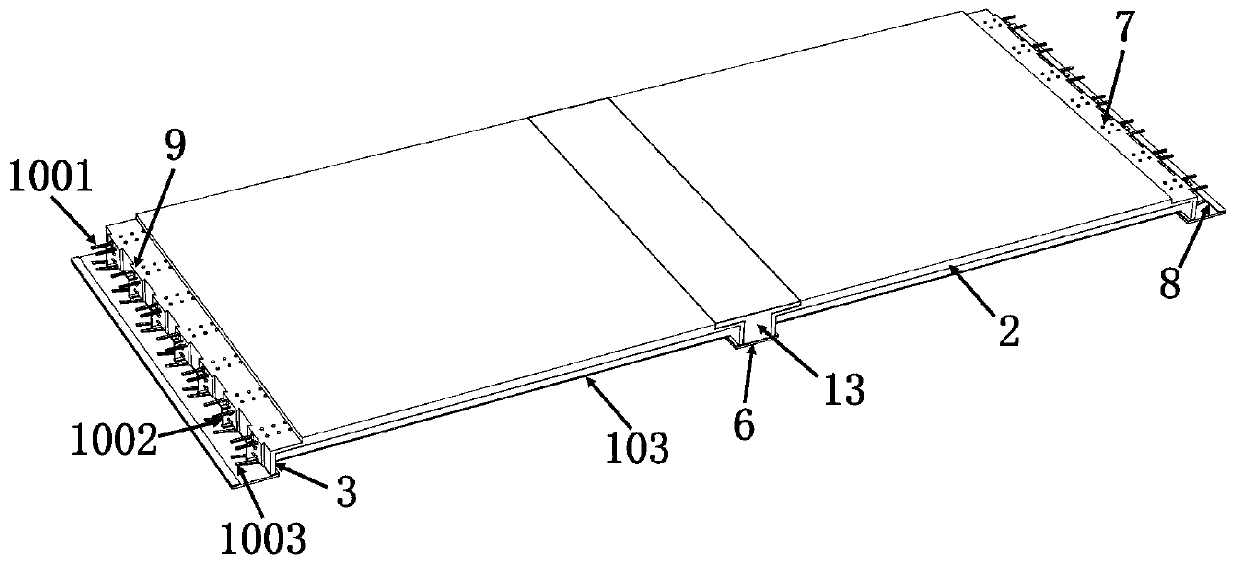

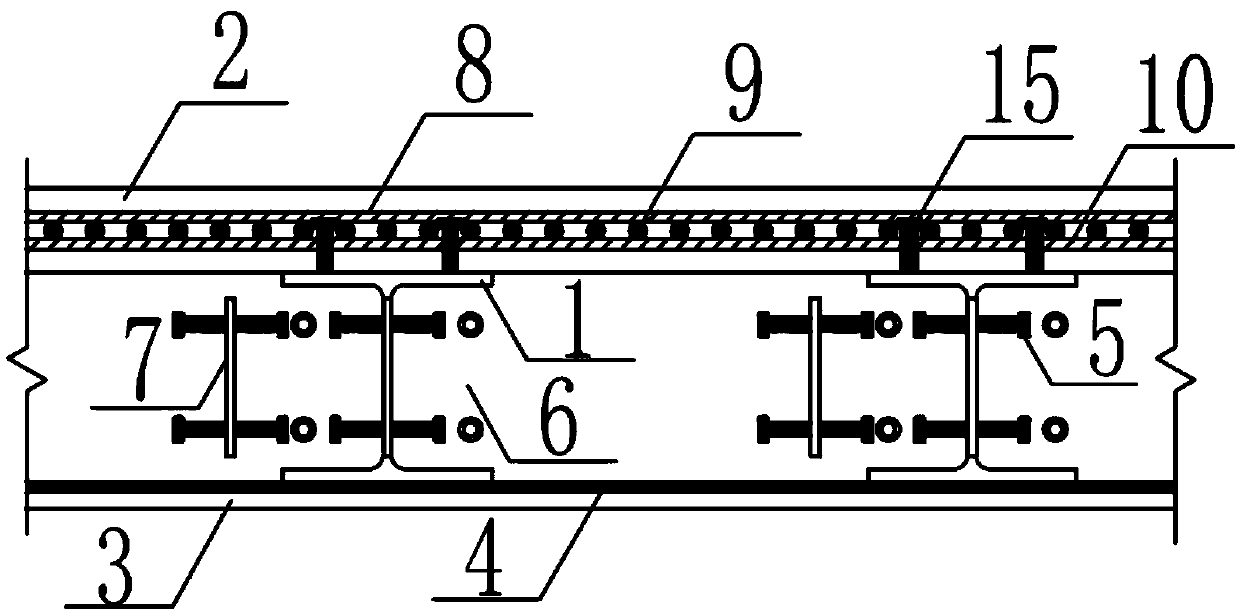

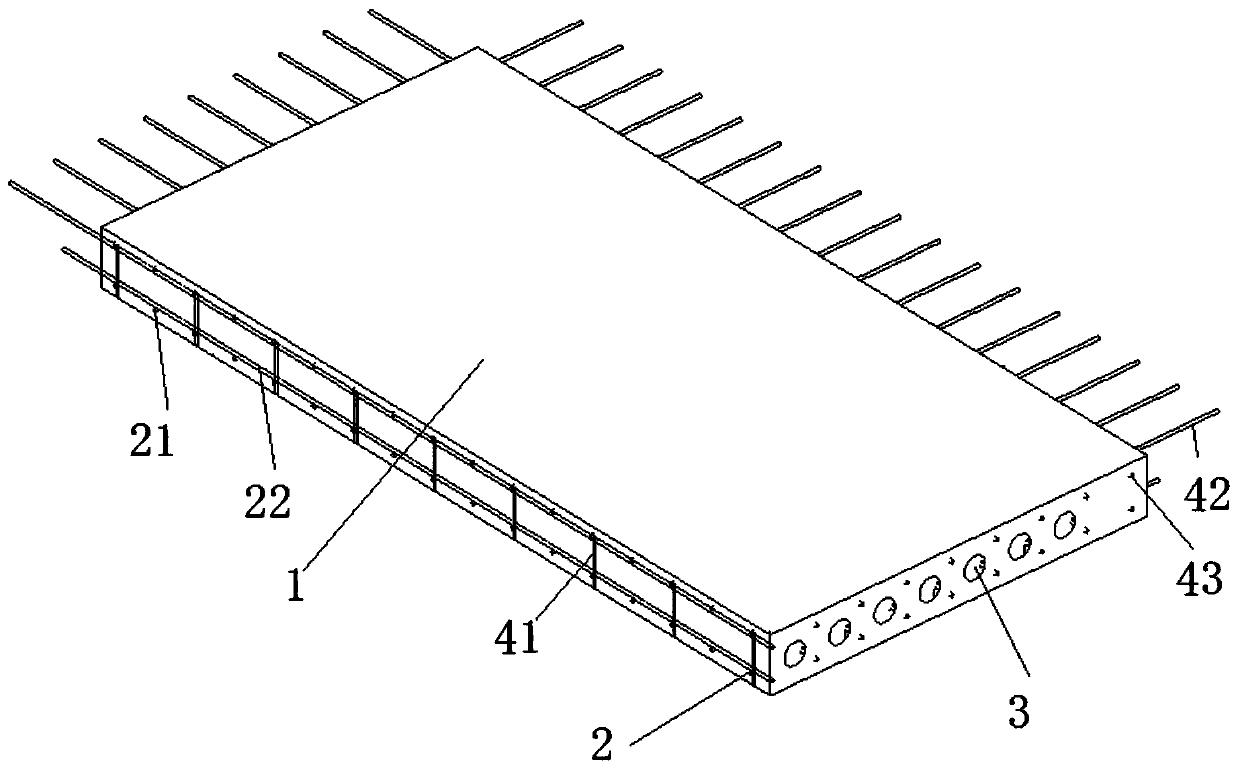

Assembly type precast light floor

InactiveCN106836627AImprove waterproof performanceImprove stress resistanceFloorsHorizontal distributionRebar

The invention provides an assembly type precast light floor. The assembly type prefabricating light floor comprises a precast concrete layer, connection channel steel, a light material plate, a steel bar truss, an upper chord steel bar, a lower chord steel bar, a slant bending steel bar and a horizontal distribution steel bar. Manufacturing of the steel bar truss and the light material plate is finished firstly in a factory, and the connection channel steel and the horizontal distribution steel bar are welded; when lower part concrete of the precast concrete layer is not yet subjected to curing molding, the light material plate is fixedly placed in the middle of the steel bar truss, then the horizontal distribution steel bar is placed in the middle of the steel bar truss in the total length, the steel bar truss is connected with the upper chord steel bar in a bound mode, and then upper part concrete is poured on the precast concrete layer, so that manufacturing of the assembly type precast light floor is completed; in a construction field, by preburying the connection channel steel in the floor, single floors are connected into one. The assembly type precast light floor fully achieves assemblage, is in accordance with the industrialized development trend of buildings, is completed by pouring in a factory at one time, and has the advantages of being less in wet work amount, convenient to construct, high in crush resistance, high in production efficiency and the like.

Owner:BEIJING UNIV OF TECH

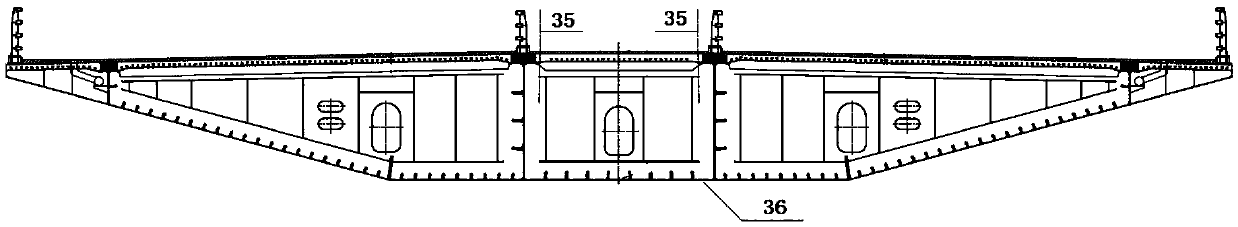

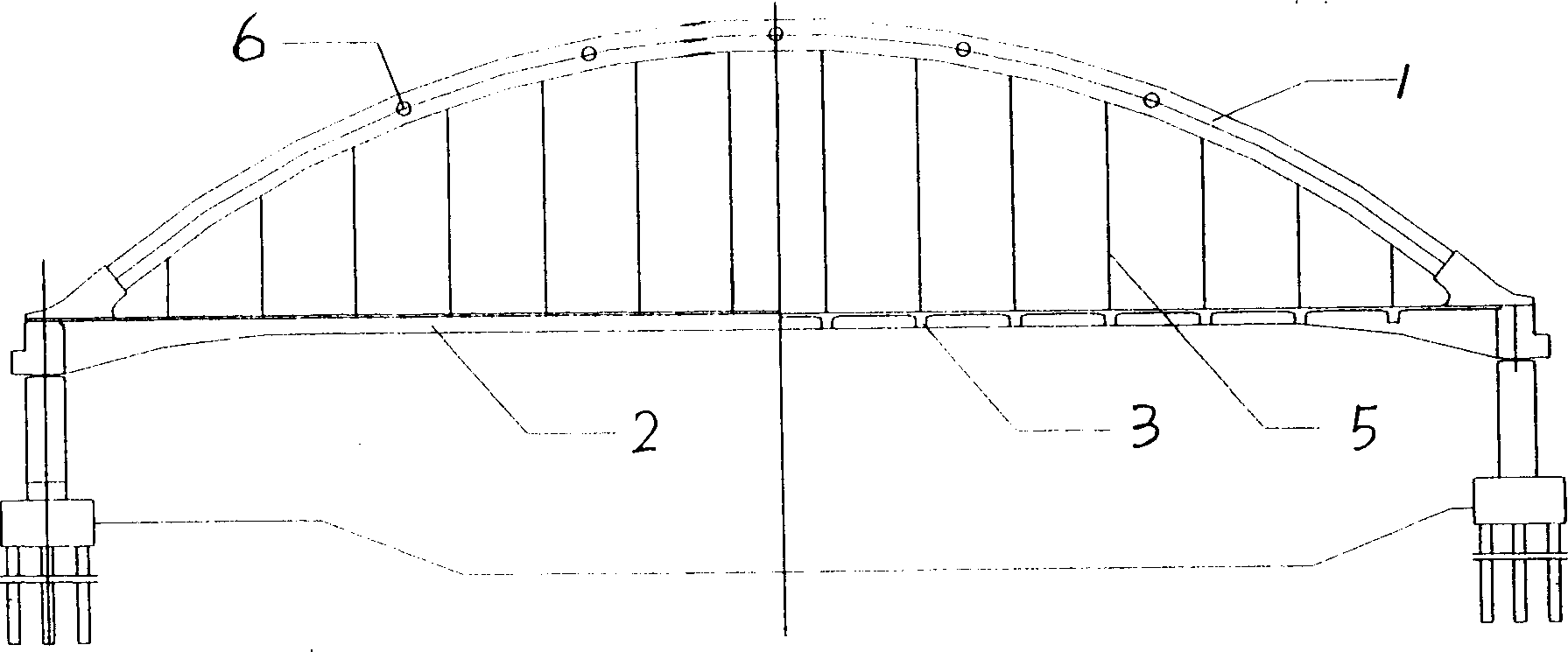

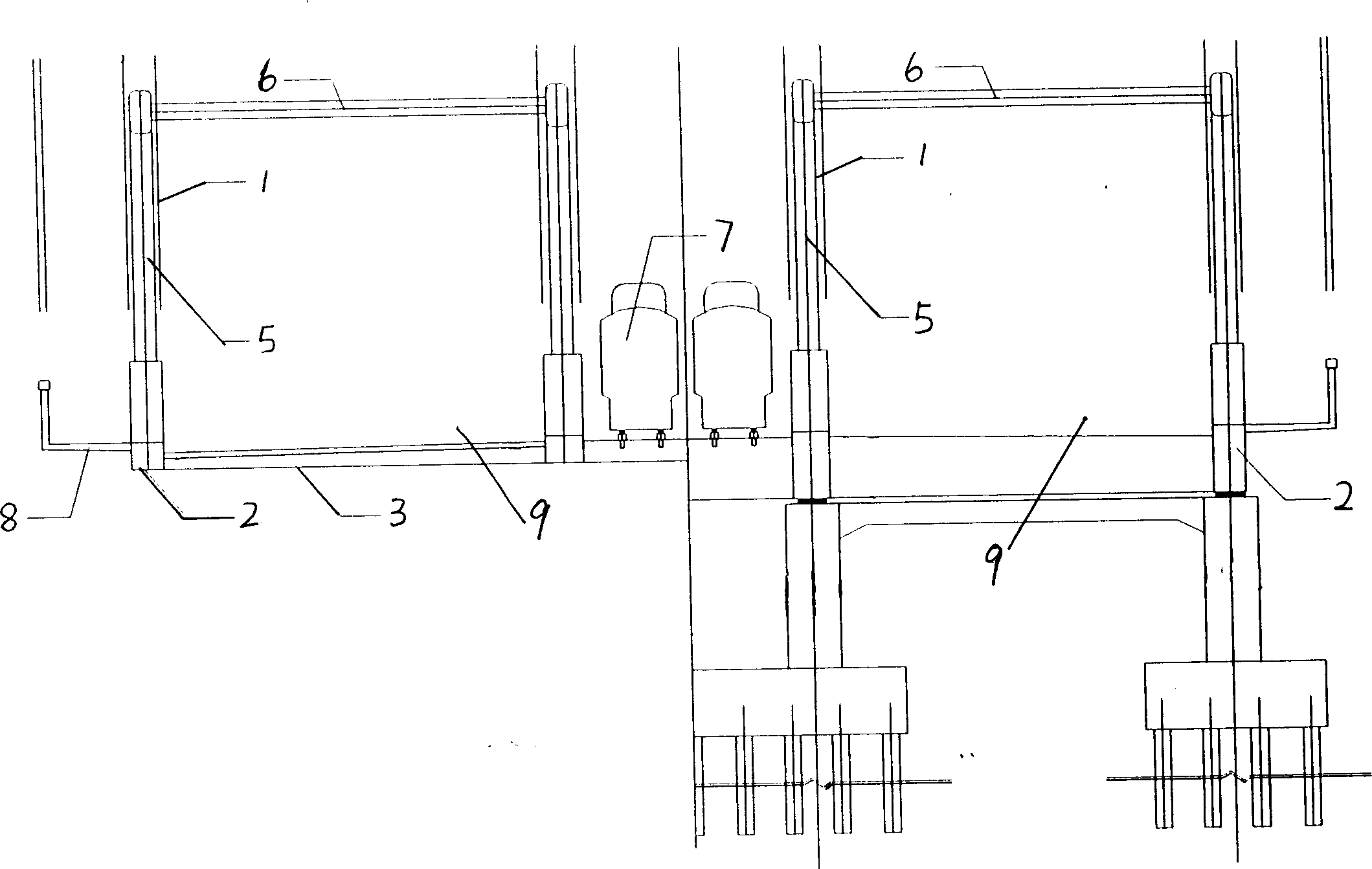

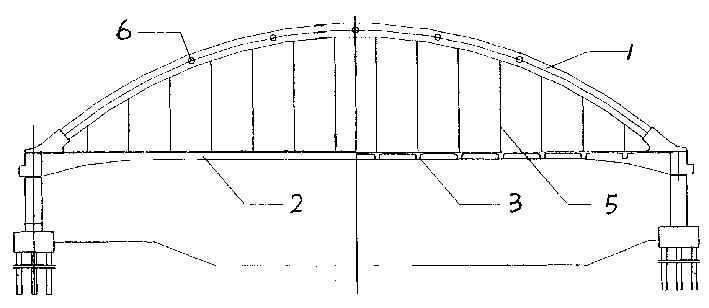

Track traffic and urban road integrated tie arch bridge

InactiveCN1483895AStringer lightThe structural form is clearly stressedRoadwaysArch-type bridgeRail transitSteel tube

The present invention relates to a track transportation and urban road integrated tied-arch bridge, and it is characterized by that the described track transportation and urban road system adopts four sheets of arch rib, the track transportation is positioned in the centre, the up-and-down traffic lanes are set at two sides, and the walkway is set at most outside. Said invention can combine track transportation bridge and urban road bridge together, can adopt steel tube concrete structure and its cost is low.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

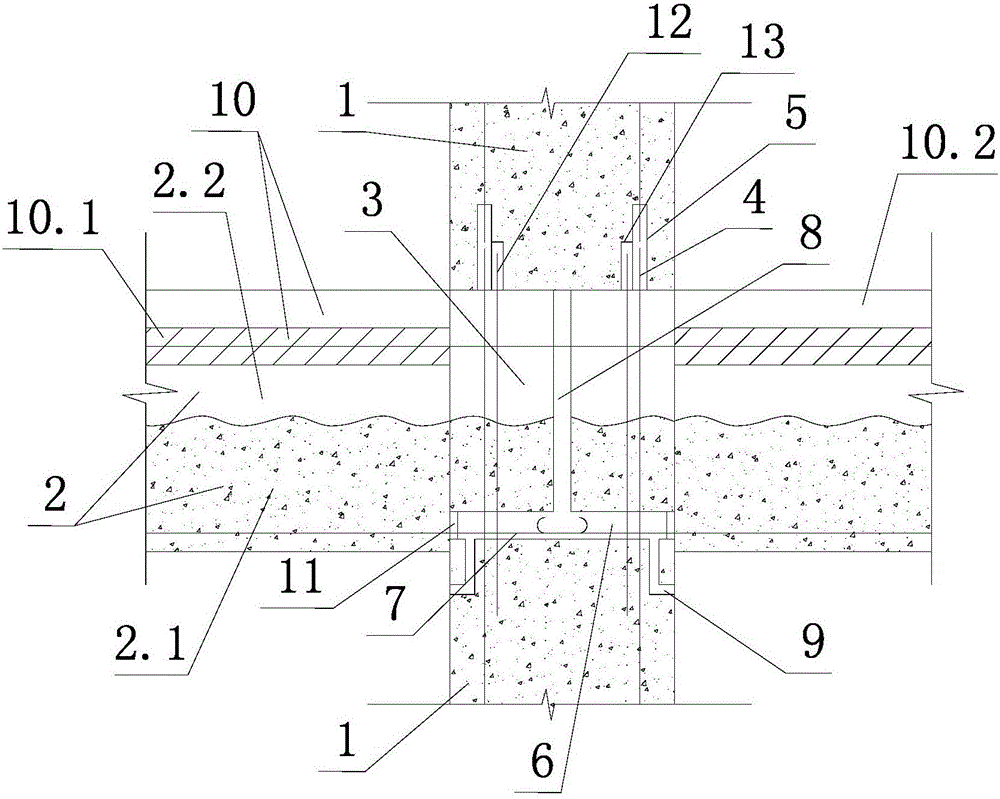

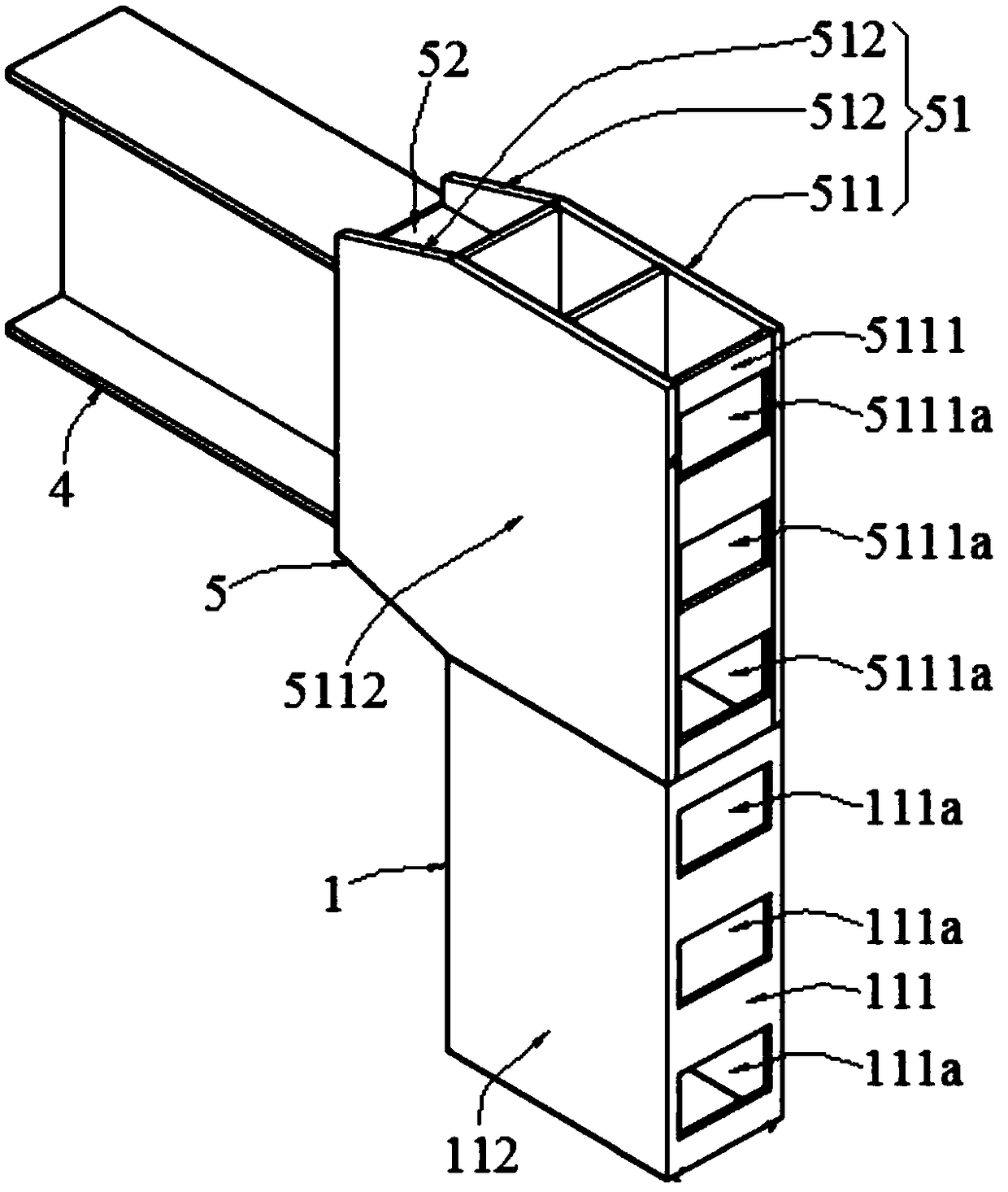

Perforating grout anchoring prefabricated assembly-type concrete-filled steel tubular frame structure

ActiveCN109339229AReduce the amount of pouringImprove assembly rateBuilding constructionsSteel tubeGrout

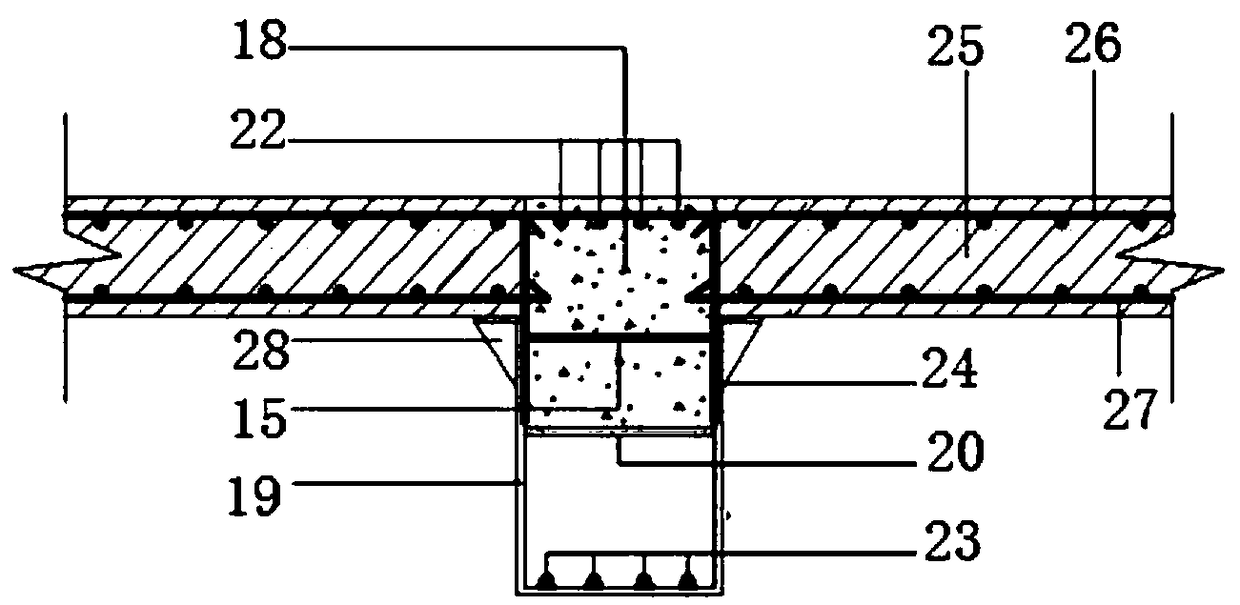

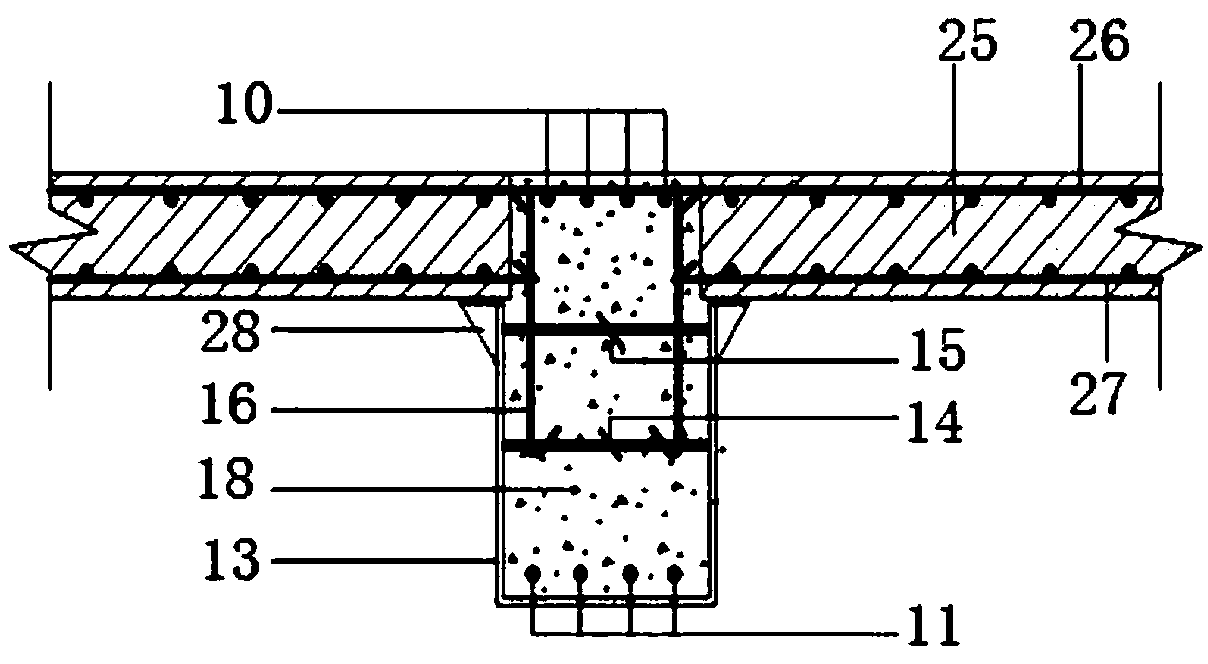

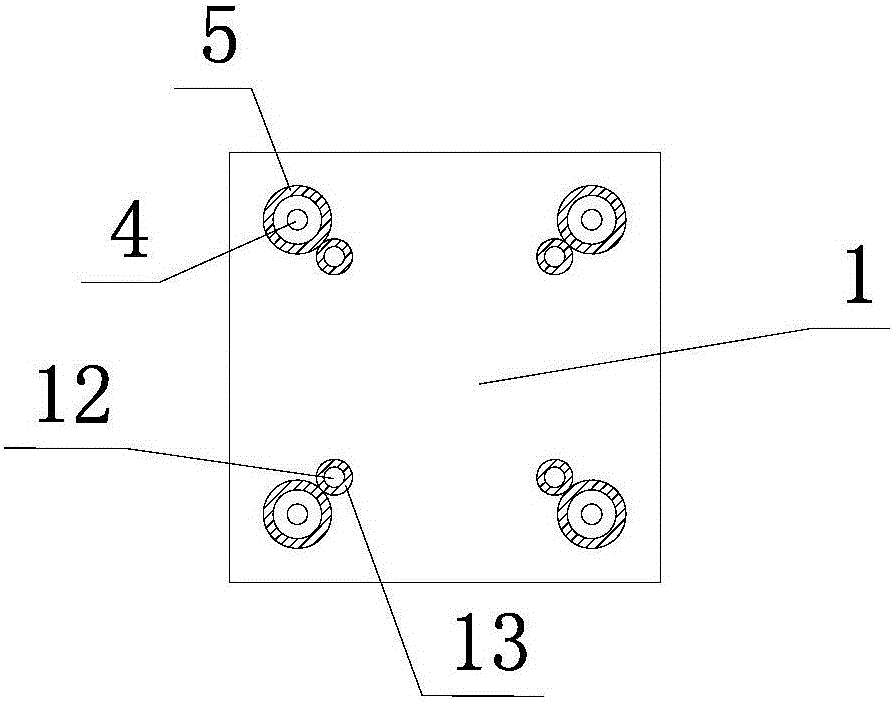

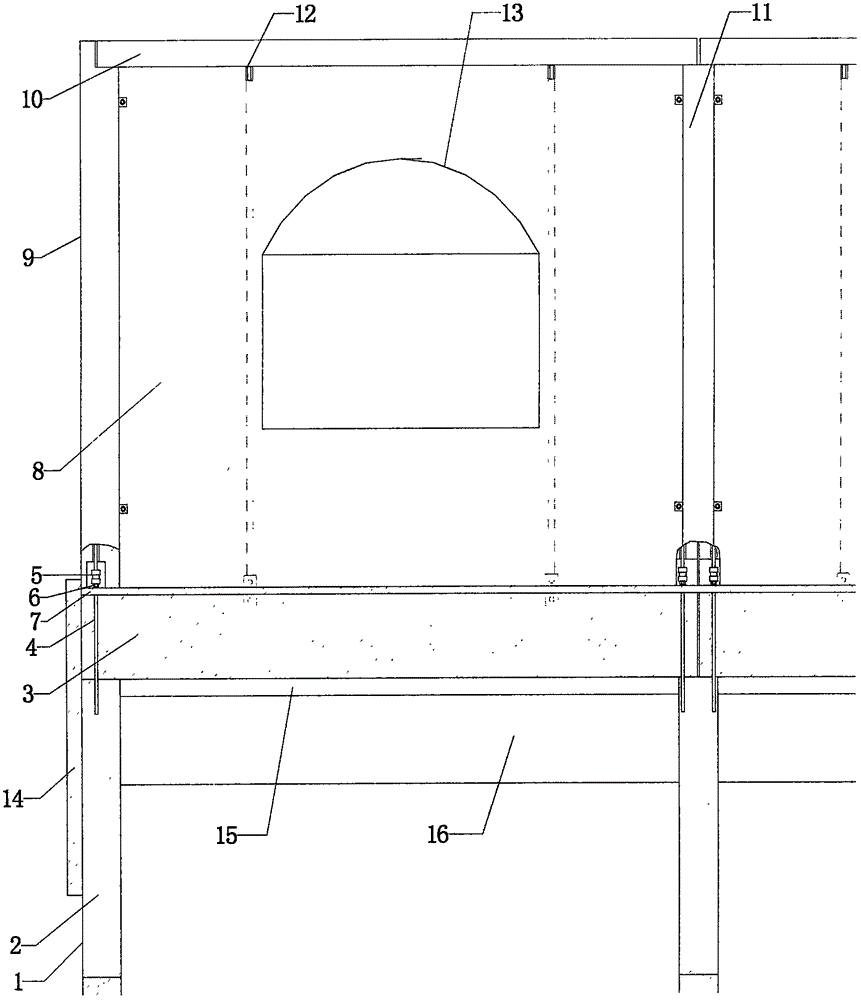

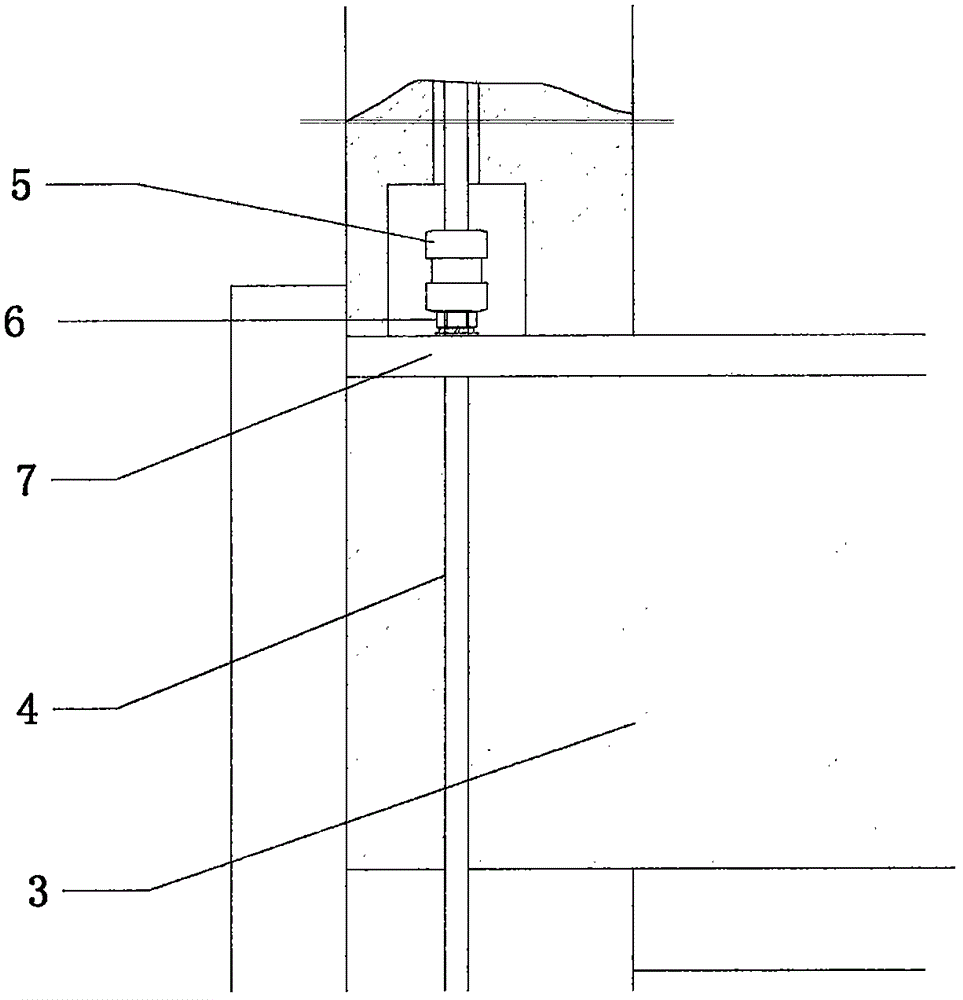

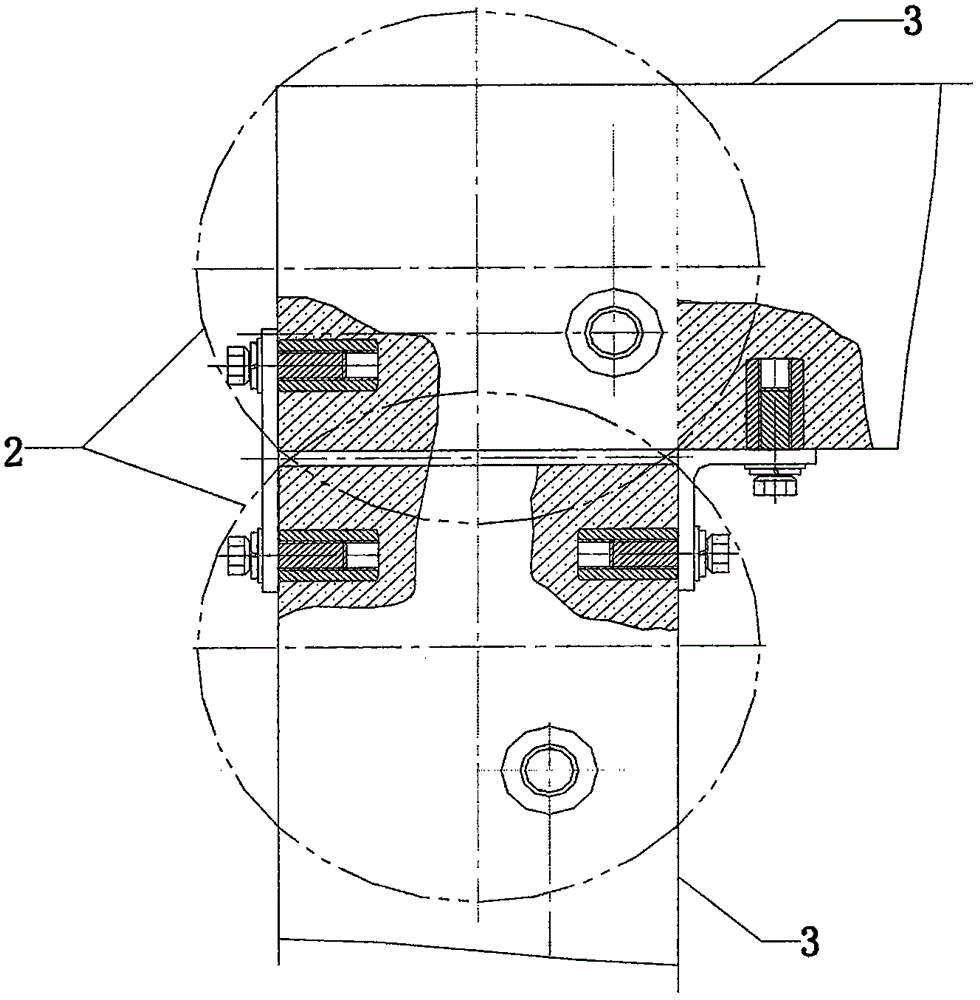

The invention discloses a perforating grout anchoring prefabricated assembly-type concrete-filled steel tubular frame structure, which comprises a square steel tube concrete lower column, a square steel tube concrete upper column, a semi-open steel box concrete composite beam, a prefabricated slab corner unit, a prefabricated slab edge unit, a prefabricated slab middle unit, column-beam post-pouring joints, column-column bolted connection joints, a prefabricated concrete slab and post-pouring concrete. The square steel tube concrete lower column, the square steel tube concrete upper column, the semi-open steel box concrete composite beam and the prefabricated concrete slab are connected into a whole in a grout anchoring mode, the pouring amount is less, the assembling rate is high, all components are in a prefabricated assembly form, onsite splicing is conducted, the construction speed is high, the construction process is simplified, and the construction environment is optimized; and secondly, the requirements of grout anchoring for the construction precision are low, operation by workers is convenient, the beam-column components are in a combined structural form, the self-weight is low, force bearing is more reasonable, the material property can be exerted sufficiently, the bearing capacity is high, the fire-resisting property is good, and shock resistance is good.

Owner:CHINA MCC17 GRP

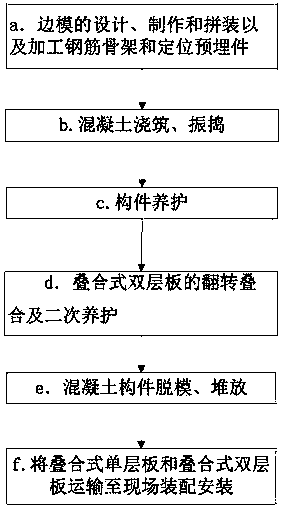

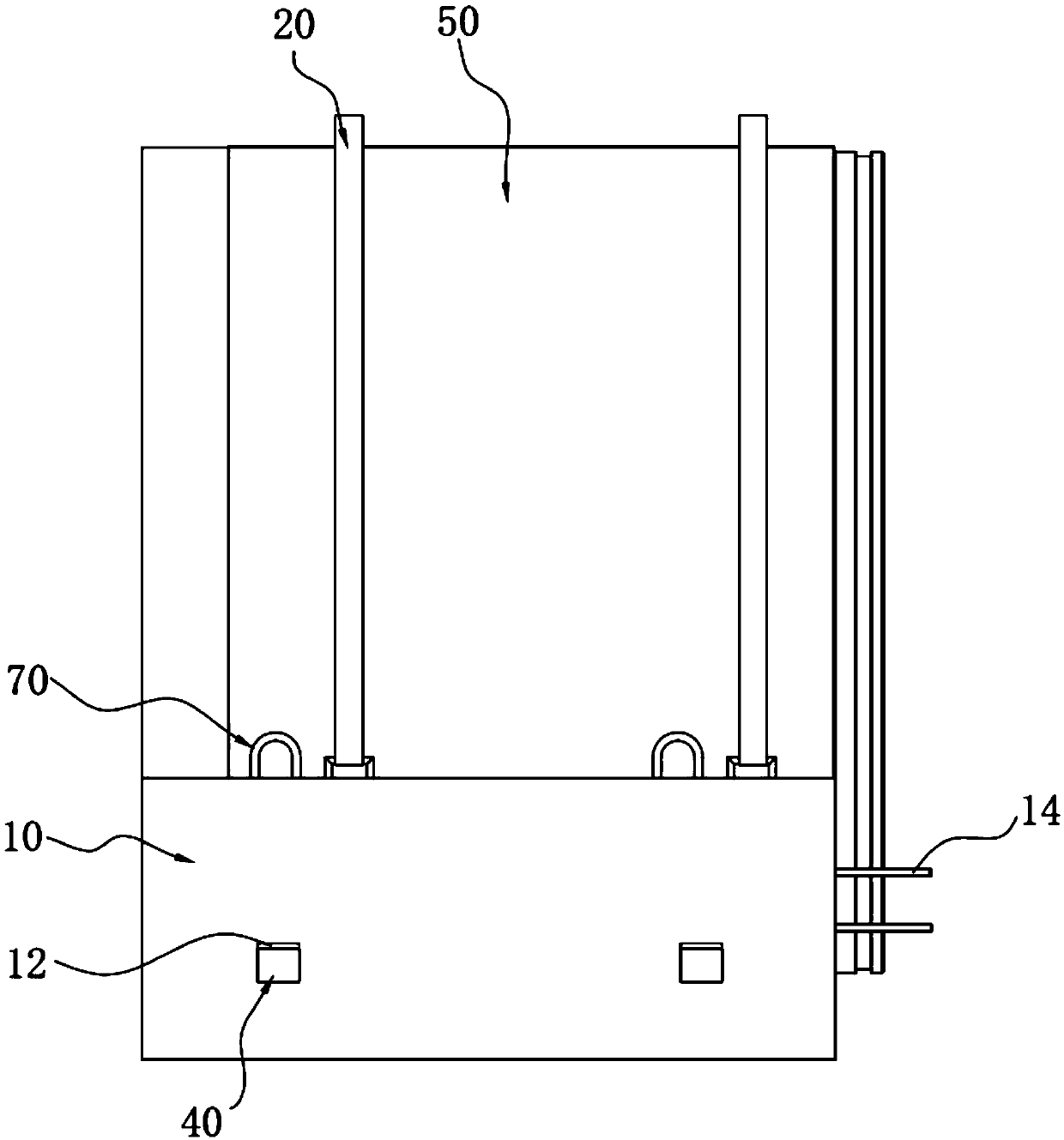

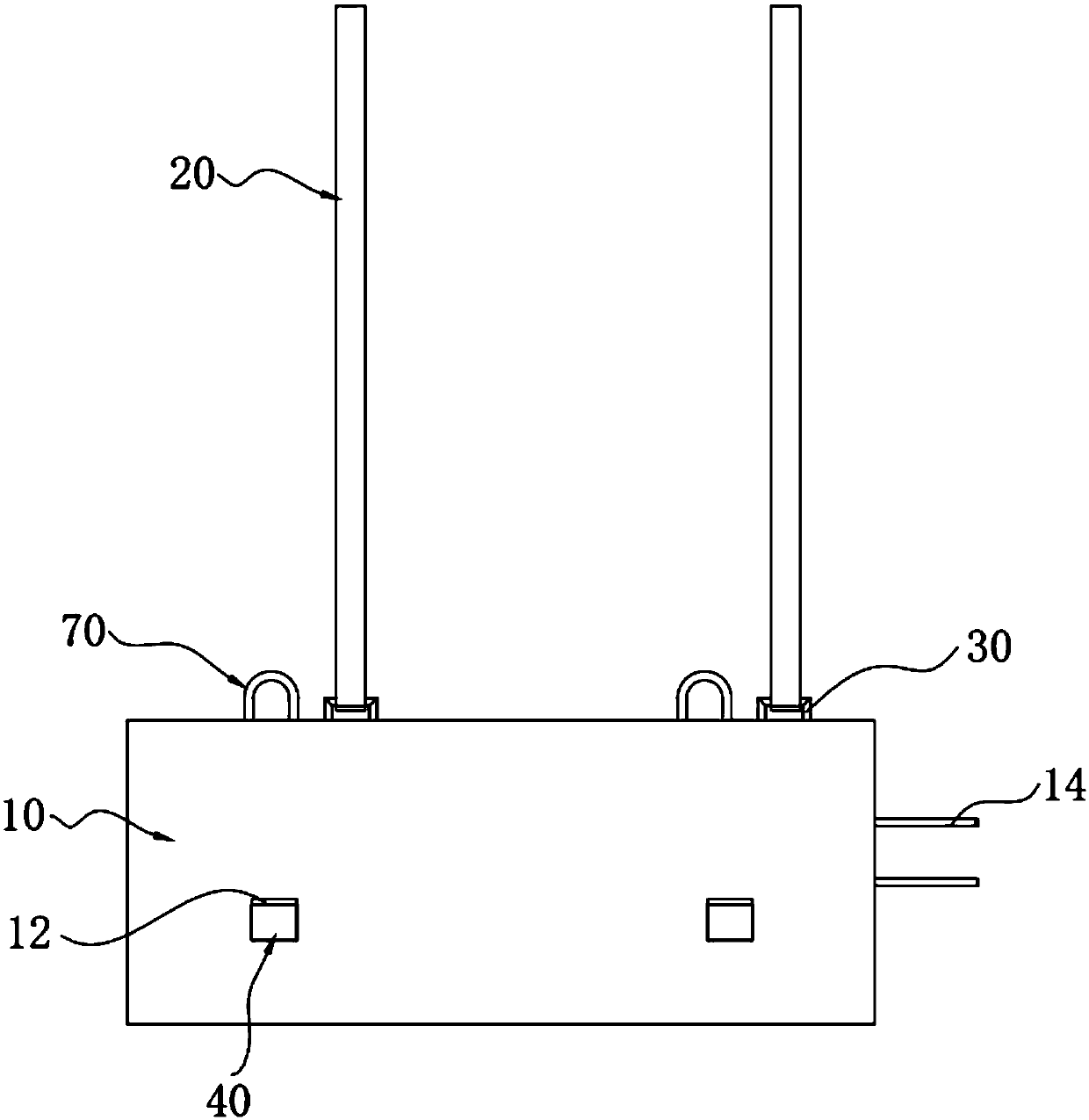

Superimposed fabricated pipe gallery structure system component industrialization construction device and method

InactiveCN108193712AGood lookingReduce usageArtificial islandsUnderwater structuresIntelligent managementRebar

The invention relates to a superimposed fabricated pipe gallery structure system component industrialization construction device and method. The superimposed fabricated pipe gallery structure system component industrialization construction device comprises a production intelligent management system. The superimposed fabricated pipe gallery structure system component industrialization constructionmethod comprises the steps that a, edge formworks are manufactured, pre-buried components are mounted on manufactured steel reinforcement frameworks, and the steel reinforcement frameworks and the edge formworks are subjected to formwork assembly operation on a formwork table; b, by adopting a distribution machine, concrete is poured onto the steel reinforcement frameworks and the edge formworks which are subjected to formwork assembly, and vibrated, and thus concrete components are obtained; c, the concrete components are cured in a curing kiln through steam; d, single sided boards loaded with superimposed-type double-layer boards are superimposed and sent to the curing kiln for secondary curing; e, the components are subjected to formwork release and stored on a component stacking field,and in the storing process, the superimposed-type single-layer boards and the superimposed-type double-layer boards are subjected to water spraying curing through a spraying system; and f, the components are conveyed to a site to be assembled and mounted. According to the superimposed fabricated pipe gallery structure system component industrialization construction device and method, on-site construction is easy, energy saving and environmental friendliness are achieved, long-time exposure of a foundation pit is reduced, the influence of weather on construction is small, and pollution emission and cost are reduced.

Owner:THE 4TH CONSTR ENG CO LTD OF CHINA RAILWAY NO 4 ENG GRP +1

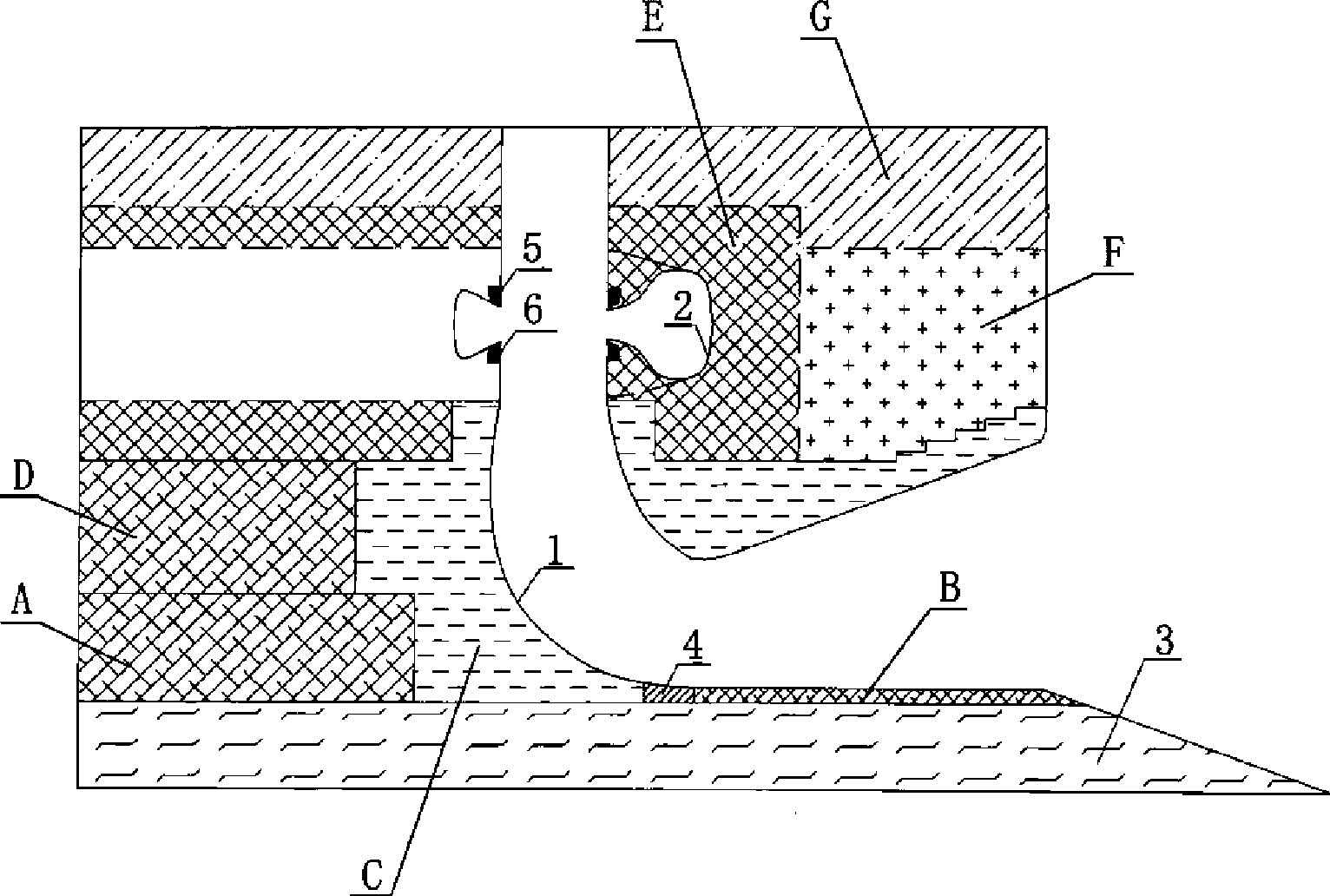

Construction method for large cast-in-situ steel reinforced concrete inlet channel and turbine housing

InactiveCN101476308AReduced likelihood of cracksConstruction quality is easy to guaranteeArtificial water canalsFoundation engineeringInlet channelReinforced concrete

The invention relates to a large-scale cast-in-situ reinforced concrete water inlet duct and scroll case construction method, the construction sequence is: bottom board of the water inlet duct, far end lower part outside the turning of the water inlet duct, far end upper part outside the turning of the water inlet duct, outer circumference of the turning of the water inlet duct, far end outside the scroll case, near end outside the scroll case, top outside the scroll case and the second pouring construction. The construction method has clear levels, reduces the concrete pouring amount at the key parts of the water inlet duct: the outer circumference of the turning of the water inlet duct and the near end outside the scroll case, by partitioning construction; ensures the concrete forming quality of the water inlet duct and the scroll case; and avoids large volume concrete cracks.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD +1

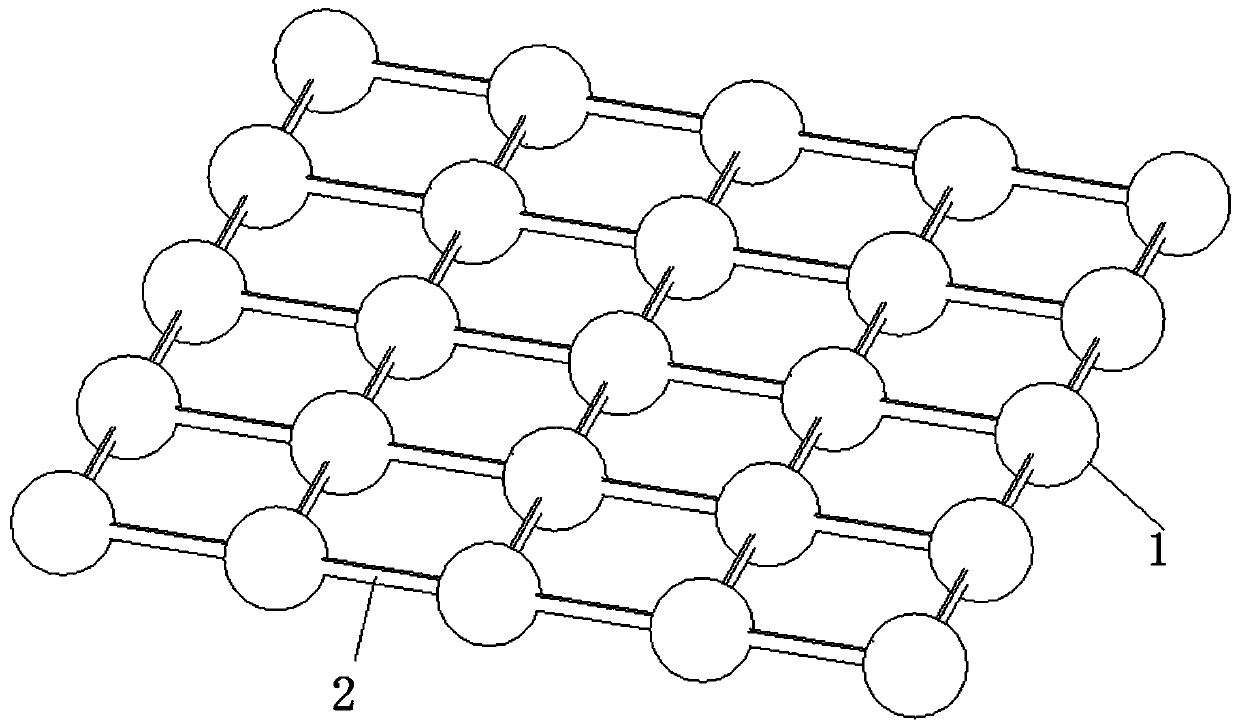

Prefabricated ball, production device, production method and use method thereof

PendingCN110424414AGood for scrollingEasy to roll freelyCeramic shaping apparatusEmbankmentsEngineeringBuilding construction

The invention relates to the technical field of large filling, and discloses a prefabricated ball applied to large filling. The ball is a foam lightweight soil product, rapid backfill of a pit can berapidly achieved, the construction period can be greatly shortened, and a production device comprises a foam lightweight soil preparing machine, a casting machine and a ball mold, the structure is simple, the cost is low, the ball mold is easy and convenient to assemble, and mold dismounting and maintaining are facilitated. A production method is simple and easy to operate, commonly, after 24 hours, mold dismounting can be achieved, and after seven days of standing and maintaining, storage can be achieved. A use method is simple, the casting amount of site foam lightweight soil can be greatlyreduced, the filling efficiency is greatly improved, the construction period is shortened, the filling effect of the gap between prefabricated balls is good, the compactness is high, and the whole effect of solidification is good.

Owner:华泰恒生科技发展(北京)有限公司

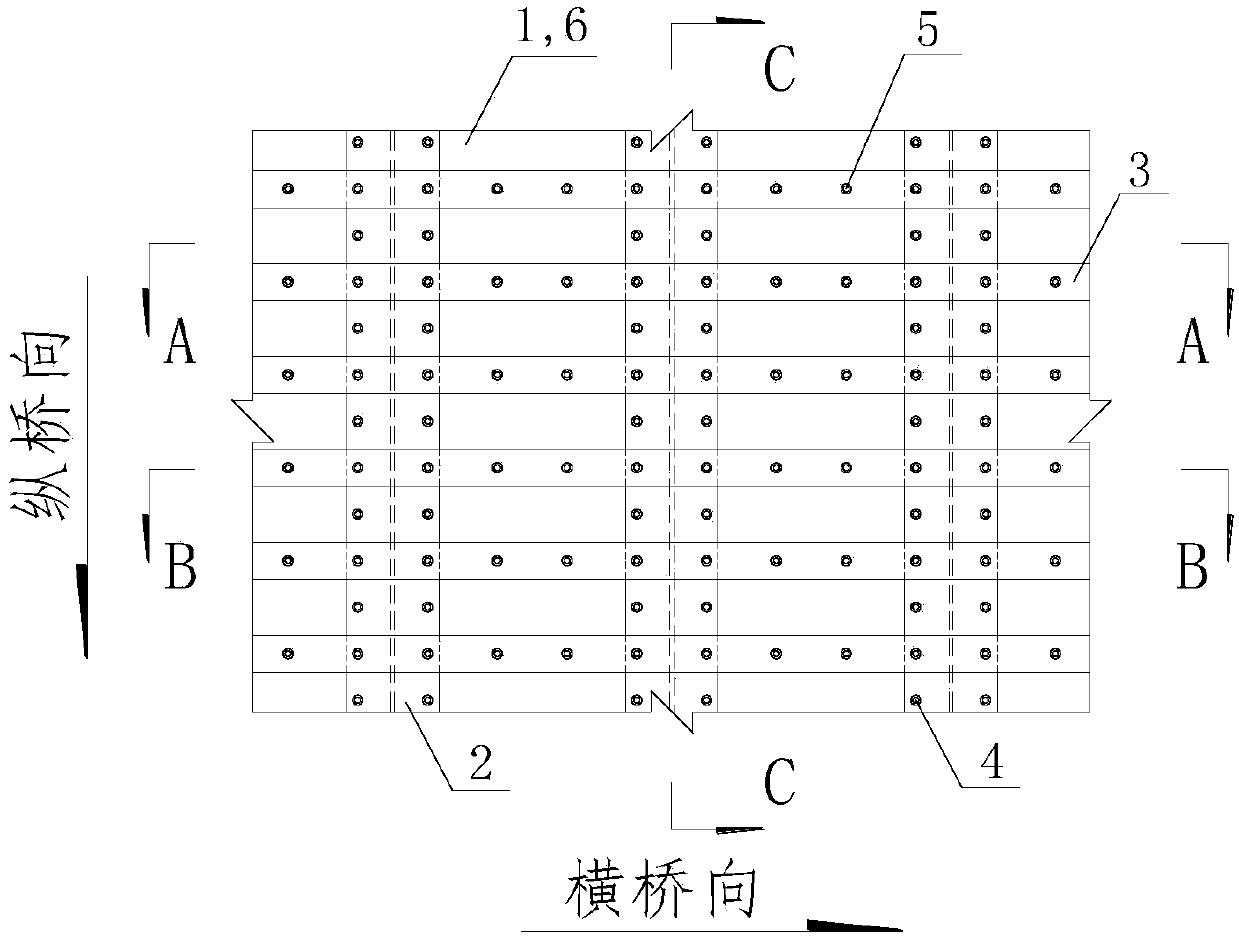

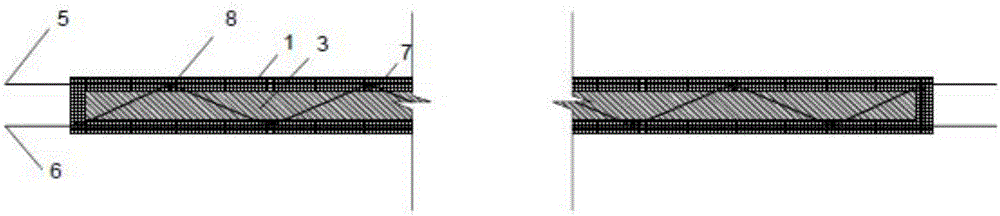

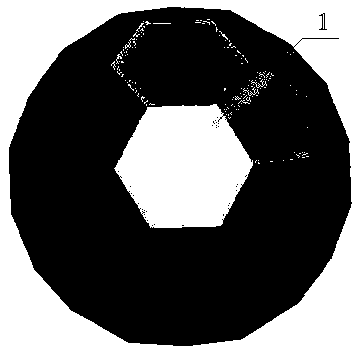

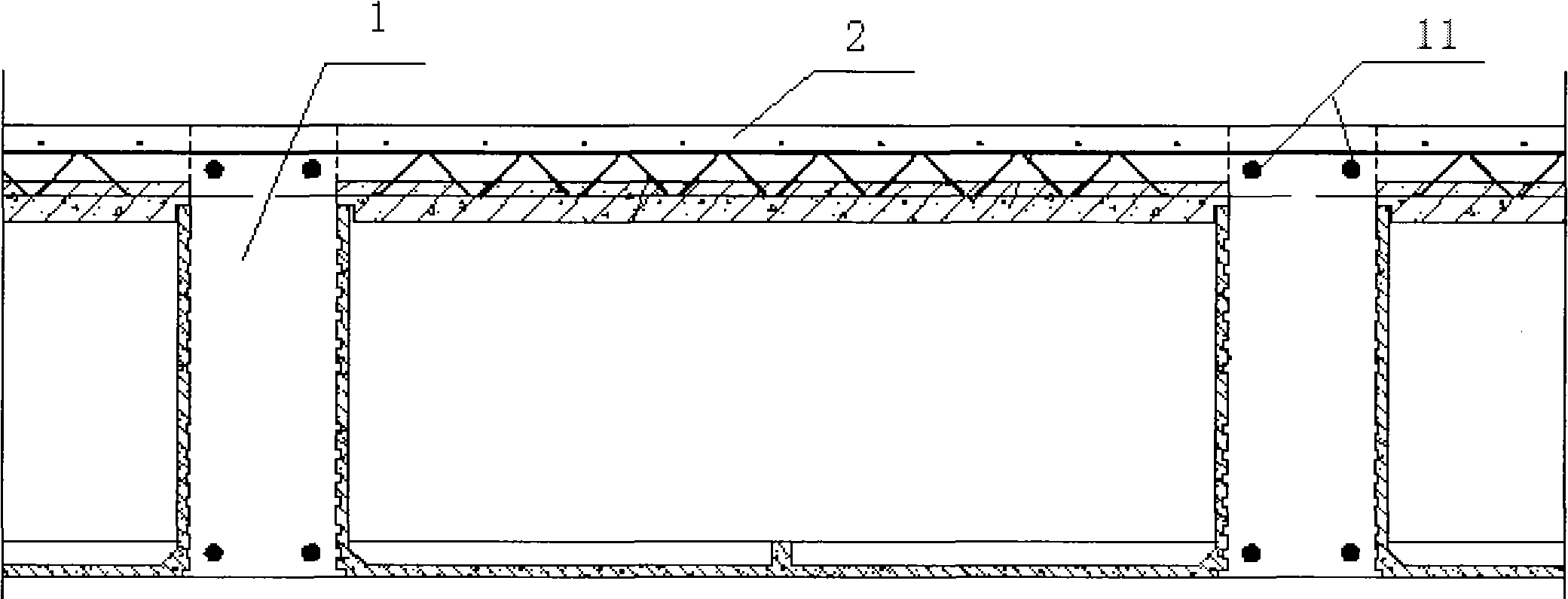

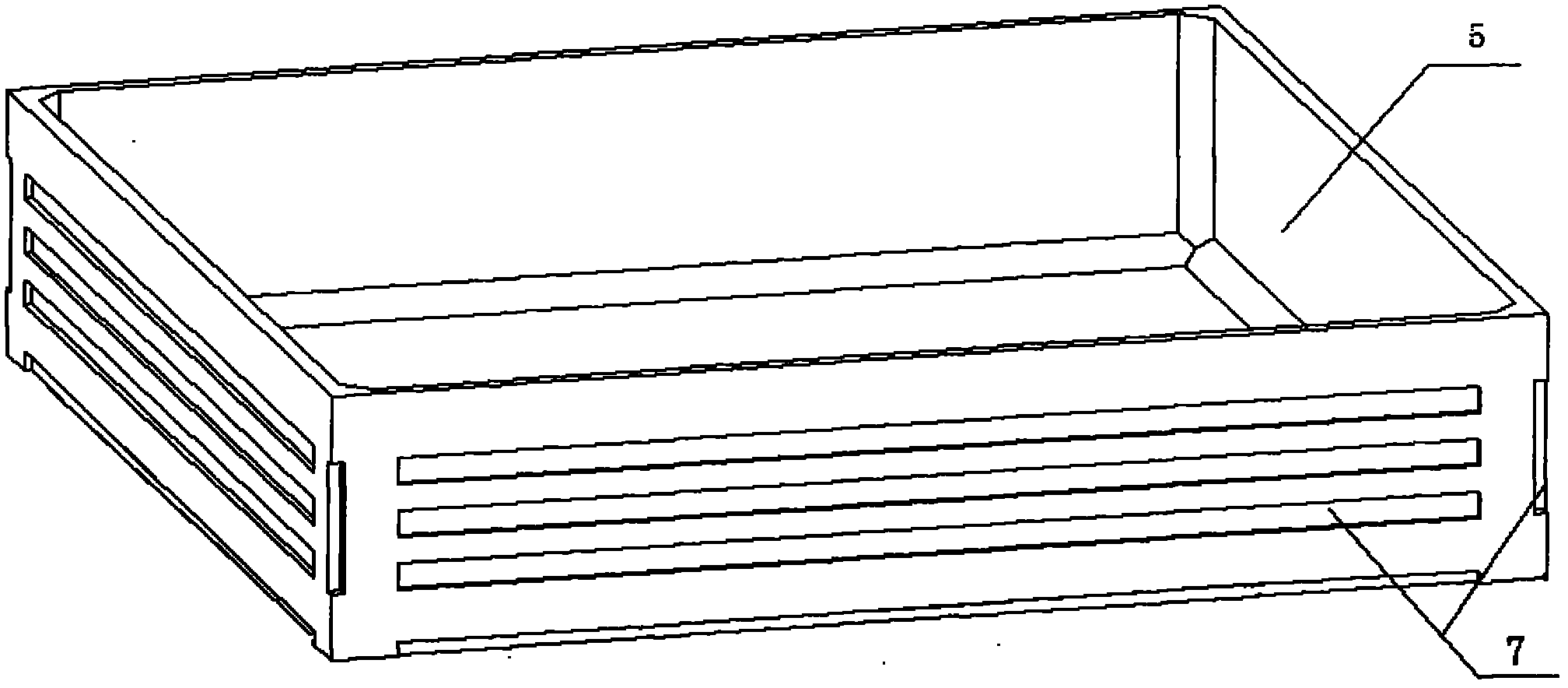

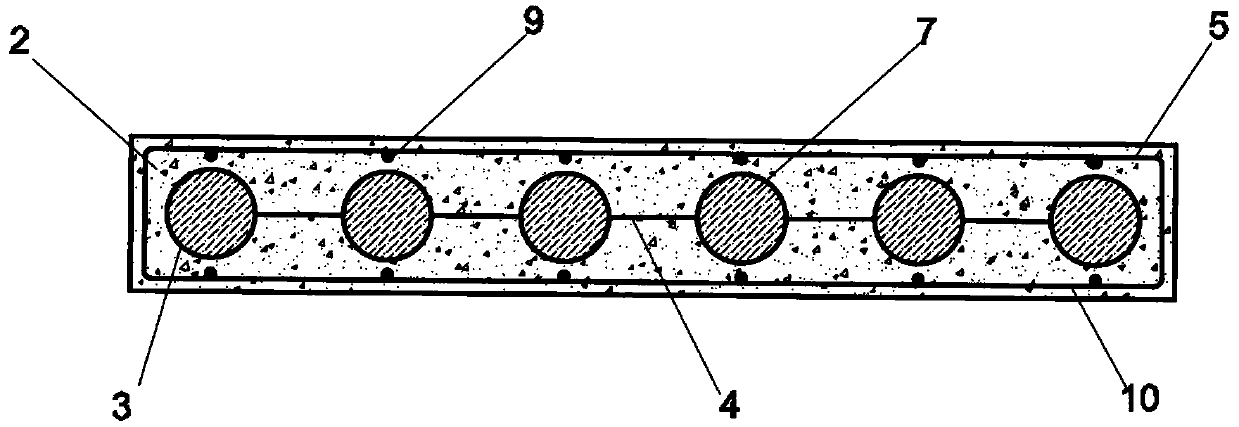

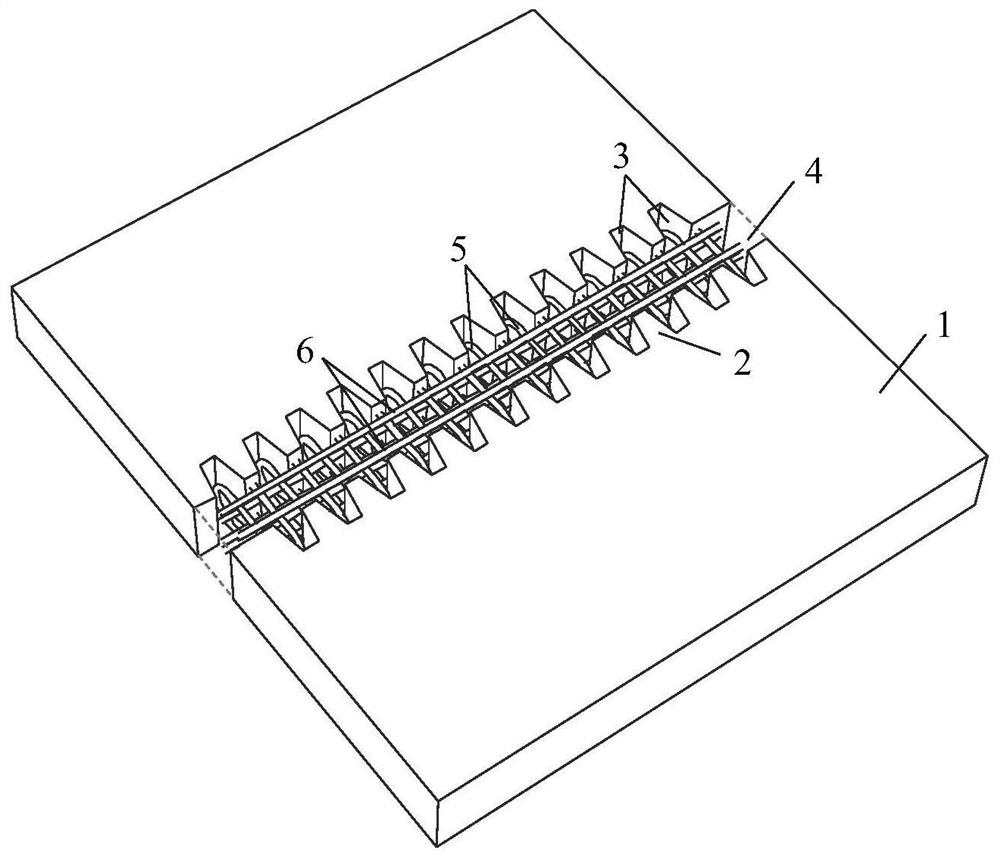

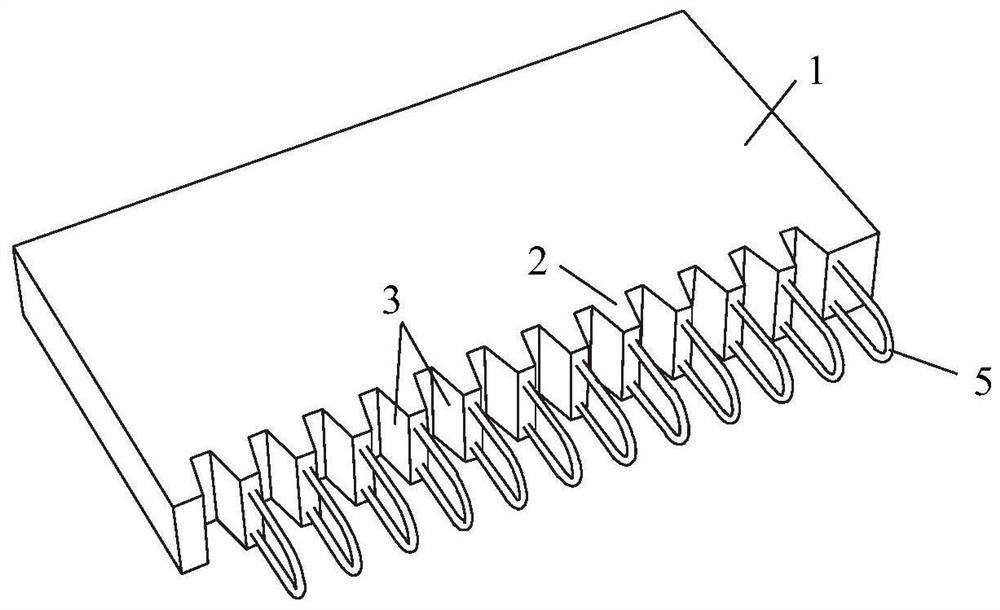

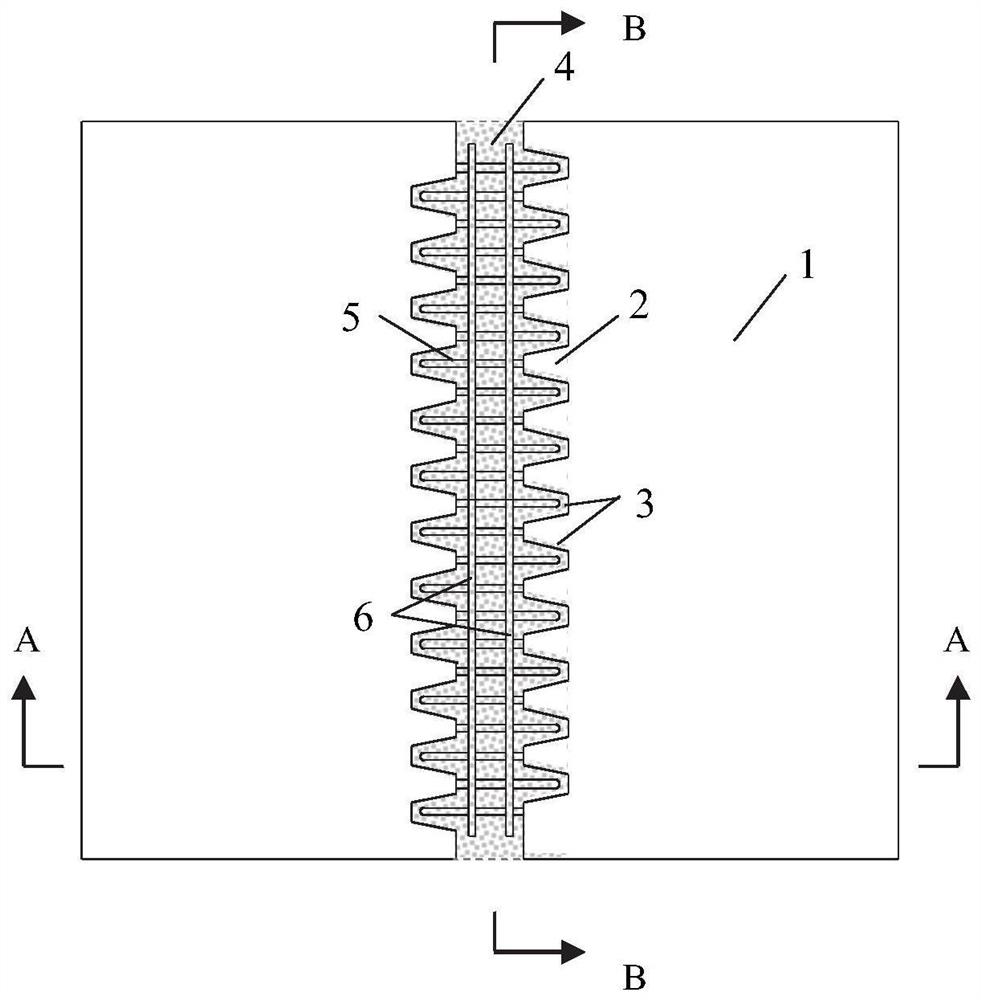

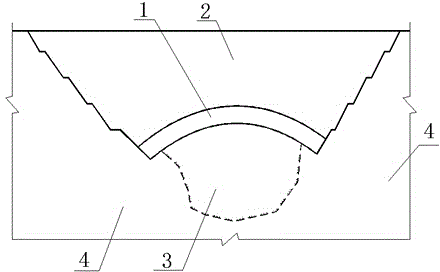

Assembled monolithic concrete ribbed hollow floor slab

InactiveCN102094481AHigh hollow rateLight weightFloorsForms/shuttering/falseworksFloor slabReinforced concrete

The invention relates to a floor slab, in particular to an assembled monolithic concrete ribbed hollow floor slab with combination of prefabrication and casting in place and joint stress, which comprises reinforced concrete rib beams (1), a reinforced concrete overlapping layer (2) and assembled box dies (3); each reinforced concrete rib beam is formed by casting in place between the adjacent assembled box dies; the reinforced concrete overlapping layer is formed by casting in place above the assembled box dies; each assembled box die (3) comprises a lattice reinforced composite slab (4) and an open box (5), and each lattice reinforced composite slab is a top slab of the open box (5); and protruding steel bars (6) are arranged in the lattice reinforced composite slabs (4), the protruding steel bars protrude into the peripheral rib beams for anchoring, longitudinal stressed steel bars (11) in the rib beams are hooked, and the rib beams (1) and the lattice reinforced composite slabs (4) are jointly stressed. The structural height of the floor slab can be greatly reduced, and higher using space for a building can be provided under the situation of same storey height.

Owner:辛崇安

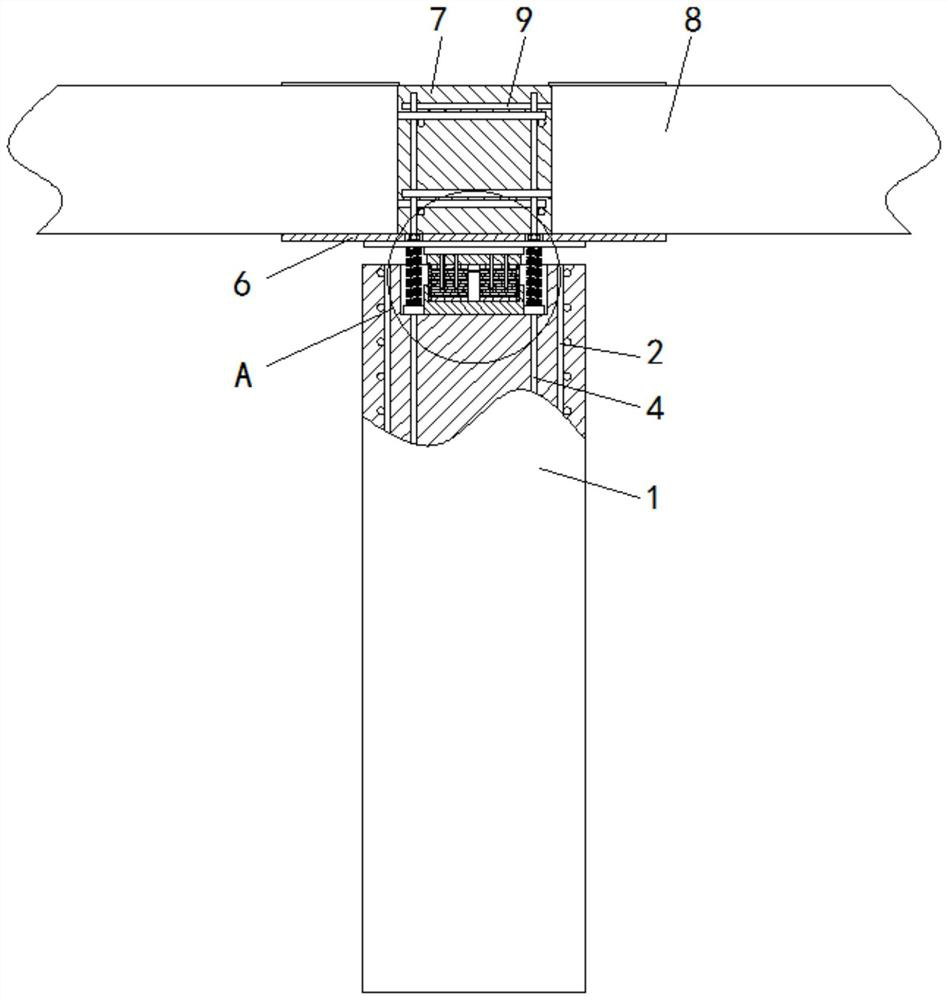

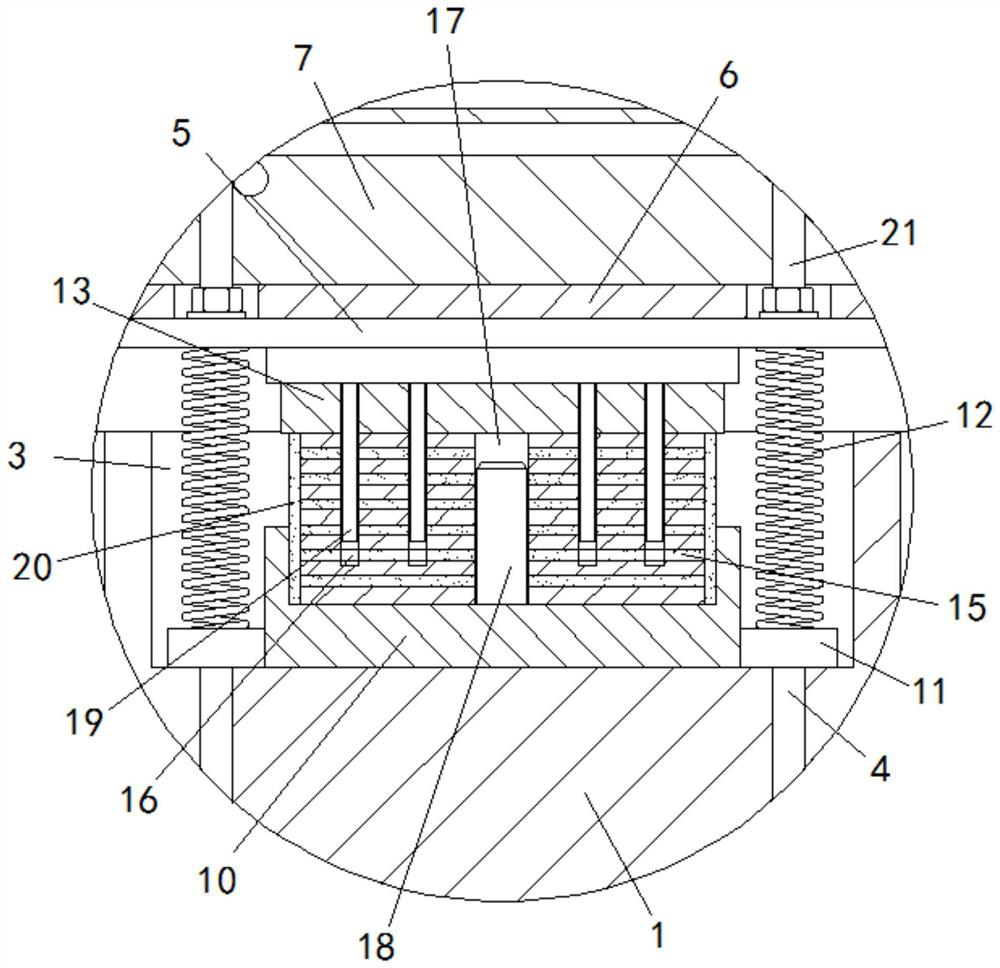

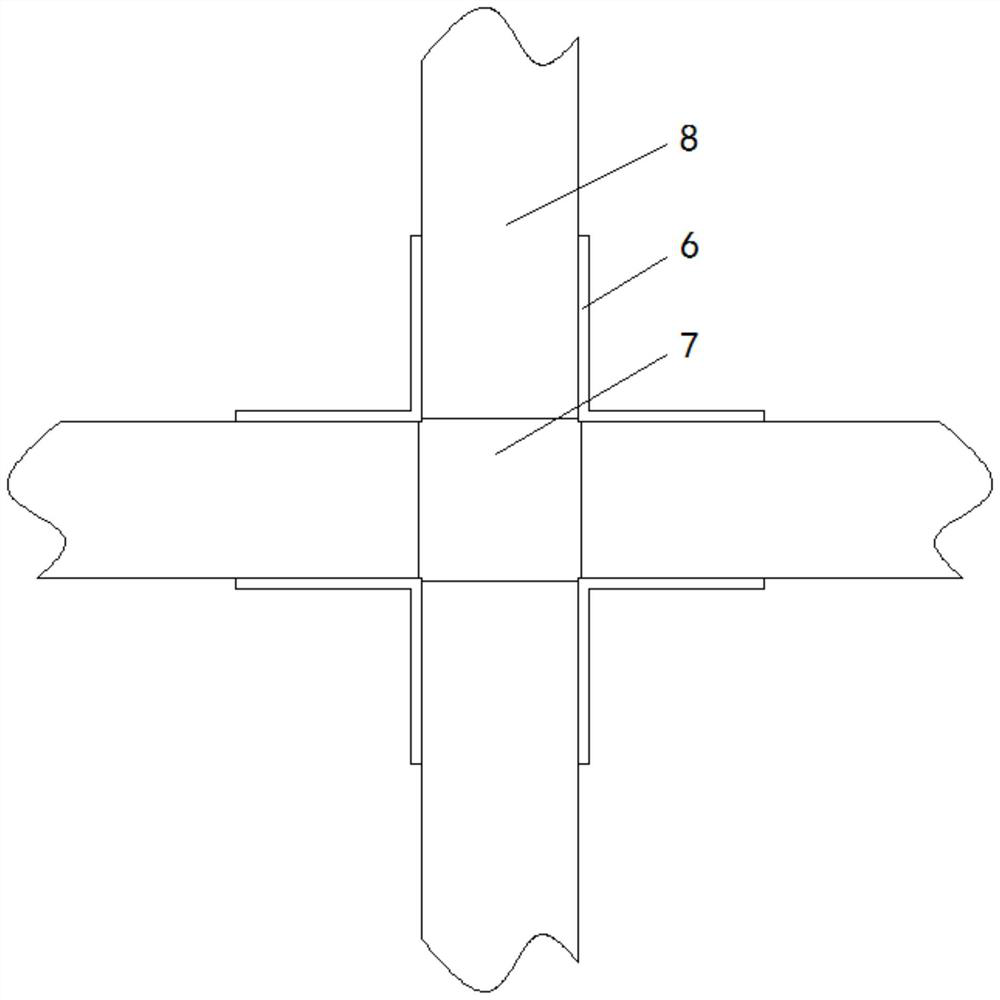

Beam-column structure for anti-seismic support of fabricated building

InactiveCN112681550AImprove structural stabilityExtended service lifeProtective buildings/sheltersShock proofingArchitectural engineeringRebar

The invention relates to the technical field of fabricated buildings, and discloses a beam-column structure for anti-seismic support of a fabricated building. The structure comprises a bearing column, wherein a reinforcing steel bar frame is fixedly mounted in the bearing column, and avoiding grooves are formed in the top of the bearing column; and four first reinforcing steel bar strips extending into the avoiding grooves are fixedly installed in the bearing column, a fixing base is fixedly installed at the bottoms of the inner walls of the avoiding grooves, and four fixing feet welded to the four first reinforcing steel bar strips are fixedly installed on each of the left side and the right side of the fixing base. According to the beam-column structure for the anti-seismic support of the fabricated building, beams and columns can be effectively fixed, assembly operation is facilitated, the pouring amount is relatively small, the time and energy required by beam-column assembly can be reduced, meanwhile, ground vibration can be effectively buffered and blocked, upward transmission of the vibration is avoided, the structural stability of the fabricated building is improved, mutual impact between structures is avoided, and the service life is prolonged.

Owner:FUJIAN JIANGXIA UNIV

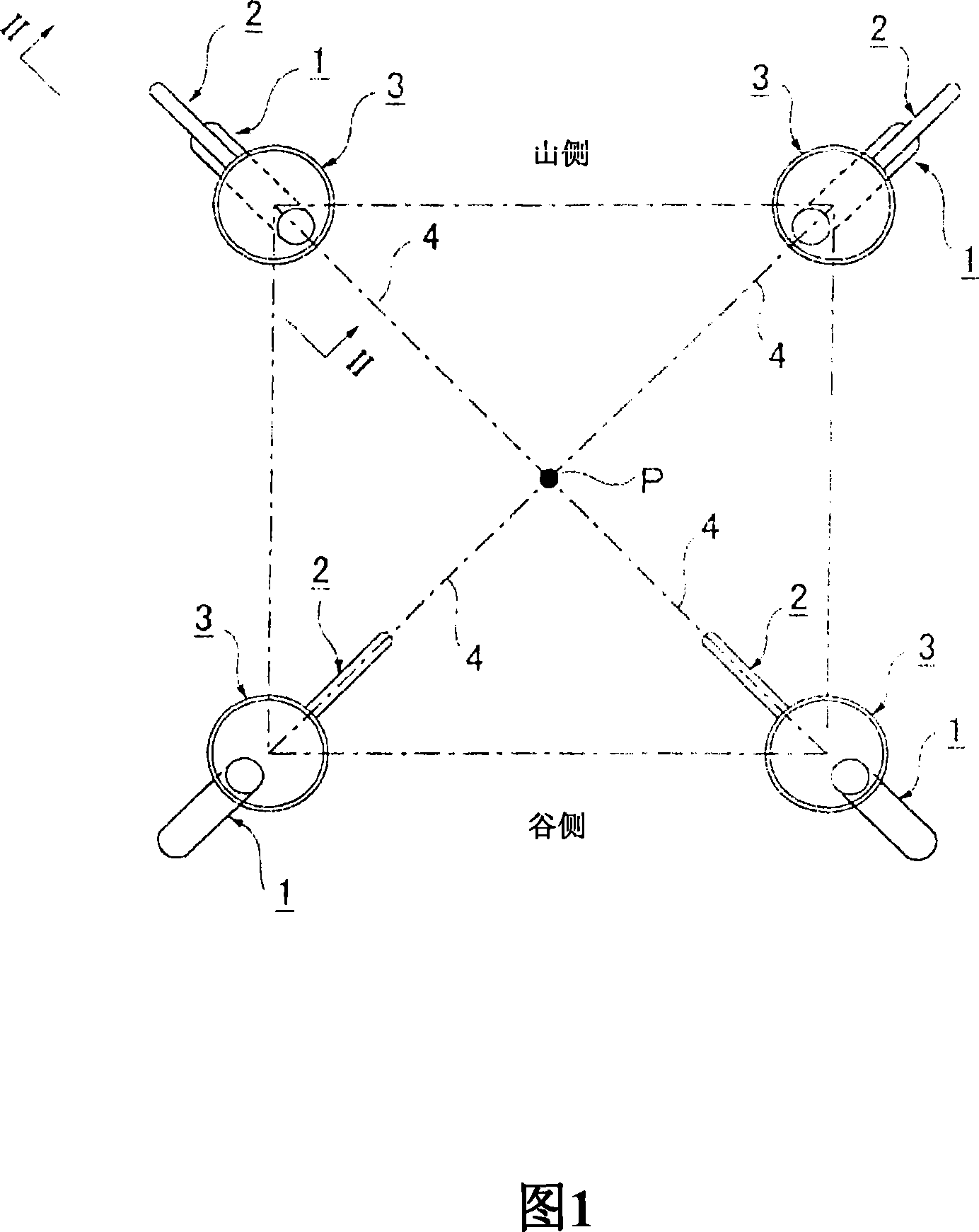

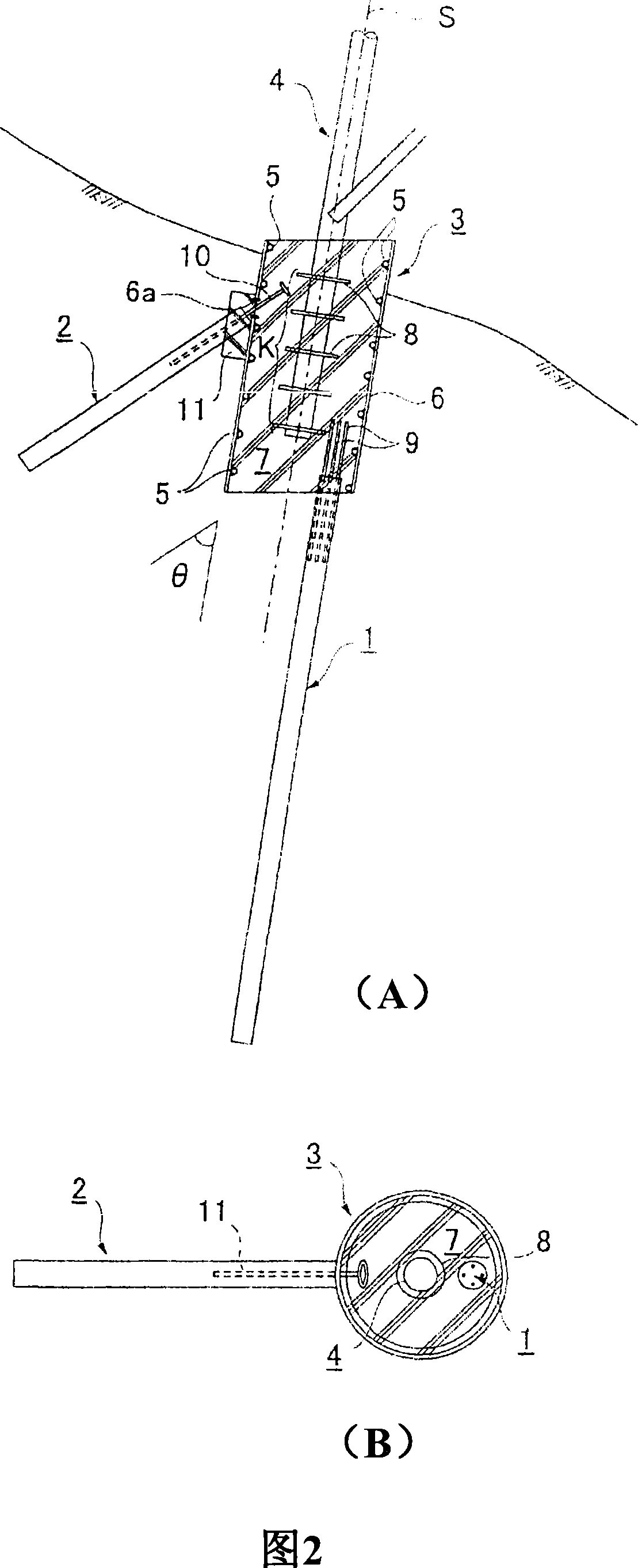

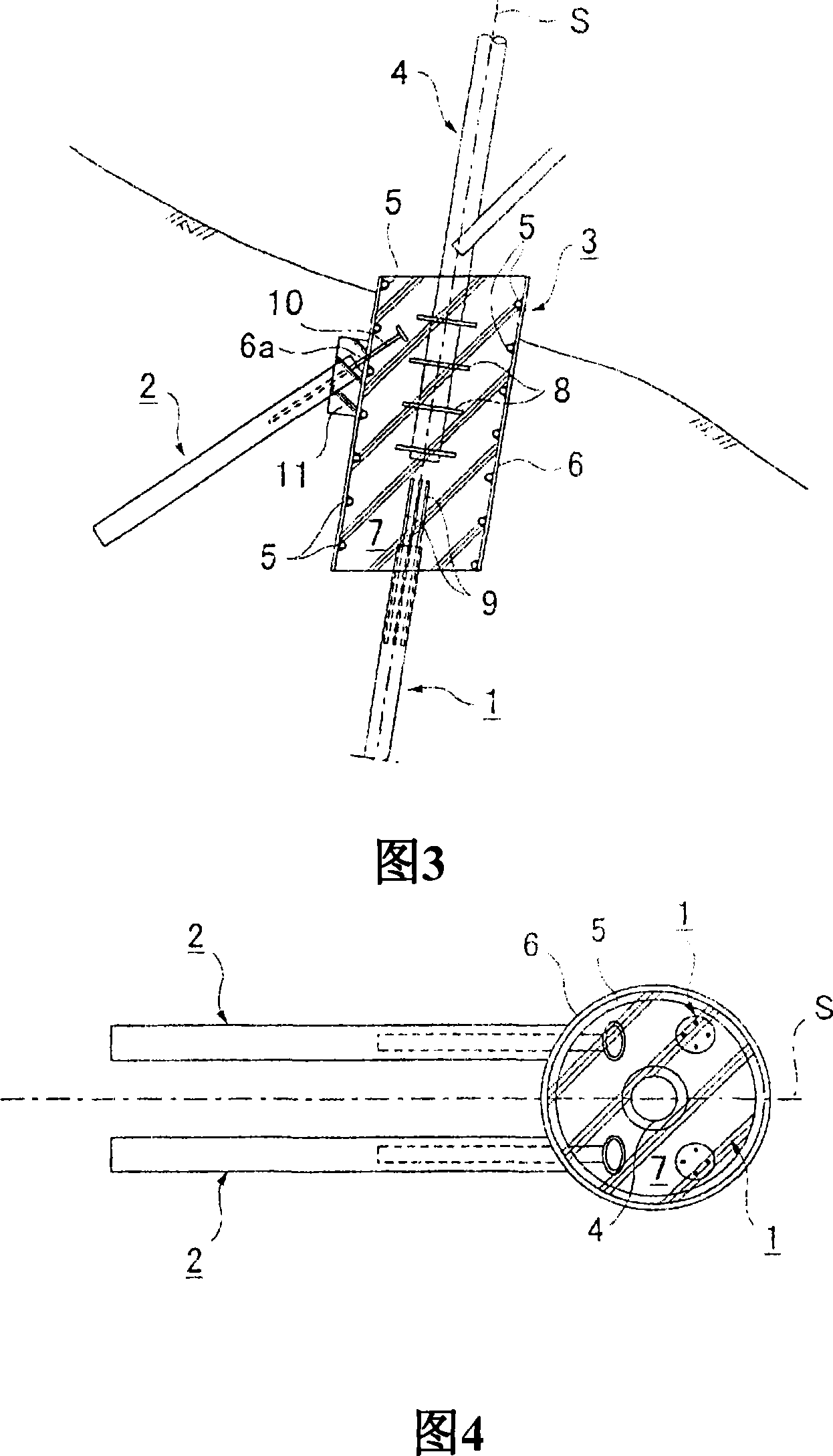

Foundation structure of steel tower

To provide a foundation structure of a tower capable of reducing labor load, construction cost, and production steps by reducing the scale of the structure of a foundation and facilitating construction. This foundation structure of the tower for supporting the main pedestals (4) of the tower comprises main piles (1) installed in the ground along directions roughly matching the directions of the main pedestals (4), auxiliary piles (2) installed in the ground along surface directions connecting the foundations to the center of the tower in plan view, and joining structures (3) joining the main piles (1) to the auxiliary piles (2) and to which the base parts of the main pedestals (4) are fixed. The joining structures (3) are built, for example, by placing a concrete (7) in a steel pipe (6). The top parts of the main piles (1) are joined to the lower surfaces of the joining structures (3), and the top parts of the auxiliary piles (2) are joined to the side faces thereof.

Owner:THE TOKYO ELECTRIC POWER CO INC

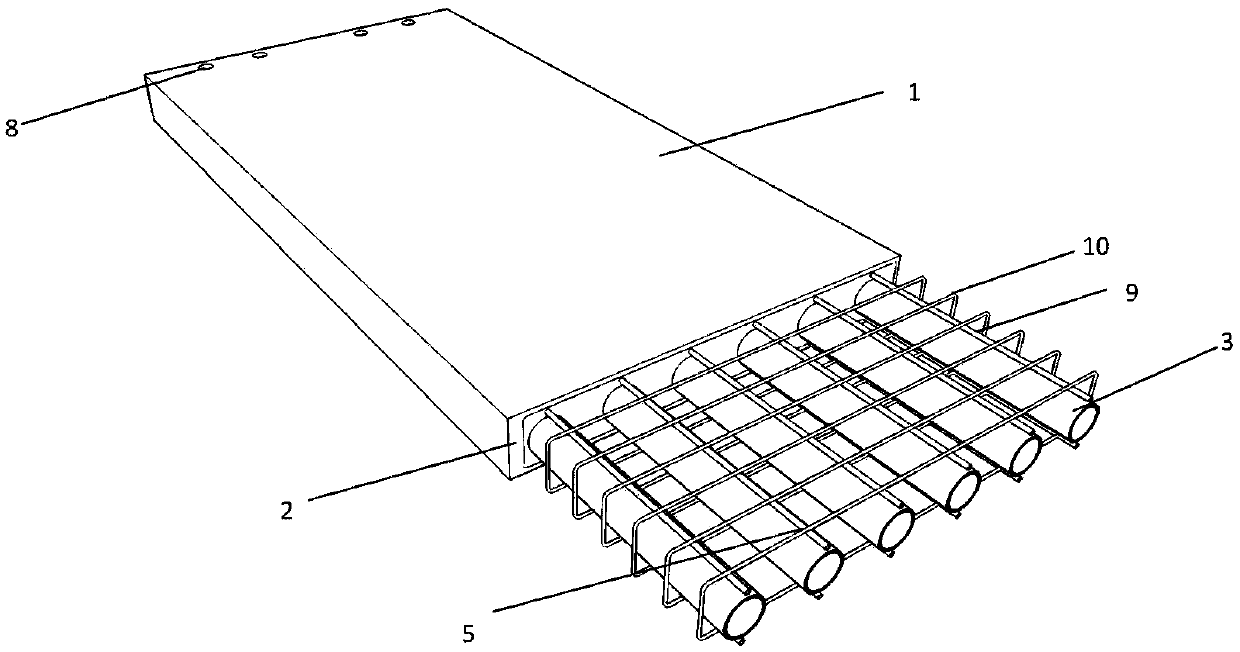

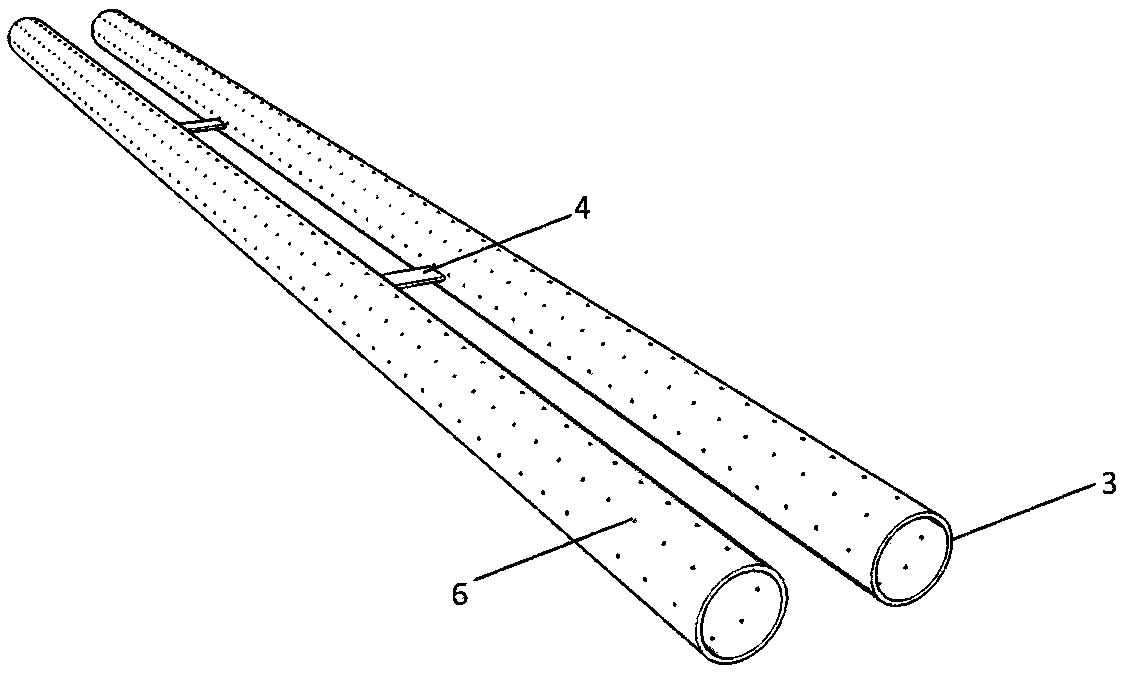

Prefabricated assembly type lightweight floor and manufacturing method thereof

The invention discloses a prefabricated assembly type lightweight floor and a manufacturing method thereof, and belongs to the technical field of building materials. The invention provides the prefabricated assembly type lightweight floor composed of a concrete matrix, a hollow steel tube, a batten plate, a reinforcing mesh frame, a hollow steel tube hole, a lightweight filling material and a toggle pin hole and the manufacturing method thereof, not only is the problem of large self-weight of a traditional cast-in-place floor solved, but also the problem of the lower intensity of lightweight concrete is solved, and the practical significance and engineering application value are significant.

Owner:JIANGNAN UNIV

Section steel-UHPC composite board and bridge deck

PendingCN109972511AIncrease spanImprove mechanical performanceBridge structural detailsBridge erection/assemblyCable stayedBridge deck

The invention discloses a section steel-UHPC composite board. The section steel-UHPC composite board comprises a plurality of pieces of section steel and UHPC boards fixedly connected to the section steel. Each piece of section steel comprises an upper flange and a web, and the end of the upper flange is provided with an outwardly extending upper flange extension section. The invention also discloses a bridge deck. The bridge deck is mainly formed by connecting a plurality of section steel-UHPC composite boards in the longitudinal bridge direction, the adjacent section steel-UHPC composite boards are connected through a cast-in-situ connection part, and the ends of the upper flanges are provided with upper flange outward extension sections and lower flange outward extension sections that extend towards the insides of the cast-in-situ connection parts respectively. The section steel-UHPC composite board and the bridge deck solve the problems of easiness in cracking of bridge decks in anegative moment region at the transverse joint of the inner fulcrum of a continuous beam bridge and easiness in cracking of a transverse joint between bridge decks at the midspan main beam in the midspan of a cable-stayed bridge.

Owner:HUNAN UNIV

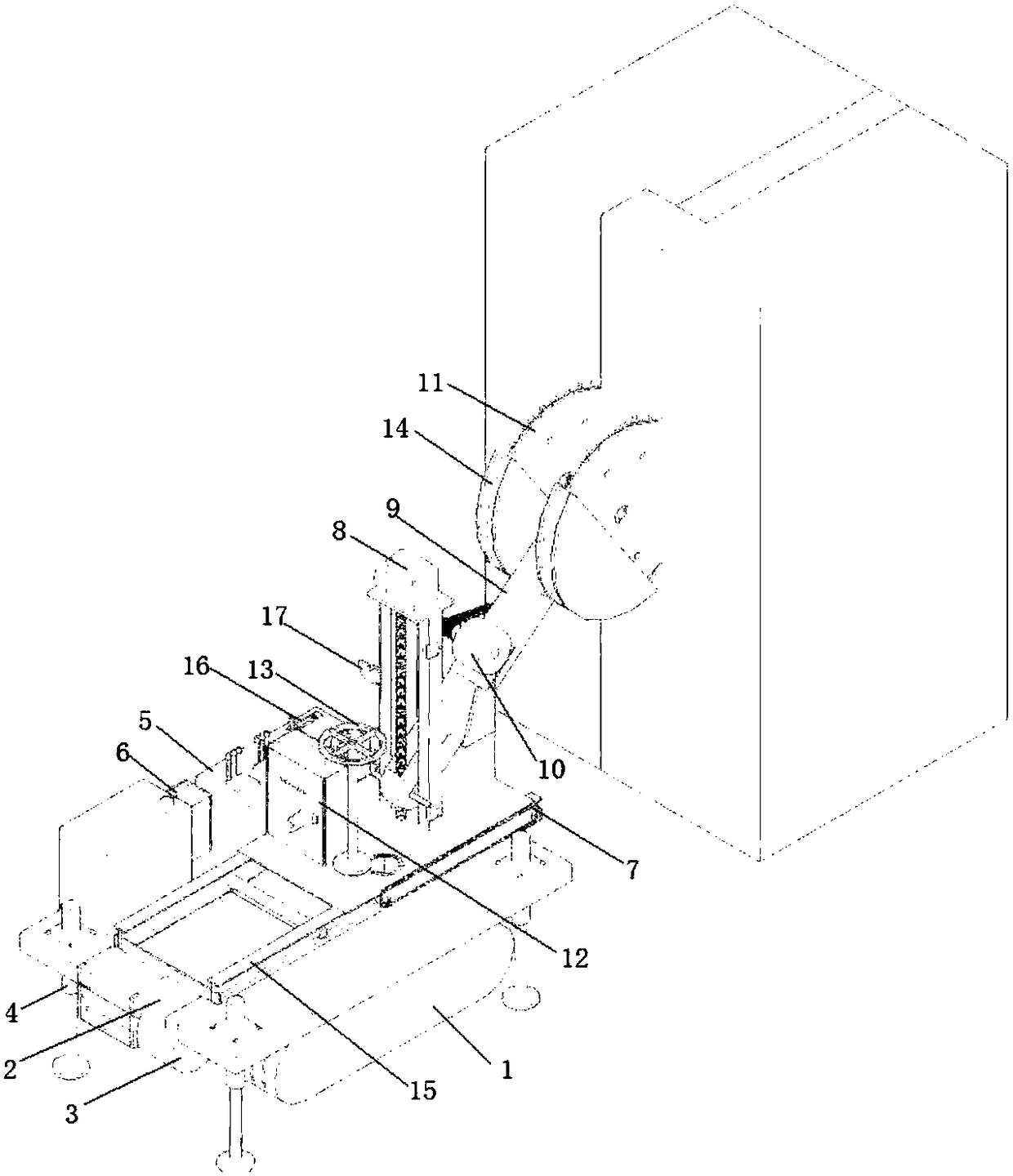

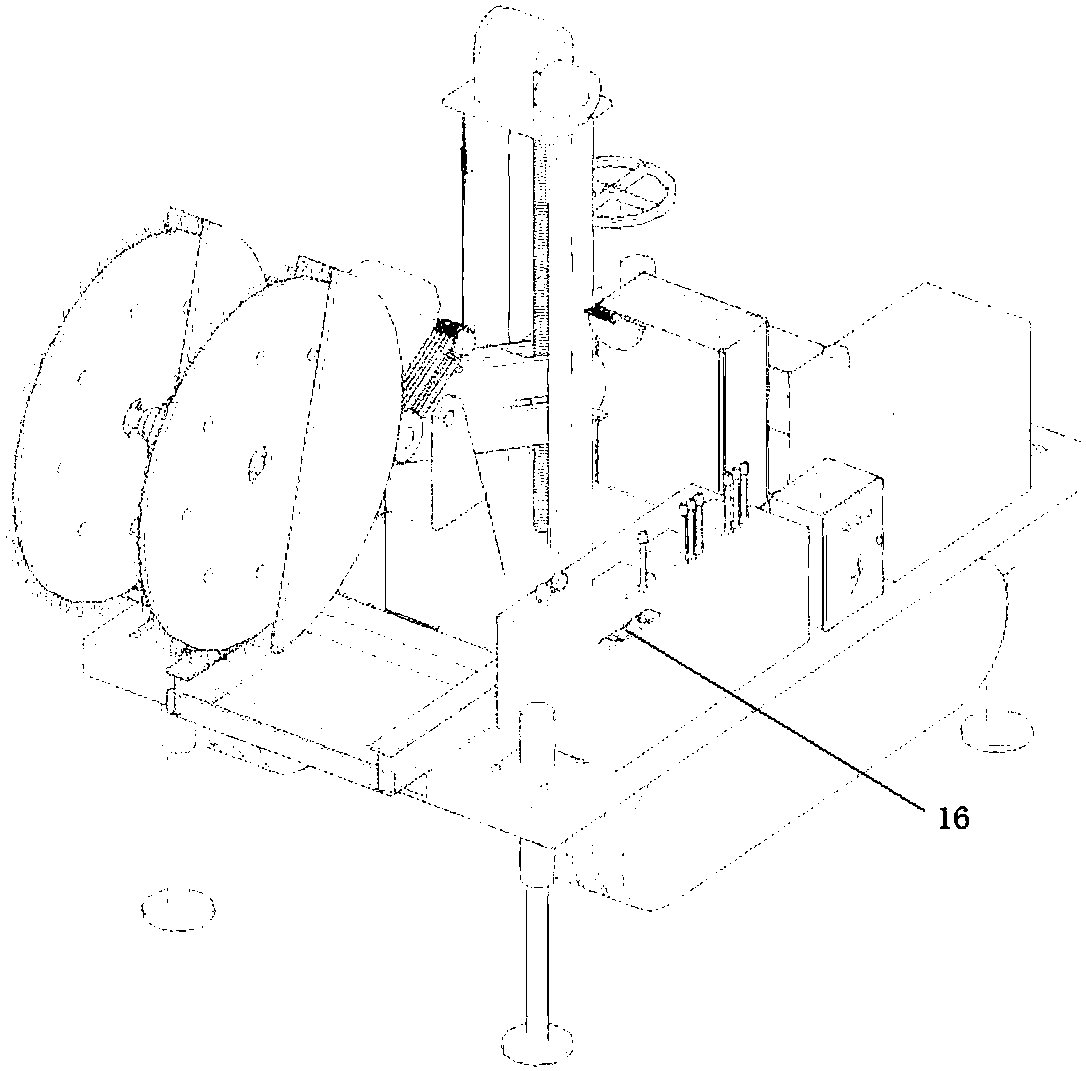

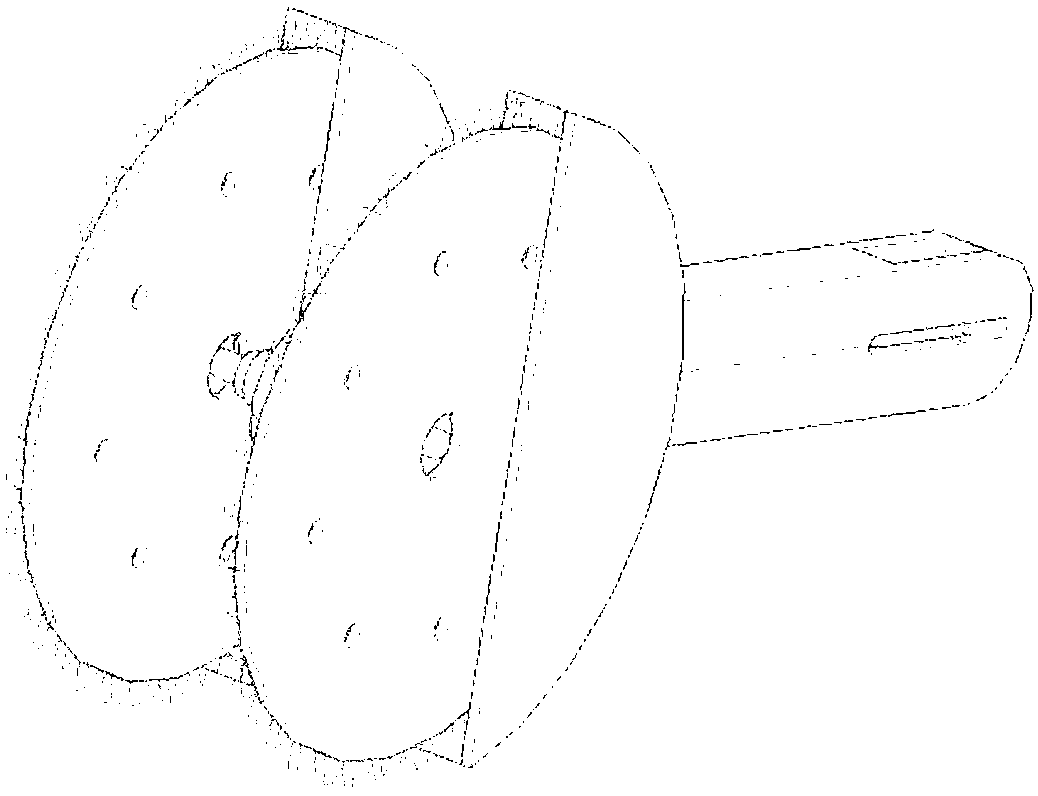

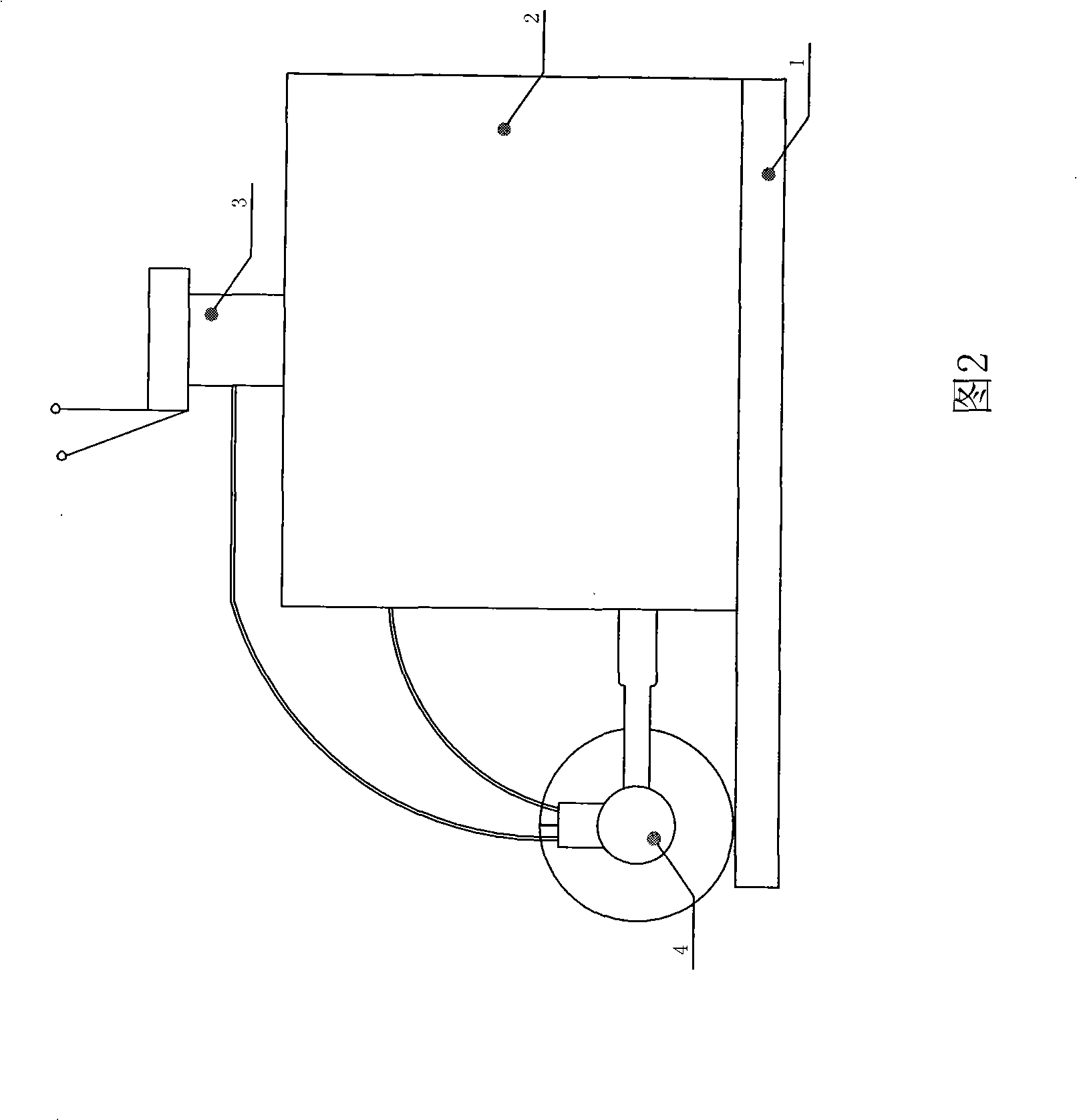

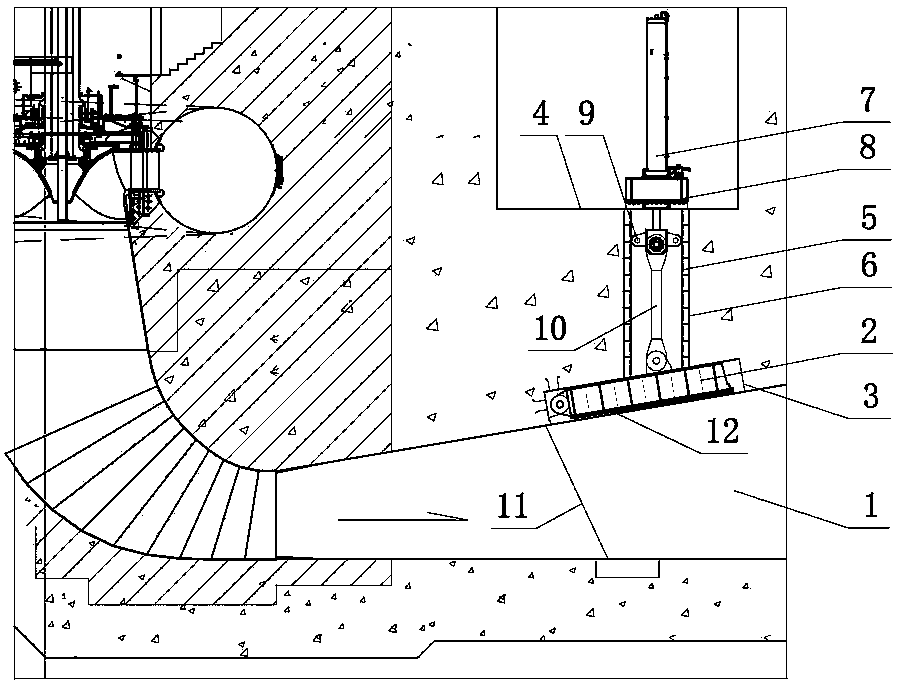

Movable facade hard rock slotting machine and construction technology thereof

ActiveCN108214945AFast cutting speedEasy to shapeWorking accessoriesStone-like material working toolsHydraulic pumpEngineering

The invention provides a movable facade hard rock slotting machine and a construction technology thereof. The movable facade hard rock slotting machine comprises a crawler travelling mechanism (1) forallowing the slotting machine to move, a working platform (2) for allowing staff to operate, an electric hydraulic pump (3) which controls circulation of hydraulic oil, levelling supporting leg cylinders (4) used for supporting the slotting machine to guarantee integral levelness of the slotting machine and perpendicularity of a cutting blade, a travelling and adjusting operation mechanism (5) used for operating the crawler travelling mechanism (1), a travelling electric control cabinet (6) which supplies power to the travelling and adjusting operation mechanism (5), a cutting machine movingrail rack (7) used for mounting the cutting blade, and a cutting blade up-down moving mechanism (8) used for adjusting the up-down displacement of the cutting blade. According to the movable facade hard rock slotting machine, an electric double-wheel cutting machine is mounted on a chassis of the crawler travelling mechanism, upright post groove lines can be cut on facade hard rock through the cutting blade capable of moving up and down and front and back, then, a cut rock body is broken through a self breaking hammer of the cutting machine or an excavator matched with construction, and upright post grooves are formed.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

Structural steel-UHPC (Ultra High Performance Concrete) composition board longitudinal rib staggered arrangement construction and construction method thereof

PendingCN109610313ALight weightImprove leaping abilityBridge structural detailsBridge erection/assemblyContinuous beamAxial force

The invention discloses a structural steel-UHPC (Ultra High Performance Concrete) composition board longitudinal rib staggered arrangement construction and a construction method of the structural steel-UHPC composition board longitudinal rib staggered arrangement construction, the structural steel-UHPC composition board longitudinal rib staggered arrangement construction comprises a structural steel-UHPC composition board at the upper part and a steel beam, the structural steel-UHPC composition board is mainly combined from a UHPC board and a structural steel, the structural steel is arrangedas a longitudinal rib along a longitudinal bridge; the longitudinal rib of the structural steel-UHPC composition board adopts a staggered arrangement mode, a web overhanging section is arranged at theend part of the structural steel on a transverse joint and extends into the transverse joint along a web of the structural steel, and the web overhanging sections on the two sides of the joint interpenetrate in a staggering way. The longitudinal ribs on the joint adopt the staggered arrangement mode, part of the UHPC is at the pressed state, the crack risk is reduced, the cross section of the joint has a better mechanical property, the longitudinal and transverse rigidity of a bridge panel is also conveniently matched, therefore, the problem of too large axial force of the bridge panel at theupper part of an inner support point of a main beam and a continuous beam near a cable bent tower is well solved, the material is also made full use, and the construction cost of the bridge is low.

Owner:HUNAN UNIV

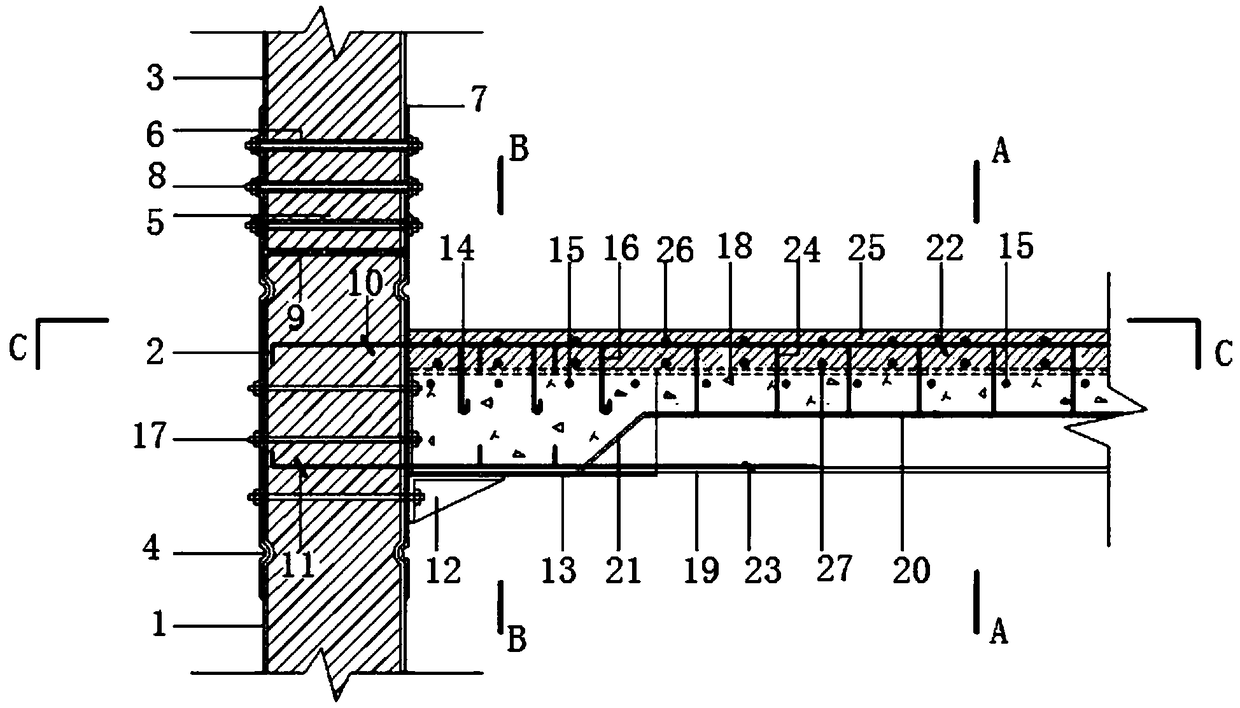

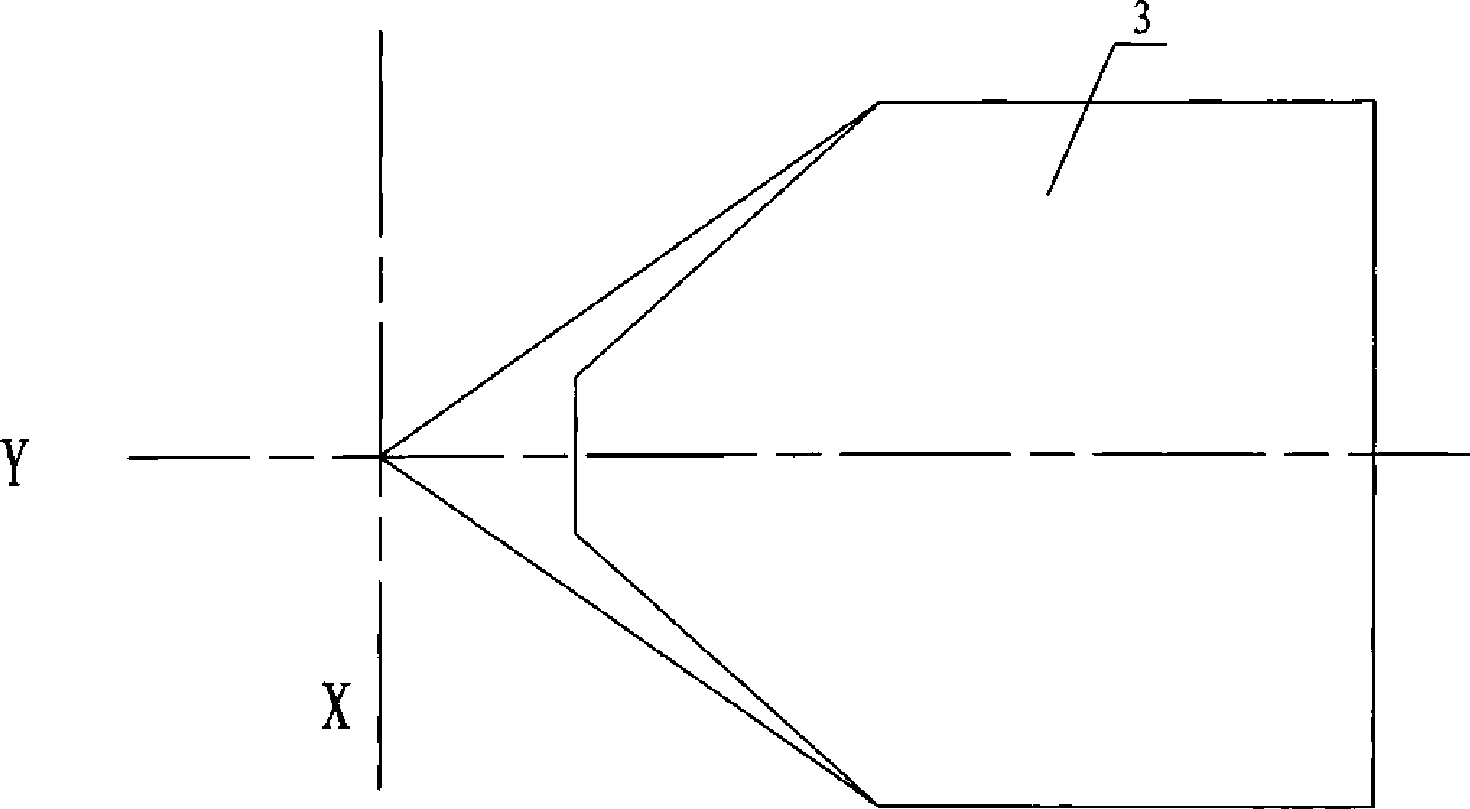

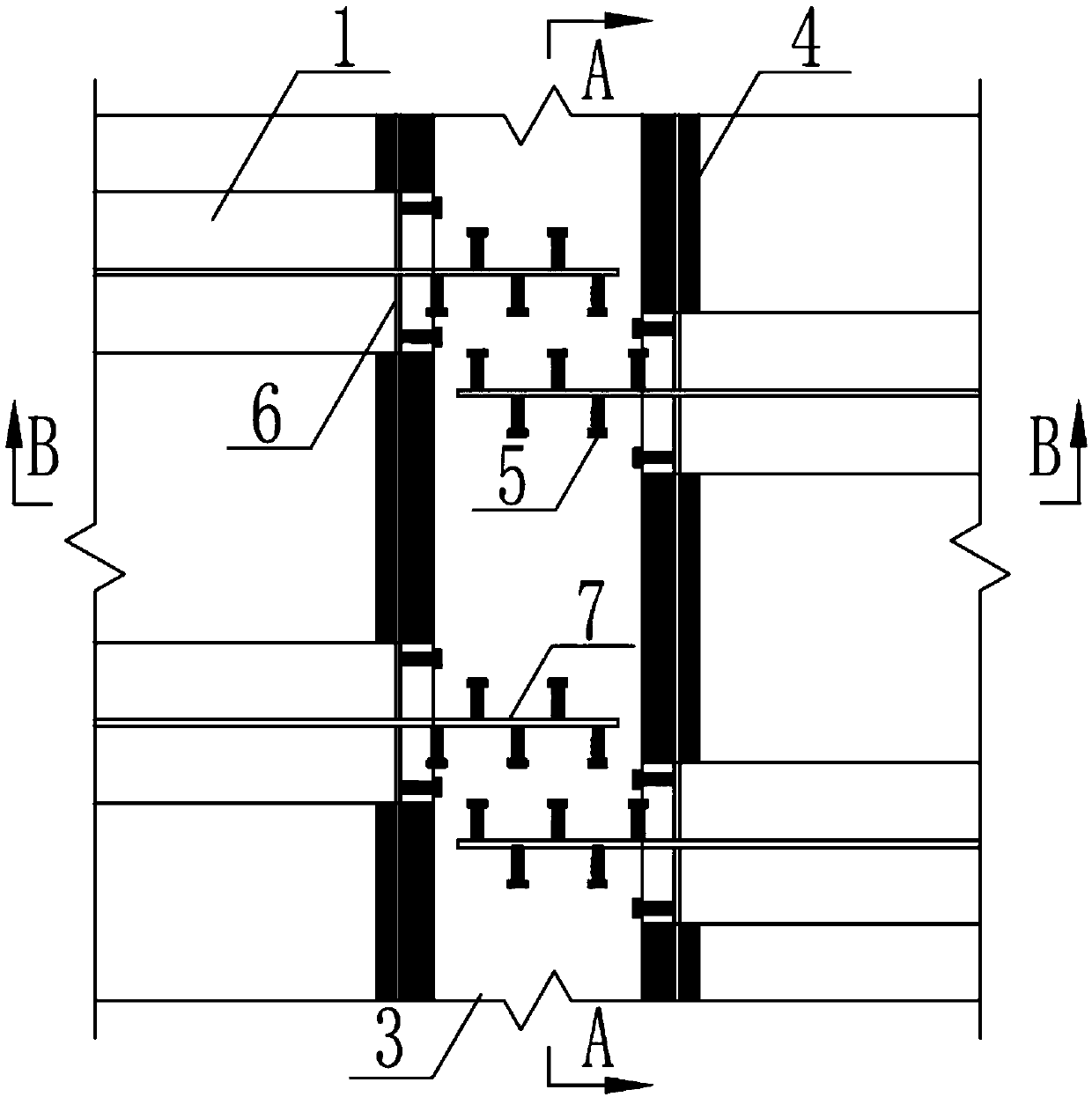

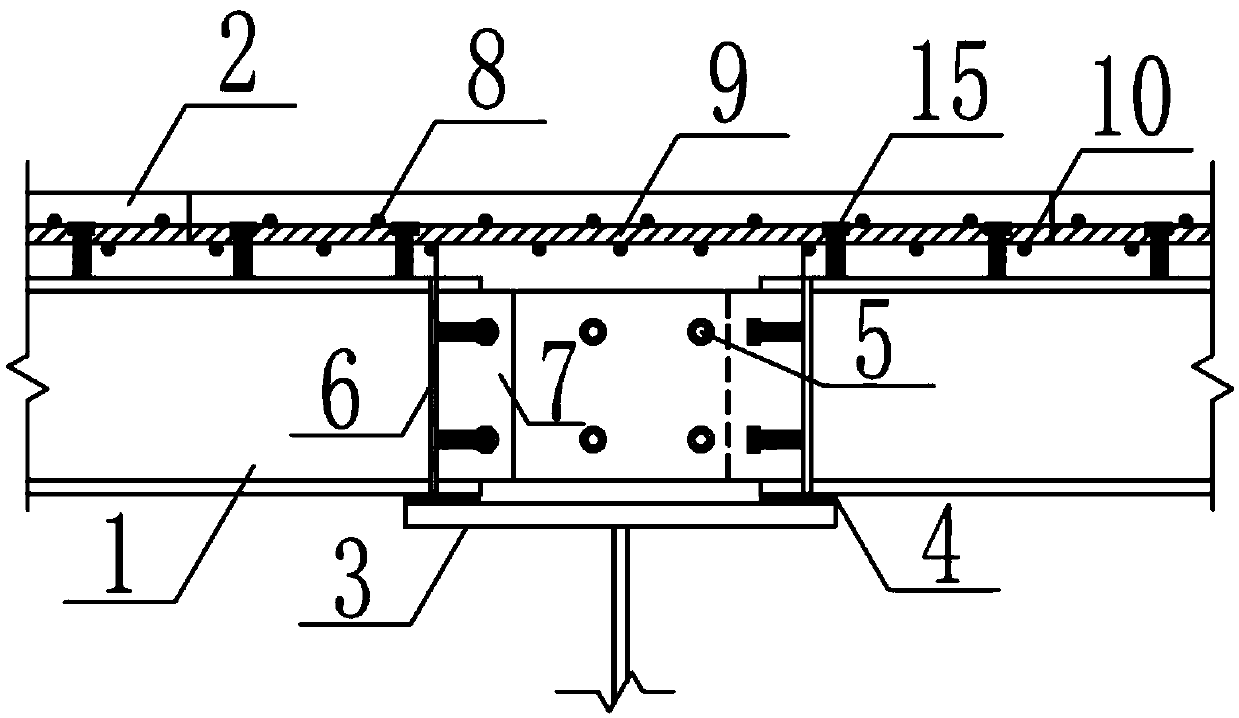

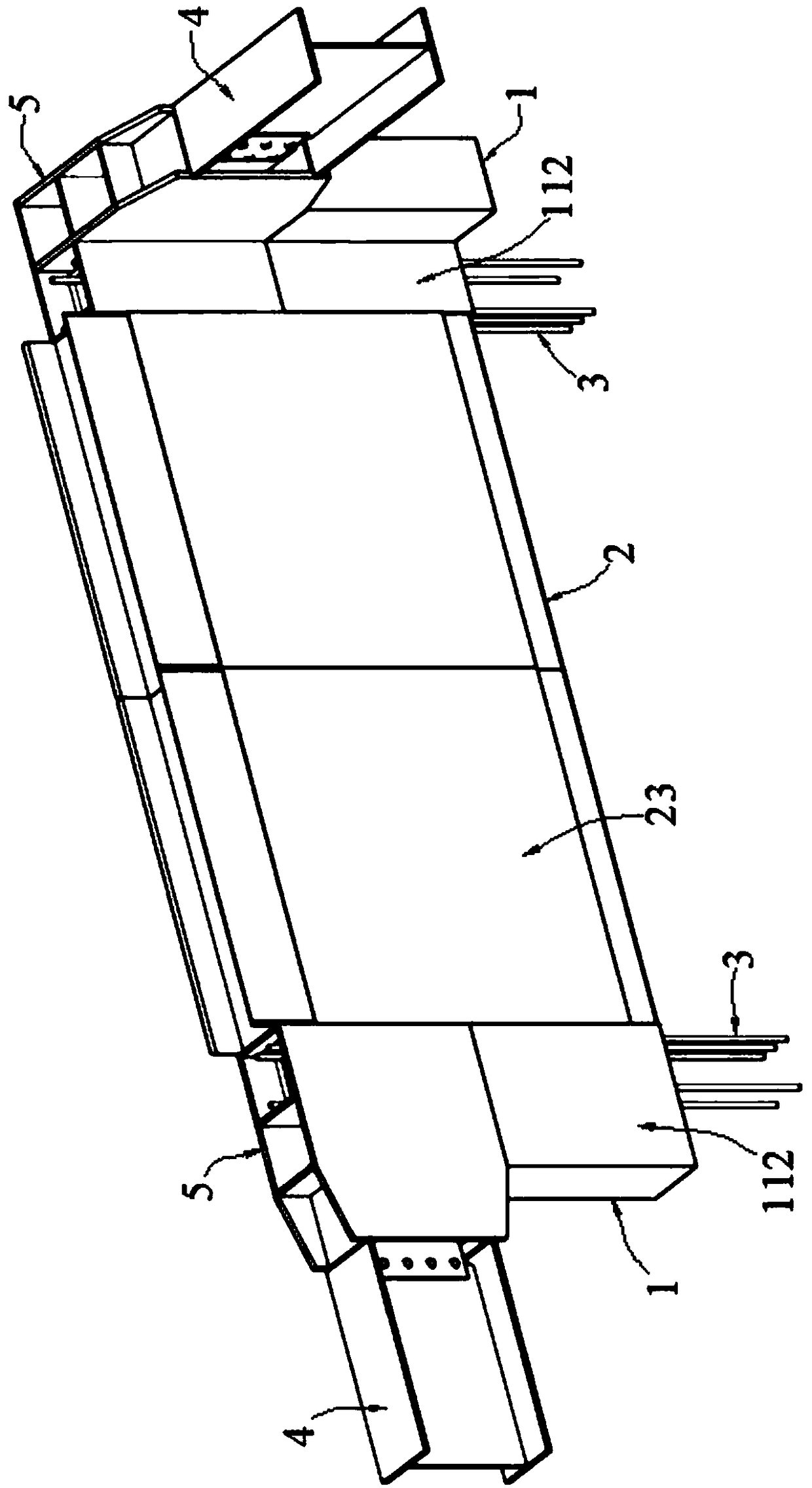

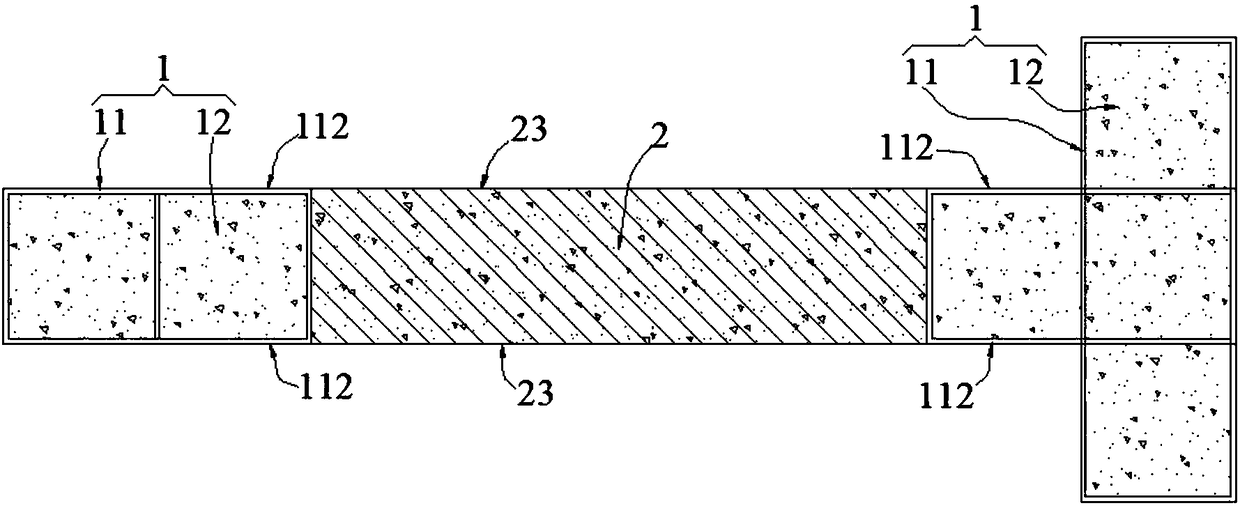

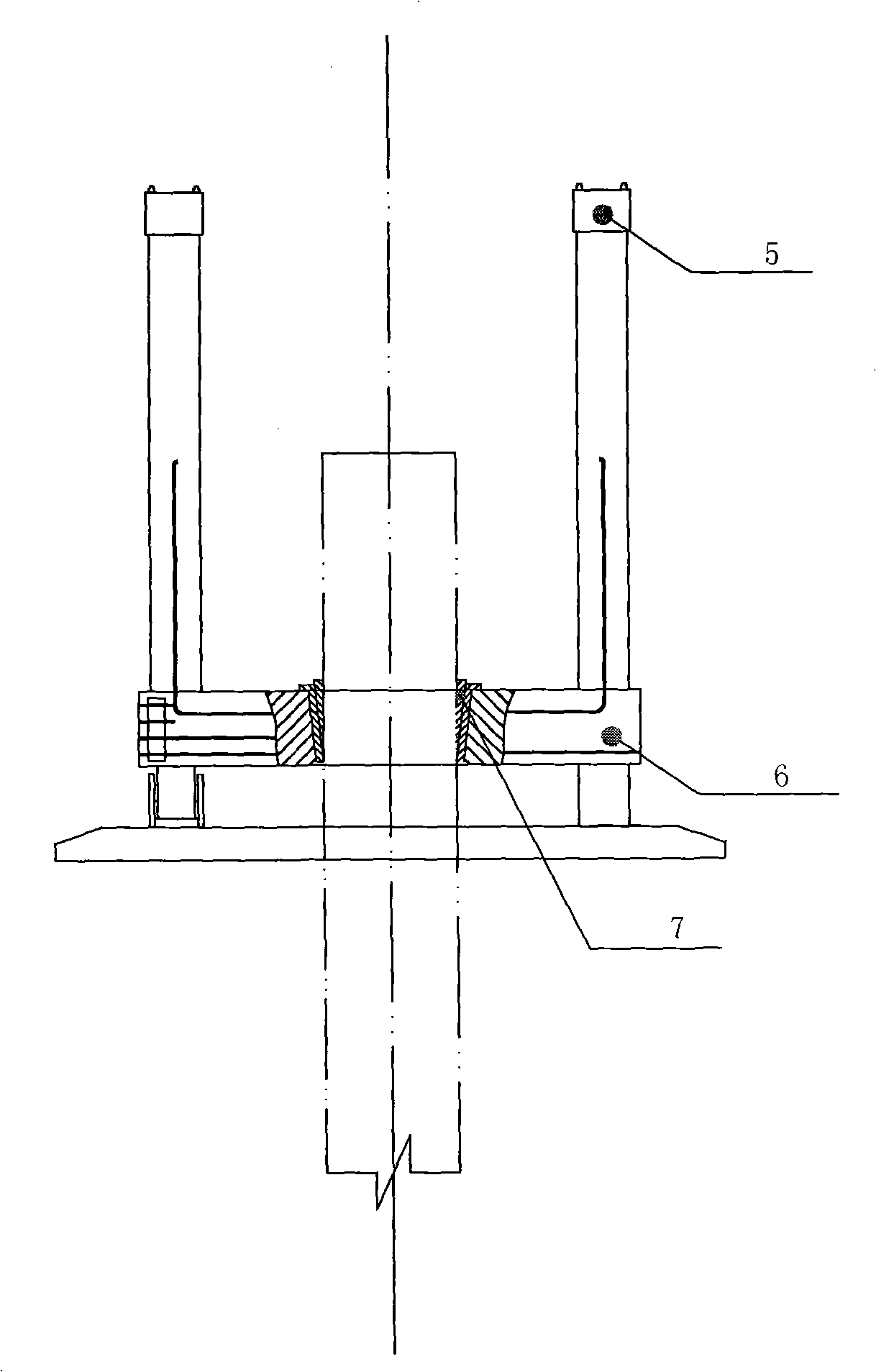

Connecting structure and method for precast column and beam and slab joints of concrete frame structure

ActiveCN106149878APrecise card positioningGuaranteed shear performanceBuilding constructionsGroutLaminated beam

The invention discloses a connecting structure and method for precast column and beam and slab joints of a concrete frame structure. The structure comprises upper and lower precast columns (1), laminated beams (2) on the two sides and a joint area (3). The top of the lower precast column (1) is flush with the laminated faces of precast beams (2.1) of the laminated beams (2) on the two sides, a transverse metal bellows (6) is arranged in the lower precast column (1) in a penetrating mode, and negative moment longitudinal force-bearing steel bars (7) at the bottoms of the precast beams (2.1) on the two sides stretch into and are anchored in the metal bellows (6). A grout pipe (8) communicated with the metal bellows (6) is anchored in the joint area (3). The method is characterized in that all the negative moment longitudinal force-bearing steel bars (7) at the bottoms of the precast beams (2.1) on the two sides stretch into the metal bellows (6) of the lower precast column (1) and are anchored. By means of the structure and the method, it can be avoided that operation at joints is difficult due to the narrow space, and the use amount of cast-in-place concrete can be reduced.

Owner:NINGBO PRECA CONSTR TECH CO LTD

Method for rapidly forming hole by using rotary drilling rig to penetrate through drift sand layer

InactiveCN102433875AIncrease friction load capacityReduce the amount of pouringBulkheads/pilesWater useWater source

The invention discloses a method for rapidly forming a hole by using a rotary drilling rig to penetrate through a drift sand layer. The method comprises the following steps of: (1) preparation of chemical polymer slurry; (2) shield-tube burying; (3) drilling for hole formation; (4) reinforcement cage lifting and lowering; (5) secondary hole cleaning; and (6) underwater concrete pouring. In the chemical polymer slurry preparing process, water used as a raw material is clean tap water; the pH value of the water source is tested by using pH test paper before the water is used; a small amount of dietary alkali is added according to a testing result; and the pH value of a slurry system is adjusted to be 9-10; 2-3% of chemical polymer is added to water with pH value of 9-10 to prepare an aqueous solution with mass concentration of 0.1-0.5%. The relative density of the slurry is 1.15-1.18, the viscosity of the slurry is 17-20 and the sand content of the slurry is not more than 3%; and before concrete casting, the relative density of the slurry is 1.03-1.1, the viscosity of the slurry is 18-19 and the sand content of the slurry is not more than 0.5%. The polymer slurry boring mud has the advantages of rapidness for precipitation and less sediment.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

Full-assembly detachable building structure and installation and construction technology

ActiveCN105672479AAvoid it happening againReduce the number of linksBuilding material handlingUltimate tensile strengthFloor plate

The invention discloses a full-assembly detachable building structure and an installation and construction technology, and relates to the field of building structures. The structure comprises a pile foundation hole formed in a foundation, a pile foundation is installed in the pile foundation hole, a foundation beam is installed above the pile foundation, a prefabricated house structure is installed on the foundation beam, and the prefabricated house structure comprises a load bearing gable wall, load bearing front and rear walls, a load bearing partition wall and a floor plate or a roof plate; according to the installation sequence, the load bearing front and back walls are installed, then the load bearing gable wall is installed, then, the load bearing partition wall is installed, and the floor plate or the roof plate is installed. The body building components of the full-assembly detachable building structure can be industrialized produced, a building can be detached and recycled, the labor intensity is lowered, the building construction speed is increased, the cost is lowered, the intensity of the house is ensured, and energy conservation and environmental protection are achieved while it is ensured that the intensity of the house achieves the anti-seismic performance.

Owner:黑龙江高格建筑科技产业(集团)有限公司

Pipeline installing method

The invention discloses a pipeline installing method. The pipeline installing method comprises the steps that a fastening belt is adopted for achieving temporary fastening of a first pipe base and a first pipe joint, and a first pipe base and pipe joint unit is formed; the first pipe base and pipe joint unit is hoisted into a base groove; the pipe inner bottom elevation of the first pipe joint inthe base groove is measured; gaps on the two sides between the first pipe joint and the first pipe base are closed; the preparing work for second pipe base and pipe joint unit installation is conducted; a second inserting port of a second pipe joint is inserted in a first port of the first pipe joint; the bell mouth end elevation of the position of a second bell mouth of the second pipe joint in the base groove is measured; a gap on the second bell mouth side between the second pipe joint and the second pipe base is closed; the steps from the fifth step to the eighth step are repeatedly conducted, and subsequent pipe base and pipe joint unit installation is finished; and cement mortar is poured into the positions between the pipe joints and the pipe bases in the same pipe base and pipe joint units and between the pipe bases between the adjacent pipe base and pipe joint units. According to the pipeline installing method, the hoisting frequency can be effectively reduced, and the advantage that construction is safe and reliable is achieved.

Owner:KUNSHAN YUTENG MUNICIPAL ENG

Composite prefabricated floor slab for fabricated building

ActiveCN110107019AReduce weightImprove sound insulationFloorsBuilding reinforcementsSupporting systemFloor slab

The invention discloses a composite prefabricated floor slab for a fabricated building, and belongs to the technical filed of fabricated buildings. The composite prefabricated floor slab comprises a concrete prefabricated plate, composite filling rings are preburied on the inner side of the concrete prefabricated plate at intervals, a center tension anchor rebar system is arranged between every two adjacent composite filling rings, reinforcing bearing beams are arranged on the inner side of the concrete prefabricated plate at intervals, and bearing beam rebar trusses are arranged in the reinforcing bearing beams. According to the composite prefabricated floor slab, the composite filling rings are adopted to effectively decrease the overall weight of the prefabricated floor slab, meanwhile,the concrete pouring amount is decreased, the soundproof and heat-insulation effects of the prefabricated floor slab are reinforced, a complete rebar supporting system is formed by tension anchor rebar meshes, the center tension anchor rebar systems and the bearing beam rebar trusses, the work load of the prefabricated floor slab is borne, lots of work procedures, labor, costs, materials and timeare saved, and the easy-machining property of prefabricated components and the building overall quality performance are improved.

Owner:CHINA MCC17 GRP

Fabricated composite shear wall and connection structure with steel beams and floors thereof

The invention discloses a fabricated composite shear wall and a connection structure with steel beams and floors thereof. The connection between edge members and walls is realized by cast-in-situ concrete poured in cavities of steel pipes of the edge members, the connection structure is simple and reliable, the quality of field construction of the shear wall can be guaranteed, and the advantages of concrete and a steel structure can be given full play, namely, the compressive performance of the concrete and convenient construction of the steel structure, and it is ensured that the fabricated composite shear wall has good lateral stiffness; and compared with existing double-layer steel plate composite shear walls, the fabricated composite shear wall and the connection structure with the steel beams and the floors thereof can save more than 50% of the amount of steel, and reduce the amount of concrete pouring in the construction site and the amount of framework construction in the construction site, so that the construction of the shear wall is speeded up and the use of workers is reduced. The connection structure of the shear wall and the steel beams realizes the connection betweenthe steel beams and the fabricated composite shear wall by using joint members, and the occupied space of the connection structures can be saved.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

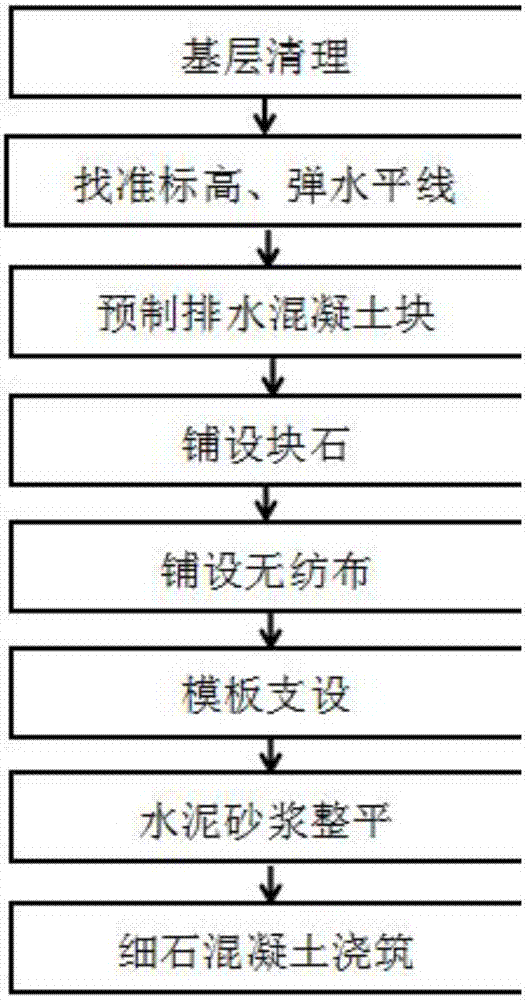

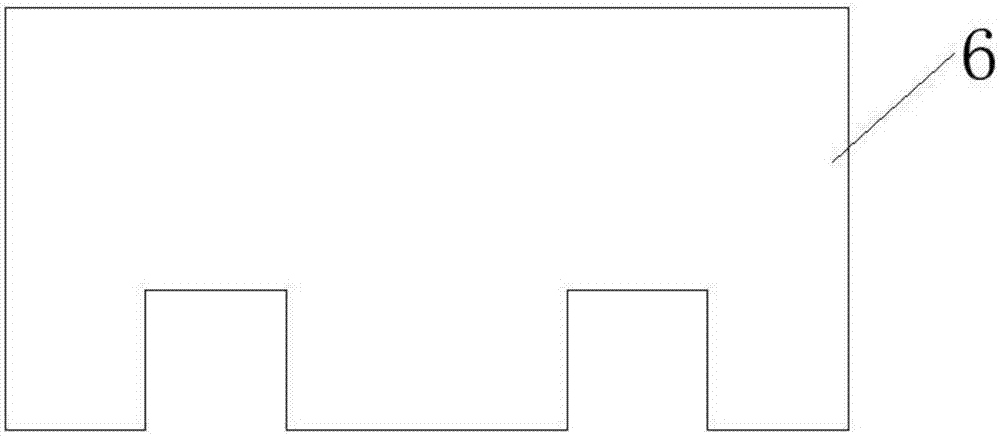

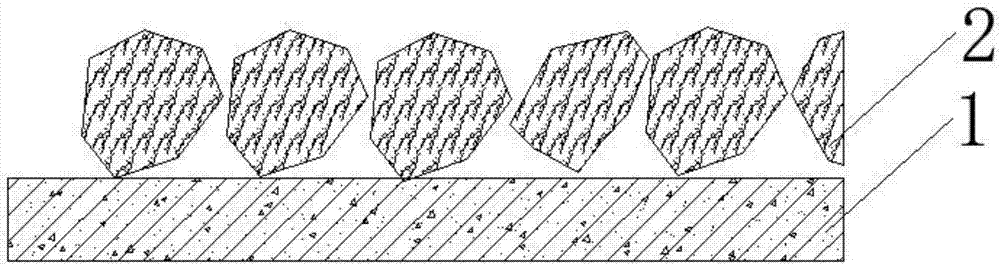

Construction method for basement large-rock-block self-draining ground

InactiveCN107386416AImprove drainage capacityEasy maintenanceSewerage structuresProtective foundationStructural waterBasement

The invention discloses a construction method for basement large-rock-block self-draining ground. The method includes the steps of 1, cleaning a base layer; 2, finding a high standard and a horizontal line; 3, prefabricating drainage concrete blocks; 4, laying rock blocks; 5, laying non-woven fabrics; 6, arranging templates; 7, leveling cement mortar; 8, pouring fine-stone concrete. On the basis of structural water prevention, the method uses the large rock blocks to enable to form all direction extending multi-layer-space drainage pathway, and the drainage ability is strong; the method takes drainage as the principal thing, greatly improves the waterproof ability of the structure, is convenient to maintain, and saves the cost.

Owner:CHINA MCC17 GRP

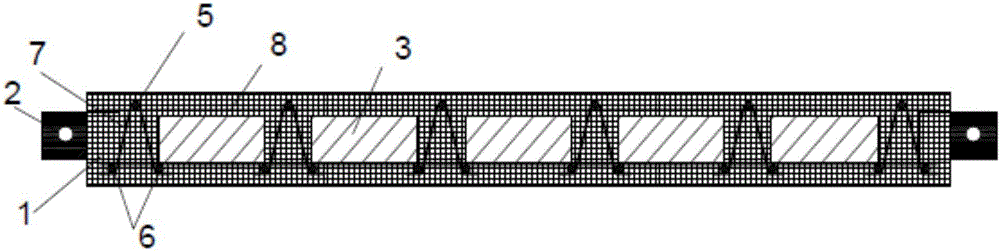

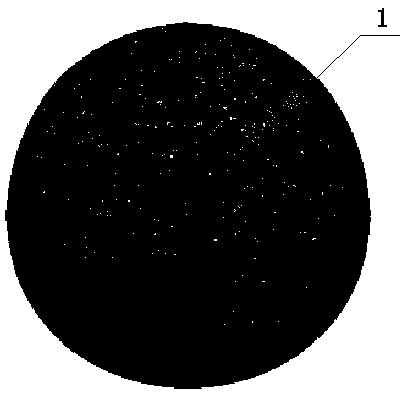

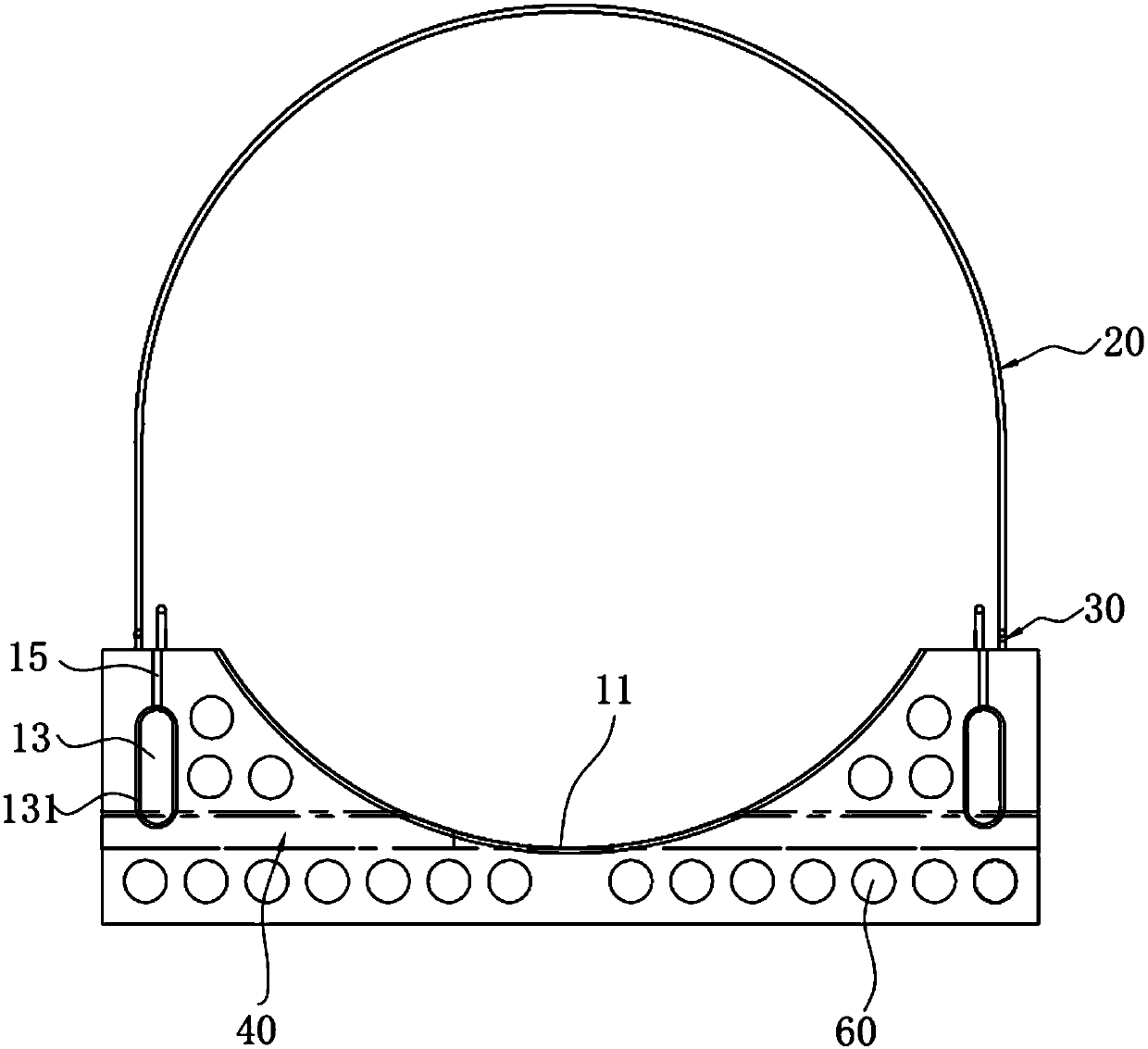

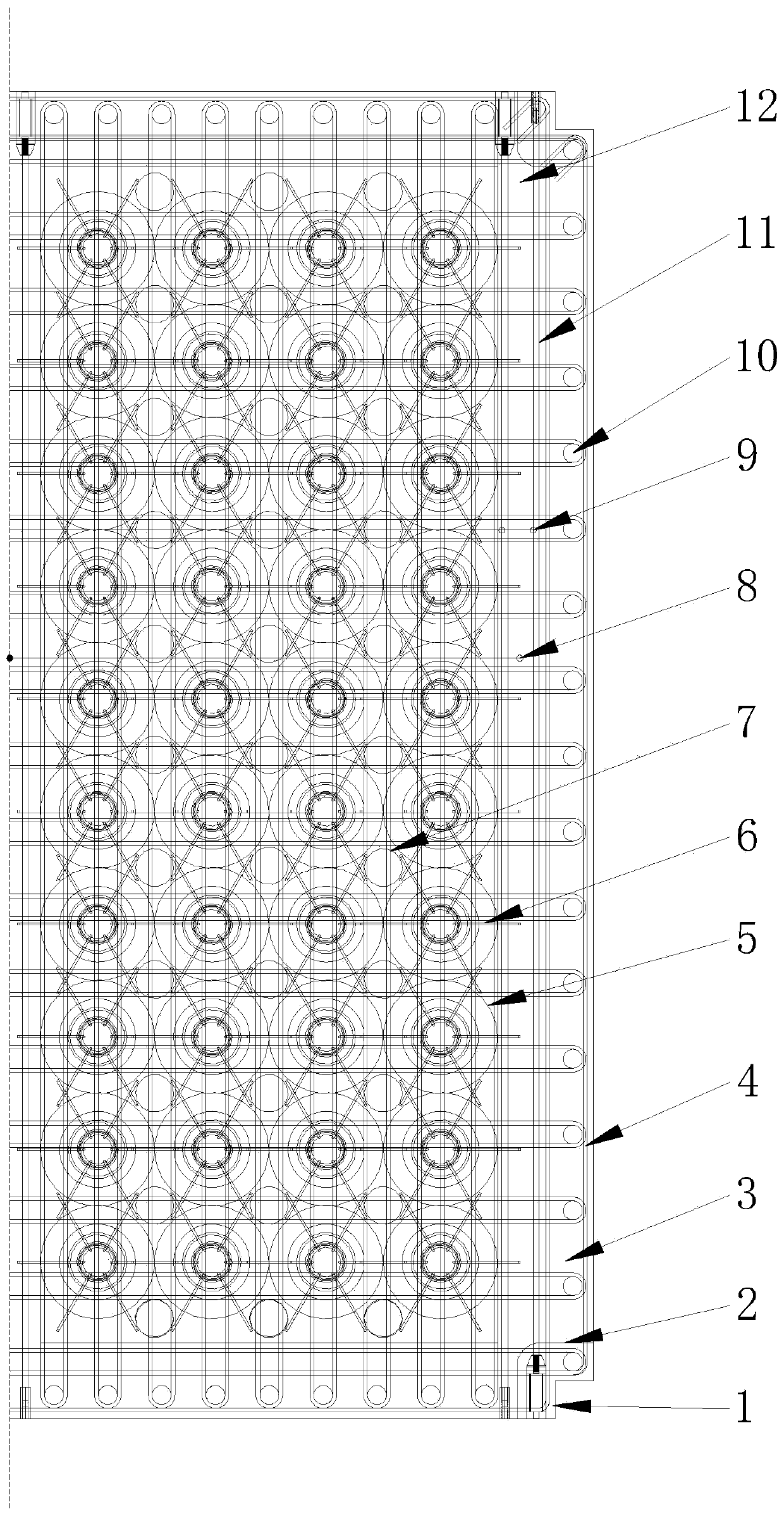

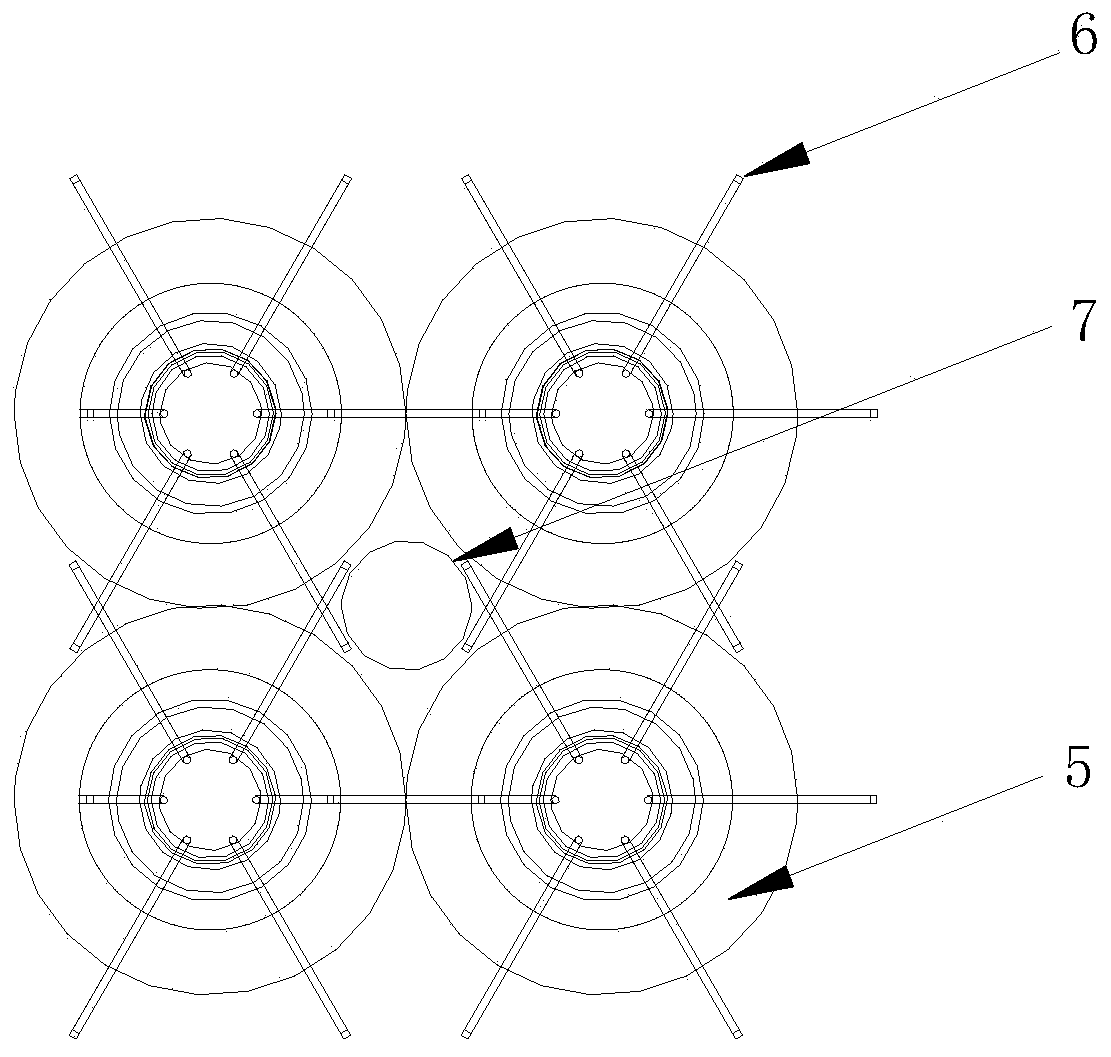

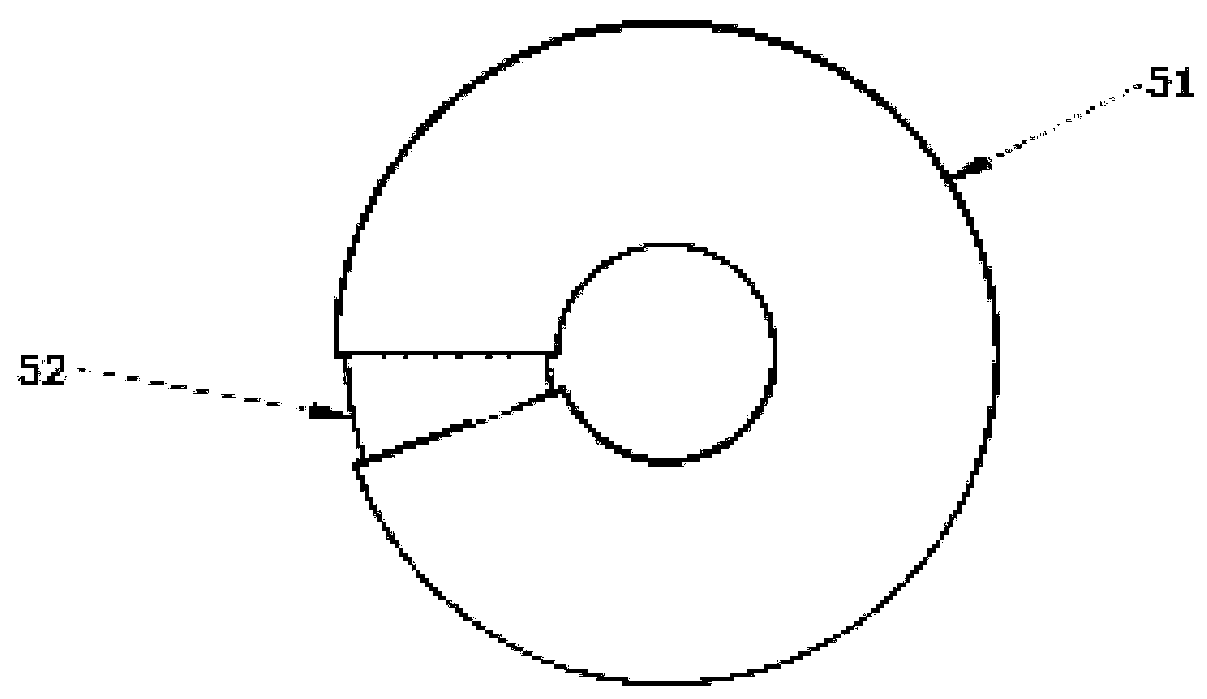

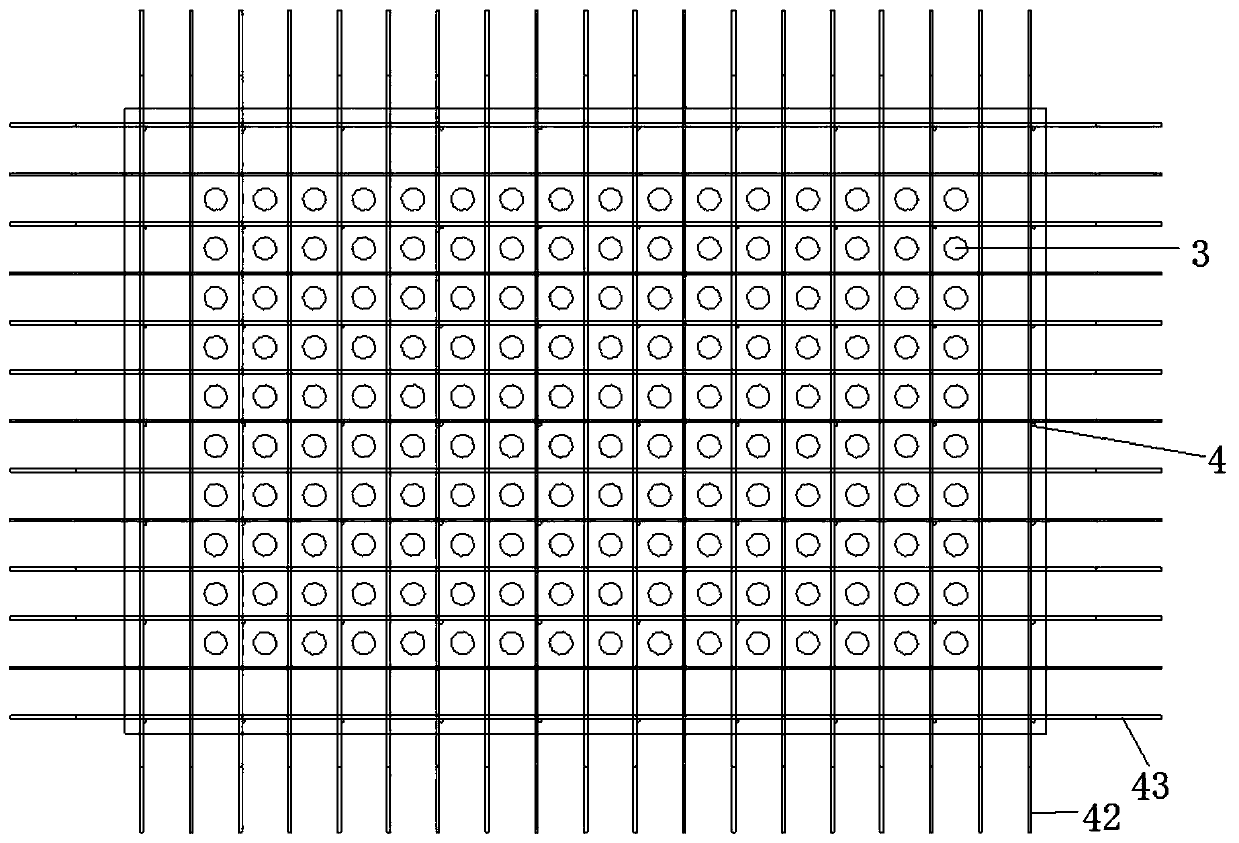

Assembly type spherical hollow plate

PendingCN110331807AReduce the amount of pouringImprove shear resistanceFloorsCeramic shaping apparatusShear capacitySpherical shaped

The invention discloses an assembly type spherical hollow plate. The assembly type spherical hollow plate comprises a prefabricated plate body, a bottom face rib net, a hollow spherical part and a plate face rib net; the bottom face rib net, the hollow spherical part and the plate face rib plate are sequentially arranged in the prefabricated plate body from bottom to top, vertical steel reinforcing ribs are evenly arranged on the bottom of the plate face rib net, and one ends of the vertical steel reinforcing ribs are fixedly connected with the bottom of the plate face rib net. According to the assembly type spherical hollow plate, the construction difficulty is low, and secondary concrete casing amount is reduced, the anti-shear capacity of the prefabricated plate is improved, the on-sitecasting concrete pouring amount is reduced, environment protection is facilitated, the number of construction persons and devices is reduced, the interval between formwork frame vertical rods can beproperly enlarged, and materials are saved.

Owner:JIANGXI THE SECOND CONSTR +1

Construction method drive type major diameter steel pipe pore-creating filling pile

InactiveCN101324066ASafe and reliable structureImprove the bearing capacity of single pileBulkheads/pilesSteel tubeRebar

The invention relates to the field of building construction, in particular to a construction method used for punching-typed large-diameter steel pipe hole-forming pouring piles, comprising the steps as follows: step 1: hole forming: the large steel pipe with the external diameter of 800-2000mm is adopted for hole-forming; step 2: reinforced cages-arranging: the reinforced cages are arranged inside the large steel pipes; step 3: pouring: concrete is poured into the hole of the reinforced cage after the installation is complete, simultaneously, the hole-forming large steel pipe is pulled out and the pile is formed. The pouring pipe construction method of the invention can replace the construction of manpower excavating pile and the mechanical hole-forming slurry wall-protection pouring pipe with large diameter, and has the obvious advantages of safe structure, greatly improving the bearing capability of single pile, environmental protection in-situ, safe construction, reducing the construction links and saving the engineering cost, etc., compared with the traditional mechanical boring pouring and manpower excavation pouring pipes.

Owner:DALIAN GREAT GOLDEN HORSE INFRASTRUCTURE

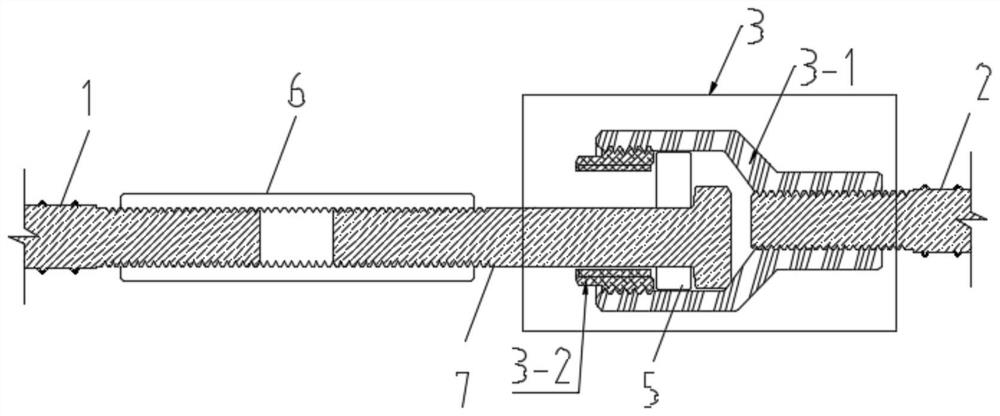

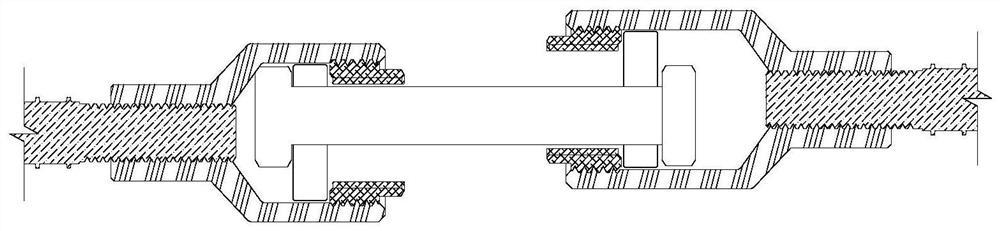

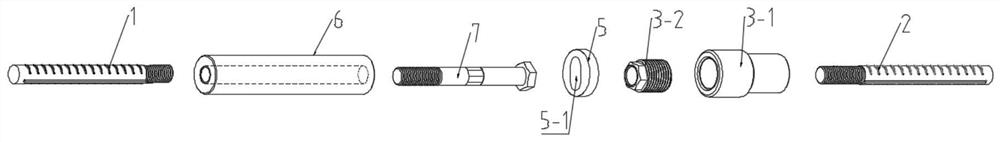

Steel bar connection device and using method thereof

PendingCN111997271AEasy to connectSimplify installation and connection stepsBuilding reinforcementsBuilding material handlingConstruction engineeringRebar

The invention belongs to the technical field of civil engineering, and particularly relates to a steel bar connection device and a using method thereof. The steel bar connection device is used for making a first steel bar connected with a second steel bar, and comprises an eccentric adjusting device, a steel bar connecting piece and an eccentric adjusting device mounting device. The eccentric adjusting device mounting device is arranged on at least one of the first steel bar and the second steel bar. The eccentric adjusting device is mounted on the eccentric adjusting device mounting device. Asliding groove is formed in the eccentric adjusting device, the sliding groove is perpendicular to the extending direction of the steel bars, the steel bar connecting piece is parallel to the extending direction of the steel bars, one end of the steel bar connecting piece is clamped to the sliding groove, and the other end of the steel bar connecting piece is connected with the other steel bar. The steel bar connecting piece slides in the sliding groove under the condition of being kept parallel to the steel bars, so that the eccentric adjusting device rotates. According to the device, the tolerance range is effectively expanded, reasonable deviations caused by production manufacturing, construction installation and the like are satisfied, and the eccentric angle and eccentric distance ofeccentric errors can be adjusted.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD +1

Prefabricated bridge deck slab wet joint connecting structure, prefabricated bridge and method

InactiveCN112127263AReduce on-site workloadImprove construction accuracyBridge structural detailsBridge erection/assemblyArchitectural engineeringBridge deck

The invention discloses a prefabricated bridge deck wet joint connecting structure, a prefabricated bridge and a method thereof. The technical proposal is as follows: prefabricating concrete bridge deck, a plurality of conical tooth grooves are formed in one side of the prefabricated concrete bridge deck and there is an annular connecting joint steel bar extending out from the end face of the prefabricated concrete bridge deck; the annular connecting joint steel bars between the two prefabricated concrete bridge decks are overlapped and staggered; transverse penetrating steel bars are arrangedon the inner sides and the outer sides of the annular connecting joint steel bars; concrete is filled between the oppositely-arranged conical tooth grooves to form a wet joint. The conical tooth grooves are formed in the connecting interface of the prefabricated concrete bridge deck slabs, the bridge deck slabs are connected through the annular steel bars. The invention has the advantages of simple structure, reasonable stress, reliable force transmission, capable of meeting various requirements of the concrete bridge deck slabs in the normal use and bearing capacity limit state; The on-sitepouring amount is small, and construction is convenient and fast.

Owner:SHANDONG TRAFFIC PLANNING DESIGN INST

Method for building gravity dam on deep and thick cover layer and spandrel concrete gravity dam structure

InactiveCN105089012AReduce foundation excavationSave engineering investmentGravity damsShoreStructural stress

The invention discloses a method for building a gravity dam on a deep and thick cover layer and a spandrel concrete gravity dam structure. The method includes the steps that dynamic compaction processing and consolidation grouting processing are carried out on the deep and thick cover layer (3), an arched-type concrete base (1) is arranged on the processed deep and thick cover layer (3), and the arch ends of the arched-type concrete base (1) are arranged on bedrock (4) of two shores; and the gravity dam (2) is arranged on the arched-type concrete base (1), the gravity dam (2) and the arched-type concrete base (1) are integrally grouted, and no structural joint is formed. According to the method and the spandrel concrete gravity dam structure, as the two arch ends of the arched-type concrete base are supported on the bedrock of the two shores, the structural stress is supported to the bedrock at the two ends through an arch span; and as a skewback and an upper dam body are connected into a whole, the anti-sliding stability requirement is met through the resistance supplied through foundation surfaces at the two ends and the arch ends at the bottom.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

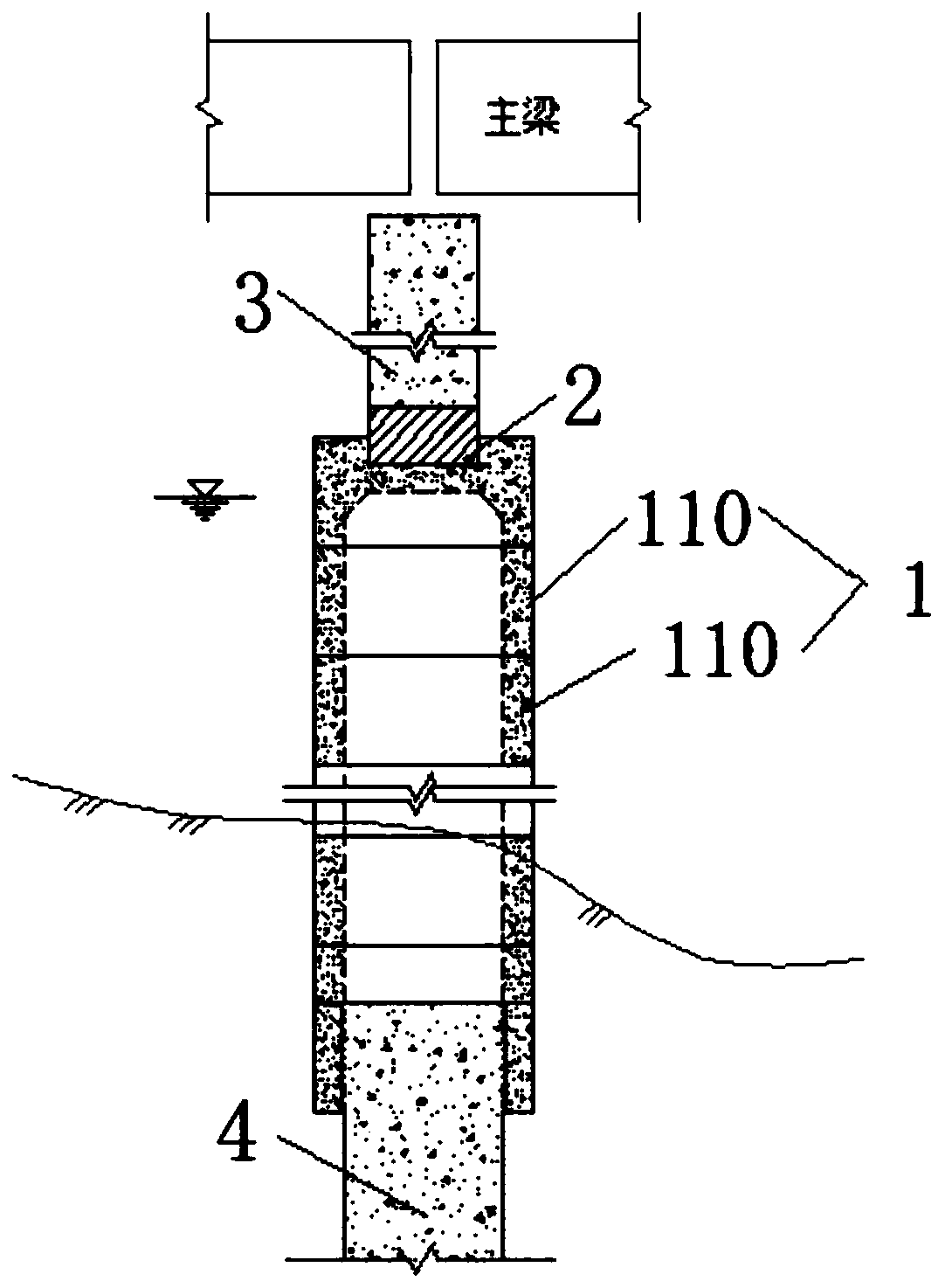

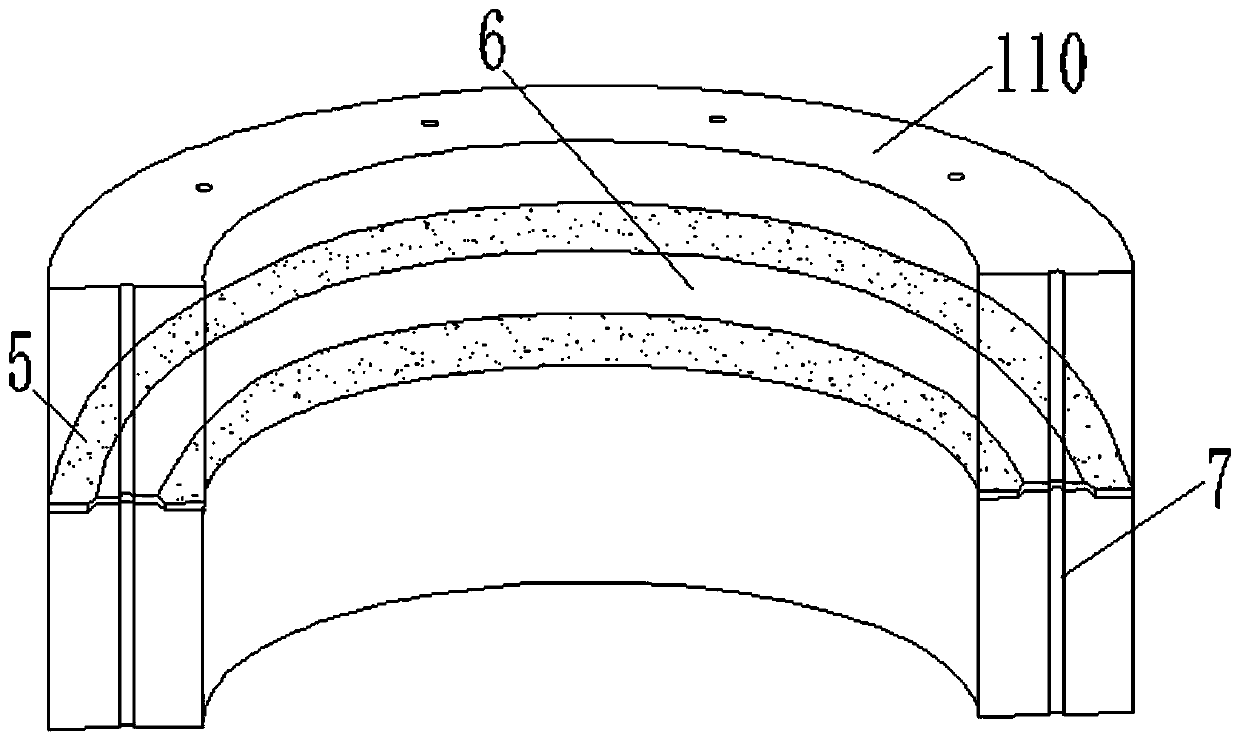

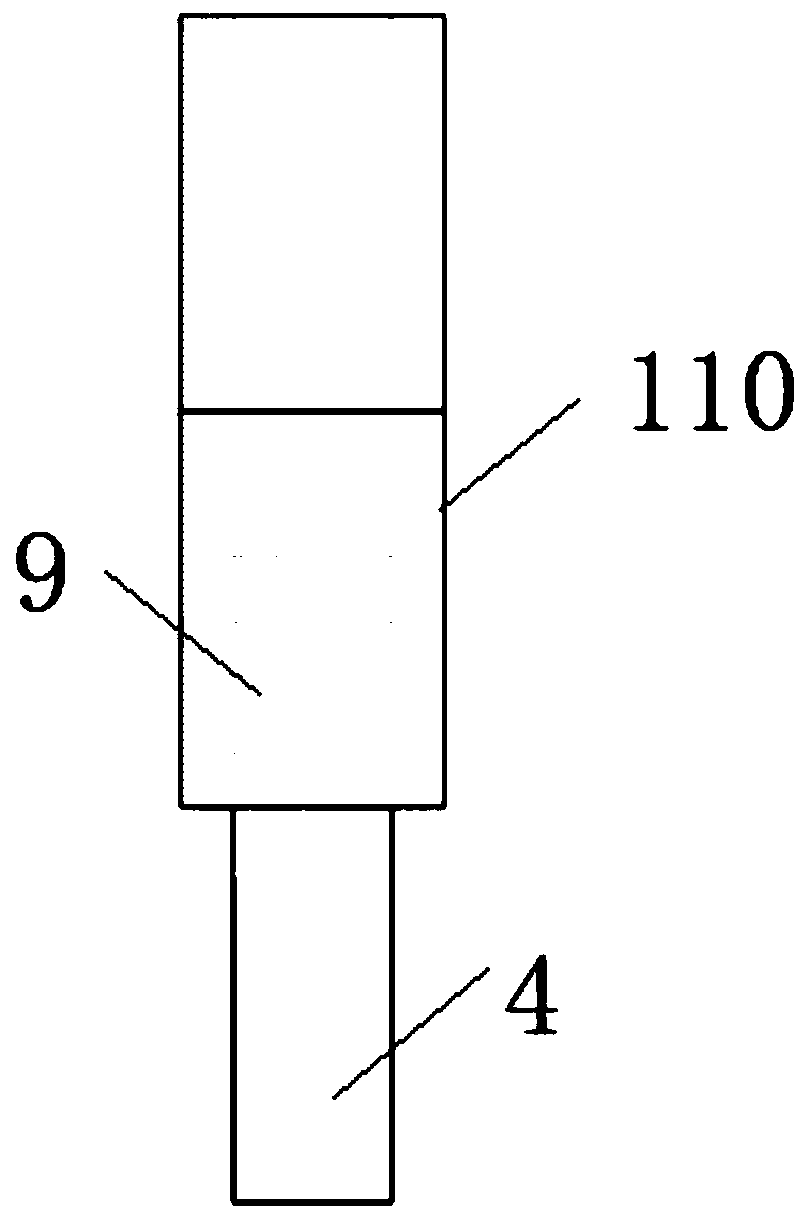

Bearing-platform-free UHPC pile and column integrated structure and construction method thereof

PendingCN109853605ASmall amount of workReduce wave forceClimate change adaptationShipping equipmentEngineeringBuilding construction

The invention discloses a bearing-platform-free UHPC pile and column integrated structure, which comprises a large-diameter UHPC pipe pile, a prefabricated pier column and a cast-in-situ bored pile. Apier column socket hole is reserved in the top of the large-diameter UHPC pipe pile, and the UHPC pipe pile is spliced by a plurality of UHPC pipe sections; the prefabricated pier column is located above the UHPC pipe pile and can be quickly spliced with the UHPC pipe pile through the socket hole; and the UHPC pipe section on the lowermost part sleeves the top of the cast-in-situ pile, the contact part of the UHPC pipe section on the lowermost part and the top of the cast-in-situ pile is glued, two spaced annular glued seams are formed, and the position between the two glued seams is filled with an annular water swelling water-stop belt. The bearing-platform-free UHPC pile and column integrated structure is particularly suitable for construction of structure foundations under marine corrosive environments, a bearing platform is omitted, thus the engineering quantity of pile foundation construction can be lowered, and meanwhile wave flow force of a single pile foundation is reduced; and by adopting the UHPC prefabricated pipe sections and the socketed pier column and carrying out fabrication construction, the construction speed can be increased, and structural durability can be improved.

Owner:CCCC SECOND HARBOR ENG +1

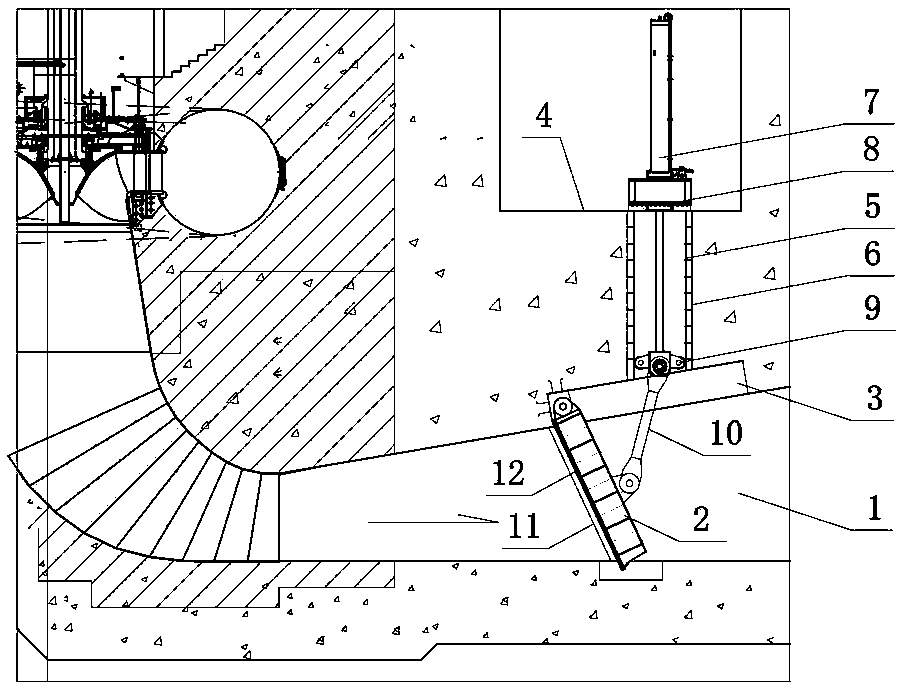

Layout structure of hydropower station underground workshop unit exit gate

PendingCN108442338AReduce operating spaceReduce excavationBarrages/weirsWater-power plantsEngineeringVertical channel

The invention discloses a layout structure of a hydropower station underground workshop unit exit gate. The layout structure comprises a gate arranged in an exit pipe on the downstream portion of a unit. A concrete structure at the top of the exit pipe is internally provided with a gate storing slot in a prefabricated manner. A hydraulic hoist platform is arranged above the gate storing slot, a vertical channel with vertical guide rails is arranged between the hydraulic hoist platform and the gate storing slot, a sealing rubber gasket is arranged between a hydraulic hoist rack and the verticalchannel, and the tail end of a hanging head of a hydraulic hoist is provided with guide wheels slidably connected with the vertical rails. The end, close to the unit, of the gate is hinged to the gate storing slot, the upper surface of the gate is hinged to the hanging head of the hydraulic hoist through a connection rod, and the circumference of the lower surface of the gate is wrapped with water sealing rubber in sealing fit with an embedded frame in the exit pipe. The hoist operation platform can be arranged below the downstream highest water level, chamber excavation and the gate slot concrete casting quantity are greatly reduced, the layout structure contributes to stability of chamber structures, and the construction cost is also saved.

Owner:YELLOW RIVER ENG CONSULTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com