Superimposed fabricated pipe gallery structure system component industrialization construction device and method

A prefabricated and factory-like technology, applied in infrastructure engineering, underwater structures, artificial islands, etc., can solve problems such as long exposure time of foundation pit safety hazards, unfavorable project production cost control, and large influence of weather factors, etc., to achieve Reduce the long-term exposure of the foundation pit, reduce the consumption of on-site resources and the amount of garbage generated, and have little impact on the weather

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

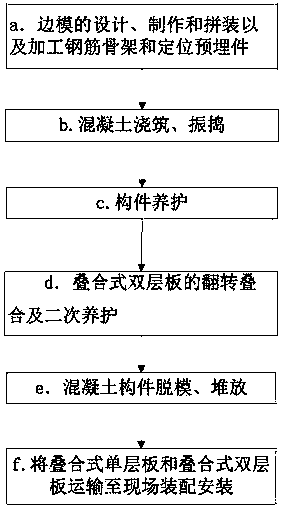

[0015] Combine below figure 1 , the present invention is described in further detail.

[0016] A factory-like construction device for a superimposed assembled pipe gallery structure system component, including a roller conveyor line and a mold table located on the roller conveyor line, the bottom of the mold table is provided with a positioning device connected to the signal port of the production intelligent management system, the The signal port of the intelligent production management system is connected to the signal port of the control module of the concrete transport vehicle, the distribution machine and the vibrating table, and the signal port of the intelligent production management system is connected to the signal port of the temperature and humidity control and detection device arranged in the curing kiln. The curing kiln is provided with a steam pipeline, and the signal port of the intelligent production management system is connected to the signal port of the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com