Patents

Literature

260results about How to "Guaranteed seismic performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prefabricated prestressed concrete frame beam-column joint making disparate use of high performance materials

ActiveCN105625572AReduce Beam SectionReduce steel consumptionShock proofingReinforced concrete columnConcrete beams

The invention discloses a prefabricated prestressed concrete frame beam-column joint making disparate use of high performance materials, comprising prefabricated concrete beams, prefabricated concrete columns, prefabricated beam-bottom prestressed tendons, common rebars, beam-top common rebars, in-column vertical rebars, sleeves, connecting rebars, and U-shaped rebars. Post-cast sections are reserved at two ends of the pre-fabricated beams, and the prestressed tendons fitted to the bottom of the prefabricated beams extend out of beam ends and are anchored to the beam-end post-cast sections, forming the prefabricated concrete beam-column joint with the prefabricated concrete beams and columns through post-cast concrete. In order to ensure the integrity of the beam-column joint, the beam-bottom common stressed rebars are connected with aseismic rebars through the sleeves and the U-shaped rebars are disposed in a joint post-cast area. In order to improve the energy dissipating capacity of the beam-column joint, the two ends of the prefabricated beams are made by casting high ultimate strain concrete. The invention reduces the production and construction difficulty, decreases the section height or steel usage of the prefabricated concrete beams and ensures the integrity and aseismic performance of the beam-column joint.

Owner:SOUTHEAST UNIV

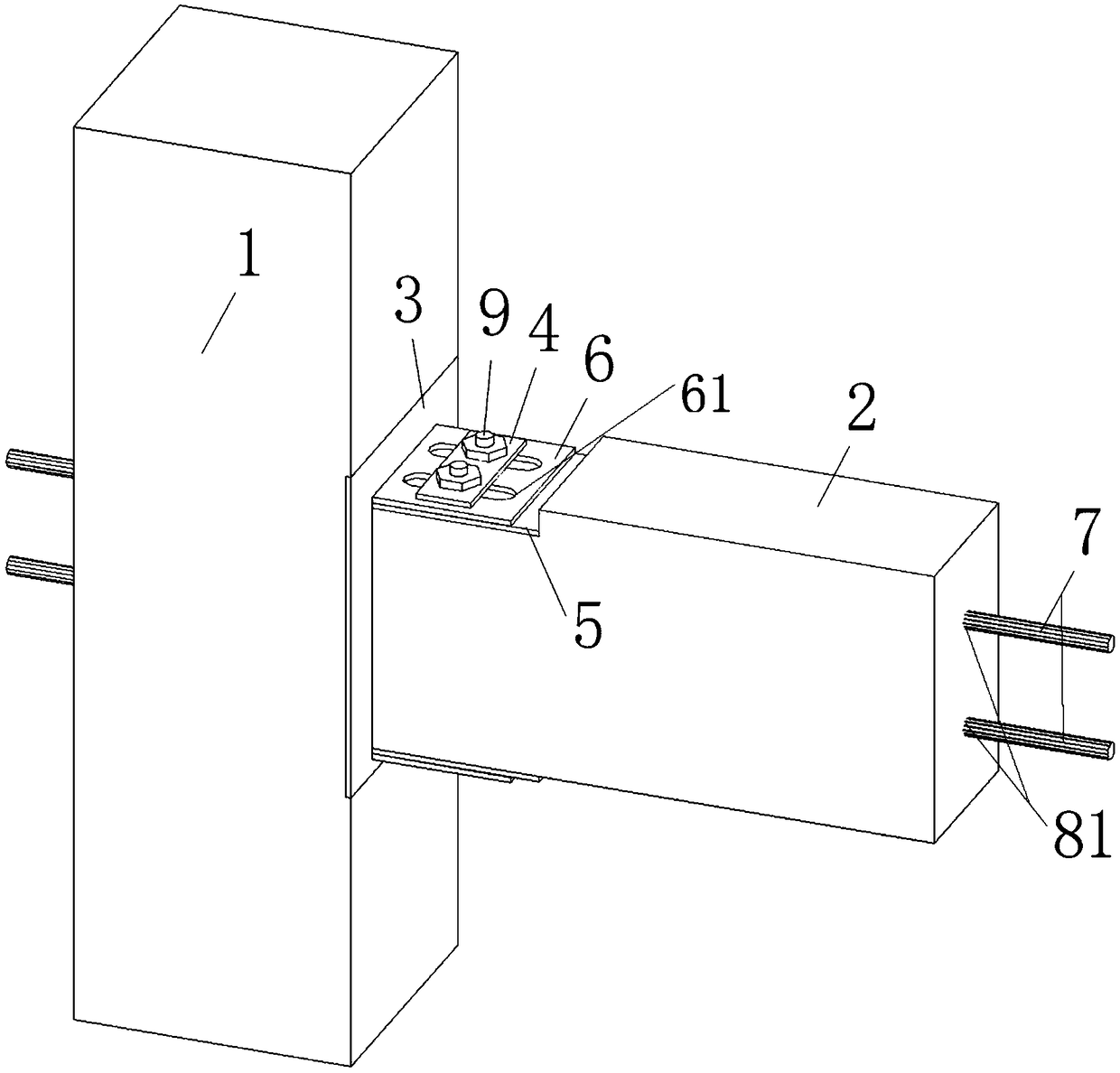

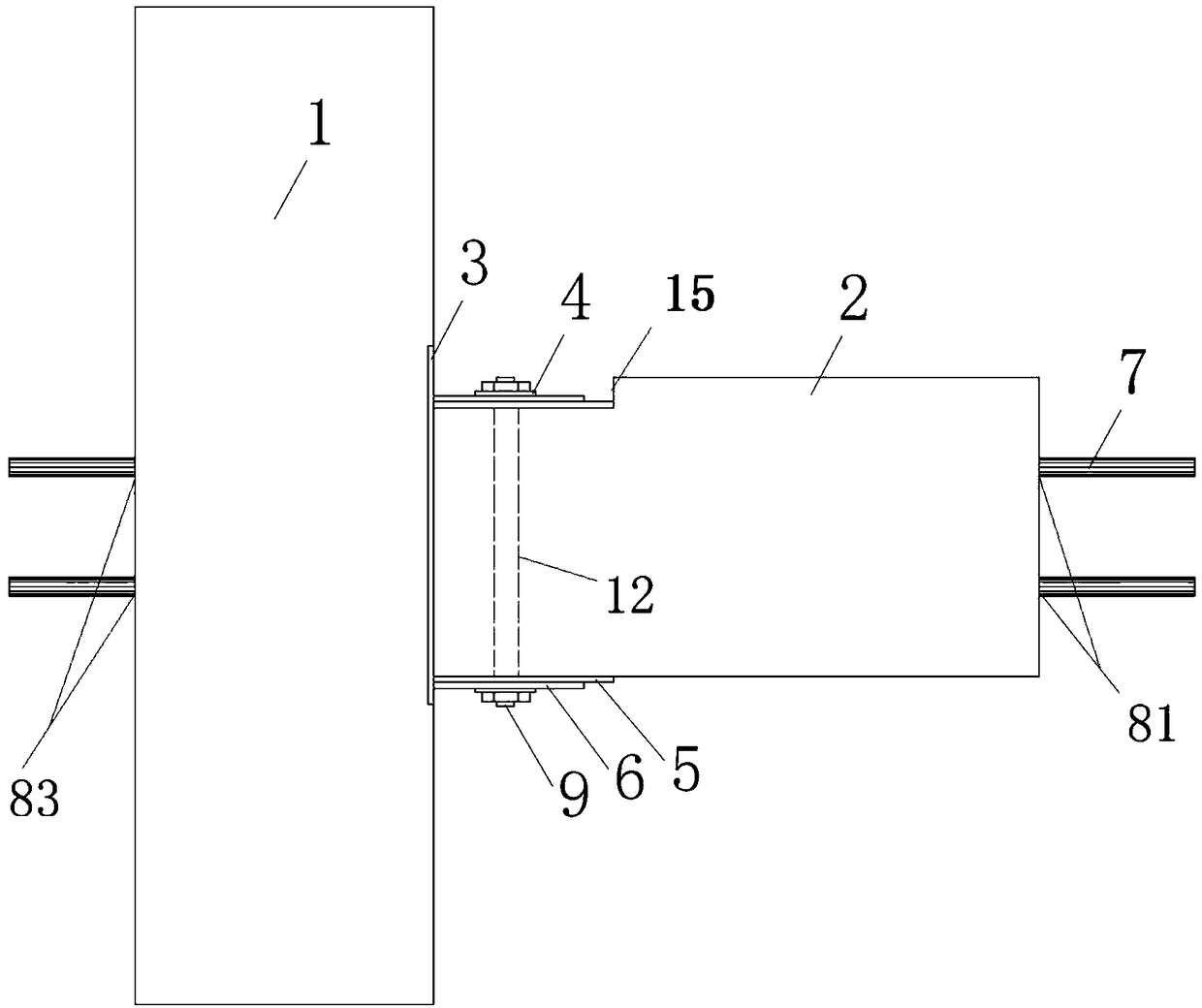

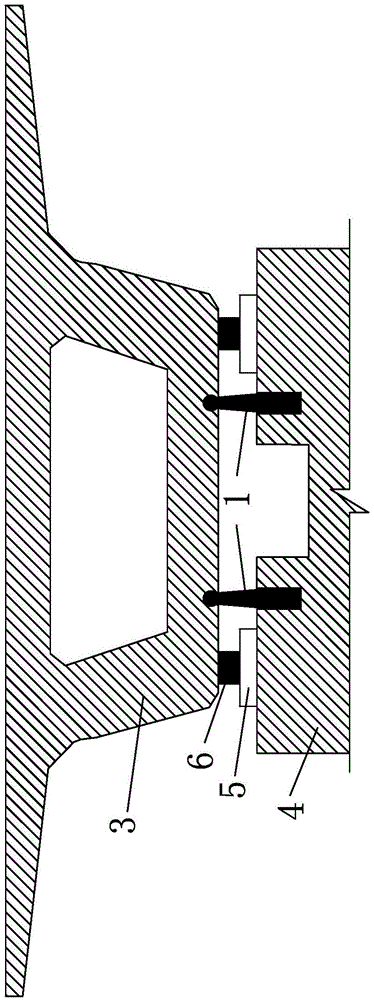

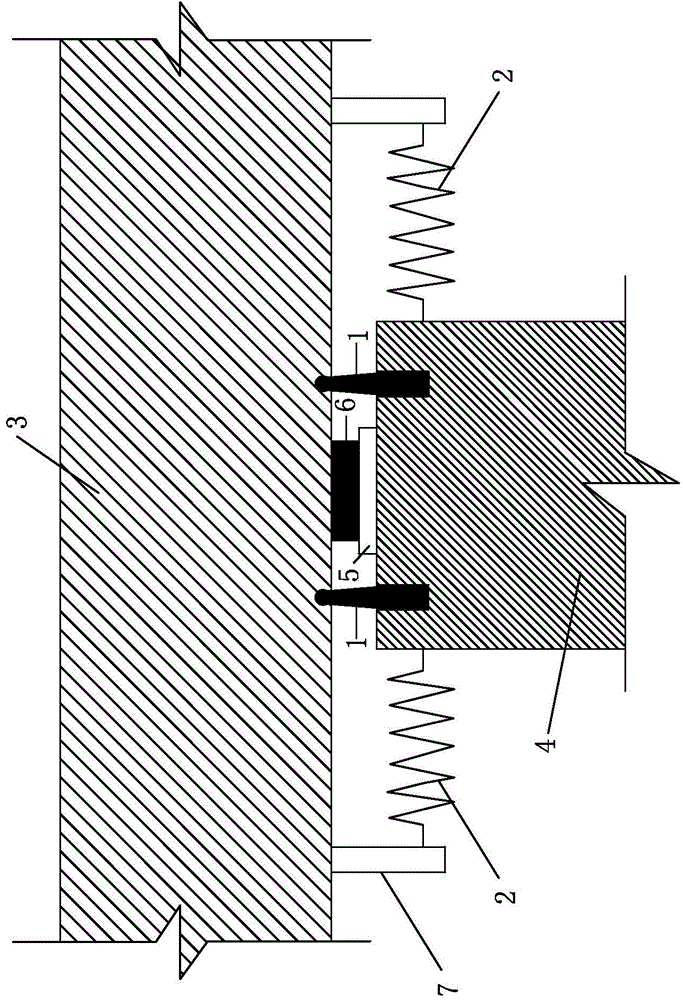

Fabricated self-resetting prestressed concrete frame friction energy dissipation node

ActiveCN108842912AReduce residual deformationReduce pollutionProtective buildings/sheltersShock proofingReinforced concrete columnPre stress

The invention discloses a fabricated self-resetting prestressed concrete frame friction energy dissipation node which comprises a prefabricated reinforced concrete column, a prefabricated reinforced concrete beam, a column end pre-embedded steel plate, friction plates, beam end pre-embedded steel plates, non-boning prestressed steel stranded wires and prestressed steel stranded wire hole channels;the column end pre-embedded steel plate is welded with end plate anchoring steel bars and friction rail steel plates; the beam end pre-embedded steel plates are welded with shear bolt nails; bolt hole channels are reserved in the prefabricated reinforced concrete beam; high-strength bolts pass through the bolt hole channels in the upper end of the prefabricated reinforced concrete beam, connect the friction plates and the friction rail steel plates located at the top and the bottom of the prefabricated reinforced concrete beam with the column end pre-embedded steel plates together, and tighten the high-strength bolts to apply pressure. According to the invention, through the friction energy dissipation and the replaceable friction plates, a prefabricated fabricated concrete frame structure is endowed with excellent anti-seismic performance and self-reset capability under high-intensity earthquakes.

Owner:上海深物控智能科技有限公司

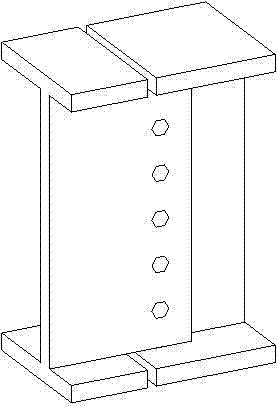

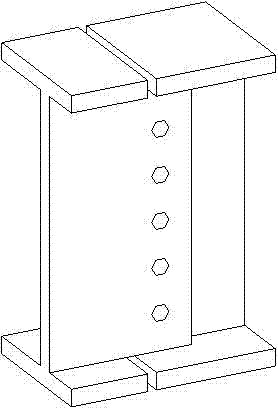

Prefabricated ECC-RC combination beam column joint component

InactiveCN103774754AReduce construction difficultyReduce labor costsClimate change adaptationBuilding constructionsJoint componentResidual deformation

The invention provides a prefabricated ECC-RC combination beam column joint component, wherein ECC refers to engineered cementitious composites, and RC refers to reinforced concrete. The prefabricated ECC-RC combination beam column joint component comprises a joint, an outward-extending column and an outward-extending beam, wherein the joint, the outward-extending beam and the outward-extending column are respectively composed of an ECC material, longitudinal bars and stirrups, the outward-extending length of the outward-extending column is about 1-2 times of the height of the column section, the outward-extending length of the outward-extending beam is about 1-2 times of the height of the beam section, H-shaped steel is embedded in the end of the outward-extending beam and the end of the outward-extending column, the embedded depth ranges from 10 cm to 20 cm, the H-shaped steel and the longitudinal bars extend out of the ends for 10-20 cm, the embedded part of the H-shaped steel is welded to the longitudinal bars, the embedded H-shaped steel of a prefabricated RC beam, the embedded H-shaped steel of a prefabricated RC column and the embedded H-shaped steel of the prefabricated ECC joint are connected through high-strength bolts, and the longitudinal bars are connected through a straight thread sleeve. According to the prefabricated ECC-RC combination beam column joint component, the prefabricated beam column joint component formed by pouring the steel bar reinforced ECC material is applied to an assembly type frame structure, compared with a general reinforced concrete joint component, the ductility and the anti-seismic property of the structure are improved remarkably, the number of joint stirrups in use is reduced substantially, pouring is facilitated, and construction is convenient; besides, the high tenacity of the ECC material can reduce residual deformation of the structure after an earthquake, and therefore post-earthquake repair expenses are reduced.

Owner:TONGJI UNIV

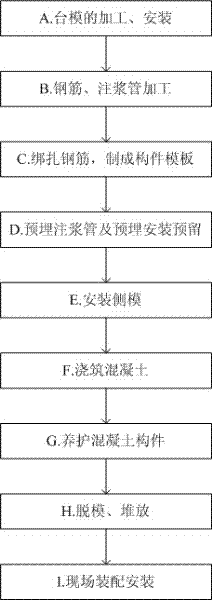

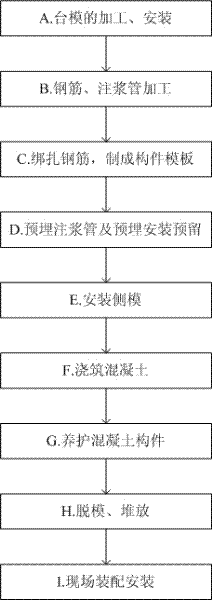

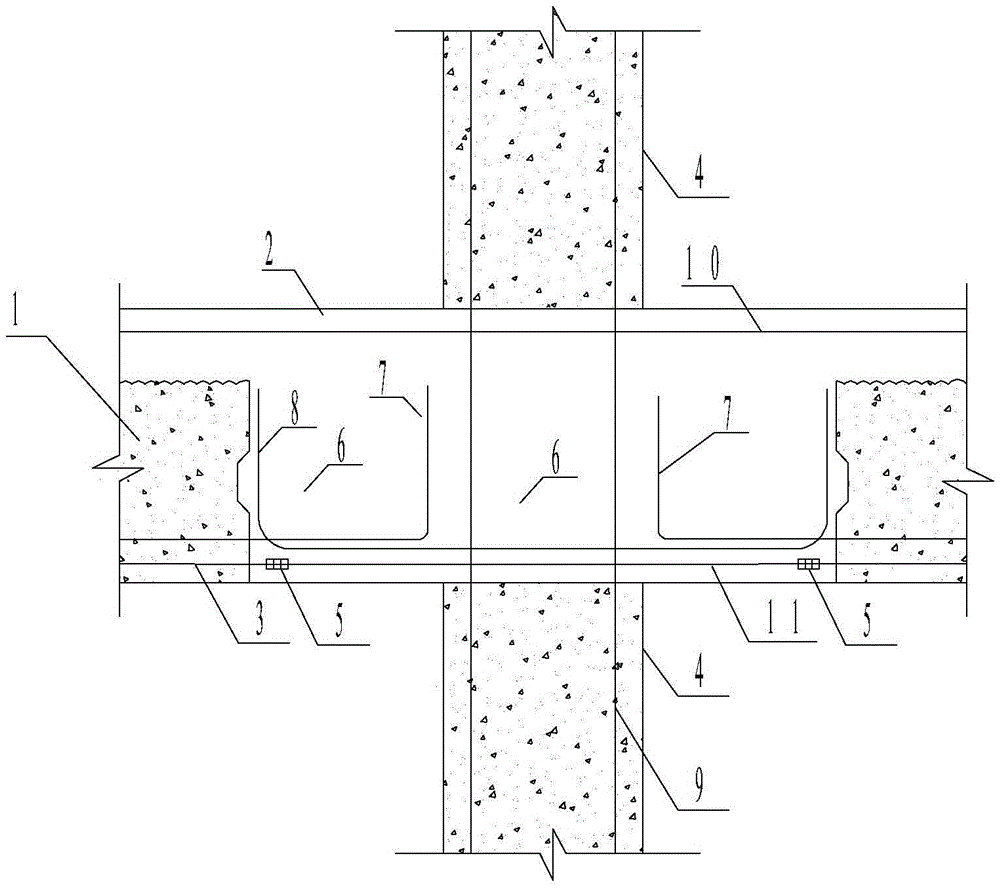

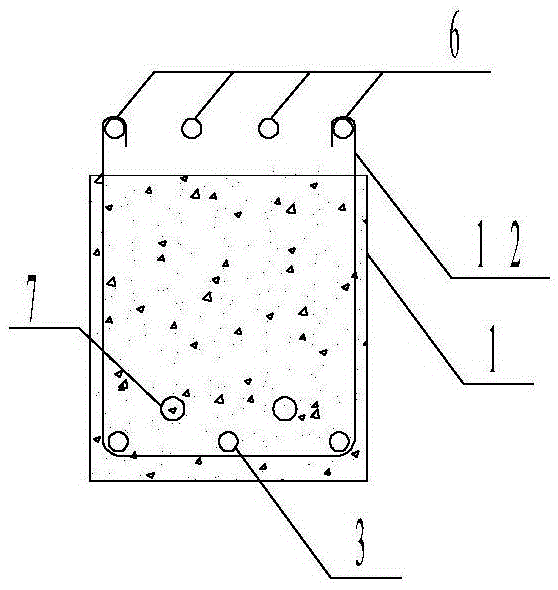

Factorial construction method for component of total prefabricated assembly integral type shear wall structure system

InactiveCN102296816AReduce usageReduce productionMouldsBuilding material handlingRebarStructure system

The invention discloses a factorial construction method for a component of a total prefabricated assembly integral type shear wall structure system. In the construction method disclosed by the invention, a basic component in the shear wall structure system is manufactured by adopting factorial prefabrication; a grouting pipe and a node reinforcing steel bar are preset in the component; and only the prefabricated component is directly assembled in the shear wall structure system for construction installation in the construction course of the shear wall structure system. In the technical scheme adopted by the invention, the adopted factorial production for producing the prefabricated component is beneficial to reduction of pollution emission, the usage amount of turnover materials such as wood and the like, water consumption, the usage amount of wood templates and the discharge amount of garbage, and is favorable for reducing construction cost whiling meeting the environmentally-friendly requirements.

Owner:NANTONG CONSTR PROJECT GENERAL CONTRACTING

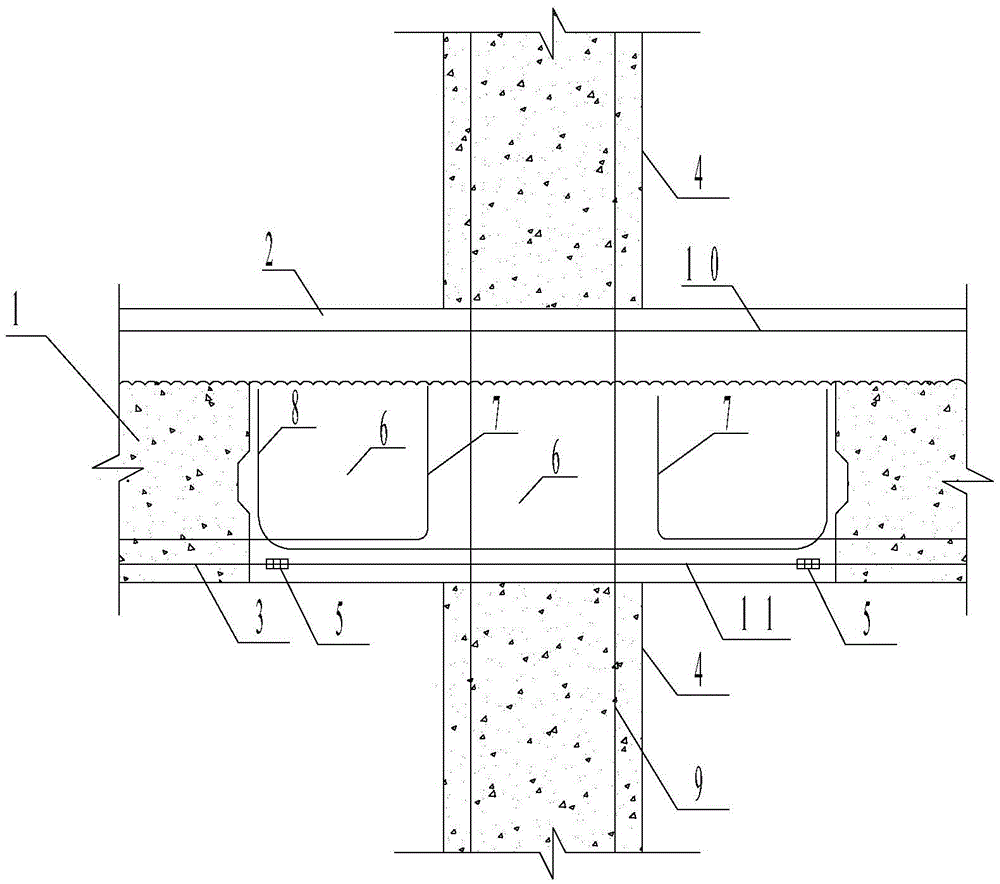

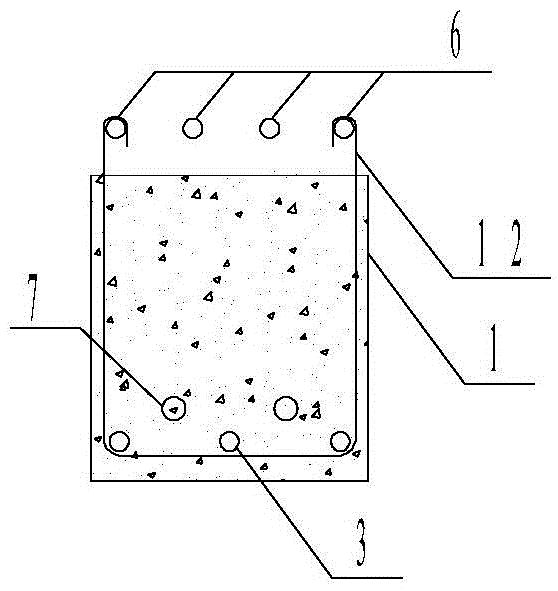

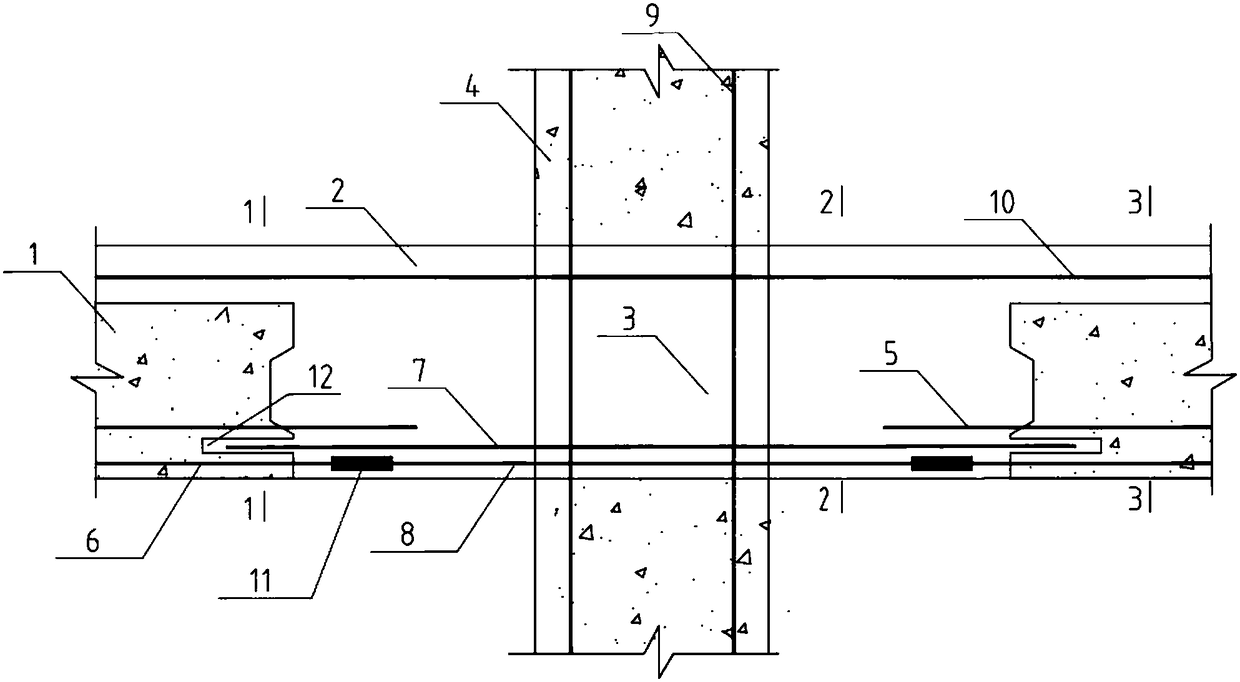

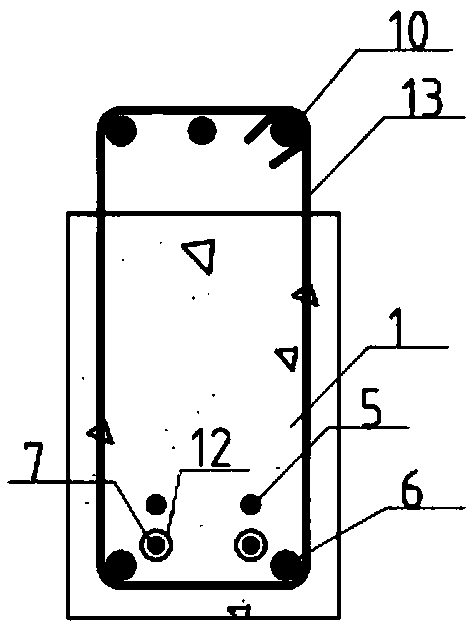

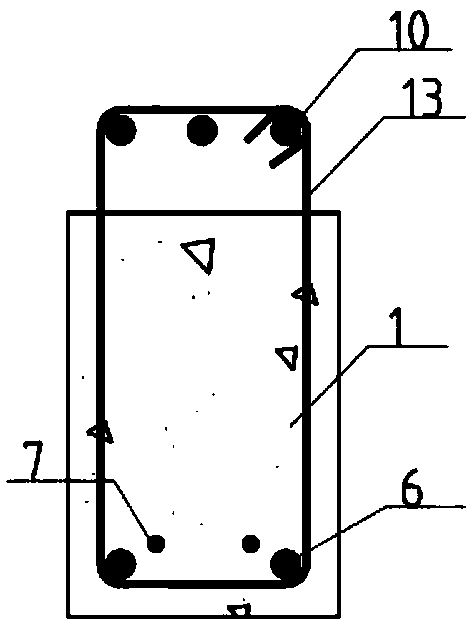

Prefabricated prestressed concrete frame beam column joint with U-shaped steel bar and sleeves

ActiveCN105649203AReduce Beam SectionReduce steel consumptionBuilding constructionsPre stressConcrete beams

The invention discloses a prefabricated prestressed concrete frame beam column joint with a U-shaped steel bar and sleeves. The prefabricated prestressed concrete frame beam column joint mainly comprises a prefabricated concrete beam, a prefabricated concrete column, prefabricated beam-bottom prestressed steel bars, prefabricated beam-bottom ordinary stressed steel bars, beam-top ordinary stressed steel bars, longitudinal steel bars in the column, the U-shaped steel bar and aseismic steel bars and the connecting sleeves thereof; post-casting sections are reserved at the two ends of the prefabricated beam, and the prestressed steel bars assembled at the bottom of the prefabricated beam stretch out of the beam ends and are anchored to the post-casting sections reserved at the beam ends to form the prefabricated concrete frame beam column joint with the prefabricated beam column through post-casting concrete. The ordinary stressed steel bars stretching out from the bottom of the beam are connected with the aseismic steel bars through the sleeves, the U-shaped steel bar is arranged on the post-casting area of the joint, and therefore the integrality of the beam column joint is enhanced. Accordingly, the production and construction difficulty is reduced, the section height or the steel dosage of the prefabricated concrete beam is decreased, and the integrality and aseismic property of the beam column joint are guaranteed.

Owner:SOUTHEAST UNIV

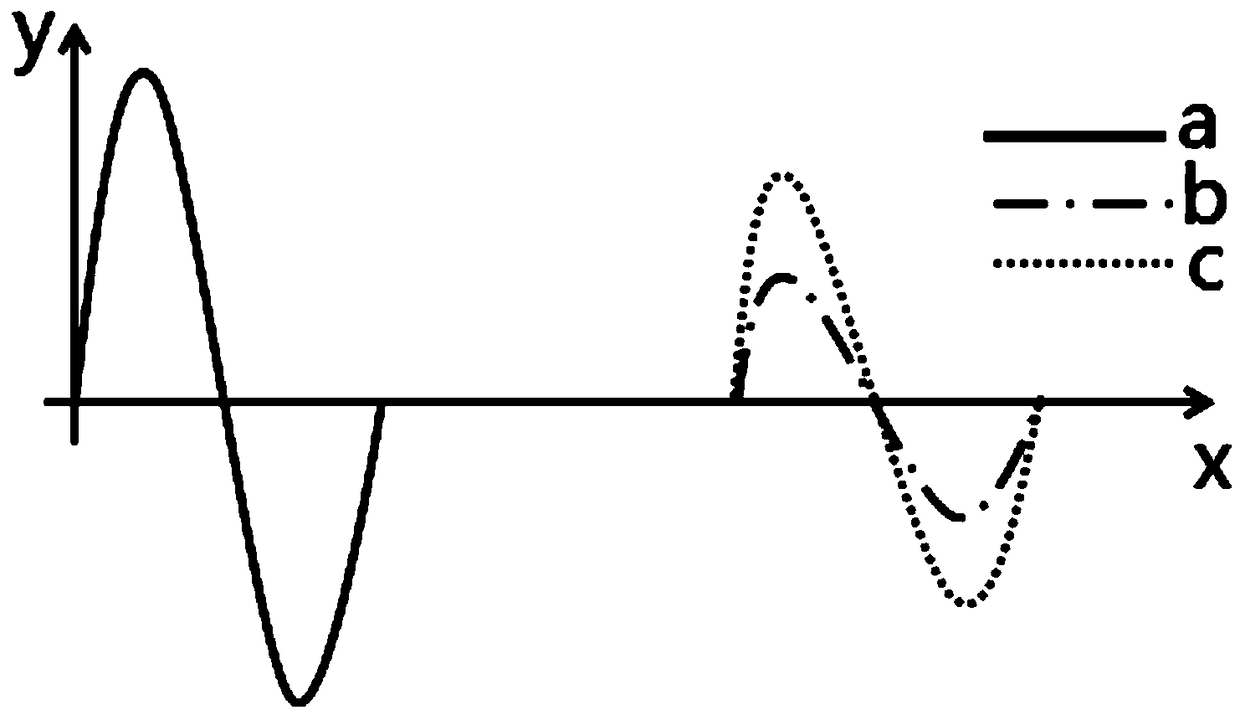

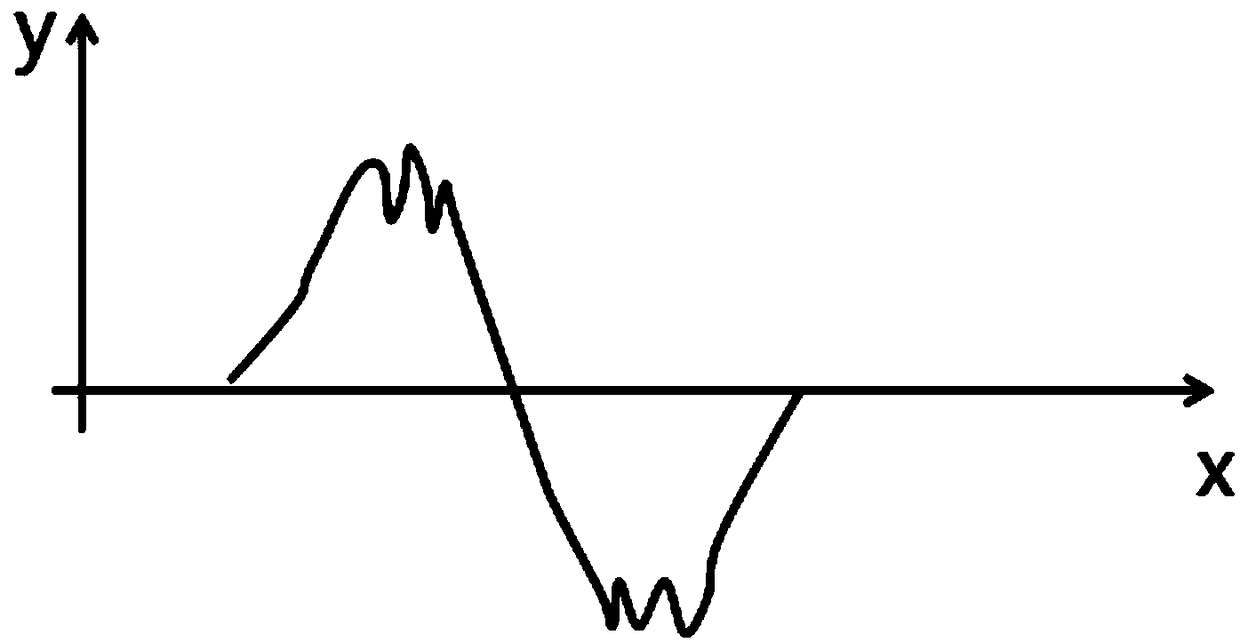

Combined shock absorption system of high-speed railway bridge and design method of combined shock absorption system

InactiveCN104153288AAvoid destructionThe power transmission path is clearBridge structural detailsSystems designNear fault

The invention discloses a combined shock absorption system of a high-speed railway bridge and a design method of the combined shock absorption system. The combined shock absorption system is used for reducing and controlling damage to and destruction of the high-speed railway bridge in a strong earthquake. Firstly, a design scheme of a combined shock absorption and limiting system with earthquake-proof bars and cable limiters used is provided on the basis of a function separate support design concept, earthquake response of the bridge is reduced through yield energy consumption of the earthquake-proof bars, and the cable limiters are used for controlling oversize deformation of the earthquake-proof bars and preventing damage caused by bridge fall; secondly, in the framework of performance-based seismic design, design methods of the earthquake-proof bars and the cable limiters are provided under the conditions of frequent earthquakes, design earthquakes and rare occurrence earthquakes respectively; accordingly, the earthquake response of the high-speed railway bridge is reduced, the earthquake-proof property of the structure is improved, and the combined shock absorption system of the high-speed railway bridge and the design method of the combined shock absorption system are particularly suitable for bridge structures suffering from near-fault pulse-like ground motions.

Owner:DALIAN MARITIME UNIVERSITY

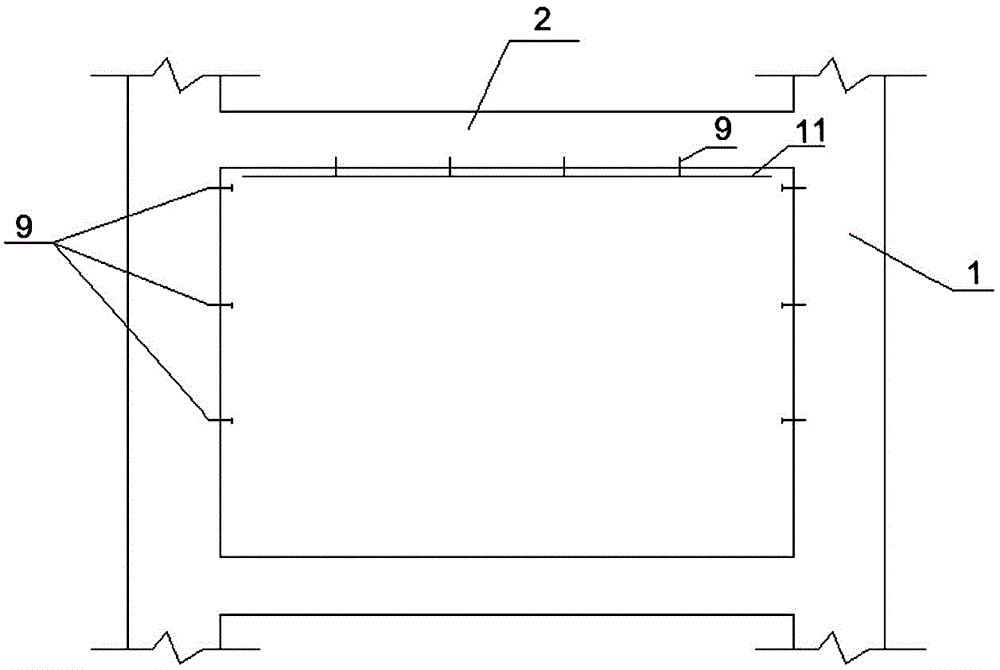

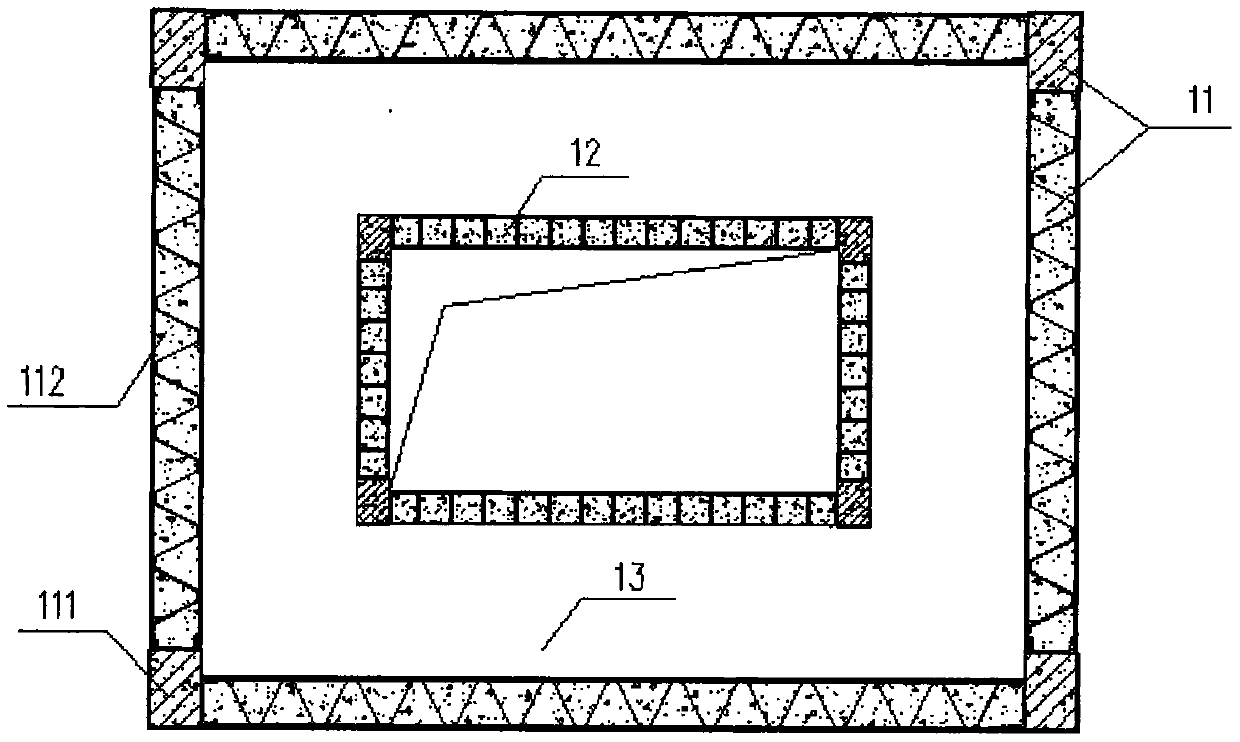

Prefabricated concrete frame infill wall system and construction method thereof

ActiveCN105937278AReduce investmentImprove construction efficiencyWallsUltimate tensile strengthInfill wall

The invention provides a prefabricated concrete frame infill wall system and a construction method thereof. The system comprises a rectangular concrete frame which is formed by concrete frame columns and concrete frame beams in an enclosing mode and an infill wall infilling the frame, anchoring ribs are implanted into the left frame columns in a uniformly spaced mode, the right frame columns and the upper frame beam on a frame inner ring, and the tail end of the anchoring rib on the upper frame beam is horizontally connected with a horizontal through long rib. According to the prefabricated concrete frame infill wall system and the construction method thereof, early cracking and corner damage of the frame infill wall are controlled by changing the structural form of the infill wall to improve the ductility of the wall and the overall anti-seismic property of the frame structure, and the anti-seismic property of the system is guaranteed by serving as the first anti-seismic defense line; in addition, the construction efficiency is high, the anti-dumping capacity is good, and the labor intensity is low. The construction method can be widely applied to concrete frame infill wall construction.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

Prestressed prefabricated ECC-RC combination beam column joint component

InactiveCN103774755AReduce construction difficultyReduce labor costsClimate change adaptationBuilding constructionsJoint componentResidual deformation

The invention relates to a prestressed prefabricated ECC-RC combination beam column joint component which comprises a prestressed rib and a joint with a bracket. The joint with the bracket is composed of an ECC material, longitudinal bars and stirrups. The joint with the bracket comprises an outward-extending column, wherein the length of the outward-extending column is about 1-2 times of the height of the column section. A hole channel is required to be reserved between the joint and a prefabricated RC beam connected with the joint. The prefabricated ECC joint is connected with the prefabricated RC beam through the post-tensioned prestressed rib which penetrates through the hole channel. H-shaped steel is embedded in the end of the outward-extending column and the end of a prefabricated RC column, wherein the embedded depth and the outward-extending length both range from 10 cm to 15 cm, the longitudinal bars at the end of the outward-extending column and the end of the prefabricated RC column respectively extend outwards by 10-15 cm, the embedded part of the H-shaped steel is welded to the longitudinal bars, the embedded H-shaped steel of the prefabricated RC column and the embedded H-shaped steel of the prefabricated joint are connected through high-strength bolts, and the longitudinal bars are connected through a straight thread sleeve. According to the prestressed prefabricated ECC-RC combination beam column joint component, the prestressed prefabricated joint component formed by pouring of the steel bar reinforced ECC material is applied to an assembly type frame structure, so that the ductility and the anti-seismic property of the structure are improved remarkably, the number of joint stirrups in use is reduced substantially, pouring is facilitated, and construction is convenient; since prestress is used as an assembly means, residual deformation of the structure after an earthquake can be reduced, the restorable function is achieved, and post-earthquake repair expenses are reduced.

Owner:TONGJI UNIV

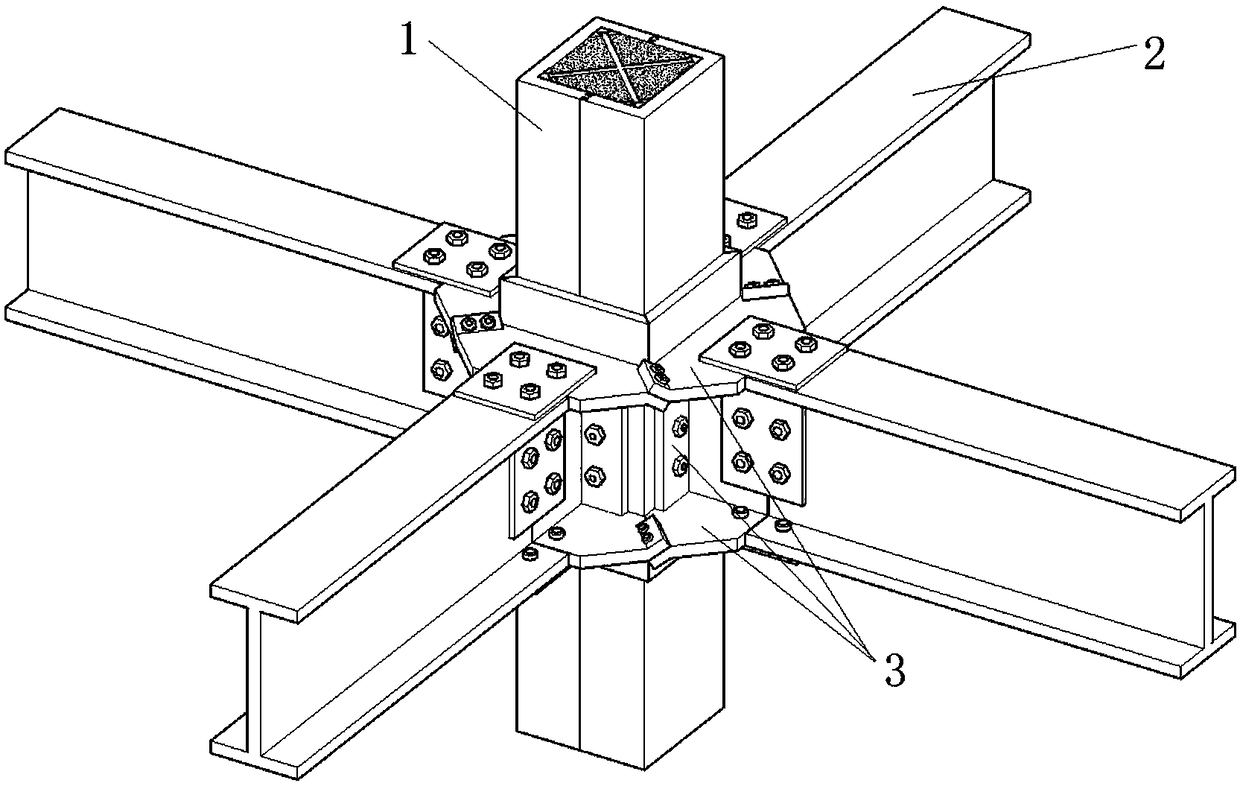

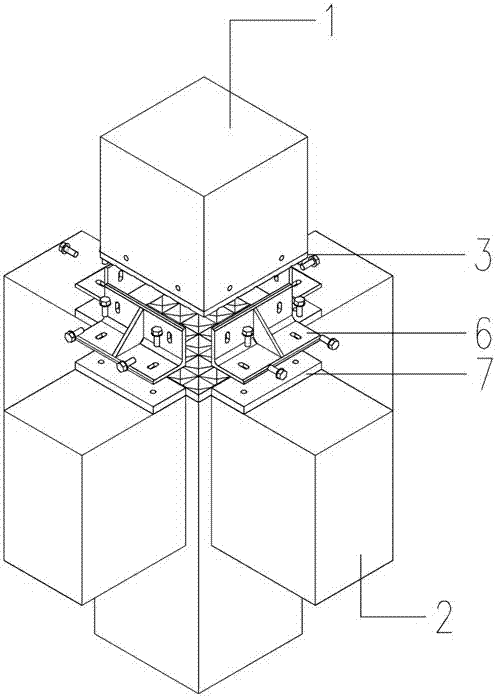

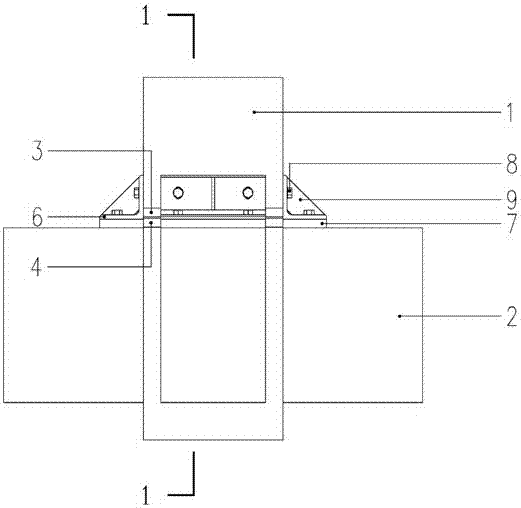

Concrete-filled rectangular steel tube column-box girder full-bolt connection node and construction method

ActiveCN102995756AAvoid weakeningMeet the seismic requirementsBuilding constructionsBox girderSteel tube

The invention belongs to the technical field of building structure engineering, and relates to a concrete-filled rectangular steel tube column-box girder full-bolt connection node. The concrete-filled rectangular steel tube column-box girder full-bolt connection node comprises a concrete-filled rectangular steel tube column, a box girder, an upper run-through clapboard, a lower run-through clapboard, a lower cover plate, a plurality of high-strength bolts, a plurality of connection plates and two shear plates. The upper run-through clapboard and the lower run-through clapboard penetrate through a concrete-filled rectangular steel tube column wall and are welded with the surrounding of the steel tube column wall of the concrete-filled rectangular steel tube column; the two webs of the box girder are welded together with the groove of the concrete-filled rectangular steel tube column via one shear plate respectively; the upper flange of the box girder is connected with the upper run-through clapboard by the high-strength bolts via the connection plates arranged in the box girder; the two webs of the box girder and the two shear plates are connected by the high-strength bolts via the connection plates arranged in the box girder respectively; and one end of the lower cover plate is connected with the lower flange of the box girder via the connection plate, and the other end of the lower cover plate is connected with the lower flange of the lower run-through clapboard via the connection plate. The invention provides a construction method for the node aforementioned simultaneously. The node and the construction method disclosed by the invention have the advantages of being convenient, fast, and easy to realize.

Owner:TIANJIN UNIV

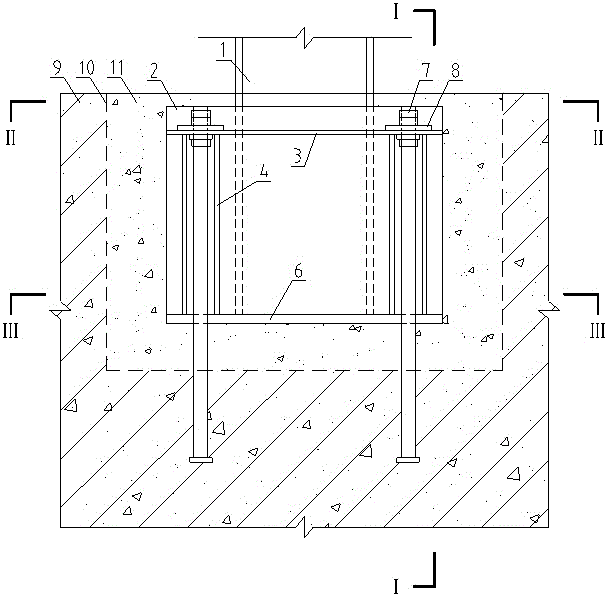

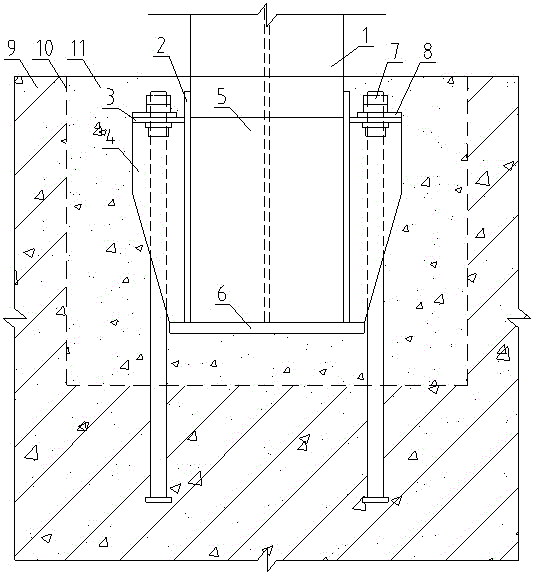

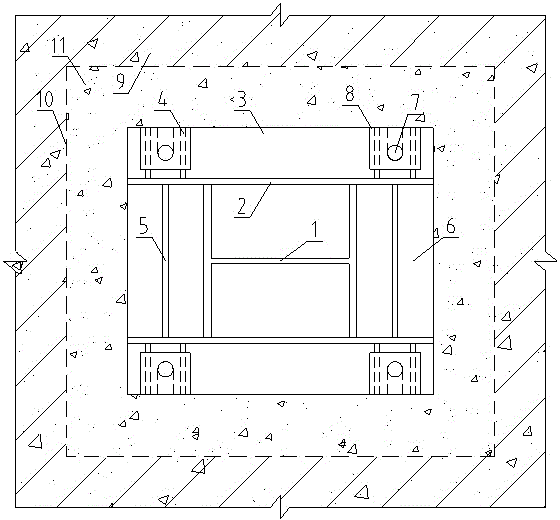

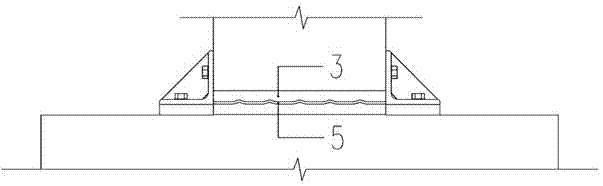

Whole body embedded type rigid pedestal and construction method thereof

ActiveCN104963354AGuaranteed stiffnessGuaranteed bearing capacityFoundation engineeringReinforced concreteWhole body

The invention relates to a whole body embedded type rigid pedestal and a construction method thereof. The whole body embedded type rigid pedestal comprises a steel column, boot-beam plates, cross plates, rib plates, partition plates, a pedestal base plate and anchor bolts, wherein the steel column is embedded in a reinforced concrete foundation, the base plate is arranged on the bottom of the pedestal, the boot-beam plates are welded to a steel column flange and the pedestal base plate, the cross plates are horizontally welded to the outer sides of the boot-beam plates, the rib plates are welded to the boot-beam plates, the cross plates and the pedestal base plate, the partition plates are welded to the boot-beam plates and the pedestal base plate, and the anchor bolts are symmetrically arranged on the outer sides of the two boot-beam plates within the range of the cross plates. According to the whole body embedded type rigid pedestal, the integral rigid pedestal is embedded in the reinforced concrete foundation, and the effective bearing area of the embedded portion of the pedestal is increased by arranging the boot-beam plates; the tensile effect of the anchor bolts is effectively utilized, transmission of bending moment and shearing force borne by pedestal joints is facilitated, pedestal embedding depth can be reduced on the premise that the overall rigidity, bearing force and anti-seismic property of the pedestal are guaranteed, and economical effectiveness is high in engineering practice.

Owner:黄冀卓 +1

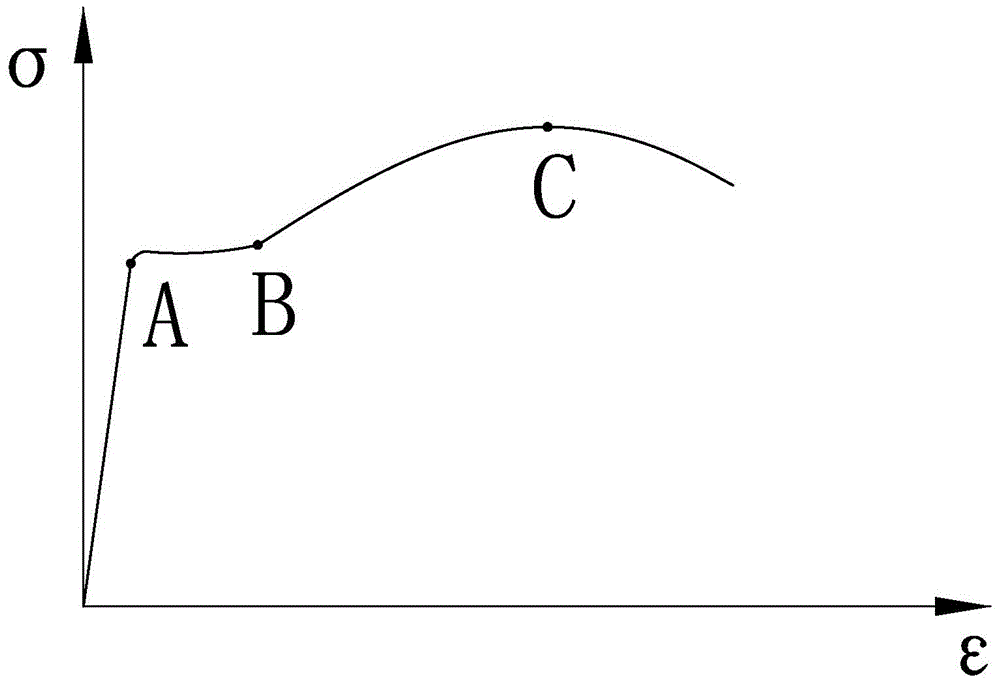

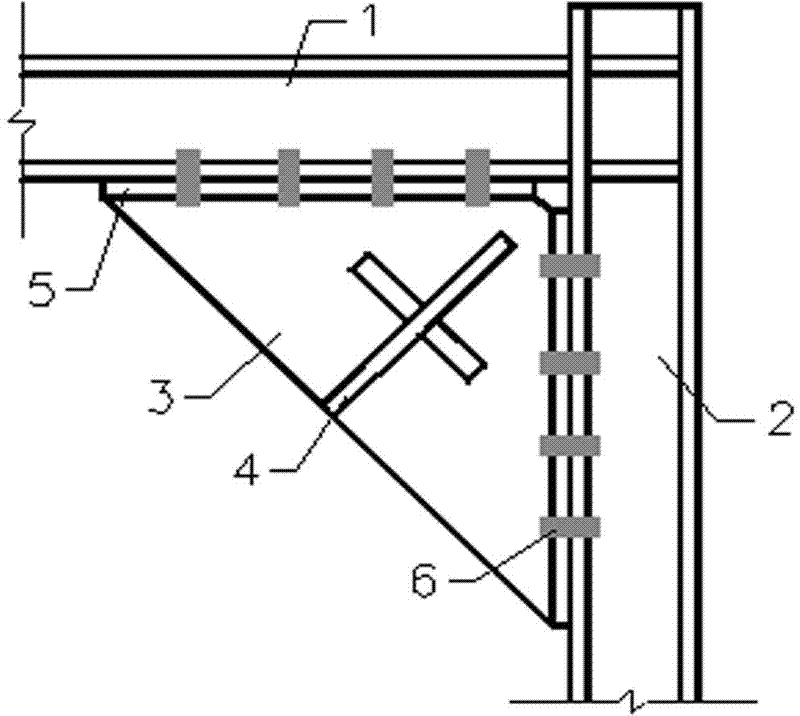

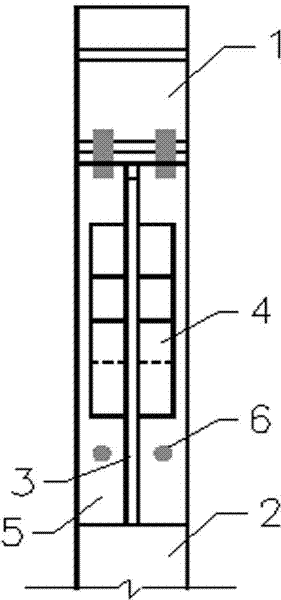

Anti-seismic structure of energy-consumption angle brace

The invention relates to a structure for strengthening anti-seismic performance of a steel frame, in particular to an anti-seismic structure of an energy-consumption angle brace. The anti-seismic structure of an energy-consumption angle brace comprises a frame beam and a frame column, wherein the node position of the frame beam and the frame column is provided with an energy-consumption angle brace plate; and the contact surface between the energy-consumption angle brace plate and the frame beam as well as the contact surface between the energy-consumption angle brace plate and the frame column are respectively fixedly connected by a connecting plate. The anti-seismic structure of an energy-consumption angle brace is favorable for flexible arrangement of frame structure space and is favorable for the arrangement and construction of a filler wall. Under the condition of no seism or under the condition of quaking frequently, the energy-consumption angle brace can perform the action of acommon angle brace to protect the node; under the action of seldom-occurred seism, when the beam and the column have great relative rotation, the energy-consumption plate of the energy-consumption angle brace can yield, energy can be continuously adsorbed and consumed by being continuously pulled and stressed to yield, and on the effects of supporting the beam and the column and protecting the node can be kept so as to protect the safety of the node, avoid node damage and reduce seismic damage.

Owner:SHENYANG JIANZHU UNIVERSITY

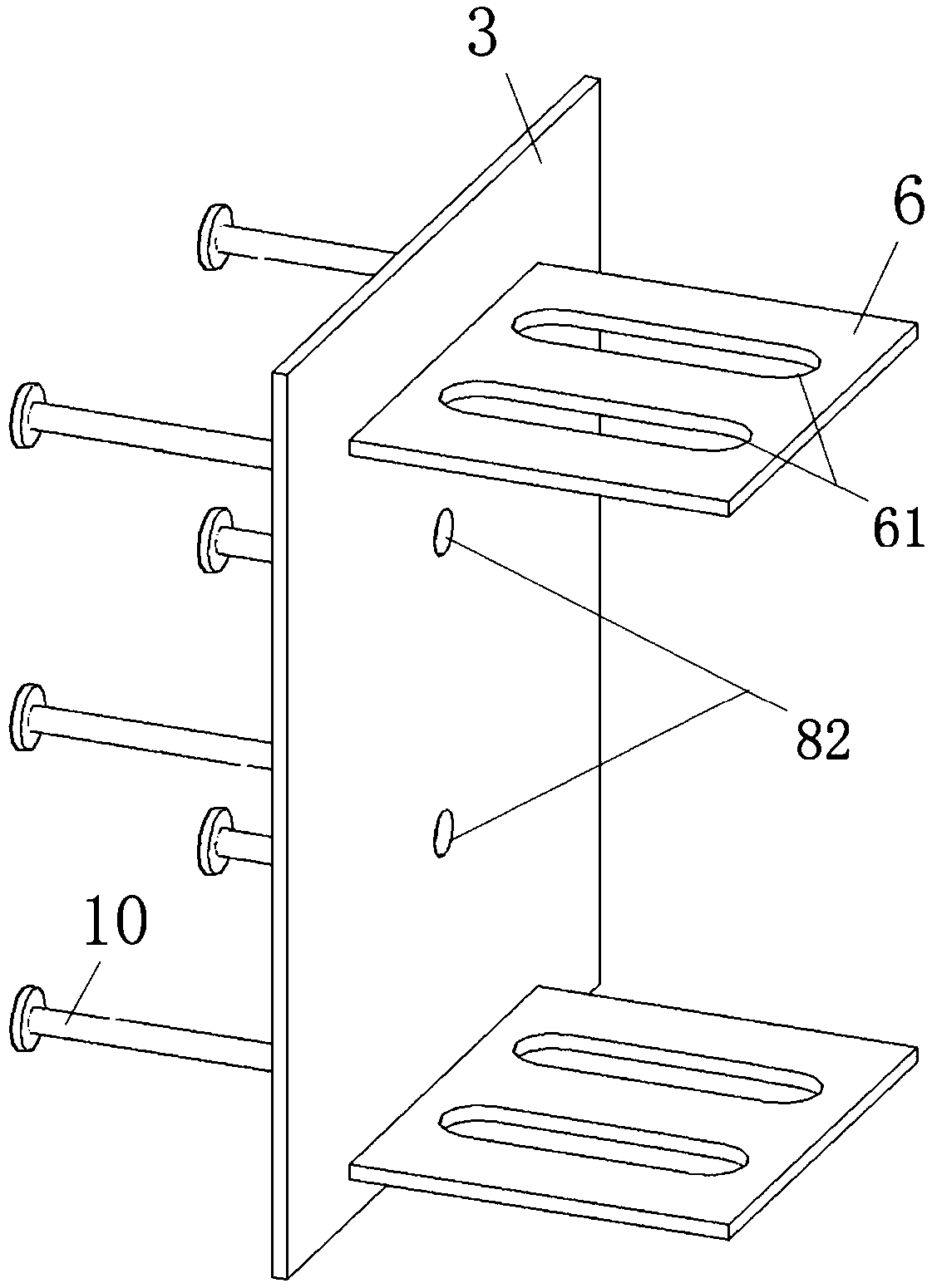

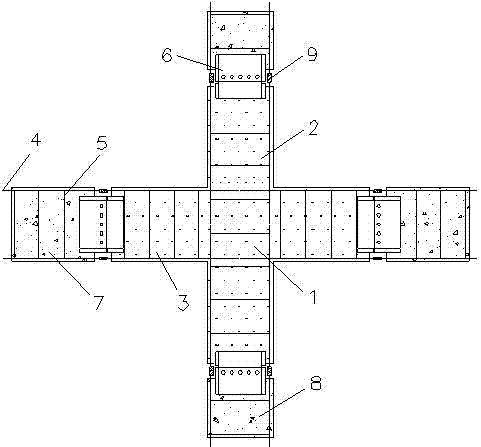

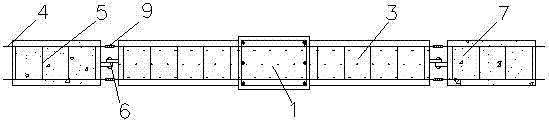

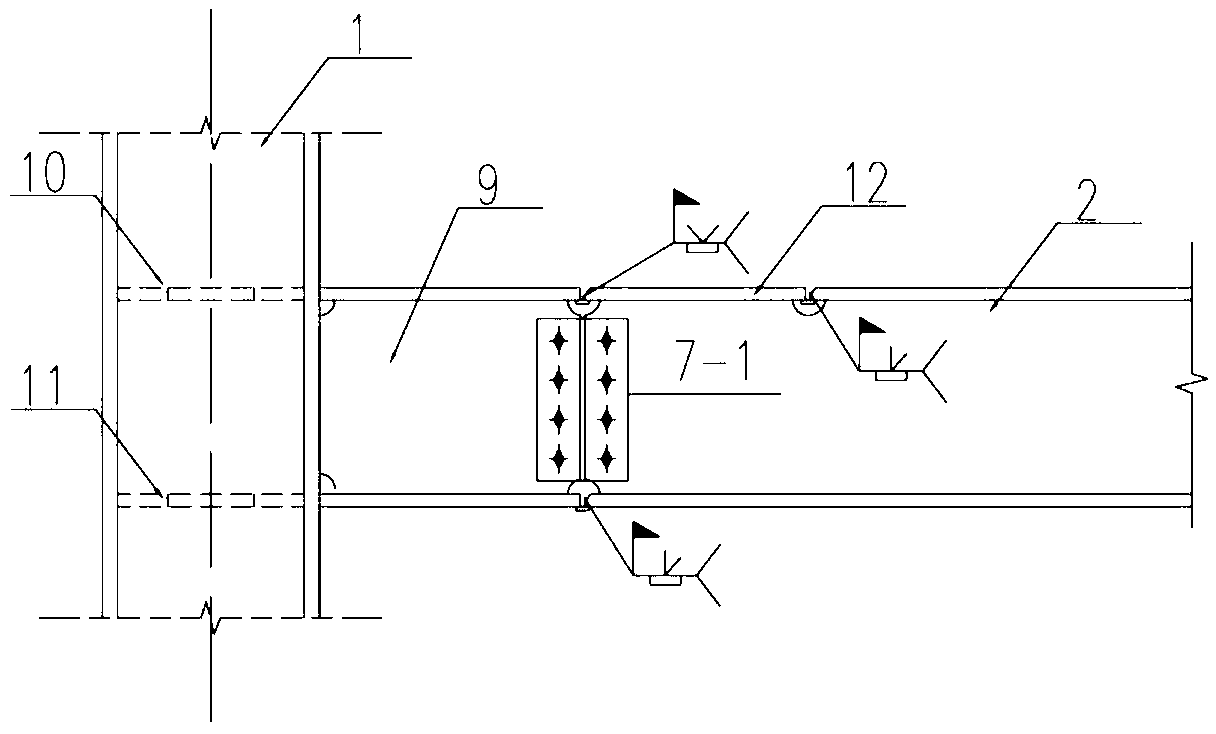

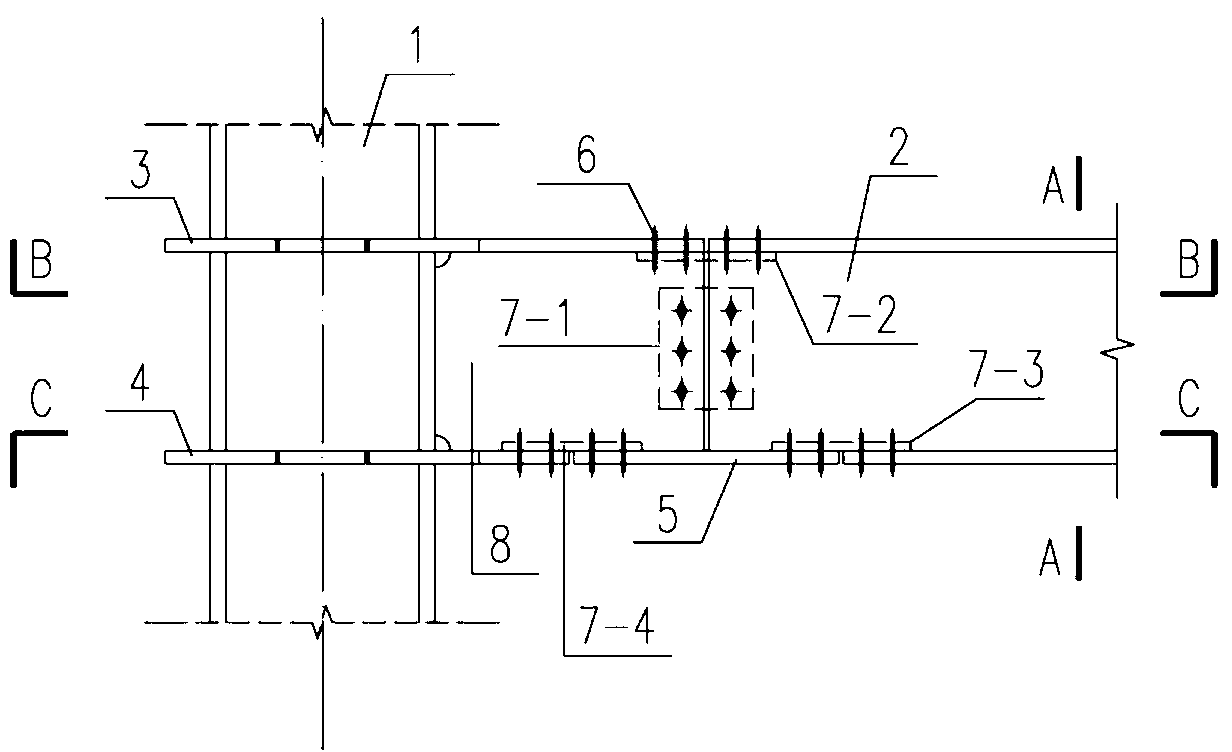

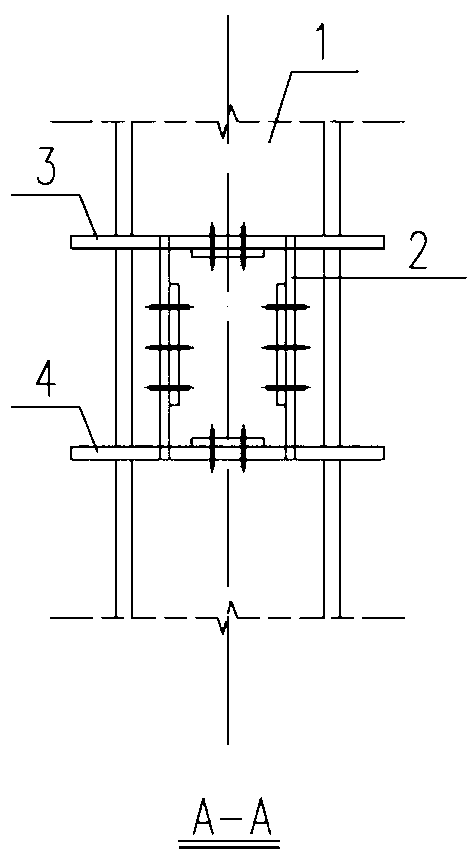

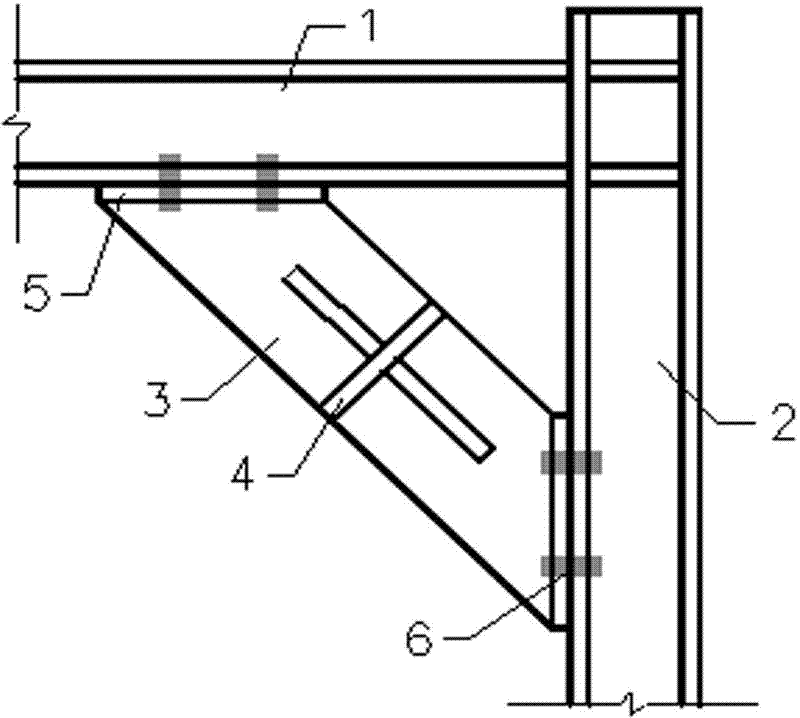

Field connecting method among prefabricated reinforced concrete columns

ActiveCN104775516AGuarantee construction quality and seismic performanceSimple structureBuilding constructionsRebarReinforced concrete column

The invention relates to a field connecting method among prefabricated reinforced concrete columns, facilitates to realize a novel prefabricated assembly technology mode of node factory prefabrication-beam column field connection, prevents the scene casting of concrete in a beam column node area, and belongs to the technical field of structural engineering. The method comprises the following steps: through long round hole ways are reserved in the prefabricated reinforced concrete columns; the ends are coated with steel sleeves; beam column nodes serve as a whole prefabricated unit for lifting on the scene; the steel sleeves at the ends of the upper and lower layers of columns are connected through butt welding joints after being aligned; and finally, concrete is cast in the round hole ways and cavities of the steel sleeves. The method has the advantages of simple configuration, convenience for construction, high field installation speed, low concrete wet operation load, little influence on surrounding environments, excellent stress performance, reliable force transfer, prevention of exposure of concrete cracks in connection areas by means of the steel sleeves, provision of restraint effect, convenience for material taking and processing, low use level of steels and good economical efficiency.

Owner:TSINGHUA UNIV

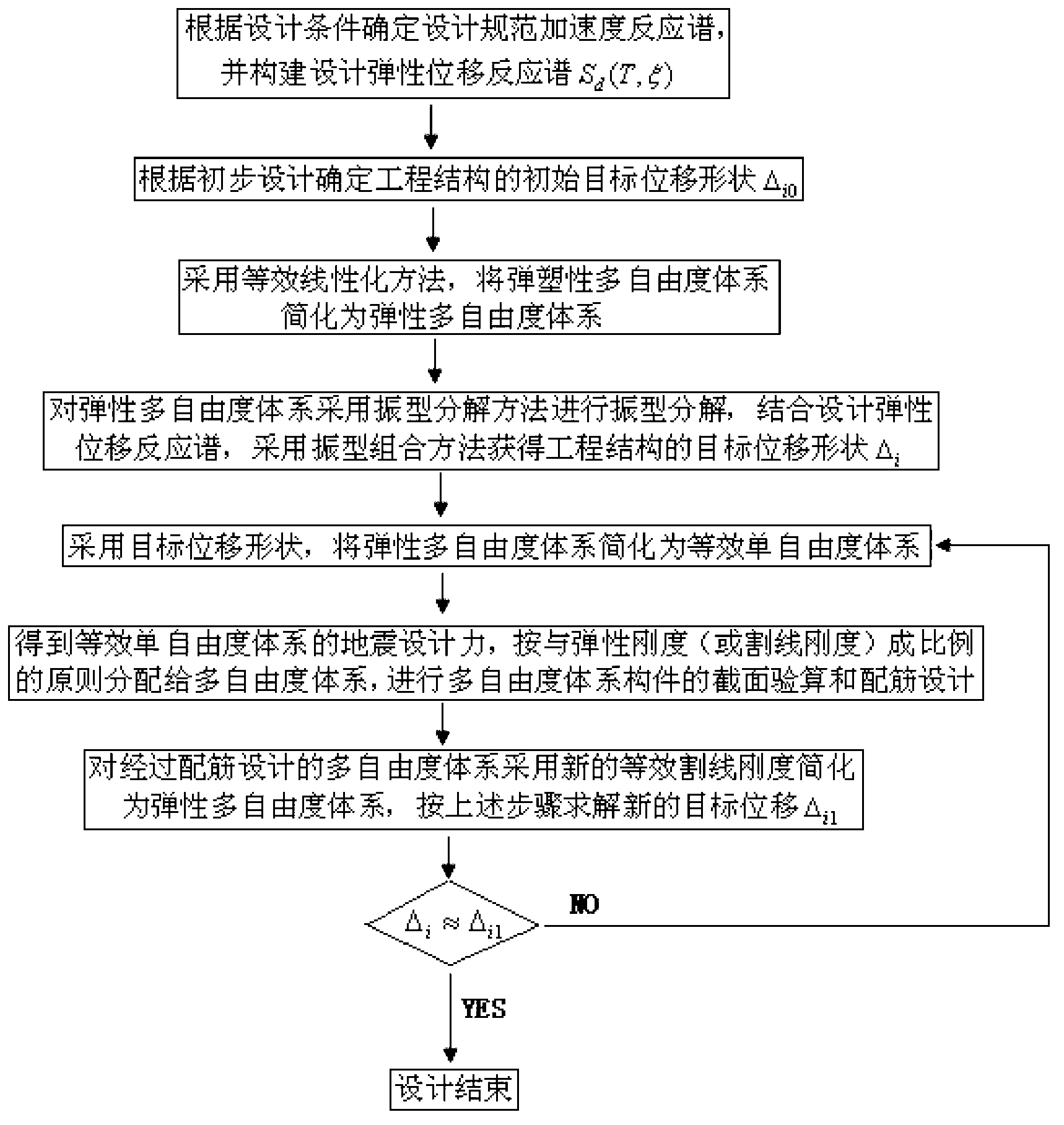

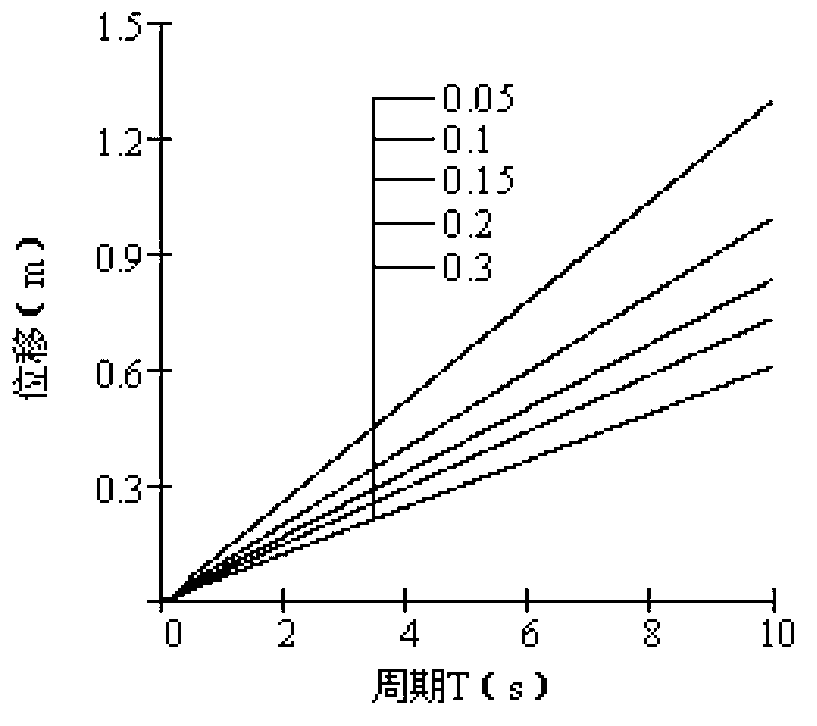

Engineering structure seismic design method based on displacement

ActiveCN103233527ASufficient displacement capacityClear performance levelShock proofingSingle degree of freedomEngineering

Owner:宇旺建工集团有限公司 +2

Inclined outer ring plate fabricated cross connecting beam-column joint

The invention relates to the technical field of connection of building structures, and discloses an inclined outer ring plate fabricated cross connecting beam-column joint. The inclined outer ring plate fabricated cross connecting beam-column joint comprises a square steel tube column, H-shaped steel beams and beam-column connecting assemblies. Each beam-column connecting assembly comprises two groups of miter plates and T-shaped connecting pieces, wherein the two groups of miter plates are arranged symmetrically in a up and down mode; each group of miter plates comprises four identical standard miter plates, each standard miter plate comprises a horizontal part, a vertical part and connecting lugs, and a T-shaped sliding piece is arranged on the back surface of each horizontal part. The T-shaped connecting pieces are provided with T-shaped sliding grooves matched with the T-shaped sliding pieces. According to the inclined outer ring plate fabricated cross connecting beam-column joint,the miter plates are used as standard splicing pieces, the integrity of an outer ring plate is ensured while the strength of a joint area is ensured, the outward movement of plastic hinges is realized, the miter plates provide sufficient construction space, the installation is convenient, and the miter plates can be replaced in time after being damaged; and welding of all components is completedin a factory, the connection is completely carried out through bolts on site, the completely fabricated construction is realized, the quality problems caused by site welding are avoided, and the construction progress is speeded up.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Internal full-height corrugated pipe prefabricated wallboard based assembly type building and construction method thereof

PendingCN108678279AGood shock resistanceThe production process is easy to operateBuilding reinforcementsBuilding material handlingWall plateFloor slab

The invention relates to the technical field of prefabricated concrete wallboards and discloses an internal full-height corrugated pipe prefabricated wallboard based assembly type building and a construction method thereof. The internal full-height corrugated pipe prefabricated wallboard based assembly type building comprises floors and prefabricated wallboards arranged between adjacent floors; one upper layer prefabricated wallboard is connected with a lower layer prefabricated wallboard through a connection piece; each prefabricated wallboard is provided with a corrugated pipe in a pre-burying manner; each corrugated pipe is arranged in a full length in a height direction of the corresponding prefabricated wallboard and is formed with a vertical through hole in a hollow manner; each vertical through hole is internally provided with the corresponding connection piece; the top end of each connection piece extends upward out of the corresponding prefabricated wallboard; the corrugated pipes of the adjacent prefabricated wallboards are arranged in a one-to-one correspondence manner; the top end of each connection piece of the lower layer prefabricated wallboard penetrates through thecorresponding floor upward and extends into the vertical through hole of the corresponding upper layer prefabricated wallboard; and through hole slurry is poured into each vertical through hole. Theinternal full-height corrugated pipe prefabricated wallboard based assembly type building provided by the invention is low in construction difficulty, is convenient, rapid and efficient and is strongin construction quality controllability, reliable in transmission force between prefabricated concrete and late poured slurry and excellent in whole structure seismic performance.

Owner:CHINA INST OF BUILDING STANDARD DESIGN & RES

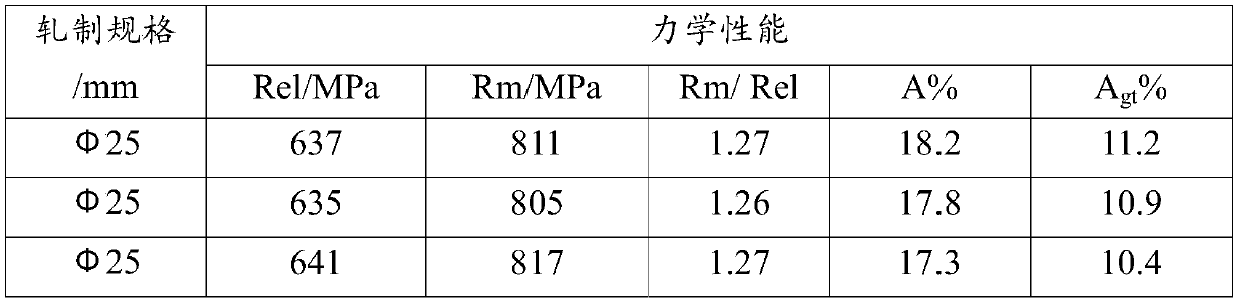

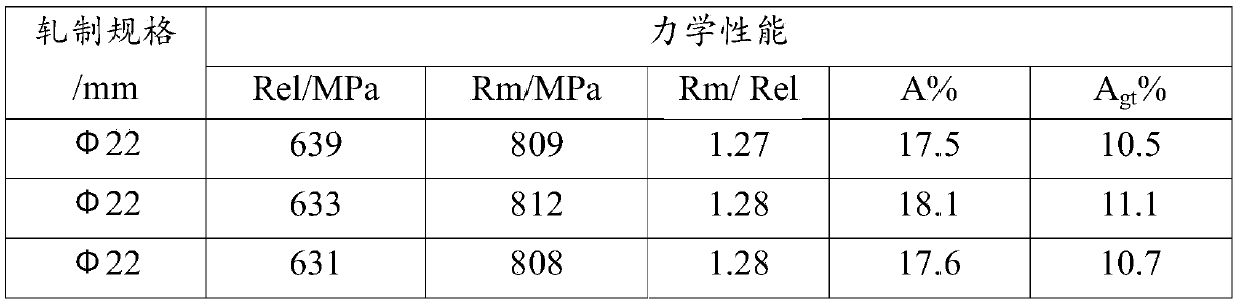

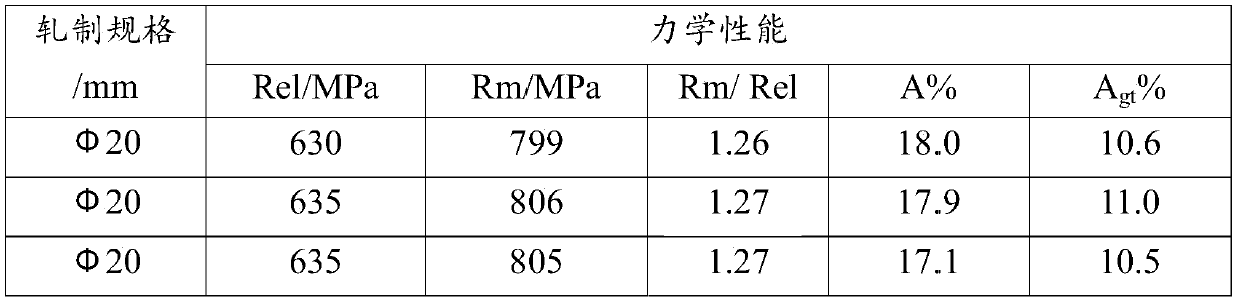

HRB600E V-Ti microalloyed high-strength anti-seismic hot-rolled steel bar

The application discloses an HRB600E V-Ti microalloyed high-strength anti-seismic hot-rolled steel bar. The HRB600E V-Ti microalloyed high-strength anti-seismic hot-rolled steel bar is characterized in that the HRB600E V-Ti microalloyed high-strength anti-seismic hot-rolled steel bar is prepared from the chemical compositions in percentage by mass: 0.22-0.28% of C, 1.50-3.00% of Si+Mn, 0.10-0.25%of V+Ti, less than or equal to 0.12% of V, less than or equal to 0.035% of P, less than or equal to 0.035% of S, 0.02-0.04% of N and the balance of Fe and inevitable impurities; Mn=(1-4)*Si, V=(1-3)*Ti, and the carbon equivalent Ceq=C+Mn / 6+(Cr+Mo+V) / 5+(Cu+Ni) / 15<=0.56. A production method includes the steps of a smelting process, a continuous casting process, a rolling process and a cooling process of a cooling bed. According to the HRB600E V-Ti microalloyed high-strength anti-seismic hot-rolled steel bar, by adding V and Ti microalloy elements, ferro-silicon nitride cored wires are fed in thesmelting process for increasing nitrogen; the process of combination of high temperature heating and low temperature opening rolling is adopted in the rolling process to ensure the solid solution ofthe V and play a fine crystalline role of TiN; and after that, in the cooling process, the dispersed and fine Ti (C / N)+V (C / N) composite particles are formed and precipitated out, and the synergisticeffect of precipitation strengthening and fine crystalline strengthening is achieved. The microstructure of screw-thread steel produced by the compositions and process is ferrite plus bainite, and thelower yield strength is greater than or equal to 620MPa.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

Anti-seismic foundation

InactiveCN101408029AReduce coefficient of frictionStrong compressionFoundation engineeringSteel barRetaining wall

The invention relates to the building technology field, in particular to an earthquake proof foundation which consists of a foundation main body, a concrete cover plate, a foundation soleplate, a downward oblique bar layer, an upward oblique bar layer, an upward longitudinal bar layer, an upward transverse bar layer, a foundation pit soleplate, a retaining wall, a quenched steel cover plate, a quenched steel support plate and a quenched steel clapboard. The foundation main body is positioned in the foundation pit, the foundation soleplate is a horizontal quenched steel plate, four bar layers forming an angle with one another are arranged between the foundation soleplate and the foundation pit soleplate, each bar layer consists of a row of cylindrical quenched steel bars which are horizontally arranged and have gaps with each other, and one horizontally positioned quenched steel clapboard is arranged between every two adjacent bar layers. The retaining wall is positioned at the peripheral walls of the foundation pit, and spaces are remained between the retaining wall and the foundation main body as well as the downward oblique bar layer, the upward oblique bar layer, the upward longitudinal bar layer, the upward transverse bar layer and the edges of the quenched steel clapboard.

Owner:梁伟

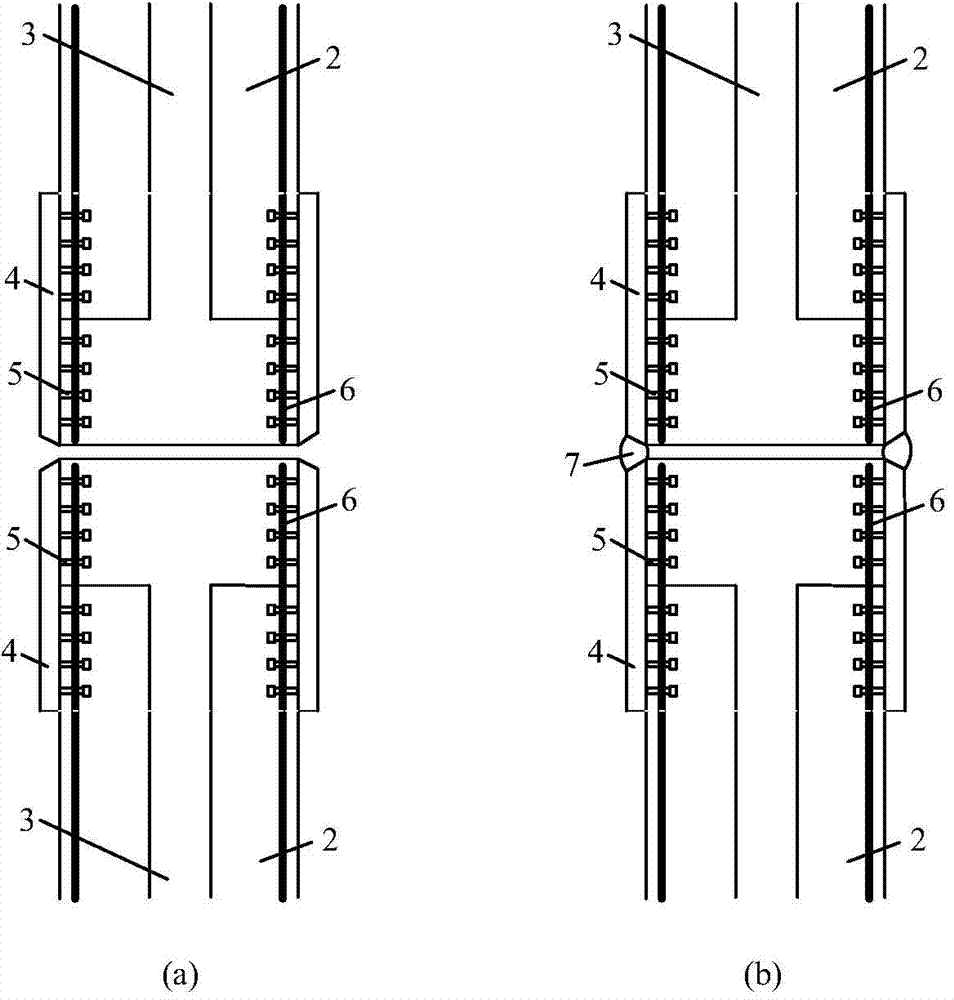

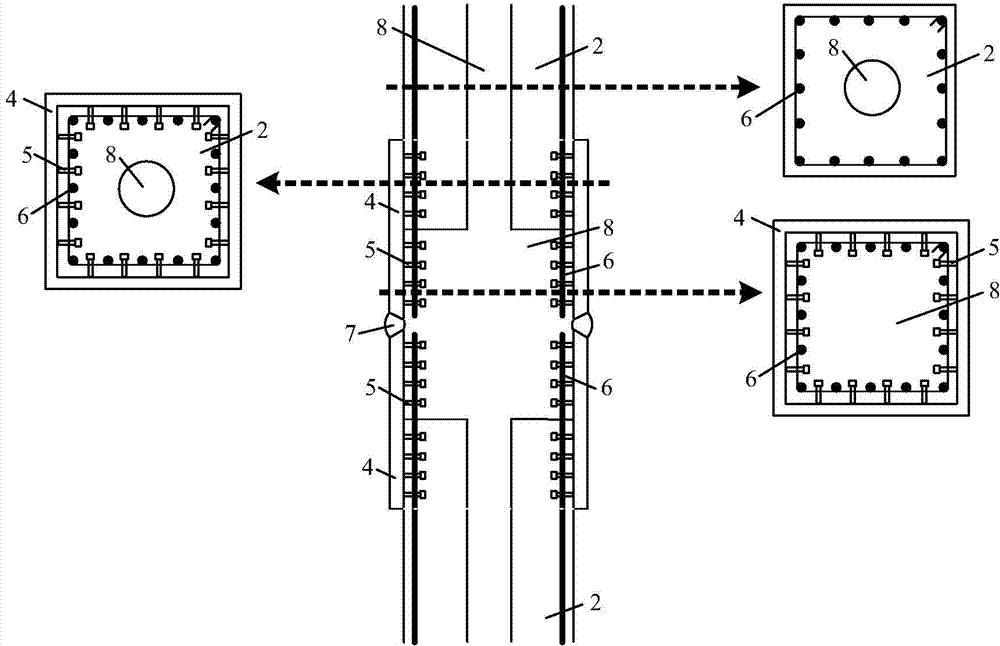

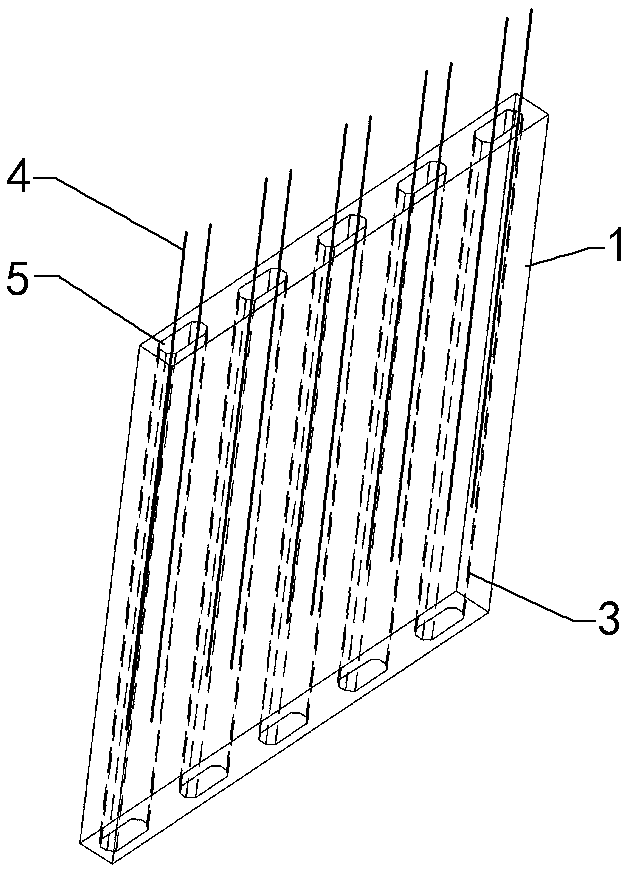

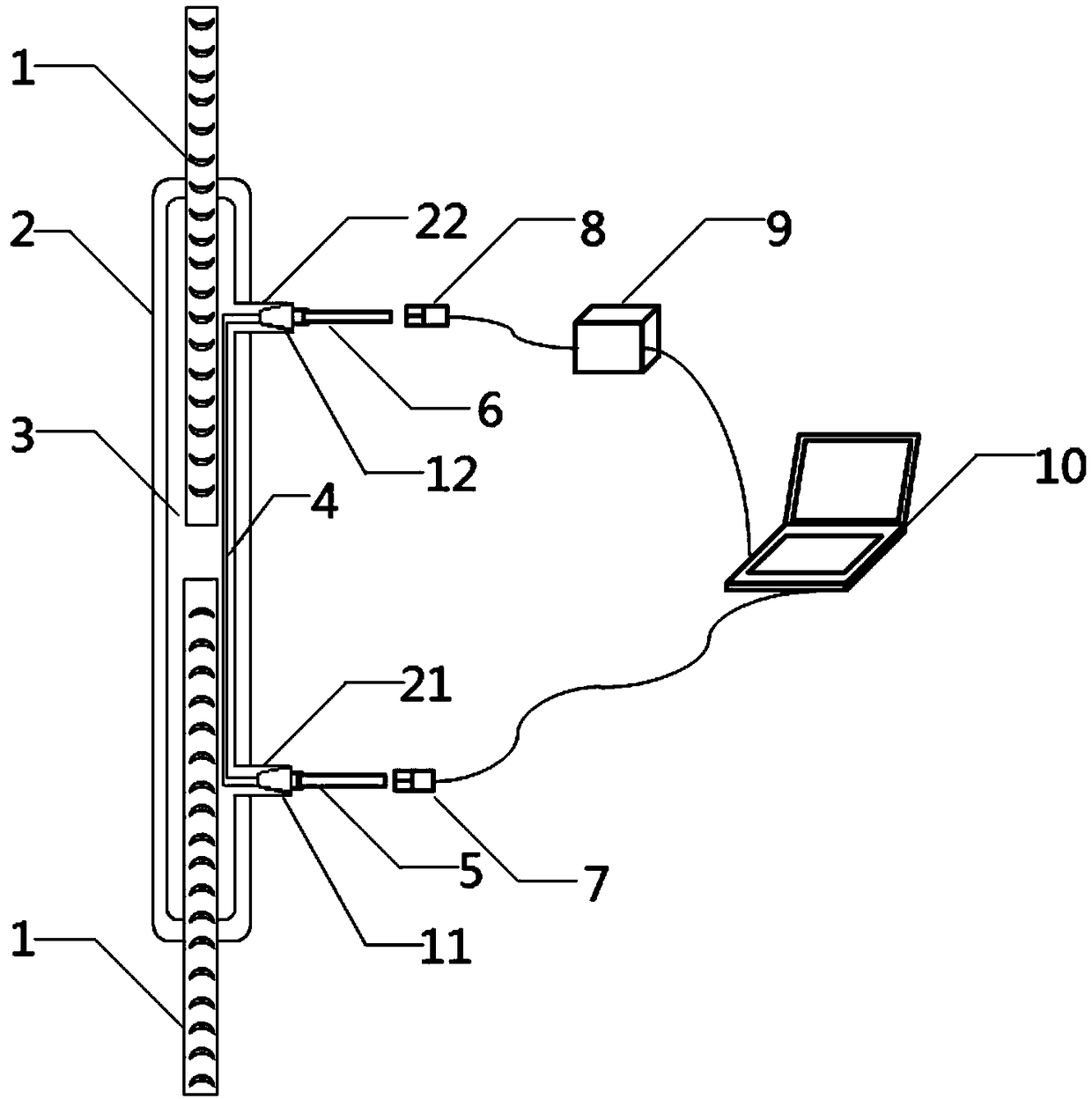

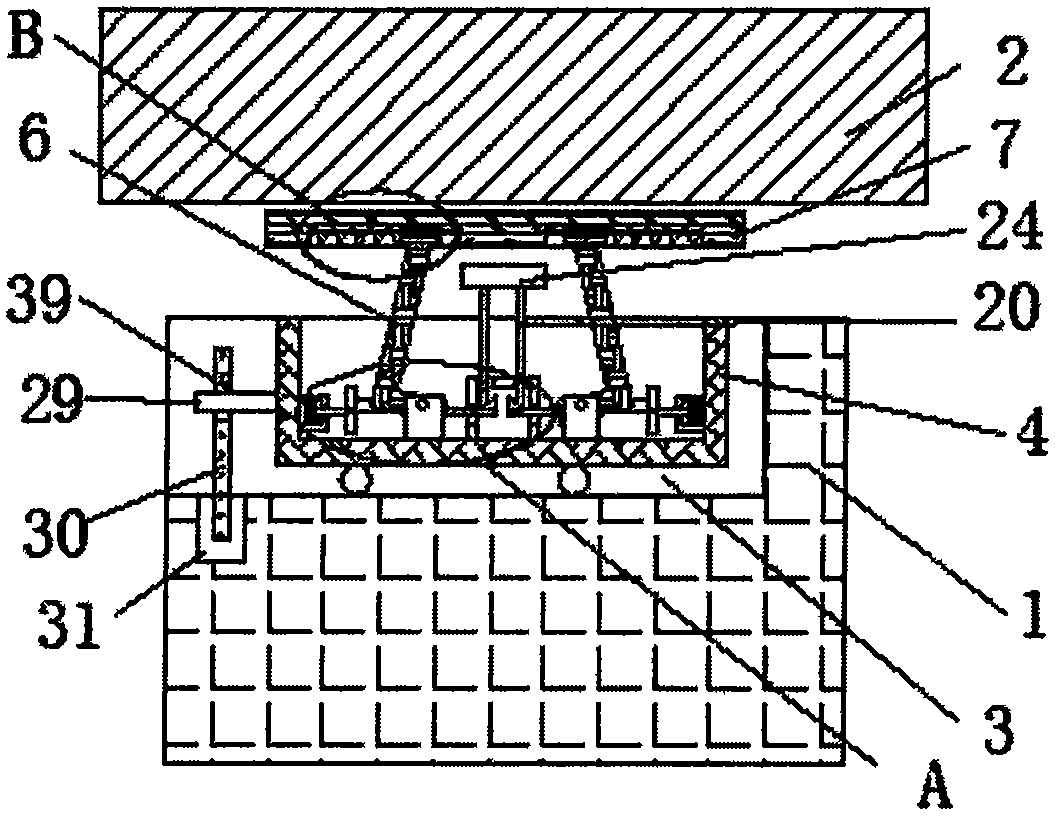

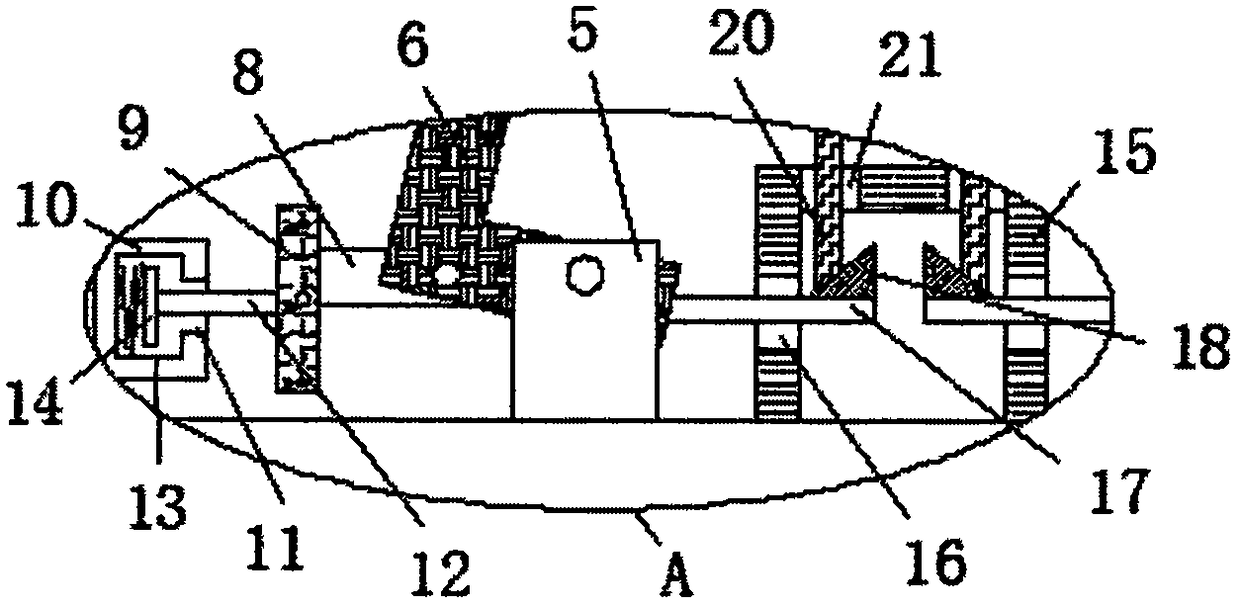

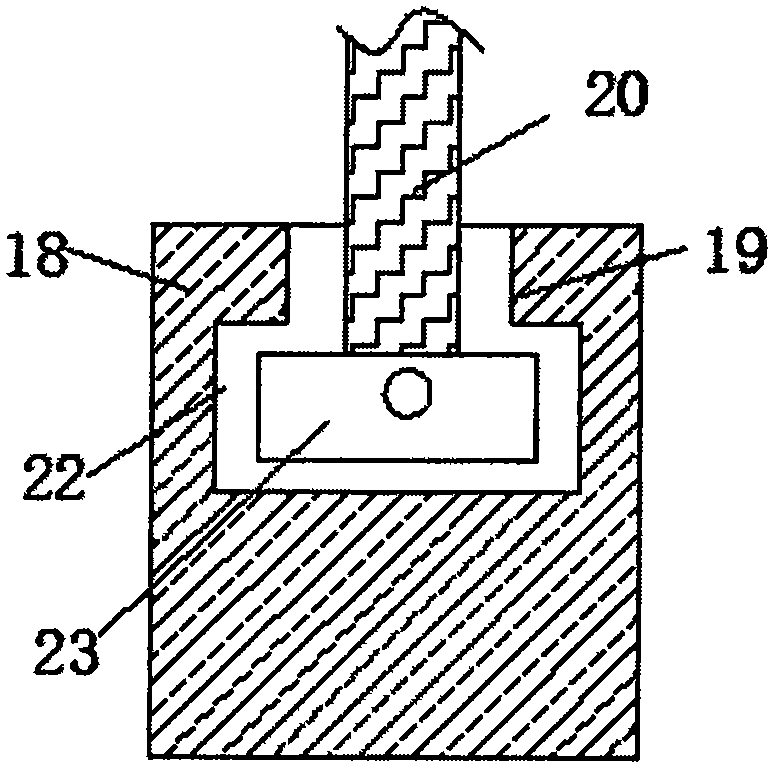

Reinforcement sleeve grouting material compactness detection system and detection method

The invention discloses a reinforcement sleeve grouting material compactness detection system which comprises a sleeve, wherein the sleeve is connected with a reinforcement part; the sleeve is filledwith a grouting material through a slurry inlet and a slurry outlet in the sleeve; the sleeve is also internally provided with a signal conduction rod; a signal transmitter, a signal receiver and a data processor for signal counting and analysis are arranged outside the sleeve; both the signal transmitter and the signal receiver are electrically connected with the data processor; one end of the signal conduction rod is connected with the signal transmitter through the slurry inlet; the other end of the signal conduction rod is connected with the signal receiver through the slurry outlet; sealing parts are arranged at both the slurry inlet and the slurry outlet. The invention further discloses a detection method of the reinforcement sleeve grouting material compactness detection system. Byadopting the reinforcement sleeve grouting material compactness detection system, not only is compactness of the grouting material in the sleeve conveniently and rapidly detected, but also accurate detection results can be achieved, and the connection reliability of the sleeve and the reinforcement part can be improved.

Owner:GUANGZHOU TESTING CENTRE OF CONSTRUCTION QUALITY AND SAFETY CO LTD

An earthquake-resistant limiting device of a bridge which is convenient to be replaced

PendingCN109056505AImprove vibrationImprove seismic performanceBridge structural detailsClimate change adaptationCushioningArchitectural engineering

The invention relates to an earthquake-resistant limiting device of a bridge which is convenient to be replaced, includes piers, the top side of the pier is provided with a mounting groove, one side of the mounting groove is provided with an opening, A mounting box is movably mount in that mounting groove, the top side of the mounting box is provided with an opening, Two fixing blocks are fixedlyinstalled on the inner wall of the bottom side of the mounting box, L-shaped plates are rotatably installed on the top sides of the two fixing blocks, the top sides of the two L-shaped plates extend out of the mounting groove and are movably installed with the same support plate, the bridge body is movably installed on the top side of the support plate, and tie rods are rotatably installed on theside of the two L-shaped plates away from each other. The invention can effectively improve the vibration received by the bridge body during the earthquake through the multi-level cushioning, therebyensuring the seismic performance of the bridge body, prolonging the service life of the bridge body, and facilitating the disassembly and replacement of the installation box, thereby further improvingthe seismic performance of the bridge body.

Owner:BEIFANG UNIV OF NATITIES

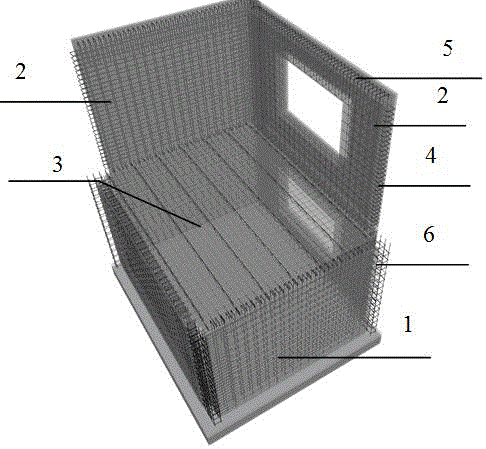

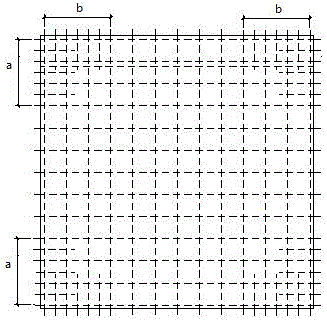

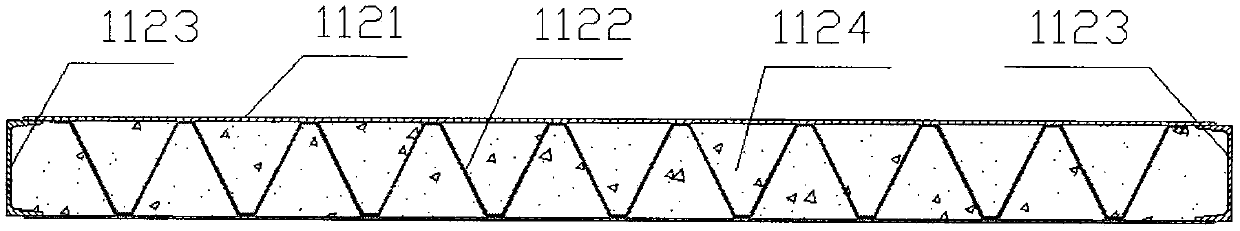

Assembled annular rebar buckling anchoring-connection concrete shear wall structure

InactiveCN106759952AGuaranteed integrityGuaranteed seismic performanceWallsFloor slabReinforced concrete

The invention discloses an assembled annular rebar buckling anchoring-connection concrete shear wall structure which is composed of an inner wallboard, an outer wallboard and a composite floor slab. Each of the inner wallboard and the outer wallboard is of a prefabricated annular reinforced concrete structure, horizontal annular rebars, vertical annular rebars and longitudinal rebars longitudinally connecting the horizontal annular rebars with the vertical annular rebars are prefabricated inside each prefabricated annular reinforced concrete structure, and two ends of the horizontal annular rebars extend outside left and right sides of the inner wallboard or the outer wallboard; when the inner wallboard and the outer wallboard are vertically connected with a wall, the horizontal annular rebars reserved on the left and right sides are matched with stirrups and vertical rebars and buckled in a hidden column area, and two ends of the vertical annular rebars extend outside upper and lower ends of the inner wallboard or the outer wallboard; when the inner wallboard and the outer wallboard on upper and lower layers are connected with the composite floor slab, the vertical annular rebars reserved at upper and lower ends are matched with stirrups and horizontal rebars and buckled in a hidden beam area, and then pouring is performed to form the whole shear wall structure.

Owner:黄坤坤

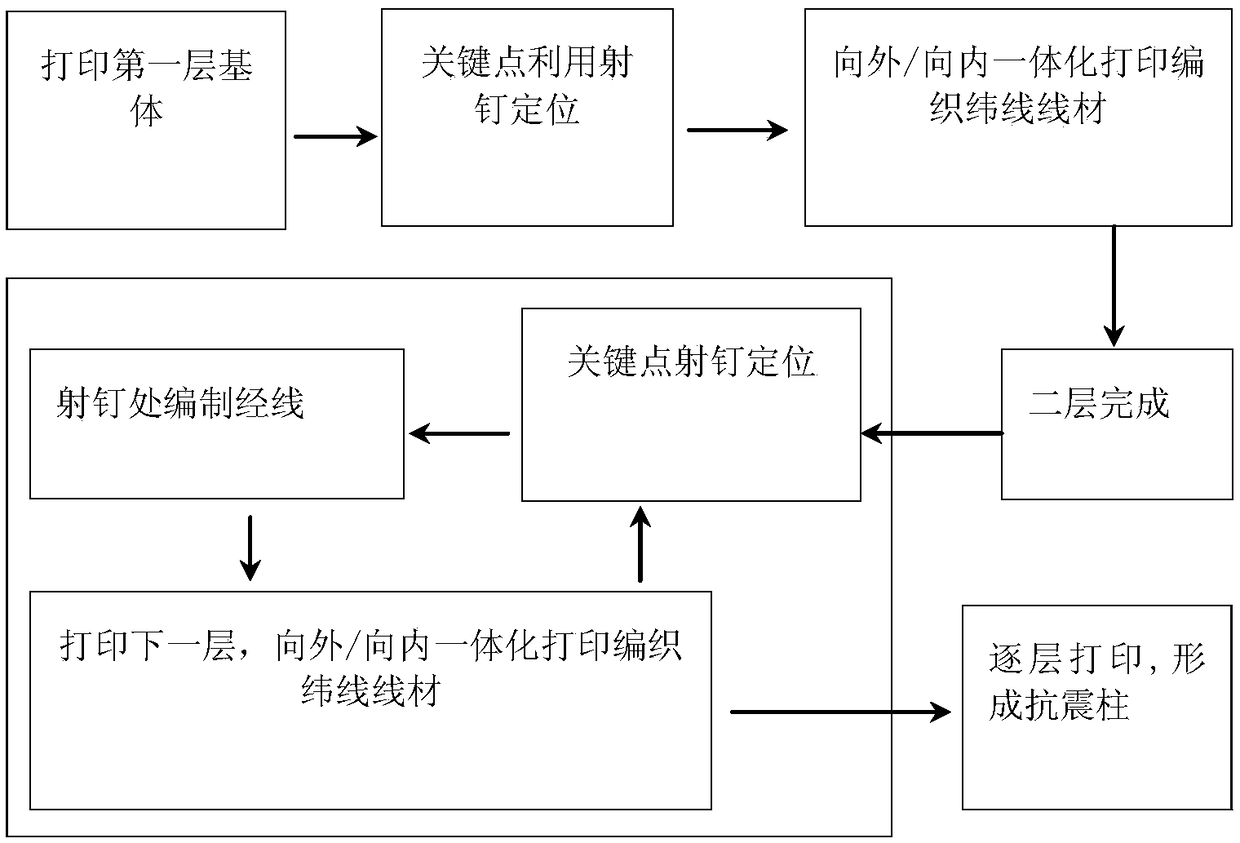

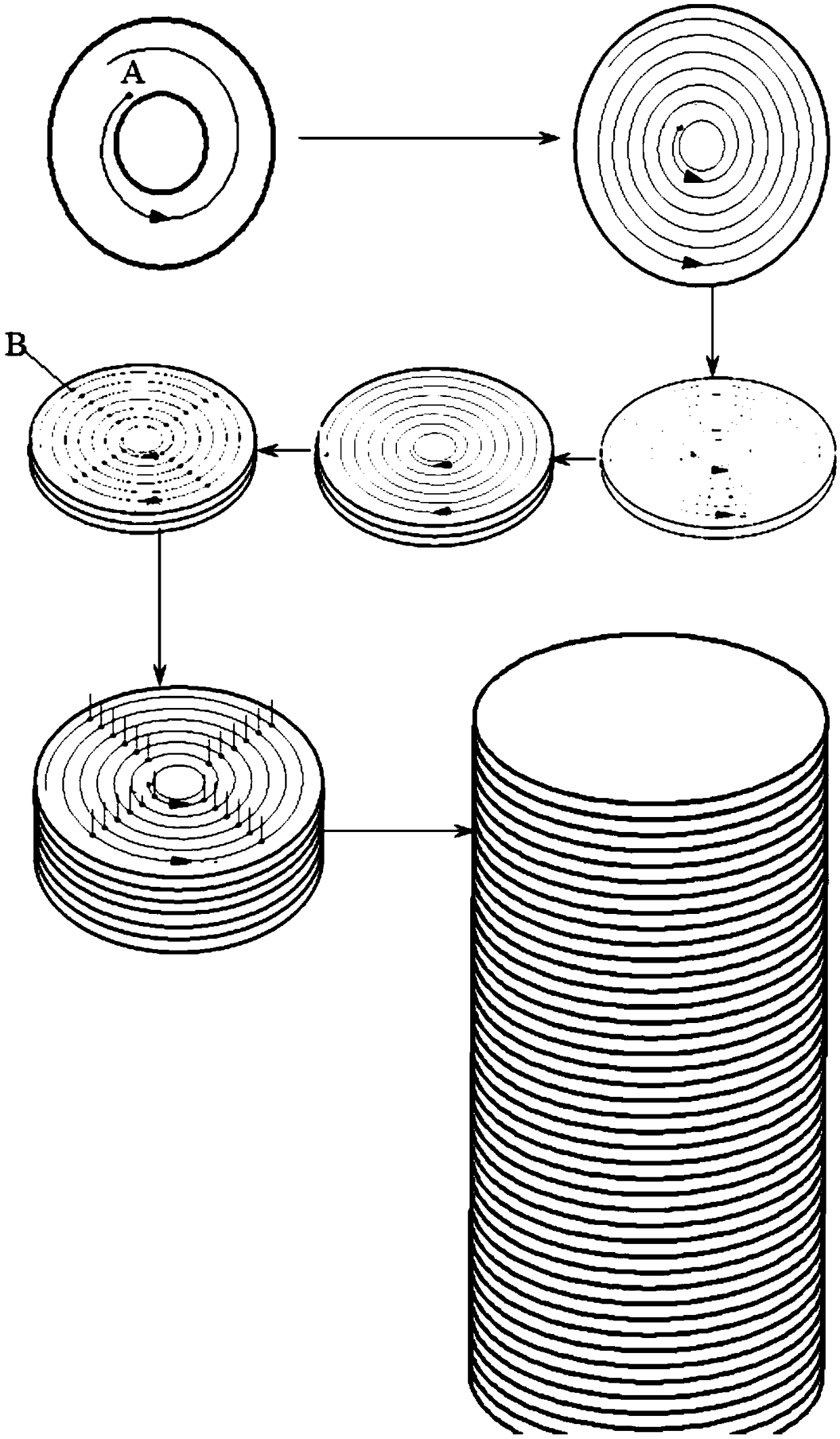

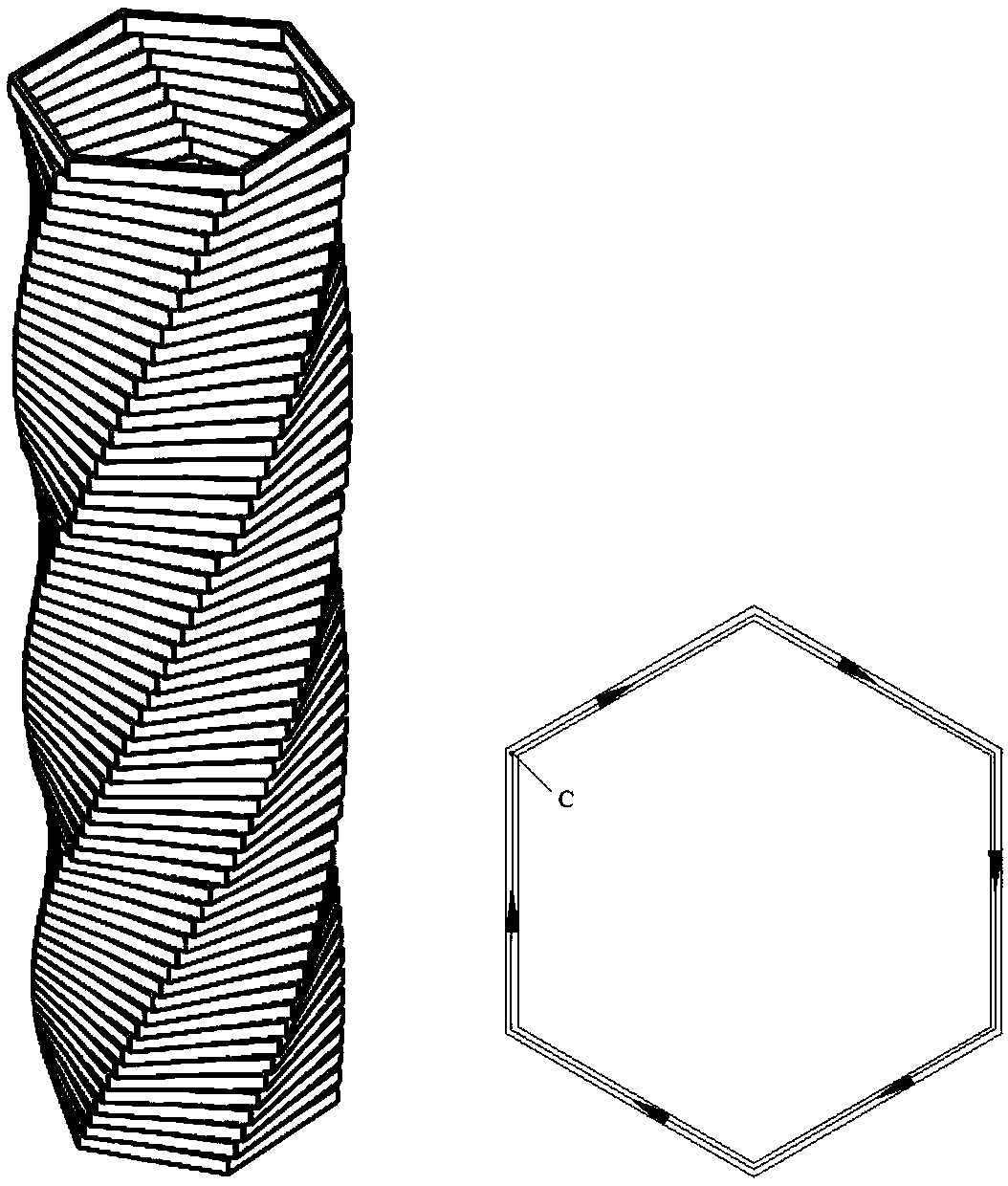

Construction method of composite column integrally formed by 3D printing and knitting and composite column

ActiveCN109129827AReduce building construction proceduresReduce labor intensityAdditive manufacturing apparatusStrutsCrack resistanceEngineering

The invention discloses a construction method of a composite column integrally formed by 3D printing and knitting and the composite column. The construction method comprises the steps that (1) after spatial modeling according to the architectural model, spatial shape optimization is performed according to the functional requirements, and the wire knitting tightness is designed according to the bearing capacity requirements; (2) according to a determined spatial shape and the determined knitting tightness, a matrix printing sequence and anchoring points of wires are arranged to obtain a printing and knitting integrated process, and 3D printing materials are prepared; and (3) according to the printing and knitting integrated process, a solid composite column or a column shell is printed layer by layer. According to the construction method of the composite column integrally formed by 3D printing and knitting, the high-strength wires are knitted in when printing a matrix, and the tensile resistance, shear resistance, abrasion resistance and crack resistance properties of the 3D printing matrix are improved while replacing a steel bar.

Owner:ZHEJIANG UNIV

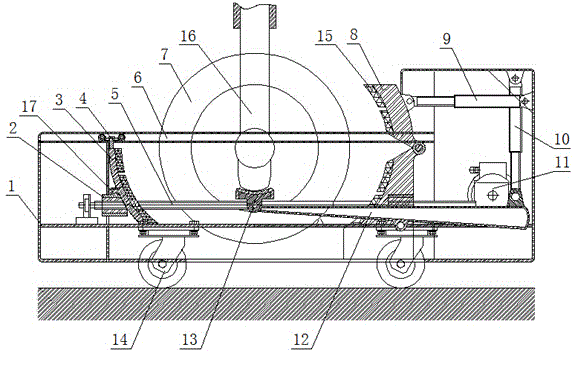

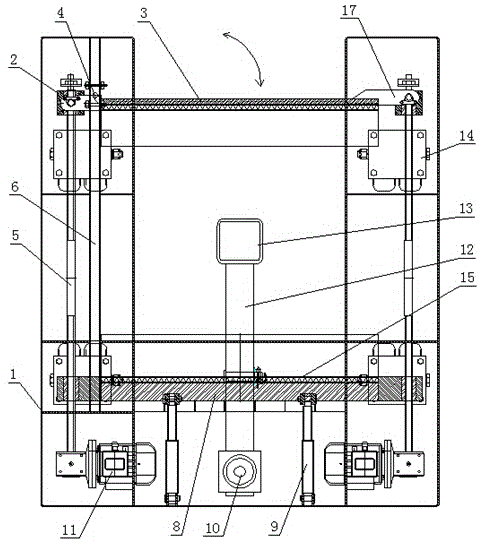

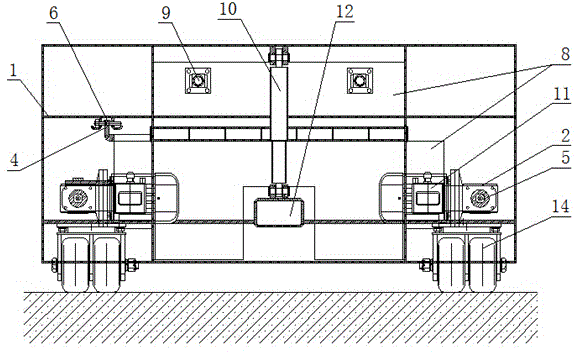

Rescue device for failure emergency of separation of aircraft undercarriages from runways

ActiveCN104590581AReasonable designThe overall structure is compactGround installationsFlight vehicleAirplane

The invention discloses a rescue device for a failure emergency of separation of aircraft undercarriages from runways. The rescue device comprises a U-shaped frame body, and a lifting mechanism and a locking mechanism of an aircraft undercarriage, wherein a plurality of bearing universal wheels are arranged at the bottom of the U-shaped frame body; the lifting mechanism and the locking mechanism are arranged on the U-shaped frame body and are driven by hydraulic cylinders and motors to move, the frame body, the lifting mechanism and the locking mechanism can be formed by the welding of high-strength steel and high-strength alloy or the butting of high-strength bolts, and controllers are connected to the hydraulic cylinders and the motors so as to perform operation and control; the butting of the device and an aircraft only comprises locking operation and lifting operation, the butting can be completed within 5 minutes, and the situation that when the aircraft has tire burst, the aircraft can be drawn to leave a runway at the first time is realized. The rescue device disclosed by the invention has the advantages of reasonable design, compact layout, small size, high efficiency, high safety, high reliability, and high practicality.

Owner:河南宜和城保装备科技实业有限公司

Prefabricated prestress concrete frame beam-column joint with additionally-arranged steel bars and sleeves

InactiveCN108487461AIncrease the reinforcement ratioCrack controlBuilding reinforcementsRebarEngineering

The invention discloses a prefabricated prestress concrete frame beam-column joint with additionally-arranged steel bars and sleeves. The prefabricated prestress concrete frame beam-column joint comprises a beam-column joint post-cast area, prefabricated concrete beams arranged on the horizontal two ends of the beam-column joint post-cast area, prefabricated concrete columns arranged at the upperend and the lower end of the beam-column joint post-cast area, and a superposed beam cast-in-situ area arranged above the prefabricated concrete beams and the beam-column joint post-cast area. Anti-seismic steel bars and the additionally-arranged steel bars are horizontally arranged on the lower portion of the beam-column joint post-cast area, the anti-seismic steel bars and stirrups in the beam-column joint post-cast area are connected, and the superposed beam cast-in-situ area and the beam-column joint post-cast area are cast into a whole. Longitudinal ordinary stress steel bars on the lowerside and the anti-seismic steel bars are connected through sleeves, and the additionally-arranged steel bars extend into bar inserting holes of the ends of the prefabricated concrete beams. Accordingto the prefabricated prestress concrete frame beam-column joint, the on-site construction difficulty is reduced, the size of a beam section and the steel using quantity are reduced, and the development and rotation performance of beam end plastic hinges and the anti-seismic performance such as integrity and ductility of the beam-column joint are ensured.

Owner:SOUTHEAST UNIV

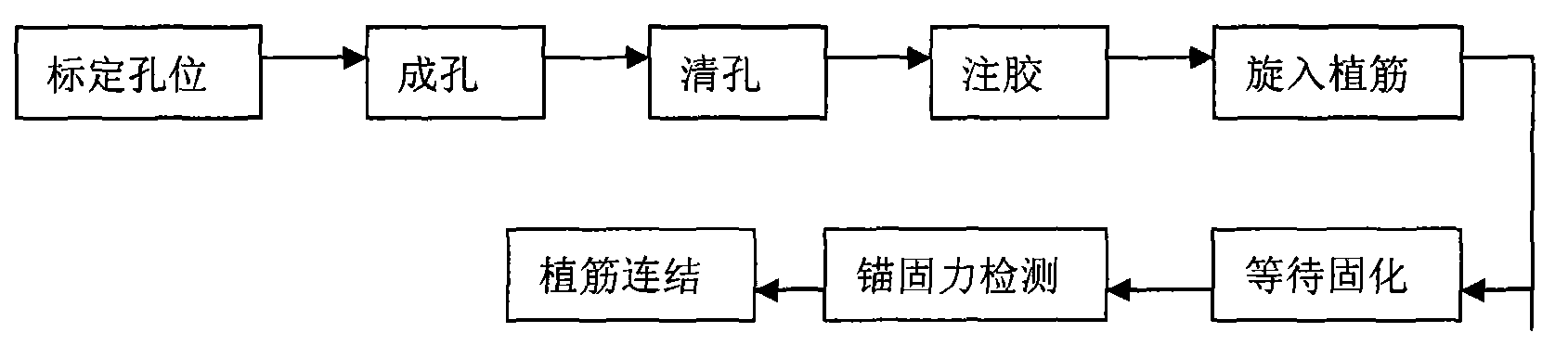

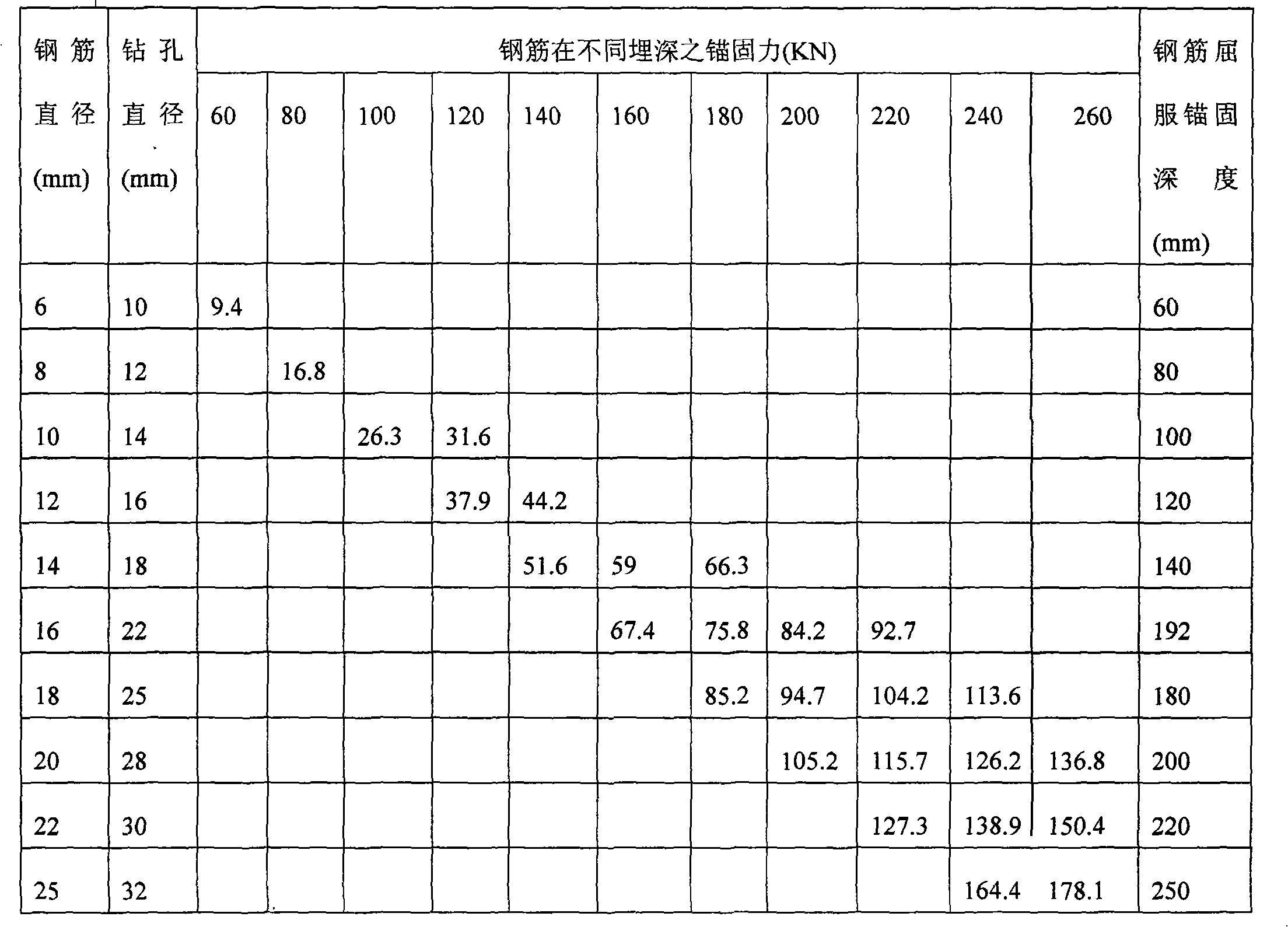

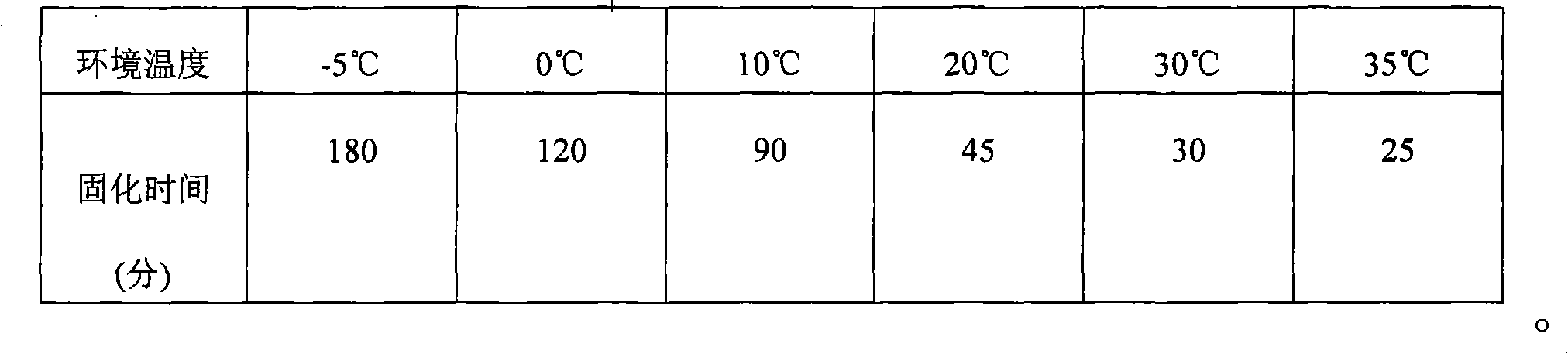

Construction method for rear planted wall steel tie

InactiveCN101899868AReduce retentionImprove the duration effectBuilding constructionsEarthquake resistanceSocial benefits

The invention discloses a construction method for a rear planted wall steel tie. The main technical process is as follows: measuring the specific position of an original rebar on an anchoring position; demarcating a hole site; drilling a hole according to a specified hole diameter; carrying out borehole cleaning and gluing evenly; before glue is solidified, planting the rebar in a mode of rotating while inserting; respectively leading the rebar and glue as well as the glue and a concrete surface to be combined and cured for 24 hours; and after detecting that the anchored force reaches to design requirements, connecting the planted rebar with the connected rebar by binding and welding. The construction method has simple and convenient operation, low construction cost and reliable construction quality, reduces reserved embedded parts and wastes of steel products, improves the whole construction period effect of construction technology and ensures the earthquake resistance of filled wall bodies; and multiple project practical applications prove that economic and social benefits of the method are remarkable.

Owner:INNER MONGOLIA XINGTAI CONSTRAL GRP CO LTD

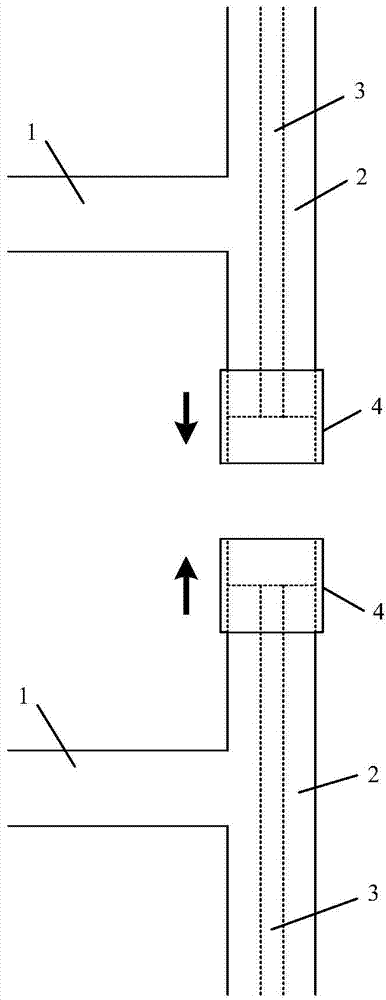

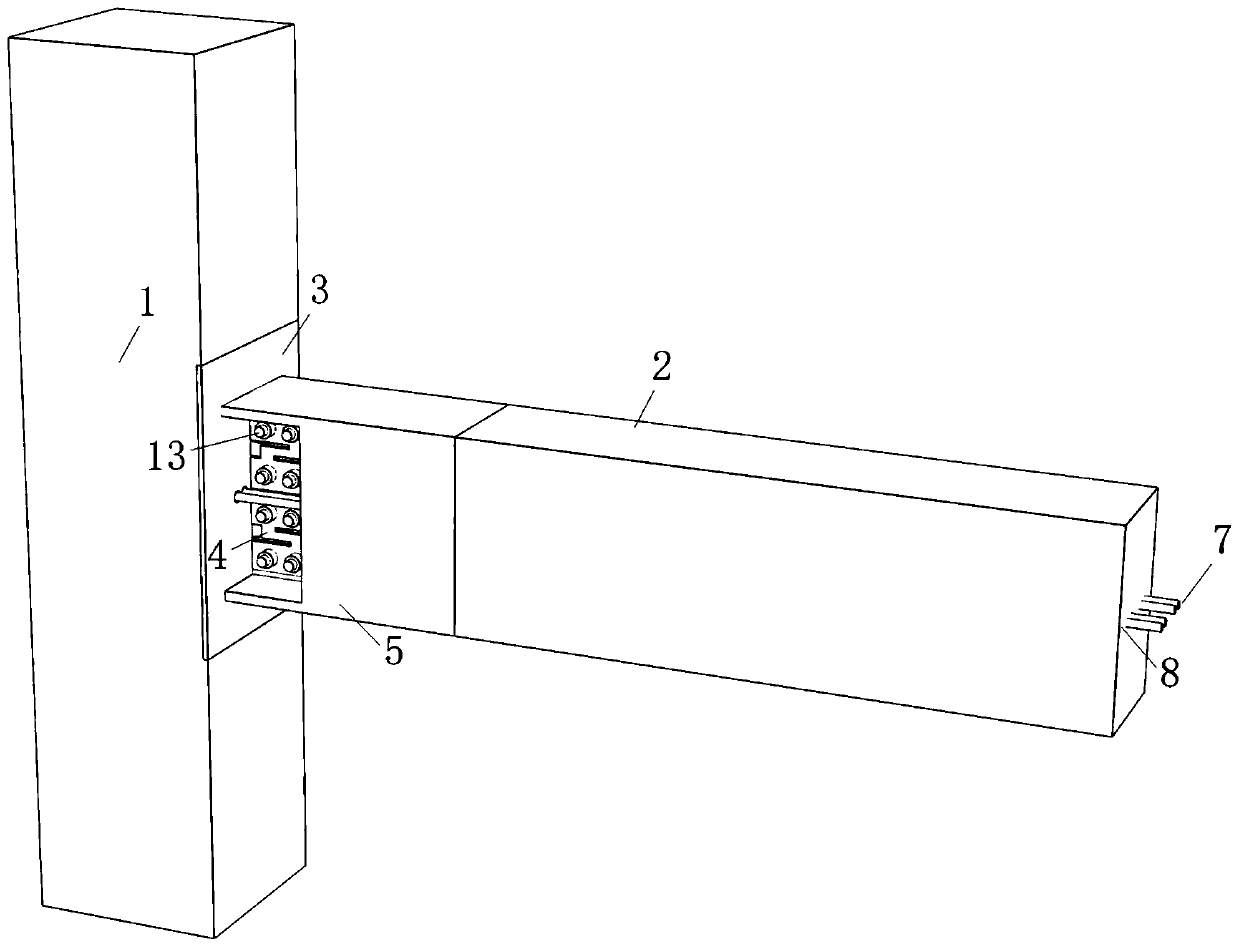

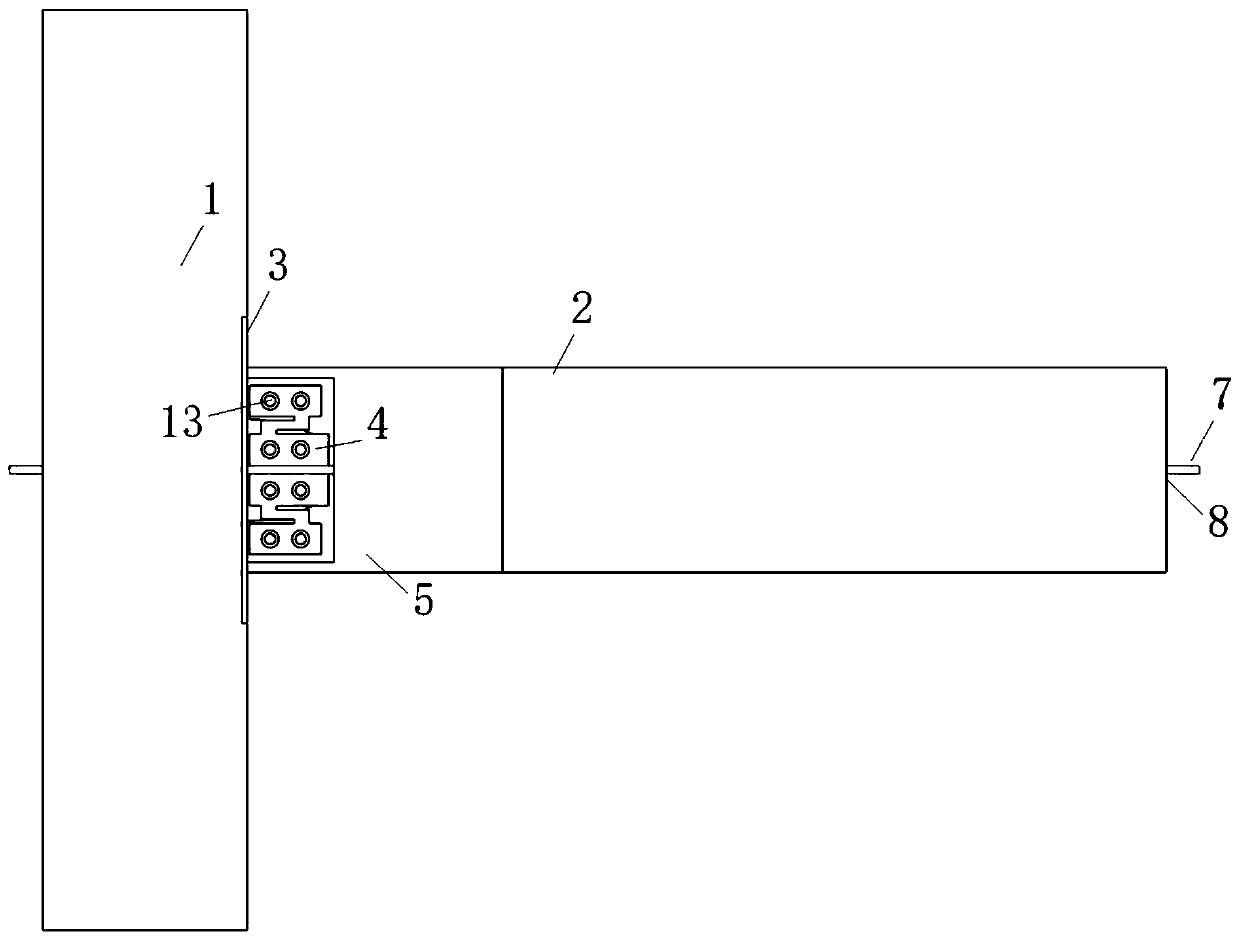

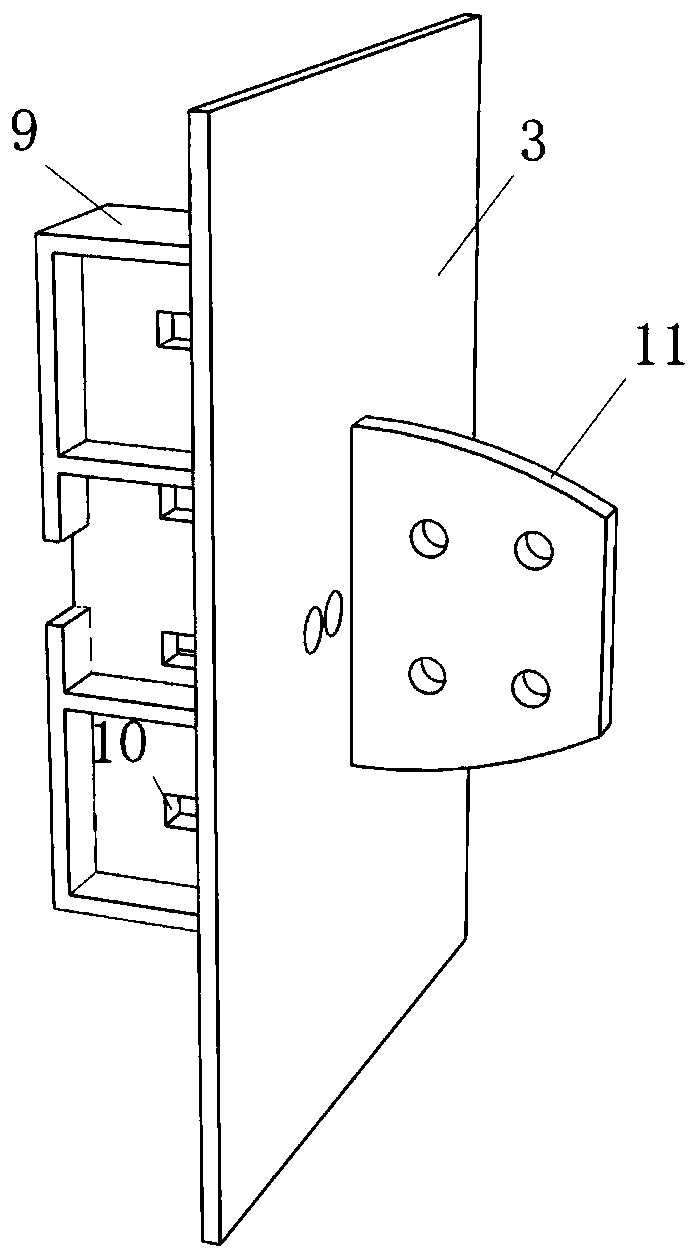

Assembly type self-resetting concrete frame low-damage joint with modularized energy dissipation part

ActiveCN110847357AImprove energy consumptionReduce pollutionProtective buildings/sheltersShock proofingReinforced concrete columnPre stress

The invention provides an assembly type self-resetting concrete frame low-damage joint with a modularized energy dissipation part. The assembly type self-resetting concrete frame low-damage joint comprises a prefabricated reinforced concrete column, a prefabricated reinforced concrete beam, a column end pre-embedded steel plate, a beam end pre-embedded profile steel sleeve, a soft steel damper, anunbonded prestressed steel strand, a prestressed steel strand pore channel and high-strength reamed hole bolts, wherein one side of the column end pre-embedded steel plate is an anchoring end and theother side of the column end pre-embedded steel plate is a column end butt joint plate; a shear key is welded on an inner wall of the beam end pre-embedded profile steel sleeve; a beam end butt jointplate is arranged at a beam end profile steel web. The soft steel damper is arranged at the beam end profile steel web and is fastened at two sides of the web through the high-strength reamed hole bolts; and beam column components are connected through the prestressed steel strand.

Owner:SOUTHEAST UNIV

Tunnel construction lighting device good in protecting effect

ActiveCN109798467ASolve the problem of unsatisfactory protection effectPrevent being smashedLighting heating/cooling arrangementsProtective devices for lightingEffect lightSlide plate

The invention discloses a tunnel construction lighting device good in protecting effect. The tunnel construction lighting device comprises a box and is characterized in that two first telescopic rodsare fixedly connected to the bottom of the inner wall of the box, and the tops of the two first telescopic rods are fixedly connected through a slide plate. The tunnel construction lighting device hasthe advantages that by the coordination of the first telescopic rods, the slide plate, first springs, sliders, slide rods, limit blocks, second springs, a fixing plate, dustproof plates, first slidegrooves, first sliders, second slide grooves, second sliders, second telescopic rods, reset springs, fixing seats, support rods, fixing grooves, squeezing blocks, third slide grooves, third sliders and third springs, the problem that a common tunnel construction lighting device is unsatisfactory in protecting effect is solved, a gravel damping effect is achieved during tunnel construction, the lighting device is prevented from being smashed, the service life of the lighting device is prolonged, potential safety hazards are avoided, and great convenience is brought to tunnel construction.

Owner:东营宏基混凝土有限公司

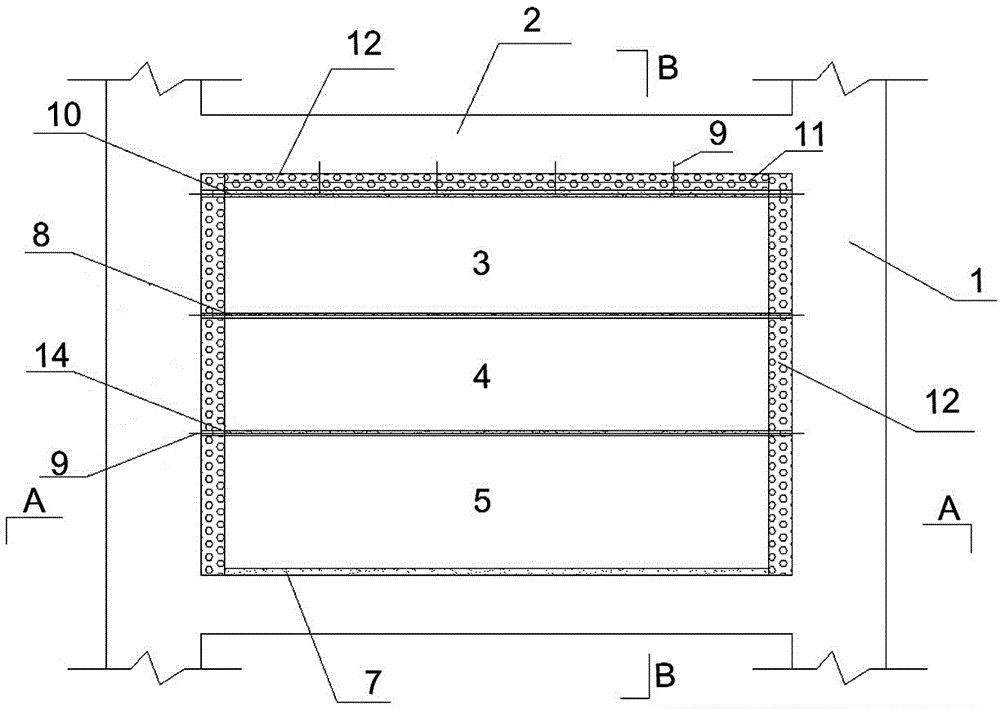

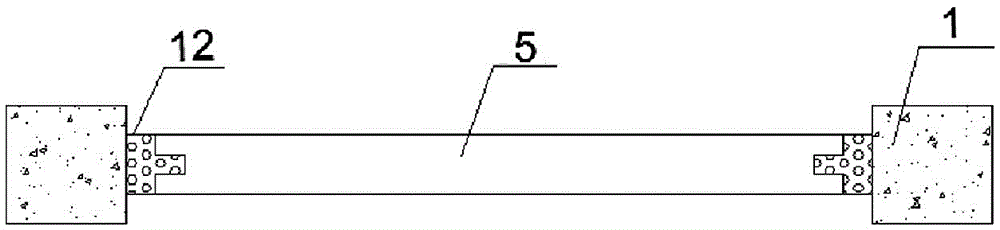

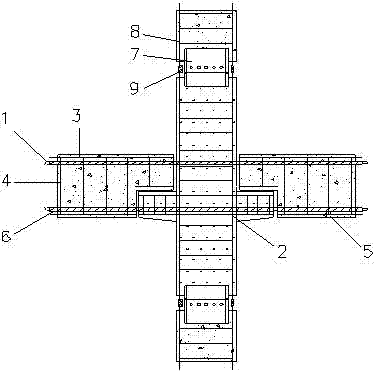

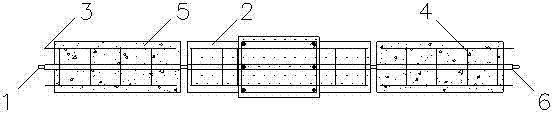

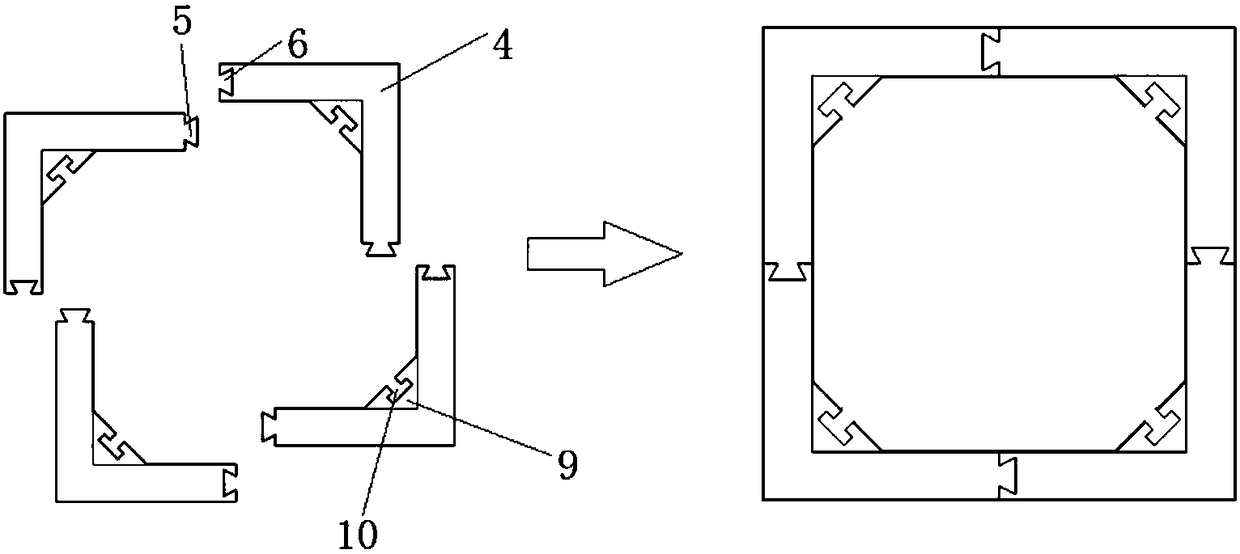

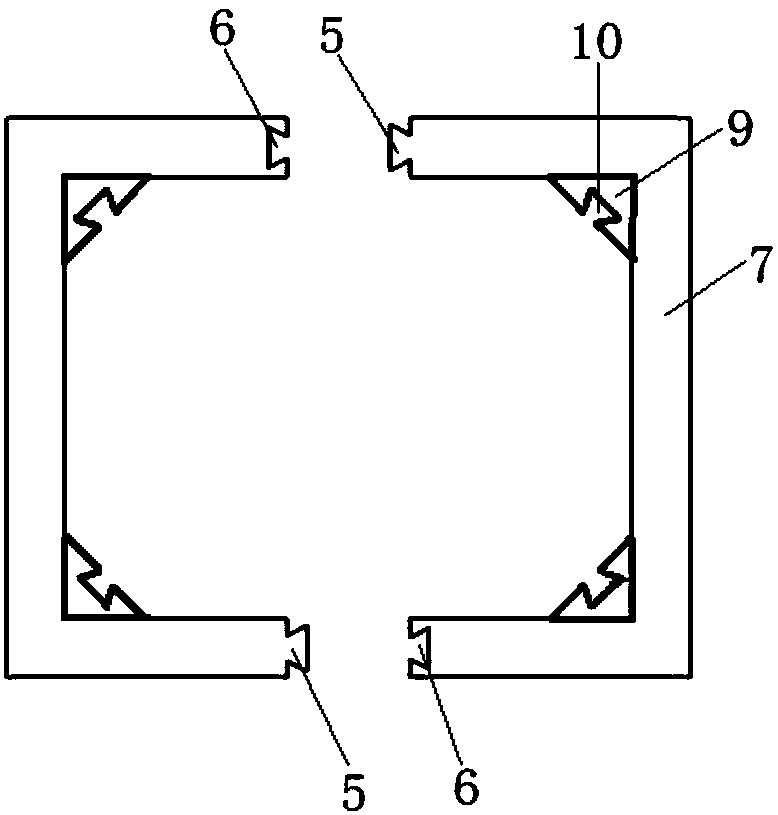

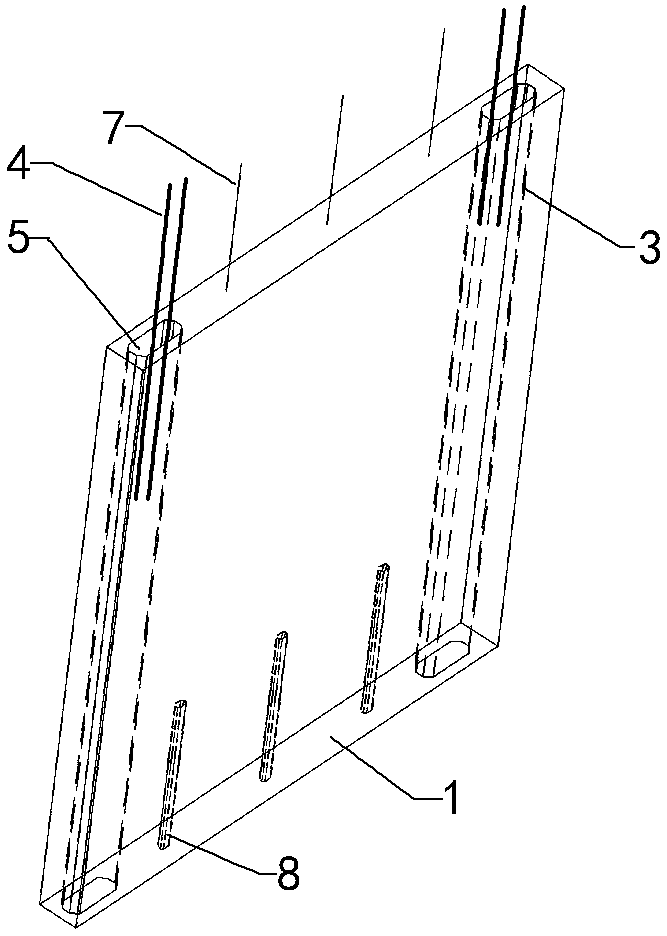

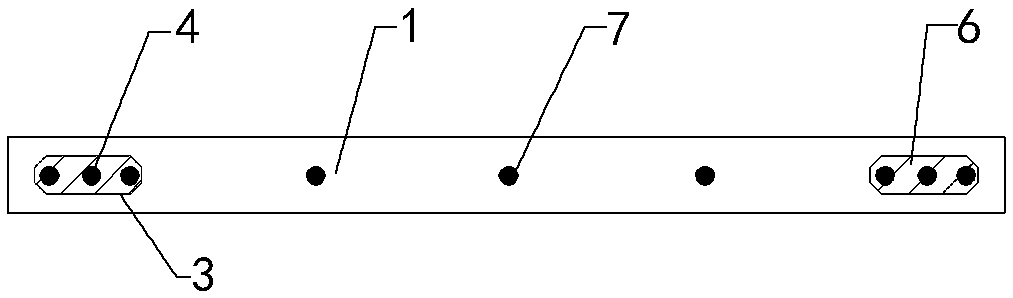

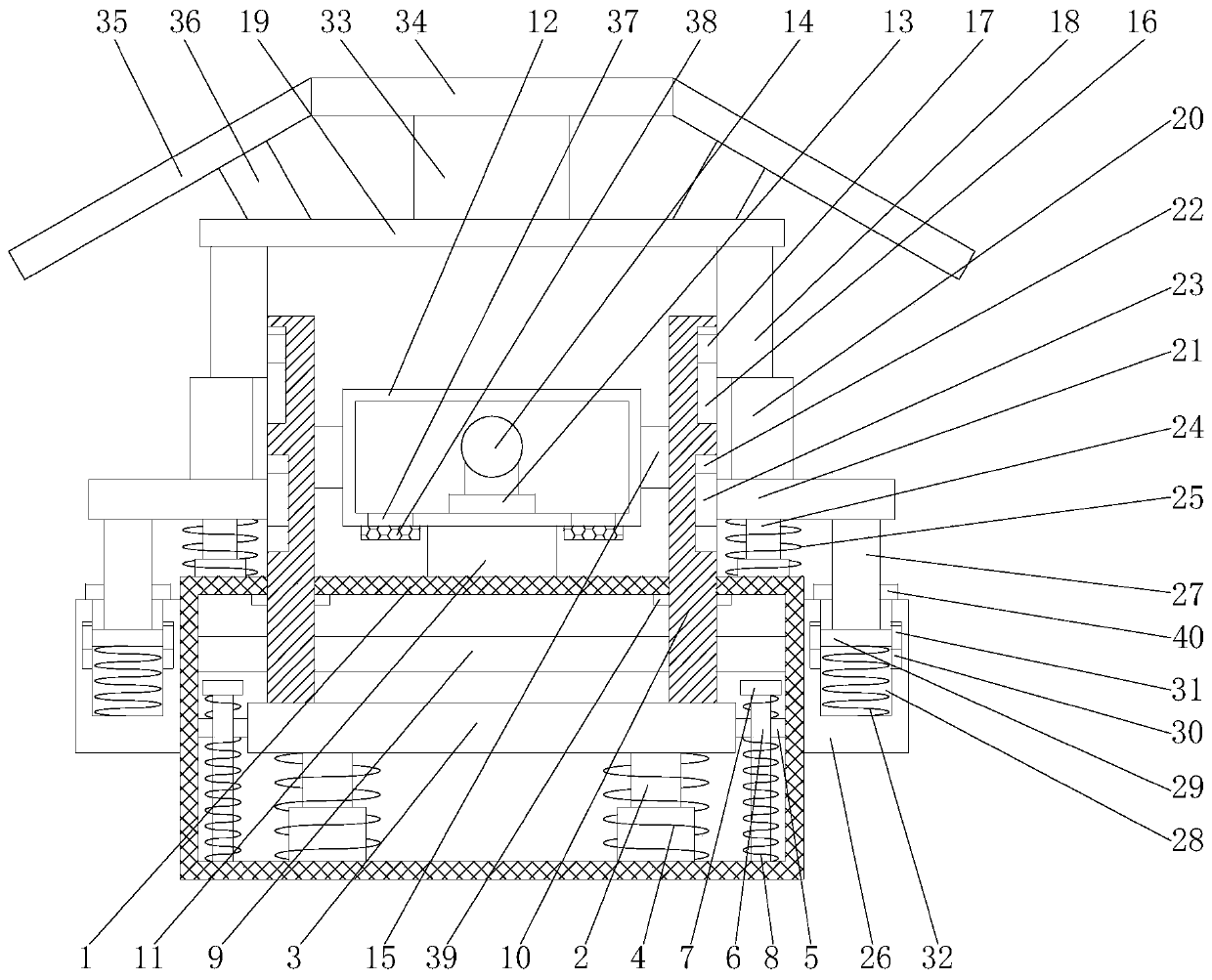

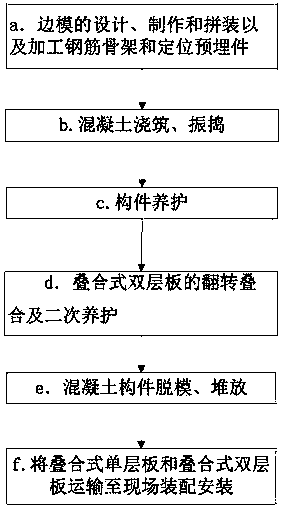

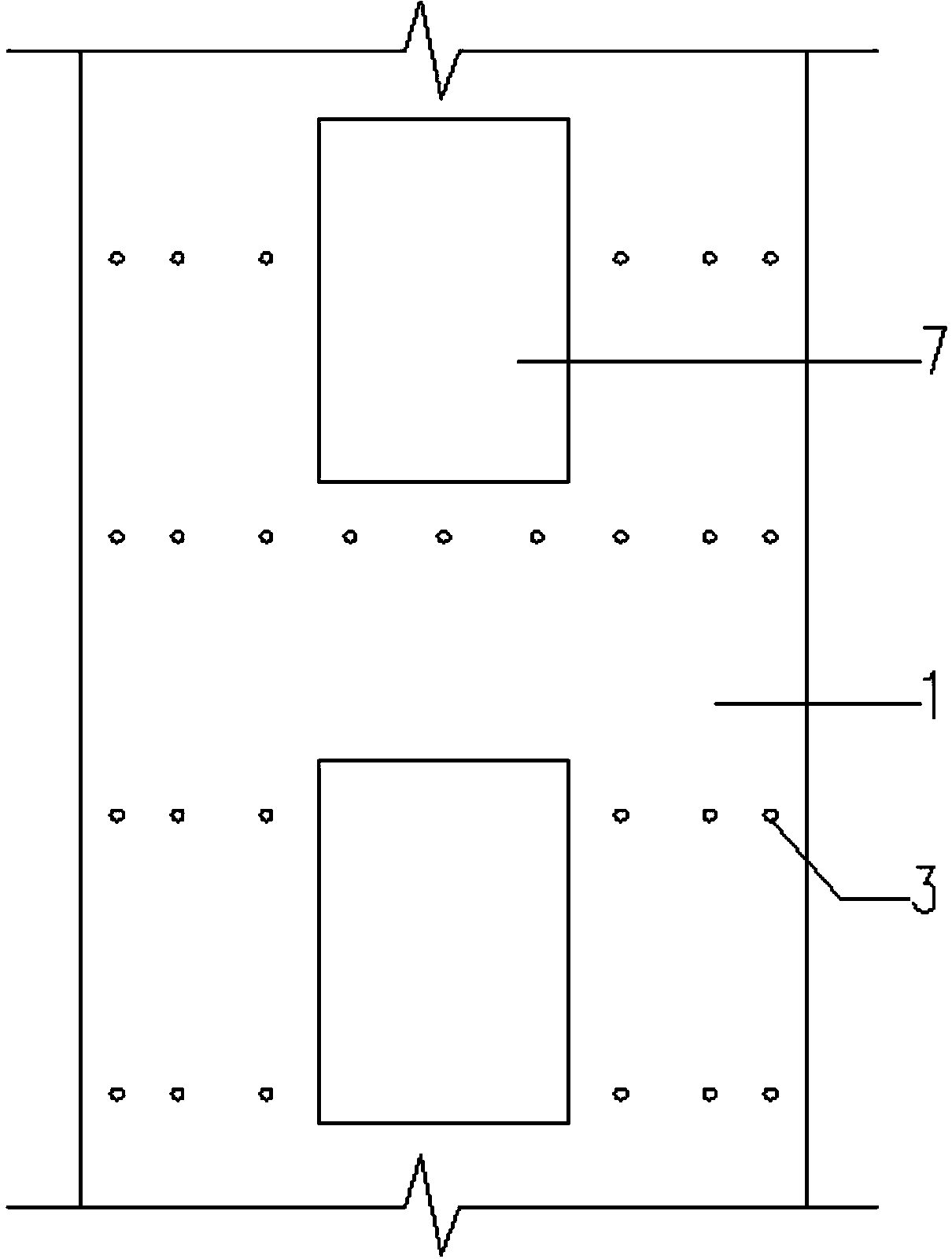

Superimposed fabricated pipe gallery structure system component industrialization construction device and method

InactiveCN108193712AGood lookingReduce usageArtificial islandsUnderwater structuresIntelligent managementRebar

The invention relates to a superimposed fabricated pipe gallery structure system component industrialization construction device and method. The superimposed fabricated pipe gallery structure system component industrialization construction device comprises a production intelligent management system. The superimposed fabricated pipe gallery structure system component industrialization constructionmethod comprises the steps that a, edge formworks are manufactured, pre-buried components are mounted on manufactured steel reinforcement frameworks, and the steel reinforcement frameworks and the edge formworks are subjected to formwork assembly operation on a formwork table; b, by adopting a distribution machine, concrete is poured onto the steel reinforcement frameworks and the edge formworks which are subjected to formwork assembly, and vibrated, and thus concrete components are obtained; c, the concrete components are cured in a curing kiln through steam; d, single sided boards loaded with superimposed-type double-layer boards are superimposed and sent to the curing kiln for secondary curing; e, the components are subjected to formwork release and stored on a component stacking field,and in the storing process, the superimposed-type single-layer boards and the superimposed-type double-layer boards are subjected to water spraying curing through a spraying system; and f, the components are conveyed to a site to be assembled and mounted. According to the superimposed fabricated pipe gallery structure system component industrialization construction device and method, on-site construction is easy, energy saving and environmental friendliness are achieved, long-time exposure of a foundation pit is reduced, the influence of weather on construction is small, and pollution emission and cost are reduced.

Owner:THE 4TH CONSTR ENG CO LTD OF CHINA RAILWAY NO 4 ENG GRP +1

Self-restoration concrete frame column sliding node

ActiveCN107882177AEnough contact areaReduce stiffnessProtective buildings/sheltersShock proofingHigh intensityPyramid

The invention relates to a self-restoration concrete frame column sliding node. The self-restoration concrete frame column sliding node is composed of members of a concrete frame beam column, an upperreset steel plate, a lower reset steel plate, a rubber plate, angle iron, a viscous damper and the like. The column is separated by the reset steel plates at the node, the four sides of the column atthe node are connected with a girder through the angle iron, a long-strip-shaped hole is formed in the angle iron, the angle iron is connected with the concrete frame beam column through a pressure-bearing high-intensity bolt, during normal use, it is guaranteed that the members jointly work as a whole, the size of adjusting holes can control that the column is sideway instead of swinging duringan earthquake, a rectangular pyramid is adopted by the surface occlusion shape of the upper reset steel plate and the lower reset steel plate, when the column is sideway, the contact surface area canstill meet the requirement, the viscous damper is arranged between the angle iron and the girder, thus the energy can be consumed during the earthquake, and the angle iron and the girder can completecolumn restoration with dead weight.

Owner:TONGJI UNIV

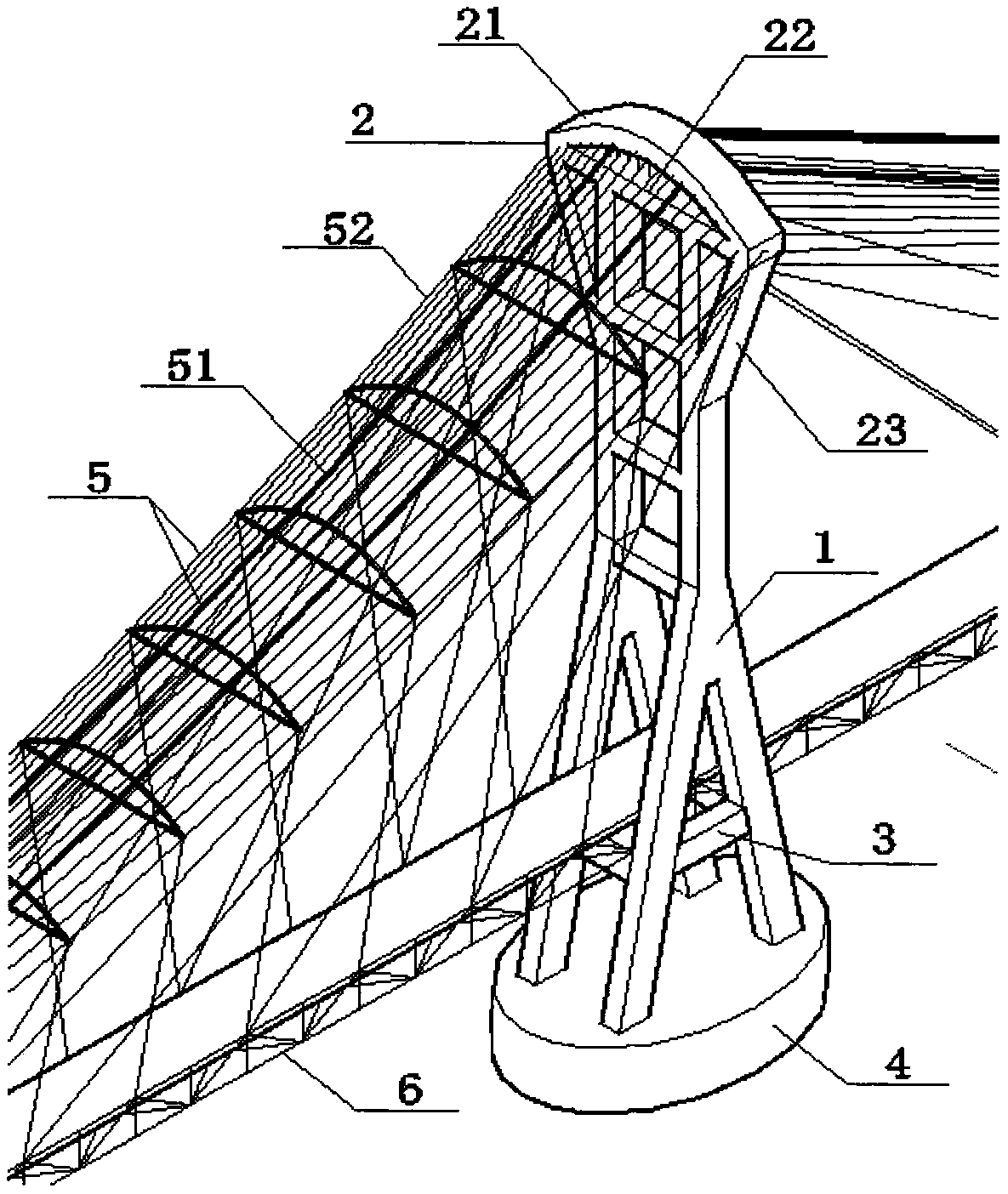

Tube-in-tube bridge tower of space hybrid cable net suspension bridge with parabolic arched tower cap

PendingCN109898415AImprove space rigidityImprove wind stabilitySuspension bridgeBridge structural detailsEarthquake resistanceFiber

The invention provides a tube-in-tube bridge tower of a space hybrid cable net suspension bridge with a parabolic arched tower cap. The tube-in-tube bridge tower of the space hybrid cable net suspension bridge with the parabolic arched tower cap is characterized in that the parabolic arched tower cap with a rigid tie rod is arranged at the top of a tube-in-tube herringbone tower column; one end ofa giant diagonal bracing is anchored to the waist of the tube-in-tube herringbone tower column; the giant diagonal bracing supports the arch foot of the parabolic arched tower cap and forms a racket-like bridge tower structure; a load-bearing steel cable is placed on the tube-in-tube herringbone tower column, and a carbon fiber space cable net is anchored on the parabolic arched tower cap to enhance the spatial stiffness of the suspension bridge and realize the cooperation between two groups of cables; a concrete-filled rectangular steel tube corner column and a grille tubular double-steel concrete composite shear wall are adopted to form a tube structure; the tube-in-tube herringbone tower column comprises an outer tube structure, a core tube structure and multiple rigid diaphragms. Thetube-in-tube bridge tower of the space hybrid cable net suspension bridge with the parabolic arched tower cap has various advantages, such as strong structural rigidity, good wind resistance stability, rich facade modeling, strong earthquake resistance, and capability of being adopted as a bridge tower structure of a space cable net suspension bridge with a super-long span of 4000 meters.

Owner:江苏交通工程咨询监理有限公司

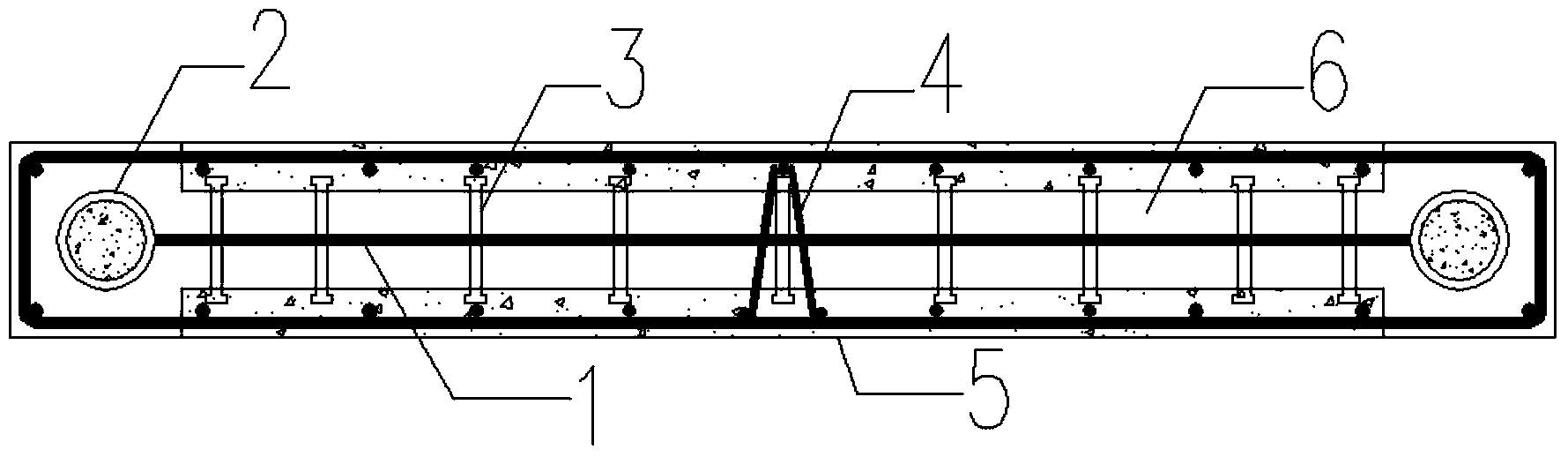

Steel plate prefabricated concrete double-plate shear wall

InactiveCN103397721AGuaranteed performanceImprove collaboration performanceConstruction materialWallsSheet steelSteel bar

The invention discloses a steel plate prefabricated concrete double-plate shear wall. The steel plate prefabricated concrete double-plate shear wall comprises a steel plate, anti-sliding keys, profile steel, prefabricated concrete wall pieces, a cavity and a truss steel rib, wherein the steel plate is placed in the center between the two prefabricated concrete wall pieces, four edges of the steel plate are respectively welded with inner end-post profile steel and an inner steel plate or the profile steel, the anti-sliding keys are arranged on the steel plate, the prefabricated concrete wall pieces and the steel plate are connected into a whole through the truss steel rib and the anti-sliding keys, and concrete is poured into the cavity in the shear wall and the profile steel. The steel plate prefabricated concrete double-plate shear wall is simple in structure, solves the problem that an upper-layer wall body is insufficiently connected with a lower-layer wall body, and strengthens the overall performance of the combining portions of the wall bodies.

Owner:NANJING UNIV OF TECH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com