Steel plate prefabricated concrete double-plate shear wall

A technology of prefabricated concrete and shear walls, applied in the direction of walls, building materials, building components, etc., can solve the problems of complex construction of edge components, prolonging the construction period, and deviation, so as to improve the ability of cooperative work, ensure the seismic performance, and ensure the overall performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

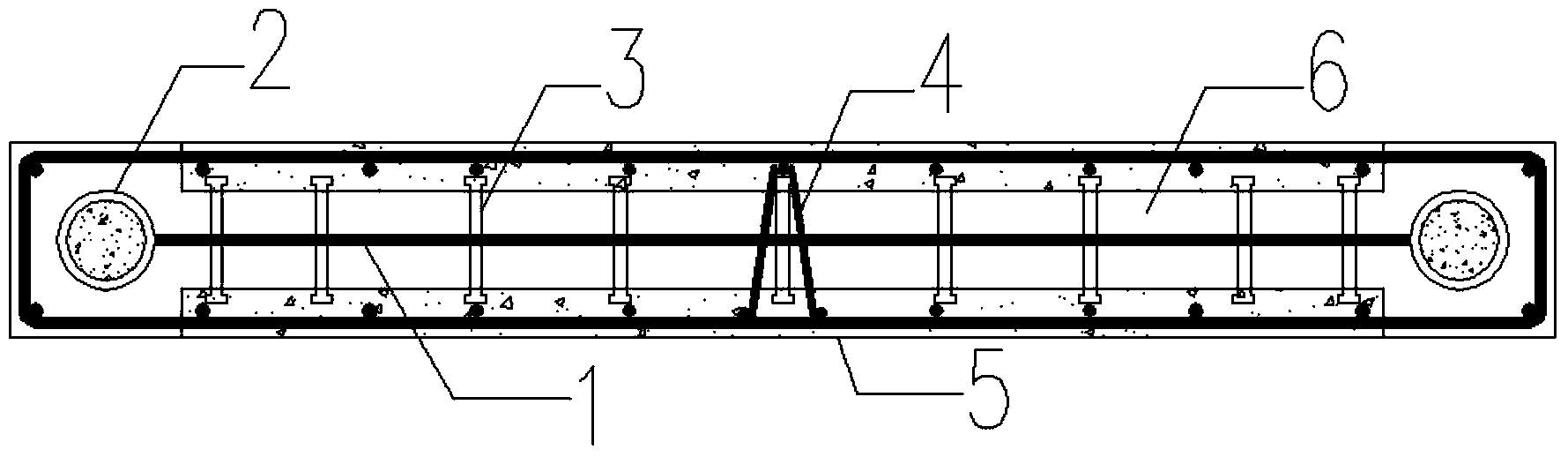

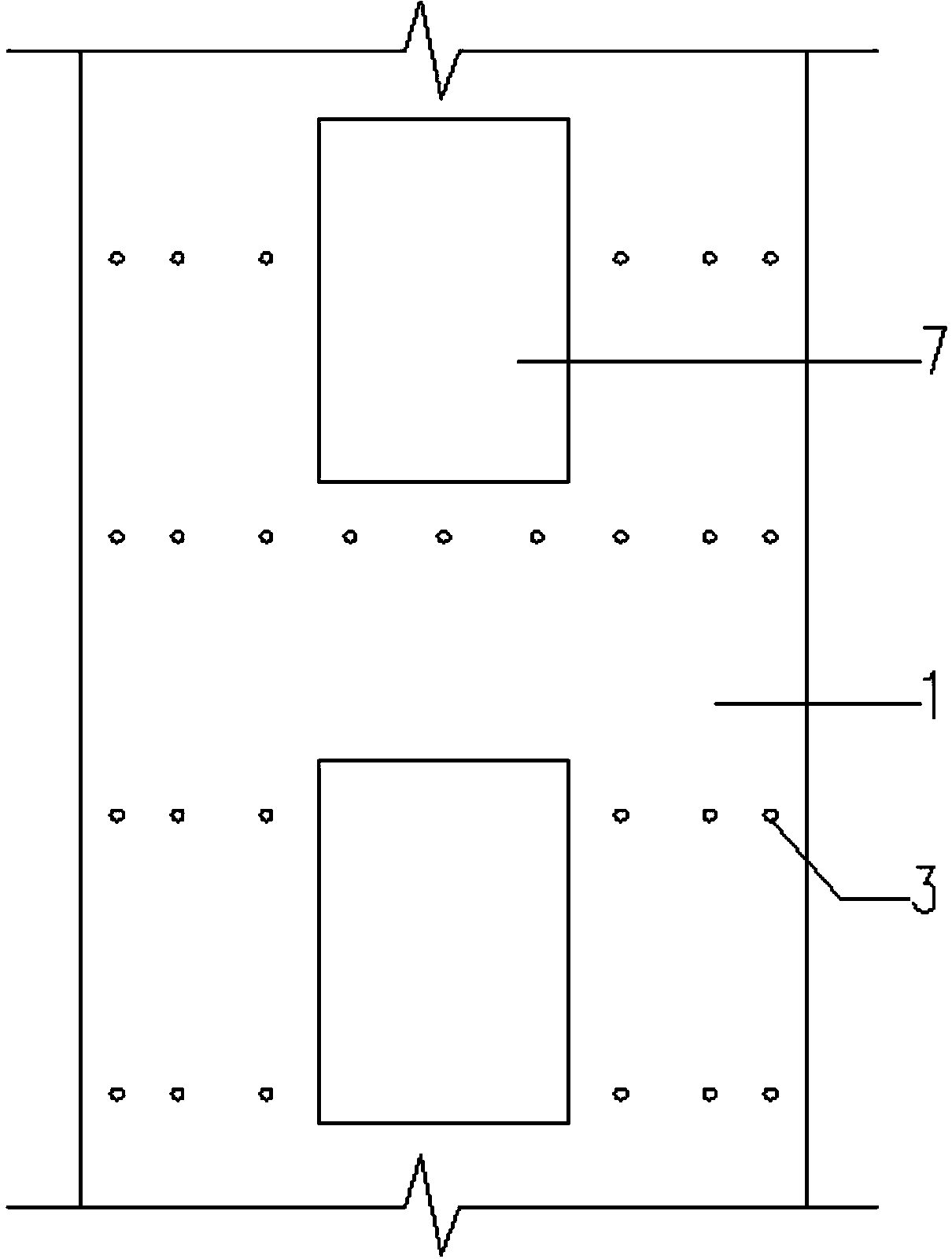

[0019] Such as figure 1 and 2 As shown, the prefabricated concrete wall pieces 5 on both sides are connected to the steel plate 1 as a whole through the truss steel bar 4 and the shear key 3 welded on the steel plate 1 . The size of the steel plate 1 is greater than that of the prefabricated concrete wall piece 5, and all extend out of the prefabricated concrete wall piece 5, which is convenient for welding during hoisting. A hole 7 is provided on the surface of the steel plate 1, which can enhance the bond between the steel plate and concrete, and reduce the amount of steel used. The section steel 2 has been completed at the same time as the lower structure on site, and the edge components of the wall are molded on site and the cavity 6 is cast-in-situ. After the wall is in place, the steel plate 1 is welded with the steel plate or section ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com