Prestressed prefabricated ECC-RC combination beam column joint component

A technology of beam-column joints and prestressing, which is applied in building construction, climate change adaptation, construction, etc., can solve problems such as low tensile strength, high repair costs after earthquakes, interface splitting and tensile failure, etc., and achieve shear bearing capacity Improvement of anti-seismic performance, reduction of construction difficulty and labor cost, improvement of deformation and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

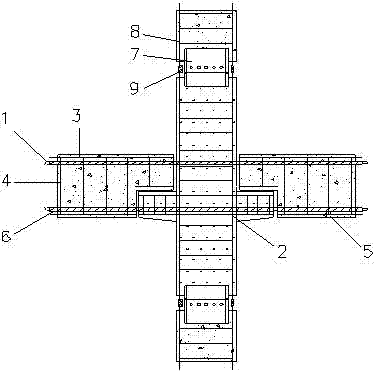

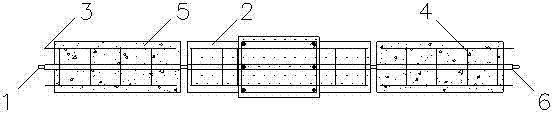

[0028] The prestressed prefabricated ECC-RC composite node component of the present invention includes a prestressed tendon 1, a node 2 with a corbel, and the node with a corbel is composed of ECC material, a longitudinal reinforcement 3 and a stirrup 4, and the node with a corbel Including outhanging columns with a length of about 1 to 2 times the height of the column section.

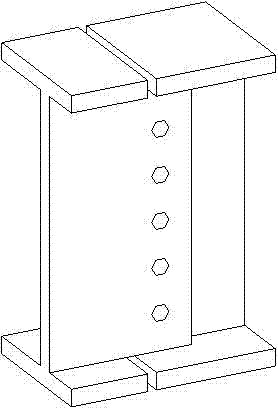

[0029] The node and the prefabricated RC beam 5 connected to it need to reserve a tunnel 6, and the prefabricated ECC-RC node 2 is connected with the prefabricated RC beam 5 through the post-tensioned prestressing bar 1 passing through the reserved tunnel 6, and the extension column ends and Prefabricated RC column 8 end is pre-embedded with I-beam 7, pre-embedded depth and external elongation are 10cm~15cm, and the external elongation of longitudinal reinforcement at both column ends is 10cm~15cm, section steel embedded part is welded with longitudinal reinforcement, prefabricated RC column 8 and The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com