Fabricated self-resetting prestressed concrete frame friction energy dissipation node

A frictional energy consumption and self-resetting technology, applied in protective buildings/shelters, building components, earthquake resistance, etc., can solve problems such as poor energy consumption capacity, improve energy consumption capacity, reduce residual deformation, and reduce environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

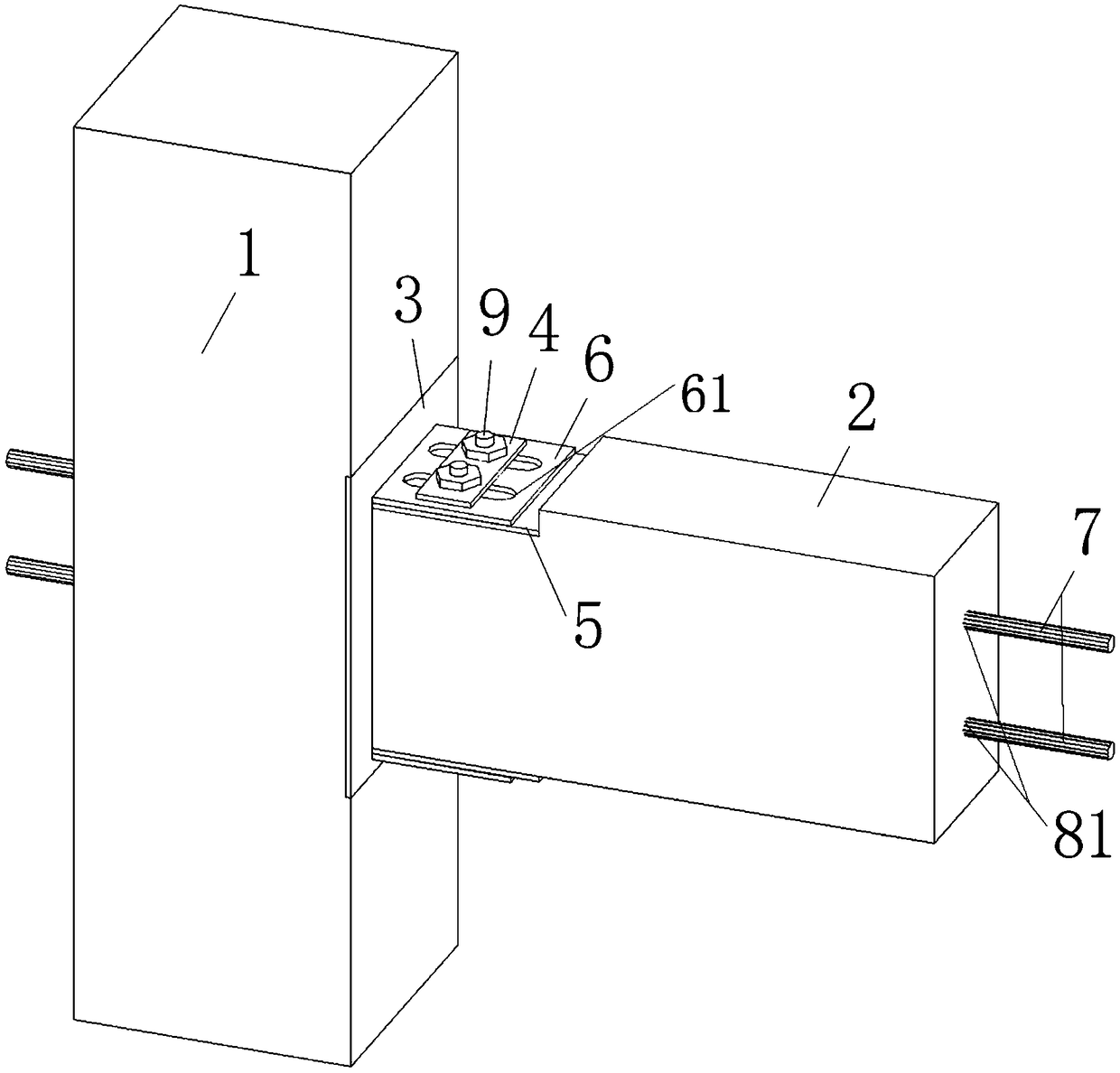

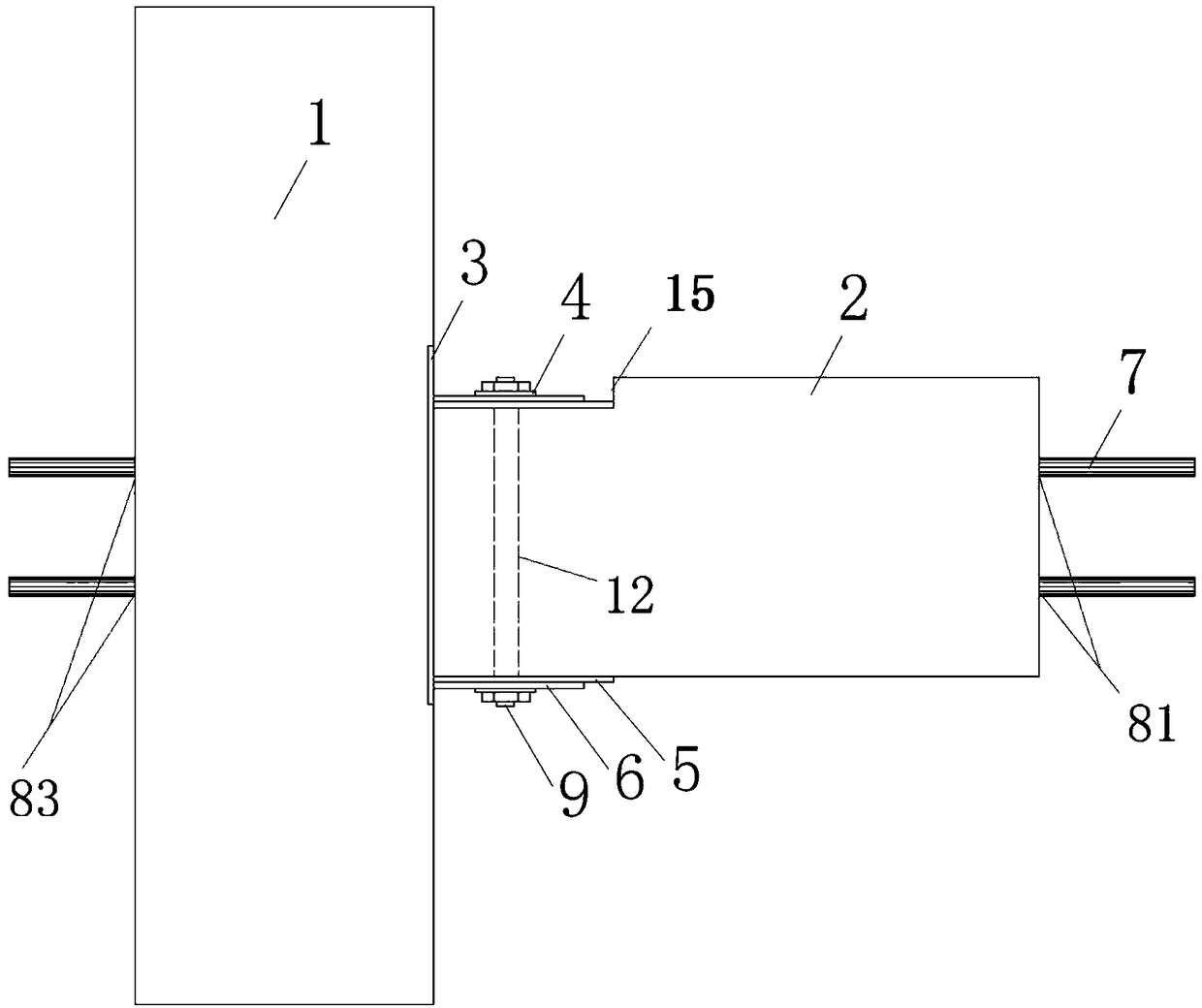

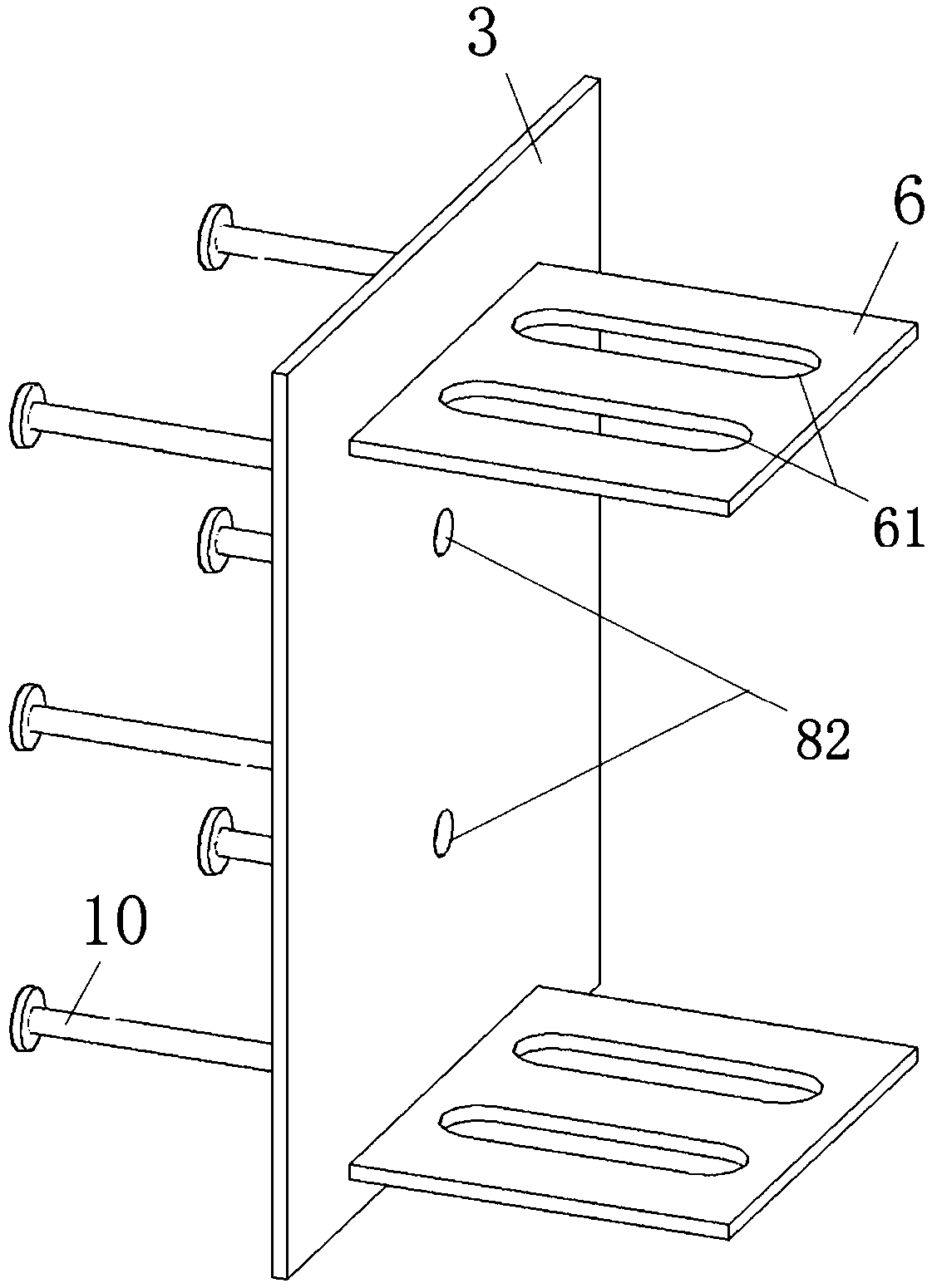

[0028] like Figure 1-Figure 6As shown, the assembled self-resetting prestressed concrete frame friction energy dissipation node of the present invention is characterized in that it includes a prefabricated reinforced concrete column 1, a prefabricated reinforced concrete beam 2, a pre-embedded steel plate 3 at the end of the column, and an unbonded prestressed steel strand Line 7, the first prestressed steel strand channel 81, the second prestressed steel strand channel 82, the third prestressed steel strand channel 83, the friction energy dissipation device 13; the friction energy dissipation device 13 includes the friction plate 4 , the pre-embedded steel plate 5 at the beam end, the friction track steel plate 6, and the high-strength bolt 9; The pre-embedded steel plate 5 is provided with a bolt port 51 and is welded with a shear stud 11; the prefabricated reinforced concrete beam 2 includes a bolt tunnel 12, a shear stud hole 14 and a first prestressed steel strand tunnel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com