Patents

Literature

39results about How to "Reduce weakening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Precast concrete beam and square-rectangular concrete-filled steel tube column combining joint employing unbonded prestressed and ordinary reinforcement for connection

ActiveCN103924680AGuaranteed reliabilityReduce weakening effectBuilding constructionsSheet steelReinforced concrete

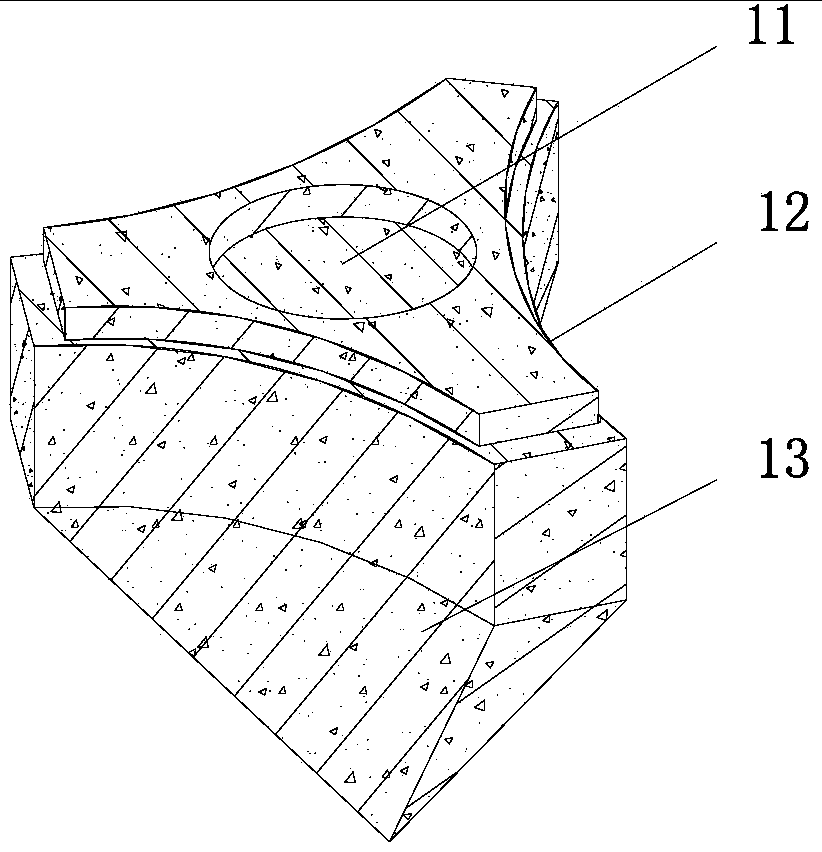

The invention relates to a precast concrete beam and square-rectangular concrete-filled steel tube column combining joint employing unbonded prestressed and ordinary reinforcement for connection and belongs to the technical field of building structures. The precast concrete beam and square-rectangular concrete-filled steel tube column combining joint employing unbonded prestressed and ordinary reinforcement for connection comprises a square-rectangular concrete-filled steel tube column, a reinforced concrete beam, prestressed bars, steel plates, and steel channels. Both the square-rectangular concrete-filled steel tube column and the reinforced concrete beam are precast. The parts, corresponding to the beam section, of the square-rectangular concrete-filled steel tube column and the precast reinforced concrete beam are provided with ducts in which metal bellows are embedded. The steel plates are welded at the connection sections of the square-rectangular concrete-filled steel tube column and the reinforced concrete beam. The steel channels are welded on the square-rectangular concrete-filled steel tube column. Ordinary rebars and unbonded prestressed rebars are passed through the metal bellows, and the prestressed rebars are tensioned so that the beam and the column are integrated. The precast concrete beam and square-rectangular concrete-filled steel tube column combining joint employing unbonded prestressed and ordinary reinforcement for connection has the advantages that construction speed is high, the field welding process is not required, joint connection reliability is guaranteed, seismic performance is good, and the joint has promising application prospect.

Owner:宝嘉智能科技(南通)有限公司

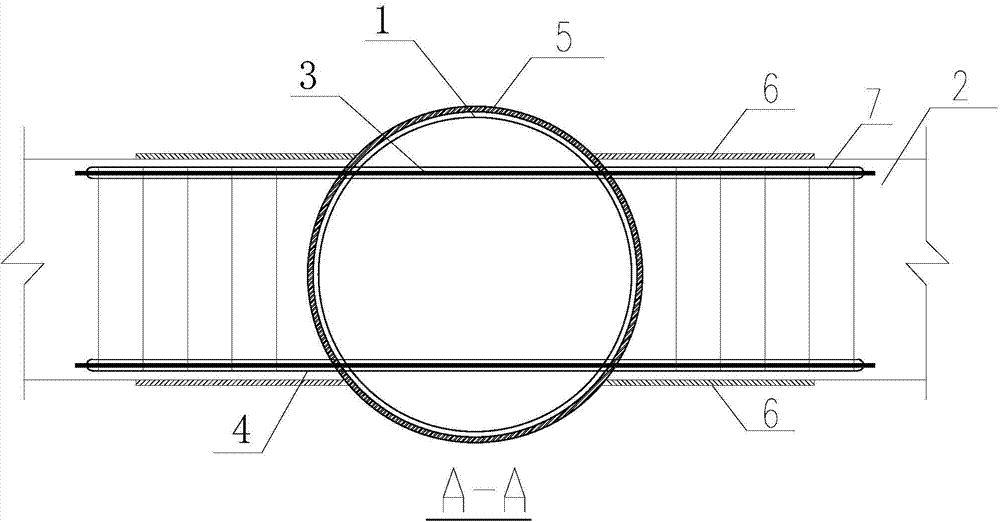

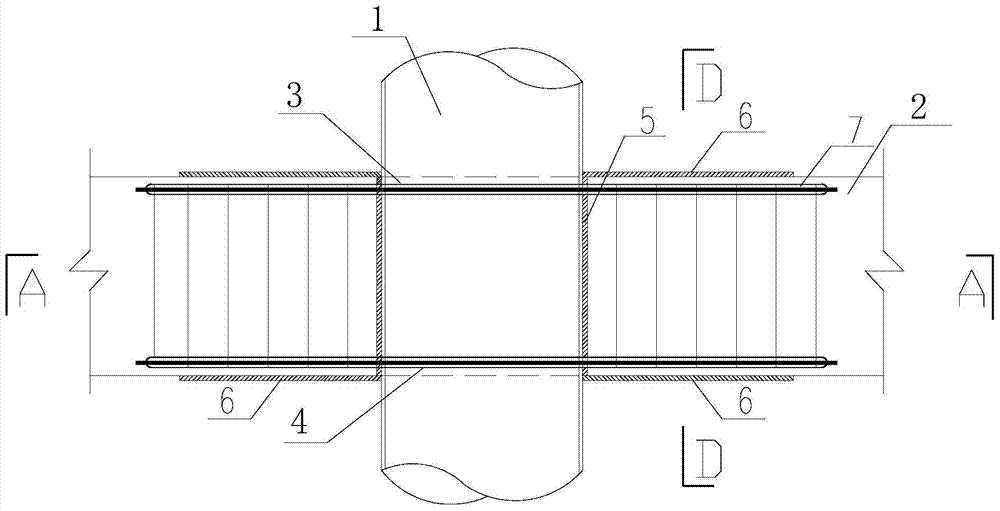

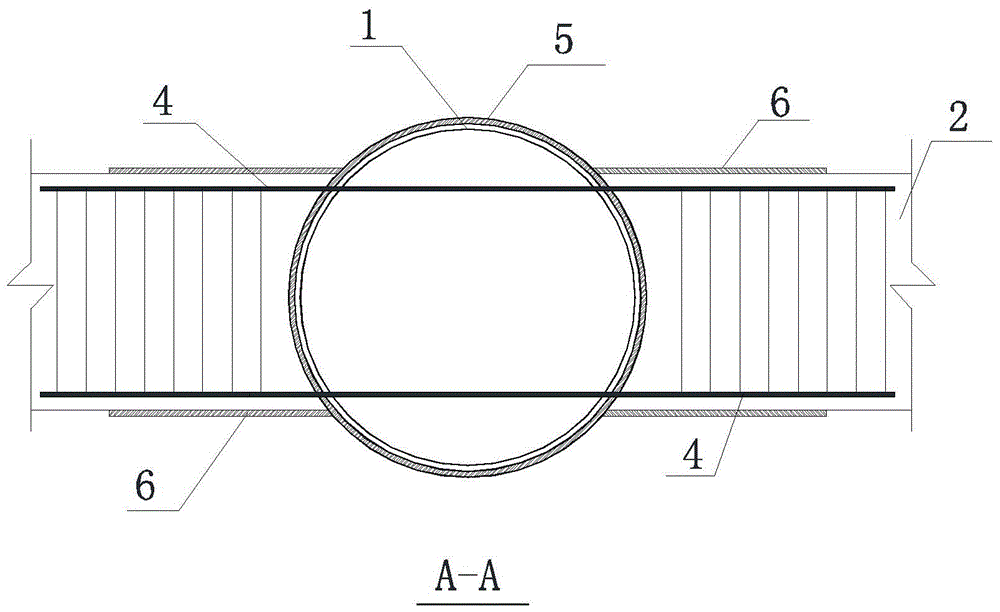

Prestressed concrete beam and circular steel pipe concrete column combined joint connected with regular rebars

InactiveCN103924679AGuaranteed reliabilityReduce weakening effectBuilding constructionsPrestressed concrete beamPre stress

The invention discloses a prestressed concrete beam and circular steel pipe concrete column combined joint connected with regular rebars and belongs to the technical field of building structures. A steel pipe concrete column and a reinforced concrete beam are cast in situ and are connected with the regular rebars through prestressed tendons, a runner is reserved at the connected position of the circular steel pipe concrete column and the reinforced concrete beam, metal bellows are buried in the runner, the prestressed tendons are inserted into the metal bellows and then grouted, a ring plate is welded at the connected position of the circular steel pipe concrete column and the concrete beam and provided with corresponding holes, and the groove steel is welded on a circular steel pipe. The prestressed concrete beam and circular steel pipe concrete column combined joint is fast in construction and wide in application prospect, and shear resistance of the combined joint is effectively improved, and connecting performance of the same is improved.

Owner:BEIJING UNIV OF TECH

Prestressed connecting joint for concrete beam and circular steel pipe concrete column

InactiveCN103924676AGuaranteed reliabilityReduce weakening effectBuilding constructionsConcrete beamsPre stress

The invention discloses a prestressed connecting joint for a concrete beam and a circular steel pipe concrete column and belongs to the technical field of building structure. The prestressed connecting joint comprises a circular steel pipe concrete column, a reinforced concrete beam, a prestressed tendon, a ring plate and channel steel. The circular steel pipe concrete column and the reinforced concrete beam are cast in situ and are connected by the prestressed tendon, a runner is reserved at the connected position of the circular steel pipe concrete column and the reinforced concrete beam, and metal bellows are buried in the runner. The ring plate is welded at the connected position of the circular steel pipe concrete column and the reinforced concrete beam and is provided with corresponding holes. The channel steel is welded on a circular steel pipe. The prestressed connecting joint for the concrete beam and the circular steel pipe concrete column is fast in construction and wide in application range, and shear resistance of the connecting joint is effectively improved, and connecting performance is improved.

Owner:BEIJING UNIV OF TECH

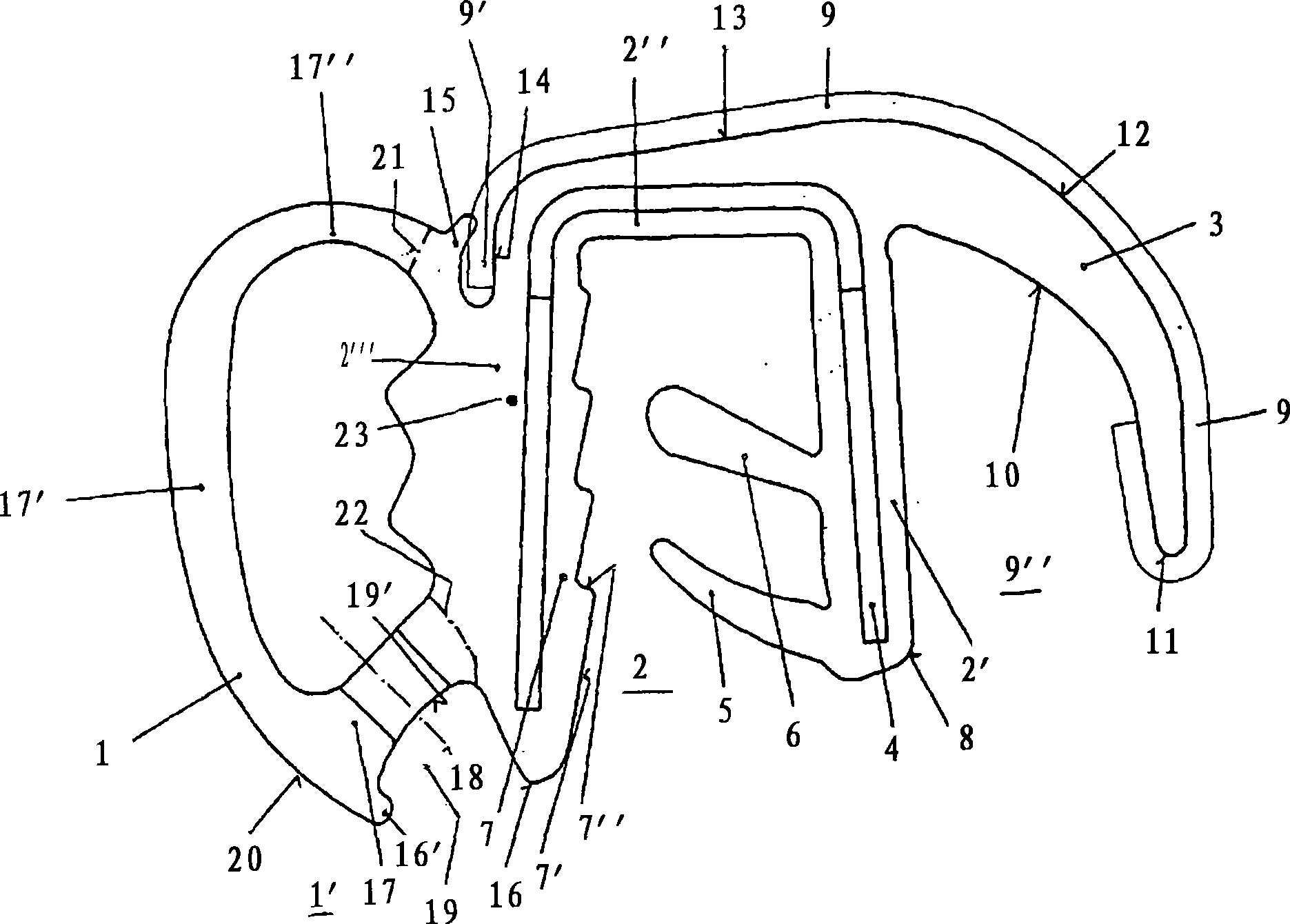

Weatherstrip with ventilation openings

InactiveCN101198486AStability impactSufficient elastic deformabilityEngine sealsVehicle sealing arrangementsEngineeringVisual appearance

The invention relates to a weatherstrip, which is to be placed onto the flange of the edge of the opening of a vehicle and which is made of a side-by-side arrangement of a tubular sealing section (1), of a U-shaped fastening section (2) and of a strip (3), which is shaped onto the side of the fastening section (2) and which, together with a limb (2') of the fastening section (2), circumscribes a cavity (9 ) open toward the underside (1') of the weatherstrip. The cross-sectional profile of the sealing section (1) is partially formed by the limb (2''') of the fastening section (2) facing the former. Ventilation holes (18) are located on the underside of the weatherstrip, which faces said edge and which forms an area of the greatest wall thickness of the sealing section (1). This arrangement of the ventilation opening is advantageous in that this results in almost no negative influence upon the flexural rigidity of the cross-sectional profile so that the weatherstrip can also be placed along small radii of curvature without the risk of the profile collapsing. To this end, the ventilation openings are located on an underside facing the edge without having any negative influence upon the visual appearance.

Owner:贝德杰流星橡胶材料合成树脂有限公司及两合公司

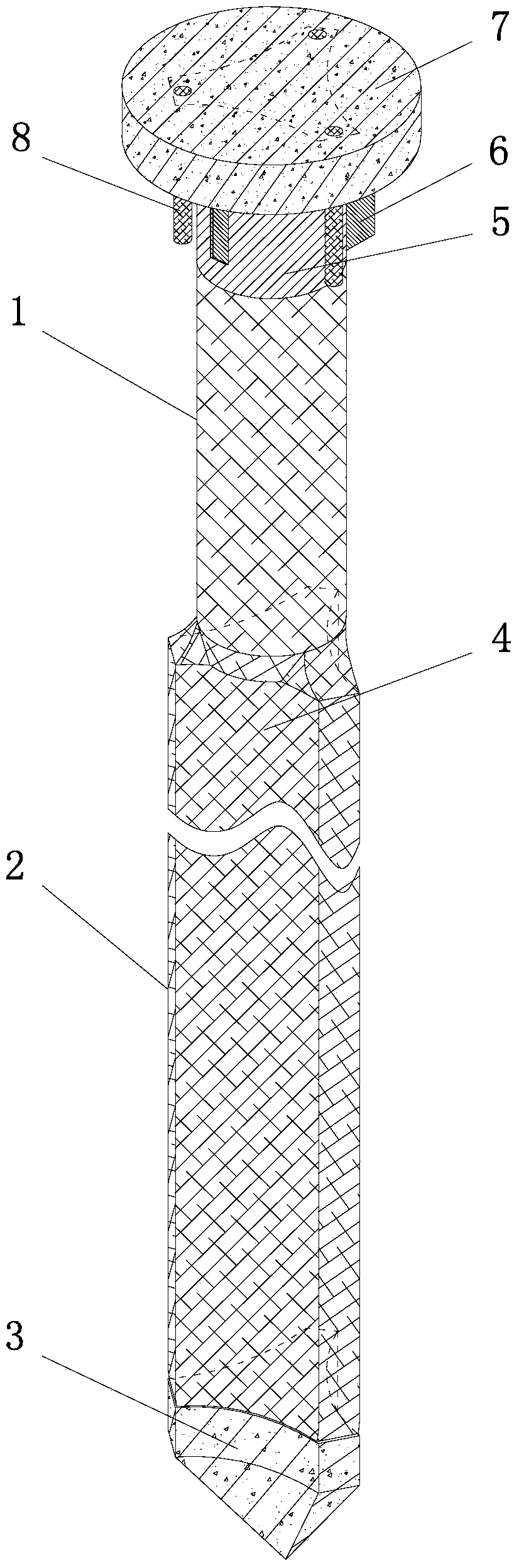

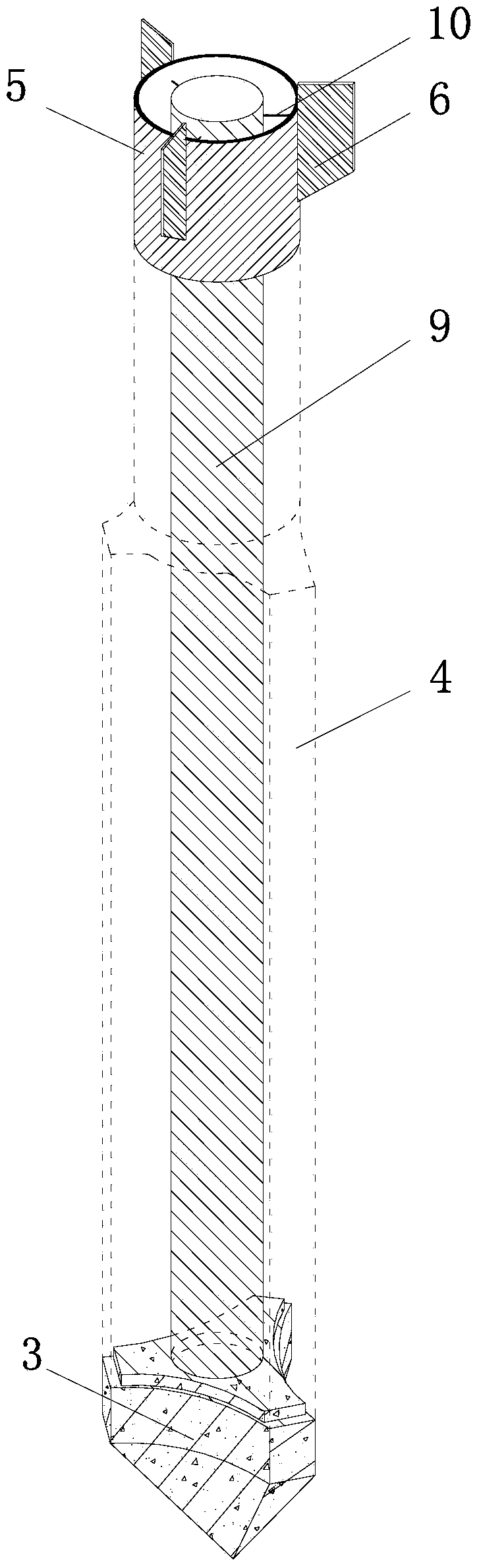

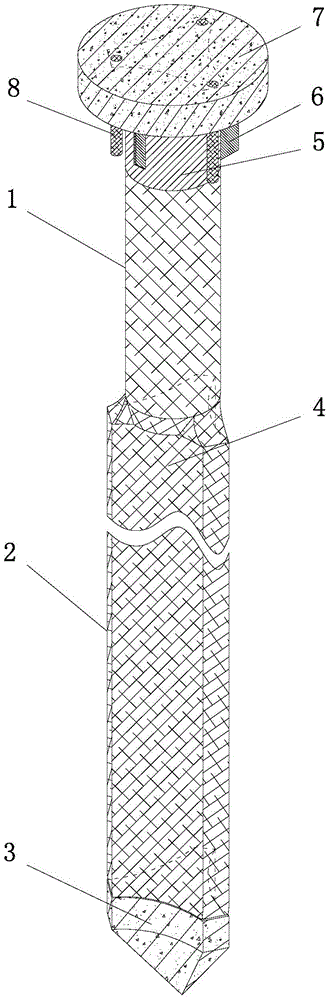

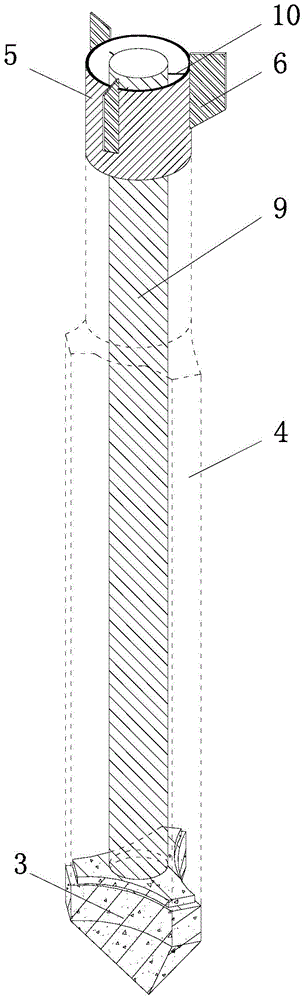

Carbon fiber cloth bag cast-in-situ anti-arch curved surface combined irregular-shaped pile and construction method thereof

InactiveCN103741682AReduce pile side squeeze effectAccelerate soil consolidationBulkheads/pilesGeotechnical engineeringStructural engineering

The invention relates to a carbon fiber cloth bag cast-in-situ anti-arch curved surface combined irregular-shaped pile, which is characterized in that the upper part of the combined irregular-shaped pile is a round pile body while the lower part thereof is an anti-arch curved surface pile body, and the pile bottom is provided with an irregular-shaped prefabricated pile tip. A carbon fiber cloth bag wraps the outside of the pile body; a steel sleeve with a reinforcing plate is arranged on the top part of the combined irregular-shaped pile; a vertical drain body is filled in the cavity at the outer side of the round pile body; a vertical drain pipe communicated with the vertical drain body is preset in a cast-in-situ cover plate on the top part of the pile. The carbon fiber cloth bag arranged on the outer side of the pile body can reinforce the pile body, improve the stress performance of the pile body and enhance the integrity of the pile body; the section of the pile body on the lower part is an anti-arch curved surface which can prevent influence from excessive fullness of concrete of the pile body to the lateral friction of the pile; the section of the pile body on the upper part is round and can reduce the influence from the lateral negative friction of the pile to the performance of the pile body. The invention also discloses a construction method of the combined irregular-shaped pile.

Owner:JIANGSU ZHONGRUI ROAD & BRIDGE CONSTR

Water plugging method suitable for shallow earth surface large-open-degree fractured rock mass roadway

InactiveCN110593807AReduce weakeningHigh strengthUnderground chambersSealing/packingWater diversionGeomorphology

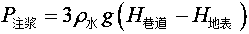

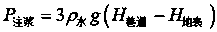

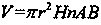

The invention belongs to the technical field of roadway water plugging and discloses a water plugging method suitable for a shallow earth surface large-open-degree fractured rock mass roadway. In order to solve problems existing in roadway water plugging modes in the prior art, the water plugging method comprises grain size selection of dry soybeans, grouting material preparation and matching, determination of grouting parameters, roadway drilling, grouting and other steps. According to the water plugging method, with the good physical property of water absorption expansion, the dry soybeans serve as coarse aggregate for water plugging to plug a large-open-degree fractured rock mass water diversion channel. Under the action of water flow of the water diversion channel, mud, calcium, rock debris and other filings put in fractures in a fractured rock mass are dissolved and flow out of the rock mass along with seepage water, meanwhile the fillings are combined with cement-sodium silicategrouting materials, the quick reaction capability and forming of a large amount of silica gel are utilized, the materials and the soybean coarse aggregate form a concrete-like structure, coarse and fine aggregate are matched, and a fast water stop effect is achieved on the large-open-degree fractured rock mass roadway in a shallow earth surface water-rich area.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

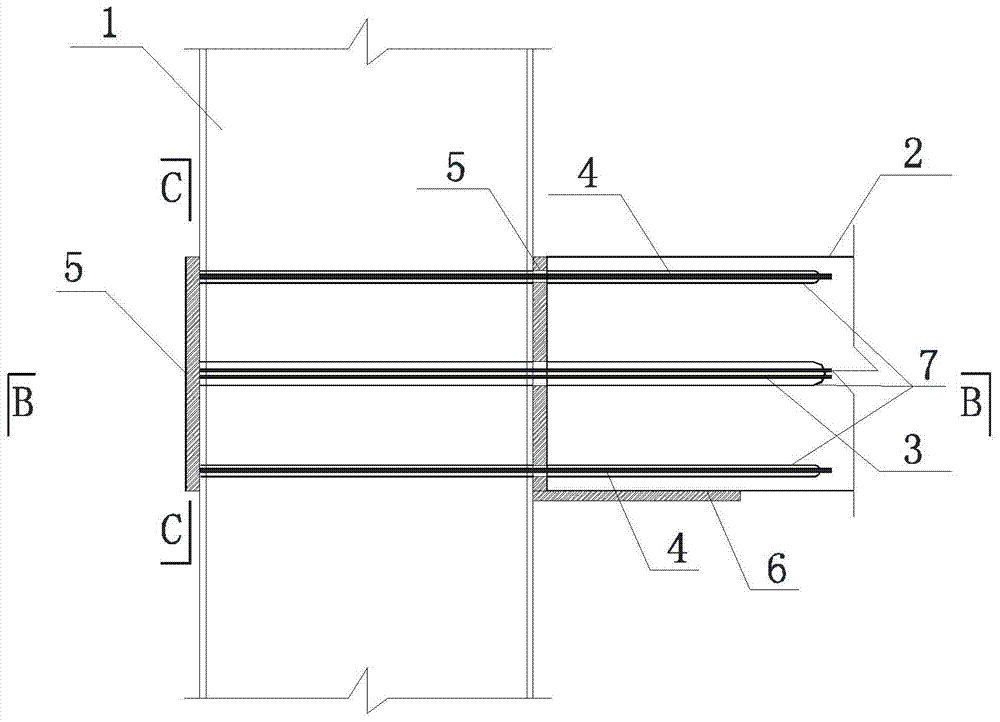

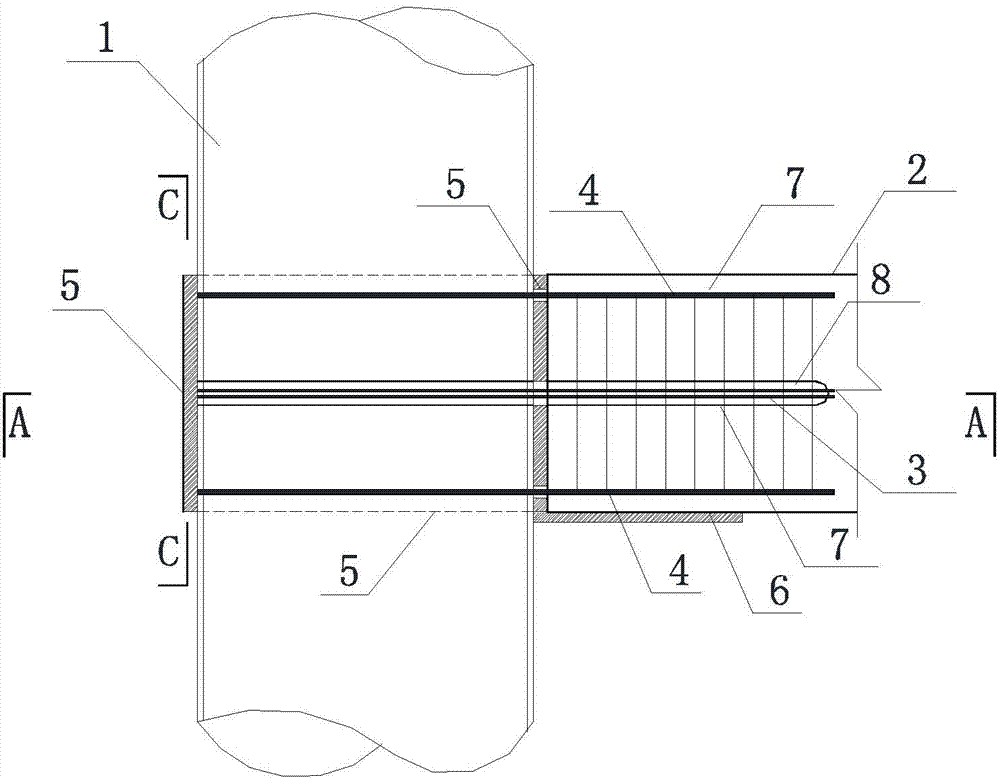

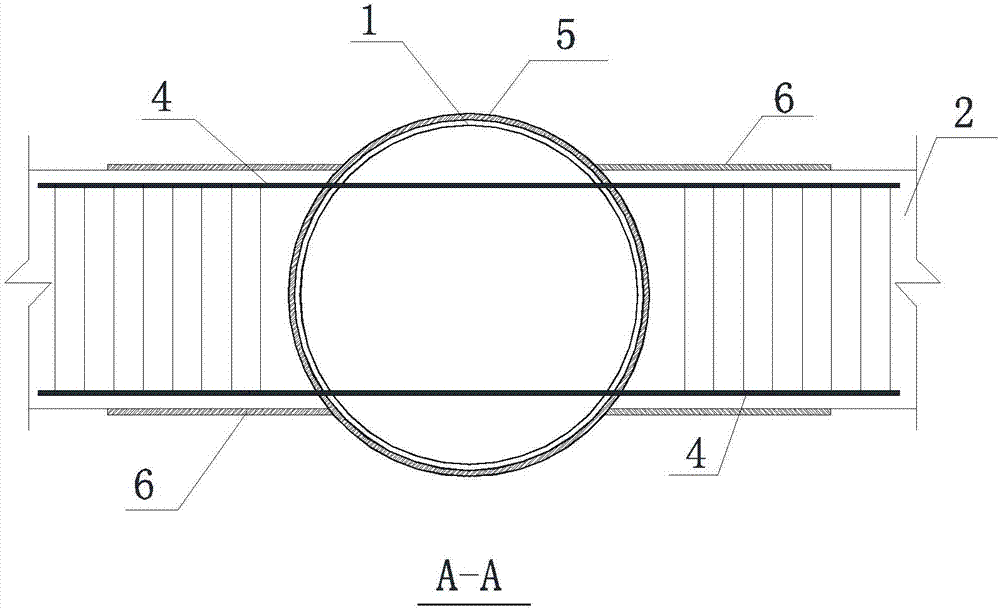

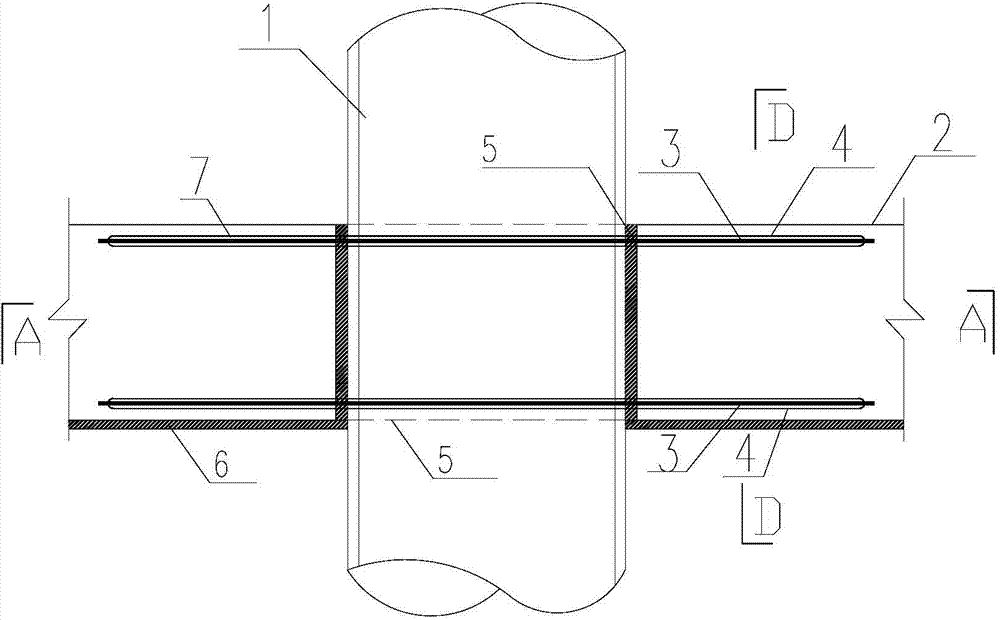

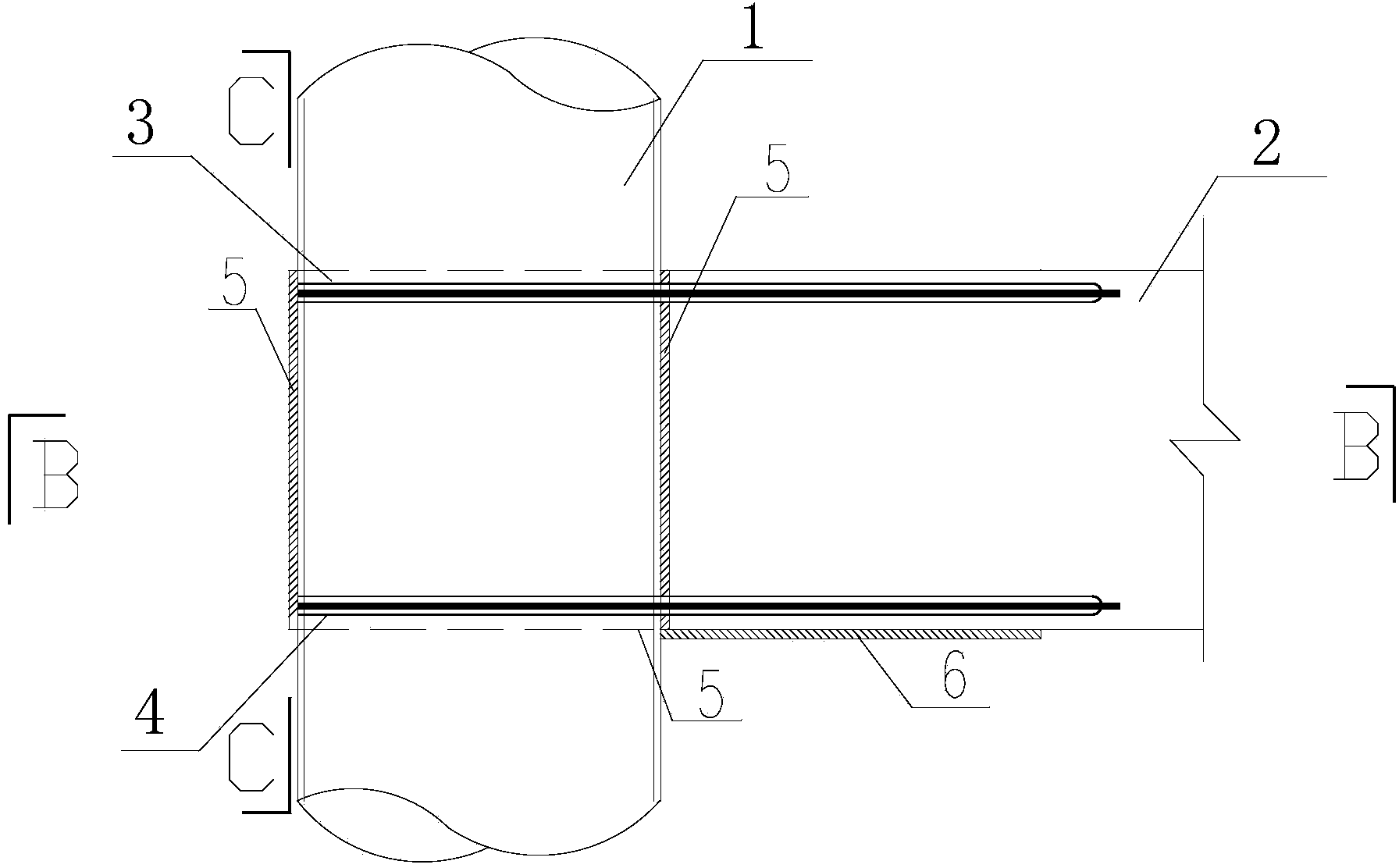

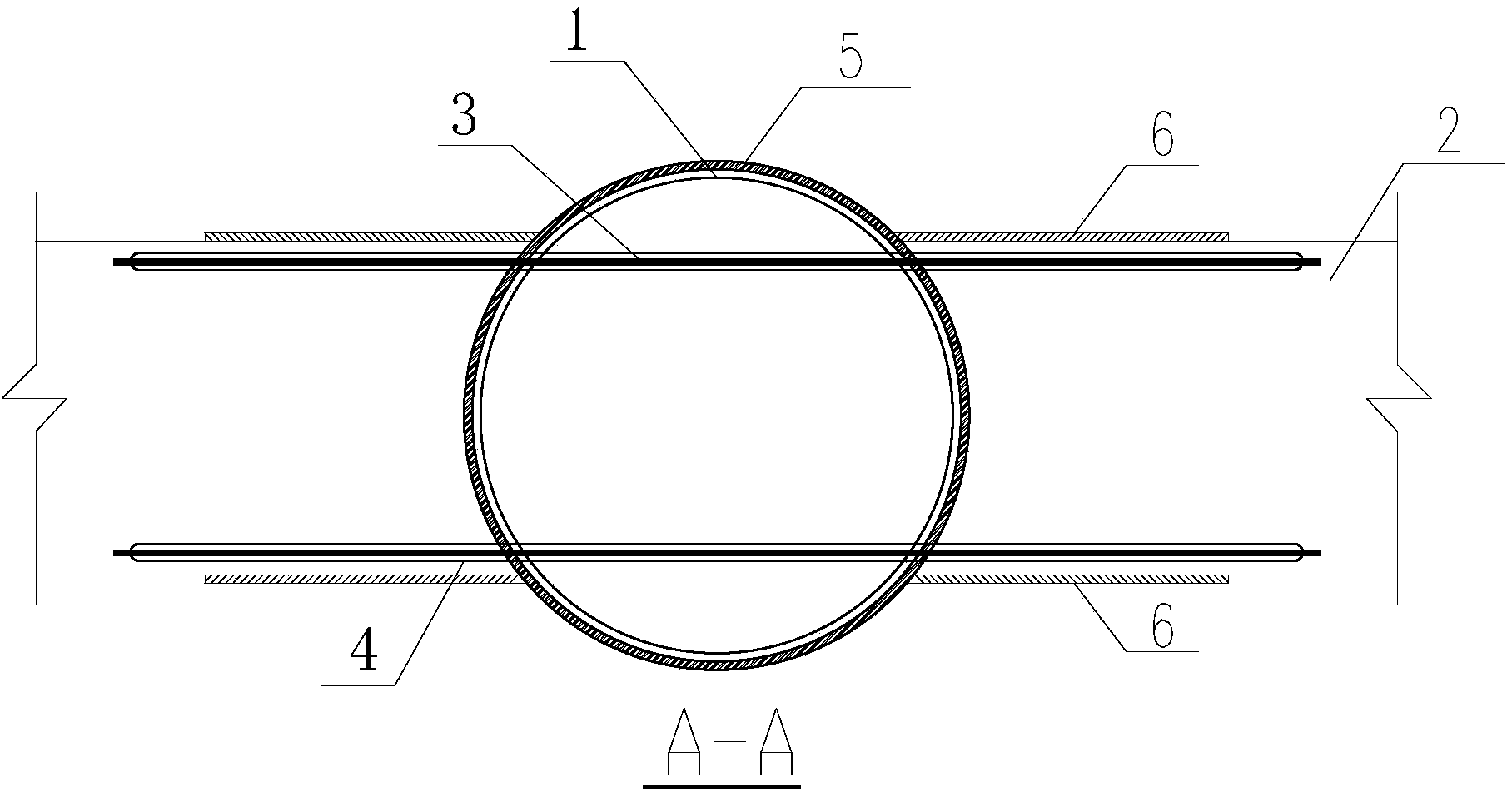

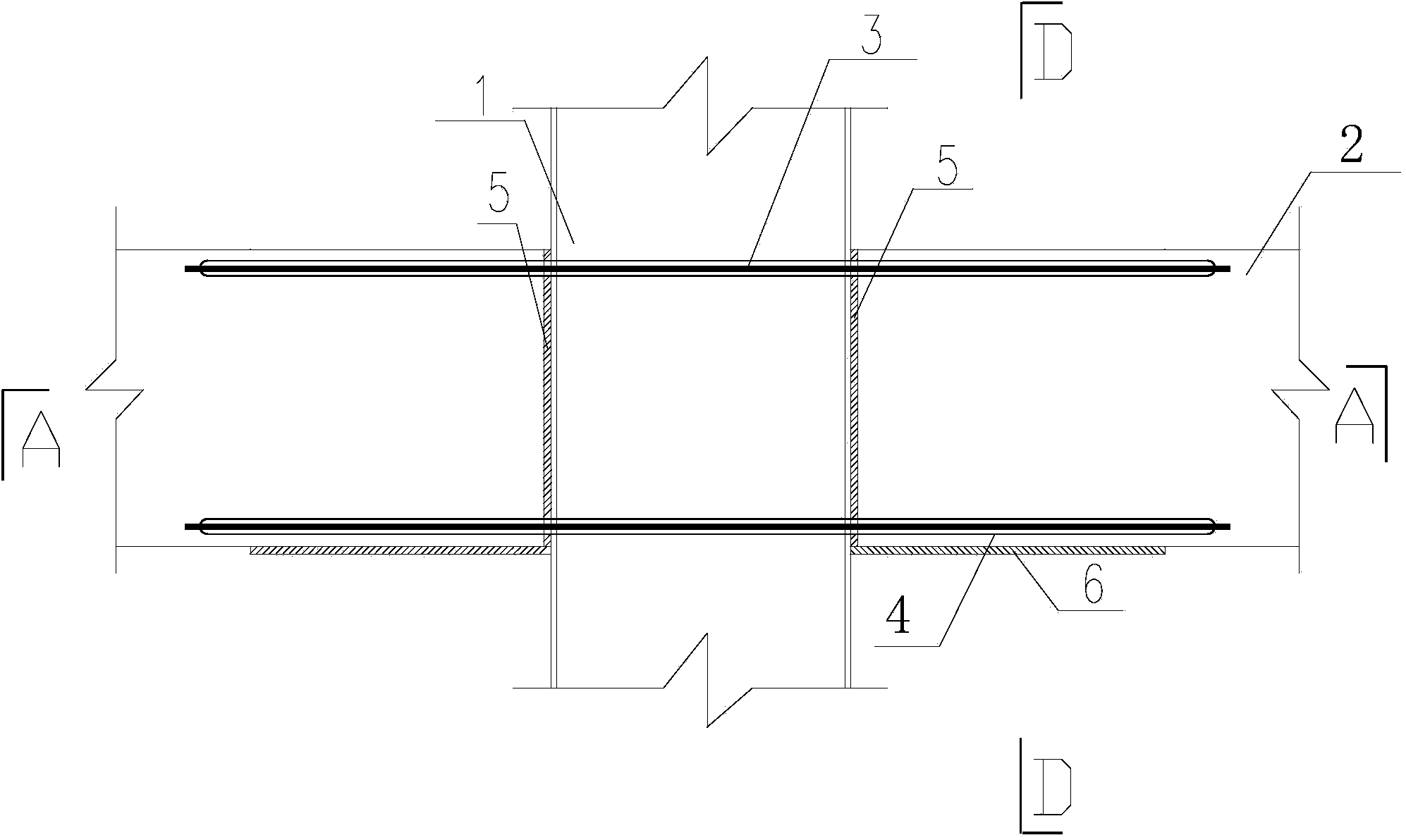

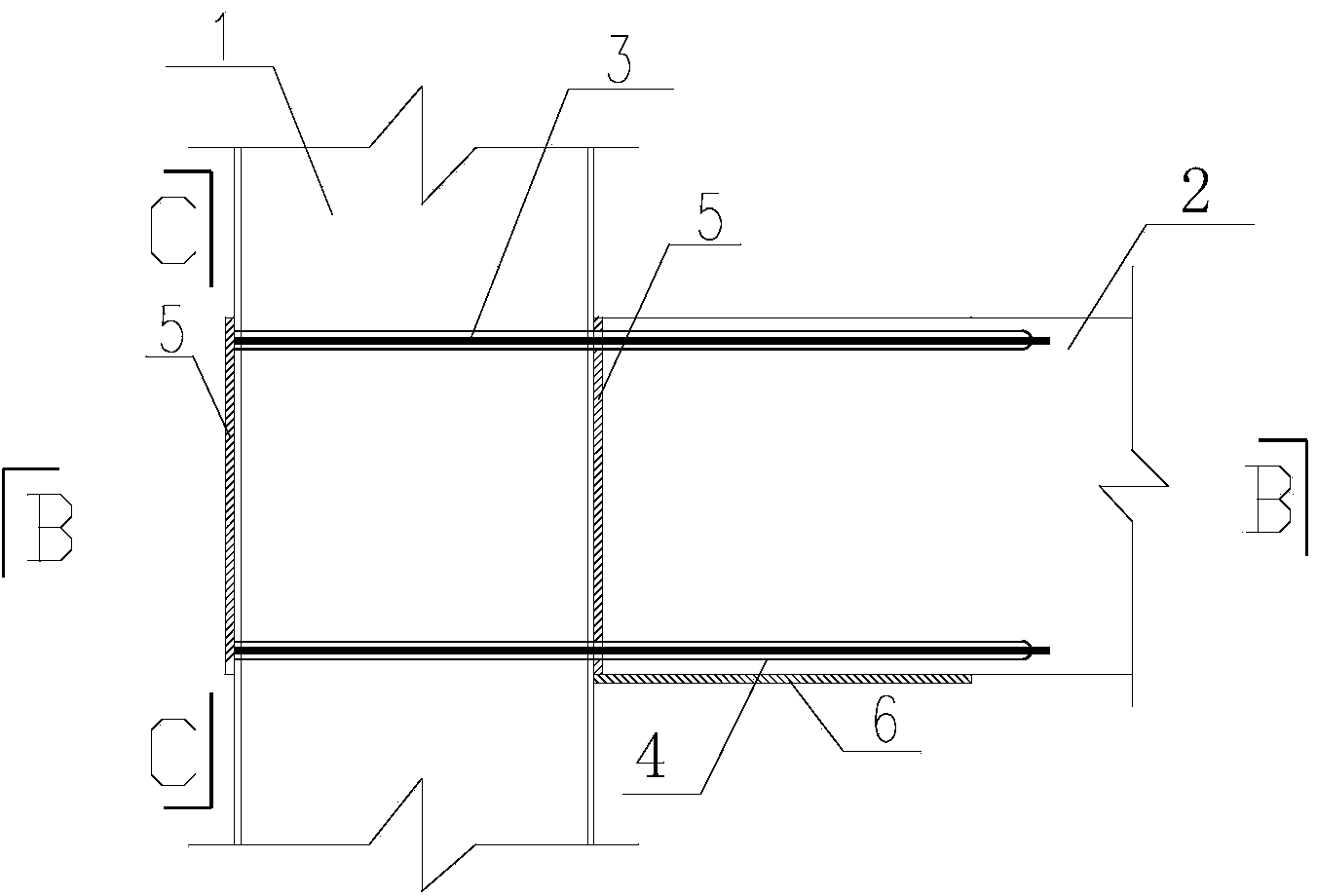

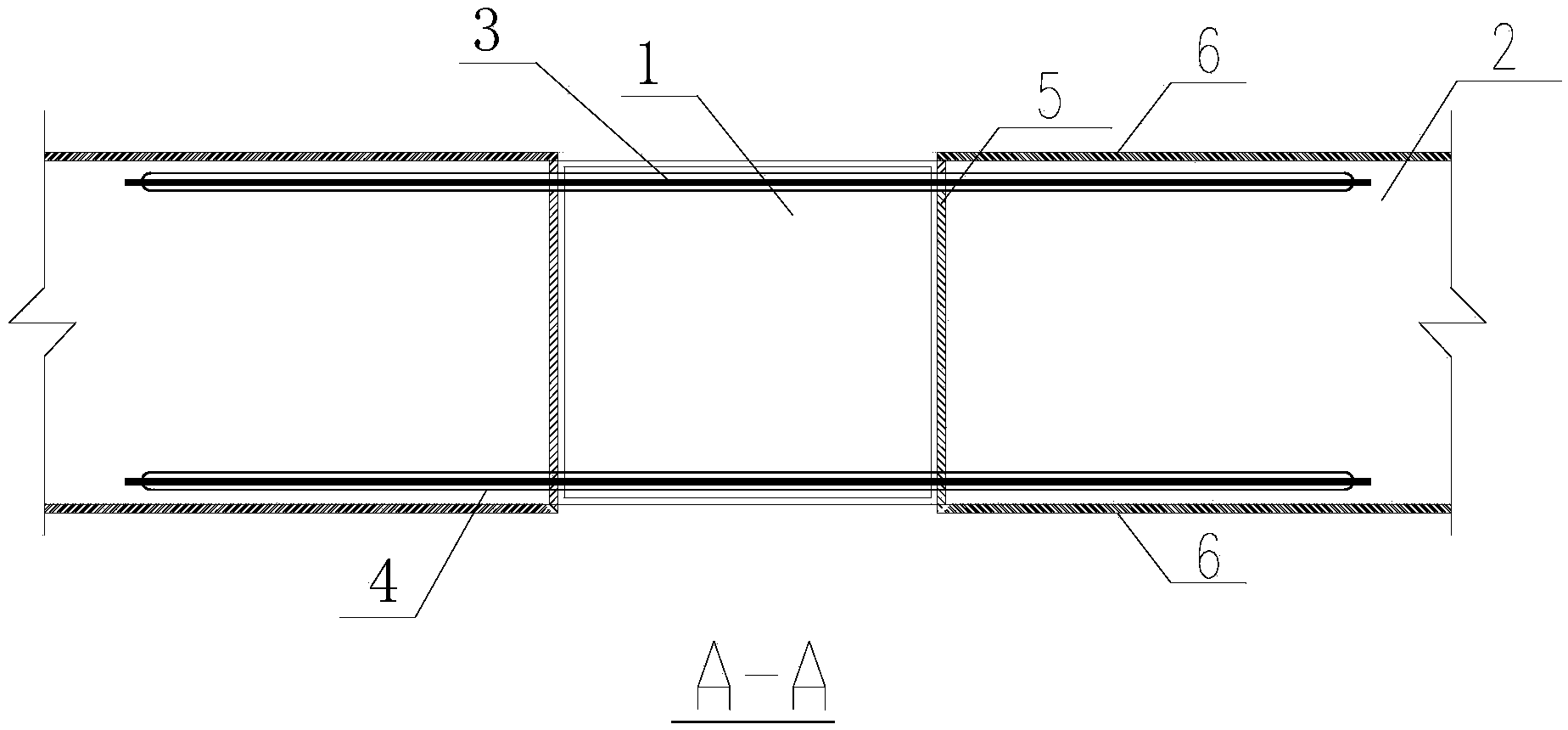

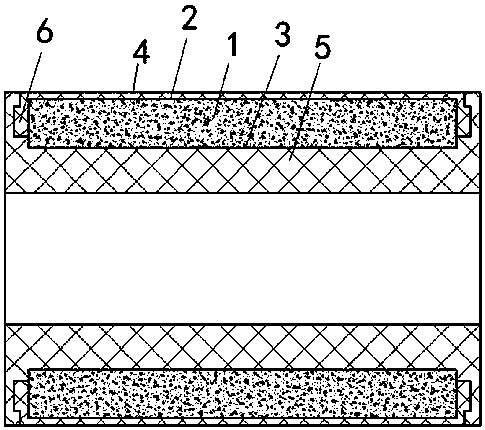

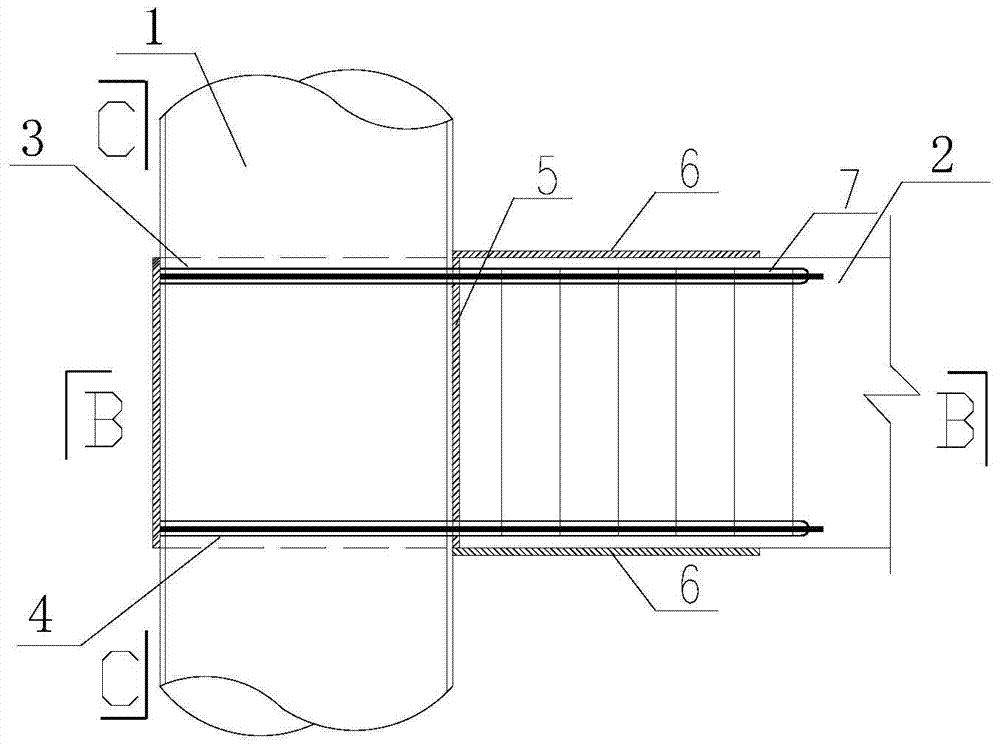

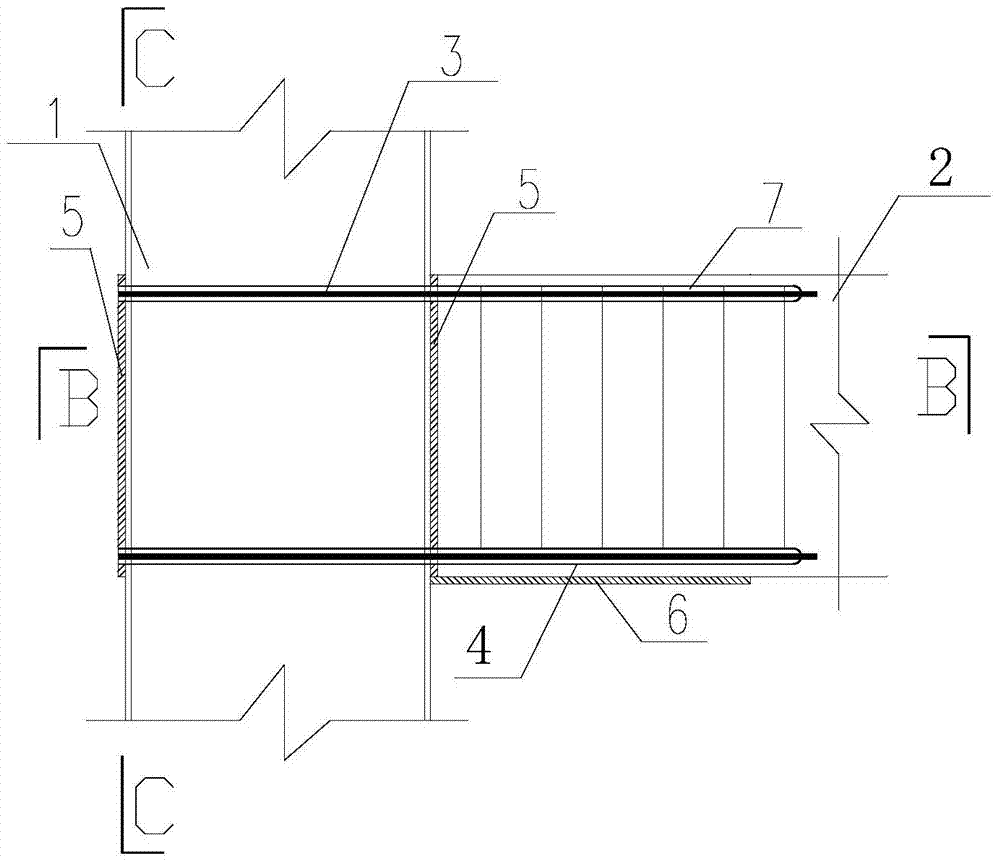

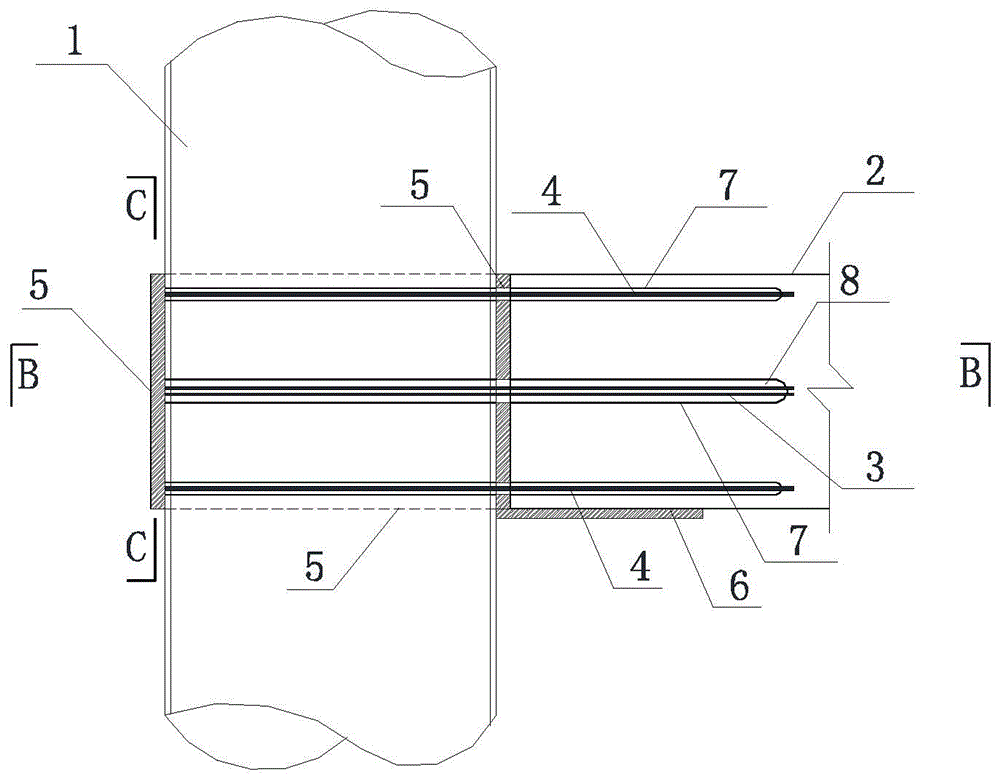

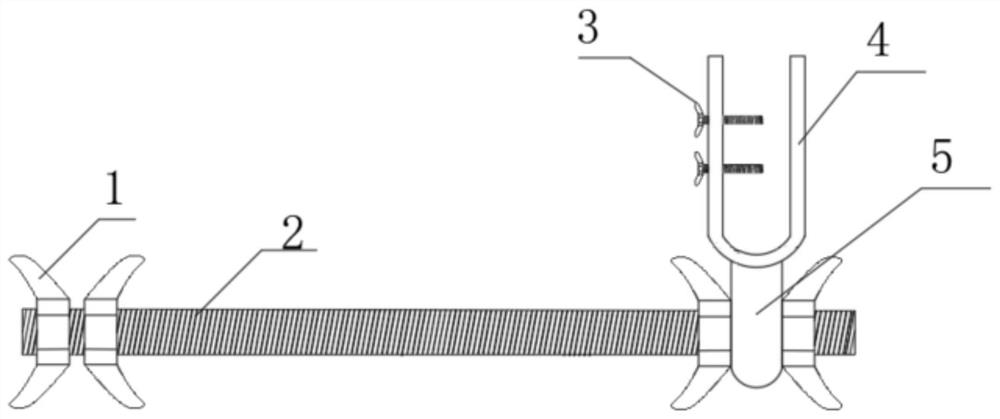

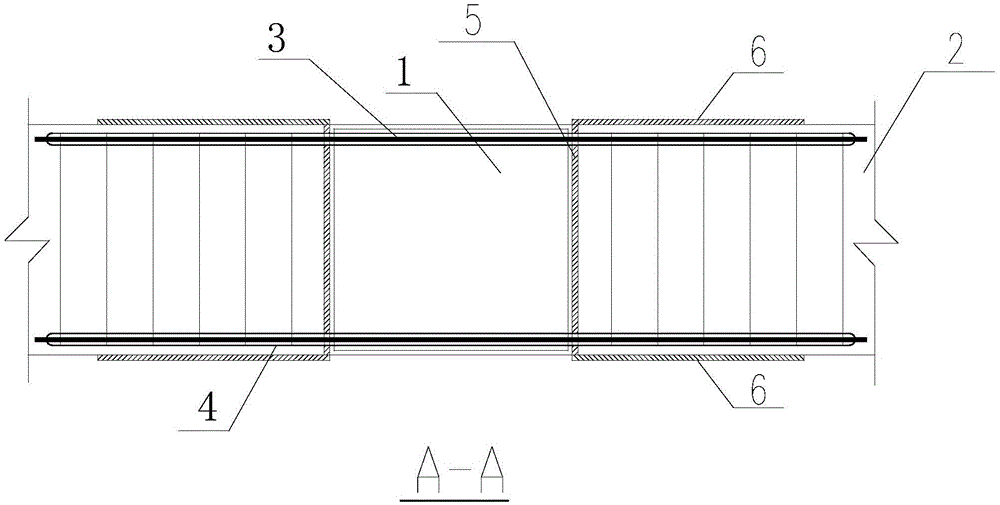

Prestress connected concrete beam round steel tube concrete column node

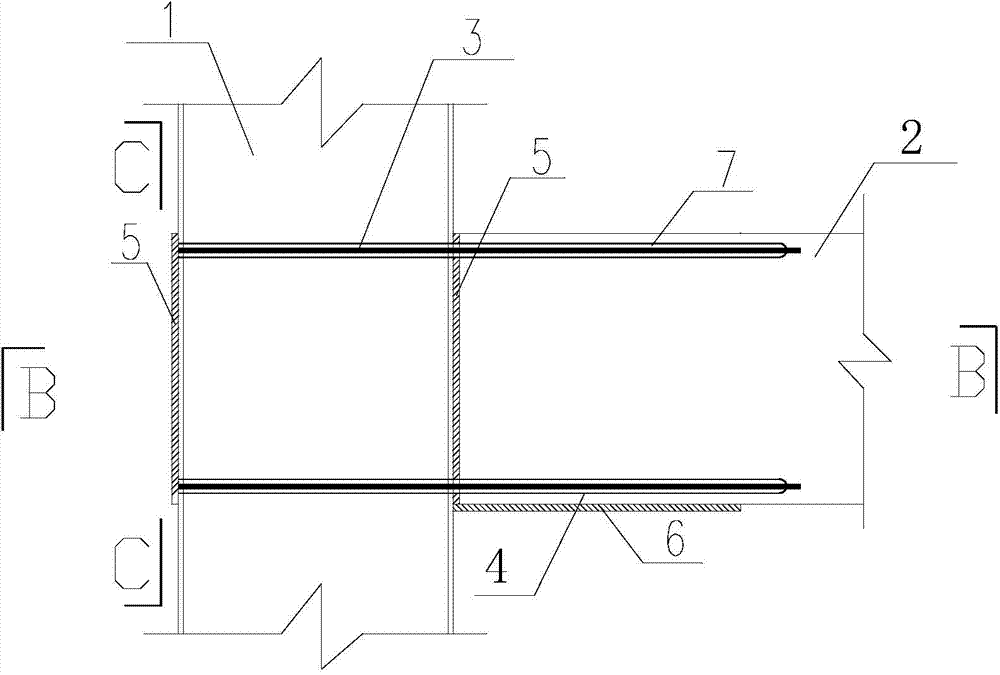

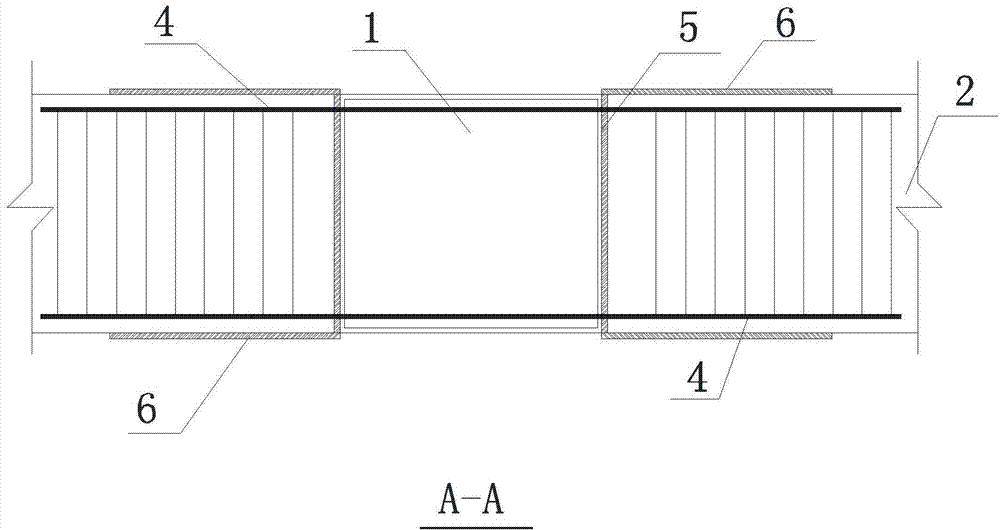

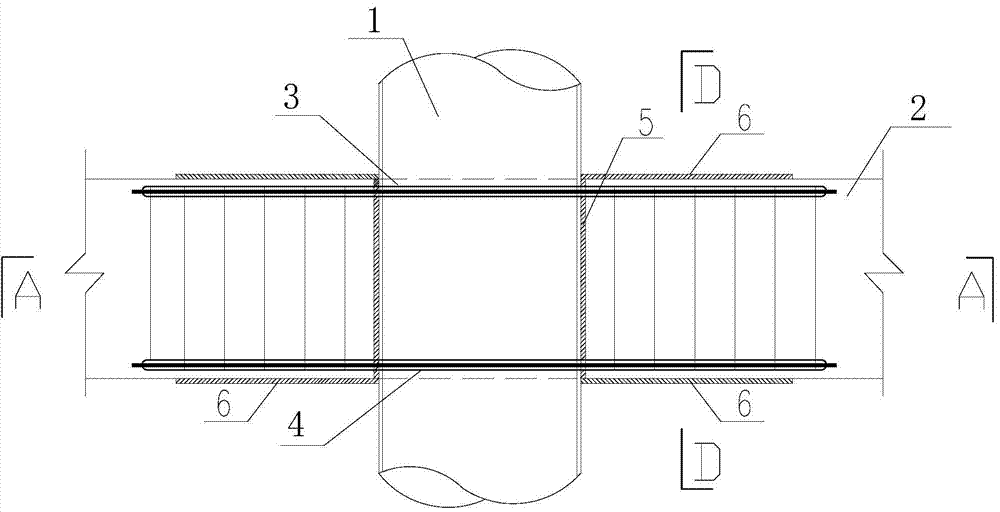

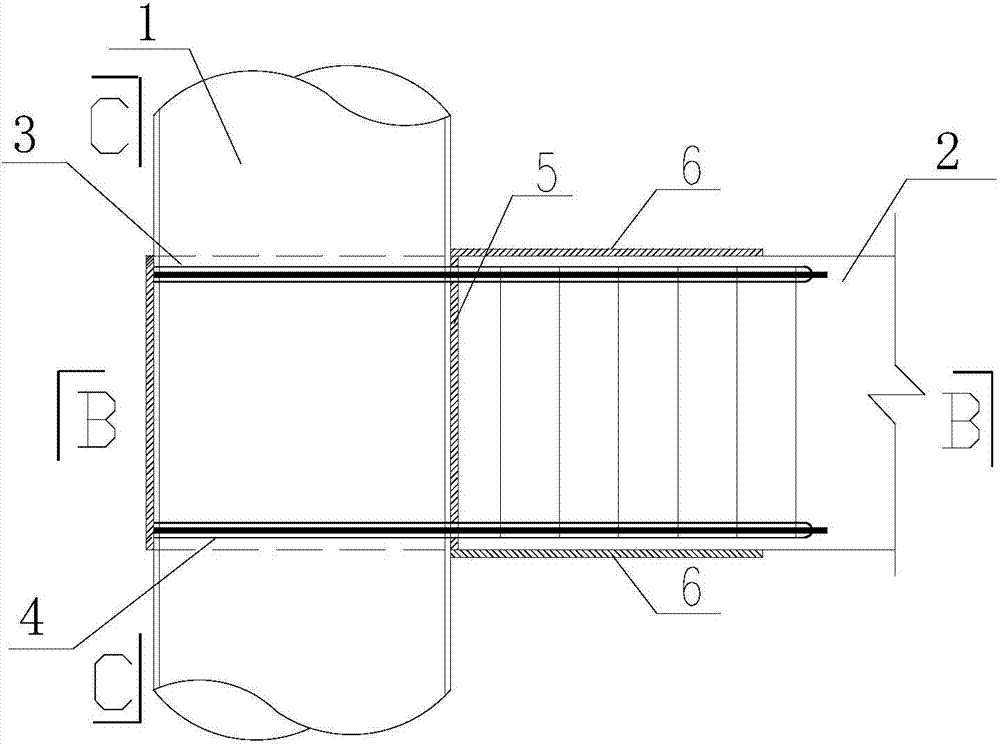

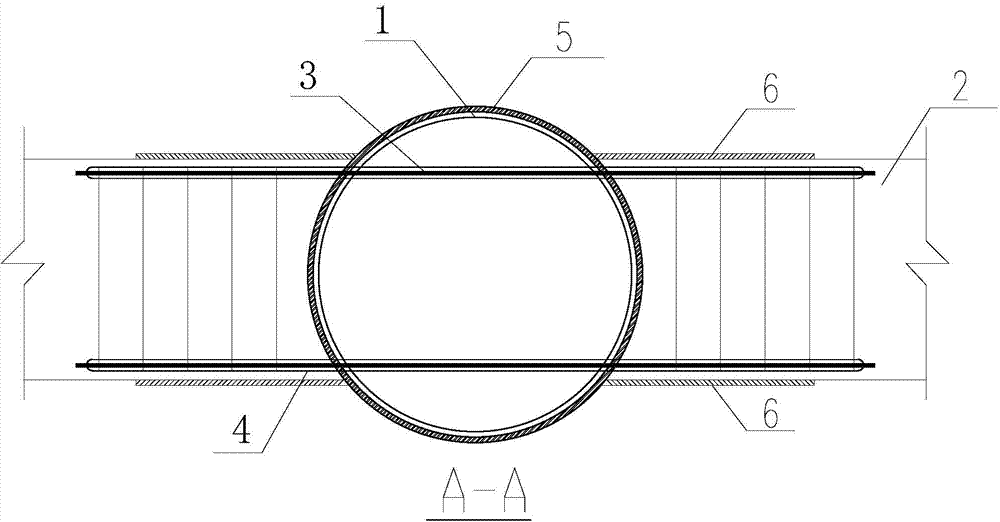

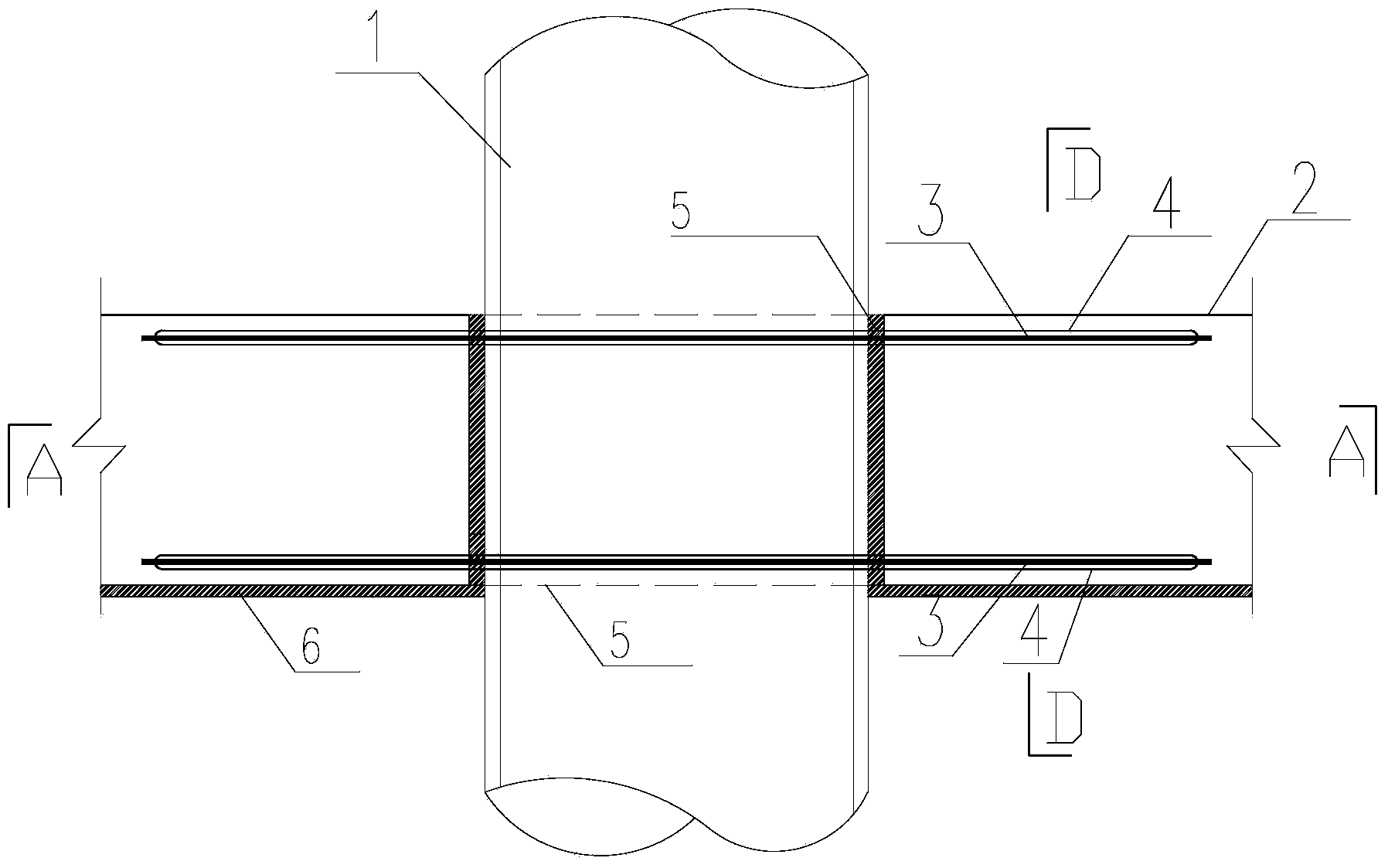

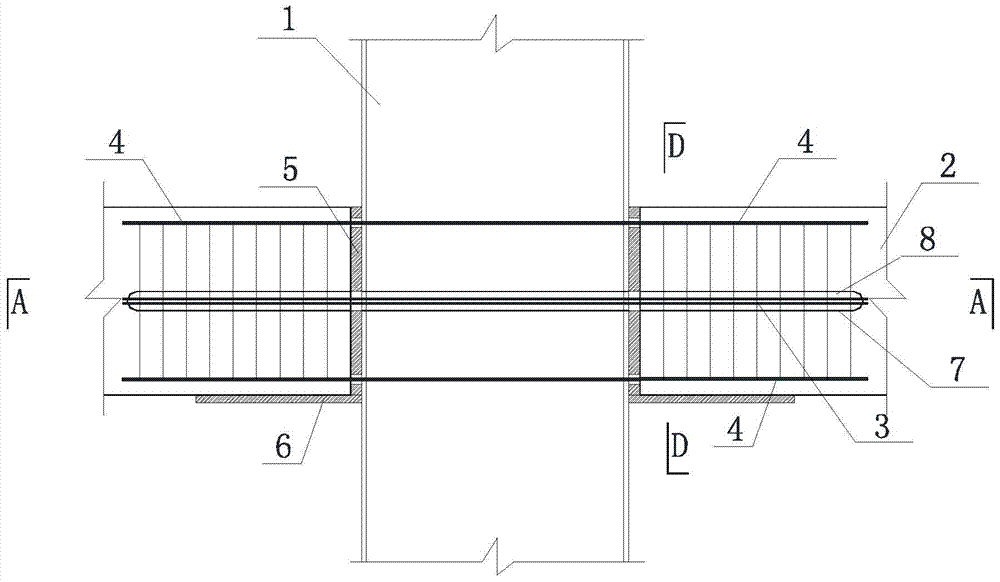

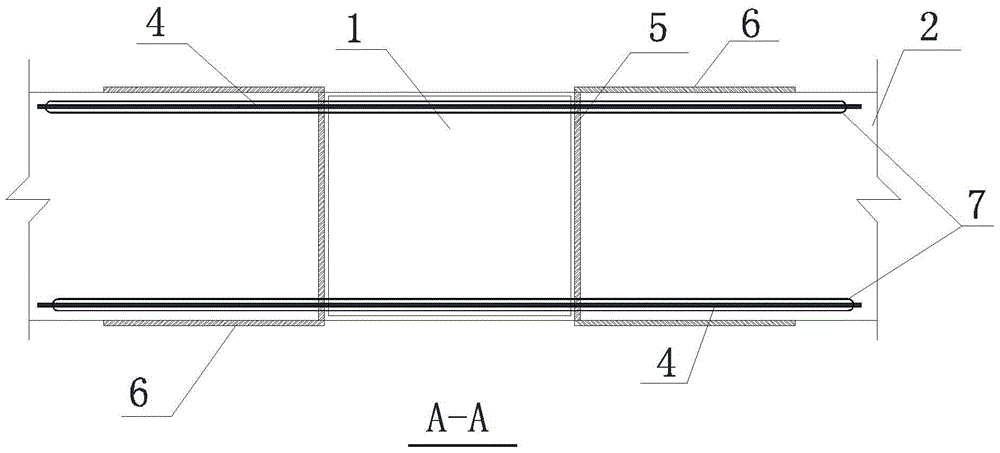

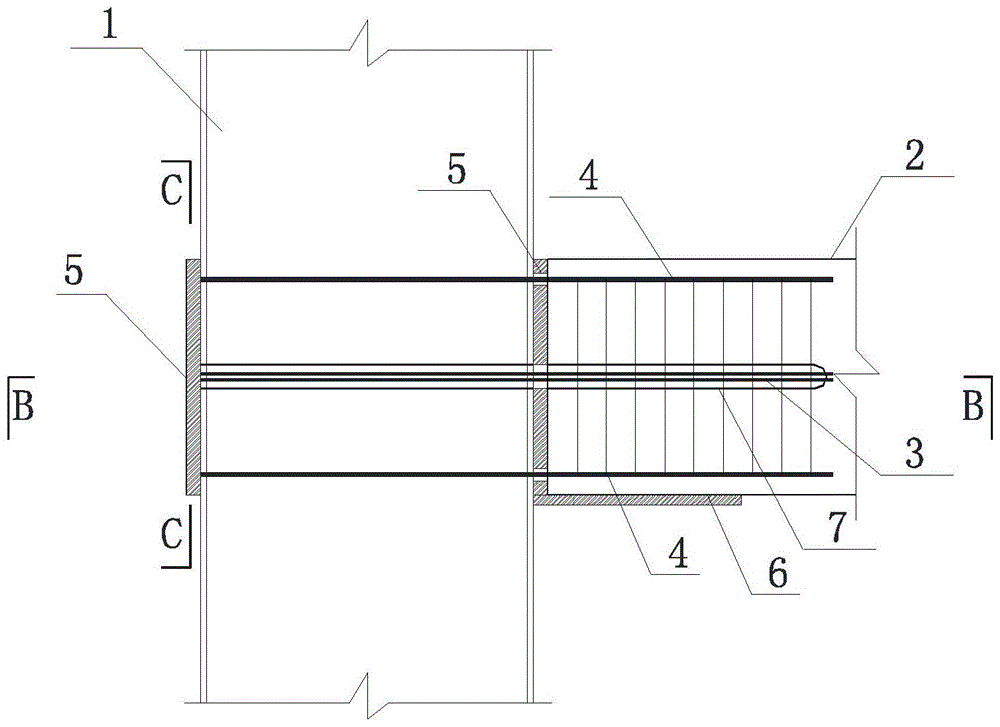

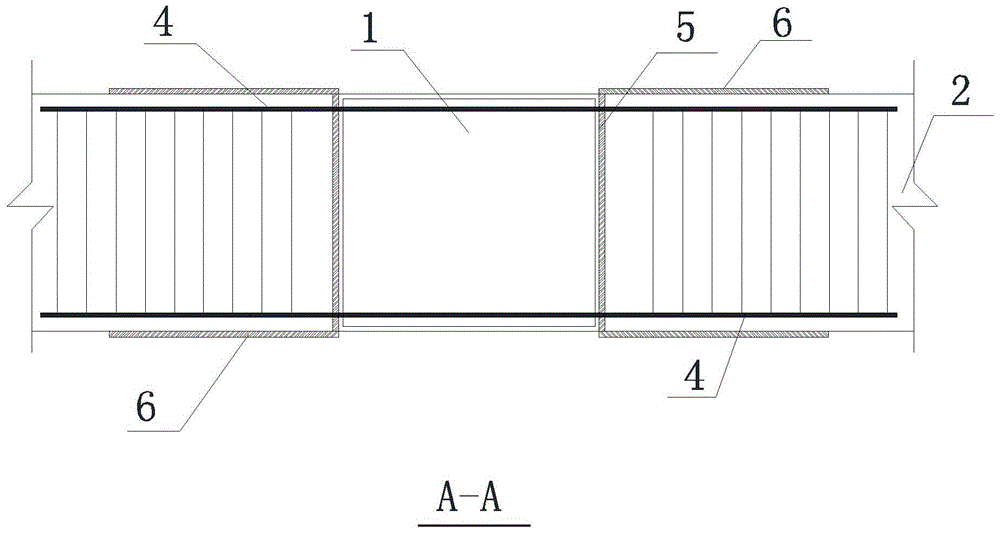

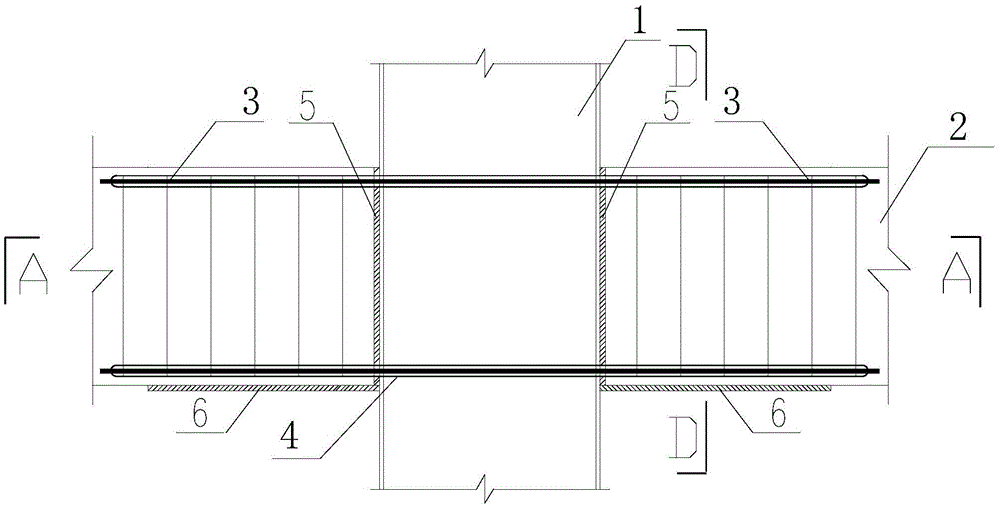

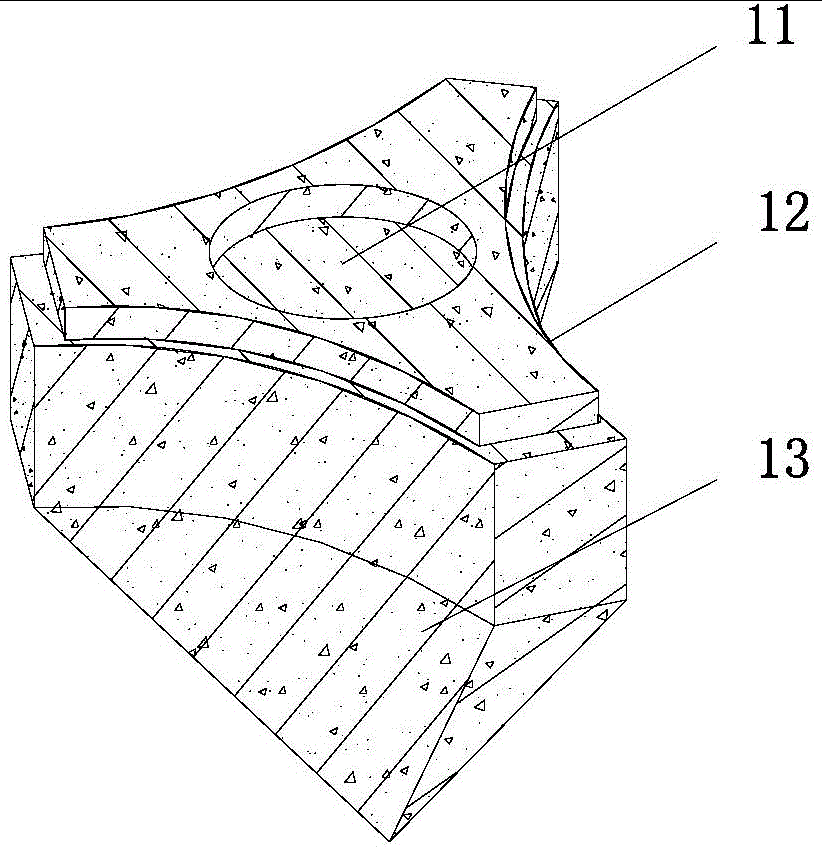

ActiveCN103924685AGuaranteed reliabilityReduce weakening effectBuilding constructionsSteel barBeam cross section

The invention provides a precast prestress connected concrete beam round steel tube concrete column node and belongs to the technical field of architectural structures. The prestress connected concrete beam round steel tube concrete column node comprises a round steel tube concrete column, a precast reinforced concrete beam, a prestress tendon, an annular plate and box iron. The round steel tube concrete column (1) and the reinforced concrete beam (2) are precast; a hole channel is formed in the position, corresponding to a beam cross-section, of the precast reinforced concrete beam and the round steel tube concrete column, and a metal bellows (4) is pre-buried in the hole channel; the annular plate (5) is welded at the joint of the round steel tube concrete column (1) and the reinforced concrete beam (2); the box iron (6) is welded on the round steel tube; the prestress tendon (3) is arranged in the metal bellows (4) in a rear penetration mode, and the prestress tendon (3) stretch-draw is conducted; hole channel grouting is finished within 48 hours after the stretch-draw, and the beam column is integrated into a whole. The prestress connected concrete beam round steel tube concrete column node is quick in construction speed, capable of increasing shear capacity of the node and enhancing the connection performance, and wide in the application prospect.

Owner:宝嘉智能科技(南通)有限公司

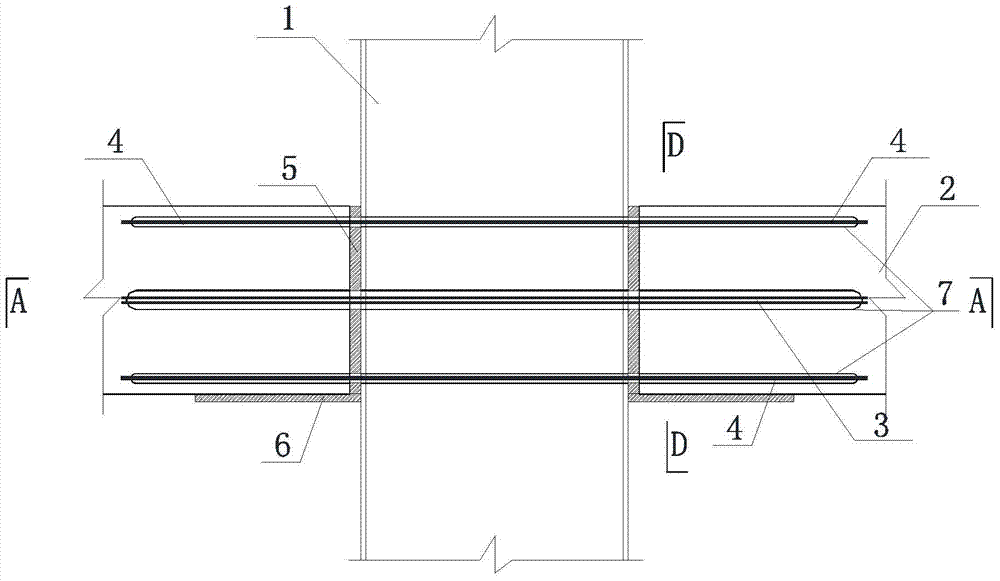

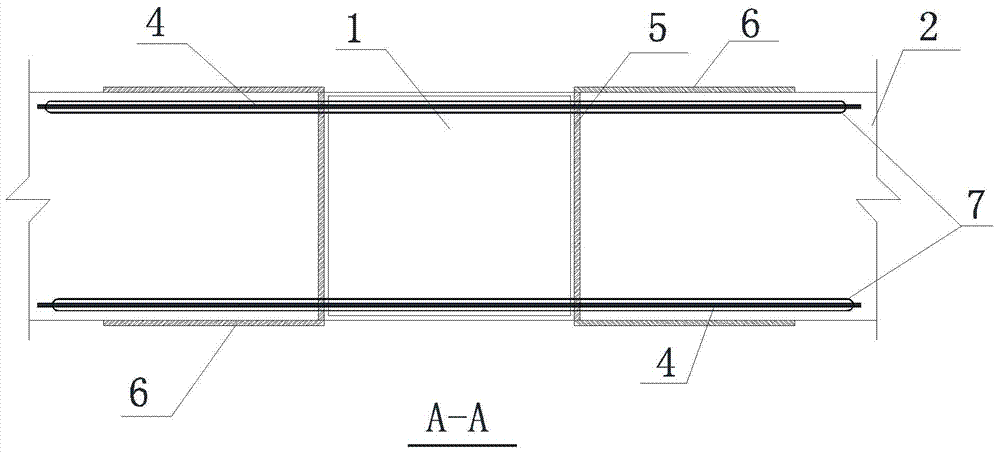

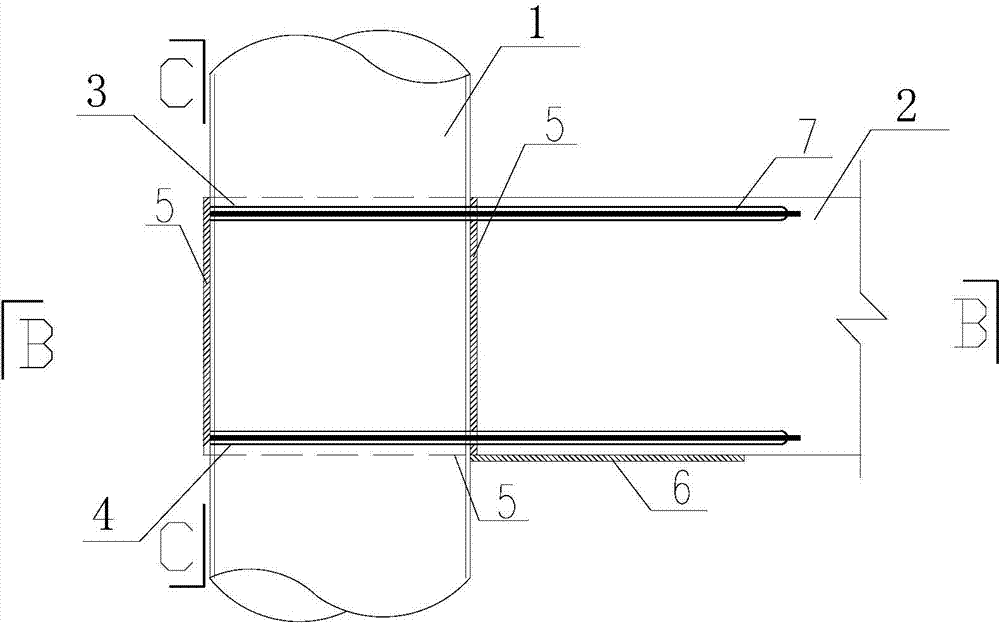

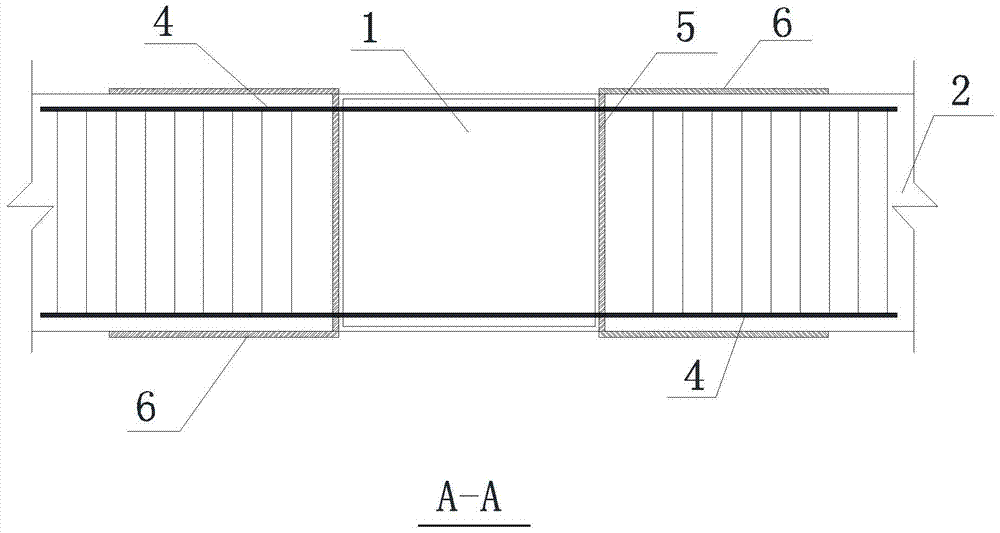

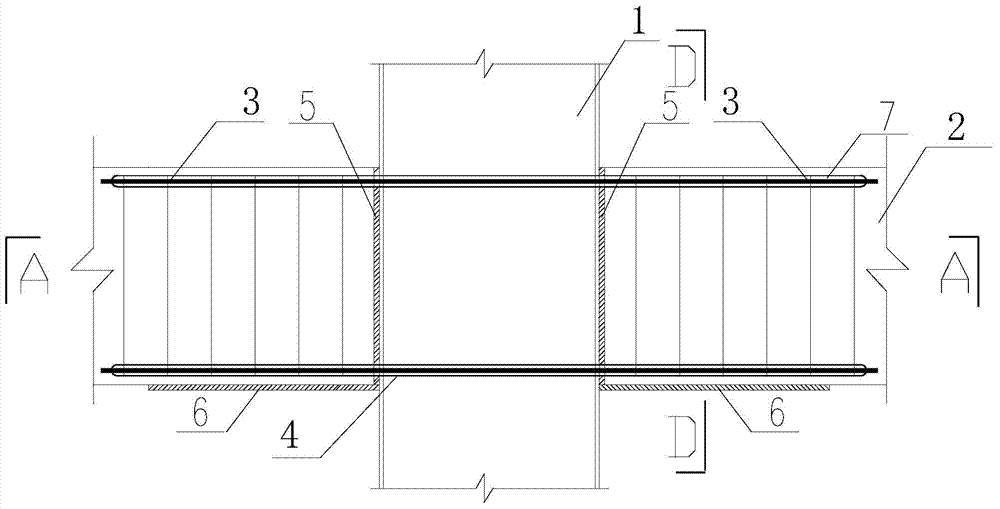

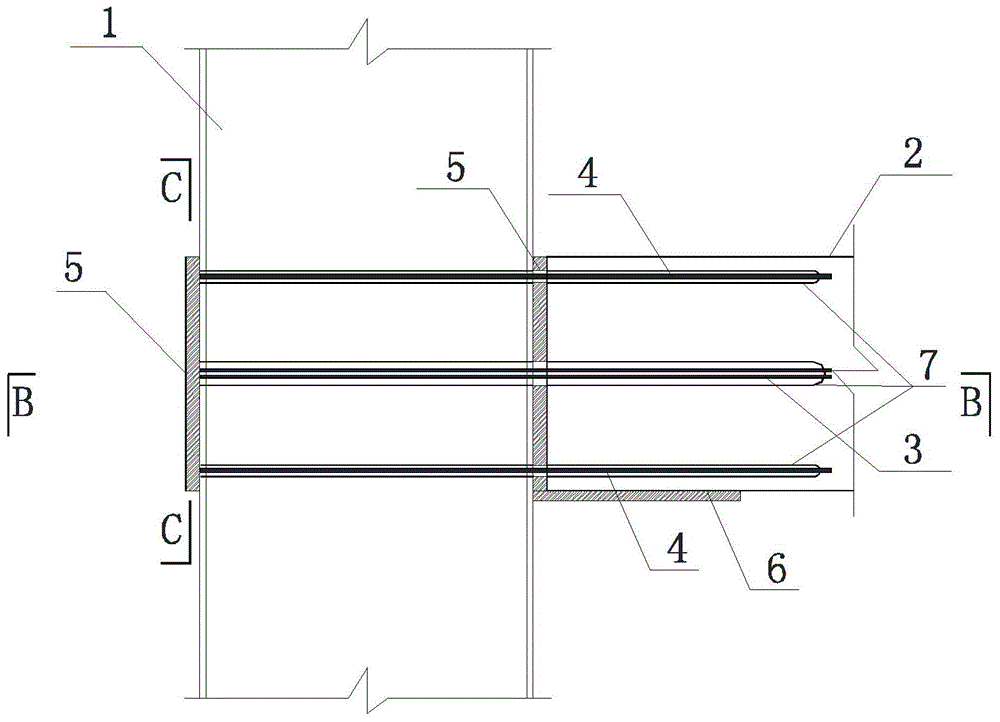

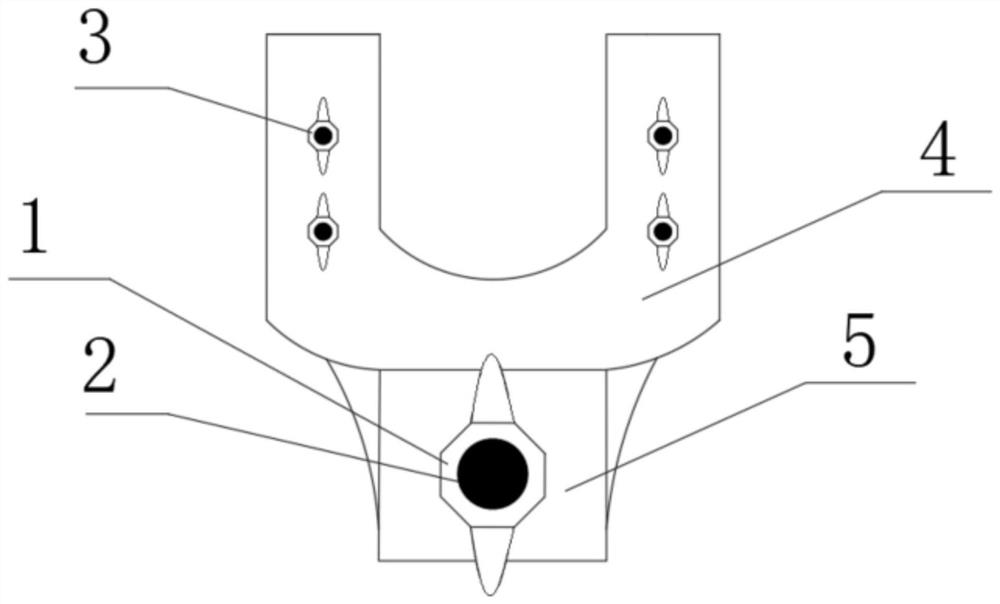

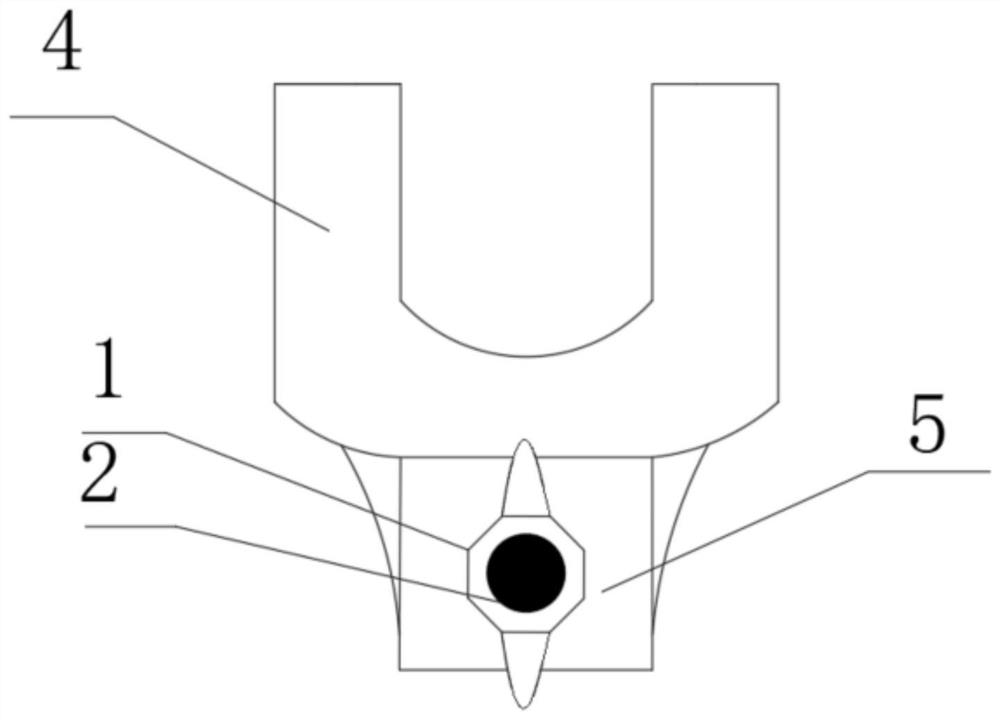

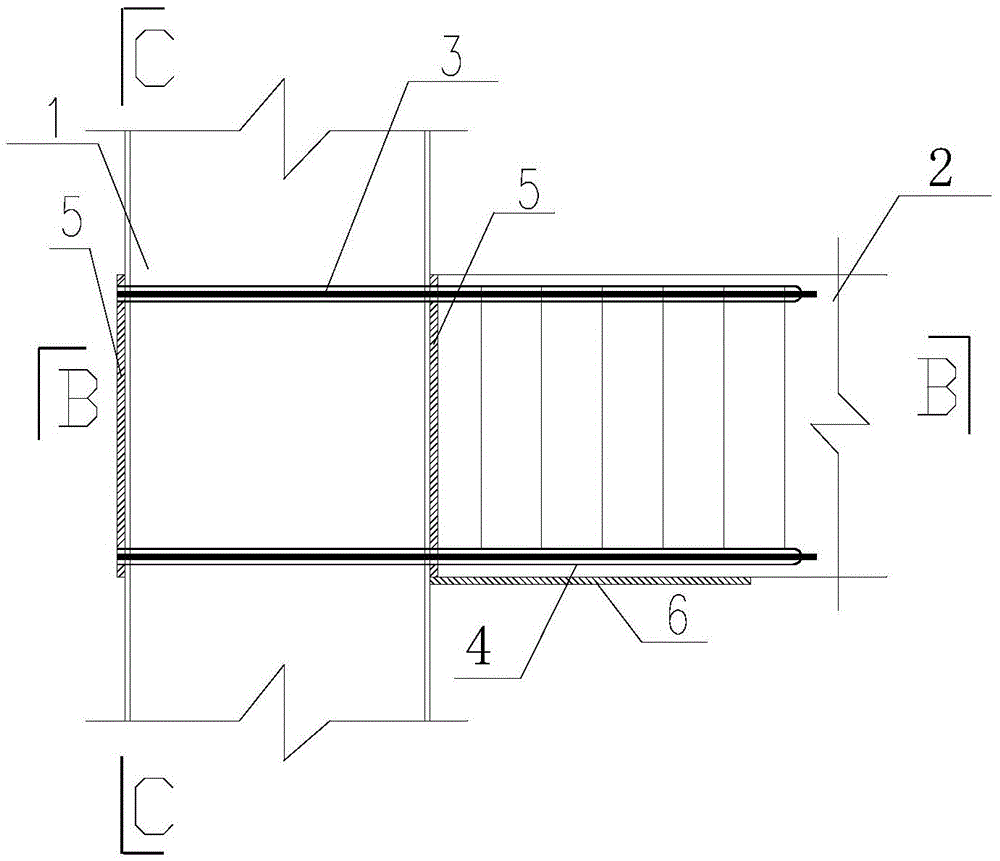

Prestress connected precast concrete beam rectangular steel tube concrete column node

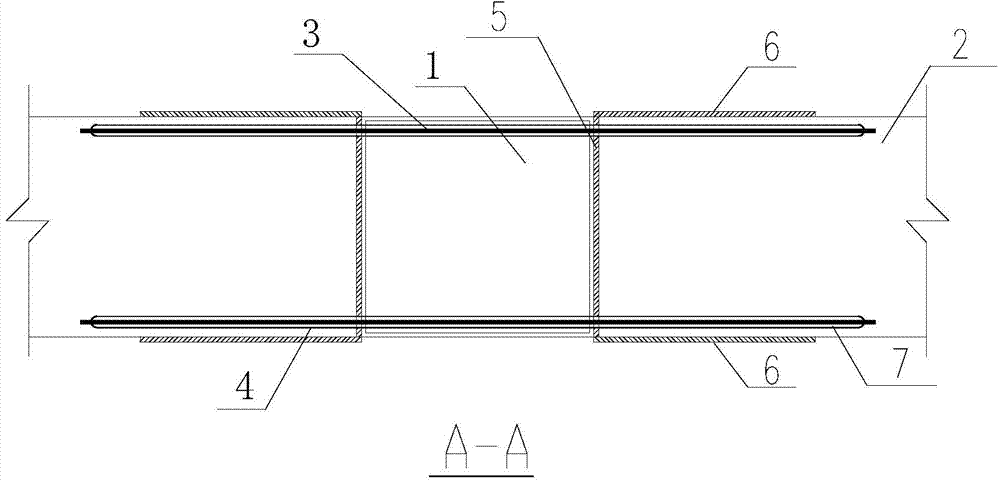

ActiveCN103924681AGuaranteed reliabilityReduce weakening effectBuilding constructionsSteel barBeam cross section

The invention provides a prestress connected precast concrete beam rectangular steel tube concrete column node, and belongs to the technical field of architecture structures. The prestress connected precast concrete beam rectangular steel tube concrete column node comprises a rectangular steel tube concrete column, a reinforced concrete beam, a prestress tendon, a steel plate and box iron. The rectangular steel tube concrete column (1) and the reinforced concrete beam (2) are precast; a hole channel is reserved at the position, corresponding to a beam cross-section, of a precast reinforced concrete beam and the rectangular steel tube concrete column, a metal bellows (4) is pre-buried in the hole channel; the steel plate (5) is welded at the connection cross-section position of the rectangular steel tube concrete column (1) and the reinforced concrete beam (2); the (6) box iron is welded on the rectangular steel tube; the prestress tendon (3) is arranged in the metal bellows (4) in a rear penetration mode; and prestress tendon (3) stretch-draw is conducted, hole channel grouting is finished within 48 hours after the stretch-draw, and the beam column is integrated into a whole. The prestress connected concrete beam round steel tube concrete column node is quick in construction speed, capable of increasing shear capacity of the node and enhancing the connection performance, and wide in the application prospect.

Owner:南通朵觅电子科技有限公司

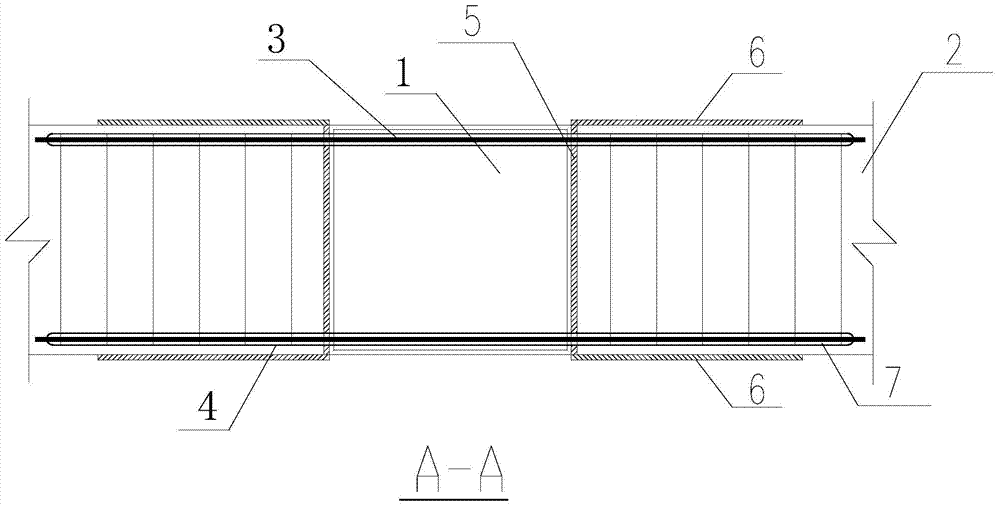

Concrete beam and square-rectangular concrete-filled steel tube column combining joint employing unbonded prestressed and common reinforcement for connection

ActiveCN103924677AGuaranteed reliabilityReduce weakening effectBuilding constructionsPre stressConcrete beams

The invention relates to a concrete beam and square-rectangular concrete-filled steel tube column combining joint employing unbonded prestress and common reinforcement for connection and belongs to the technical field of building structures. The concrete beam and square-rectangular concrete-filled steel tube column combining joint employing unbonded prestress and common reinforcement for connection comprises a square-rectangular concrete-filled steel tube column, a reinforced concrete beam, unbonded prestressed bars, steel plates, and steel channels. Both the square-rectangular concrete-filled steel tube column and the reinforced concrete beam are both cast in place. The connection sections of the square-rectangular concrete-filled steel tube column and the reinforced concrete beam is provided with ducts in which metal bellows are embedded; the steel plates are welded at the connection sections of the square-rectangular concrete-filled steel tube column and the reinforced concrete beam and are provided with corresponding holes; the steel channels are welded on the square-rectangular concrete-filled steel tube column. The concrete beam and square-rectangular concrete-filled steel tube column combining joint employing unbonded prestress and common reinforcement for connection has the advantages that construction speed is high, the field welding process is not required, joint connection reliability can be guaranteed, seismic performance is good, a connection way of the joint is applicable to side column joints in structures and also applicable to middle column joints, and the joint has promising application prospect.

Owner:北京中联浩科技服务有限公司

Circular concrete-filled steel tubular column node of unbonded pre-stressing connecting concrete beam

InactiveCN103924682AFast constructionGuaranteed reliabilityBuilding constructionsSteel tubePre stressing

The invention relates to a circular concrete-filled steel tubular column node of an unbonded pre-stressing connecting concrete beam, and belongs to the technical field of building structures. The circular concrete-filled steel tubular column node comprises a circular concrete-filled steel tubular column, a reinforced concrete beam, unbonded pre-stressing tendons, an annular plate and channel steel. The circular concrete-filled steel tubular column and the reinforced concrete beam are both formed in a cast-in-situ mode and connected through the unbonded pre-stressing tendons; a hole way is reserved in the connecting position of the circular concrete-filled steel tubular column and the reinforced concrete beam, and a metal corrugated pipe is embedded in the hole way; the annular plate is welded to the connecting position of the circular concrete-filled steel tubular column and the reinforced concrete beam, and a corresponding hole is formed in the annular plate; the channel steel is welded to a circular steel tube. By means of the circular concrete-filled steel tubular column node, the site welding technology is not needed, the reliability of node connection can be guaranteed, the node has the good shock resistance, the node connecting mode can be used for side column nodes in the structure and can also be used for middle column nodes, and the application prospect is wide.

Owner:BEIJING UNIV OF TECH

Allochroic silica gel mask capable of representing electrostatic adsorption capacity

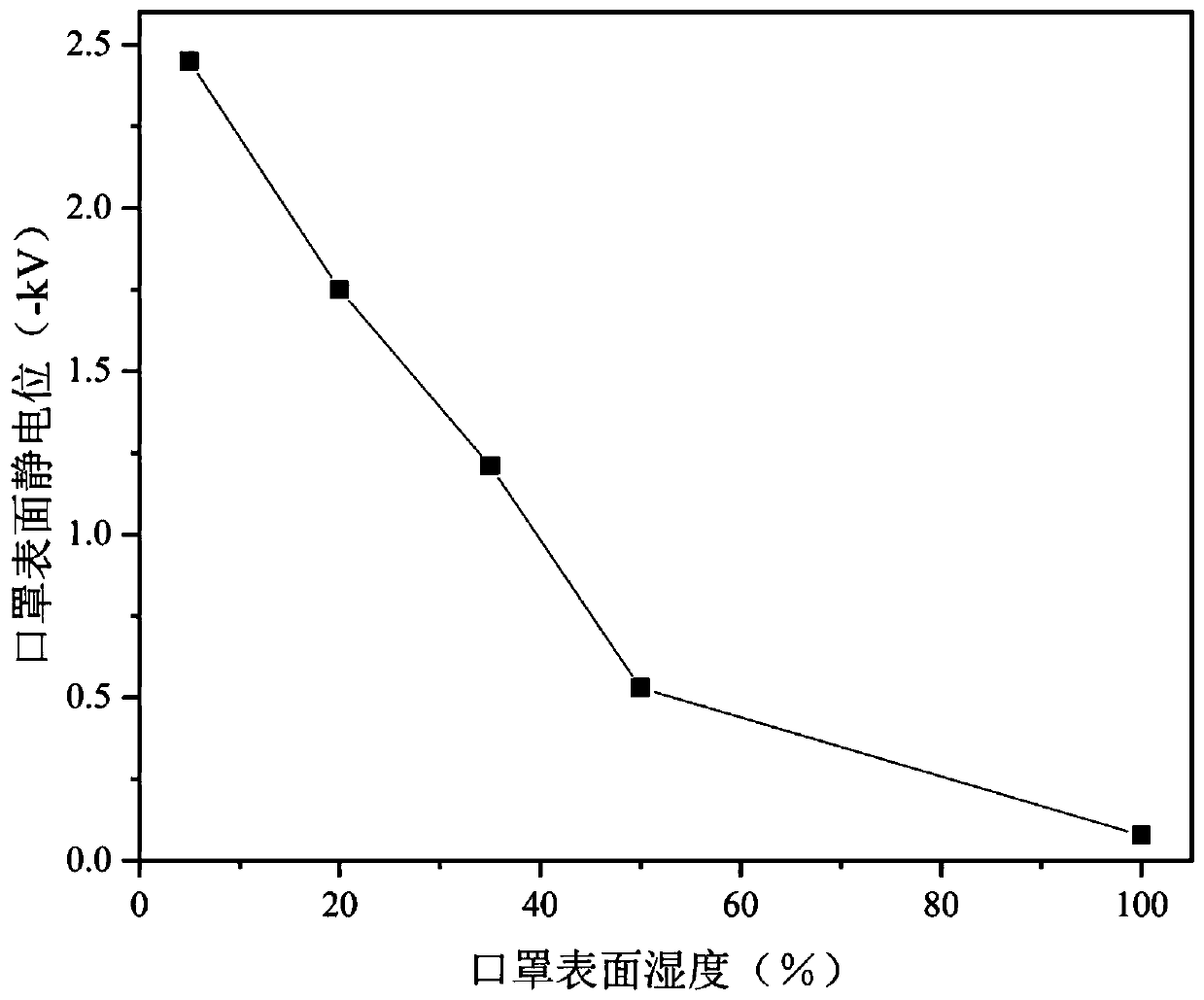

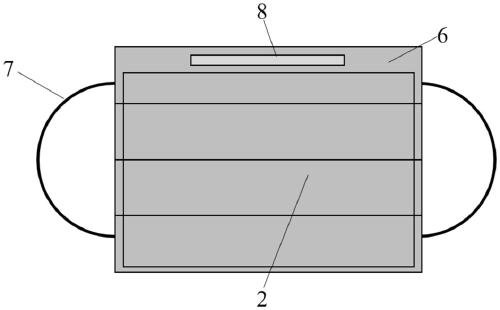

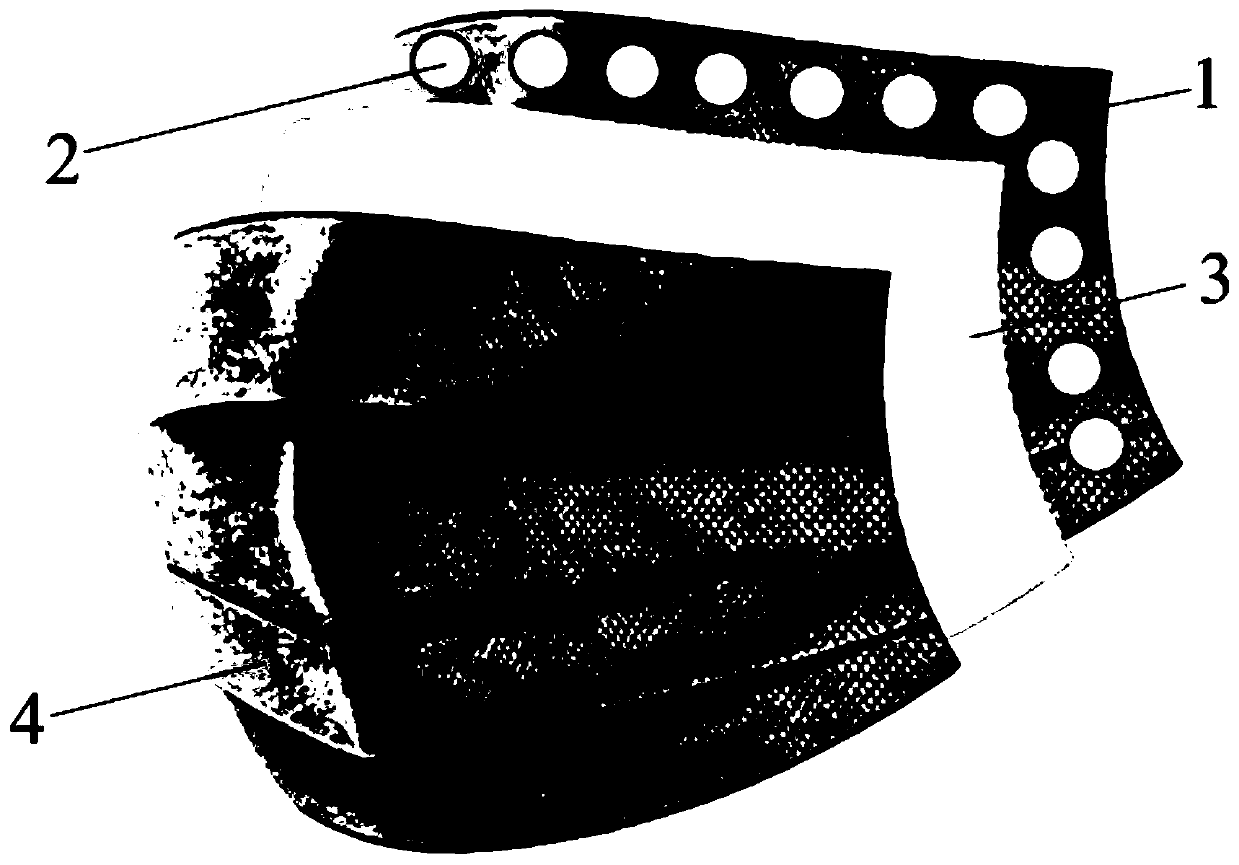

PendingCN111528551AGood ventilationEasy to observeMaterial analysis by observing effect on chemical indicatorProtective garmentElectrostatic adsorptionEngineering

The present invention discloses an allochroic silica gel mask capable of representing the electrostatic adsorption capacity which comprises an allochroic silicagel layer, the allochroic silicagel layer is arranged on a mask body, and the allochroic silicagel layer can change color according to humidity and is used for representing the electrostatic adsorption capacity of the surface of the mask. The electrostatic adsorption performance of the mask is indirectly sensed through visual change of the color change degree of the allochroic silicagel, used materials are non-toxic, environmentally friendly, harmless to the human body, simple in structure, convenient to use and operate and wide in market application prospect.

Owner:XI AN JIAOTONG UNIV

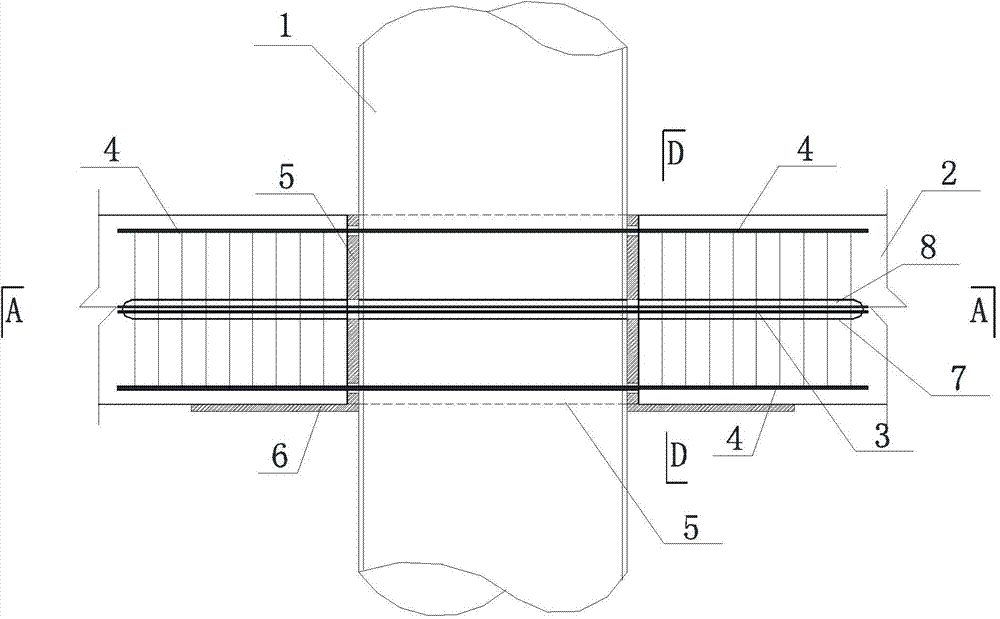

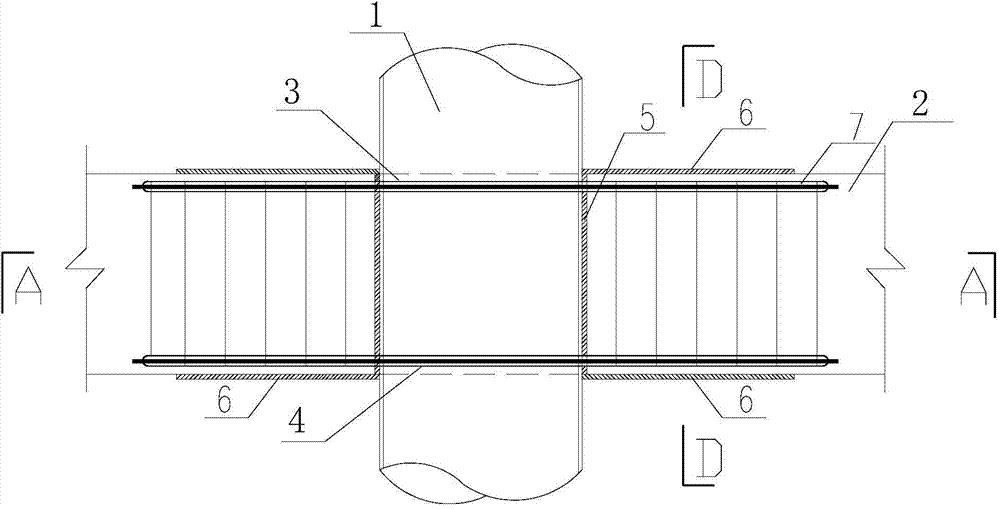

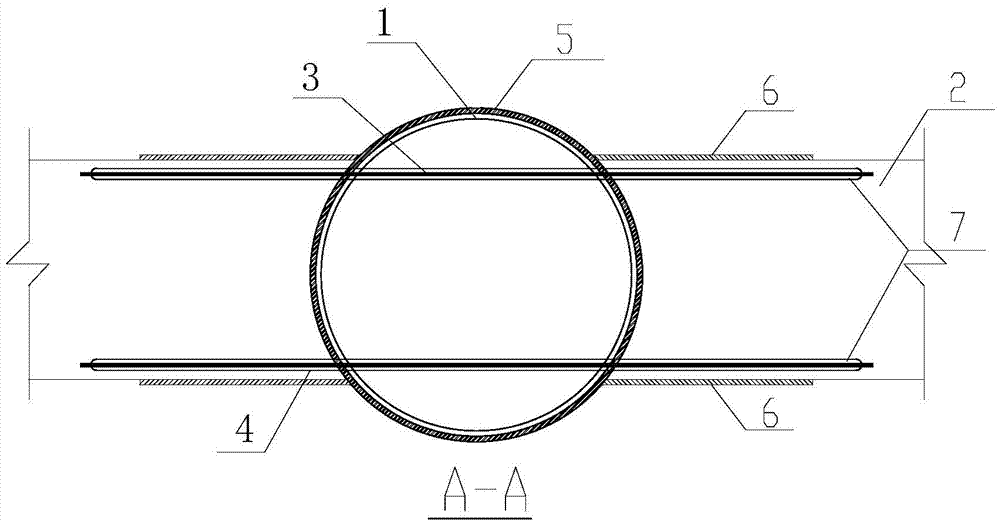

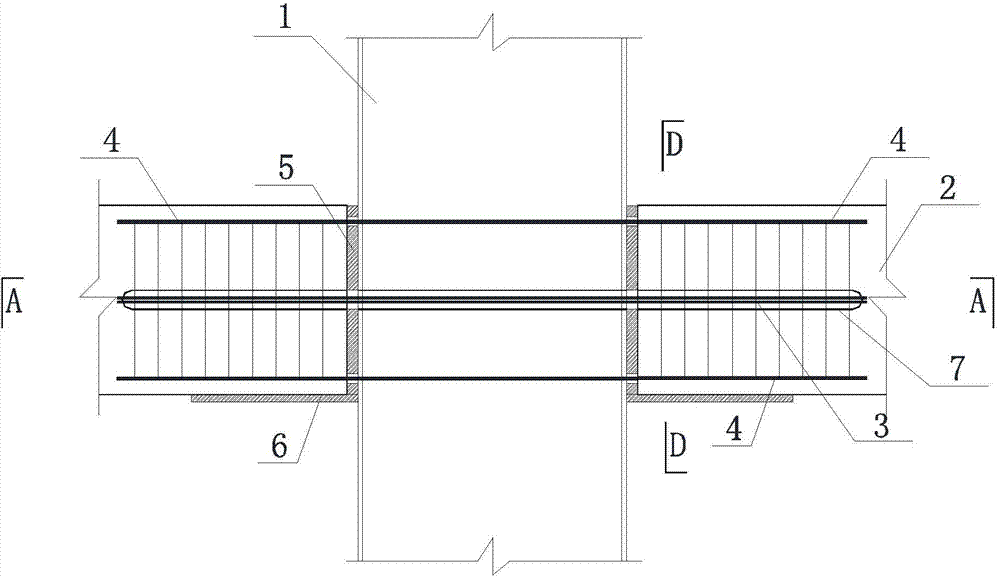

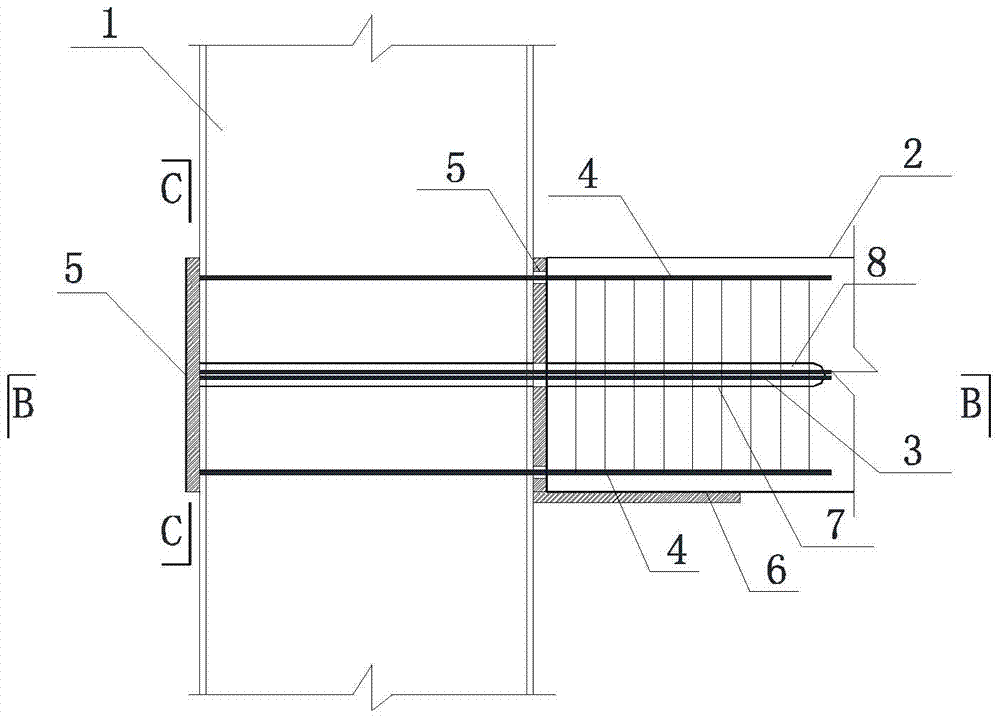

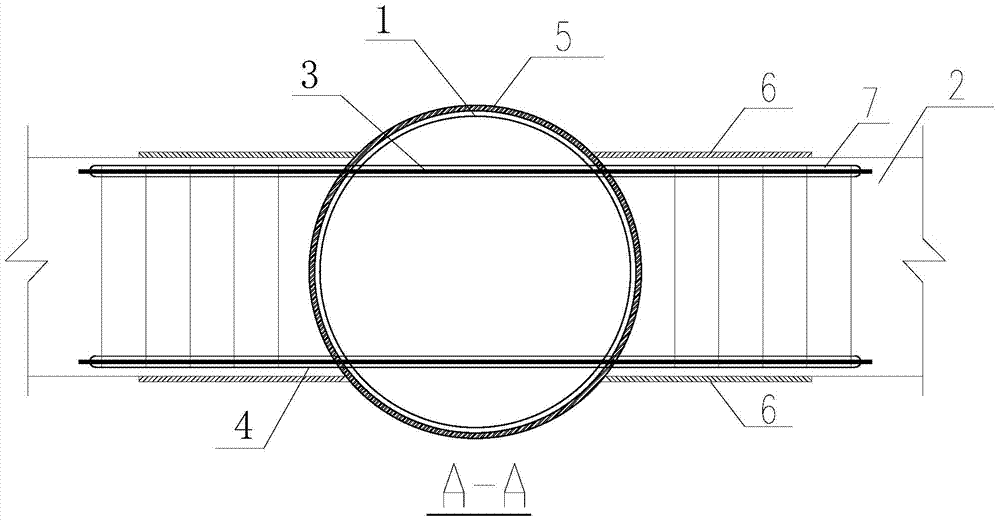

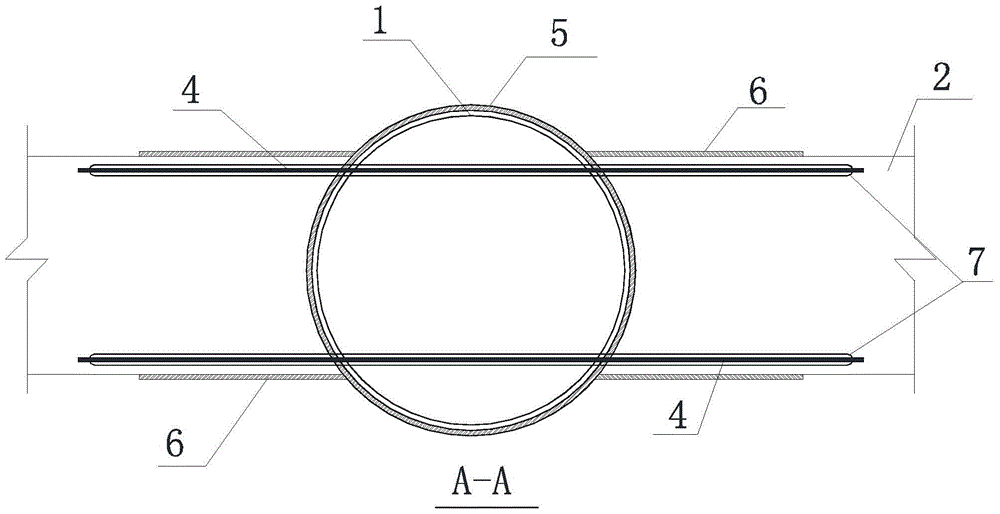

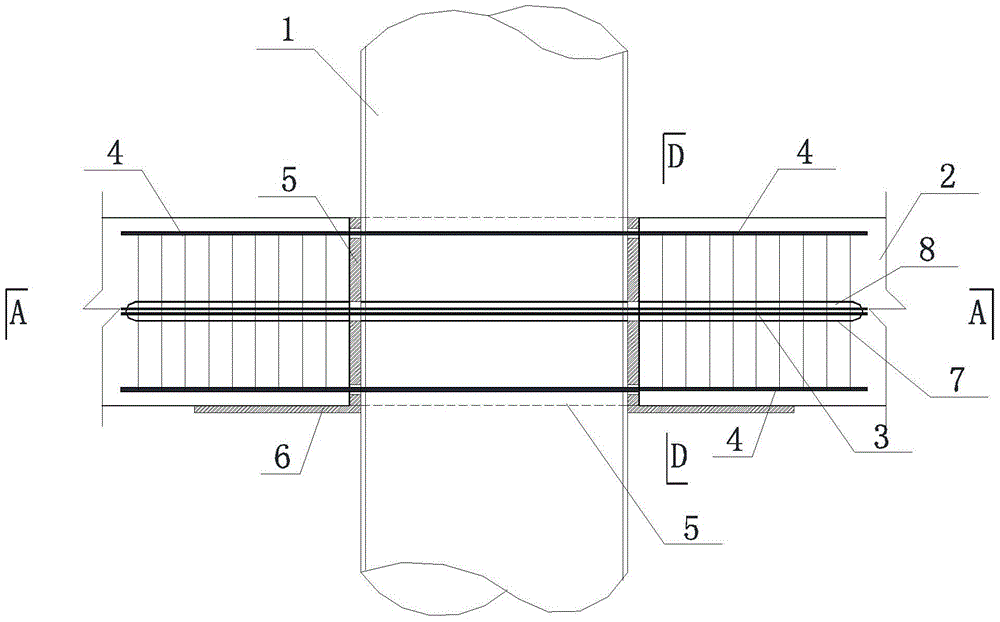

Node for connecting prefabricated concrete beam with round steel tube concrete column through unbonded prestressed ribs

ActiveCN103938729AGuaranteed reliabilityReduce weakening effectBuilding constructionsPre stressConcrete beams

The invention provides a node for connecting a prefabricated concrete beam with a round steel tube concrete column through unbonded prestressed ribs, and belongs to the technical field of building structures. The node comprises the round steel tube concrete column, the reinforced concrete beam, the unbonded prestressed ribs, an annular plate and channel steel. The round steel tube concrete column (1) and the reinforced concrete beam (2) are both prefabricated; the positions, corresponding to beam sections, of the reinforced concrete beam and of the round steel tube concrete column are provided with hole channels; metal corrugated tubes (4) are pre-buried in the hole channels; the portion, connected with the reinforced concrete beam (2), of the round steel tube concrete column (1) is provided with the annular plate in a welded mode; the channel steel (6) is welded to a round steel tube; the unbonded prestressed ribs (3) penetrate through the metal corrugated tubes (4) and are tensioned so that the beam and the column can be connected into a whole. The construction speed is high, the onsite welding process is needless, reliability of node connection can be guaranteed, good anti-seismic performance is achieved, the node connection mode can be used for a side column node in a structure and can also be used for a middle column node and application prospects are wide.

Owner:南京易蔚均科技有限公司

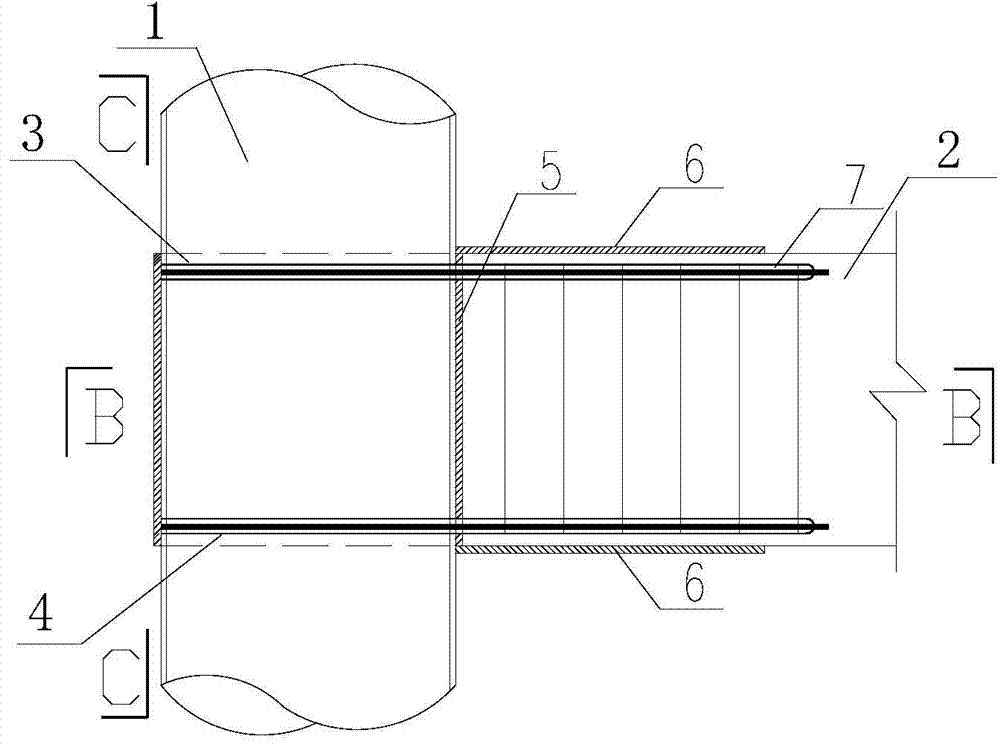

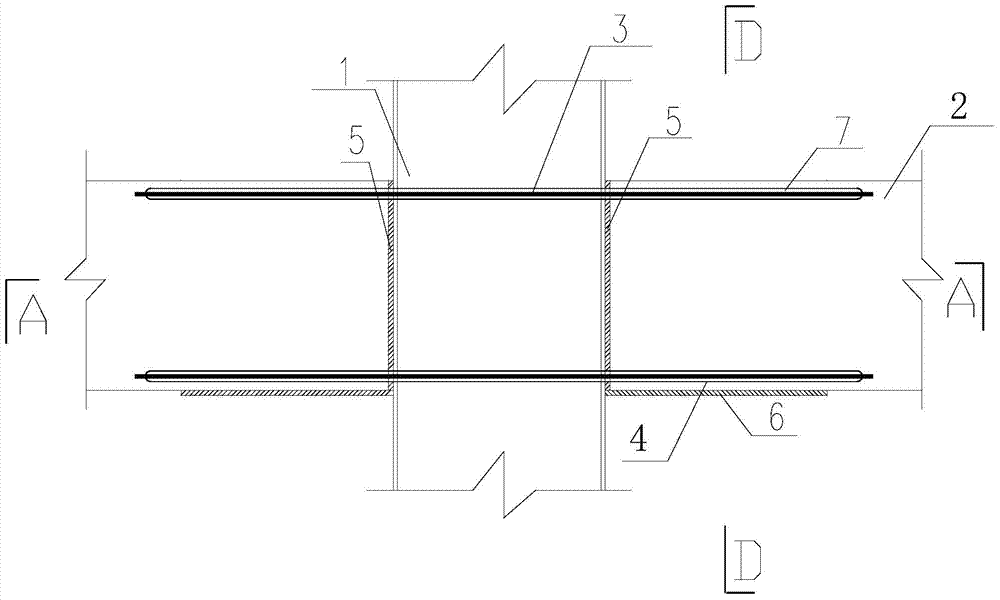

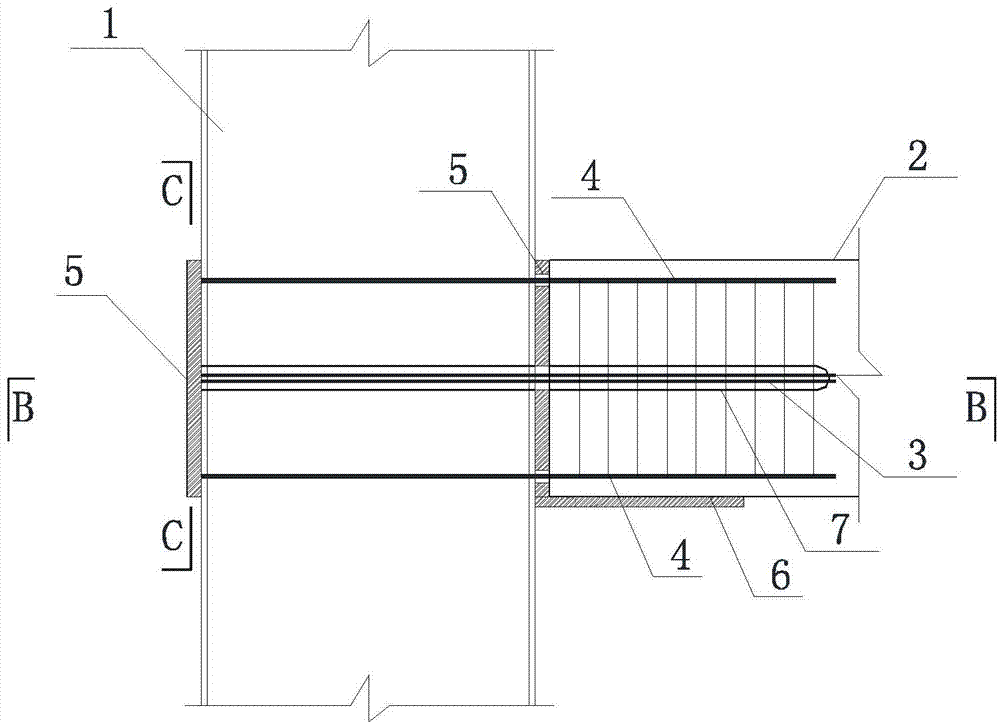

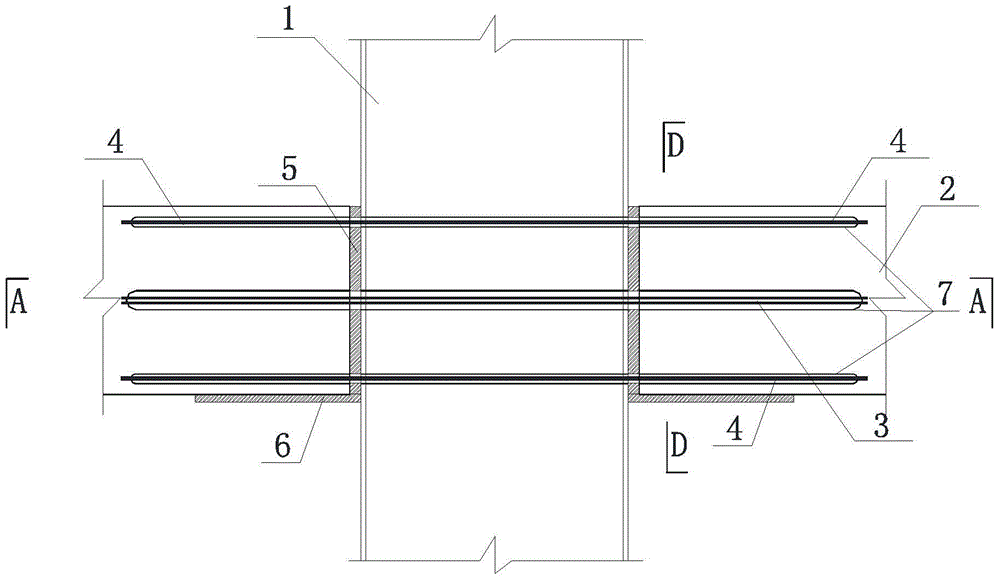

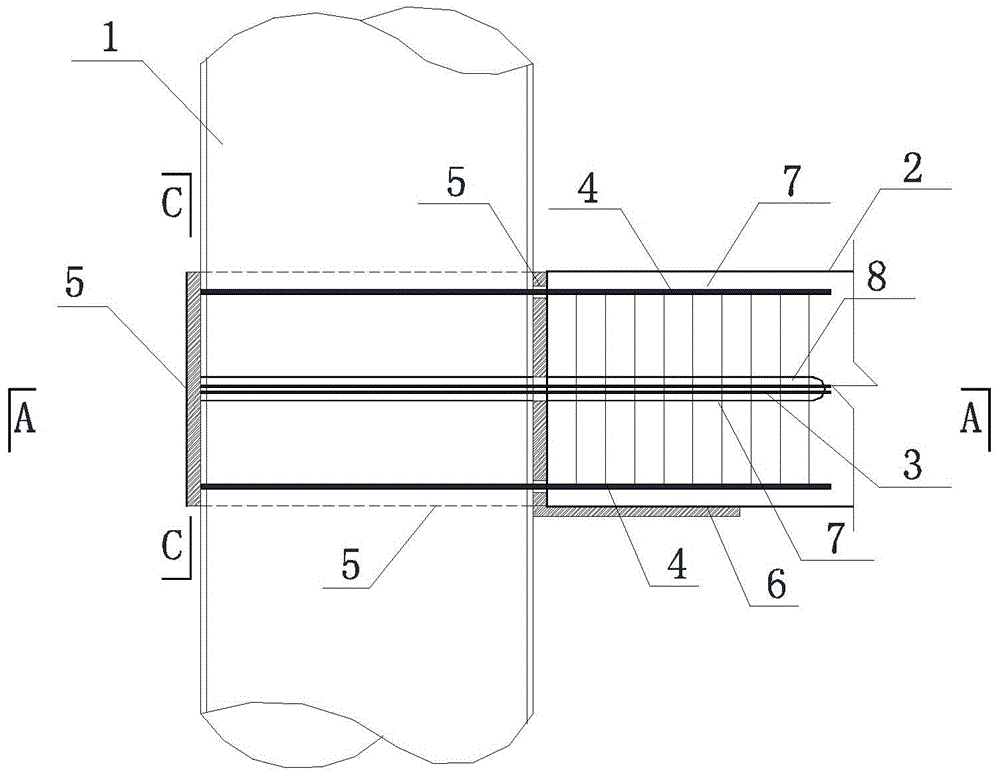

Node for connecting prefabricated concrete beam with rectangular steel tube concrete column through unbonded prestressed ribs

ActiveCN103938733AGuaranteed reliabilityReduce weakening effectBuilding constructionsConcrete beamsPre stress

The invention provides a node for connecting a prefabricated concrete beam with a rectangular steel tube concrete column through unbonded prestressed ribs, and belongs to the technical field of building structures. The node comprises the rectangular steel tube concrete column, the reinforced concrete beam, the unbonded prestressed ribs, a steel plate and channel steel. The rectangular steel tube concrete column and the reinforced concrete beam are prefabricated; the positions, corresponding to a section of the reinforced concrete beam, of the prefabricated reinforced concrete beam and of the rectangular steel tube concrete column are provided with hole channels; metal corrugated tubes are pre-buried in the hole channels; the section of the portion, connected with the reinforced concrete beam, of the rectangular steel tube concrete column is provided with the steel plate in a welded mode; the channel steel is welded to a rectangular steel tube; the unbonded prestressed ribs penetrate through the metal corrugated tubes and are tensioned so that the beam and the column can be connected into a whole. The construction speed is high, the onsite welding process is needless, reliability of node connection can be guaranteed, good anti-seismic performance is achieved, the node connection mode can be used for a side column node in a structure and can also be used for a middle column node and application prospects are wide.

Owner:北京中联浩科技服务有限公司

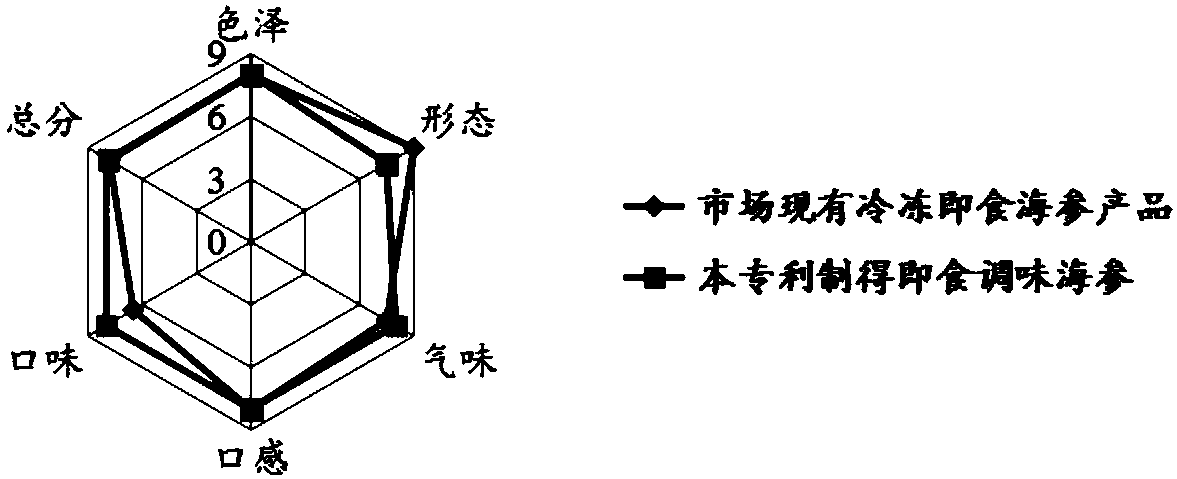

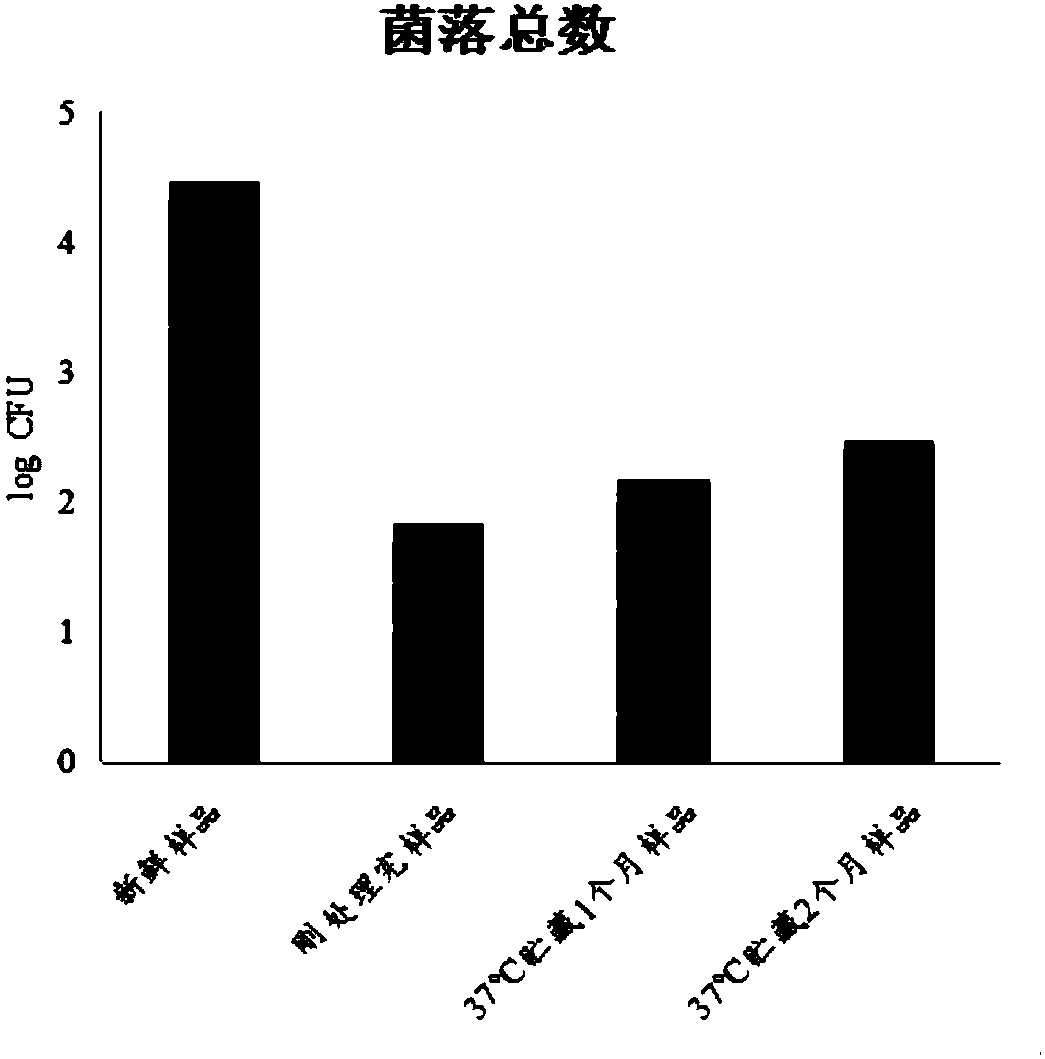

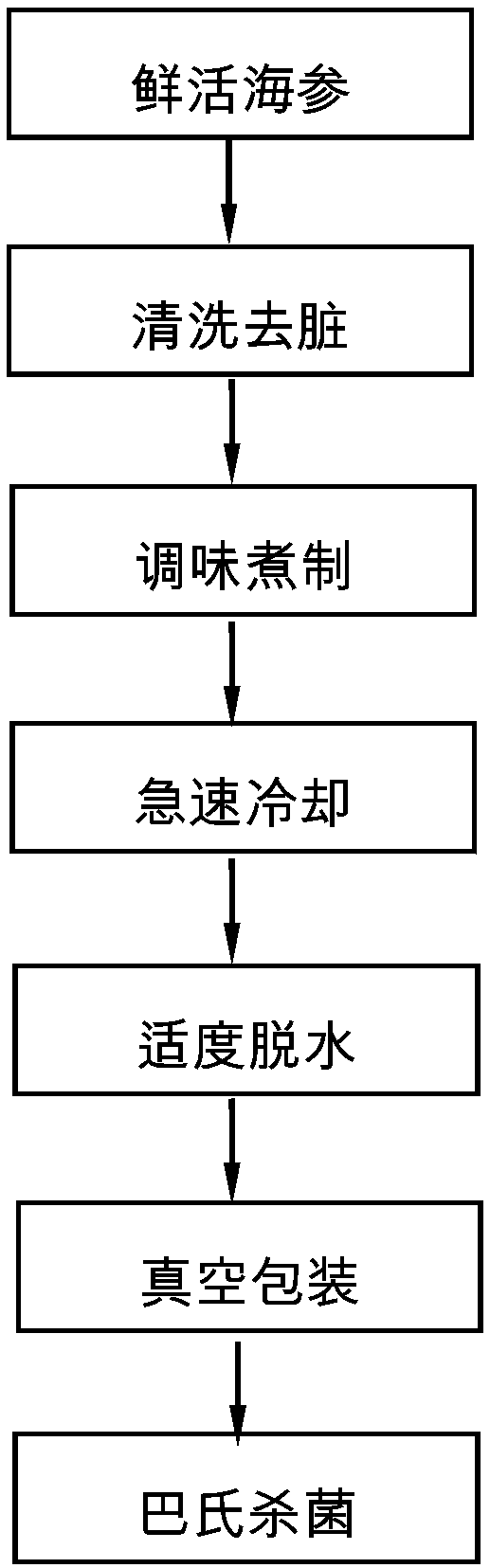

Preparation method of instant flavored sea cucumbers preserved at normal temperature

PendingCN108378264AGuaranteed sensory qualityAvoid hydrolysisFood preservationRoom temperatureOrganoleptic

The invention discloses a preparation method of instant flavored sea cucumbers preserved at normal temperature. The preparation method comprises the steps as follows: cleaning and removal of internalorgans: removing internal organs and mouths of sea cucumbers, and thoroughly cleaning the sea cucumbers; flavoring boiling: boiling the cleaned sea cucumbers with internal organs removed in a flavoring liquid; cooling: cooling the sea cucumbers obtained after flavoring boiling to the room temperature; and drying and dehydration: drying and dehydrating the quickly cooled sea cucumbers. Interactionbetween instant enzyme deactivation, quick chilling and control of drying and dehydrating parameters is realized, the synergistic interaction is realized by screening the type and concentration of a flavoring agent with oxidation resistance, all steps cannot be replaced with one another, instant sea cucumbers are preserved under the normal temperature condition for 6 months or longer, and the seacucumbers have very good sensory quality and texture characteristics.

Owner:JIANGNAN UNIV

Plastic-coated magnet and manufacturing method thereof

PendingCN108520812AAchieving tightnessImprove reliabilityPermanent magnetsEncapsulation/impregnationUltimate tensile strengthMachining

The invention belongs to the technical field of magnet application, and particularly relates to a plastic-coated magnet and a manufacturing method thereof. The plastic-coated magnet comprises a magnetbody and plastic-coated layers with which the magnet body is coated; the magnet body comprises a magnetic working area and an assembling area, the magnetic working area is coated with a first plastic-coated layer, the assembly area is coated with a second plastic-coated layer, sealing matching exits between the first plastic-coated layer and the second plastic-coated layer, and the injection molding liquidity of a first plastic-coated layer material is larger than the injection molding liquidity of a second plastic-coated layer material. According to the plastic-coated magnet and the manufacturing method thereof, it is guaranteed that the plastic-coated layers of a plastic-coated magnet product have reliable strength, and the adverse influence on the magnetic performance of the magnet canalso be reduced; as the first plastic-coated layer is formed through injection molding, compared with a traditional manufacturing method, the machining step is also omitted, the manufacturing processis simplified, waste of plastic-coated materials during machining is also avoided, and the manufacture cost is thus reduced.

Owner:CHENGDU GALAXY MAGNETAB

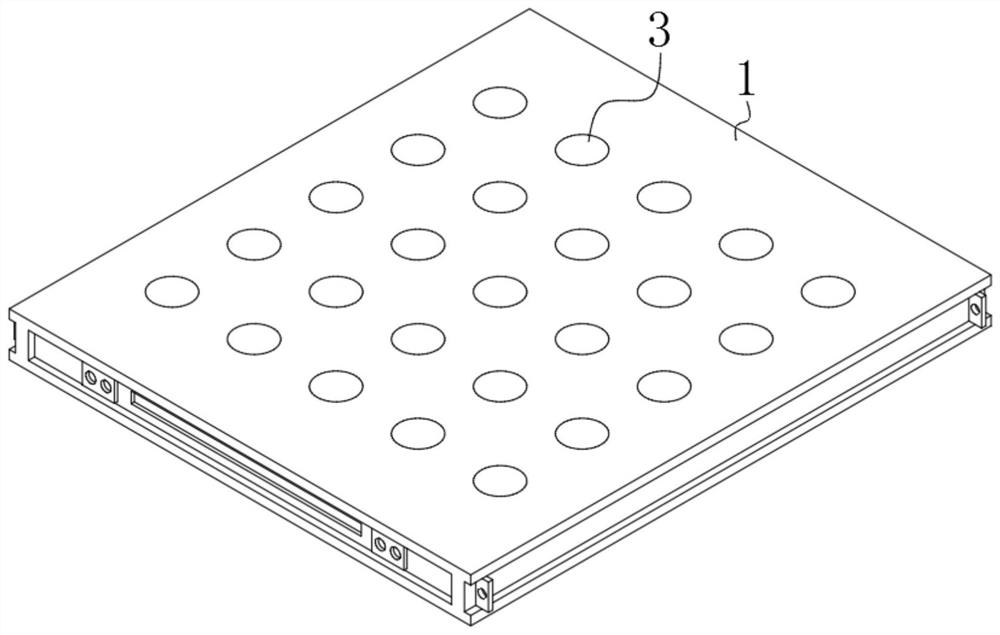

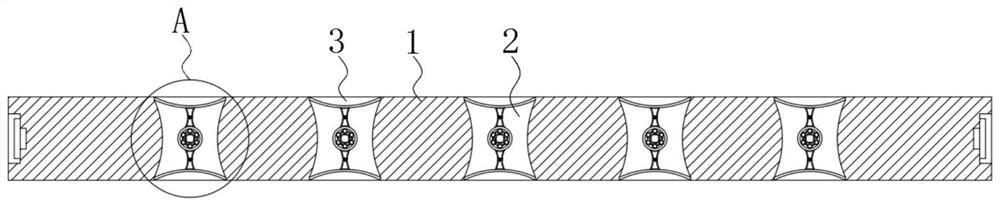

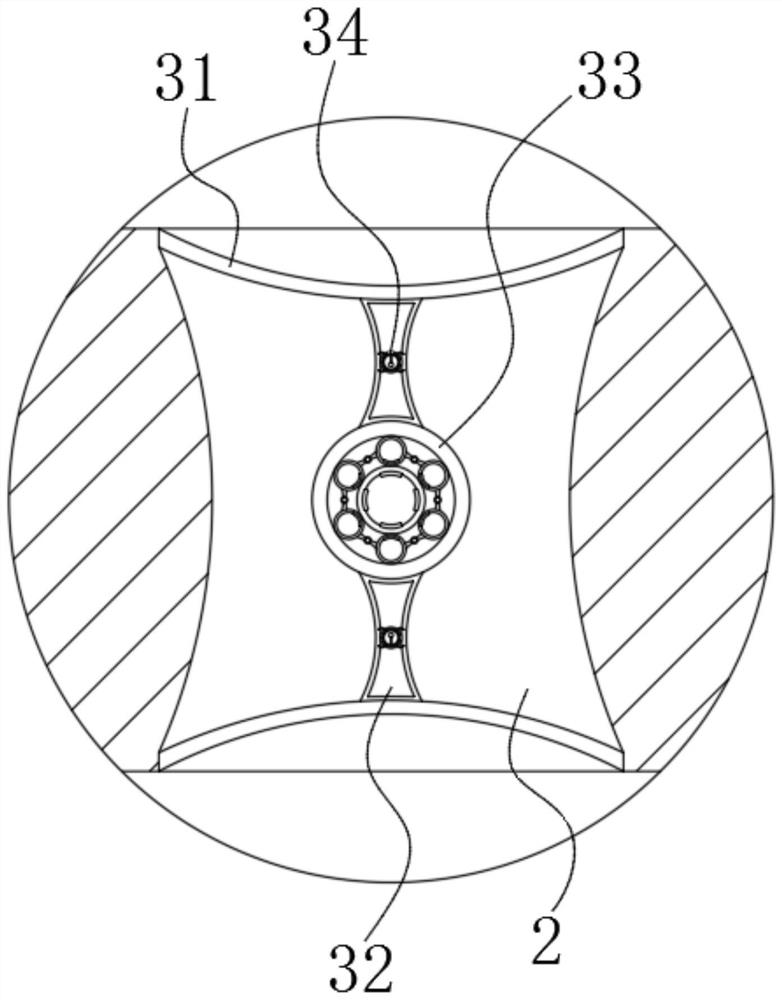

Steel building formwork with noise reduction function

ActiveCN112681721AReduce vibration amplitudeReduce the vibration amplitude by weakening the vibration amplitude of the board surfaceForming/stuttering elementsStructural engineeringMechanical engineering

The invention discloses a steel building formwork with a noise reduction function, and relates to the technical field of building formworks. The steel building formwork with the noise reduction function comprises a plate surface, mounting holes distributed in an equidistant array mode are formed in the plate surface, noise reduction mechanisms are arranged in the mounting holes, the upper ends and the lower ends of the mounting holes penetrate through the upper side and the lower side of the plate surface respectively, and each noise reduction mechanism comprises flexible films, deformation bags, a kinetic energy consumption mechanism and matched vibration reduction mechanisms; and the number of the flexible films is two, the outer edges of the two flexible films are bonded to the upper side and the lower side of the inner wall of the corresponding mounting hole correspondingly, and the deformation bags are fixedly connected to the middles of the opposite sides of the two flexible films. According to the steel building formwork with the noise reduction function, the noise reduction mechanisms and the matched vibration reduction mechanisms operate, it is effectively guaranteed that the formwork can be subjected to effective amplitude treatment in any horizontal state and in any weather environment, and therefore it is guaranteed that noise with large loudness cannot be generated in the collision and impact process of the formwork.

Owner:武汉鼎鑫宏钢模有限公司

Composite joints of square and rectangular concrete-filled steel tube columns in concrete beams connected by prestressed and ordinary steel bars

InactiveCN103938734BGuaranteed reliabilityReduce weakening effectBuilding constructionsConcrete beamsPre stress

The invention discloses a combination joint of a concrete beam and a rectangular concrete filled steel tubular column connected through pre-stressed steel bars and common steel bars, and belongs to the technical field of building structures. The combination joint comprises the rectangular concrete filled steel tubular column, the reinforced concrete beam, pre-stressed steel bars, steel plates and channel steel. The rectangular concrete filled steel tubular column and the reinforced concrete beam are both cast in place; the rectangular concrete filled steel tubular column and the reinforced concrete beam are connected through the pre-stressed steel bars and the common steel bars; a hole channel is reserved in the cross section, connected with the reinforced concrete beam, of the rectangular concrete filled steel tubular column, and a metal corrugated pipe is pre-buried in the hole channel; the steel plates are welded to the cross section, connected with the reinforced concrete beam, of the rectangular concrete filled steel tubular column, and corresponding holes are formed in the steel plates; the channel steel is welded onto a rectangular steel pipe. The combination joint is high in construction speed, the anti-shear bearing capacity of the joint can be effectively increased, the connecting performance of the joint is enhanced and the application prospects are wide.

Owner:BEIJING UNIV OF TECH

Prestressed Connected Concrete Beam Circular Concrete Steel Tube Column Joints

InactiveCN103924676BGuaranteed reliabilityReduce weakening effectBuilding constructionsConcrete beamsPre stress

Owner:BEIJING UNIV OF TECH

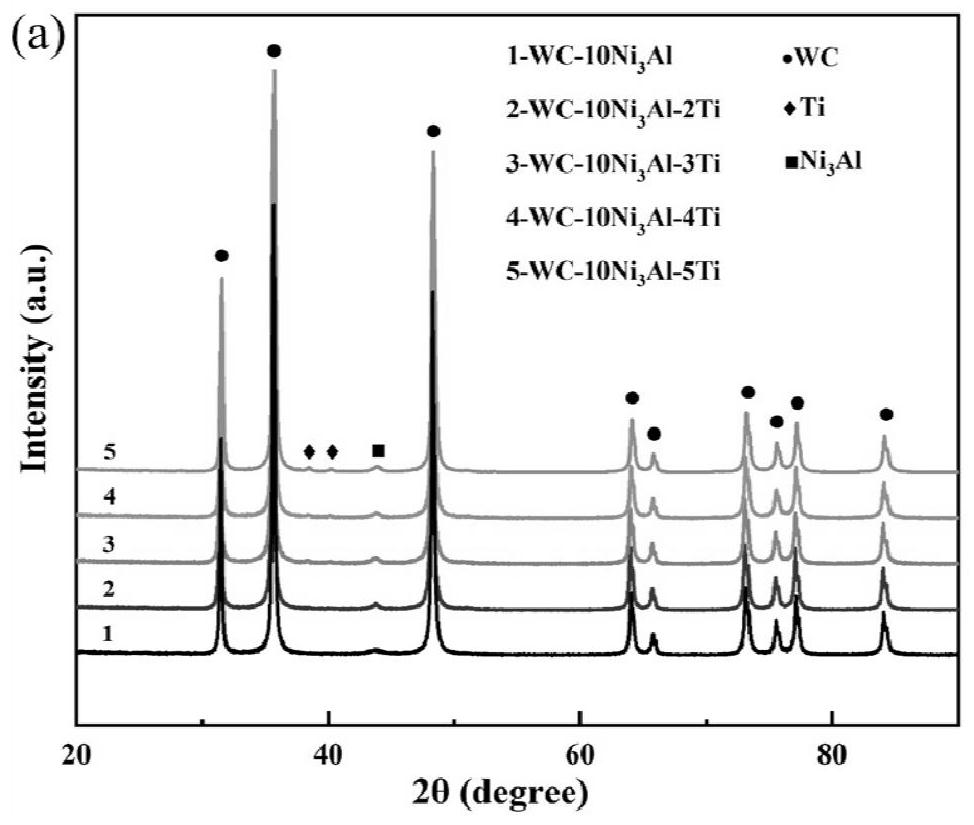

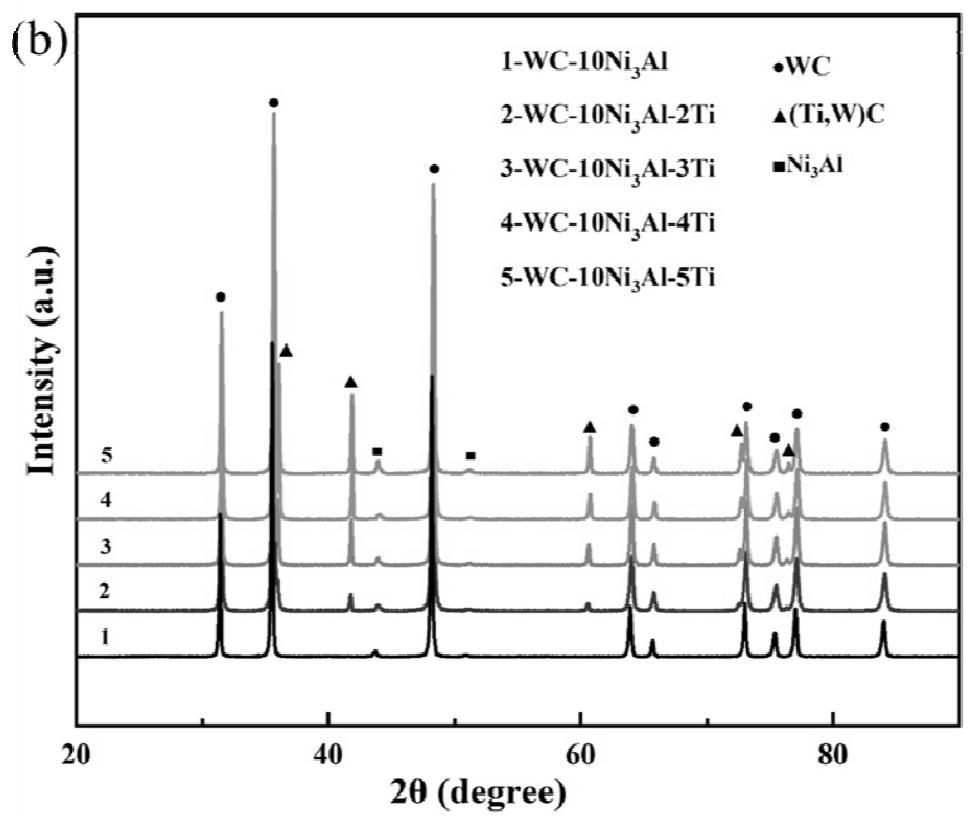

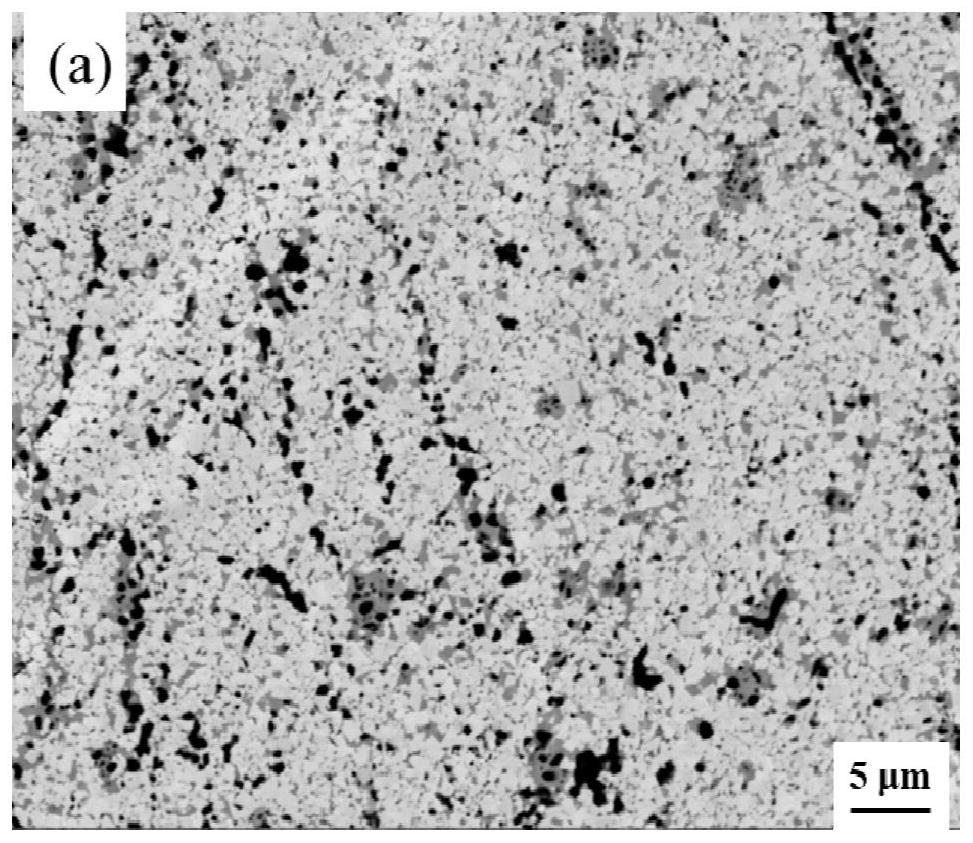

Preparation method for in-situ generation of (Ti, W) C reinforced WC-Ni3Al composite material by adding Ti powder

The invention discloses a preparation method for in-situ generation of a (Ti, W) C reinforced WC-Ni3Al composite material by adding Ti powder. The method comprises the following preparation steps: preparing Ni3Al powder by mechanical alloying, wherein the Ni3Al powder comprises Ni, Al, Cr, Mo and B; the raw material powder is placed in a ball mill for dry ball milling, and Ni3Al intermetallic compound powder is prepared; ni3Al intermetallic compound powder, titanium powder and WC powder are placed in an organic solvent to be subjected to wet ball milling, mixed slurry is prepared, then the mixed slurry is dried, pulverized and sieved, and mixed powder is obtained; and sintering to obtain the product. On the premise that titanium powder is added, (Ti, W) C is generated in a WC matrix by adopting an in-situ generation method, the added Ti powder firstly consumes part of O elements in the sintering process to form an oxide of Ti, then TiC is formed at high temperature, and then the TiC and WC form a (Ti, W) C solid solution.

Owner:SOUTH CHINA UNIV OF TECH

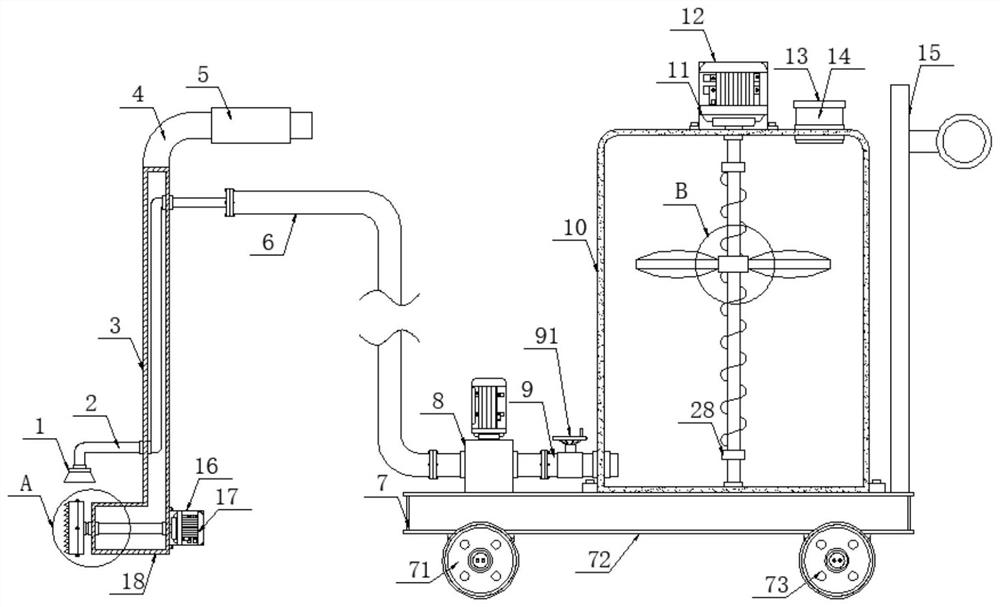

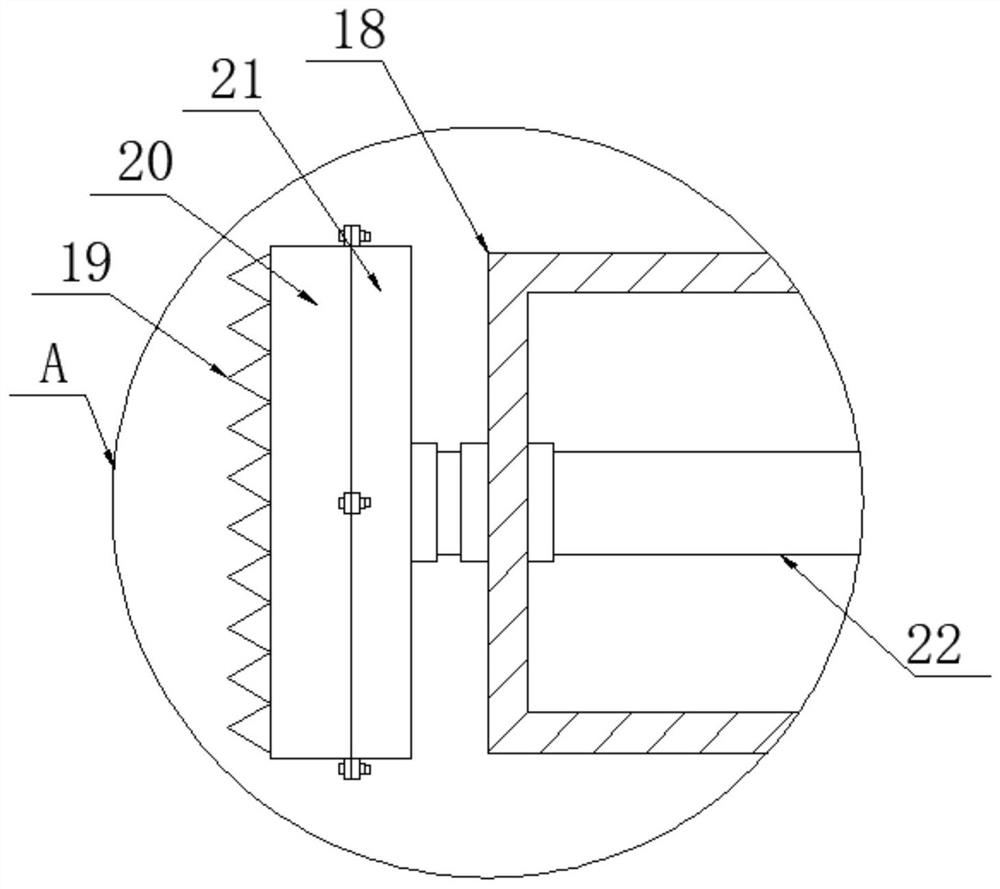

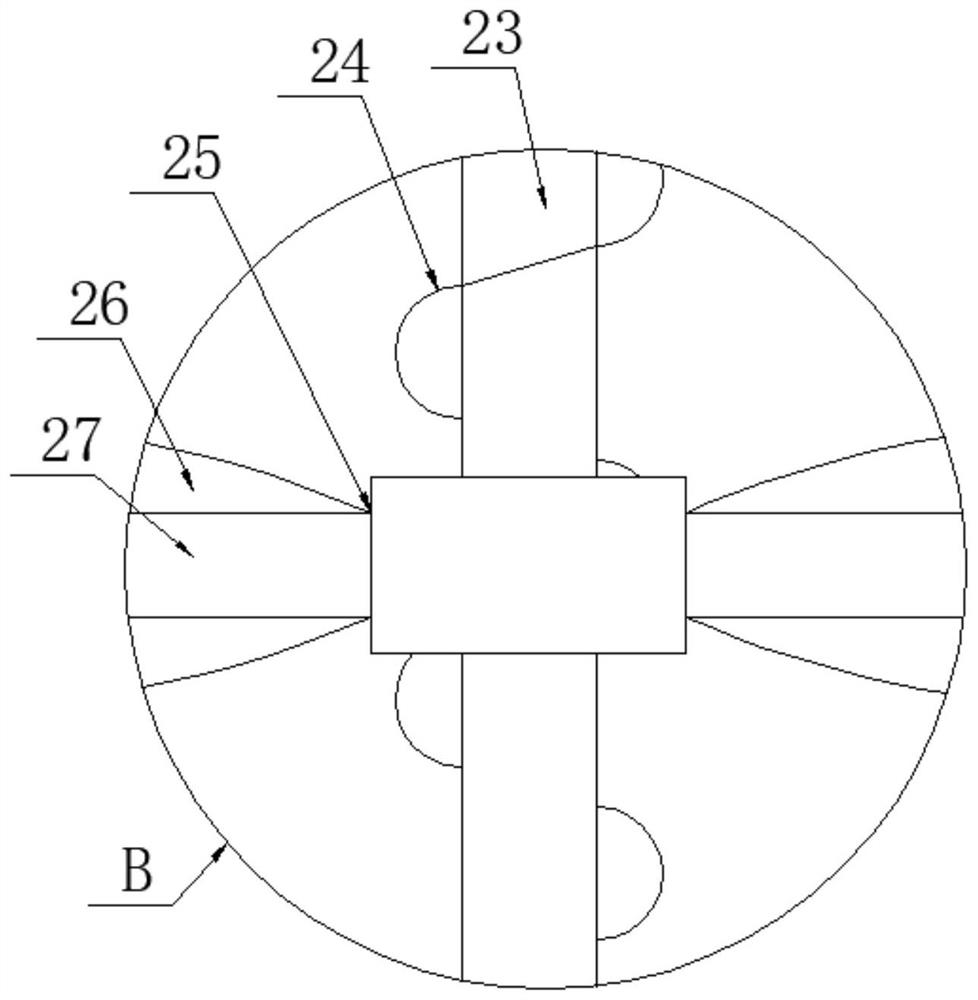

Municipal public engineering sewer decontamination device

InactiveCN112814133AEasy to operateEffective exportTransportation and packagingSewer cleaningSteering wheelArchitectural engineering

The invention discloses a municipal public engineering sewer decontamination device in the technical field of sewer decontamination. The municipal public engineering sewer decontamination device comprises a moving trolley, a first fixed shell and a second fixed shell, wherein the moving trolley comprises steering wheels, a bottom plate and moving wheels; the first fixed shell is fixedly connected with the second fixed shell; a crushing device in movable connection is arranged on the second fixed shell; a spray head is arranged above the crushing device; the top end surface of the spray head is fixedly connected with a spraying pipeline communicated with an inner cavity; a box body is arranged on the top end surface of the bottom plate; a stirring device in movable connection is arranged in the inner cavity of the box body; the top end surface of the box body is fixedly connected with a water inlet pipeline; a water outlet pipeline is arranged in a position, near the bottom end surface of the box body, of the left side end surface of the box body; a booster pump is arranged at the left side part of the water outlet pipeline; and a communication hose in flange connection is arranged between the booster pump and the spraying pipeline. The municipal public engineering sewer decontamination device aims at solving the problem that dirt on the inner wall of a sewer is inconvenient to remove.

Owner:胡永礼

Prestressed Connected Concrete Beam Square Rectangular Steel Tube Concrete Column Joints

InactiveCN103924683BGuaranteed reliabilityReduce weakening effectBuilding constructionsPrestressed concrete beamRebar

The invention relates to a prestressed connected concrete beam square rectangular steel tube concrete column joint, which belongs to the technical field of building structures. Including square and rectangular steel pipe concrete columns, reinforced concrete beams, prestressed tendons, steel plates, channel steel. It is characterized in that: the square rectangular concrete filled steel pipe column and the reinforced concrete beam are all cast-in-situ; Metal bellows are pre-embedded in the channel; steel plates are welded at the connection section between square and rectangular steel pipe concrete and beams, and there are corresponding holes on the steel plates; channel steel is welded on square and rectangular steel pipes. The invention has fast construction speed, can effectively increase the shear bearing capacity of nodes, enhance its connection performance, and has broad application prospects.

Owner:BEIJING UNIV OF TECH

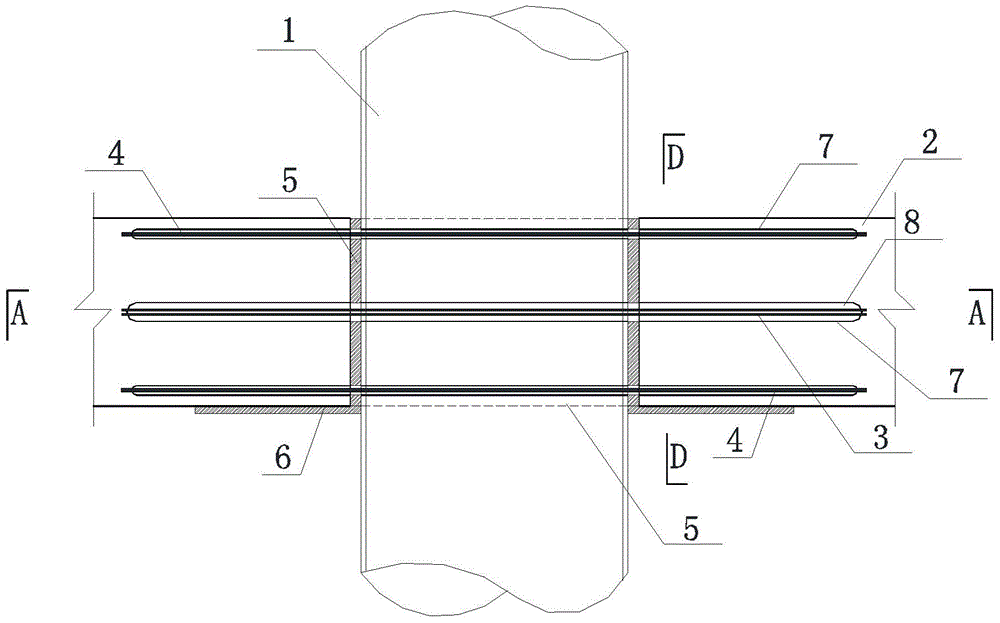

Composite joints of prestressed and ordinary steel bars connecting precast concrete beams with circular concrete-filled steel tube columns

ActiveCN103938731BGuaranteed reliabilityAlleviate the transfer prestressing effectBuilding constructionsConcrete beamsPre stress

The invention discloses a combination joint of a prefabricated concrete beam and a round concrete filled steel tubular column connected through pre-stressed steel bars and common steel bars, and belongs to the technical field of building structures. The round concrete filled steel tubular column and the reinforced concrete beam are both prefabricated; a hole channel is reserved in the cross section, corresponding to the round concrete filled steel tubular column, of the prefabricated concrete beam, and a metal corrugated pipe is pre-buried in the hole channel; annular plates are welded to the position, connected with the reinforced concrete beam, of the round concrete filled steel tubular column; channel steel is welded onto a round steel pipe; the common steel bars, the pre-stressed steel bars and tension pre-stressed steel bars penetrate through the metal corrugated pipe backwards; after tension is completed, hole channel grouting is completed within forty eight hours, and therefore the beam and the column form a whole. The combination joint is high in construction speed, the anti-shear bearing capacity of the joint can be effectively increased, the connecting performance of the joint is enhanced and the application prospects are wide.

Owner:福建省凡澈建设发展有限公司

Unbonded prestress and ordinary steel bars connecting precast concrete beams with square and rectangular concrete-filled steel tube column composite joints

ActiveCN103924680BGuaranteed reliabilityReduce weakening effectBuilding constructionsSheet steelReinforced concrete

Owner:宝嘉智能科技(南通)有限公司

Composite joints of circular concrete-filled steel tube columns in concrete beams connected by prestressed and ordinary steel bars

InactiveCN103924679BGuaranteed reliabilityReduce weakening effectBuilding constructionsPrestressed concrete beamConcrete beams

The invention discloses a prestressed concrete beam and circular steel pipe concrete column combined joint connected with regular rebars and belongs to the technical field of building structures. A steel pipe concrete column and a reinforced concrete beam are cast in situ and are connected with the regular rebars through prestressed tendons, a runner is reserved at the connected position of the circular steel pipe concrete column and the reinforced concrete beam, metal bellows are buried in the runner, the prestressed tendons are inserted into the metal bellows and then grouted, a ring plate is welded at the connected position of the circular steel pipe concrete column and the concrete beam and provided with corresponding holes, and the groove steel is welded on a circular steel pipe. The prestressed concrete beam and circular steel pipe concrete column combined joint is fast in construction and wide in application prospect, and shear resistance of the combined joint is effectively improved, and connecting performance of the same is improved.

Owner:BEIJING UNIV OF TECH

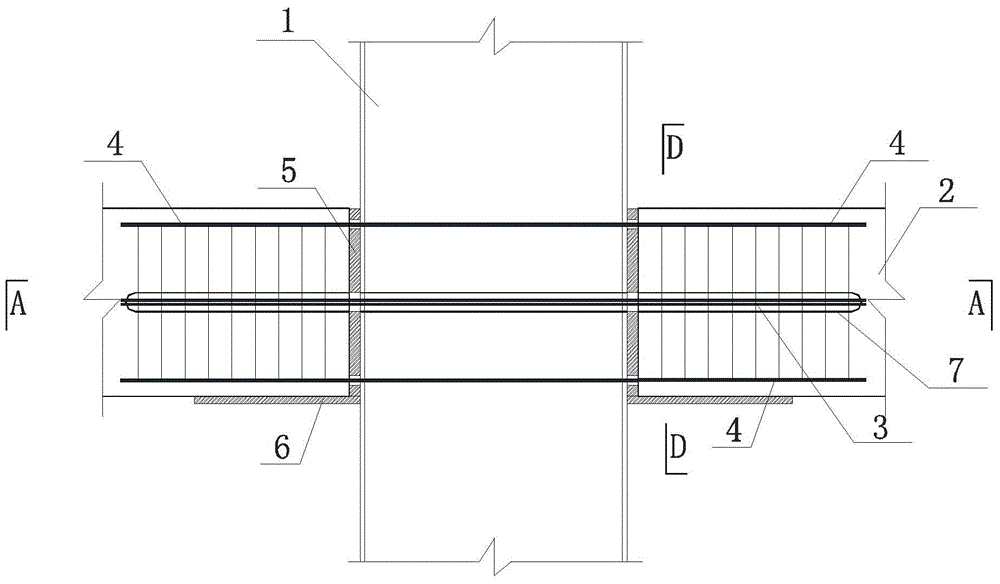

Laboratory model test displacement meter fixing device and mounting method

PendingCN111855253AEasy to operateSimple structureStructural/machines measurementSecuring devicesEngineeringTunnel wall

The invention relates to a laboratory model test displacement meter fixing device, which comprises a screw, a clamp, claw nuts and claw fastening screws, wherein the clamp is mainly composed of a clamping piece, a clamping piece base and a screw insertion hole, the clamping piece and the clamping piece base are welded into a whole, the screw insertion hole is punched in the clamping piece base, the clamping piece is made of a U-shaped steel sheet, a clamping groove is formed in the side face of the U-shaped steel sheet, and the clamping groove is matched with the end part of a displacement meter; the claw nuts penetrate through the two ends of the screw, one end of the screw penetrates through the tunnel wall and is fixed to the tunnel wall through the claw nuts located on the inner side and the outer side of the tunnel wall, and the clamp penetrates through the other end of the screw and is fixed through the claw nuts; and each clamping piece is provided with the claw fastening screwon the side away from the displacement meter. The device has the beneficial effects that the device is composed of the screw and the clamp, the structure is simple, the use is convenient, direct manual screwing can be achieved by adopting the claw nuts and the claw fastening screws, and no external tool is needed.

Owner:ZHEJIANG UNIV CITY COLLEGE

A metal structure test block for ultrasonic testing and its preparation process

ActiveCN108918688BImprove structural qualityIncrease elasticityMaterial analysis using sonic/ultrasonic/infrasonic wavesCarbide siliconLongitudinal wave

The invention provides a metal structure test block for ultrasonic testing. The metal structure test block comprises an inner sand core block, a transition composite layer and an outer metal layer which are sequentially cast. The surface of the inner sand core block is crossedly provided with a plurality of communicated channels. The inner diameter of the channel opening is larger than the widestinner diameter of the channel. The inner sand core block comprises sandstone, soft refractory clay and water glass. The transition composite layer comprises composite molten iron containing silicon carbide. The outer metal layer comprises composite molten iron without silicon carbide. Through the reasonable structure design and material matching, the test block for ultrasonic testing has stable structural quality. The metal structure test block has good internal compactness and retractable elasticity and low transverse wave and longitudinal wave dampening effects, can be used for an ultrasonictest on the diagonal welding joint and has high detection sensitivity.

Owner:浙江方圆金属材料检测有限公司 +1

Composite joints of square rectangular concrete-filled steel tube columns in concrete beams connected by unbonded prestress and ordinary steel bars

ActiveCN103924677BGuaranteed reliabilityReduce weakening effectBuilding constructionsPre stressConcrete beams

The invention relates to a concrete beam and square-rectangular concrete-filled steel tube column combining joint employing unbonded prestress and common reinforcement for connection and belongs to the technical field of building structures. The concrete beam and square-rectangular concrete-filled steel tube column combining joint employing unbonded prestress and common reinforcement for connection comprises a square-rectangular concrete-filled steel tube column, a reinforced concrete beam, unbonded prestressed bars, steel plates, and steel channels. Both the square-rectangular concrete-filled steel tube column and the reinforced concrete beam are both cast in place. The connection sections of the square-rectangular concrete-filled steel tube column and the reinforced concrete beam is provided with ducts in which metal bellows are embedded; the steel plates are welded at the connection sections of the square-rectangular concrete-filled steel tube column and the reinforced concrete beam and are provided with corresponding holes; the steel channels are welded on the square-rectangular concrete-filled steel tube column. The concrete beam and square-rectangular concrete-filled steel tube column combining joint employing unbonded prestress and common reinforcement for connection has the advantages that construction speed is high, the field welding process is not required, joint connection reliability can be guaranteed, seismic performance is good, a connection way of the joint is applicable to side column joints in structures and also applicable to middle column joints, and the joint has promising application prospect.

Owner:北京中联浩科技服务有限公司

Tungsten-base alloy material and preparation method therefor

PendingUS20220325380A1High tensile strengthHigh strengthTransportation and packagingMetal-working apparatusMetallurgyAlloy

A tungsten-base alloy material and a preparation method therefor. The preparation method comprises: 1) evenly grinding composite powder containing tungsten and zirconium oxide, and then performing annealing treatment at 700-1000° C. to obtain powder A; and 2) grinding and then compression moulding the powder A, and then performing liquid-phase sintering to obtain a tungsten-base alloy blank so as to obtain the tungsten-base alloy material.

Owner:HENAN UNIV OF SCI & TECH

Unbonded Prestressed Connected Concrete Beam Square Rectangular Steel Tube Concrete Column Joints

ActiveCN103924684BGuaranteed reliabilityReduce weakening effectBuilding constructionsPre stressingShock resistance

The invention relates to a rectangular concrete-filled steel tubular column node of an unbonded pre-stressing connecting concrete beam, and belongs to the technical field of building structures. The rectangular concrete-filled steel tubular column node comprises a rectangular concrete-filled steel tubular column, a reinforced concrete beam, unbonded pre-stressing tendons, a steel plate and channel steel. The rectangular concrete-filled steel tubular column and the reinforced concrete beam are both formed in a cast-in-situ mode and connected through the unbonded pre-stressing tendons; a hole way is reserved in the connecting cross section of the rectangular concrete-filled steel tubular column and the reinforced concrete beam, and a metal corrugated pipe is embedded in the hole way; the steel plate is welded to the connecting cross section of the rectangular concrete-filled steel tubular column and the reinforced concrete beam, and a corresponding hole is formed in the steel plate; the channel steel is welded to a rectangular steel tube. The rectangular concrete-filled steel tubular column node is high in construction speed, the site welding technology is not needed, the reliability of node connection can be guaranteed, the node has the good shock resistance, the node connecting mode can be used for side column nodes in the structure and can also be used for middle column nodes, and the application prospect is wide.

Owner:湖州市双林工业园区开发有限公司

A construction method of special-shaped piles with carbon fiber bag cast-in-place anti-arch curved surface combination

Owner:JIANGSU ZHONGRUI ROAD & BRIDGE CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com