Prestress connected precast concrete beam rectangular steel tube concrete column node

A technology of concrete-filled steel tubular columns and precast concrete, which is applied in the directions of buildings and building structures to achieve the effects of reducing weakening effect, improving performance and having broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

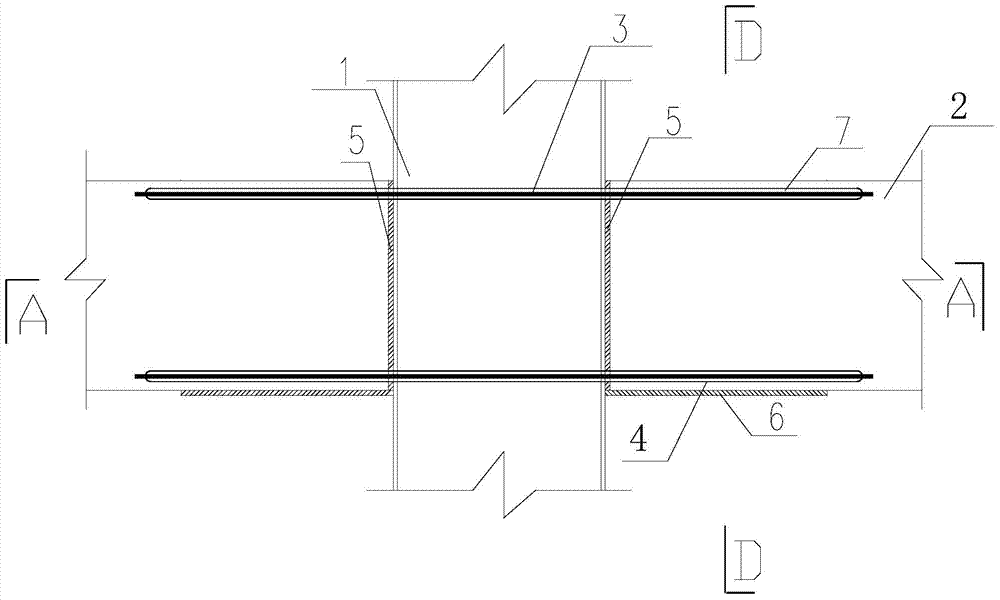

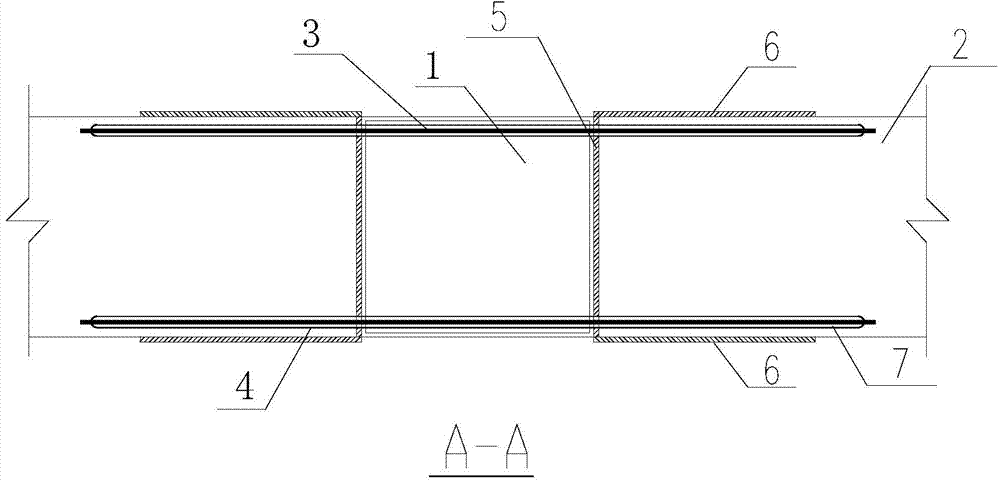

[0022] The joint structure of prestressed concrete beam square rectangular concrete filled steel tube column is as follows: figure 1 Shown:

[0023] 1. Manufacture of square and rectangular steel pipe concrete and reinforced concrete beams

[0024] Square rectangular concrete-filled steel tube columns (1) and reinforced concrete beams (2) are produced in the factory in strict accordance with relevant specifications and drawings. Four corresponding channels are reserved during prefabrication. The corrugated pipe (4) is welded to the ring plate (5) and the channel steel (6) at the interface of the connecting beam on the square rectangular concrete filled steel pipe column (1) by means of surrounding welding.

[0025] 2. Assembly of beam-column joints

[0026] After the square-rectangular concrete-filled steel tube column (1) is positioned, the reinforced concrete beam (2) is hoisted and positioned through support.

[0027] 3. Tensile prestressed tendons

[0028] Wear the pre...

Embodiment 2

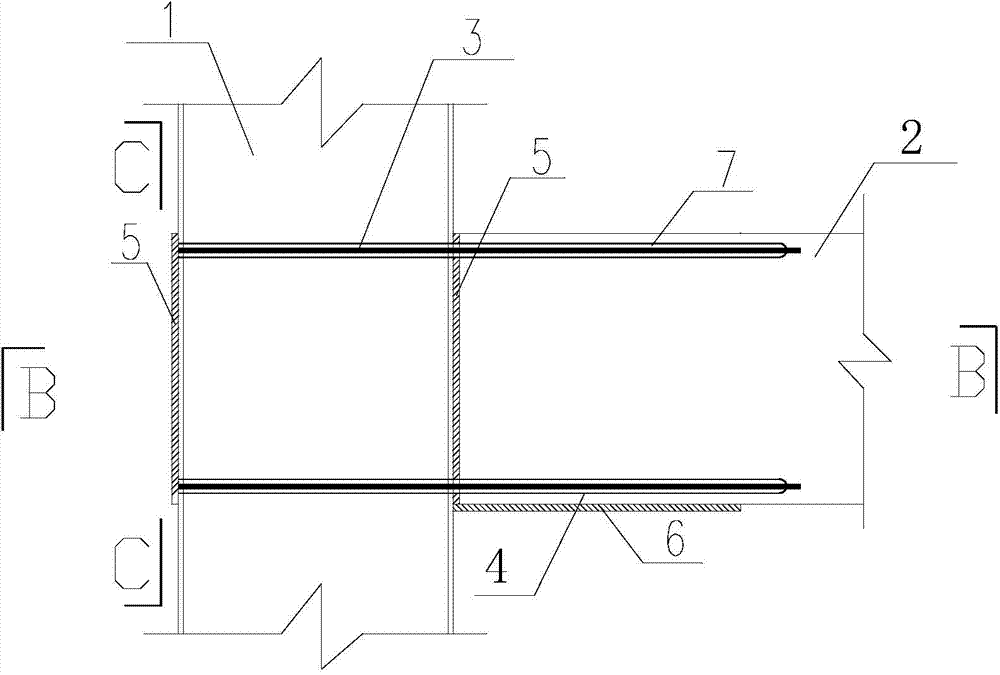

[0034] See when it is a side column node figure 2 , other measures are the same as embodiment 1, except that the prestressed tendon is welded on the ring plate (5) at the end of the side column, and this ring plate can be used as a pressure bearing plate when the prestressed tendon is stretched.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com