Allochroic silica gel mask capable of representing electrostatic adsorption capacity

A technology of color-changing silica gel and electrostatic adsorption, which is used in material analysis, clothing, and chemical reaction of materials by observing the impact on chemical indicators. It also has the problems of anti-virus effect and reduction of electrostatic adsorption effect, so as to achieve excellent adsorption and filtration effect, excellent filtration and adsorption capacity, and improve the effect of effective use time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

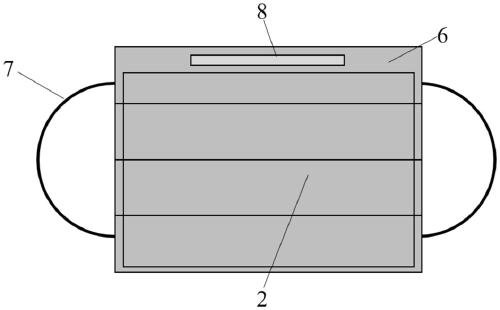

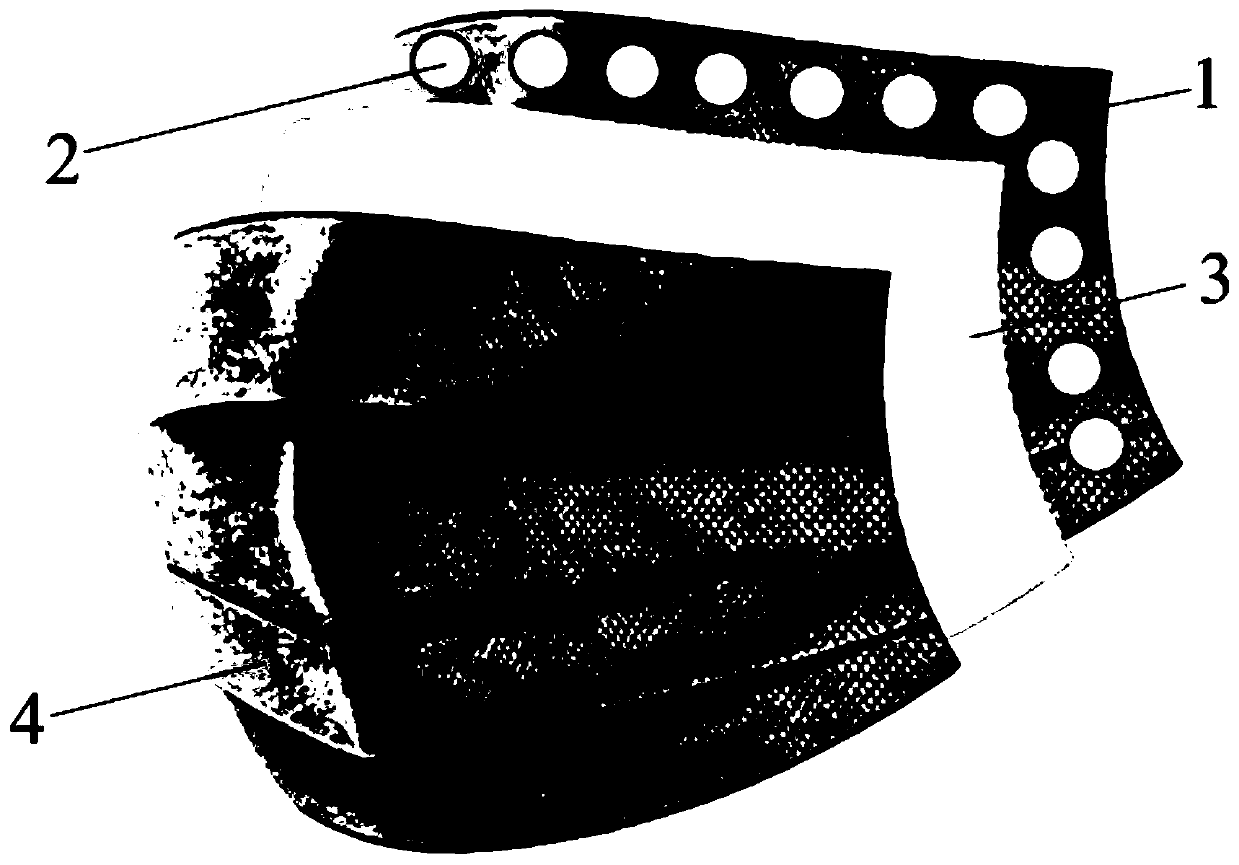

[0037] A color-changing silicone mask that can characterize the electrostatic adsorption capacity provided in this embodiment includes: a mask body 6 , a mask belt 7 and a variable bead 8 . The mask body 6 includes a four-layer structure from the outside to the inside, which are the outer layer 1 of transparent non-woven fabric, the layer 2 of color-changing silica gel, the layer 3 of melt-blown cloth and the inner layer 4 of non-woven fabric.

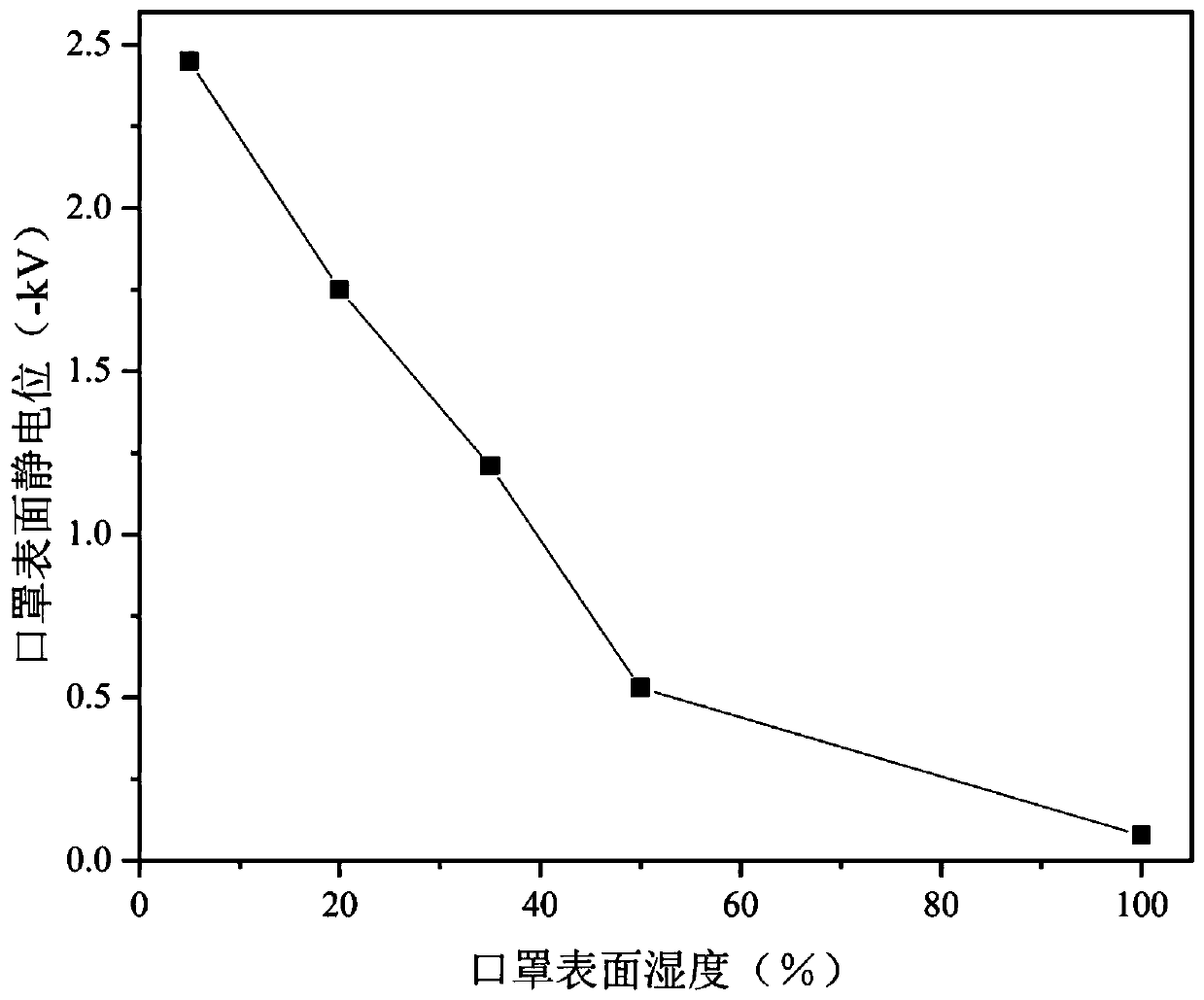

[0038] (1) Use a humidifier to simulate mouth and nose breathing, and measure the ambient relative humidity at room temperature before humidification to be 5%;

[0039] (2) Test the electrostatic charge of the melt-blown cloth layer of the medical mask at the humidity;

[0040] (3) Take 15g of color-changing silica gel beads and place them in (2) on the outer layer of the melt-blown cloth and cover them with transparent non-woven fabric, observe and record the degree of discoloration.

Embodiment 2

[0042] A color-changing silicone mask that can characterize the electrostatic adsorption capacity provided in this embodiment includes: a mask body 6 , a mask belt 7 and a variable bead 8 . The mask body 6 includes a four-layer structure from the outside to the inside, followed by a color-changing silica gel layer 2, a transparent non-woven outer layer 1, a melt-blown cloth layer 3 and a non-woven inner layer 4.

[0043] (1) Use a humidifier to simulate mouth and nose breathing, and adjust the relative humidity of the environment to be 20%;

[0044] (2) Test the electrostatic charge of the melt-blown cloth layer of the medical mask at the humidity;

[0045] (3) Take 15g of color-changing silica gel beads and place them in (2) on the outer layer of the melt-blown cloth and cover them with transparent non-woven fabric, observe and record the degree of discoloration.

Embodiment 3

[0047] A color-changing silicone mask that can characterize the electrostatic adsorption capacity provided in this embodiment includes a mask body 6 , a mask belt 7 and a variable bead 8 . The mask body 6 includes a four-layer structure from the outside to the inside, which are the outer layer 1 of transparent non-woven fabric, the layer 2 of color-changing silica gel, the layer 3 of melt-blown cloth and the inner layer 4 of non-woven fabric.

[0048] (1) Use a humidifier to simulate mouth and nose breathing, and adjust the relative humidity of the environment to be 35%;

[0049] (2) Test the electrostatic charge of the melt-blown cloth layer of the medical mask at the humidity;

[0050] (3) Take 15g of color-changing silica gel particles and place them in (2) on the outer layer of the melt-blown cloth and cover the transparent non-woven fabric, observe and record the degree of discoloration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com