Patents

Literature

39results about How to "Improve filtration performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel process for producing lithium salt by aid of sulfuric acid methods

ActiveCN106044804AImprove filtration performanceImprove the separation and filtration effectLithium carbonates/bicarbonatesLithium carbonateChemistry

The invention relates to a novel process for producing lithium salt by the aid of sulfuric acid methods. The novel process includes calcining and then cooling spodumene concentrate to obtain spodumene calcined sand; grinding the spodumene calcined sand to obtain spodumene mineral powder; adding sulfuric acid into the spodumene mineral powder and calcining the spodumene mineral powder to obtain acid clinker; adding calcium carbonate into the acid clinker to obtain mixtures, adding water into the mixtures and filtering the mixtures when a pH (potential of hydrogen) value of the mixtures reaches 5.5-6.0 so as to obtain lithium sulfate leach liquor with the solid content higher than 10%; filtering the lithium sulfate leach liquor by the aid of micro-filtration membranes, removing solid impurities, softening filter liquor to obtain softened filter liquor with the Li+ content of 20-25 g / L, concentrating the softened filter liquor to obtain concentrated liquor with the Li+ content of 40-05 g / L, collecting wastewater obtained after the softened filter liquor is concentrated and recycling the wastewater; adding soda saturated solution into the concentrated liquor, precipitating lithium carbonate, filtering and separating lithium carbonate precipitates, washing the calcium carbonate precipitates by the aid of hot water and drying the calcium carbonate precipitates to obtain lithium carbonate finished products.

Owner:SICHUAN SIDANENG ENVIRONMENTAL PROTECTION TECH CO LTD

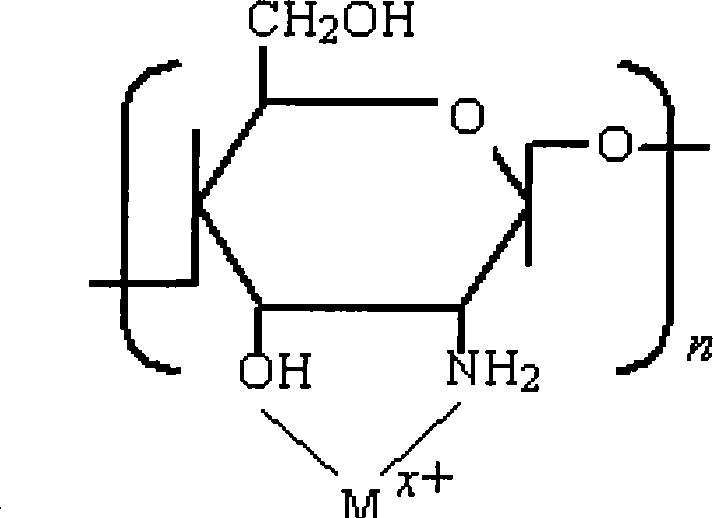

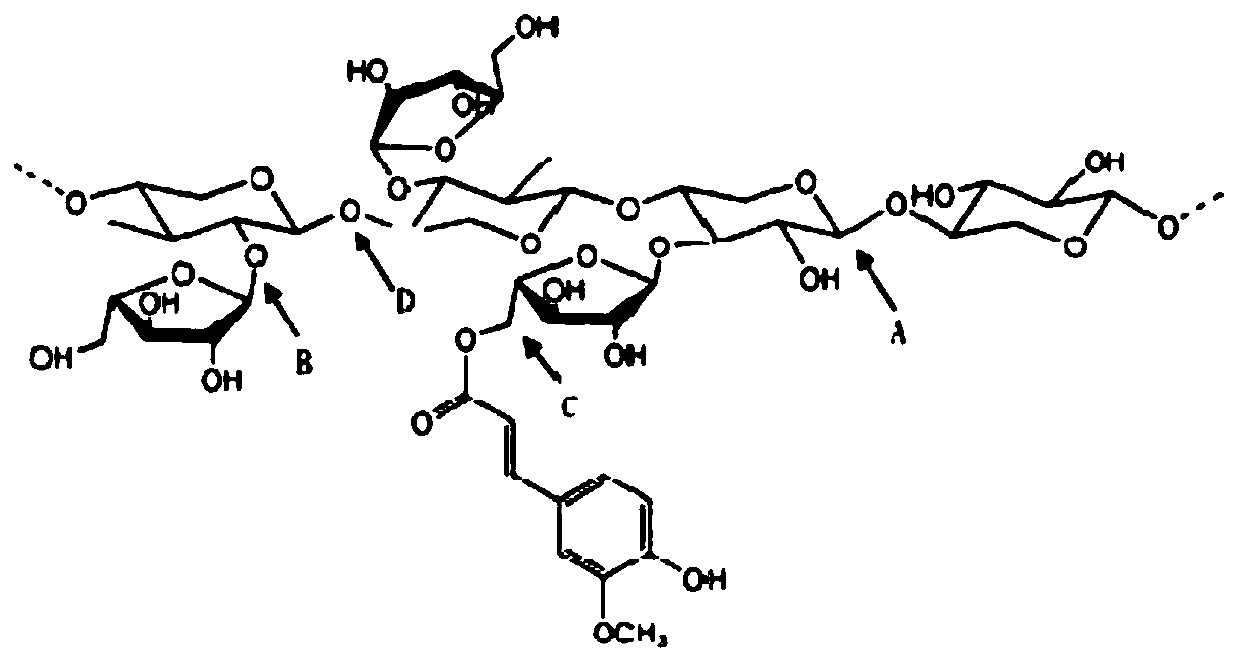

Application of chitosan complex for cigarette filter tip and preparation thereof

InactiveCN101194756AImprove filtration performanceReduce harmful ingredientsTobacco smoke filtersIonTar

The invention relates to an application of chitose complex on the cigarette filter up and belongs to the field of cigarette filter up process technique, wherein the chitose complex is used as the cigarette acetate fiber surface modification and additive agent; the chitose in the chitose complex is in a mole ratio with the total metal ions as 5:1 to 12:1. The invention has simple process and good utility, can improve the filtering property of the acetate fiber cigarette filter up, and can effectively lower the poisonous components, in particular coke tar, hydrocyanic acid and volatile aldehude in the cigarette smoke through the application of the modification and addition agents of the chitose complex in the acetate fiber. Compared with the cigarette made by the common acetate fiber tow of the filter up rod, the coke tar is lowered by 15.8 %, aldehyde substance is lowered by 27.1 % and the hydrocyanic acid is lowered by 29.2 % in the cigarette made by the invention process.

Owner:CHINA TOBACCO HUNAN INDAL CORP

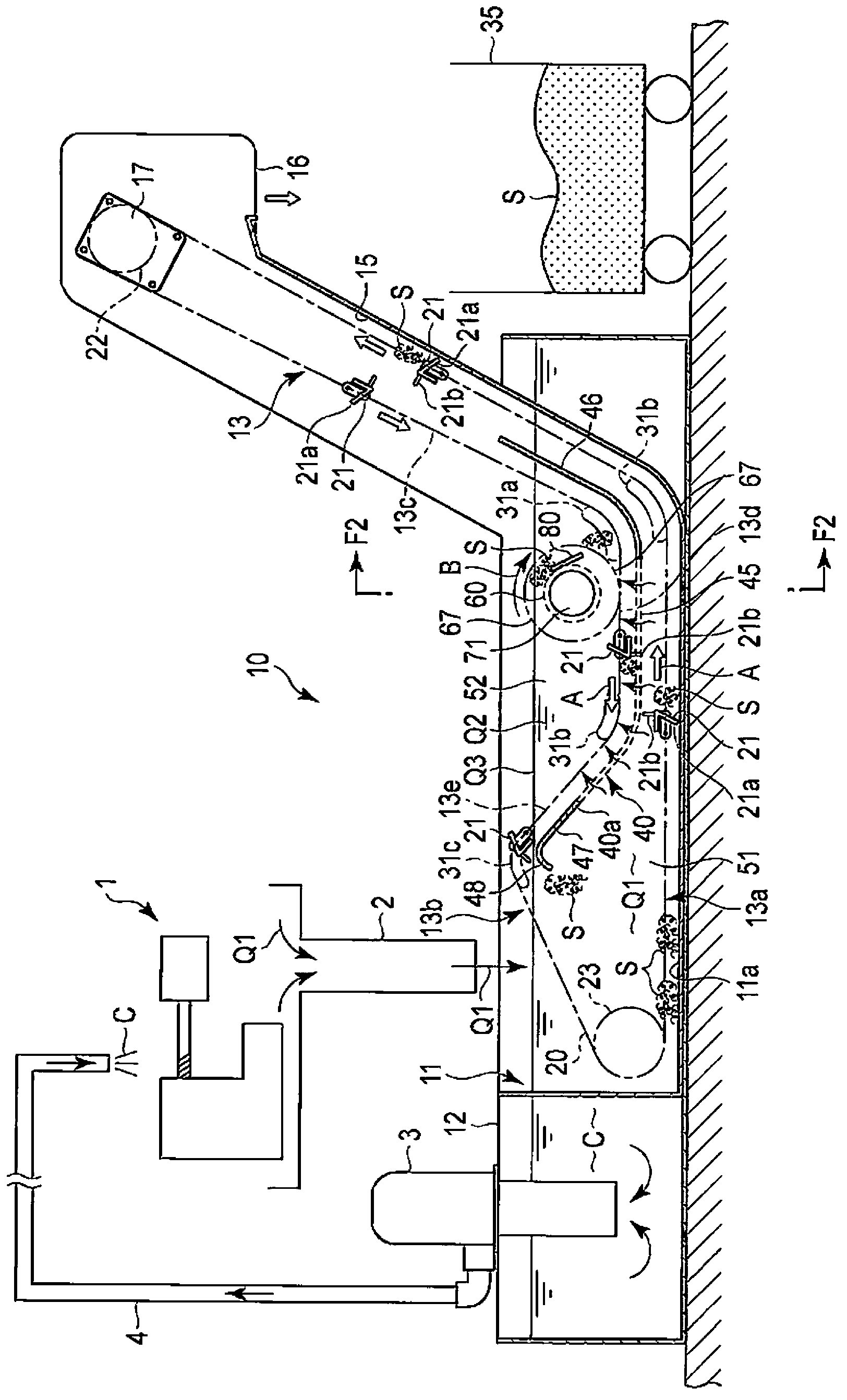

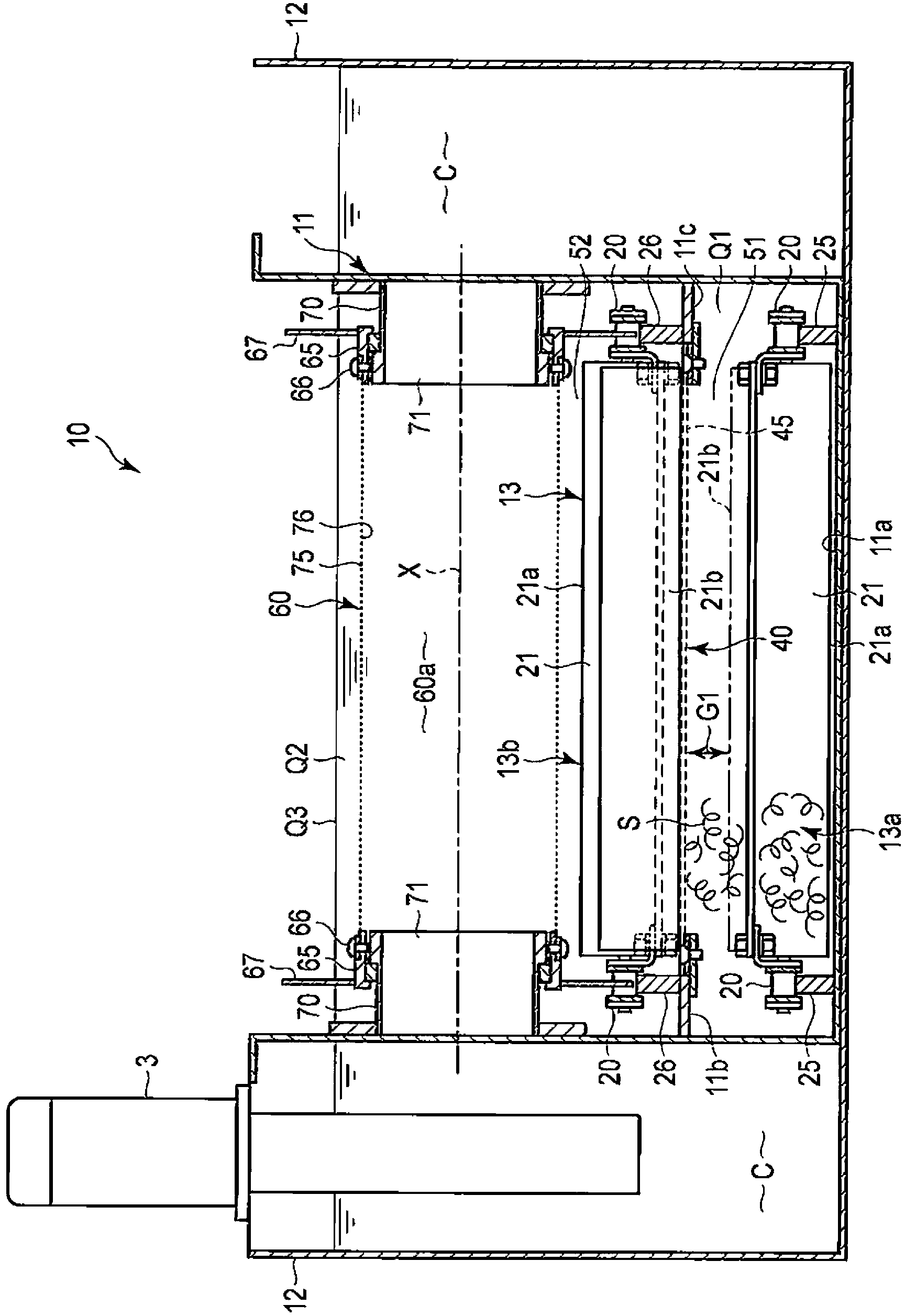

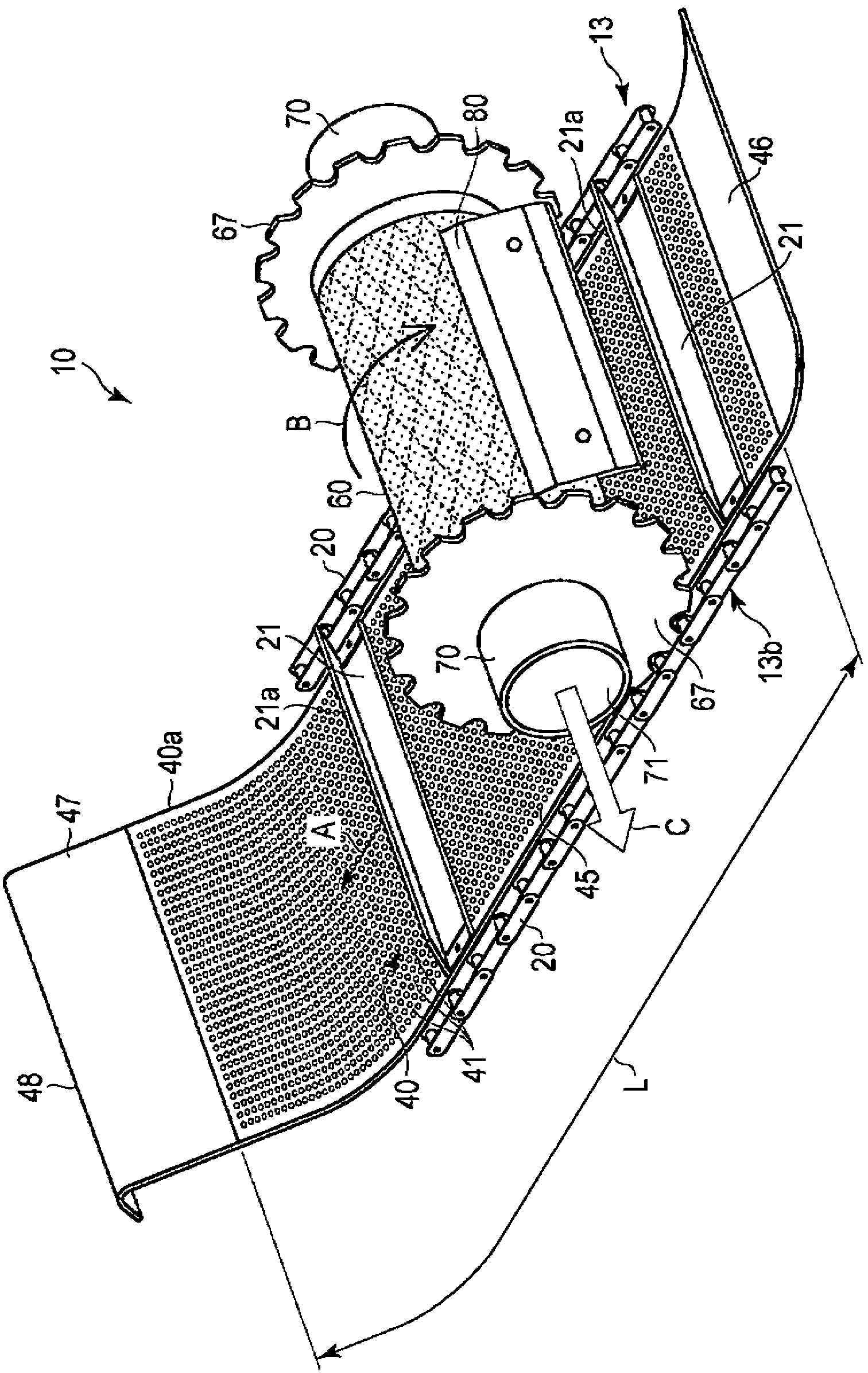

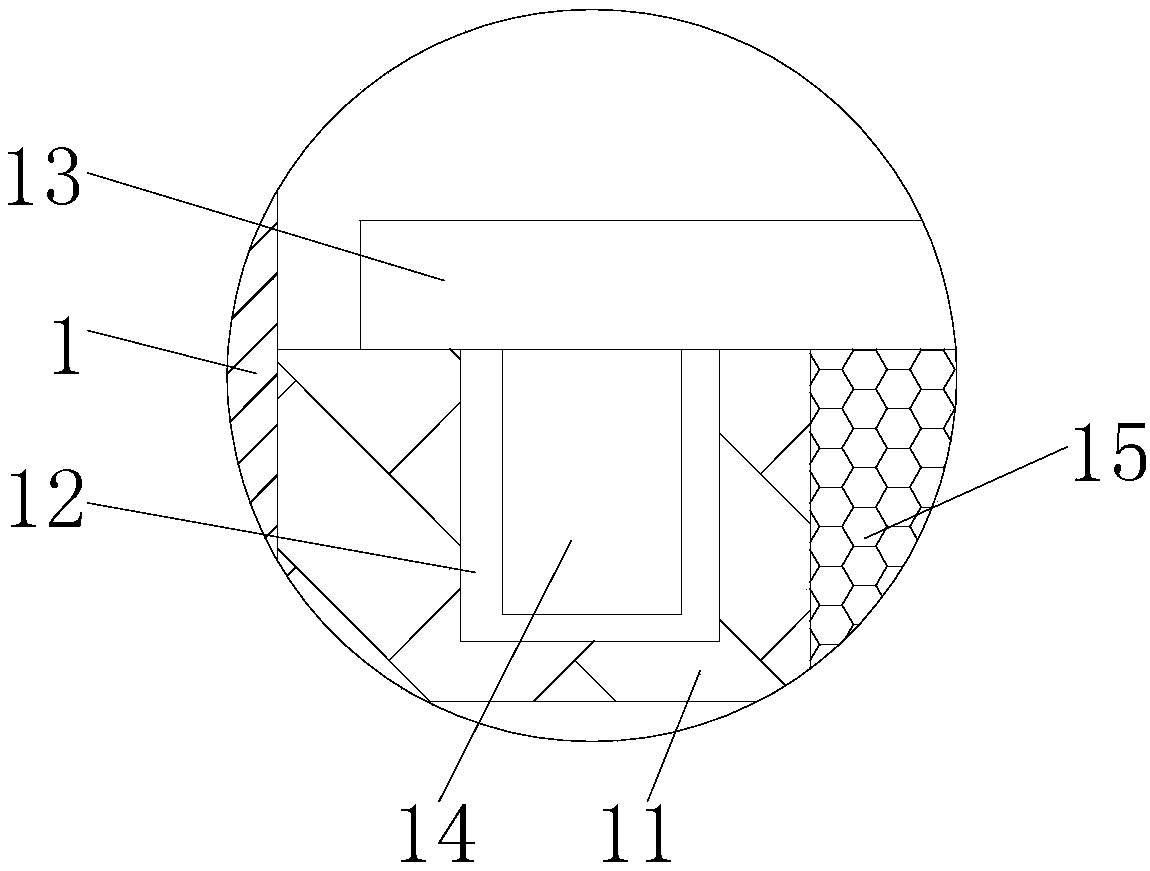

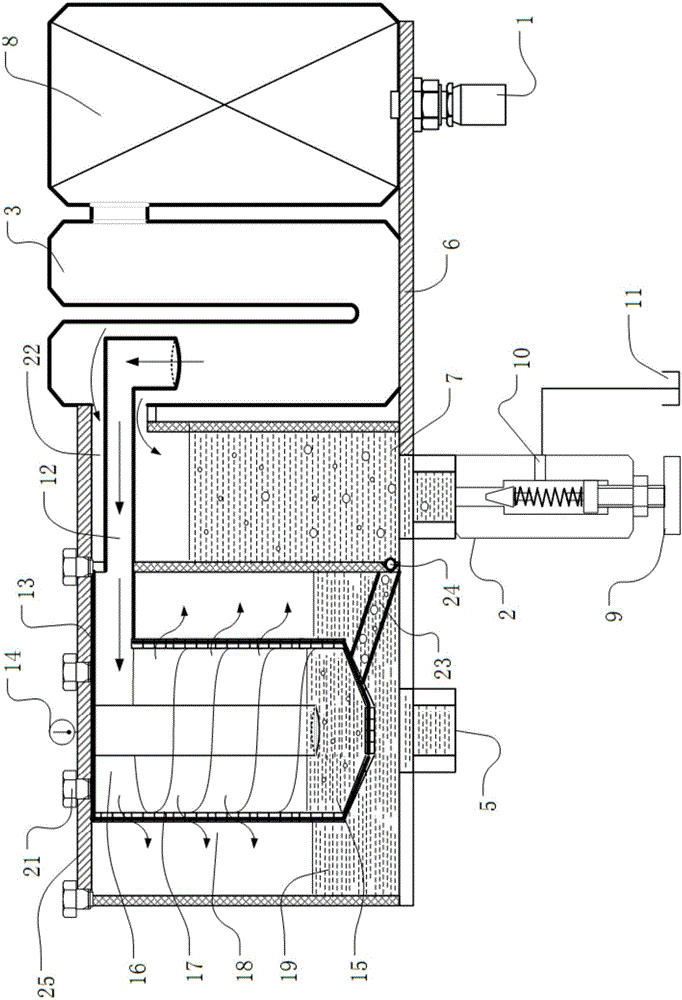

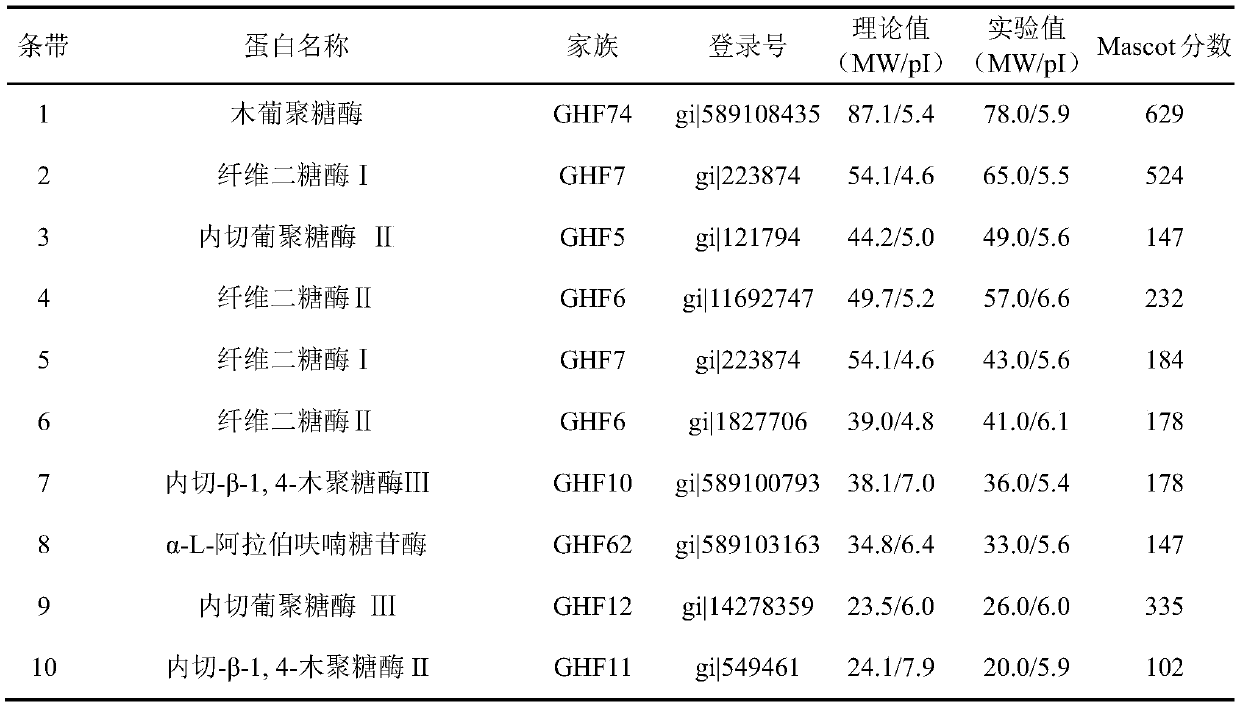

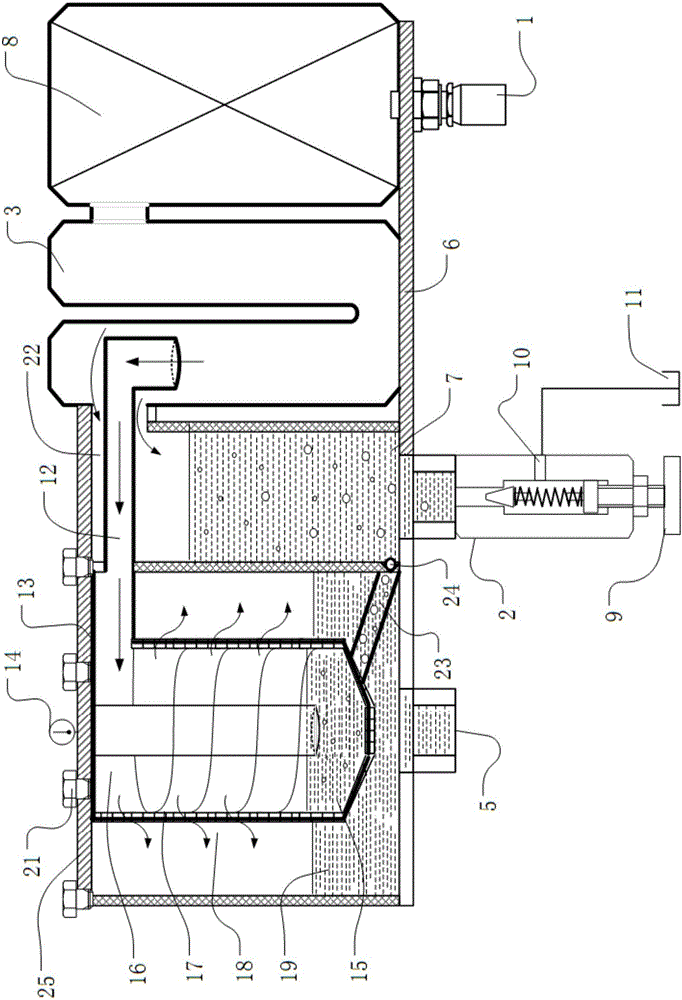

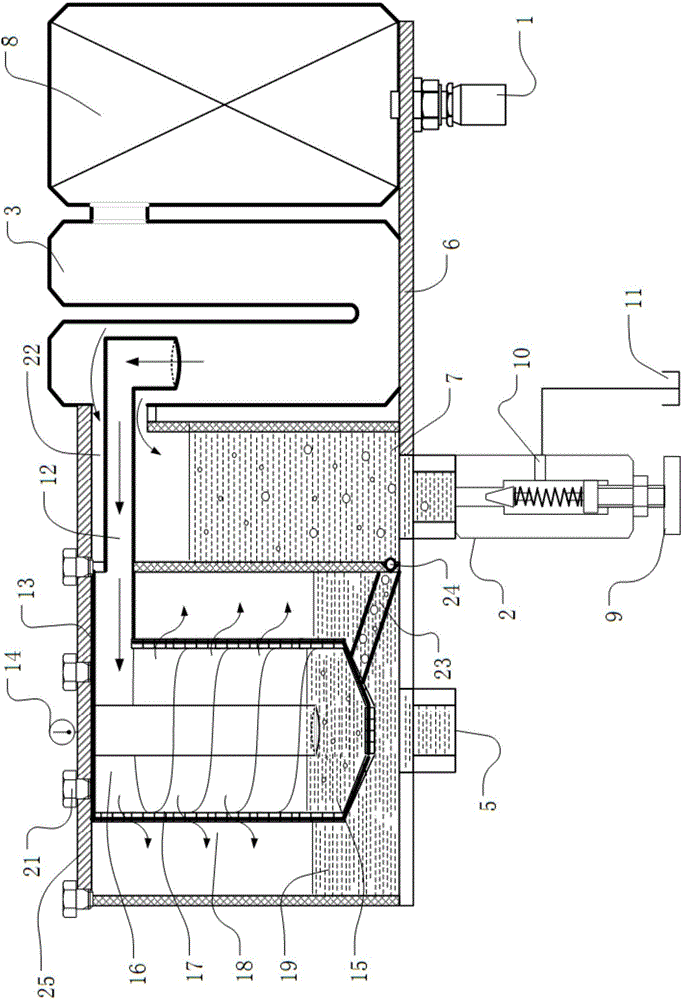

Filtration device

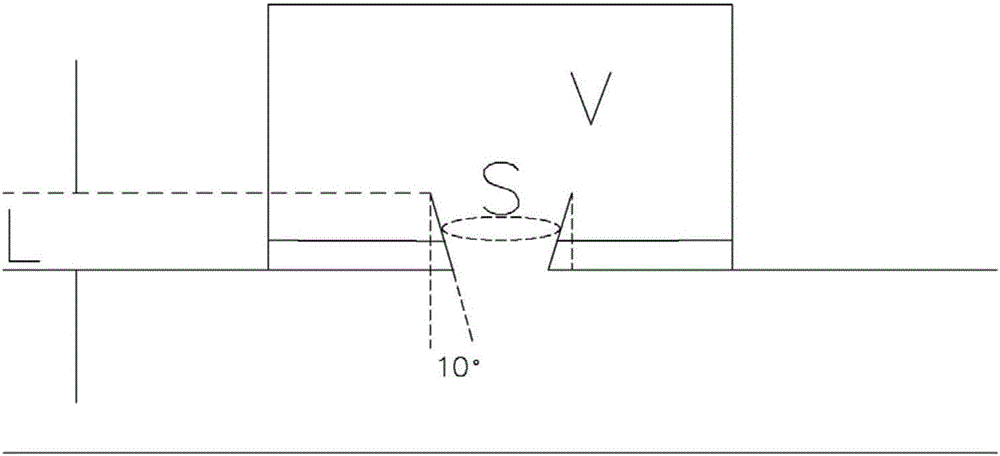

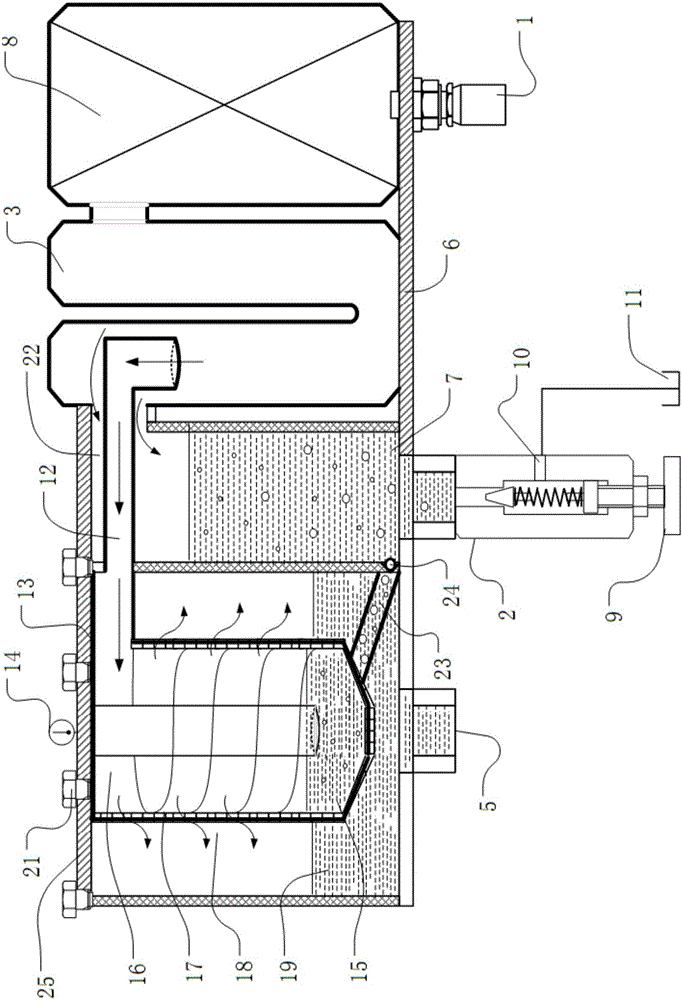

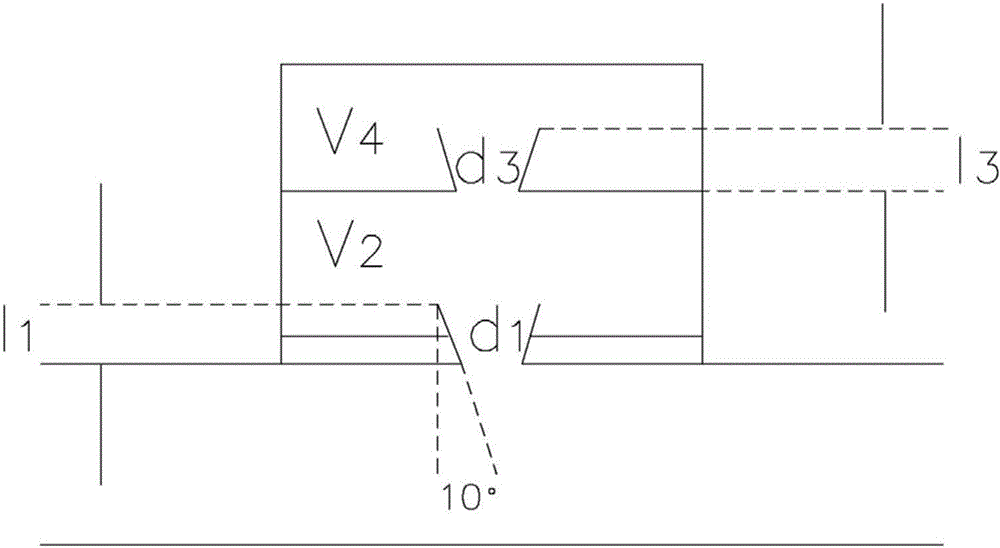

InactiveCN103189121ACompact and filter performanceImprove filtration performanceSettling tanks feed/dischargeMembrane filtersSludgeFiltration

A filtration device (10) includes: a filtration tank (11); a conveyor (13) having a scraper (21); a first filter (40); and a cylindrical second filter (60) that rotates. The inside of the filtration tank (11) is divided into a first filtration tank portion (51) and a second filtration tank portion (52) by the first filter (40). A sludge (S) that has sunk to the bottom of the first filtration tank portion (51) is conveyed toward a sludge discharge portion (16) by a first portion (21a) of the scraper (21). A liquid (Q1) in the first filtration tank portion (51) is filtered by the first filter (40) and flows into the second filtration tank portion (52). A liquid (Q2) in the second filtration tank portion (52) is filtered by the second filter (60) and conveyed to a clean tank (12). The sludge (S) adhered to the second filter (60) is dropped on the first filter (40) and discharged toward the first filtration tank portion (51) by a second portion (21b) of the scraper (21).

Owner:BUNRI

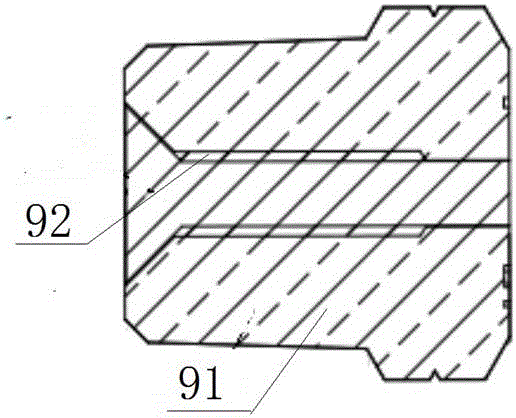

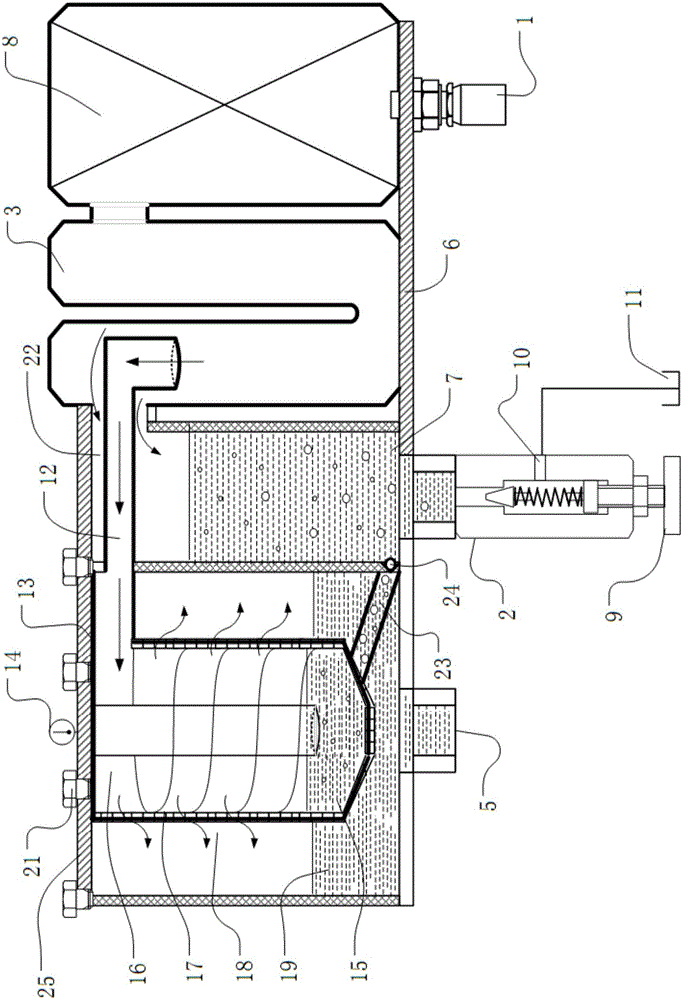

Magnetic filter for automatic transmission

InactiveCN102661382AExtended service lifeImprove filtration performanceGear lubrication/coolingLubrication elementsL-shellFilter element

The invention relates to a magnetic filter for an automatic transmission, comprising an upper shell (3), a lower shell (1), an oil inlet (5) and an oil outlet pipe correspondingly disposed in the shells, and a filter element (2) arranged at the joint position of the two shells. The magnetic filter is characterized in that a set of permanent magnets (6) is disposed on the lower shell. The beneficial effects of the magnetic filter for an automatic transmission are that with the permanent magnets playing a role in filter of fine iron powders, the service life of the automatic transmission is increased, and filtering performance of the filter is improved.

Owner:吴军红

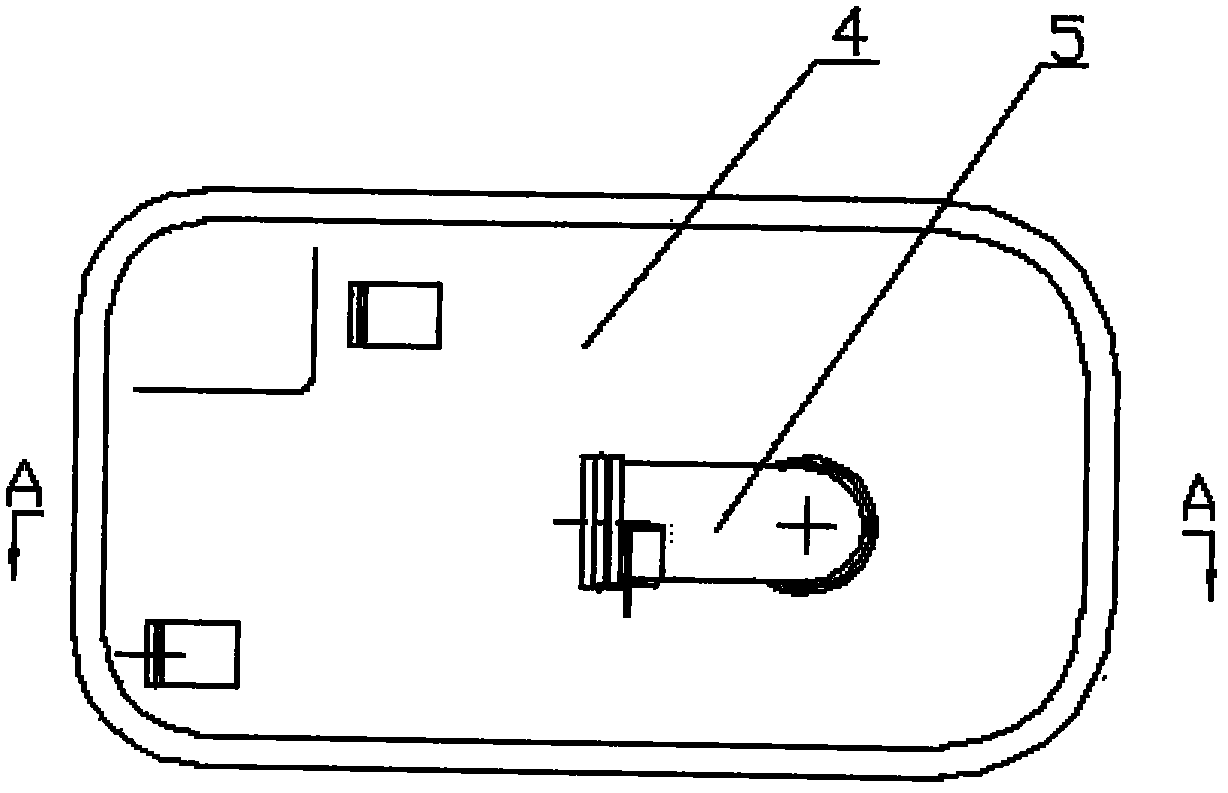

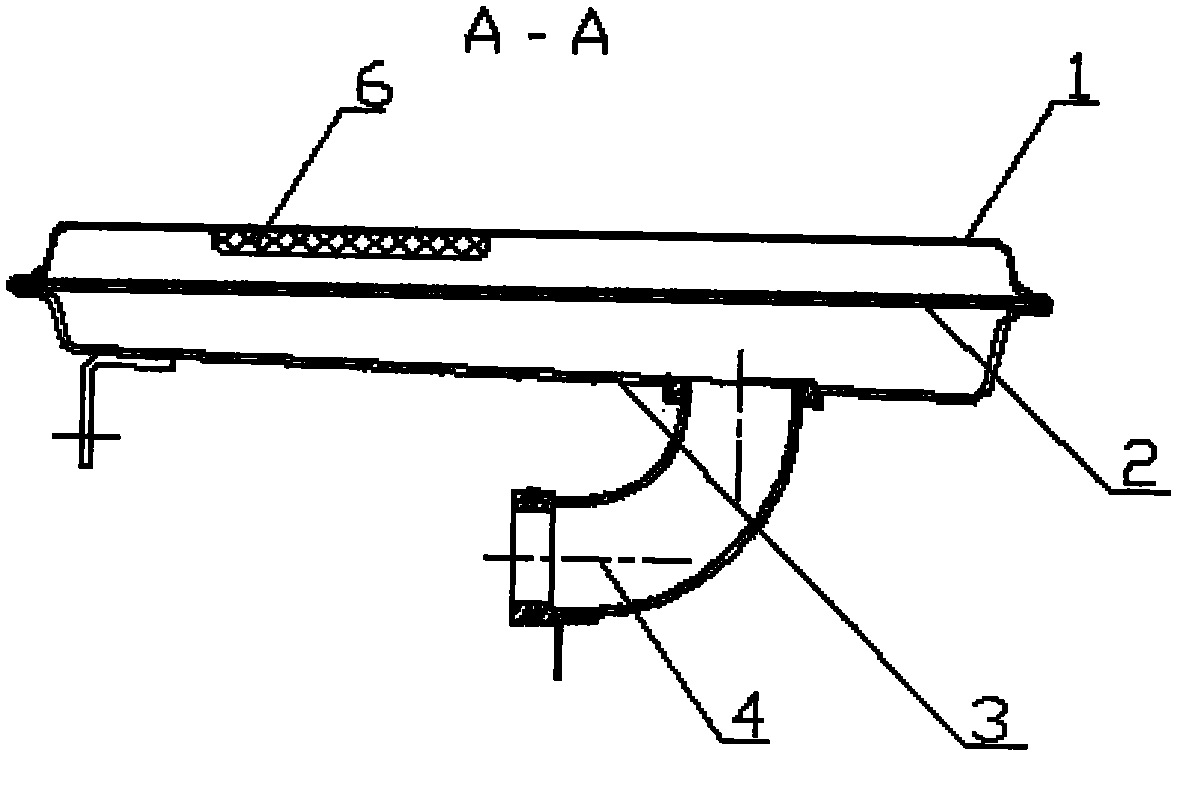

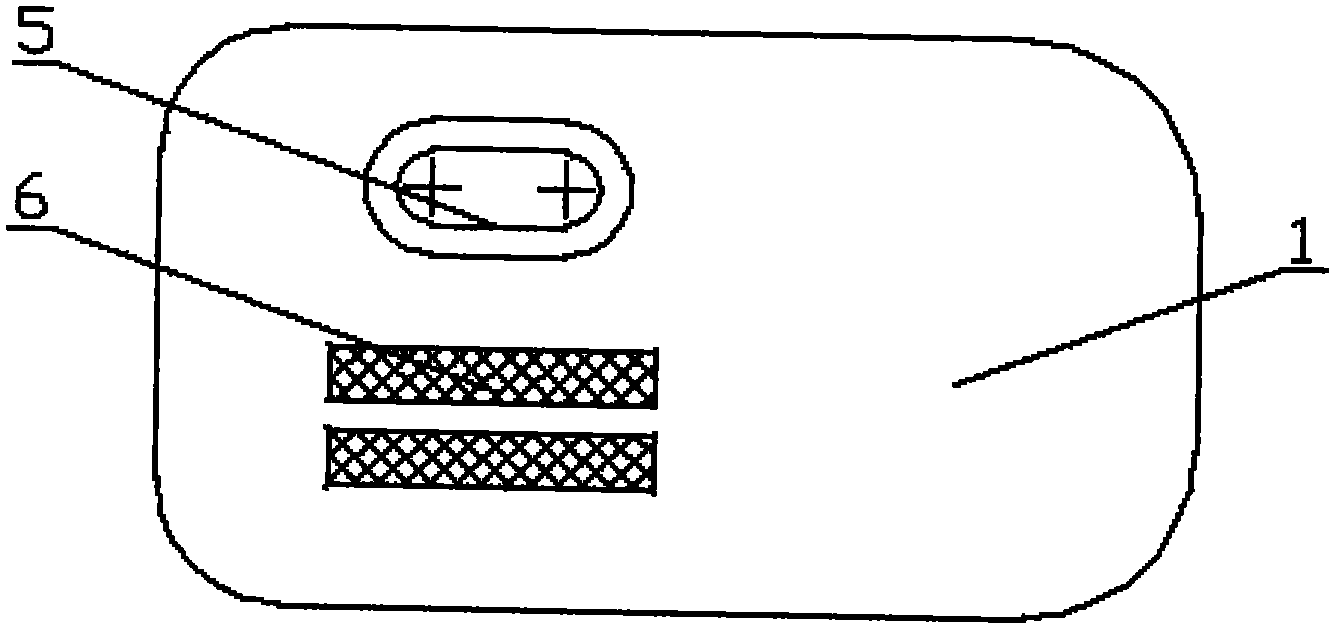

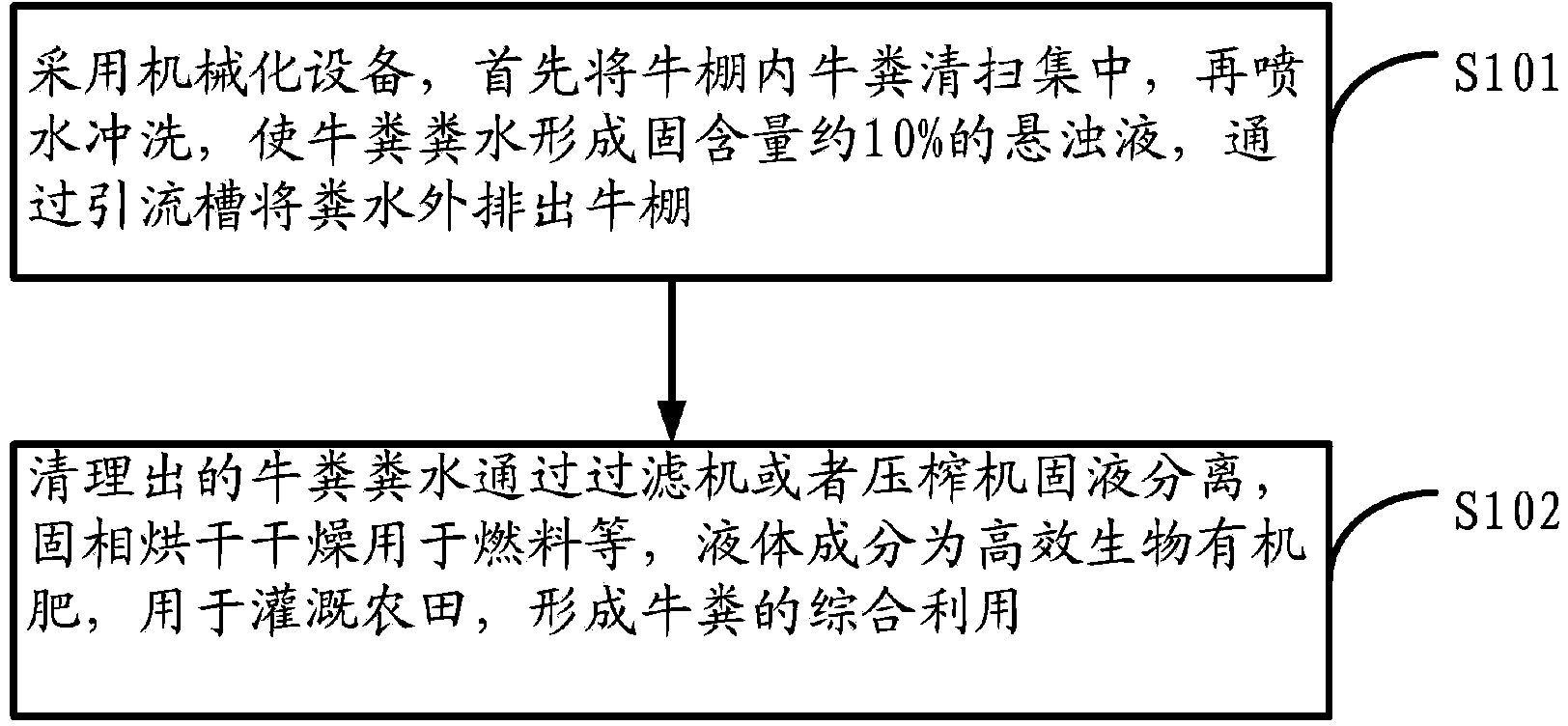

Method for cleaning and utilizing cow dung of cowshed

ActiveCN103934257AImprove filtration performanceSimple processSolid waste disposalSolid phasesLiquid composition

The invention discloses a method for cleaning and utilizing cow dung of a cowshed. The method comprises the following steps: first, cleaning and centralizing the cow dung in the cowshed by adopting mechanical equipment, spraying water and cleaning the cow dung so that liquid cow dung forms suspension with the solid content of about 10 percent, and discharging the liquid cow dung out of the cowshed through a drainage trough; then, performing solid-liquid separation on the cleaned liquid cow dung by using a filter or a presser, drying the solid phase to be used as a fuel and the like, and using the liquid component as a high-efficiency bio-organic fertilizer for irrigating a farmland, so that the cow dung is comprehensively utilized. According to the method for cleaning and utilizing the cow dung of the cowshed disclosed by the invention, an additive is added into the liquid cow dung so that the solid phase in the liquid cow dung achieves an effect of aggregating and increasing particles, and the aim of improving filtering performance is improved; the method has a simple process and is high in efficiency and low in cost.

Owner:GANSU HUARUI AGRI

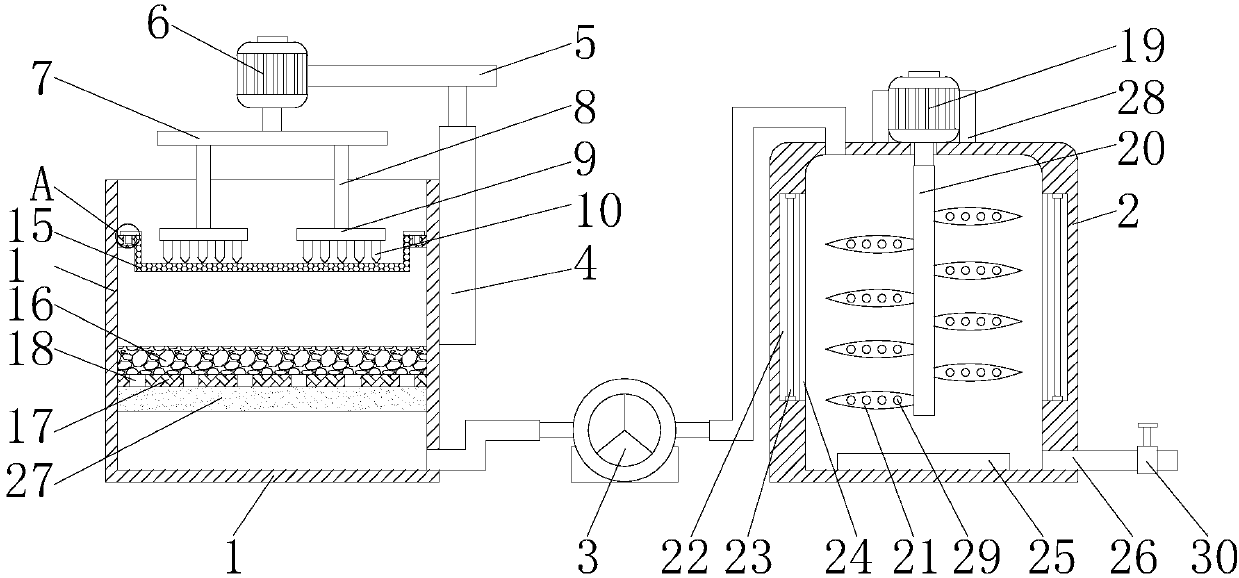

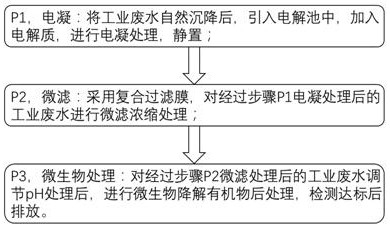

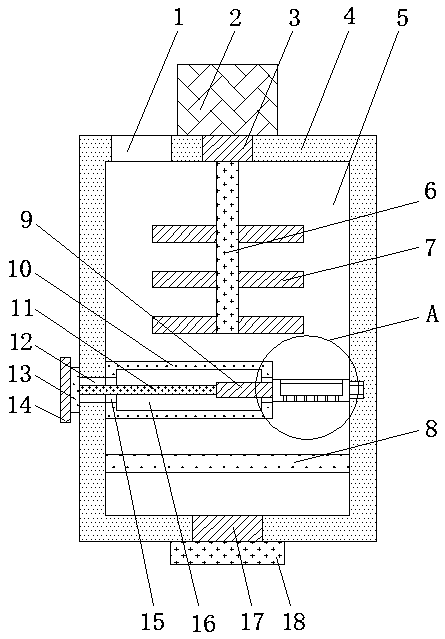

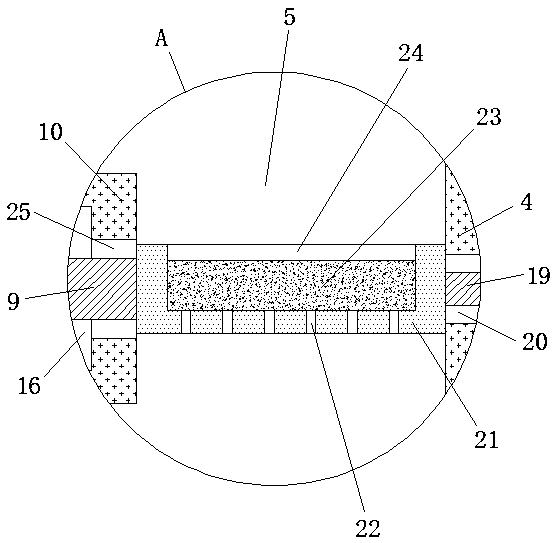

Efficient wastewater treatment device

InactiveCN107651802AImprove filtering effectImprove filtration performanceWater/sewage treatment by irradiationSpecific water treatment objectivesEngineeringWater treatment

The invention discloses a high-efficiency wastewater treatment device, which includes a box body 1 and a box body 2, the box body 1 is located on the left side of the box body 2, and the bottom of the box body 1 right side is connected with a water pump through a water pipe. The outlet pipe of the water pump communicates with the top of the box body 2 through the water pipe. The right side of the box body 1 is fixedly connected with an electric extension rod, and the top of the electric extension rod is fixedly connected with a horizontal plate. The side is fixedly connected with a first motor, the rotating shaft of the first motor is fixedly connected with a turntable, both sides of the bottom of the turntable are fixedly connected with vertical rods, and the bottom of the vertical rods extends to the inner cavity of the box body 1 and is fixed There are discs attached. The setting of the heating block of the present invention can heat and sterilize the water in the second inner cavity of the box body, and the setting of the ultraviolet searchlight can irradiate and sterilize the water in the second inner cavity of the box body, which enhances the filtering effect of the wastewater treatment device and improves the efficiency of the wastewater treatment device. filtration efficiency.

Owner:陈礼成

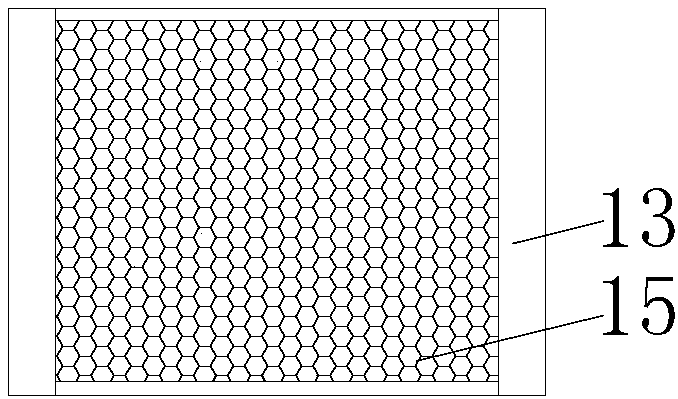

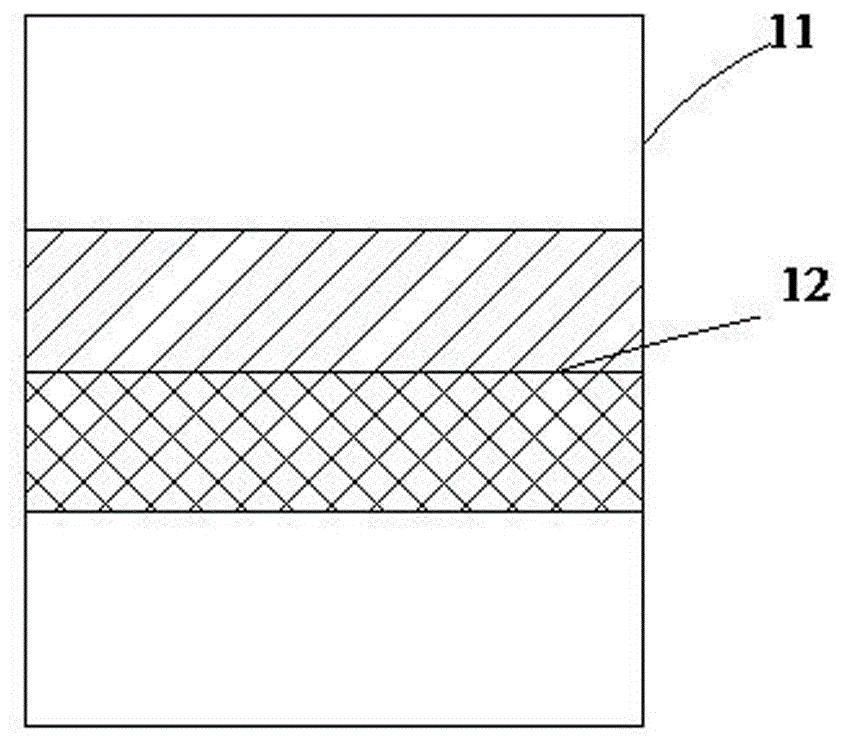

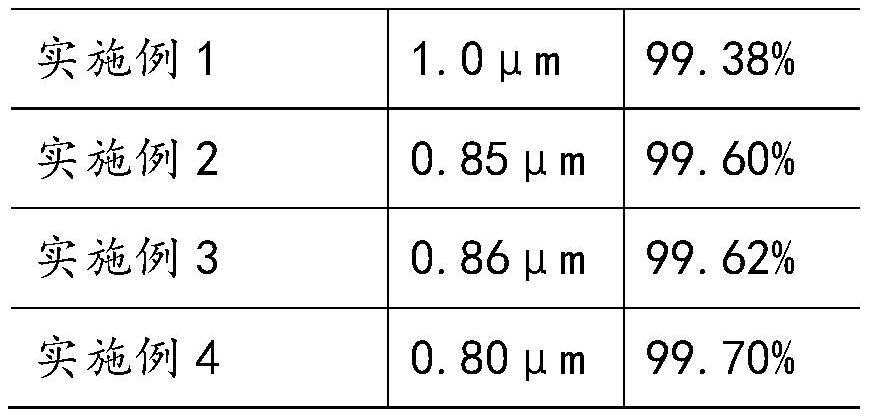

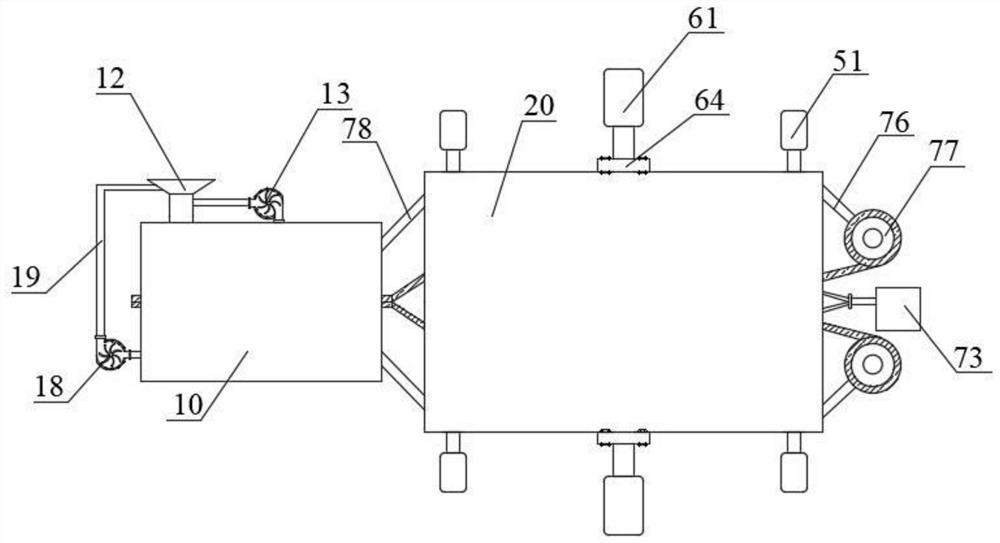

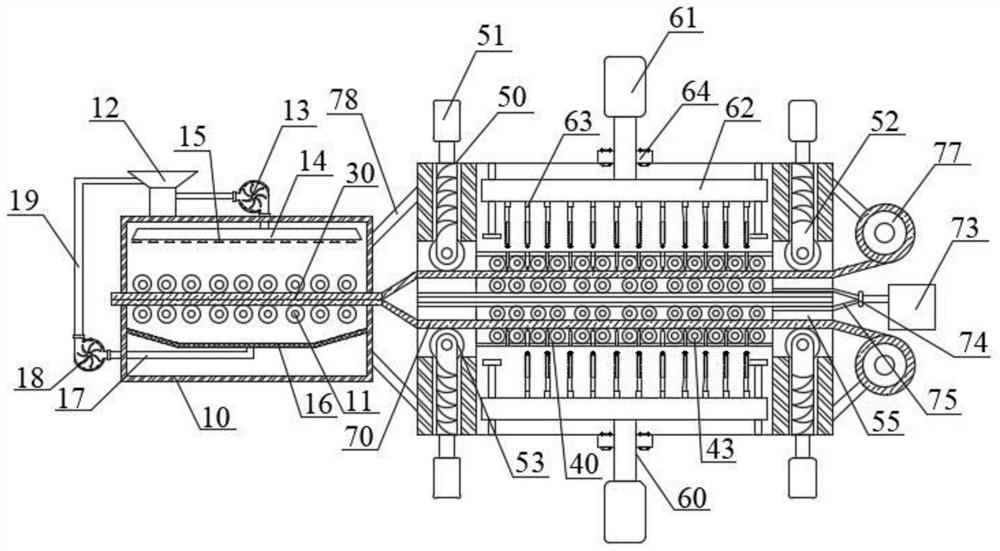

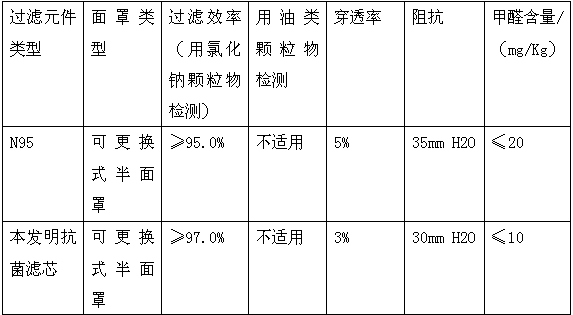

Preparation method of mask interlayer interlayer filter material

ActiveCN109011918AHigh porosityImprove filtration performanceDispersed particle filtrationFiltration separationElectrospinningFilter material

The invention provides a preparation method of a mask interlayer interlayer filter material, comprising the following steps: S1. preparing a fibrillated plant fiber solution; S2. preparing a hydrogelfilm; S3. preparing a fibroin electrolytic spinning film by electrospinning of a spinning solution, and coating both sides of the fibroin electrolytic film with a composite solution prepared in Step S2, and then compounding the hydrogel film on both sides to obtain a composite film; S4. putting the composite film in a freeze-dryer and freeze-drying to obtain a freeze-dried film; and S5. fixing thefreeze-dried film on a receiving plate of an electrospinning machine, and carrying out electrospinning on both sides of the freeze-dried film through the same spinning solution in the Step S3 so as to obtain the mask interlayer interlayer filter material. The mask interlayer interlayer filter material has good adsorption and filtration effects.

Owner:TAICANG AN YOU NO WOVEN SCI TECH CO LTD

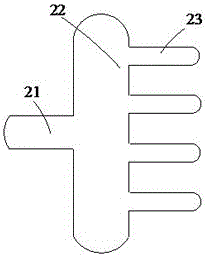

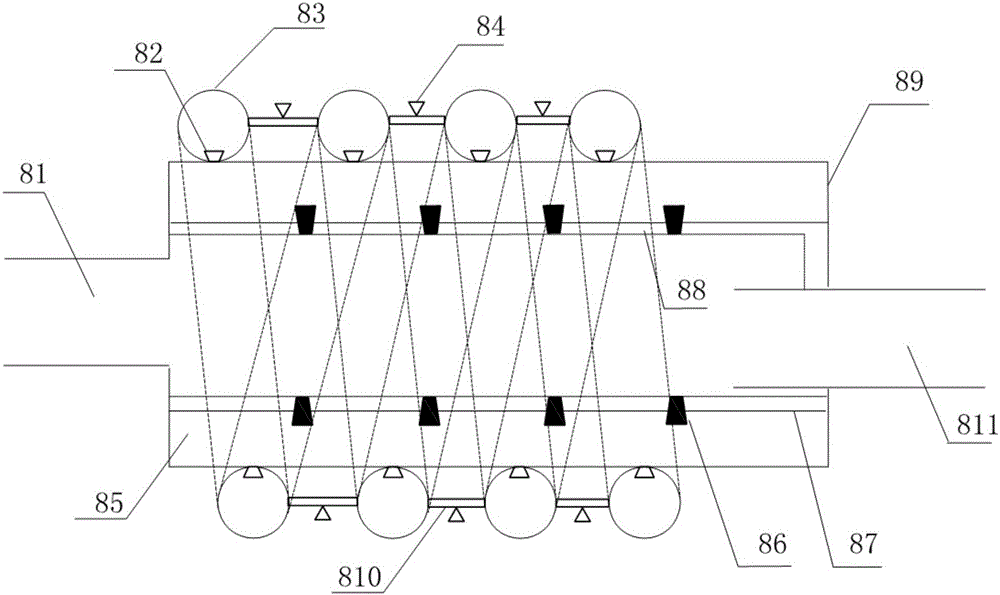

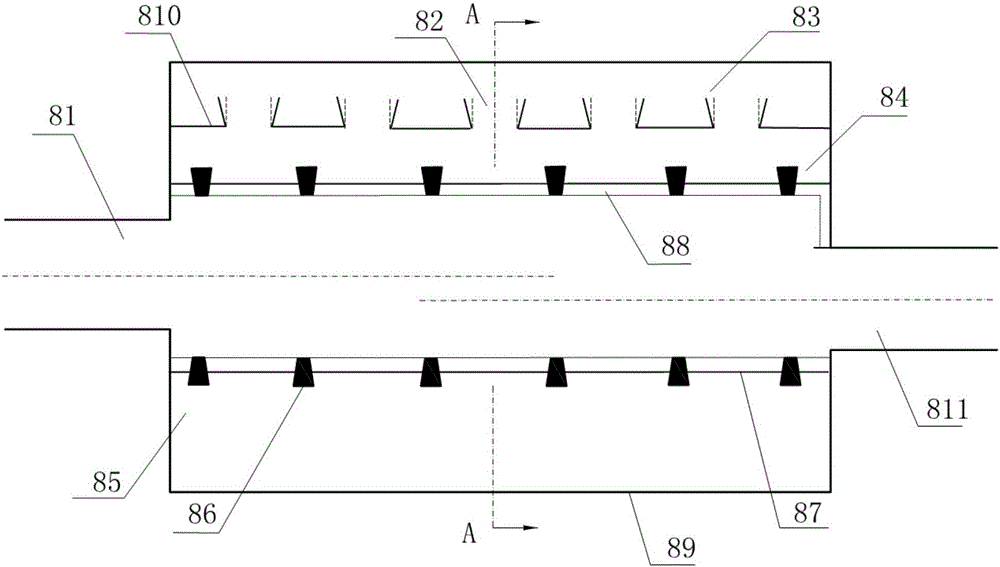

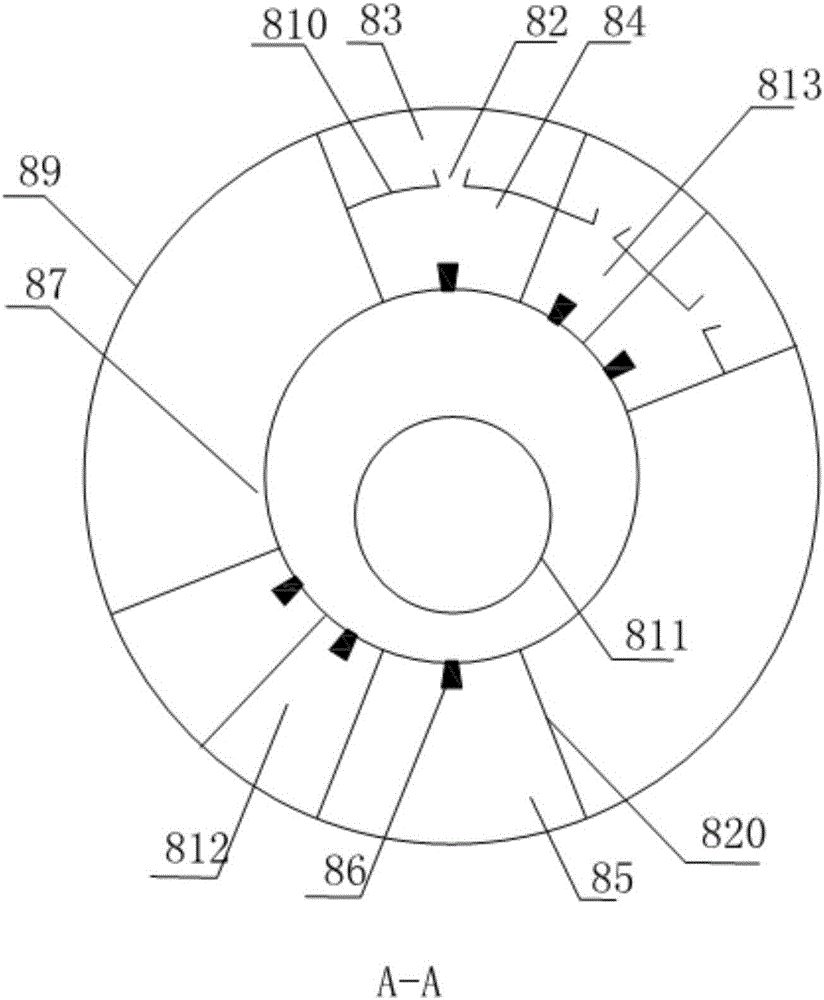

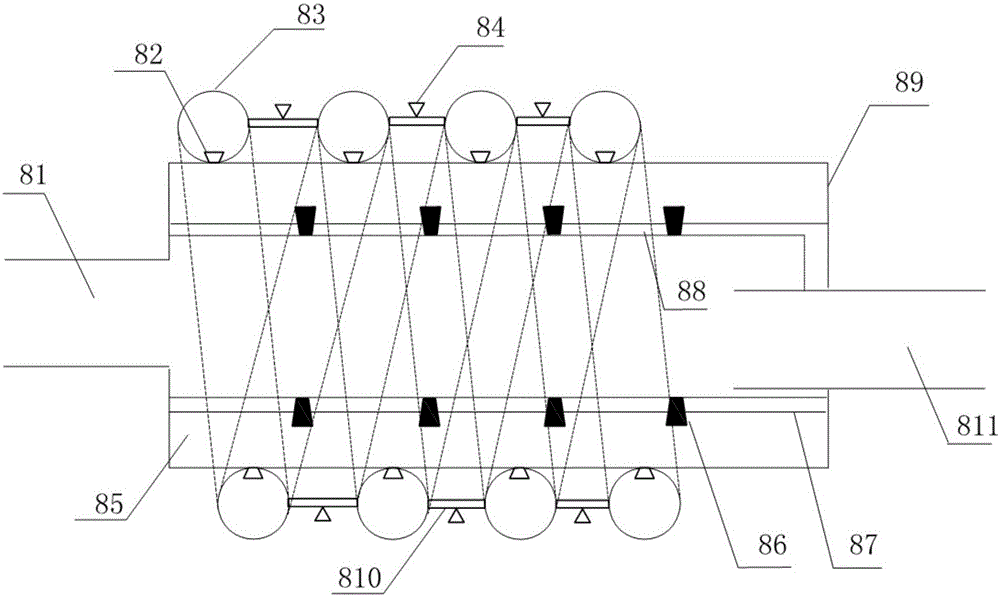

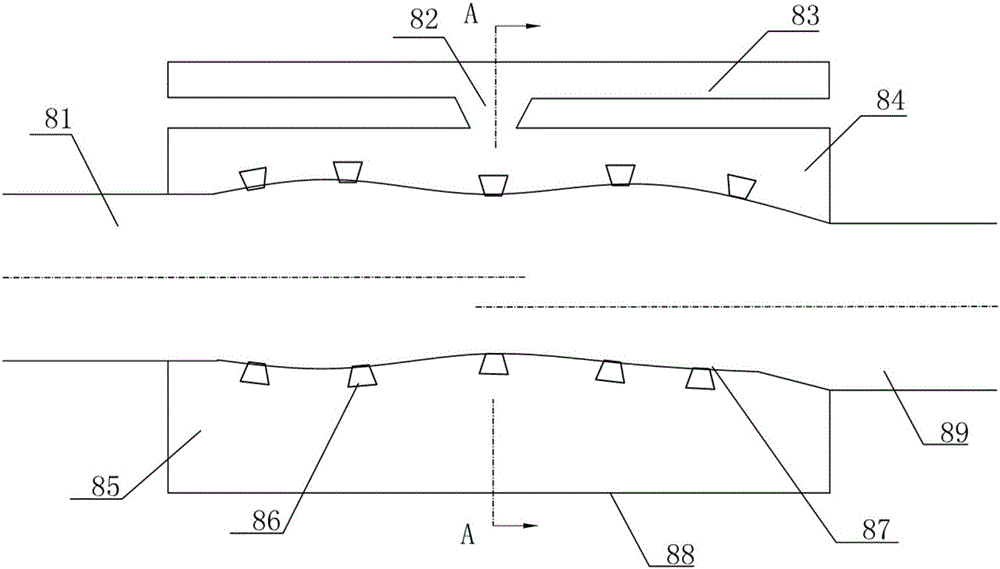

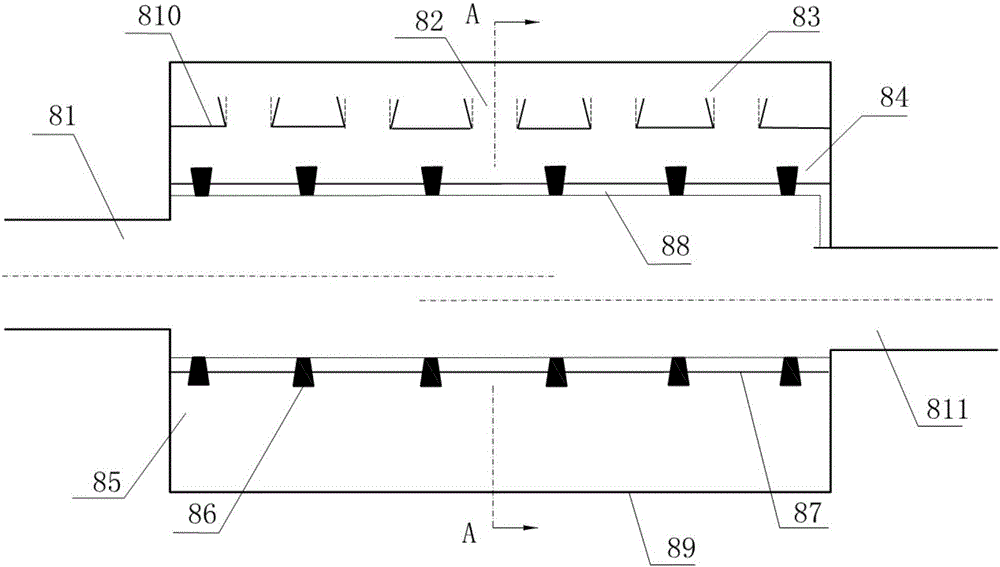

Multi-layer filtration gas-liquid separation device for low-pressure gas well

InactiveCN106215545AImprove filtration performanceSimple structureCombination devicesDispersed particle filtrationTrach tubeEngineering

The invention discloses a multi-layer filtration gas-liquid separation device for a low-pressure gas well, comprising a barrel; the upper end of the barrel is provided with an upper end cover, the lower end of the barrel is provided with a lower end cover, the wall of the barrel close to the upper end is provided with an intake pipe, the upper end cover is provided with an exhaust pipe, the sidewall of the lower end cover is provided with a drain pipe, a T-section filter element is disposed in the barrel and comprises a horizontally arranged connecting portion, a vertically arranged filter tube and a plurality of filter sheets arranged in the filter tube, the connecting portion connects the inner wall of the barrel to the upper end surface of the filter tube, a collection strainer bent to the lower end cover along the axis of the barrel is arranged at the bottom of the filter element in the barrel, and a corrugated strainer is mounted at the upper end of the collection strainer; by forming triple filtration through the connecting portion of the filter element, the filter tube and the multiple filter sheets, filtering performance of the device is improved; solid impurities in gas-liquid mixture are filtered doubly through the collection strainer and the corrugated strainer so as to prevent the drain pipe from being blocked.

Owner:CHENGDU ZHENGSHENG ENERGY TECH DEV CO LTD

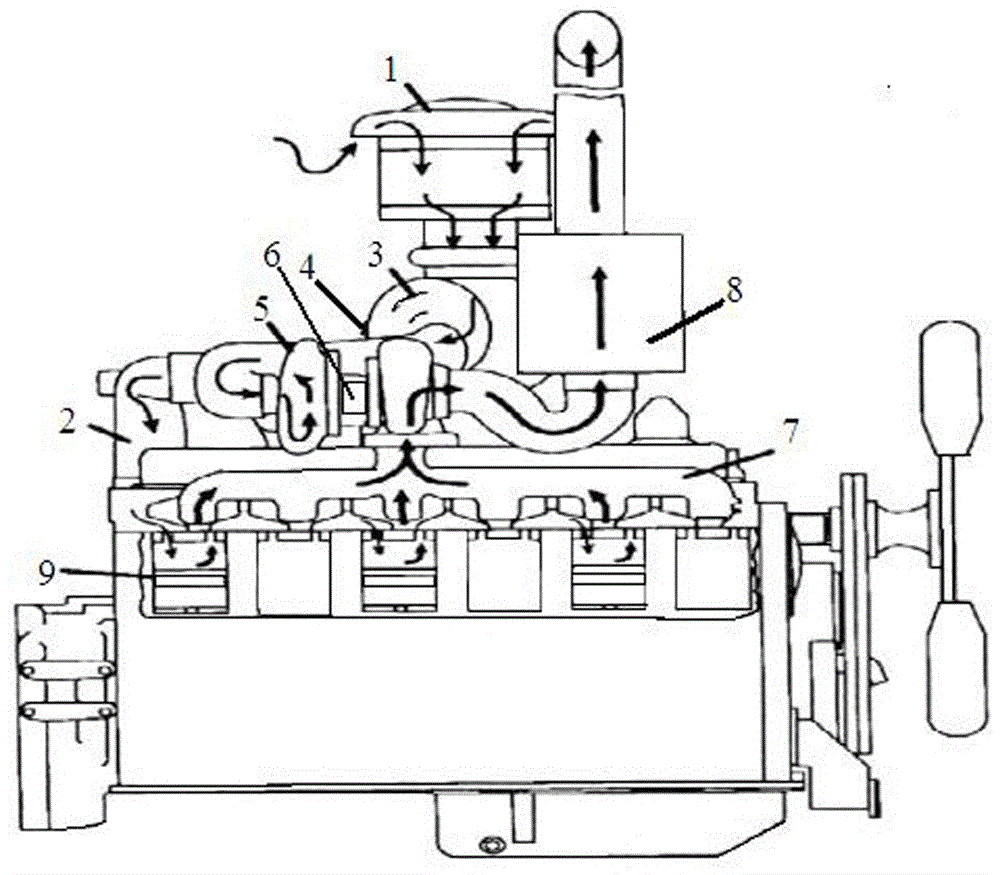

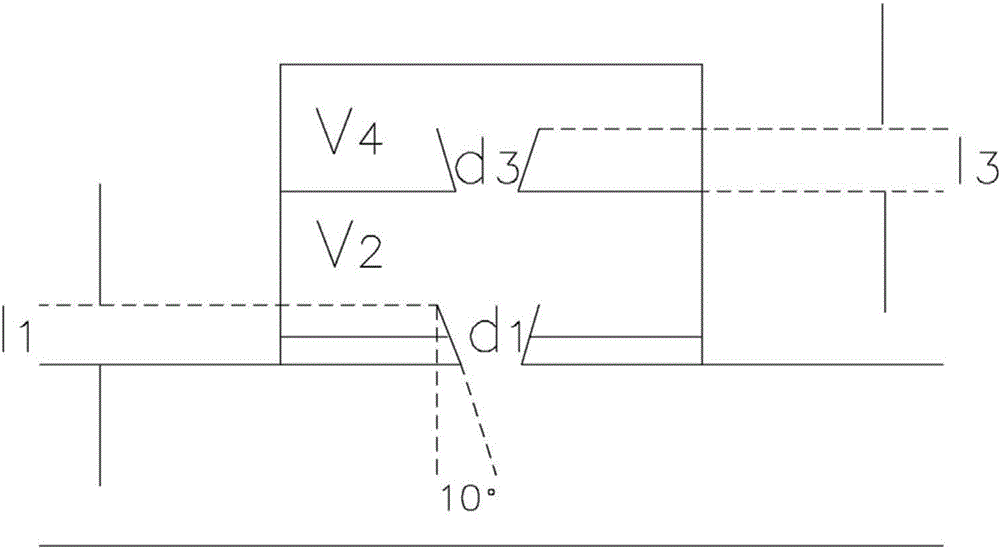

Intake and exhaust system of gas engine

InactiveCN105715420AHigh power outputImprove filtration performanceInternal combustion piston enginesSilencing apparatusIntercoolerForced induction

The invention belongs to the technical field of gas engines, and particularly relates to an intake and exhaust system of a gas engine. The intake and exhaust system comprises a prefilter, an intake manifold, an air filter, an air filter maintenance indicator, a turbocharger, a water-cooling intercooler, an exhaust manifold and an exhaust silencer. The prefilter is connected with the turbocharger through the air filter. The turbocharger is connected with the intake manifold which is connected with an air inlet of a cylinder of the gas engine. An air outlet of the cylinder of the gas engine is connected with the exhaust manifold which is connected with the exhaust silencer. Compared with the prior art, by arranging the water-cooling intercooler, the disadvantage due to temperature rising after a gas mixture of air and gas passes through the turbocharger can be reduced; and part of cooling liquid out of a water pump is utilized and flows to the water-cooling intercooler, so that the temperature of the gas mixture is lowered, more air can be pressed into the cylinder of the engine, the gas mixture of the engine can be completely and fully burnt, and larger power output is generated.

Owner:广东康菱动力科技有限公司

Copper oxide-containing composite air filter paper and making method thereof

InactiveCN104005276AImprove adsorptionImprove filtration performanceFiltration separationInorganic compound additionRosinChitin

The invention discloses a copper oxide-containing composite air filter paper. The copper oxide-containing composite air filter paper is made by using the following raw materials, by weight, 53-56 parts of a poplar pulp, 44-48 parts of a rag pulp, 1-2 parts of green bamboo bark, 1-2 parts of durian shell, 2-3 parts of nanometer silicon carbide, 2-3 parts of nanometer titanium dioxide, 1-2 parts of copper oxide, 0.7-1 part of a titanate coupling agent TC-9, 0.3-0.5 parts of chitin, 0.3-0.4 parts of rosin size, 0.6-0.8 parts of turpentine, 6-8 parts of a polyvinyl acetate emulsion adhesive, 3-5 parts of a melamine-formaldehyde resin, 0.5-0.6 parts of sucrose fatty ester, 1-2 parts of an assistant, and a proper amount of water. Titanium dioxide and copper oxide added in the invention have a catalysis performance, and can purify air; and the assistant added in the invention is safe and environmentally friendly, and forms tiny apertures on the surface of filter paper, so the adsorptivity is increased, and the filtering performance is improved.

Owner:BENGBU DEMO FILTRATION TECH

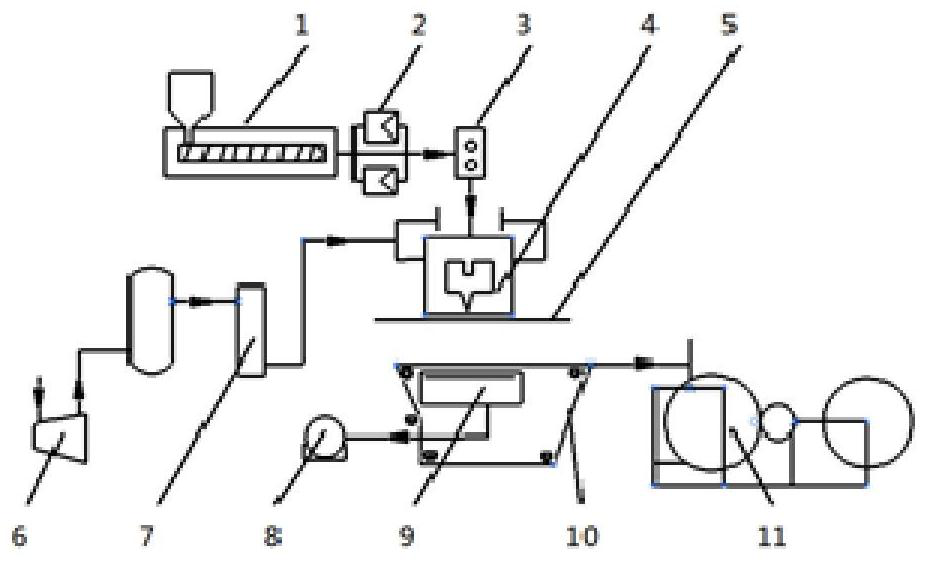

Method of filtering oil through full-band filtering, electrification, separation and adsorption

InactiveCN106015184AImprove filtration performanceExtended service lifeMagnetic separationFluid-pressure actuator componentsFull bandCheck valve

The invention relates to a method of filtering oil through full-band filtering, electrification, separation and adsorption. According to the method, the pressure and flow pulsation of hydraulic oil is attenuated by a full-band wave filter; the separation of solid particles is realized by a U-shaped particle separation module, so that the solid particles in oil move toward the wall of a pipe, enter a return oil drum through an air inlet pipe of the return oil drum and then reversely flow to an oil tank, and oil containing trace amount of particles with small particle sizes in the center of a pipeline enters an inner drum through an oil inlet pipe of the inner drum to suffer high-accuracy filtration, thereby prolonging the service life of a filter element; the oil entering the oil inlet pipe of the inner drum flows into a spiral channel of the inner drum in a tangent inflowing manner; the wall of the inner drum serves as a filter element, so that filtrate flows in a manner of clinging to the filter element under the action of centrifugal force, parallels to the surface of the filter element and quickly flow, and the filtered hydraulic oil is vertical to the surface direction of the filter element and outflows to the outer drum; and polluted particles deposited at the bottom of the inner drum can be discharged to the return oil drum timely by an electronic control check valve, thereby prolonging the service life of the filter element.

Owner:王雅莉

Preparation method of superfine fiber melt-blown cloth

InactiveCN112359486AImprove filtration performanceImprove filtering effectHollow filament manufactureMelt spinning methodsWoven fabricYarn

The invention discloses a preparation method of a superfine fiber melt-blown fabric. The preparation method comprises the following step: carrying out supercritical carbon dioxide permeation treatmenton raw material particles suitable for a melt-blown non-woven fabric; and carrying out melt-blowing by taking the particles prepared in the previous step as raw materials, arranging a high-voltage electrostatic field between a melt-blowing nozzle and a receiving device, and stretching a melt sprayed from the melt-blowing nozzle onto the receiving device by electrostatic traction. The inventor accidentally finds in tests that after the raw material particles of the melt-blown non-woven fabric are subjected to supercritical carbon dioxide permeation treatment, a large number of micro-bubble holes can appear in the surface of fiber yarn obtained through re-melt-blowing, the specific surface area is increased, the porosity is increased, the filtering performance of the melt-blown fabric formed by the fiber yarn is greatly improved, in addition, the plasticizing performance of fluid sprayed out from the melt-blowing nozzle is enhanced, the melt-blown fabric formed by superfine fibers can be easily formed through traction and stretching of the high-voltage electrostatic field, and the filtering performance of the melt-blown fabric is further improved.

Owner:武汉多戈科技有限公司

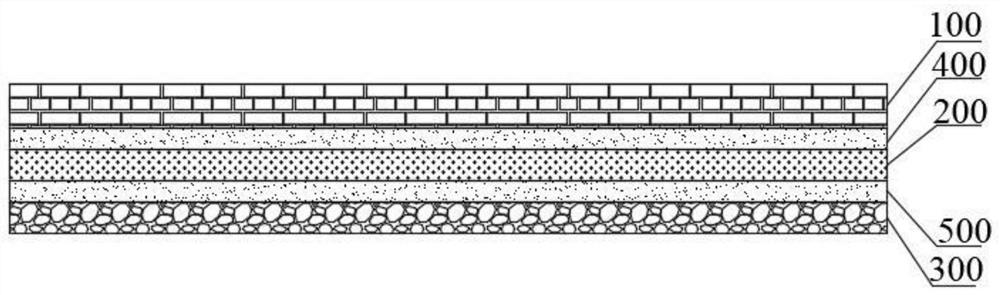

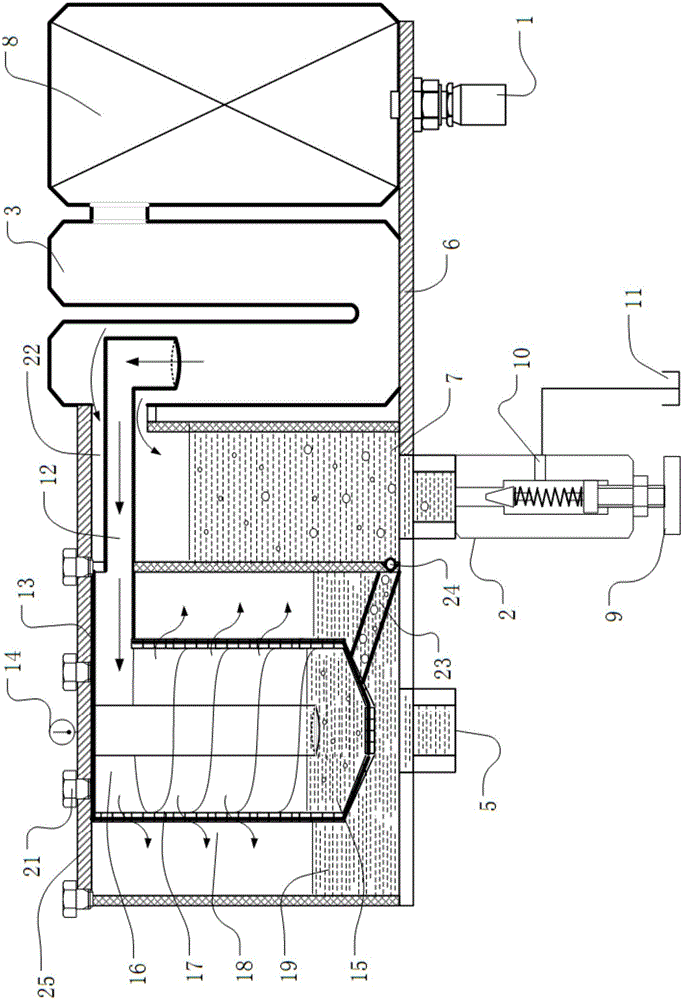

Ecological geotextile material used for slope protection and capable of effectively preventing water and soil loss

PendingCN113910708AHigh strengthImprove corrosion resistanceSynthetic resin layered productsGeotextilesFiltrationAnti bacteria

The invention discloses an ecological geotextile material used for slope protection and capable of effectively preventing water and soil loss, and relates to the technical field of ecological geotextile. The ecological geotextile material comprises a grating surface layer, a first bonding layer, a filter cloth layer, a second bonding layer and a water-permeable enhancement layer from outside to inside, wherein the grating surface layer improves the reinforcement effect of the geotextile material; the filter cloth layer improves the strength, corrosion resistance, ultraviolet resistance, antibiosis, filtration and water permeability of the geotextile material; the strength, the ultraviolet resistance and the corrosion resistance of the geotextile material are further improved by the permeable reinforcing layer; after the ecological geotextile material is used for slope protection, water and soil loss can be effectively prevented for a long time, and the service life is long. The needling shaping device conducts continuous treatment of oil spraying finishing, needling reinforcing and heat shaping on the fiber net to obtain the filter cloth, the passing guide mechanism, the buffering guide mechanism and the needling mechanism are matched, the stability in the guide process is kept, and the strength of the fiber net is improved.

Owner:安徽海兴生态科技有限公司

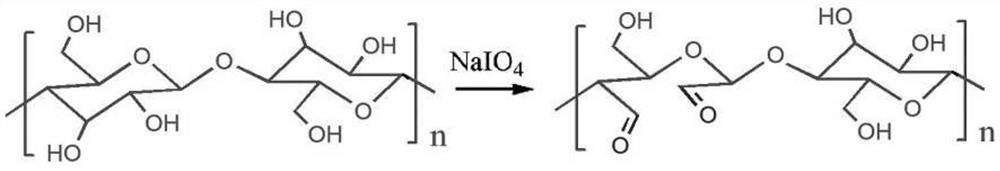

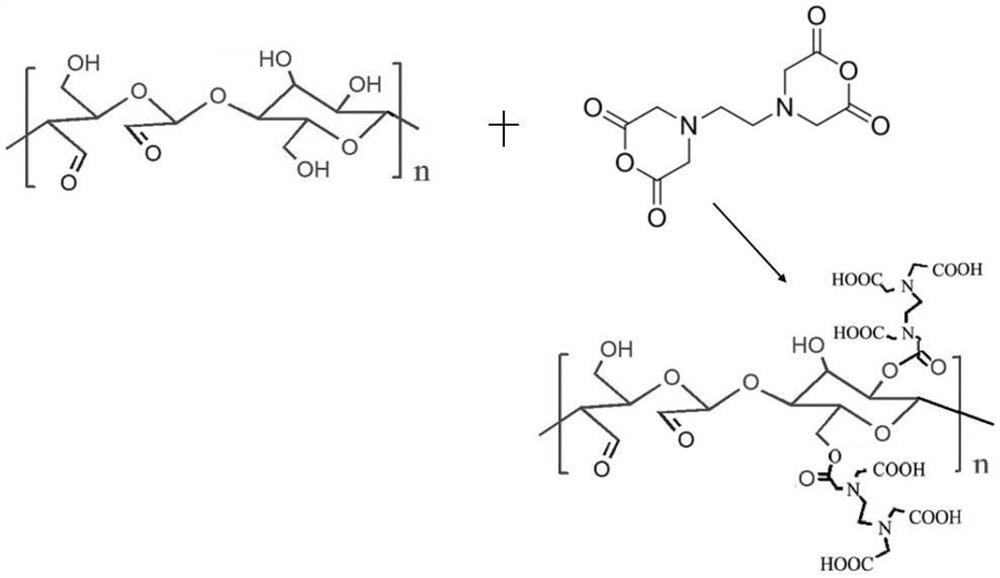

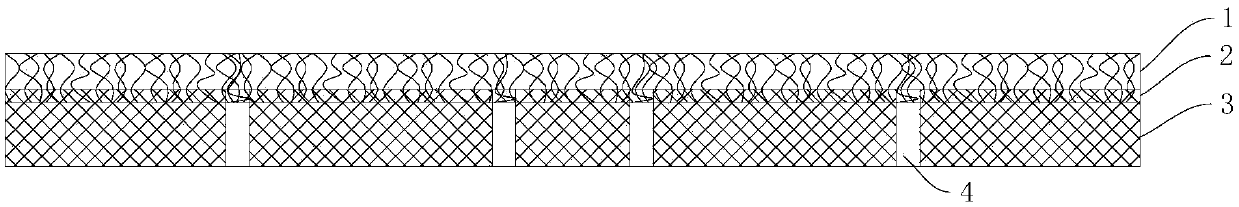

Composite filter membrane, preparation method thereof and industrial wastewater treatment method

ActiveCN112028393AImprove filtration performanceImprove dispersibility and stabilityUltrafiltrationWater/sewage treatmentPolyvinylidene fluorideIndustrial wastewater treatment

The invention provides a composite filter membrane, a preparation method thereof and an industrial wastewater treatment method. The preparation method comprises the following steps: firstly, carryingout carboxylation and formylation modification treatment on cellulose nanocrystals; then blending, melting and granulating the modified cellulose nanocrystals and a thermoplastic polymer to obtain blended master batches, and carrying out double-component melt spinning, drafting, reinforcing and splitting post-treatment on the blended master batches and polyvinylidene fluoride to obtain a compositenon-woven fabric base layer; then carrying out melt blending on polyvinylidene fluoride and the modified cellulose nanocrystals to obtain a blended material, preparing composite nanofibers by adopting a melt blending extrusion phase separation method, and dispersing the composite nanofibers into a solution to obtain a composite nanofiber suspension; and finally, immersing the composite non-wovenfabric base layer in the composite nanofiber suspension, and carrying out freeze drying to obtain the composite filter membrane with excellent filtering performance, pollutant adsorption performance and mechanical strength. By adopting an electrocoagulation microfiltration microbiological treatment combined process, the method has an efficient treatment effect on industrial wastewater.

Owner:浙江环之美环保科技有限公司

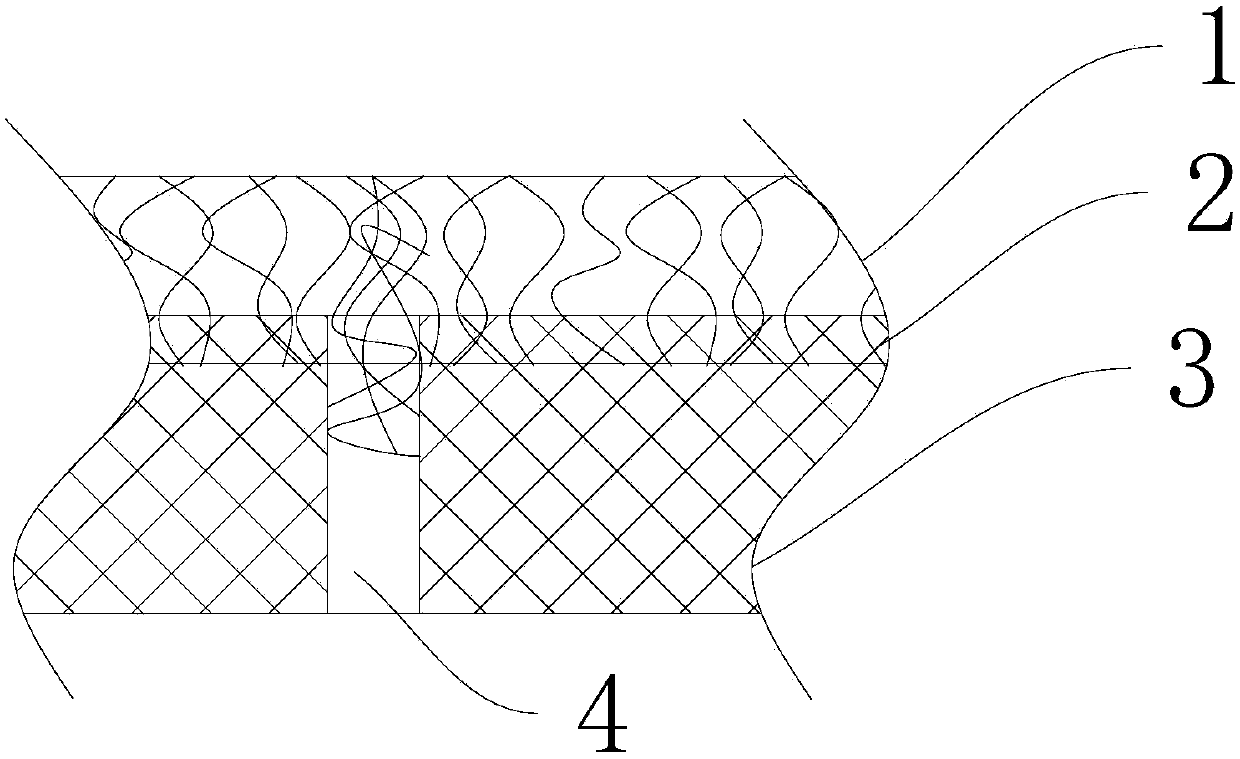

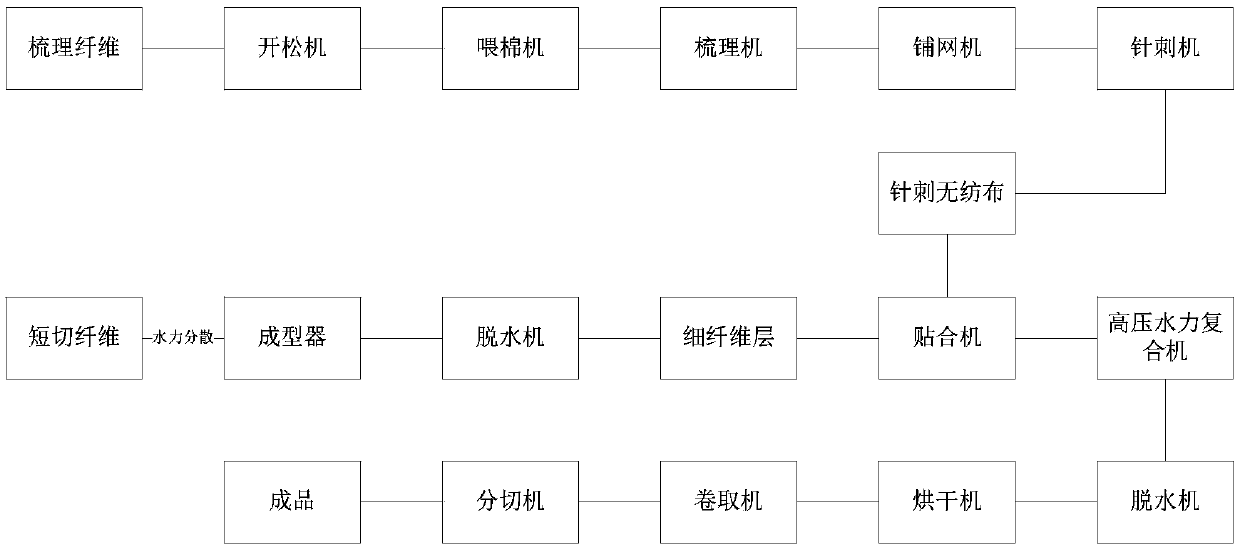

Composite non-woven fabric for filtering dust and manufacturing process thereof

PendingCN108031187AImprove filtration performanceImprove performanceDispersed particle filtrationSynthetic resin layered productsWoven fabricBiomedical engineering

The invention discloses a composite non-woven fabric for filtering dust and a manufacturing process thereof, which belong to the field of non-woven fabric weaving. A needle punched non-woven fabric base layer is formed on the bottom part of the composite non-woven fabric; a layer of chopped fiber is densely distributed above the needle punched non-woven fabric base layer, is partially embedded into the needle punched non-woven fabric base layer and fills in needle punched holes on the needle punched non-woven fabric, so that a layer of composite layer is formed on an upper surface of the needle punched non-woven fabric base layer. According to the composite material provided by the invention, not only can the filter precision requirement meeting 99.99 percent (up to 99.999 percent) be ensured, but also the permeation volume, the dust holding capacity and the service life are well ensured, the energy consumption during use is greatly reduced, and the normal production is fully guaranteed.

Owner:ZHEJIANG YUBANG FILTER MATERIAL TECH CO LTD +1

Anticorrosive filter paper and preparation method thereof

InactiveCN103382678AImprove filtration performanceExtended service lifeNon-macromolecular organic additionFiltration separationEmulsionOxide

The invention discloses an anticorrosive filter paper. The anticorrosive filter paper comprises the following raw materials by weight: 65 to 70 parts of waste paper pulp, 40 to 50 parts of slag slurry, 6 to 8 parts of an acrylic emulsion, 12 to 18 parts of a cotton fiber, 8 to 10 parts of a glass fiber, 2 to 3 parts of fatty acid polyethylene glycol ester, 1 to 2 parts of nanometer titanium dioxide, 2 to 3 parts of nanometer zinc oxide, 1 to 2 parts of dibutyl phithalate, 1 to 2 parts of anilmomethyl triethoxy silane, 0.1 to 0.2 part of ethylene glycol ethyl ether, 0.3 to 0.5 part of alkylolamide, 16 to 20 parts of a VAE emulsion DA101, 2 to 3 parts of glycerin, 0.4 to 0.6 part of 1,2-aminoazophenylene, 1 to 2 parts of ethylene glycol tert-butyl ether, 1 to 2 parts of sodium alkyl benzene sulfonate and a proper amount of water. The filter paper produced in the invention has high filterability, a long service life, environment friendliness and stable quality; an impregnation liquid used in the invention has good cohesiveness and film forming ability; and after impregnation, the filter paper has enhanced dry and wet strength and toughness, and filtration efficiency of a filter is improved.

Owner:BENGBU PIONEER FILTER

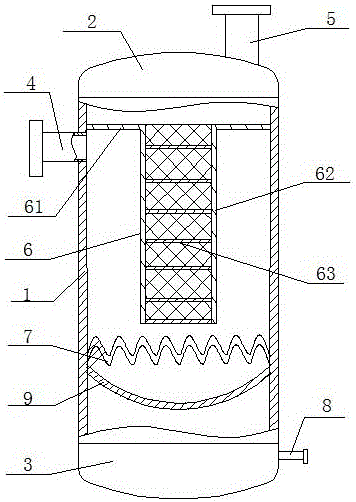

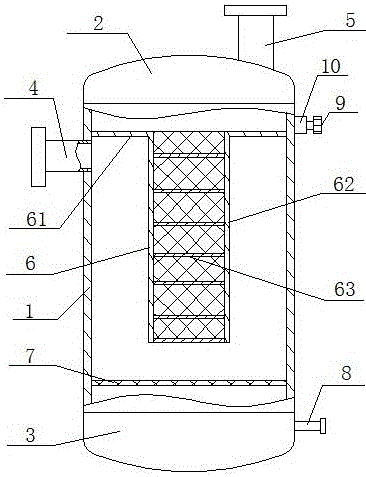

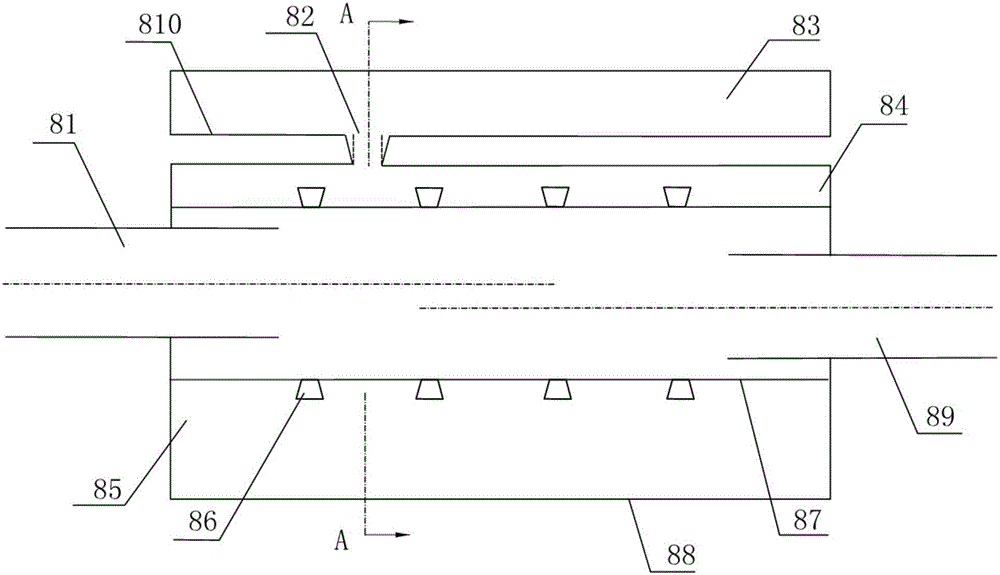

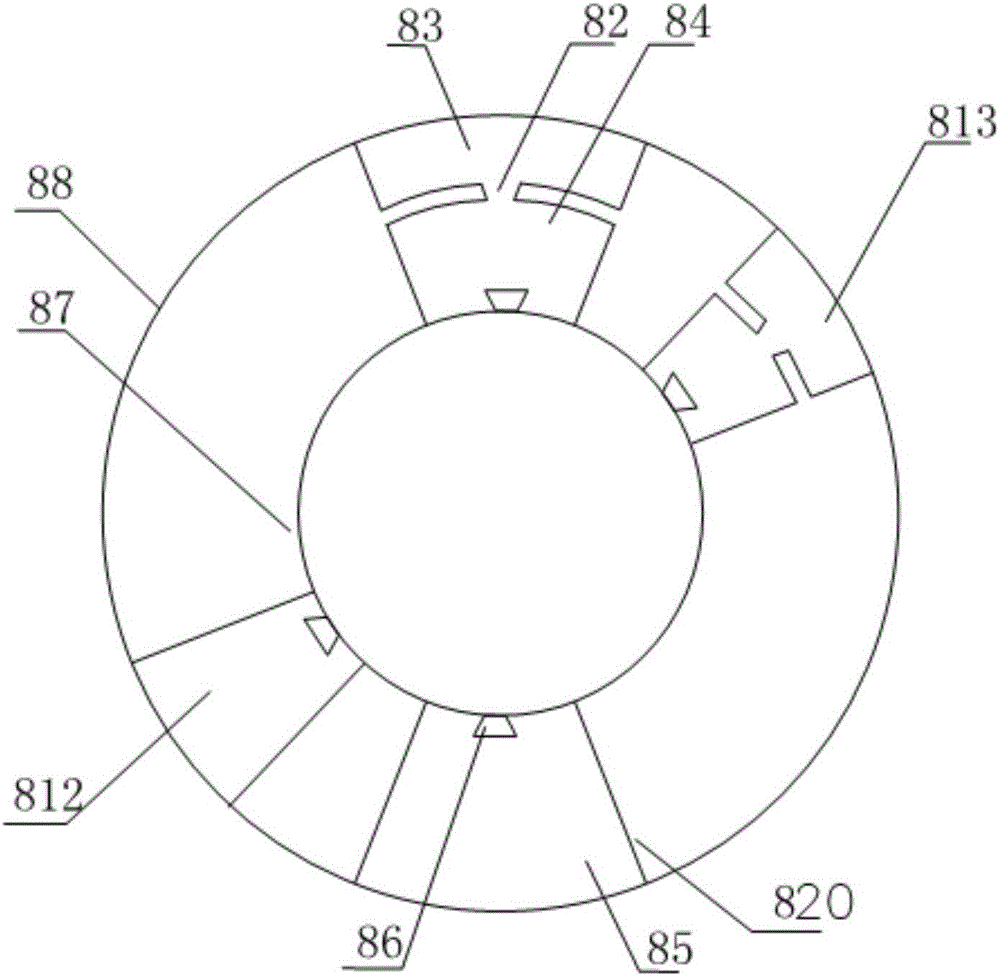

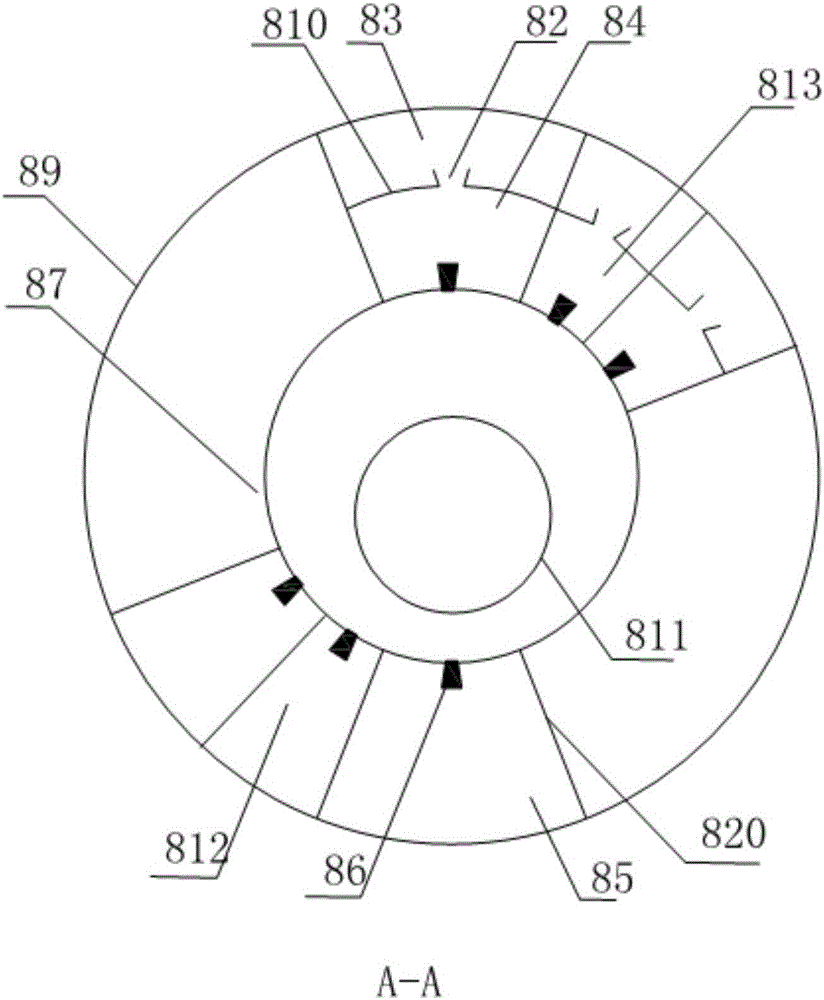

Gas-liquid separation tank for single well booster set

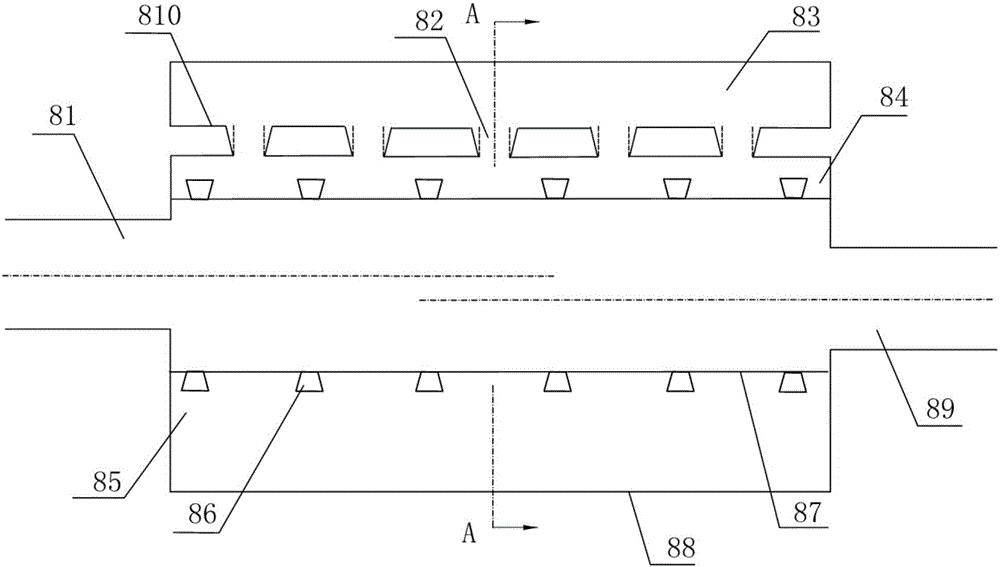

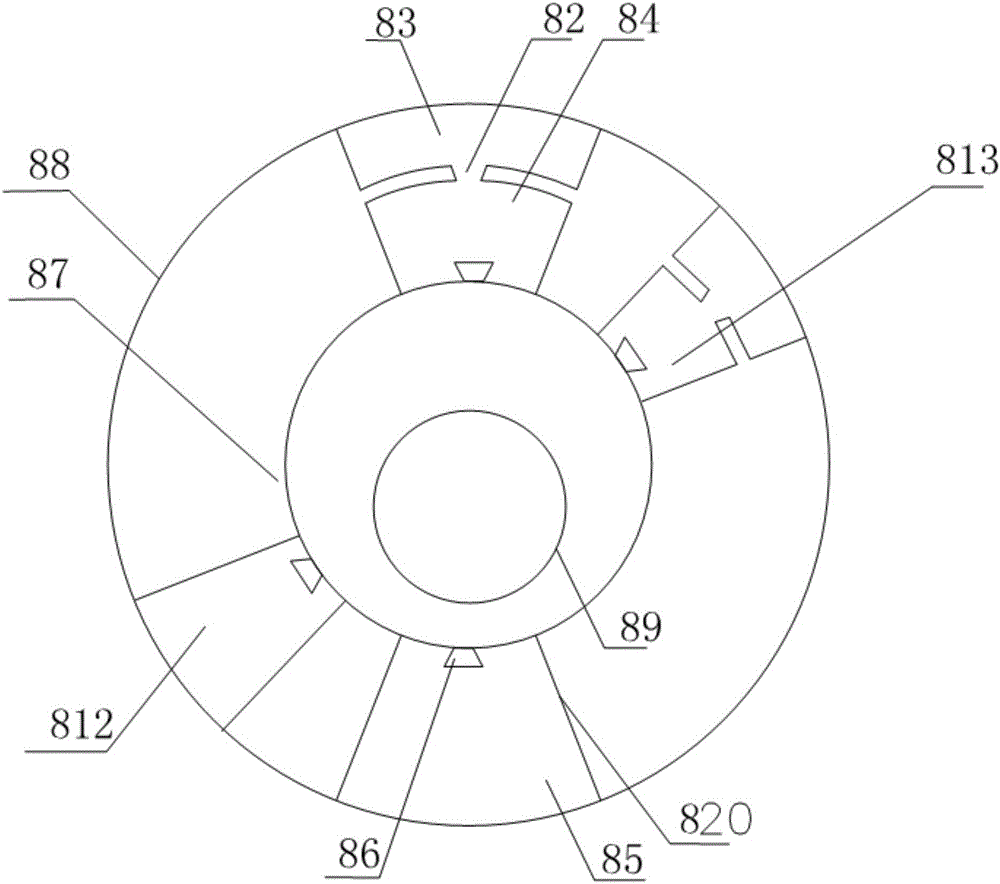

InactiveCN106215589AImprove filtration performanceSimple structureCombination devicesDispersed particle filtrationEngineeringThree stage

The invention discloses a gas-liquid separation tank for a single well booster set. The gas-liquid separation tank comprises a cylinder, wherein an upper end cap is arranged at the upper end of the cylinder, a lower end cap is arranged at the lower end of the cylinder, a gas inlet pipe is arranged on the cylindrical wall, close to the upper end, of the cylinder, a gas outlet pipe is arranged on the upper end cap, a liquid discharging pipe is arranged on the side wall of the lower end cap, a pressure reducing valve is arranged on the side wall, on the side opposite to the gas inlet pipe, of the cylinder, a filter element with a T-shaped cross section is arranged in the cylinder and comprises a horizontally arranged connecting portion, a vertically arranged filter cartridge and a plurality of filter pieces arranged in the filter cartridge, and the connecting portion is connected with the inner wall of the cylinder and the upper end face of the filter cartridge. The connecting portion of the filter element, the filter cartridge and multiple filter pieces form three-stage filtration, liquid components in a gas-liquid mixture can be filtered and settle to the most degree, the filtering performance of the gas-liquid separation tank is improved, and the gas-liquid separation tank is simple in structure and low in manufacturing cost.

Owner:CHENGDU ZHENGSHENG ENERGY TECH DEV CO LTD

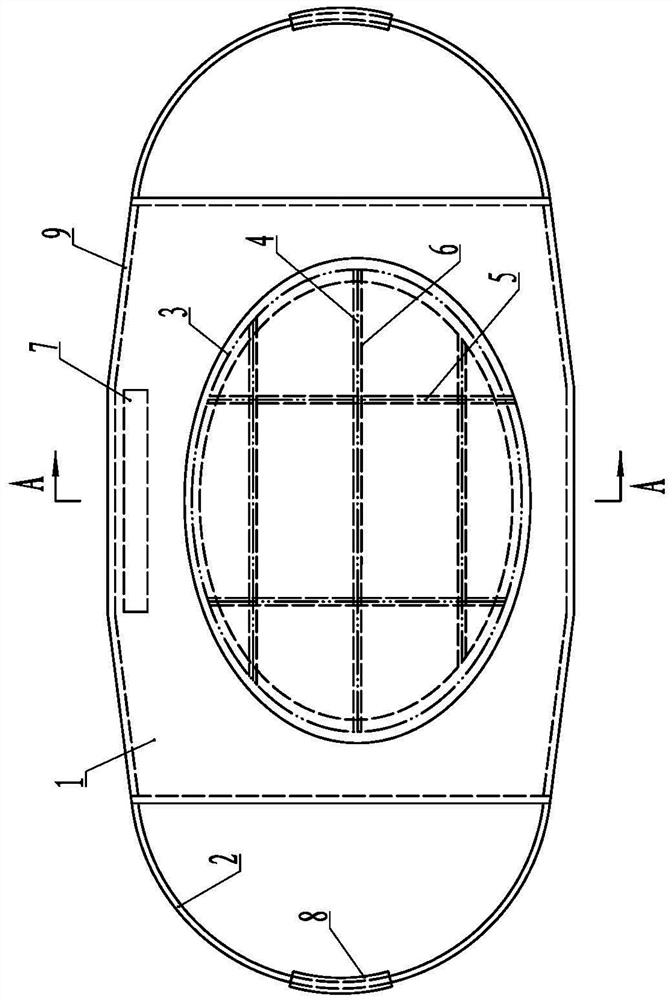

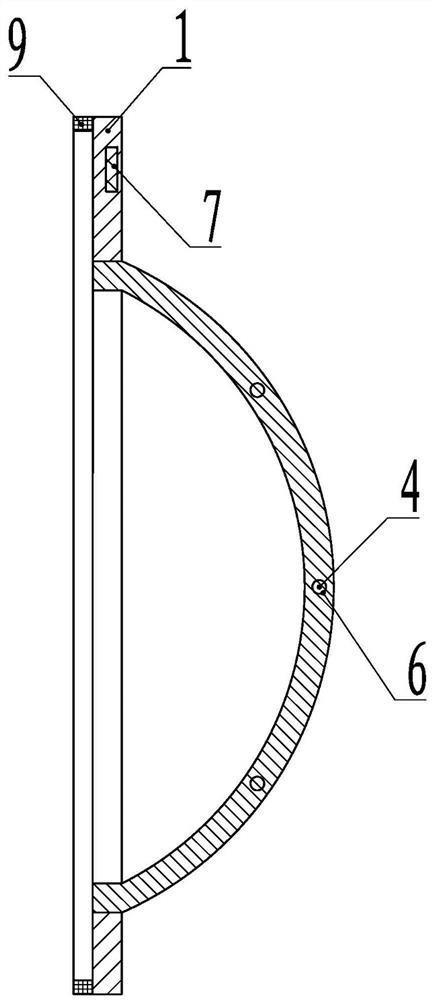

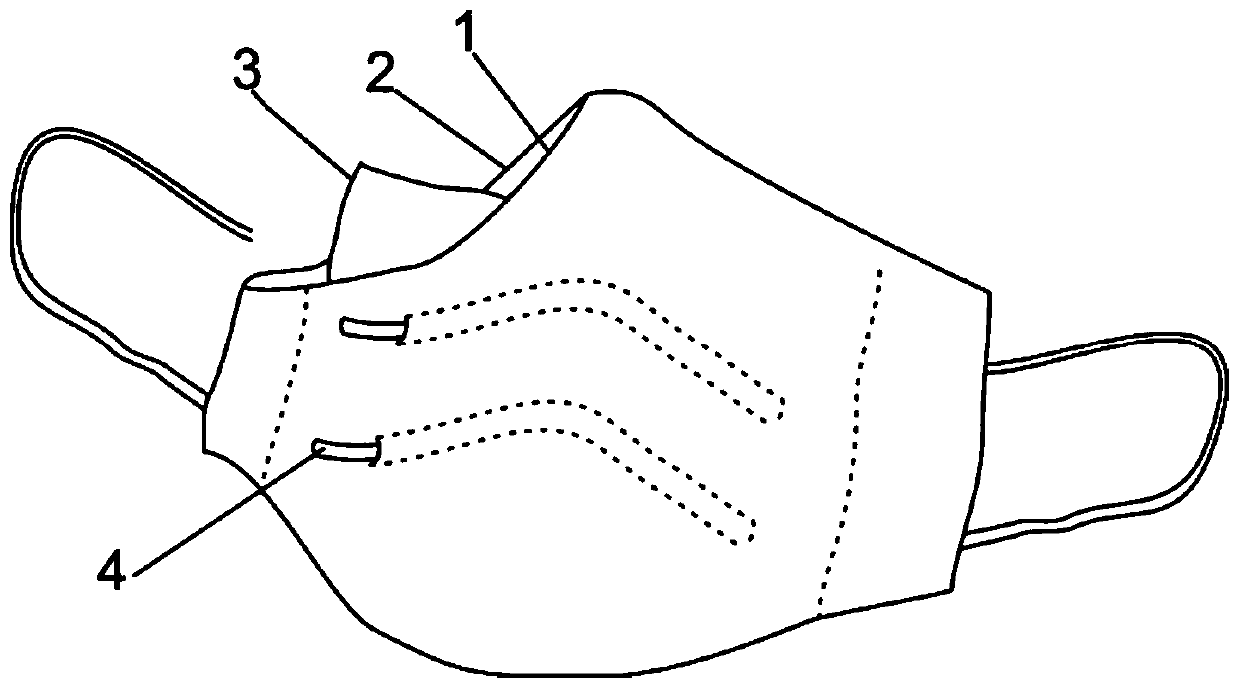

Three-dimensional protective mask

PendingCN112335961AAvoid breathing difficultiesImprove filtration performanceGarment special featuresProtective garmentFacial skinBreathing

The invention discloses a three-dimensional protective mask, and relates to the technical field of mask manufacturing. The three-dimensional protective mask comprises a mask body and hanging ropes arranged on the two sides of the mask body, the mask body is provided with a breathing part protruding outwards, a supporting frame is arranged in the breathing part and comprises a fixing ring arrangedon the edge of the breathing part, and a plurality of transverse rods and a plurality of vertical rods are arranged on the inner side of the fixing ring in a crossed mode. The transverse rods and thevertical rods are all in an outwards-protruding arc shape, and rod sleeves are arranged on the outer surfaces of the transverse rods and the outer surfaces of the vertical rods. Compared with the prior art, the three-dimensional protective mask can solve the problem that an existing medical mask is prone to deformation and collapse after being wetted and adheres to the mouth, the nose and other facial skins, and therefore a user cannot breathe difficultly.

Owner:广西德福莱医疗器械有限公司

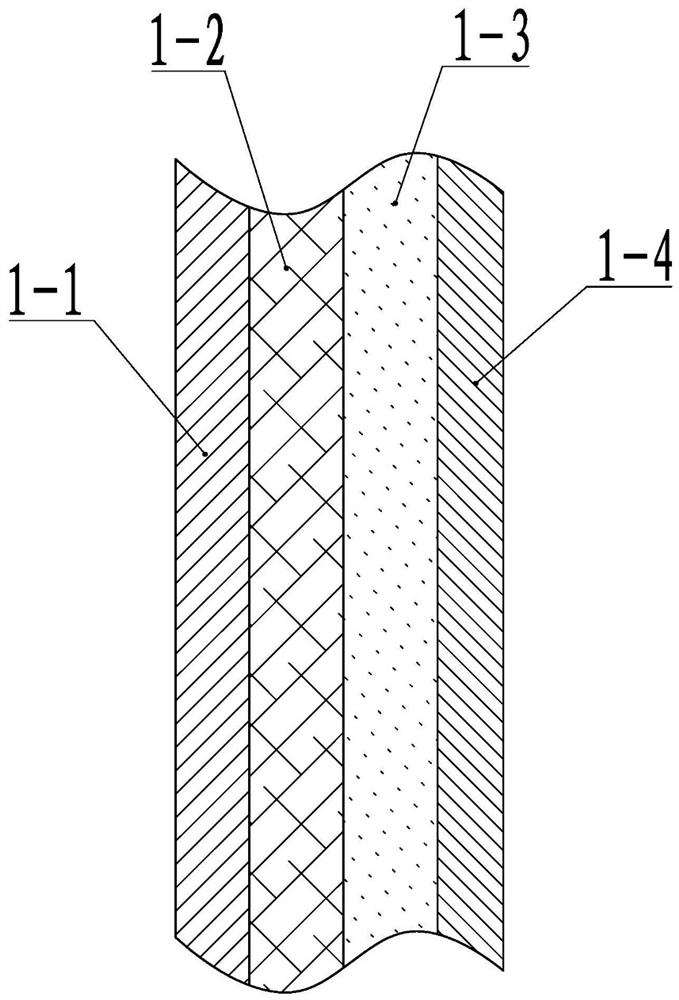

Recyclable protective mask

InactiveCN111264934AReduce riskImprove filtration performanceStain/soil resistant fibresUltrasonic/sonic fibre treatmentAnti bacterialWoven fabric

The invention belongs to the technical field of masks, and particularly relates to a recyclable protective mask which comprises a mask body and fixing straps, the mask body comprises an outer layer, amiddle layer and an inner layer, an inserting opening is formed between the outer layer and the inner layer, and the middle layer is inserted into or pulled out of the inserting opening to achieve replacement of the middle layer; the outer layer is a waterproof, oil-proof and antifouling fabric, the middle layer is a melt-blown non-woven fabric chip, and the inner layer is an antibacterial and deodorant fabric. According to the outer-layer three-proofing fabric of the protective mask, on one hand, dust, bacteria and viruses can be prevented from being attached and infiltrated in an aerosol orliquid foam particle mode, and risks are reduced; on the other hand, a tension field can be formed, filtering performance is improved, the thickness of filtering materials is reduced, and breathing smoothness is facilitated; on one hand, bacteria in the leakage net are killed, and on the other hand, odor caused by long-time breathing for more than one hour is eliminated.

Owner:浙江康洁丝新材料科技有限公司

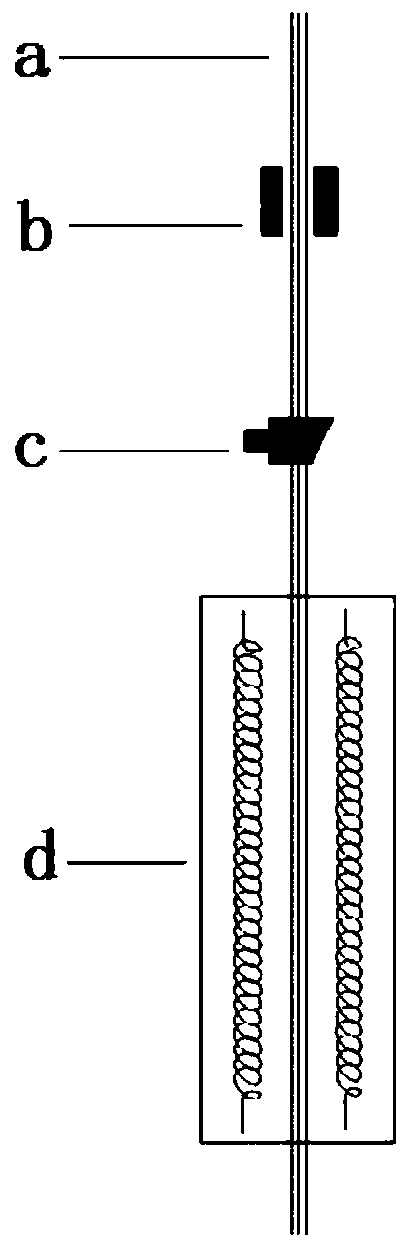

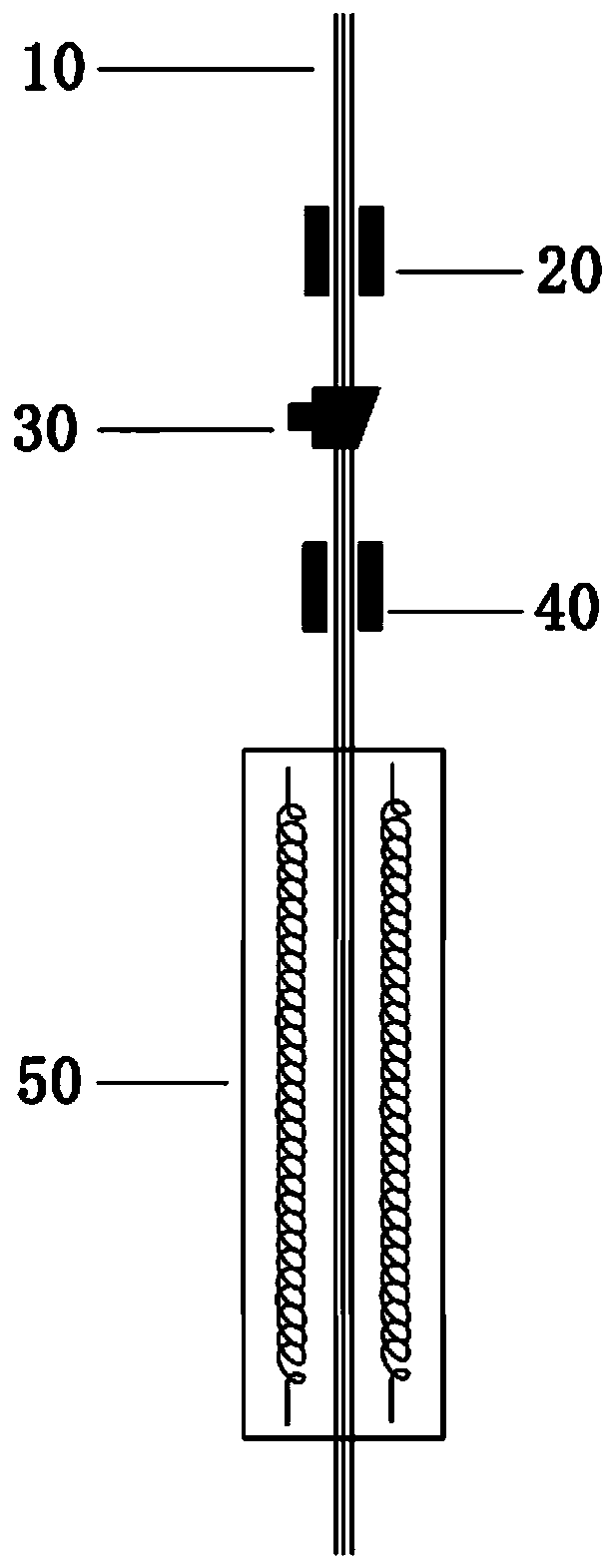

Graphene filter particle respirator anti-microbial filter element preparing method and prepared filter element

InactiveCN111544795AGood adsorption performanceImprove filtration performanceBreathing filtersAnti bacterialGraphite oxide

The invention relates to the technical field of mask filter elements, in particular to a graphene filter particle respirator anti-microbial filter element preparing method and a prepared filter element. The graphene filter particle respirator anti-microbial filter element preparing method comprises the following steps that firstly, graphite oxide is prepared; secondly, a graphene oxide viscous solution is prepared; and thirdly, melt-blown non-woven fabrics continuously pass through the obtained viscous solution and then are dried through rolling liquid and a roller, and a graphene oxide melt-blown non-woven fabric composite film is prepared to serve as the mask anti-microbial filter element. According to the graphene filter particle respirator anti-microbial filter element preparing methodand the prepared filter element, the excellent adsorption performance, obstruction performance and anti-microbial performance of graphene are utilized, the graphene material is used for the mask filter element so that the filter performance of a mask for solid particles in air can be effectively improved, meanwhile, the function of peculiar smell removal is achieved, and good anti-microbial performance is achieved.

Owner:常州美洛医疗科技有限公司

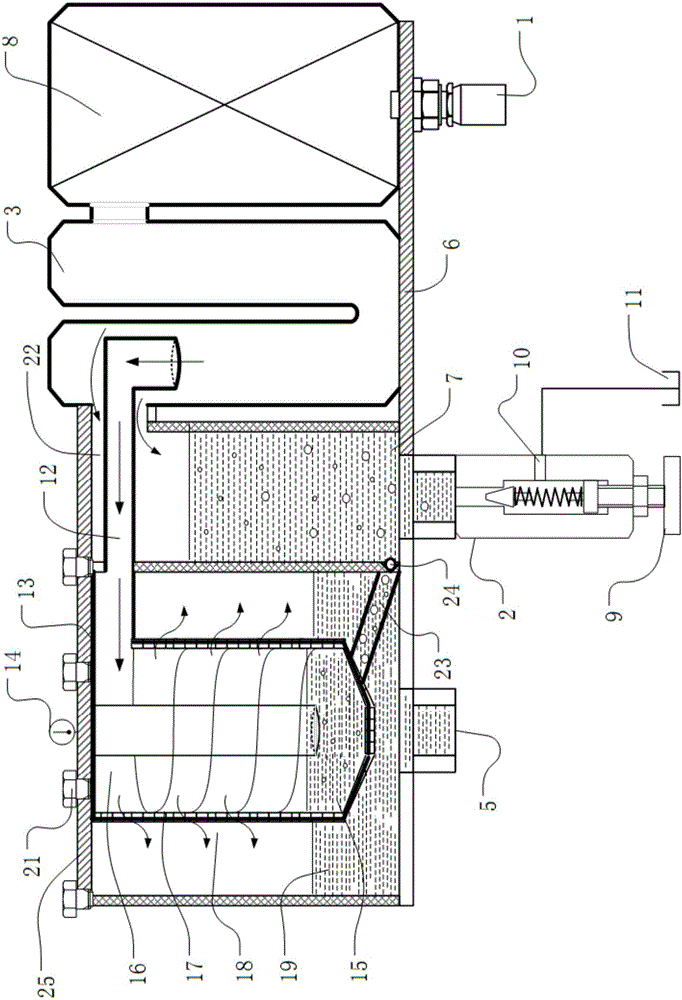

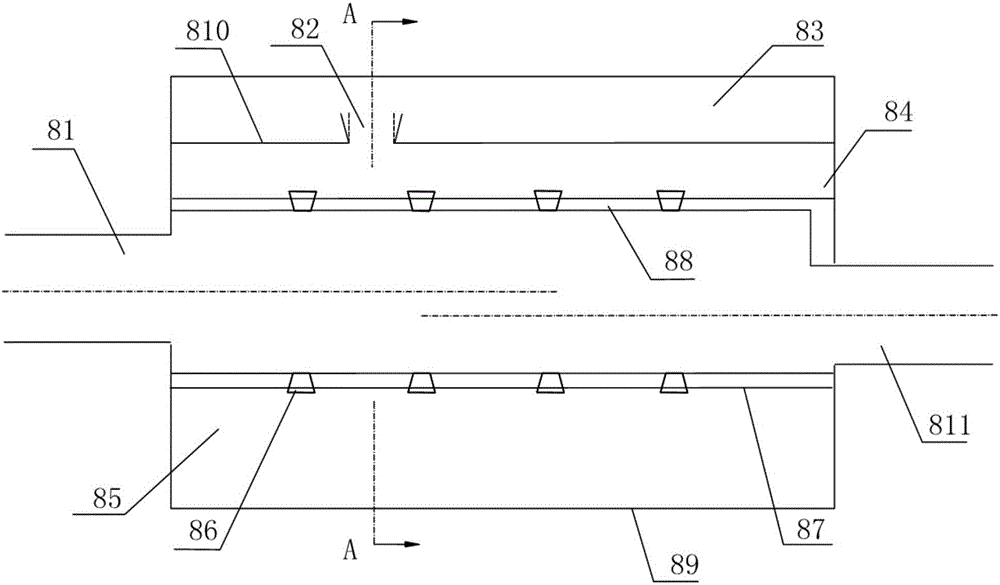

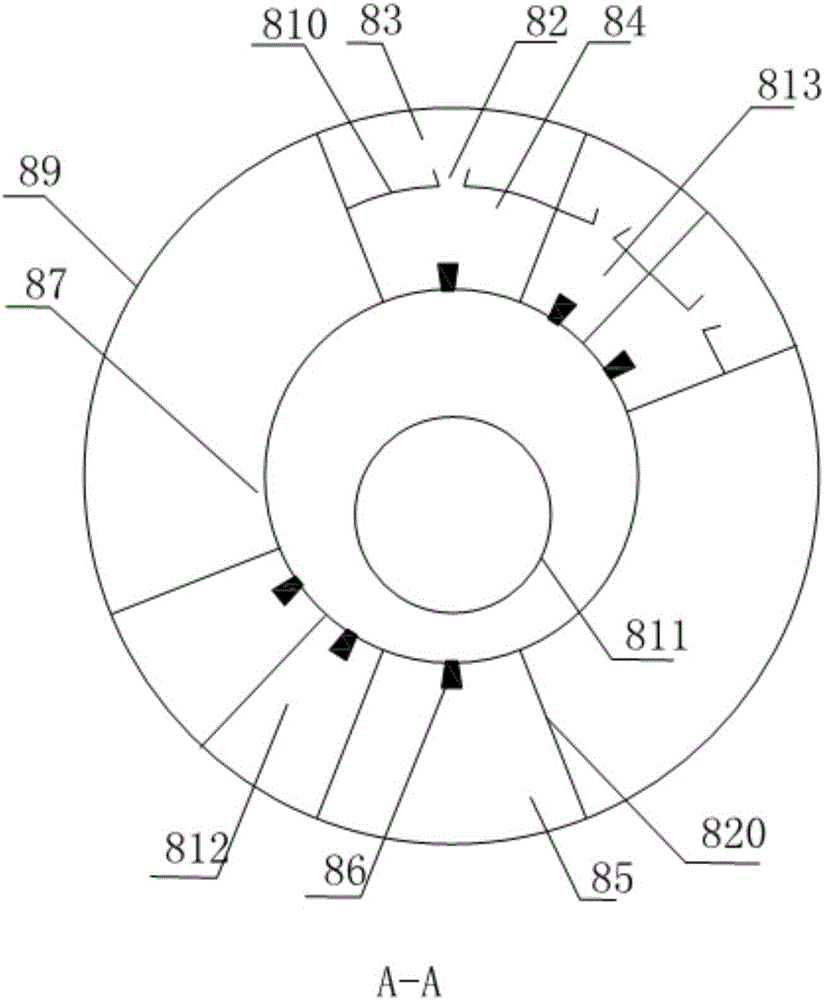

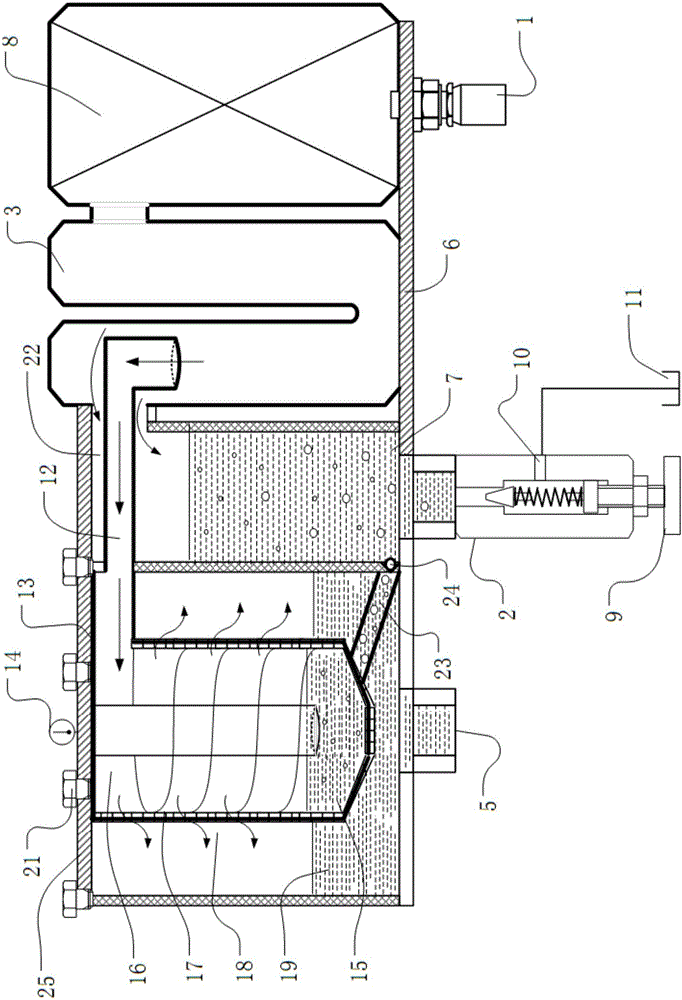

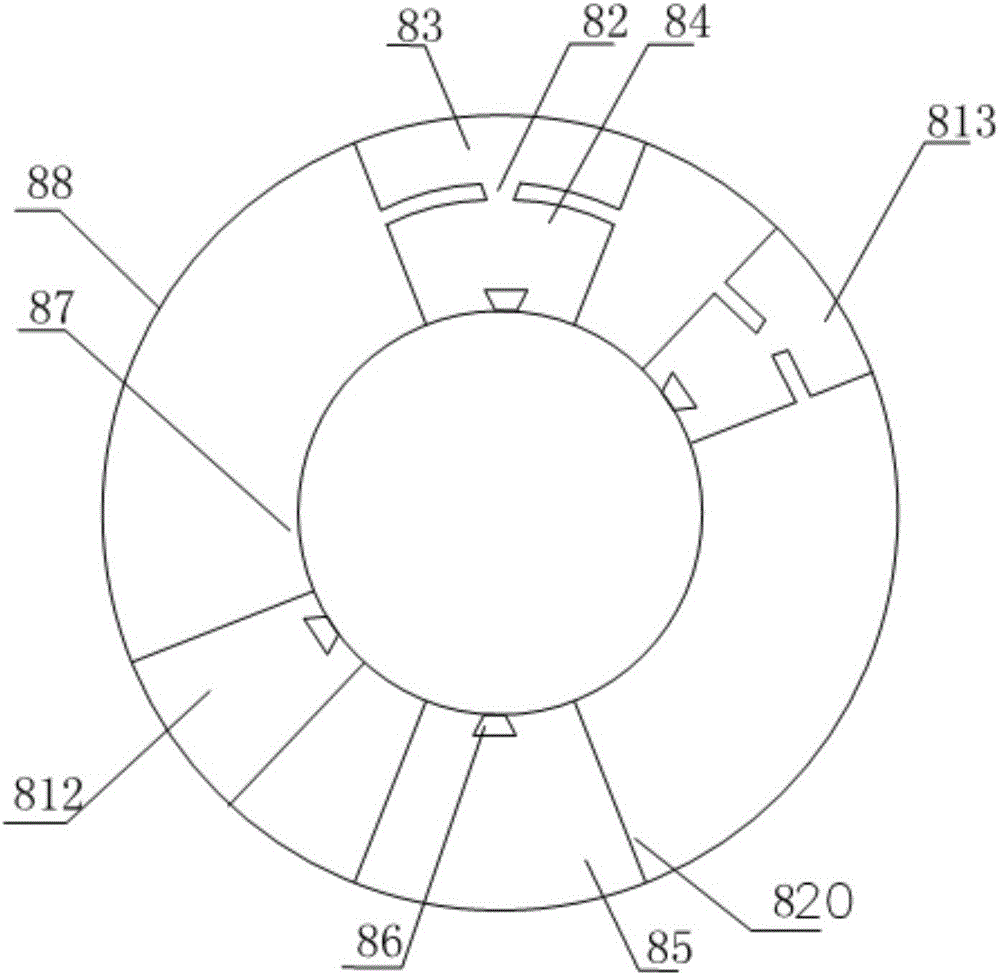

Filter tank adopting work-condition-adaptive filtering, magnetization, rotary magnetic field and centrifugation

InactiveCN105864200AImprove filtration performanceExtended service lifeFluid-pressure actuator componentsAdaptive filterSelf adaptive

The invention relates to a filter box with working condition adaptive filtering, magnetization, rotating magnetic field and centrifugal. The filter, U-shaped particle separation module, oil return cylinder and outer barrel are placed on the bottom plate in sequence; the filter and U-shaped particle The separation module is connected, which adopts a working condition adaptive filter; the U-shaped particle separation module includes a U-shaped tube, and the U-shaped tube is sequentially installed with a temperature control module, a magnetization module, a mechanical centrifuge module, a first adsorption module, and a rotating magnetic field centrifuge. module, the second adsorption module and the degaussing module; the U-shaped particle separation module and the upper part of the oil return cylinder are connected through the oil return pipe of the oil return cylinder; the inner cylinder is placed in the outer barrel, which is installed on the end cover; the spiral flow channel is contained in the In the barrel, it is connected with the U-shaped particle separation module through the oil inlet pipe of the inner barrel; the oil inlet pipe of the inner barrel is located in the oil inlet pipe of the oil return barrel; the filter element is arranged on the inner wall of the inner barrel. The invention has many advantages such as good filtering performance, high adaptability and integration, long service life and the like.

Owner:谢阿招

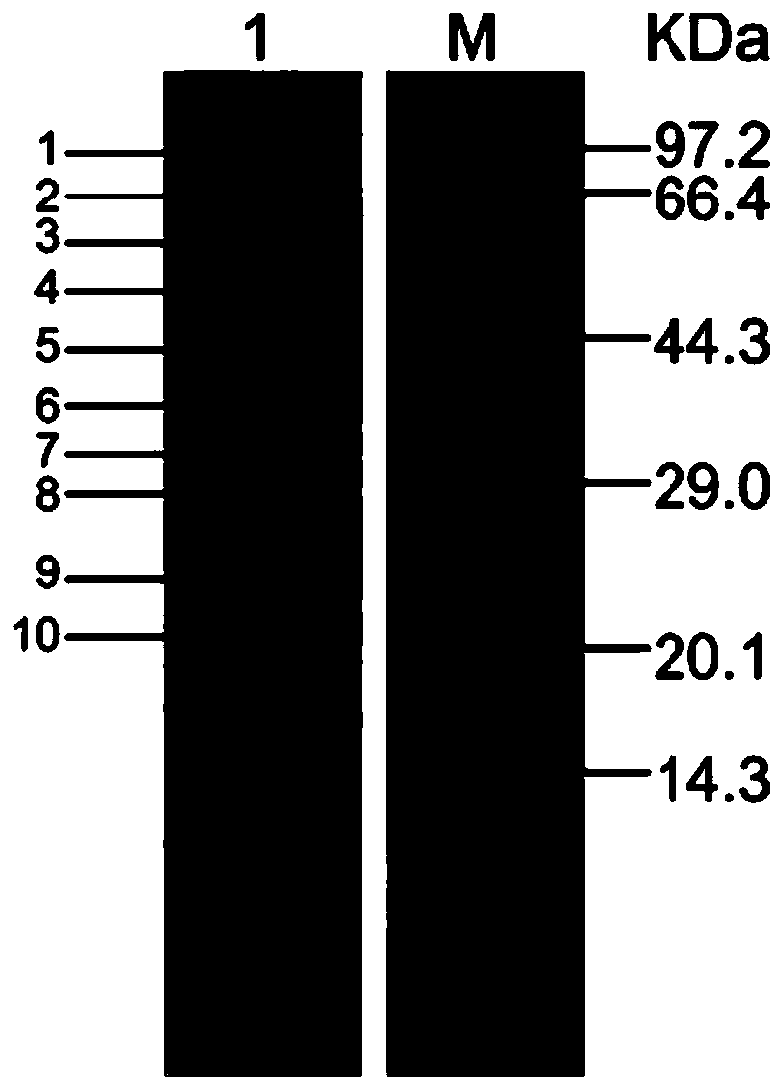

Application of strain of trichoderma reesei to barley malt production

ActiveCN110734823AImprove filtration performanceImprove filtering effectMicroorganism based processesMalt preparationArabinoxylanTrichoderma reesei

The invention relates to application of a strain of trichoderma reesei to barley malt production. The trichoderma reesei CICC41495 is used for treating Jiangsu barley malt; the content of high-molecular-weight arabinoxylan in the agreement wort of the treated barley malt is reduced from 876 mg / L to 235 mg / L, and is reduced by 73.2 percent; the viscosity is reduced from 1.59 mPa.s to 1.43 mPa.s, and is reduced by 10.1 percent; and the filtering speed is accelerated from 3.5 mL / min to 6.2mL / min, and is improved by 77 percent. The method provided by the invention has the advantages that by usingthe barley sprouting environment conditions, the trichoderma reesei grows on the surface of the barley; meanwhile, an araboxylan degrading enzyme system is secreted; the degradation of the high-molecular-weight arabinoxylan in the Jiangsu barley malt is promoted; the filtering speed of the agreement wort of the Jiangsu barley malt is accelerated; and conventional physicochemical indexes reach thelevel of first-grade products in the industrial standard QB / T 1686-2008.

Owner:JIANGNAN UNIV

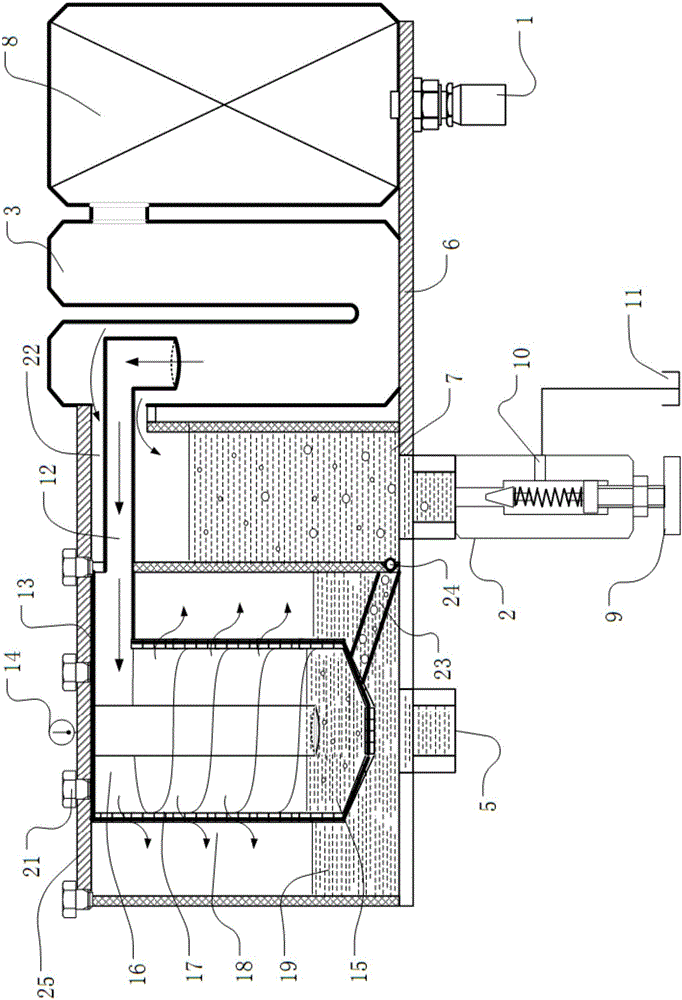

Oil filter adopting full-band variable-structure work condition self-adaptive filtering, magnetization and adsorption

InactiveCN105864180AImprove filtration performanceExtended service lifeFluid-pressure actuator componentsAdaptive filterSelf adaptive

The invention relates to an oil filter which adopts self-adaptive filtering, magnetization and adsorption under full-frequency variable structure working conditions. The structural condition adaptive filter is connected with the U-shaped particle separation module; the U-shaped particle separation module includes a U-shaped tube, and the U-shaped tube is equipped with a temperature control module, a magnetization module, an adsorption module and a degaussing module; the U-shaped particle separation module The separation module and the oil return cylinder are connected through the oil inlet pipe of the oil return cylinder; the inner cylinder is placed in the outer barrel, which is installed on the end cover; the spiral flow channel is accommodated in the inner cylinder, and it and the U-shaped particle separation module enter through an inner cylinder. The oil pipe is connected; the oil inlet pipe of the inner barrel is located in the oil inlet pipe of the oil return barrel and extends into the center of the U-shaped particle separation module; the filter element is arranged on the inner wall of the inner barrel; a hydraulic oil outlet is provided at the bottom of the outer barrel. The invention has many advantages such as good filtering performance, high adaptability and integration, long service life and the like.

Owner:SHAOXING UNIVERSITY

Oil filtering method adopting full-frequency-band filtering, magnetization, adsorption and centrifuging

InactiveCN105736525AImprove filtration performanceExtended service lifeFluid-pressure actuator componentsFrequency bandFuel tank

The invention relates to an oil filtering method using full-band filtering, magnetization, adsorption and centrifugation, which attenuates the pressure / flow pulsation of hydraulic oil through the filter, which adopts a full-band filter; realizes the separation of solid particles through a U-shaped particle separation module Separation, so that the solid particles in the oil move to the pipe wall, and enter the oil return cylinder through the oil return tube inlet pipe and then return to the oil tank. The oil in the center of the pipeline containing trace small particles enters the inner cylinder through the inner cylinder oil inlet pipe Perform high-precision filtration to improve the service life of the filter element; the oil entering the oil inlet pipe of the inner cylinder flows into the spiral flow channel of the inner cylinder in a tangential flow, and the inner cylinder wall is the filter element, and the filtrate flows close to the filter element under the action of centrifugal force , the filtrate flows quickly parallel to the surface of the filter element, and the filtered hydraulic oil flows out to the outer cylinder perpendicular to the surface of the filter element; the pollution particles deposited on the bottom of the inner cylinder can be discharged to the oil return cylinder through the electronically controlled check valve at regular intervals to improve the use of the filter element life.

Owner:徐燚超

Oil filtering device adopting variable structure filtering, magnetizing and adsorbing and rotating magnetic field

InactiveCN105864194AImprove filtration performanceExtended service lifeFluid-pressure actuator componentsParticle separationTemperature control

The invention relates to an oil filter device adopting variable structure filtering, magnetization, adsorption and rotating magnetic field. The filter, U-shaped particle separation module, oil return cylinder and outer barrel are sequentially placed on the bottom plate; the filter and U-shaped particle separation Module connection, which adopts a variable structure filter; the U-shaped particle separation module includes a U-shaped tube, and the U-shaped tube is sequentially installed with a temperature control module, a magnetization module, a first adsorption module, a rotating magnetic field centrifugal module, a second adsorption module and Degaussing module; the U-shaped particle separation module and the upper part of the oil return cylinder are connected through the oil return pipe of the oil return cylinder; the inner cylinder is placed in the outer barrel, which is installed on the end cover; the spiral flow channel is contained in the inner cylinder, which is connected with the U-shaped The particle separation modules are connected by the oil inlet pipe of the inner cylinder; the oil inlet pipe of the inner cylinder is located in the oil inlet pipe of the oil return cylinder and extends into the center of the U-shaped particle separation module; the filter element is arranged on the inner wall of the inner cylinder. The invention has many advantages such as good filtering performance, high adaptability and integration, long service life and the like.

Owner:SHAOXING UNIVERSITY

Filtering method adopting wave suppression, magnetization, adsorption and rotating magnetic field

InactiveCN105864212AImprove filtration performanceExtended service lifeFluid-pressure actuator componentsSelf adaptiveFuel tank

The invention relates to a filter method using wave suppression, magnetization, adsorption and rotating magnetic field, which attenuates the pressure / flow pulsation of hydraulic oil through the filter, and adopts the working condition self-adaptive wave suppression filter; realizes it through the U-shaped particle separation module The separation of solid particles makes the solid particles in the oil move to the pipe wall, and enter the oil return cylinder through the oil return tube inlet pipe and then return to the oil tank. It enters the inner cylinder for high-precision filtration, which improves the service life of the filter element; the oil entering the oil inlet pipe of the inner cylinder flows into the spiral flow channel of the inner cylinder in a tangential flow, and the inner cylinder wall is the filter element, and the filtrate is under the action of centrifugal force It flows close to the filter element, the filtrate flows quickly parallel to the surface of the filter element, and the filtered hydraulic oil flows out to the outer cylinder perpendicular to the surface of the filter element; the pollution particles deposited on the bottom of the inner cylinder can be discharged to the return oil through the electronically controlled check valve at regular intervals cartridge, thereby increasing the service life of the filter element.

Owner:王雅莉

Filtering method adopting full-frequency-band variable-structure filtering, electrification, adsorption and rotating magnetic field

InactiveCN105889186AImprove filtration performanceExtended service lifeFluid-pressure actuator componentsFrequency bandCheck valve

The invention relates to a filtering method adopting full-frequency-band variable-structure filtering, electrification, adsorption and a rotating magnetic field. Pressure and flow pulsation of hydraulic oil is attenuated by means of a filter, and a full-frequency-band variable-structure filter is adopted as the filter; separation of solid particles can be achieved by means of a U-type particle separation module, so that the solid particles in oil move to a pipe wall, the solid particles flow back to an oil tank after entering an oil return cylinder through an oil return cylinder oil inlet pipe, oil in the center of a pipeline containing a small quantity of small-grain-size particles enters an inner cylinder through an inner cylinder oil inlet pipe for high-precision filtering, and the service life of a filter element is prolonged; the oil entering the inner cylinder oil inlet pipe flows into a spiral channel of the inner cylinder in a tangential inflow mode, an inner cylinder wall serves as the filter element, filter liquid is attached to the filter element to flow under the action of centrifugal force, the filter liquid quickly flows parallel to the surface of the filter element, and filtered hydraulic oil flows out of an outer cylinder in the direction perpendicular to the surface of the filter element; pollution particles deposited at the bottom of the inner cylinder can be periodically discharged out of the oil return cylinder through an electric control check valve, and accordingly the service life of the filter element is prolonged.

Owner:李昊

Sewage treatment device

InactiveCN108439494AImprove filtration performanceImprove sewage filtration effectTreatment involving filtrationWater/sewage treatment apparatusPollutantSewage treatment

The invention discloses a sewage treatment device comprising a filter box body, the filter box body is internally provided with a first cavity, a bearing is arranged in the middle portion of the innertop wall of the first cavity, the lower part of the inner side wall of the first cavity is provided with a first through hole, the lower part of the inner side wall, far away from the first through hole, of the first cavity is provided with a clamping groove, a motor is fixedly connected to the middle portion of the upper surface of the filter box body, and a stirring rod is fixedly connected tothe output end of the motor. The bottom end of the stirring rod penetrates the bearing and extends to the inside of the first cavity, the outer surface of the stirring rod is fixedly connected with the inner ring of the bearing, the lower parts of the left and right sides of the stirring rod are fixedly connected with stirring blades arranged equidistantly, and a fixing block is fixedly connectedto the lower portion of the inner side wall of the first cavity. The sewage treatment device achieves the effect of adsorbing pollutants in sewage, has the function of sewage filtering, has the advantage of improving the effect of sewage filtering, and can further separate impurities in the sewage.

Owner:张斐斐

Oil filter adopting full-frequency-band working-condition self-adaption smoothing, electrification and rotational magnetic field

InactiveCN105864225AImprove filtration performanceExtended service lifeServometer circuitsFluid-pressure actuator componentsFrequency bandAdaptive filter

The present invention relates to an oil filter with self-adaptive filtering, electrification and rotating magnetic field under full-frequency working conditions. The filter, U-shaped particle separation module, oil return cylinder and outer barrel are sequentially placed on the bottom plate; the filter and U The U-shaped particle separation module is connected with a full-band working condition adaptive filter; the U-shaped particle separation module includes a U-shaped tube, and the U-shaped tube is sequentially installed with an electrification module, a separation module, a first adsorption module, and a rotating magnetic field centrifuge. module, the second adsorption module and degaussing module; the U-shaped particle separation module and the upper part of the oil return cylinder are connected through the oil return pipe of the oil return cylinder; the inner cylinder is placed in the outer barrel, which is installed on the end cover; the spiral flow channel is contained in the Inside the cylinder, it is connected with the U-shaped particle separation module through the oil inlet pipe of the inner cylinder; the oil inlet pipe of the inner cylinder is located in the oil inlet pipe of the oil return cylinder; the filter element is arranged on the inner wall of the inner cylinder. The invention has many advantages such as good filtering performance, high adaptability and integration, long service life and the like.

Owner:SHAOXING UNIVERSITY

Filtering device adopting working condition adaptive filtering, magnetization, adsorption and centrifuging

InactiveCN105971989AImprove filtration performanceExtended service lifeFluid-pressure actuator componentsSelf adaptiveTemperature control

The invention relates to a filter device adopting working condition self-adaptive filtering, magnetization, adsorption and centrifugation. The filter, U-shaped particle separation module, oil return cylinder and outer barrel are sequentially placed on the bottom plate; the filter and U-shaped particle separation Module connection; the U-shaped particle separation module includes a U-shaped tube, and the U-shaped tube is sequentially installed with a temperature control module, a magnetization module, a mechanical centrifugal module, an adsorption module, and a degaussing module; the U-shaped particle separation module and the oil return cylinder pass through An oil return tube is connected to the oil inlet pipe; the inner cylinder is placed in the outer barrel, which is installed on the end cover; the spiral flow channel is accommodated in the inner cylinder, and it is connected to the U-shaped particle separation module through an inner cylinder oil inlet pipe; The oil inlet pipe of the cylinder is located in the oil inlet pipe of the oil return cylinder, and extends into the center of the U-shaped particle separation module; the filter element is arranged on the inner wall of the inner cylinder. The invention has many advantages such as good filtering performance, high adaptability and integration, long service life and the like.

Owner:SHAOXING UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com