Recyclable protective mask

A mask and socket technology, applied in the field of masks, can solve problems such as affecting the willingness to wear masks, and achieve the effect of facilitating smooth breathing, reducing risks, and improving smooth breathing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

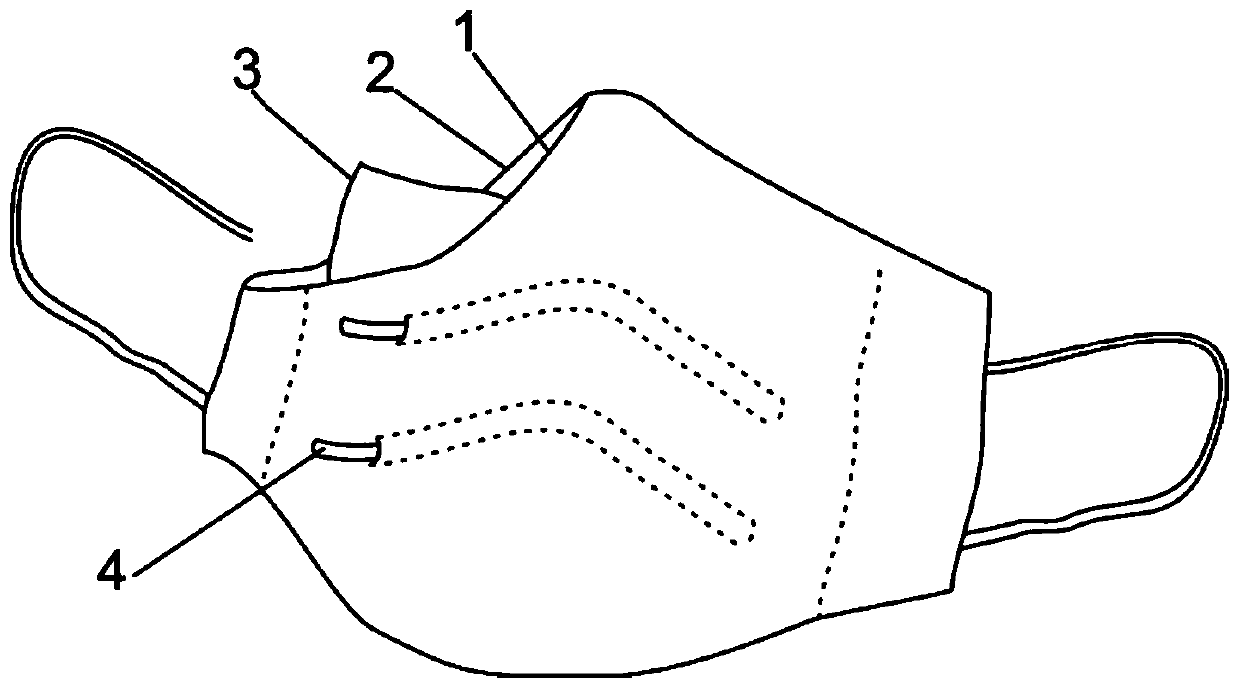

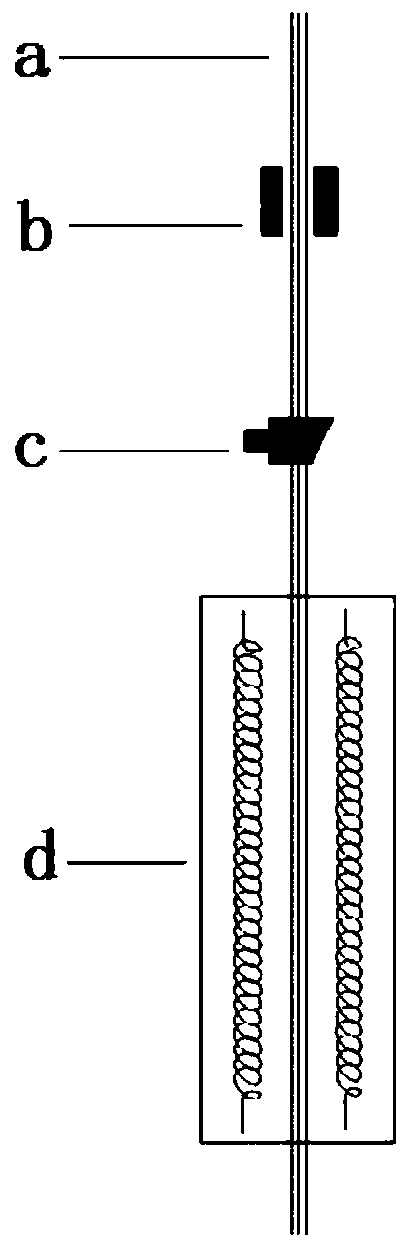

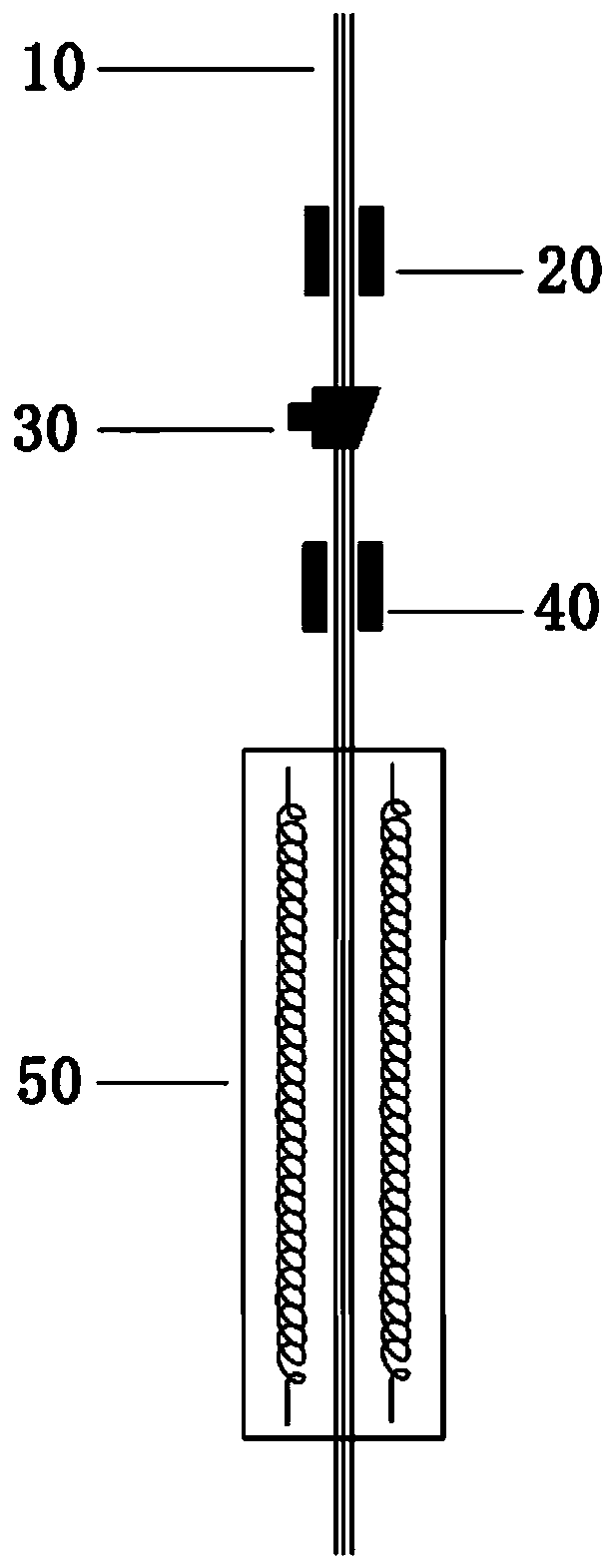

[0049] Such as figure 1 As shown, the recyclable protective mask of the present embodiment includes a mask body and a fixing belt. Wherein, the mask body includes an outer layer 2, an intermediate layer 3 and an inner layer 1, and a socket is formed between the outer layer 2 and the inner layer 1, and the middle layer 3 is inserted into or pulled out of the socket to realize the replacement of the middle layer 3. The outer layer 2 is a waterproof, oil-proof and antifouling fabric, the middle layer 3 is a melt-blown non-woven fabric chip, and the inner layer 1 is an antibacterial and deodorant fabric.

[0050] The waterproof, oil-proof and anti-fouling three-proof fabric of the outer layer of this embodiment is a plain weave woven fabric woven by plasma-modified waterproof, oil-proof and anti-fouling three-proof polyester, with a fiber fineness of 50D and a weaving density of 350T (the sum of the number of warp and weft fibers in 1 inch) ).

[0051] Wherein, the preparation m...

Embodiment 2

[0068] The difference between the recyclable protective mask of the present embodiment and the first embodiment is:

[0069] In the preparation method of plasma-modified waterproof, oil-proof and anti-fouling three-proof polyester, the order of plasma treatment and waterproof, oil-proof and anti-fouling treatment is interchanged, that is, the polyester POY long fiber first enters the water-proof, oil-proof and anti-fouling agent adding device. Water-proof, oil-proof and anti-fouling treatment, then plasma treatment by plasma treatment device, and finally high-temperature reaction and drying by high-temperature device.

[0070] For other structures and corresponding preparation methods, please refer to Example 1.

Embodiment 3

[0072] The difference between the recyclable protective mask of the present embodiment and the first embodiment is:

[0073] In this embodiment, the outer layer is replaced by the plasma-modified waterproof, oil-proof and anti-fouling three-proof polyester in Example 1 with waterproof, oil-proof and anti-fouling three-proof polypropylene fiber. The specific preparation method includes the following steps:

[0074] S1. Perform plasma treatment and waterproof, oil-proof and anti-fouling treatment on the single fiber;

[0075] The single-strand fiber of this embodiment is made of polypropylene long fiber, and the product is waterproof, oil-proof, and anti-fouling three-proof polypropylene DTY. The polypropylene long fiber is first treated with plasma by a plasma treatment device, and then enters a waterproof, oil-proof, and anti-fouling agent adding device for waterproofing. Anti-oil and anti-fouling treatment, that is, the gas-liquid phase grafting treatment process, and finally...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com