Patents

Literature

307results about How to "Increase the ventilation area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ventilation member

Owner:NITTO DENKO CORP

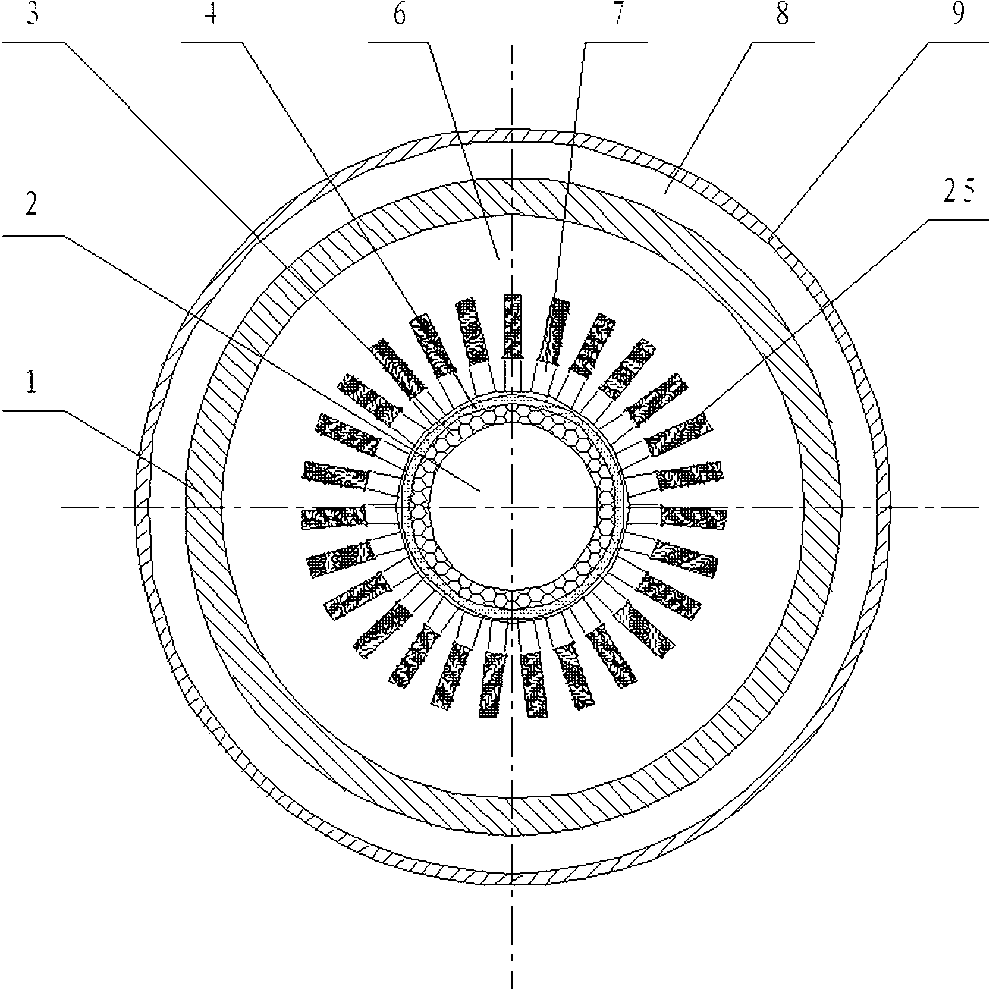

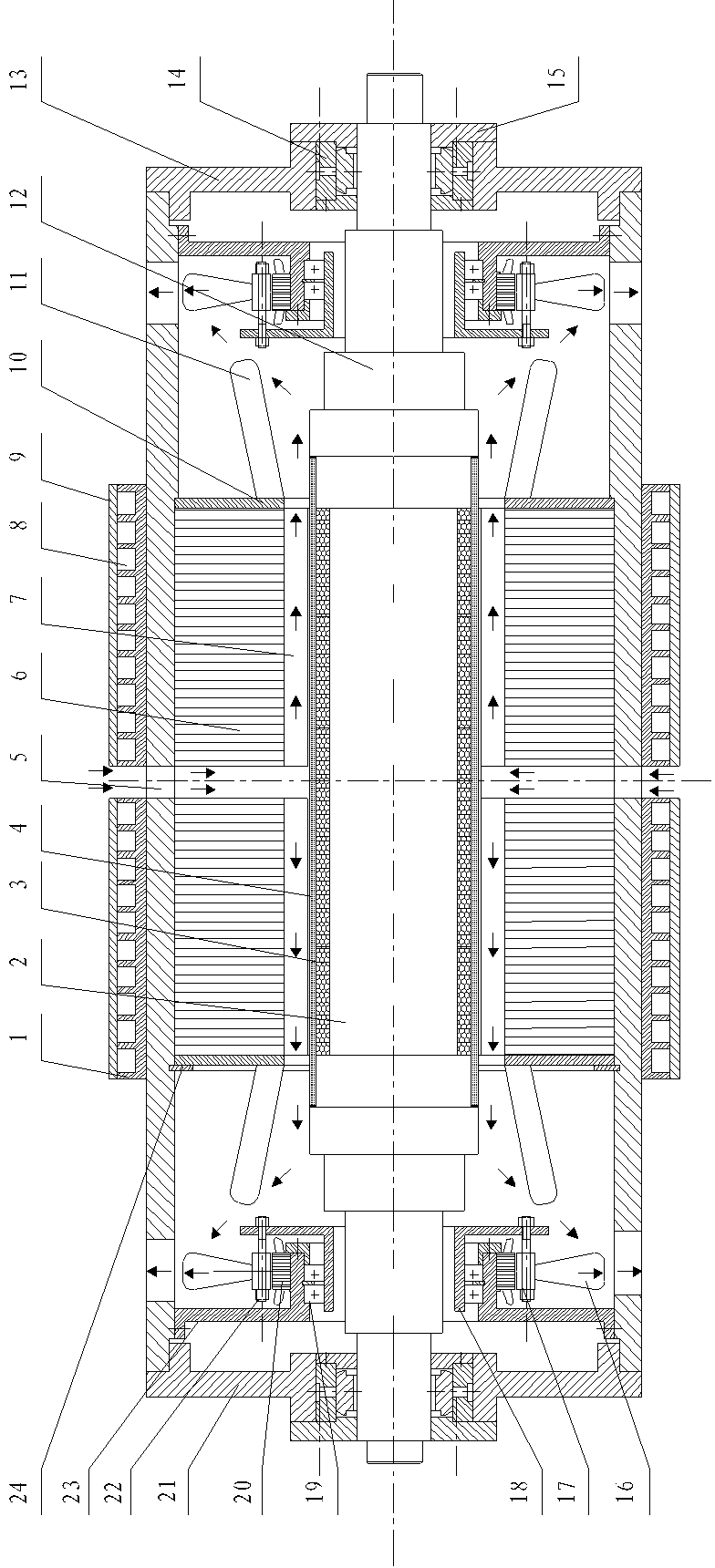

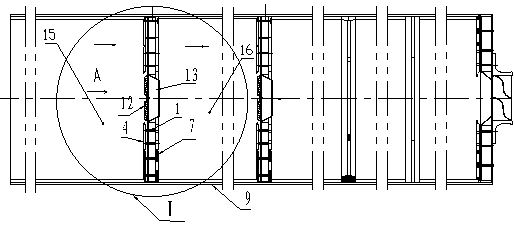

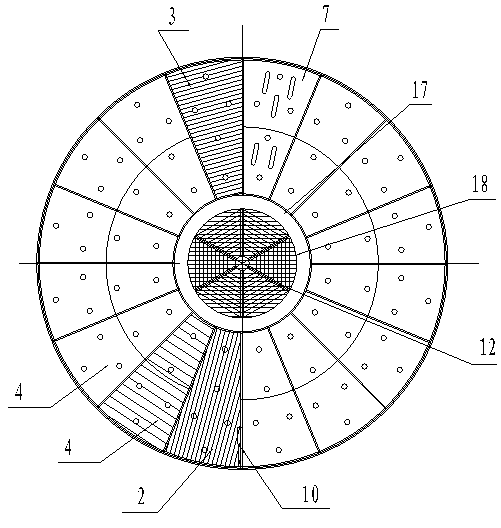

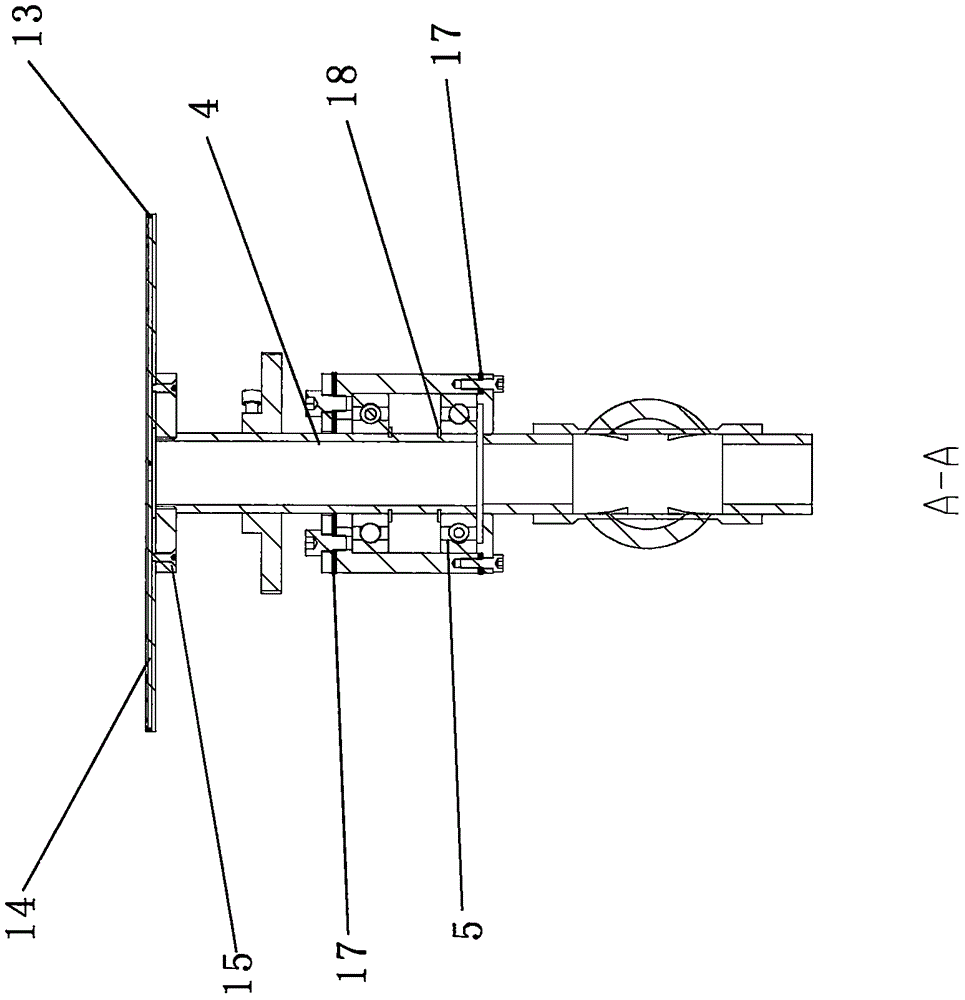

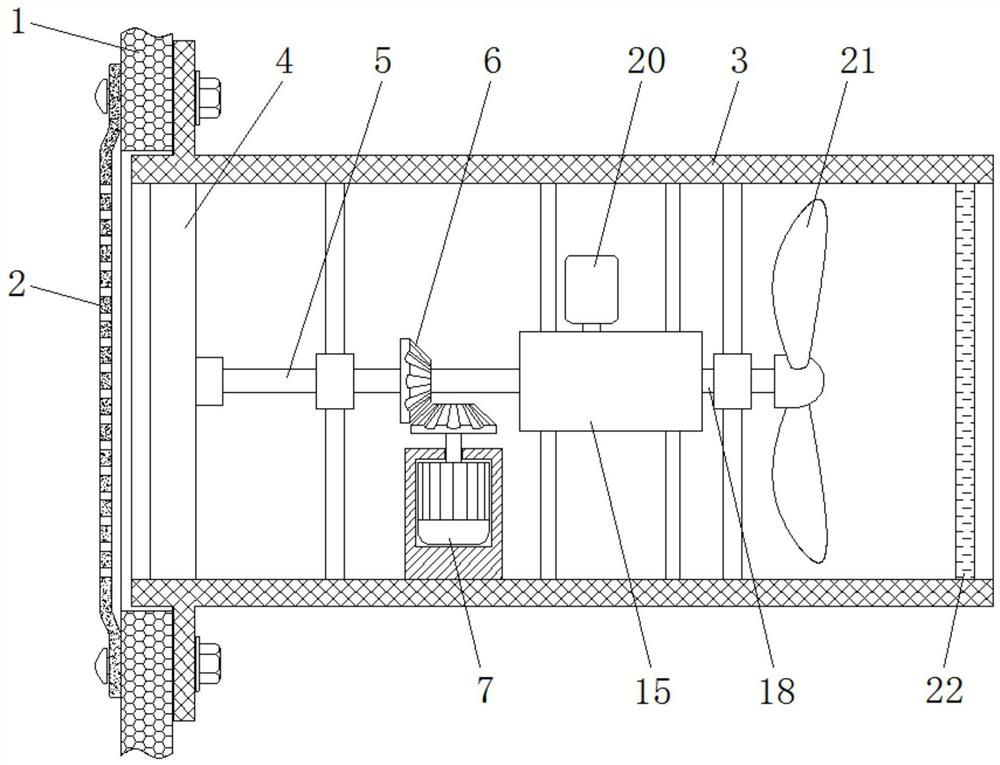

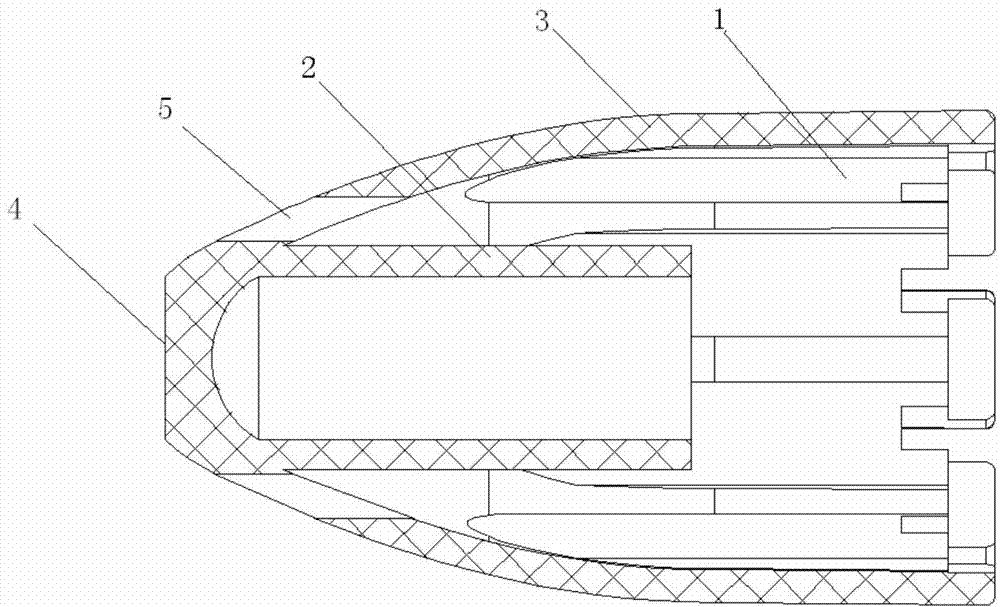

Air and water hybrid cooling high-speed permanent-magnet motor

InactiveCN102983680AReduce eddy current lossLow heat generationMagnetic circuit rotating partsMagnetic circuit stationary partsWater flowPermanent magnet motor

The invention discloses an air and water hybrid cooling high-speed permanent-magnet motor and belongs to the technical field of motors. The large-power high-speed permanent-magnet motor comprises a casing, a cooling water jacket, a stator core, a stator radial air duct, a stator inner air duct, a motor rotor, an outer rotor axial fan, an outer rotor fan fixing frame and two sliding bearings. The stator core is divided into two sections, the radial air duct is reserved in the middle, and the inner air duct is reserved in a stator slot close to the air gap position. The cooling water jacket is arranged outside the stator casing, a spiral water way is arranged in the water jacket, and water flows into the water way from the middle of the water way and flows out from a left spiral water outlet and a right spiral water outlet which are arranged at two ends of the water way. The air and water hybrid cooling high-speed permanent-magnet motor can mechanically solve the problem that a permanent magnet is broken when bearing large pulling stress during high-speed rotating, further solves the problems that the large-power high-speed motor is large in loss density, difficult in heat dissipation and over high in temperature rising, and prevents the permanent magnet from having irreversible demagnetization easily at high temperature.

Owner:SHENYANG POLYTECHNIC UNIV

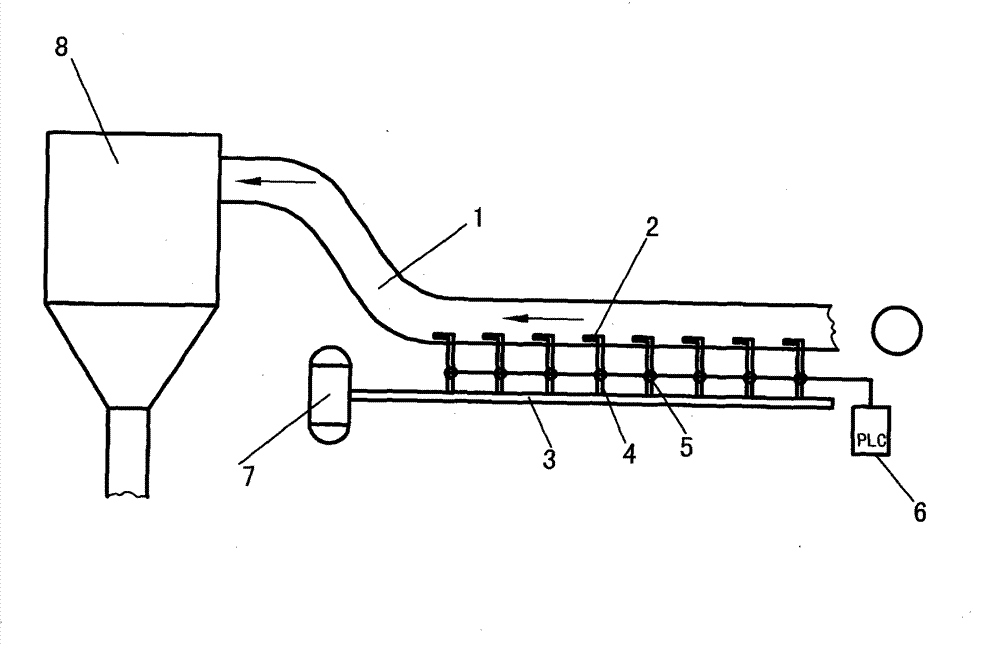

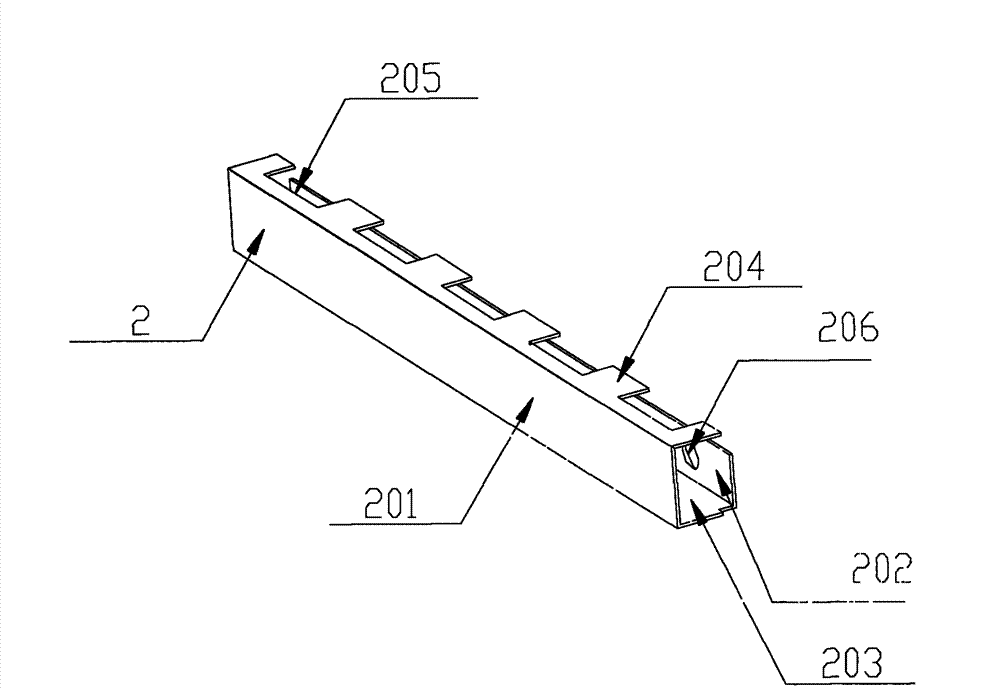

Automatic small-dip-angle dusty pipeline cleaning device

InactiveCN103042015AIncrease the ventilation areaDoes not affect normal productionHollow article cleaningDirt cleaningProgrammable logic controllerHigh pressure

An automatic small-dip-angle dusty pipeline cleaning device comprises a high-pressure main pipeline, a plurality of blowing nozzles, electromagnetic valves, branch pipes, a pneumatic supply and a PLC (programmable logic controller) control cabinet, wherein the electromagnetic valves and the branch pipes are corresponding to the blowing nozzles in number. The automatic small-dip-angle dusty pipeline cleaning device is characterized in that the blowing nozzles are mounted at one ends of the branch pipes which are mounted at the bottom of an air inlet pipeline or a dust pipeline of a dust collector according to a set distance, the electromagnetic valves are mounted in the middles of the branch pipes, the other ends of the branch pipes are communicated with the high-pressure main pipeline, the blowing direction of the blowing nozzles is consistent with the air flow direction in the air inlet pipeline or the dust pipeline of the dust collector, the electromagnetic valves are communicated with the PLC control cabinet, one end of the high-pressure main pipeline is communicated with the pneumatic supply, and the dust collector is mounted at one end of the air inlet pipeline or the dust pipeline. With normal production unaffected, the automatic small-dip-angle dusty pipeline cleaning device automatically cleans accumulated dust inside the small-dip-angle and horizontally arranged dust collecting pipelines and air ducts on line; and dust is guaranteed to be not accumulated inside the pipelines, pipeline ventilation area is increased, normal operation of a system is guaranteed, and product quality is improved while product output is increased.

Owner:DENGFENG SONGJI CEMENT

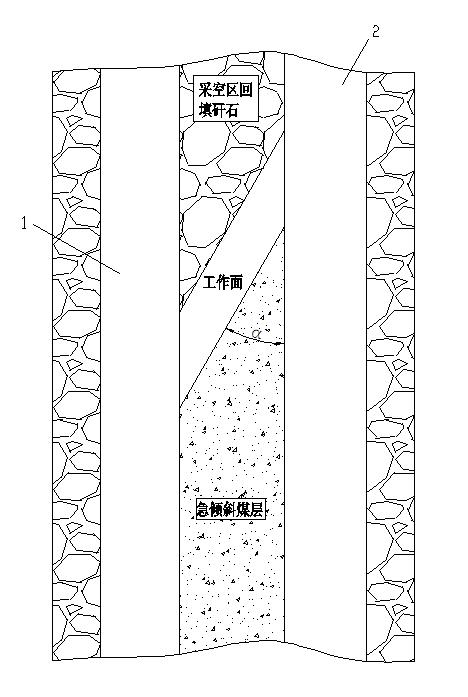

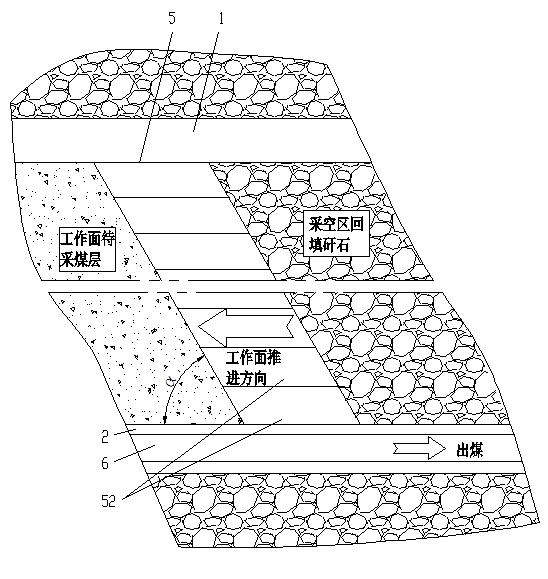

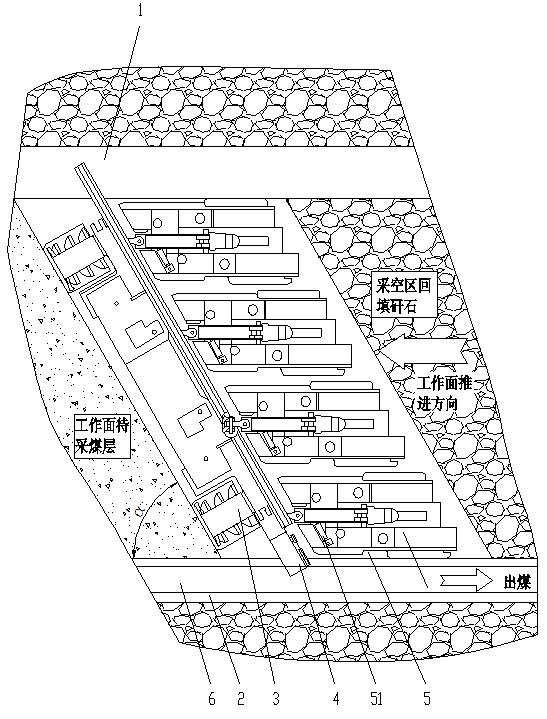

Steeply inclined seam dip oblique strike longwall comprehensive mechanical coal mining method

InactiveCN102587913ADecrease the inclinationReduce coal lossUnderground miningSurface miningSupporting systemResource utilization

The invention discloses a steeply inclined seam dip oblique strike longwall comprehensive mechanical coal mining method. The method comprises the following steps: preparation: digging a first laneway and a second laneway at the upper end and the lower end of the steeply inclined seam respectively; forming an initial mining working surface with the pitching oblique mining angle alpha of 25 to 35 degrees between the two laneways; arranging a coal mining machine, a scraper plate conveying machine, and a plurality of hydraulic brackets which are parallelogram-shaped in the overhead view and form a supporting system on the initial mining working surface; arranging the machine head of the scraper plate conveying machine behind relative to the machine tail while the hydraulic brackets in the propelling direction are sequentially behind a certain distance from the machine tail of the scraper plate conveying machine; arranging a reversed loader on the second laneway; coal mining: cutting coal up and low by using the coal-mining head of a coal-mining machine; moving the brackets: moving the hydraulic brackets sequentially from bottom to top; pushing and sliding: pushing and sliding by using a scraper trough conveyor of the scraper plate conveying machine in strokes to finish one time pushing and sliding quantity; and transporting coal: transporting coal to the outside by using the reversed loader. According to the method, the steeply inclined seam comprehensive mining operation is realized conveniently, and recovery ratio and resource utilization ratio are increased.

Owner:重庆市能源投资集团科技有限责任公司 +1

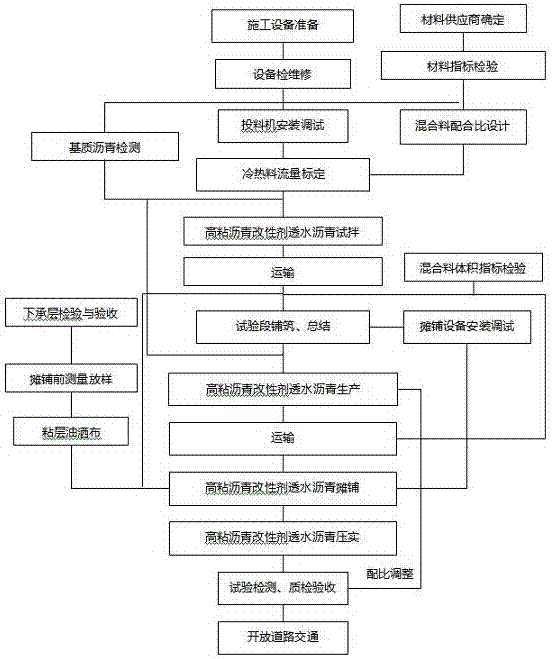

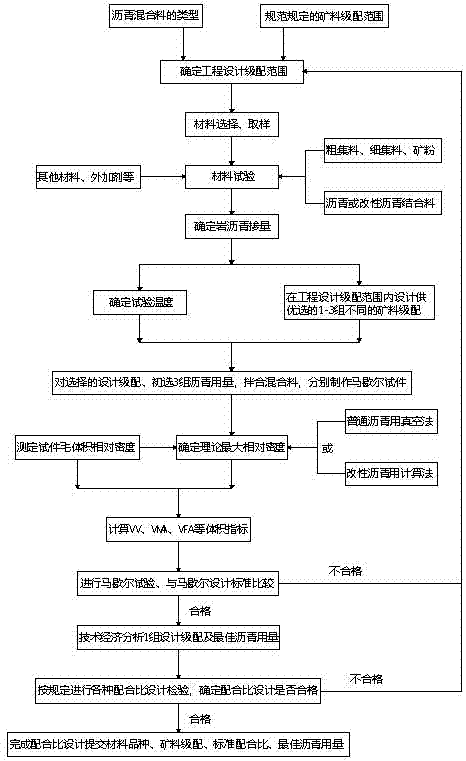

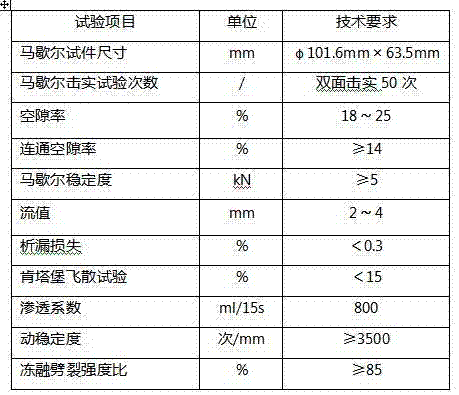

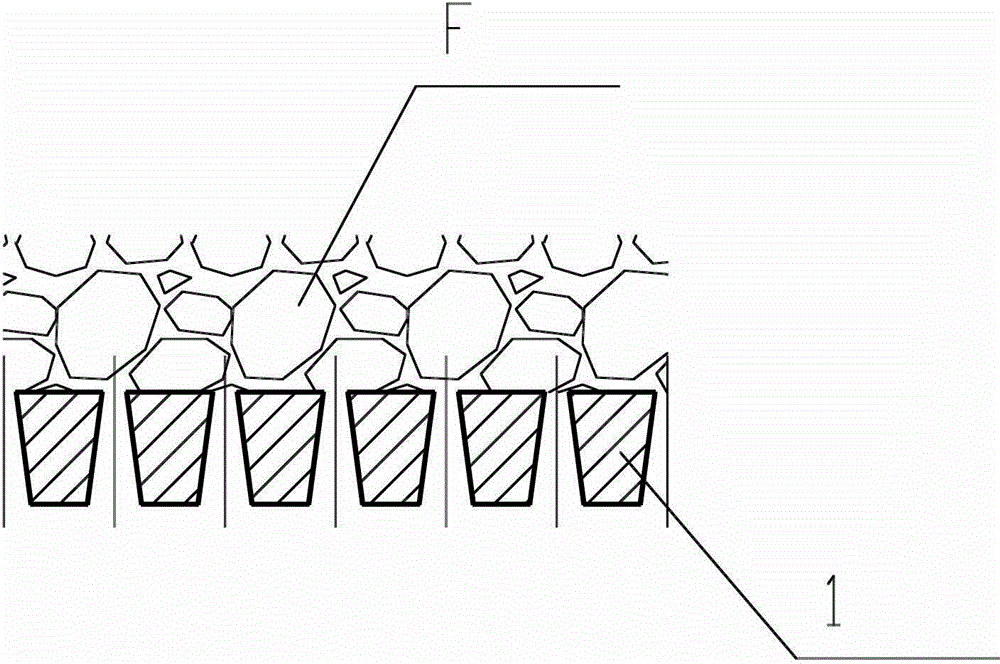

High-viscosity asphalt modifier porous asphalt pavement construction method

InactiveCN107142810ASimple production processNot easy to wasteIn situ pavingsRoads maintainencePorous asphaltRoad engineering

The invention belongs to the technical field of road engineering construction, and particularly relates to a high-viscosity asphalt modifier porous asphalt pavement construction method. The high-viscosity asphalt modifier porous asphalt pavement construction method is characterized by sequentially including the steps that construction equipment prepares to work; the mixing proportion of a direct-putting high-viscosity asphalt modifier porous asphalt mixture is designed; the direct-putting high-viscosity asphalt modifier porous asphalt mixture is produced; the direct-putting high-viscosity asphalt modifier porous asphalt mixture is transported; preparation work is conducted before the direct-putting high-viscosity asphalt modifier porous asphalt mixture is laid; use parameters of a laying machine are selected and adjusted; laying work is conducted; the direct-putting high-viscosity asphalt modifier porous asphalt mixture is rolled and formed; joint treatment is conducted. The method has the advantages of obvious construction method advantages and economic and social benefits.

Owner:SHANDONG HUITONG CONSTR GRP CO LTD

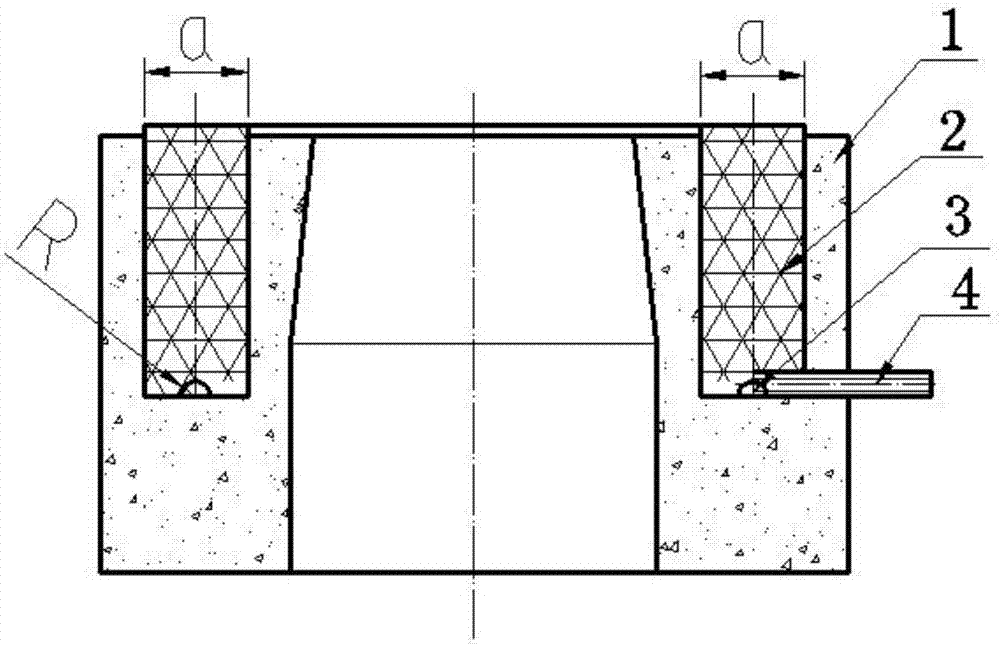

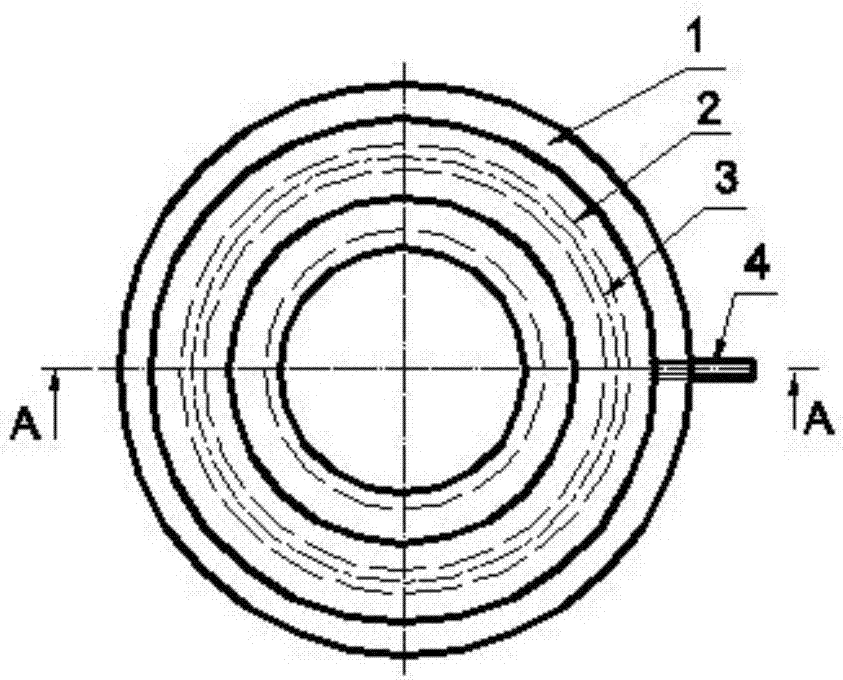

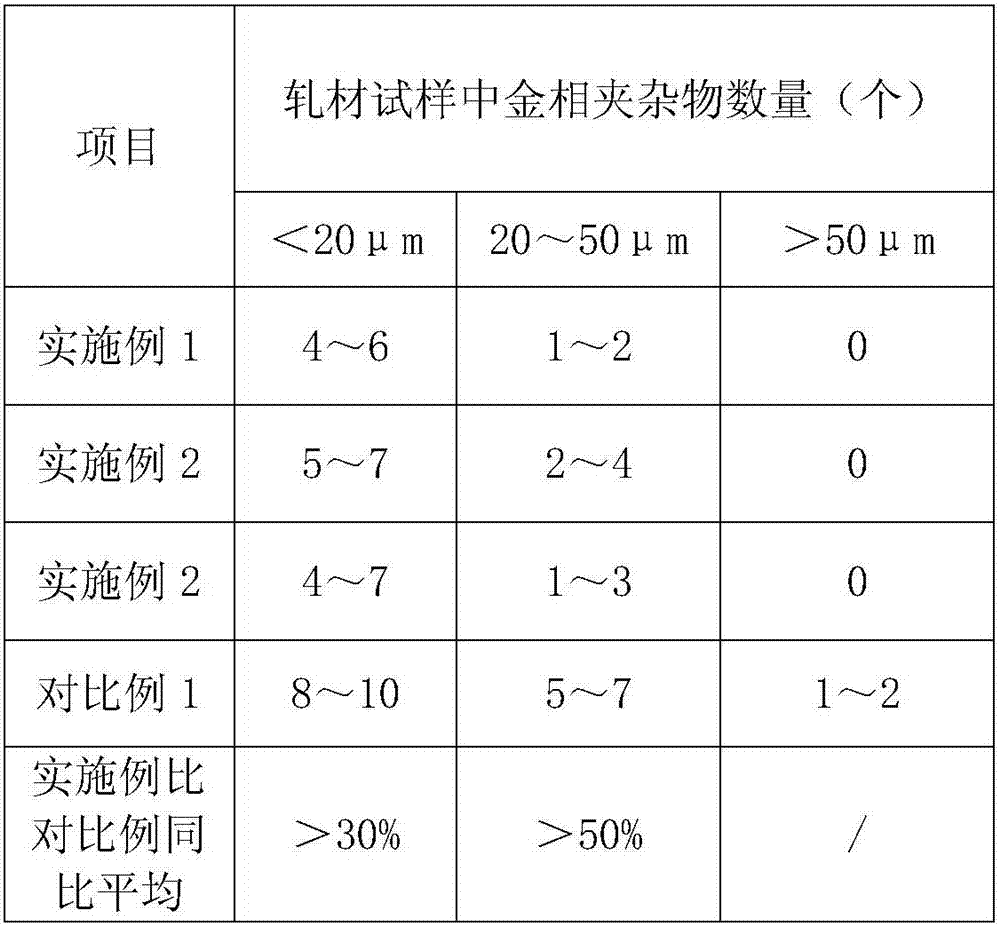

Method for removing slag inclusion of continuous casting tundish purging upper nozzle seating brick through argon blowing

The invention provides a method for removing slag inclusion of a continuous casting tundish purging upper nozzle seating brick through argon blowing. The proper amount of high-alkalinity low-carbon tundish covering agent is added to the molten steel liquid face of the area over the continuous casting tundish purging upper nozzle seating brick per charge, the problem that due to argon blowing of the continuous casting tundish purging upper nozzle seating brick, the molten steel liquid face greatly fluctuates is solved, the problem of molten steel secondary oxidization and slag entrapment can be effectively prevented, the argon bubble capture inclusion floats to the tundish liquid face to be absorbed timely by the high-alkalinity low-carbon tundish covering agent and be removed more effectively, and the metallurgical results of argon blowing slag inclusion removal of the continuous casting tundish purging upper nozzle seating brick is improved.

Owner:SHANDONG IRON & STEEL CO LTD

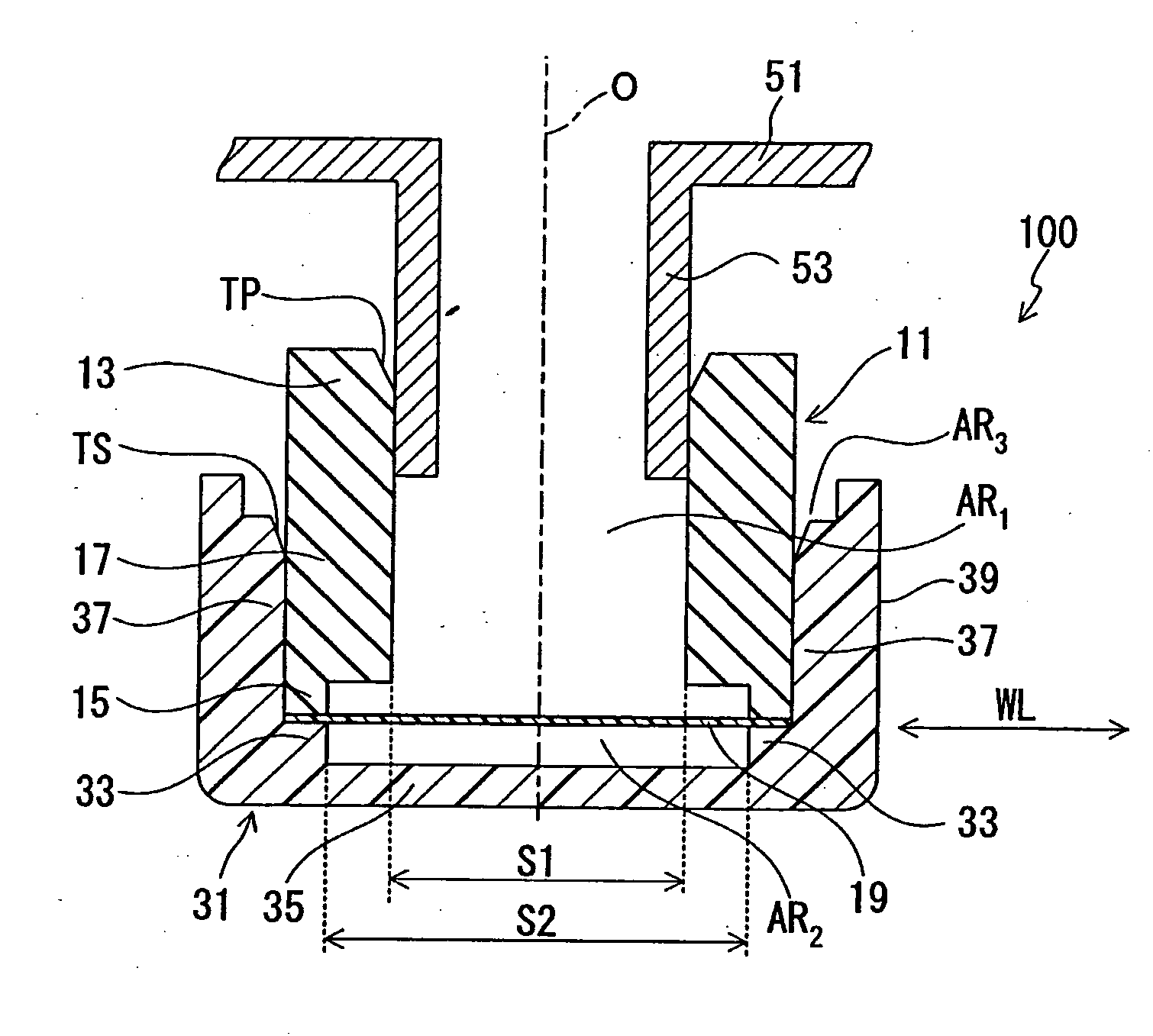

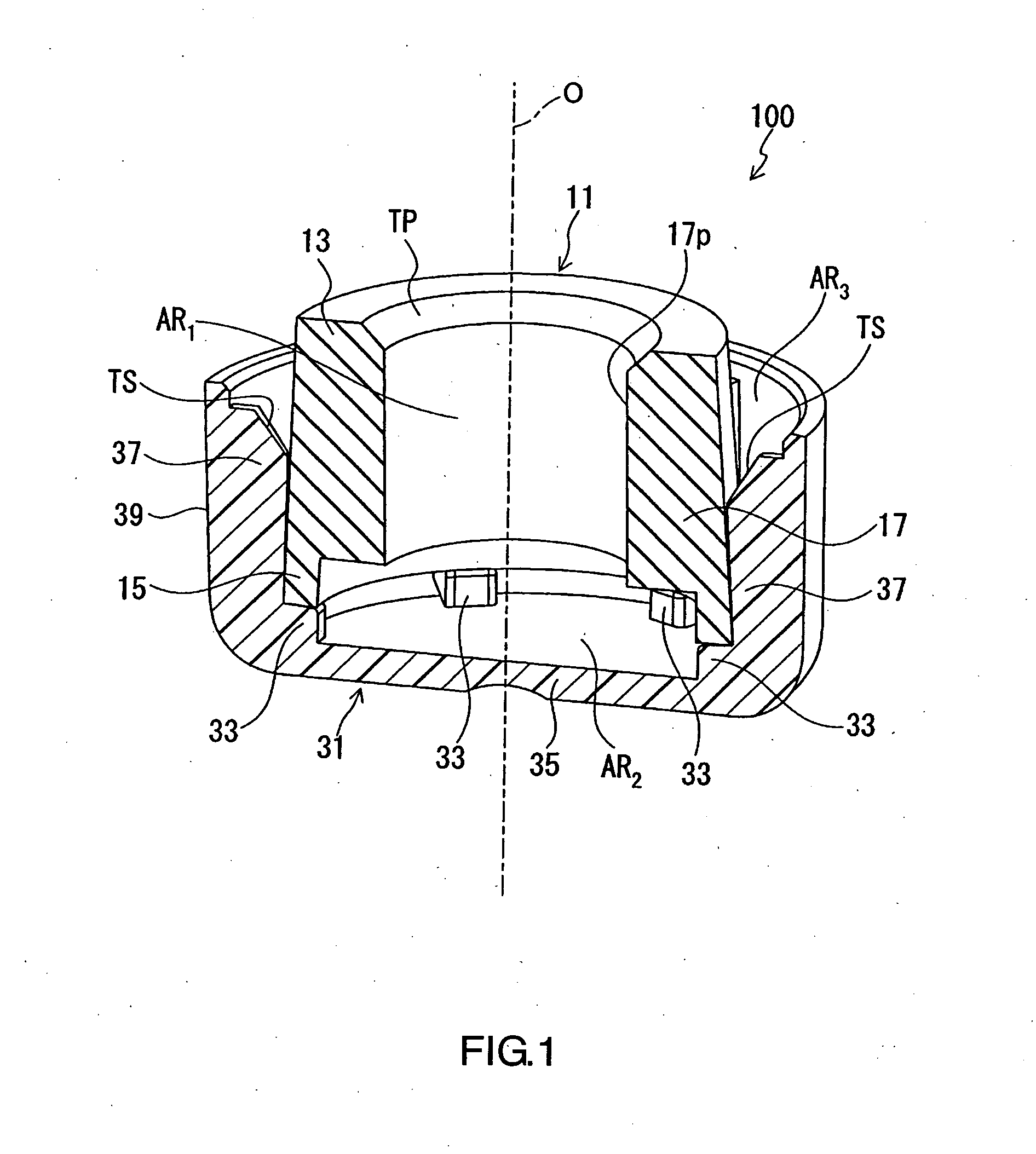

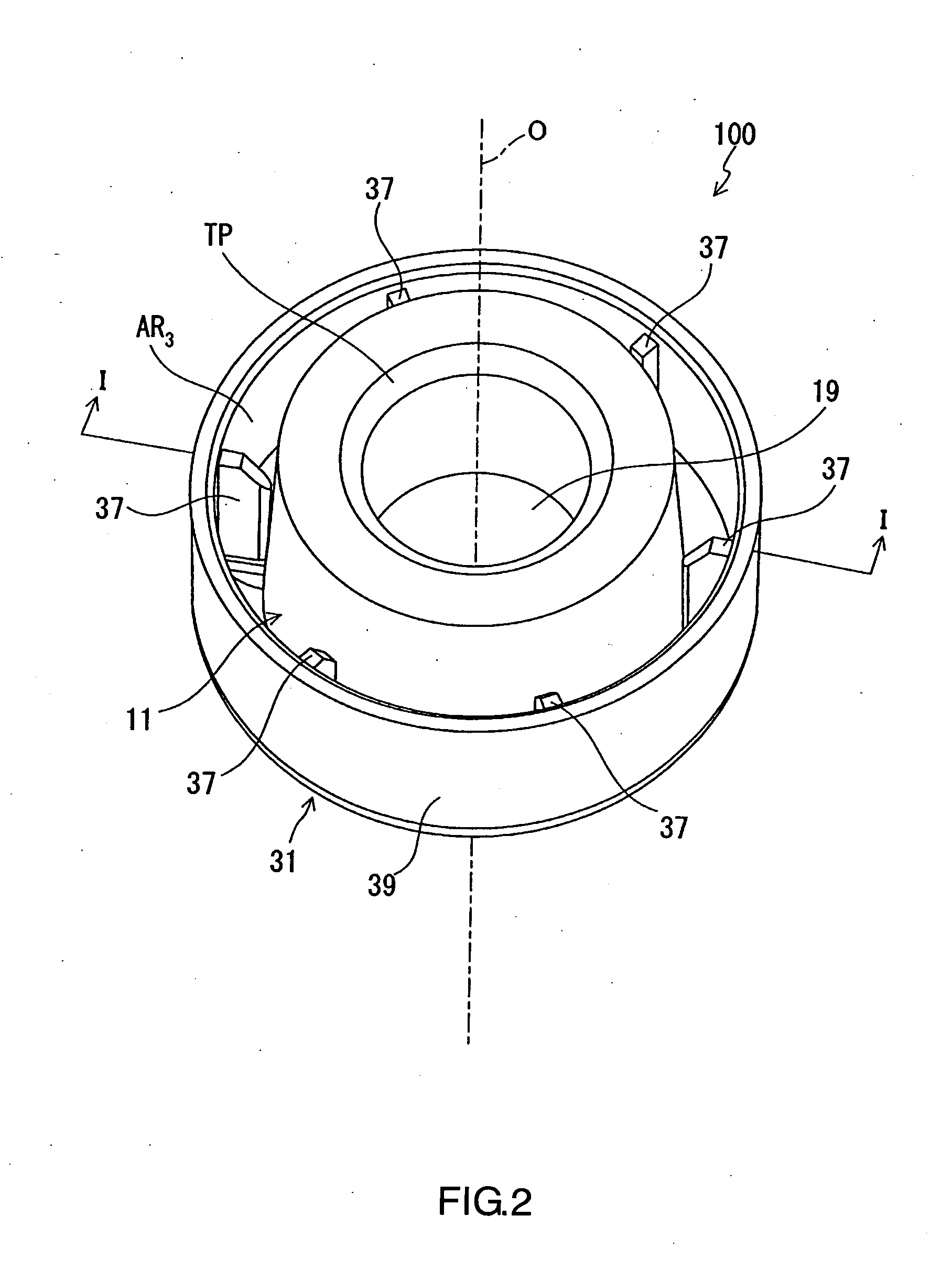

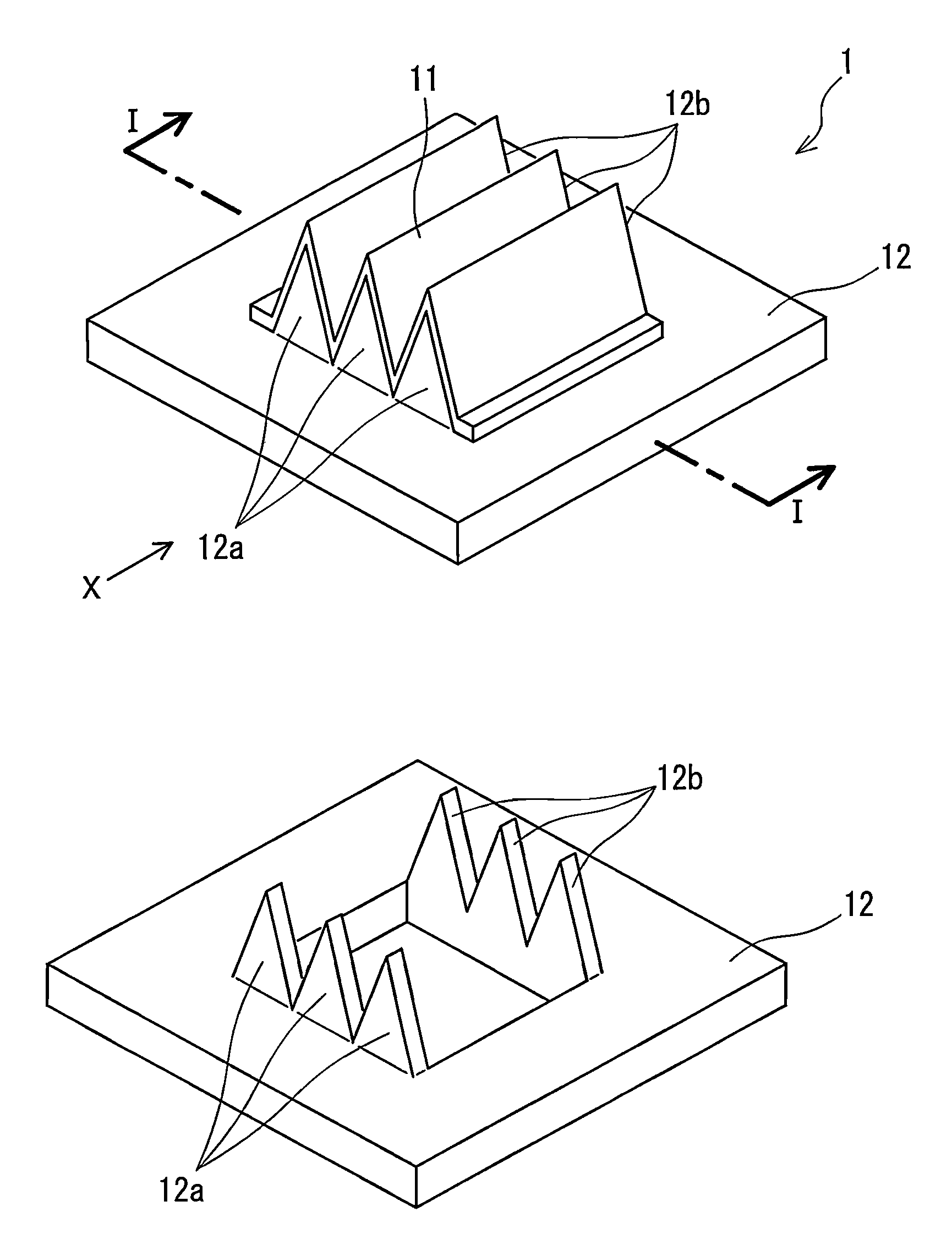

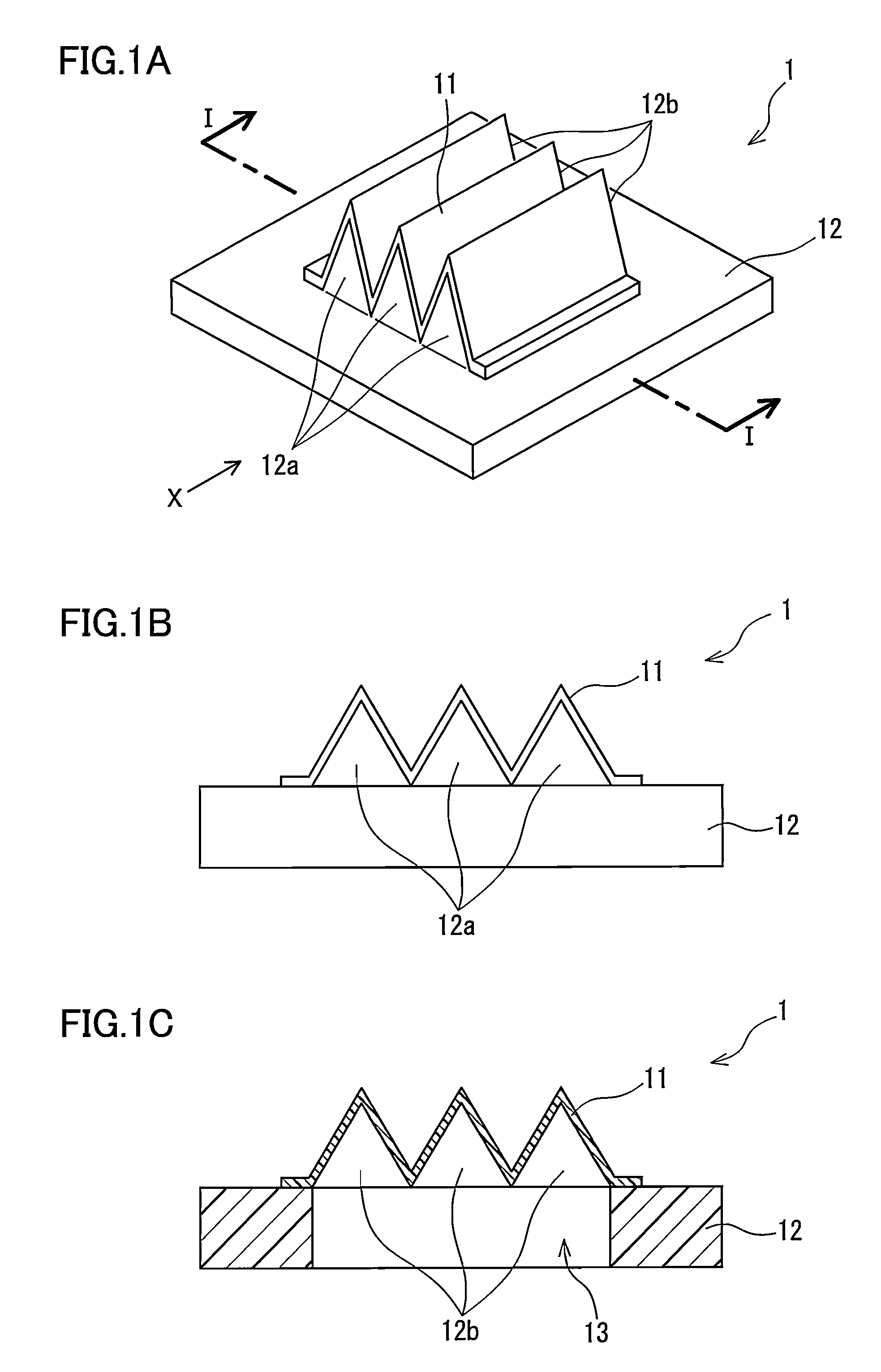

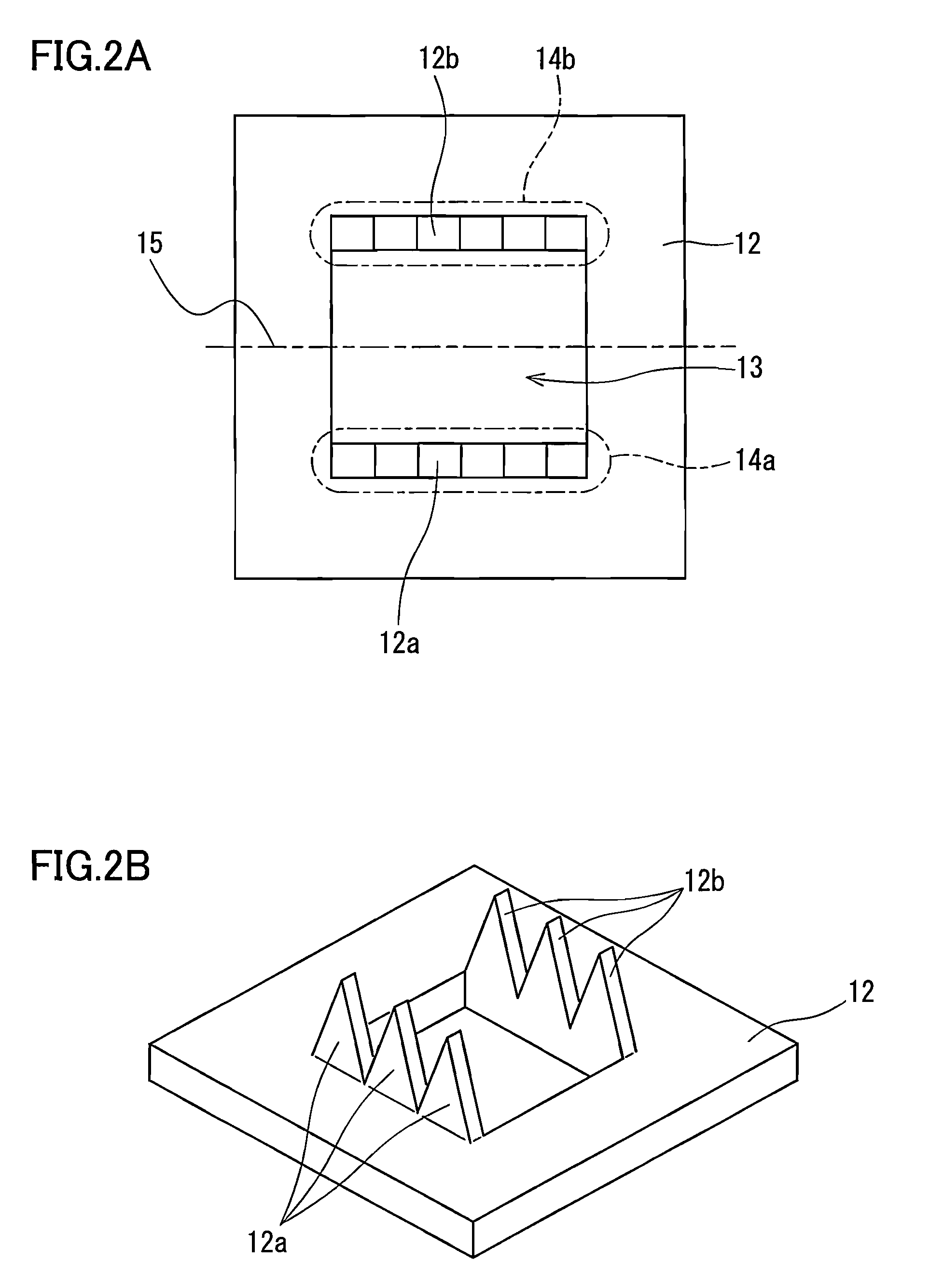

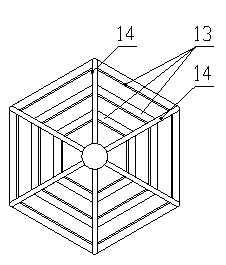

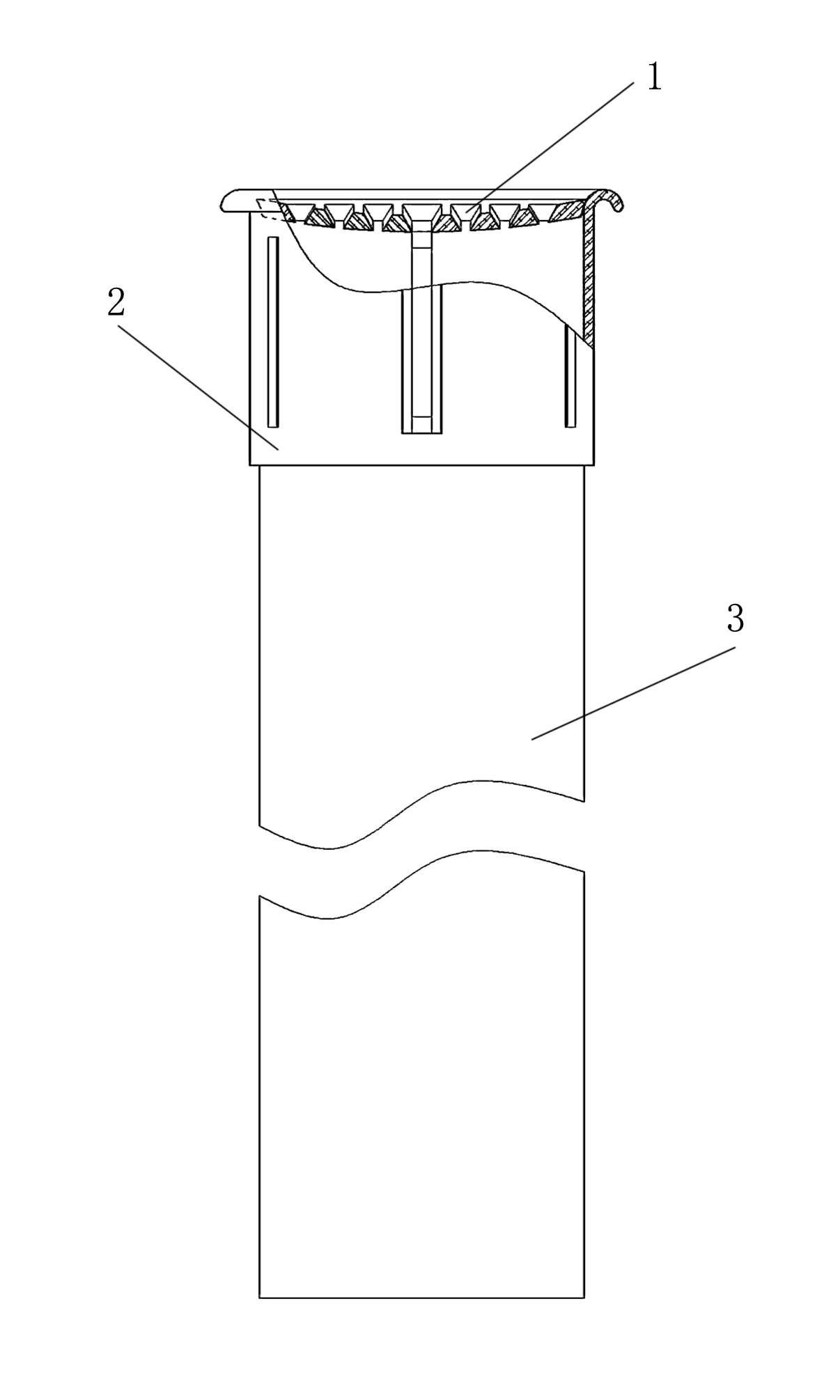

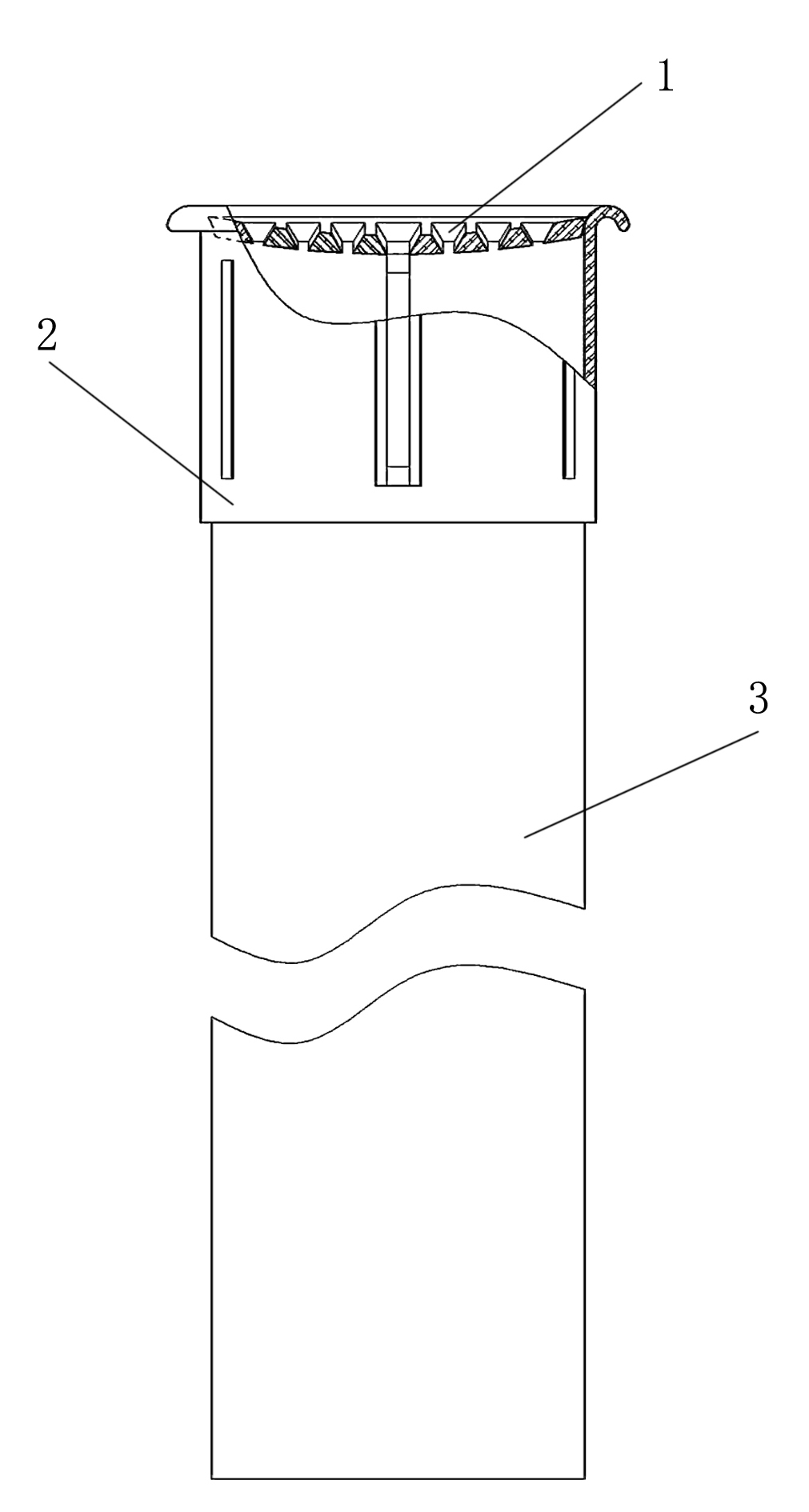

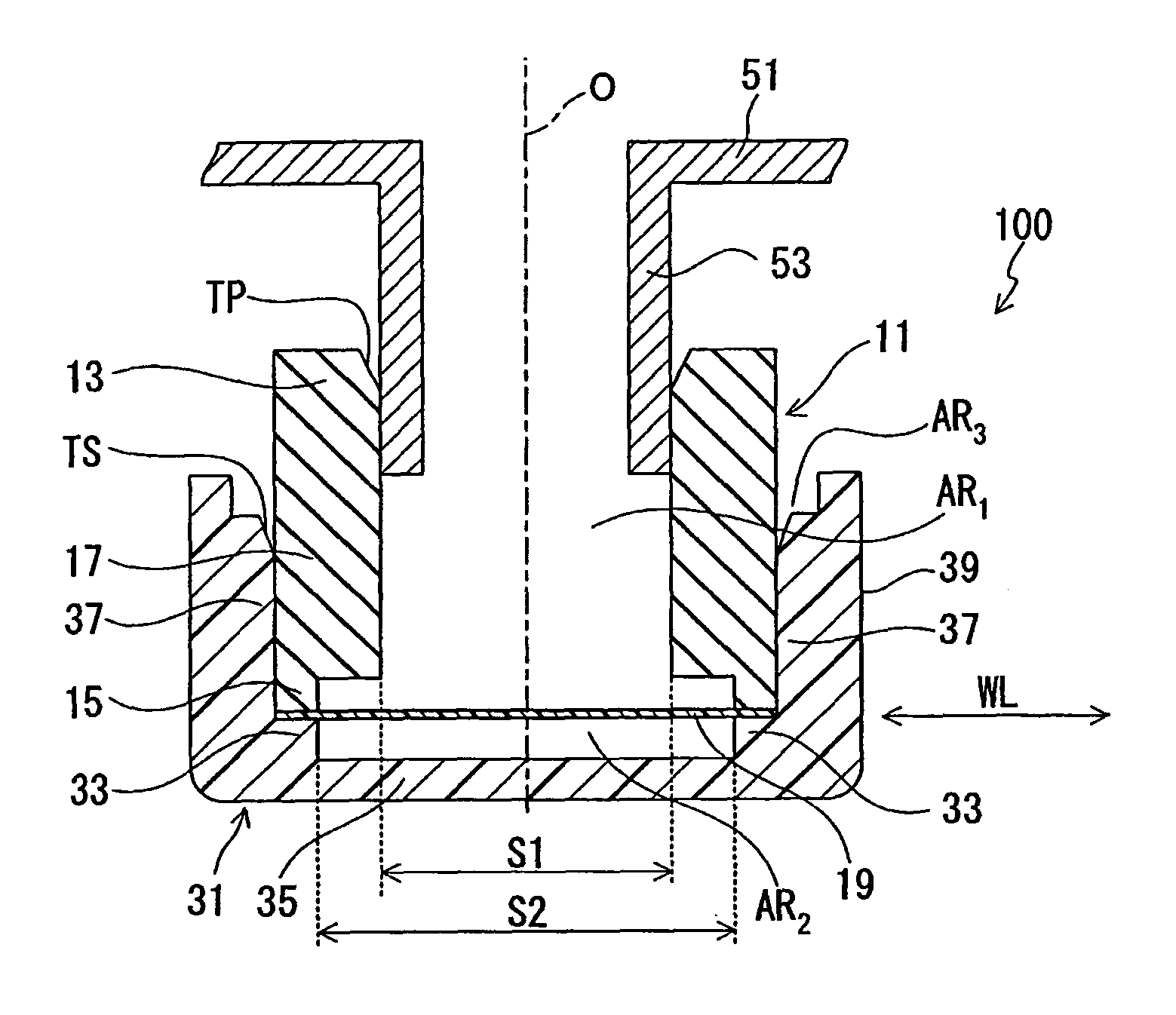

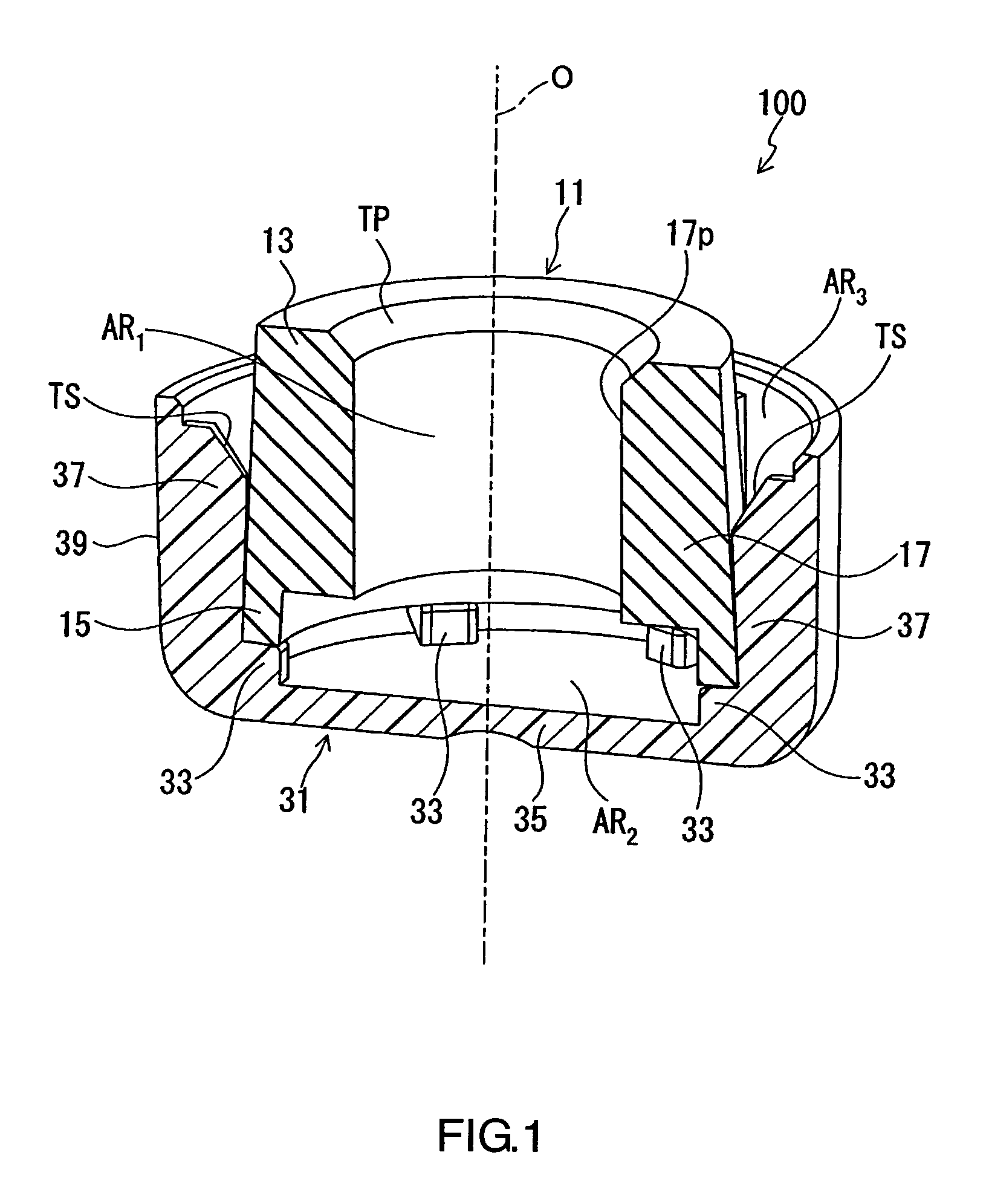

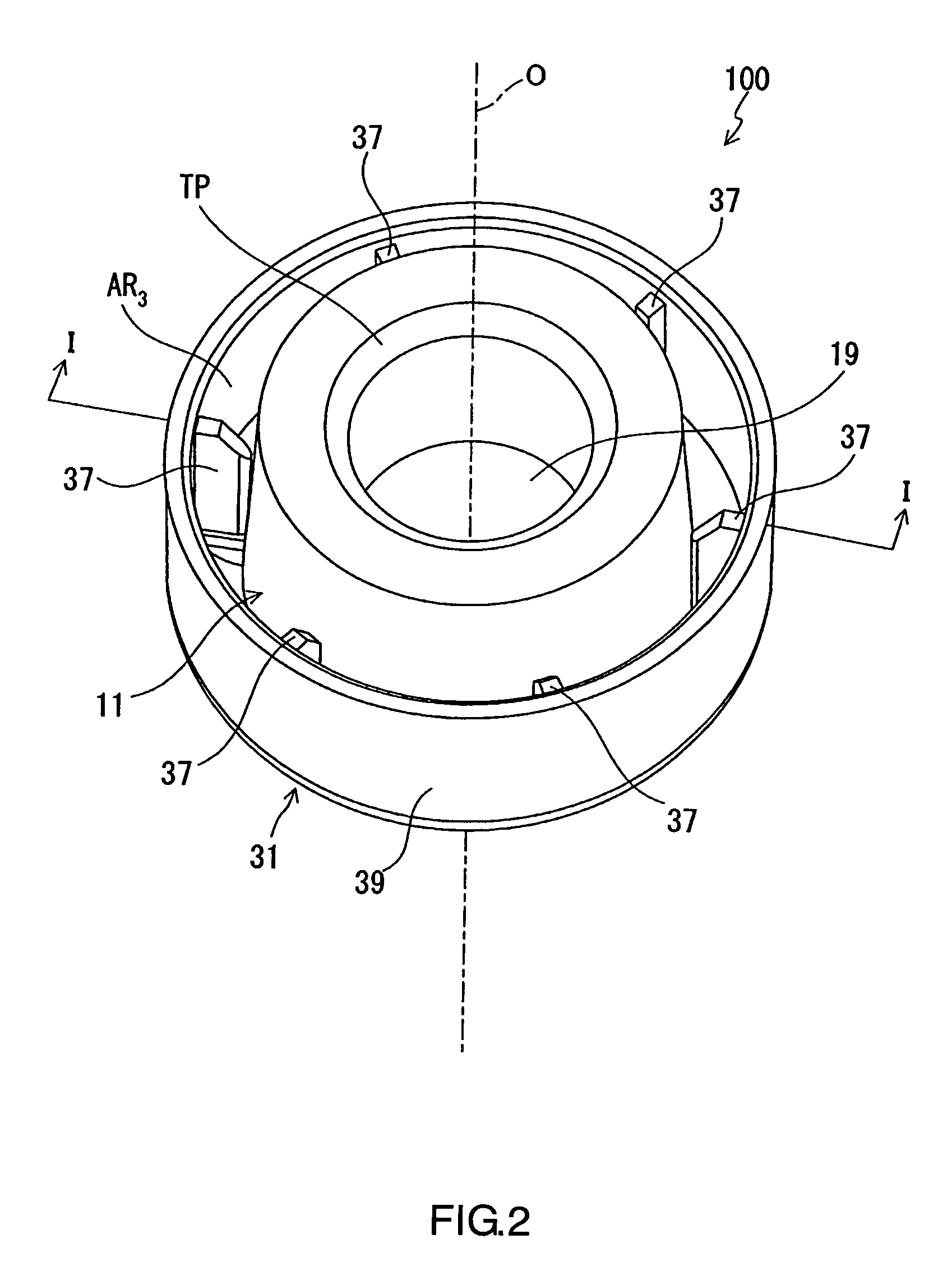

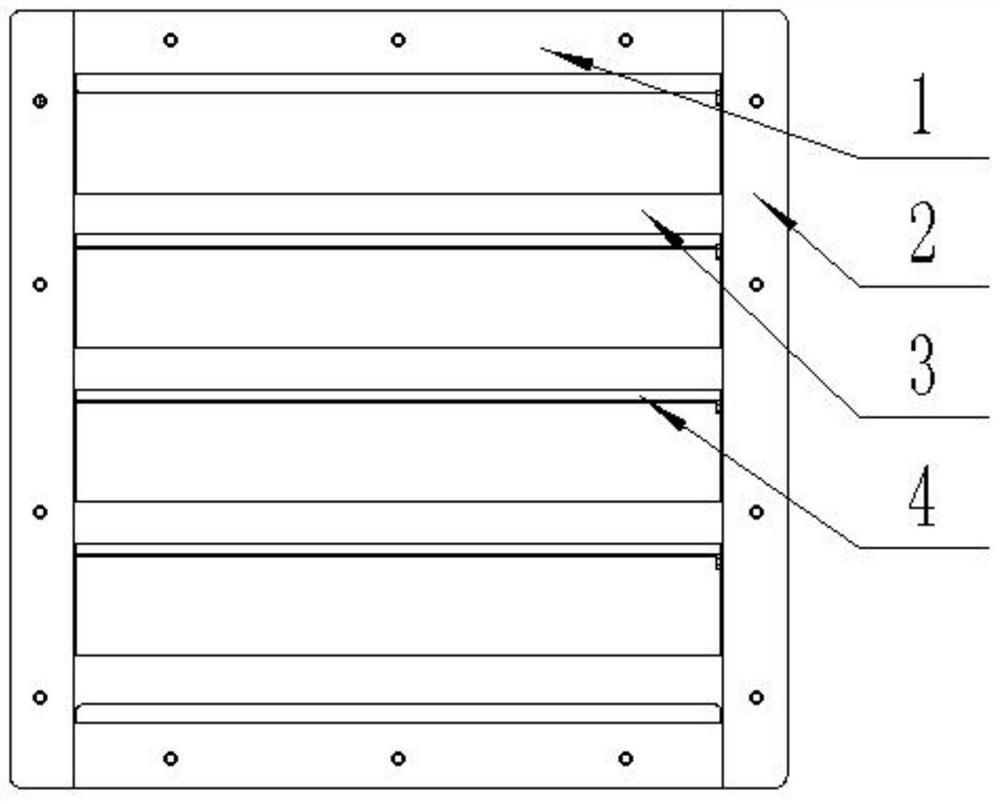

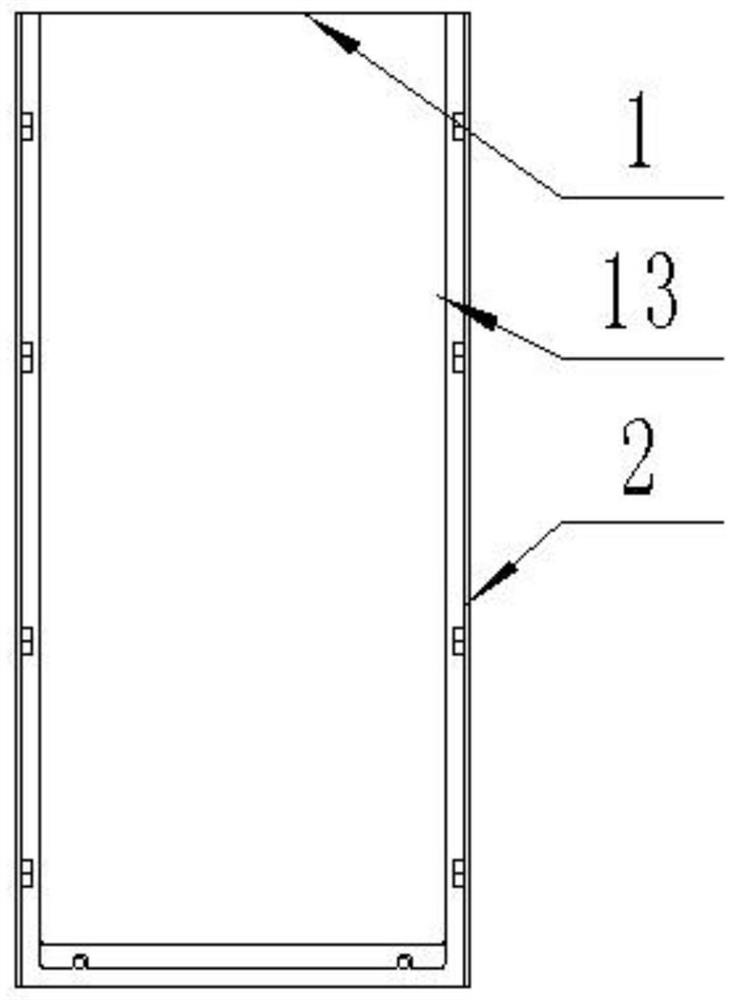

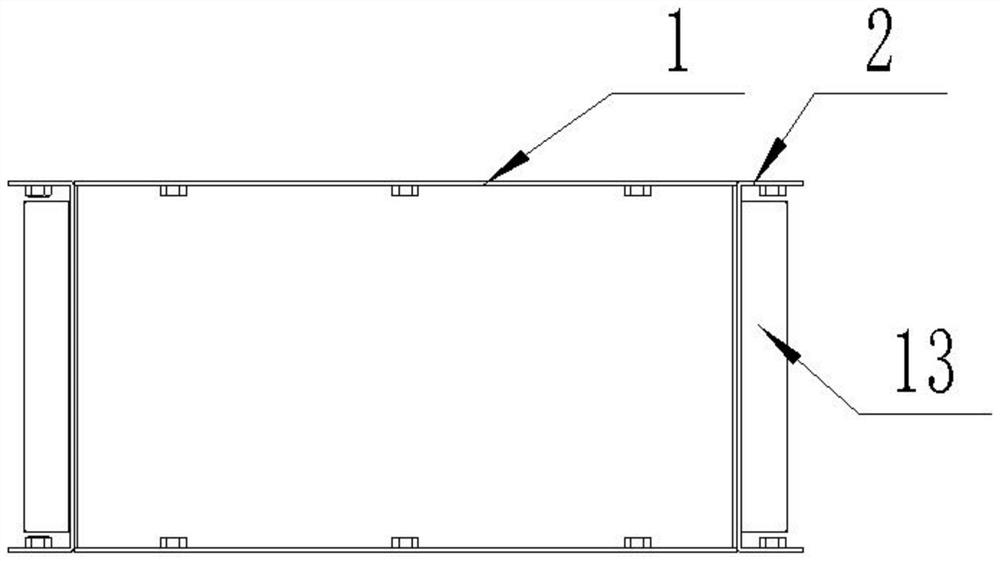

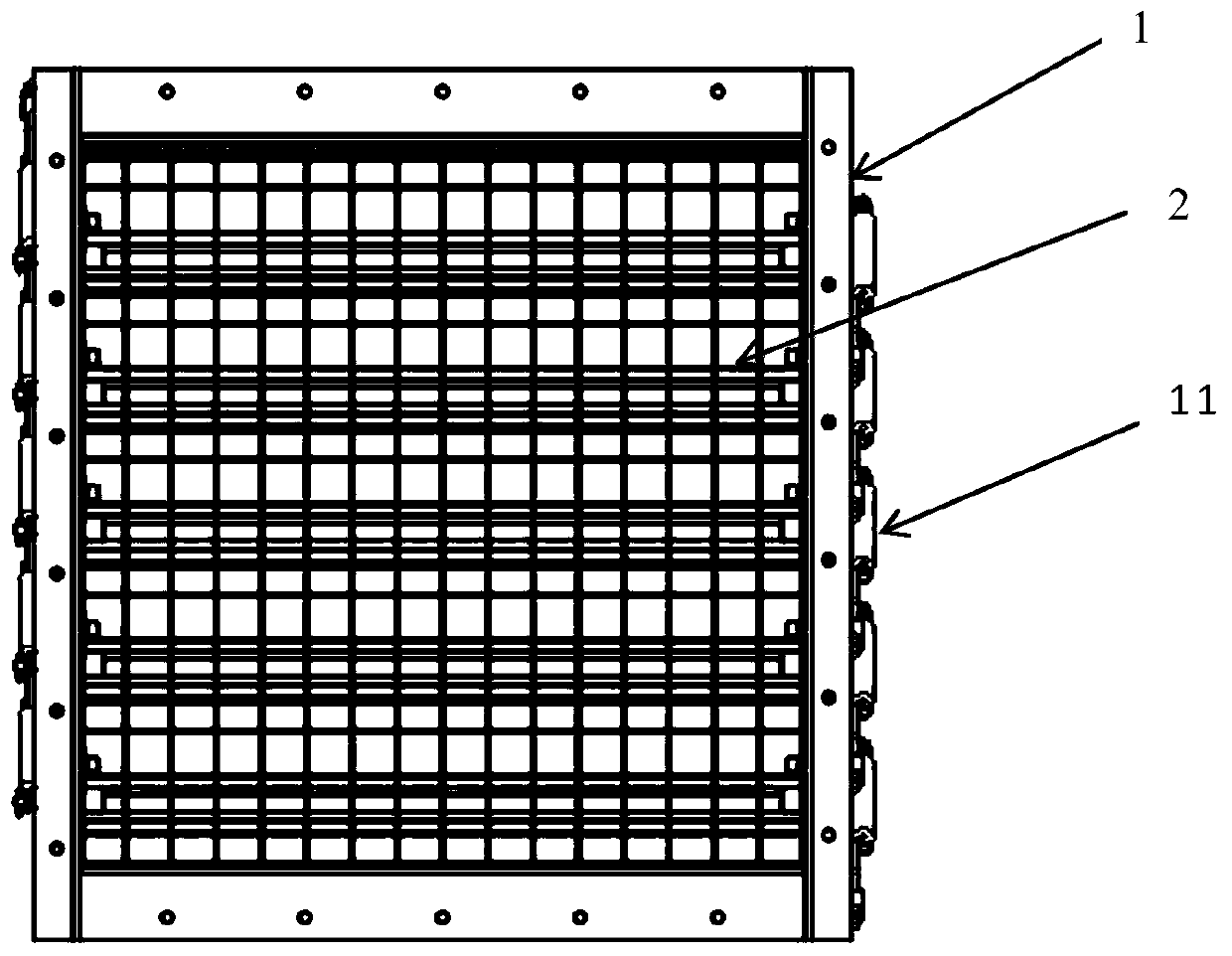

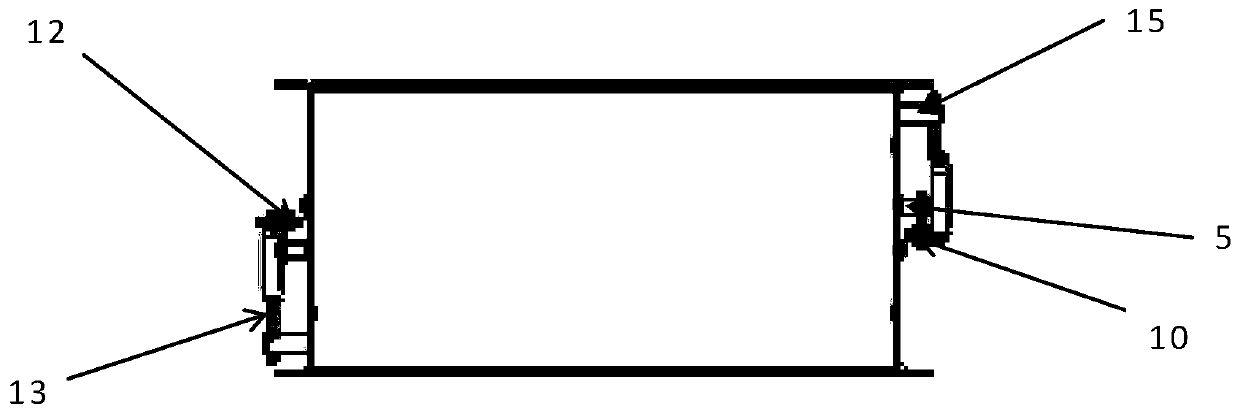

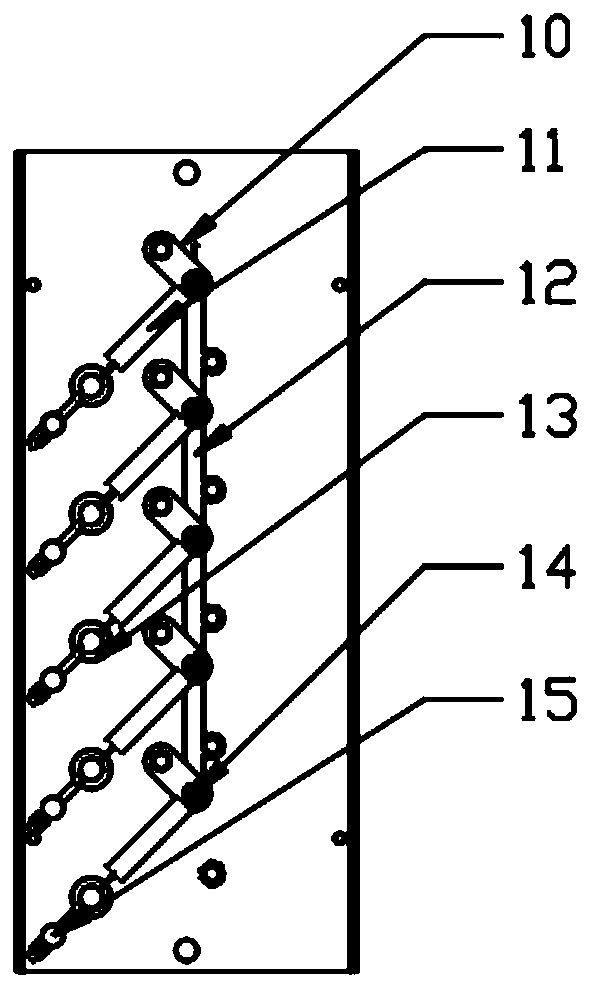

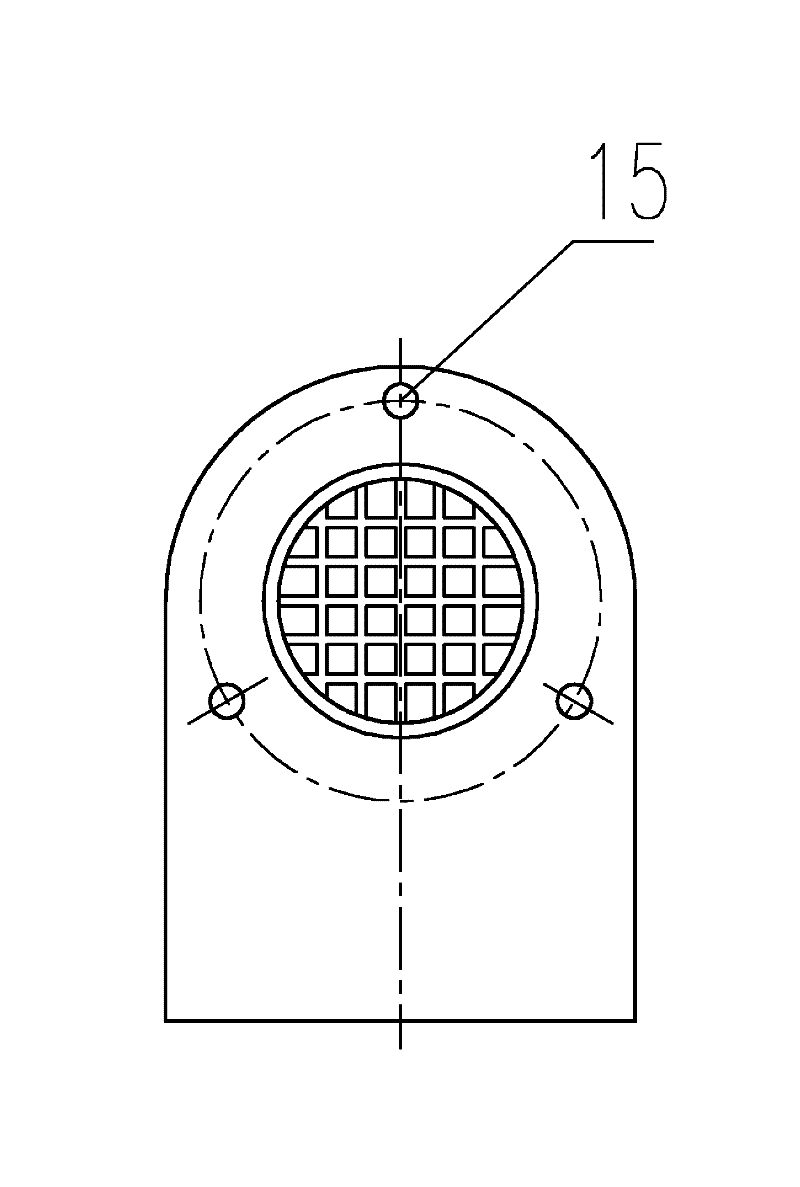

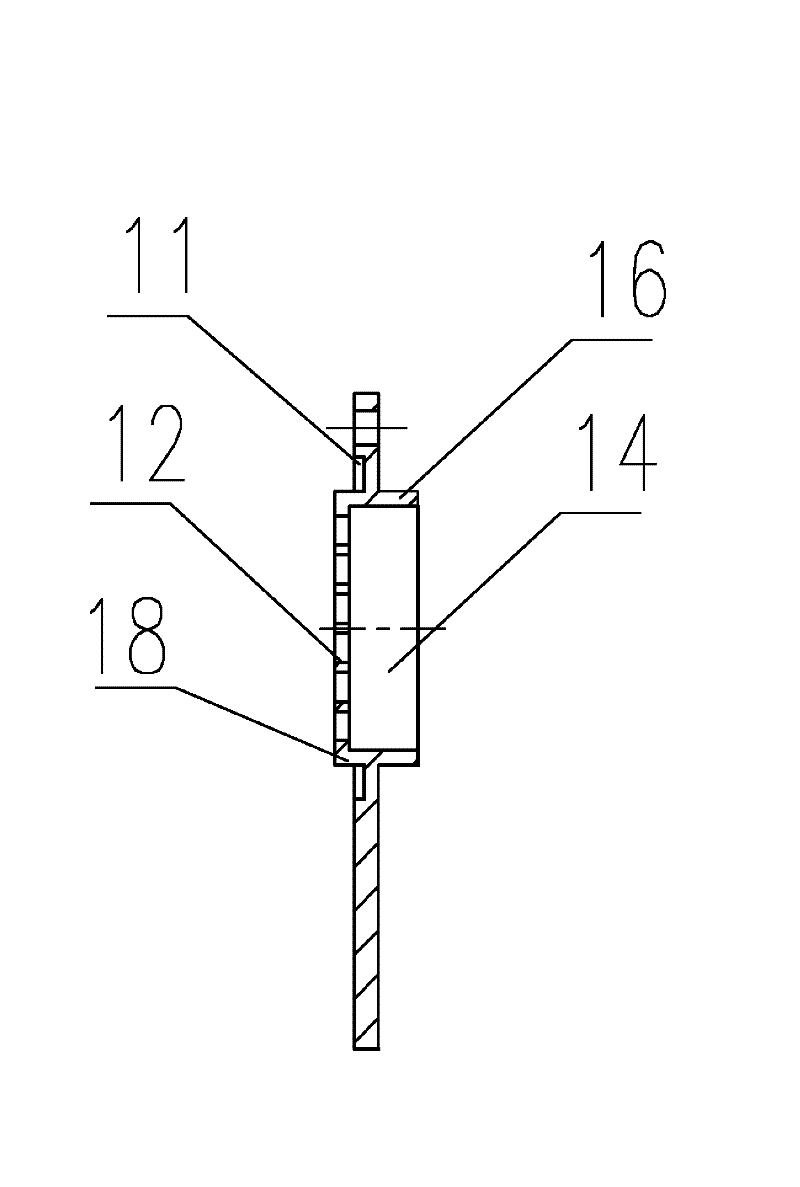

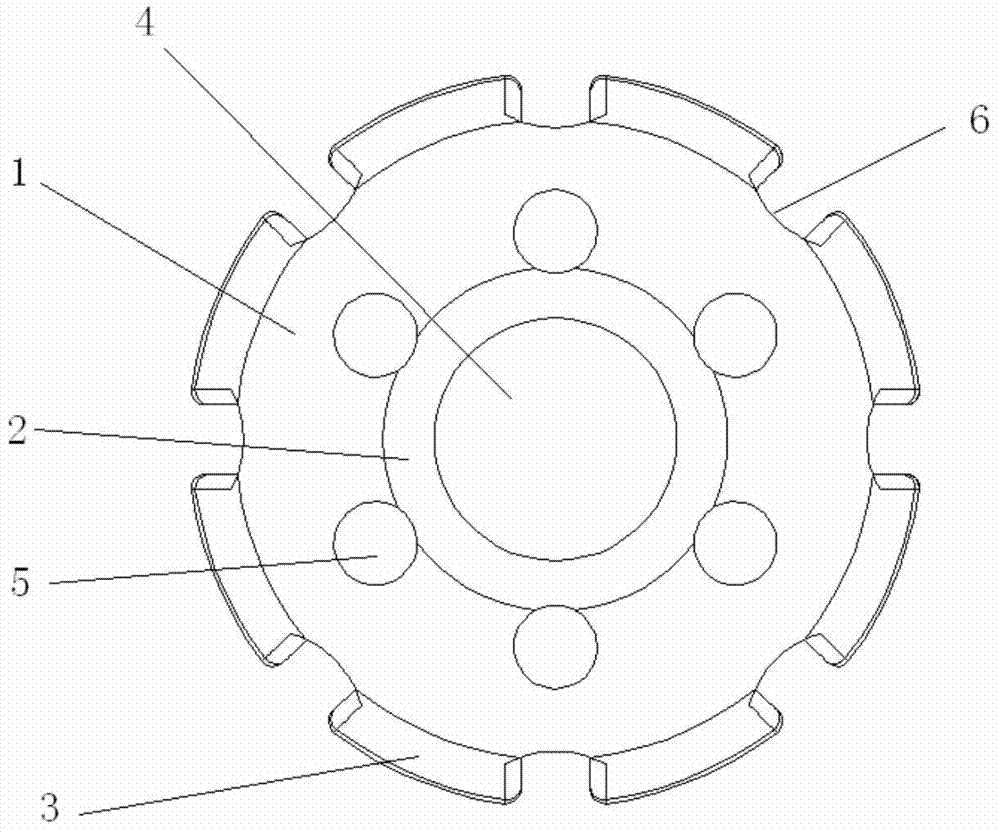

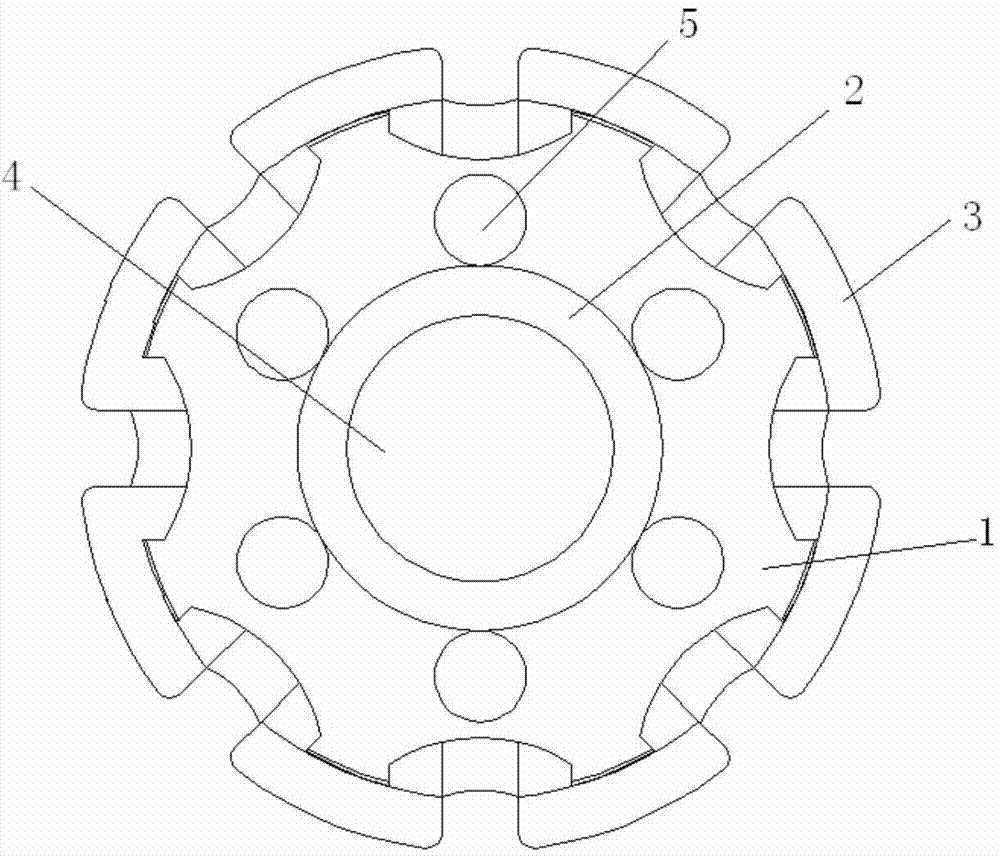

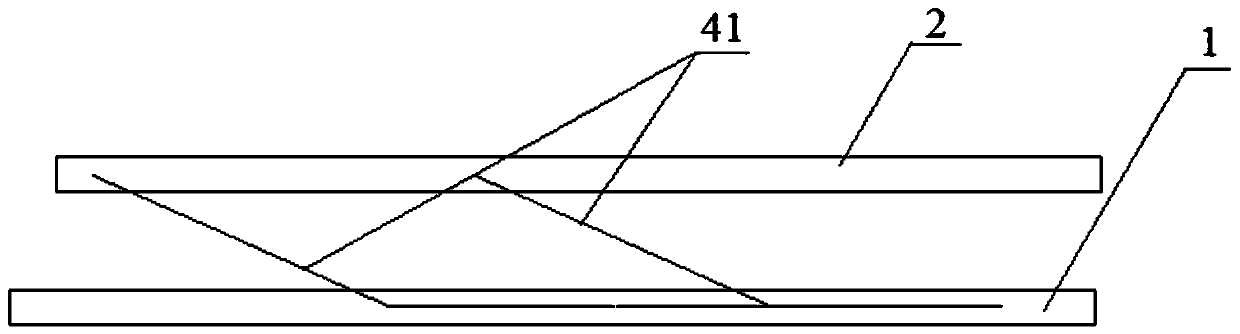

Ventilation member

ActiveUS8828125B2Increase the ventilation areaIncrease the number ofCombination devicesSemi-permeable membranesWave shapeEngineering

The ventilation member of the present invention includes a waterproof gas permeable membrane (11), and a support body (12) having a through hole (13). One opening of the through hole (13) is closed by the gas permeable membrane (11). The support body (12) includes, at an edge of the opening closed by the gas permeable membrane (11), a first region and a second region facing each other with the opening located therebetween. A first angled protrusion (12a) in which a peak and a trough are arranged alternately along the edge of the opening is provided in the first region, and a second angled protrusion (12b) in which a peak and a trough are arranged alternately along the edge of the opening is provided in the second region. The gas permeable membrane (11) is joined onto the first angled protrusion (12a) and the second angled protrusion (12b), and has a pleat shape or a wave shape in which a peak and a trough are arranged alternately along shapes of the first angled protrusion (12a) and the second angled protrusion (12b).

Owner:NITTO DENKO CORP

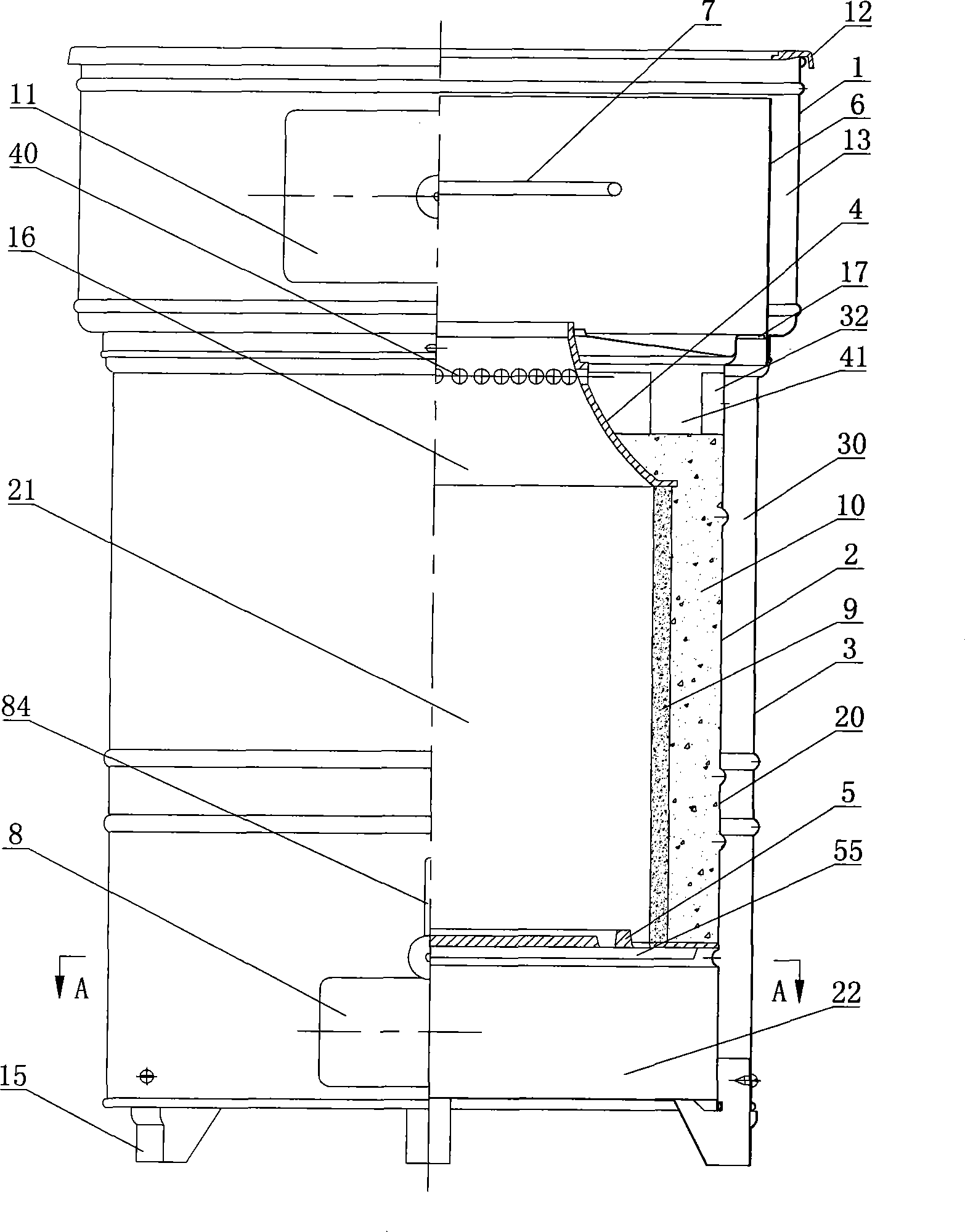

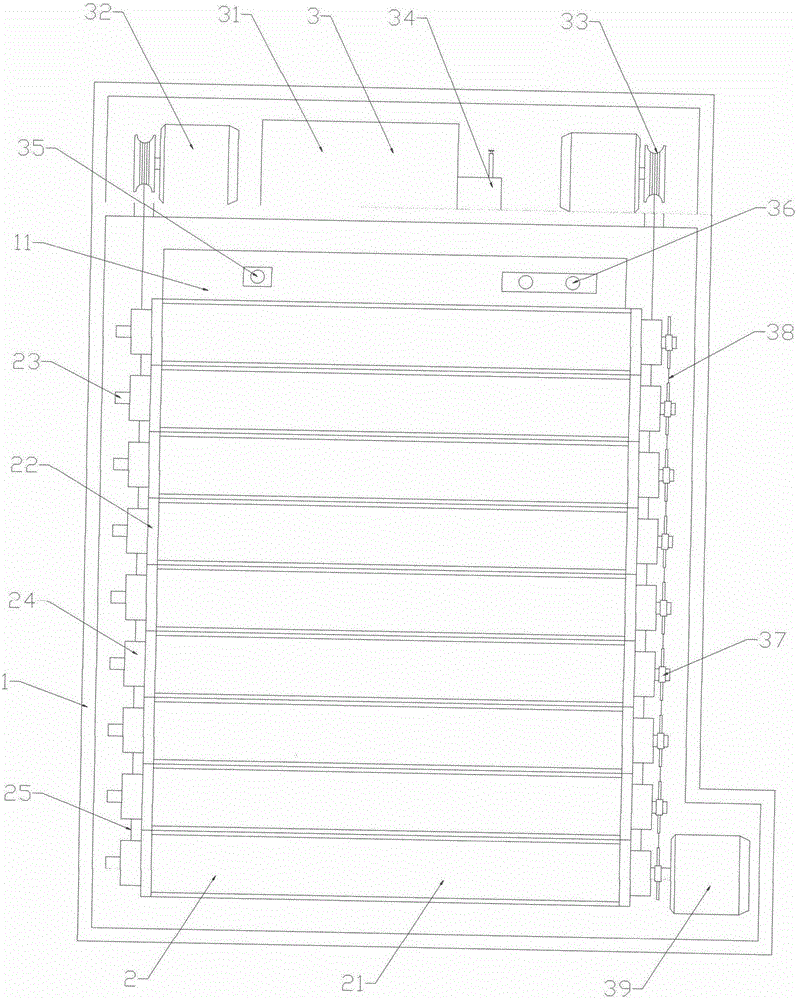

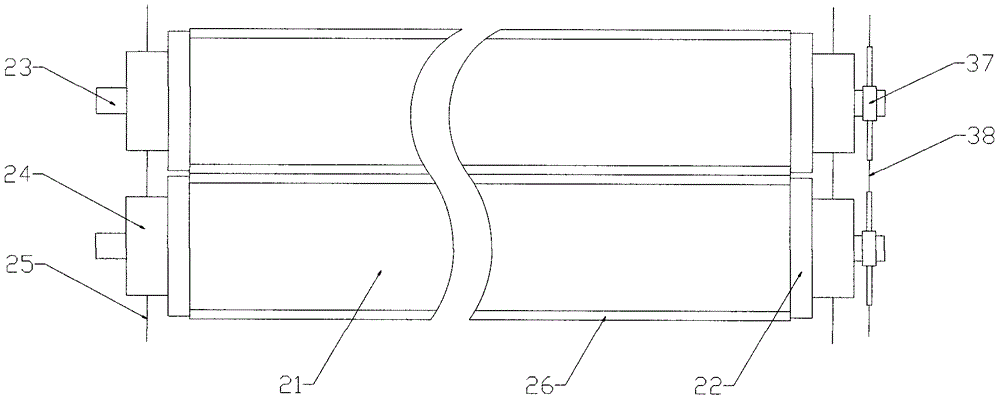

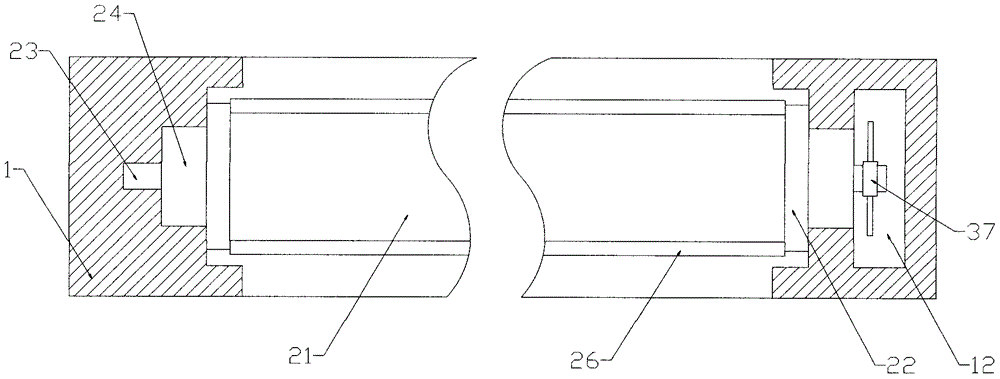

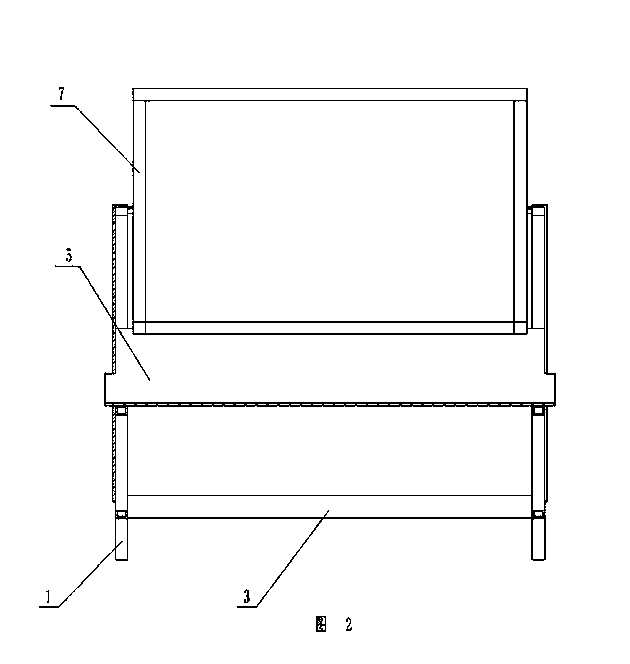

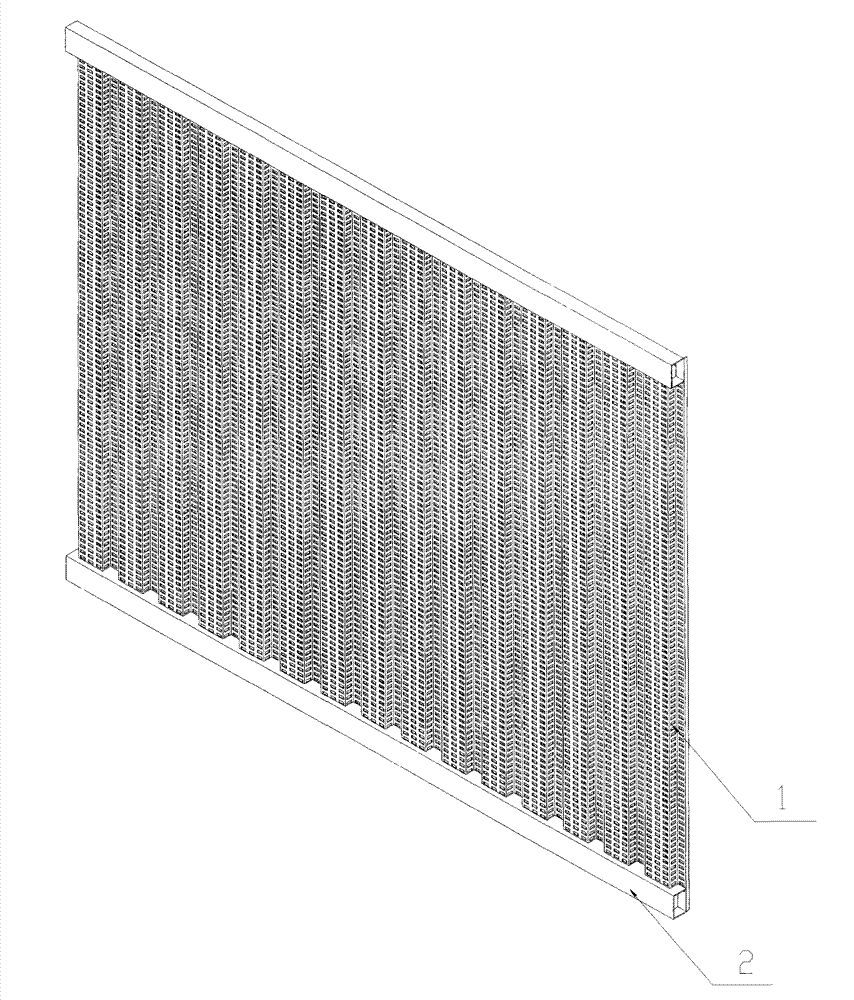

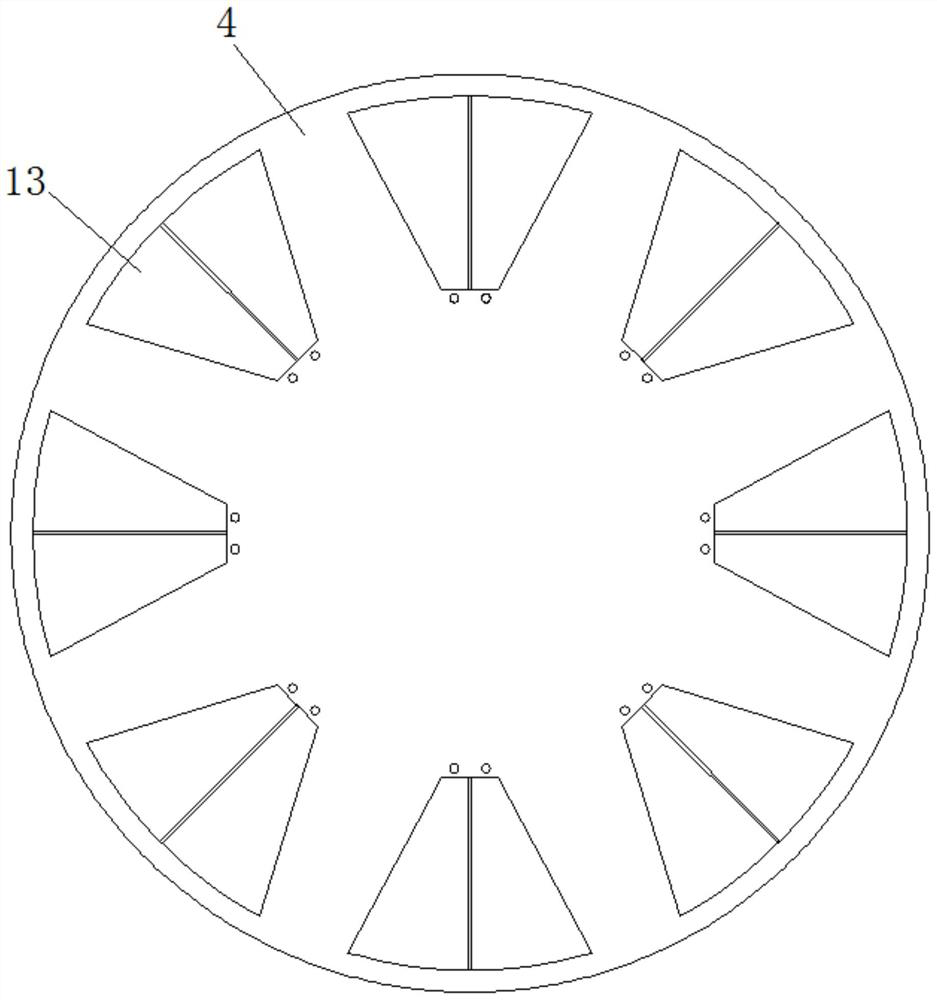

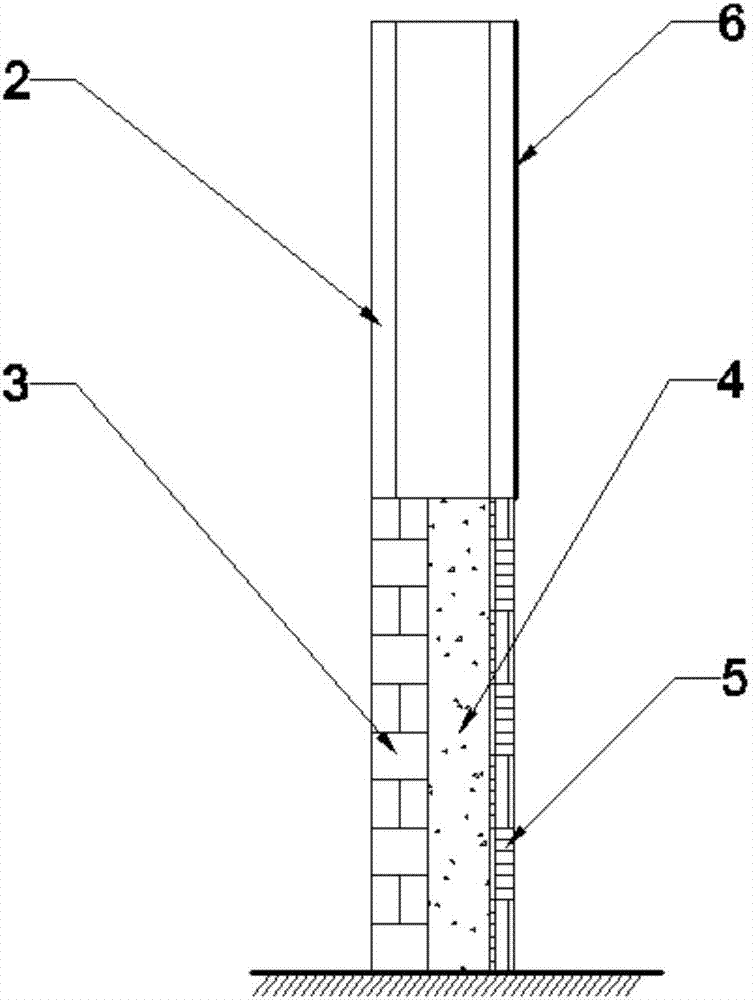

Screening device in super-fine grinding mill

ActiveCN103316754AIncrease the ventilation areaImprove ventilationGrain treatmentsEngineeringCement grinding

A screening device in a super-fine grinding mill comprises a barrel body and a bracket in the barrel body, wherein a bracket bottom plate is arranged at the periphery of the bracket; a front chamber and a rear chamber in the super-fine grinding mill are arranged on the left side and the right side of the bracket respectively; a front screen plate and a rear screen plate are connected with the left side and the right side of the bracket respectively; a front grate plate is connected with the left side of the front screen plate; a boss projecting out of the right side surface is arranged on the right side surface of the front grate plate; a screening chamber is formed between the right side surface of the front grate plate and the left side surface of the front screen plate; the top end of the boss props against the left side surface of the front screen plate. According to the screening device, a conventional cement grinding mill cabin baffle and a blind plate in the screening device are replaced with a rear grate plate, a ventilation area in the mill is enlarged, a smooth ventilation effect is achieved, powder can timely enter a rear cabin for grinding through the screening device from a front cabin, the excessive grinding and cushion effects of the front cabin are reduced, the grinding capability of a grinding cabin is improved, and the operation hour of the grinding mill is prolonged.

Owner:渑池德惠石油支撑剂有限公司

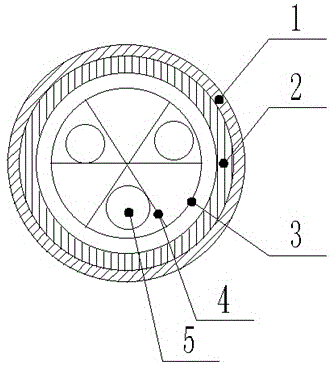

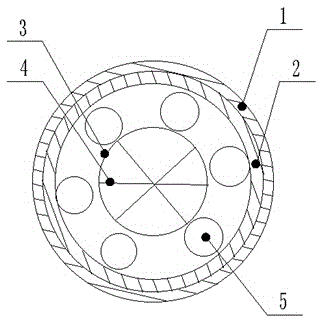

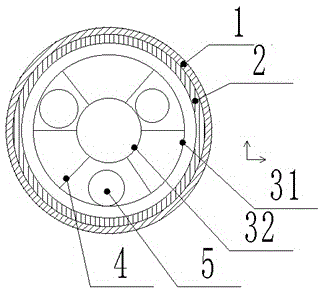

Self-cooling cable and cooling method thereof

ActiveCN104575813APrevent spontaneous combustionIncrease the ventilation areaTemperatue controlClimate change adaptationInsulation layerAutomatic control

The invention discloses a self-cooling cable and a cooling method thereof. The self-cooling cable can realize self-cooling. The cable comprises a plurality of cable cores with insulation layers, wherein the insulation layers are wrapped with wrapping belt layers and external sheath layers, hollow ventilation layers for heat dissipation are arranged in the cable, the hollow ventilation layers are arranged in the wrapping belt layers, through holes are formed in the cable at intervals, and the through holes penetrate through the wrapping belt layers and the external sheath layers from the hollow ventilation layers, therefore, heat dissipation of the cable is realized by using the through holes. The cable disclosed by the invention further comprises a PLC (programmable logic controller), a temperature and water amount sensor and a sliding block for blocking small holes to be waterproof, thereby alarming when the temperature is too high, realizing automatic control of the sliding block to block the through holes in rainy days, and preventing rainwater from entering the cable and destructing the cable. The self-cooling cable disclosed by the invention has a simple structure, is easy to implement and can further realize fully automated control.

Owner:湘潭神舟特种电缆有限公司

Fertilizer moisture well

InactiveCN101965794AGood water permeabilityIncrease the ventilation areaGeneral water supply conservationSelf-acting watering devicesMoistureGeotextile

The invention relates to a fertilizer moisture well comprising a well lid, a well mouth and a well body, wherein the well mouth and the well body are in cylinder shapes; the well mouth is connected above the well body; the well lid is arranged on the upper part inside the well mouth; the middle of the well lid is downwards recessed; the well lid is provided with a through hole with a top down shape; the well body is a pipeline with a micropore; and the lower part of the well body is provided with a geotextile back cover. The invention improves the physicochemical property of soil and has the characteristics of convenient fertilization, watering and rainwater collection.

Owner:崔洪涛

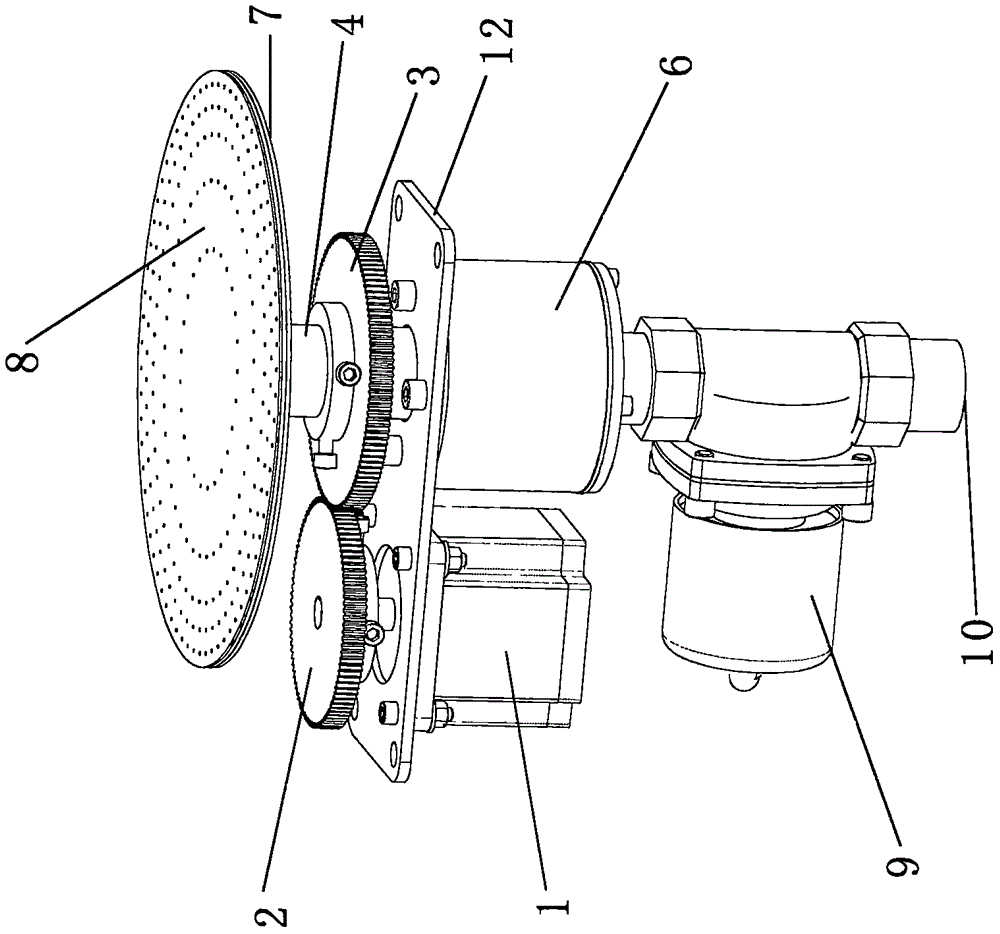

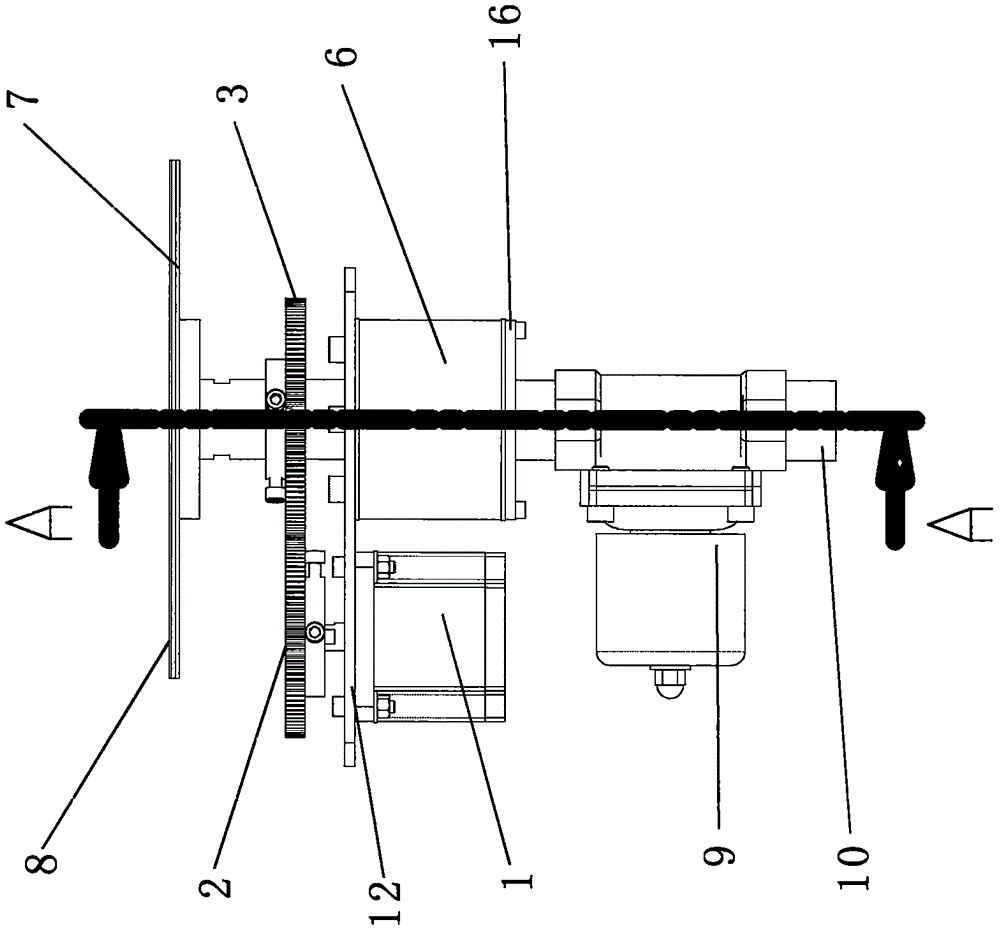

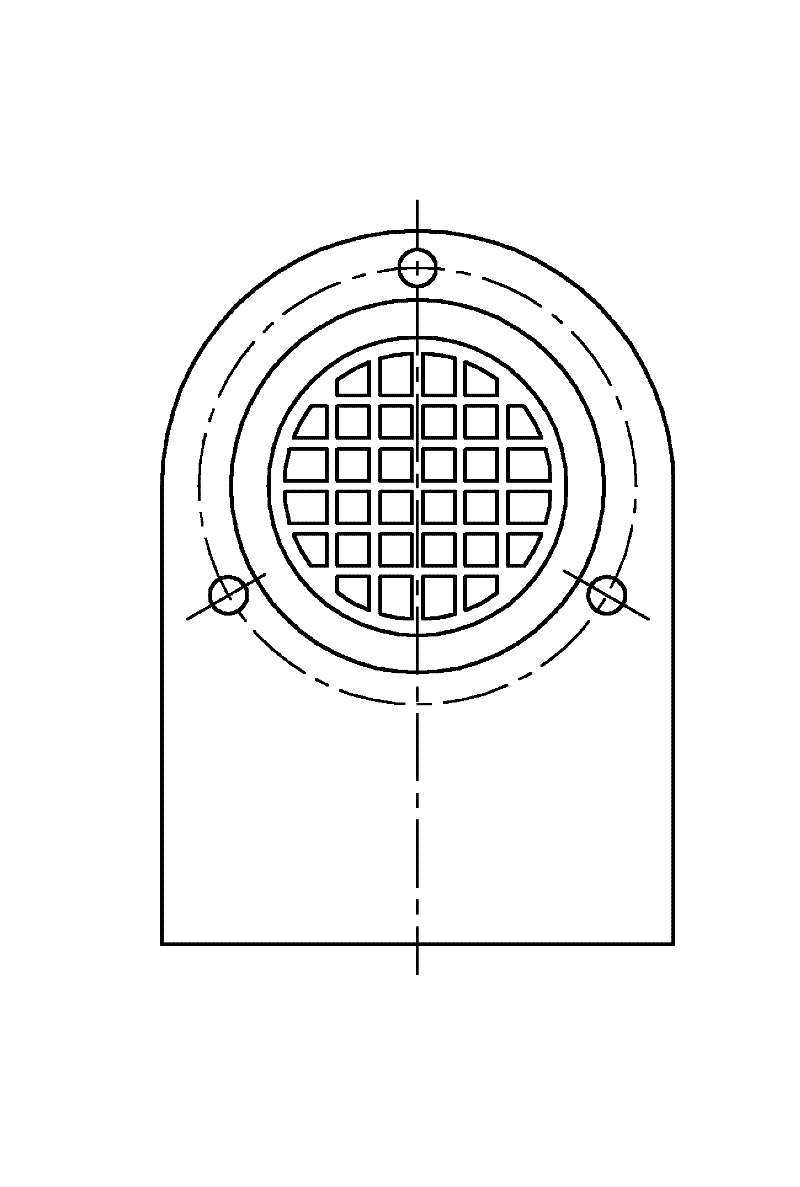

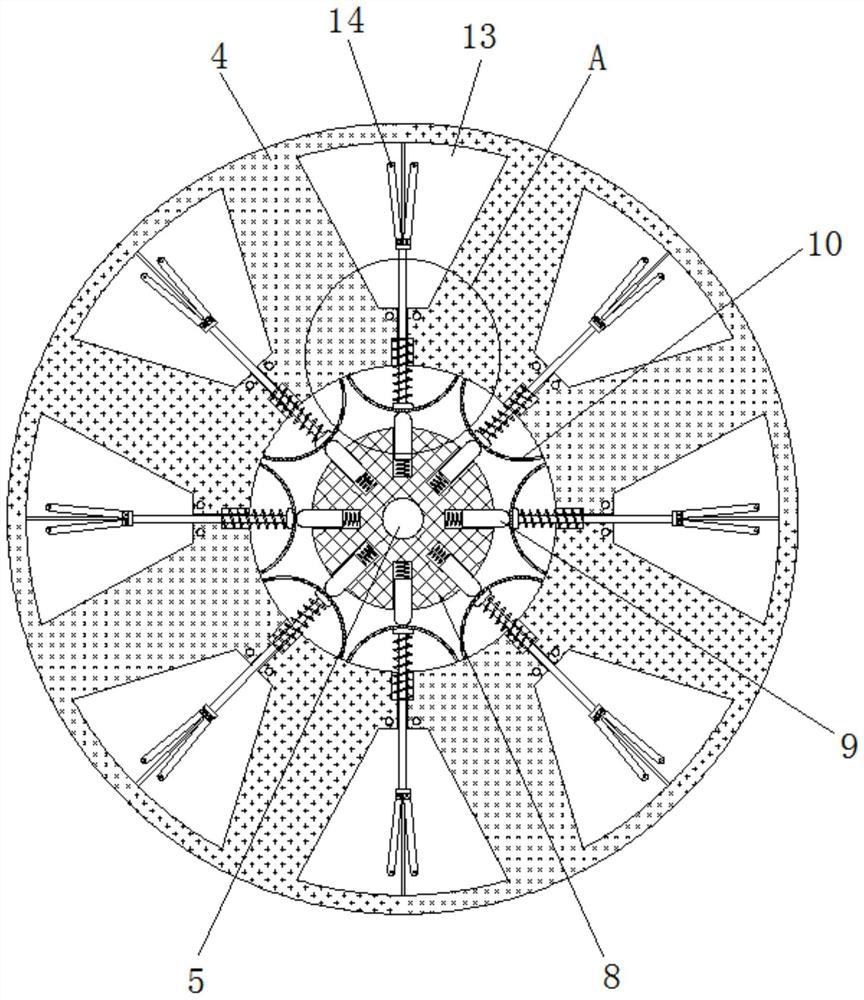

Adsorbing fixed-type synchronous rotating auxiliary device for sewing round cut pieces

ActiveCN105887356AImprove adsorption capacityIncrease the ventilation areaWork-feeding meansControl systemEngineering

The invention discloses an adsorbing fixed-type synchronous rotating auxiliary device for sewing round cut pieces. The auxiliary device comprises a control system, a transmission system and an adsorbing system. The control system is connected with the transmission system, the adsorbing system and a drive system of a sewing machine through a PLC. The transmission system comprises a stepping motor, a gear I, a gear II, a hollow shaft, a bearing, a bearing pedestal, a disc I and a disc II, wherein the gear I and the gear II are connected with the stepping motor, the hollow shaft penetrates through the center of the gear II, the bearing and the bearing pedestal are arranged in the middle of the hollow shaft and are parallel to the stepping motor, and the disc I and the disc II are arranged at the top of the hollow shaft. The round cut pieces manufactured by means of assistance of the auxiliary device are good in sewing quality, efficiency is high, two locating working procedures can be omitted, the total benefits can be increased by ten times or more, product uniformity can be ensured by operation of different personnel, and dependency on the technology of operators is reduced.

Owner:刘玉银

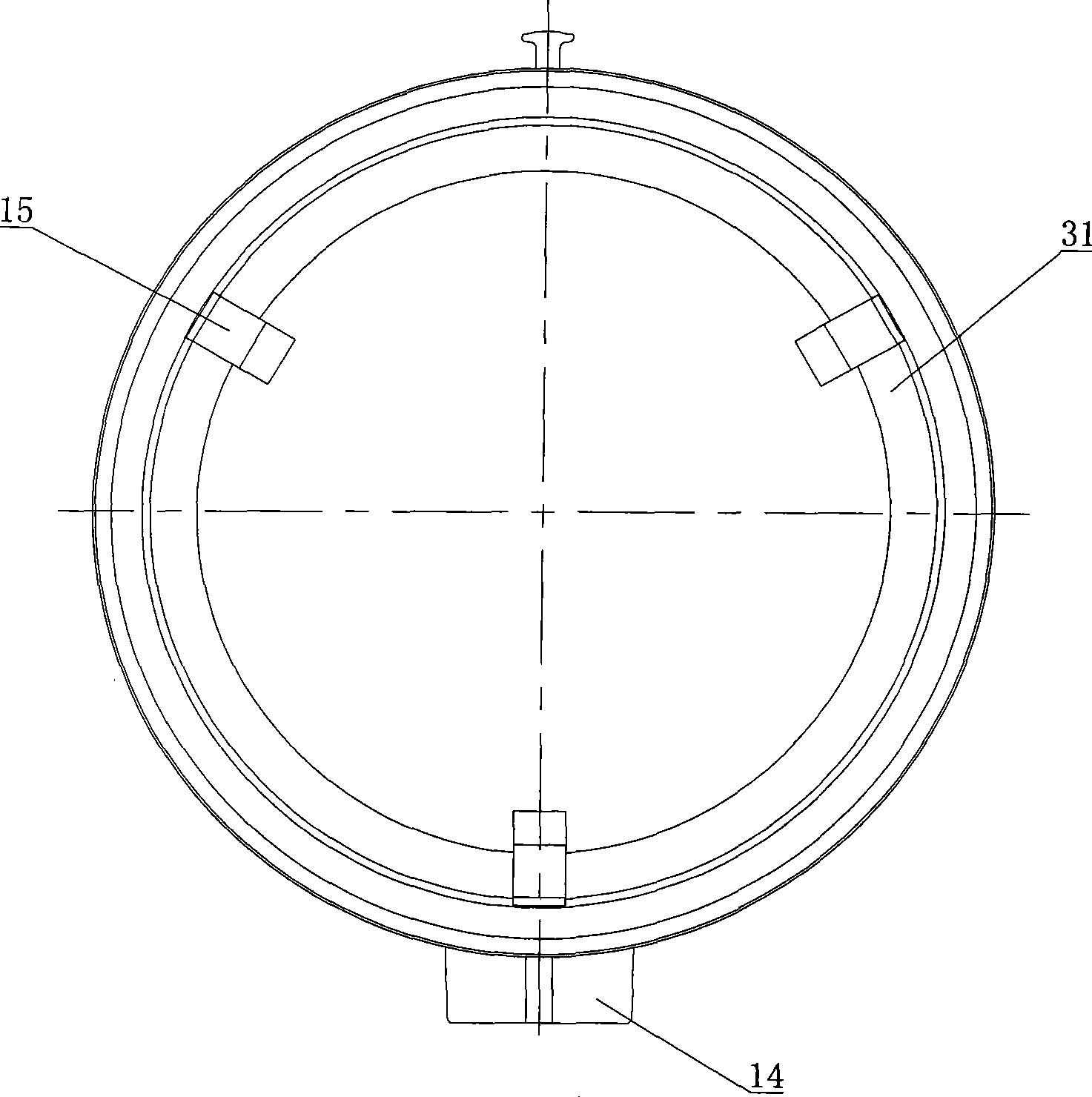

Multifunctional sintering blowing ring circular cooler

ActiveCN103604301AGuaranteed StrengthGuaranteed stiffnessHandling discharged materialEngineeringGranular media

The invention relates to a multifunctional sintering blowing ring circular cooler comprising a cooler frame, inner and outer support rolls, inner and outer rotating frames, a connecting beam, a trolley, a trolley shaft, inner and outer trolley panels, a U-shaped sealing hood, a transmission device, first inner and outer seals, and second inner and outer seals. The multifunctional sintering blowing ring circular cooler is characterized in that the section of the connecting beam is in the shape of a round tubular part, two ends of the connecting beam are connected with sides, in contact with material, of the lower portions of vertical plates, close to the sintering trolley, of the inner and outer rotating frames respectively, the first and outer seals are composed of U-sectioned inner and outer sealing channels disposed on a bellows frame, particles disposed in the inner and outer sealing channels, and inner and outer circular sealing plates, one ends of the inner and outer circular sealing plates are fixedly connected with the inner and outer rotating frames of the sintering trolley respectively, the other ends of the inner and outer circular sealing plates are inserted into the particles in the inner and outer sealing channels respectively, and the second inner and outer seals are lap seals. The multifunctional sintering blowing ring circular cooler has the advantages of good airtightness, energy saving, and environmental friendliness.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Biomass semi-gasification stove

ActiveCN101487597AIncrease the ventilation areaImprove combustion efficiencyDomestic stoves or rangesSpecial form destructive distillationCombustion chamberCombustor

The invention discloses a biomass semi-gasification furnace which comprises a panel fire surrounding cover and an internal furnace, wherein, an inflamer is arranged at the upper part of the internal furnace, a combustion chamber is surrounded by the inflamer, the panel fire surrounding cover is arranged above the internal furnace and covered at the periphery of the inflamer, a secondary fan housing is sheathed outside the internal furnace, a ring-shaped secondary air channel is encircled by an inner shell of the internal furnace and the secondary fan housing, a ring-shaped secondary air chamber is encircled by the inflamer, the panel fire surrounding cover and the inner shell of the internal furnace, the lower end of the secondary air channel is provided with a secondary air inlet communicated with the outside, the upper end of the secondary air channel is provided with a secondary air outlet communicated with the secondary air chamber, and a plurality of secondary air holes that are communicated with the secondary air chamber and the combustion chamber are evenly arranged at the upper edge of the inflamer along the ring direction. The biomass semi-gasification furnace has the advantages of even secondary air intake, improved combustion-supporting efficiency, simple and ingenious structure, small occupying space, low manufacturing cost and convenient installation.

Owner:湖南万家工贸实业有限公司

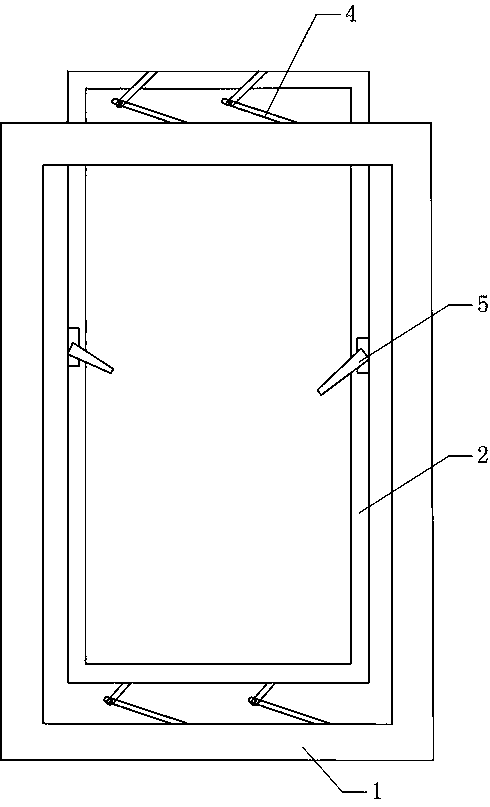

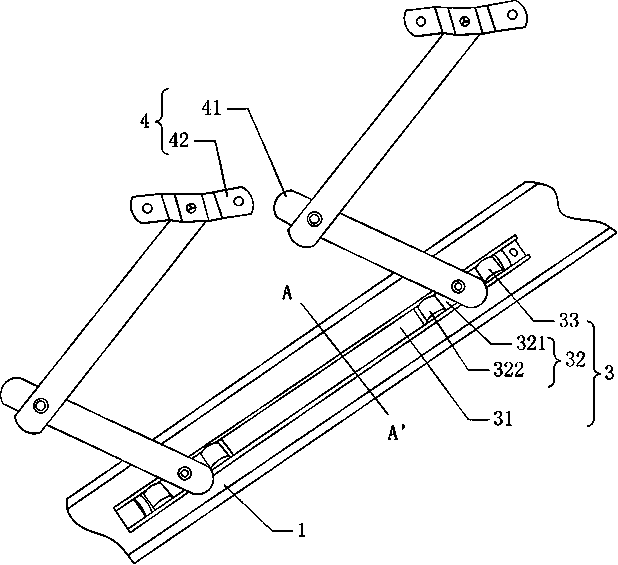

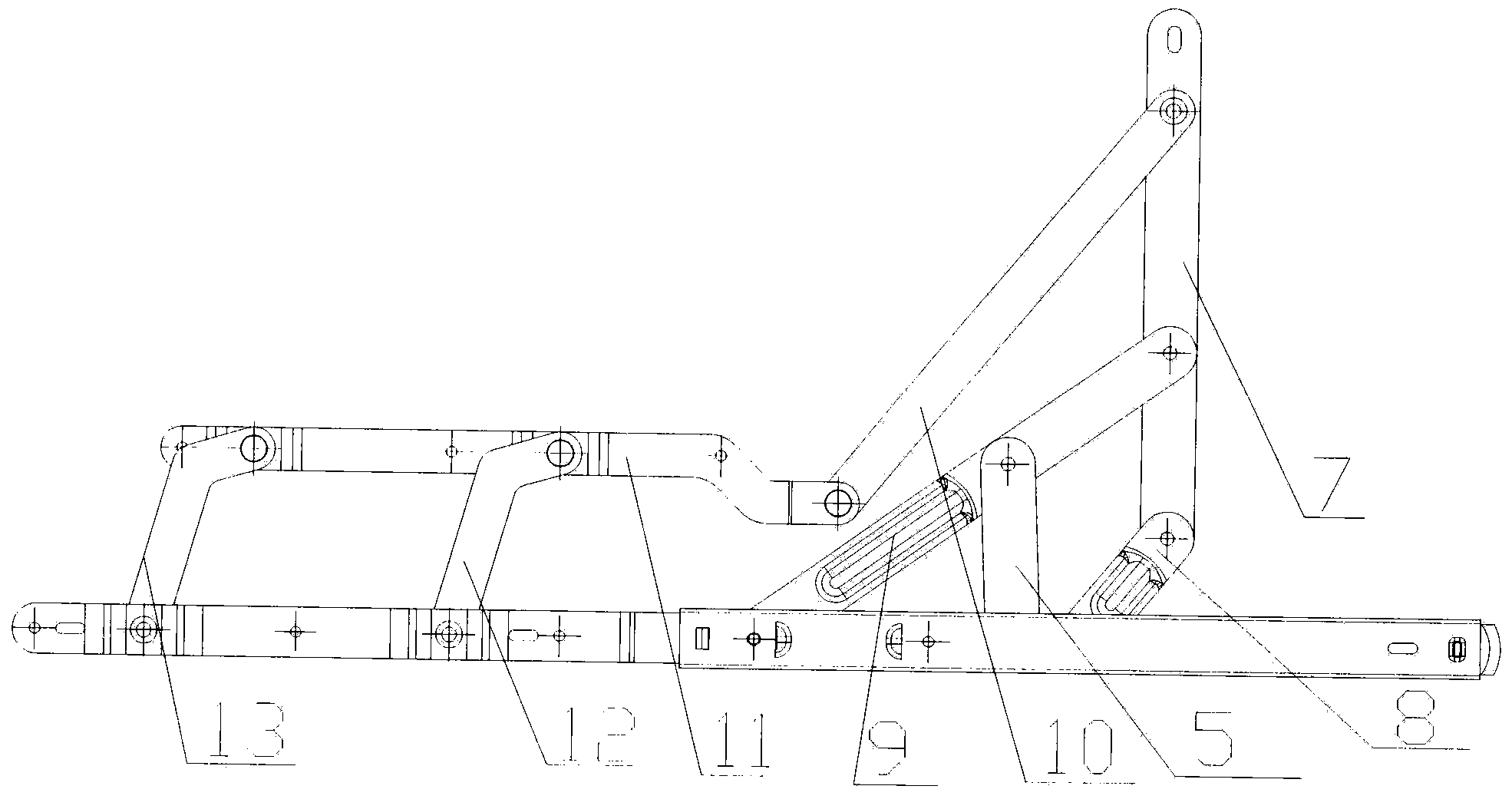

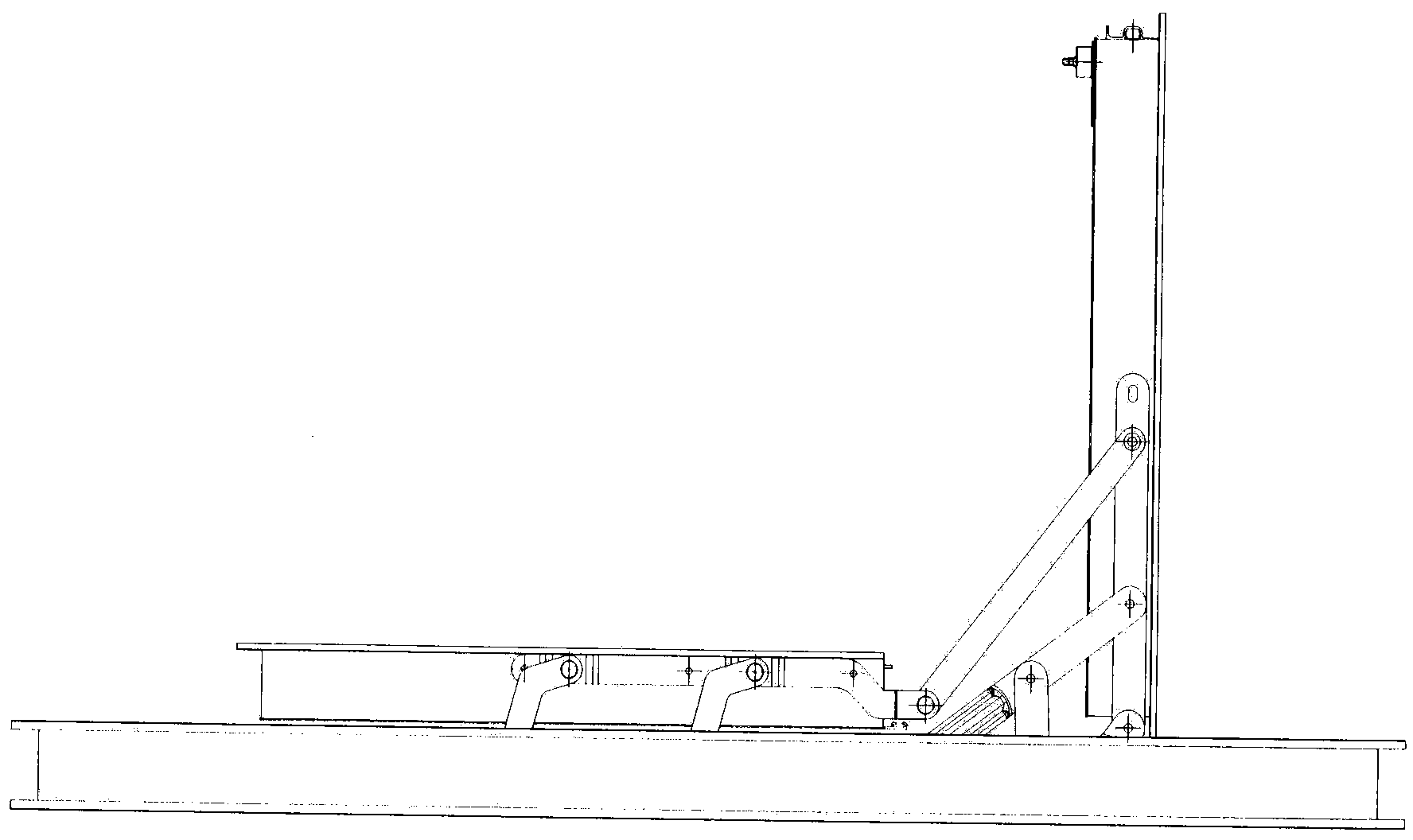

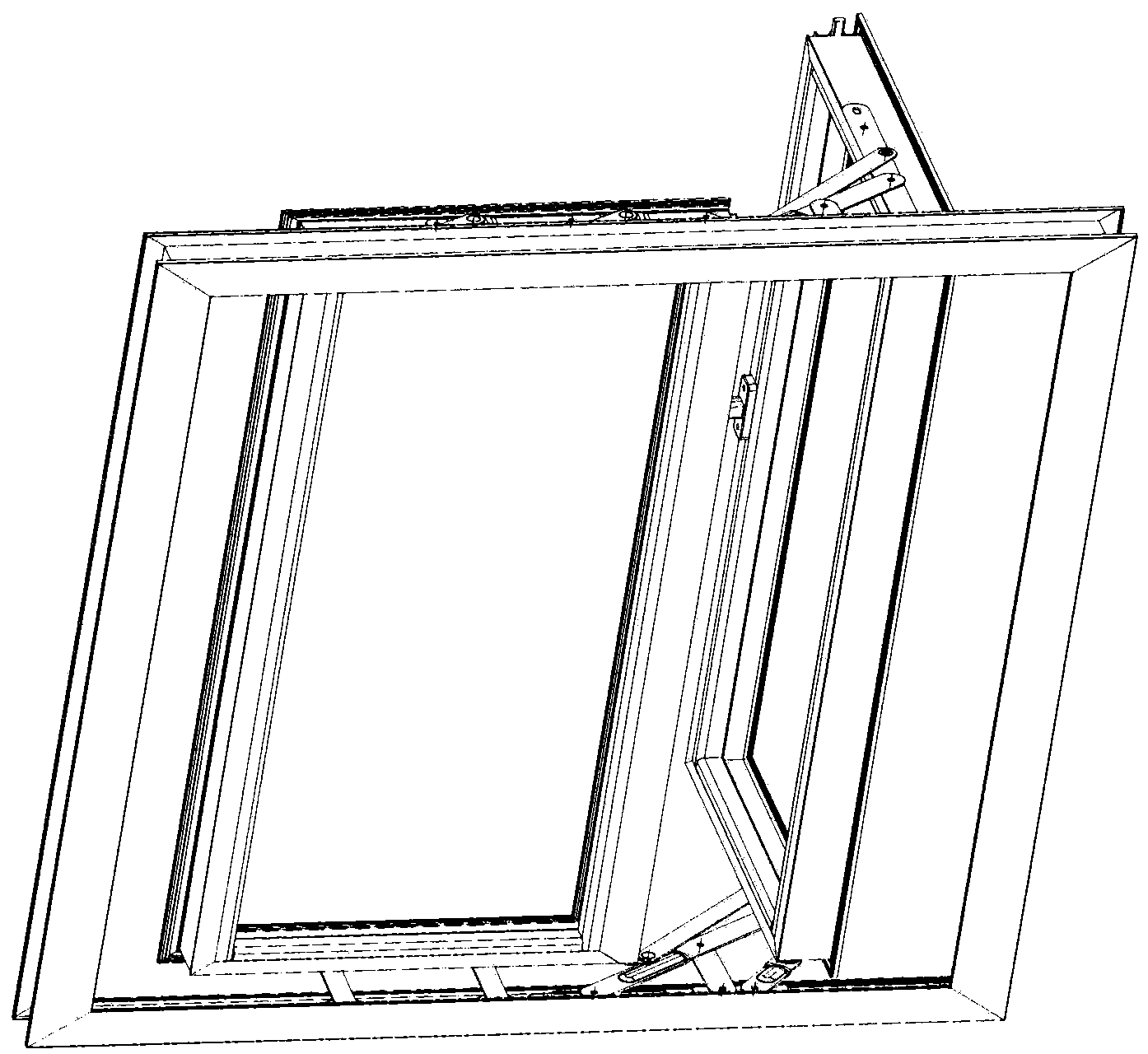

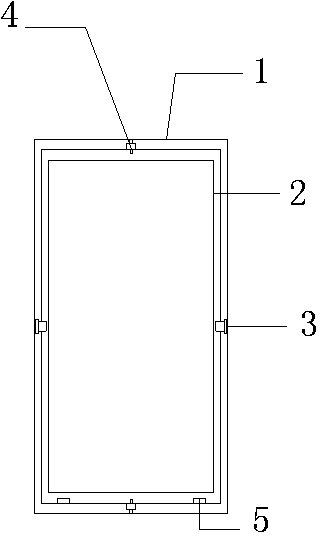

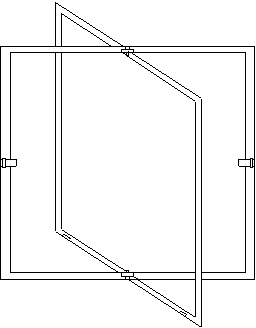

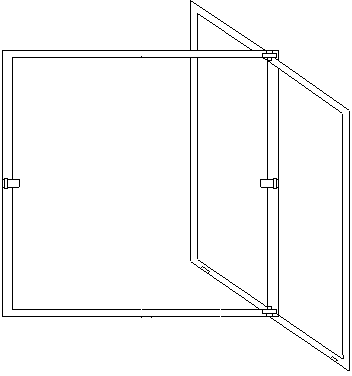

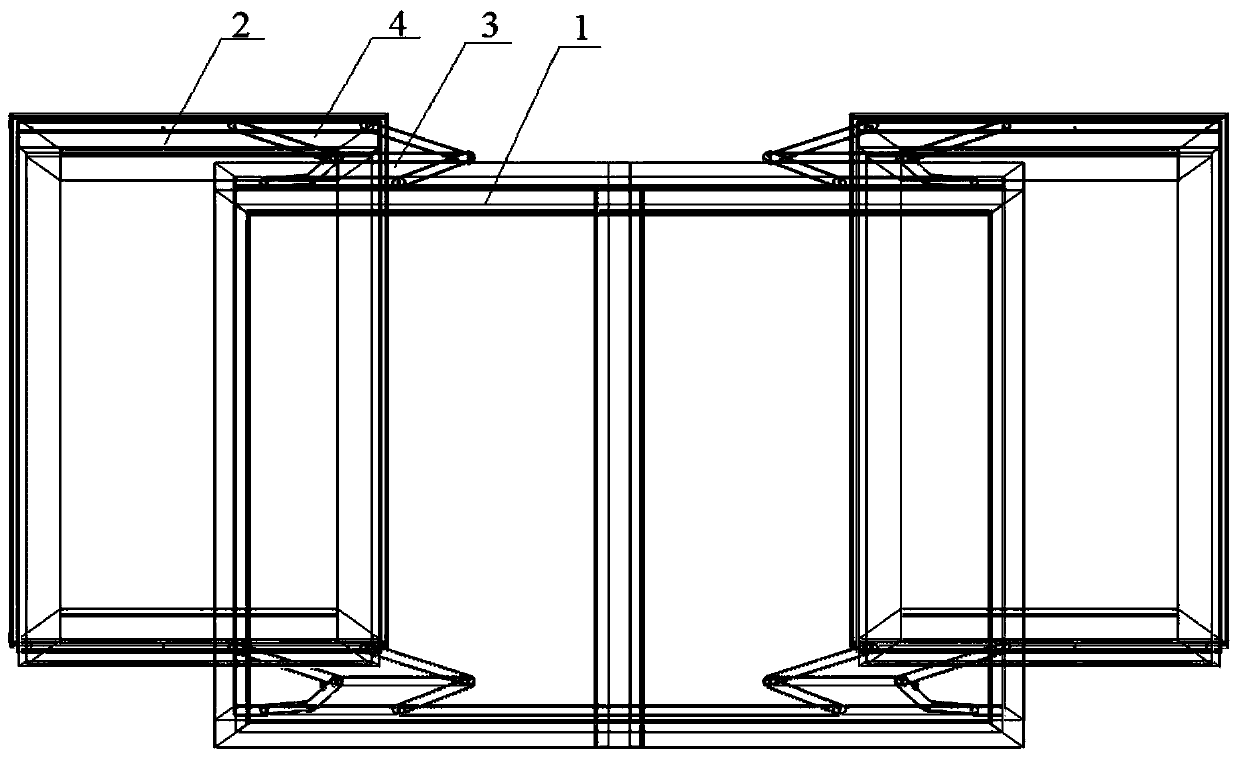

Outswinging casement window capable of moving horizontally

InactiveCN108331496AEasy to cleanIncrease the ventilation areaWing arrangementsEngineeringCasement window

The invention discloses an outswinging casement window capable of moving horizontally. The outswinging casement window comprises a window frame, a window body fixed to the window frame, sliding partsarranged on the upper portion and the lower portion of the window frame, and a supporting part with the two ends being connected to the sliding parts and the window body correspondingly; and the sliding parts comprise sliding grooves and sliding blocks, the sliding blocks are movably connected with the sliding grooves, the sliding grooves are fixedly connected with the window frame, and the windowbody is fixedly connected with the window frame through the sliding parts and the supporting part. Due to the fact that the window body in the window can completely move leftwards or rightwards without shielding the window frame, compared with a general outswinging casement window, the ventilation and daylighting areas are increased, the view is wider, and the exterior of the window body is easyto clean.

Owner:FOSHAN GAOMING YANGHE METAL MATERIAL PROFESSIONALTOWN TECH INNOVATION CENT

Ventilation member

ActiveUS8414672B2Increased durabilityIncrease the ventilation areaCombination devicesGas treatmentIn planeEngineering

Owner:NITTO DENKO CORP

Folding type self-regulation window structure for intelligent building outer wall vertical face

ActiveCN106088987AHigh degree of intelligenceIncrease the ventilation areaSpecial door/window arrangementsElectric machineryAutomatic control

Owner:扬州福腾门窗幕墙有限公司

Side-hung push-pull safety protection window

InactiveCN104165012APrevents the danger of poking your playing head outIncrease the ventilation areaWing fastenersWing arrangementsSash windowWindow opening

The invention discloses a side-hung push-pull safety protection window. The side-hung push-pull safety protection window comprises a window frame, a first window sash and a second window sash. The window frame is provided with sliding ways, and sliding blocks and push-pull fixing plates are arranged in the sliding ways. Side-hung fixing plates are arranged on the upper side and the lower side of the first window sash, each side-hung fixing plate is hinged to a first sliding way hinge, a second sliding way hinge and a linkage rod from top to bottom, the other ends of the first sliding way hinges are hinged to the sliding blocks, and the other ends of the second sliding way hinges are hinged to the push-pull fixing plates. Push-pull rods are arranged on the upper side and the lower side of the second window sash, and the push-pull rods are hinged to first push-pull hinges and second push-pull hinges and hinged to the push-pull fixing plates respectively through the first push-pull hinges and the second push-pull hinges. The upper ends of the push-pull rods are hinged to the other ends of the linkage rods. A two-way switching window locking device is arranged in the middle of the end, close to the second window sash, of the first window sash. The safety protection window is provided with three ventilation openings, so that the ventilation area is large, and the window opening area and the ventilation quantity are large, the first window sash is supported by the second sliding way hinges after being opened, safety is high, and safety is higher after third sliding way hinges are additionally arranged.

Owner:周付刚 +1

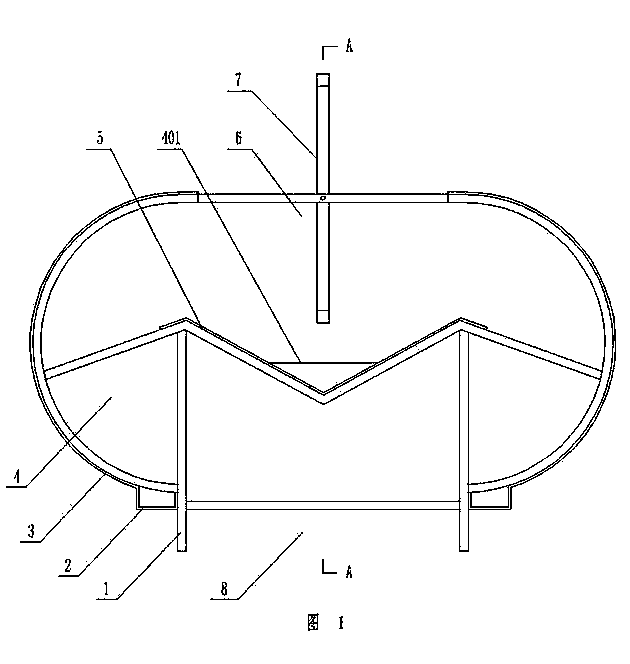

Unpowered hood

ActiveCN103628661AReduce lossesIncrease the effective ventilation areaLighting and heating apparatusVertical ductsHeat lossesEngineering

An unpowered hood comprises a structure support. The two sides of the structure support are respectively provided with an arc-shaped outer protecting plate and a ditch in a symmetric mode, and the two ends of the structure support are provided with end plates. An air inlet and an air outlet are formed between the outer protecting plates on the two sides in the bottom and the upper end of the structure support respectively. The unpowered hood is characterized in that a V-shaped rain sheltering plate with the width being larger than that of the air inlet and that of the air outlet is arranged in the middle inside the structure support, the two ends of the V-shaped rain sheltering plate are led out from the end plates respectively, water discharging openings are formed in the positions, corresponding to the leading-out portions of the V-shaped rain blocking plate, of the end plates, and a wind sheltering plate which can be used for closing the air outlet is hinged to the upper end of the structure support. The unpowered hood has the advantages that the effective ventilation area is large, the ventilation effect is good, weather variations do not have to be worried during ventilation, and product ventilation is not affected by outside wind; movement abrasion is small, and the service life is long; the air outlet can be closed through the wind sheltering plate, building ventilation heat loss is reduced, and rain and snow backward flowing due to the weather variations does not have to be worried; manufacturing process is simple, construction cost is low, and application and popularization are easy.

Owner:锦州鹏翔电力轻钢设备有限公司

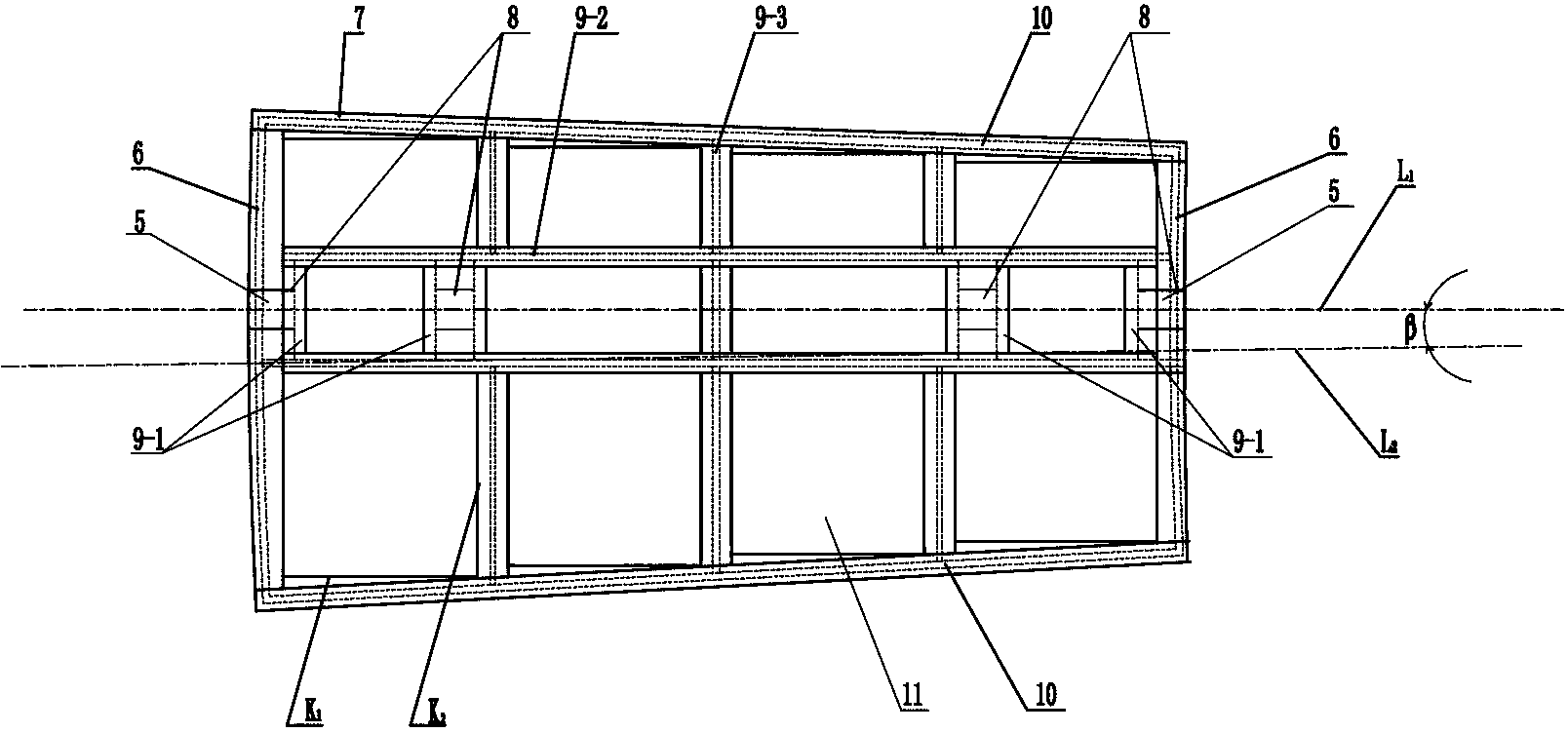

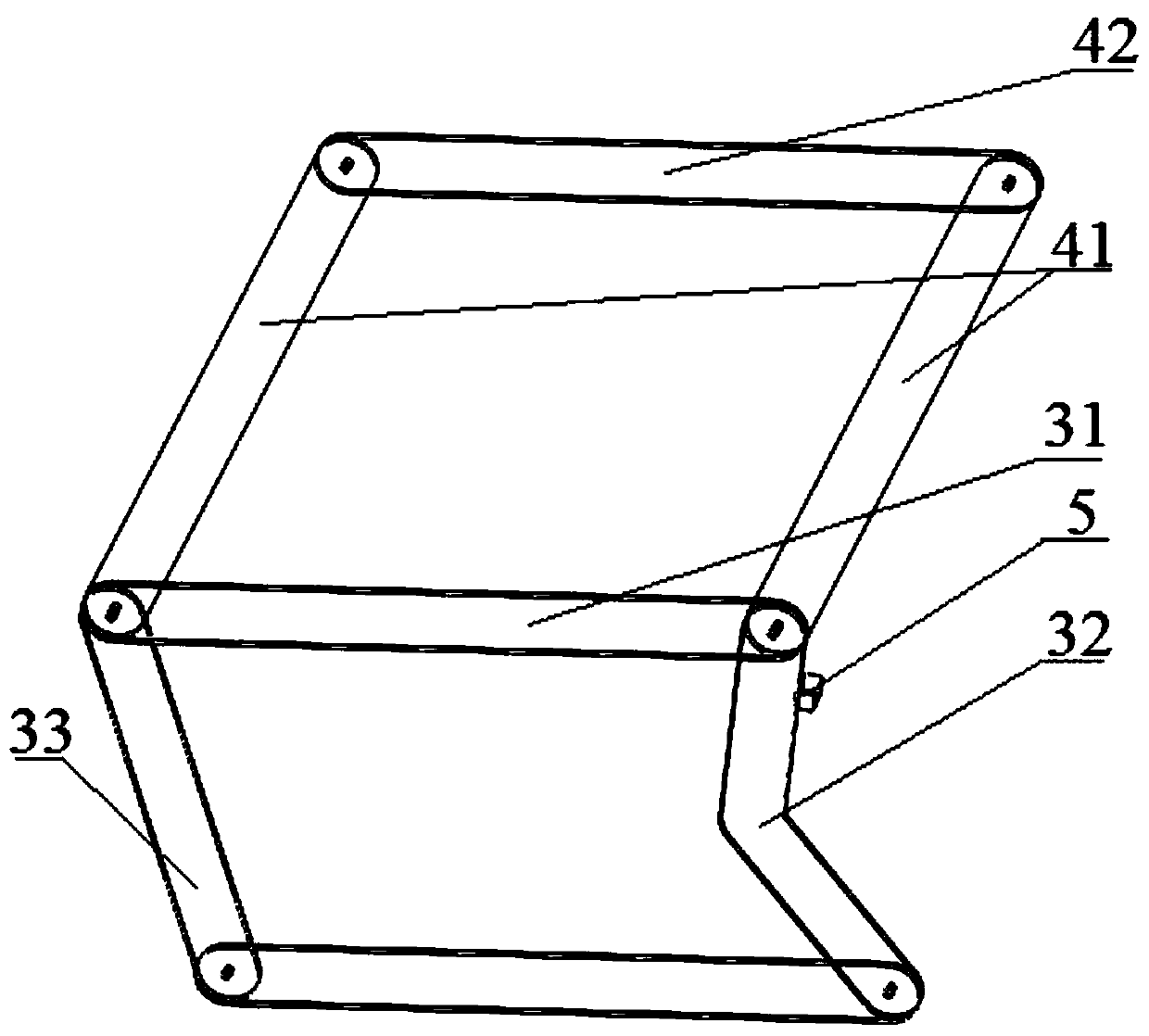

Anti-explosion valve capable of bidirectionally protecting large air volume

PendingCN111927998AEffective closeEffective fast closingEqualizing valvesSafety valvesPhysicsAir volume

The invention discloses an anti-explosion valve capable of bidirectionally protecting large air volume. The anti-explosion valve comprises a valve frame assembly and a group of valve blade assemblies;the valve frame assembly comprises a rectangular frame defined by an upper end plate, a lower end plate, a left end plate and a right end plate, and two baffles arranged at the front-back symmetricalpositions of the upper end plate and the lower end plate correspondingly; the valve blade assembly comprises shafts, valve blades, first rotary positioning pieces, connecting rods, second rotary positioning pieces, positioning bolts, springs and positioning blocks; the shafts are distributed in the rectangular frame at equal intervals, the two ends of each shaft penetrate through the opposite positions of the left end plate and the right end plate respectively, the valve blades are arranged between the left end plate and the right end plate and connected with the shafts, the first rotary positioning pieces are vertically arranged on the surface of one side of the rectangular frame and located between the shafts and the valve blades, the connecting rods are connected with the first rotarypositioning pieces, the second rotary positioning pieces are arranged on the other side of the rectangular frame and located between the shafts and the valve blades, the positioning bolts are arrangedon the second rotary positioning pieces, one ends of the springs are connected with the tensioning bolts, the other ends of the springs are connected with the positioning bolts, and the positioning blocks are arranged above the second rotary positioning pieces and make contact with the upper side faces of the second rotary positioning pieces.

Owner:上海震业环境科技有限公司

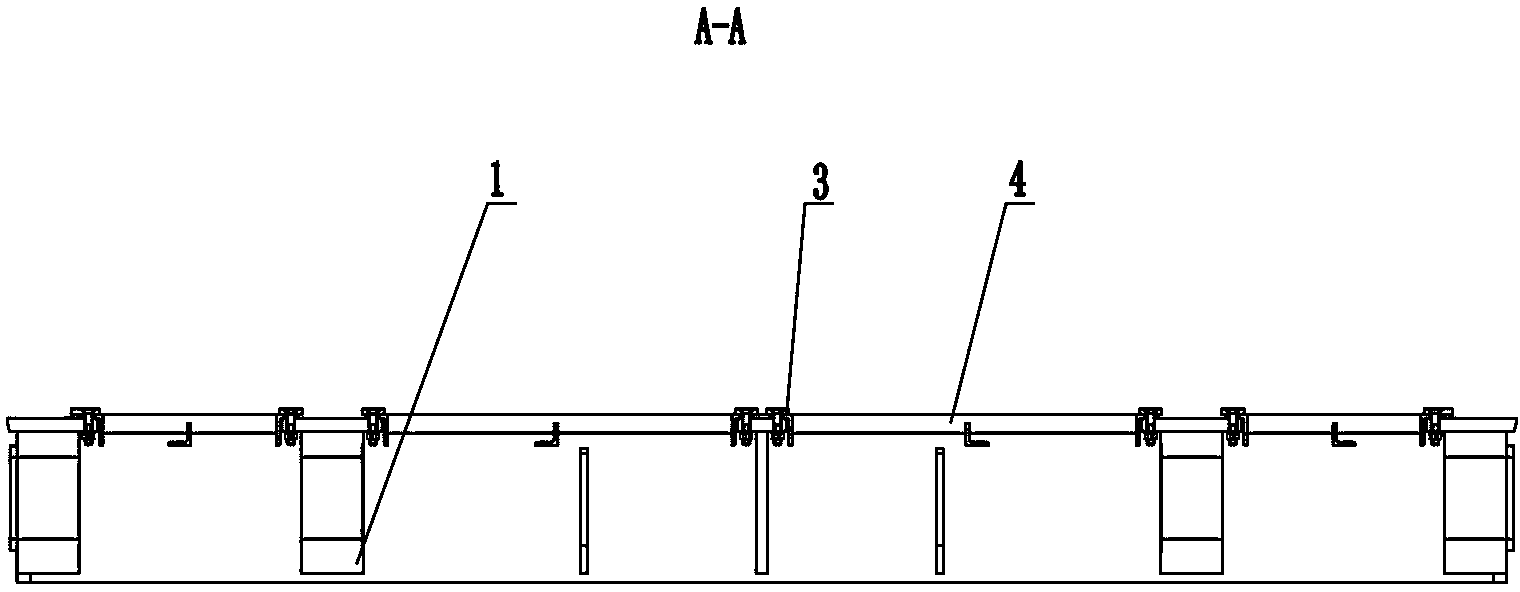

Venting Assembly for a Casting Mould

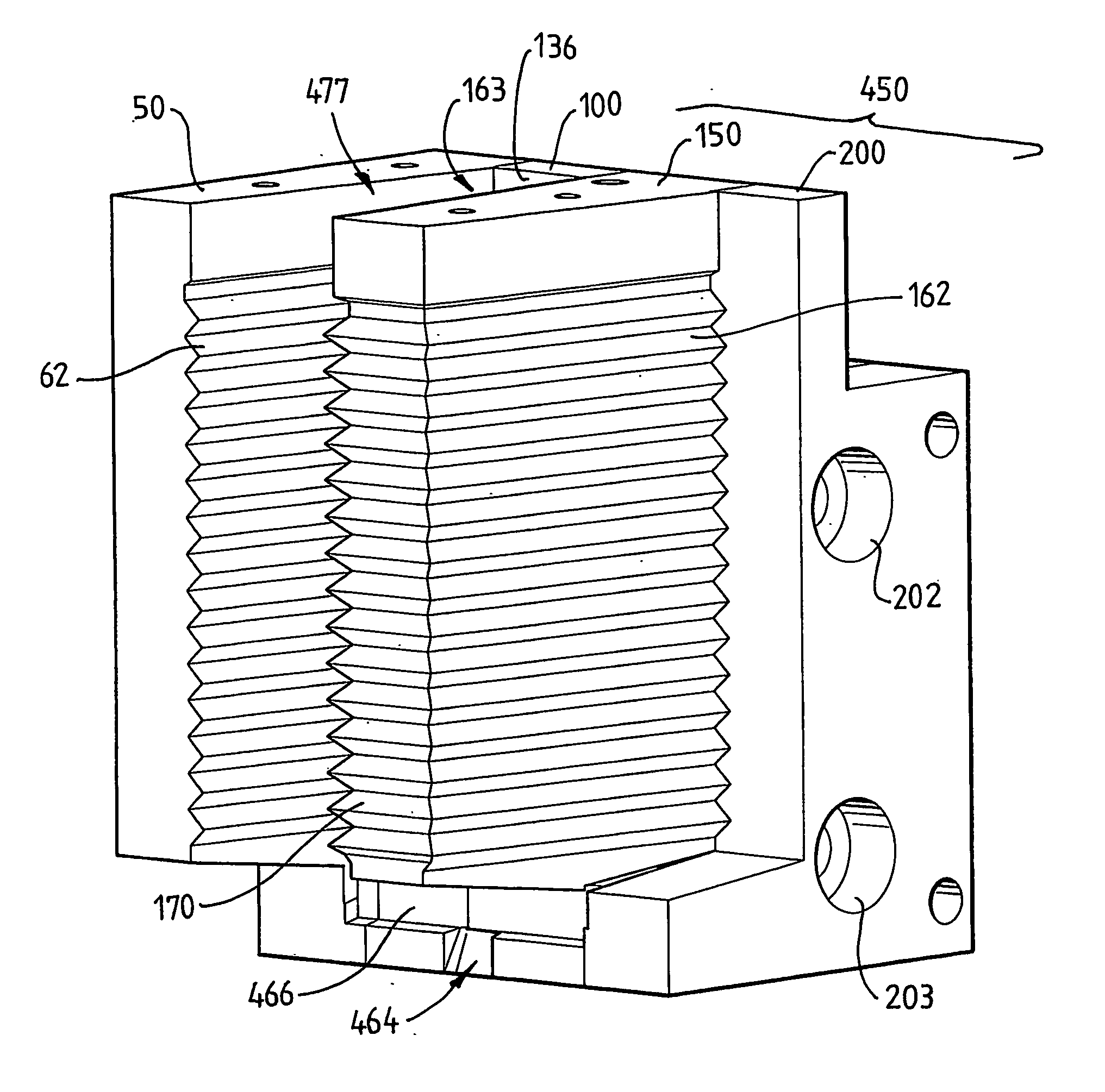

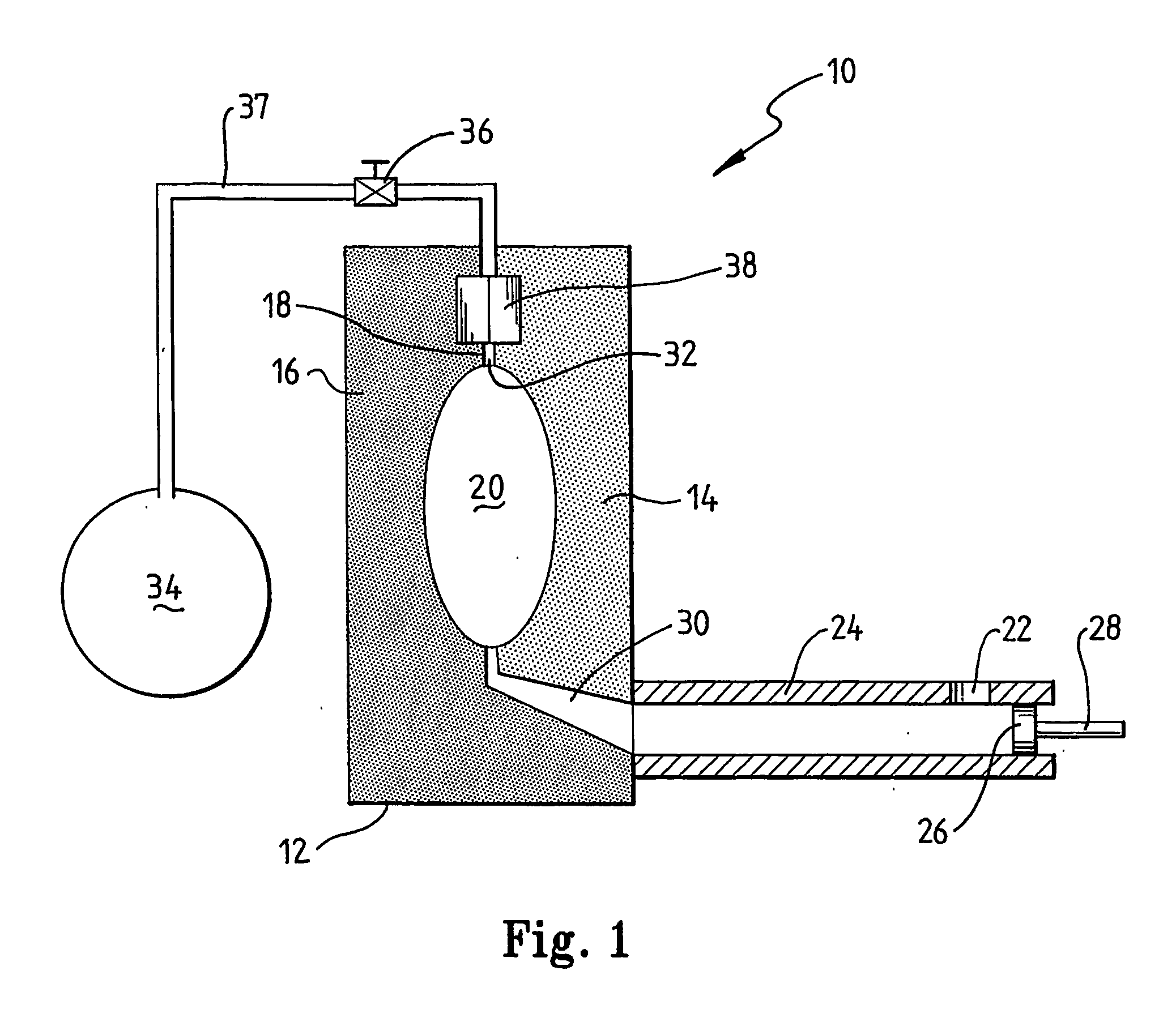

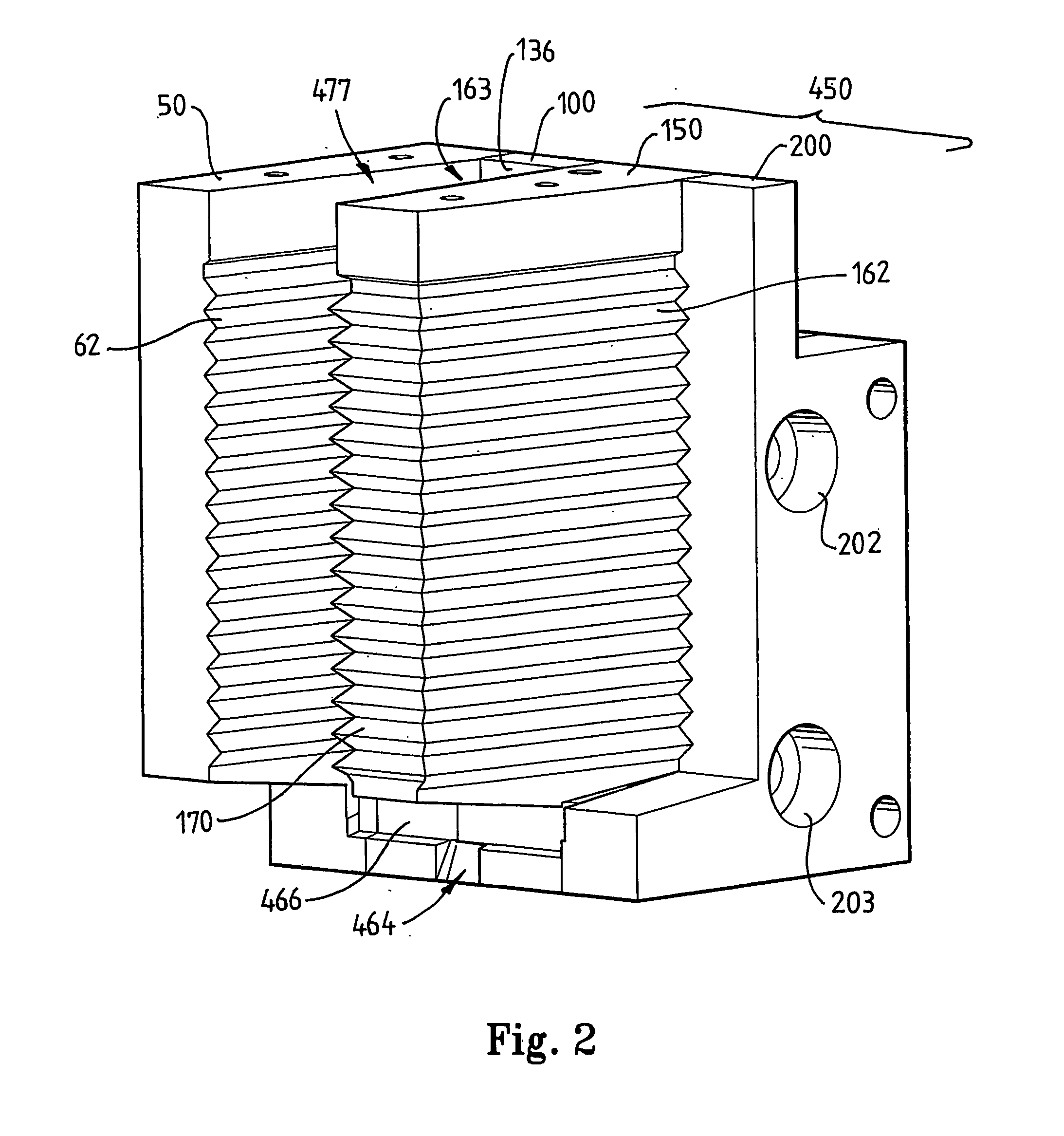

InactiveUS20080041550A1Increase the ventilation areaIncreasing die spaceMoulding toolsDomestic articlesDie castingEngineering

A vent assembly (453) for a high pressure die casting system comprising a pair of opposed chill blocks (450, 452) having corresponding chill surfaces defining a continuous vent chamber therebetween, each of the chill surfaces comprising a plurality of adjoining chill faces (62, 136, 162, 163, 170) extending the length of the vent chamber, each chill face having a corresponding chill face on the paired chill block defining a section of the vent chamber, the plane of each chill face being oriented at an angle to an adjoining chill face on the corresponding block. Preferably the chill face on a chill block is substantially equidistant from the chill face of the corresponding chill block defining the respective section of the vent chamber.

Owner:WANDA TECH PTY

Bidirectional shock wave resistant valve

PendingCN110715086AIncrease the effective ventilation areaIncrease the ventilation areaEqualizing valvesSafety valvesEngineeringMechanical engineering

The invention provides a bidirectional shock wave resistant valve. The bidirectional shock wave resistant valve comprises a valve body and rotating shafts mounted in an inner cavity of the valve body,wherein valve blades are mounted on the rotating shafts and can rotate along with the rotating shafts; one ends of the rotating shafts penetrate through sleeve through holes, and the other ends of the rotating shafts are connected with the side wall of the valve body; sleeves are connected with connecting rods through connecting pieces; the connecting pieces are connected with one ends of springs; the other ends of the springs are connected with one ends of hooks; the other ends of the hooks are connected with fixing blocks; the fixing blocks are arranged on the outer surface of the side wallof the valve body; the two rows of valve blades are arranged; valve blade baffles are mounted in the inner cavity of the valve body; and sealing frames and sealing strips are further arranged in theinner cavity of the valve body. The bidirectional shock wave resistant valve solves the problem that a bidirectional shock wave resistant valve is lacked in the prior art, promotes improvement of social productivity, promotes economic development, consolidates production safety and guarantees life safety of people.

Owner:江苏爵格工业集团有限公司

Concave-convex structure filter screen device of range hood

InactiveCN102853467AIncrease surface areaIncrease the ventilation areaDomestic stoves or rangesLighting and heating apparatusConvex structureMaterial consumption

The invention relates to a concave-convex structure filter screen device of a range hood. The concave-convex structure filter screen device at least comprises a concave-convex structure filter screen and a filter screen frame, wherein a concave-convex structure of the concave-convex structure filter screen is formed by connecting a single or a plurality of strip-type convex sections with adjacent planar sections or adjacent curved sections, by connecting a single or a plurality of ring-shaped convex sections with the adjacent planar sections or the adjacent curved sections, or by arranging a single or a plurality of convex closures or lug bosses on a plane or a curved surface according to a certain rule; the concave-convex structure filter screen at least comprises any structure of a metal pore plate filter screen, a metal screen plate filter screen and a metal gauze filter screen, and a metal filter plate structure comprising flanging ventilation holes; the concave-convex structure filter screen is large in surface area and ventilation area, and is favorable for oil smoke purification and reduction of air loss; the three-dimensional ventilation holes of the concave-convex structure filter screen are favorable for separation, attachment, condensation and purification of oil smoke; and the concave-convex structure filter screen can ensure that the structural rigidity of the filter screen is multiplied, and is favorable for reducing the material consumption.

Owner:广东恒业电器有限公司

Protective device for electrical system box vent hole

InactiveCN102386574AIncrease the ventilation areaEasy to fixSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringBlind hole

The invention discloses a protective device for an electrical system box vent hole. The protective device comprises a shell, wherein the shell comprises a bridging plate, two side plates which are arranged on the two sides of the bridging plate and are connected through the bridging plate, and an end plate which is used for sealing the rear ends of the two side plates and the bridging plate. The protective device is characterized in that the front end of the shell is provided with a shell seat, a communicating hole which is used to communicate with the vent hole is arranged on the shell seat, a dust screen which is used to seal the communicating hole is arranged on the shell, each inner edge wall of the bridging plate the two side plates of the shell is provided with at least one assembly bulge for assembling, the assembly bulges are provided with tapped blind holes, the parts of the shell seat, corresponding to the assembly bulges, are provided with assembly through holes. In the invention, since the shell seat is arranged between the shell and the outer wall of the box, a fixed structure is firmer; since assembly bulges are arranged on the inner edge walls of the bridging plate and the two side plates in a rasied manner, firmer assembly is achieved; meanwhile, the ventilation area of the protective device is increased so that the good ventilation effect can be reached; and since the dust screen is fixedly arranged on the shell seat the dust screen is fixed more firmly.

Owner:PINGGAO GRP

Heat dissipation device for computer case based on rotating centrifugal force

ActiveCN111857279AGuaranteed circulationGuaranteed uptimePump controlDigital processing power distributionElectric machineEngineering

The invention provides a heat dissipation device for a computer case based on a rotating centrifugal force, and relates to the technical field of computer heat dissipation. The heat dissipation devicecomprises a case rear wall, a protection plate is fixedly connected to the left end of the case rear wall, a heat dissipation cylinder is fixedly connected to the right end of the case rear wall, anair outlet plate is fixedly installed on the left side of the interior of the heat dissipation cylinder, a rotating shaft is rotatably connected to the right side of the air outlet plate, and a motoris in transmission connection to the periphery of the middle of the rotating shaft through a bevel gear. When the heat dissipation device is used for heat dissipation, an opening and closing plate canbe opened to ensure air circulation, and the opening and closing plate can be closed when heat dissipation is finished, so dust is prevented from entering, normal operation of components in the caseis ensured, the heat dissipation efficiency can be better adjusted according to the heat in the case, and the practicability of the heat dissipation device is improved.

Owner:西藏帝辰科技有限公司

Disposable laser radiation aid

InactiveCN104707266AAvoid easy cloggingComfortable to useRadiation therapyOptoelectronicsVentilation mode

The invention relates to a disposable laser radiation aid. The disposable laser radiation aid comprises a shell, the axial section of the shell is in the U shape, and the shell comprises a bottom and a sidewall. The disposable laser radiation aid is characterized by further comprising a cylindrical optical fiber sleeve, wherein one end of the optical fiber sleeve and the inner side of the bottom are connected into a whole, and the other end of the optical fiber sleeve is a free end. Because the shell and the optical fiber sleeve are of an integrated structure, the shell and the optical fiber sleeve can be manufactured in an integrated forming mode, and the working procedure of manufacturing the shell and the optical fiber sleeve respectively and then installing the shell and the optical fiber sleeve is omitted. Ventilation grooves are formed in the outer surface of the sidewall, so that the ventilation area is enlarged; compared with a traditional ventilation mode that air holes are formed in the sidewall, the ventilation grooves are hardly blocked by increta of nasal cavities or auditory meatus, even if the ventilation grooves are blocked, the ventilation grooves are easier to clean, and a patient can feel more comfortable in the use process.

Owner:南宁市磁汇科技有限公司

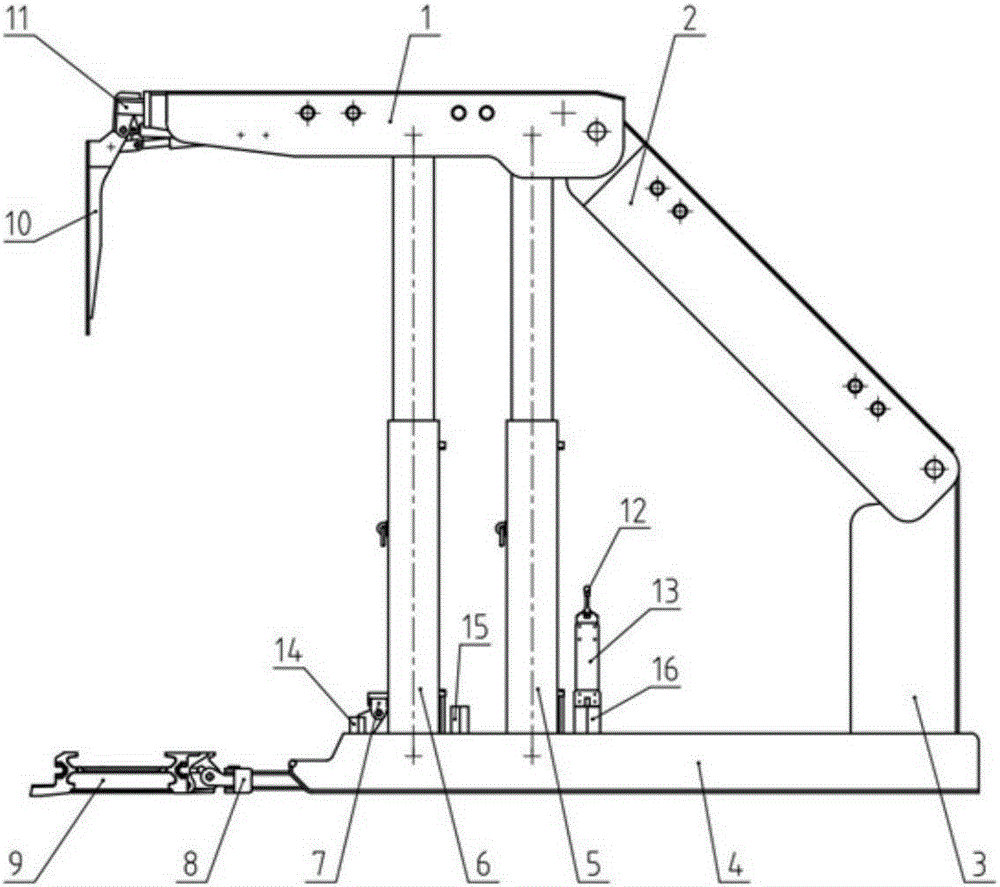

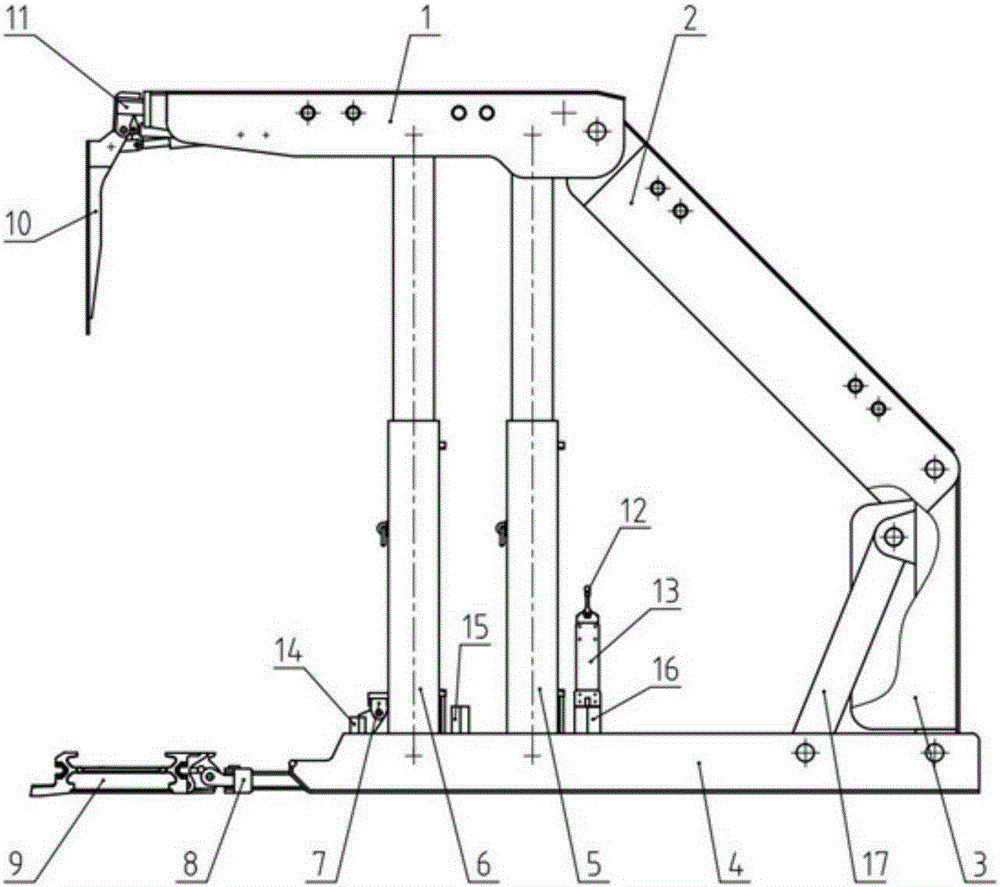

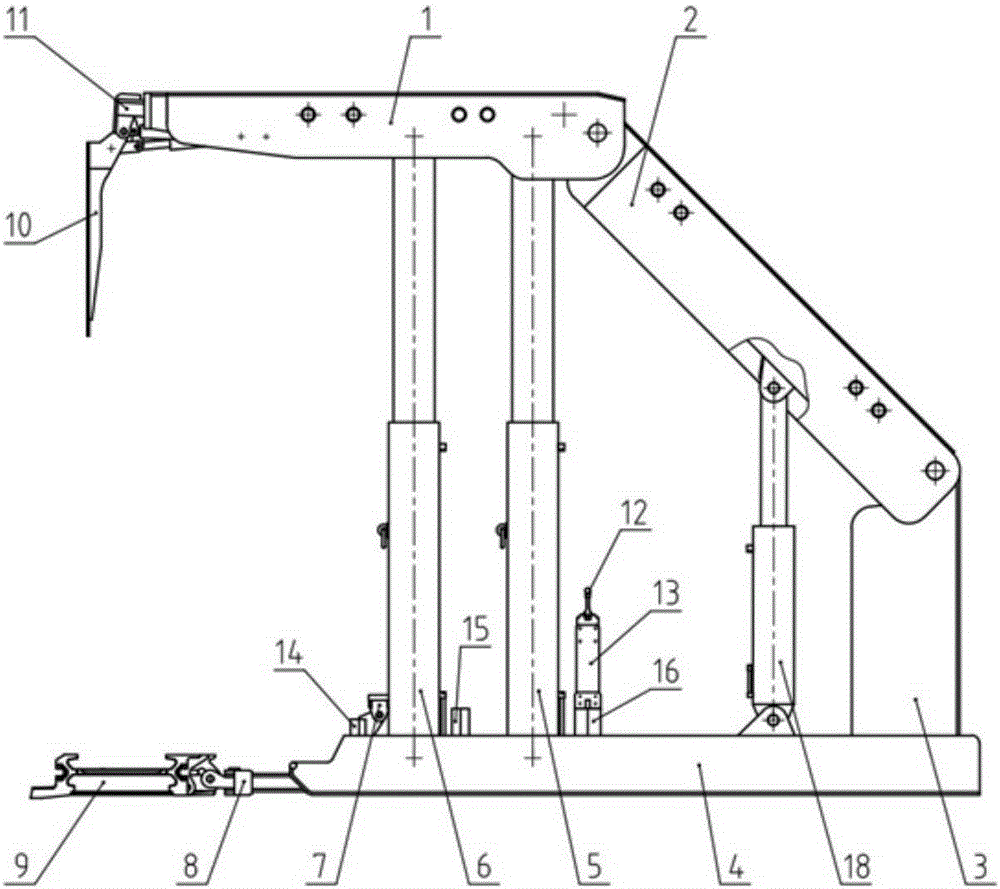

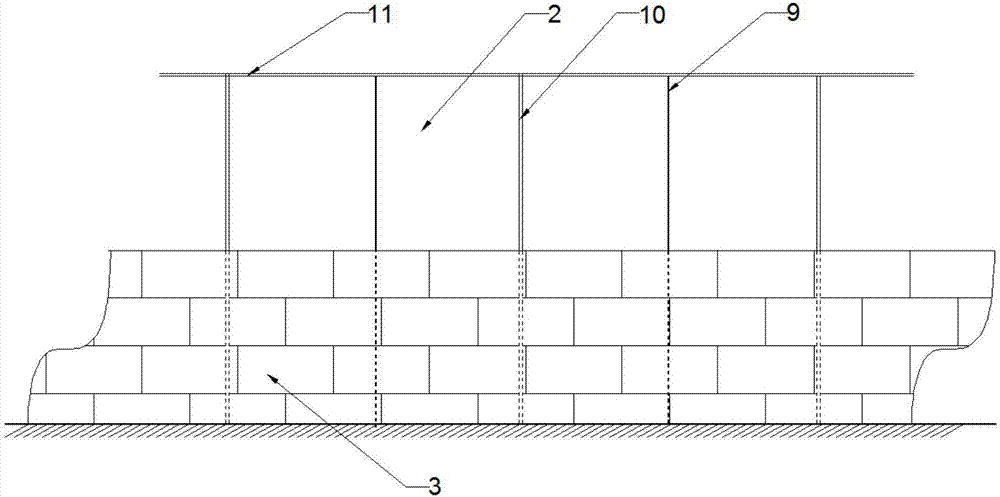

Four-column suspending and rocking hydraulic support

InactiveCN105221177AImprove securityImprove stabilityMine roof supportsProps/chocksModular designEngineering

A four-column suspending and rocking hydraulic support comprises a top beam, a shield beam, an elevating frame, a base, four suspending hydraulic stand columns, a bottom lifting device, a pushing device, a sidewall protecting device, a telescopic beam device, a hydraulic control valve bank and a valve bank support. The four suspending hydraulic stand columns are arranged between the top beam and the base in parallel in two rows, the upper ends of the four suspending hydraulic stand columns are connected with the top beam through spherical hinges, and the lower ends of the four suspending hydraulic stand columns are connected with the base through spherical hinges. The telescopic beam device is arranged in the front end of the top beam, and the sidewall protecting device is hinged to the telescopic beam device. The upper end of the shield beam is hinged to the top beam, and the lower end of the shield beam is hinged to the upper end of the elevating frame. The base and the elevating frame are welded into a whole, and a gap bridge and the base are welded into a whole. The front end and the rear end of the pushing device are hinged to a scraper conveyer and the base respectively. The four-column suspending and rocking hydraulic support is suitable for fully-mechanized coal mining faces of underground coal mines, achieves modular design, standardized design and serialized design and has the advantages of being large in working space, ventilating area and working resistance, safe, reliable, good in stability and the like.

Owner:CHINA UNIV OF MINING & TECH

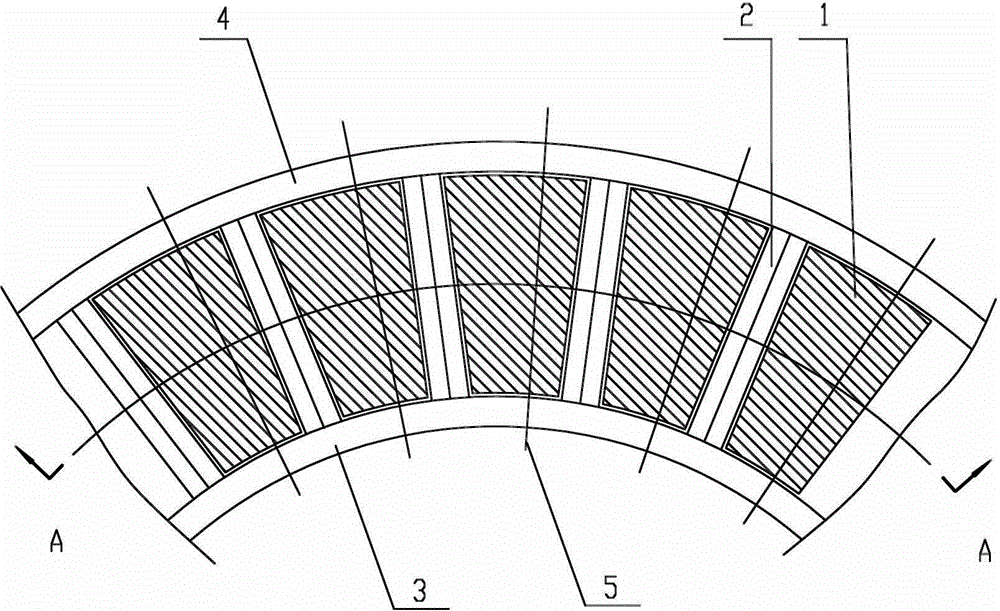

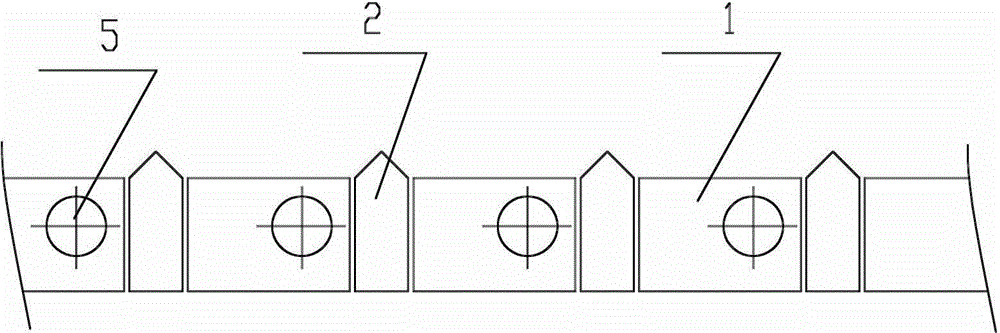

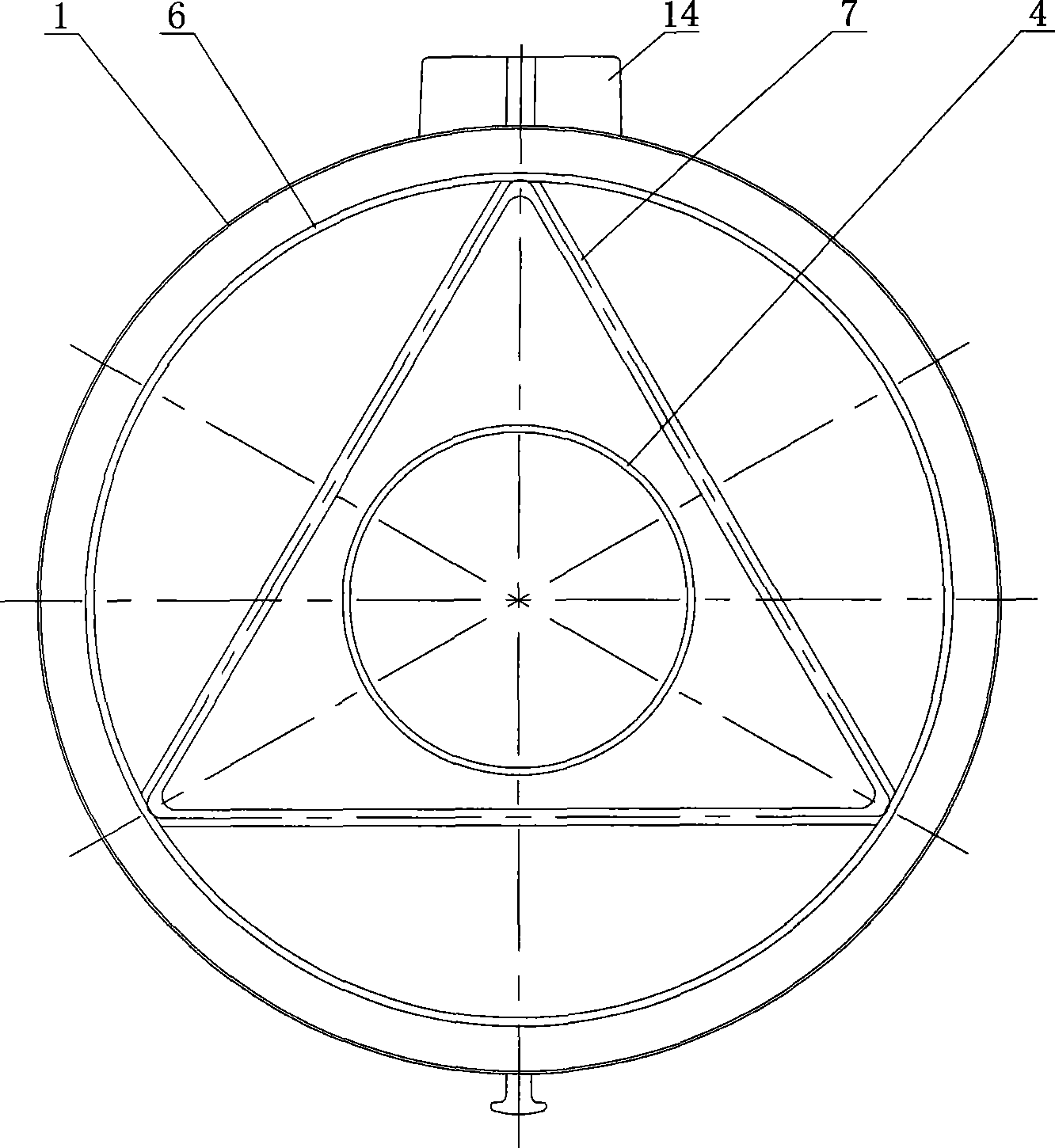

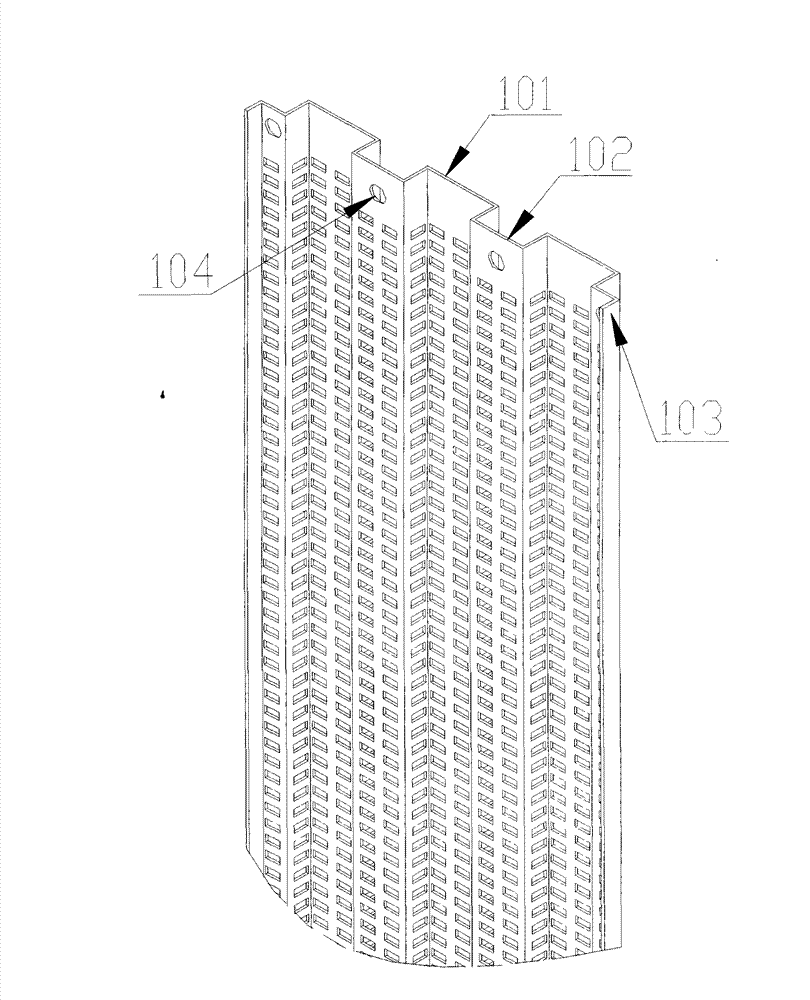

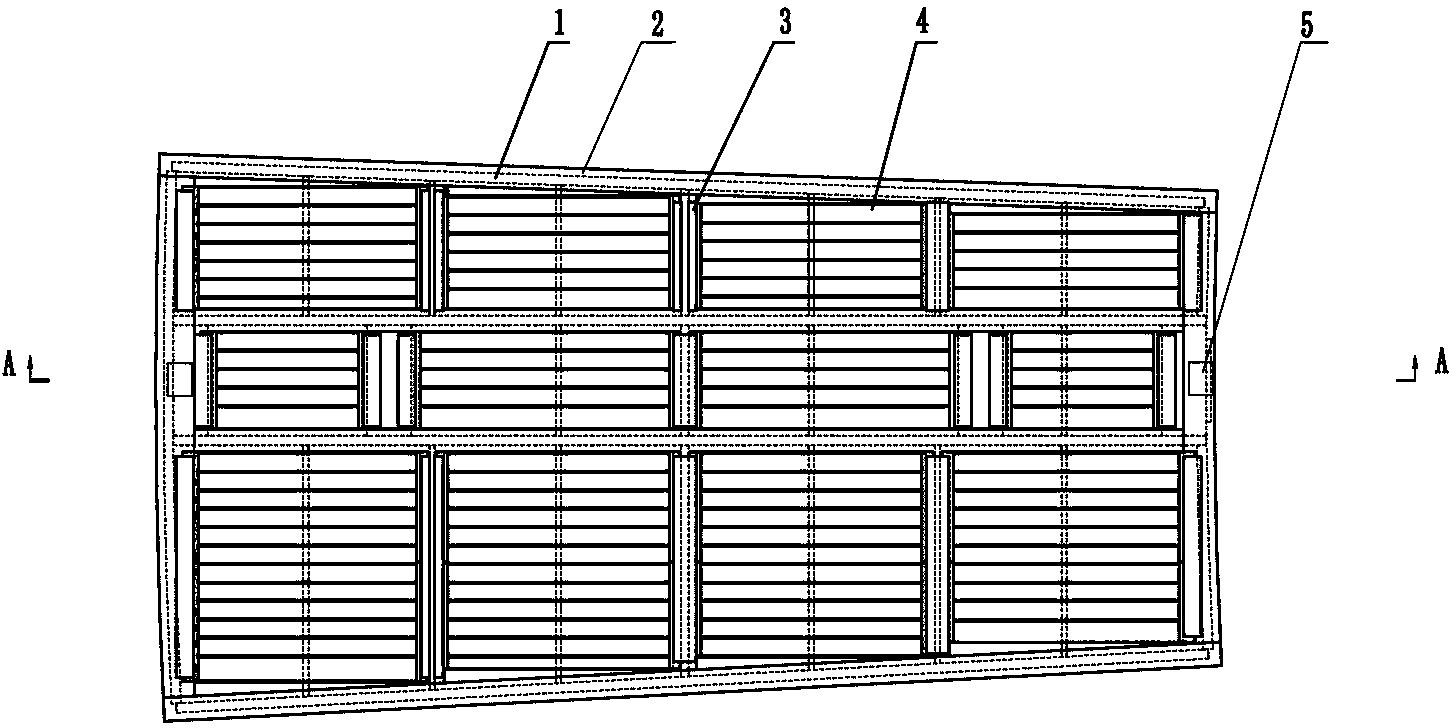

Sintering annular cooler pallet

ActiveCN103256814AAvoid Structural DefectsIncrease the ventilation areaFurnace typesHandling discharged materialMaterial resourcesEngineering

The invention belongs to the technical field of metallurgical equipment and particularly relates to a sintering annular cooler pallet which comprises a set of separated type pallets which are sequentially arrayed in the circumferential direction of an annular cooler. The sintering annular cooler pallet is characterized in that each separated type pallet comprises a fan-shaped pallet body, a panel and a set of grates, wherein the fan-shaped pallet body is connected with a revolving frame of the annular cooler through two eccentric gudgeons,, the panel is arranged on a fan-shaped pallet body frame and the set of grates are connected with the panel through a set of pressing plates. According to the sintering annular cooler pallet, the structural defects of an original sintering annular cooler pallet are overcome. The pallet bodies are fan-shaped pallet bodies with eccentric shafts. An original triangle beam structure is cancelled and the ventilation area of the annular cooler is increased so that a sinter can be cooled more fully and sealing can be easier to achieve. In addition, the grates of the pallet are assembly type blind window grates. Therefore, when the pallet grates are damaged, the pallet does not need to be replaced integrally. Manpower and material resources are saved, and cost is saved.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Rotating and moving type glass window

InactiveCN103899217AIncrease the light areaIncrease the ventilation areaWing arrangementsSash windowEngineering

Provided is a rotating and moving type glass window. Slide rails are fixed in the upper side and the lower side of a window frame, the middle of the upper side of a window sash and the middle of the lower side of the window sash are respectively provided with a rotating bearing, a sliding wheel is arranged on each rotating bearing, and each sliding wheel can slide leftwards and rightwards in the corresponding guide rail. When window locks are opened, the window sash can be rotated by 90 degrees, and then the window sash is moved and slides to one side of the window frame. Thus, the window can be opened as much as possible, and the ventilation effect is enhanced.

Owner:SHANDONG UNIV OF SCI & TECH

Casement window

ActiveCN110130789AIncrease the ventilation areaSmall footprintWing arrangementsWing suspension devicesParallelogramElectrical and Electronics engineering

The invention discloses a casement window, which includes a window frame and a window sash. A first parallelogram connecting rod part is hinged to the window frame, a second parallelogram connecting rod part is hinged between a first top rod and the window sash of the first parallelogram connecting rod part, and the first parallelogram connecting rod part and the second parallelogram connecting rod part are used for driving the window sash to open or close translationally. The window sash translationally rotates outwards and is always parallel to the window frame, when the first parallelogramconnecting rod part rotates to the limiting position, the second parallelogram connecting rod part rotates outwards with two hinge points of the first top rod as the rotation center so that the windowsash can be fully opened, the window sash cannot shield the window frame, the ventilation area is larger, the window frame is closely attached to a wall, the occupied space of the window sash after being opened is decreased, the wind area of the window sash is small, wind resistance is correspondingly minimized, the window sash is not prone to being blown off, and the safety of the casement window is further improved.

Owner:GUANGDONG UNIV OF TECH

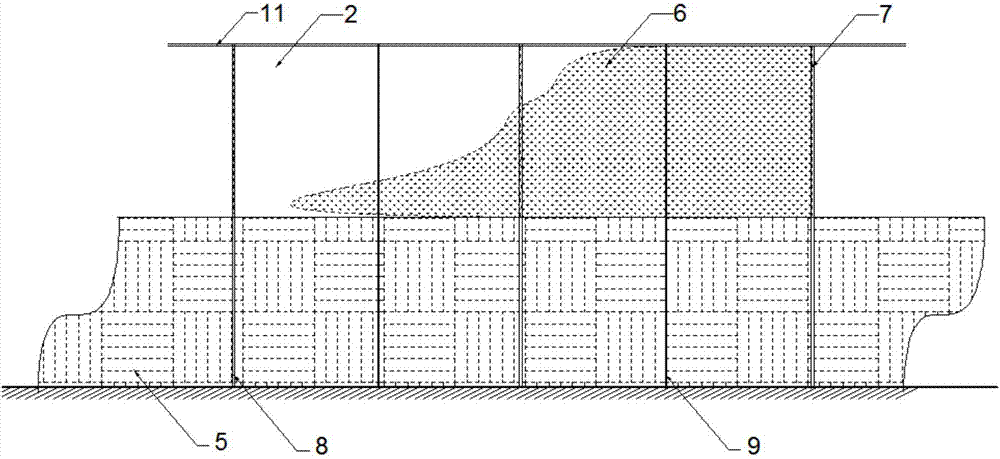

Semi-dismounting-type greenhouse back wall

ActiveCN106912322ASolve the problem that the annual production cannot be carried outLow structural costClimate change adaptationGreenhouse cultivationFiberInsulation layer

The invention discloses a semi-dismounting-type greenhouse back wall structure comprising a lower half section composite wall body and an upper half section composite wall body. The lower half section composite wall body comprises a heat radiation layer, a heat-accumulating layer and a heat-insulation layer from the inside out; the dismounting-type wall body comprises a back wall column supporting structure, a detachable inner layer jute fiber board and a detachable outer layer jute fiber board which are respectively installed at the inner side and outer side of the back wall column supporting structure; the jute fiber board can be freely installed and dismounted; the installation of the jute fiber board can reduce the indoor heat dissipation to the outside in winter and has the function of heat insulation; the jute fiber board can be dismounted in summer for increasing ventilation area of the greenhouse and therefore the indoor temperature can be effectively reduced. The semi-dismounting-type greenhouse back wall of the invention can be used in Jiangsu areas for overwintering production and over summer production, thereby solving the problem that year-round production cannot be carried out in greenhouses in the south and increasing the soil utilization rate; meanwhile, the cost for the greenhouse back wall structure is low; the construction is convenient and economic benefit is increased.

Owner:NANJING AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com