Sintering annular cooler pallet

A sintering ring cooler and ring cooler technology, applied in the furnace type, processing discharged materials, furnace and other directions, can solve the problems of increasing the air volume of the cooling fan, reducing the cooling effect of the ring cooler, and large air leakage rate, etc. Ventilation area, increased productivity, simple effect of sealing components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

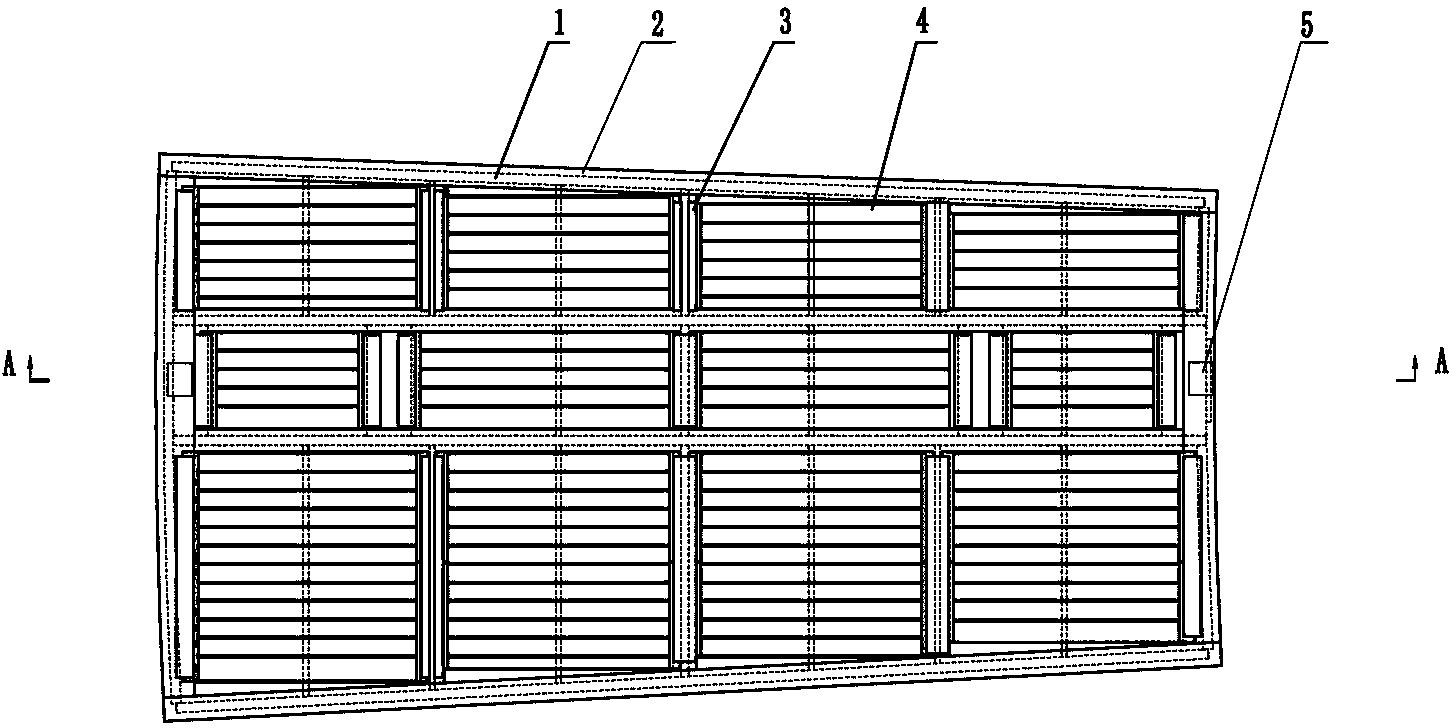

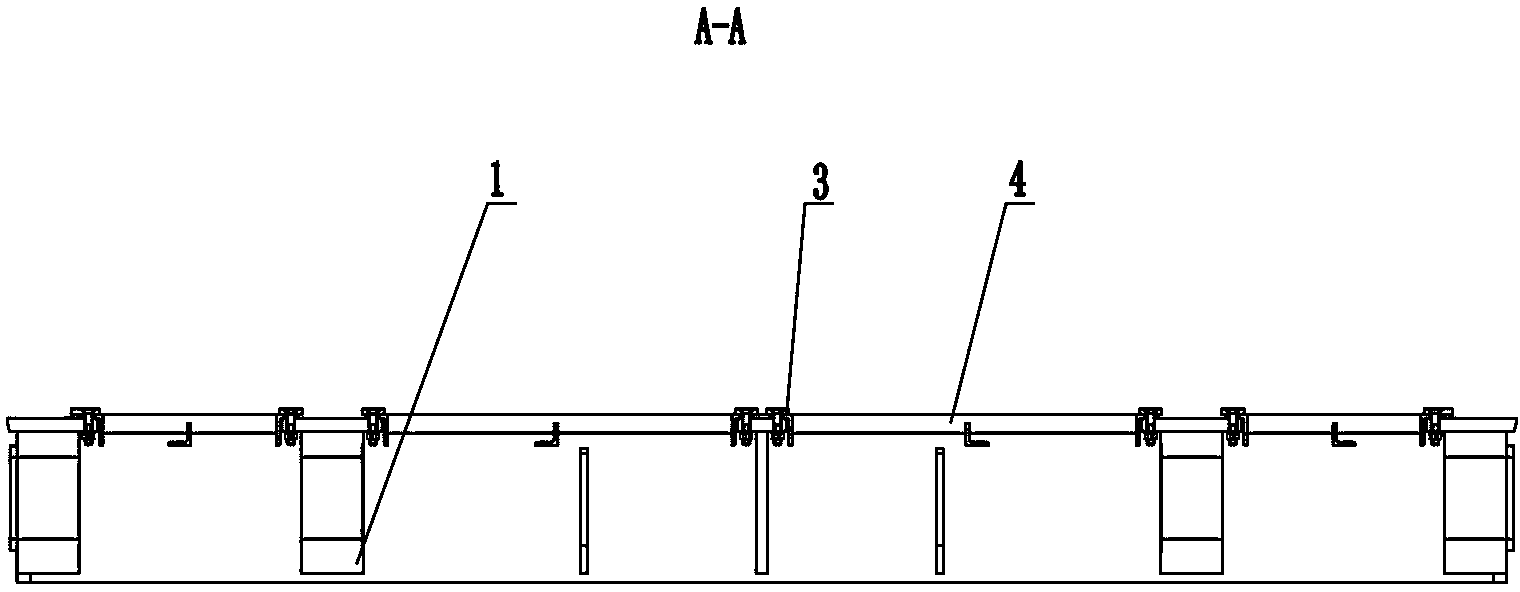

[0024] Such as figure 1 As shown, a trolley for a sintered annular cooler of the present invention includes a group of body trolleys arranged in sequence along the circumferential direction of the annular cooler, and is characterized in that the split trolley includes two eccentric trunnions 5 The fan-shaped trolley body 1 connected to the rotary frame of the annular cooler, the panel 2 provided on the fan-shaped trolley body, a set of grate plates 4 connected to the panel through a set of pressure plates 3,

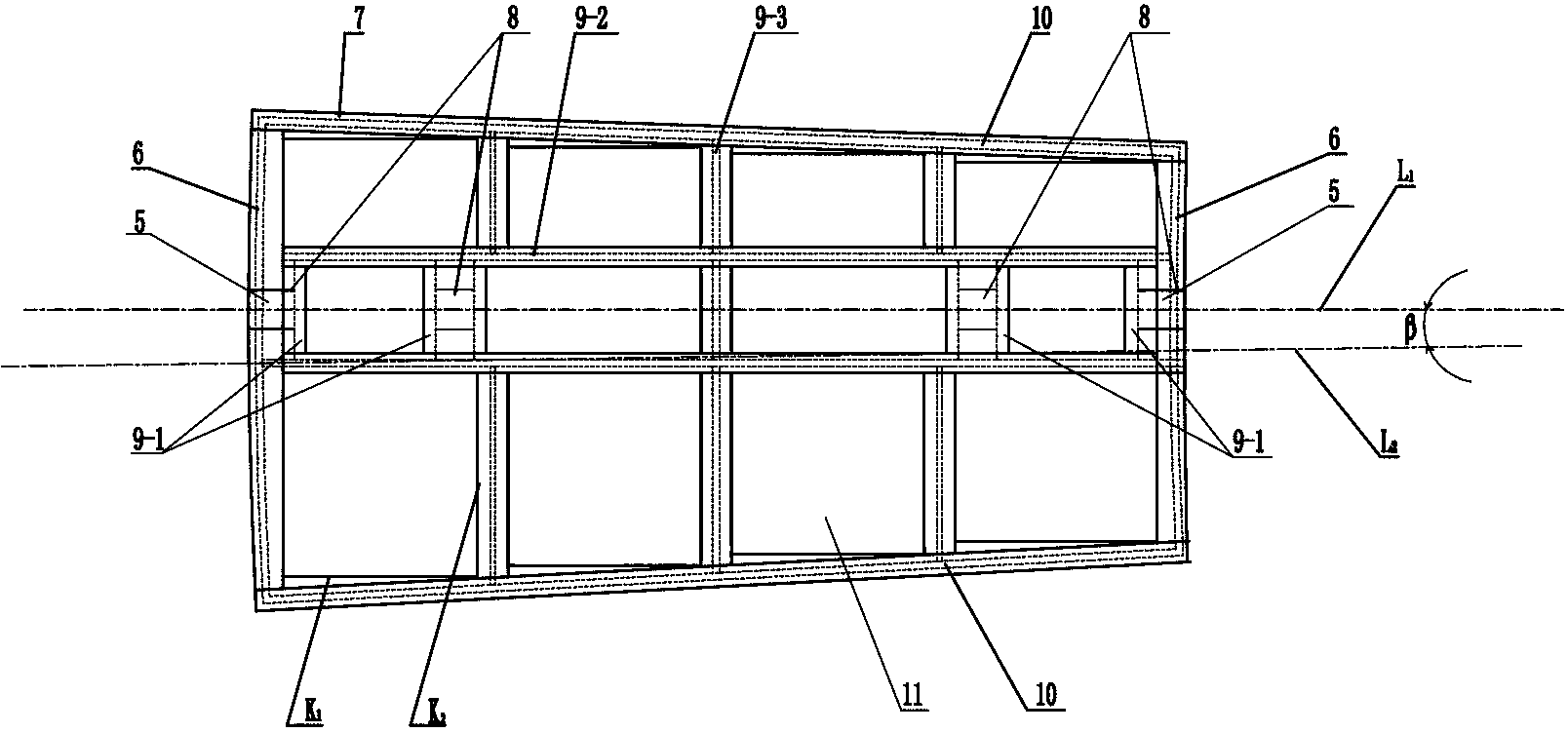

[0025] Such as figure 2 , 3 , 6, the fan-shaped trolley body 1 is a fan-shaped column frame structure with a cross-section surrounded by two arc-shaped vertical plates 6 and two plane vertical plates 10, and the inside of this frame structure is surrounded by a group of transverse ribs 9-2 and a group of longitudinal rein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com