Patents

Literature

181results about How to "Avoid Structural Defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

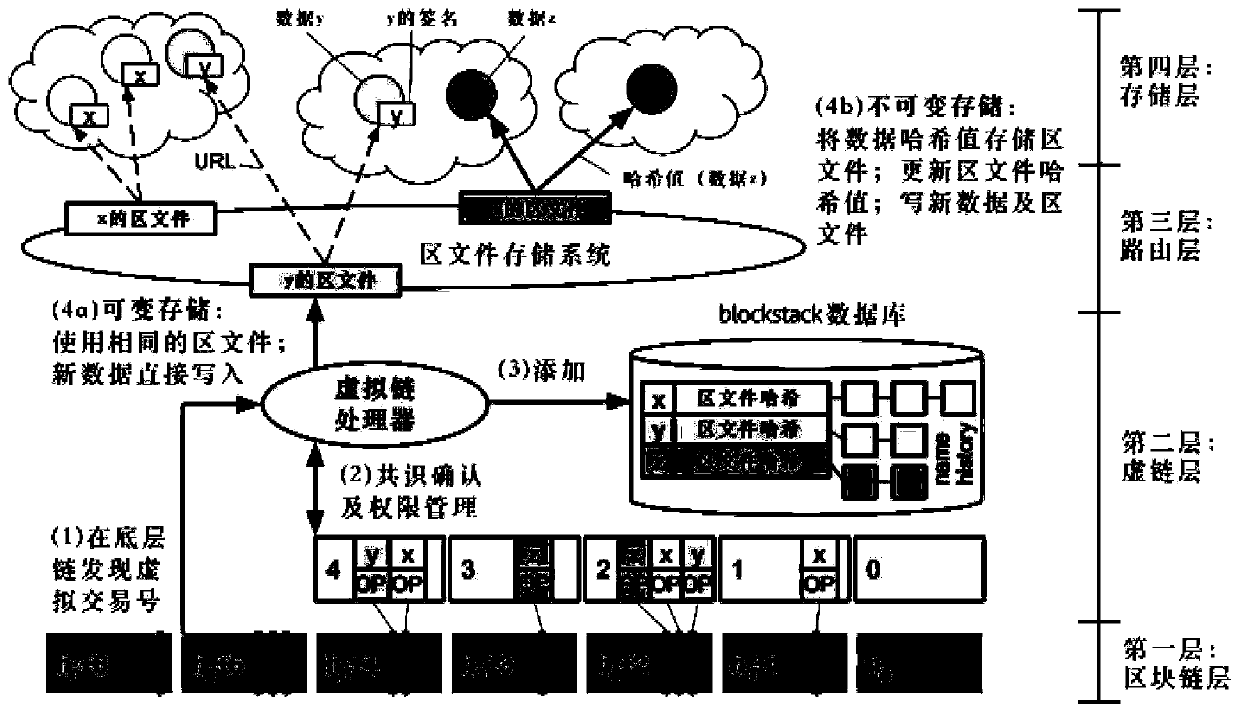

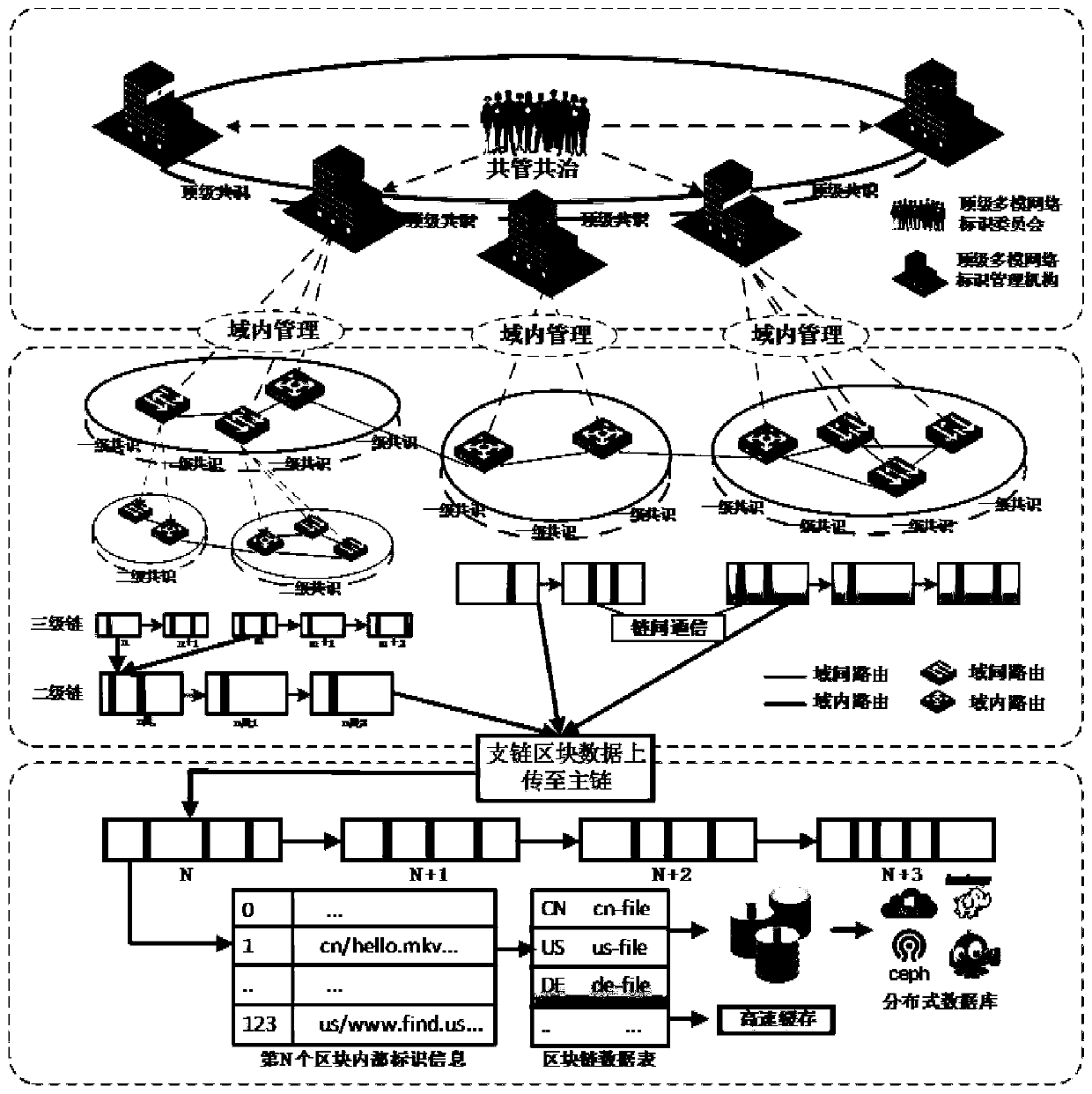

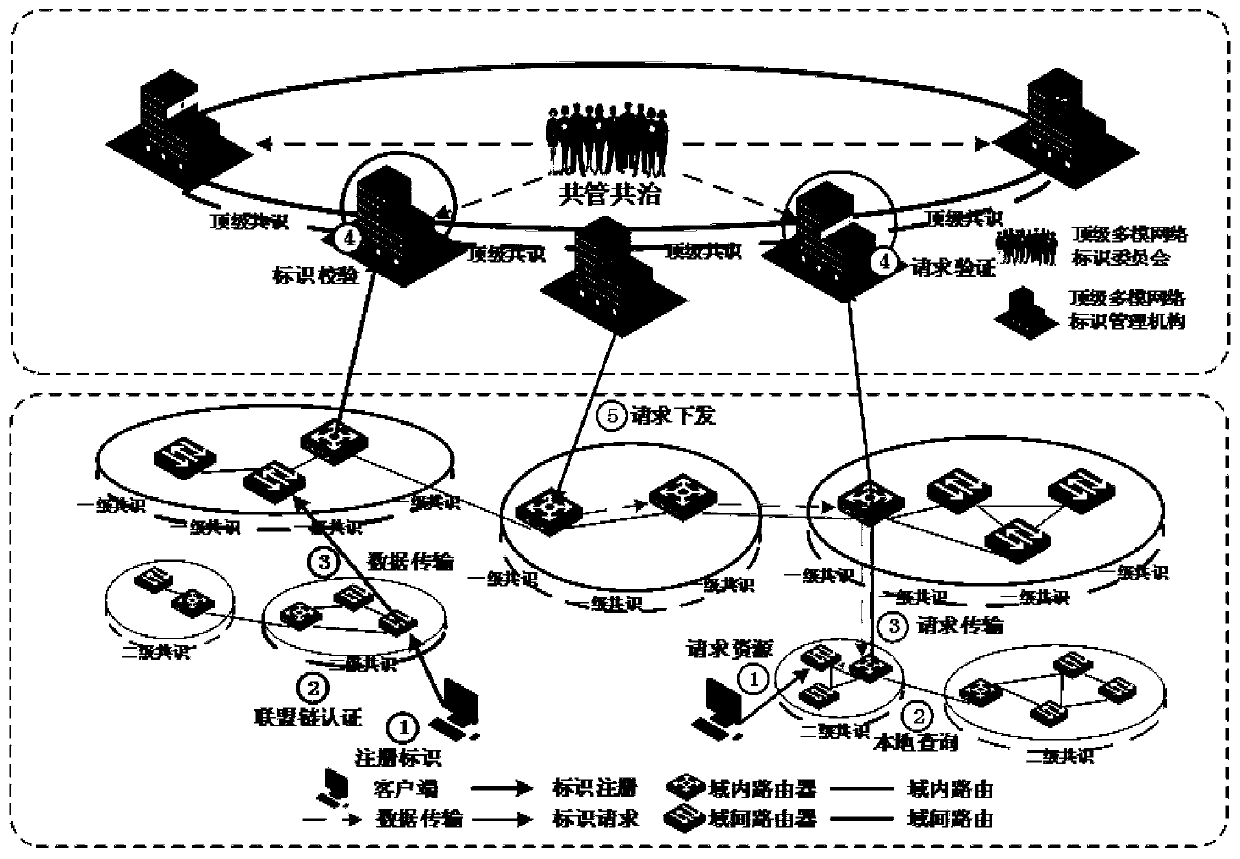

Method for producing and managing multi-mode labeled network based on consortium blockchain voting consensus algorithm

ActiveCN110945853AEffective supervisionAvoid malicious squattingData switching networksBlockchainRapid access

The invention relates to the field of blockchain technology improvement, and provides a method for producing and managing a multi-mode labeled network based on a consortium blockchain voting consensusalgorithm. The method comprises following steps: step one, utilizing a blockchain technology to labeling and addressing contents in a network to generate a multimode labeled network; step two, subjecting the multimode labeled network to domain division to form a layered block system, and managing each block system through a PoV voting consensus algorithm; step three, converting the multimode labeled network into a multimode labeled network system according to a blockchain architecture; and step four, utilizing a consortium blockchain consensus algorithm to carry out whole network consensus management on the multimode labeled network system. A multilayer and segmented blockchain model architecture is adopted, and thus the processing performance of the system is largely improved. The blockchain network nodes in each layer can all rapidly access related route information of blockchains of other layers through steward nodes and committee nodes in corresponding domains.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL +1

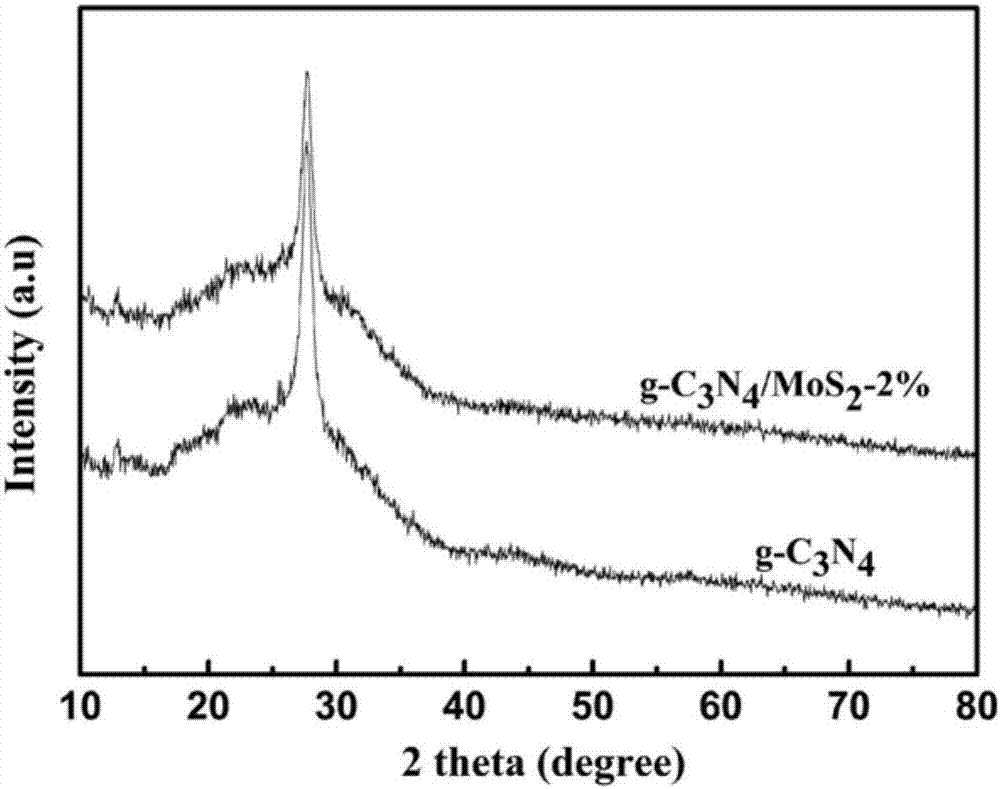

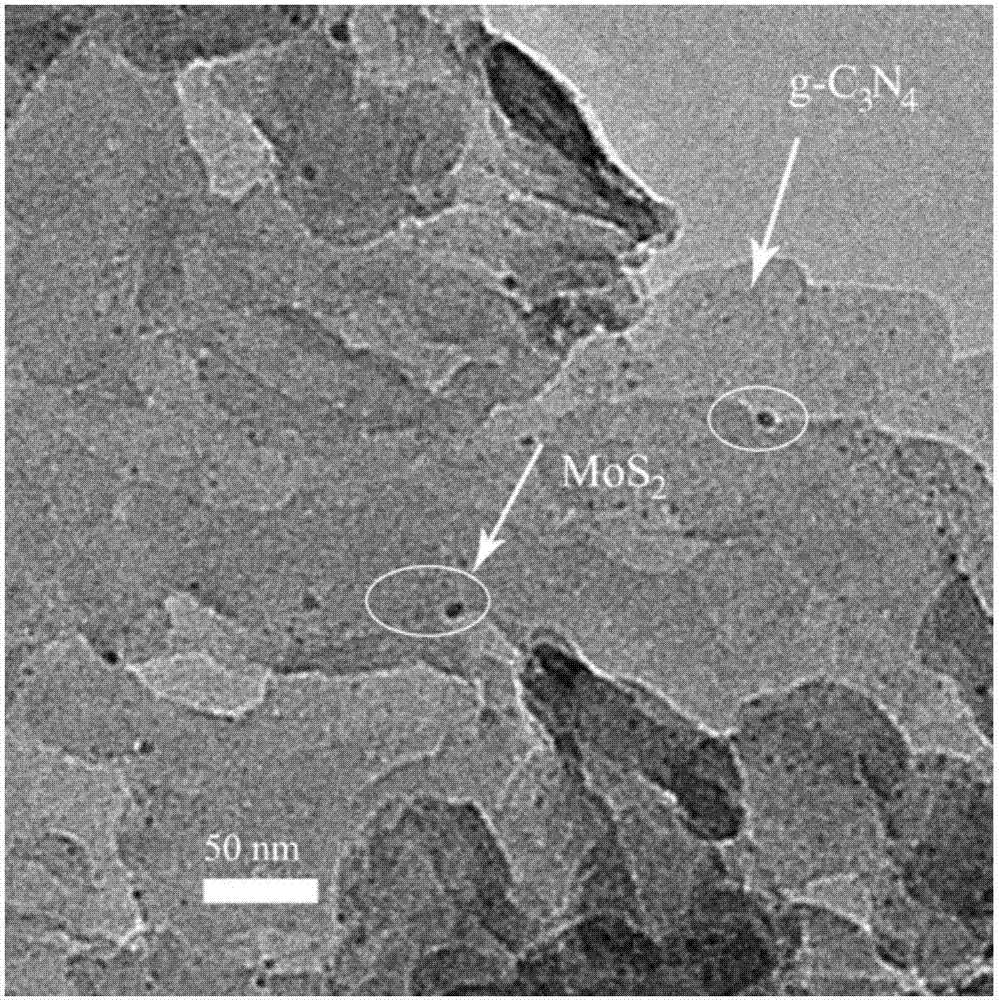

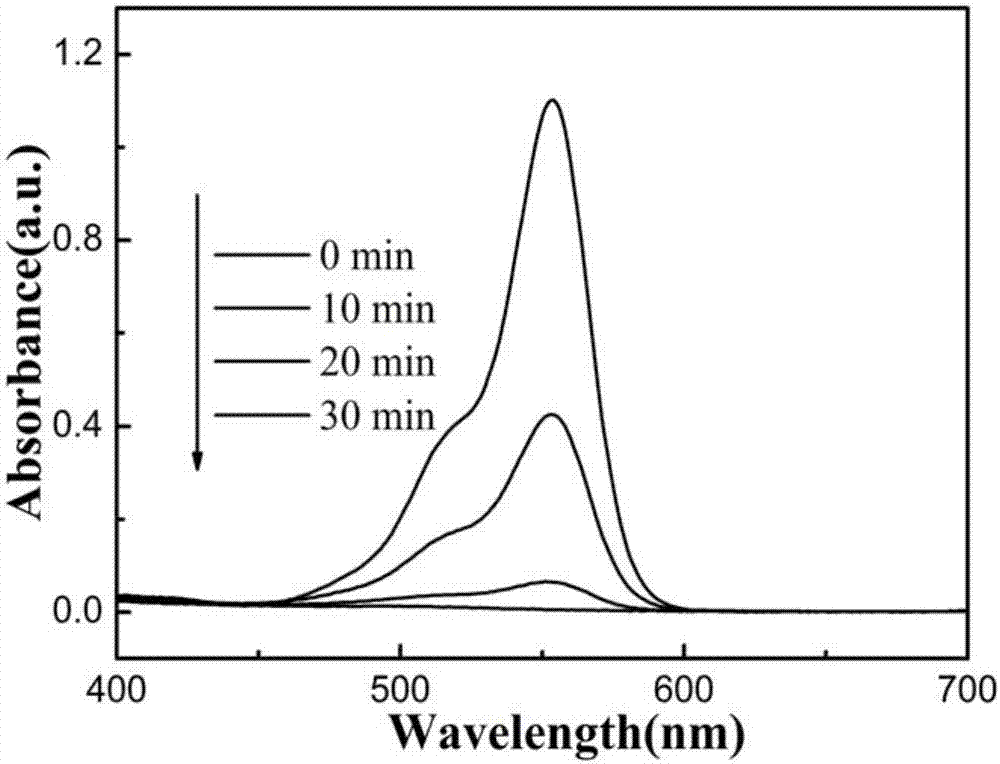

Synthetic method of graphite-like carbon nitride/molybdenum disulfide nanocomposite material

ActiveCN107376971AWidely used valueHigh purityPhysical/chemical process catalystsWater/sewage treatment by irradiationWater bathsThermal insulation

The invention relates to a synthetic method of a graphite-like carbon nitride / molybdenum disulfide (g-C3N4 / MoS2) nanocomposite material. The synthetic method comprises the following steps: firstly, weighing a certain amount of urea and then putting the urea into a corundum crucible; secondly, putting the corundum crucible holding the urea into a muffle furnace and then calcining at a certain temperature to obtain the g-C3N4; thirdly, weighing a certain amount of ammonium molybdate ((NH4)6Mo7O24.4H2O) and thioacetamide (CH3CSNH2)) and respectively dissolving the two substances in deionized water to obtain uniform solutions; fourthly, slowly dropwise adding the ammonium molybdate solution into the thioacetamide solution; fifthly, stirring, then transferring the mixed solution into a reaction still, carrying out thermal insulation under the hydrothermal condition that the temperature is 195 DEG C for 30 hours to obtain MoS2 nanopowder, and then carrying out separation, washing and drying; sixthly, taking a certain amount of the g-C3N4 and a certain amount of the MoS2, and then dissolving the substances in absolute ethyl alcohol, carrying out constant temperature ultrasonic operation for 2 hours and then drying in a water bath kettle with the temperature of 40 DEG C to obtain a finished product. The graphite-like carbon nitride / molybdenum disulfide (g-C3N4 / MoS2) nanocomposite material disclosed by the invention has the advantages of simple synthetic technology, large specific surface area (65 to 75m<2> / g) and excellent visible light photocatalytic performance.

Owner:LUOYANG INST OF SCI & TECH

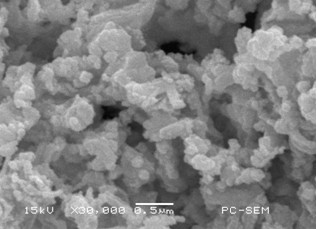

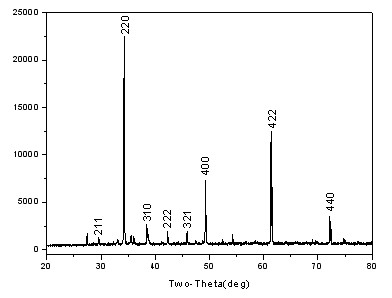

Preparation method of perovskite-like varistor ceramic material CaCu3Ti4O12 with high dielectric constant

ActiveCN102432062AOvercome energy consumptionOvercome granularityTitanium compoundsNitrateVaristor ceramics

Belonging to the technical field of preparation and application of electronic ceramics, the invention relates to a preparation method of a perovskite-like varistor ceramic material CaCu3Ti4O12 (CCTO) with a high dielectric constant. With nitrates of Cu and Ca as well as Ti (OC4H9)4 as starting materials, the method of the invention combines a hydrothermal method for preparing nanometer CCTO powder so as to prepare high performance CCTO varistor ceramics, thus realizing the purposes of lowering temperature, and improving varistor as well as dielectric properties.

Owner:江苏津沂菊源生物健康产业研究院有限公司

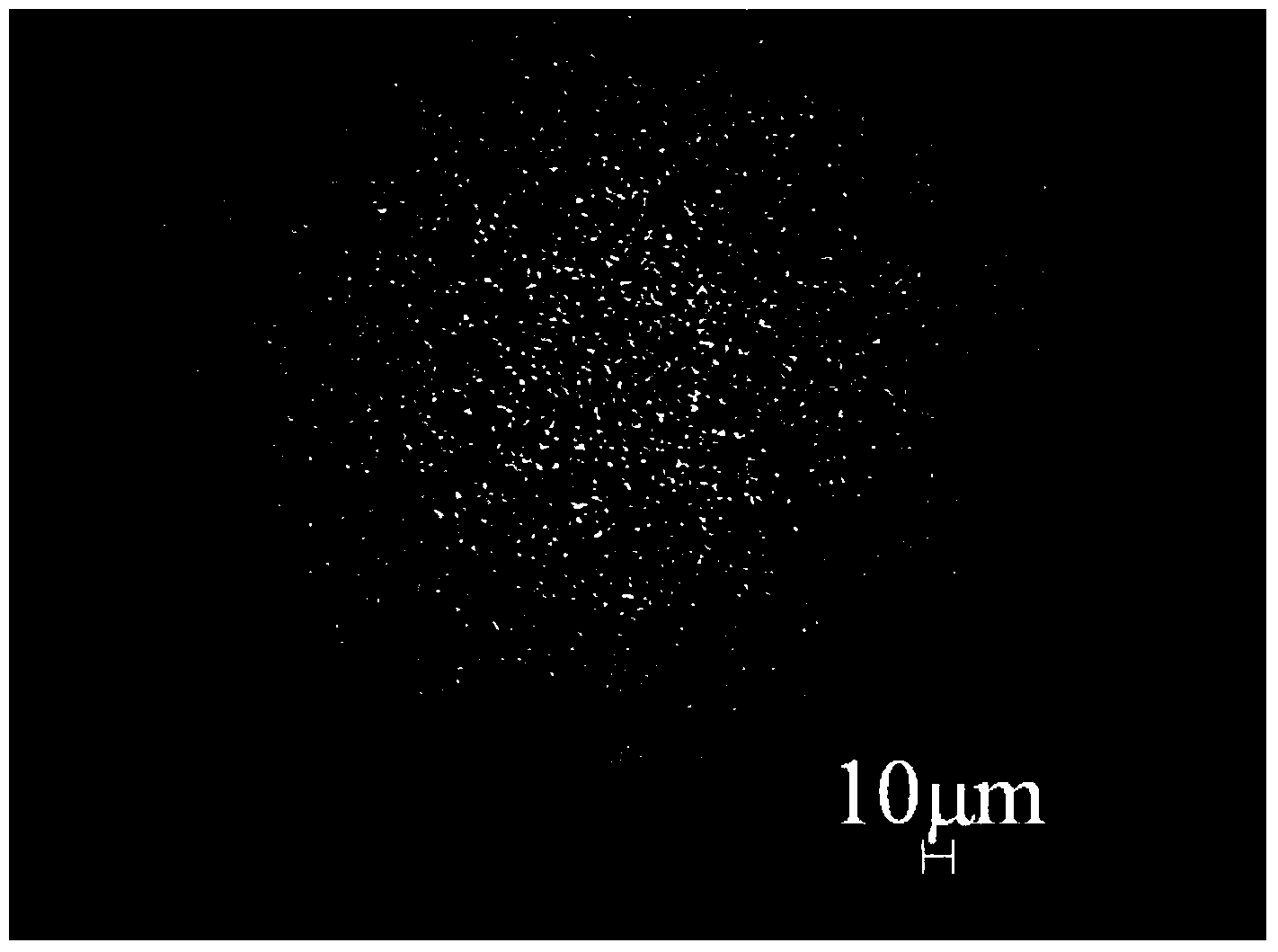

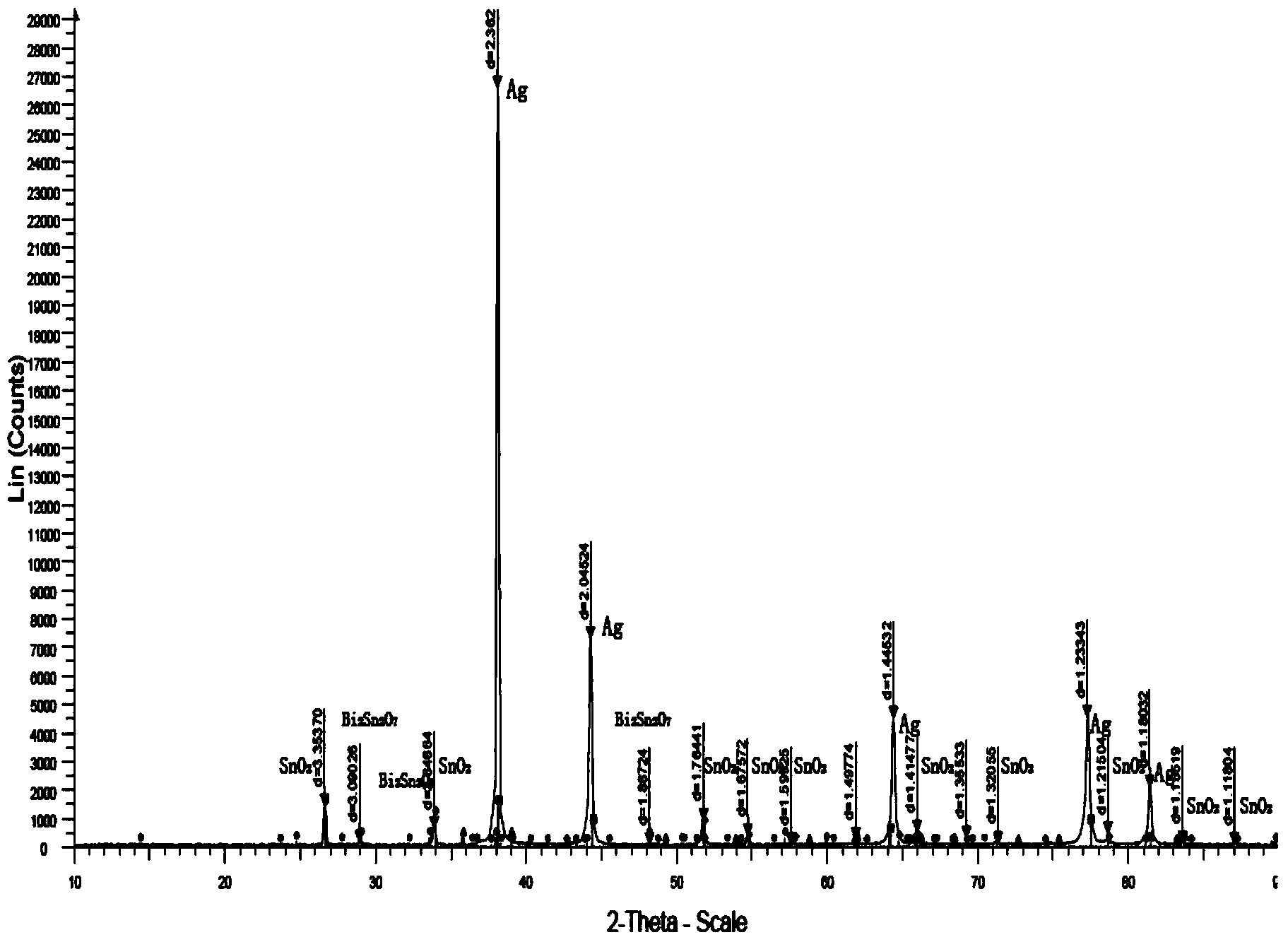

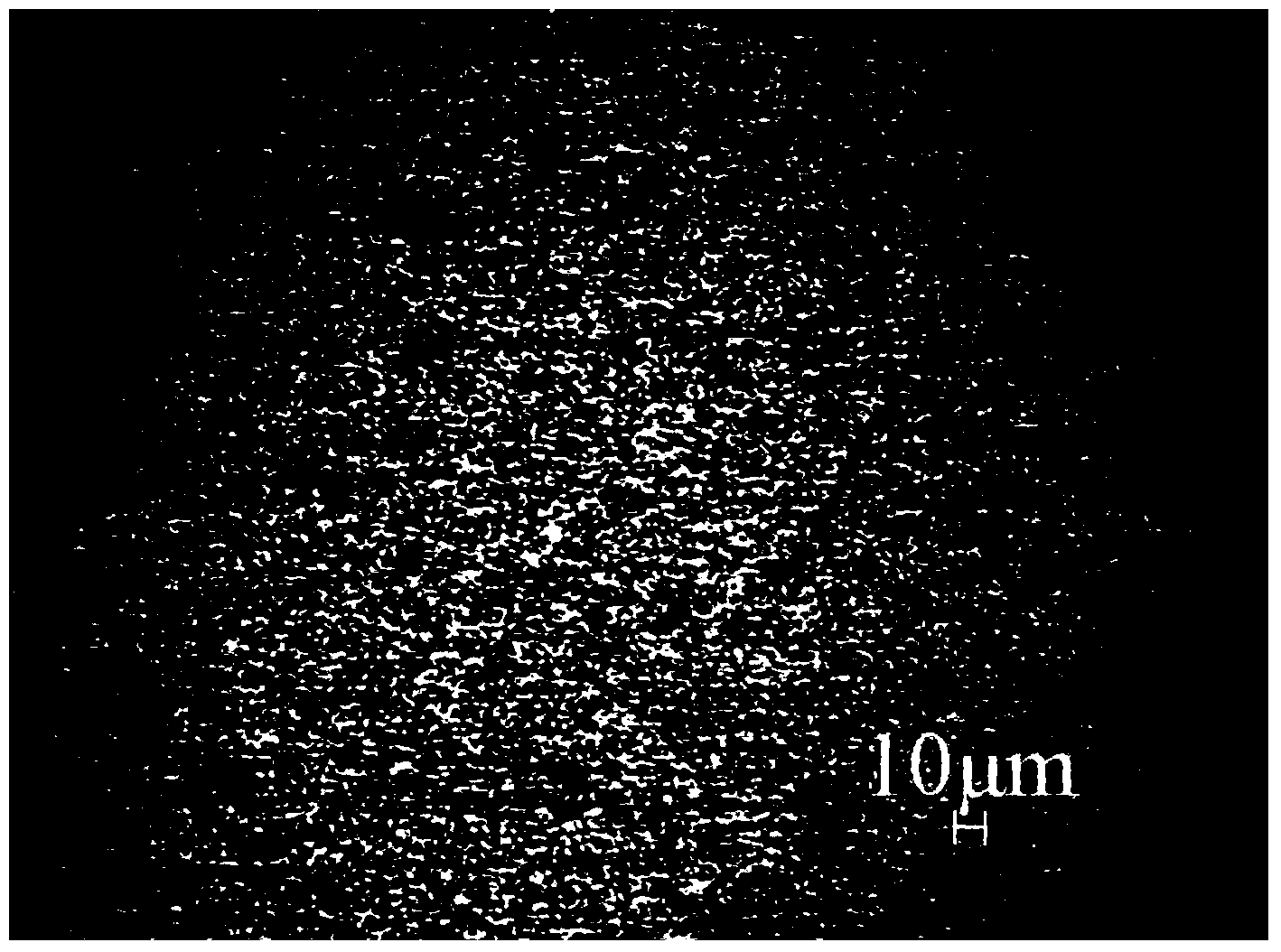

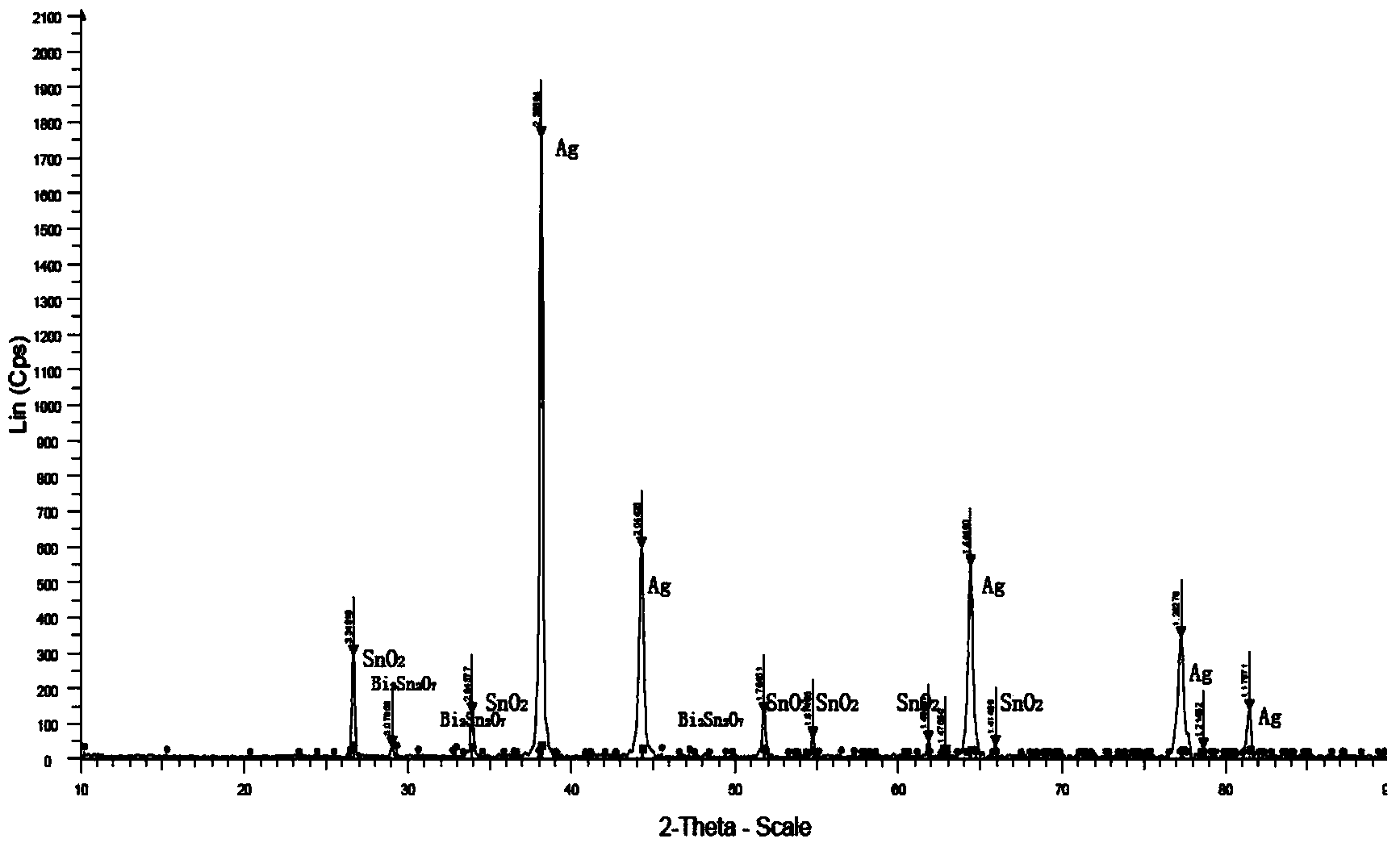

Preparation method for flaky AgSnO2 contact

ActiveCN103643074AGuaranteed uniformity of distributionGuaranteed uniformityCable/conductor manufactureIngotMetal

The invention discloses a preparation method for a flaky AgSnO2 contact. The method comprises the following steps of smelting 0.2 to 2 mass percent of metal additive and the balance of Ag in an intermediate-frequency smelting furnace to form a molten alloy, and performing atomization to prepare Ag alloy powder; mixing the Ag alloy powder with SnO2 powder in a three-dimensional mixer, and mixing the mixture in a V-shaped mixer to obtain mixed AgSnO2 powder; preparing an ingot blank from the mixed AgSnO2 powder according to a conventional method, sintering the ingot blank at high temperature in an oxygen-containing atmosphere, and performing hot extrusion and hot-rolling bonding to obtain a composite AgSnO2 / Ag strip; performing cold rolling, finish rolling and press forming on the composite AgSnO2 / Ag strip to obtain the required flaky AgSnO2 contact. The flaky AgSnO2 contact prepared by the method has the advantages of uniform distribution of SnO2 particles and a trace of additive, stable electrical properties and the like, and a process is simple and suitable for batch production.

Owner:桂林金格电工电子材料科技有限公司

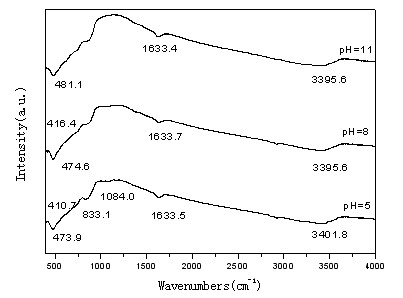

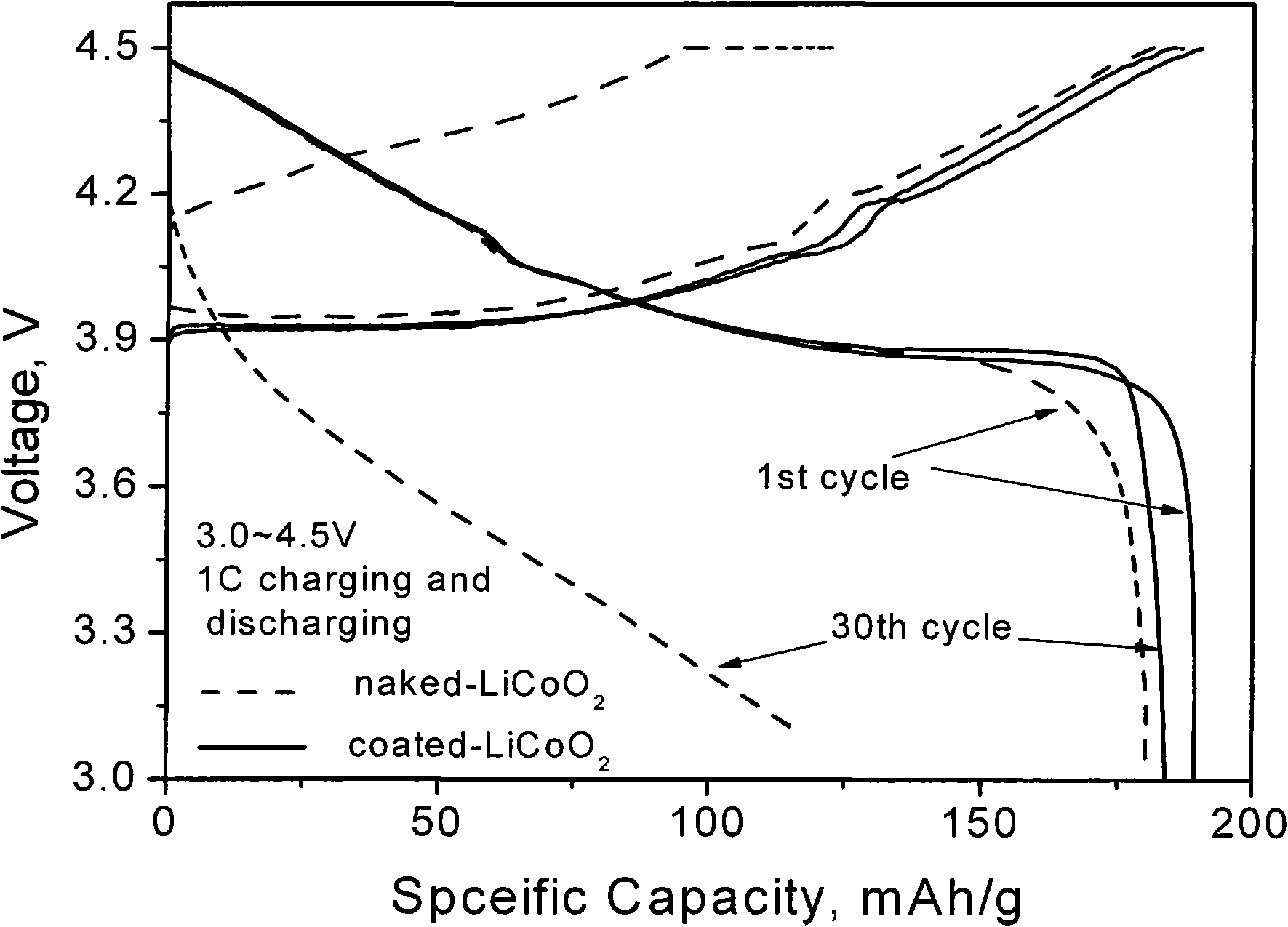

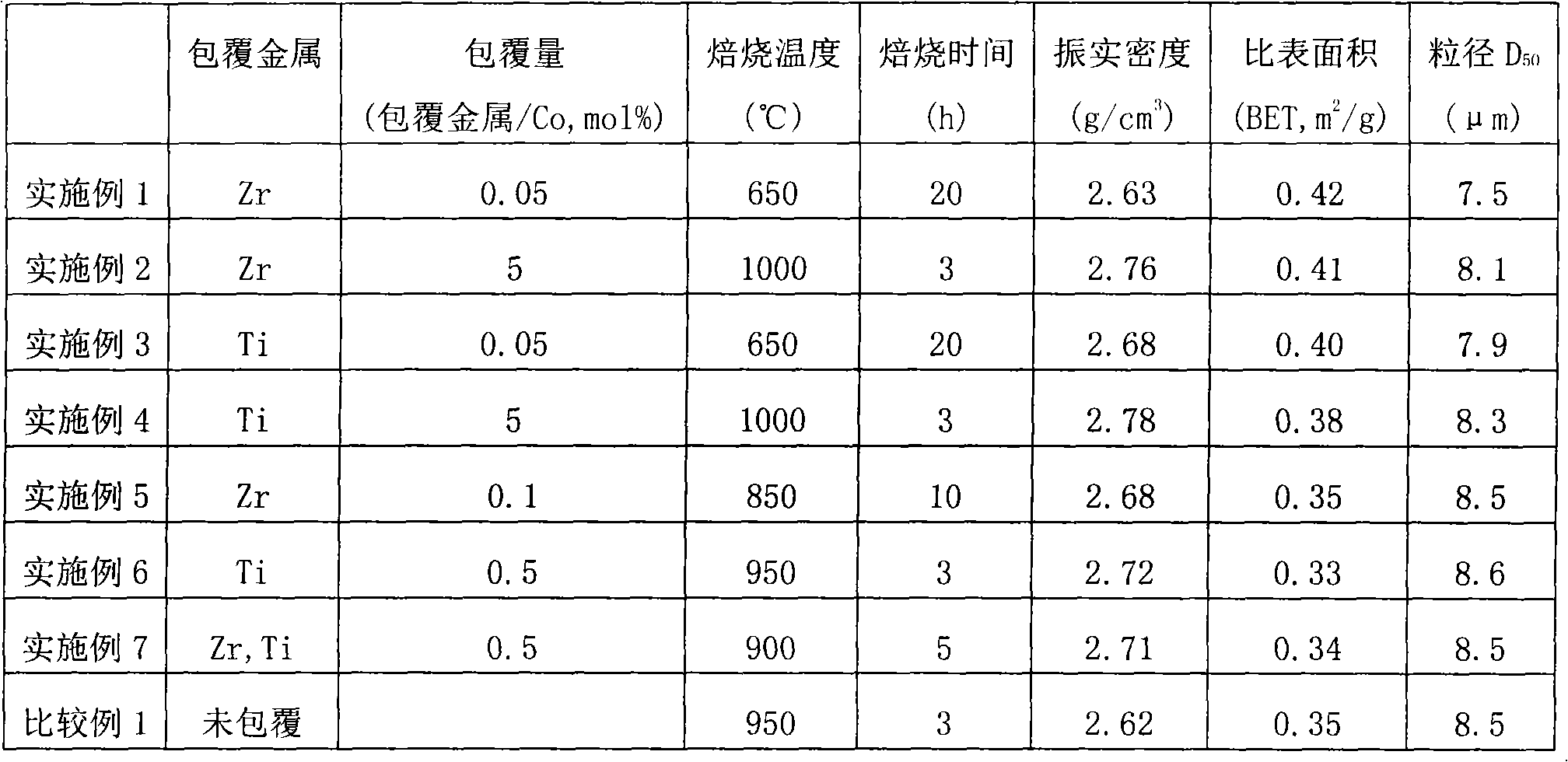

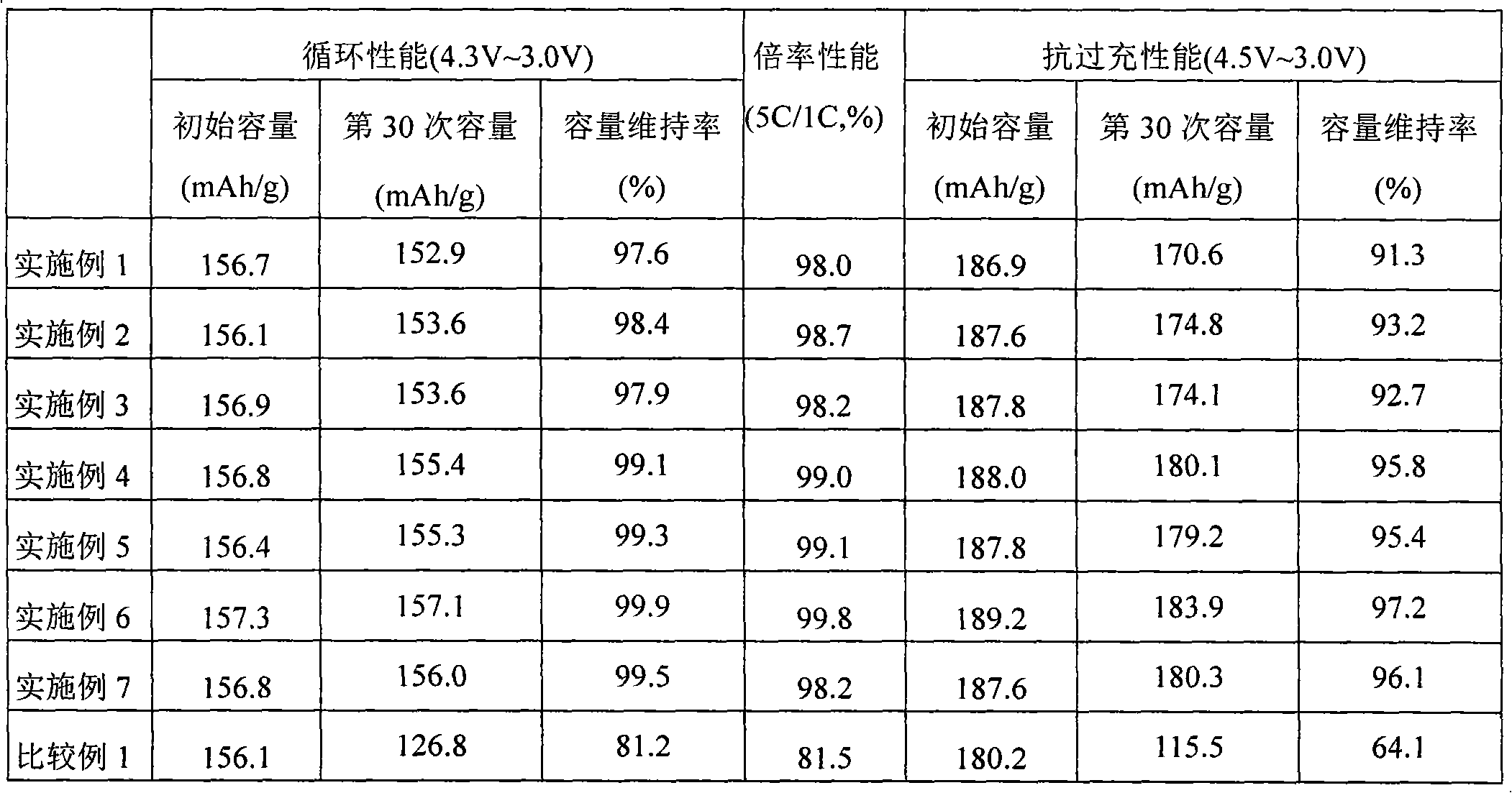

Lithium cobaltate composite oxide coated by hydrolytic precipitation-roasting method and manufacturing method thereof

InactiveCN101872859AImprove cycle stabilityImprove anti-overcharge performanceElectrode manufacturing processesActive material electrodesLithium-ion batteryAqueous solution

The invention provides a lithium cobaltate composite oxide coated by a hydrolytic precipitation-roasting method. When being used as an anode material of a lithium ion battery, the lithium cobaltate composite oxide can enable the performance of the lithium ion battery, especially cycle performance and overcharge resistance to be excellent. The invention is characterized in that a manufacturing method comprises the following steps: adjusting the pH value of a water solution containing metallic ions to be coated by using a liquid phase hydrolytic precipitation method to obtain a coating precursor; roasting at high temperature; and using metal oxides (the metal is at least one of Ti or Zr) to coat the particle surface of lithium cobaltate which is represented by the general formula of Li1+xCoO2-a (x is greater than or equal to -0.1 and less than or equal to 0.1, and a is greater than or equal to -0.1 and less than or equal to 0.1).

Owner:北京圣比和科技有限公司

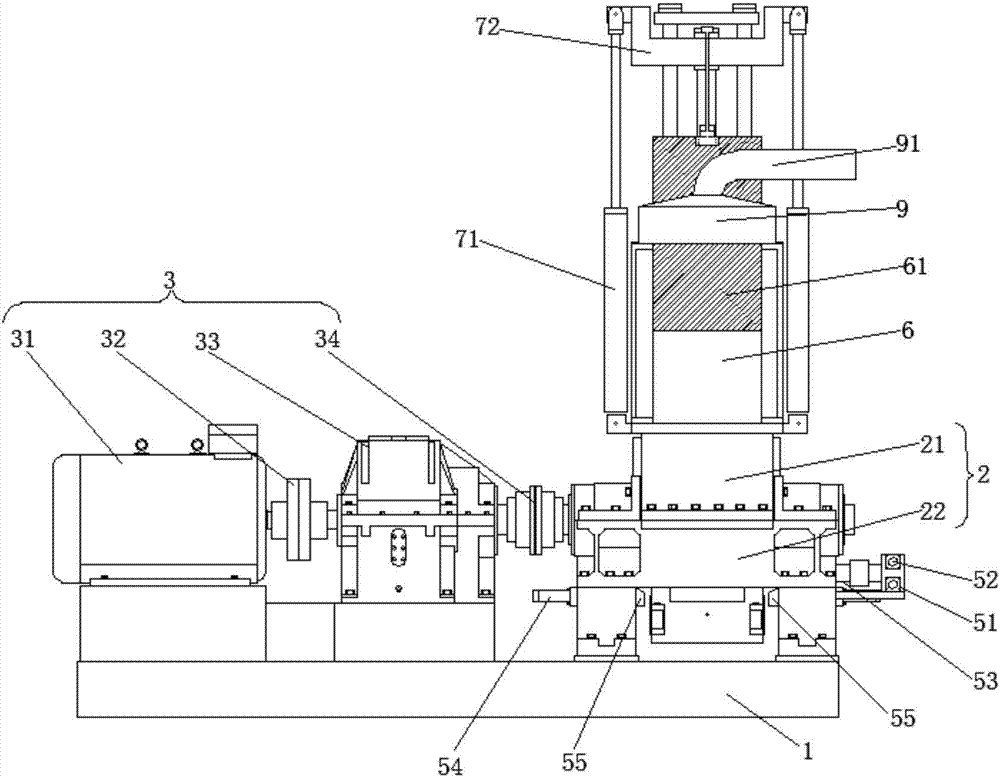

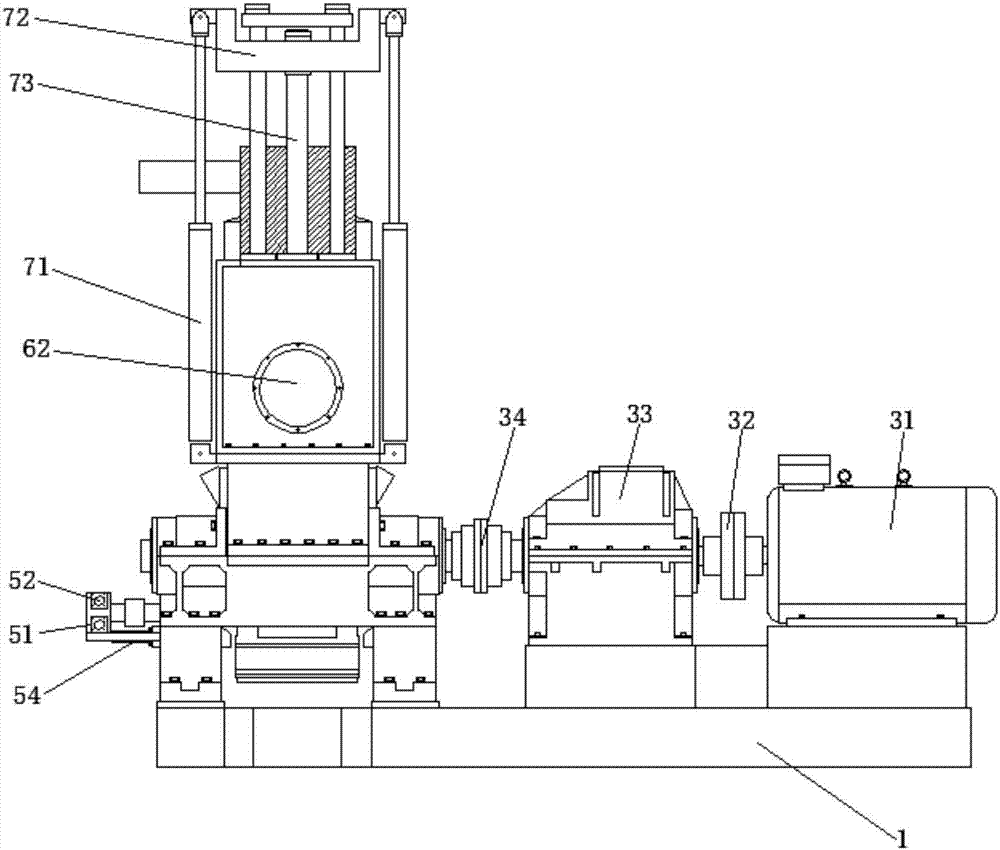

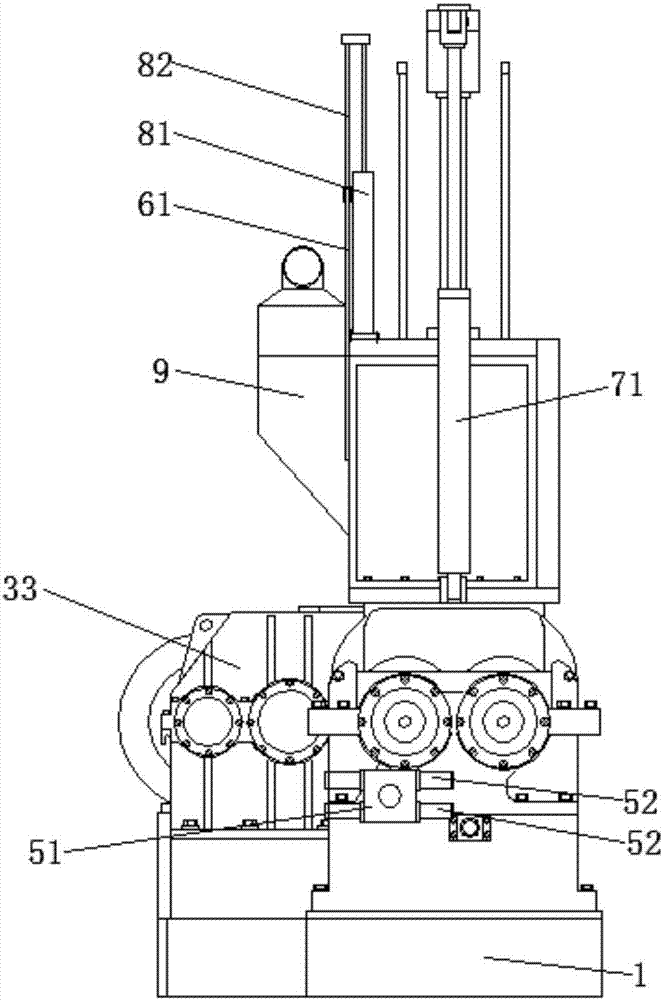

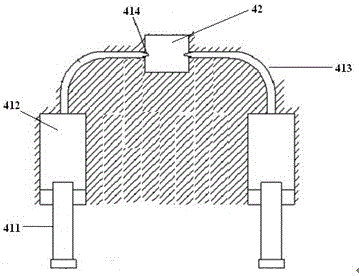

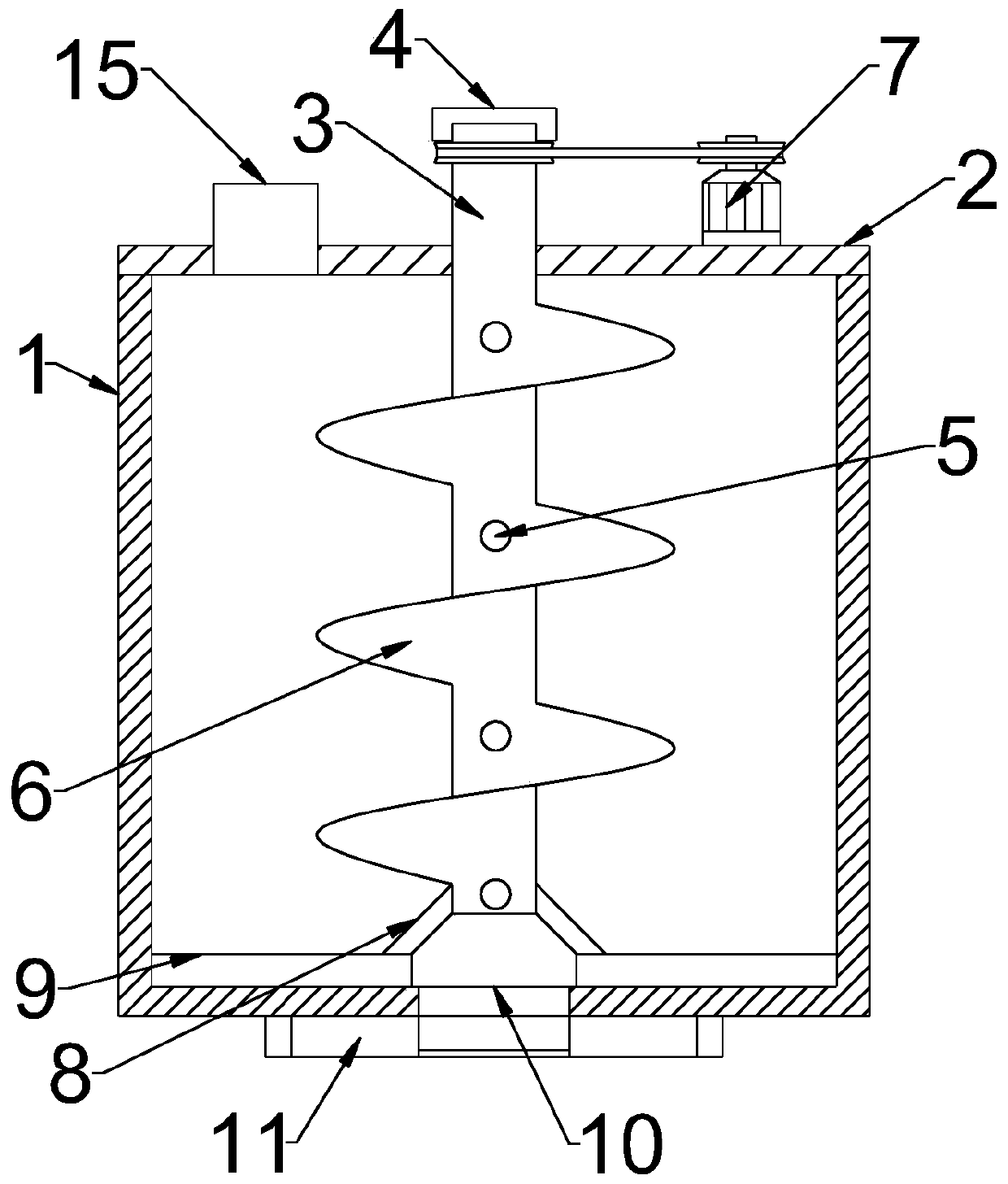

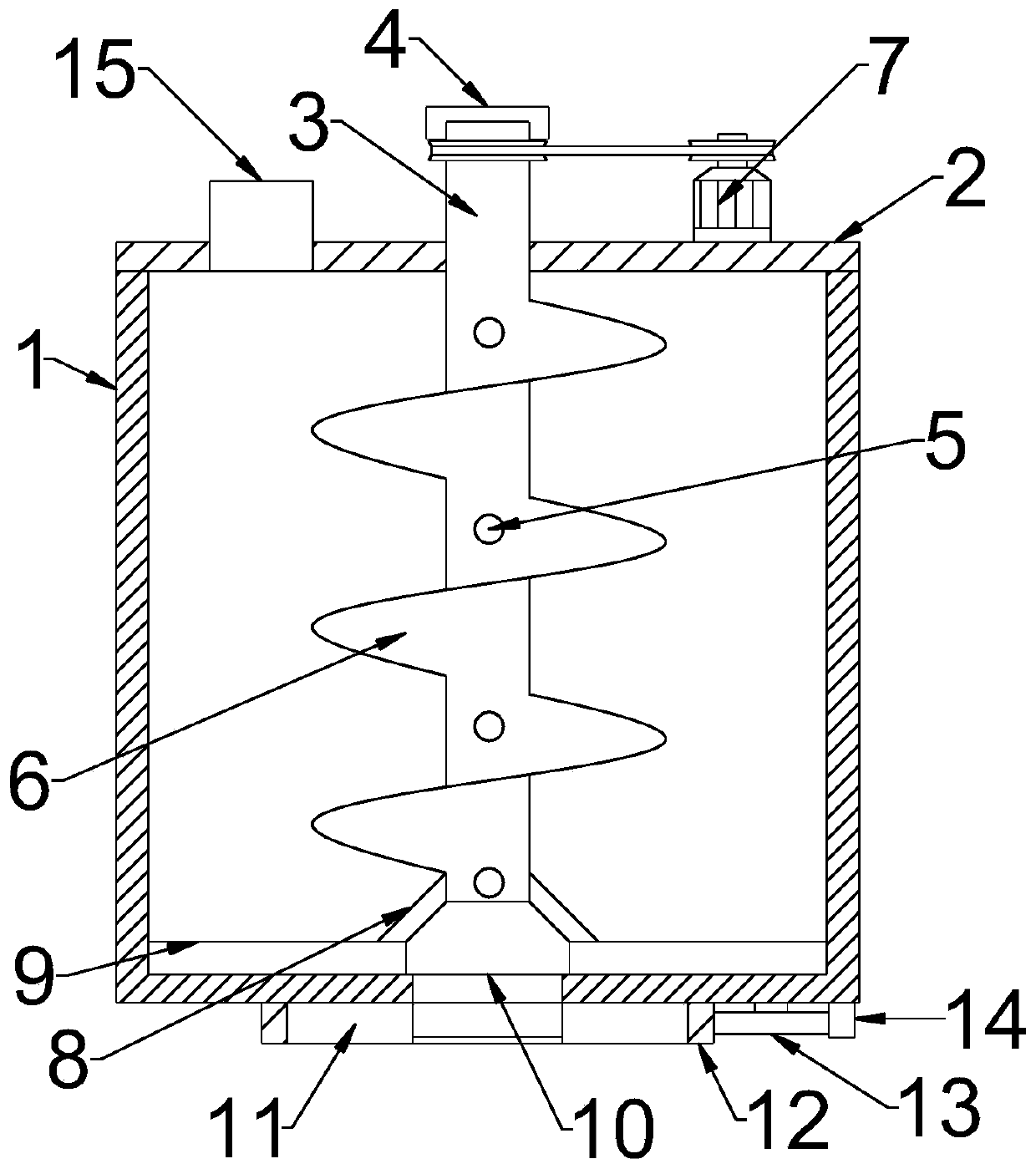

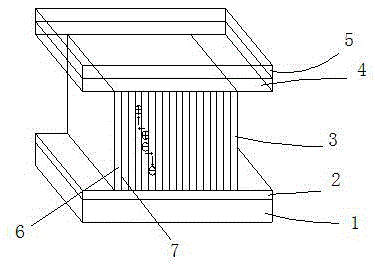

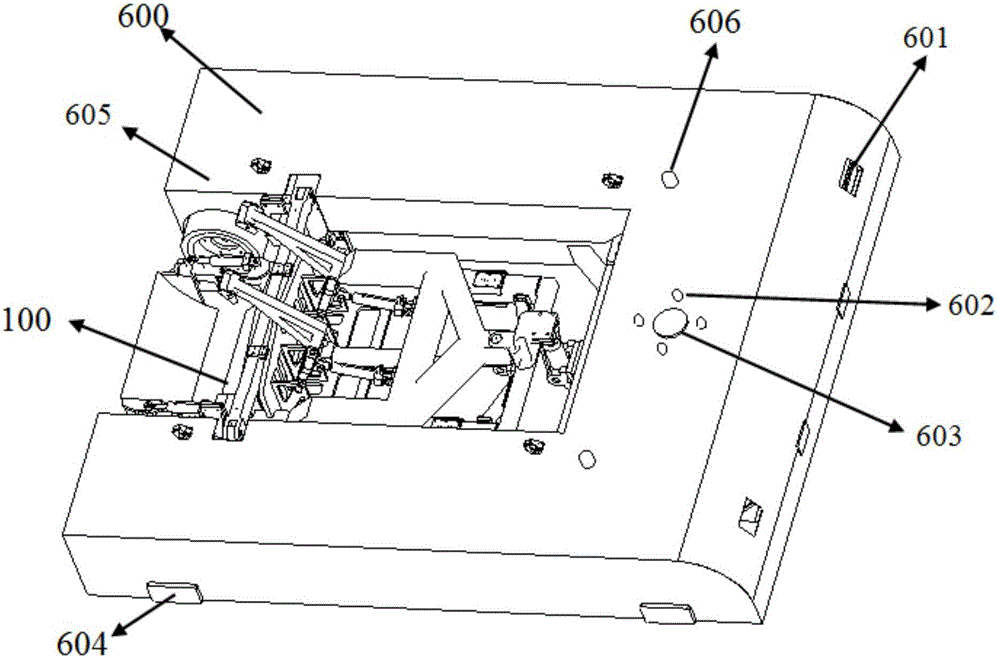

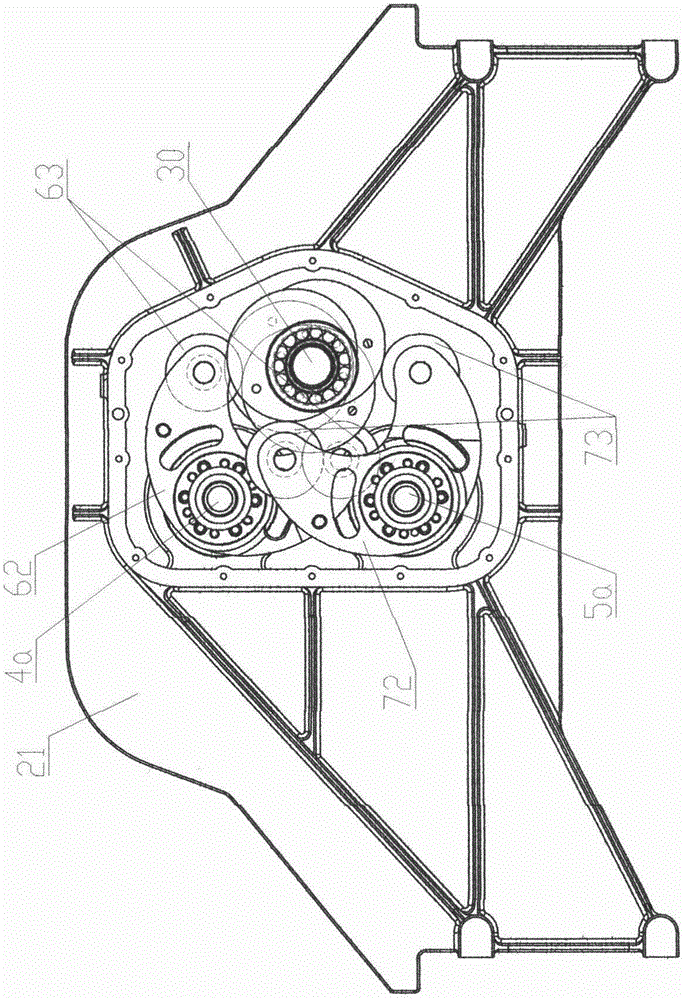

Seating-type internal mixer

The invention relates to a seating-type internal mixer which comprises a base, a mixing chamber, a transmission mechanism, rotors, a discharging mechanism, a feeding chamber, a material pressing mechanism and a feeding mechanism, wherein the mixing chamber is mounted above the base; the two rotors are mounted in the mixing chamber; the transmission mechanism is mounted on one side of the mixing chamber; the feeding chamber is mounted above the mixing chamber; the feeding chamber is communicated with the mixing chamber; a feeding door is arranged on one side of the feeding chamber; the feeding mechanism drives the feeding door to move upwards to open the hermetically sealed feeding chamber. According to the seating-type internal mixer, the structural design is reasonable and compact, the advantages of a falling type internal mixer and a turnover type internal mixer are integrated, the structural defects of the conventional internal mixer are overcome, the production speed is high, the requirement on the height of a factory space during installation is low, the space is economized, the mixing capacity is high, the mixing time is short, the production efficiency is high, the degree of automation is high, the product quality and the working environment are improved, the operation is safe and convenient, the labor intensity is reduced, and the labor cost is reduced.

Owner:广东维钠智能密炼机械科技有限公司

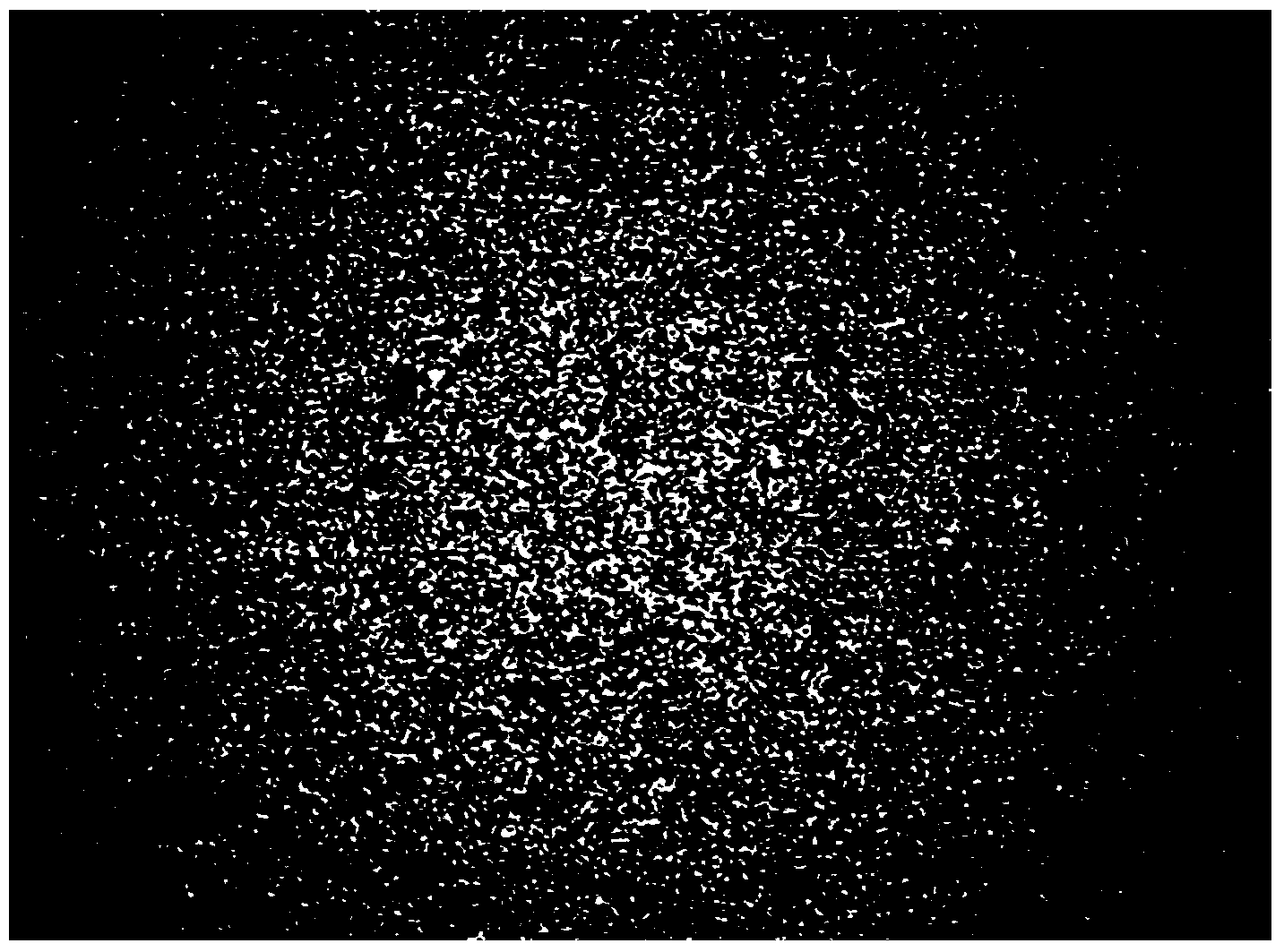

Method for preparing AgSnO2 wire

ActiveCN103639232AGuaranteed uniformity of distributionGuaranteed uniformityWire rodIntermediate frequency

The invention discloses a method for preparing an AgSnO2 wire. The method comprises the following steps: smelting 0.2-2 percent by mass of metal additive and the balance of Ag into alloy melt in an intermediate frequency smelting furnace, and atomizing to prepare Ag alloy powder, wherein the metal additive is selected from one or more of Bi, Cu, In and Sb; mixing the Ag alloy powder and SnO2 powder in a three-dimensional mixer, mixing the mixture in a V-shaped mixer to obtain mixed AgSnO2 powder; preparing the mixed AgSnO2 powder into an ingot blank according to a conventional method, sintering the ingot blank at high temperature in an oxygen-containing atmosphere, and performing hot extrusion and drawing to obtain the AgSnO2 wire. The AgSnO2 wire prepared by the method has the advantages that the SnO2 particles and trace additives are uniform in distribution, the material processability is excellent, the electrical performance is stable and the like, and the preparation method is simple in process and suitable for batch production.

Owner:桂林金格电工电子材料科技有限公司

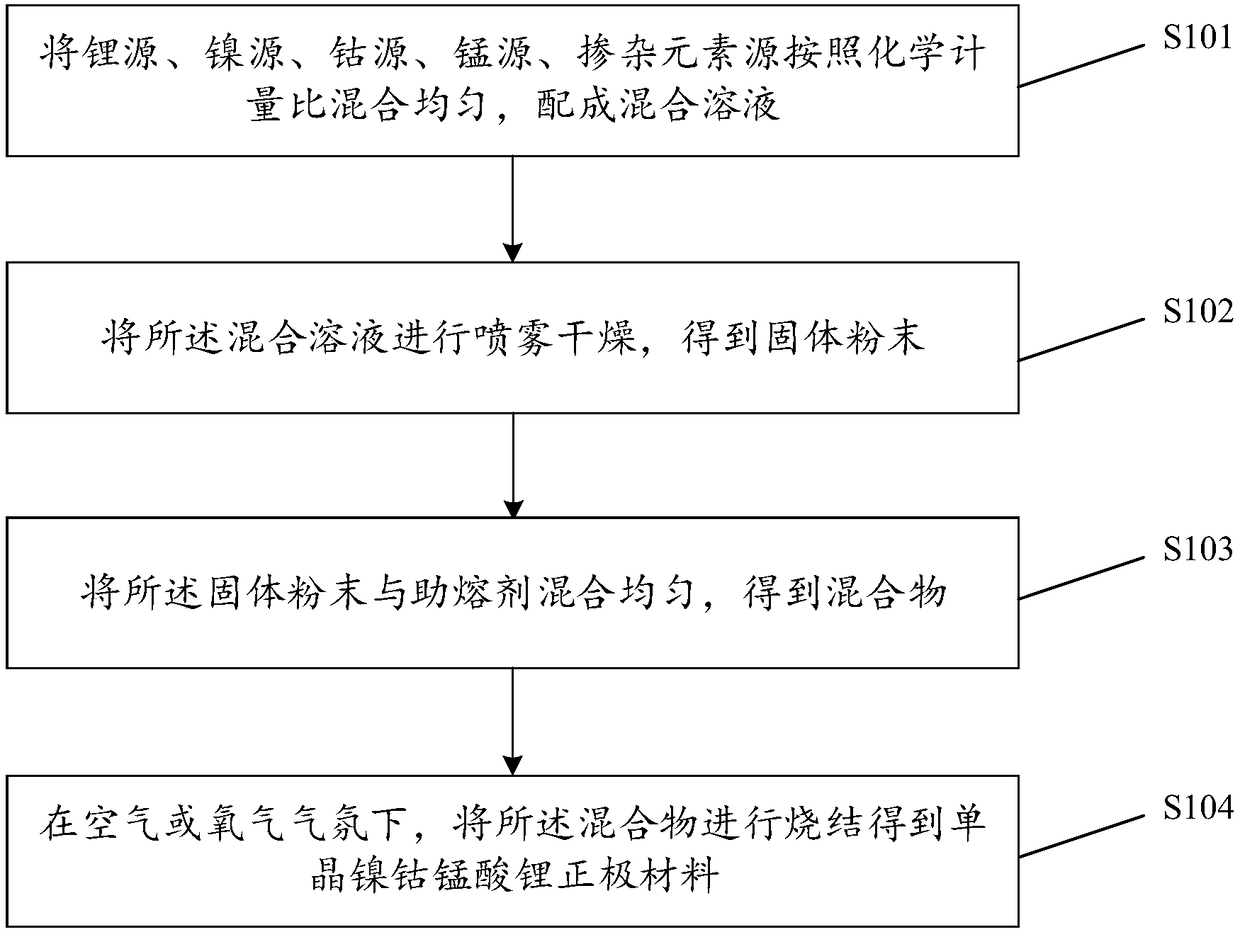

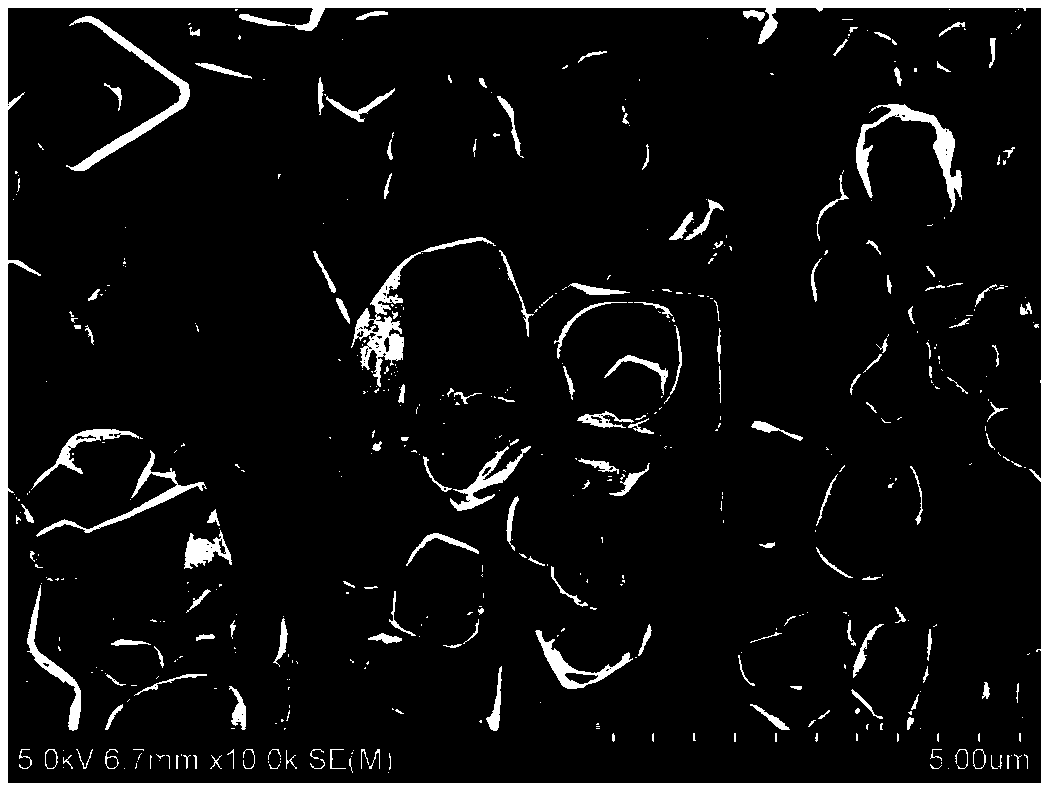

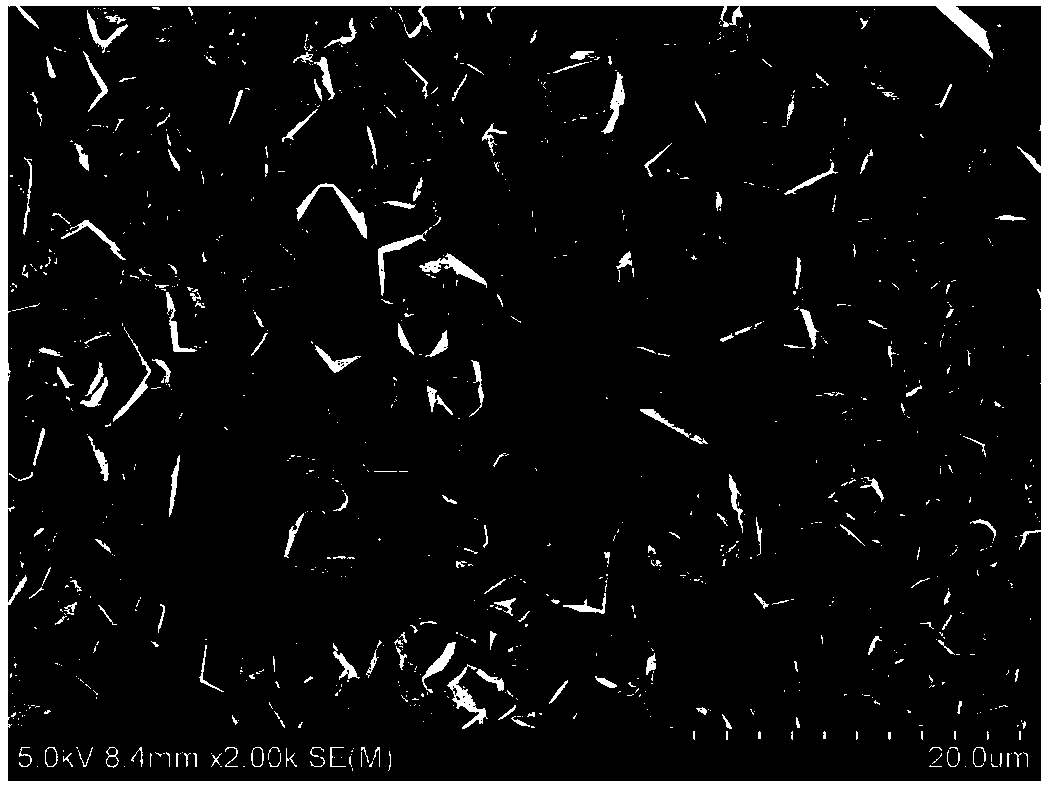

Monocrystalline nickel-cobalt-lithium manganate cathode material and preparation method and applications thereof

ActiveCN108306014AReduce internal clearanceImprove cycle stabilityCell electrodesSecondary cellsRare-earth elementNiobium

The invention provides a monocrystalline nickel-cobalt-lithium manganate cathode material. The chemical formula of the cathode material is Li<z>Ni<x>Co<y>Mn<1-x-y>MO2, wherein 1<=z<=1.05, 0<x<0.8,0<y<0.4, 0<x+y<1, 0<=a<0.1, and M represents a doping element and is one or more of magnesium, aluminum, zinc, titanium, zirconium, niobium, chromium, and rare earth elements. The size of the monocrystalline nickel-cobalt-lithium manganate cathode material is uniform and is in a micrometer level. The compaction density can reach 3.8-3.9 g / cm3. The circulation stability is improved, when the cathode material is used in a battery. The invention also provides a preparation method of the monocrystalline nickel-cobalt-lithium manganate cathode material. The cathode material is prepared by spray drying and a one-time sintering technology, the internal gaps of the cathode material are reduced, the structural defect is avoided, and the service life and safety of the cathode material are both improved.

Owner:SHENZHEN DYNANONIC

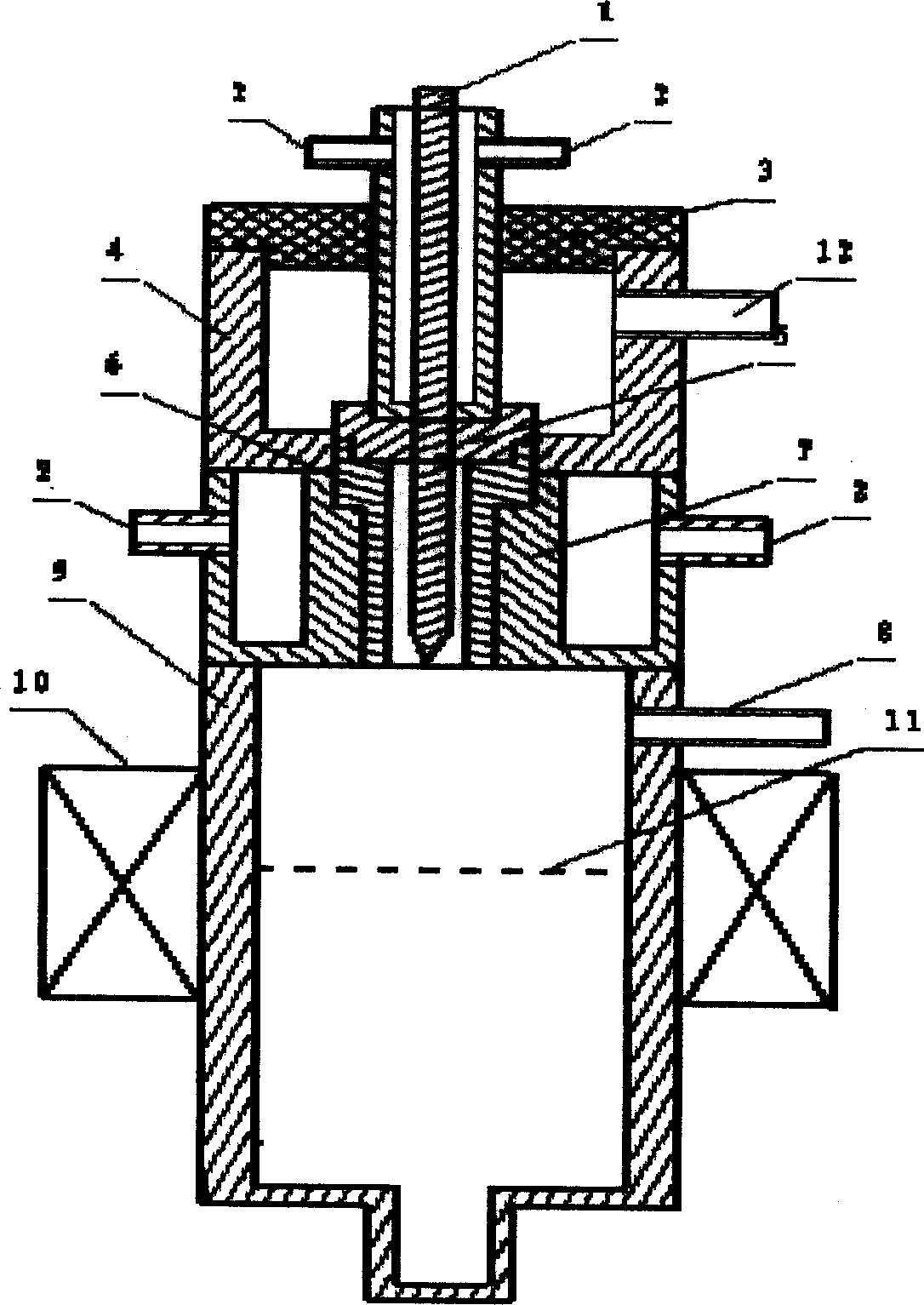

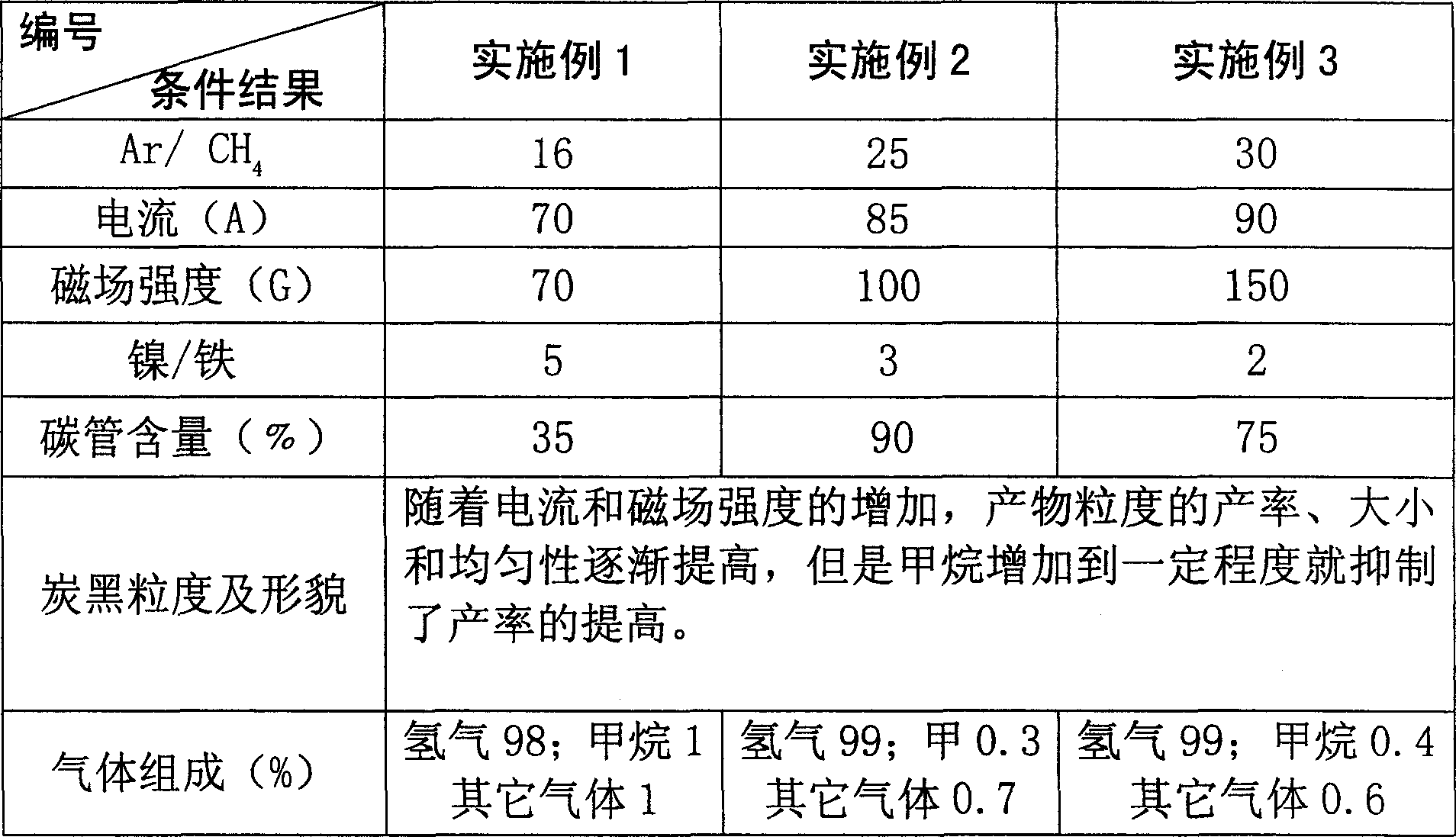

Technology and equipment for preparing magnetic carbon nanometer tube by plasma

InactiveCN1547225AWell mixedEasy to mix well with hydrocarbon cracking productsInductances/transformers/magnets manufacturePlasma techniquePlasma generatorCarbon nanotube

The invention is a technology for using plasma to produce the magnetic carbon nano pipe. The argon is blown into the plasma generator, there forms the plasma efflux under the effect of the current; the methane is blended with the plasma in condition without oxygen, it is ionized and decomposed into nano grade active carbon particles, and enters the reactor whose magnetism intensity if 70-200G, and uses the nickel sieve carrying load iron powder or ferric oxide powder to generate the magnetic carbon nano pipe. The structure is simple, the device is cheap, and it can avoid the structure deficiencies.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

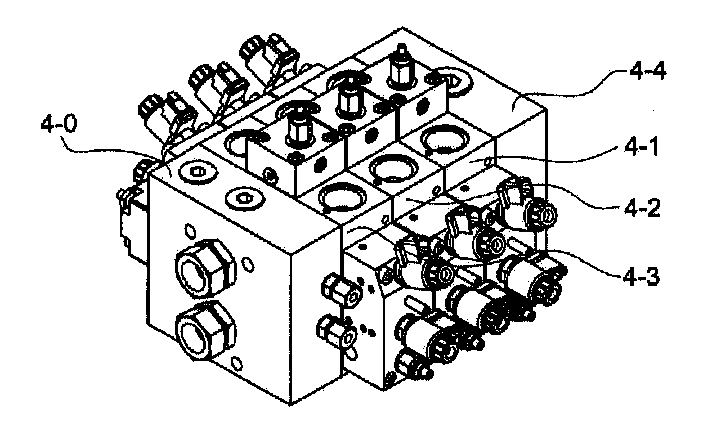

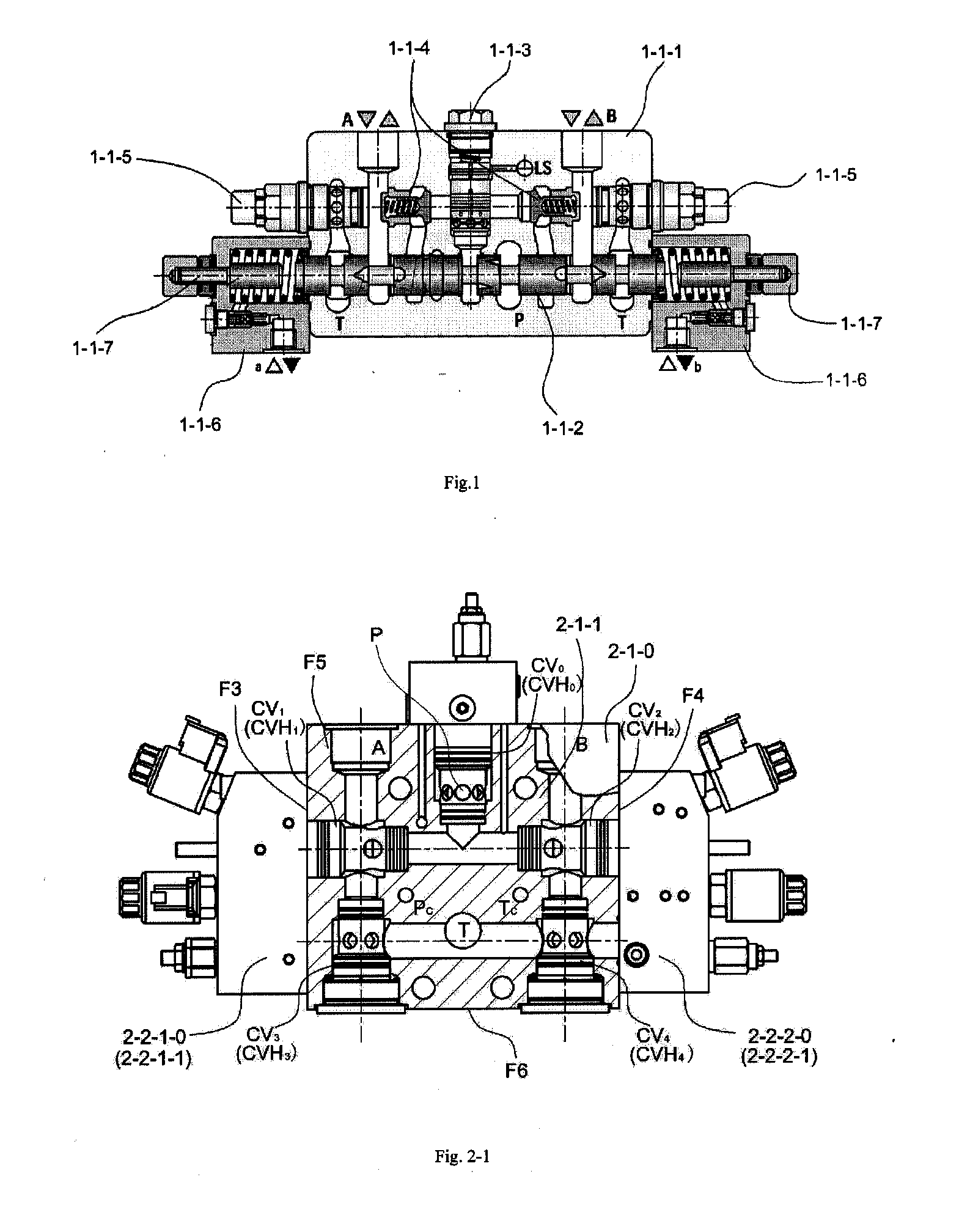

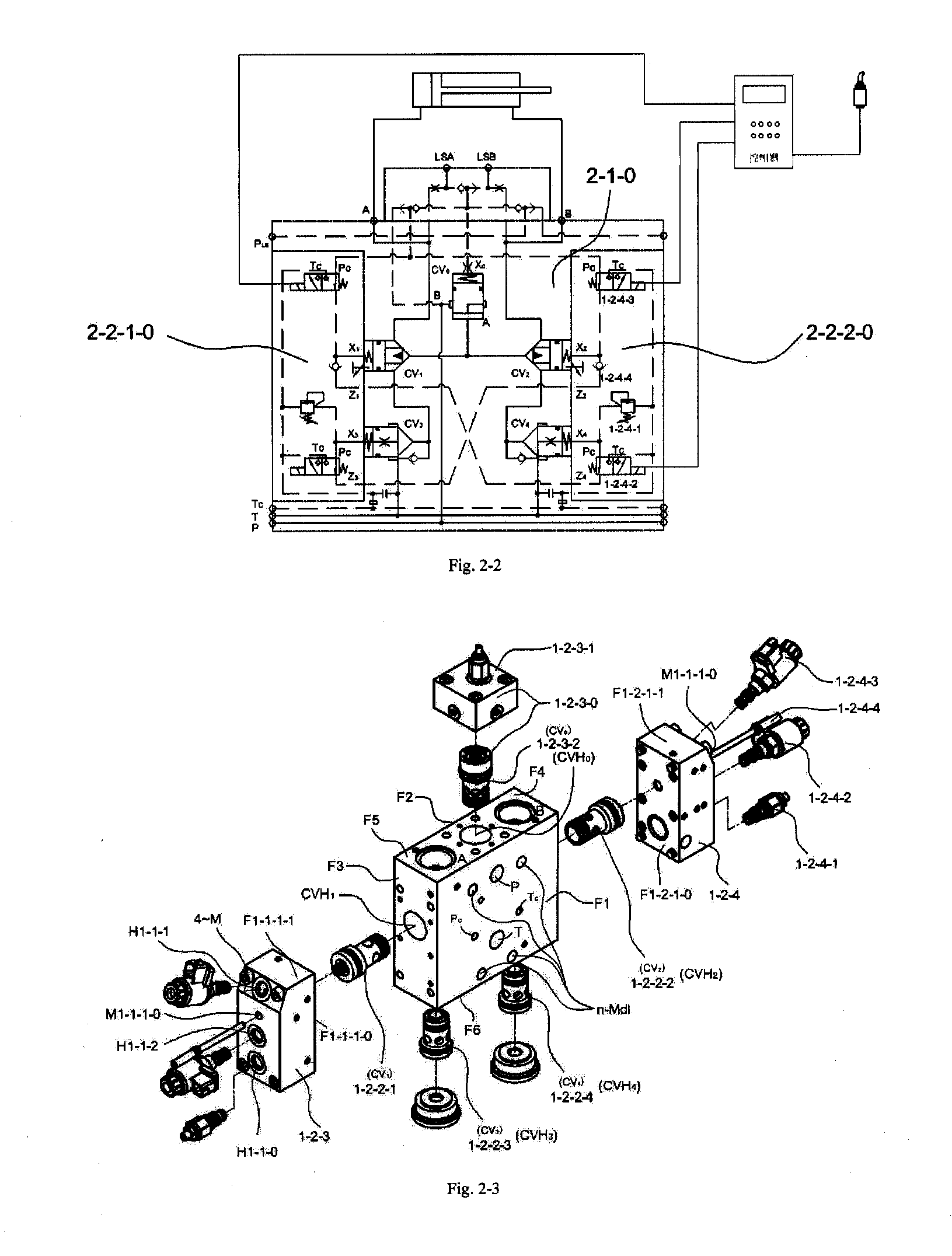

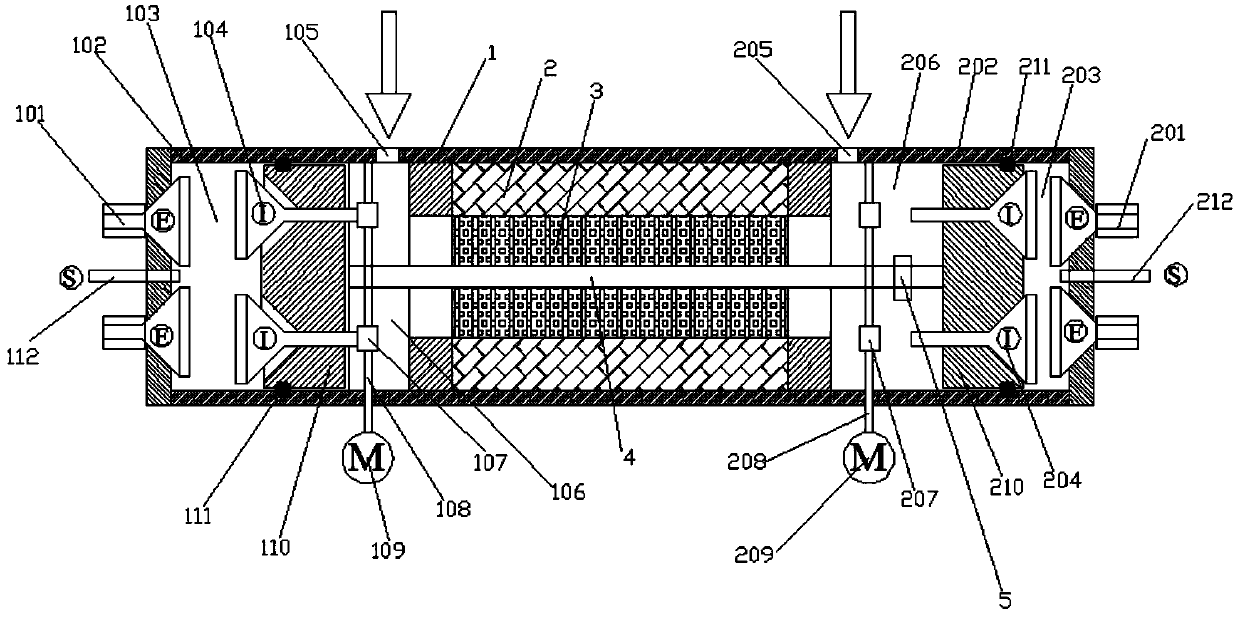

Modular combined electro-hydraulic multi-way valve system using compact two-way cartridge valves

InactiveUS20150267720A1Avoid Structural DefectsImprove efficiencyOperating means/releasing devices for valvesServomotor componentsModular compositionCoupling

The invention is to provide a modular combined electro-hydraulic multi-way valve system using compact two-way cartridge valves. Two sets of seat valve main stages including two compact two-way cartridge valves separately are used to control two reversible controlled cavities, a cartridge pressure compensation control assembly is used to control load compensation, and valve body forms the main part of electro-hydraulic multi-way valve; The main body has the function of self-supply-oil pilot control by two side flange control plates; The main part of electro-hydraulic multi-way valve, side flange control plates, pilot stages and auxiliaries combine sandwich self-supply-oil high-voltage electro-hydraulic multi-way valve reversing league with four main ports P, T, A, B and multiple control ports Pc, Tc, Ls and auxiliary ports; The system can satisfy the requirements of higher efficiency, energy saving, low emission and diversity raised by equipment manufacturers through more kinds and more reasonable modular combined configurable solutions.

Owner:SHANGHAI RENHAO HYDRAULIC TECH

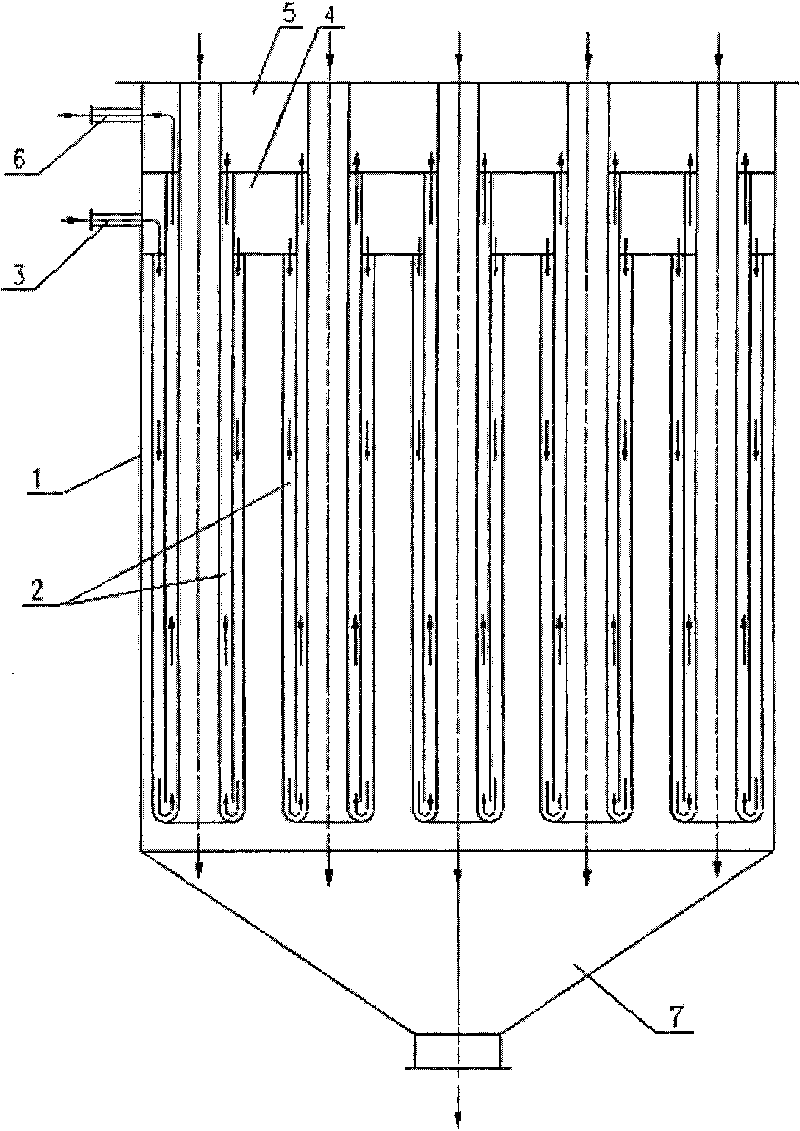

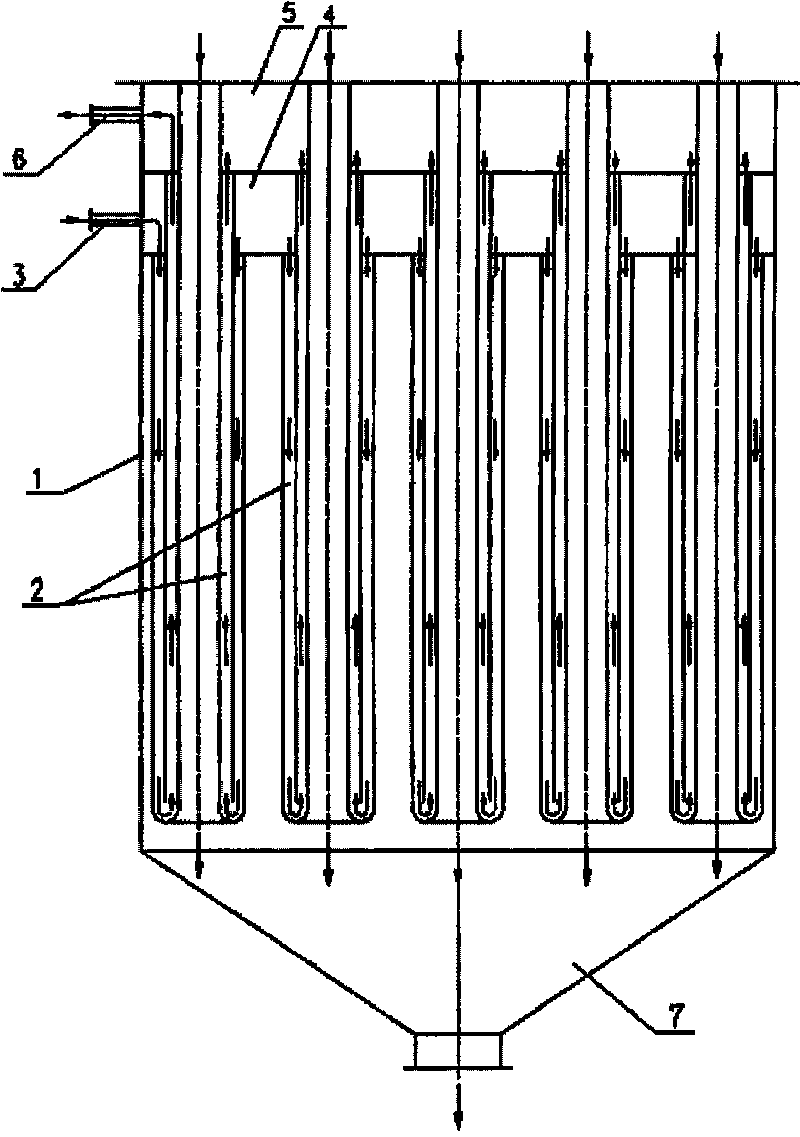

Novel coke powder cooling device

InactiveCN101709221AAvoid Structural DefectsIncrease cooling areaCoke quenchingCooling pipeQuenching

The invention relates to the field of dry quenching furnaces, in particular to a novel coke powder cooling device for a one-time deduster of a dry quenching furnace, which comprises cooling pipes, a water inlet distribution box, a water outlet header, a water inlet pipe and a water outlet pipe, wherein the upper ends of a plurality of groups of parallel cooling pipes are hung on the upper part of a machine shell, and the lower ends are free ends; the water inlet pipe is connected with the water inlet distribution box which is connected with the plurality of groups of cooling pipes; and the water outlet pipe is connected with the water outlet header. The novel coke powder cooling device has the advantages that: the cooling device overcomes the structural defect of a cooling sleeve, increases a cooling area by connecting a plurality of cooling pipes with water-cooling walls in parallel, improves the cooling efficiency, has large treatment capacity in a unit time, reduces maintenance workload, can be used reliably for a long time, and is particularly suitable for a large-scale dry quenching device.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

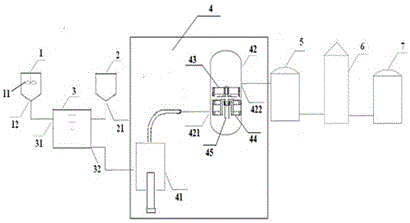

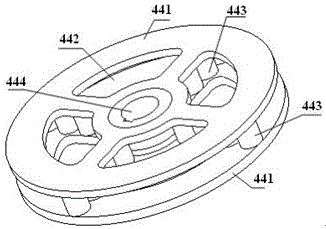

Device for continuously preparing graphene and method for producing graphene

The invention belongs to the technical field of graphene and particularly relates to a device for continuously preparing graphene and a method for producing graphene. The device comprises a raw material grinding tank, a grinding medium storage bin, a stirring tank, a continuous grinding mechanism, a material storage tank, a centrifugal filtering device and a drying device. A blade type stirring mill is arranged in the raw material grinding tank. The continuous grinding mechanism comprises a high-pressure pump, the grinding bin, a flow guide ring, a dispersion impeller and a transmission shaft. The flow guide ring is located in the middle of the grinding bin and fixedly connected with the transmission shaft, the dispersion impeller is located between the flow guide ring and the bottom of the grinding bin, and the transmission shaft passes through the center of the dispersion impeller. The probability that graphene is smashed is reduced through continuous stripping step by step, structural defects of graphene are reduced, and meanwhile the situation that structural defects are caused again to stripped graphene due to re-grinding is avoided. The invention further discloses the method for producing graphene by means of the device for continuously preparing graphene from the slurry.

Owner:淮安双洋新材料有限公司

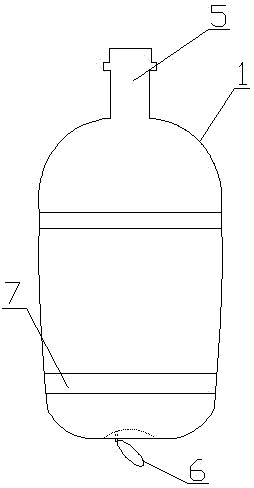

Three-layer medical infusion bag and manufacturing method thereof

InactiveCN103893012AImprove oxygen barrierImprove water resistanceInfusion devicesPharmaceutical containersPolypropyleneBiomedical engineering

The invention aims to provide a three-layer medical infusion bag. The three-layer medical infusion bag comprises a flat infusion bag body of a three-layer structure. The three-layer structure comprises an inner bag layer made of polyethylene material, a middle bag layer made of polypropylene and styrene-ethylene / butylene-styrene segmented copolymer material and an outer bag layer which is a blended layer of polypropylene, carboxylated styrene-ethylene / butylene-styrene segmented copolymer and anionic polymerization nylon nanocomposite. The barrier performance of the anionic polymerization nylon nanocomposite of the outer bag layer is excellent. Air inlet is not needed in the infusion process and medicine liquid can automatically flow and is completely drained through the design of the thickness and the width of the infusion bag body, and therefore the whole infusion bag is good in safety, barrier property and infusion performance. The invention further provides a manufacturing method of the three-layer medical infusion bag. One-time injection molding and air blowing are conducted through a three-die-head injection molding die, the whole process is simple and advanced, one-time forming is achieved, the method is suitable for production of the infusion bag, and the manufactured infusion bag meets the infusion requirement.

Owner:ANHUI DOUBLE CRANE PHARMA

Batch-type uniform-speed discharging stirring device and construction method for self-leveling terrace

ActiveCN110453900ALift up movementEvenly mixedCement mixing apparatusFlooringElectric machineryEngineering

The invention discloses a batch-type uniform-speed discharging stirring device. The batch-type uniform-speed discharging stirring device comprises a kettle structure formed by assembling of a shell and an upper cover, the upper cover is provided with a stirring mechanism in a connected mode, a discharging hole is formed in the lower end of the shell in a penetrating mode, the stirring mechanism iscomposed of spiral fan blades connected to the periphery of a rotating shaft and used for introducing additives, the upper end of the rotating shaft is connected with a motor in a transmission mode,and a discharging mechanism opened in a mechanical and batch-type mode is further arranged at the lower end, of the periphery of the discharging hole, of the shell in a connected mode. A constructionmethod of a self-leveling terrace comprises the following steps that a base layer is checked, pulling-drawing detecting is conducted, and the base layer is cleaned; grinding, leveling by pushing and dust suction treatment are conducted; repairing treatment is conducted on gaps and hollowing parts; coating and painting of an interfacial agent are conducted, and line snapping and area division are conducted; mixed slurry is machined by using the device, and pumping construction is conducted after testing; and still standing and solidification, coating and painting of a protective agent, divisiondismantling and filling of joint mixture are conducted. The batch-type uniform-speed discharging stirring device can be matched with division-type construction to realize equal-amount batch-type material injection, and thus the structure problem of large-area construction is solved.

Owner:福建磊鑫(集团)有限公司

Opposed piston three-stroke internal combustion linear power generator unit

PendingCN109736945AAccelerate emissionsOvercome inherent shortcomingsMachines/enginesExhaust valveCombustion

The invention discloses an opposed piston three-stroke internal combustion linear power generator unit and belongs to the field of piston type internal combustion engines. The opposed piston three-stroke internal combustion linear power generator unit structurally comprises a machine body; a coil winding, an armature and a main shaft are sequentially arranged from the machine body to the interiorof the machine body; a main shaft position sensor is fixed to the main shaft; the most point lies in that two pistons are arranged in an opposed manner, and in other words, the two pistons are mountedat the two ends of the main shaft in an opposed manner; in addition, the pistons and the armature are coaxially mounted; and each piston is provided with corresponding accessories including a hydraulic exhaust valve, an air inlet valve, an air inlet, a sparking plug and the like. The opposed piston three-stroke internal combustion linear power generator unit is provided with the opposed pistons,and the air inlet valves are arranged on the pistons, so that the structural defect that a two-stroke engine has a scavenging port is overcome; meanwhile, strokes of the engine are reorganized, and inherent defects of the two-stroke engine are overcome; and the emission and oil consumption levels of the engine can be raised conveniently.

Owner:XIHUA UNIV

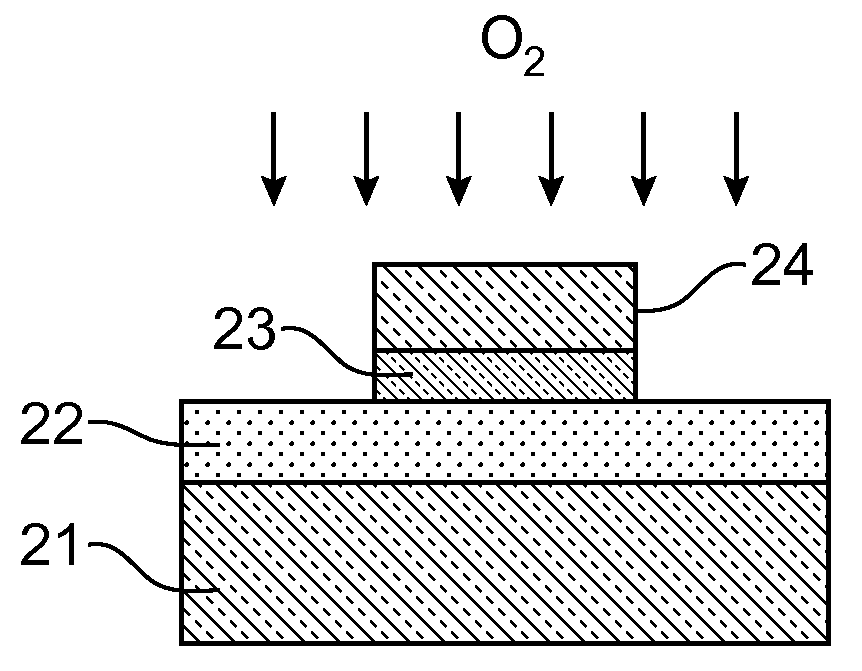

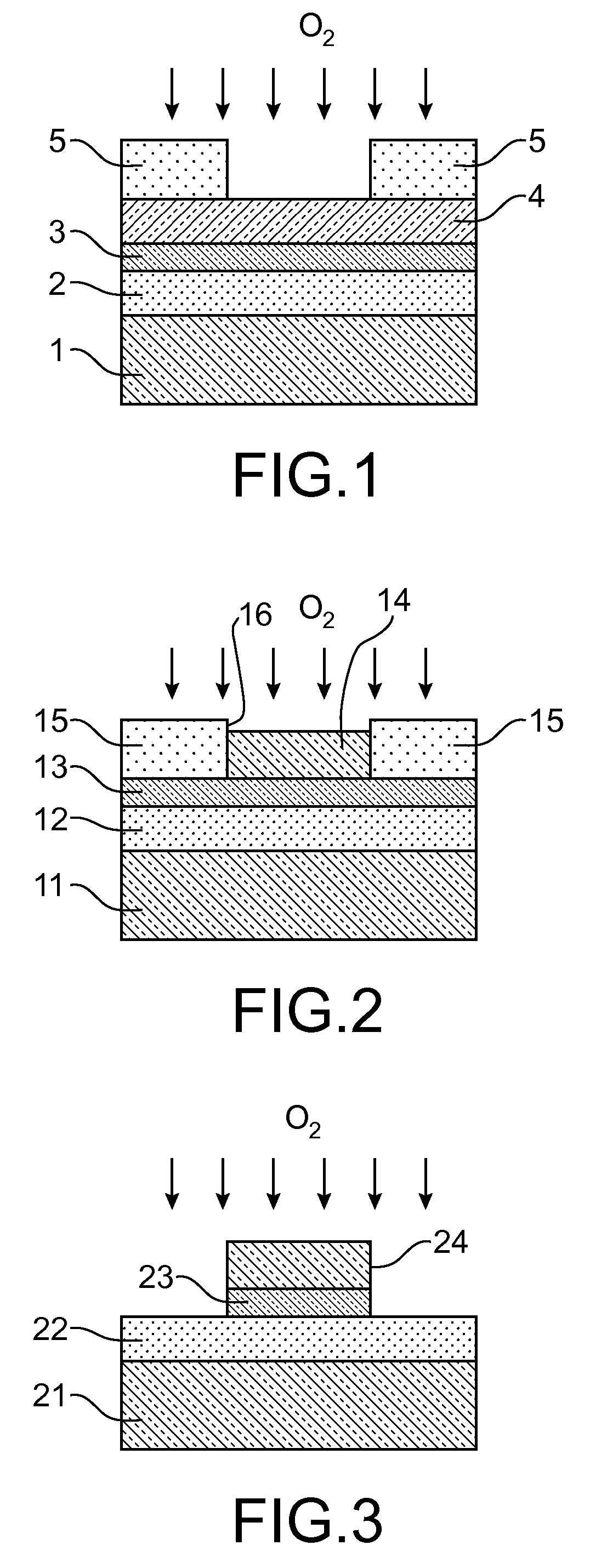

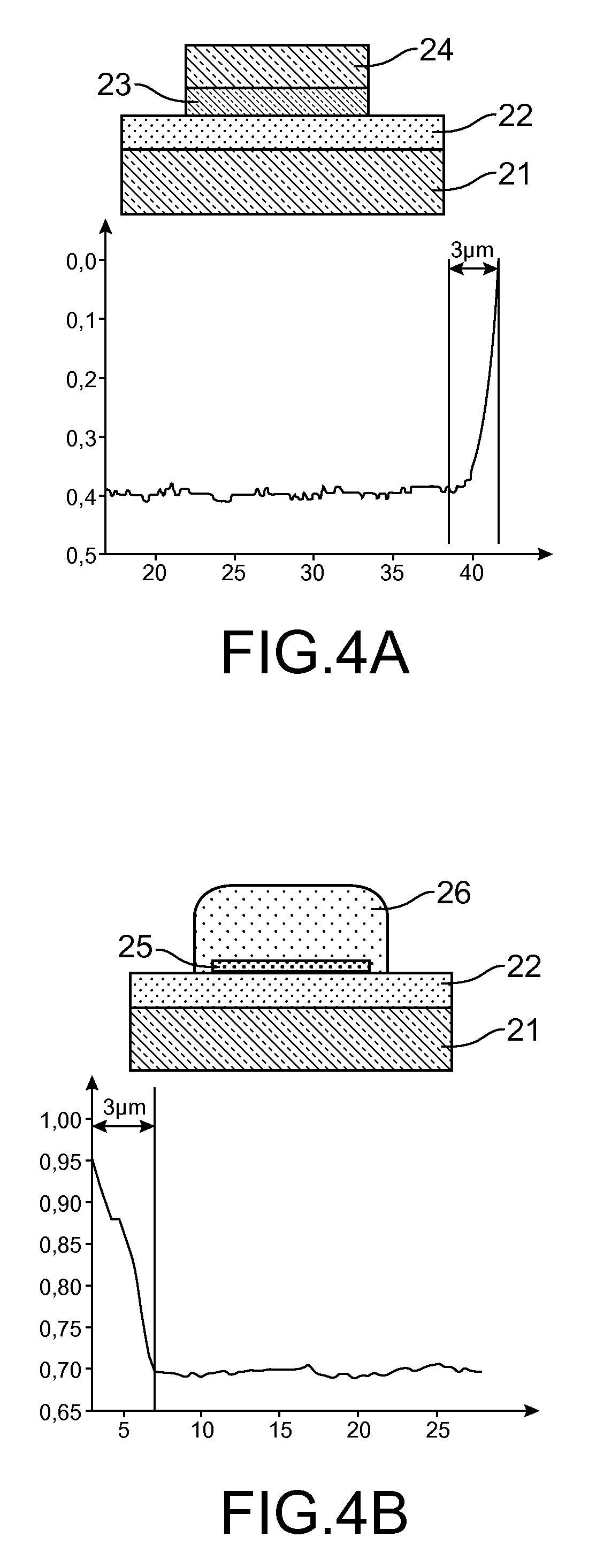

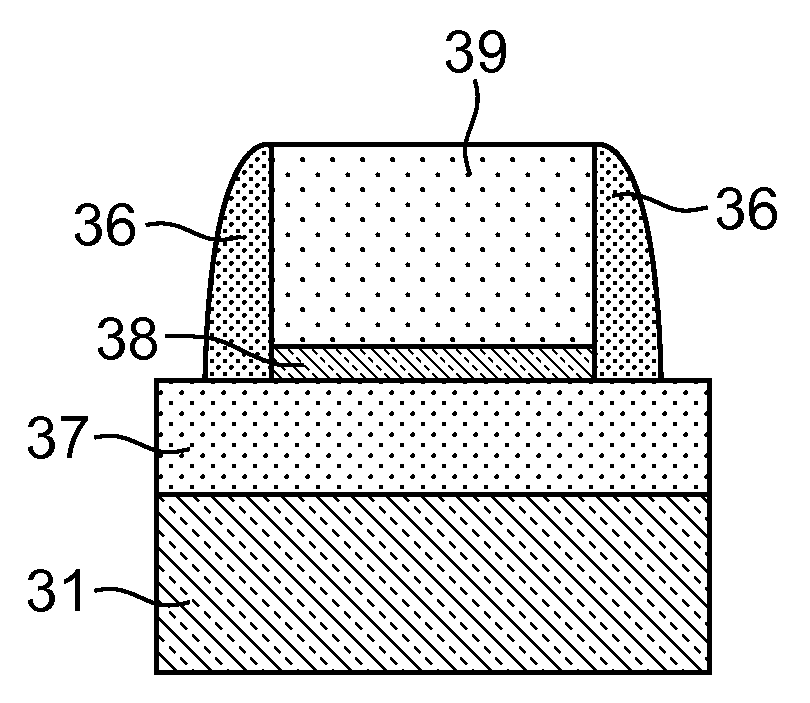

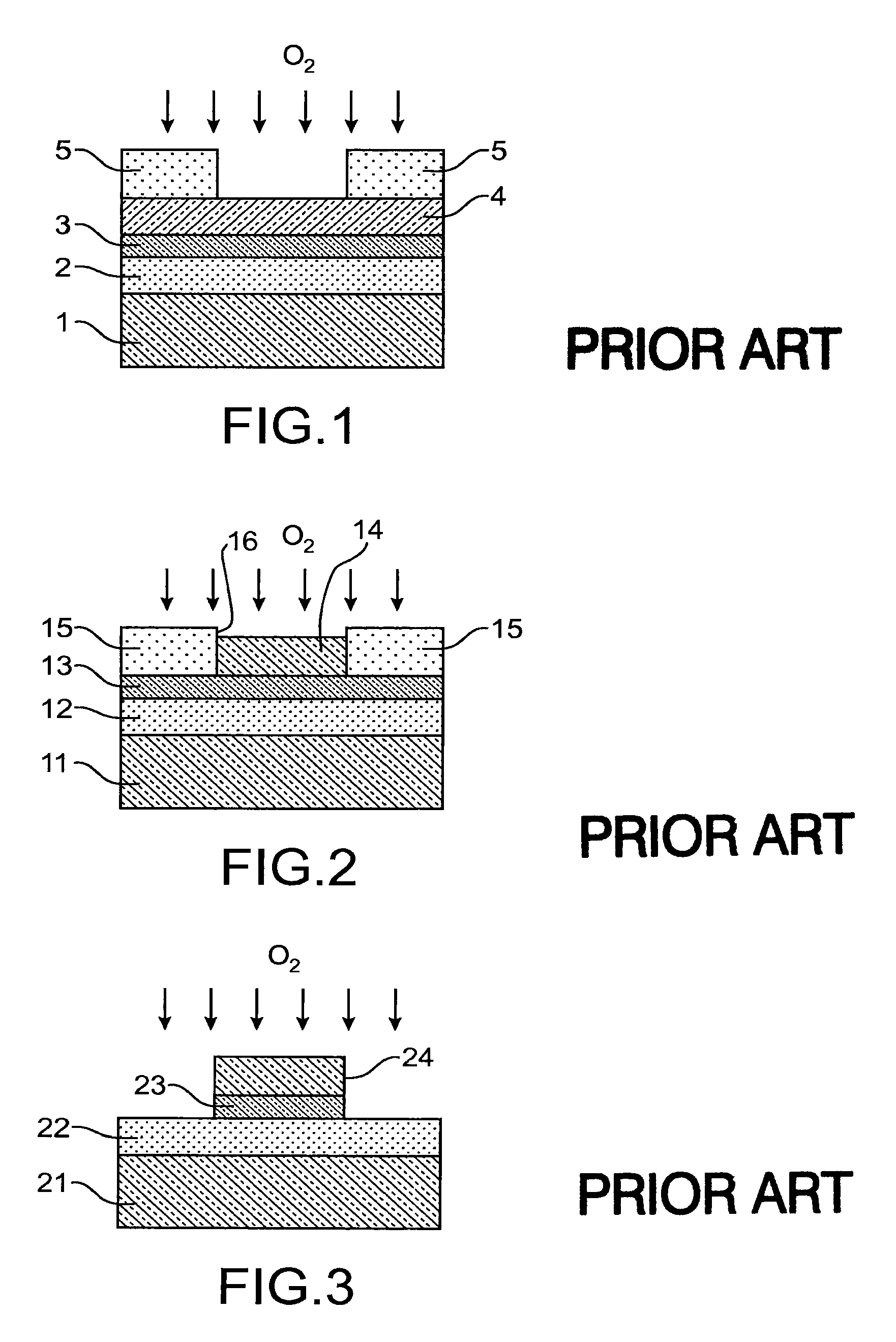

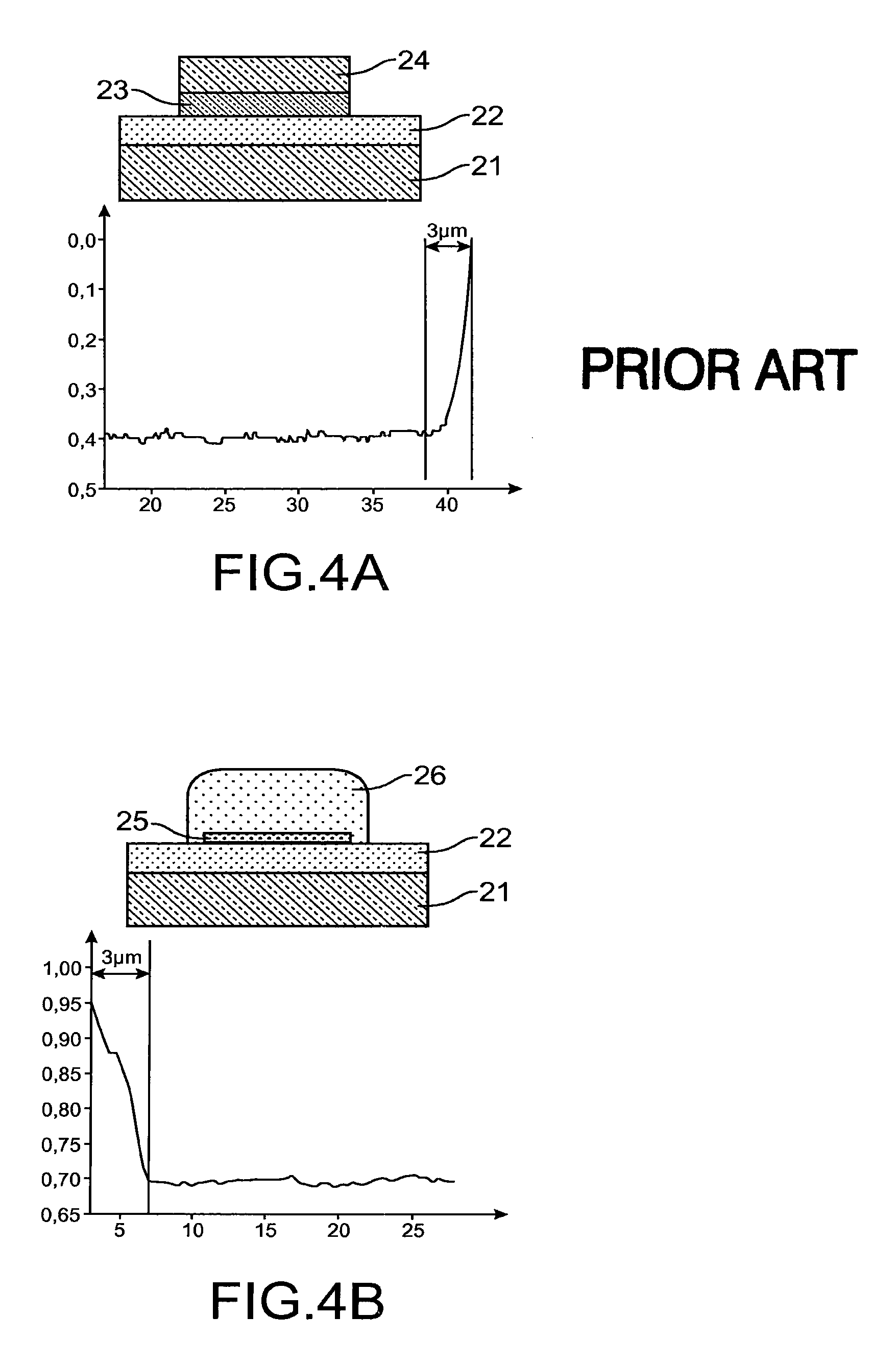

PROCESS FOR PRODUCING LOCALISED Ge0I STRUCTURES, OBTAINED BY GERMANIUM CONDENSATION

ActiveUS20100044836A1Avoid Structural DefectsAvoid storage problemsSemiconductor/solid-state device manufacturingSemiconductor devicesSilicon oxideChemistry

The invention relates to a process for making at least one GeOI structure by germanium condensation of a SiGe layer supported by a layer of silicon oxide. The layer of silicon oxide is doped with germanium, the concentration of germanium in the layer of silicon oxide being such that it lowers the flow temperature of the layer of silicon oxide below the oxidation temperature allowing germanium condensation of the SiGe layer.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

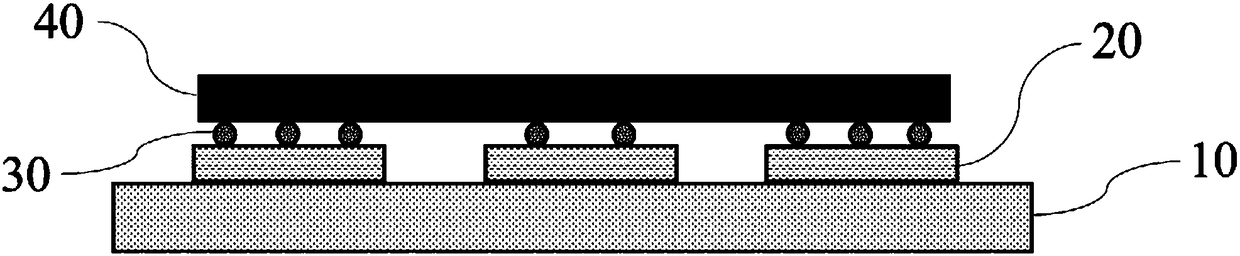

Multi-heterojunction interface perovskite solar cell and preparation method thereof

InactiveCN105576127AOvercoming Structural Deficiencies of Interfacial RecombinationAvoid Structural DefectsMaterial nanotechnologyFinal product manufactureHeterojunctionPerovskite solar cell

The invention discloses a multi-heterojunction interface perovskite solar cell. The multi-heterojunction interface perovskite solar cell adopts a multi-planar-heterojunction interface structure growing vertically and comprises FTO glass, a compact layer, a multi-heterojunction interface layer, a cavity transmission layer and a back electrode. The compact layer is arranged on the FTO glass. The multi-heterojunction interface layer grows vertically on the compact layer in a multi-layer sheet-shaped manner. The back electrode is arranged above the multi-heterojunction interface layer and is located on the cavity transmission layer. The multi-heterojunction interface layer is composed of a plurality of nano-sheets growing vertically and a light absorber filled among the nano-sheets. According to the invention, the multi-planar-heterojunction interface structure growing vertically is adopted, electron and cavity transmission layers are isolated by a light absorption layer, so that the structural defect of interface combination in the electron and cavity transmission process is overcome; in addition, a complete preparation technology, having an industrial potential, of the multi-heterojunction interface perovskite solar cell is provided, and by adopting the technology, the photoelectric conversion efficiency of the solar cell is improved, and industrial production is facilitated.

Owner:HUAIBEI NORMAL UNIVERSITY

Efficient and oxygen-permeable ITO target material placing and sintering method

The invention discloses an efficient and oxygen-permeable ITO target material placing and sintering method. The method comprises the following steps of 1, forming ITO powder to obtain an ITO target blank, and then drying the ITO target blank; 2, placing a gasket on a load bearing plate, then placing a layer of porcelain balls of which the diameters are 0.5-1 mm on the gasket, and then placing theITO target blank on the porcelain balls; 3, putting the load bearing plate provided with the ITO target blank in step 2 into a sintering surface to be sintered, and then grinding to obtain the ITO target material. According to the efficient and oxygen-permeable ITO target material placing and sintering method, the oxygen-permeable rate during sintering of the ITO target blank can be greatly increased, the density of the sintered ITO target material is increased, and the quality of the ITO target material is improved; meanwhile, after sintering, gasket marks cannot be generated on the bottom face of the ITO target material, the target material cannot be polluted, and the consumption of the target material due to grinding in the after-processing process is reduced.

Owner:GUANGDONG KAISHENG PV TTECH RES INST +1

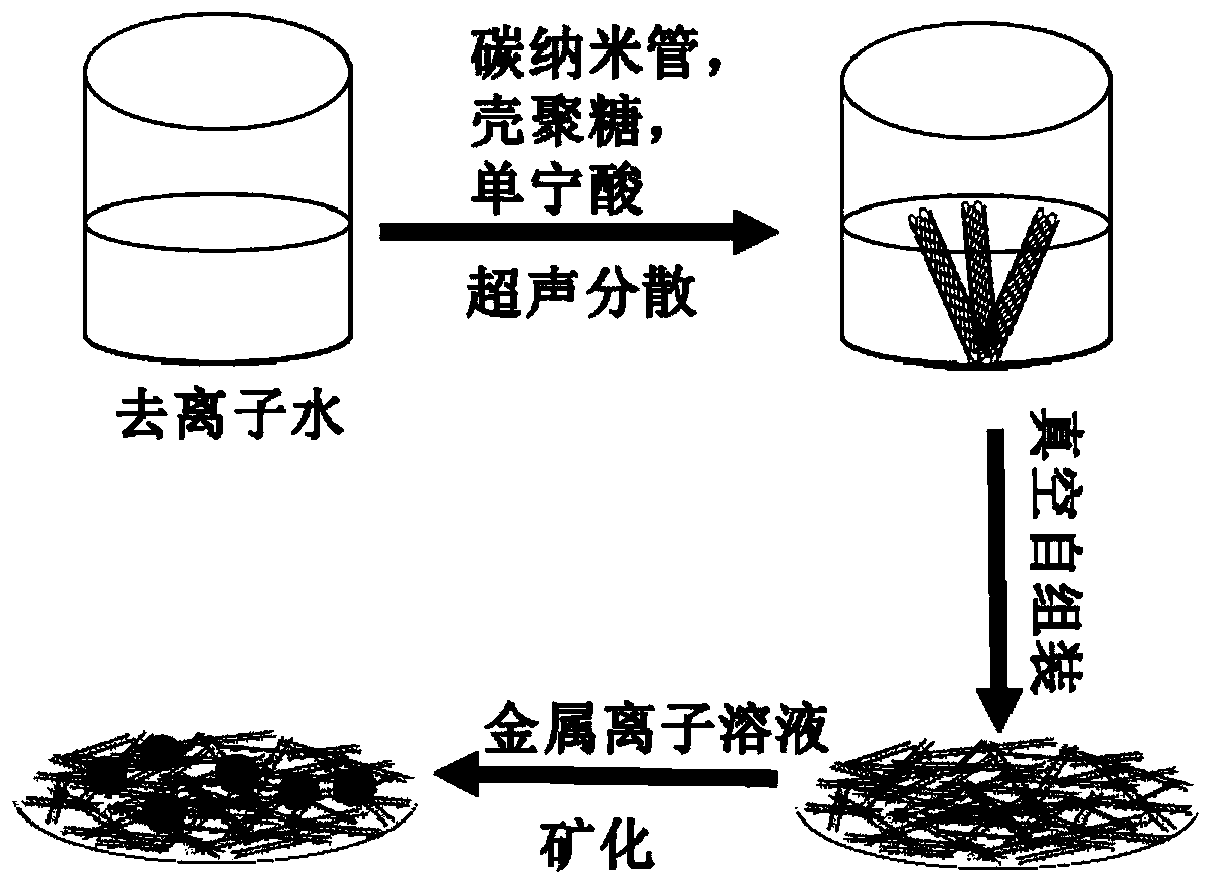

Preparation method for super-hydrophilic carbon nanotube nano-porous membrane

ActiveCN110038450ACreate a hydrophilic chemical compositionCreate structureMembranesSemi-permeable membranesCelluloseHydrogen

The invention relates to a preparation method for a super-hydrophilic carbon nanotube nano-porous membrane. The method comprises the following steps: adding a carbon nanotube, tannic acid and chitosaninto water, regulating pH (Potential of Hydrogen), and carrying out ultrasonic dispersion to form dispersion liquid; after standing, carrying out vacuum filtering on the diluted dispersion liquid toa mixed cellulose membrane to obtain a carbon nanotube self-assembled membrane; after the carbon nanotube self-assembled membrane is subjected to vacuum drying, dipping into a metal ion solution, taking out the membrane after a period of time, and washing and drying to obtain the super-hydrophilic carbon nanotube nano-porous membrane. The preparation method has the advantages of simple process, easy operation and low cost, and the obtained carbon nanotube nano-porous membrane has a super-hydrophilicity characteristic.

Owner:ZHEJIANG UNIV OF TECH

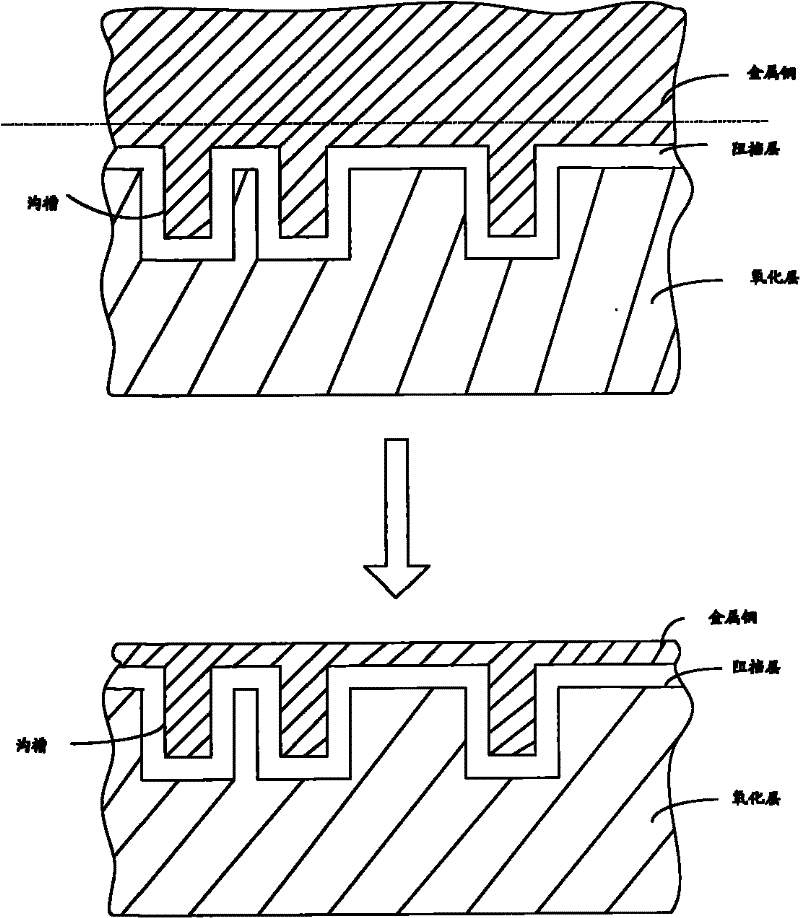

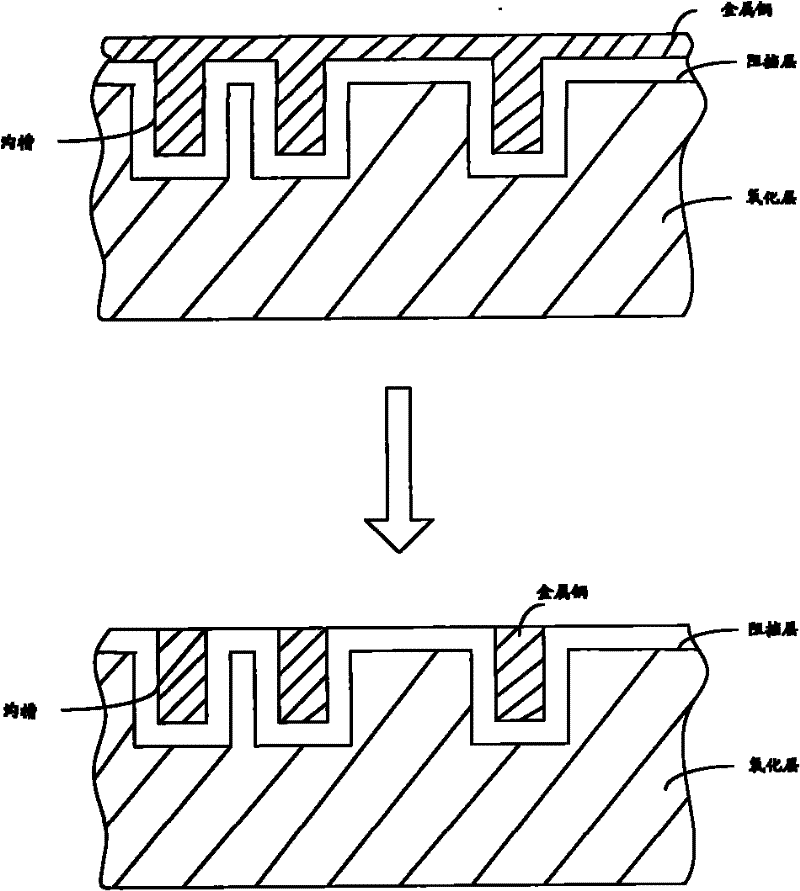

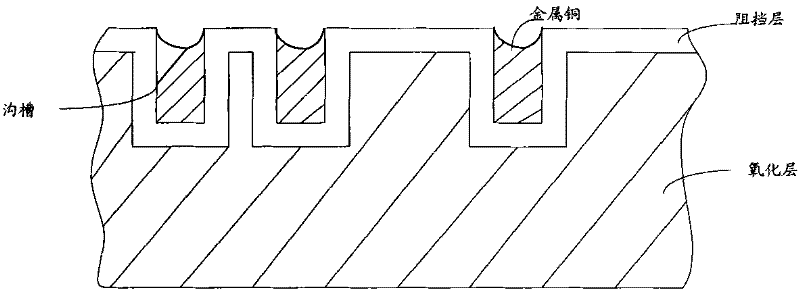

Method for chemical mechanical grinding of metal

ActiveCN102294648AOvercoming prominent structural flawsAvoid Structural DefectsSemiconductor/solid-state device manufacturingLapping machinesMetalOxide

The invention provides a method for chemically and mechanically polishing a metal. The method comprises a step of performing grinding on three grinding tables. While performing grinding on the third grinding table, the method comprises the following steps of: presetting first grinding time and second grinding time, and performing the first step of grinding on the third grinding table within the first grinding time, and performing the second step of grinding on the third grinding table within the second grinding time; grinding an oxide layer and a metal by employing a grinding fluid having a grinding selection ratio greater than 1 to the oxide layer and the metal; when the first predetermined grinding time expires, grinding the oxide layer and the metal by employing a grinding fluid havinga grinding selection not greater than 1 to the oxide layer and the metal; and when the second predetermined grinding time expires, enabling the metal to reach a predetermined thickness and keep as high as the oxide layer. The method greatly improves the planarization degree of the metal in the chemical mechanical polishing process.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

High-strength silicon carbide ceramic and preparation method thereof

The invention relates to a ceramic material. The invention relates to high-strength silicon carbide ceramic. The high-strength silicon carbide ceramic comprises the following components in parts by weight: 70-80 parts of silicon carbide powder, 10-20 parts of silicon carbide fibers, 20-25 parts of a binder, 5-10 parts of a pore-forming agent, 5-10 parts of a sintering aid, 5-10 parts of a dispersing agent and 2-3 parts of a toughening agent. The invention also provides a preparation method of the high-strength silicon carbide ceramic. The preparation method comprises the following steps: uniformly mixing raw materials to obtain raw material slurry, then carrying out vacuum treatment on the raw material slurry, injecting the ceramic slurry subjected to vacuum degassing into a mould, sealingthe mould, carrying out heating, carrying out heat preservation, then carrying out natural cooling, carrying out drying in a drying oven for 12-72 hours to obtain a ceramic biscuit, and carrying outsintering treatment on the ceramic biscuit, wherein the time of the sintering treatment is 1-5 hours, and the sintering temperature is 1500-1800 DEG C. The high-strength silicon carbide ceramic has the advantages that the pores in the silicon carbide ceramic are uniform and the silicon carbide ceramic has high strength.

Owner:长兴科创科技咨询有限公司

Process for producing localised GeOI structures, obtained by germanium condensation

ActiveUS9040391B2Avoid Structural DefectsAvoid storage problemsSemiconductor/solid-state device manufacturingSemiconductor devicesSilicon oxideChemistry

The invention relates to a process for making at least one GeOI structure by germanium condensation of a SiGe layer supported by a layer of silicon oxide. The layer of silicon oxide is doped with germanium, the concentration of germanium in the layer of silicon oxide being such that it lowers the flow temperature of the layer of silicon oxide below the oxidation temperature allowing germanium condensation of the SiGe layer.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

True random number generation method and device with detection and correction function

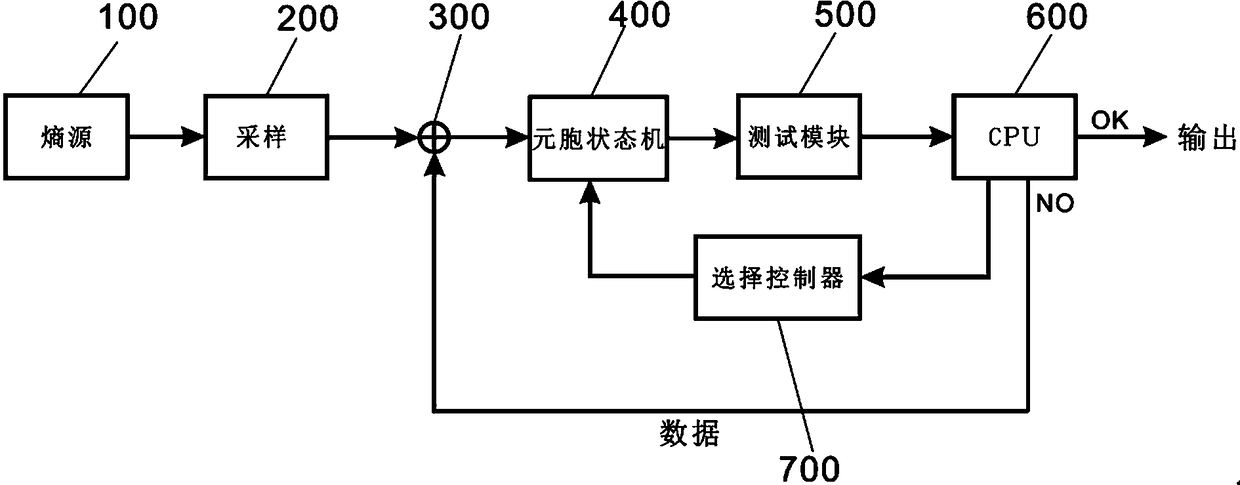

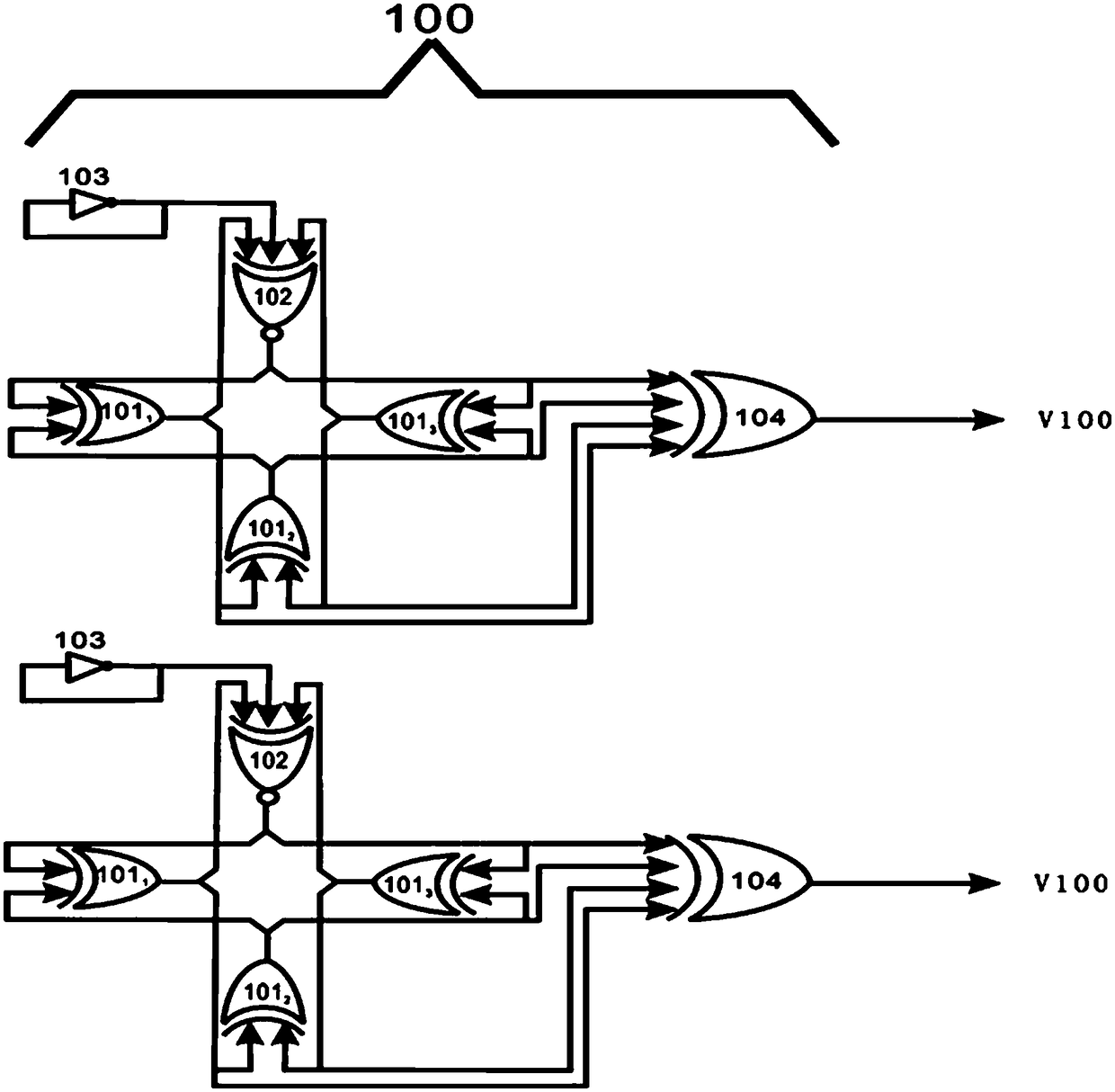

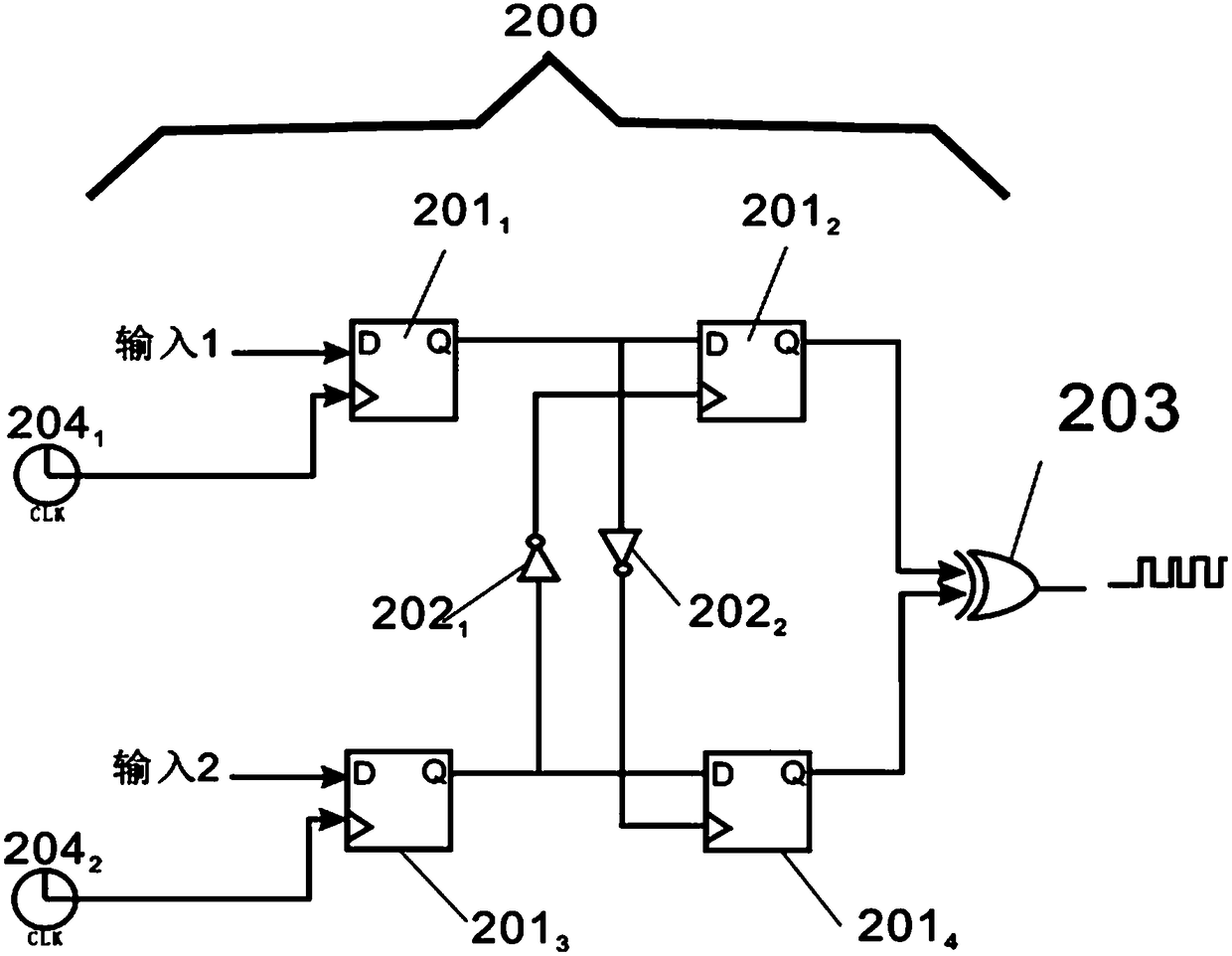

ActiveCN108717353AQuality improvementIncrease randomnessRandom number generatorsFrequency spectrumCryptosystem

The invention discloses a true random number generation method and device with a detection and correction function. A random number is taken as an important component of a cryptosystem and is widely applied to a security system. The random number comprises a session key, an initial vector and a digital signature. The device is composed of an entropy source module, a sampling module, an XOR logic gate, a cellular finite state machine, a test module, a CPU and a selection controller. The entropy source module is composed of two identical oscillator structures. Each oscillator is a chaotic oscillator structure based on an autonomous Boolean network. The entropy source module can generate wide spectrum and high bandwidth chaotic signals. After a random sequence is tested through the test module, whether the sequence passes the test or not is judged through the CPU. The sequence is directly output if the sequence passes the test. Data is returned and enters a postprocessing module through an XOR circuit if the sequence does not pass the test. Moreover, a selection controller selects different postprocessing modes to process the data. The processed data enters the test module for test again, until the data passes the test. A random code sequence generated by the invention can pass a random number industry standard test.

Owner:TAIYUAN UNIV OF TECH

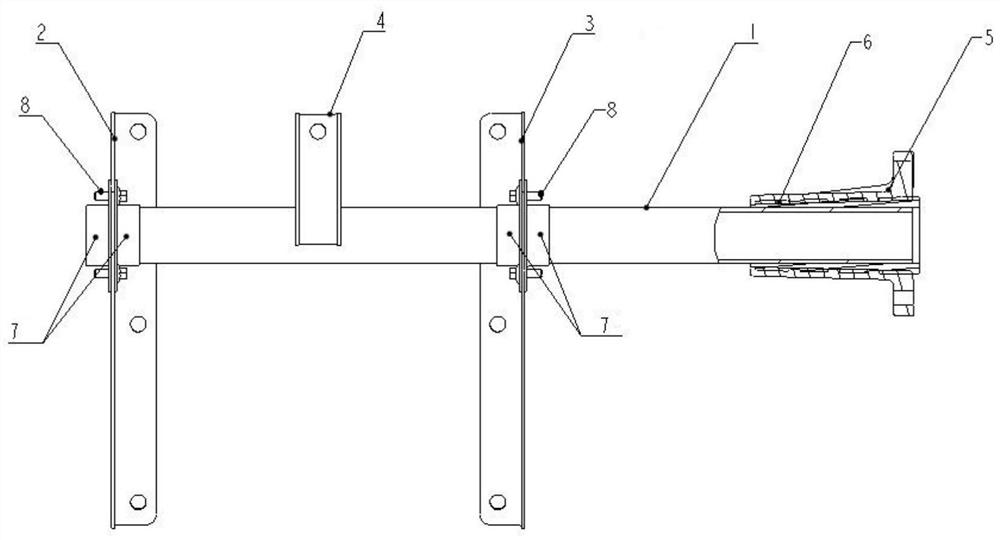

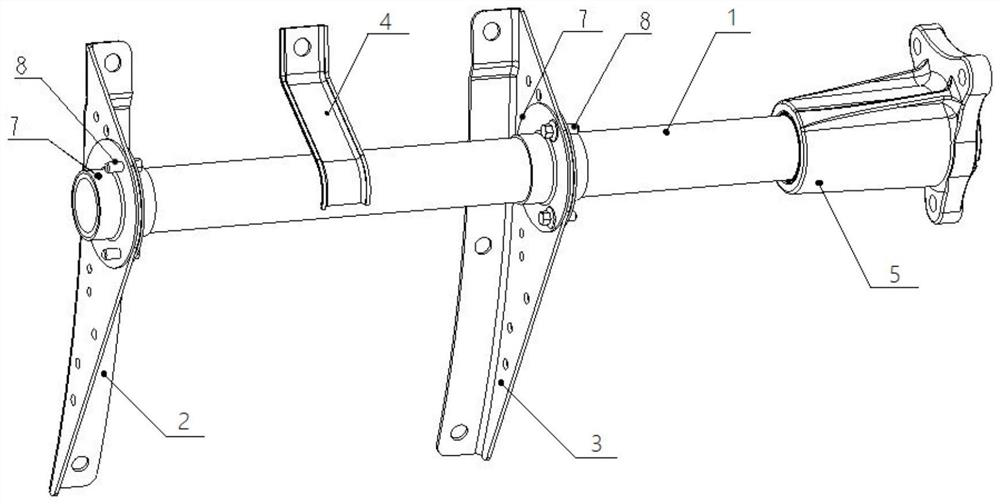

Aluminum alloy fender bracket connecting structure

ActiveCN111791958AImprove structural strengthExtended service lifeSuperstructure subunitsFenderAdhesive

The application relates to an aluminum alloy fender bracket connecting structure which is characterized by comprising a fender supporting rod and a fender connecting bracket. One end of the fender supporting rod is provided with a base connected with a vehicle body. The fender connecting bracket is fixedly connected with the fender supporting rod through a flange; meanwhile, the flange sleeves thefender supporting rod and is connected with the fender supporting rod through adhesives, and the fender connecting bracket is detachably connected with the flange. According to the aluminum alloy fender bracket connecting structure, the fender connecting bracket is connected with the fender supporting rod through the flange, the flange is connected with the fender supporting rod through the adhesives, and the flange is detachably connected with the fender connecting bracket. Structural defects caused by the adoption of a welding connection mode are overcome, the problem that a welding area where the fender supporting rod and the fender connecting bracket are welded to the joint is broken is solved, the structural strength of the aluminum alloy fender support connecting structure is improved, and the service life of the aluminum alloy fender support connecting structure is prolonged.

Owner:DONGFENG COMML VEHICLE CO LTD

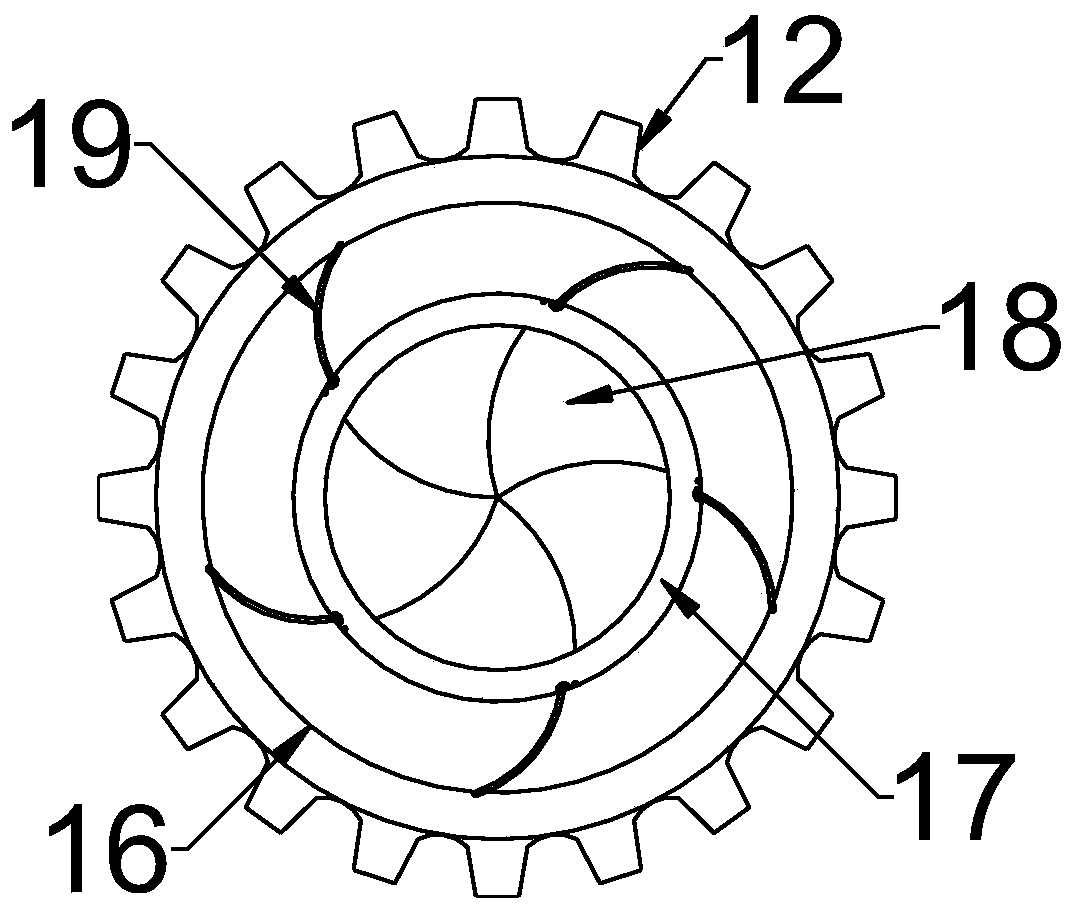

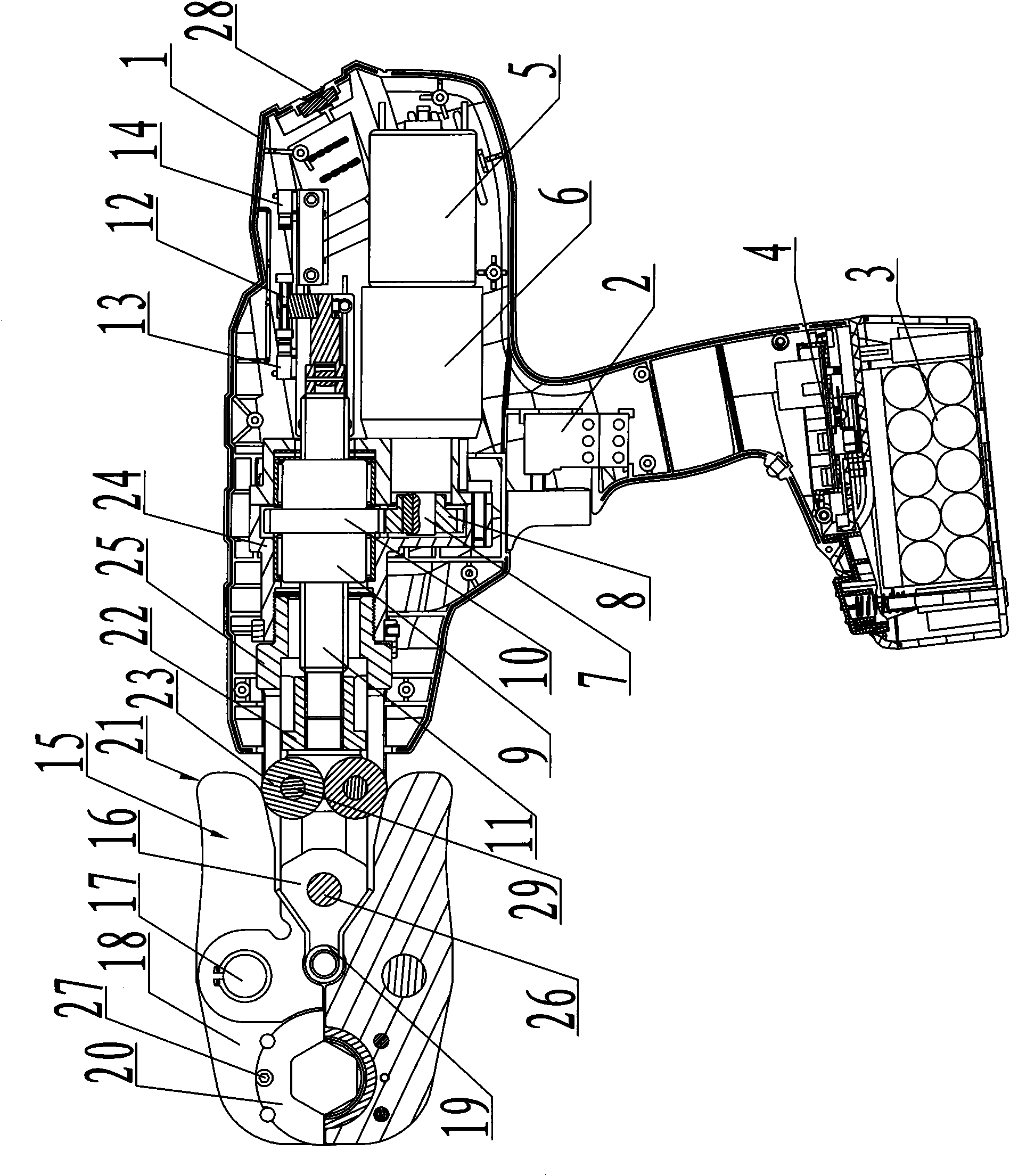

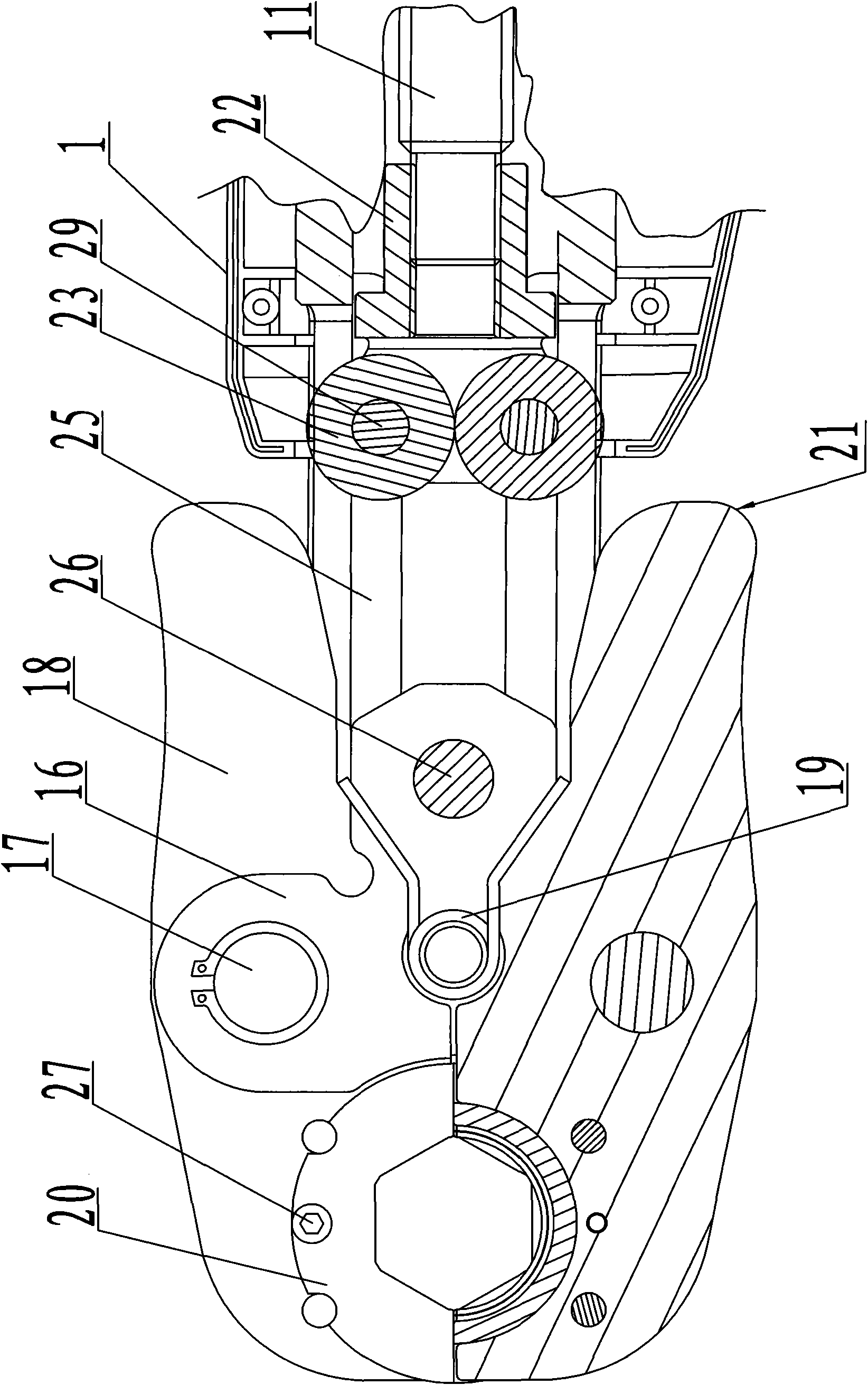

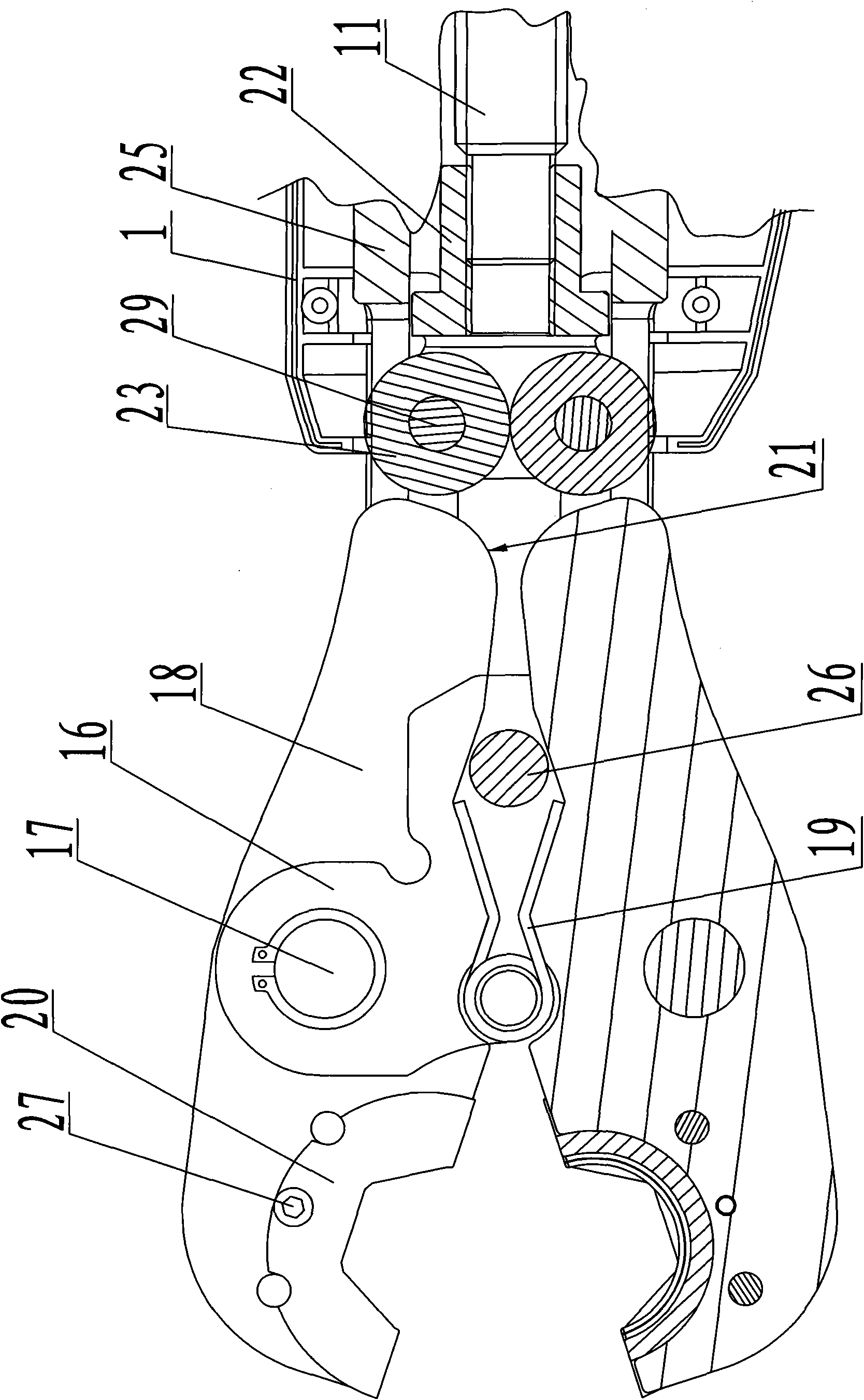

Electric press plier

InactiveCN102120319AEasy crimpingReduce volumePortable power-driven toolsMetal-working hand toolsControl systemGear wheel

The invention discloses an electric press plier which comprises a shell, wherein a switch is arranged on the shell, the inside of the lower end of the shell is provided with a power supply and a circuit control device, the inside of the upper end of the shell is provide with a motor and a speed reducer, a drive gear is arranged on an output shaft of the speed reducer and mutually matched with a driven gear fixedly arranged on a screw barrel, the screw barrel is sleeved on a screw in the shell and mutually and helically matched with the screw, a knocking block is arranged on the screw, the shell is internally and respectively provided with a front stroke switch and a rear stroke switch which are mutually matched with the knocking block, a digital display device is arranged on the rear end of the shell, and the front end of the screw is mutually matched with a plier assembly arranged at the front end of the shell. The invention has the advantages of avoidance of structural defects of hydraulic compression joint, convenience for compression joint, small volume, light weight, convenience for carrying, high automation, convenience for use and management because the compression joint frequency is measured by a control system and displayed by the digital display device, and the like.

Owner:ZHANGJIAGANG CHUANGJI MACHINERY MFG

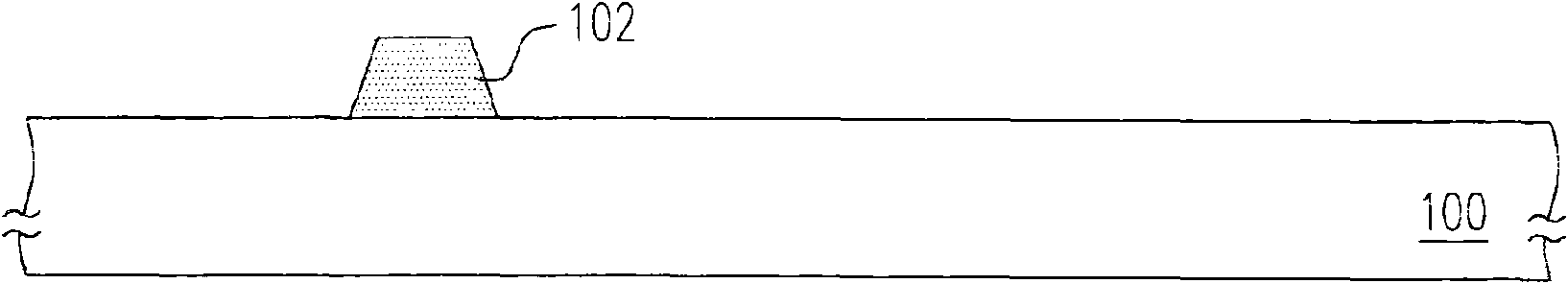

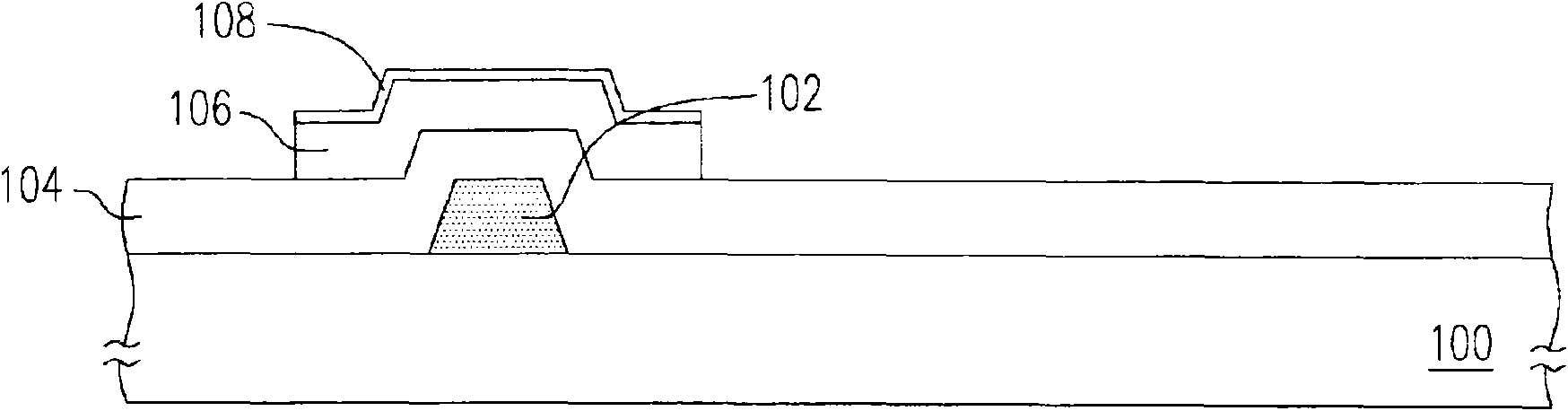

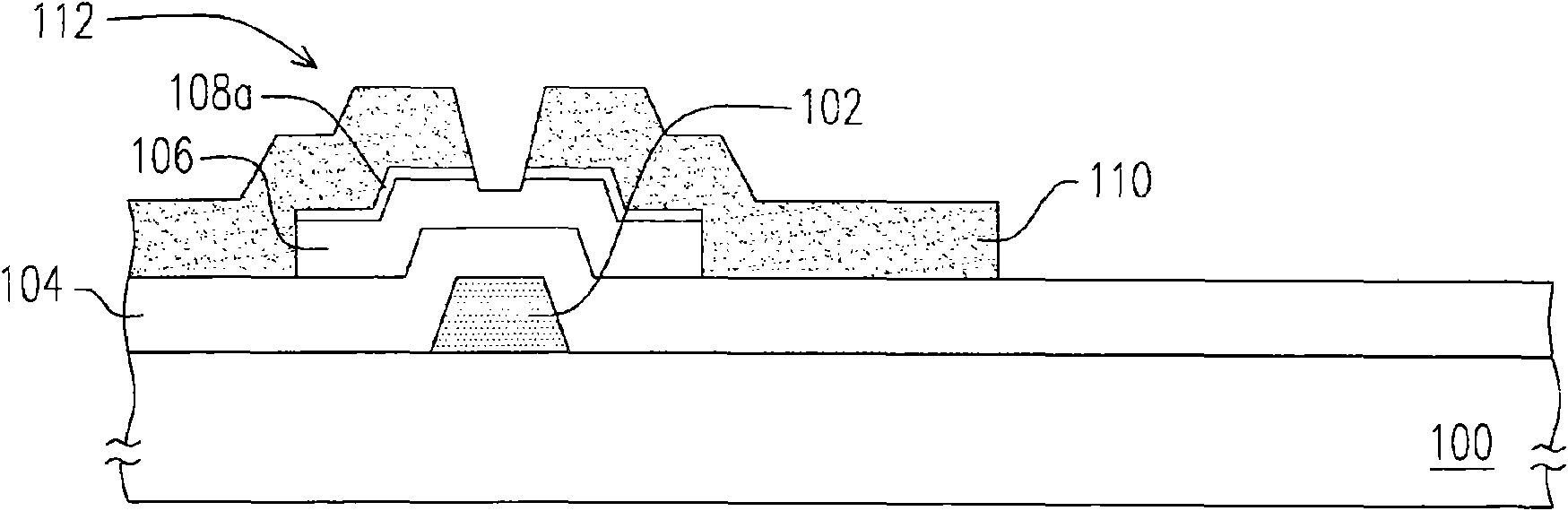

Etching solution, active component array substrate and method for manufacturing active component array substrate

InactiveCN101807572ABest etch performanceBest electrical performanceSemiconductor/solid-state device detailsSolid-state devicesActive componentPhosphoric acid

The invention provides etching solution, an active component array substrate and a method for manufacturing the active component array substrate. The active component array substrate is provided with at least one multi-layer patterned metallic layer, wherein the multi-layer patterned metallic layer is an aluminum / copper layer, an aluminum alloy / copper layer, an aluminum alloy / copper / aluminum alloy layer, a copper alloy / copper layer or a copper alloy / copper / copper alloy layer, and is etched by the etching solution; and the etching solution comprises water, 0.1 to 0.4 weight percent of nitric acid, 50 to 78 weight percent of phosphoric acid and 0.1 to 15 weight percent of acetic acid. The active component array substrate of the invention is endowed with relatively better electrical property.

Owner:AU OPTRONICS CORP

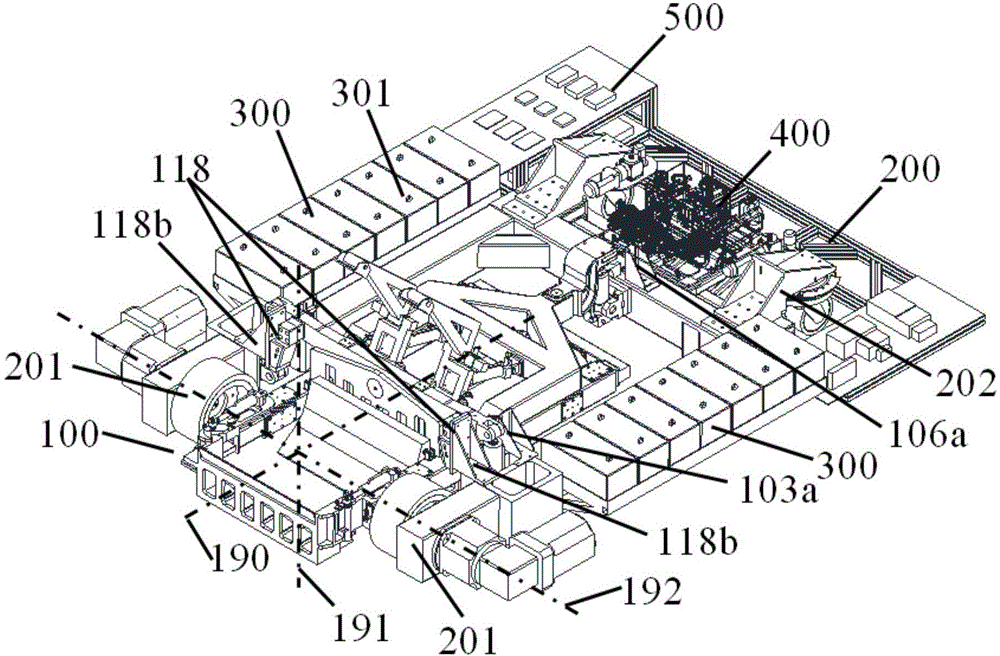

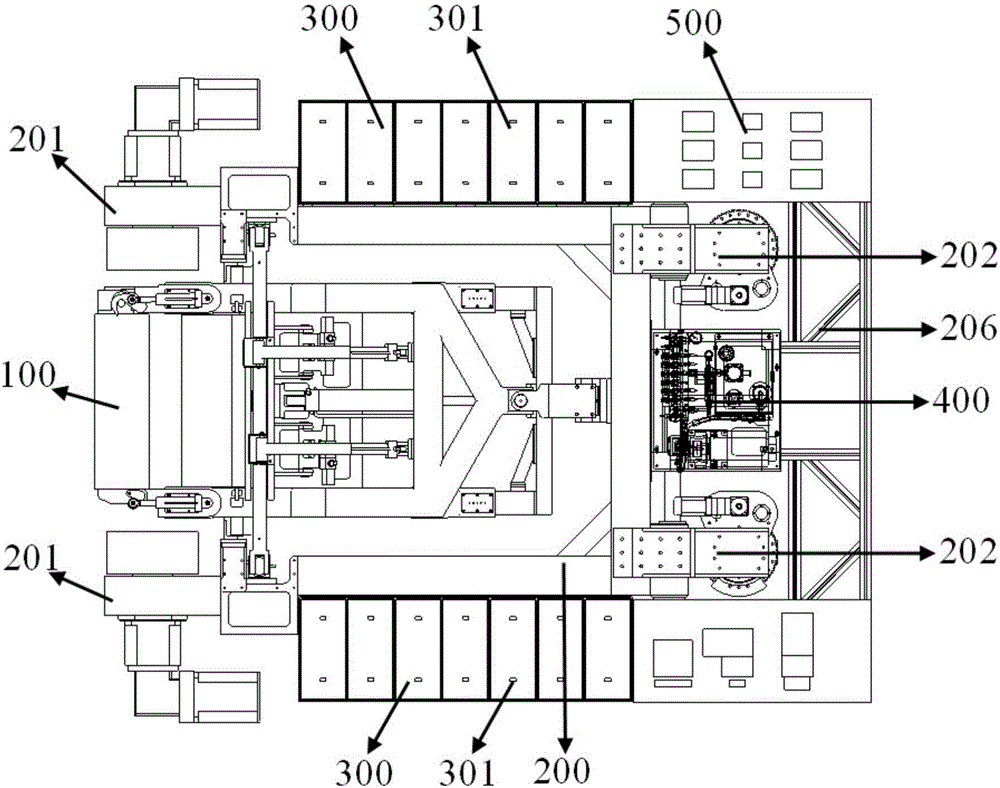

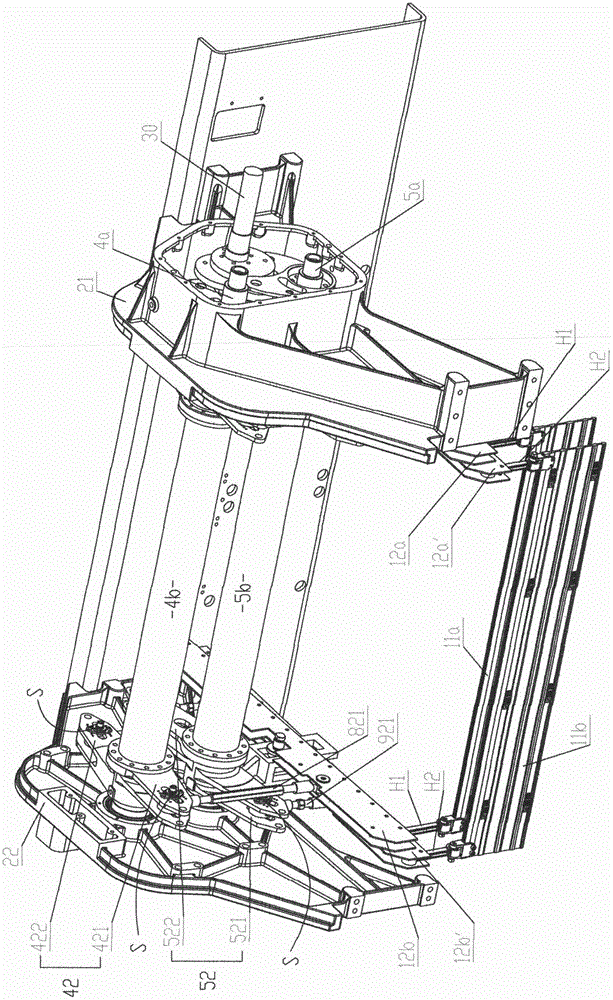

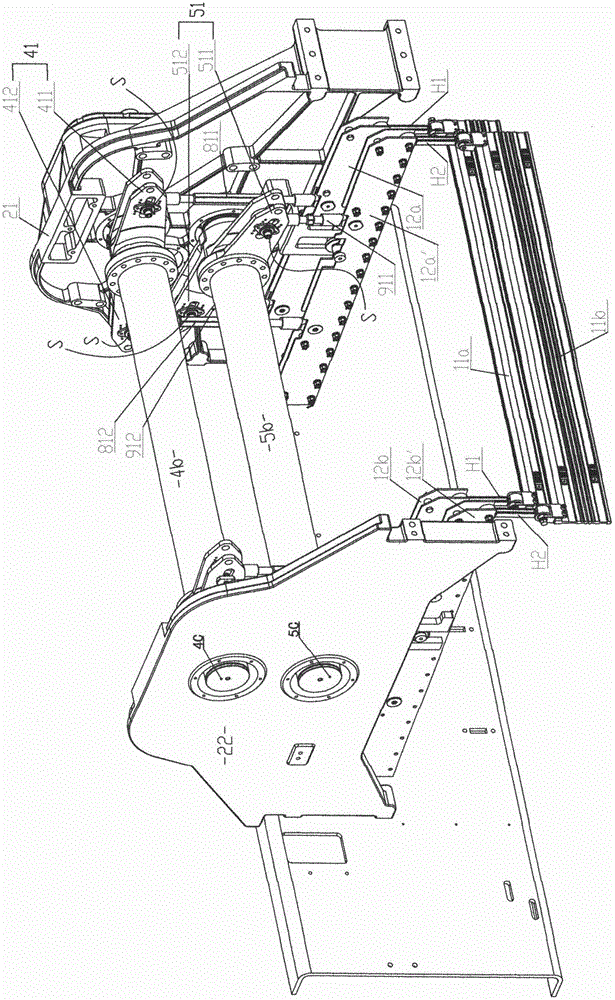

Towbarless aircraft towing tractor holding wheel climbing mechanism

PendingCN106628231AEnsure safetyAvoid Structural DefectsGround installationsWeight reductionDegrees of freedomSafe operation

The invention relates to a towbarless aircraft towing tractor holding wheel climbing mechanism capable of adaptively moving with airplane wheels. The towbarless aircraft towing tractor holding wheel climbing mechanism comprises a holding wheel mechanism, a lifting mechanism and a connecting mechanism, wherein the holding wheel mechanism and the connecting mechanism are respectively arranged on two sides of the lifting mechanism; the holding wheel mechanism is capable of holding the airplane wheels; the connecting mechanism is capable of connecting the holding wheel mechanism and the lifting mechanism to a bottom main frame of the aircraft towing tractor and realizing follow-up; the lifting mechanism is capable of climbing and descending the holding wheel mechanism; the holding wheel mechanism has translational degree of freedom in the Z axis direction. According to the towbarless aircraft towing tractor holding wheel climbing mechanism disclosed by the invention, the structure defects of the existing towing tractor and the potential safety hazard problems in the operating process are solved, the adaptive movement of the towing tractor and the airplane wheels is realized, stable and safe operations can be realized, and the towbarless aircraft towing tractor holding wheel climbing mechanism is widely applicable to the airplane wheels of different models and sizes and different operating environment conditions and is capable of conveniently and rapidly realizing the security operation of the tractor.

Owner:TIANJIN AEROSPACE ELECTROMECHANICAL EQUIP RES INST

Conjugate cam jacquard shedding device

The invention discloses a conjugate cam jacquard shedding device, and belongs to the technical field of jacquard loom shedding. The conjugate cam jacquard shedding device comprises two swinging mechanisms, a cam rotating shaft, an inner conjugate cam set and an outer conjugate cam set. The swinging mechanisms comprise an upper swinging shaft, a lower swinging shaft, a linkage upper swinging shaft, a linkage lower swinging shaft, an upper swinging shaft tube and a lower swinging shaft tube, wherein the upper swinging shaft and the lower swinging shaft are supported by bearings on a box-type side wall board and bearings on a box cover, the linkage upper swinging shaft and the linkage lower swinging shaft are supported by bearings on a plate-type side wall board, the upper swinging shaft and the linkage upper swinging shaft are in rigid connection through the upper swinging shaft tube, the lower swinging shaft and the linkage lower swinging shaft are in rigid connection through the lower swinging shaft tube, and the upper swinging shaft and the lower swinging shaft right facing the upper swinging shaft are located on the same side of the cam rotating shaft in the manner that the upper swinging shaft and the lower swinging shaft are arranged at an upper position and a lower position relative to the cam rotating shaft. The inner conjugate cam set and the outer conjugate cam set are in closure transmission connection with birotor rocking bars rigidly arranged on the upper swinging shaft and the lower swinging shaft respectively so as to control the upper swinging shaft and the lower swinging shaft to swing reversely in an equal-amplitude mode. Two pairs of tool rests are hinged to a double-end upper swinging arm, a double-end lower swinging arm, a linkage double-end upper swinging arm and a linkage double-end lower swinging arm through vertical connecting bars, wherein the double-end upper swinging arm and the double-end lower swinging arm are rigidly fixed to the upper swinging shaft and the lower swinging shaft and are single parts, and the linkage double-end upper swinging arm and the linkage double-end lower swinging arm are linked with the upper swinging shaft and the lower swinging shaft and are single parts. The device is reliable in operation, high in transmission precision and easy to assemble and maintain.

Owner:张军波

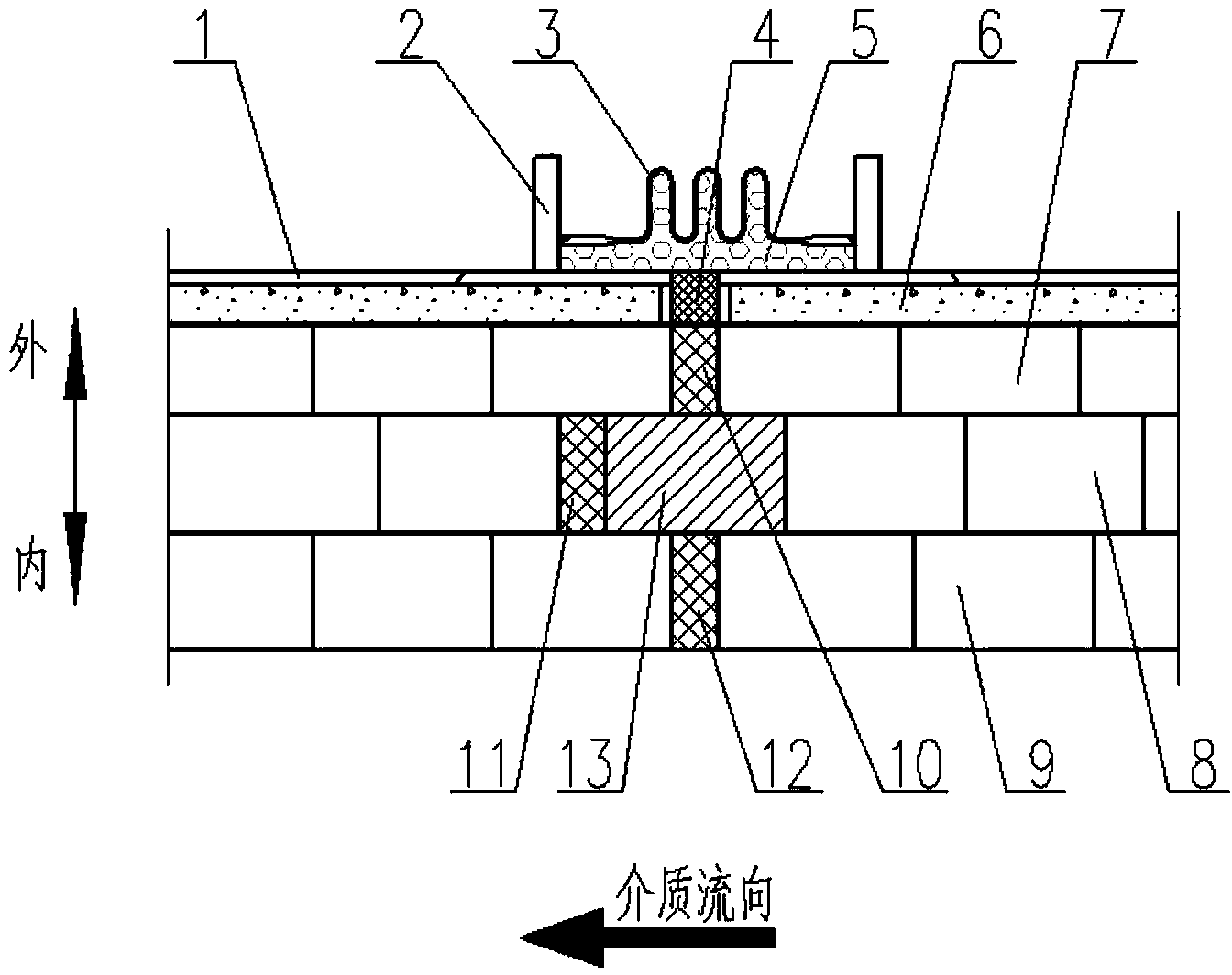

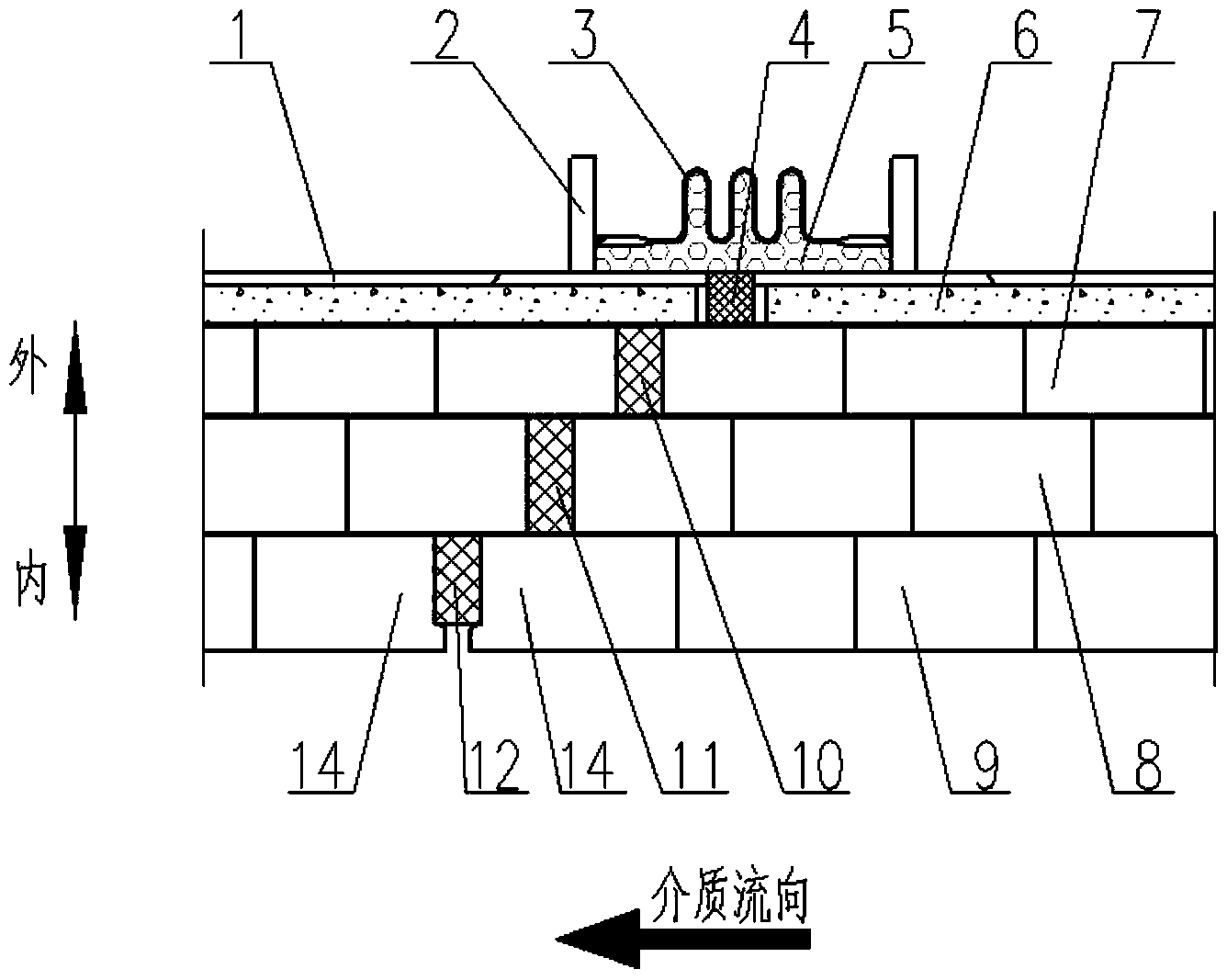

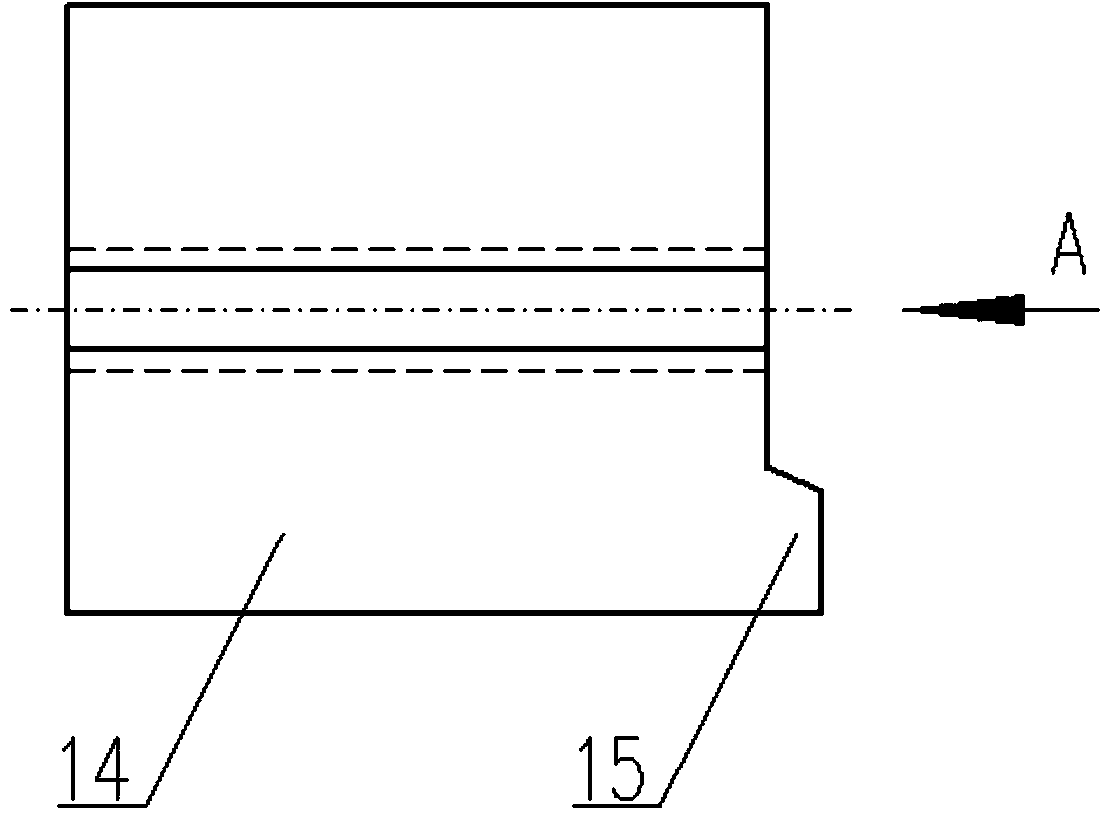

Hot-blast duct compensator masonry structure of hot-blast furnace

ActiveCN103451341AAvoid being swept awayWon't roll awayBlast furnace detailsHeating stovesFiberWork period

The invention relates to a hot-blast duct compensator masonry structure of a hot-blast furnace, belonging to the technical field of hot-blast furnaces in the metallurgical industry. The masonry structure comprises a duct steel shell, an annular plate, a corrugated tube, expansion joints, a heat insulation layer, fireproof spray paint, a first heat insulation brick layer, a second heat insulation brick layer, refractory bricks, dilation joints of the first heat insulation brick layer, dilation joints of the second heat insulation brick layer, dilation joints of the refractory bricks, and special-shaped refractory bricks. According to the invention, the special-shaped refractory bricks effectively protect refractory fiber blankets filled in the dilation joints, thus preventing the refractory fiber blankets from being carried away by high-temperature high-pressure air flow in the working period of a hot-blast duct, especially in the early working stage; under the double action of the special-shaped refractory bricks and heated compaction, the refractory fiber blankets can stably work for long time and absorb heat to dilate, thus protecting the corrugated tube; the arrangement of the inverse labyrinth dilation joints is opposite to the direction of air flow, thus ensuring that the air flow is more difficult to leak into the corrugated tube and forming multiple protection on the corrugated tube; and latching of the refractory bricks and the special-shaped refractory bricks increases the overall stability of the masonry, thus ensuring the long-time stable work of the hot-blast duct.

Owner:BEIJING SHOUGANG INT ENG TECH

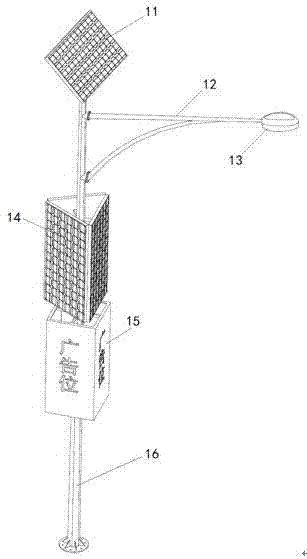

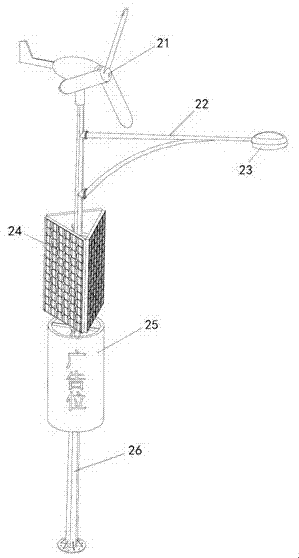

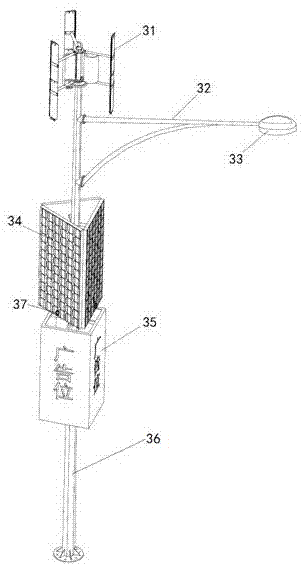

Intelligent type new energy advertising street lamp

PendingCN106931392AReduce areaReduce weightMechanical apparatusLighting elementsNew energyEngineering

The invention relates to an intelligent type new energy advertising street lamp. The intelligent type new energy advertising street lamp has the characteristics that an intelligent crystalline silicon photovoltaic power generating assembly or an intelligent wind driven generator are arranged at the top end of a lamp rod; an intelligent thin film photovoltaic power generating assembly is arranged at the upper part of the lamp rod; an intelligent advertisement carrier is arranged at the lower part of the lamp rod; an optical fibre metering communication module and various parts of the street lamp are combined and form a street lamp metering communication network through a plastic optical fibre; the network optical fibre metering communication module exchanges acquired street lamp electric energy metering information and working condition information with optical fibre metering communication modules of nearby street lamps, or summarizes and uploads the acquired street lamp electric energy metering information and the working condition information to a master station through a wireless or Bluetooth technology. The intelligent type new energy advertising street lamp is reasonable in structure, and attractive in appearance. The design of an advertising lamp box develops a new way for the application of the new energy street lamp, and meanwhile, the near-ground illumination is also improved. The intelligent type new energy advertising street lamp also provides the working condition information, including the electric energy metering information, for a street lamp management department, and provides a technical means for real-time control and scientific management of the new energy street lamp.

Owner:NANJING YUNENG NEW ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com