Preparation method for flaky AgSnO2 contact

A silver tin oxide, flake technology, applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of high technical difficulty, high manufacturing cost, adverse effects of additive distribution uniformity, etc., to ensure distribution uniformity, Effect of avoiding structural defects and improving tissue uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

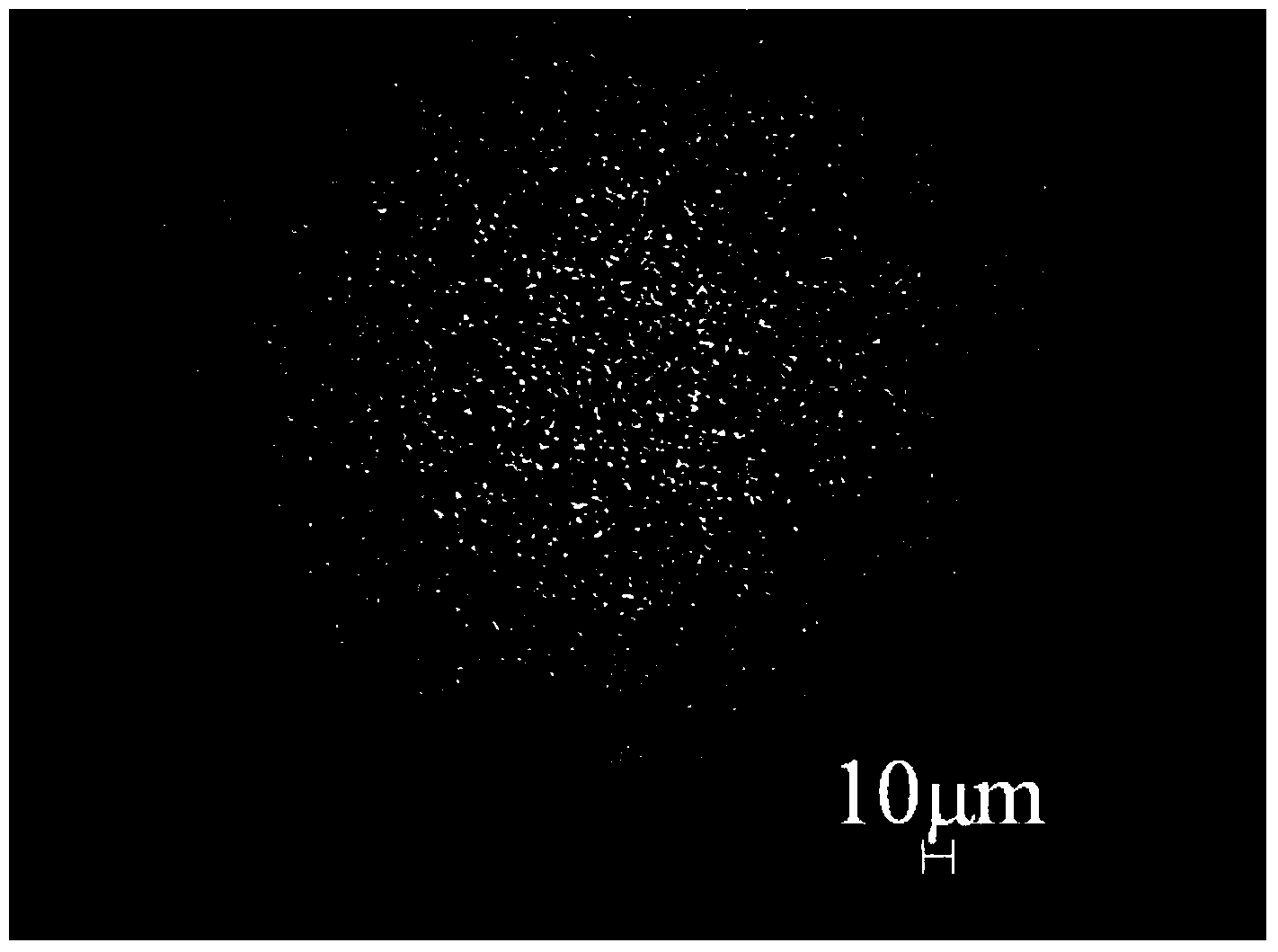

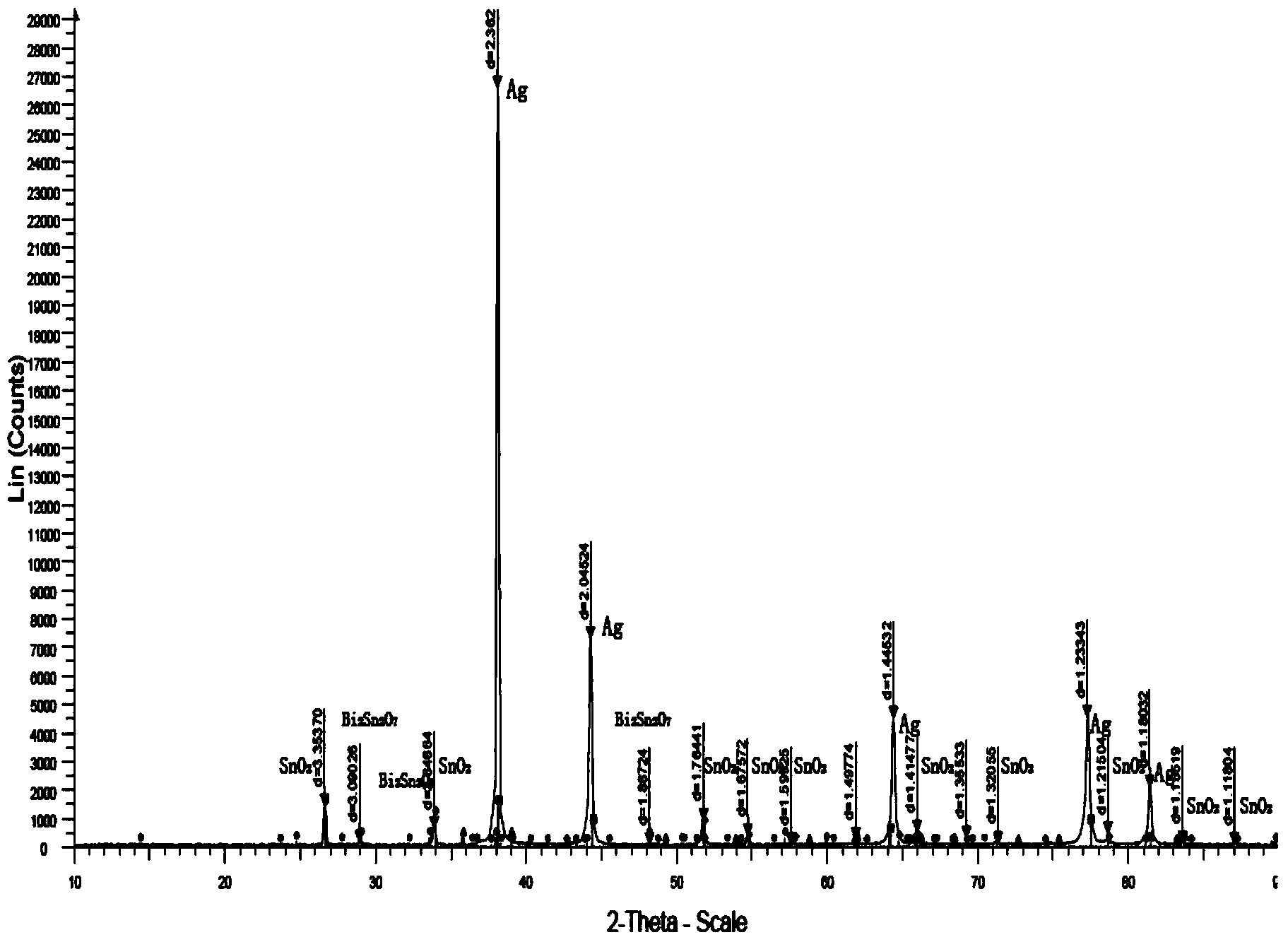

[0040] 1) Weigh 19.96kg of pure Ag block and 0.04kg of pure Bi block, place them in an intermediate frequency induction melting furnace to melt into a uniform alloy melt, and then atomize through high-pressure water atomization equipment, and the obtained powder slurry Dried and passed through a 300-mesh sieve;

[0041] 2) Weigh the -300 mesh Ag alloy powder prepared in the above step 1) and the SnO powder with an average particle size (D50) of 1 μm according to the mass ratio of 92%:8%. 2 powder, placed in a three-dimensional mixer and mixed for 2 hours at a speed of 20r / min, and then placed in a V-shaped mixer and mixed for 3 hours at a speed of 35r / min to obtain AgSnO 2 mixed powder;

[0042] 3) placing the above-mentioned mixed powder in an isostatic press and forming under a pressure of 130MPa to obtain a cylindrical ingot with a diameter of φ85mm;

[0043] 4) Place the ingot in a box-type resistance furnace, heat-preserve and sinter it in air at 850°C for 2 hours, and ...

Embodiment 2

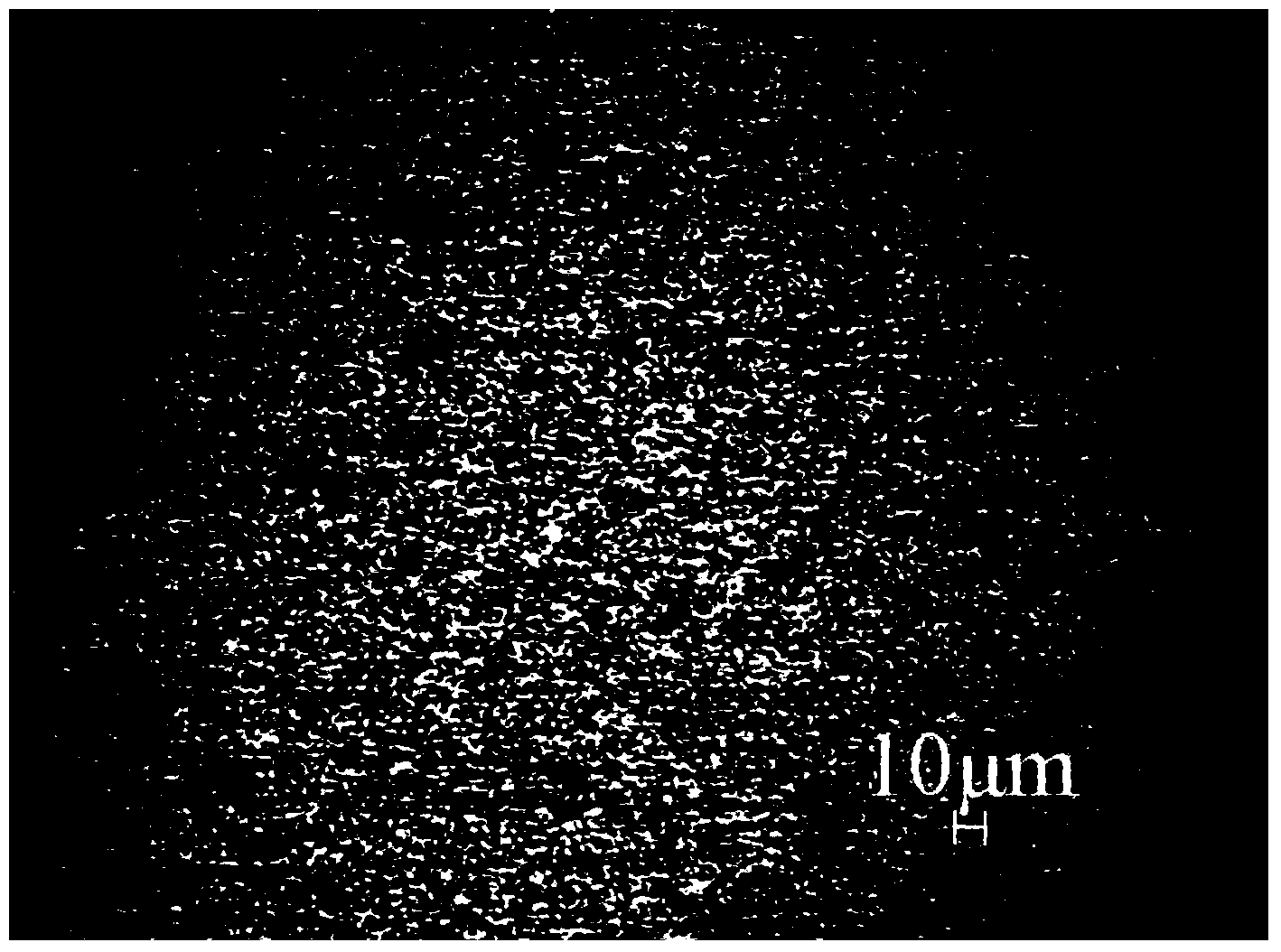

[0050] 1) Weigh 19.8kg of pure Ag block, 0.14kg of pure Bi block and 0.06kg of pure Cu block, place them in an intermediate frequency induction melting furnace to melt into a uniform alloy melt, and then atomize them through high-pressure water atomization equipment , drying the obtained powder slurry and passing through a 300-mesh sieve;

[0051] 2) Weigh the -300 mesh Ag alloy powder prepared in the above step 1) and the SnO with an average particle size (D50) of 3 μm according to the mass ratio of 88%:12%. 2 powder, placed in a three-dimensional mixer and mixed for 2 hours at a speed of 20r / min, and then placed in a V-shaped mixer and mixed for 3 hours at a speed of 35r / min to obtain AgSnO 2 mixed powder;

[0052] 3) Place the mixed powder above in an isostatic press and form it under a pressure of 150MPa to obtain a cylindrical ingot with a diameter of φ85mm;

[0053] 4) Place the ingot in a high-pressure oxidation furnace, and heat-preserve and sinter it at 870°C for 3 ...

Embodiment 3

[0060] 1) Weigh 19.6kg of pure Ag block, 0.14kg of pure Bi block and 0.26kg of pure In block, place them in an intermediate frequency induction melting furnace to melt into a uniform alloy melt, and then atomize them through high-pressure water atomization equipment , drying the obtained powder slurry and passing through a 300-mesh sieve;

[0061] 2) Weigh the -300 mesh Ag alloy powder prepared in the above step 1) and the SnO with an average particle size (D50) of 5 μm according to the mass ratio of 86%:14%. 2 powder, placed in a three-dimensional mixer and mixed at a speed of 20r / min for 1.5h, and then placed in a V-shaped mixer and mixed at a speed of 35r / min for 2.5h to obtain AgSnO 2 mixed powder;

[0062] 3) Place the above mixed powder in an isostatic press and form it under a pressure of 180MPa to obtain a cylindrical ingot with a diameter of φ85mm;

[0063] 4) Place the ingot in a high-pressure oxidation furnace, heat-preserve and sinter it for 4 hours at an oxygen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com