Method for smelting high-nitrogen die steel through vacuum induction furnace and pressurized electroslag furnace

A technology of vacuum induction furnace and pressurized slag, applied in the field of iron and steel metallurgy, can solve the problem of not forming large-scale industrial production, and achieve the effects of facilitating large-scale industrial production, reducing oxygen content and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

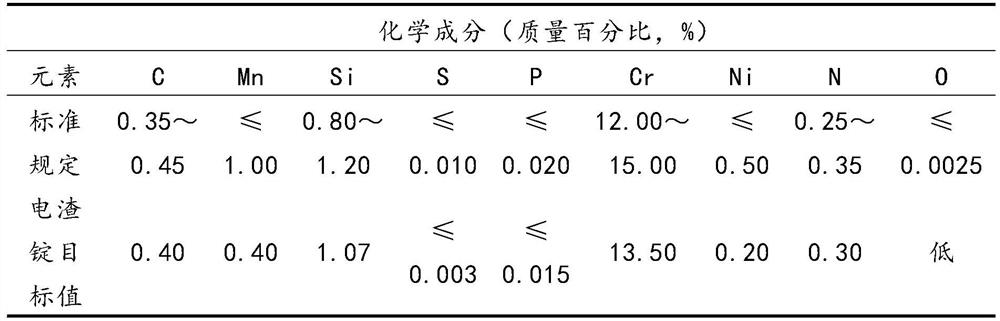

[0035] Vacuum induction furnace + pressurized electroslag furnace is used to smelt high-nitrogen mold steel Φ610mm electroslag ingot. The target steel grade is 40Cr13NiN0.3. The alloy composition and target value of electroslag ingot are shown in Table 1.

[0036] Table 1

[0037]

[0038] (1) According to the target composition and process requirements of the steel grade, the batching target of the vacuum induction furnace is implemented in accordance with Table 2.

[0039] Table 2

[0040]

[0041](2) Choose a vacuum induction furnace with a 6t crucible, and ensure that the argon pressure is at 20,000Pa during the argon filling stage. After the alloy composition reaches the target value, add 15kg of (FeCr)N to increase nitrogen, and add Ni-Mg and Si-Ca powder for deoxidation.

[0042] (3) The size of the electrode rod 4 is Φ400mm, and the oxide skin on the surface is cleaned.

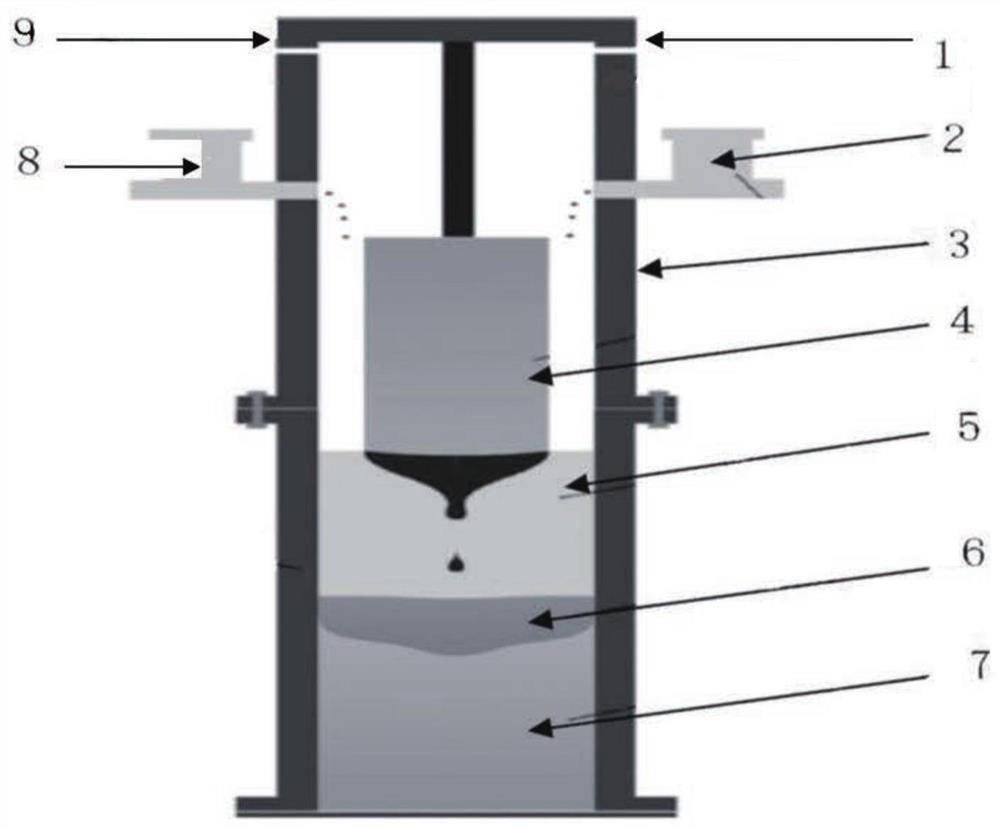

[0043] ⑷Pressure electroslag furnace (see figure 1 ) during preparation, pave 5kg of (Fe...

Embodiment 2

[0052] Vacuum induction furnace + pressurized electroslag furnace is used to smelt high-nitrogen mold steel Φ610mm electroslag ingot. The target steel grade is 30Cr13NiN0.35. The alloy composition and target value of electroslag ingot are shown in Table 4.

[0053] Table 4

[0054]

[0055] ⑴According to the target composition and process requirements of the steel type, the batching target of the vacuum induction furnace is implemented according to Table 5:

[0056] table 5

[0057]

[0058] (2) Choose a vacuum induction furnace with a 6t crucible, and ensure that the argon pressure is at 20,000Pa during the argon filling stage. After the alloy composition reaches the target value, add 16kg of (FeCr)N for nitrogen increase, and add Ni-Mg and Si-Ca powder for deoxidation.

[0059] (3) The size of the electrode rod 4 is Φ400mm, and the oxide skin on the surface is cleaned.

[0060] ⑷ When preparing the pressurized electroslag furnace, lay 5kg of (FeCr)N on the bottom pa...

Embodiment 3

[0070] Vacuum induction furnace + pressurized electroslag furnace is used to smelt high-nitrogen mold steel Φ610mm steel ingot. The target steel grade is 30Cr15Mo1NiN0.4. The alloy composition and target value of electroslag ingot are shown in Table 7.

[0071] Table 7

[0072]

[0073] (1) According to the target composition and process requirements of the steel grade, the batching target of the vacuum induction furnace is implemented according to Table 8.

[0074] Table 8

[0075]

[0076] (2) Choose a vacuum induction furnace with a 6t crucible, and ensure that the argon pressure is at 25,000Pa during the argon filling stage. After the alloy composition reaches the target value, add 15kg of (FeCr)N to increase nitrogen, and add Ni-Mg and Si-Ca powder for deoxidation.

[0077] (3) The size of the electrode rod 4 is Φ400mm, and the oxide skin on the surface is cleaned.

[0078] ⑷ When preparing the pressurized electroslag furnace, lay 6kg of (FeCr)N on the bottom pad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com