Patents

Literature

117results about How to "Guaranteed uniformity of distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

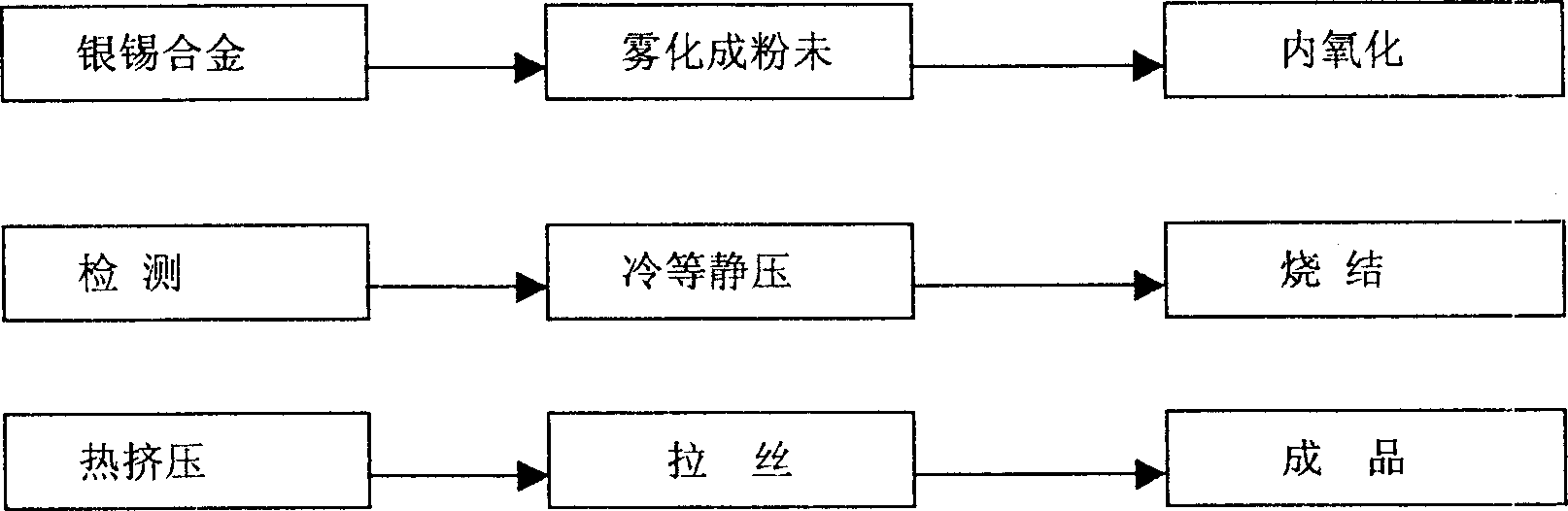

Process for preparing silver tin oxide material

InactiveCN1425790AGuaranteed uniformity of distributionNot limited by product sizeMedium frequencyIngot

The present invention relates to the preparation of contact material and is especially the preparation of silver-tin oxide material. The preparation process includes smelting silver and tin in certain ratio in a medium frequency furnace, alloy atomizing inside one high pressure water atomizing equipment, stoving to obtain powder, sieving, oxidation inside aninternal oxodizing furnace at certain temperature and oxygen pressure, cold hydrostatic processing to obtain ingot, sintering, extruding into wire and drawing into the product. The silver-tin oxide material has full oxidation of tin, firm combination between tin oxide and silver base and high comprehensive performance.

Owner:陈达峰

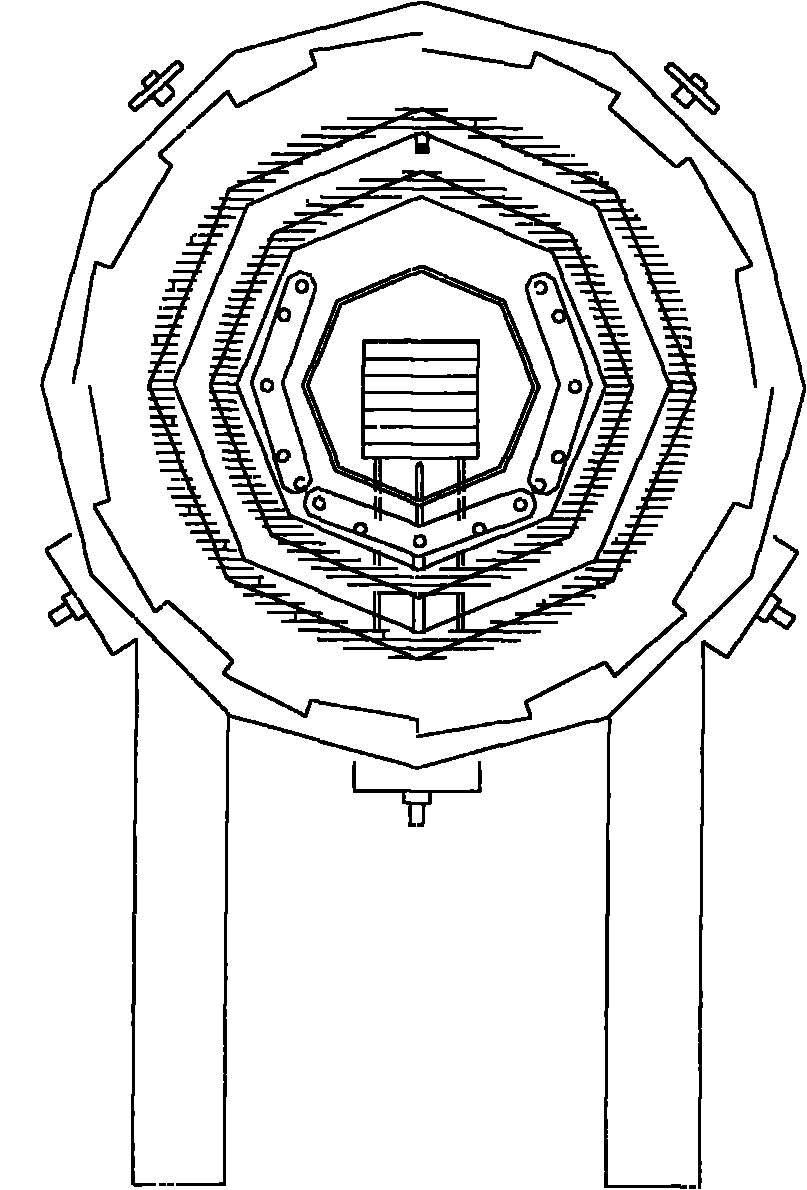

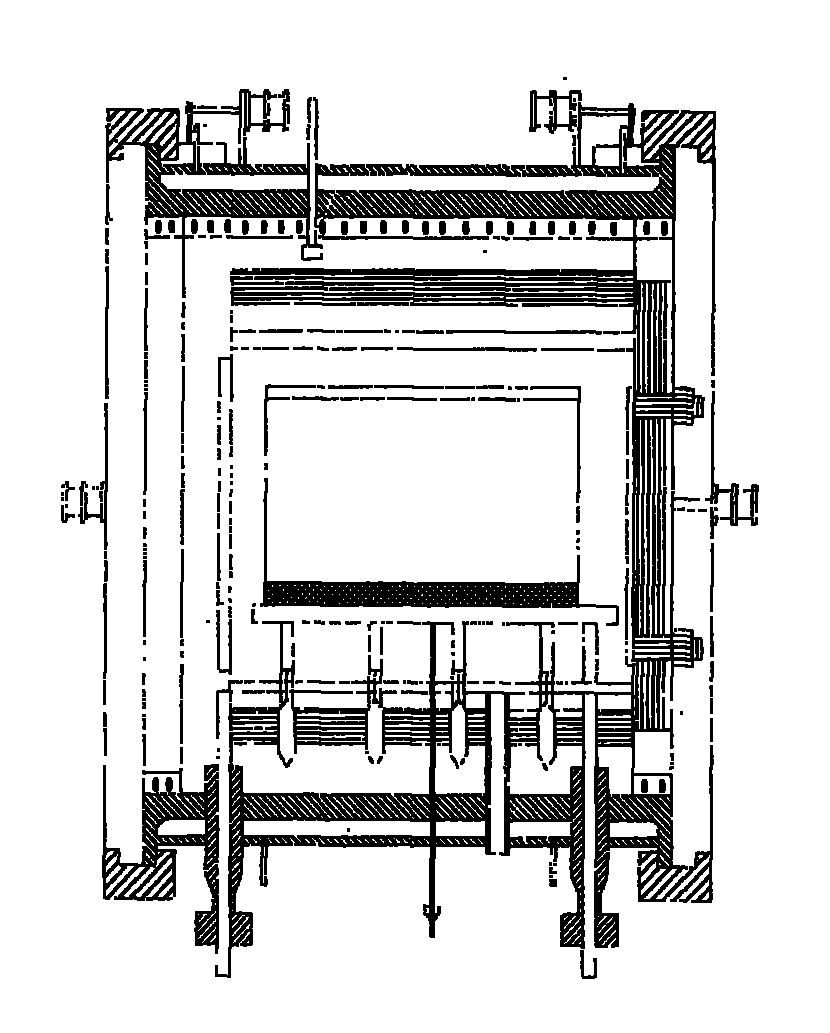

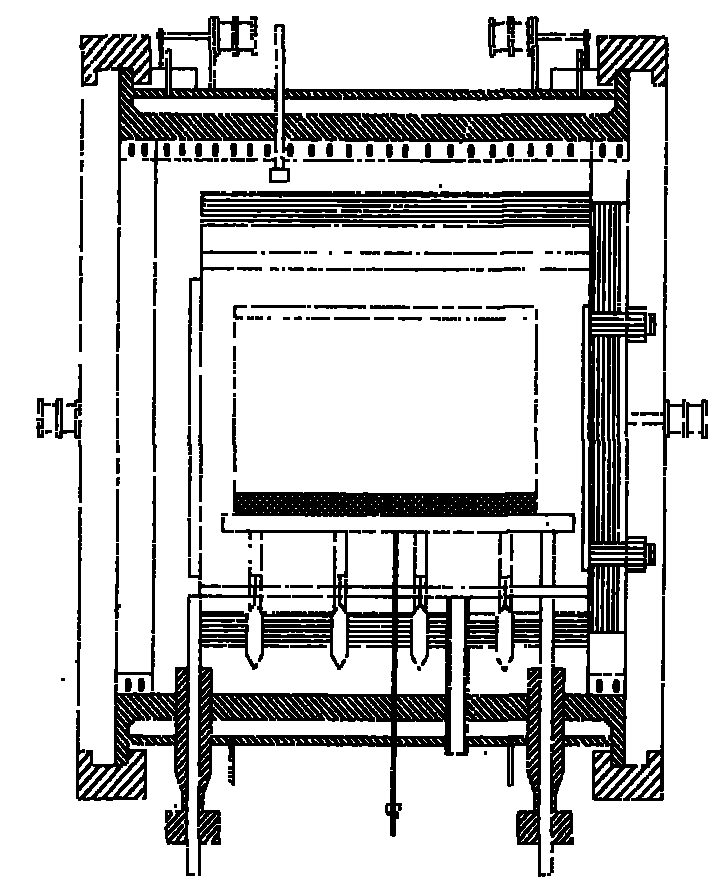

Pressure sintering furnace

InactiveCN101788226AAchieve elastic compressionSolve elastic compression problemsFurnace componentsMuffle furnacesCouplingDistribution system

The invention relates to a pressure sintering furnace used for producing hard alloys. The pressure sintering furnace comprises a furnace shell, a vacuum system, an air distribution system, a heating and thermal-insulating device, a compression system, a cooling system and a decompression device. The pressure sintering furnace is characterized in that the furnace shell is a horizontal cylinder provided with a double-wall water jacket, the furnace door on the furnace shell has a quick-opening hydraulic side-rotating structure, the furnace door of the furnace shell comprises a thermal-insulating door on the external layer of the furnace and a graphite door on the internal side of the furnace, the opening of the furnace door is controlled by a hydraulic locking device with a door-closing air cylinder, the door-closing air cylinder is provided with an elastic coupling device, and the thermal-insulating door of the furnace door is a boss thermal-insulating door. The pressure sintering furnace has stable performance and low cost and safety production can be realized by using the pressure sintering furnace, thus the uniformity of temperature field distribution in the furnace can be effectively improved and the qualification rate of products can be more than 90%.

Owner:ZHUZHOU CEMENTED CARBIDE EQUIP

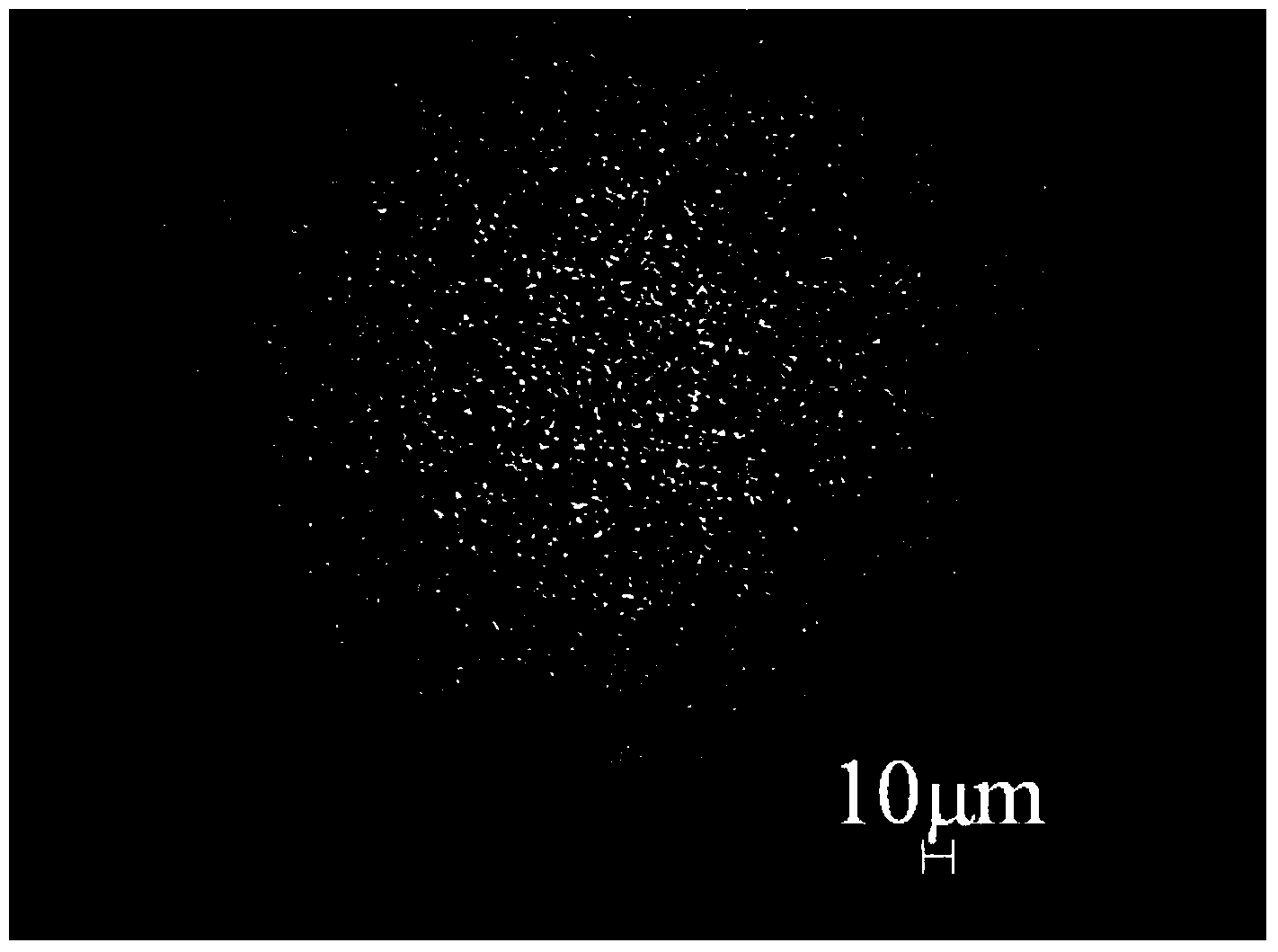

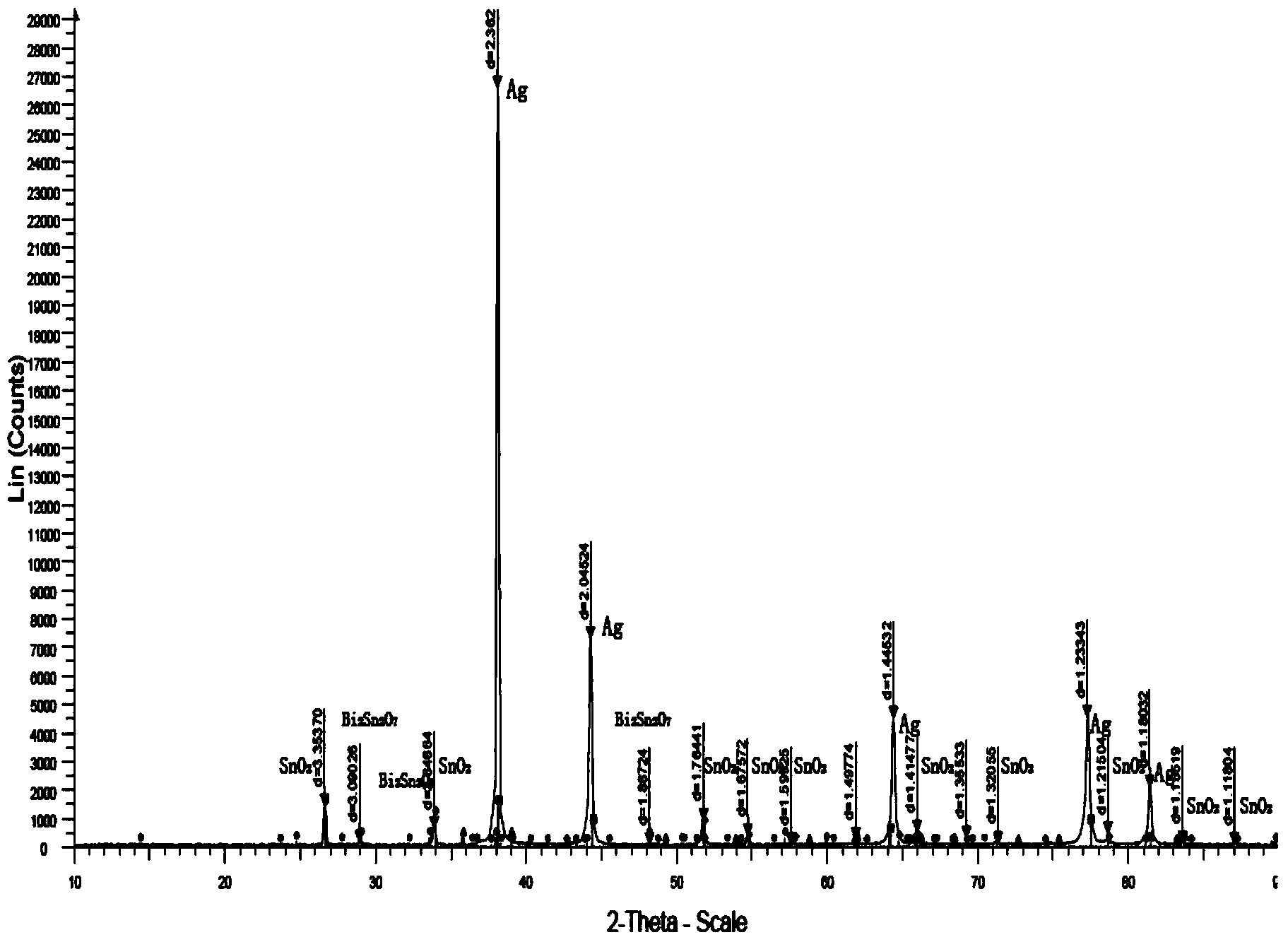

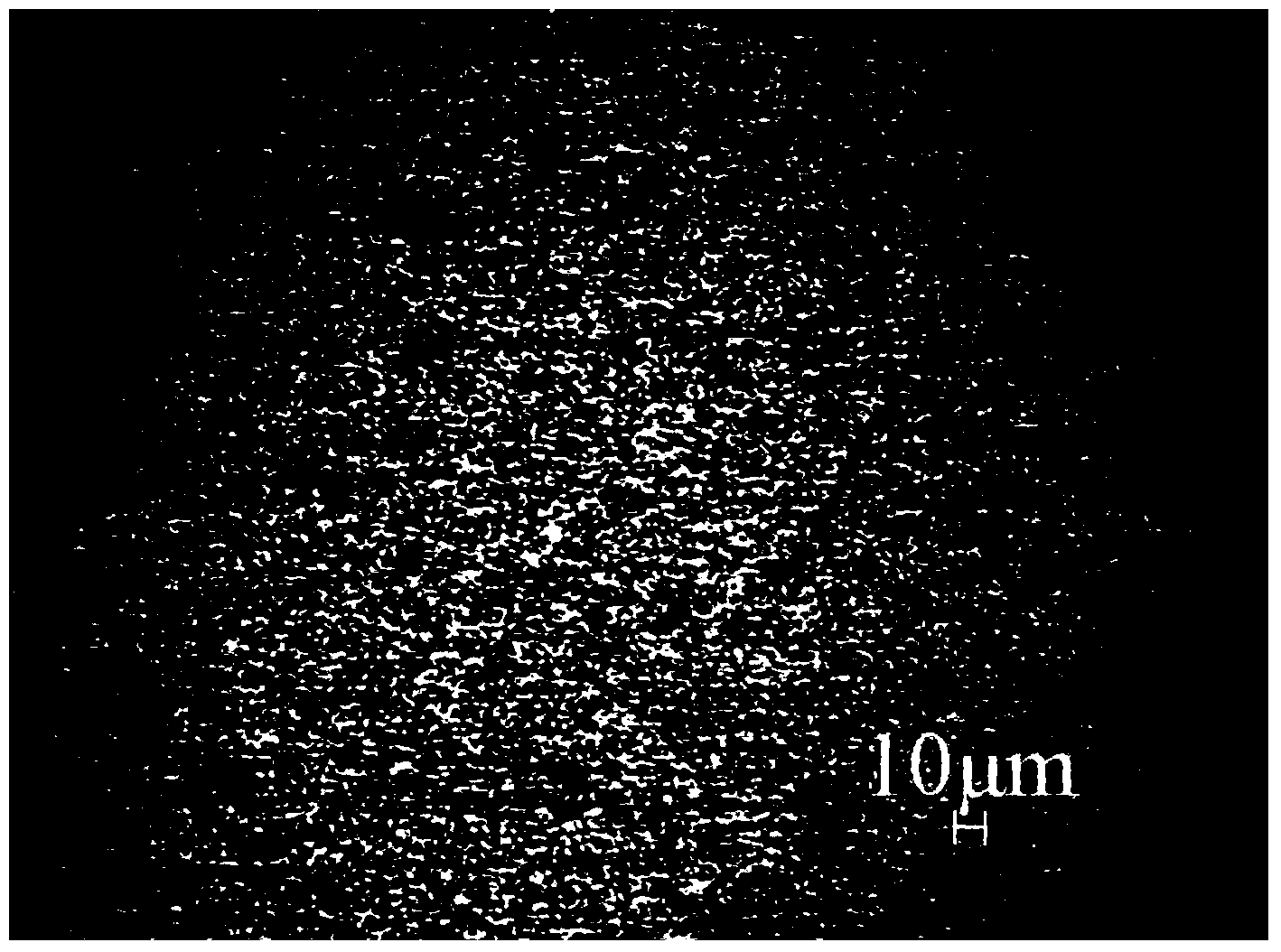

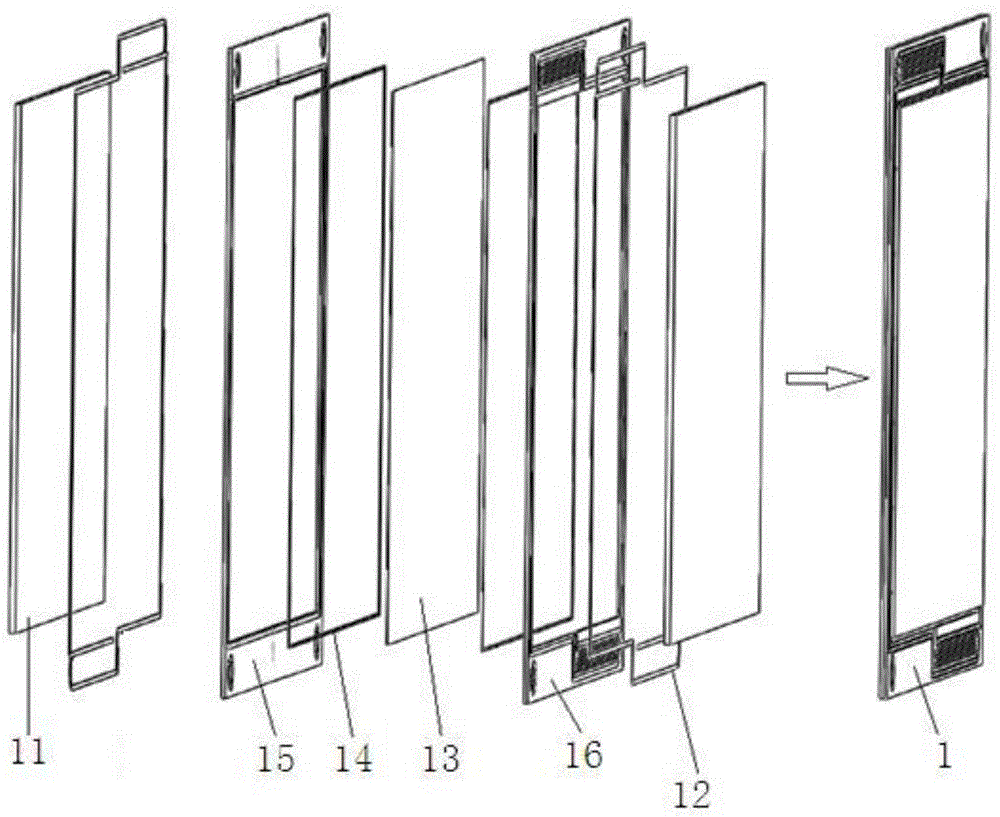

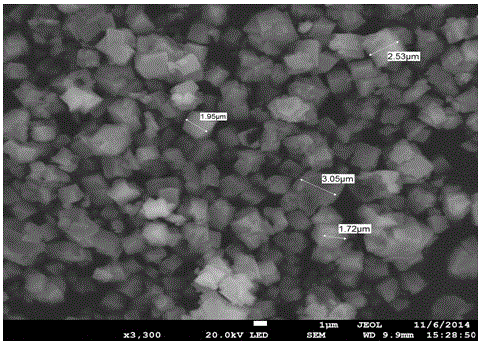

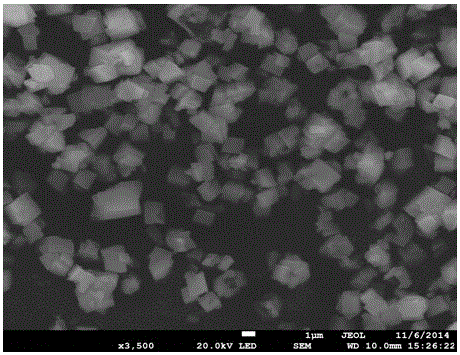

Preparation method for flaky AgSnO2 contact

ActiveCN103643074AGuaranteed uniformity of distributionGuaranteed uniformityCable/conductor manufactureIngotMetal

The invention discloses a preparation method for a flaky AgSnO2 contact. The method comprises the following steps of smelting 0.2 to 2 mass percent of metal additive and the balance of Ag in an intermediate-frequency smelting furnace to form a molten alloy, and performing atomization to prepare Ag alloy powder; mixing the Ag alloy powder with SnO2 powder in a three-dimensional mixer, and mixing the mixture in a V-shaped mixer to obtain mixed AgSnO2 powder; preparing an ingot blank from the mixed AgSnO2 powder according to a conventional method, sintering the ingot blank at high temperature in an oxygen-containing atmosphere, and performing hot extrusion and hot-rolling bonding to obtain a composite AgSnO2 / Ag strip; performing cold rolling, finish rolling and press forming on the composite AgSnO2 / Ag strip to obtain the required flaky AgSnO2 contact. The flaky AgSnO2 contact prepared by the method has the advantages of uniform distribution of SnO2 particles and a trace of additive, stable electrical properties and the like, and a process is simple and suitable for batch production.

Owner:桂林金格电工电子材料科技有限公司

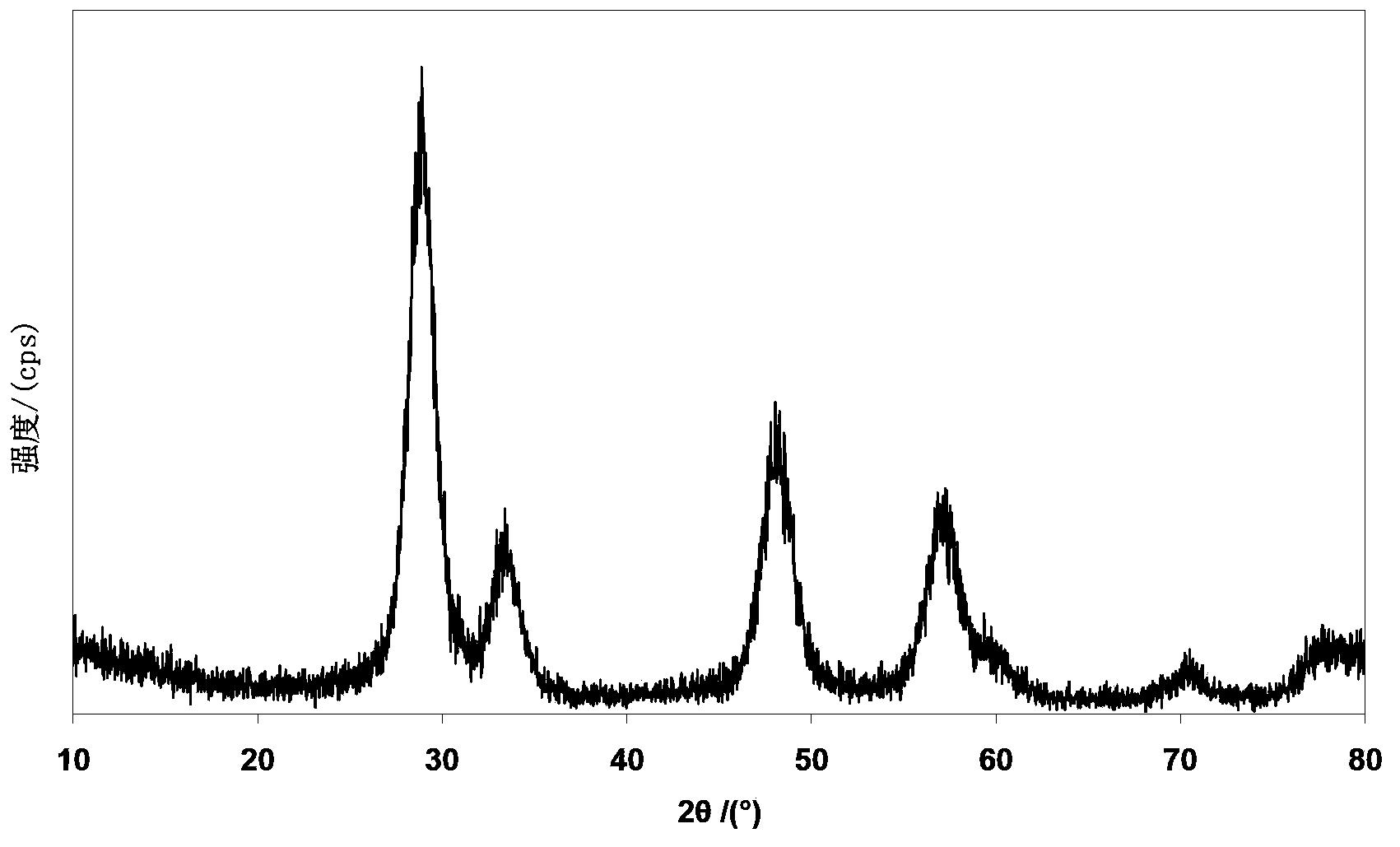

Multi-ion-doped carbon-coated lithium iron phosphate battery material and preparation method thereof

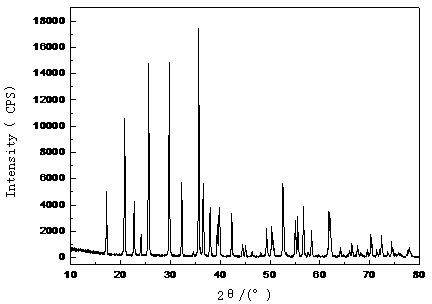

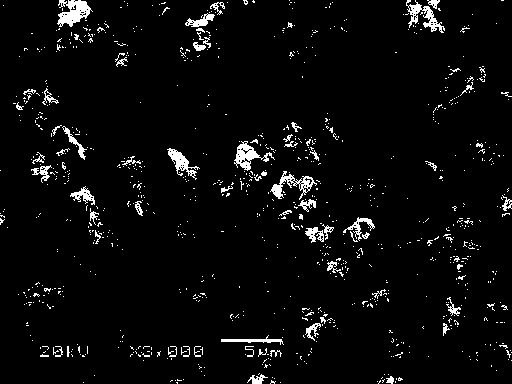

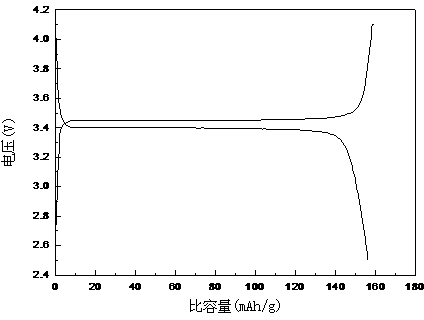

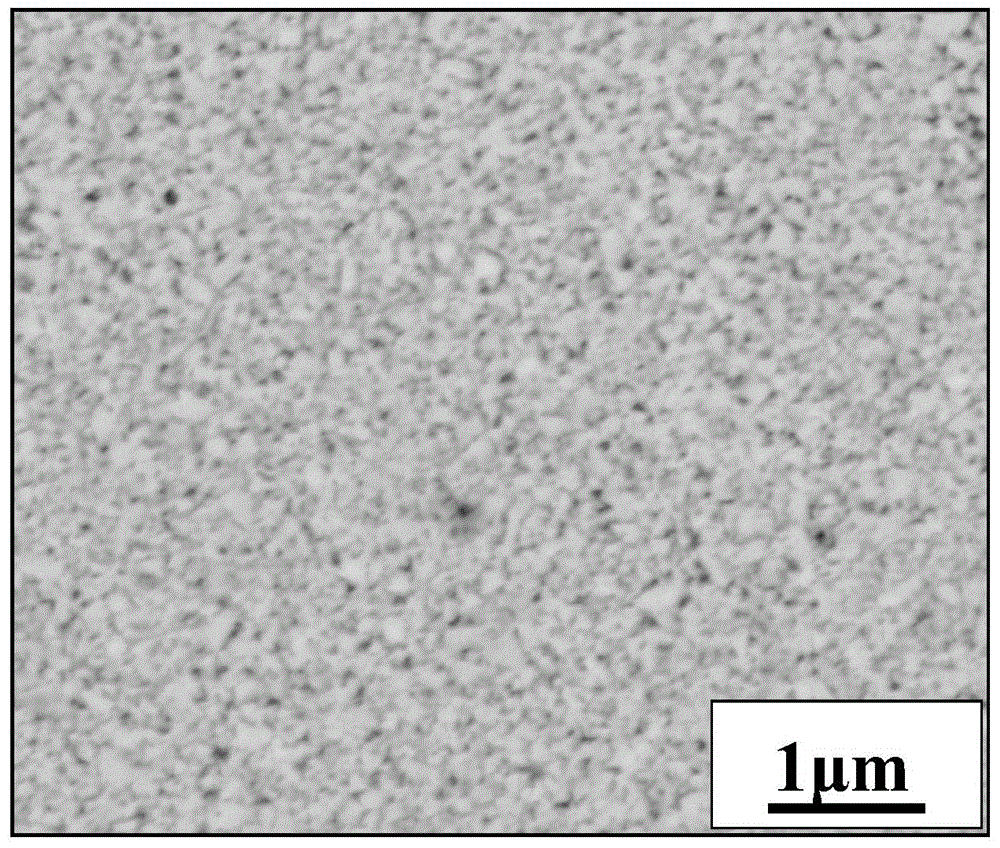

InactiveCN103367746AGuaranteed uniformityImprove electronic conductivityCell electrodesChemistryCrystal

The invention discloses a multi-ion-doped carbon-coated lithium iron phosphate battery material and a preparation method thereof. The material has a structure of Li1-x M'x Fe1-y My (PO4)1-zFz / C, wherein x is more than or equal to 0.001 and less than or equal to 0.1, y is more than or equal to 0.001 and less than or equal to 0.1, z is more than or equal to 0.001 and less than or equal to 0.1, M' and M are respectively metal ions doped at the lithium position and the iron position, C is organic matter pyrolysis carbon covered on the surface of lithium iron phosphate, and M' and F come from fluoride M' Fn (n is equal to 1, 2, 3 or 4). The preparation method comprises the steps of: (1) preparing doped iron phosphate containing crystal water by a coprecipitation method; (2) carrying out heat treatment on the iron phosphate containing the crystal water, and removing the crystal water; and (3) mixing the doped iron phosphate, lithium source, the fluoride M' Fn and organic carbon source, carrying out ball-milling, drying and roasting to obtain the multi-ion-doped carbon-coated lithium iron phosphate battery material. The preparation method is simple and easy in technology, and the prepared lithium iron phosphate is high in specific discharge capacity and excellent in rate capability, thus having application prospect in the field of a power battery.

Owner:YANTAI ZHUONENG BATTERY MATERIAL

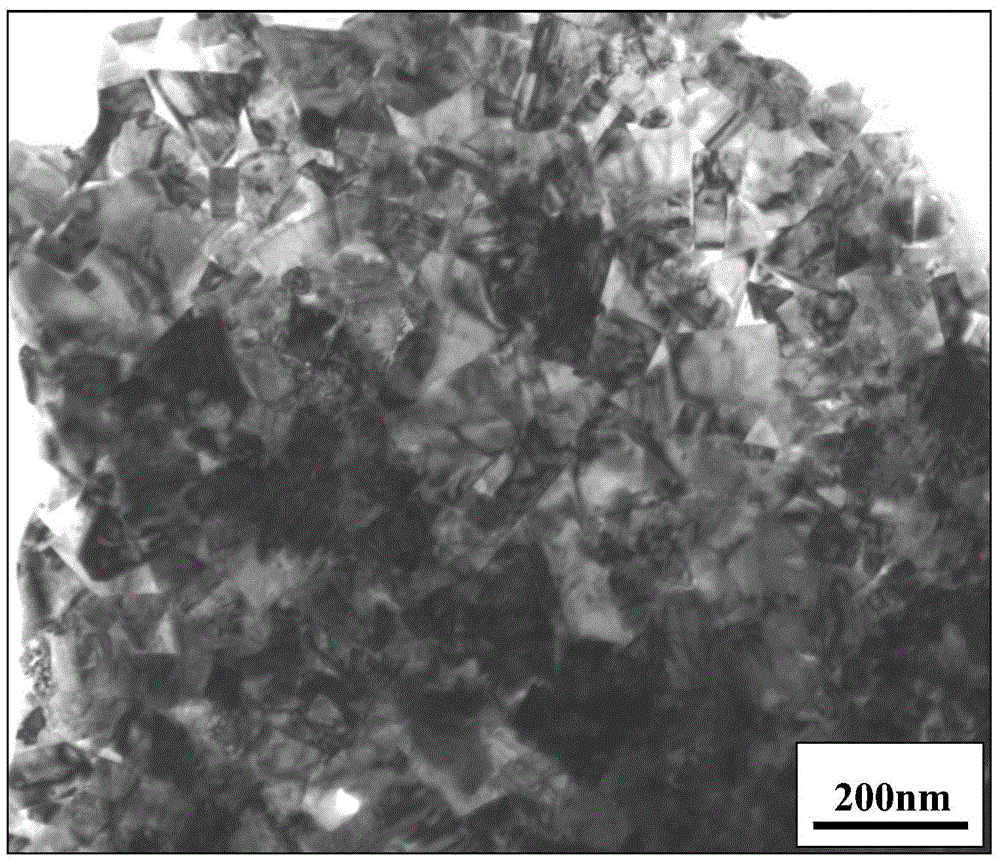

Method for preparing high density nanocrystalline hard alloy by step sintering

The invention provides a method for preparing a high density nanocrystalline hard alloy by step sintering, and belongs to the technical field of novel materials and novel powder metallurgy. The method comprises the following steps: firstly determining the dosage of the raw materials according to the requirements on the content of Co in the final hard alloy based on nanoscale purple tungsten oxide, cobaltous oxide, carbon black and mixed powder of vanadium oxide and chromic oxide as raw materials, mixing the raw materials and performing ball milling, then pressing the raw materials to blocks and conveying the pressed raw materials into a vacuum pump to perform a in-situ reaction to prepare nanometer composite powder with uniform distribution and good dispersity; filling the nanometer composite powder into a high density hard alloy mold, performing discharge plasma sintering, and performing segmented heating, heating up and heat preservation processes to obtain a pre-sintered block with controllable length and size of crystalline grain; finally, putting the pre-sintered block in a high-strength graphite mold to perform high temperature instant discharge plasma quick sintering densification to finally obtain a dense nanocrystalline hard alloy block material. The method provided by the invention can be used for effectively improving the density and mechanical properties of the hard alloy block material.

Owner:BEIJING UNIV OF TECH

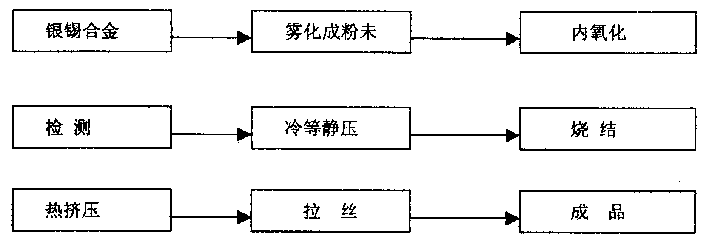

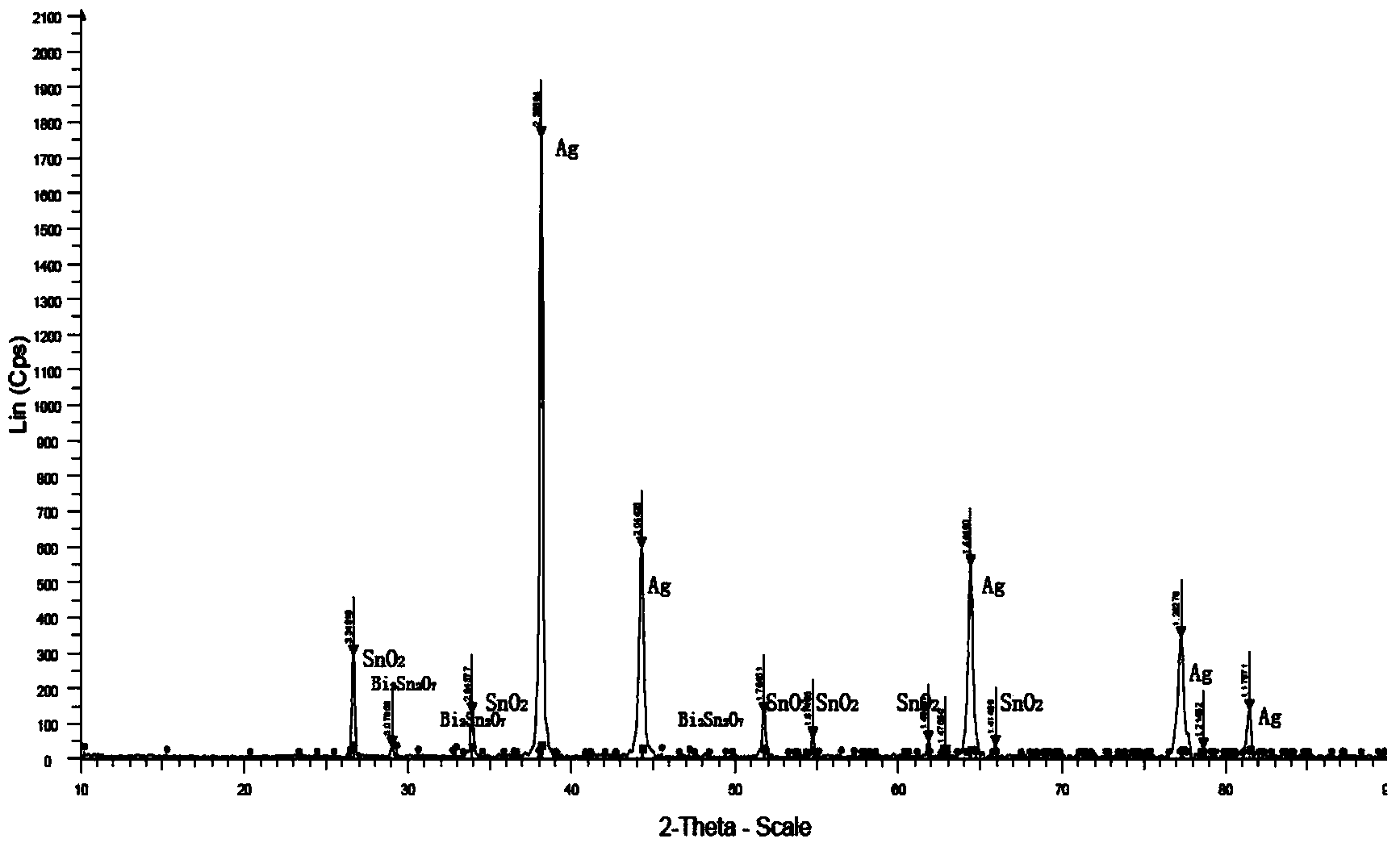

Method for preparing AgSnO2 wire

ActiveCN103639232AGuaranteed uniformity of distributionGuaranteed uniformityWire rodIntermediate frequency

The invention discloses a method for preparing an AgSnO2 wire. The method comprises the following steps: smelting 0.2-2 percent by mass of metal additive and the balance of Ag into alloy melt in an intermediate frequency smelting furnace, and atomizing to prepare Ag alloy powder, wherein the metal additive is selected from one or more of Bi, Cu, In and Sb; mixing the Ag alloy powder and SnO2 powder in a three-dimensional mixer, mixing the mixture in a V-shaped mixer to obtain mixed AgSnO2 powder; preparing the mixed AgSnO2 powder into an ingot blank according to a conventional method, sintering the ingot blank at high temperature in an oxygen-containing atmosphere, and performing hot extrusion and drawing to obtain the AgSnO2 wire. The AgSnO2 wire prepared by the method has the advantages that the SnO2 particles and trace additives are uniform in distribution, the material processability is excellent, the electrical performance is stable and the like, and the preparation method is simple in process and suitable for batch production.

Owner:桂林金格电工电子材料科技有限公司

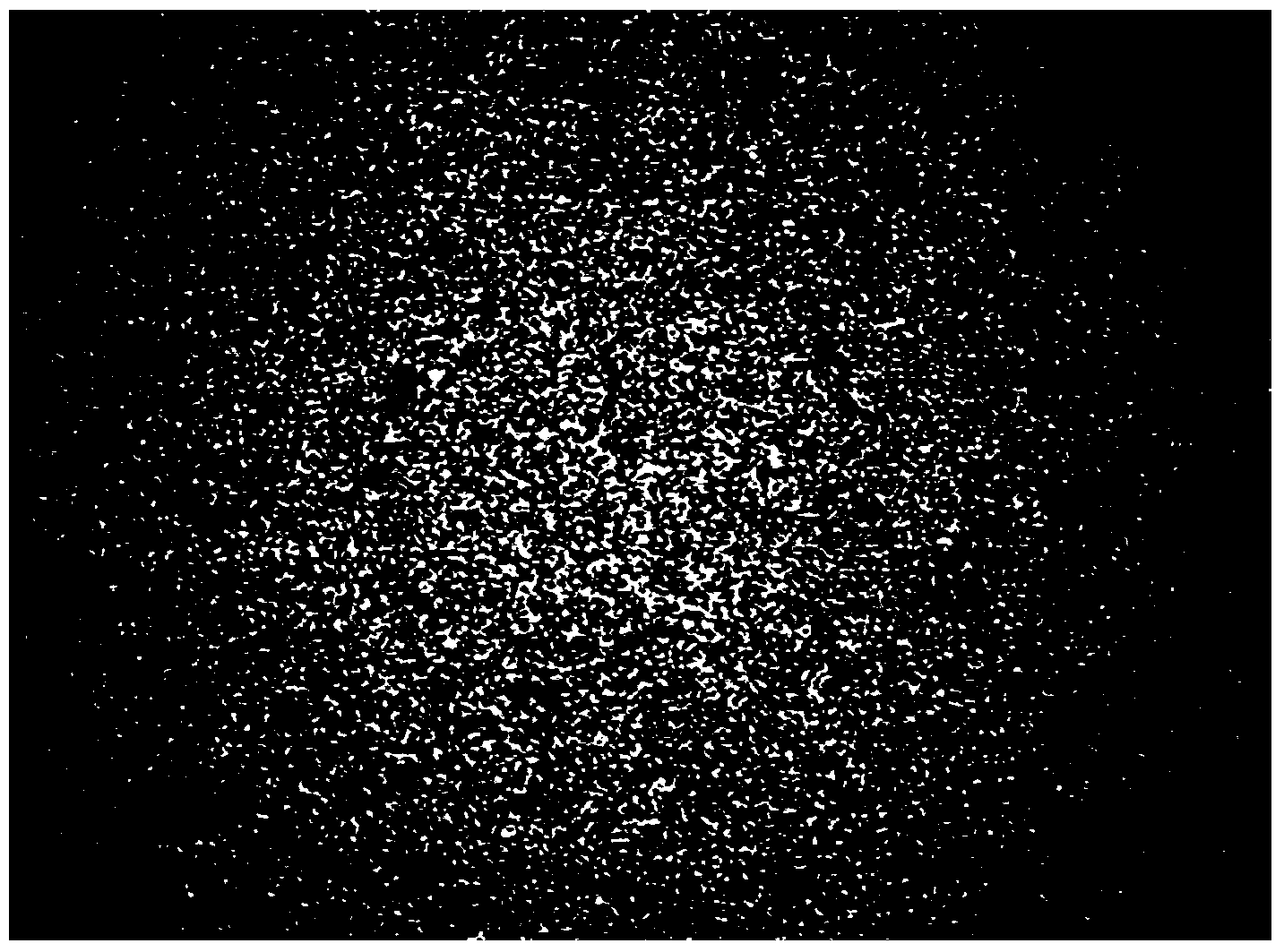

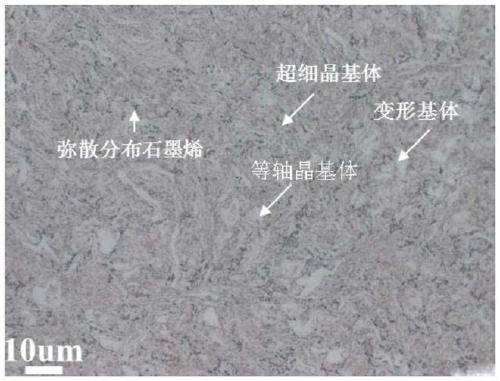

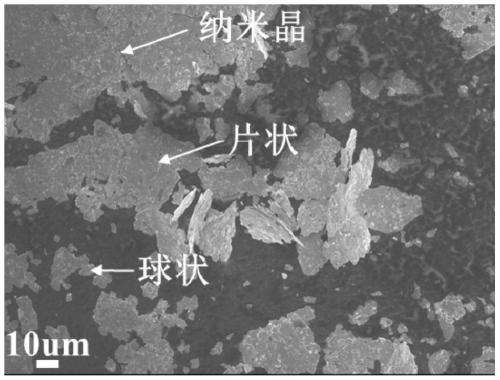

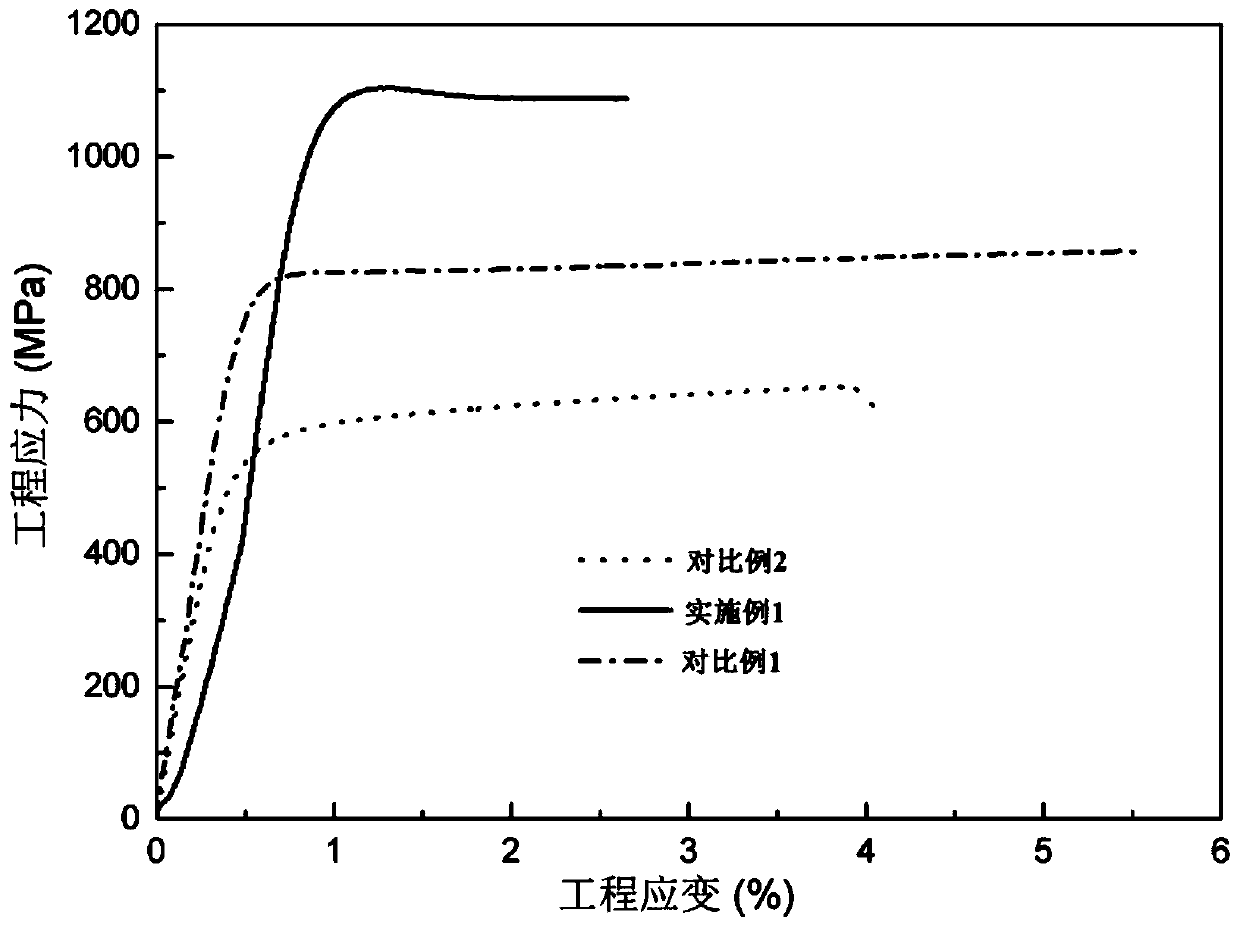

Preparation method of graphene enhanced FCC-type high-entropy alloy

ActiveCN111534712AImprove strong plasticityGood strength and plasticity matchingHigh entropy alloysGraphite

The invention discloses a preparation method of a graphene enhanced FCC-type high-entropy alloy. The method comprises the steps that 1, FCC-type high-entropy alloy powder is prepared by a gas atomization method; 2, the FCC-type high-entropy alloy powder is subjected to ball milling and then dried; 3, the dried FCC-type high-entropy alloy powder is mixed with graphene nanoflakes, then composite powder is obtained by ball milling; and 4, the composite powder is subjected to spark plasma sintering, and the graphene enhanced FCC-type high-entropy alloy is obtained after cooled in a furnace. According to the preparation method, short-time high-energy ball milling is adopted, so that the FCC-type high-entropy alloy powder forms multi-scale lamellar structures and produces fine nanocrystals, combined with low-energy ball milling, the graphene nanoflakes are completely and evenly dispersed between the lamellar structures, the graphene enhanced FCC-type high-entropy alloy with multi-scale crystals is prepared, the strengthening effect is effectively enhanced, and the good matching of strength and plasticity is achieved.

Owner:西安稀有金属材料研究院有限公司 +1

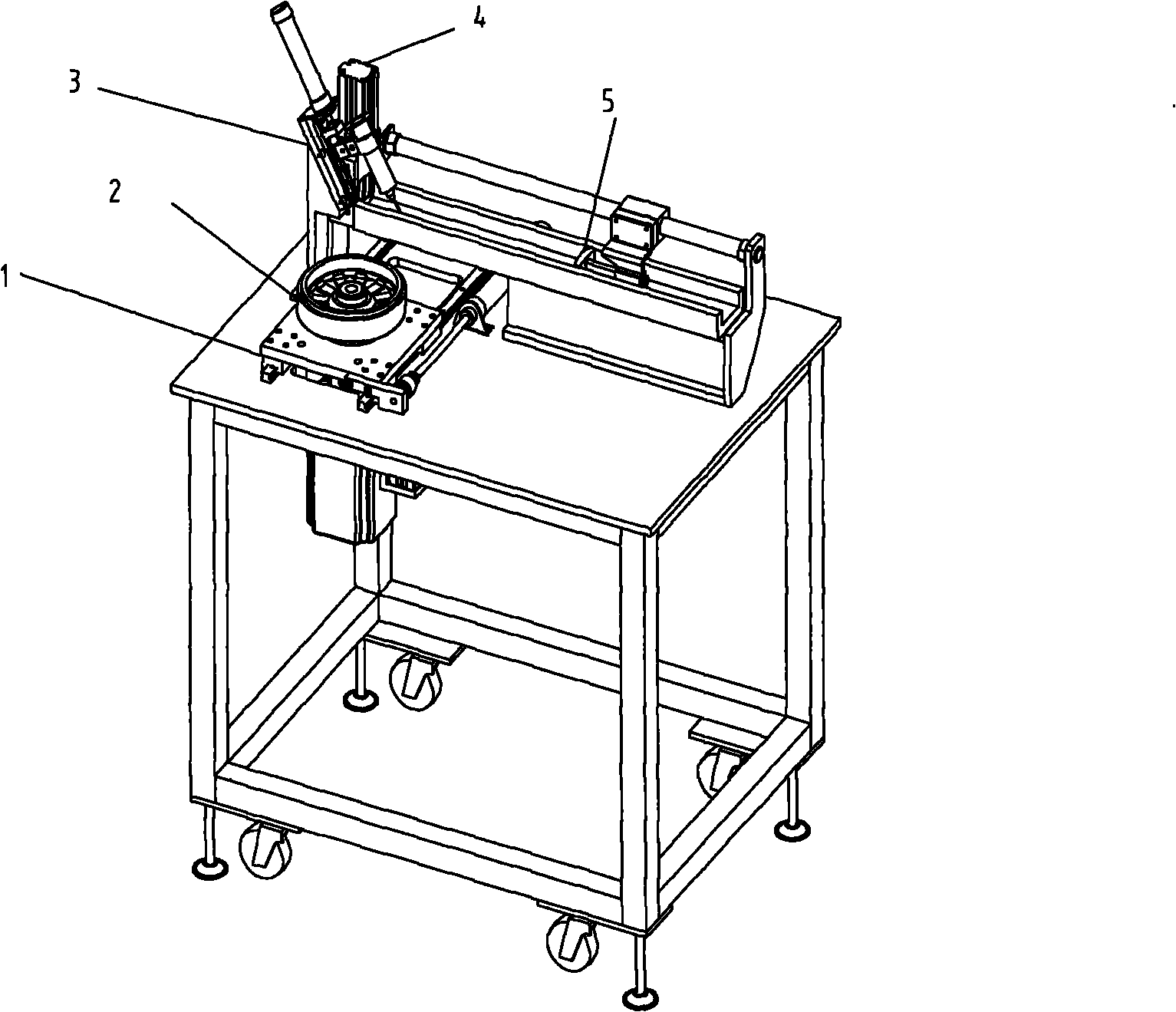

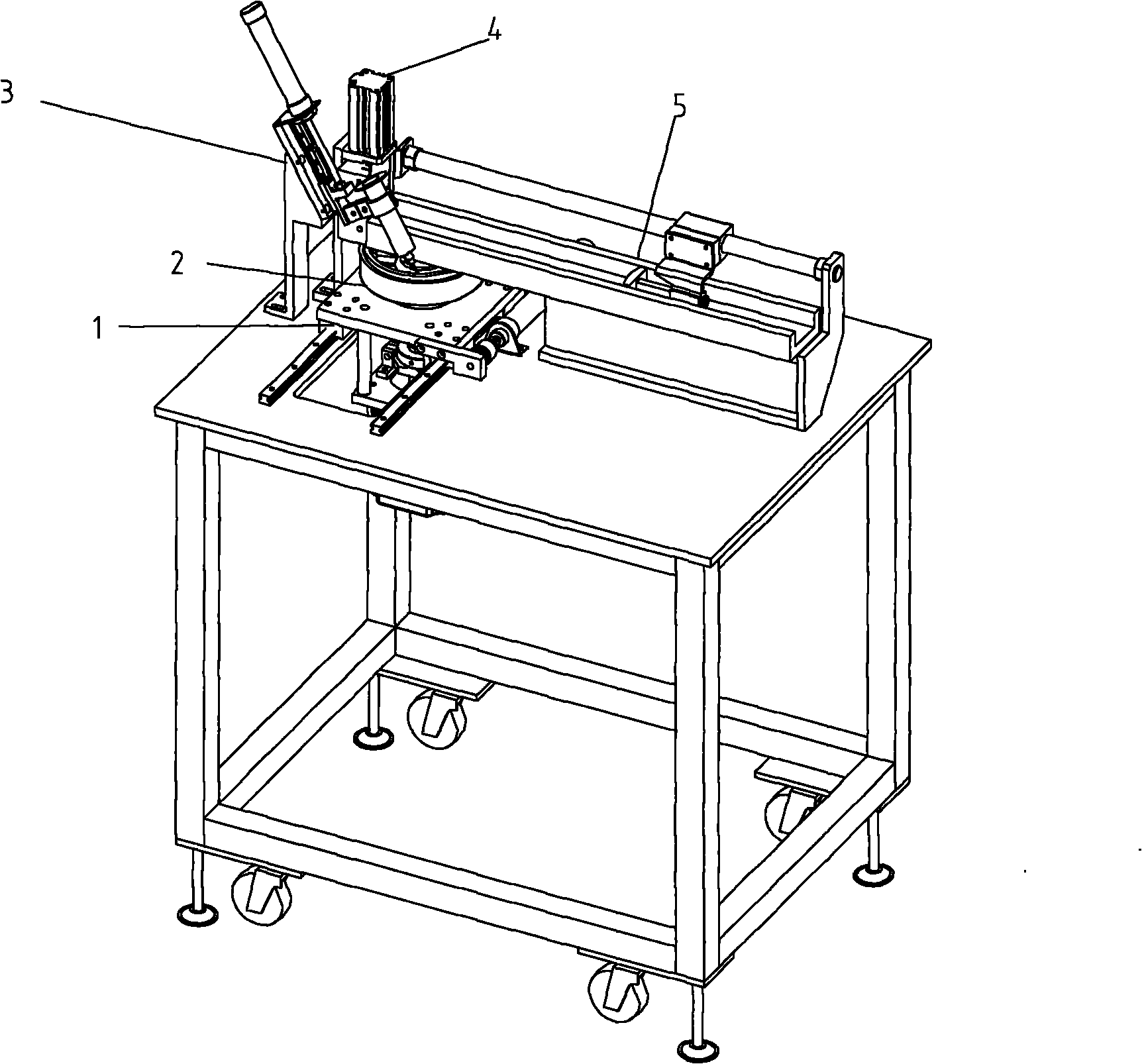

Automatic insertion machine of magnetic steel of motor

InactiveCN101877516AImprove insertion efficiencyGuaranteed uniformity of distributionManufacturing stator/rotor bodiesMagnetStator

The invention relates to an automatic insertion machine of magnetic steel of a motor, which comprises a telescopic platform with a stator, a motor driving the stator to rotate and a track erected above the platform and used for conveying the magnetic steel. The automatic insertion machine is characterized in that one end of the track is provided with a magnet used for attracting the magnetic steel above the stator, and a cylinder used for pressing the magnetic steel into the installing position inside the stator is arranged above the installing position; and the operation of the insertion machine is controlled by program, thereby realizing automatic operation.

Owner:SUZHOU INDAL PARK TAIGE ELECTRONICS SCI &TECH

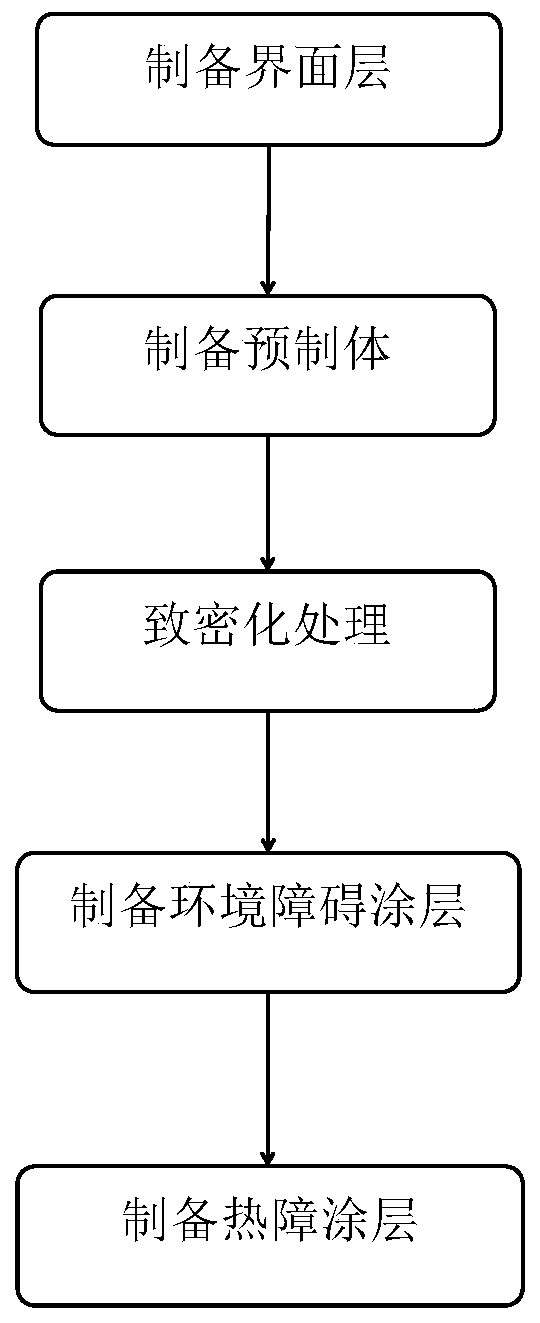

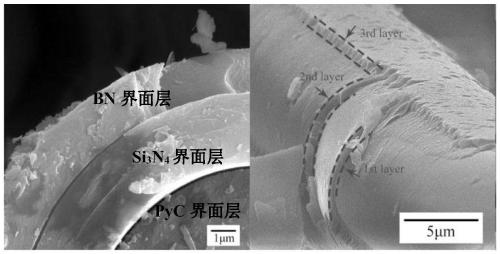

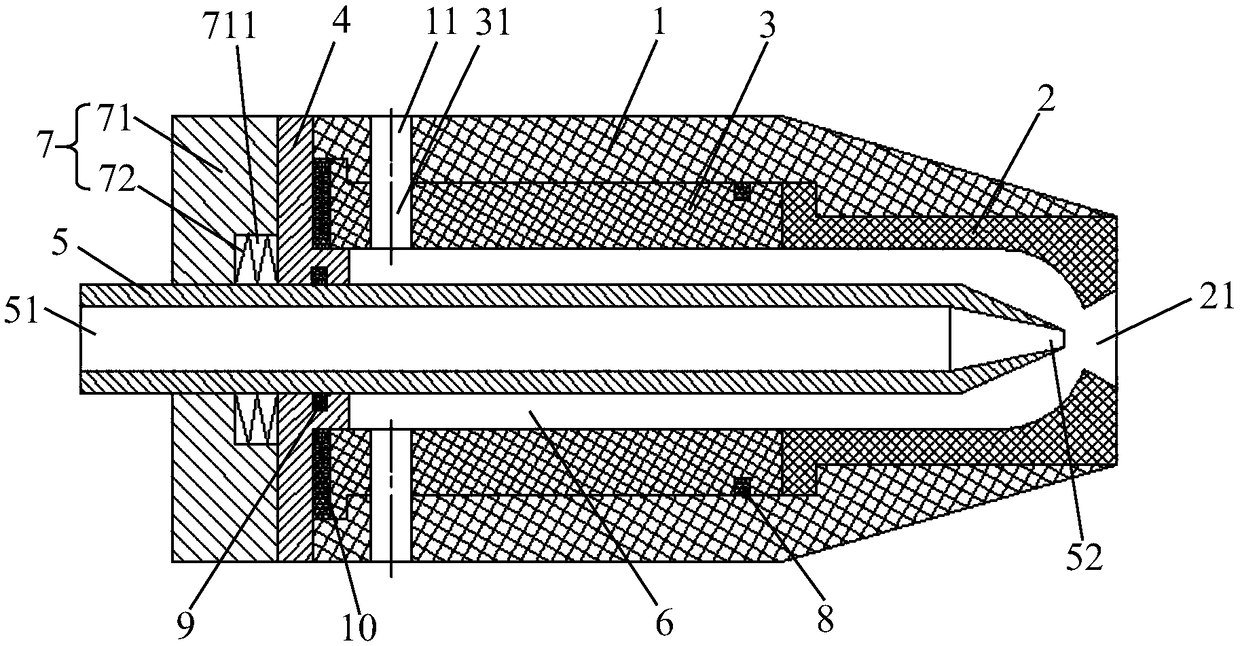

SiCf/SiC composite material flame tube and automatic preparation method thereof

ActiveCN110330353AHigh mechanical strengthCorrosion protectionContinuous combustion chamberCeramic layered productsPolymer scienceGas phase

The invention discloses an automatic preparation method of a SiCf / SiC composite material flame tube. The preparation method comprises the following steps: preparing an interface layer from SiC fibersby adopting chemical vapor deposition, so as to obtain SiC fibers with a continuous interface layer; performing unidirectional tape laying and filament winding on the SiC fibers with the continuous interface layer according to the fiber volume and fiber orientation obtained by simulation calculation, so as to obtain net size forming preform; performing densifying treatment on the obtained preformby adopting a reactive melt infiltration process and the chemical vapor deposition process; preparing an environmental barrier coating on the surface of the obtained preform; finally, continuously preparing a thermal barrier coating on the surface, thereby fully intelligently obtaining the high-density SiCf / SiC composite material flame tube. The SiCf / SiC composite material flame tube prepared withthe method disclosed by the invention has the characteristics of high temperature resistance and long service life and also has the advantages such as low thermal expansion coefficient, high thermalconductivity, high thermal shock resistance and excellent mechanical property. Meanwhile, the preparation method is high in degree of automation, short in production cycle, low in cost and controllable in quality.

Owner:CENT SOUTH UNIV

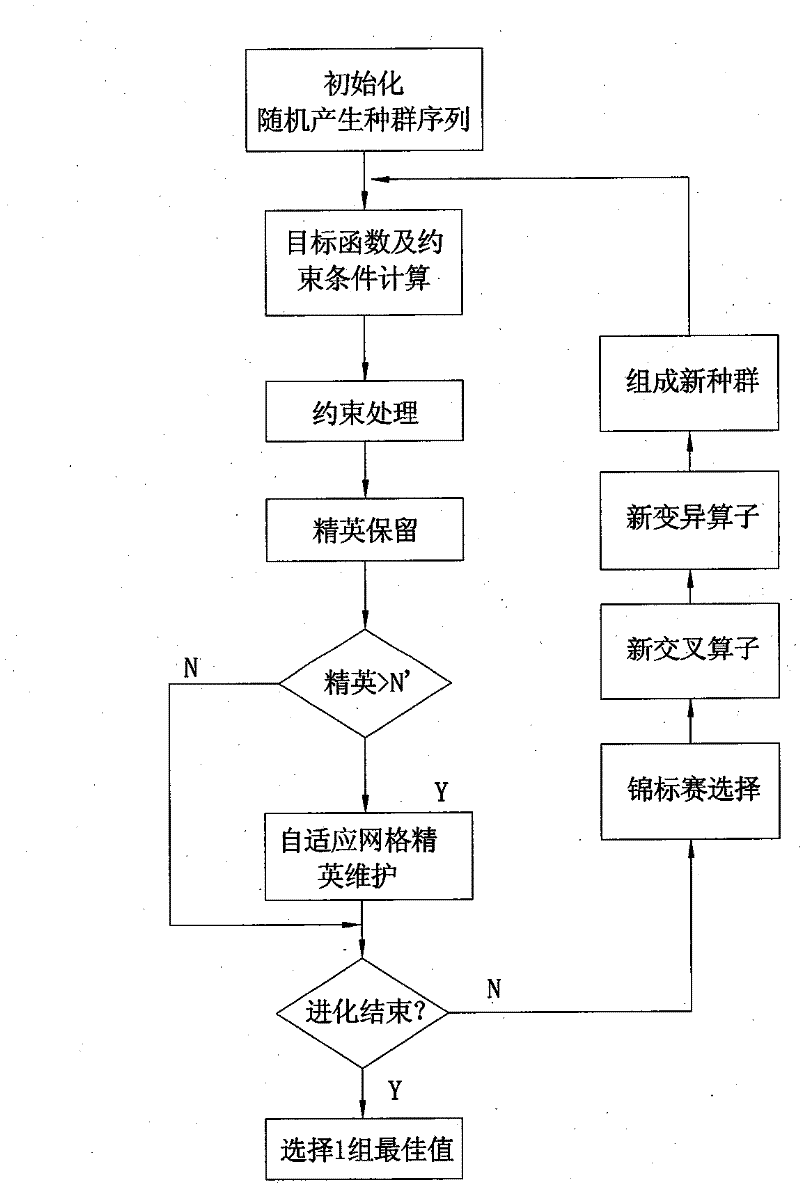

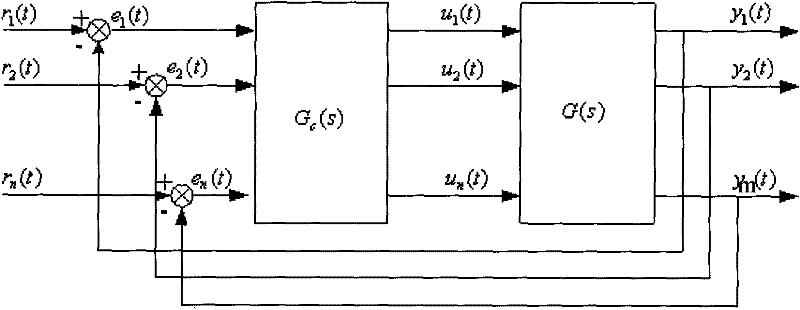

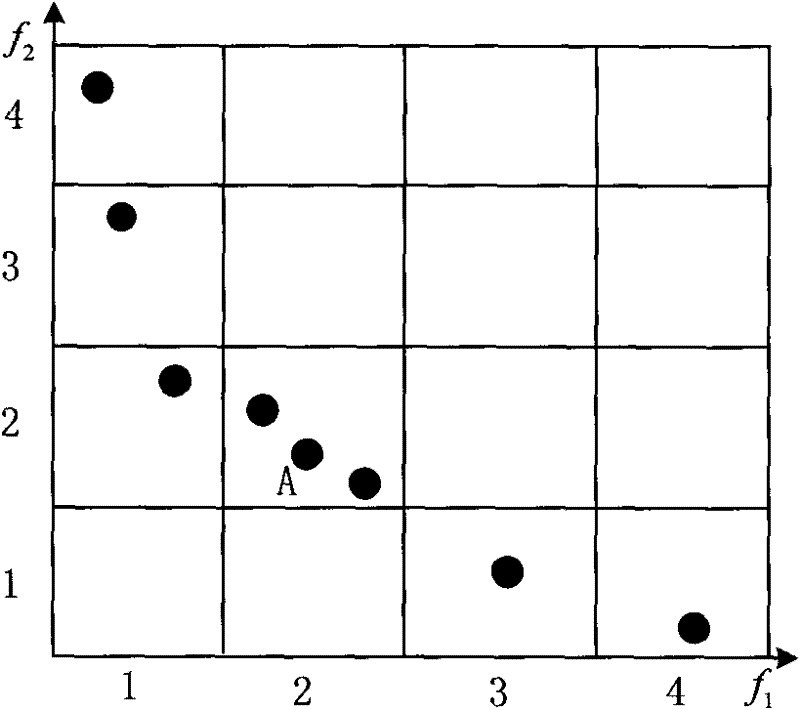

Method for carrying out multi-objective optimization on parameters of nonlinear MIMO (multiple input multiple output) PID (proportional-integral-derivative) controller

The invention discloses a method for carrying out multi-objective optimization on parameters of a nonlinear MIMO (multiple input multiple output) PID (proportional-integral-derivative) controller, and is characterized in that: 1. optimization objective: under the premise of satisfying a condition that the maximum overshoot is 50% less than a preset value and the static error is 1% less than a preset value, the sum of accumulated errors is minimized, and the energy consumption is lowest; 2. an operation of optimization problem solving is performed by using a multi-objective genetic algorithm; and an operation of algorithm improvement comprises a step of introducing quaternary codes, crossover and mutation operators and an adaptive density information based elite reservation and strategy; and 3. the numeric selection range of parameters is set according to the algorithm provided by the method, and the parameters of the controller is optimized. The method disclosed by the invention has the advantages that an operation of repeated debugging is not required to be performed, the multi-objective optimization can be performed on parameters in a given mode, and parameters with small static error, small overshoot and low energy consumption can be found out quickly; the method is intuitive, easy to operate and can carry out multivariable control on the expansion of objects; and a first-order time delay model and a PID controller are widely used in the existing industrial process, and an object model facilitates the industrial measurement.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

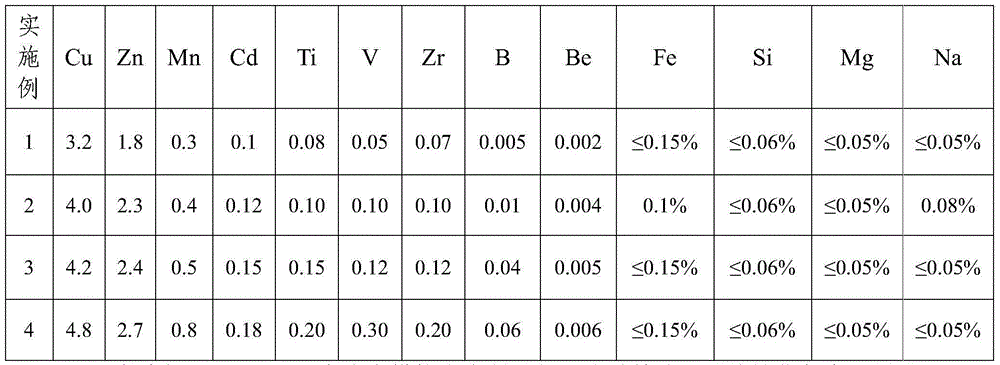

Liquid forging Al-Cu-Zn aluminum alloy and preparation method thereof

Belonging to the light alloy design and preparation field, the invention relates to a moderately strong high toughness aluminum alloy material for liquid forging, in particular to a liquid forging Al-Cu-Zn aluminum alloy and a preparation method thereof. The alloy comprises the following main components by mass: 3.2-4.8% of Cu, 1.8-3.0% of Zn, 0.3-0.8% of Mn, 0.08-0.22% of Cd, 0.06-0.24% of Ti, 0.05-0.15% of V, 0.07-0.16% of Zr, 0.005-0.06% of B, 0.002-0.006% of Be, less than or equal to 0.15% of impurity element Fe, less than or equal to 0.1% of Mg, less than or equal to 0.06% of Si, less than or equal to 0.05% of other single impurity element, less than or equal to 0.3% of total impurities, and the balance Al. The Al-Cu-Zn system moderately strong high toughness aluminum alloy mentioned in the invention has the advantages of excellent formability during liquid forging forming, no hot cracking tendency, low porosity and low segregation. After heat treatment, the components prepared from the alloy have excellent strength and plasticity, superiority unmatched by other active alloys, and have broad application prospects.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

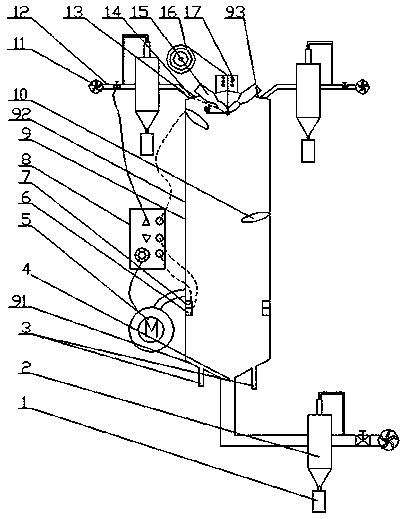

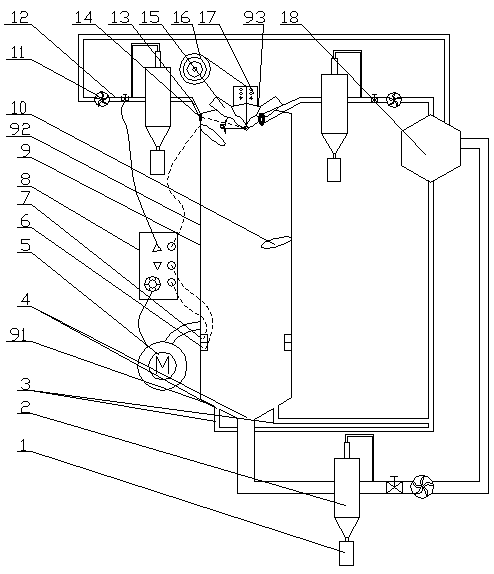

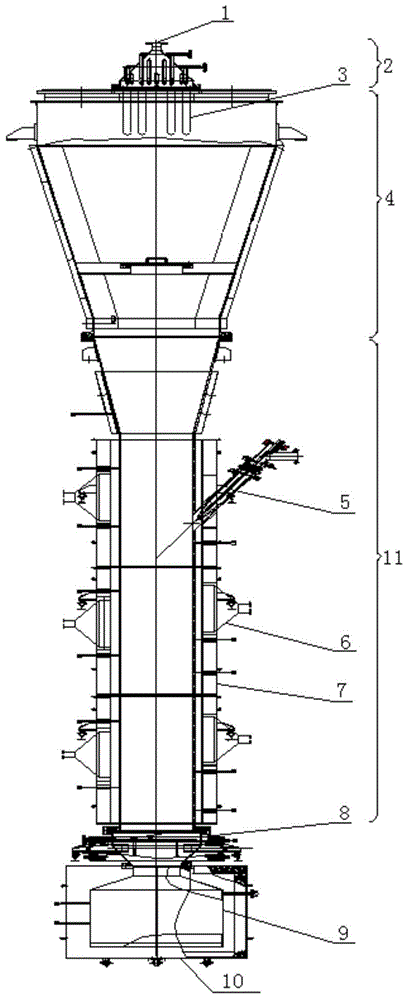

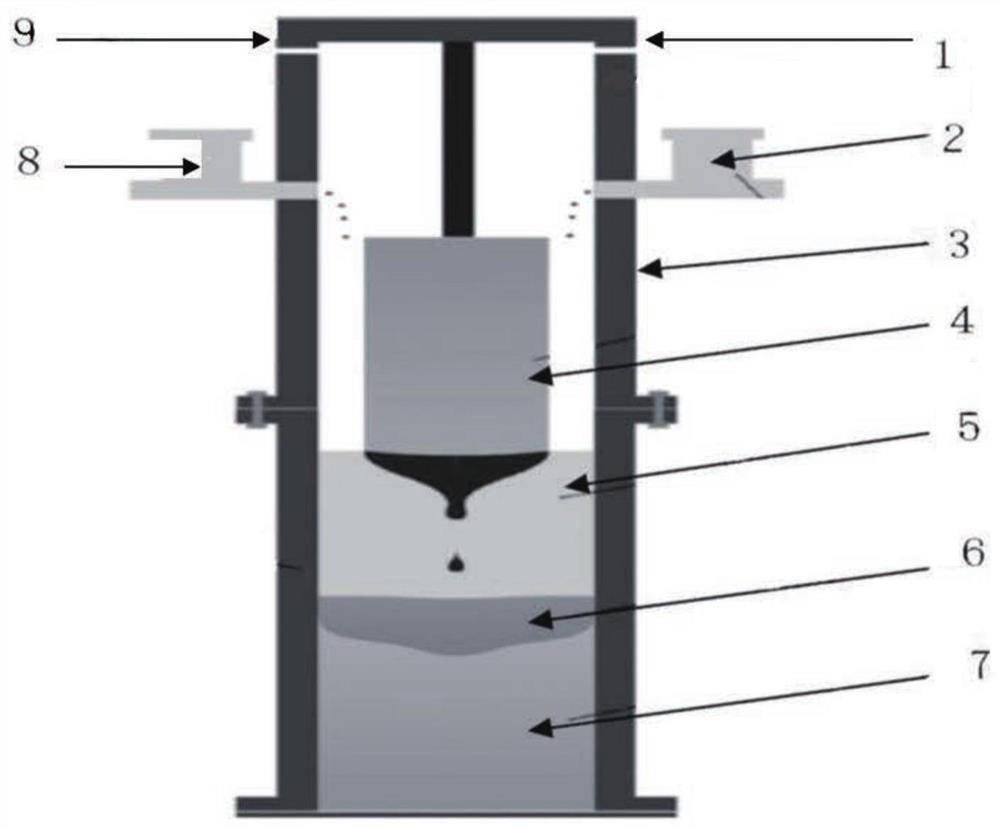

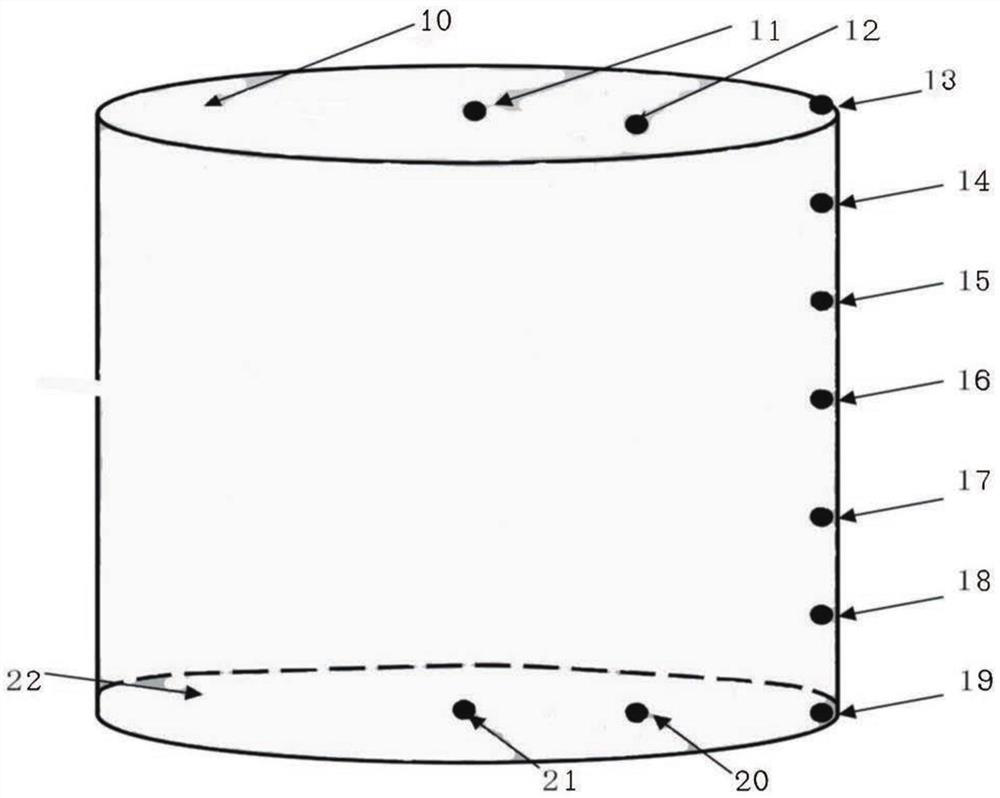

Metal atomization pulverizing equipment with low satellite sphere content

ActiveCN107661983AIncrease heat exchange rateReduce the chance of satellite formationGranularityTower

The invention provides metal atomization pulverizing equipment with low satellite sphere content. The metal atomization pulverizing equipment comprises a metal feeding mechanism, an atomization device, an atomization tower and a powder separation device, wherein the metal feeding mechanism is connected with the atomization device; the atomization device is mounted at the top of the atomization tower; a main powder outlet is formed in the bottom of the atomization tower; the main powder outlet is communicated with the powder separation device; no less than three powder outlet holes are formed in the upper end or a sealing end of a side wall of the atomization tower; the powder outlet holes are formed in the periphery of an atomization powder output and coke collection region at the bottom of the atomization device; the powder outlet holes are connected with the powder separation device through a powder output pipeline. The metal atomization pulverizing equipment with the low satellite sphere content, provided by the invention, is simple in structure and convenient to use; metal atomization powder prepared by the equipment has uniform and small granularity, high spherical degree, good flowability and low satellite sphere content, and performance requirements on various types of metal powder in the market can be met; the equipment is low in manufacturing cost and is convenient forbatch production; urgent requirements on high-performance metal powder at home and abroad can be met.

Owner:HUNAN TIANJI SMART MATERIAL TECH CO LTD

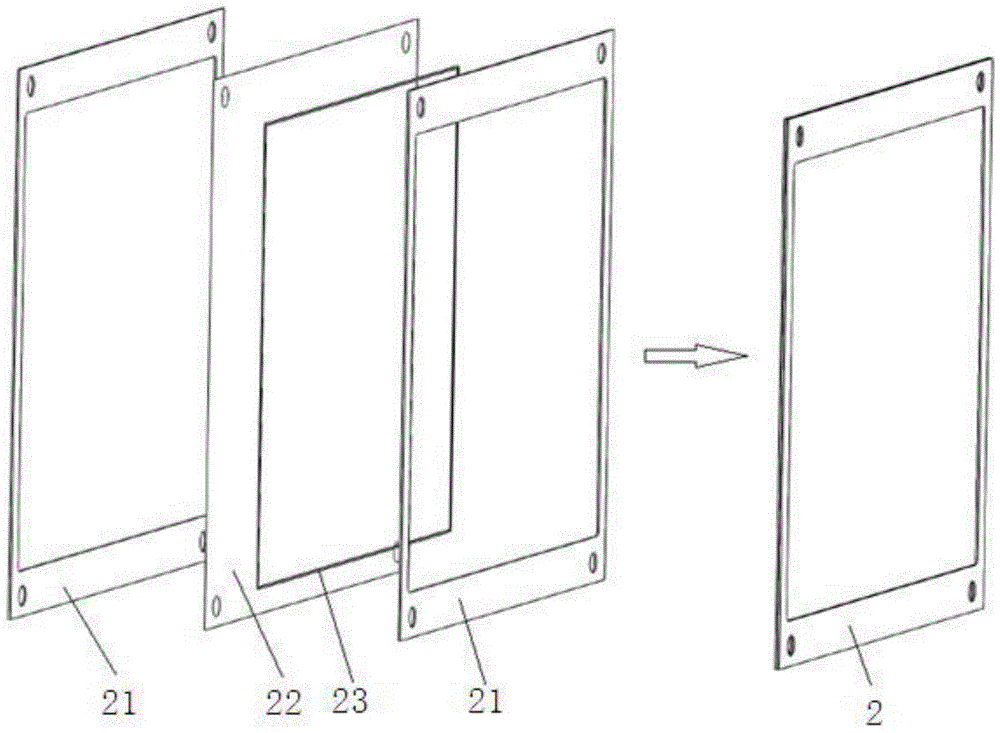

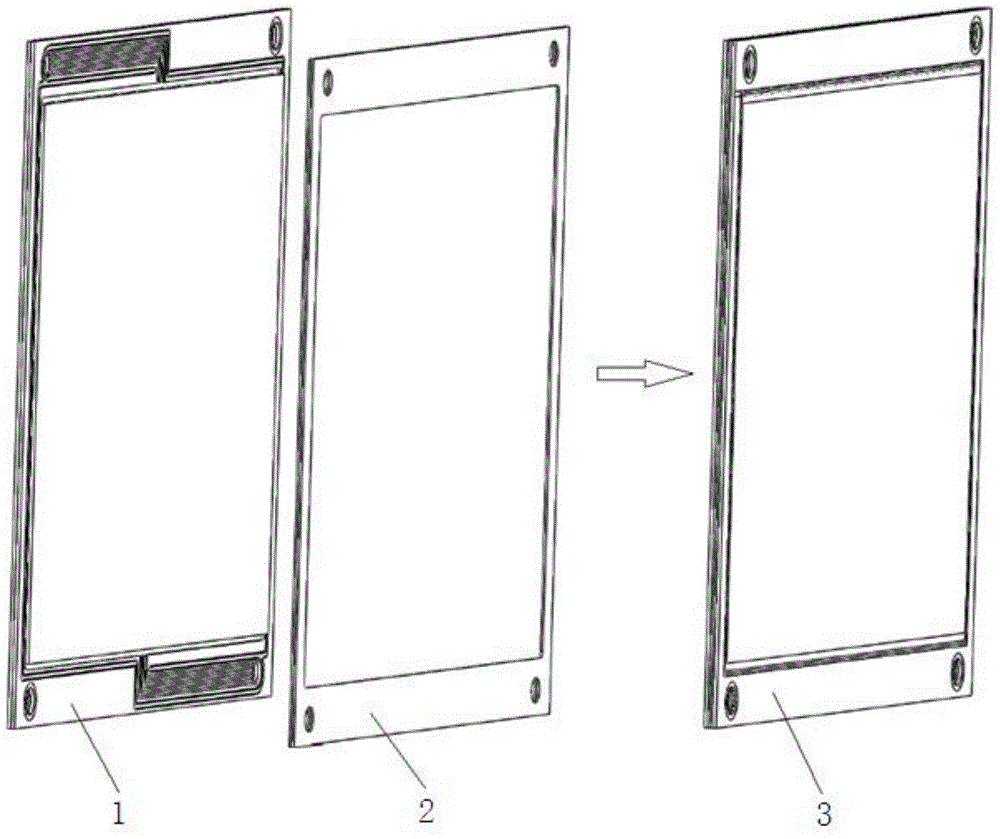

Electrode frame structure of single batteries in redox flow battery as well as single battery and electric pile

ActiveCN104600340AImproved physical structure stabilityEasy to assembleFuel cells groupingRegenerative fuel cellsOxidation-Reduction AgentElectrical battery

The invention discloses an electrode frame structure of single batteries in a redox flow battery as well as the single battery and an electric pile, wherein the structure of the electric pile is formed by sequentially combining a cover plate, an end plate, a collector plate, a plurality of single batteries, a collector plate, a shunt plate, a collector plate, a plurality of single batteries, a collector plate, an end plate and a cover plate, and the two cover plates arranged at the two ends are respectively fastened by a fastener in a mechanical way; an electrode frame assembly comprises a film frame and an electrode frame which are sealed by a sealing strip or a buckle, or in a combining way; the physical structure stability of an ionic membrane is greatly improved by the structure of the film frame in the assembly process, the electric pile is convenient to assemble, and the stability of an electric pile module is improved; due to the design that the film frame is integrated with the electrode frame, the distribution of a flow field is optimized, the contact resistance between the membrane and an electrode is reduced, and the battery efficiency is improved. The electric pile is formed by N half piles, so that the power of the single pile can be improved, the distribution uniformity of electrolyte of a main pipeline can be effectively guaranteed, the effects of pre-assembling and pre-checking the half piles for the assembly of the electric pile can be achieved, and the electric pile is convenient to maintain.

Owner:SHANGHAI ELECTRICGROUP CORP

Novel columnar vertical fluorination reactor

InactiveCN104437273AImprove Primary UtilizationLower control temperatureChemical/physical processesProduction rateProduction line

The invention provides a novel columnar vertical fluorination reactor. The novel columnar vertical fluorination reactor comprises a furnace gas outlet upper flange, dust removing devices, a filter pipe, an upper expanded section, a discharging inclined pipe, an air exhausting opening, a heating device, a gas chamber, a slag pot, a lead layer shielding sleeve and a main reactor. The novel columnar vertical fluorination reactor has the characteristics that the primary utilization rate of fluorine gas is high, the slag production rate is low, the control temperature is low, the structure is simple, the operation is simple, the maintenance is convenient and the like, and is suitable for a uranium conversion fluorination process production line which takes refined uranium tetrafluoride as a raw material and enables uranium tetrafluoride to react with the fluorine gas to generate uranium hexafluoride.

Owner:THE 404 CO LTD CHINA NAT NUCLEAR

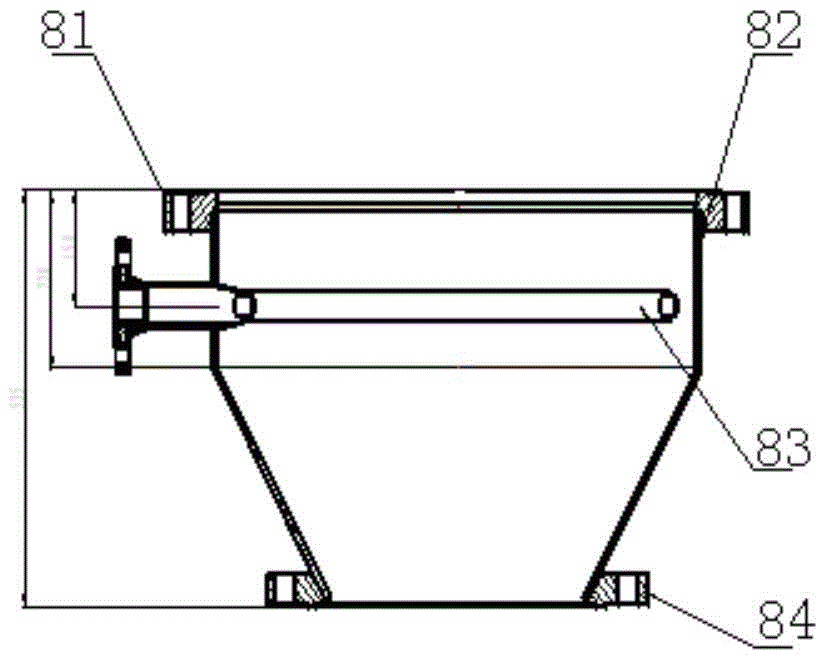

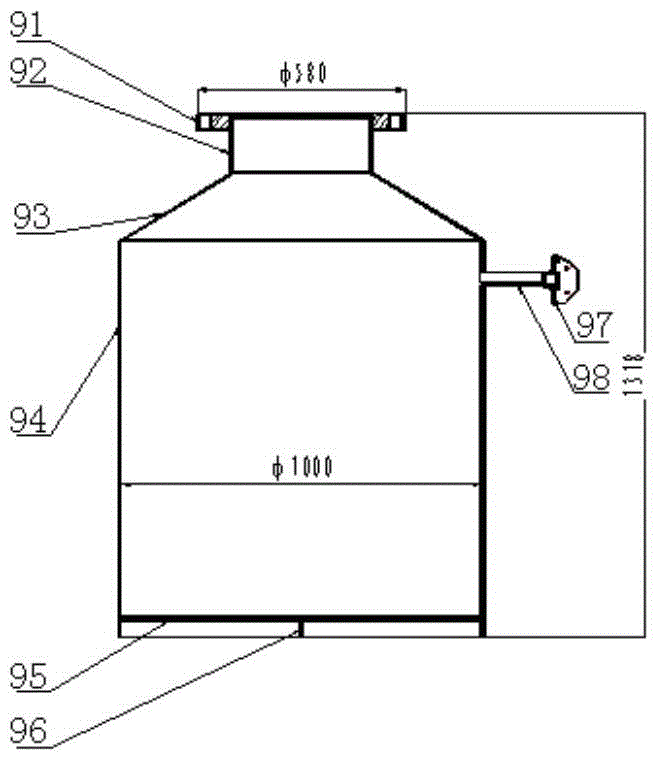

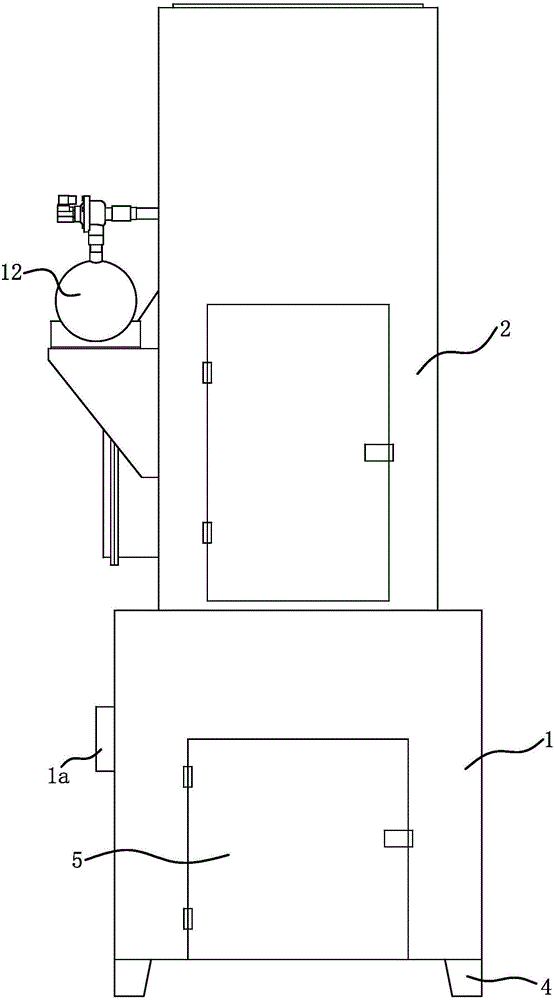

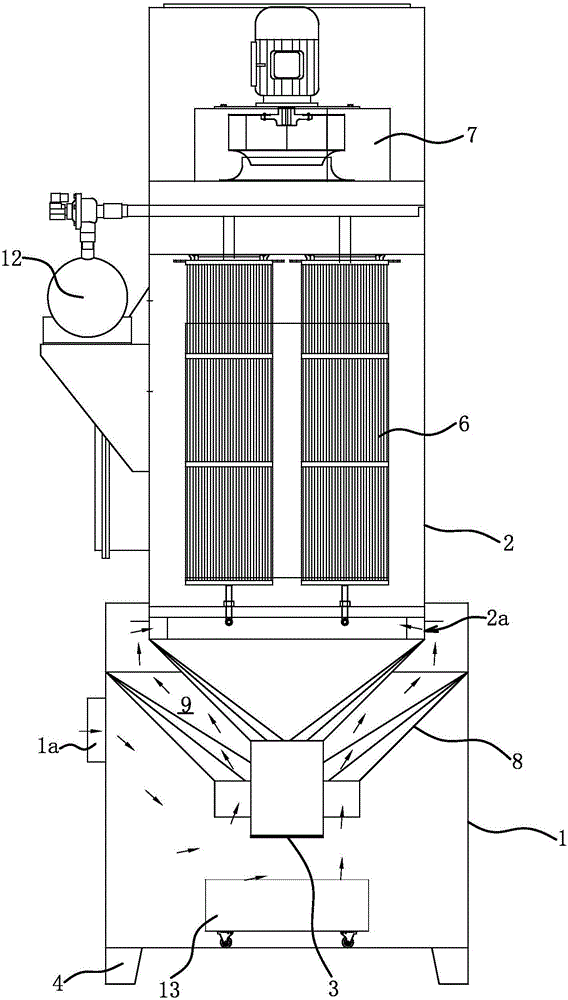

Dust remover

The invention provides a dust remover, belongs to the technical field of work, and solves the problems of short service life of a filter element and high unit energy consumption of the existing dust remover. The dust remover comprises a dust pre-removal box and a fine dust removal box; the bottom of the fine dust removal box is located in the dust pre-removal box; an ash discharging opening is formed in the bottom of the fine dust removal box; the dust remover further comprises an ash discharging control valve for controlling the ash discharging opening to be communicated with an inner cavity of the dust pre-removal box; a fan is arranged at the top of the fine dust removal box; the filter element is arranged in the fine dust removal box; a ventilating pipe sleeves the outer side of the bottom of the fine dust removal box; the upper end of the ventilating pipe communicates with a cavity on the outer side of the filter element in the fine dust removal box. The dust remover guarantees the spark eliminating rate, reduces the dust content of air flow entering the fine dust removal box and improves the distribution uniformity of dust in the fine dust removal box so as to guarantee the use safety of the filter element, reduce the dust removal amount of the filter element and improve the consistency of dust treatment amounts of all the filter elements; therefore, the ventilating smoothness of the filter element is improved, and the back-blowing interval of the air flow is prolonged.

Owner:玉环太平洋机械有限公司

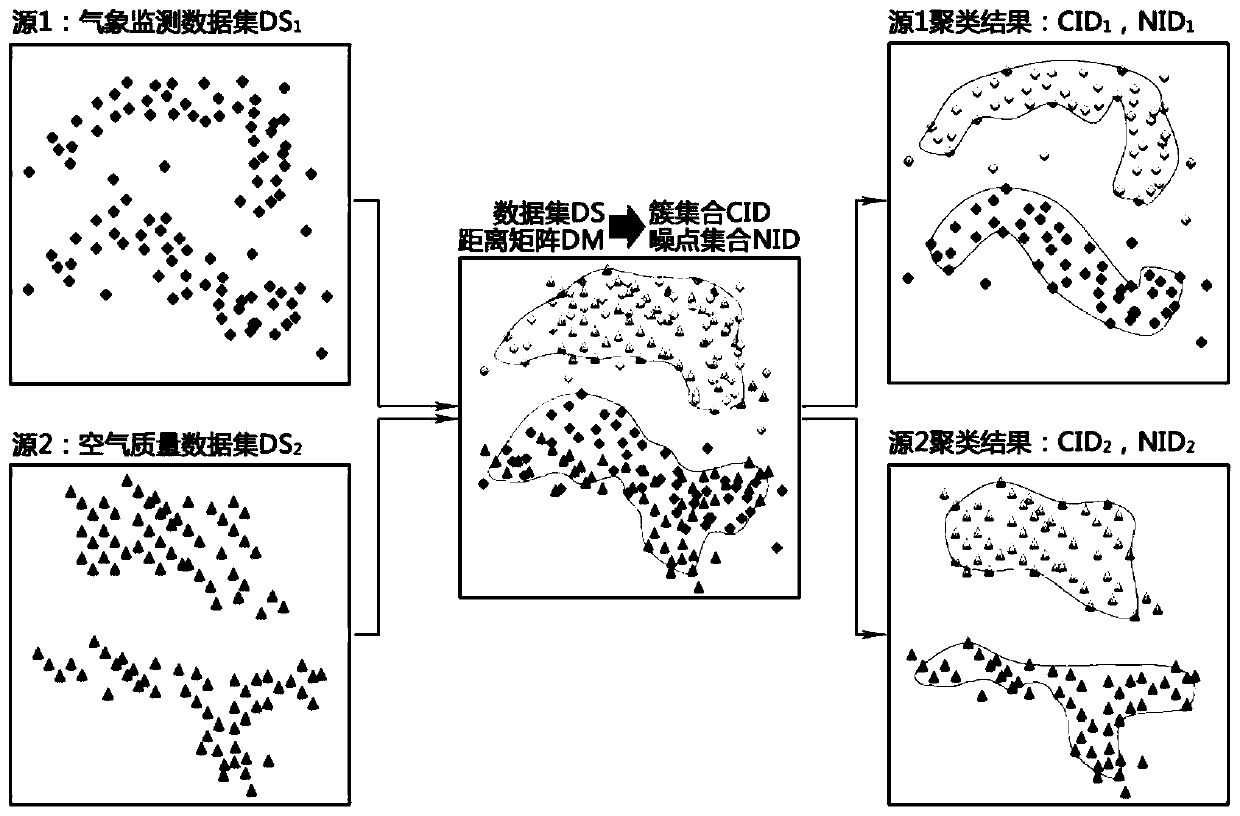

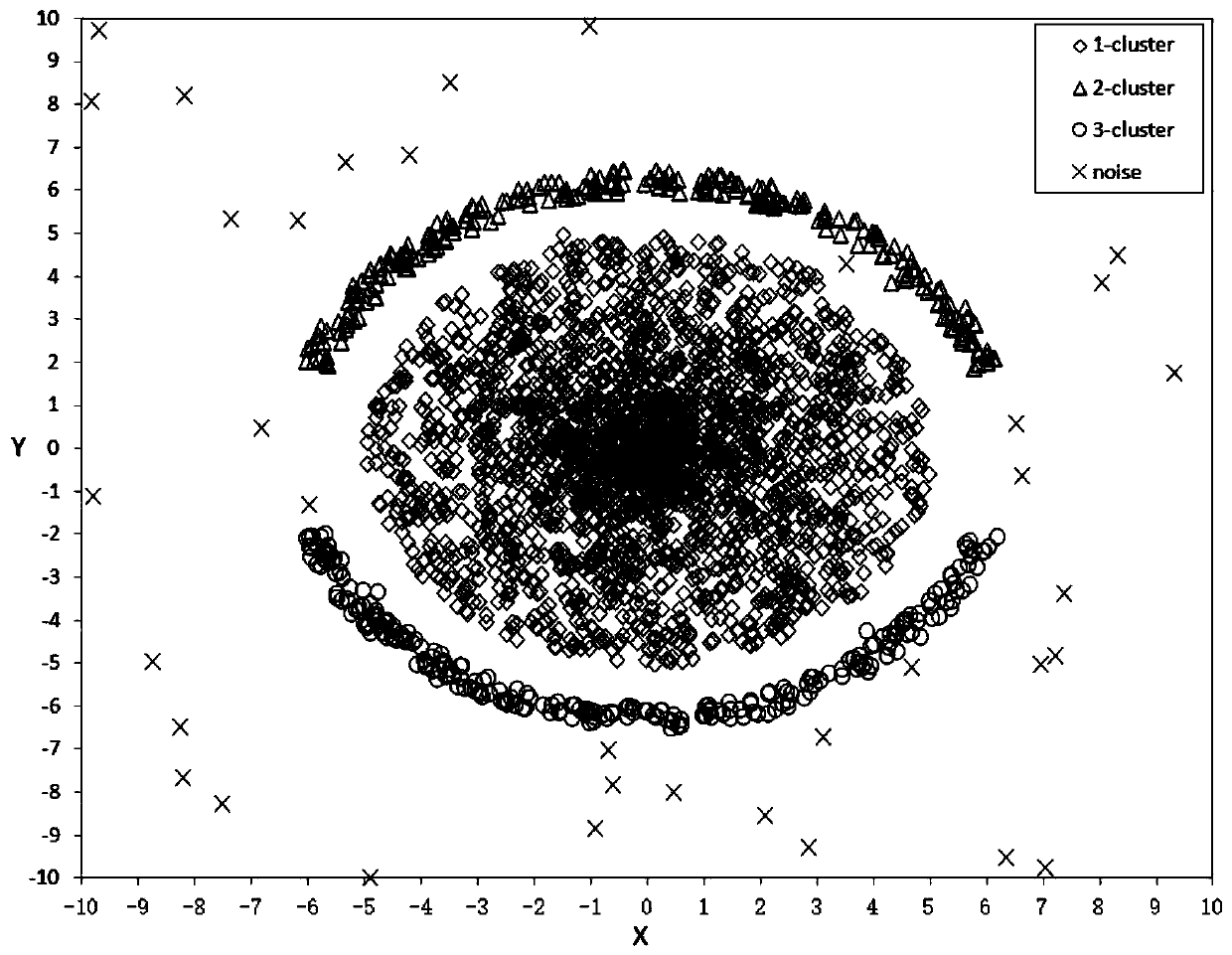

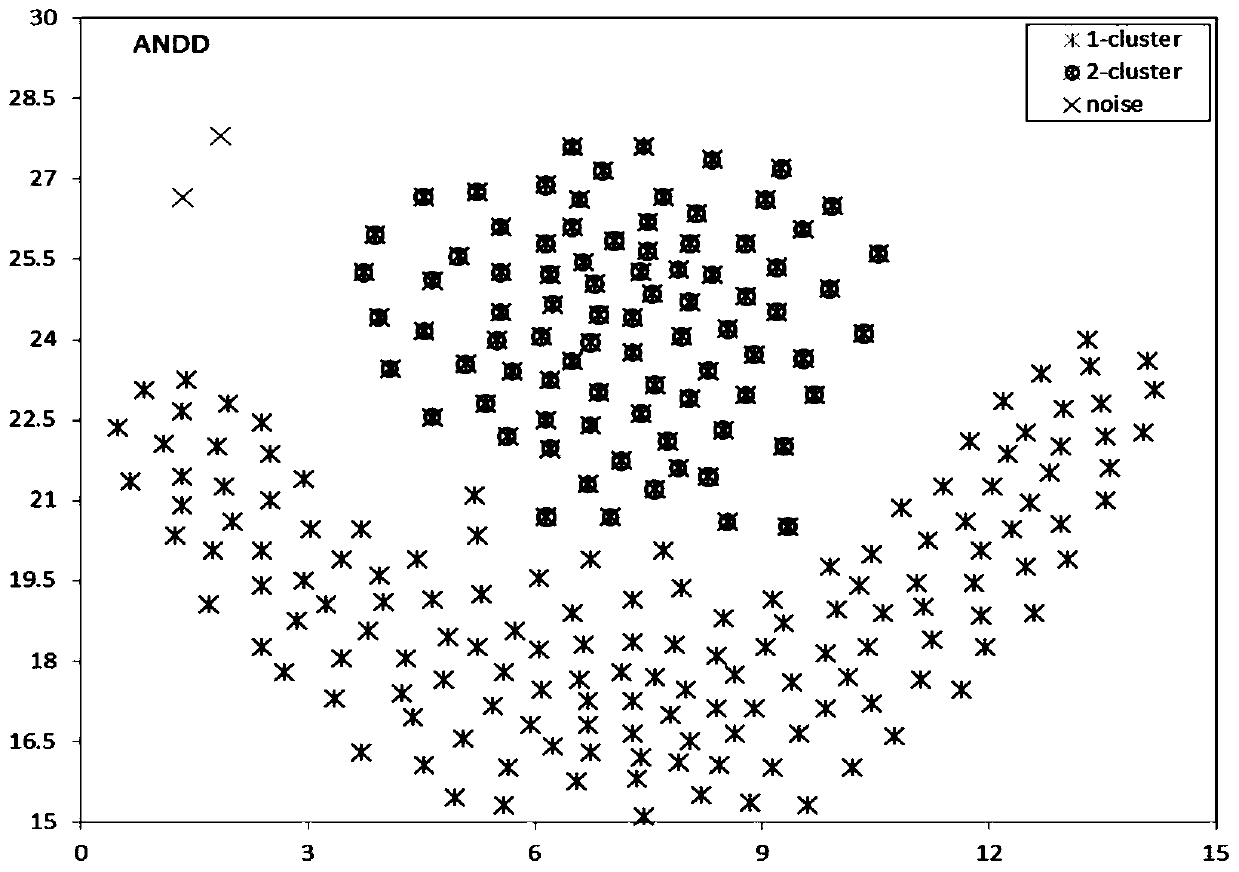

Multi-source atmospheric data clustering method based on distribution density

PendingCN111507415AGuaranteed uniformity of distributionCharacter and pattern recognitionOther databases indexingMeteorologyCluster result

The invention discloses a multi-source atmospheric data clustering method based on distribution density. The method comprises the following steps: firstly constructing a data set DS which is composedof M-dimensional data and is N in data size, and judging the clustering trend of the data set DS; secondly, generating a full neighborhood distribution density matrix DDM of a distance matrix DM of the data set; then, taking a distribution density threshold ddth as a parameter, and dividing a density peak value and discrete points of the full neighborhood distribution density matrix DDM; and finally, intercepting an edge matrix E of all the data, and merging part of discrete point into the density peak value to obtain a clustering result. The clustering result is controlled only by using a single parameter of the distribution density threshold, and data with any distribution shape and distribution uniformity can be clustered; and noisy points can be automatically separated.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Cerium-zirconium-aluminium-based composite oxide catalytic material and preparation method thereof

InactiveCN103349978AEnhanced interactionGuaranteed uniformity of distributionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsComposite oxideNatural gas

The invention discloses a cerium-zirconium-aluminium-based composite oxide catalytic material and a preparation method thereof. The cerium-zirconium-aluminium-based composite oxide catalytic material is characterized by comprising cerium oxide, zirconium oxide, aluminium oxide and composite oxide consisting of other rare-soil oxides except cerium. According to the preparation method, the hydrolytic treatment is carried out on the aluminium oxide to form aluminium hydroxide, and then the aluminium hydroxide is fully mixed with mixed metal salt solution. The preparation merthod provided by the invention has the advantages that the mutual action between the aluminium oxide and the cerium-zirconium-aluminium-based composite oxide is enhanced, the distribution uniformity between the aluminium oxide and the cerium-zirconium-aluminium-based composite oxide is fully guaranteed, and a product has the characteristics of large specific surface area, good high-temperature ageing resistance and high oxygen storage capability and the like, and is applicable to waste-gas purification or catalytic combustion such as automobile tail-gas purification, organic-waste-gas elimination and natural-gas catalytic combustion.

Owner:上海华明高纳稀土新材料有限公司

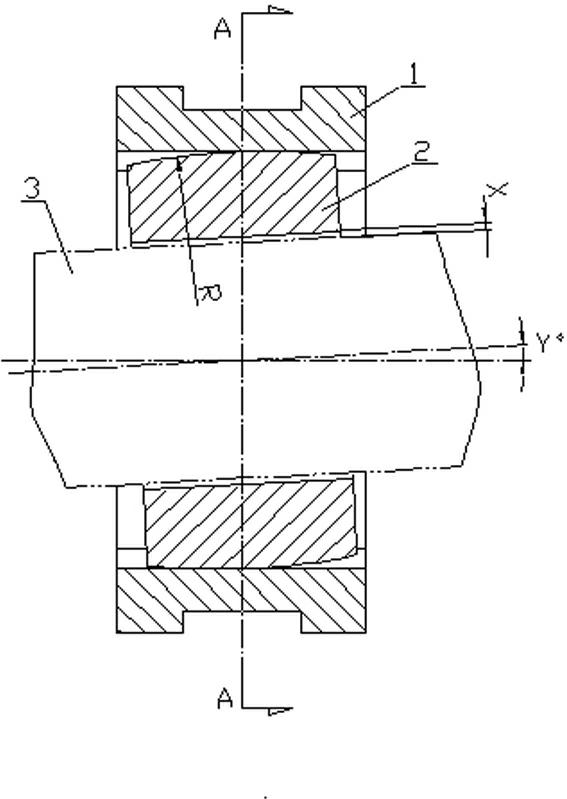

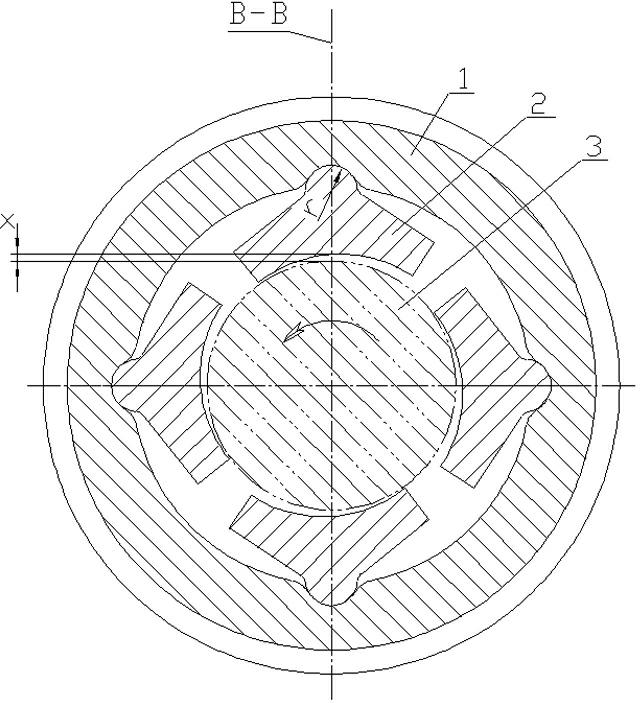

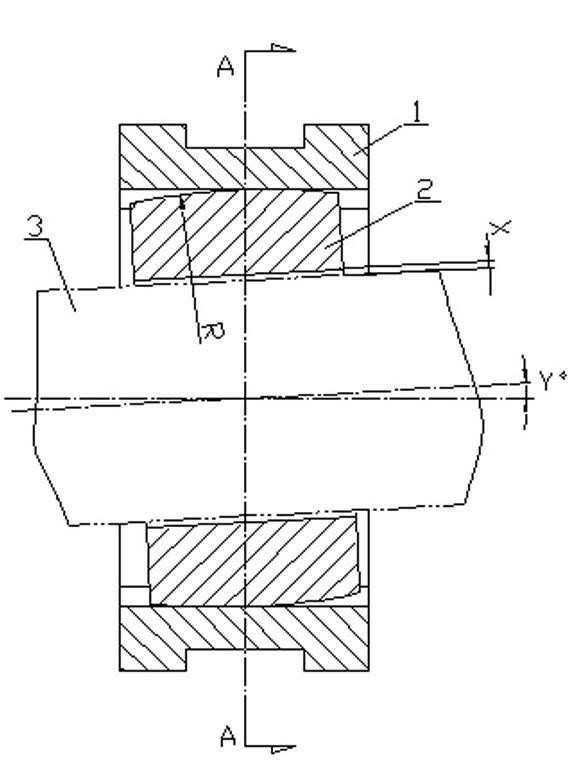

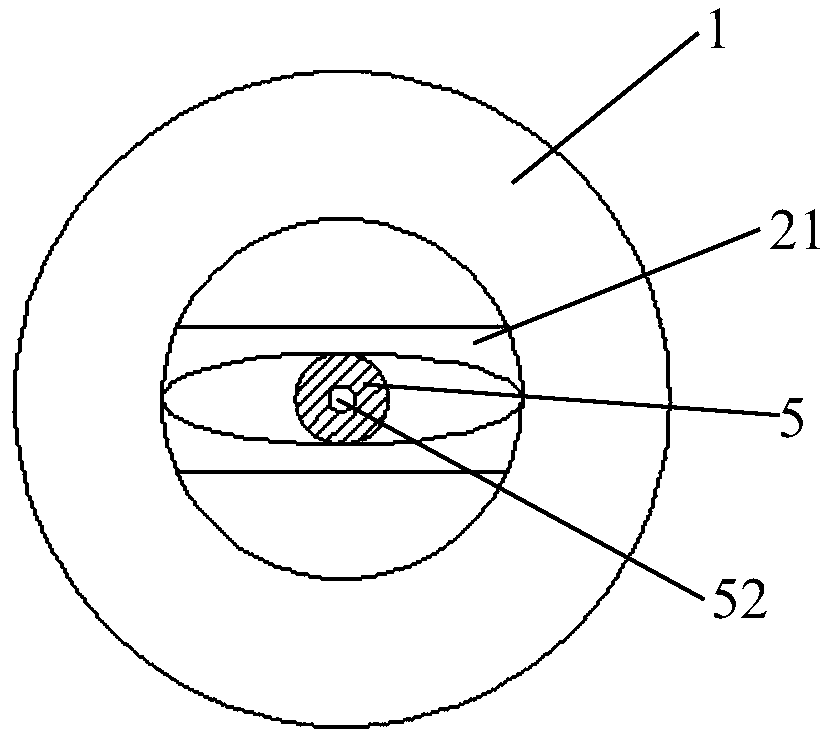

A bearing pad structure of a tilting pad radial bearing

InactiveCN102287446ACompact structureGuaranteed uniformity of distributionBearing componentsSliding contact bearingsRadial planeMechanical engineering

The invention discloses a bearing shell structure of a tilting pad radial bearing, which comprises a bearing body, a bearing shell and a journal. A bearing shell is arranged between the journal and the bearing body. A boss is arranged on the outside of the bearing bush. On the radial plane, it is in the shape of a small arc, and on the axial plane, the boss is in the shape of a large arc. The radial small arc radius r of the boss is between 3-20mm. The radius R of the large axial arc of the boss is not less than 800mm. The invention has a compact and reasonable structure; the bearing bush can swing in the axial plane to ensure the uniform distribution of the oil wedge in the axial direction, thereby improving the working stability of the bearing.

Owner:WUXI GL TUBRO COMPRESSOR

High-voltage lithium nickel-cobalt manganate cathode material and preparation method thereof

ActiveCN109786697AImprove structural stabilityImprove cycle performanceCell electrodesSecondary cellsPhosphateManganate

The invention discloses a high-voltage lithium nickel-cobalt manganate cathode material and a preparation method thereof. The lithium nickel-cobalt manganate cathode material is lithium nickel-cobaltmanganate doping material coated with the phosphate, the lithium nickel-cobalt manganate doping material means that the lithium nickel-cobalt manganate doping material is doped with a lanthanum element and a fluorine element; the phosphate is prepared by mixing the aluminum phosphate and diammonium phosphate aqueous solution. The doping of the lanthanum element and the fluorine element can increase the interplanar spacing so as to promote the lithium ion migration and improving the structure stability; the material surface has good lithium ion conductivity feature and a certain electronic conductivity feature by coating the phosphate on the surface, so that the material has higher lithium-removing state stability under high voltage; the residual lithium quantity of the material surface isreduced, the surface side reaction is inhibited, and the structure stability and the cycle performance of the material under high voltage are obviously improved.

Owner:HEFEI RONGJIE ENERGY MATERIALS CO LTD

High-purity ultrafine oxalate ferromanganese and preparation method thereof

ActiveCN106025282AEfficient removalPrevent oxidationOrganic compound preparationCell electrodesUltrasonic cavitationFerrous salts

The invention discloses high-purity ultrafine oxalate ferromanganese of which the purity is greater than 99.6%, the median particle diameter is 0.5-4.0 microns and the metal proportion is adjustable, and a preparation method of the high-purity ultrafine oxalate ferromanganese, and belongs to the technical field of inorganic fine chemical engineering. According to the main points of the technical scheme, under inert gas protection, a ferrous salt and a manganous salt are dissolved into deionized water at a certain molar ratio; the mixed solution and a solid oxalic acid or oxalate are directly subjected to co-precipitation reaction under the common action of mechanical stirring and ultrasonic cavitation; and filtering, multiple ultrasonic laundering and drying are sequentially carried out on a generated oxalate ferromanganese suspension to obtain oxalate ferromanganese powder. The oxalate ferromanganese product obtained by the method has the advantages that the purity is high, metal ions are evenly distributed, the powder granularity is controllable, the distribution range is narrow, the technology is simple, the cost is relatively low and industrial mass production is easy to implement.

Owner:ZAOZHUANG UNIV

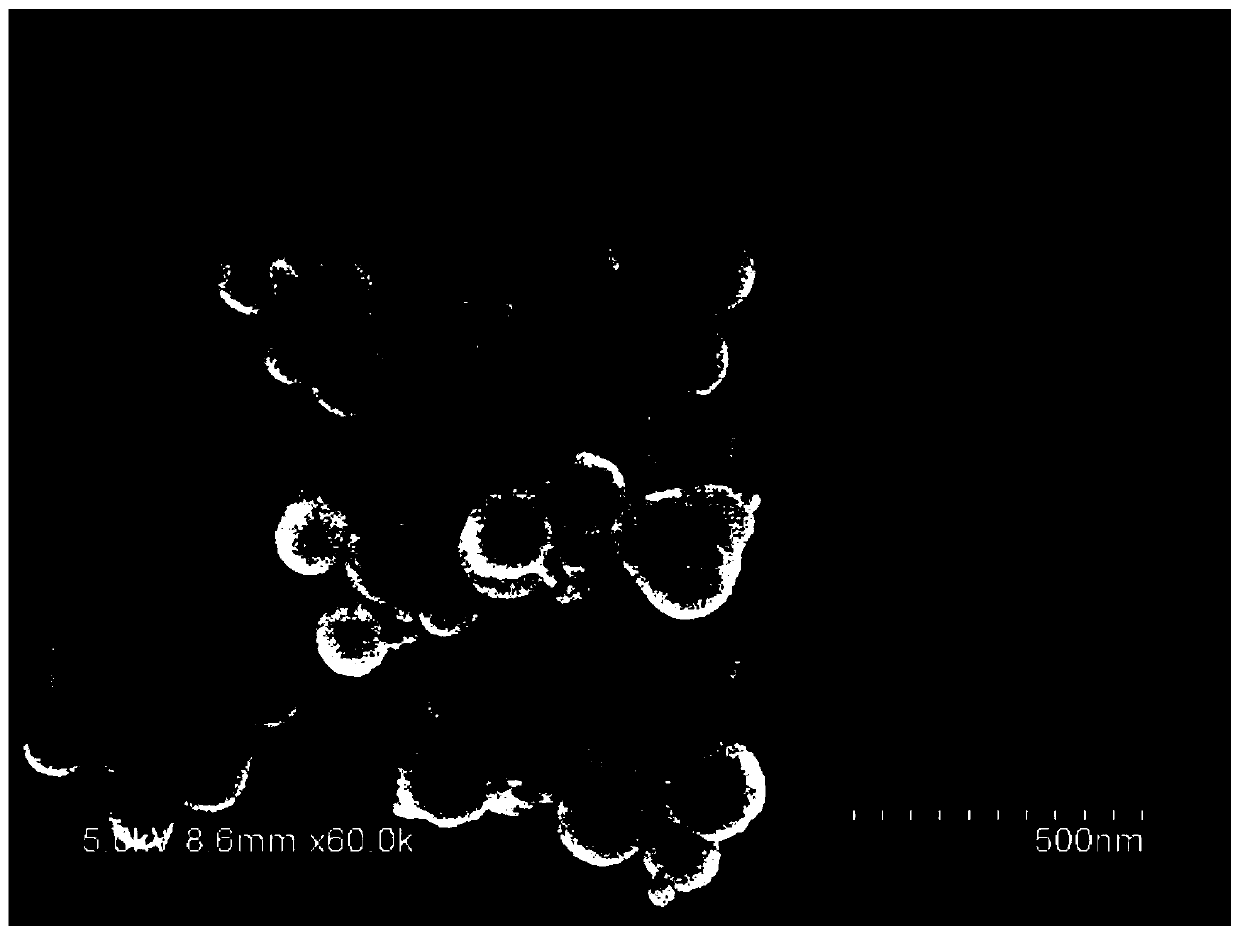

Metal-doped hollow silicon dioxide microsphere and preparation method and application thereof

ActiveCN111013507AUniform particle size distributionLarge specific surface areaMicroballoon preparationMetal/metal-oxides/metal-hydroxide catalystsMicrosphereSilicon oxide

The invention discloses a metal-doped hollow silicon dioxide microsphere and a preparation method and application thereof, belonging to the technical field of material preparation. The preparation method comprises the following steps: firstly, preparing undoped silicon dioxide microspheres by adopting a reversed-phase microemulsion method; then, adding the undoped silicon dioxide microspheres intoa mixed solution of an inorganic salt containing Mn, Cu and Ce, and conducting hydrothermal treatment so as to obtain a metal doped silicon dioxide microsphere; and finally, carrying out water bath treatment on the metal-doped silicon dioxide microsphere to obtain the metal-doped hollow silicon dioxide microsphere. According to the invention, the metal-doped hollow silicon dioxide microsphere with a firm skeleton and uniform granularity are obtained by adjusting the adding sequence of raw materials and controlling the synthesis conditions.

Owner:NANJING UNIV YANCHENG ENVIRONMENTAL PROTECTION TECH & ENG RES INST +1

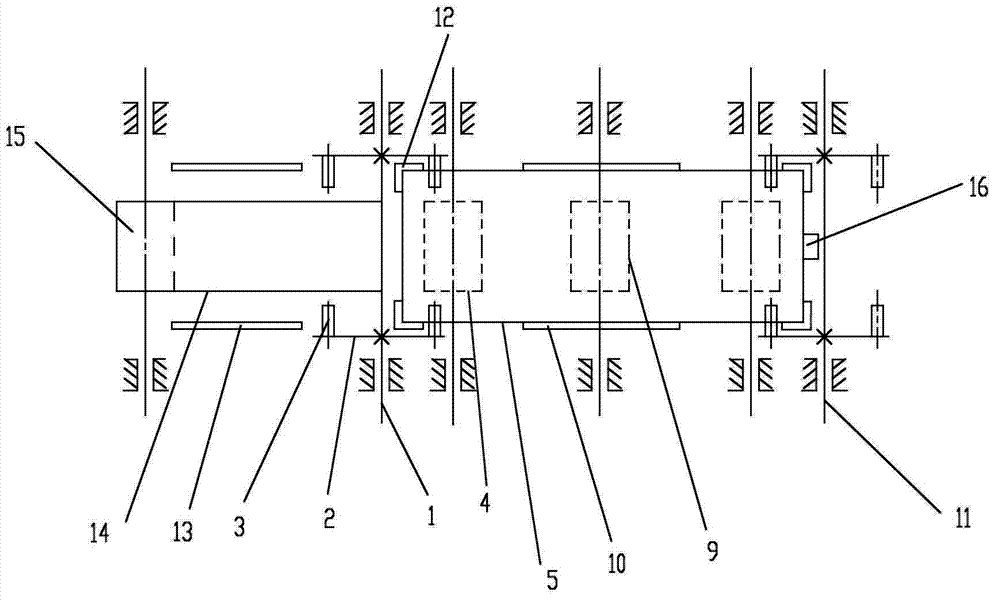

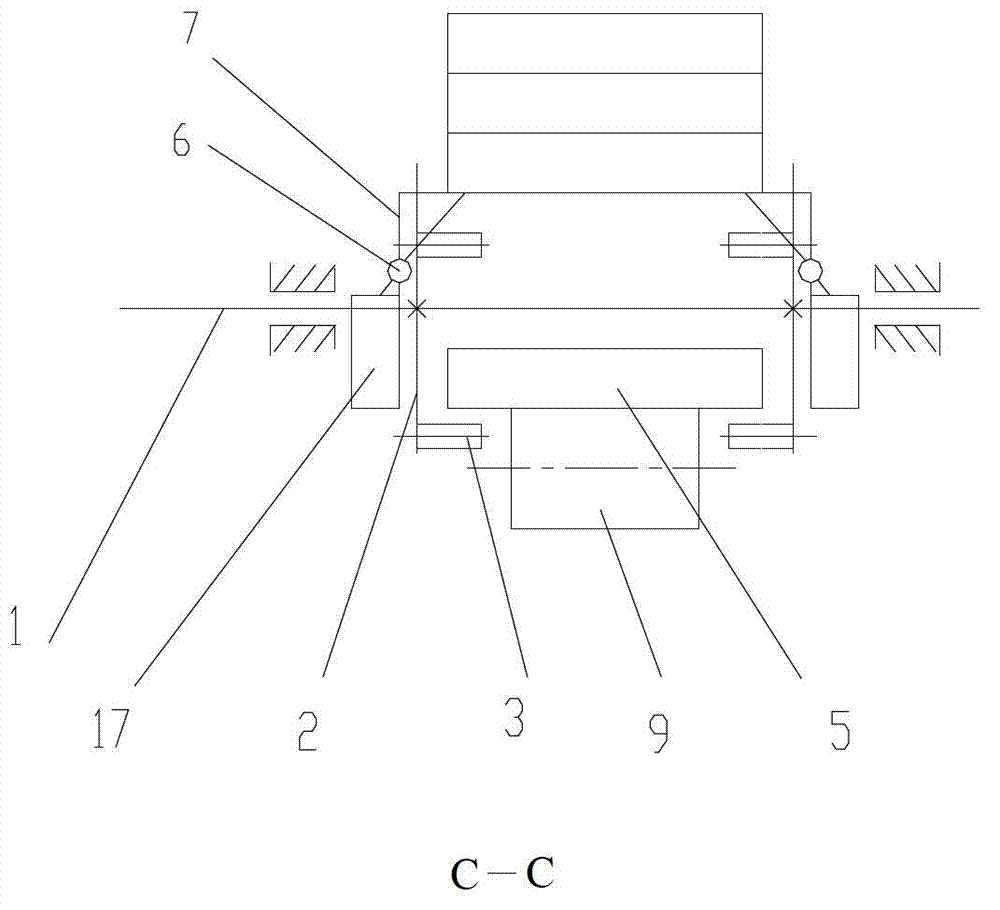

Drive plate type seedling plate stacking machine

InactiveCN103086157AShort time intervalIncrease the speed of stackingStacking articlesDrive shaftEngineering

The invention discloses a drive plate type seedling plate stacking machine. A seedling feeding belt is sleeved on a seedling feeding belt driving wheel and a seedling feeding belt driven wheel, seedling feeding belt side face limiting plates are fixed on machine frames on two sides of the seedling feeding belt, a rotating shaft of the seedling feeding belt driving wheel is arranged below a front drive plate shaft and close to a back drive plate shaft, and the top surface of the seedling feeding belt is higher than the positions of short drive shafts when the short drive shafts are in the lowest states. The front drive plate shaft is parallel with the back drive plate shaft, and the distance between the front drive plate shaft and the back drive plate shaft is larger than the length of a seedling plate. The machine frames between the front drive plate shaft and the back drive plate shaft are provided with a plurality of seedling plate supporting rollers, and the top surfaces of the seedling plate supporting rollers are equal to or slightly lower than the height of the seedling feeding belt. Seedling plate rising limiting frames are arranged between the front drive plate shaft and the back drive plate shaft and fixedly connected with the machine frames. Each machine frame between the front drive plate shaft and the back drive plate shaft is provided with a plurality of swinging ejection plate frames, the swinging ejection plate frames and ejection plate frame return springs are connected with the machine frames through swinging ejection plate frame shafts. The drive plate type seedling plate stacking machine is high in working efficiency, simple in structure, and easy to repair and maintain.

Owner:ZHEJIANG SCI-TECH UNIV

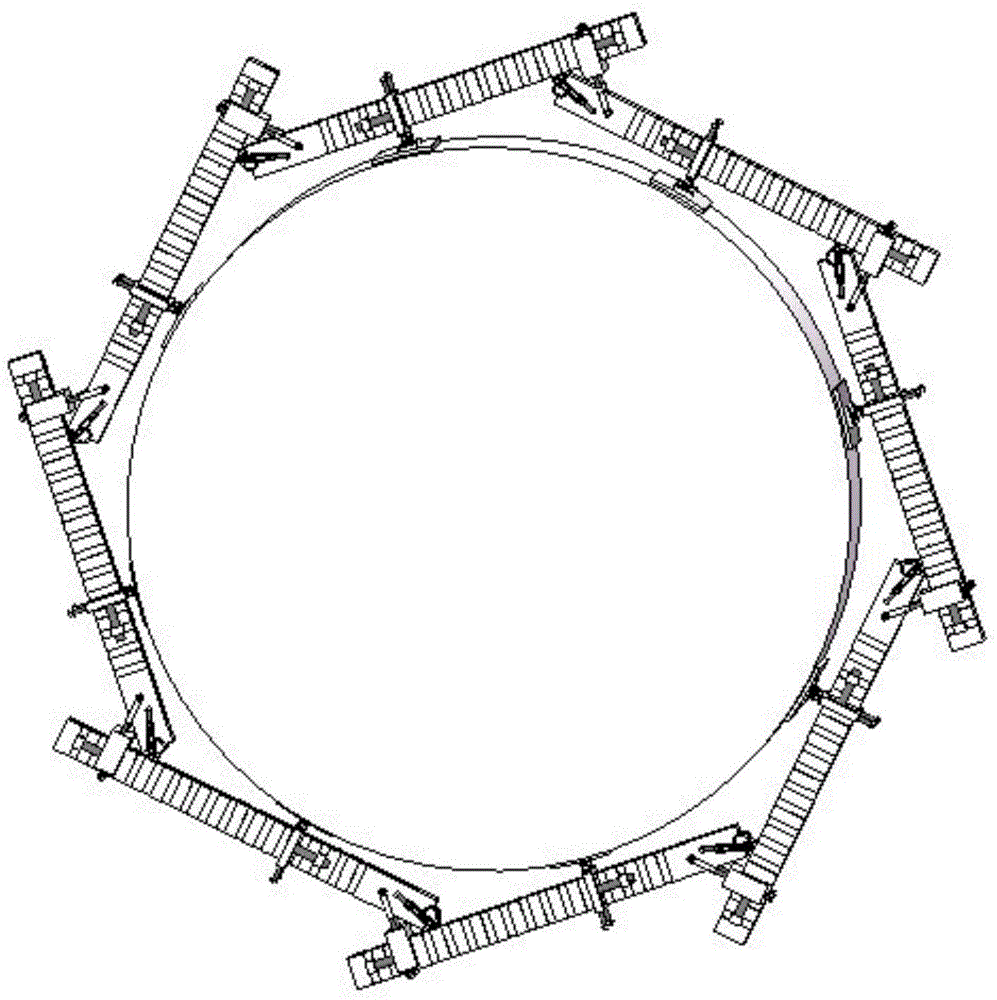

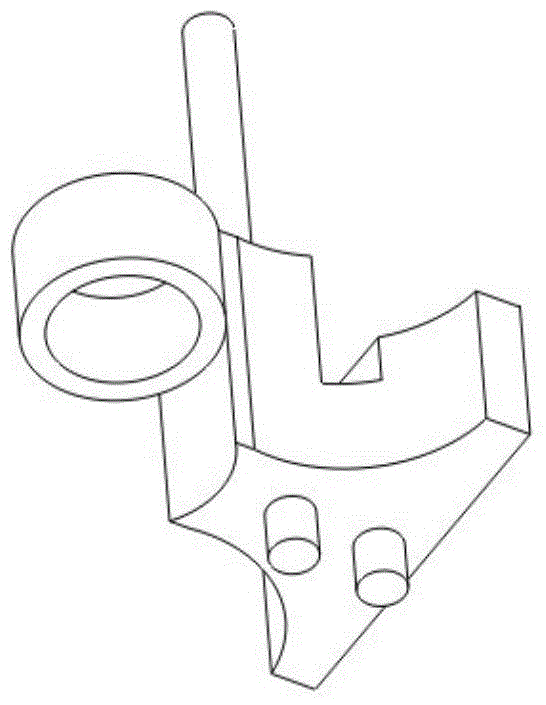

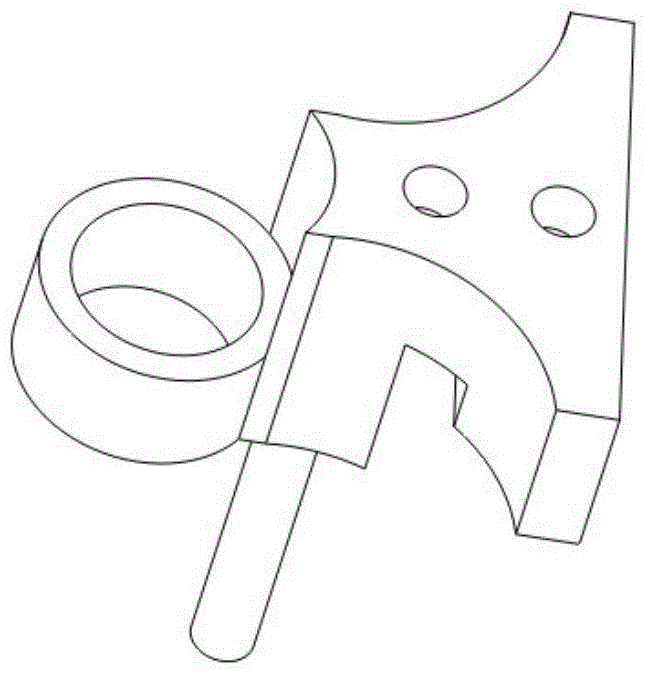

Multi-parameter adjustable clamp device for ECT sensor

The invention relates to a multi-parameter adjustable clamp device for an ECT sensor and belongs to the field of auxiliary detection. The clamp mainly comprises a rotating joint, a rod piece, a clamping sliding block, a flat-end screw, a locating clamping part, a bolt, a T-shaped turning piece, a hexagon nut, a pole plate pressing block, an angle locating buckle, an L-shaped supporting rod and a supporting sliding block. The multi-parameter adjustable clamp device enables each pole plate of the sensor to be in tight contact with a pipeline and be firmly fixed and be easy to assemble and disassemble; the coplanarity of each pole plate of the sensor on the circumferential plane and distribution uniformity of a pole plate array (the central angle between adjacent probes is the same) can be guaranteed; and the multi-parameter adjustable clamp device can be suitable for installing cylindrical pipelines of different diameters. The designed clamp can be used for auxiliary measurement of the capacitance of the specific ECT sensor; and the clamp has a certain universality and is flexible and convenient.

Owner:BEIJING UNIV OF TECH

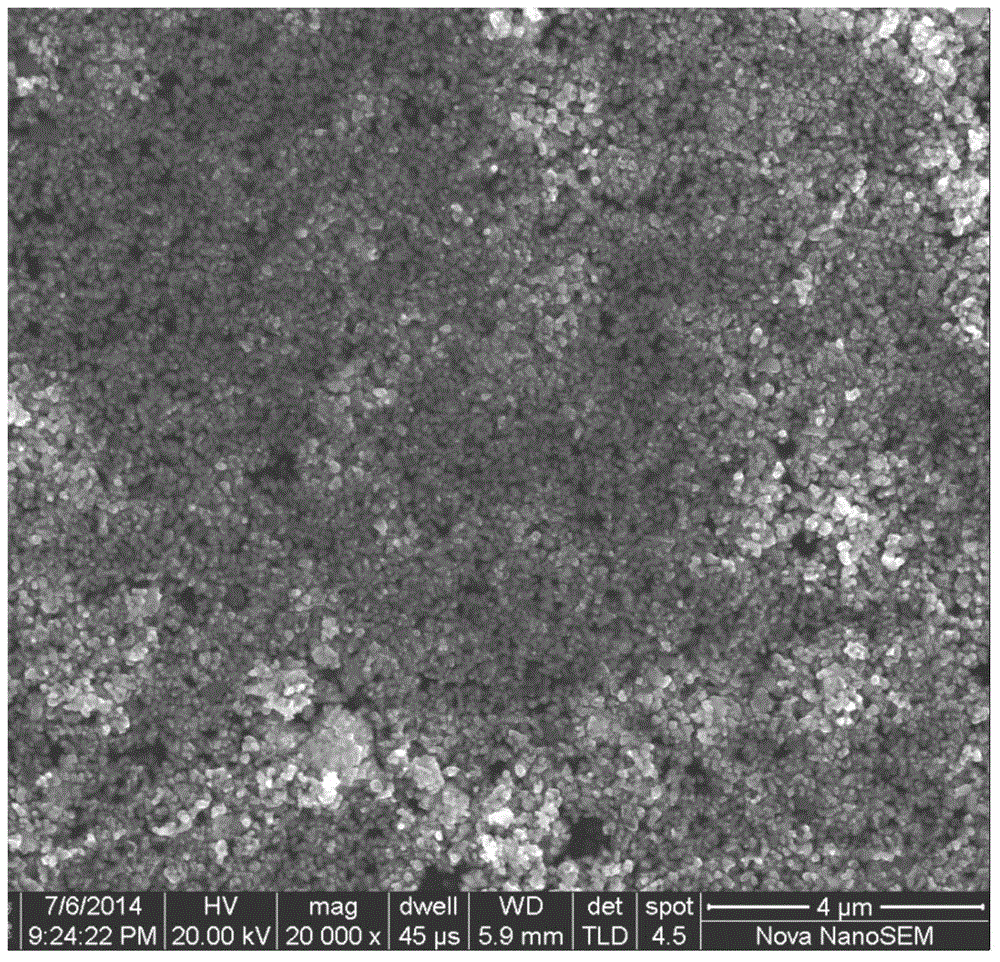

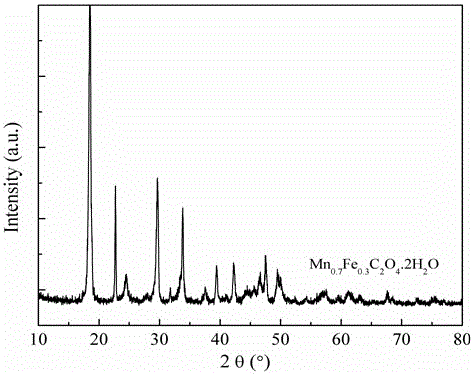

Multi-ion co-doping lithium iron phosphate material and preparation method thereof

InactiveCN105845913AGuaranteed uniformityImprove rate discharge performanceCell electrodesChemistryIron phosphate

The invention provides a multi-ion co-doping lithium iron phosphate material and a preparation method thereof. The chemical formula of the multi-ion co-doping lithium iron phosphate material is Li<1-z>M<2>Fe<1-y>V<y>(PO<4>)<1-x>F<x> / C, wherein x is more than or equal to 0.001 but less than or equal to 0.1, y is more than or equal to 0.001 but less than or equal to 0.1, z is more than or equal to 0.001 but less than or equal to 0.1, and M is lithium position doping metal ion. The preparation method comprises the following steps of firstly, preparing vanadium ion doping iron phosphate Fe<1-y>V<y>PO<4>.2H<2>O containing crystal water; secondly, obtaining vanadium doping iron phosphate Fe<1-y>V<y>PO<4> which does not contain the crystal water by thermal processing; and finally, adding a ball-milling medium, carrying out ball-milling mixing, carrying out pre-sintering and then calcination in a high temperature, and cooling and grinding the mixture to obtain the multi-ion co-doping lithium iron phosphate powder material. The method is simple in process, energy consumption is relatively low, the raw material is low in cost, and industrial production at a large scale is facilitated.

Owner:WUXI JIABANG ELECTRIC POWER PIPE FACTORY

Outer mixing double fluid fan-shaped spray nozzle

PendingCN108654870AReduce erosion wearMeet the characteristicsSpray nozzlesLiquid spraying apparatusPest controlSolid particle

The invention discloses an outer mixing double fluid fan-shaped spray nozzle which comprises a nozzle body, a nozzle, a supporting pipe, a seal cover and a central pipe, wherein a through hole is formed in the central position of the seal cover; one end of the central pipe is inserted into the supporting pipe through the through hole and the inner part of the nozzle is hermetically connected to the seal cover; and an annular cavity where water circulates is formed between the outer side wall of the central pipe and the inner side walls of the supporting pipe and the nozzle. According to the nozzle structure, a biological pesticide and water are sprayed out through the central pipe and the annular cavity, separately, solid particles such as biological living bodies and auxiliary agents in apesticide are prevented from being in contact with and colliding with the nozzle under protection of water, the erosive wear of the nozzle is reduced, and the damage of microbial cells at the nozzleis also reduced, so that a pest control purpose is achieved.

Owner:NANJING FORESTRY UNIV

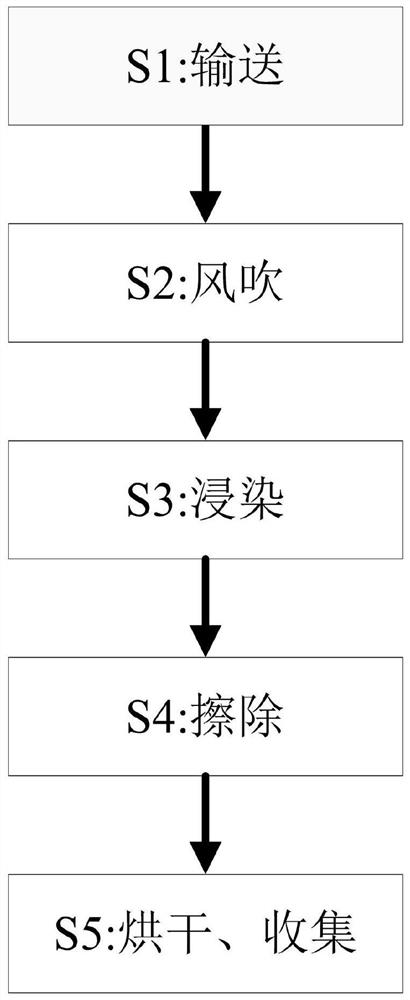

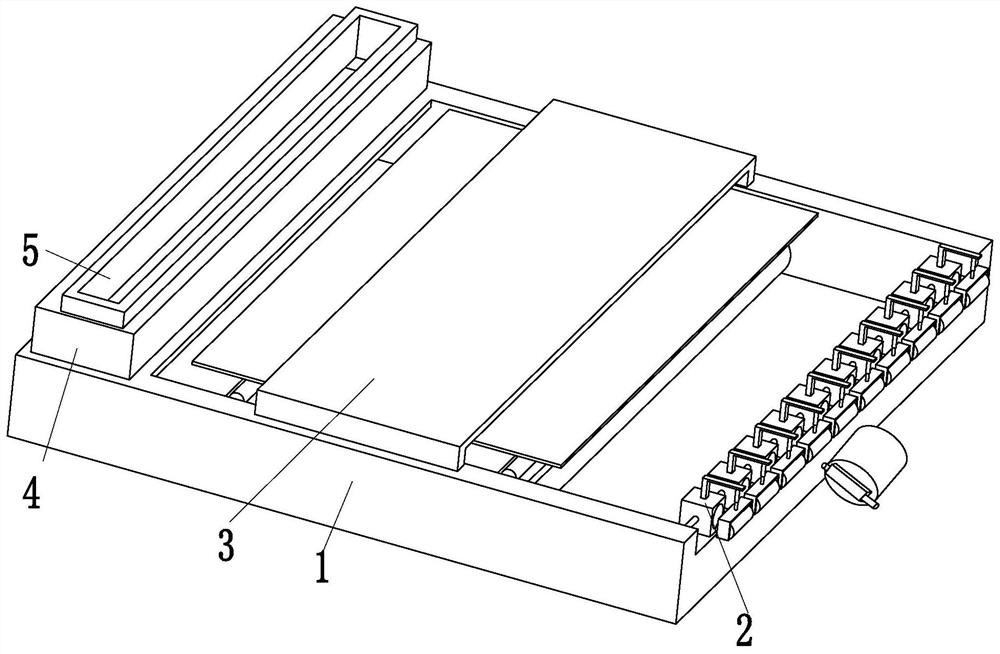

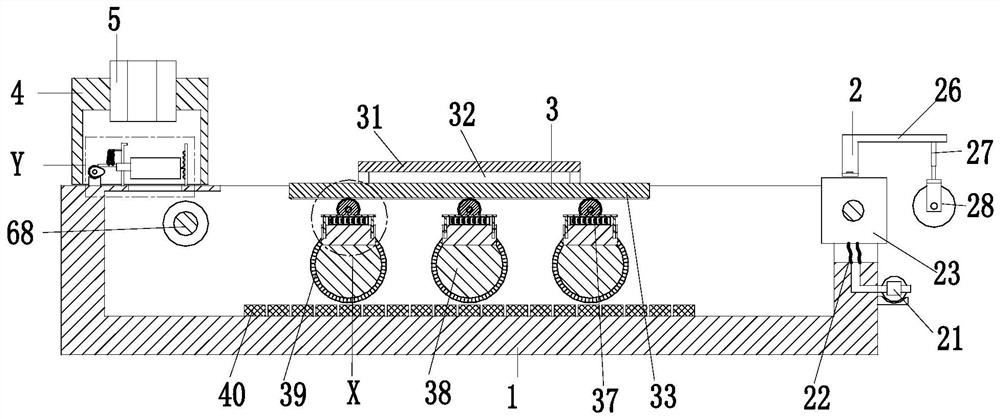

Batch dyeing and drying treatment process for textile yarn

InactiveCN112391757AFast soaking speedUniform soaking effectLiquid/gas/vapor removal by squeezingTextile treatment carriersTextile yarnProcess engineering

The invention provides a batch dyeing and drying treatment process for textile yarn. The process is completed through cooperation of a base, a tightening type turning device, an accelerated dipping device, a sealing cover, a drying frame and a wiping device, and can solve the problems that dust particles may be attached to the surface of the yarn in a conveying process, and the state during conveying is not in a tightening state, so that the above-mentioned conditions influence a dip dyeing effect; and the traditional dip dyeing time is short, the yarn is possibly not soaked thoroughly, dye separation is facilitated, and the dye on the separated yarn is distributed unevenly, so that part of the redundant dye is directly attached to the yarn after being dried, and thus a solidified fuel layer appears on the surface of the yarn, and the percent of pass of the yarn is influenced.

Owner:黄远明

Multiple ions co-doped lithium iron phosphate material and preparation method thereof

InactiveCN105152155AHigh crystallinityImprove uniformityPhosphatesHybrid capacitor electrodesLithium iron phosphateVanadium doping

The invention provides a multiple ions co-doped lithium iron phosphate material and a preparation method thereof. This material has a chemical general formula: Li1-zMzFe1-yVy(PO4)1-xFx / C, wherein 0.001< / =x< / =0.1, 0.001< / =y< / =0.1, 0.001< / =z< / =0.1, and M is lithium-doped metal ions. The preparation method includes: preparing vanadium ion doped iron phosphate Fe1-yVyPO4.2H2O containing crystal water, and performing thermal treatment to obtain vanadium doped iron phosphate Fe1-yVyPO4 not containing crystal water; adding a ball-milling medium, allowing ball milling and mixing, performing pre-sintering, performing calcining at high temperature, and performing grinding after cooling to obtain multiple ions co-doped lithium iron phosphate powdered material. The preparation method is simple, energy consumption is low, raw materials are low in price, and industrial production of the material is facilitated.

Owner:WUXI JIABANG ELECTRIC POWER PIPE FACTORY

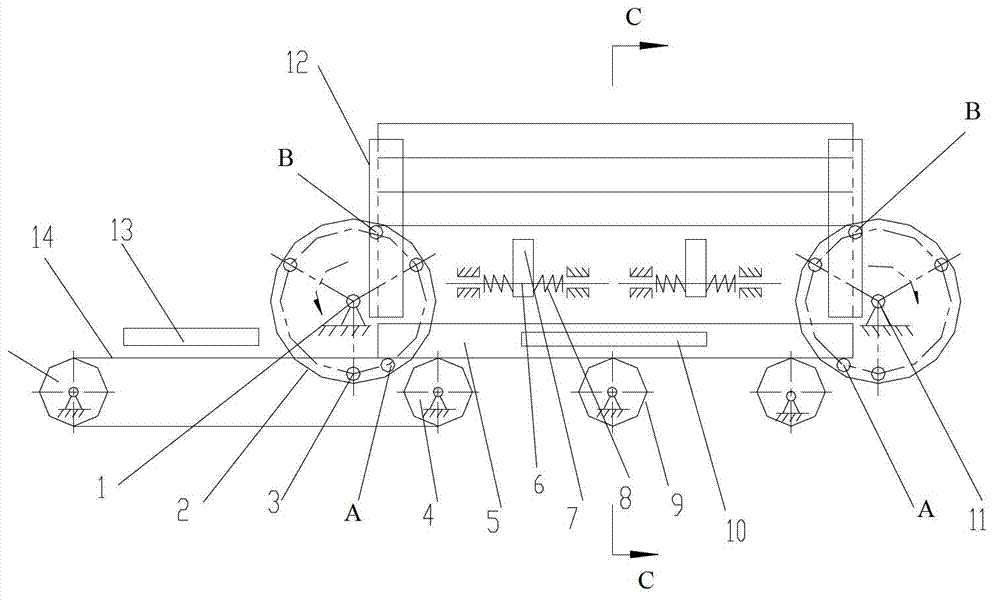

Drive wheel type seedling plate stacking machine

InactiveCN103086158AShort time intervalIncrease the speed of stackingStacking articlesEngineeringSeedling

The invention discloses a drive wheel type seedling plate stacking machine. A seedling feeding belt is sleeved on a seedling feeding belt driving wheel and a seedling feeding belt driven wheel, seedling feeding belt side face limiting plates are fixed on machine frames on two sides of the seedling feeding belt, a rotating shaft of the seedling feeding belt driving wheel is arranged below a front wheel shaft and close to a back wheel shaft, and the top surface of the seedling feeding belt is higher than the positions of side shafts when the side shafts are in the lowest states. The front wheel shaft is parallel with the back wheel shaft, and the distance between the front wheel shaft and the back wheel shaft is larger than the length of a seedling plate. The machine frames between the front wheel shaft and the back wheel shaft are provided with a plurality of seedling plate supporting rollers, and the top surfaces of the seedling plate supporting rollers are equal to or slightly lower than the height of the seedling feeding belt. Seedling plate rising limiting frames are arranged between the front wheel shaft and the back wheel shaft and fixedly connected with the machine frames. Each machine frame between the front wheel shaft and the back wheel shaft is provided with a plurality of swinging ejection plate frames, the swinging ejection plate frames and ejection plate frame return springs are connected with the machine frames through swinging ejection plate frame shafts. The drive wheel type seedling plate stacking machine is high in working efficiency, simple in structure, and easy to repair and maintain.

Owner:ZHEJIANG SCI-TECH UNIV

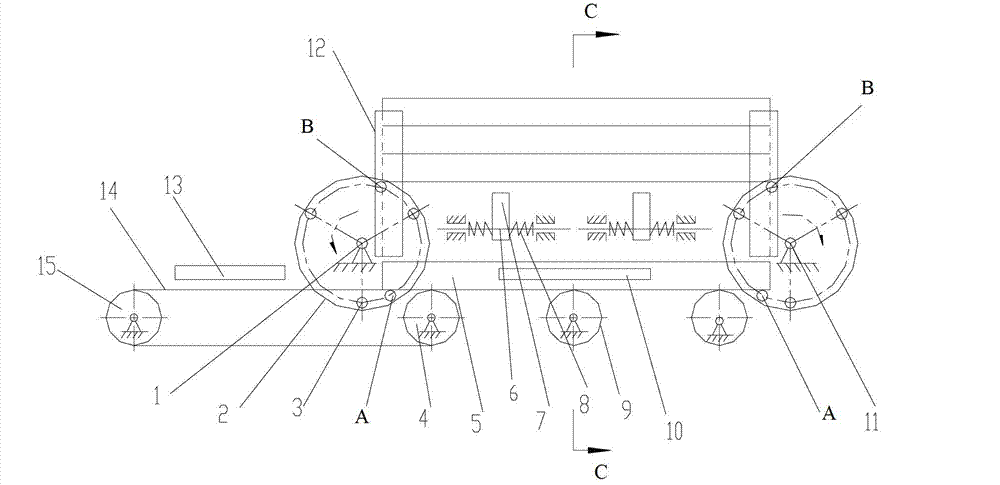

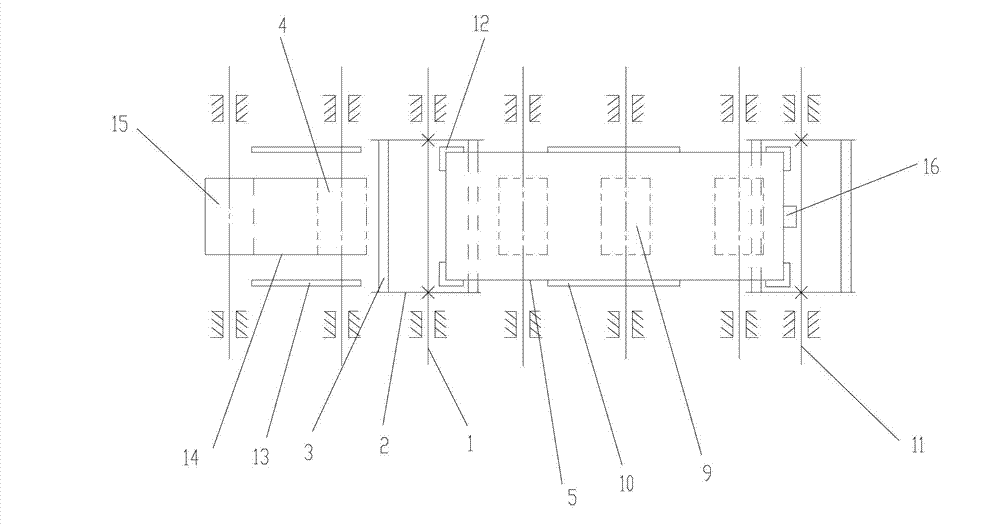

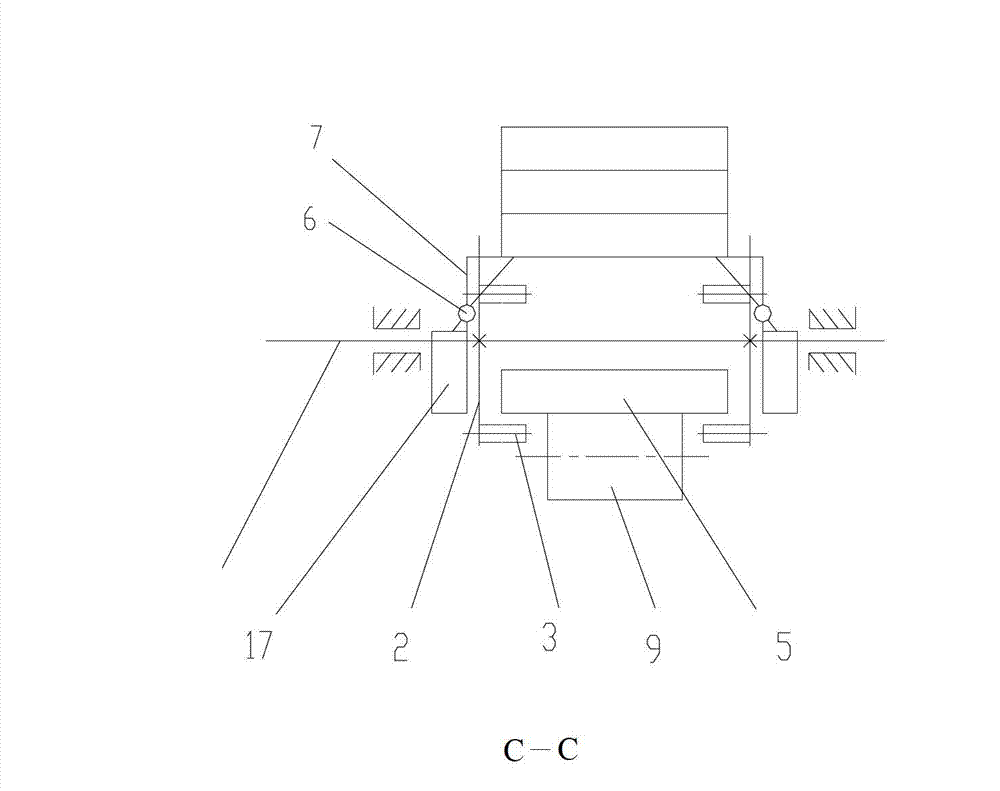

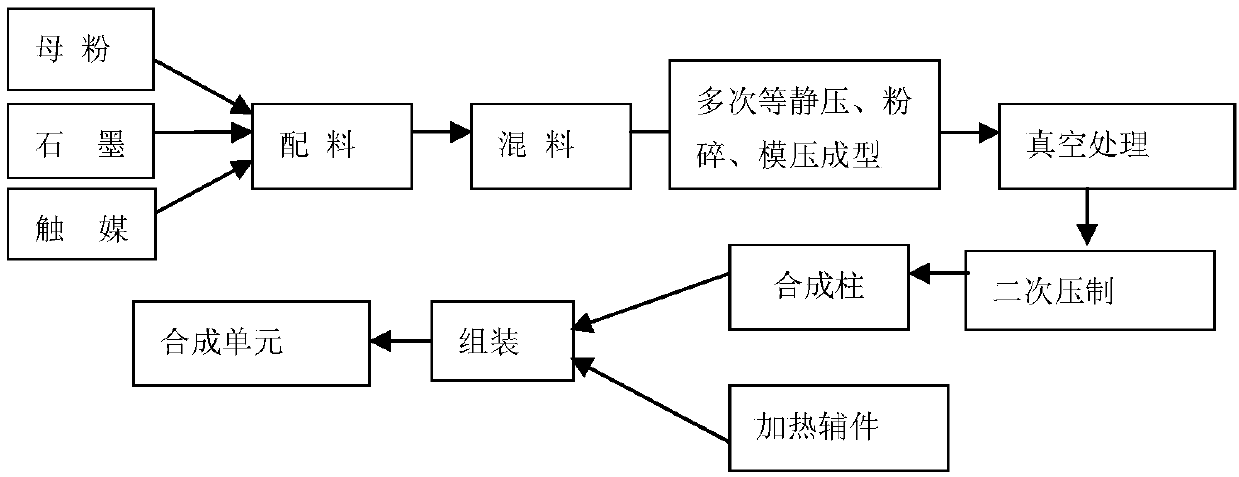

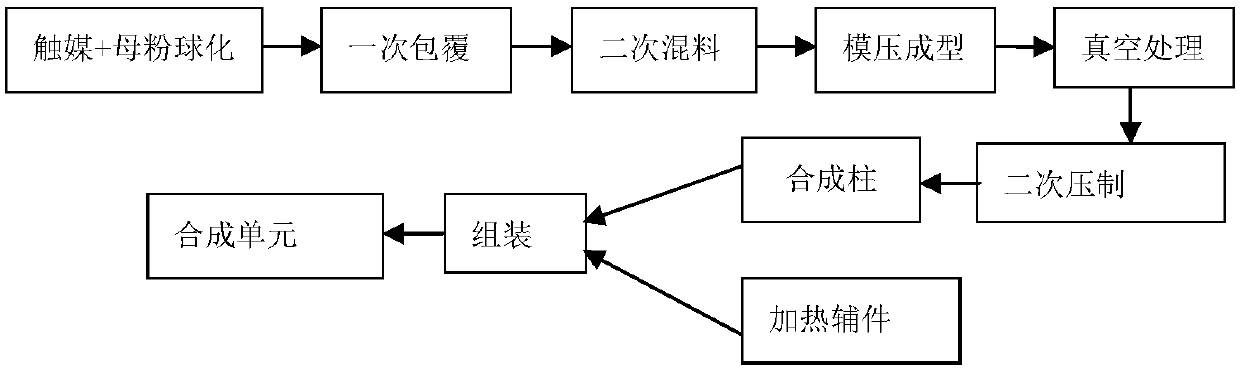

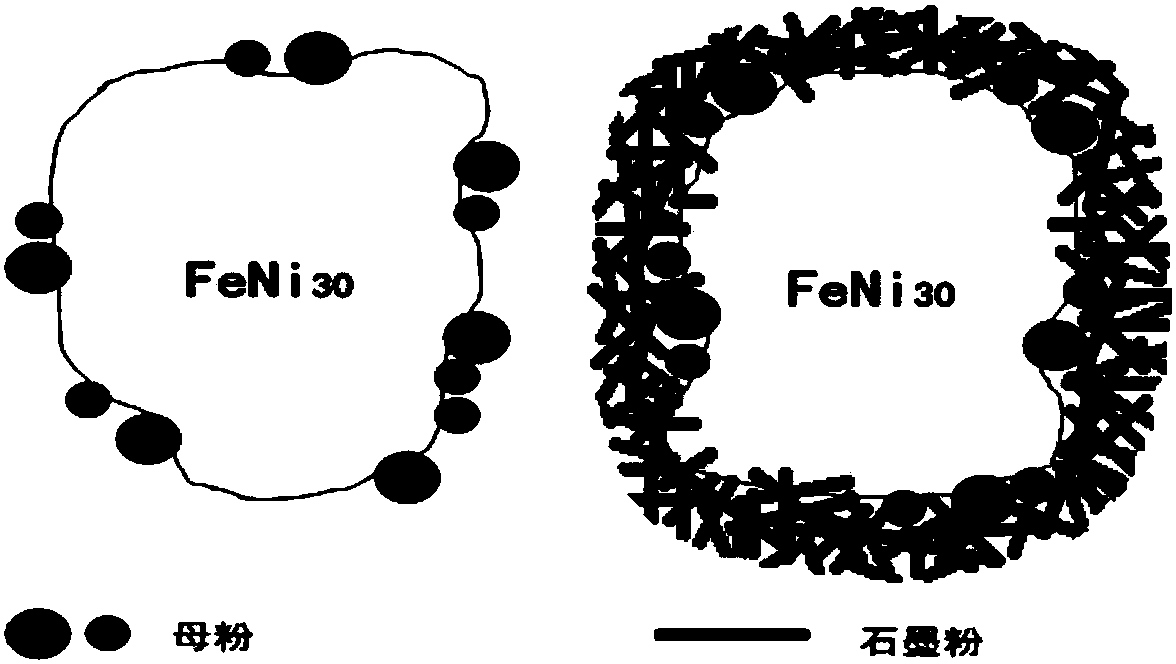

Preparation method of artificial diamond synthetic column

ActiveCN109966992AWell mixedEasy to manufactureUltra-high pressure processesHigh concentrationSuperhard material

Belonging to the field of superhard material synthesis technology and special new material preparation technology, the invention discloses a preparation method of an artificial diamond synthetic column. The method includes: mixing catalyst powder with high concentration dust, then performing spheroidizing by a shaping machine to press or embed high concentration dust particles into the surfaces ofcatalyst particles; mixing the spheroidized catalyst powder with graphite powder to form graphite coated composite catalyst particles; adding graphite powder into the composite catalyst particles again, and mixing the substances evenly by a three-dimensional mixer; selecting a die for pressing into a synthetic column by a four-column press; and subjecting the synthetic column to vacuum heat treatment, then conducting secondary pressing and shaping, and then performing assembly to obtain a synthetic unit. The artificial diamond synthesized from the synthetic column prepared by the method has the advantages of complete crystal form, uniform growth, fewer twin crystal and high grade.

Owner:有研增材技术有限公司

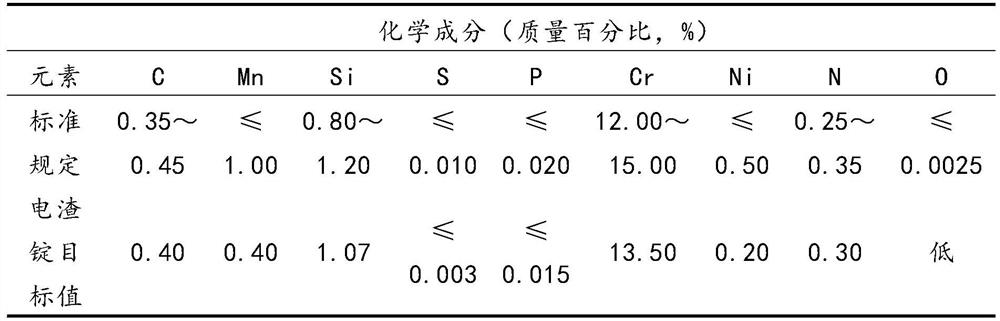

Method for smelting high-nitrogen die steel through vacuum induction furnace and pressurized electroslag furnace

ActiveCN114318109AImprove uniformityImprove pass rateIncreasing energy efficiencySmelting processIngot

The invention discloses a method for smelting high-nitrogen die steel through a vacuum induction furnace and a pressurized electroslag furnace. The blank of the high-nitrogen die steel smelting process is filled. According to the technical scheme, a smelting method of a vacuum induction furnace and a pressurized electroslag furnace is adopted, and the die steel with the nitrogen content being 0.20%-0.40% is produced; two nitriding alloy materials (FeCr) N and Si3N4 are respectively added in the smelting process of a vacuum induction furnace and a pressurized electroslag furnace so as to achieve the technical requirement target of nitrogen. The method has the following advantages: (1) nitrogen is increased in the vacuum induction furnace, so that the addition of Si3N4 in a pressurized electroslag furnace in the later period can be reduced, the cost is reduced, and the uniformity and the qualification rate of nitrogen are improved; (2) Si3N4 added in pressurized electroslag remelting enables molten steel to obtain higher nitrogen content, process stability, accurate nitrogen element control and uniform distribution; the electrode bar is remelted and purified, so that the oxygen content of the steel ingot is further reduced, and the steel ingot has better structure and performance than other smelting modes; the production efficiency is high and industrial production is facilitated.

Owner:FUSHUN SPECIAL STEEL SHARES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com