Patents

Literature

302 results about "Film frame" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

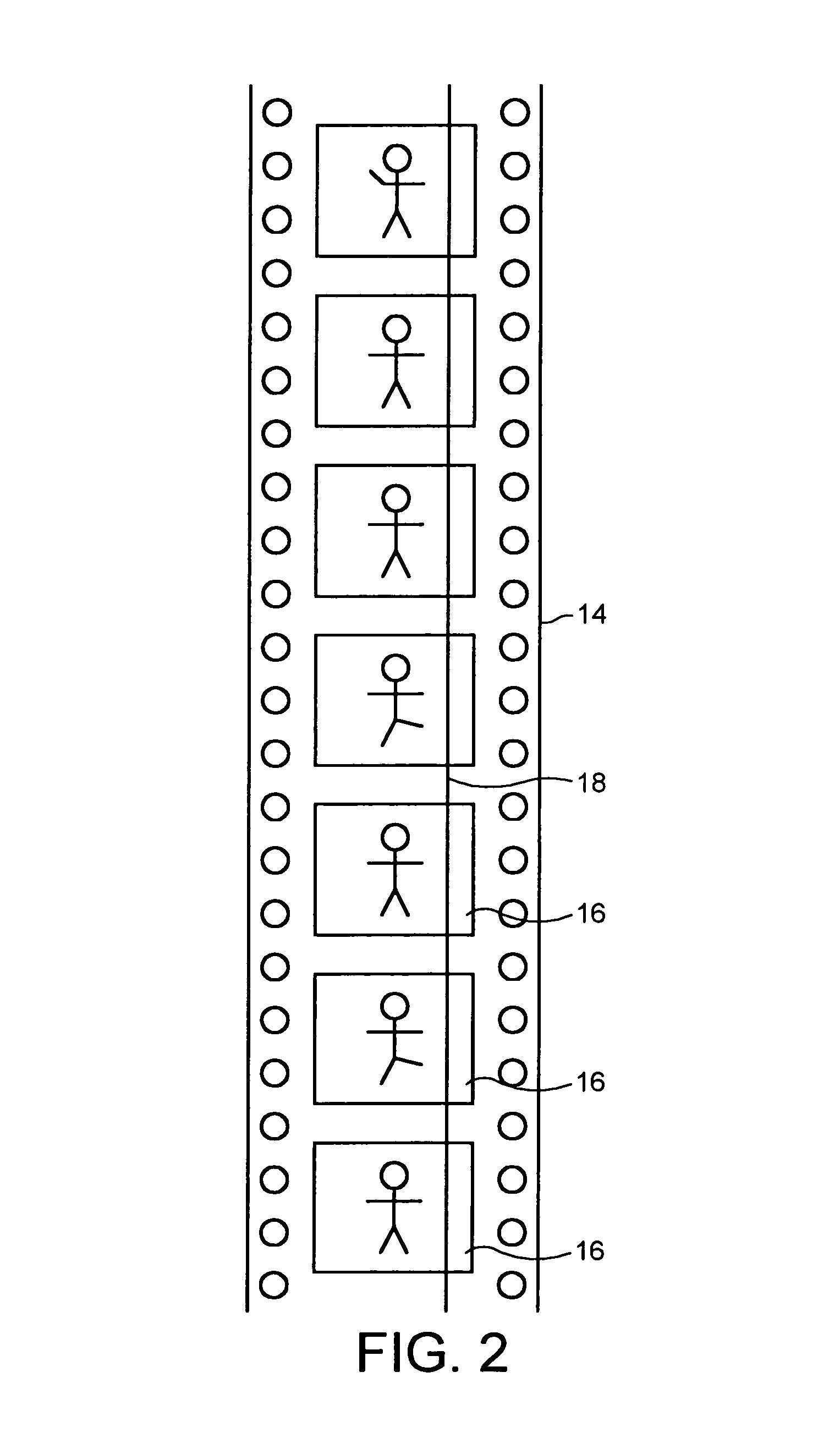

In filmmaking, video production, animation, and related fields, a frame is one of the many still images which compose the complete moving picture. The term is derived from the fact that, from the beginning of modern filmmaking toward the end of the 20th century, and in many places still up to the present, the single images have been recorded on a strip of photographic film that quickly increased in length, historically; each image on such a strip looks rather like a framed picture when examined individually.

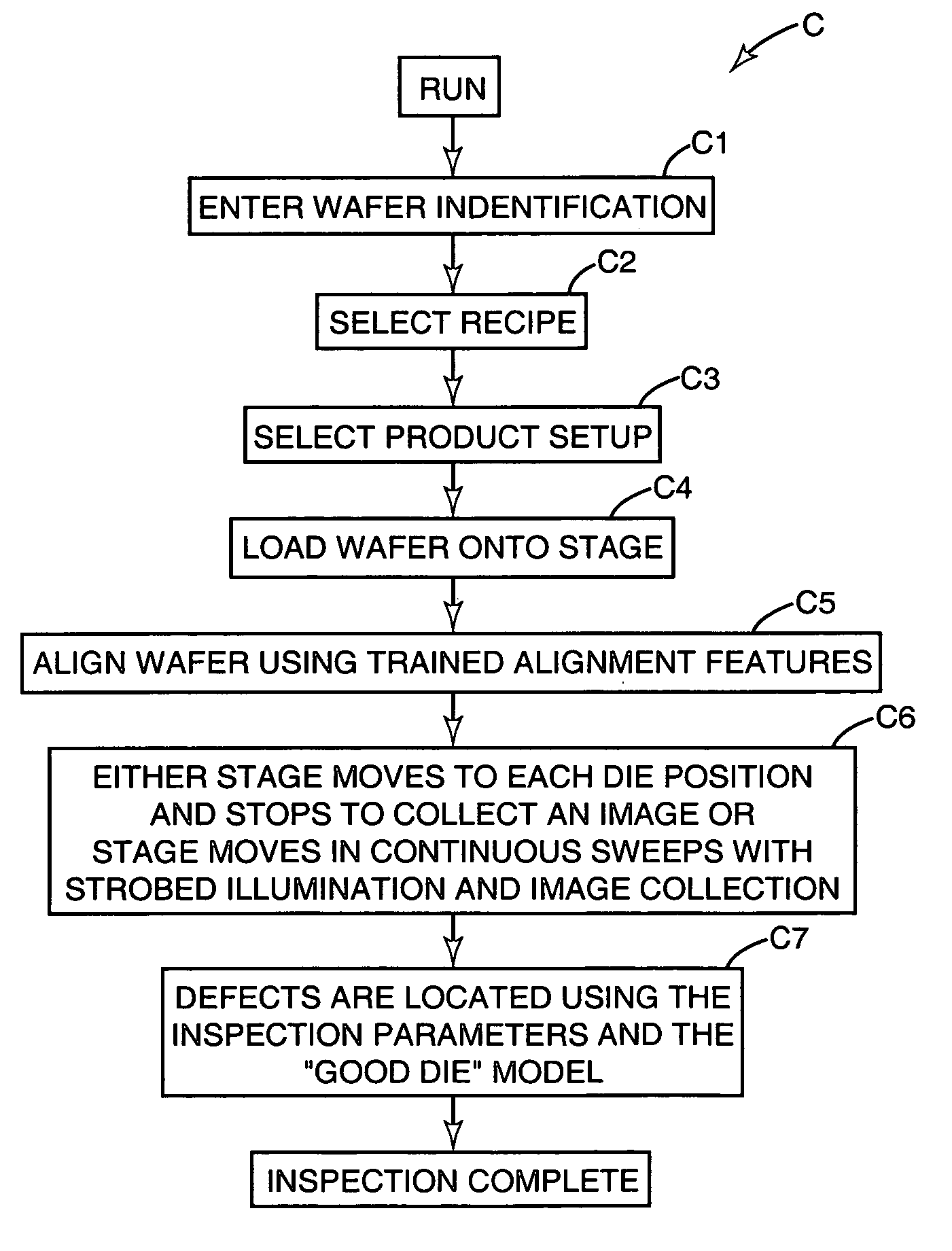

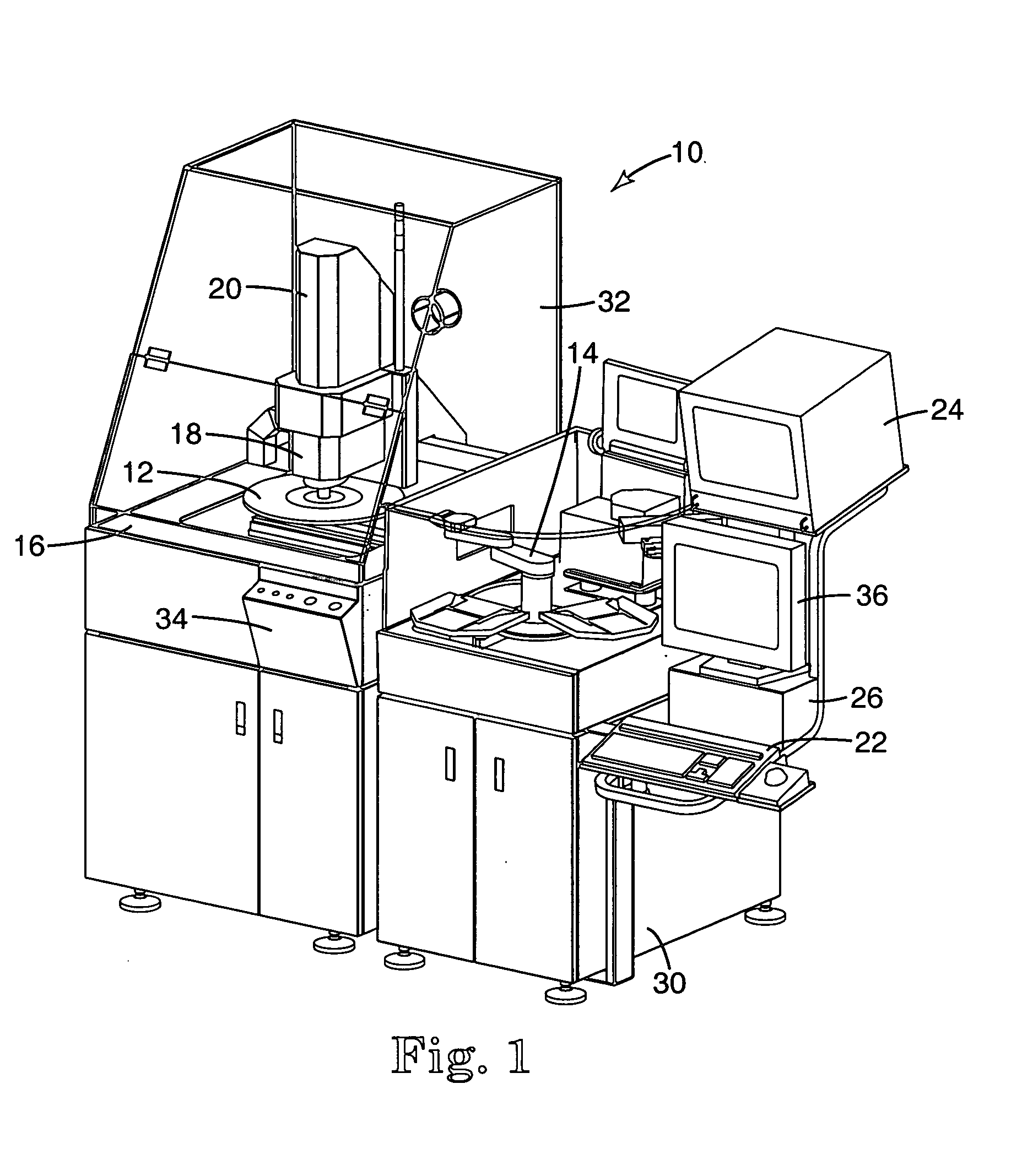

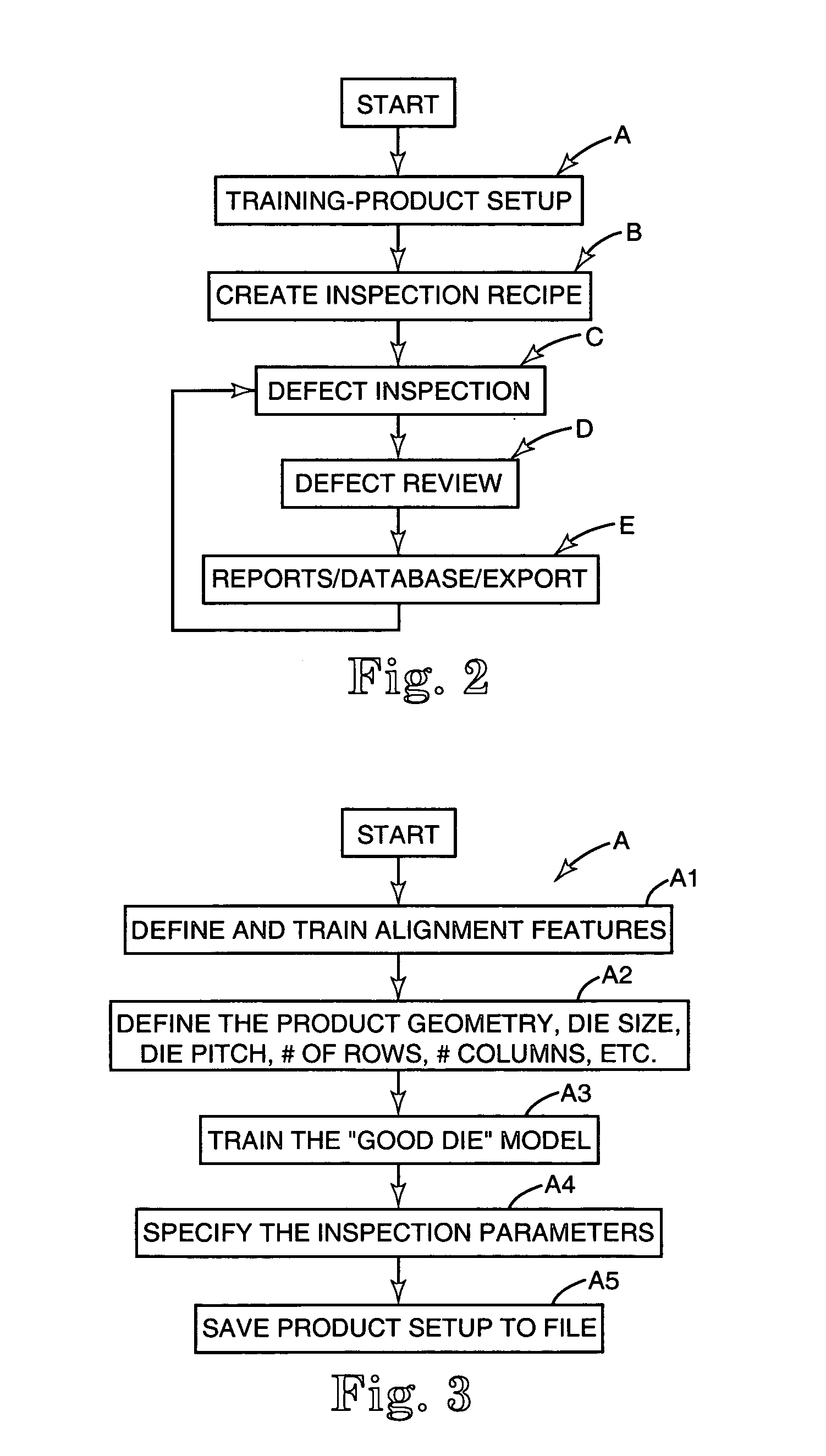

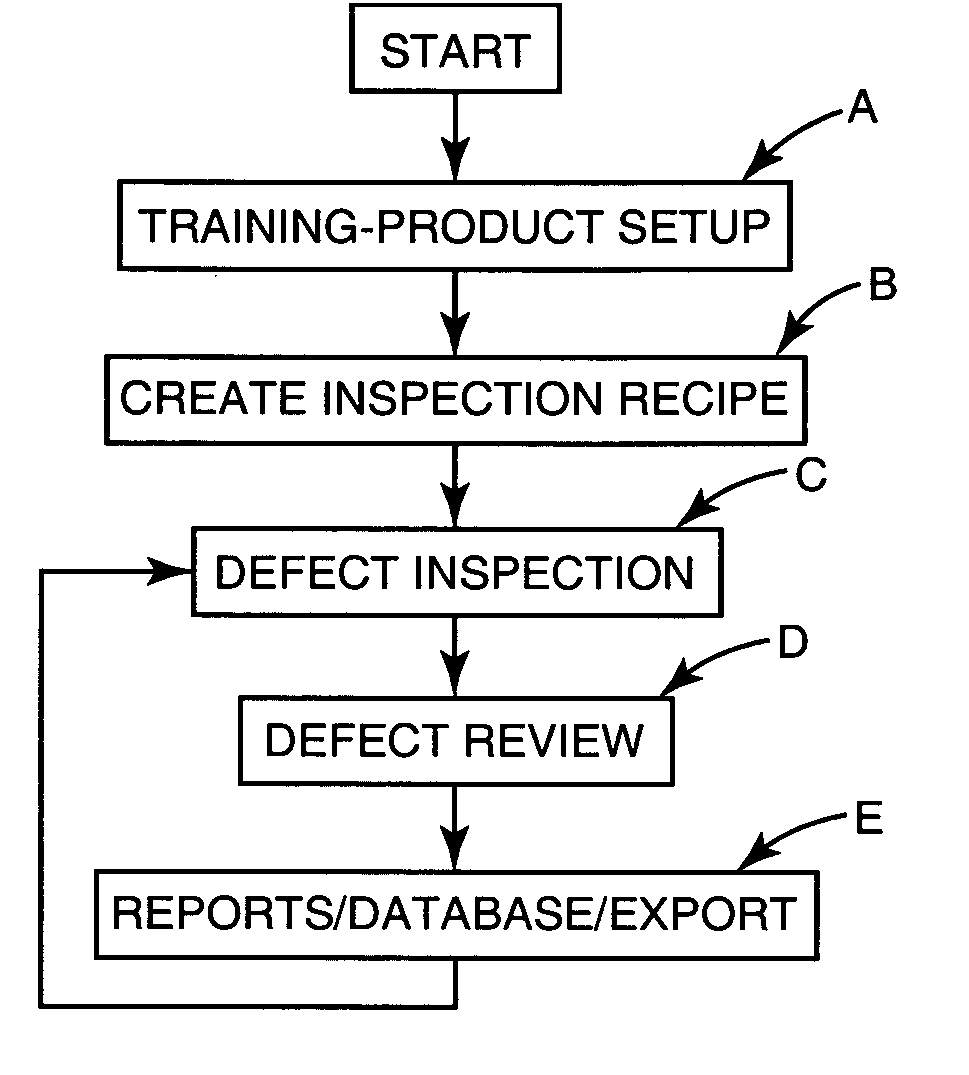

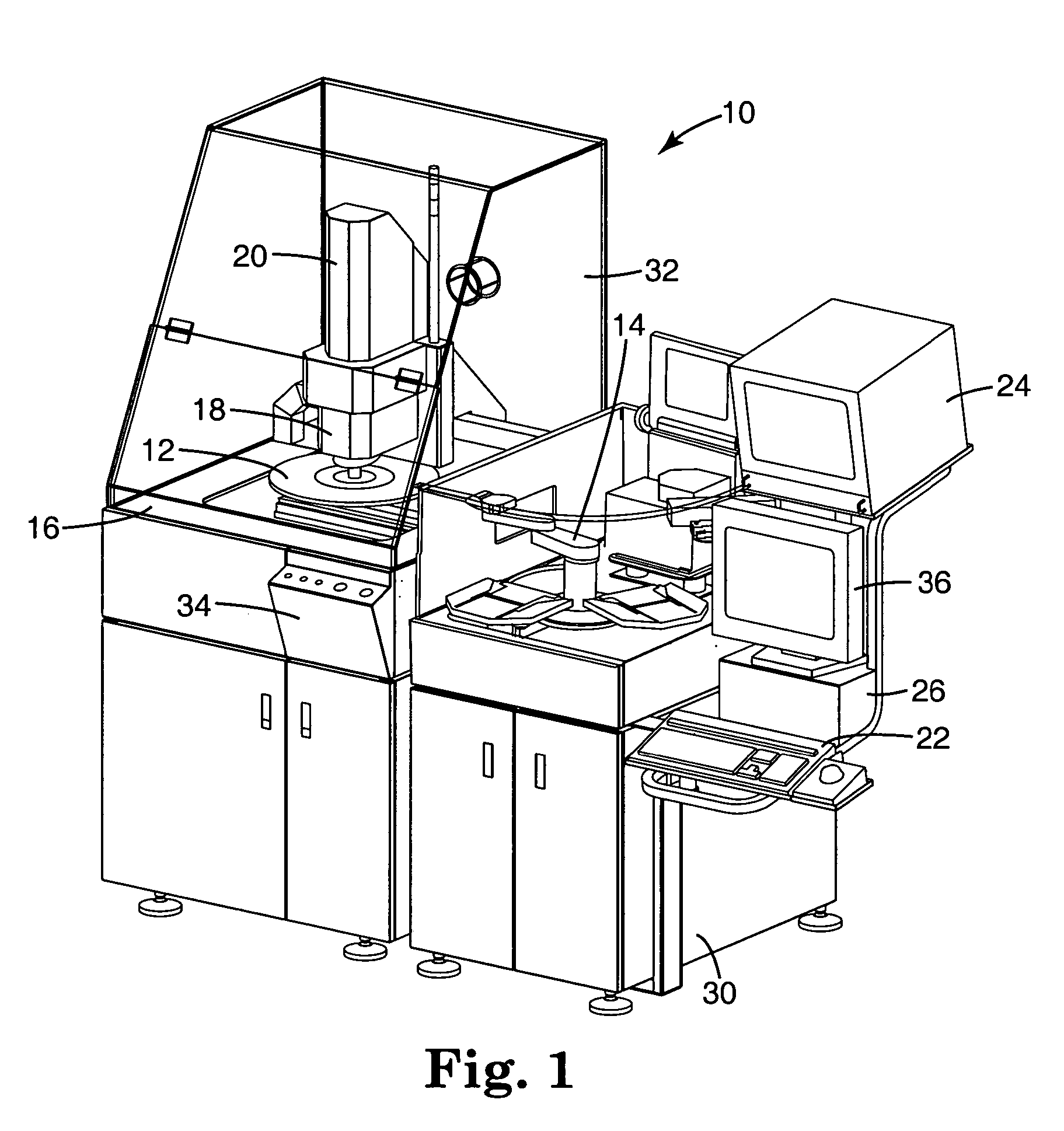

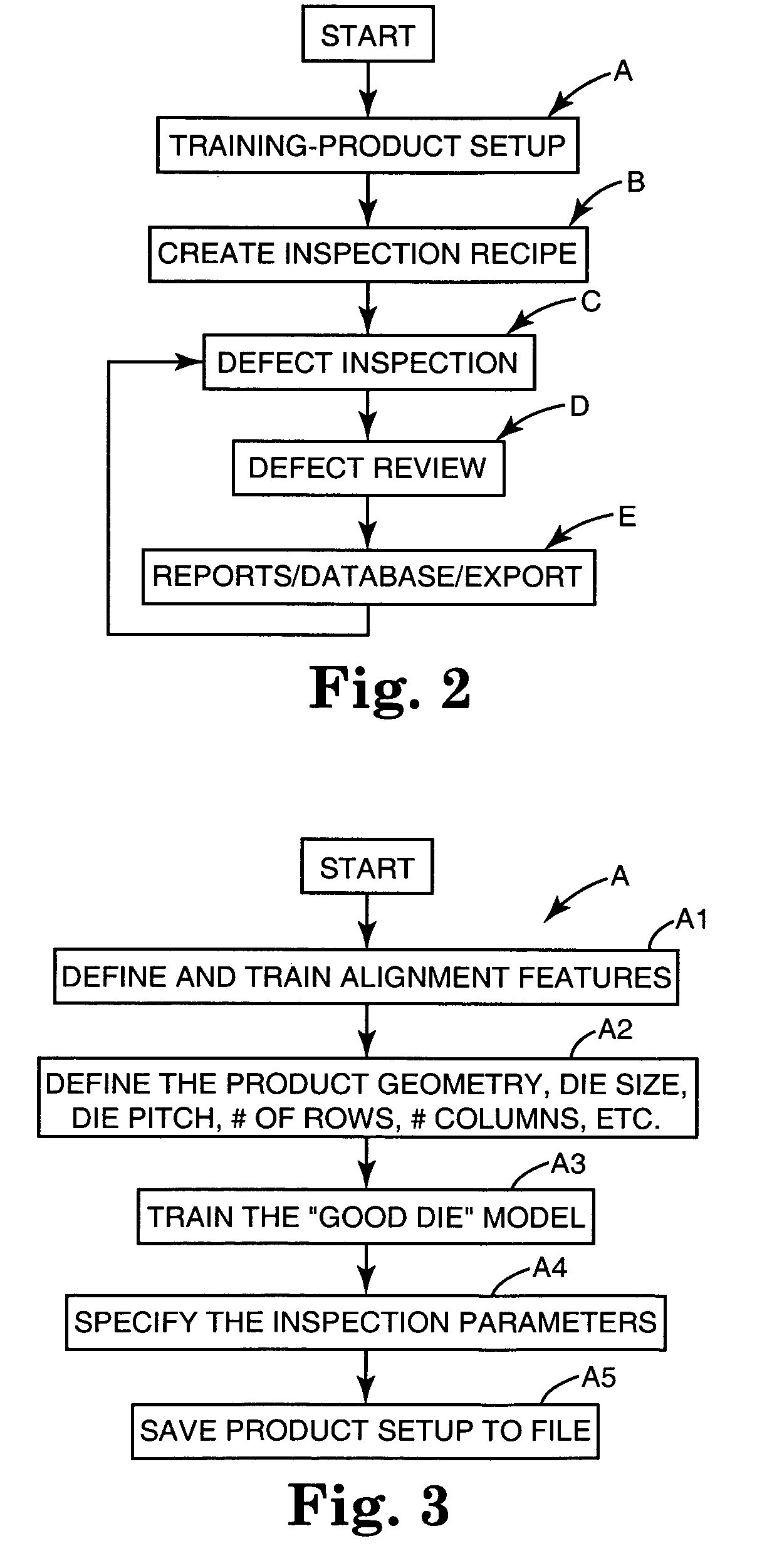

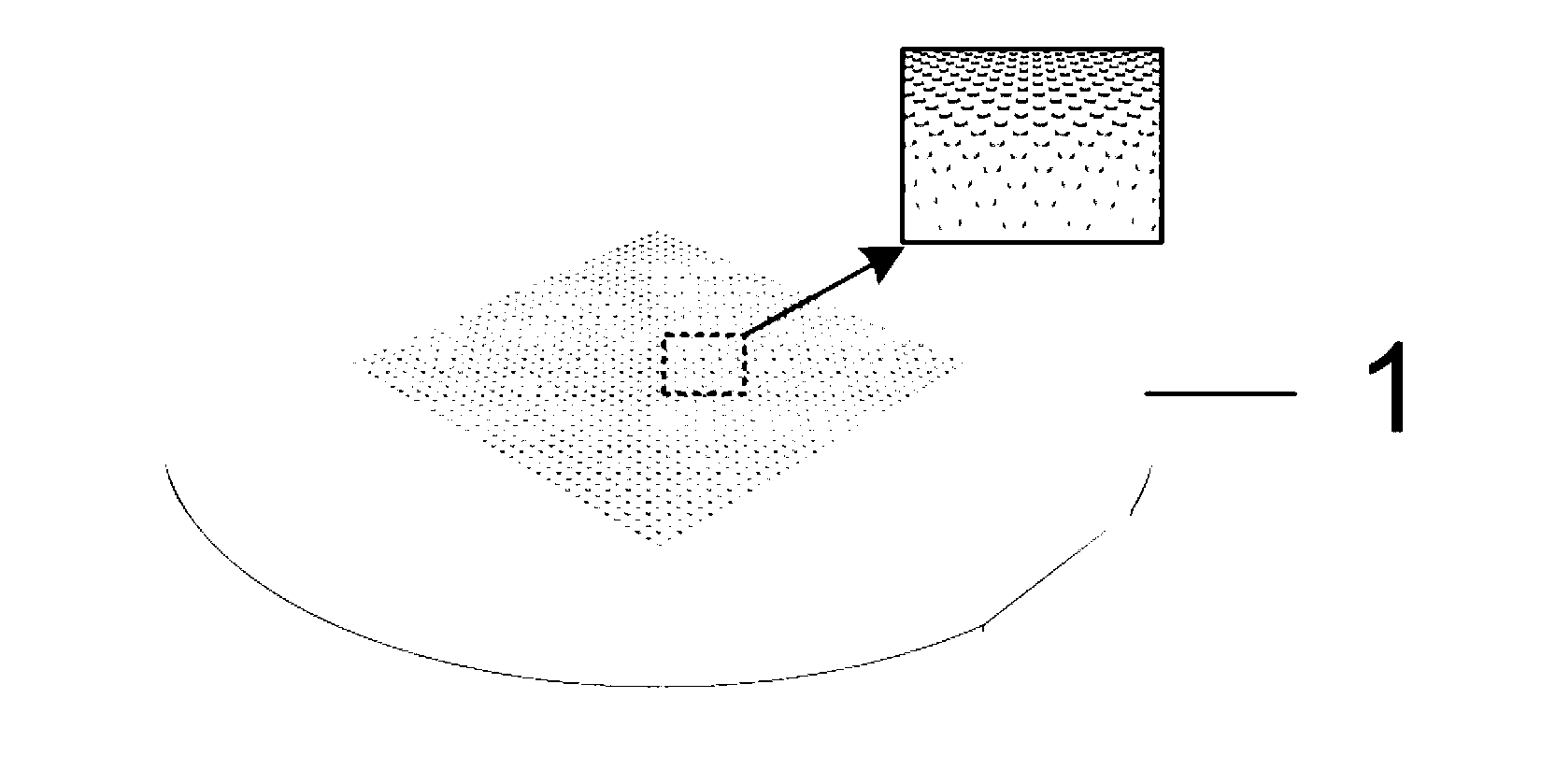

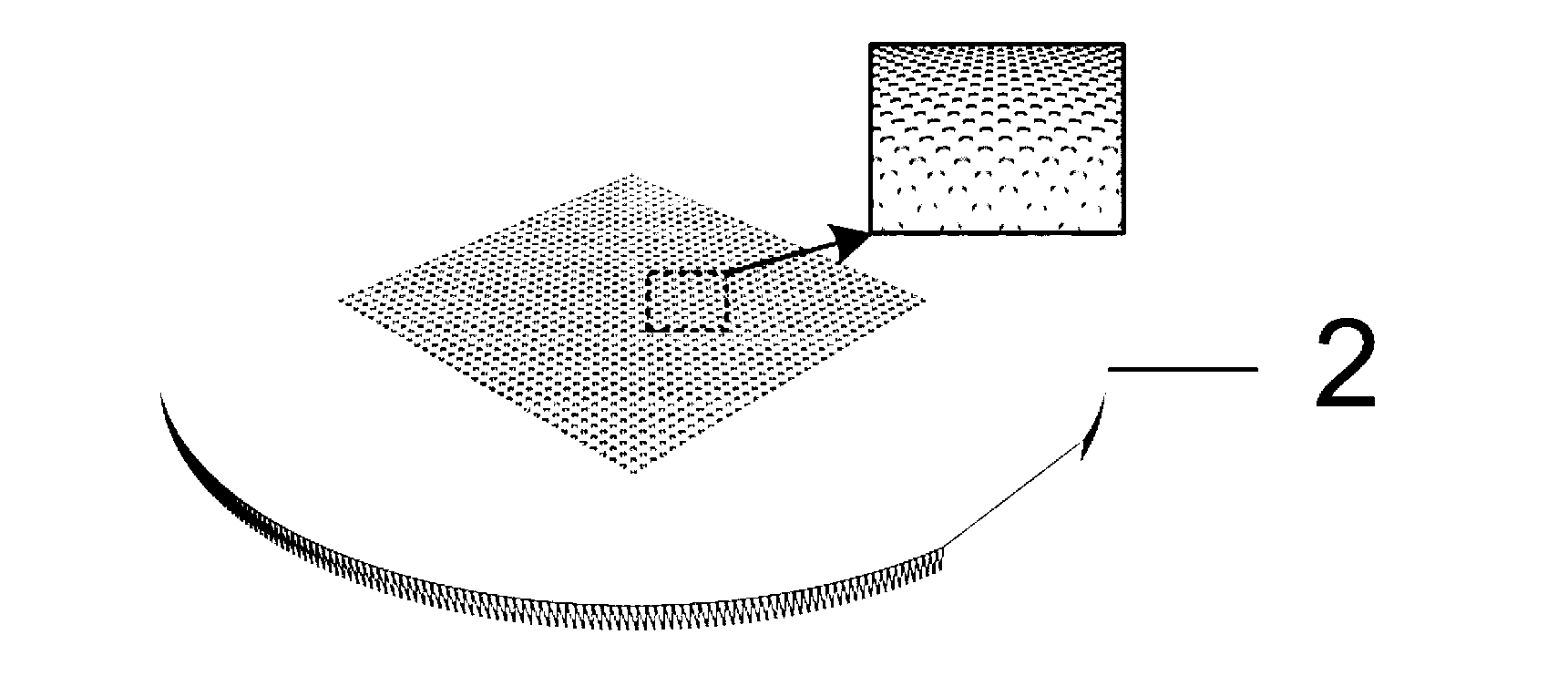

Automated wafer defect inspection system and a process of performing such inspection

An automated defect inspection system has been invented and is used on patterned wafers, whole wafers, broken wafers, partial wafers, sawn wafers such as on film frames, JEDEC trays, Auer boats, die in gel or waffle packs, MCMs, etc. and is specifically intended and designed for second optical wafer inspection for such defects as metalization defects (such as scratches, voids, corrosion, and bridging), diffusion defects, passivation layer defects, scribing defects, glassivation defects, chips and cracks from sawing, solder bump defects, and bond pad area defects.

Owner:RUDOLPH TECHNOLOGIES INC

Automated wafer defect inspection system and a process of performing such inspection

InactiveUS20050008218A1Improve inspection qualityEasy to controlImage enhancementImage analysisCrazingEngineering

An automated defect inspection system has been invented and is used on patterned wafers, whole wafers, broken wafers, partial wafers, sawn wafers such as on film frames, JEDEC trays, Auer boats, die in gel or waffle packs, MCMs, etc. and is specifically intended and designed for second optical wafer inspection for such defects as metalization defects (such as scratches, voids, corrosion, and bridging), diffusion defects, passivation layer defects, scribing defects, glassivation defects, chips and cracks from sawing, solder bump defects, and bond pad area defects.

Owner:RUDOLPH TECHNOLOGIES INC

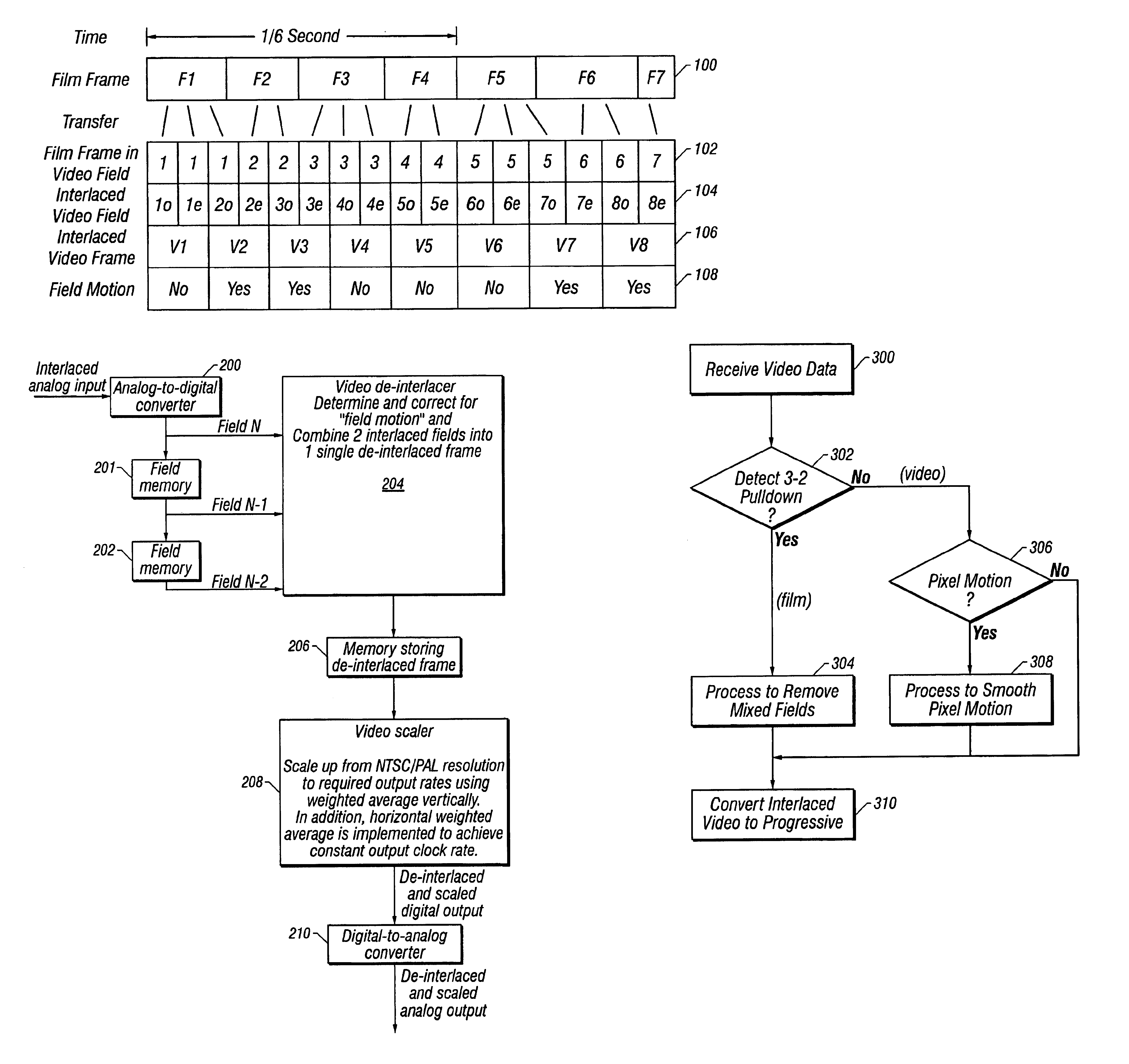

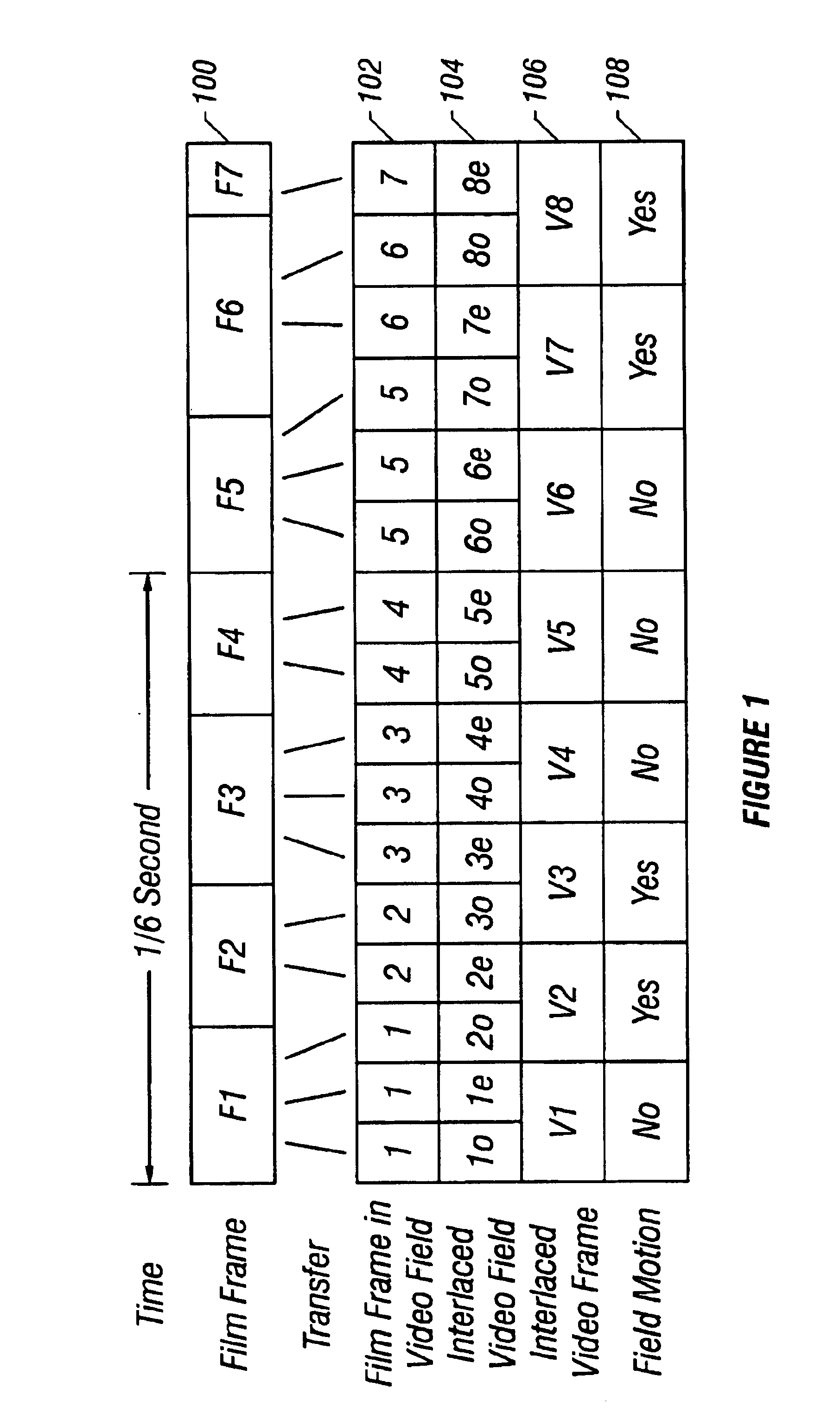

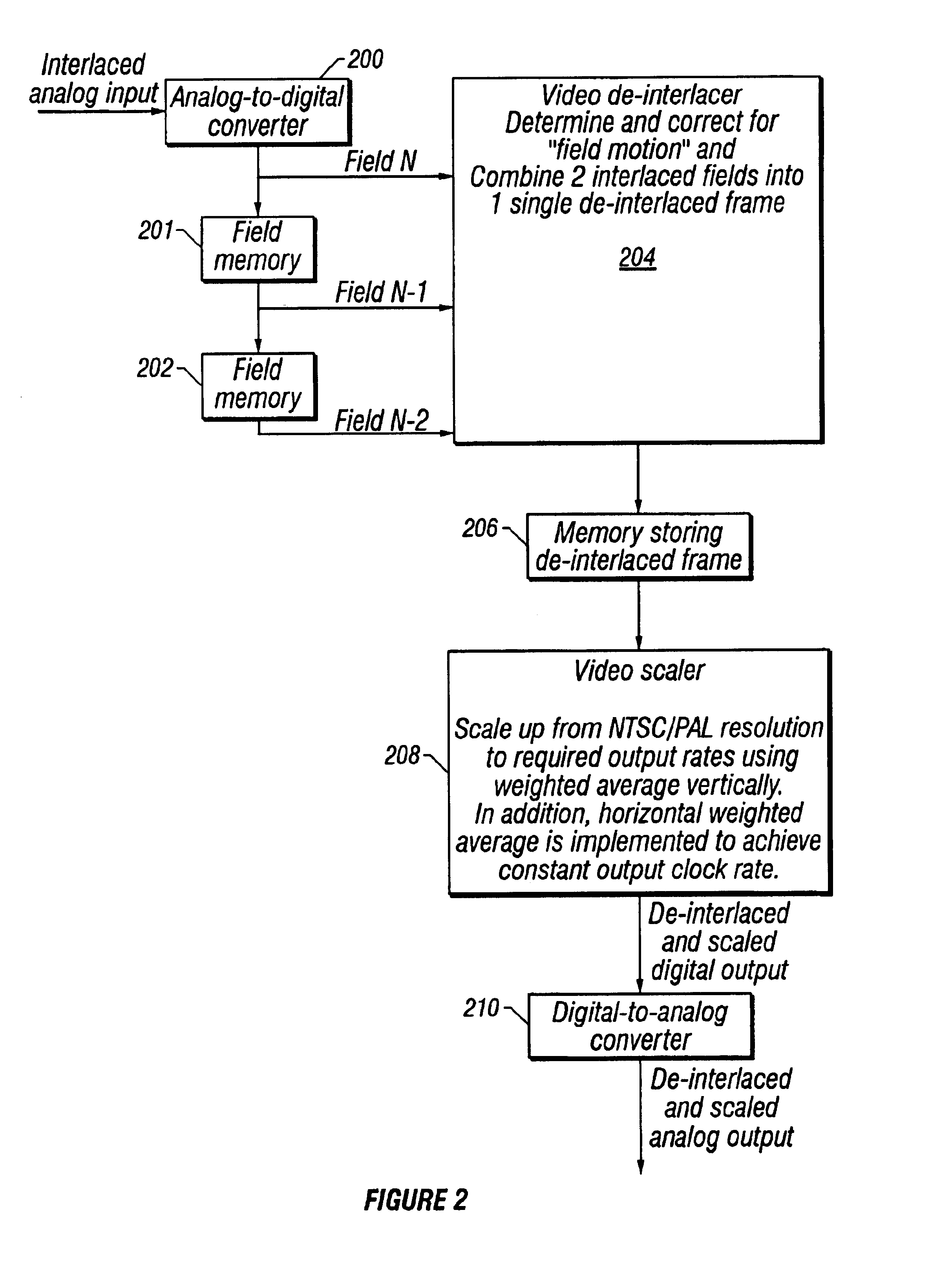

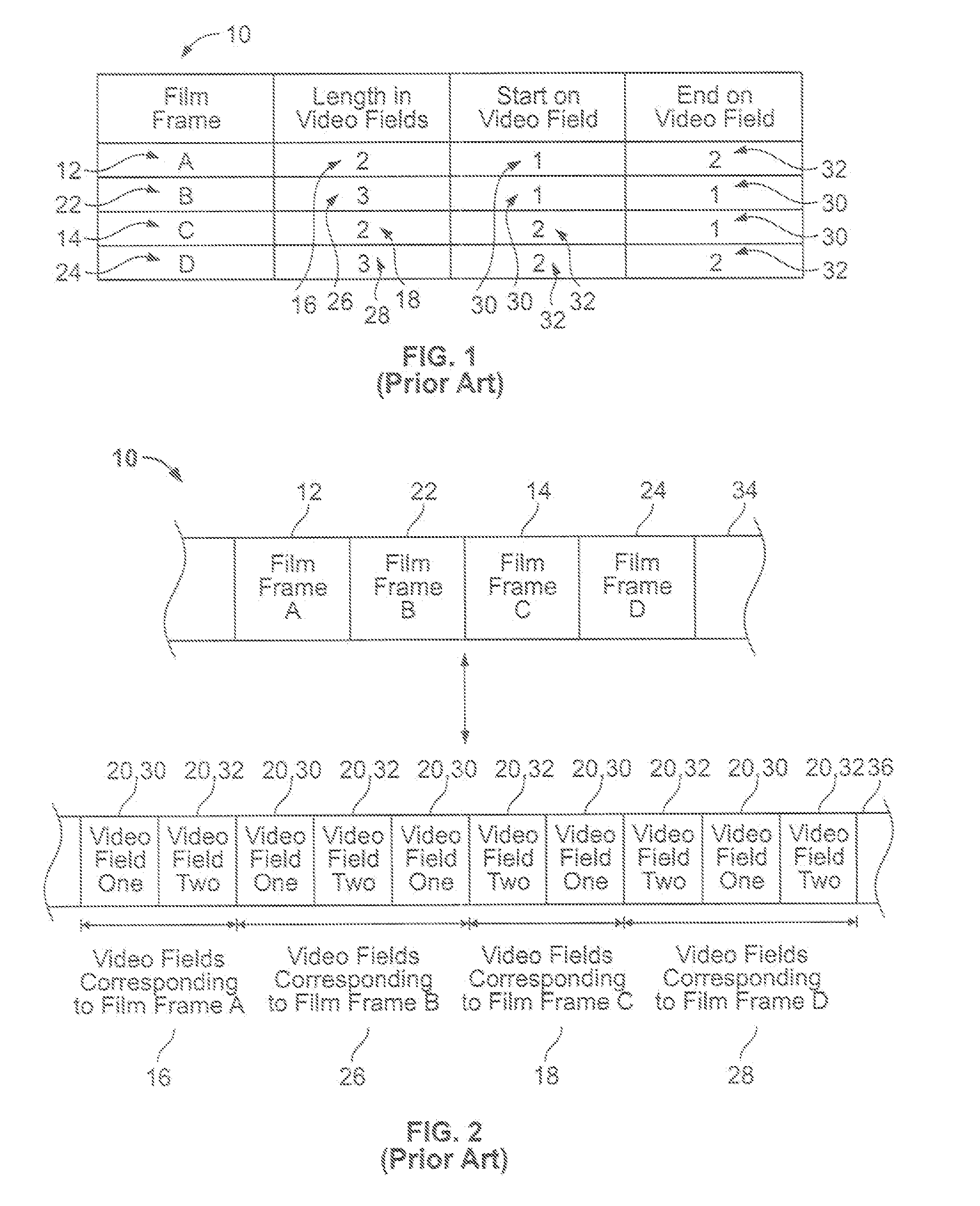

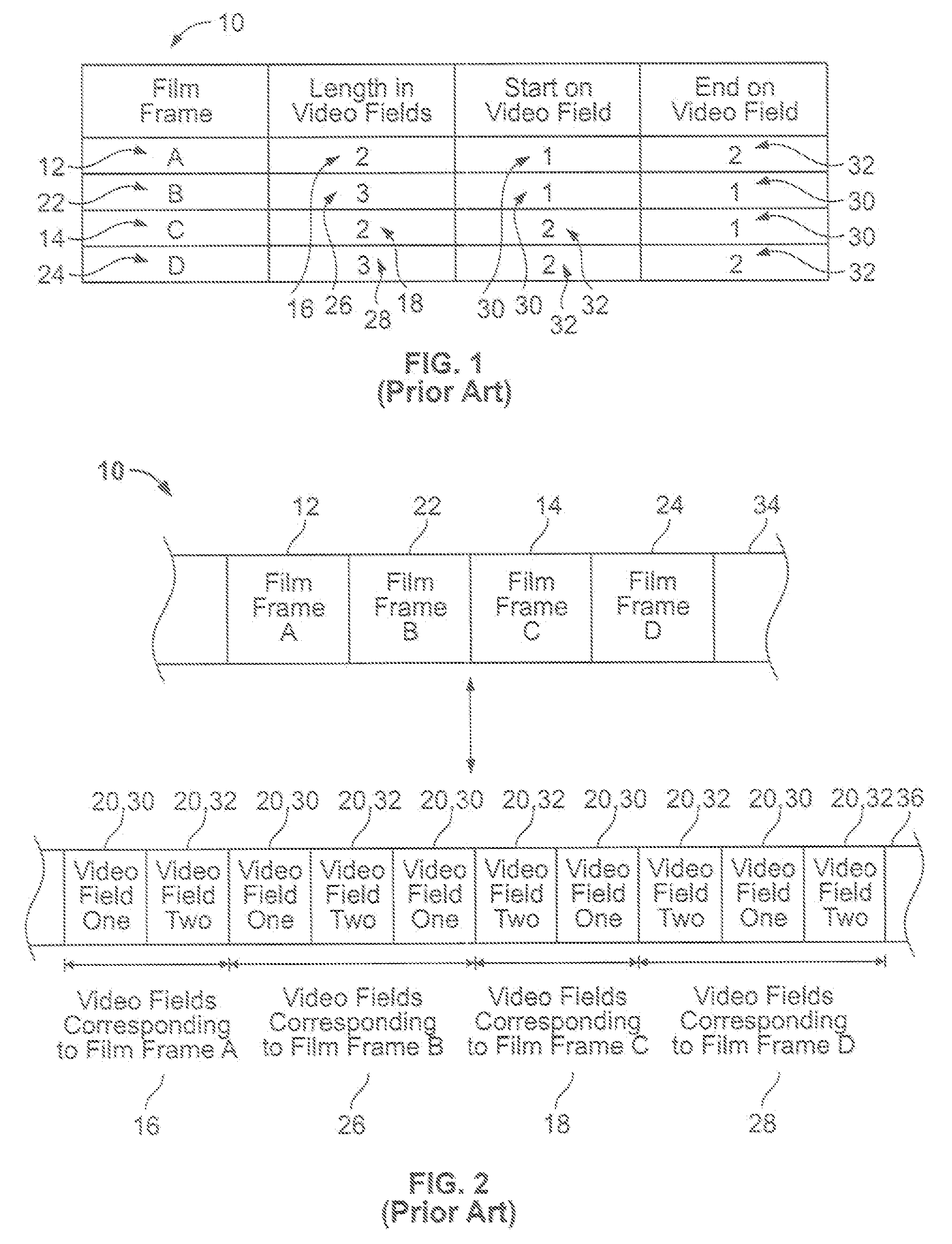

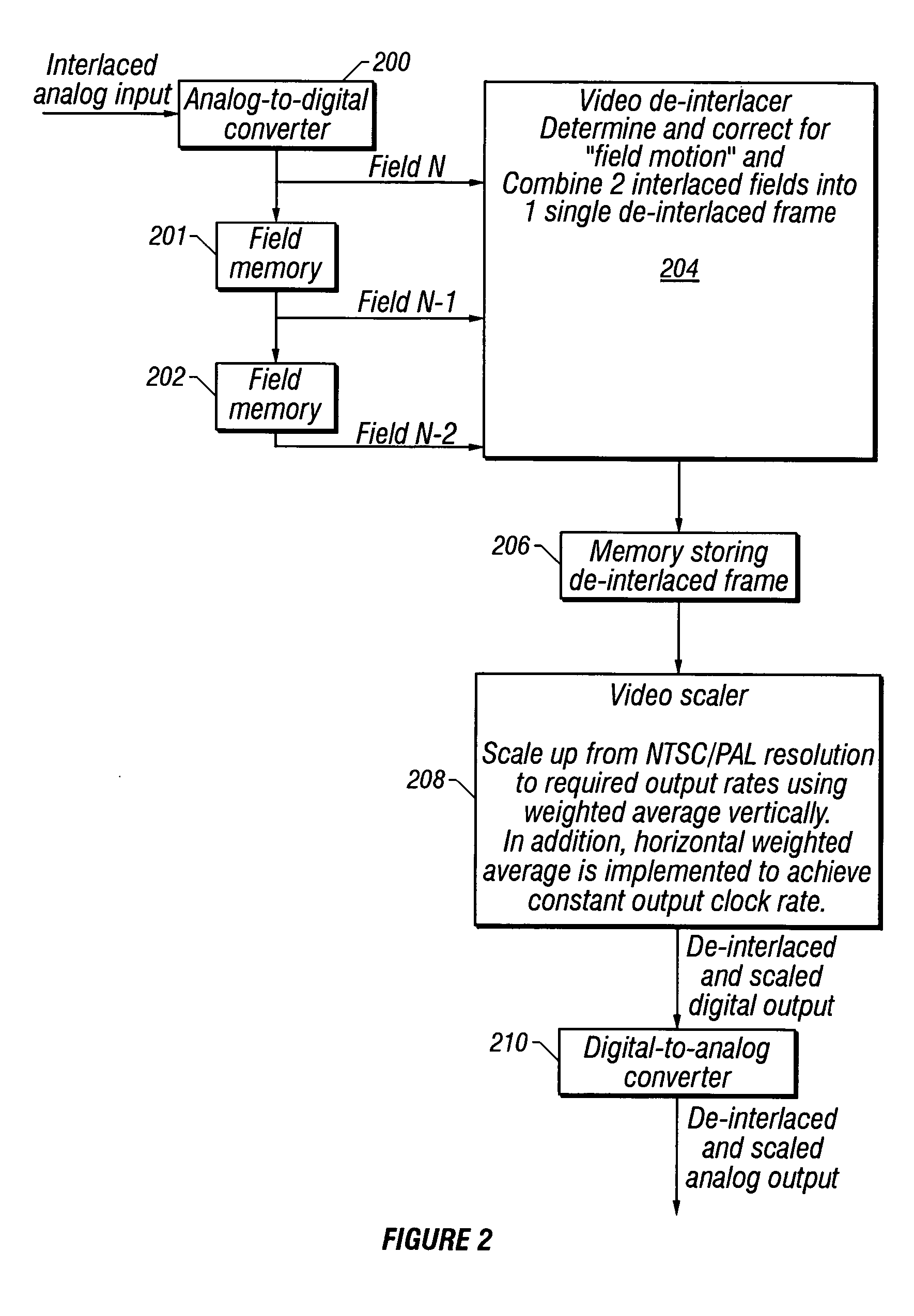

Method and apparatus for eliminating motion artifacts from video

InactiveUS6839094B2Television system detailsColor signal processing circuitsInterlaced videoContinuous field

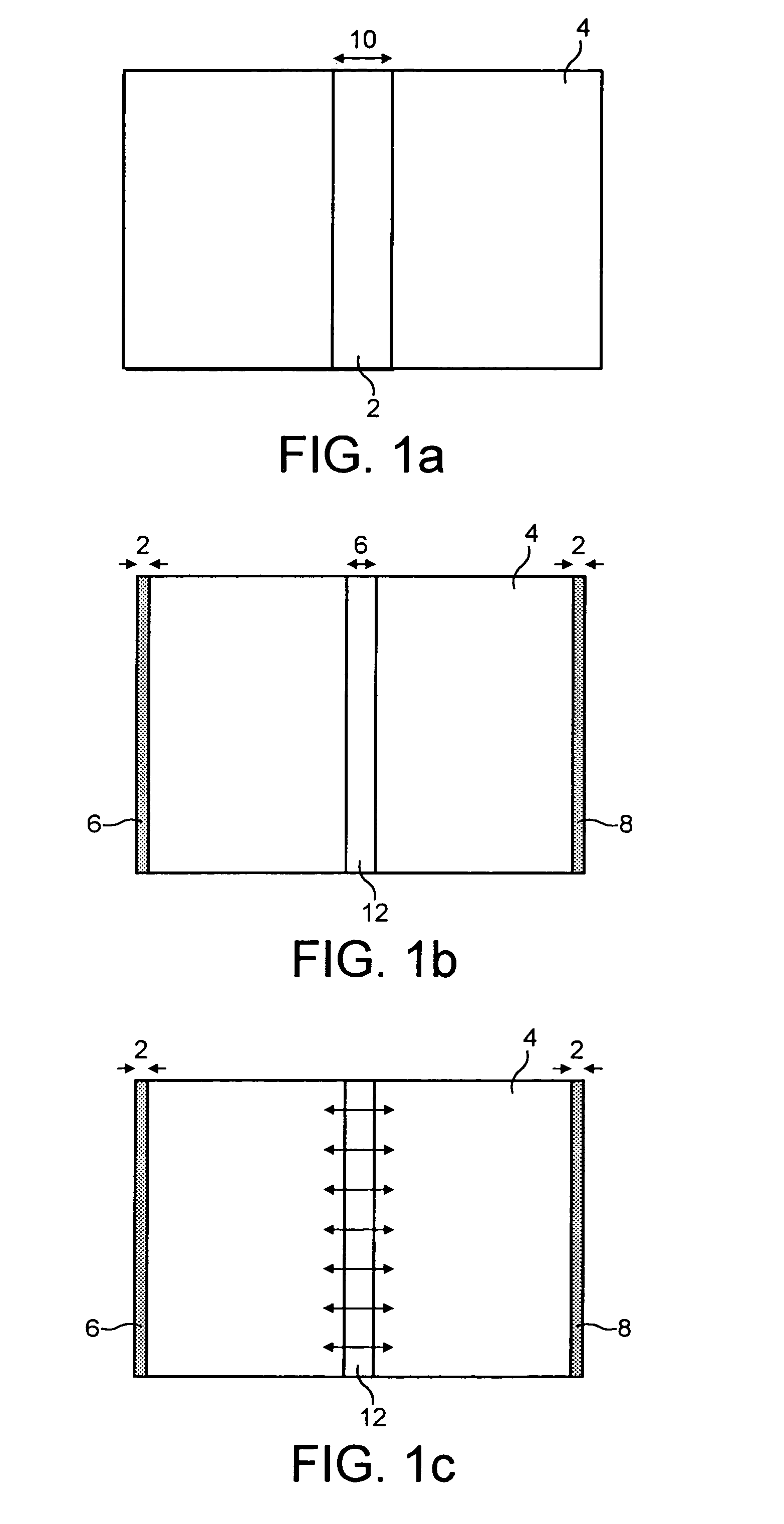

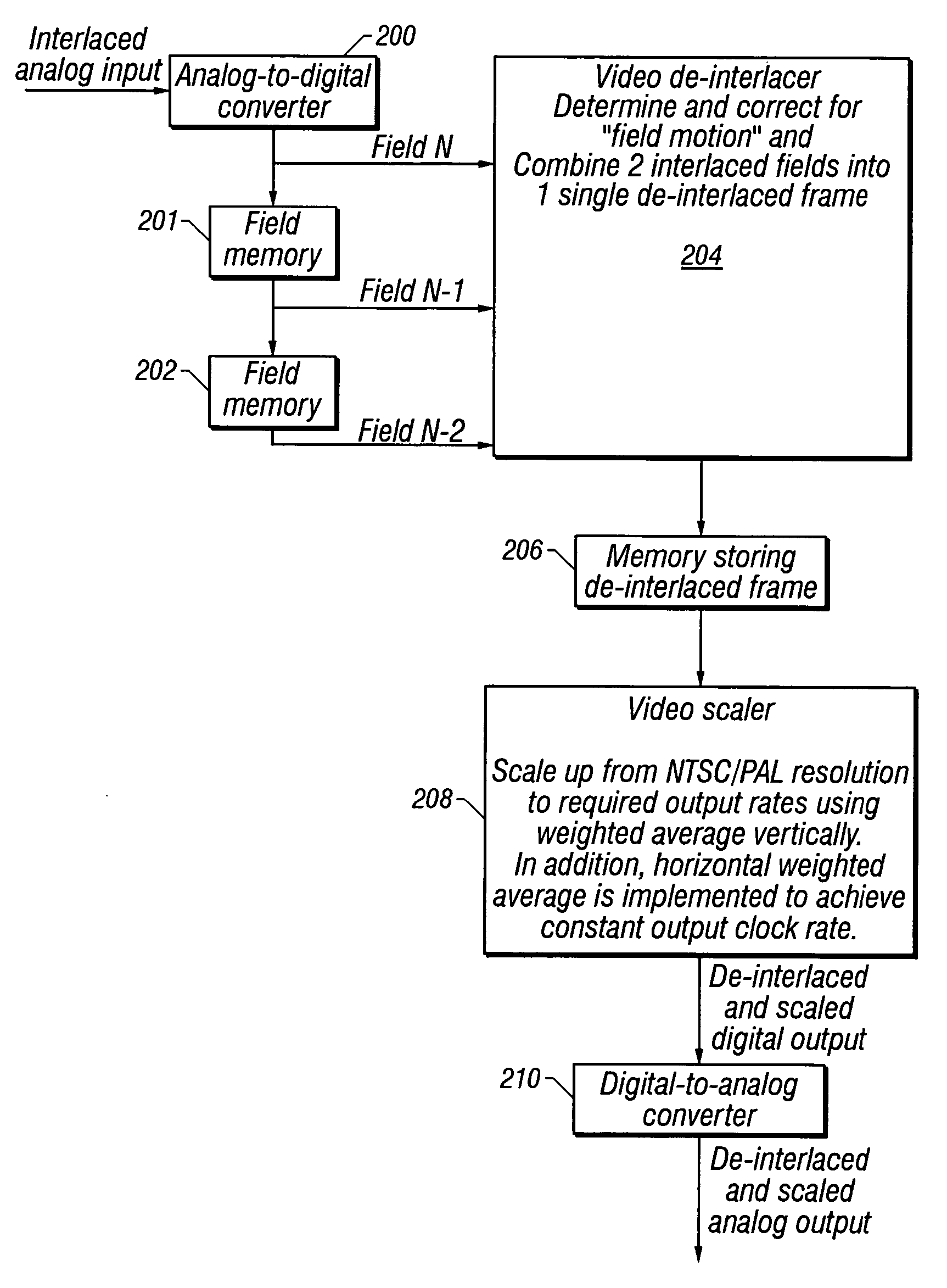

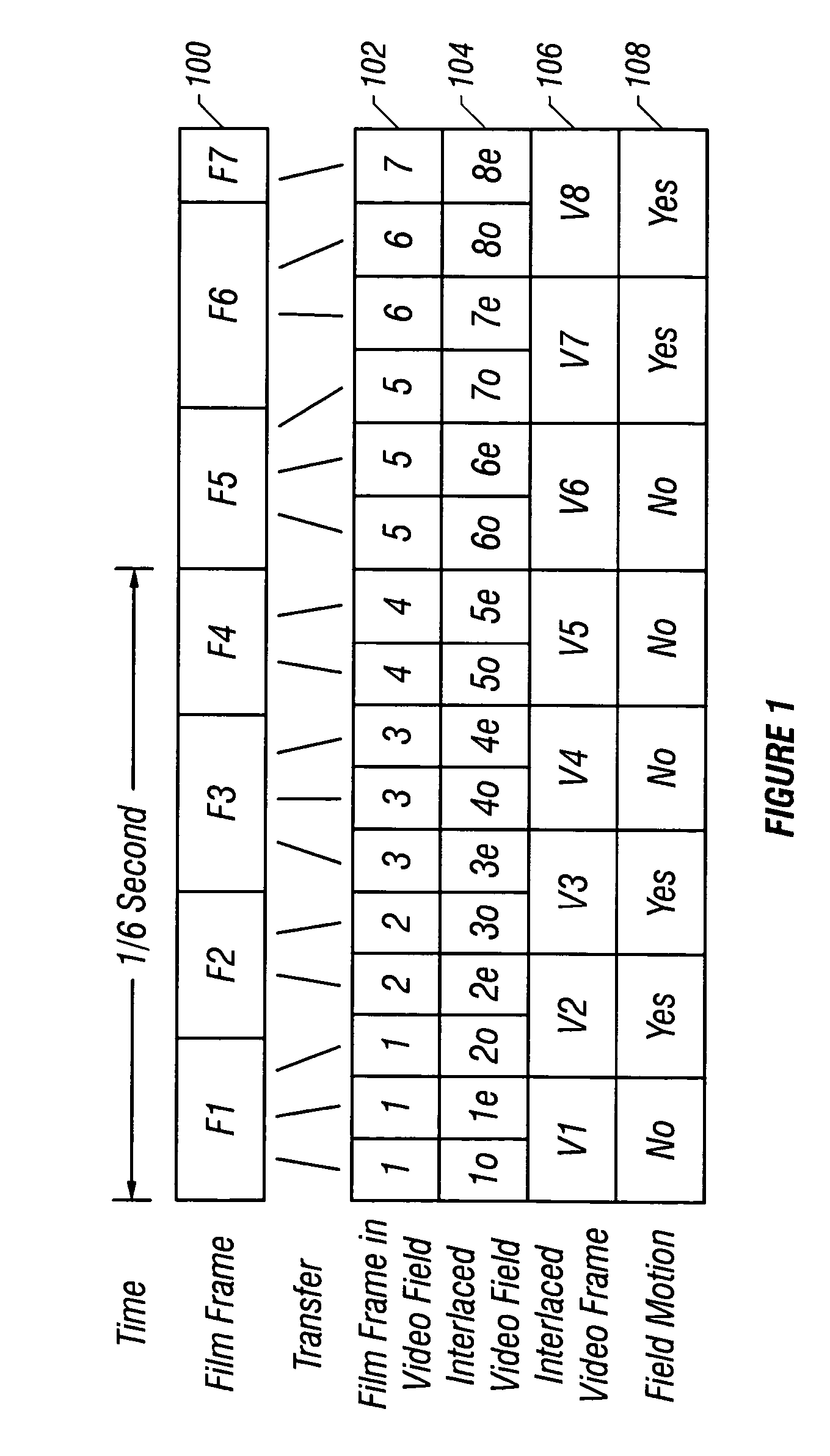

A method and apparatus for detecting and correcting motion artifacts in interlaced video signal converted for progressive video display. A correction is applied where interlaced video material is determined to originate from film source, thereby having been converted to video using a process known as 3-2 pulldown. Where the video material is not a result of the 3-2 pulldown process, a check is made for the presence of “pixel motion” so that corrections may be applied to smooth out the pixel motion. To determine 3-2 pulldown or field motion, a video field is compared to the field prior to the previous field to generate field error. Field errors are generated for five consecutive fields and a local minimum error repeated every five fields indicate the origination of the video material from film source using the 3-2 pulldown process. Upon confirmation of 3-2 pulldown, the video material is modified to correct for the mixing of two film frames into one interlaced video frame by assuring that the two fields of the de-interlaced video frame contain data from the same film frame. Where the video material did not originate from a film source, but pixel motion is detected, the pixel motion is smoothed out by an averaging method. The odd and even fields of the resulting video data are subsequently combined to form a progressive video material.

Owner:RGB SYST INC

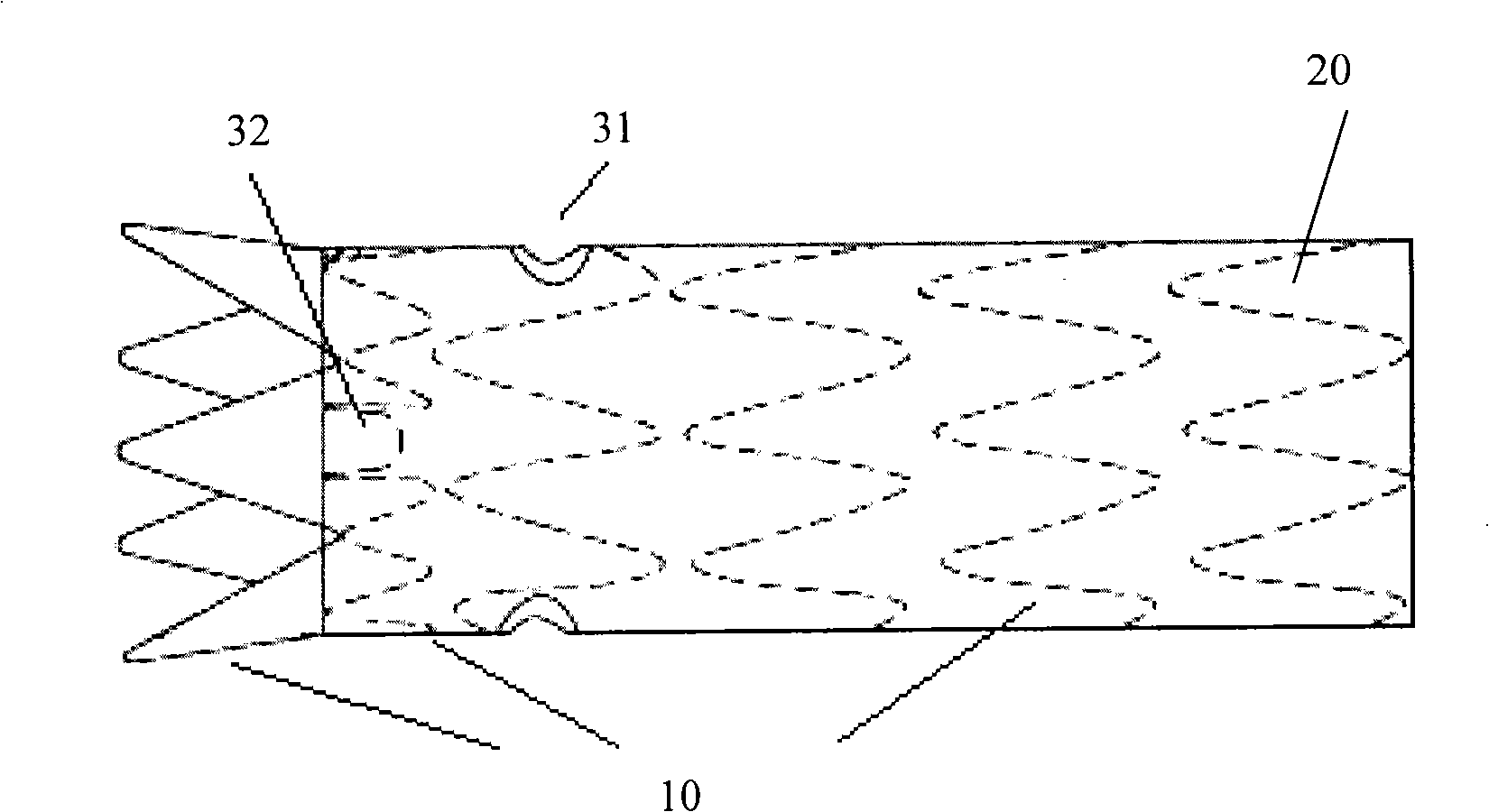

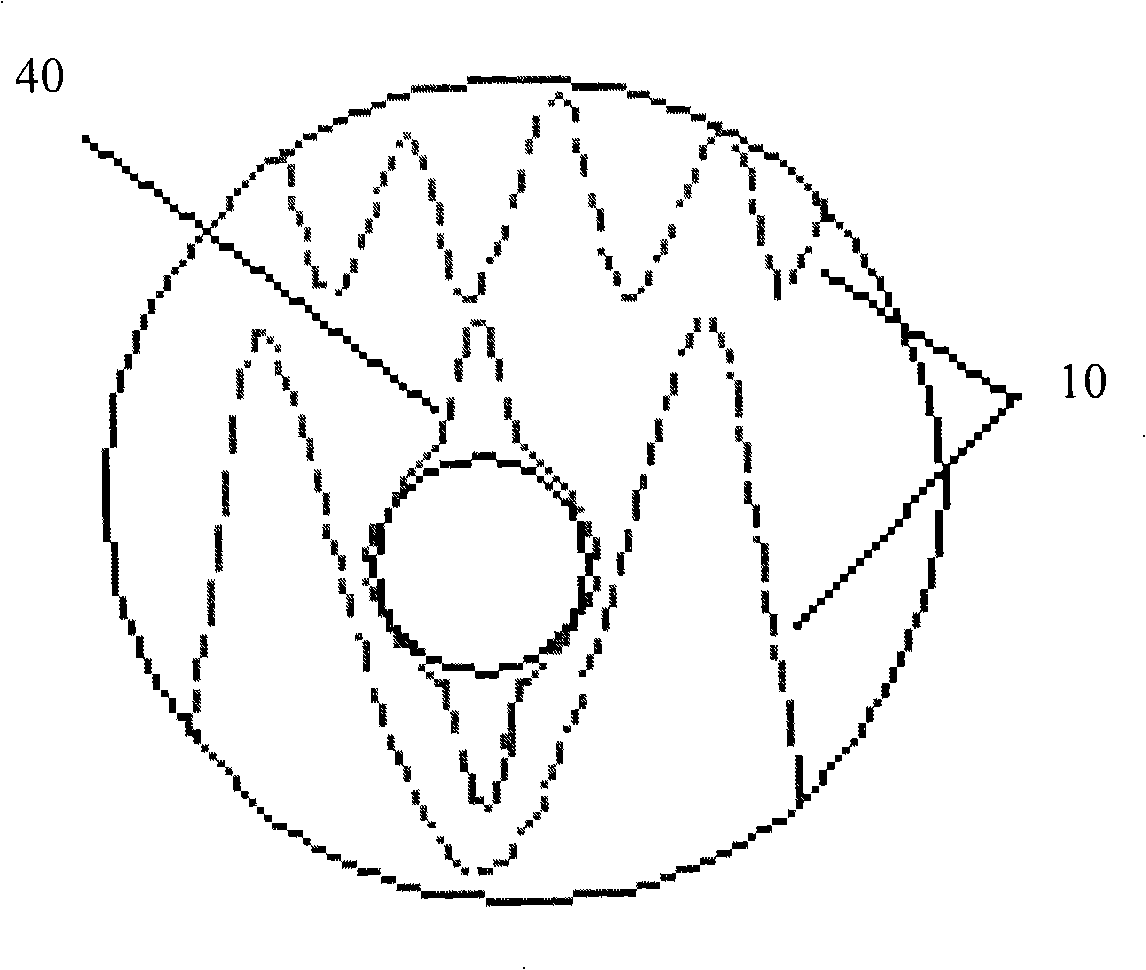

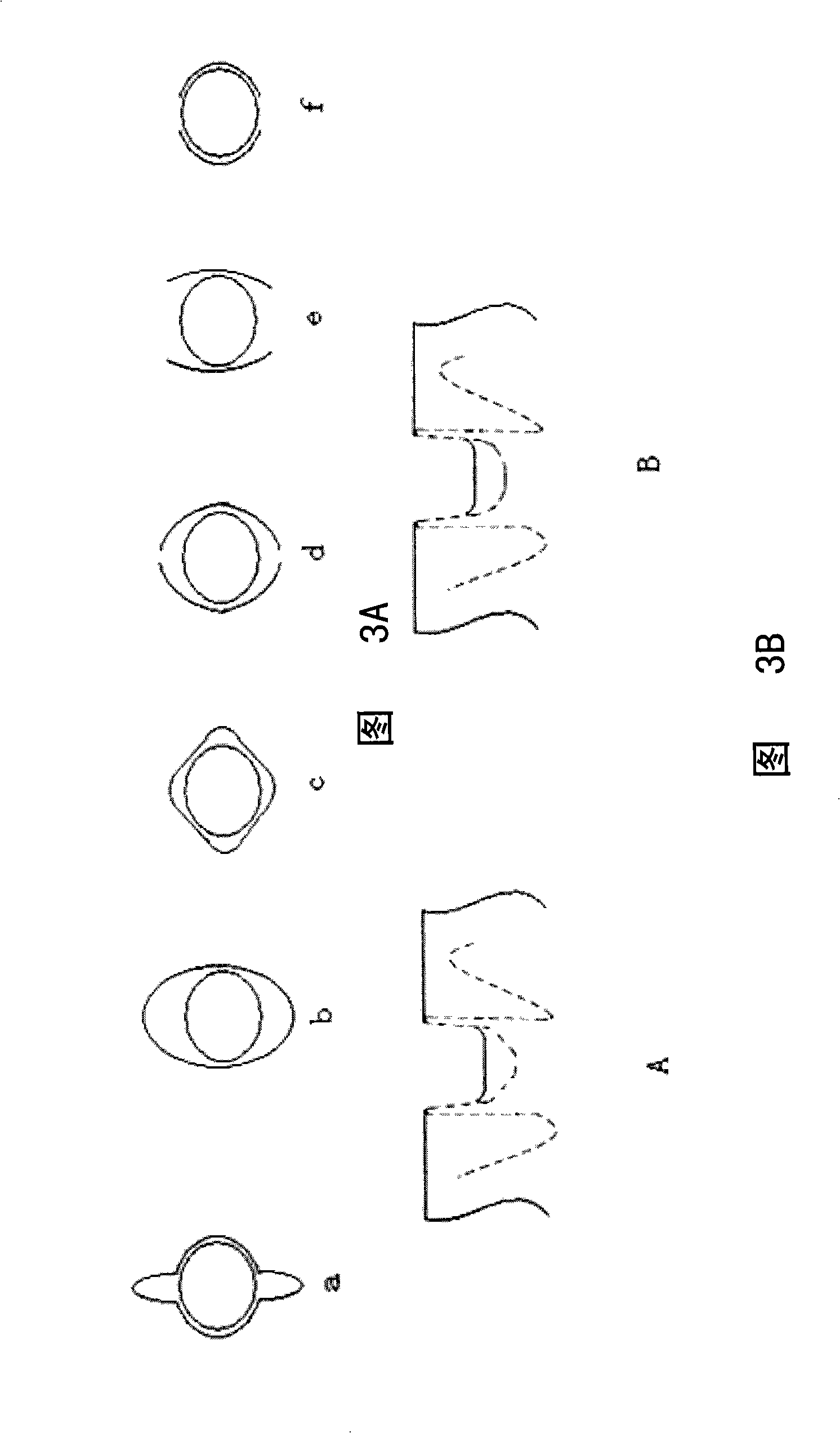

Overlay film frame with an opening and bonding method of the overlay film frame

ActiveCN101283937AOvercome the overlockOvercome the defect that the opening is easily deformedStentsBlood vesselsSurgical operationInsertion stent

The invention discloses a covered stent with side openings and a binding method of the covered stent. The covered stent is helpful for accurately positioning stent openings and renal artery openings, so as to improve the operation success ratio. The covered stent comprises a plurality of ring-shaped waveform stent units and a membrane sewn up with the stent units to form a tubular piece, wherein at least one side opening is opened on the tubular piece, an opening fixing filament is sewn on the opening site to support the opening. The covered stent can be used in surgical operation equipment.

Owner:SHANGHAI MICROPORT ENDOVASCULAR MEDTECH (GRP) CO LTD

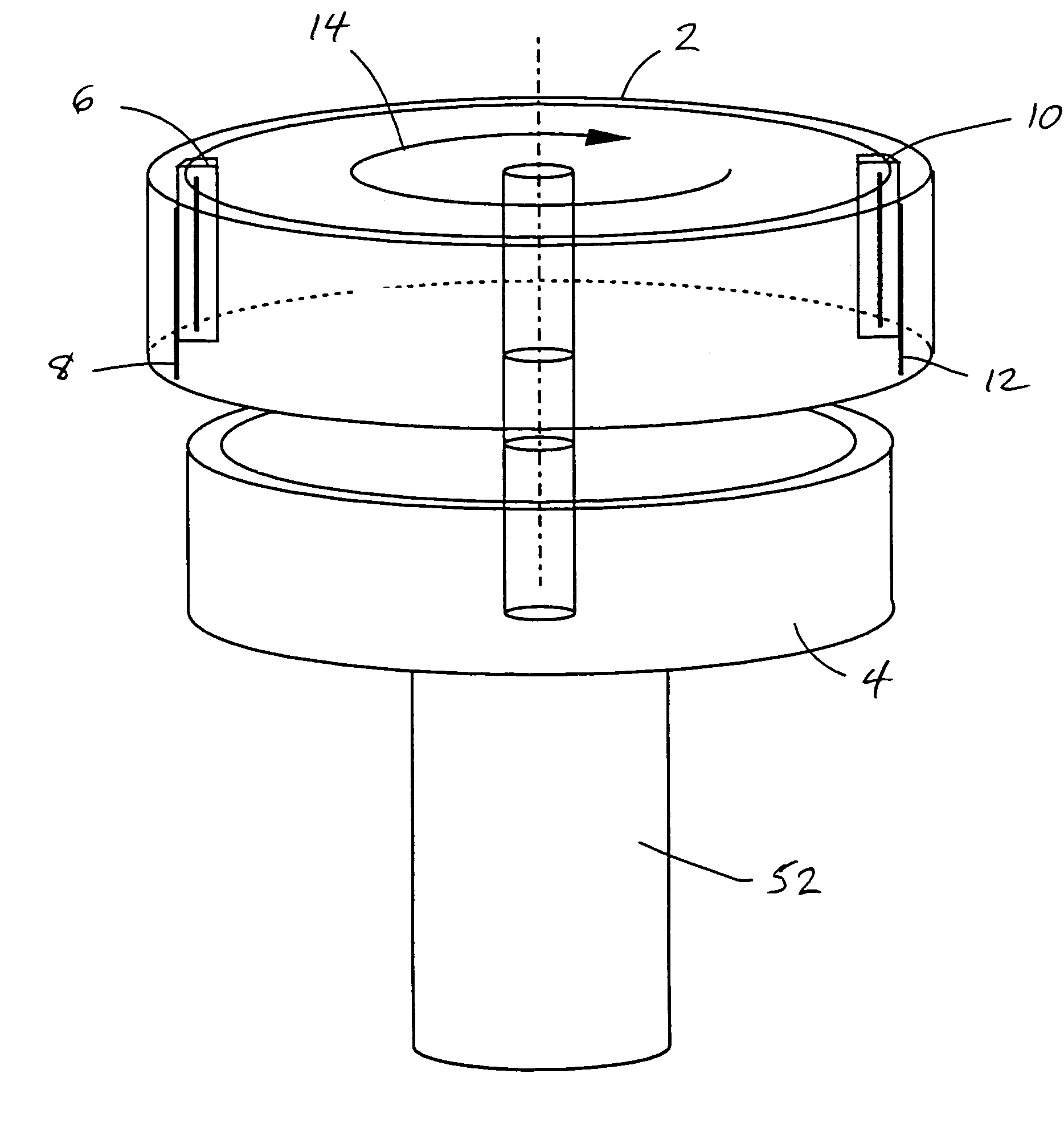

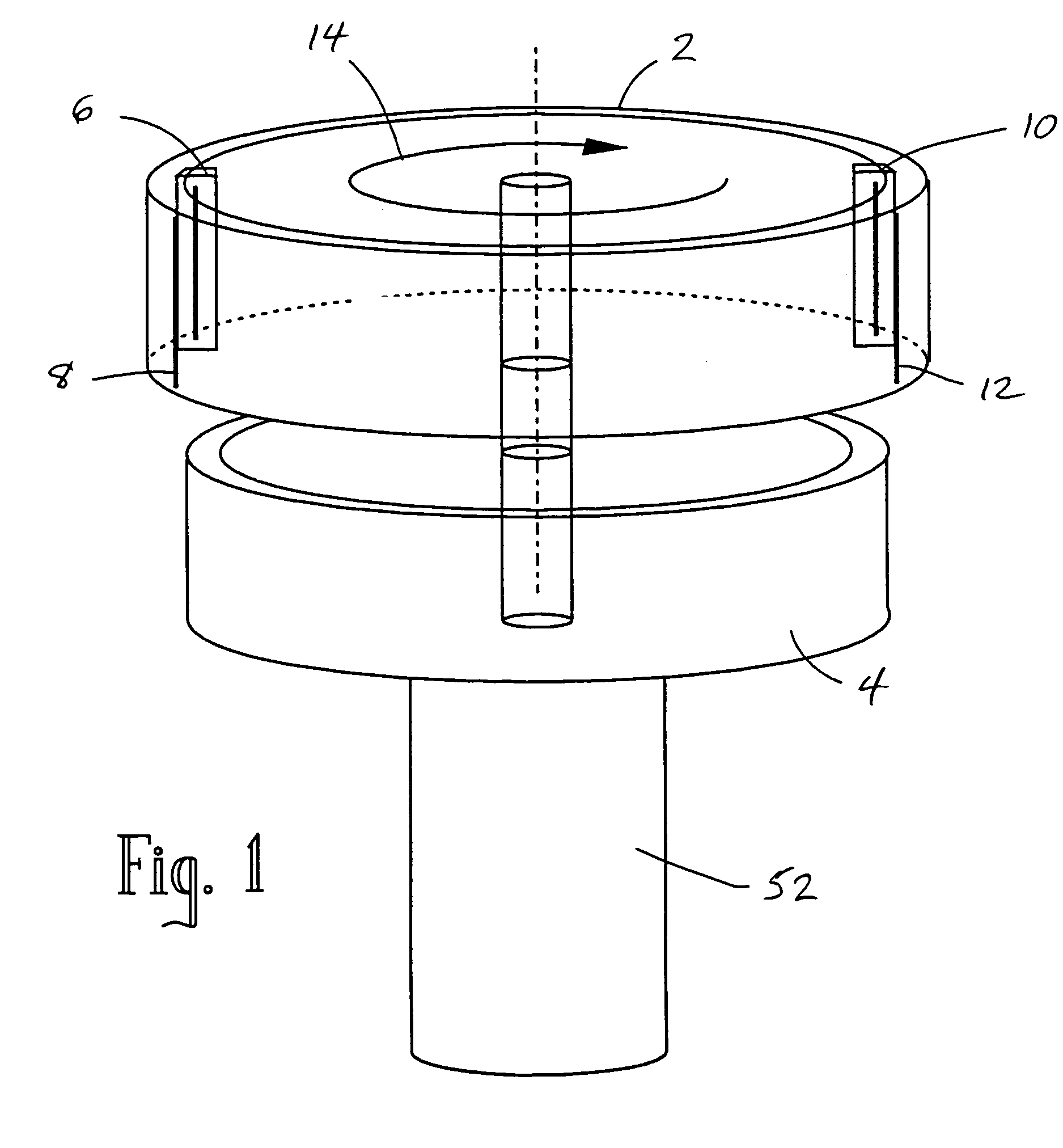

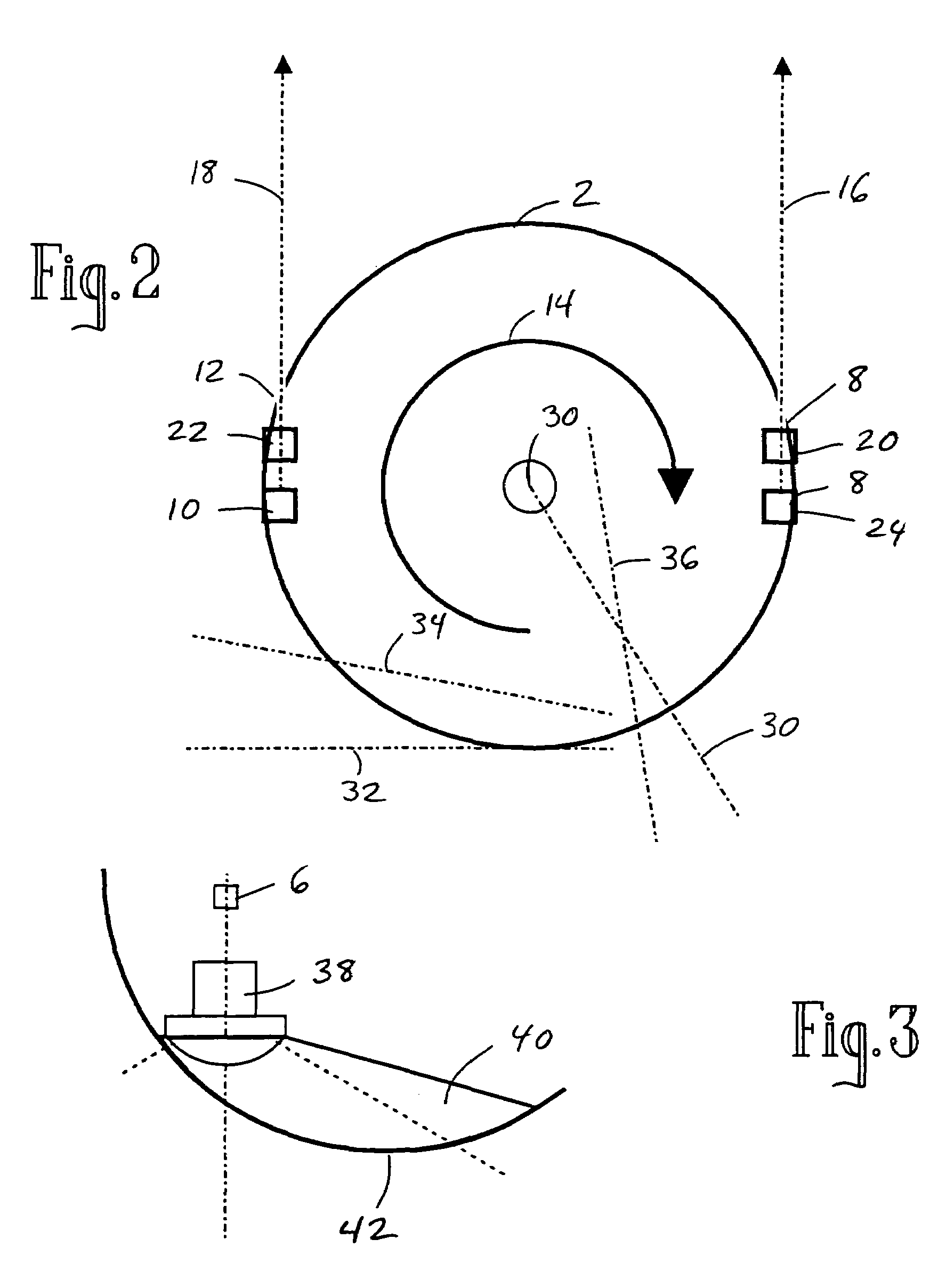

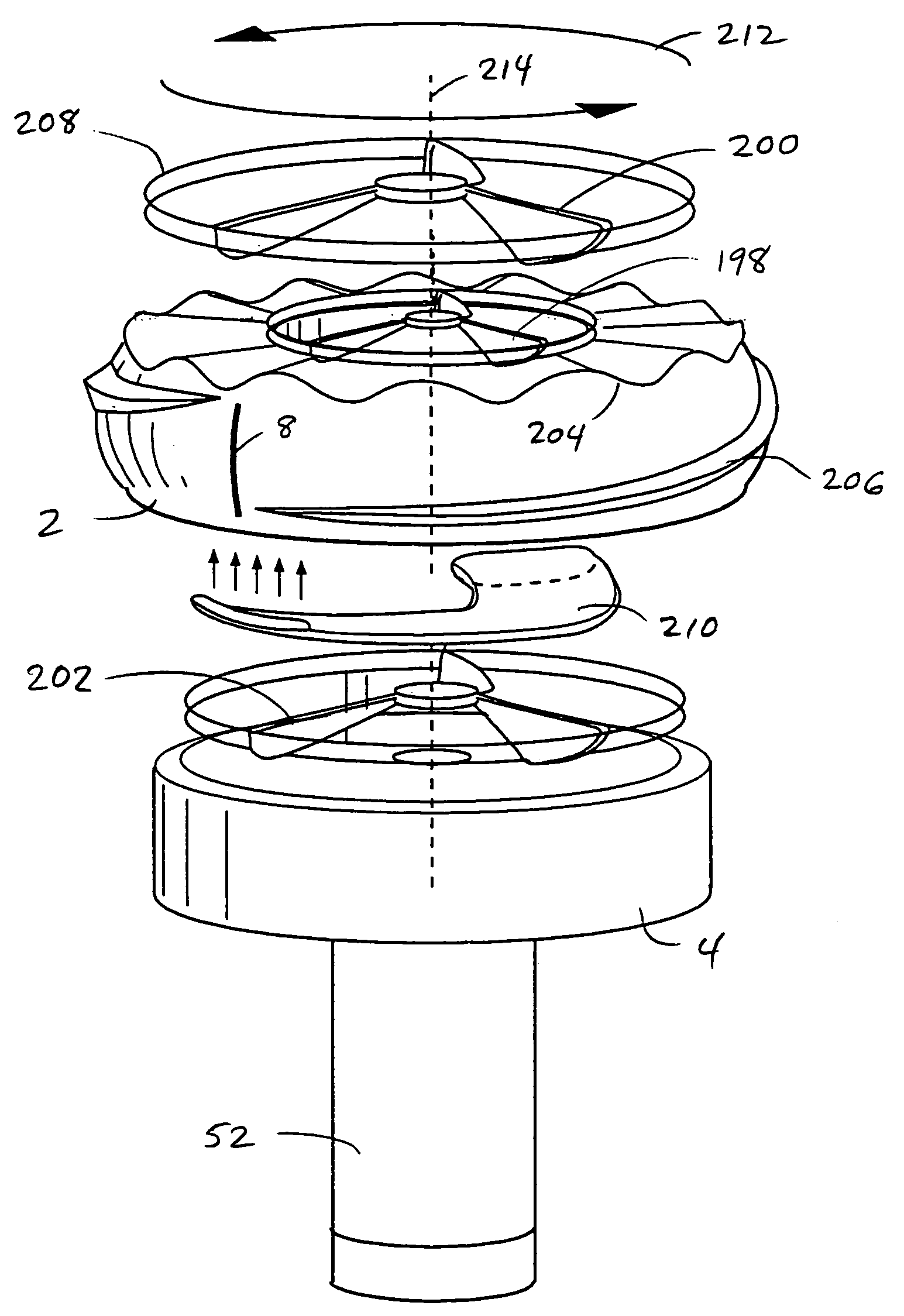

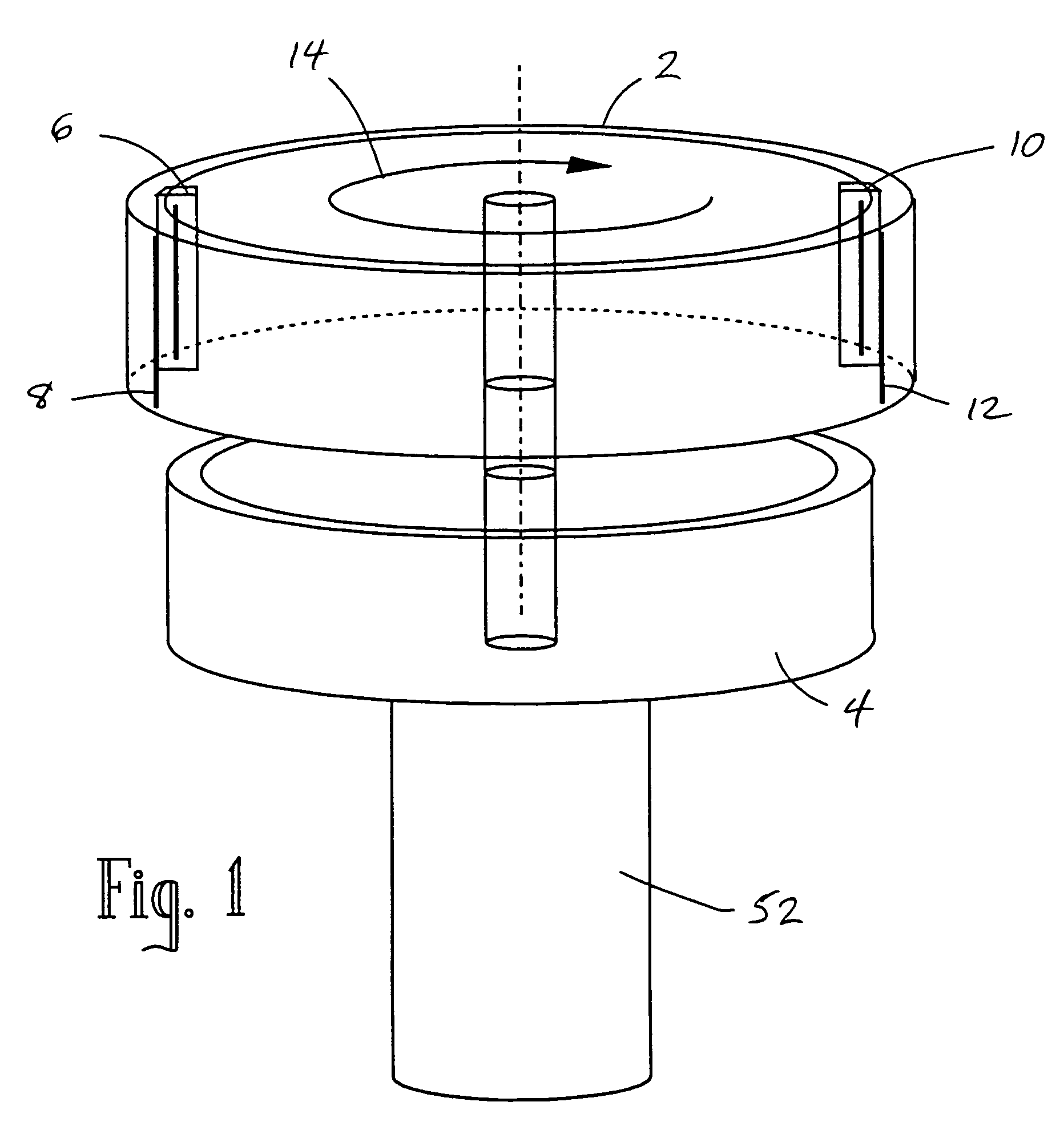

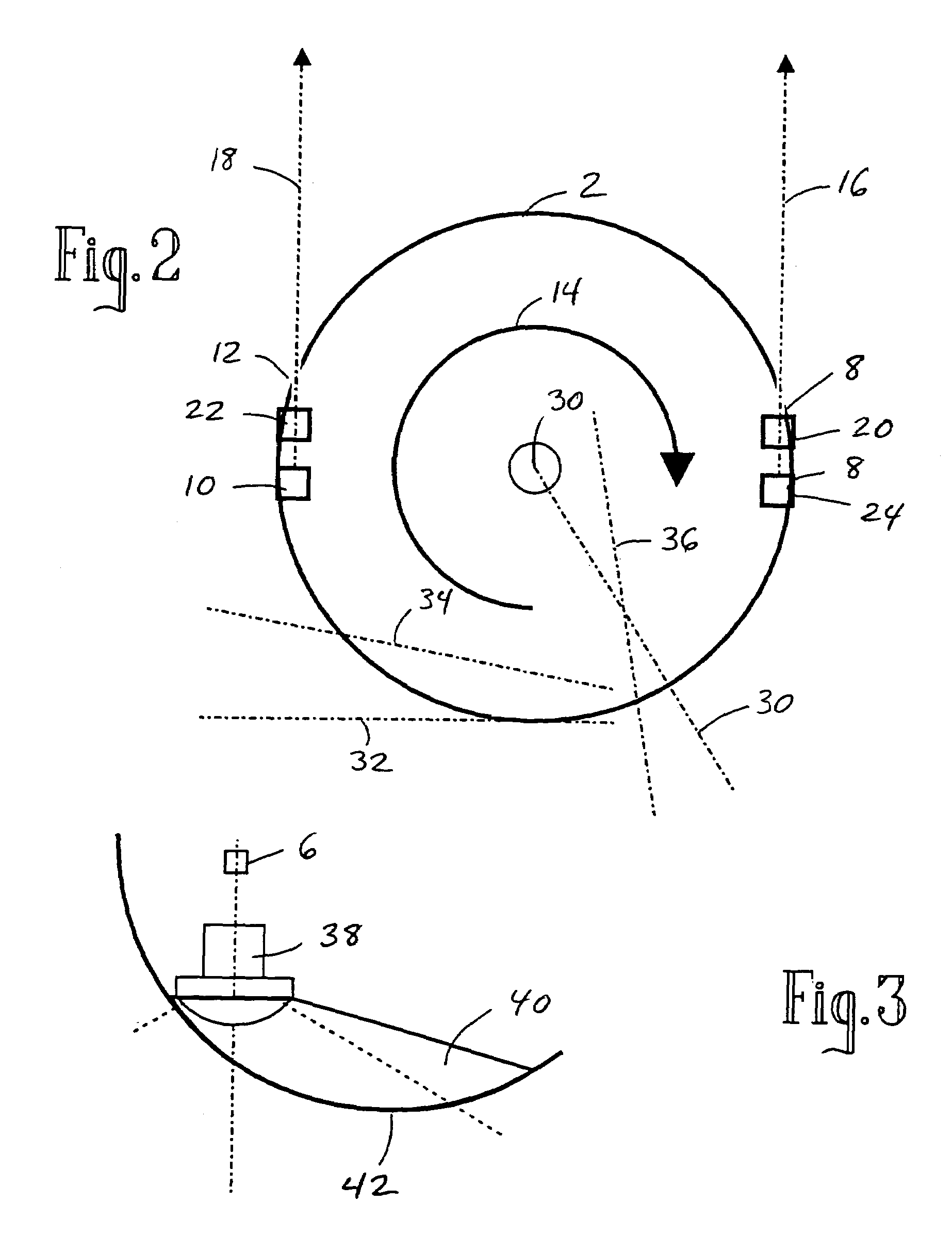

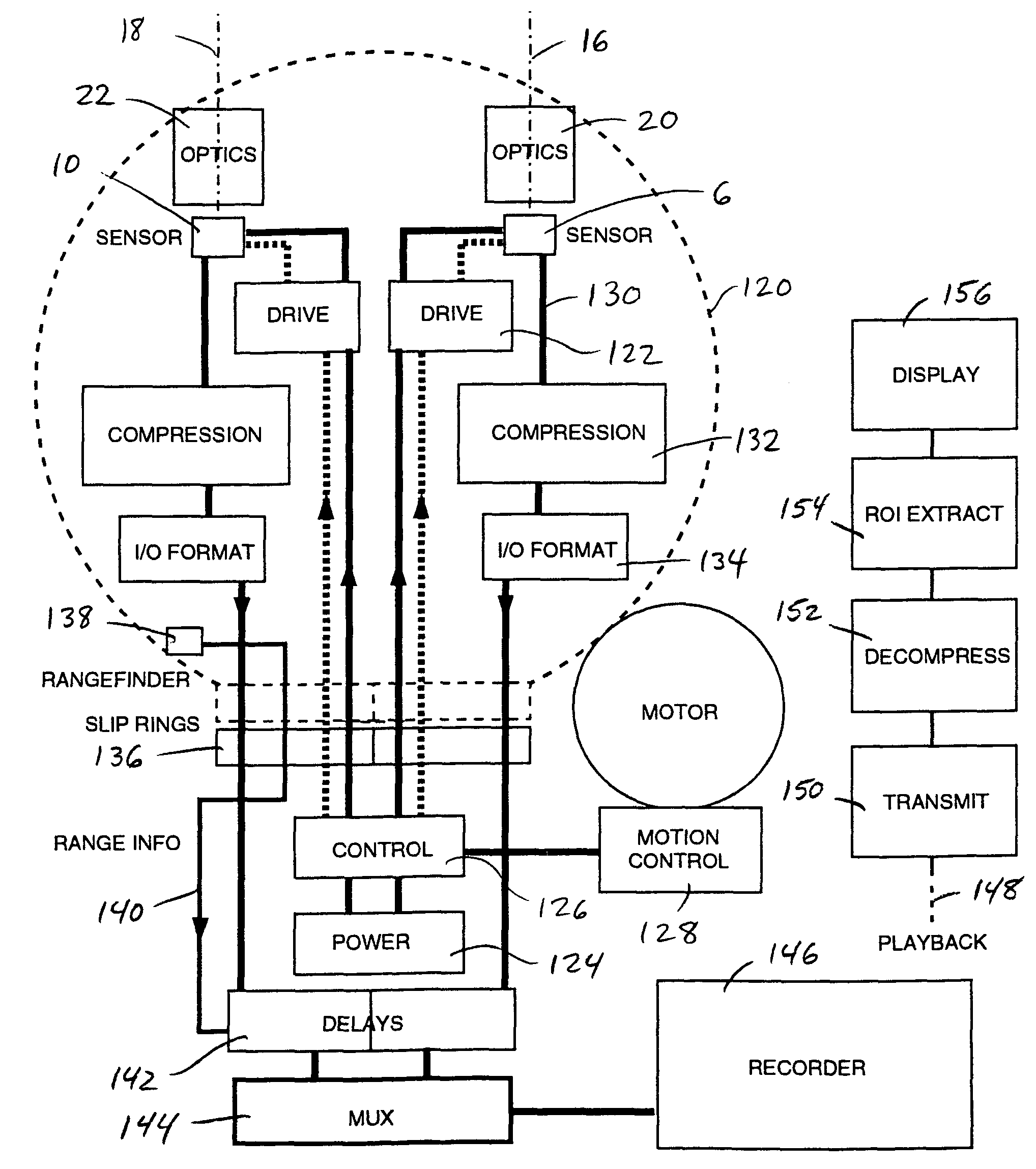

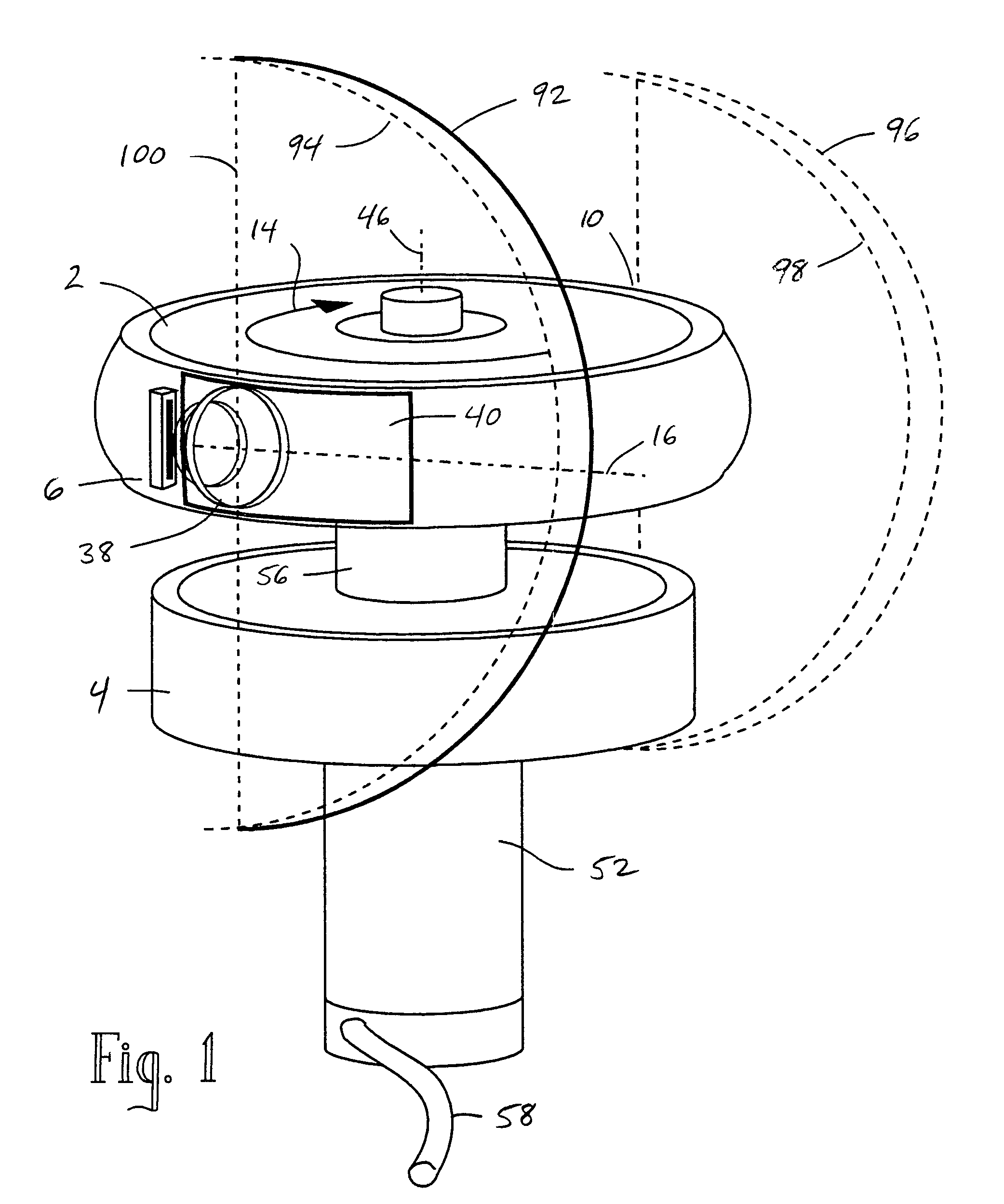

Recording a stereoscopic image of a wide field of view

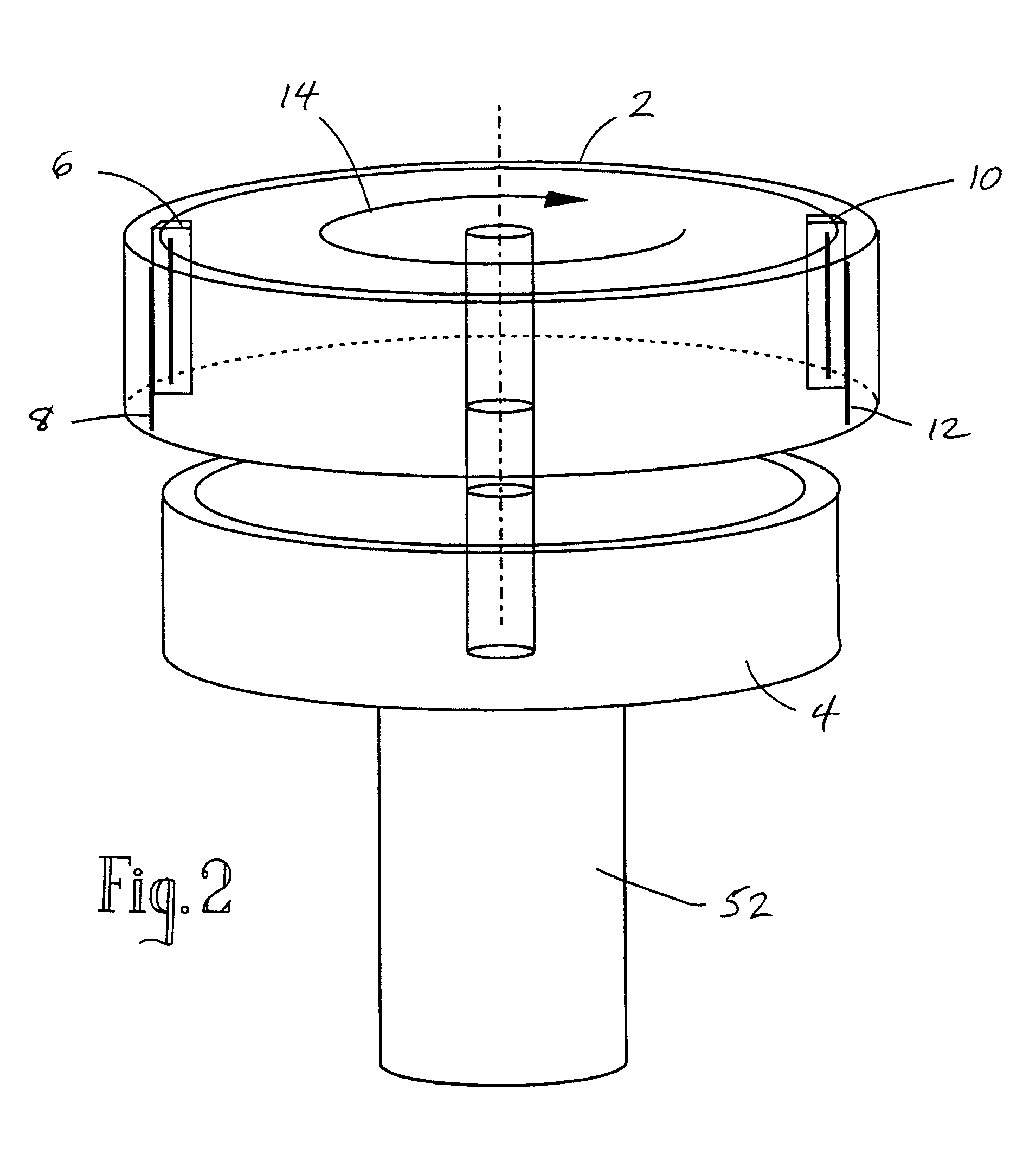

InactiveUS7525567B2Improve stabilityEliminate the problemTelevision system detailsTelevision system scanning detailsRapid rotationRotating drum

A scanning camera with a rotating drum has one or more sensors characterized by a non-radial optical axis. With two sensors on opposite sides of the drum and facing in substantially the same direction, stereoscopic recording of a panorama is accomplished as the drum rotates. Rapid rotation of the scanning camera produces panoramic motion picture recording, with the final frame speed dependent on the sensitivity and speed of the sensor, the resolution desired, and the capabilities of the recording device. The preferred embodiment employs rotating fisheye lenses for a substantially fill-sphere field of view. Streamlining of the lens elements on the drum surface is described for quiet operation of the camera, even at high rotation speeds. The rapid rotation of the drum characteristic of motion picture frame rates can improve both the stability and portability of the camera. The gyroscopic effect of the rotating weight of the drum can increase the stability of the camera, and the apparent weight of the camera can be reduced by the lifting effect of aerodynamic elements such as rotors added to the rotating drum. The adjustment of convergence are described that improve the viewing of stereoscopic images. Additional sensors in the same arrangement are used to increase resolution through multiplexed recording of the image data. Recording image information using film, either internal or external to the camera drum, is also described as a cost-effective alternative to digital media storage.

Owner:IMMERSIVE LICENSING

Rotating scan self-cleaning camera

InactiveUS7129971B2Improve stabilityLighter apparent weightTelevision system detailsTelevision system scanning detailsRapid rotationFilm frame

A scanning camera with a rotating drum has one or more sensors characterized by a non-radial optical axis. With two sensors on opposite sides of the drum and facing in substantially the same direction, stereoscopic recording of a panorama is accomplished as the drum rotates. Rapid rotation of the scanning camera produces panoramic motion picture recording, with the final frame speed dependent on the sensitivity and speed of the sensor, the resolution desired, and the capabilities of the recording device. The preferred embodiment employs rotating fisheye lenses for a substantially full-sphere field of view. Streamlining of the lens elements on the drum surface is described for quiet operation of the camera, even at high rotation speeds. The rapid rotation of the drum characteristic of motion picture frame rates can improve both the stability and portability of the camera. The gyroscopic effect of the rotating weight of the drum can increase the stability of the camera, and the apparent weight of the camera can be reduced by the lifting effect of aerodynamic elements such as rotors added to the rotating drum. The adjustment of convergence are described that improve the viewing of stereoscopic images. Additional sensors in the same arrangement are used to increase resolution through multiplexed recording of the image data. Recording image information using film, either internal or external to the camera drum, is also described as a cost-effective alternative to digital media storage.

Owner:IMMERSIVE LICENSING

Rotating scan camera

InactiveUS7791638B2Television system detailsTelevision system scanning detailsMultiplexingViewpoints

A scanning camera with a rotating drum has one or more sensors characterized by a non-radial optical axis. With two sensors on opposite sides of the drum and facing in substantially the same direction, stereoscopic recording of a panorama is accomplished as the drum rotates. The adjustment of convergence between stereoscopic viewpoints is described that improves the viewing and interpretation of stereoscopic images. Rapid rotation of the scanning camera produces panoramic motion picture recording, with the final frame speed dependent on the sensitivity and speed of the sensor, the resolution desired, and the capabilities of the recording device. The preferred embodiment employs rotating fisheye lenses for a substantially full-sphere field of view. Additional sensors in the same arrangement are used to increase resolution and light sensitivity through multiplexed or additive recording of the image data. Recording image information using film, either internal or external to the camera drum, is also described as a cost-effective alternative to digital media storage.

Owner:IMMERSIVE LICENSING

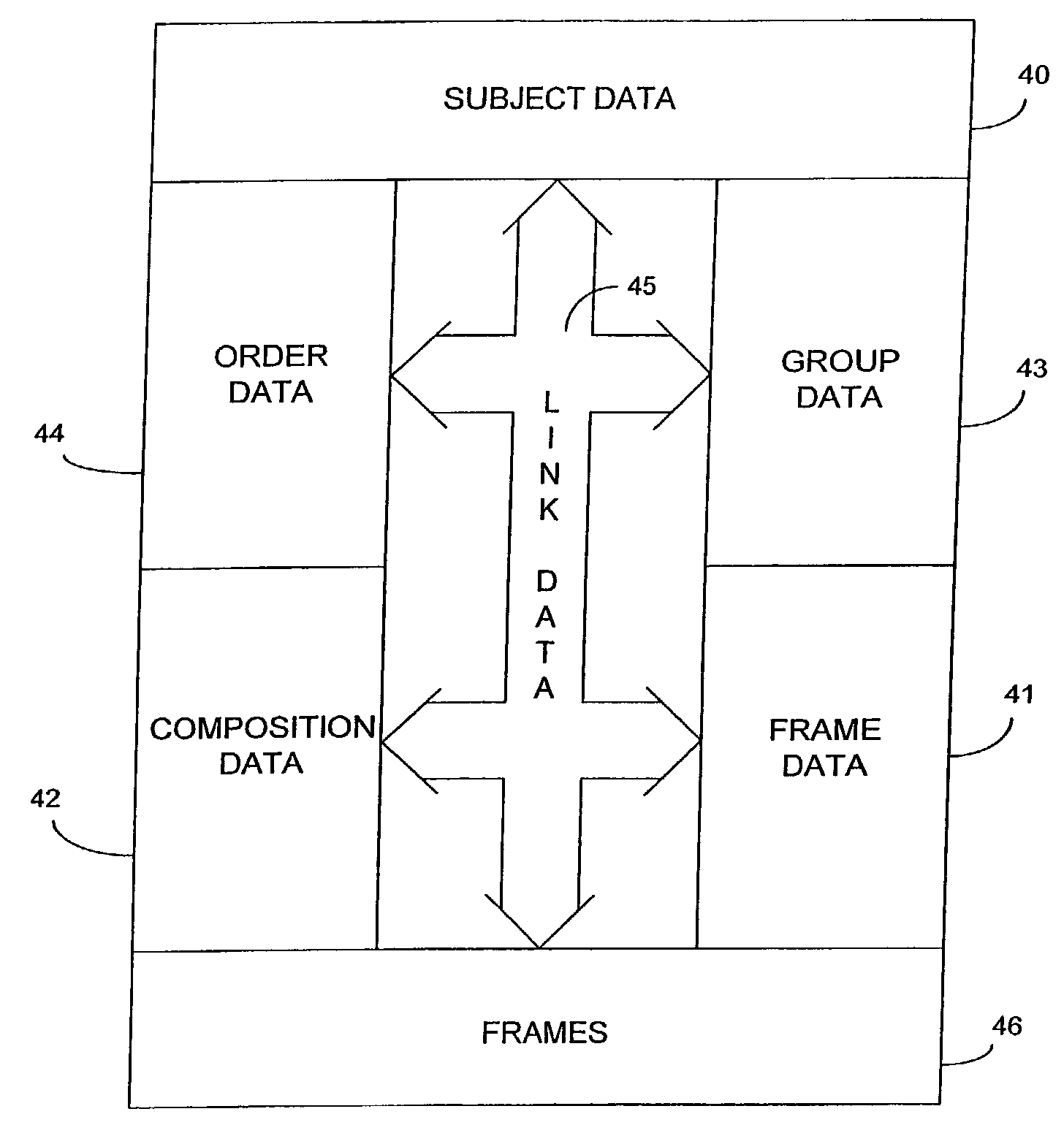

Methods for linking photographs to data related to the subjects of the photographs

ActiveUS7446800B2Efficient fillingTelevision system detailsPicture signal generatorsPhotographic processorHandling system

A photographic processing system is provided that is capable of storing subject and other data in a database and automatically linking such data to photographs as they are taken using either a film or digital camera.

Owner:SHUTTERFLY LLC

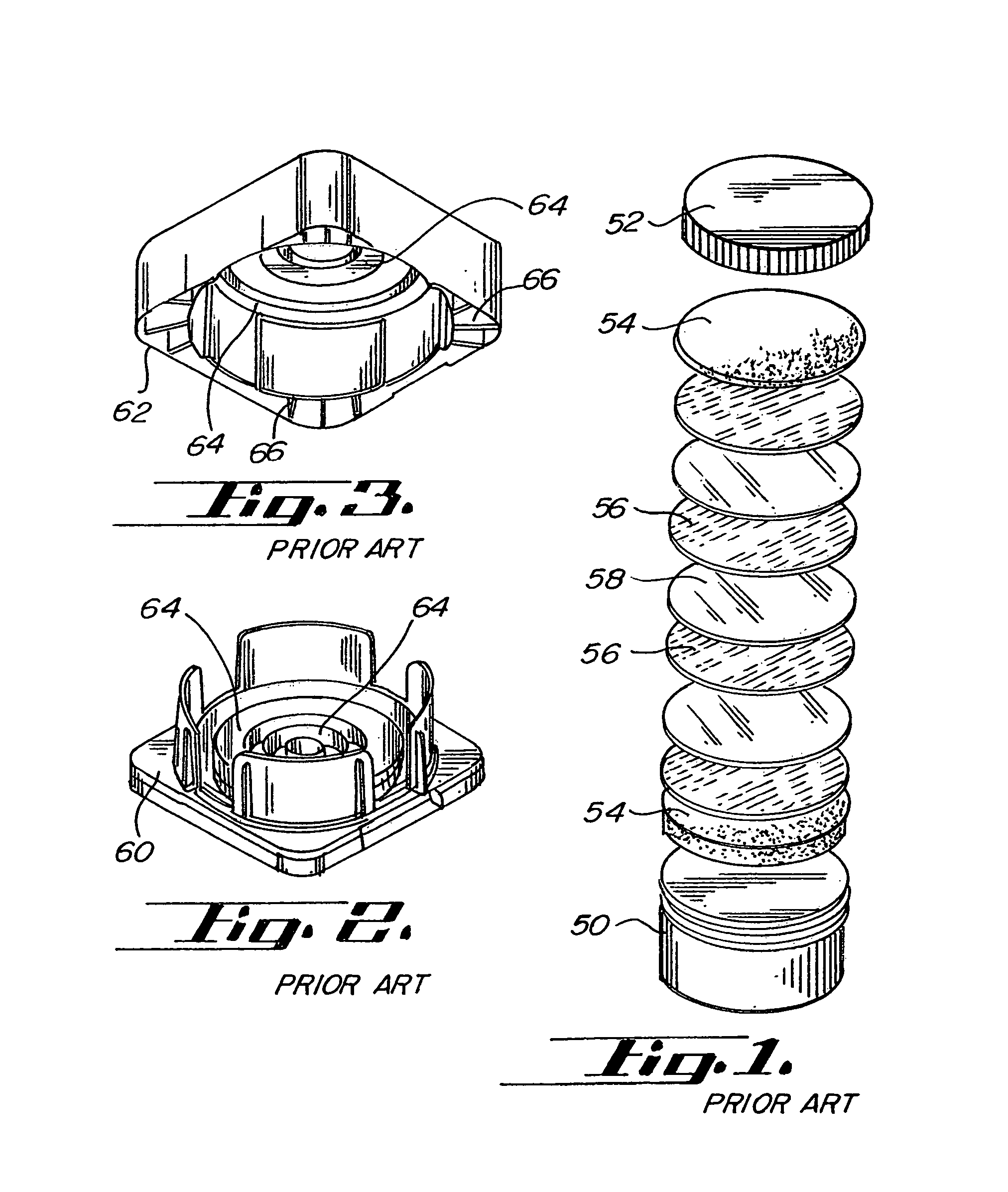

Protective shipper

InactiveUS7040487B2Improve handlingEasy to stackContainers for annular articlesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A protective shipper comprises a cover and a base that are held together by a latching member. The base is configurable to retain and protect semiconductor wafers or film frames with wafers within a storage pocket. The base comprises latching member and a support wall that defines a storage pocket. The cover encloses the storage pocket. One or both of the cover may receive recesses for gripability. The cover may receive one or more latching apertures configured to minimize unintended unlatching. The shipper of the present invention may be manufactured in a mold capable of producing film frame or wafer containing configurations of the shipper by using an interchangeable mold insert.

Owner:ENTEGRIS INC

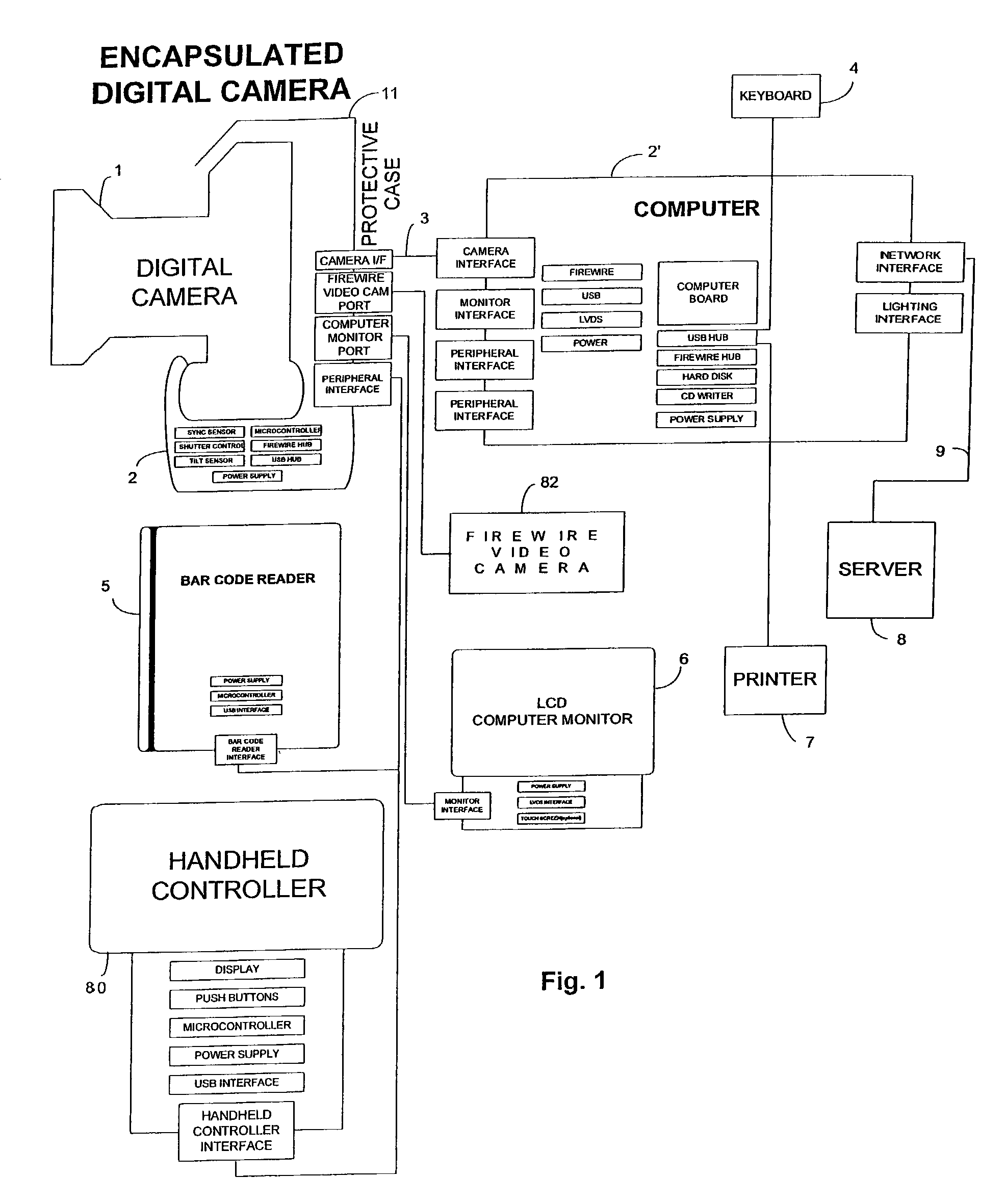

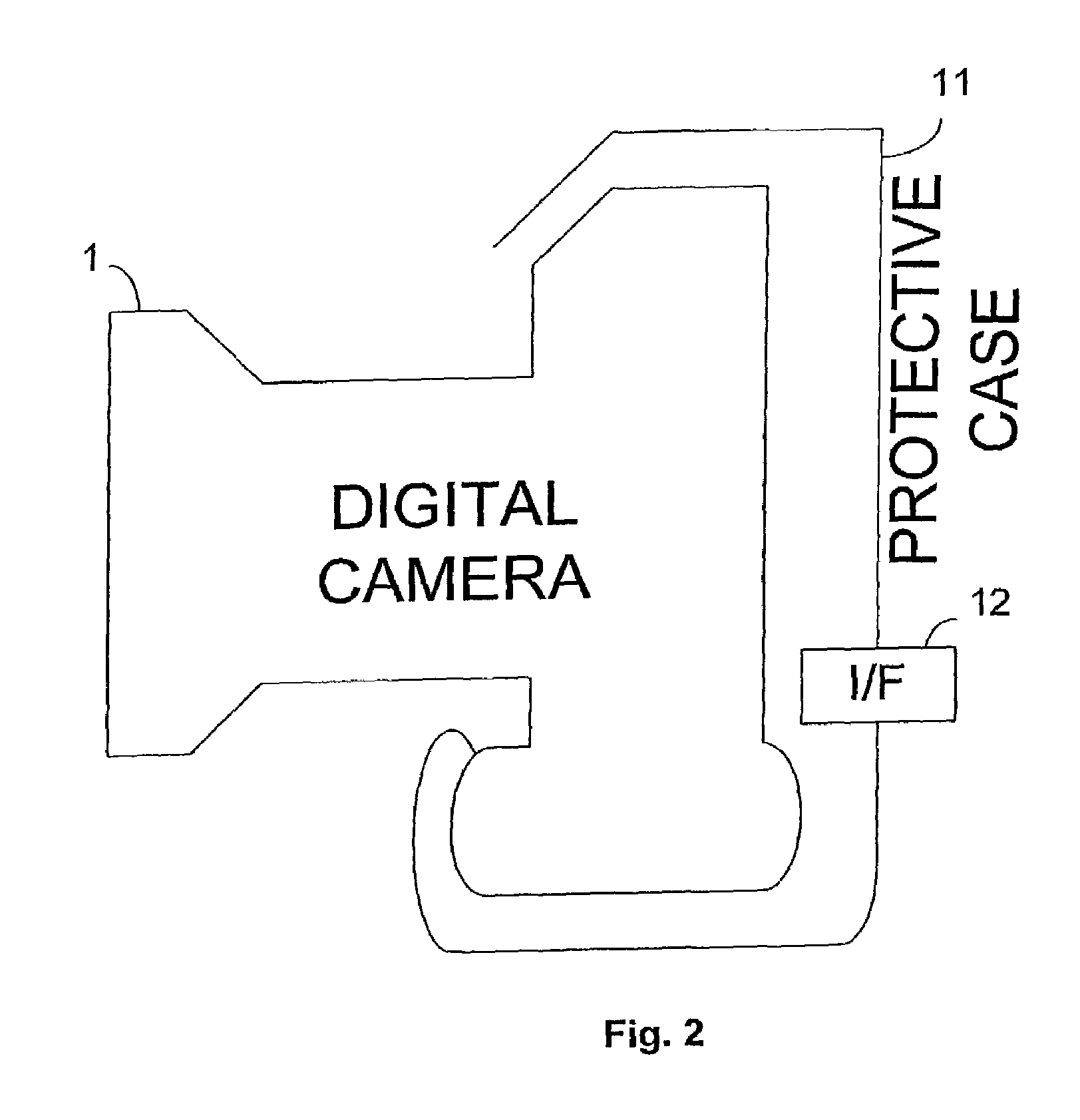

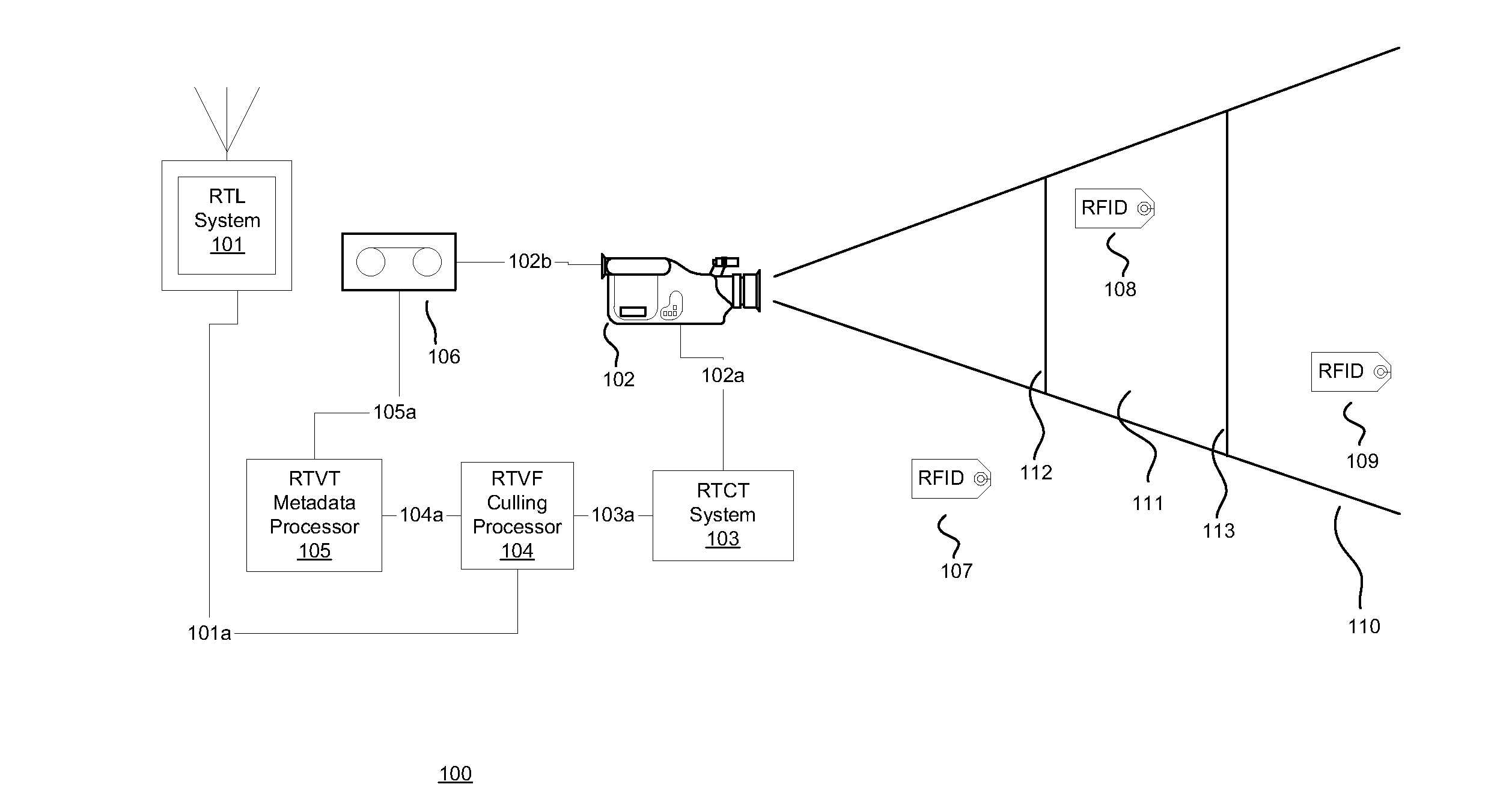

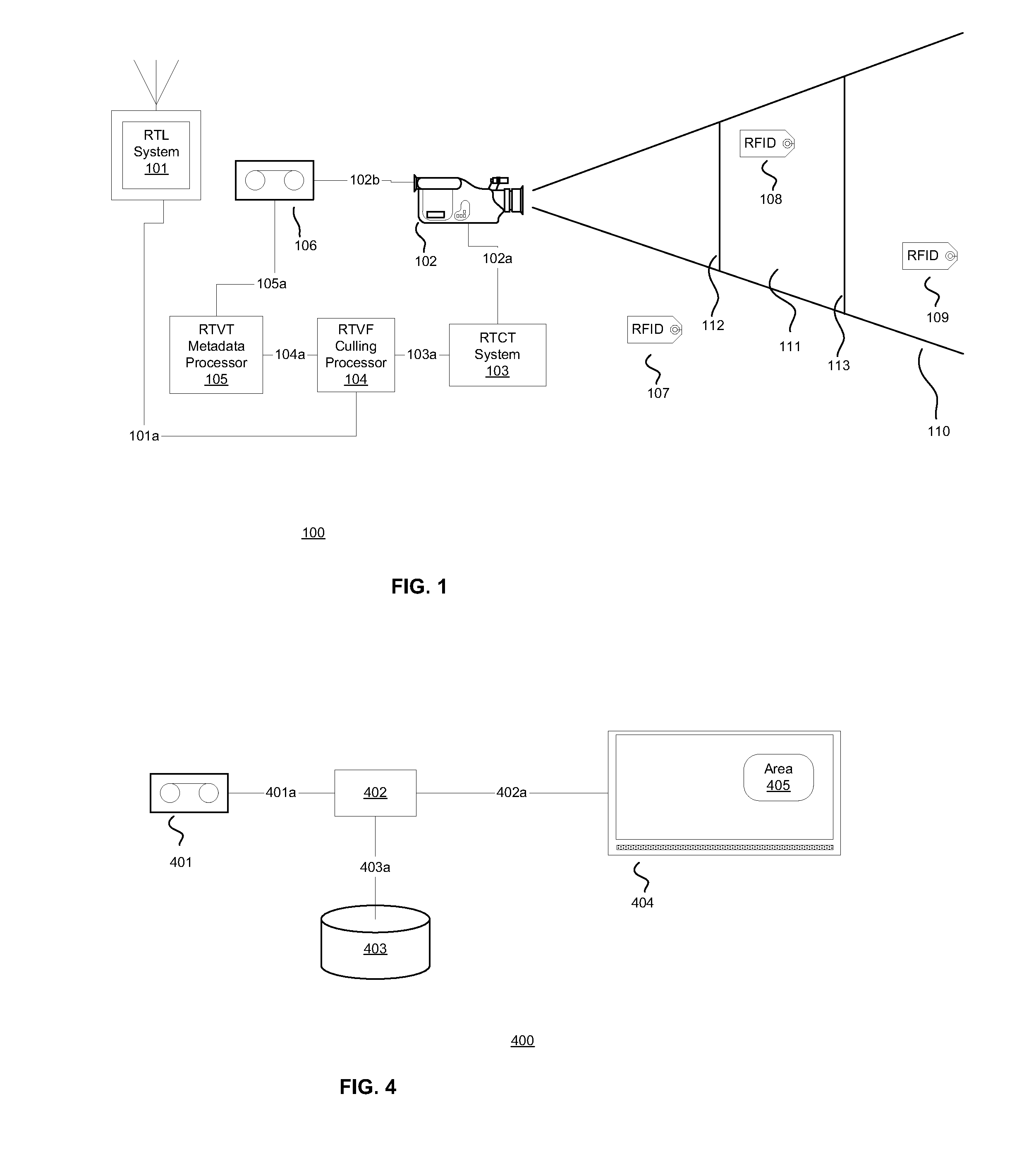

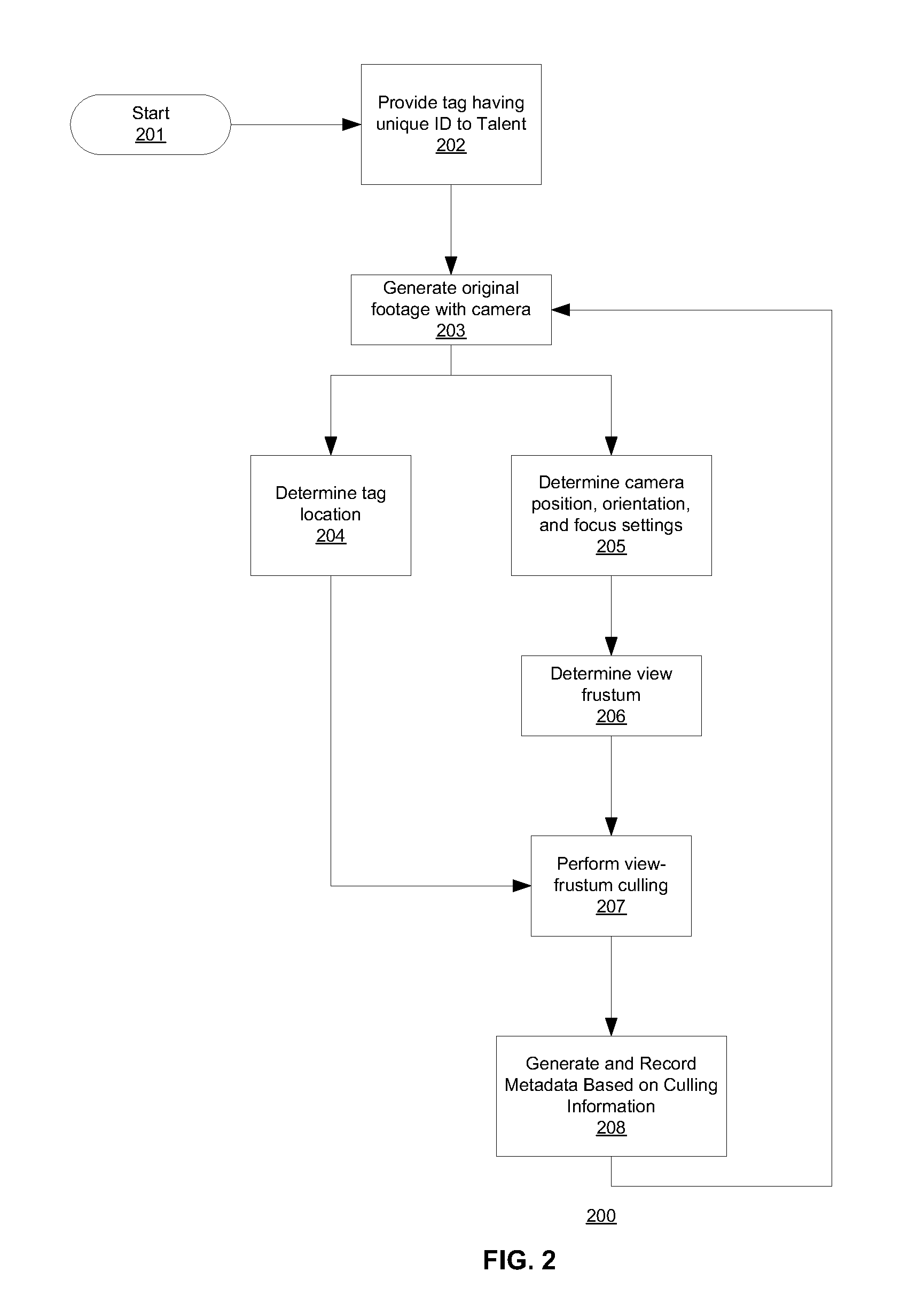

Real-time visible-talent tracking system

ActiveUS20120195574A1Television system detailsRecording carrier detailsPattern recognitionComputer graphics (images)

In one embodiment, a movie set includes a motion-picture camera and a visible-talent tracking system having several elements. Based on the camera's characteristics, items in a portion of the movie set called the view frustum will appear in focus in the film. The camera and a camera-tracking system provide camera-location, orientation, and settings information to a culling processor. The culling processor delineates the location and dimensions of the view frustum based on the received camera information. Wireless tags are attached to talent on set. A tag-locating system tracks the real-time respective locations of the wireless tags and provides real-time spatial information regarding the tags to the culling processor, which determines which tags, if any, are considered to be within the view frustum, and provides information associated with the intra-frustum tags to a track recorder for recording along with the corresponding film frames. That information is variously used after editing.

Owner:HOME BOX OFFICE INC

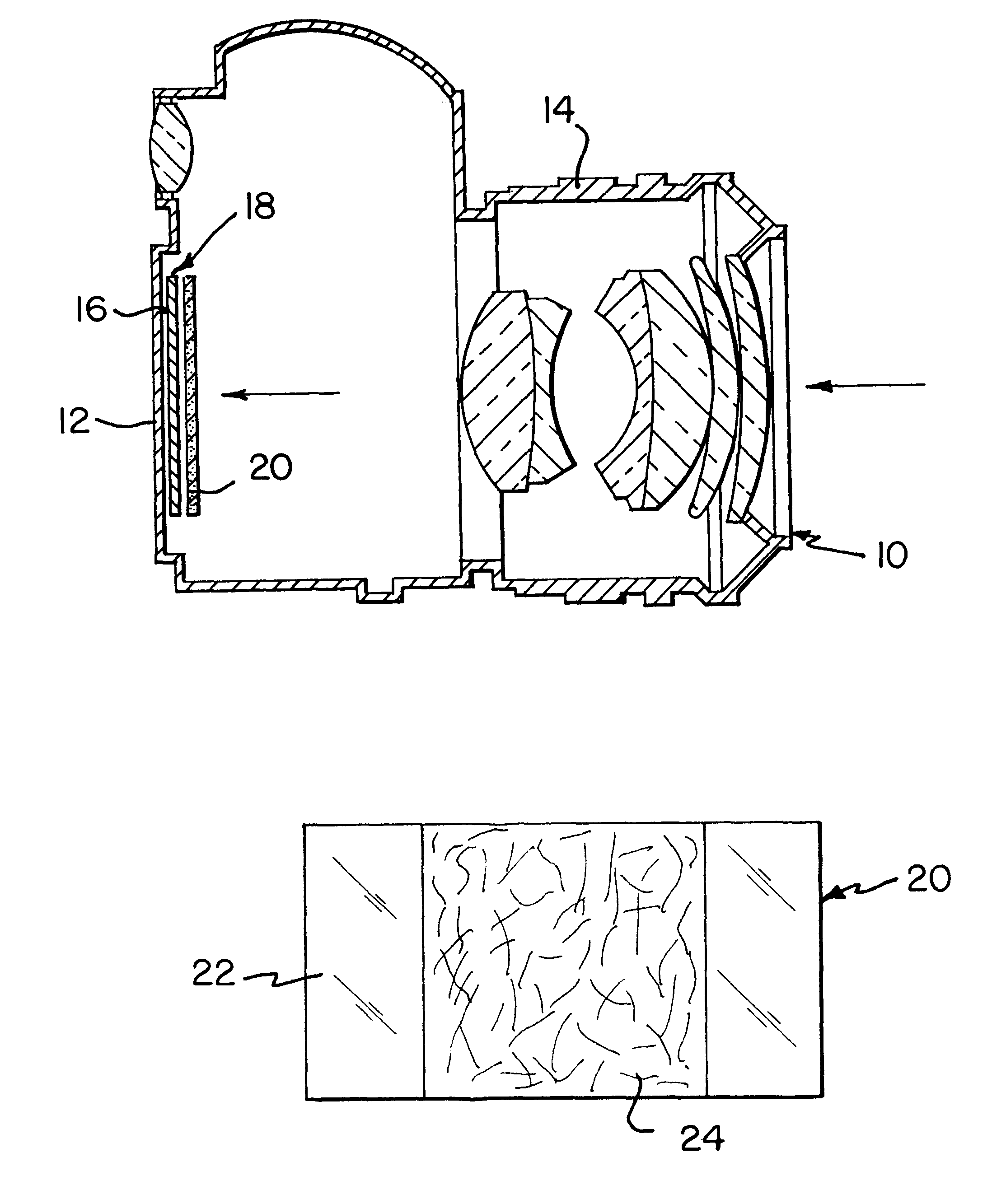

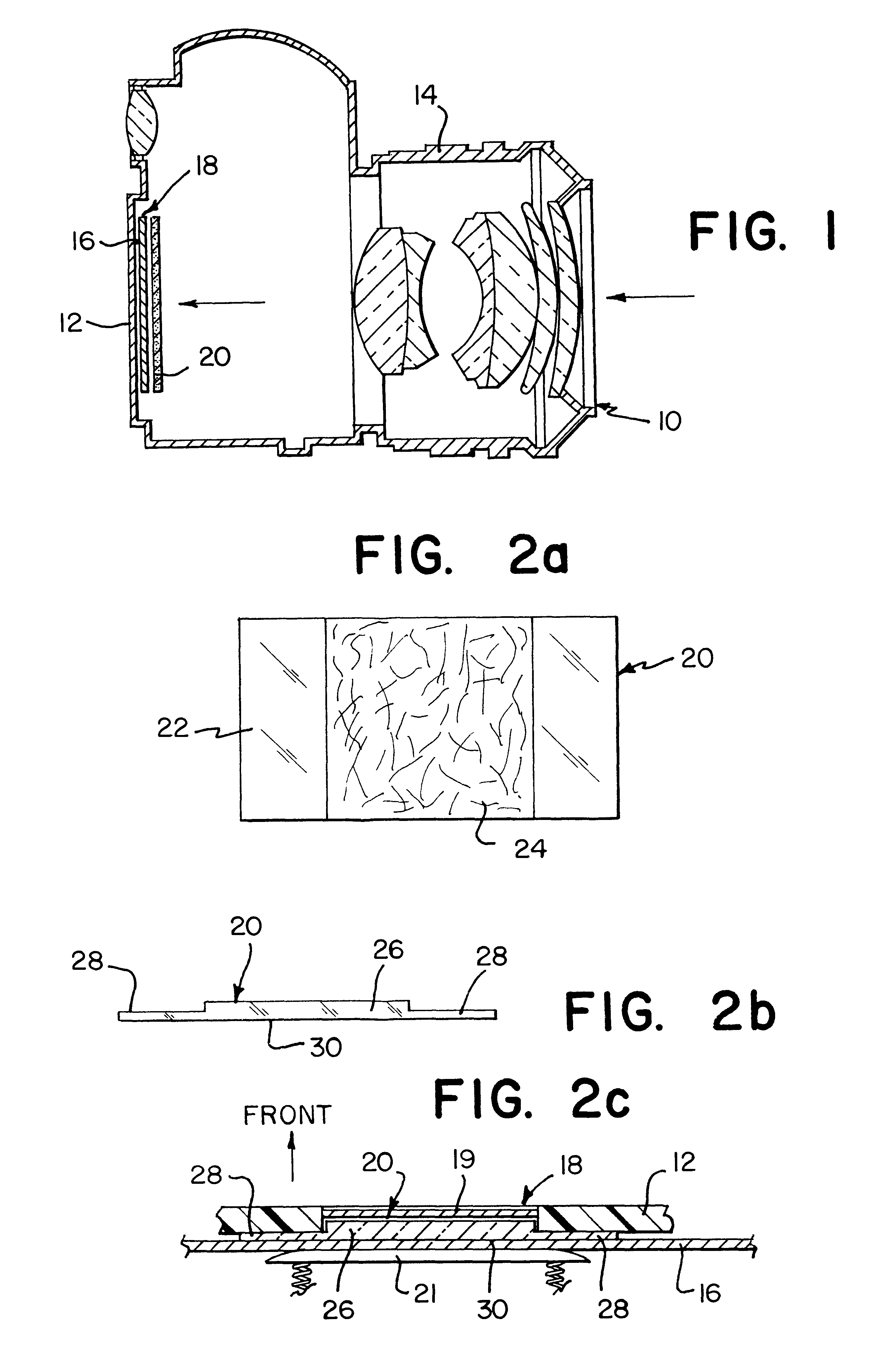

Image modifiers for use in photography

InactiveUS6285834B1Easy to replaceProjector film strip handlingCamera film strip handlingDiffusionFilm plane

In a first embodiment of the invention, a transparent plate is mounted at the film plane within a camera. The transparent plate includes a translucent diffusion pattern which diffuses incoming light rays reflected from the subject and effectively repositions them in a controlled manner prior to the light exposing the film. Proposed diffusion patterns may alter the light rays to create characteristics indicative of various types of paintings or may produce a controlled grainy appearance to an image recorded on film.In another embodiment of the invention, the transparent plate is mounted in a film cartridge.In another embodiment of the invention, a length of plastic film (a pattern strip) is positioned adjacent to a similar length of photographic film (film strip). An appropriate translucent diffusion pattern is provided onto one surface of the pattern strip, along its entire length. Both strips are rolled into a conventional 35 mm film canister and dispensed simultaneously, as needed (within the camera) so that each frame of film has a separate mask in front of it, at the film gate of the camera.In another embodiment of the invention, a transparent plate having a translucent diffusion pattern is positioned between the main lens of the camera, and the camera body. In this arrangement, a correcting lens is required to bring the pattern of the particular pattern into sharp focus with the image at the film plane to be exposed on film.

Owner:SMARTLENS CORP

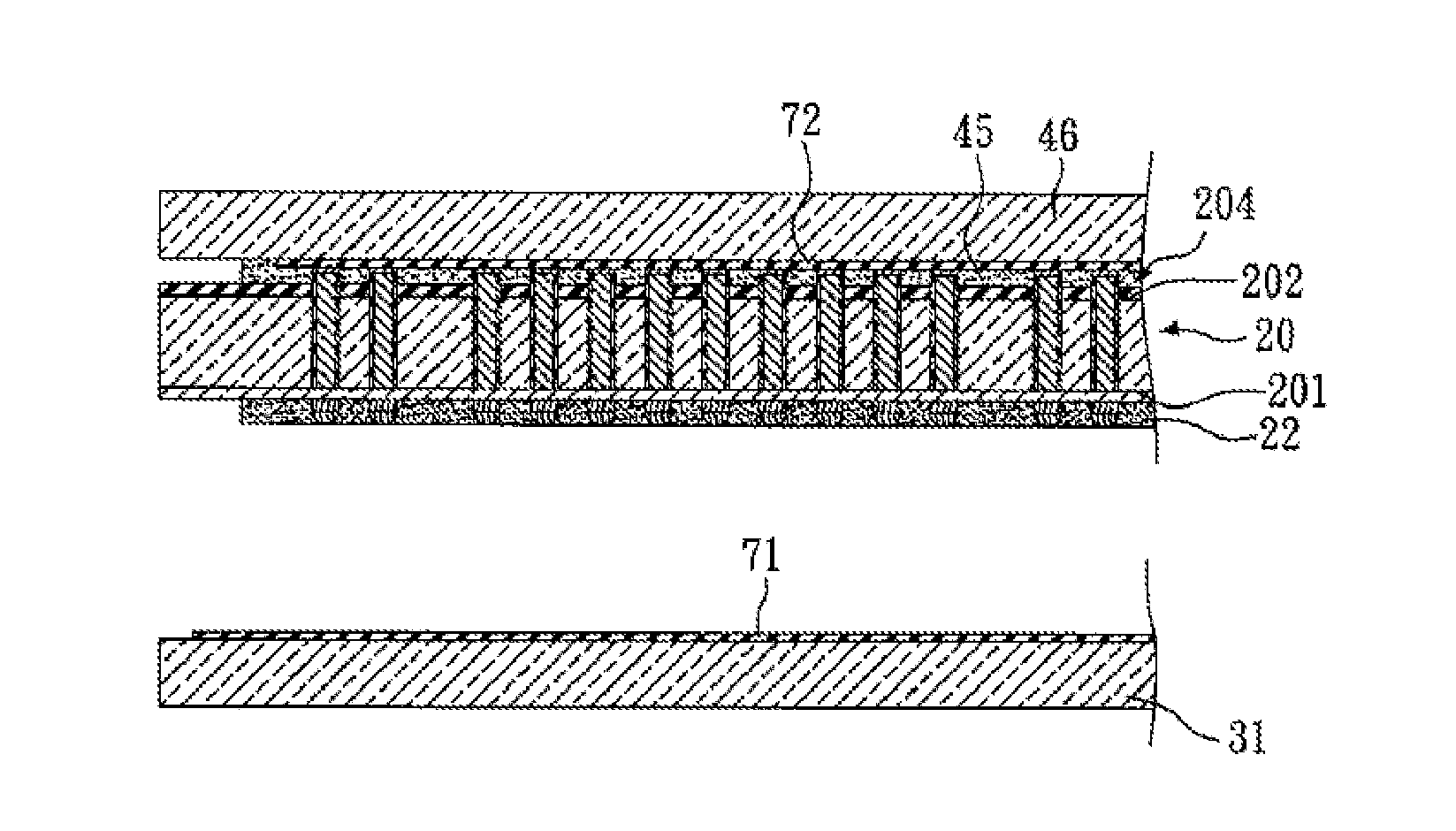

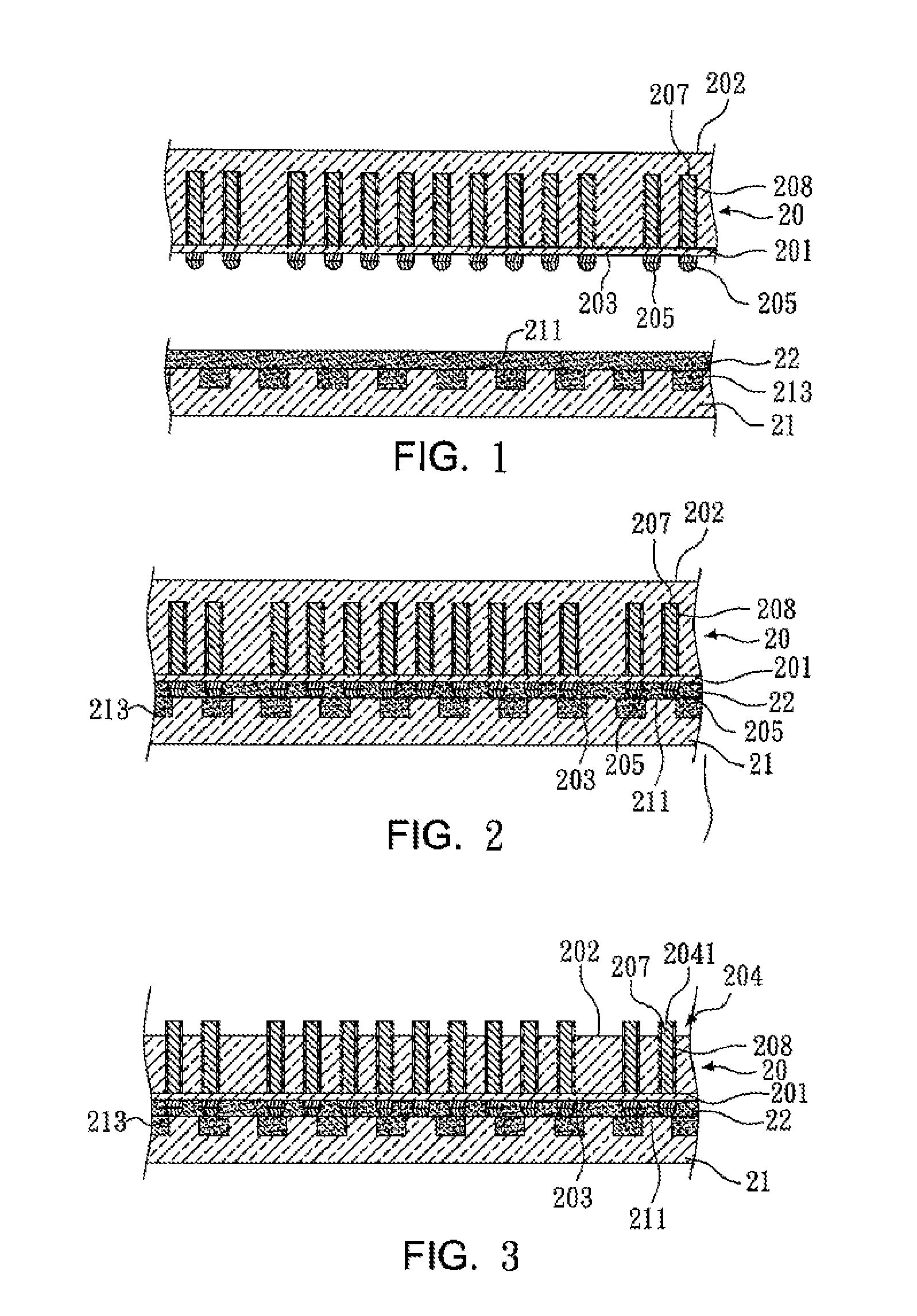

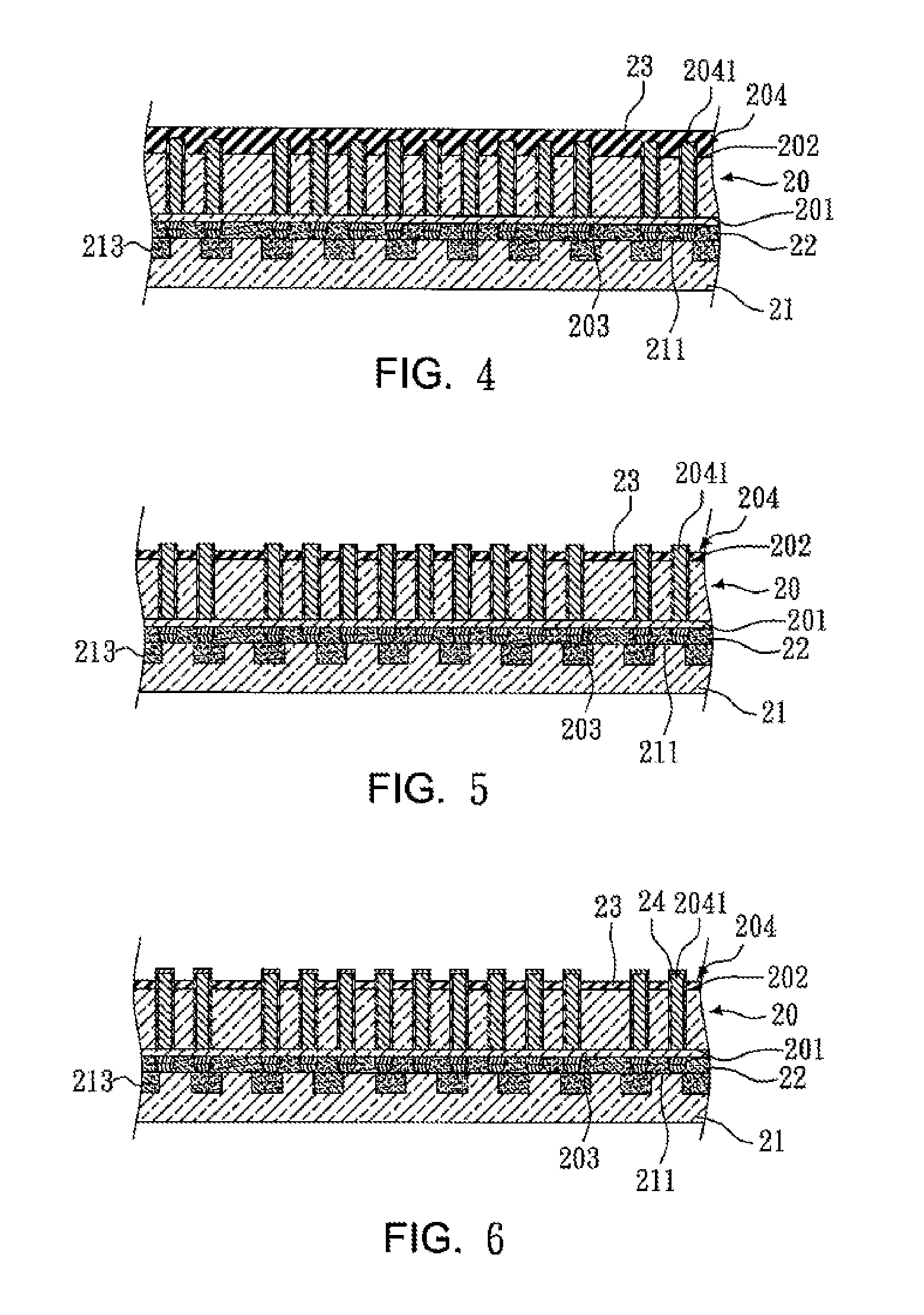

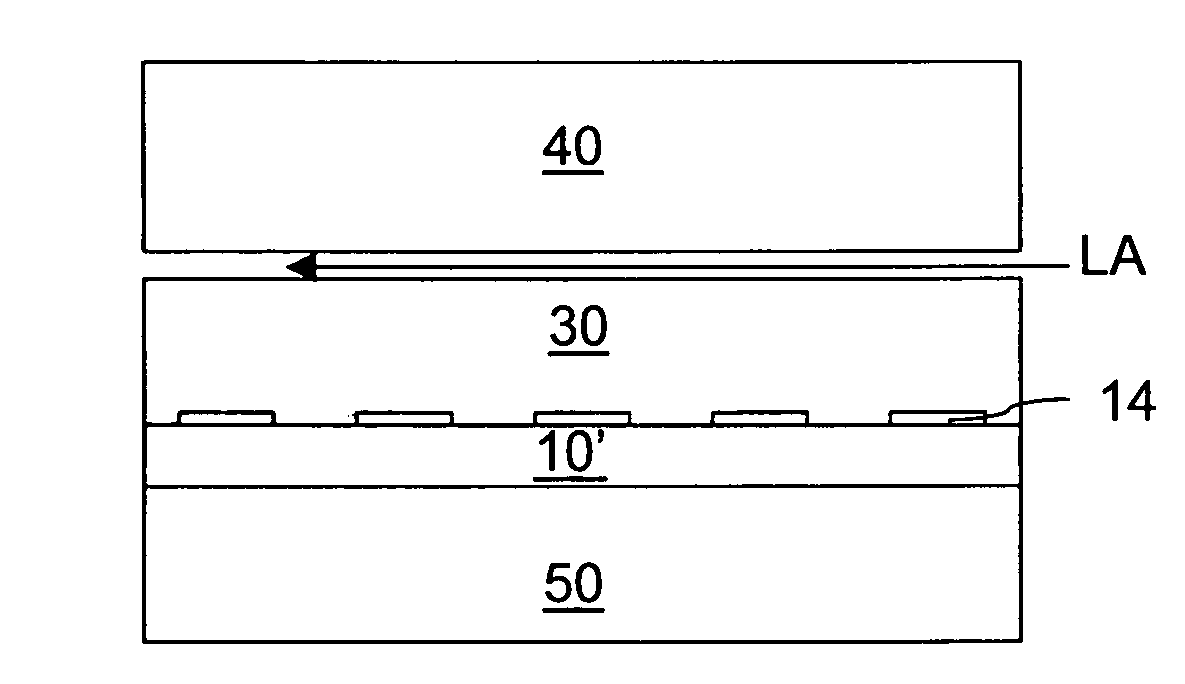

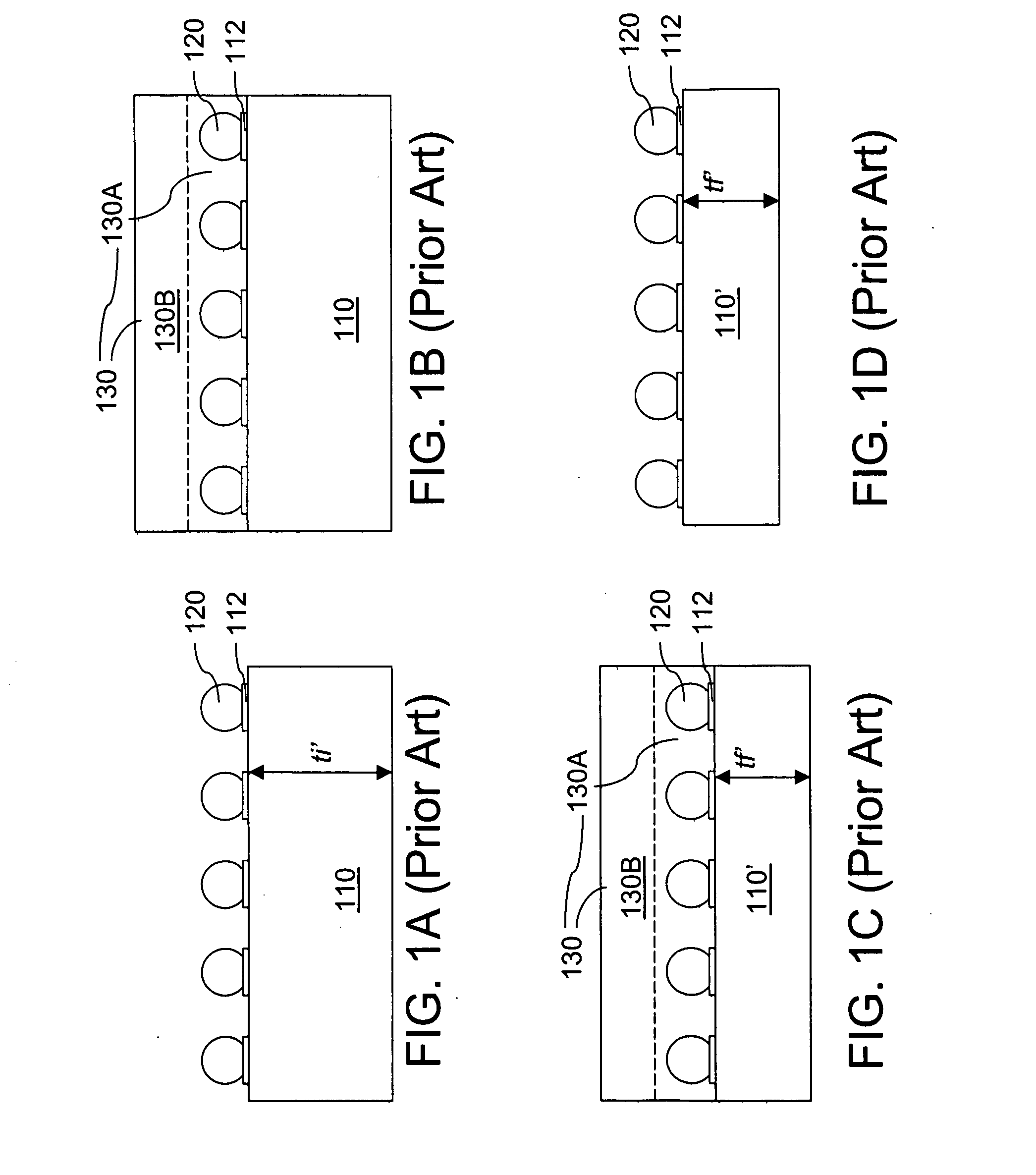

Carrier bonding and detaching processes for a semiconductor wafer

InactiveUS20120052654A1Easy to separateReduce adhesionSolid-state devicesSemiconductor/solid-state device manufacturingWaferingSurface mounting

The present invention provides a temporary carrier bonding and detaching process. A first surface of a semiconductor wafer is mounted on a first carrier by a first adhesive layer, and a first isolation coating disposed between the first adhesive layer and the first carrier. Then, a second carrier is mounted on the second surface of the semiconductor wafer. The first carrier is detached. Then, the first surface of the semiconductor wafer is mounted on a film frame. The second carrier is detached. The method of the present invention utilizes the second carrier to support and protect the semiconductor wafer, after which the first carrier is detached. Therefore, the semiconductor wafer will not be damaged or broken, thereby improving the yield rate of the semiconductor process. Furthermore, the simplicity of the detaching method for the first carrier allows for improvement in efficiency of the semiconductor process.

Owner:ADVANCED SEMICON ENG INC

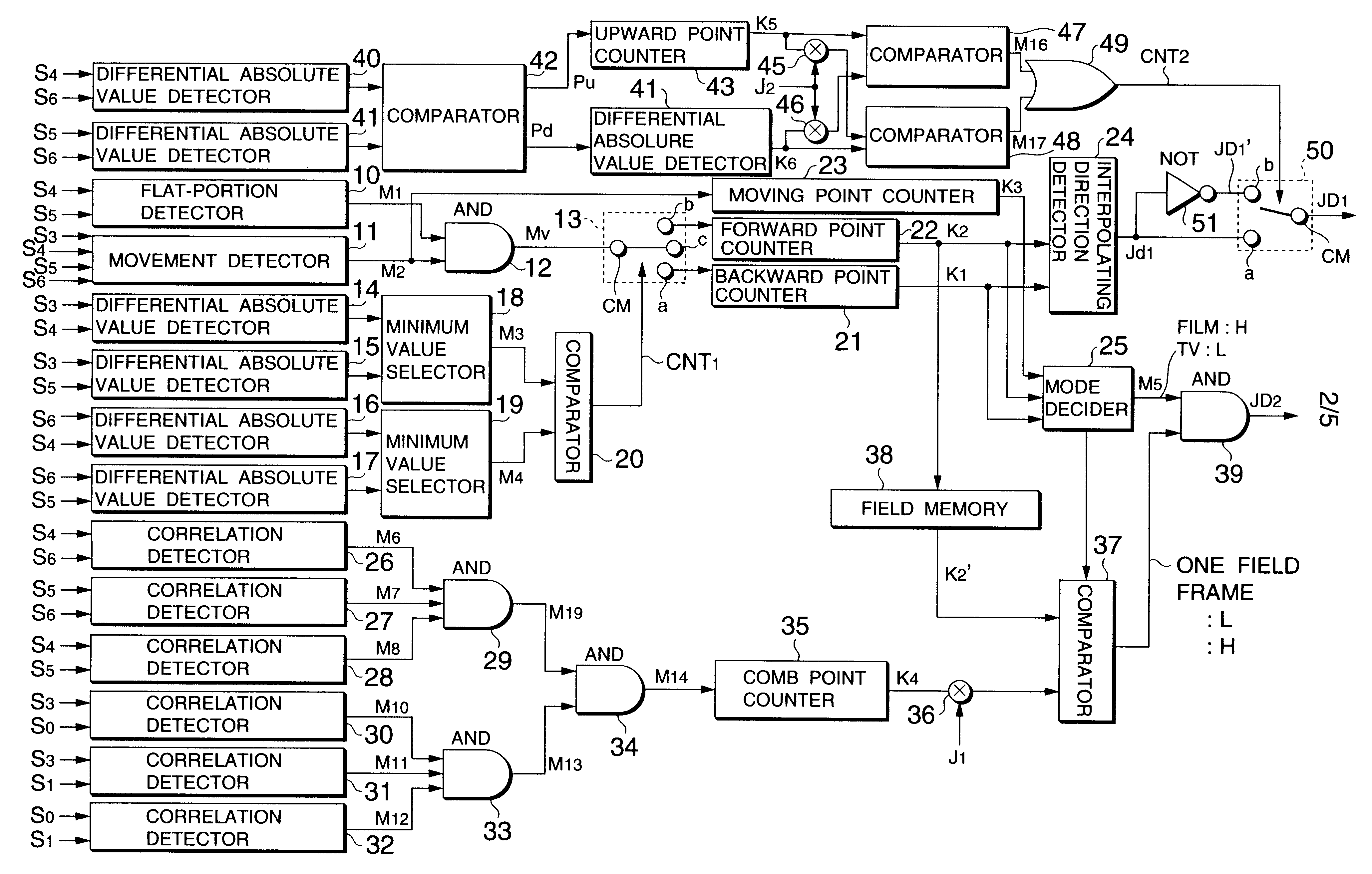

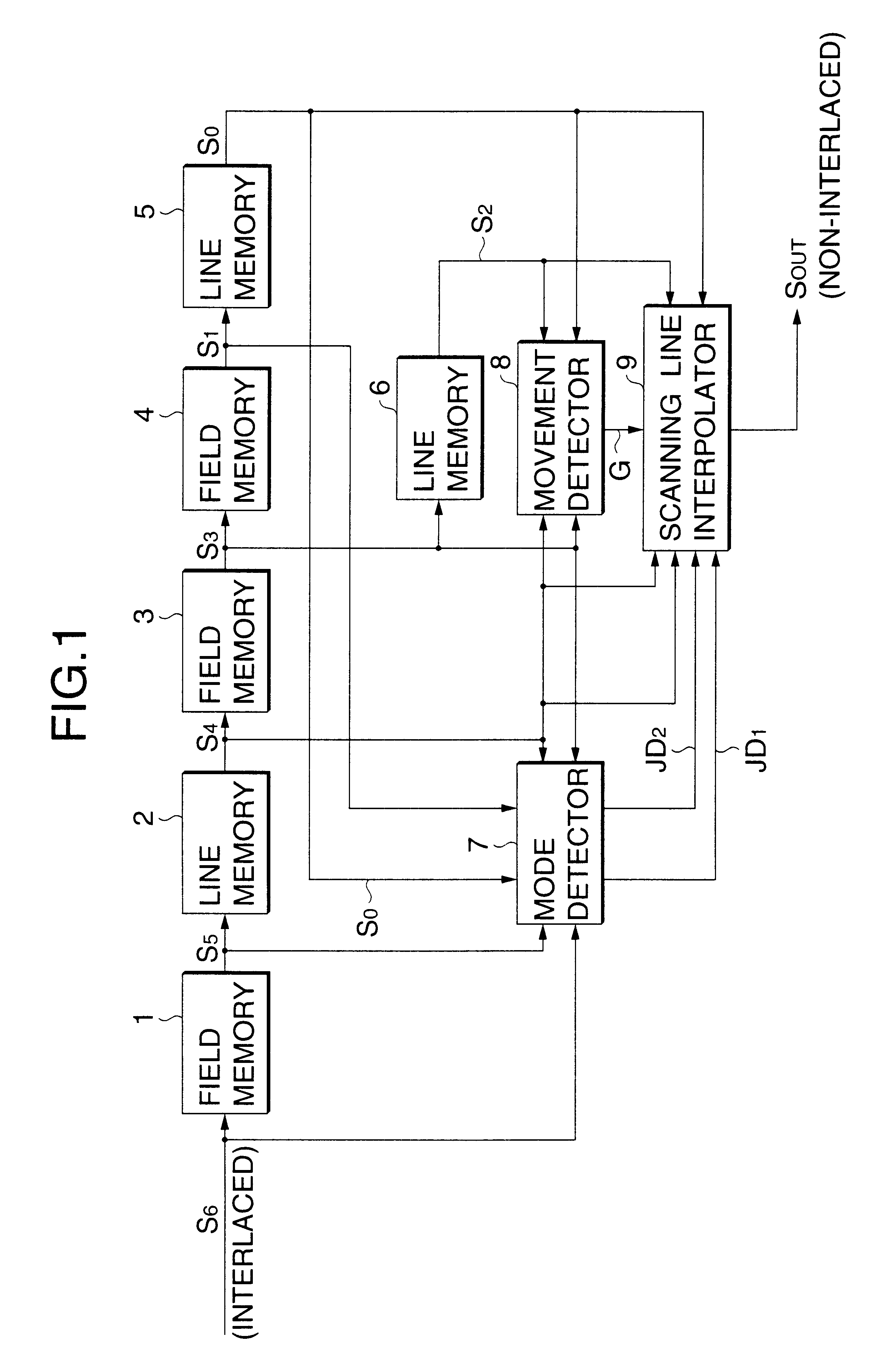

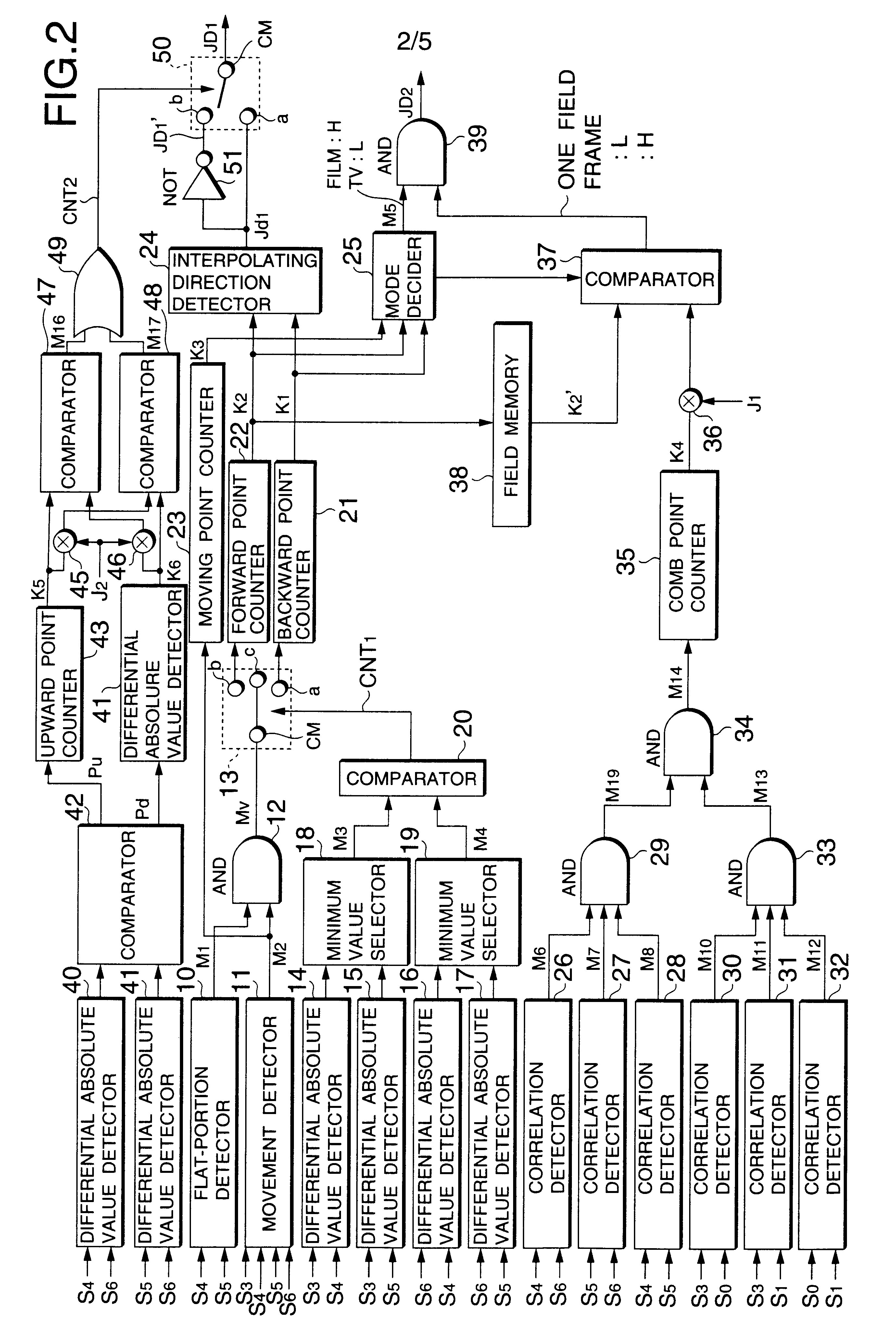

Video signal converting apparatus

InactiveUS6509933B1Detected quickly and surelyImprove display qualityTelevision system detailsTelevision system scanning detailsTelecineSelf adaptive

Whether or not an input video signal is an video signal telecine-converted is decided on the basis of correlation values between an interpolated field and fields located one-field-period before and after the interpolated field. Where the interpolated field is an editing point field of a film frame of one field, adaptive interpolating processing is executed instead of film interpolating processing.

Owner:PIONEER CORP

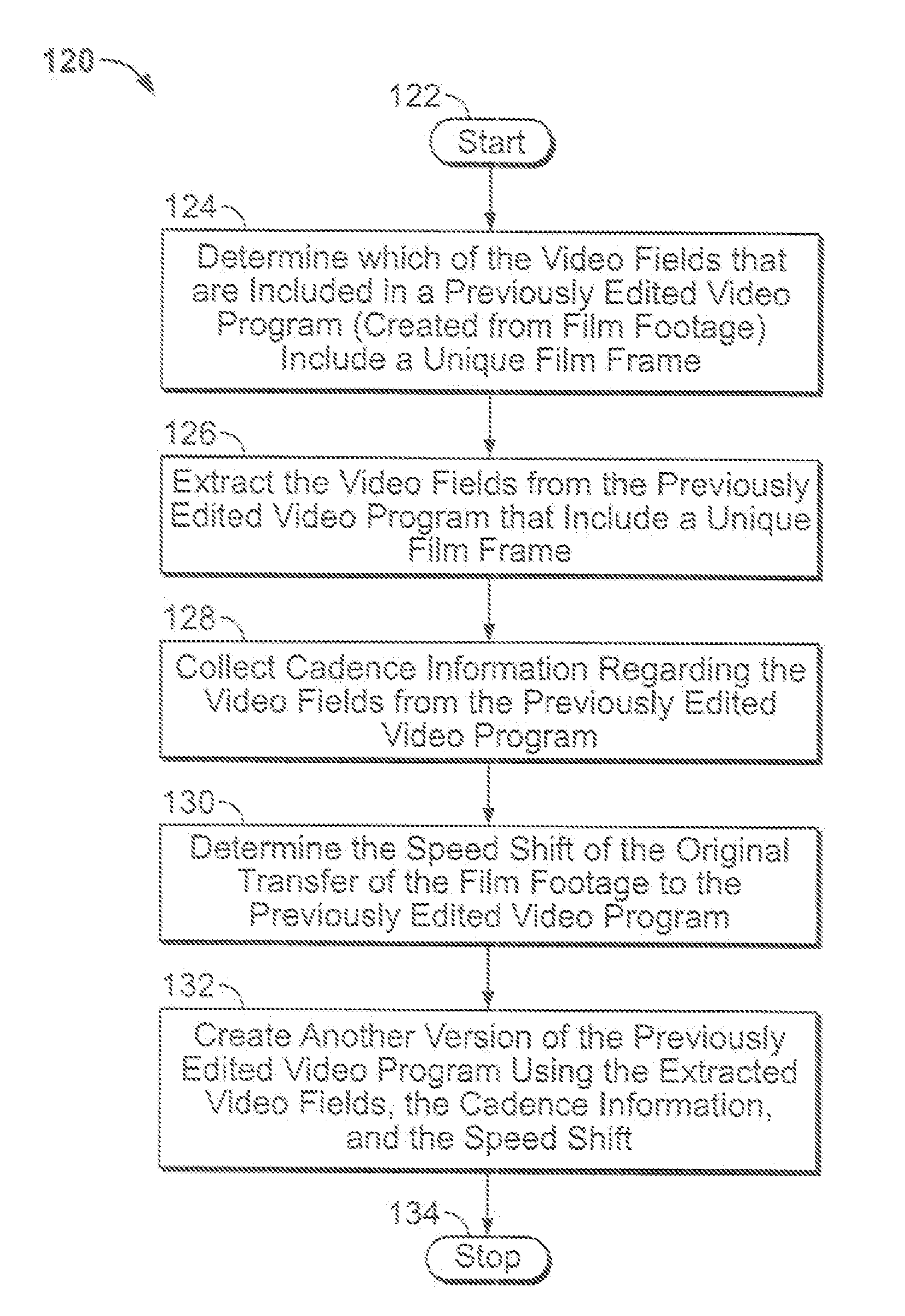

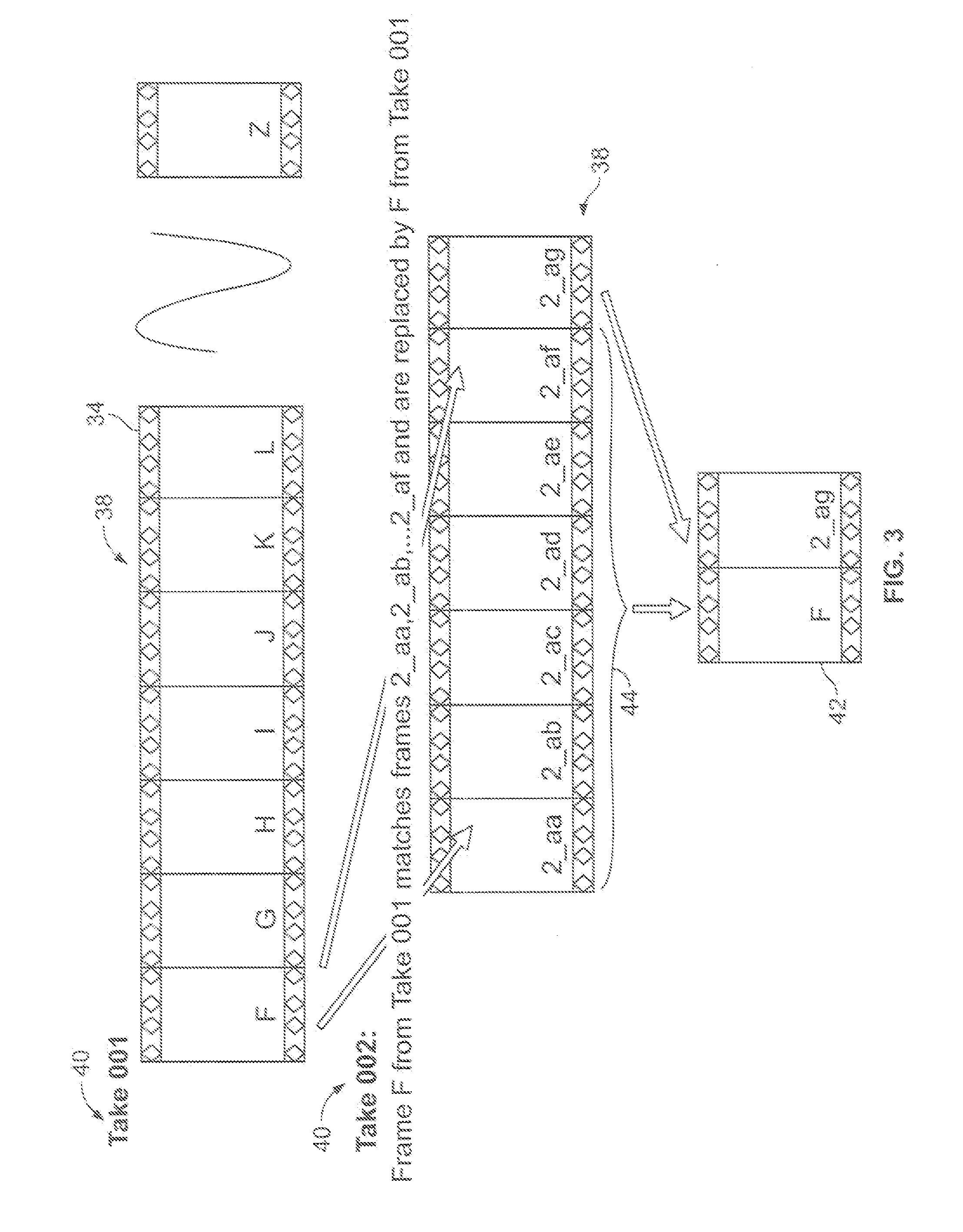

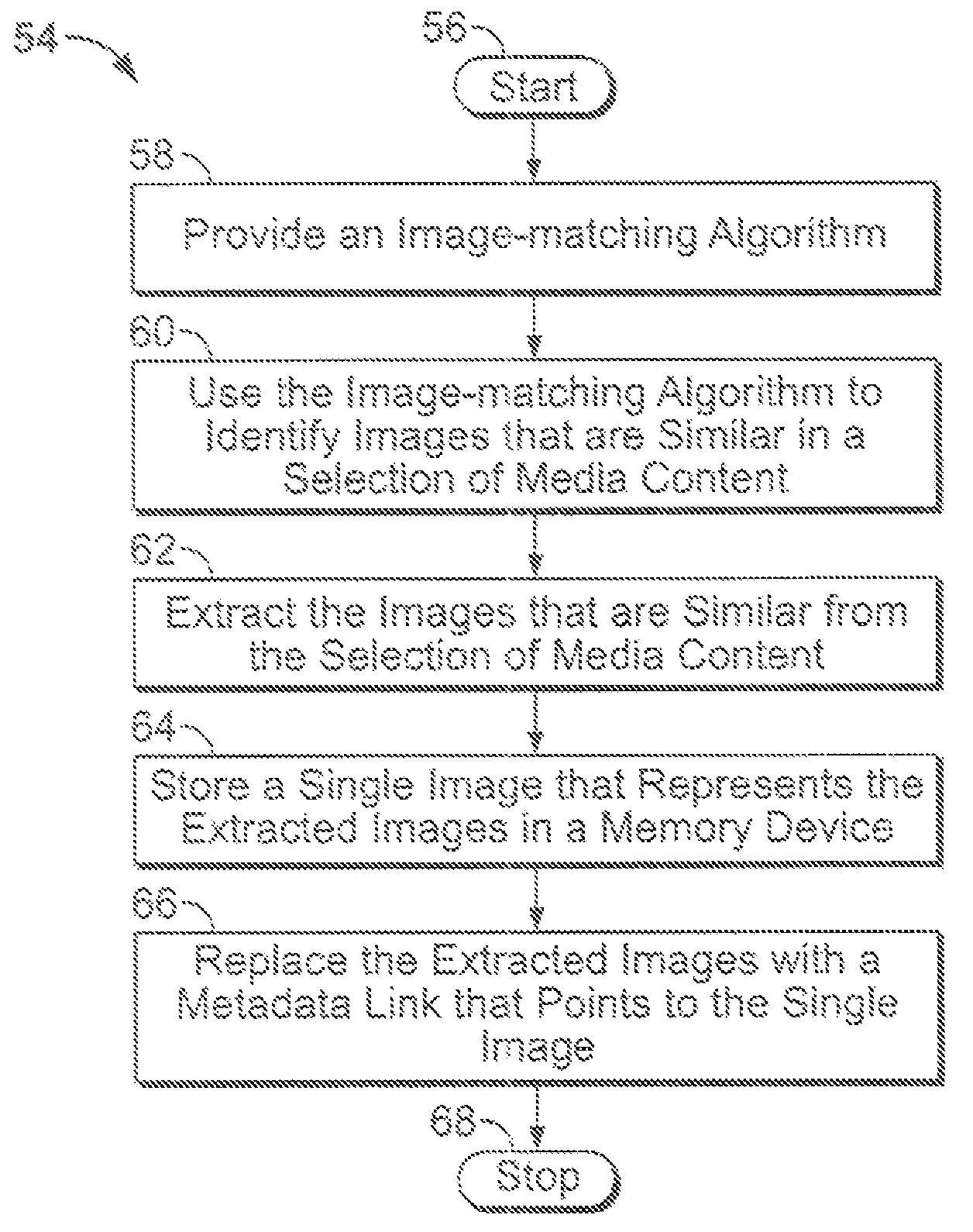

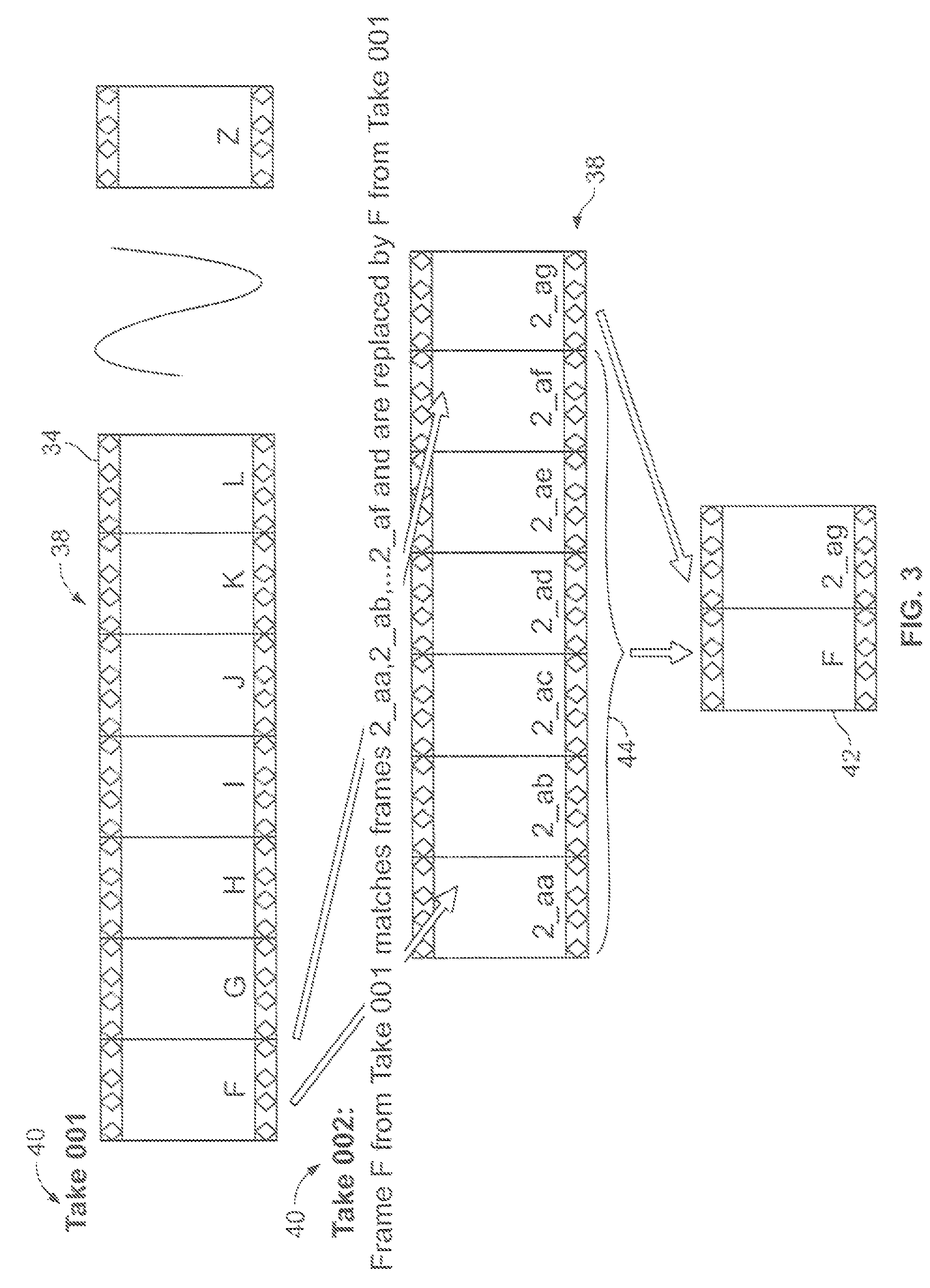

Method And Apparatus For Providing Lossless Data Compression And Editing Media Content

ActiveUS20080063287A1Electronic editing digitised analogue information signalsRecord information storageMatch algorithmsComputer graphics (images)

A method and a related apparatus for compressing images included in media content and editing the media content. The method can include providing an image-matching algorithm and a memory device, using the image-matching algorithm to identify images that are similar in a selection of media content extracting the images that are similar from the selection of media content, storing a single image that represents the extracted images in the memory device, and replacing the extracted images in the selection of media content with a metadata link that points to the single image. The method can further include providing a previously edited video program that originally was created from film footage, determining which of the video fields from the program include a unique film frame from the footage, and extracting the video fields from the program that include a unique film frame.

Owner:WARNER BROS ENTERTAINMENT INC

Method for manufacturing polydimethylsiloxane (PDMS) film with integrated microstructure

The invention discloses a method for manufacturing a polydimethylsiloxane (PDMS) film with an integrated microstructure. The method is characterized in that firstly a PDMS rotary die technology is utilized to replicate a targeted microstructure from a female die manufactured based on micro-processing technology to the surface of a hot melting or water soluble material so as to form a sacrificial layer die with a meltable or dissolution characteristic; and then the surface of the manufactured sacrificial layer die is coated with a thin layer of PDMS rotationally, simultaneously an outer film frame is attached to the PDMS in a pressing manner, finally a PDMS film structure is released through hearing or smelting in water or dissolving the sacrificial layer die after the PDMS is cured, and the transferring and application of the PDMS film are achieved with the assistance of the outer film frame. The method utilizes the sacrificial layer die to manufacture and release the PDMS film with the integrated structure, prevents traditional manual mechanical peeling methods from damaging the PDMS film, substantially reduces difficulty in manufacturing of fragile PDMS film structure, increases the success rate of manufacturing the PDMS film and can achieve the high-yield mass production of the PDMS film structure.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Method and apparatus for providing lossless data compression and editing media content

ActiveUS7805011B2Electronic editing digitised analogue information signalsRecord information storageMatch algorithmsComputer graphics (images)

A method and a related apparatus for compressing images included in media content and editing the media content. The method can include providing an image-matching algorithm and a memory device, using the image-matching algorithm to identify images that are similar in a selection of media content extracting the images that are similar from the selection of media content, storing a single image that represents the extracted images in the memory device, and replacing the extracted images in the selection of media content with a metadata link that points to the single image. The method can further include providing a previously edited video program that originally was created from film footage, determining which of the video fields from the program include a unique film frame from the footage, and extracting the video fields from the program that include a unique film frame.

Owner:WARNER BROS ENTERTAINMENT INC

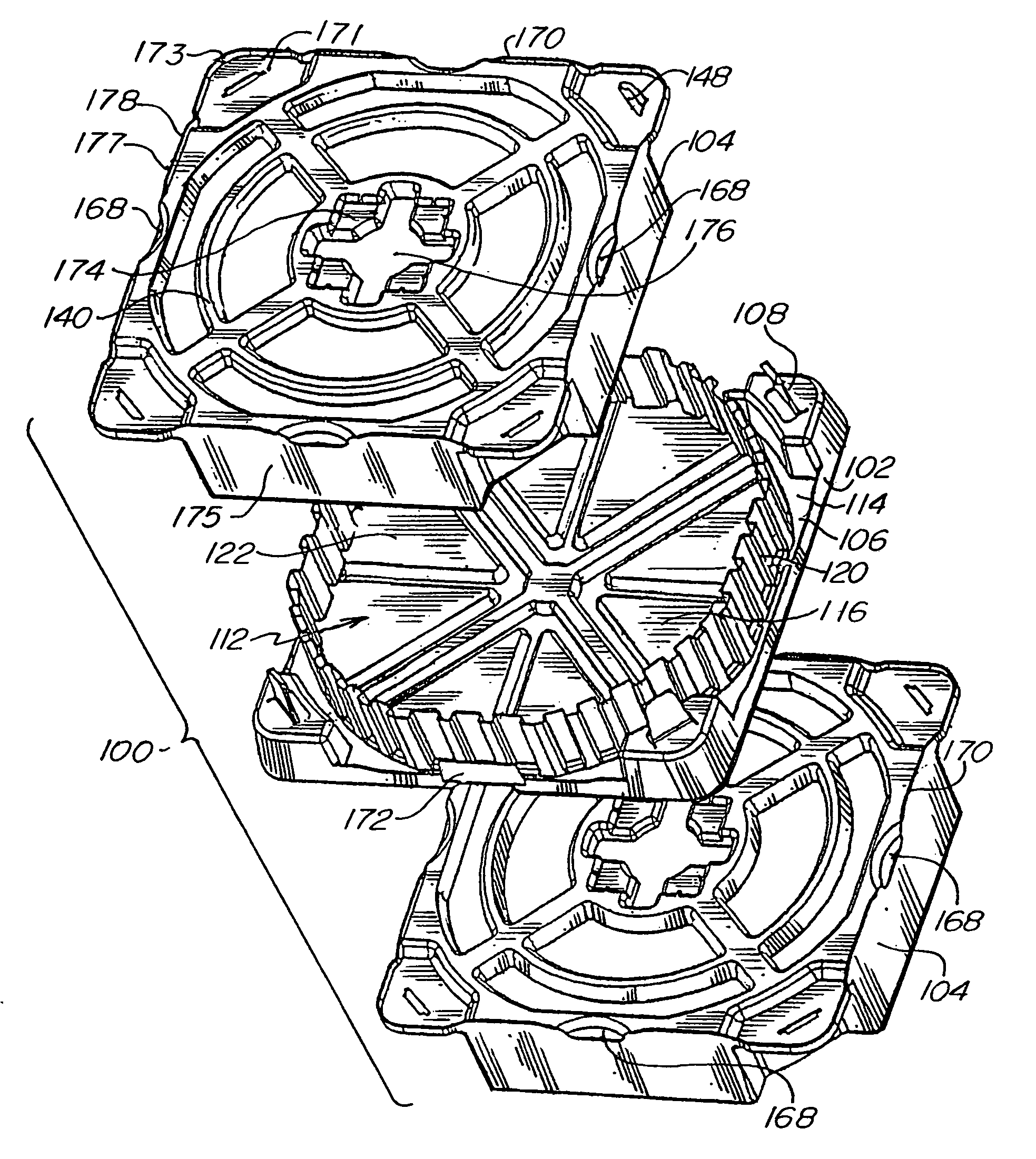

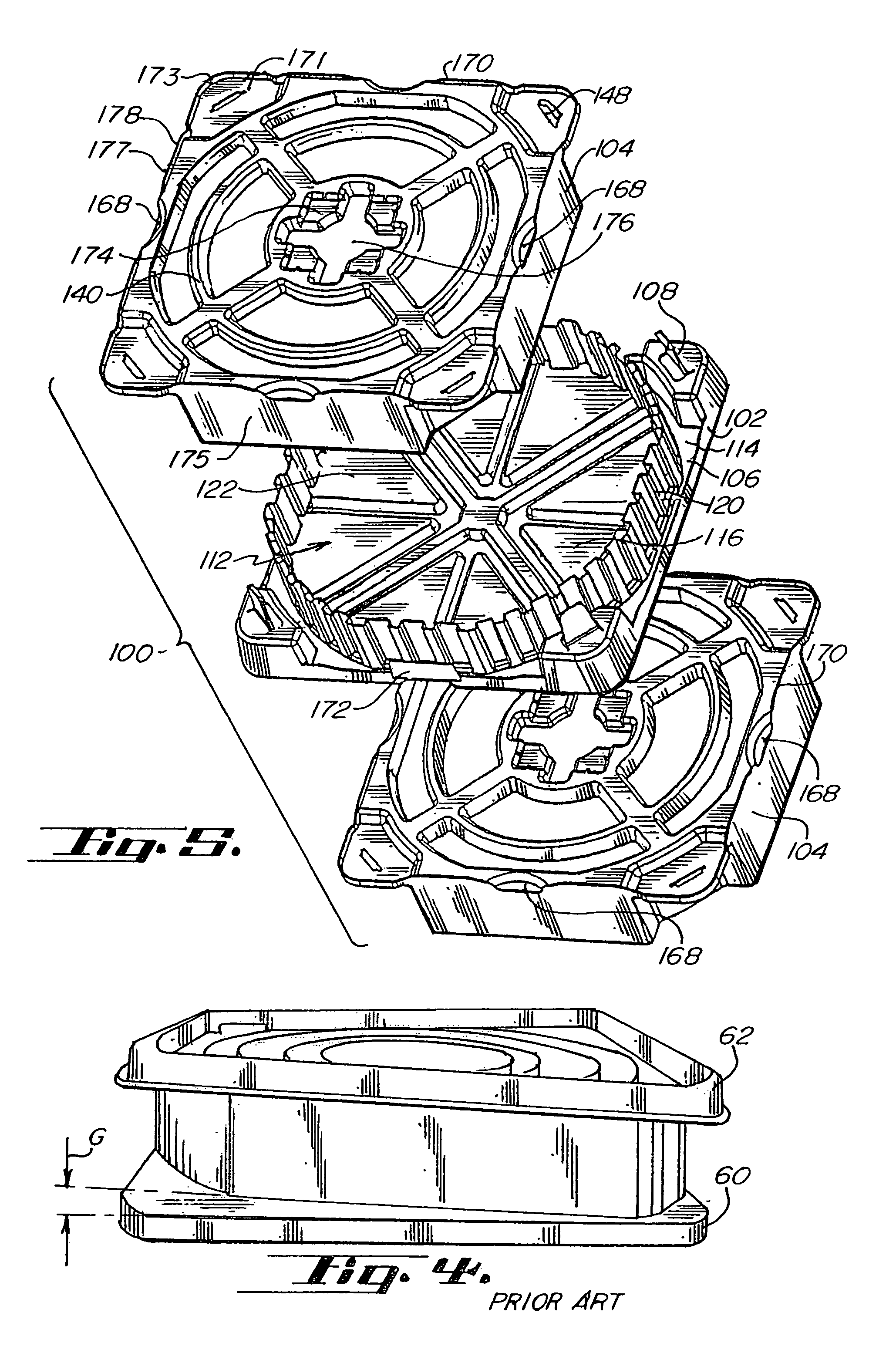

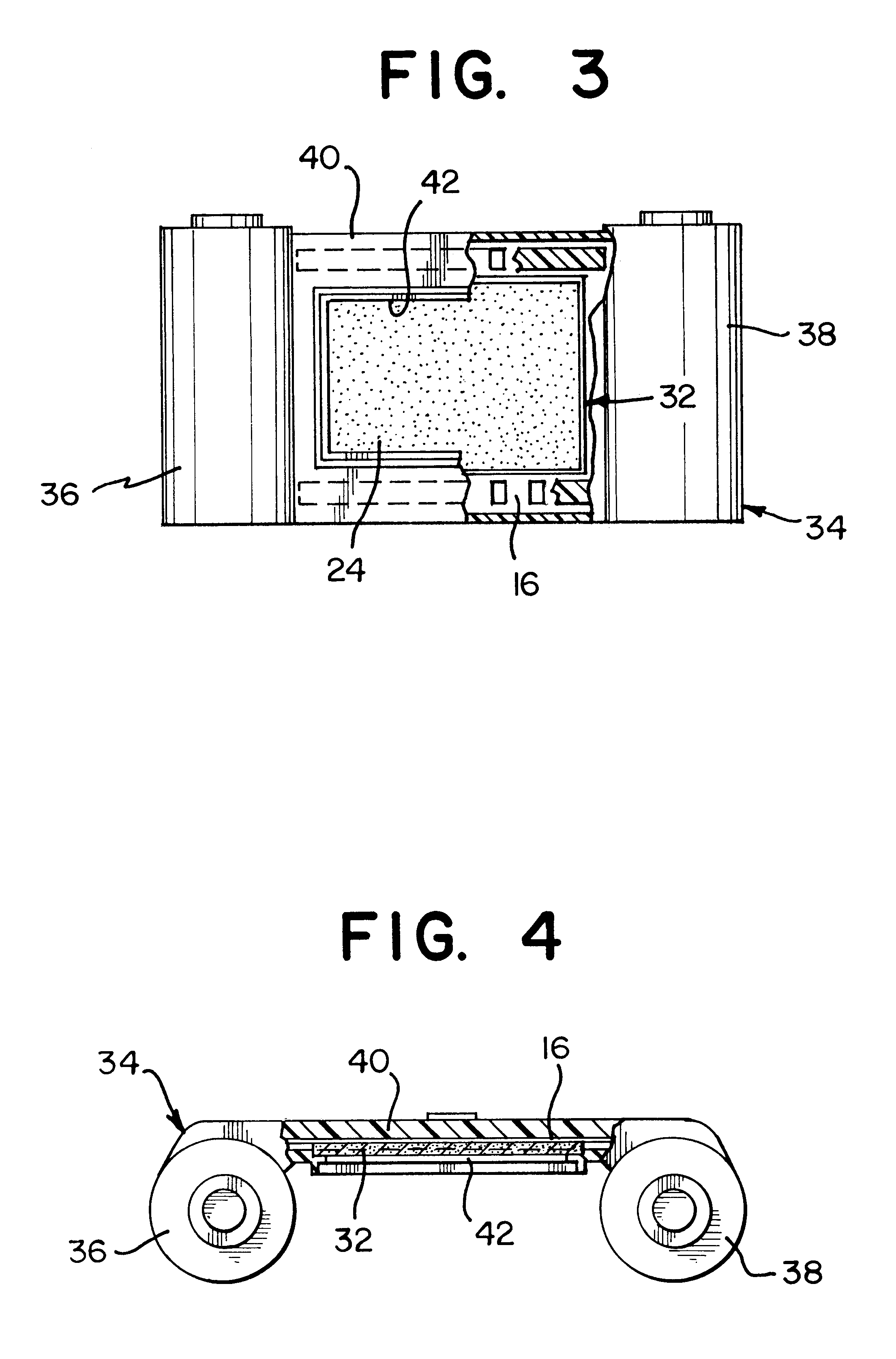

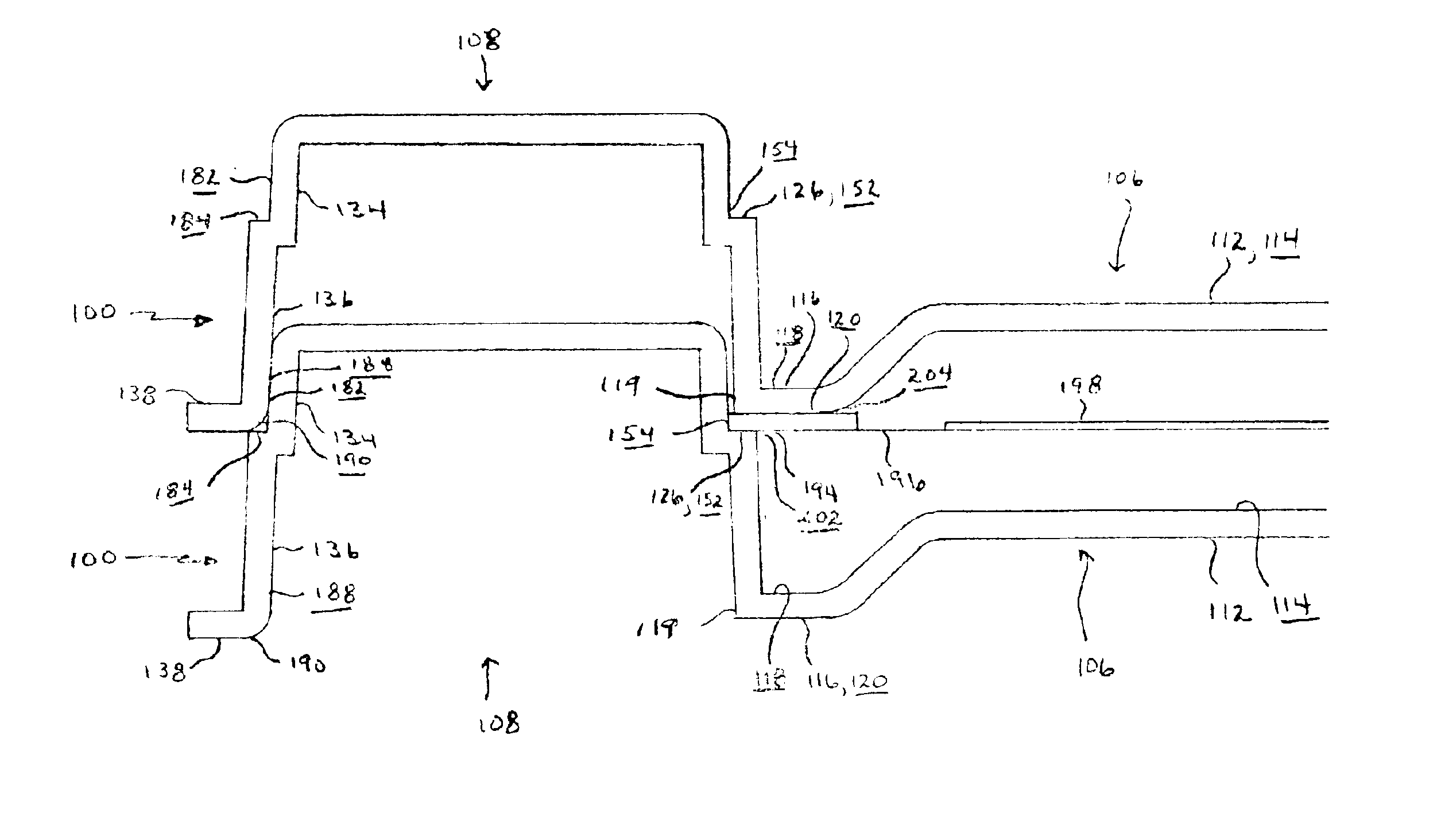

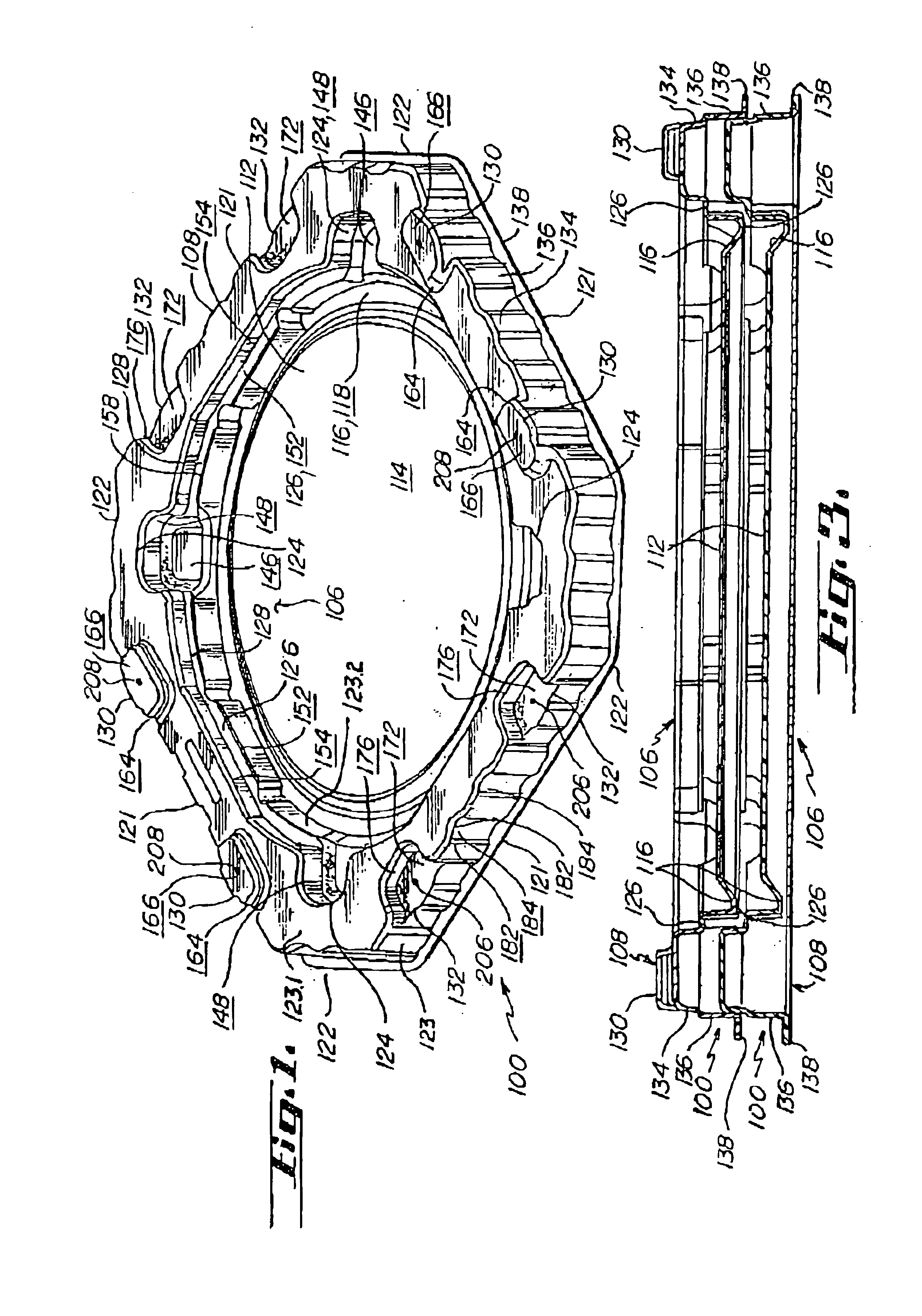

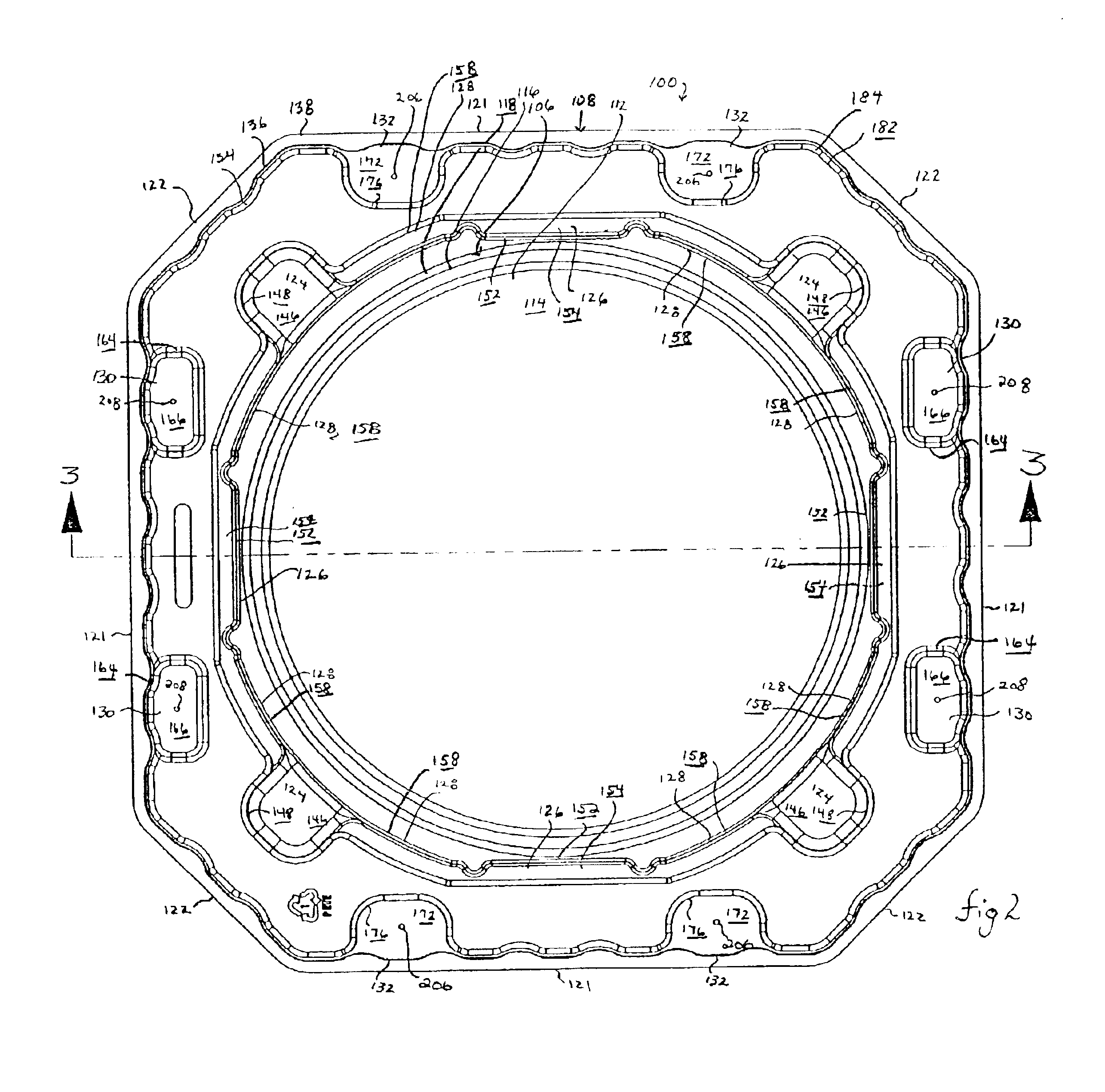

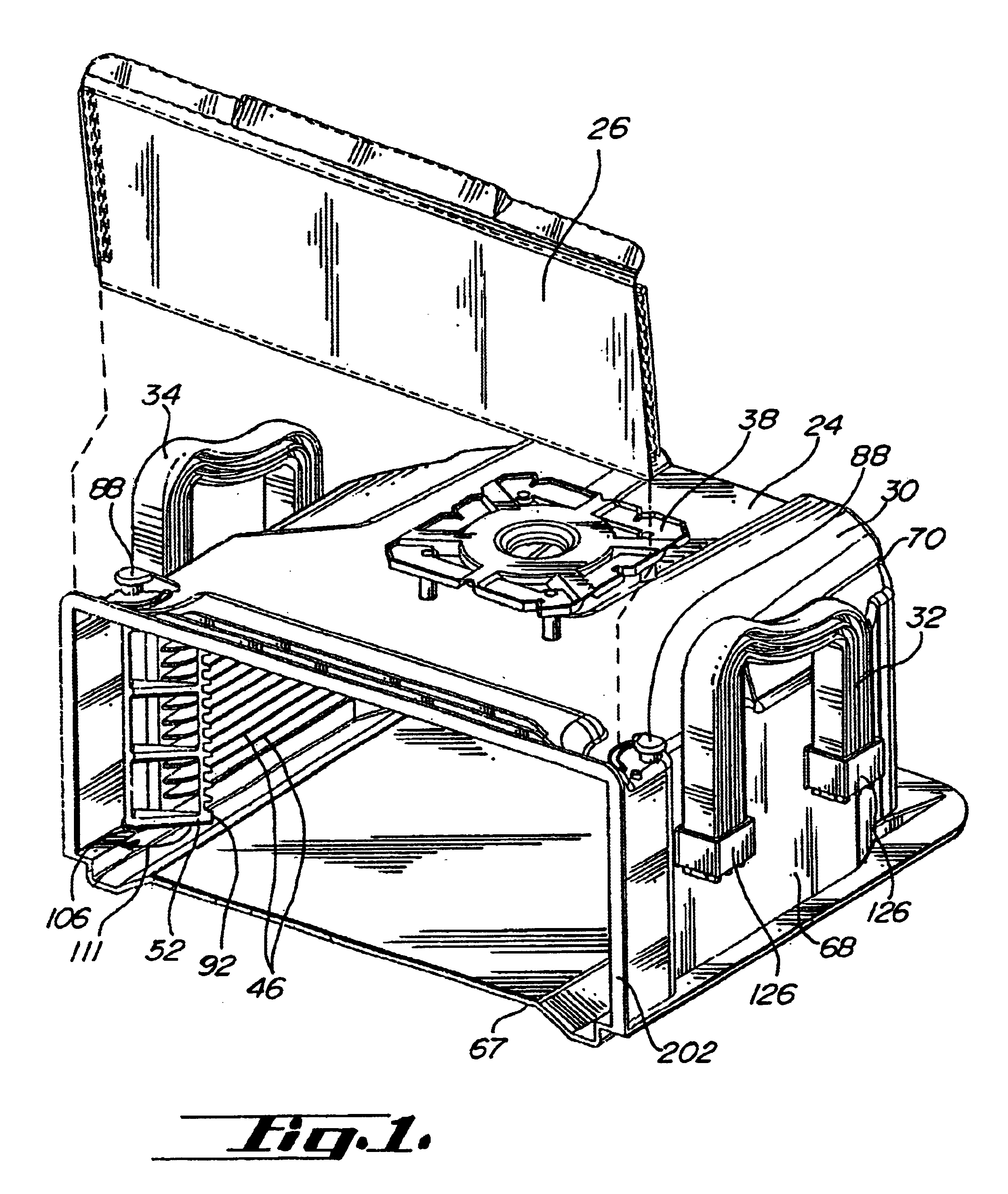

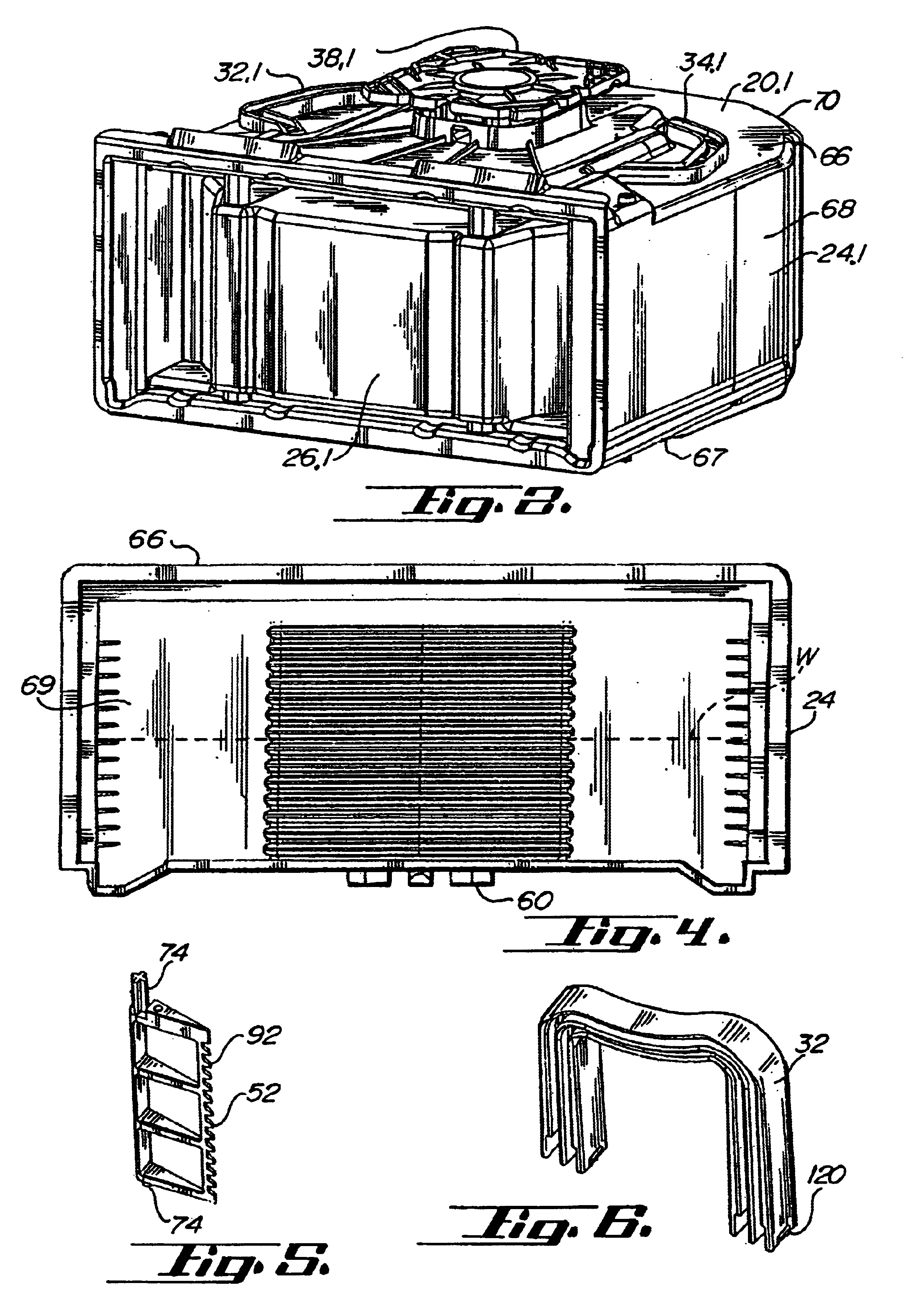

300MM single stackable film frame carrier

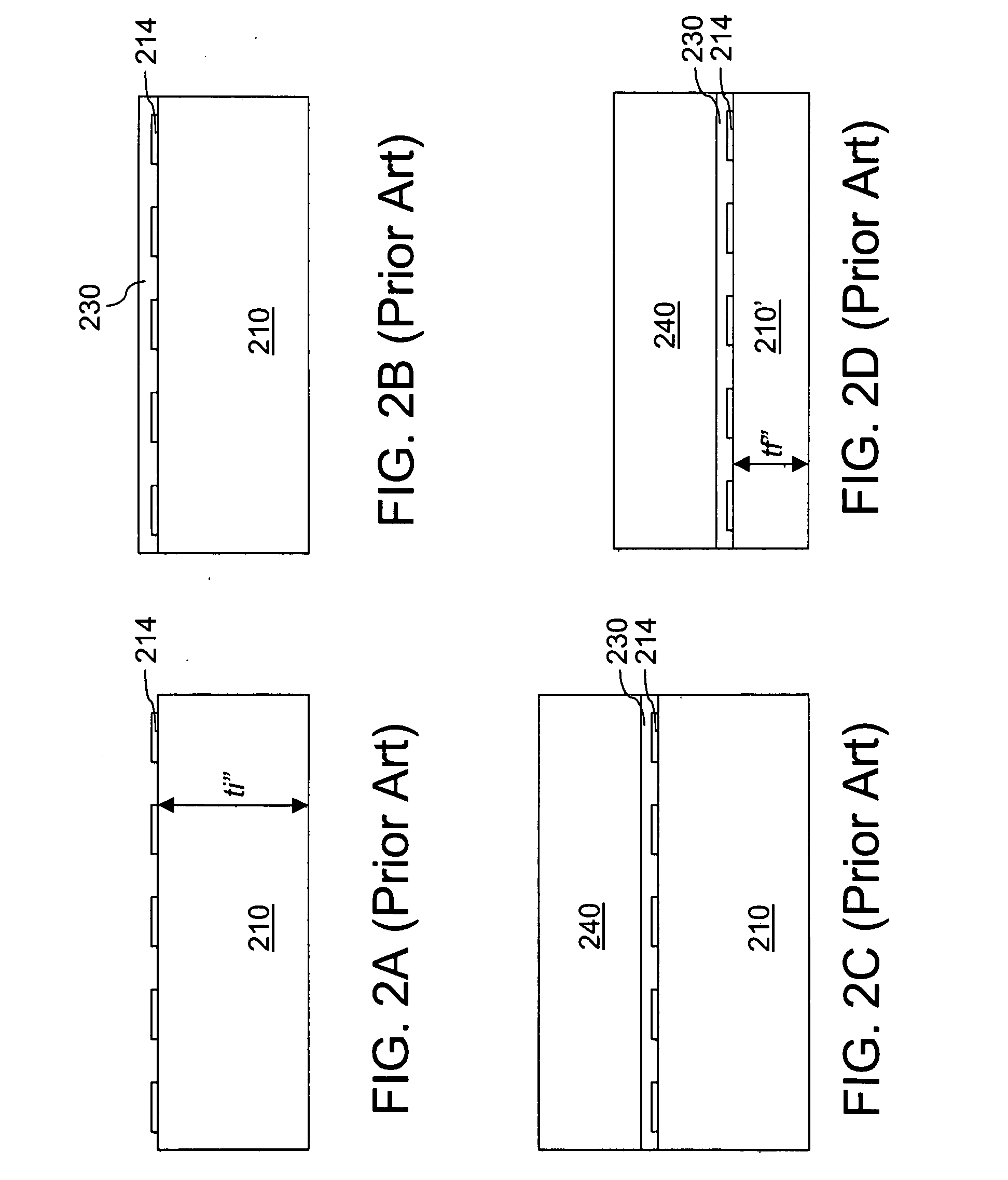

InactiveUS6837374B2Improve economyHorizontally stableSemiconductor/solid-state device manufacturingWood working apparatusSheet filmSubject matter

An interlockable film frame carrier has central and peripheral portions for securely storing a film frame, the film frame supporting a film, a semiconductor wafer disposed on the film. The central portion has structure for supporting the semiconductor wafer and for allowing access to a lower surface of the stored film frame. The peripheral portion of the film frame carrier includes structure for supporting a peripheral portion of the film frame and matable stacking members. When the film frame is stored, two film frame carriers are interlocked by mating the stacking members. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims. 37 CFR §1.72 (b).

Owner:ENTEGRIS INC

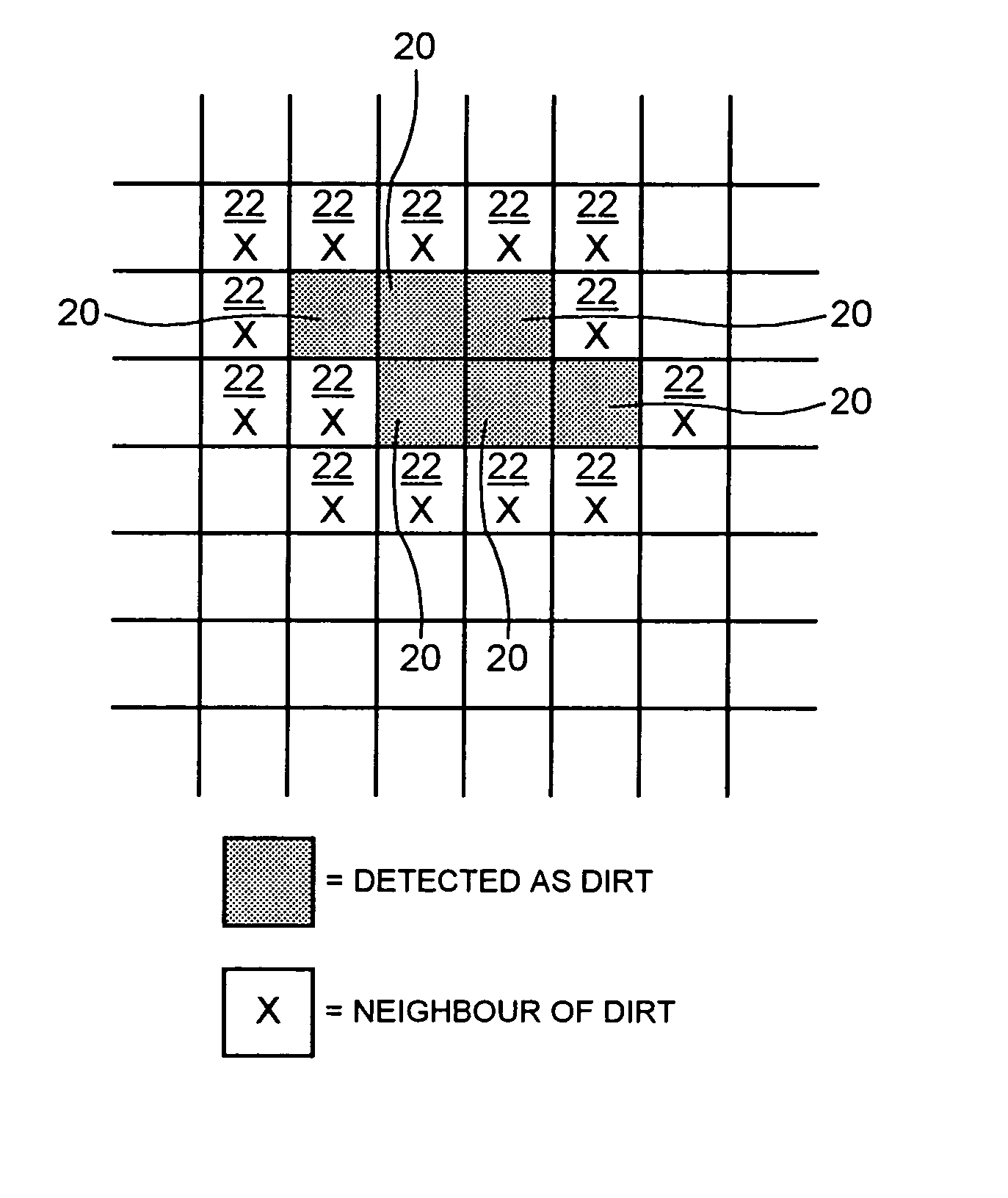

Method for adjusting digital images to compensate for defects on film material

InactiveUS7012642B1Shorten the timeCompensation effectTelevision system detailsTelevision system scanning detailsFilm-outDigital image

A method of scanning frames of cinematographic film to generate digital values of pixels constituting images on the film frames is provided in which pixels corresponding to defects on the film are identified and the values of such pixels are adjusted to compensate for the defects, the identification of the pixels corresponding to defects on the film being carried out by identifying pixels whose value is beyond a predetermined threshold.A method of correcting for flicker in digital images obtained by scanning cinematographic film is also provided. This method comprises the steps of identifying frames in which flicker is present; identifying relatively bright regions in those frames whose brightness is above a predetermined level, and correcting digital pixels in those relatively bright regions so as to compensate for the effect of flicker.

Owner:PANDORA INT

Method and apparatus for eliminating motion artifacts from video

InactiveUS20050062891A1Enhancing and improving quality of video imageTelevision system detailsPicture reproducers using cathode ray tubesInterlaced videoFilm frame

A method and apparatus for detecting and correcting motion artifacts in interlaced video signal converted for progressive video display. A correction is applied where interlaced video material is determined to originate from film source, thereby having been converted to video using a process known as 3-2 pulldown. Where the video material is not a result of the 3-2 pulldown process, a check is made for the presence of “pixel motion” so that corrections may be applied to smooth out the pixel motion. To determine 3-2 pulldown or field motion, a video field is compared to the field prior to the previous field to generate field error. Field errors are generated for five consecutive fields and a local minimum error repeated every five fields indicate the origination of the video material from film source using the 3-2 pulldown process. Upon confirmation of 3-2 pulldown, the video material is modified to correct for the mixing of two film frames into one interlaced video frame by assuring that the two fields of the de-interlaced video frame contain data from the same film frame. Where the video material did not originate from a film source, but pixel motion is detected, the pixel motion is smoothed out by an averaging method. The odd and even fields of the resulting video data are subsequently combined to form a progressive video material.

Owner:RGB SYST INC

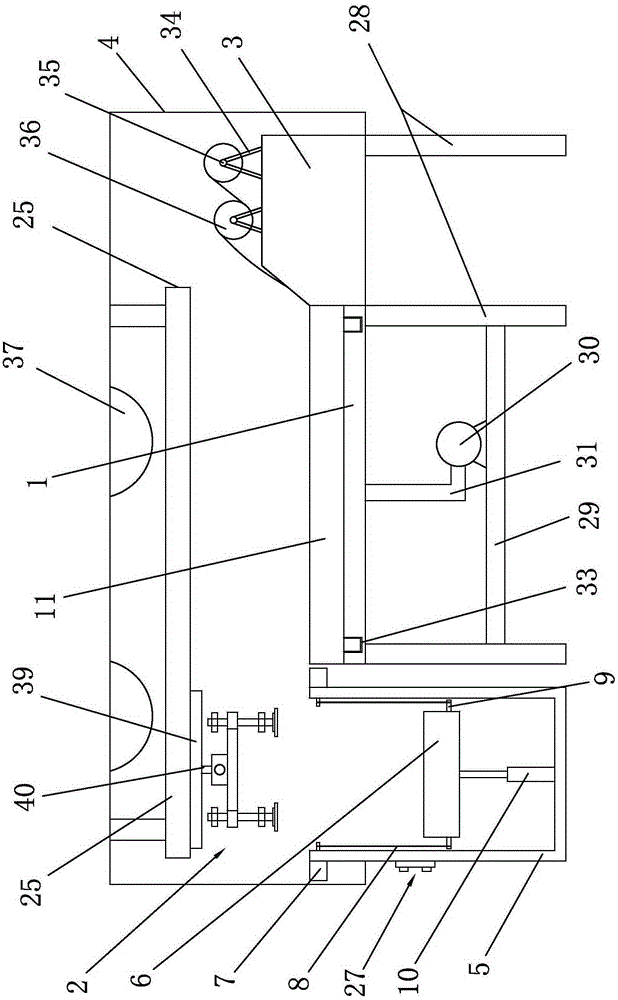

Glass lamination machine for producing insulating glass

InactiveCN105174753AImprove securityFeeding is simple and convenientCharge manipulationConveyor partsFixed frameEnergy consumption

The invention discloses a glass lamination machine for producing insulating glass. The glass lamination machine for producing the insulating glass comprises a feeding device, a lamination working table, a suction cup device, a film frame and a protective cover, the feeding device comprises a feeding rack and a feeding plate, the lamination working table is provided with a cushion, vent holes are evenly formed in the surface of the cushion, supporting springs and a horizontal sliding device are arranged in a cavity of the cushion, the suction cup device comprises fixing frames and vertical suction cups, the two adjacent fixing frames are connected through a connecting rod, and a lead screw is arranged at the upper end of each vertical suction cup. The glass lamination machine for producing the insulating glass is simple in structure and strong in practicability; the original design of feeding through an escalator is improved; by means of a traction motor, feeding of glass is more convenient and simple, and the safety performance of operation is improved; by means of the cushion, a protective effect on the glass can be achieved, the placed glass can be firmly sucked by horizontal suction cups in the cushion, the movement of the glass is avoided, the energy consumption is reduced, and the comprehensive utilization efficiency is increased.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

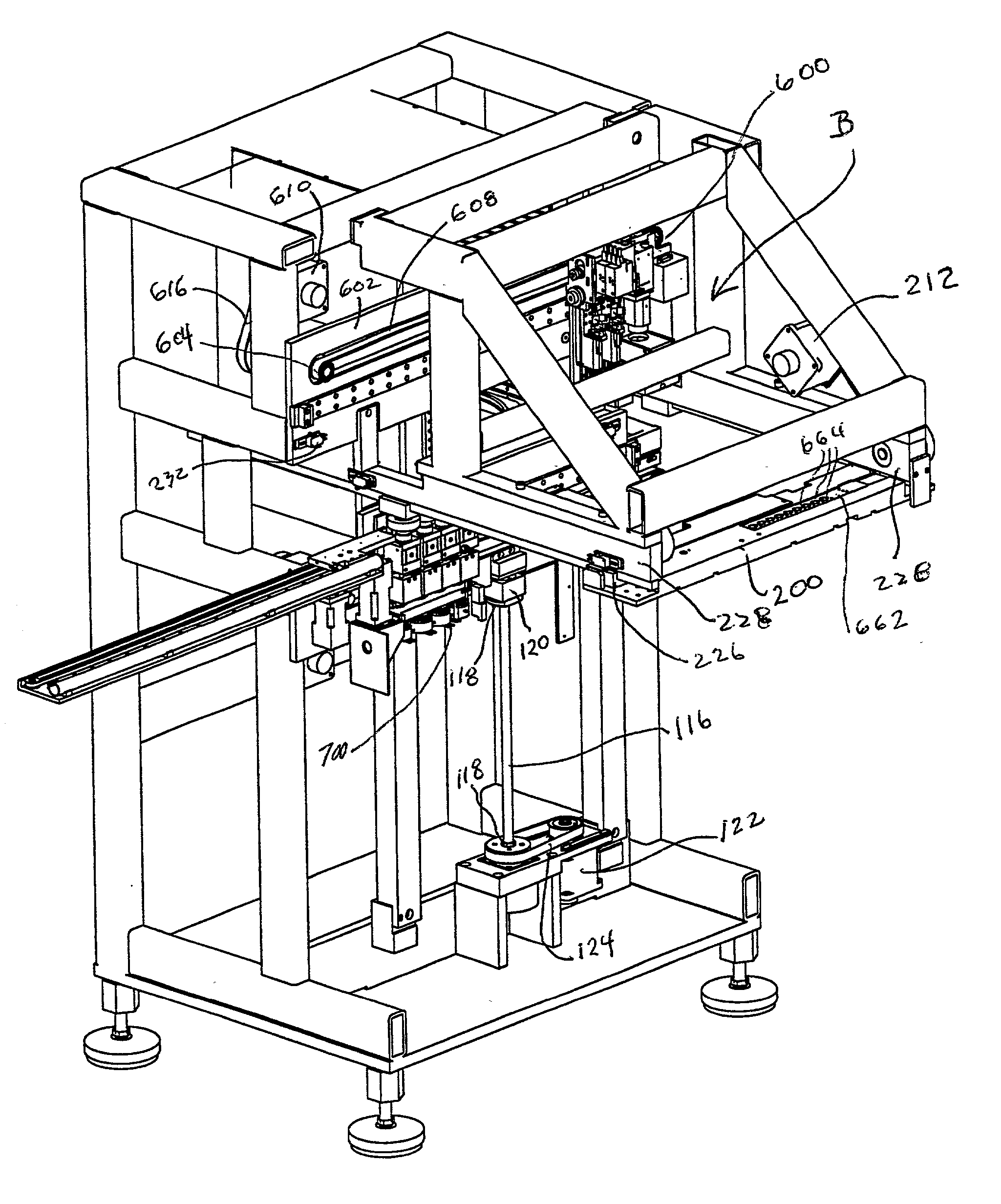

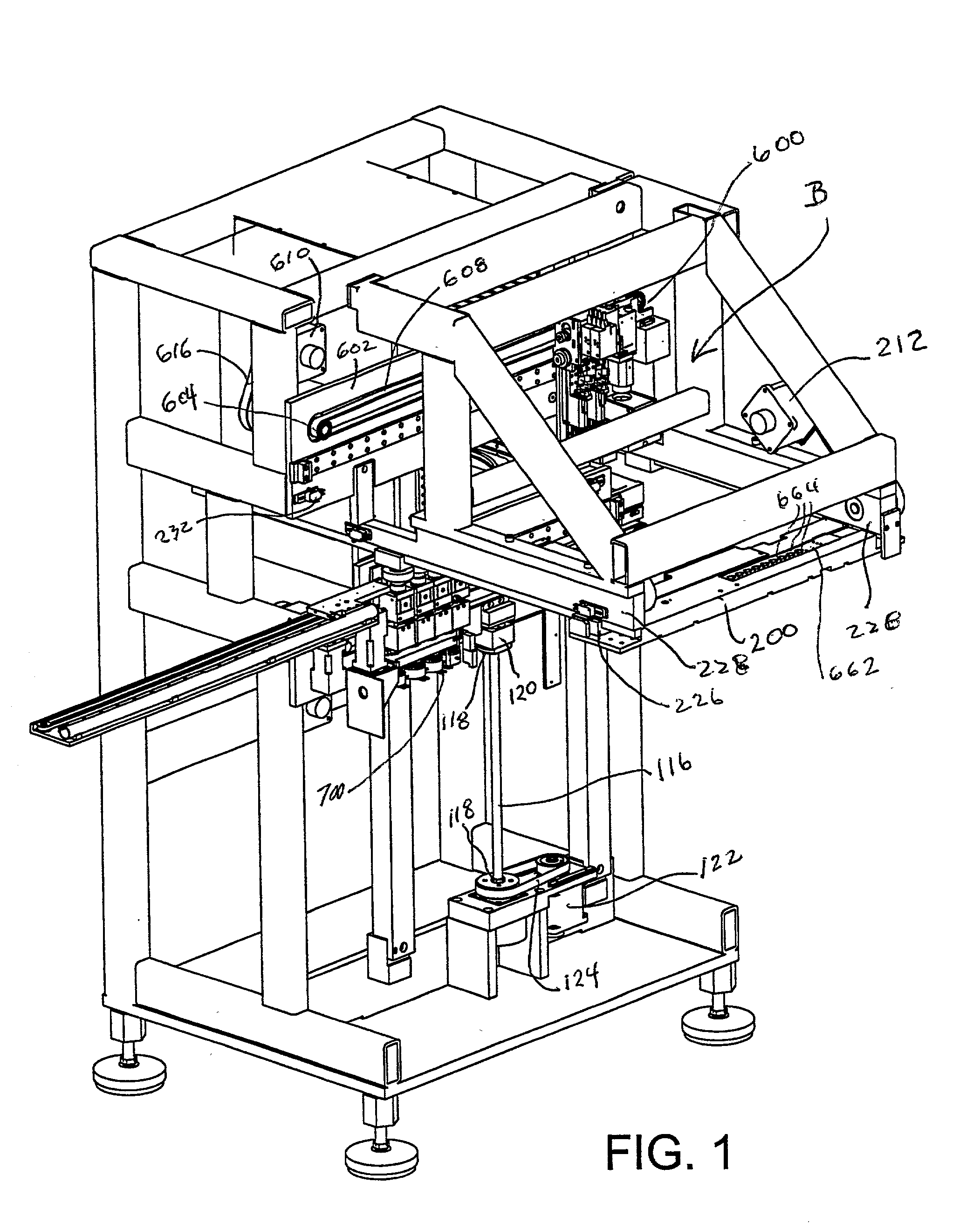

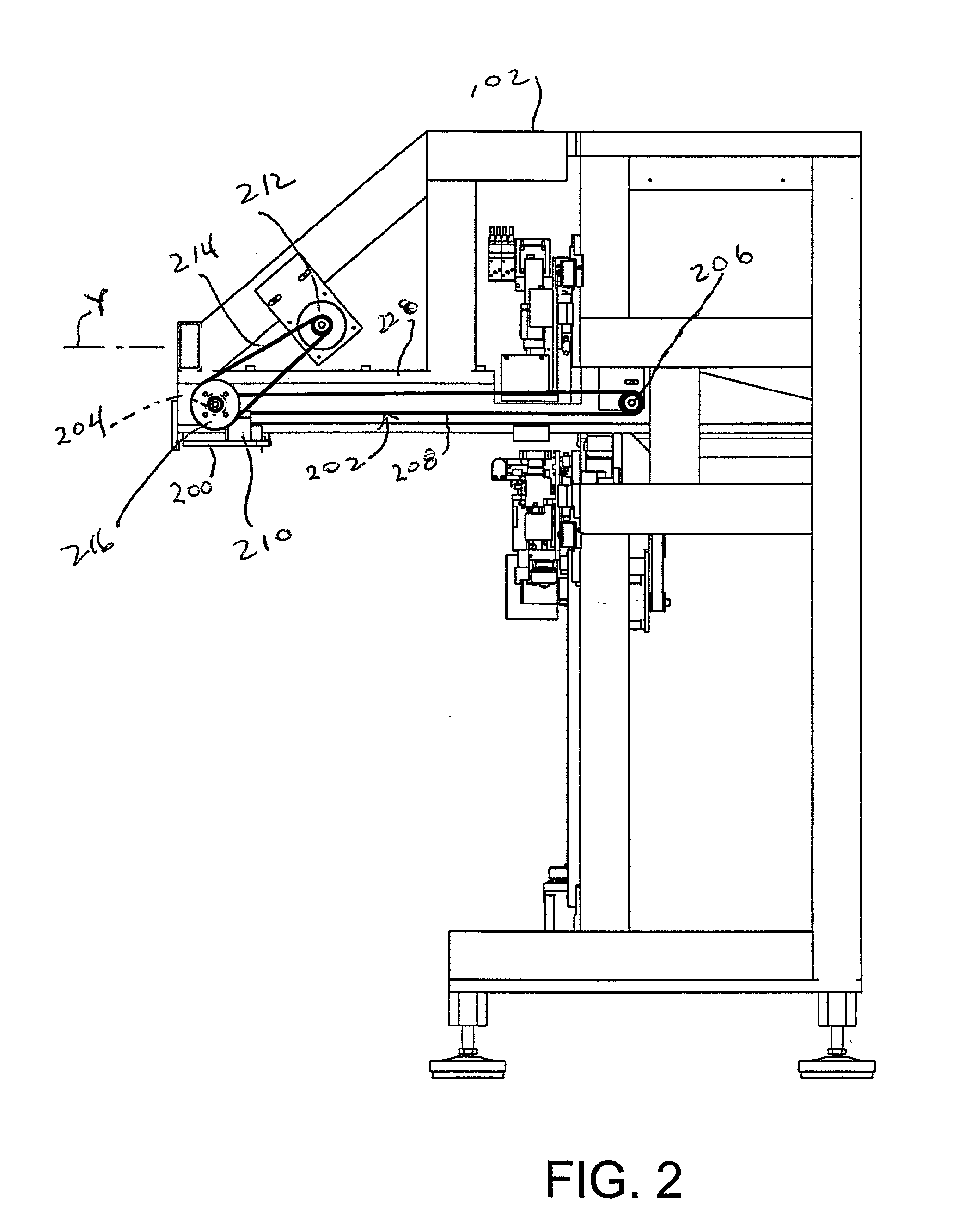

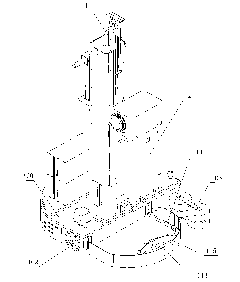

Methods and apparatus for transferring electrical components

InactiveUS20020192059A1Semiconductor/solid-state device manufacturingArticle unpackingFilm frameTransfer mechanism

A mechanism for handling semiconductor wafers includes a feed section which comprises a vertically movable elevator able to hold a number of vertically spaced carriers. Each carrier has a film frame mounted thereon for supporting a wafer. A pulling mechanism pulls a selected carrier out of the elevator along a first axis and into a pick and place section. A transfer mechanism removes individual dies from the wafer and moves them to a flip station along a second axis oriented perpendicularly to the first axis. The transfer mechanism can move different distances along the second axis to be able to remove dies arranged in a row along the second axis. The flip station is driven by a single motor to both lower and invert the dies.

Owner:DELAWARE CAPITAL FORMATION

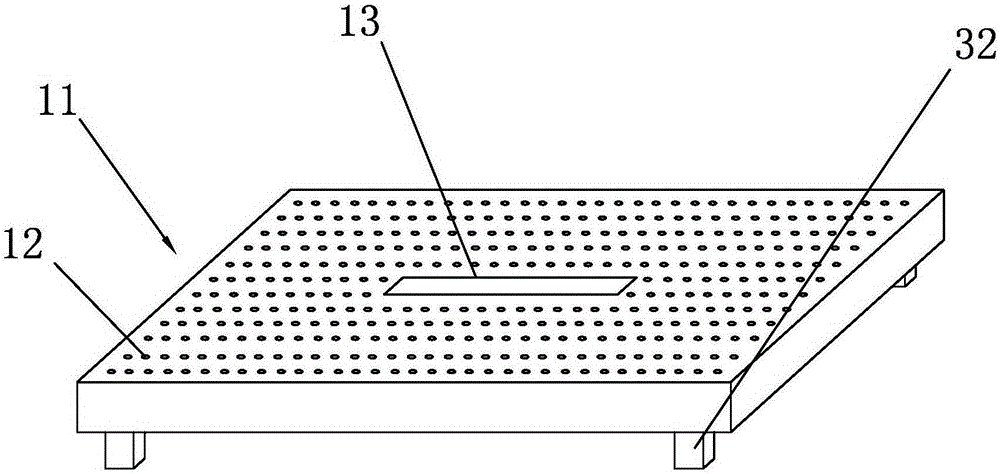

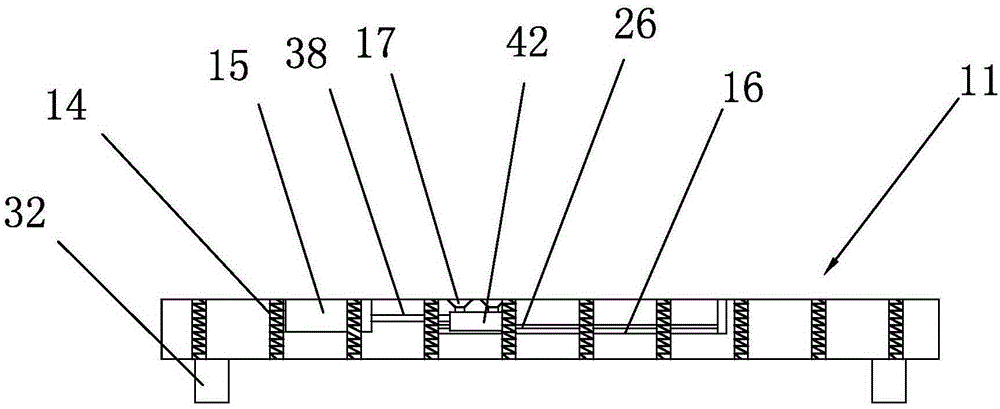

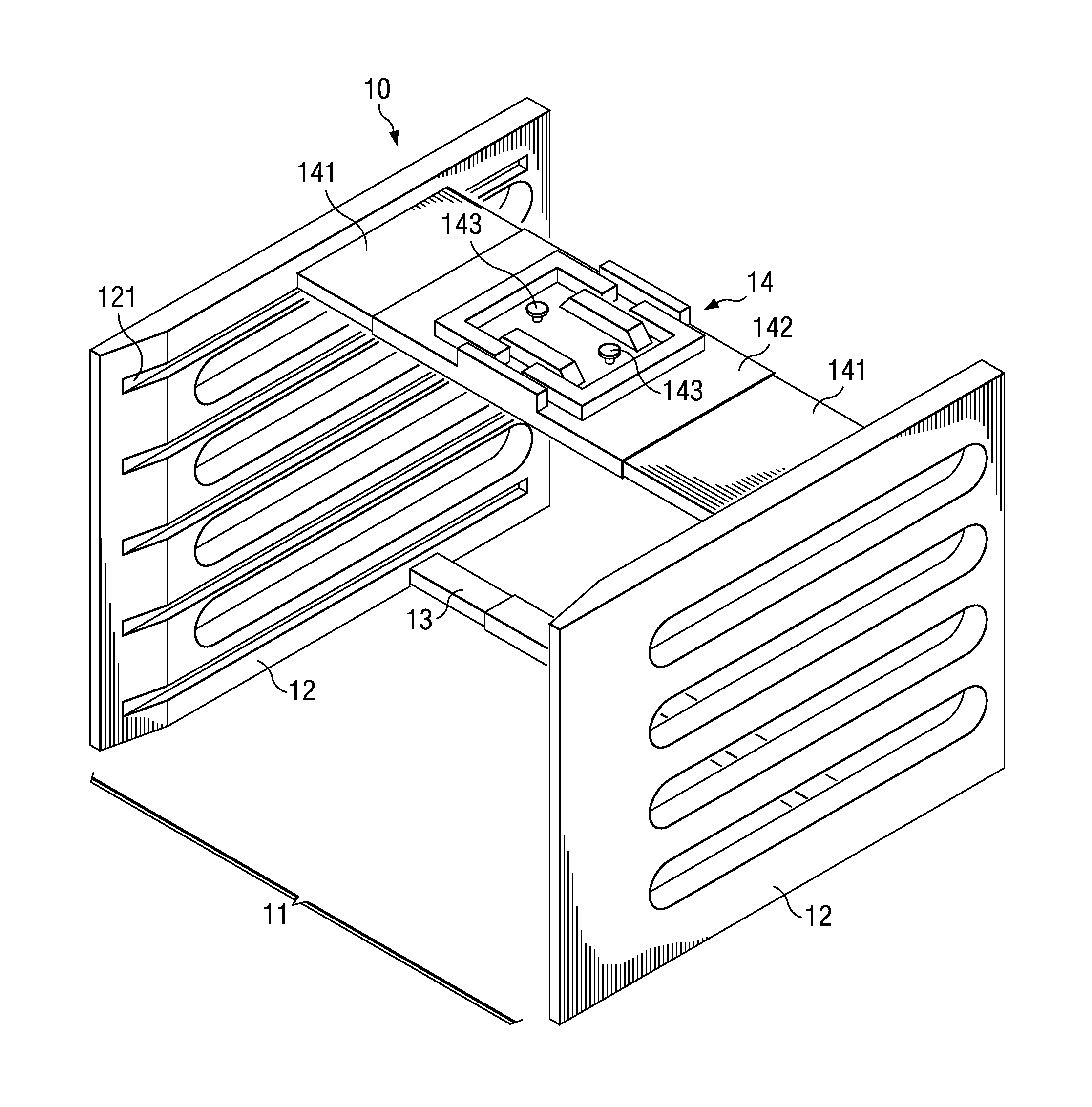

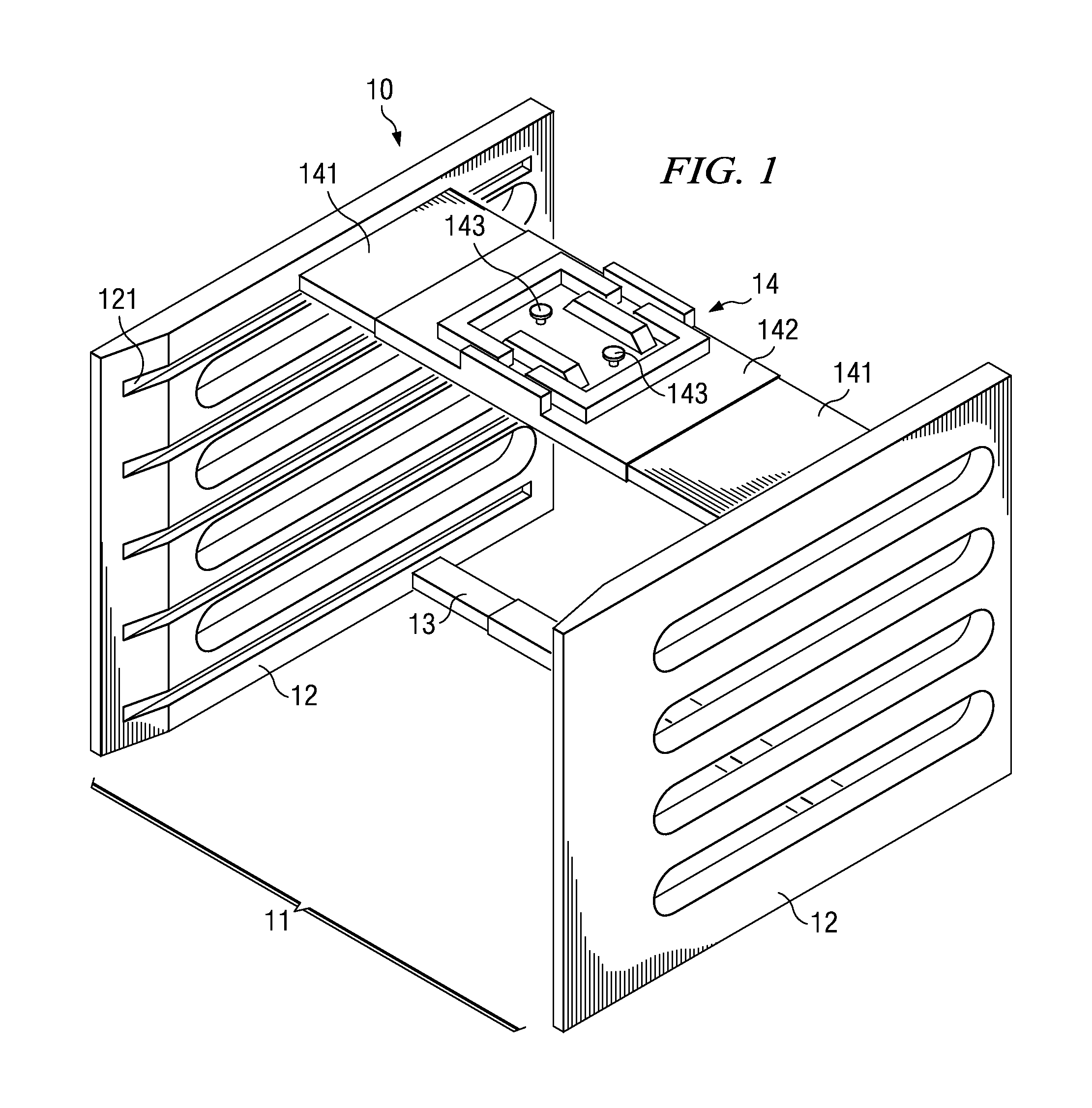

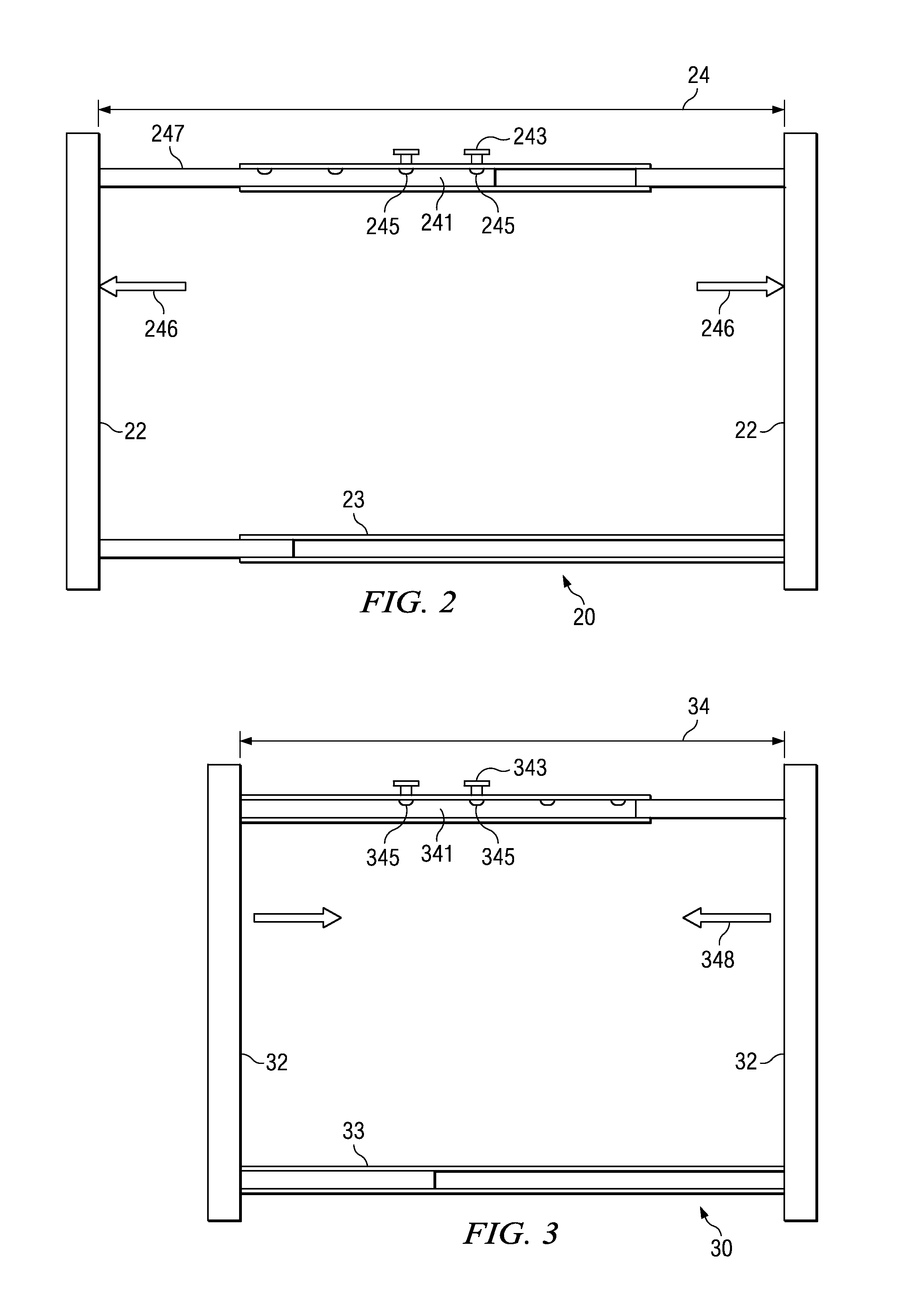

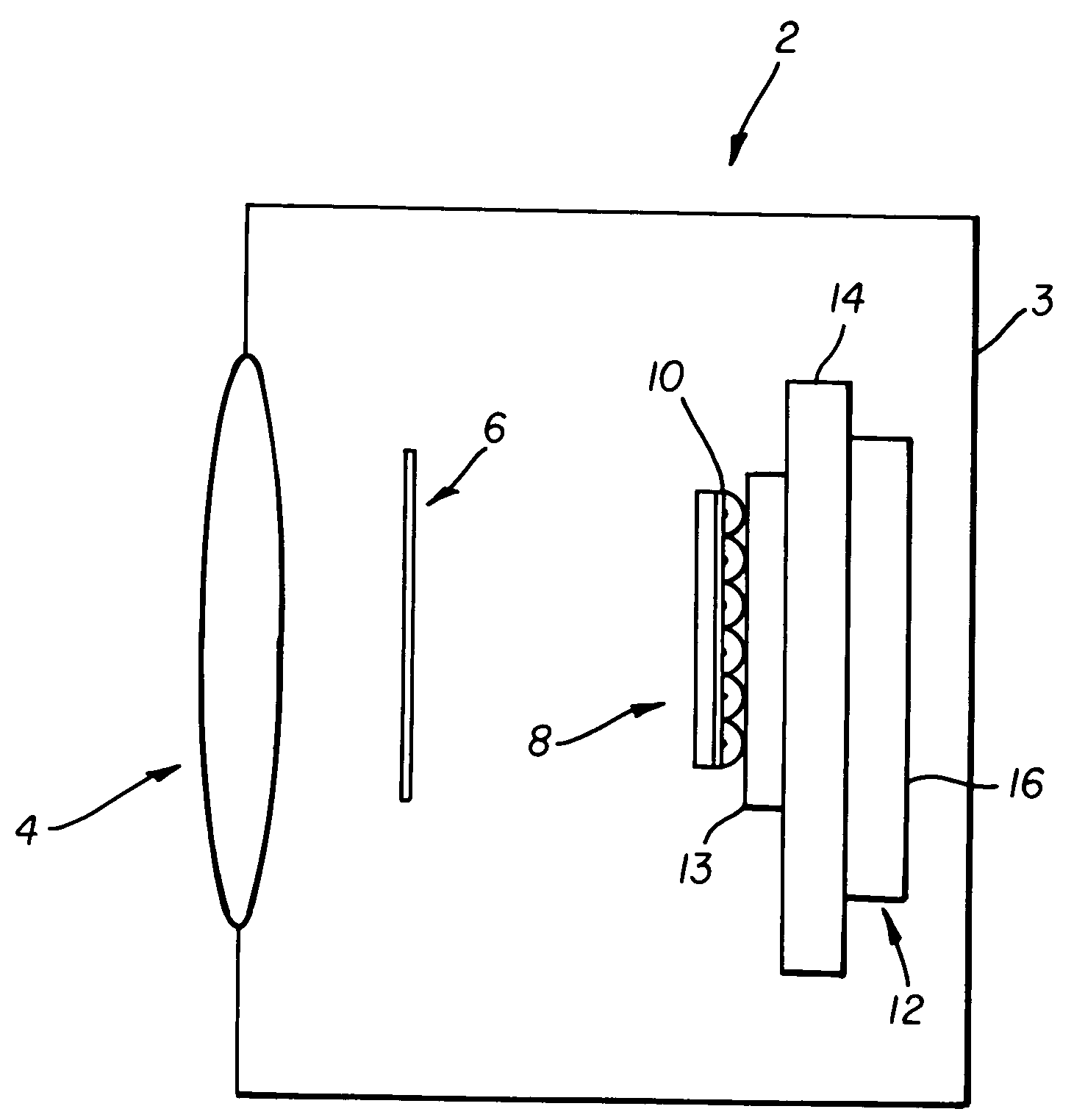

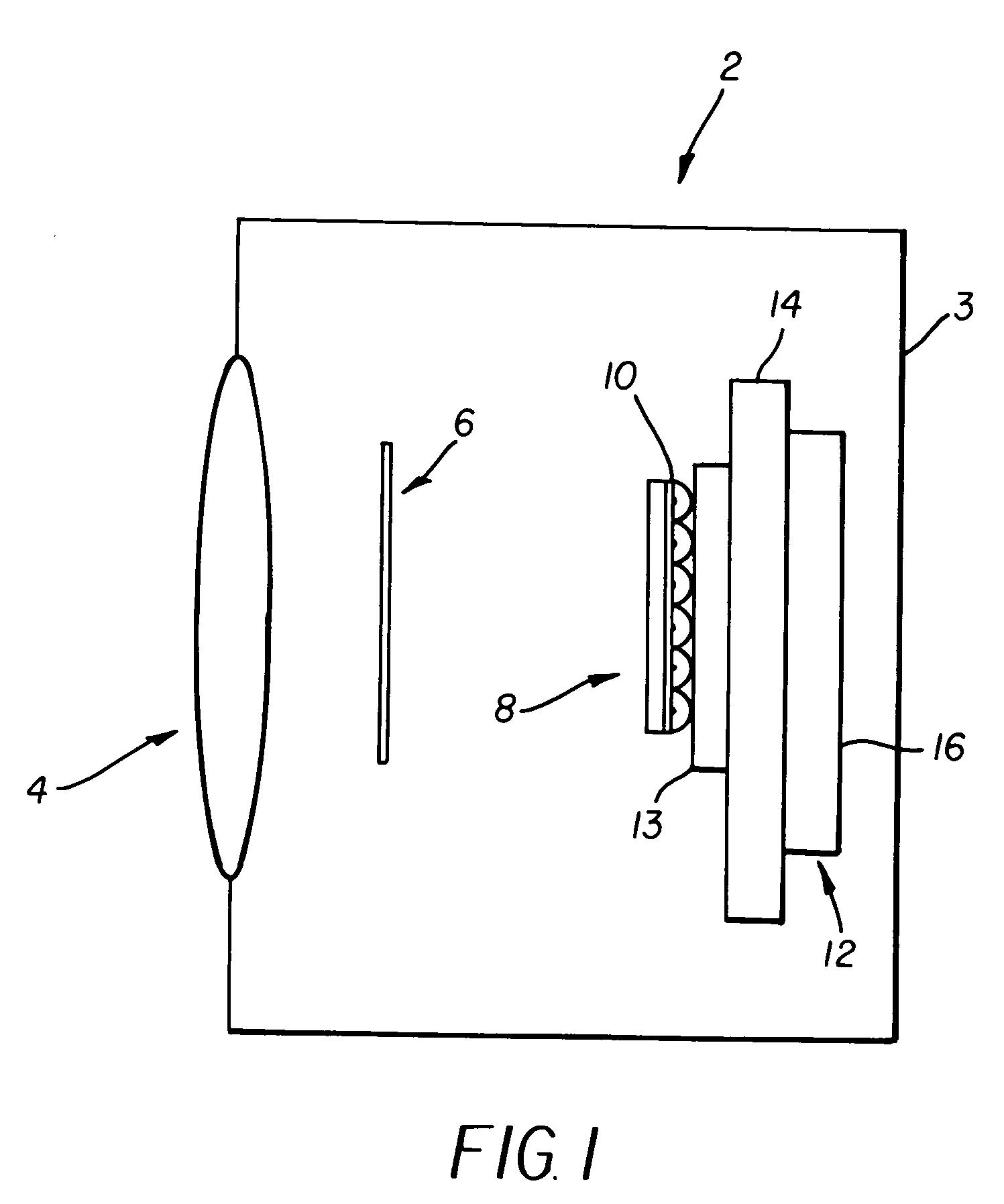

Adjustable Width Cassette for Wafer Film Frames

InactiveUS20110100937A1Avoid chipping and damageError minimizationSemiconductor/solid-state device manufacturingPackagingMagnetic tapeEngineering

An expandable width cassette for storing and transporting thin planar objects of different widths is provided. The cassette 10 includes two side panels 12 of fixed height opposite and parallel to one another having a series of elongated slots on the inner surface of the side panels for supporting planar objects, a sliding bar assembly 13 on the bottom side of the cassette, and an adjustable length panel 14 on the top side of the cassette. Spring loaded press screws 143 disengaged from locator holes at predefined locations in the top panel allow the cassette width to be altered by pushing or pulling the side panels. A wafer film frame cassette includes a back stop mechanism which further serves to align with a frame notch.

Owner:TEXAS INSTR INC

Method of thinning a semiconductor substrate

ActiveUS20100155936A1Reduced adhesion strengthSemiconductor/solid-state device detailsSolid-state devicesAdhesiveUltraviolet lights

A C4 grind tape and a laser-ablative adhesive layer are formed on a front side of a semiconductor substrate. A carrier substrate is thereafter attached to the laser-ablative adhesive layer. The back side of the semiconductor substrate is thinned by polishing or grinding, during which the carrier substrate provides mechanical support to enable thinning of the semiconductor substrate to a thickness of about 25 μm. A film frame tape is attached to the back side of the thinned semiconductor substrate and the laser-ablative adhesive layer is ablated by laser, thereby dissociating the carrier substrate from the back side of the C4 grind tape. The assembly of the film frame tape, the thinned semiconductor substrate, and the C4 grind tape is diced. The C4 grind tape is irradiated by ultraviolet light to become less adhesive, and is subsequently removed.

Owner:IBM CORP

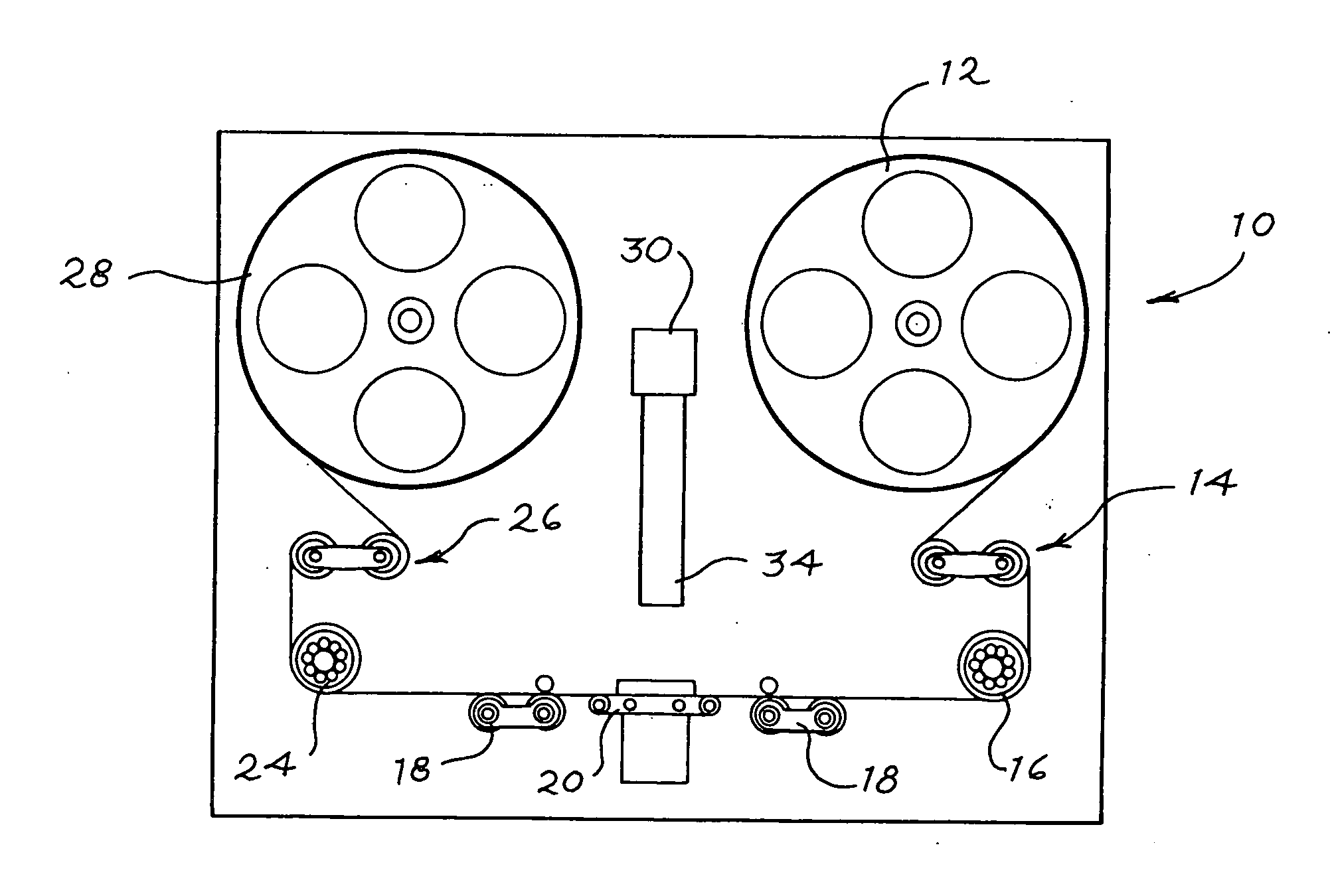

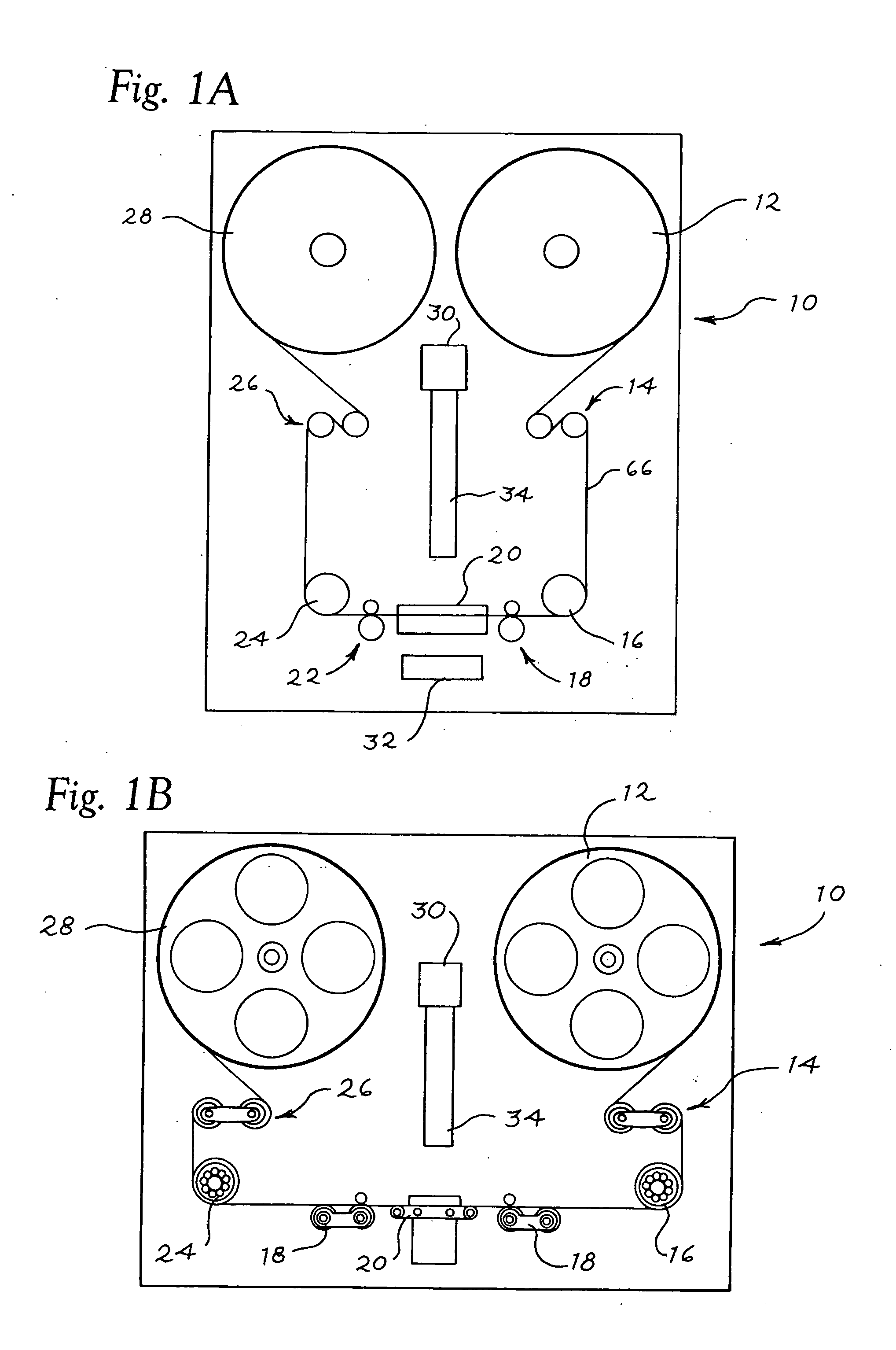

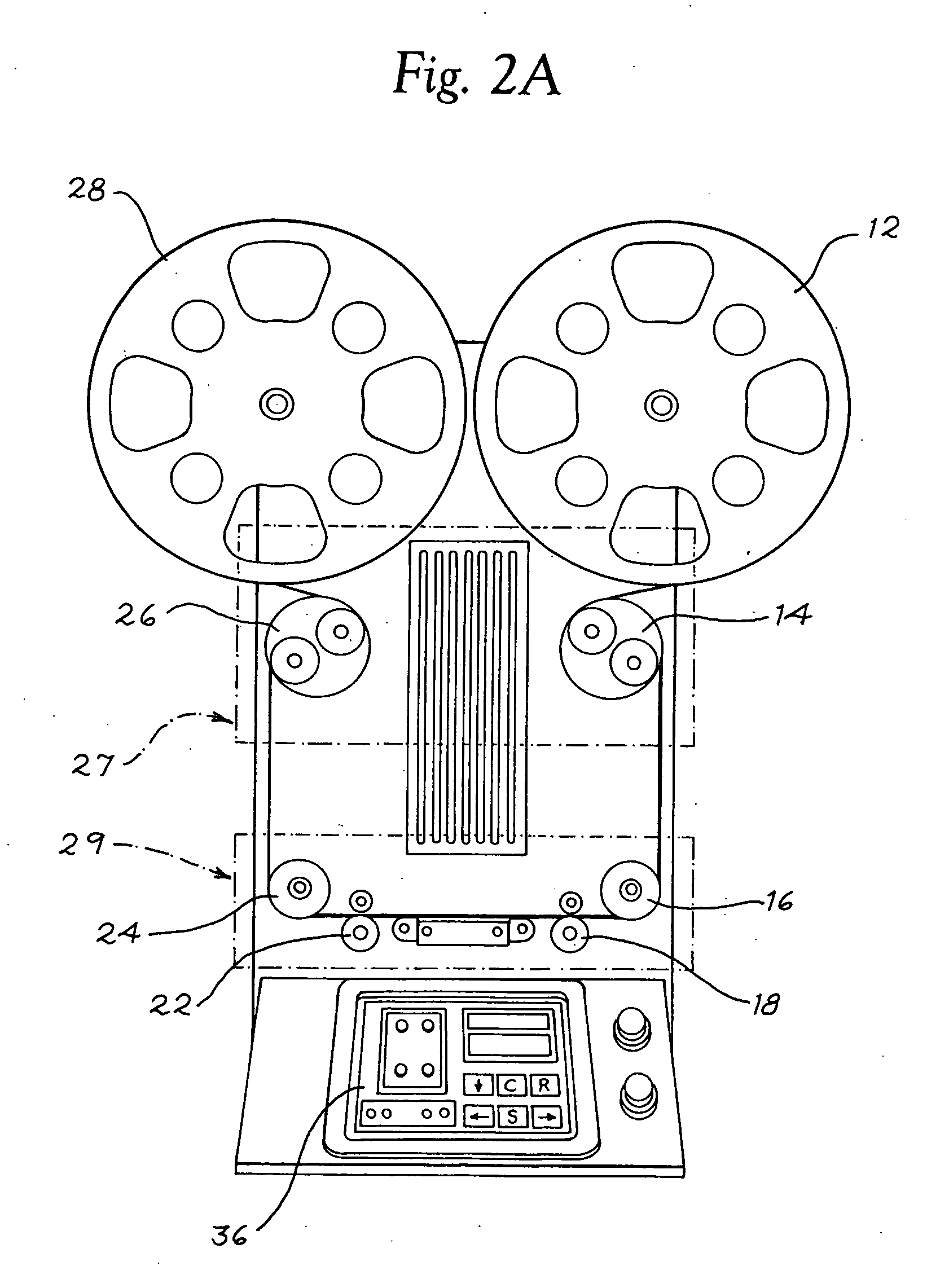

Method and apparatus for continuous motion film scanning

ActiveUS20130076890A1Facilitates high resolution digital duplicationSignificant informationTelevision system detailsTelevision system scanning detailsFilm-outDigital image

A continuous film scanning system for high resolution digital archival and duplication of motion picture film on a frame by frame basis. Film is driven through the film scanning system through the use of rollers and maintained at a consistent tension throughout the scanning process. Optical interrogation of the perforations associated with each film frame is used to trigger digital image capture. The continuous film scanning system is particularly well adapted to safely handle imperfect or damaged film stock.

Owner:REFLEX TECH

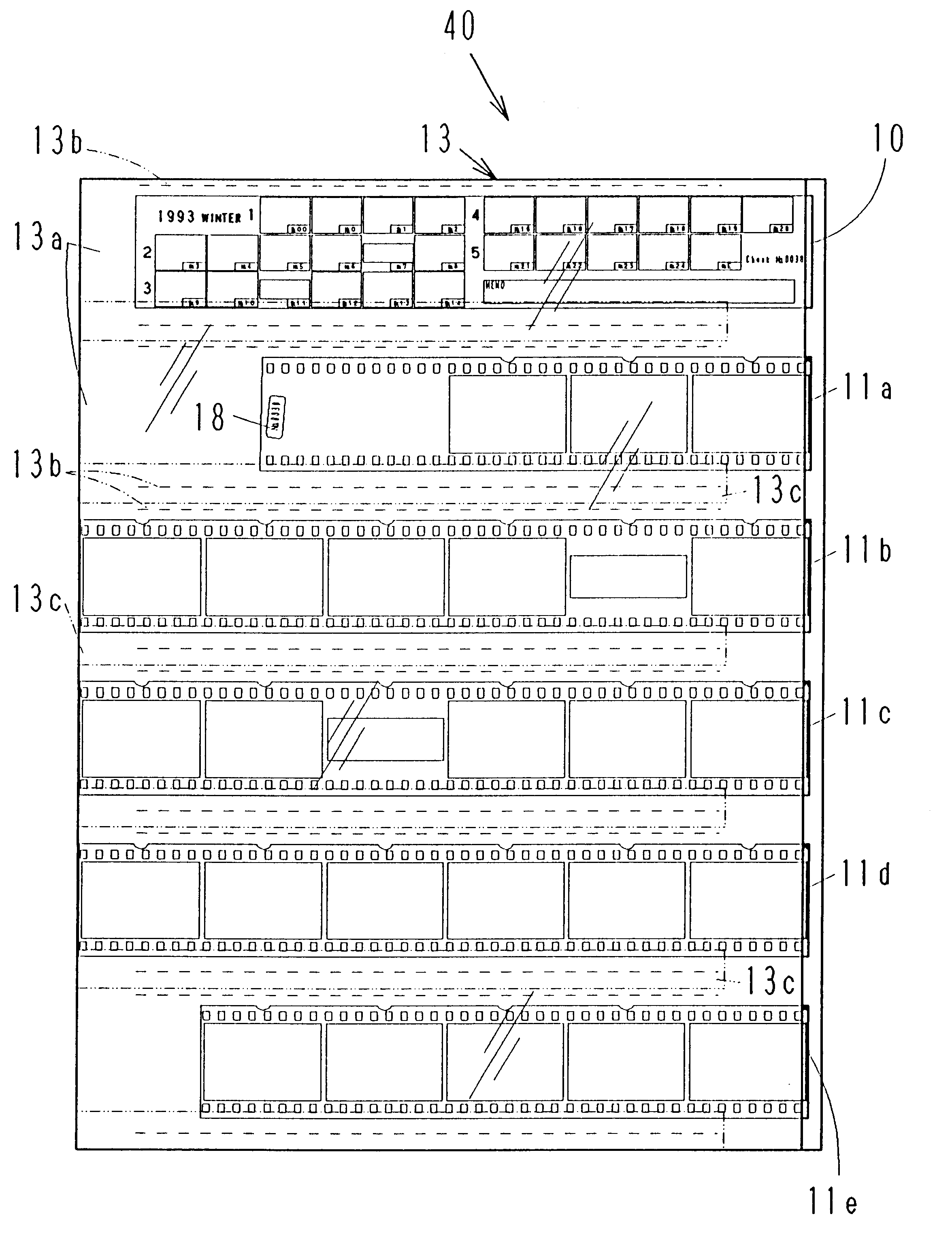

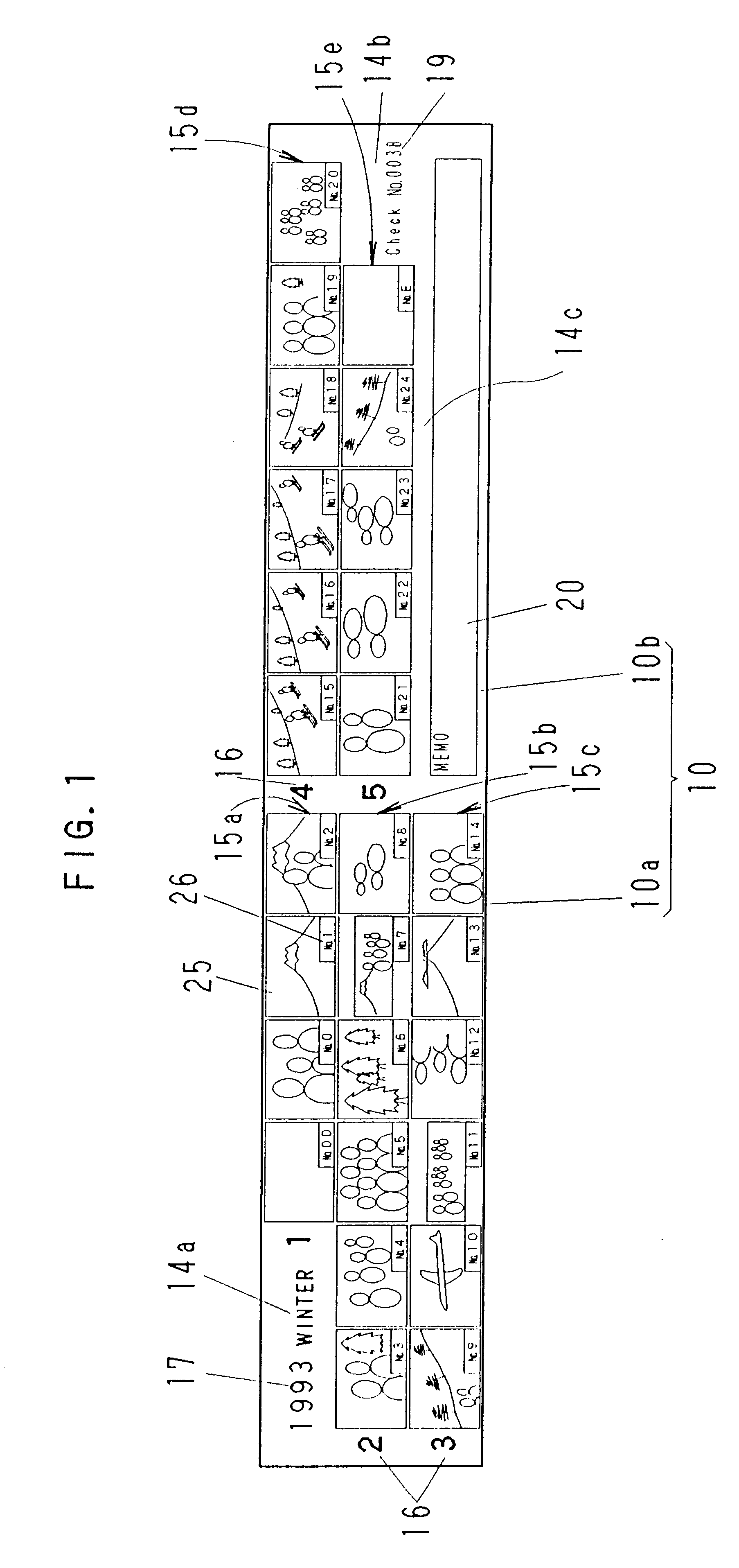

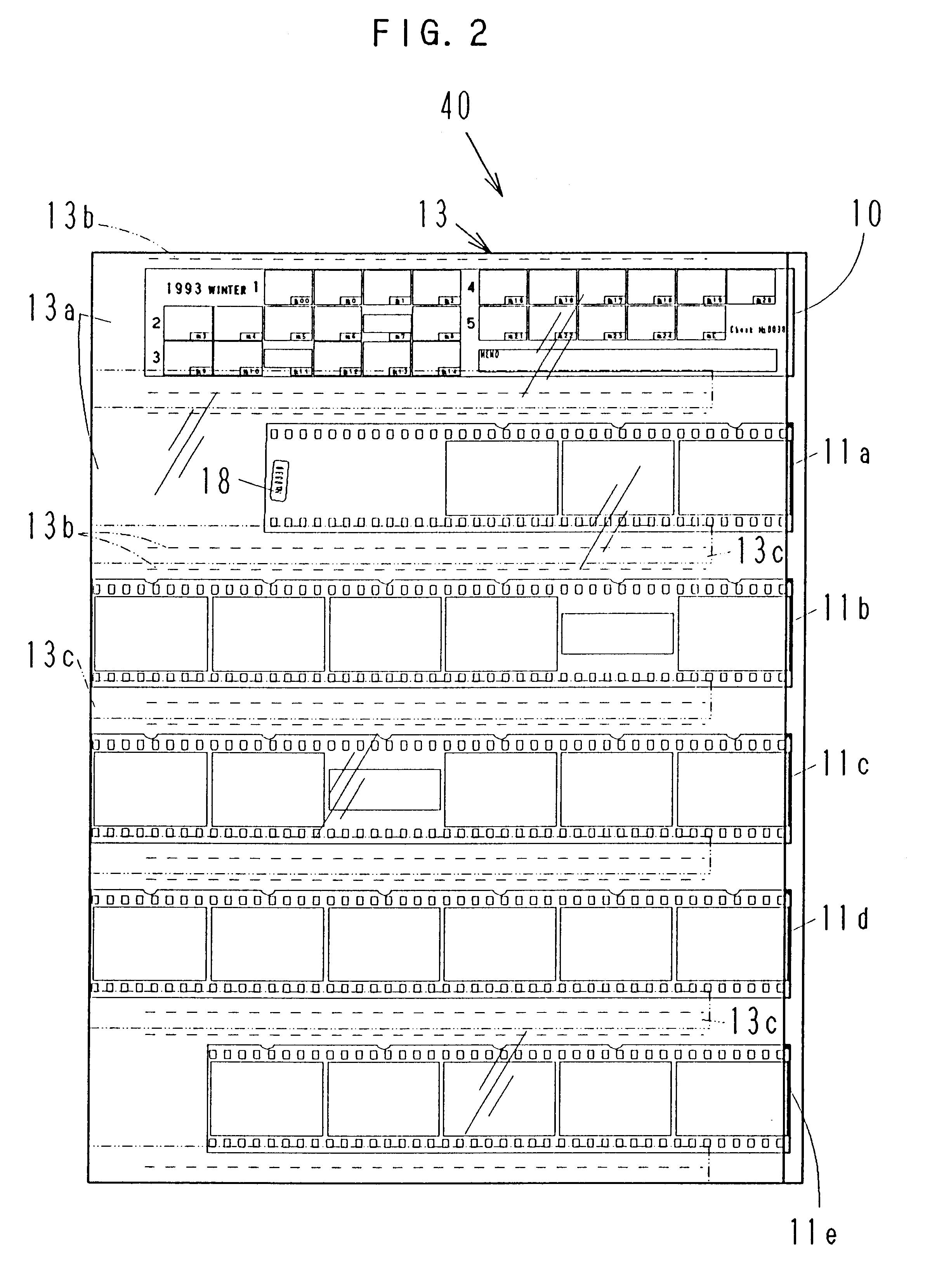

Index photograph, exposed film package, and film package producing system

InactiveUS6270932B2Easy to identifyPhotography auxillary processesRadiation applicationsPhotographic paperEngineering

An exposed film package for preserving one strip of exposed photographic film includes a film sheath, which has plural pockets. Plural film pieces are formed by cutting the one strip of the exposed film, and contained respectively in the pockets in the film sheath. An index photograph is constituted of photographic paper, on which positive images of frames from the one strip of the exposed film are printed. The photographic paper has a size substantially equal to the film pieces. The positive images are formed in reducing a size of the frames, and grouped in association with the film pieces. Groups of the positive images are arranged in consideration of an order of exposure of the frames. The index photograph is contained in one of the pockets in association with the film pieces constituting the one strip.

Owner:FUJIFILM CORP

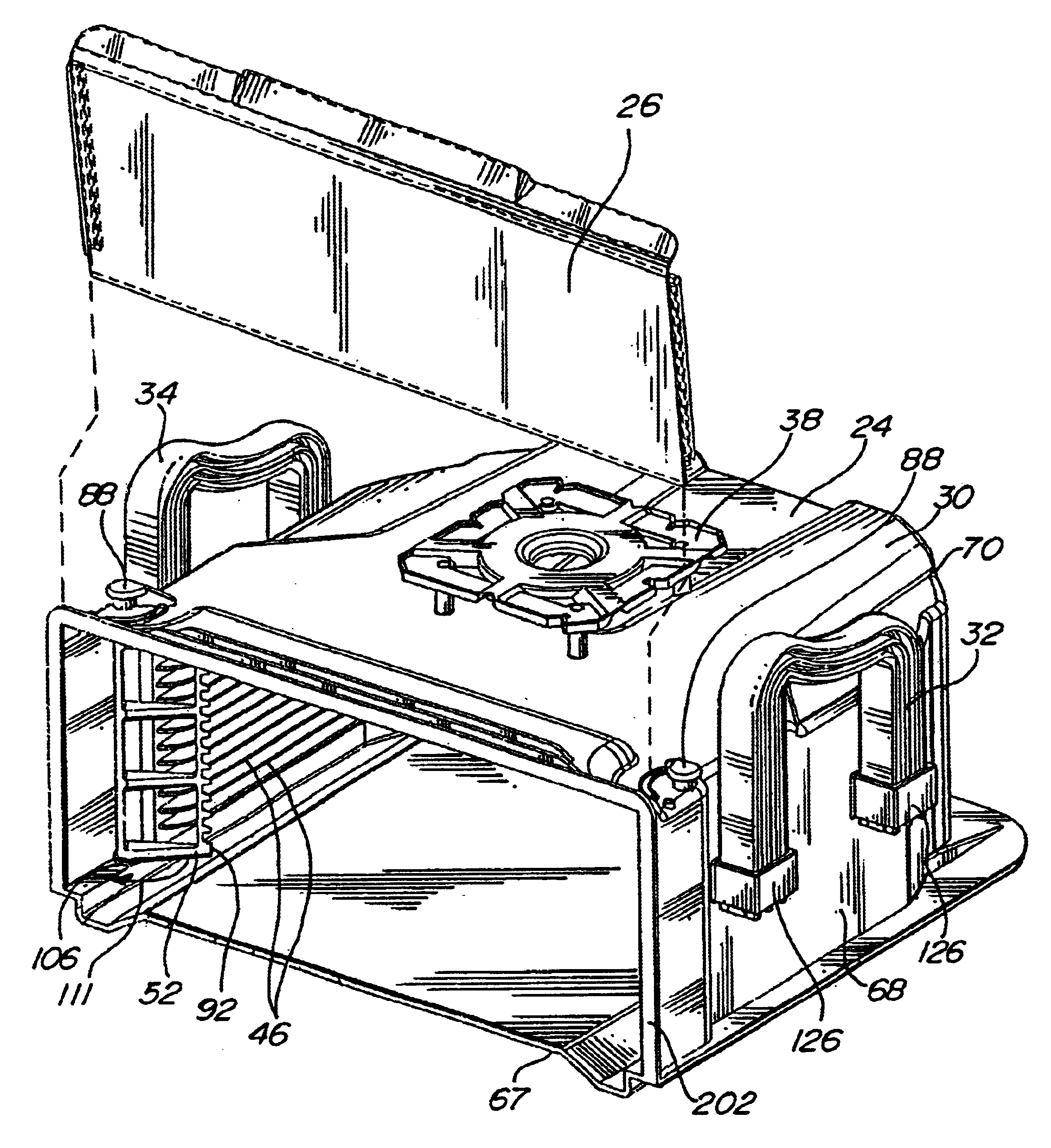

Horizontal cassette

A cassette, particularly suitable for storing film frames, in a preferred embodiment utilizes an integral shell portion with a plurality of shelves to support a plurality of axially aligned horizontally stacked film frames. A door, preferably vacuum-formed, covers the open front of the shell to enclose the film frames therein. The cassette may have a robotic top and collapsible handles. In a preferred embodiment the handles are U-shaped and slideably engaged with a pair of brackets integral with the sidewall. In another embodiment the handles pivot about an axis parallel to the top of the cassette and attach by a pair of split prongs insertable into a pair of receiving holes. A pair of film frame retention members are pivotally and rotatably attached at the sides of the shell inside the front opening. The restraints are pivotable between an open position where they are aligned with the sidewalls and pointing toward the open front to a film frame retention position where they are rotated to face inwardly in an approximately radial direction. The film frame retention members may be actuated by handles positioned on the top of the enclosure. Alternatively, the retention members may be automatically actuated by a helical cam mechanism with a engagement portion extending below the cassette to contact a surface upon which the cassette is placed. The members may be biased and spring loaded such that they remain in the retention position and / or the open position when so placed.

Owner:ENTEGRIS INC

Walking winding machine

The invention relates to a walking winding machine, which is provided with a walking mechanism, a base plate, an upright post and a film frame, wherein the film frame is arranged on the upright post, a lifting device is arranged on the base plate, the upright post is connected on the lifting device, the walking mechanism is provided with walking wheels which comprise a left wheel and a right wheel, the walking mechanism is also provided with a sensor, the sensor controls the work of a driving motor of the walking wheels positioned at the side of a rolling element, the rolling element is connected on a swinging mechanism, and the sensor induces the action of the swinging mechanism. The invention can realize the maneuvering under the driven effect by the motor, the automatic turning can be realized, and the film winding work can be completed automatically when the walking winding machine is maneuvered to the position of an object. At the same time, the upright post of the invention can be lifted. Because the upright post per se is a height orientation part, the invention can still make the film frame have a certain lifting height to be applicable to the film winding on an large-sized object under the condition that the upright post does not have the same height as the traditional upright post, and the external shape of the winding machine is more applicable to the maneuvering.

Owner:HANGZHOU YOUNGSUN INTELLIGENT EQUIP

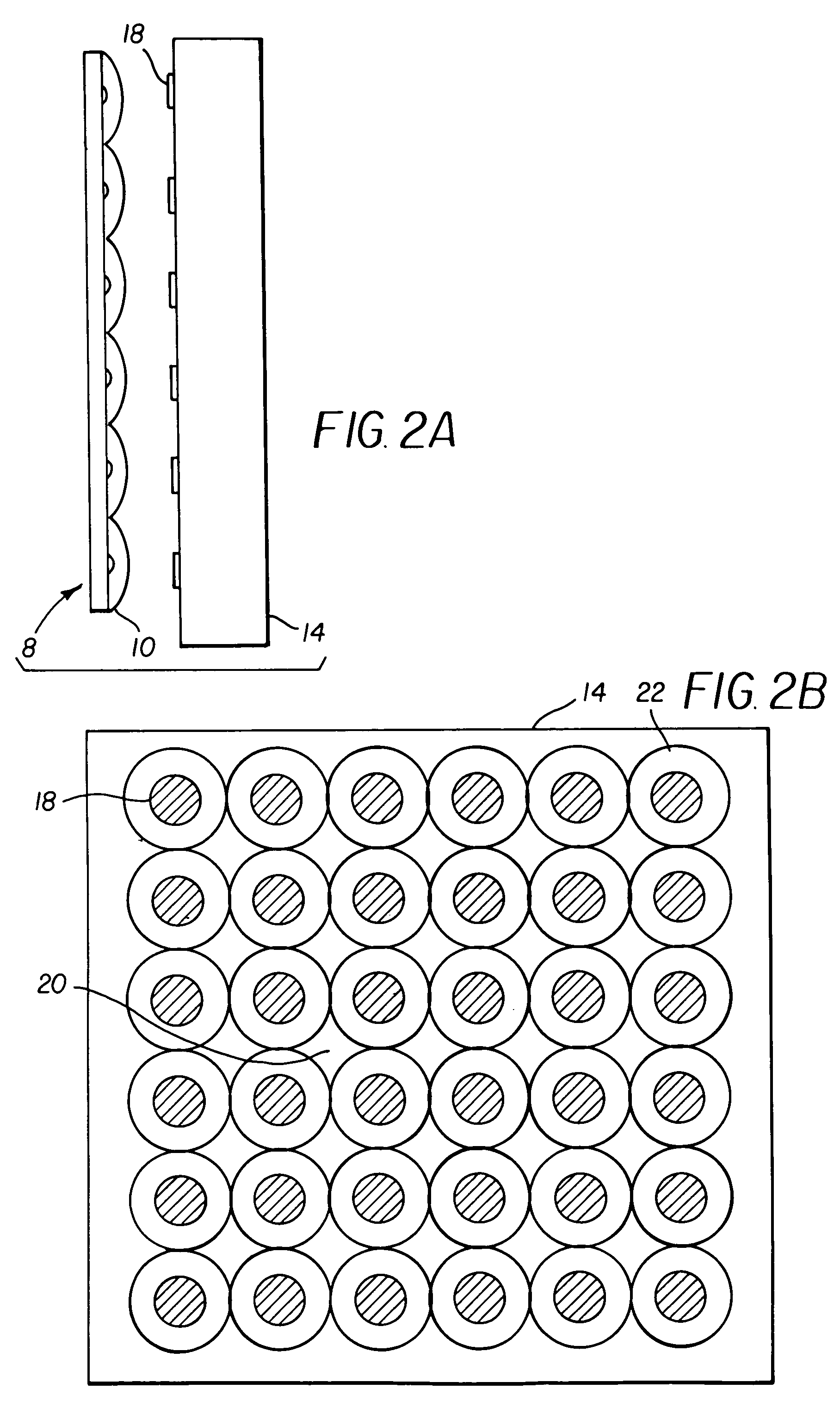

Capture of multiple interlaced images on a single film frame using micro-lenses and method of providing multiple images to customers

Cameras and methods are provided for recording more than one image on a photosensitive element. The cameras and methods record the images in the form of separate patterns of concentrated image elements. Apparatuses and methods are provided for recovering images from the concentrated image elements.

Owner:EASTMAN KODAK CO

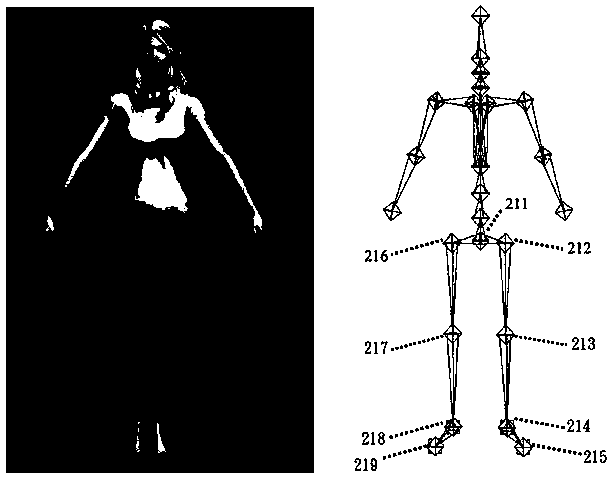

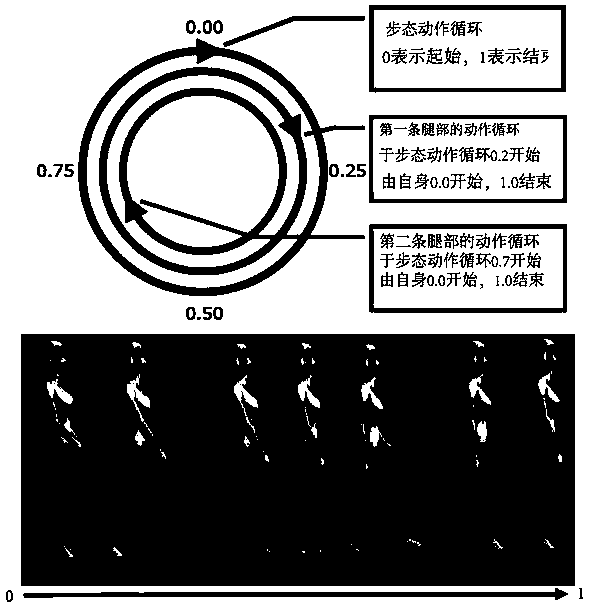

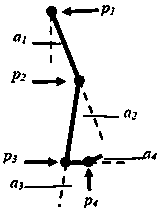

System and method for automatically adapting gait of virtual character to terrain

InactiveCN103514622ANatural and realistic simulation effectImprove the level ofAnimationTerrainProduction effect

The invention relates to a system and a method for automatically adapting the gait of a virtual character to the terrain. The system and the method use input gait action of the character as reference data, the system automatically analyze key film frames of leg motion in the gait action, and use analyzed information to automatically generate various leg motion parameter combinations required by different terrains, thereby enabling input gait action data to be suitable for various terrains, and enabling generated results of gait animation to approach referenced motion capture data as much as possible. Through the system and the method in the invention, a user can achieve the animation production effect of automatically adapting the gait to any landform in real time only by inputting a virtual character and a segment of ideal gait motion data (a motion clip) of the character without giving a walking path and information of obstacles in the virtual environment in advance.

Owner:REALLUSION

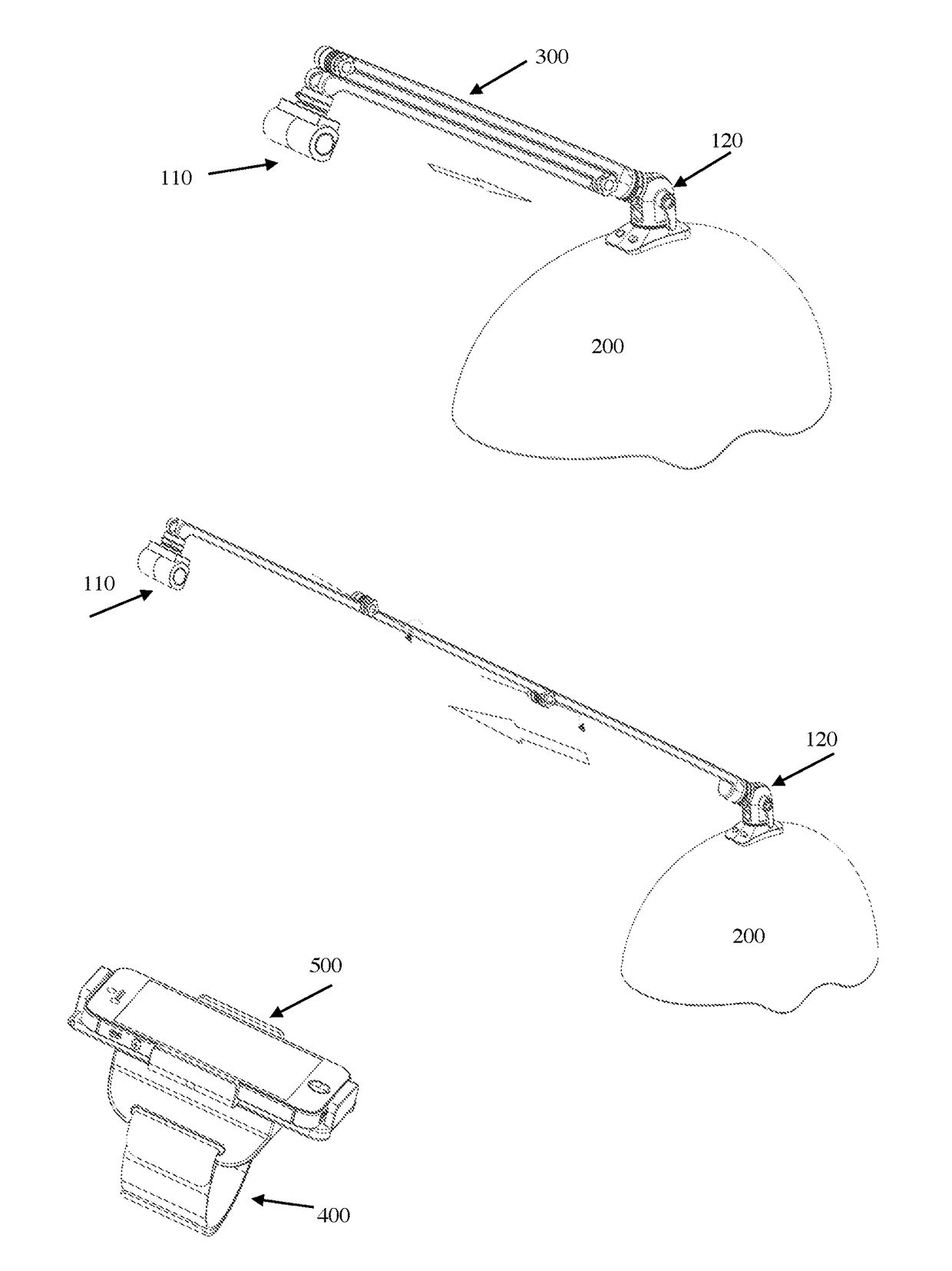

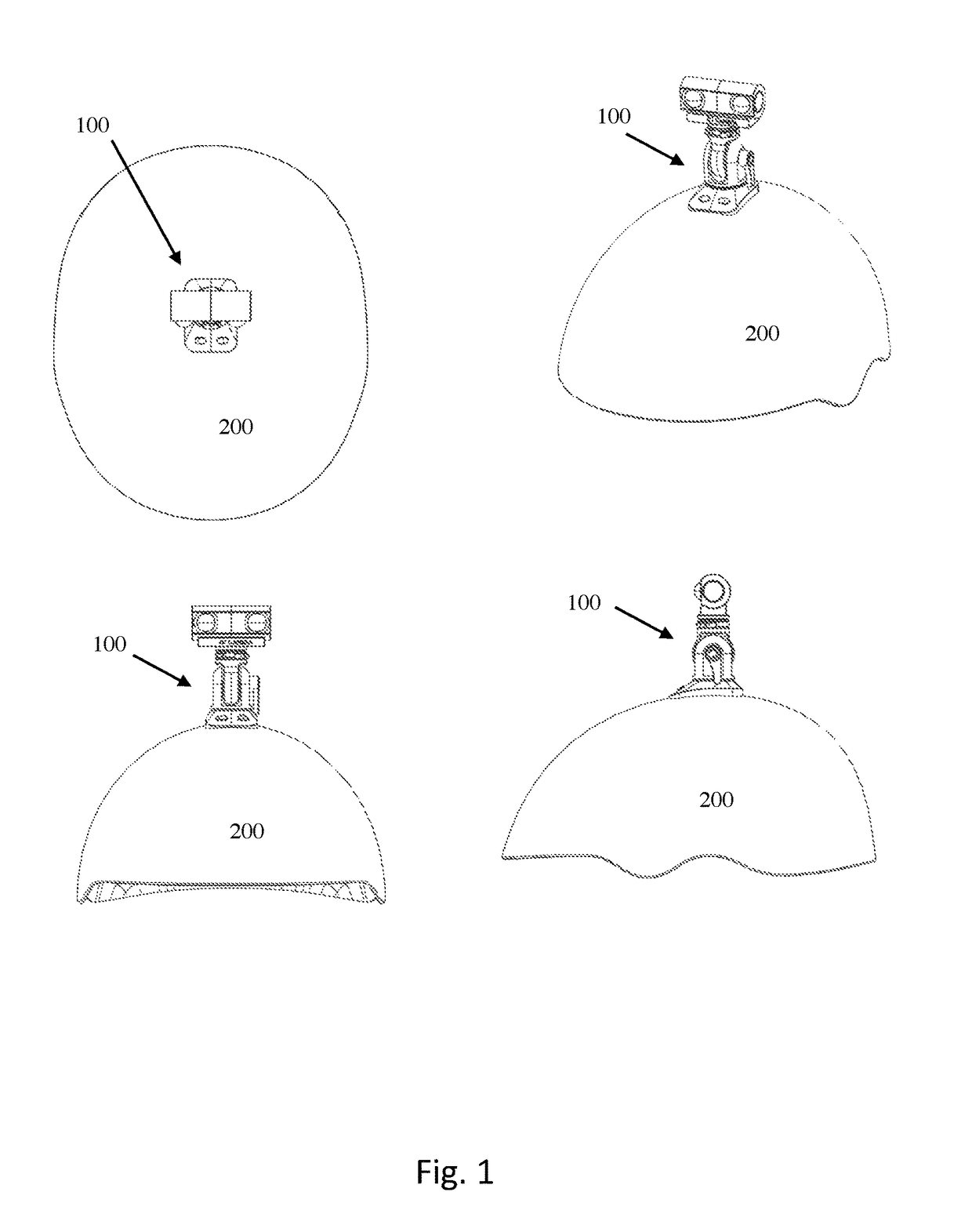

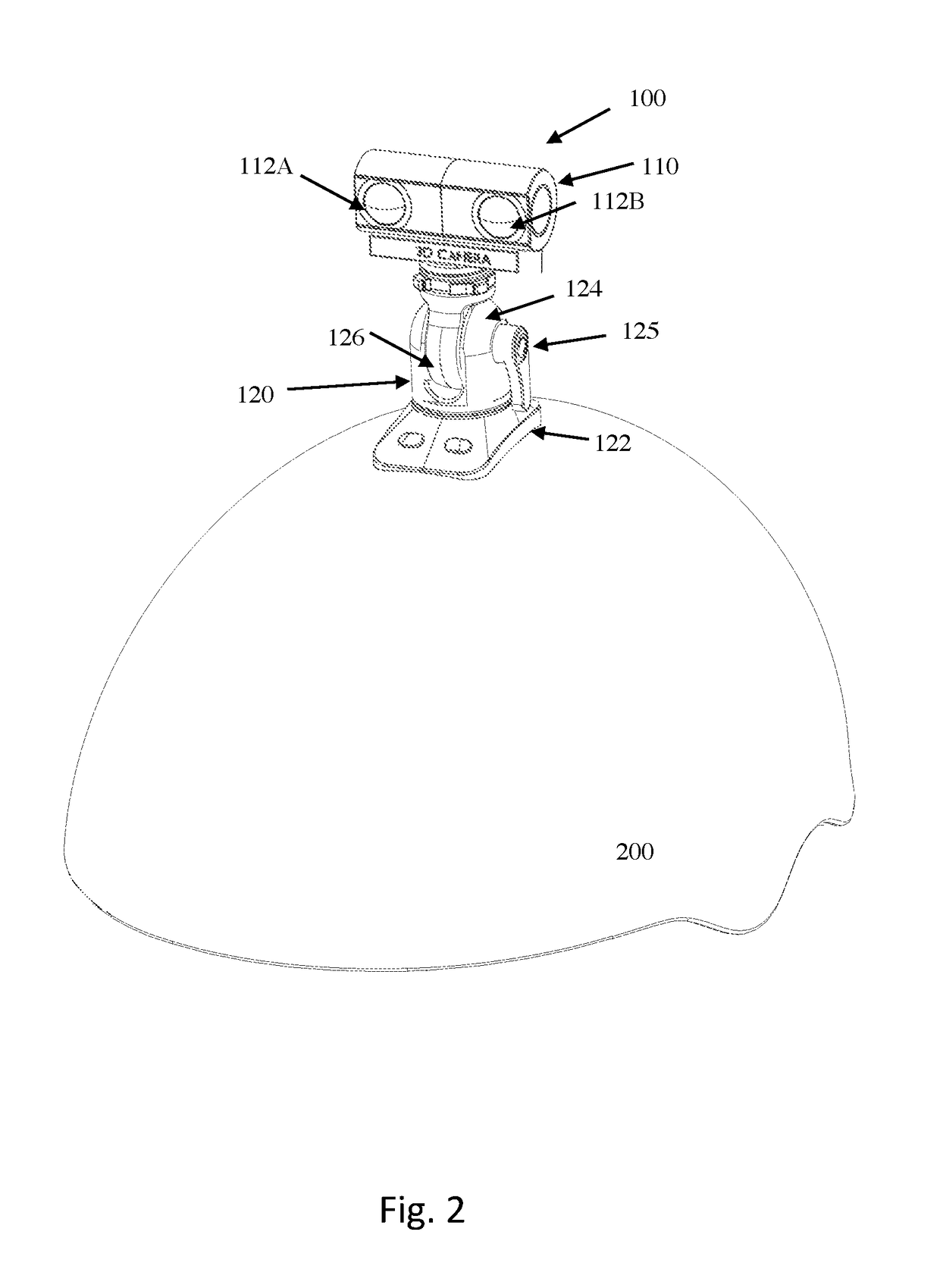

Modular action camera system

ActiveUS20180017850A1Improve battery performanceIncreased battery sizeTelevision system detailsColor television detailsCamera lensModularity

An action camera system is disclosed that comprises an action camera and a mount where the mount is configured to detachably couple the camera. The mount comprises a battery, a base, a body, and a vertical support. The base can be attached to a helmet, a harness, an armband, a board, or a ski pole. The battery powers the action camera when it is attached to the mount. The action camera comprises two lenses with a separate image sensor or film frame for each lens. The action camera may be connected to the mount via a folding extension. The action camera communicates wirelessly with a smartphone or a control device. The smartphone can be attached to an armband. A ski pole mount may comprise a computer, a display, and user interface.

Owner:PATHWAY INNOVATIONS & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com