Walking winding machine

A winding machine and traveling mechanism technology, which is applied in the directions of packaging/bundling items, packaging, and wrapping items, etc., can solve the problems of troublesome winding and packaging operations, unsuitable for maneuvering, and large size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

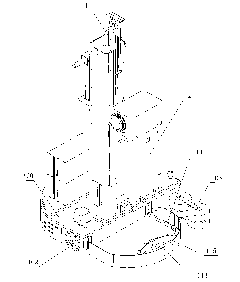

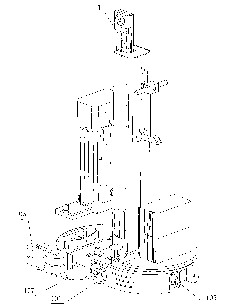

[0013] Refer to attached picture. The present invention is provided with walking mechanism, chassis 100, column 1 and membrane frame 2 installed on the column, the lifting device is installed on the chassis, the column is connected to the lifting device, and the winding machine is also provided with a guide for lifting the column device;

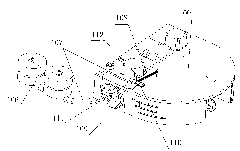

[0014] Described traveling mechanism is provided with traveling wheel, and described traveling wheel comprises left wheel 101 and right wheel 102, and described traveling mechanism is respectively provided with the driving motor 103,104 of left wheel and right wheel, and described traveling mechanism is also provided with universal rear wheel 105;

[0015] Described walking mechanism is also provided with the automatic switching mechanism of driving motor 103 or driving motor 104, makes the driving motor of left wheel or right wheel turn off or decelerates, and described automatic switching mechanism controls the driving motor of left wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com