Continuous production device and method for glass fiber reinforced belt polyethylene composite pipe

A polyethylene composite pipe and production device technology, applied in the field of plastic pipes, can solve the problems of not having the continuous winding function of the reinforcing layer, the inability to realize continuous online production of the inner pipe, and the inability to realize continuous production, etc., and achieve a scientific and reasonable production method principle, Low production cost and environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

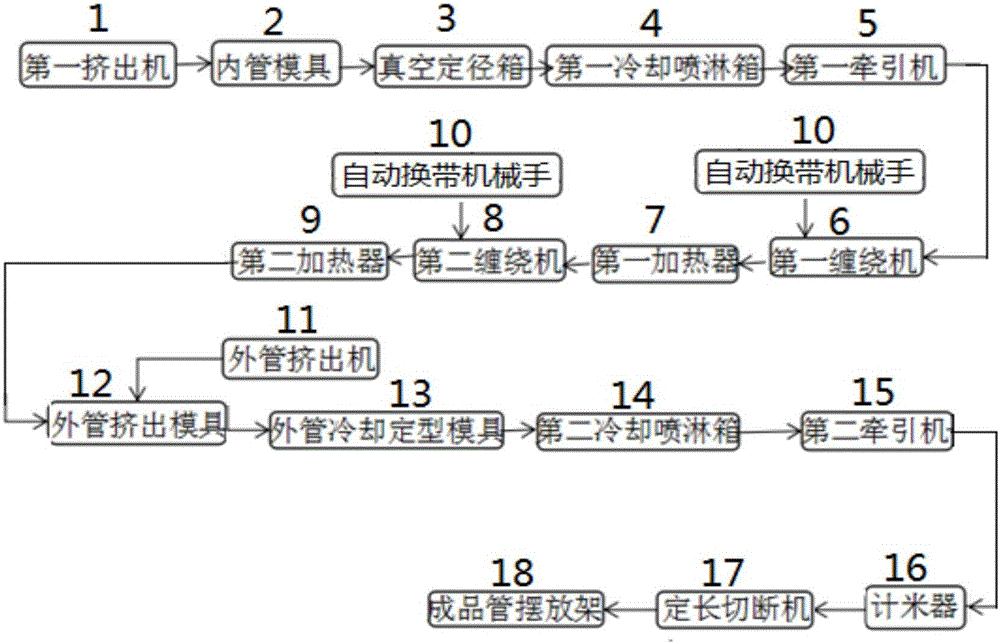

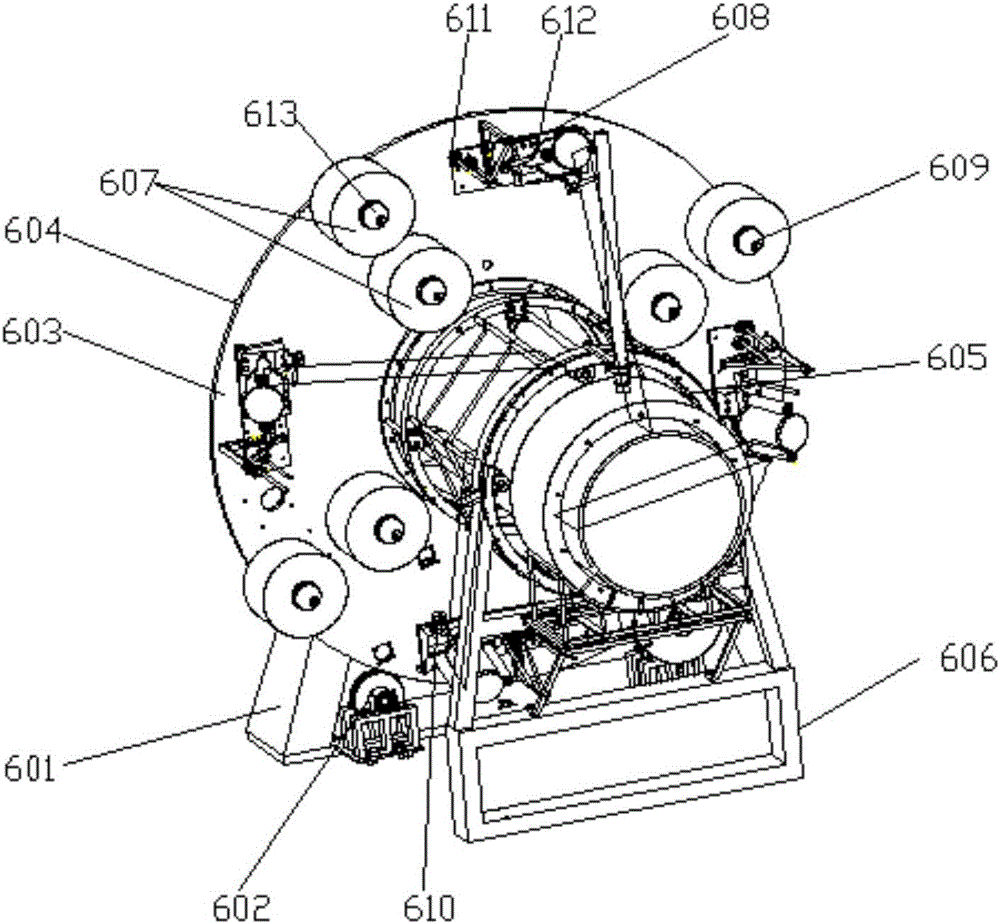

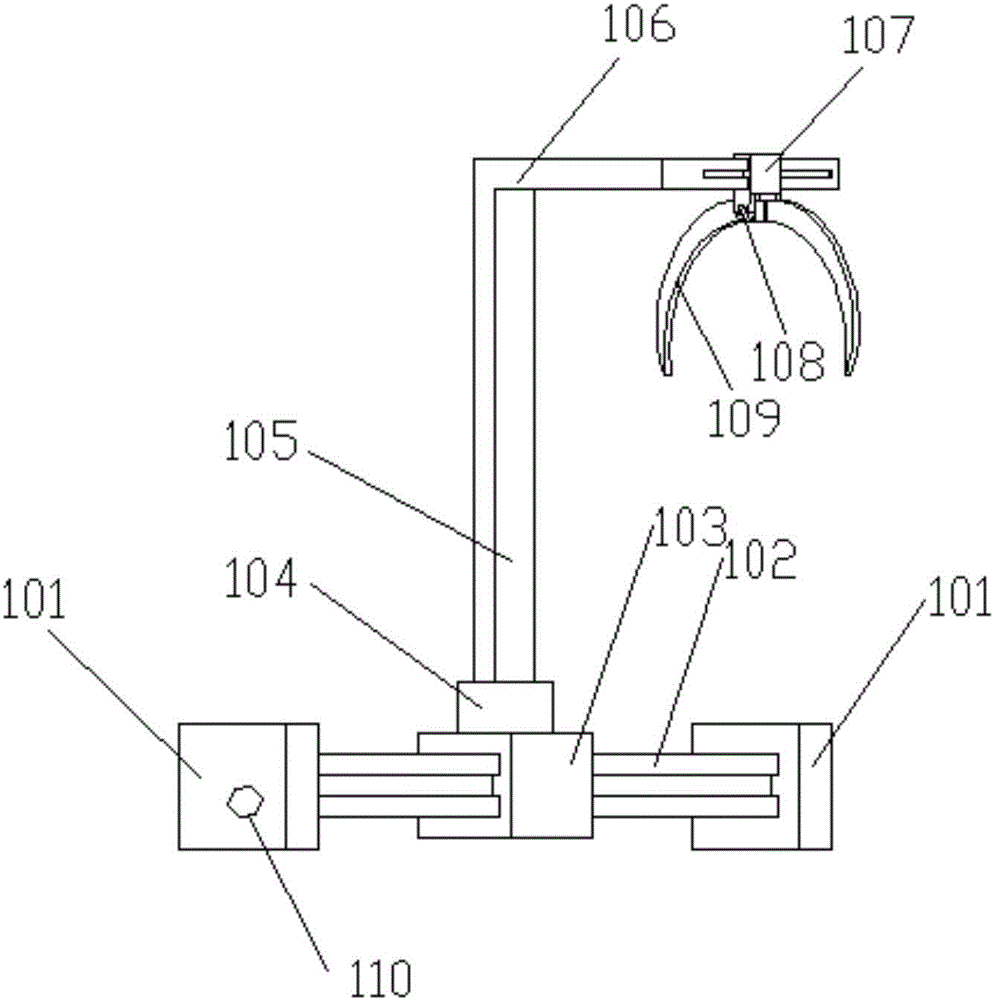

[0022] The main structure of the glass fiber reinforced polyethylene composite pipe continuous production device involved in this embodiment includes a first extruder 1, an inner pipe mold 2, a vacuum sizing box 3, a first cooling spray box 4, and a first traction machine. Machine 5, first winding machine 6, first heater 7, second winding machine 8, second heater 9, automatic belt changing manipulator 10, outer tube extruder 11, outer tube extrusion die 12, outer tube cooling The shaping mold 13, the second cooling spray box 14, the second tractor 15, the meter counter 16, the fixed length cutting machine 17 and the finished pipe placing rack 18; between the inner pipe mold 2 and the vacuum sizing box 3, vacuum Between the sizing box 3 and the first cooling spray box 4, between the first cooling spray box 4 and the first tractor 5, between the first tractor 5 and the first winding machine 6, the first winding machine 6 Between the first heater 7, the first heater 7 and the seco...

Embodiment 2

[0028] The process of the continuous production method of the glass fiber reinforced polyethylene composite pipe involved in this embodiment includes four steps: inner pipe extrusion molding, composite tape continuous winding, outer pipe extrusion coating, and cutting and warehousing:

[0029] (1) Extrusion molding of inner tube: The first extruder 1 is a JWS75 / 33 high-efficiency single-screw extruder. The temperature of the first extruder 1 in the 4 heating zones is 100℃, 130℃, 150℃ and Extrude the inner tube at 170℃, the die temperature is 170℃, and the inner tube extrusion speed is 1m / min. The outer diameter of the inner tube is 105.4mm. The inner tube passes through the forming of the inner tube mold 2 and the vacuum sizing box. The sizing of 3 and the cooling and shaping of the first cooling spray box 4 enter the first winding machine 6 under the traction of the first tractor 5. The traction speed of the first tractor 5 is the same as that of the first extruder 1 and the inne...

Embodiment 3

[0035] The process of the continuous production method of the glass fiber reinforced polyethylene composite pipe involved in this embodiment includes four steps: inner pipe extrusion molding, composite tape continuous winding, outer pipe extrusion coating, and cutting and warehousing:

[0036] (1) Extrusion molding of inner tube: The first extruder 1 is a JWS120 / 33 high-efficiency single-screw extruder. The temperature of the first extruder 1 in the 4 heating zones is 100℃, 130℃, 150℃ and Extrude the inner tube at 170℃, the die temperature is 170℃, the inner tube extrusion speed is 0.5m / min, the outer diameter of the inner tube is 273.6mm, the inner tube is formed by the inner tube mold 2 and vacuum sizing in turn The sizing of the box 3 and the cooling and shaping of the first cooling spray box 4 enter the first winding machine 6 under the traction of the first tractor 5. The traction speed of the first tractor 5 is the same as that of the first extruder 1 and the inner The spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com