Patents

Literature

831results about How to "Avoid stratification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

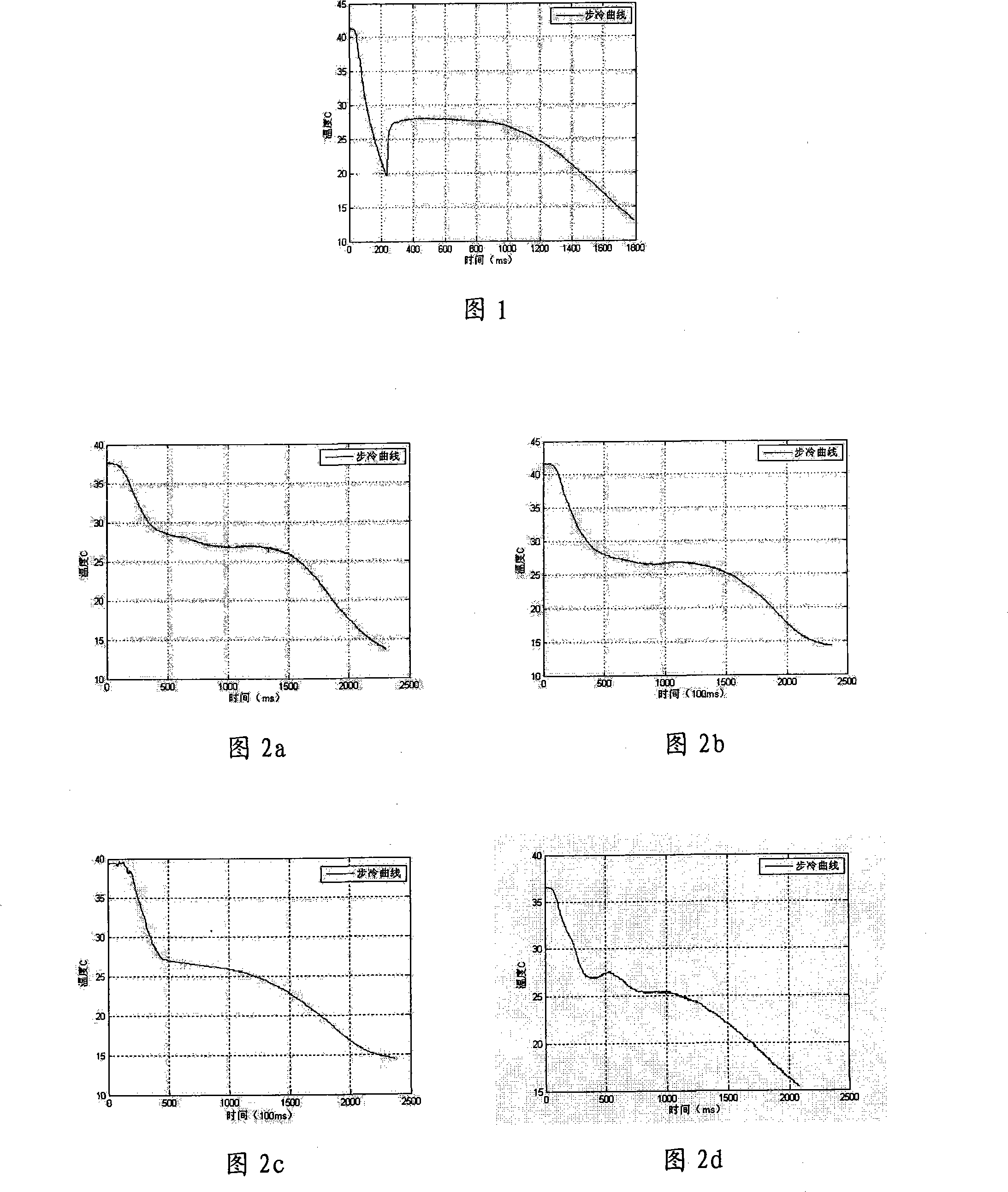

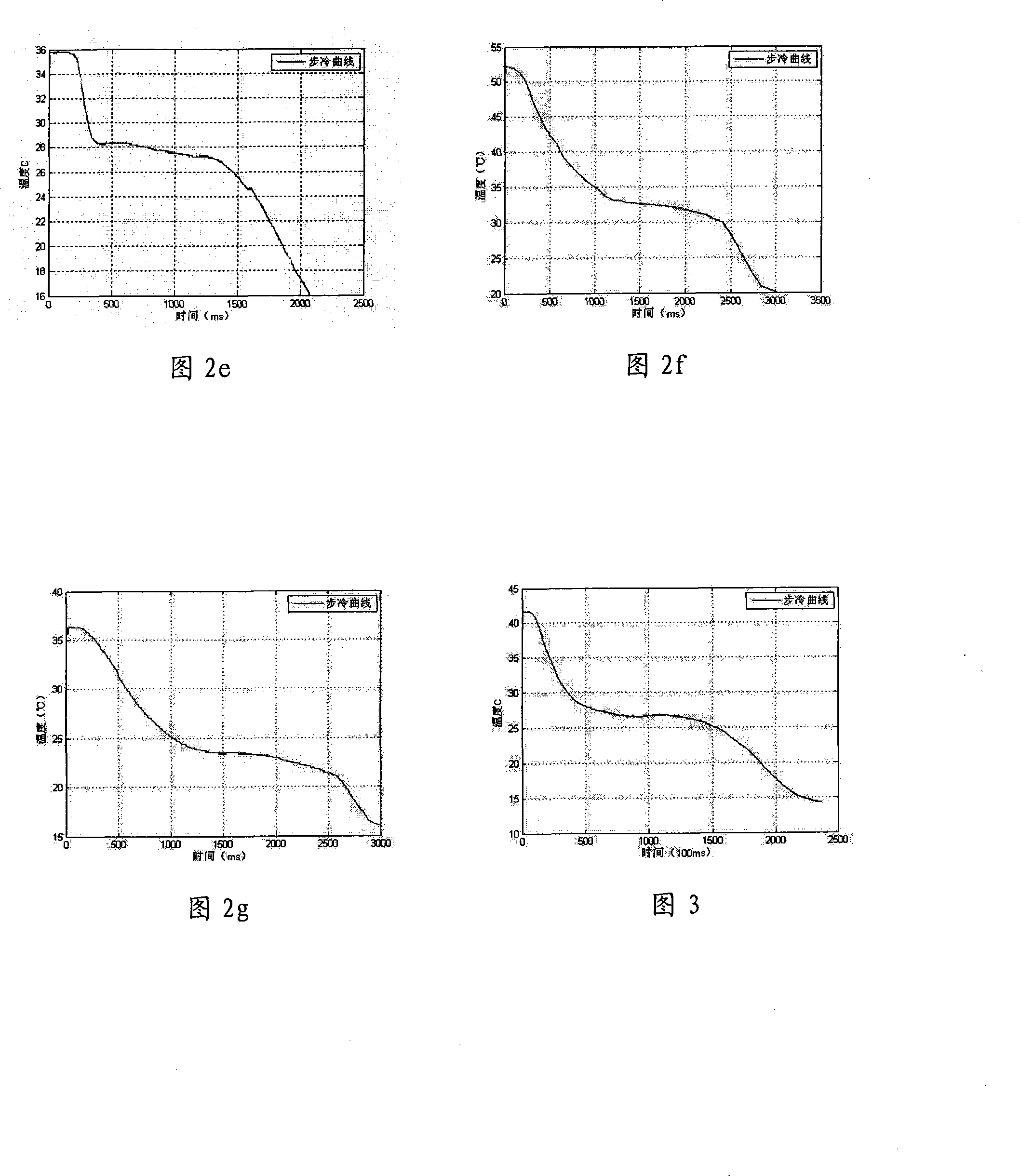

Method for preparing inorganic hydrous salt phase transition energy-storing material

ActiveCN101235272APrevent overcoolingAvoid separabilityHeat-exchange elementsInorganic saltsPhase change

The invention discloses a preparation process of inorganic salt hydrate phase-change energy-storage material, comprises the following steps that adding 40-60g inorganic salt particles and 3-5g overcooling- resistance agent in 100g water, stirring and mixing to prepare hydrating inorganic salt solution, adding 5-10g poly-sodium acrylate in the hydrating inorganic salt solution, and stirring and mixing to prepare viscous hydrating inorganic salt mixed solution. The preparation process of hydrating inorganic salt phase-change material which is provided by the invention is added with overcooling- resistance agent and poly-sodium acrylate in the preparation process, which can effectively avoid the hydrating inorganic salt phase-change material from generating the phenomenon of over-cooling and phase separation in the phase change process, and ensures hydrating inorganic salt phase-change material to keep uniformity after repeated circulating.

Owner:SHENZHEN INST OF ADVANCED TECH

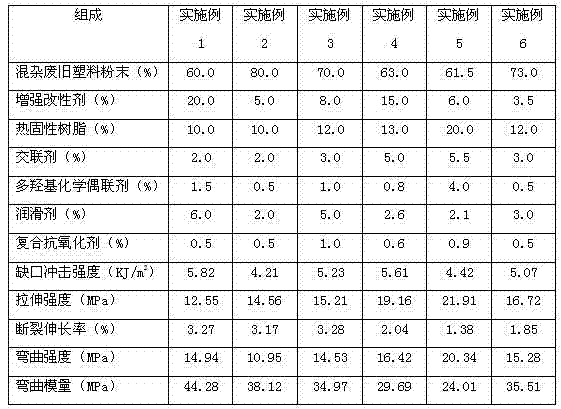

Composite board based on mixed waste polymers and preparation method thereof

The present invention discloses a composite board based on mixed waste polymers and a preparation method thereof. The preparation method of the composite board based on the mixed waste polymers is characterized by comprising the following steps of: (1) weighing the raw materials according to a certain proportion, adding the raw materials to a high-speed mixer, mixing at the temperature of 40-60 DEG C and the rotation speed of 800-2000 rpm for 20-30 minutes, cooling to room temperature and discharging; and (2) adding the mixed material to a mold, vulcanizing at the temperature of 150-180 DEG C and the pressure of 10-15 MPa for 10-20 minutes, cooling and relieving pressure. The composite board based on the mixed waste polymers provided by the invention does not need to consider the complex compatibility and plasticizing problems of multiple polymers, effectively solves the problems that the existing mixed waste polymers can not be classified and are discarded, and can be used as the substitute for wood to be applied in the tray manufacturing field and other fields. The production process provided by the invention is simple, uses existing equipment and is suitable for mass production.

Owner:佛山市南海承骏科技有限公司 +1

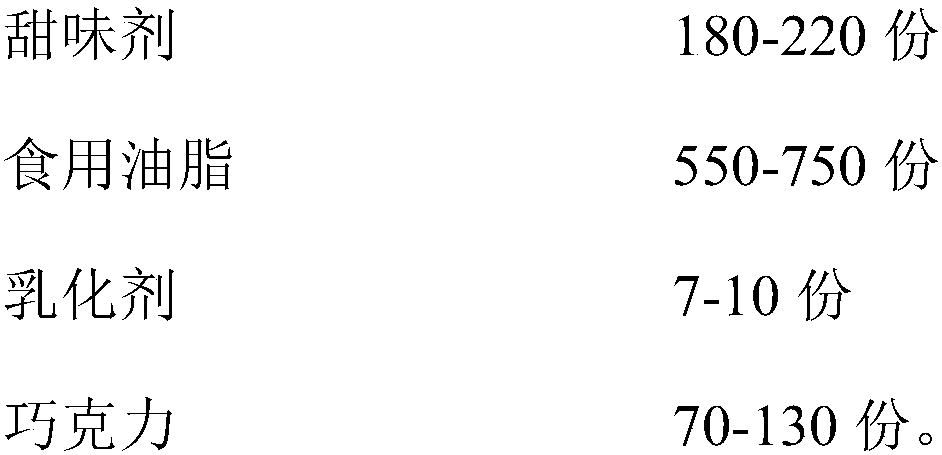

Chocolate composition, coating layer and preparation method thereof and frozen drink coated with the coating layer

The present invention discloses a chocolate composition, a coating layer and a preparation method thereof and frozen drink coated with the coating layer. The chocolate composition is prepared by a combined use of oil and an emulsifier at a specific ratio, reduces viscosity, improves fluidity of slurry, finally improves uniformity of coating of the chocolate coating layer, can flexibly adjust thickness of the chocolate coating layer, can prepare the chocolate coating layer of 2 mm or more, and can also prepare the chocolate coating layer with the thickness of 1 mm or less. At the same time, through combined cooperation and synergistic effects of a sweetener, edible oil, an emulsifier and chocolate at a specific ratio, the preparation method also avoids problems of cracking, material discharging and waxing feeling problems caused by too thin thickness of the chocolate coating layer, improves coating effects of the chocolate coating layer, and also improves taste and mouthfeel of the chocolate coating layer.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

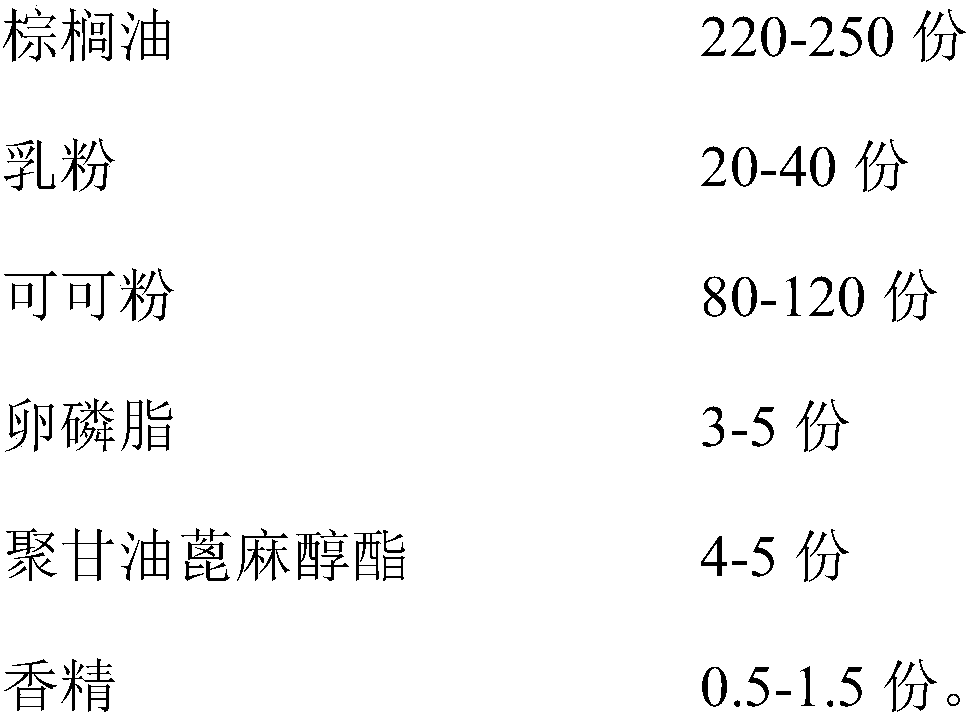

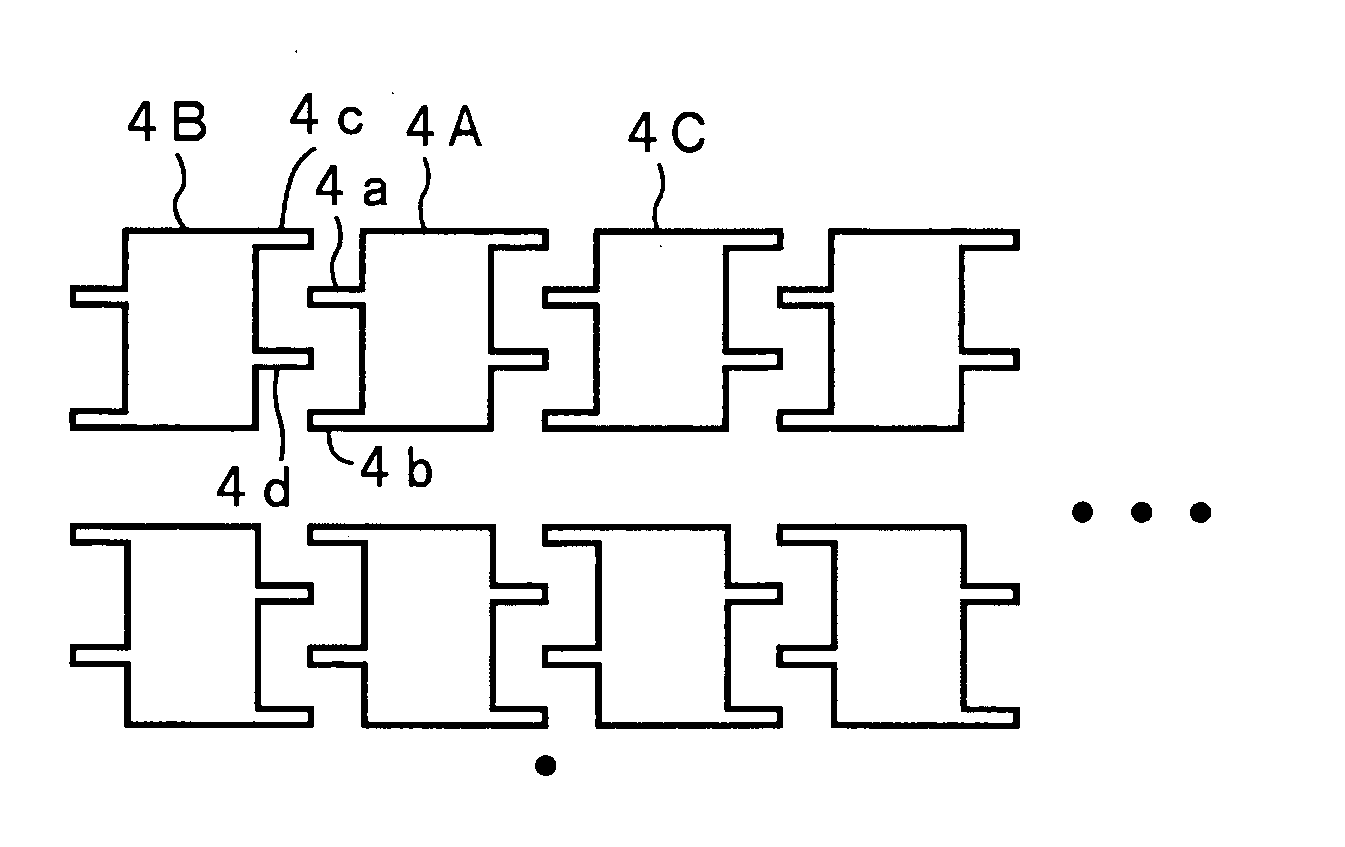

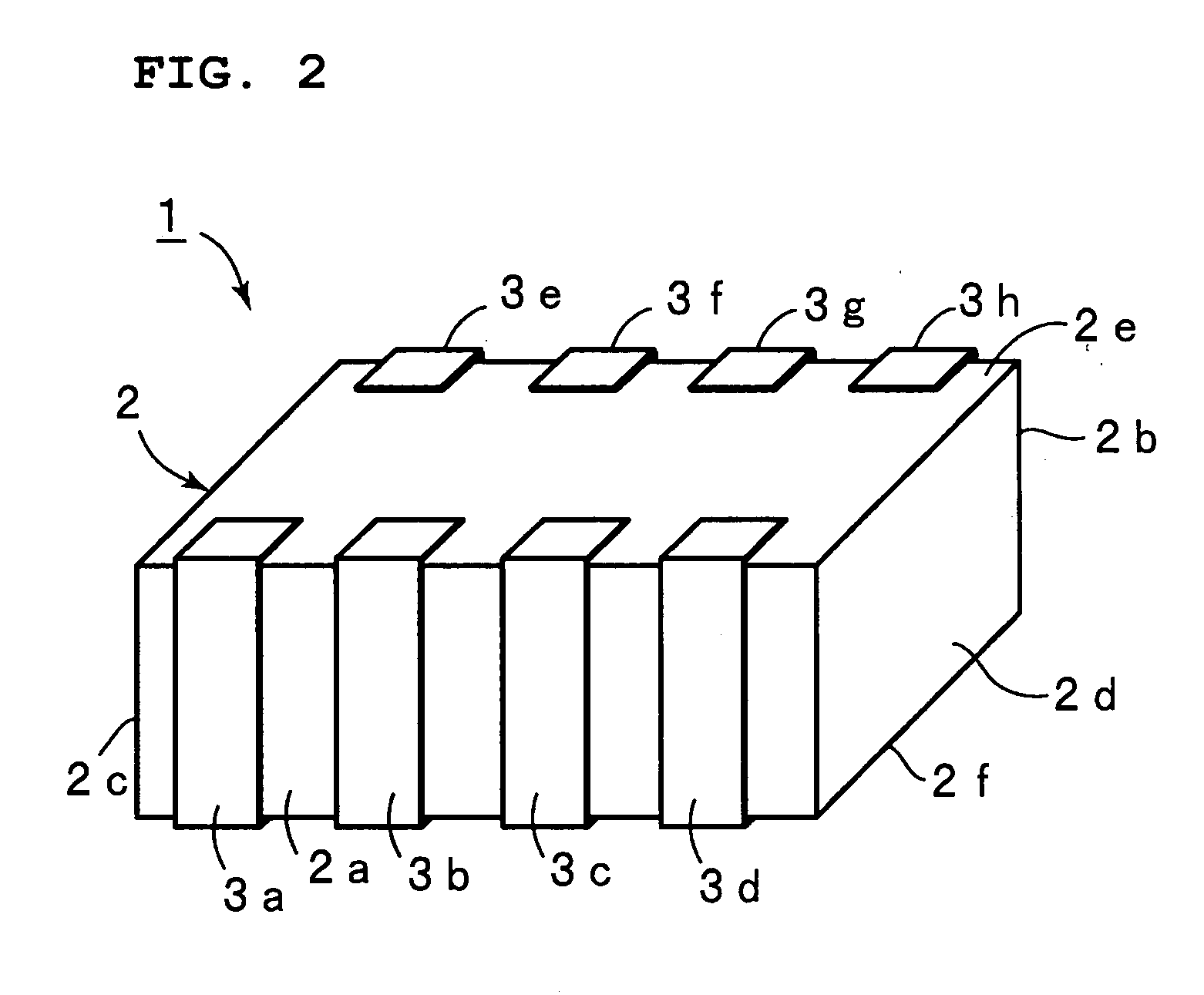

Method of producing multi-terminal type laminated ceramic electronic component

ActiveUS20050067086A1Improve accuracyImprove printing accuracyMultiple fixed capacitorsFixed capacitor dielectricElectronic componentMaterials science

In a method of producing a multi-terminal type laminated ceramic electronic component in which internal electrodes are embedded in a sintered ceramic member, and the internal electrodes have plural first lead-out electrodes led out to a first side surface and plural second lead-out electrodes led out to a second side surface, the plural second lead-out electrodes of one of the adjacent internal electrodes in each internal electrode pattern are not continuous with the plural first lead-out electrodes of the other of the adjacent internal electrodes, and the plural second lead-out electrodes and the plural first lead-out electrodes are alternately arranged in a direction that is substantially perpendicular to the direction of a line connecting the first and second side surfaces.

Owner:MURATA MFG CO LTD

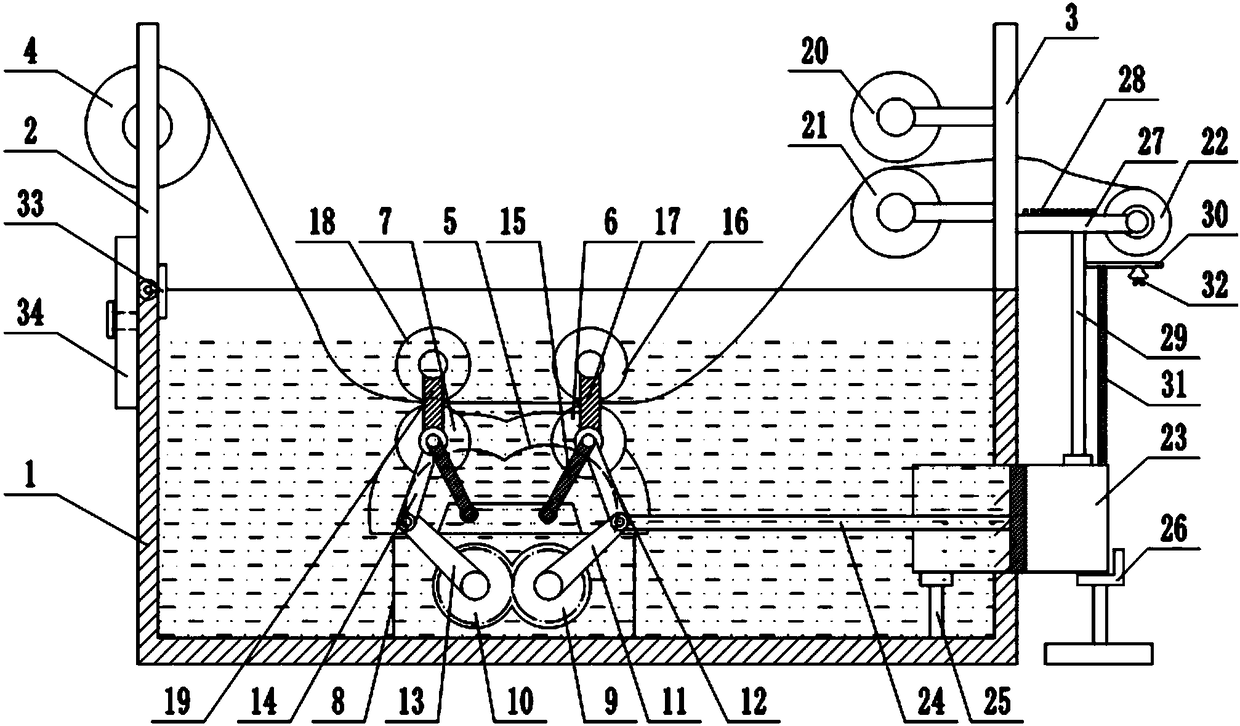

Cloth dyeing equipment

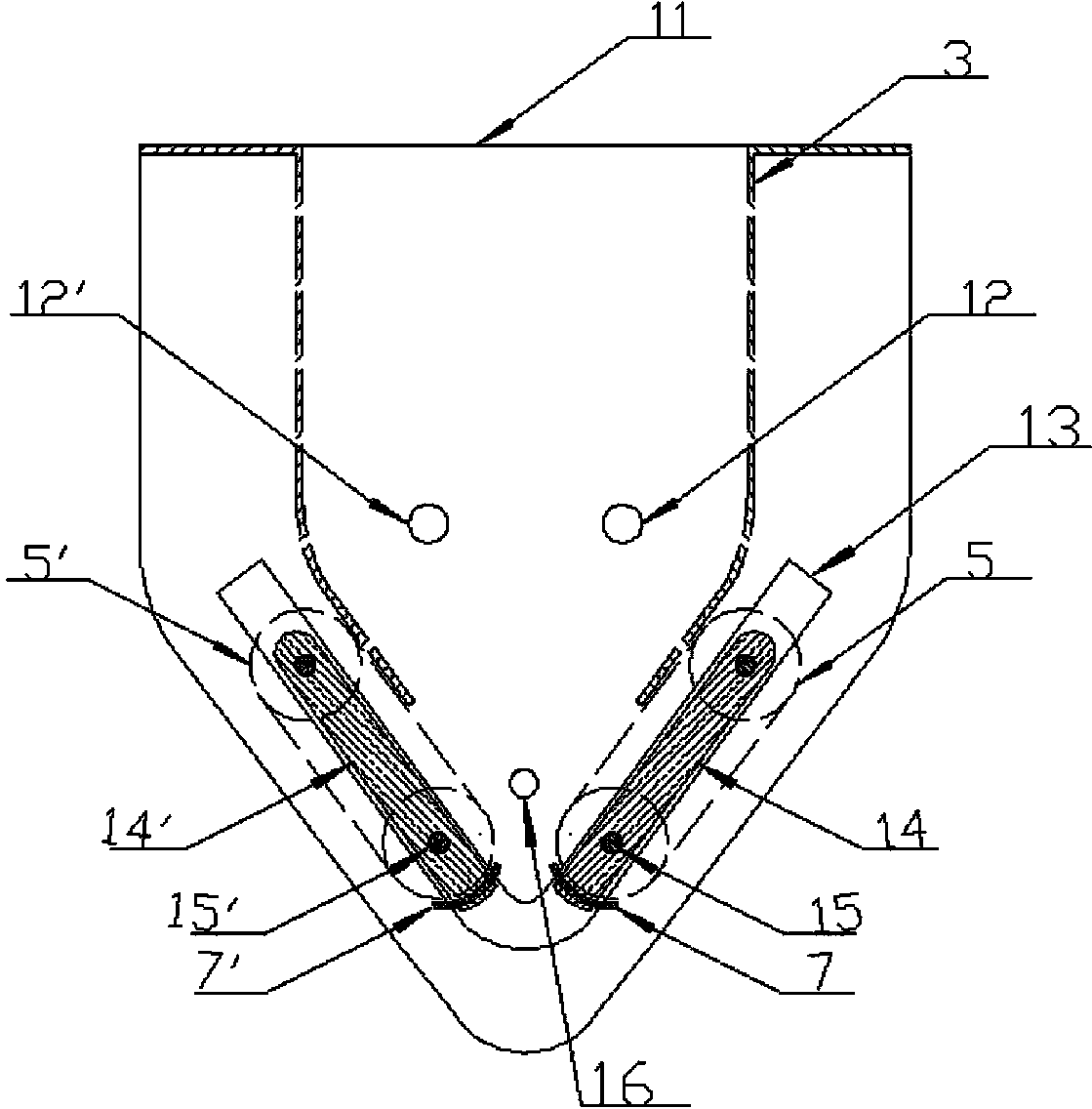

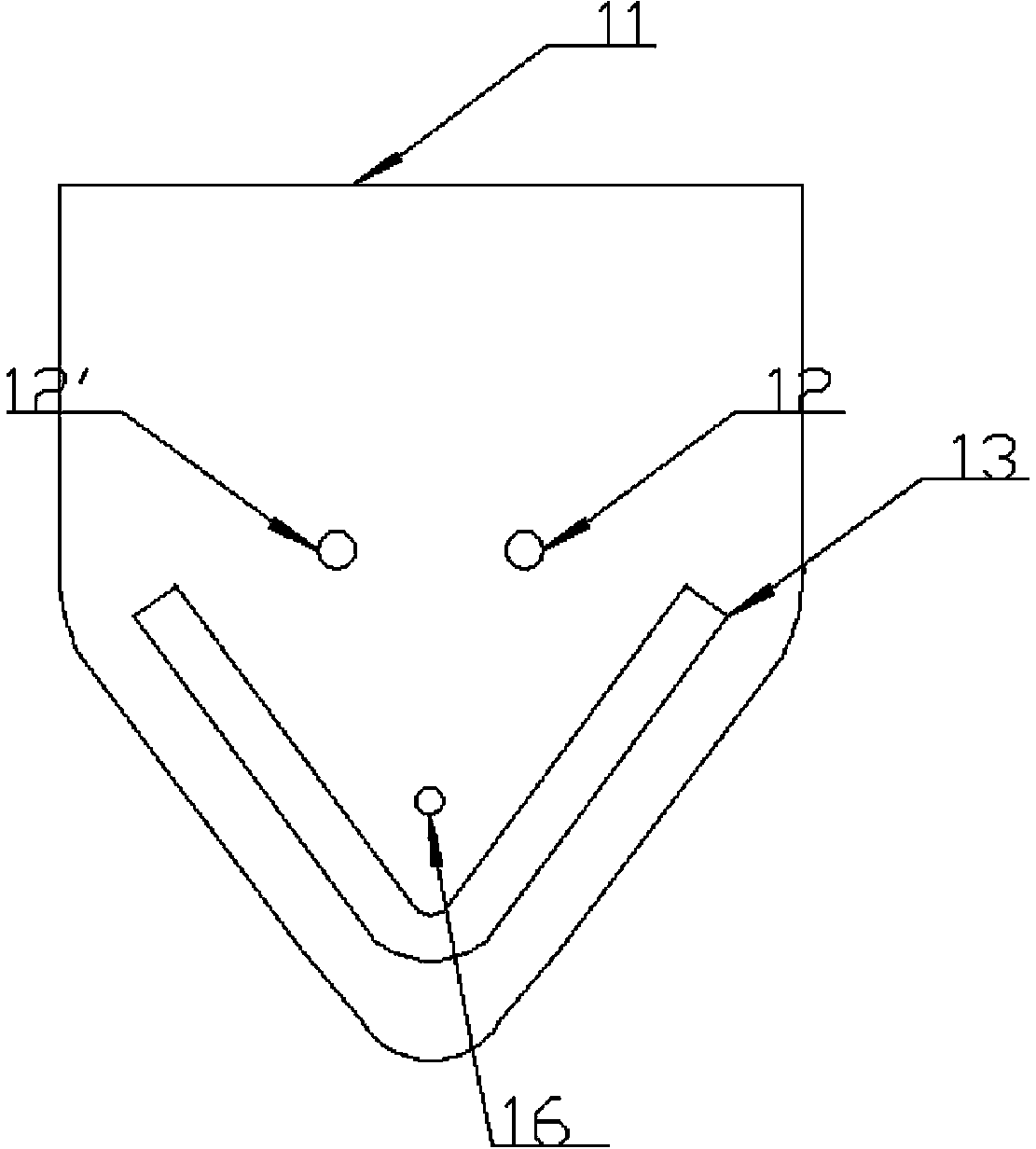

PendingCN108517634AAvoid the problem of uneven dyeingSpeed up dippingLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsDyeingEngineering

The invention relates to cloth processing field and discloses cloth dyeing equipment. The cloth dyeing equipment comprises a dyeing tank, wherein a first support rod is rotationally connected to one side of the dyeing tank, a second support rod is fixedly connected to the other side of the dyeing tank, a feeding roll is rotationally connected to the first support rod, and a first transfer roll anda second transfer roll are movably connected to the inner wall of the dyeing tank; a driving gear and a driven gear are rotationally connected to the inner wall of the dyeing tank, the driven gear ismeshed with the driving gear, a driving rod is fixedly connected to the driving gear, a first connecting rod is rotationally connected to a free end of the driving rod, and a free end of the first connecting rod is rotationally connected to the first transfer roll; a driven rod is fixedly connected to the driven gear, a second connecting rod is rotationally connected to a free end of the driven rod, and a free end of the second connecting rod is rotationally connected to the second transfer roll; and a discharging roll is rotationally connected to one side of the second support rod, an air cylinder is fixedly connected to the side wall of the dyeing tank, and a piston rod of the air cylinder is rotationally connected to the driving rod. According to the cloth dyeing equipment, the problemthat the stacked cloth cannot be uniformly dyed by virtue of an existing dyeing machine during the dip dyeing is solved.

Owner:重庆曹浩思瑗电子商务有限公司

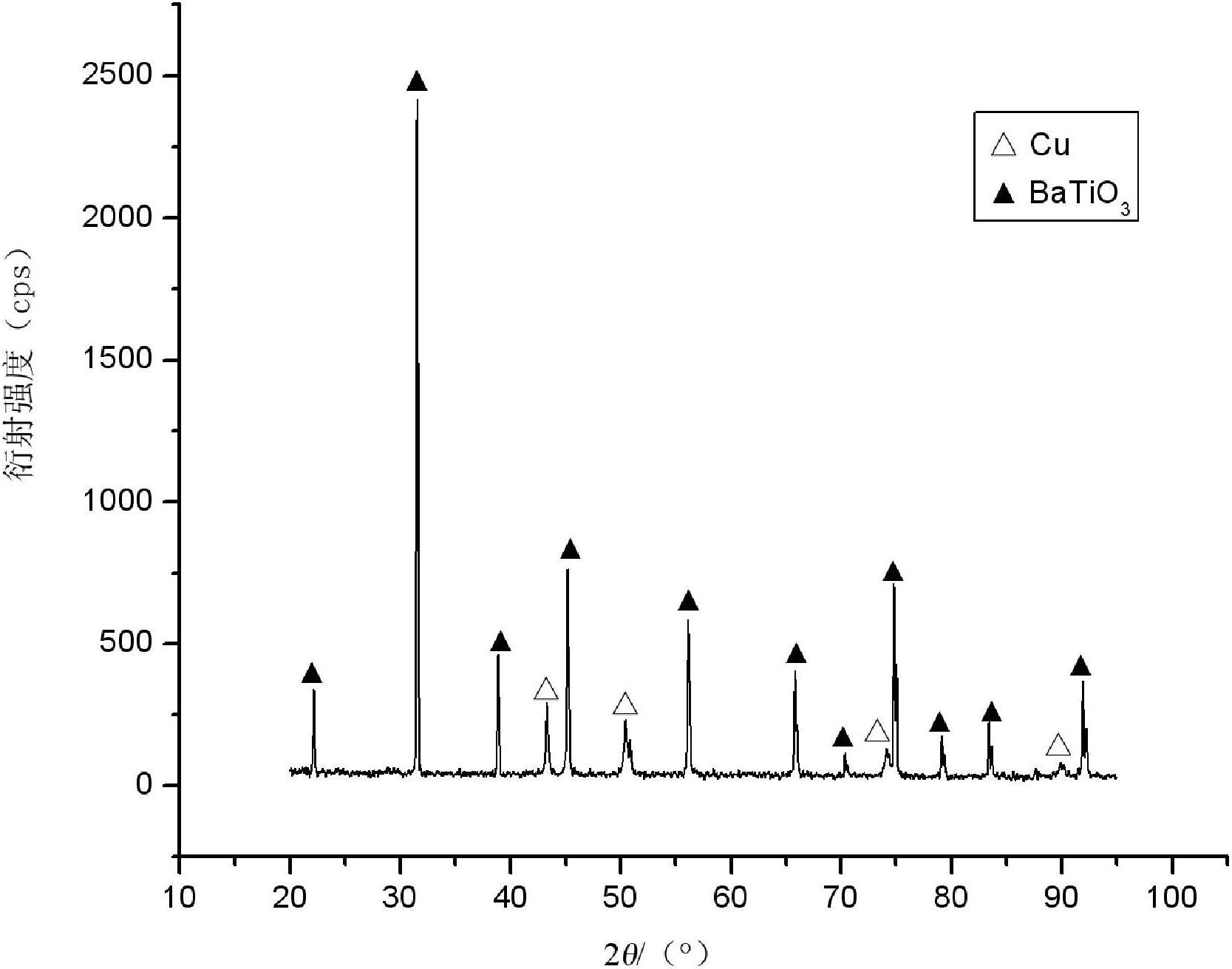

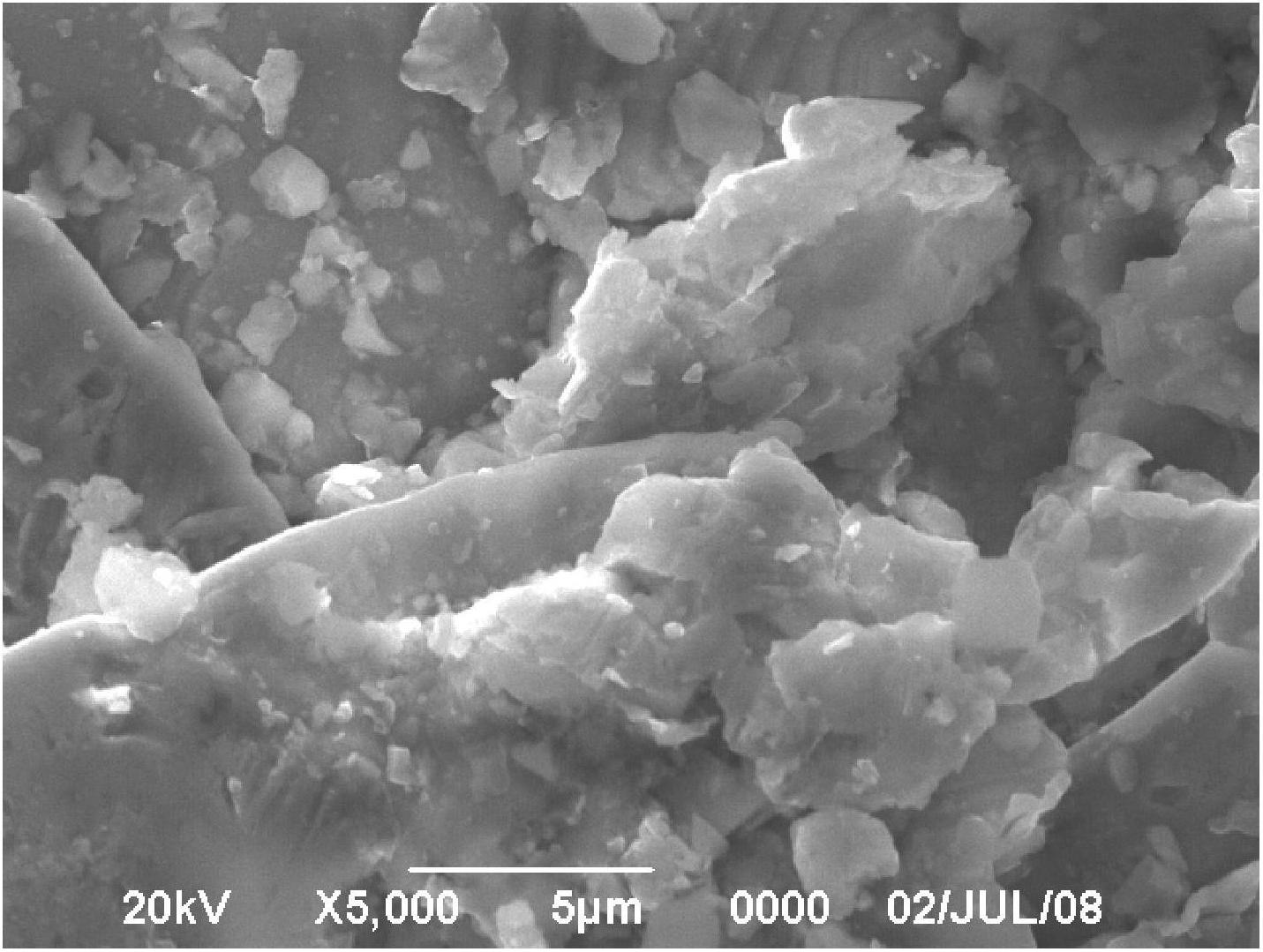

Conductive copper paste for surface electrodes of chip ceramic capacitor and preparation method thereof

InactiveCN102664057AMeet technical requirementsImprove liquidityFixed capacitor electrodesNon-conductive material with dispersed conductive materialScreen printingSilver paste

The invention discloses conductive copper paste for surface electrodes of a chip ceramic capacitor. The conductive copper paste comprises the following raw materials in percentage by mass: 65 to 72 percent of metal powder, 4 to 7 percent of glass powder and 24 to 30 percent of organic binder, wherein the metal powder consists of Cu and W or Cu and Mo; the glass powder consists of CaO, ZnO, Bi2O3, BaO, SiO2, B2O3 and Al2O3; and the organic binder consists of solvent, ethyl cellulose, silane coupling agent and surfactant. The conductive copper paste is printed through silk screens and sintered under the protection of N2 gas, the performance of the obtained finished product of the chip ceramic capacitor can completely meet the technical requirements of the ceramic capacitor, and the conductive copper paste can be used for replacing conductive silver paste on the surface of the corresponding chip ceramic capacitor.

Owner:HEFEI UNIV OF TECH

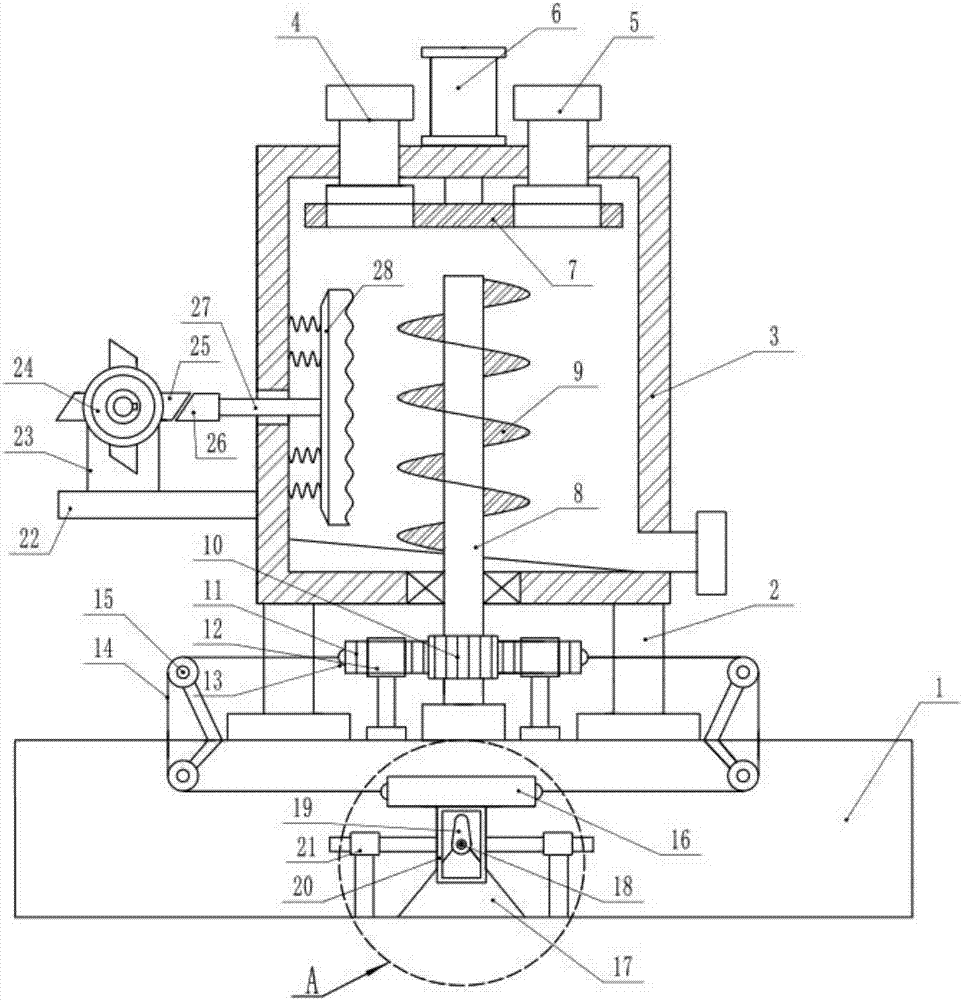

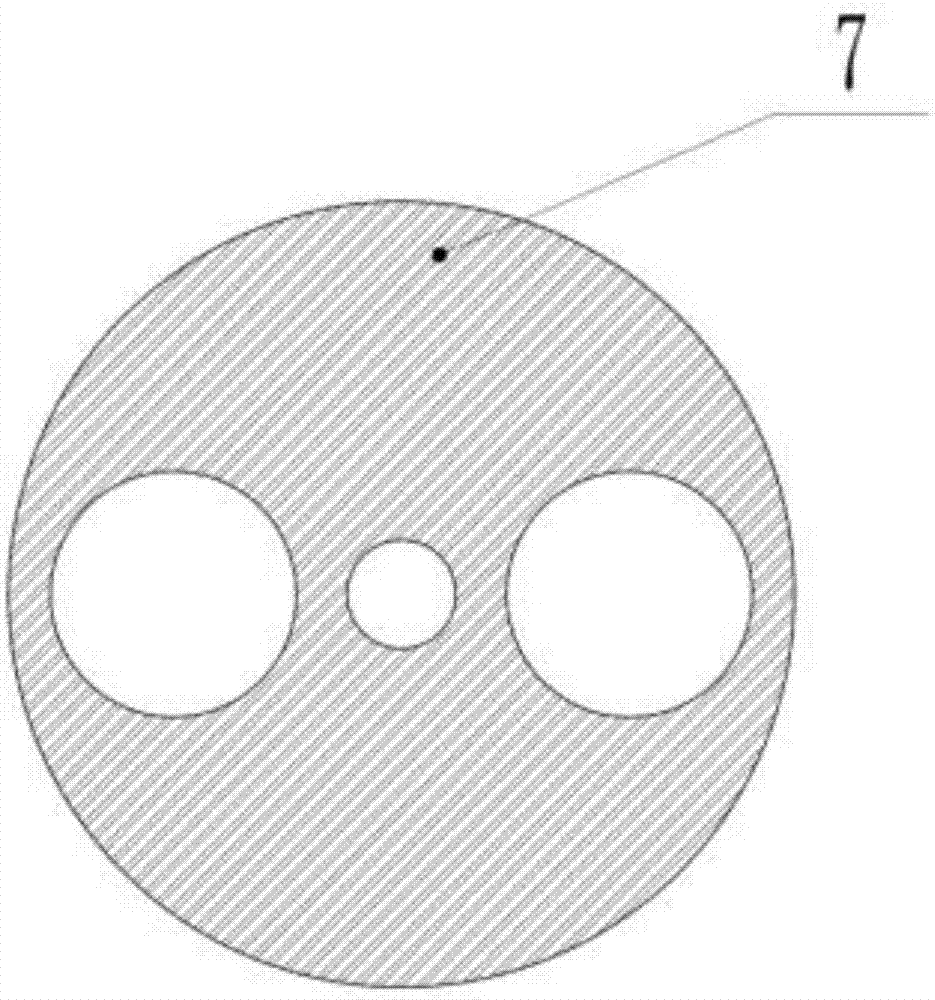

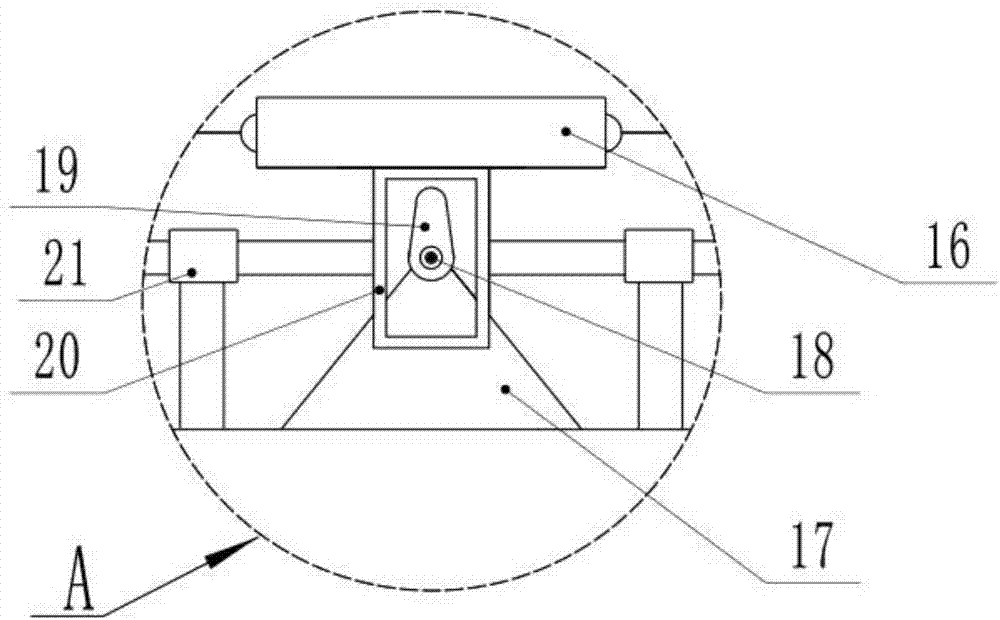

Device for quantitatively mixing double chemical liquid reagents

PendingCN107511100ARealize interval feedingChange direction of agitationMixing methodsTransportation and packagingGear wheelDrive motor

The invention discloses a device for quantitatively mixing double chemical liquid reagents. The device comprises a mixing box, a material adding motor, a feeding turnplate, a first drive motor, a cam, a second drive motor and a ripple spoiler, wherein the upper side of a support post is fixedly provided with the mixing box, the lower end of an output shaft of the material adding motor is fixedly connected with the feeding turnplate, a stirring shaft is also fixedly provided with a gear, the rear side of the gear is meshed with a rack, the left and right sides of the rack are provided with pothooks, the pothook is connected with a connecting rope, a housing of the left side of the mixing box is further slidingly provided with a connecting rod, and the connecting rod extends into the mixing box and is fixedly connected with the ripple spoiler. By adopting the liquid mixing device, material adding at intervals can be realized, and quantitative material adding can be realized by controlling the rotary speed of the material adding motor; spoiling can be performed inside the mixing box by the ripple spoiler, so that a layering phenomenon appearing during mixing can be effectively avoided, and the mixing effect is improved to the greatest extent.

Owner:ZHENGZHOU UNIV

Emulsified machine oil release agent and preparation method thereof

InactiveCN101812353AReduce contentGood water solubilityCeramic shaping apparatusAdditivesSolubilityWater soluble

The invention discloses an emulsified machine oil release agent and a preparation method thereof. The release agent is prepared from the following raw materials in percentage by weight: 2 percent of sodium hydroxide, 8 percent of rosin, 6 percent of ethanol, 7 percent of emulsifying agent, 12 percent of stearic acid, 55 percent of machine oil, 9.9 percent of water and a proper amount of stabling agent, wherein the emulsifying agent is one or a mixture of two of an OP emulsifying agent, a Span emulsifying agent and a Tween emulsifying agent; and after the raw materials are prepared, the release agent is prepared by steps. The release agent has strong water solubility, can be diluted freely by water, has low cost, solves the problem that the release agent in the prior art has oil stain residue and high cost, saves cost for construction technology and ensures quality safety of building members.

Owner:河南省绿韵建材有限公司

Bactericidal laundry detergent containing traditional Chinese medicine components and preparation method thereof

InactiveCN104178370AAvoid stratificationChange mobilityOrganic detergent compounding agentsAmpholytes/electroneutral surface-active compoundsBetaineGlycan

The invention discloses a bactericidal laundry detergent containing traditional Chinese medicine components. The bactericidal laundry detergent containing traditional Chinese medicine components comprises the following raw materials in parts by weight: 10-20 parts of benzalkonium bromide, 20-25 parts of fatty alcohol-polyoxyethylene ether, 20-25 parts of glycine betaine, 1-6 parts of potassium sorbate, 1-4 parts of sodium alginate, 1-4 parts of glycan, 10-35 parts of deionized water, 2-10 parts of a pH adjusting agent and 2-5 parts of a traditional Chinese medicine extract, wherein the traditional Chinese medicine extract is an extract with a concentration of 2g / ml; the extract is prepared from rheum officinale and radix scutellariae according to a mass ratio of (2-3) to 1. The bactericidal laundry detergent containing traditional Chinese medicine components has the advantages of good bactericidal and antibacterial effects and strong cleaning power.

Owner:CHENGDU SHUNFA DISINFECTANT & WASHING TECH

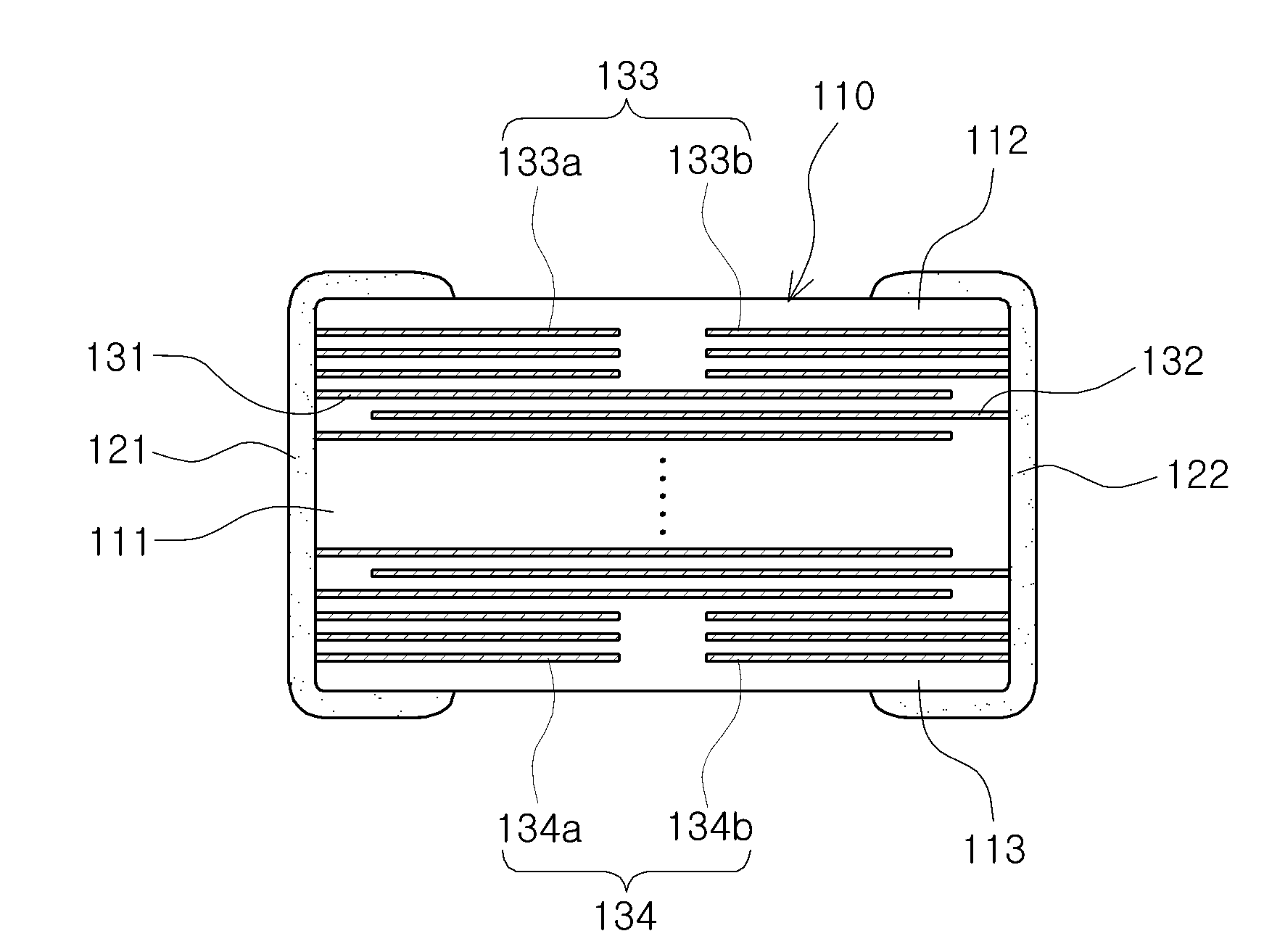

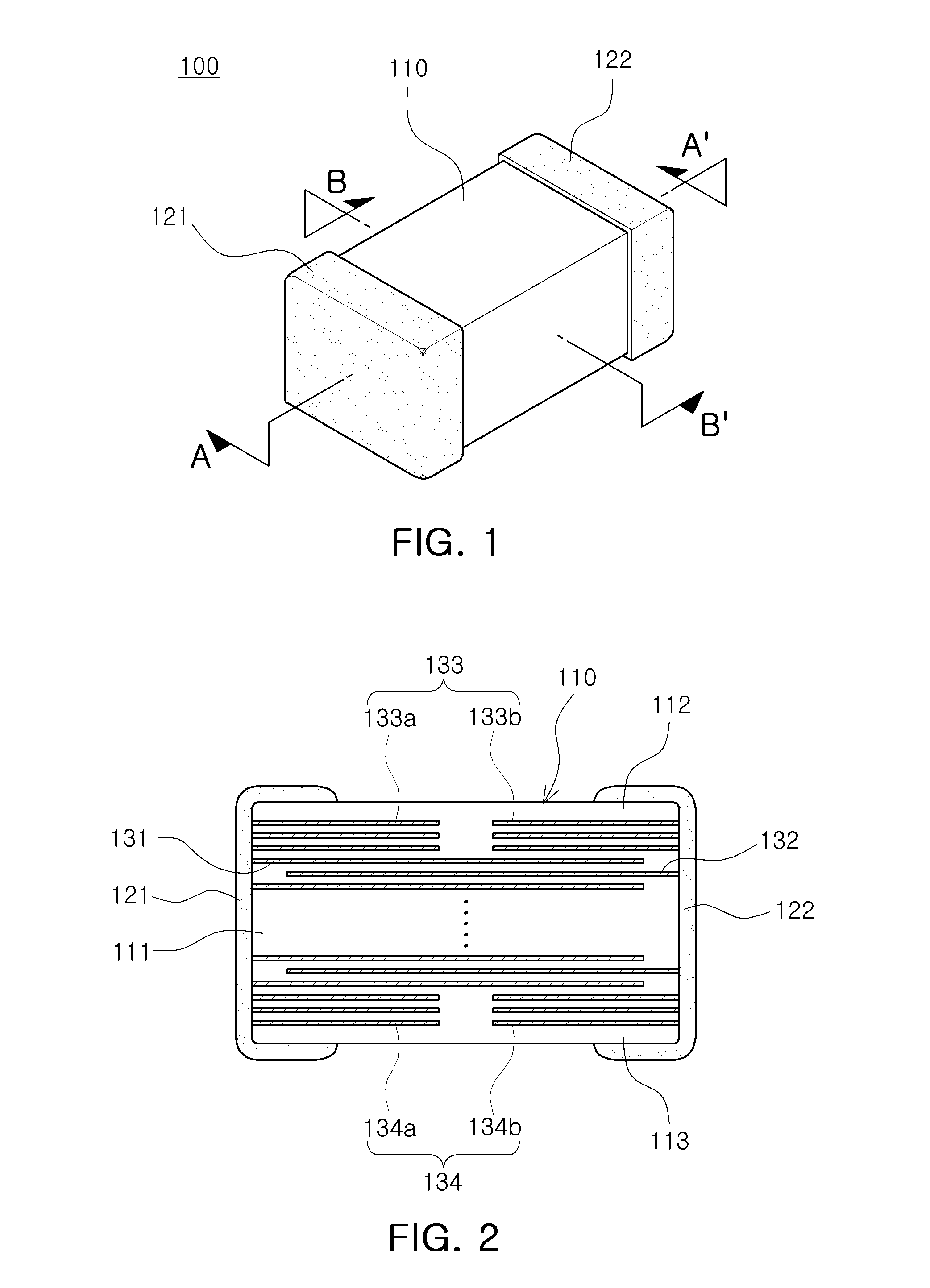

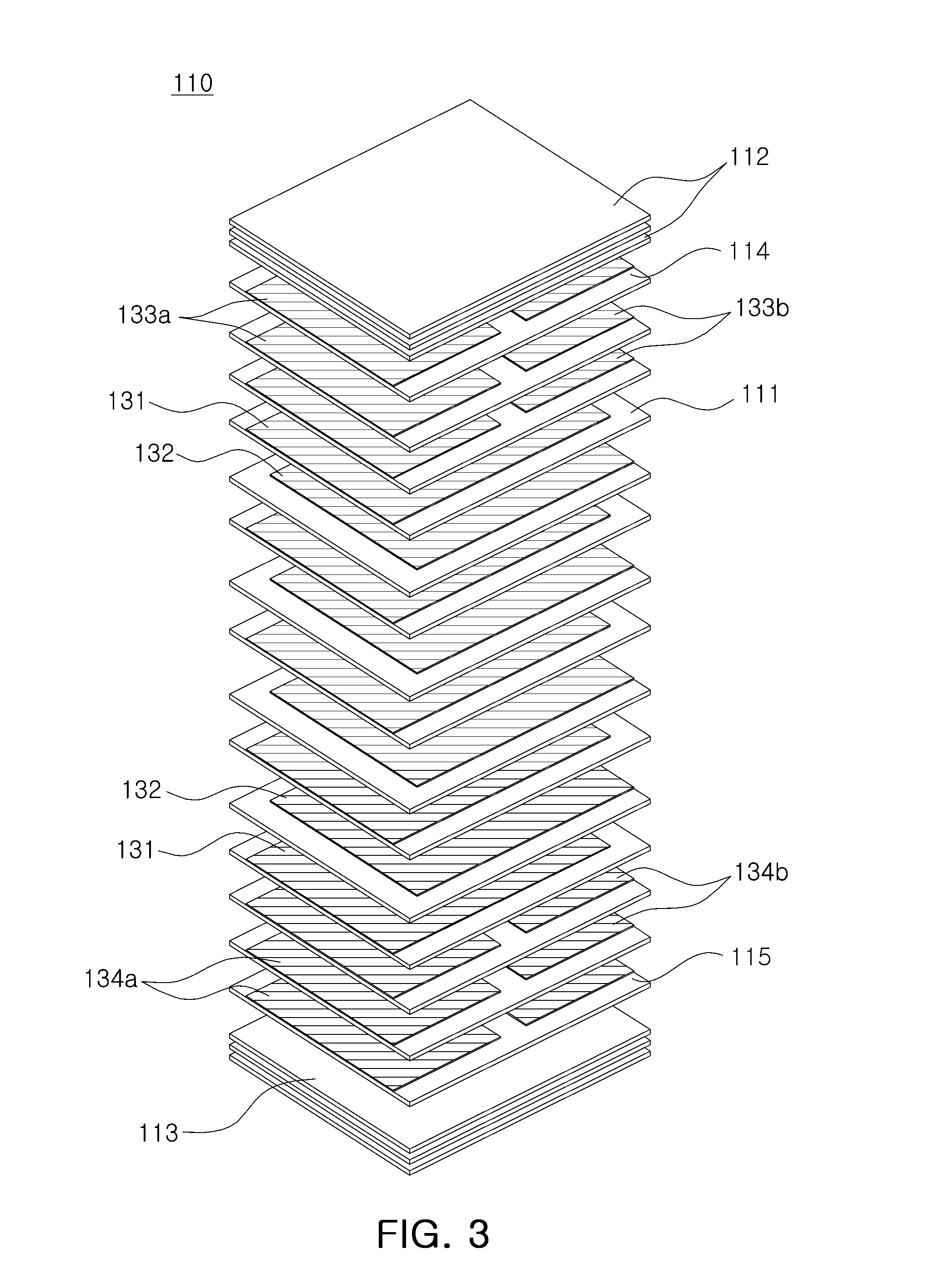

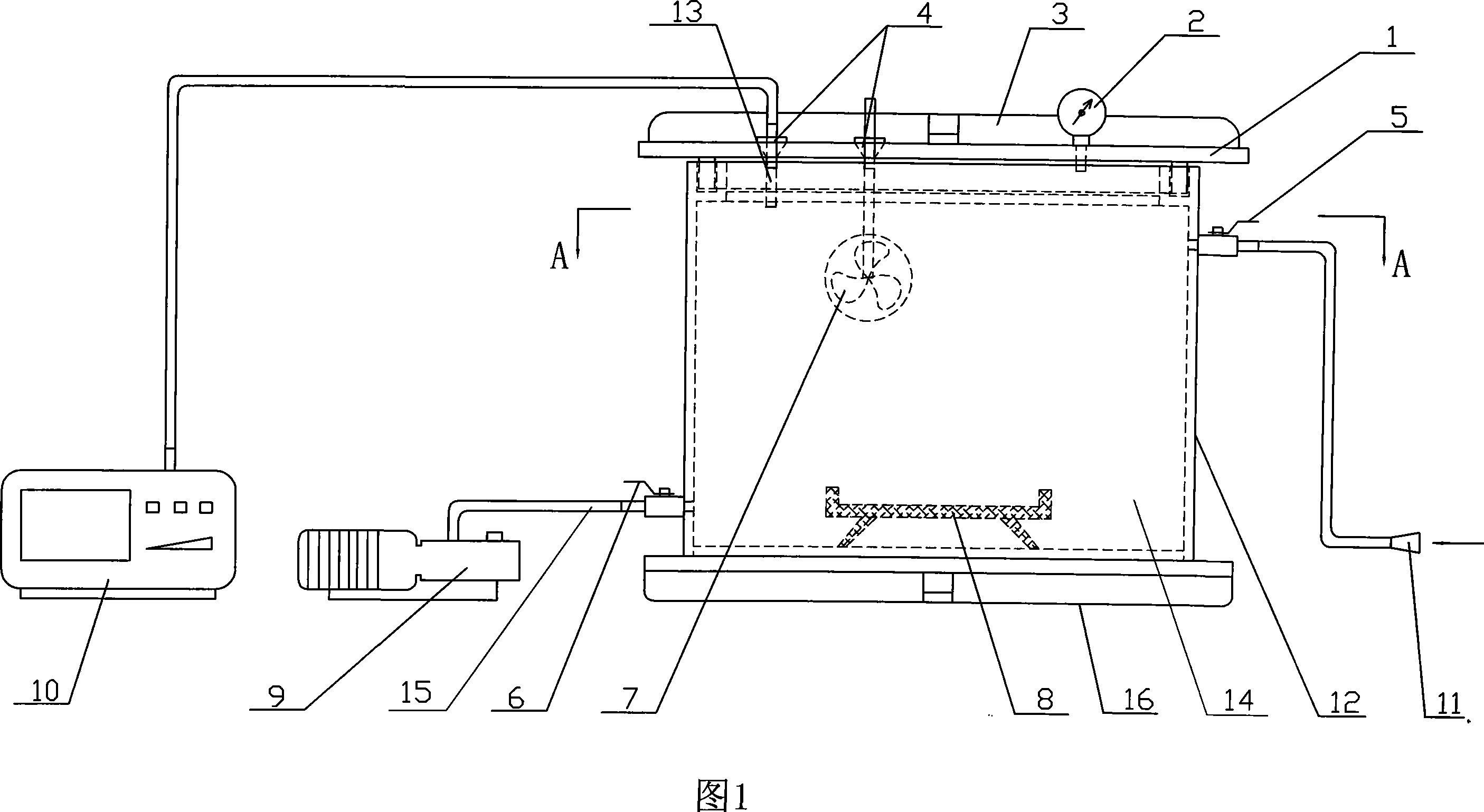

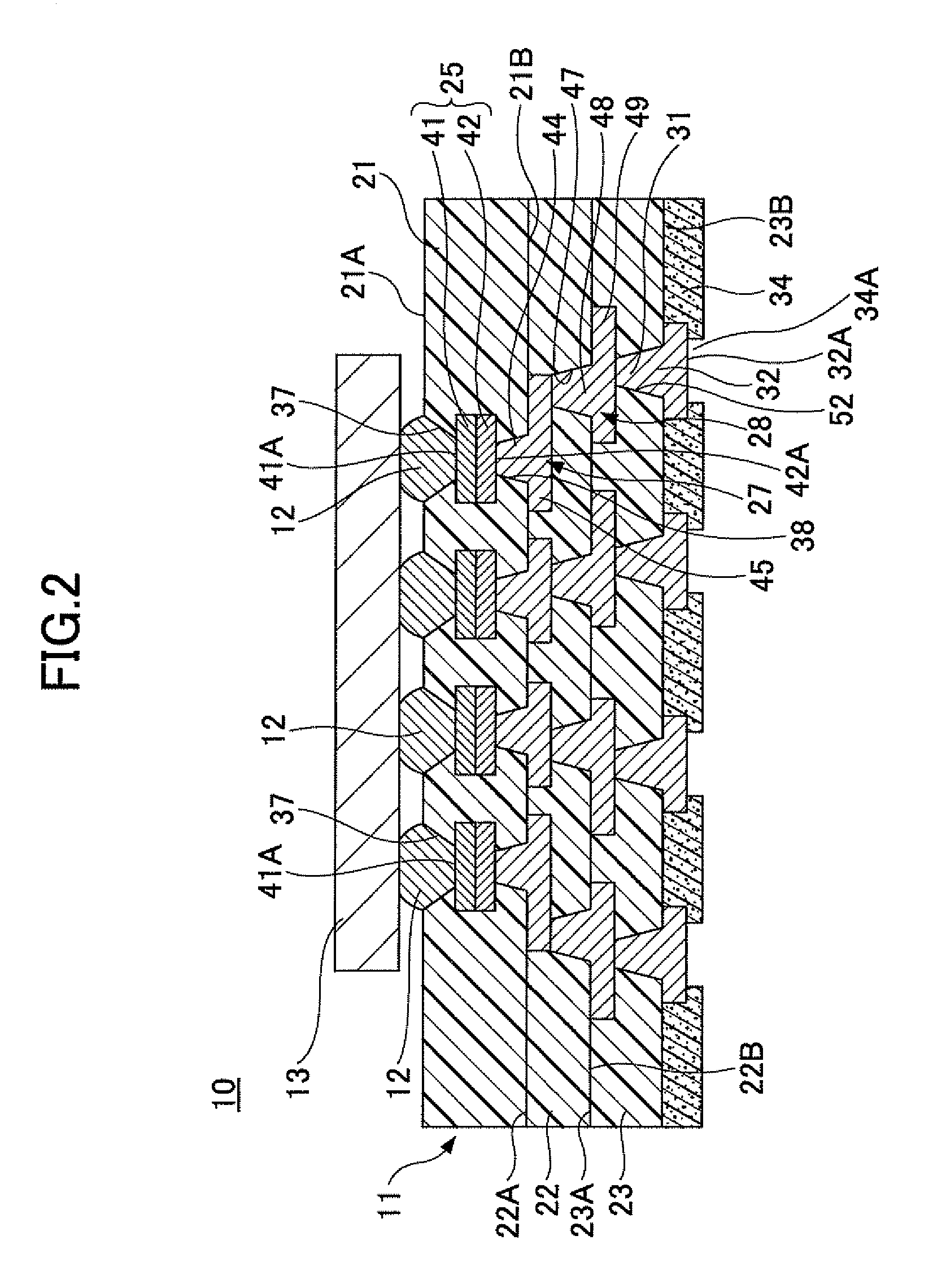

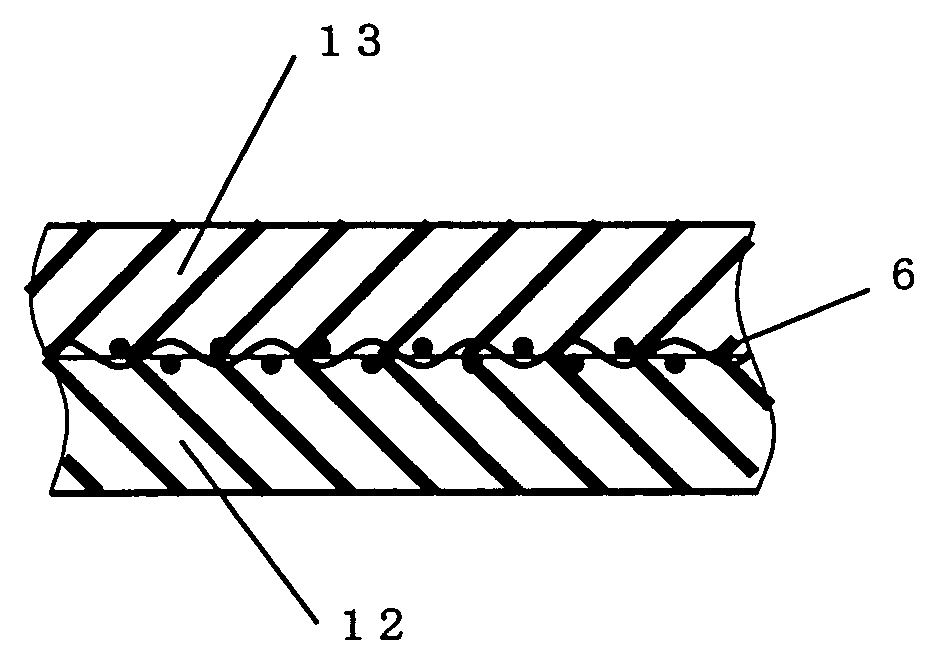

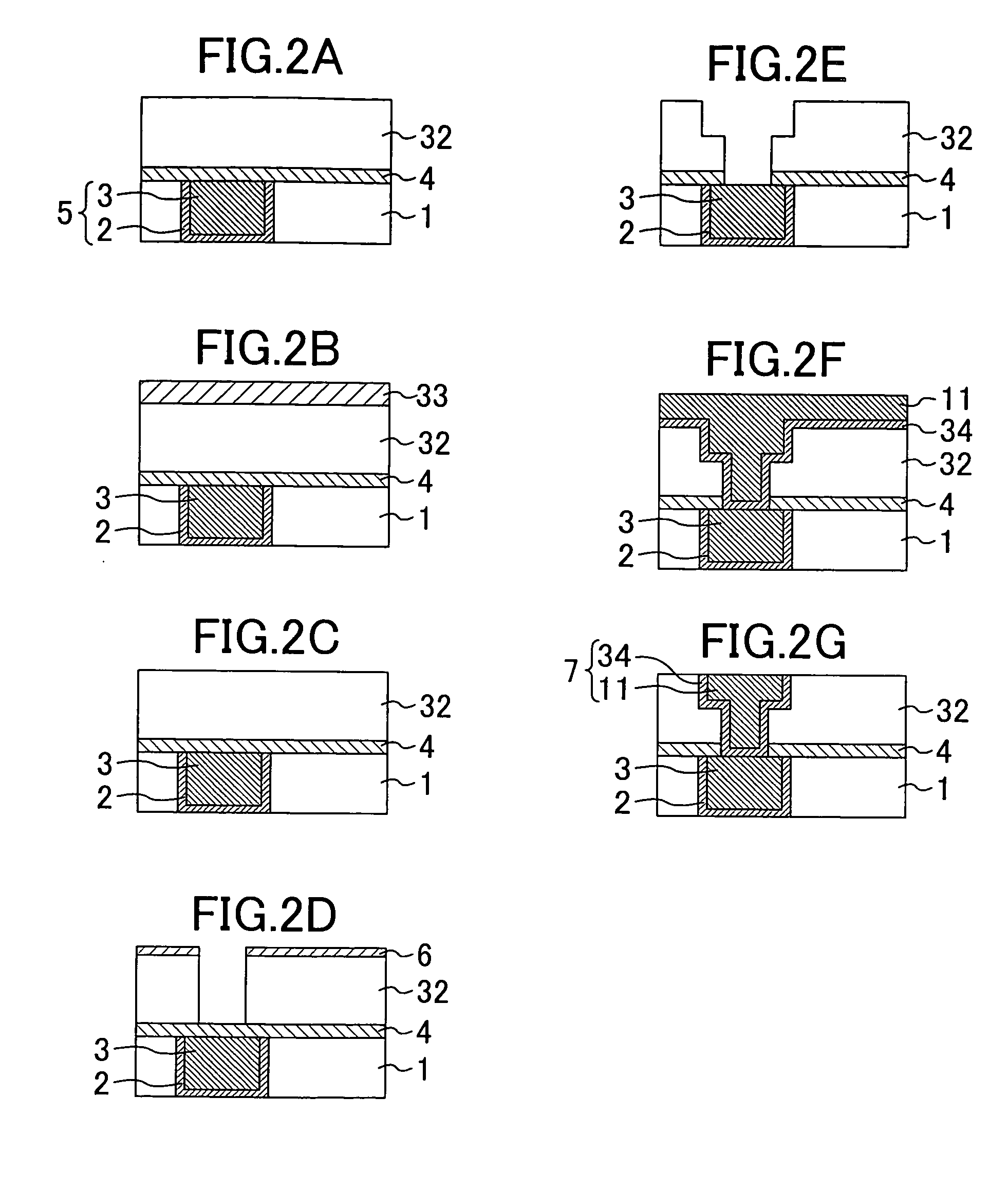

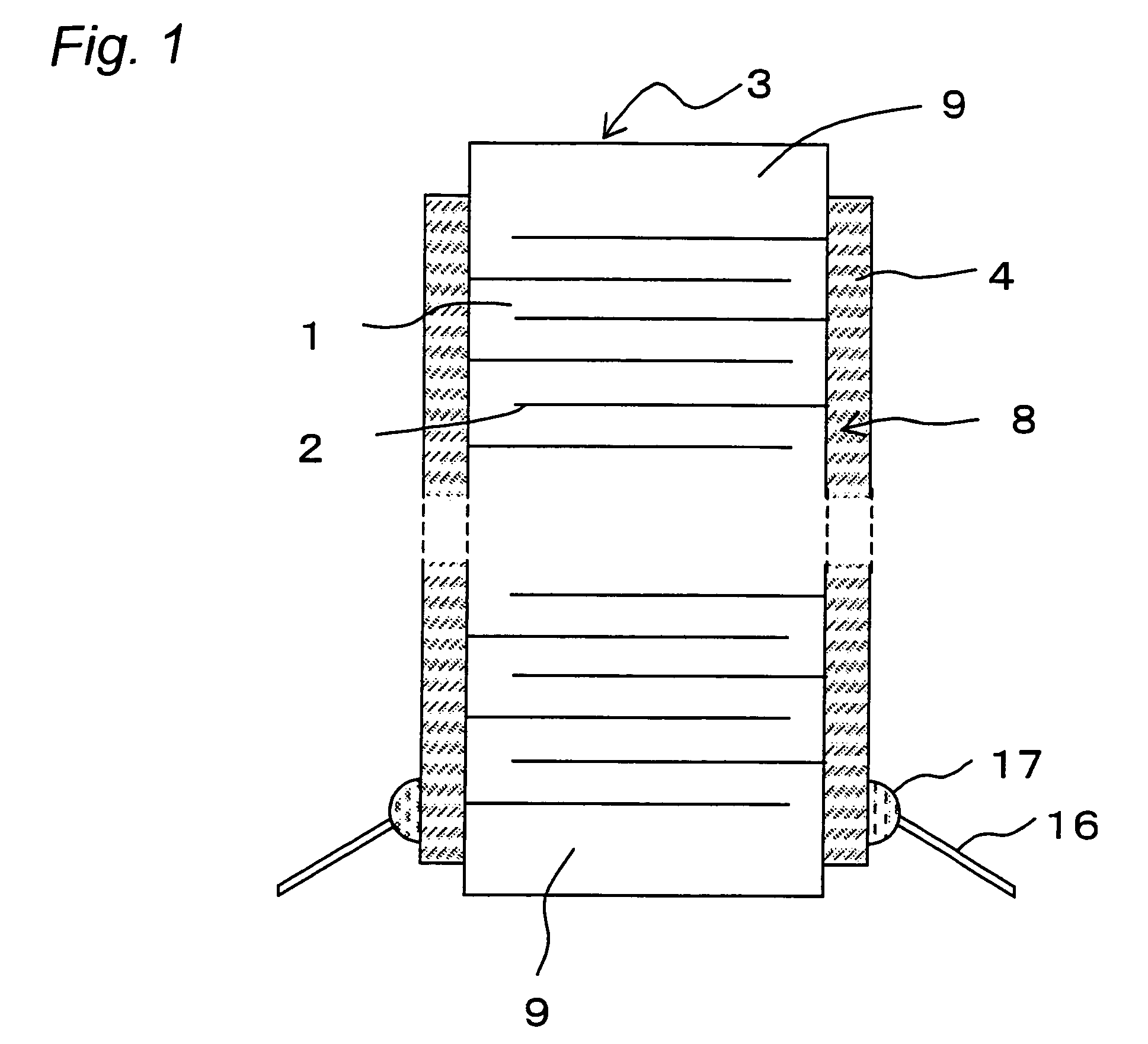

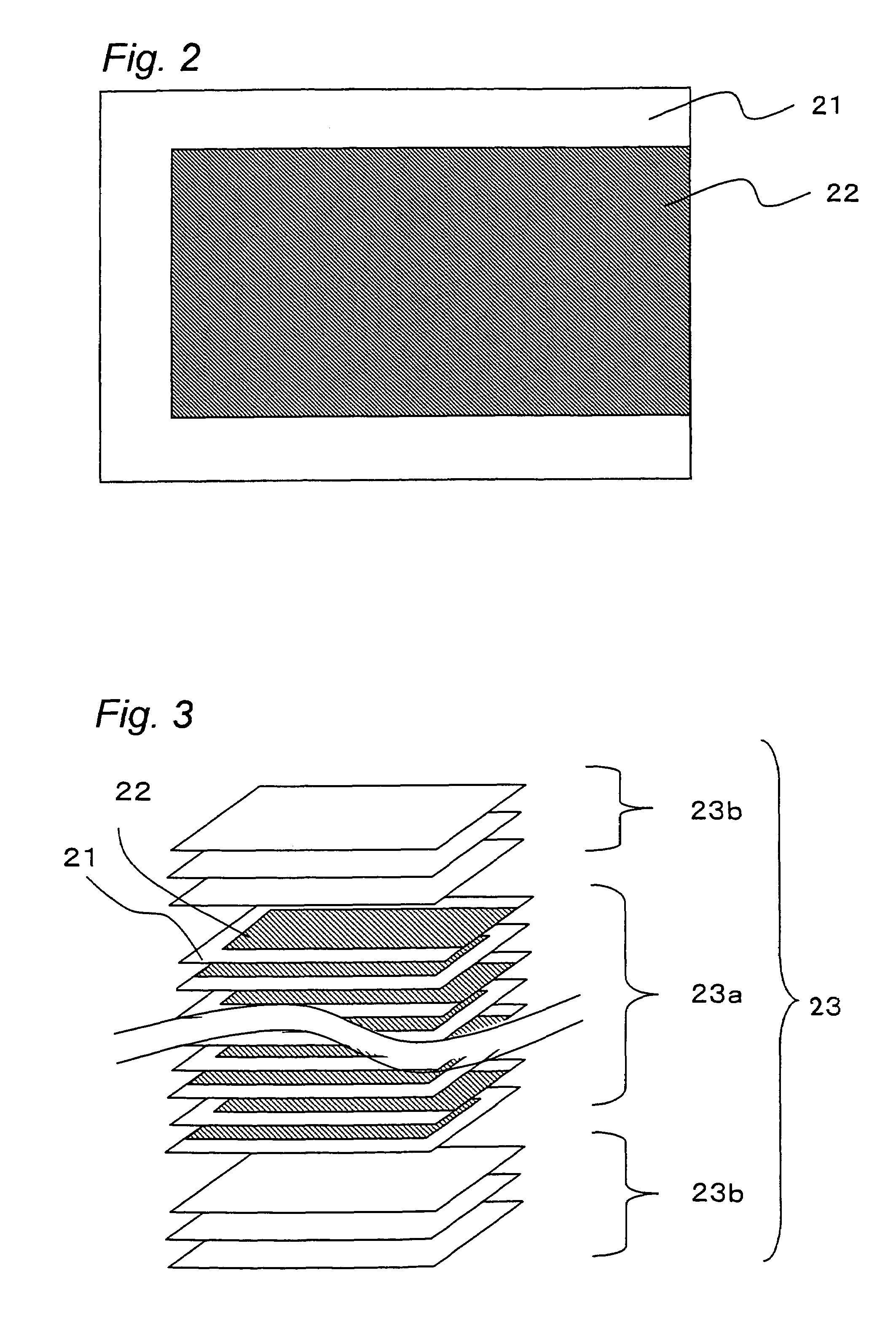

Multilayer ceramic electronic component and fabrication method thereof

InactiveUS20130241361A1Avoid stratificationReduce penetrationPiezoelectric/electrostriction/magnetostriction machinesInductances/transformers/magnets manufactureMetallurgyElectronic component

There is provided a multilayer ceramic electronic component, including: a ceramic element including a plurality of dielectric layers laminated therein; a plurality of first and second internal electrodes formed on dielectric layers positioned in a middle portion of the ceramic element and alternately exposed from both ends of the ceramic element; a plurality of dummy electrodes formed on dielectric layers positioned in upper and lower portions of the ceramic element, respectively; and first and second external electrodes formed on both ends of the ceramic element and electrically connected to the exposed portions of the first and second internal electrodes, wherein the length of each of the dummy electrodes is longer than that of the first and second external electrodes covering the ceramic element.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

High-performance lightweight aggregate concrete

InactiveCN101747006AImprove the way of forceImprove mechanical propertiesSolid waste managementSlagExpanded clay aggregate

The invention discloses high-performance lightweight aggregate concrete. The high-performance lightweight aggregate concrete is characterized in that: high-performance porcelain granules are taken as lightweight aggregate; and the high-performance lightweight aggregate concrete is prepared by mixing the following raw materials in proportion: 400 to 430 kg / m<3> of cement, 500 to 570 kg / m<3> of high-performance porcelain granule, 40 to 55 kg / m<3> of fly ash, 40 to 55 kg / m<3> of grounded furnace slag, 540 to 565 kg / m<3> of sand, 180 to 185 kg / m<3> of water and 6 to 10 kg / m<3> of water reducing agent, wherein the performance indexes of the high-performance porcelain granule is that stacking density is less than and equal to 700 kg / m<3>, cylinder pressure strength is greater than and equal to 6.0 MPa, strength mark is greater than and equal to 35 MPa and water absorbing capacity is less than and equal to 1.0 percent. The high-performance lightweight aggregate has the advantages that the strength is high, and workability and pumpability can meet design and construction requirements.

Owner:NINGBO UNIV

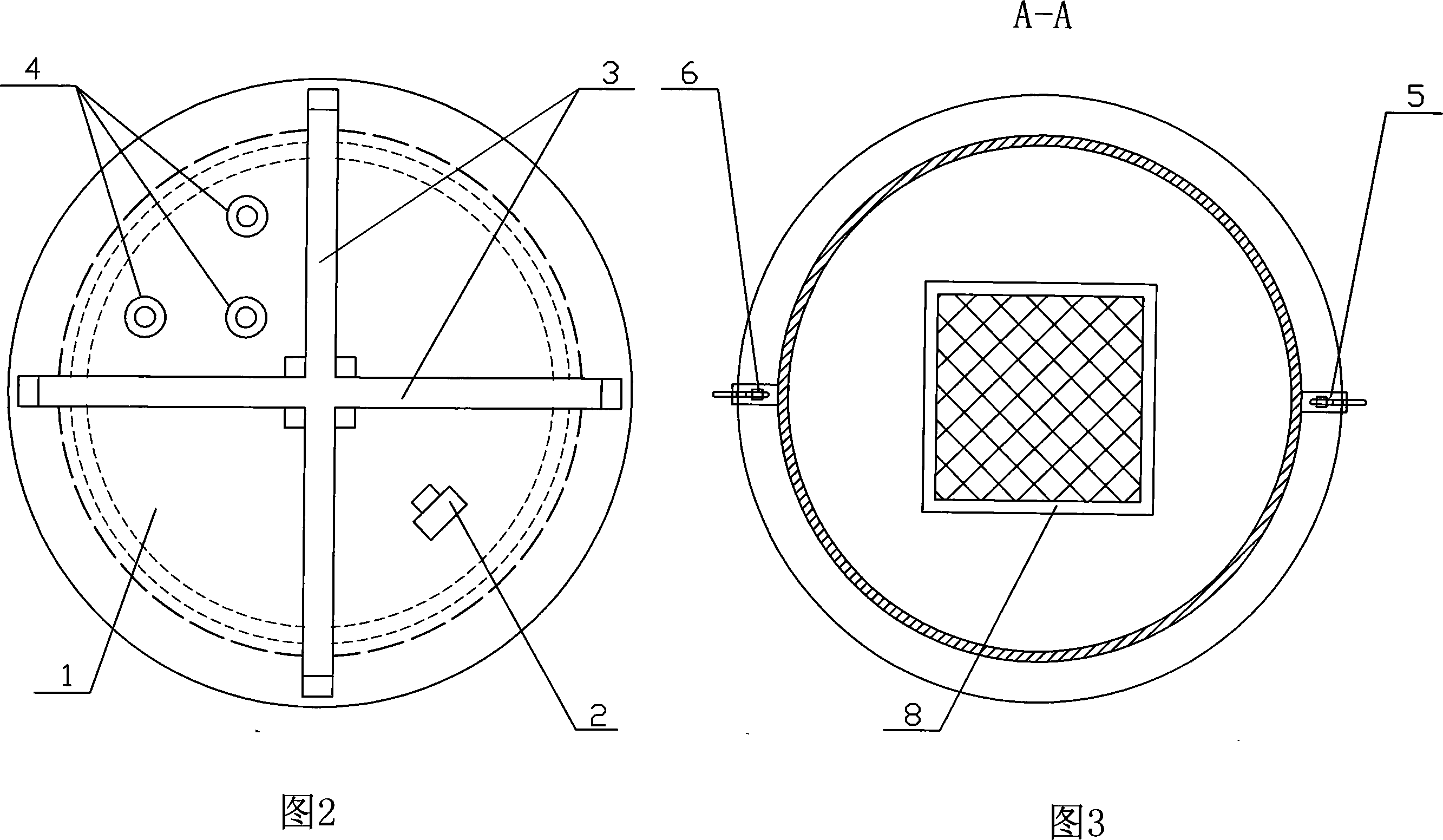

Tester for testing the performance of new material degrading tail gas

InactiveCN101162222AEasy to observeAvoid stratificationChemical methods analysisSolar lightPhotocatalytic reaction

A tester for testing the performance of a new material degrading tail gas relates to a testing unit. The invention solves the problem of limited usage range, light-tightness of a gas reaction chamber, unstable testing result due to the change of temperature and environment, high cost of equipment and complicated structure, all of which are caused by that the prior test equipment does not have light conditions necessary for light-catalyzed reaction. A gas reaction chamber (12) of the invention is made from light transmissible materials, and consists of a cover gasket (1) and a reaction chamber vessel (14) which are in closed connection with each other; a sensor probe (13) is inserted in a jack (4) on the cover gasket (1), and is connected with a tail gas analyzer (10); a vacuum air pump (9) is connected with the bottom of the reaction chamber vessel (14) through a connecting hose (15). The invention has the advantages of unlimited usage range, direct use of solar light source as the reaction condition by the gas reaction chamber, accurate testing result, low cost of equipment and simple structure.

Owner:HARBIN INST OF TECH

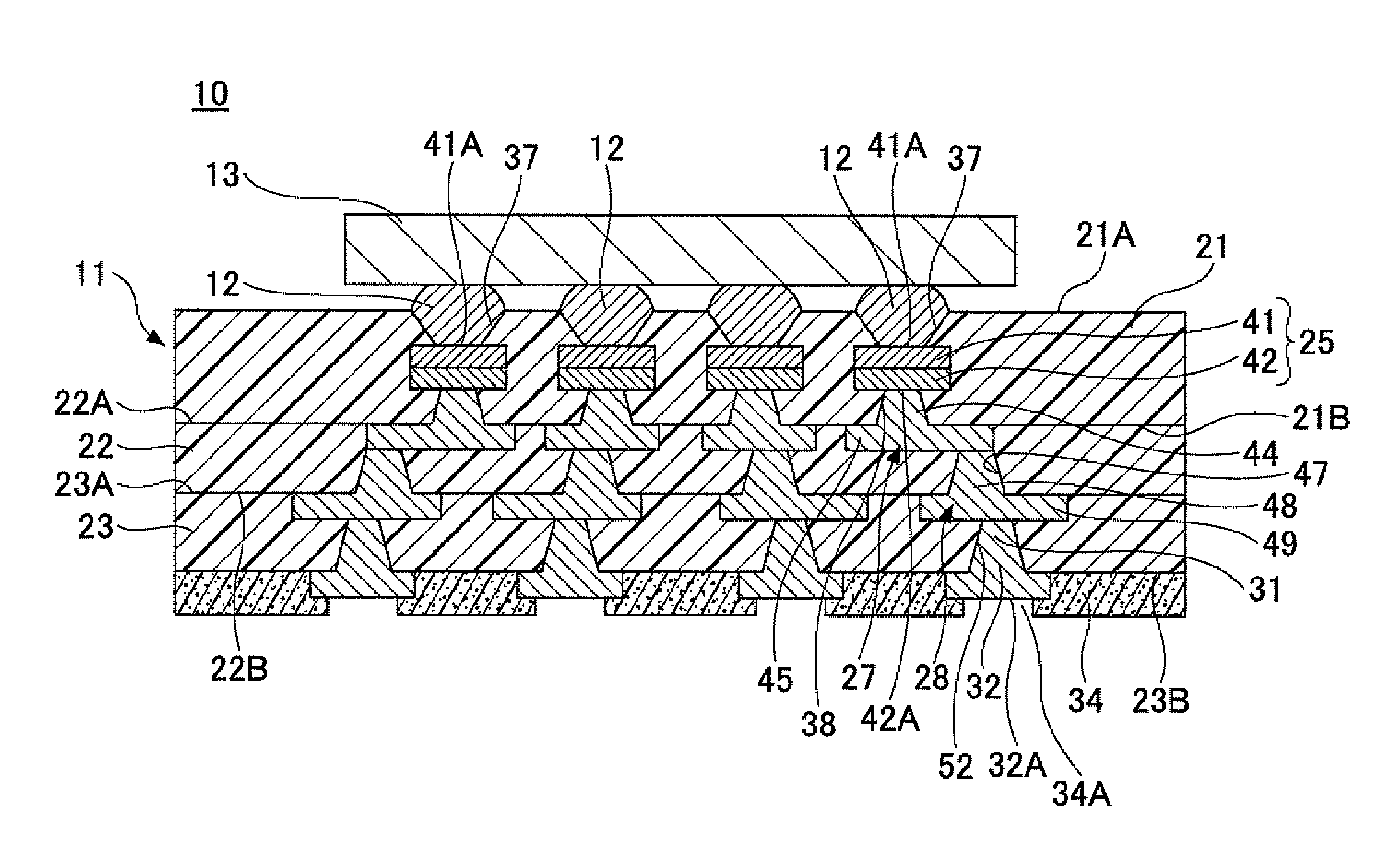

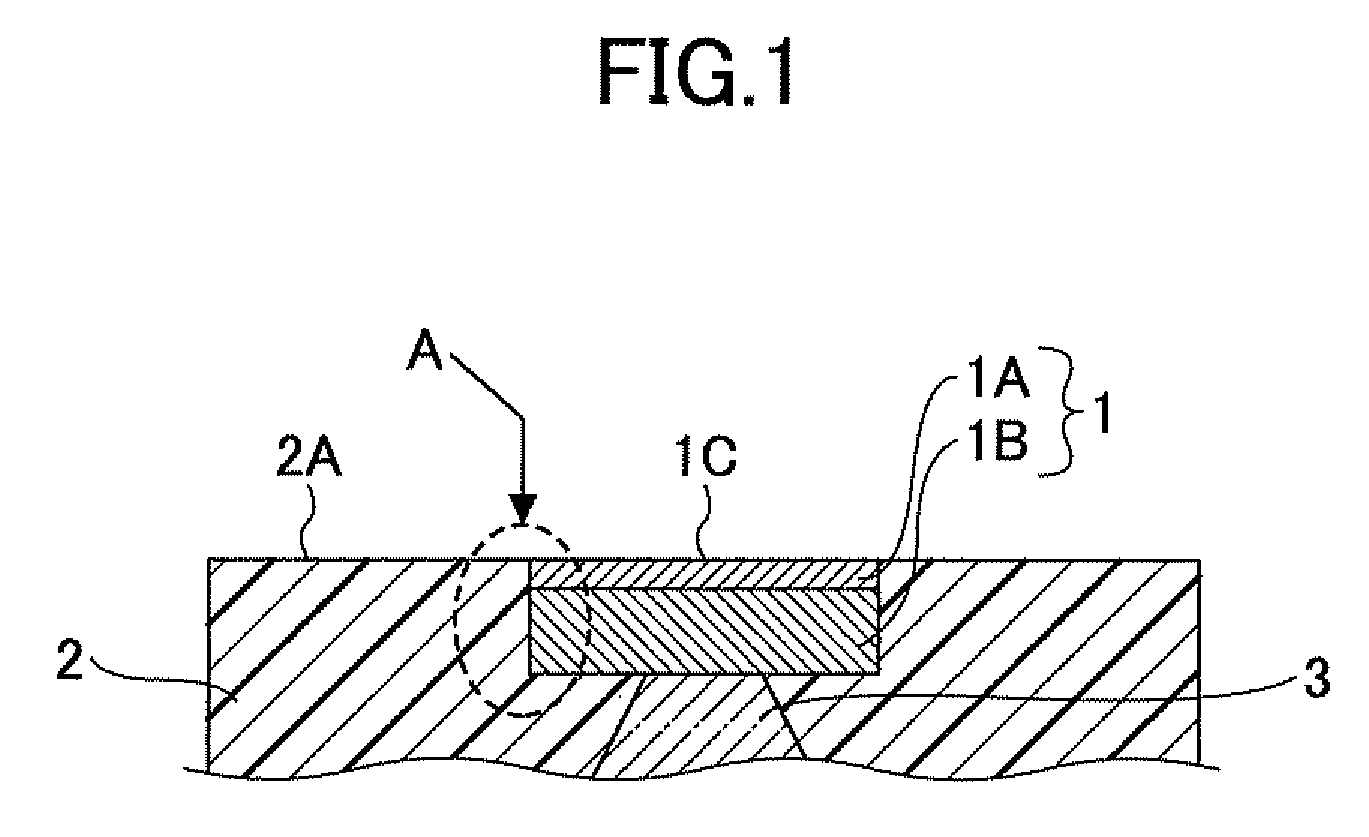

Wiring board and method of fabricating the same

InactiveUS20100084163A1Improve reliabilityAvoid stratificationDecorative surface effectsSemiconductor/solid-state device detailsElectrical conductorEngineering

A wiring board includes an electrode pad having a first surface and a second surface located on an opposite side from the first surface, a conductor pattern connected to the first surface of the electrode pad, and an insulator layer embedded with the electrode pad and the conductor pattern. The insulator layer covers an outer peripheral portion of the second surface of the electrode pad.

Owner:SHINKO ELECTRIC IND CO LTD

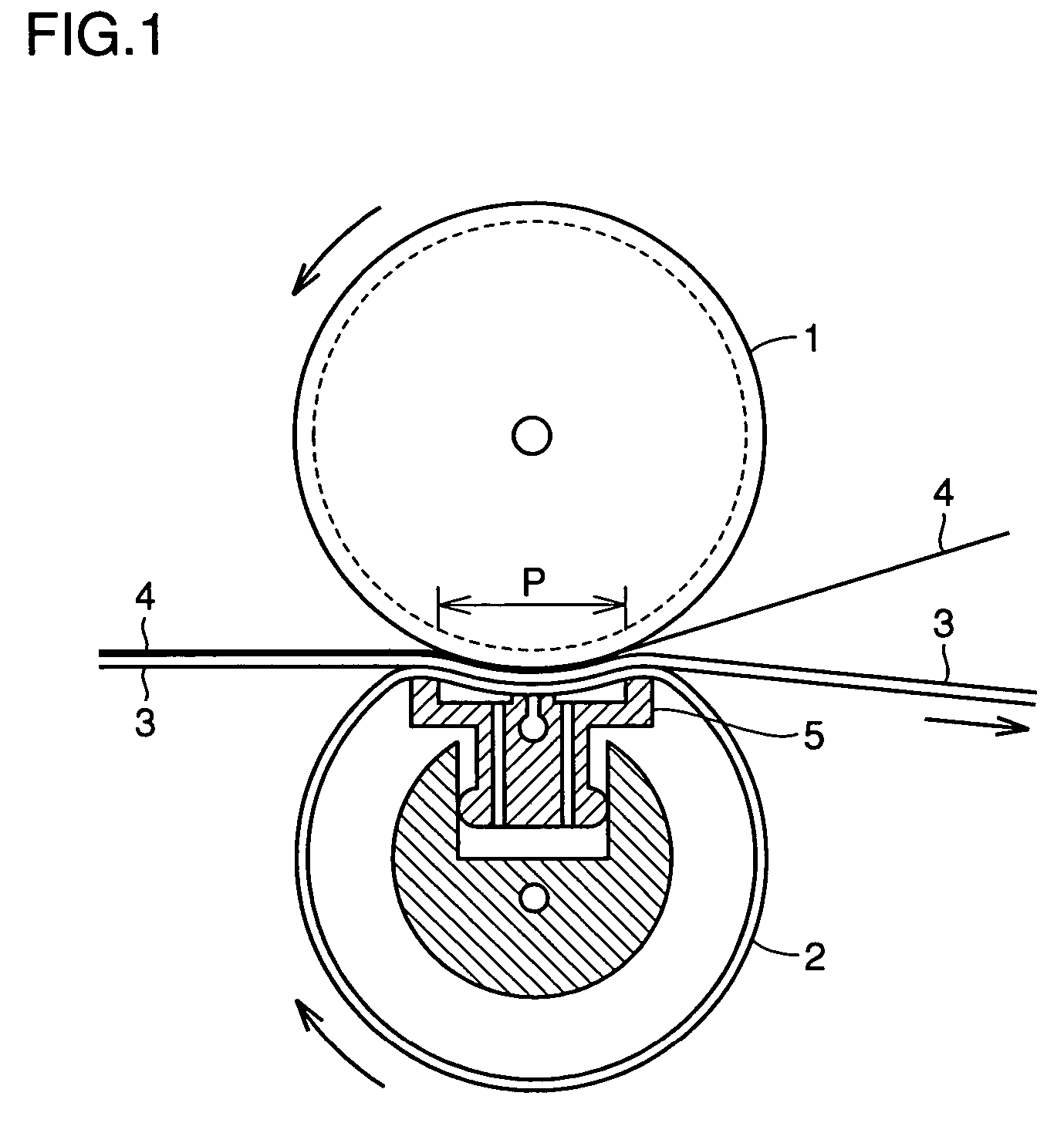

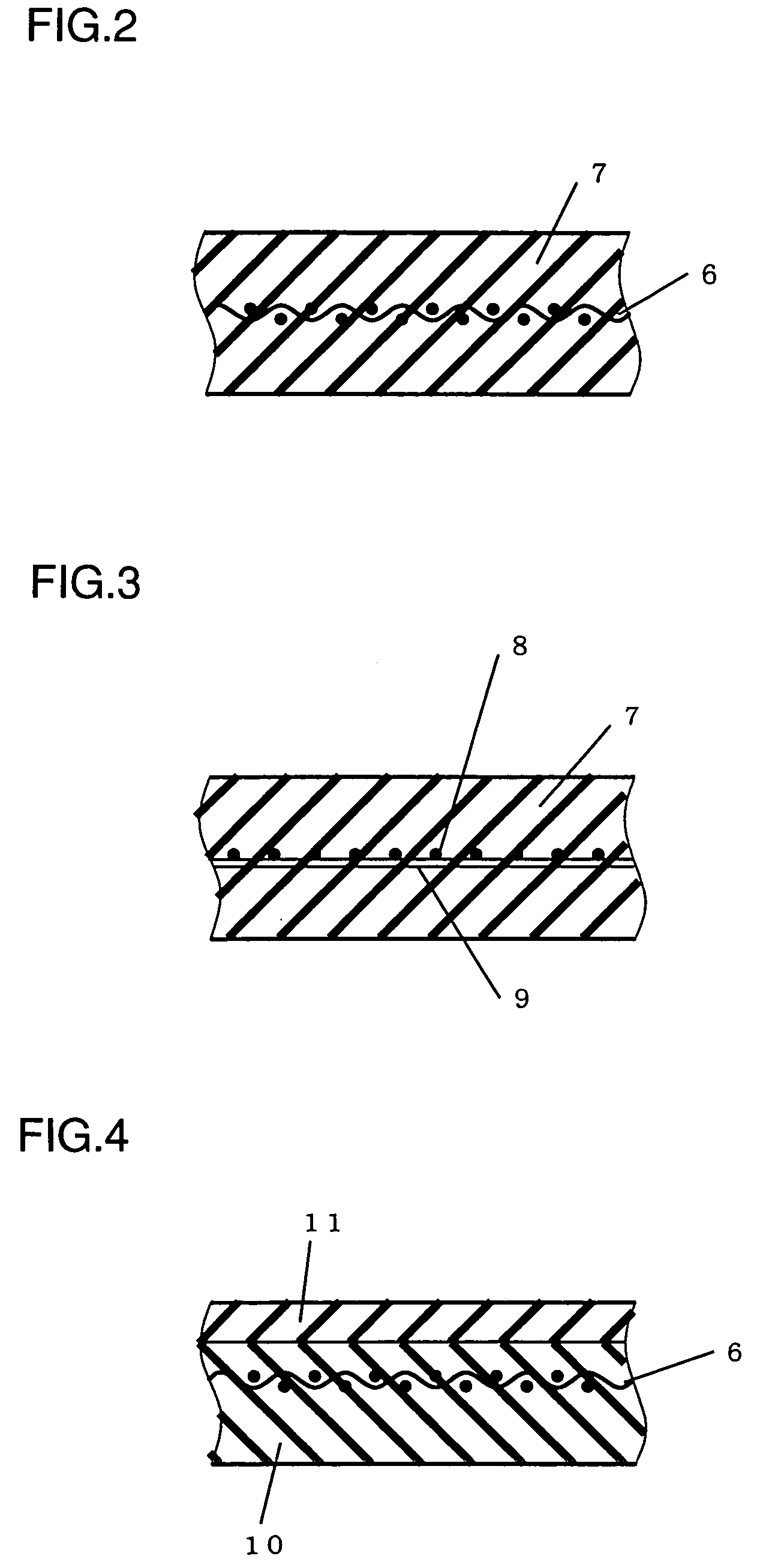

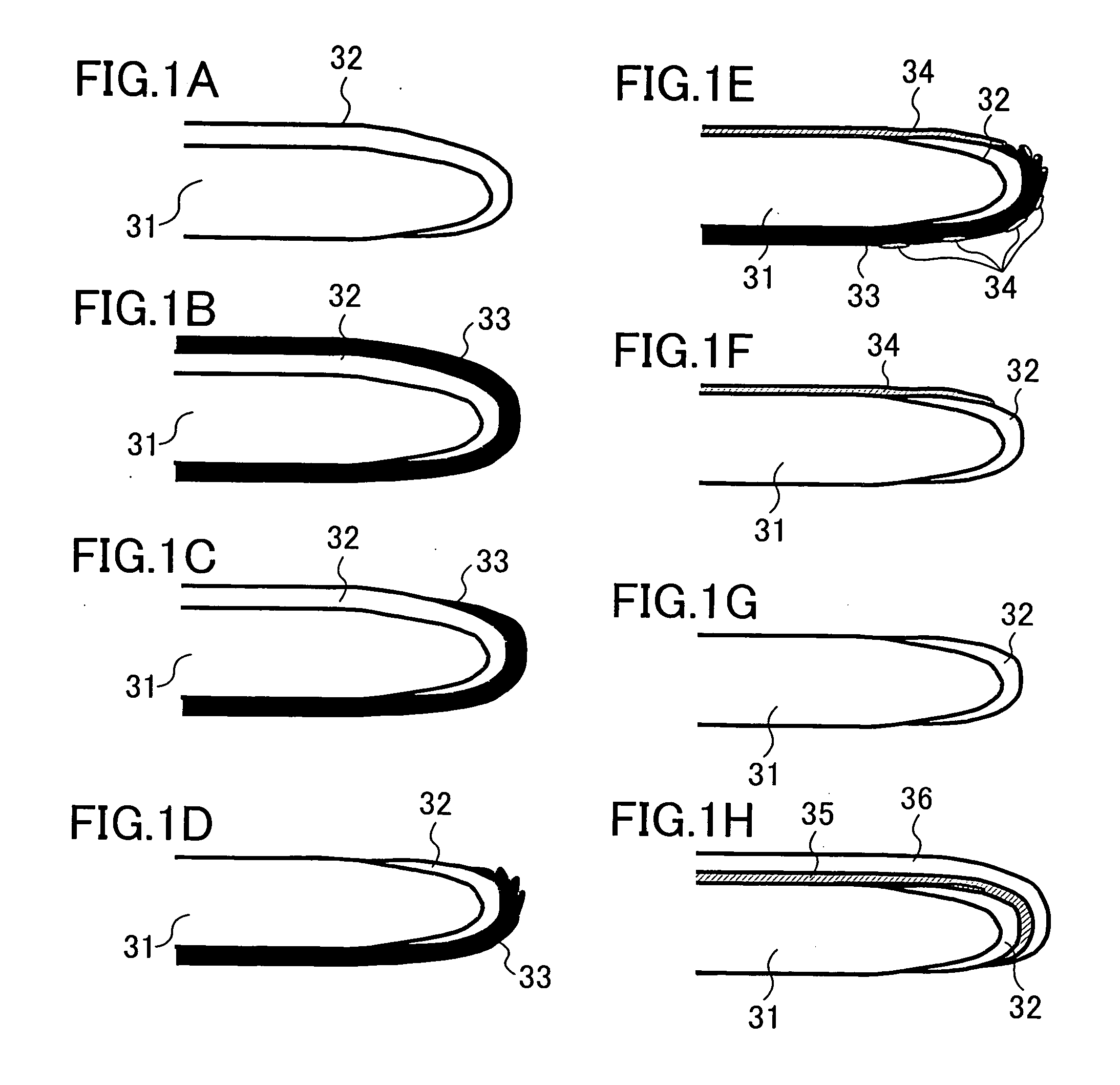

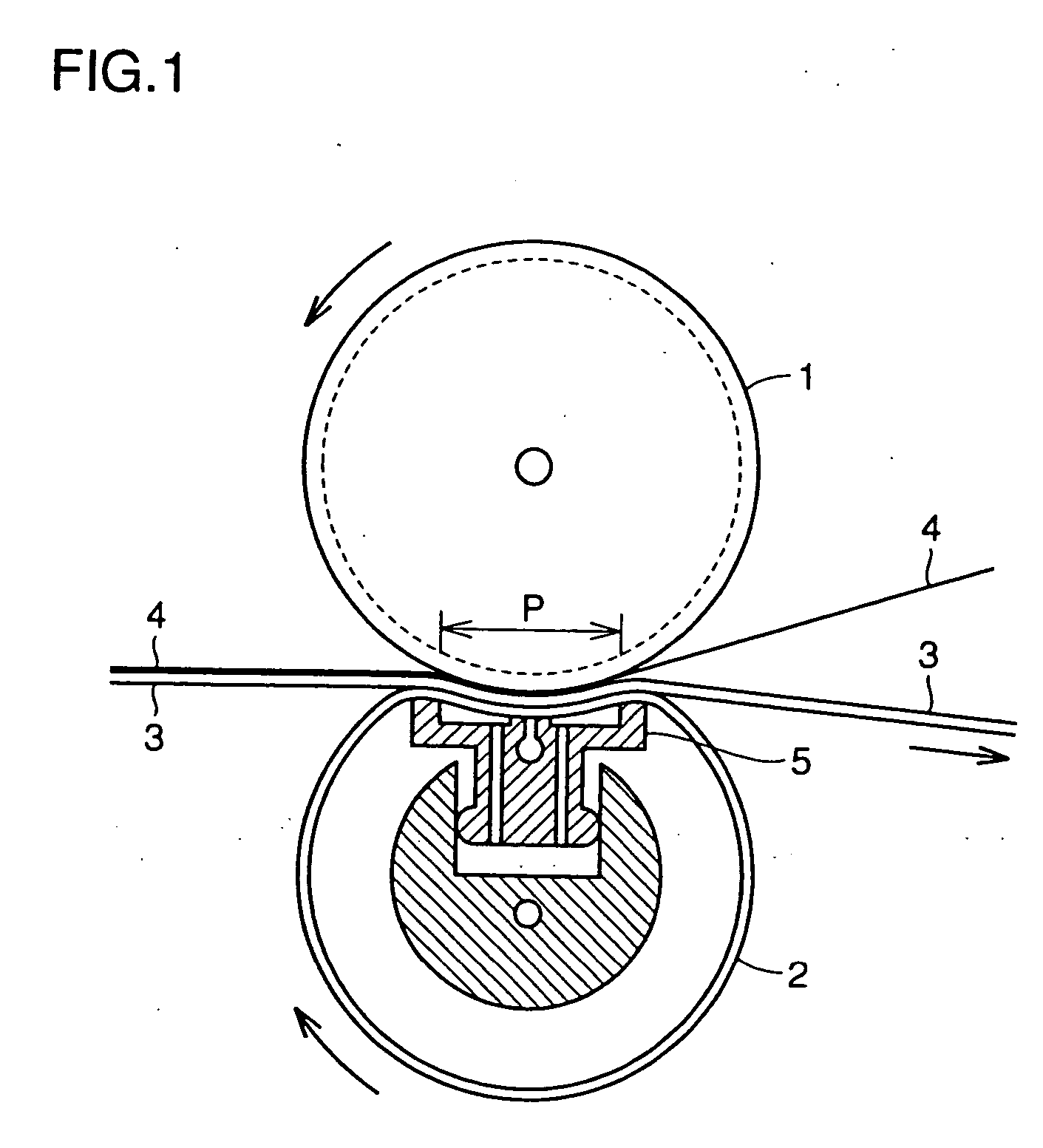

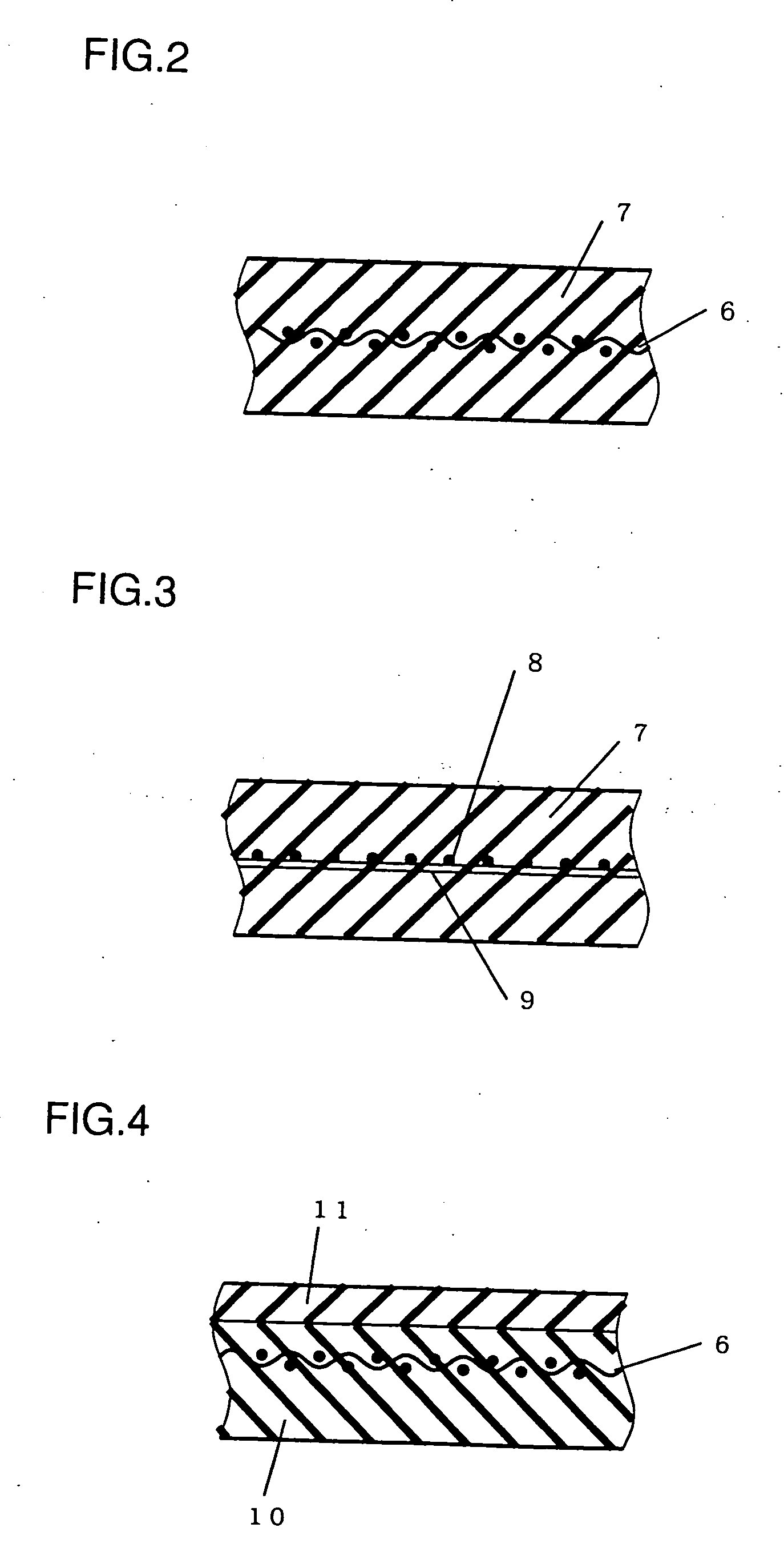

Belt for papermarking and process for producing papermaking belt

InactiveUS7090747B2Prevent crack growthAvoid stratificationLiquid surface applicatorsSynthetic resin layered productsPulp and paper industryPrepolymer

A papermaking belt which prevents cracking and inhibits crack growth which includes a reinforcing substrate embedded in a thermosetting polyurethane layer so that the reinforcing substrate and the thermosetting polyurethane layer are integrated with each other and the outer peripheral surface and the inner peripheral surface of the belt are formed by polyurethane layers, the polyurethane layer forming the outer peripheral surface being made of a composition containing a urethane prepolymer having isocyanate groups on its ends and a hardener containing dimethylthiotoluenediamine.

Owner:YAMAUCHI CORP

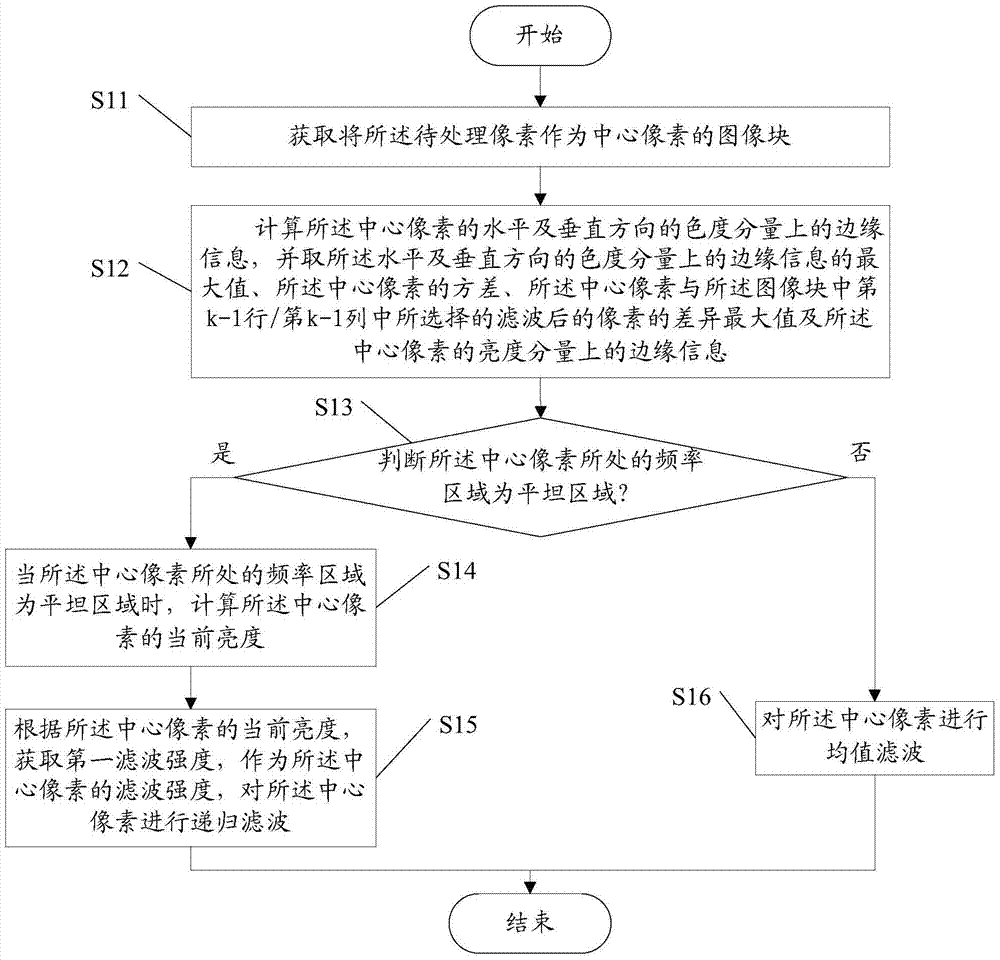

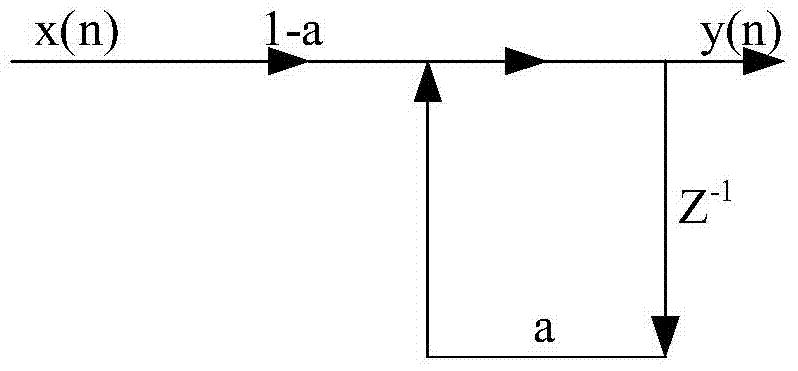

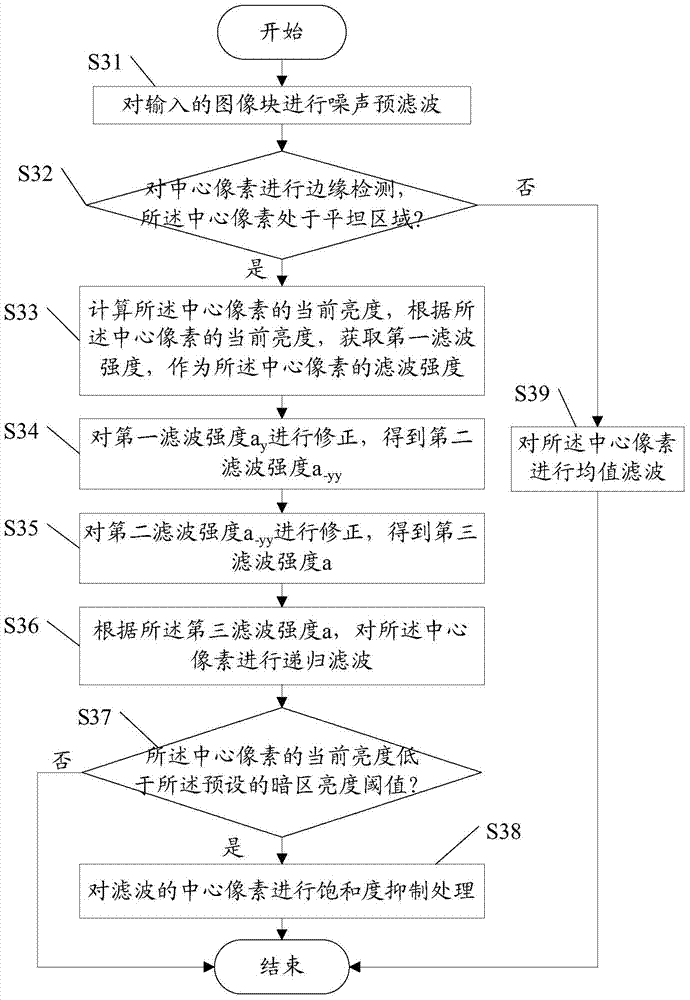

Image de-noising method and device

ActiveCN106934768AAccurate filter strengthAvoid smearingImage enhancementNoise removalHorizontal and vertical

The invention relates to an image de-noising method and device. According to the image de-noising method, pixels in an image are recursively filtered, and the following modes are adopted to obtain the filtering intensity of pixels to be processed currently: edge information on the chrominance component in the horizontal and vertical direction of a central pixel is calculated, a maximum value is selected as a first edge information maximum value; the variance of an image block is calculated; the maximum value of the first difference of the central pixel and filtered pixels selected from the (k-1)-th row / (k-1)-th column of the image block is calculated; edge information on the luminance component of the central pixel is calculated; whether a frequency region where the center pixel is located a flat region is determined; if the frequency region where the center pixel is located a flat region, the current brightness of the center pixel is calculated; and first filter intensity is obtained according to the current brightness and is adopted as the filtering intensity of the center pixel. With the image de-noising method and device provided by the above technical schemes of the invention adopted, the noise removal effect of noises can be ensured, and the tailing phenomenon of the de-noised image can be avoided.

Owner:SPREADTRUM COMM (TIANJIN) INC

Urea resin additive

InactiveCN1834183APrevent infiltrationEasy to useMacromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesSulfonatePVA - Polyvinyl alcohol

This invention discloses a method for manufacturing a urea-formaldehyde resin additive, which is composed of active attapulgite clay, magnesium oxide, polyvinyl alcohol, polyacrylamide and sodium dodecyl sulfonate. The method comprises the steps of mixing the raw materials, pulverizing and packaging to obtain the final product. The urea-formaldehyde resin additive is a neutral additive containing active minerals and polymers, and once added into urea-formaldehyde resin it can improve the quality of urea-formaldehyde resin, reduce the release of formaldehyde and alleviate environmental pollution.

Owner:许盛英

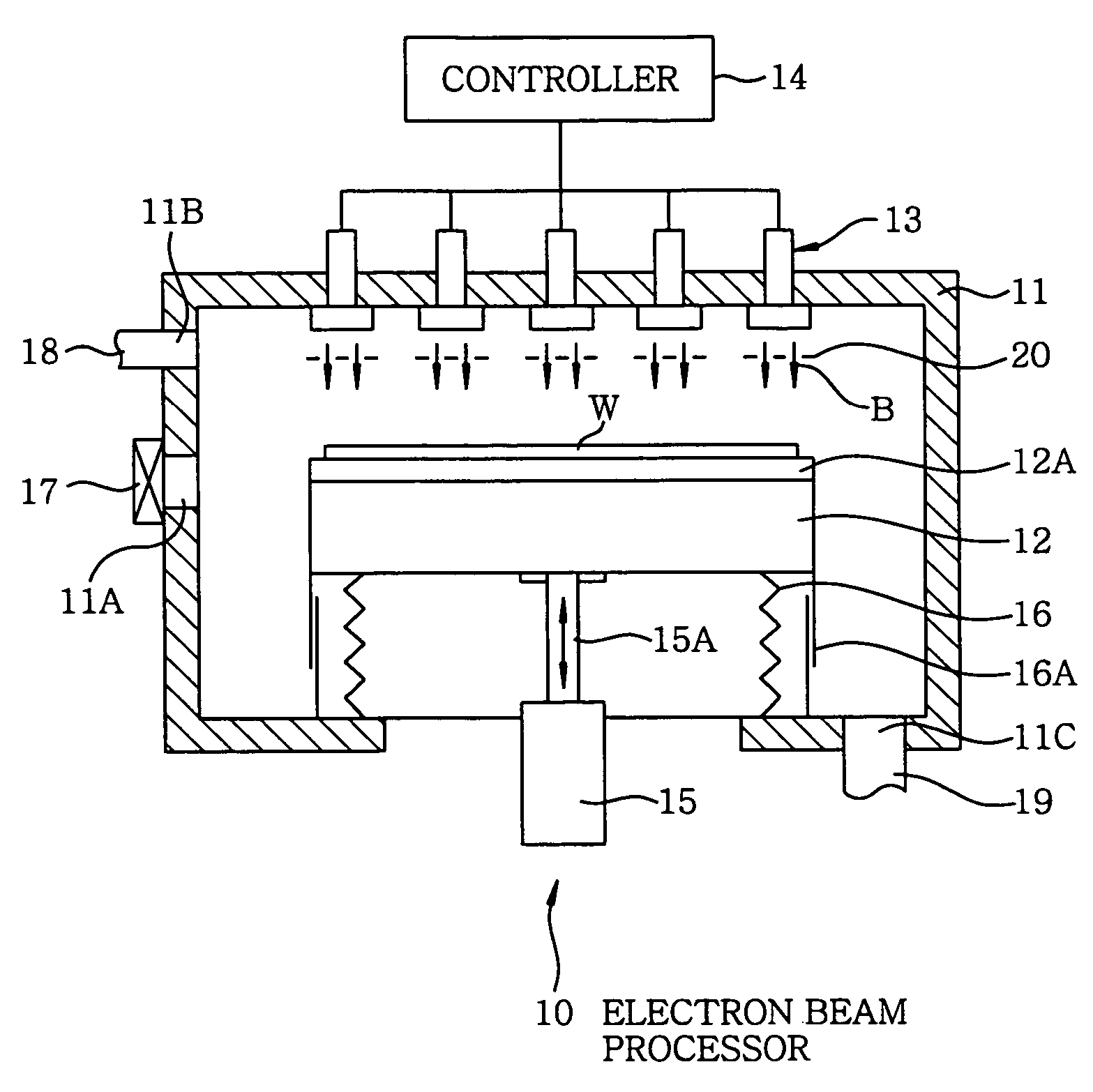

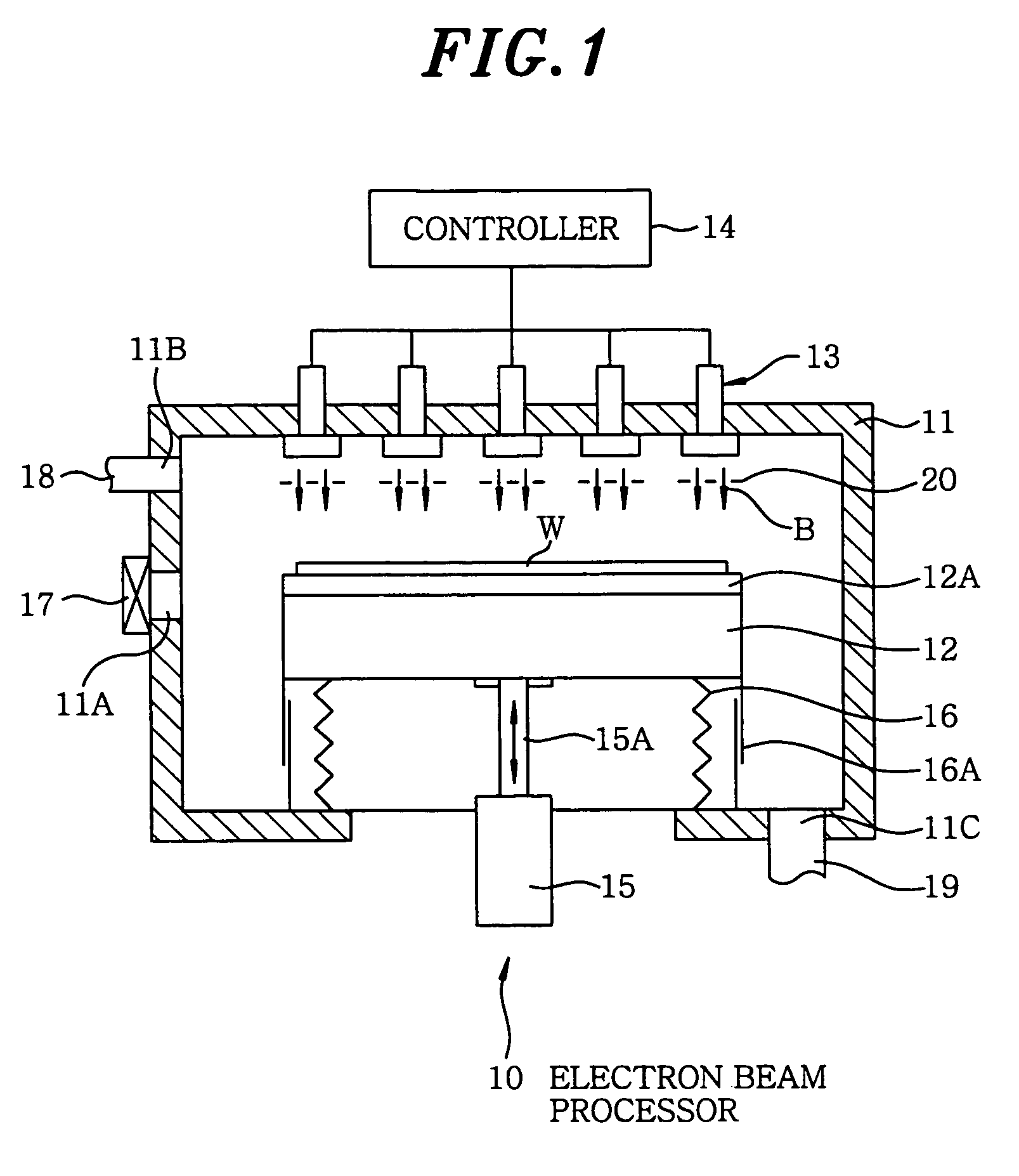

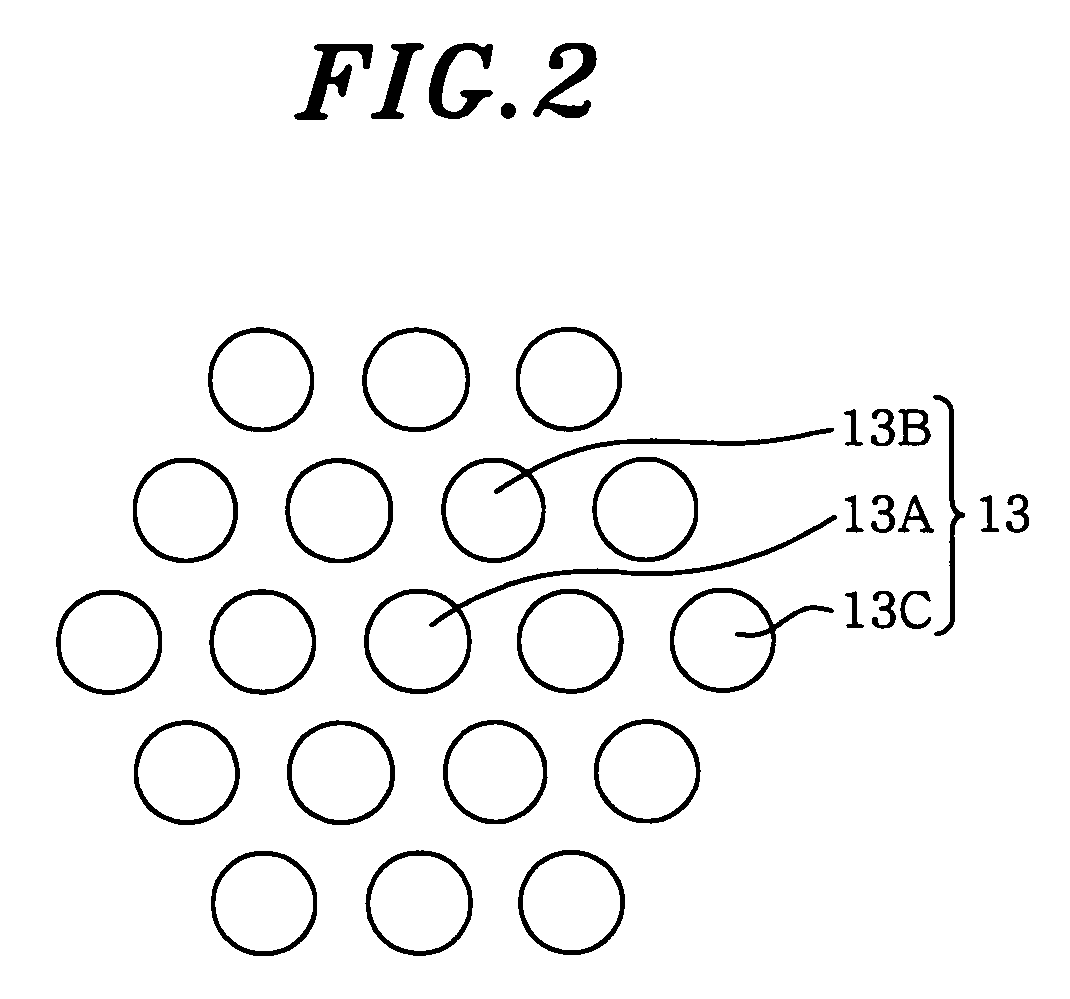

Method and apparatus for reforming laminated films and laminated films manufactured thereby

InactiveUS20050212179A1Improve throughputImprove interlayer strengthElectric discharge tubesSemiconductor/solid-state device manufacturingBeam tubeEngineering

There is provided a method for reforming laminated films, which simultaneously reforms a plurality of laminated films by irradiating electron beams on the laminated films. The method for reforming laminated films includes the steps of forming a lower film by coating a first low dielectric material in liquid form on a surface of a substrate; forming an upper film by coating a second low dielectric material in liquid form on the lower film; and irradiating electron beams on the lower and upper film. A laminated film manufacturing system includes a mounting table for mounting thereon a substrate on which the laminated films are formed; and an electron beam unit having a plurality of electron beam tubes for irradiating electron beams on the laminated films to thereby simultaneously reform the films.

Owner:TOKYO ELECTRON LTD

Method for preparing metal/polyaniline/plastic composite film through electrochemical in-situ polymerization

ActiveCN102876037ASolve the difficulty of processingSolve defects such as low conductivityElectrolytic organic material coatingComposite filmConductive polymer

The invention discloses a method for preparing a metal / polyaniline / plastic composite film through electrochemical in-situ polymerization. The method comprises the following steps of: 1) preparing a polyaniline / plastic conductive composite film, namely performing electrooxidation polymerization of polyaniline in an aniline-acid solution by taking a plastic microporous film as a base film to obtain the polyaniline / plastic conductive composite plastic film, wherein the electric conductivity of the polyaniline / plastic conductive composite plastic film is 1 to 59.5S.cm<-1>; and 2) preparing a polyaniline / plastic / metal conductive composite film, namely electrodepositing silver on the surface of the polyaniline / plastic conductive composite film to obtain the polyaniline / plastic / metal conductive plastic composite film, wherein the electric conductivity of the polyaniline / plastic / metal conductive plastic composite film is 10<2> to 10<4>S.cm<-1>. The conductive plastic composite film prepared by the method has high electric conductivity and thermal stability and excellent mechanical properties, is high in performance price ratio and light in mass, realizes the organic combination of conductive polymers and metal particles, overcomes the unworkability of the polyaniline, and expands the application range of the conductive polymers. The method is simple and easy; and the obtained composite film can be used as a photoelectronic device, and is used for various fields such as detection and sensing, and electromagnetic shielding.

Owner:CENT SOUTH UNIV

Method for fabricating semiconductor device

InactiveUS20070042600A1Unacceptable delaminationPromote stratificationSemiconductor/solid-state device manufacturingLithography processWafering

In a Cu interconnect process, an organic-based low-dielectric-constant interlayer film is formed, and then a protective film is deposited on the side and back surfaces of a wafer bevel and the back surface of a wafer edge. Thereafter, a lithography process and an etching process are carried out, a copper film is formed, and then the protective film is removed.

Owner:PANASONIC CORP

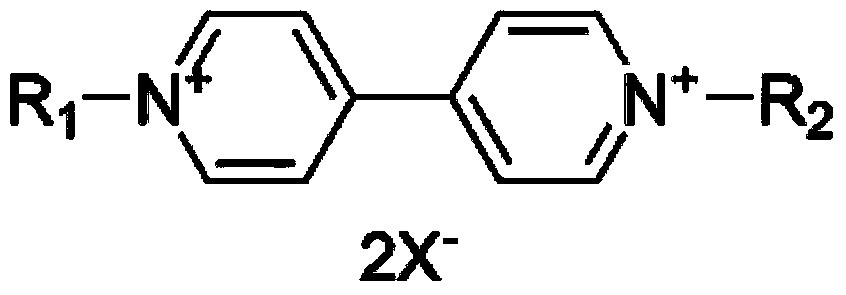

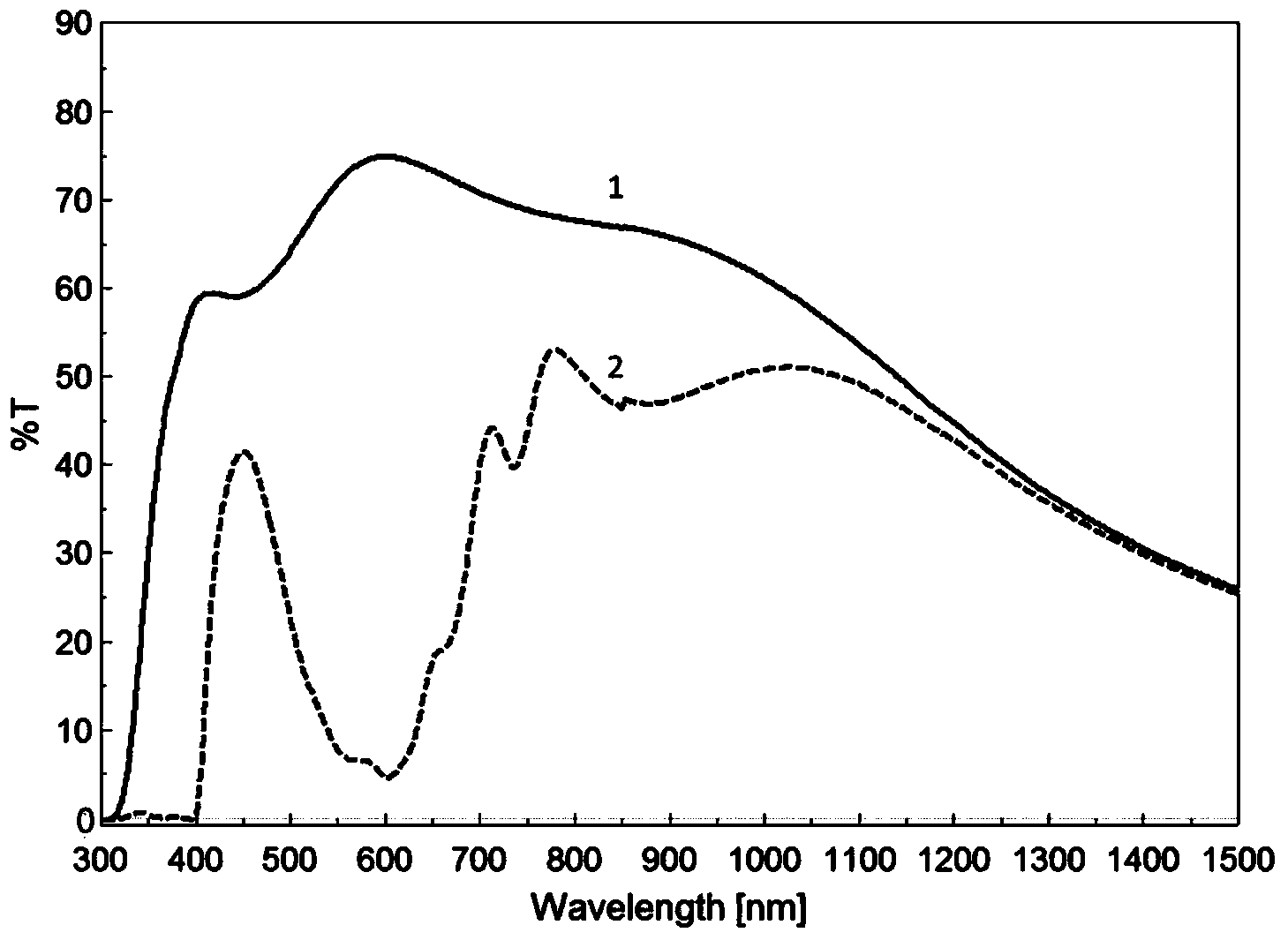

Multifunctional controllable electrochromic device and manufacturing method thereof

The invention discloses a multifunctional controllable electrochromic device and a manufacturing method of the multifunctional controllable electrochromic device. The multifunctional controllable electrochromic device comprises a first substrate and a second substrate opposite to the first substrate. A first conductive material layer and a second conductive material layer are arranged on the inner side of the first substrate and the inner side of the second substrate respectively, an electroactive material layer is arranged on the inner side of the first conductive material layer, sealing adhesives are arranged on the periphery of the second conductive material layer and the periphery of the electroactive material layer, the sealing adhesives, the second conductive material layer and the electroactive material layer form a cavity in an encircling mode, and the cavity is filled with an electrochromic electrolyte solution. Compared with the prior art, the multifunctional controllable electrochromic device and the manufacturing method of the multifunctional controllable electrochromic device have the advantages that the semi-fixed and semi-free electrochromic device can solve the matching problem of a full-fixed electrochromic device and the layering problem caused by long-term voltage applying of a full-free electrochromic device and has good controllability, and the color and the optical properties of the whole device can be adjusted by adjusting the material of a free part.

Owner:HEFEI BOYI ENVIRONMENTAL PROTECTION TECH

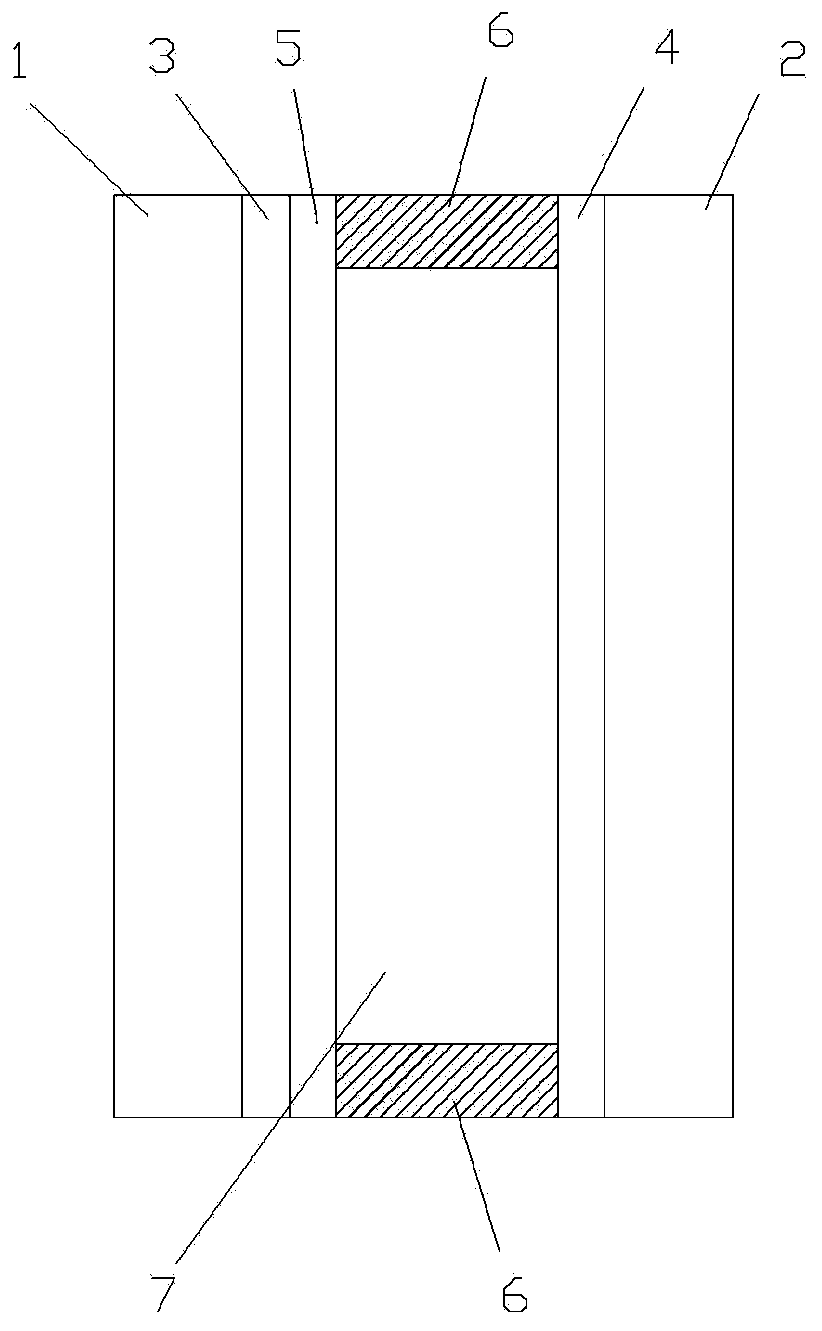

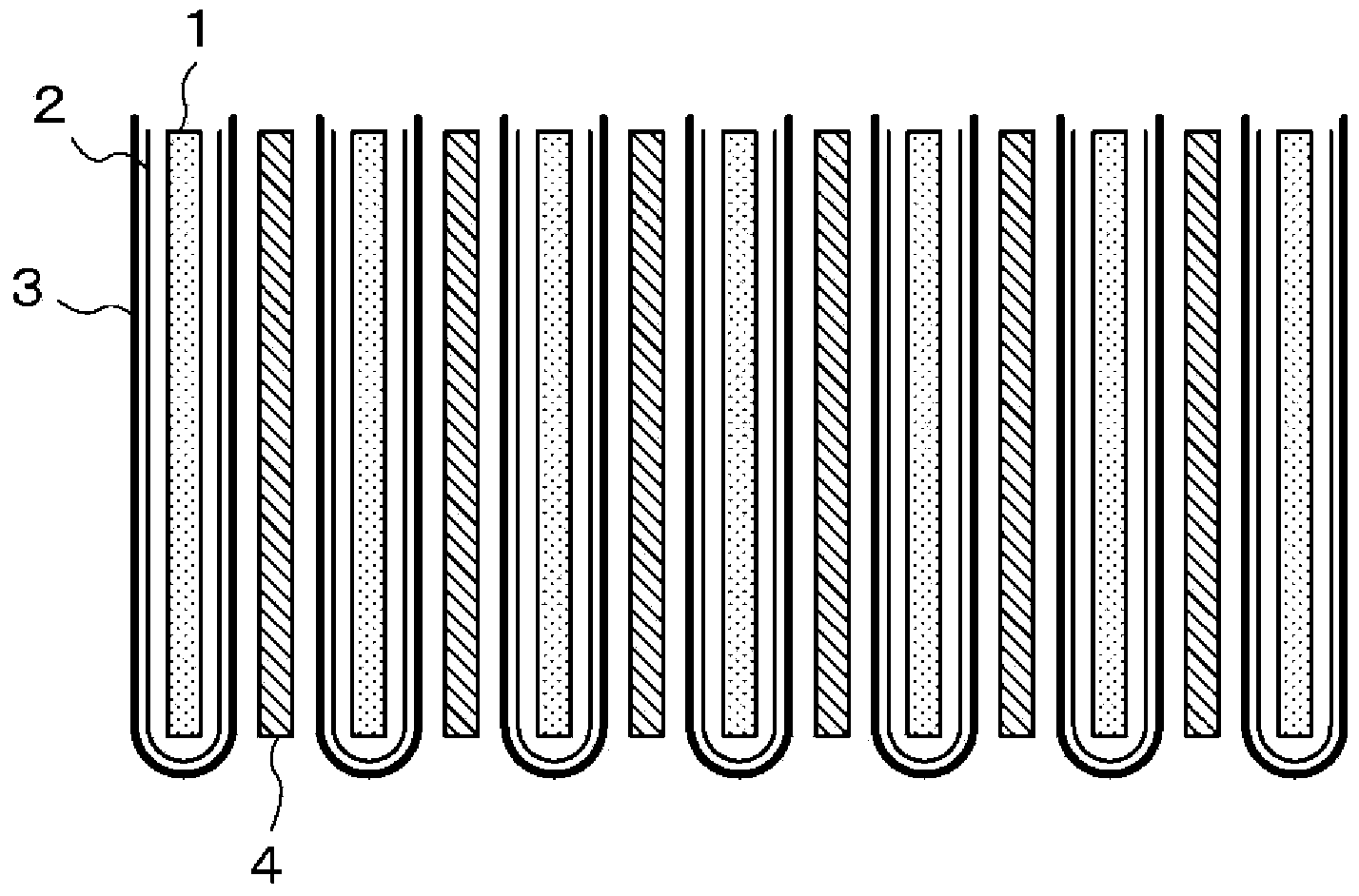

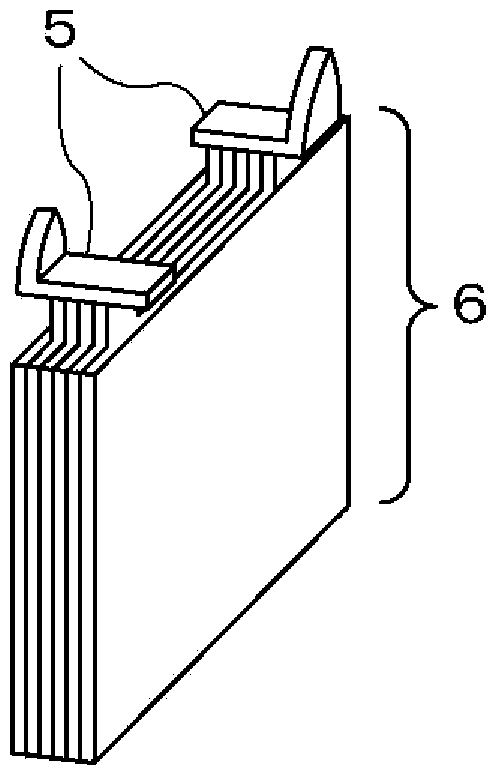

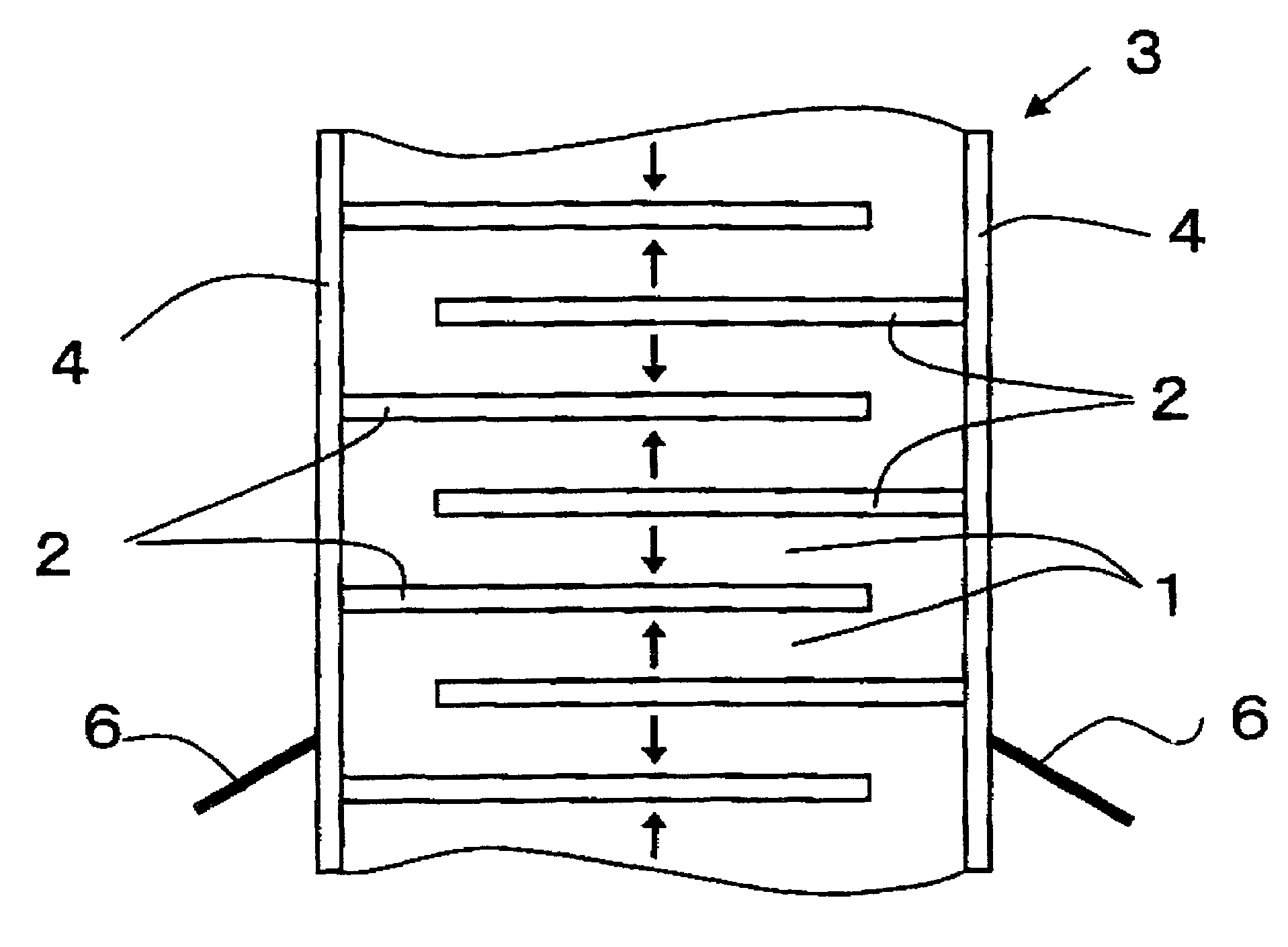

Lead battery

ActiveCN103534864APrevent fallingAvoid stratificationCell seperators/membranes/diaphragms/spacersFinal product manufactureGlass fiberElectricity

In a fluid-type lead battery in which discharging to a load is carried out in a partially charged state, since the battery does not become fully charged in a PSOC, stratification of the electrolyte is minimized, thereby improving life performance, even if agitation of the electrolyte is made difficult by gas production. On each negative plate (1), a non-woven fabric (2) composed of fibers of at least one material selected from a group of materials comprising glass, pulp and polyolefins comes into contact with the entire surface of the plate without being integrated with the plate. Each negative plate (1), which is in contact with the non-woven fabric (2), is contained in a bag-like separator (3) comprising a microporous synthetic resin sheet, and is laminated with a positive plate (4). The non-woven fabric undergoes a sheet-making process in which glass fibers, pulp and silica powder are preferably used as the main components.

Owner:RESONAC CORP

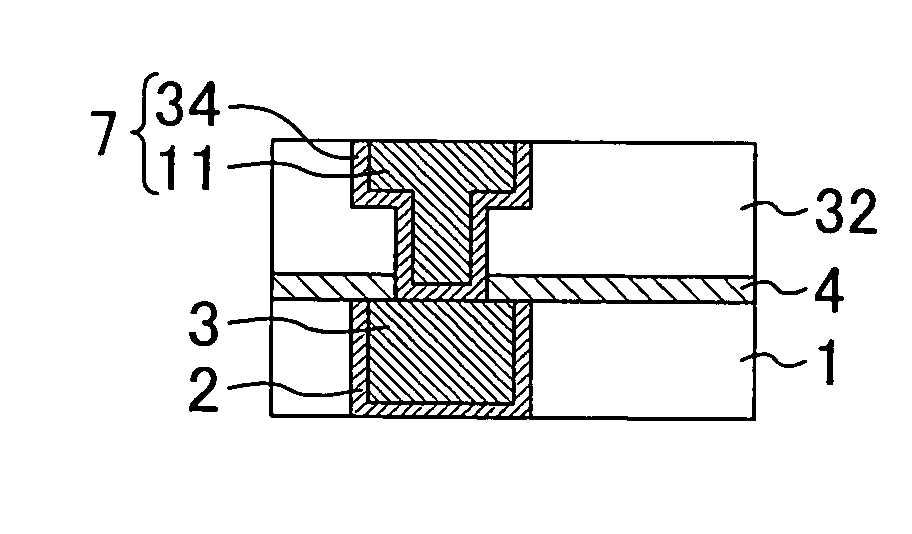

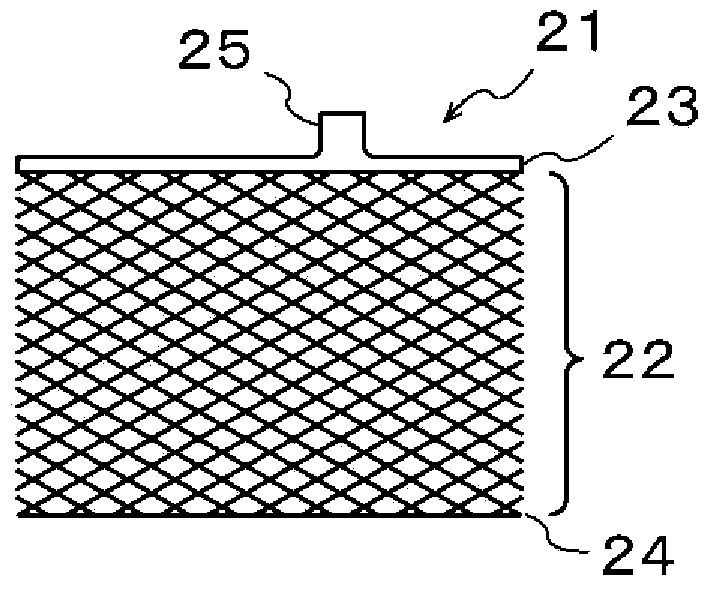

Multi-layer electronic component and method for manufacturing the same, multi-layer piezoelectric element

ActiveUS7633210B2Increased durabilityAvoid stratificationPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesElectronic componentElectron

In order to provide a multi-layer electronic component in which the occurrence of delamination between the ceramic layer and the internal electrode is restricted and a method for manufacturing the same, the multi-layer electronic component of the present invention comprises a stack formed by stacking piezoelectric layers and internal electrodes one on another alternately and a pair of external electrodes formed on two opposing side faces of the stack, wherein the internal electrode consists of a first internal electrode connected to the external electrode formed on one of the two side faces and a second internal electrode located between the first internal electrode and connected to the external electrode formed on the other one of the two side faces, and wherein the internal electrodes and the piezoelectric layers are faced in proximity so that a space between them is 2 μm or less over an area occupying 50% or more of the active region where the first internal electrode and the second internal electrode oppose each other.

Owner:KYOCERA CORP

Preparation method for three-dimensional cover glaze

The invention provides a preparation method for three-dimensional cover glaze. The preparation method comprises the following steps: I, selecting at least one monochrome from an image to prepare a silk screen plate; II, applying cover glaze on a semi-finished blank in a silk screen printing pattern, wherein the cover glaze is powder; III, baking in a kiln to obtain ceramic with the three-dimensional cover glaze. In the preparation method for the three-dimensional cover glaze, an image pre-treating scheme is adopted, and the advantage of bright color of silk screen printing is utilized, so that a ceramic product with a bright image is obtained.

Owner:XINLAILI CERAMIC DEV CO LTD

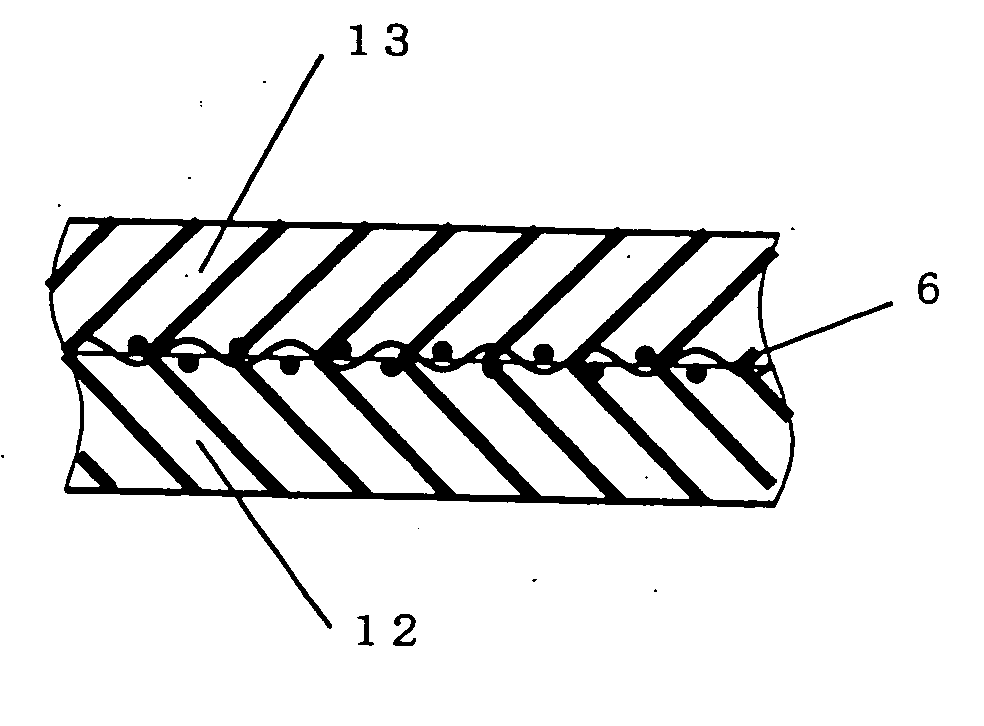

Papermaking belt and method of manufacturing papermaking belt

InactiveUS20060191658A1Prevent crack growthAvoid stratificationLiquid surface applicatorsPaper/cardboardPulp and paper industryPrepolymer

Owner:YAMAUCHI CORP

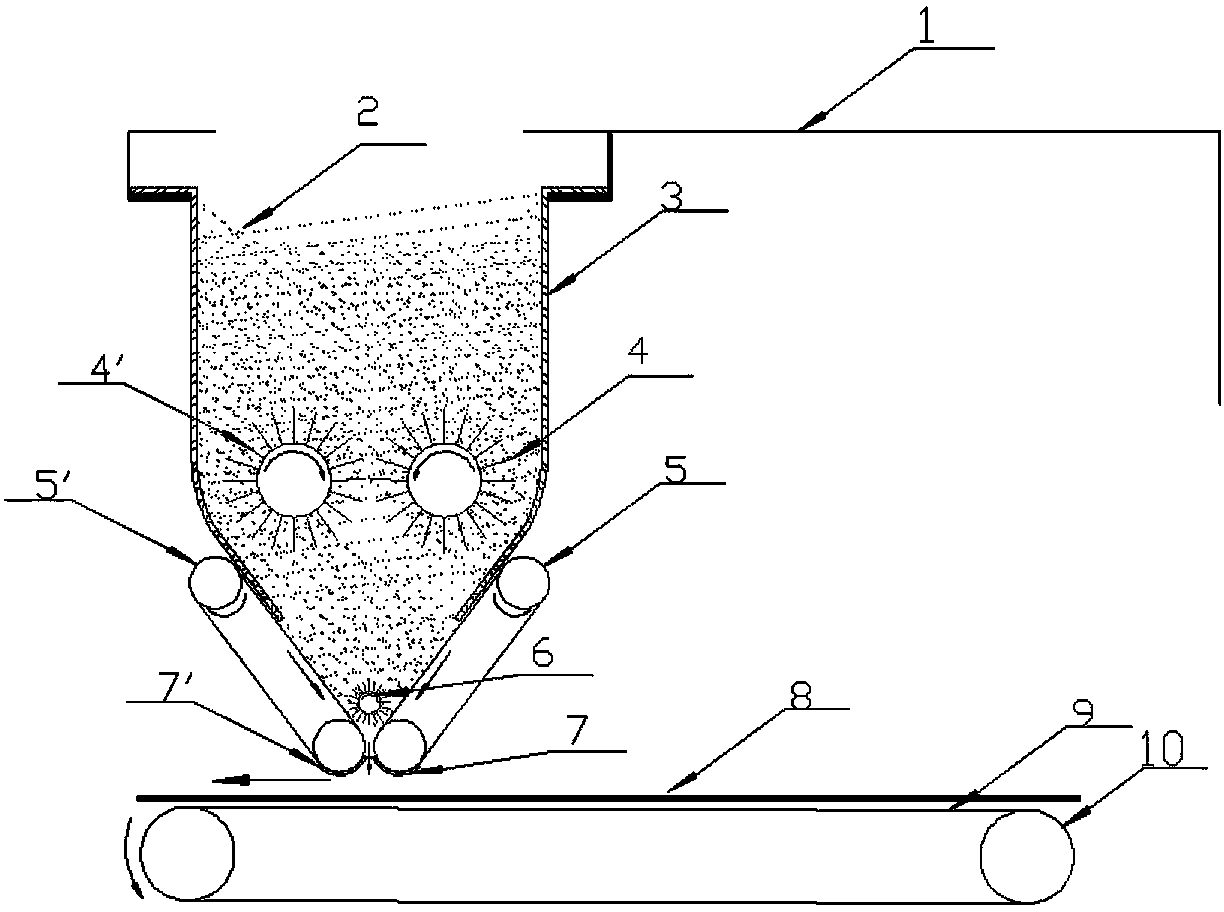

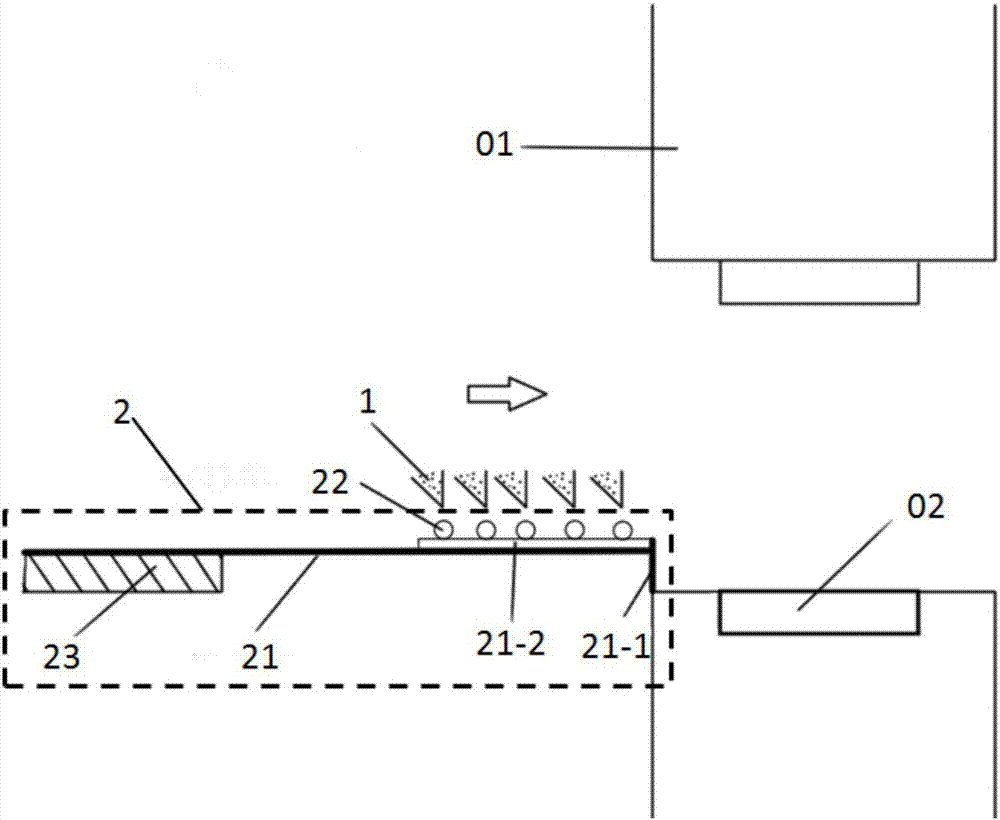

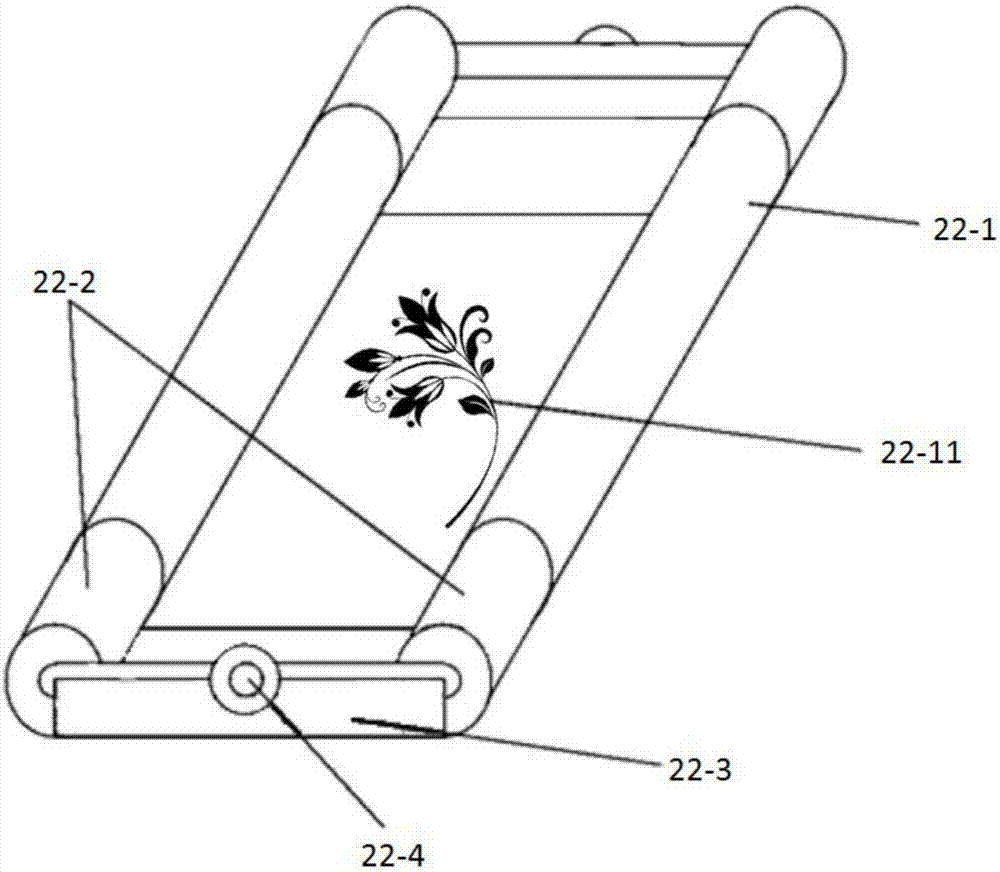

Mixed powder quantitative conveying and paving device

A mixed powder quantitative conveying and paving device comprises a silo, a powder conveying device, a powder paving device, a powder scattering device and an anti-blocking device. The powder scattering device is two large pin shafts fixed to the middle of the silo and rotating in the opposite directions, and scattering and carding are conducted on mixed powder through the powder scattering device. The anti-blocking device is a small rotatable pin shaft fixed to the upper portion of a silo outlet, and the mixed powder is prevented from being blocked through rotation, the powder conveying device comprises a symmetrically arranged and synchronously operated belt pulley pair, the two belt pulley pair is fixed in belt pulley pair bearing holes through sliding groove rails, bearing sliding blocks are fixedly arranged between spindles of the belt pulley pairs, the bearing sliding blocks can slide in the sliding groove rails, and the belt pulley pair can slide along with sliding of the bearing sliding block to adjust the size of a gap of the outlet. The mixed powder quantitative conveying and paving device is suitable for quantitative and even paving conveying of various mixed powders of different particle sizes.

Owner:CHINA THREE GORGES UNIV +1

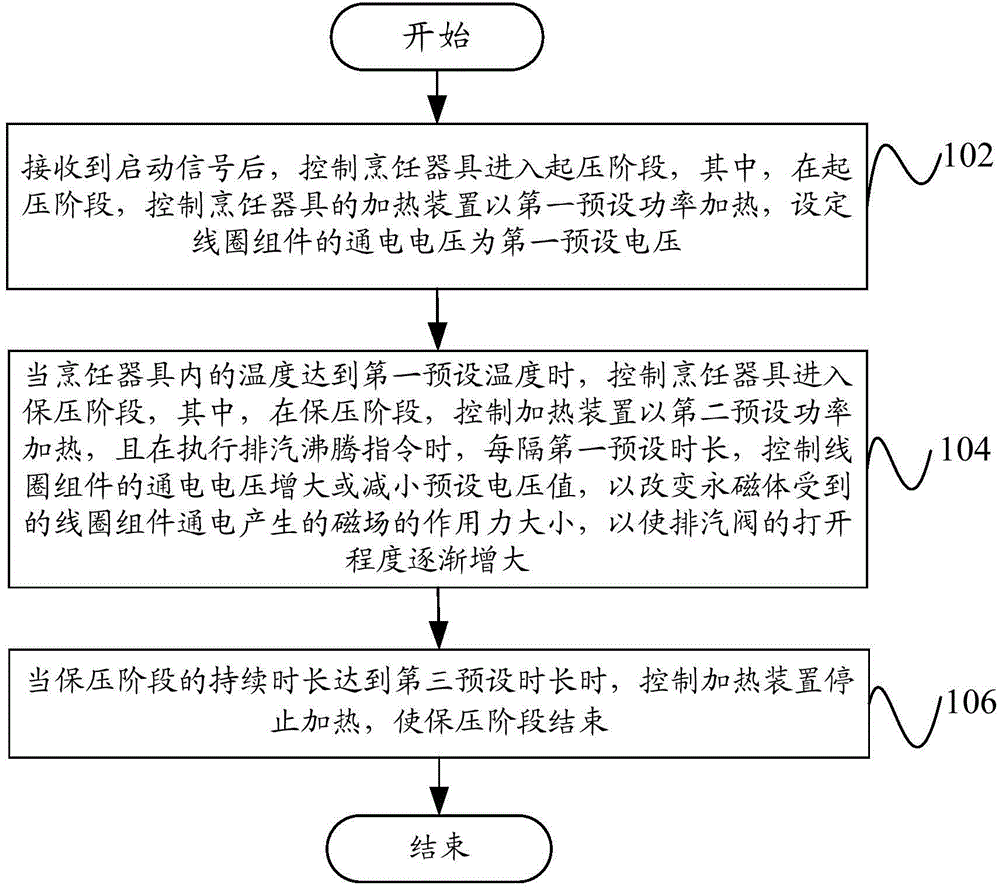

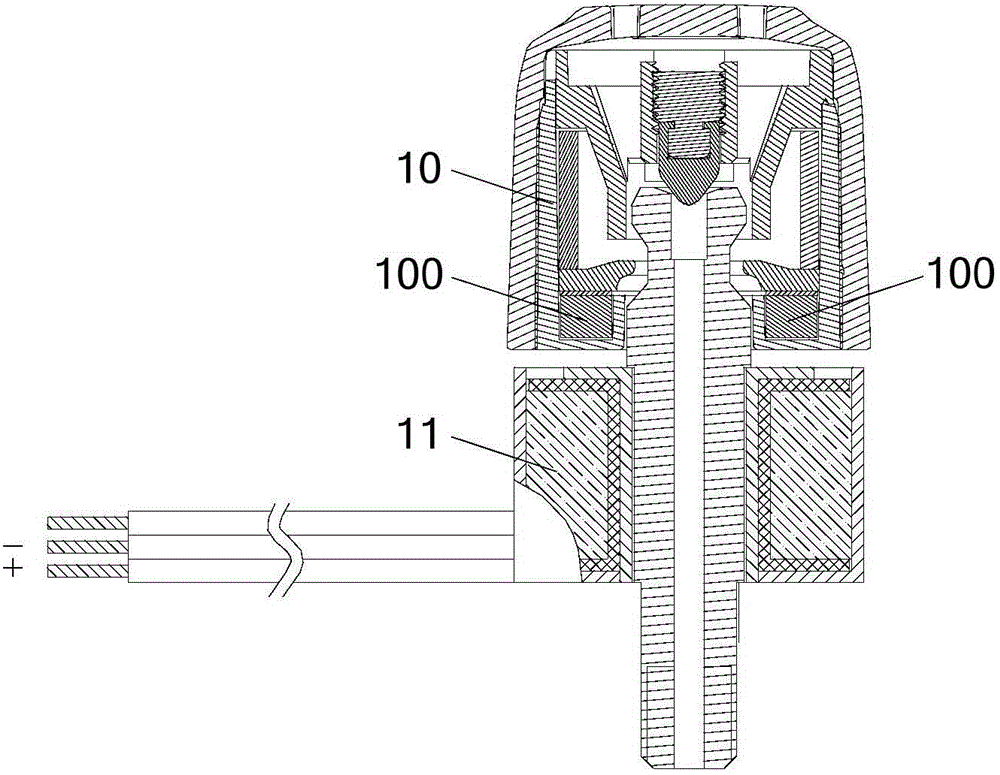

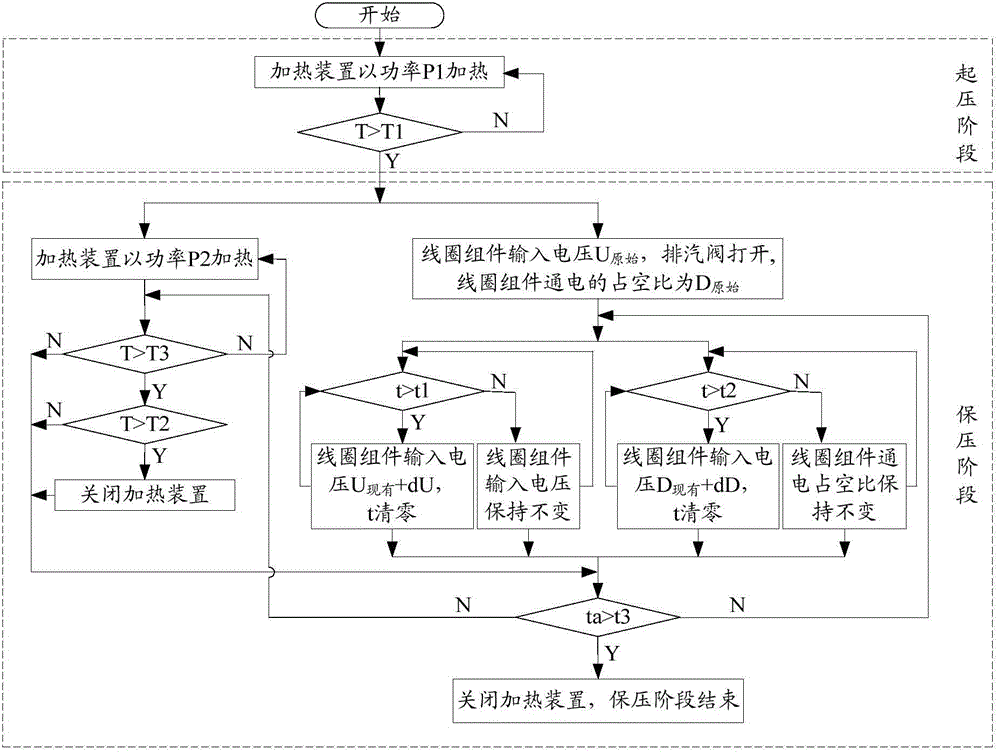

Control method, control device and cooking appliance

ActiveCN106136874AEffectively control the degree of openingRealize the boiling and tumbling effectPressure-cookersPressure riseExhaust valve

The invention provides a control method, a control device and a cooking appliance. The control method comprises the following steps: after a start signal is received, the cooking appliance is controlled to enter a pressure rising stage, a heating device of the cooking appliance is controlled for heating with first preset power, and the power-on voltage of a coil assembly is set as first preset voltage; when the temperature in the cooking appliance reaches a first preset temperature, the cooking appliance enters a pressure maintaining stage, the heating device is controlled for heating with second preset power, and third preset duration is lasted; moreover, when an exhaust and boiling order is executed, the power-on voltage of the coil assembly is controlled to increase or decrease a preset voltage value at an interval of first preset duration, so that the opening degree of an exhaust steam valve is gradually enlarged. The control method provided by the invention dynamically adjusts the magnitude of the power-on voltage of the coil assembly when the cooking appliance enters the pressure maintaining stage, so as to control the opening degree of the exhaust steam valve, effectively improve the intensity of food boiling and rolling, and improve the food cooking taste.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

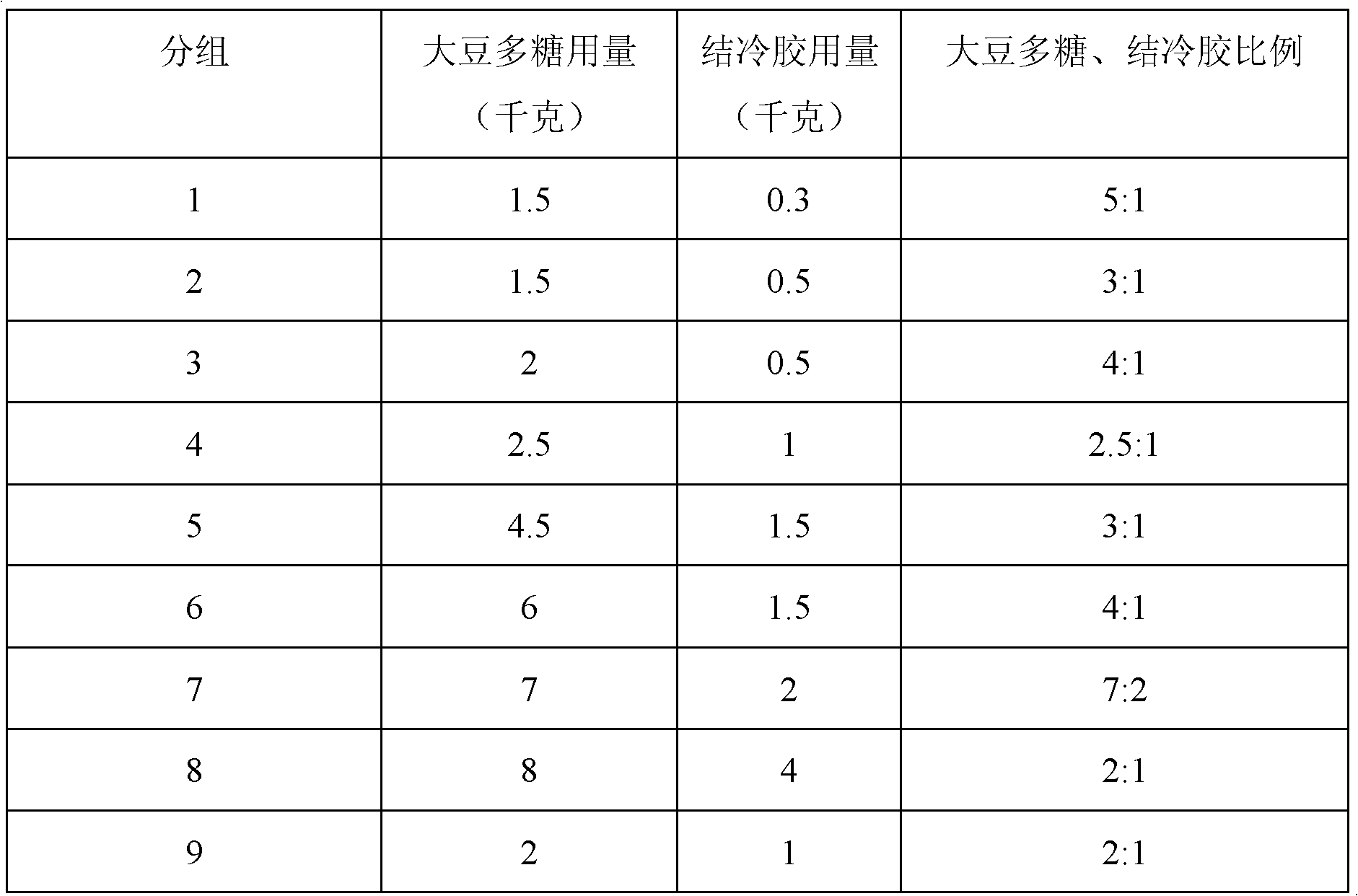

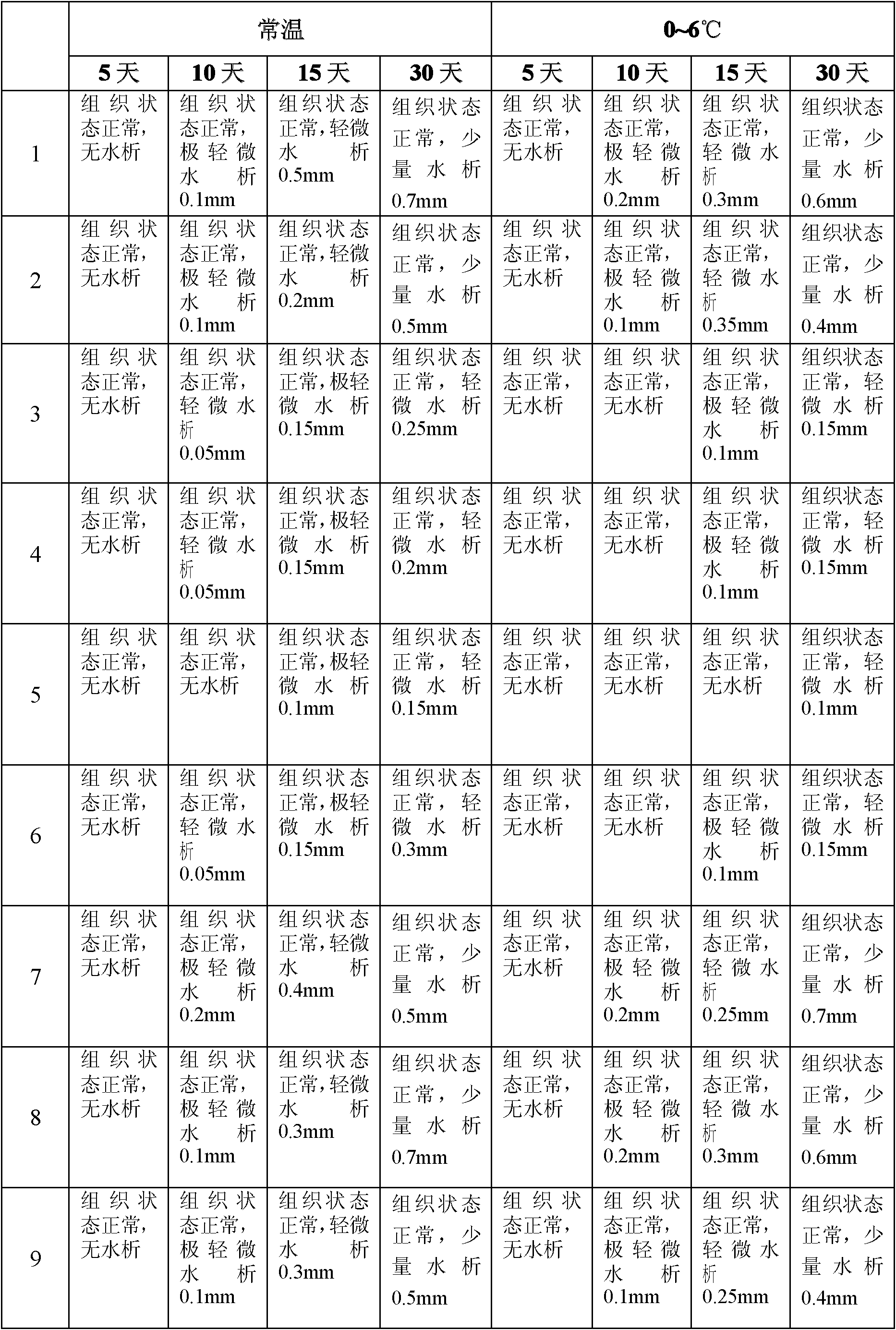

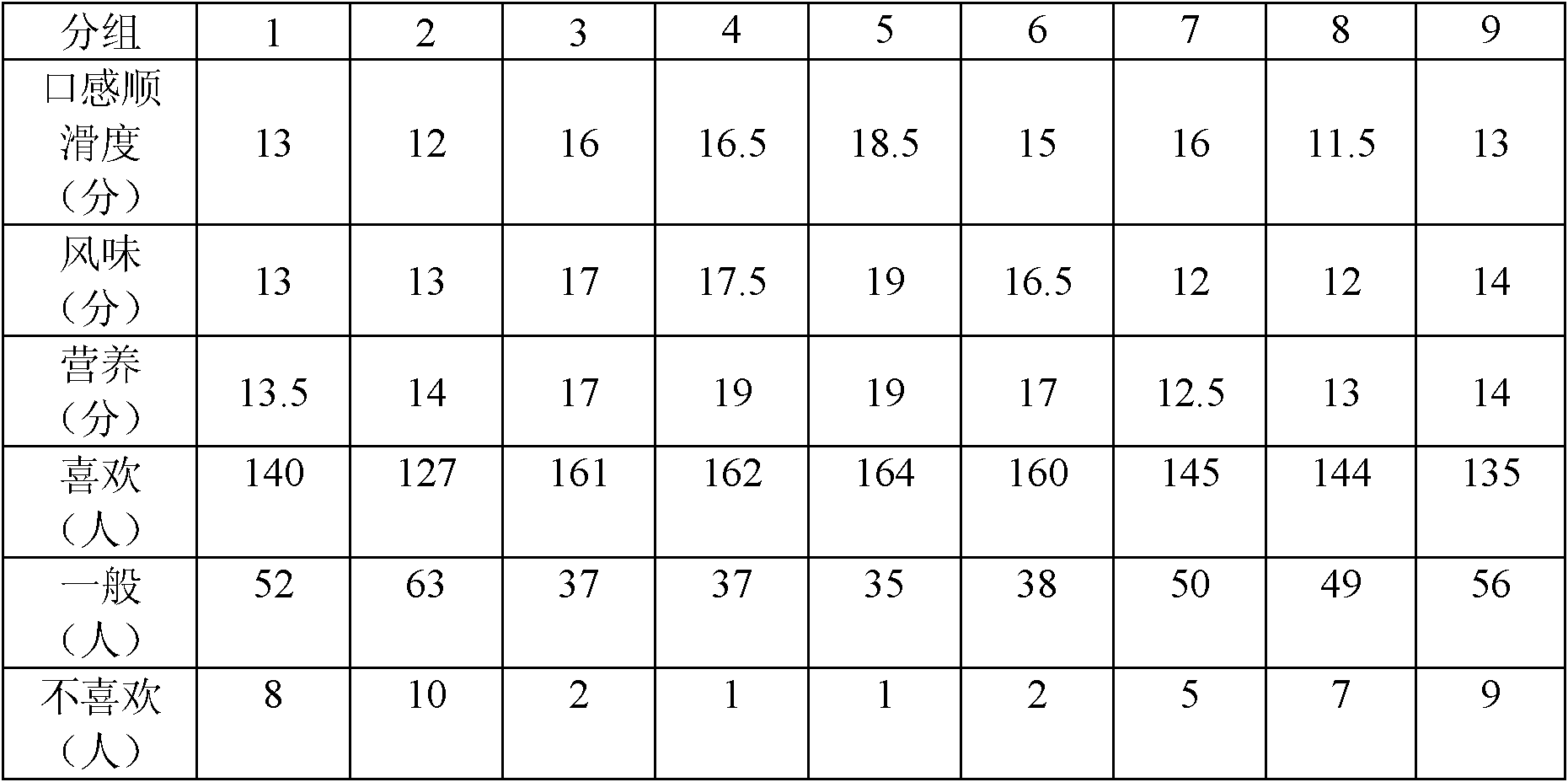

High-fiber low-sugar brown active lactobacillus beverage and preparation method thereof

The invention relates to the field of dairy processing, and particularly relates to a high-fiber low-sugar brown active lactobacillus beverage and a preparation method of the High-fiber low-sugar brown active lactobacillus beverage. The High-fiber low-sugar brown active lactobacillus beverage comprises the following materials by weight percent:25%-50% of yoghourt, 0.3-1.0% of stabilizing agent, 0.1%-0.3% of acidity regulator,0.01%-0.05% of salt material, 3%-5% of sweet material, 3.5%-5% of dietary fiber, and the balance of water. In the invention, the dietary fiber with higher content is added in the existing brown active lactobacillus beverage for improving the extra value of the brown active lactobacillus beverage product; a high-sweetness sweetener is added for replacing quantitative sugar and is combined with small amount of sugar for use, and a product-stabilizing system is reasonably established, so that the aim of low sugar is realized. Therefore, the content of sugar of the product is reduced, the product has better flavor and mouthfeel, and the phenomena of elutriation, precipitation and delamination of the product are avoided.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Preparation method of rubus parvifolius and mulberry vinegar beverage

The invention discloses a preparation method of a rubus parvifolius and mulberry vinegar beverage which adopts rubus parvifolius and mulberries as the main raw materials. The preparation method comprises the following steps: raw material juicing, enzymolysis, ultra-high temperature sterilization, alcohol fermentation, acetic fermentation, filtration, blending, homogenization, sterilization, filling and storage. The preparation method for the rubus parvifolius and mulberry vinegar beverage which is comprehensive in nutrition and pure in taste can fully maintain the nutrient substances of both rubus parvifolius and mulberries, improves the raw material utilization ratio, enables the end rubus parvifolius and mulberry vinegar beverage to be stable in color through homogenization, avoids delamination and precipitation, reduces damage to the active ingredient through ultra-high temperature sterilization, and ensures that the finished product of rubus parvifolius and mulberry vinegar beverage has the effects of promoting the production of body fluid to relieve thirst, benefiting liver and kidney, promoting the production of body fluid to moisten the intestines, blacking hair and improving eyesight, promoting digestion and the like.

Owner:彭常安

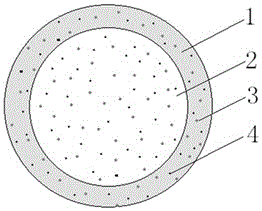

Microcapsule phase change material and preparation method thereof

InactiveCN106753261AAvoid stratificationImprove physical stabilityHeat-exchange elementsHigh densityNanoparticle

The invention provides a microcapsule phase change material. The microcapsule phase change material comprises a core material, wherein a wall material is arranged on the outer side of the core material; aluminum nanoparticles and graphite nanoparticles are contained in both the core material and the wall material. The invention further provides a preparation method of the microcapsule phase change material. The preparation method comprises the following steps: weighing the core material and the wall material; preparing a mixture of the aluminum nanoparticles and the graphite nanoparticles; determining the composite content of the nanoparticles; preparing a composite solution of the core material; preparing a composite solution of a first wall material; moulding a microcapsule; washing and drying the microcapsule. According to the microcapsule phase change material provided by the invention, three characteristics are improved at the same time by adding the composite aluminum and graphite nanoparticles into the core material and the wall material, namely the particle density of the microcapsule phase change material is adjusted, the thermal conductivity is increased, and the overcooling degree is reduced; the microcapsule phase change material which contains the composite aluminum and graphite nanoparticles and has high density, high thermal conductivity and low overcooling degree is obtained.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Preparation method of dry powder ceramic tile and green tile thereof, and finished product

ActiveCN107337427AThe solution is not fine enoughAddress controllabilityFeeding arrangmentsCeramic materials productionGreen materialsMaterial distribution

The invention relates to a preparation method of a dry powder ceramic tile and a green tile thereof, and a finished product. The preparation method of the green tile comprises the following steps: A. bottom material distribution; B. facing material distribution in press mold cavity: distributing one or a plurality of dry powders on a green material layer by using a screen provided with a hollow decorating pattern; and C. punch forming. In the method, the step A and step B are in no particular order, the step A-C sequence is a reverse punching mode; and when the step A and step B are in the reverse order, the sequence is a forward punching mode. The invention provides the preparation method of the dry powder ceramic tile and green tile thereof; and the method solves the problem that the decorative pattern is not fine enough and is not controllable or variable in the existing powder full-body tile or unglazed ceramic tile. In addition, according to the semifinished product green tile and the finished product ceramic tile, the decorative effects on the tile surfaces are wear-resistant; and the surface of the ceramic tile can be subjected to slot broaching, trimming or chamfering, and the exposed part of the cut surface has the same pattern, texture and tactile sensation as the surface of the ceramic tile, thereby enhancing the grade of the decorating effect of the ceramic tile and widening the application range of the ceramic tile.

Owner:FOSHAN DONGPENG CERAMIC +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com