Mixed powder quantitative conveying and paving device

A technology for mixing powder and powder conveying, which is applied in the direction of conveyor objects, transportation and packaging to avoid agglomeration, avoid delamination, and achieve accurate control and paving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

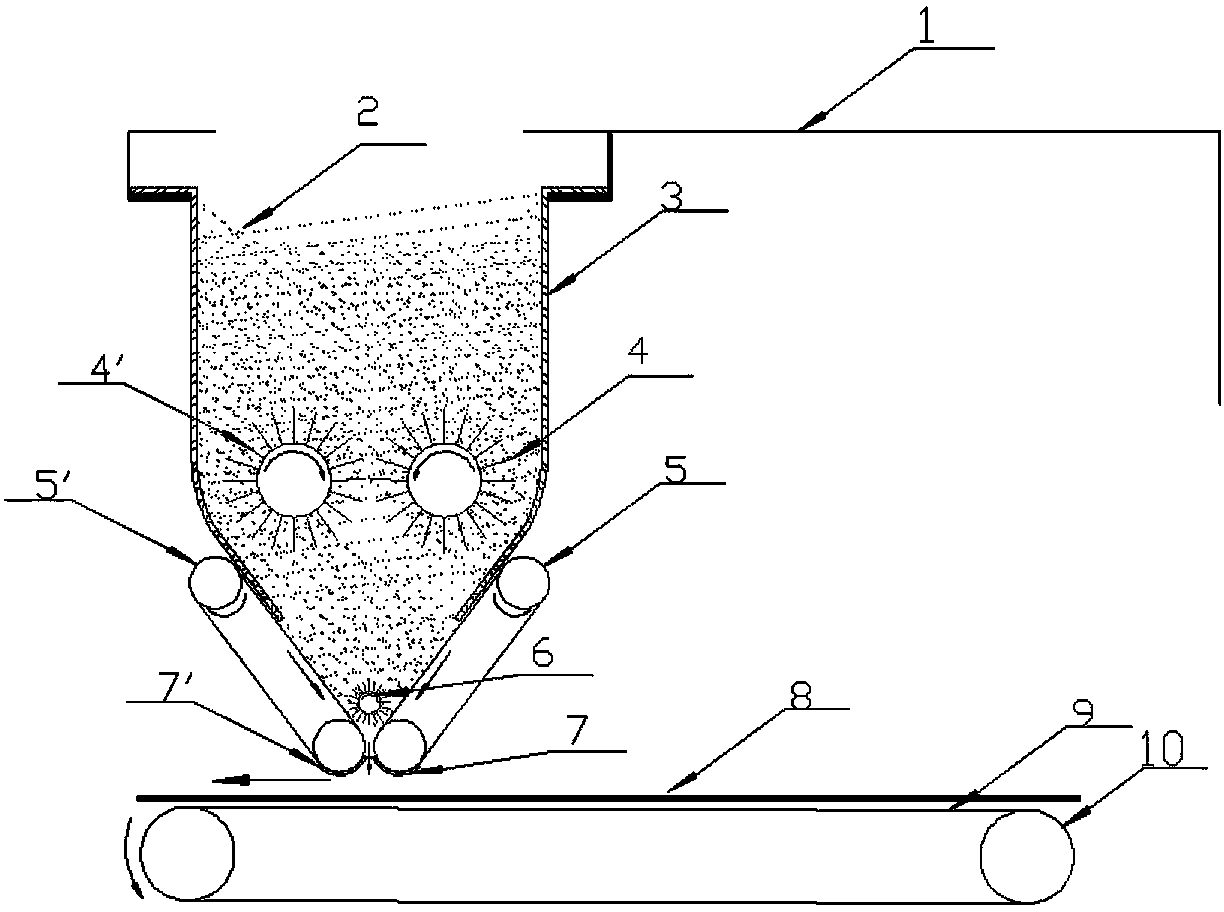

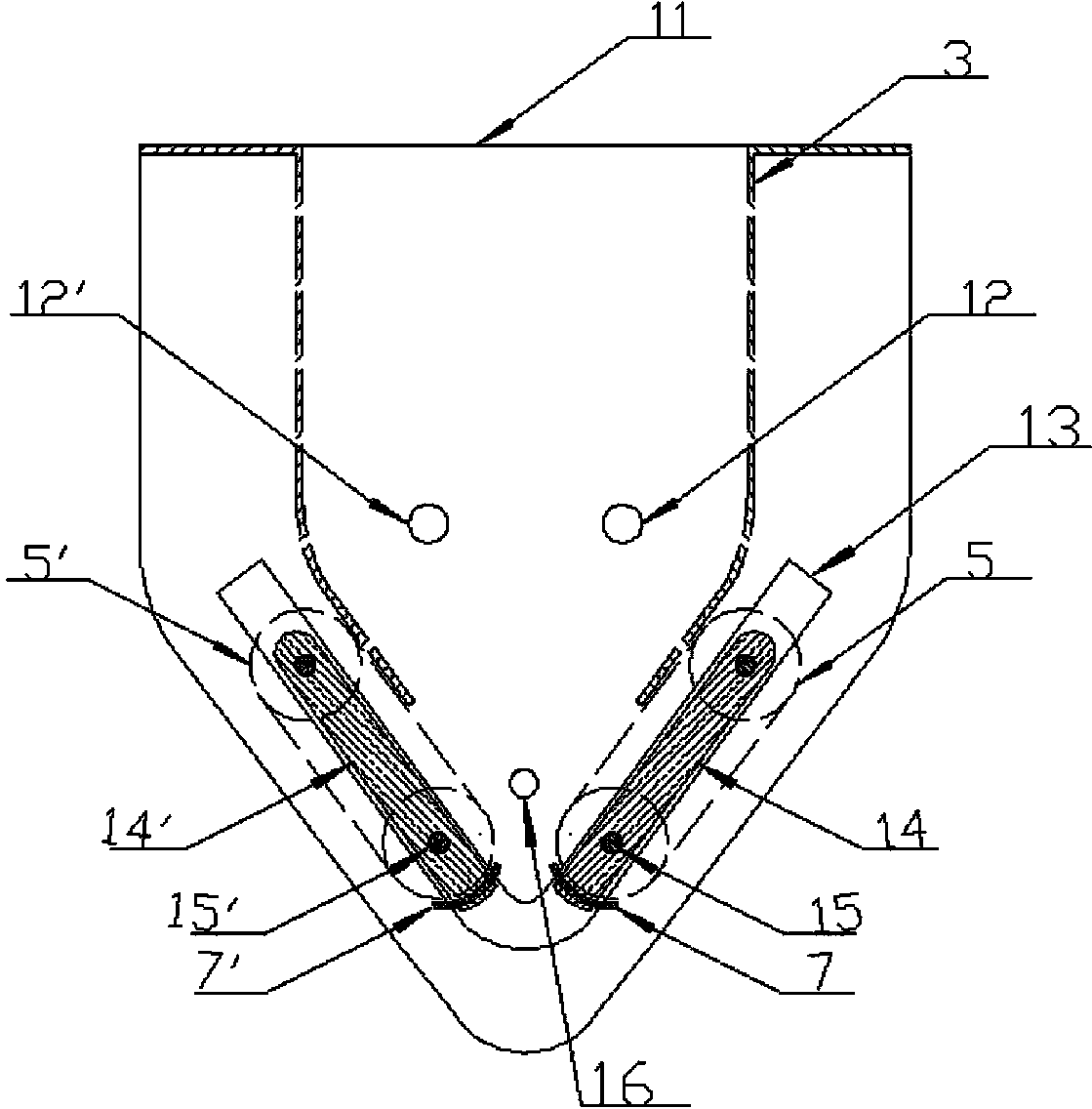

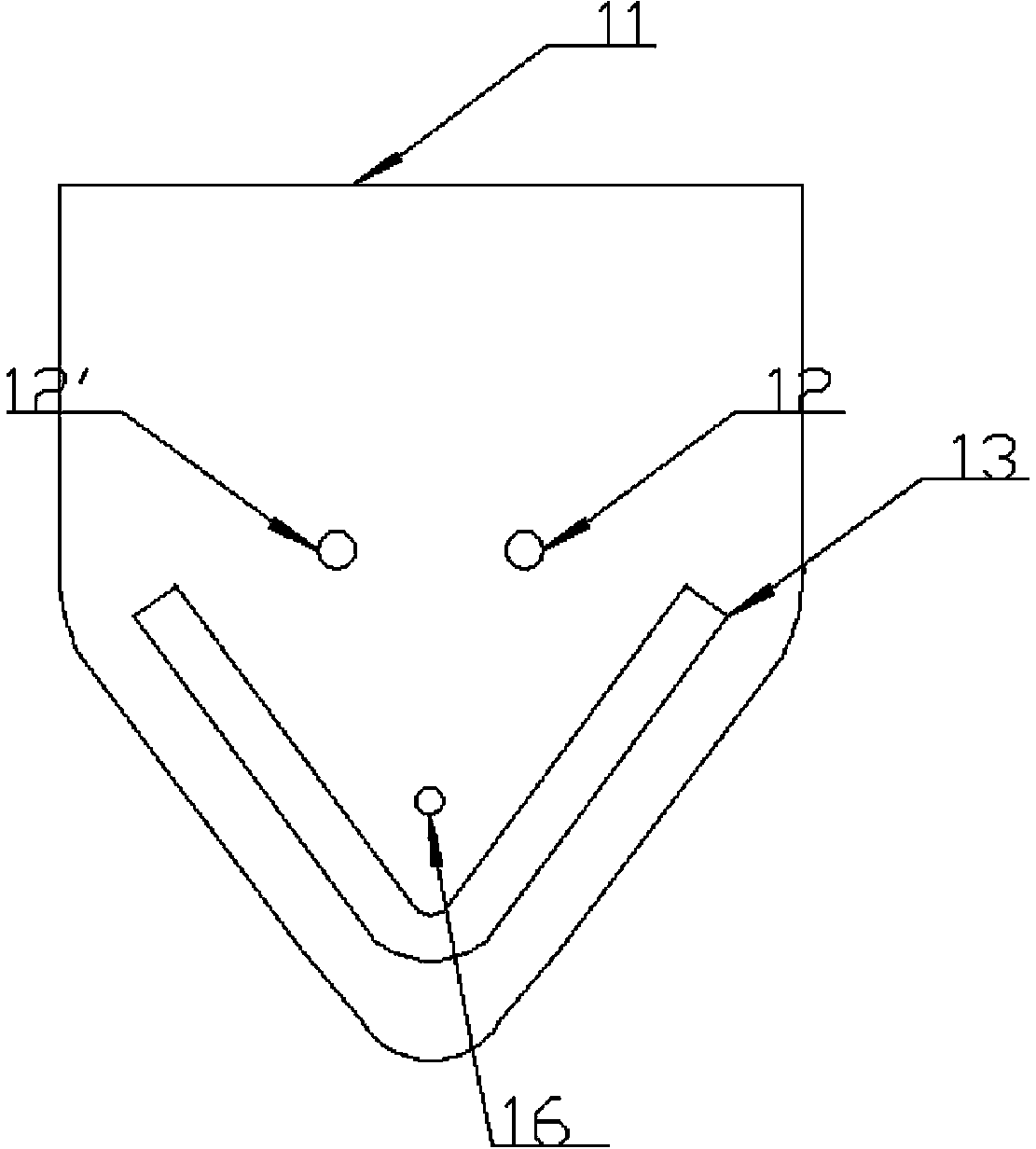

[0023] figure 1 It is a schematic diagram of the structure principle of the present invention. The mixed powder quantitative conveying and paving device includes a silo 3, a powder conveying device, a powder paving device, a powder dispersing device and an anti-blocking device.

[0024] The powder dispersing device is two oppositely rotating large needle shafts 4, 4' fixed in the middle of the silo 3, and the two large needle shafts 4, 4' are symmetrically installed in the large needle shaft bearing holes on the front and rear walls of the silo 3 via the main shaft. 12, within 12'.

[0025] The anti-blocking device is a rotatable small needle shaft 6 fixed on the upper part of the feed bin outlet, and the small needle shaft 6 is installed in the small needle shaft bearing hole 16 of the front and rear walls of the feed bin 3 through the main shaft.

[0026] The feed bin 3 is fixed on the support 1, and the support 1 can move up and down.

[0027] The powder conveying device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com