High-fiber low-sugar brown active lactobacillus beverage and preparation method thereof

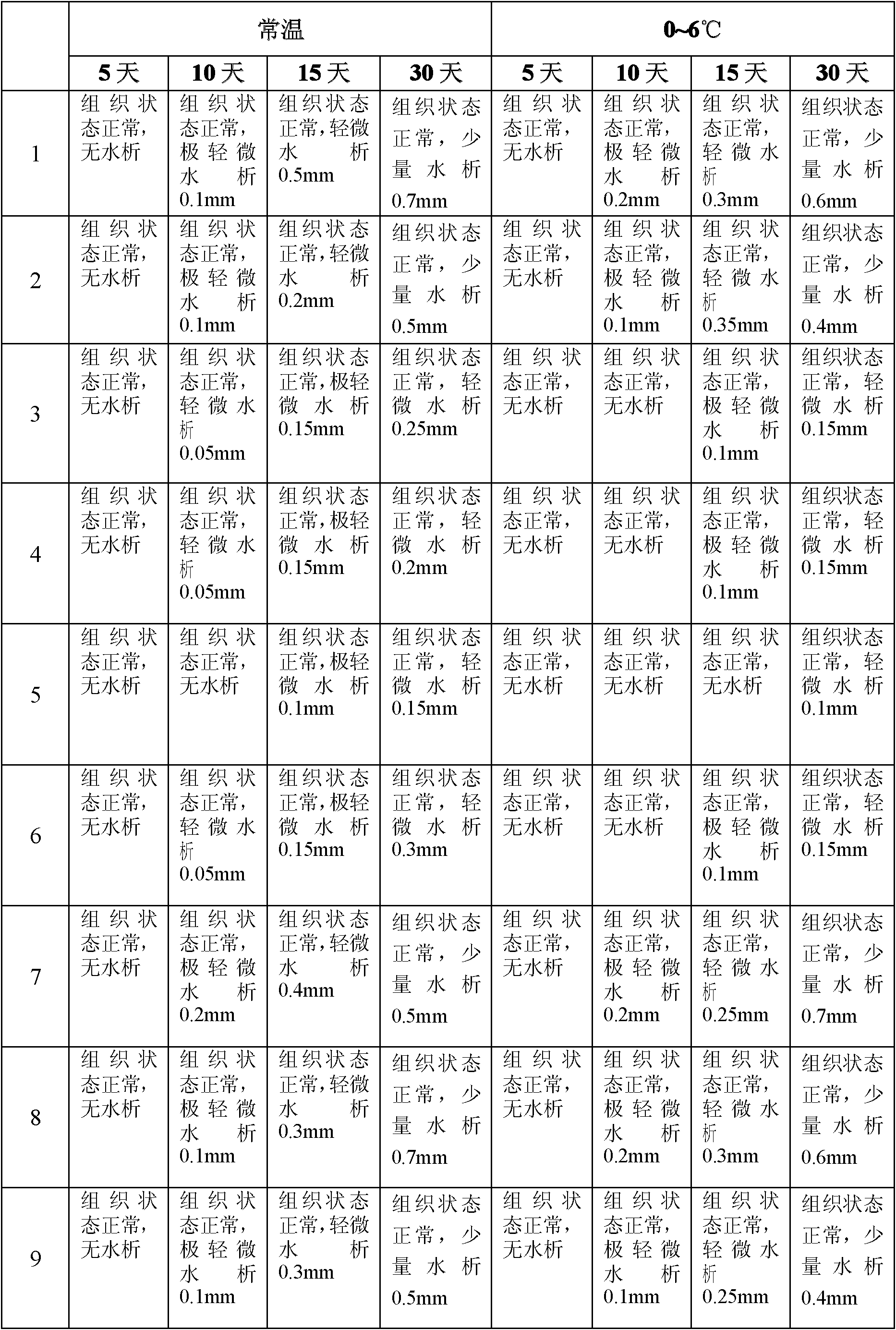

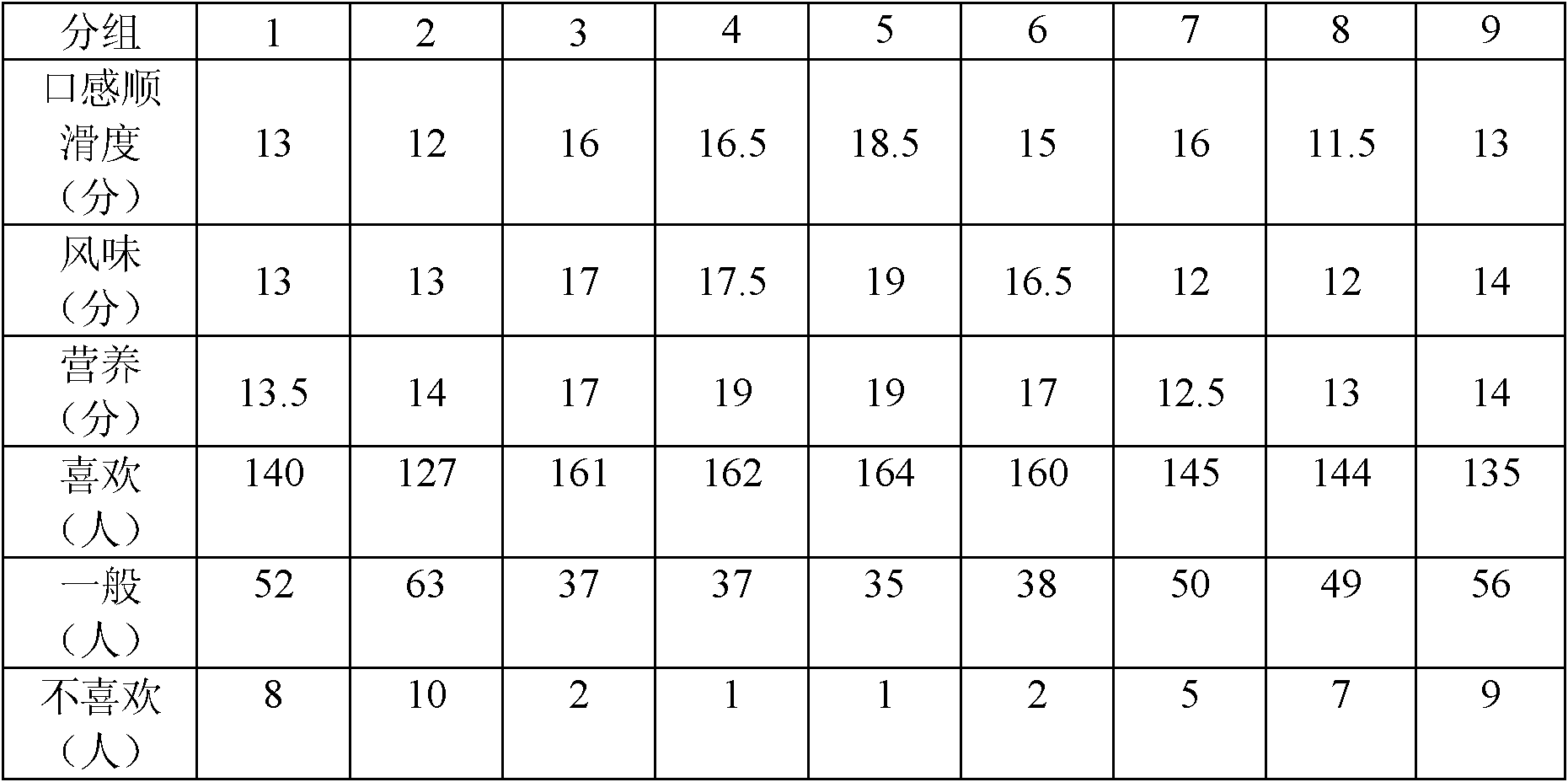

A technology of active lactic acid bacteria and sugar type, used in dairy products, milk preparations, applications, etc., can solve the problems of precipitation and stratification, decrease in beverage viscosity, water precipitation, etc., and achieve reduced sucrose content, good stability, and rich nutrition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1 prepares yoghurt

[0053] Yogurt raw materials include 70%-90% of milk, 0.5%-0.8% of anhydrous glucose, 0.1%-8% of white granulated sugar, 0.02%-0.05% of fermented bacteria and water as the balance.

[0054] The preparation method comprises the following steps:

[0055] 1. Add batching water into the chemical tank and heat to 45-50°C. In the state of stirring the ingredients with water, dry mix the milk, white sugar and anhydrous glucose, then slowly add them into the chemical tank through the sieve, and stir to disperse. After the solid is fully dissolved, stand at constant temperature and hydrate for 30-40 minutes to obtain a feed liquid.

[0056] 2. Homogenize the feed liquid with a pressure of 50 / 180 Bar.

[0057] 3. The homogenized feed liquid is subjected to browning at 121°C / 10min or 95°C / 120min.

[0058] 4. Cool down the browned feed solution to the inoculation temperature of 36-38°C.

[0059] 5. When the cooled feed liquid enters the yogurt fe...

Embodiment 2

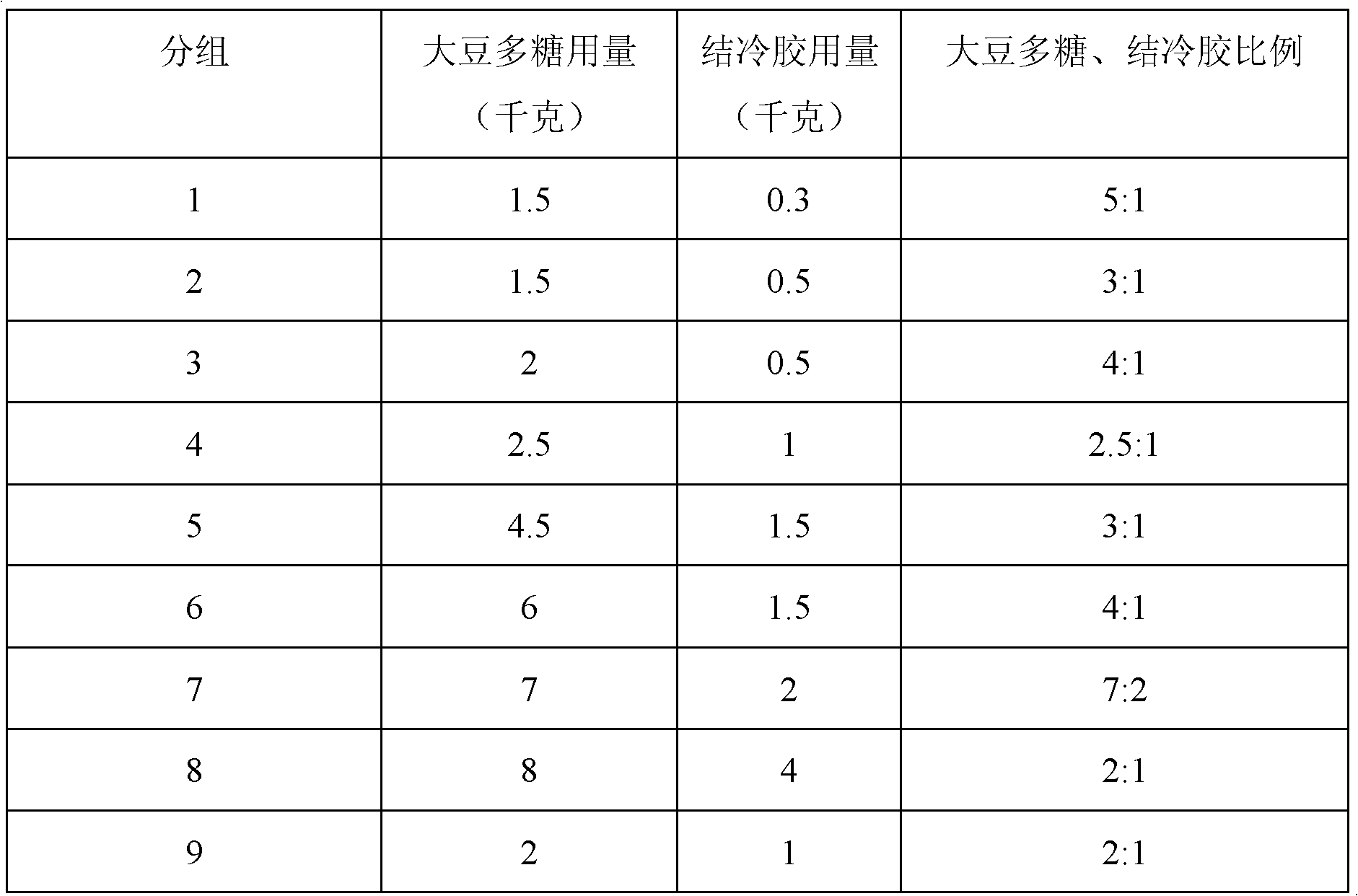

[0062] Embodiment 2, high-fiber low-sugar type brown active lactic acid bacteria beverage (1000 kilograms)

[0063] Yogurt: 250 kg;

[0064] White sugar: 2 kg

[0065] Neotame: 1 kg;

[0066] Polydextrose: 30 kg;

[0067] Isomalto-oligosaccharide: 20 kg;

[0068] Soybean polysaccharide: 2 kg;

[0069] Gellan gum: 0.5 kg;

[0070] Monoglyceride tartrate: 0.5 kg;

[0071] Lactic acid: 2 kg;

[0072] Citric acid: 1 kg;

[0073] Sodium citrate: 0.1 kg;

[0074] Purified water up to: 1000 kg.

[0075] The preparation method comprises the following steps:

[0076] 1) Add pure water for ingredients into the chemical tank and heat to 90-95°C. In the state of stirring the ingredients with water, slowly add the dry mixture such as dietary fiber, sweetener, stabilizer, and salt into the chemical tank through the screen, and stir and disperse for 15-20 minutes;

[0077] 2) Cool the dispersed feed liquid below 20°C;

[0078] 3) Add the yogurt into the cooled feed liquid and mi...

Embodiment 3

[0083] Embodiment 3, high-fiber low-sugar type brown active lactic acid bacteria beverage (1000kg)

[0084] Yogurt: 350 kg;

[0085] White sugar: 2 kg

[0086] Acesulfame K: 1 kg;

[0087] Aspartame: 1 kg;

[0088] Fructo-oligosaccharide: 35 kg;

[0089] Soybean polysaccharide: 4.5 kg;

[0090] Gellan gum: 1.5 kg;

[0091] Glyceryl monostearate: 0.5 kg;

[0092] Polyglycerol ester: 0.5 kg;

[0093] Sodium stearoyl lactylate: 1 kg

[0094] Malic acid: 2 kg;

[0095] Sodium tripolyphosphate: 0.3 kg;

[0096] Sodium citrate: 0.2 kg;

[0097] Purified water up to: 1000 kg.

[0098] The preparation method is the same as in Example 2.

[0099] The protein content of the high-fiber and low-sugar brown active lactic acid bacteria beverage in this embodiment is about 1.05%, the pH value is about 3.5-3.7, the acidity is 60-70°T, and the sucrose content is 3.6g / 100mL. The overall state of the product is uniform, and the taste is full and smooth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com