Chocolate composition, coating layer and preparation method thereof and frozen drink coated with the coating layer

A chocolate coating and chocolate technology, which is applied in frozen desserts, food science, food ingredients as taste improvers, etc., can solve the problems of coating hanging or thick coating, chocolate coating hanging or coating thickness unevenness, etc. Achieve the effects of improving fluidity, improving coating effect and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

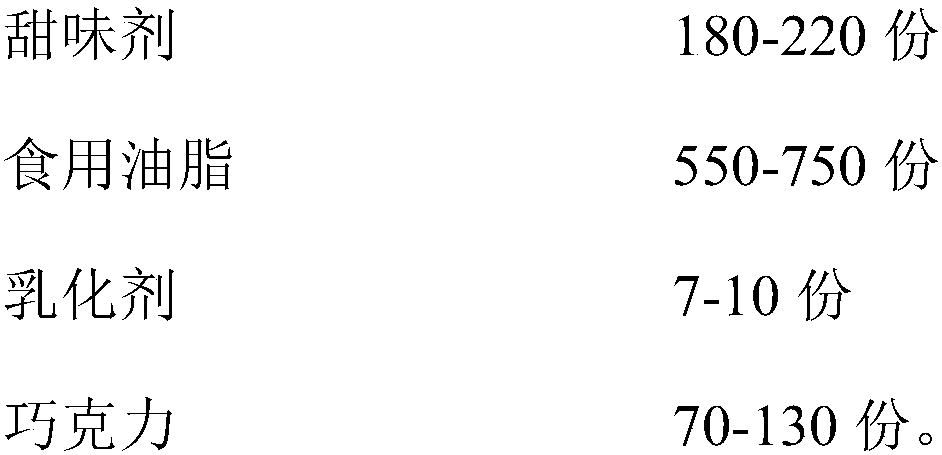

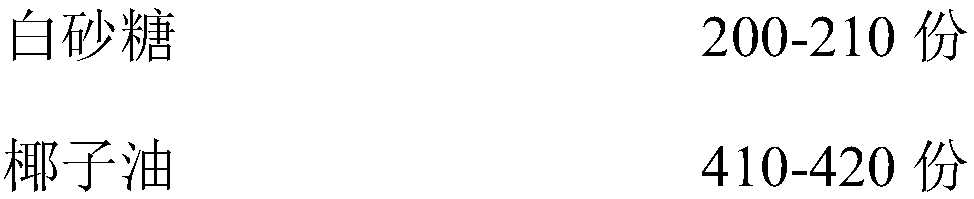

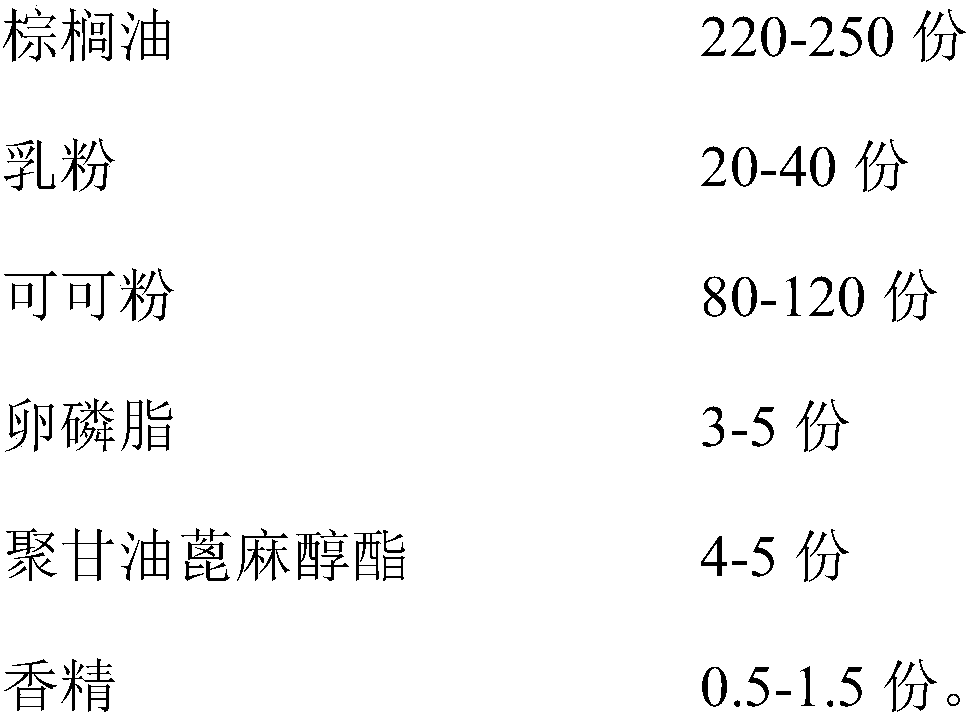

[0041] This embodiment provides a chocolate composition, which is composed of the following raw materials in terms of 1000 kg: 210 kg of white granulated sugar, 420 kg of coconut oil, 250 kg of palm oil, 20 kg of whole milk powder, 90 kg of low-fat cocoa powder, 5 kg of lecithin, polyglycerin Ricinol ester 4kg and essence 1kg;

[0042] A chocolate coating obtained by coating the above-mentioned chocolate composition, the coating thickness of which is less than 1mm;

[0043] The preparation method of above-mentioned chocolate coating, comprises the steps:

[0044] 1) Coconut oil and palm oil are preheated and melted at a temperature <60°C, mixed to obtain a mixed oil for use, and the white sugar is crushed and ground into powder for use;

[0045] 2) Mix and stir low-fat cocoa powder, crushed white granulated sugar, and 268kg of mixed oil (accounting for 40% of the total mass of mixed oil), and then pre-grind it until the material fineness reaches 100 μm, and finally put it und...

Embodiment 2

[0052] This embodiment provides a kind of chocolate composition, by 1000kg, is made up of following raw material: white granulated sugar 200kg, coconut oil 420kg, palm oil 240kg, whole milk powder 30kg, medium-fat cocoa powder 100kg, lecithin 5kg, polyglycerin Ricinol ester 4kg and essence 1kg;

[0053] A chocolate coating obtained by coating the above-mentioned chocolate composition, the coating thickness of which is less than 1mm;

[0054] The preparation method of above-mentioned chocolate coating, comprises the steps:

[0055] 1) Coconut oil and palm oil are preheated and melted at a temperature <60°C, mixed to obtain a mixed oil for use, and the white sugar is crushed and ground into powder for use;

[0056] 2) Mix and stir medium-fat cocoa powder, crushed white granulated sugar and an appropriate amount of mixed oil (accounting for 35% of the total mass of the mixed oil), then pre-refined it until the material fineness reaches 90 μm, and finally refined it at 40°C Grin...

Embodiment 3

[0063] This embodiment provides a chocolate composition, which is composed of the following raw materials in terms of 1000 kg: 200 kg of white granulated sugar, 410 kg of coconut oil, 230 kg of palm oil, 30 kg of skim milk powder, 120 kg of high-fat cocoa powder, 5 kg of lecithin, polyglycerin castor 4kg of steroidal alcohol ester and 1kg of essence;

[0064] A chocolate coating obtained by coating the above-mentioned chocolate composition, the coating thickness of which is less than 1mm;

[0065] The preparation method of above-mentioned chocolate coating, comprises the steps:

[0066] 1) Coconut oil and palm oil are preheated and melted at a temperature <60°C, mixed to obtain a mixed oil for use, and the white sugar is crushed and ground into powder for use;

[0067] 2) Mix and stir high-fat cocoa powder, crushed white granulated sugar and an appropriate amount of mixed oil (accounting for 45% of the total mass of the mixed oil), and then pre-refine it until the material fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com