Yarn winding machine

A yarn winding machine and yarn technology, applied in textiles and papermaking, conveying filamentous materials, thin material processing, etc., can solve the problem of increased slack in the bobbin, and achieve the effect of a simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

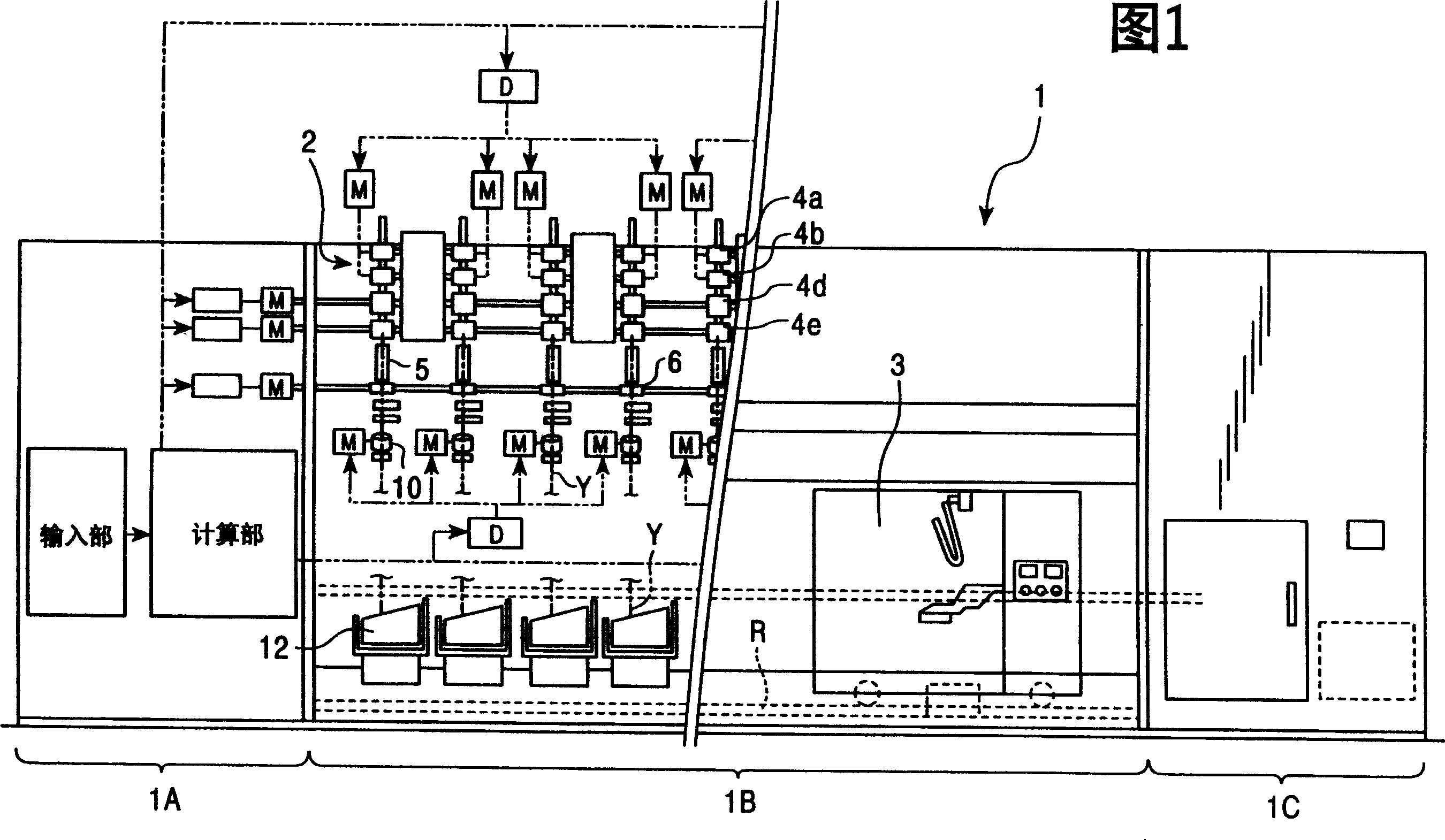

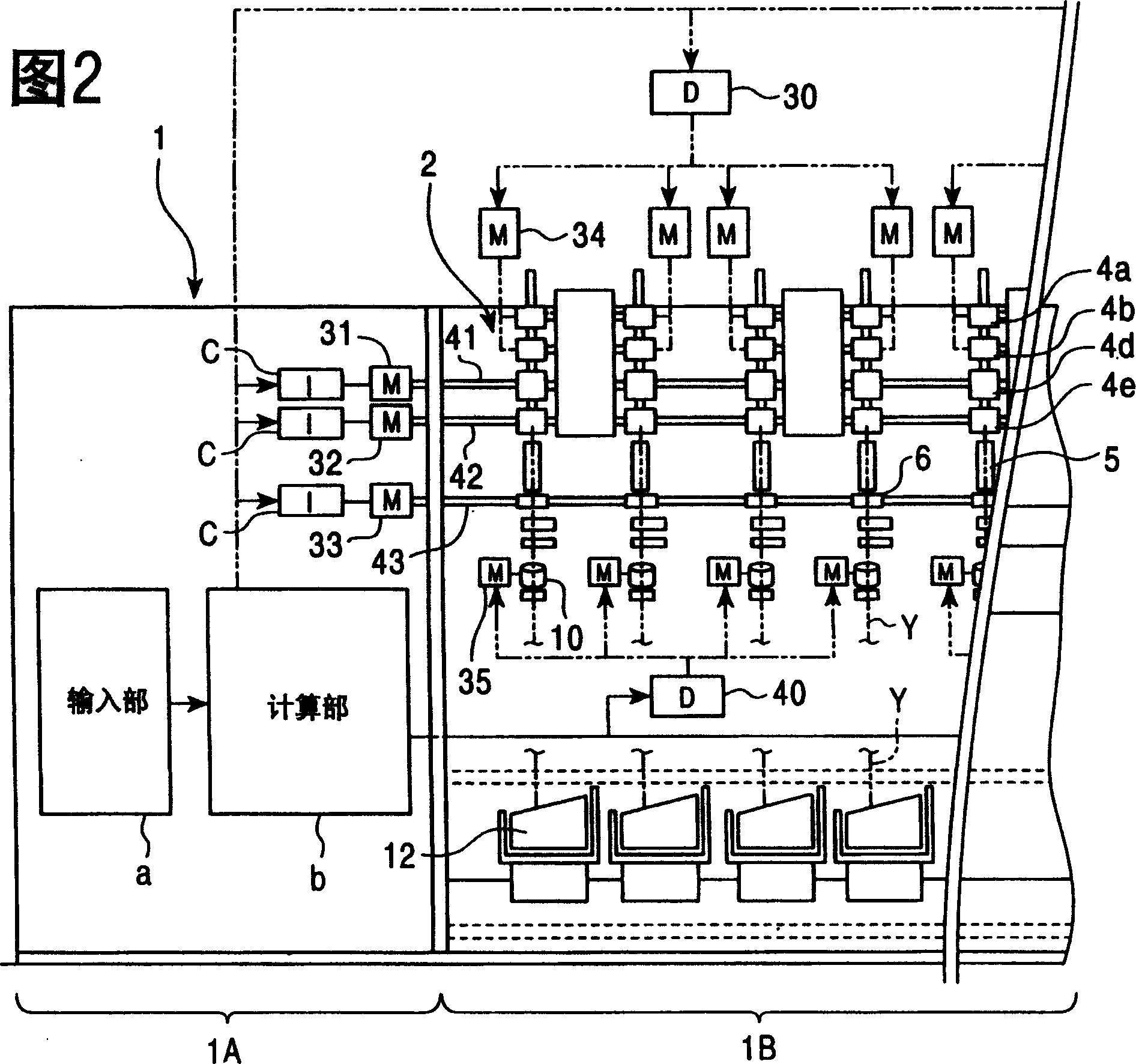

[0032] Fig. 1 is a front view of an example of a spinning machine 1 to which the present invention is applied. FIG. 2 is a schematic enlarged view of a part of the internal structure of the spinning machine 1 .

[0033] The spinning machine is constituted by, for example, an air spinning machine. The main components of the spinning machine 1 include: a control section 1A; a spinning section 1B, in which a large number of spinning units 2 are arranged side by side; a blower section 1C; and a work trolley 3, which includes a yarn Splicing device, and can run freely between the spinning units 2 along the track R. In the present embodiment, the spinning machine 1 is used to form cone yarns, however, it may also be used to form parallel cheese packages.

[0034] The control section 1A of the spinning machine 1 implements the following control: controlling the operation of the drive motors 31, 32, 33 of the drive shafts 41, 42, 43 for supplying all spinning units 2 constituting th...

no. 2 example

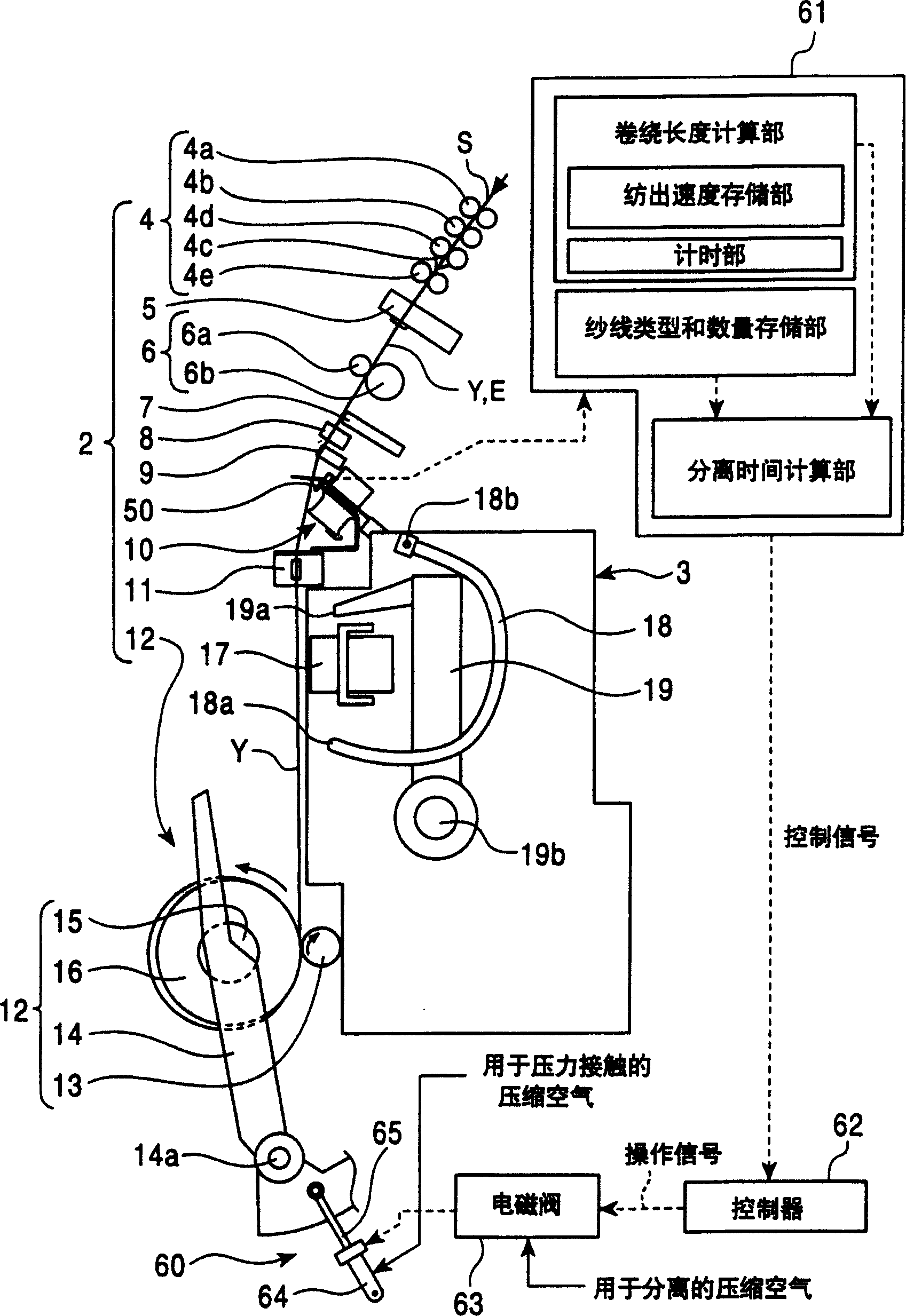

[0080] For the spinning machine 1, it can adopt such an embodiment that the winding speed of the bobbin 16 is reduced according to a preset deceleration program to increase the amount of slack, regardless of the slack remaining in the yarn. The slack of the device 10 eliminates slack on the roller 21 . For example, it is conceivable that the amount of slack residing on the slack removing roller 21 can be recovered for a specified period of time by repeatedly performing the steps of rotating the rocker arm 14 to keep the package 16 separated from the drum 13 for a predetermined period of time. , and then the rocker arm is rotated in the return direction so that the bobbin 16 is in contact with the drum 13 again. This embodiment ensures that the slack is recovered within a certain time. As a result, even if the amount of slack residing on the slack eliminating roller 21 decreases during the operation of the spinning machine, the tension adjustment in the yarn winding procedure ...

no. 3 example

[0083] A yarn take-up machine used in a spinning machine, a twisting machine, and a false twisting machine can wind a yarn fed by a yarn feeding device while using a traversing device to traverse the yarn. Such yarn winding machines are usually configured to form several bobbins simultaneously. In this case, as described in Japanese Patent Laid-Open Document No. 2871595, the traversing device may be constructed such that the traversing guides for the individual packages are fixed on a common drive shaft (traversing rod) , the common drive shaft is used to collectively drive all traverse guides.

[0084] It is known that both laps and saddle humping problems occur when yarn winding machines wind yarn into packages by means of traversing devices comprising reciprocating traversing guides. Lapping is a phenomenon that occurs when yarn is wound multiple times at the same location. Saddle humping is a phenomenon that occurs when the yarn is wound more at the opposite ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com