Patents

Literature

214results about How to "Good automation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

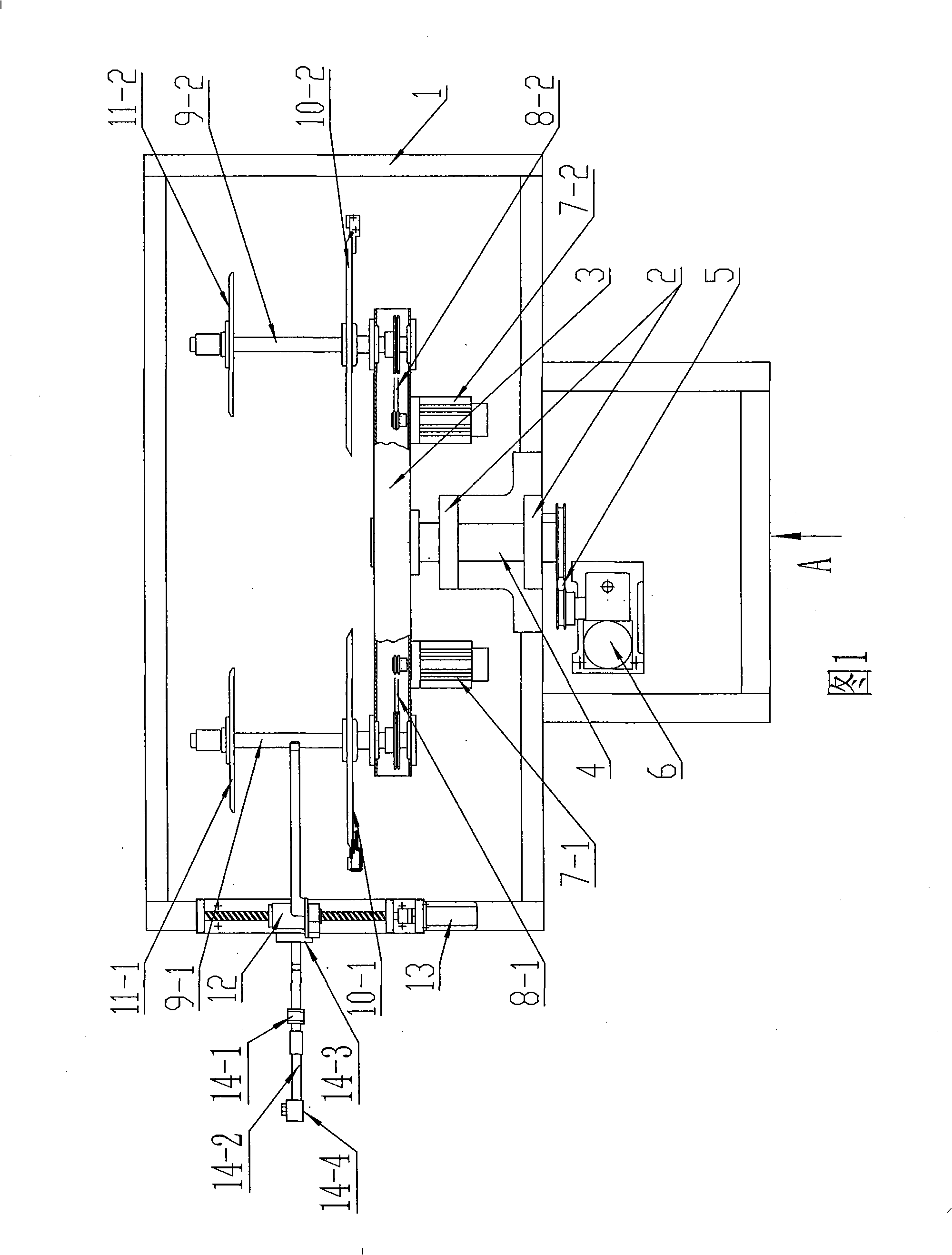

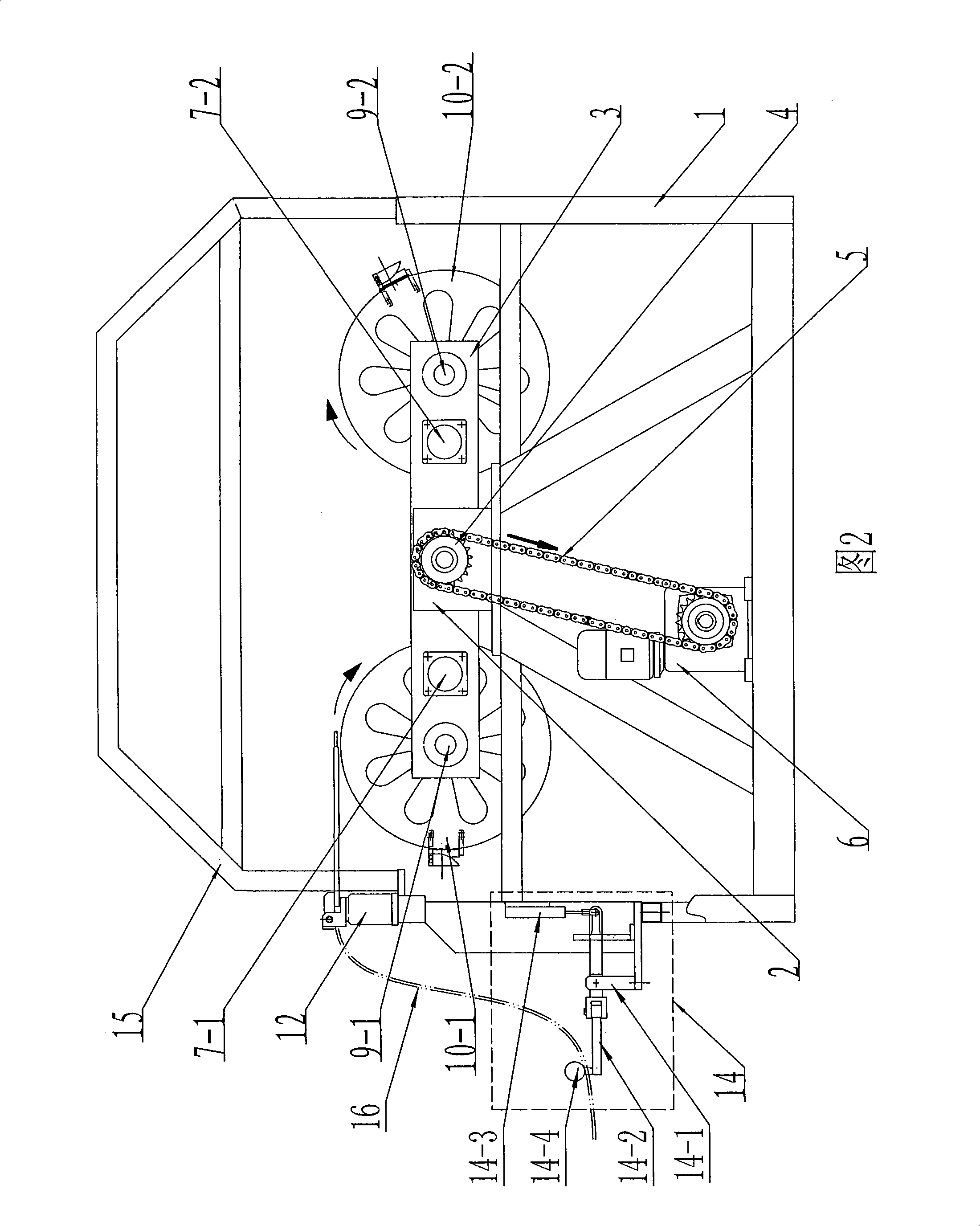

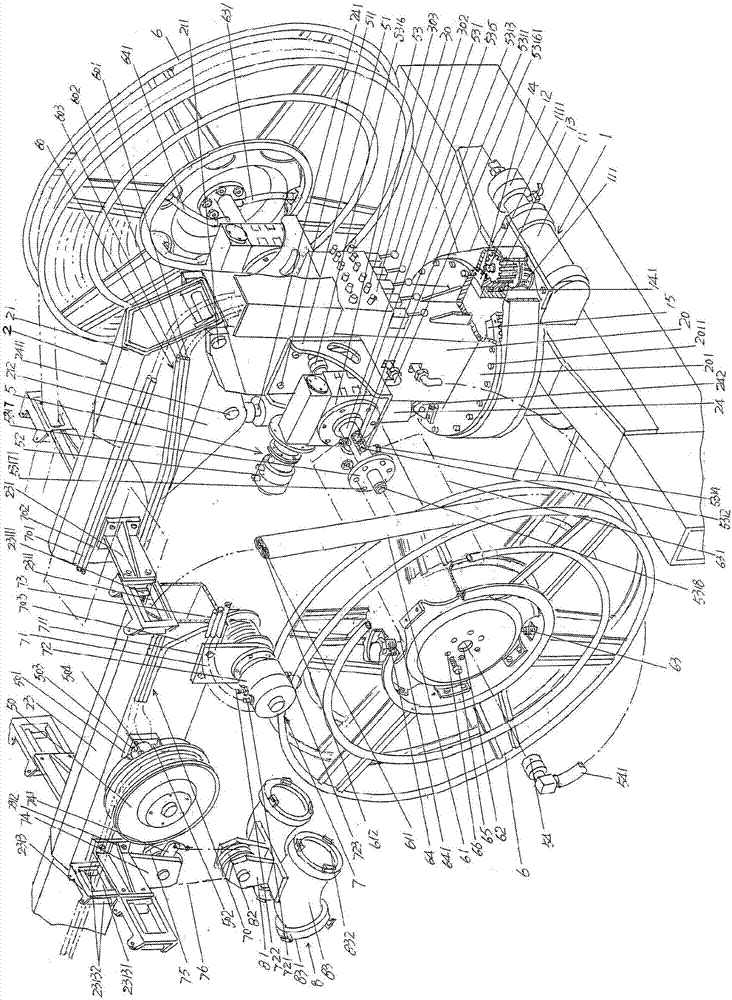

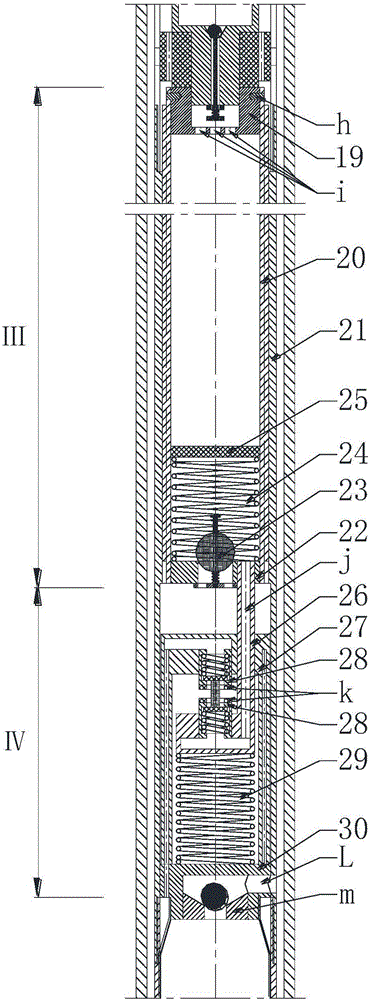

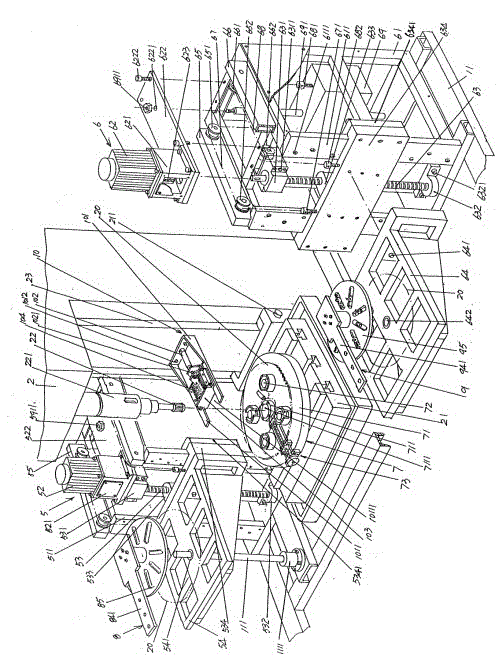

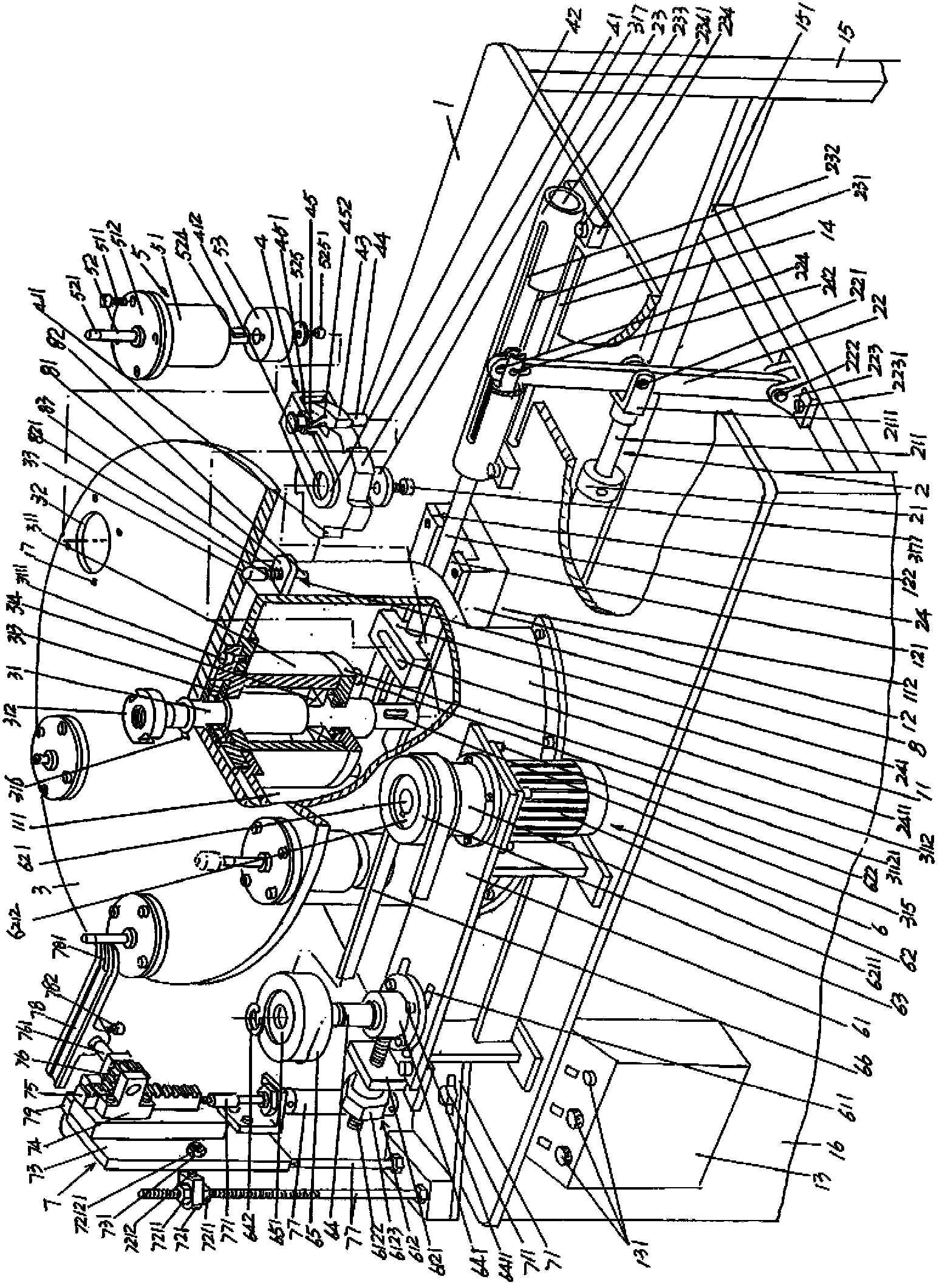

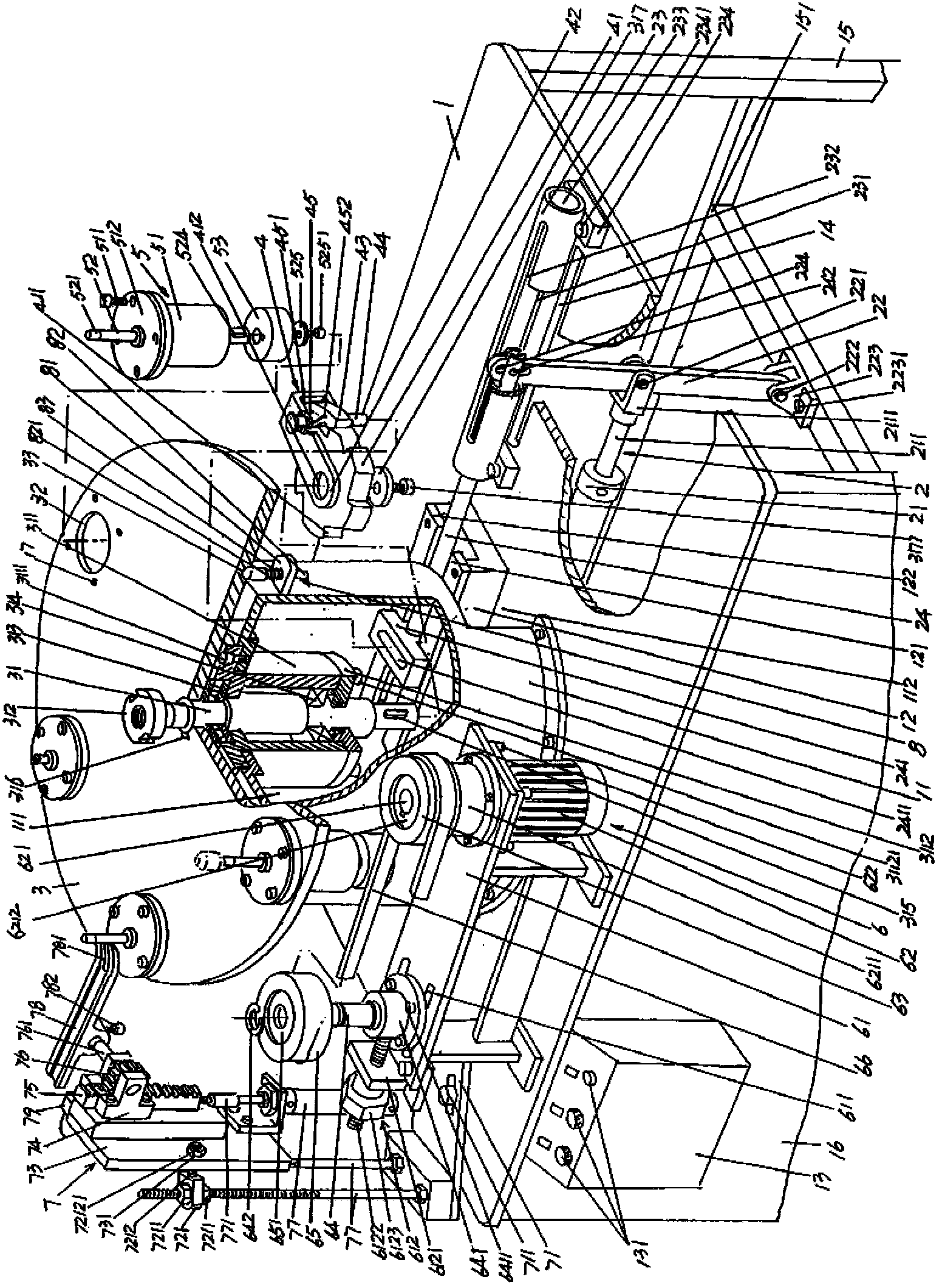

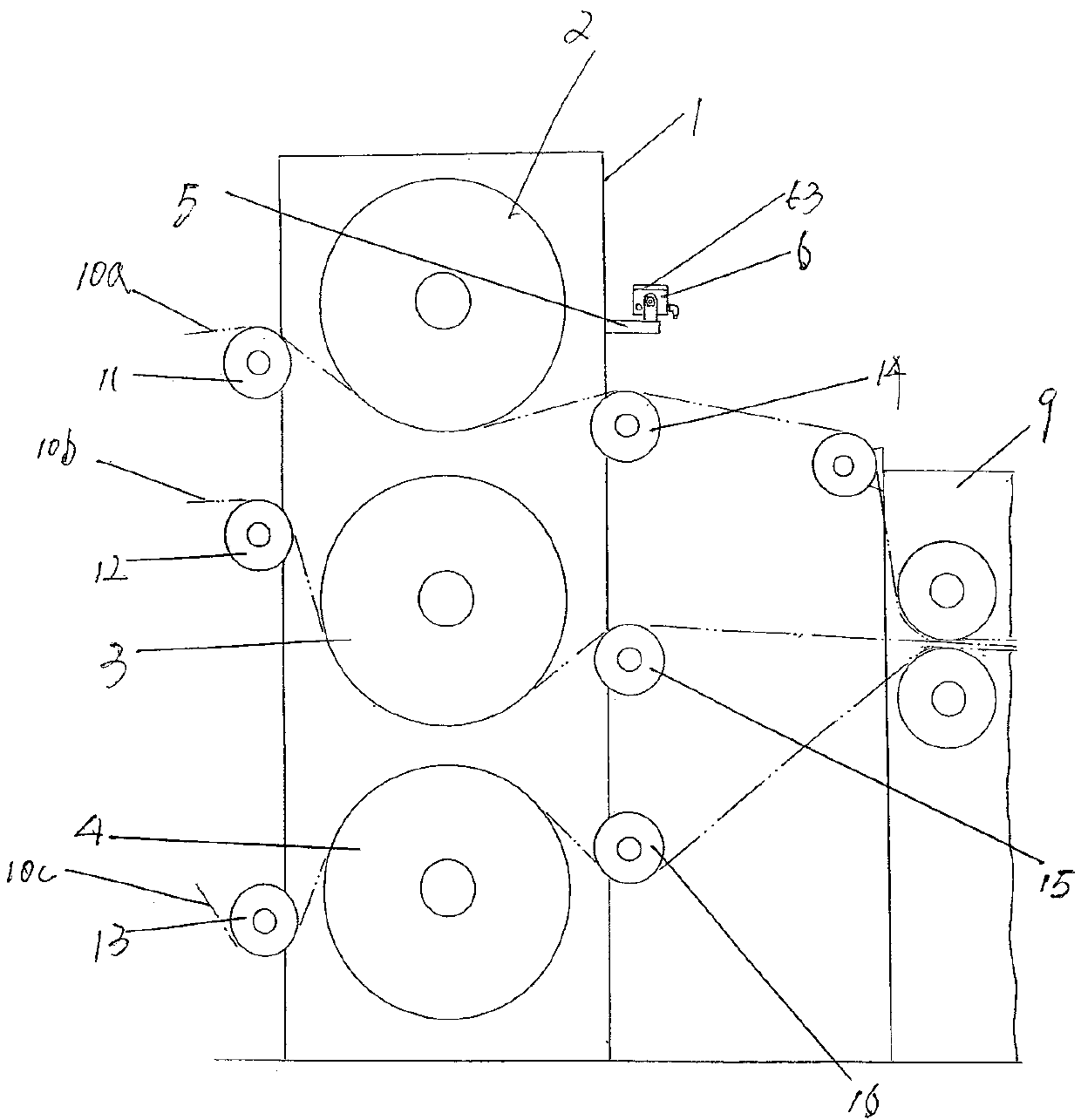

Full-automatic winding machine for winding plastic pipe

InactiveCN101301971AImprove work efficiencyGood automation effectFilament handlingWinding machineElectric machinery

The invention relates to a full-automatic winding machine used for winding plastic tubes, aiming at simplifying the complicated structure of the winding machine and comprising a main-machine base, a rotary big arm arranged on the main-machine base, a tube-distributing mechanism and a tension control mechanism, wherein, two winding disks are symmetrically arranged on the rotary big arm, and after improvement, two winding-disk driving motors are symmetrically arranged on the rotary big arm and respectively connected with the two winding disks in a transmission way. The invention adopts the design of configuring driving sources respectively for the two winding disks to overcome the defects of complicated winding disk supporting and jointing devices, etc. existing by sharing one driving source, and the improvement reduces parts and reduces the manufacturing accuracy of the parts so as to simplify action program and distinctly enhance the reliability of equipment. The full-automatic winding machine of the invention improves the automation capability of plastic hose winding, enhances winding efficiency and is suitable for the automatic manufacturing line of various plastic hoses.

Owner:武志生

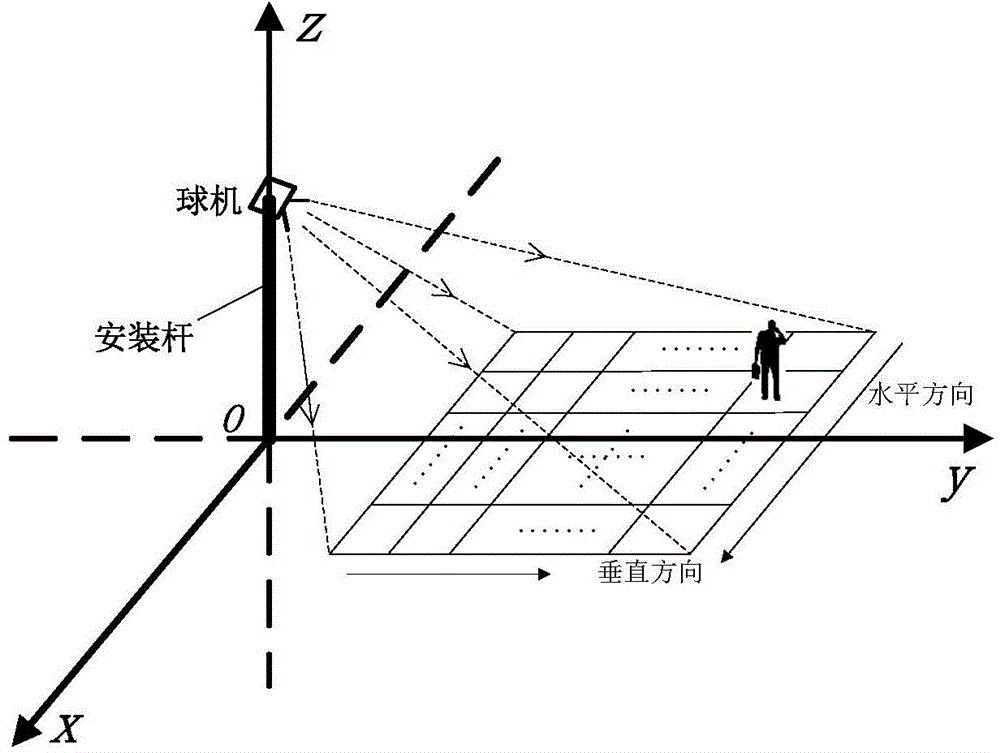

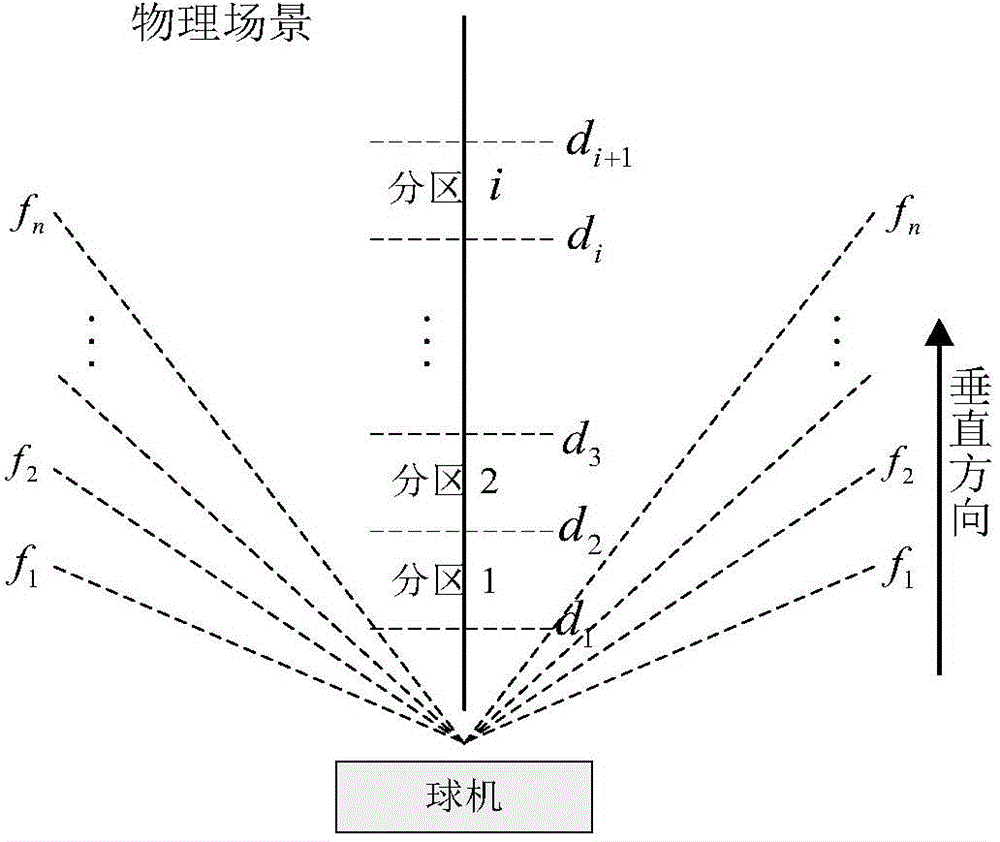

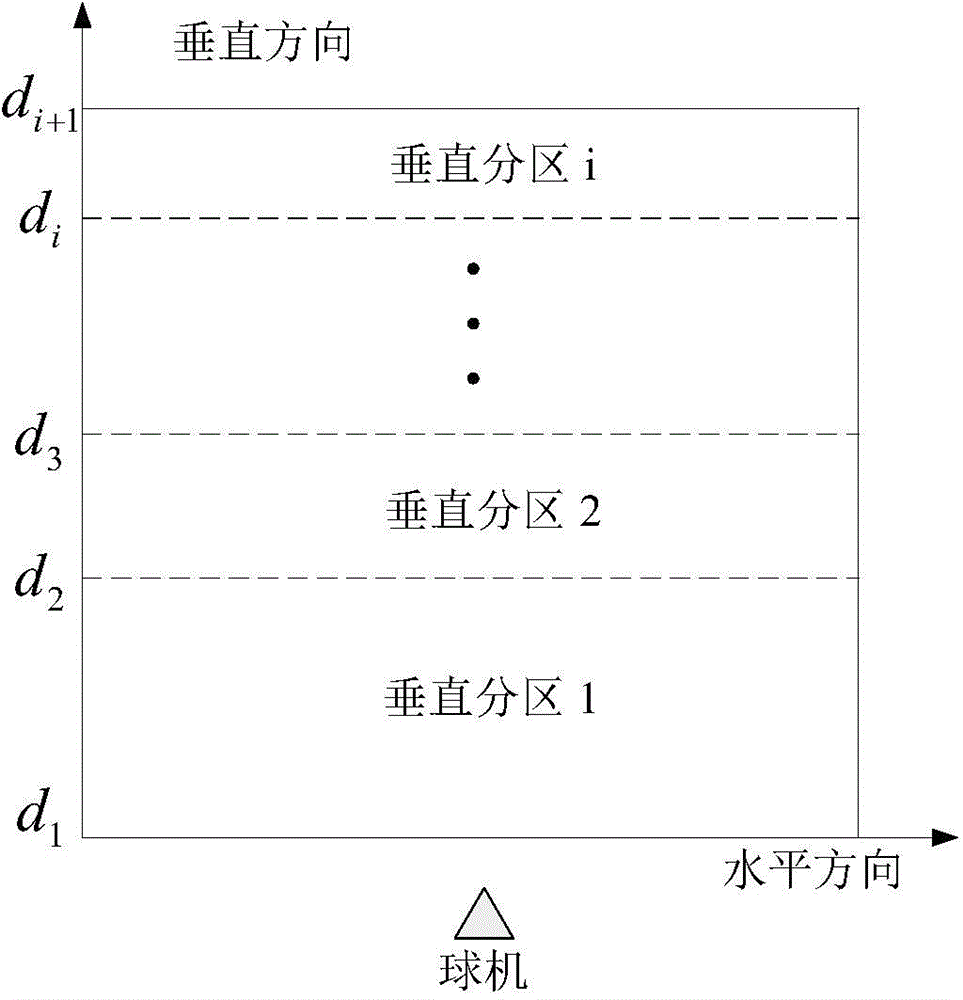

Control method of monitoring ball machine

InactiveCN104639908AFast captureGuaranteed shooting effectImage analysisClosed circuit television systemsVideo monitoringControl engineering

The invention discloses a control method of a monitoring ball machine. The method comprises the following steps of (1) vertically and horizontally dividing a to-be-monitored space into a plurality of small partitions, and setting a shooting focal distance for each small partition; (2) setting corresponding preset positions for a central point position and an edge point position of each small partition, and storing horizontal position information, vertical position information and shooting focal distance information of the ball machine; (3) reading a video frame, and performing target detection on the video frame; (4) according to direction information of a detected target in a monitoring scene, mapping the target to the corresponding preset position; (5) calling the preset position by the ball machine to acquire a monitored image. The defects that the automation degree of control is not high, the real-time property and the flexibility are not enough, and human manual interference is required in a ball machine of the traditional video monitoring system are overcome; the control method is convenient in operation, high in automation degree of control and good in instantaneity, and is particularly good in capture effect on the monitored image of a quickly moving target.

Owner:HUAZHONG UNIV OF SCI & TECH

Automatic cleaning system for solar cell panel

ActiveCN105680789AImprove cleanlinessEfficient cleaningPhotovoltaicsPhotovoltaic energy generationDrive wheelHeight difference

Owner:SHANDONG HAOWO ELECTRICAL CO LTD

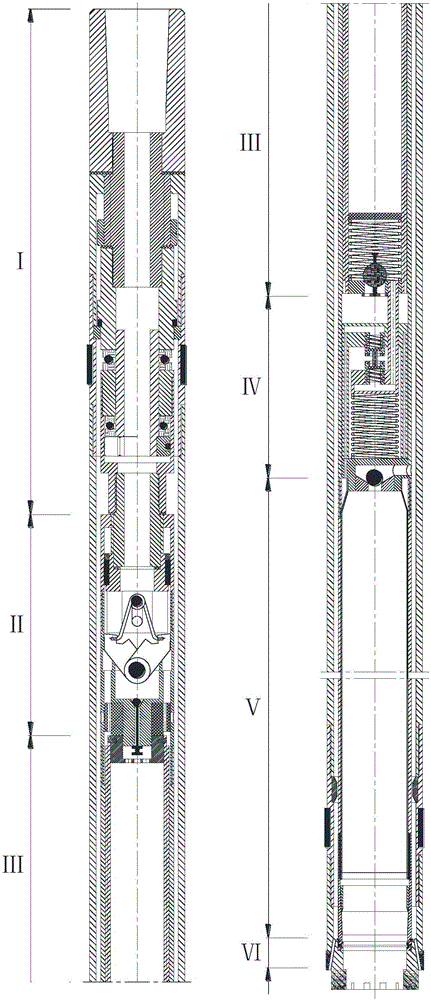

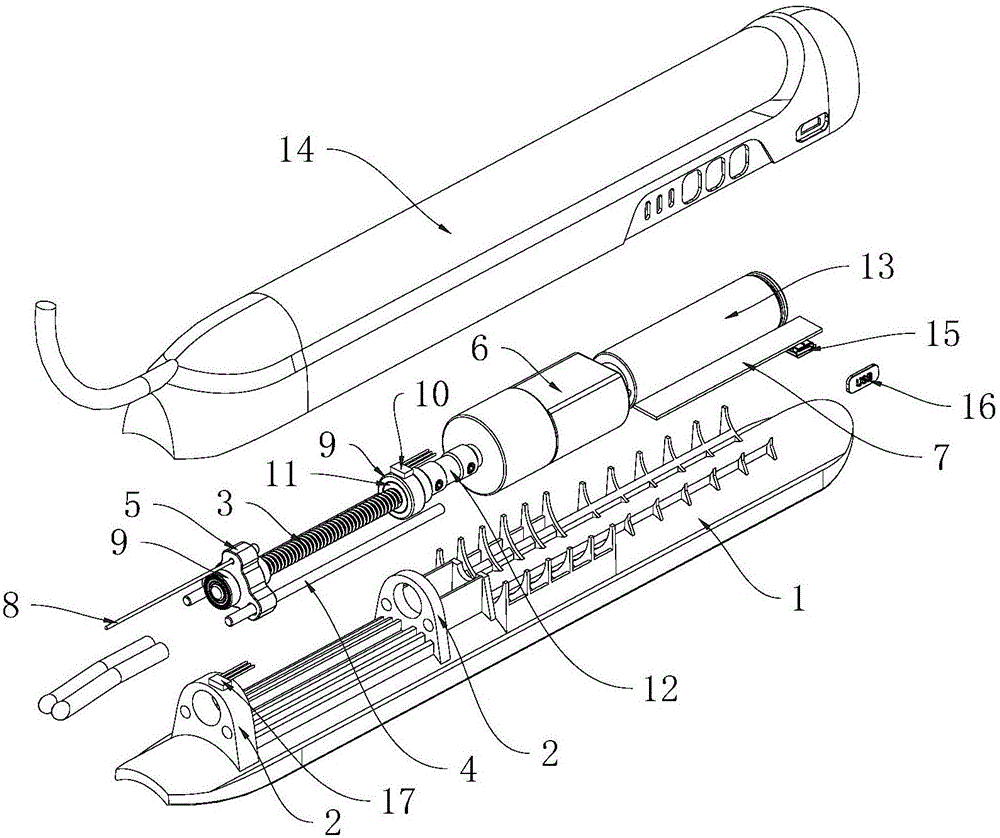

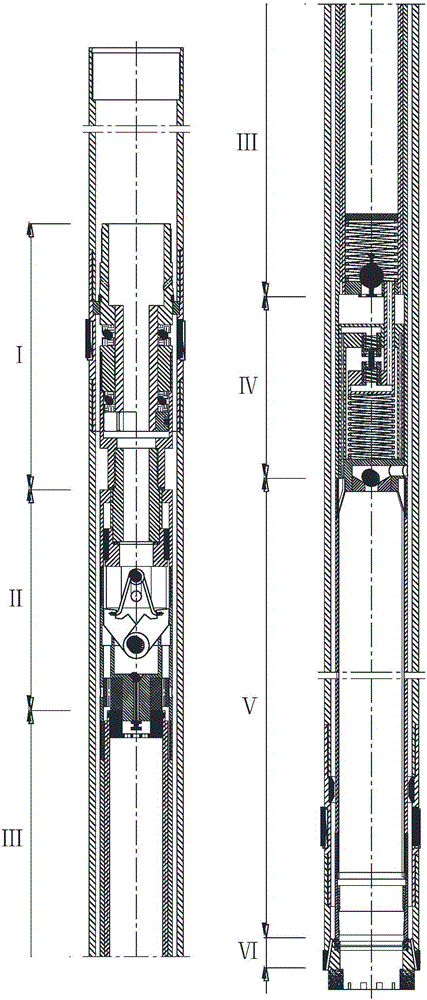

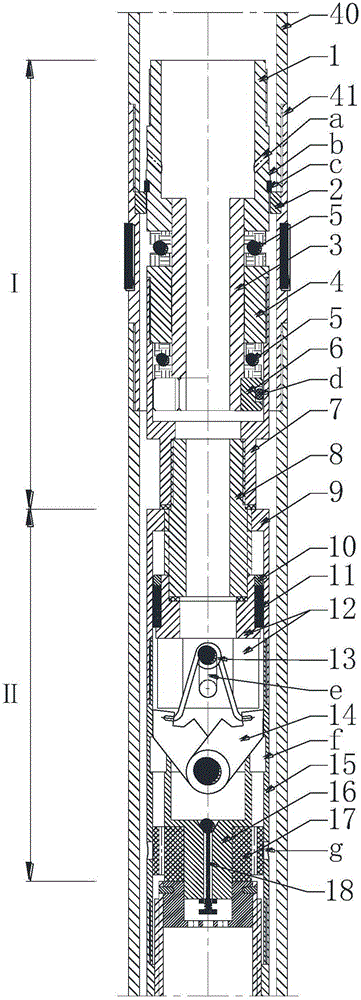

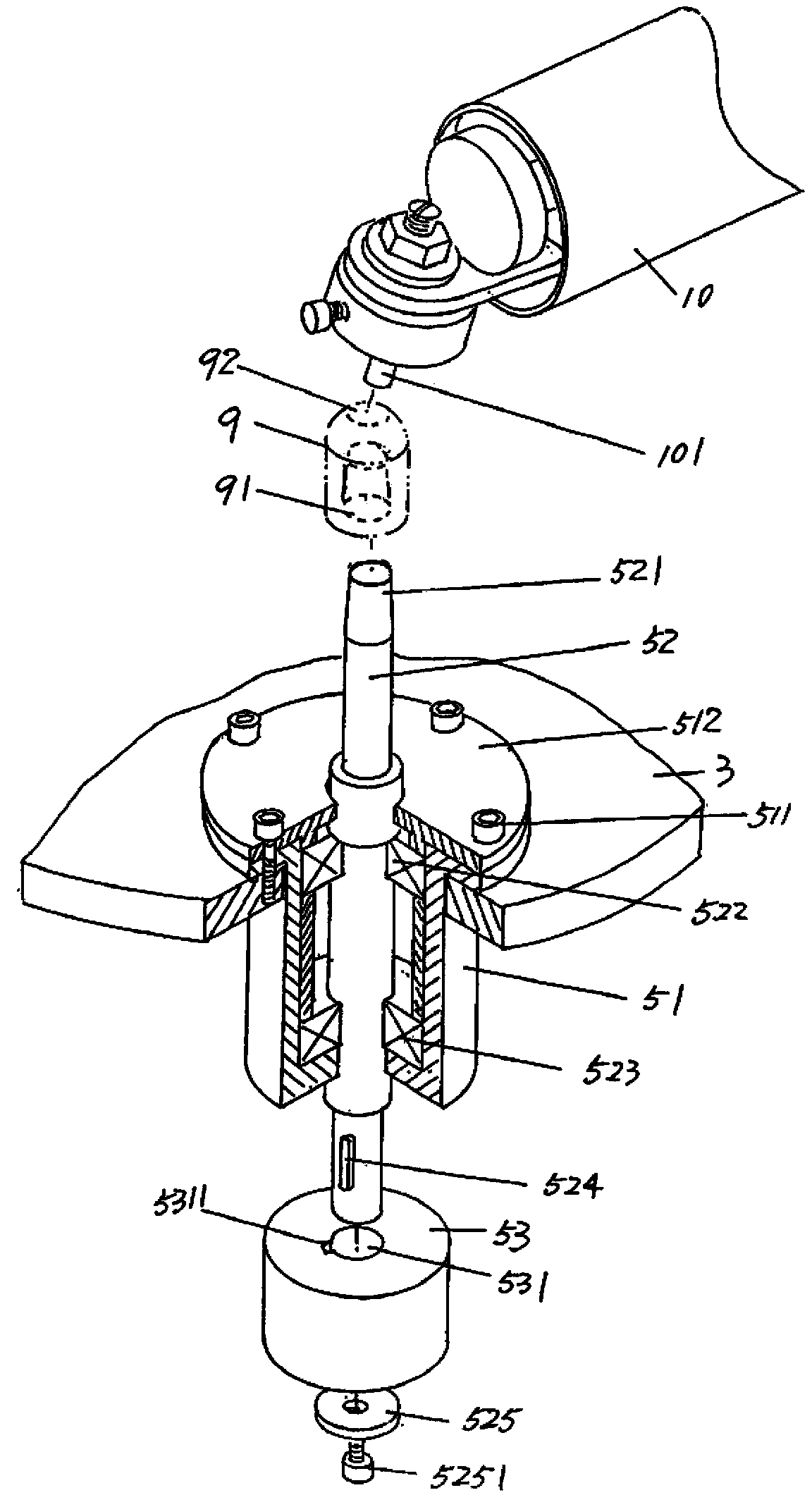

Coring drilling tool based on hydraulic clamping coring

ActiveCN105909202AIncrease heart rateGuarantee the quality of coringEngine sealsCore removalDrill bitPressure injection

The invention discloses a coring drilling tool based on hydraulic clamping coring. The coring drilling tool comprises a force transferring power distribution mechanism, a guide limiting mechanism, a pressure storage mechanism, a lifting pressure injection mechanism, a hydraulic core clamping mechanism, a side spraying drill bit power distribution mechanism, an outer tube assembly and a sealing system, wherein the guide limiting mechanism is butted with the force transferring power distribution mechanism; the pressure storage mechanism is butted with the guide limiting mechanism; the lifting pressure injection mechanism is butted with the pressure storage mechanism; the hydraulic core clamping mechanism is butted with the lifting pressure injection mechanism; the side spraying drill bit power distribution mechanism is butted with the hydraulic core clamping mechanism; the hydraulic core clamping mechanism comprises a bottom bearing platform, a hydraulic membrane, a core inner tube, a clamp spring seat and a clamp spring. The coring drilling tool can reach 100 percent coring rate in soft, loose and broken complex stratums where coring is difficult, provides fully automatic three-dimensional stress to clamp, bind and control cores based on hydraulic pressure, meanwhile is matched with a conventional core clamping and cutting device, and has the characteristics of high reliability, high coring efficiency, high coring quality, high core recovery percentage, wide applicable stratum range and good automation property.

Owner:CCCC FHDI ENG

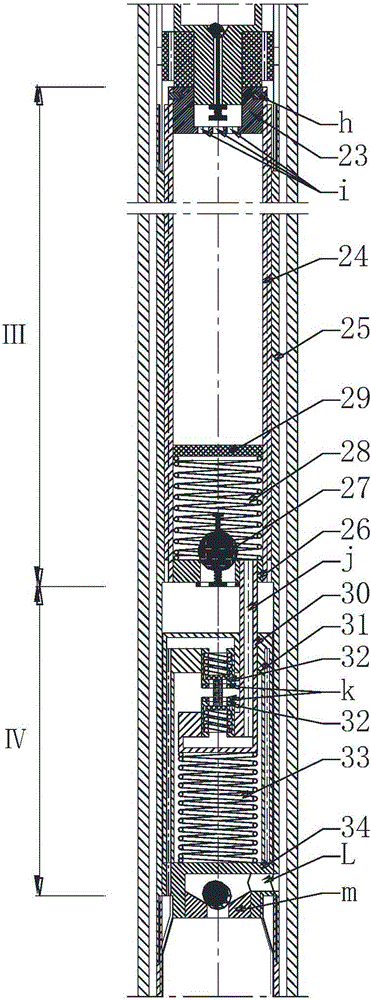

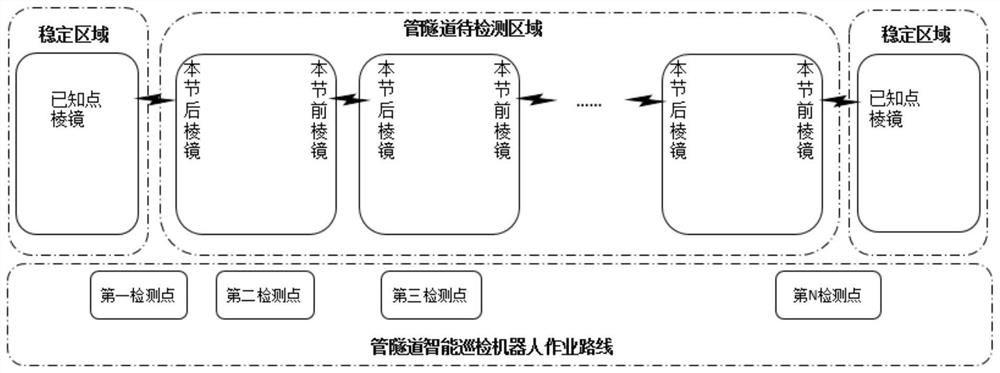

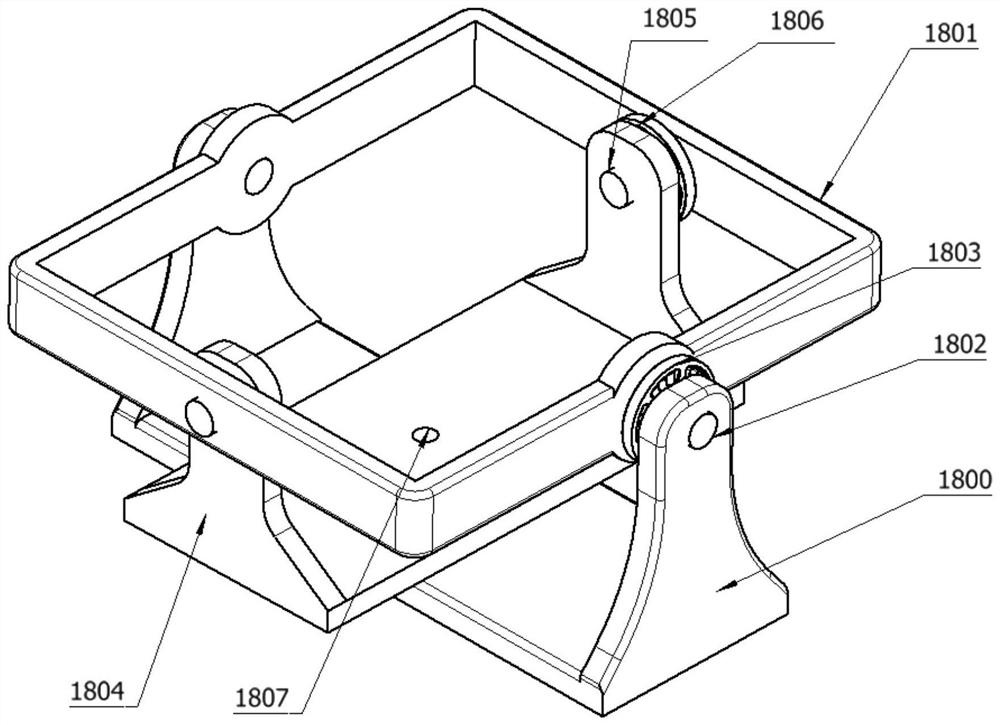

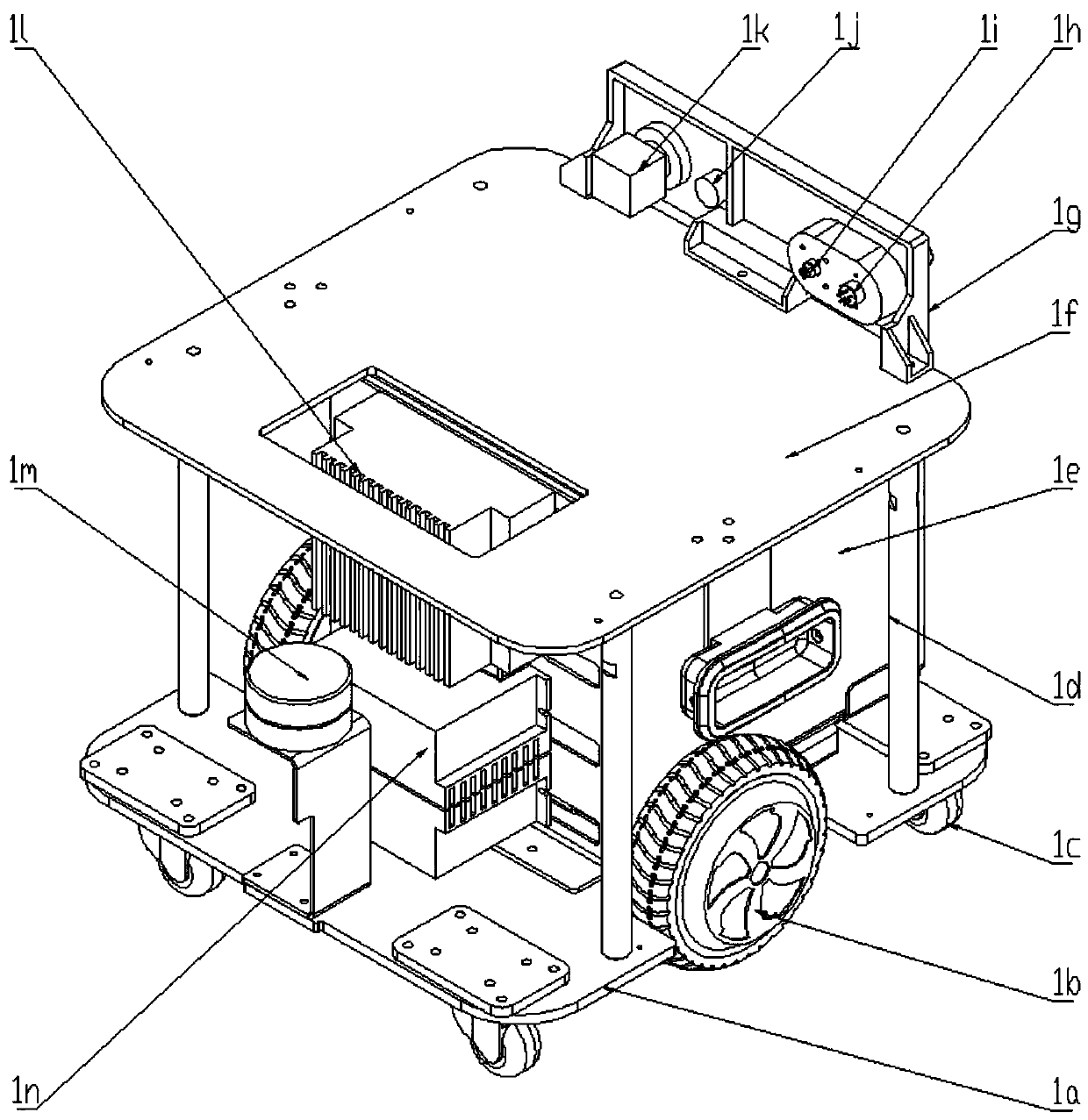

Intelligent inspection robot and inspection method

InactiveCN111866337APrecise positioningSmooth goingTelevision system detailsConnection managementWater leakageMeasuring instrument

The invention discloses an intelligent inspection robot and an inspection method. The intelligent inspection robot consists of a robot body, a mobile platform, a positioning navigation device, an automatic leveling device, a measurement instrument, an image collection device, a communication device, and a built-in server. According to the intelligent inspection robot, the robot performs inspectionaccording to a preset route through the positioning navigation device, staying at different preset detection positions for operation is performed, the self-leveling device provides a strictly horizontal basic platform for the measurement instrument, the robot guides the measurement instrument to measure a prism in the pipe tunnel, stores and calculates detection data, gives a settlement deformation measurement result, and can give a detection result of water leakage and other diseases, and the whole device can replace manual measurement, solves a problem of automatic detection of the pipe tunnel, and is convenient and fast to use and high in practicability.

Owner:北京福瑶科技有限公司

Automatic diversion fire truck

The invention discloses an automatic diversion fire truck. The automatic diversion fire truck comprises a truck body, a hoisting mechanism, a pair of oil pipe winch disc driving mechanisms, a pulley base lifting mechanism and a fire-fighting water lead-out mechanism, wherein an upright post is arranged on a revolving driving mechanism of the upright post, and a hydraulic oil distribution valve is fixed on the upright post; the hydraulic oil distribution valve is connected with a hydraulic oil pipe of a hydraulic station by a pipeline; the hydraulic station is arranged on a chassis of a vehicle body; the revolving driving mechanism of the upright post is arranged on the chassis and is positioned at the right end of the chassis; the hoisting mechanism is connected with the upright post; a diversion mechanism is connected with a traction mechanism which is arranged on the hoisting mechanism; the pair of oil pipe winch disc driving mechanisms are arranged on the front side and the rear side of the upright post and are respectively connected with oil pipe winch discs; a winch disc oil pipe is arranged on the oil pipe winch disc, and the diversion mechanism is connected with the winch disc oil pipe; the pulley base lifting mechanism is arranged on the hoisting mechanism and is connected with a hydraulic oil distribution valve oil path; and the fire-fighting water lead-out mechanism is rolled by the pulley base lifting mechanism and is assembled with the diversion mechanism. The automatic diversion fire truck has an ideal automatic effect and reduces the operation strength; the sludge influence in water domain caused by sinking is avoided, and the diversion mechanism can be kept at a position away from the shoreside so as to ensure the diversion effect.

Owner:JIEDA FIRE PROTECTION VEHICLE EQUIP CO LTD SUZHOU CITY

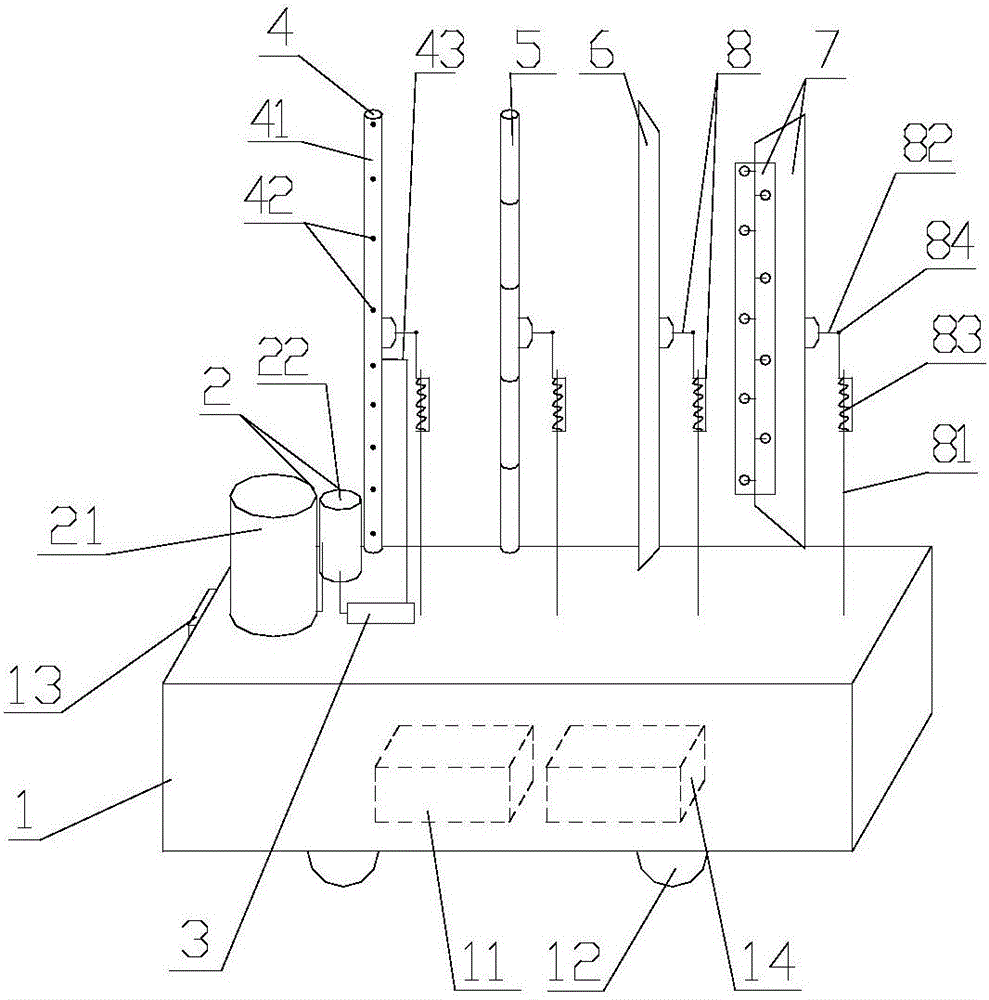

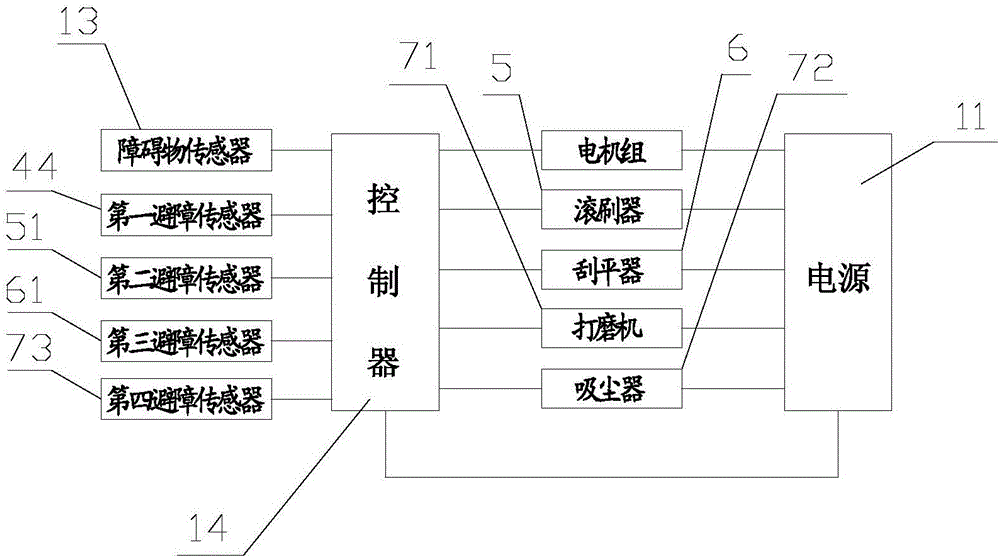

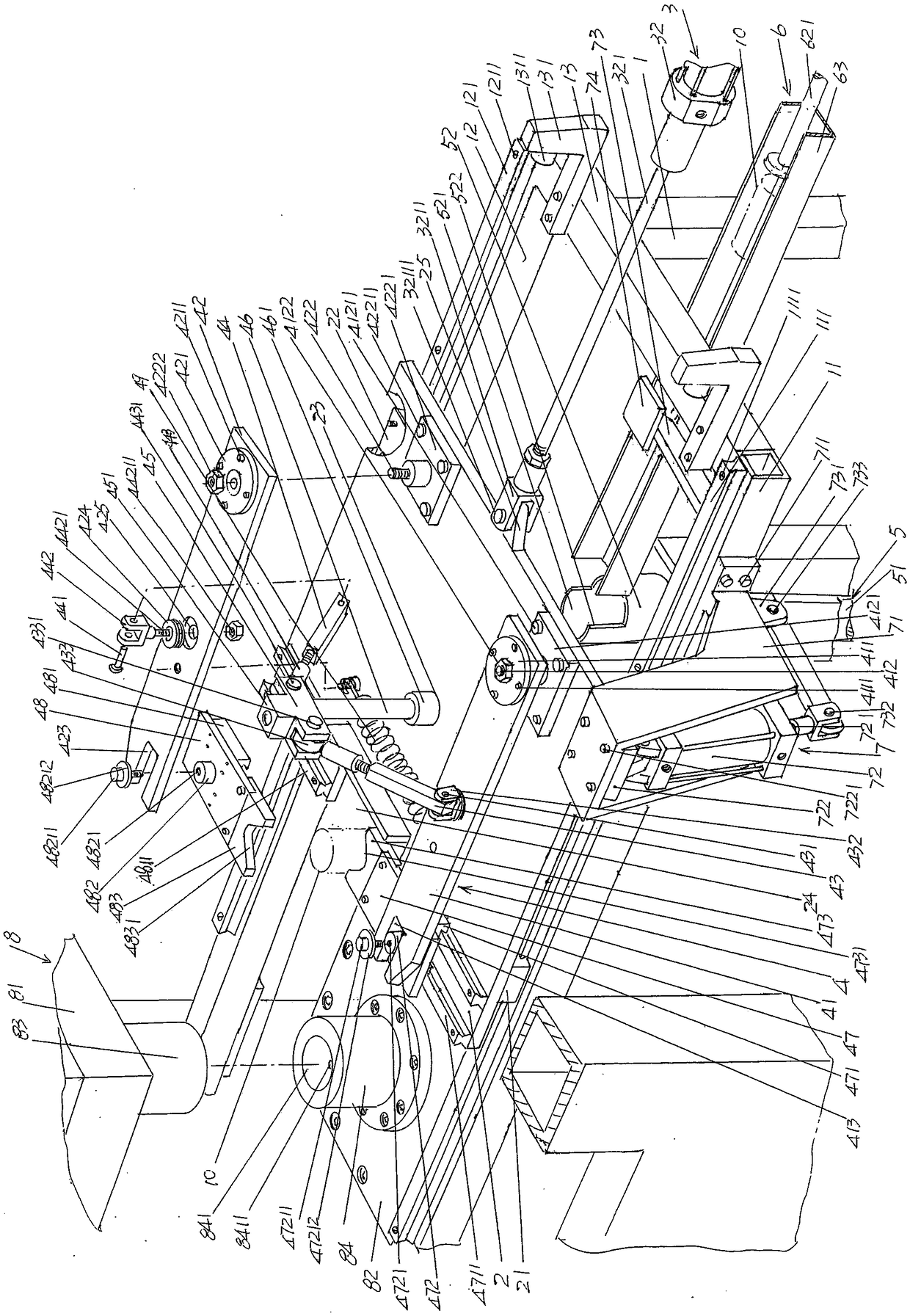

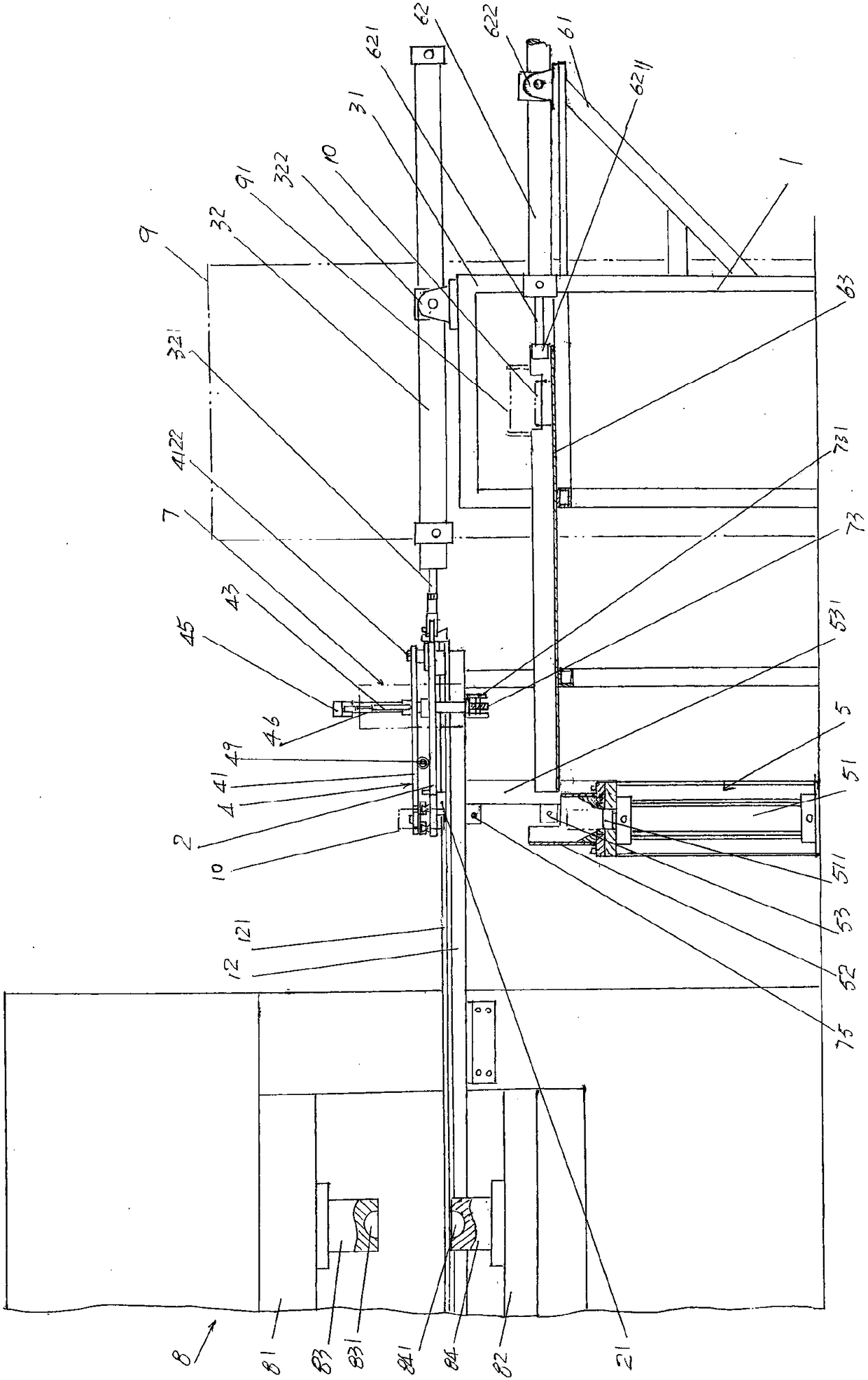

All-in-one full-automatic wall surface plastering unit and use method thereof

ActiveCN106499159AEasy to move and controllableHighly integratedBuilding constructionsElectricityControl system

The invention discloses an all-in-one full-automatic wall surface plastering unit and a use method thereof. The all-in-one full-automatic wall surface plastering unit comprises a transportation vehicle, four identical bracket structures arranged on the transportation vehicle in sequence, a plastering mechanism arranged above the bracket structure, and a control system, wherein a power supply for supplying power to the whole plastering unit is arranged in the transportation vehicle; the plastering mechanism comprises a spraying system, a roller device, a scraper device and grinding units which are connected with the power supply and are arranged above the four bracket structures in sequence; the control system comprises a controller arranged in the transportation vehicle and a motor set connected in series with the power supply and the controller; and the controller is further electrically connected with the roller device, the scraper device, small-size grinding machines and a dust collector. The plastering unit can replace a worker to realize at least 95 percent of the working amount in the construction project; the height and the width of construction can be controlled by the controller; and the all-in-one full-automatic wall surface plastering unit is high in construction speed, high in efficiency and suitable for popularization and application and can effectively avoid the risk caused by high-place work of personnel.

Owner:罗天才

Automatic speed-changing method and apparatus for speed change bicycle

InactiveCN106103263APrecise shiftOvercoming the defects of setting up a separate programCycle actuatorsEngineeringAutomation

The invention discloses an automatic speed-changing method for a speed change bicycle. The method comprises the following steps: a self-learning step including: adjusting a speed-changing wire to an initial position, when the speed-changing wire is located at the initial position, setting the tap position of a chain-moving device to be 1, recording and saving the initial position by an MCU, when each tap position is changed in a riding simulation process, recording and saving the corresponding position or displacement of the speed-changing wire by the MCU, and ending the self-learning step after all the tap positions are traversed; and a riding step including: when tap position change is needed during a riding process, controlling the tap position change according to the corresponding position or displacement of the speed-changing wire, which is recorded by the MCU when each tap position is changed. The apparatus and method are good in universality and automation, and bring convenience to production, after sale and bicycle DIY fans.

Owner:SHENZHEN QISHANG TECH

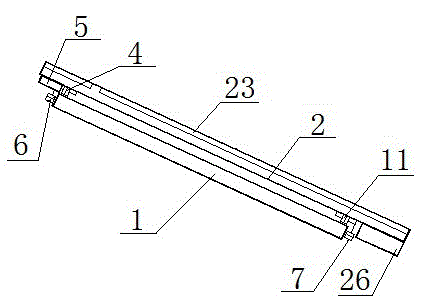

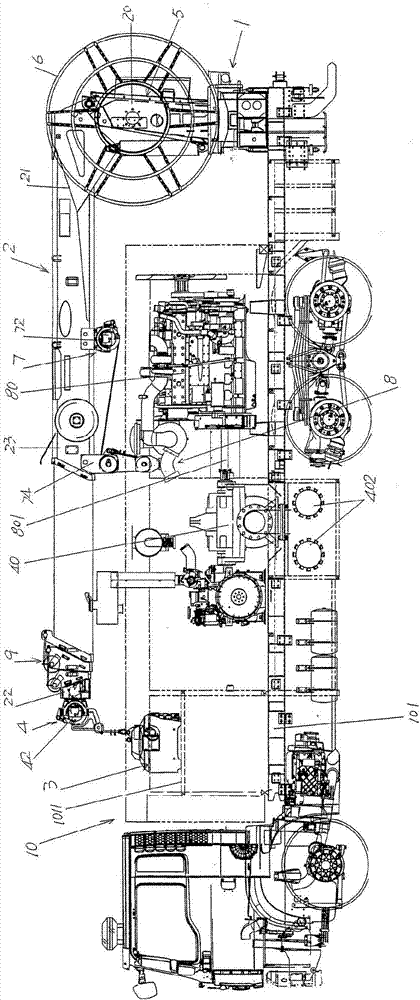

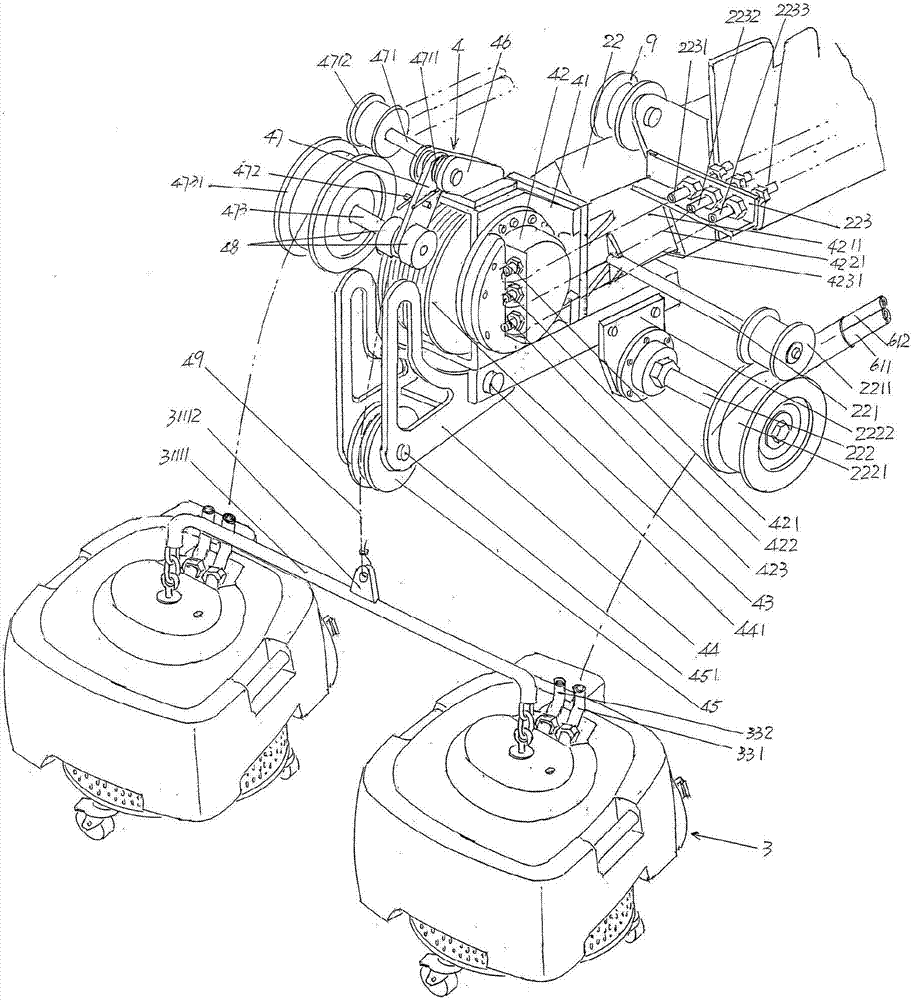

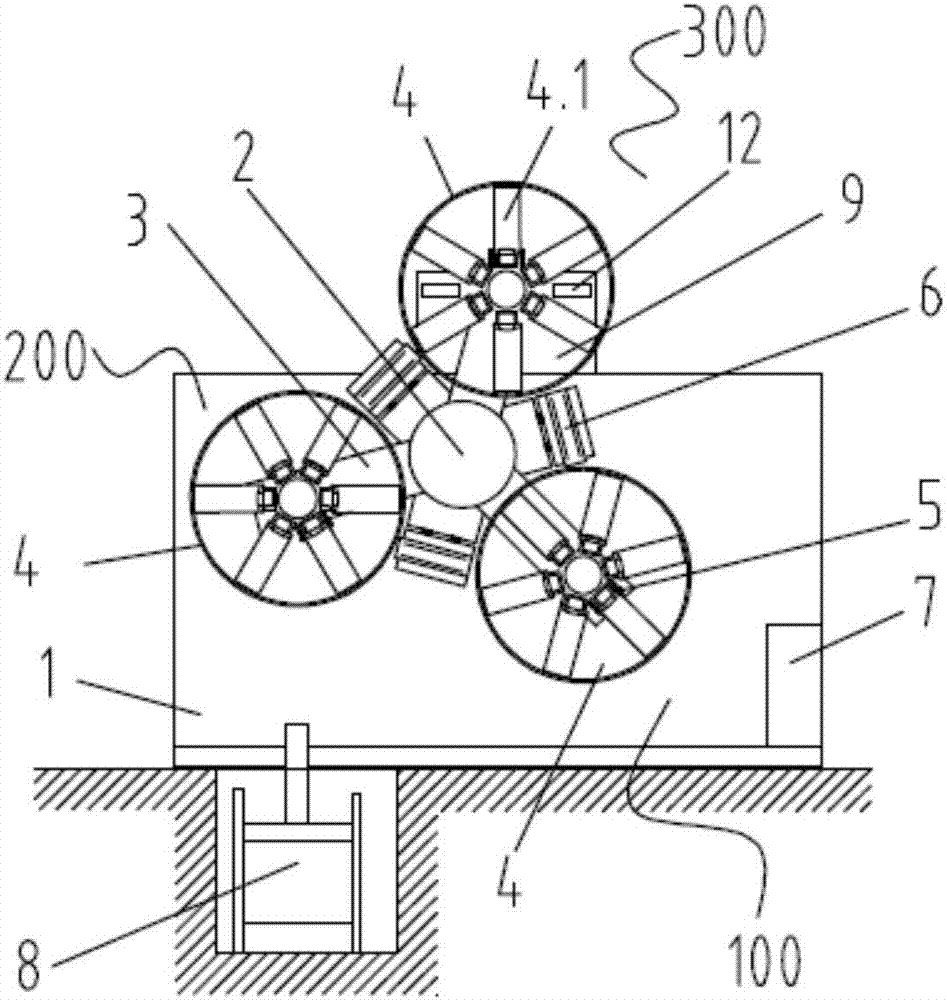

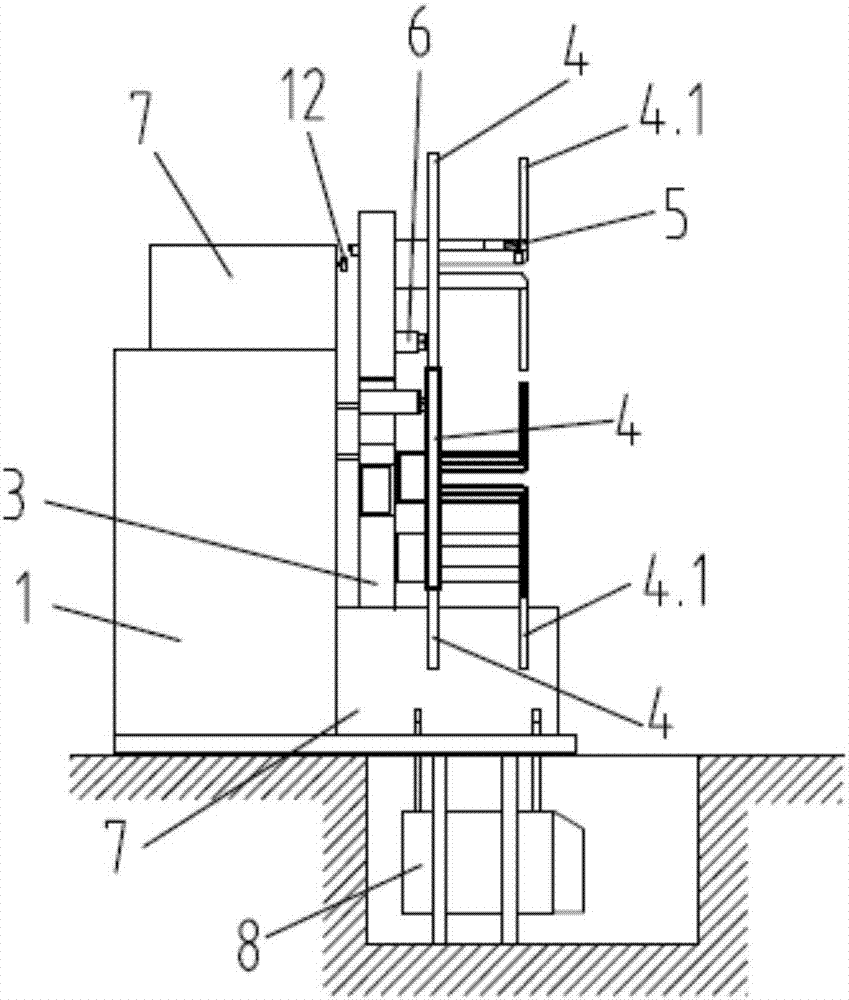

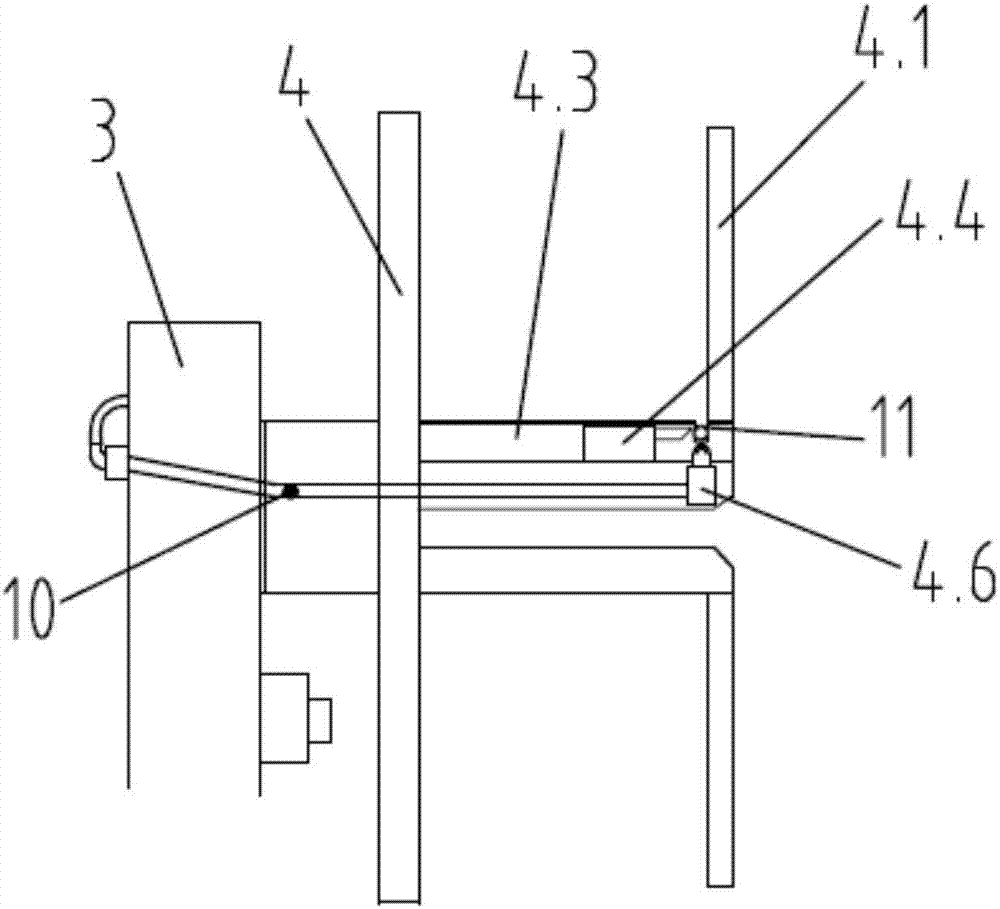

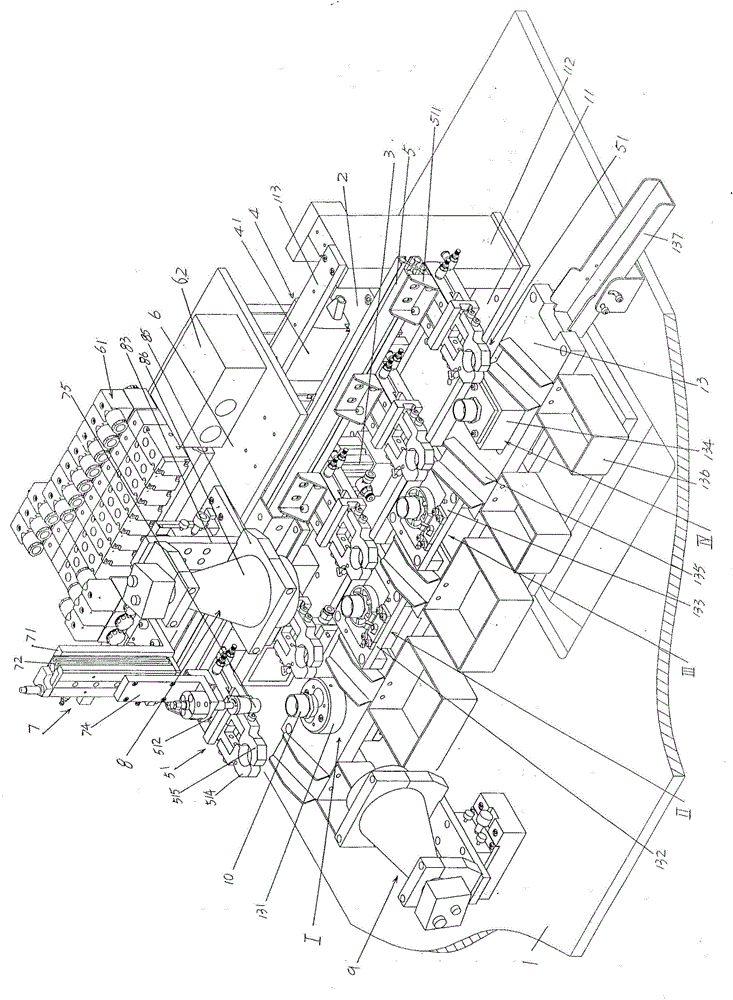

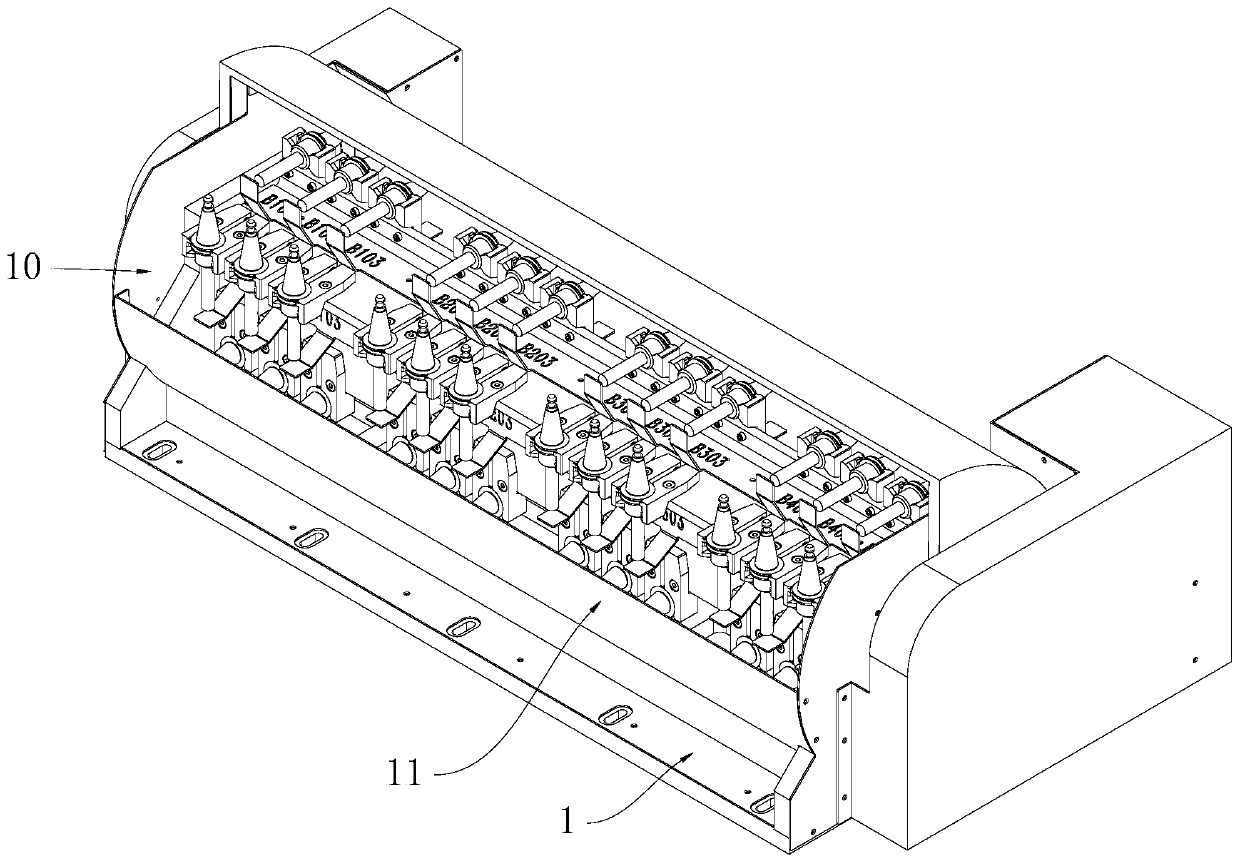

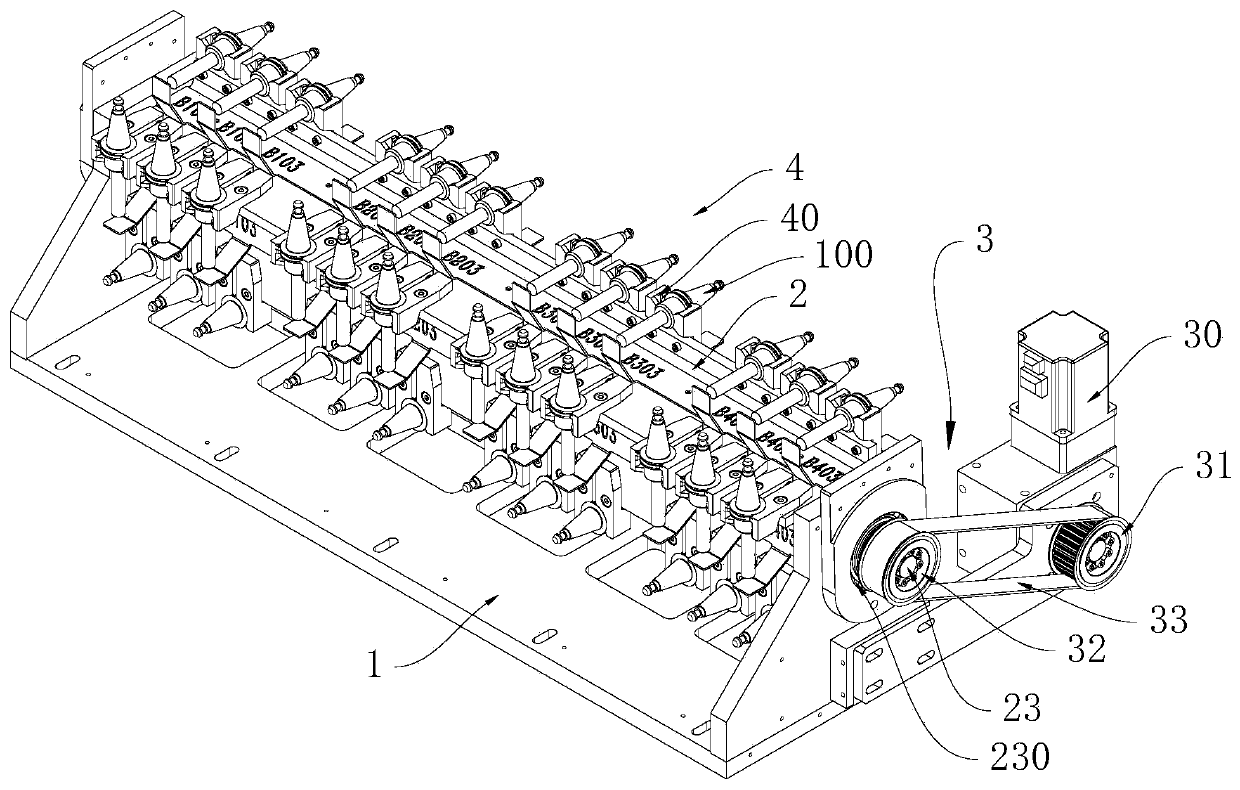

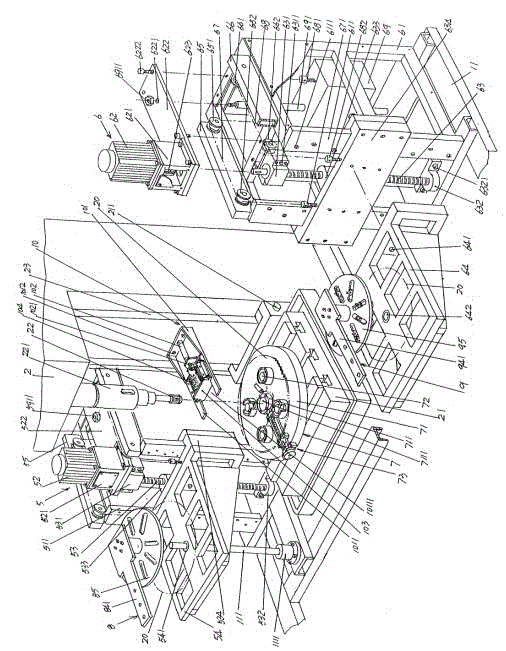

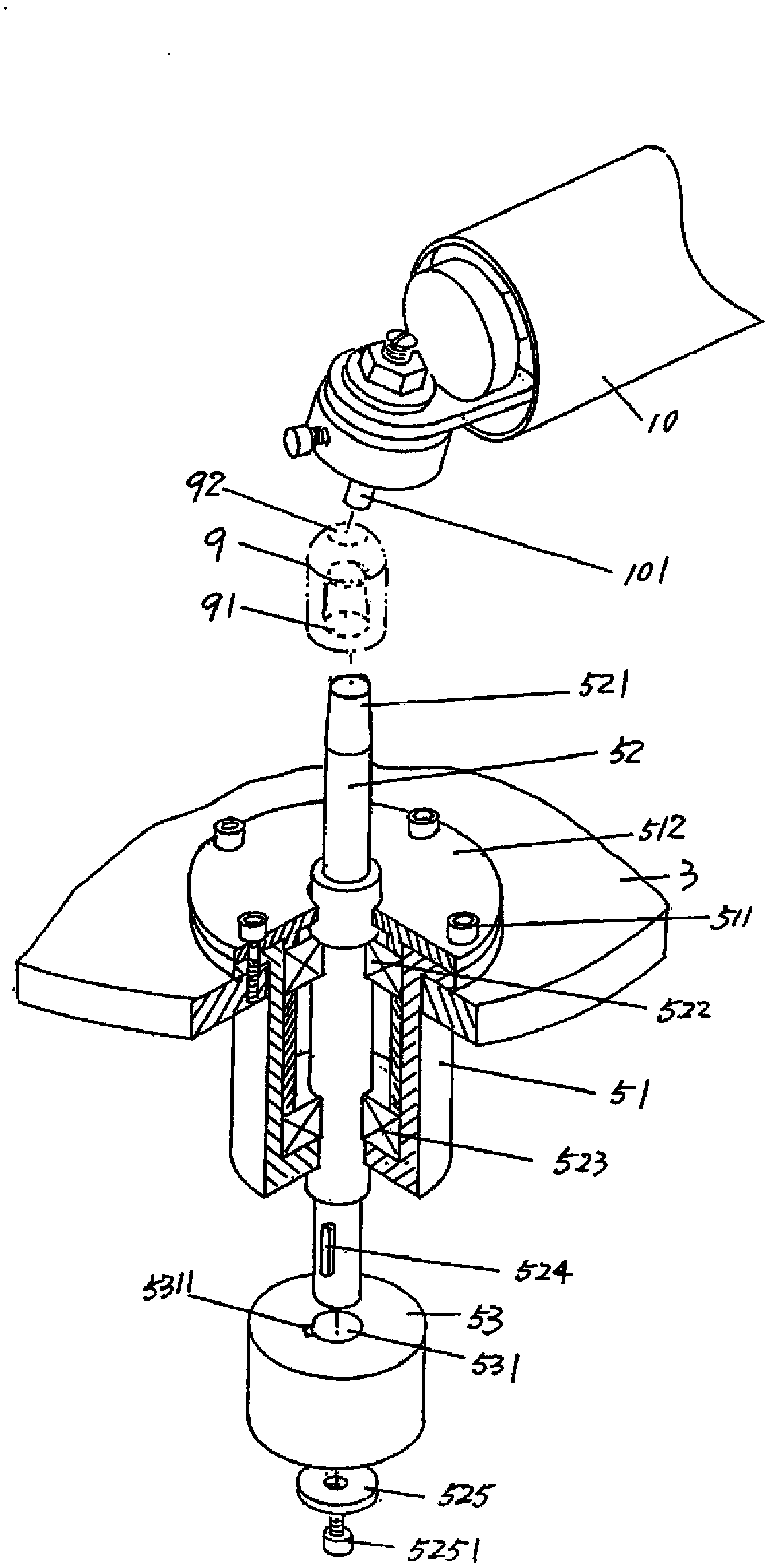

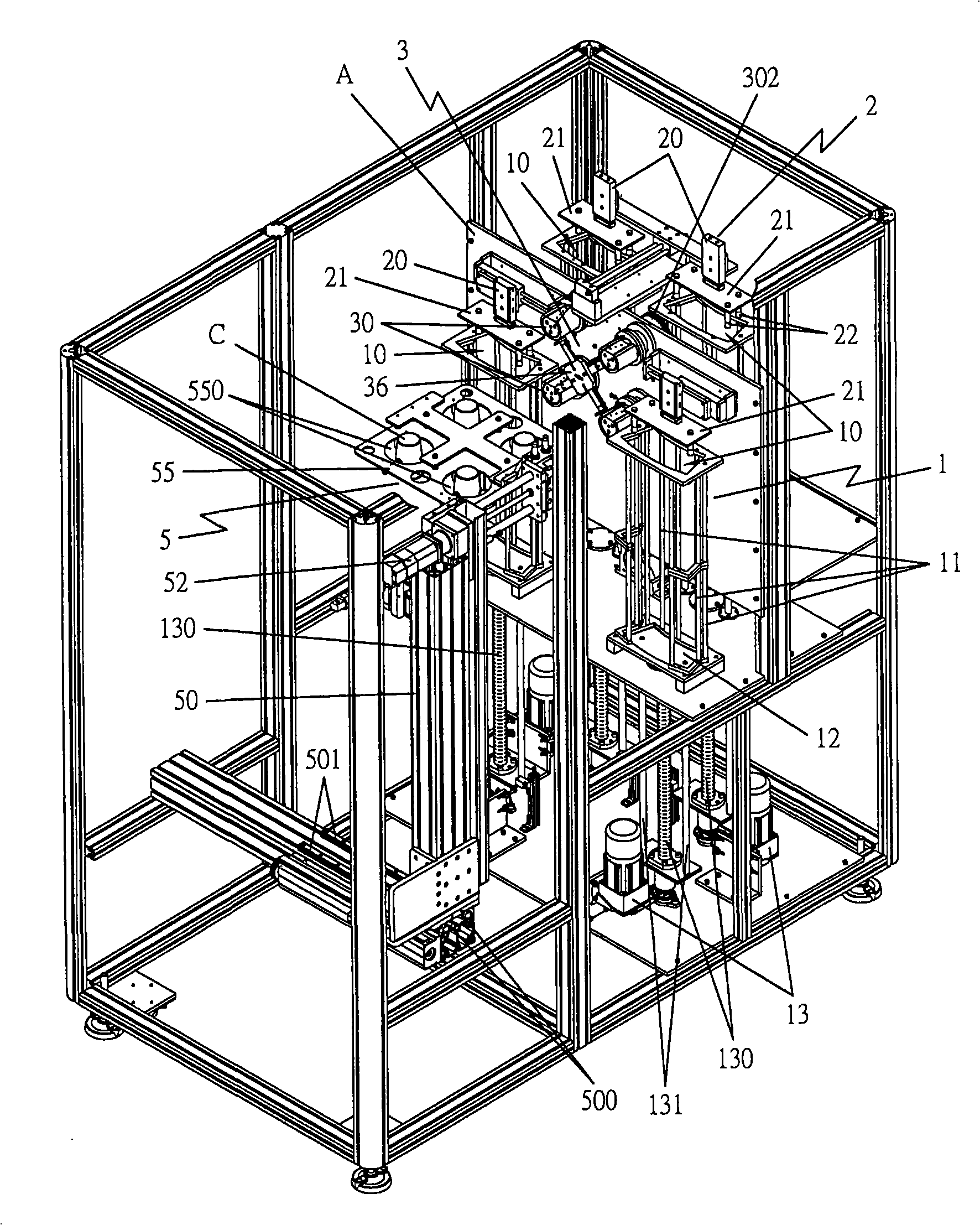

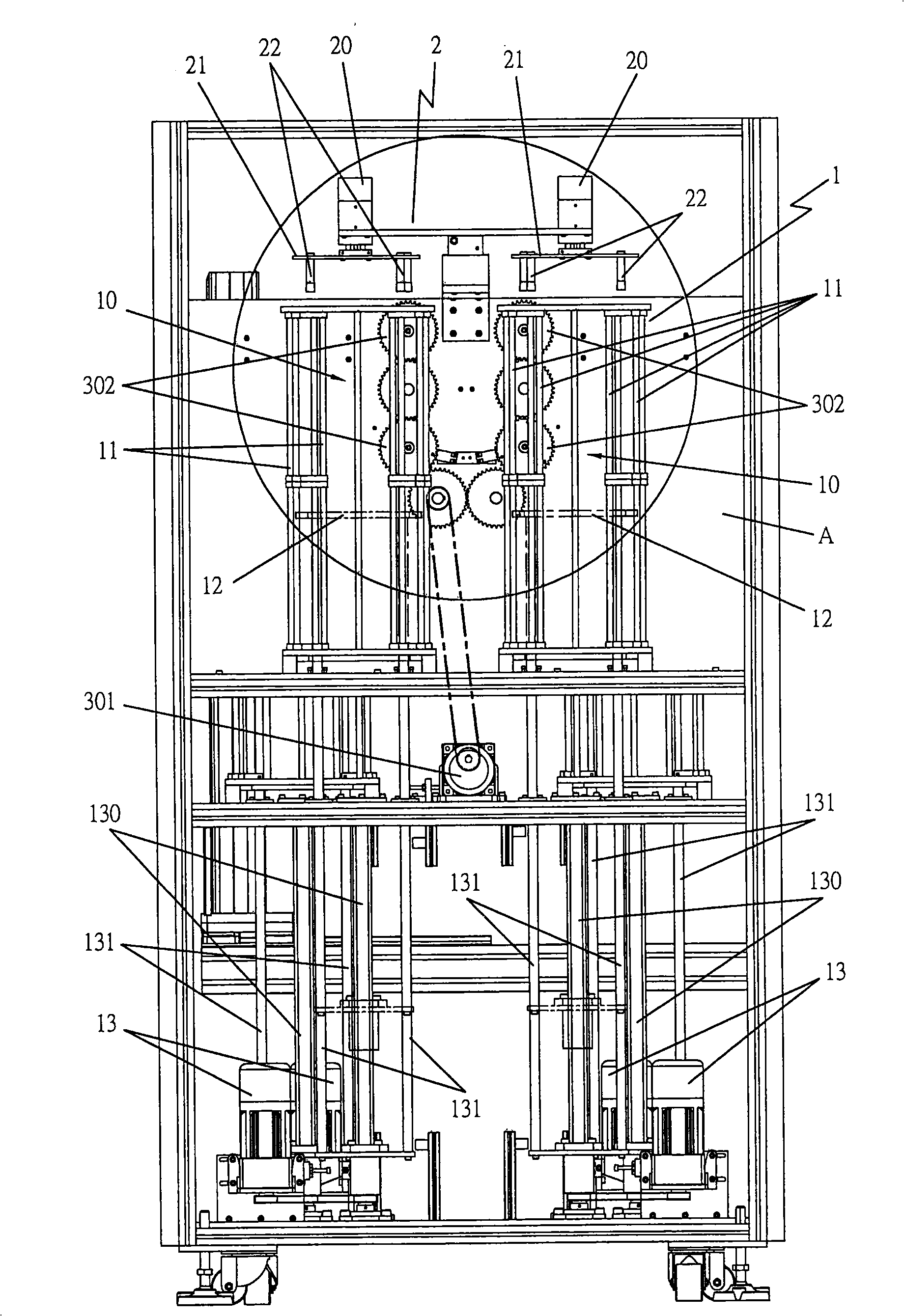

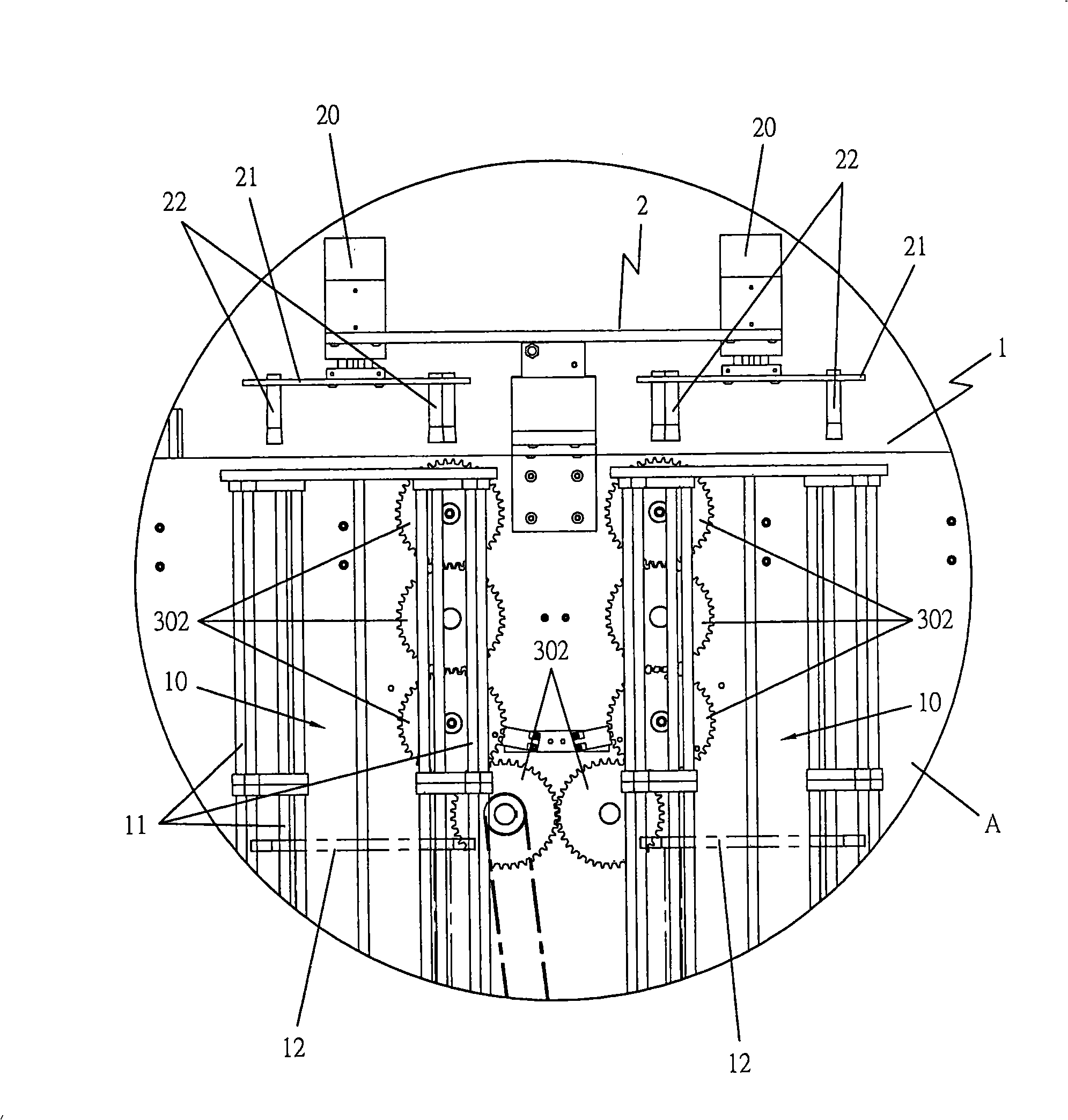

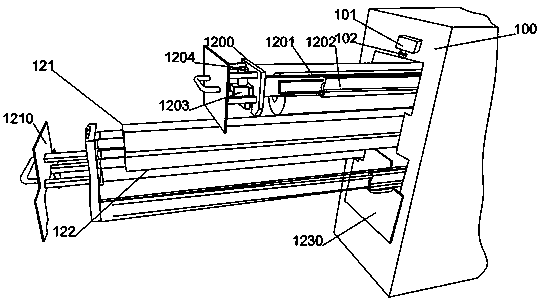

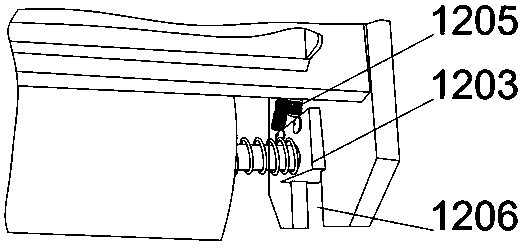

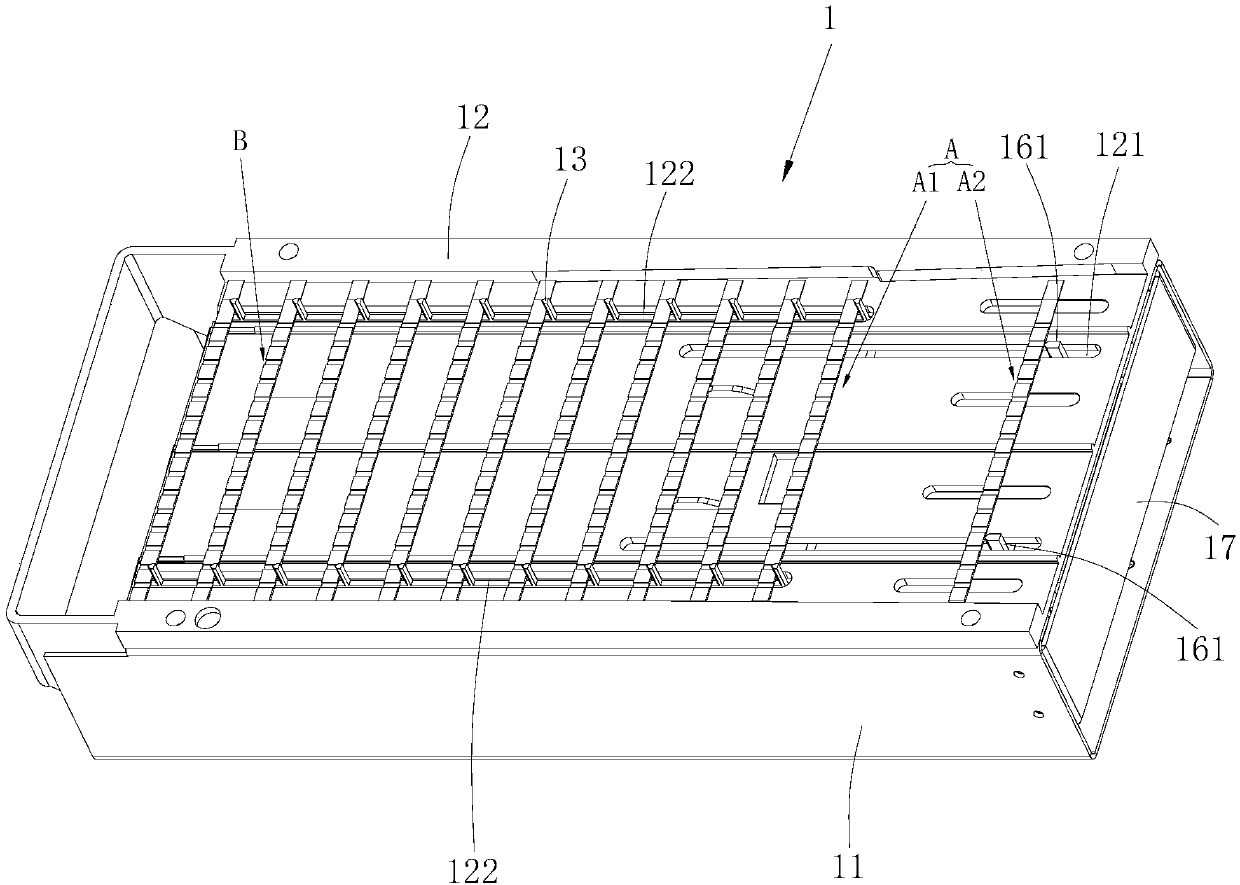

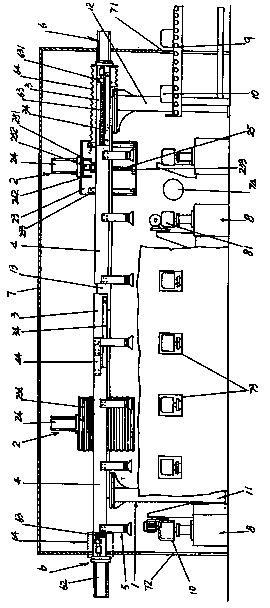

Multi-station full-automatic winding machine for winding plastic pipe and using method of multi-station full-automatic winding machine

PendingCN106927308AReduce wasteReduce labor intensityFilament handlingPackaging automatic controlWinding machineCircular disc

The invention discloses a multi-station full-automatic winding machine for winding a plastic pipe. The multi-station full-automatic winding machine for winding the plastic pipe comprises a main seat, and is characterized in that a rotating disc is mounted on the main seat; a plurality of rotating big arms are uniformly arranged on the rotating disc in the radial direction; the tail end of each rotating big arm is fixedly connected with a reel mechanism; each reel mechanism is provided with a pipe sampling mechanism and an online drift-diameter ball blowing and air pressing testing mechanism; and the main seat is further provided with a pipe discharging mechanism, a bundling mechanism and an unloading mechanism. By the multi-station full-automatic winding machine for winding the plastic pipe, shortcomings of multi-procedure arrangement manual operations such as winding, manual bundling, manual sampling, offline manual drift-diameter ball blowing detection and offline manual air pressure testing are overcome, waste of space and personnel due to various procedures of products is reduced, therefore, the production costs of the products is reduced, and the labor intensity of the personnel is also reduced.

Owner:WUHAN KINGBULL ECONOMIC DEV

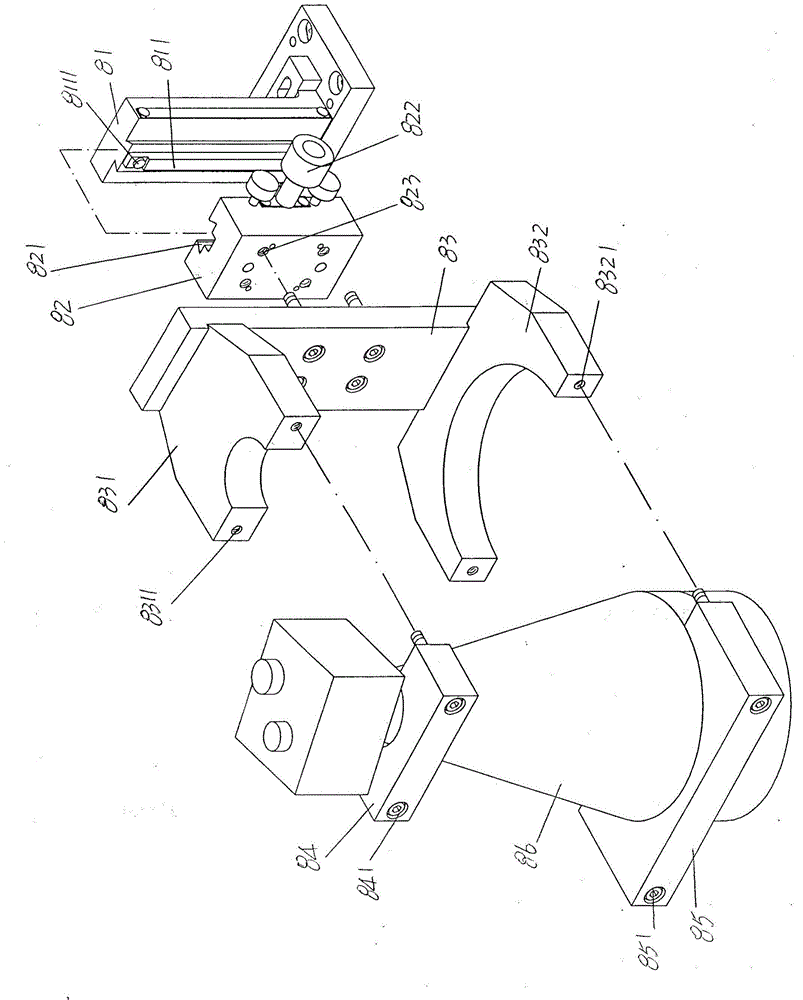

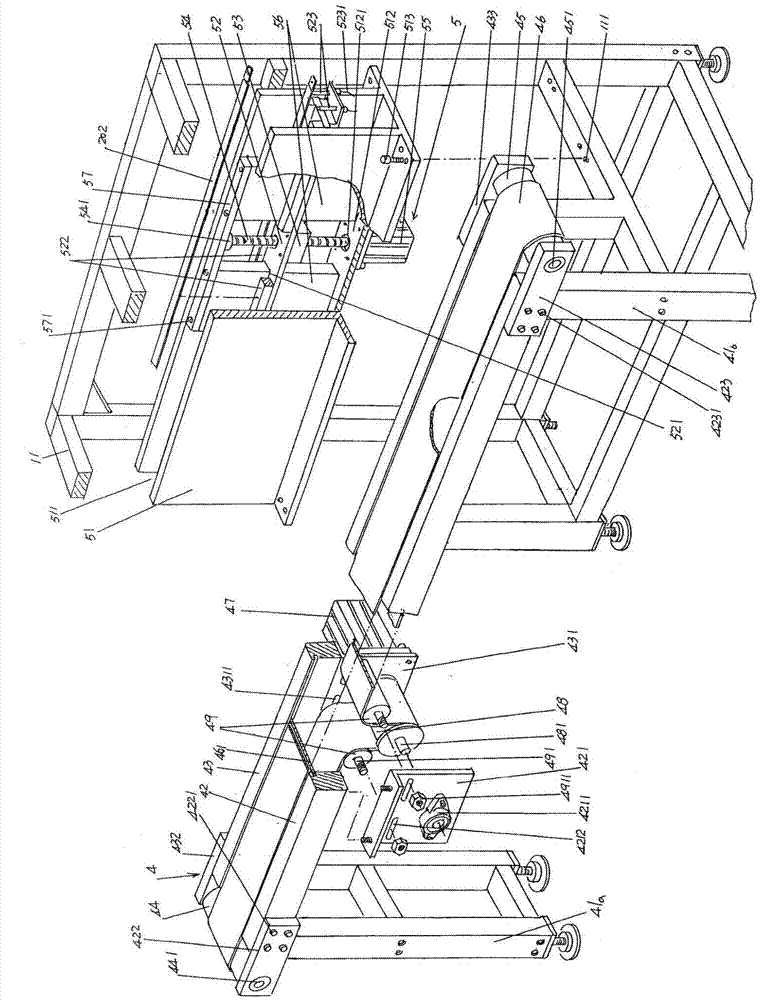

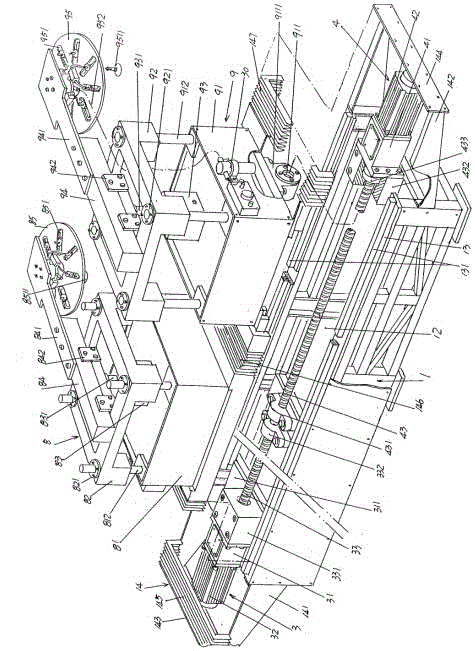

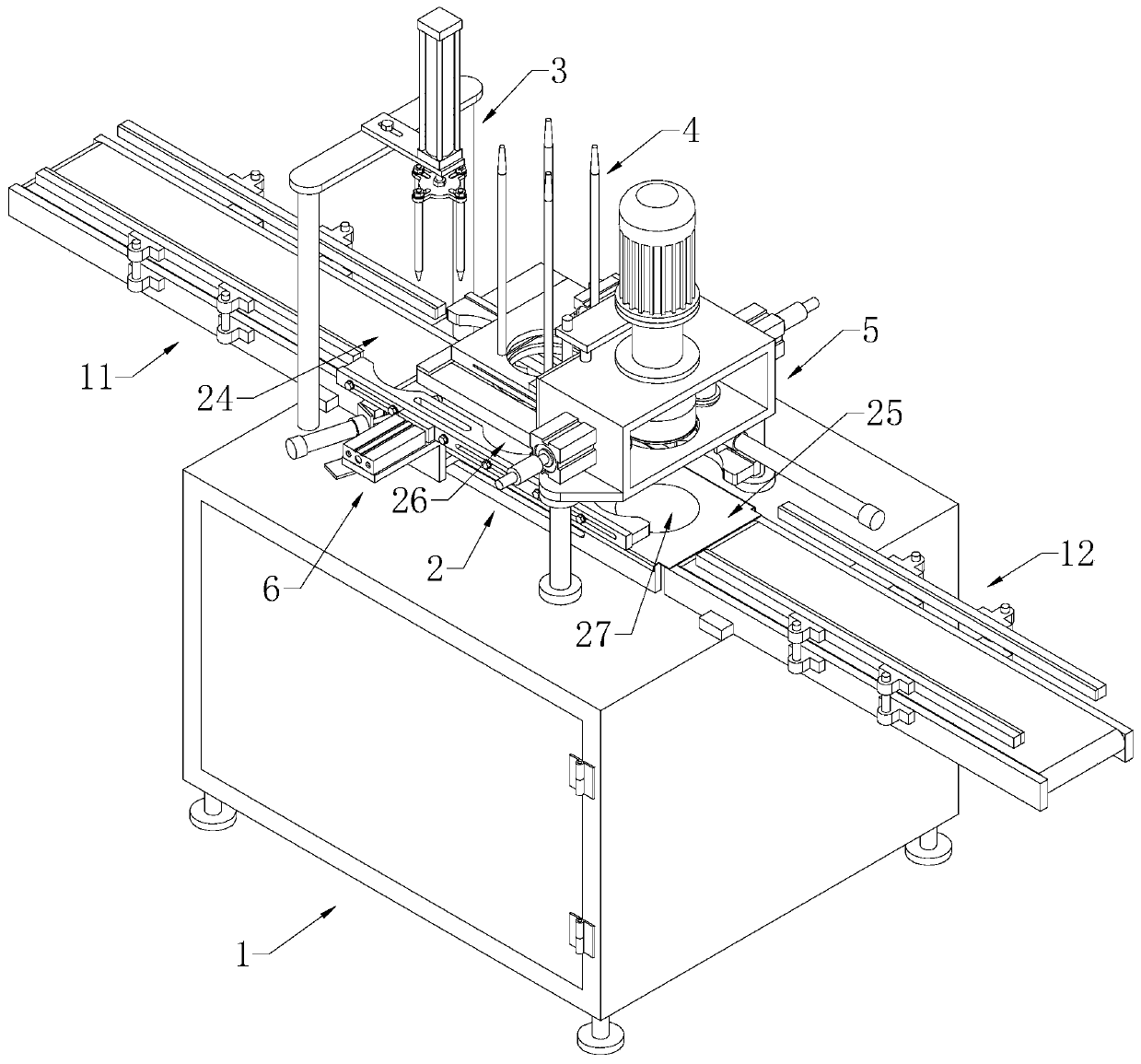

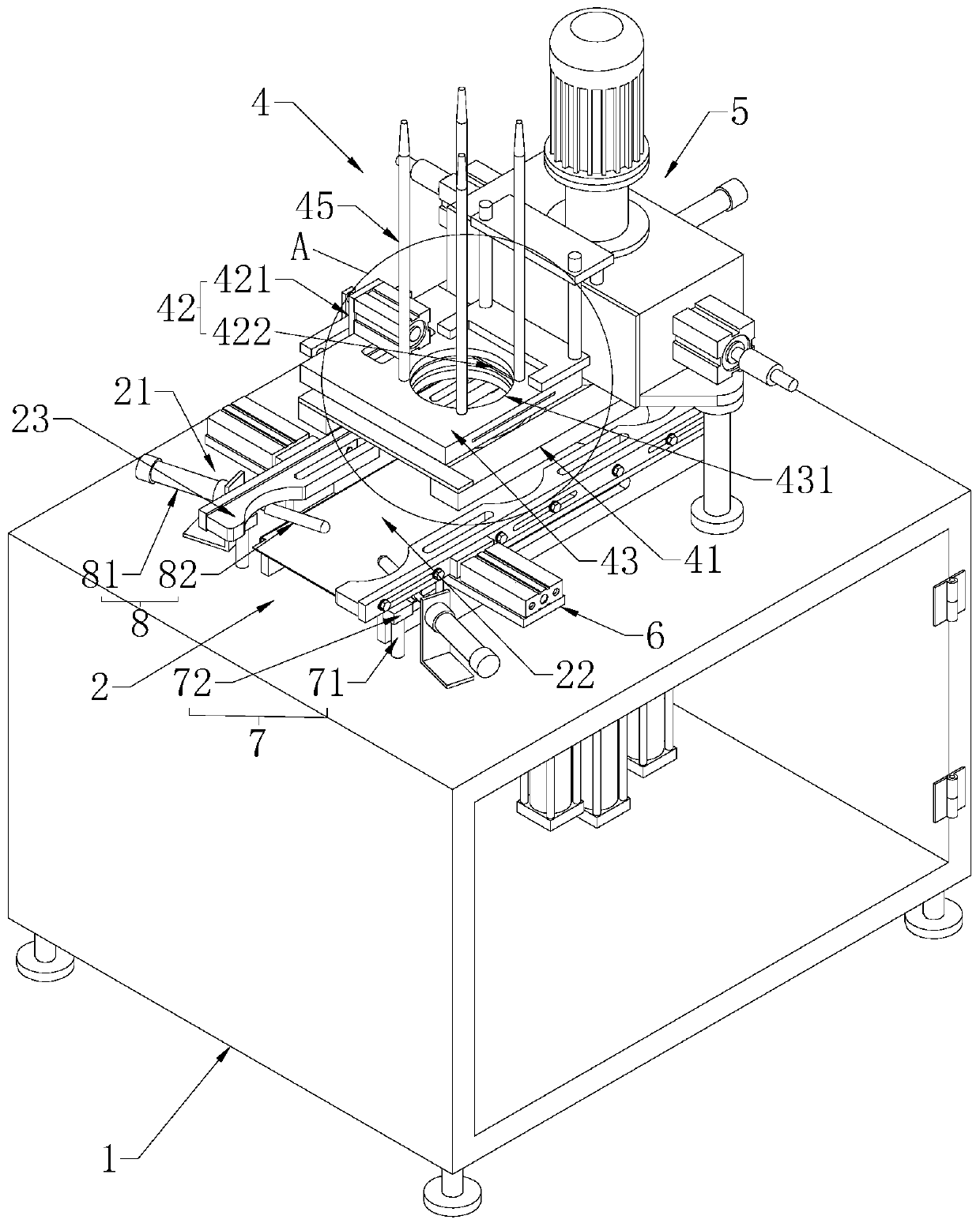

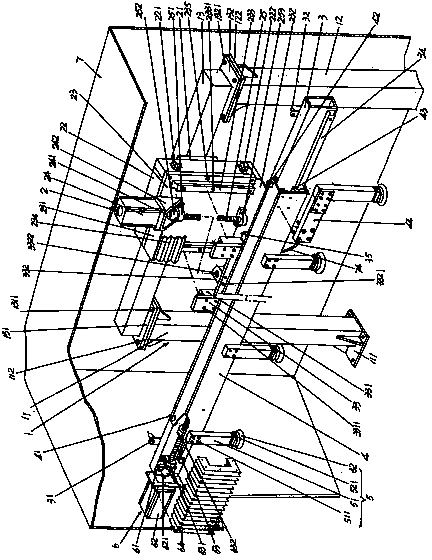

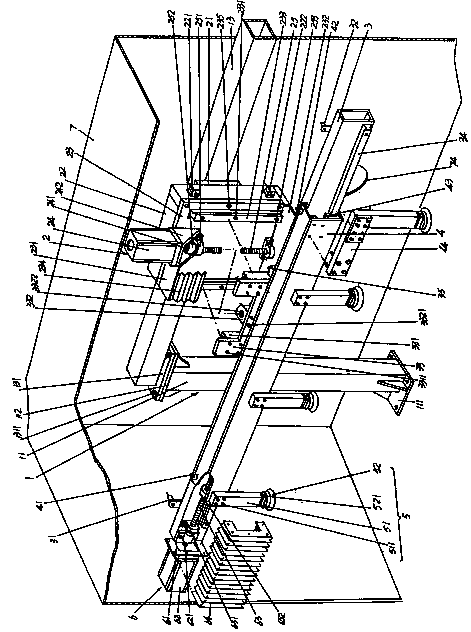

Mechanical arm used for propeller boss detection

ActiveCN104802170AReduce work intensityGood automation effectMeasurement devicesManipulatorPropellerEngineering

The invention discloses a mechanical arm used for propeller boss detection and belongs to the technical field of automated machines. The mechanical arm comprises a detecting worktable, a lifting beam, a lifting beam driving acting cylinder, a mechanical arm moving beam driving mechanism, a mechanical arm moving beam, a top plate, a plug track lifting mechanism, an overlook photographic mechanism and a horizontal photographic mechanism, wherein a guide rail stand column bottom plate and a main stand column bottom plate are fixed on the detecting work table; a left guide rail stand column is fixed at the left end of the guide rail stand column bottom plate while a right guide rail stand column is fixed at the right end of the guide rail stand column bottom plate; a lifting beam left sliding guide rail is fixed on one side of the left guide rail stand column; a lifting beam right sliding guide rail is fixed on one side of the right guide rail stand column; a left main stand column is fixed at the left end of the stand column bottom plate while a right main stand column is fixed at the right end of the stand column bottom plate; a sliding seat guide rail is arranged at the upper part of the lifting beam; the lifting beam driving acting cylinder is fixed on the guide rail stand column bottom plate; the mechanical arm moving beam driving mechanism is arranged on the lifting beam; the mechanical arm moving beam is connected with the mechanical arm moving beam driving mechanism; an electronic control valve is arranged on the top plate; the plug track lifting mechanism is arranged at the left end of the front side of the top plate; the overlook photographic mechanism is arranged on the top plate; the horizontal photographic mechanism is arranged on the detecting work table. The mechanical arm used for the propeller boss detection is high in detection efficiency and capable of reducing the manpower investment and ensuring the detection quality.

Owner:SOHBI CRAFT CHANGSHU

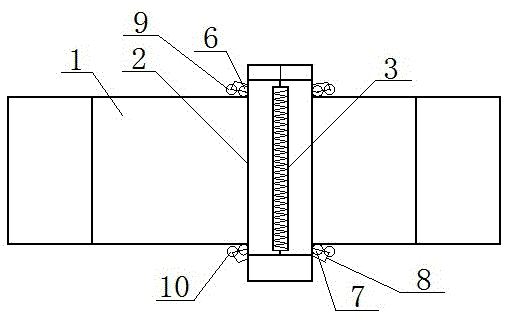

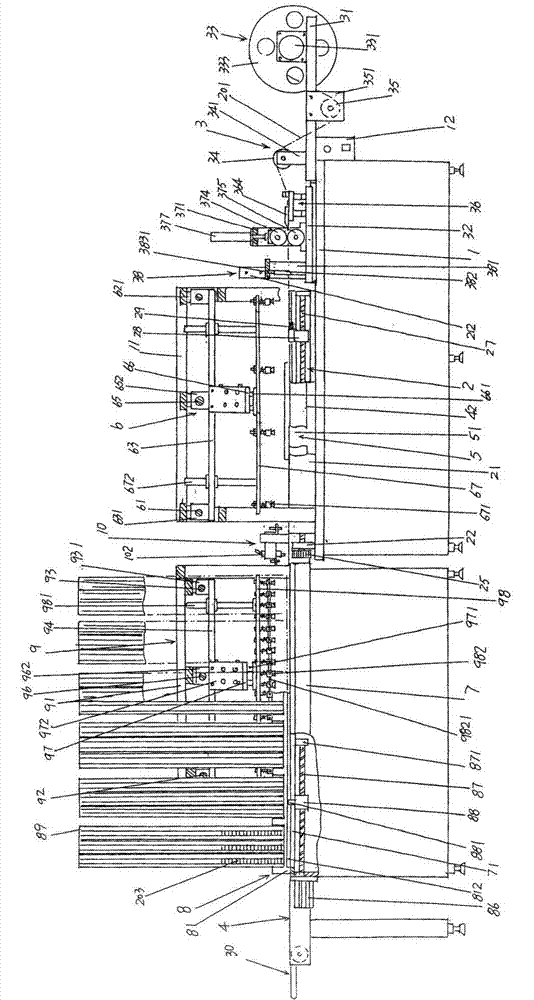

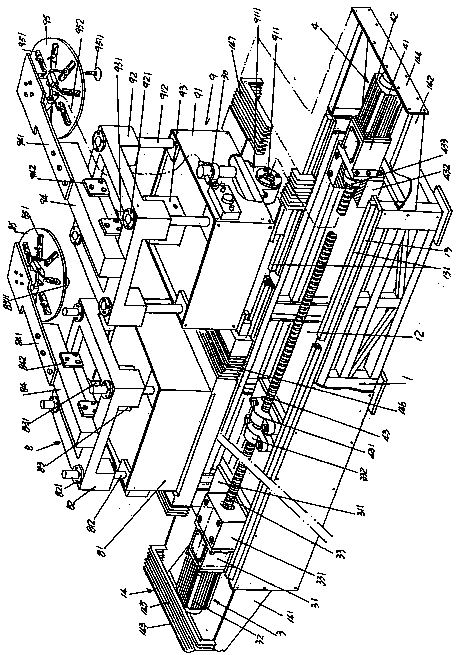

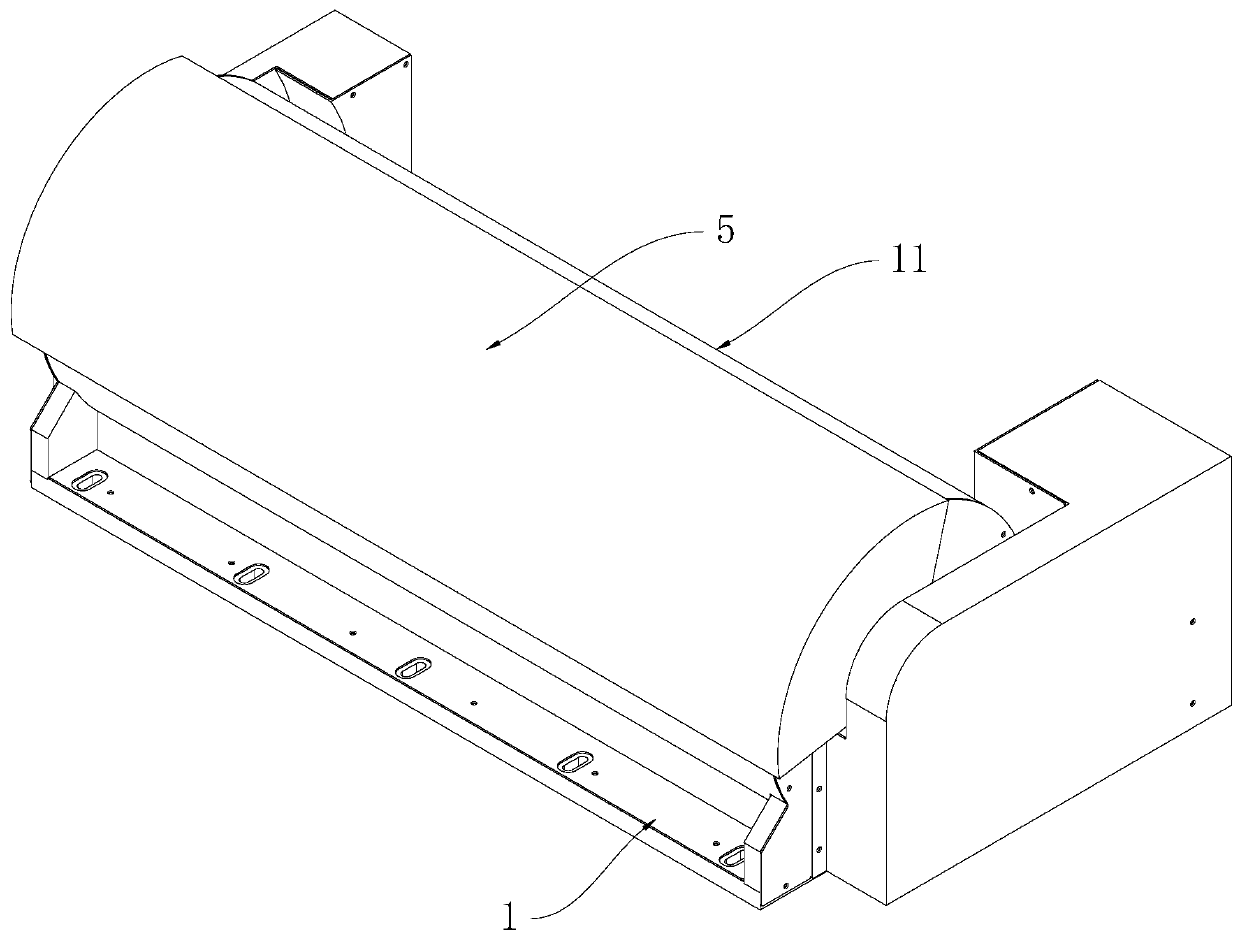

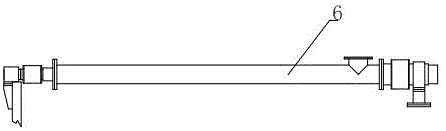

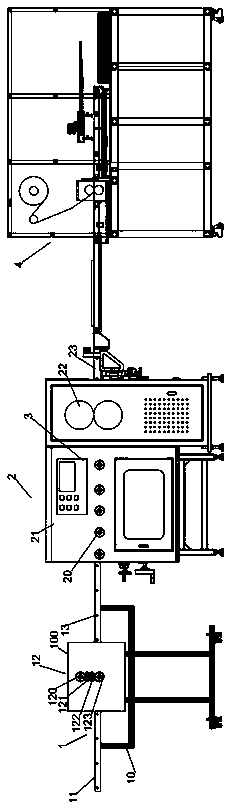

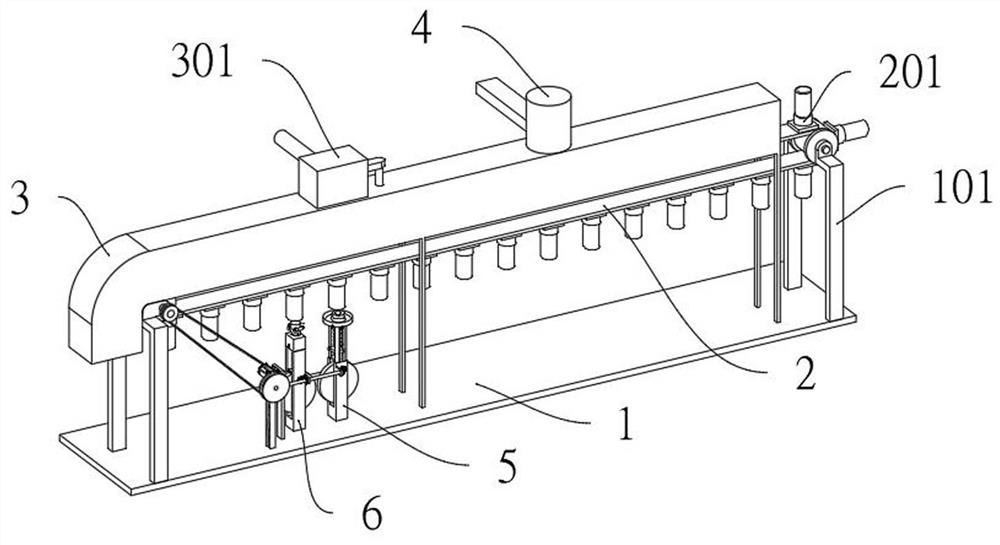

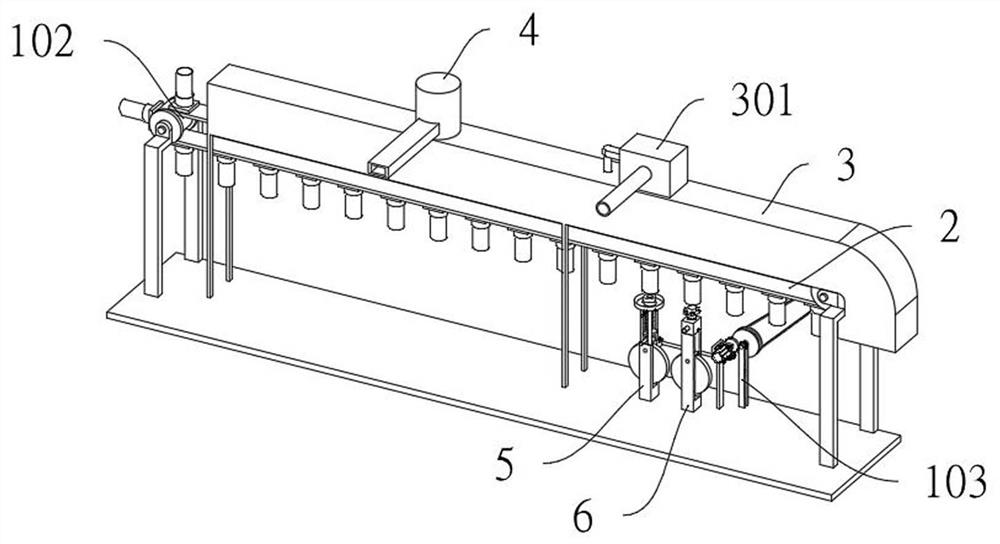

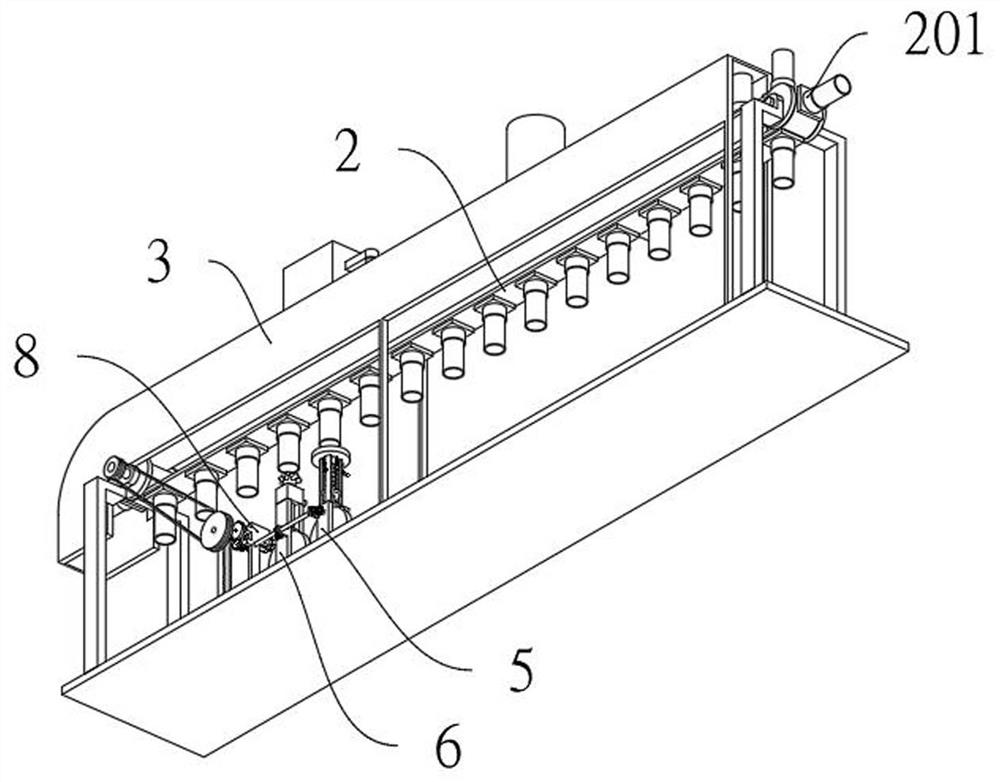

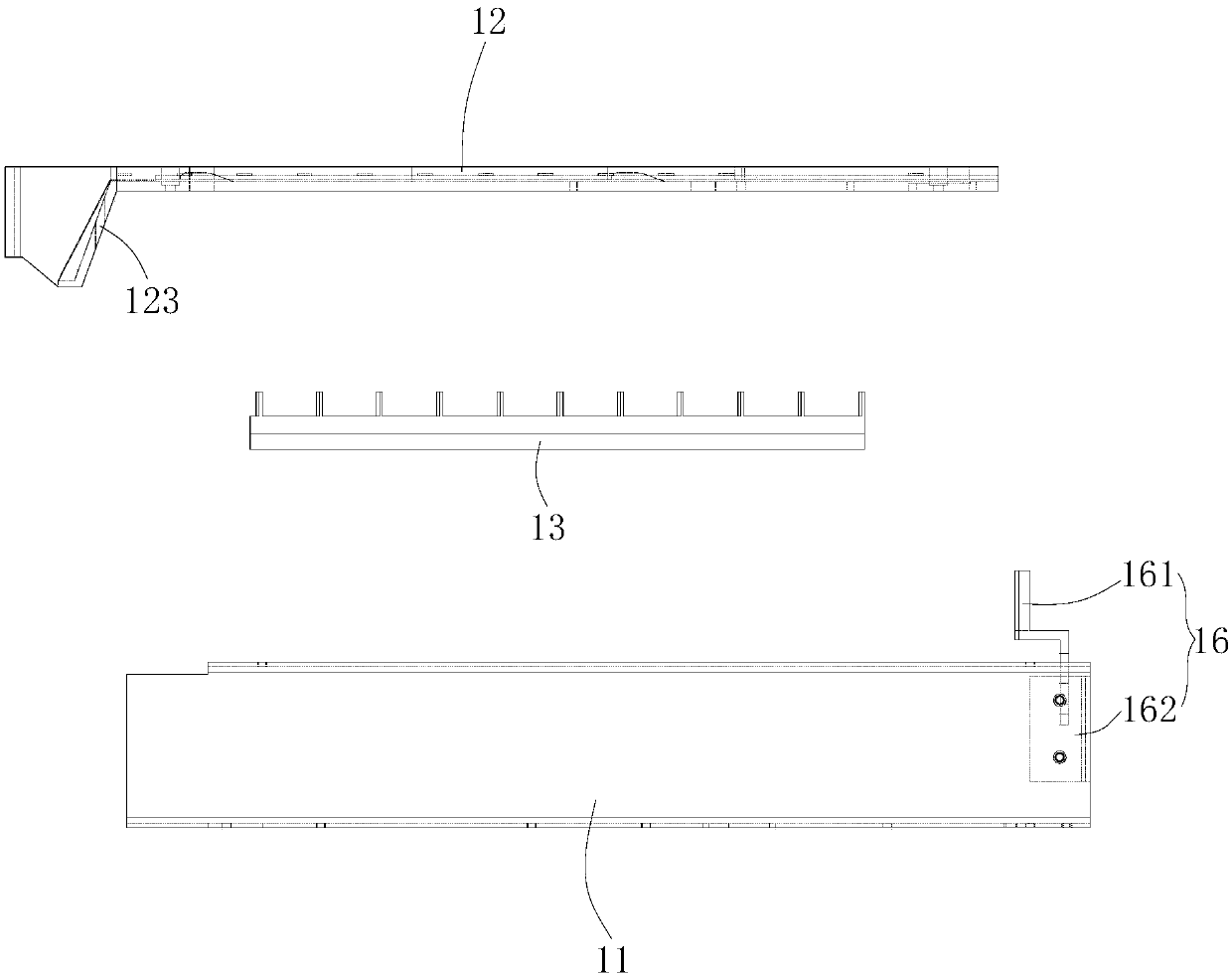

Insulating thin film belt traction structure for automatic PTC heating core assembling device

ActiveCN103879828AMeet the use requirementsAbandon manual operationArticle deliveryWebs handlingTransmission beltThin membrane

The invention belongs to the field of automatic machines, and relates to an insulating thin film belt traction structure for an automatic PTC heating core assembling device. The automatic PTC heating core assembling device comprises an insulating thin film belt conveying workbench and an insulating thin film belt conveying mechanism. The insulating thin film belt traction structure comprises an insulating thin film belt traction mechanism, and is characterized in that the insulating thin film belt traction mechanism comprises a pair of insulating thin film belt guiding frames, a pair of traction guide rod bases, a traction motor, a traction drive wheel, a traction driven wheel, a traction transmission belt, a traction screw, a traction nut and an air cylinder clamp. Insulating thin film belts conveyed through the insulating thin film belt conveying mechanism can be automatically clamped through the air cylinder clamp, the insulating thin film belts clamped by the air cylinder clamp are dragged and smoothly laid between the insulating thin film belt guiding frames while the air cylinder clamp moves in the direction back away from the insulating thin film belt conveying mechanism along with the traction nut, and therefore the using requirement of a subsequent station can be met; labor resources can be saved, and the insulating thin film belt traction structure has the good automation effect.

Owner:浙江西塘实业有限公司

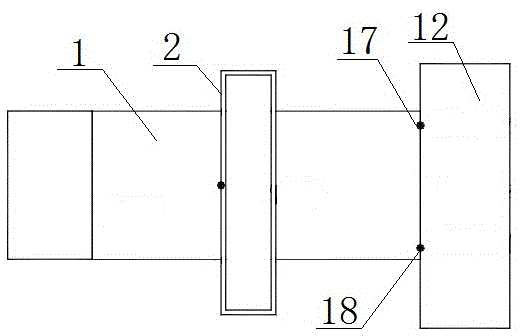

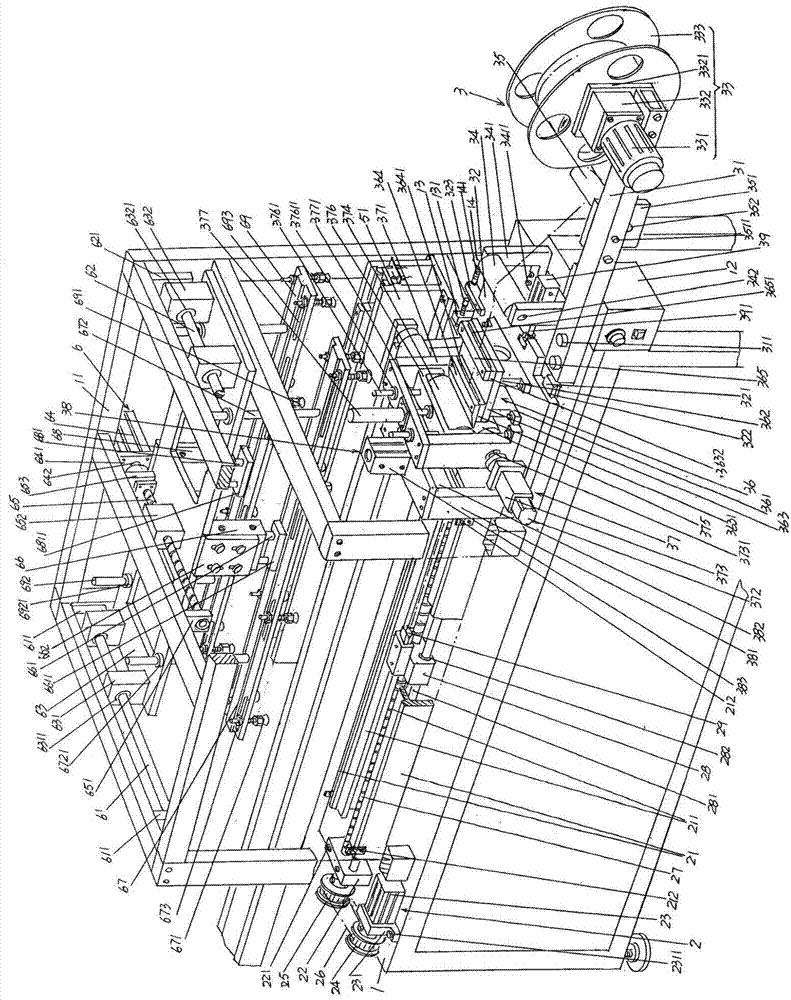

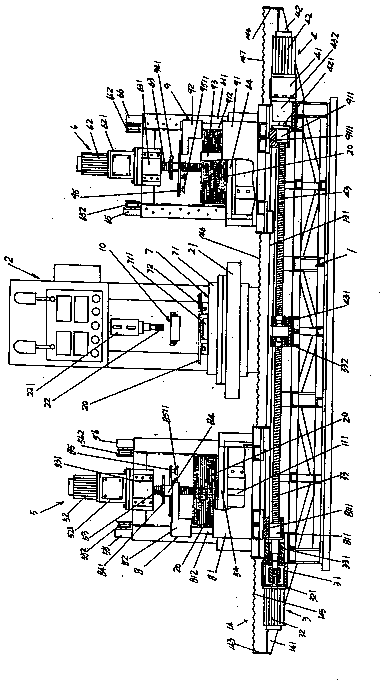

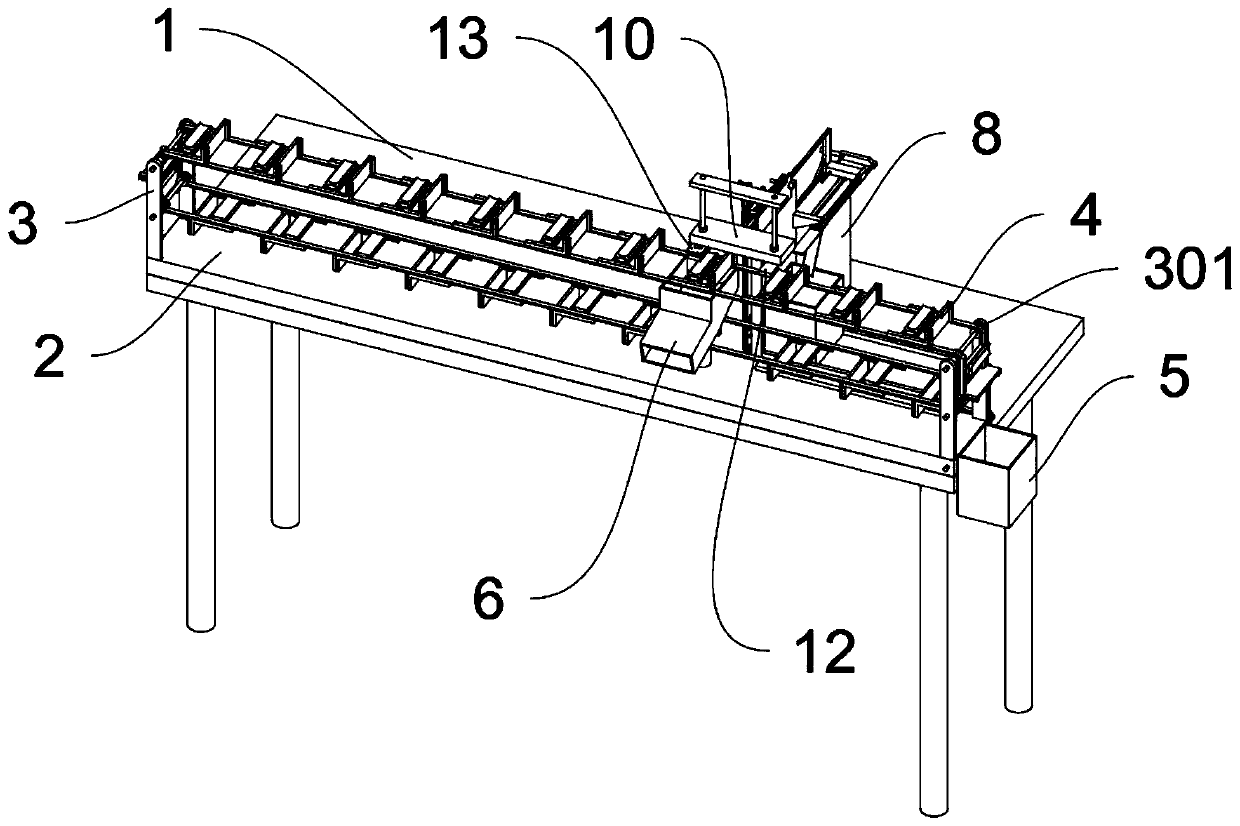

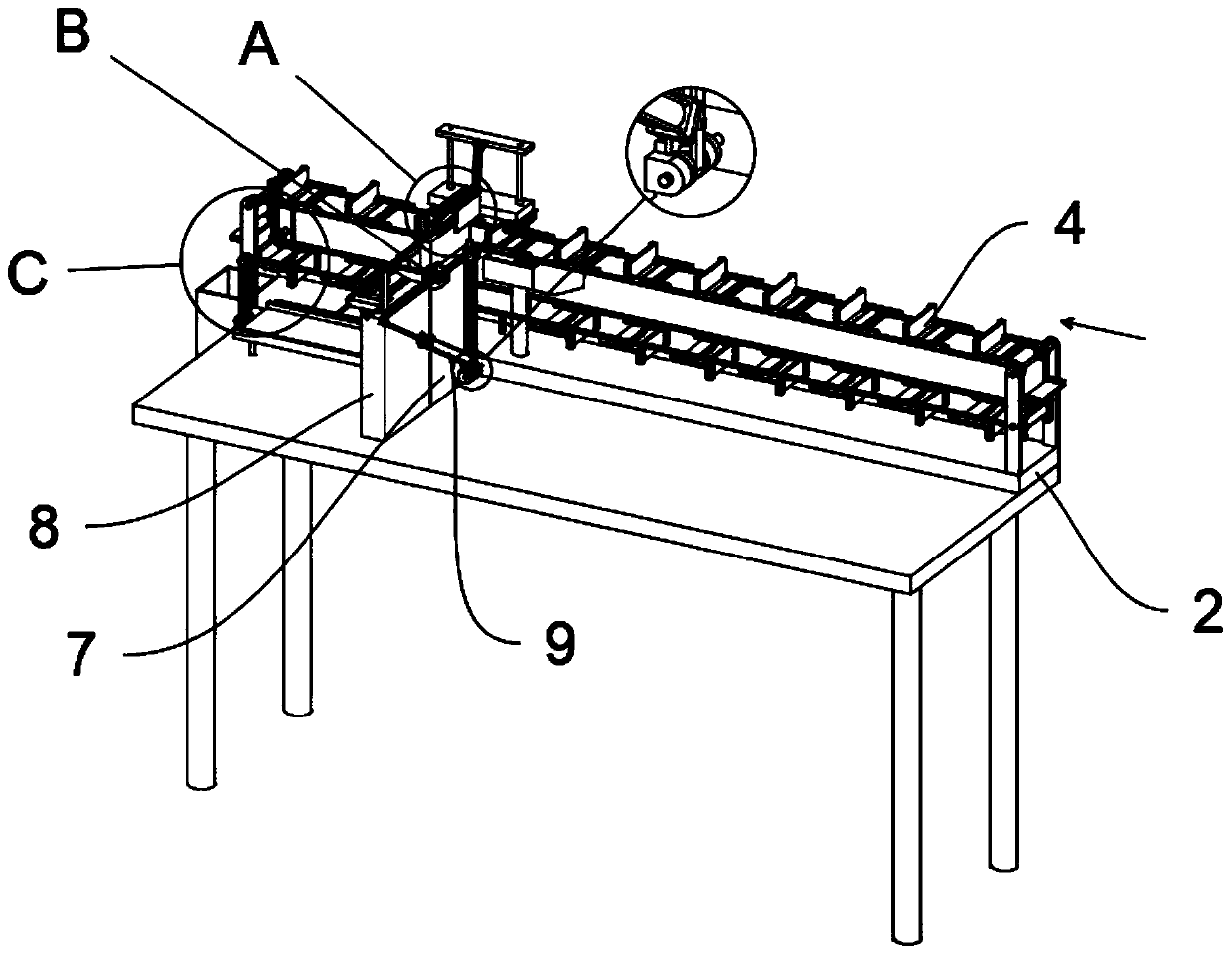

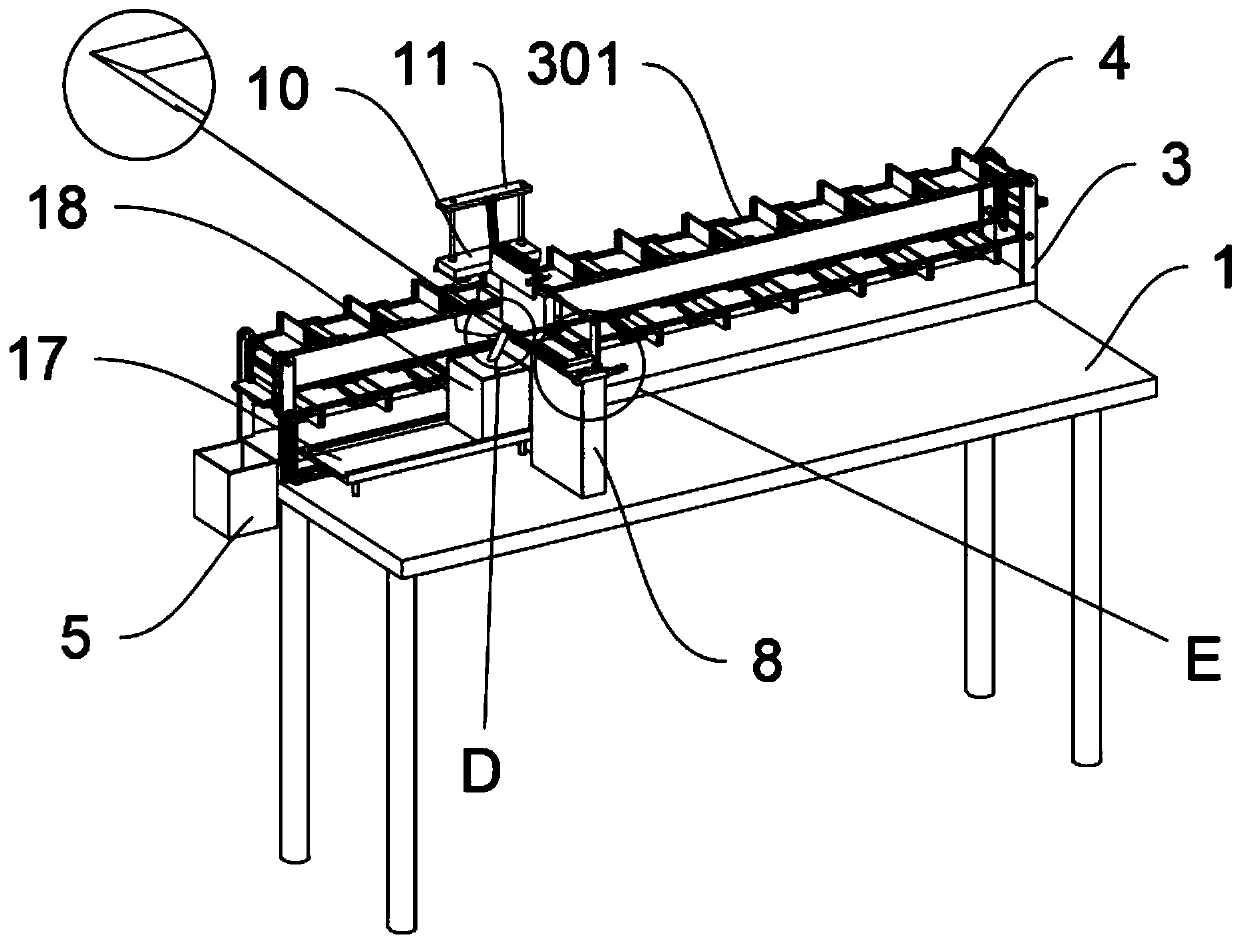

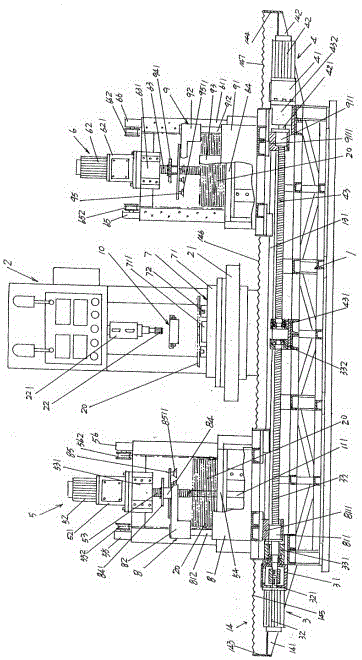

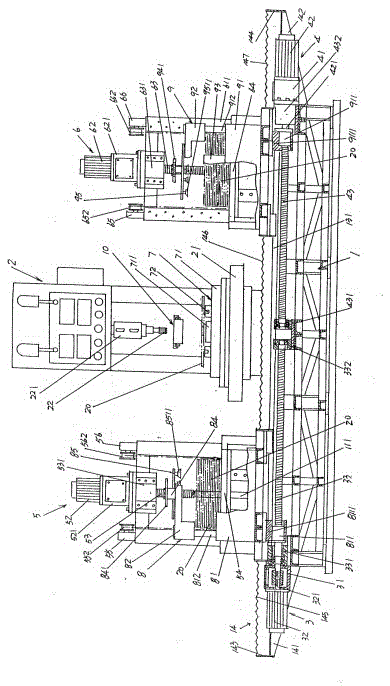

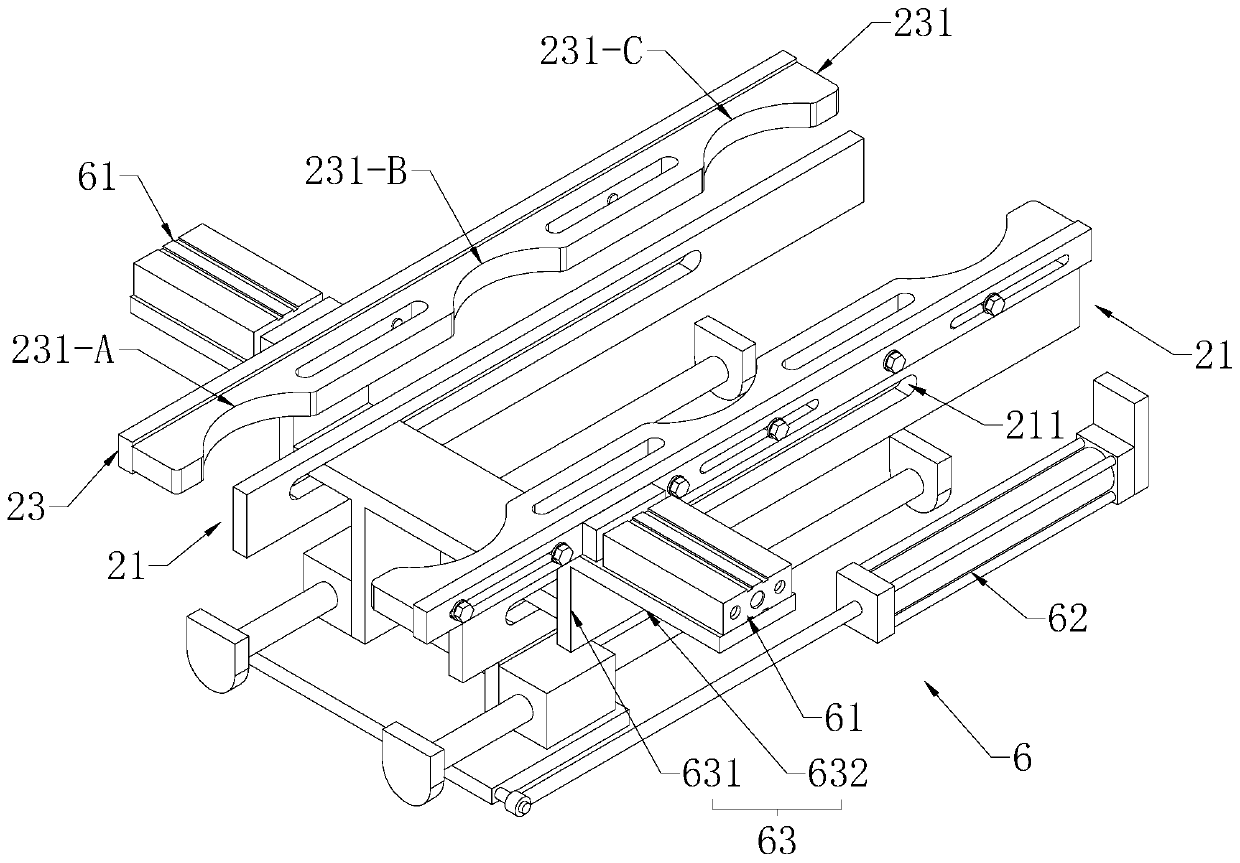

Disk saw blade feeding and receiving device of automatic reaming device for disk saw blade center hole

InactiveCN104289962AReduce work intensityImprove adaptabilityReaming devicesMetal working apparatusManipulatorUltimate tensile strength

The invention discloses a disk saw blade feeding and receiving device of and an automatic reaming device for a disk saw blade center hole, and belongs to the technical field of metal saw blade processing machinery. The automatic reaming device for the disk saw blade center hole comprises a base, a vertical drill, a receiving manipulator translating and driving mechanism, a feeding and receiving manipulator; the disk saw blade feeding and receiving device comprises a feeding and lifting gear and a receiving and lifting gear, the feeding and lifting gear comprises a feeding rack, a feeding motor, a feeding screw, a feeding and lifting gear, a left chain wheel seat of a feeding frame, a chain seat of the feeding mechanism, a first chain, a second chain and a balance block; the receiving and lifting gear comprises a receiving frame, a receiving motor, a receiving screw, a receiving and lifting platform, a left chain wheel seat of a receiving frame, a chain block of the receiving frame, a first lifting chain, a second lifting chain and a balance hammer. The disk saw blade feeding and receiving device is good in automation effect, working strength can be alleviated, safety can be ensured, the applicability to an operation place can be improved, human input can be reduced, and labor resource can be saved.

Owner:SUZHOU VOCATIONAL UNIV

Automatic peeling and sorting device for aloe flesh in previous working procedure of cosmetic production

InactiveCN111202252AEasy to recycle separatelyRealization of automatic peeling and sortingVegetable peelingMetal working apparatusProcess engineeringMechanical engineering

The invention discloses an automatic peeling and sorting device for aloe flesh in a previous working procedure of cosmetic production, and relates to the technical field of cosmetic processing. The automatic peeling and sorting device solves the problems that the peeling on aloes by an existing peeling device is not accurate enough; much colloid is wasted; a fine sorting function cannot be realized; meanwhile, the linkage capability is poor; a plurality of power sources are needed for completing peeling and feeding actions; and the operation is extremely inconvenient. The automatic peeling andsorting device for aloe flesh in the previous working procedure of cosmetic production comprises a processing table, wherein a feeding table is fixedly arranged at one side of the top of the processing table through screw bolts; four groups of conveying frames are fixedly arranged at the top of the feeding table; the middle of the top of the processing table is connected and fixedly provided withan inner power table and an outer power table; and the inner power table is in contact with the feeding table. Through the arrangement of a straight knife, an arc knife and a cutting device, diversified multi-step differentiation processing is provided for the peeling device; the automatic sorting in the peeling process is realized; useful aloe peels can be conveniently and singly recycled for other purposes; and convenience and environment protection are realized.

Owner:冯文豪

Annular multi-row tool magazine and tool supply method

PendingCN111113115ALarge capacityRealize the function of picking up tools automaticallyPositioning apparatusMaintainance and safety accessoriesControl engineeringMechanical engineering

The invention discloses an annular multi-row tool magazine which comprises a supporting seat. The supporting seat is provided with a rotating seat and a driving mechanism used for driving the rotatingseat to rotate, the rotating seat is provided with at least one group of clamping mechanisms, the clamping mechanisms comprise a plurality of clamping jaws used for clamping tools, the clamping jawsare uniformly distributed along the circumferential direction of the rotating seat, and when the tools are taken out, the driving mechanism drives the rotating seat to rotate by a preset angle, so that the tools are conveyed to a preset tool taking position. The application requirement of clamping more tools in a small space is realized, in practical application, the number of the tools which canbe accommodated by the tool magazine can be several times that of a straight-row type tool magazine, so that the tool capacity is increased by multiple times, and in addition, the rotating seat is driven by the driving mechanism to realize rotating control, better automatic performance is realized, the annular multi-row tool magazine can be better matched with intelligent machine tool equipment for use, and application requirements are well met.

Owner:深圳市环球同创机械有限公司

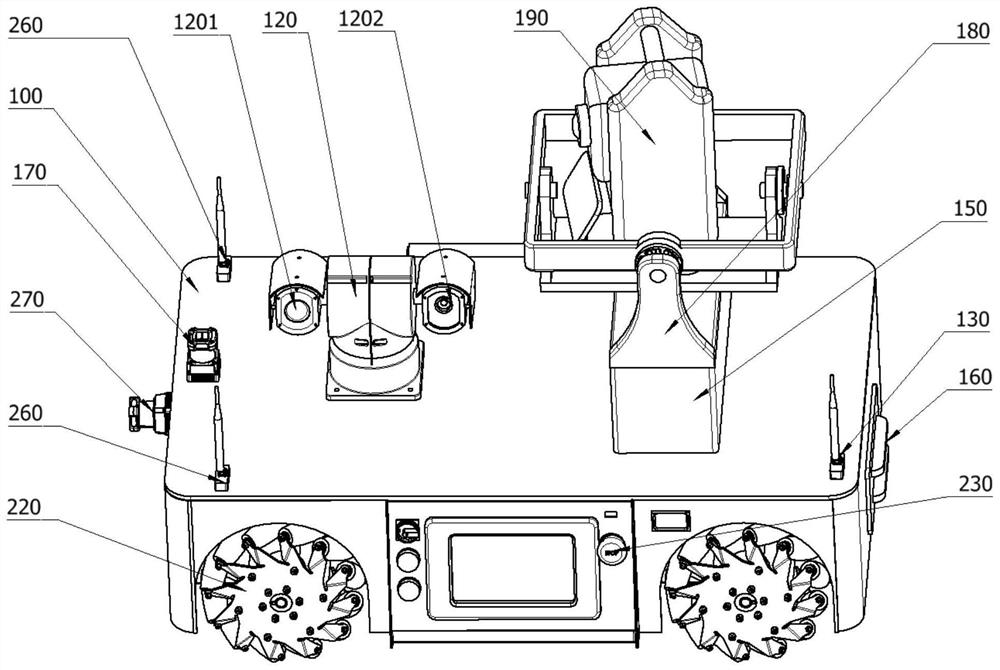

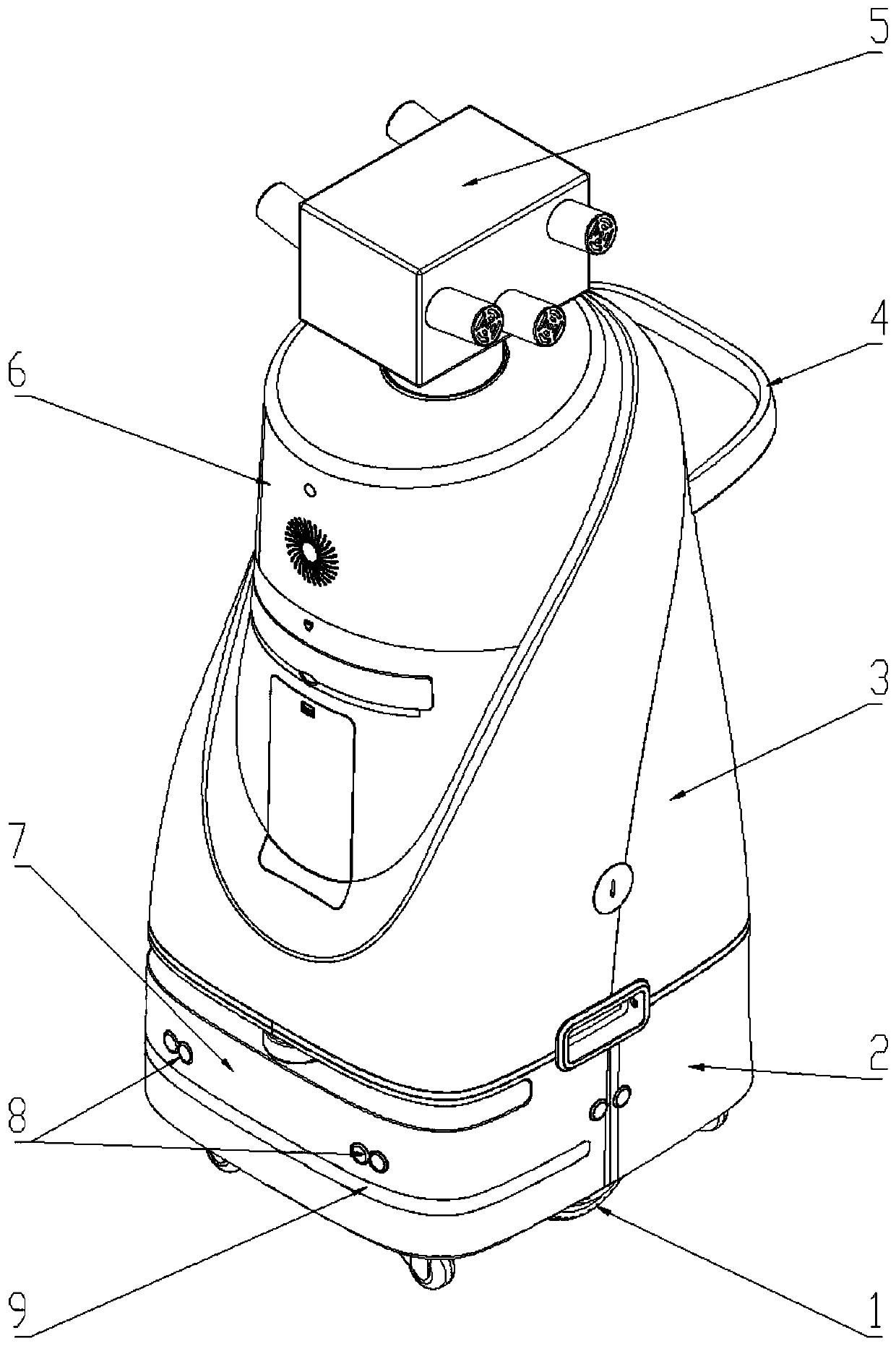

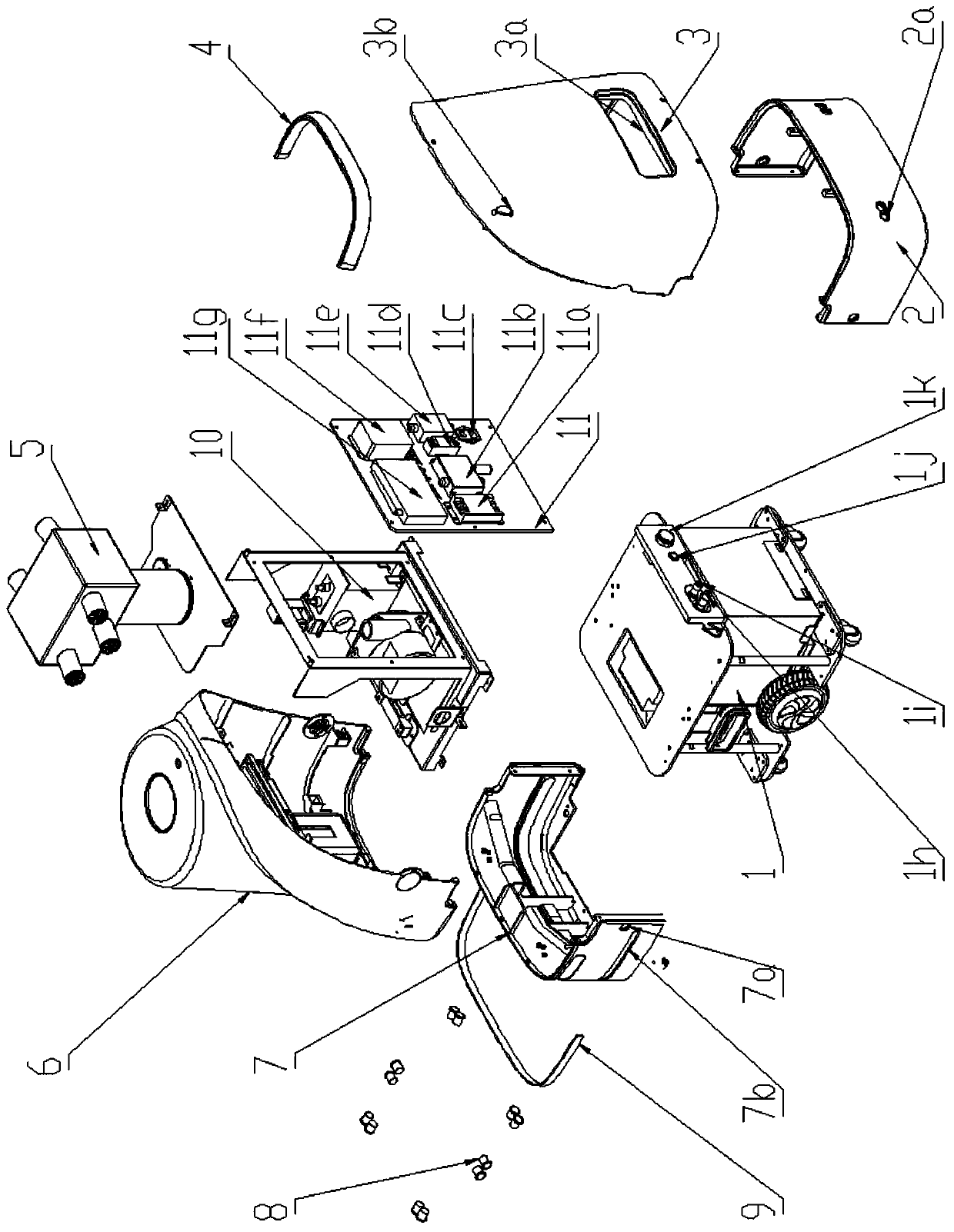

Self walking type atomization disinfection robot

PendingCN111530652AConvenient automatic walkingEasy steeringProgramme-controlled manipulatorMovable spraying apparatusLaser probeSprayer

The invention provides a self walking type atomization disinfection robot which belongs to the technical field of intelligent disinfection equipment and is used for solving the problems that an existing disinfection robot has poor disinfectant atomization and spraying effects and cannot effectively avoid obstacles. The self walking type atomization disinfection robot comprises a walking mechanismand a rotating sprayer, wherein a front lower cover and a back lower cover are respectively fixed at the two sides of the upper end of the walking mechanism; the upper end of the front lower cover isfixed to a front upper cover assembly; the upper end of the back lower cover is fixed to a back upper cover; the upper end of the walking mechanism is provided with an atomization mechanism; a monitoring assembly is arranged on the atomization mechanism; the front upper cover assembly comprises a front upper cover body and a liquid storage tank; a placement chamber is arranged inside the front upper cover body; the liquid storage tank is detachably arranged inside the placement chamber; and the rotating sprayer is arranged on the atomization mechanism. The walking mechanism of the self walkingtype atomization disinfection robot uses a motor driver to control a wheel hub motor wheel and to cooperate with a universal wheel; automatic walking and steering are realized; cooperation with a laser probe and a camera is realized; obstacle avoidance can be effectively realized; the atomization mechanism can fast atomize a disinfectant; the rotating sprayer can effectively and uniformly performspray disinfection; and the disinfection range is wide.

Owner:安徽伽马莱恩机器人有限公司

Forged material conveying device for stamping steel balls

PendingCN108326225AFast reciprocating sliding speedImprove delivery efficiencyEngine componentsHandling devicesStructural engineeringSteel ball

The invention discloses a forging material conveying device for stamping steel balls, and belongs to the technical field of auxiliary equipment for steel ball stamping and forming. The conveying device comprises a sliding table machine frame, a sliding table, a pneumatic sliding table driving mechanism, a forging material clamping and releasing mechanism, a forging material pushing and feeding mechanism, a forging material pushing mechanism and a clamping driving mechanism, wherein the sliding table is arranged on the sliding table machine frame, the pneumatic sliding table driving mechanism is arranged on the right side of the sliding table machine frame and is connected to the sliding table, the forging material clamping and releasing mechanism is arranged on the sliding table, the forging material pushing and feeding mechanism is fixed to the sliding table machine frame at a position corresponding to the left side of the sliding table machine frame, the forging material pushing mechanism is arranged on the pneumatic sliding driving mechanism in a state corresponding to the forging material pushing and feeding mechanism and is further connected to the sliding table machine frame,and the clamping driving mechanism is fixed to the front side or rear side of the sliding table machine frame and extends to the position below the sliding table to correspond to the forging materialclamping and releasing mechanism. The conveying device has the advantages that the reciprocating sliding speed of the sliding table is high, and the forging material conveying efficiency can be improved; the reliability of the forging material clamping and releasing mechanism, arranged by taking the sliding table as a carrier, for clamping and releasing a forging material can be guaranteed; the economic performance of equipment can be embodied, and the daily use, inspection and protection cost can be lowered; and the automatic effect is ideal.

Owner:CHANGSHU FEIFAN METALWORK

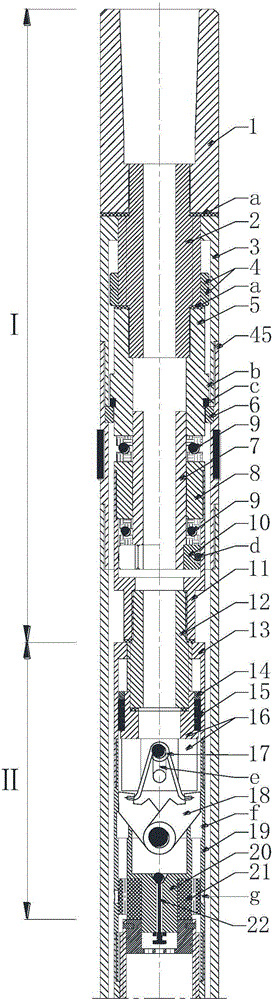

Hydraulic rock core lifting device for exploratory boring

ActiveCN106014314AIncrease heart rateGuarantee the quality of coringCore removalDouble tubeRock core

The invention discloses a hydraulic rock core lifting device for exploratory boring. The device comprises a waterproof transfer mechanism, a diversion limiting mechanism, a pressure storage mechanism, an elevation injection molding mechanism, a hydraulic core clamping mechanism, a lateral jet drill bit transfer mechanism and a sealing system, wherein the diversion limiting mechanism is butted with the waterproof transfer mechanism; the pressure storage mechanism is butted with the diversion limiting mechanism; the elevation injection molding mechanism is butted with the pressure storage mechanism; the hydraulic core clamping mechanism is butted with the elevation injection molding mechanism; the lateral jet drill bit transfer mechanism is butted with the hydraulic core clamping mechanism. The device can be directly matched with a double-tube drilling tool and a rope core drill to achieve a coring rate of 100 percent for a complicated difficult-to-core formation such as a soft and loose formation and a broken formation; in addition, a rock core can be fully automatically lifted, bundled and controlled under three-dimensional stress on the basis of hydraulic pressure; moreover, a conventional core clamping and cutting device is matched to achieve the characteristics of high reliability, high coring efficiency, high coring quality, high rock core collection rate, wide applicable formation range, high automation performance and the like.

Owner:CCCC FHDI ENG

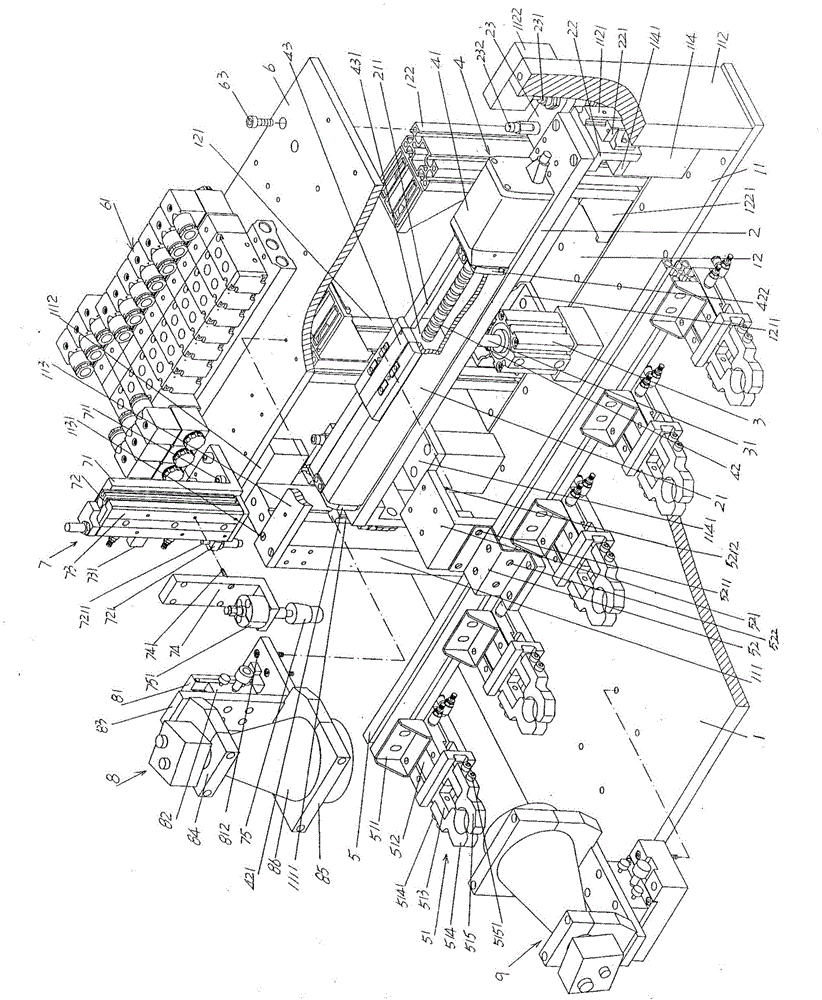

Automatic reaming device for center hole of circular saw blade

InactiveCN104308268BEnsure reaming qualityEnsure job safetyReaming devicesMetal working apparatusCircular sawReamer

The invention discloses an automatic reaming device for the center hole of a disc saw blade, and belongs to the technical field of metal saw blade processing machinery. The automatic reaming device comprises a base, a vertical drilling machine, a material feeding mechanical arm translation driving mechanism, a material receiving mechanical arm translation driving mechanism, a material feeding lifting mechanism, a material receiving lifting mechanism, a reaming saw blade carrying mechanism, a material feeding mechanical arm and a material receiving mechanical arm. The vertical drilling machine is provided with a drilling machine worktable and a reamer; the material feeding mechanical arm translation driving mechanism and the material receiving mechanical arm translation driving mechanism are arranged on the base and on the left end and the right end of the base in the length direction; the material feeding lifting mechanism and the material receiving lifting mechanism are arranged on the back side of the left end of the base and the back side of the right end of the base; the reaming saw blade carrying mechanism is arranged on the drilling machine worktable; the material feeding mechanical arm is in sliding fit with the upper part of the left end of the base and is in connection with the material feeding mechanical arm translation driving mechanism; the material receiving mechanical arm is in sliding fit with the upper part of the right end of the base and is in connection with the material receiving mechanical arm translation driving mechanism. The equipment input quantity is reduced, and the labor resource is saved; the operation safety of workers is ensured; the operation intensity is reduced; the reaming quality of the center hole of the disc saw blade is ensured, and flaws are eradicated; mechanized automatic reaming is realized, the environment of a workplace where the workers work is standard and orderly.

Owner:广州市鸿铨模具制造有限公司

Circular saw blade supply and receiving device for automatic reaming device for central hole of circular saw blade

InactiveCN104289962BReduce work intensityImprove adaptabilityReaming devicesMetal working apparatusCircular sawManipulator

The invention discloses a disk saw blade feeding and receiving device of and an automatic reaming device for a disk saw blade center hole, and belongs to the technical field of metal saw blade processing machinery. The automatic reaming device for the disk saw blade center hole comprises a base, a vertical drill, a receiving manipulator translating and driving mechanism, a feeding and receiving manipulator; the disk saw blade feeding and receiving device comprises a feeding and lifting gear and a receiving and lifting gear, the feeding and lifting gear comprises a feeding rack, a feeding motor, a feeding screw, a feeding and lifting gear, a left chain wheel seat of a feeding frame, a chain seat of the feeding mechanism, a first chain, a second chain and a balance block; the receiving and lifting gear comprises a receiving frame, a receiving motor, a receiving screw, a receiving and lifting platform, a left chain wheel seat of a receiving frame, a chain block of the receiving frame, a first lifting chain, a second lifting chain and a balance hammer. The disk saw blade feeding and receiving device is good in automation effect, working strength can be alleviated, safety can be ensured, the applicability to an operation place can be improved, human input can be reduced, and labor resource can be saved.

Owner:SUZHOU VOCATIONAL UNIV

Vacuumizing and nitrogen filling sealing machine

InactiveCN110171611AImprove the effect of punching and looseningSolve compactionPackaging by pressurising/gasifyingNitrogenEngineering

The invention discloses a vacuumizing and nitrogen filling sealing machine and relates to the technical field of can sealing machines. The vacuumizing and nitrogen filling sealing machine comprises anorganic rack and a conveying track. A sealing device is arranged on the rack, a perforating device is arranged at the feed inlet of the conveying track on the rack and comprises a mounting rack, a power part and perforating parts which are driven by the power part to move vertically are arranged on the mounting rack, and the perforating parts of needle structures are matched to form a columnar structure which is matched with a tank body. Perforating and loosening effects of the perforating device are improved favorably and the problem of powder hardening is also solved favorably according tothe shape of a perforated hole. The columnar structure formed by matching the perforating parts is matched with the tank body in shape to meet the perforating and loosening operational demands of tankbodies of different shapes. By perforating and loosening powder and carrying out vacuumizing and nitrogen filling operations, a purpose of reducing the residual oxygen content in the powder in the vacuumizing operating process is achieved. Therefore, the residual oxygen content in the tank body after vacuumizing and nitrogen filling meets the demand.

Owner:上海仅上包装设备有限公司

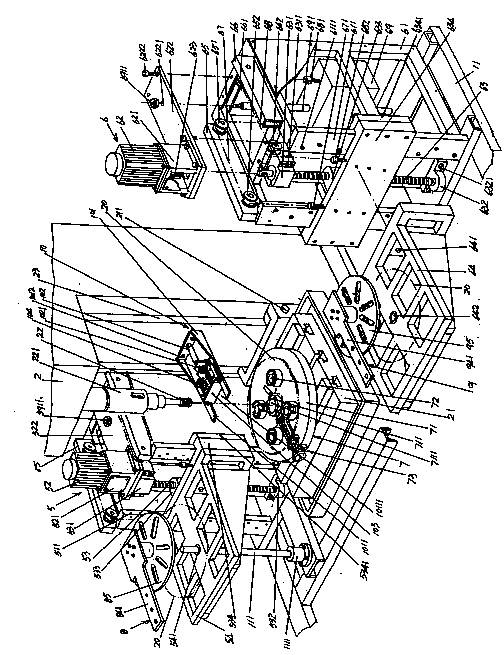

Semi-automatic electrode cap surfacing machine

InactiveCN103433655AReduce labor costsGuaranteed sports performanceWelding/cutting auxillary devicesAuxillary welding devicesSemi automaticEngineering

The invention relates to a semi-automatic electrode cap surfacing machine, and belongs to the processing machinery of spot welding electrodes. The semi-automatic electrode cap surfacing machine comprises a worktable, a pawl shaft driving mechanism, a rotary table, a rotary table shaft driving mechanism, a group of electrode cap pivotal supporting mechanisms, a power transmission mechanism and an automatic electrode cap driving mechanism, wherein a cylinder seat and a guide rail seat are fixedly arranged on the worktable, and one side of the cylinder seat forms a push rod abdicating cavity; the guide rail seat is positioned in a cylinder seat cavity, and a protective plate is arranged at the front side of the worktable; an electric control box is arranged at the left end of the protective plate, and the pawl shaft driving mechanism is arranged on the worktable; the rotary table shaft is fixedly arranged at the center of the rotary table, and the rotary table shaft driving mechanism is connected with the lower end of the rotary table shaft; the group of electrode cap pivotal supporting mechanisms are arranged around the edge part of the rotary table in the circumferential direction at intervals, and the power transmission mechanism and the automatic electrode cap driving mechanism are arranged on the worktable; and the power transmission mechanism comprises a motor support, a motor, a driving transmission wheel, a driven transmission axle, a driven transmission wheel and a conveyor belt. The semi-automatic electrode cap surfacing machine has the advantages of simple structure, low work intensity, ideal automation effect, reduction in human input, and low labor cost, and ensures the movement effect of the electrode cap pivotal supporting mechanism.

Owner:苏州飞泰精工科技有限公司

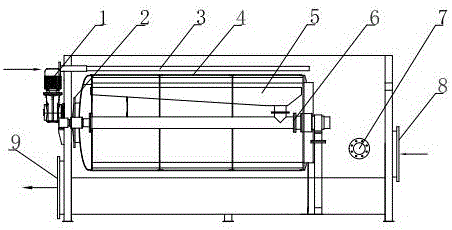

Drum-shaped precision filter

InactiveCN106178663AHigh corrosion resistance impact resistanceEasy to replaceMoving filtering element filtersSewageSewage treatment

The invention discloses a drum-shaped precision filter which comprises a rotary filter cartridge. The filter cartridge is a cartridge in the shape of a circular drum and is supported on a framework by a central support shaft, and bearings are arranged at two ends of the central support shaft; a water inlet is formed in an opening side of the filter cartridge, and sewage can flow into the filter cartridge; the filter cartridge can be driven by a driving device via a transmission mechanism to slowly rotate; a washing pipe is arranged on the outer side of the top of the filter cartridge, and a residue collecting hopper is arranged inside the filter cartridge and is positioned below the washing pipe. The drum-shaped precision filter has the advantages that stainless steel finished plates are punched to obtain support modules for individual filter units, and a filter screen is a stainless steel woven mesh and is good in corrosion resistance and impact resistance; the operating weight of the filter cartridge can be reduced to a great extent owing to intermediate support and intermediate transmission designs, the drum-shaped precision filter can bear long-term uninterrupted operating modes, the service life of equipment can be greatly prolonged, and the reliability of the equipment can be greatly improved; the filter cartridge is low in rotational speed, and accordingly the rotary bearings of the central support shaft are hardly abraded; good washing effects can be realized by the drum-shaped precision filter, and the drum-shaped precision filter is excellent in sewage treatment index.

Owner:无锡宜工环保设备有限公司

In-mold label multifunctional conveying system

InactiveCN101337406APrecise suctionPrecise windingStacking articlesPlastic forming machineEngineering

The invention relates to a multi-functional in-mould label conveying system, which comprises a volume label positioning device, a volume label sucking device, a rolling bar, a detecting component, a manipulator and a stacking device. The volume label positioning device is provided with a volume label tank to contain a large quantity of volume labels; a power component is arranged under the volume label tank to drive a pushing plate and push the volume labels upward; the volume label sucking device is arranged on the front side of the machine support, and is also provided with a power component to drive a moving part; the moving part is provided with a sucking component, which can be used for sucking the volume labels from the volume label positioning device to a rolling device; the rolling device is provided with the rolling bar; the rolling bar is provided with a C-shaped rolling tank, and can adsorb the volume labels first; after the rolling bar starts rotating, the C-shaped rolling tank is utilized to roll the volume labels into appropriate shape smoothly; the rolling device is provided with the detecting component to control the rotating radian and distance of the rolling bar of the rolling device; the manipulator is used for clamping rolled volume labels and is positioned into the cavity of the forming die of a plastic forming machine; plastic end products are taken out from the forming die of the plastic forming machine; the stacking device receives the plastic end products from the manipulator and conveys the end products to a packing place after the end products are stacked on a conveying belt.

Owner:黄胜昌 +1

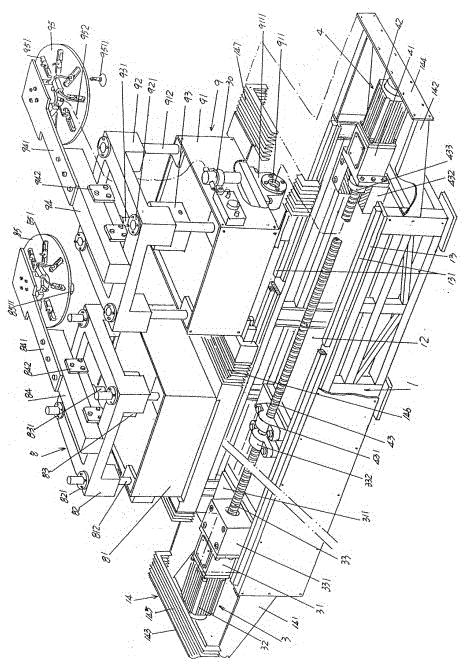

Automatic light guide plate hot-press transfer and lamination integrated equipment

ActiveCN109049958ALow costImprove processing efficiencyCylinder pressesTransfer printingLight guideEngineering

The invention discloses automatic light guide plate hot-press transfer and lamination integrated equipment. The equipment comprises a feeding device, a hot press, a lamination machine and a PLC control terminal, wherein the feeding device comprises a feeding rack, a first feeding transmission device, a second feeding transmission device and a cleaning roll group; the first feeding transmission device, the second feeding transmission device and the cleaning roll group are mounted on the feeding rack; the hot press comprises a hot press rack, a third feeding transmission device, a hot press rollwheel and a first discharging transmission device; the third feeding transmission device, the hot press roll wheel and the first discharging transmission device are mounted on the hot press rack; thelamination machine comprises a lamination machine rack, a fourth feeding transmission device, a lamination assembly, a trimming assembly, a second discharging transmission device and a material sucking manipulator; the fourth feeding transmission device, the lamination assembly, the trimming assembly and the second discharging transmission device are mounted on the lamination machine rack; the PLC control terminal is electrically connected with the feeding device, the hot press and the lamination machine; and inductive probes on the third feeding transmission device, the first discharging transmission device and the fourth feeding transmission device are electrically connected with the PLC control terminal. According to the equipment, the automatic operations of light guide plate heat transfer printing and lamination are realized, the machining efficiency is high, the labor cost is reduced and the product machining accuracy is ensured.

Owner:嘉兴市创杰电子科技有限公司

Electrode cap overlay welding device with automation function

InactiveCN103433595AReduce labor costsReduce the intensity of surfacing operationWelding/cutting auxillary devicesArc welding apparatusEngineeringSpot welding

The invention relates to an electrode cap overlay welding device with an automation function and belongs to the technical field of spot-welding electrode manufacturing machinery. The electrode cap overlay welding device comprises a workbench, a pawl shaft driving mechanism, a rotary disc, a rotary disc shaft driving mechanism, a group of electrode cap pivoting support mechanisms, a power transmission mechanism and an automatic electrode cap expelling mechanism, wherein a tubular seat and a guide rail seat are fixedly arranged on the workbench, a push rod yielding chamber is formed at one side, facing to the pawl shaft driving mechanism, of the tubular seat, and the pawl shaft driving mechanism is arranged on the workbench and is matched with the guide rail seat; a rotary disc shaft is fixedly arranged at the center of the rotary disc and supports the tubular seat, and the lower end of the rotary disc shaft extends into a tubular seat chamber; the rotary disc shaft driving mechanism is fixedly connected with the lower end of the rotary disc shaft; the electrode cap pivoting support mechanisms are equidistantly distributed around the edge positions of the rotary disc in a spaced manner; the power transmission mechanism is arranged on the workbench; the automatic electrode cap expelling mechanism is arranged on the workbench and is matched with the electrode cap pivoting support mechanisms. The electrode cap overlay welding device with the automation function has the advantages that the dependence on clamping devices of complicated structures is not required; the intensity of overlay welding operation is reduced; an ideal automatic effect can be embodied; the labor cost is reduced.

Owner:苏州飞泰精工科技有限公司

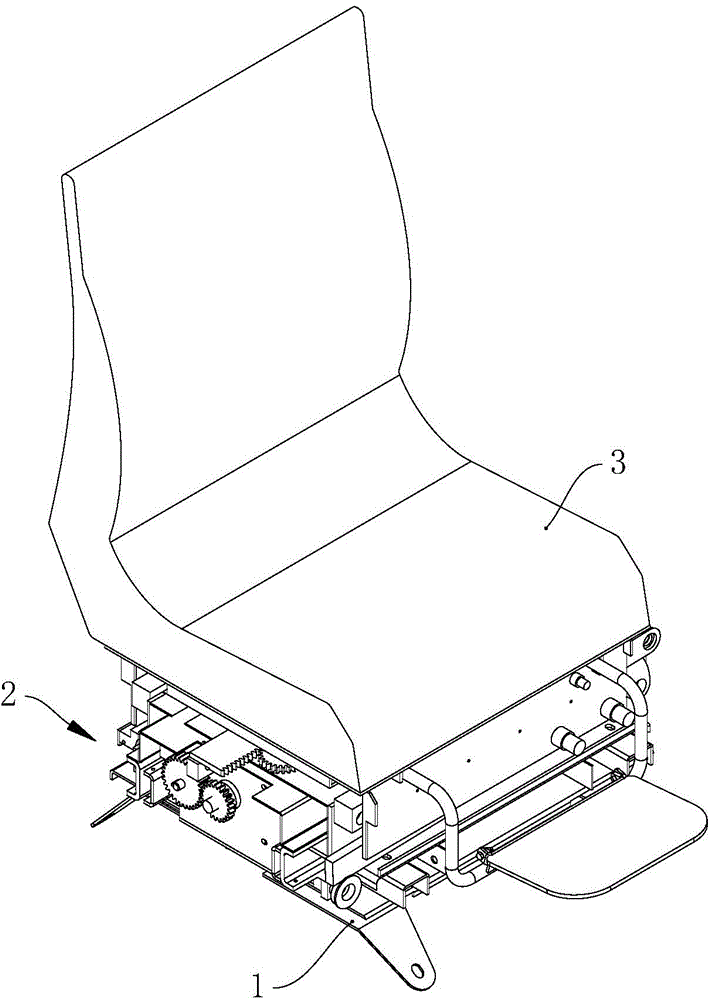

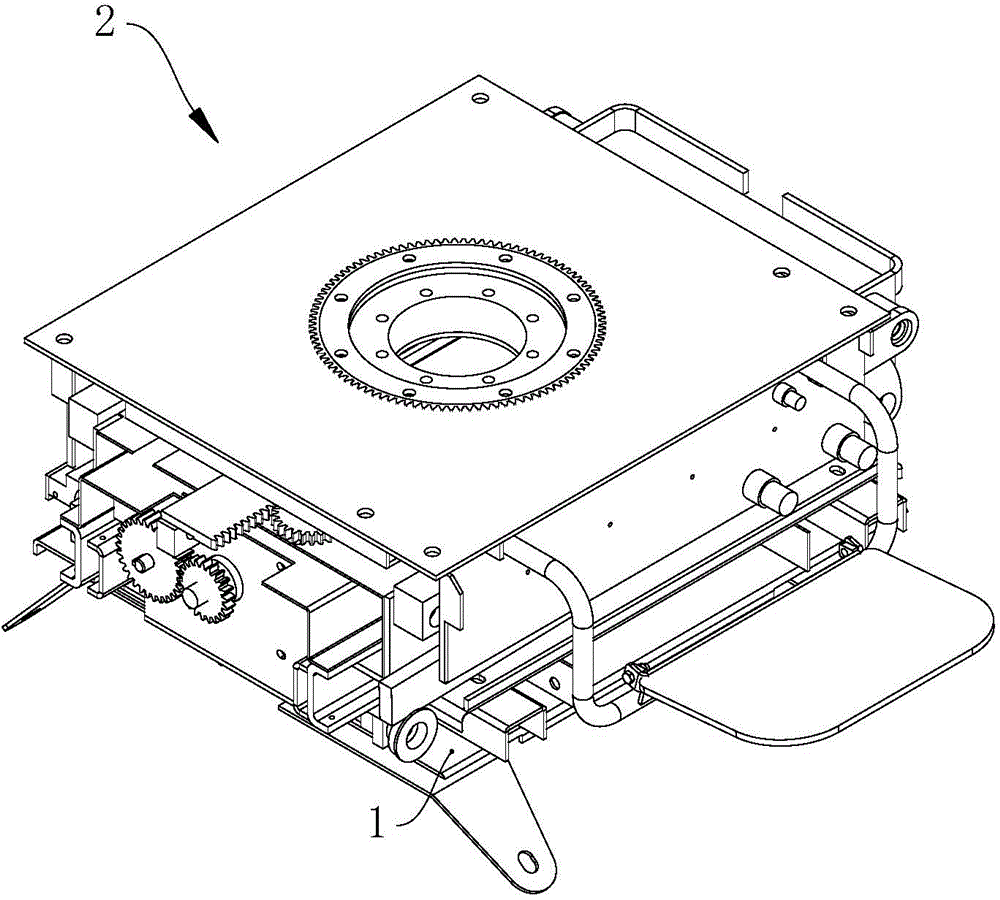

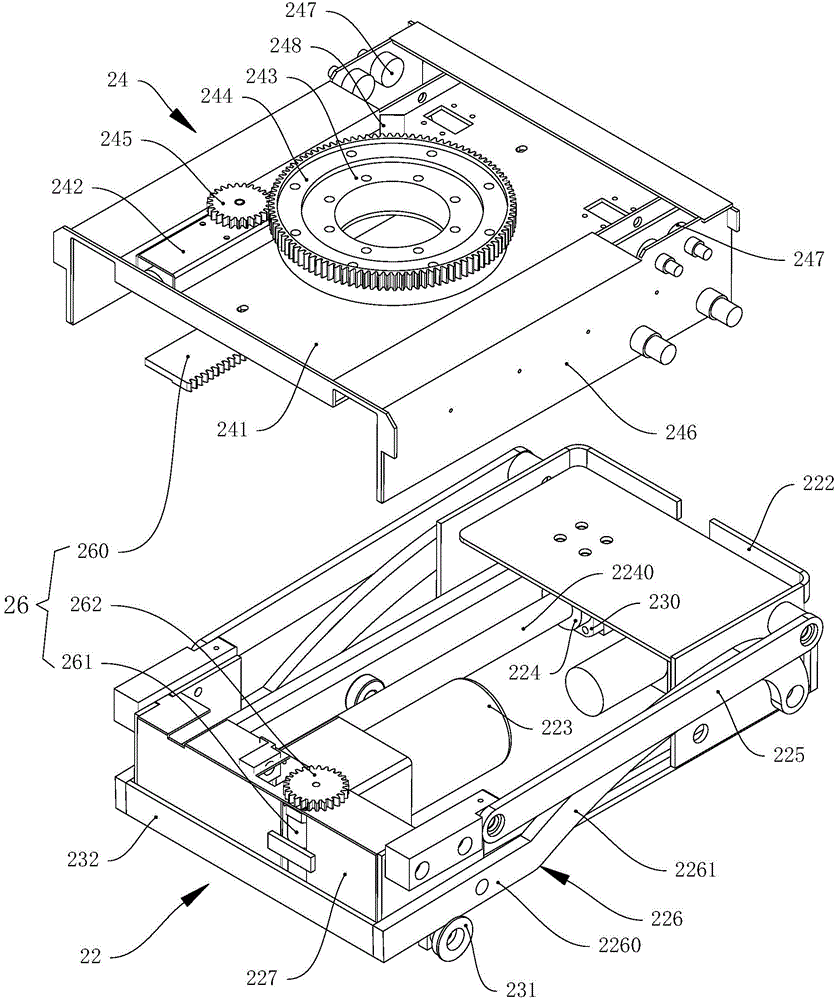

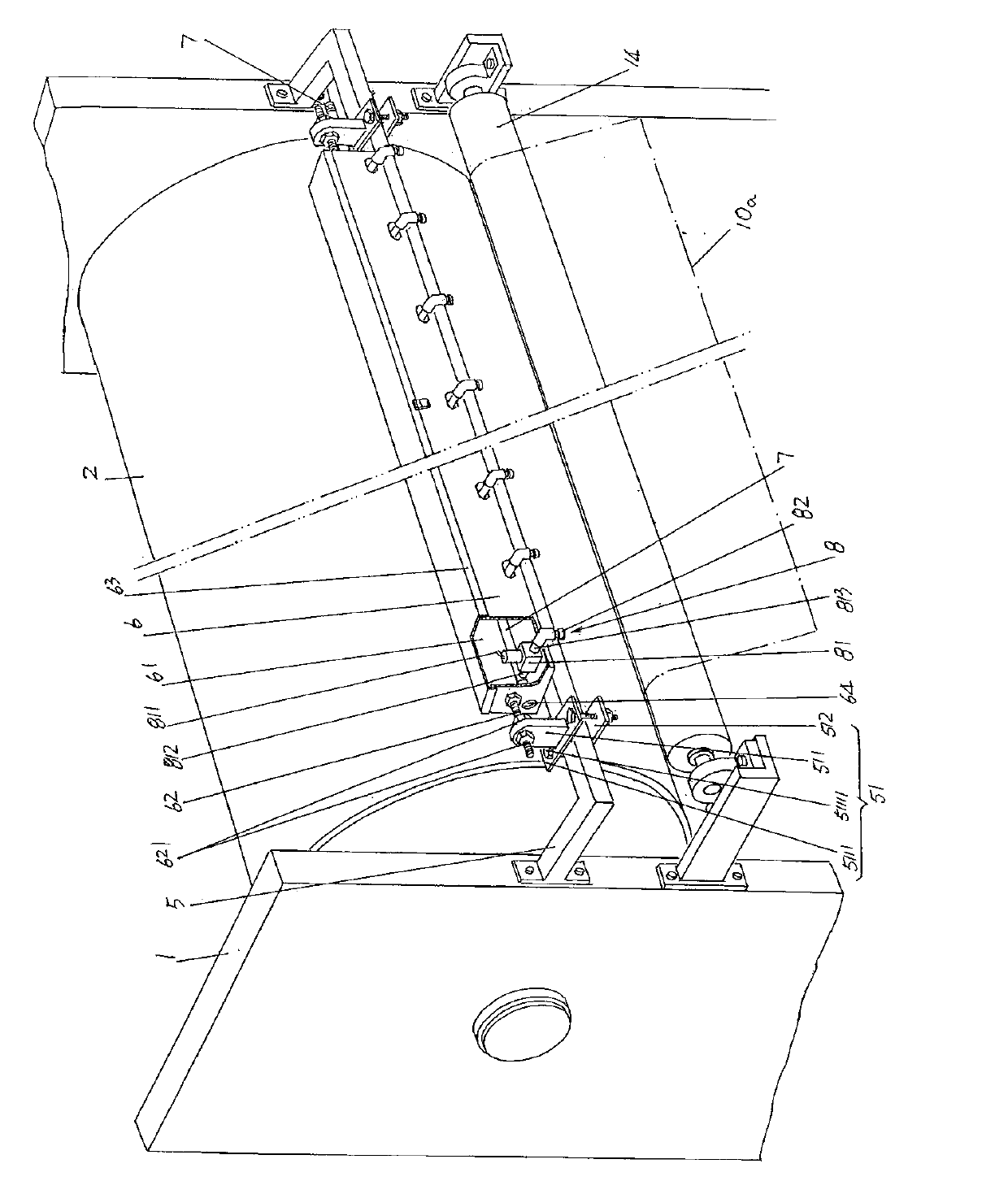

Seat moving device and automobile seat

The invention discloses a seat moving device and an automobile seat. A first transverse moving mechanism drives a seat body to move transversely. A lifting mechanism drives the seat body to ascend or descend. In the ascending and descending process, under the drive of a main motor, a parallel four-bar mechanism moves forwards and backwards, and meanwhile cranked levers slide along pulleys; due to the fact that the cranked levers have the curve-shaped structural characteristic, when the tail ends of the cranked levers slide to the positions of the pulleys, the portion, located at the front end of the parallel four-bar mechanism, of the seat body descends to the lowest position, and when the front ends of the cranked levers slide to the positions of the pulleys, the portion, located at the front end of the parallel four-bar mechanism, of the seat body ascends to be reset. The above simple structure is adopted in the seat moving device, so that the transverse movement, ascent and descent of the seat body are achieved, the fault rate is low, operation is easy, and the automatic performance is good.

Owner:SHENZHEN CANYOU BARRIER FREE SERVICE

Mist spray humidifying device for triple preheating cylinder

InactiveCN103342010AGuaranteed uniformityAvoid stayingMechanical working/deformationWater sourceElectrical control

The invention provides a mist spray humidifying device for a triple preheating cylinder and belongs to the technical field of paper packaging material combined machinery. The triple preheating cylinder comprises a rack, an inner-layer paper preheating cylinder, a corrugated paper preheating cylinder and an outer-layer paper preheating cylinder. An inner-layer paper lead-in roller, a corrugated paper lead-in roller and an outer-layer paper lead-in roller are arranged at one side of the rack, and an inner-layer paper lead-out roller, a corrugated paper lead-out roller and an outer-layer paper lead-out roller are arranged at the other side of the rack. The mist spray humidifying device comprises a support, a spray box, a water pipe and a automatic mist spray mechanism set. The support is fixed on the rack and corresponds to the portion above the inner-layer paper lead-out roller in the length direction of the inner-layer paper lead-out roller. The spray box is fixed on the support. The water pipe is arranged in a box cavity of the spray box and is connected with a water source pipeline. The automatic mist spray mechanism set is connected to the water pipe and is connected with an electrical control cabinet in a controlled mode. The mist spray humidifying device for the triple preheating cylinder guarantees the evenness of the amount of humidification water and avoids the phenomenon that water stains appear on a corrugated board. In addition, the mist spray humidifying device for the triple preheating cylinder can reflect the good automatic effect, relieves the operation intensity of workers, reflects scientificity, and guarantees the quality of the corrugated board.

Owner:张家港市天时利包装制品有限公司

Fruit can cleaning, filling and storing device

ActiveCN113387315ADrain fastEasy to drainThreaded caps applicationHollow article cleaningCanned fruitEngineering

The invention discloses a fruit can cleaning, filling and storing device, and relates to the technical field of mechanical conveying food processing. The device solves the problems that bottles and cans are directly conveyed into a washing sink to be cleaned through a conveying belt generally, an automatic flushing cleaning mechanism allowing rapid drainage and recycling is not available, and rapid drainage is not facilitated. The fruit can cleaning, filling and storing device comprises a base, wherein four sets of conveying supports are fixedly arranged at the top of the base, and two sets of conveying rollers are rotationally arranged at the tops of the four sets of conveying supports; and a linkage shaft frame is fixedly arranged at the top of the base, and an output shaft is rotationally arranged at the top of the linkage shaft frame. According to the device, by arranging a cleaning support, an automatic flushing cleaning mechanism allowing rapid drainage and recycling is provided, so that convenience is brought to cleaning; an eccentric wheel A jacks up a lifting piece to enable a drain pipe to move upwards, a sealing sleeve moves upwards at the same time, a drain hole, when higher than the sealing sleeve, automatically sprays water to flush the interiors of the bottles and cans, and therefore the automation effect is good; and the device can be used for disinfection.

Owner:南通绿萌食品有限公司

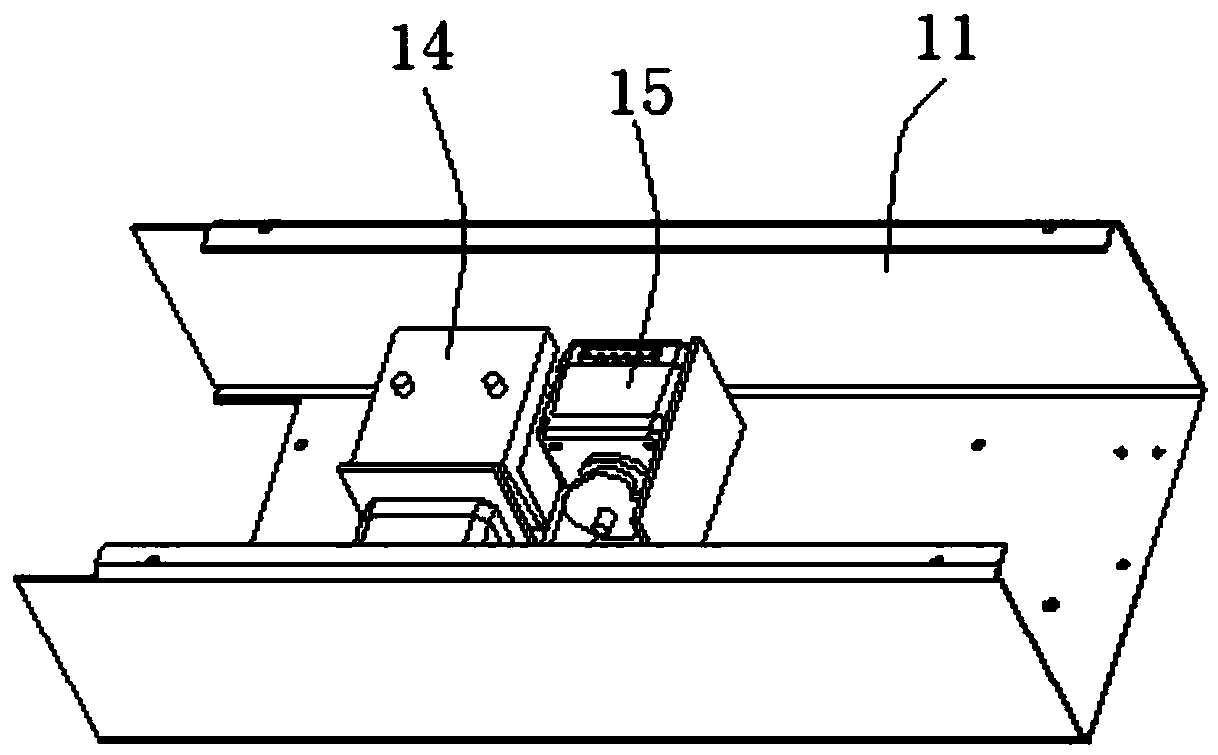

Test paper pushing method and device and urine analyzer

ActiveCN110342291AReliable and continuous pushThe steps are cleverly setMaterial analysis by observing effect on chemical indicatorArticle feedersPulp and paper industryTest strips

The invention is applicable to the field of medical instruments, and provides a test paper pushing method and device and a urine analyzer. The test paper pushing method comprises the steps that a paper pushing piece is driven to rise, the paper pushing piece is used for horizontally moving test paper, the paper pushing piece is lowered, and the paper pushing piece is horizontally moved and reset.The test paper pushing device comprises a bottom box and a tray, wherein the tray covers the bottom box, the tray comprises a sampling position and a detection position, the paper pushing piece is arranged in the bottom box, and the paper pushing piece is connected with a first driving assembly and a second driving assembly. The urine analyzer comprises a sample application device and a urine analysis device, and further comprises the test paper pushing device. According to the test paper pushing method and device and the urine analyzer, the test paper pushing method is ingenious in step arranged, and is accurate and reliable in conveying, in addition, the test paper pushing device is simple and convenient to manufacture and low in manufacturing cost, the production cost of the urine analyzer is reduced, the detection performance of the urine analyzer is improved, and meanwhile, the detection cost is reduced.

Owner:SUZHOU MINDRAY SCI CO LTD

Manipulator structure for automatic polishing production line

InactiveCN104261130ASatisfy high-efficiency polishing requirementsReduce work intensityProgramme-controlled manipulatorControl devices for conveyorsProduction lineEngineering

The invention discloses a manipulator structure for an automatic polishing production line, and belongs to the technical field of automatic polishing facilities. The manipulator structure comprises a rack born on a terrace where the polishing machines of the automatic polishing production line are located, a beam automatic lifting mechanism fixed on the upper portion of the rack, a lifting cross beam connected with the automatic lifting mechanism, a moving beam horizontally arranged and matched with the lifting cross beam, a group of workpiece extraction and release mechanisms arranged on the moving beam, and a moving beam drive mechanism arranged on the lifting cross beam and in transmission connection with the lifting cross beam. The manipulator structure has no need of assigning operating personnel for the working position where each polishing machine is located, as well as is capable of saving labour resources, free from dust and noise influences generated by the polishing machines during a polishing process, good in automation effect, and capable of meeting high-efficiency polishing requirements on the polishing machines and reducing the working intensity of the operating personnel, ensuring safety, and reducing the operating personnel.

Owner:常熟市隆成无纺机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com