Mist spray humidifying device for triple preheating cylinder

A humidification device and preheating cylinder technology, applied in the direction of machining/deformation, can solve the problems of affecting the quality of packaging cardboard, prone to warping, uneven humidification, etc., achieve good automation effects, reduce operating intensity, and ensure uniformity degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

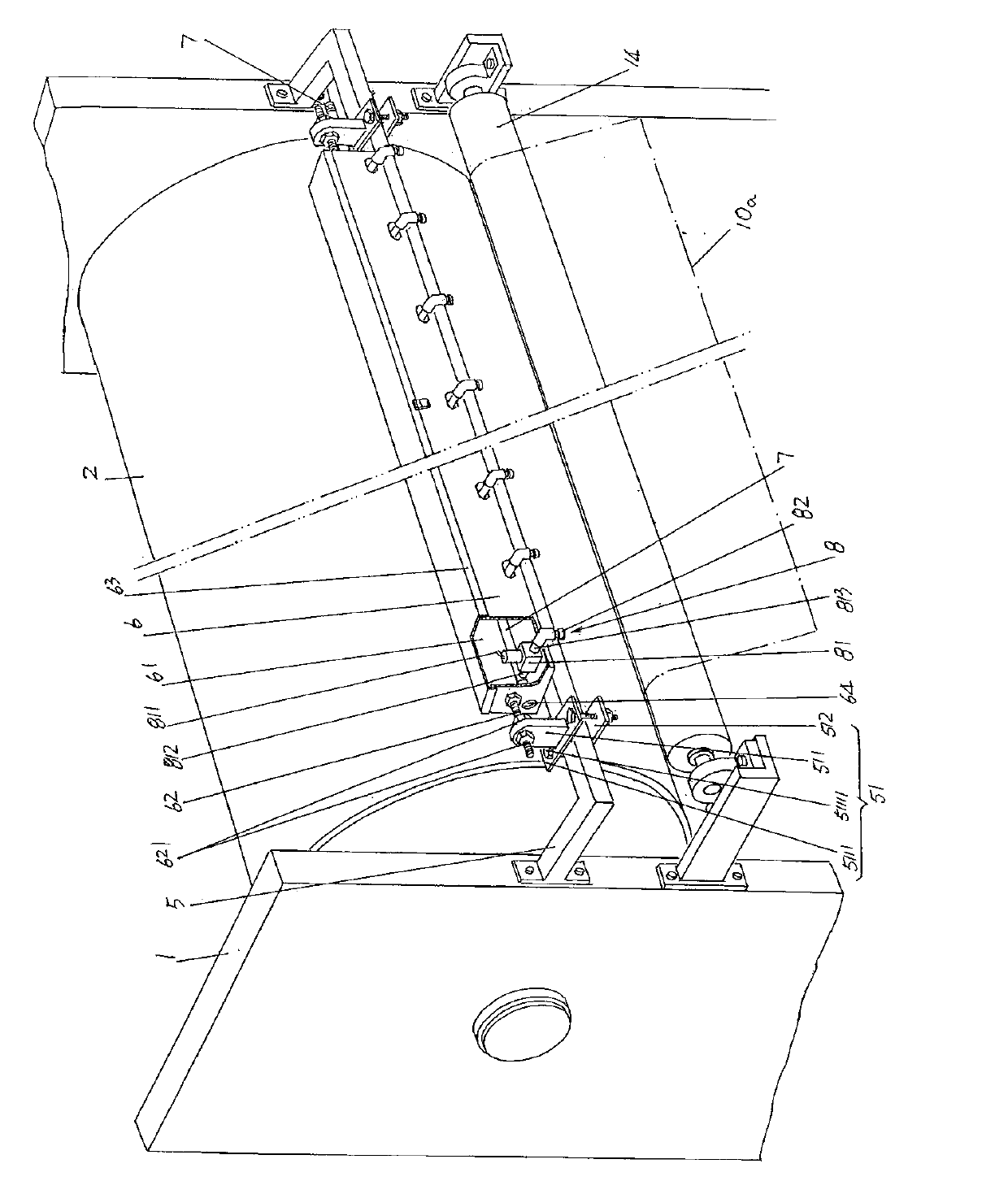

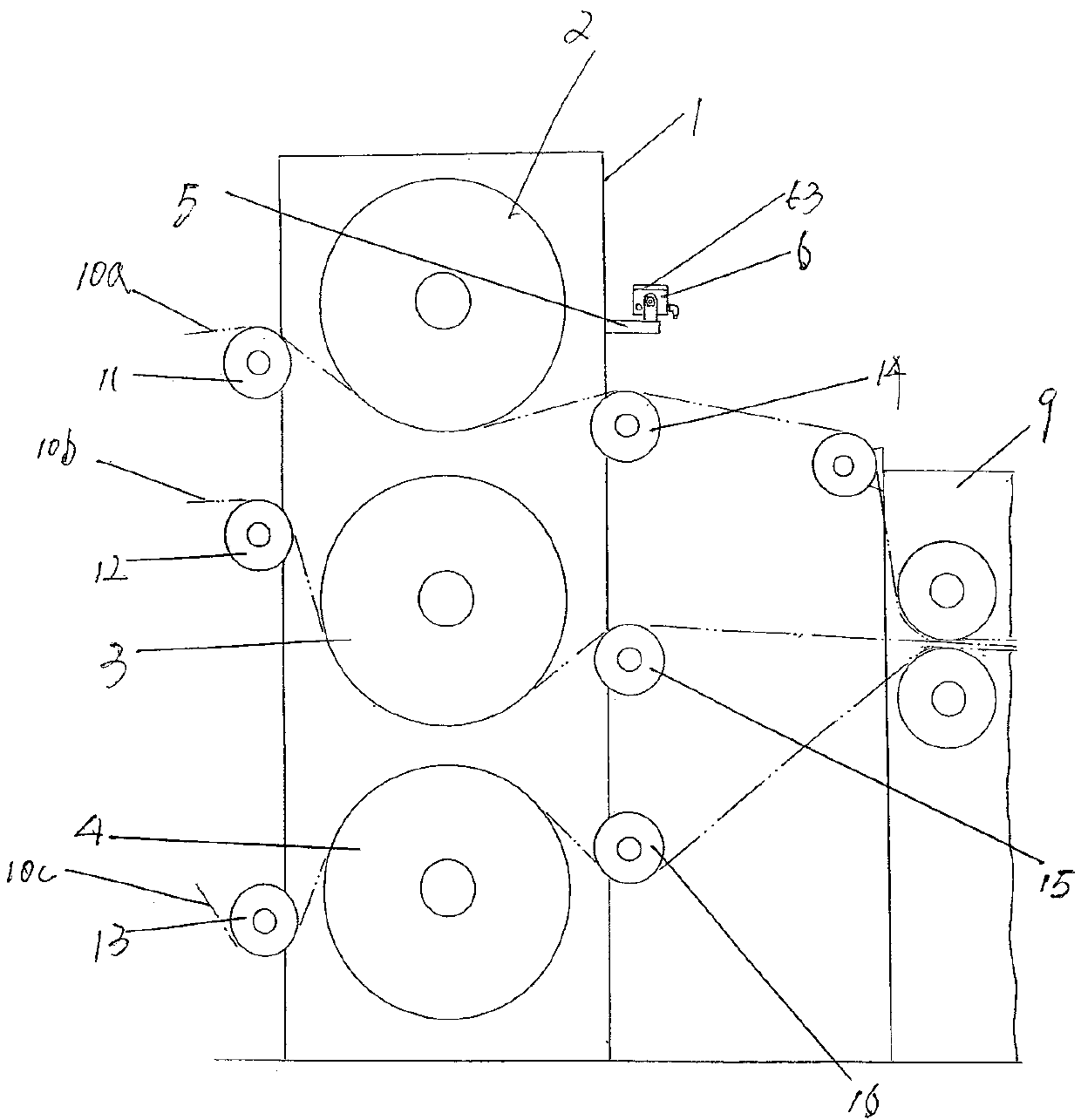

[0019] See figure 1 and figure 2 ,exist figure 2 The figure shows a frame 1 and an inner paper preheating cylinder 2, a corrugated paper preheating cylinder 3 and an outer layer paper preheating cylinder 4 arranged on the frame 1 from top to bottom and rotating in a horizontal state , in order to facilitate public understanding, the applicant in figure 2 Also shown in the composite machine 9 and shows the inner paper 10a, corrugated paper 10b and outer paper 10c. Depend on figure 2 As shown, on one side of rack 1 i.e. figure 2 The left side of the shown position state is arranged from top to bottom and rotated in turn in a horizontal state with an inner layer paper introduction roller 11, a corrugated paper introduction roller 12 and an outer layer paper layer entry roller 13; on the other side of the frame 1 which is figure 2 The right side of the position state shown is from top to bottom and is provided with an inner layer paper exporting roller 14, a corrugate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com