Patents

Literature

115results about How to "Precise winding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

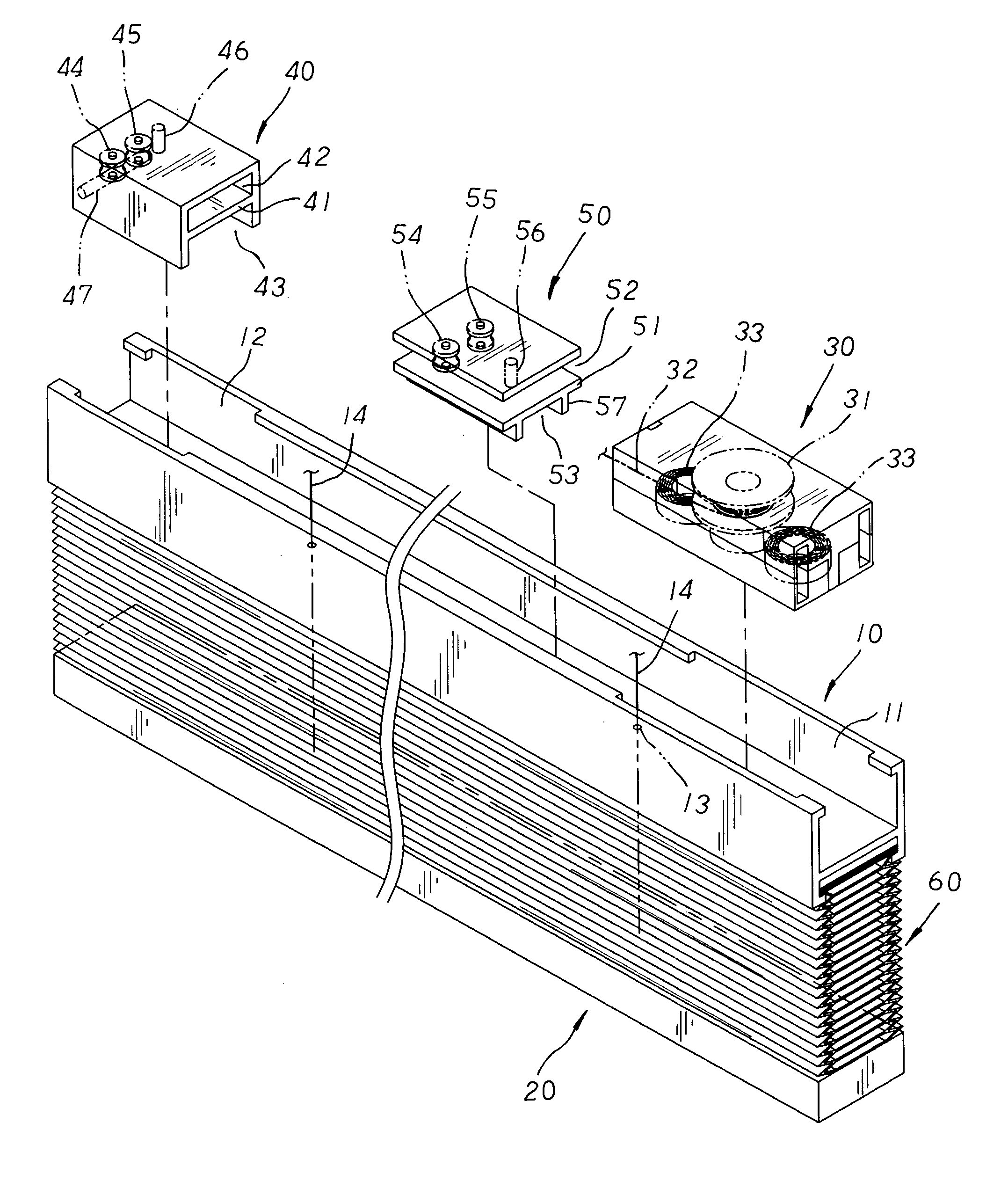

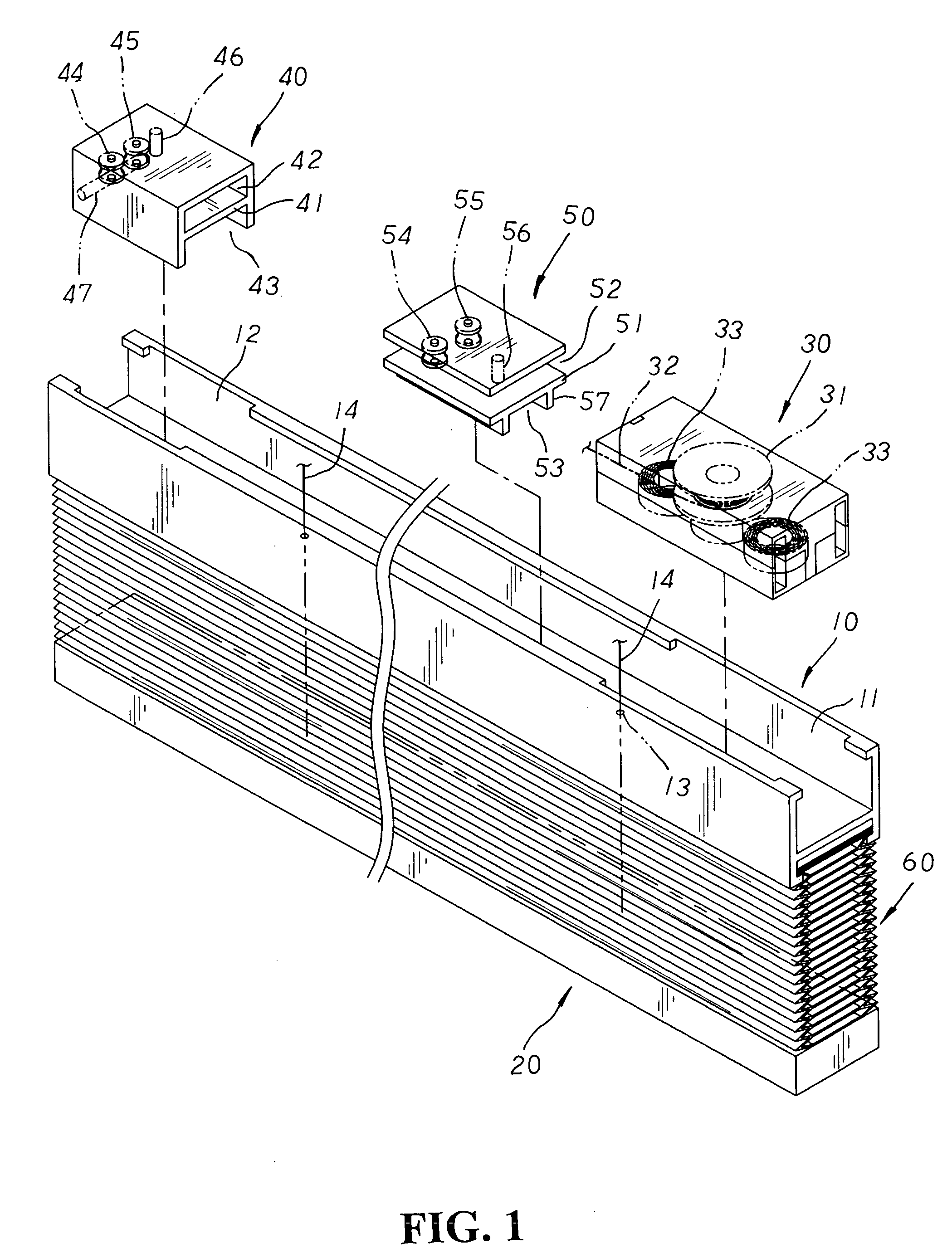

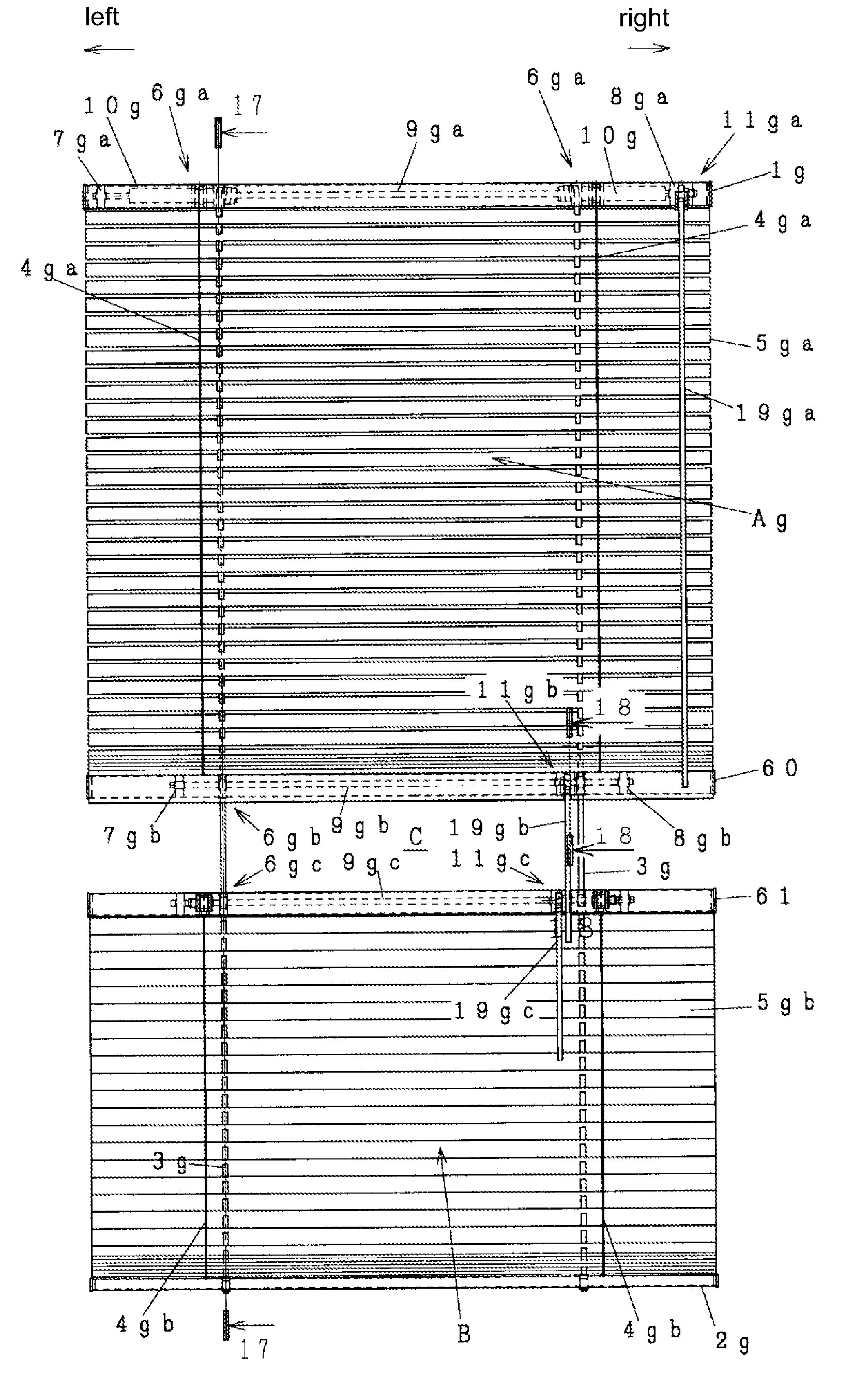

Cordless window blind structure

InactiveUS20070119547A1Best state of applicationAccuracy and simplicity in operationLight protection screensEngineeringMechanical engineering

A cordless window blind structure comprises a head rail having a fixed seat and a cord-winding control unit with an operating cord attached thereto mounted in both ends, and a movable seat accommodated to situate there-between wherein the operating cord is attached to the movable seat at one end, and retrieving cords are guided through the bottom surface of the head rail. The retrieving cords are respectively led through a blind body to fix to a bottom rail at the bottommost ends, while the other ends thereof are synchronically wound onto the fixed seat and the movable seat before firmly attached to the fixed seat. Therefore, the bottom rail is pushed or pulled by hands to loosen or tighten the retrieving cords and actuate the movement of the operating cord therewith to form a state of counterbalance there-between for easy adjustment of the blind body into a desirable position.

Owner:CHING FENG BLINDS INC CO LTD

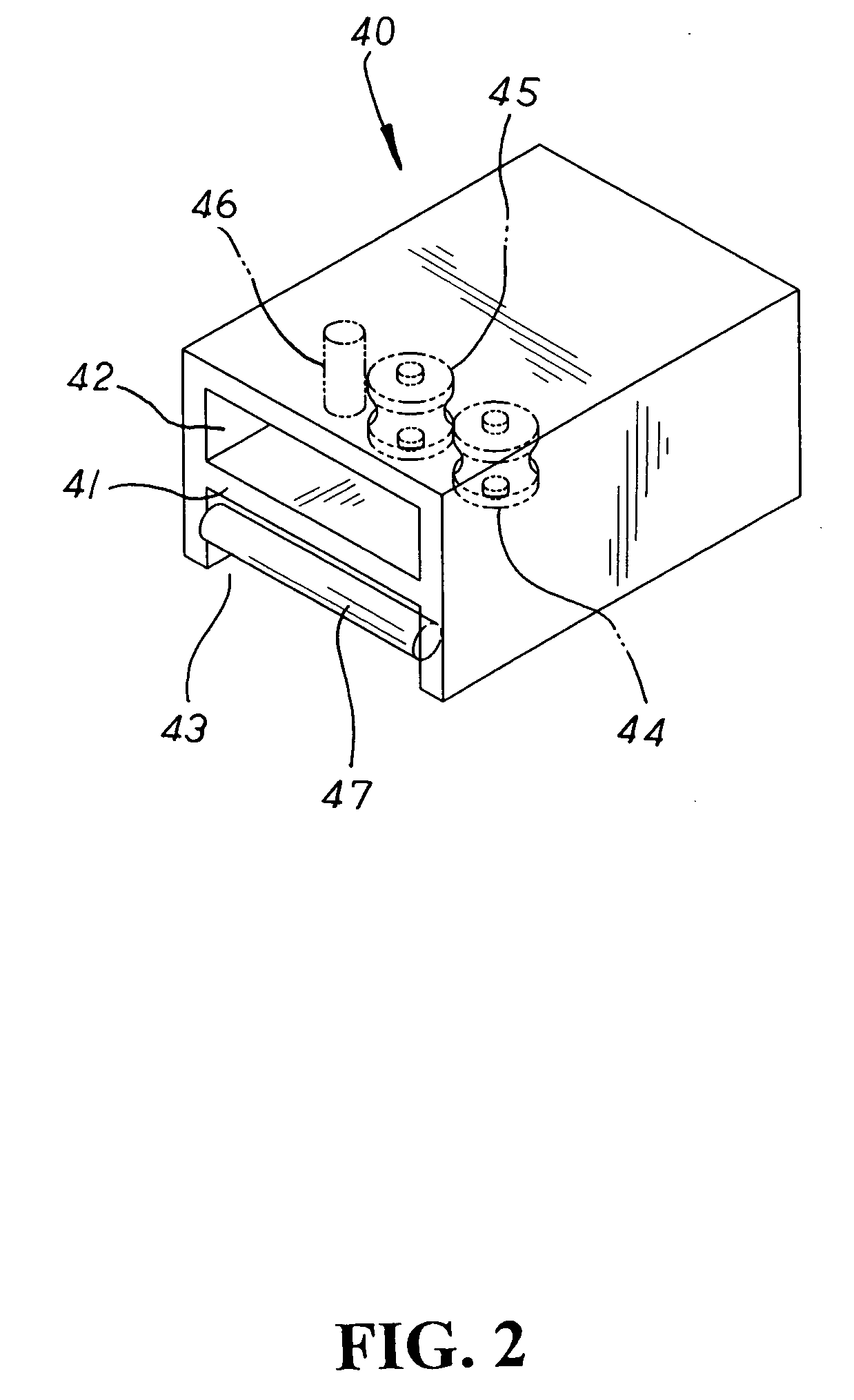

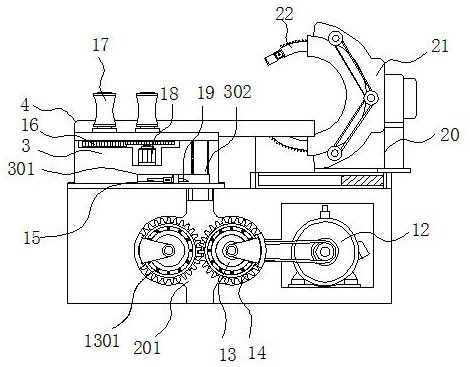

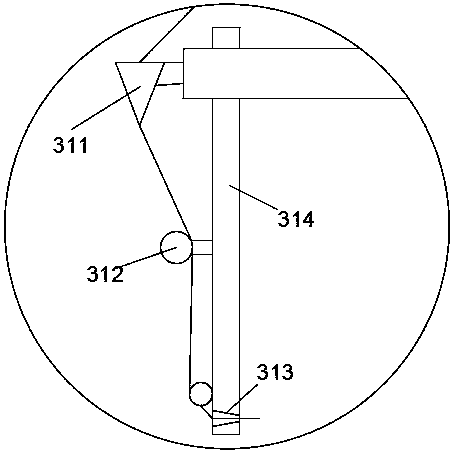

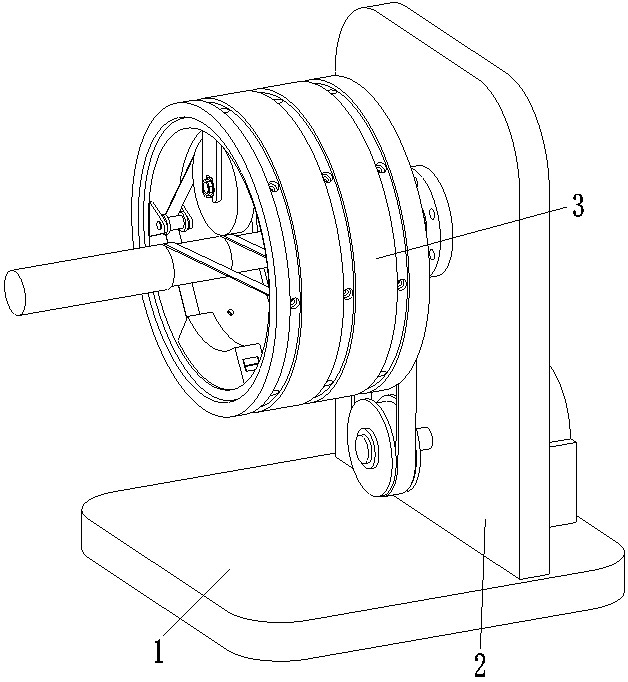

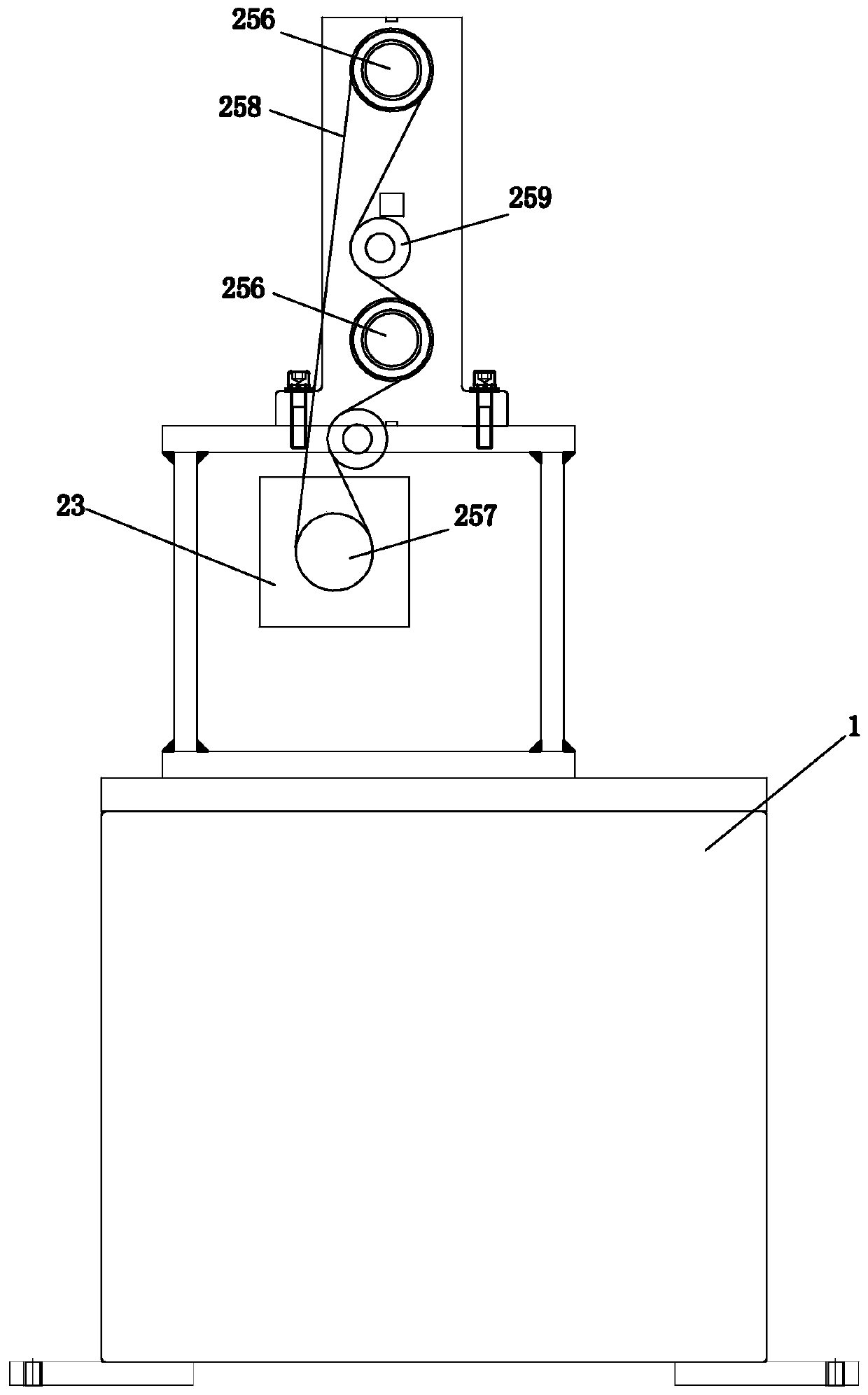

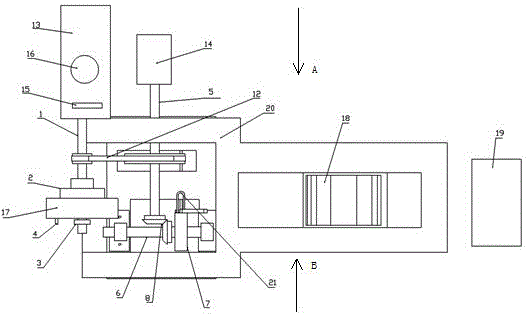

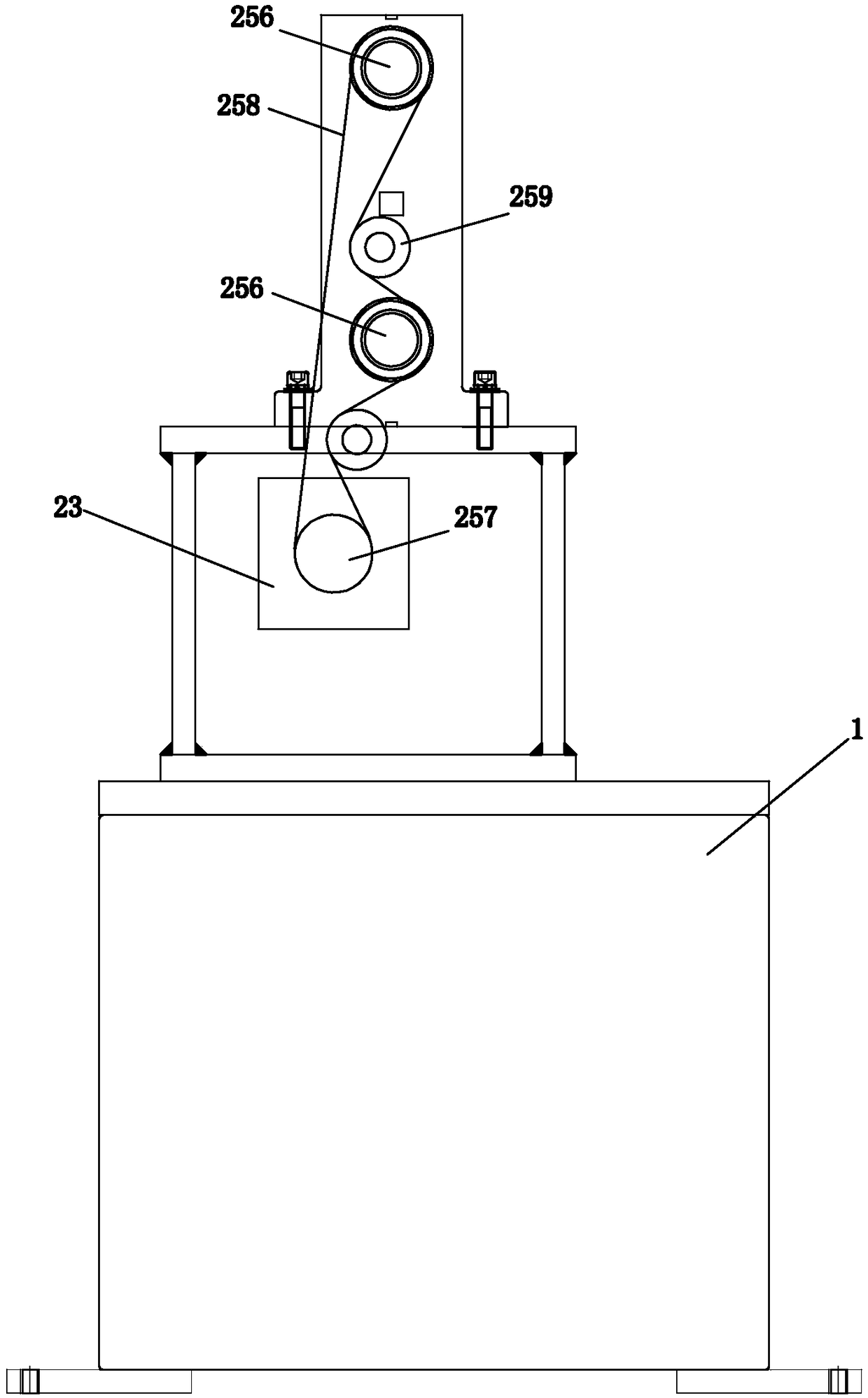

Automatic rope arrangement control device for roller

The invention discloses an automatic rope arrangement control device for a roller. The automatic rope arrangement control device comprises a rope arrangement device bracket, wherein a movable support is connected to the rope arrangement device bracket through a guide rail and moves with a lead screw in a matching mode; a deviation correction rack is arranged on the movable support; a servo motor is arranged on the rope arrangement device bracket; the output of the servo motor is connected with the lead screw; the servo motor is controlled by a servo controller; the servo controller is connected with a programmable logic controller (PLC); a rotary speed sensor is arranged on the roller; two sides of the rope arrangement device bracket are provided with reversing switches for controlling the servo motor; and a deviation correction switch is arranged on the deviation correction rack. According to the automatic rope arrangement control device for the roller, steel wire ropes for operation can be neatly wound on the roller, manual involvement is not required in the whole operating process, and automation is completely realized.

Owner:NANYANG HUAMEI GASOLINEEUM EQUIP

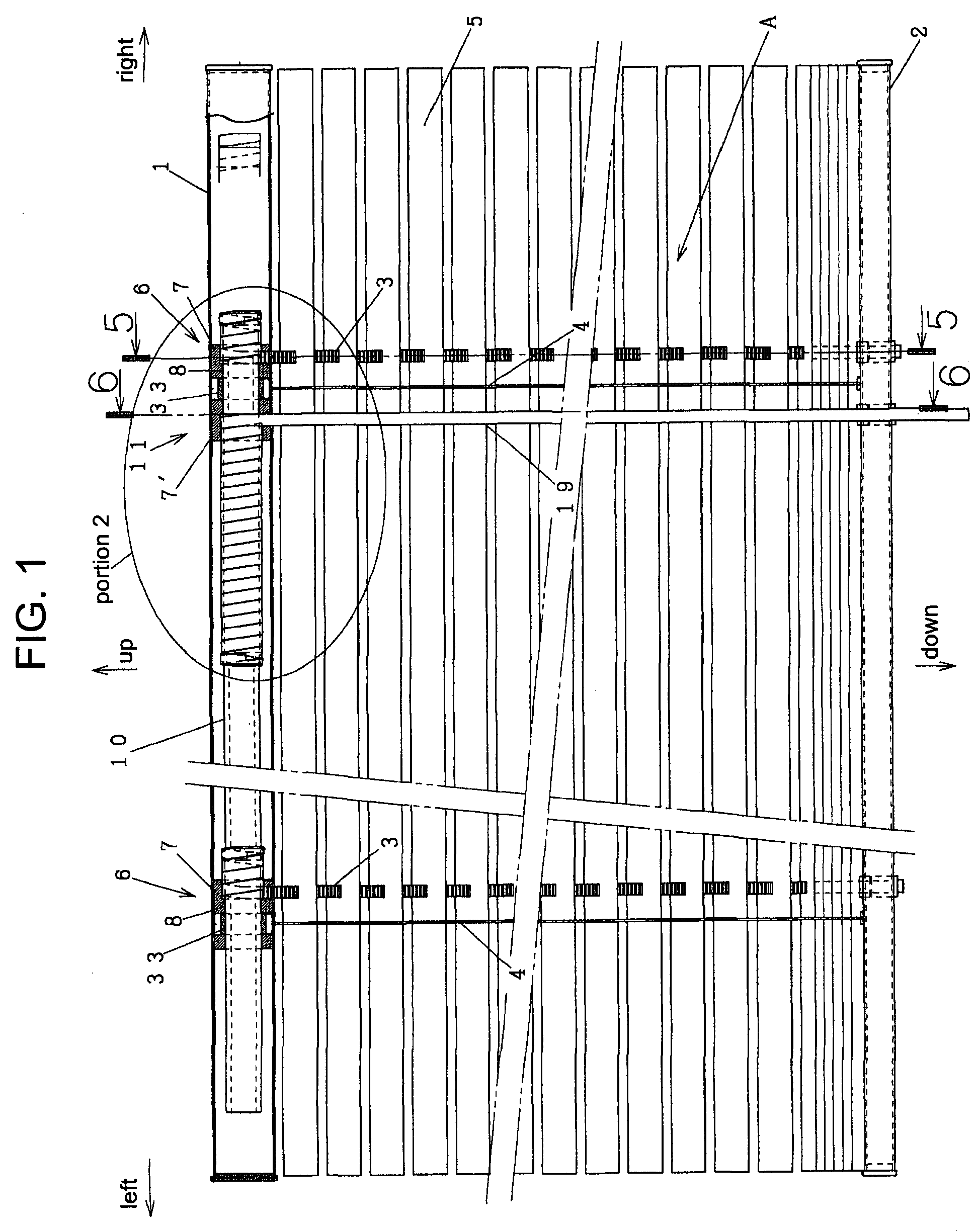

Blind

InactiveUS8079398B2Increase elasticityIncrease flexibilityExtensible doors/windowsCurtain accessoriesEngineeringMechanical engineering

Owner:TSUKAMOTO TATUSABU

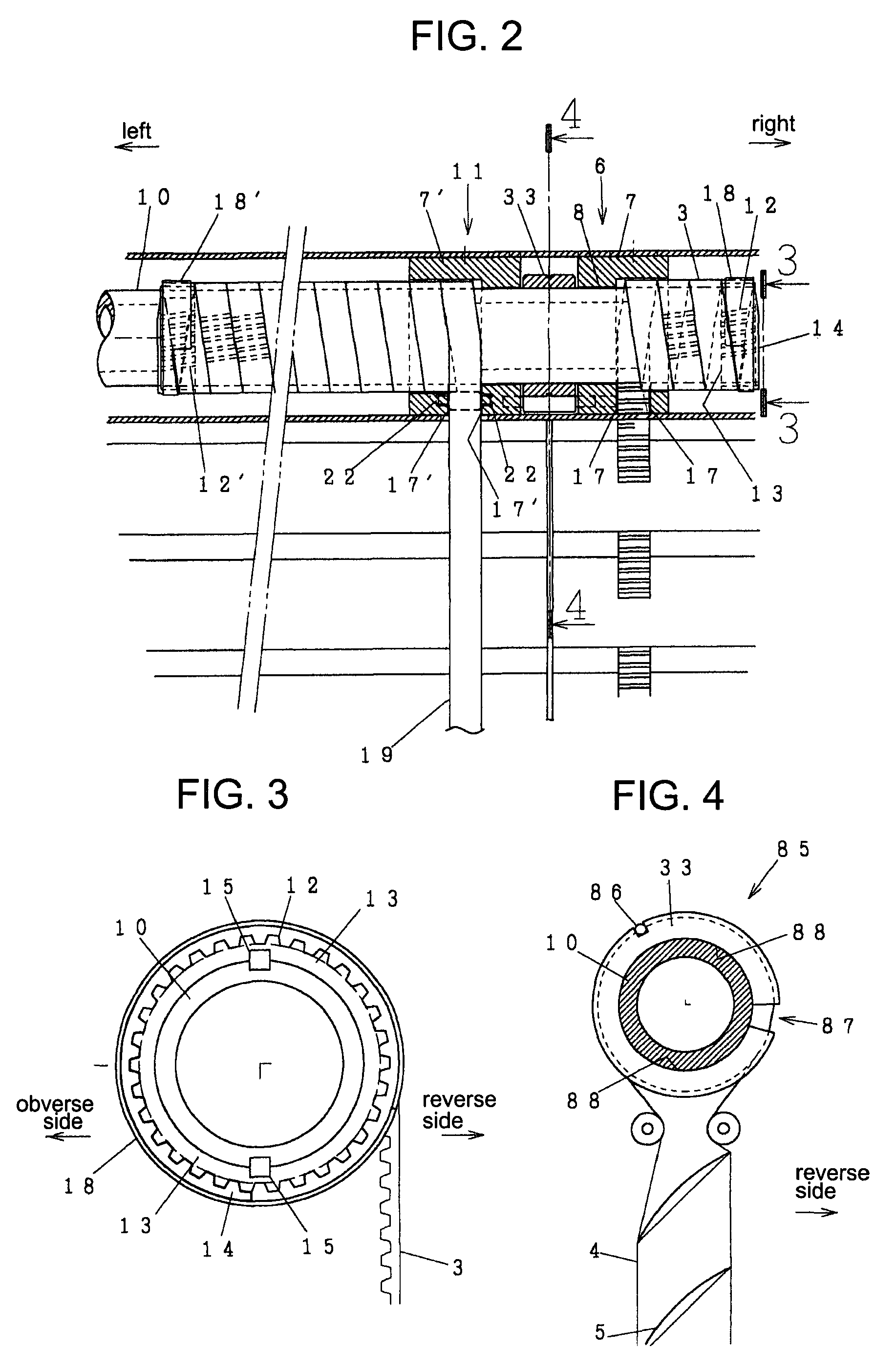

Vane-type camshaft adjuster

Owner:HYDRAULIK RING

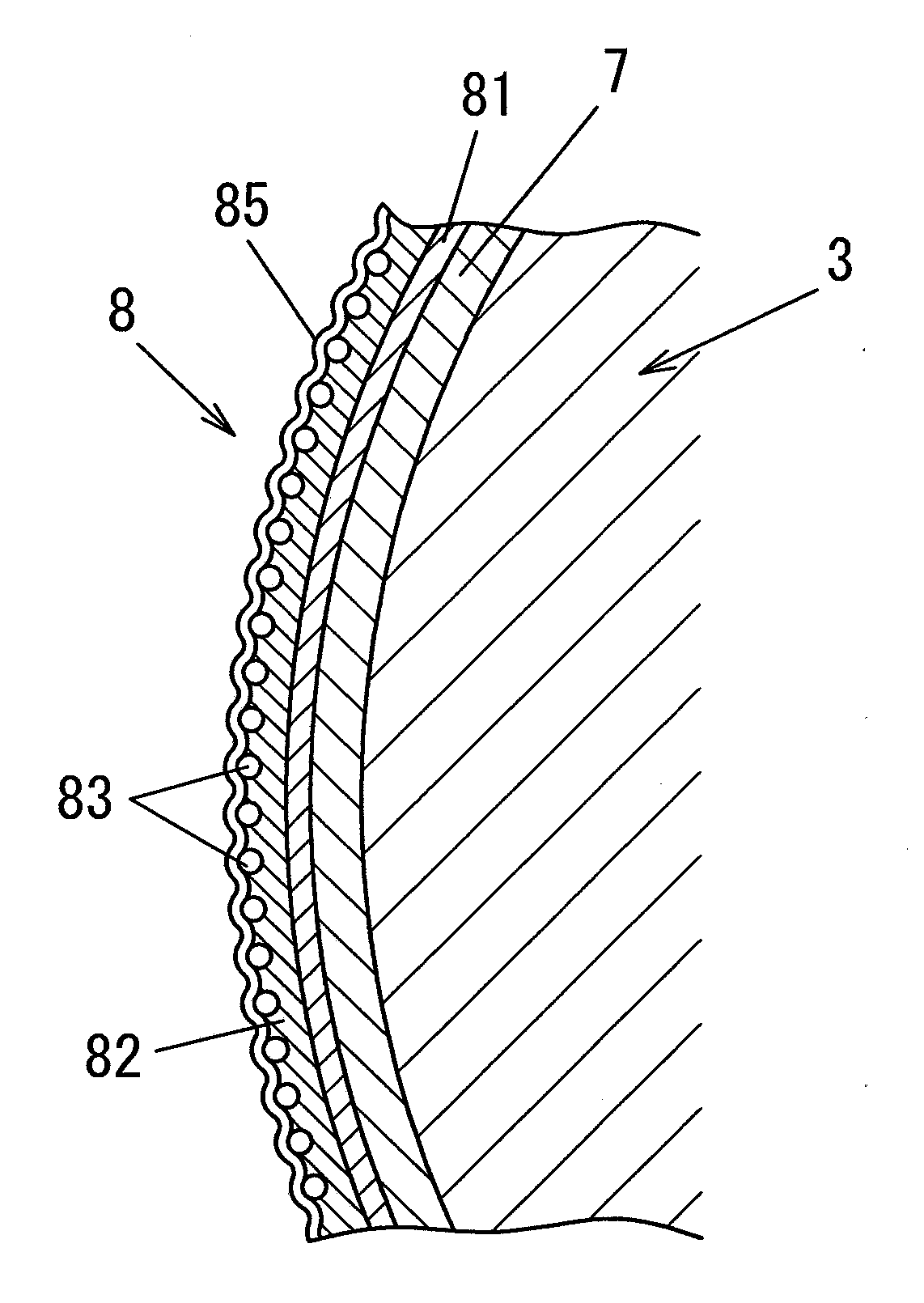

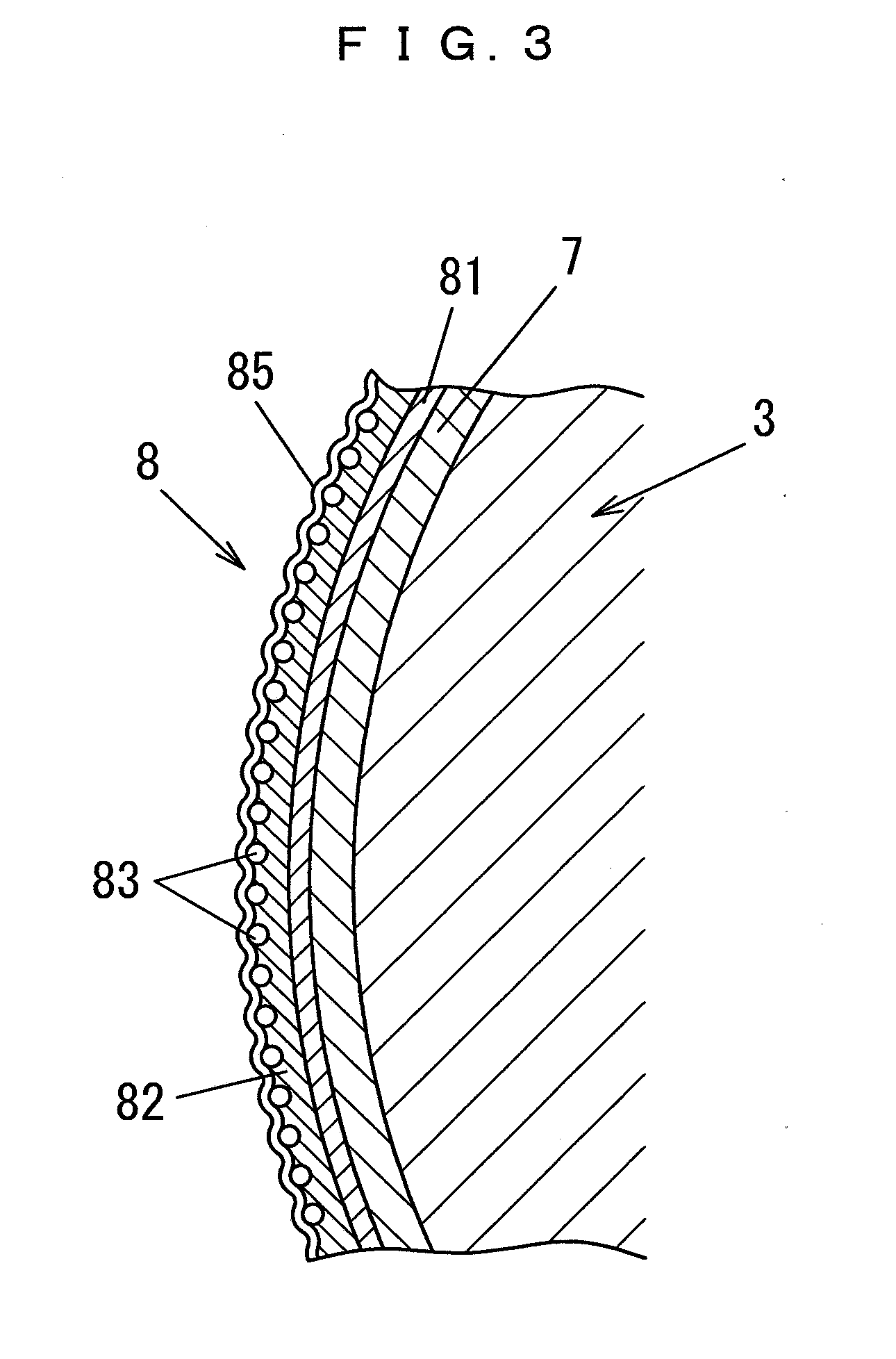

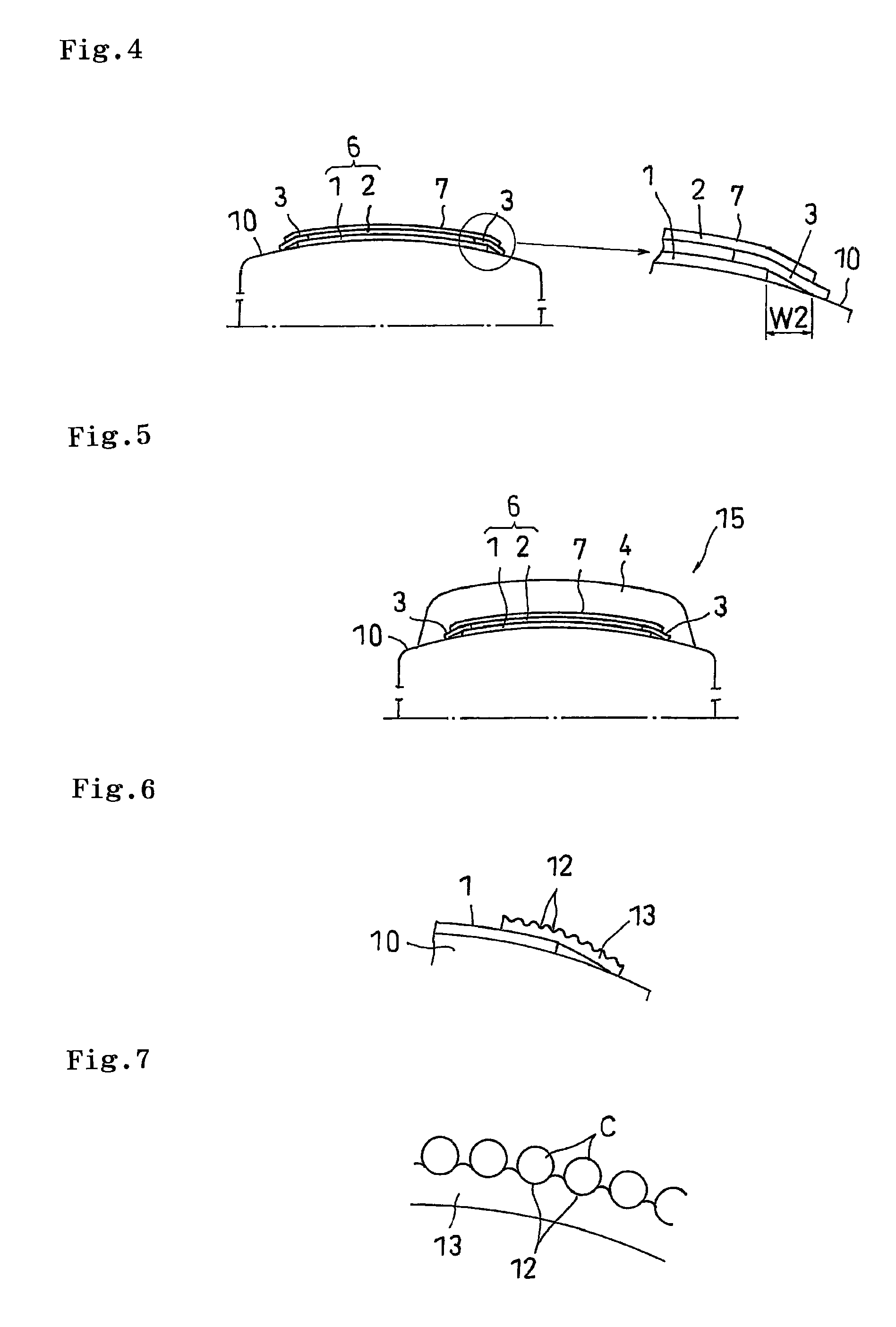

Jacket for impression cylinder or transfer cylinder and method for manufacturing the same

InactiveUS20110056397A1Good shape retentionSufficient flexibilityMetal-working apparatusRotary pressesConvex structureEngineering

A composite structure for application to an impression cylinder or a transfer cylinder includes an ink smear preventing sheet having flexibility as a whole backed by a flexible metal thin plate. The work surface of the ink smear preventing sheet has an ink smear preventing structure in the form of a concave-convex configuration. The ink smear preventing sheet is of a flexible sheet of resin having an adhesive layer thereon in which are partially embedded many small balls to form the concave-convex structure.

Owner:SHINODA

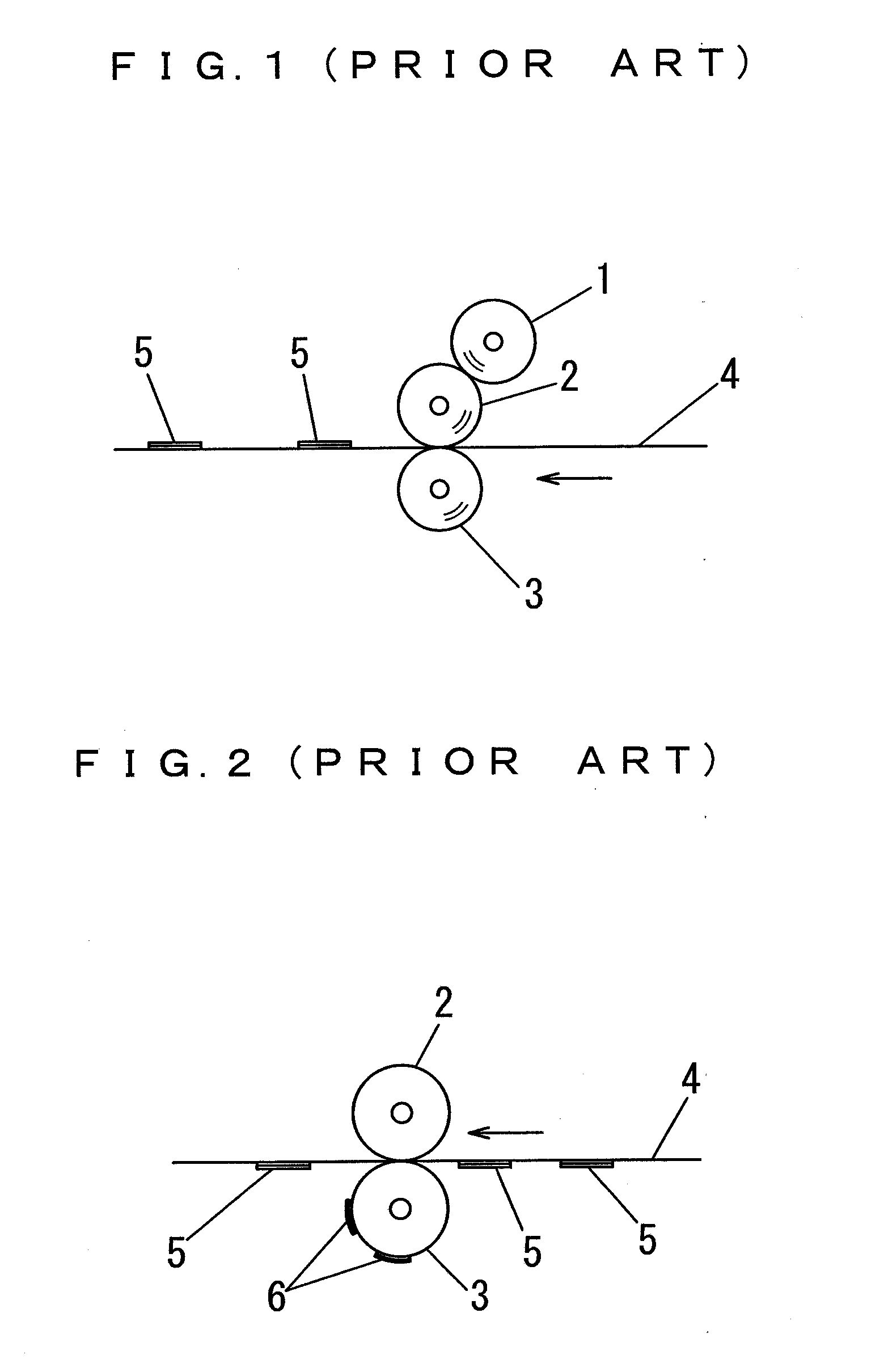

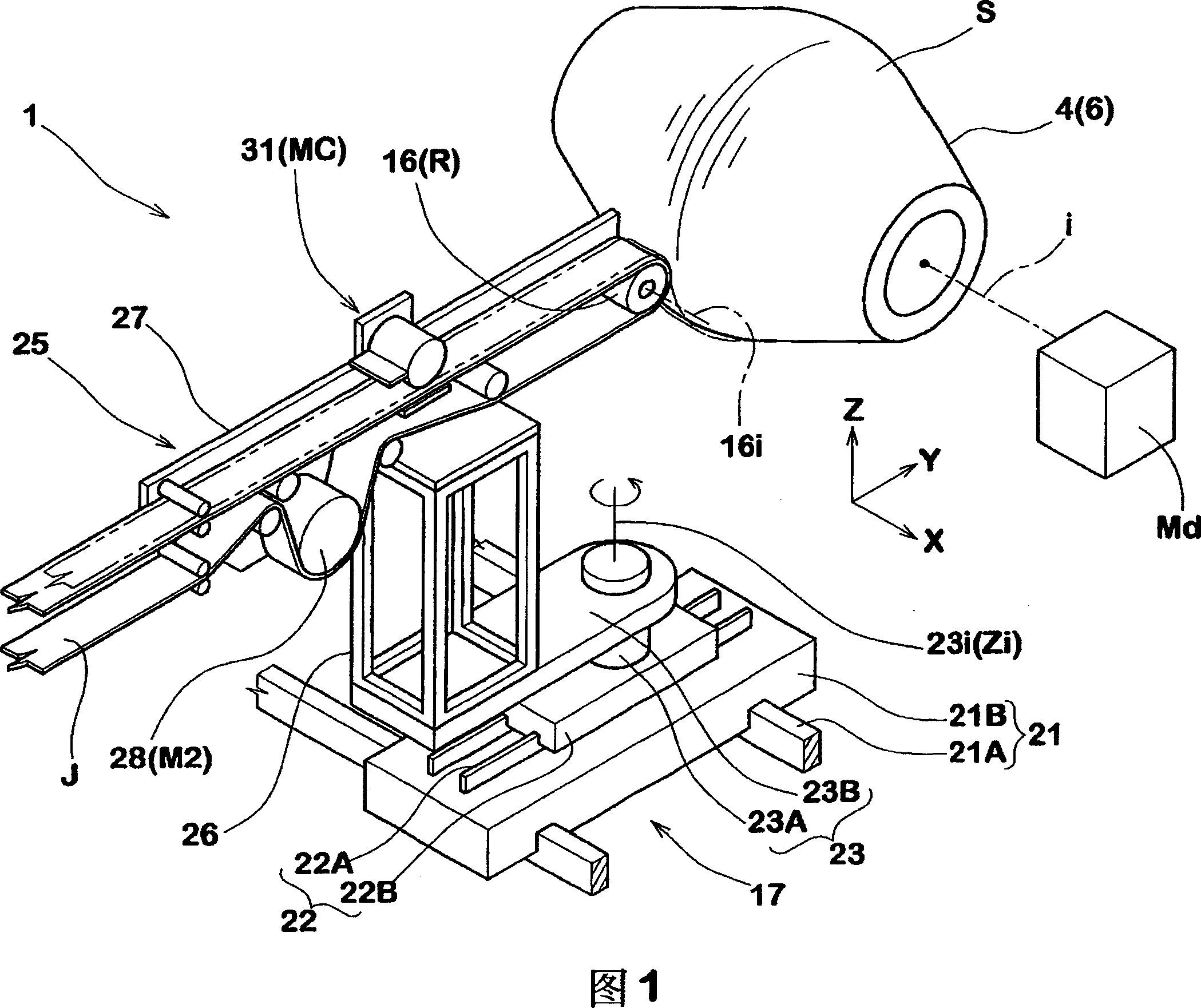

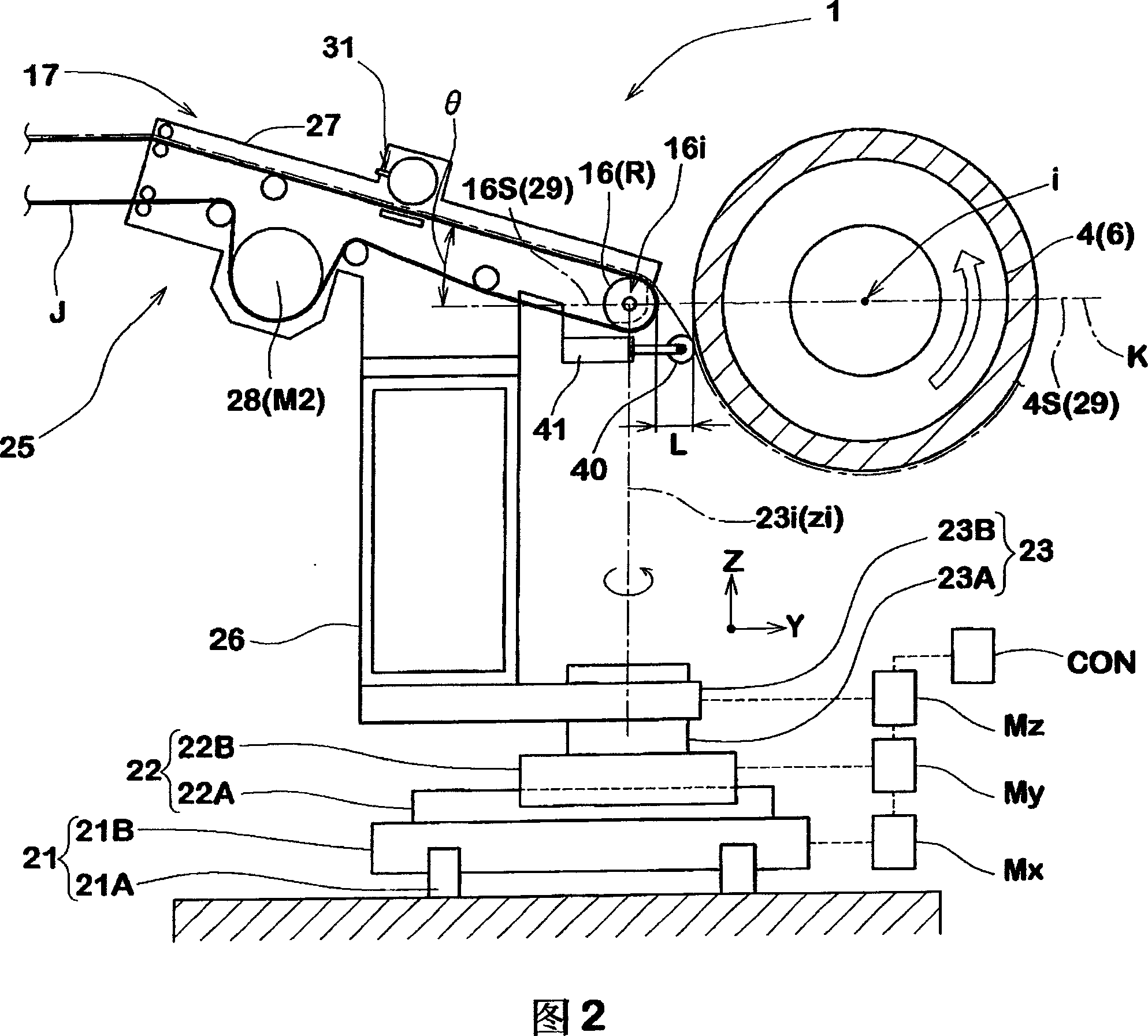

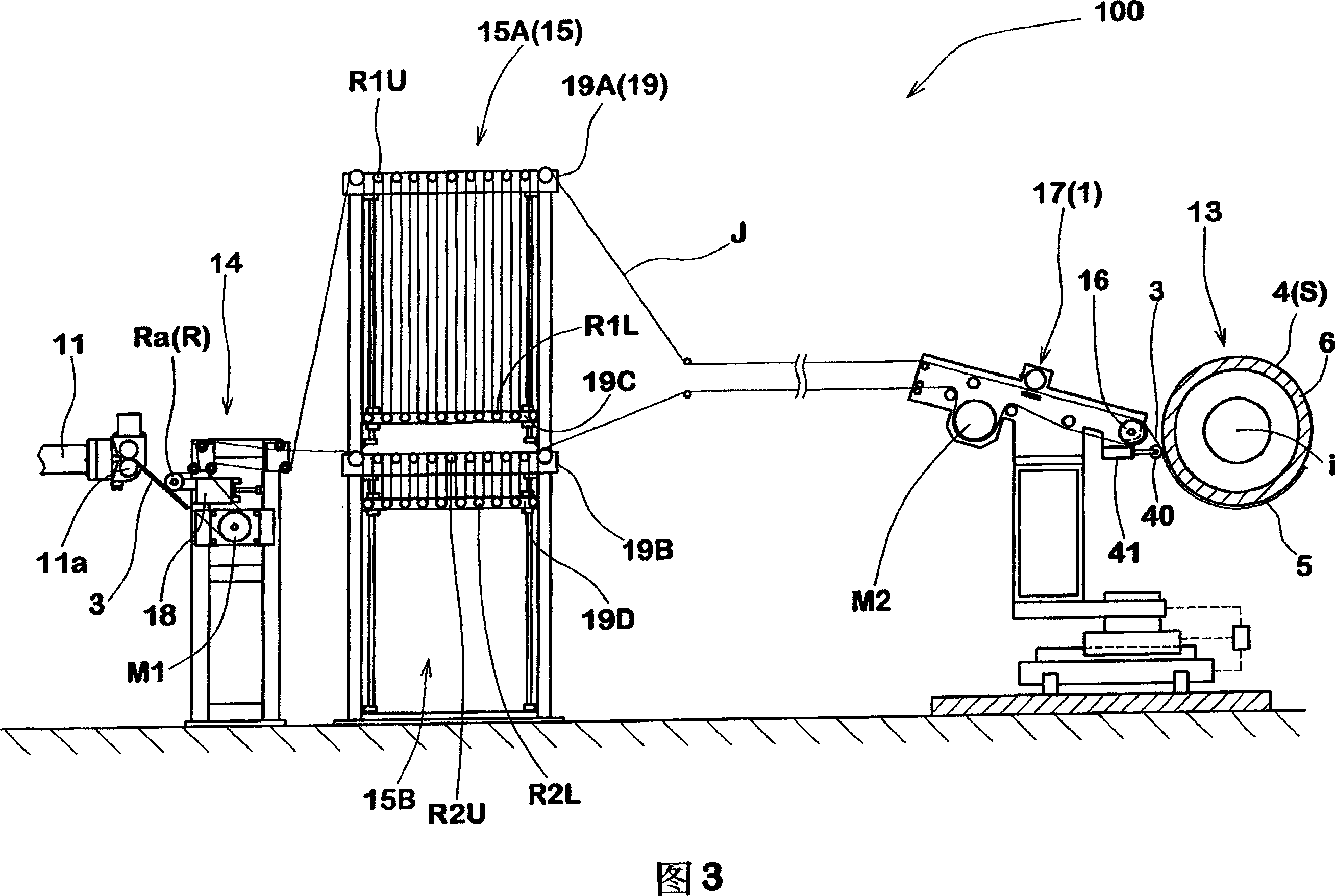

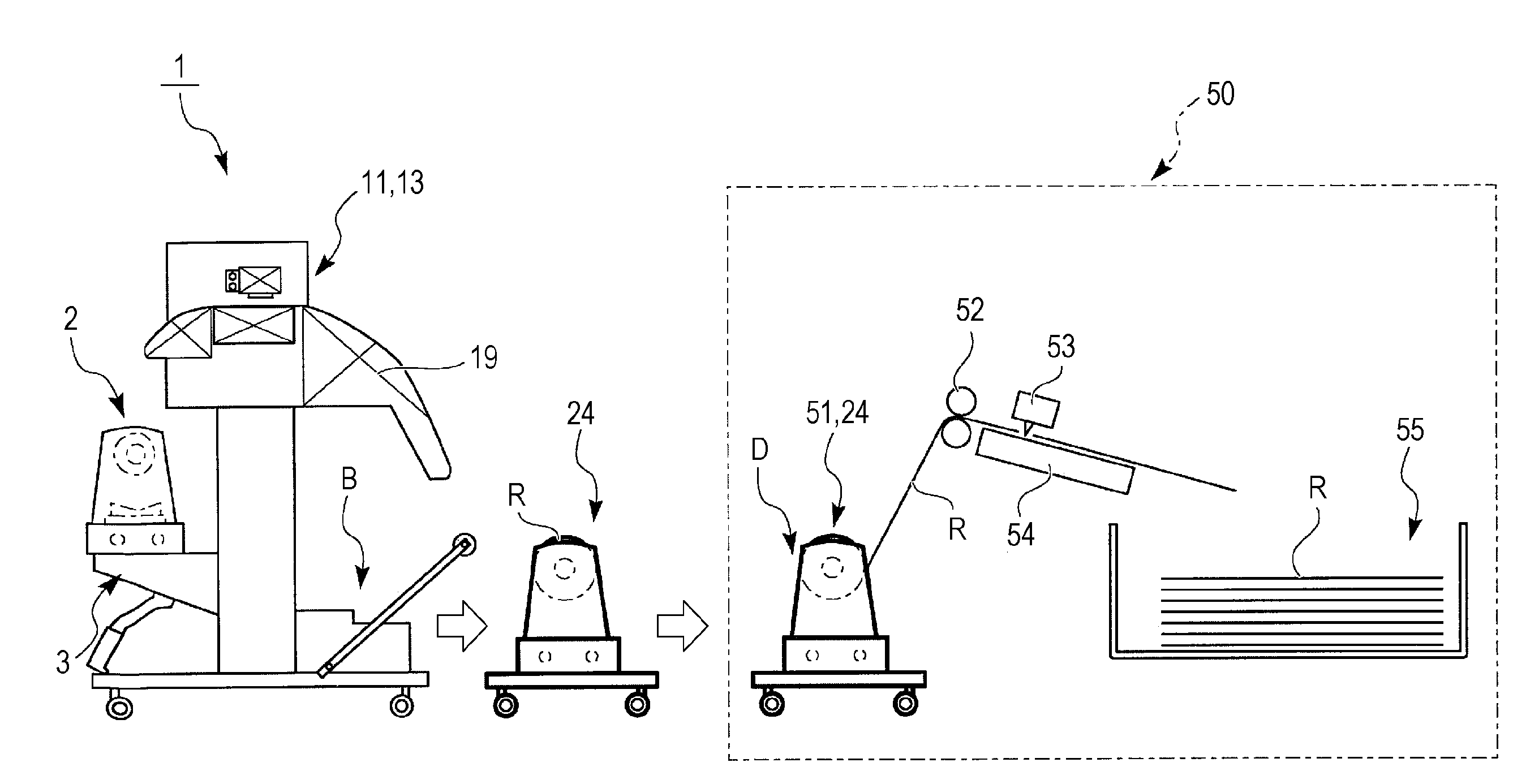

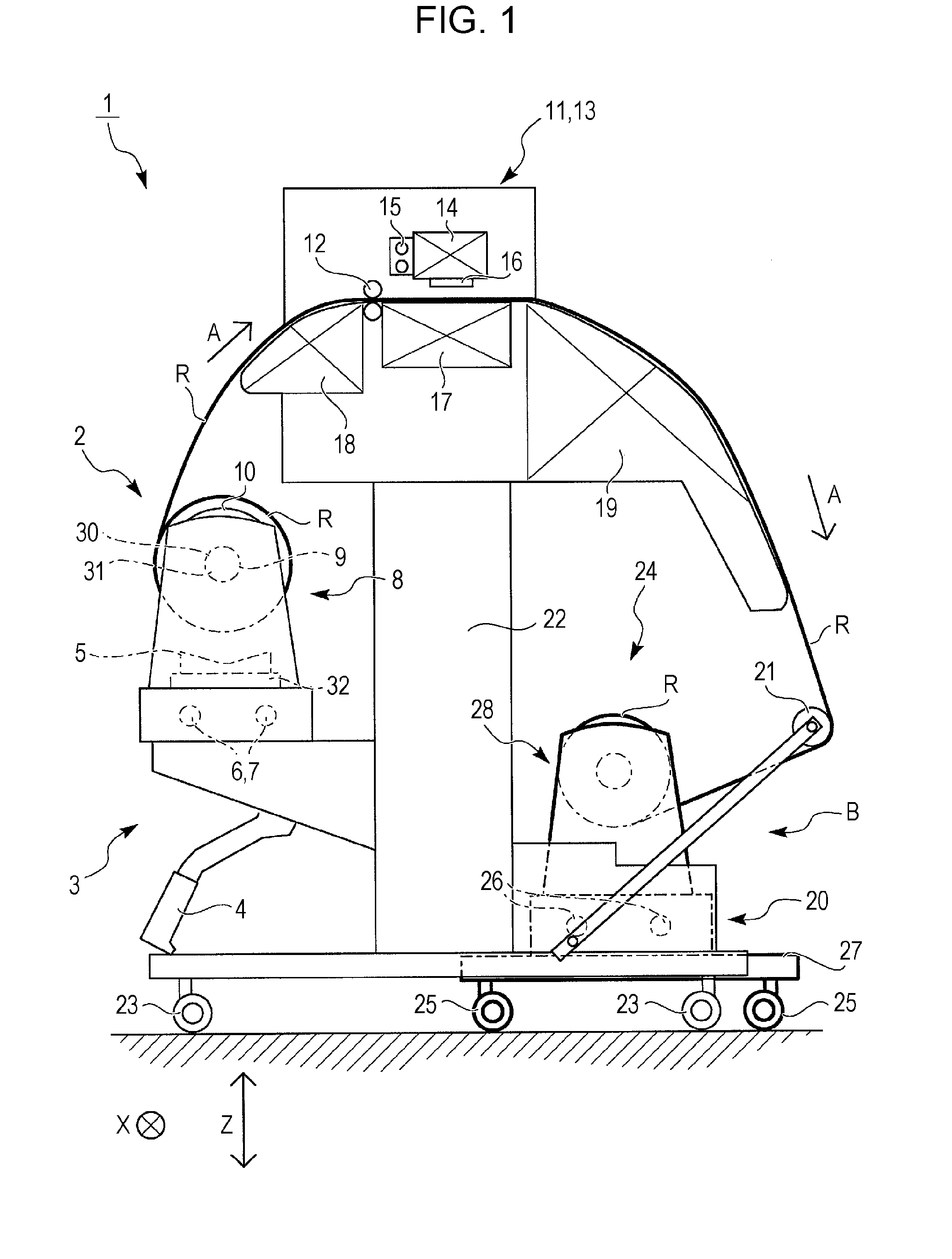

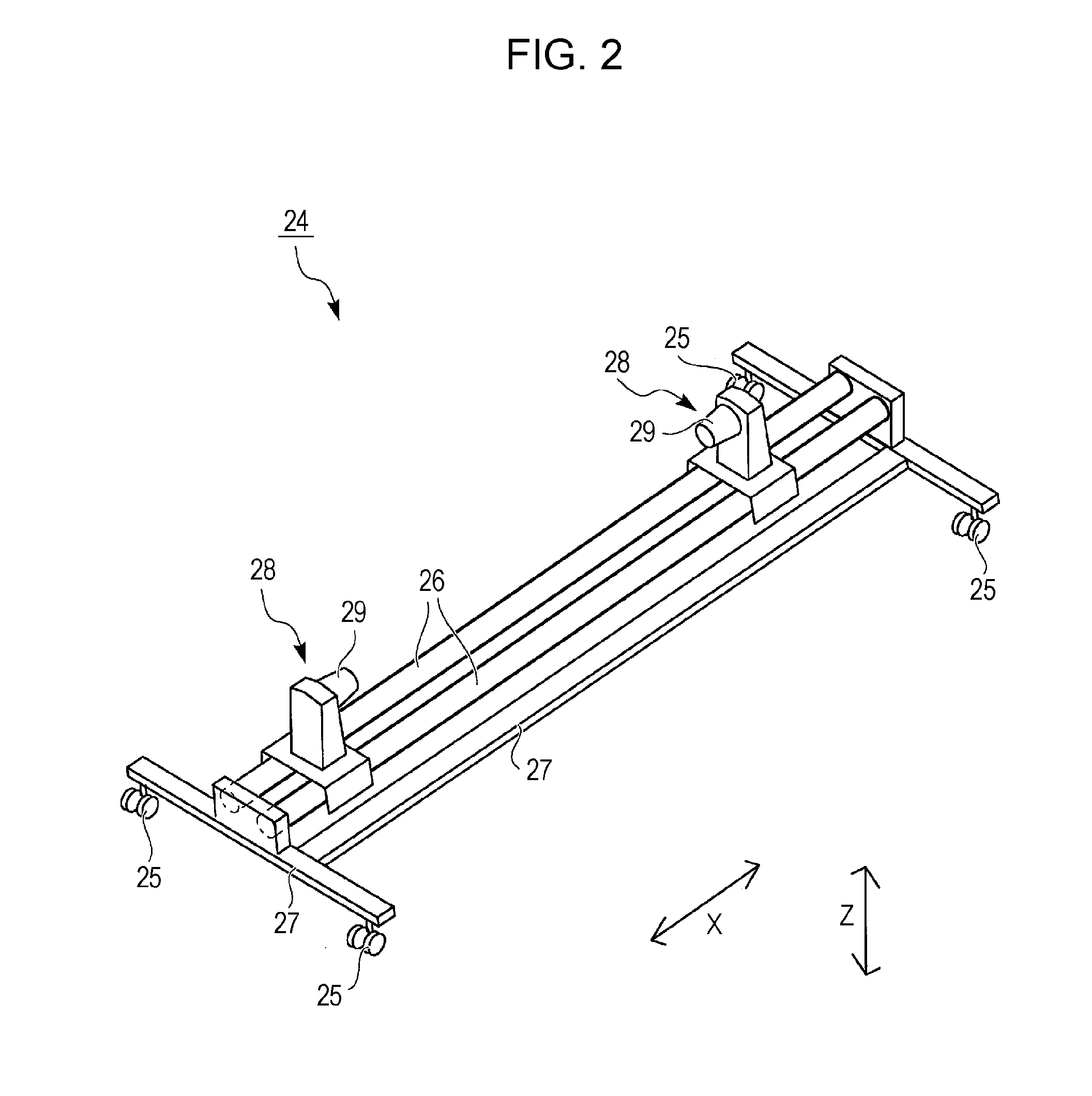

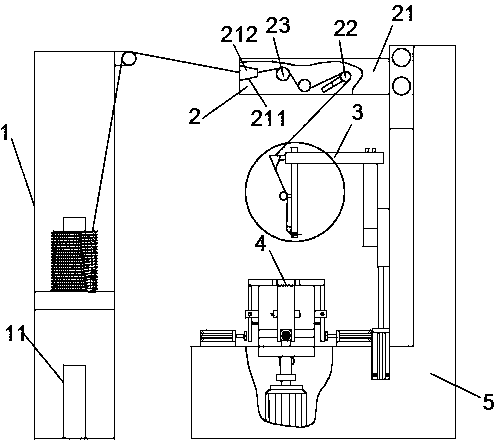

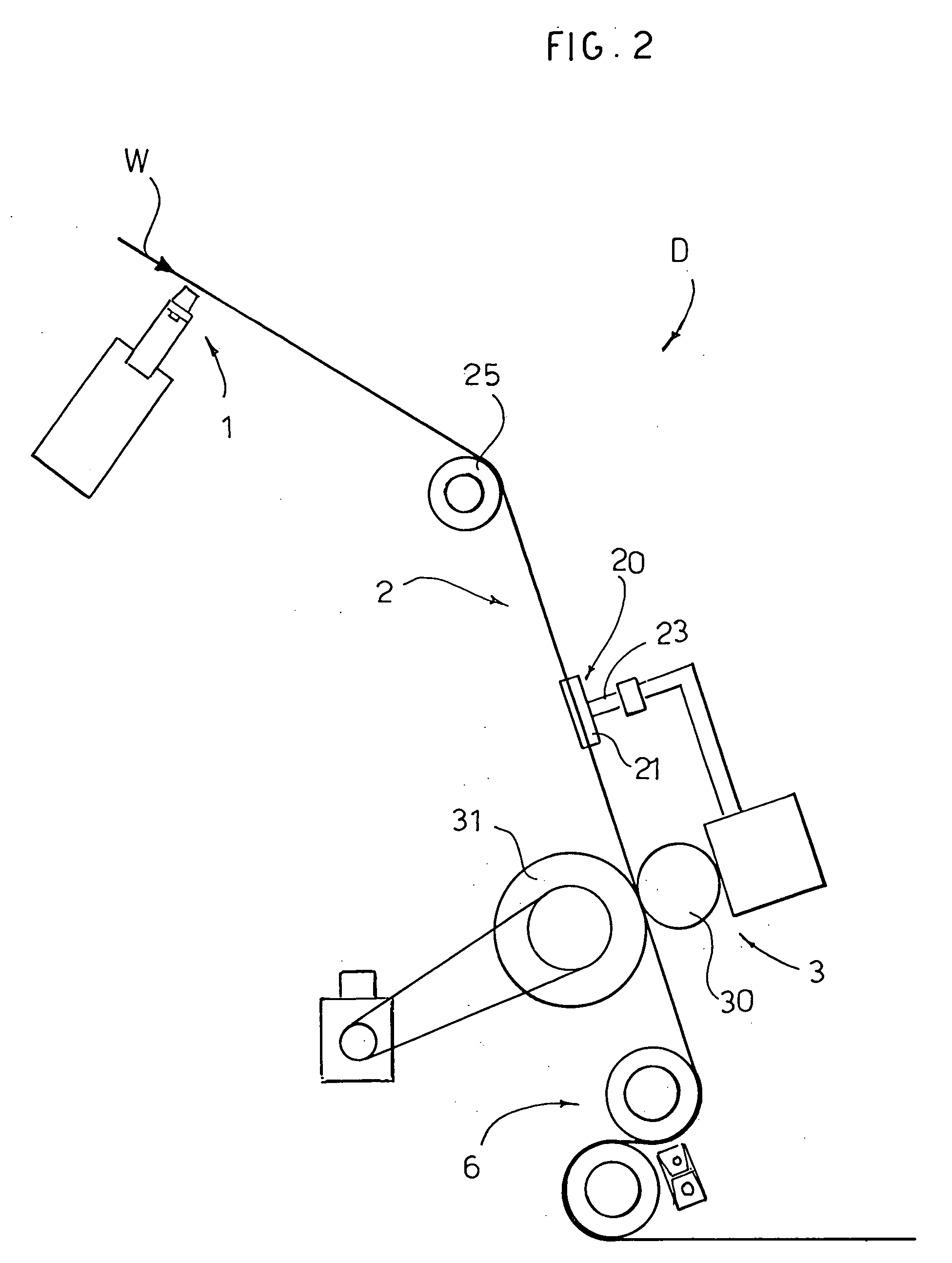

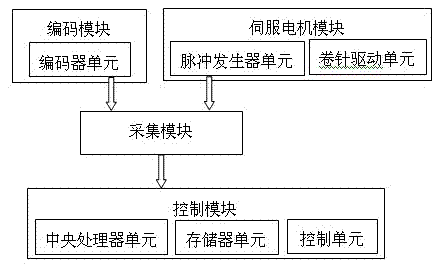

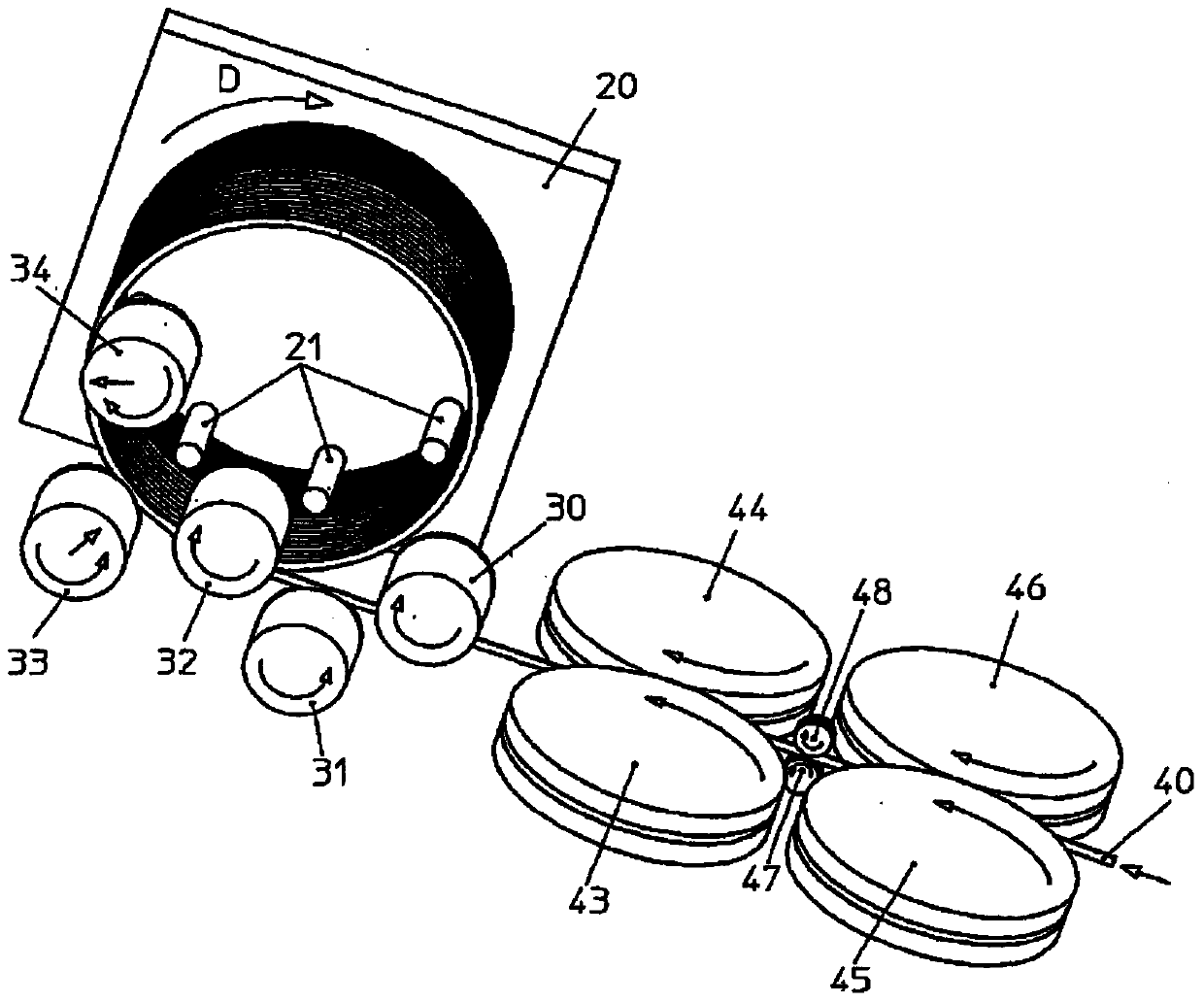

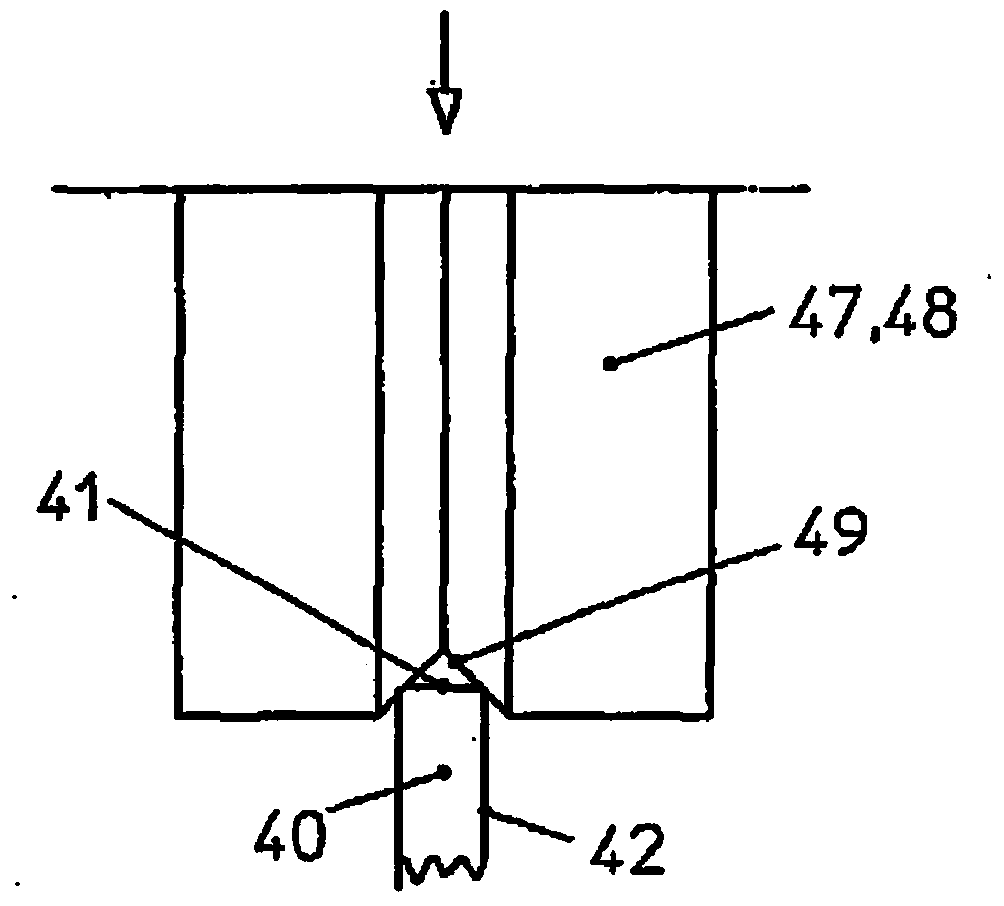

Device to apply rubber tape

A device to apply a thin narrow rubber tape to a rotating object (4), which can be suitably utilized for making a rubber component of a pneumatic tire, is disclosed. The device comprises: a conveyer belt; a let-off roller (16) on which the conveyer belt runs and from which the rubber tape is let off; a traverser (21) to move the let-off roller (16) in an X-axis direction parallel to the rotational axis of the object; a radial shifter to move the let-off roller in a Y-axis direction perpendicular to the X-axis direction; a tilter (23) to turn the rotational axis of the let-off roller (16) around a reference axis which is parallel to a Z-axis direction perpendicular to the X-axis direction and Y-axis direction. Said conveyer belt provided with a substantially straight part extending for a certain distance from the let-off roller to the upstream side thereof at a substantially constant inclination angle theta of more than 0 but not more than 70 degrees with respect to a reference plane including the rotational axis of the let-off roller and the rotational axis of the object.

Owner:SUMITOMO RUBBER IND LTD

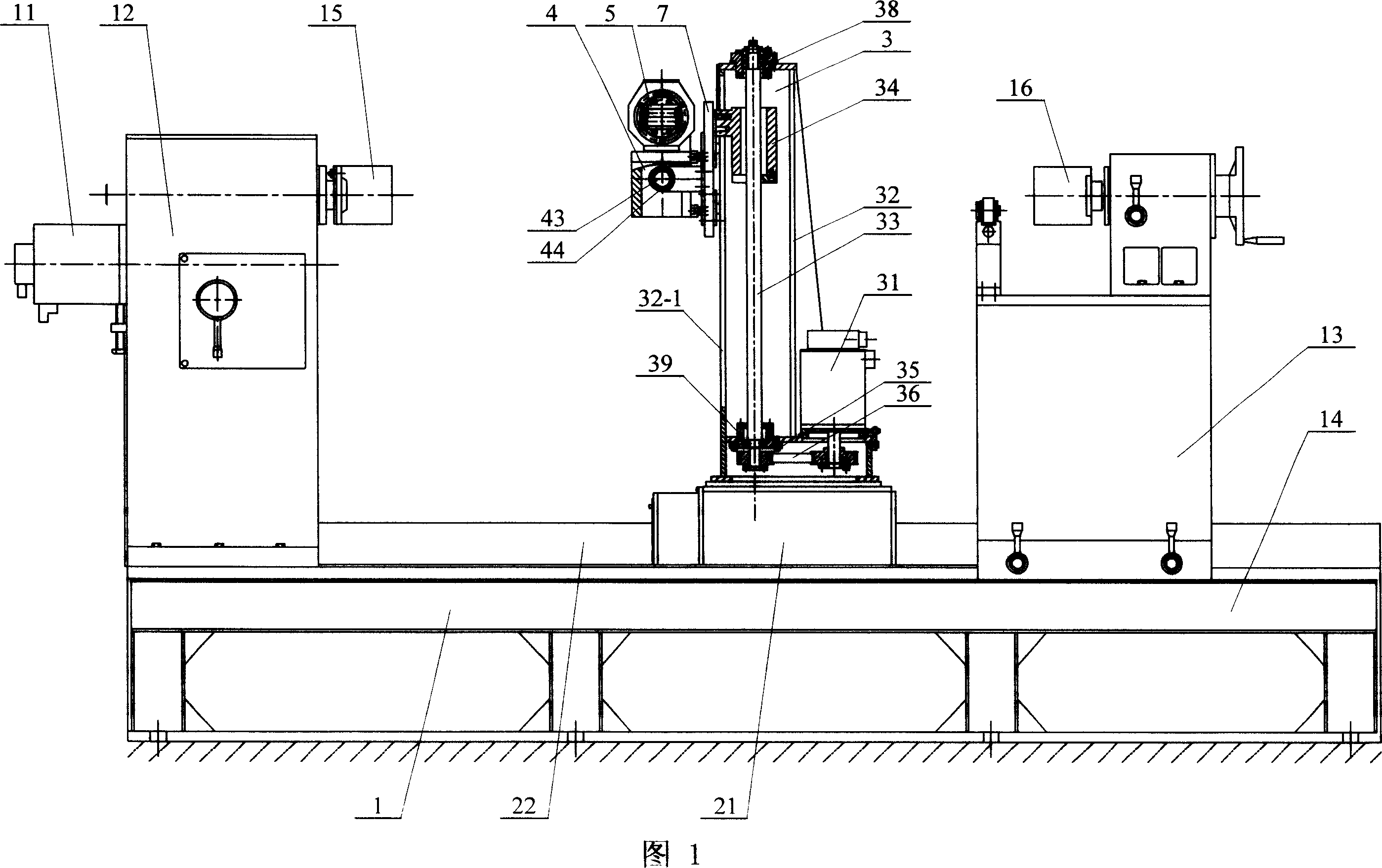

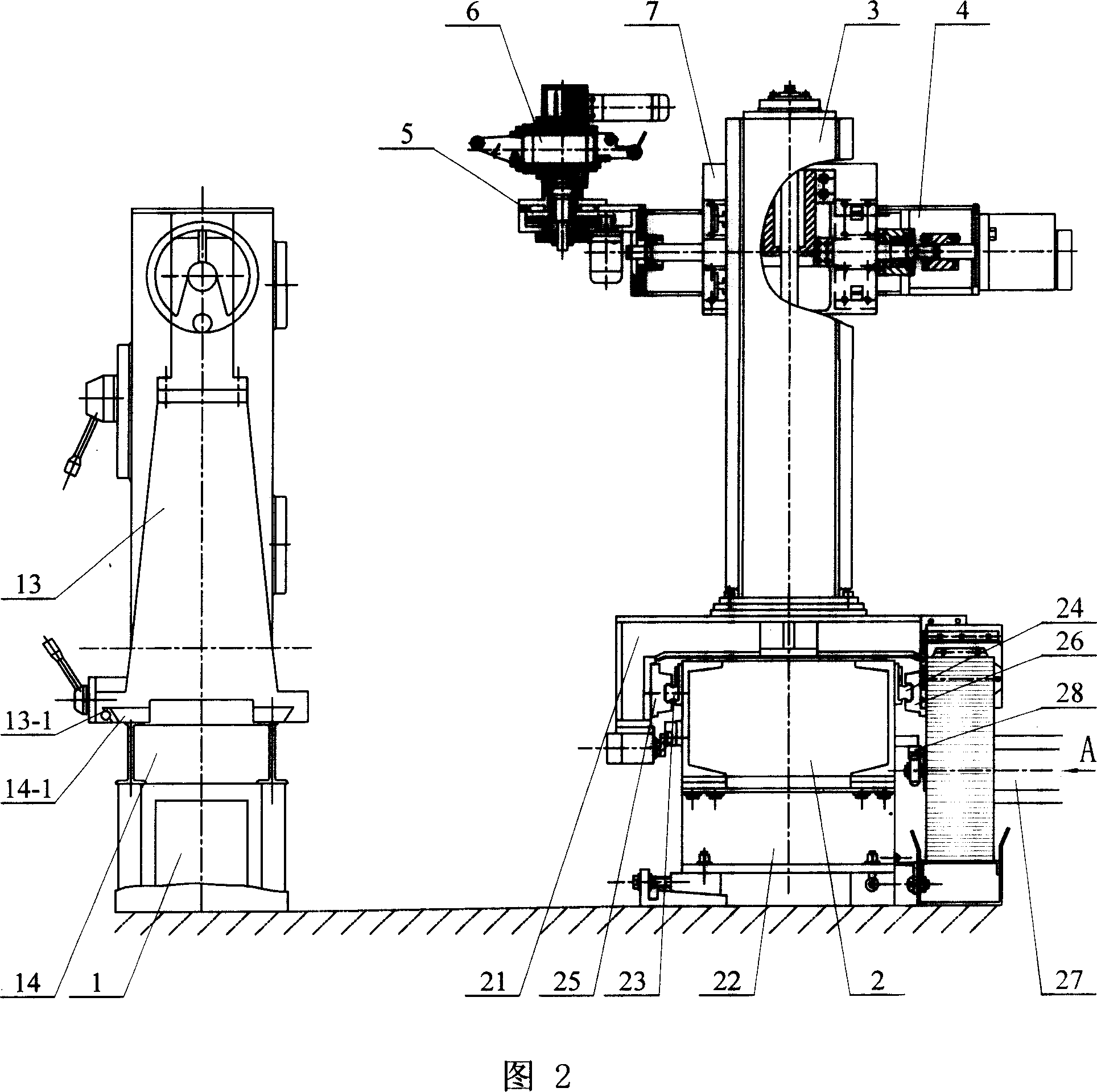

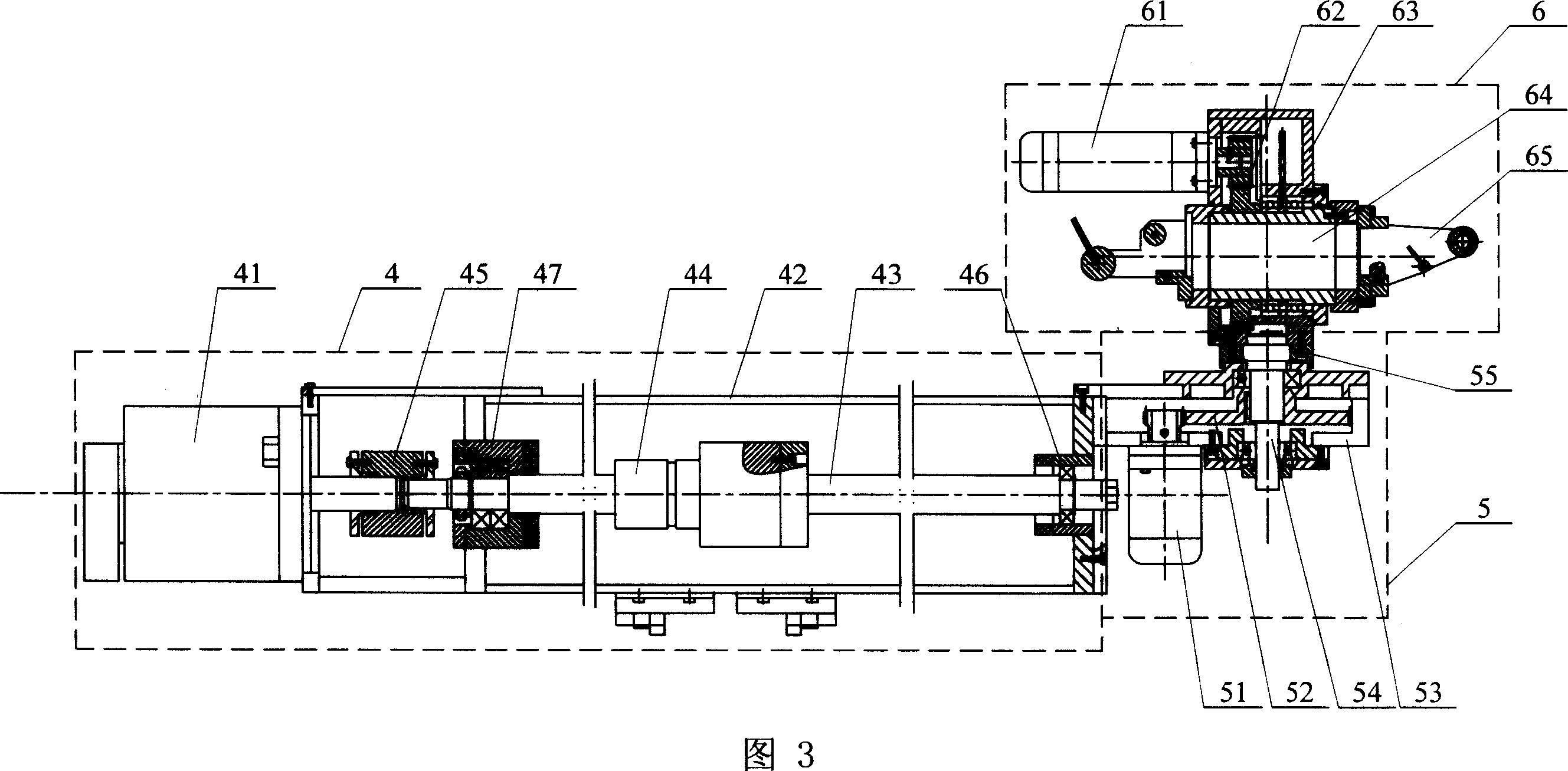

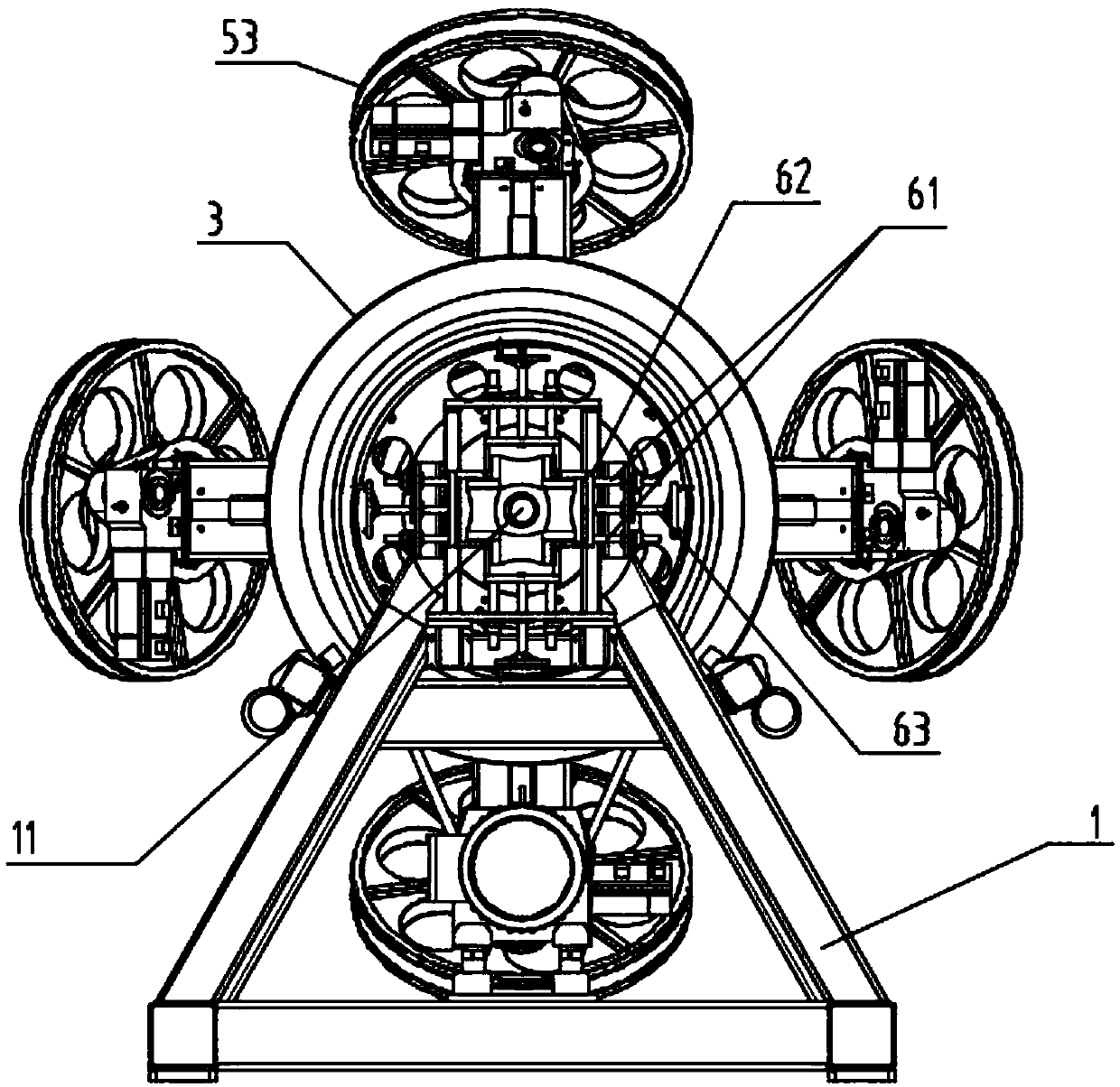

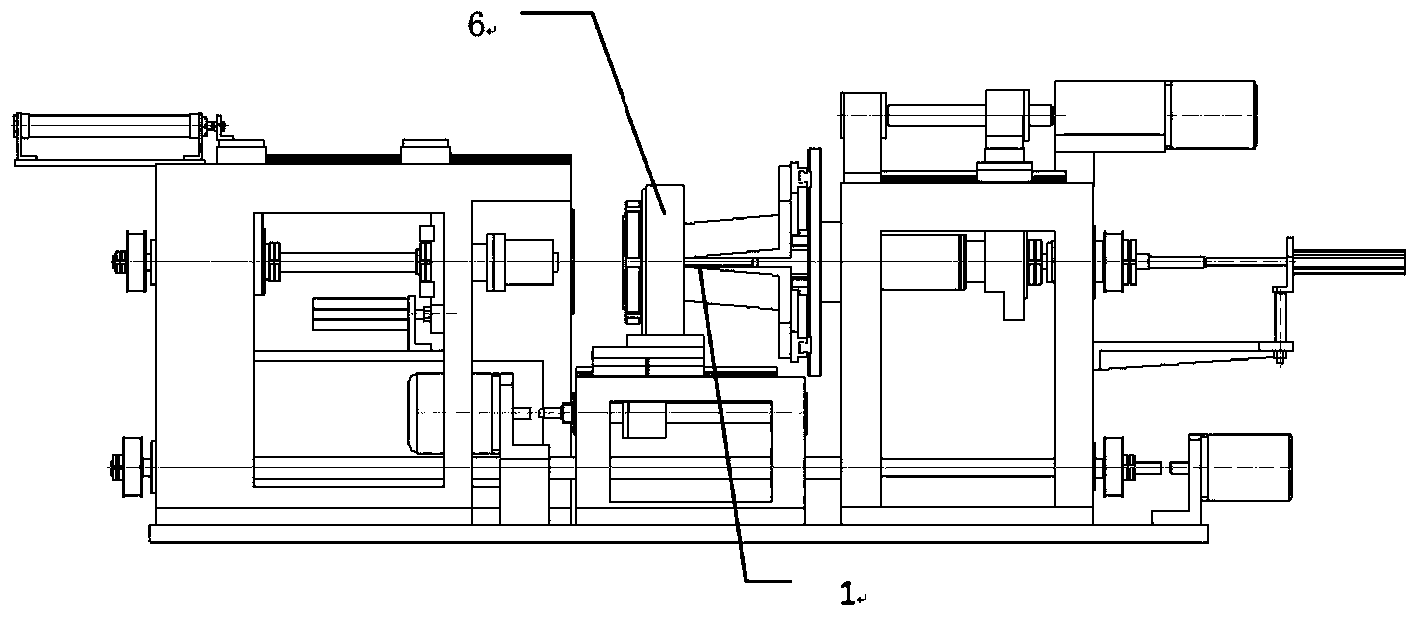

Six-coordinate linkage fibre wrapping machine

InactiveCN1919585AMeet the requirements of winding wire typePrecise Winding TypeDrive shaftEngineering

The invention discloses a six-coordinate linked fiber coiler, which is characterized by the following: the movement of six-coordinate is realized by controlling six servo motors, the back driving axial line of core mould C shaft parallels the moving direction of Z-coordinate straight-line movement unit assemblage (2), the X-coordinate straight-line movement unit assemblage (4) is set on one side of Y-coordinate straight-line movement unit assemblage (3), the B-axle rotary moving unit assemblage (5) is fixed on one end of near-core mould C rotary moving unit assemblage on the case (42) of X-coordinate straight-line moving unit assemblage, the bottom of second box (63) of A-axle rotary moving unit assemblage (6) connects the connecting flannel (55) of B-axle rotary moving unit assemblage (5), the spinning swaying head (65) is fixed on the opposite end of core mould C-axle rotary moving unit assemblage on the second driving shaft (64).

Owner:HARBIN INST OF TECH

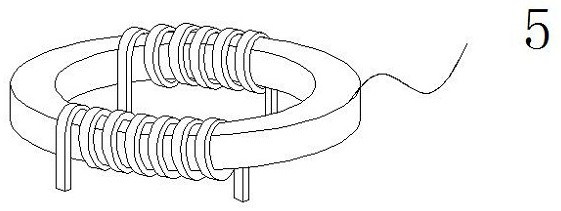

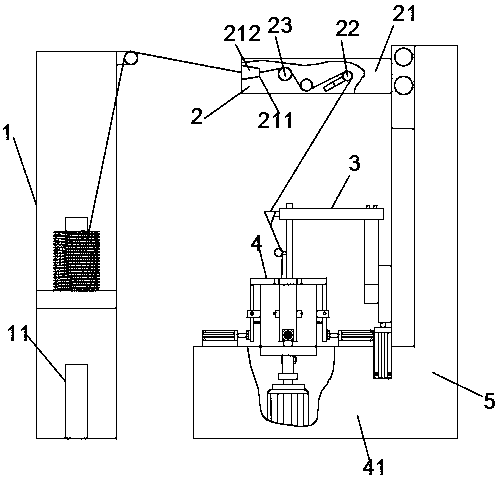

Automatic inductor winding device capable of controlling winding density

InactiveCN112259368AConsistent densityHigh precisionCoils manufactureWinding machineInductor windings

The invention discloses an automatic inductor winding device capable of controlling winding density. The automatic inductor winding device specifically comprises a base, a workbench, a coil placing frame, a winding mechanism and a rotating sleeve, wherein the workbench is mounted on one side of the top of the base, a winding wheel is fixed on the other side of the top of the base, a guide wheel ismounted on the base between the winding wheel and the workbench, and a positioning ring is fixed to the side, close to the guide wheel, in the winding wheel through a support. According to the automatic inductor winding device capable of controlling the winding density, the winding mechanism and a driving roller are arranged, the winding mechanism can drive an enameled wire to be wound on a coil,the driving roller clamps the coil and rotates relatively while winding is conducted so as to allow the coil to rotate at a constant speed, and therefore, uniform winding effect is obtained; comparedwith manual winding, the method has the advantages that efficiency is higher, the winding density can be controlled, it is guaranteed that the winding density is consistent, winding displacement is tidier, and winding precision is higher.

Owner:东莞市夯实科技有限公司

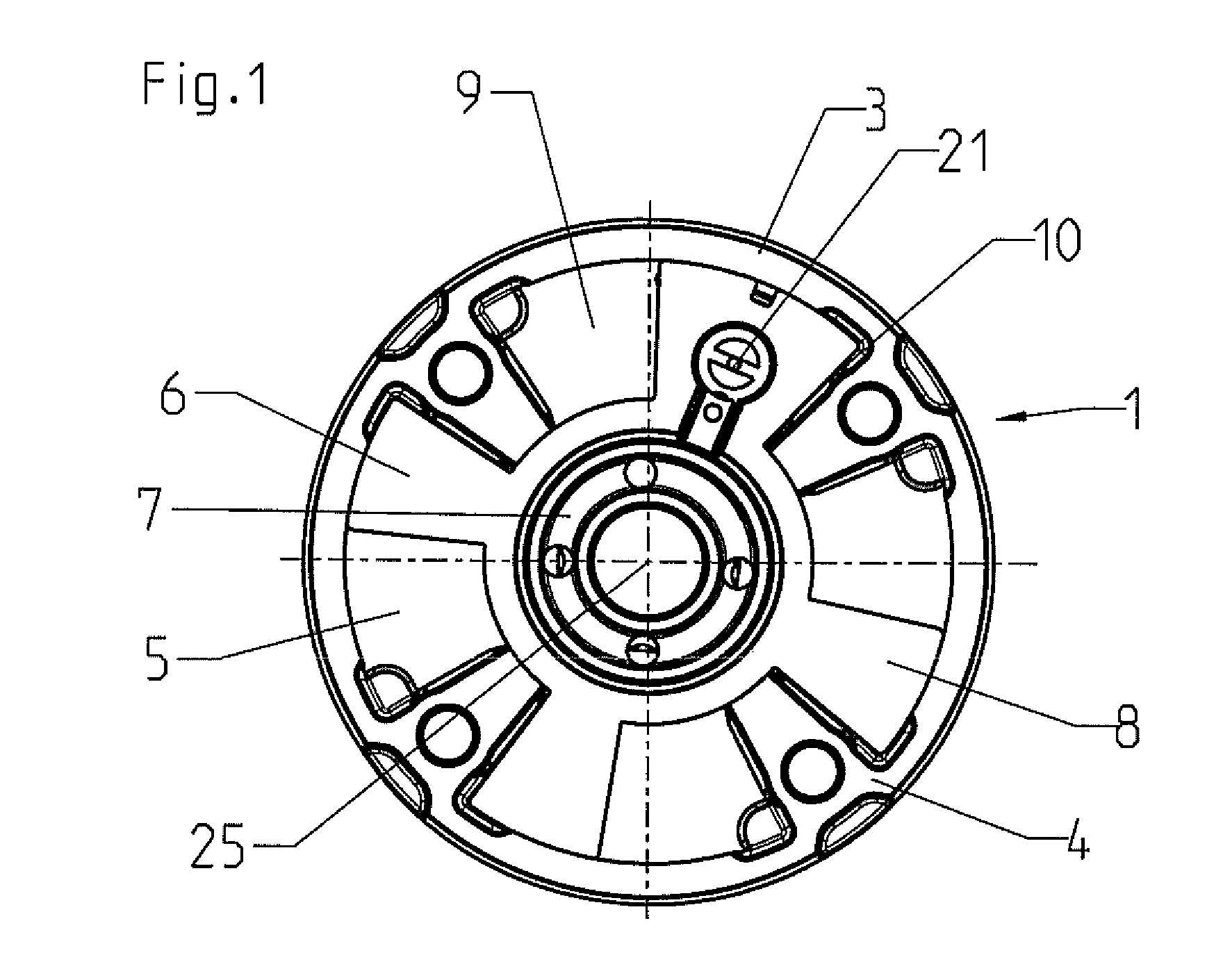

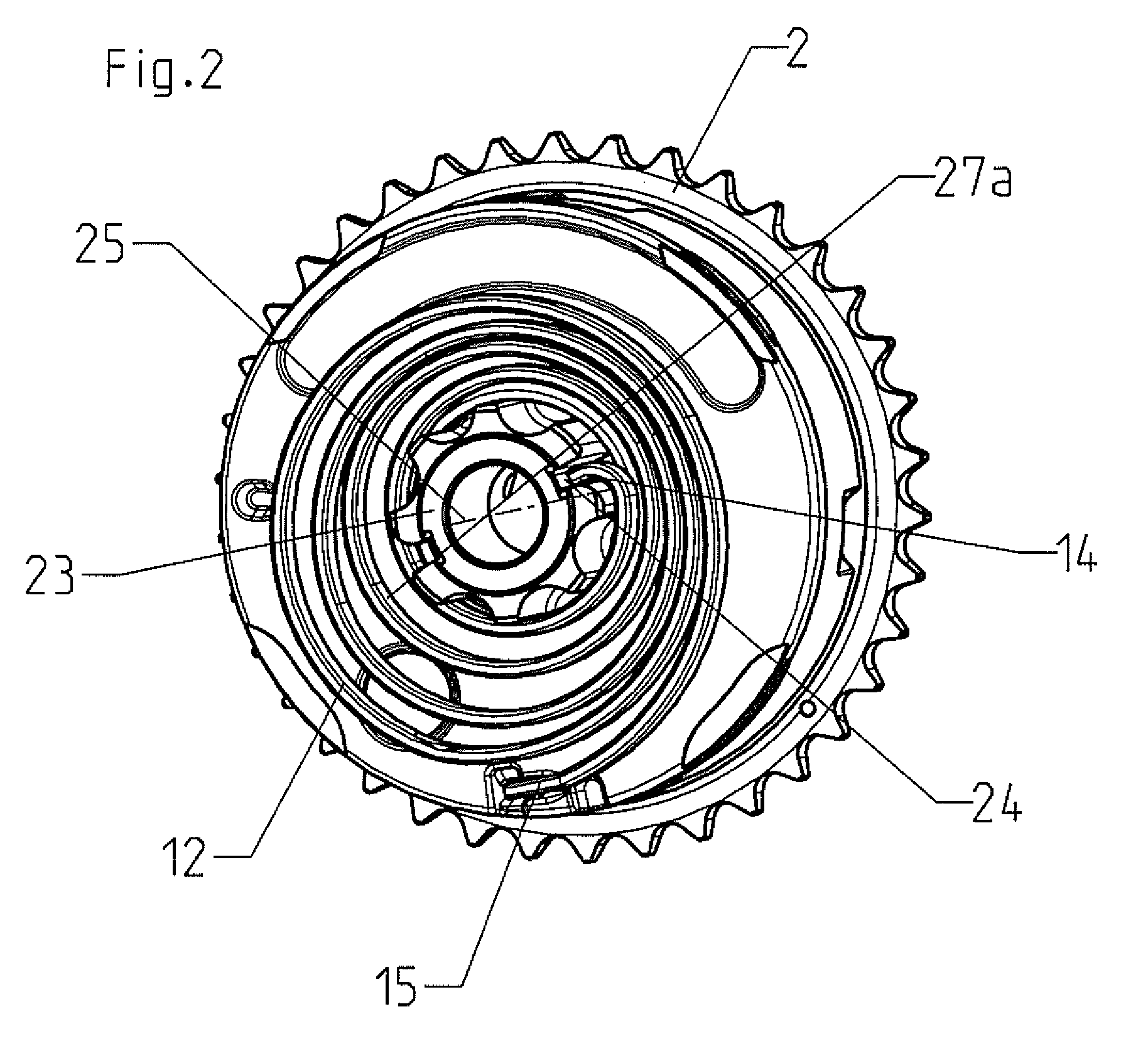

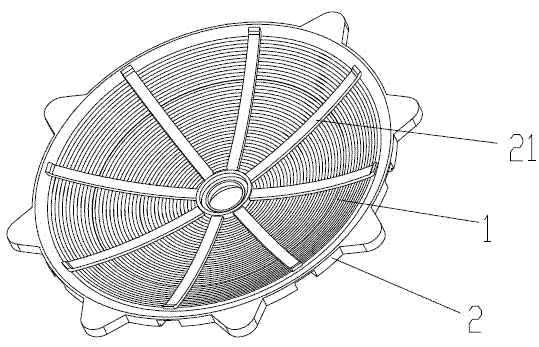

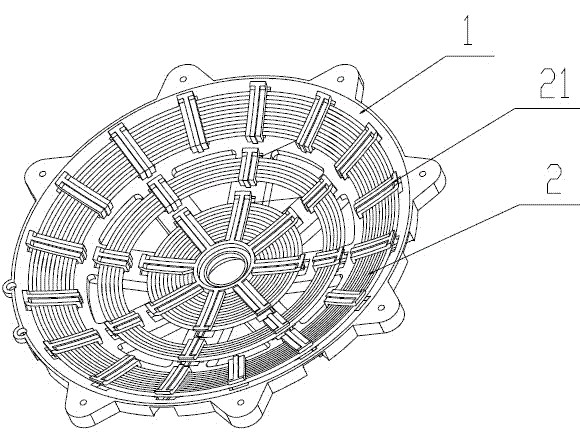

Coil disc of electromagnetic oven

ActiveCN102523643AGuaranteed performance and stabilityImprove performanceCoil arrangementsCoil procedureEngineering

The invention discloses a coil disc of an electromagnetic oven, comprising a coiling bracket and coil windings arranged on the coiling bracket, wherein the coiling bracket is provided with a plurality of wire buckles which are distributed in a ring shape and are convenient for winding fixed enamelled wires; and the coil windings are formed by winding of the enamelled wires which penetrate through the wire buckles distributed in a ring shape. The coil disc is characterized in that due to adoption of the structure with wire buckles, adhesive-less winding on the coiling bracket can be realized, and no matching of a coiling mold is needed, so that the coiling procedure is greatly simplified, the safe and convenient effects are achieved, the production efficiency is improved and the manufacturing cost is saved. Especially for multiple circles of windings, the coil disc can realize accurate coiling of multiple windings and ensures that the distance among wire rings is constant all the time, thus ensuring the performance stability of the coil disc in batch production. According to the coil disc, not only can the manual fast and accurate coiling be realized and is the operation simple and convenient, but also the high-speed coiling also can be realized by matching of simple mechanical equipment, and the requirement for corresponding equipment is lower, the production efficiency is greatly improved and the manufacturing cost is reduced. The coil disc is ingenious in design and is convenient and practical.

Owner:MIDEA GRP CO LTD

Recording apparatus

InactiveUS20120205418A1Cleanly windEasy accessOther printing apparatusWebs handlingEngineeringElectrical and Electronics engineering

Owner:SEIKO EPSON CORP

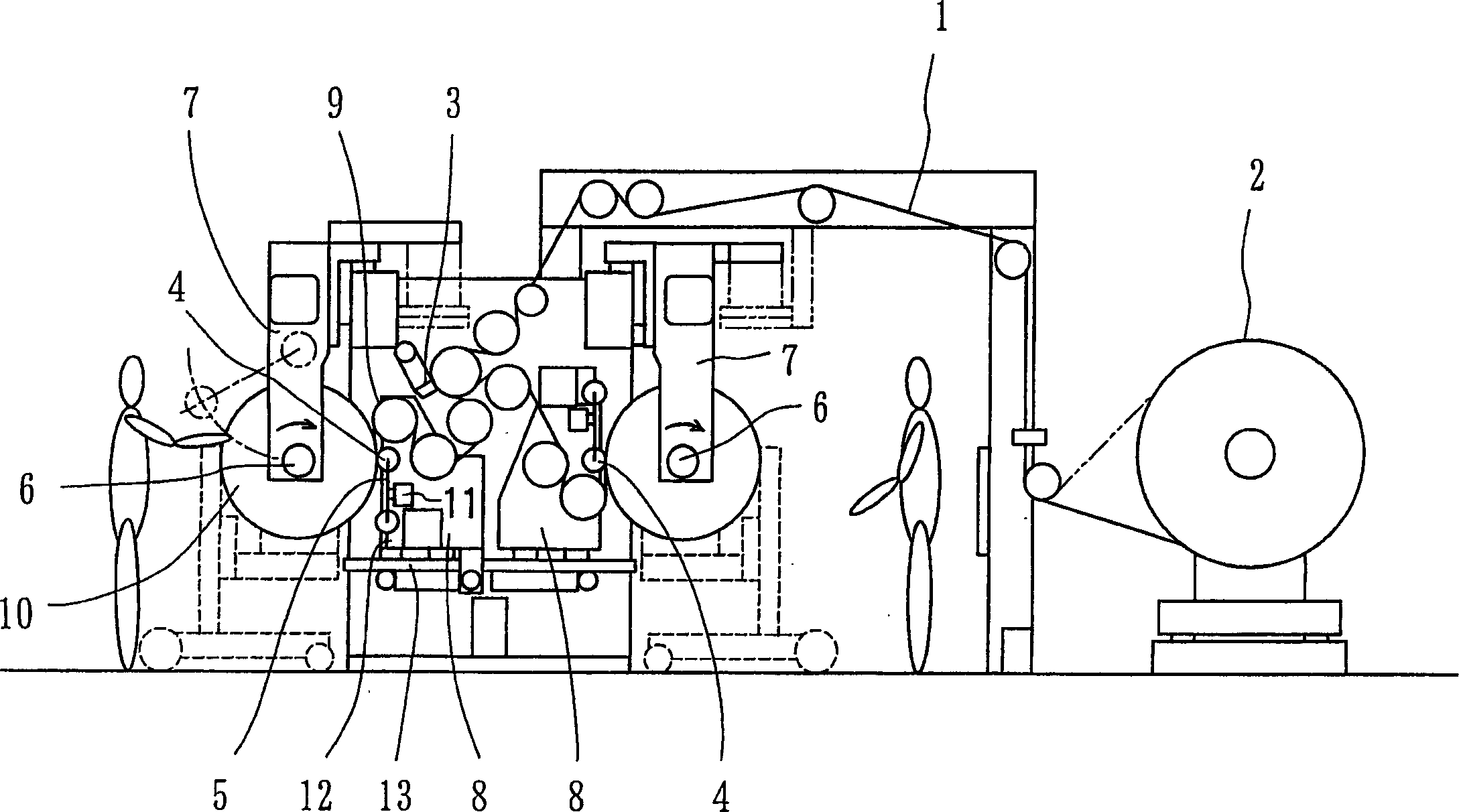

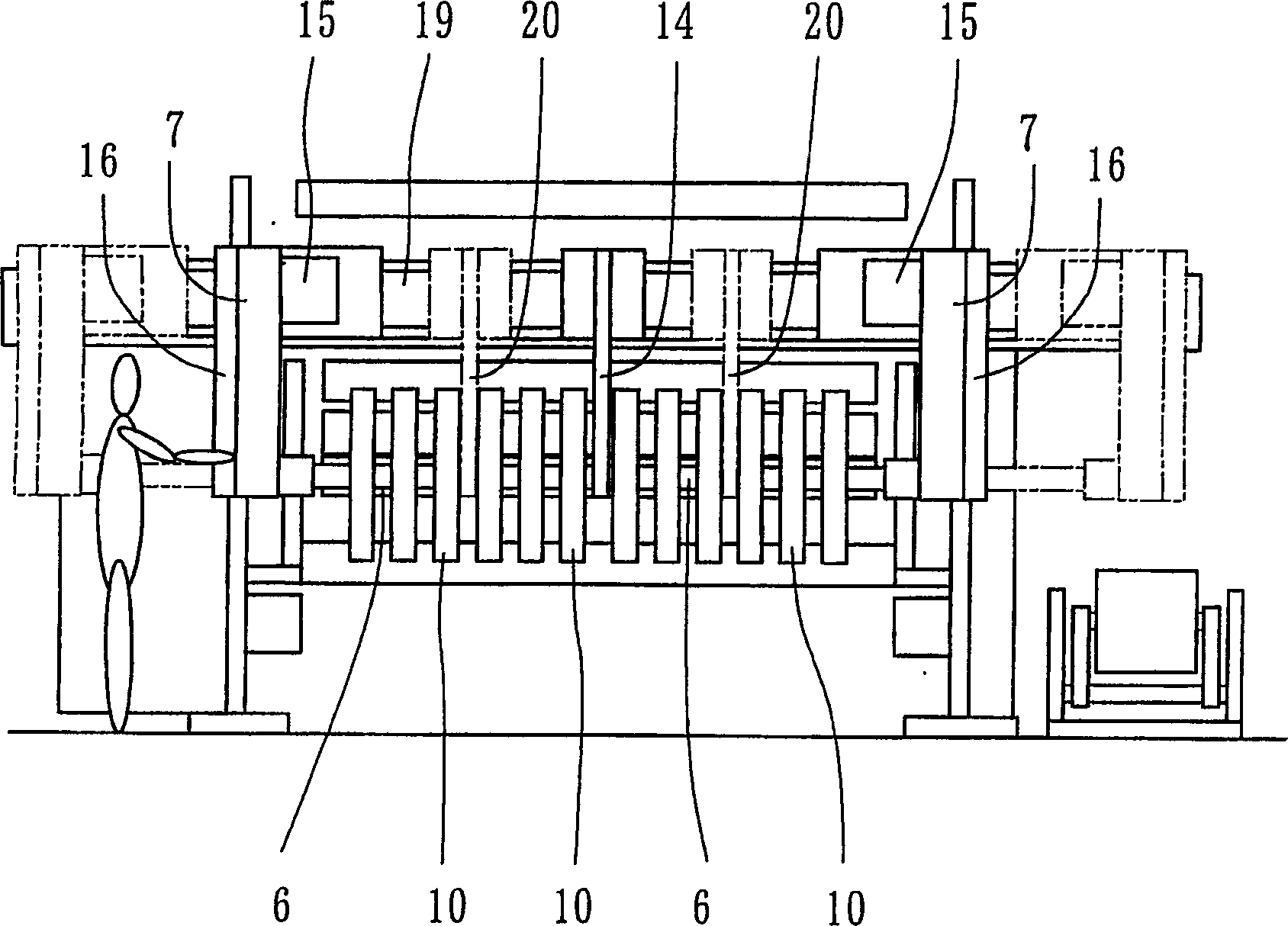

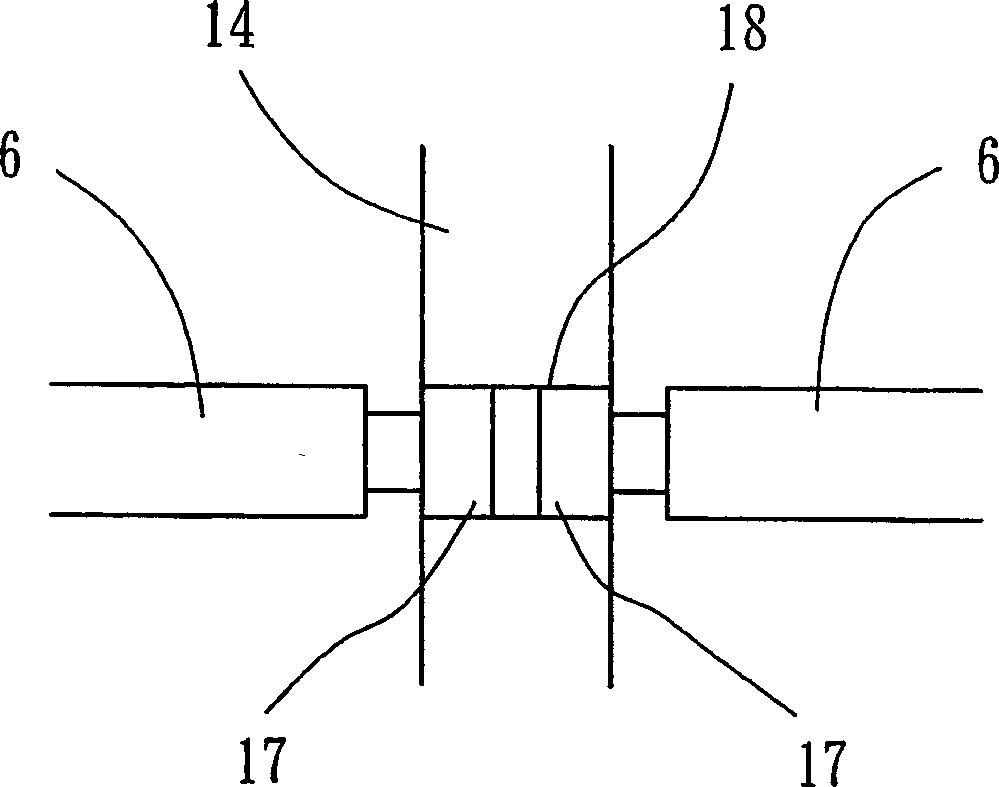

Multi-stage treatment and recovery system and method for PET release films

ActiveCN110435044AReach the purpose of recyclingIncrease profitPlastic recyclingDrying gas arrangementsRecovery methodEngineering

A multi-stage treatment and recovery system for PET release films comprises a mechanical dust removal mechanism, a cleaning mechanism, a drying mechanism and a winding mechanism, wherein the release film sequentially passes through the mechanical dust removal mechanism, the cleaning mechanism and the drying mechanism and is wound on the winding mechanism; traveling of the release films in the mechanical dust removal mechanism, the cleaning mechanism, the drying mechanism and the winding mechanism and transition among the mechanisms are guided by a guide roller in rolling fit with the release films; and the actions of the mechanical dedusting mechanism, the cleaning mechanism, the drying mechanism and the winding mechanism are uniformly and coordinately controlled by an electric control system. According to the multi-stage treatment and recovery system for the PET release films, the release films are subjected to dust removal, cleaning, drying and winding in sequence, so that surface impurities of the used release films can be effectively removed, wound and recycled, the purpose of recycling the release films is achieved, the utilization rate of the release films is improved, and the production cost is reduced. The invention also provides a multi-stage treatment and recovery method for the PET release films.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

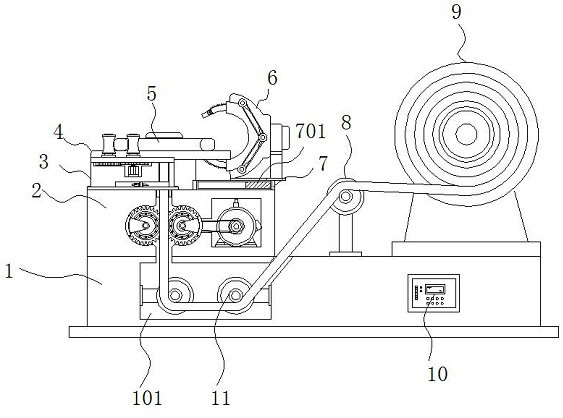

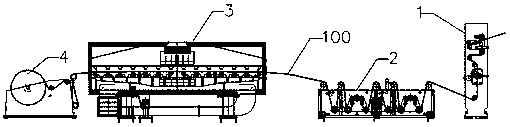

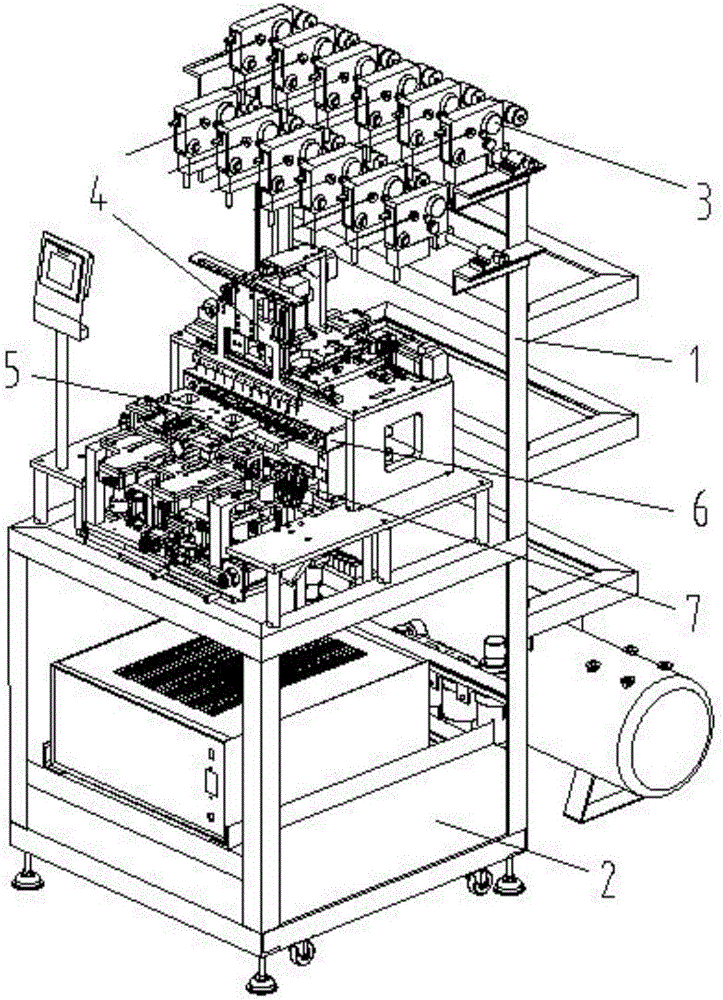

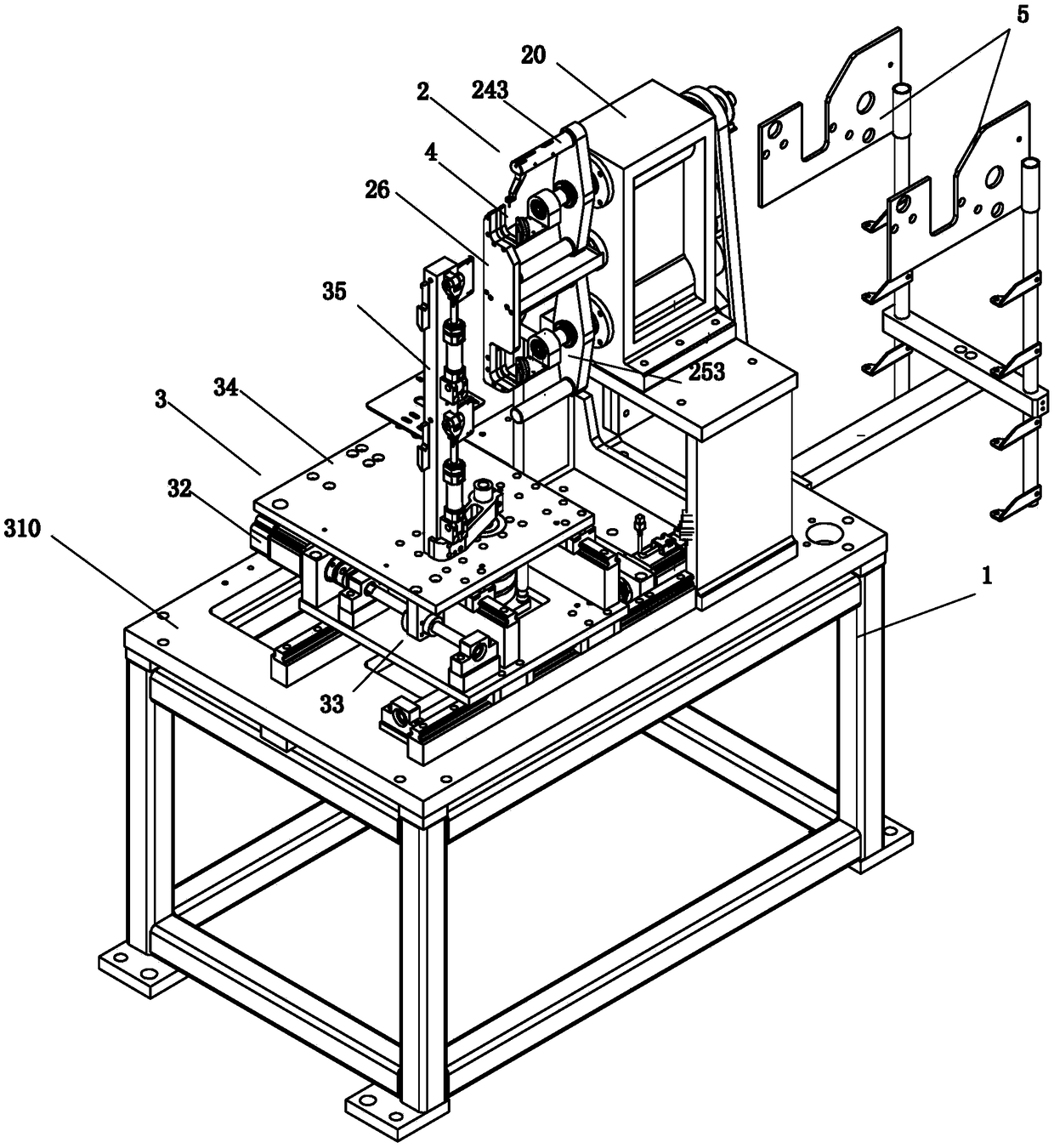

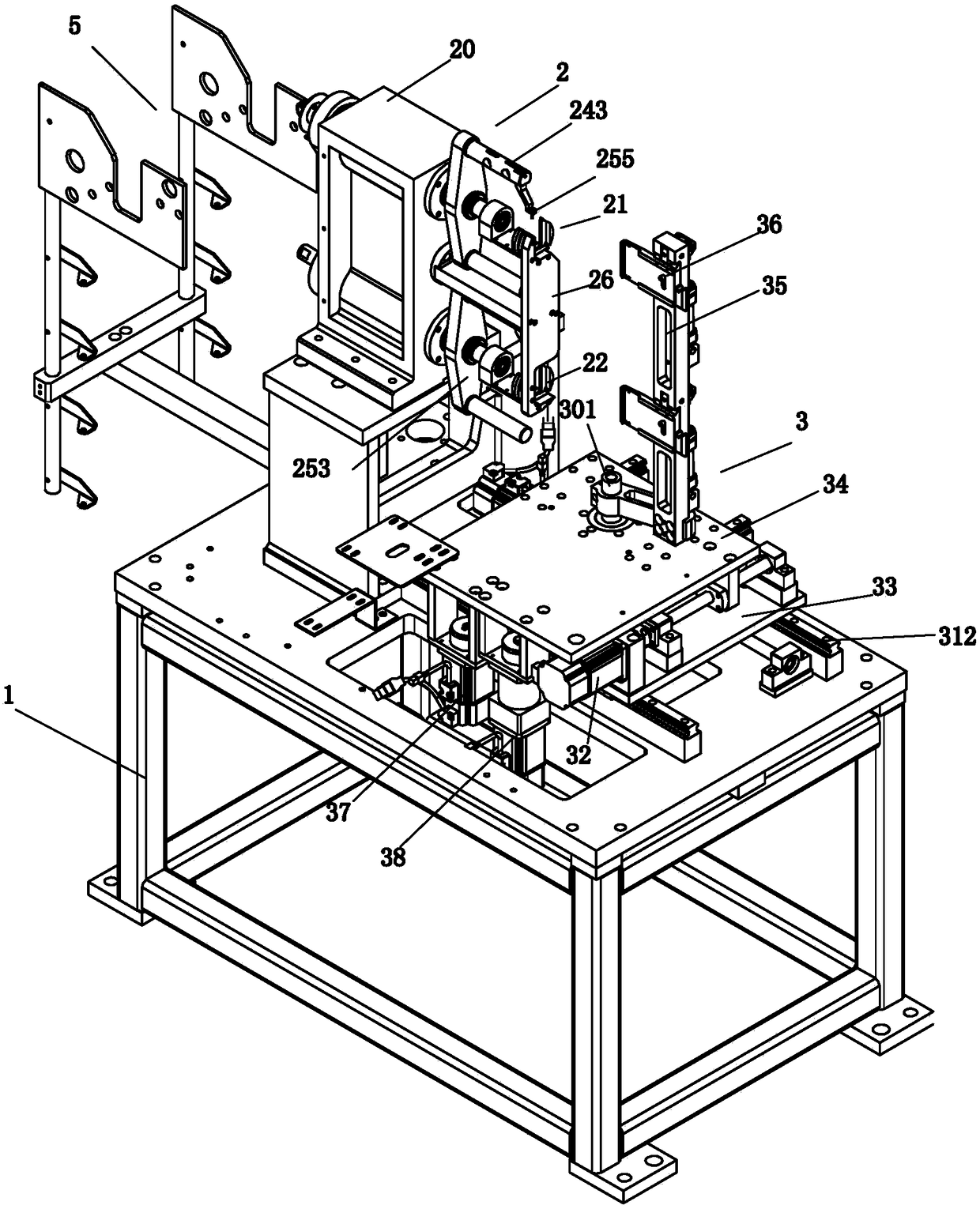

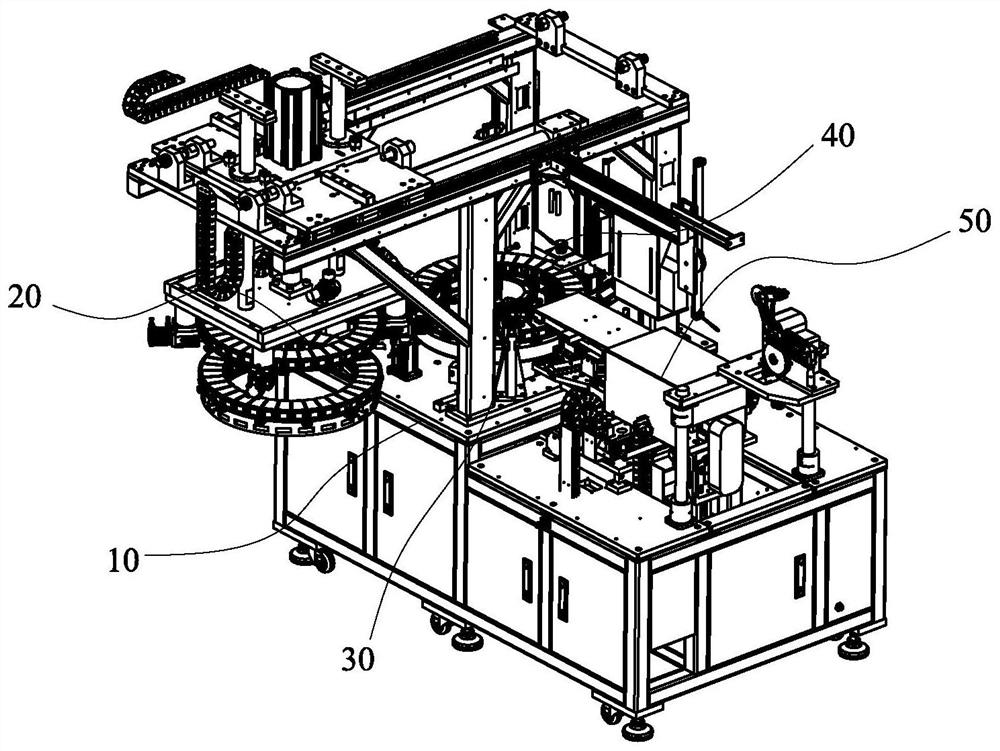

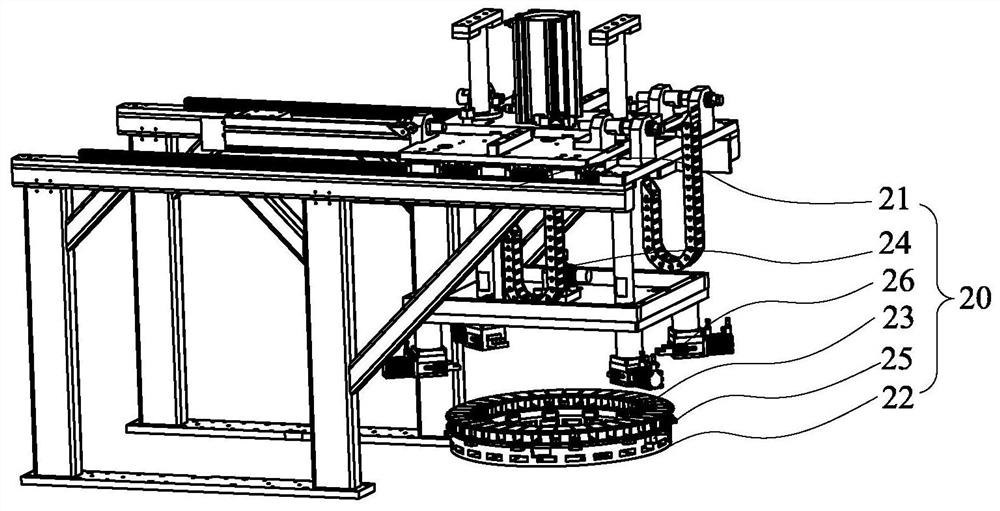

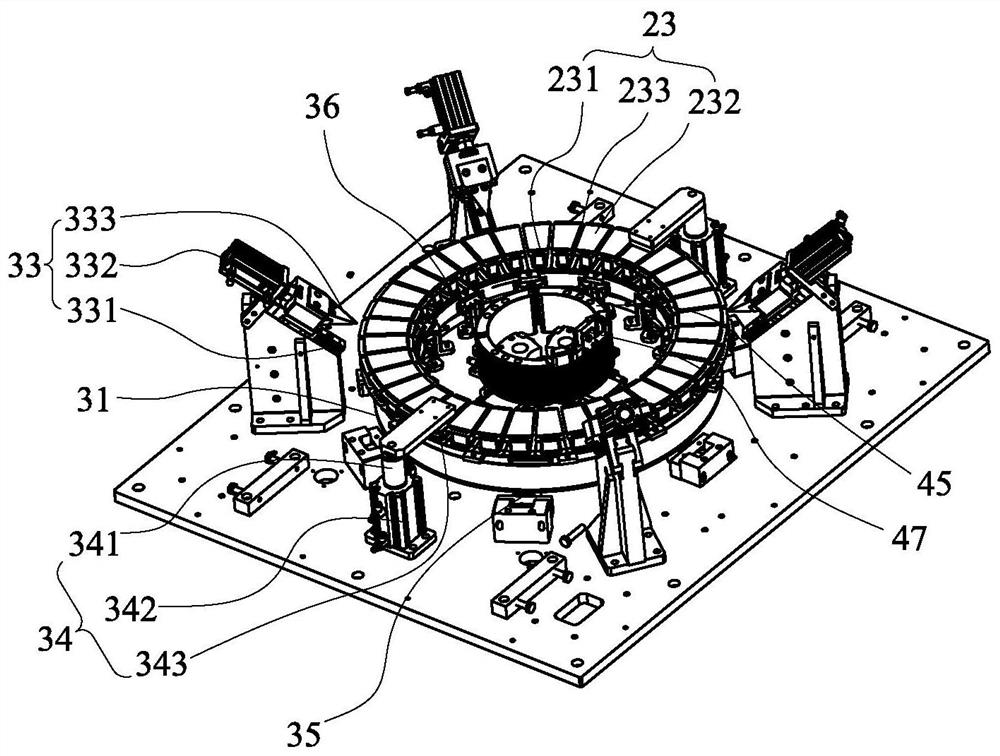

Automatic winding equipment and winding method for motor coil

ActiveCN109687660AFast windingPrecise windingManufacturing dynamo-electric machinesCopper wireLocking mechanism

The invention relates to automatic winding equipment and a winding method for a motor coil, which are mainly used for winding the motor coil and aim to solve the problems of low winding efficiency andeasy error in the prior art. The invention provides a technical scheme that the automatic winding equipment and the winding method for the motor coil. The automatic winding equipment for the motor coil comprises a coil frame, a wire feeding mechanism, a frame, a clamping and breaking mechanism and a winding mechanism; the winding mechanism comprises a winding device for clamping and winding copper wires, and a winding die fixing device for clamping and rotating the winding die; the winding device comprises a winding mechanical arm, a rotating wheel, a lifting module and a translation module;the winding die fixing device comprises a rotating motor, a bearing, a second rotating connecting component, a coil sleeve and a locking mechanism. According to the automatic winding equipment and thewinding method for the motor coil, winding is carried out by utilizing the lifting of the winding mechanical arm in the winding device and the rotary reciprocating of the winding die fixing device, so that the winding step is simplified into two single reciprocating processes, and the production efficiency is effectively improved.

Owner:ZHEJIANG JEAMO MOTOR

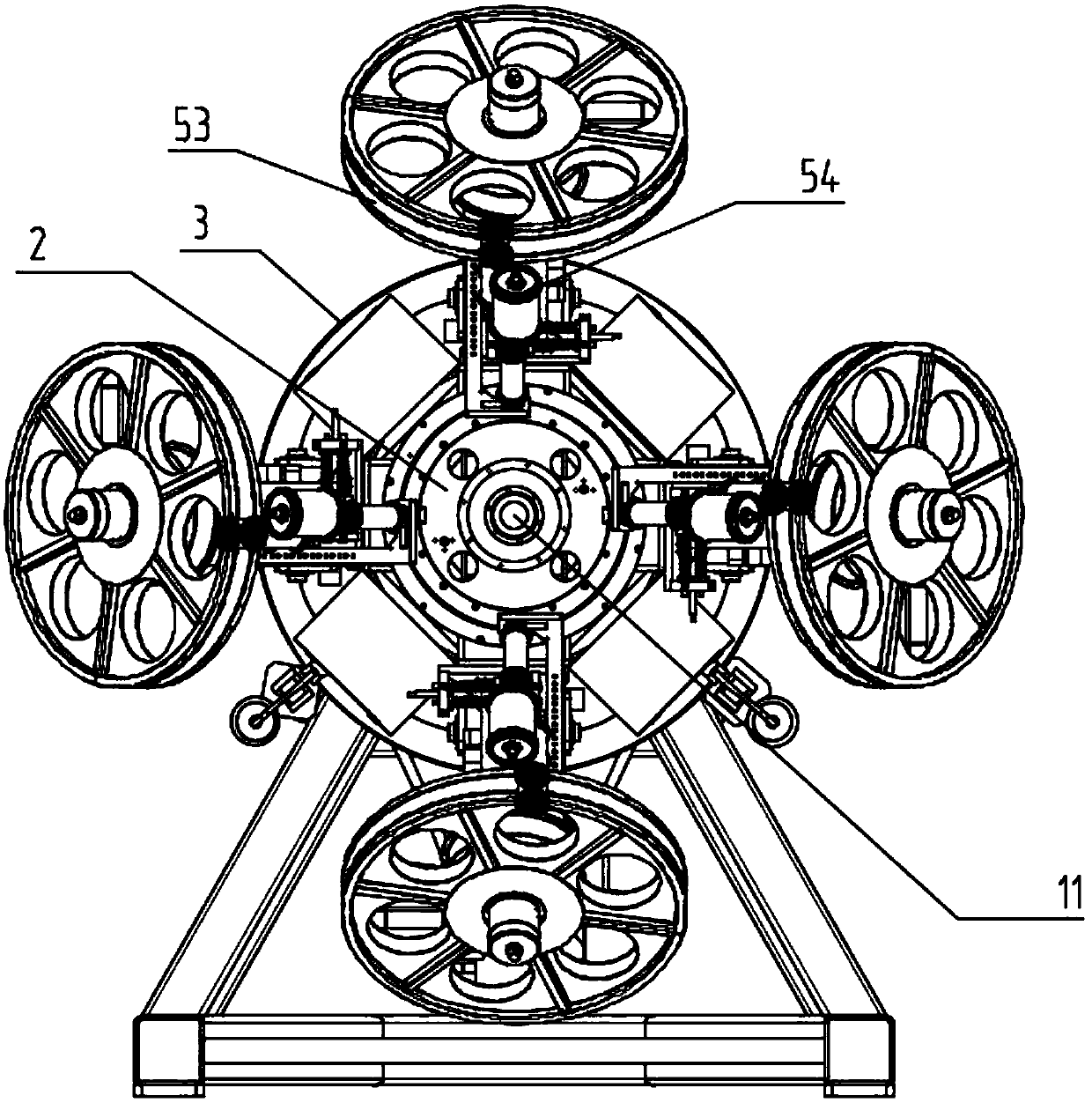

Composite pipe enhanced tape winding machine

PendingCN107627594APrecise windingPerformance impactWinding machineElectrical and Electronics engineering

The invention relates to the field of composite pipeline production equipment, in particular to a composite pipe enhanced tape winding machine. The winding machine comprises a supporting frame, a mainshaft, a rotating cylinder, a rotating power mechanism, a conductive device and tape spool devices; the rotating power mechanism is arranged at the bottom plate of the supporting frame; the top end of the supporting frame is fixedly connected with the main shaft; the rotating cylinder is arranged on the main shaft in a sleeving manner and is rotatably connected with the main shaft; the main shaftis a hollow cylinder; the conductive device is fixed to the main shaft; the rotating cylinder is connected with the rotating power mechanism through a transmission part; and an even number of the tape spool devices are uniformly distributed on the rotating cylinder. The invention provides the composite pipe enhanced tape winding machine; and a tape material can be directly wound on a pipeline precisely through the tape spool devices, so that the influence on the using performance of the tape material caused by twisting a corner in a conveying process of the tape material is avoided.

Owner:昆山吉玛格机械制造有限公司

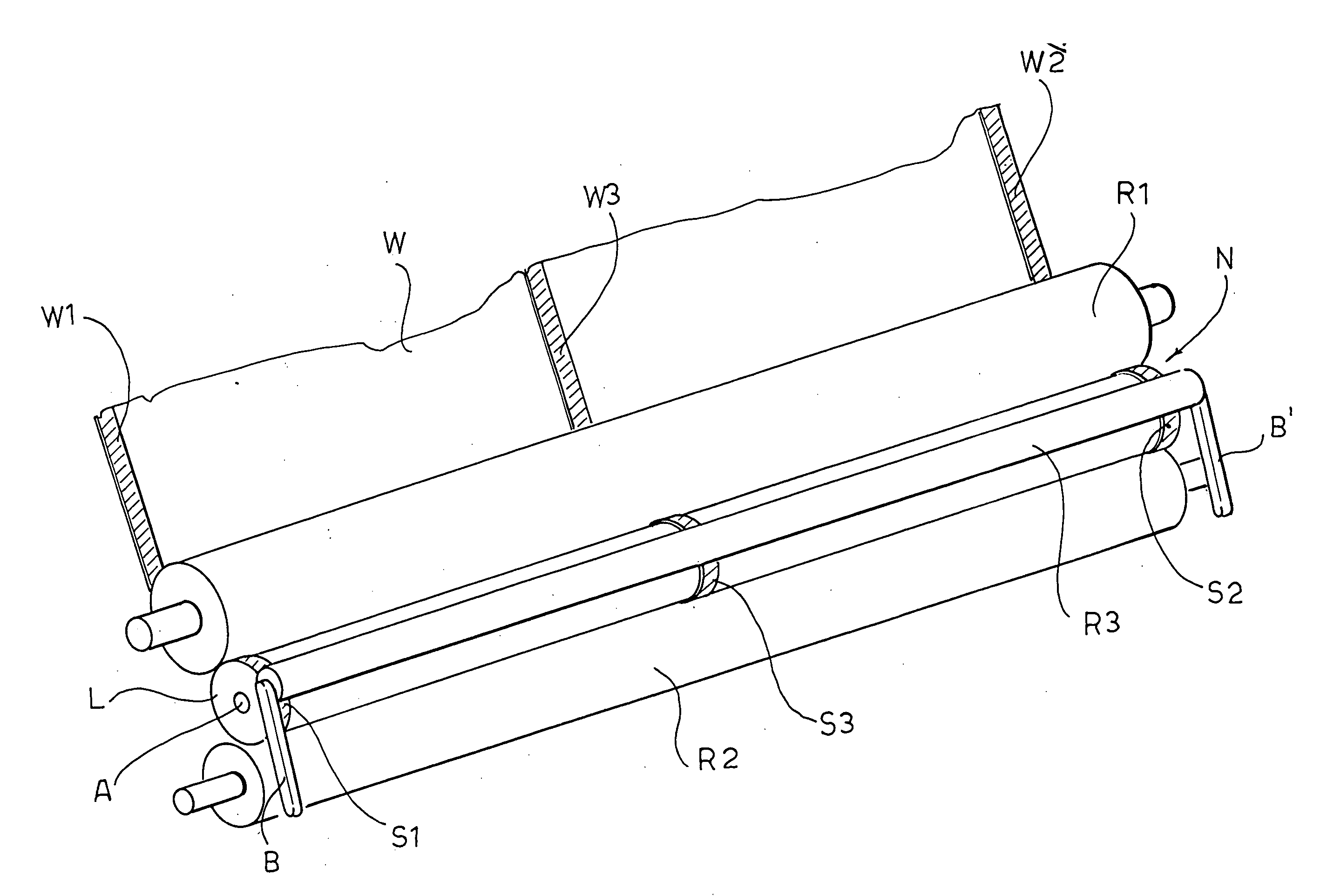

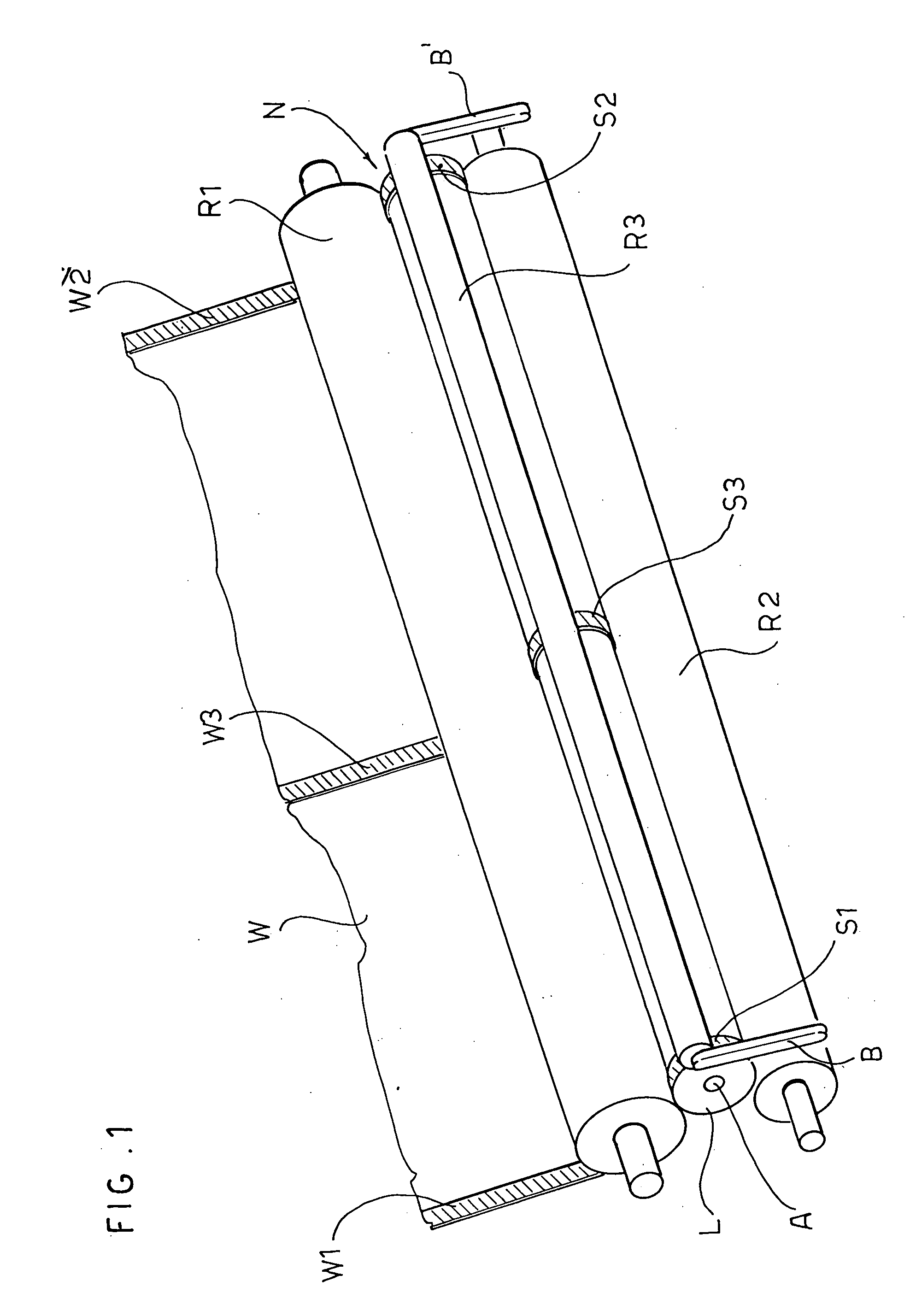

Device and method for stiffening a web destined to be wound in logs

InactiveUS20070187022A1Avoid deformationGreat stiffnessLayered productsAbsorbent padsWinding machineEngineering

A stiffening device for a web destined to be wound in a log by a winding unit of a re-winding machine forms on the web at least one longitudinal strip of greater thickness, so as to obtain in the log at least one sector with a greater stiffness to avoid deformation of the log during winding.

Owner:PAPER CONVERTING MASCH CO INC

Winding device of slitter

Owner:NISHIMURA MFG

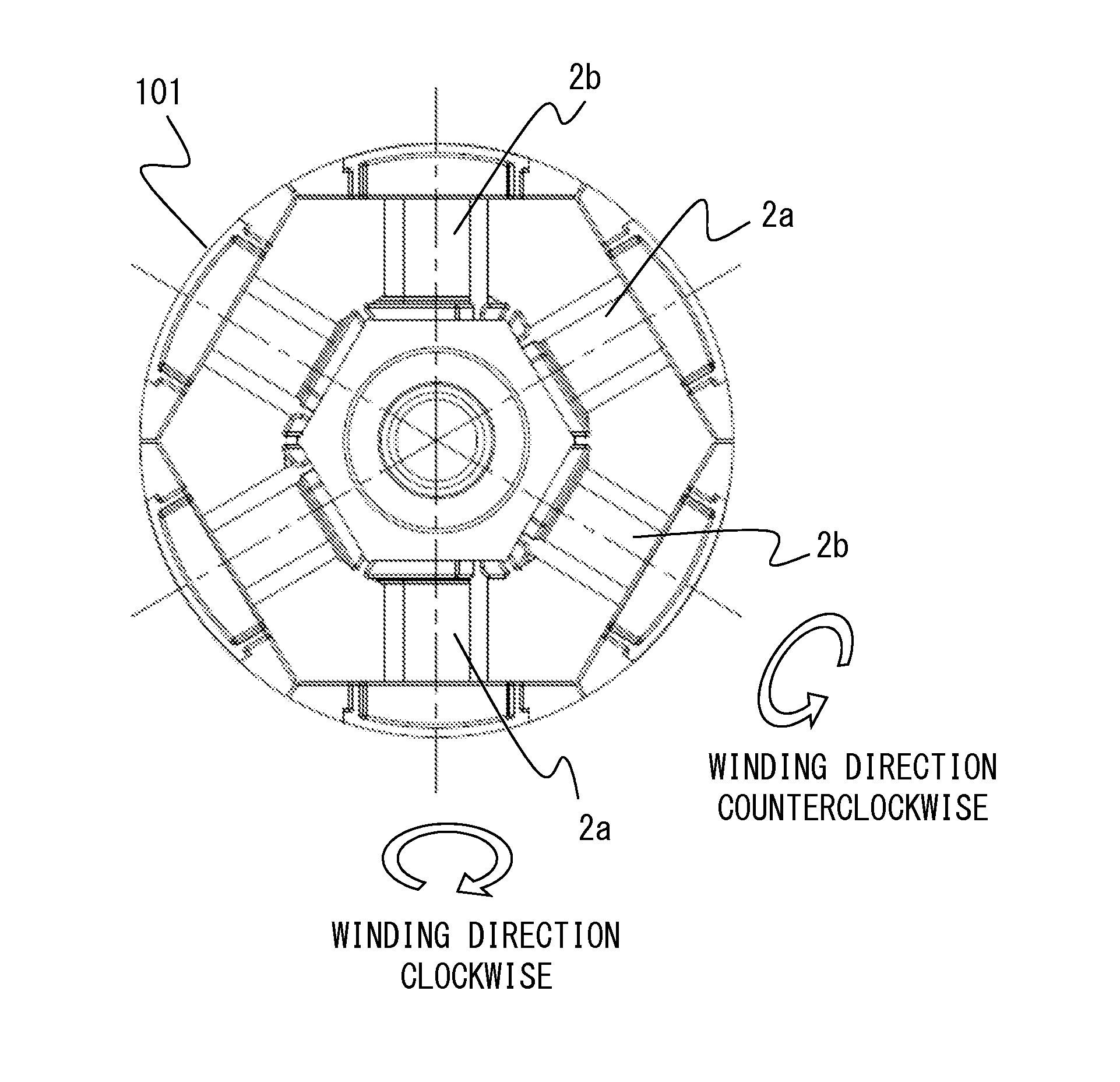

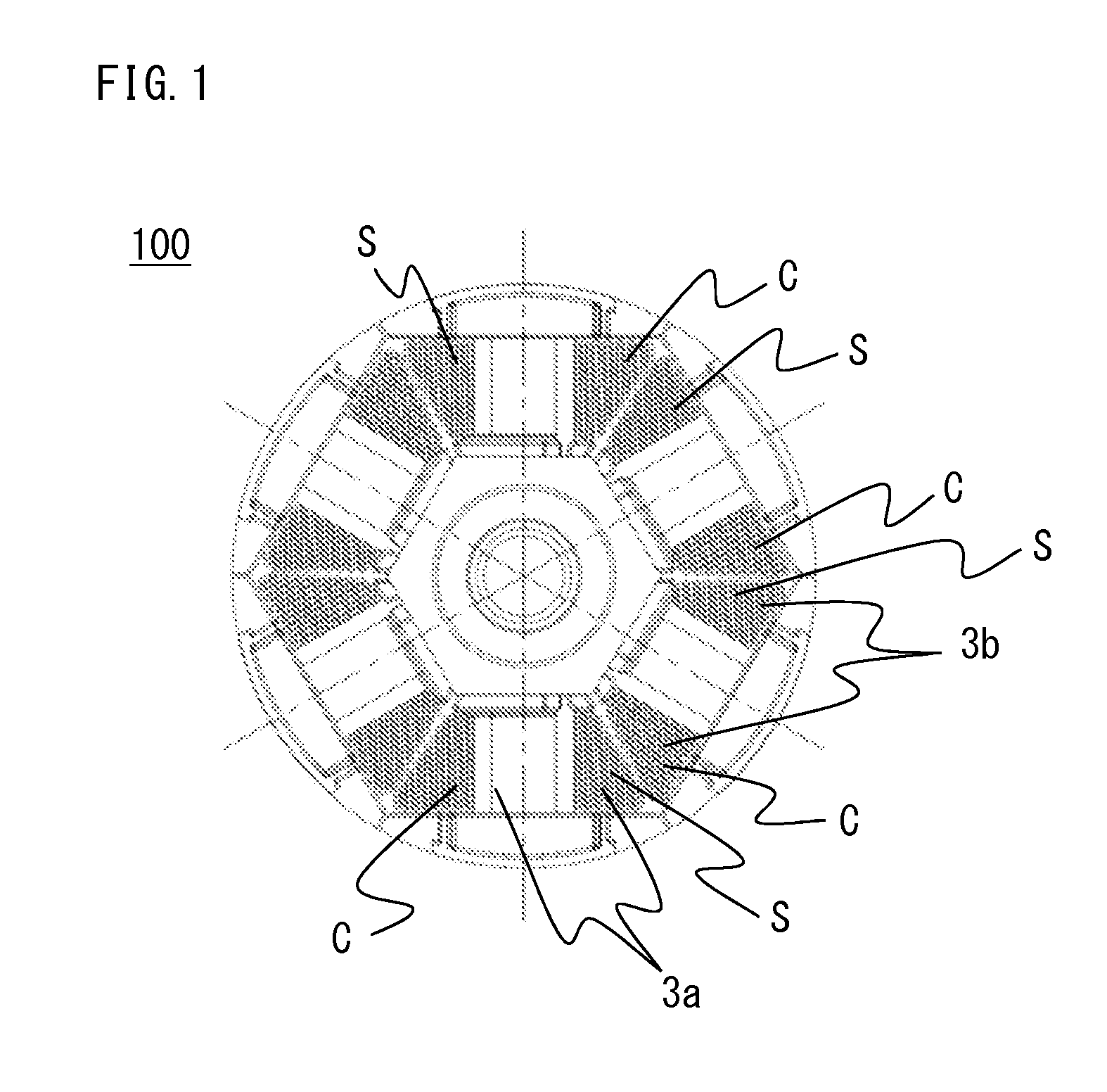

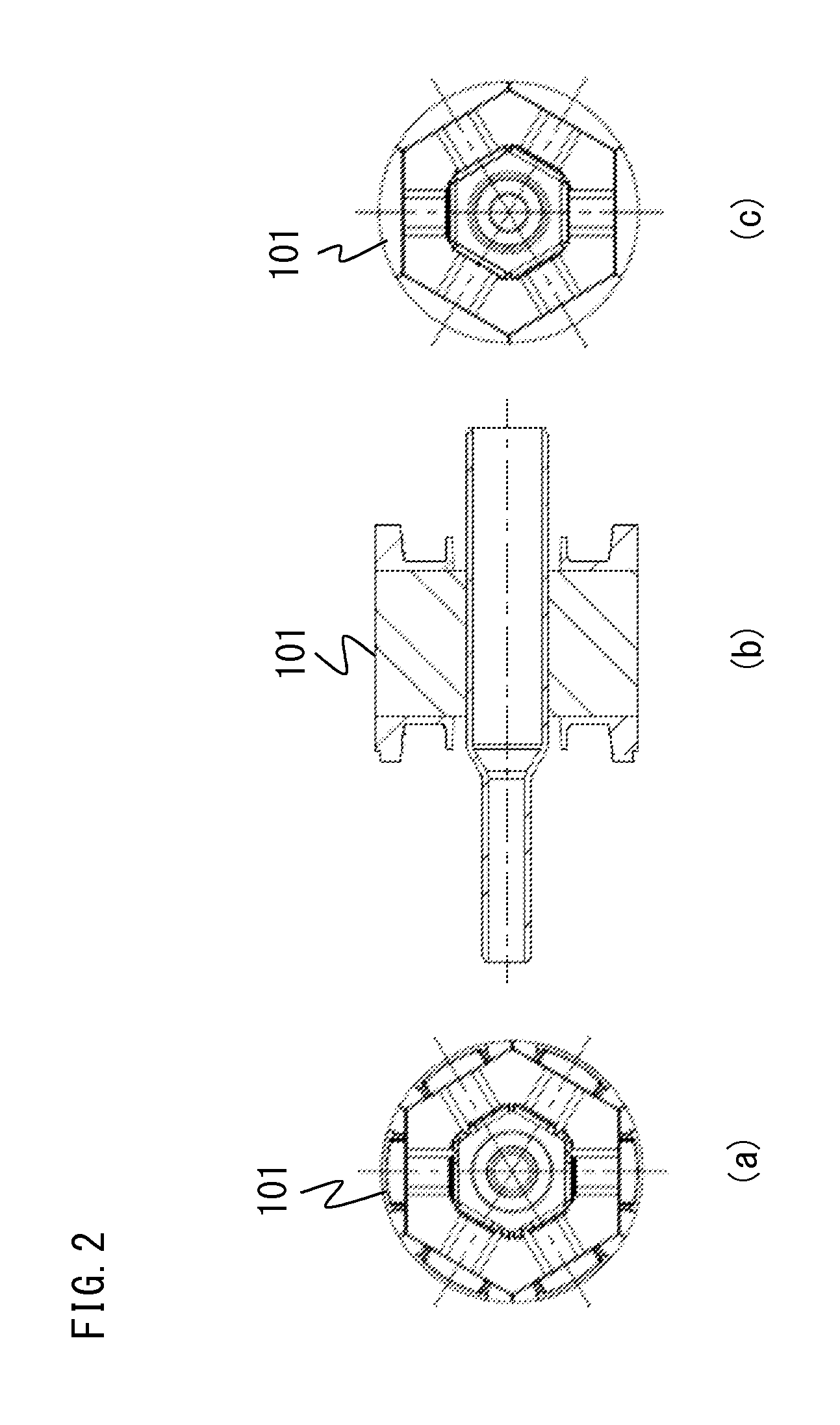

Rotating electrical machine armature

ActiveUS20150022048A1Precise windingPrecise alignmentWindings insulation shape/form/constructionSynchronous machinesElectric machineEngineering

Provided are an armature for rotary electric machine, an insulator therefor, and a coil winding device for winding a conductive wire on a tooth to which the insulator has been attached, wherein in each of all forward-wound coils and reversely-wound coils, a part wound on a first side surface of two side surfaces of each tooth that are opposed to the respective adjacent teeth forms a straight portion in which conductive wires in respective layers of the coil are parallel, a part wound on a second side surface forms a cross portion in which the conductive wire in an upper layer is wound in a crossed manner on the conductive wire in an adjacent lower layer, and an insulator has a guide for guiding the conductive wire along a base of an inner flange of the insulator at a first turn of each coil.

Owner:MITSUBISHI ELECTRIC CORP

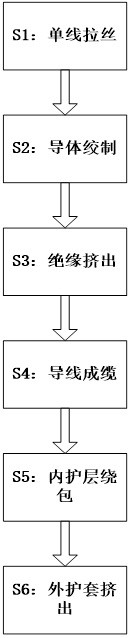

Wire and cable preparation process

ActiveCN113808792AReduce processing stepsAvoid efficiencyLiquid surface applicatorsCoatingsStructural engineeringElectric cables

The invention relates to a wire and cable preparation process. The wire and cable preparation process adopts the following processing equipment, the processing equipment comprises a bottom plate frame, a baffle frame and a wrapping assembly, the baffle frame is installed on the right side of the upper end of the bottom plate frame, the upper end of the baffle frame is provided with a feeding port, and the wrapping assembly is installed on the left side of the feeding port. The problems that when the existing wire and cable are subjected to wrapping processing, wrapping processing of multiple wrapping materials can not be conducted at the same time, the processing effect of a wire core is poor and the efficiency is low; as the surface of the wrapping material cannot be glued, the adhesion effect of the wrapping material is influenced; when the existing wire and cable are subjected to wrapping processing, as the angle of the wrapping material is generally fixed, so that the winding angle of the wrapping material cannot be effectively and accurately adjusted, and the preparation effect of the cable is influenced can be solved.

Owner:广东程通电线电缆厂有限公司

In-mold label multifunctional conveying system

InactiveCN101337406APrecise suctionPrecise windingStacking articlesPlastic forming machineEngineering

The invention relates to a multi-functional in-mould label conveying system, which comprises a volume label positioning device, a volume label sucking device, a rolling bar, a detecting component, a manipulator and a stacking device. The volume label positioning device is provided with a volume label tank to contain a large quantity of volume labels; a power component is arranged under the volume label tank to drive a pushing plate and push the volume labels upward; the volume label sucking device is arranged on the front side of the machine support, and is also provided with a power component to drive a moving part; the moving part is provided with a sucking component, which can be used for sucking the volume labels from the volume label positioning device to a rolling device; the rolling device is provided with the rolling bar; the rolling bar is provided with a C-shaped rolling tank, and can adsorb the volume labels first; after the rolling bar starts rotating, the C-shaped rolling tank is utilized to roll the volume labels into appropriate shape smoothly; the rolling device is provided with the detecting component to control the rotating radian and distance of the rolling bar of the rolling device; the manipulator is used for clamping rolled volume labels and is positioned into the cavity of the forming die of a plastic forming machine; plastic end products are taken out from the forming die of the plastic forming machine; the stacking device receives the plastic end products from the manipulator and conveys the end products to a packing place after the end products are stacked on a conveying belt.

Owner:黄胜昌 +1

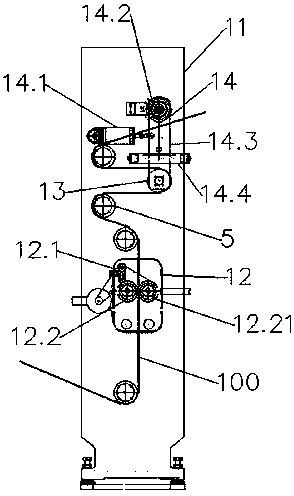

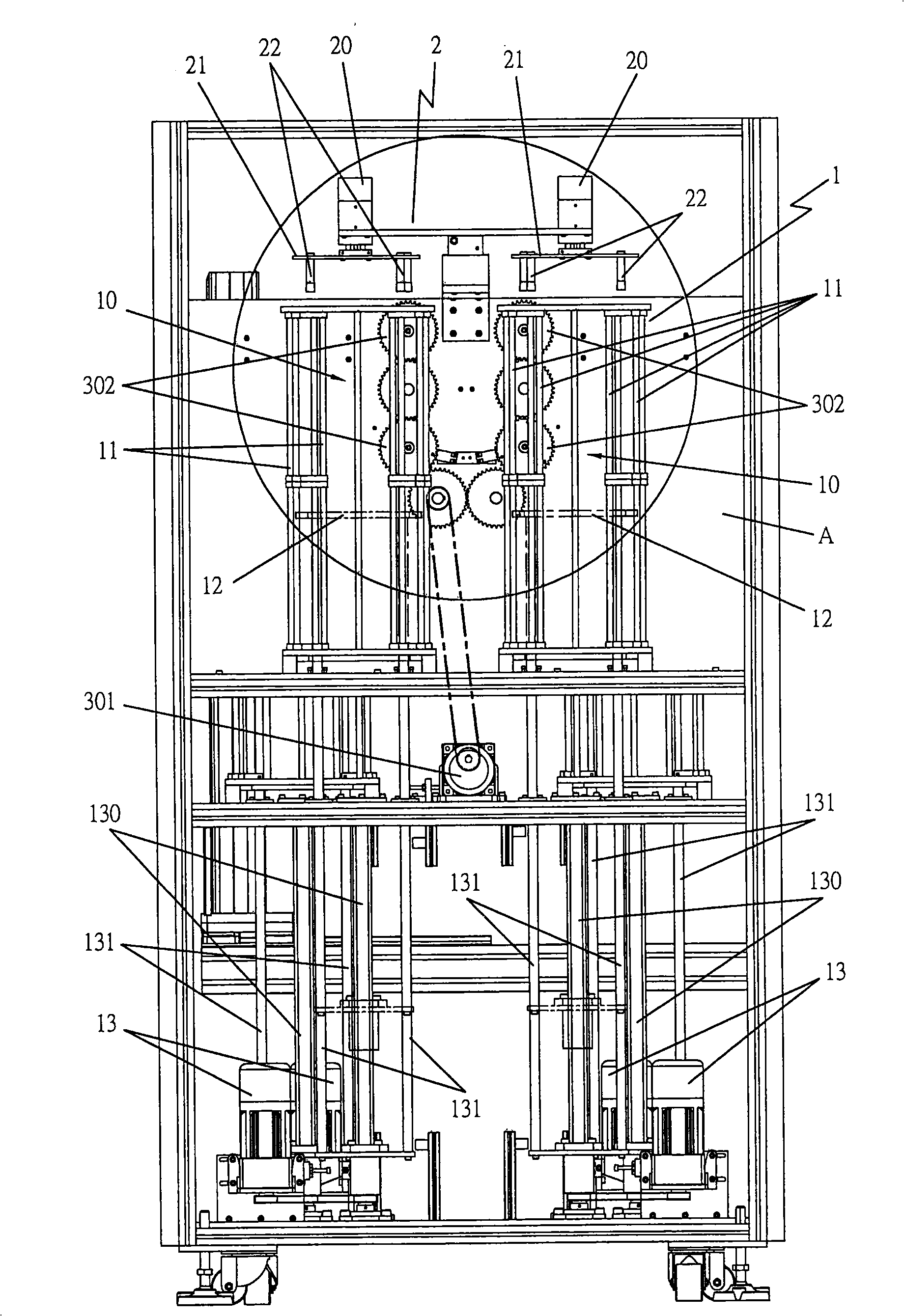

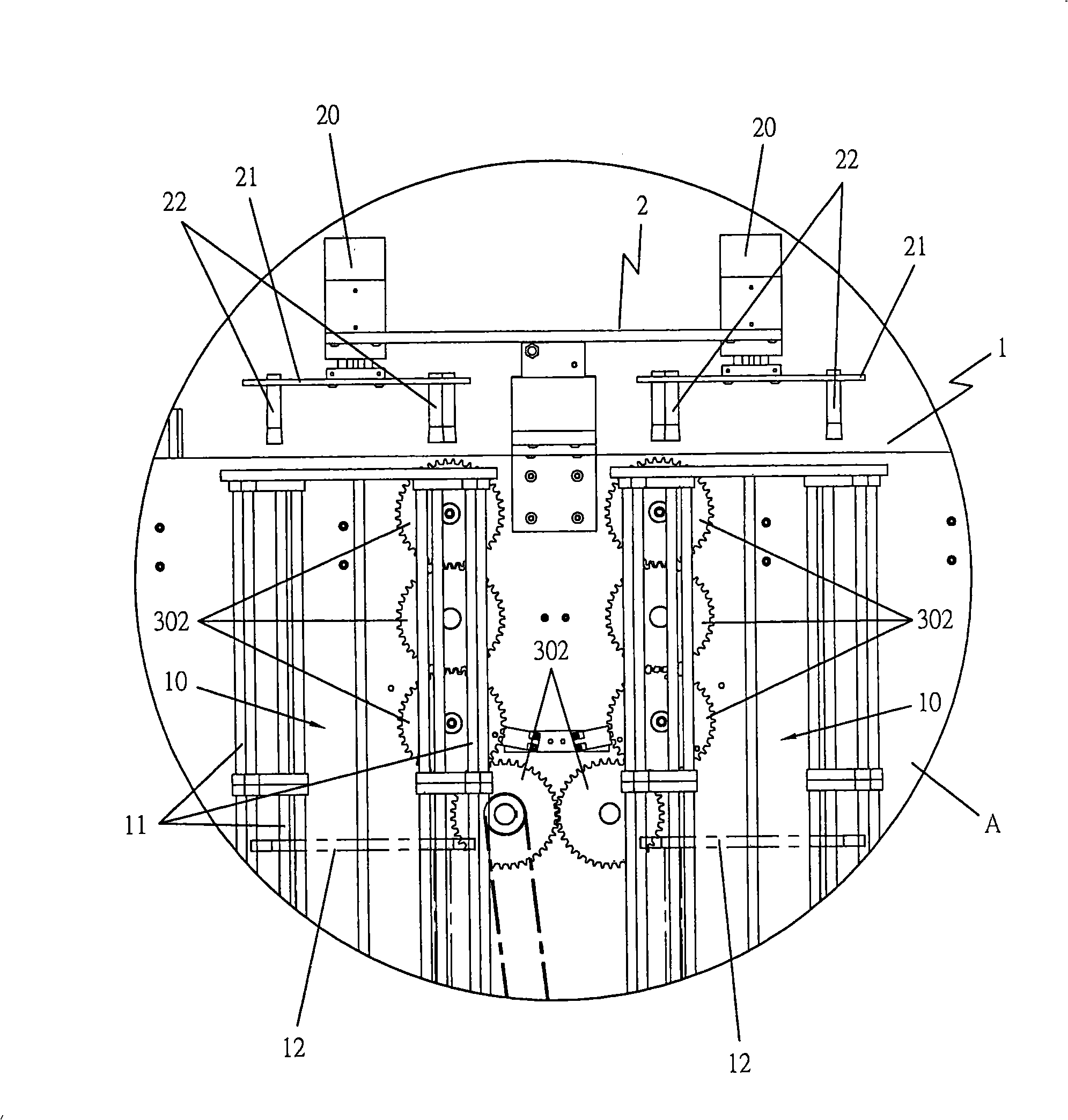

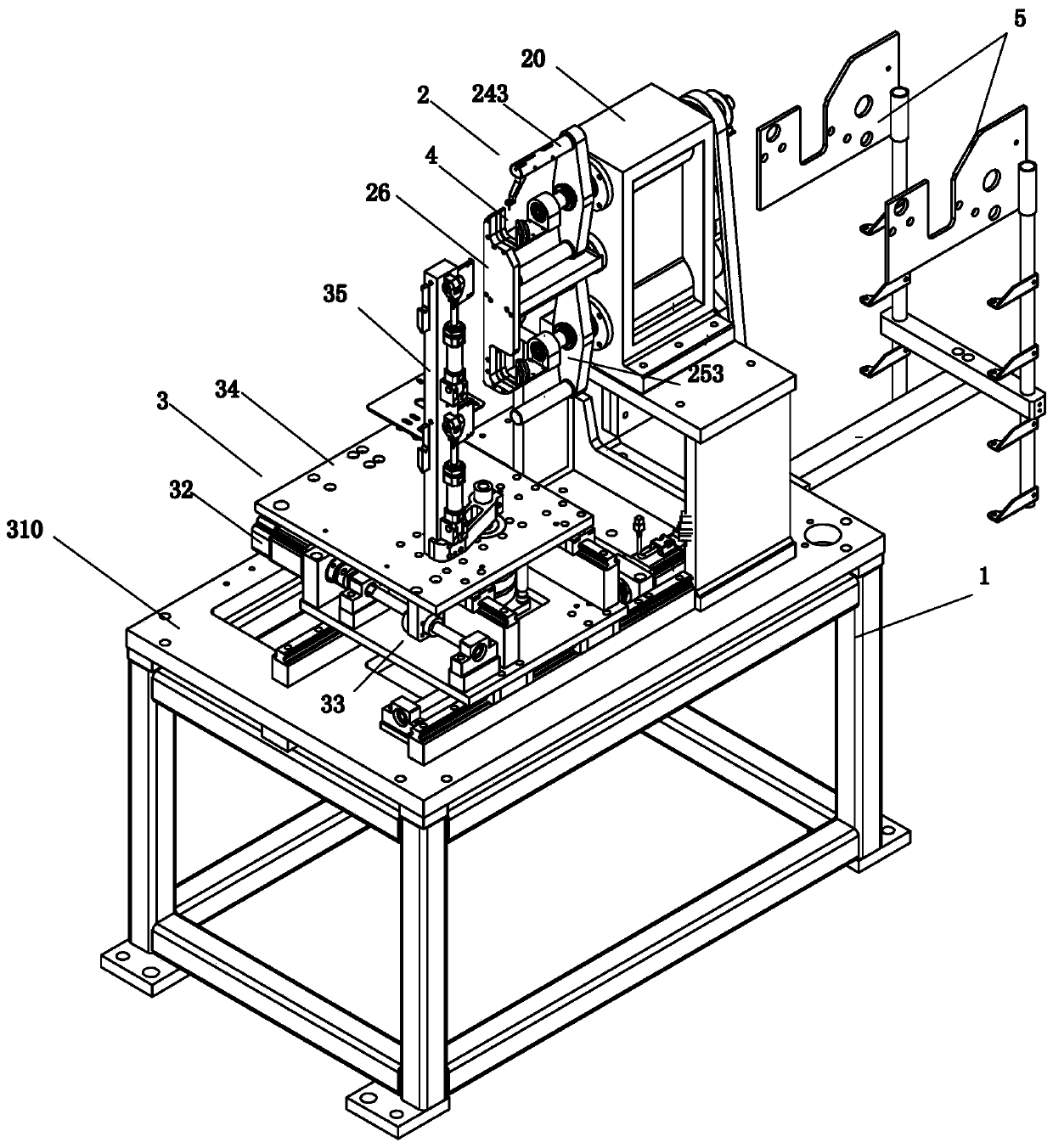

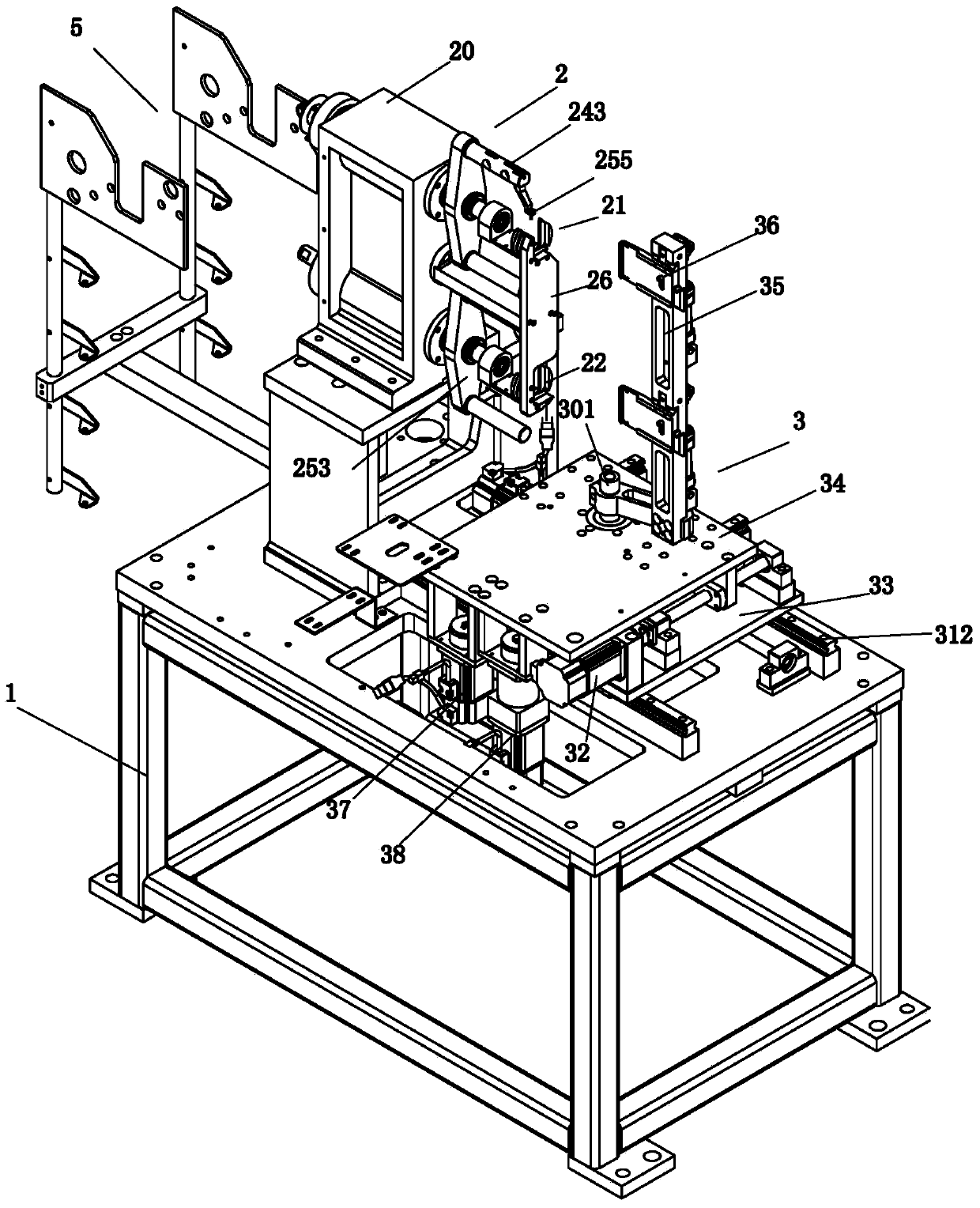

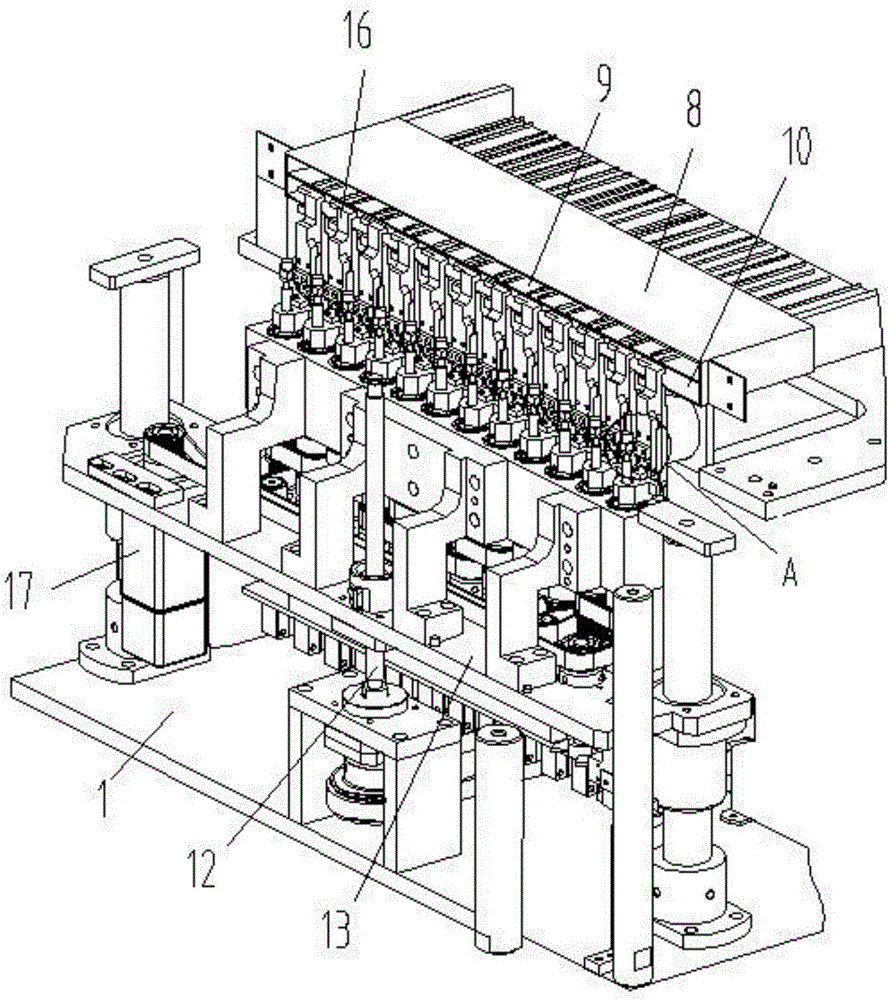

Stator fixture mechanism for half-iron-core stator pin-type winding machine

PendingCN109921585ARealize 4-axis linkagePrecise windingManufacturing dynamo-electric machinesElectric machinesWinding machineStator

The invention relates to a stator fixture mechanism for a half-iron-core stator pin-type winding machine. The stator fixture mechanism comprises a rack, a front-and-back movement motor, a left-and-right movement motor, a front-and-back movement plate, a left-and-right movement plate, a lifting rotation shaft assembly and a fixture supporting frame; the lifting rotation shaft assembly comprises a rotation motor, a lifting motor, a lifting rotation shaft, a screw nut and a spline housing; the lifting rotation shaft is vertically and rotationally arranged on the left-and-right movement plate; thescrew nut is in threaded connection with the lifting rotation shaft; the spline housing is connected with the lifting rotation shaft by a spline; the rotation motor drives the spline housing to rotate; and the lifting motor drives the screw nut to rotate. According to the invention, a half-iron-core stator is respectively driven by a plurality of motors to carry out front-and-back movement, left-and-right movement, rotation motion and lifting movement and then four-shaft linkage is implemented, so that the half-iron-core stator is aligned with a winding opening to be inserted and then each trunking of the half-iron-core stator is aligned with a winding gap each time, thereby facilitating carrying out accurate winding on all the trunkings on the pin-type winding machine by the pin-type winding machine.

Owner:SANHE IND AUTOMATION EQUIP CO LTD SHUNDE DISTRICT FOSHAN CITY

Automatic feed winding machine for inductance

ActiveCN106783143AQuality assuranceAvoid shakingInductances/transformers/magnets manufactureWinding machineDistribution control

The invention relates to an automatic feed winding machine for inductance. The automatic feed winding machine comprises a rack and a distribution control box, a load rotating device is arranged in the middle of the rack, the upper portion of the load rotating device is matched with a wire plugging device and a wire conveying device, a feed docking device is fittingly arranged at the front portion of the load rotating device, the feed docking device is matched with a feeding device at the lower portion of the rack, the feed docking device comprises a docking seat arranged on the rack, a docking lifting cylinder is arranged on the docking seat and is connected with a docking lifting seat, a forward and backward receiving motion cylinder is arranged at the lower portion of the docking lifting seat and is connected with a receiving block made from electromagnet, receiving grooves matched with products are evenly formed in the receiving block, a forward and backward pushing motion cylinder is arranged at the upper portion of the docking lifting seat and is connected with a forward and backward pushing motion seat, and rotating pushing heads matched with the products are evenly arranged on the forward and backward pushing motion seat. By the arrangement, feeding efficiency is guaranteed, and meanwhile, quality in feeding and subsequent winding is guaranteed as well.

Owner:TONGXIANG YAORUN ELECTRONICS

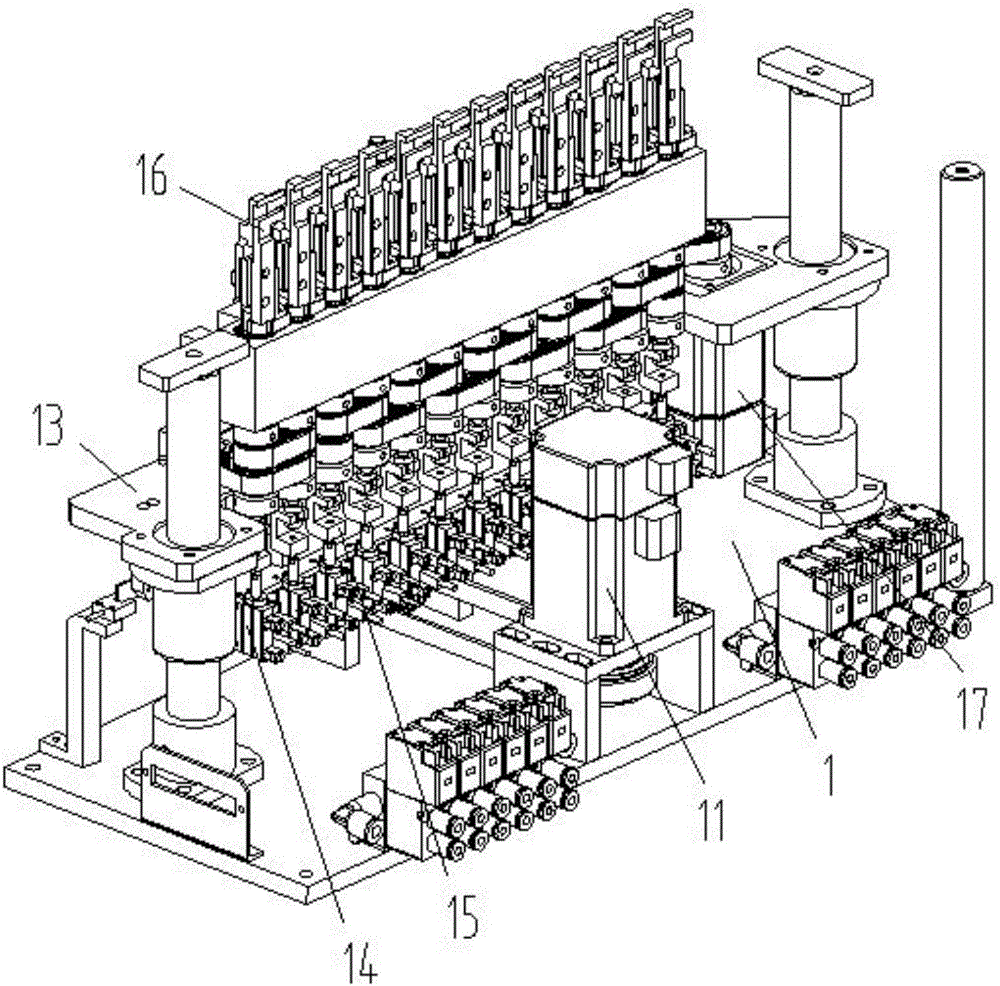

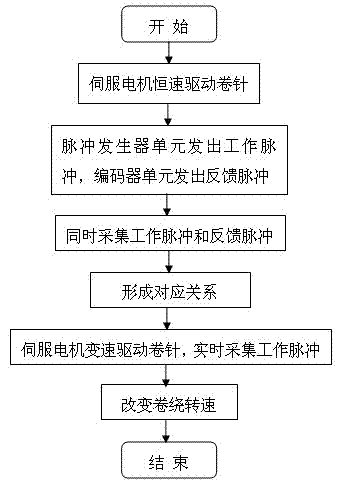

A system and method for variable speed winding of a square winder

ActiveCN102290608AReduce distortionIncrease wind speedFinal product manufactureSecondary cellsEngineeringConductor Coil

The invention provides a square winder variable-speed winding system and a method. The square winder variable-speed winding system comprises a servomotor module, a coding module, an acquisition module and a control module, the servomotor module comprises a winding pin-driving unit and a pulse generator unit, and the pulse generator unit outputs the working pulses of the servomotor module; the coding module adopts a coder unit to periodically interrupt and output feedback pulses; the acquisition module simultaneously acquires the working pulses and the feedback pulses; the control module comprises a central processor unit, a memory unit and a control unit, the central processor unit is used for calculating the winding speed corresponding to the feedback pulses and storing the corresponding relation between the winding speed, the working pulses and the feedback pulses into the memory unit, and the control unit changes the winding speed of the system according to the corresponding relation between the working pulses and the corresponding relation.

Owner:GEESUN AUTOMATION TECH

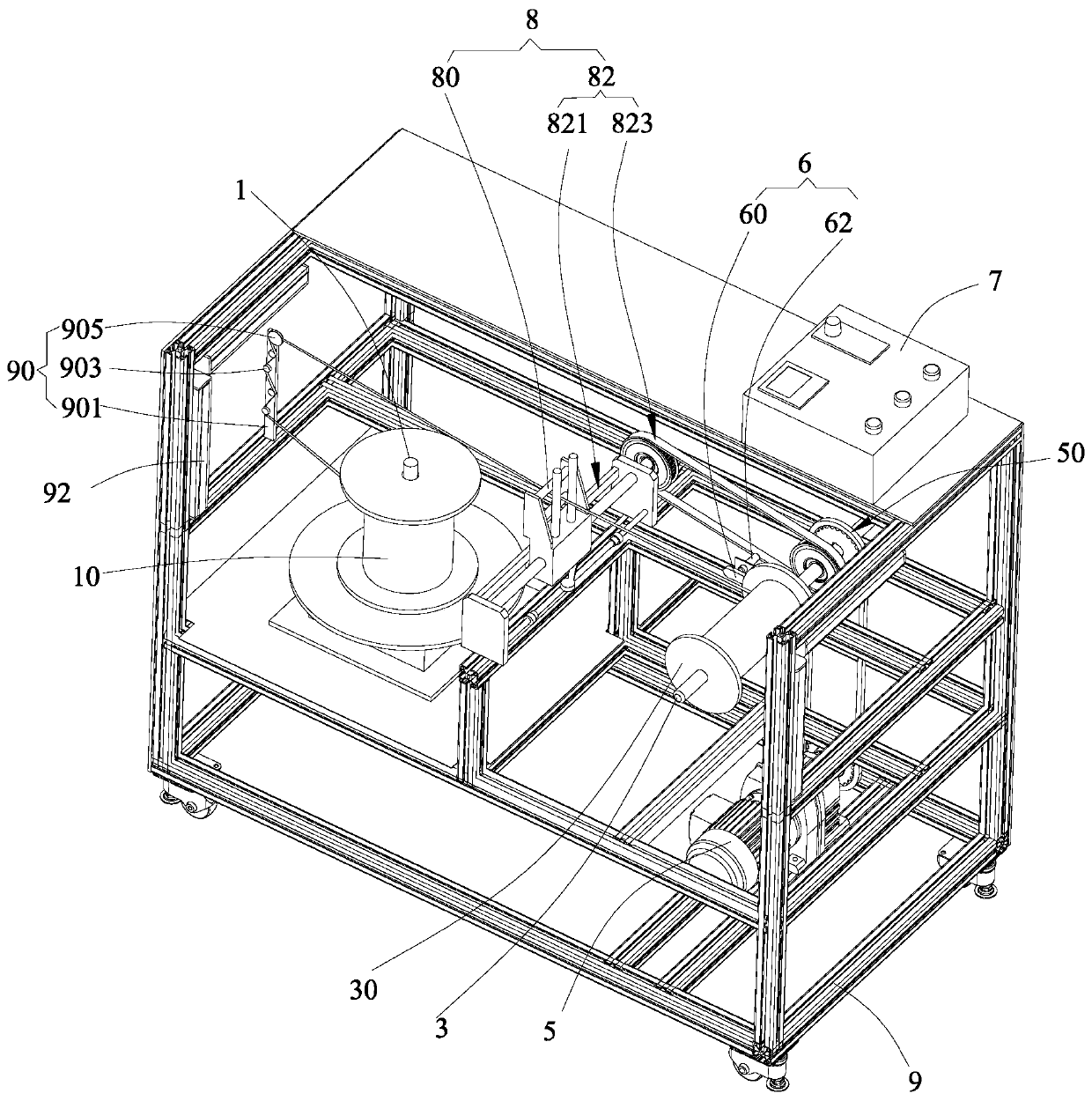

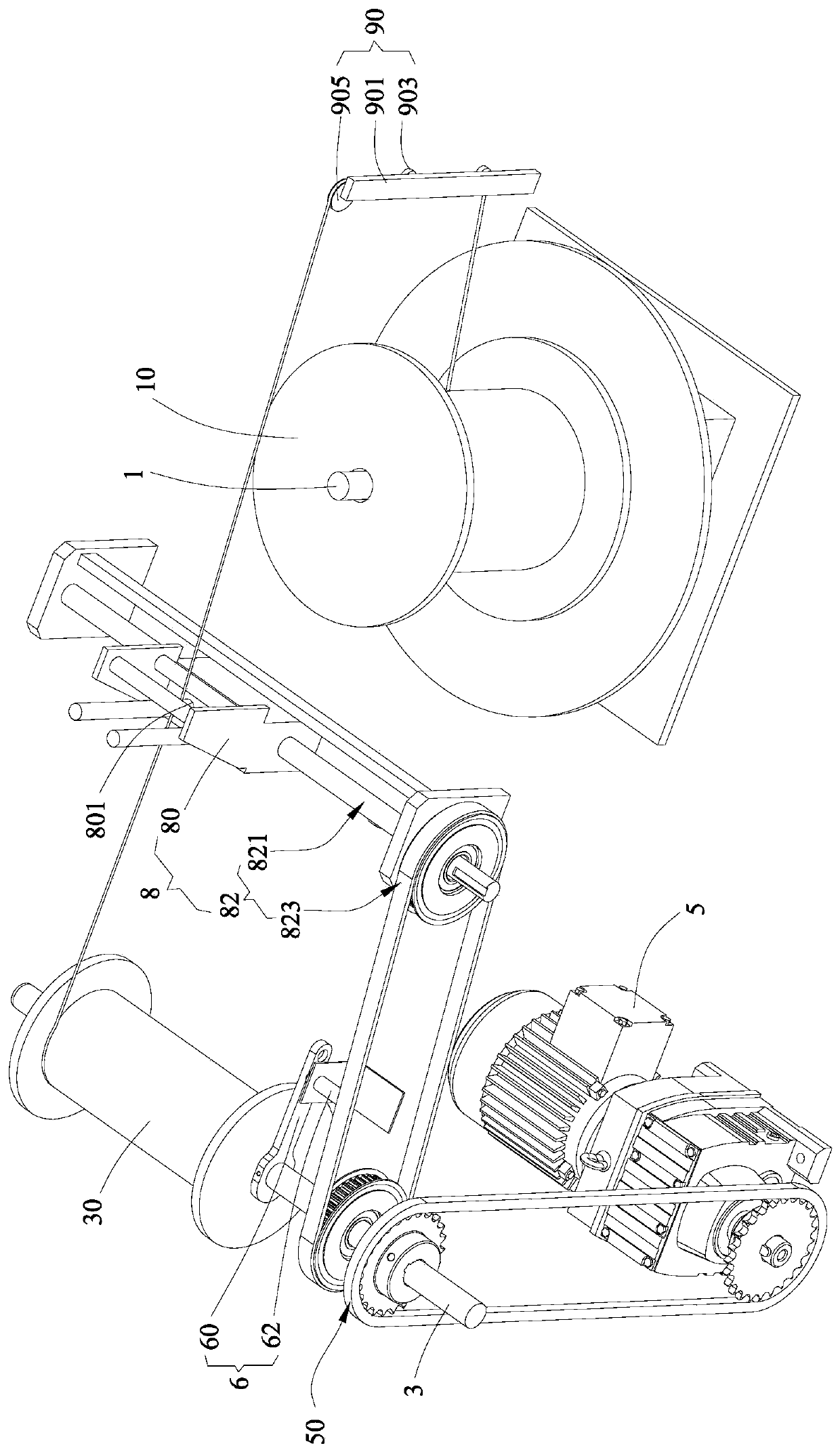

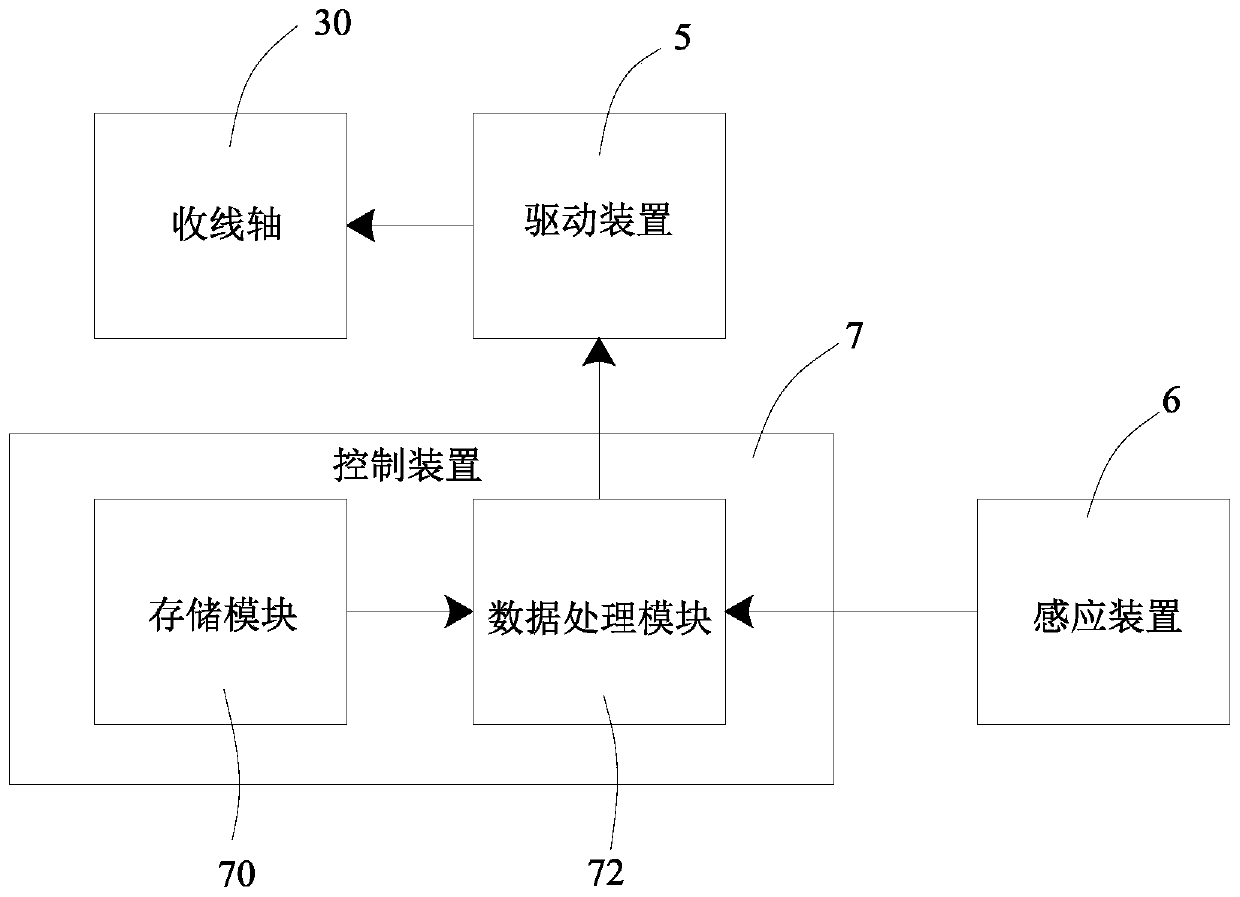

Automatic wire winding machine

PendingCN110422686AEasy to controlControl device for precise winding at startFilament handlingWinding machineWire rod

The embodiment of the invention provides an automatic wire winding machine. The automatic wire winding machine comprises a feed shaft, a take-up shaft, a drive device, an induction device and a control device, wherein a wire feed disc where a wire is wound is arranged on the feed shaft in a pivotal manner, a take-up disc used for receiving and winding the wire of a preset length value is coaxiallyfixed to the take-up shaft, the drive device is used for driving the take-up shaft to drive the take-up disc to synchronously rotate for wire winding, the induction device is used for detecting the number of turns of rotating of the take-up disc, and the control device is connected with the induction device and the drive device. The control device comprises a storage module pre-storing the presetlength value and a data processing module, wherein the data processing module generates the practical receiving length value through calculation according to the number, sent by the induction device,of turns of rotating of the take-up disc, and the data processing module controls the drive device to stop working when the practical receiving length value is increased to the preset length value. The control device is arranged, the detected number of turns of rotating of the take-up disc is sent to the control device through the induction device, the length of the wound wire can be made quite precise, and operation is quite convenient.

Owner:SHENZHEN EX LIGHTING TECH HLDG

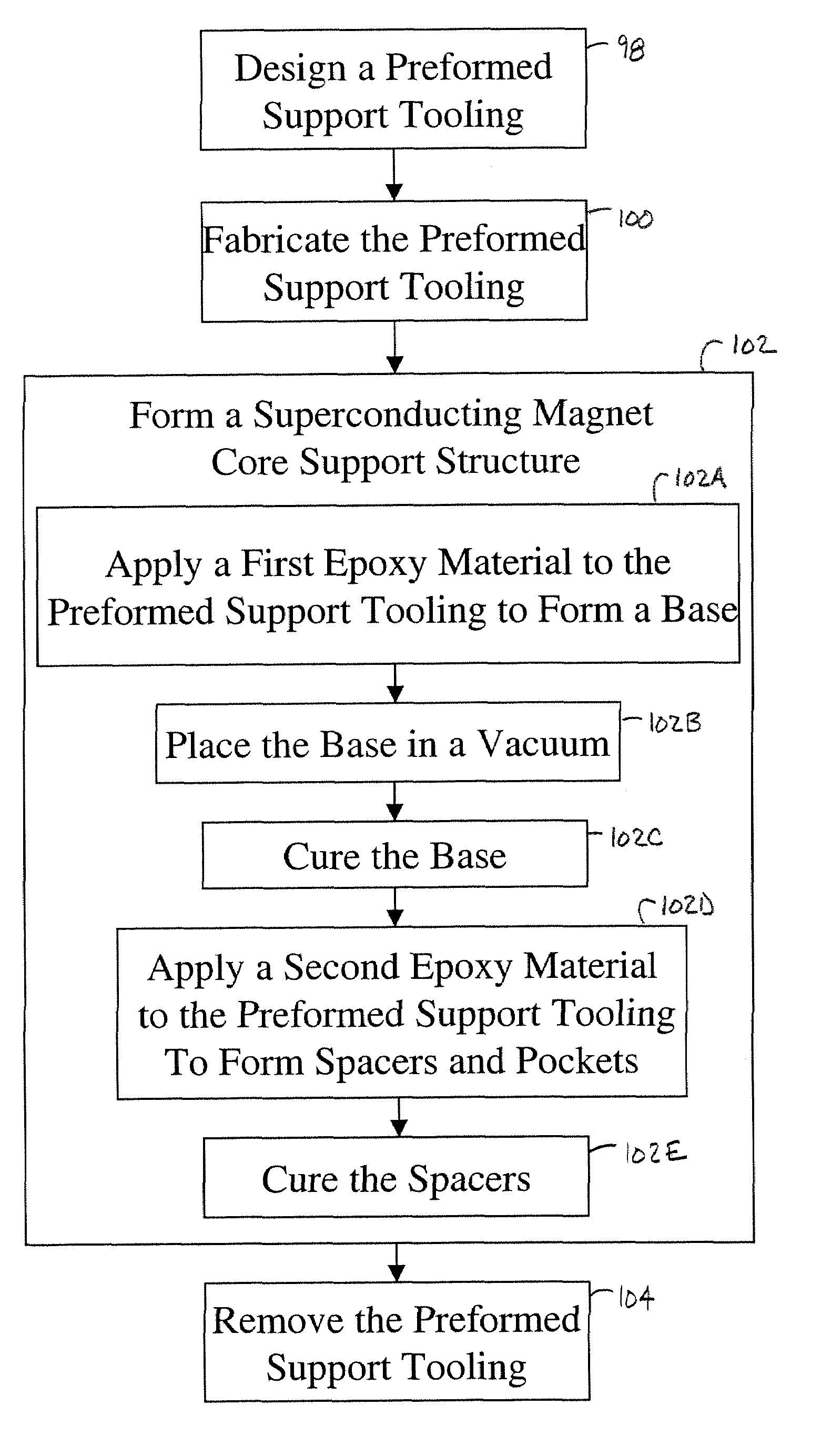

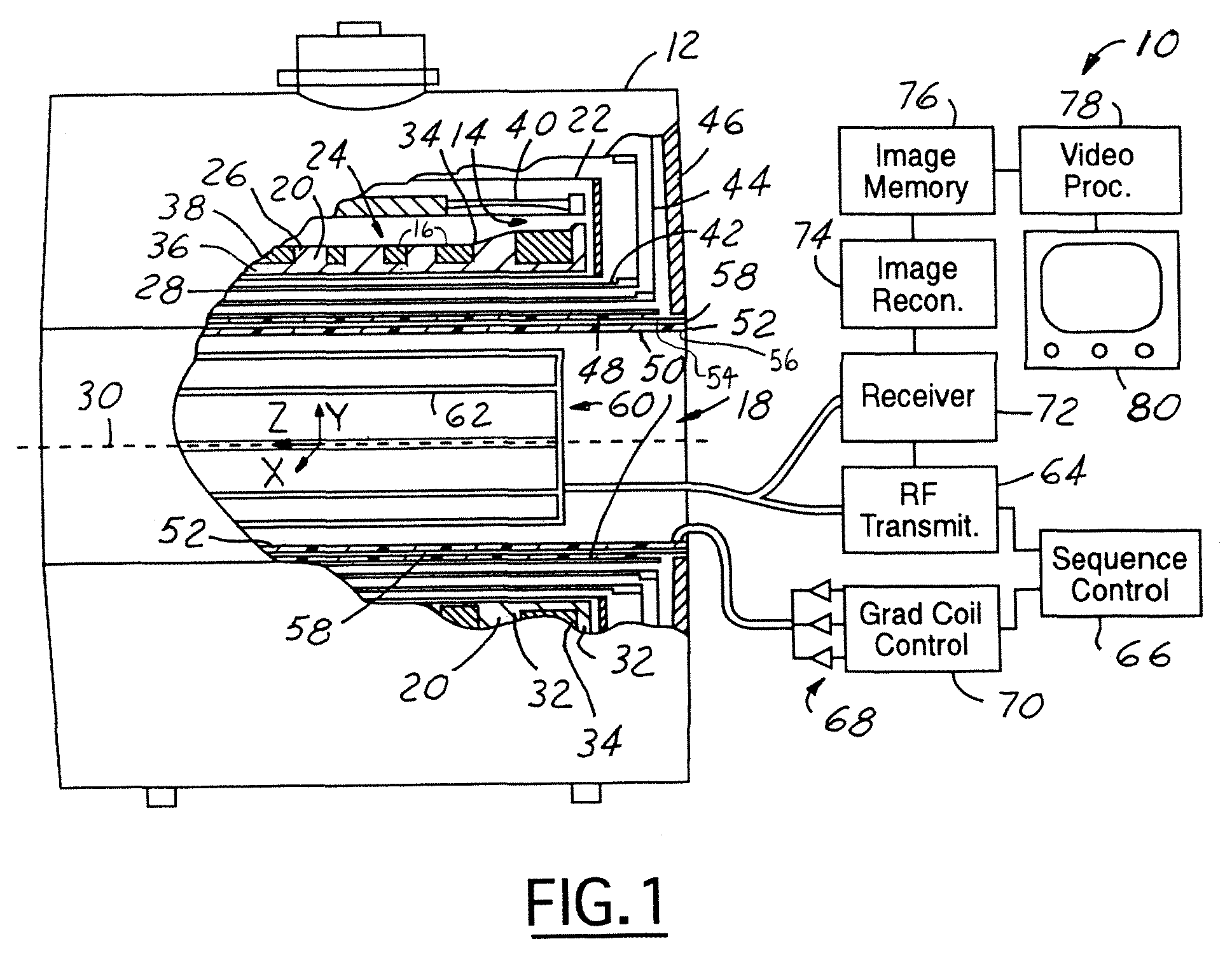

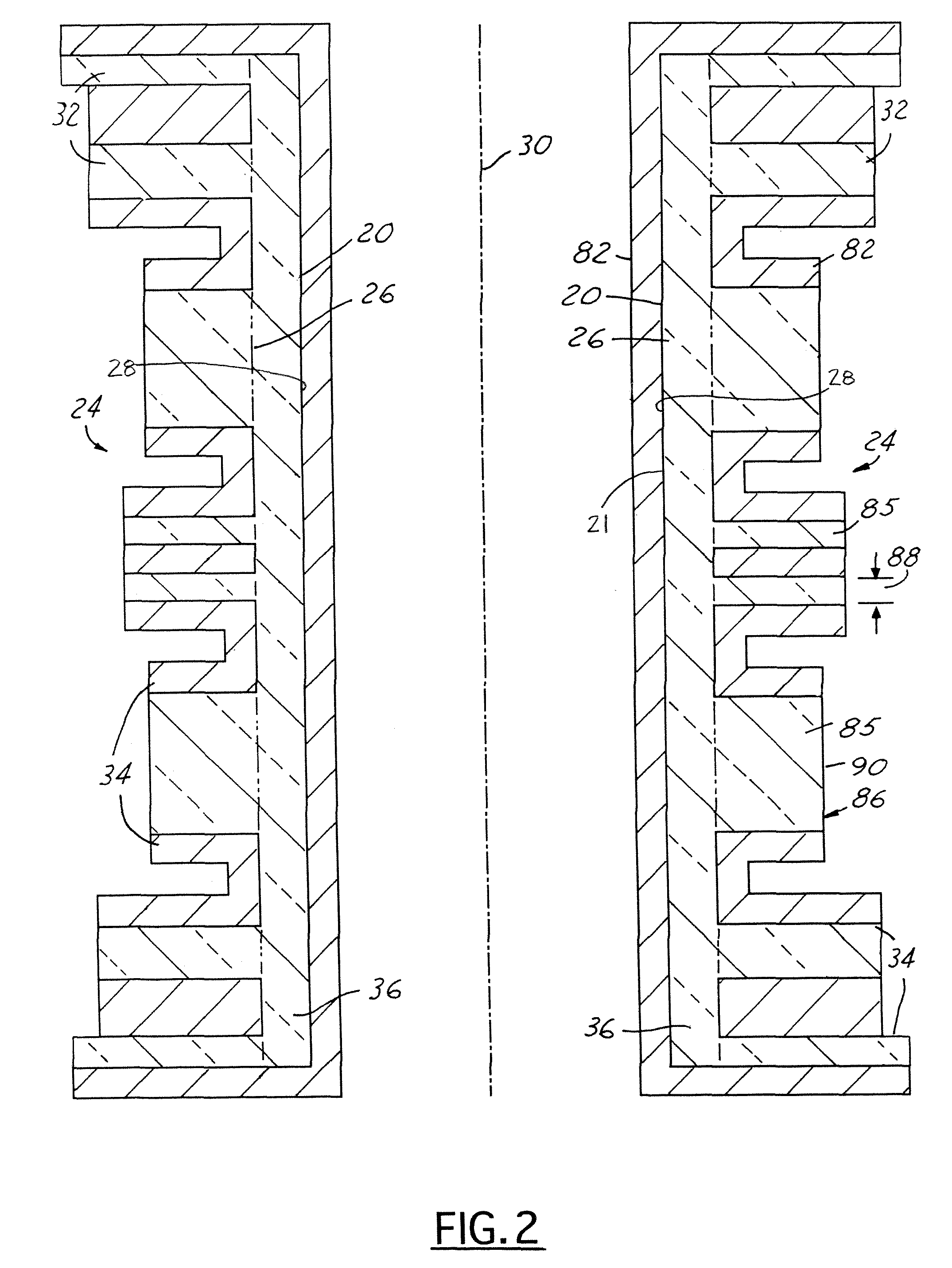

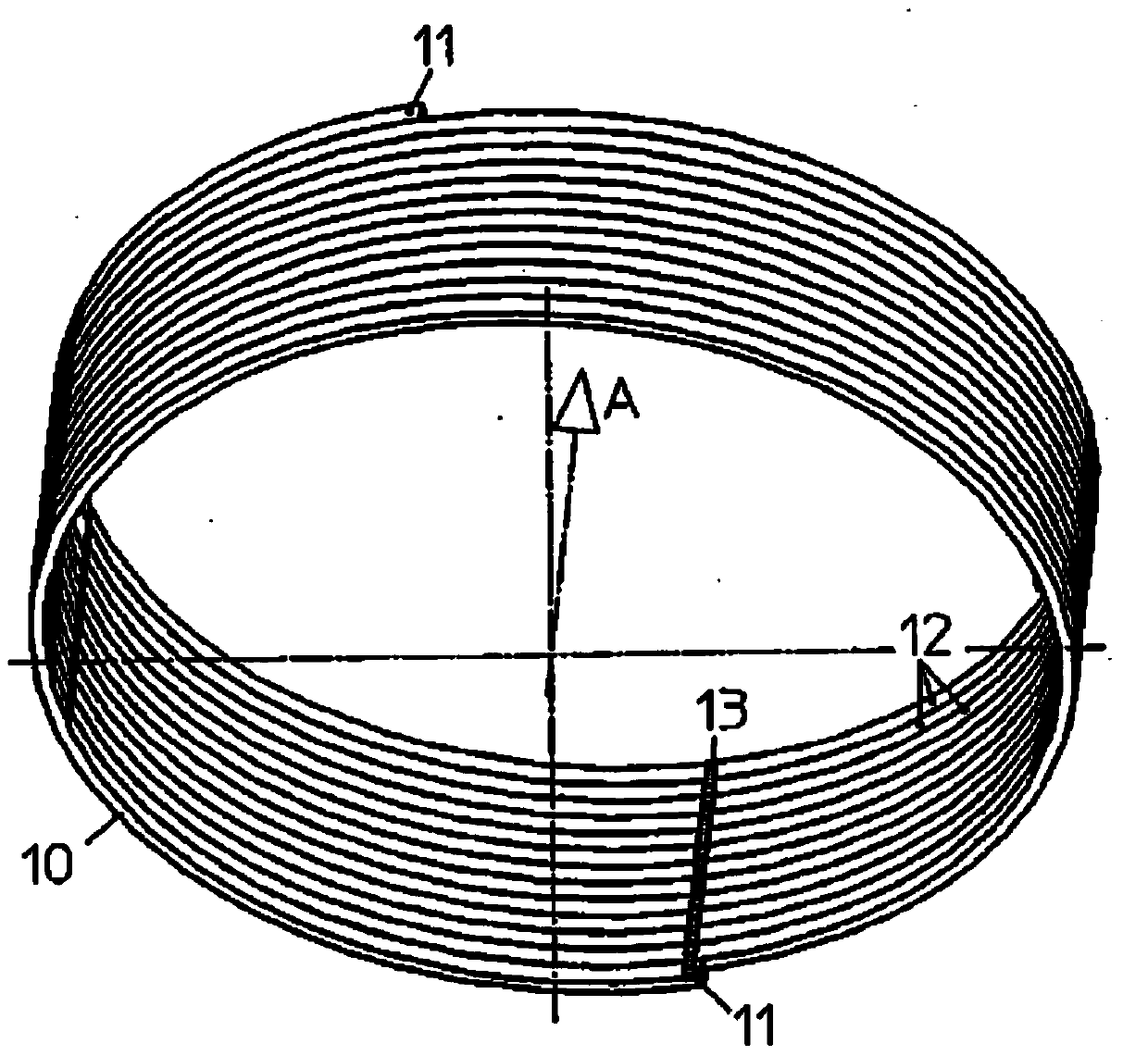

Superconducting magnet coil support structure

InactiveUS7013553B2Improve accuracyImprove efficiencyAdditive manufacturing apparatusMagnetic measurementsSuperconducting CoilsEngineering

A superconducting magnet coil support structure (20) includes a solid body (21) having an exterior side (24), an interior portion (26), and an interior side (28). The interior portion has a base (36) that is formed of a first resin material. The exterior side (24) has multiple spacers (32) and multiple pockets (34) with dimensions that correspond to dimensions of a superconducting magnet (14). The spacers (32) are coupled to the base (36) and are formed of a second resin material. The exterior side (24), the interior portion (26), and the interior side (28) include varying width material.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

System and method for manufacturing honeycomb body

InactiveCN103906905APrecise windingEven by forcePhysical/chemical process catalystsLayered productsHoneycombBiomedical engineering

Owner:BASF CORP

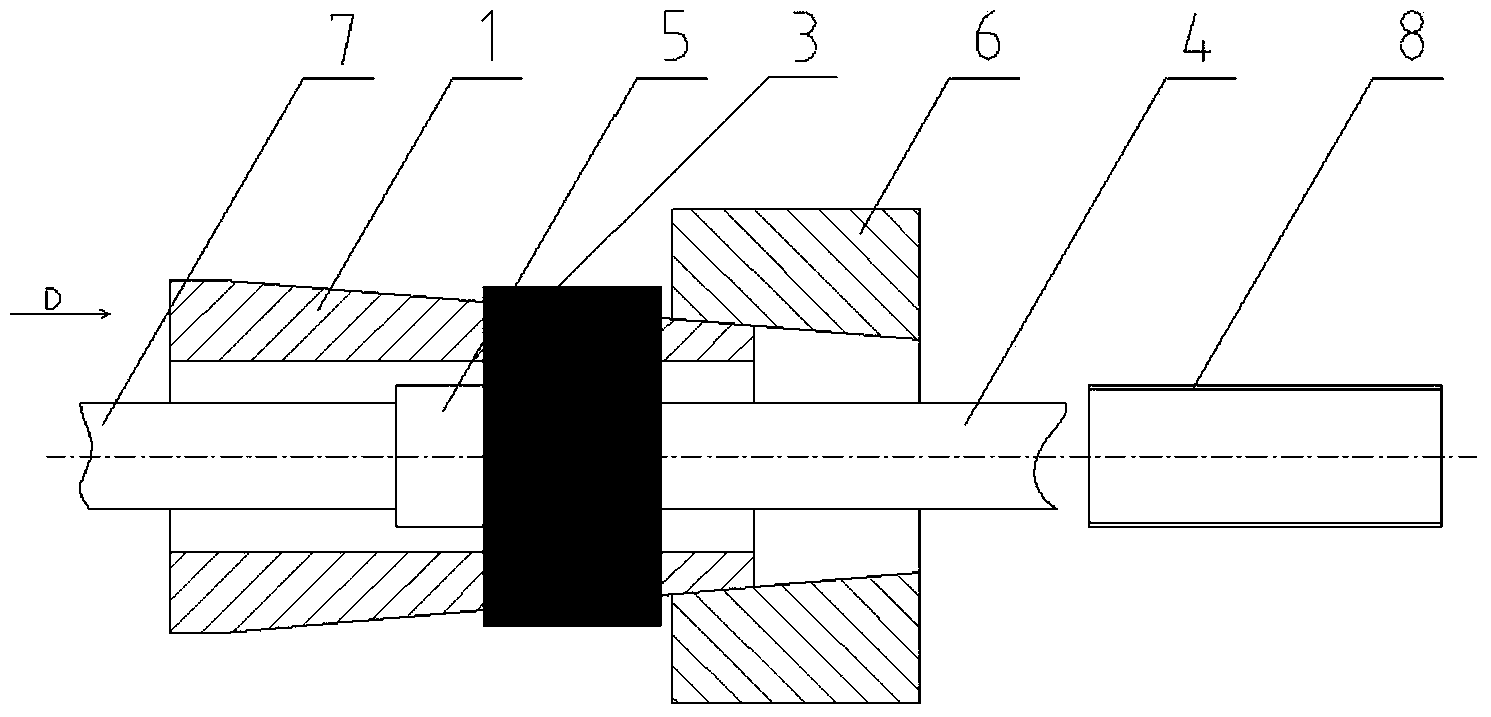

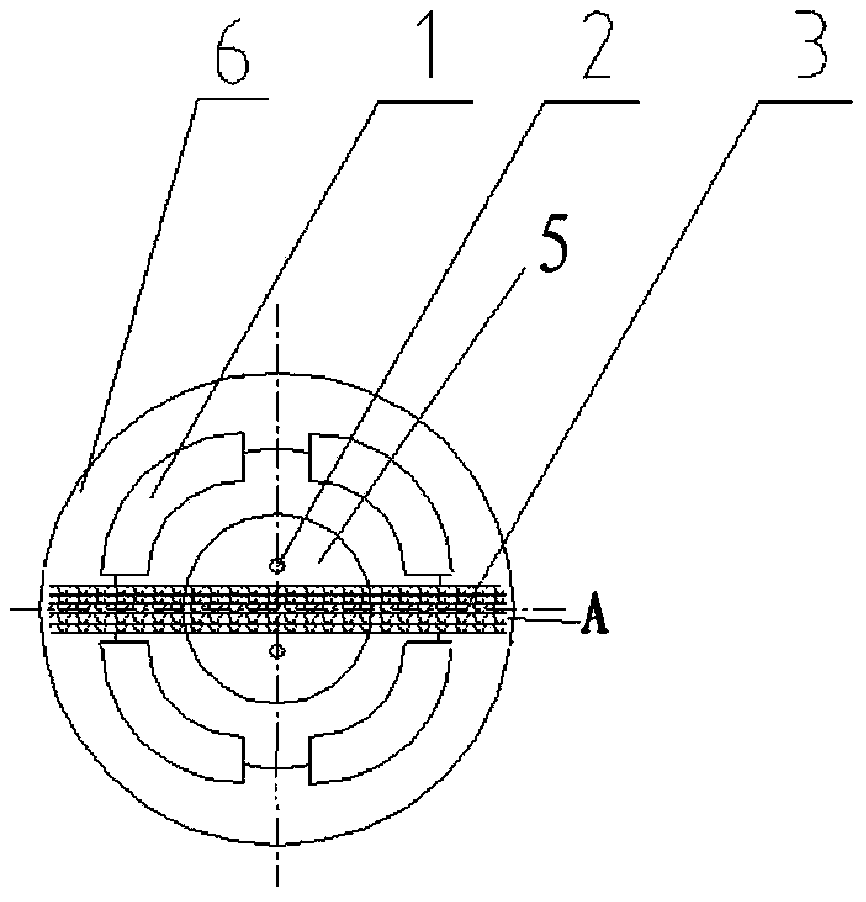

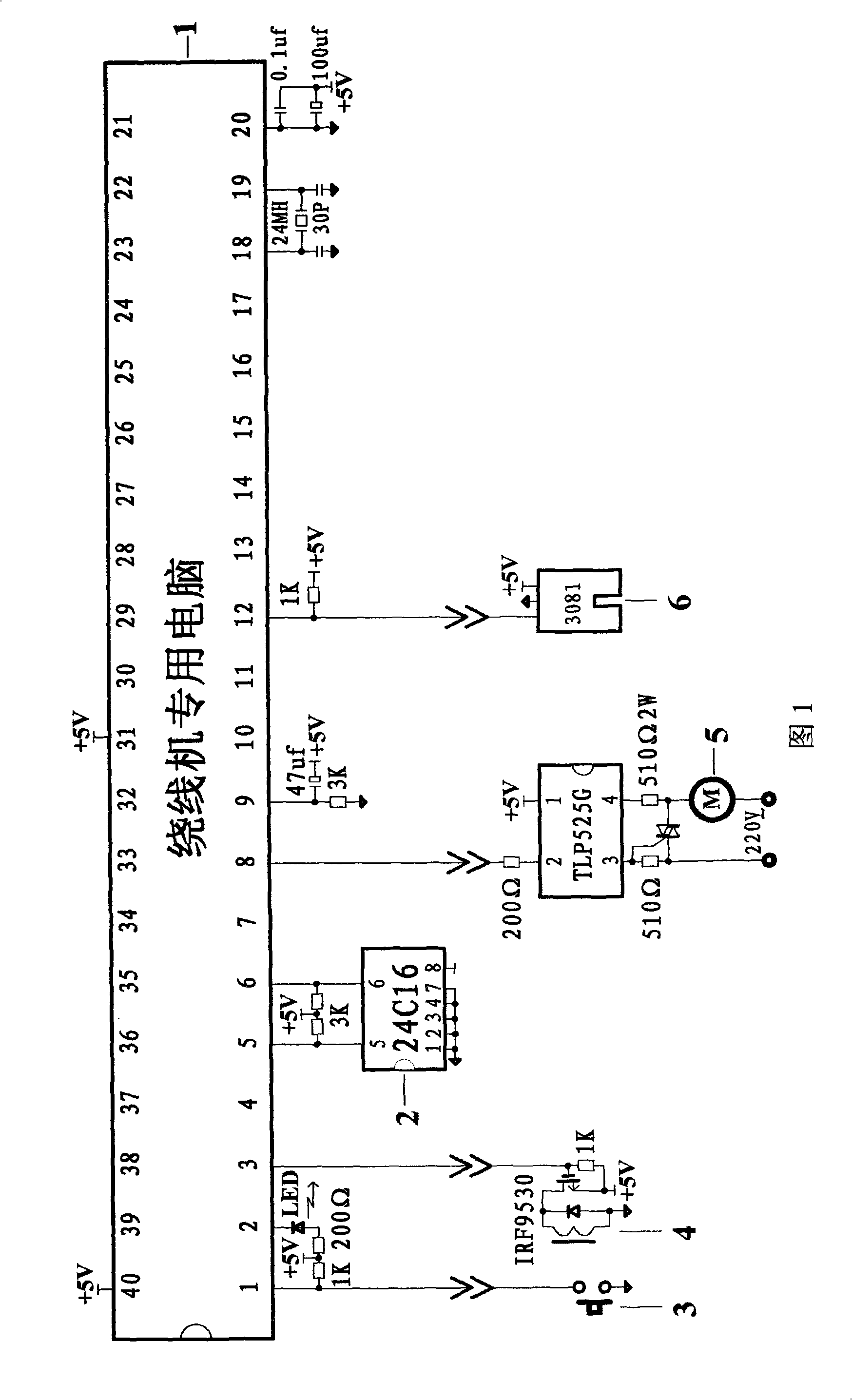

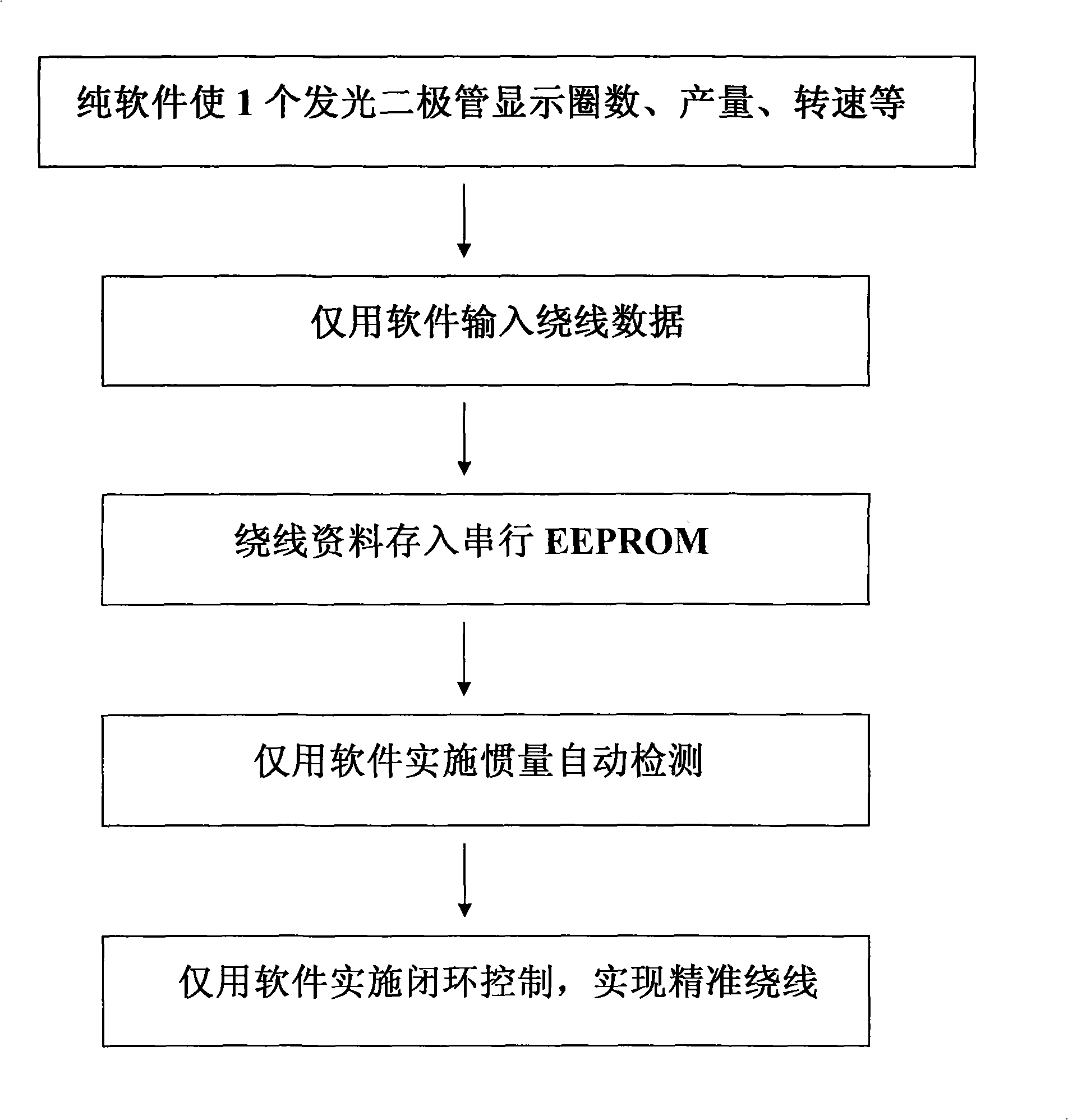

Minitype wire winder special-purpose computer without digital tube and keyboard

InactiveCN101349894AGuaranteed accuracyNo troubleComputer controlInput/output processes for data processingWinding machineClosed loop

The invention provides a micro winding machine special computer, without numeral tubes and keyboards, which uses software to simplify hardware, uses a 87F51 single chip as the hardware of the winding machine special computer, adopts one integrated circuit for its integrate, and can only use software to display the rings, yield and rotation speed by one light emitting diode, only use software to input winding data, use software to realize inertia automatic check, use software to realized closed loop control for accurate winding, and only use one 5V direct current power supply. The micro winding machine special computer has the advantages of few interface elements, simplified circuit, simple production, accurate winding rings, eliminated keyboard accidents, low cost and high reliability.

Owner:彭桉泉

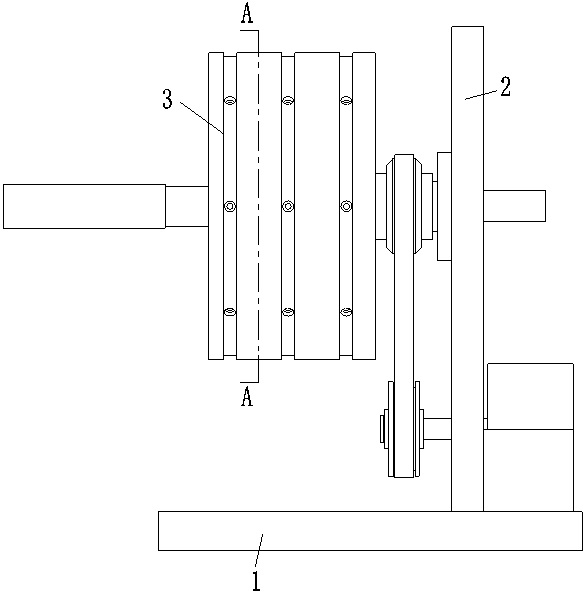

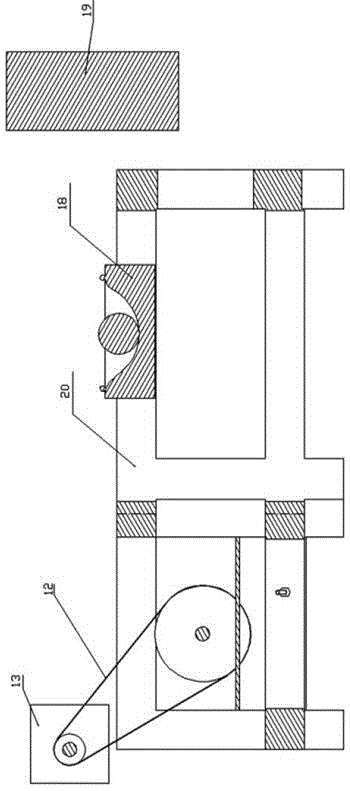

Fiber reinforced composite material ring test sample winding device

ActiveCN104527087APrecise windingHigh winding precisionPreparing sample for investigationYarnDrive shaft

The invention provides a fiber reinforced composite material ring test sample winding device comprising a die and a ring test sample winding mechanism. The ring test sample winding mechanism comprises a stepless variable-speed motor, a main shaft, a die locating assembly, a transmission assembly and a yarn guiding assembly. The die locating assembly comprises a locating disk, a screwing nut and a die locating bolt. The transmission assembly comprises a transmission shaft, an auxiliary shaft and a conveying belt. The yarn guiding assembly comprises an oval iron disk, a swing arm and an extensible spring. By the adoption of the fiber reinforced composite material ring test sample winding device, the winding precision of a rotating body is improved, the whole winding process is stable and reliable, mechanical degree is high, operation is convenient, high-quality ring test samples can be wound accurately, and cost is low.

Owner:HENGSHEN

Back iron, in particular for an electrical motor and method for producing a back iron for a rotor or stator of an electrical motor

InactiveCN103688451AExact cross sectionImprove usage characteristicsMagnetic circuit stationary partsManufacturing stator/rotor bodiesSpring forceMetal

The invention relates to a back iron, in particular for a rotor or a stator of an electrical motor, having a plurality of layers made of metal plate or wire, wherein the layers are arranged in a spiral or screw shape. In order to improve the accuracy of the geometry of the backing iron, in particular of the surface lines thereof, according to the invention, the weight of the individual layers is greater than the spring force of the metal plate or metal wire acting between the layers in the back iron axis direction. This is achieved in particular by winding the metal plate or metal wire.

Owner:HIDRIA BAUSCH

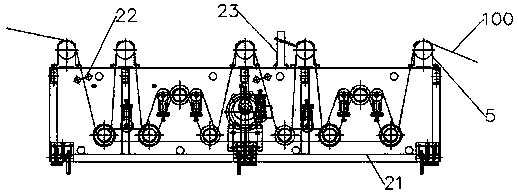

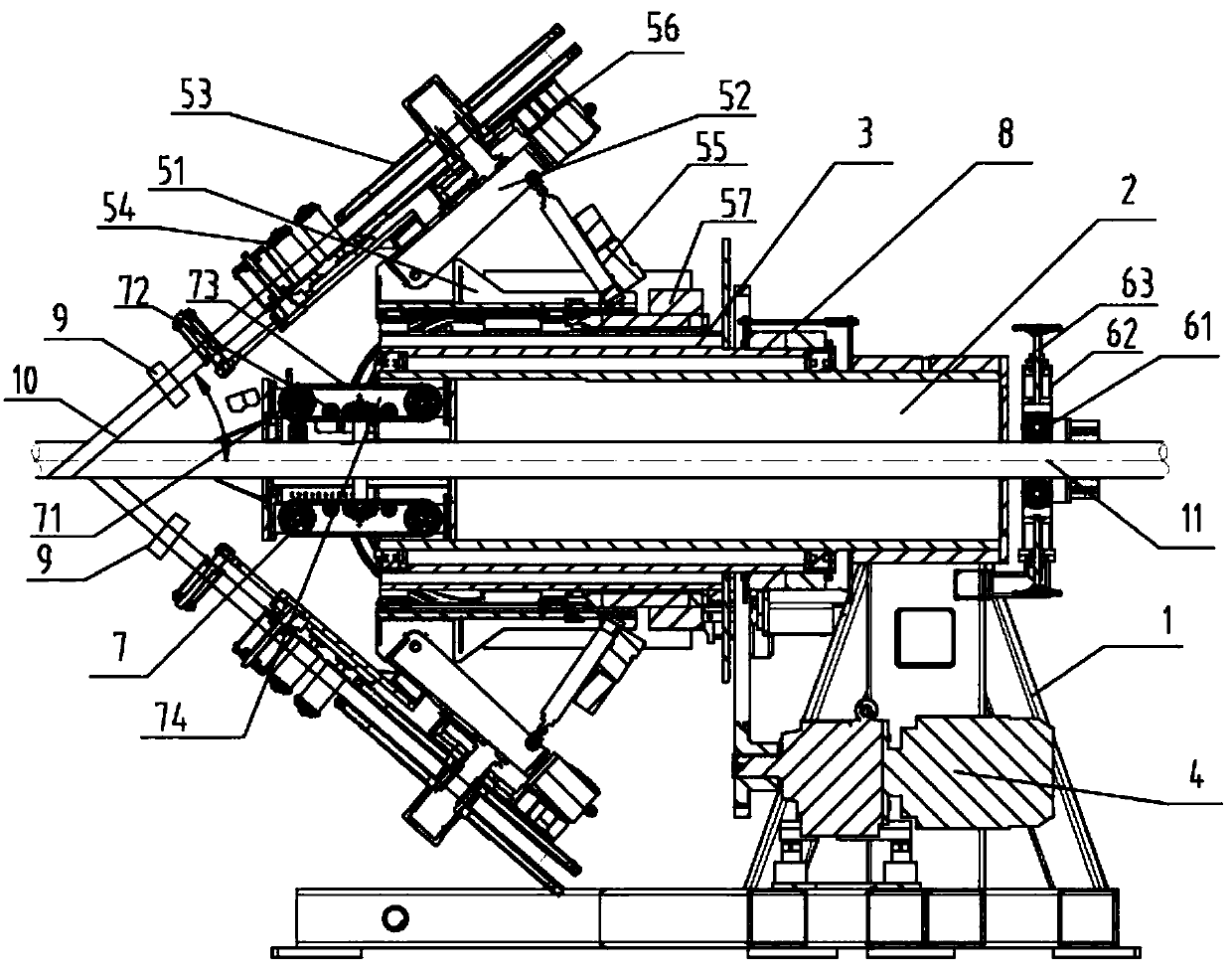

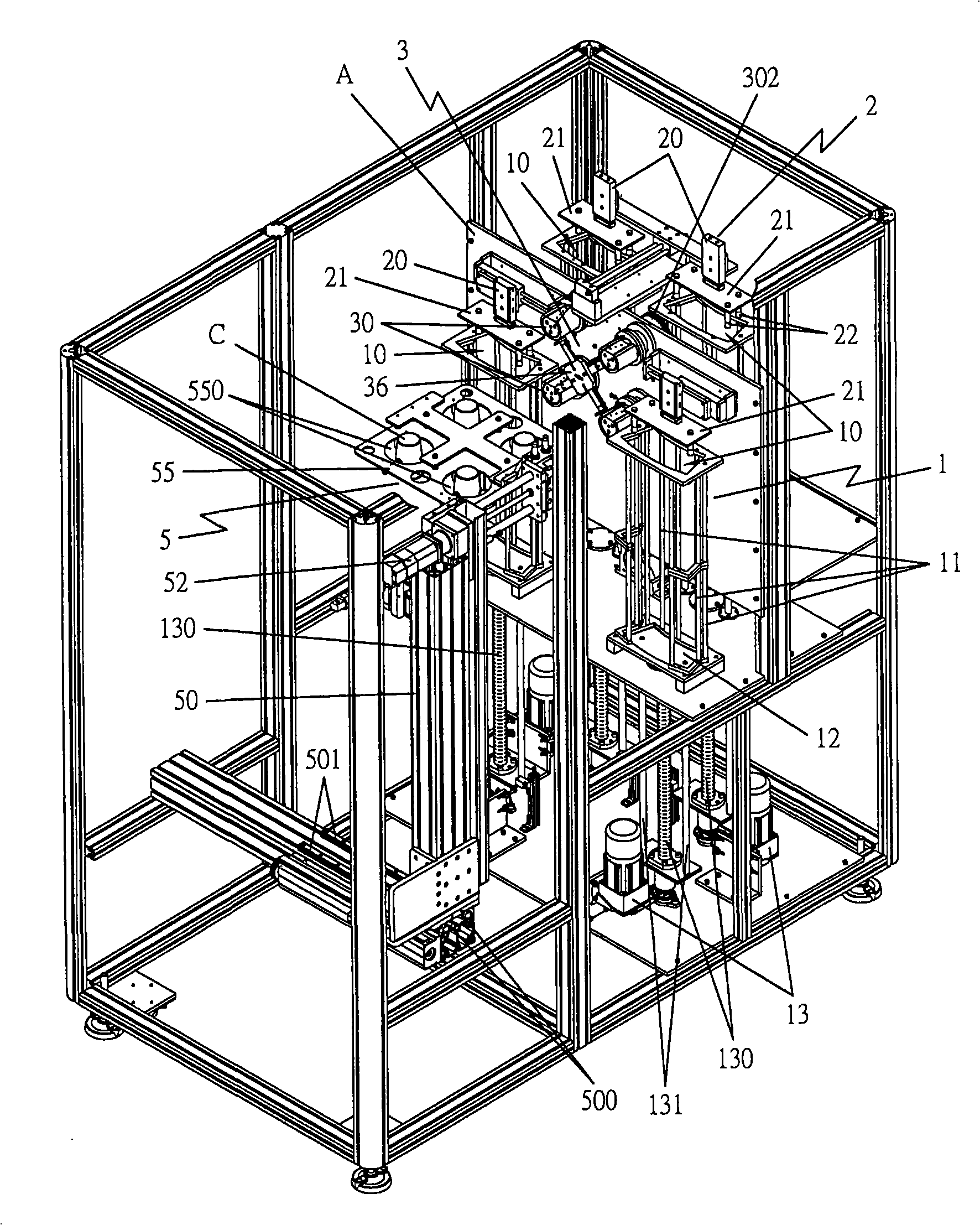

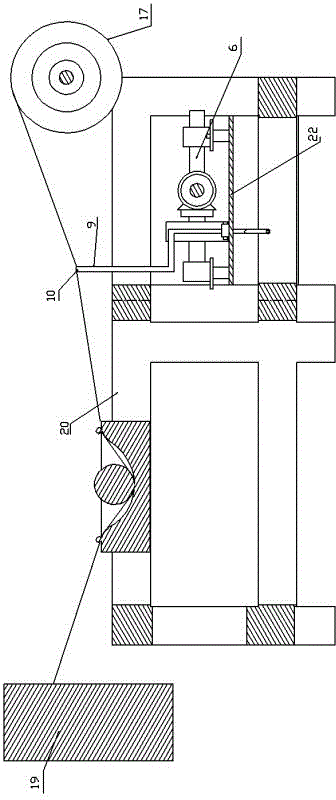

Half-iron-core stator pin type winding machine

PendingCN108964385AReduce manufacturing costCompact structureManufacturing dynamo-electric machinesWinding machineEngineering

The invention relates to a half-iron-core stator pin type winding machine comprising a rack, a line tensioner, a winding mechanism, a wire guiding and baffle mechanism, and a stator clamp mechanism. The winding mechanism is used for winding a wire around a plurality wire grooves of a half-iron-core stator. The wire guiding and baffle mechanism is used for guiding the wire to wind around the plurality wire grooves of the half-iron-core stator. The stator clamp mechanism is used for clamping the half-iron-core stator, driving the half-iron-core stator to move back and forth, left and right, or up and down or rotate, and conveying the half-iron-core stator to the wire guiding and baffle mechanism, so that the winding mechanism carries out winding on the wire grooves of the half-iron-core stator. According to the invention, the double winding stations are set to be an upper winding station and a lower winding station and share the winding motor and the stator clamp mechanism. Therefore, the production cost is lowered; the structure becomes compact; the size is reduced; and the occupied area is reduced.

Owner:SANHE IND AUTOMATION EQUIP CO LTD SHUNDE DISTRICT FOSHAN CITY

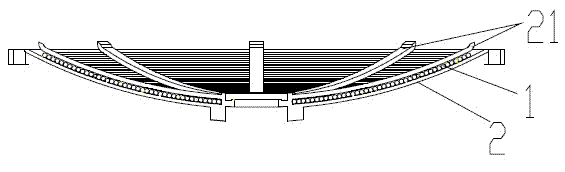

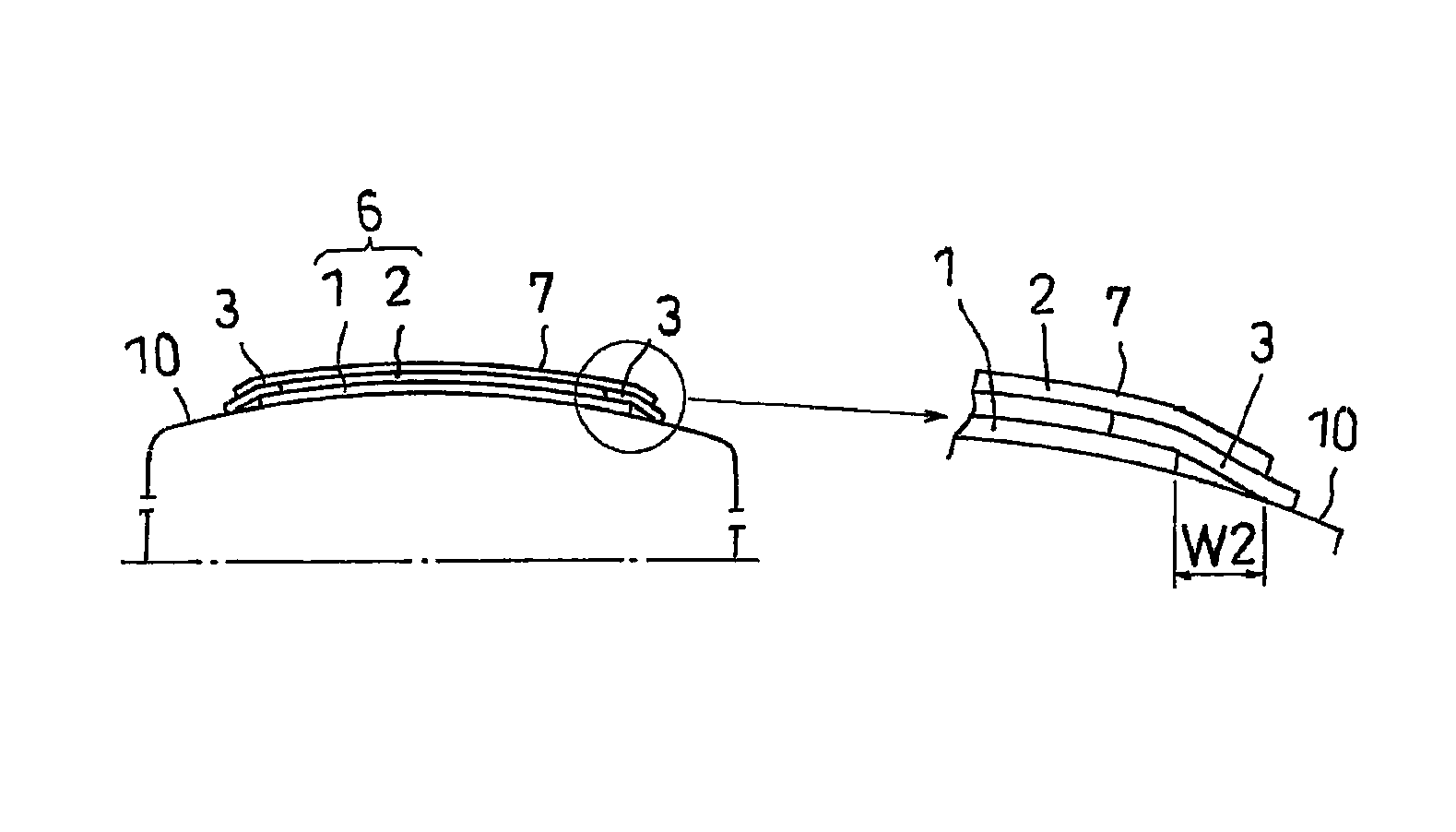

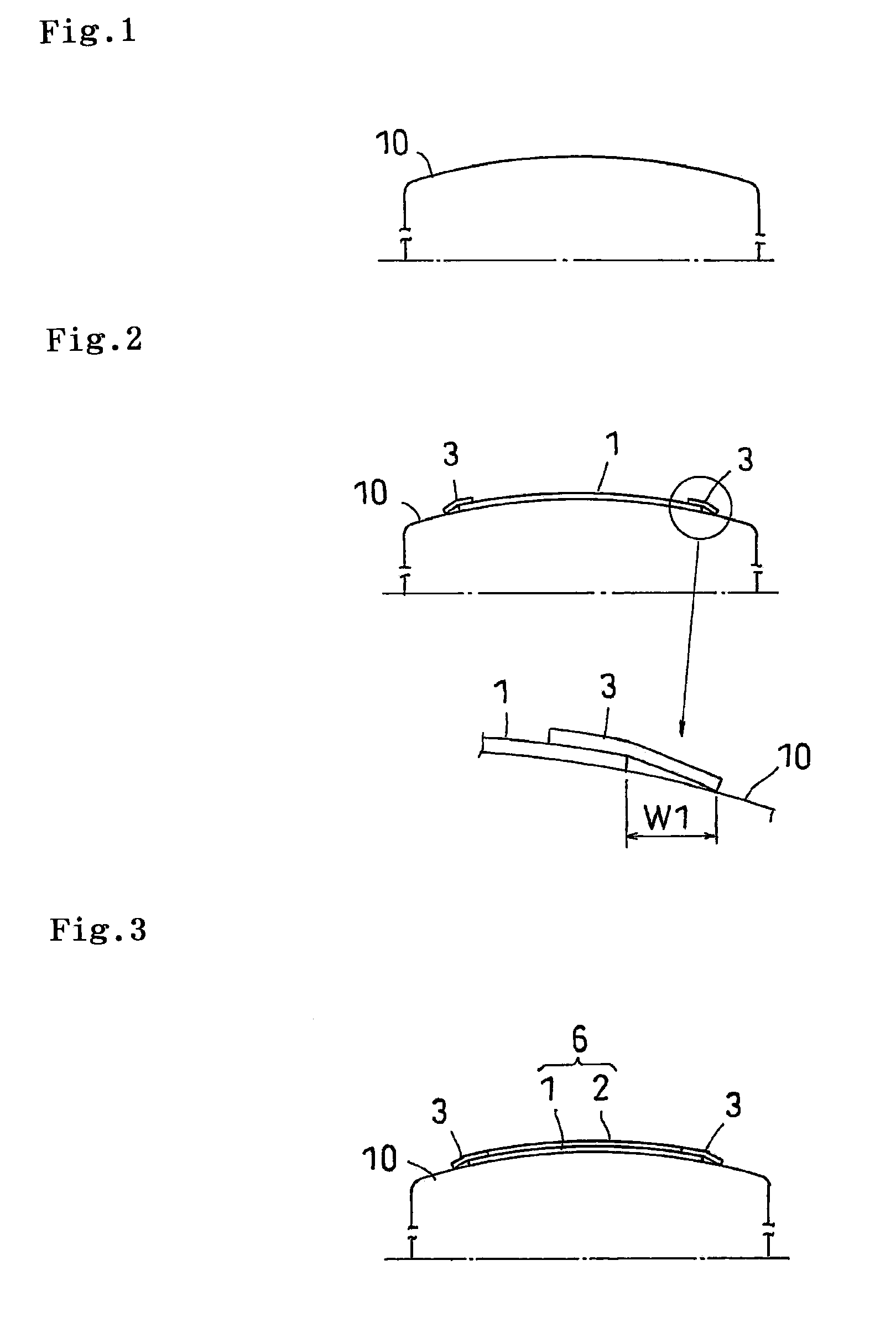

Manufacturing method of pneumatic tire

First, a first belt ply is wound around an outer peripheral surface of a belt drum having a curvature so as to be formed as a tubular shape, and a rubber layer protruding to an outer side than an end portion in a width direction of a belt reinforcing layer is arranged in an outer periphery of an end portion in a width direction of the first belt ply. Further, a second belt ply which is narrower than the first belt ply is wound around an outer periphery of the second belt ply so as to be formed as a tubular shape, and a belt layer is formed in such a manner that the first belt ply and the second belt ply are laminated. The belt reinforcing layer is formed by spirally winding a rubber-coated reinforcing cord around an outer peripheral side of the formed belt layer, and an end portion in a width direction of the belt reinforcing layer is arranged in an outer side than the first belt ply.

Owner:TOYO TIRE & RUBBER CO LTD

Winding system of motor coil

ActiveCN113328591AClear intervalImprove winding efficiencyManufacturing dynamo-electric machinesContinuous/uninterruptedControl engineering

A winding system of a motor coil comprises a machine table, a conveying device arranged on the machine table, a positioning and clamping device arranged on the machine table, a central coil positioning device arranged on the machine table and a stator winding device arranged on the machine table. The positioning and clamping device comprises a framework positioning table arranged on the machine table, a rotary driving mechanism arranged below the framework positioning table, at least one angle positioning structure arranged on the machine table and located on the outer side of the framework positioning table in the circumferential direction, and a pressing structure arranged on the machine table and located on the outer side of the framework positioning table in the circumferential direction. The winding system of the motor coil is high in overall equipment automation degree, small in occupied space, accurate in positioning and stable in winding without interference, the center coil is wound in the center of the positioning framework between winding of each winding, the winding process is continuous, and the winding efficiency of the stator framework is improved.

Owner:TANAC AUTOMATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com