Coil disc of electromagnetic oven

A coil disk and induction cooker technology, applied in coil devices, induction heating, etc., can solve the problems of multiple assembly processes, numerous processes, and high production costs, and achieve the effects of simplifying the winding process, simple and convenient operation, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

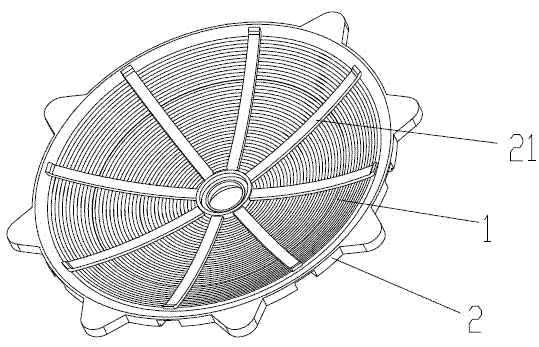

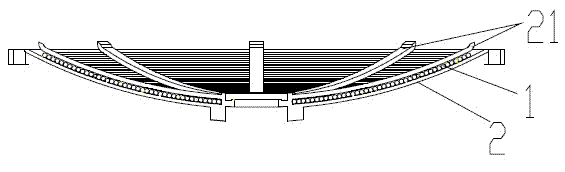

[0021] like figure 1 , figure 2 As shown, the electromagnetic cooker coil disk of the present invention includes a winding support 2 and a coil winding 1 installed on the winding support 2. The winding support 2 is provided with a number of ring-shaped distribution, which is convenient for winding fixed enameled wires. The wire buckle 21, the coil winding 1 is formed by winding the enameled wire through the wire buckle 21 distributed in a ring.

[0022] The winding surface of the above-mentioned winding support 1 is a plane or an arc surface. In this embodiment, the winding surface of the above-mentioned winding support 1 is an arc surface.

[0023] In this embodiment, the above-mentioned wire buckle 21 is a strip-shaped wire buckle.

[0024] In this embodiment, the wire winding support 2 is radially provided with a group of 8 wire buckles 21 with the same length and evenly distributed in a ring. The length of the wire buckles 21 is greater than the winding width of the co...

Embodiment 2

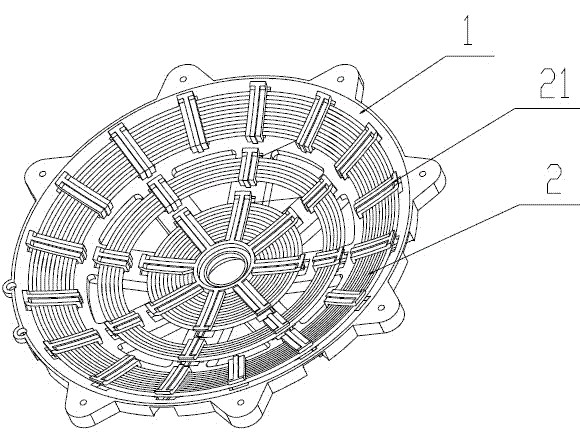

[0026] like image 3 , Figure 4 , Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the wire winding support 2 is provided with three sets of wire buckles 21 arranged in a ring along the radial direction, and there is a gap between each set of wire buckles 21 for wire entry. The numbers of each set of wire buckles 21 from inside to outside in the radial direction are 8, 8, and 16 respectively, and enameled wires are wound in three sets of wire buckles 21 sequentially from inside to outside, forming three annular heating zones.

Embodiment 3

[0028] like Image 6 , Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that the winding surface of the winding support 2 is a plane, and three groups of wire buckles 21 arranged in a ring are arranged in the radial direction, and each group of wire buckles 21 The number is equal, both are 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com