Efficient water reducer of concrete

A high-efficiency water-reducing agent and concrete technology, which is applied in the preparation of water-reducing agent and the field of air-entraining high-efficiency water-reducing agent, can solve the problems of concrete use strength influence, unstable air bubble properties, complex preparation process, etc., and achieve adaptability Good, improved workability, increased development speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

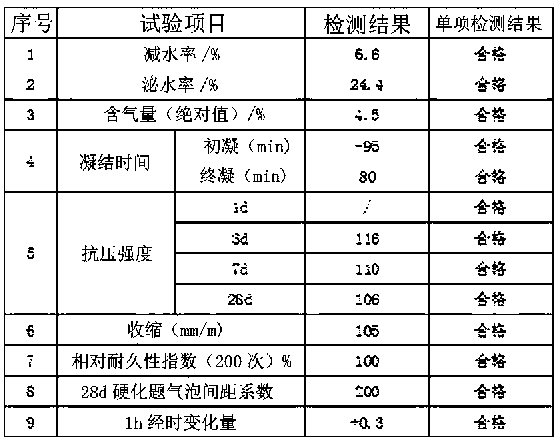

Image

Examples

Embodiment 1

[0034]A high-efficiency water reducer for concrete, mainly composed of modified naphthalene sulfonate, lignosulfonate, sodium sulfate, fly ash, triethanolamine, sodium gluconate, sodium dodecylbenzenesulfonate, silicone resin Composed of polyether emulsions and sodium nitrite, its weight ratio is: 350 parts of modified naphthalene sulfonate, 60 parts of lignosulfonate, 12 parts of sodium sulfate, 6 parts of fly ash, 0.04 part of triethanolamine, 12 parts of sodium gluconate, 0.04 parts of sodium dodecylbenzenesulfonate, 0.6 parts of silicone resin polyether emulsion, 0.6 parts of sodium nitrite.

Embodiment 2

[0036] A high-efficiency water reducer for concrete, mainly composed of modified naphthalene sulfonate, lignosulfonate, sodium sulfate, fly ash, triethanolamine, sodium gluconate, sodium dodecylbenzenesulfonate, silicone resin Composed of polyether emulsions and sodium nitrite, its weight ratio is: 250 parts of modified naphthalene sulfonate, 40 parts of lignosulfonate, 8 parts of sodium sulfate, 4 parts of fly ash, and 0.02 part of triethanolamine , 8 parts of sodium gluconate, 0.02 parts of sodium dodecylbenzenesulfonate, 0.4 parts of silicone resin polyether emulsions, and 0.4 parts of sodium nitrite.

Embodiment 3

[0038] The high-efficiency water reducer for concrete, the weight ratio of its components is 300 parts of modified naphthalene sulfonate, 50 parts of lignosulfonate, 10 parts of sodium sulfate, 5 parts of fly ash, and 0.03 part of triethanolamine , 10 parts of sodium gluconate, 0.03 parts of sodium dodecylbenzenesulfonate, 0.5 parts of silicone resin polyether emulsions, and 0.5 parts of sodium nitrite.

[0039] The high-grade water reducer for concrete also contains organic silicon, and the weight of organic silicon accounts for 0.01% of the weight component of the concrete used.

[0040] The high-efficiency water reducer for concrete, its preparation method is:

[0041] a. Add 300 parts of modified naphthalene sulfonate, 50 parts of lignosulfonate, 10 parts of sodium sulfate, 5 parts of fly ash, 0.03 parts of triethanolamine, 10 parts of sodium gluconate, 0.03 parts of Sodium dodecylbenzene sulfonate, 0.5 parts of silicone polyether emulsions, 0.5 parts of sodium nitrite; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com