Composite polycarboxylic acid water reducing agent

A technology for compounding polycarboxylic acid and water reducing agent, which is applied in the field of concrete additives, can solve the problems of restricting the popularization and application of polycarboxylic acid water reducing agent, rough concrete surface, and not very long time, and achieves good pumping construction and water reduction. High rate and good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

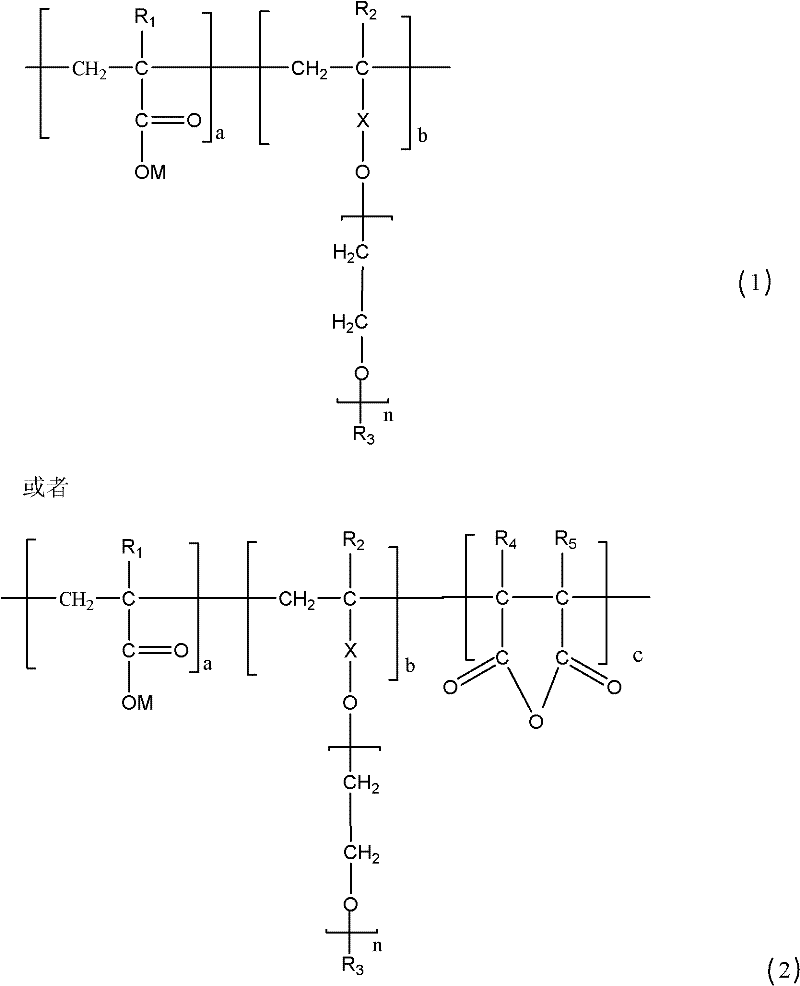

Method used

Image

Examples

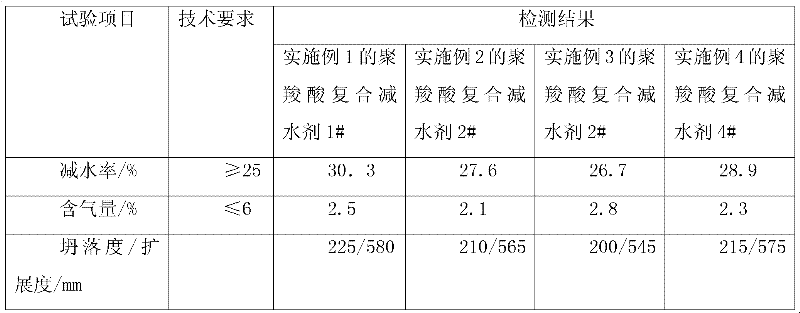

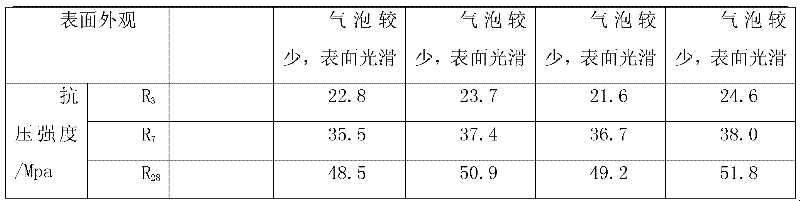

Embodiment 1

[0022] 200kg of modified polyether polycarboxylate high-performance water reducer (solid content 40%, zj-ss-01 polycarboxylate water reducer produced by China Construction Commercial Concrete Co., Ltd. , sodium gluconate 30kg, functional additives 0.1kg (polypropylene glycol ether 0.04kg, polypropylene glycol ether 0.06kg), paraben preservatives (Wuxi Jiangda Baitai Technology Co., Ltd., p-hydroxybenzene Sodium methyl formate) 1.5kg, tap water 768kg, stirred about 20 minutes and made it dissolve into a homogeneous solution, and its prepared solution concentration was 11.16% (solid content) to obtain polycarboxylic acid composite water reducer 1#.

Embodiment 2

[0024] 400kg of ester polycarboxylate high-performance water reducer (20% solid content, zj-ss-02 polycarboxylate water reducer produced by China Construction Commercial Concrete Co., Ltd. 30kg, sodium tripolyphosphate 20kg, functional additives 1kg (polypropylene glycol ether 0.75kg, polypropylene propylene glycol ether 0.25kg), paraben preservatives (Wuxi Jiangda Baitai Technology Co., Ltd., p-hydroxy Sodium methyl benzoate) 2.0kg, tap water 547kg, stir about 20 minutes and make it dissolve into uniform solution, the solution concentration of its preparation is 13.3% (solid content), obtains polycarboxylate composite superplasticizer 2#.

Embodiment 3

[0026] 200 kg of maleic anhydride-based polycarboxylate high-performance water reducer (solid content 40%, zj-ss-03 polycarboxylate water reducer produced by China Construction Commodity Concrete Co., Ltd. Sodium citrate 26kg, borax 4kg, functional additives 0.03kg (polypropylene glycol ether 0.01kg, polypropylene glycol ether 0.02kg), paraben preservative 1.5kg, tap water 790kg, stir for about 20 minutes to make It was dissolved into a uniform solution, and the concentration of the prepared solution was 11.15% (mass), to obtain polycarboxylic acid composite water reducer 3#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com