Patents

Literature

421results about How to "Reduce air content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

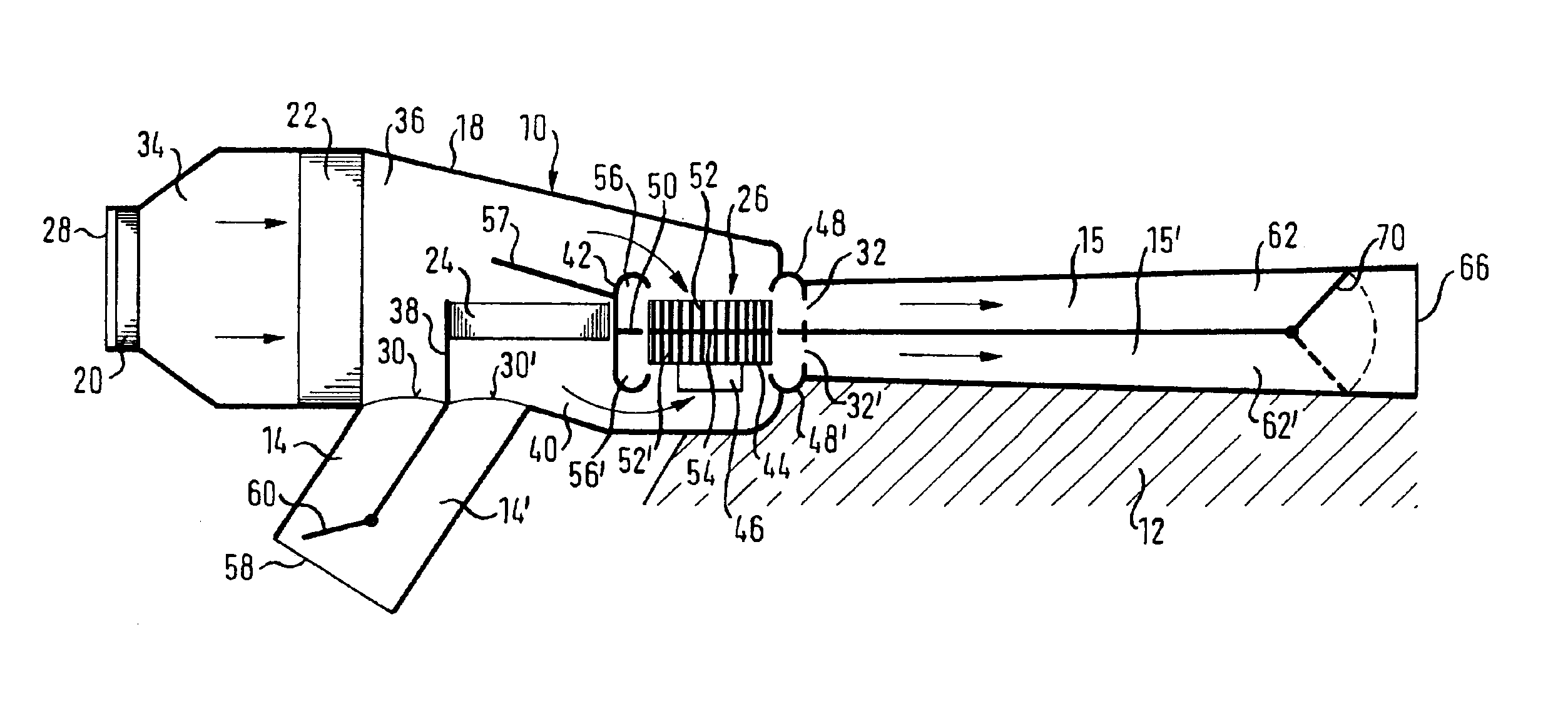

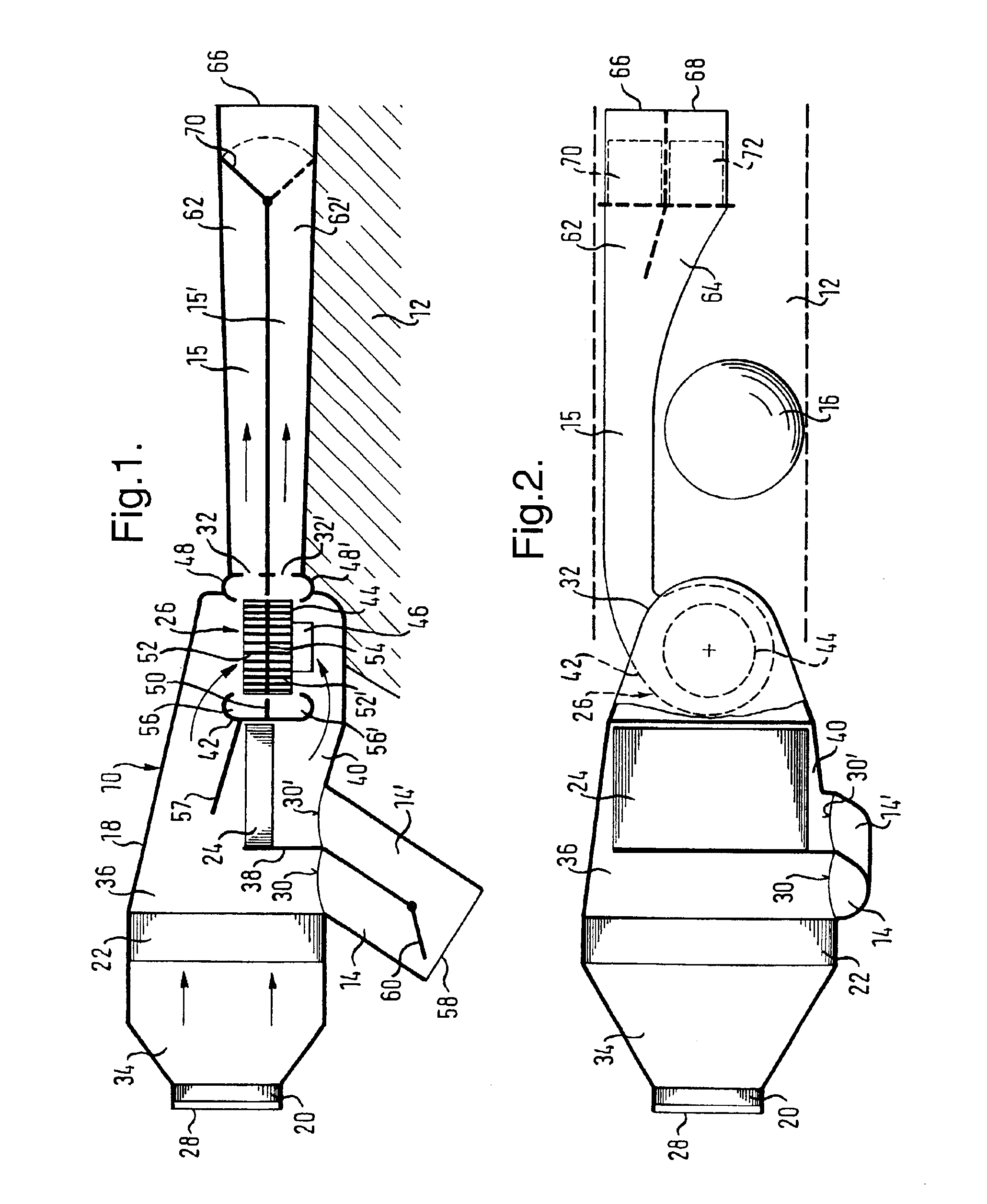

Air-to-air atmospheric heat exchanger for condensing cooling tower effluent

InactiveUS20050077637A1Reduce air contentThin materialCarburetting airUsing liquid separation agentCooling towerEngineering

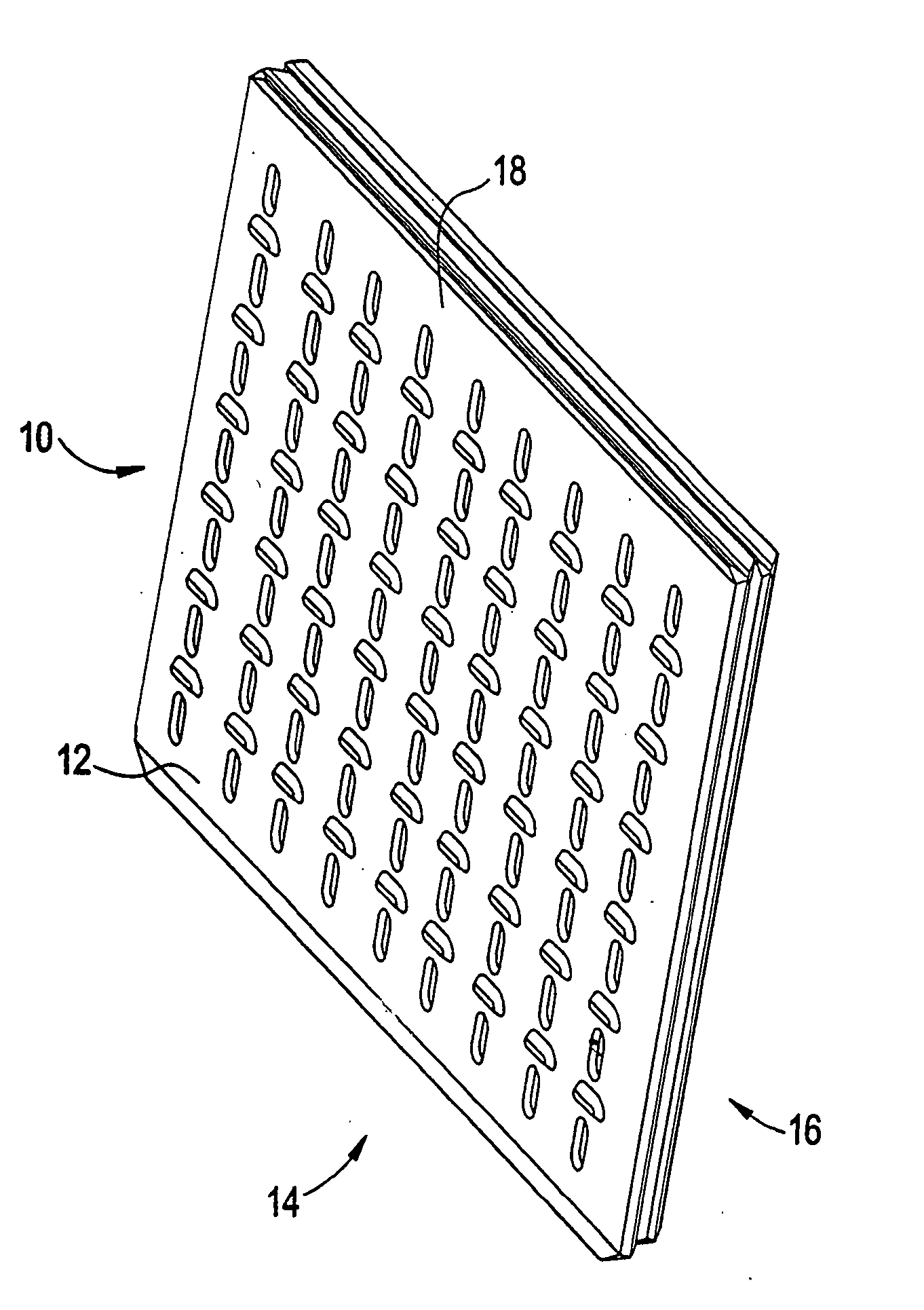

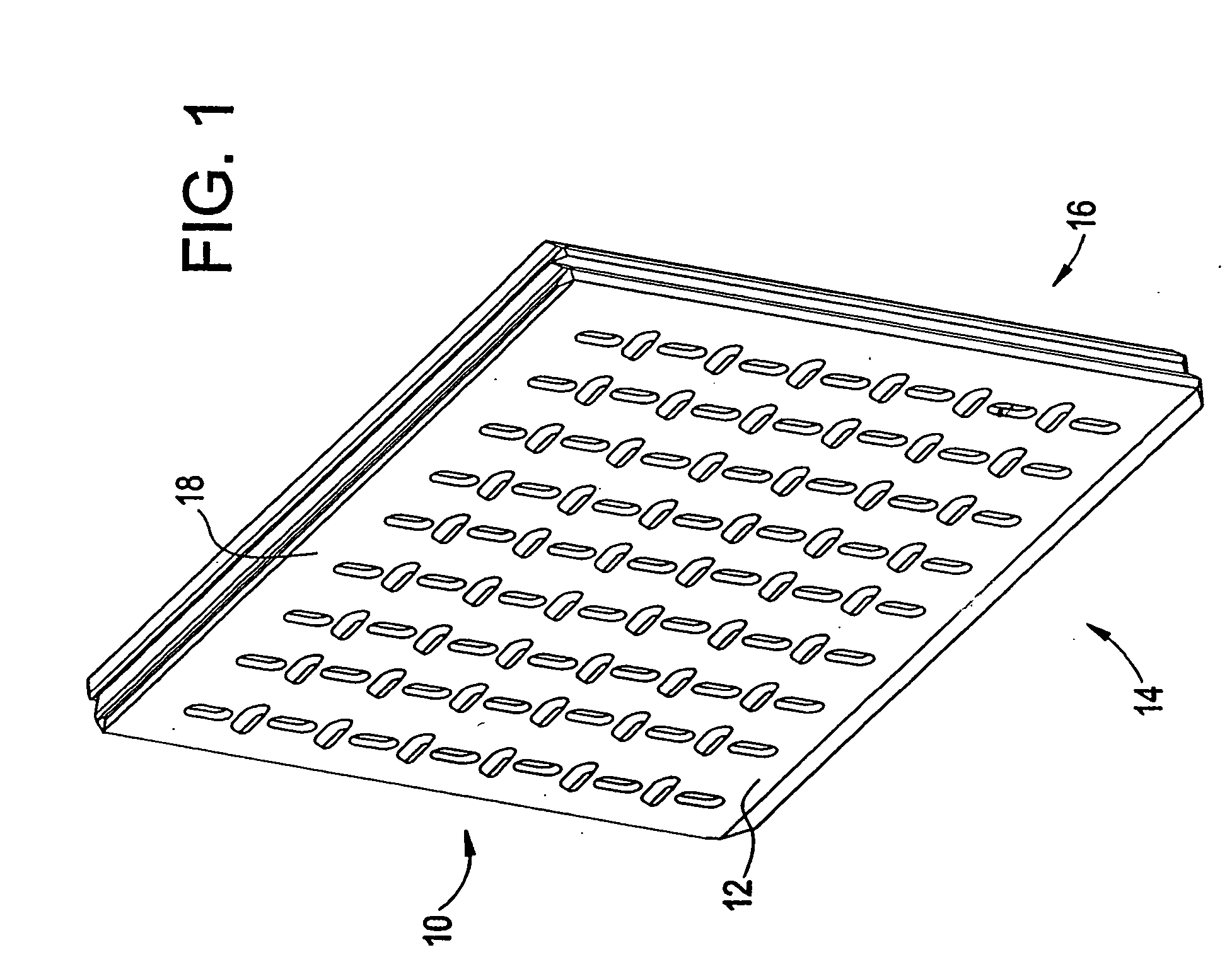

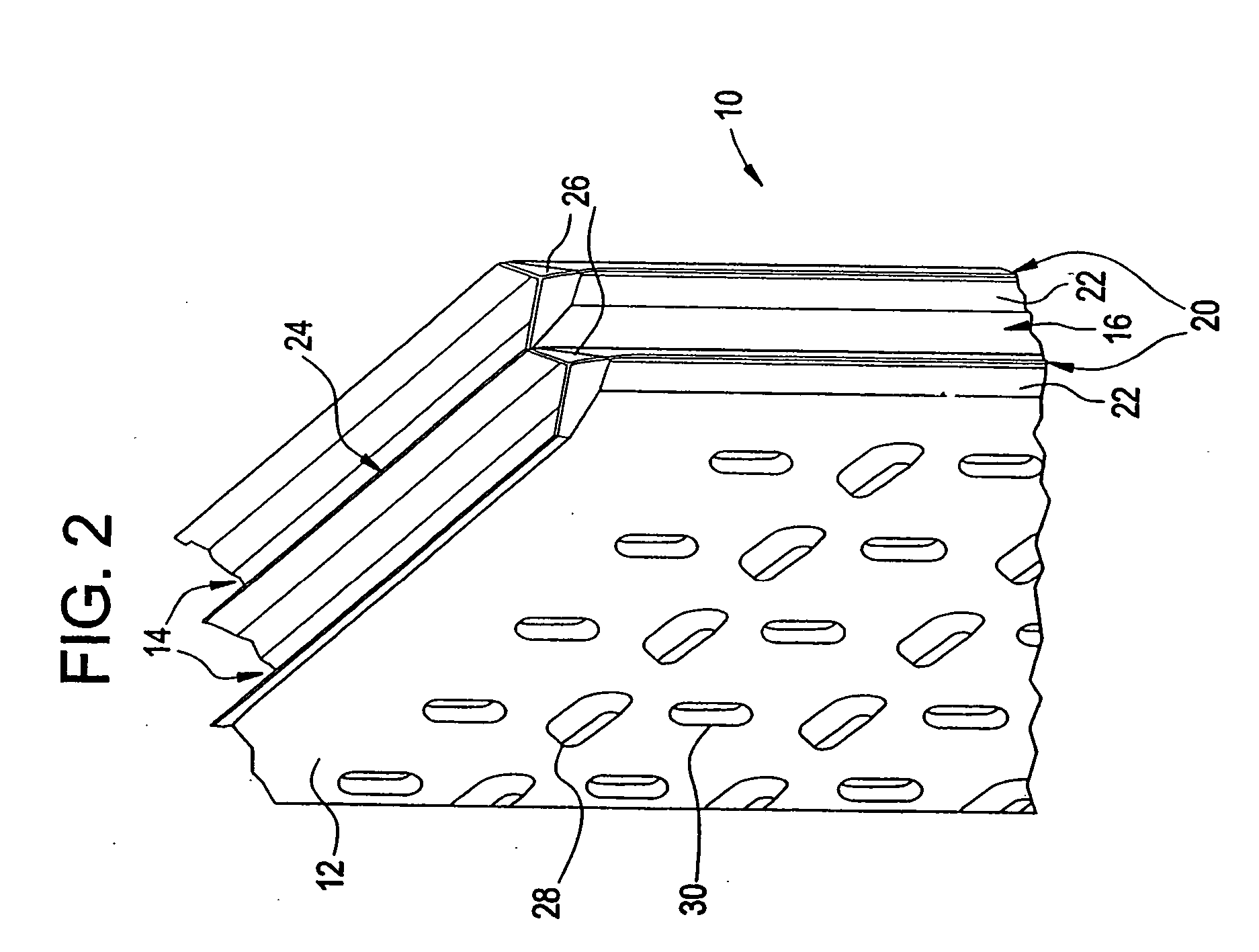

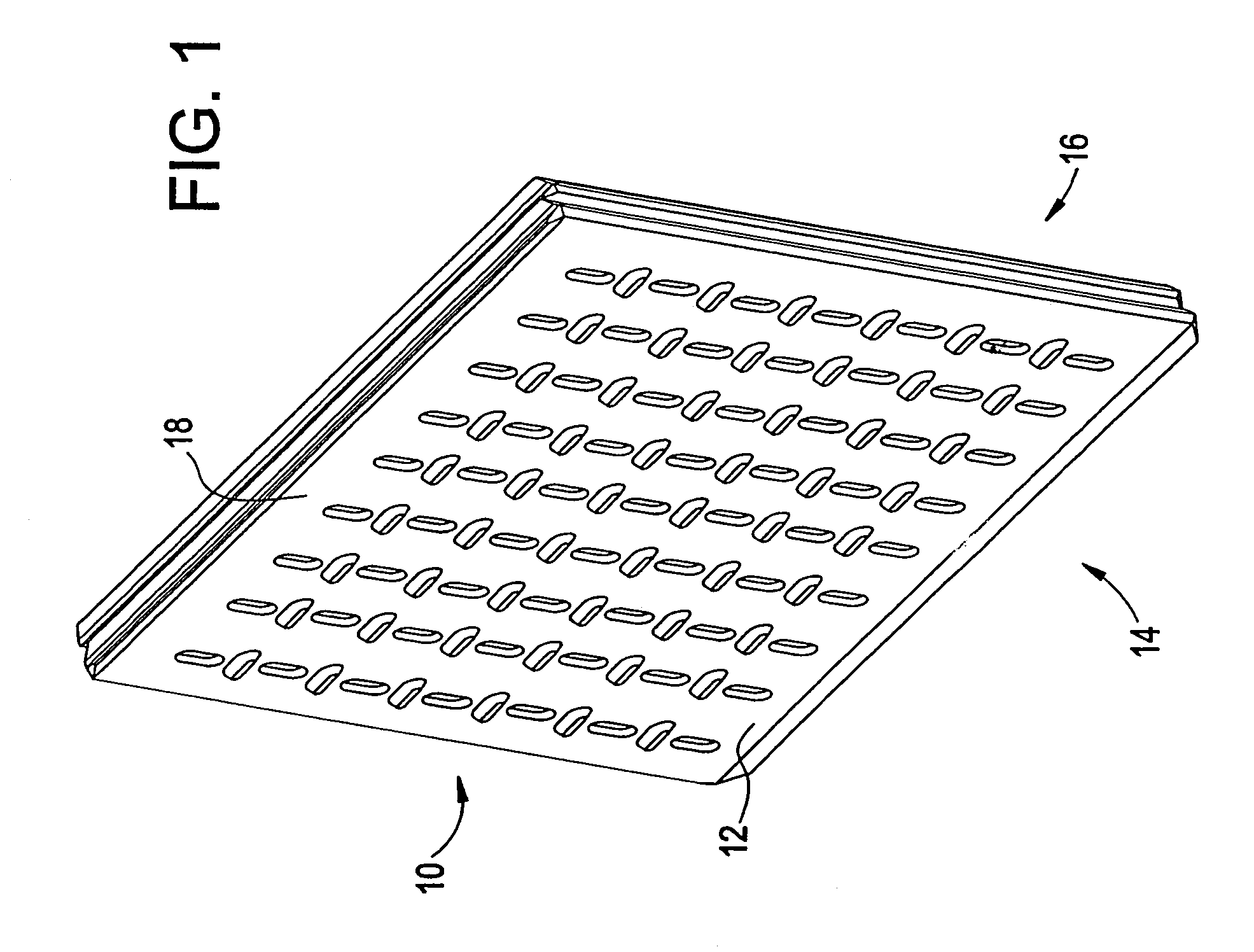

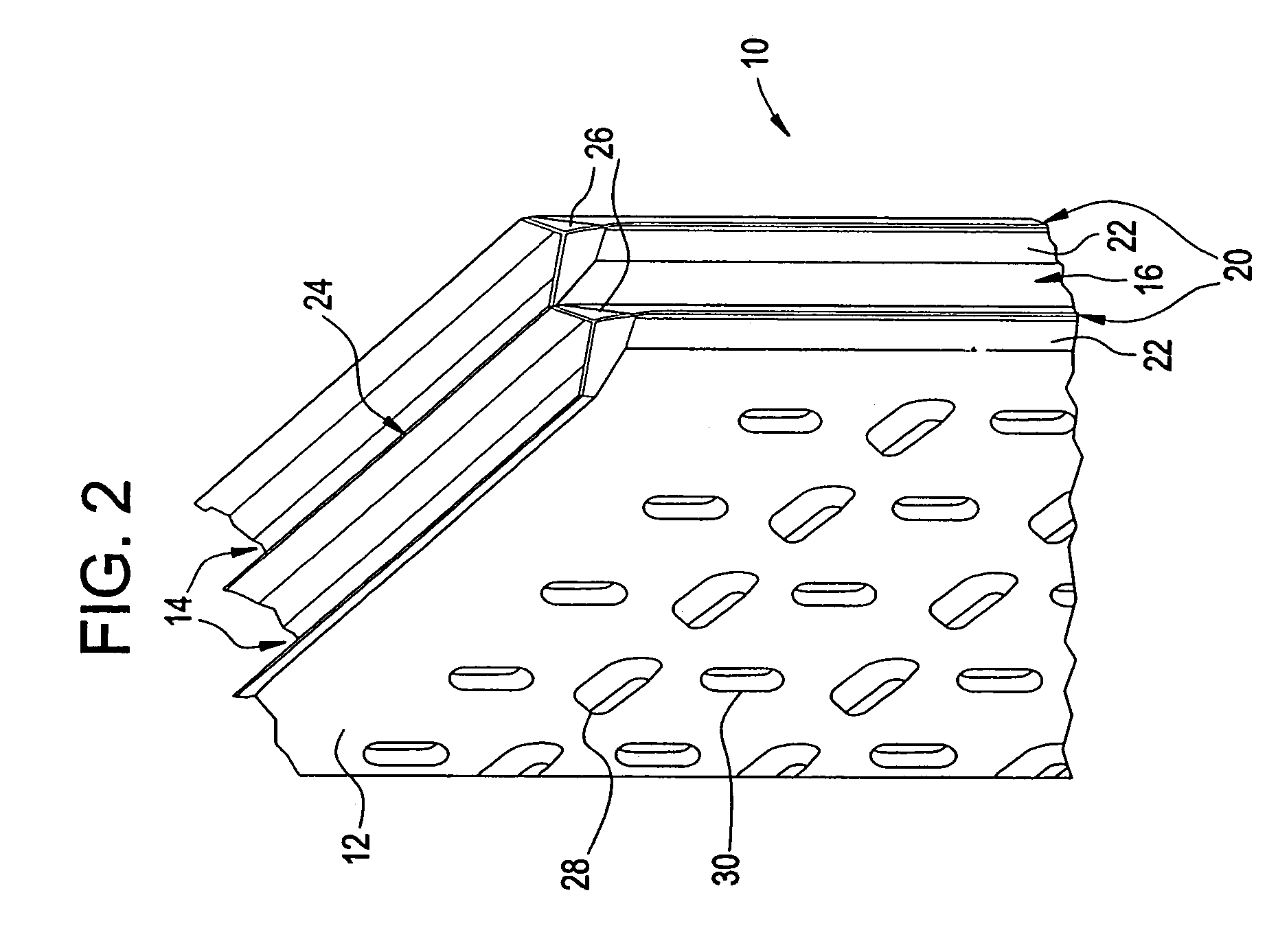

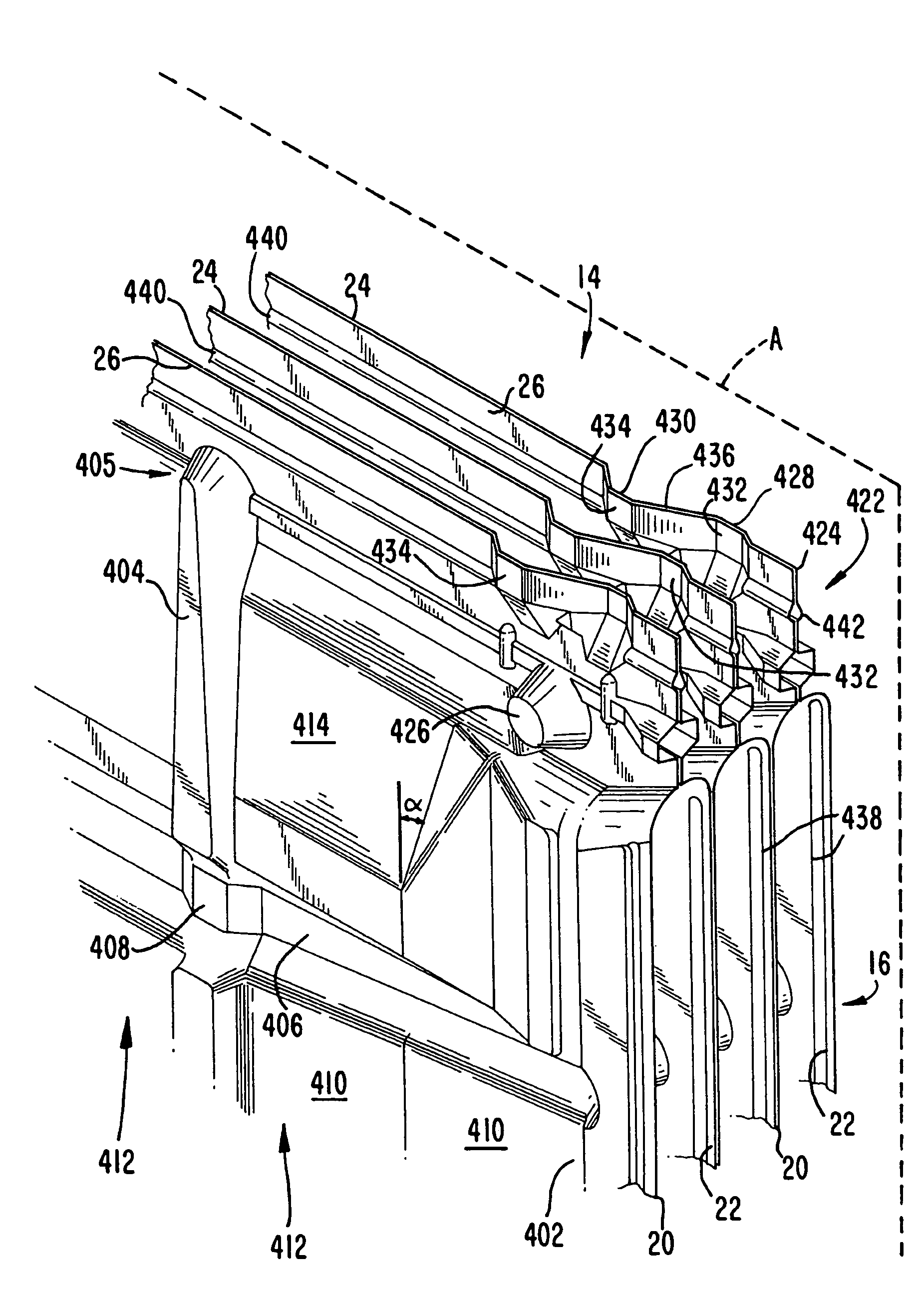

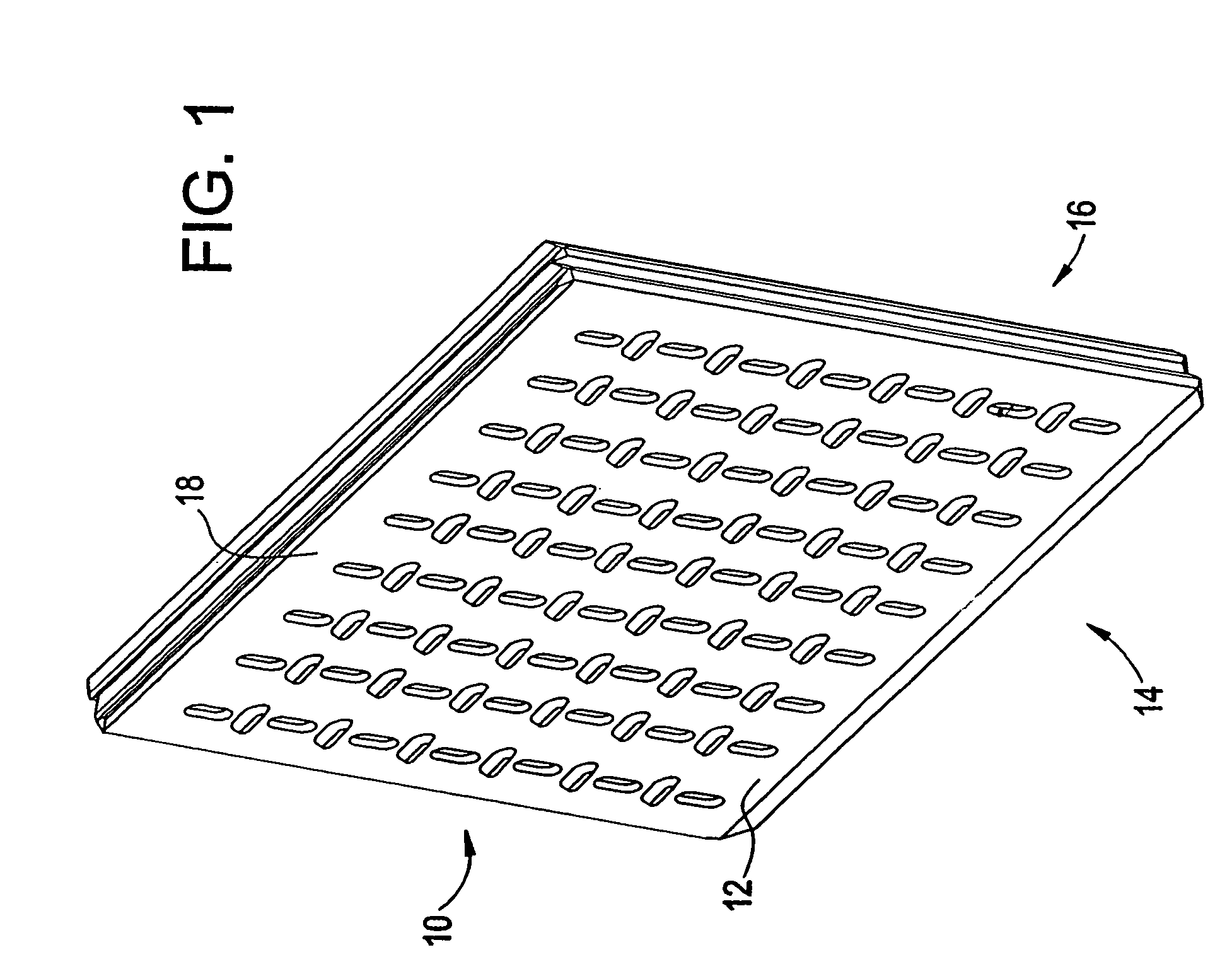

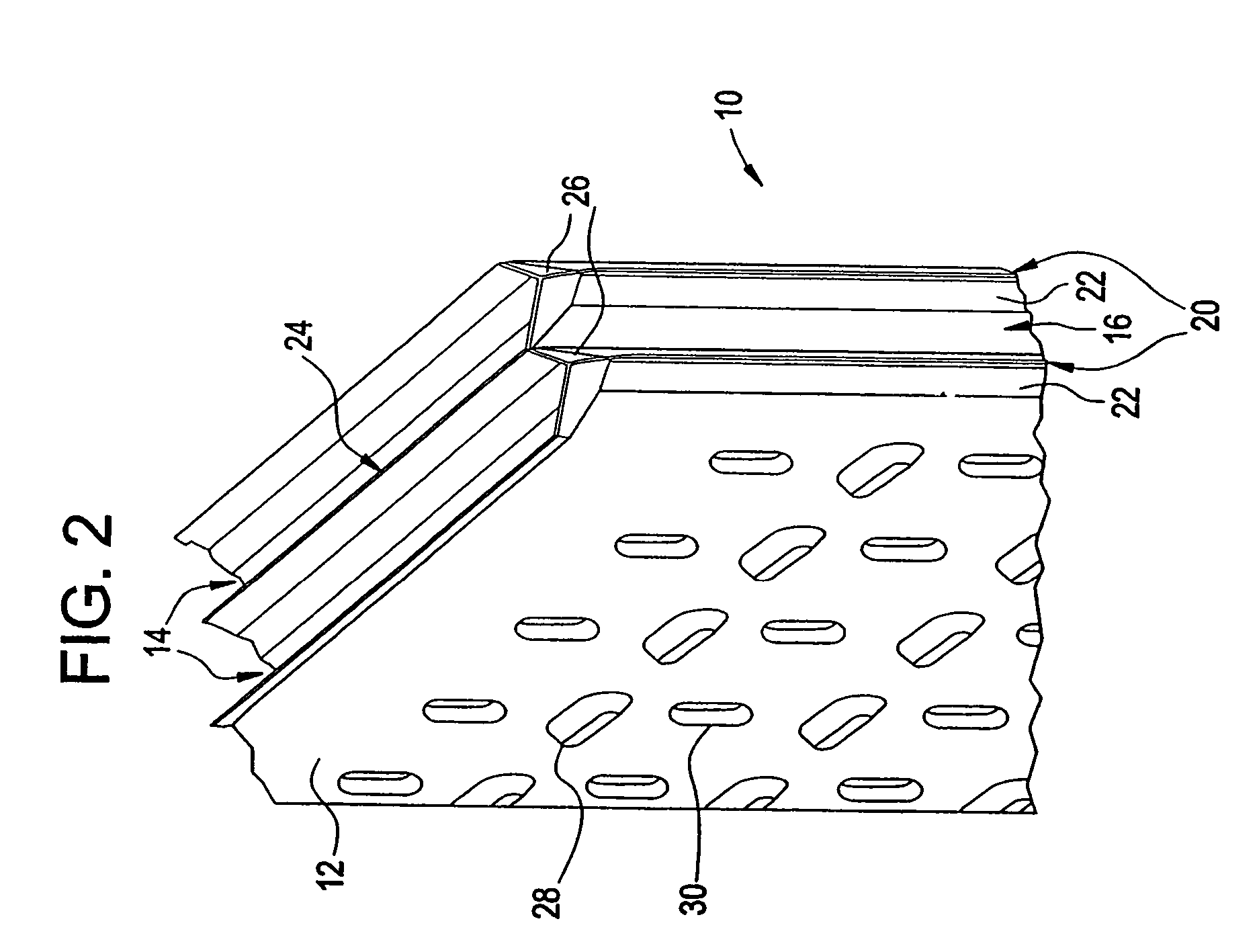

A sheet for use in a heat exchange apparatus. The sheet includes a first vertical rib that extends in a first direction generally parallel to the vertical axis of the heat exchange apparatus, wherein said first vertical rib protrudes in a second direction out of the plane. The sheet also includes a second vertical rib that extends in the first direction along the sheet, substantially all the way between the first and second edges of the sheet generally parallel to the first vertical rib. The second vertical rib also protrudes in the second direction out of the plane. The sheet further includes a first horizontal rib that extends in a third direction along the sheet substantially all the way between the third and fourth edges of the sheet, wherein the first horizontal rib protrudes in a fourth direction opposite said second direction. The sheet additionally includes a second horizontal rib that extends in the third direction along the sheet substantially all the way between the third and fourth edges of the sheet generally parallel to the first horizontal rib. The second horizontal rib protrudes in a fourth direction opposite the second direction, into the plane and intersects said second vertical rib.

Owner:SPX COOLING TECH

Air-to-air atmospheric heat exchanger for condensing cooling tower effluent

InactiveUS7128310B2Reduce air contentThin materialCarburetting airUsing liquid separation agentCooling towerWater source

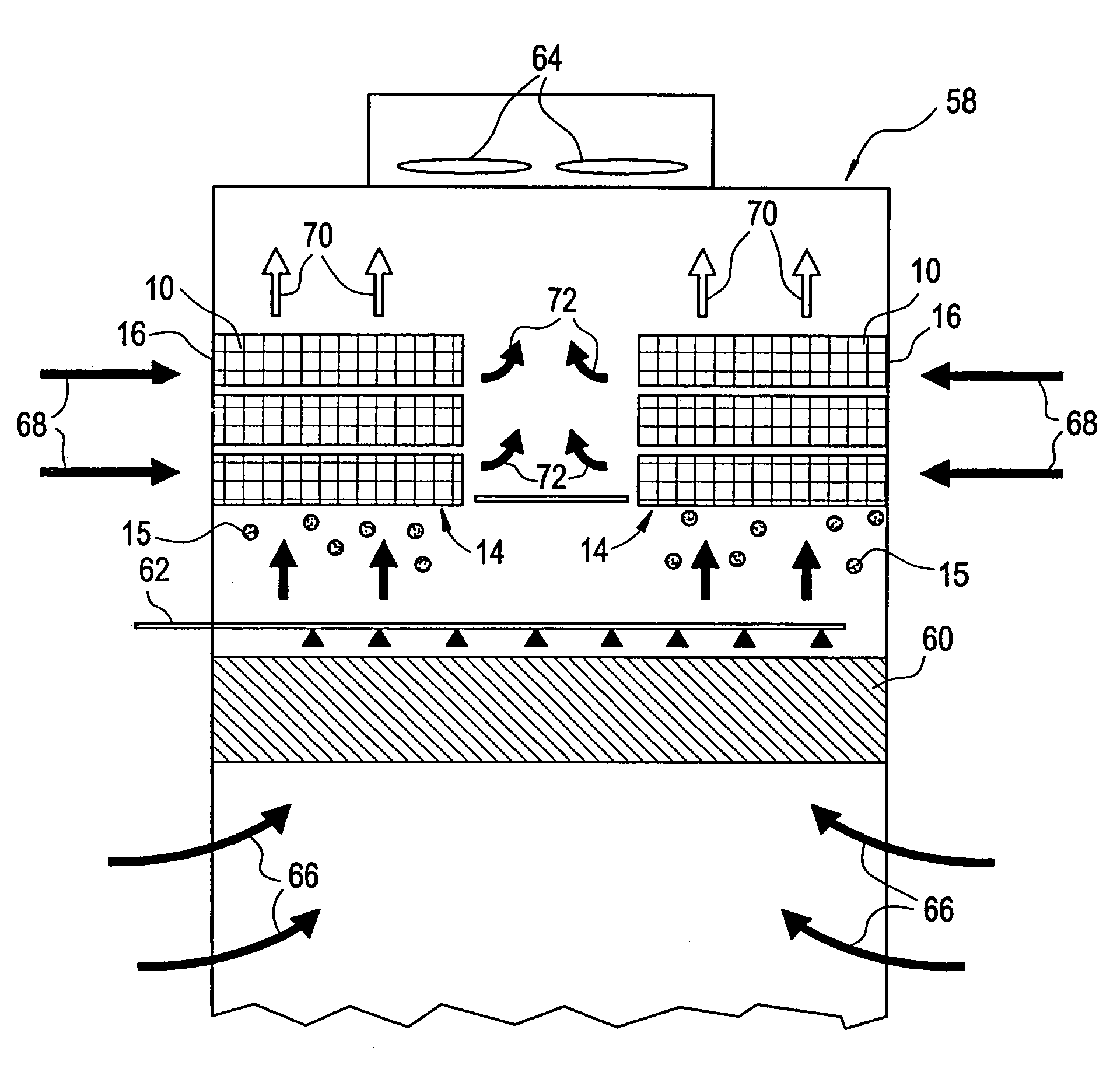

A cooling tower having a heat exchanger. The heat exchanger includes at least one heat exchanger pack having a generally diamond shape. The heat exchanger pack includes a first set of passageways for receiving a stream of warm, water laden air and a second set of passageways for receiving ambient air. The first set of passageways and second set of passageways are separate. Cooling tower configurations including the heat exchanger pack are disclosed for achieving effluent plume abatement, and capture of a portion of the effluent for replacement back into the cooling tower reservoir or as a source of purified water.

Owner:SPX COOLING TECH

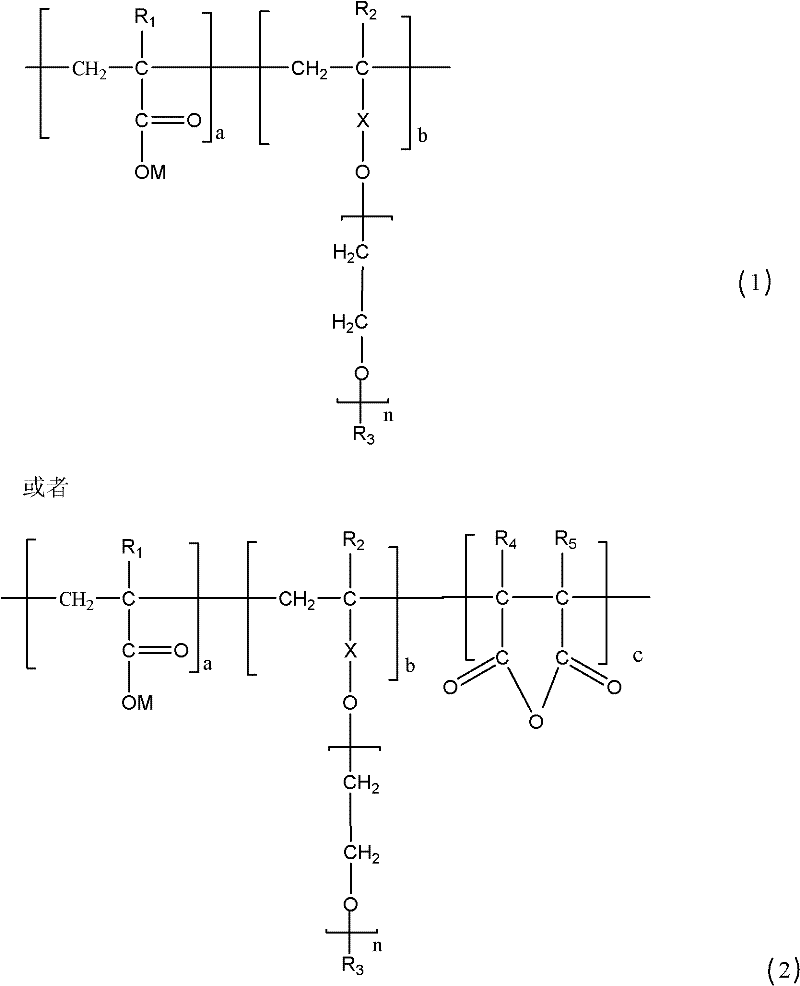

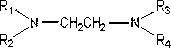

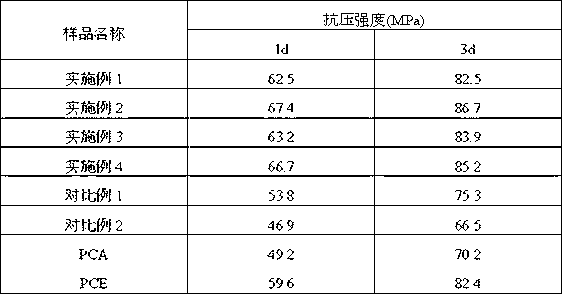

Unsaturated polyether monomer, comb-like branched copolymer cement dispersant prepared by the same, and preparation method thereof

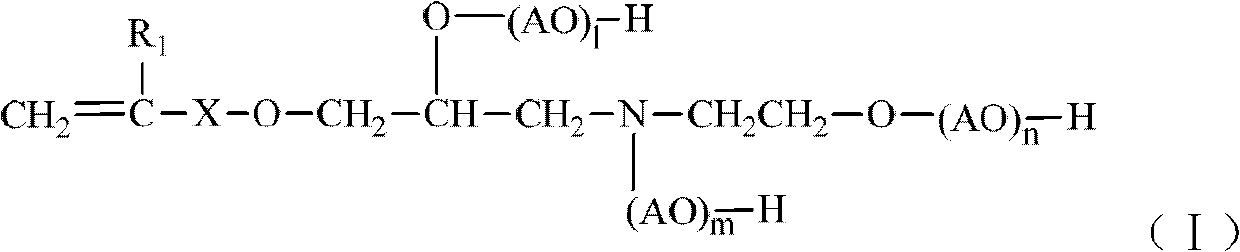

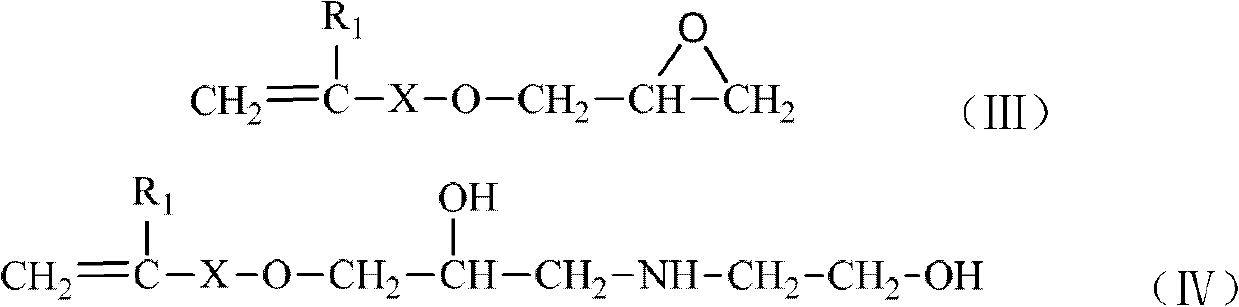

The invention relates to an unsaturated polyether monomer, a comb-like branched copolymer cement dispersant prepared by the monomer, and preparation methods of the monomer and the dispersant. The unsaturated polyether monomer has the general formula (I), wherein R1 is H or -CH3; X is a linking group selected from -CH2-, -CH2CH2-, -OCH2CH2-, -OCH2CH2CH2CH2-; AO is ethylene oxide group and / or propene oxide group; l, m and n are all repeating units of AO; and the sum of l, m and n is an natural number of 10 to 50. The dispersant has the following chemical structure (VI), wherein x, y and z represent mole percentages of three structural units in the copolymer, and the sum of x, y and z is 100%. Preferably, x is 10% to 50%, y is 40% to 80% and z is 0% to 30%. The preparation method of the dispersant is simple and does not need organic solvents or complex esterification. The dispersant is advantageous in low dosage, good dispersibility and small slump loss.

Owner:连云港苏博特新材料有限公司 +2

Air-to-air atmospheric heat exchanger for condensing cooling tower effluent

InactiveUS7328886B2Reduce air contentThin materialCarburetting airUsing liquid separation agentCooling towerEngineering

A sheet for use in a heat exchange apparatus. The sheet includes a first vertical rib that extends in a first direction generally parallel to the vertical axis of the heat exchange apparatus, wherein said first vertical rib protrudes in a second direction out of the plane. The sheet also includes a second vertical rib that extends in the first direction along the sheet, substantially all the way between the first and second edges of the sheet generally parallel to the first vertical rib. The second vertical rib also protrudes in the second direction out of the plane. The sheet further includes a first horizontal rib that extends in a third direction along the sheet substantially all the way between the third and fourth edges of the sheet, wherein the first horizontal rib protrudes in a fourth direction opposite said second direction. The sheet additionally includes a second horizontal rib that extends in the third direction along the sheet substantially all the way between the third and fourth edges of the sheet generally parallel to the first horizontal rib. The second horizontal rib protrudes in a fourth direction opposite the second direction, into the plane and intersects said second vertical rib.

Owner:SPX COOLING TECH

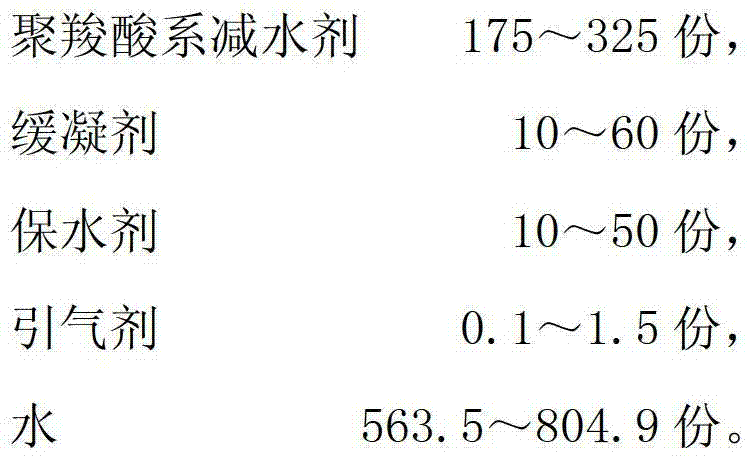

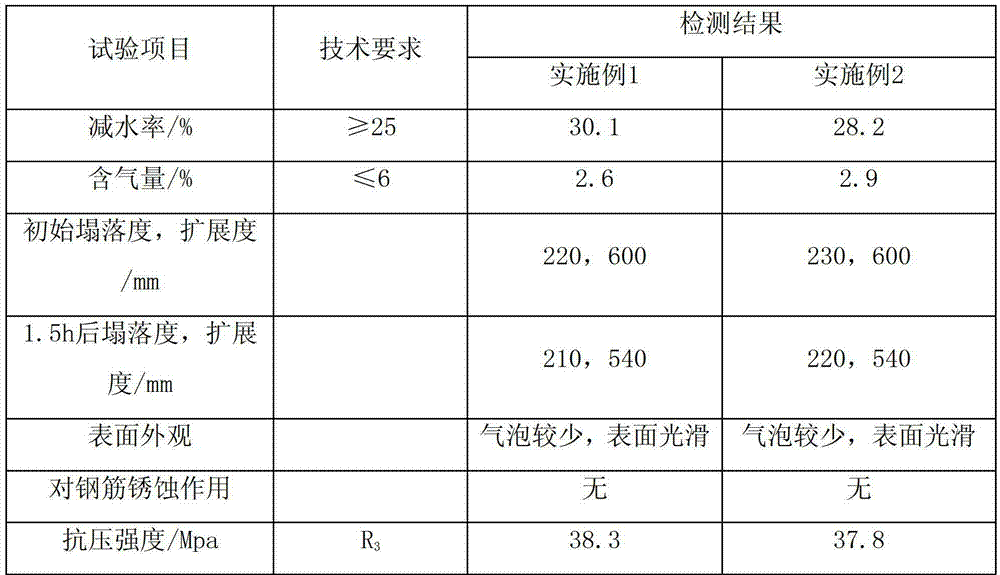

Pumping agent and application thereof

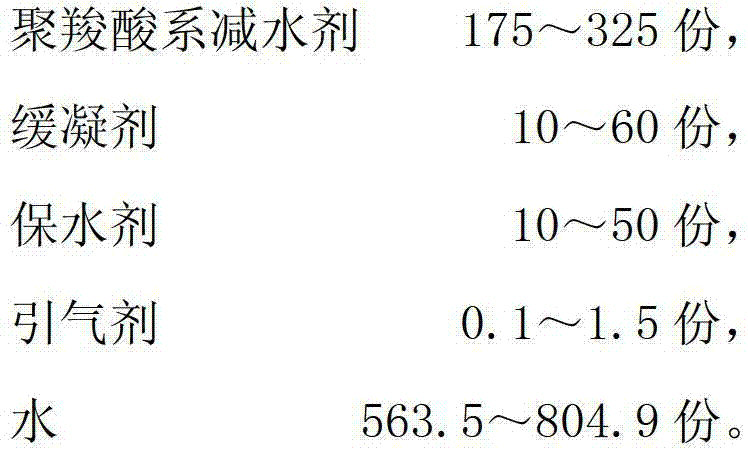

The invention relates to a pumping agent and application thereof, belonging to the field of construction materials. The invention aims to provide the pumping agent and the application thereof. The pumping agent provided by the invention comprises 175-325 parts by weight of polycarboxylic acid water reducing agent, 10-60 parts by weight of retarder, 10-50 parts by weight of water retention agent, 0.1-1.5 parts by weight of air entraining agent and 563.5-804.9 parts by weight of water. The invention also relates to the application of the pumping agent in C15-C70 concrete. The addition amount of the pumping agent accounts for 0.9-2.2 wt% of a cementing material in the concrete. The pumping agent prepared by the invention has the advantages of favorable material adaptability, low addition amount, high water reducing rate, low air content, high concrete strength contribution and the like, mainly solves the problem that the polycarboxylic acid pumping agent is easily subjected to over-addition in practical situations, can effectively prevent the defects of the concrete such as weepage, isolation and the like, and ensures the quality of the concrete.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR +1

Environment friendly low-gas-content aluminum alloy ingot and production method thereof

The invention discloses an environment friendly low-gas-content aluminum alloy ingot which comprises the following components in percentage by weight: 1.6-3.3 percent of Cu, 9.8-11.8 percent of Si, 0-0.29 percent of Mg, 0-0.08 percent of Zn, 0-0.8 percent of Fe, 0-0.48 percent of Mn, 0-0.48 percent of Ni, 0-0.1 percent of Ti, 0-0.1 percent of Pb, 0-0.2 percent of Sn, 0-0.25 percent of other trace elements and the balance of aluminum. Meanwhile, the invention also discloses a production method of the environment friendly low-gas-content aluminum alloy ingot. The environment friendly low-gas-content aluminum alloy ingot has the advantages of low gas and dreg content, high aluminum liquid cleanness and good mechanical and machining properties. The production method has the advantages of low production cost and high efficiency and effectively solves the pollution problem of the secondary aluminum industry.

Owner:YE CHIU METAL RECYCLINGCHINALTD

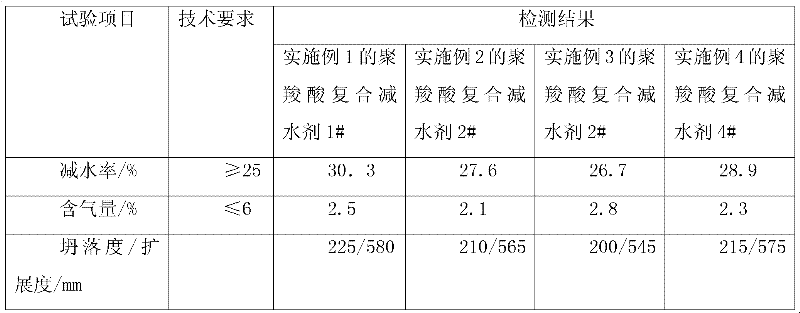

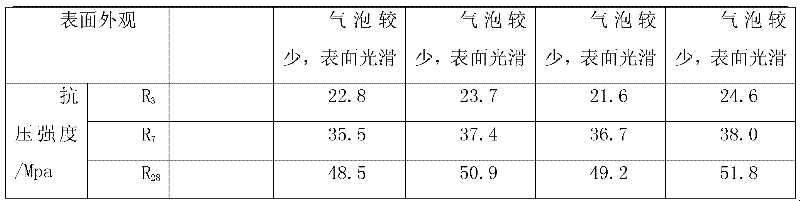

Composite polycarboxylic acid water reducing agent

The invention belongs to the technical field of concrete additives, in particular relates to a water reducing agent, and more particularly a composite polycarboxylic acid water reducing agent. The composite polycarboxylic acid water reducing agent is characterized by being prepared from the following components in percentage by mass: 8-28.6 percent of polycarboxylic acid high-performance water reducing agent, 0.5-7.36 percent of inhibiting agent, 0.001-0.15 percent of functional aid, 0.01-0.65 percent of preservative and the balance of water, wherein the total mass percentage of the components is 100 percent. The composite polycarboxylic acid water reducing agent is applied to freshly mixed concrete. After a template coated with waste engine oil or rosinate soap is dismantled, the surface of hardened concrete is smooth, air bubbles are reduced remarkably, and the construction requirement is fully met. By adopting the composite polycarboxylic acid water reducing agent, the problem of a large quantity of air bubbles on the surface of concrete, produced after the use of demolding agents such as waste engine oil or rosinate soap and the like is solved.

Owner:CHINA STATE CONSTR ENG CORP TIANJIN +1

Method of providing temperature controlled air and an apparatus usable for this

InactiveUS6886350B2Simple meansSimple processAir-treating devicesRailway heating/coolingCold airTemperature control

Owner:MAHLE INT GMBH

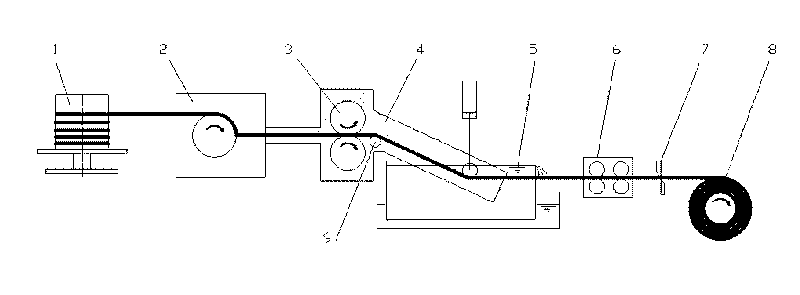

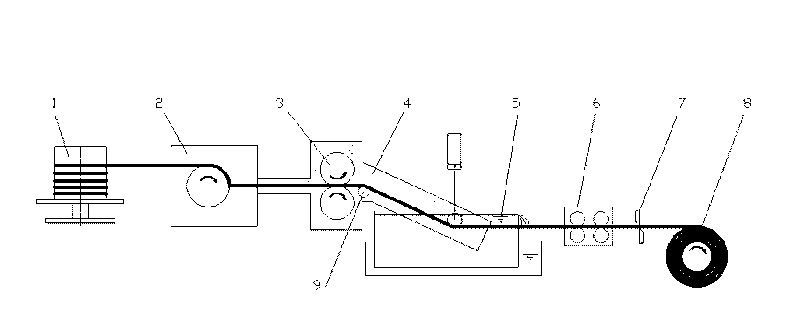

Continuous extrusion and continuous rolling process method and production line used for producing oxygen-free copper strip billet

ActiveCN101712050ARealize continuous productionReduce heatingMetal rolling arrangementsProduction lineShielding gas

The invention belongs to the field of copper processing, relating to the process method of the production of copper strip material, and in addition, relating to a copper strip material continuous extrusion and continuous rolling device. The invention provides a continuous extrusion and continuous rolling method used for producing oxygen-free copper strip billet, comprising the following steps: taking the oxygen-free copper rod as a raw material to carry out continuous extrusion to obtain the copper slabs; utilizing the heat generated in extrusion to carry out continuous hot rolling on the copper slabs; and cooling the copper bandlets after hot rolling, discharging to obtain the copper strips, wherein protective gas is adopted to protect the space between the extrusion outlet and the cooling inlet. The invention combines the advantages of low content of oxygen of the upper-draw process, great deformation of the continuous extrusion method and good performance of hot rolling method; the product has the advantages of low content of oxygen, compact organization, fine grains and excellent comprehensive performance; and the process method has the advantages of short flow, less heating and annealing processes, energy saving and environmental protection and the like.

Owner:大连康丰科技有限公司

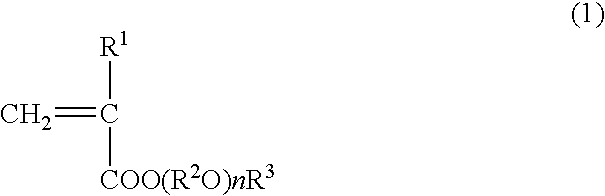

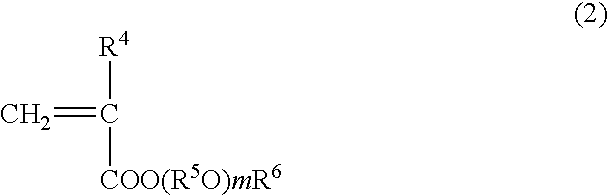

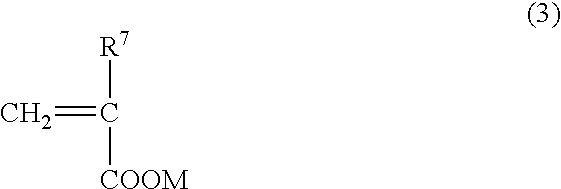

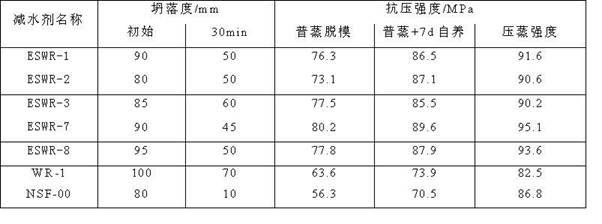

Cement additive

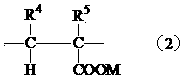

The present invention is thus directed to a cement additive which comprises a copolymer (A) obtained by polymerizing a monomer mixture (K), wherein;said monomer mixture (K) comprises a polyalkylene glycol ester monomer (I) represented by the general formula (1): a polyalkylene glycol ester monomer (II) represented by the general formula (2): and a carboxylic acid monomer (III) represented by the general formula (3):

Owner:NIPPON SHOKUBAI CO LTD

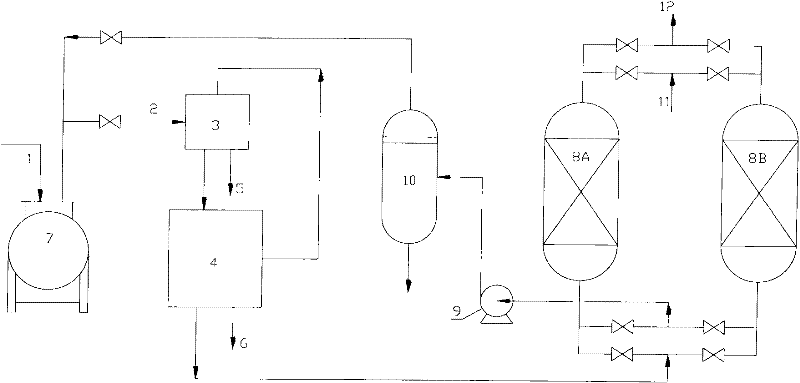

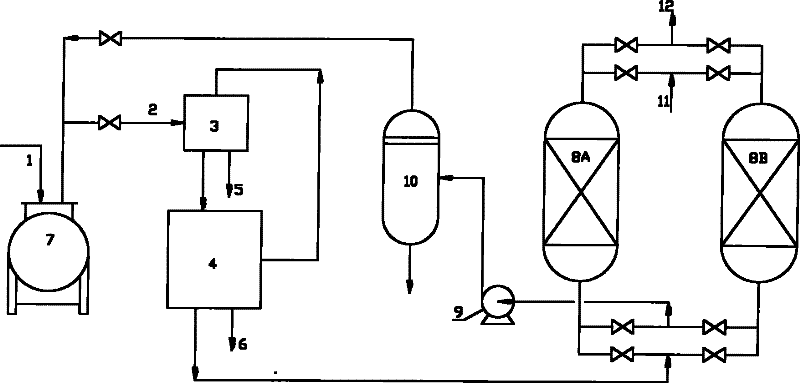

Method for recovering oil gas and device

InactiveCN102441310AExtended service lifeReduce the temperatureDispersed particle separationVapor condensationRecovery methodGas phase

The invention relates to a method for recovering oil gas and a device. Oil gas exhausted from an oil product storage device is firstly condensed; condensate is recovered; uncondensed gas phase enters an adsorption device for adsorption; after being in adsorption saturation, the adsorption device is regenerated by adopting a vacuum regeneration manner; and concentrated oil generated by vacuum regeneration is recycled to the oil product storage device. According to the method and the device, provided by the invention, the oil gas is recovered by combining the mode of returning the oil gas to the oil product storage device and an oil gas recovery technology, desorbed oil gas is returned to the gas-liquid balanced system of the oil product storage device, the partial pressure of the oil gas is increased, and the loss of an oil product, caused by evaporating, is fundamentally reduced. The method and the device, provided by the invention, have the characteristics of large operating flexibility, low energy consumption, small investment, no potential safety hazard, reachability in tail gas emission standards, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

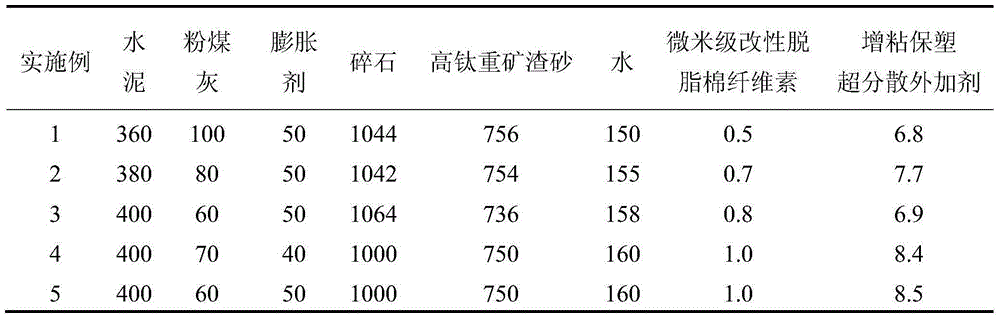

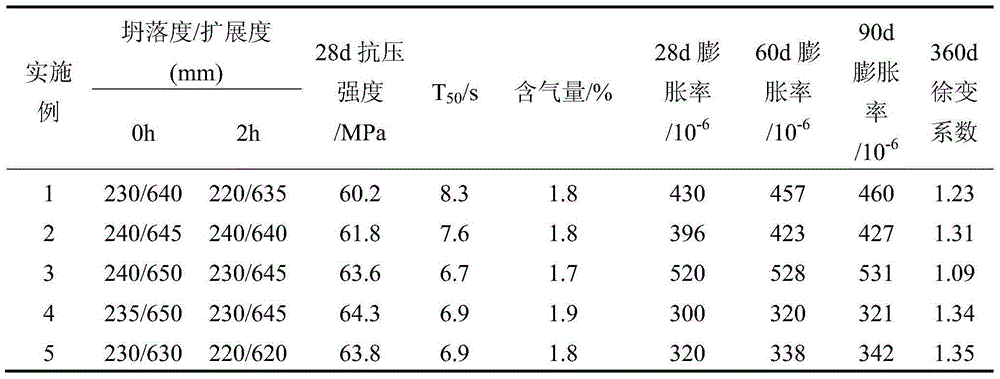

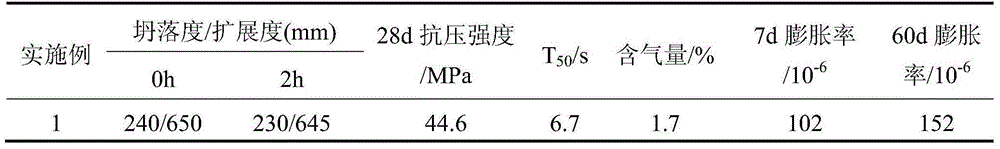

High titanium-bearing heavy slag C50 self-compacting weakly expansive concrete-filled steel tube and preparation method thereof

ActiveCN105060793AImprove cementing performanceFull hydration activitySolid waste managementCelluloseCompensation effect

The invention discloses a high titanium-bearing heavy slag C50 self-compacting weakly expansive concrete-filled steel tube, and belongs to the field of building materials. The concrete-filled steel tube is prepared from the following raw materials: cement, coal ash, composite expanding agent, macadam, high titanium-bearing heavy slag, a tackifying plasticity-maintaining super-dispersing additive, micron-sized modified absorbent cotton cellulose and water. The prepared concrete-filled steel tube has the characteristics of high flow state, low gas content, large strength extra coefficient and stable expansibility; the problem of poor working performance caused by application of high titanium-bearing heavy slag to concrete is solved; due to the water absorption and water releasing effect of the porous structure, the internal maintenance effect on the concrete-filled steel tube can be realized, the shrinkage compensation effect of the expanding agent on the concrete-filled steel tube is improved, the concrete-filled steel tube is weakly expansive to be suitable for jacking pouring of upper chord pipes and lower chord pipes of a concrete-filled steel tube arched bridge and a concrete-filled steel tube truss bridge, as well as high-casting pouring of a concrete-filled steel tube pier column. Therefore, the problem of disengaging caused by poor-density pouring of the concrete-filled steel tube is solved effectively.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

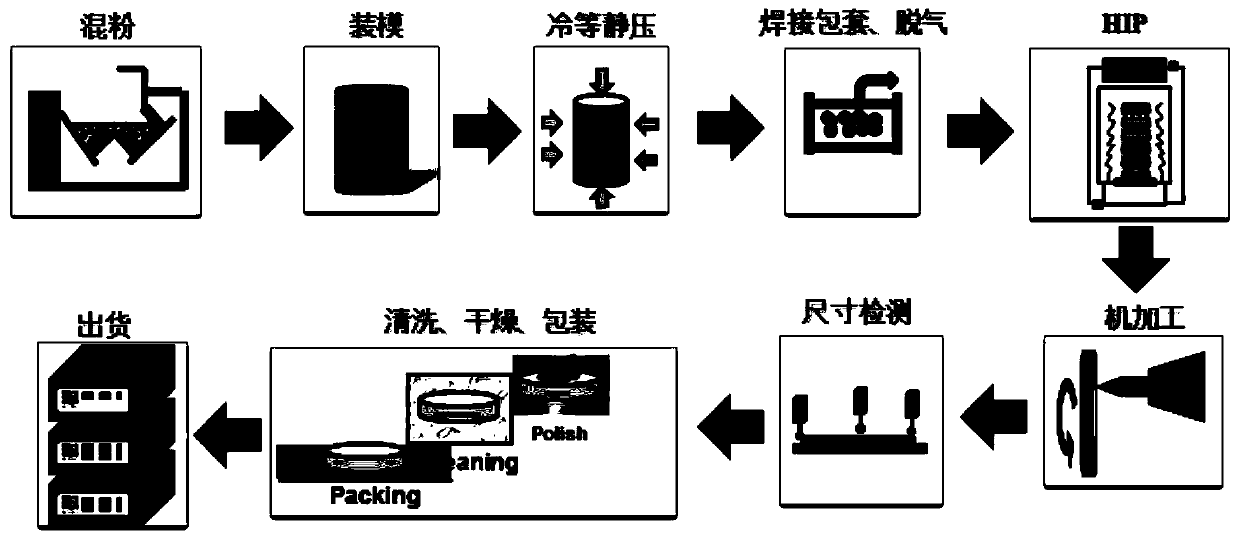

Tantalum-silicon alloy sputtering target material and preparation method thereof

InactiveCN110952064AUniform structureAvoid direct contactTransportation and packagingMetal-working apparatusSilicon alloyTantalum

The invention relates to a tantalum-silicon alloy sputtering target material and a preparation method thereof. The preparation method comprises the steps: (1) tantalum powder and silicon powder are mixed; (2) a mixture is loaded into a mold, and the mold is sealed; (3) the sealed mold is subjected to cold isostatic pressing treatment, and a tantalum-silicon blank is obtained; (4) the obtained tantalum-silicon blank is subjected to degassing treatment; (5) a degassed casing is subjected to hot isostatic pressing treatment at 1050-1350 DEG C, and a tantalum-silicon alloy sputtering target material crude product is obtained; and (6) the tantalum-silicon alloy sputtering target material is obtained by machining. According to the preparation method, oxidation of the silicon powder is effectively prevented, the product purity is guaranteed, the prepared tantalum-silicon alloy sputtering target material can further reach the density of 99% or above, the requirements of uniform density and internal organization structure of the tantalum-silicon alloy sputtering target material are met, a more excellent performance guarantee is provided for subsequent sputtering use, and the characteristicsof simple process, convenient operation and short production cycle are achieved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

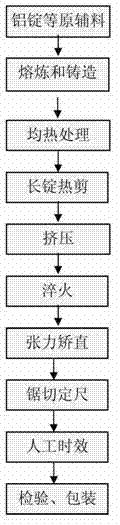

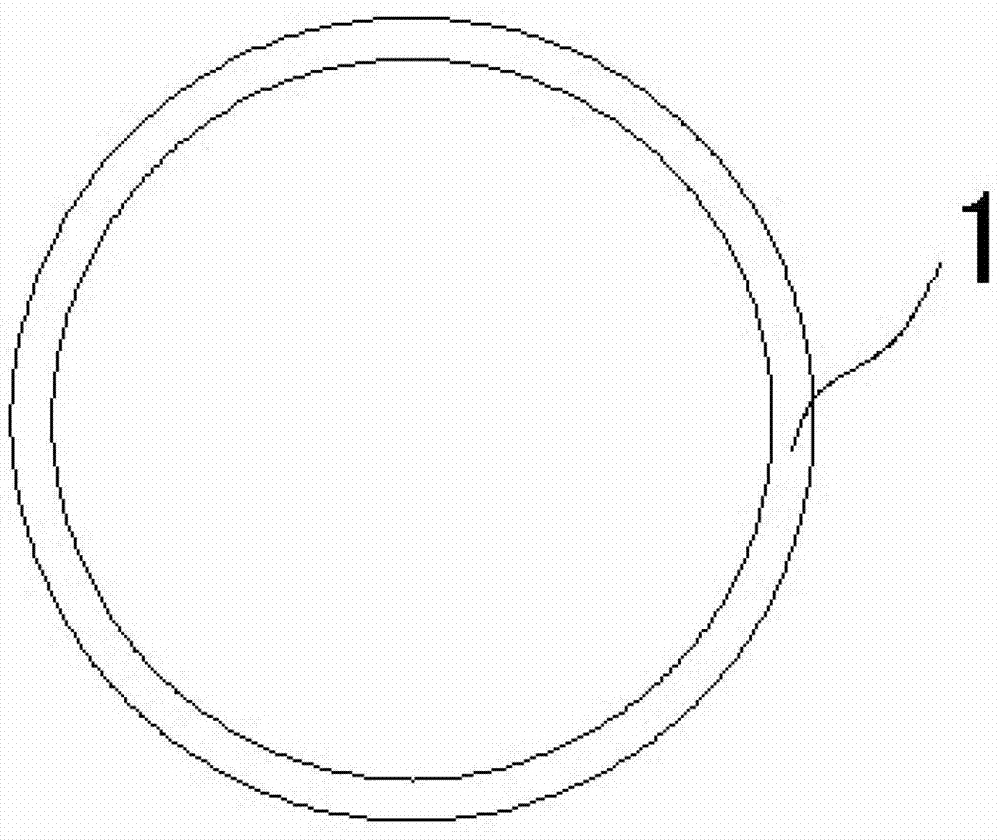

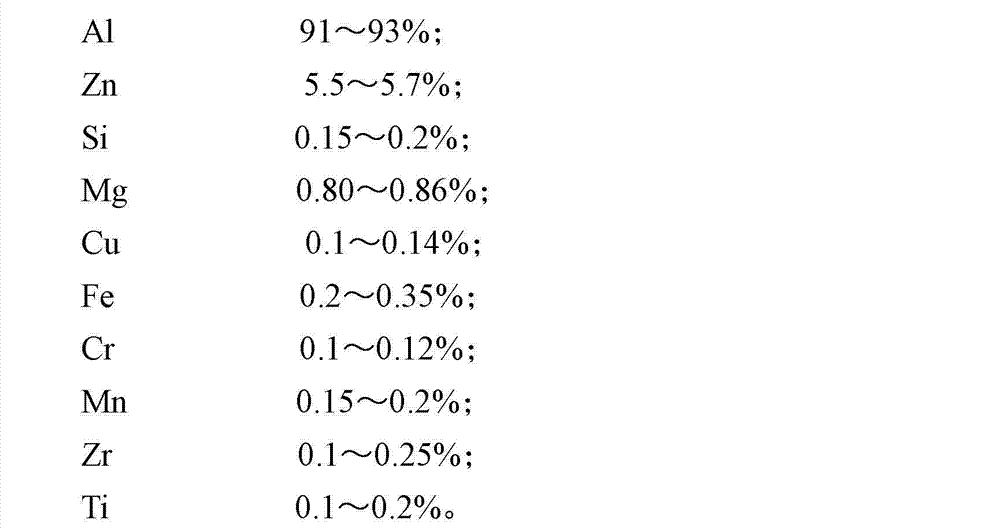

Aluminum profile and heating processing technology thereof

An aluminum profile is annular and is prepared by components in percentage by weight: 91-93% of Al, 5.5-5.7% of Zn, 0.15-0.2% of Si, 0.80-0.86% of Mg, 0.1-0.14% of Cu, 0.2-0.35% of Fe, 0.1-0.12% of Cr, 0.15-0.2% of Mn, 0.1-0.25% of Zr and 0.1-0.2% of Ti. A heating processing technology comprises following steps of: (1) smelting and casting raw material aluminum ingots, enabling a casting speed to be 85-95mm / min, enabling a pouring temperature to be 715-730 DEG C, and enabling cooling water pressure to be 0.04-0.08MPa; (2) extruding, enabling an extruding temperature to be 440-460DEG C, and enabling an extruding speed to be 3-6M / min; (3) conducting stretcher strengthening, and enabling strengthening deformation quantity to be 0.5%-1.5%; (4) conducting aging furnace heating, enabling a furnace temperature of an aging furnace at a first section of aging to be 100 DEG C, enabling heat preservation time to be 3h, enabling the furnace temperature of the aging furnace at a second section of aging to be 160 DEG C, and enabling heat preservation time to be 5h; and (5) testing and packaging. The aluminum profile mainly solves the problem that the aluminum profile in the prior art is not high in strength, poor in breakage toughness and poor in fatigue performance.

Owner:张家港市金邦铝业股份有限公司

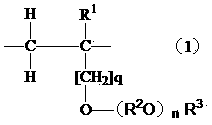

Early strength type water reducing agent for precast concrete

The invention discloses an early strength type water reducing agent for precast concrete. The early strength type water reducing agent comprises the following components by weight percent: 5.00-6.00% of polycarboxylic acid water reducing agent, 0.50-2.00% of inorganic lithium salt, 1.00-5.00% of inorganic sodium salt, 0.00-10.00% of inorganic calcium salt, 0.01-0.30% of deformer and the balance of filling material. The early strength type water reducing agent has the characteristics that the doped amount is low, the air bleeding is low, the water reduction is high, slump is well maintained, and the early strength is rapidly increased; and by utilizing the early strength type water reducing agent, the steam heating and maintenance of the precast concrete are shortened or avoided, thereby reducing the production cost of the precast concrete.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

Polycarboxylic acid water reducer for preparing fair-faced concrete

The invention discloses a polycarboxylic acid water reducer for preparing fair-faced concrete. The water reducer is composed of following components in percentage by weight: 5.00% to 60.00% of polycarboxylic acid copolymer, 0.02% to 1.00% of slow-release antifoaming agent, 0.01% to 1.00% of antifoaming agent, 0.01% to 1.00% of air-entrainer, 0.00% to 10.00% of delayed coagulant, and the balance being water. The polycarboxylic acid water reducer for preparing fair-faced concrete has the characteristics of low mixing amount, low air-entraining, low consistency, continuous defoaming ability, and improvement on concrete uniformity, is capable of producing green concrete, which has the advantages of excellent construction performance, low consistency, and good concrete wrapping ability, and also can produce fair-faced concrete, which has a mirror-face effect.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

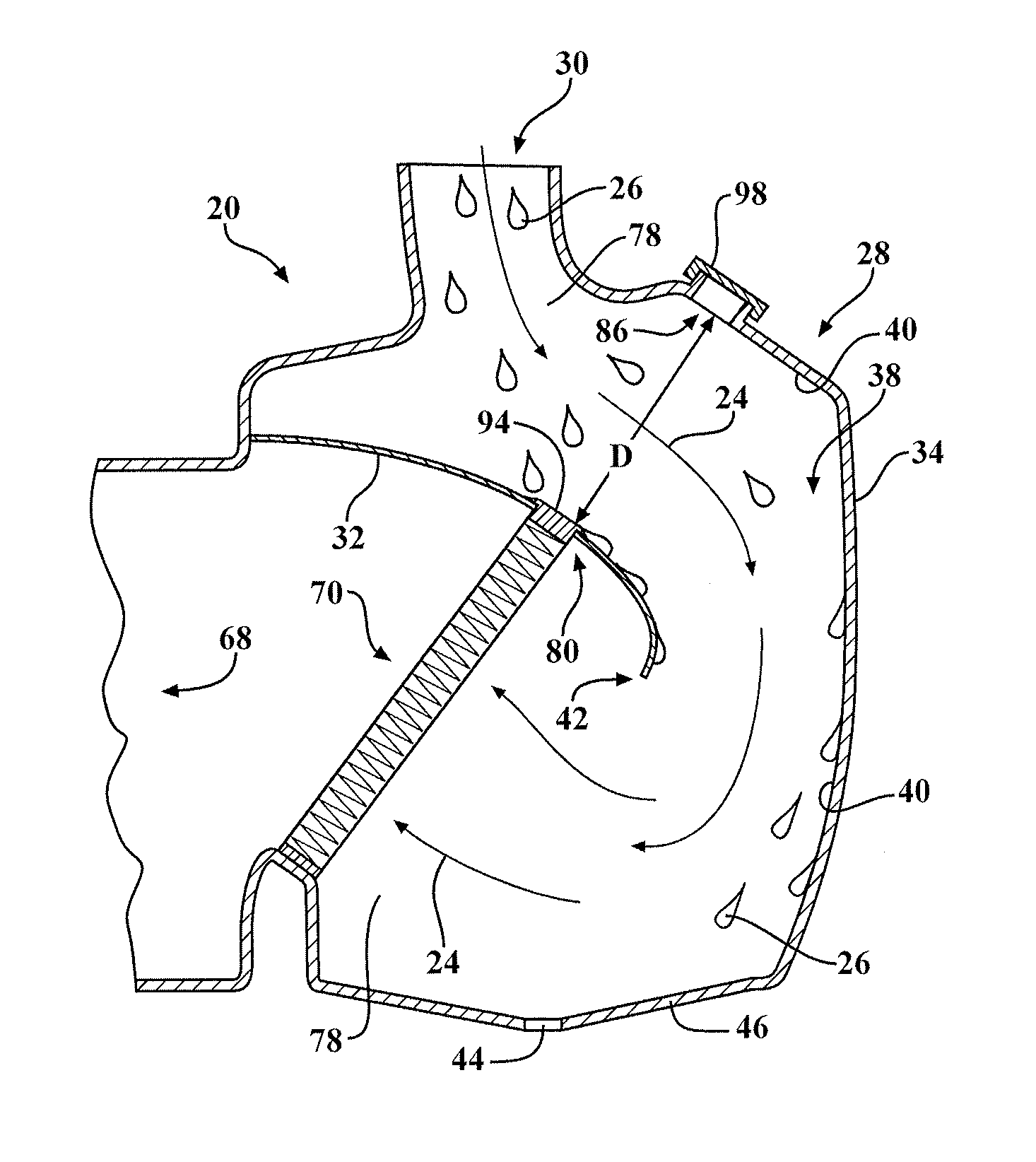

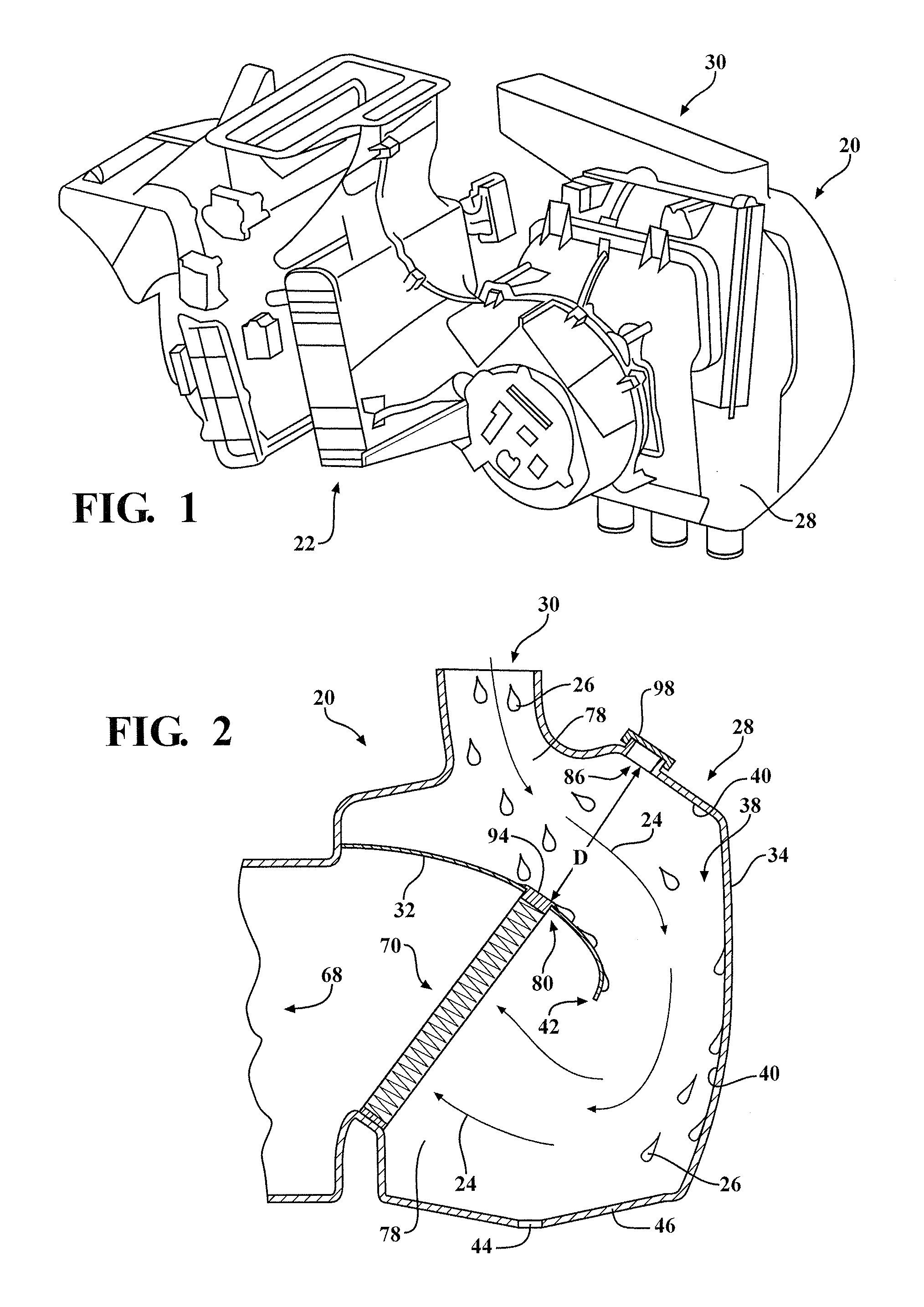

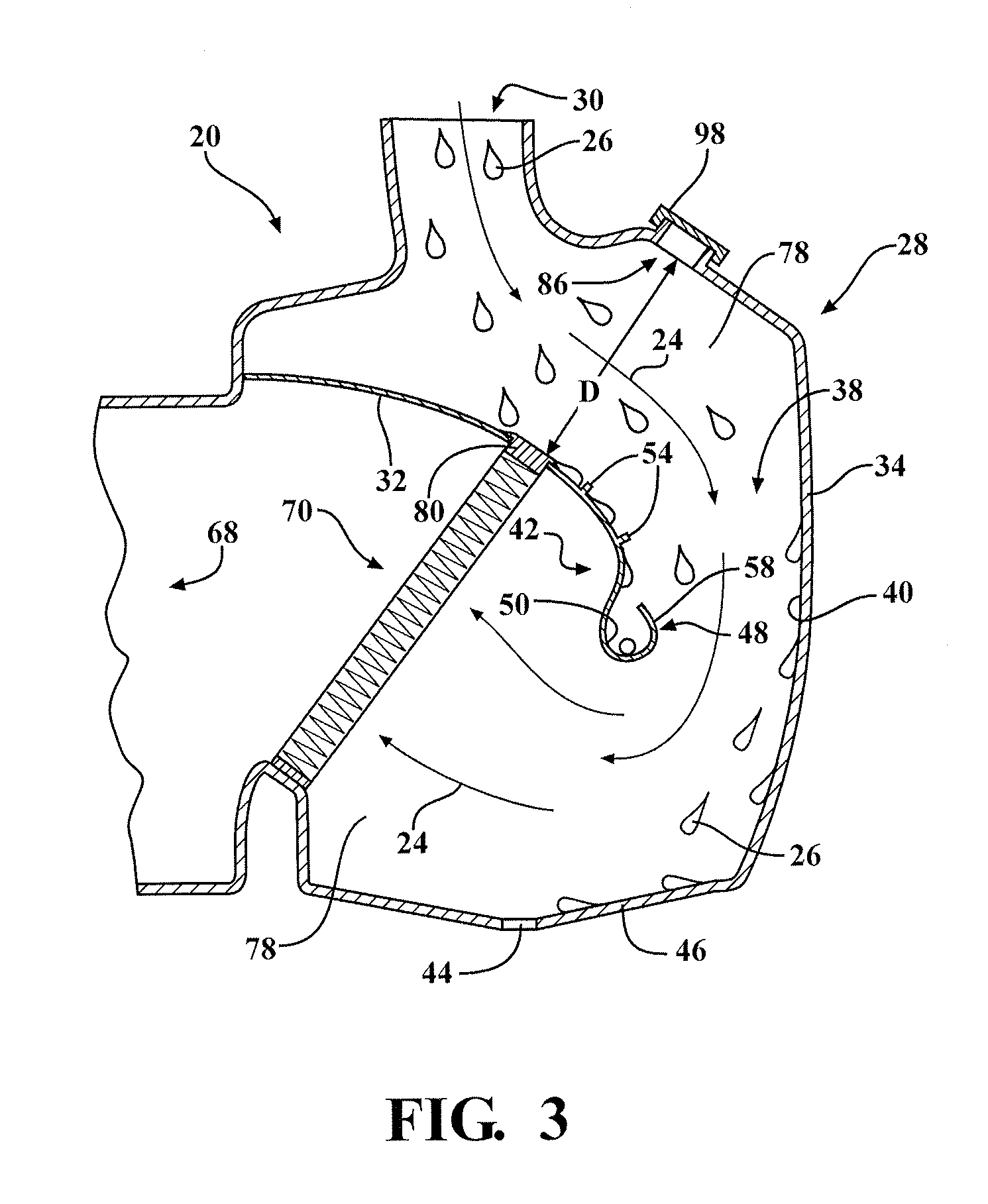

Water separator having a filter assembly

InactiveUS20130160648A1Reduce moistureEasy to disassembleCombination devicesGas treatmentFlow diverterWater content

A water separator reduces a water content of an air stream, which is used in an HVAC unit for a vehicle. The water separator includes a diverter wall and an adjacent wall spaced from the diverter wall to define an air passage. The diverter wall has a terminal end extending into the air passage for changing a direction of the air stream to reduce the water content of the air stream. A filter assembly is disposed through a receiving slot in the diverter wall and is within the air passage downstream of the terminal end.

Owner:VALEO CLIMATE CONTROL

Early-strength polycarboxylate superplasticizer and preparation method thereof

The invention discloses an early-strength polycarboxylate superplasticizer, which is prepared through aqueous solution polymerization on 75-90% of monomer A, 0.5-2.0% of monomer B, 0.8-3.2% of monomer C, 5-20% of monomer D and 1-3.5% of monomer E under action of an oxidation-reduction system. A preparation method comprises the following steps: 1) putting the monomer A, the monomer B and the monomer E into a reaction kettle, heating to 30 DEG C, stirring to uniformly dissolve into water, heating to 50 DEG C and adding an oxidant; 2) respectively dripping a mixed aqueous solution of the monomer C and the monomer D and a mixed aqueous solution of a reductant and a chain transfer agent, dripping off within 2-4 hours at the same time, maintaining the temperature at 50 DEG C, and further stirring for 1 hour; and 3) cooling to room temperature, adding water and liquid alkali, and regulating pH to 5-6.5 and the solid content to about 40%. The early-strength polycarboxylate superplasticizer has significant early strength enhancing performance, and the middle strength and the later strength thereof are stably improved; and the preparation method is easy to operate, short in production cycle and low in cost.

Owner:NANJING RUIDI HIGH TECH

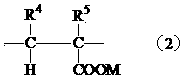

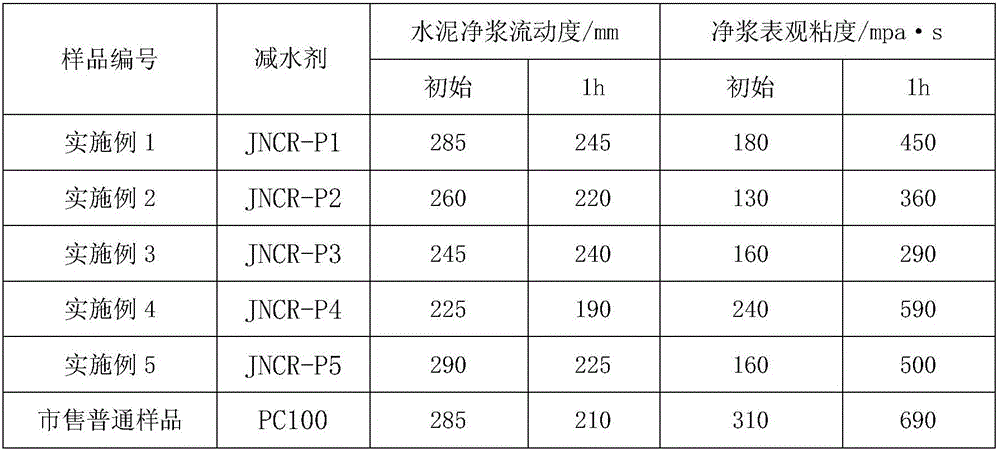

Polycarboxylate superplasticizer for reducing viscosity of high-grade concrete and preparation method thereof

The invention relates to a polycarboxylate superplasticizer for reducing the viscosity of high-grade concrete and a preparation method thereof. The polycarboxylate superplasticizer is prepared by: adding an initiator into the monomer alkenyl terminated polyoxyethylene ether shown as formula (1), unsaturated acid and unsaturated ester, carrying out random copolymerization reaction through an aqueous solution at room temperature, then adding a viscosity reduction regulator to conduct molecular rearrangement, and employing an alkaline regulator to adjust the product to neutral. The invention also includes a preparation method of the polycarboxylate superplasticizer for reducing the viscosity of high-grade concrete. The polycarboxylate superplasticizer provided by the invention has high water-reducing rate, can achieve good viscosity reducing effect when applied in high-grade concrete, and has the advantages of good adaptability, low gas content, good retainability and good pumpability.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

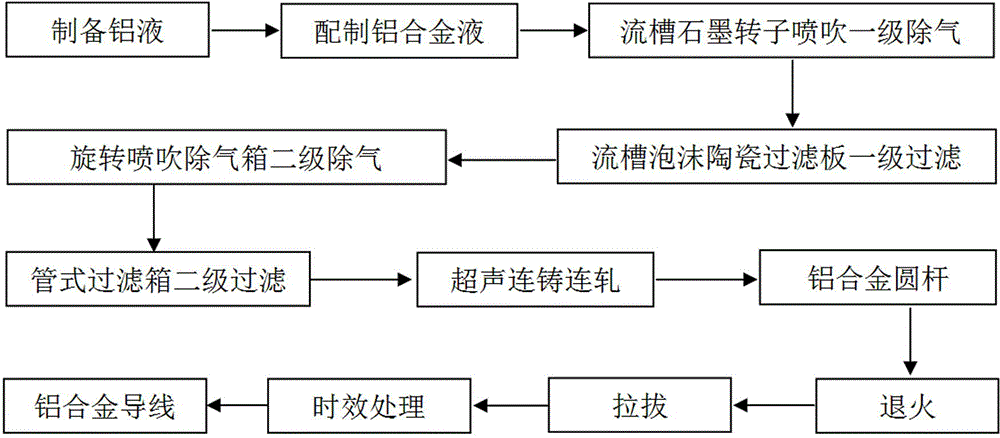

Method for producing high-strength high-conductivity aluminum alloy conductor

ActiveCN104538116AHigh strengthAvoid the effects of conductivityMetal/alloy conductorsCable/conductor manufactureRound barHigh conductivity

A method for producing a high-strength high-conductivity aluminum alloy conductor comprises the following steps that molten aluminum is manufactured, molten aluminum alloy with 1.2 percent to 1.8 percent of Mg and 1.0 percent to 1.5 percent of Si by mass is prepared, two-stage degassing and two-stage filtering outside a furnace are carried out, and ultraphonic continuous casting and rolling, annealing, drawing and aging treatment are carried out. The purity of the molten aluminum alloy is improved by improving the content of Mg and Si through two-stage degassing and two-stage filtering outside the furnace, the produced aluminum alloy conductor has high strength and high conductivity at the same time, ultraphonic continuous casting and rolling are adopted, the problem that an aluminum alloy round bar is prone to being broken is solved, an enterprise can produce the high-strength high-conductivity aluminum alloy conductor continuously and stably, the tensile strength of the aluminum alloy conductor is 330 MPa to 365 MPa, the conductivity is 56 percent IACS to 58 percent IACS, the need of construction of a long-distance large-span overhead transmission line for a full-aluminum-alloy strand is met, and the electric energy loss of the transmission line is lowered.

Owner:GUANGDONG SHINE CABLES

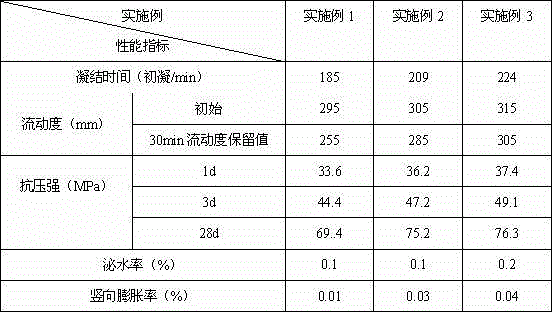

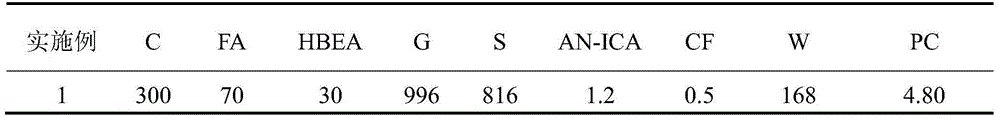

A cement-based shrinkage-free grouting material doped with phosphorus slag powder and a using method thereof

The invention relates to a cement-based shrinkage-free grouting material doped with phosphorus slag powder and a using method thereof. The cement-based shrinkage-free grouting material comprises common silicate cement, the phosphorus slag powder, ultrafine slag powder, flue gas desulfurization gypsum, medium sand, fine sand, an expanding agent, sepiolite powder, a water reducer, an antifoaming agent and a water-retaining agent. For the phosphorus slag powder, the average particle size of is 20-40 [mu]m, the weight percent of the residue on sieve having a size of 45 [mu]m is not more than 25%, the specific surface area is 350-400 m<2> / kg, and the quality factor K is 1.0-1.3. For the ultrafine slag powder, the average particle size of is 10-20 [mu]m, the specific surface area measured by a nitrogen adsorption method is 600-700 m<2> / kg, and the quality factor K is 1.7-2.0. The ultrafine slag powder has high gelatinization activity which is almost equal to or even slightly superior to the gelatinization activity of 52.5 common silicate cement. The grouting material adopts a composite gelatinization material and can be used on sites by adding water and stirring. The grouting material has excellent performances, such as good fluidity, no shrinkage, rapid intensity development in the earlier period, high intensity in the later period, good anti-permeability and good erosion resistance. The grouting material is suitable for bar splicing and fixation of supports, etc., and is also suitable for grouting of prefabricated parts, cementation of fissures for prestressed bridges, modification, reinforcement and repair of concrete constructions, and the like.

Owner:TONGJI UNIV

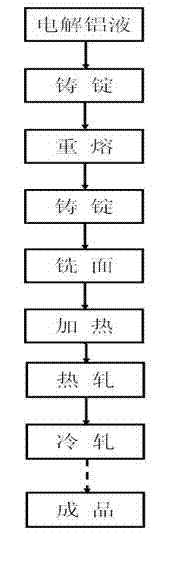

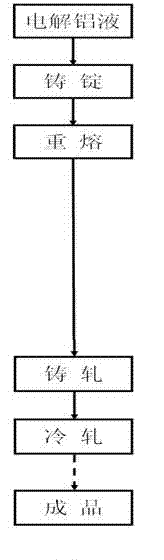

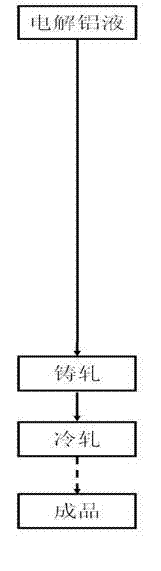

Method for producing ultra-wide and ultra-thin cast-rolled aluminium foil blanks by directly cast-rolling blanks with electrolytic aluminium liquid

InactiveCN102728614AShort production processReduce energy consumptionProcess efficiency improvementMetal rolling arrangementsIngotHydrogen treatment

The invention discloses a method for producing ultra-wide and ultra-thin cast-rolled aluminium foil blanks by directly cast-rolling blanks with electrolytic aluminium liquid. The method comprises the following steps: firstly melting raw materials; carrying out electromagnetic stirring 2-3 times after all the solid materials are molten; spraying carbon tetrachloride into the melt for refining by using argon as a carrier when the temperature of the aluminium liquid in the furnace reaches 740-760 DEG C; controlling the height of the surged waves during refining to be 50-100 mm and the amount of carbon tetrachloride to be 1.8-2.4 kilograms / ton of aluminium; after remaining aluminium liquid refining for 10-30 minutes for slagging off, adding solid aluminium ingots or intermediate alloys or waste materials for adjustment according to the requirements of alloy grades, and carrying out refining and slagging off again within 25-35 minutes after composition adjustment; controlling the temperature of the aluminium liquid to be 750-760 DEG C during conversion; carrying out standing; carrying out filtration; carrying out online dehydrogenation; carrying out re-filtration; and carrying out grain refinement and cast-rolling. By adopting the method, the whole production process of the aluminium foil is greatly shortened, and the energy consumption of the unit product is reduced.

Owner:CENT SOUTH UNIV +1

Aluminum titanium boron carbon zirconium rare earth refiner, preparation method and application thereof

The invention discloses an aluminum titanium boron carbon zirconium rare earth refiner, a preparation method and application thereof. The aluminum titanium boron carbon zirconium rare earth refiner comprises the following components by mass percent: 3% to 5% of titanium, 0.3% to 0.5% of boron, 0.08% to 0.15% of carbon, 0.08% to 0.22% of zirconium, 0.8% to 1.2% of rare earth, 0.10% or less of impurity Fe, 0.03% or less of impurity V, 0.08% or less of impurity Si and 0.15% or less of other impurities, and the balance being aluminum, wherein the content of each of the other single impurity elements is smaller than 0.03%. According to the aluminum titanium boron carbon zirconium rare earth refiner, through control of the reasonable addition amount of the zirconium element and preparation conditions, cylindrical objects and needle-shaped objects of TiAl3 are effectively decreased, TiB2 aggregation is reduced, generated harmful Al4C3 phases are decreased, size and distribution problems of TiAl3 phase particles are solved, the internal air content of an alloy is decreased, the refining time of the obtained refiner is short (10s), and the refining duration is long (larger than 12 h).

Owner:NANJING YUNKAI ALLOY CO LTD

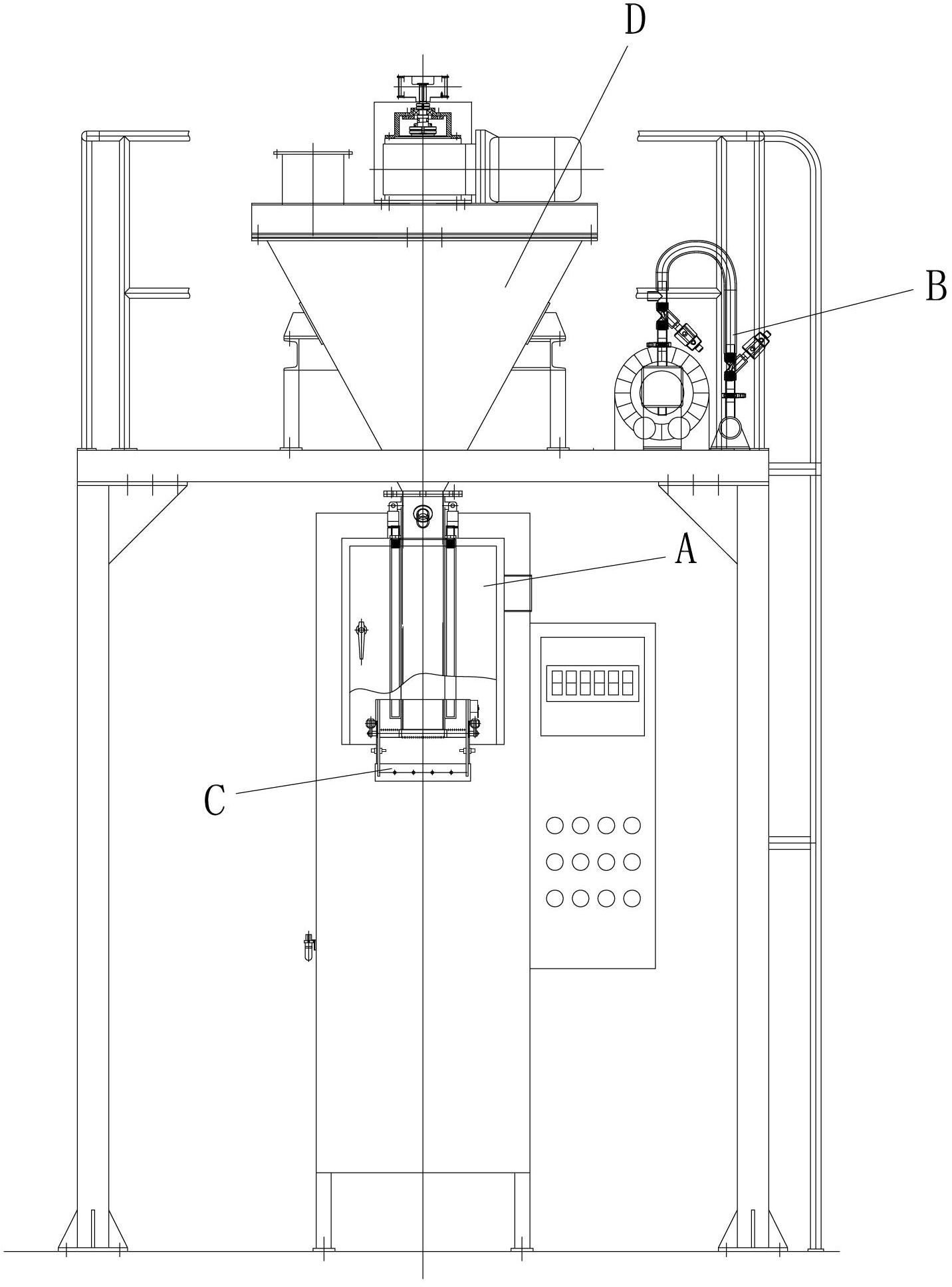

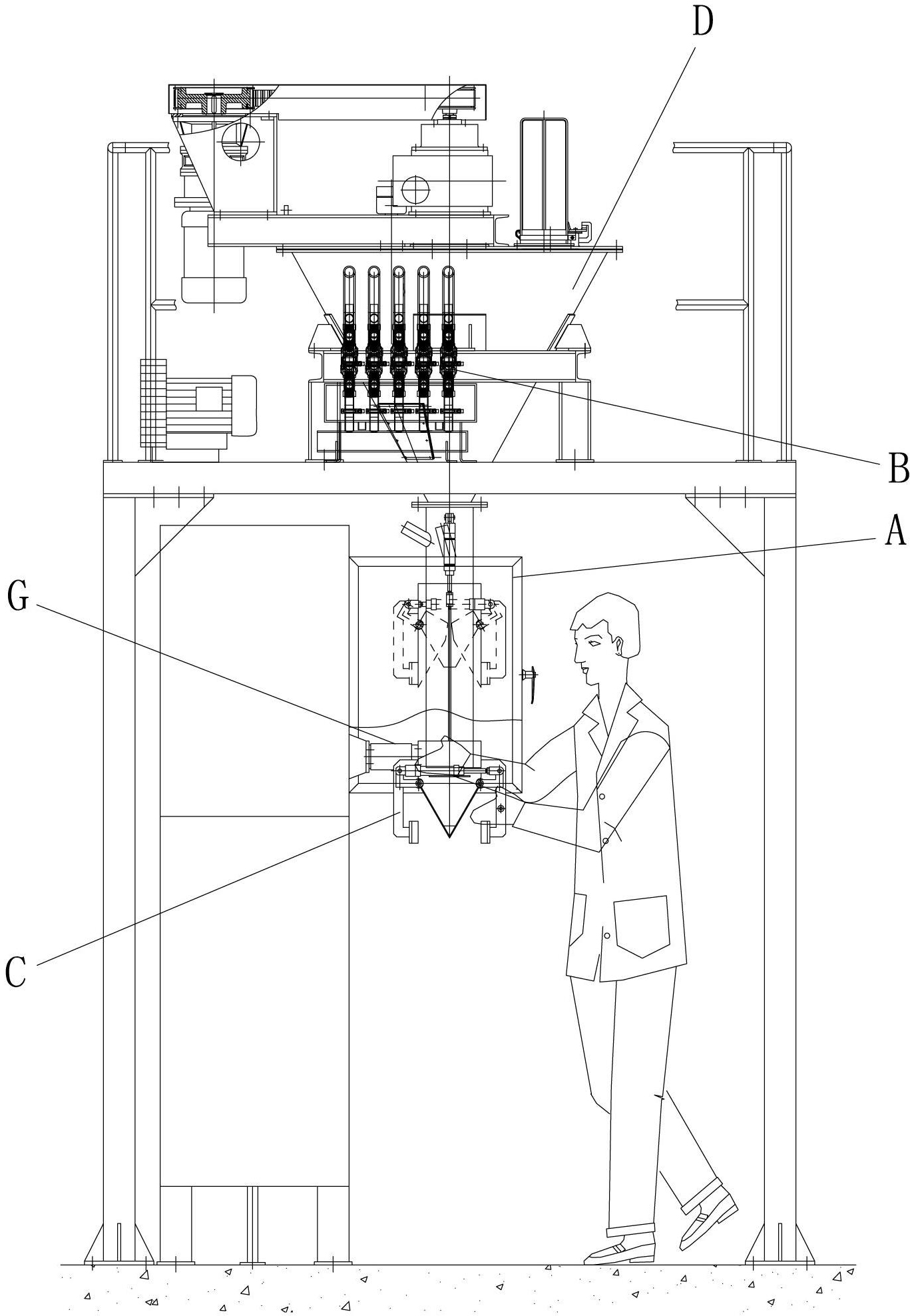

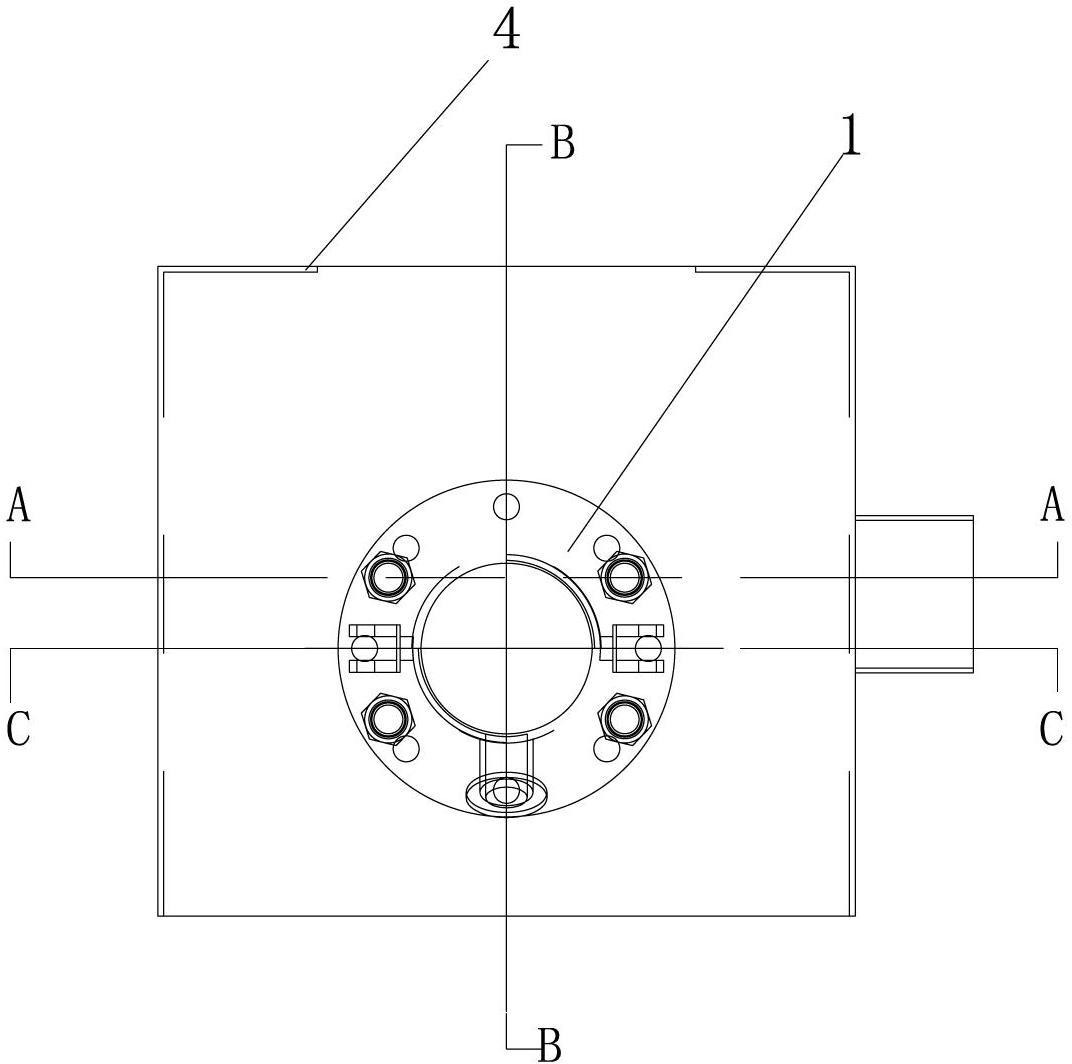

Operating method of powder material packing scale

The invention relates to an operating method of a powder material packing scale, which is suitable to solve the problems that the packaging bag is unable to be vertically placed and the rated quantity of materials are difficultly put into the bag within a normal time when powder materials with high gas contents enter a packaging bag; and the dust is easy to fly everywhere, after the packaging equipment is used, a better effect is obtained, and the efficiency is improved. The packaging scale comprises a degassing blanking device which is arranged on an outlet at the bottom of a hopper, an air suction blowing combination valve group and a vacuum pump which are used for degassing, blowing and blockage removing and are connected with the degassing blanking device, and a pneumatic bag-clamping lifting mechanism which is arranged at the bottom of the degassing blanking device; and the degassing blanking device comprises a blanking barrel, integrated microporous filter elements are arranged at both the inner wall and the outer wall of the blanking barrel, and the pore diameters of the filter elements can be set according to the sizes of material particles, and can range between 50 mum and 1mum. Ports which are communicated with a clearance between the inner wall of the blanking barrel and the inner filter elements are arranged in the outer wall of the blanking barrel; and the ports are connected with air suction blowing combination valves.

Owner:CHANGZHOU CHANGHENG DEYU POWDER INTEGRATIVE SYST

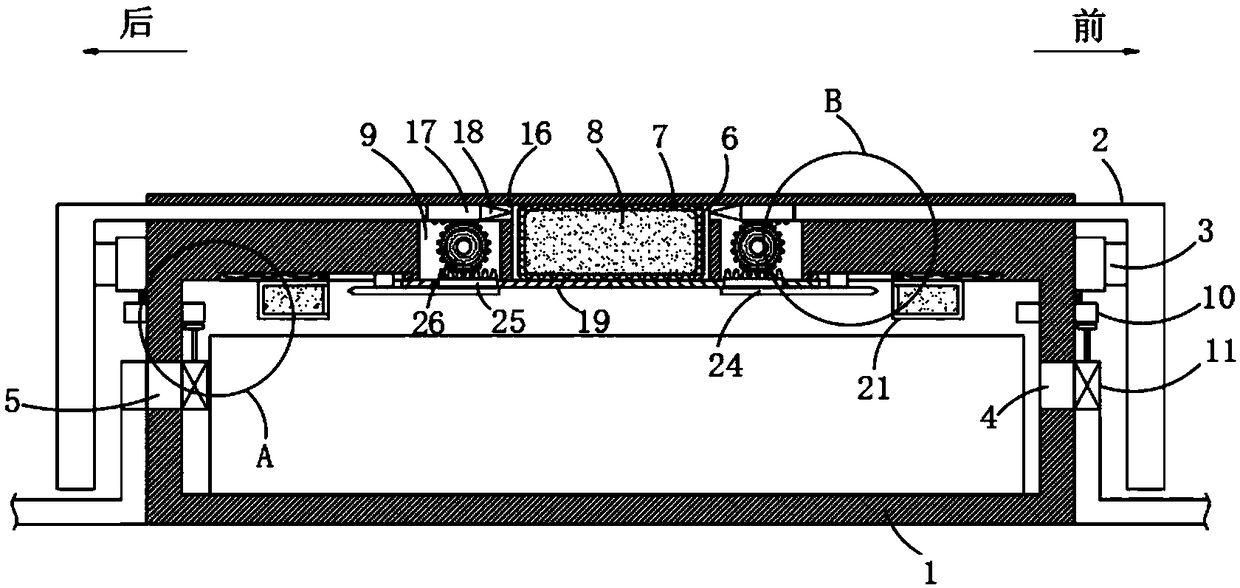

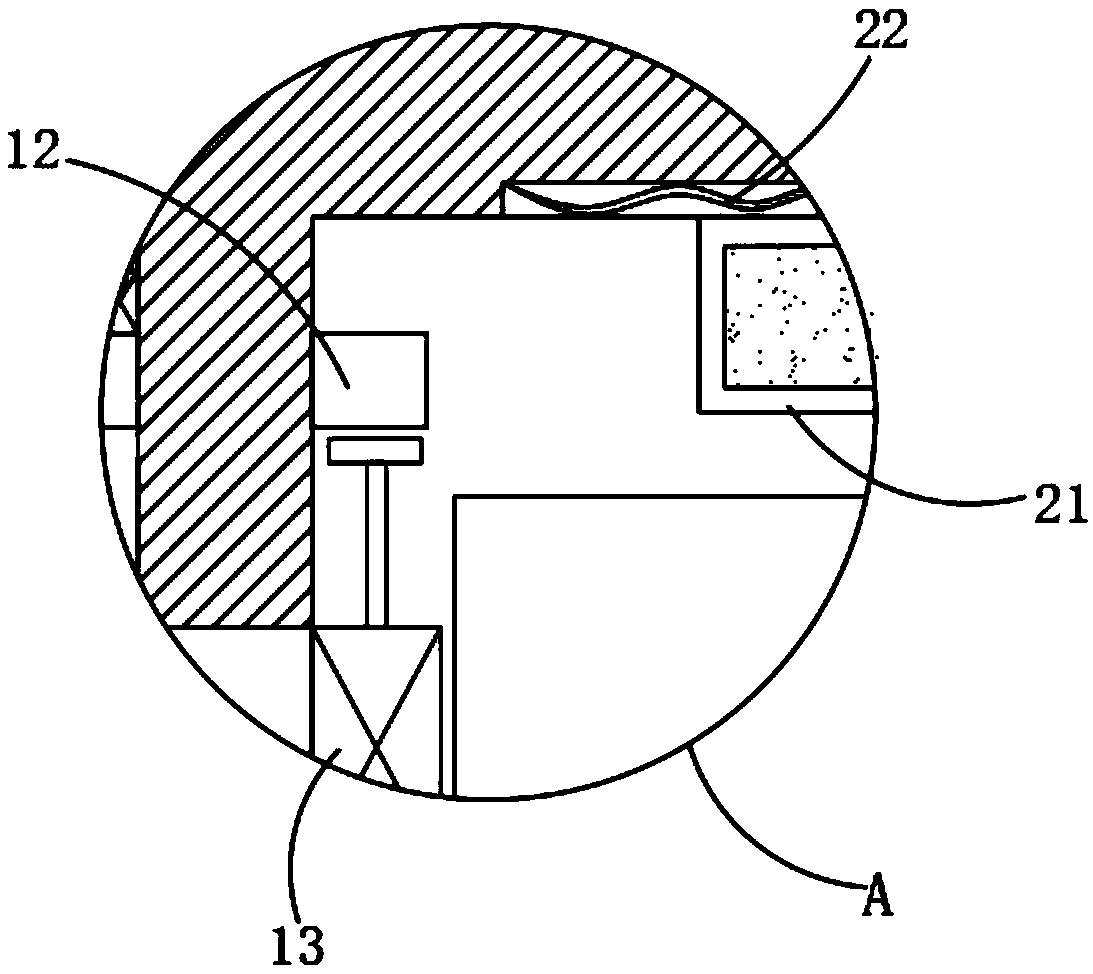

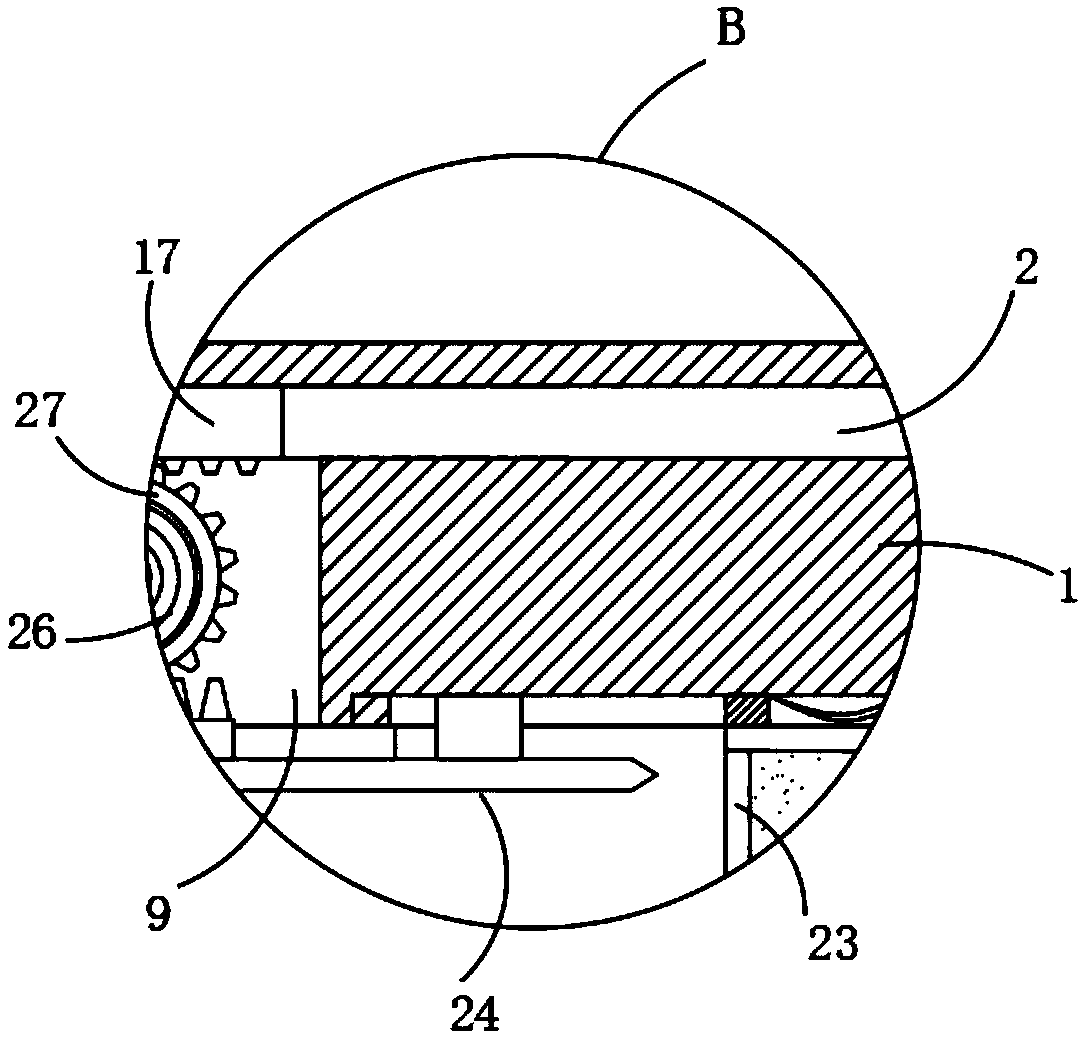

New energy automobile battery protective device

InactiveCN109378415AReduce air contentStop burningFire rescueCell component detailsNew energyElectrical battery

The invention discloses a new energy automobile battery protective device. The new energy automobile battery protective device comprises a battery holder for placing a battery and a protective mechanism located outside the battery holder, wherein the protective mechanism comprises two L-shaped plates which are respectively located at the front side and rear side of the battery holder; the verticalparts of the L-shaped plates are connected to the battery holder through buffering air cylinders; an air inlet and an air outlet are respectively formed in the front end and rear end of the battery holder; a front blocking mechanism for blocking the air inlet is arranged on the side wall of the battery holder; the buffering air cylinders drive the front blocking mechanism to move; a rear blockingmechanism for blocking the air outlet is arranged on the inner wall of the battery holder; and a storage tank is arranged on the inner top wall of the battery holder. When an automobile is collided,the new energy automobile battery protective device timely sprays dry powder into the battery holder; if the automobile meets the open fire, the new energy automobile battery protective device can generate carbon dioxide by decomposing to play a role in flame retardant, and further reduce the oxygen content in the battery holder, can seal and isolate the battery holder and further prevents a battery from burning.

Owner:赵鹏凯

C30 self-compaction microexpanded concrete-filled steel tube and preparation method thereof

ActiveCN105084836ASolve the "out of the air" problemImprove cementing performanceSolid waste managementCelluloseCoal

The invention discloses a C30 self-compaction microexpanded concrete-filled steel tube and belongs to the field of building materials. The C30 self-compaction microexpanded concrete-filled steel tube is prepared by taking cement, coal ash, composite expansion agents, gravel, river sand, tackifying plasticity-maintaining ultra-dispersed additive, internal maintaining materials, micro-grade modified degreasing cotton cellulose and water as raw materials. The number of binding materials adopted in the C30 self-compaction microexpanded concrete-filled steel tube is small, and the C30 self-compaction microexpanded concrete-filled steel tube has the advantages of being good in self-compaction performance, low in gas content and high in durability, being slightly expanded and the like, is suitable for compact pouring of intensely reinforced large-pipe-diameter thin-wall steel tube concrete-filled steel tube underwater piles with complex shapes and a small section size, string tube pumping pouring of upper and lower concrete-filled steel tubes of concrete-filled steel tube truss bridges and high-throwing vibration-free pouring of concrete-filled steel tube pier studs. The problem of disengaging of the concrete-filled steel tube can be effectively solved, and wide application prospects are achieved.

Owner:WUHAN UNIV OF TECH

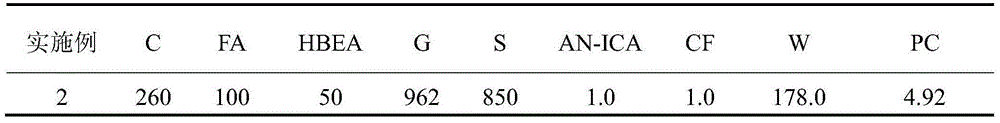

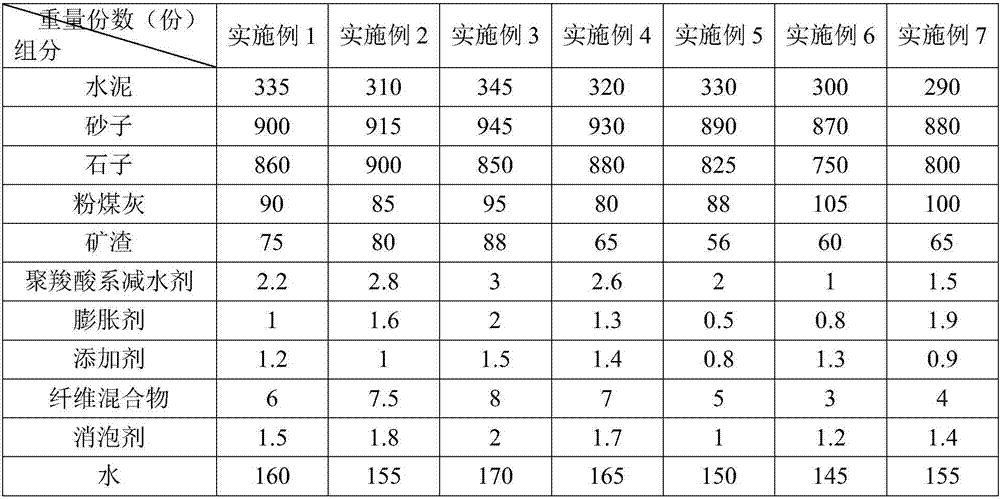

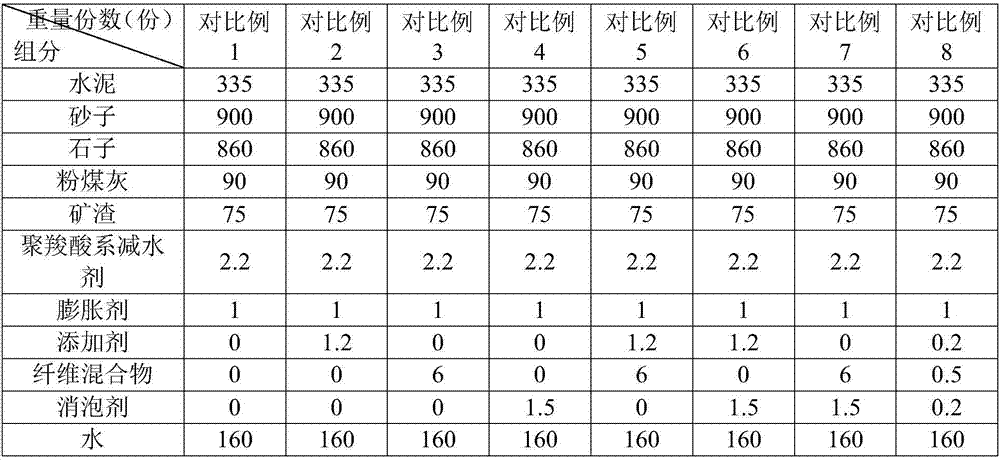

Concrete and preparation technology thereof

The invention discloses concrete and a preparation technology thereof. The concrete comprises, by weight, 290-345 parts of cement, 870-945 parts of sand, 750-900 parts of stones, 80-105 parts of fly ash, 56-88 parts of slag, 1-3 parts of polycarboxylate-type water reducing agent, 0.5-2 parts of expanding agent, 0.8-1.5 parts of addictive, 3-8 parts of fiber mixtures, 1-2 parts of defoaming agent and 145-170 parts of water. The cement is P.O 42.5 cement, the additive comprises MCC, xanthan gum and polyvinylpyrrolidone, the fiber mixtures comprise at least two kinds of glass fiber, steel fiber and carbon fiber, and the defoaming agent comprises at least one kind of polysiloxane and polyether modified polysiloxane. The concrete and the preparation technology have the advantages that the air content is lowered, and the impervious performance and the crack resistance of the solidified concrete are improved.

Owner:深圳市圣威宝混凝土有限公司

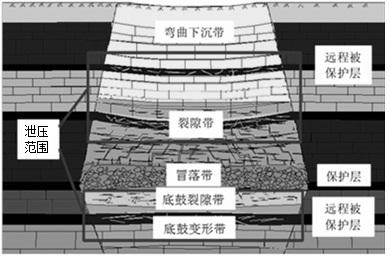

Ground and underground combined coal and coal-bed gas co-mining method for low-permeability coal bed group

ActiveCN111042791AReduce penetrationReduce air contentUnderground miningFluid removalMining engineeringCoal mine methane

The invention discloses a ground and underground combined coal and coal-bed gas co-mining method for a low-permeability coal seam group. The method is applied to a gas outburst mine, a mode that the protective layer mining is combined with the ground gas extraction is used for a coal reservoir with the characteristics of low permeability and low gas content, so that an adjacent coal bed is subjected to rapid pressure relief, coal-bed gas is efficiently and rapidly extracted from the ground, and a co-mining technology system that ground and underground are combined to extract the coal-bed gas and coal and the coal bed gas are extracted while being pumped is provided, so that a highly-located drainage roadway and an end-located drainage roadway are replaced to the maximum extent, the coal mine gas treatment cost is effectively reduced, the ground coal-bed gas well yield is increased, the coal mine gas outburst risk and the gas overrun accident occurrence frequency is reduced, the coal mining efficiency is improved, and the coal mine mining safety and efficiency are realized.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

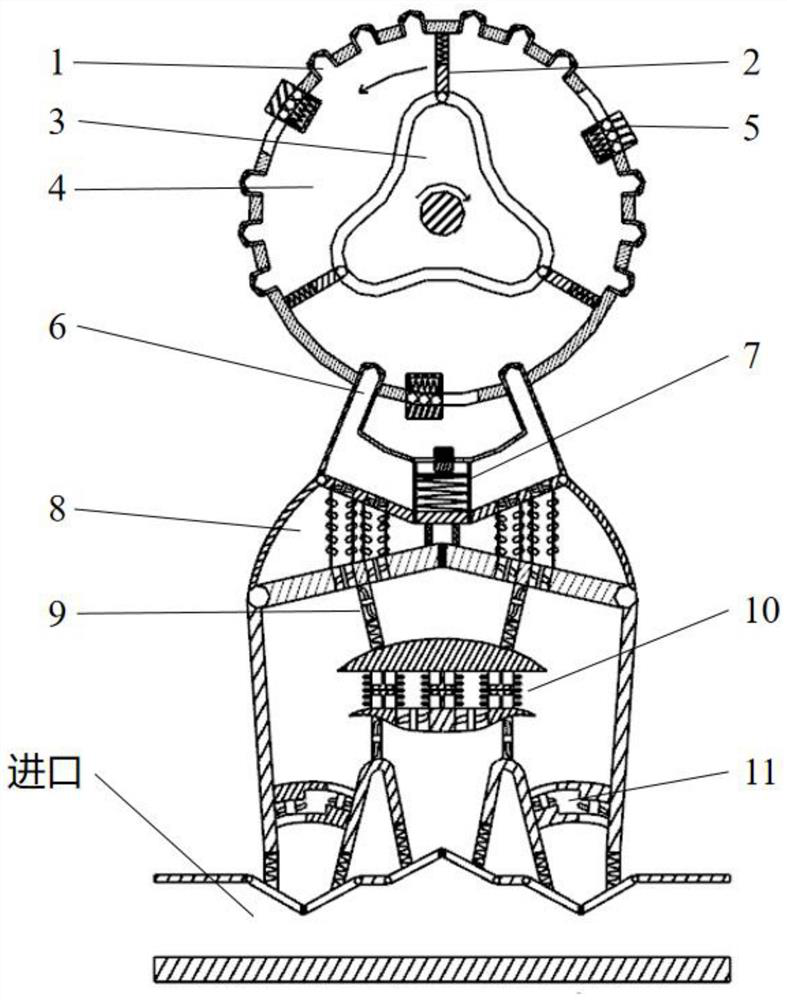

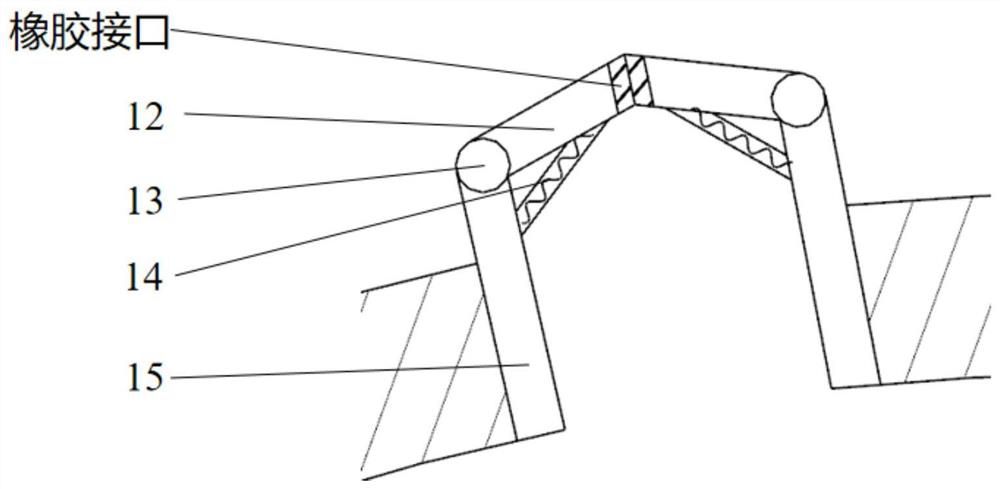

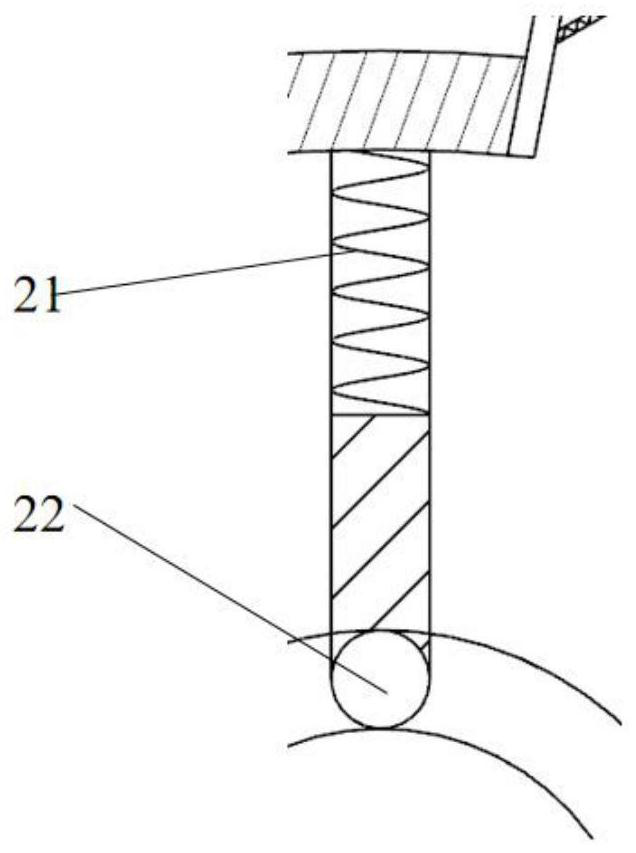

Quick water-free starting device applied to centrifugal pump

ActiveCN113464450AImprove sealingImprove exhaust capacityPriming pumpNon-positive displacement fluid enginesCentrifugal pumpEngineering

The invention provides a quick water-free starting device applied to a centrifugal pump. The quick water-free starting device comprises a one-way channel, a self-suction cavity shell, a sliding device, a self-suction cavity, a concave-convex impeller, two side inlet flow channels connected with the self-suction cavity, a spring device of an upper side x-shaped gas-liquid separation device, an upper side x-shaped gas-liquid separation device, an upper and middle side gas-liquid separation device connecting shaft, a middle side gas-liquid separation device, a lower side backflow type gas-liquid separation device, a v-shaped backflow flow channel, an inverted v-shaped inlet flow channel and an inlet which are sequentially arranged from top to bottom. According to the quick water-free starting device, the centrifugal pump can directly enter the normal operation working condition after water-free starting, and 36 times of exhaust can be completed by rotating an impeller in a self-suction cavity by a circle in the earlier stage. In addition, the device is provided with an upper gas-liquid separation device, a middle gas-liquid separation device and a lower gas-liquid separation device, gas-liquid separation is fully achieved, gas can be exhausted more quickly, a cavity is filled with water, the working efficiency can be remarkably improved, and the operation process is greatly simplified.

Owner:JIANGSU UNIV

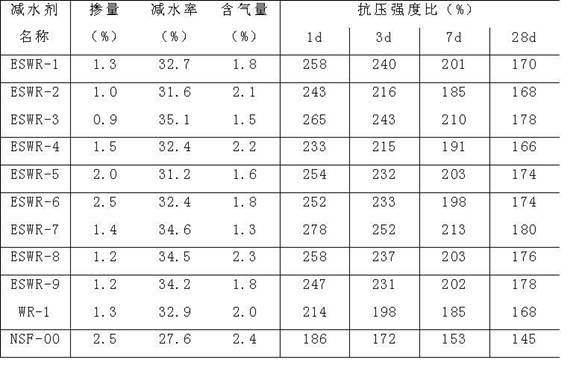

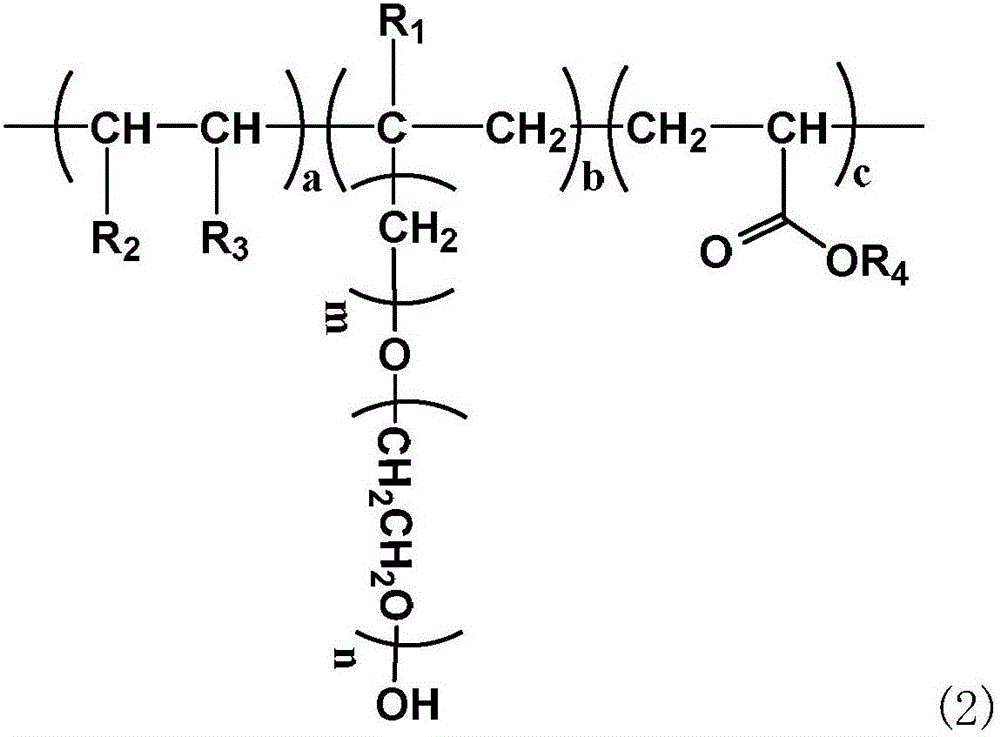

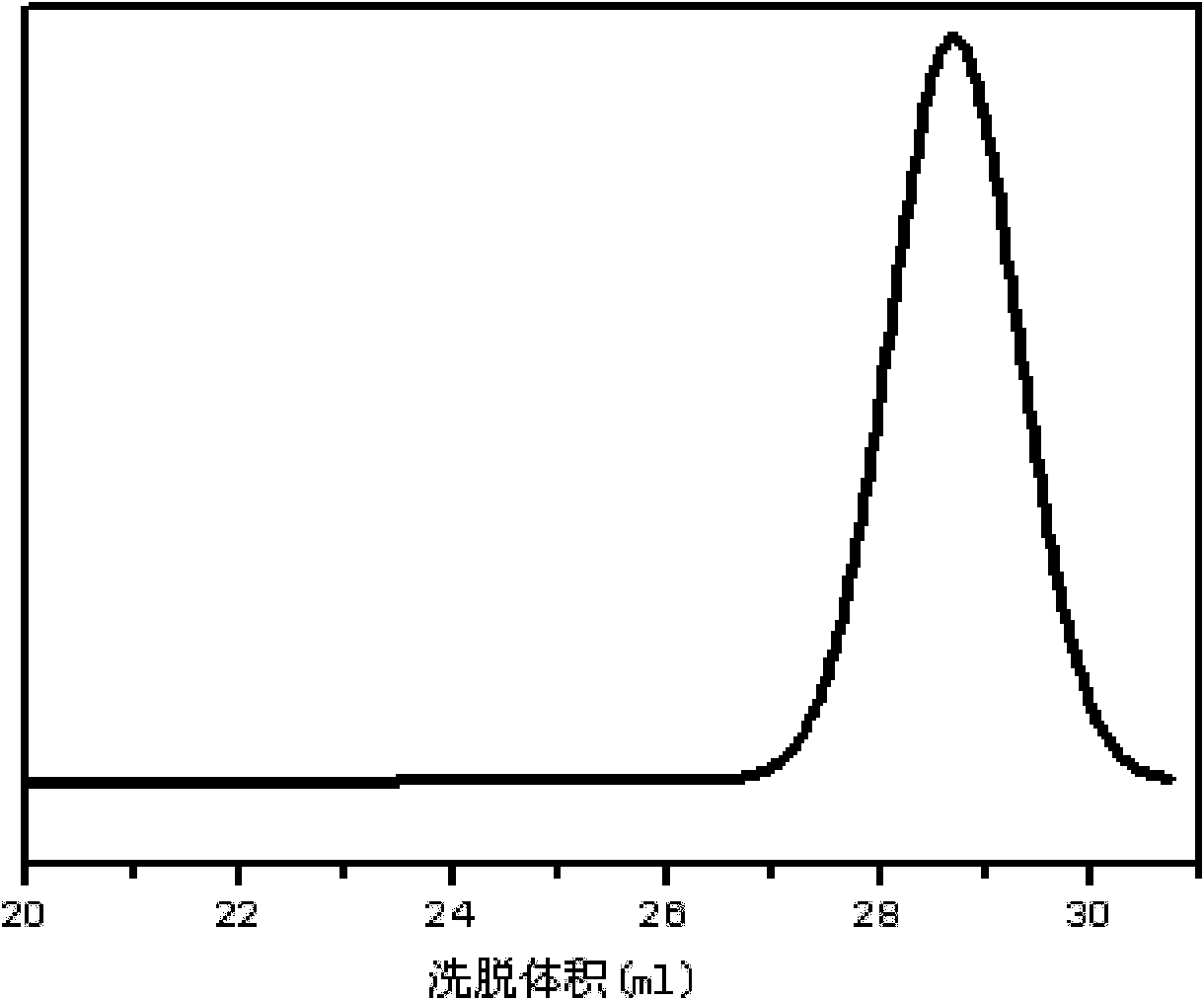

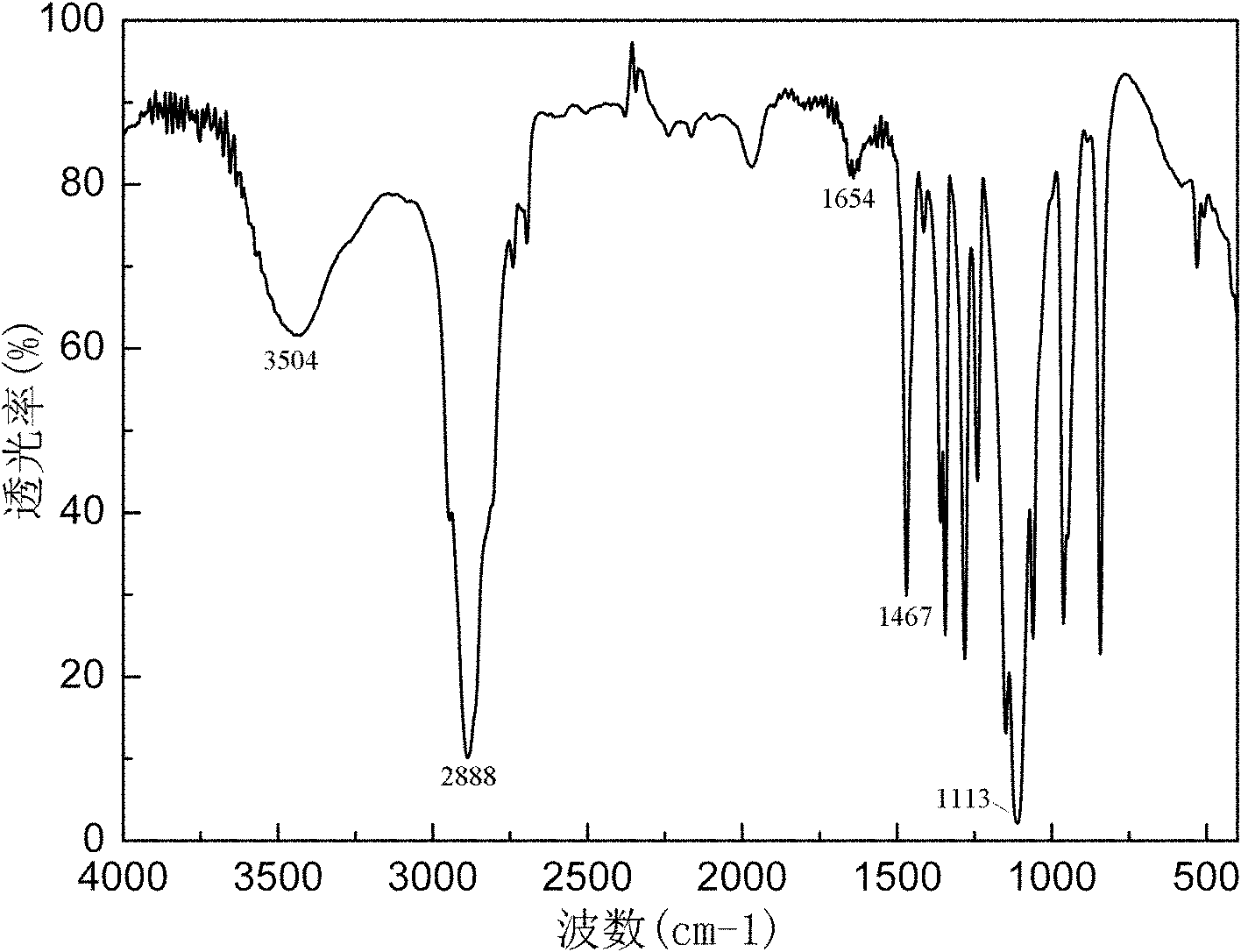

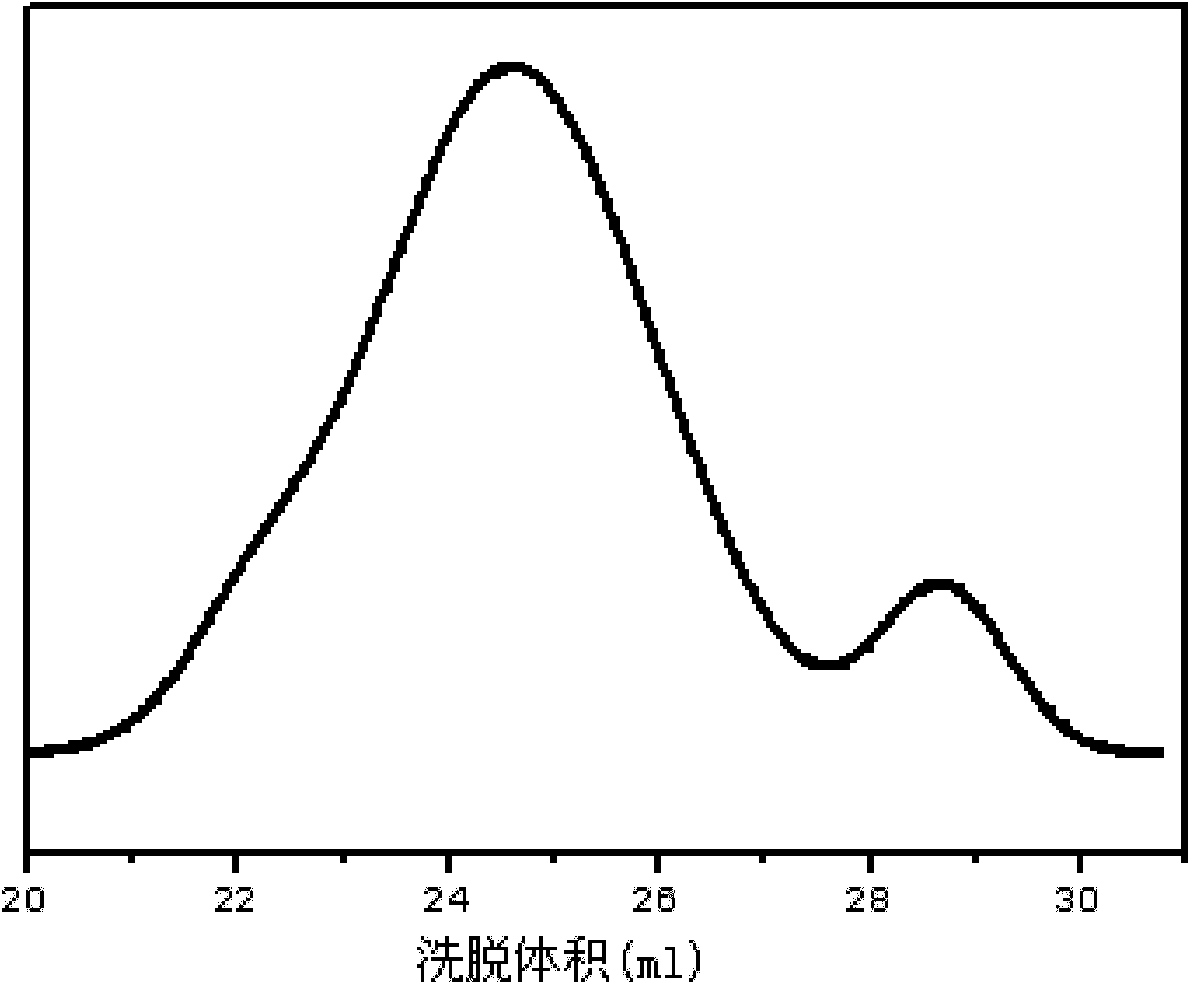

Preparation method for comb-shaped copolymer cement dispersant, monomer used therein and prepared comb-shaped copolymer cement dispersant

InactiveCN102115516AImprove dispersion stabilityEasy to operateOrganic chemistryDispersion stabilityDouble bond

The invention relates to a preparation method for a comb-shaped copolymer cement dispersant, a monomer used in the comb-shaped copolymer cement dispersant and the prepared comb-shaped copolymer cement dispersant. The preparation method for the comb-shaped copolymer cement dispersant comprises the following steps: a monomer (a) and a monomer (b) are subjected to free-radical copolymerization in aqueous medium, wherein the monomer (a) is expressed with a general formula (I), and the monomer (b) is expressed with a general formula (II); and the mol ratio of the monomer (a) and the monomer (b) is preferably 1:(1 to 10). The structure formula of the comb-shaped copolymer cement dispersant obtained by the preparation method is shown in (VI). The new monomer (a) is introduced in the comb-shaped copolymer cement dispersant, and the molecular structure of the monomer (a) has an unsaturated reactive double bond and two branching polyoxyalkylene long chains, so that the steric hindrance among cement particles can be greatly enhanced, and the dispersion stability of cement can be enhanced. The preparation method for the comb-shaped copolymer cement dispersant is simple and convenient for production operation, and meanwhile, the prepared comb-shaped copolymer cement dispersant has the advantages of low dosage, good dispersivity, high water-reducing rate, small slump loss and low gas content.

Owner:JIANGSU SUBOTE MATERIAL +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com