Method for producing high-strength high-conductivity aluminum alloy conductor

An aluminum alloy wire, high conductivity technology, applied in the direction of metal/alloy conductors, circuits, electrical components, etc., can solve the problem that continuous casting and rolling aluminum alloy round rods are prone to breakage, difficult to meet the requirements of all-aluminum alloy strands, and the impact of Production continuity and stability, etc., to achieve the effect of improving plasticity and tissue density, enhancing strength, and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

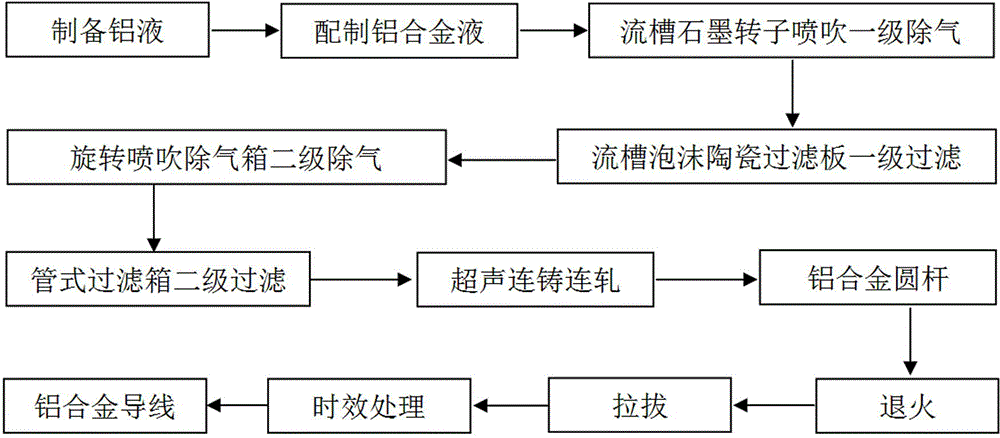

Image

Examples

Embodiment 1

[0026] Adopt the present invention to produce the aluminum alloy wire that diameter is 5 millimeters. The main production equipment is a 15-ton natural gas aluminum melting furnace, a 15-ton tilting holding furnace, a four-wheel belt continuous casting machine, and a 15-stand Y-shaped continuous rolling mill. The diameter of the crystallization wheel of the continuous casting machine is 1.5 meters, and the cross-sectional area of the wheel groove of the continuous casting machine is 2400 square millimeters. An ultrasonic vibrating rod is arranged obliquely at the injection port of the aluminum alloy liquid of the continuous casting machine. The lower end of the ultrasonic vibrating rod It is located in the center of the wheel groove of the crystal wheel of the continuous casting machine, and its upper end is fixedly connected with the ultrasonic transducer. The ultrasonic transducer is connected with the ultrasonic generator through a cable, and the ultrasonic transducer and ...

Embodiment 2

[0036] Adopt the present invention to produce the aluminum alloy wire that diameter is 2.5 millimeters. The main production equipment is a 15-ton natural gas aluminum melting furnace, a 15-ton tilting holding furnace, a four-wheel belt continuous casting machine, and a 15-stand Y-shaped continuous rolling mill. The diameter of the crystallization wheel of the continuous casting machine is 1.5 meters, and the cross-sectional area of the wheel groove of the continuous casting machine is 2400 square millimeters. An ultrasonic vibrating rod is arranged obliquely at the injection port of the aluminum alloy liquid of the continuous casting machine. The lower end of the ultrasonic vibrating rod It is located in the center of the wheel groove of the crystal wheel of the continuous casting machine, and its upper end is fixedly connected with the ultrasonic transducer. The ultrasonic transducer is connected with the ultrasonic generator through a cable, and the ultrasonic transducer an...

Embodiment 3

[0046] Adopt the present invention to produce the aluminum alloy wire that diameter is 1 millimeter. The main production equipment is a 15-ton natural gas aluminum melting furnace, a 15-ton tilting holding furnace, a four-wheel belt continuous casting machine, and a 15-stand Y-shaped continuous rolling mill. The diameter of the crystallization wheel of the continuous casting machine is 1.5 meters, and the cross-sectional area of the wheel groove of the continuous casting machine is 2400 square millimeters. An ultrasonic vibrating rod is arranged obliquely at the injection port of the aluminum alloy liquid of the continuous casting machine. The lower end of the ultrasonic vibrating rod It is located in the center of the wheel groove of the crystal wheel of the continuous casting machine, and its upper end is fixedly connected with the ultrasonic transducer. The ultrasonic transducer is connected with the ultrasonic generator through a cable, and the ultrasonic transducer and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com